An anti-wind and wave device for offshore piles

A kind of anti-wind, wave, rubber technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of increasing the cost of pile foundation construction, and achieve the effect of low engineering cost, fast operation, and reduction of horizontal displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

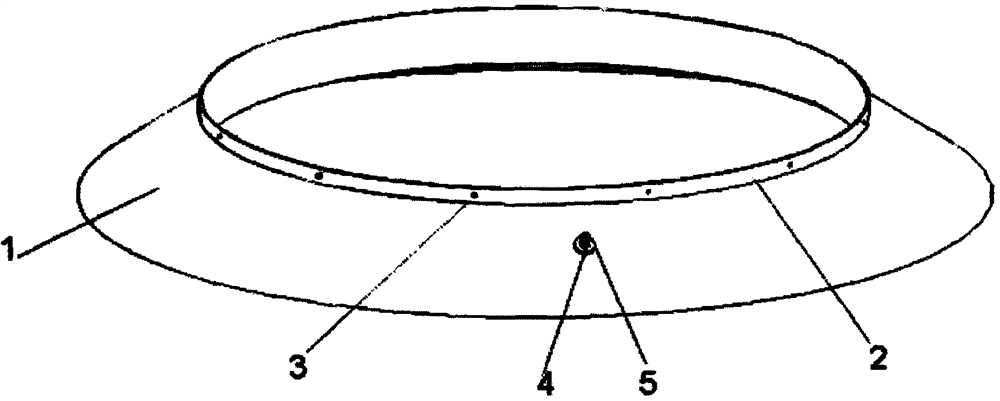

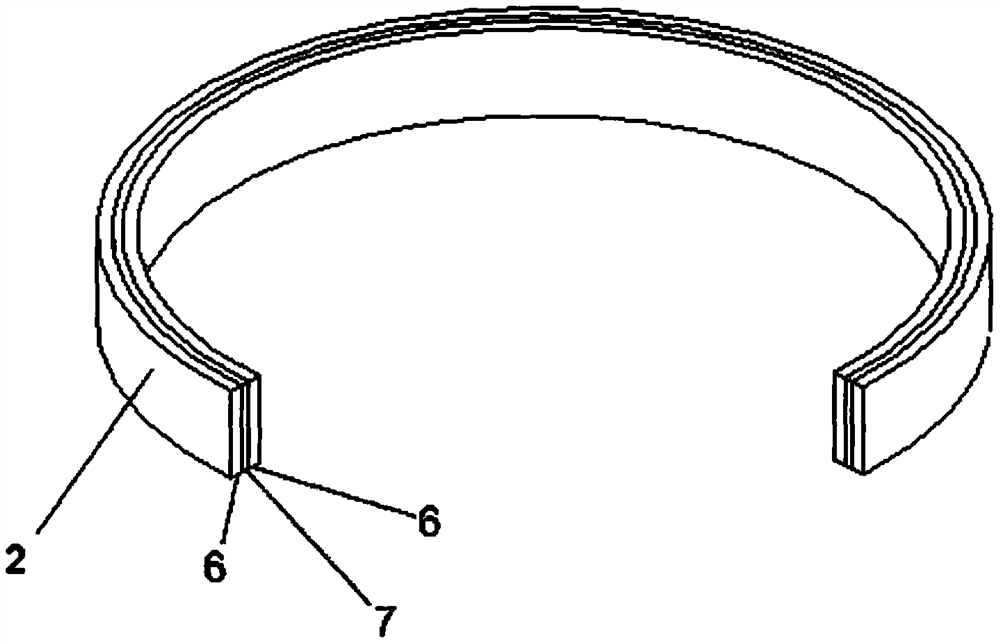

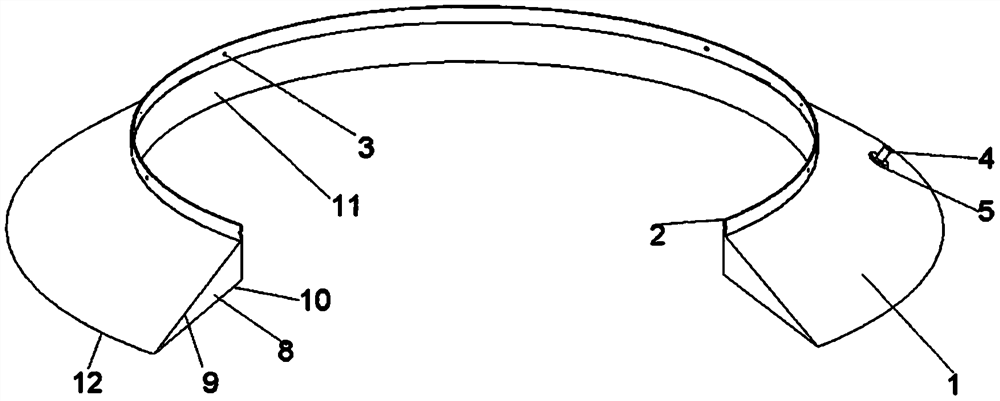

[0031] like Figure 1-Figure 4 As shown, an offshore pile anti-wind and wave device of the present invention includes a rubber disc body 1 , an air cavity inflation matching device for the rubber disc body, and a ring thin-walled steel ferrule 2 screws.

[0032] The connection at the flange 12 of the rubber upper plate 9 and the rubber lower plate 10 is made in one piece.

[0033] When the rubber disc body 1 is prefabricated, a space for installation and operation is reserved according to the diameter of the designed pile.

[0034] Inflatable holes are prefabricated on the surface of the rubber upper plate 9. The inner space of the rubber upper plate 9 and the rubber lower plate 10 forms an inflatable cavity 12 that can be filled with gas. Under a certain air pressure, the surface of the rubber lower plate 10 is gradually expanded, and the expanded rubber upper plate 9 The rubber lower plate 10 is in the shape of a downwardly convex ring, and the rubber lower plate 10 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com