Industrial aquaculture automatic feeding system

An aquaculture and automatic technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of high labor intensity and low quantitative accuracy, and achieve the goals of reducing labor intensity, improving mechanization and automation, and saving labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

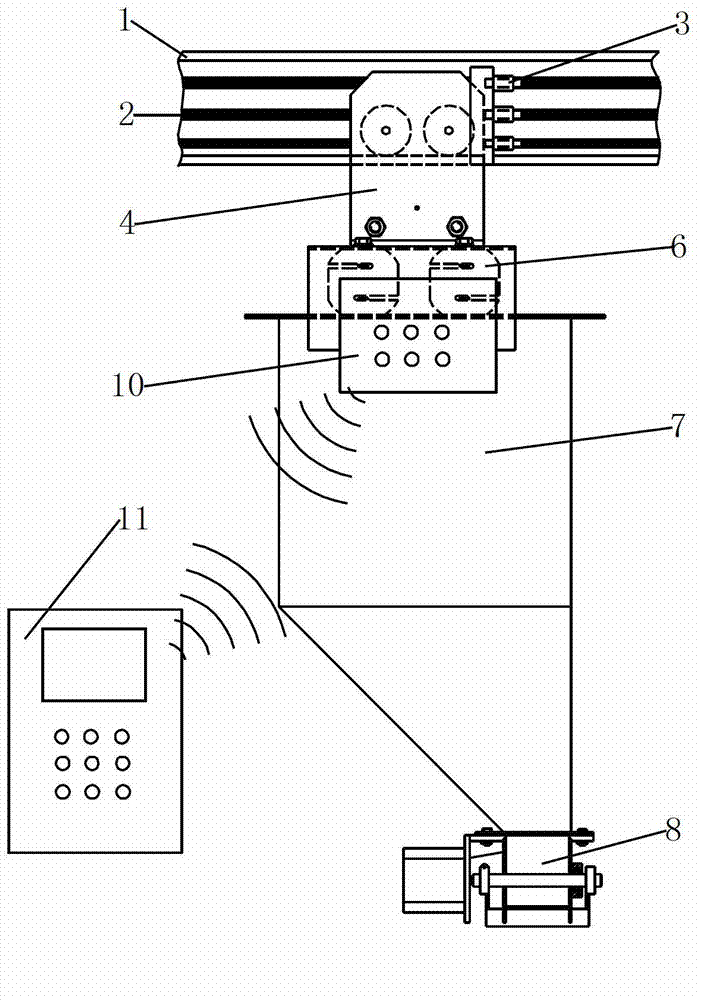

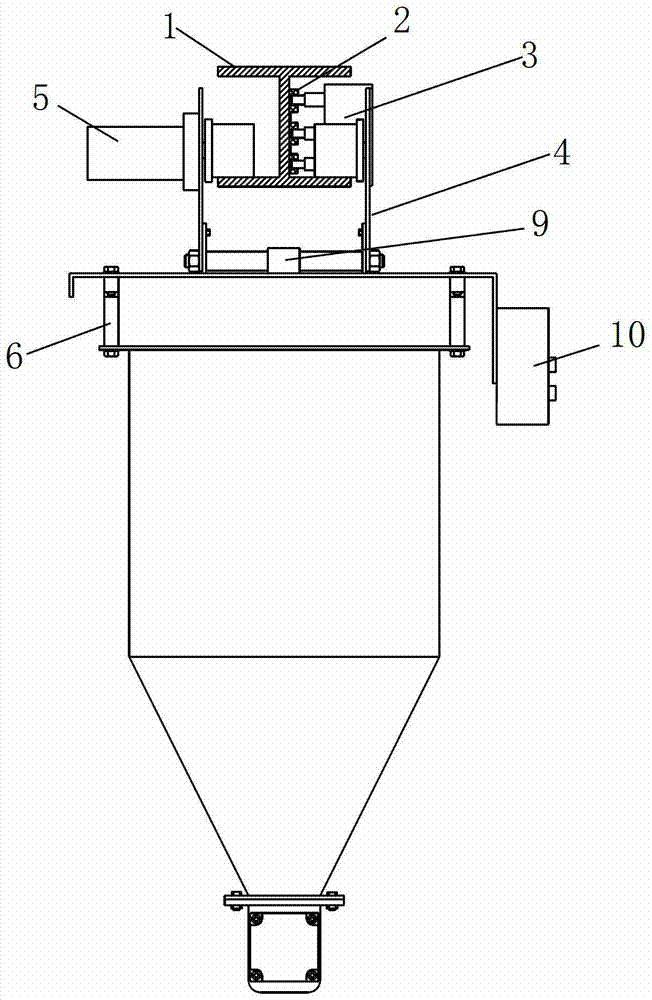

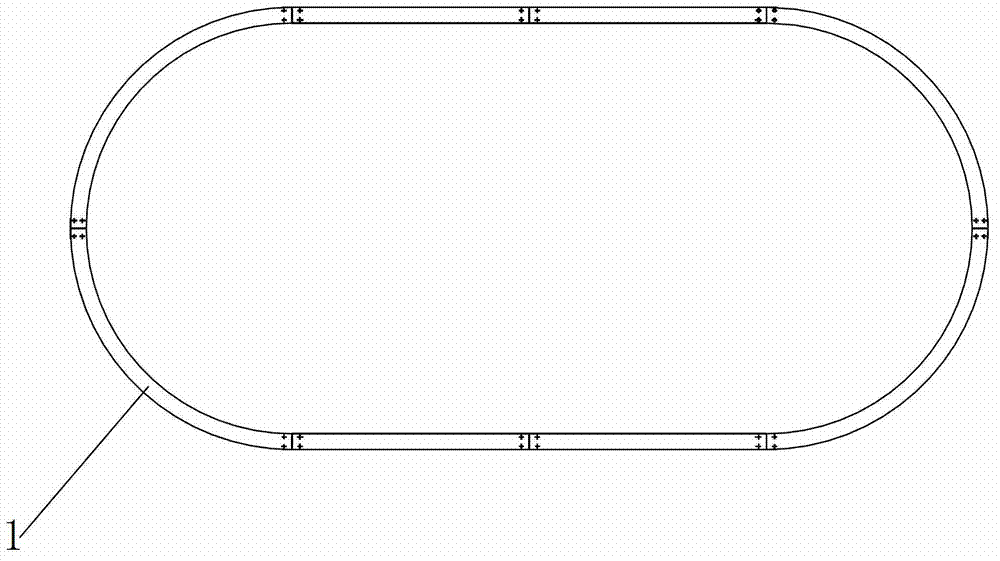

[0031] A newly designed factory automatic feeding system for aquaculture is mainly composed of walking system, feeding device, power system and control system. figure 1 As shown in the schematic diagram. The basic principle is: erect H-shaped steel track 1 above the fish pond, and set corresponding positioning identification boards corresponding to each fish pond on the track. After the feeding device walks along the track to the identification board, according to the feeding instructions issued by the automatic control system, the feeding is completed. corresponding feeding action. The opening and closing and opening of the feed bin outlet 20 are mainly controlled by the pull pressure sensor 6 in cooperation with the stepping motor 21, thereby accurately controlling the feeding speed and feeding amount.

[0032] Walking system is mainly made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com