Patents

Literature

33results about How to "Reduce horizontal load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

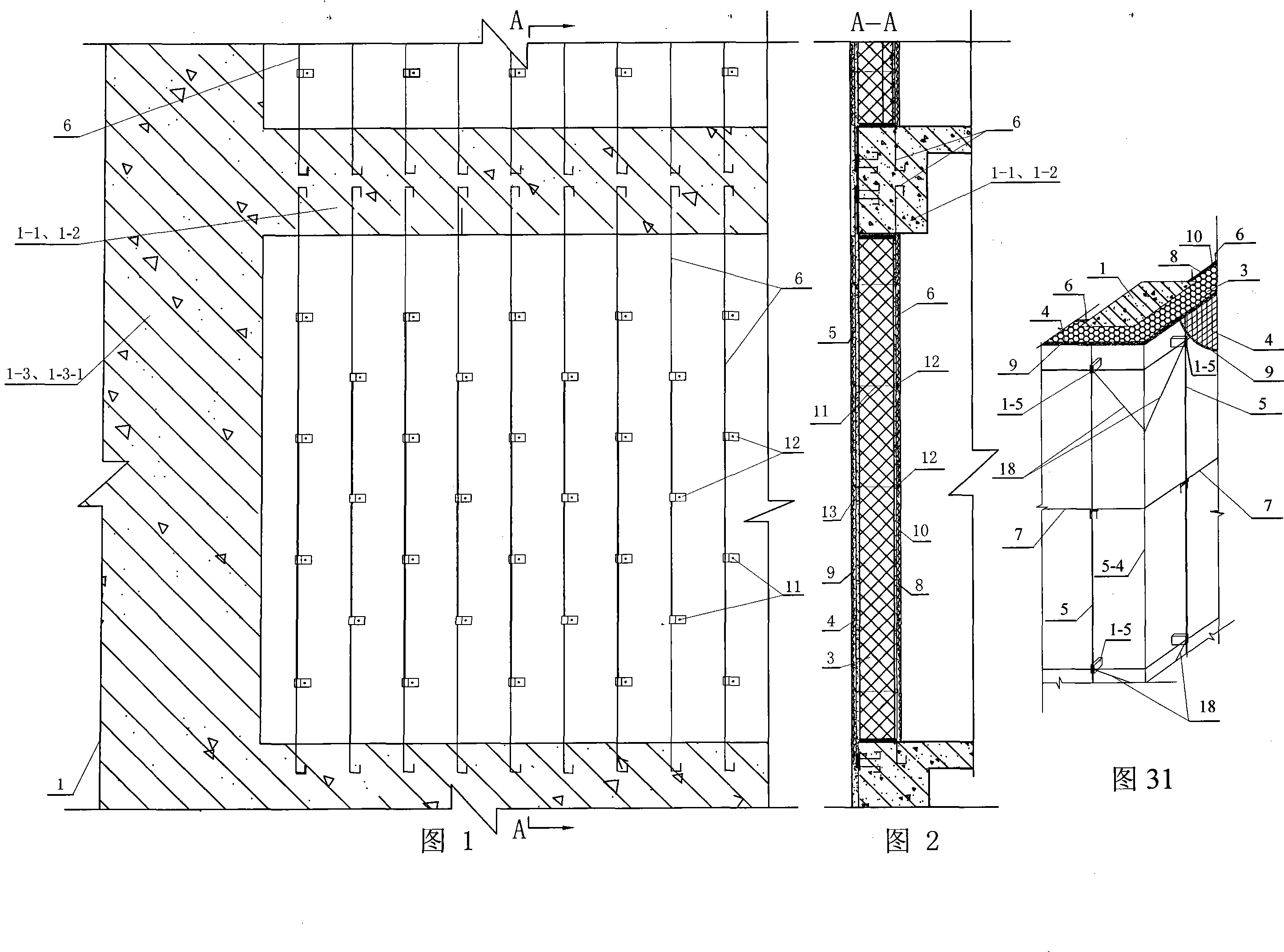

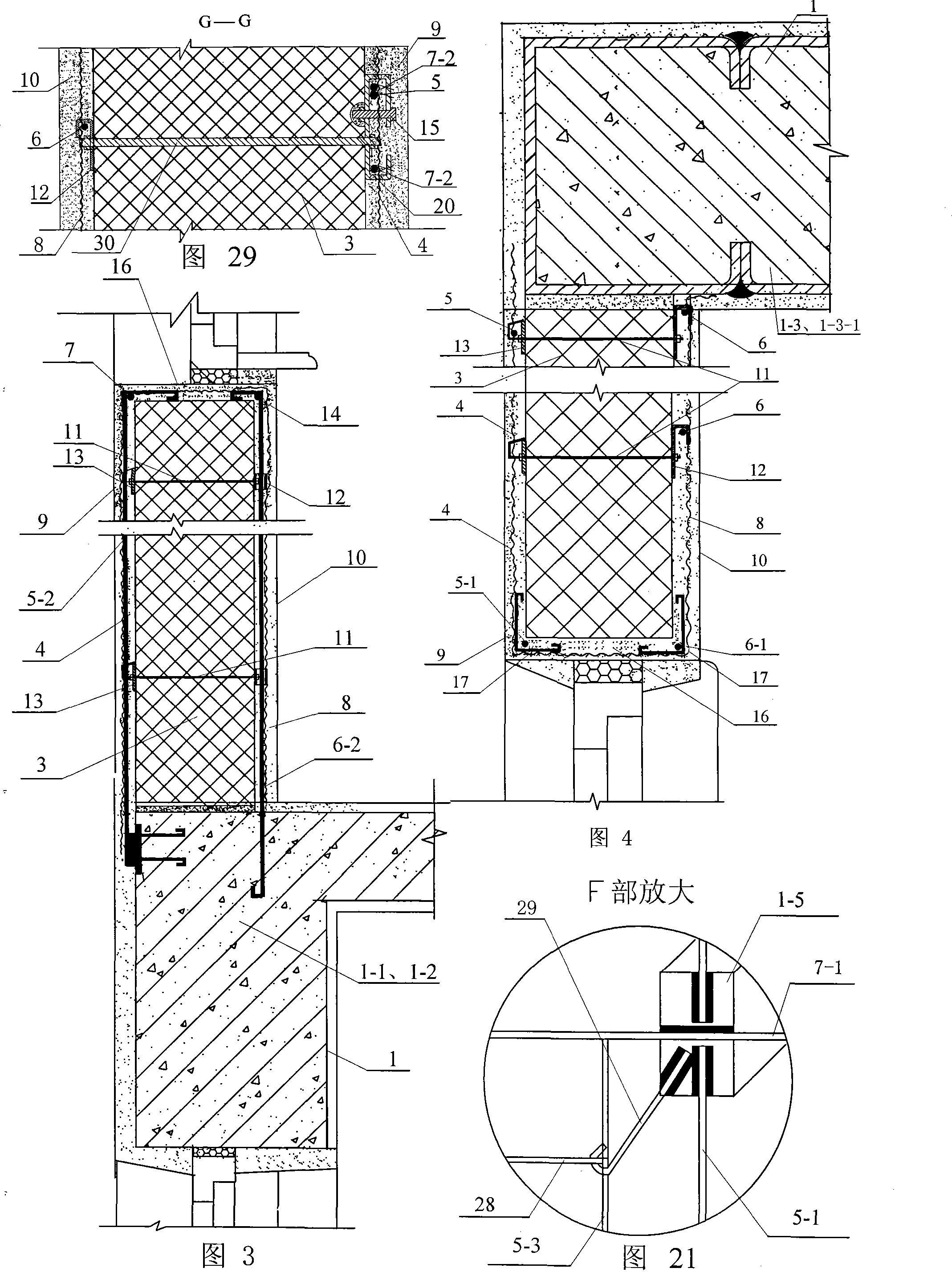

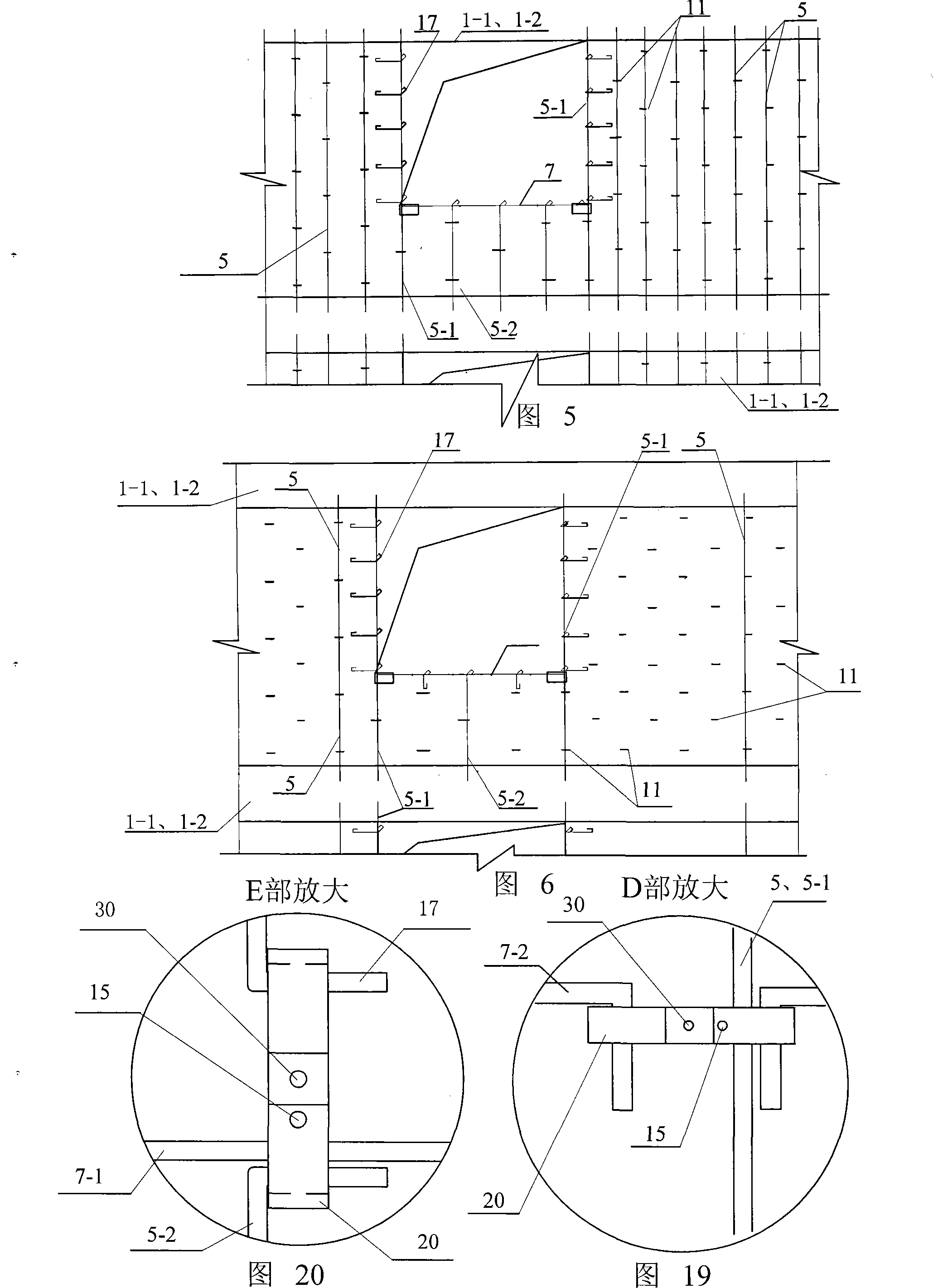

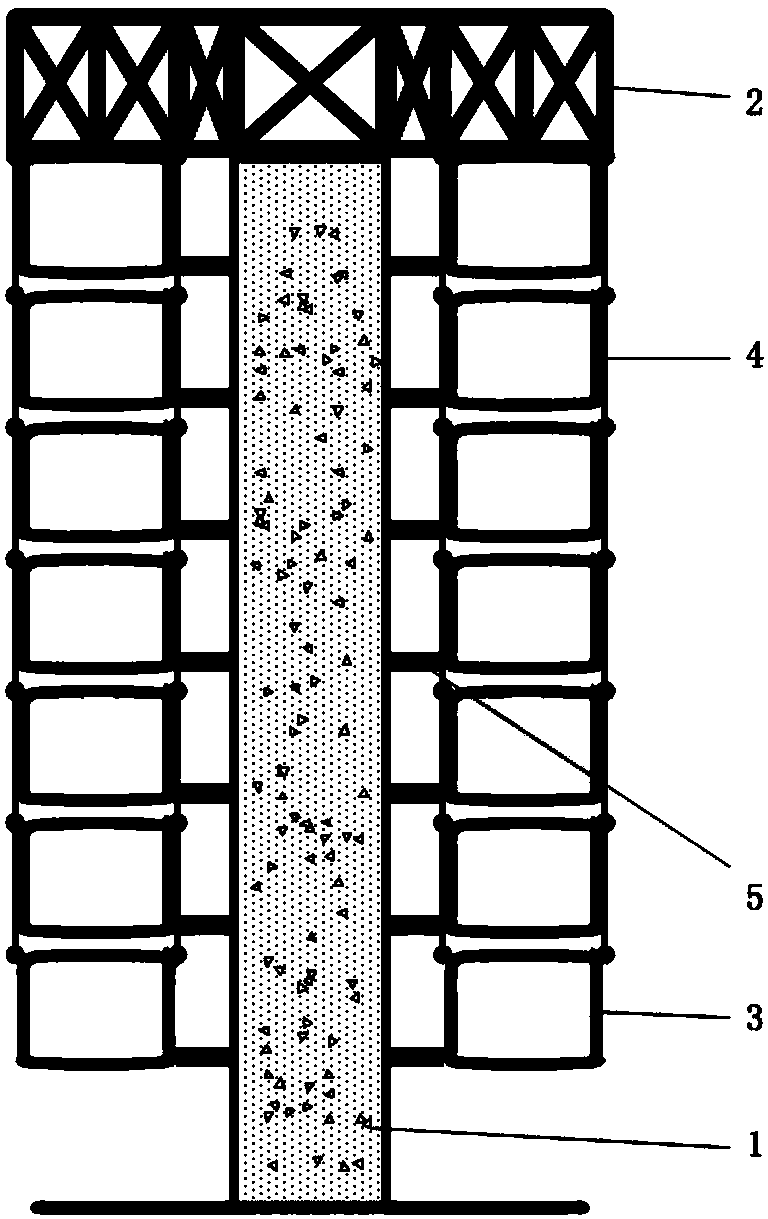

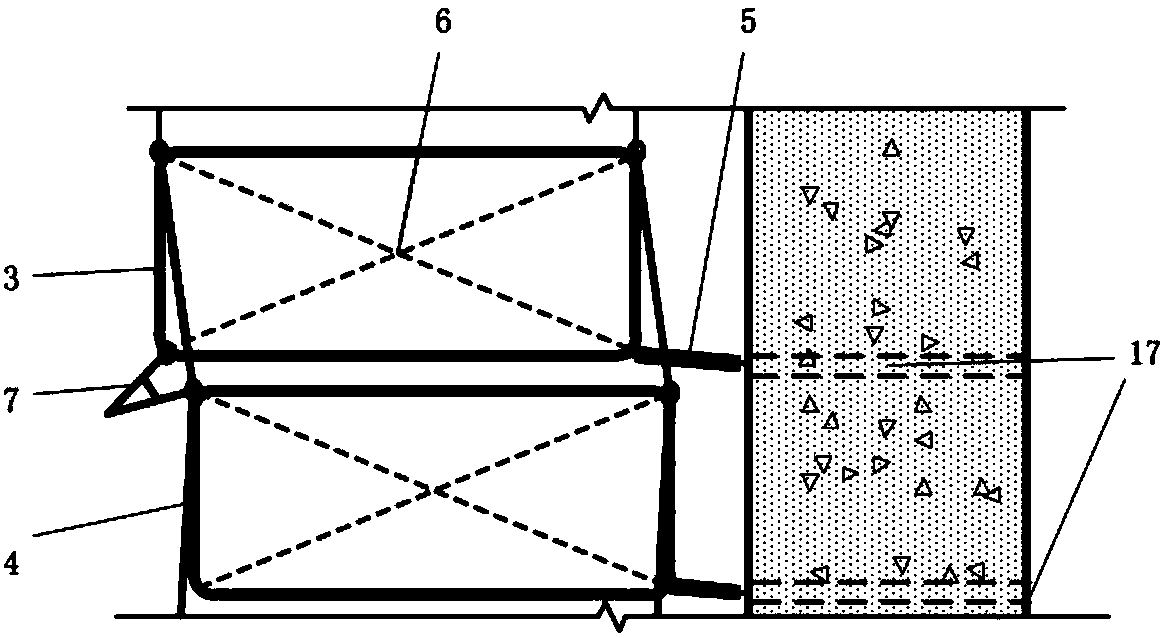

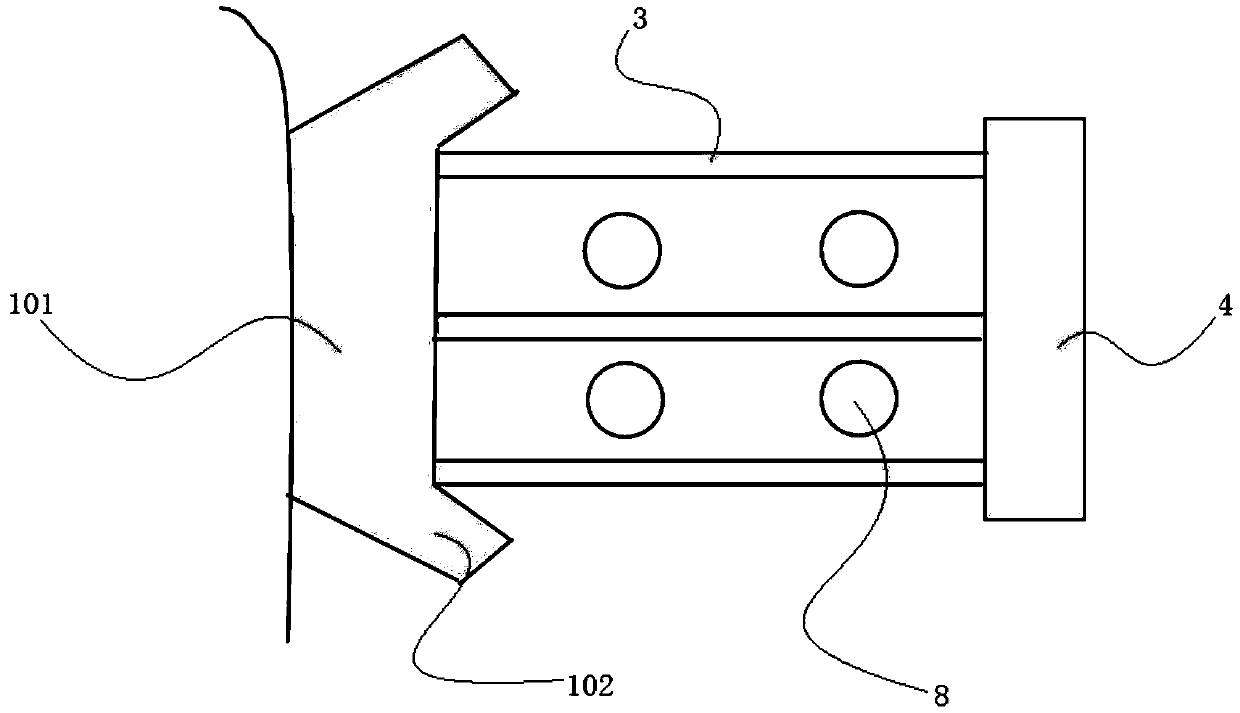

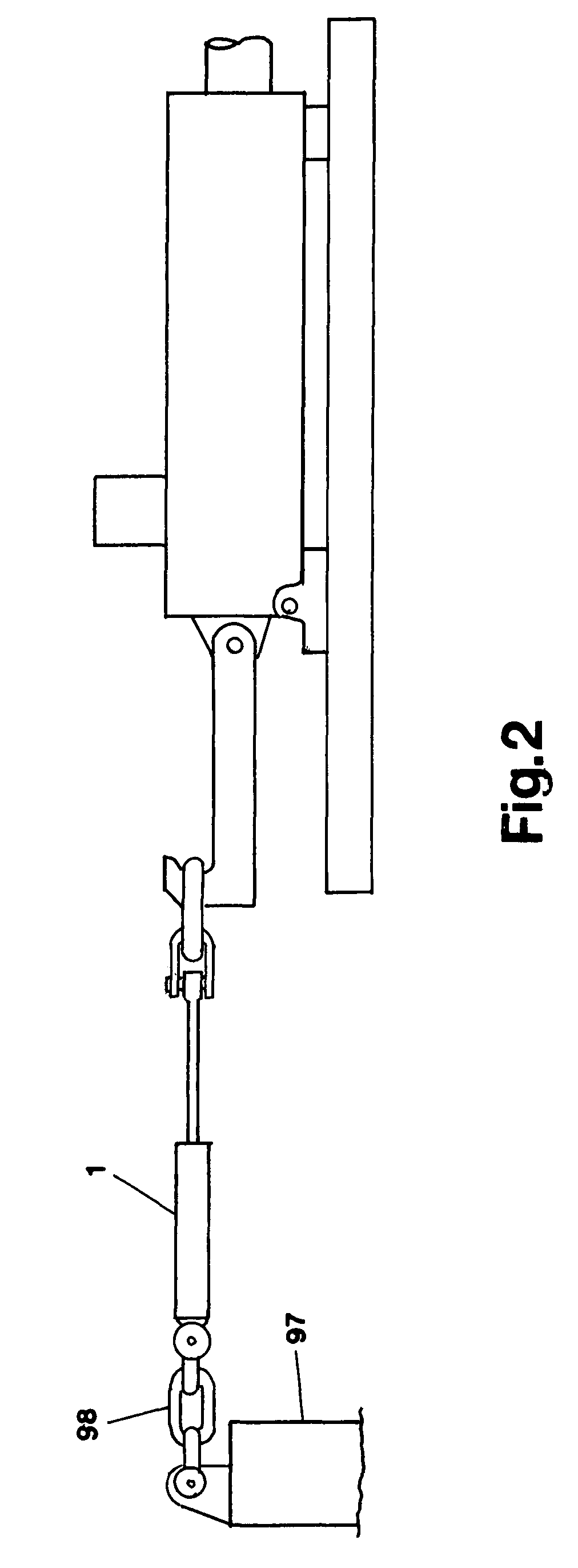

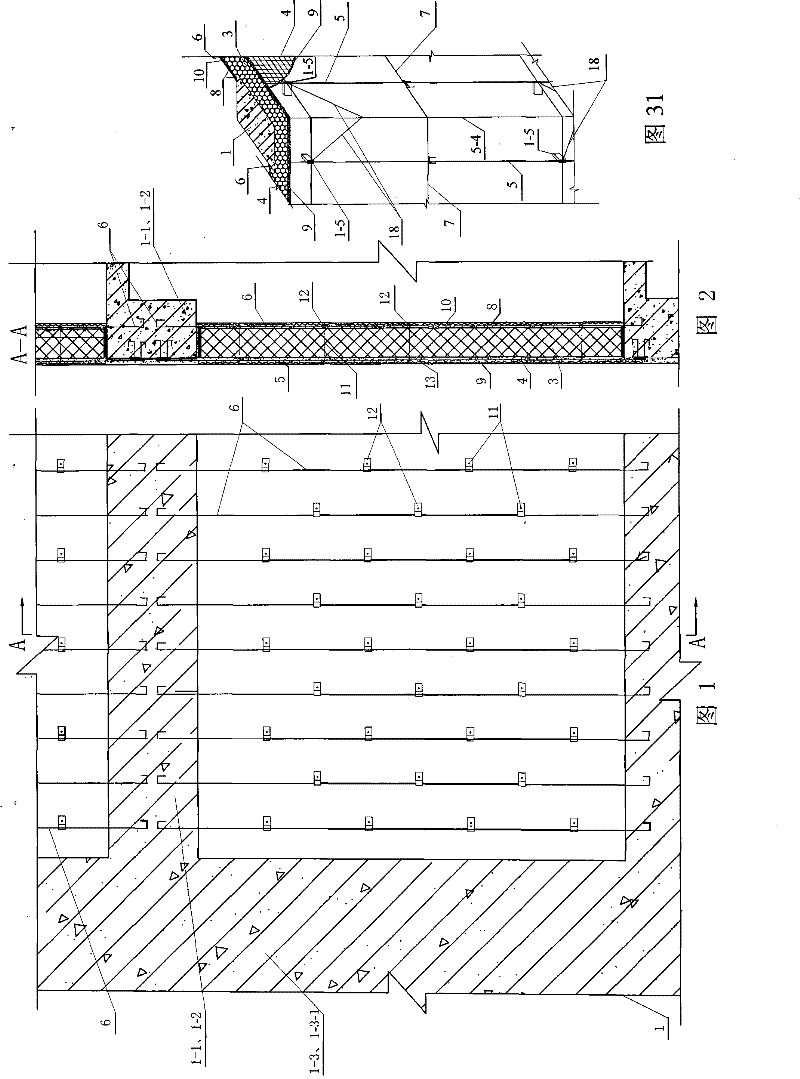

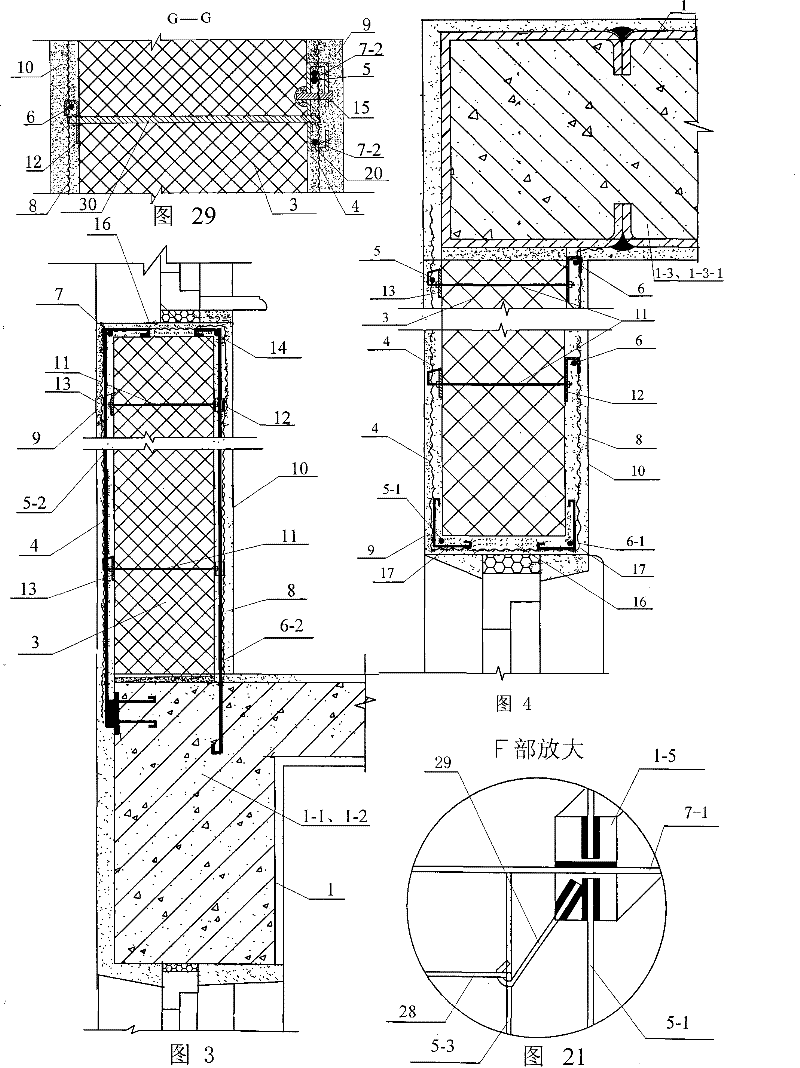

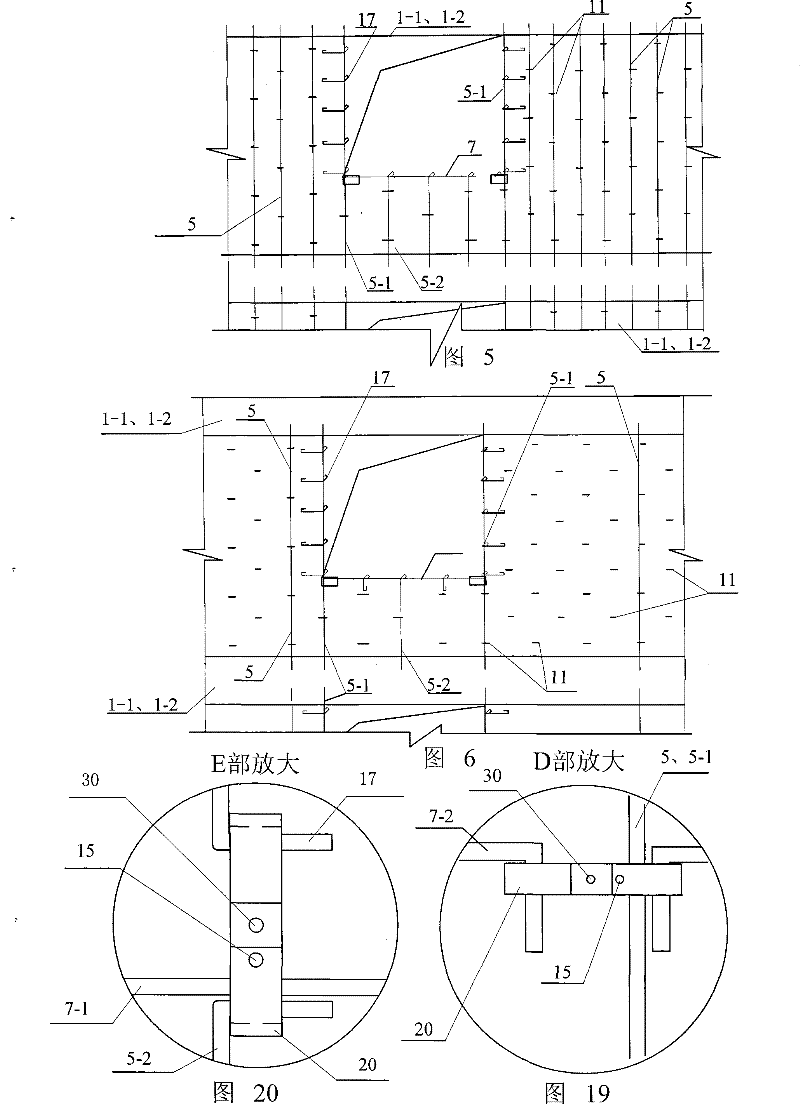

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

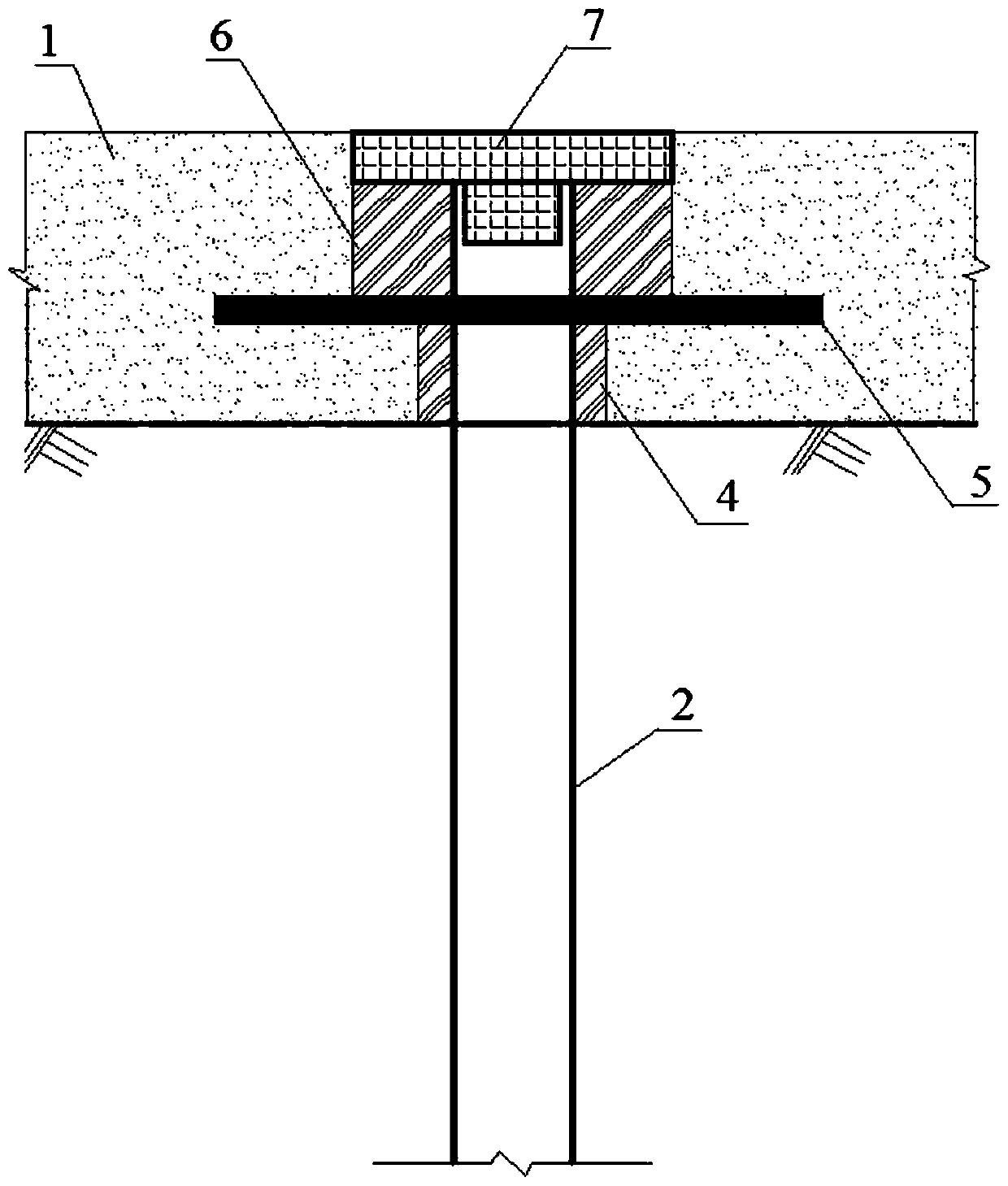

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

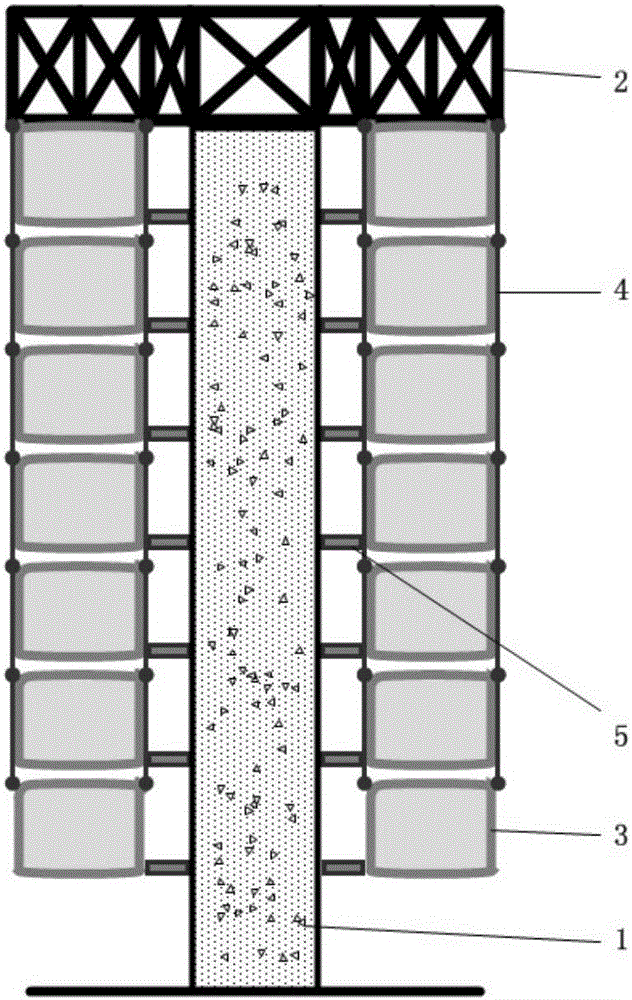

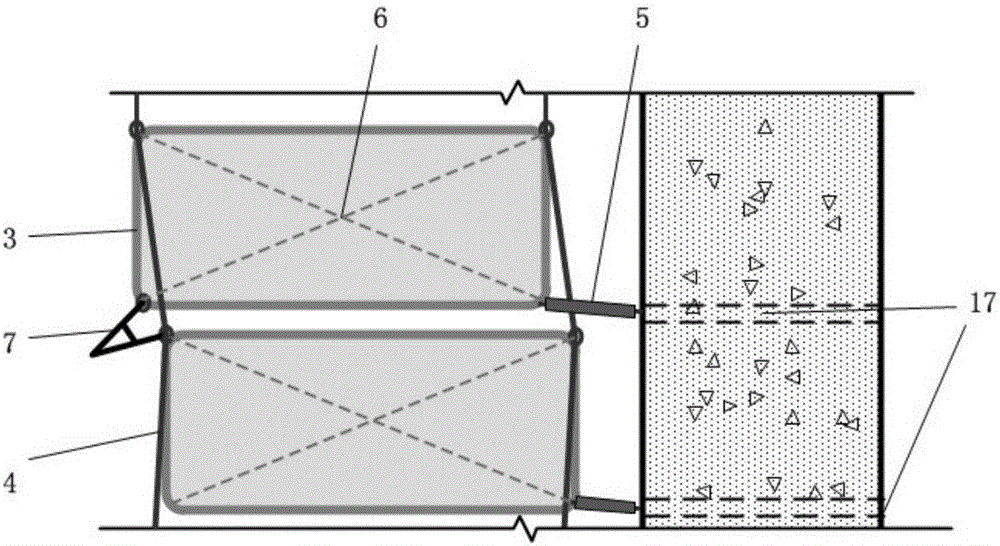

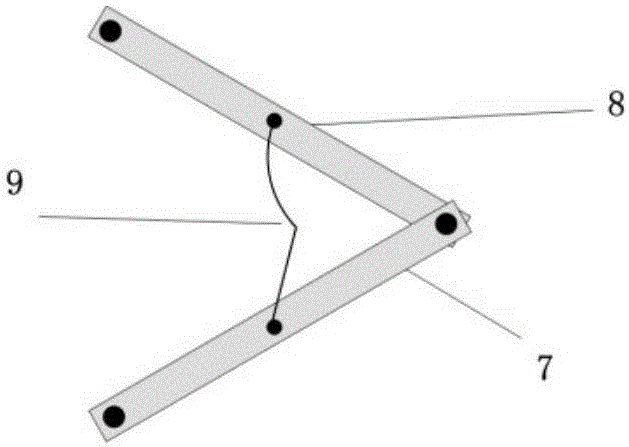

Flexible hanging type module building structure

ActiveCN106013452AReduce dosageAvoid damageProtective buildings/sheltersExtraordinary structuresMaterial consumptionStructural element

The invention discloses a flexible hanging type module building structure which comprises a vertical core cylinder structure. A conversion layer is arranged at the upper end of the core cylinder structure. A plurality of modules with certain spaces reserved in between are hung below the conversion layer. Every two modules adjacent in the vertical direction are connected through a set of hanging rods. The upper end of each hanging rod is movably connected to a ceiling beam of the corresponding upper module. The lower end of each hanging rod is movably connected to a ceiling beam of the corresponding lower module. The hanging rod arranged on the uppermost module is movably connected with the conversion layer. Dampers are arranged between floors of all the modules and the core cylinder structure. By means of the hanging shock absorption technology, the horizontal loads input by the modules to the core cylinder structure are remarkably reduced, and the material consumption of the core cylinder structure is saved. A module building allows substructure interlayer displacement, non-structural elements are prevented from damage, the limit value of substructure interlayer displacement is loosened, and then energy dissipation and shock absorption efficiency is improved. Through the combination of a limiting and buffering device, relative movement between the modules is controlled, and collision is avoided.

Owner:SOUTHEAST UNIV

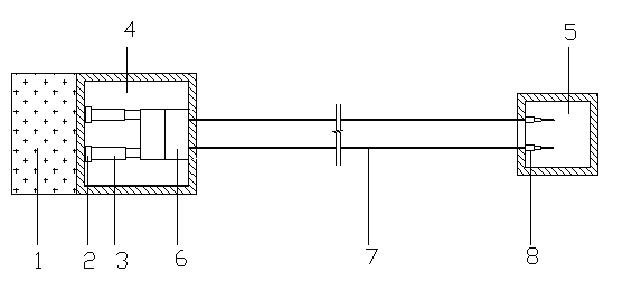

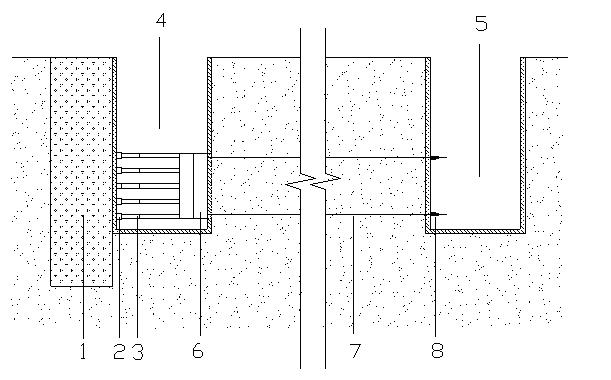

Synchronous towing, pushing and tunneling device of underground box culvert or pipeline construction

InactiveCN101922297ASmall footprintImprove adaptabilityPipe laying and repairTunnelsRebarReinforced concrete

The invention provides a synchronous towing, pushing and tunneling device of underground box culvert or pipeline construction, relating the technical field of building construction machinery. The invention solves the technical problems of increasing suitability for a construction field, tunneling length and construction work efficiency. The synchronous towing, pushing and tunneling device comprises a push jack set, a tunneling machine head, a pull jack set and a plurality of cables, wherein the push jack set is arranged in a starting well, a cable reactive wall is arranged in a receiving well, the pull jack set is arranged on the cable reactive wall, at least four horizontal directional holes are drilled between the starting well and the receiving well along a designed axis direction, the cables are respectively laid into the horizontal directional holes, one end of each cable is connected and fixedly locked with the pull jack set in the receiving well, the other end of each cable is fixedly connected with the head of the tunneling machine head, and a cable self-locking mechanism which is used for stopping the cables is arranged on the pull jack set. The synchronous towing, pushing and tunneling device of underground box culvert or pipeline construction is suitable for various sizes of reinforced concrete or steel structure culverts or pipelines with rectangular and circular sections.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

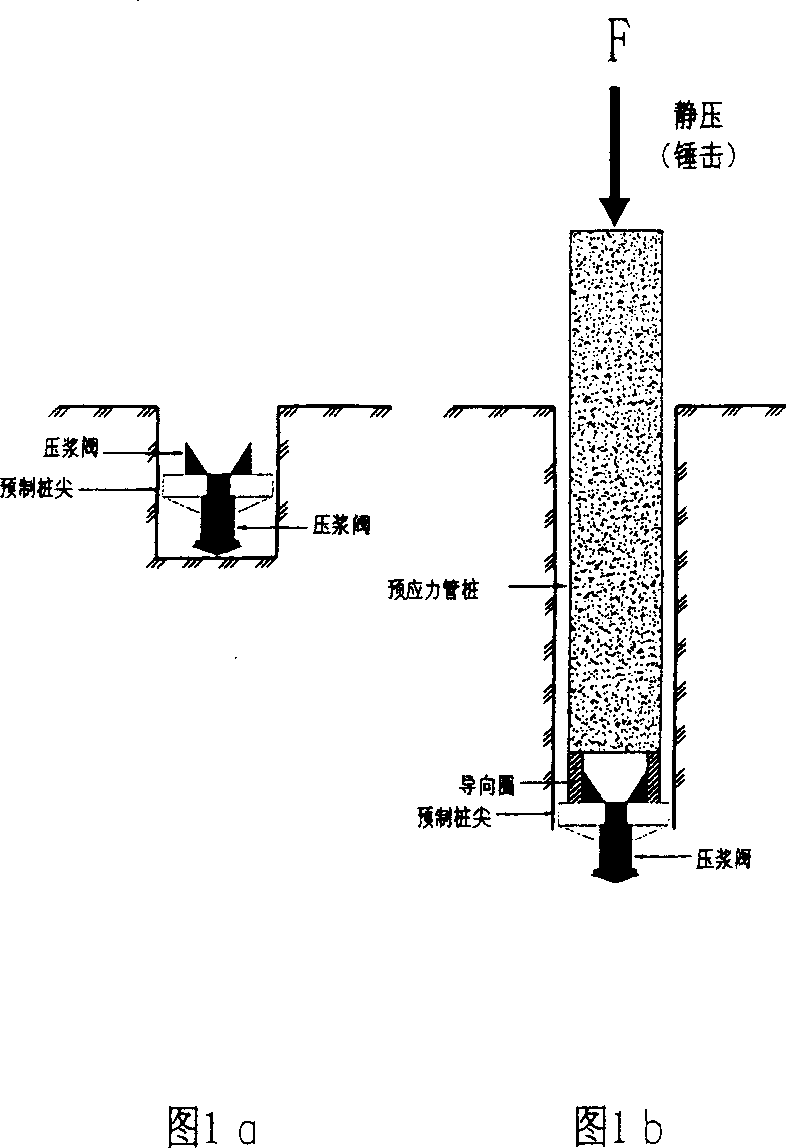

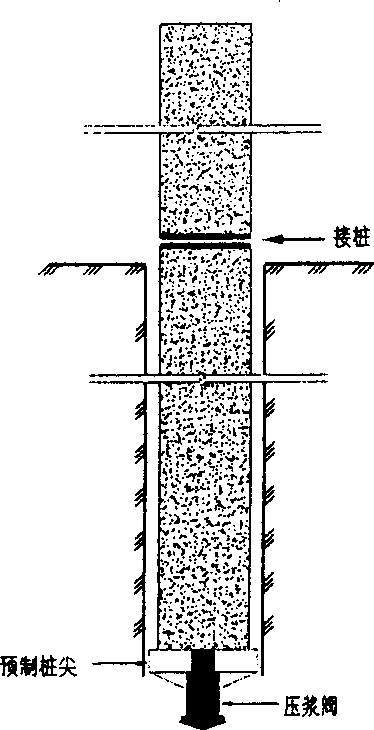

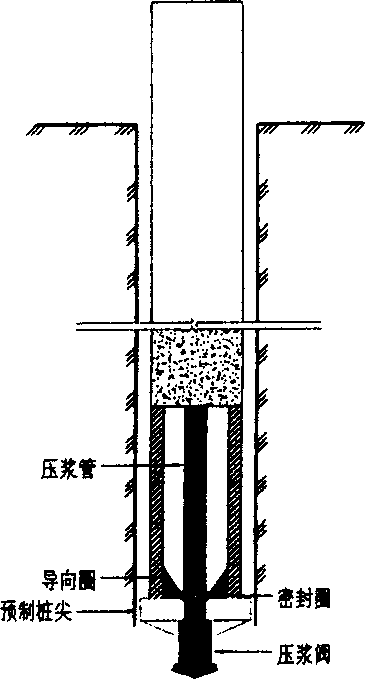

Construction method of prestressed tubular pile

InactiveCN1912253AReduce horizontal loadAvoid the disadvantage of weak horizontal bearing capacityBulkheads/pilesReinforced concretePre stress

A method for constructing prestressed tubular pile includes burying prefabricated pile pointer with mud jacking valve and guide coil at certain depth of underground and connecting prestressed tubular piles to press said pile pointer up to desired depth, connecting mud jacking pipe with said valve and jacketing clasp at top of pile body, using triplet to connect mud jack with said pipe to carry out mud jacking, disassembling triplet and lifting out said pipe, placing precast reinforced concrete cap at top of pile body and connecting it.

Owner:闫雪晖

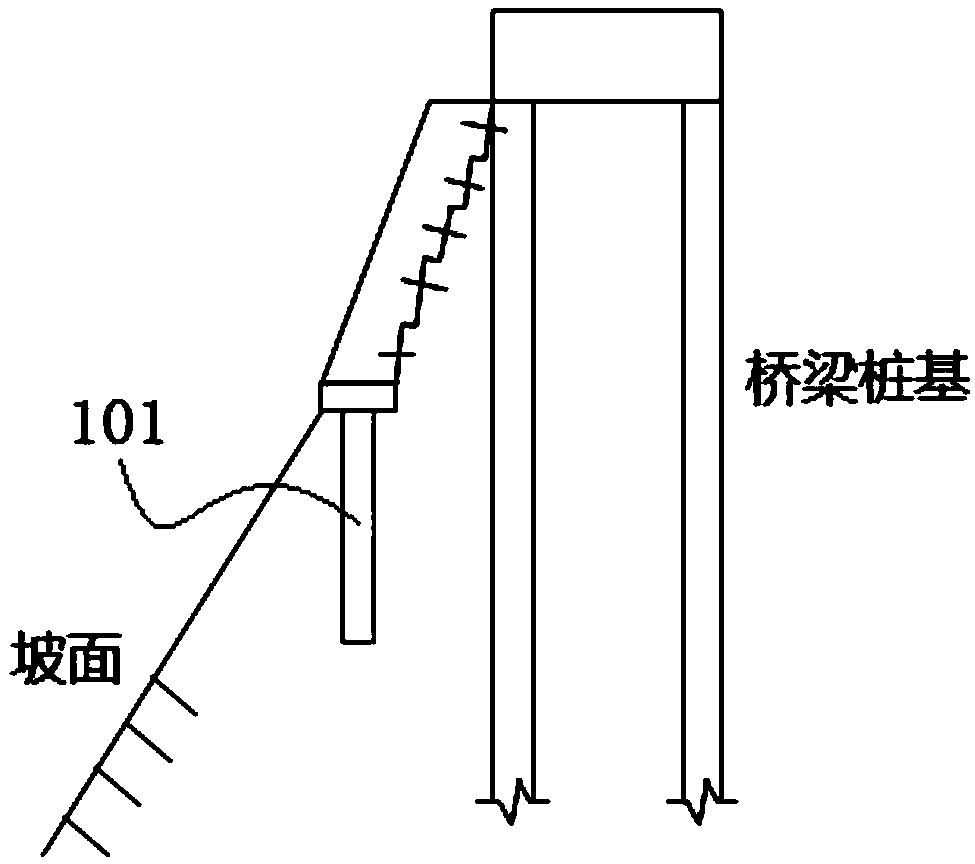

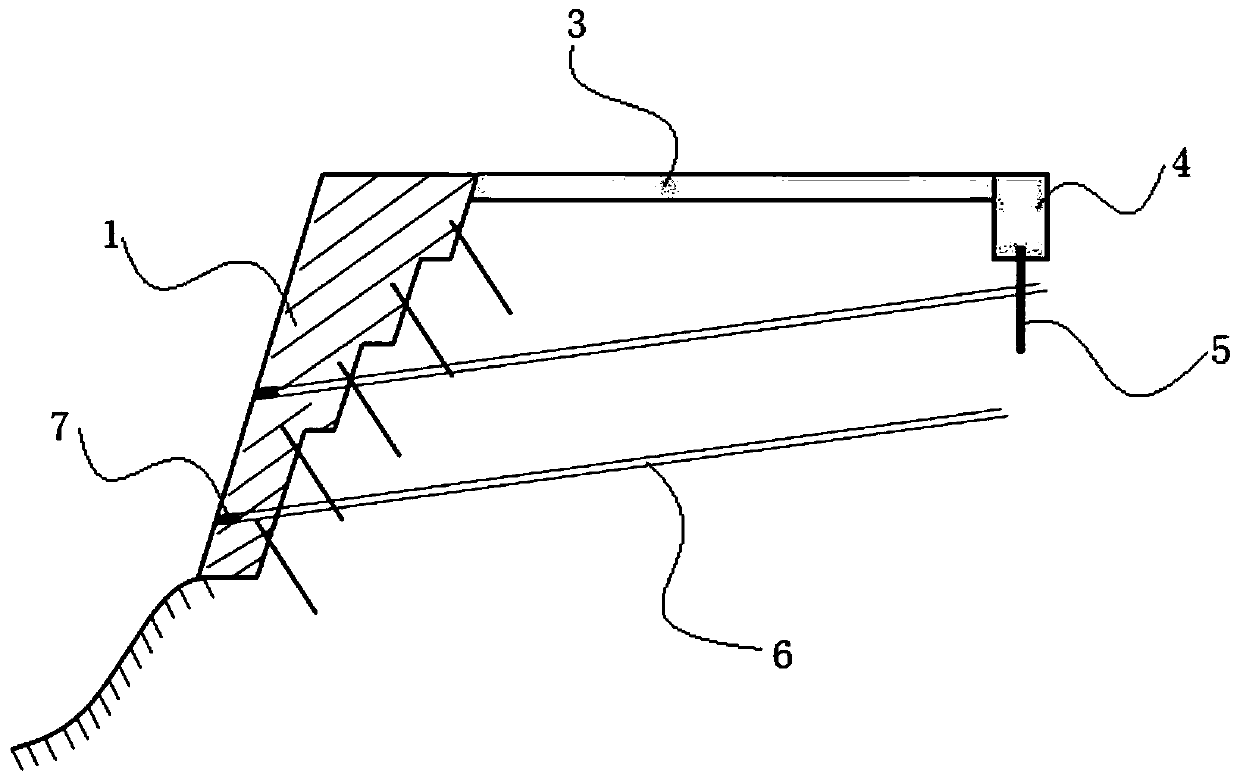

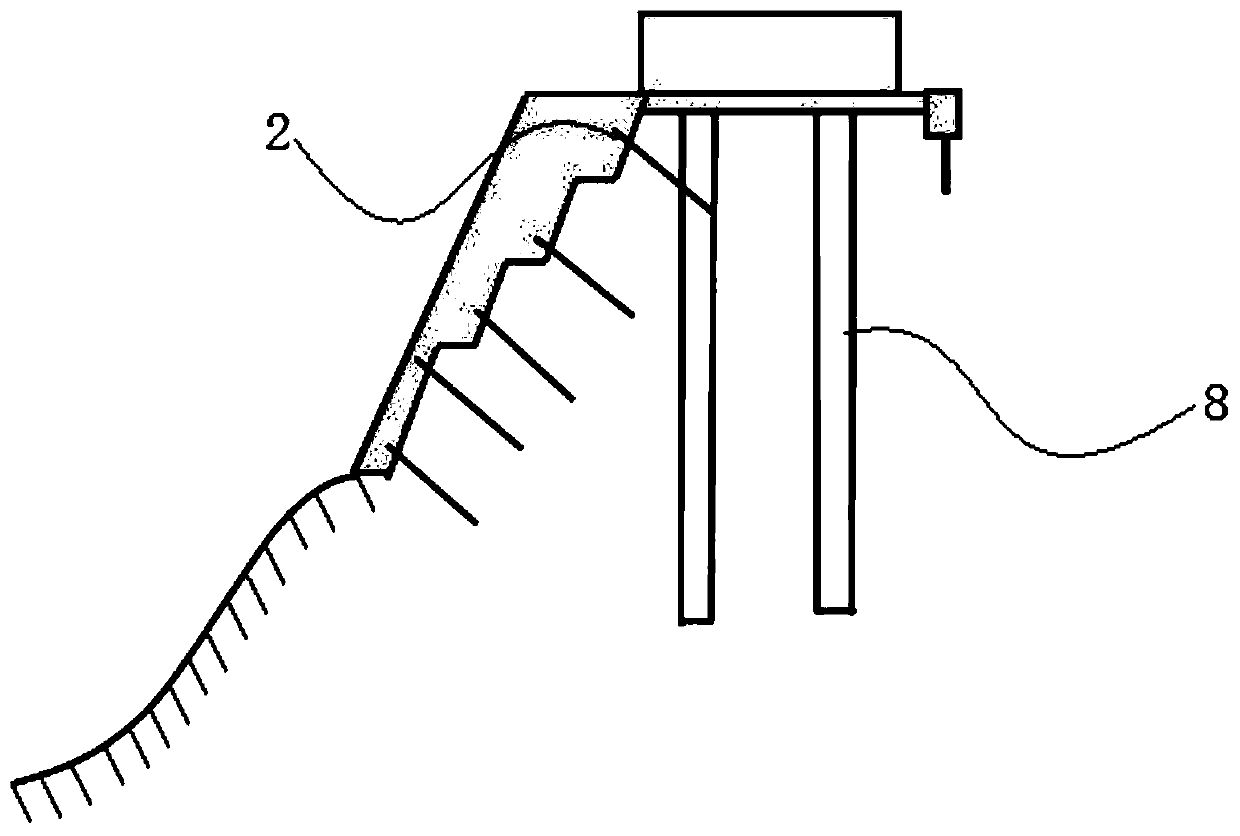

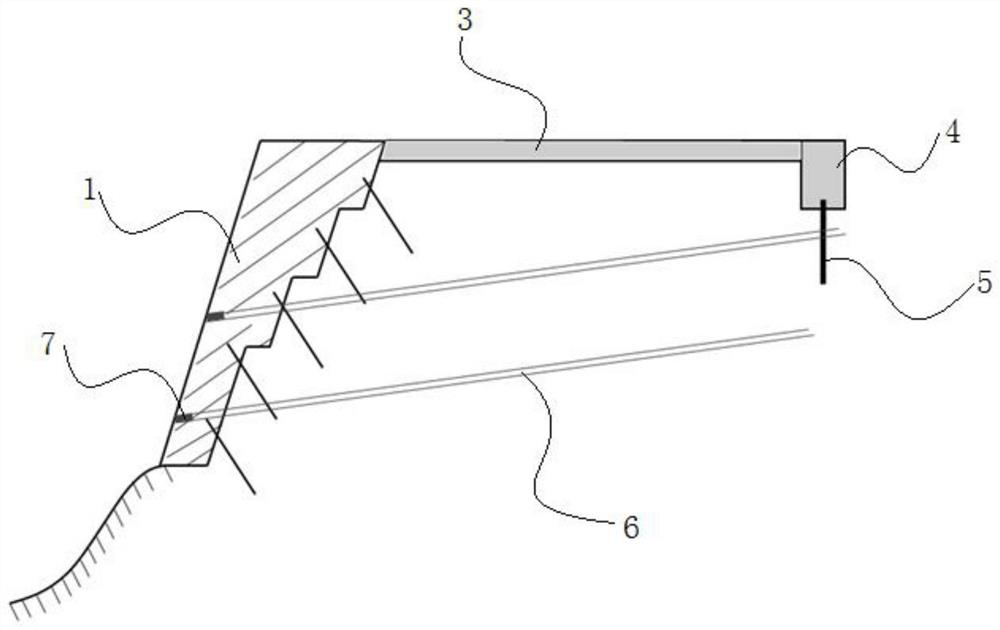

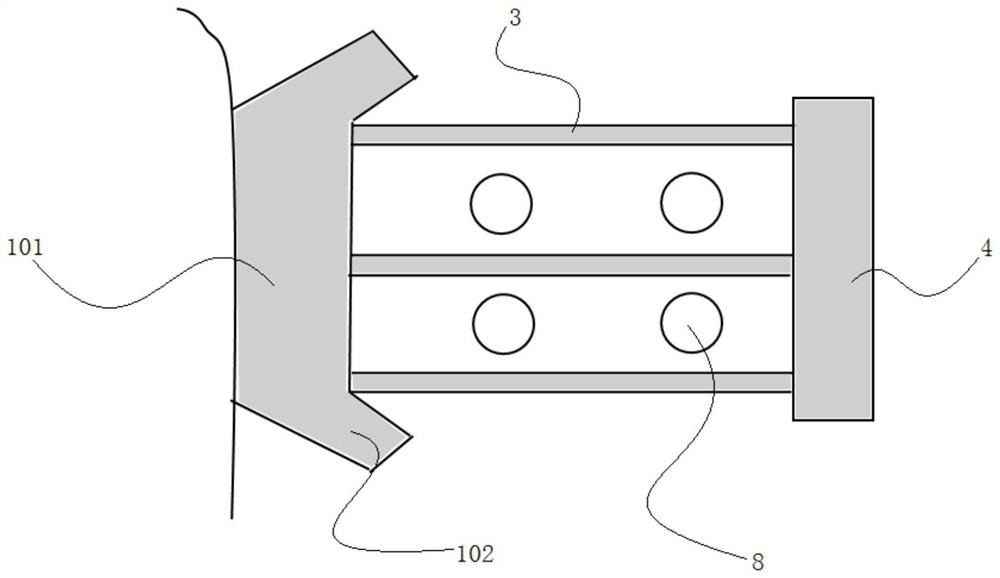

Piled drainage anchor rod retaining wall structure and construction method thereof

PendingCN109577365AAdvanced technologyImprove economyArtificial islandsUnderwater structuresCheck valveRetaining wall

The invention provides a piled drainage anchor rod retaining wall structure and a construction method thereof. The retaining wall structure comprises a pile foundation, a beam, a retaining wall and aplurality of anchor rods, the pile foundation comprises a plurality of bearing piles embedded in a bank slope stable rock soil body, the beam is arranged above the pile foundation, the retaining wallis arranged on the upper surface of the beam, and the retaining wall structure further comprises a drainage hole. The construction method includes steps: constructing the pile foundation; constructingthe beam; constructing the anchor rods; constructing the drainage hole; constructing the retaining wall; mounting a check valve. The retaining wall structure can effectively solve the problem in large reservoir hydro-fluctuation belt shoreside gully area bridge pile foundation protection technology and is advanced in technology and high in economic efficiency.

Owner:CHONGQING JIAOTONG UNIVERSITY

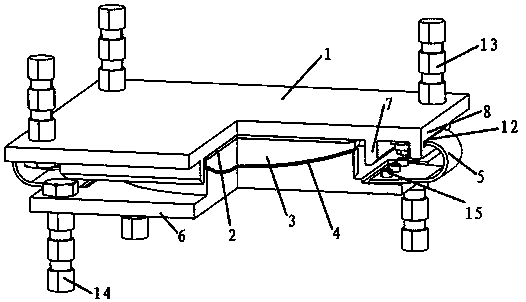

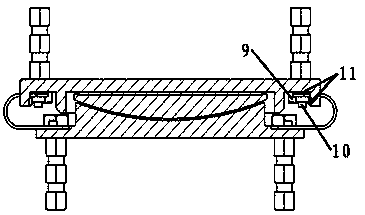

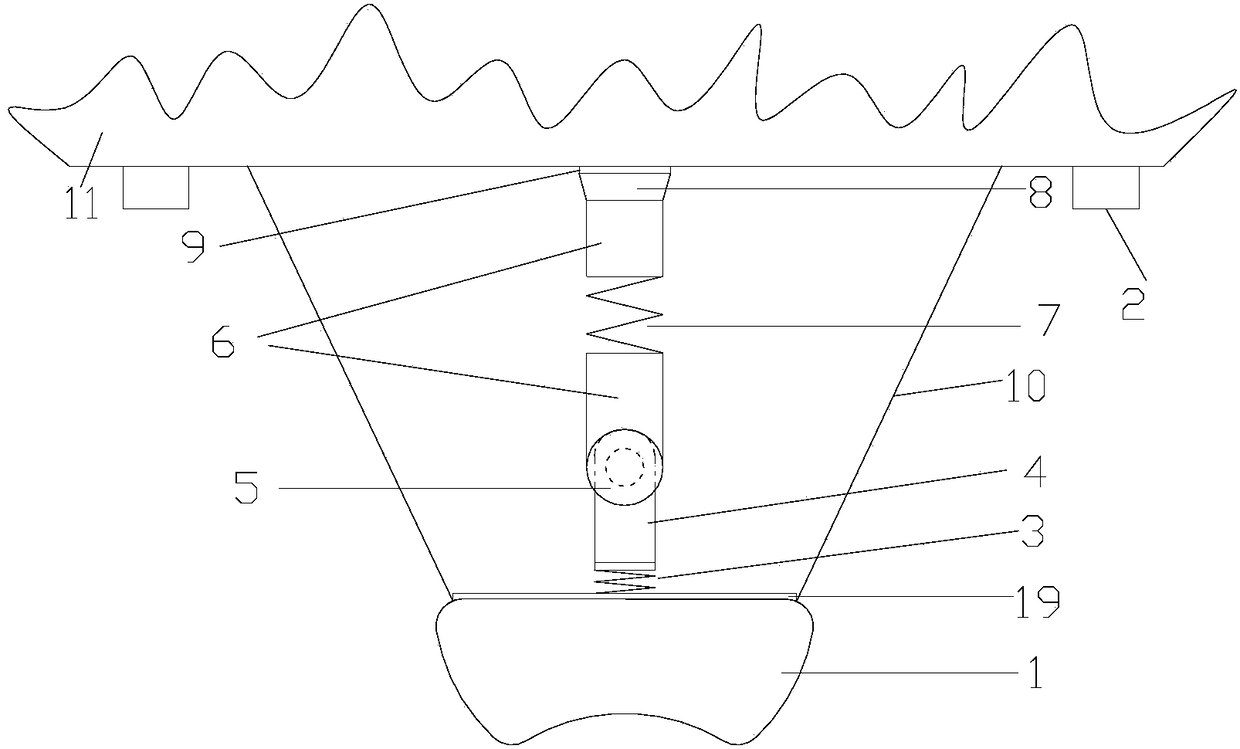

Bridge damping support and damping method

PendingCN107815962AIncrease horizontal stiffnessIncrease vertical stiffnessBridge structural detailsStructural engineeringEnergy consumption

The invention discloses a bridge damping support and a damping method. The bridge damping seat comprises an upper seat board, a lower seat board, a spherical cap liner plate, a steel damping element with variable cross section, an upper anchor bar connected with the upper seat board, and a lower anchor bar connected with the lower sat board, wherein the spherical cap liner plate is connected between the upper seat board and the lower seat board, and the steel damping element with variable cross section is connected at two sides or the periphery of the upper seat board and the lower seat board;and the upper end of the steel damping element with variable cross section is connected with the upper seat board, and the lower end is connected with the lower seat board. By adopting the bridge damping support for damping, the steel damping element with variable cross section is arranged at the periphery or two sides of the upper seat board and the lower seat board to reduce the space utilization rate of the damping element; and in severe earthquake, the steel damping element with variable cross section can reduce vibration and energy consumption and limit the displacement of the bridge damping support, so as to achieve the aim of reducing bridge earthquake response and preventing bridge falling. According to the invention, not only can a function of normal use of the support be realized, but also a vertical drawing effect is achieved by the limited displacement and vibration reduction and energy consumption reduction of the support to prevent bridge falling in severe earthquake.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

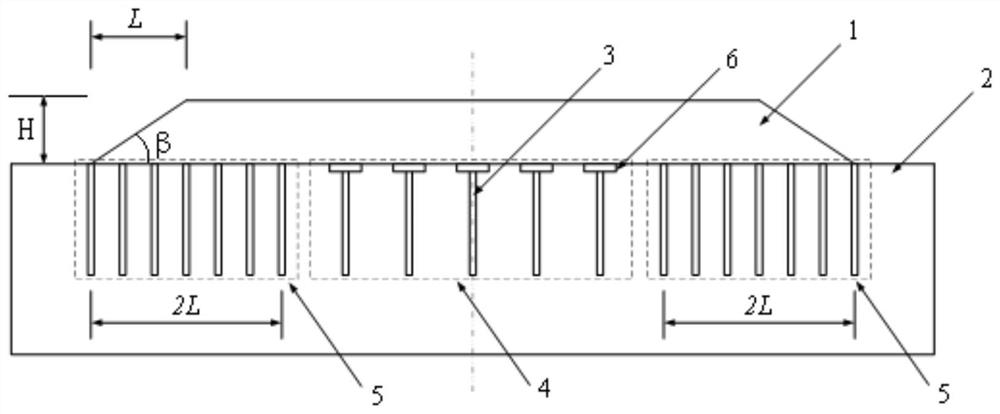

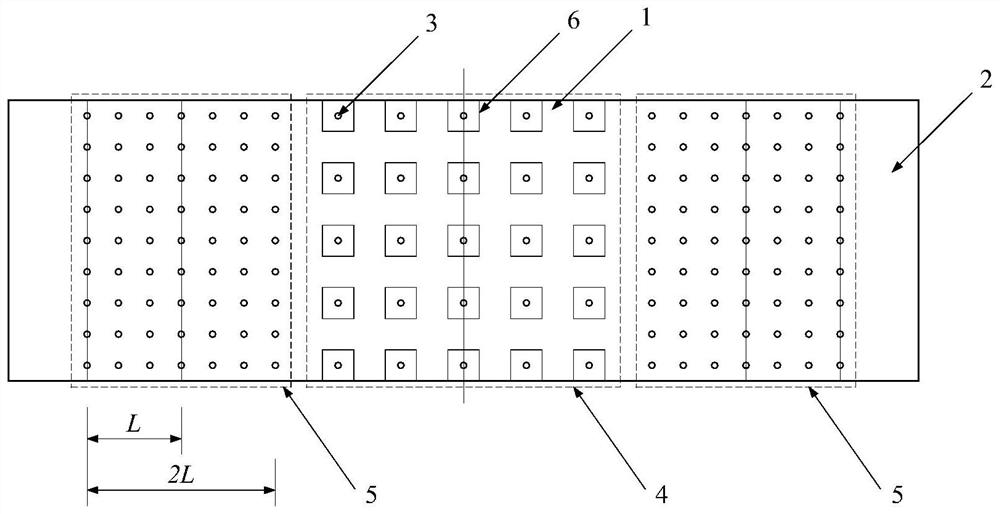

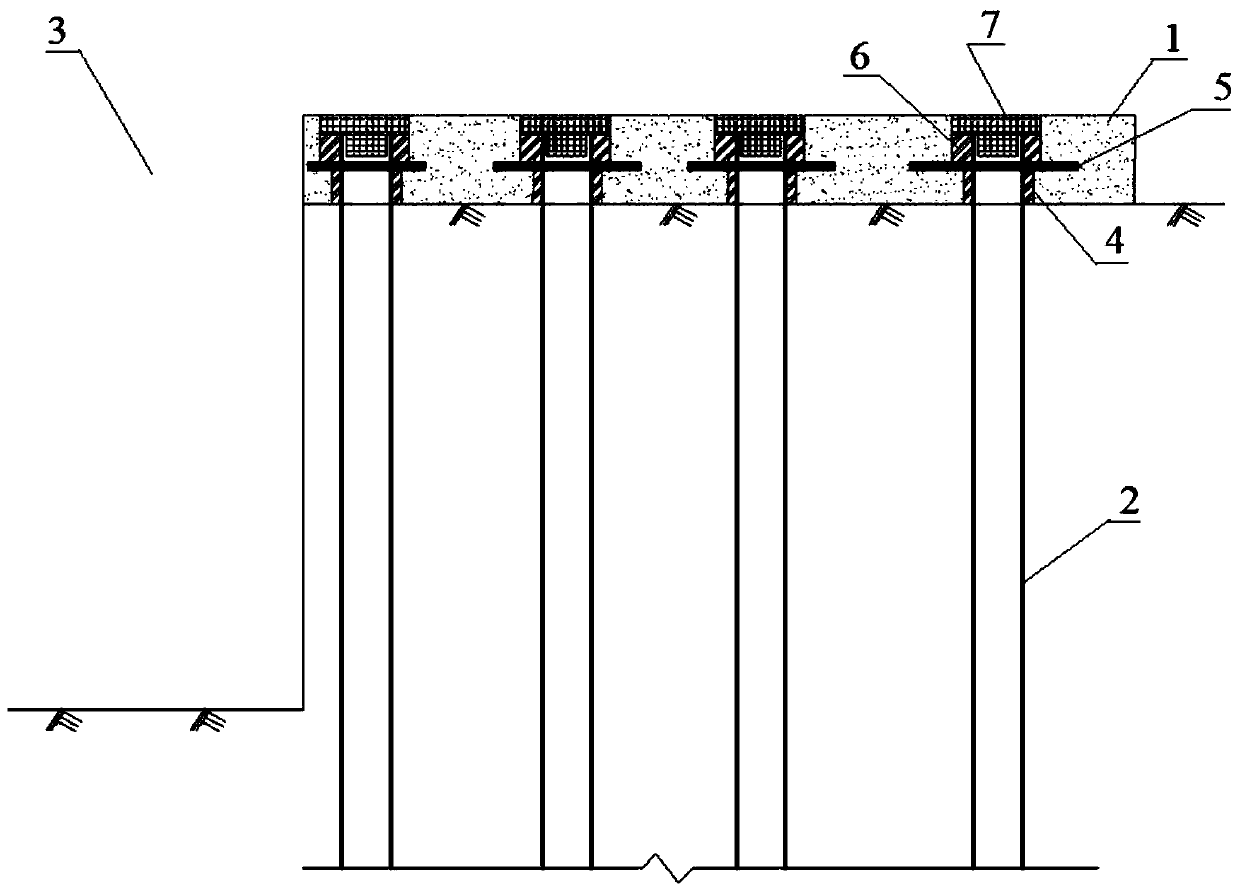

Variable-spacing rigid pile composite foundation for improving embankment stability

PendingCN111893809AReduce load capacityGuaranteed bearing capacityRailway tracksPile capBrittle fracture

The invention discloses a variable-spacing rigid pile composite foundation for improving embankment stability. The distance from a slope toe to a slope shoulder of an embankment side slope is L, and the arrangement area of all rigid piles is an area covered by an embankment and is divided into an arrangement area of large-spacing piles on the inner side and an arrangement area of small-spacing piles on the outer side; the small-spacing rigid piles adopt rigid piles which have a small spacing and certain ductility and are not provided with pile caps, and the large-spacing rigid piles adopt rigid piles which have a large spacing and are provided with pile caps. The variable-spacing rigid pile composite foundation solves the engineering problems of embankment instability and greatly reduced bearing capacity caused by sequential brittle fracture of the inner side pile bodies due to the fact that the outer side pile bodies of the rigid pile composite foundation are prone to brittle fractureunder large bending moment, and the large-spacing inner side piles with the pile caps can greatly reduce the construction cost on the basis that sedimentation and uneven sedimentation are effectivelycontrolled. The variable-spacing rigid pile composite foundation is simple in construction, good in total settlement control effect, capable of greatly improving the stability of the embankment, highin safety, high in applicability and good in economical efficiency.

Owner:TIANJIN UNIV

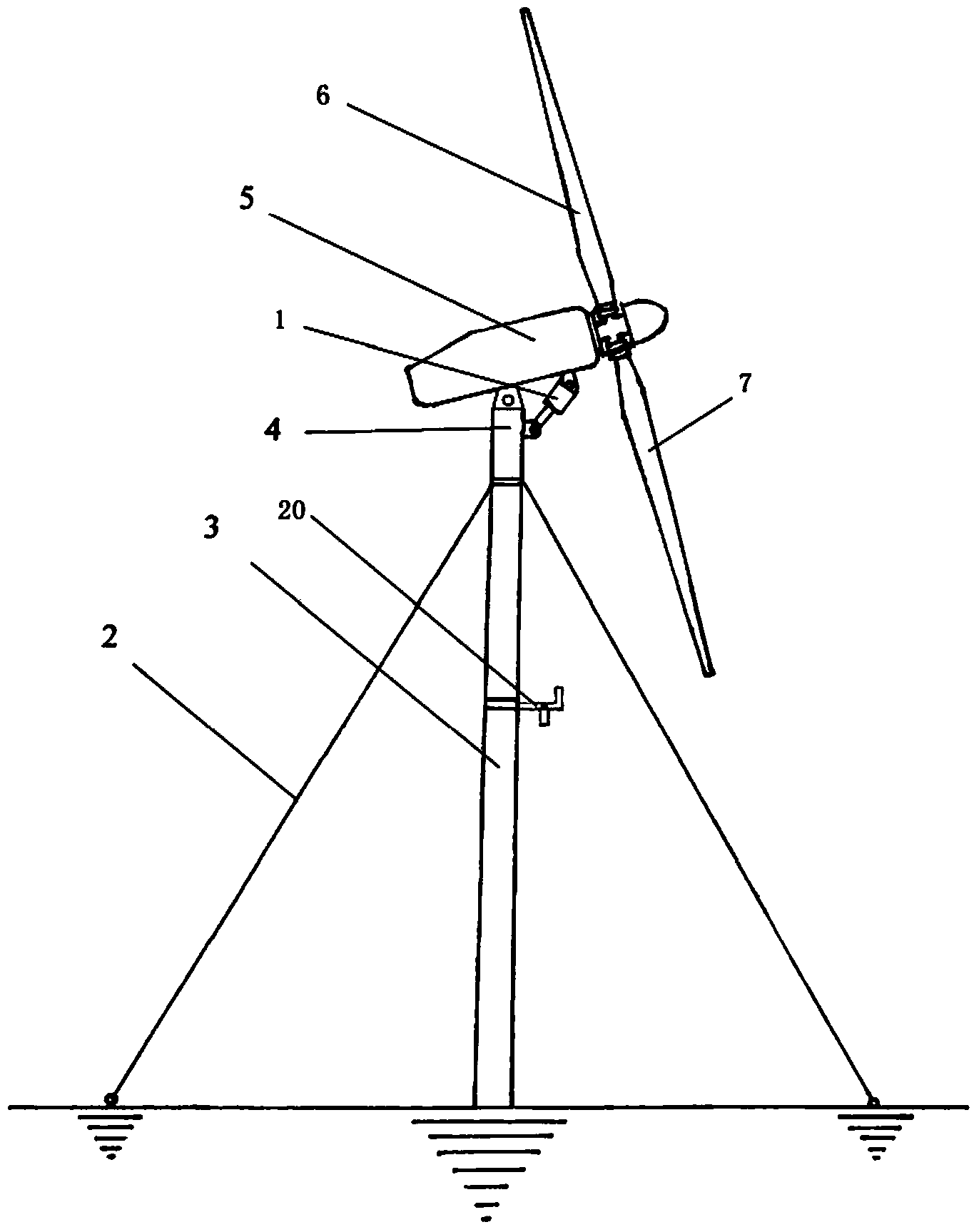

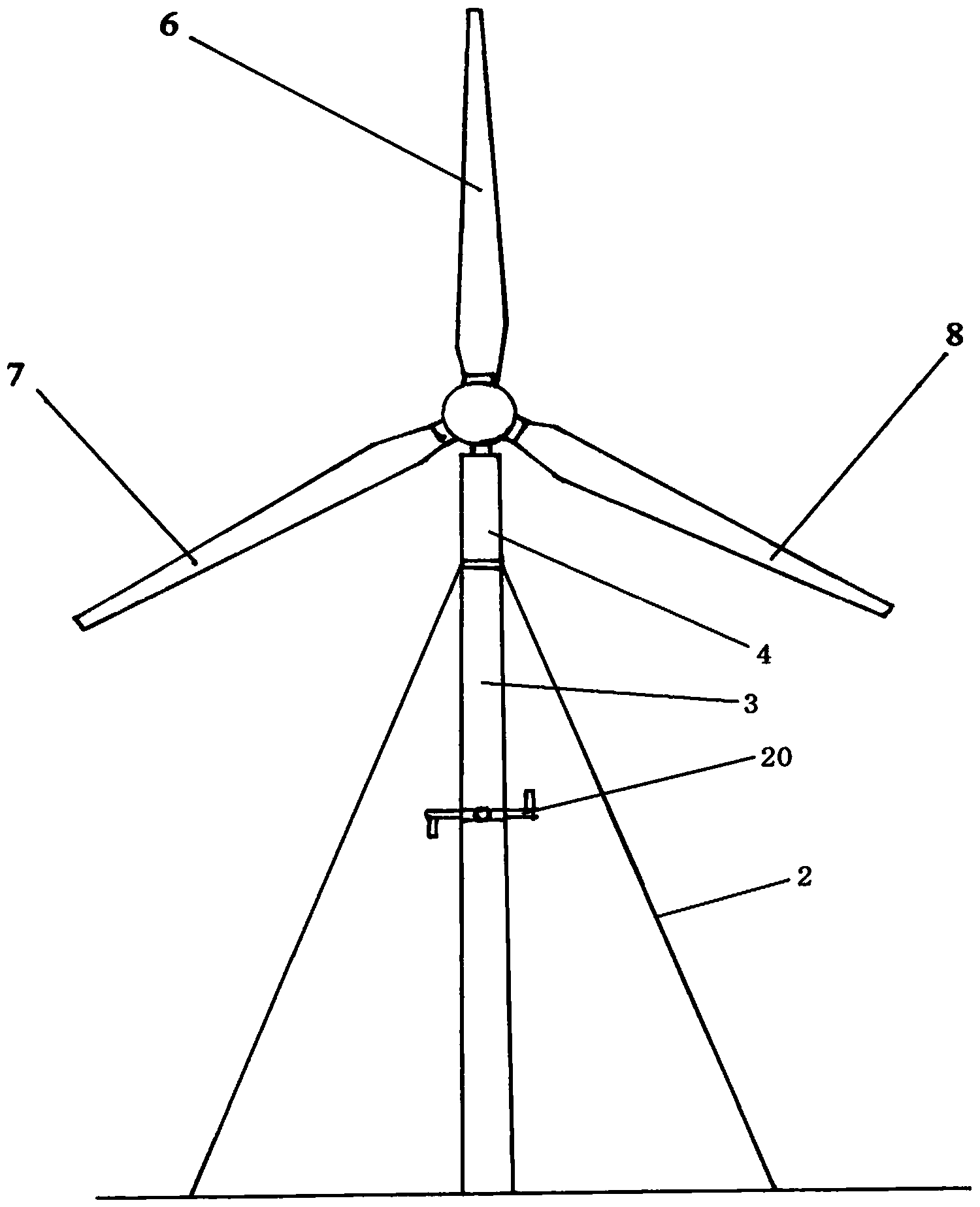

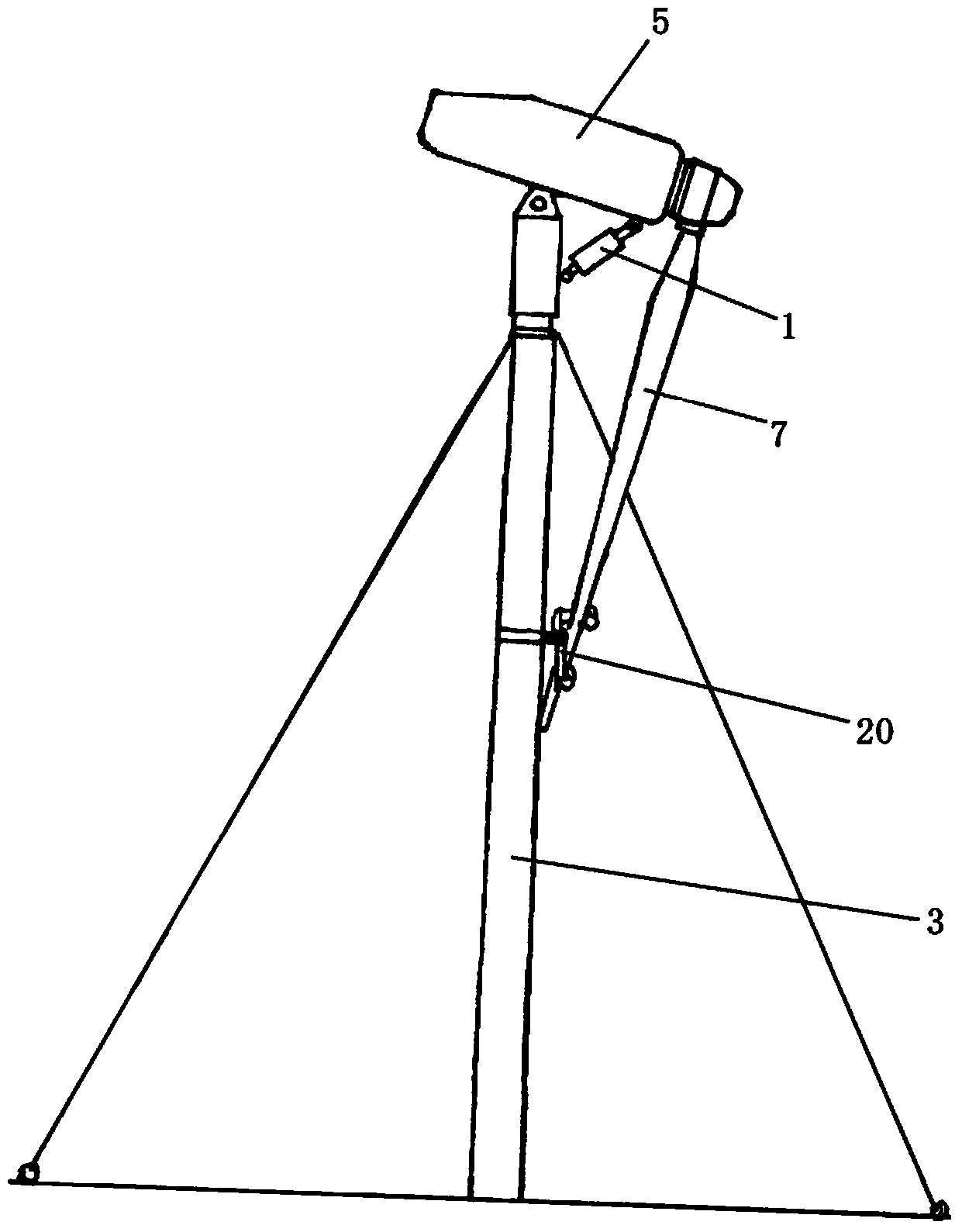

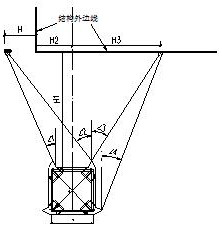

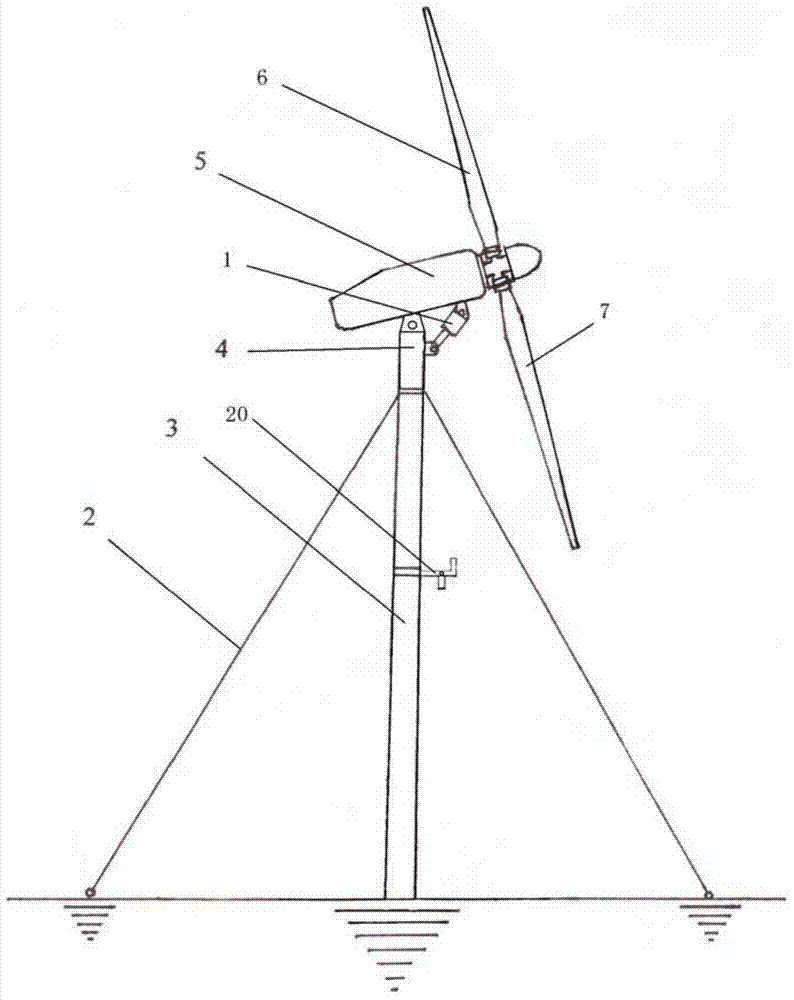

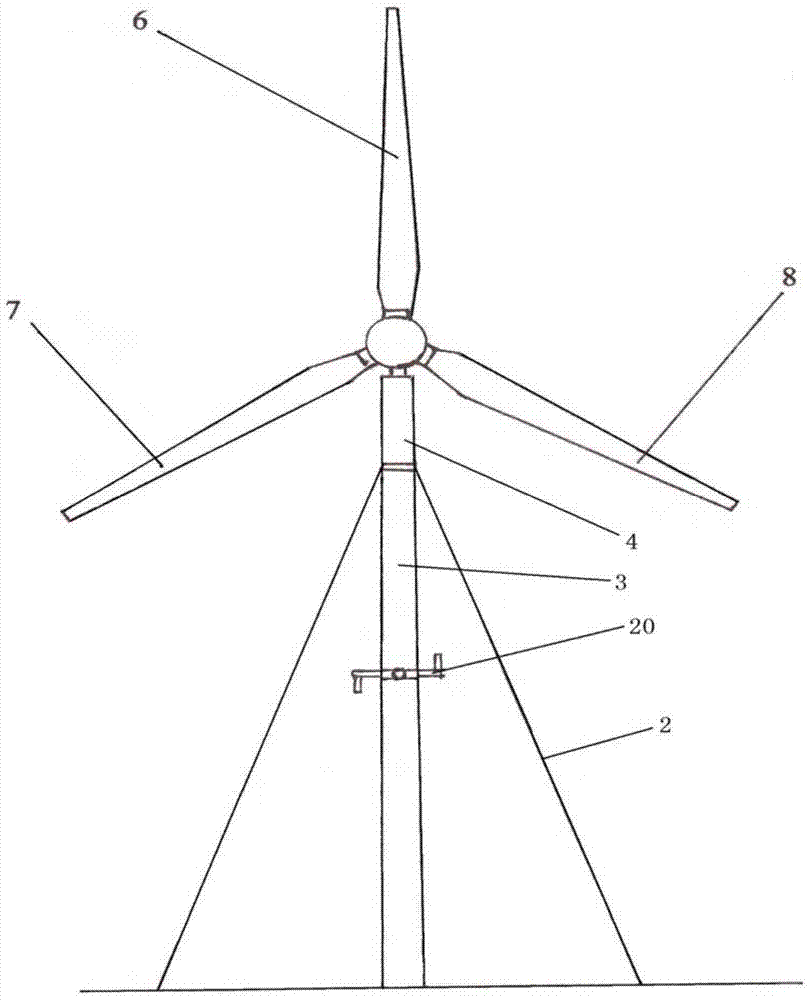

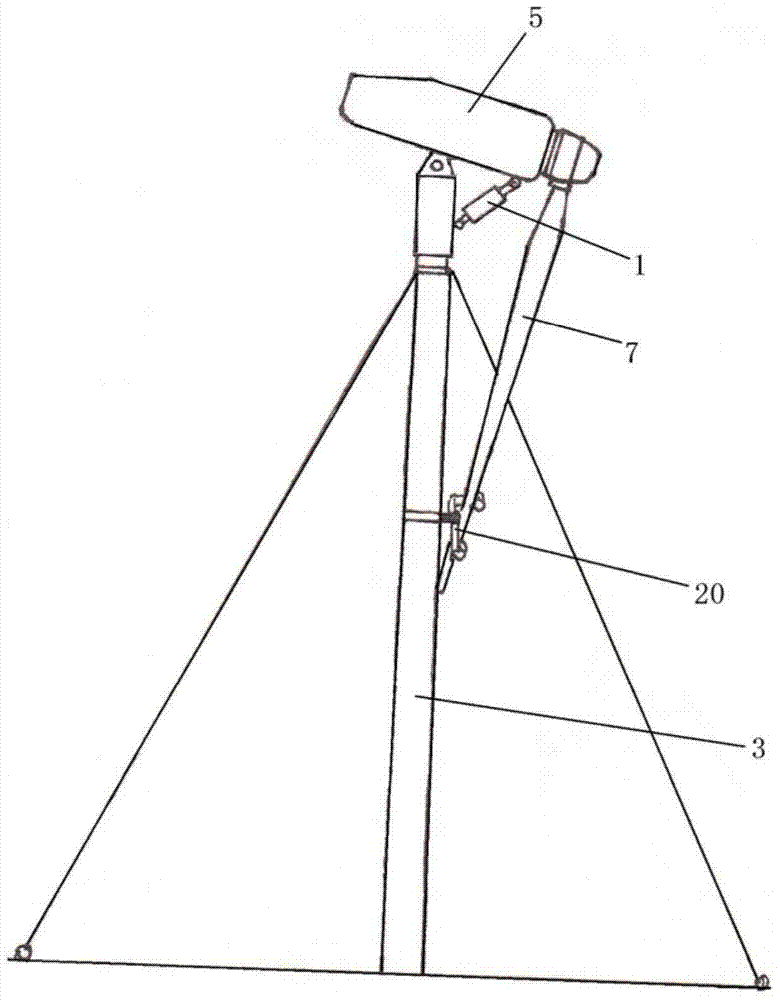

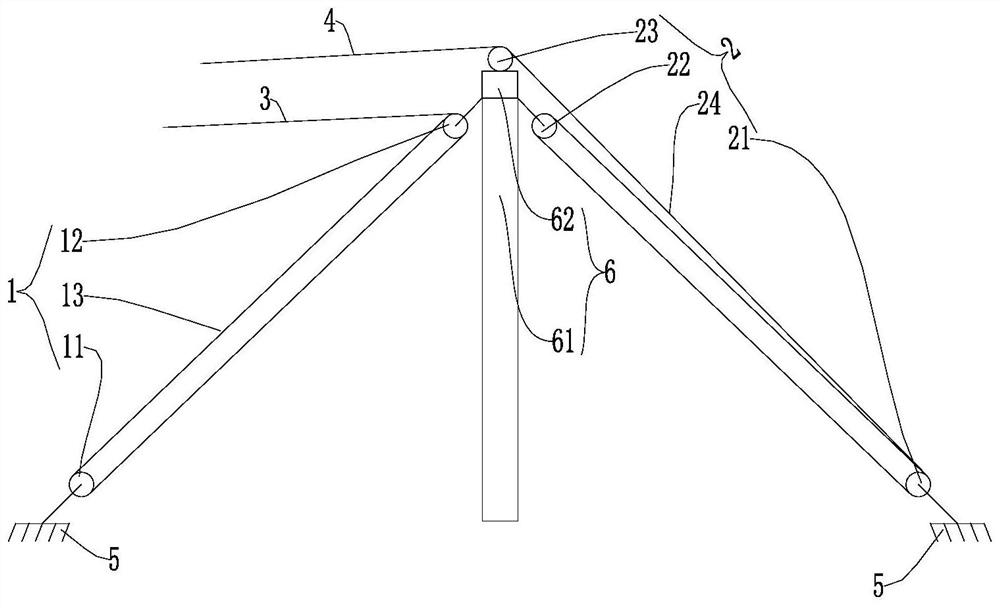

Wind power generation device with rear-mounted blades

ActiveCN104295449AIncreased sweep diameterIncrease powerWind motor controlWind motor combinationsCable stayedLoad following power plant

The invention discloses a wind power generation device with rear-mounted blades. The wind power generation device comprises a stand column, a wind power generation main engine and the blades. The main engine is hinged to the top of the stand column. The blades are installed on the tail of the main engine in a rear-mounted mode. A hydraulic piston cylinder capable of moving telescopically is further hinged between the upper portion of the stand column and the rear portion of the main engine. A piston of the hydraulic piston cylinder moves telescopically to adjust changes of the pitching dip angle, on the stand column, of the main engine. At least three steel cables are uniformly distributed on the upper portion of the stand column and fixedly connected to the upper portion of the stand column. The other ends of the steel cables are fixedly connected with a ground pile in a cable-stayed mode. Due to the design, the steel cables of the stand column and the blades do not interfere with each other in the cable-stayed process of the cables, wind resistance influence is small, diameter space of the blades is enlarged, the swept area of wind power is increased, power is increased, the dip angle can be controlled, adjusted and rotated for harmonizing loads of wind power, and the wind power can be tracked automatically; due to high-gradient hilly area arrangement, the blades rotate in an inclined mode to make the front side face wind, and the wind power is fully utilized; with assistance of the cable-stayed steel cables, the structural cost can be reduced, the defect of the poor wind-proof capacity in tradition is overcome, and the wind power generation device is suitable for being arranged on coasts with strong wind.

Owner:丁健威

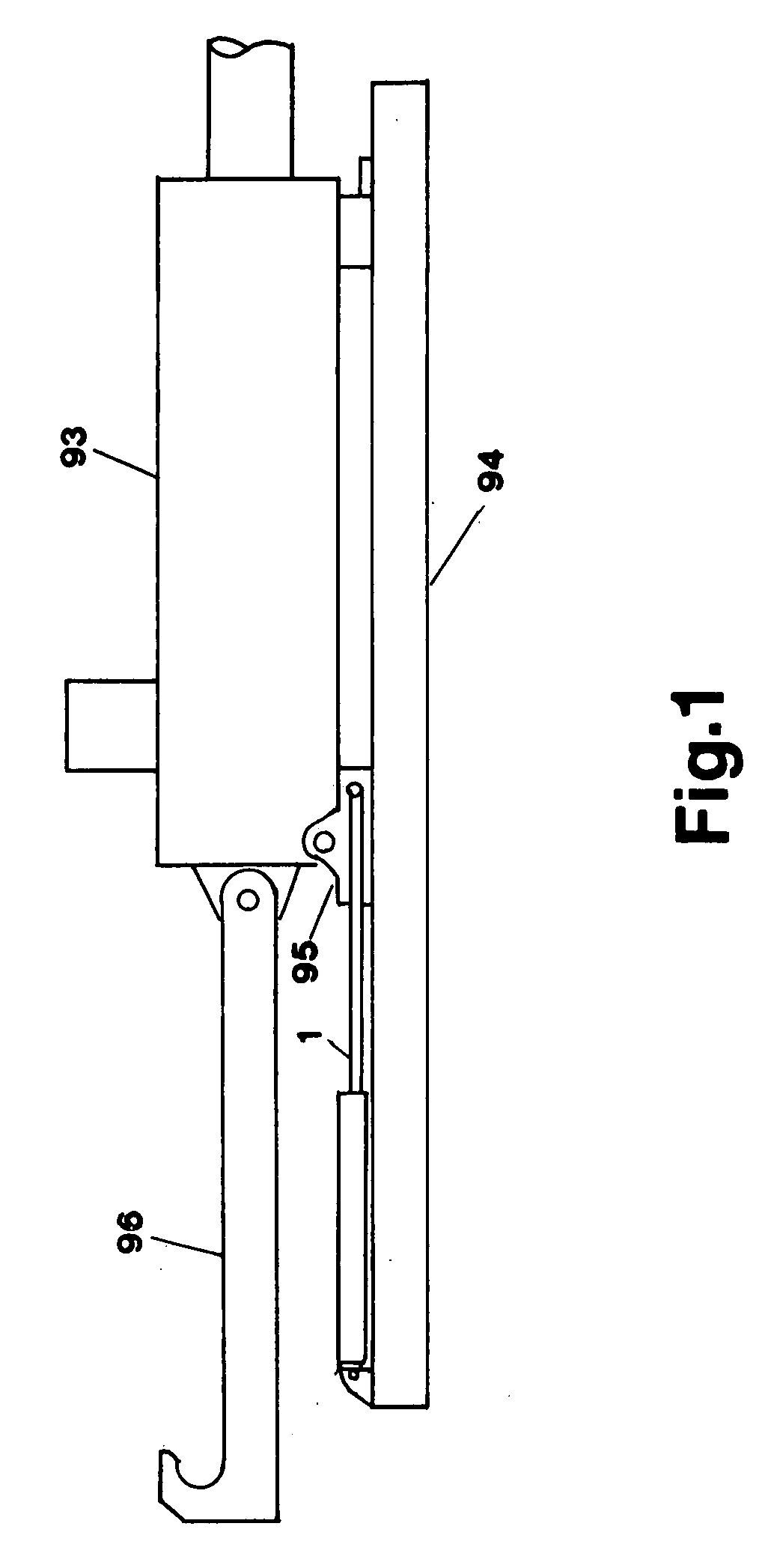

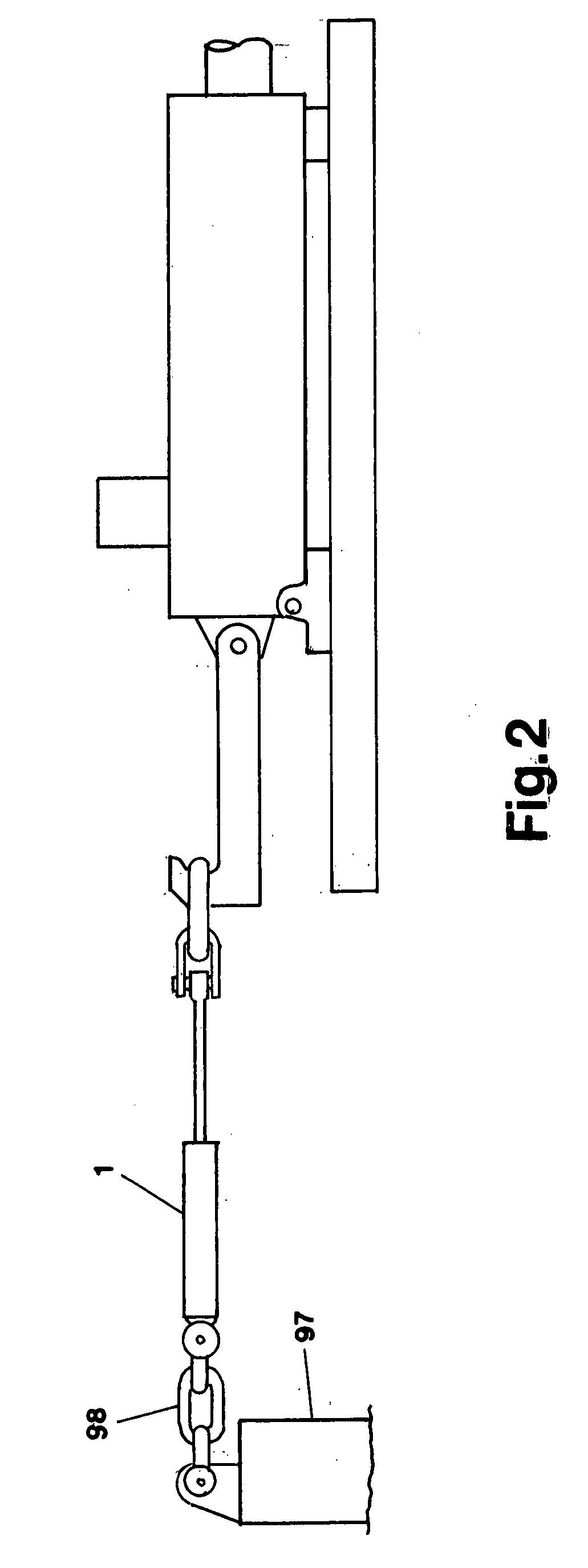

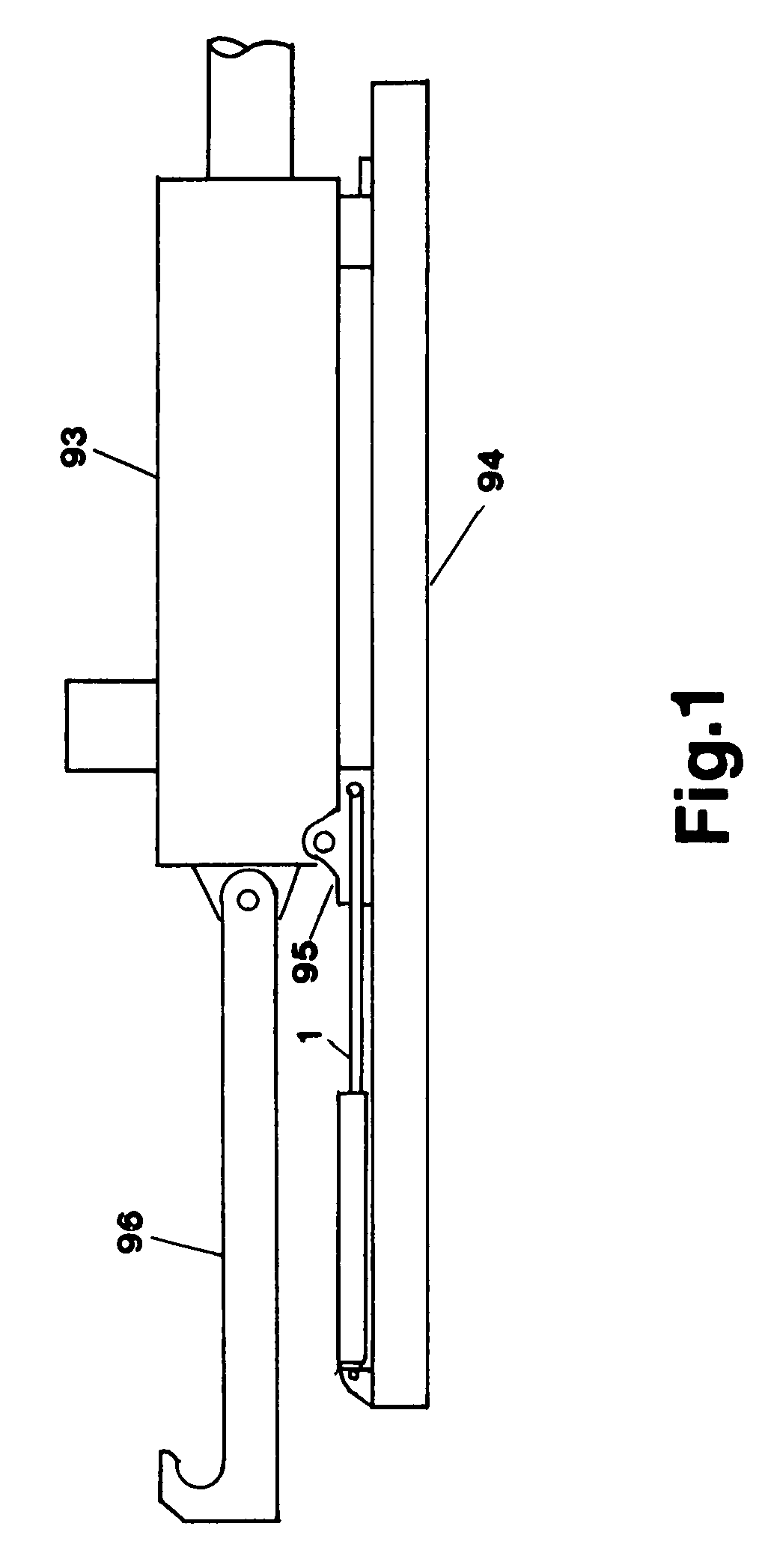

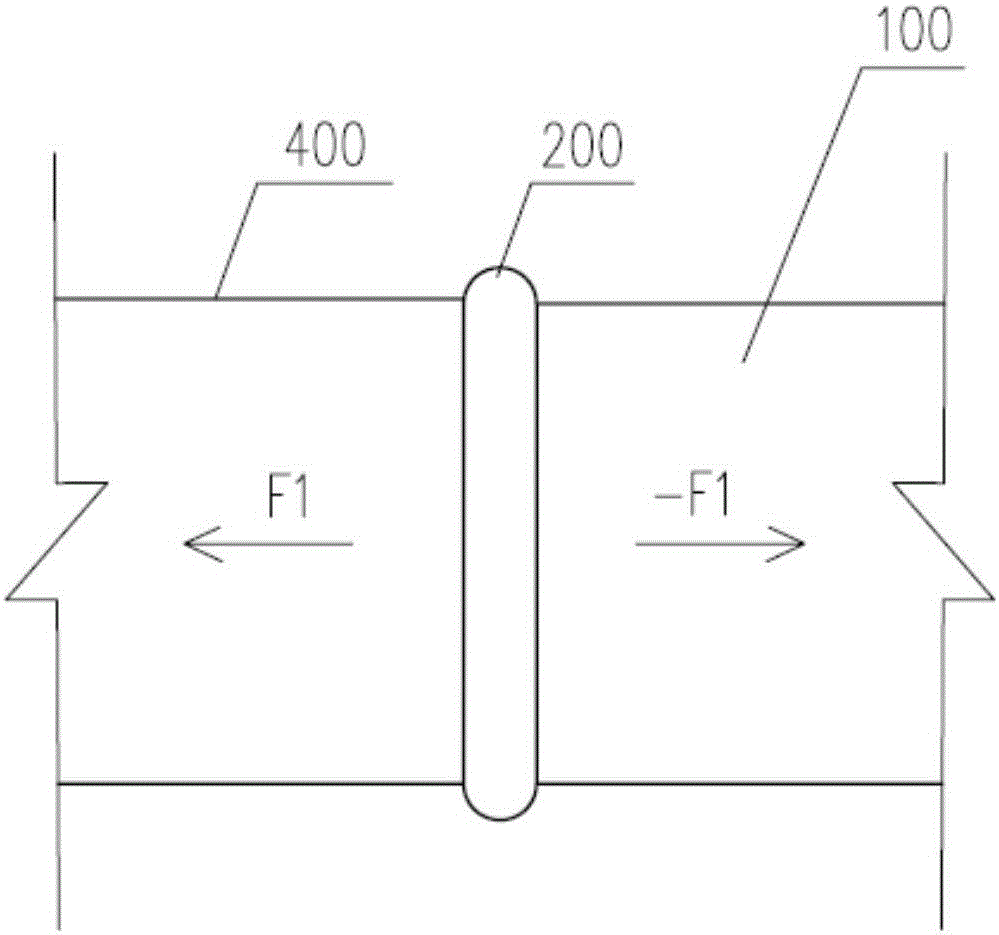

Constant thrust restraint of pipeline walking

ActiveUS20090041547A1Eliminate thermal walkingReduce horizontal loadPipe supportsPipe laying and repairAxial forceEngineering

The invention is a means to eliminate thermal or pressure walking of a subset pipeline by applying a constant axial force to the pipeline through the interposition of a constant-thrust device between a point fixed to the pipeline and a point on a foundation, which pair of points are otherwise unconstrained relative to each other in the longitudinal direction of the pipeline.

Owner:NOCK MENDEL

A flexible suspended modular building structure

ActiveCN106013452BReduce horizontal loadReduce dosageProtective buildings/sheltersExtraordinary structuresRelative displacementMaterial consumption

The invention discloses a flexibly suspended modular building structure, which comprises a vertical core tube structure. A conversion story is arranged at the upper end of the core tube structure, multiple modules with certain spaces reserved therebetween are hung below the conversion layer, the modules adjacent in the vertical direction are connected through a set of hanging rod members, the upper end of each hanging rod member is pin-connected to a ceiling beam located in the upper module, the lower end of each hanging rod member is pin-connected to a ceiling beam located in the lower module, the hanging rod member arranged on the uppermost module is pin-connected to the transfer story, and dampers are connected between floors of all the modules and the core tube structure. By means of suspension shock absorption technology, the horizontal loads inputted by the modules to the core tube structure are remarkably reduced, and the material consumption of the core tube structure is saved. The module building allows inter-story drift of secondary structure, prevents non-structural elements from damage, and extends the limit value of inter-story drift between modules, thus improving the energy dissipation and shock absorption efficiency. By introducing a limiting buffer device, relative displacement between the modules is controlled, and collision is avoided.

Owner:SOUTHEAST UNIV

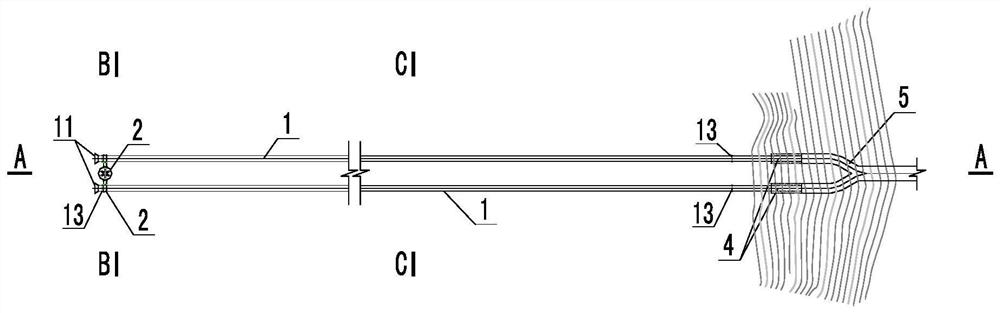

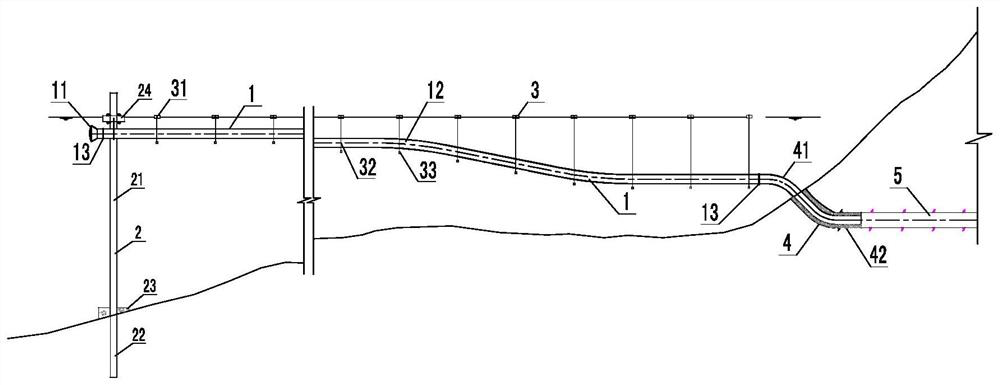

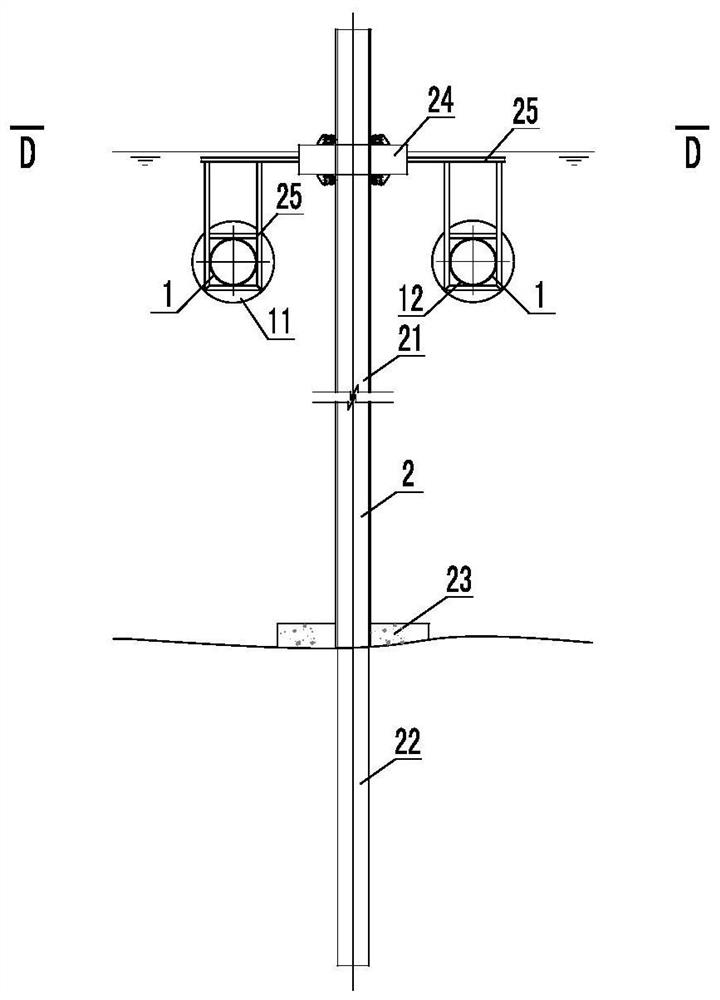

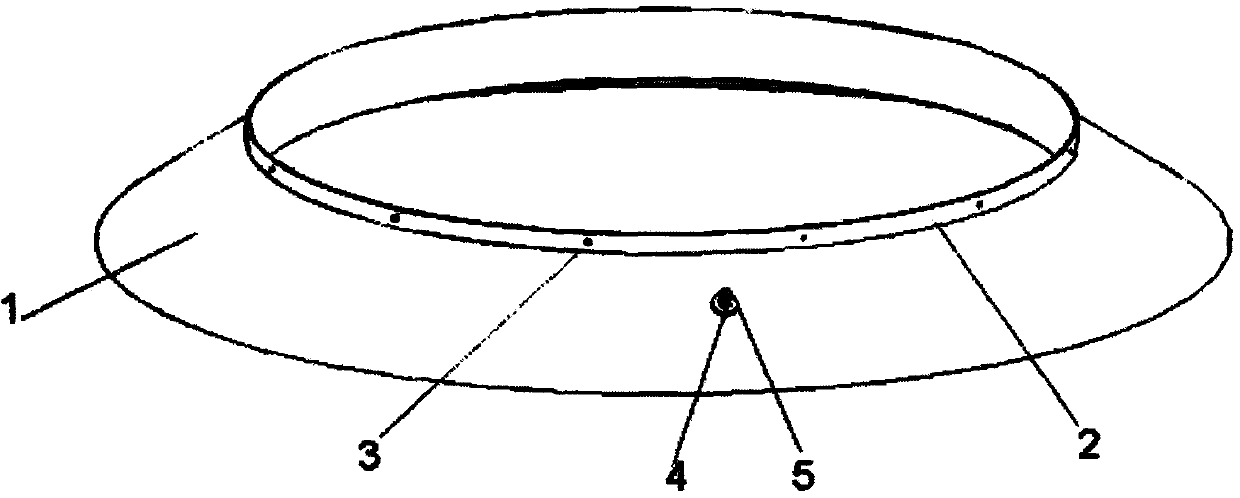

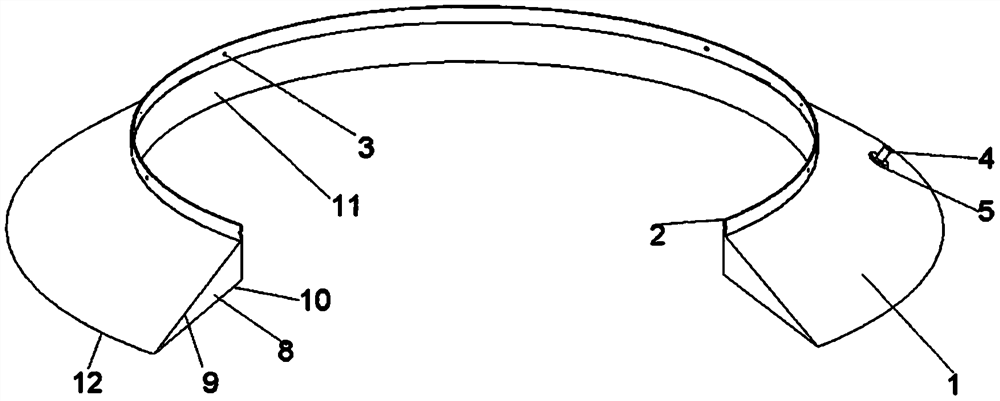

Movable water inlet with head positioned by adopting upright post and buoy

PendingCN112031070AFlexible water pointFlexible water intake elevationWater-power plantsHydro energy generationWind waveBuoy

The invention discloses a movable water inlet with a head positioned by adopting an upright post and a buoy. The movable water inlet comprises a pipeline system, a positioning system, a buoy system and a tunnel plugging section, wherein the pipeline system comprises a water taking head, a floating pipe and a flange joint, and is a main water delivery structure for extending the water inlet to a reservoir for taking water; the positioning system is positioned at the front end of the pipeline system, comprises the upright post, a cast-in-place pile, an upright post expansion foundation, an O-shaped steel buoy, a steel frame and a positioning wheel, and is used for fixing the water taking head at the front end of the pipeline system on a plane and at an elevation; the buoy system comprises the buoy, a steel wire rope and a balancing weight, and is used for fixing the floating pipe at a certain depth below the water surface; and the tunnel plugging section is positioned at the tail end ofthe pipeline system, is a water retaining structure, and is also an overflowing channel for water in the pipeline system to flow to a downstream water delivery tunnel along a built-in fixed pipeline of the tunnel plugging section. The movable water inlet has the advantages of flexible water taking point and water taking elevation, good wind wave resistance of a system structure, high automatic degree along with water level rise and fall, and suitability for water diversion and supply projects with high requirements on water quality.

Owner:浙江省水利水电勘测设计院有限责任公司

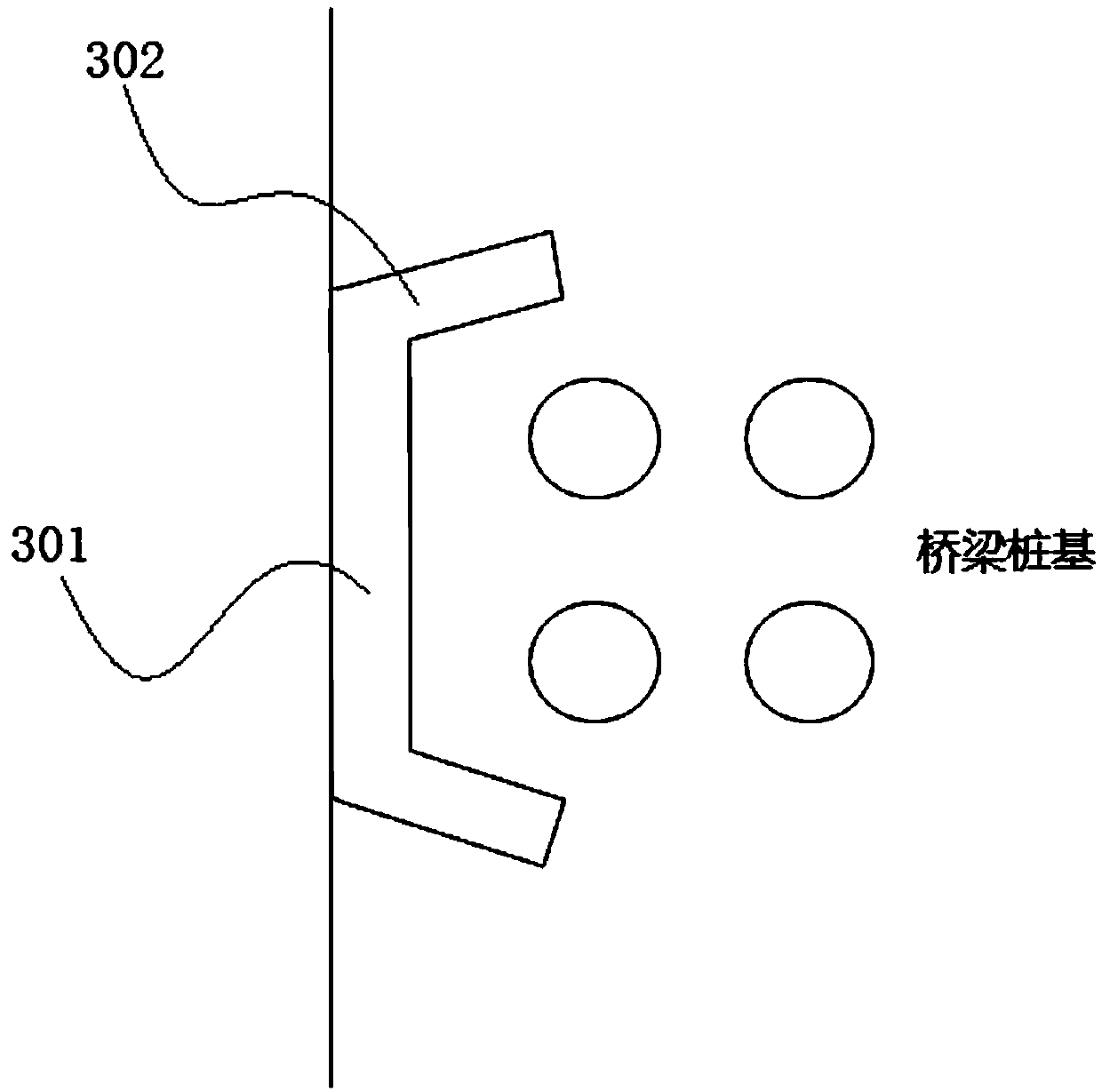

Wall-mounted draining anchor rod barricade structure and construction method thereof

ActiveCN109577277AAdvanced technologyImprove economyArtificial islandsClimate change adaptationEngineeringWall mount

The invention provides a wall-mounted draining anchor rod barricade structure and a construction method thereof. The barricade structure comprises a longitudinal beam embedded in the top of a bank slope, a barricade and an anchor rod. The barricade is arranged at a by-water side of the bank slope. The longitudinal beam is positioned at a fundamental inner side of a protected bridge pile foundation. A plurality of cross beams is connected between a barricade body and the longitudinal beam. The construction method for the barricade structure comprises steps of constructing the anchor rod, constructing a draining hole, constructing the barricade, constructing an anchor pile, constructing the longitudinal beam, constructing the cross beams and installing a cut-off valve and the like. The barricade structure is capable of effectively solving problems existing in a large-scale reservoir hydro-fluctuation belt bank side cleugh area bridge pile foundation protecting technology, and advanced intechnology, and well in economy.

Owner:CHONGQING JIAOTONG UNIVERSITY

Constant thrust restraint of pipeline walking

ActiveUS8011856B2Reduce horizontal loadEliminate thermal walkingPipe supportsPipe laying and repairClassical mechanicsEngineering

The invention is a means to eliminate thermal or pressure walking of a pipeline by applying a constant axial force to the pipeline through the interposition of a constant-thrust device between a point fixed to the pipeline and a point on a foundation, which pair of points are otherwise unconstrained relative to each other in the longitudinal direction of the pipeline.

Owner:NOCK MENDEL

Foundation pit support and construction road integrated structure and construction method

PendingCN111501782AImprove reliabilityReduce horizontal loadPaving reinforcementsIn situ pavingsArchitectural engineeringPipe

The invention discloses a foundation pit support and construction road integrated structure and a construction method. The integrated structure is an integral structure formed by a foundation pit support structure and a construction road, wherein the foundation pit support structure comprises a plurality of rows of steel pipe piles; the steel pipe piles are inserted into a soil body around a foundation pit; the upper portions of the adjacent steel pipe piles are connected through a structural layer of the construction road; and the upper portions of the steel pipe piles and the structural layer of the construction road form the integral structure. The construction method comprises the steps that firstly, a site is leveled; secondly, surveying and setting out are carried out; thirdly, the steel pipe piles are driven in; fourthly, a first sleeve is sleeved; fifthly, a cover plate and a second sleeve are installed; sixthly, the structural layer of the construction road is poured; and seventhly, a top cover is arranged in a covering manner. The foundation pit support and construction road integrated structure and the construction method have the beneficial effects that the operation form of support excavation is adopted in construction, and the construction period can be effectively shortened. The adopted steel pipe piles, the sleeves, the cover plate and the concrete top cover areall detachable, easy to manufacture and convenient to transport, and development of adjacent underground space is not affected.

Owner:HUNAN UNIV OF SCI & TECH

Device for adjusting and positioning horizontal offset for working rollers of rolling mill

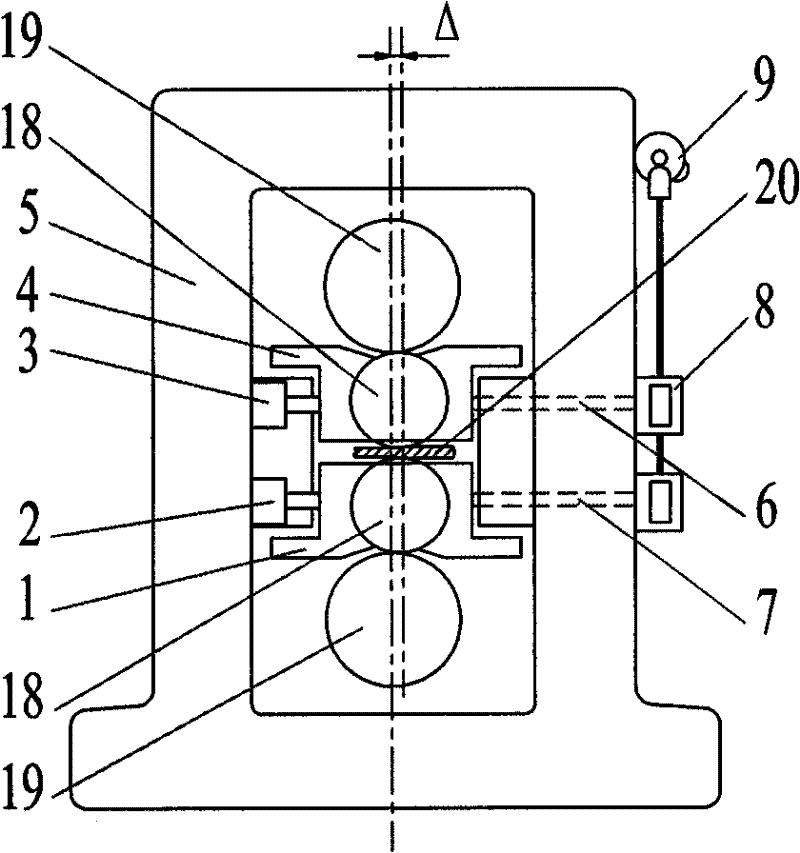

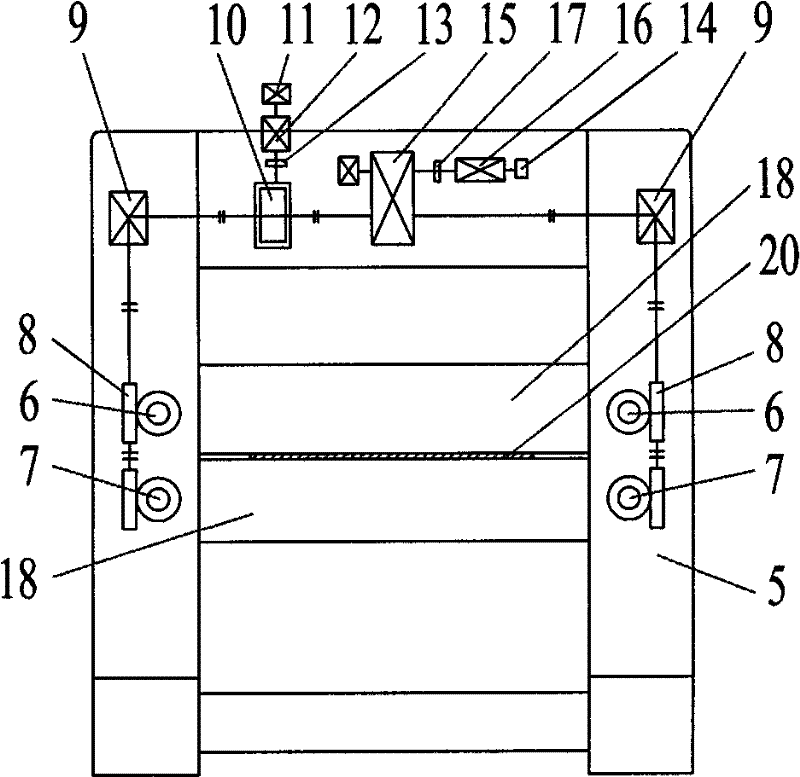

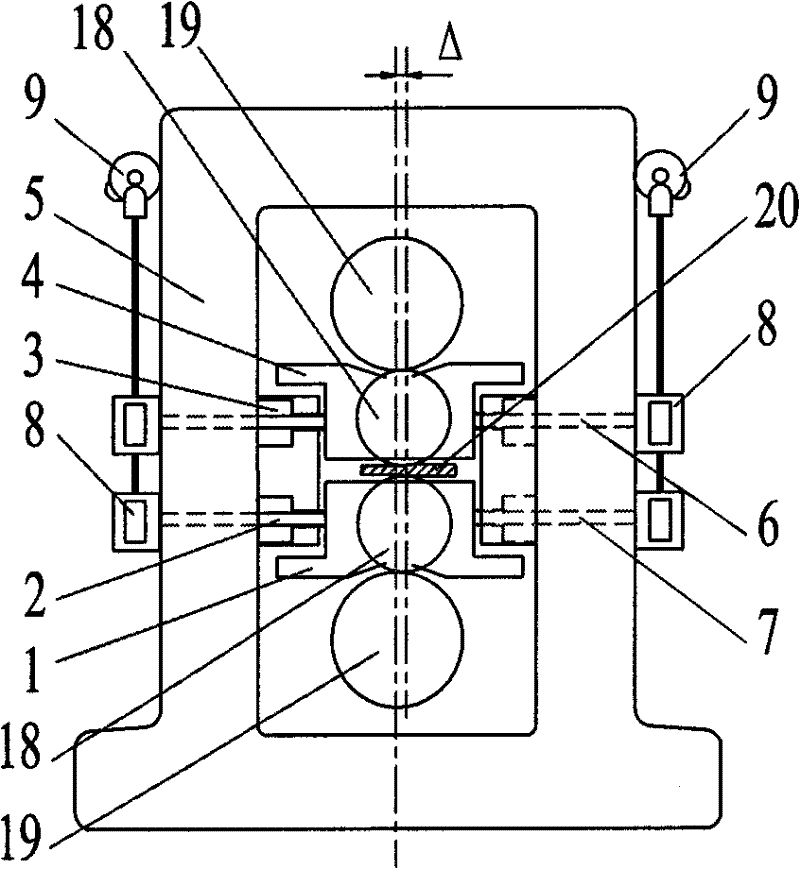

ActiveCN101733287BReduce horizontal forceReduce bending stressMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderHorizontal force

The invention discloses a device for adjusting and positioning horizontal offset for working rollers of a rolling mill, which comprises a position control mechanism which is arranged on an upright post on an entrance side of a frame (5) of the rolling mill and arranged opposite to bearing seats (4, 1) at two ends of an upper working roller and a lower working roller, and a pressure balance mechanism which is arranged on an upright post on an exit side of the frame of the rolling mill and is opposite to the position control mechanism. The position control mechanism comprises an upper push rod (6) and a lower push rod (7) which pass through the upright post. One end of each of the upper push rod (6) and the lower push rod (7) is propped against one side of each of the bearing seats of the upper working roller and the lower working roller, while the other end is connected with a push rod transmission mechanism. The pressure balance mechanism comprises an upper balance hydraulic cylinder (3) and a lower balance hydraulic cylinder (2). The device is applied to a four-roller or a six-roller cold-rolling mill or a reversing cold mill of which the working rollers have no side supports. The working rollers can be horizontally moved correspondingly according to rolling parameters. The horizontal offset of the working rollers is adjusted and positioned, so that the horizontal force thereof is reduced, and the working rollers smaller than the conventional design are realized and roll strip steel in thin specification.

Owner:CERI TECH

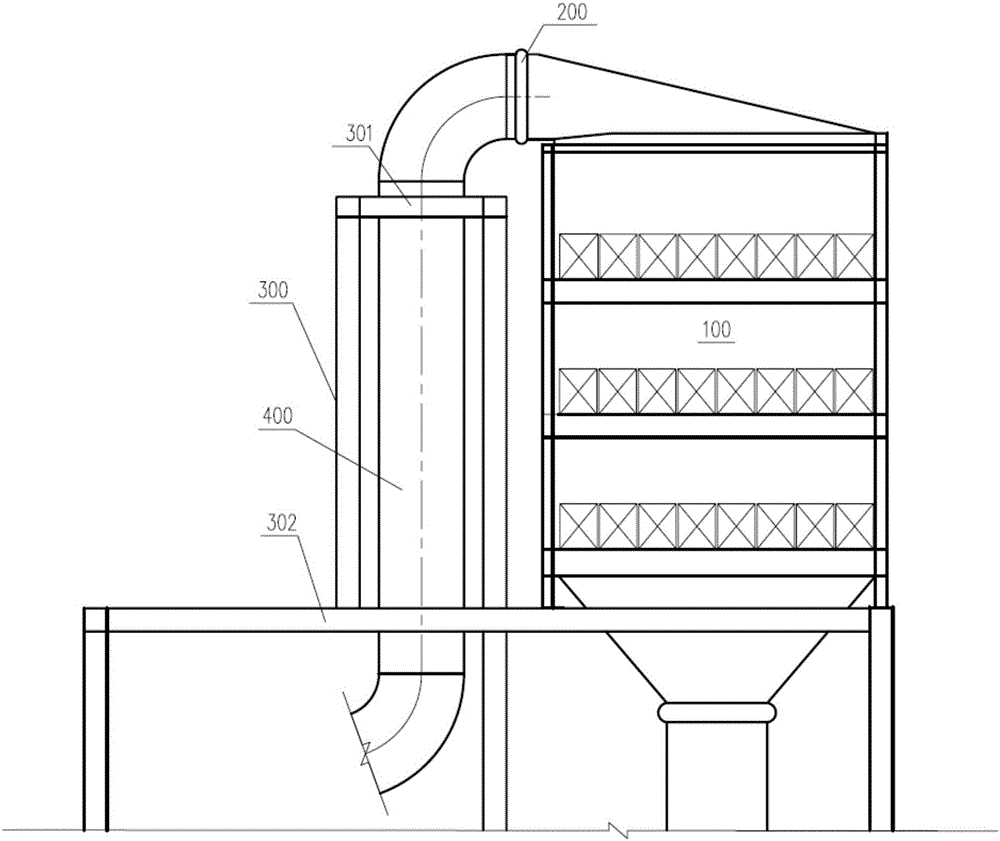

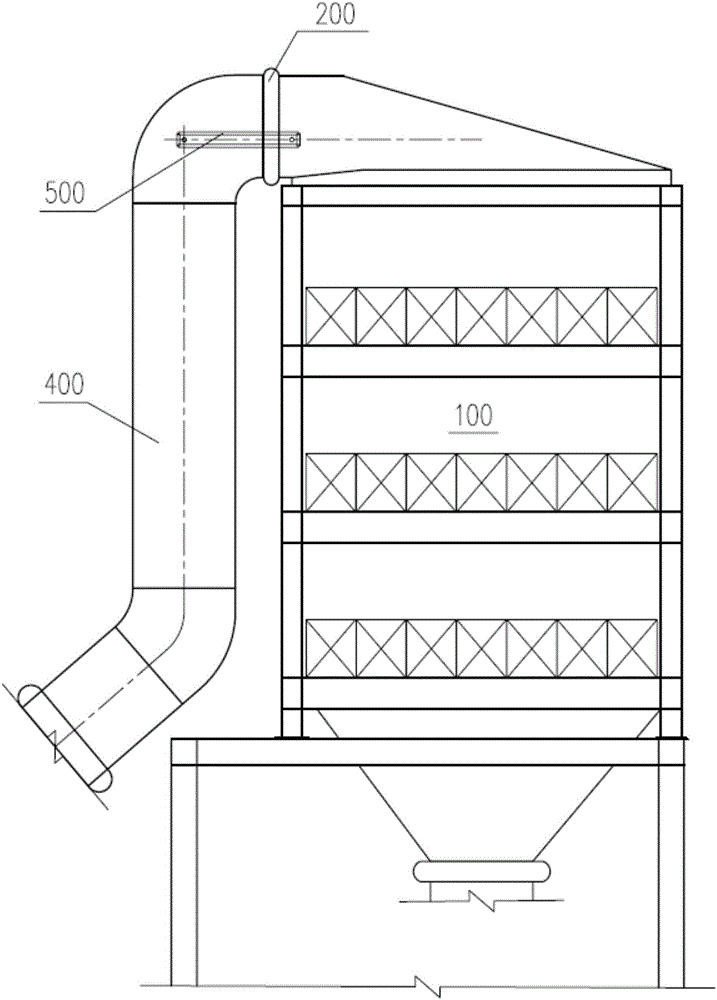

Combination body of flue gas desulfurization absorption tower and chimney

InactiveCN101856582ASmall footprintShorten the lengthDispersed particle separationWaste heat treatmentEngineeringFlue-gas desulfurization

The invention relates to an absorption tower, a chimney and a chimney bracket in a flue gas desulfurization device. A combination body of the absorption tower and the chimney is a whole which is formed by connecting and combining the absorption tower, the chimney and the chimney bracket; the chimney is superposed on the top part of the absorption tower; cylindrical shell sections of the chimney are flexibly connected with each other; pipe nipples on the top of the absorption tower are flexibly connected with the cylindrical shell sections of the chimney; the weights of the cylindrical shell sections in the chimney are borne by sections of the chimney bracket; and an upright post of the chimney bracket is connected with a barrel of the absorption tower in positioning connecting modes, such as welding, threading and pivoting and the like into a whole. Compared with a device in which the chimney and the absorption tower are arranged separately, the combination body of the absorption tower and the chimney can reduce the floor area needed by the arrangement of the absorption tower and the chimney and reduce the construction investment and maintenance cost of the combination body of the absorption tower and the chimney.

Owner:成都华西工业气体有限公司

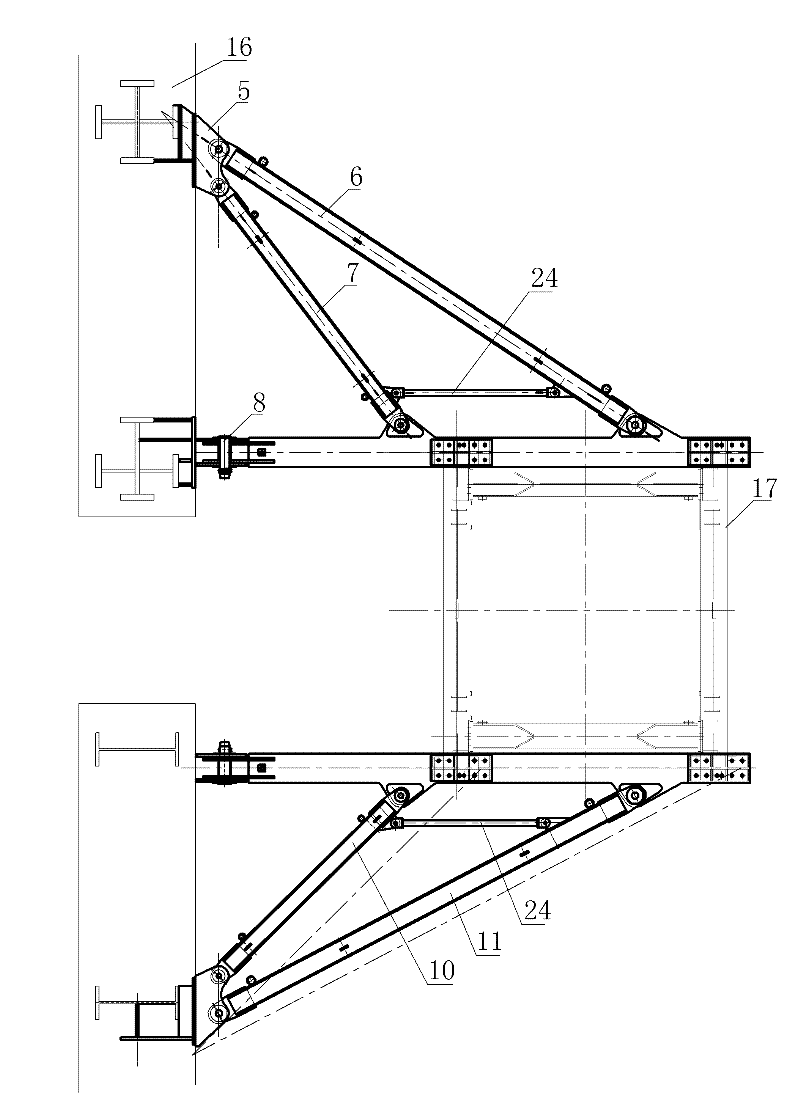

Fabricated building tower crane attached external suspension type auxiliary supporting structure and construction method

ActiveCN114046061AAvoid systematic errorsExpand the range that can be installedWallsBuilding material handlingArchitectural engineeringTower crane

The invention discloses a fabricated building tower crane attached external suspension type auxiliary supporting structure and a construction method thereof.The fabricated building tower crane attached external suspension type auxiliary supporting structure comprises a main beam, the main beam is welded to the outer surface of a building and connected with a tower crane through a connecting piece, and a horizontal inclined supporting beam is fixedly welded to the side edge of the main beam in the horizontal direction, a vertical inclined supporting beam is fixedly welded to the bottom of the main beam, and the horizontal inclined supporting beam and the vertical inclined supporting beam are fixedly connected with the outer surface of a building. The method has the beneficial effects that the bidirectional triangular statically indeterminate structure is utilized, the tower crane is attached to the horizontal direction and the vertical direction to form bidirectional support, the triangular stable structure is utilized to decompose the stress of the overhanging profile steel of the supporting component, part of the stress is transmitted to the profile steel inclined strut, the profile steel deflection change and the horizontal load are reduced, and therefore the attachment supporting requirement is met.

Owner:QINGDAO HAICHUAN CONSTR GROUP

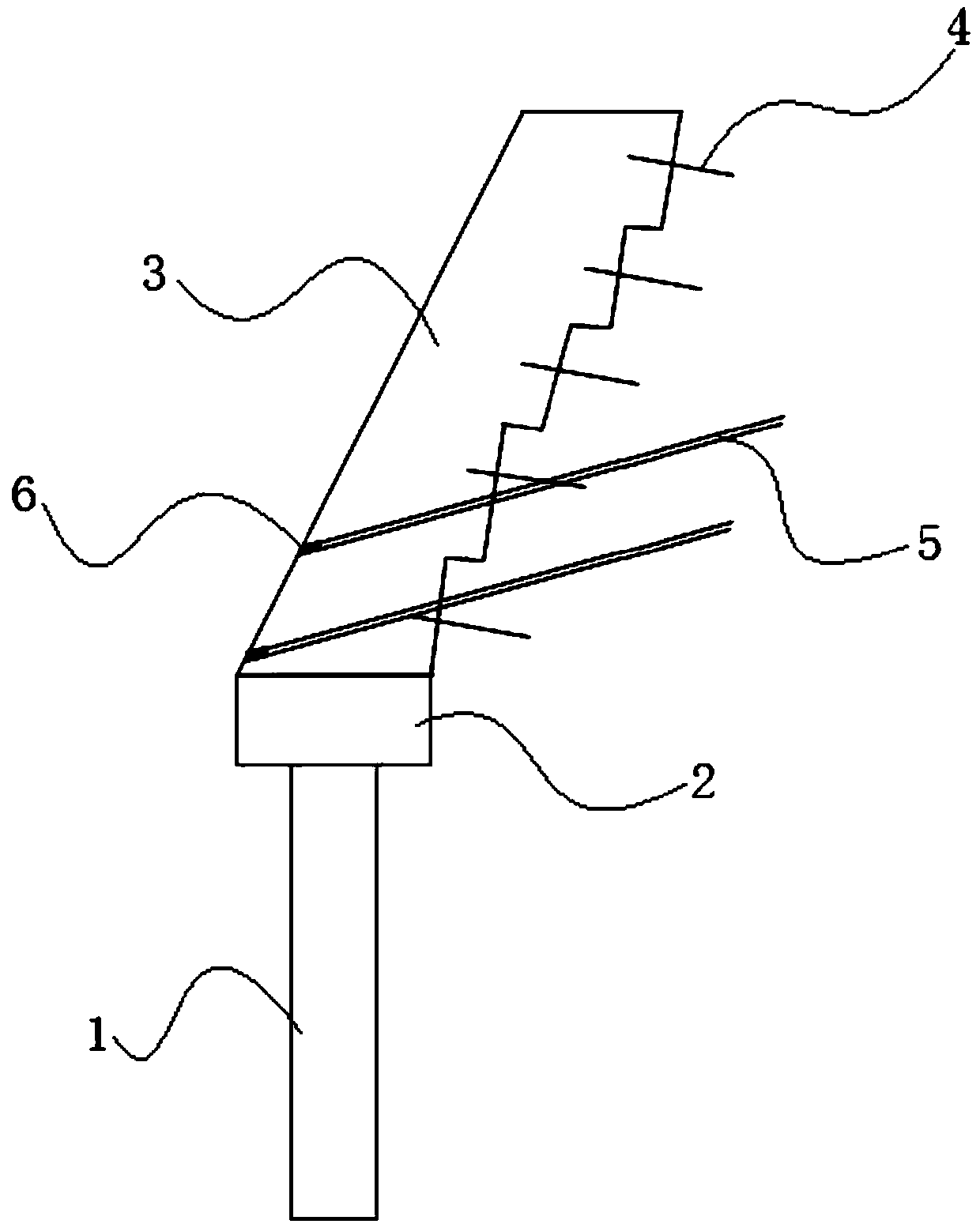

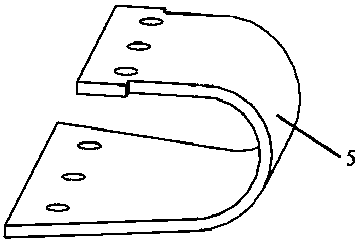

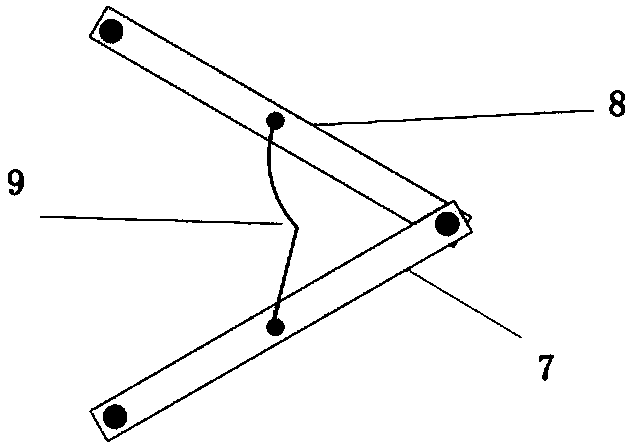

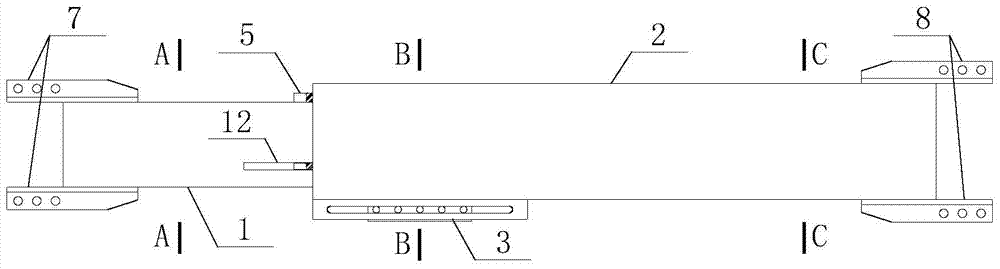

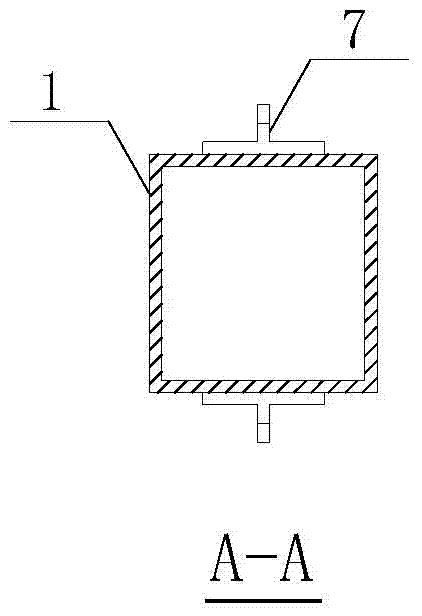

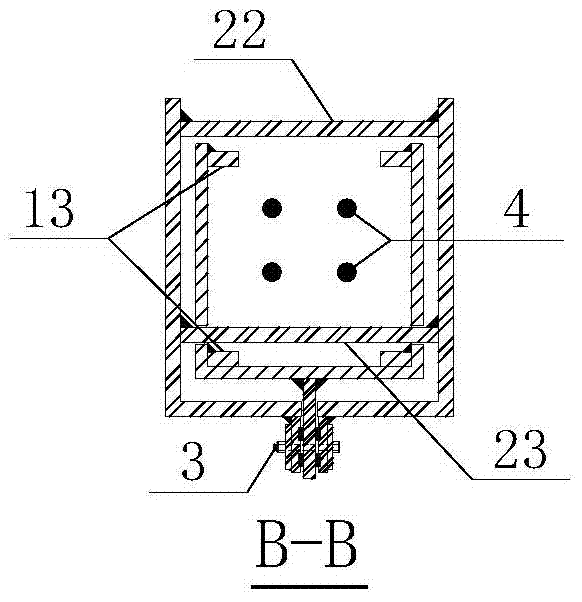

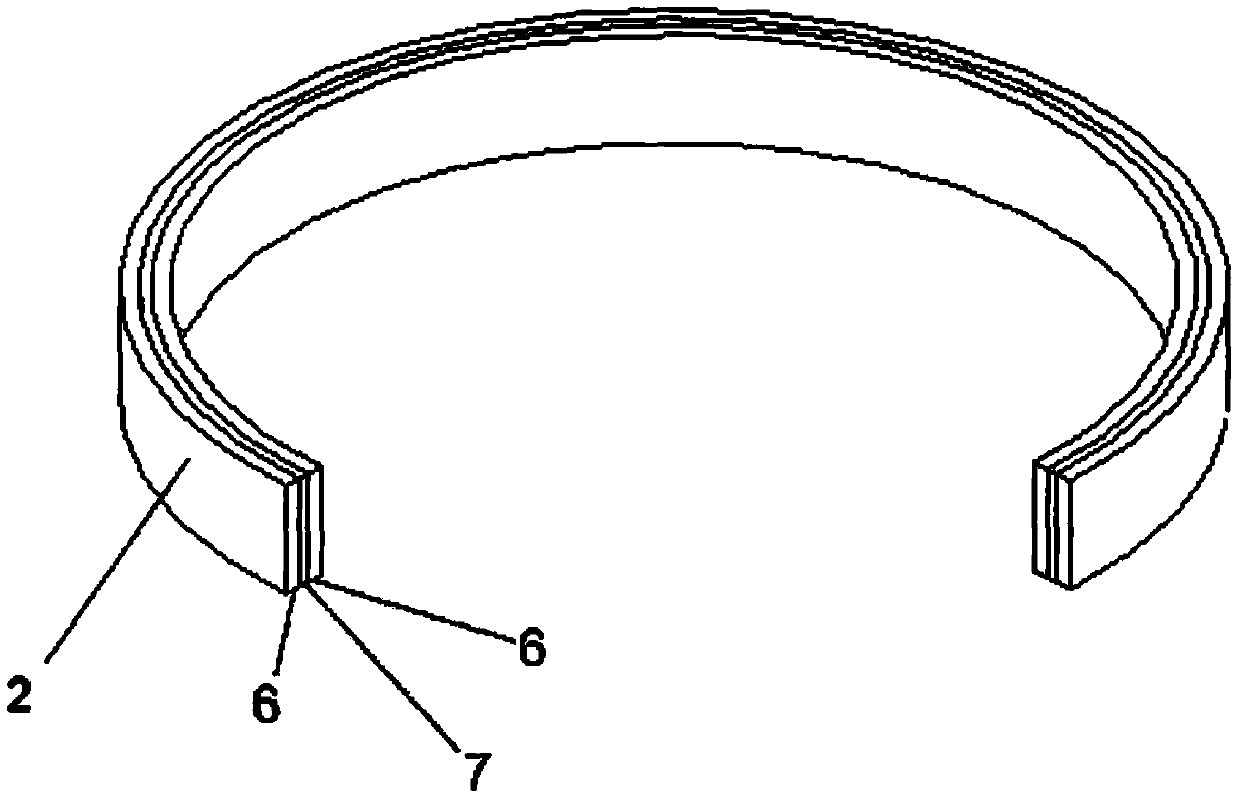

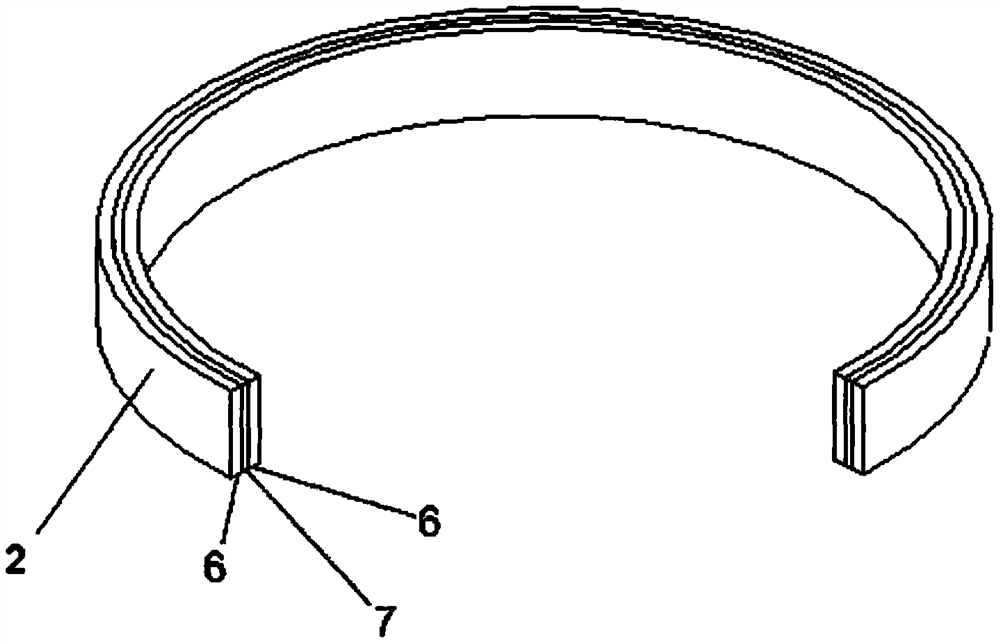

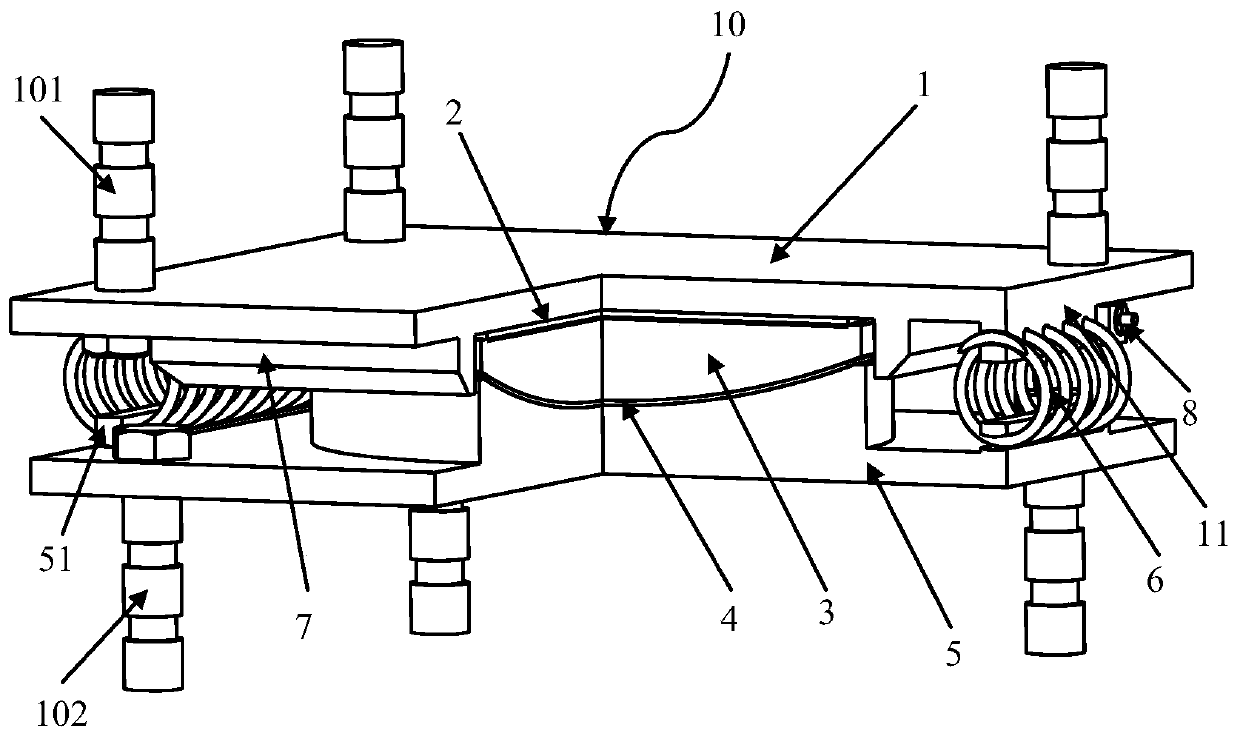

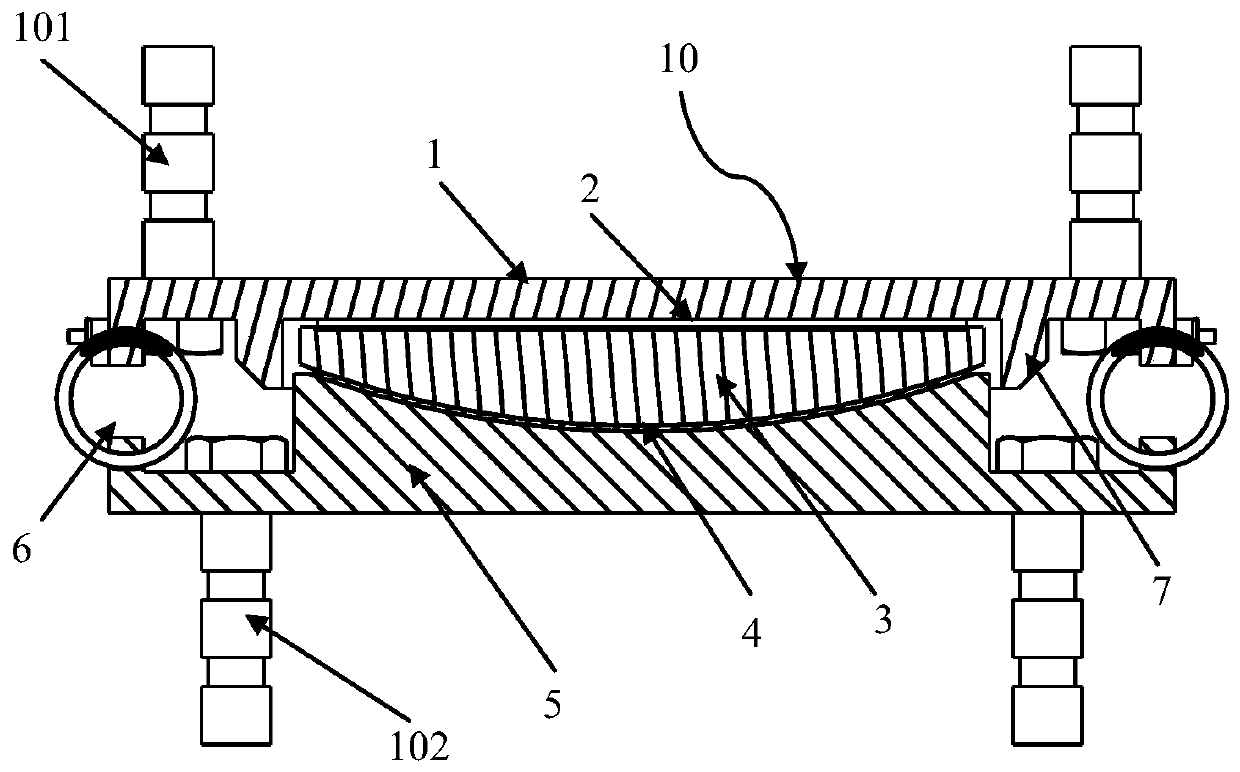

A lap joint self-centering friction energy dissipation support

ActiveCN104947824BReduce horizontal loadLimit lengthShock proofingOuter CannulaMechanical engineering

The invention discloses a lap joint type self-centering frictional energy dissipation support, which comprises a rectangular inner sleeve, a rectangular outer sleeve, a frictional energy dissipation part connecting the bottom plate of the inner sleeve and the bottom plate of the outer sleeve, and a first The end plate, the second end plate arranged in the outer casing, the pre-tension rod arranged in the inner casing and anchored to the first end plate and the second end plate at both ends respectively, a part of the inner casing is inserted into the outer casing and connected with it Overlapping, the end of the inner sleeve inserted into the outer sleeve is in contact with the second end plate, the first end plate is in contact with one end of the outer sleeve, the top plate and the bottom plate of the non-lapped end of the inner sleeve are respectively connected with the first connecting plate, and the outer sleeve The top plate and the bottom plate of the non-overlapping end of the pipe are respectively connected with a second connecting plate; the first end plate is in contact with the push plate of the inner casing through the set first end plate rubber pad, and the second end plate is set through the set second end plate rubber pad. The pad is in contact with the inner casing push plate.

Owner:SOUTHEAST UNIV

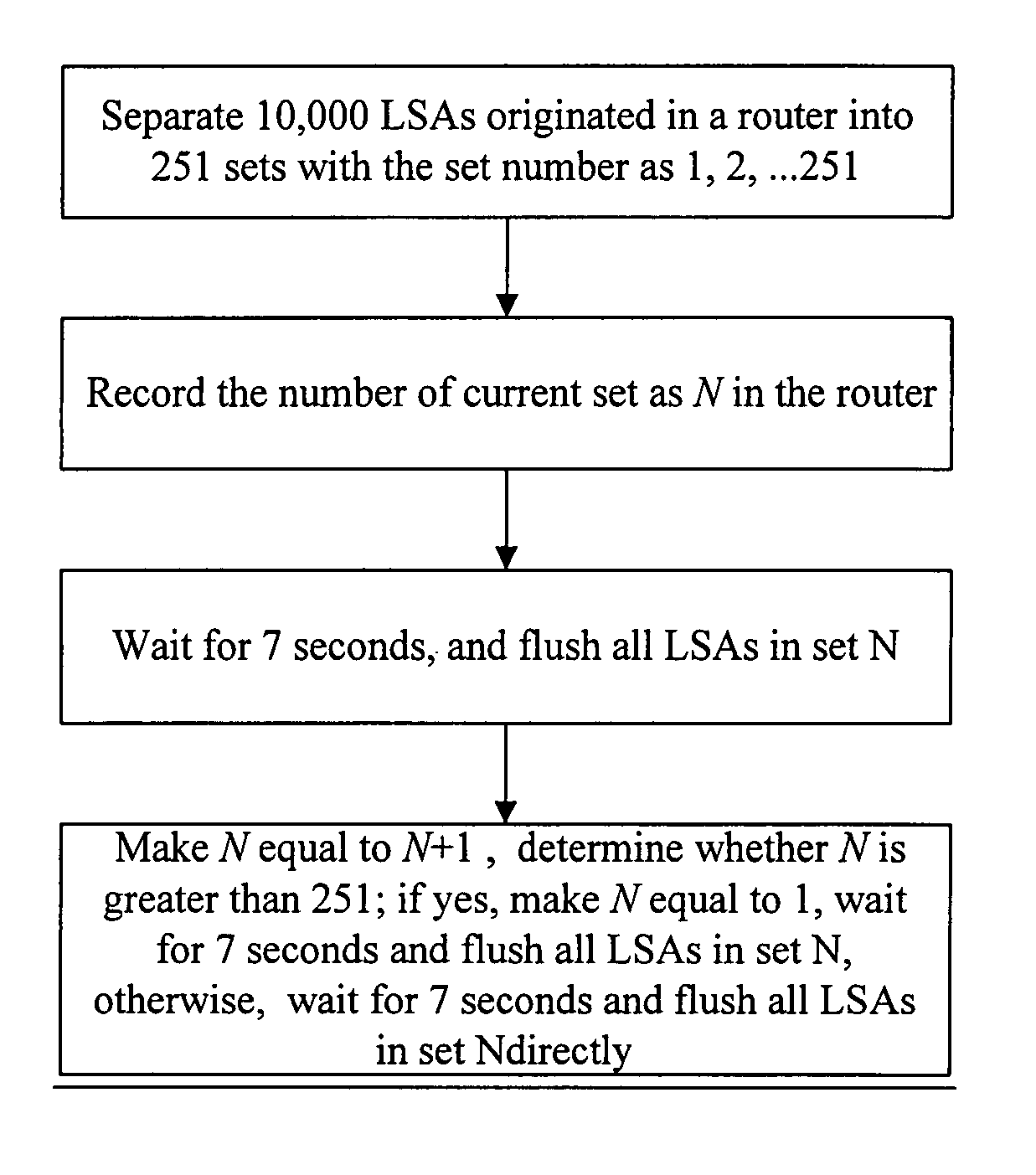

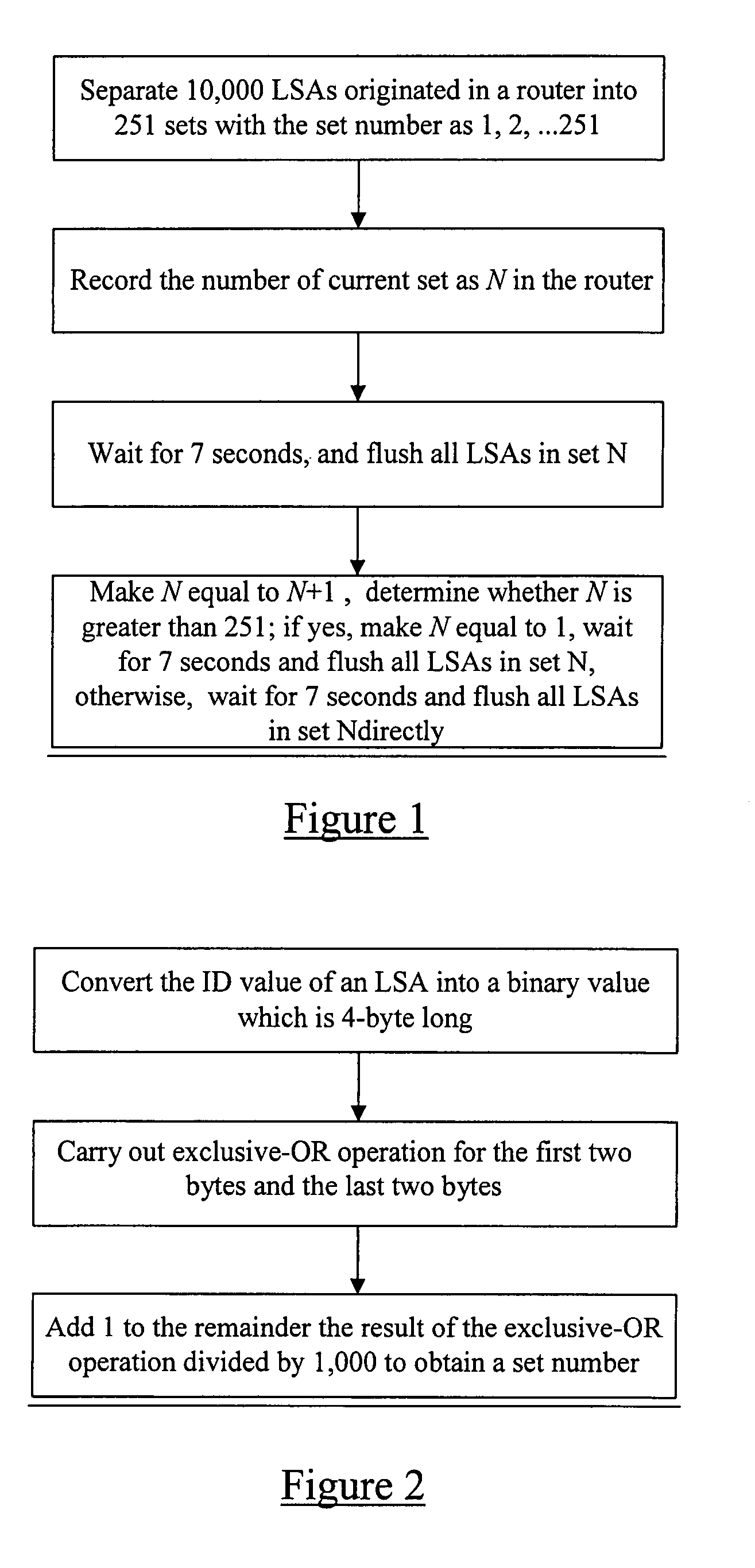

Flushing method with separated sets for type 5 link state advertisement in open shortest path first protocol

ActiveUS7327733B2Reduce the impactReduce horizontal loadData switching by path configurationTraffic volumeTraffic capacity

Disclosed is a flushing method with separated sets for type 5 Link State Advertisement (LSA) in the Open Shortest Path First (OSPF) protocol. All LSAs originated in a network device are separated into S sets with a mapping method in advance. Only one set of LSAs are flushed at first; then another set of LSAs are flushed in order at a flushing interval. The method reduces the instantaneous traffic impact on a network by the LSAs greatly, so the network keeps a low level load. Furthermore, the method guarantees that all LSAs are flushed once every network flush interval, so the OSPF protocol can be implemented normally.

Owner:HUAWEI TECH CO LTD

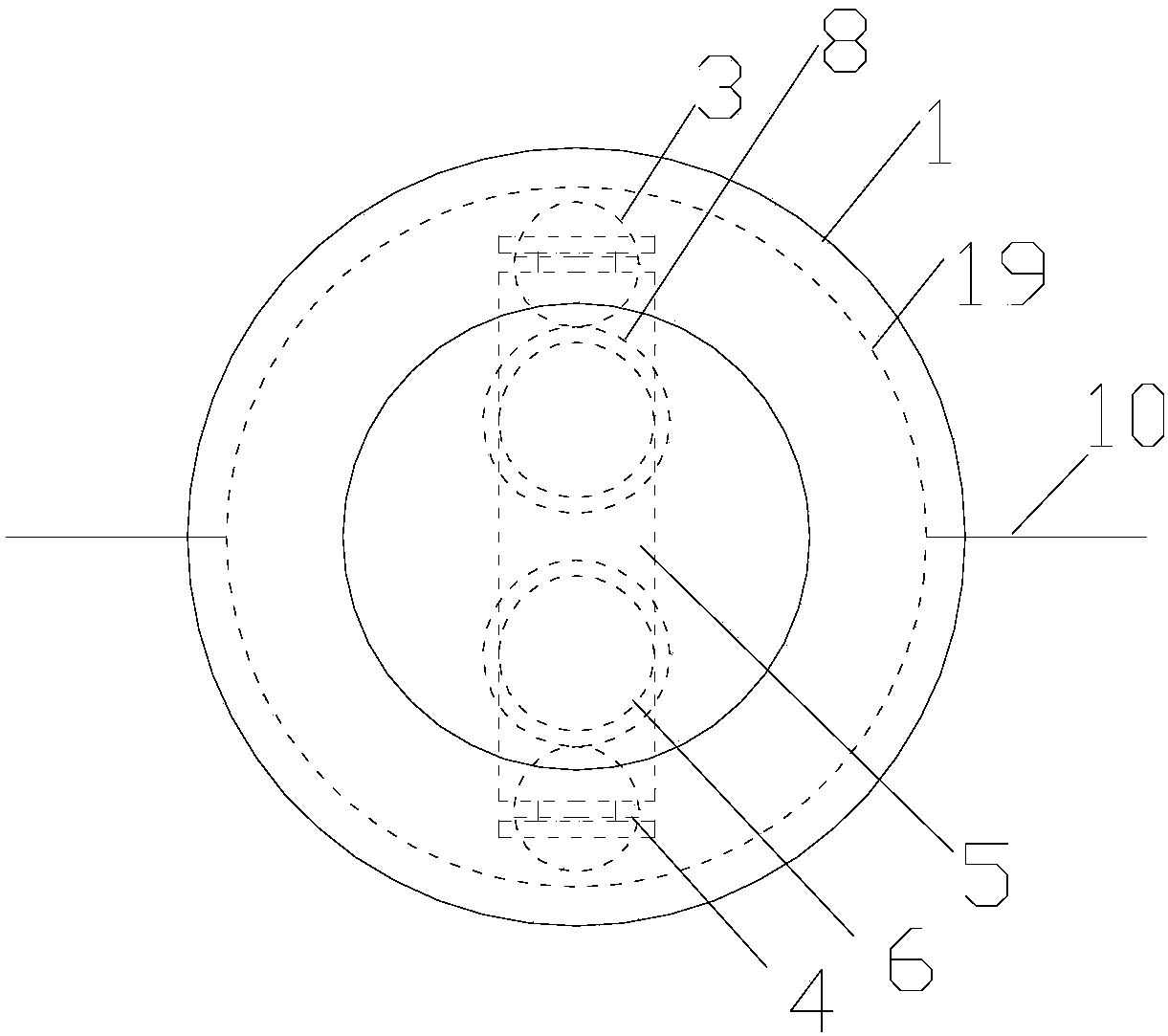

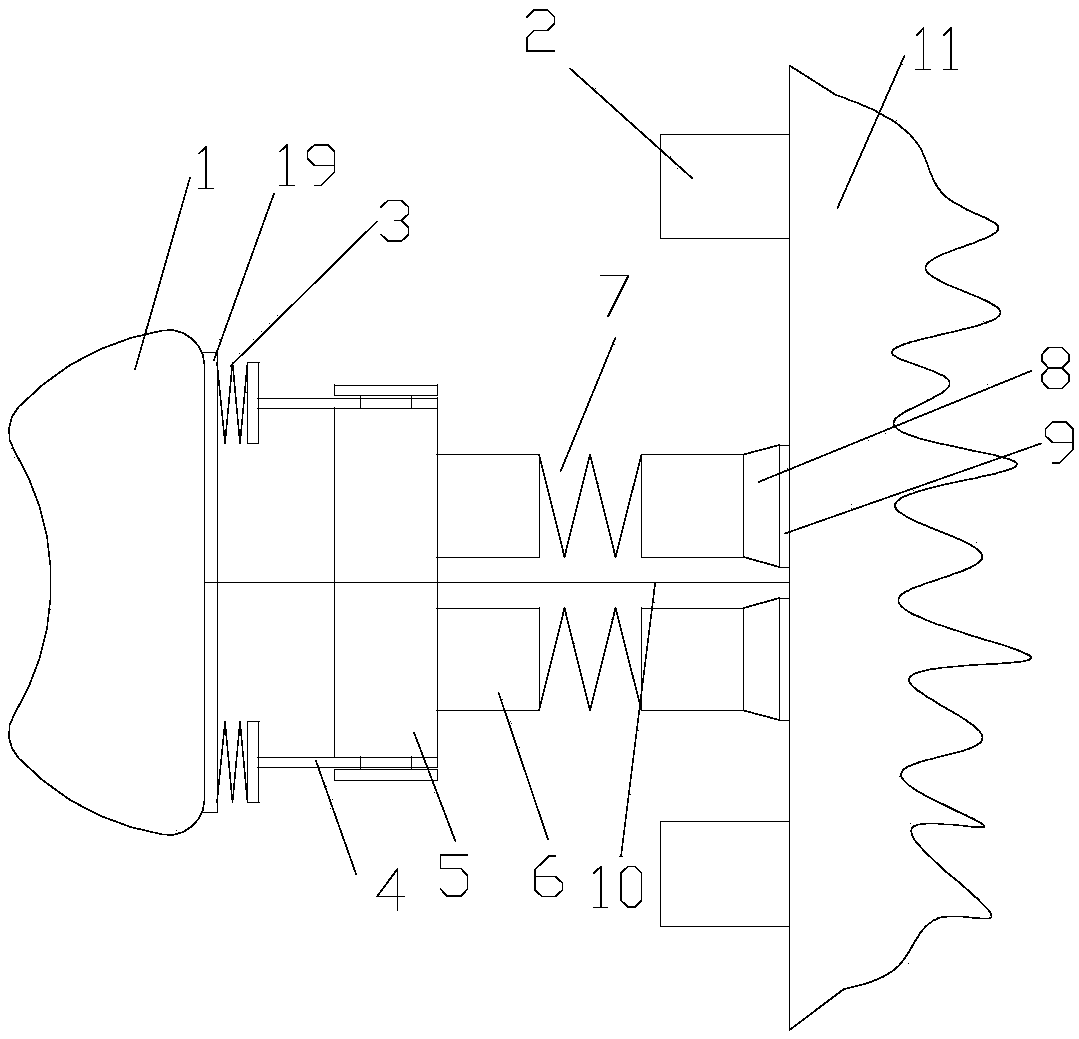

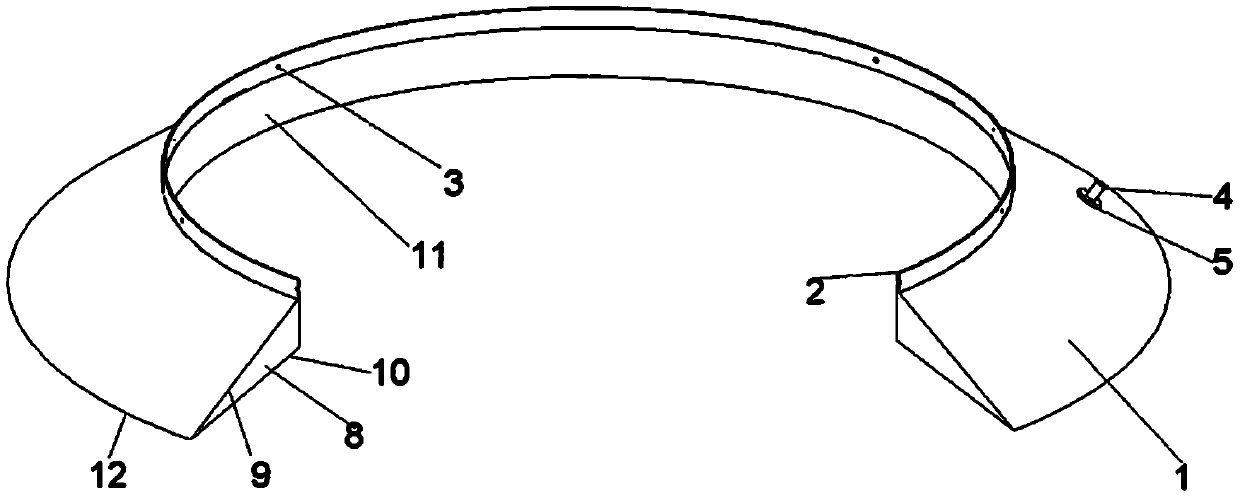

A rotatable multi-layer energy-absorbing dock fender

InactiveCN106436651BReduce vertical pressureReduce friction damageClimate change adaptationShipping equipmentEnergy absorptionEngineering

The invention discloses a rotatable multi-layer energy absorption quay fender. The rotatable multi-layer energy absorption quay fender comprises a fender body, wherein the fender body is connected with an impingement plate; the impingement plate is connected with a pair of springs; the springs are fixedly connected with rotating arms respectively; the two rotating arms are respectively mounted at the two ends of a pivot; two upper connecting pillars are connected under the pivot; the upper connecting pillars are connected with lower connecting pillars through rubber springs; and the lower connecting pillars are connected with a quay through substrates. According to the rotatable multi-layer energy absorption quay fender, the purposes of multi-layer energy absorption and counterforce decrease are achieved under the situation that the quay fender does not occupy redundant space through the polyurethane fender body, the impingement plate, spring layers and the rubber springs between the connecting pillars, and the energy absorption ability and impact resistance are greatly improved; and in the structural form, the fender and the quay are connected through a rotating system, the fender surface has certain horizontal speed when a ship body is moored alongside, and the fender body can rotate by a certain angle in the speed direction of the ship body and in the direction perpendicular to the pivot direction, so that the friction between the fender and the ship body is reduced, the horizontal load is reduced, and the friction damage to the ship body is reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

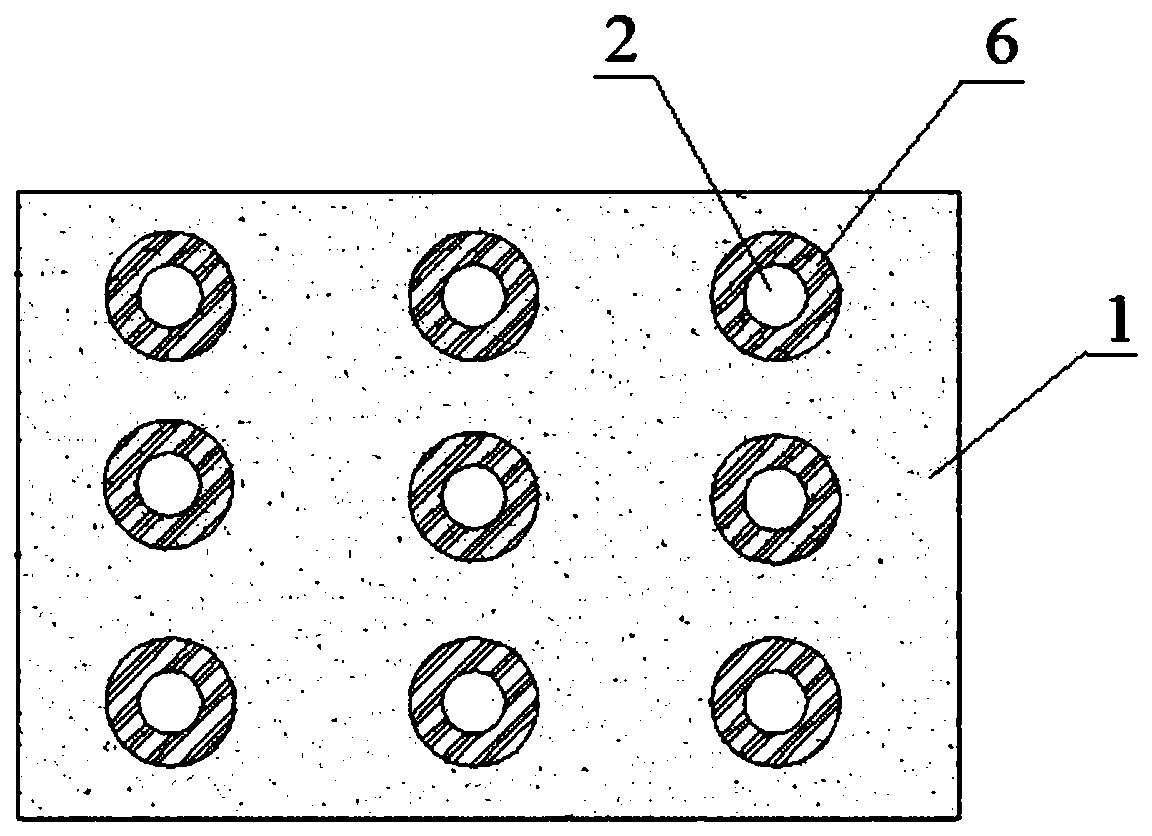

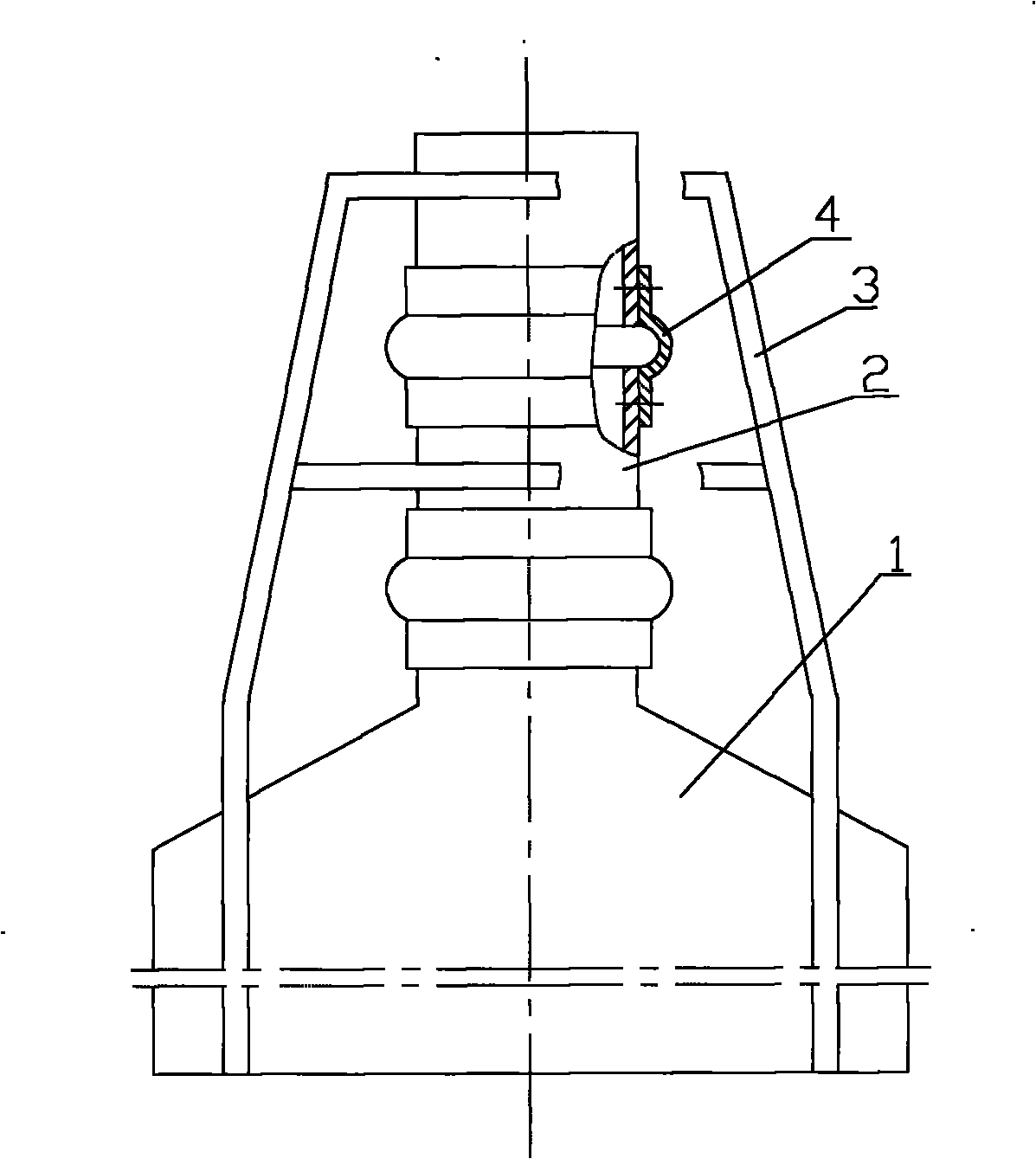

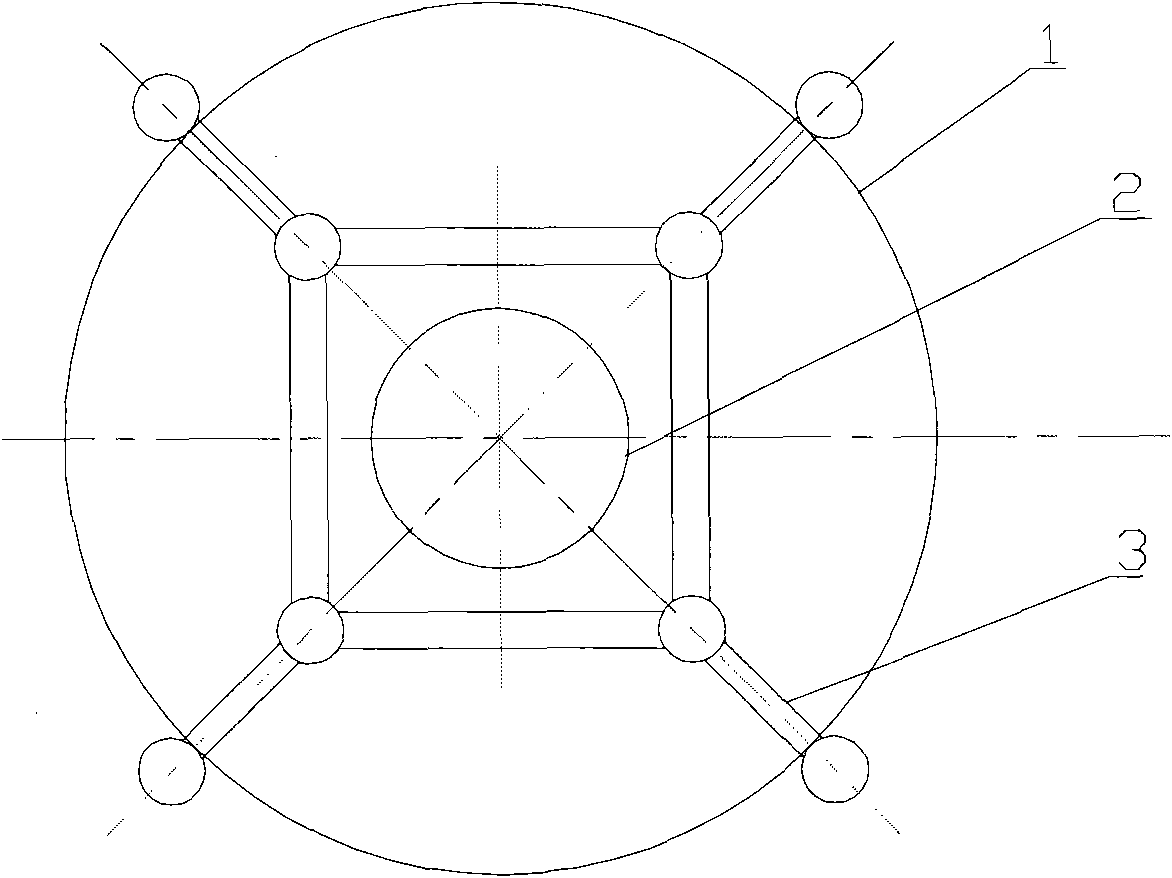

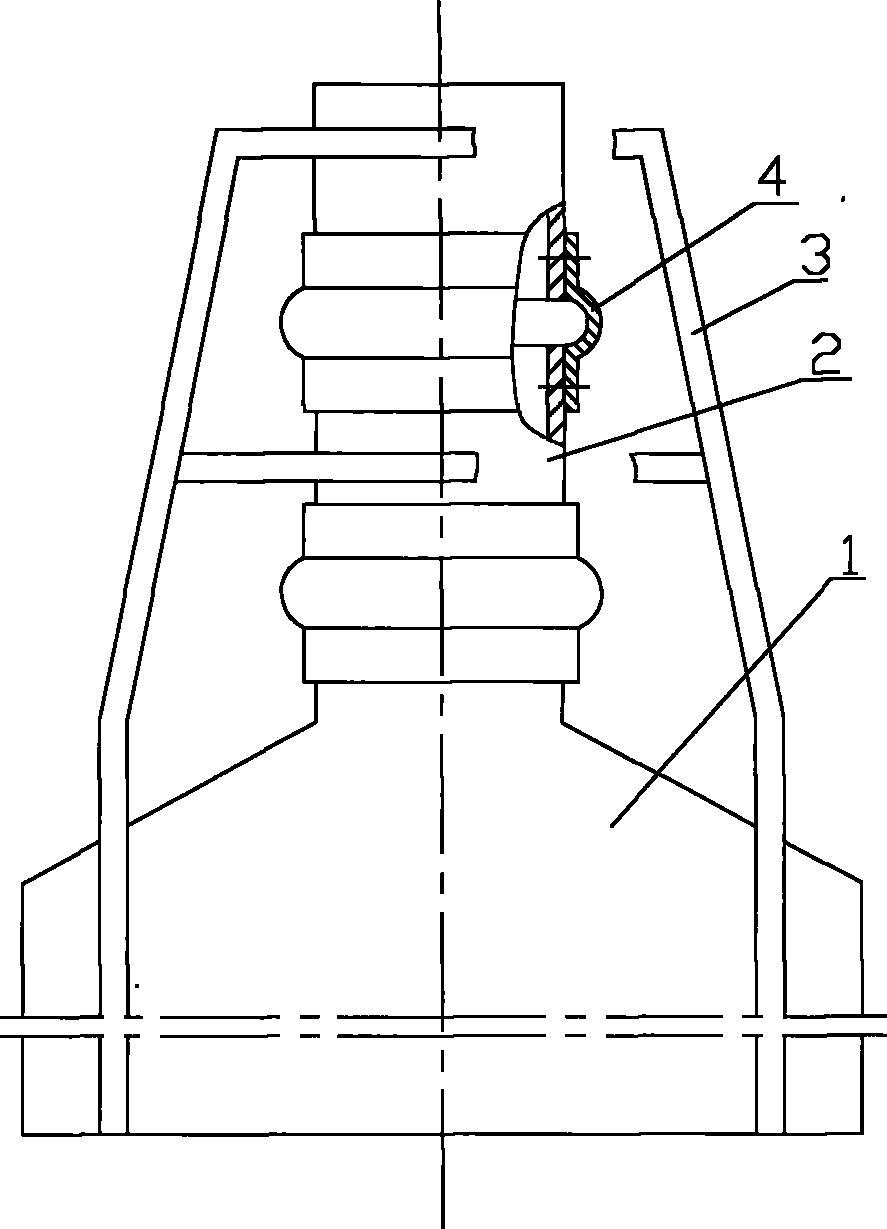

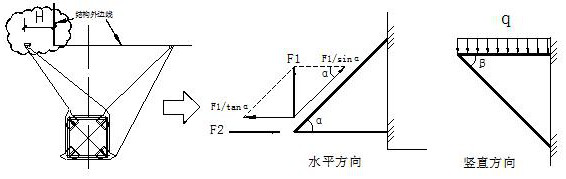

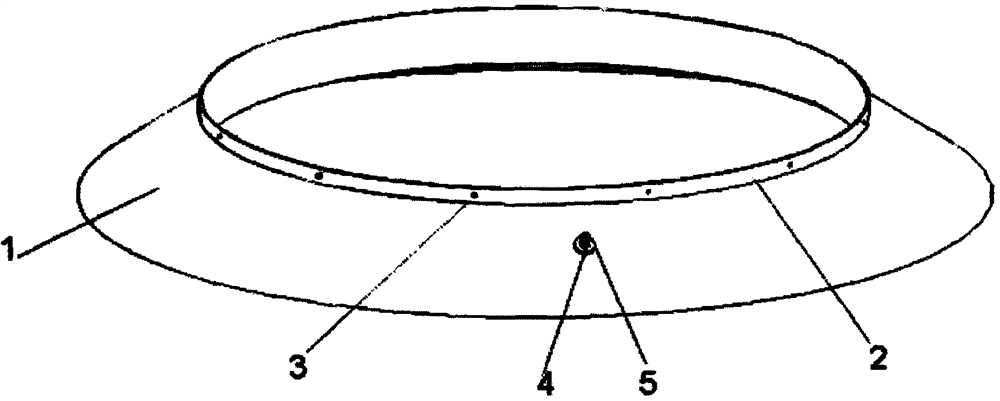

Novel offshore pile anti-stormy-wave device

A novel offshore pile anti-stormy-wave device comprises a rubber plate body, a plate body internal inflation matched device, a circular thin-walled steel sleeve and a screw. The rubber plate body comprises a rubber upper plate and a rubber lower plate. The lower surface of the circular edge of the rubber upper plate and the upper surface of the circular edge of the rubber lower plate are connectedinto a whole. The rubber plate body air cavity inflation matched device comprises an inflation nozzle, an eight-square screw nut, an air guide pipe, an air valve switch, an air pressure gauge and aninflation air pump. The novel offshore pile anti-stormy-wave device has the advantages that when a pile body generates great displacement and deformation under the action of horizontal loads, the lower surface of the plate body makes contact with silt and a vacuum negative pressure effect is generated, the anti-stormy-wave device has a stabilizing effect for allowing a high-pile marine building toresist horizontal loads, horizontal displacement is reduced, and compared with other methods, construction operation is rapid and construction cost is low.

Owner:HEBEI UNIV OF ENG

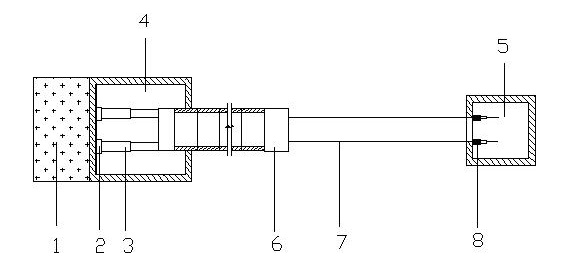

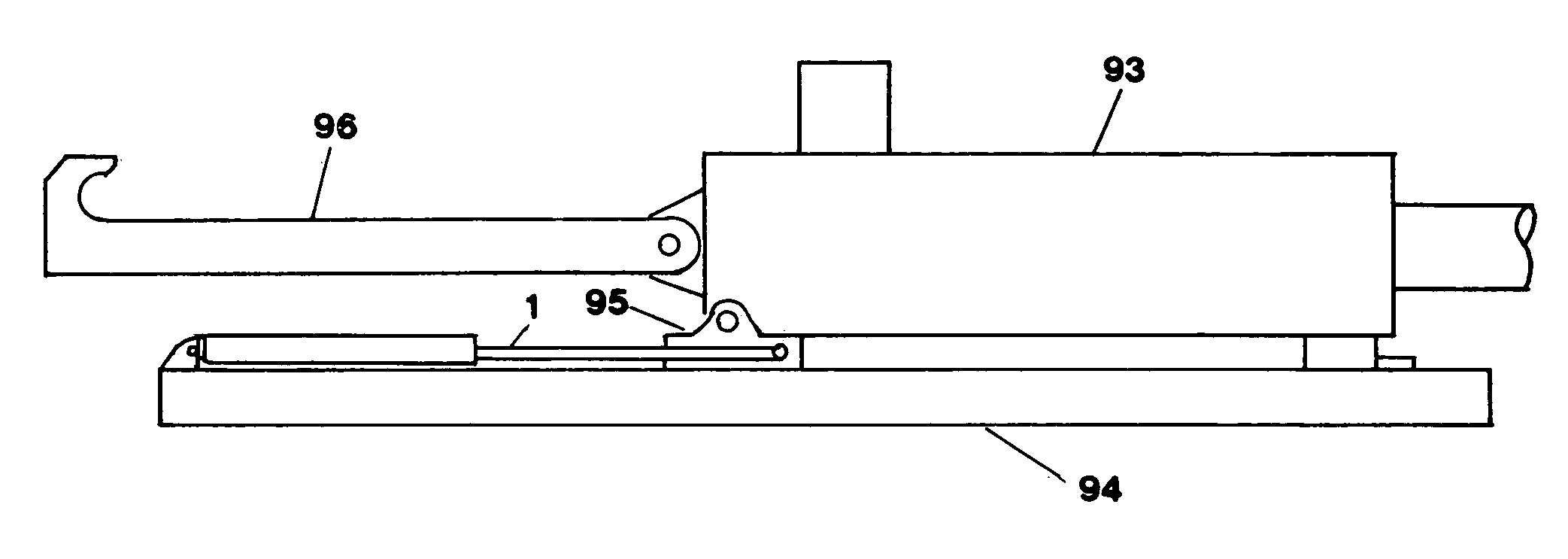

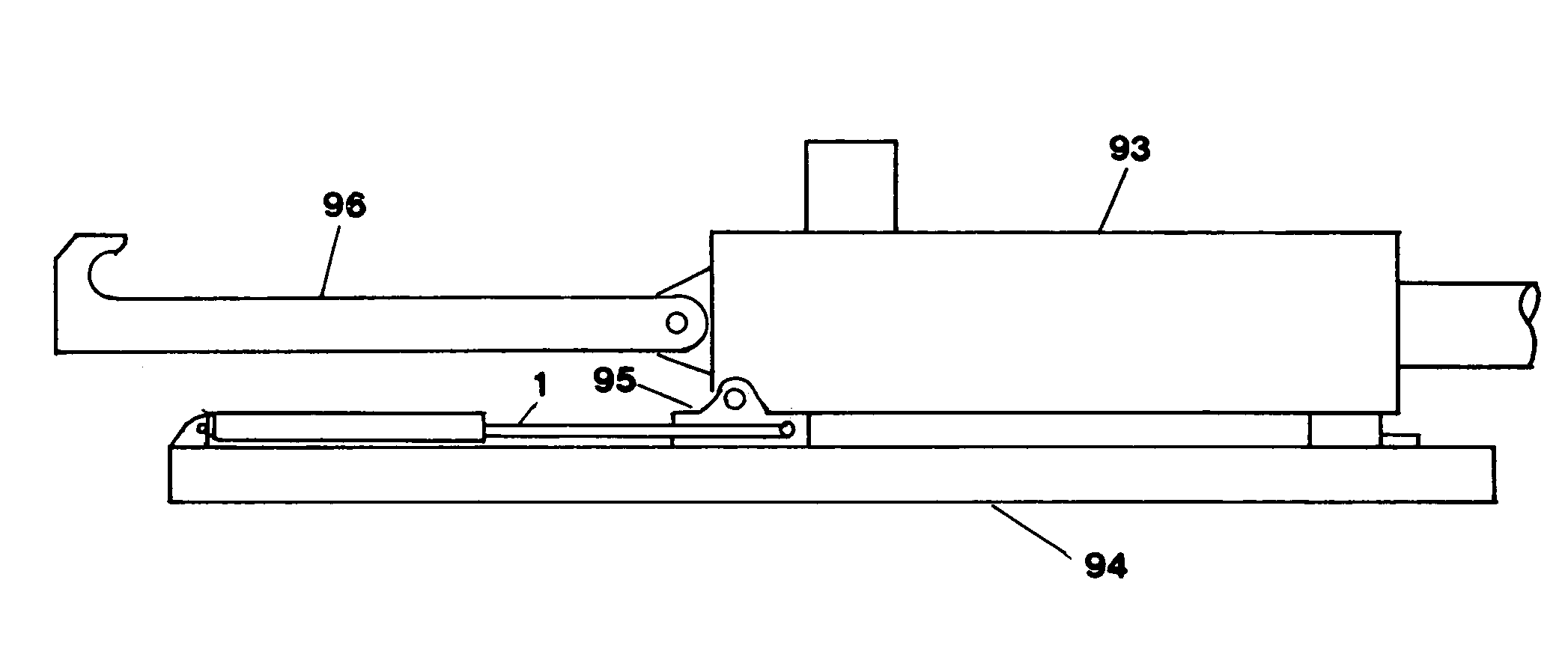

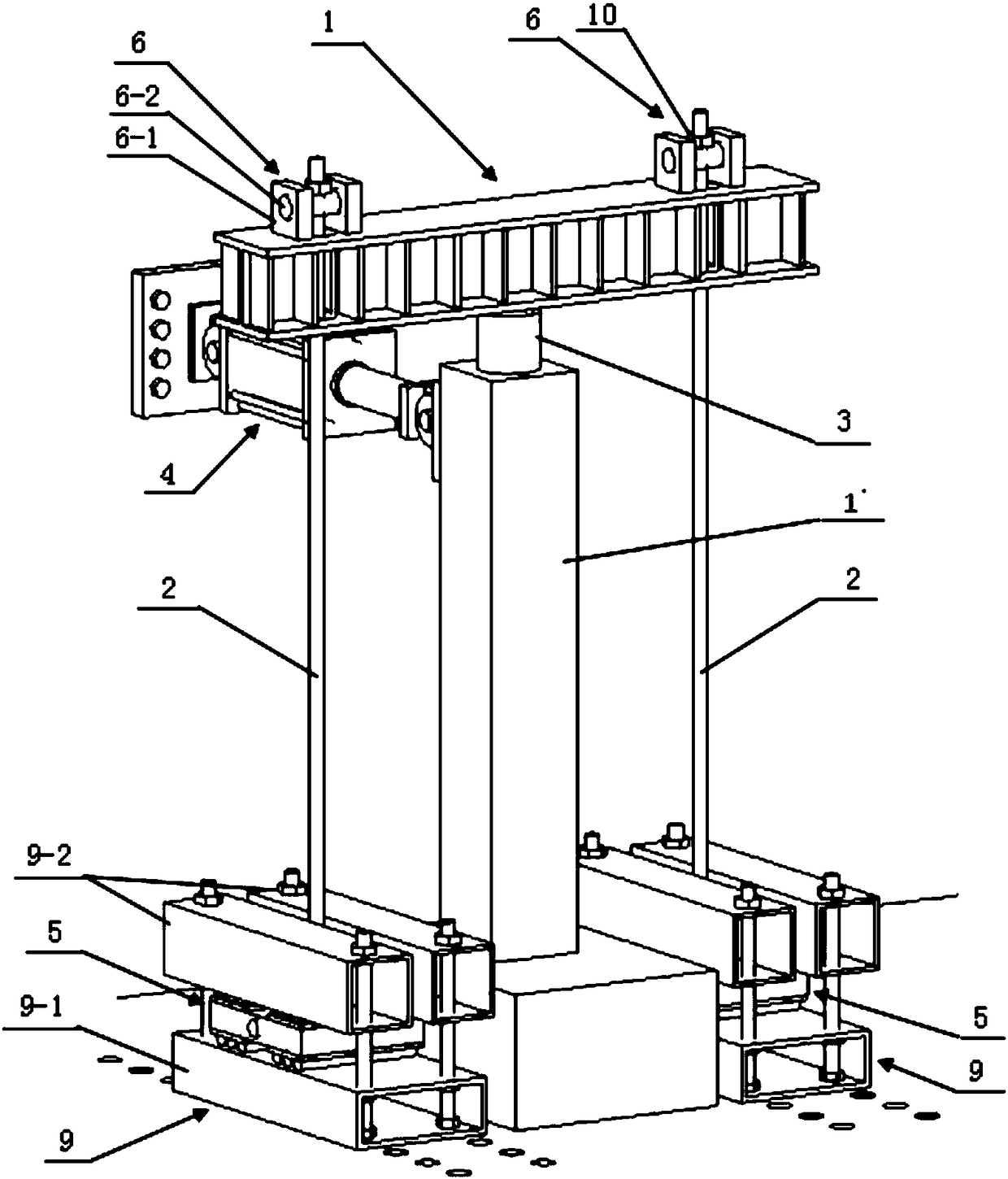

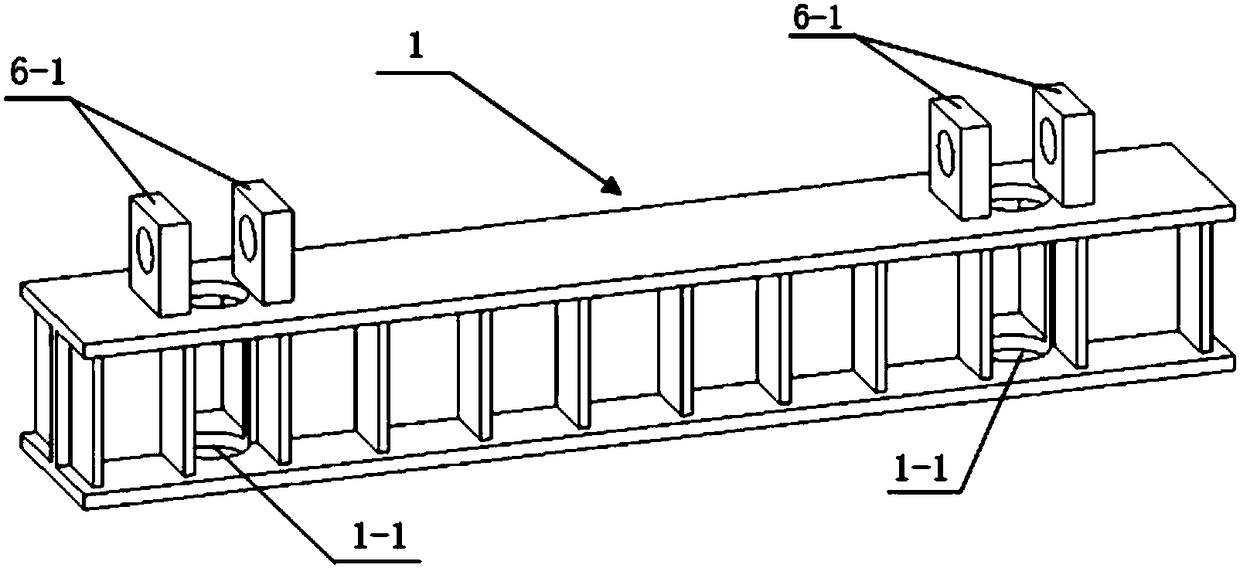

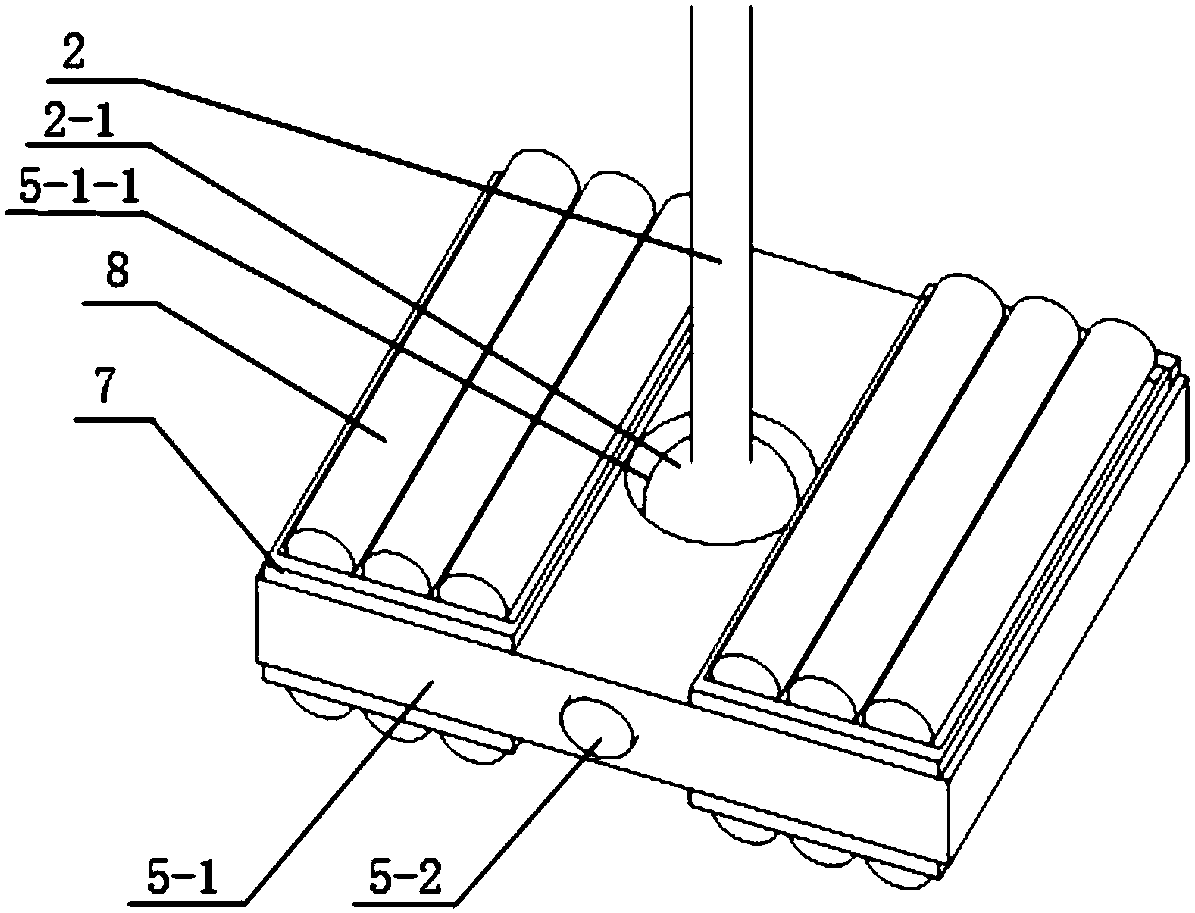

Roller type low friction vertical loading system with tracking function

The invention relates to a roller type low friction vertical loading system with a tracking function. The roller type low friction vertical loading system comprises a beam, two pulling rods, a hydraulic jack, an actuator, two lower hinging seats. The roller type low friction vertical loading system is characterized in that two upper hinging seats which are respectively hinged to upper ends of thepulling rods are arranged above the beam; each of the two lower hinging seat includes a guide block and a first pin shaft; the lower ends of the two pulling rods are hinged to the first pin shafts ofthe corresponding lower hinging seats; roller mounting brackets are arranged on upper and lower ends of the guiding blocks and two sides of the first pin shafts; a group of rolling shafts are arrangedin each roller mounting bracket; two guide bottom seats are provided; the lower hinging seats are arranged in space between two pressing beams and a bottom beam; the two groups of rollers on an upperpart contact lower ends of the two pressing beams; the two groups of rollers on a lower part contact an upper end of the bottom beam. In the system, when a test component pulls the beam to horizontally shift under the action of a horizontal load, the bottom ends of the pulling rods can follow up the tops of the pulling rods, so that the pulling rods are basically vertical during the test.

Owner:TIANJIN CHENGJIAN UNIV

Wind power generation device with rear-mounted blades

ActiveCN104295449BIncreased sweep diameterIncrease powerWind motor controlWind motor combinationsCable stayedEngineering

The invention discloses a wind power generation device with rear-mounted blades. The wind power generation device comprises a stand column, a wind power generation main engine and the blades. The main engine is hinged to the top of the stand column. The blades are installed on the tail of the main engine in a rear-mounted mode. A hydraulic piston cylinder capable of moving telescopically is further hinged between the upper portion of the stand column and the rear portion of the main engine. A piston of the hydraulic piston cylinder moves telescopically to adjust changes of the pitching dip angle, on the stand column, of the main engine. At least three steel cables are uniformly distributed on the upper portion of the stand column and fixedly connected to the upper portion of the stand column. The other ends of the steel cables are fixedly connected with a ground pile in a cable-stayed mode. Due to the design, the steel cables of the stand column and the blades do not interfere with each other in the cable-stayed process of the cables, wind resistance influence is small, diameter space of the blades is enlarged, the swept area of wind power is increased, power is increased, the dip angle can be controlled, adjusted and rotated for harmonizing loads of wind power, and the wind power can be tracked automatically; due to high-gradient hilly area arrangement, the blades rotate in an inclined mode to make the front side face wind, and the wind power is fully utilized; with assistance of the cable-stayed steel cables, the structural cost can be reduced, the defect of the poor wind-proof capacity in tradition is overcome, and the wind power generation device is suitable for being arranged on coasts with strong wind.

Owner:丁健威

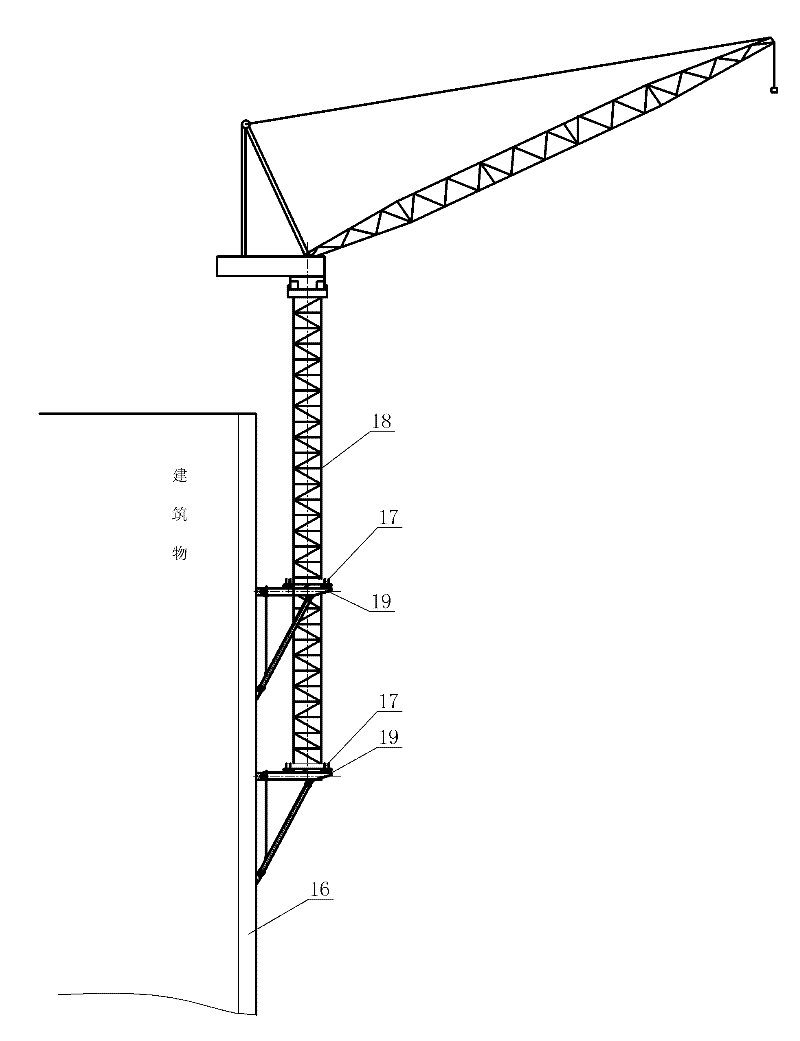

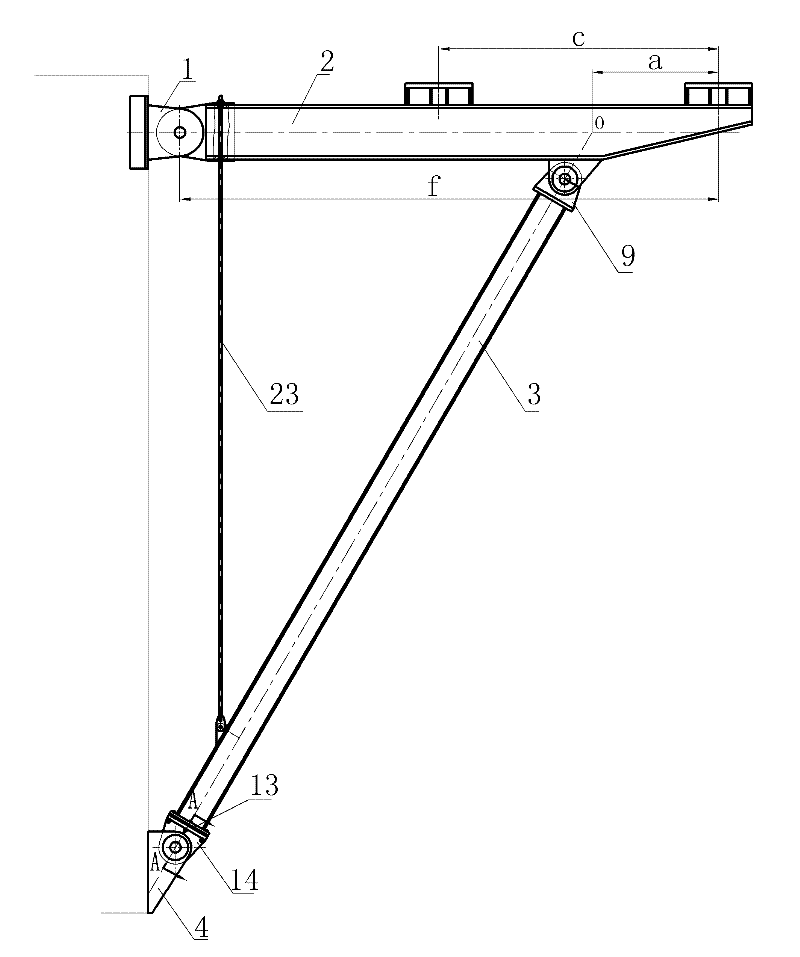

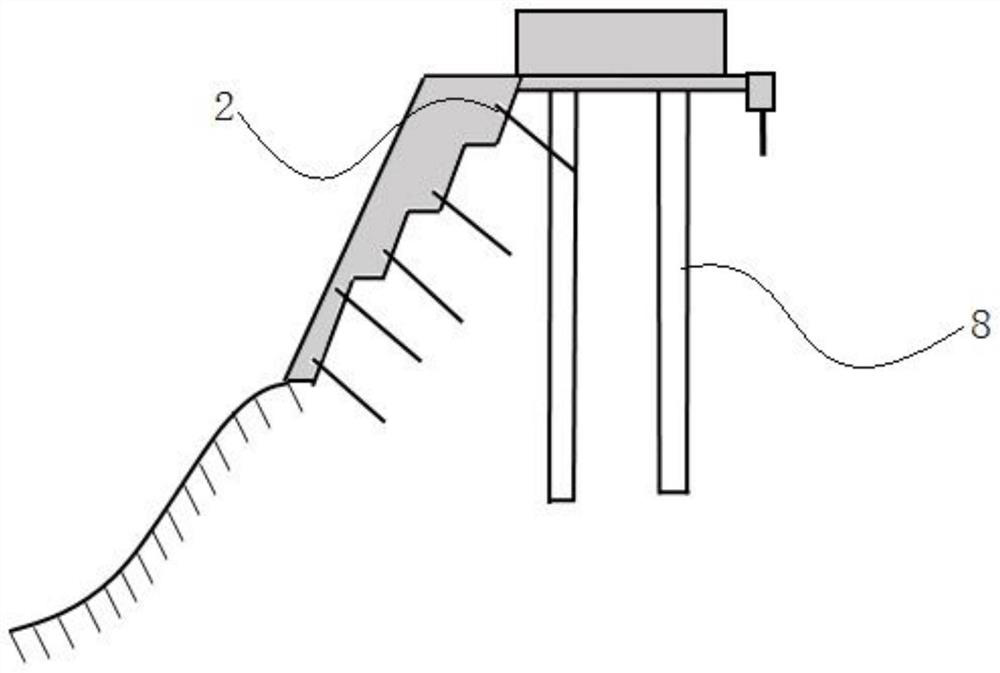

Suspended-rising support system of tower crane

InactiveCN102079489BSave materialReduce the maximum bending momentCranesSupporting systemBraced frame

The invention relates to a suspended-rising support system of a tower crane, belonging to the field of building machinery. The suspended-rising support system comprises three sets of support structures which have same structure and are arranged up and down. When the suspended-rising support system works, the adjacent two sets of support structures support a tower body; each support structure comprises a support frame, a main girder, two symmetrical inclined struts as well as a first strut, a second strut, a third strut and a fourth strut, wherein the two symmetrical inclined struts are arranged at the lower part of the main girder and support the main girder; the first strut, the second strut, the third strut and the fourth strut support the main girder in the horizontal direction; the main girder, the two inclined struts and one ends of the four horizontal struts are respectively connected with the wall body; the upper part of the main girder is connected with the support frame; an expression of a pivot position of the main girder and the inclined struts is as follow: c(f-c)=a(f-a)+2a(f-c), wherein a is a distance from the action point of the frame at the outer side of a pivot O to the pivot O, c is the midline length of the frame along the main frame direction, and f is the calculation length of the main girder. The suspended-rising support system disclosed by the invention reduces the rigidity of the cantilever end, improves the action force of two main branches of the tower body near one side of a building to the main girder, enables the gravity of the tower body actedto the main girder to move inwards and reduces the horizontal load of the support structures to the building.

Owner:SHENYANG JIANZHU UNIVERSITY

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977BImprove securityImprove mechanical performanceCovering/liningsWallsSurface layerFloor slab

The invention discloses a composite wall provided with reinforced bars and / or metal mesh plaster on the inner and the outer sides or the both sides, and relates to a building composite wall, aiming at the problem that the prior binding composite insulating wall has incomprehensive structural form. Proposal one: outdoor vertical reinforced bars (5) and indoor vertical reinforced bars (6) are fixed and connected with the outside and the inside of load bearing components (1) of the main structure of the building, and the inner side and the outer side of a sandwich layer (3) are provided with an inner protection layer and an outer protection layer; proposal two: vertical reinforced bars (5-2) under an outdoor window sill and vertical reinforced bars (6-2) under an indoor window sill are fixed and connected with overhanging plates (1-2); proposal three: the indoor vertical reinforced bars (6) arranged on the two sides of the sandwich layer 3 are fixed and connected with the load bearing components (1) of the main structure of the building; proposal four: the inner sides and the outer sides of the indoor vertical reinforced bars (6) on the two sides of an air layer and an indoor metal mesh are provided with protective layers (10-1), and the air layer (3-1) is positioned between the protective layers (10-1) on the two sides. The invention has the advantages that the shock resistance is good, the wind proof load is good, the fabricating cost is low, the security of the outer decoration surface layer is good, the indoor usable area is increased, and the requirements on low energy consumption buildings are met.

Owner:吴淑环

A wall-mounted drainage anchor retaining wall structure and its construction method

ActiveCN109577277BAdvanced technologyImprove economyArtificial islandsClimate change adaptationArchitectural engineeringRock bolt

The invention provides a wall-mounted draining anchor rod barricade structure and a construction method thereof. The barricade structure comprises a longitudinal beam embedded in the top of a bank slope, a barricade and an anchor rod. The barricade is arranged at a by-water side of the bank slope. The longitudinal beam is positioned at a fundamental inner side of a protected bridge pile foundation. A plurality of cross beams is connected between a barricade body and the longitudinal beam. The construction method for the barricade structure comprises steps of constructing the anchor rod, constructing a draining hole, constructing the barricade, constructing an anchor pile, constructing the longitudinal beam, constructing the cross beams and installing a cut-off valve and the like. The barricade structure is capable of effectively solving problems existing in a large-scale reservoir hydro-fluctuation belt bank side cleugh area bridge pile foundation protecting technology, and advanced intechnology, and well in economy.

Owner:CHONGQING JIAOTONG UNIVERSITY

An anti-wind and wave device for offshore piles

ActiveCN110820736BLow costPlay a stabilizing roleBulkheads/pilesMarine architectureMarine engineering

Owner:HEBEI UNIV OF ENG

Self-adaptive cable wind system of cable crane and using method thereof

PendingCN112520590AReduce horizontal offsetReduce unbalanced horizontal force peaksPortable liftingCable carsMarine engineeringWind system

The invention discloses a self-adaptive cable wind system of a cable crane and a using method thereof, and relates to the technical field of tower cable wind. The self-adaptive cable wind system of the cable crane comprises a tower frame, cable wind equipment and driving equipment, wherein the cable wind equipment comprises a front cable wind mechanism and a rear cable wind mechanism, and the front cable wind mechanism and the rear cable wind mechanism are oppositely arranged on the two sides of the tower frame in the bridge direction; and meanwhile, the upper ends of the front cable wind mechanism and the rear cable wind mechanism are mounted on the tower, and the lower ends of the front cable wind mechanism and the rear cable wind mechanism are anchored; the driving equipment and the front cable wind mechanism are arranged on the same side, and the driving equipment comprises a front driving mechanism and a rear driving mechanism; the front driving mechanism is connected with the front cable wind mechanism and is used for driving the front cable wind mechanism to pull the tower frame forwards; and the rear driving mechanism comprises a hoisting cable and a lifting appliance, wherein the hoisting cable is connected with the free end of the rear cable wind mechanism, and the lifting appliance is connected with the hoisting cable. The self-adaptive cable wind system of the cablecrane has the advantages that the peak value of the unbalanced horizontal force of the tower top of the tower frame in the bridge direction can be reduced, the horizontal deviation displacement of the tower frame is reduced, the structure is simple, the stress is clear, and the cost is saved.

Owner:中铁大桥局集团第八工程有限公司 +1

Denitration high-temperature flue pull rod fixing structure

ActiveCN106310934AReduce horizontal loadLow costPipe supportsGas treatmentEngineeringExpansion joint

The invention provides a denitration high-temperature flue pull rod fixing structure arranged outside a nonmetal expansion joint connecting a denitration reactor and an inlet flue. The inlet flue comprises a vertical-section flue positioned on the lower portion and a horizontal-section flue positioned at the top. The denitration high-temperature flue pull rod fixing structure comprises two pull rod components symmetrically arranged on two sides of the denitration reactor and the inlet flue, and each pull rod component comprises a first pull rod fixing member fixedly arranged outside the denitration reactor, a second pull rod fixing member fixedly arranged outside the inlet flue and a pull rod with two ends respectively connected with the pull rod fixing members through shear bolts; one shear bolt is coaxial with an intersecting line of a vertical bisecting face of the vertical-section flue and a horizontal bisecting face of the horizontal-section flue, and another shear bolt is coaxial with an intersecting line of the horizontal bisecting face of the horizontal-section flue and a vertical bisecting face of a supporting leg, close to one side of the inlet flue, of the denitration reactor. By the structure, the supporting problem of a denitration flue in front of an inlet of the denitration reactor can be solved without designing a steel-structure frame beam individually.

Owner:DATANG ENVIRONMENT IND GRP

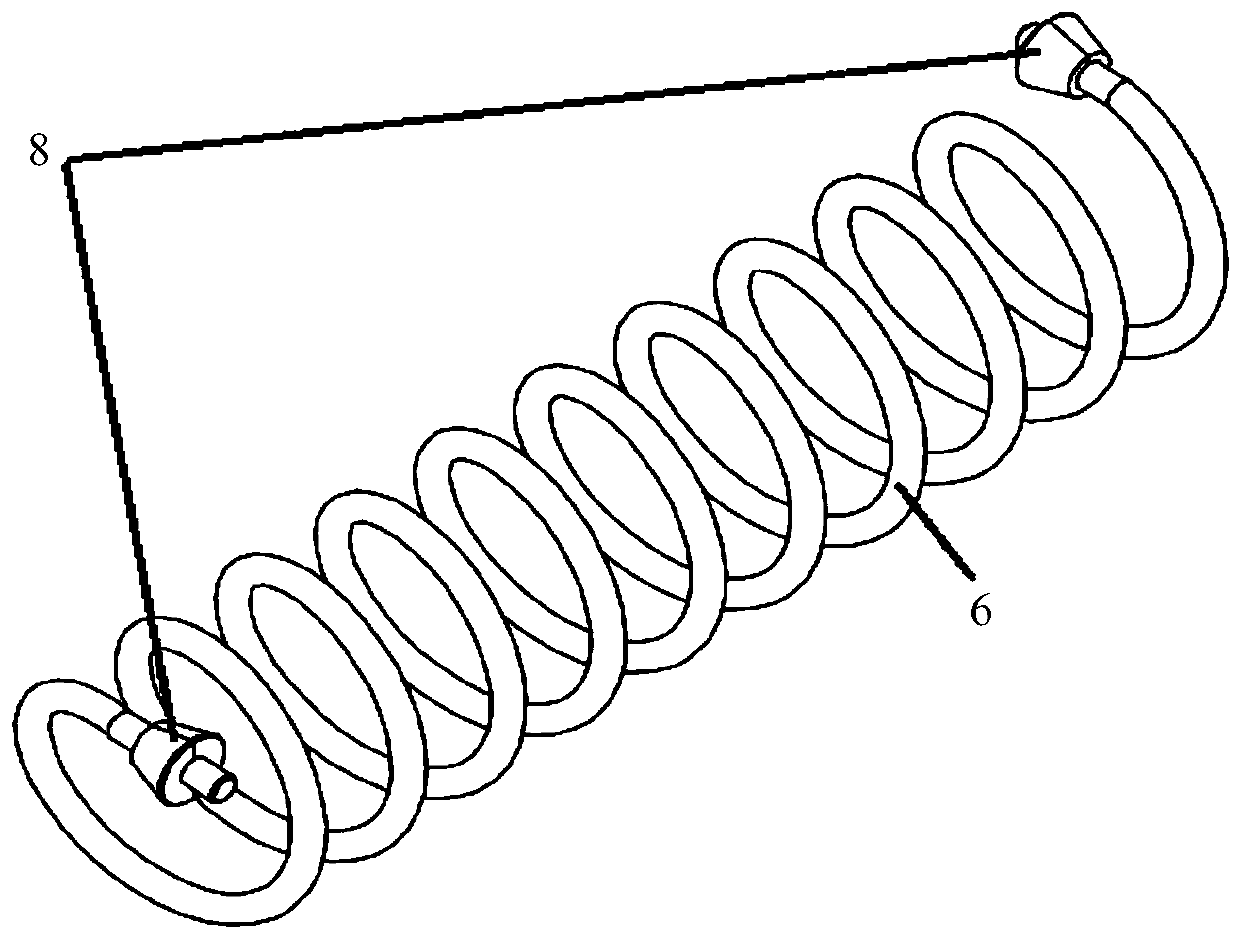

A spiral cable support

ActiveCN108797324BReduce space occupancyEasy to installBridge structural detailsBridge materialsSlide plate

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com