Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

A technology for converting joints and reinforced concrete, which is applied in building construction and construction, and can solve problems such as enhanced steel and steel bar synergy, uneven force on steel supports, and unequal connections, so that the construction quality is easy to guarantee, Improvement of anti-seismic performance, effect of improving anti-seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

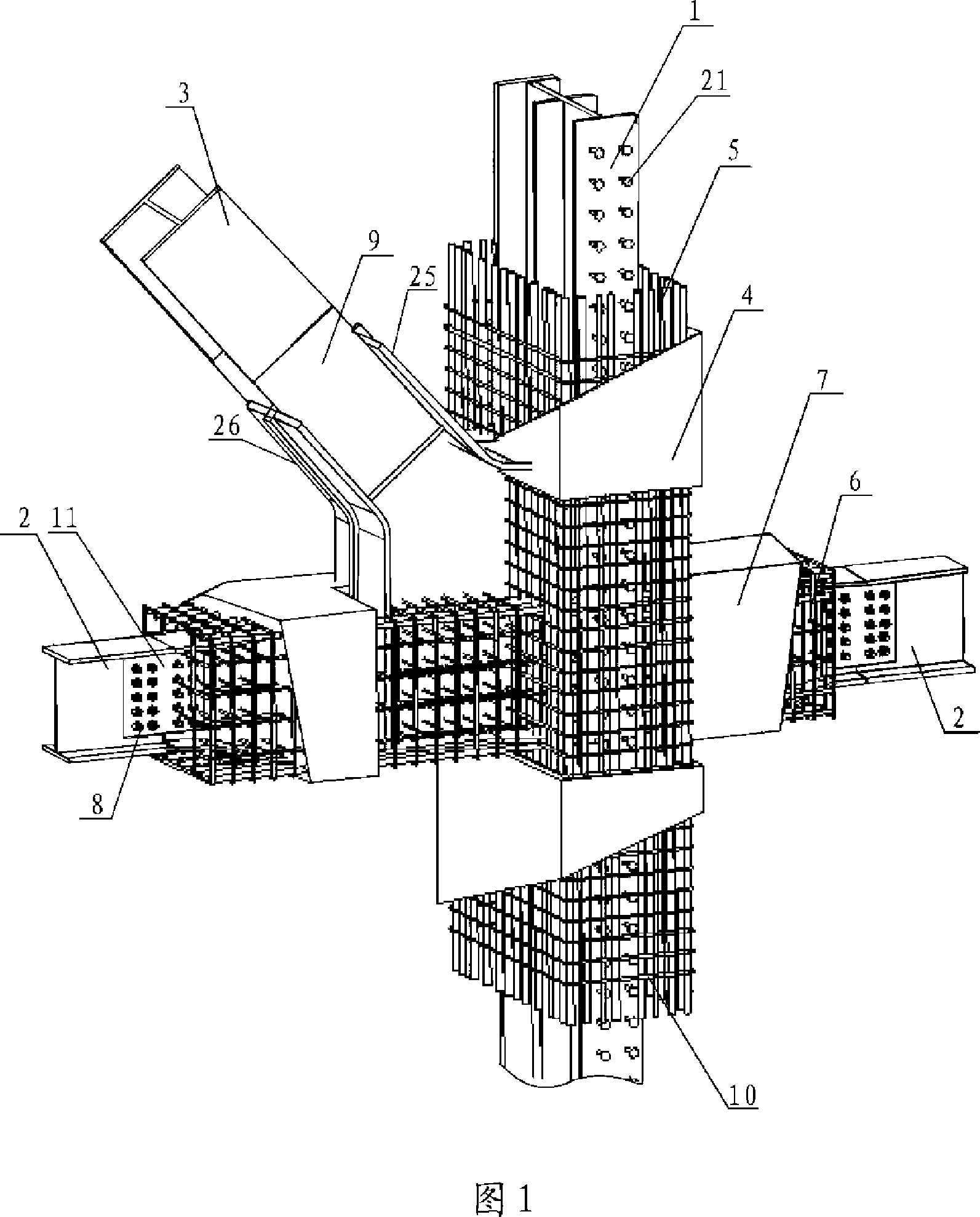

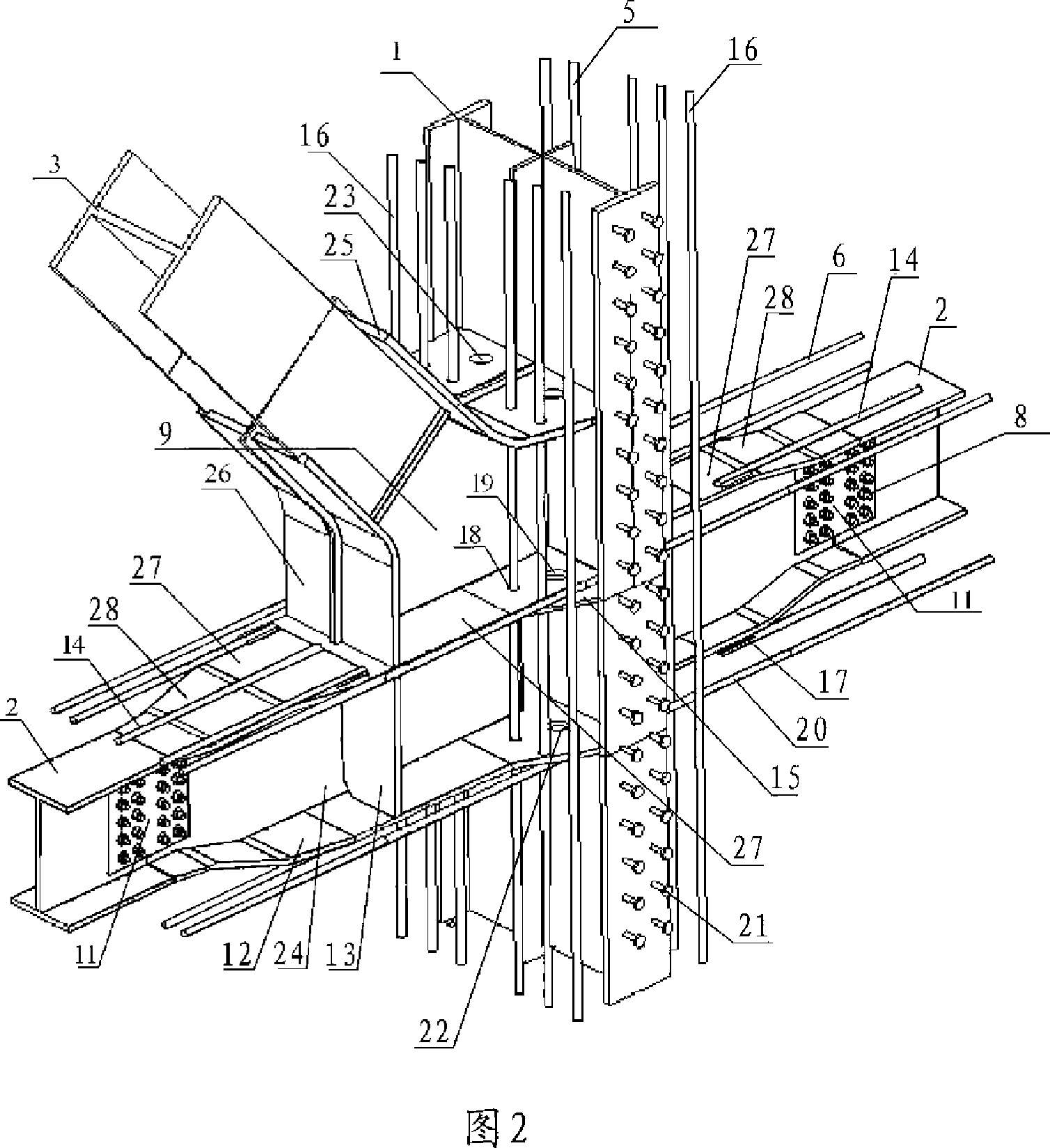

[0038] Embodiment 1 Referring to Fig. 1 and Fig. 2, the variable cross-section transition node of the steel-concrete frame steel support structure is handed over by the column medium steel 1, the beam medium steel 2, the steel support 3, the column reinforced concrete 4, and the beam reinforced concrete 7 And poured into one, the steel support 3 is handed over to the column medium steel 1 and the beam medium steel 2, which is characterized in that:

[0039] Column main reinforcement 5 and column stirrup 10 are distributed on the outer periphery of the column medium-shaped steel 1, and some column main reinforcement 5 passes through the ribs of the curved upper flange 25, the curved lower flange 26, and the widened and variable-section upper flange 27. hole 18. The corner reinforcement 16 in the main reinforcement of the column is located at the corner.

[0040] Beam steel bars 6 are distributed on the outer periphery of the beam medium steel 2; the upper iron 14 in the beam s...

Embodiment 2

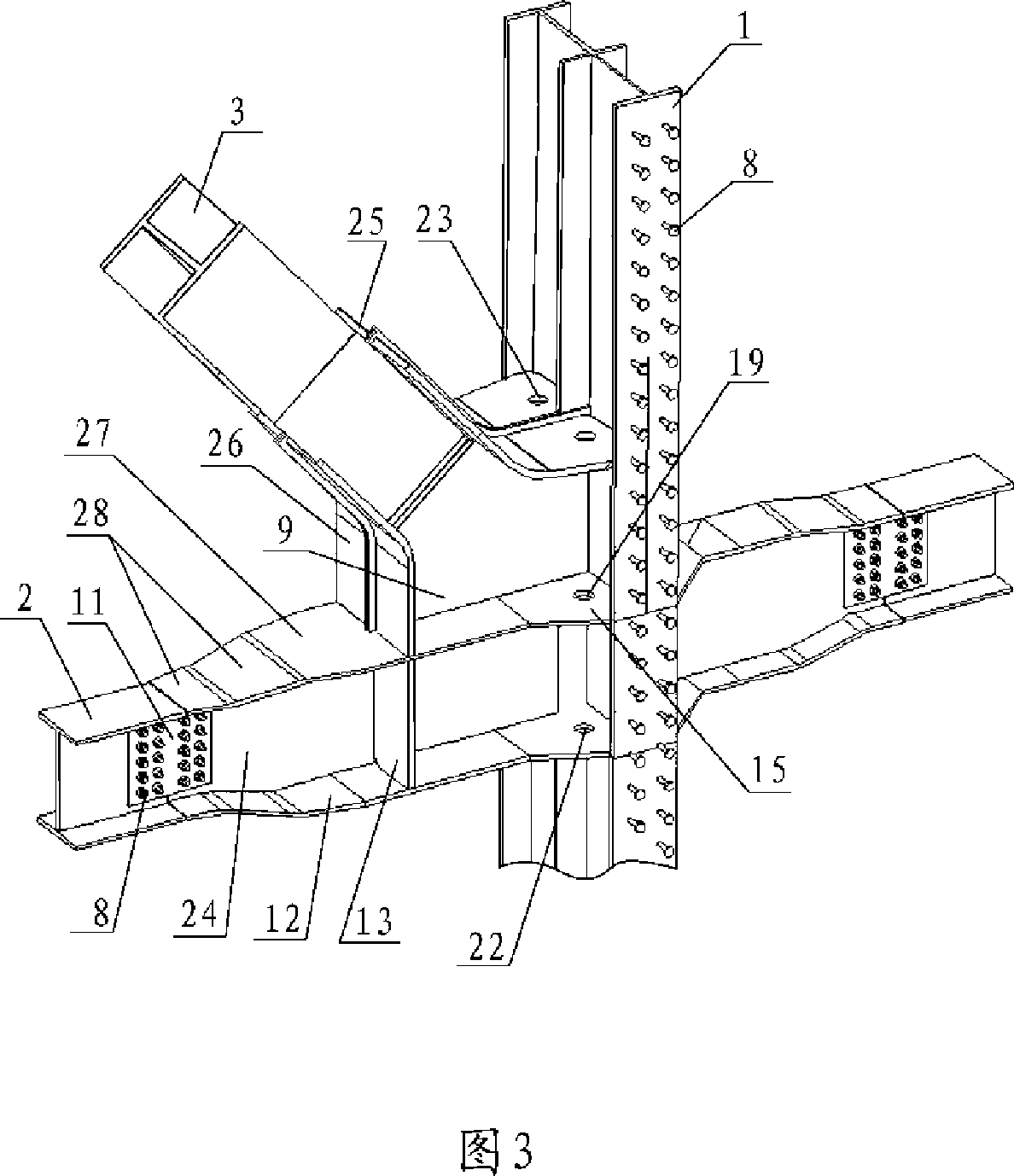

[0049] Embodiment 2 Referring to FIG. 3 , the difference from embodiment 1 is that there are no column main bars 3 and column stirrups 10 on the periphery of the column medium steel 1 , and there is no beam reinforcement 6 on the periphery of the beam medium steel 2 .

Embodiment 3

[0050] Referring to Fig. 4 of embodiment 3, the difference from embodiment 2 is that two orthogonal I-shaped steel shapes are selected for the column medium steel 1, so as to meet the needs of steel supports that can be connected in eight directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com