Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

A composite wall and external metal mesh technology, applied in the field of building composite walls, can solve the problems of incomplete connection structure, troublesome construction and high cost, and achieve the effects of reducing horizontal seismic action, high safety and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

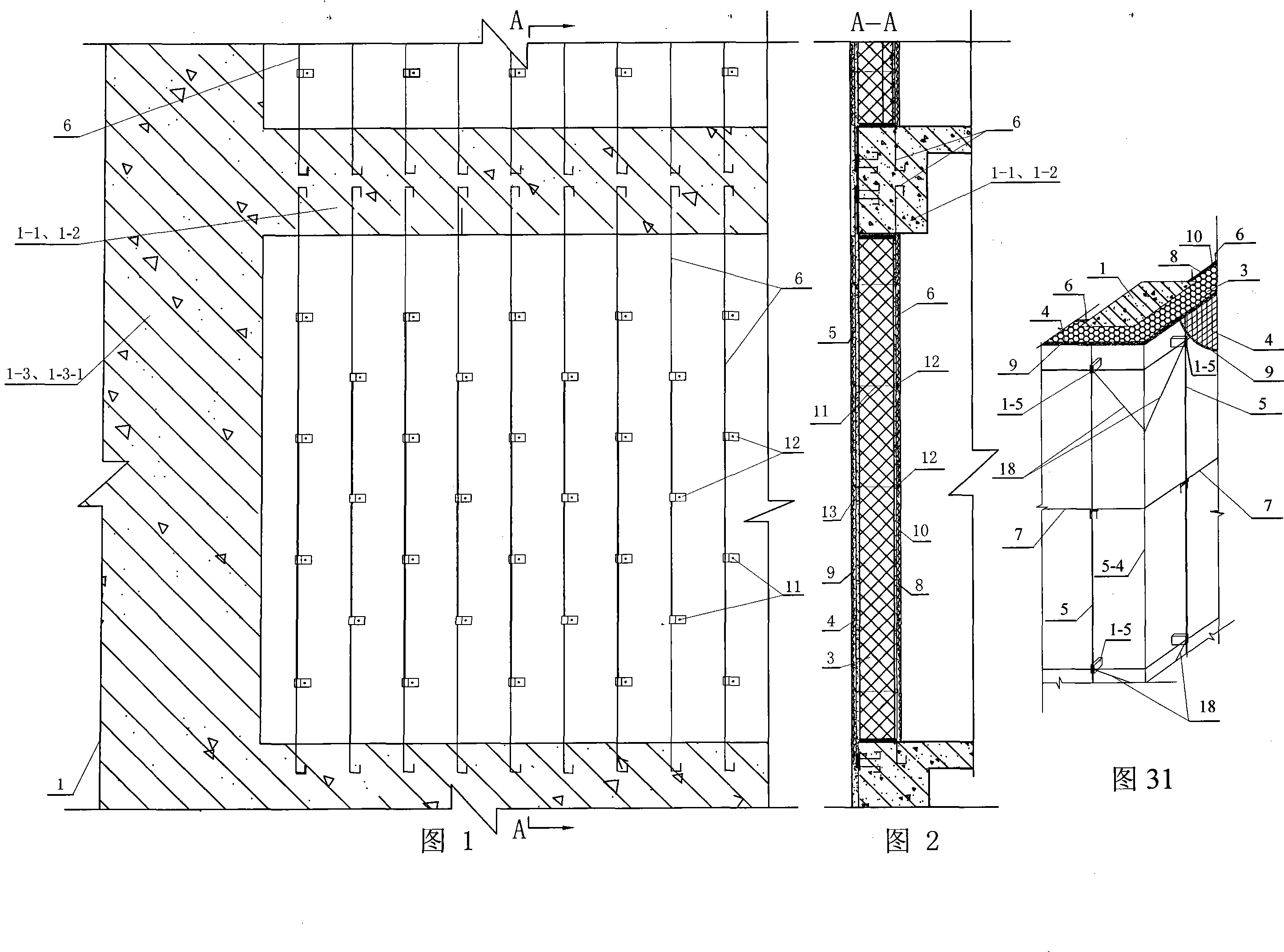

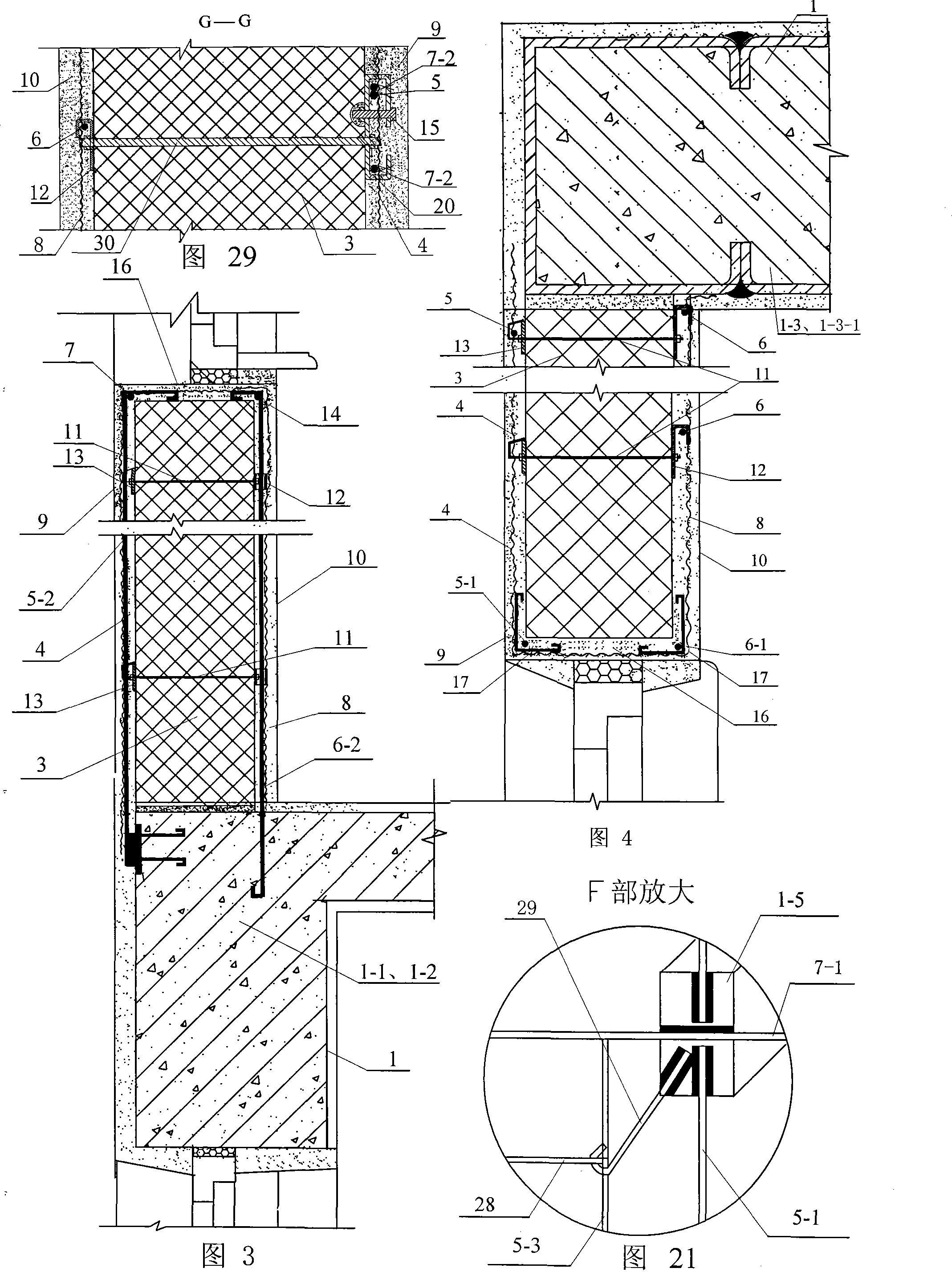

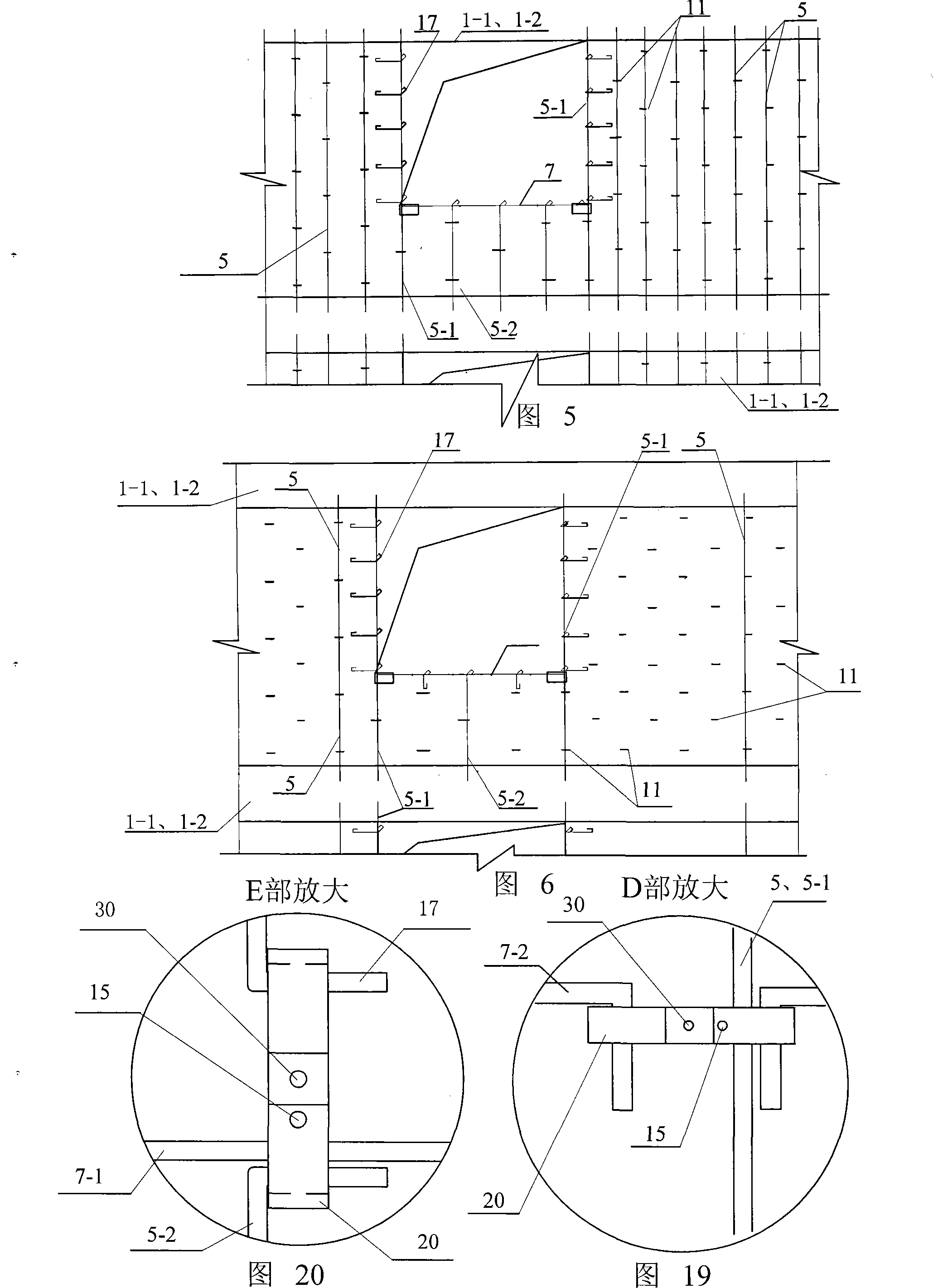

[0009] Specific Embodiment 1: The embodiment is described with reference to FIGS. 1 to 6. A structure of a composite wall in this embodiment consists of a load-bearing member 1 of the main structure of the building, a core layer 3, an outdoor vertical steel bar 5, and vertical vertical bars on the side edges of outdoor doors and windows. Directional reinforcement 5-1, vertical reinforcement below the outdoor window sill 5-2, indoor vertical reinforcement 6, indoor door and window side edge vertical reinforcement 6-1, indoor vertical reinforcement 6-2 under the window sill, outdoor horizontal horizontal reinforcement 7, and indoor window sill horizontal Steel bars 14, outer protective layer 9, inner protective layer 10, and opening protective layer 16; the load-bearing member 1 of the main structure of the building is a beam 1-1, a cantilevered plate 1-2, a column 1-3 or a short limb shear force Wall 1-3-1; the upper and lower ends of the outdoor vertical steel bar 5, the vertic...

specific Embodiment approach 2

[0011] Specific embodiment 2: This embodiment is described with reference to FIGS. Two steel gaskets 13; the first steel gasket 12 has a hook fixed on the indoor vertical reinforcement 6, the vertical reinforcement 6-2 under the indoor window sill and the vertical reinforcement 6-1 at the side edge of the indoor door and window, the core layer 3 and the second A steel gasket 12 is attached, and one end of the steel wire 11 is connected from the inside to the outside in turn through the first steel gasket 12, the core layer 3 and the second steel gasket 13. The outer end of the steel wire 11 is bent and fixedly connected with the outdoor vertical steel bar 5, the vertical steel bar 5-2 under the outdoor window sill and the vertical steel bar 5-1 at the side edge of the outdoor door and window. When the core layer 3 is a polymer insulation board, it is advisable to adopt this embodiment. The internal and external drawing and connecting steel wire 11 can be used for M3 stainless ...

specific Embodiment approach 3

[0012] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 to Fig. 6. The difference between this embodiment and specific embodiment two is: this embodiment also adds an outdoor metal mesh 4; the outdoor metal mesh 4 is located at the outdoor vertical steel bar 5 1. The vertical steel bar 5-1 on the side edge of the outdoor door and window, the inner side or the outer side of the vertical steel bar 5-2 under the outdoor window sill and fastened, and the outer end of the steel wire 11 connected inside and outside is bent and hooked to the outdoor vertical steel bar 5, under the outdoor window sill The vertical reinforcement 5-2 and / or the outer end of the internal and external tensioning steel wire 11 is bent and hooked to the outdoor metal mesh 4 for fastening connection, and the outdoor metal mesh 4 is horizontally connected to the outdoor window sill at the door and window opening. Bind and connect to steel bar 5-1, and bend it into the room to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com