Wind power generation device with rear-mounted blades

A wind power generation device, rear-mounted technology, applied in the direction of wind power generation, wind engine, wind engine consistent with the wind direction, etc., can solve the problems of not being able to make full use of climbing updraft, complex folding of blades, and easy damage by strong wind, etc. Improve the performance of anti-bending, reduce floc disturbance, and reduce wind energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

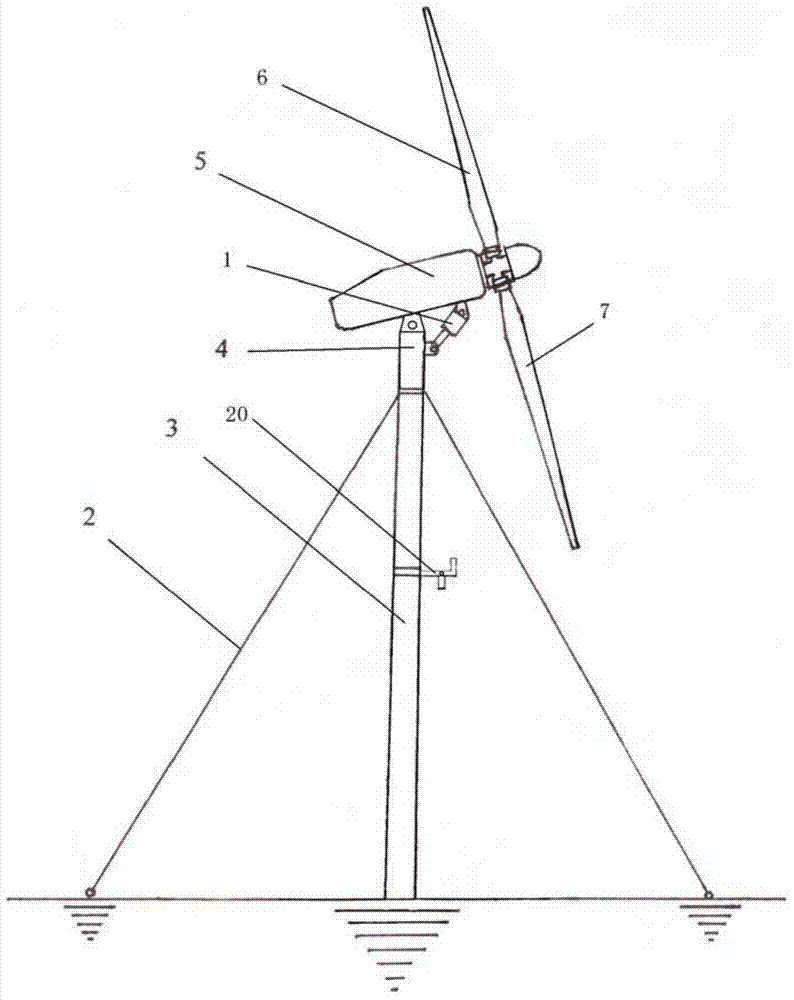

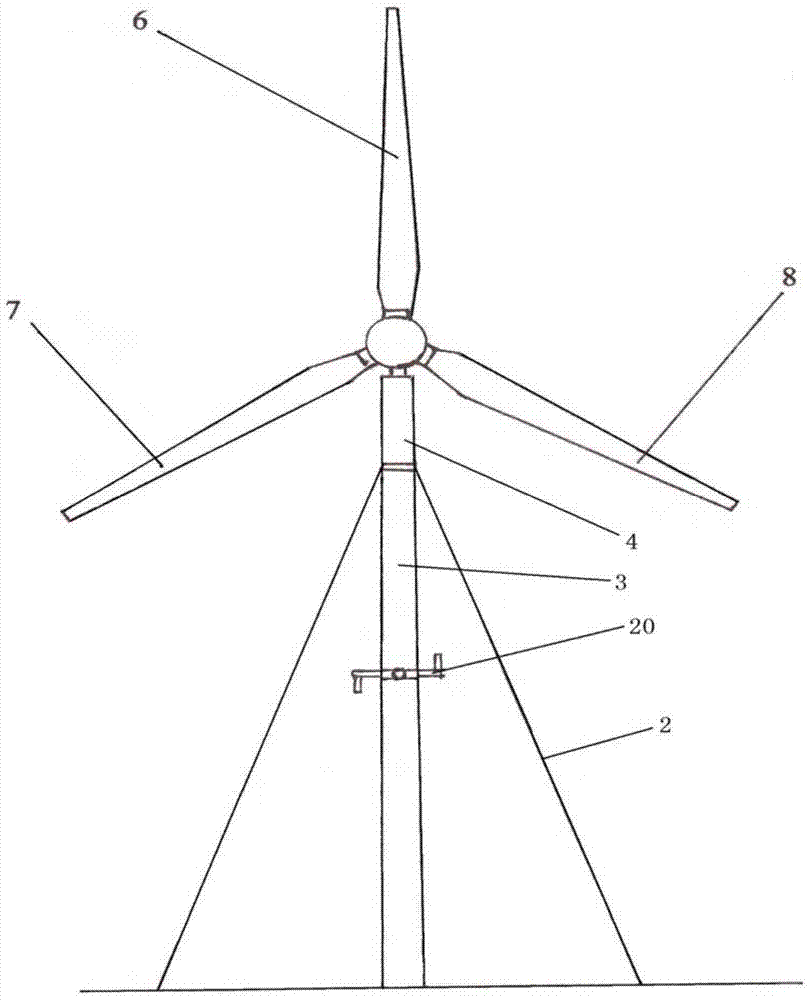

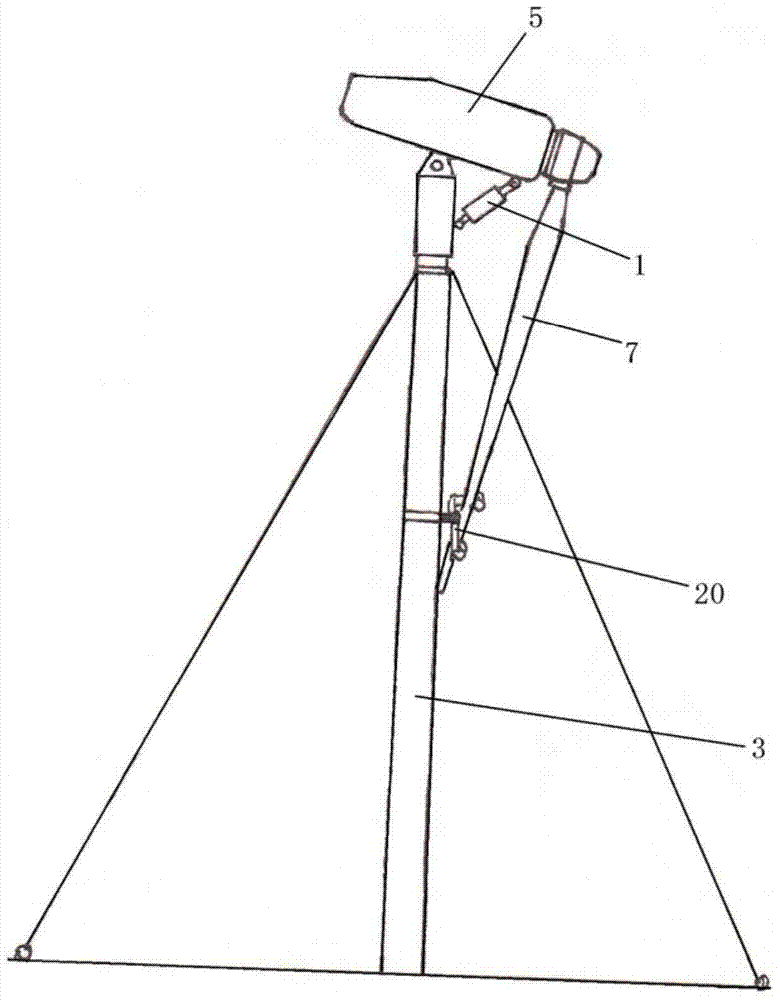

[0031] Embodiment one: see figure 1 — Figure 4 , The main body of the wind power generation device of this embodiment includes a hydraulic piston cylinder 1, a steel cable 2, a column 3, a casing 4, a main engine 5, a fixed blade 6, movable blades 7, 8 and ground piles. Four steel cables 2 are obliquely pulled from the upper part of the column 3 to the ground, and fastened on the ground piles. The bottom center and the rear of the main engine 5 are respectively equipped with hinges, and the upper part of the column 3 is provided with a casing 4 that can rotate 360°. The top of the pipe 4 is hinged with the center of the bottom of the main engine 5 through a pivot pin 9, the side wall of the casing 4 is hinged with one end of the hydraulic piston cylinder 1, and the other end of the hydraulic piston cylinder 1 is hinged with the rear of the main engine 5. Hydraulic piston cylinder 1 is provided and recovered pressure oil by a remote control small-sized oil pressure station, man...

Embodiment 2

[0033] Embodiment two: see Figure 5 — Figure 9 In this embodiment, the blades are unfolded and folded on the power shaft 16. In this embodiment, the power shaft 16 of the main engine 5 is installed on the main shaft 22 through a rolling bearing 23. One end of the power shaft 16 is provided with a circular baffle 13, and the circular The baffle plate 13 is processed with a plurality of pin holes 26 (26A) connecting the blade seats 27, the other end of the power shaft 16 is provided with a gear 18 and a gear step 19, and the gear step 19 is provided with the pin hole 26 of the circular baffle plate 13. Corresponding concentric pin holes, the gear 18 transmits power to the main engine 5 responsible for power generation, and the action motor 21 meshes with the gear 18, wherein the blade seat of the fixed blade 6 is fixed by the long cylindrical pin 24 through the connecting pin hole 14 and the pin hole 26 in an interspersed manner. Connected between the circular baffle plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com