Patents

Literature

1038 results about "Lower wing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

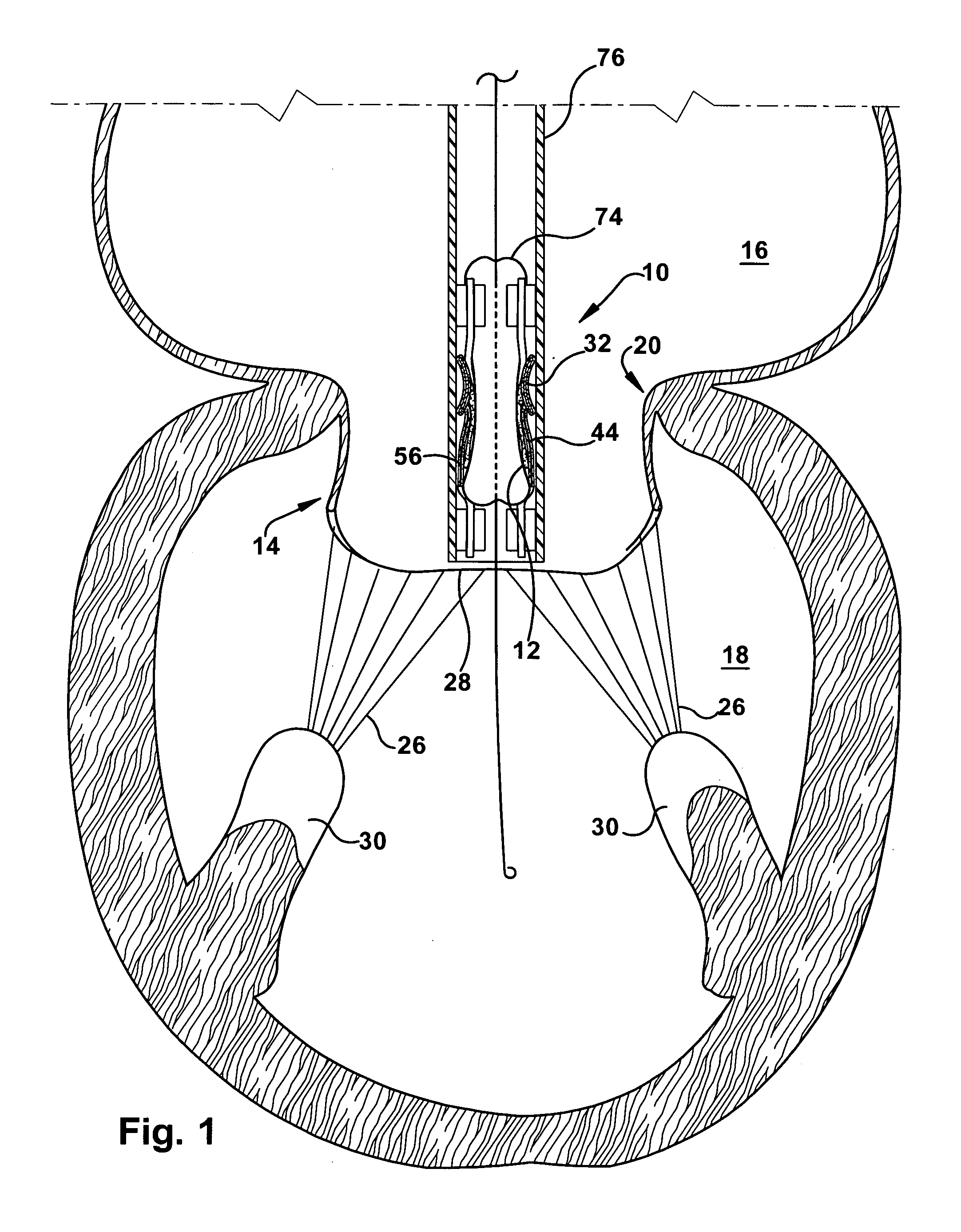

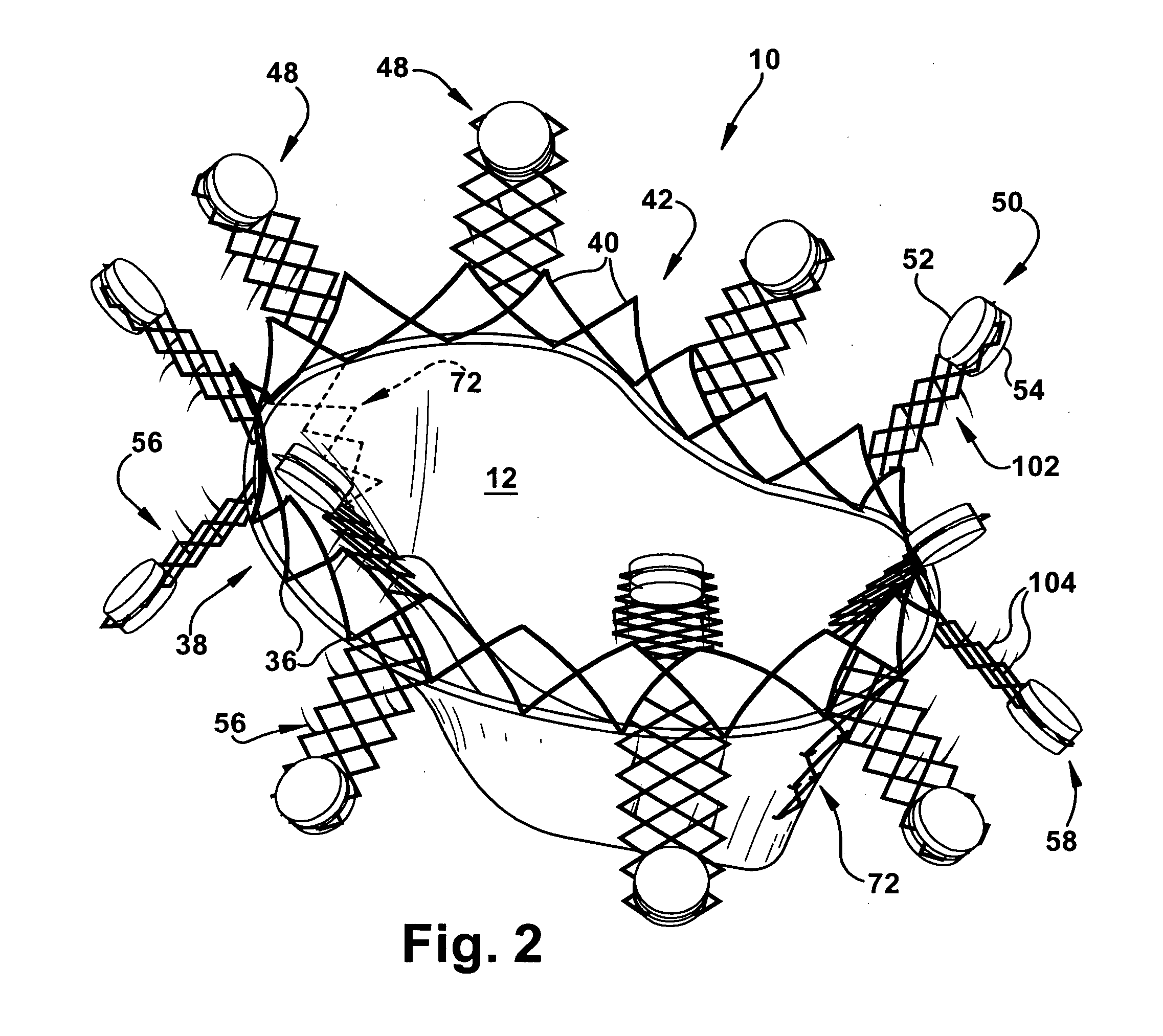

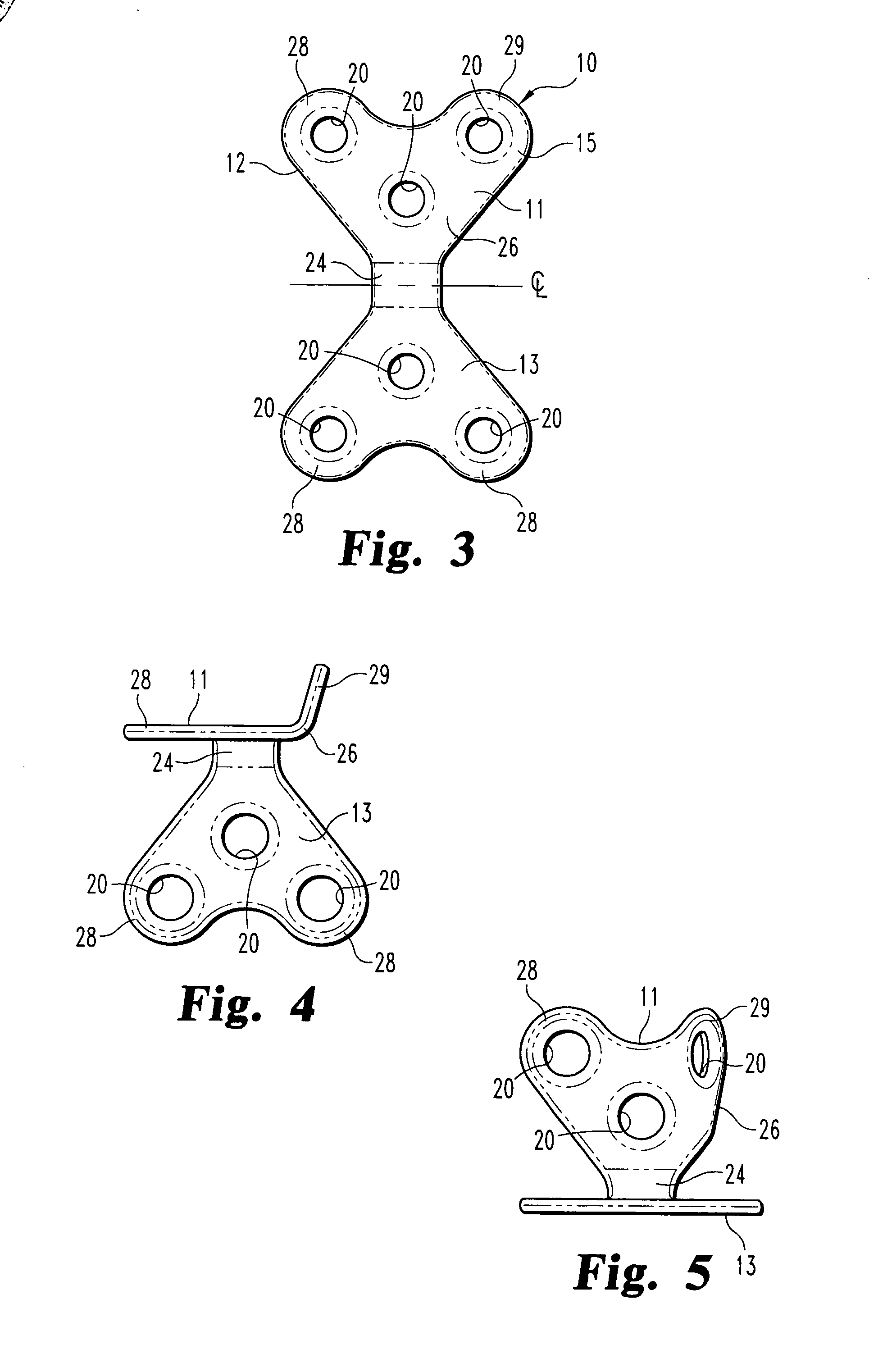

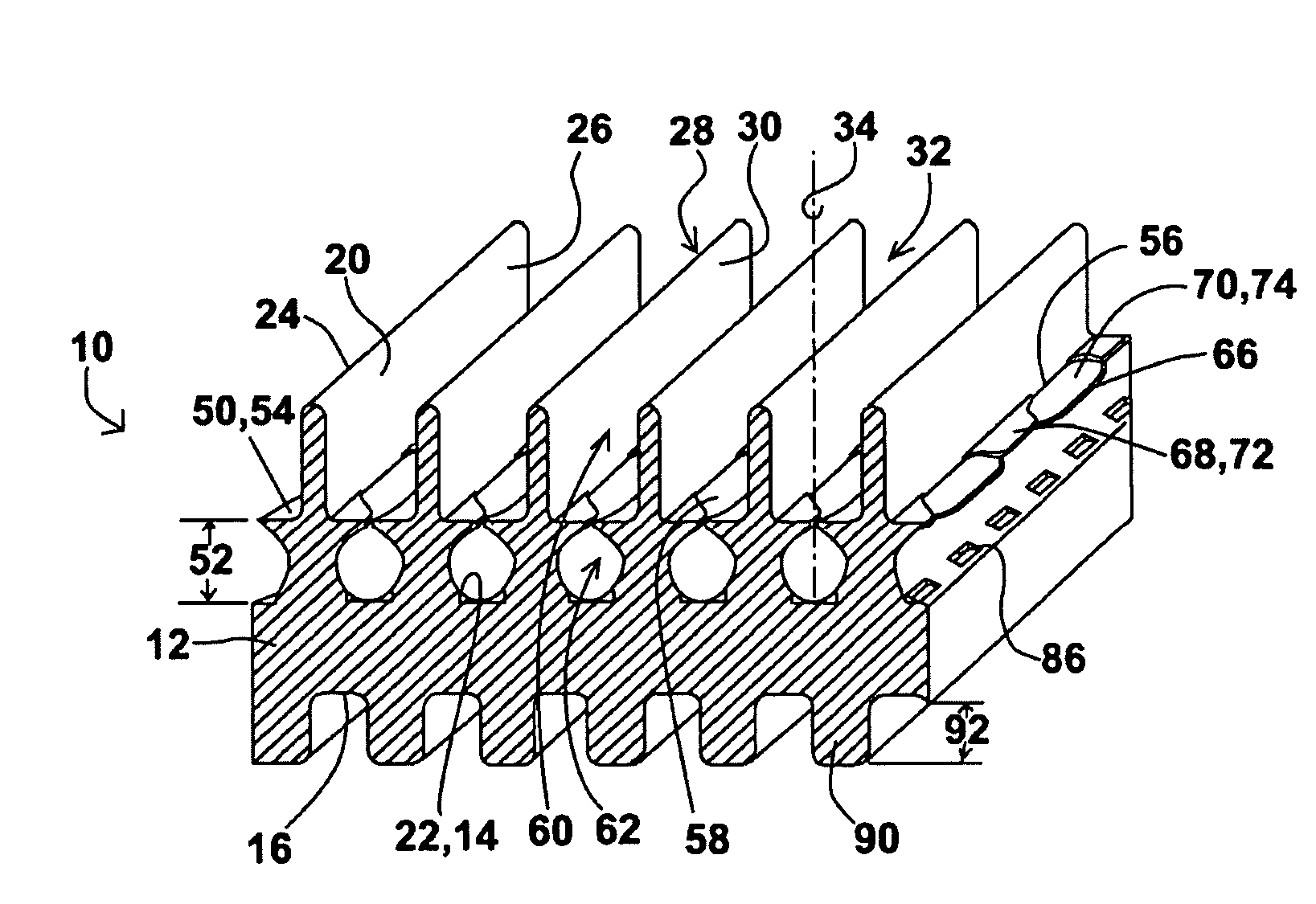

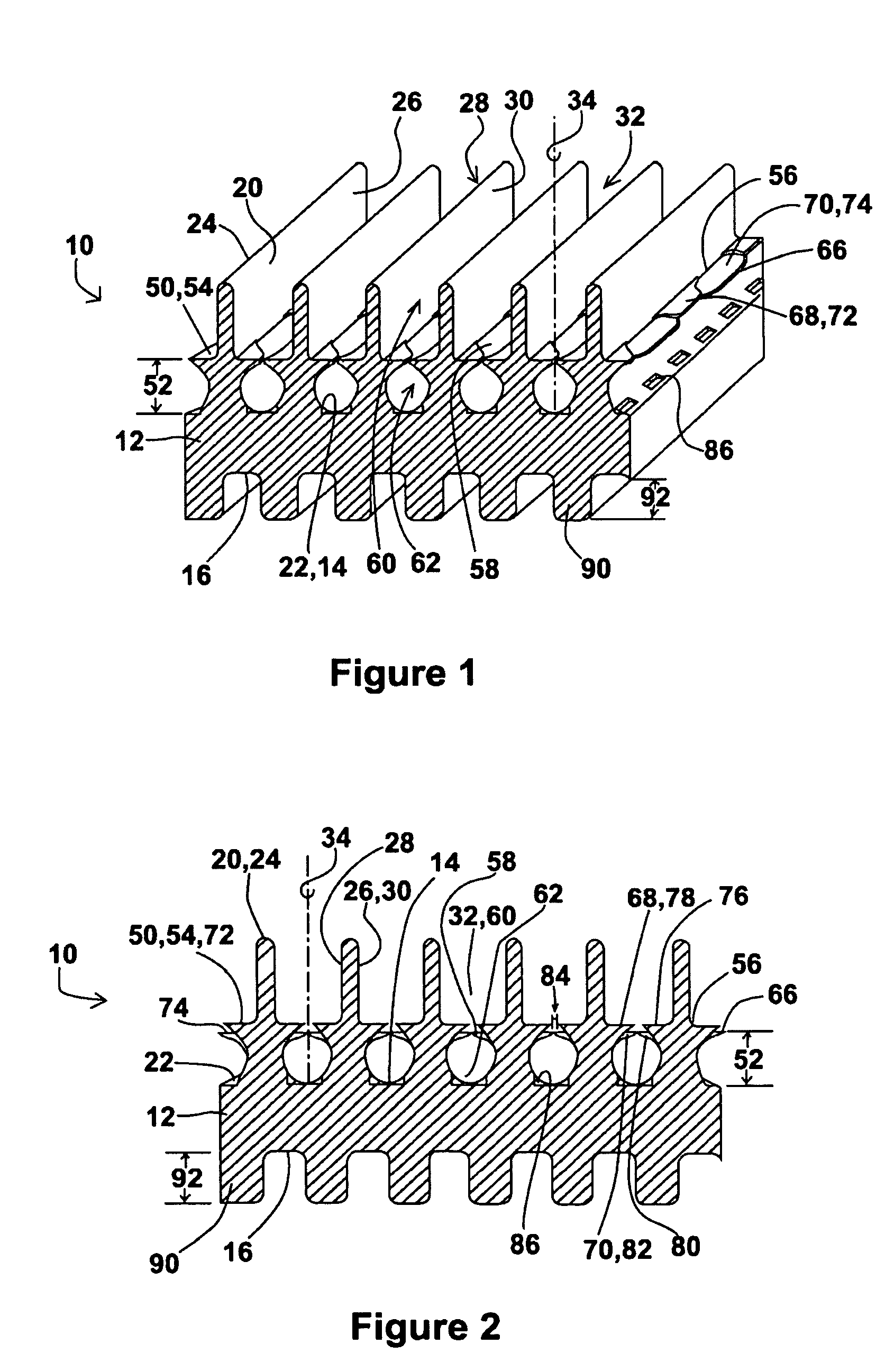

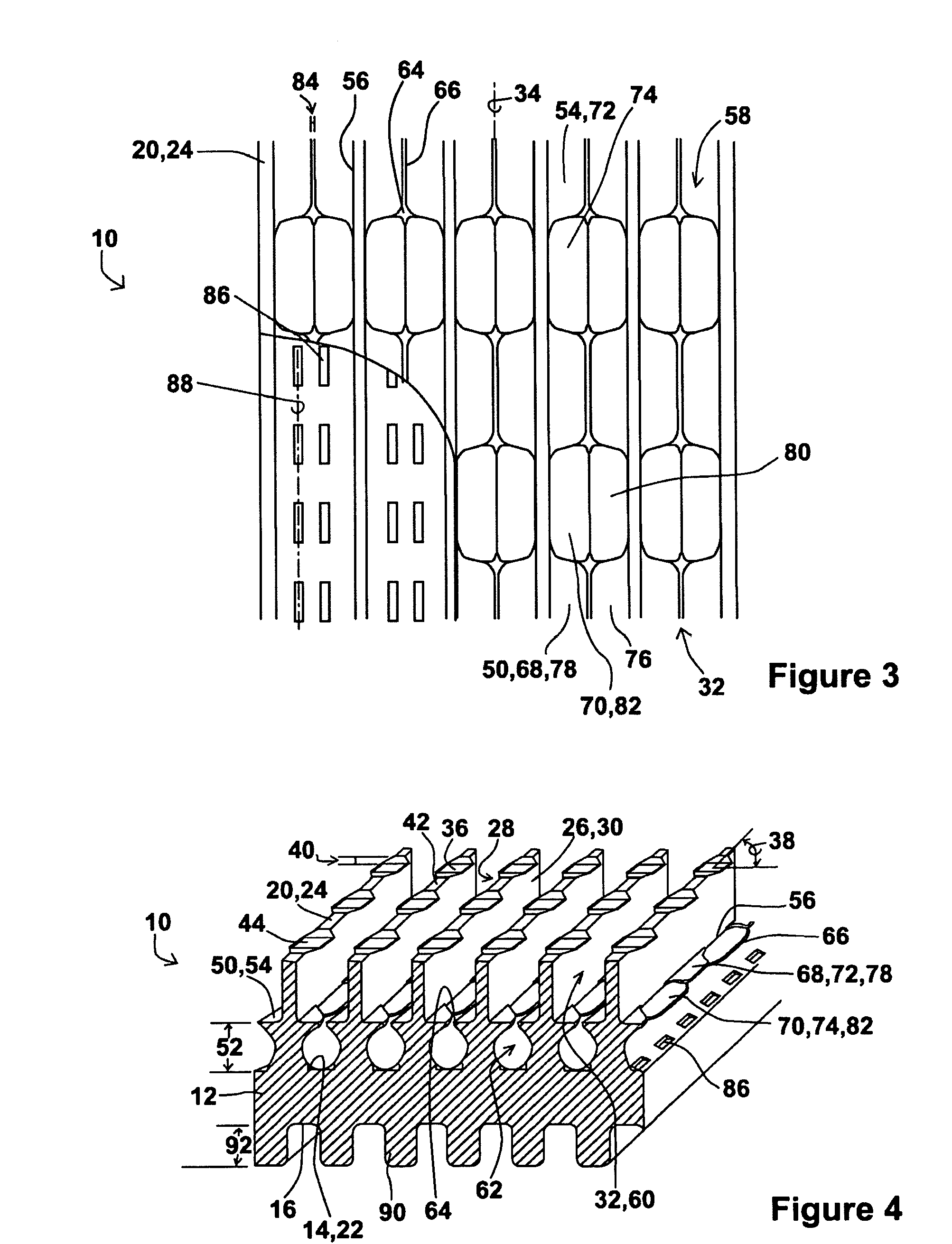

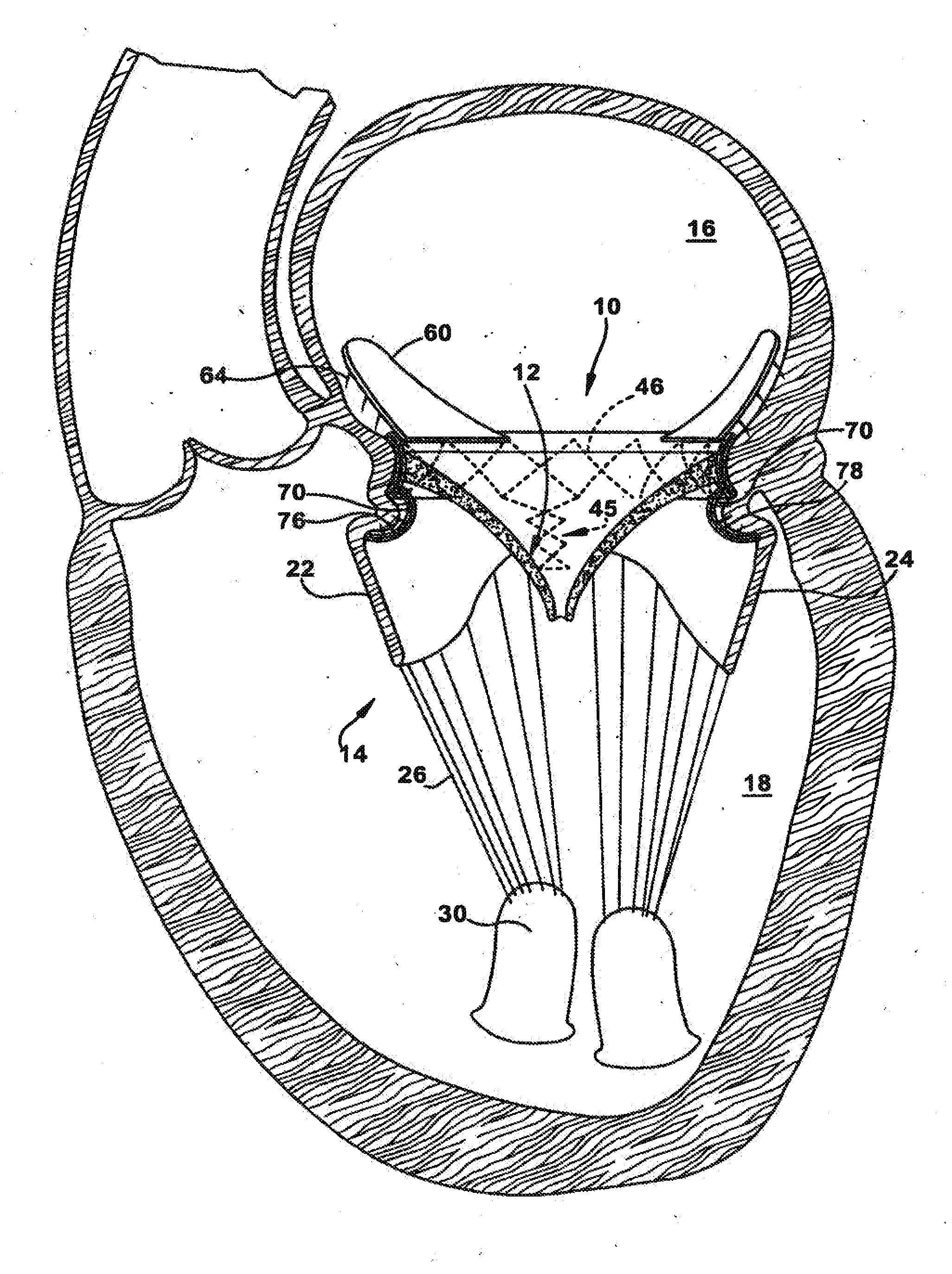

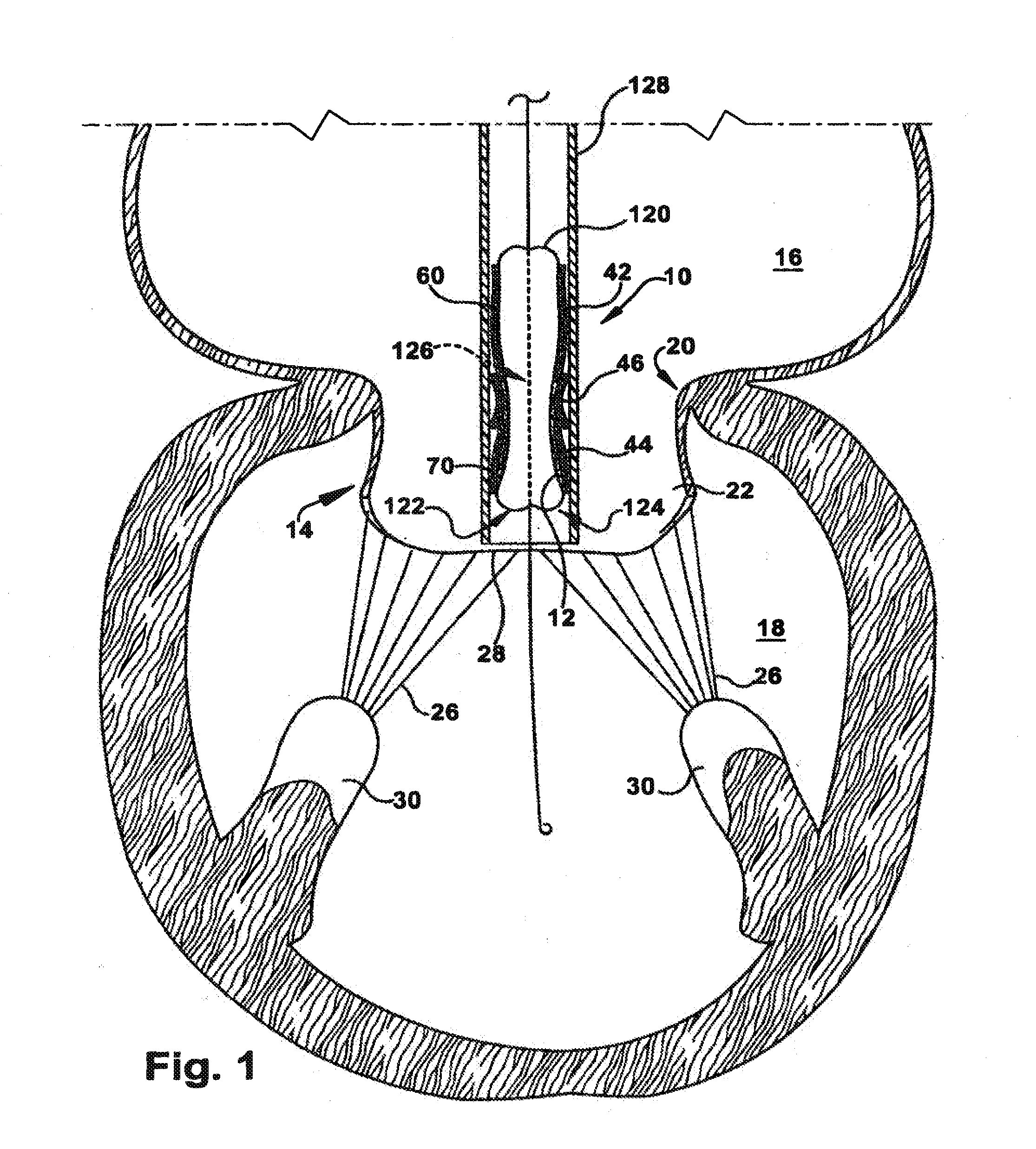

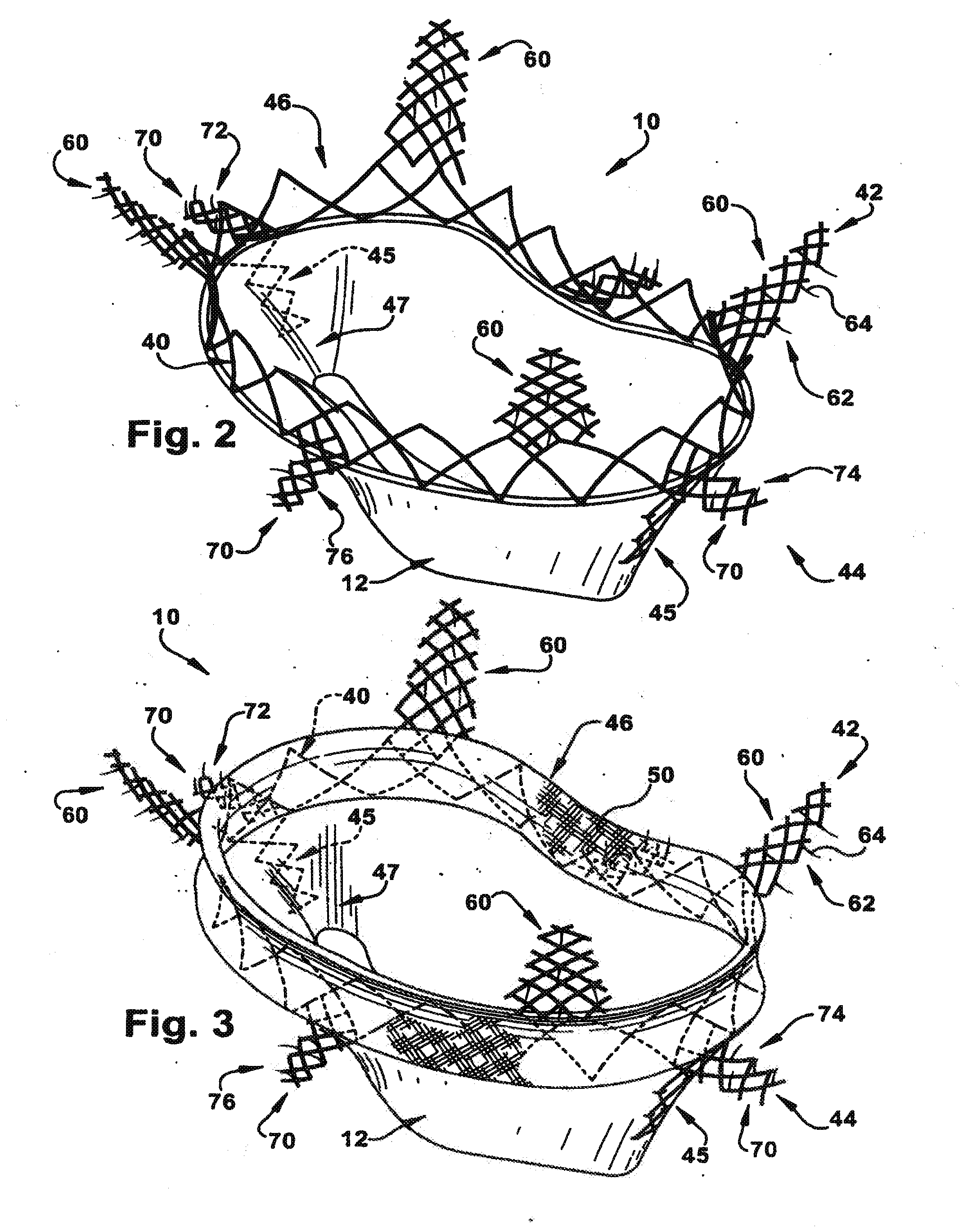

Apparatus and methods for replacing a cardiac valve

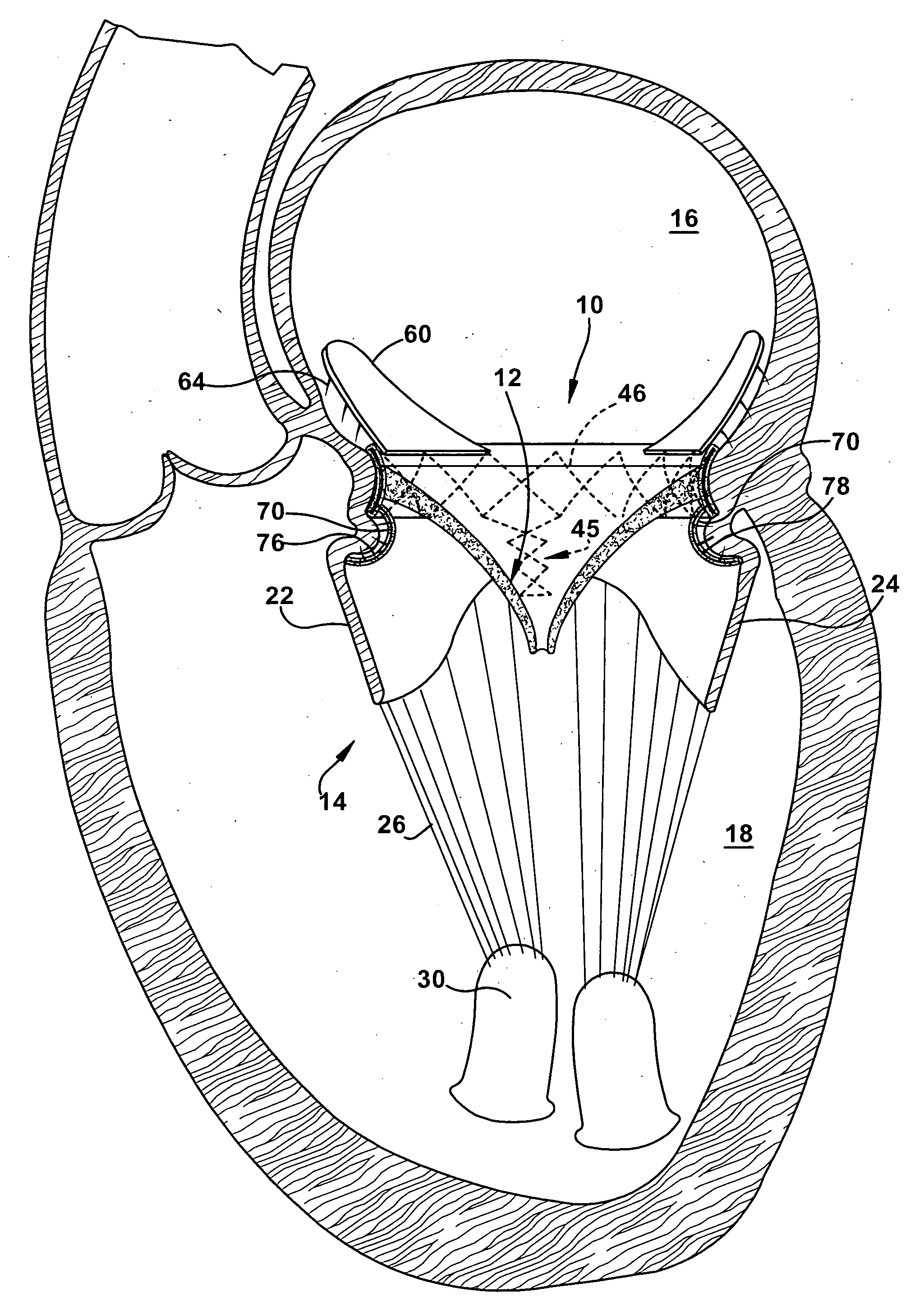

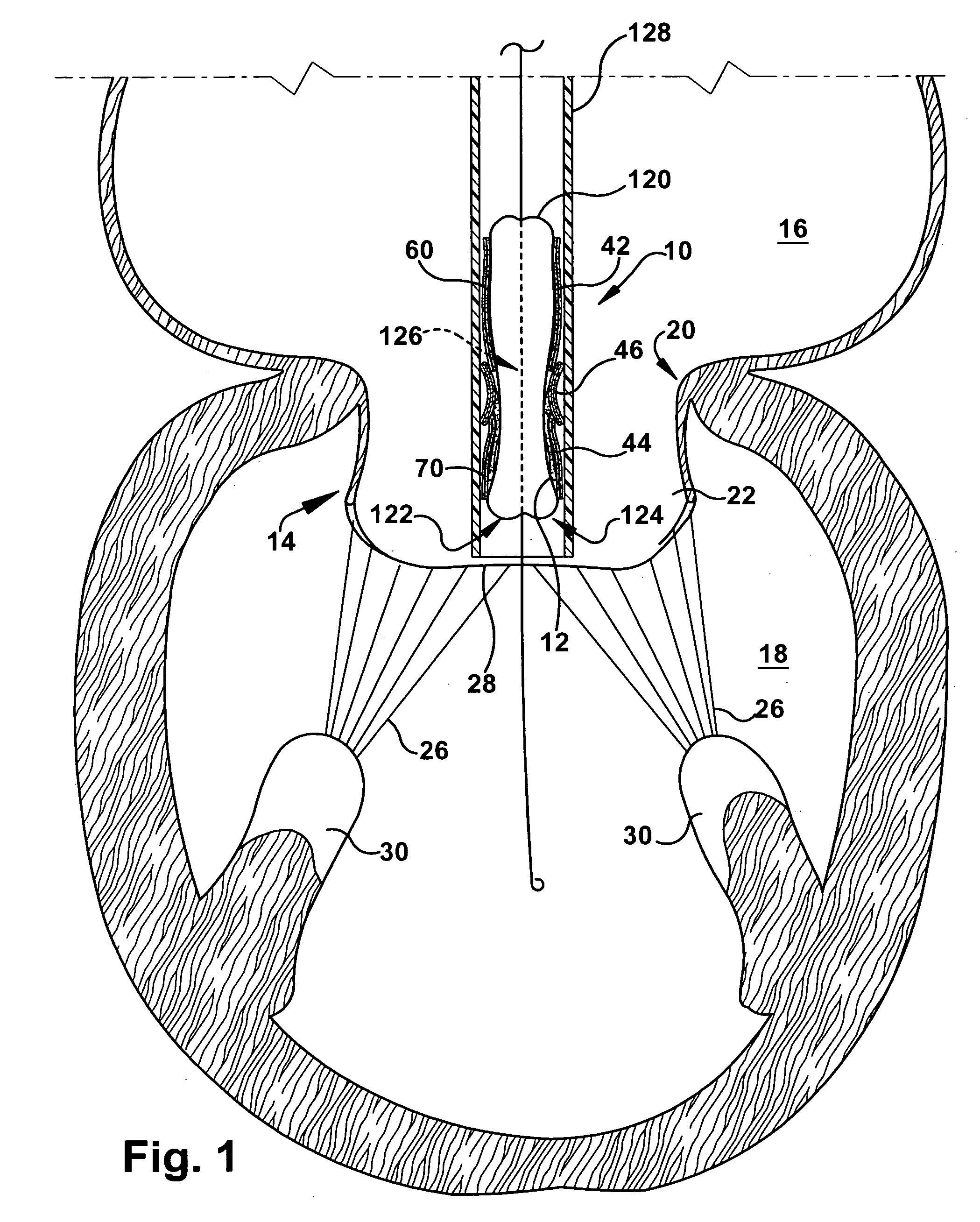

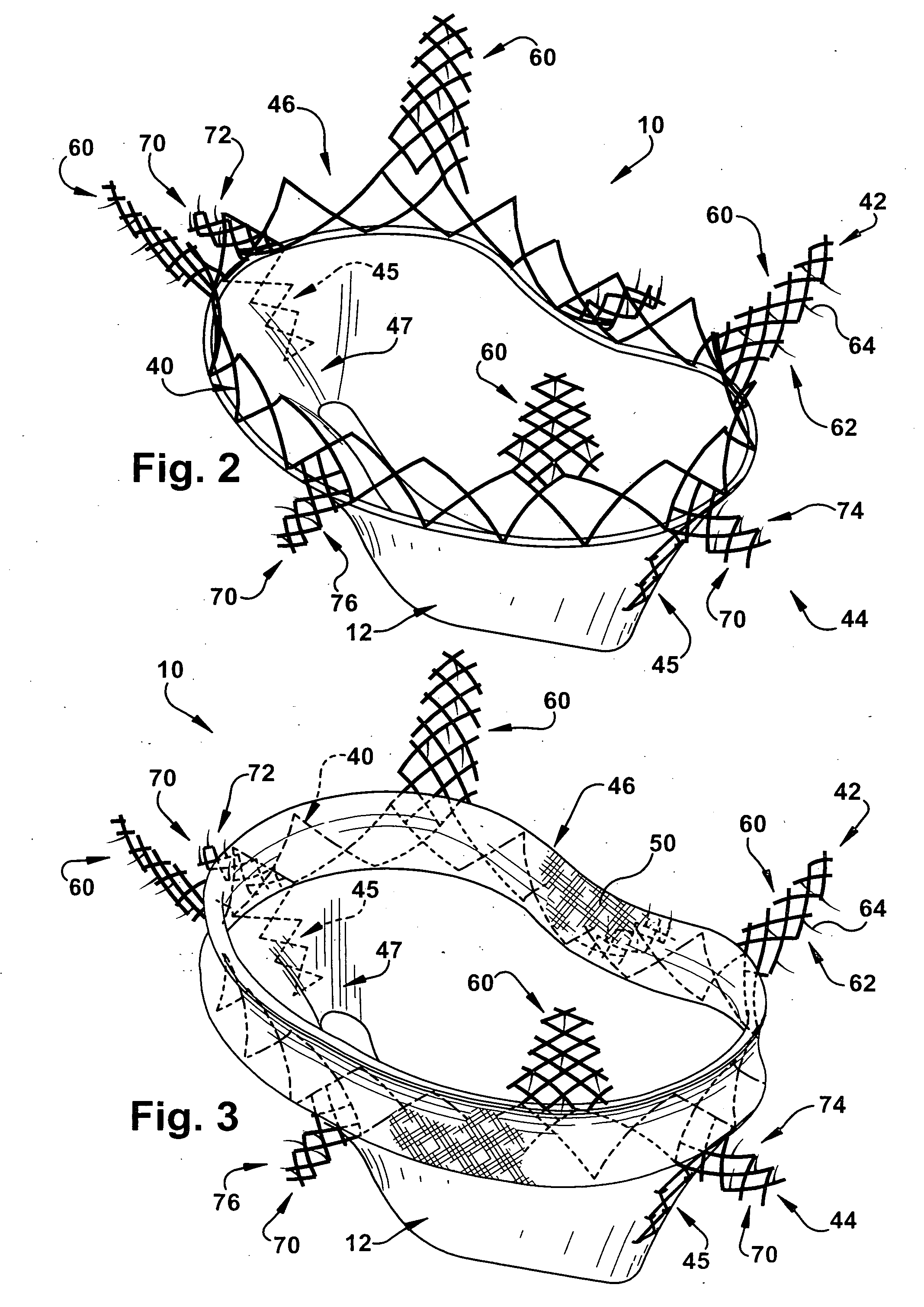

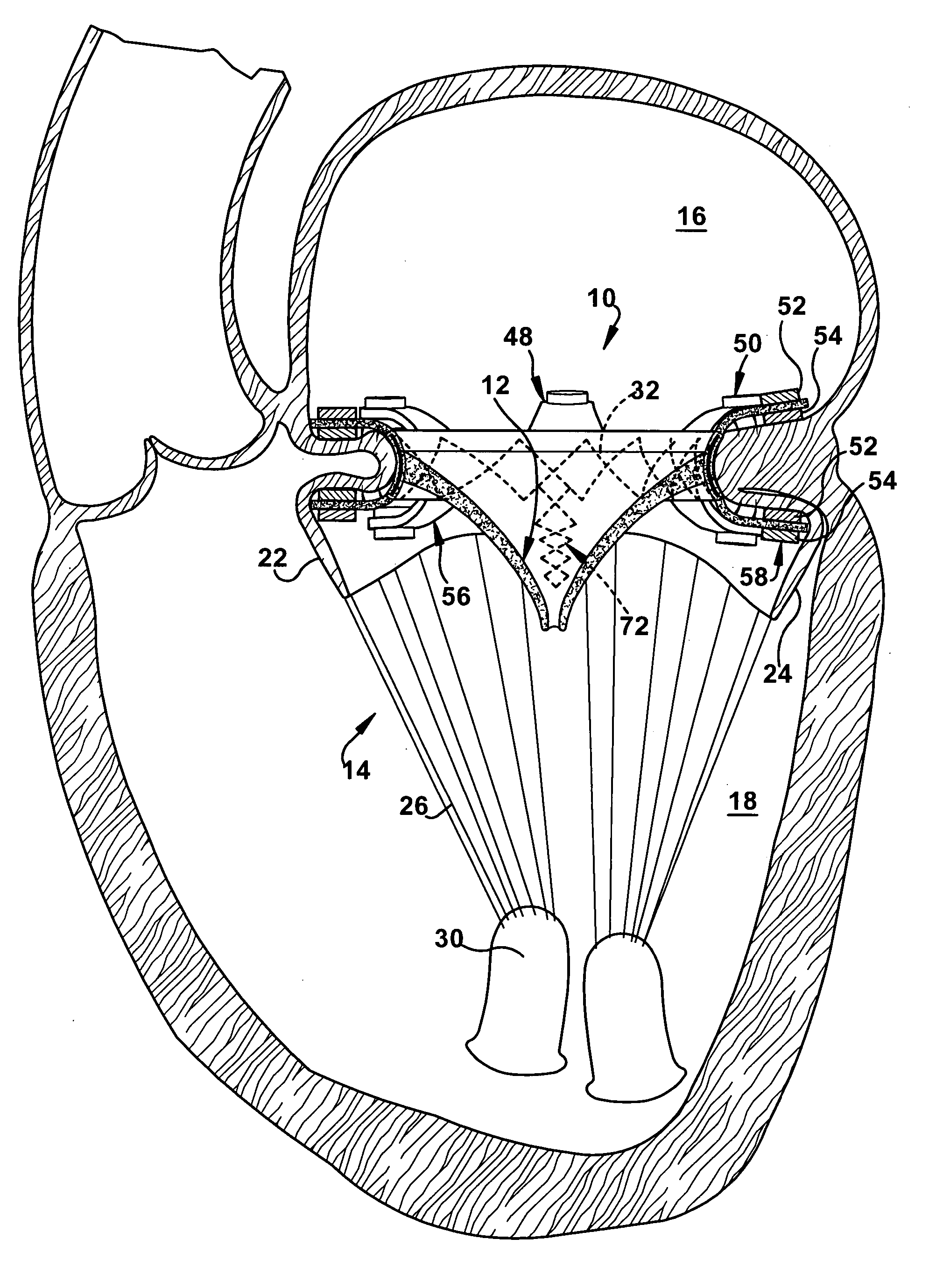

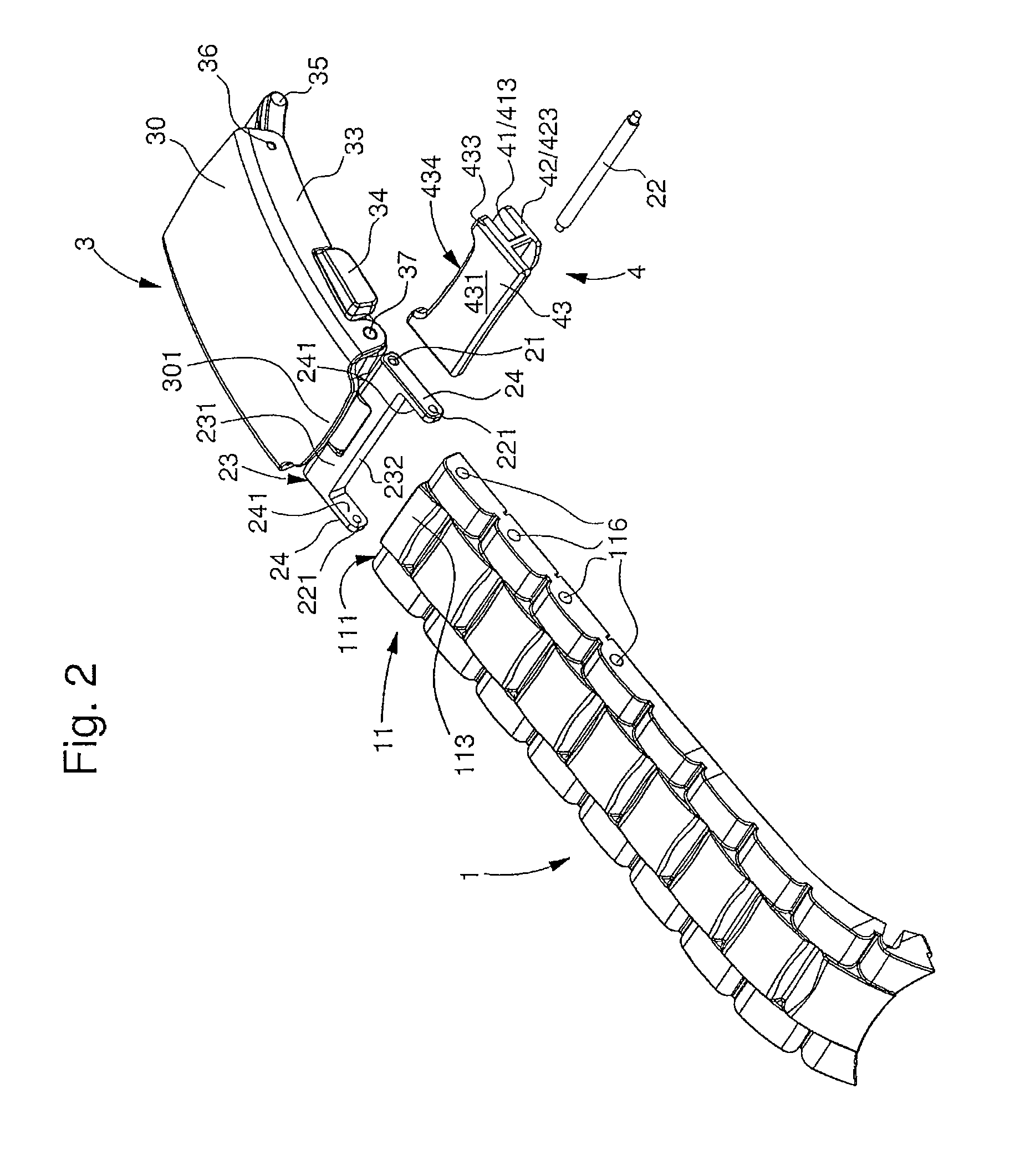

An apparatus and method for replacing a cardiac valve includes an expandable support member having oppositely disposed first and second ends, a main body portion extending between the ends, and a prosthetic valve within the main body portion. The main body portion has an annular shape for expanding into position in the annulus of the valve. The first and second ends include a plurality of upper and lower wing members movable from a collapsed condition into an extended condition for respectively engaging a first section of cardiac tissue surrounding the valve and for engaging a portion of the native valve leaflets to pin the leaflets back against the annulus. The second end further includes at least two strut members spaced apart from each other. A respective one of the strut members is attached to at least one commissural section of the prosthetic valve to prevent prolapse of the valve leaflets.

Owner:THE CLEVELAND CLINIC FOUND

Apparatus and method for replacing a cardiac valve

An apparatus for replacing a cardiac valve having at least two native valve leaflets includes an expandable support member with oppositely disposed first and second ends and a main body portion extending between the ends. The first and second ends respectively include a plurality of upper and lower wing members respectively having first and second magnetic components. The wing members extend from the main body portion and are spaced circumferentially thereabout. Secured within the main body portion is a prosthetic valve having at least two valve leaflets. The second end further includes at least two strut members spaced apart from each other and attached to at least one commissural section of the prosthetic valve. The magnetic components are magnetically attracted to one another so that, when the apparatus is placed in the valve annulus, the wing members are pulled toward one another to secure the prosthetic valve in the annulus.

Owner:THE CLEVELAND CLINIC FOUND

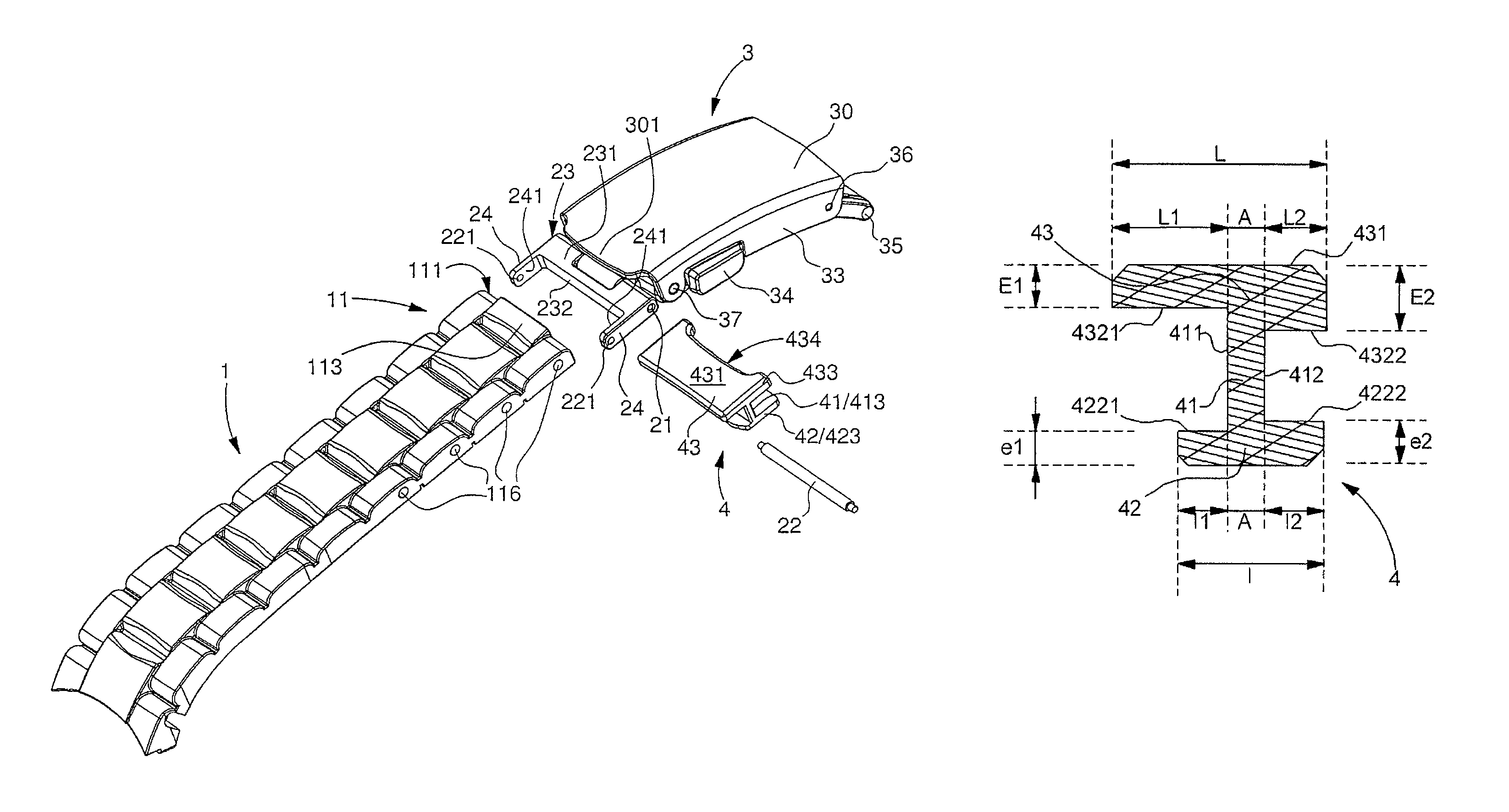

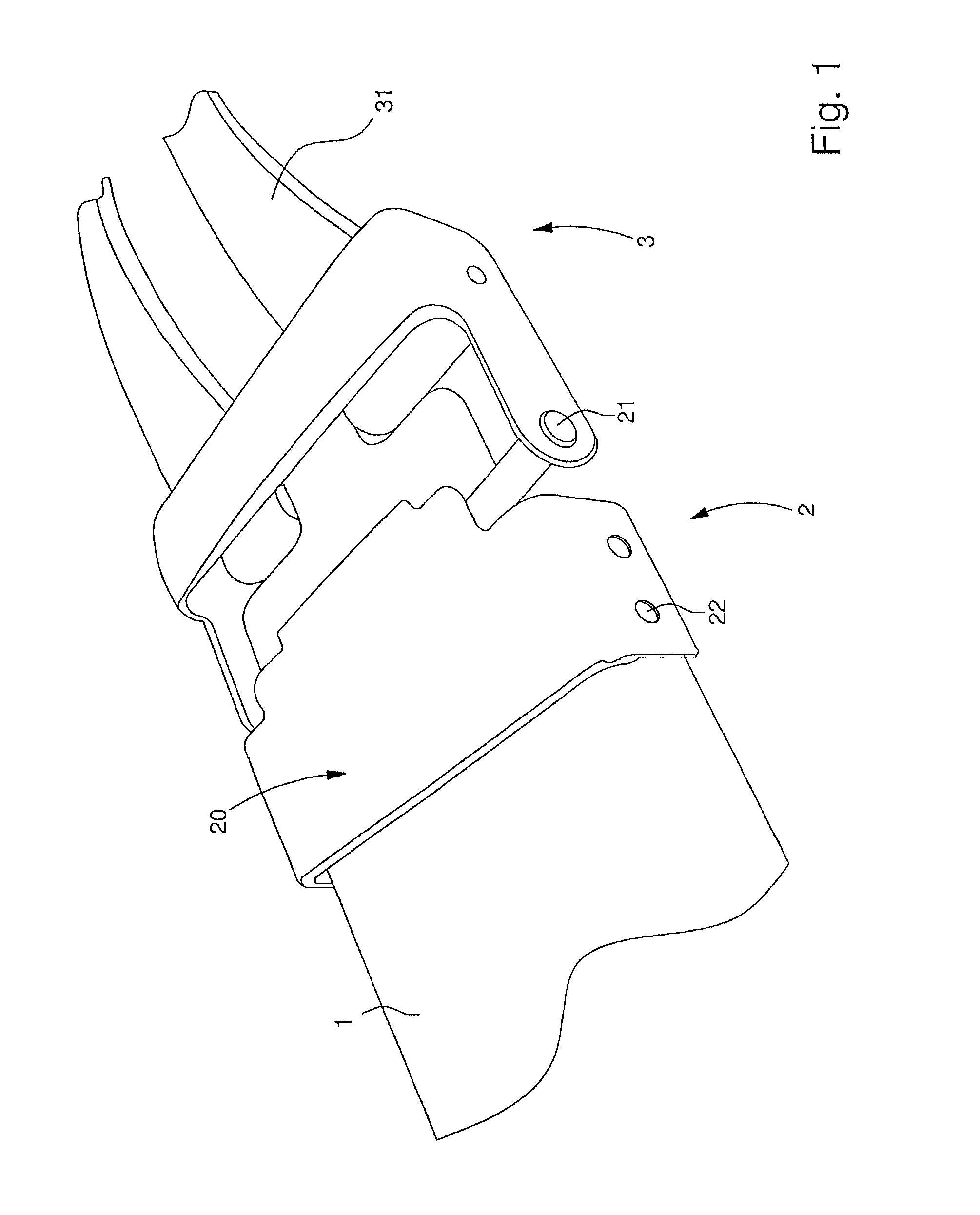

Anti-rotation link

ActiveUS8601784B2Easy to adjust the lengthImprove aestheticsBraceletsWrist-watch strapsLower wingUpper wing

Link for a wristwatch, characterized in that it comprises a central core connecting a lower wing and an upper wing.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

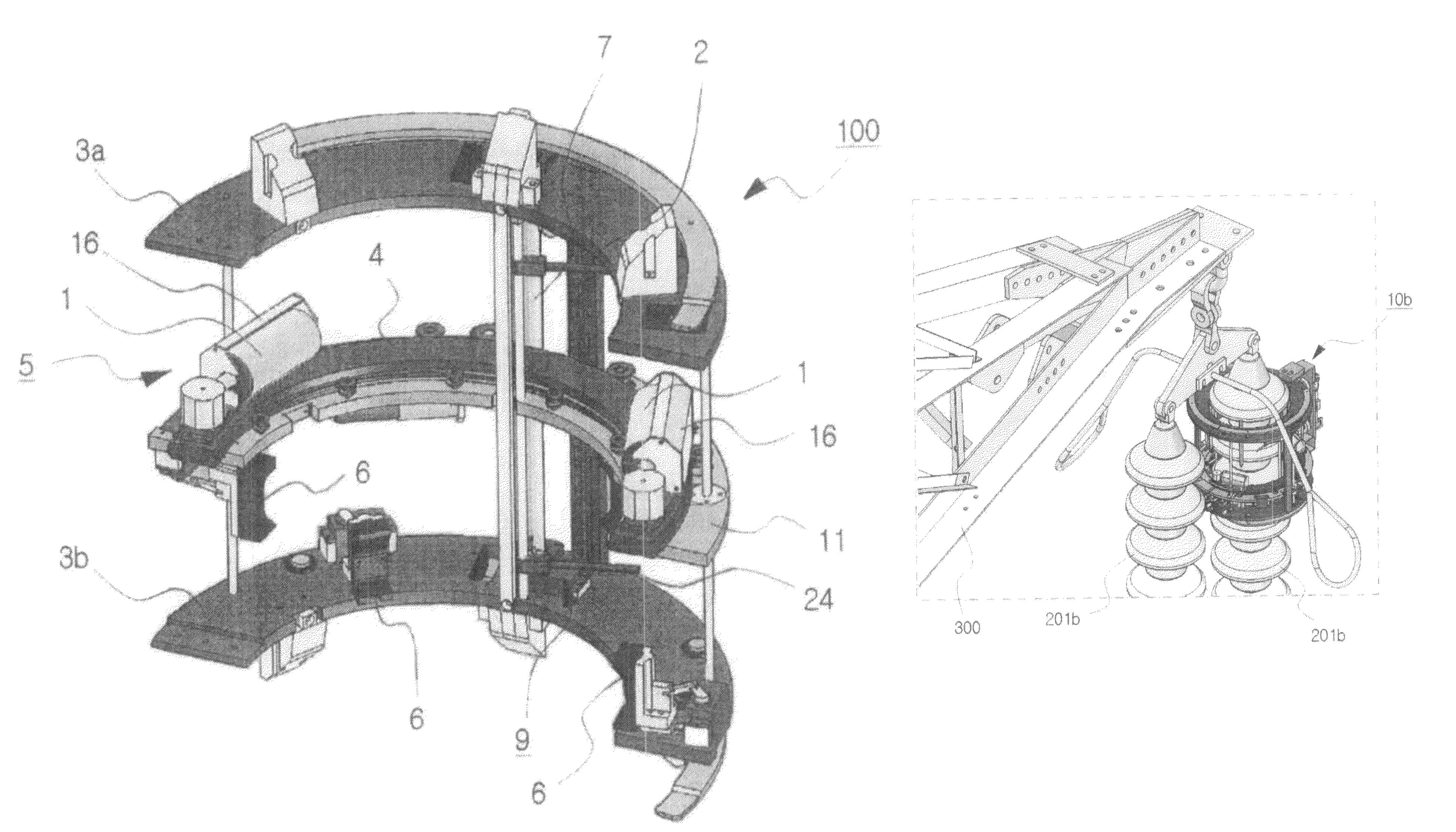

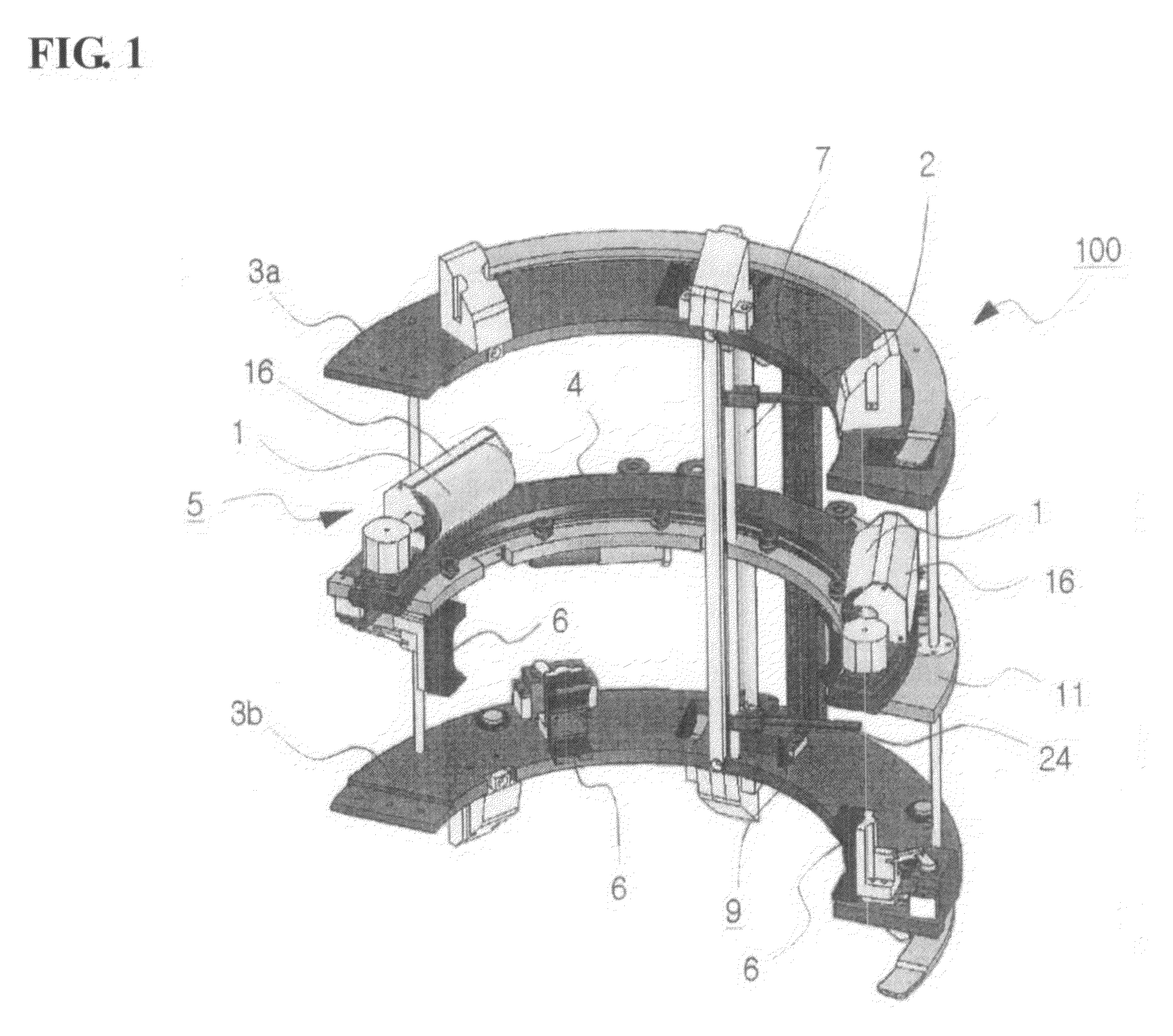

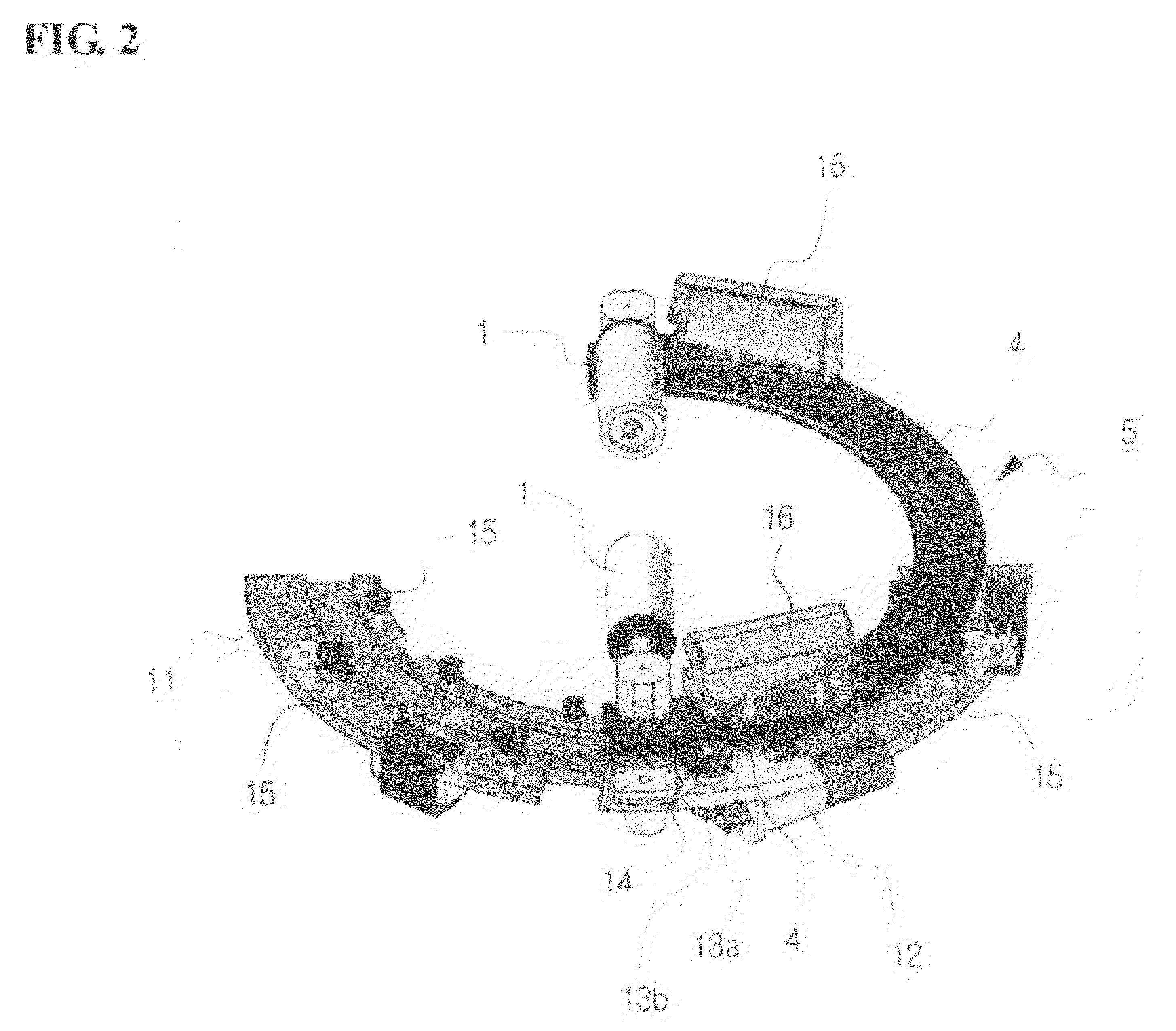

Robot mechanism for cleaning and inspection of live-line insulators

ActiveUS20080301891A1Improve efficiencyImprove securityBowling gamesCarpet cleanersBall bearingMechanical engineering

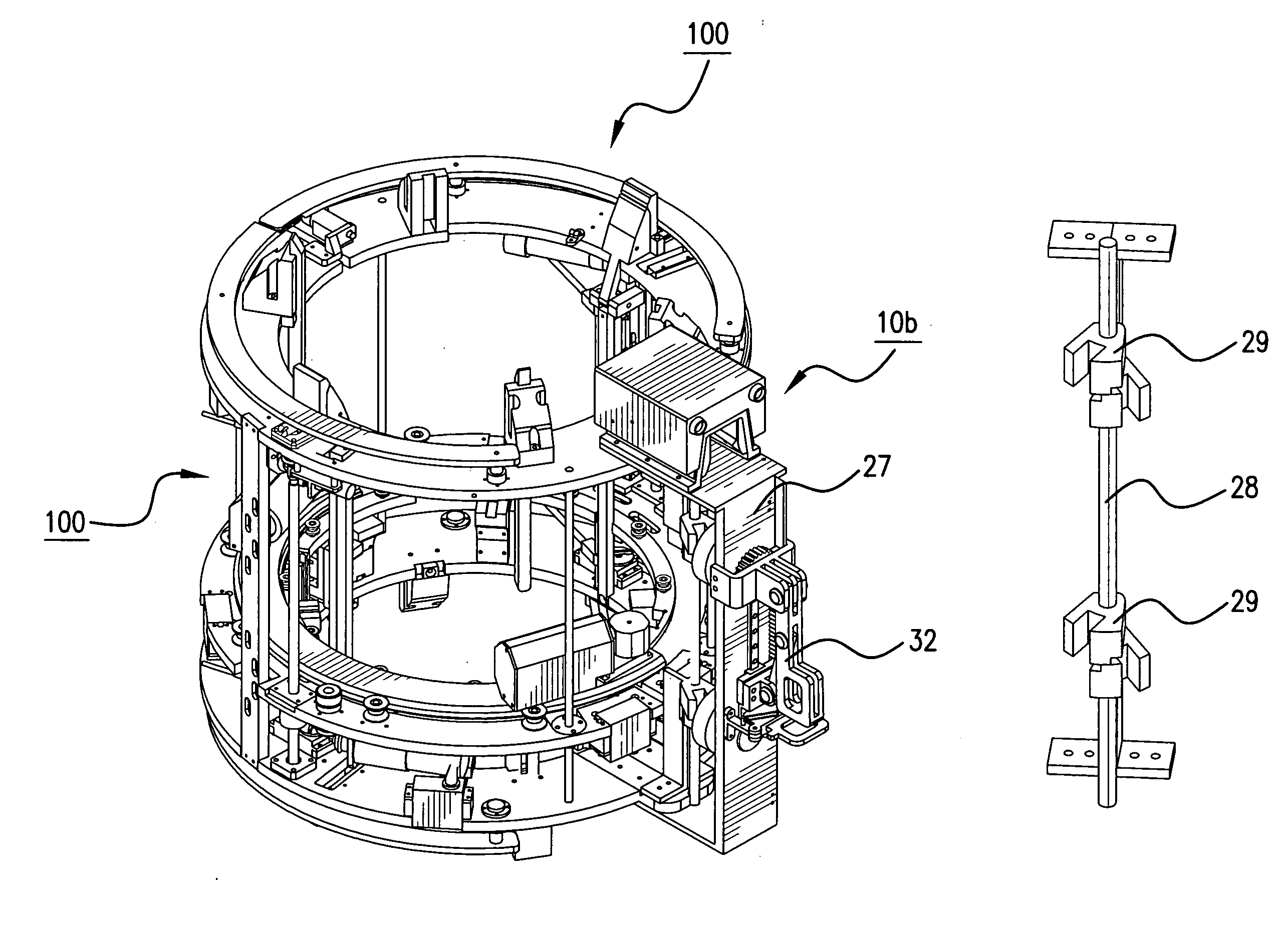

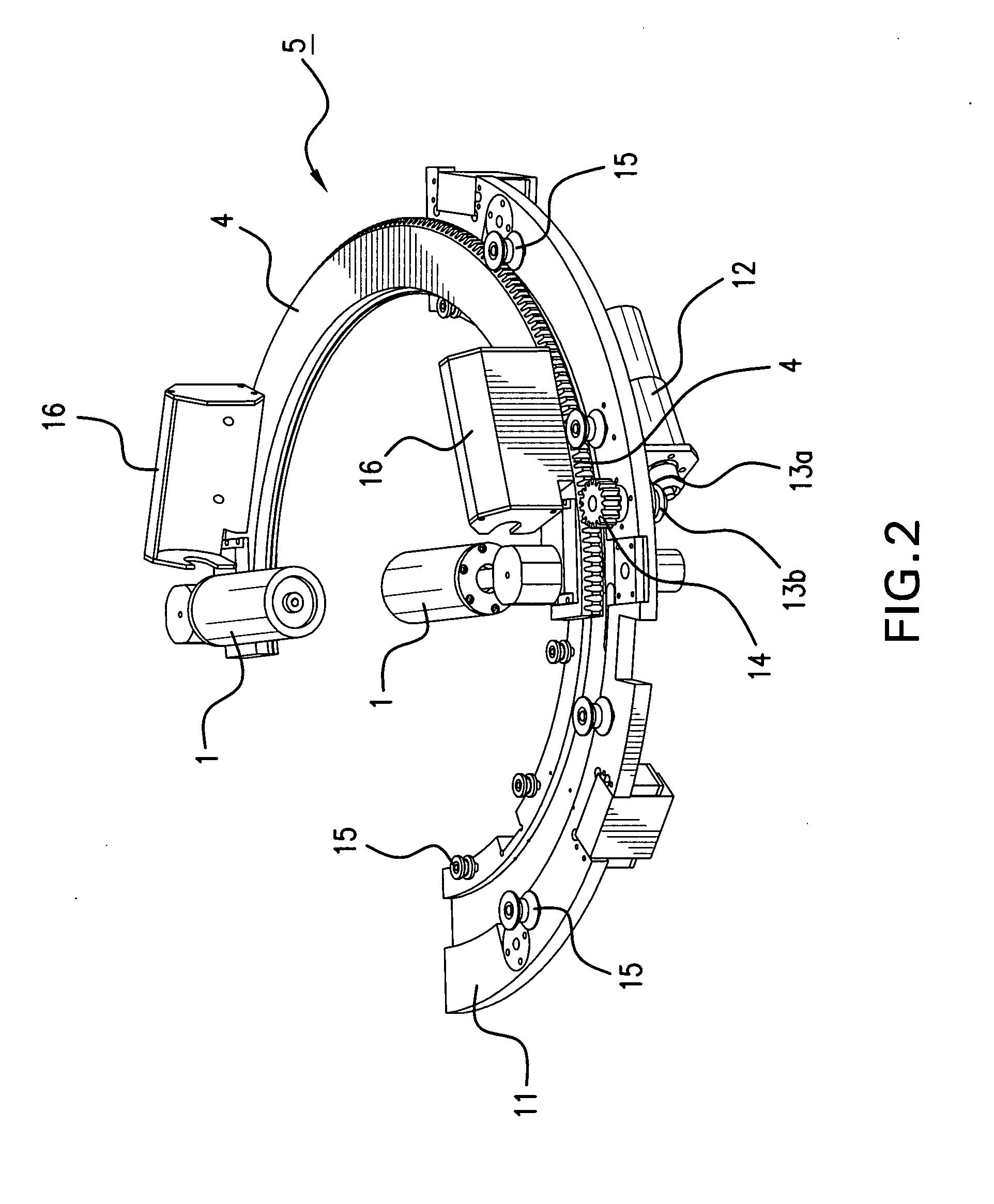

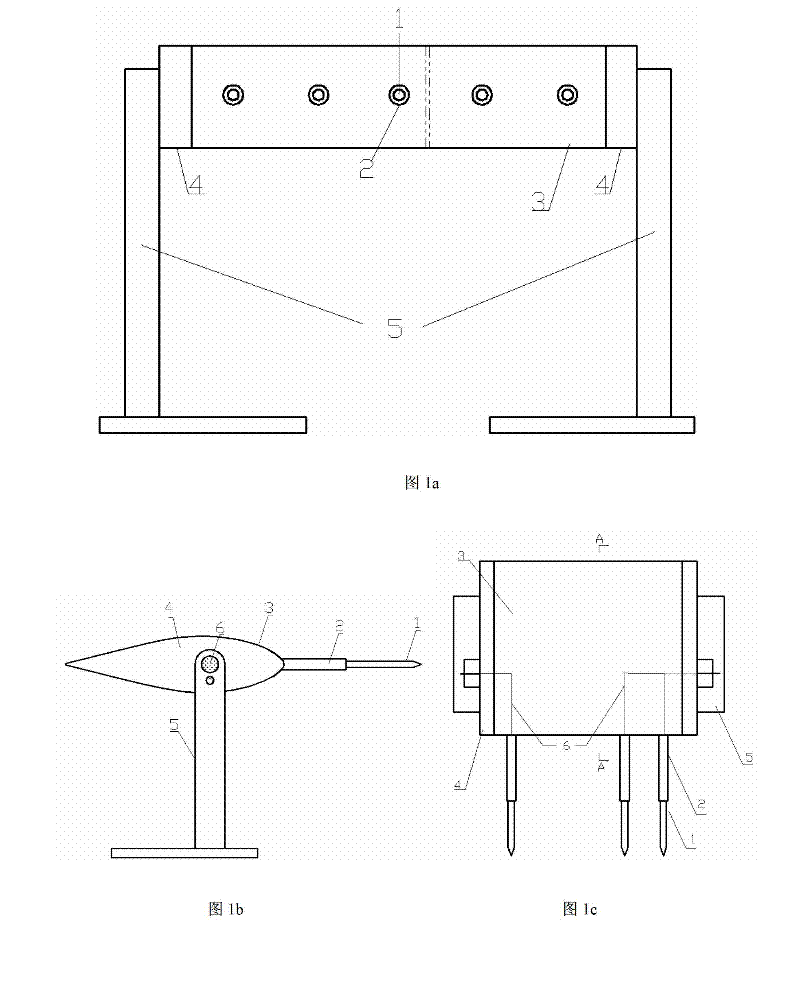

A robot mechanism adopts a dry cleaning method to clean the surface of live-line insulators without: using water and can perform cleaning and inspection of the surface of the live-line insulators while automatically moving along an insulator string. The robot mechanism includes a main unit having upper and lower wing frames connected with each other by a connecting bracket to surround the insulator string, a cleaning unit disposed between the upper and lower wing frames and including a base frame to perform dry cleaning with a rotational brush and a CM guide, a lift unit including a clamp and a ball-bearing screw to move the main unit up or down, and an inspection unit to electrically inspect the insulators; and a coupling unit to couple a pair of the main units to allow the pair of main units to move along a tension insulator string or a suspension insulator string.

Owner:KOREA ELECTRIC POWER CORP

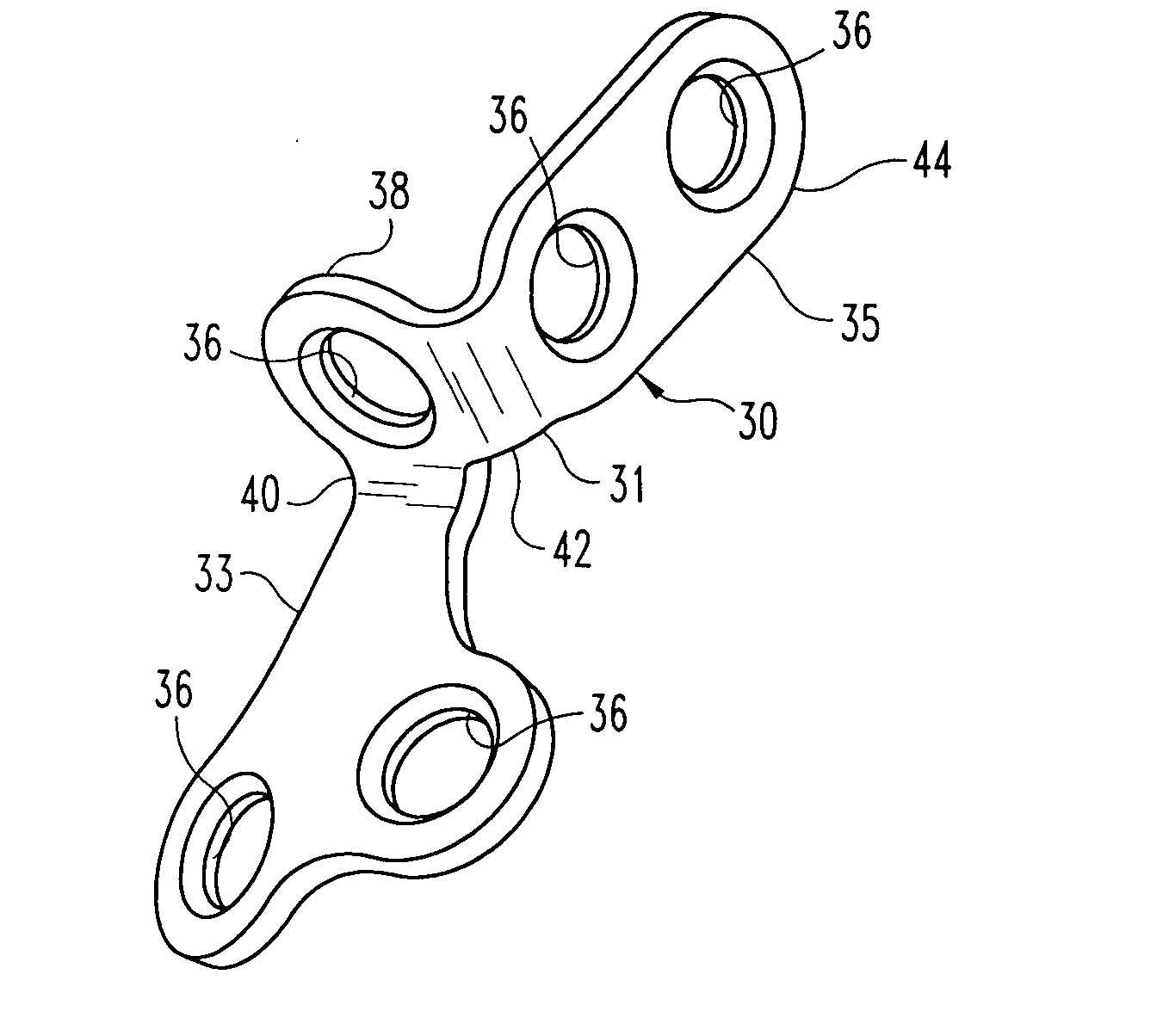

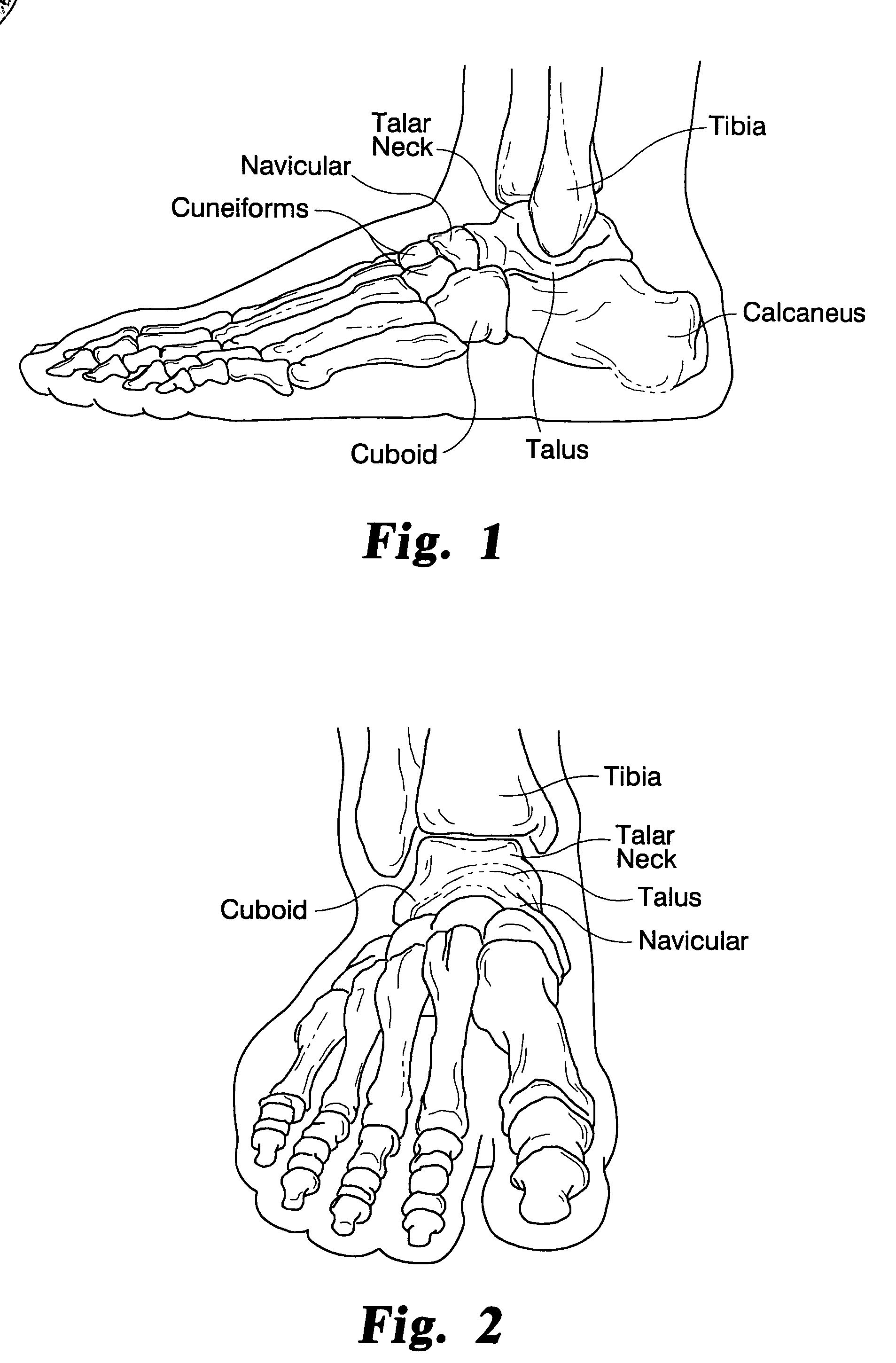

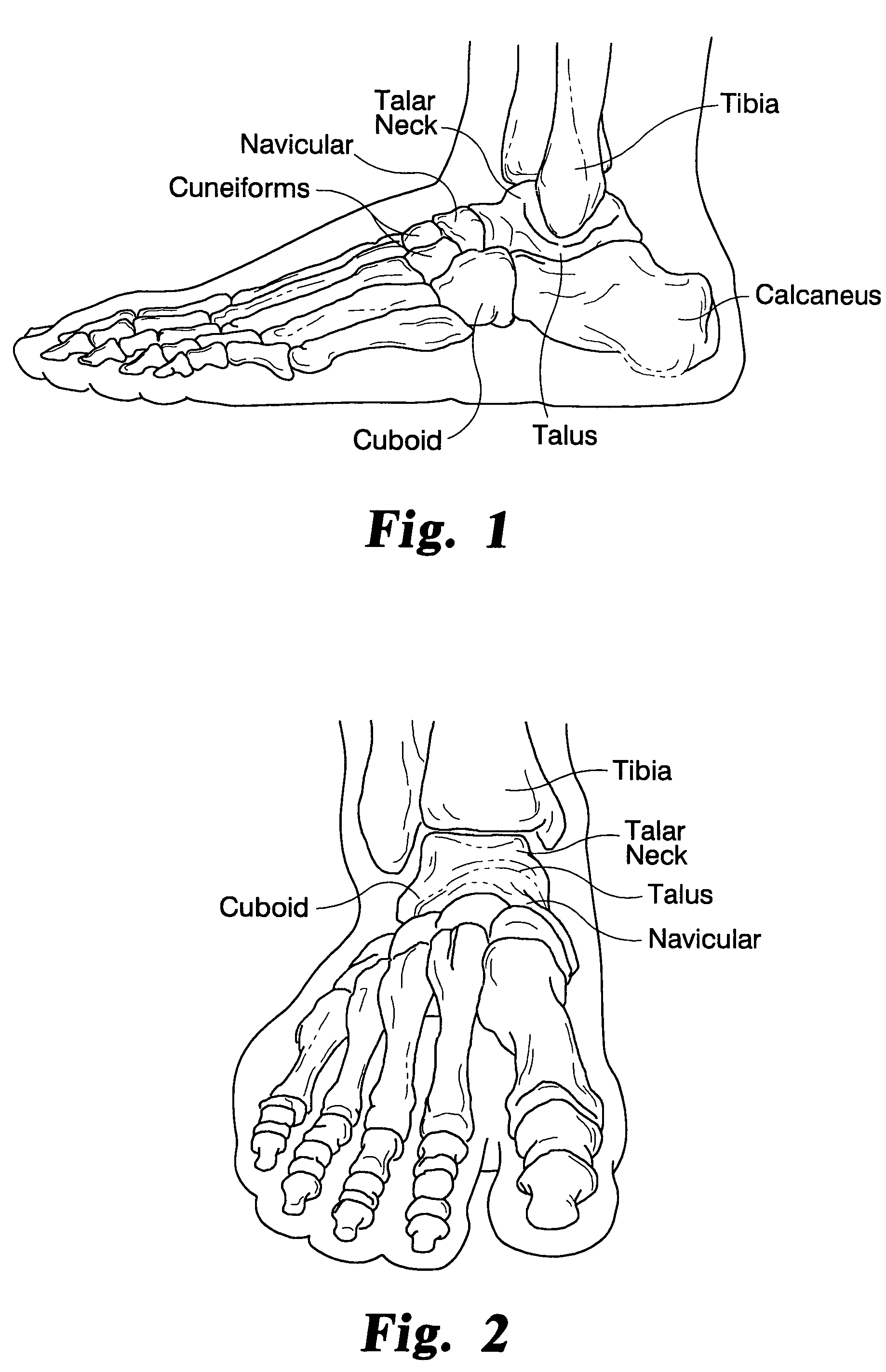

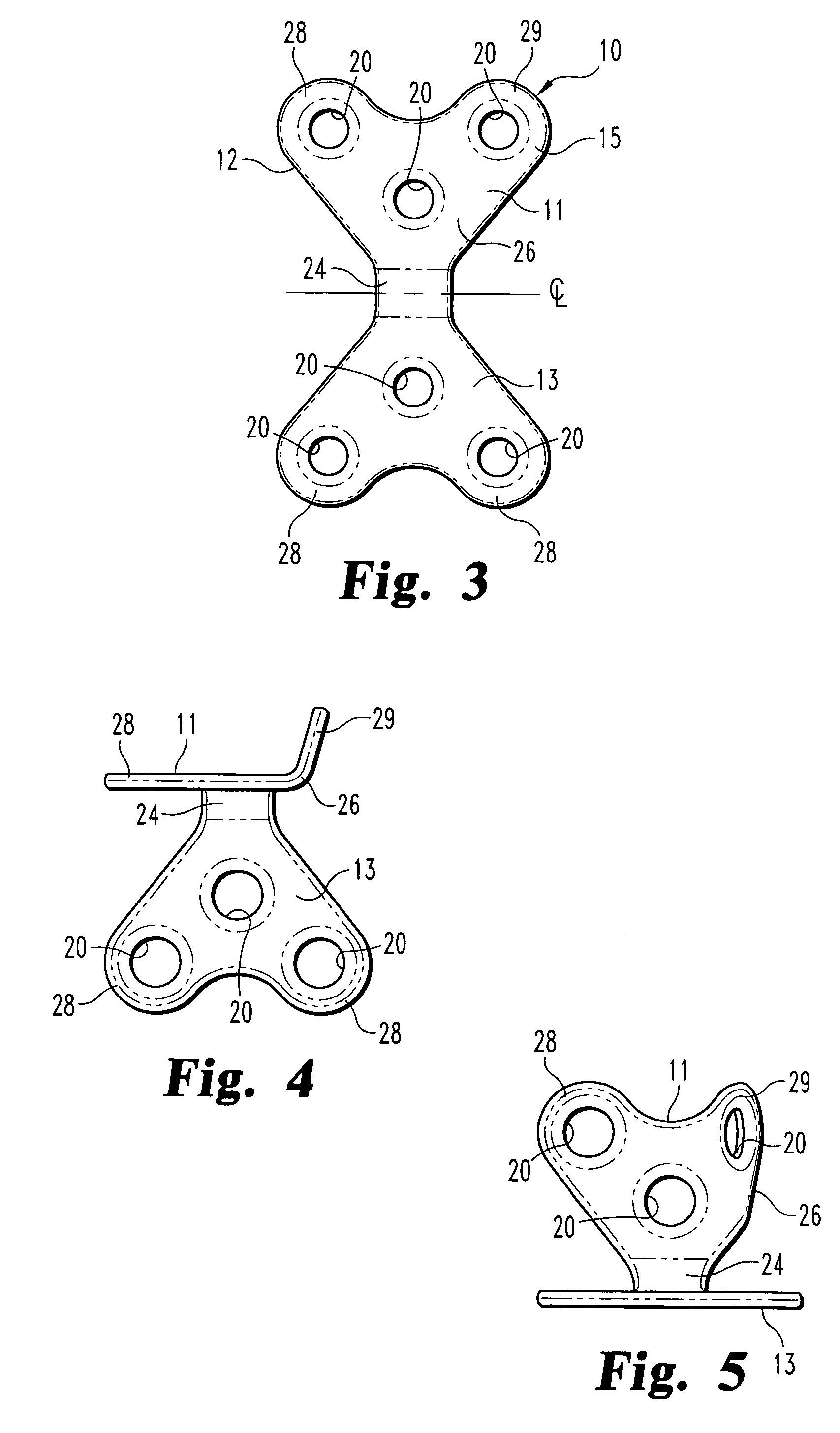

Fixation device for the talus

A fixation device for reduction and fixation of fractures of the talus bone of the foot includes a thin titanium alloy plate having a lower wing configured for attachment to the lateral aspect of the talus and an upper wing configured for attachment to the dorsal aspect of the talus. The plate includes a substantially perpendicular or right angle bend between the lower and upper wings. In one embodiment, each wing includes three screw holes arranged in a generally triangular pattern. Two holes on each plate are situated in tabs and the center of the plate has a reduced width so that the plate presents a minimal profile. One of the tabs on the upper wing is bent away from the lower wing at a pre-determined angle so that the wing conforms to the shape of the talus. In an alternative embodiment, the upper wing includes a step portion between the lower wing and the bent tab and carrying one screw hole. In this embodiment, the bent tab is generally elongated with one or two screw holes disposed along its length.

Owner:BIOMET CV

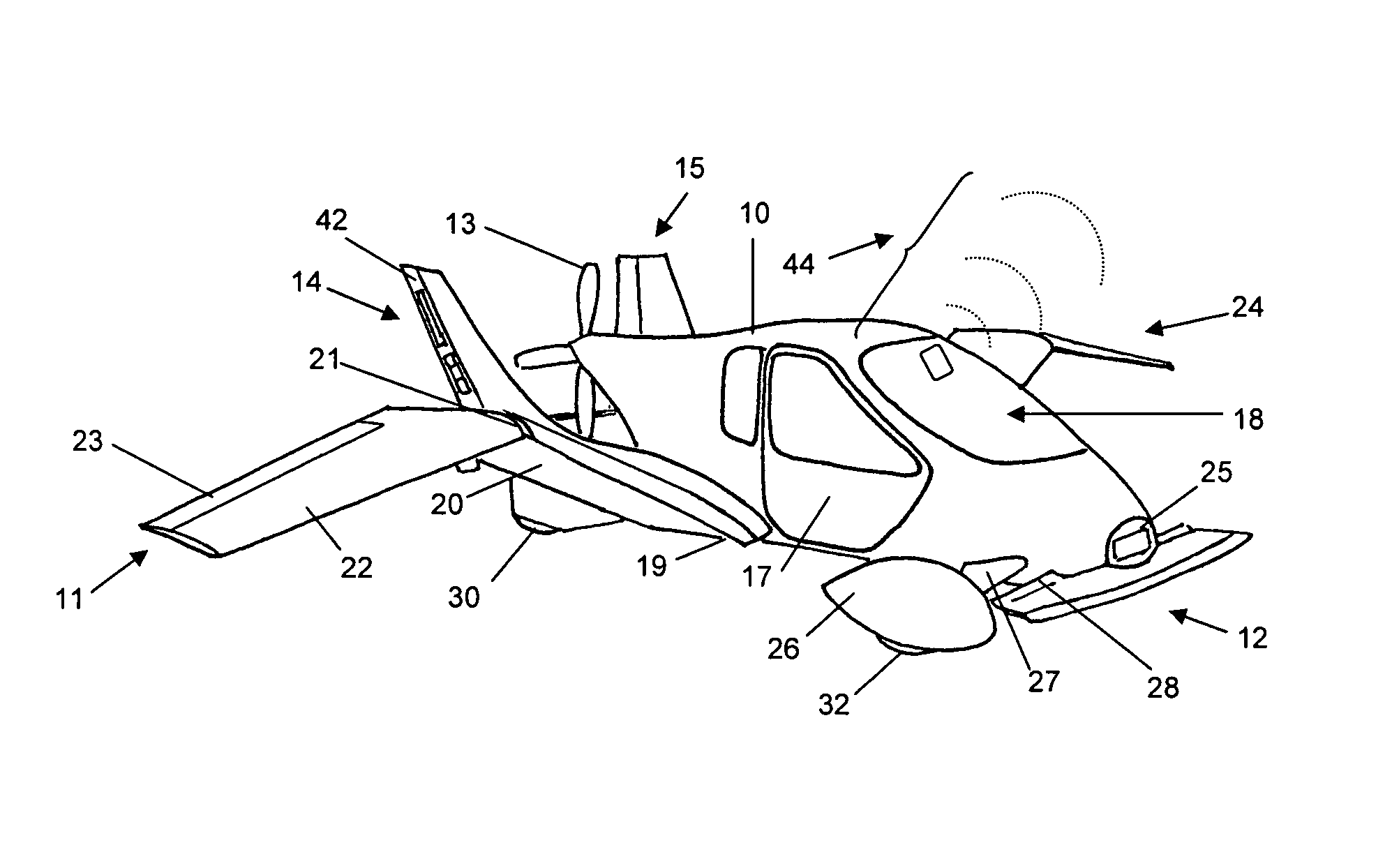

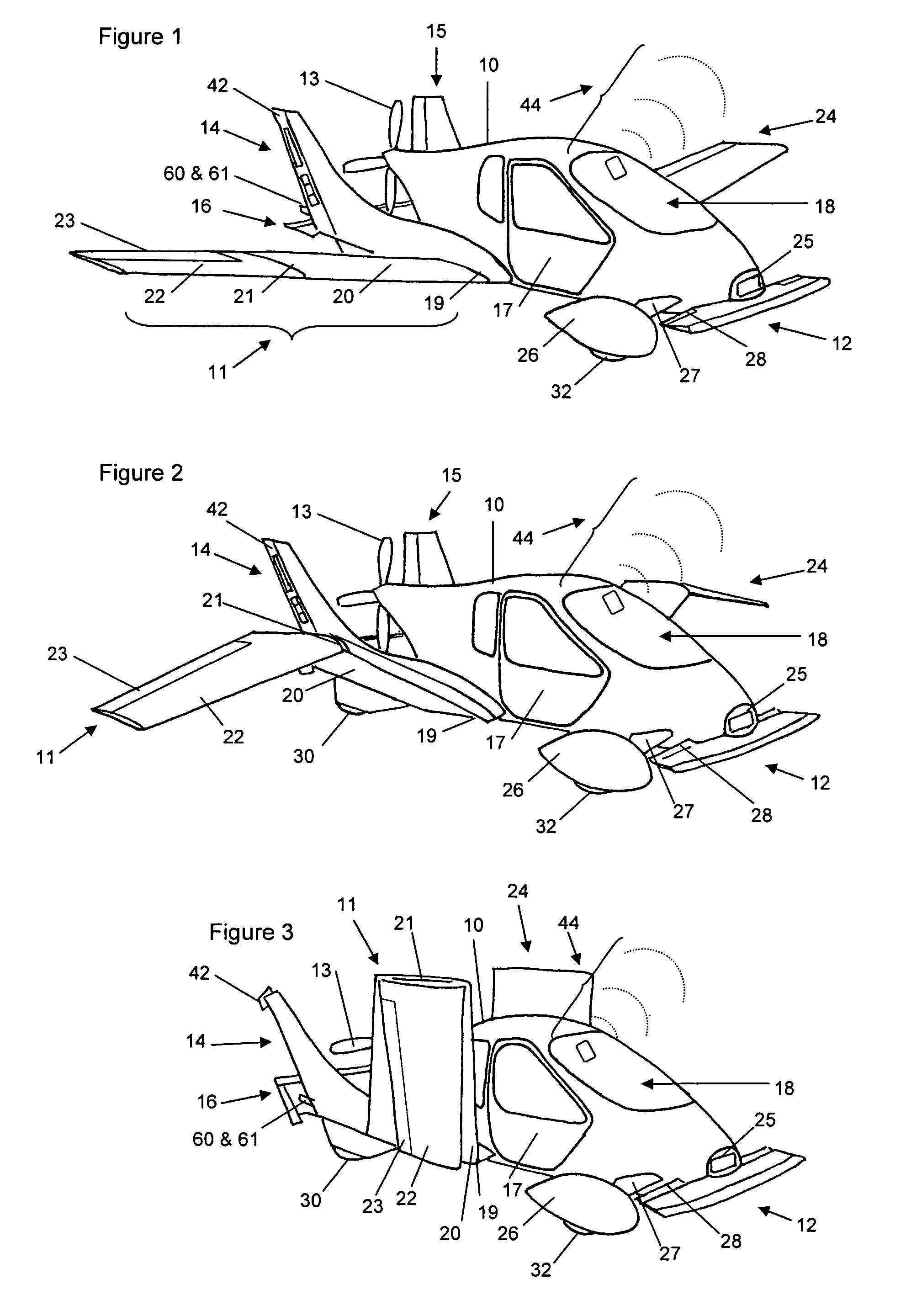

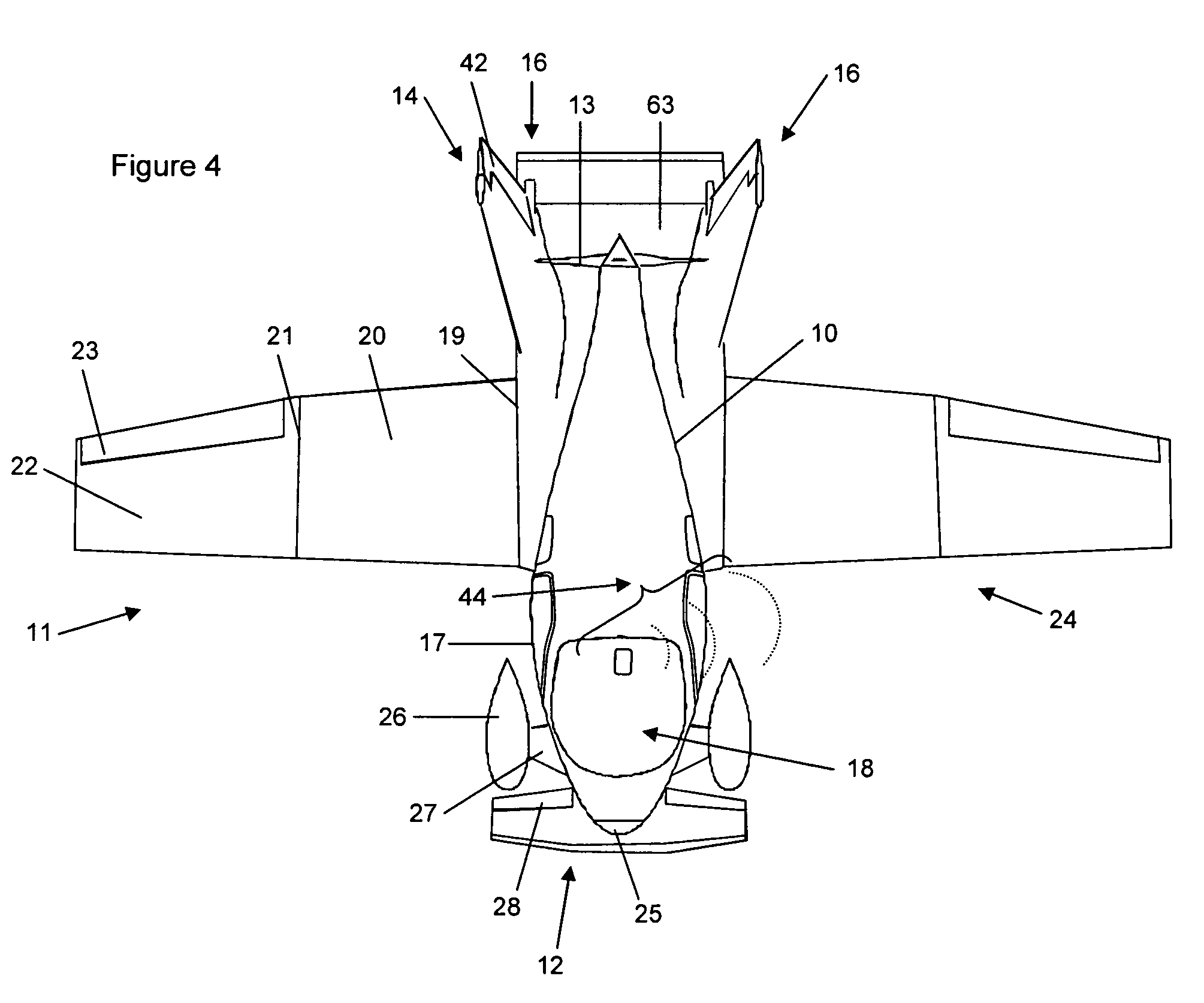

Roadable aircraft with folding wings and integrated bumpers and lighting

A low-wing, low-span canard aircraft with a protected pusher-style propeller is designed to transition simply between use in the air and use on the ground, without any mechanical effort on the part of the pilot. The vehicle may include deformable aerodynamic bumpers, embedded road-safety vehicle lighting and license plates, a protected propeller, and an integrated RFID airport access system. The vehicle may be designed for potential certification by the Federal Aviation Administration as a Light Sport Aircraft.

Owner:TERRAFUGIA

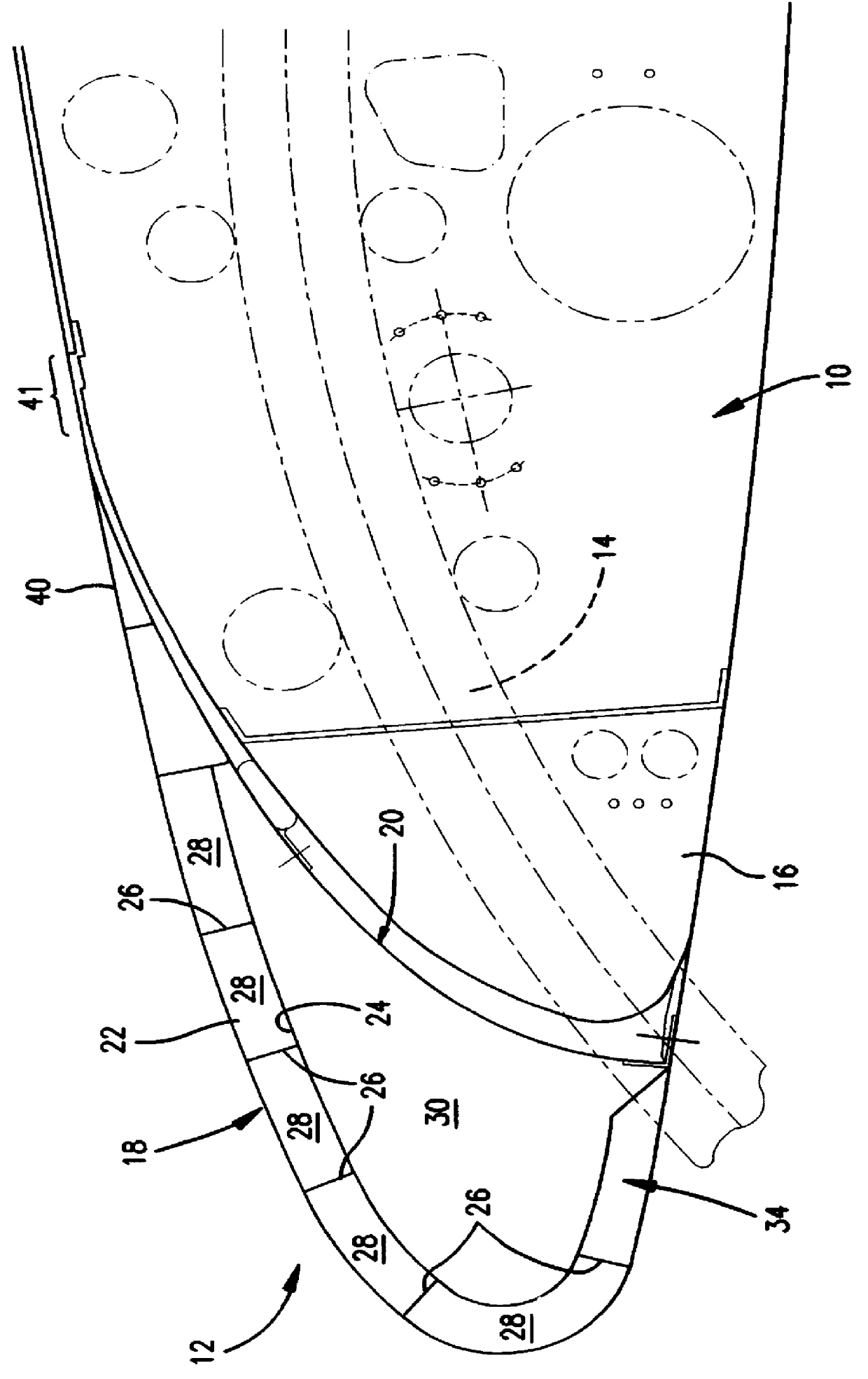

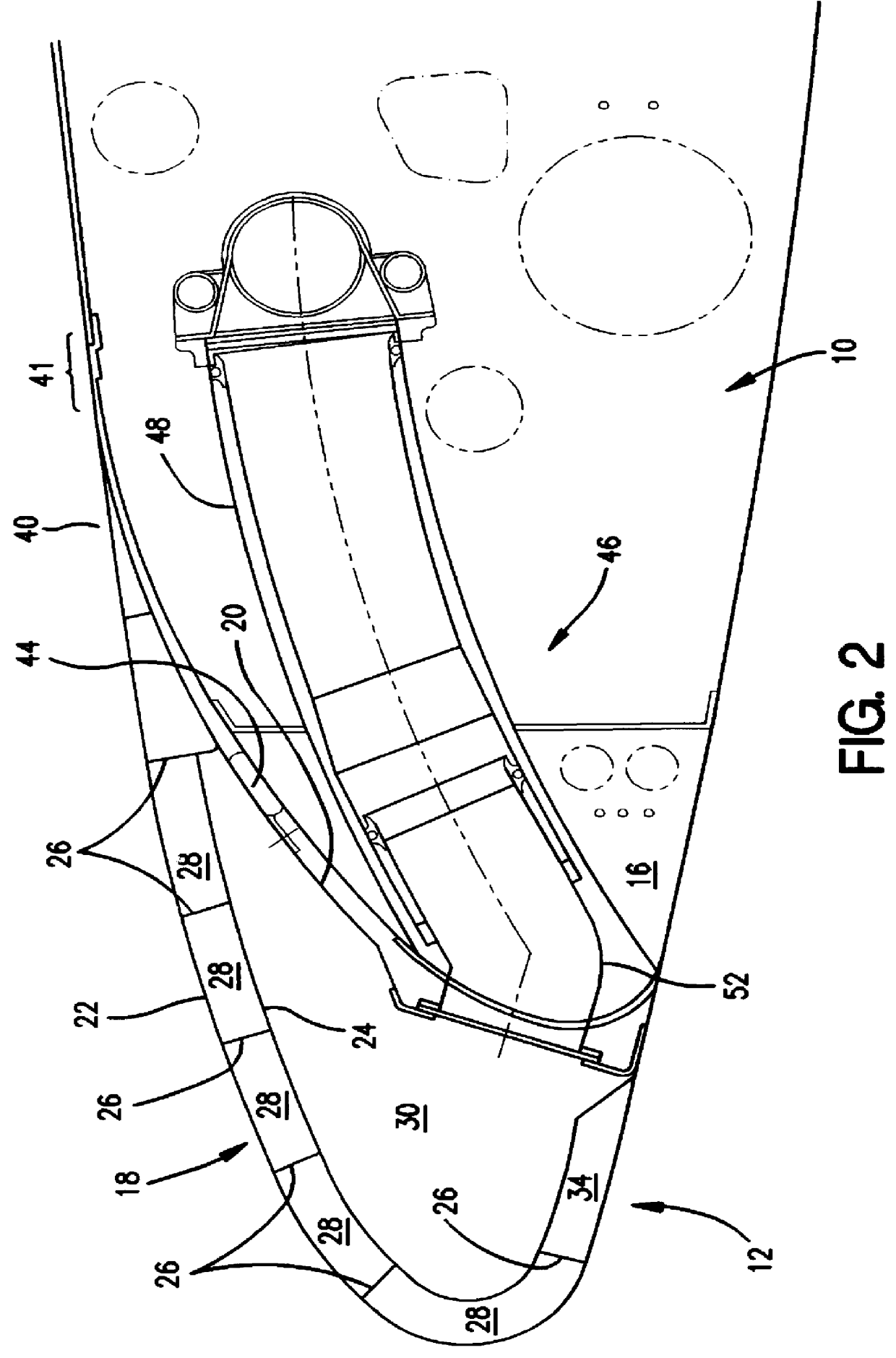

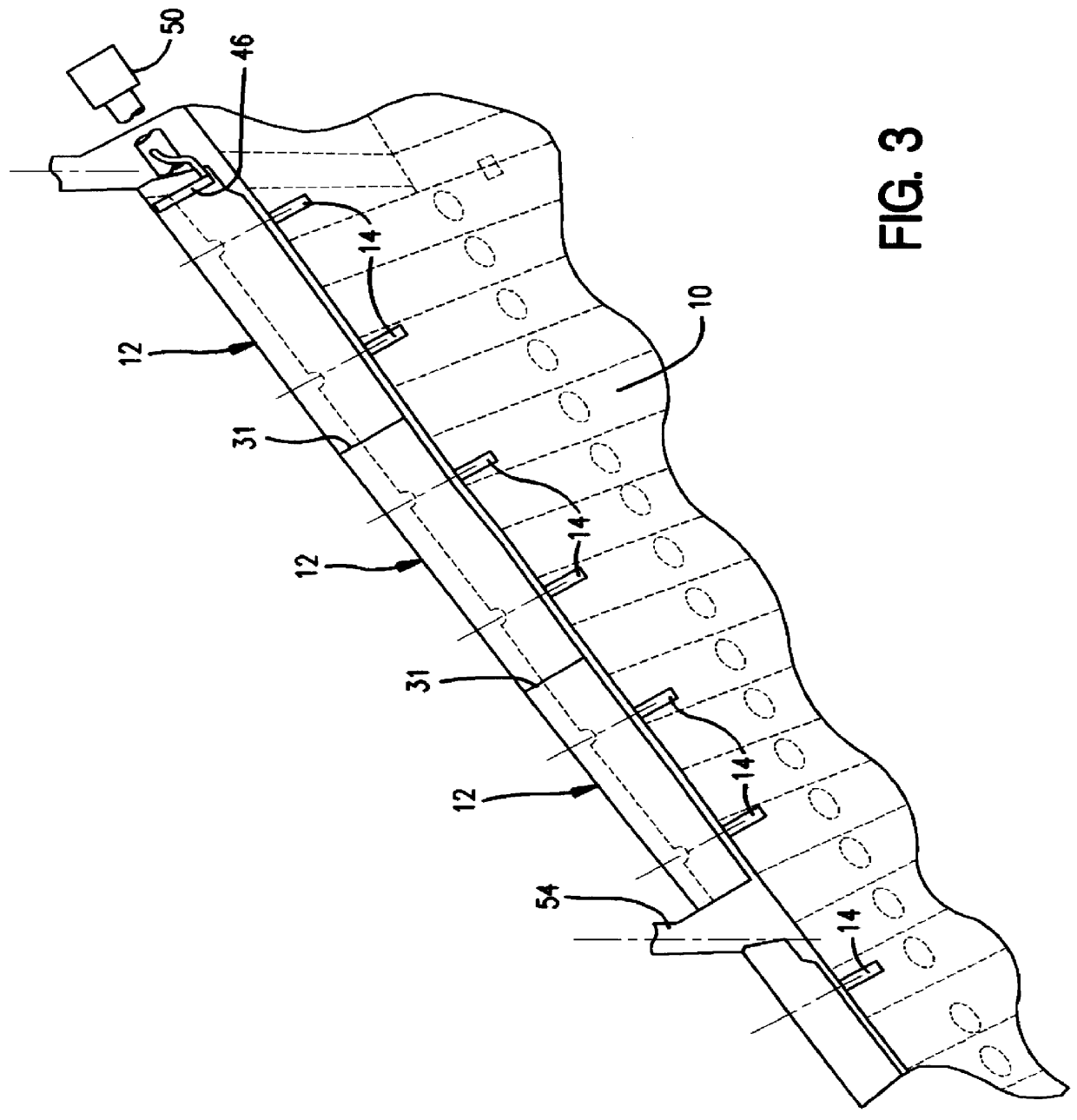

Aircraft wing leading edge high lift device with suction

InactiveUS6135395AReduce resistanceReduce layeringBoundary layer controlsFluid dynamicsLeading edgeAircraft landing

An aircraft wing, wing assembly and method of reducing drag are provided. The wing asembly includes a main wing portion (10) and a leading edge high lift portion (12). The high lift portion is movable between a retracted position in which it generally merges with the main wing portion and a deployed position forwardly thereof. At least a substantial part of an upper surface (22) of the high lift portion is air permeable or perforated and in flow communication with a suction passage (30) in it. In flight, suction may be applied to the suction passage to reduce the chordwise extent of the turbulent boundary layer over the upper or lower wing surface.

Owner:AIRBUS OPERATIONS LTD

Robot mechanism for cleaning and inspection of live-line insulators

ActiveUS7797781B2Improve safety and efficiencyReduce weightBrush bodiesVehicle cleaning apparatusBall bearingEngineering

A robot mechanism adopts a dry cleaning method to clean the surface of live-line insulators without using water and can perform cleaning and inspection of the surface of the live-line insulators while automatically moving along an insulator string. The robot mechanism includes a main unit having upper and lower wing frames connected with each other by a connecting bracket to surround the insulator string, a cleaning unit disposed between the upper and lower wing frames and including a base frame to perform dry cleaning with a rotational brush and a CM guide, a lift unit including a clamp and a ball-bearing screw to move the main unit up or down, and an inspection unit to electrically inspect the insulators; and a coupling unit to couple a pair of the main units to allow the pair of main units to move along a tension insulator string or a suspension insulator string.

Owner:KOREA ELECTRIC POWER CORP

Finned tube for condensation and evaporation

ActiveUS20080196876A1Increase surface areaImprove heat transfer performanceMetal-working apparatusCorrosion preventionEvaporationMechanical engineering

Owner:WIELAND WERKE AG

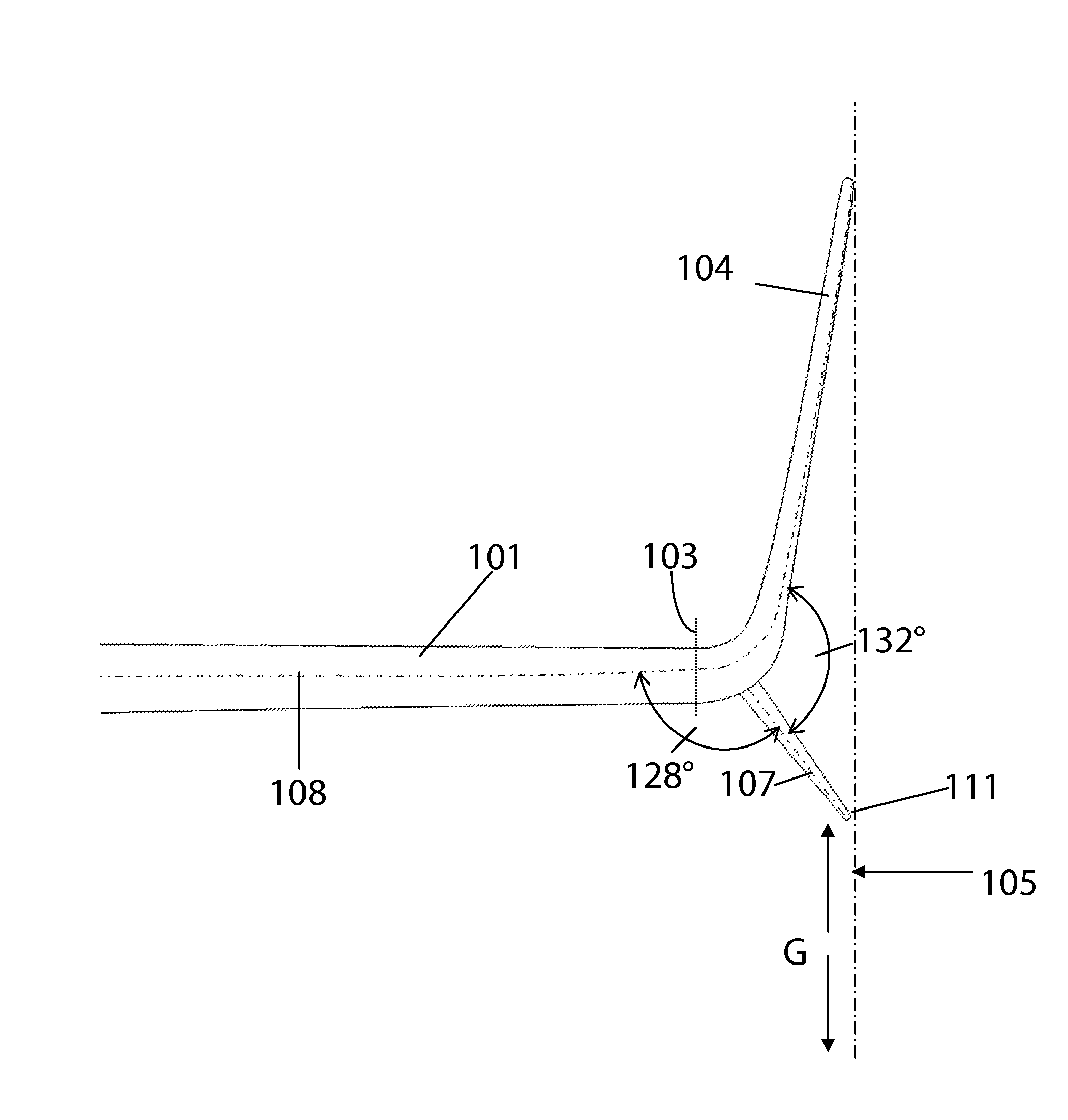

Wing tip device

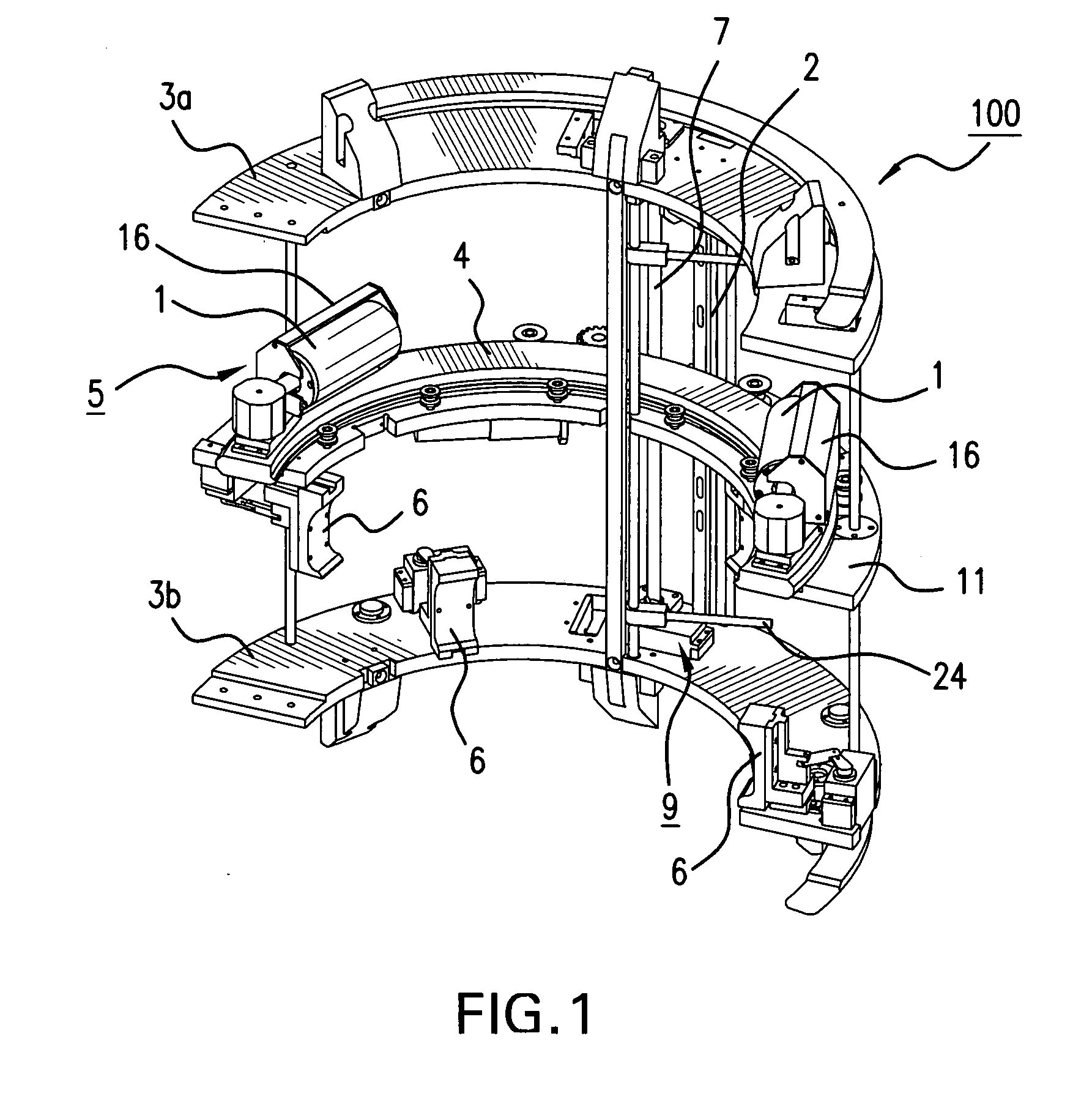

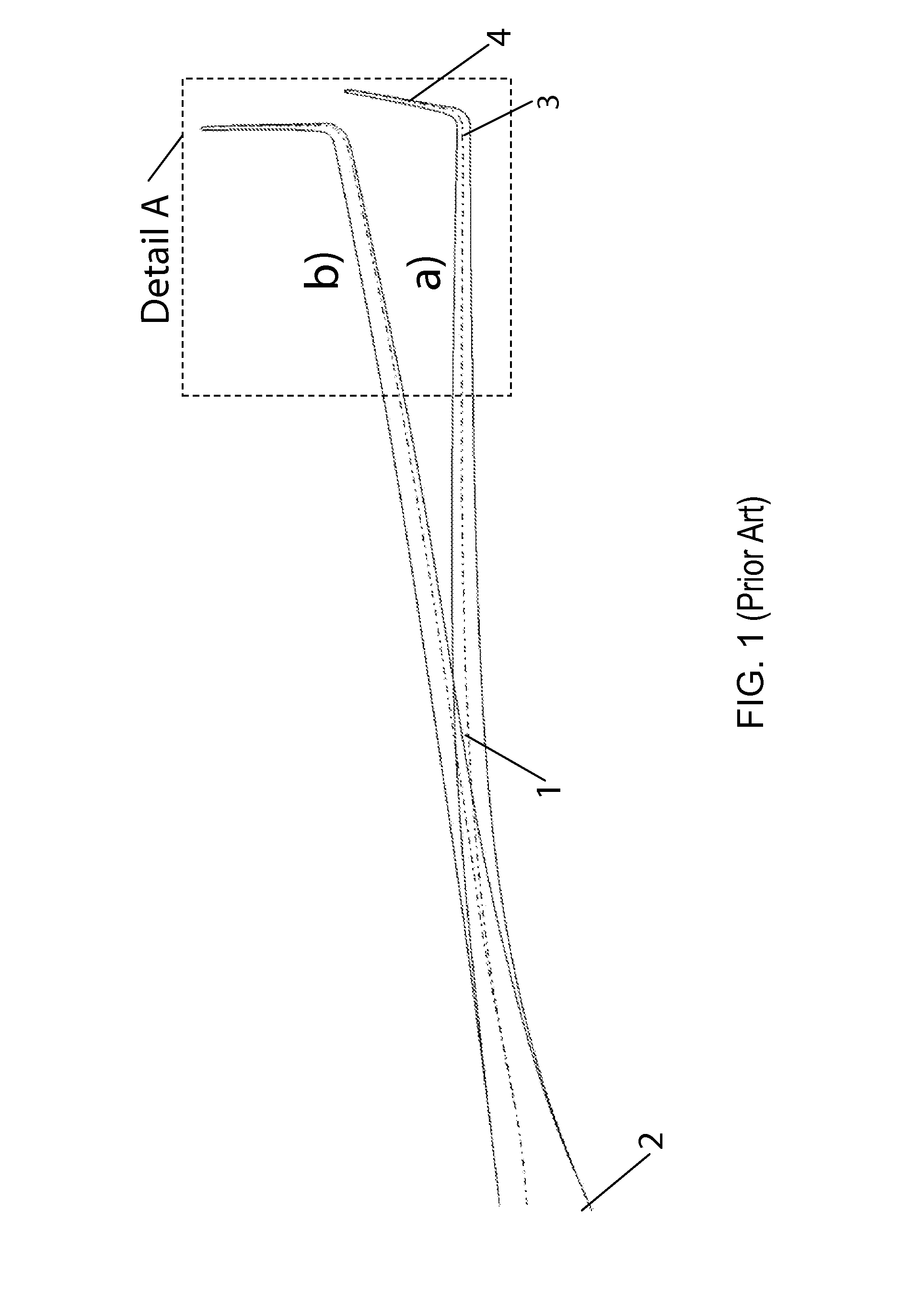

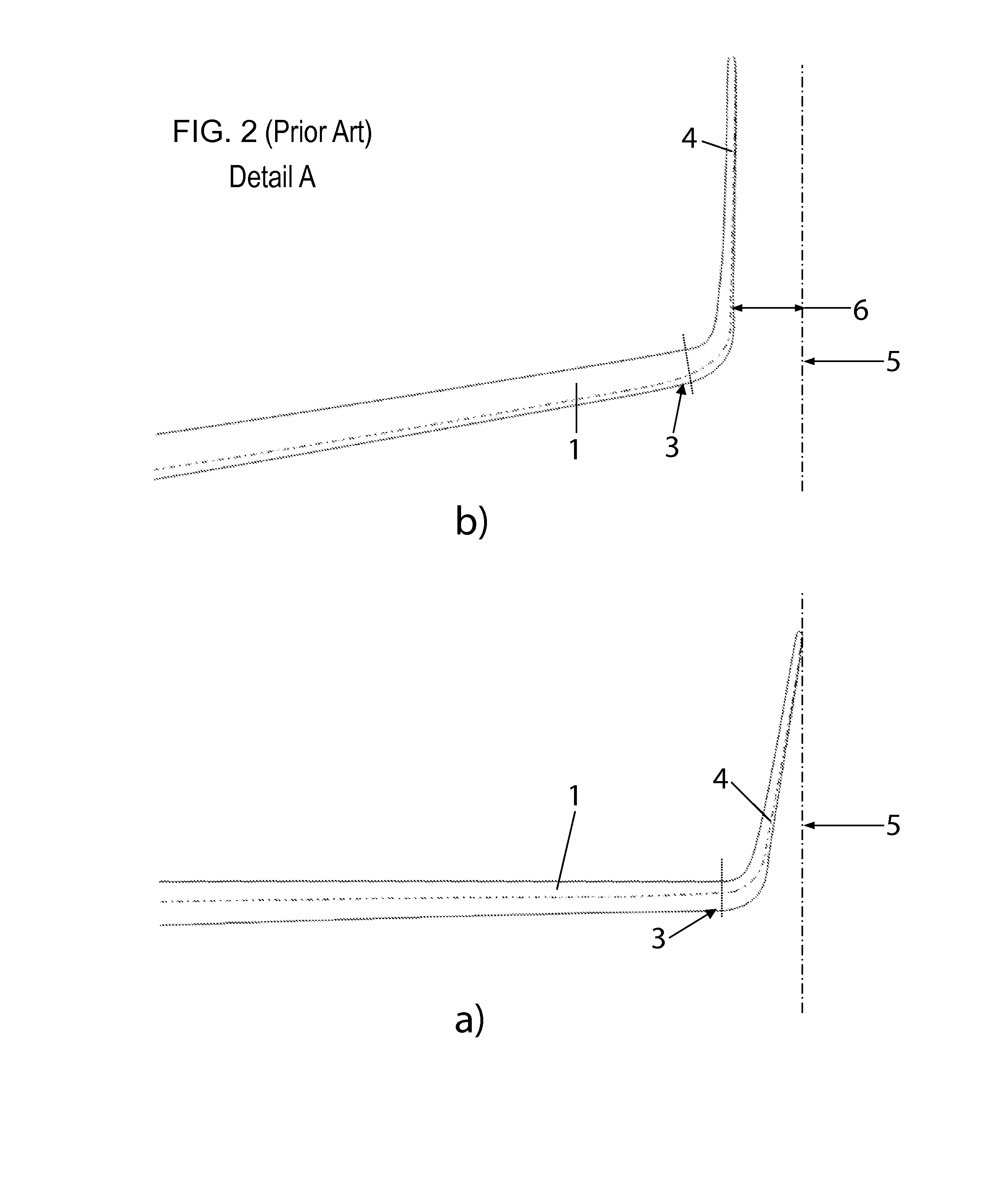

ActiveUS20130092797A1Reduce interference drag effectWell mixedInfluencers by generating vorticesAircraft stabilisationTrailing edgeLower wing

A wing tip device for fixing to the outboard end of a wing, the wing defining a wing plane, includes: an upper wing-like element projecting upwardly with respect to the wing plane and having a trailing edge; and a lower wing-like element fixed with respect to the upper wing-like element and having a root chord and a trailing edge, the lower wing-like element root chord intersecting with the upper wing-like element, and the lower wing-like element projecting downwardly from the intersection. The upper wing-like element is larger than the lower wing-like element and the trailing edge of the lower wing-like element is adjacent the trailing edge of the upper wing-like element at the intersection. An included angle between the upper and lower wing-like elements at the intersection is less than, or equal to, 160 degrees.

Owner:AIRBUS OPERATIONS LTD +1

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS6569542B2Pig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight):Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

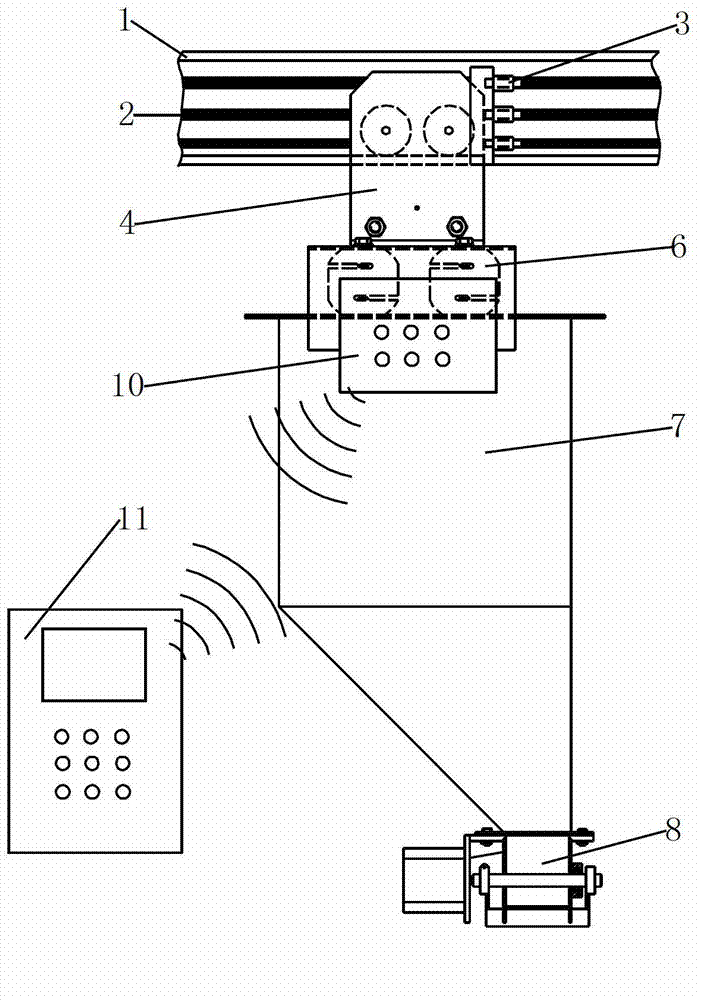

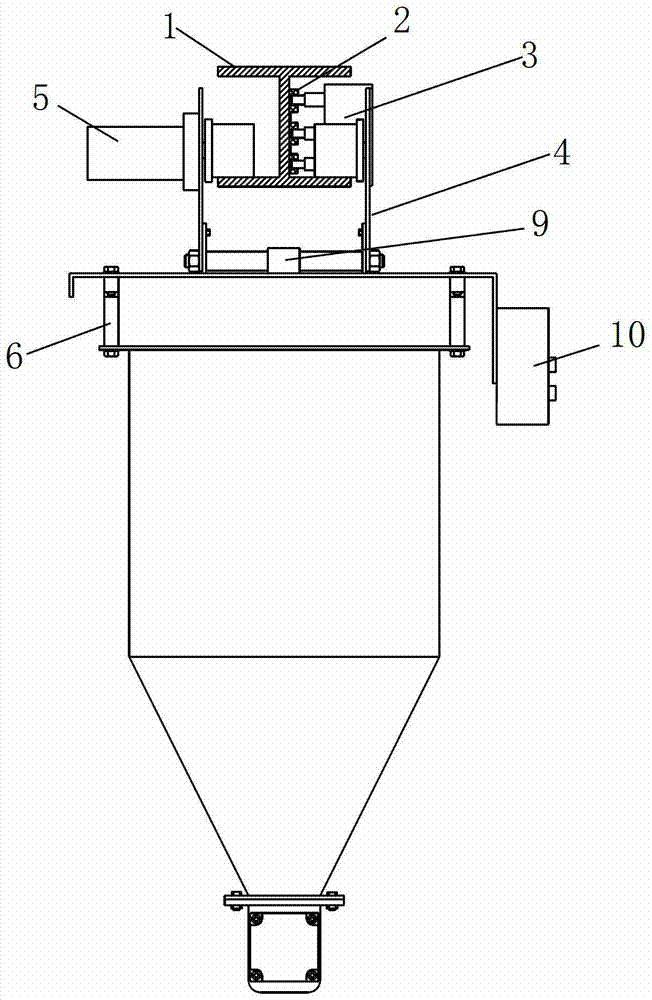

Industrial aquaculture automatic feeding system

InactiveCN103039395AImprove mechanical propertiesIncrease the level of automationPisciculture and aquariaEngineeringDistance sensors

The invention relates to an aquaculture feeding system and belongs to the field of aquaculture. An industrial aquaculture automatic feeding system is characterized in that H-shaped steel tracks are erected above indoor fishponds, feeding devices are arranged on the tracks and comprise walking tackles arranged on the steel tracks, feed bins are hung below the walking tackles, and discharge mechanisms are arranged at the positions of feed bin outlets. Positioning identification plates are arranged below lower wing plates of the H-shaped steel tracks above each fishpond, distance sensors are arranged above the feed bins or below the walking tackles, the distances between the positioning identification plates and the distance sensors are different, and the walking tackles hang the feed bins through pulling pressure sensors. After the feed devices move along the tracks to arrive at identification points of the positioning identification plates, control boxes determine positions according to positioning points sent by the distance sensors, and feeding is controlled accurately according to feeding requirements of a corresponding fishpond at the position.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

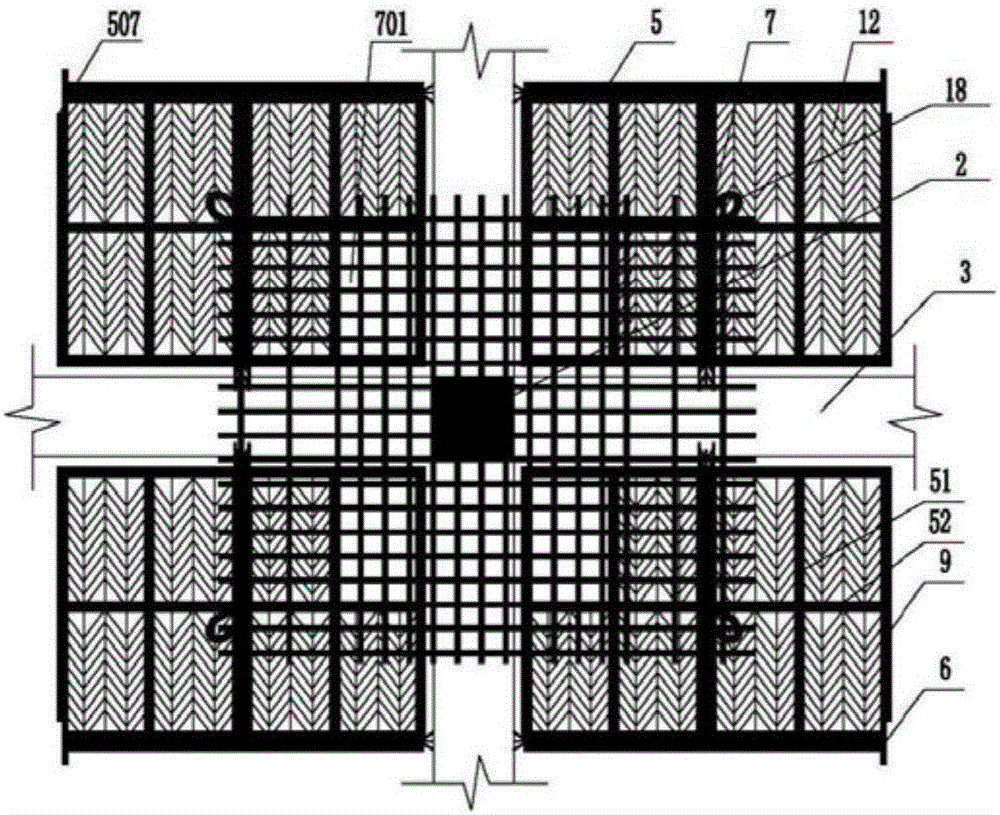

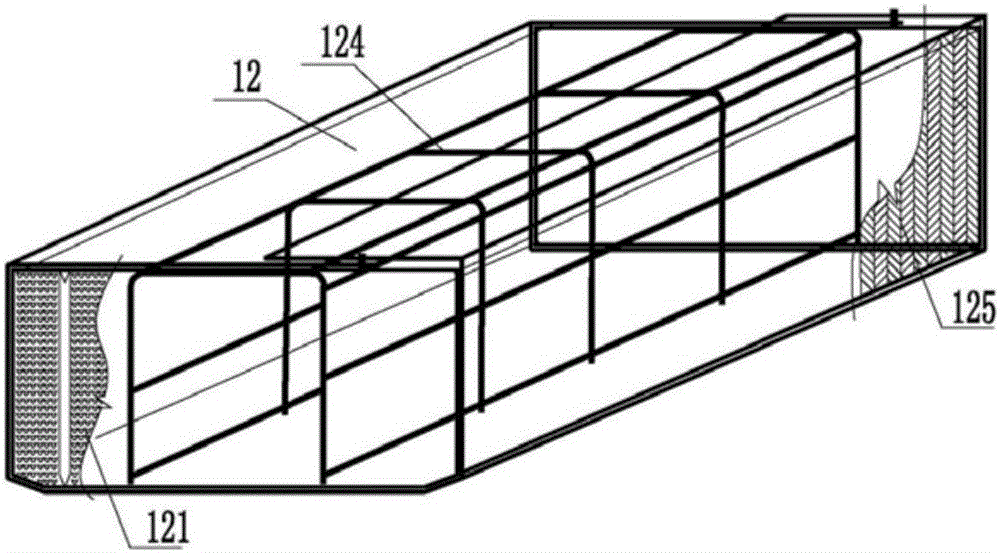

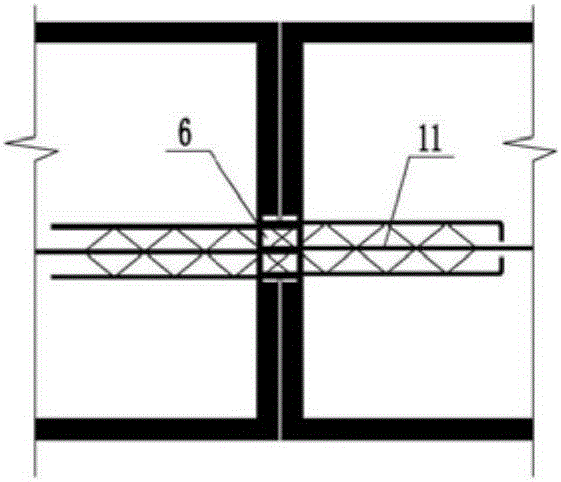

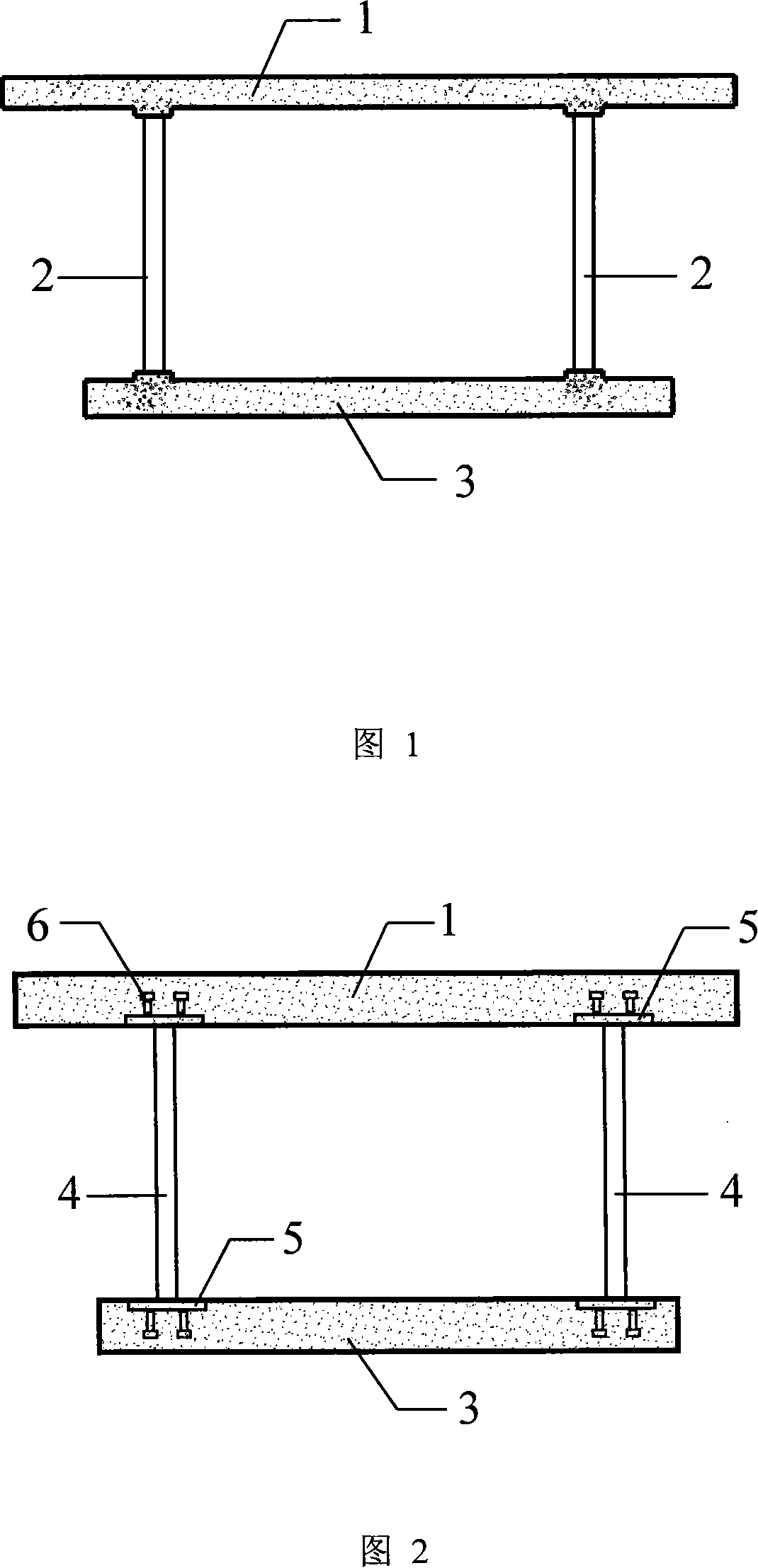

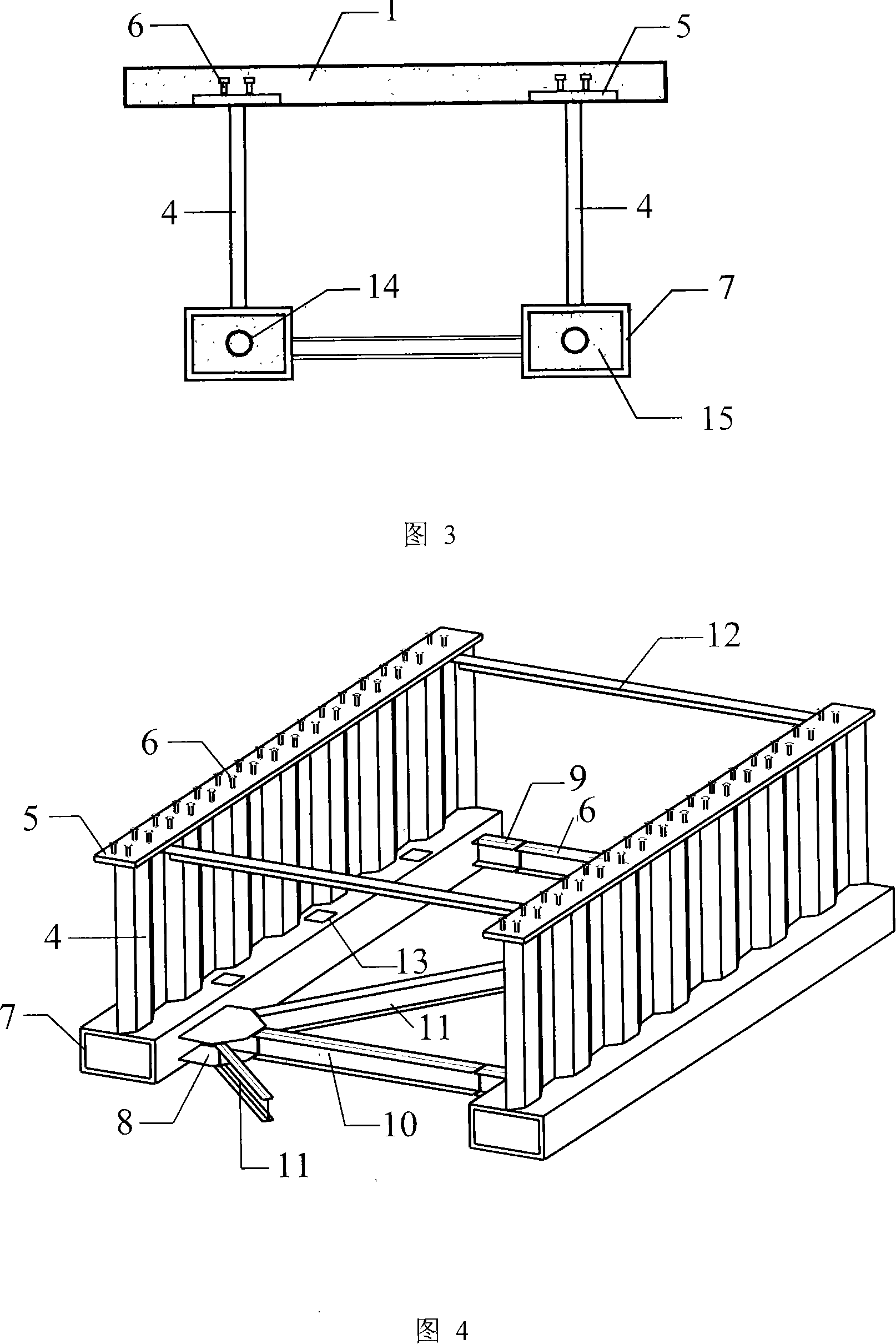

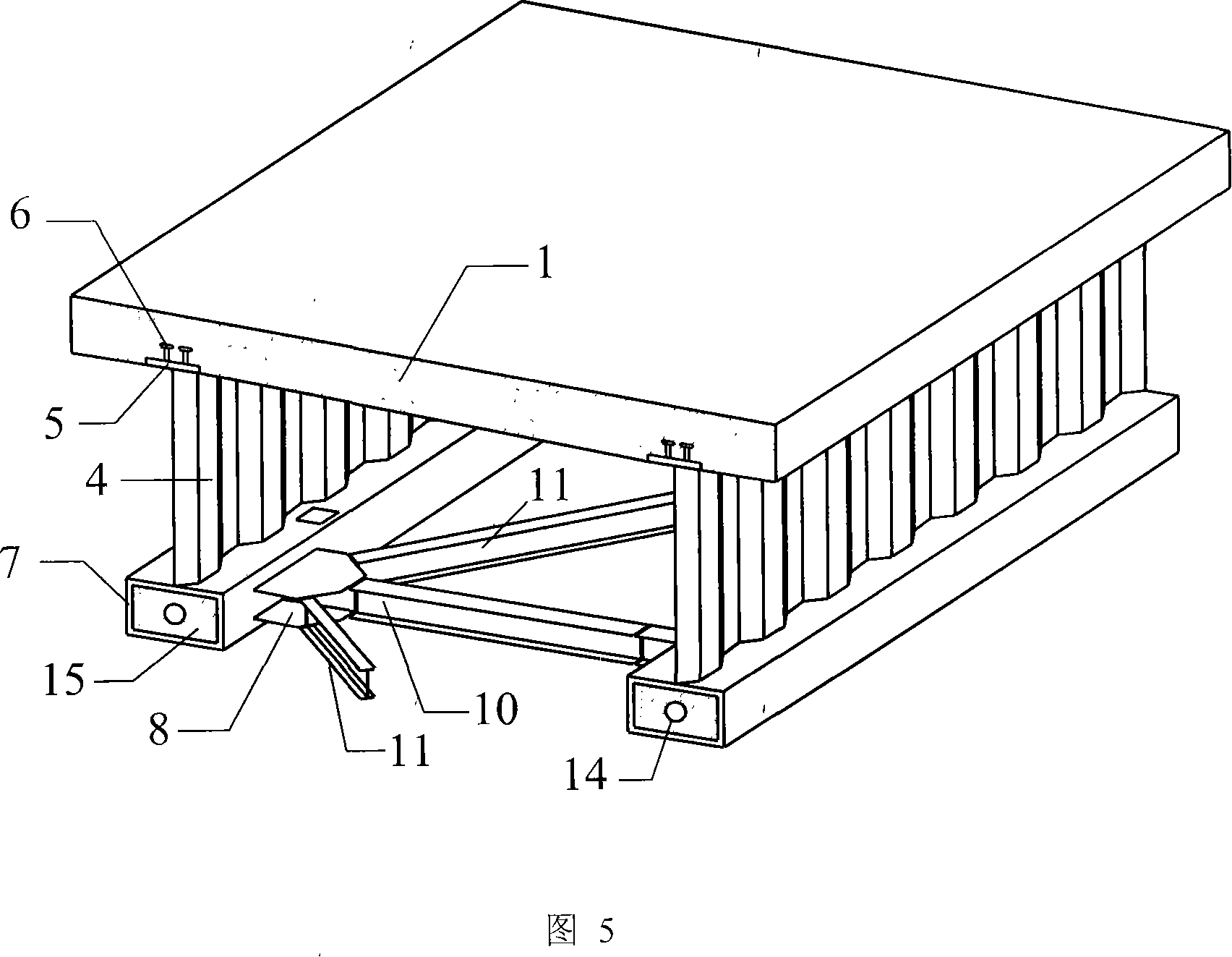

Stress island assembled type hollow floor

ActiveCN106351375AIncrease the force sectionIncrease the effective joint cross sectionFloorsEngineeringRebar

The invention provides astress island assembled type hollow floor, comprising a column, a main beam, an assembled type hollow plate, a stress island, an upper wing plate of the assembled type hollow floor, and a joint seam, wherein the assembled type hollow plate consists of a longitudinal rib, a bidirectional loading-formed regeneration rib, a hollow hole forming member, a lower wing plate, a rib or local stirrup exposure of the rib and a stress island reserved corner; the longitudinal rib of the assembled type hollow plate is provided with two exposed ends; the stress island is arranged in such a manner that, in the fabrication of the assembled type hollow plate, a space larger than 0.18mm<2> for the stress island reserved corner is assembled at the periphery of an outer edge of the column, a column rib, a main beam rib, an upper wing plate rib and a rib in the space for the stress island reserved corner form stress island ribs, and concrete is cast to form the stress island; the joint seam is formed in a lower surface of the stress island assembled type hollow floor, and is in an intermittent state, and the joint seam is only part of thickness of the hollow floor.

Owner:王本淼 +3

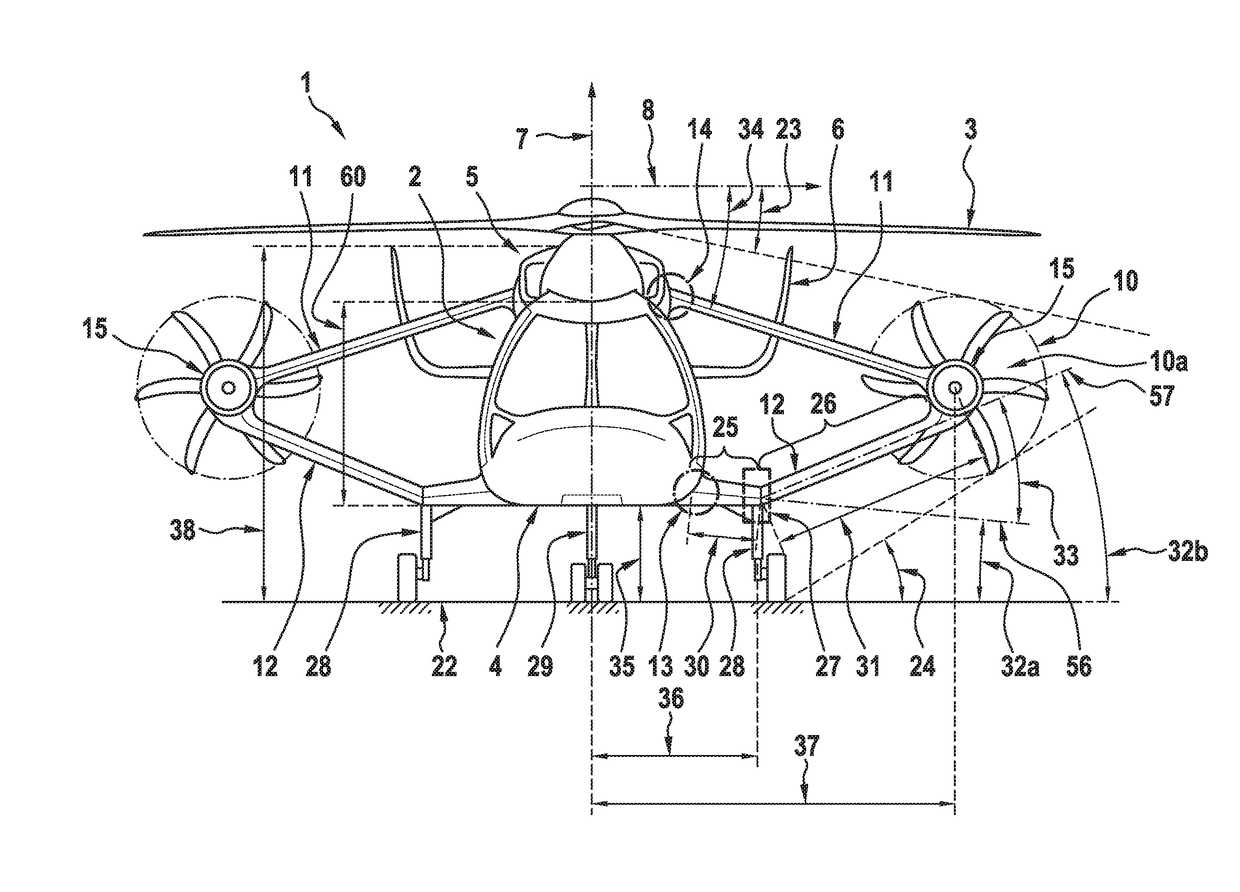

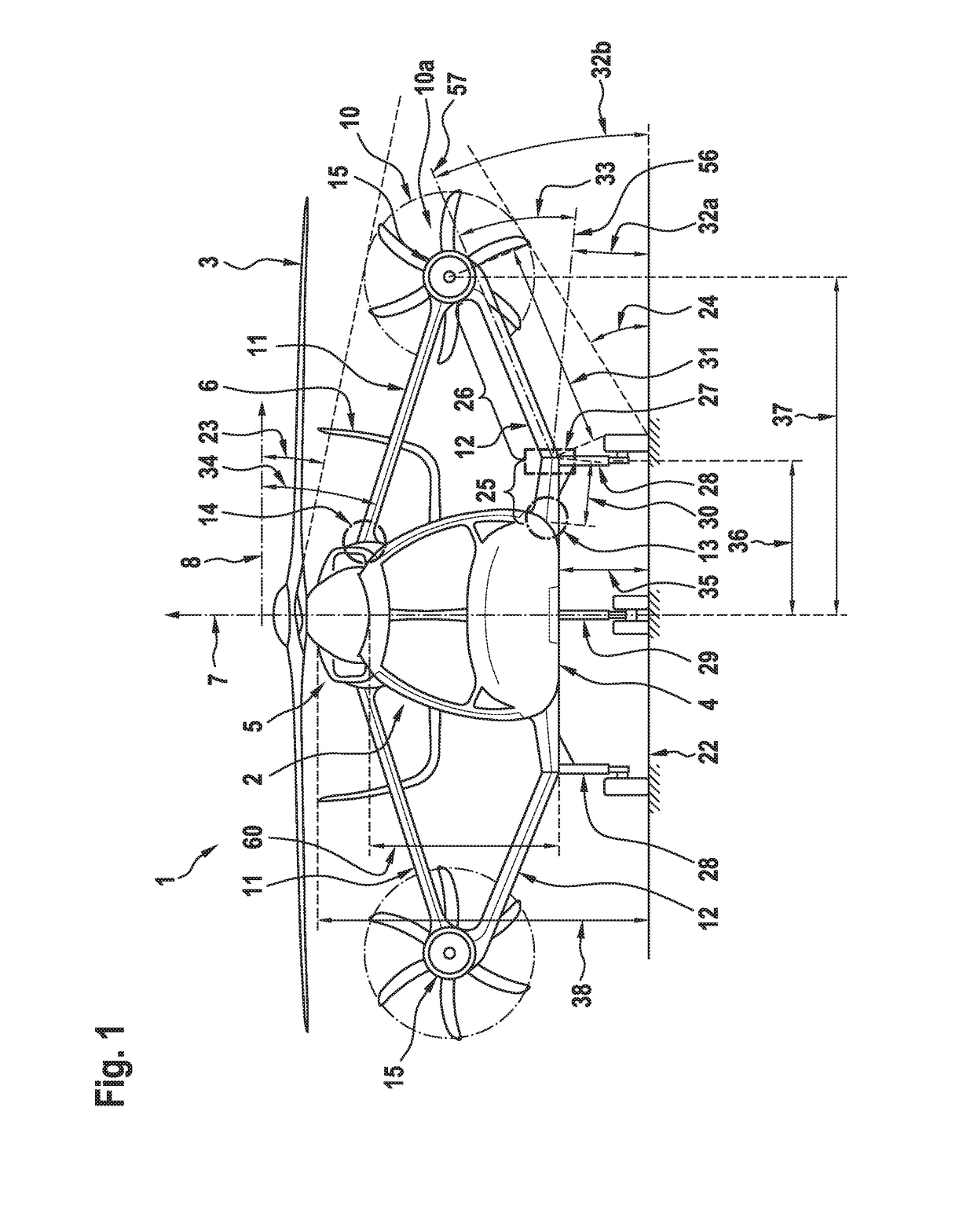

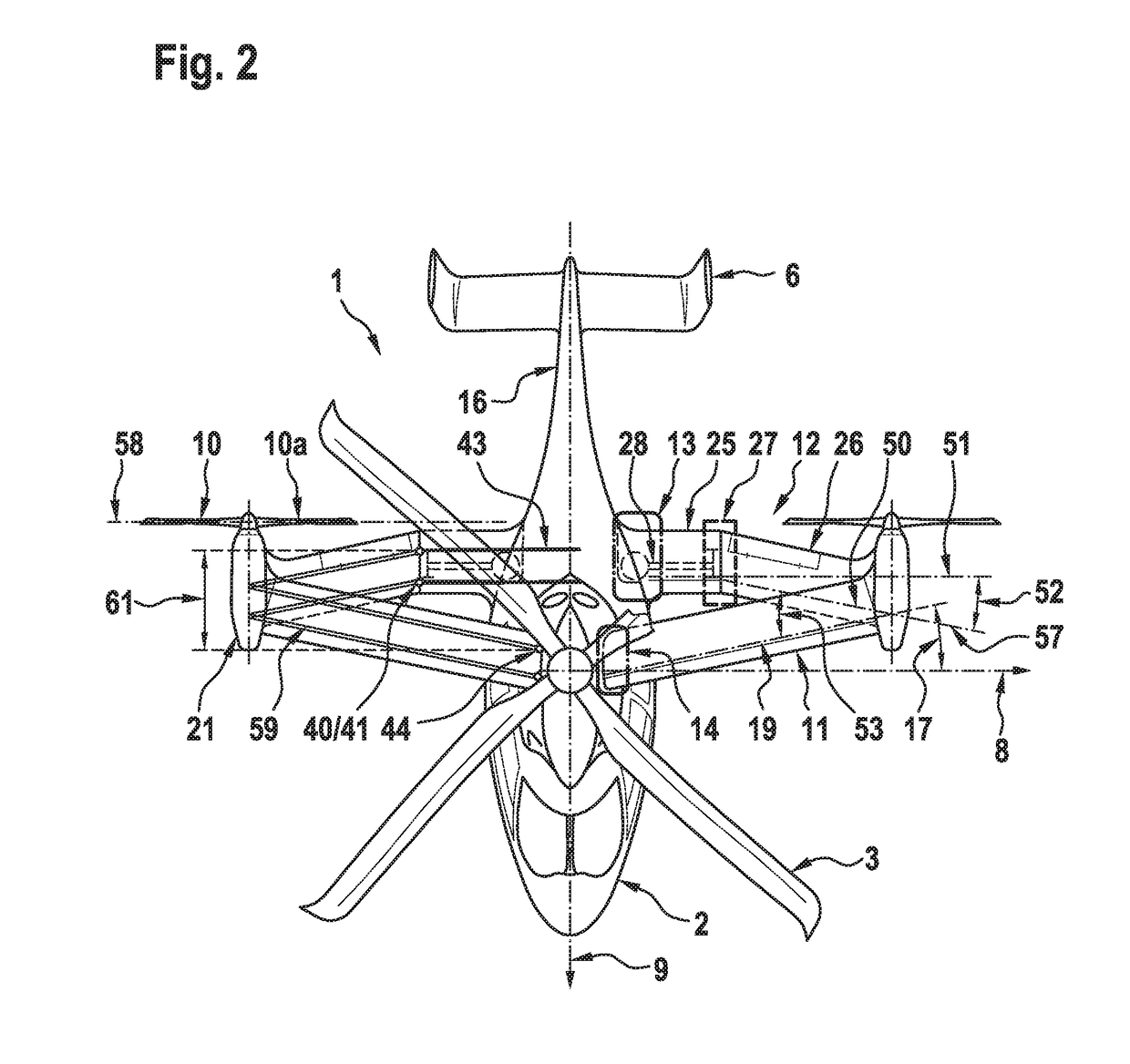

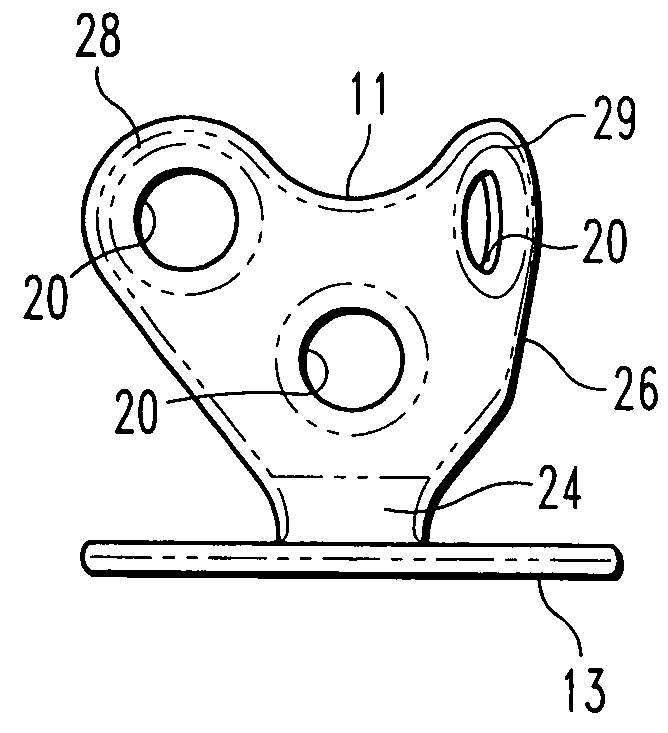

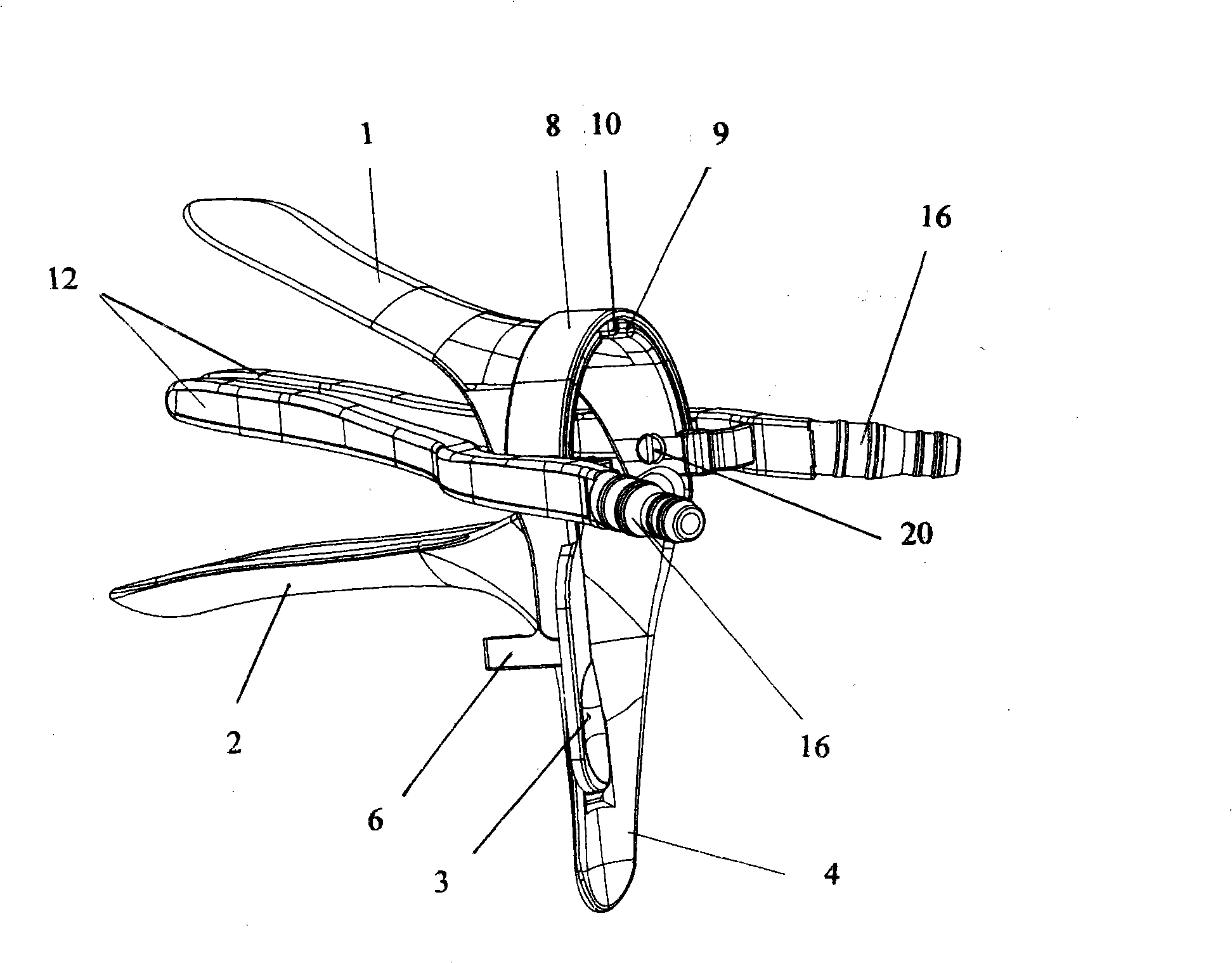

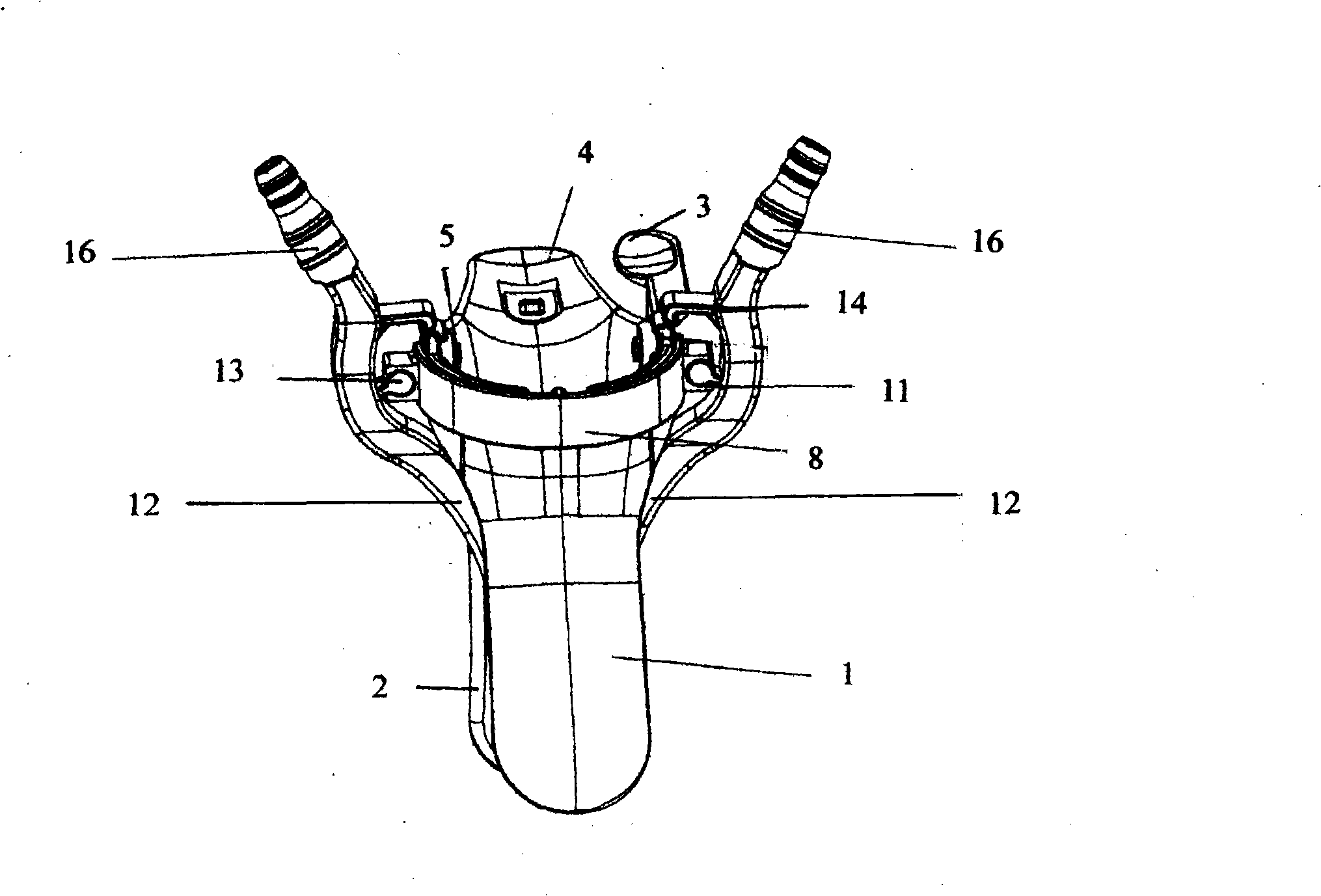

Compound rotorcraft

ActiveUS20170197709A1Improve aerodynamic efficiencyReduction of the dihedral angle of the lower wingWing shapesSpars/stringersPropellerFixed wing

A compound rotorcraft with a fuselage and at least one main rotor, the fuselage comprising a lower side and an upper side that is opposed to the lower side, the at least one main rotor being arranged at the upper side, wherein at least one propeller is provided and mounted to a fixed wing arrangement that is laterally attached to the fuselage, the fixed wing arrangement comprising at least one upper wing that is arranged at an upper wing root joint area provided at the upper side of the fuselage and at least one lower wing that is arranged at a lower wing root joint area provided at the lower side of the fuselage, the upper and lower wings being at least interconnected at an associated interconnection region.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Fixation device for the talus

Owner:BIOMET CV

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS20010006082A1Lower wing skin panelsEasy to weldPig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight): Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

Lower edge open truss style corrugated steel web combination beam

InactiveCN101139812AImprove crack resistanceIncreased durabilityLoad-supporting elementsBridge materialsFalseworkCrack resistance

A truss-type corrugated steel web composite beam with an open bottom chord belongs to a bridge support member. The bottom chord opened and truss-type corrugated steel web composite beam comprises an upper wing edge concrete slab, a corrugated steel web and a bottom chord opened truss-type rectanglar steel tube concrete member. Compared with steel truss-type web composite corss section, the invention adopts the corrugated steel web with rather high shear strength to replace a steel web member, so as to guarantee quite high shear bearing capacity. The opened truss-type bottom chord is composed of two parallel-arranged rectanglar steel tubes arranged in parallel and internally cast concrete, as well as horizontal braces and batter braces between the rectanglar steel tubes. Moreover, the bottom chord adopts the steel tube concrete member to overcome the problem of rather high work volume that, in traditional composite cross section of corrugated steel web box beams and steel truss-type webs, such execution measures as scaffolding, formwork-support, concrete casting and etc. should be taken for lower wing edge concrete slabs. Meanwhie, the invention can effectively improve structure crack resistance, avoid crackage exposure and etc, and considerably increase structure durability. The bottom chord is a brace-connected open-type structure with advantages of simple structure and fast, smooth and convenient execution.

Owner:TSINGHUA UNIV

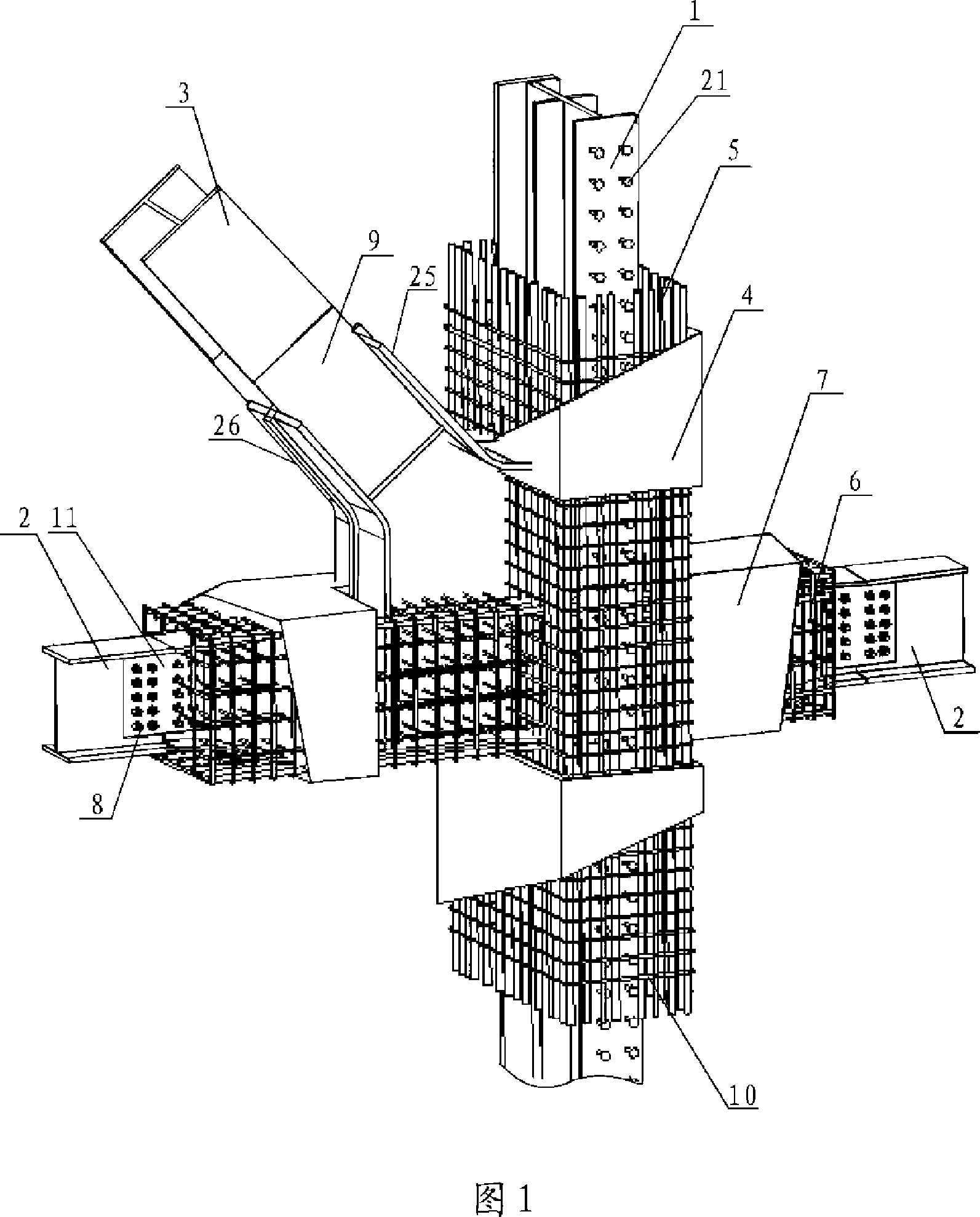

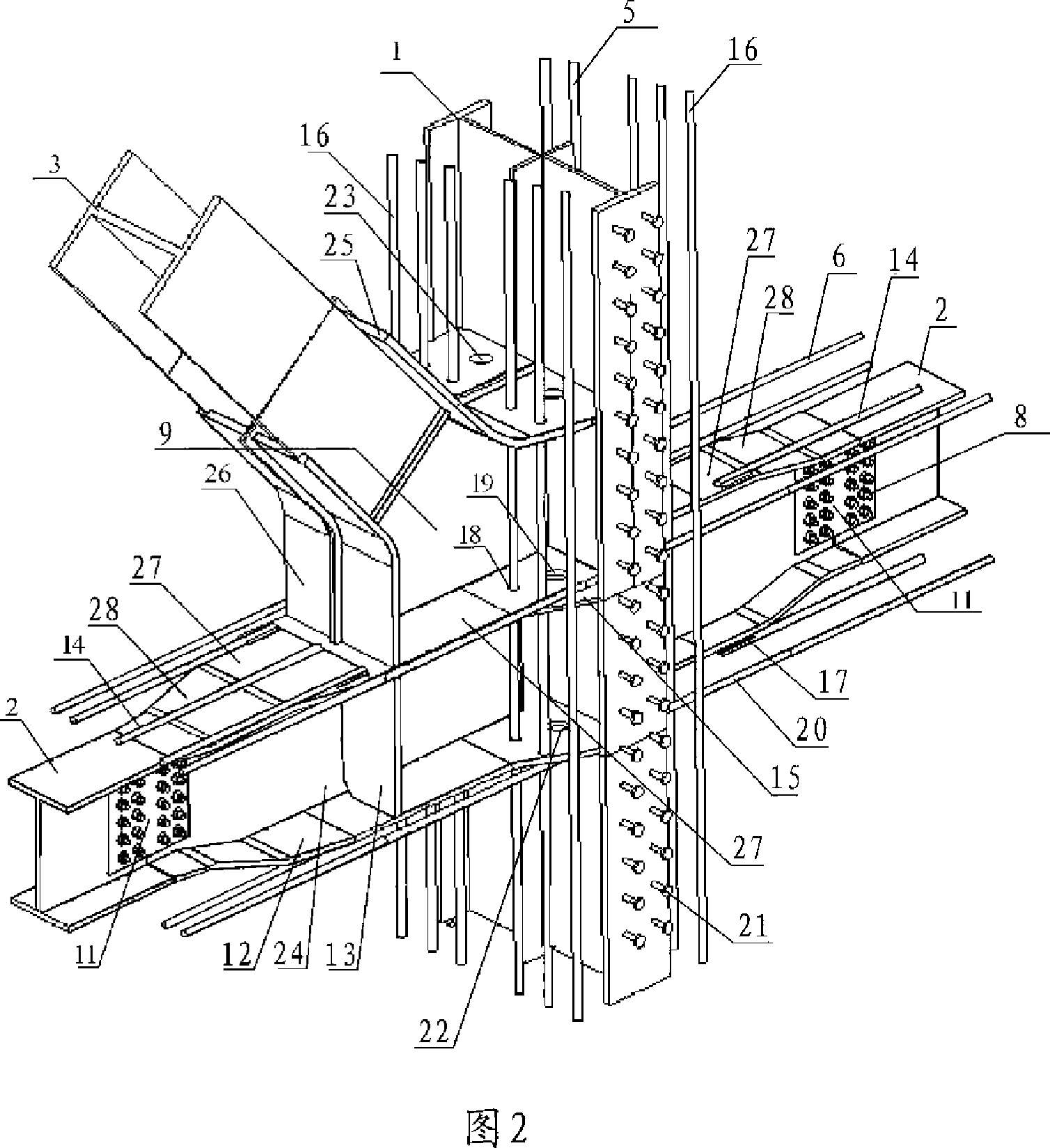

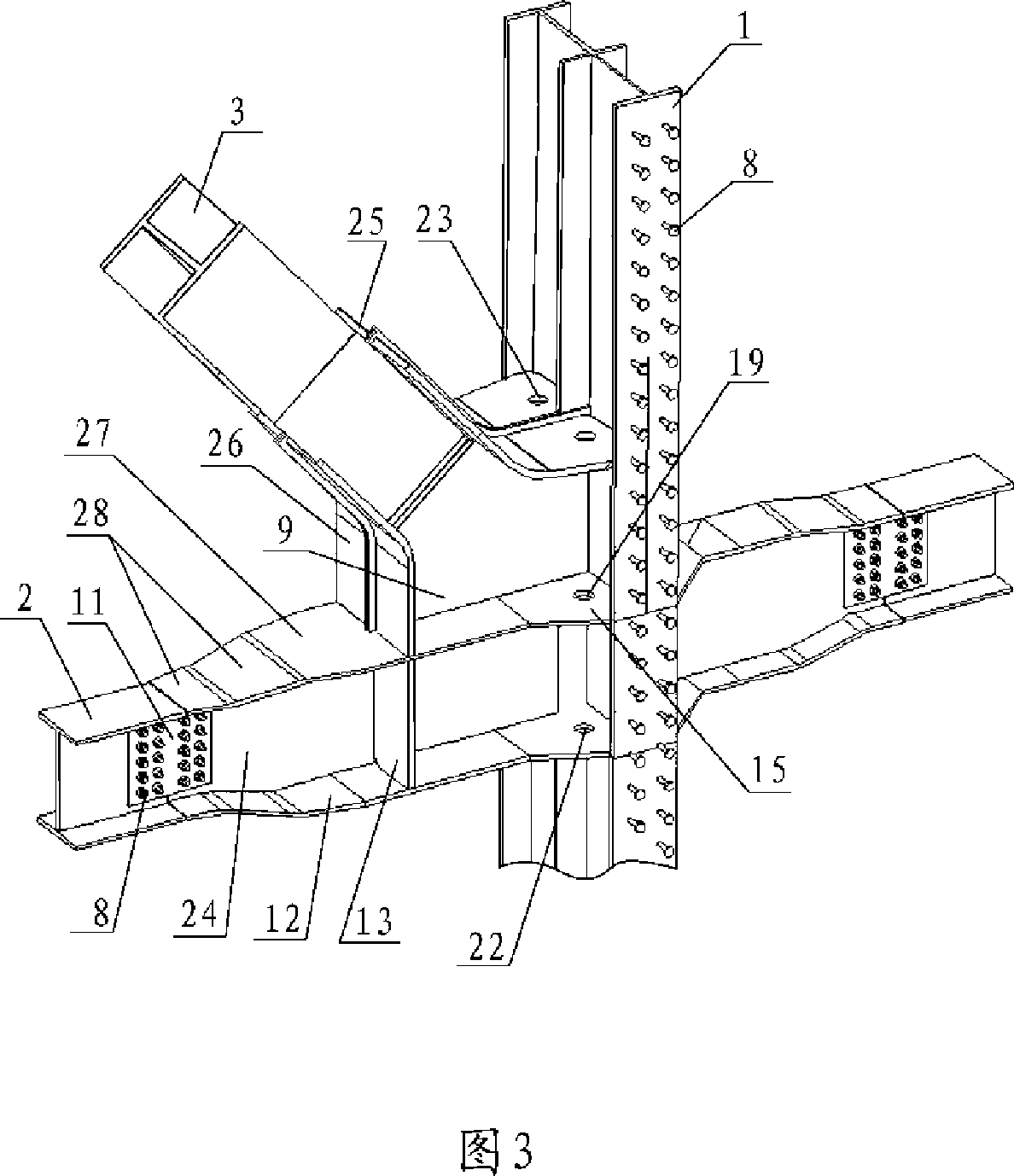

Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

ActiveCN101024975AImprove seismic performanceImprove synergyBuilding constructionsReinforced concreteInto-structure

The invention is a variable section conversion node for profiled steel concrete framework-steel support structure, interconnecting in-pillar profiled steel, in-beam profiled steel, steel support, in-pillar reinforced concrete and in-beam reinforced concrete and pouring then into an organic whole, where the steel support is orthogonally connected with in-pillar an in-beam profiled steel flange plates by section conversion, the web of the in-beam profiled steel in the node connection position is converted into heightening variable section web and the top surface of the heightening variable section web is welded with widening variable section upper wing plate, the bottom surface of the heightening variable section web is welded with widening variable section lower wing plate; the shape of the steel support in the node connecting position is converted into structure of variable section node conversion region and two flange plates of the steel support in variable section conversion region are orthogonally connected with the in-pillar and in-beam profiled steel respectively. And the invention intensifies fore bearing performance of node regions of the profiled steel concrete framework-steel support structure and ability of cooperating of profiled steel and reinforced concrete.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

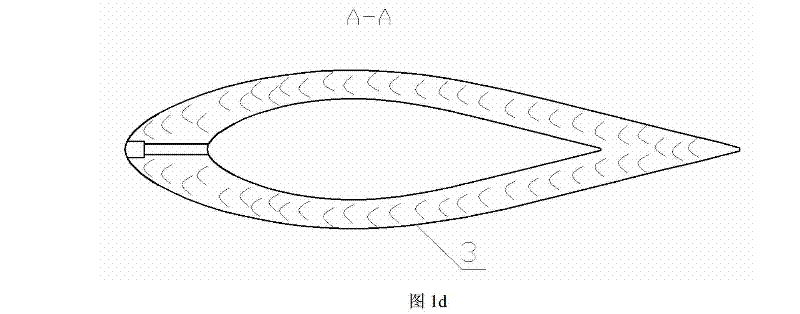

Three-hole probe type pressure measurement tail rake for wind tunnel test

ActiveCN102692310AAccurate calculation of velocity componentsAccurate calculationAerodynamic testingLeading edgeProbe type

The invention provides a three-hole probe type pressure measurement tail rake for a wind tunnel test. A plurality of connecting rods are distributed at the top end of a support platform; a three-hole probe is fixed on each connecting rod; a total pressure hole is arranged at the conical top end of each three-hole probe, and two static pressure holes symmetrically distributed on the conical surface of the three-hole probe, and the central line of the total pressure hole and the central lines of the two static pressure holes are in the same horizontal plane. According to the three-hole probe type pressure measurement tail rake, the actual total pressure, static pressure and airflow drift angle at each probe can be obtained through one total pressure hole and two static pressure holes on each probe; then, two velocity components u and v at each probe in the axial direction of a tunnel and in the horizontal plane of the height center of the tunnel can be obtained in combination with measurement of fluid density; according to the obtained static pressure distribution and the distribution of the two velocity components u and v at each three-hole probes, the resistance of a wing section can be obtained on the basis of the momentum theory, so that the two-dimensional velocity and speed drift angles of all points of wake flow can be captured at the same time. The three-hole probe type pressure measurement tail rake for the wind tunnel test is suitable for the situation that the lift force is large and the wake flow inclines to a lower wing face greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

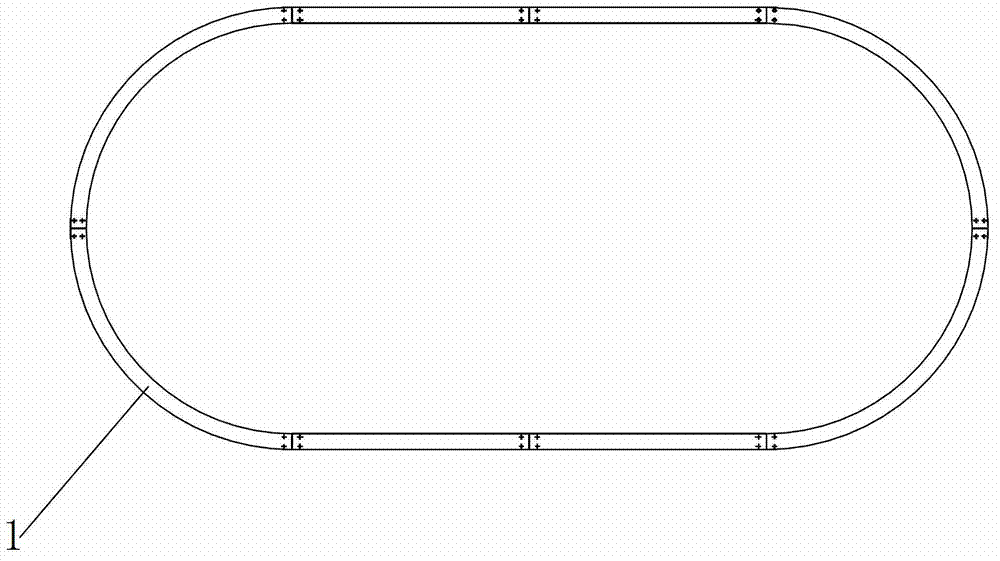

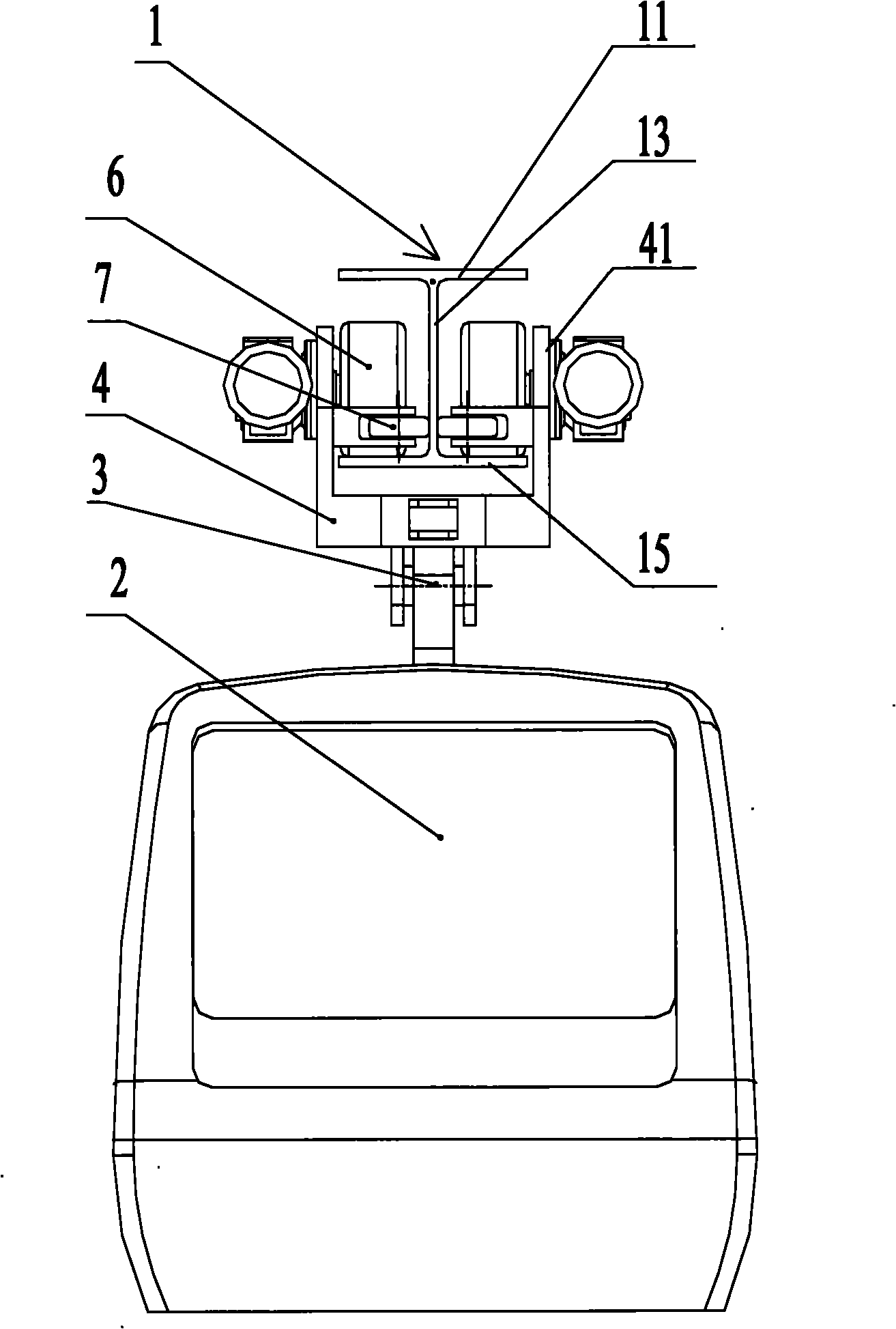

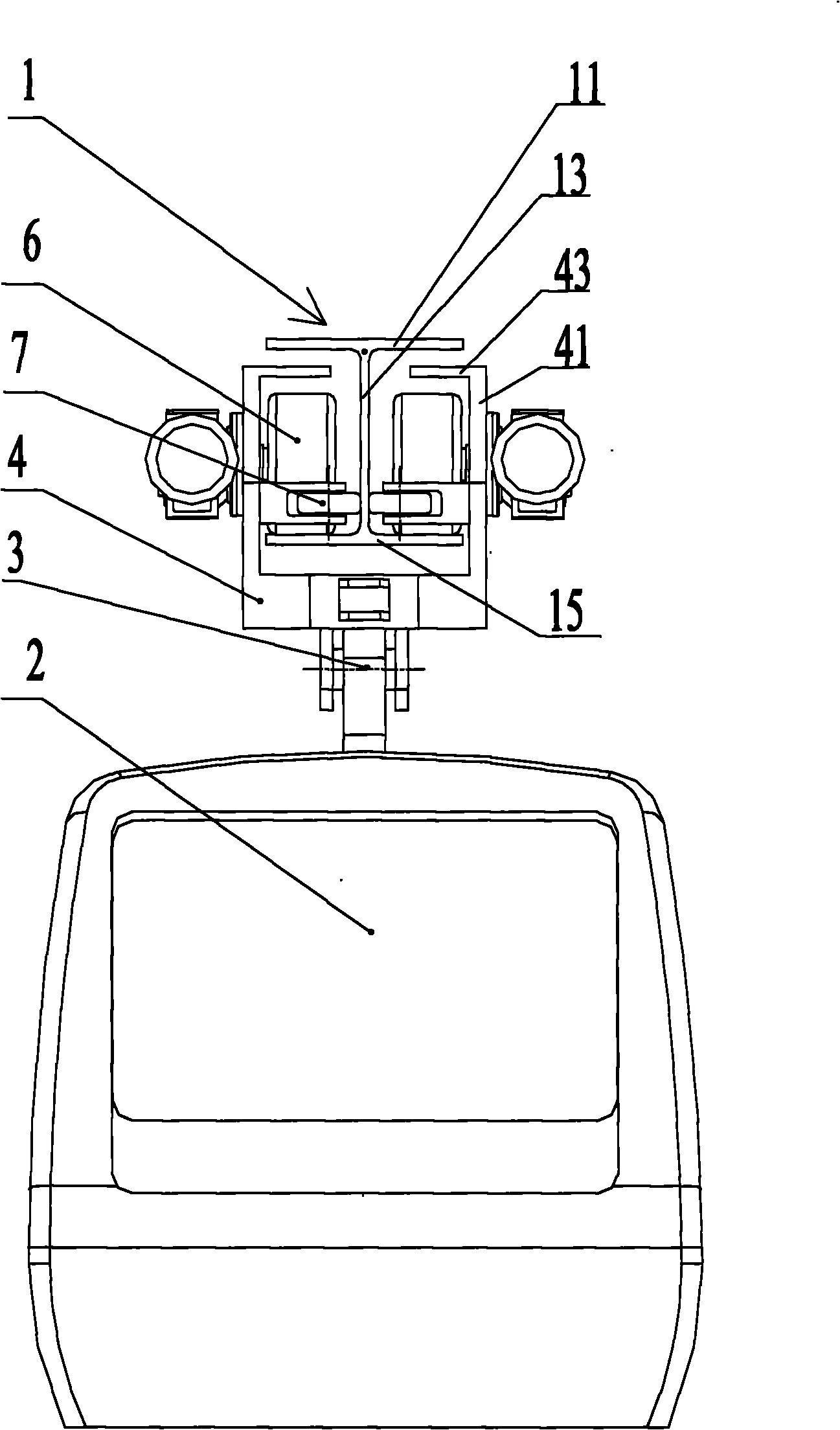

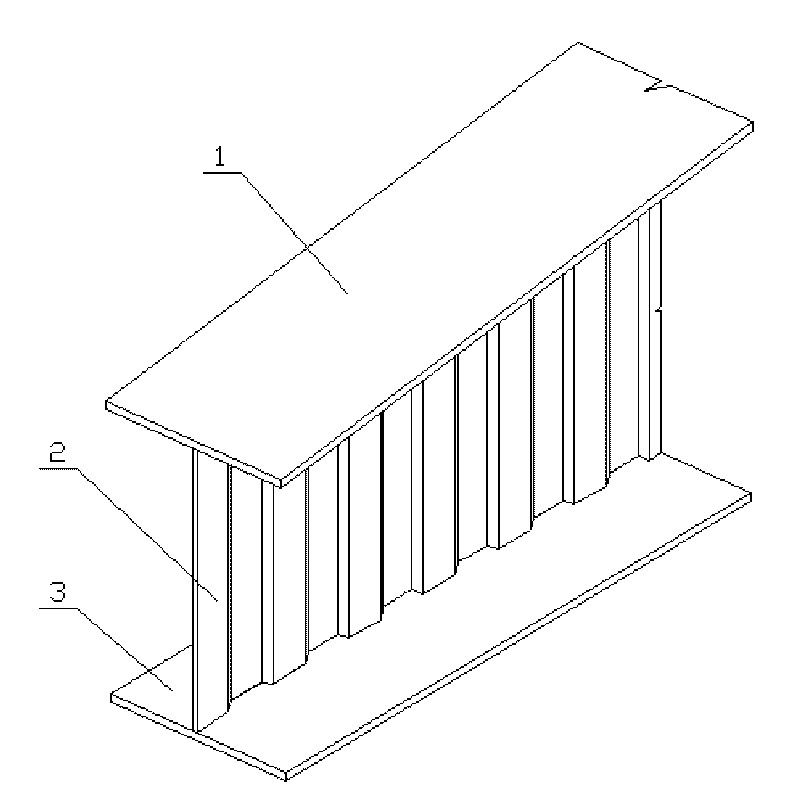

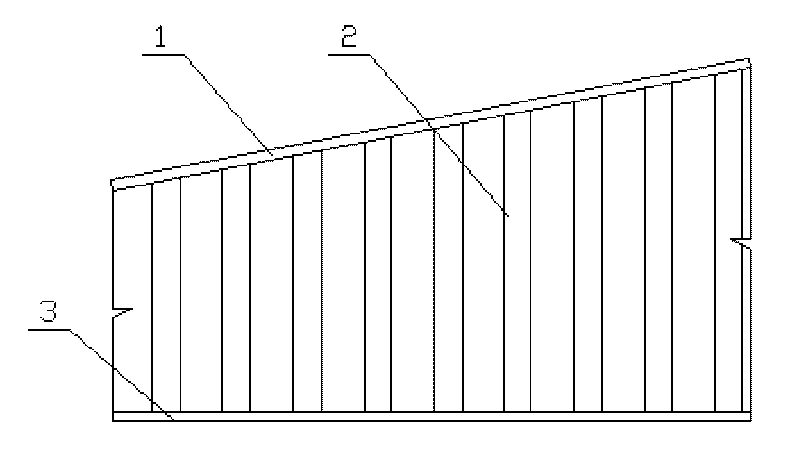

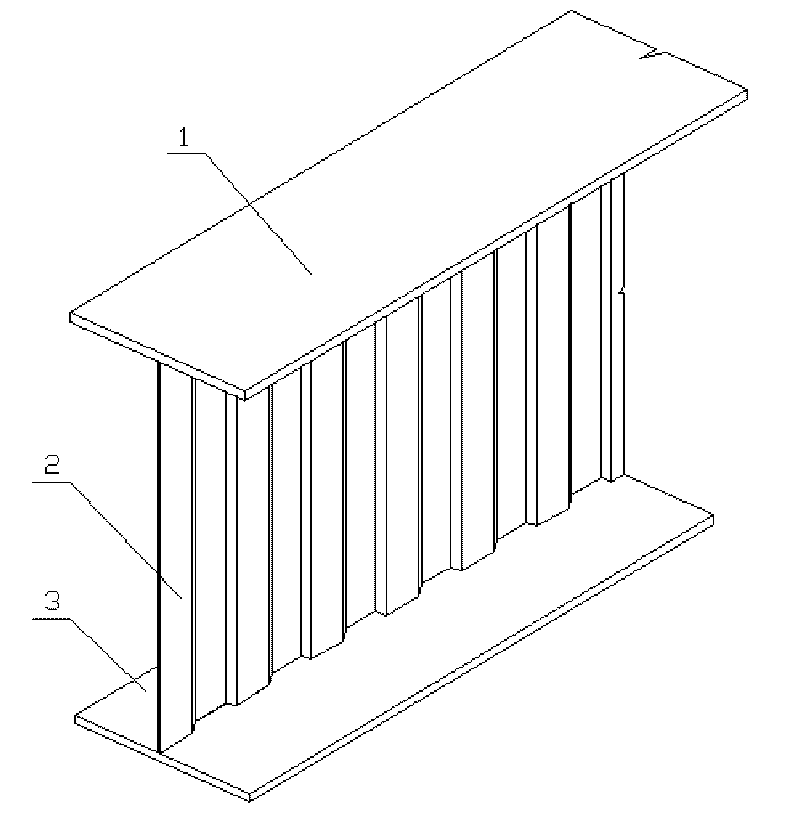

Suspension type monorail traffic system

The invention provides a suspension type monorail traffic system, which comprises a rail beam, an upright post for supporting the rail beam, a truck frame arranged on the rail beam, a carriage suspended below the truck frame, and a driving wheel and a guide wheel which are arranged on the truck frame, wherein the rail beam is a transverse H-shaped beam; the transverse H-shaped beam comprises an upper wing plate and a lower wing plate which are arranged at an interval; the upper wing plate is parallel to the lower wing plate or is at an included angle to but not intersected with the lower wing plate, and a webplate is connected between the upper wing plate and the lower wing plate; and the lower wing plate provides a rolling rail for the driving wheel, and the webplate provides the rolling rail for the guide wheel. The suspension type monorail traffic system has the advantages of compact structure, low cost, simple installation and convenient maintenance.

Owner:ZHUZHOU CSR SPECIAL EQUIP TECH

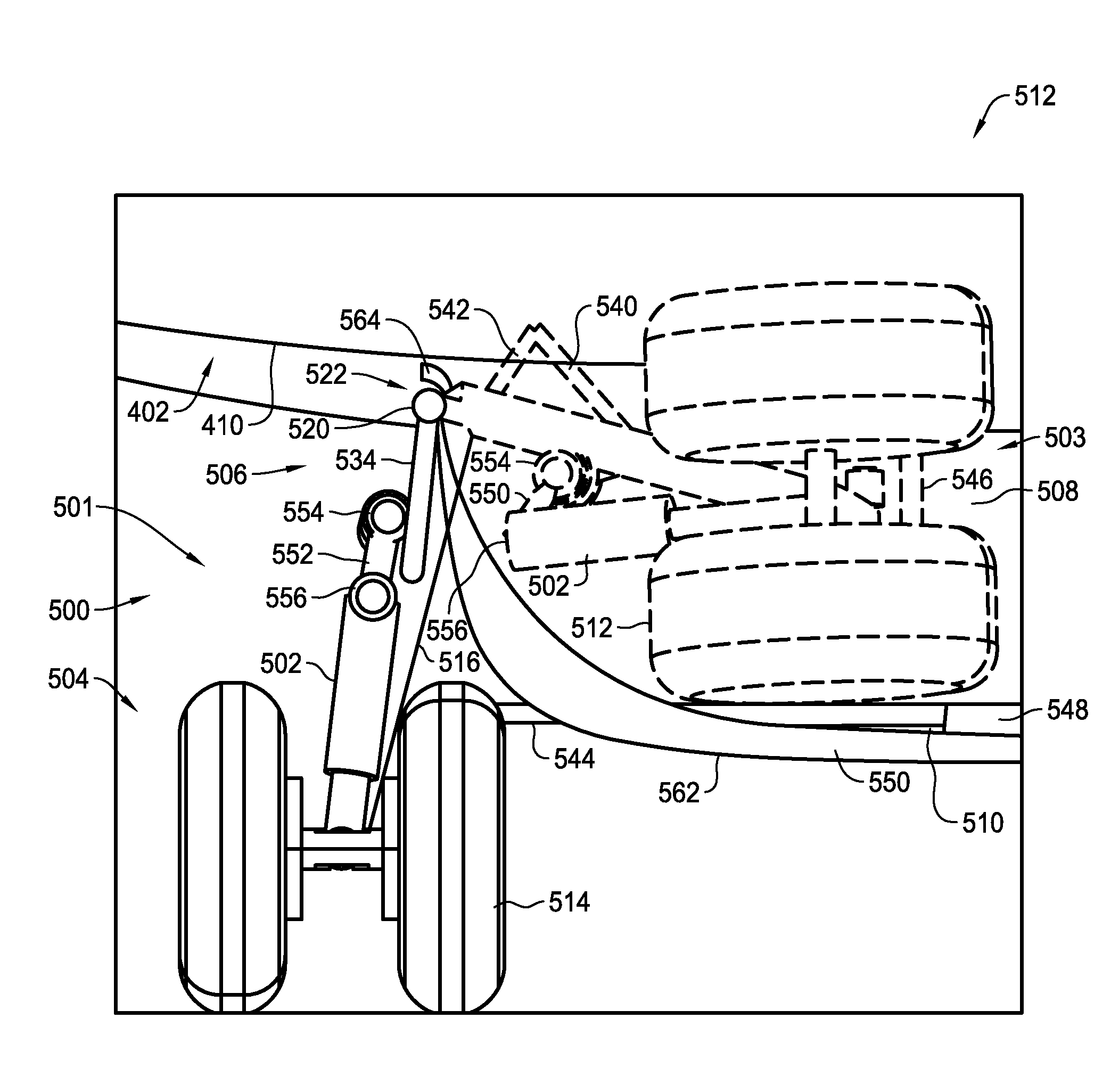

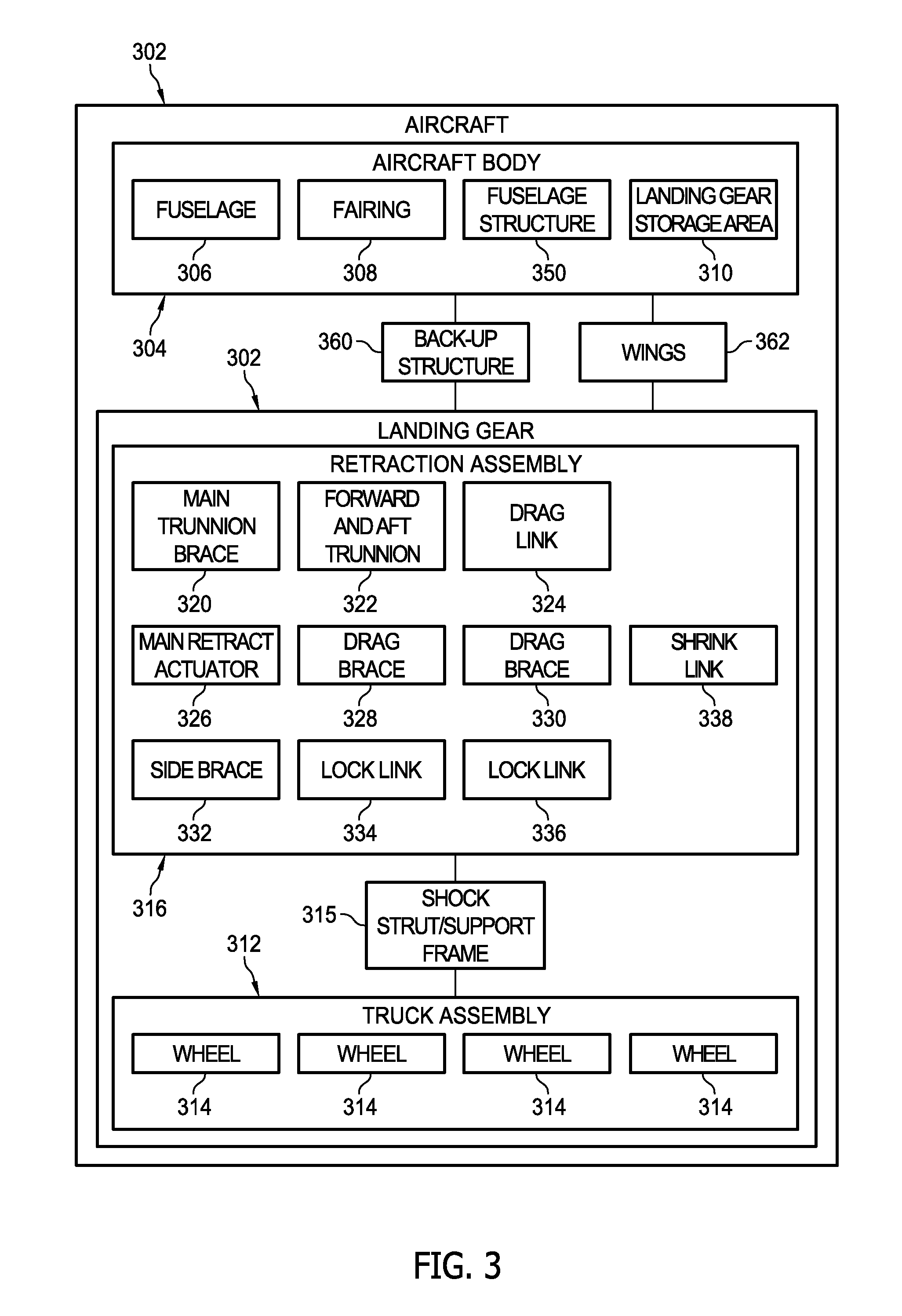

Fuselage-mounted landing gear assembly for use with a low wing aircraft

An aircraft comprises at least one wing comprising a trailing edge flap that is selectively moveable between a stowed position and an extended position. The aircraft also includes a fuselage comprising a first gear door on a side of the fuselage and a second gear door on a bottom of the fuselage. The first gear door is moveable in a gear door envelope between a closed position and an open position. The wing is coupled to the fuselage in a low-wing configuration. A landing gear assembly is coupled to the fuselage and is selectively moveable between a retracted position and a deployed position. The trailing edge flap may be extended simultaneously with, before, or after deployment of the landing gear assembly and opening of the first gear door.

Owner:THE BOEING CO

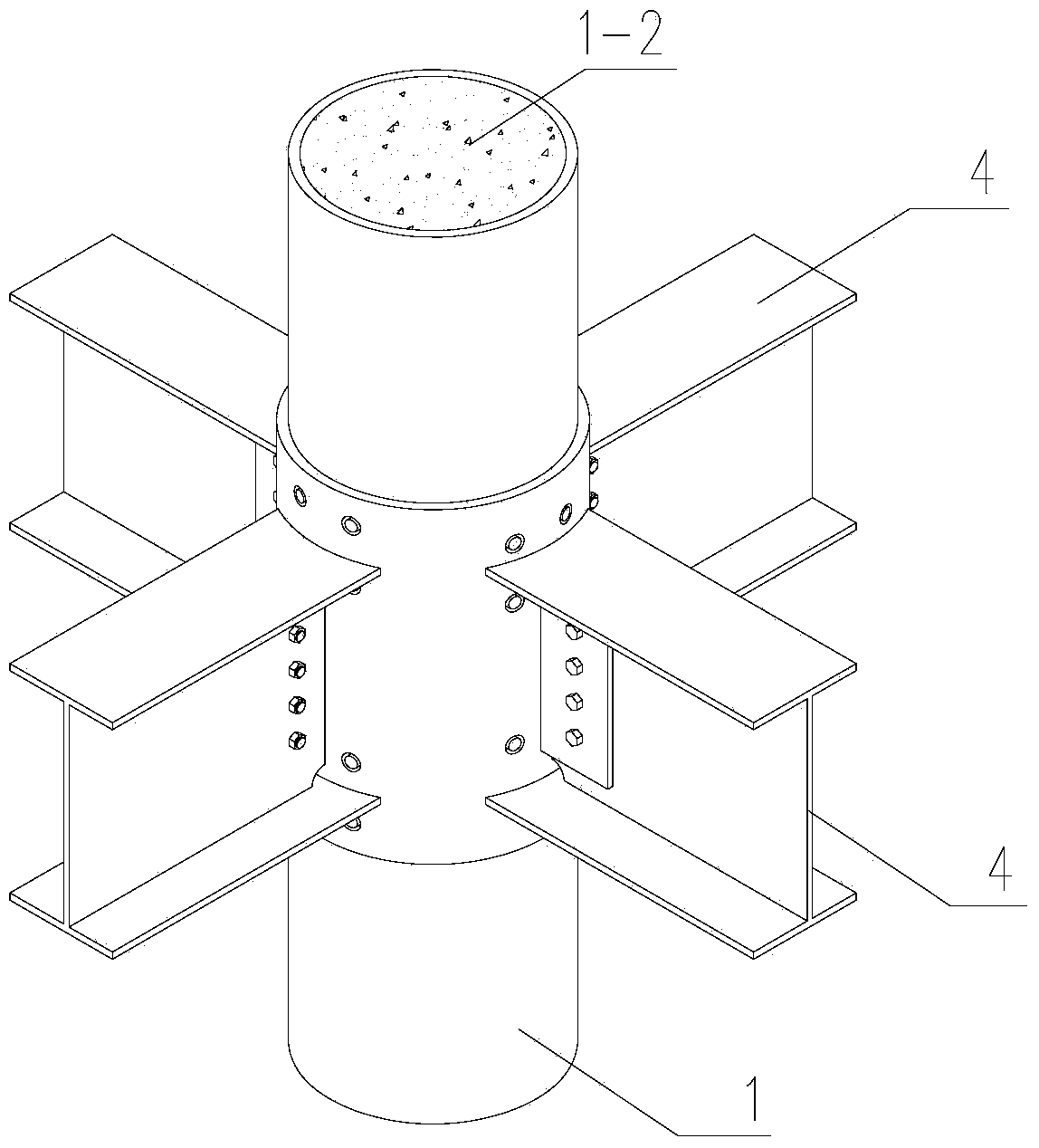

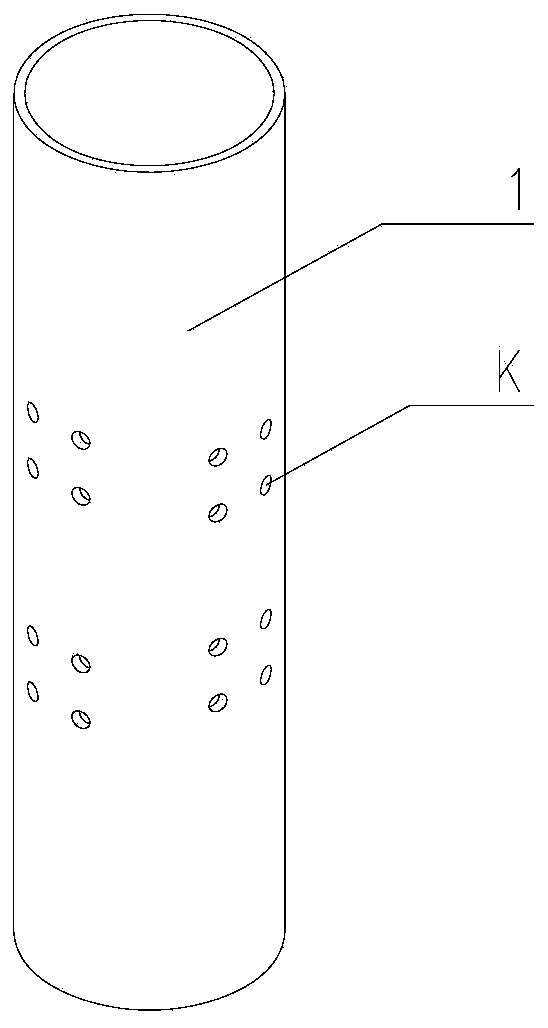

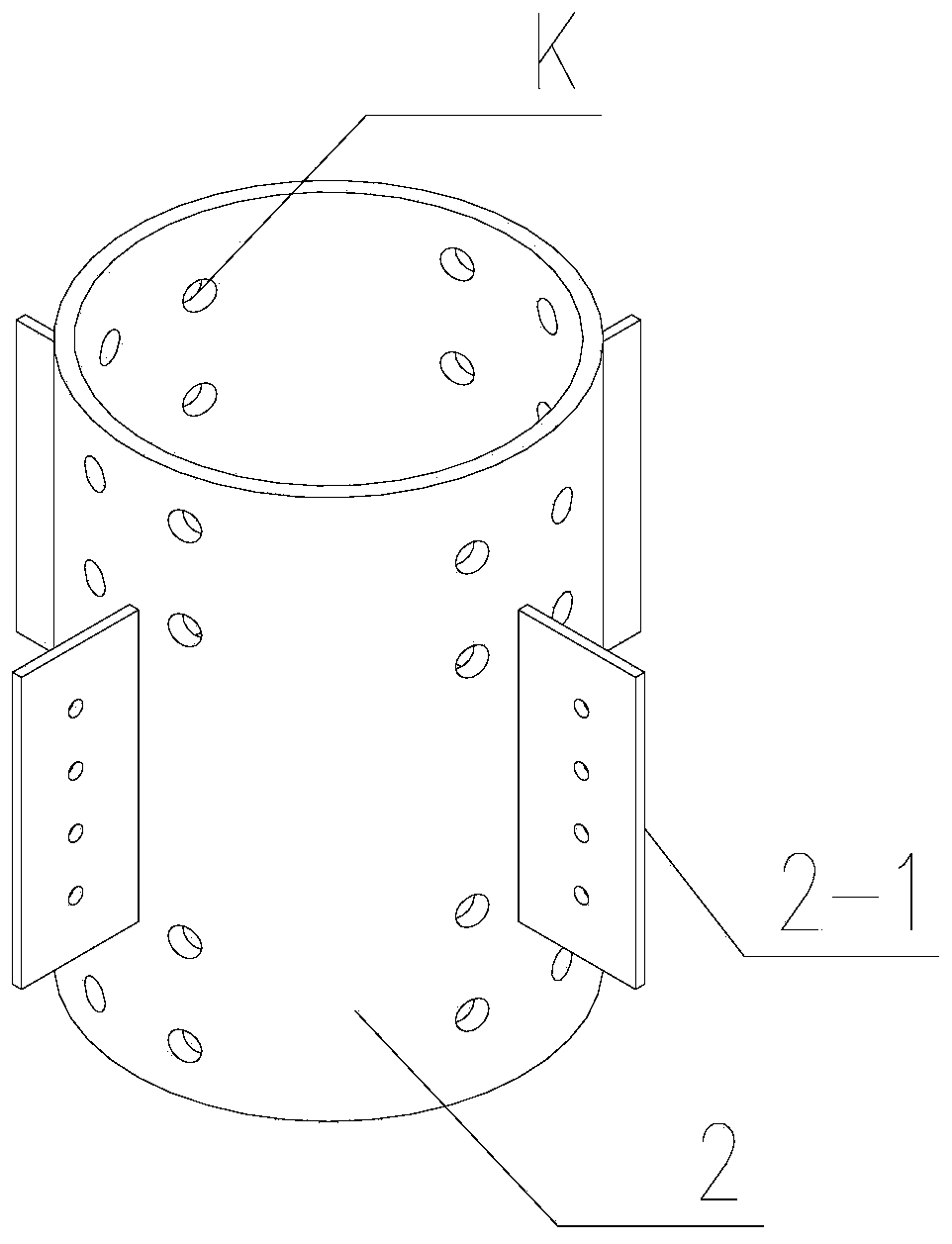

Connection joint of concrete filled steel tubular column and beams

InactiveCN104032838AIncrease stiffnessGuaranteed continuityBuilding constructionsSteel barSteel columns

The invention provides a connection joint of a concrete filled steel tubular column and beams, and belongs to the field of architectural structures. The peripheral surface of a steel column jacket at the connection joint bodies of the concrete filled steel tubular column and the beam ends is sleeved with a steel sleeve in a matched mode, the edge of the upper end and the edge of the lower end of the steel sleeve are fixedly welded to the steel column jacket, the peripheral surface of the steel sleeve is radially connected with steel connection boards corresponding to the beam ends at intervals, a circle of upper opposite-pull steel bar hole set and a circle of lower opposite-pull steel bar hole set which are correspondingly through are formed in the periphery of the steel sleeve and the inner layer of the steel column jacket, opposite-pull steel bars correspondingly penetrate through the upper opposite-pull steel bar hole set and the lower opposite-pull steel bar hole set, and namely an upper opposite-pull steel bar grid net and a lower opposite-pull steel bar grid net are formed in the steel column jacket of the concrete filled steel tubular column; the steel connection boards and the sleeve wall of the steel sleeve outside the concrete filled steel tubular column are correspondingly connected with webs of H-type steel connectors at the beam ends and upper and lower wing edge board ends respectively, and the concrete filled steel tubular column and the beams are connected in an integrated mode after a concrete layer in the steel column jacket of the concrete filled steel tubular column is poured. According to the connection joint, the overall strength of the concrete filled steel tubular column is enhanced by enhancing the joint bodies.

Owner:HUBEI HONGYI STEEL CONSTR ENG

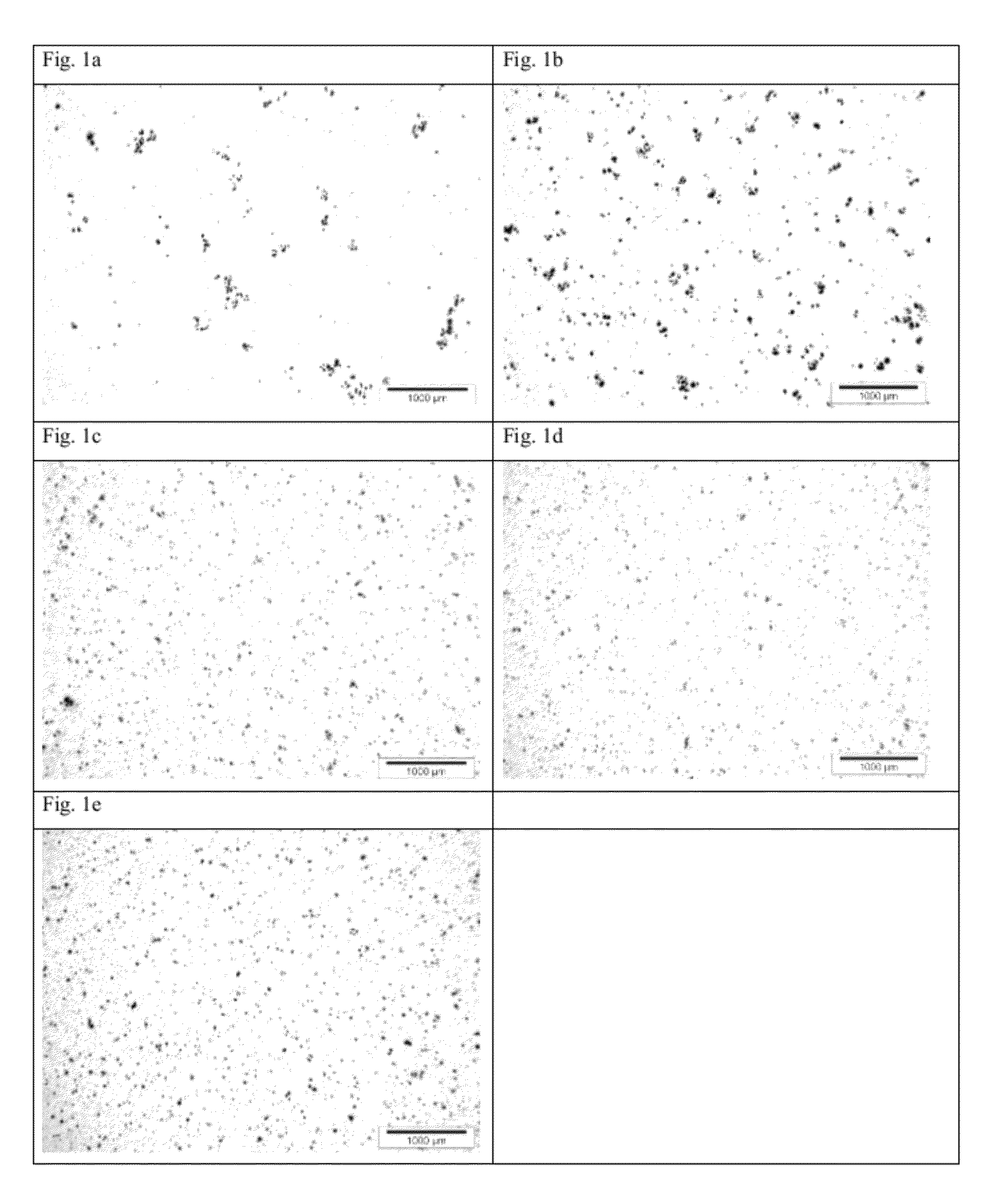

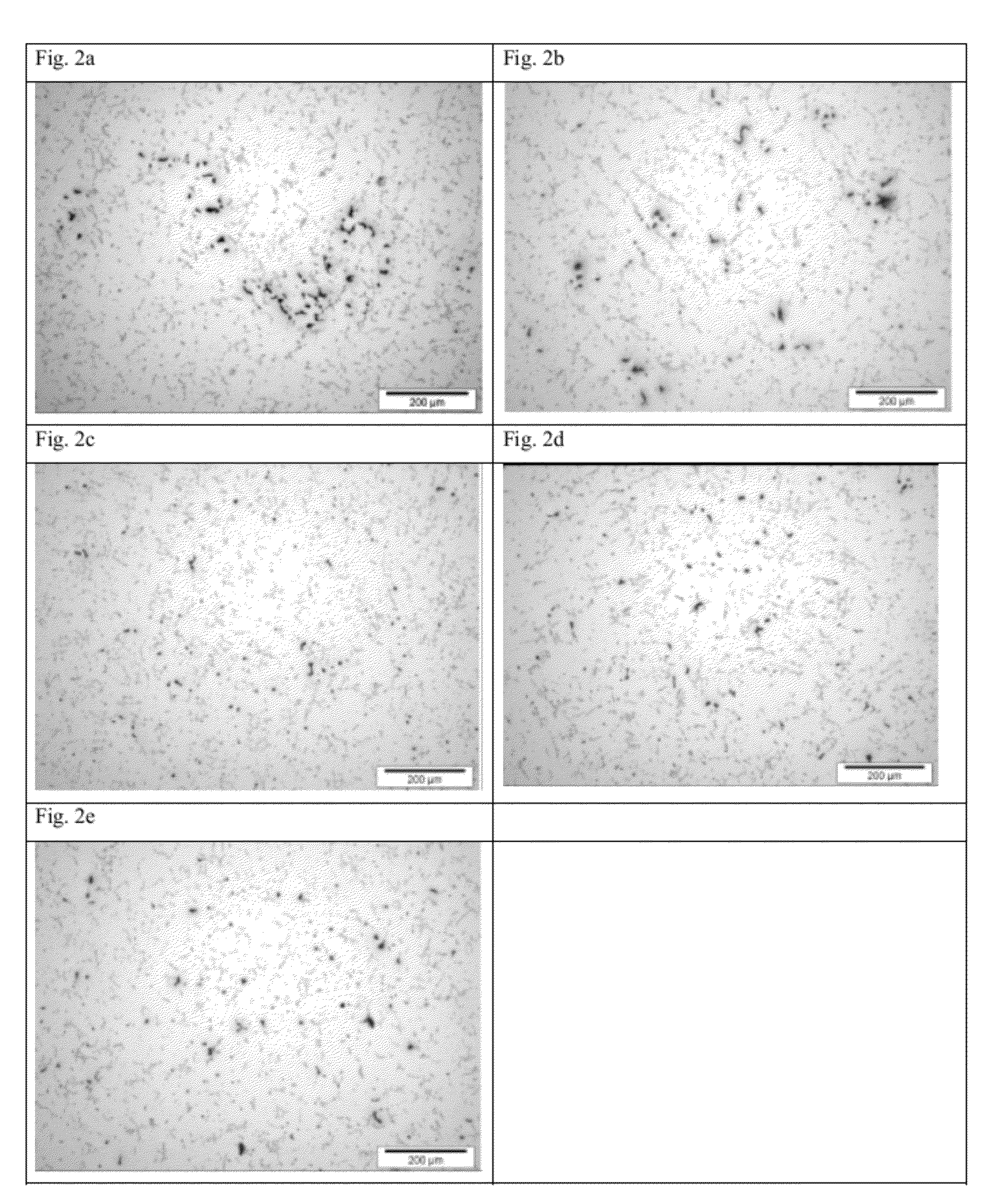

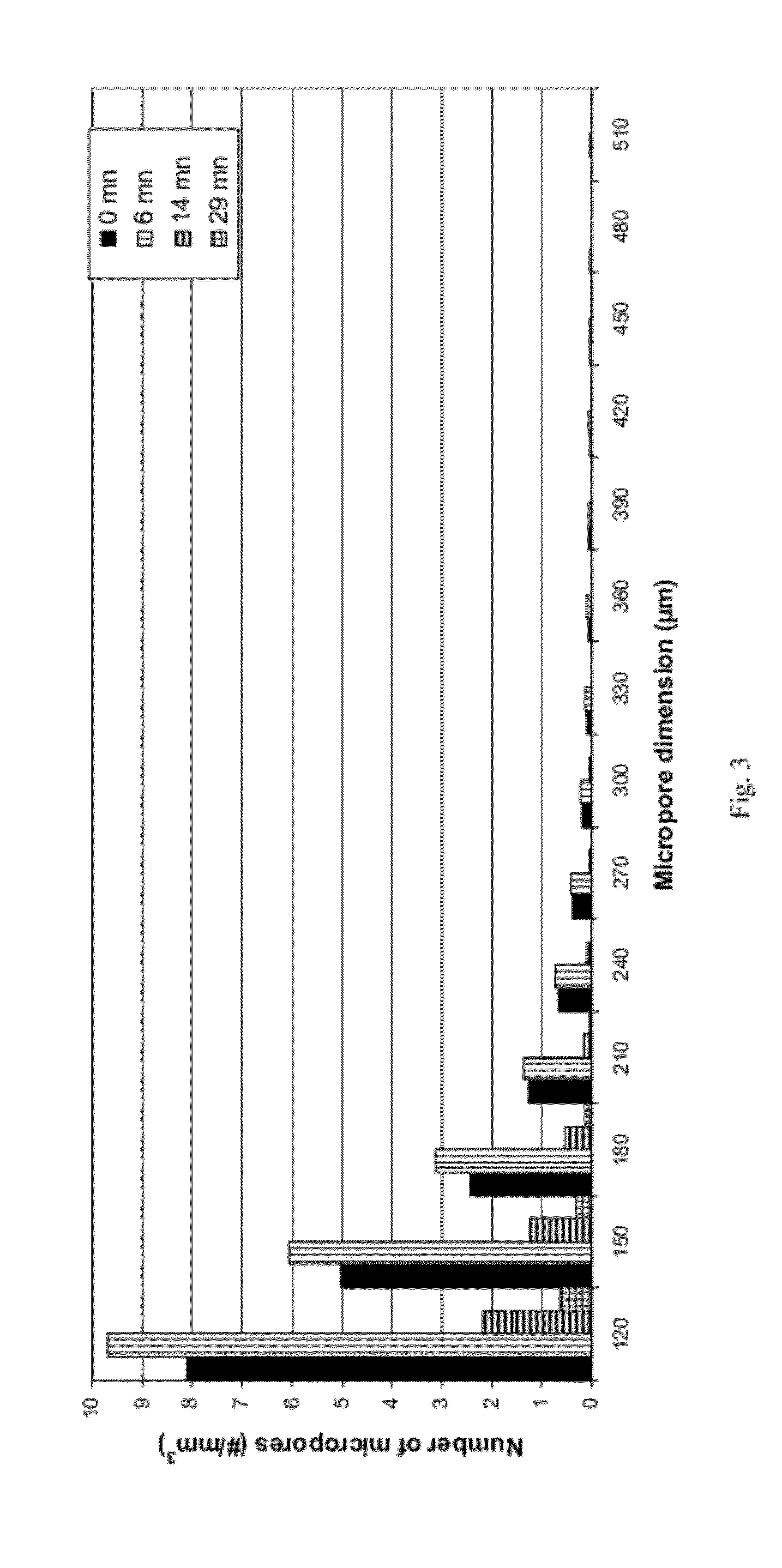

Manufacturing method of making aluminum alloy semi-finished product with improved microporosity

The invention relates to a manufacturing method for making an unwrought semi-finished product having at mid thickness a density of micropores of size greater than 90 μm less than 50% and preferably less than 20% of the density of micropores of size greater than 90 μm obtained by a method according to prior art. The method according to the invention comprises in particular an ultrasound treatment step for the molten metal bath in a furnace and / or a vessel using an immersed device comprising at least one ultrasound transmitter. The semi-finished products obtained according to the method of the invention are particularly advantageous for manufacturing by rolling sheets designed for the aircraft industry to produce spars, ribs, upper and lower wing skins and for manufacturing by extrusion sections designed for the aircraft industry to produce stiffeners.

Owner:CONSTELLIUM ISSOIRE

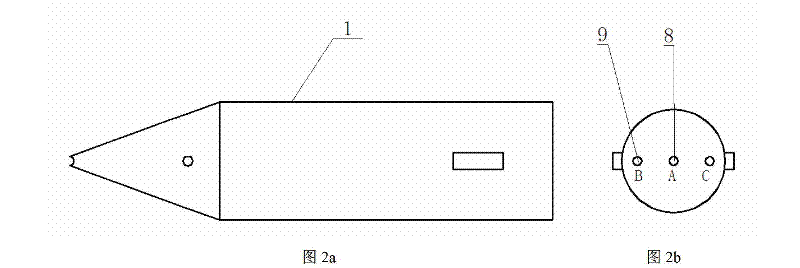

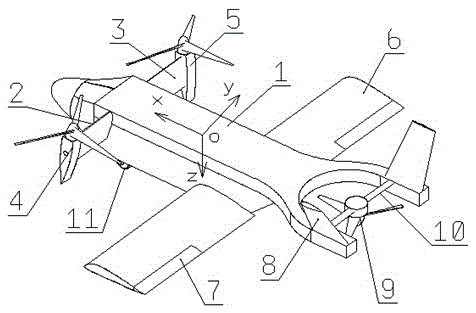

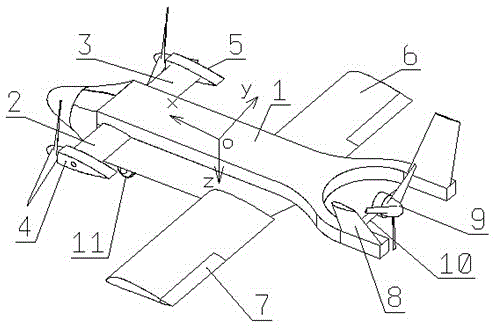

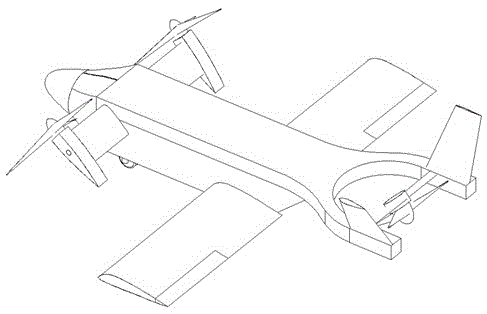

Power-driven tilt three-rotor unmanned aerial vehicle

InactiveCN106800089AImprove flight efficiencyImprove applicabilityCanard-type aircraftVertical landing/take-off aircraftsRotational axisShortest distance

The invention provides a power-driven tilt three-rotor unmanned aerial vehicle. The power-driven tilt three-rotator unmanned aerial vehicle has flight characteristics of both a helicopter and a fixed-wing aircraft and can take off and land in a vertical and short-distance way. The integral structure of the power-driven tilt three-rotor unmanned aerial vehicle is composed of all-moving canard wings, straight low wings and a fixed V tail. Two motors and rotors of the unmanned aerial vehicle are fixed at the wing tips of the canard wings and can independently tilt by certain angles along with the canard wings, and another motor and rotor of the unmanned aerial vehicle are installed in the V tail and can tilt by certain angles around a rotating shaft. When the rotating shafts of the thee rotors of the unmanned aerial vehicle tilt to a position near a Z axis, the unmanned aerial vehicle can fly like the helicopter; and when the thee rotors tilt to a position near an X axis, the unmanned aerial vehicle can fly like the fixed-wing aircraft. Through simultaneous control of the thrust and directions of the thee rotors, the reaction torque of the rotors is overcome and the posture of the unmanned aerial vehicle is controlled. The unmanned aerial vehicle provided by the invention can take off and land in a limited place or runway to execute special tasks and is improved in flight speed, duration of flight and payload.

Owner:AVIC GUIZHOU AIRPLANE

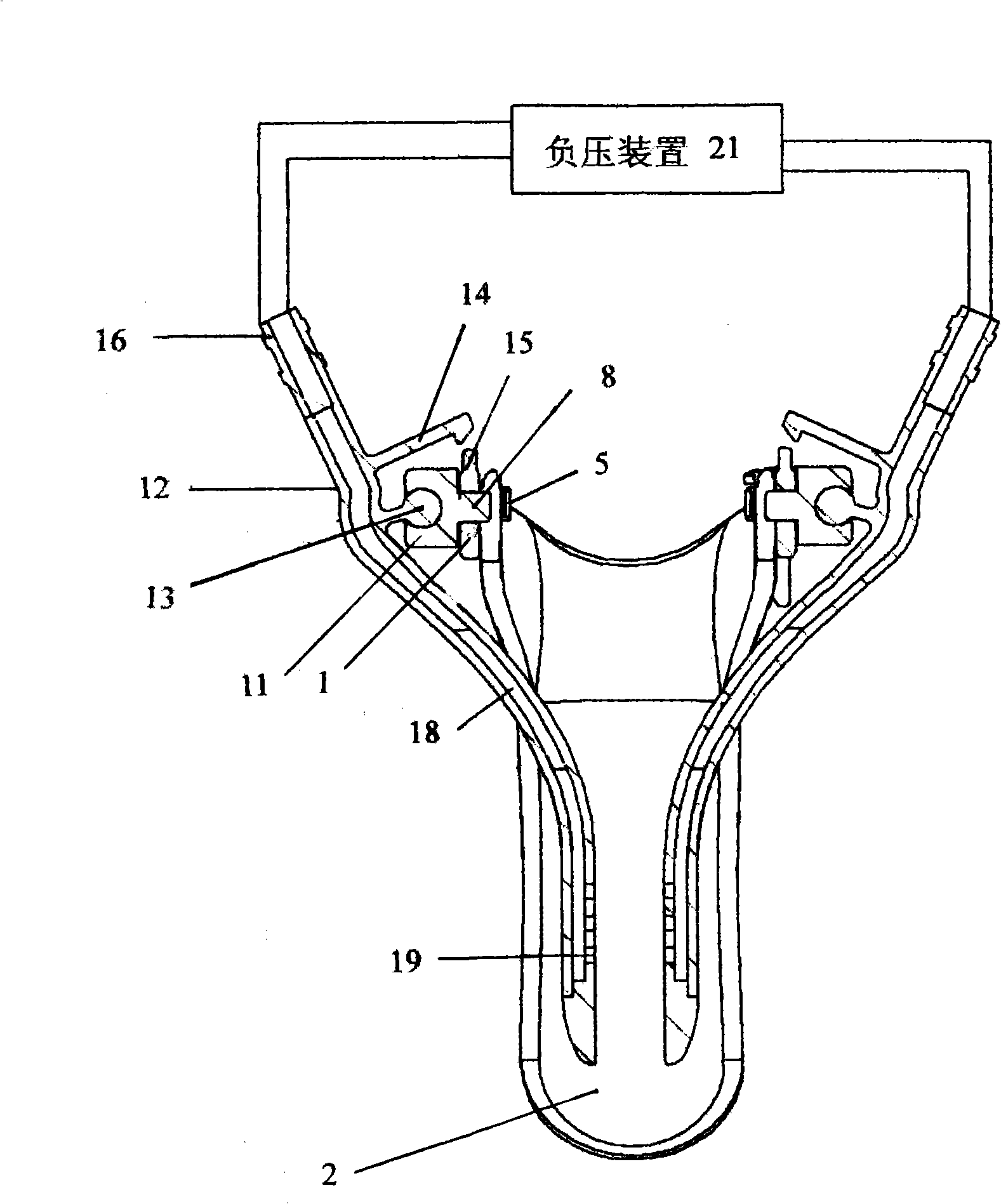

Vaginal dilator with double side wings

The invention provides a vaginal dilator with double side wings, comprising an upper wing, a pressing handle, a lower wing, and a handle; the upper wing and the lower wing are connected through a pin; the pressing handle and the handle are meshed with each other through a first dilation fixing structure; the vaginal dilator further comprises an arc flexible locating sleeve rotatably connected with the upper wing; both ends of the sleeve are respectively provided with a mounting base; the base is provided with a mounting hole for holding the side wings capable of being held between the upper and the lower wings; the rear part of the side wings is provided with a second dilation fixing device meshed with the upper part of the rear end of the upper wing; and a passage can be installed in the side wing. Compared with the prior art, the vaginal dilator with double side wings has the advantages of wider field range, simple structure and easy manufacturing.

Owner:江苏奥博金医药科技有限公司

Methods for replacing a cardiac valve

Owner:THE CLEVELAND CLINIC FOUND

Tall V/STOL aircraft

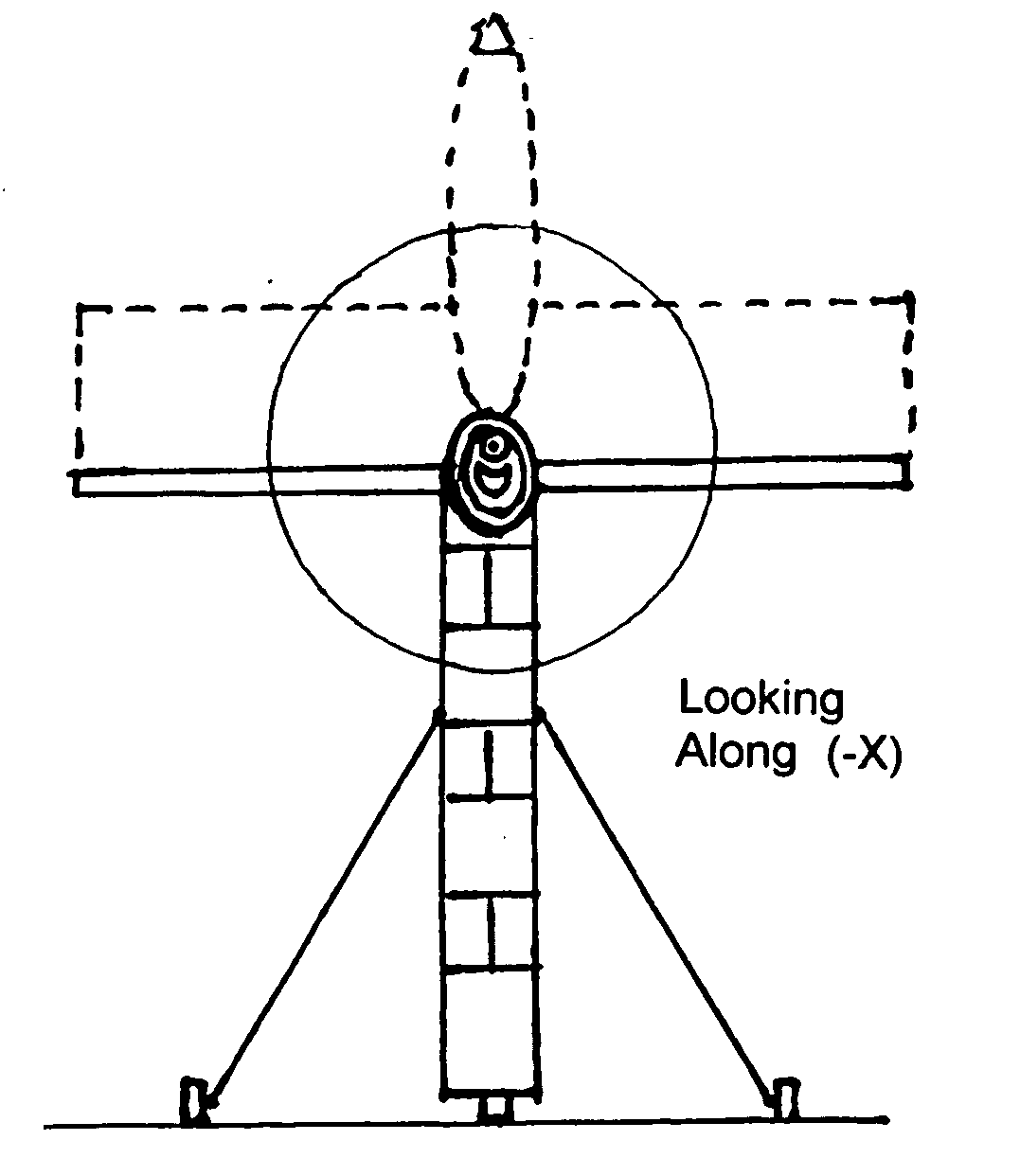

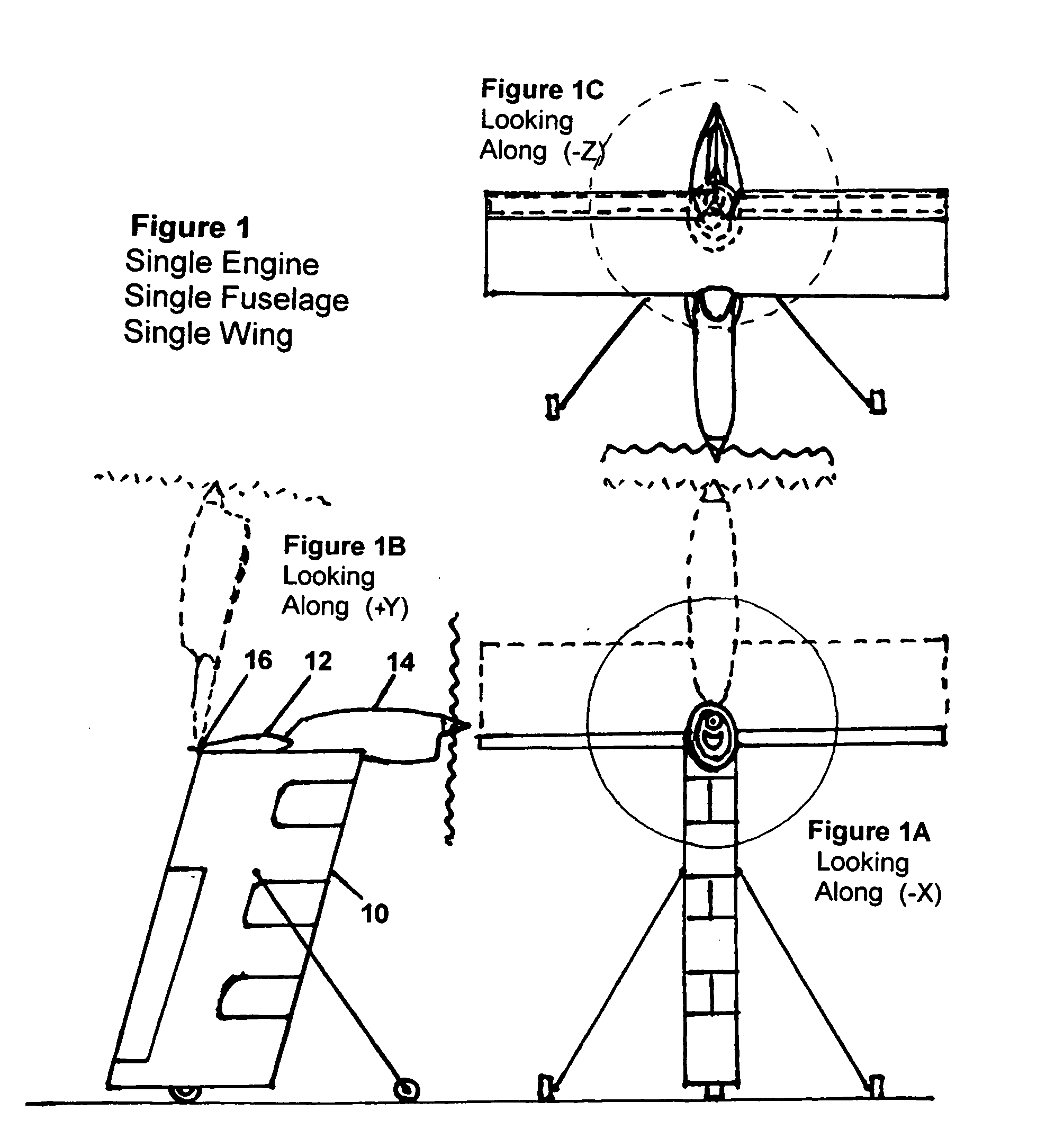

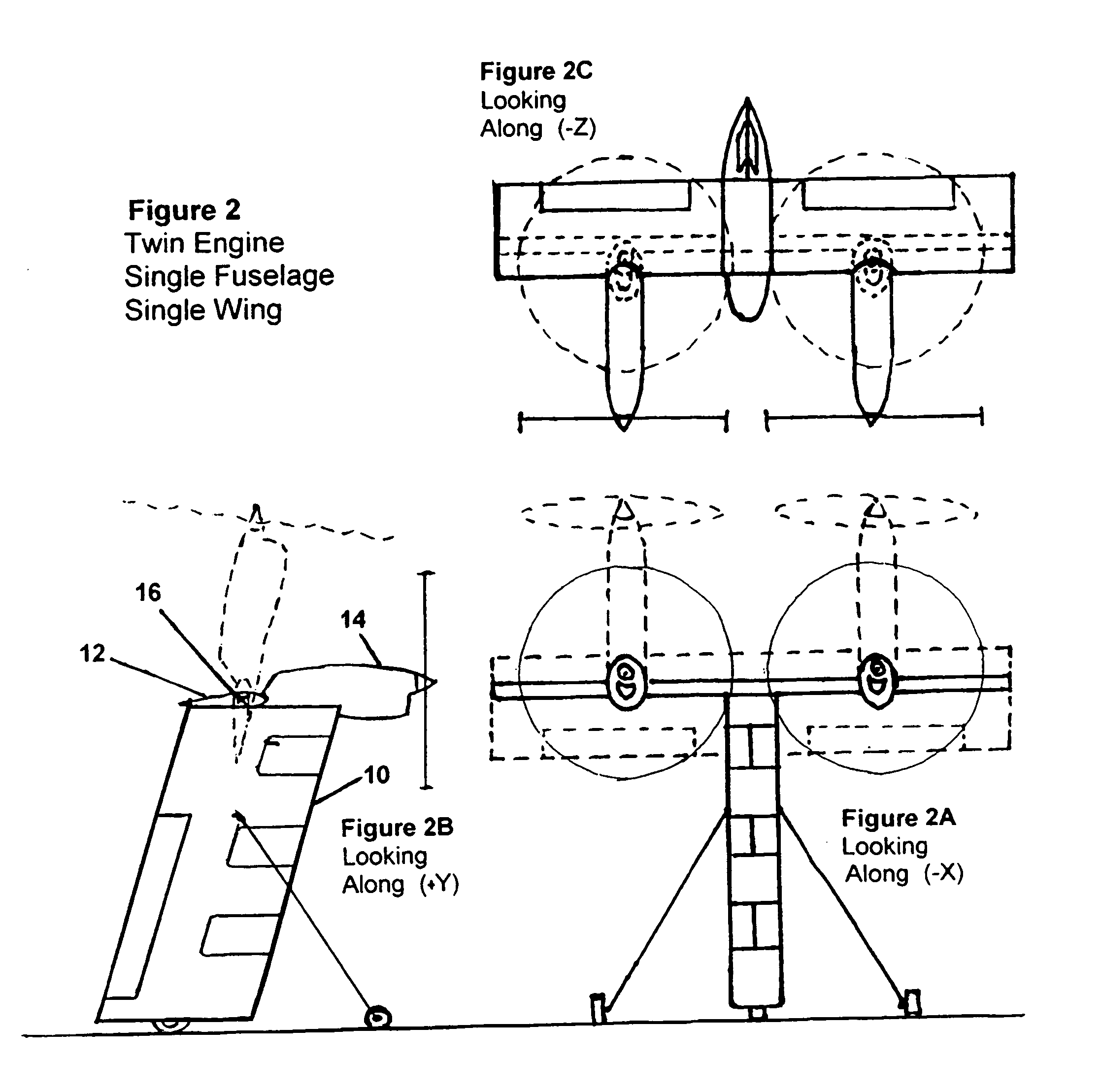

InactiveUS20060032970A1Improve the stability of actionMinimizes ground effectAircraft stabilisationAll-wing aircraftLeading edgeHorizontal axis

A vertical or short takeoff and landing (V / STOL) airplane is described having a vertical form factor. Making the airplane tall has many advantages when operating in hover mode close to the ground. Several variations of the design are described. The preferred embodiment consists of two tall fuselage2 structures having an airfoil shape in plan view. As high above the ground as practical a “lift wing” spans the space between these fuselages. This wing may be equipped with lift augmentation systems to facilitate V / STOL flight. In the center of the span on the leading edge of the lift wing is placed a turboprop engine. Alternatively, the wing and attached engine can be made to tilt about a horizontal axis. For takeoff the wing will be tilted skyward. A second wing slightly below and behind the lift wing has a pusher engine located on the trailing edge. This lower wing and engine is also able to tilt about a horizontal axis parallel to the lift wing. During takeoff this lower engine is pointed downward toward the ground. This lower wing contains aerodynamic control surfaces to provide attitude and position control. Subsequent to liftoff the wings and engines tilt into a horizontal position to provide cruise lift and thrust. At the end of the flight the wings and attached engines are tilted back to provide vertical lift for hover, maneuvering, and soft landing. 2 “Fuselage” is used here even though it substantially differs from the conventional fuselage (and its French origins meaning, “spindle shaped”) since in plan view it is an airfoil shape of large thickness. It will be used here for lack of a better word. Think of fuselage as meaning “where the pilot, passengers and cargo are located”.

Owner:ALLEN NORMAN CARTER

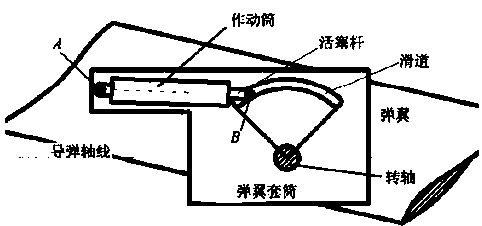

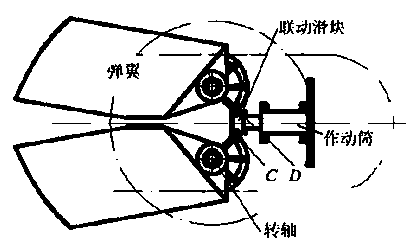

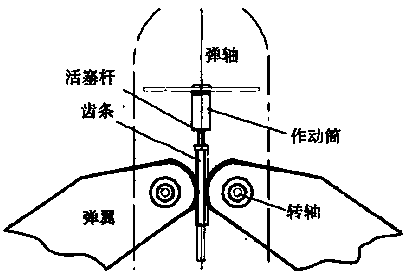

Wing folding and unfolding mechanism of unmanned aerial vehicle

The invention discloses a wing folding and unfolding mechanism of an unmanned aerial vehicle. The mechanism mainly comprises a vehicle body reinforcing frame, a wing rotary shaft, a rotary body driving part, an upper wing, a lower wing and a coaxial contrarotation mechanism. When the unmanned aerial vehicle is launched, a fixed cylinder is opened, and coaxial contrarotation equal-angle movement of the upper and lower wings is realized through the coaxial contrarotation mechanism under the effect of a torsional spring. The mechanism disclosed by the invention is simple in integral structure, compact, high in transmission efficiency by applying gear drive and small in frictional force. The two wings share the rotary shaft, so that the area occupied by the wings is reduced and the unmanned aerial vehicle is convenient to transport and launch, thereby further improving the capacity of systematic combat.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

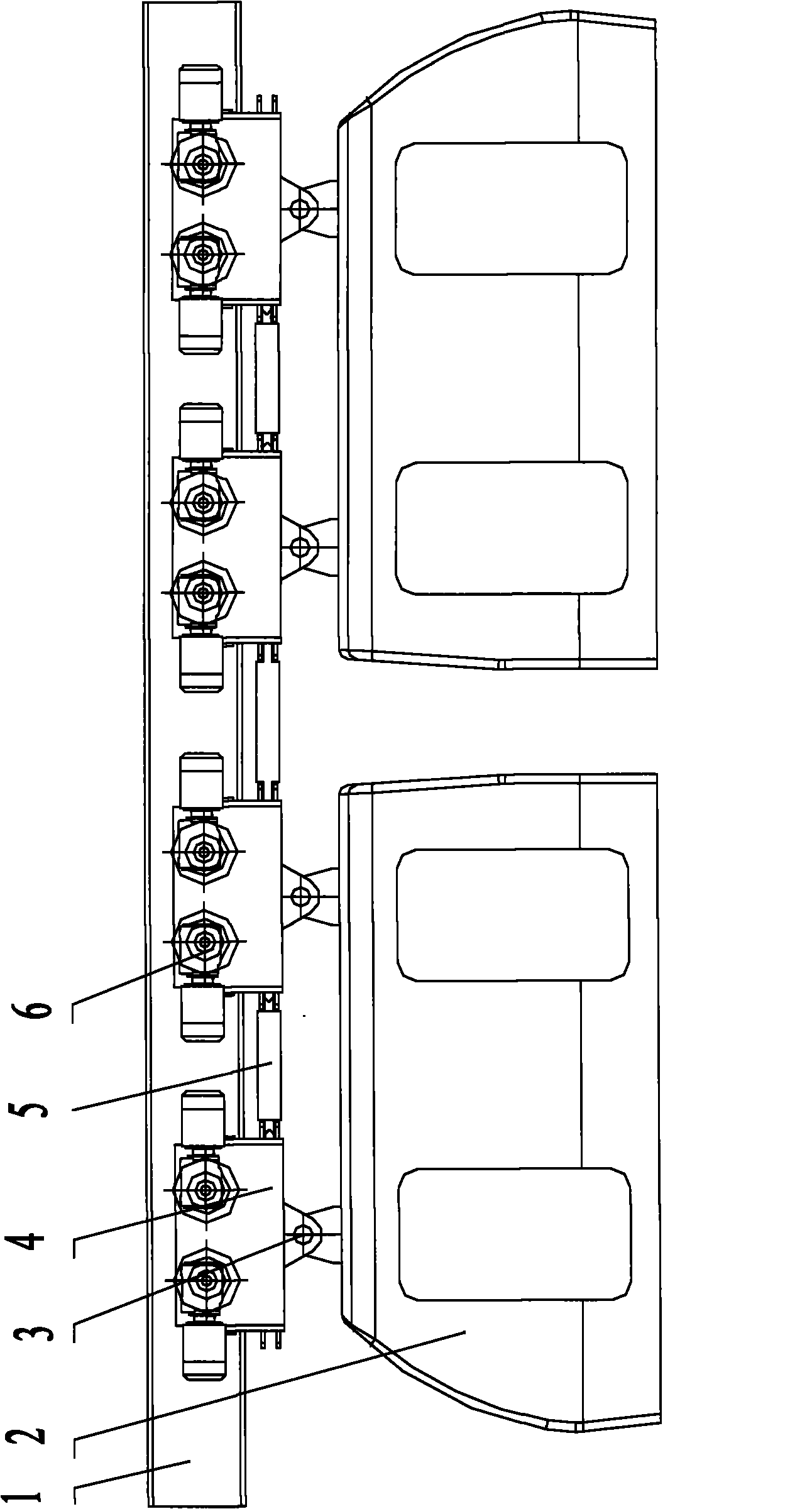

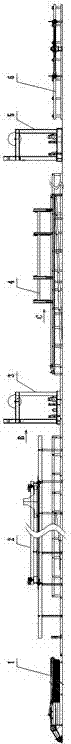

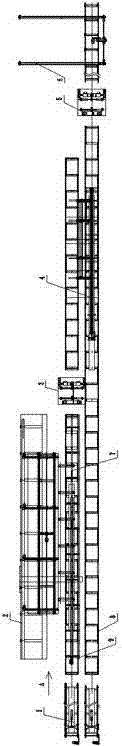

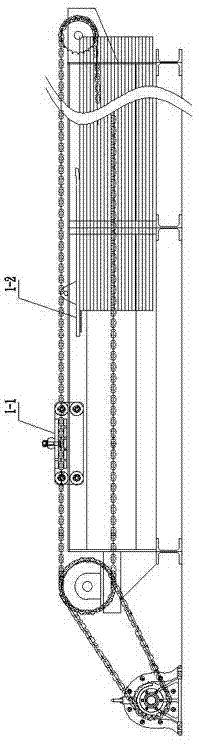

Automatic non-standard steel welding production line

ActiveCN104842083ARealize continuous automatic welding productionReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

An automatic non-standard steel welding production line comprises an automatic wing plate pushing system, wing plate conveying systems, an automatic web discharging and feeding system, an automatic T-steel welding system, an automatic T-steel turnover system, an automatic H-steel welding system and an automatic finished product conveying system. The wing plate conveying systems include an upper wing plate conveying system and a lower wing plate conveying system, and the wing plate conveying systems and the automatic web discharging and feeding system are arranged vertically. In the automatic non-standard steel welding production line, all the devices are simple in structure, easy to operate, stable in mutual connection, continuous automatic welding production of non-standard steel can be realized, weld seams on two sides of a plate are welded at the same time, and the automatic non-standard steel welding production line is small in distortion, less in capital investment, small in space occupation, suitable for non-standard steel manufactures with various scales, timesaving, laborsaving, manpower saving, high in working efficiency and good in product quality.

Owner:LUANXIAN ZHONGXING STEEL STRUCTURE

Steel column and beam structure with corrugated steel web and special welding device thereof

InactiveCN101761184AReduce weightImprove seismic performanceWelding/cutting auxillary devicesGirdersEarthquake resistanceDrive wheel

The invention relates to a steel column and beam structure used in the building and a welding device thereof, particularly discloses a steel column and beam structure with a corrugated steel web and a special welding device thereof. The steel column and beam structure comprises an upper wing plate, a lower wing plate and a web plate arranged between the upper wing plate and the lower wing plate, wherein the upper wing plate and the lower wing plate are made of plates with the thickness of 4-30mm, the web plate is a corrugated steel web plate with the thickness of 4-10mm, and the surfaces of the upper wing plate, the lower wing plate and the web plate are prepared with 50-500Mu m of roughness; the welding device of the steel column and beam structure with the corrugated steel web comprises a welding tractor and a welding gun arranged on the welding tractor, wherein tool sliding bars which are symmetrical are arranged on the welding tractor, a magnetic adsorption piece is arranged at the bottom of the welding tractor, four driving wheels are symmetrically arranged at two sides of the magnetic adsorption piece, and a track positioning retainer is arranged in a bracket at the middle part of the welding tractor. The middle web plate adopts the corrugated steel web plate, the steel beam and column with the corrugated steel web is welded by using the special welding device, therefore, the invention has the advantages of light weight and strong earthquake resistance.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com