Patents

Literature

32results about How to "Fast construction operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

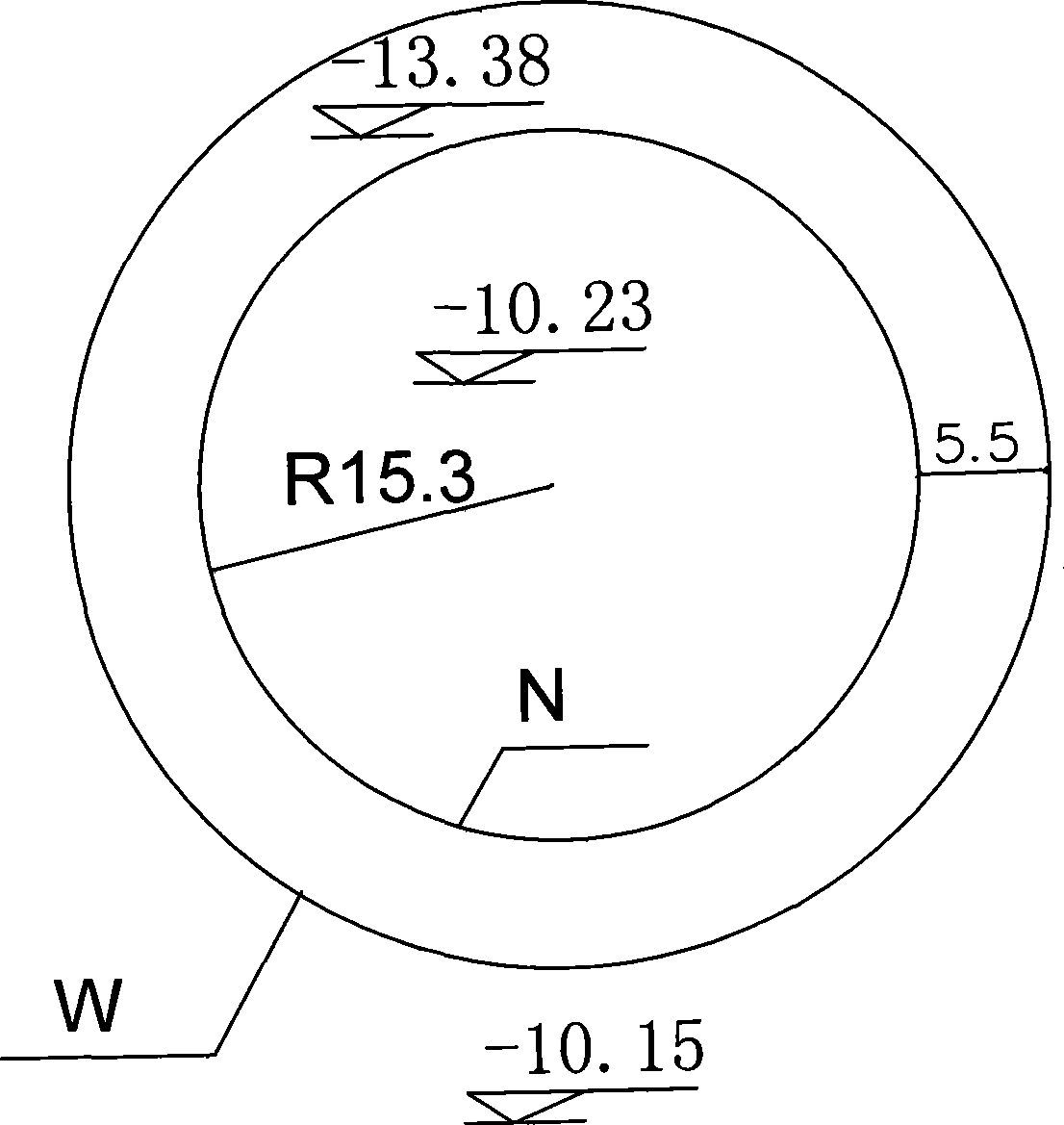

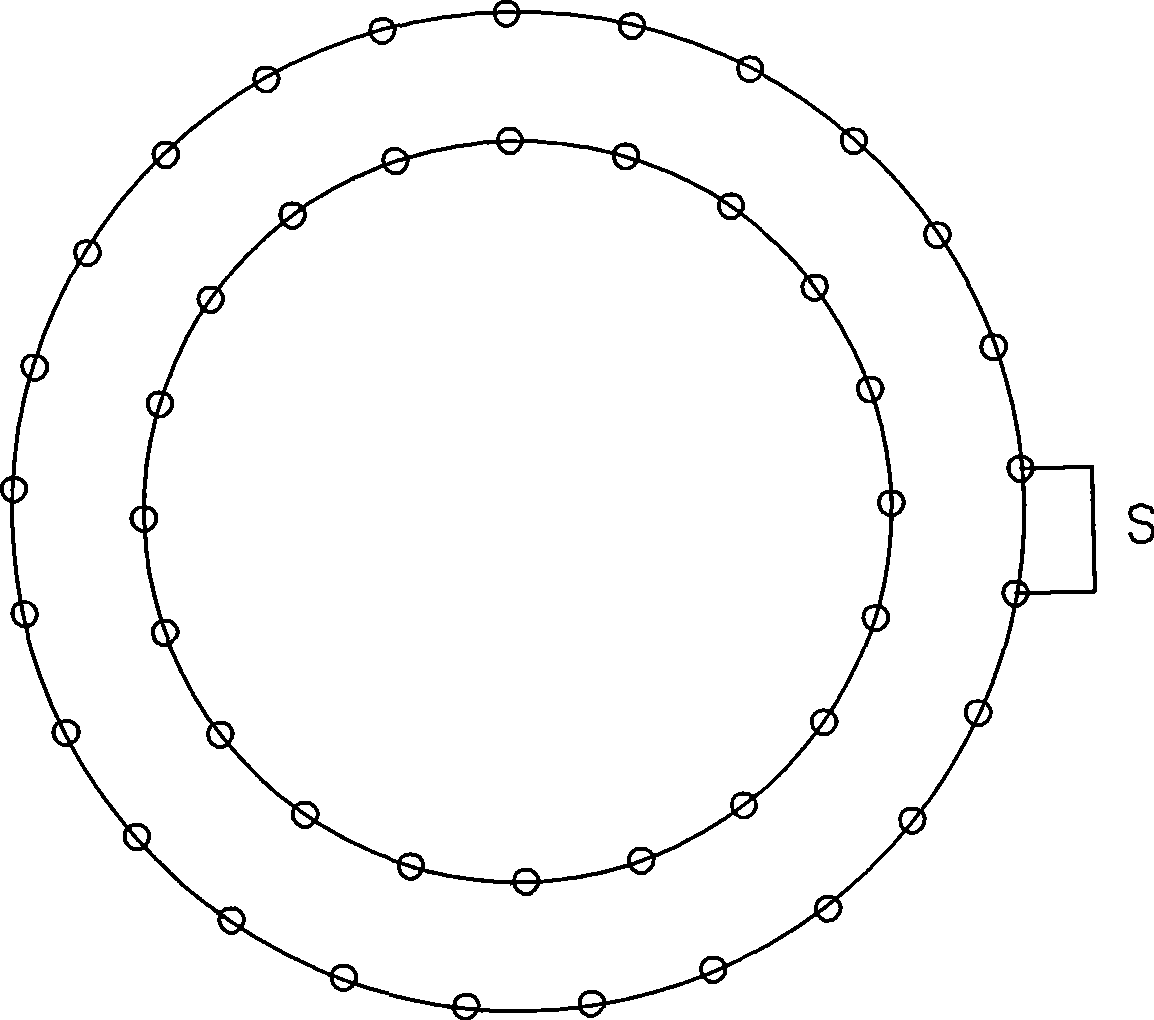

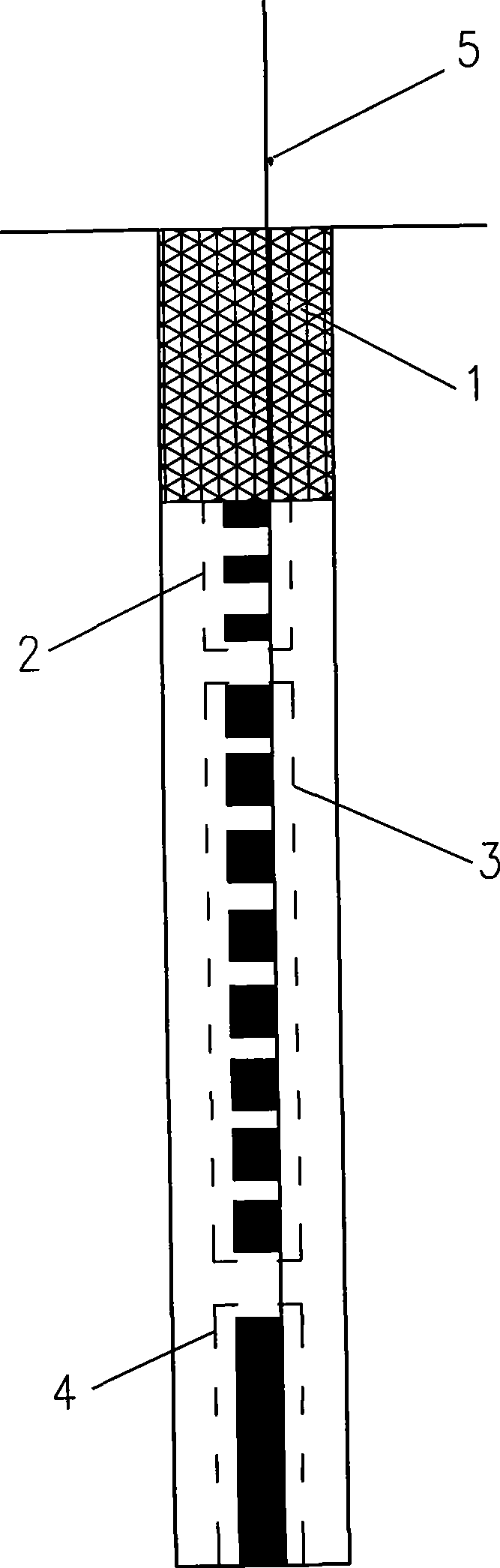

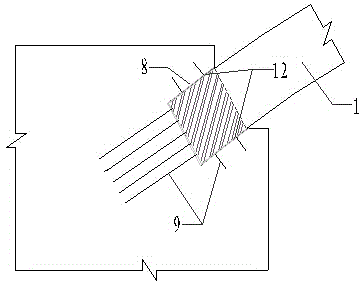

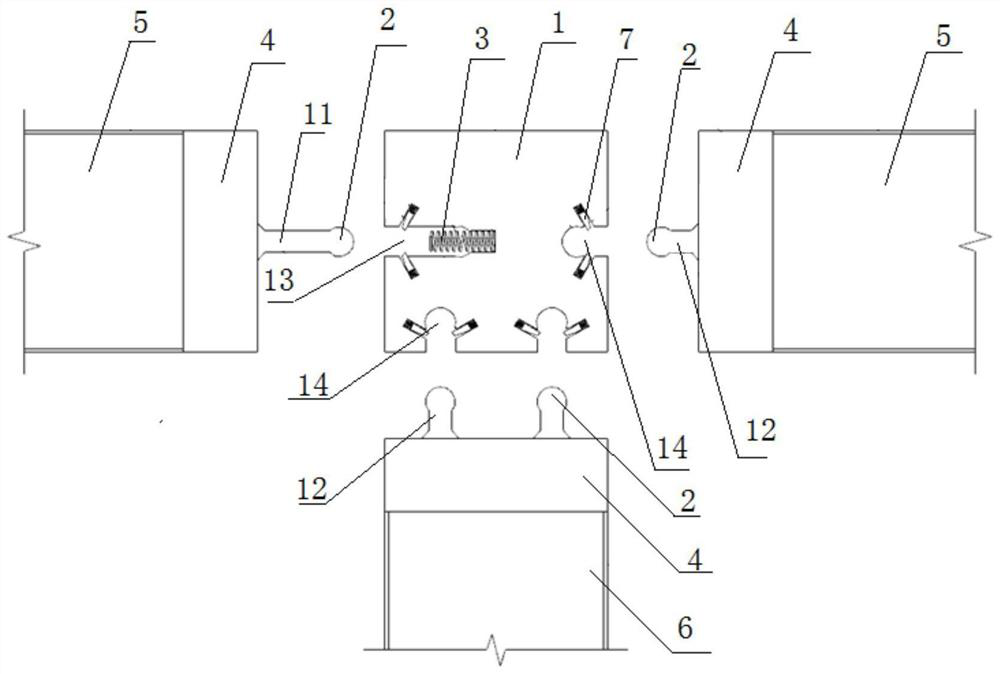

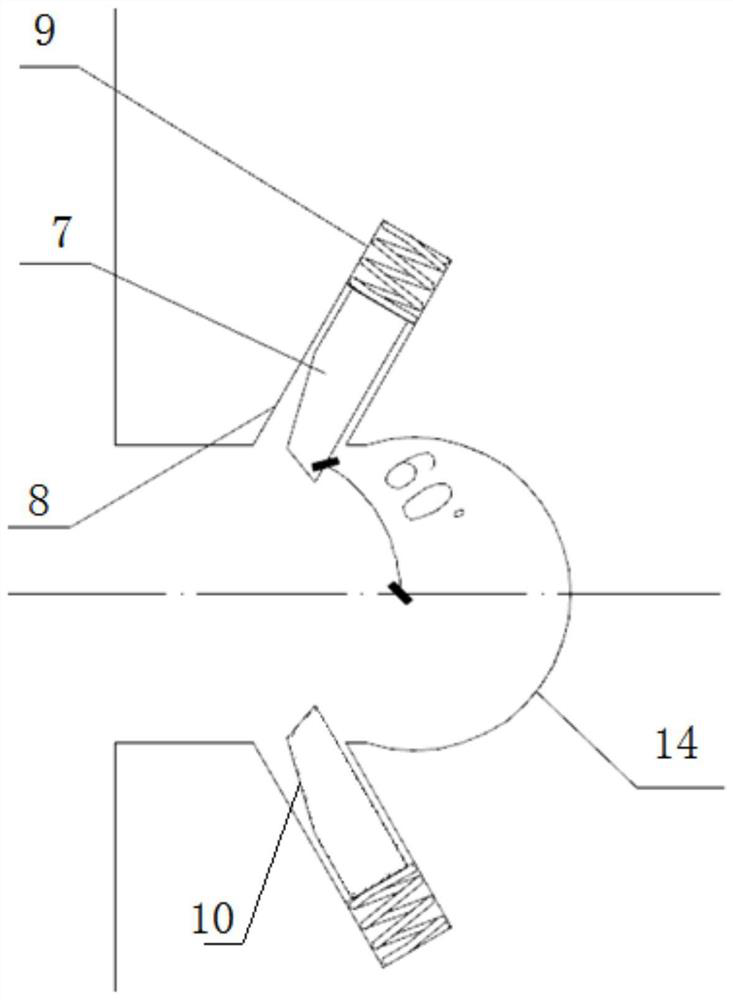

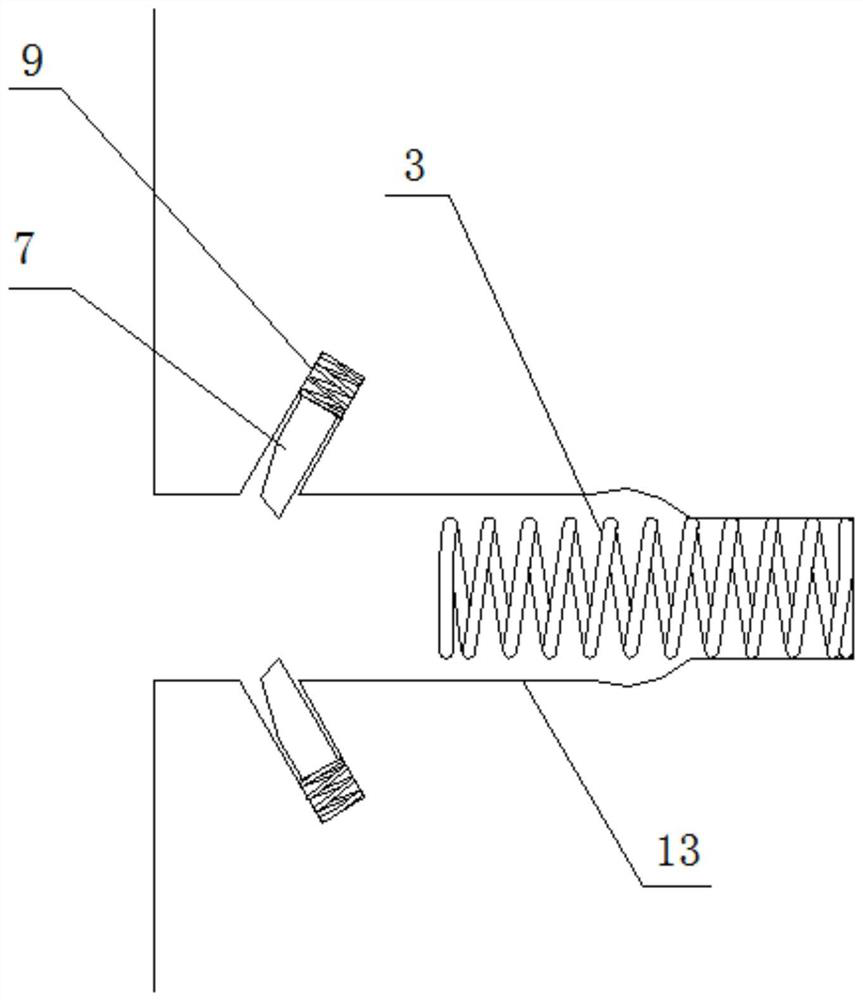

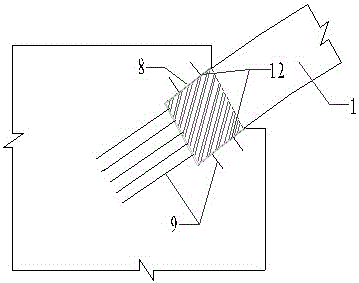

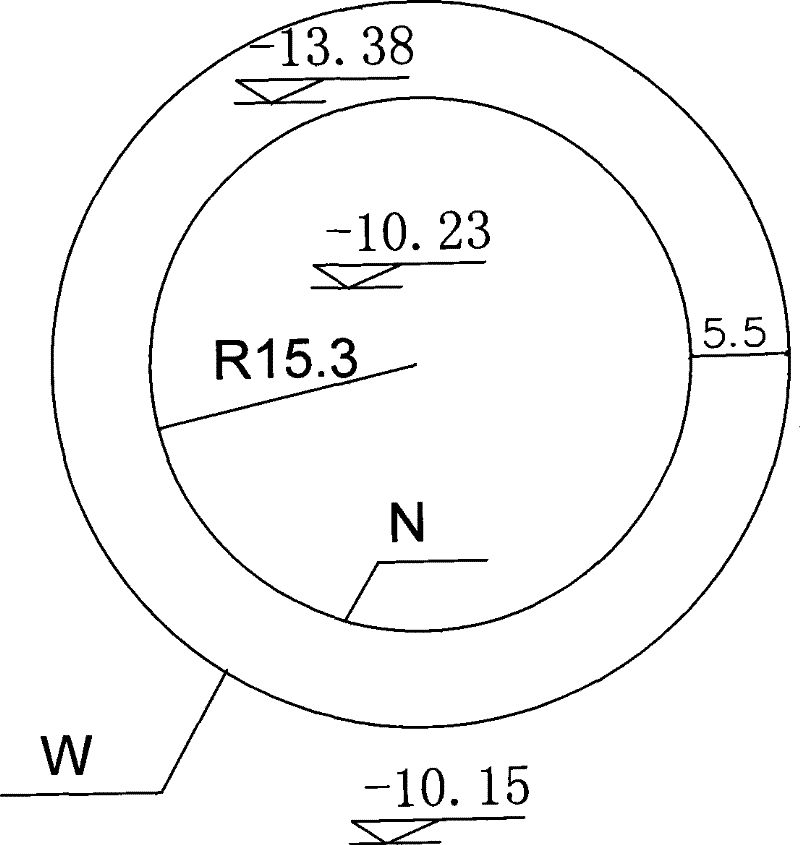

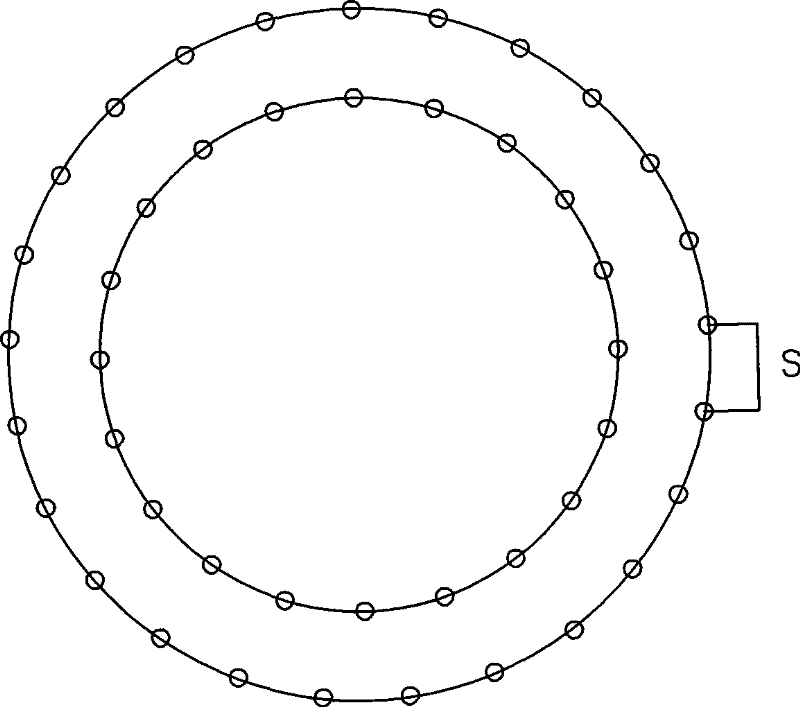

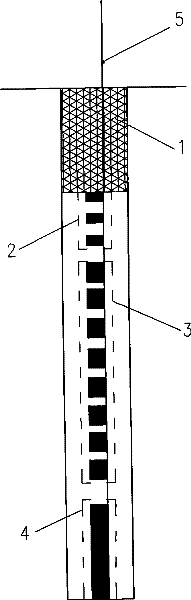

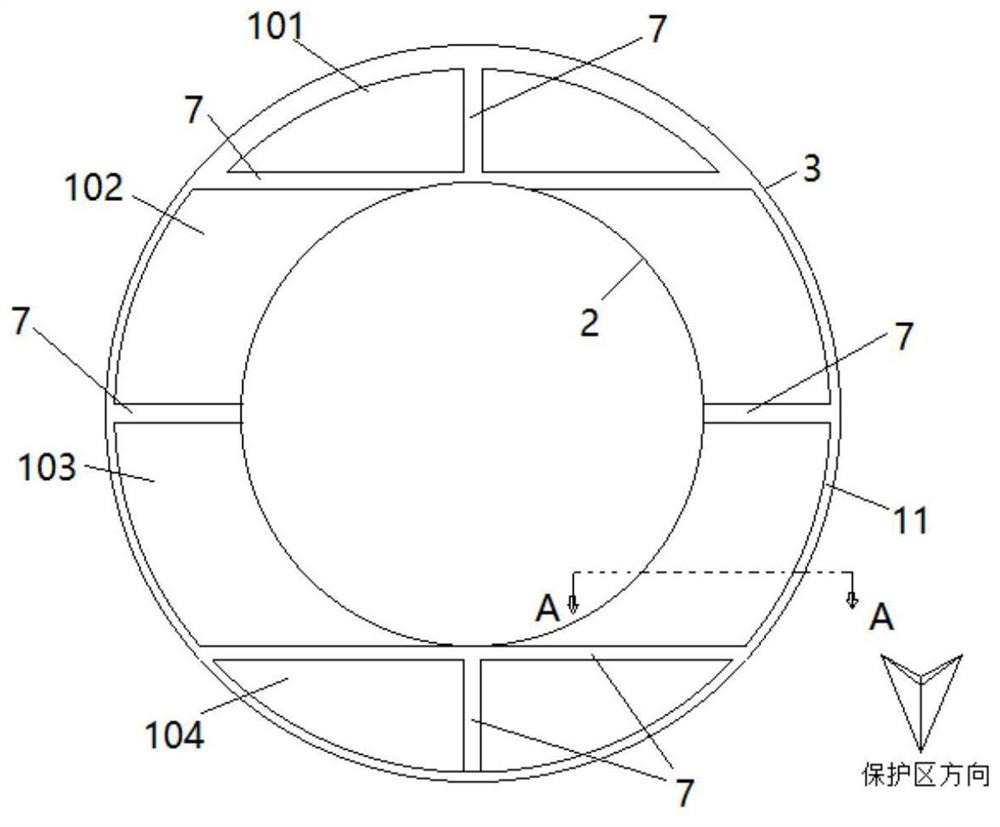

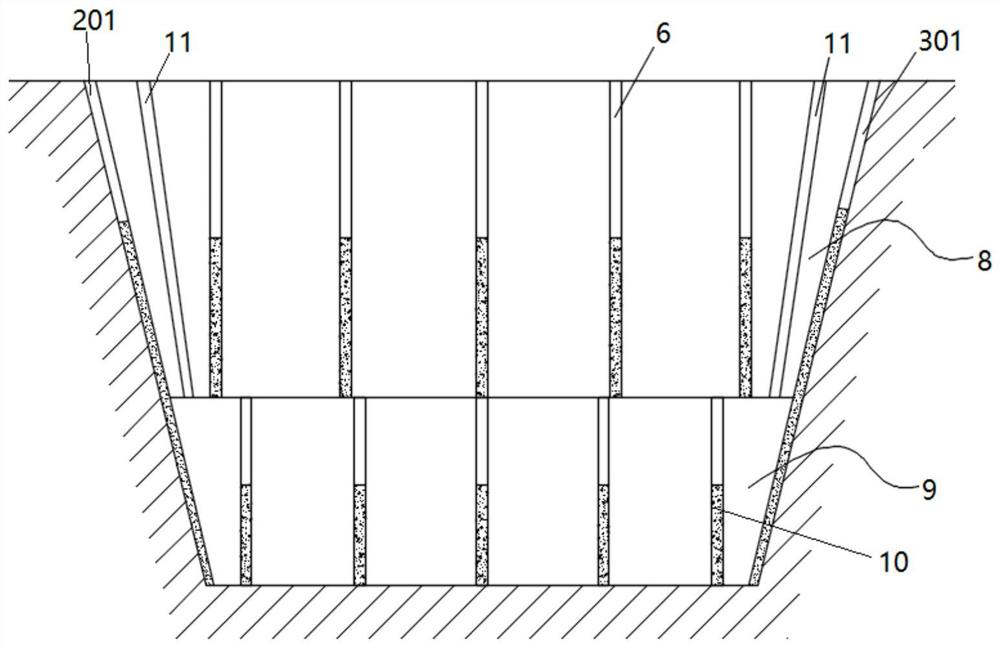

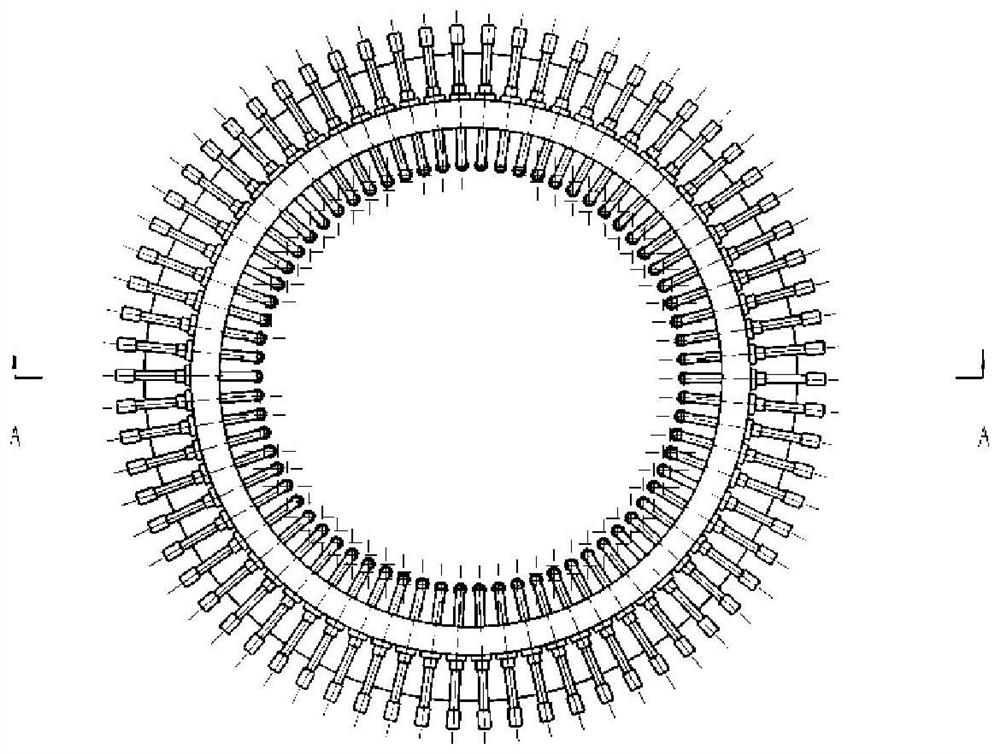

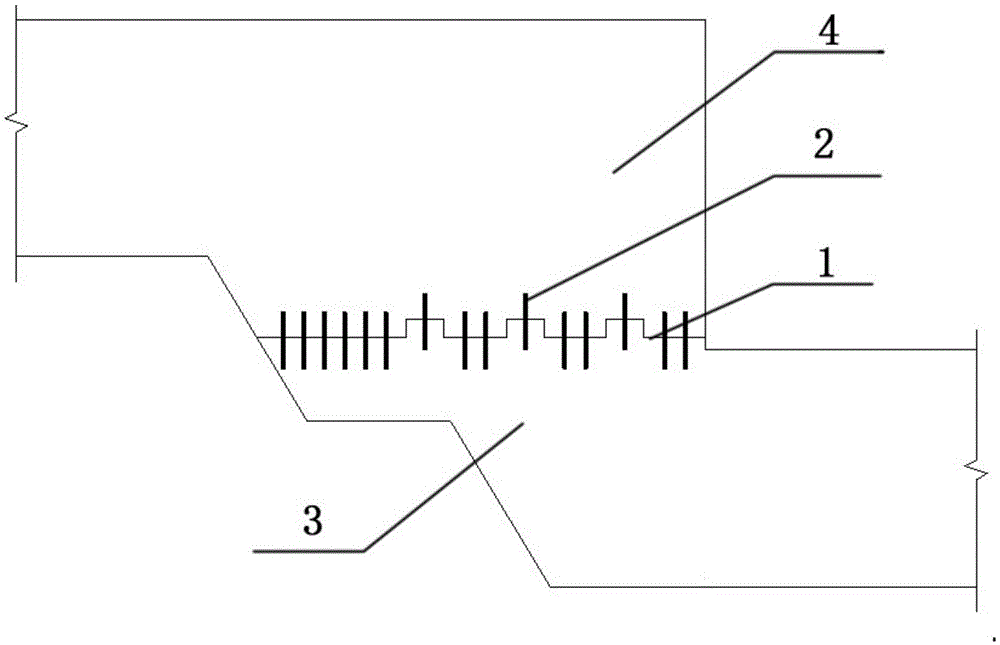

Nuclear island negative excavation ring corridor presplit blasting method

The invention relates to a nuclear island negative excavation circle corridor pre-split blasting method, belonging to the technical field of earthwork construction methods. The method has the following steps: excavating downward at the elevation at the heart of the nuclear island, and reserving a retaining layer; drilling holes along the inner and outer circumferences of the circle corridor at equal space interval respectively; filling flexible material into the bottom of the holes to serve as cushion layers; filling the explosive into the holes which are provided with the cushion layers and the loading depth at the orifices in three sections, wherein, the bottom part is a strengthening explosive filling section, the top part is a weakening explosive filling section, and the middle part is a normal explosive filling section; after the explosives are loaded into the holes, filling the loading depth at the orifices with conventional materials; and detonating the explosives to form cracks along the inner and outer circumferences of the circle corridor. The invention can form desired cracks along the inner and outer circumferences of the circle corridor at the predetermined location of the rock foundation so as to carry out the main bursting aiming to remove the rocks in the circle corridor; at the same time, taking into account the vibration, tolerance and other technical requirements, the invention takes corresponding reasonable measures so as to rapidly complete the construction work of the nuclear island negative excavation circle corridor with high quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

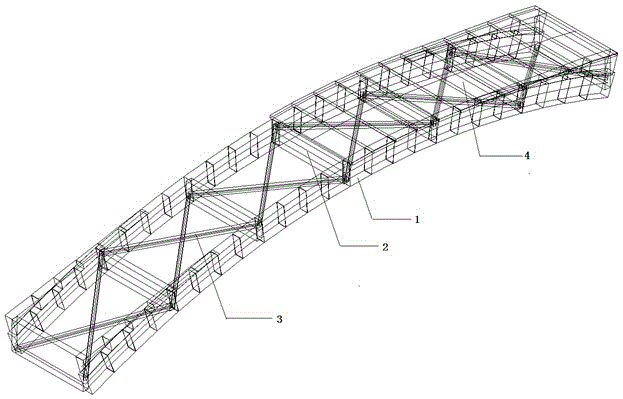

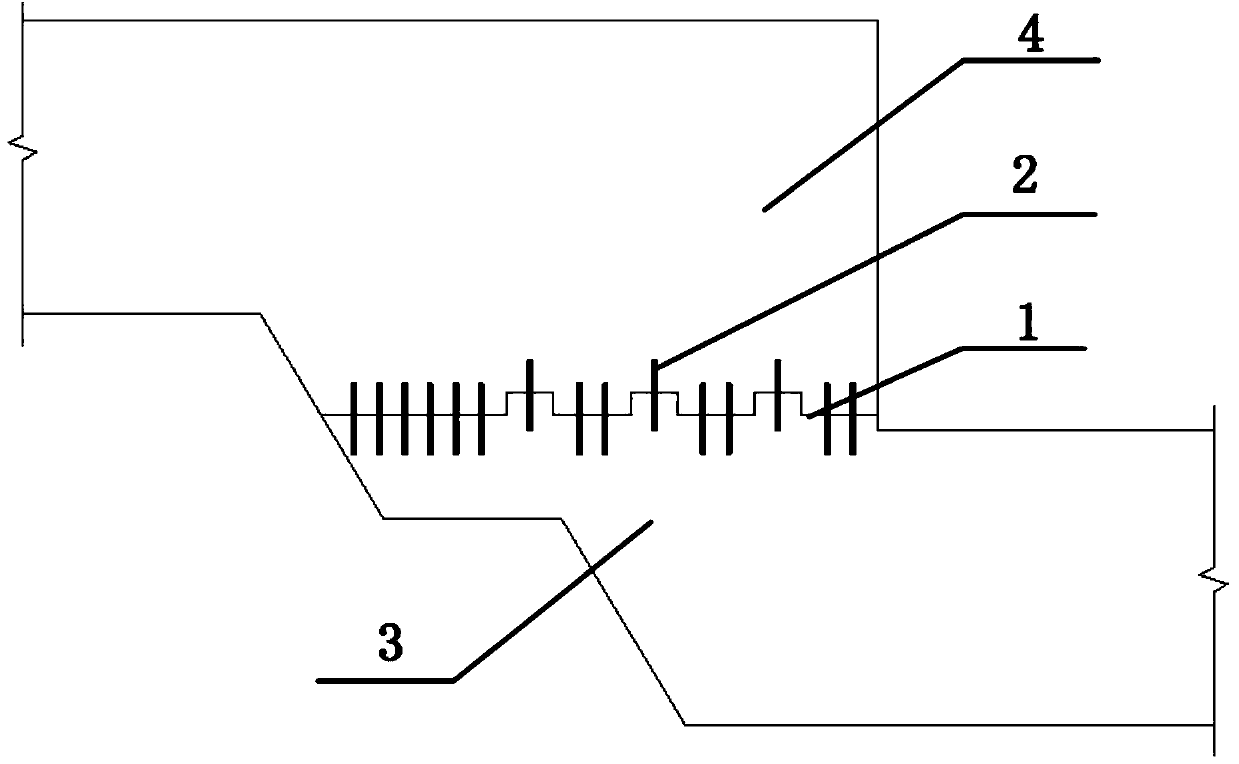

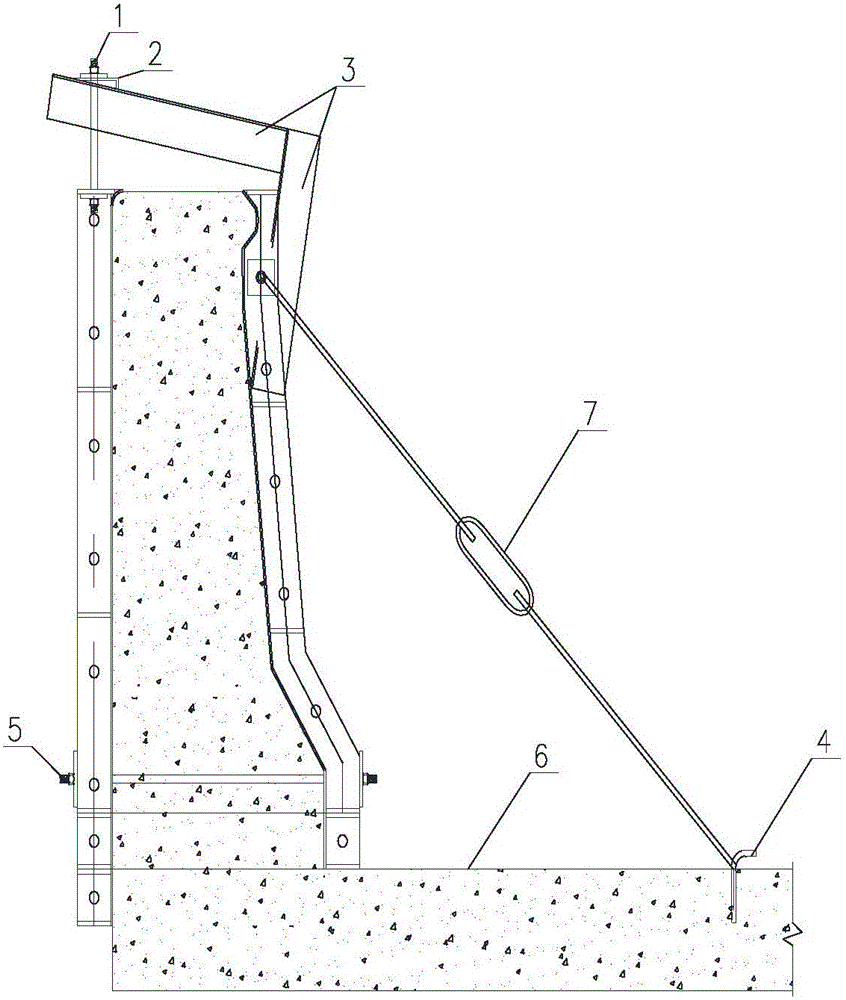

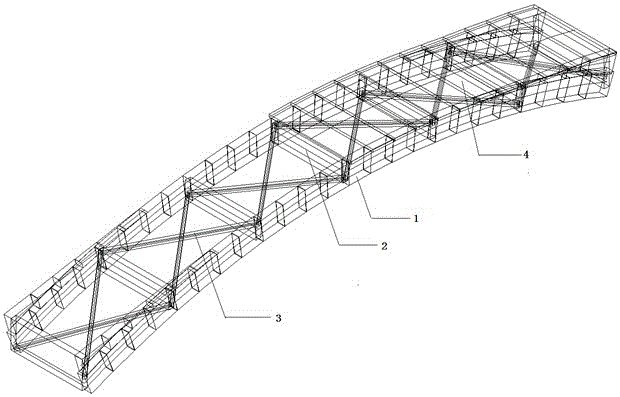

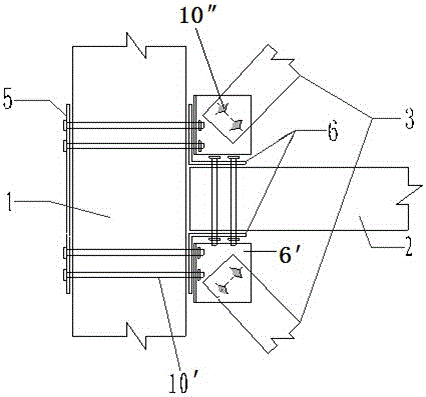

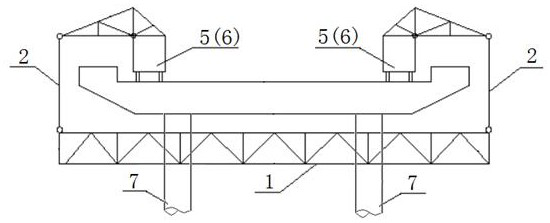

Modern arch type bamboo bridge and construction method thereof

InactiveCN104594175AImprove power transmissionImprove mechanical performanceBridge erection/assemblyArch-type bridgeDuctilityStructural element

The invention discloses a modern arch type bamboo bridge. The modern arch type bamboo bridge is characterized by comprising bamboo arch ribs, bamboo beams, diagonal bracings, bamboo panels and steel shoes, wherein the bamboo arch ribs, the bamboo beams, the diagonal bracings and the bamboo panels are made of reconsolidated bamboo materials; the steel shoes are made of steel materials. The invention further discloses a construction method of the modern arch type bamboo bridge. The construction method of the modern arch type bamboo bridge is characterized in that the bamboo arch ribs, the bamboo beams, the diagonal bracings, the bamboo panels and the steel shoes are prefabricated, installation of the steel shoes and a bridge abutment skewback is finished, then installation of the bamboo arch ribs and the steel shoes is finished, the bridge abutment skewback is poured, and finally the bamboo beams, the diagonal bracings and the bamboo panels are installed. The construction method of the modern arch type bamboo bridge has the advantages that the manufacturing process is simple, the cost is low, factorization and standardization of structural components are good, the assembly degree is high, the building time is short, the structural intensity is high, rigidity is large, ductility is good, and the seismic performance is good, and the obtained arch type bamboo bridge has the effects of being environmentally friendly and low in carbon.

Owner:CHONGQING JIAOTONG UNIVERSITY

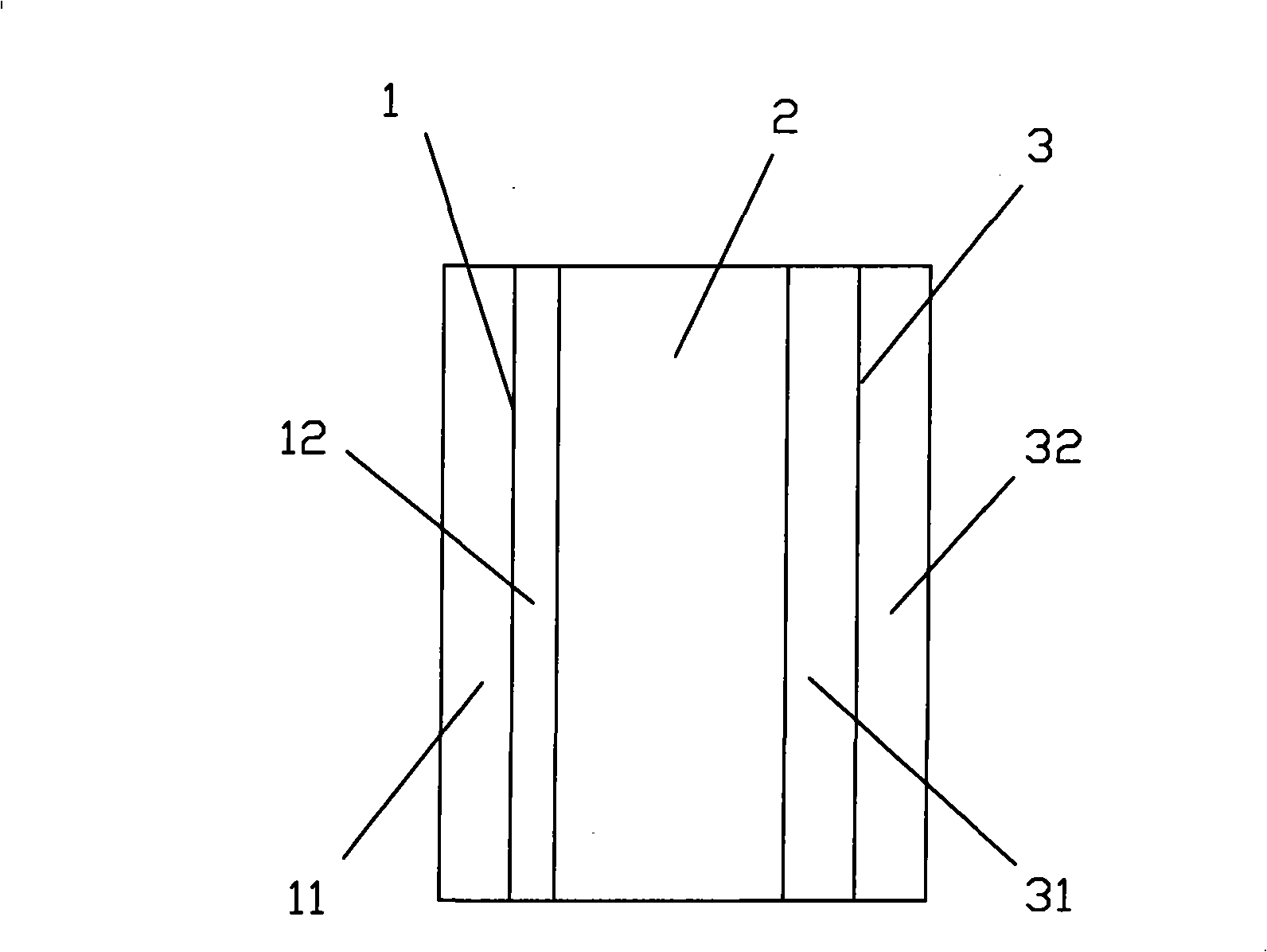

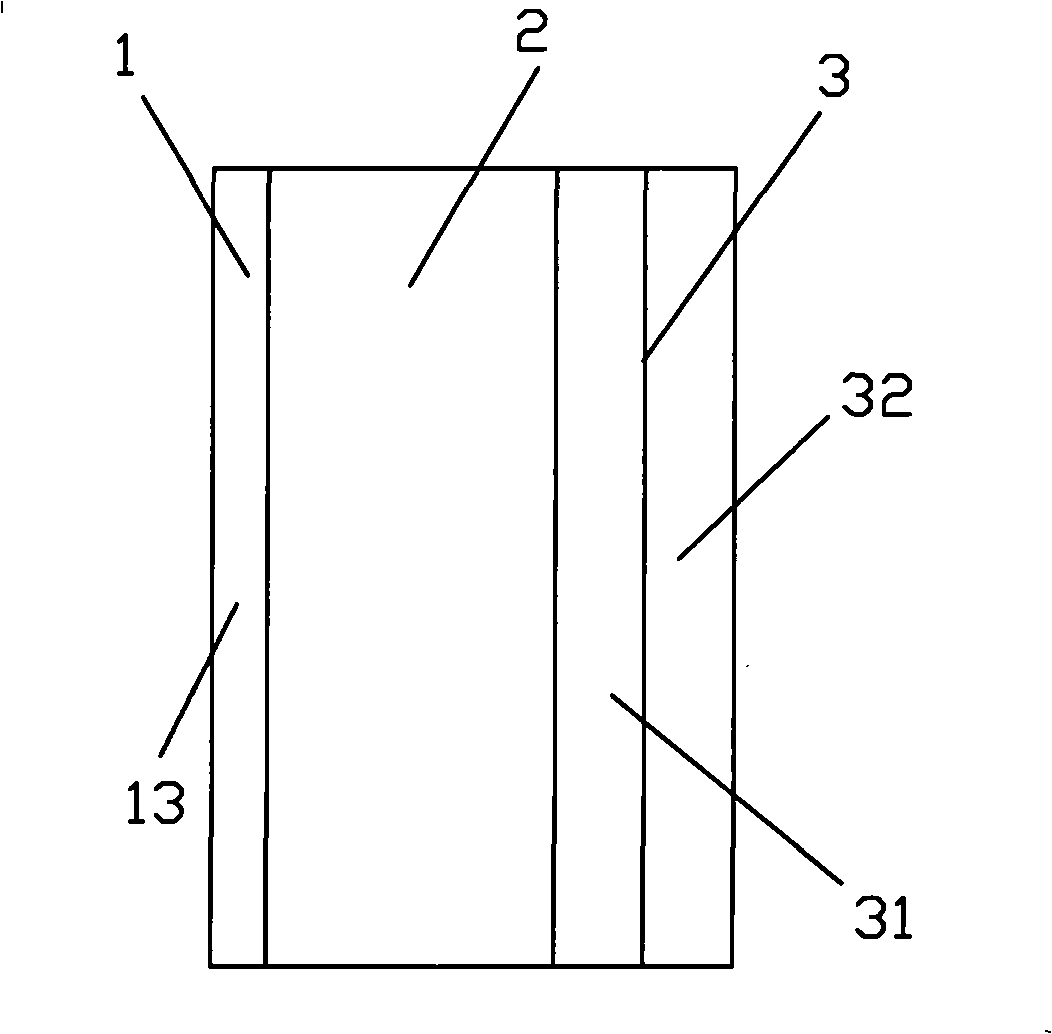

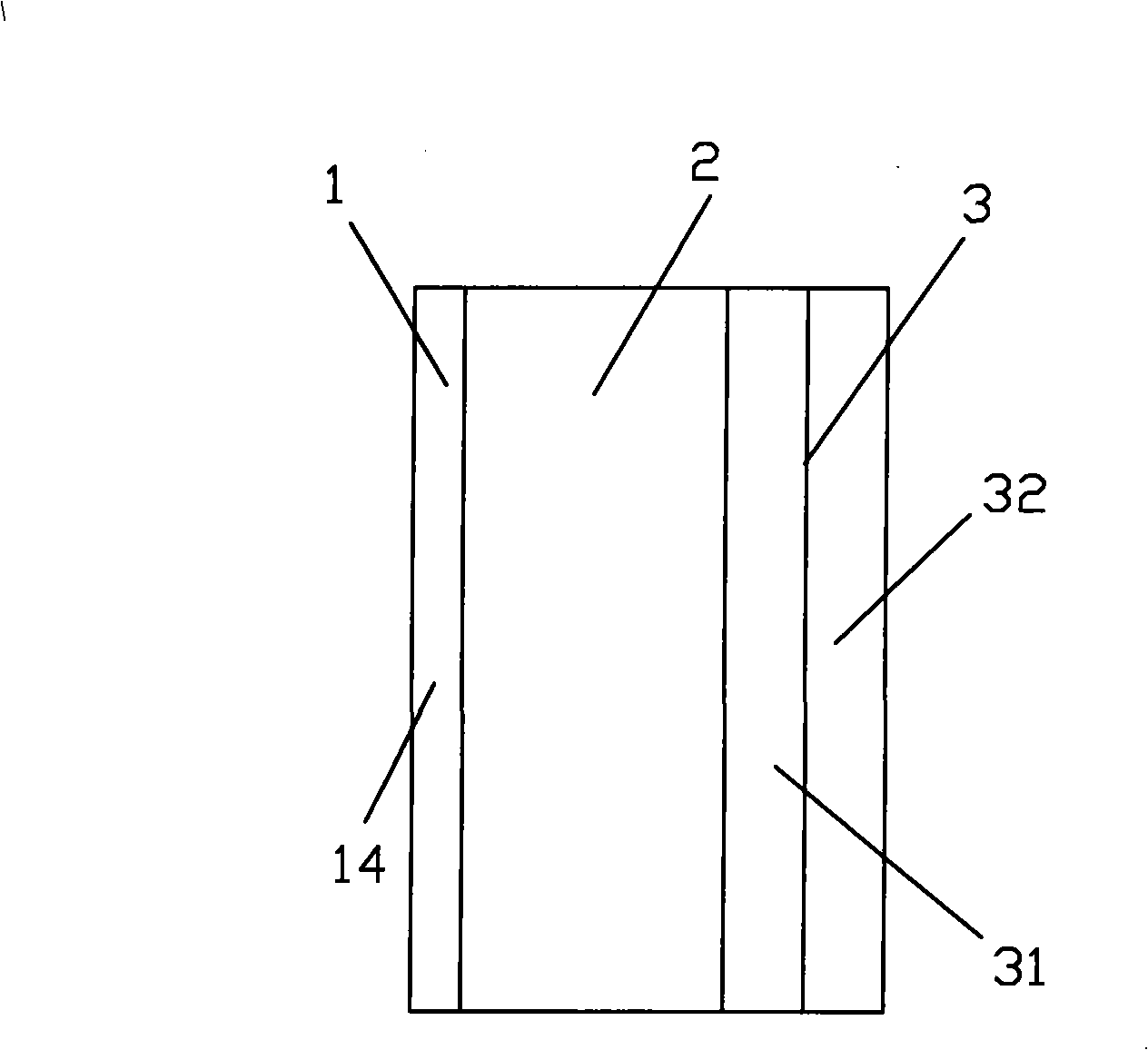

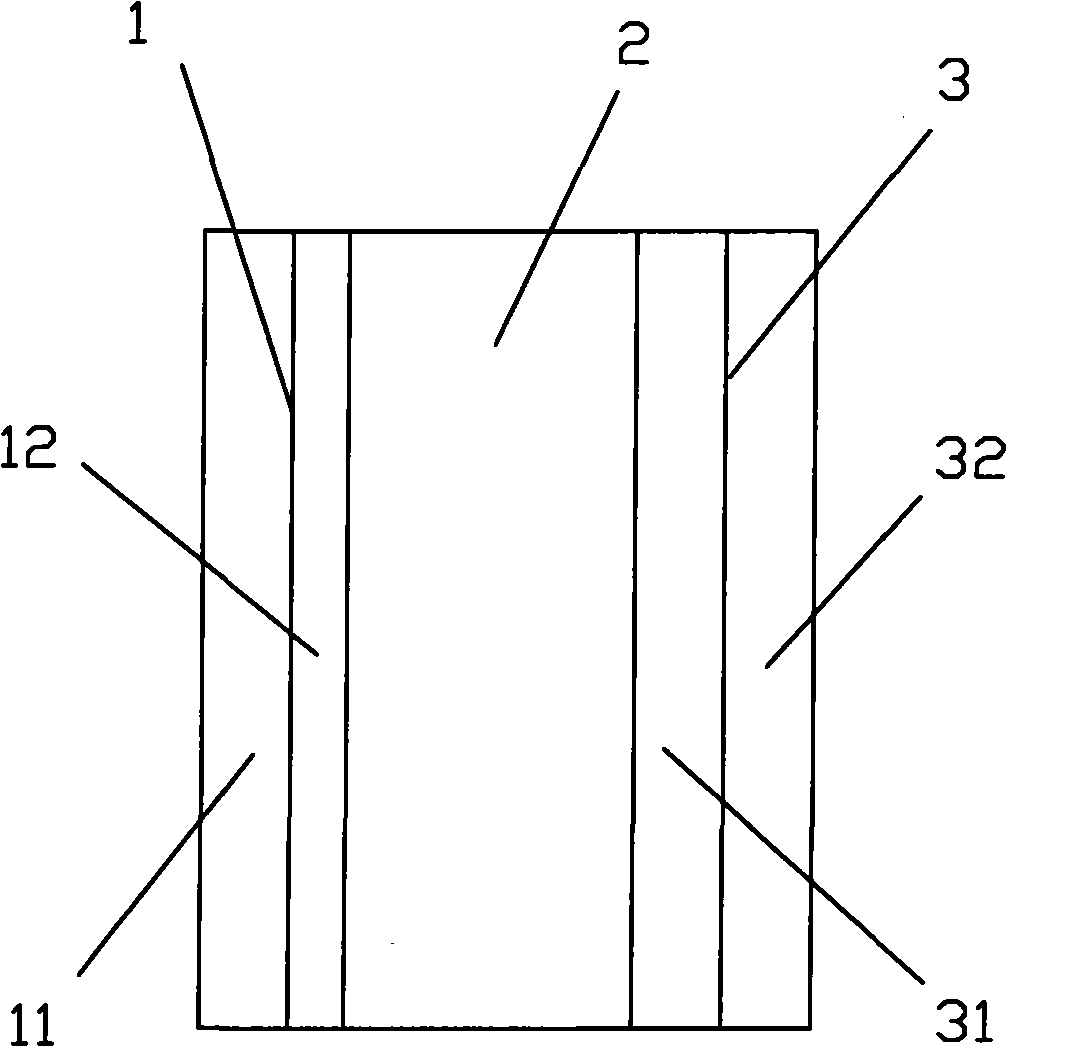

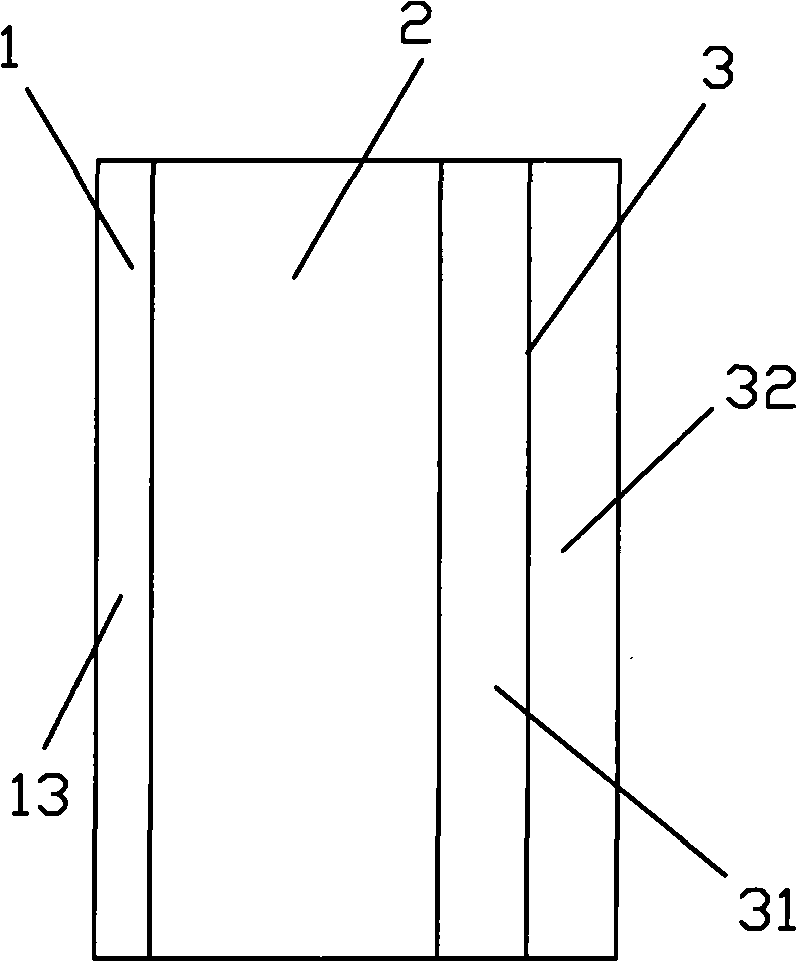

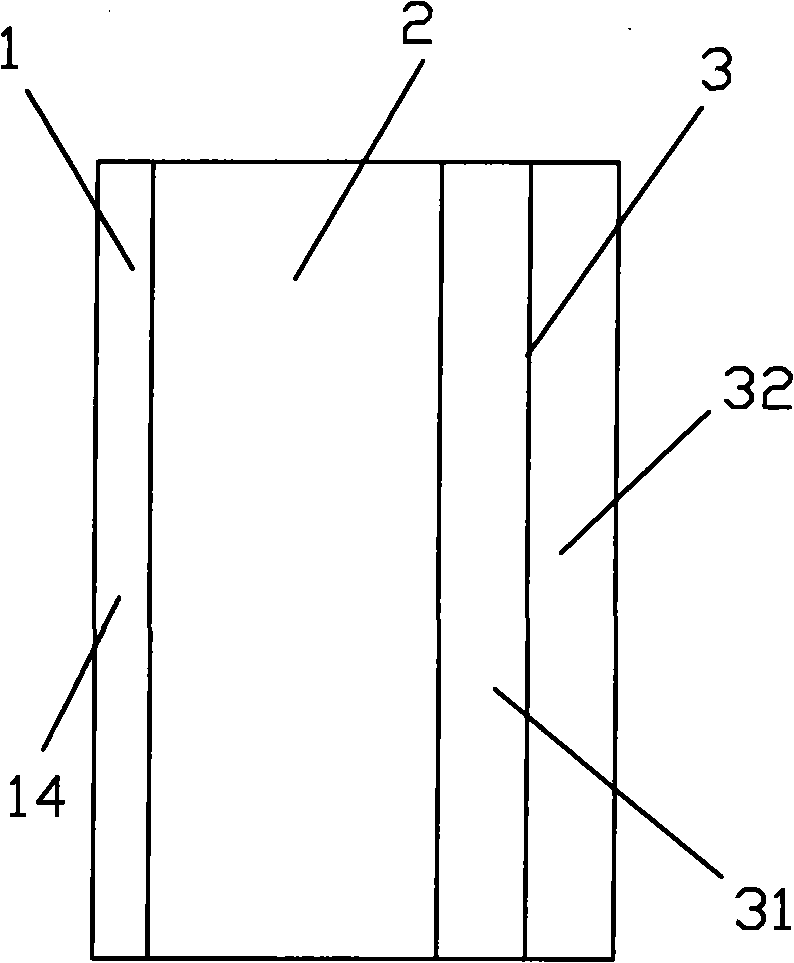

Multifunctional furring brick

InactiveCN101294440ASimple processQuick operationFireproof paintsCovering/liningsPrepolymerLower face

The invention discloses a multifunctional furring brick which consists of a finishing coat, a multifunctional layer, and a bonding layer. The multifunctional layer is manufactured and molded at a time with multifunctional liquid and foaming equipment. The finishing coat and the bonding layer are manufactured on the upper face and the lower face of the multifunctional layer respectively. The multifunctional liquid adopts polyfunctionality polyether glycol, polyester polyol prepolymer, vegetable oil polyhydric alcohol and hydramine as initiators, and polyether glycol, a fire retardant, a foam uniformizing agent, a foaming agent, postassium acetate, triethylenediamine, acetal mixture, a delaying catalyst, an ultraviolet absorbent and isocyanate as raw materials. The finishing coat can be an ordinary finishing coat, a fashionable finishing coat, a luxurious finishing coat or a fireproof finishing coat as required. The multifunctional furring brick has the characteristics of energy conservation, water resistance, decoration and portability. Wet land construction with the multifunctional furring brick can be carried out as the construction with ceramic mosaic and porcelain facing bricks, and the multifunctional furring brick can also be cast with concrete in a molding board. In addition, the multifunctional furring brick can also be bonded with an adhesive. The process is simple and operation is quick. The multifunctional furring brick integrates a plurality of functions, such as decoration, thermal insulation, water resistance and imperviousness, antisepsis, sound insulation, light weight, hardness and so on.

Owner:刘建永

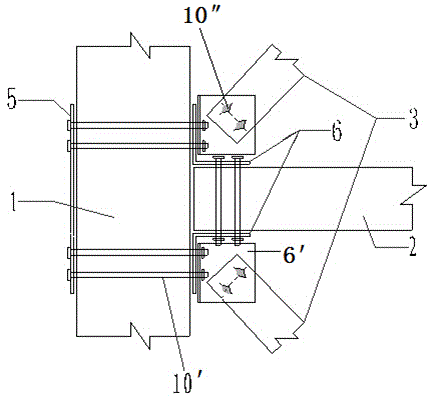

Large-altitude-difference variable-section concrete structure construction joint and construction method thereof

ActiveCN103628575AEasy to set upSolve the relative slip problemBuilding constructionsMarine site engineeringEngineeringBuilding construction

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

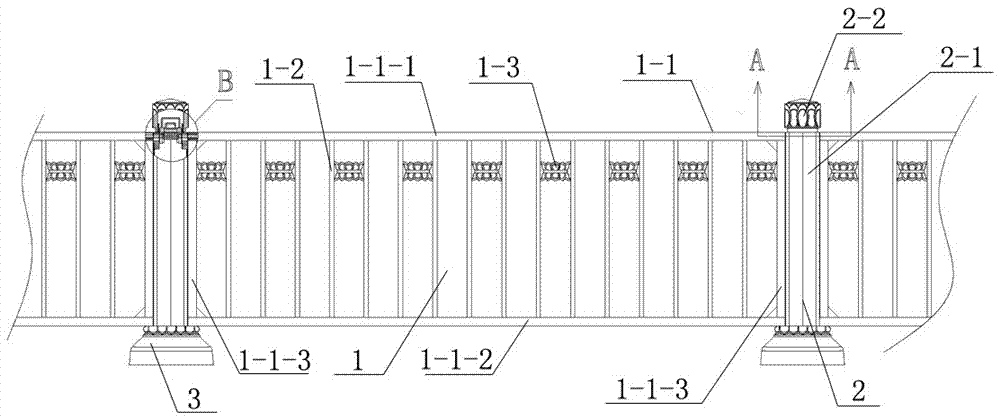

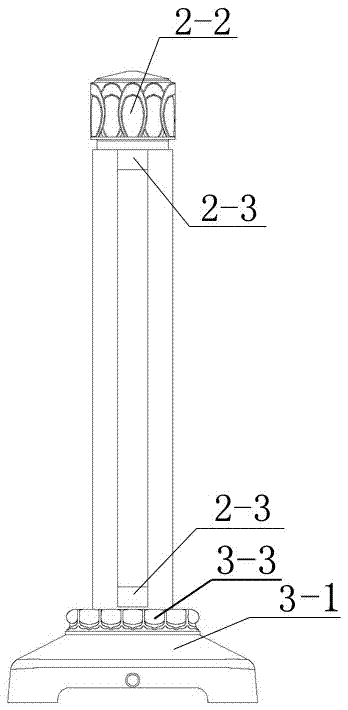

Composite aluminium alloy guard rail

ActiveCN107514181AFirmly connectedImprove impact resistanceFencingRoadway safety arrangementsStructural engineeringShock resistance

The invention discloses a composite aluminium alloy guard rail. The guard rail includes a composite base the inner layer iron core of which is completely wrapped by an aluminium alloy shell on the surface layer, aluminium alloy grid sheets and aluminium alloy columns are all provided with hollow channels communicated with one another, the hollow channel of each aluminium alloy grid sheet is internally provided with a steel reinforced rope, the hollow channel of each aluminium alloy column is internally provided with a steel self-locking clamping base, the clamping heads of the two steel reinforced ropes adjacent to each aluminium alloy column are placed in the inner cavity of the corresponding steel self-locking clamping base and fixedly locked, and the aluminium alloy columns are internally and fixedly provided with reinforced steel core rods in a lengthwise direction. Since the combined aluminium alloy guard rail is internally provided with a high-strength core framework net which is interlaced in the horizontal and vertical directions, only aluminium alloy profiles can be adopted on all the external portion and non-important portions of the combined aluminium alloy guard rail, and therefore not only can costs be greatly saved, but the guard rail is elegant in appearance and not likely to rust, and meanwhile, the stability and anti-shock resistance of the combined aluminium alloy guard rail are ensured.

Owner:佛山市圣田智能科技有限公司

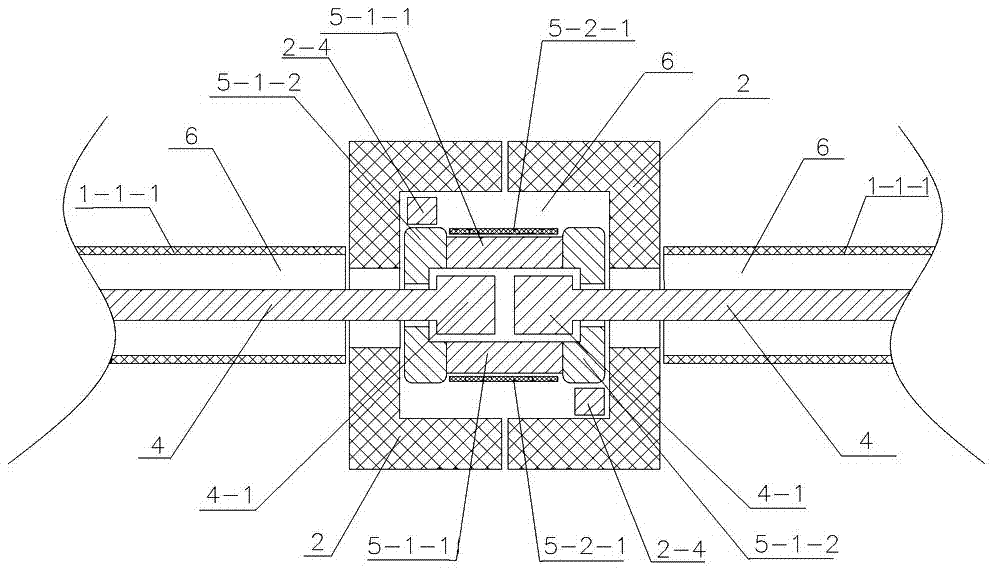

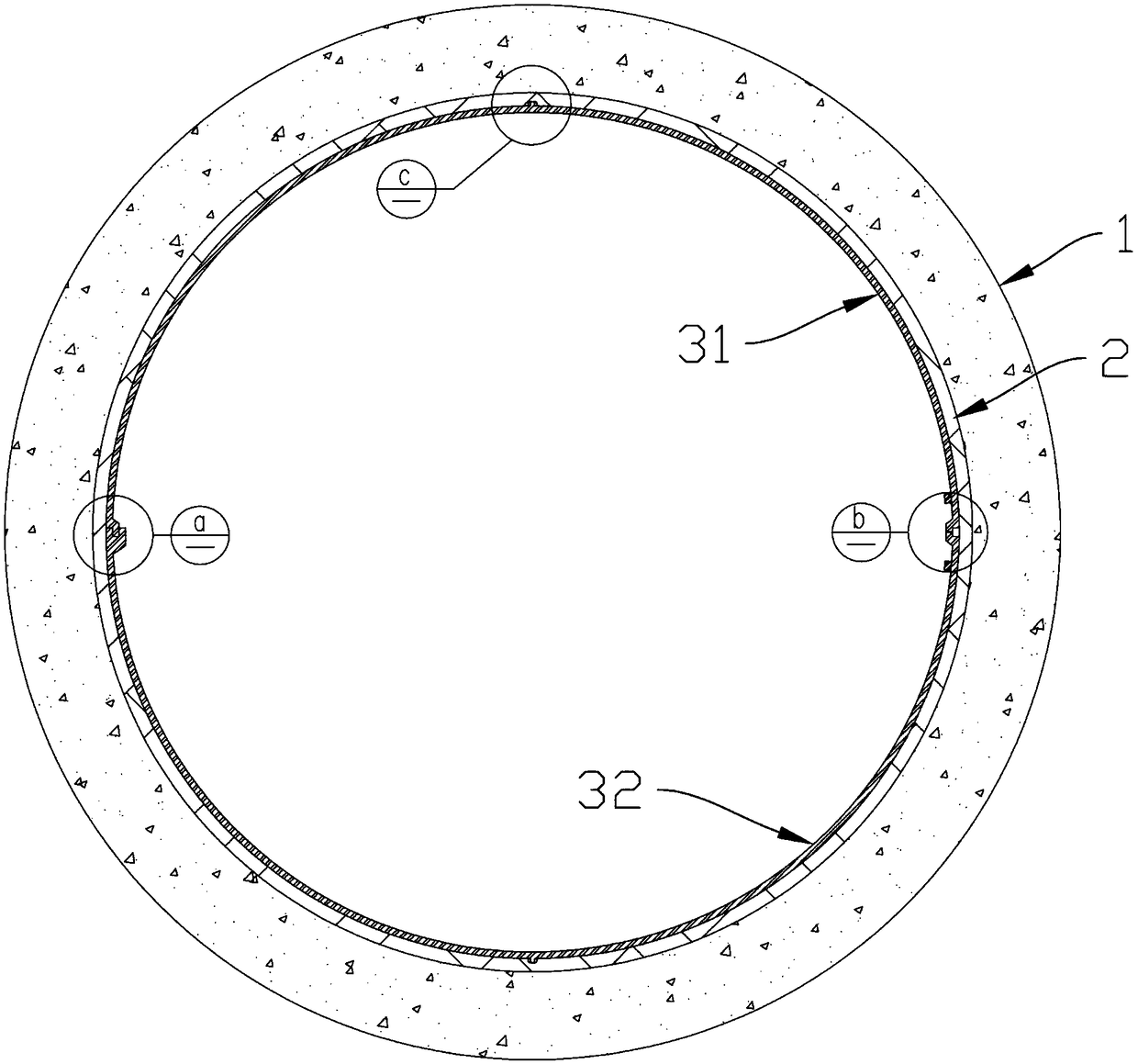

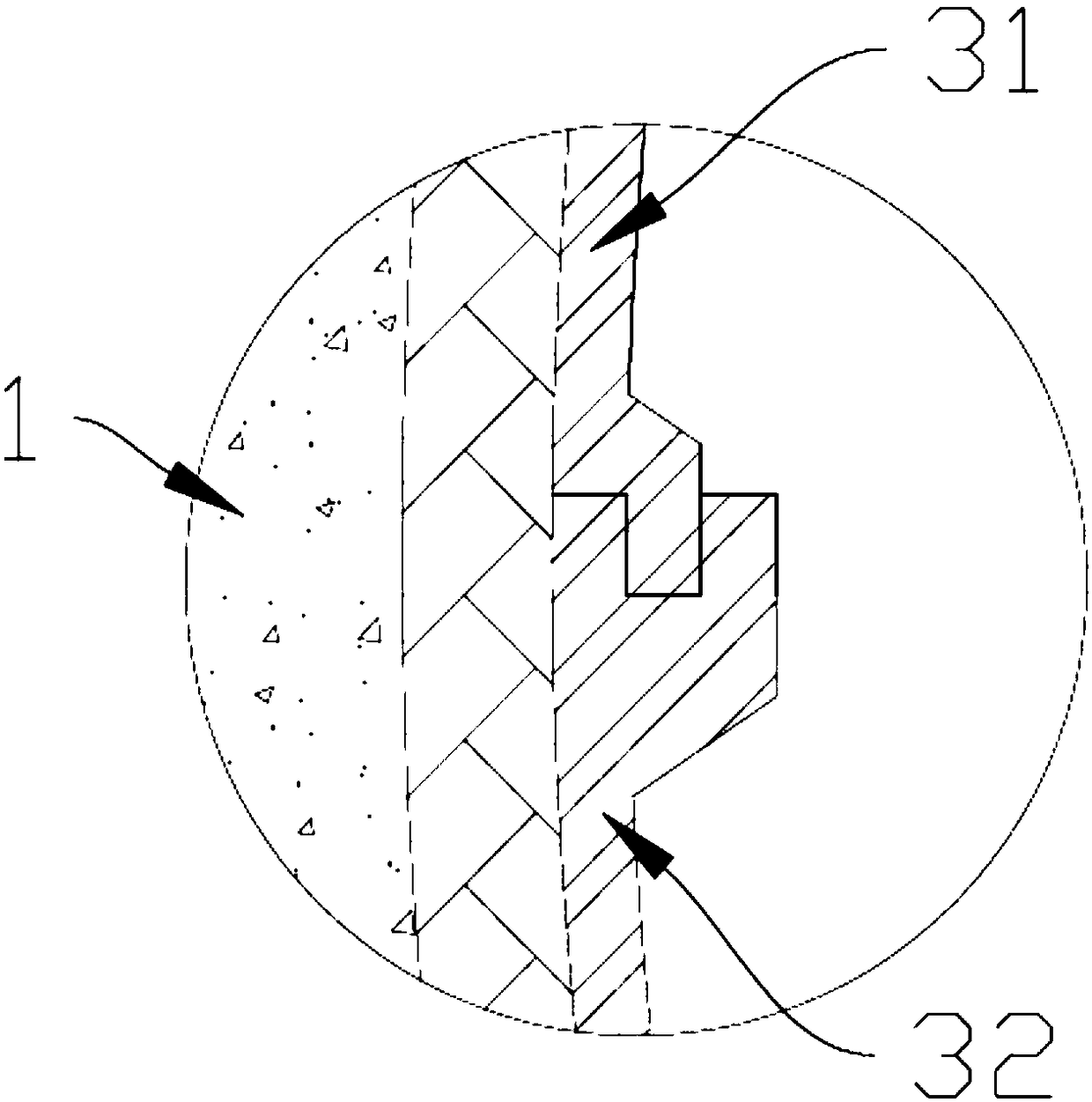

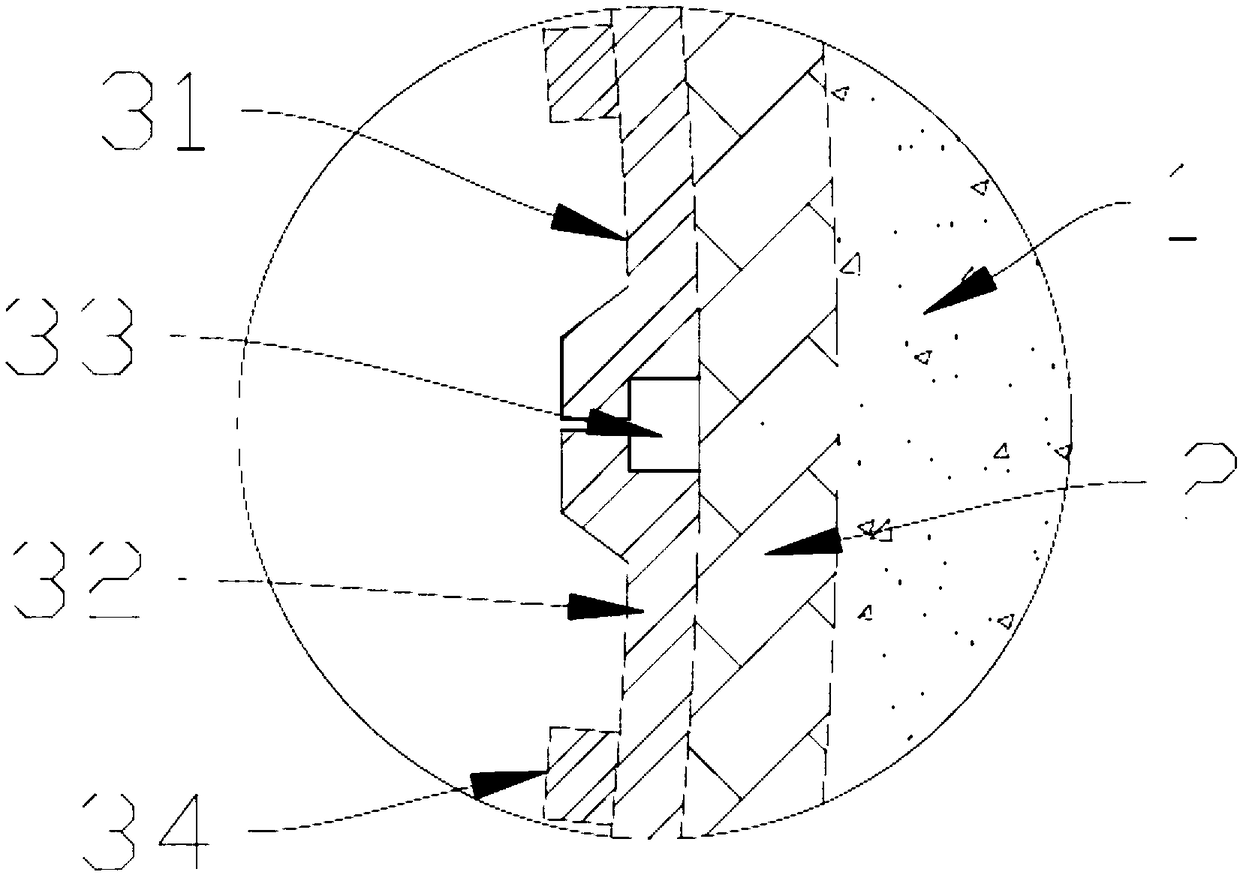

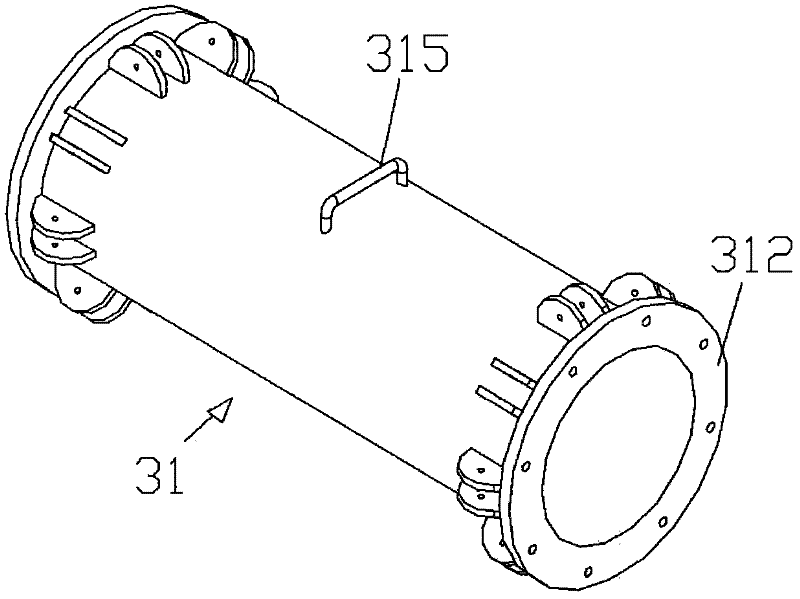

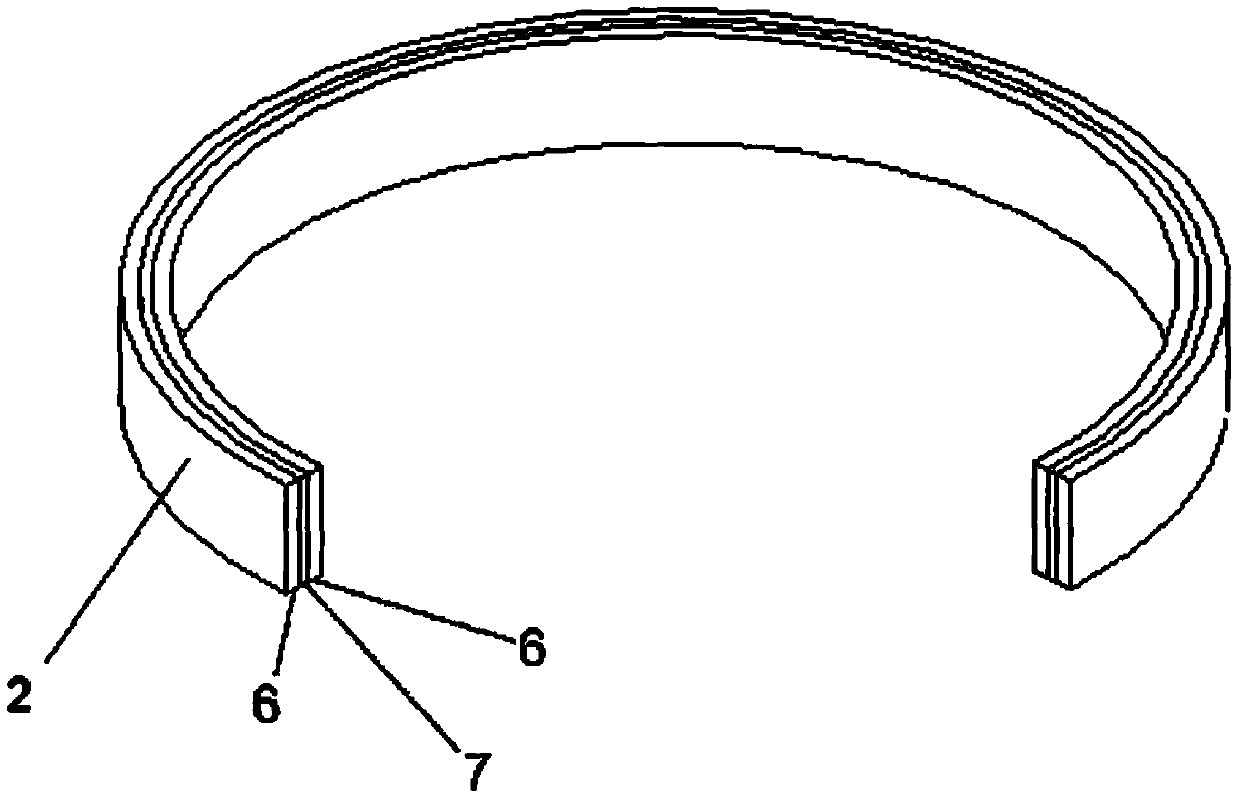

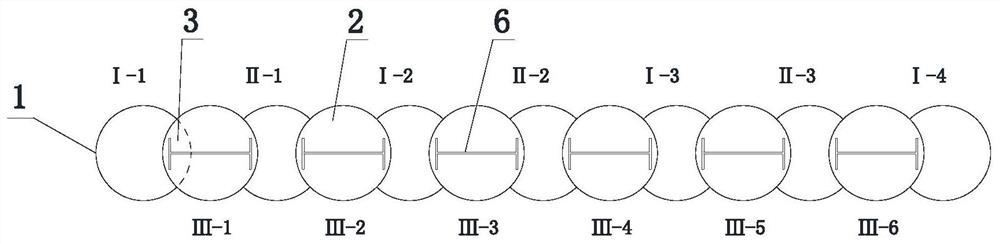

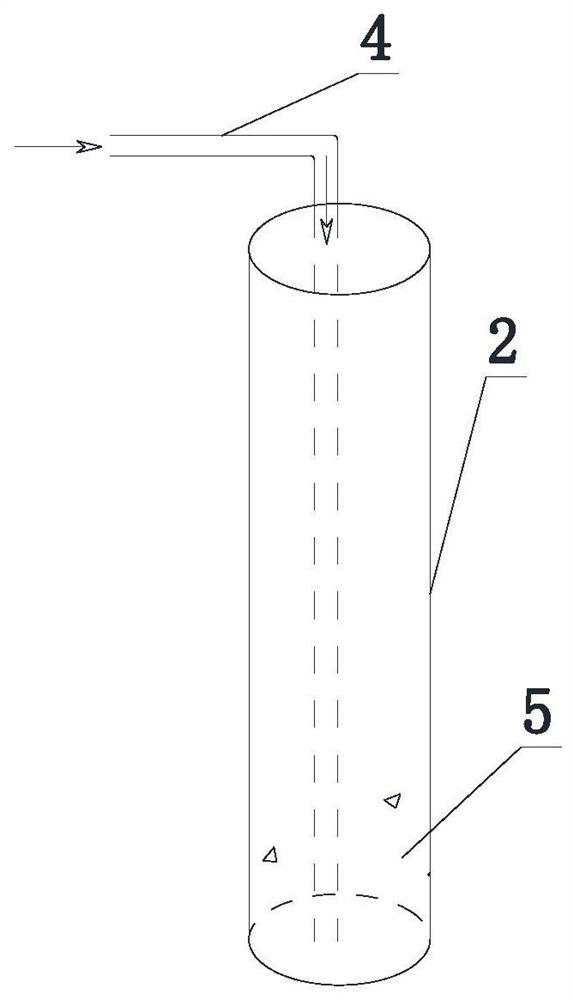

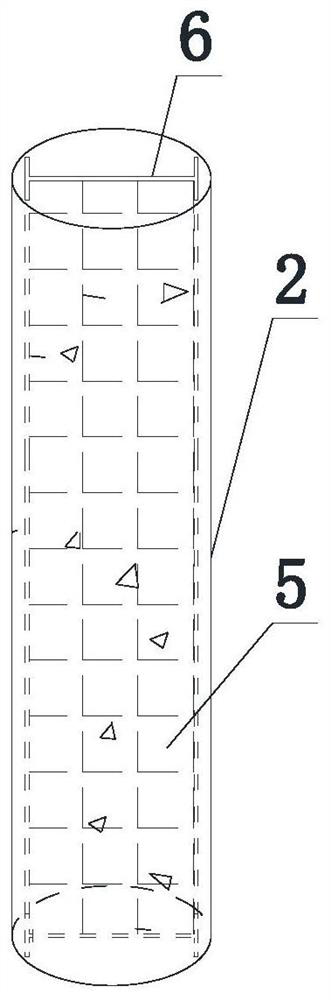

Pipeline repair method and repaired pipeline

PendingCN108730671ANo structural damageFast construction operationPipe elementsEngineeringMechanical engineering

The invention provides a pipeline repair method and a repaired pipeline. The pipeline repair method comprises the steps that firstly, an annular seal part is put in a reserve area of the pipeline, then a rigid annular adjusting unit is installed on the inner surface of the annular seal part and is adjusted, the outer contour of the rigid annular adjusting unit is expanded, thus the rigid annular adjusting unit tightly presses the annular seal part, and the annular seal part is tightly attached to the pipeline face of the reserve area. The pipeline repaired with the pipeline repair method comprises a pipeline body, a rigid annular adjusting assembly and a rubber seal layer arranged between the pipeline body and the rigid annular adjusting assembly. The pipeline repair method provided by theinvention is simple to operate, structure damage of the pipeline is avoided, and the pipeline repaired with the pipeline repair method can achieve a better leakproof effect.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

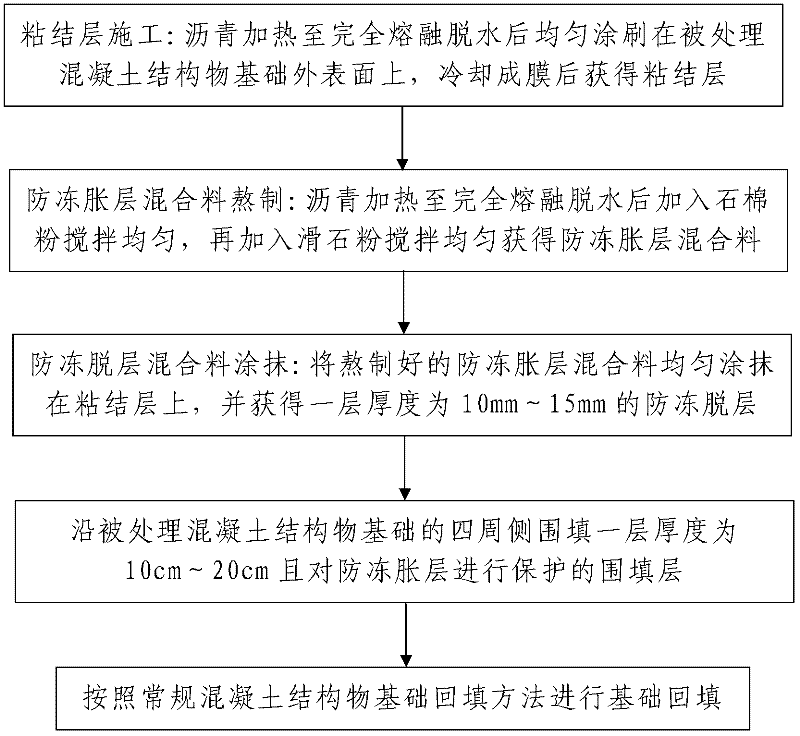

Anti-freezing treatment method for concrete structure foundation in severe cold region

The invention discloses an anti-freezing treatment method for a concrete structure foundation in a severe cold region. The anti-freezing treatment method includes steps of 1, construction of an adhesion layer; 2, construction of a frost heaving preventing layer; and 3, backfilling of the foundation. The construction of the adhesion layer includes steps of heating asphalt to a completely melted state, dehydrating the asphalt, uniformly coating the asphalt on the outer surface of the treated concrete structure foundation, and cooling to form a membrane so that the adhesion layer is obtained. The construction of the frost heaving preventing layer includes steps of 201, stewing mixture materials of a frost heaving preventing layer, heating asphalt to a completely melted state, dehydrating the asphalt, adding asbestos powder in the asphalt, uniformly stirring the asphalt, adding talcum powder in the asphalt, and then uniformly stirring the asphalt so as to obtain the mixture materials of the frost heaving preventing layer; and 202, coating the mixture materials of the frost heaving preventing layer. The mass ratio of the asphalt, the asbestos powder and the talcum powder is 1.0+ / -0.01:0.34+ / -0.02:0.11+ / -0.02. The anti-freezing treatment method has simple steps, is low in investment cost, convenient in construction, fine in anti-freezing treatment effect, can effectively relieve or eliminate damage to the structure foundation due to frost heaving force, and increases the structure of a structure, and the frost heaving preventing quality can be guaranteed easily.

Owner:CHINA RAILWAY FIRST GRP CO LTD

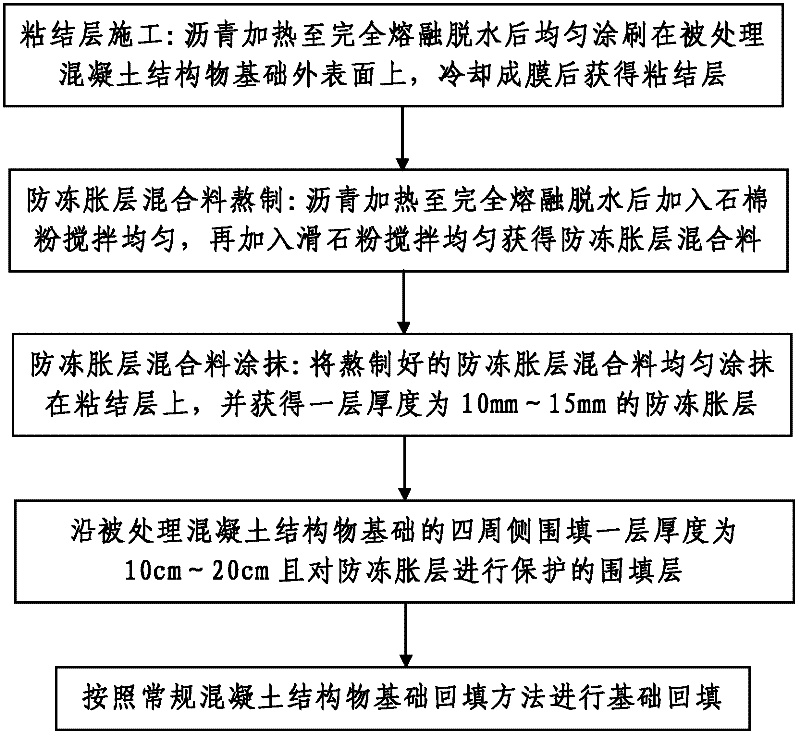

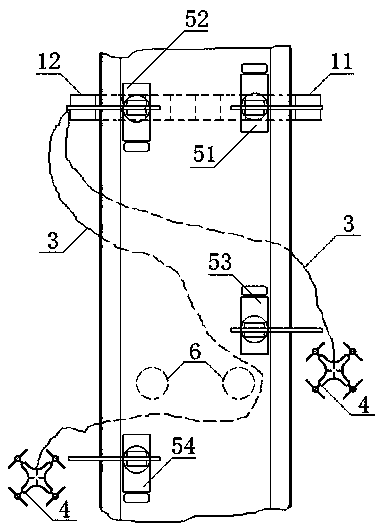

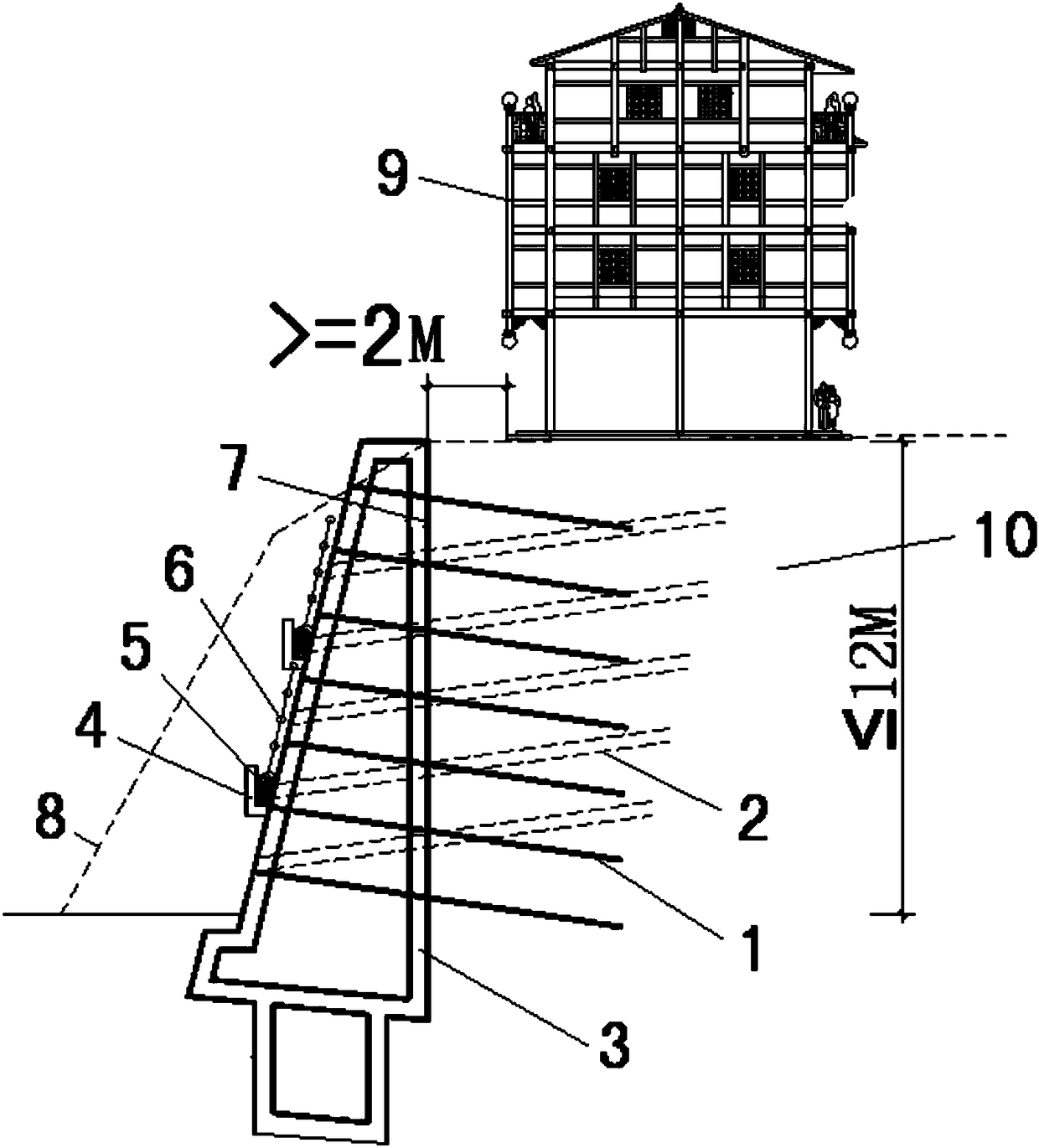

Support method and device for preventing mud rock landslides

ActiveCN106120822AFull securitySimple structureExcavationsReceptacle cultivationStructure of the EarthSlag

The invention discloses a support method and device for preventing mud rock landslides. A design excavation line is set at the position away from a slope top building outer wall by 2 M or above; during construction, excavation is conducted according to the sloping slope ratio required by the design from top to bottom, excavation is paused every time when excavation is downwards conducted by 1.5 m, temporary anchor rod support is conducted on the layer, and a drainage pipe is driven into a slope body to conduct drainage treatment; downward excavation is conducted while support and drainage are conducted layer by layer till the slope bottom is reached; a foundation trench is dug in the slope bottom, the outer wall of the foundation trench is a concrete pouring body, the foundation trench is filled with mud rock materials obtained after excavation to be compacted; then, a concrete cavity is constructed above the foundation trench in a layering pouring manner, and the cavity is filled with the mud rock materials to be compacted till the slope top is reached; and finally, anchor rods, the drainage pipes and the outer side of the concrete cavity are fixed. According to the support method and device, the structure is simple, the cost is low, little waste slag exists, the safety performance is high, and construction and operation are fast.

Owner:贵州建工第八建设集团有限公司

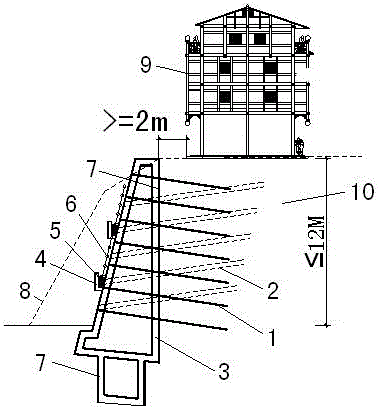

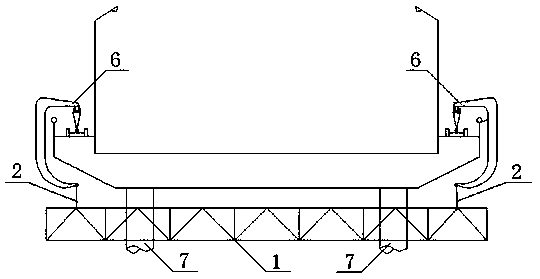

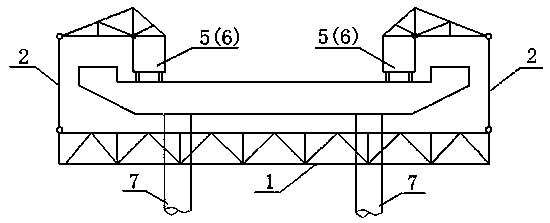

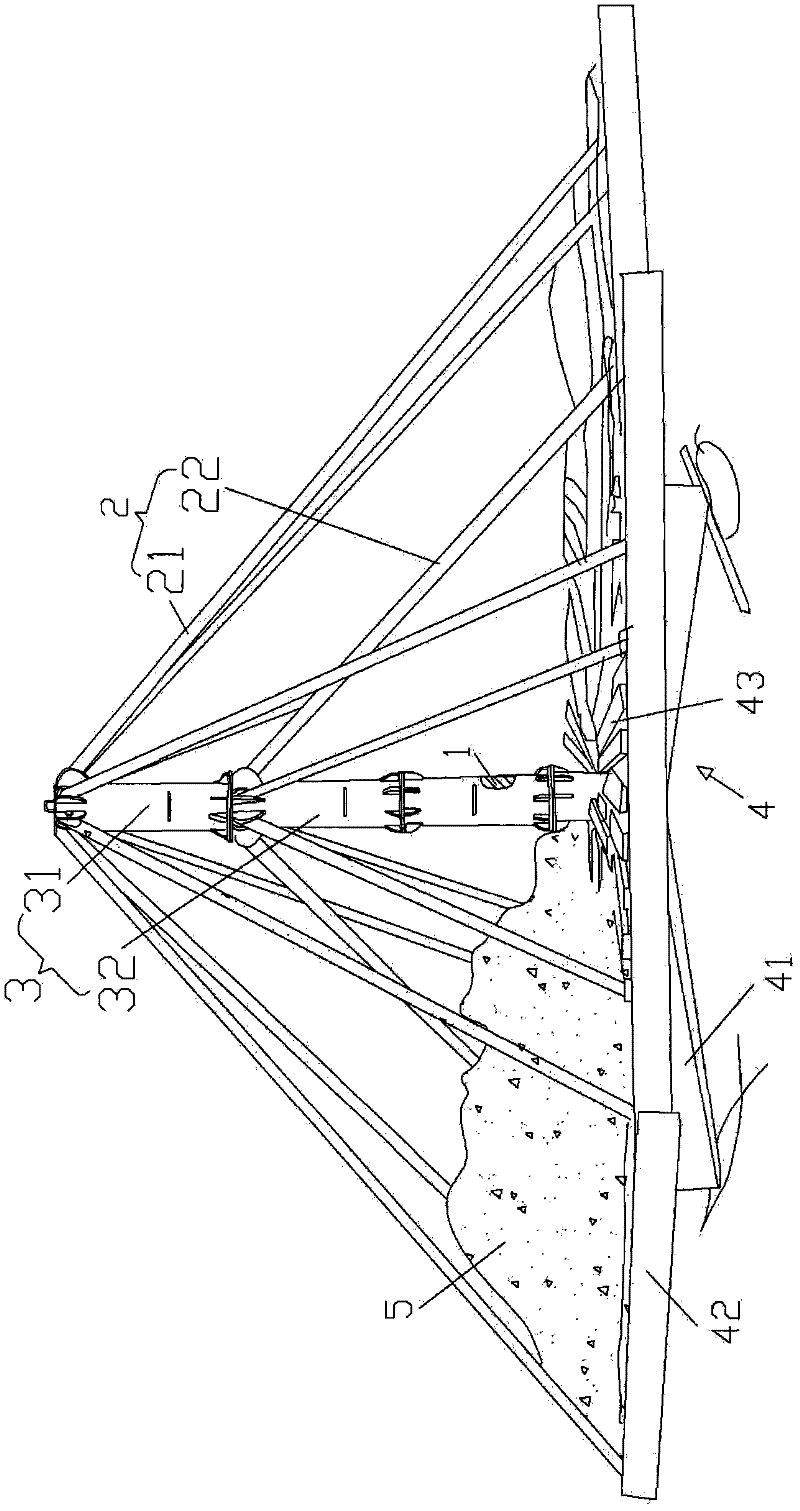

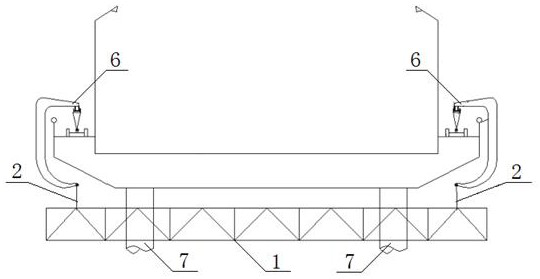

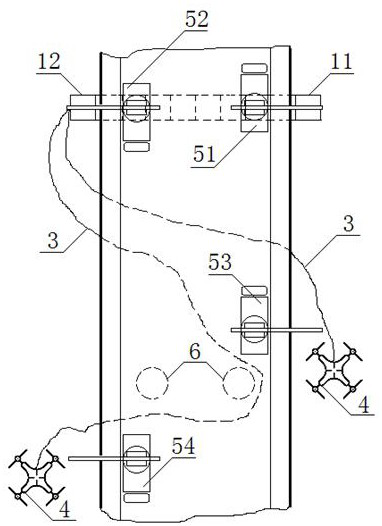

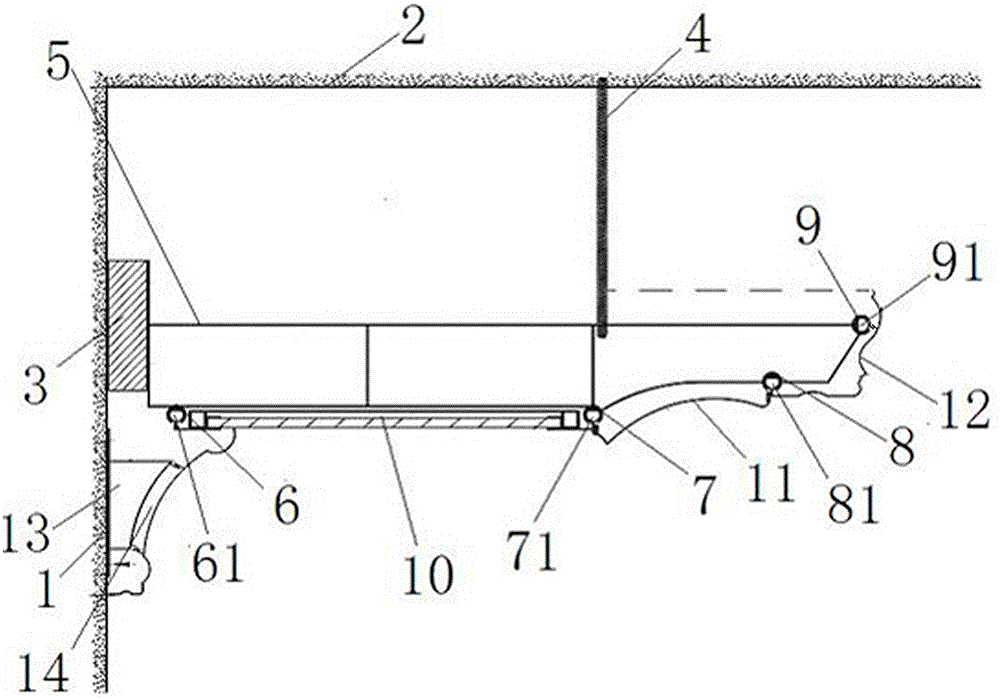

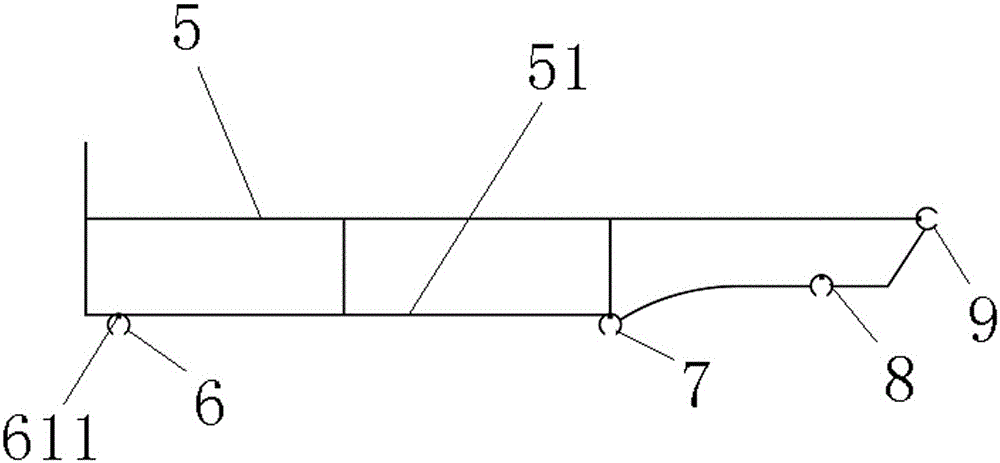

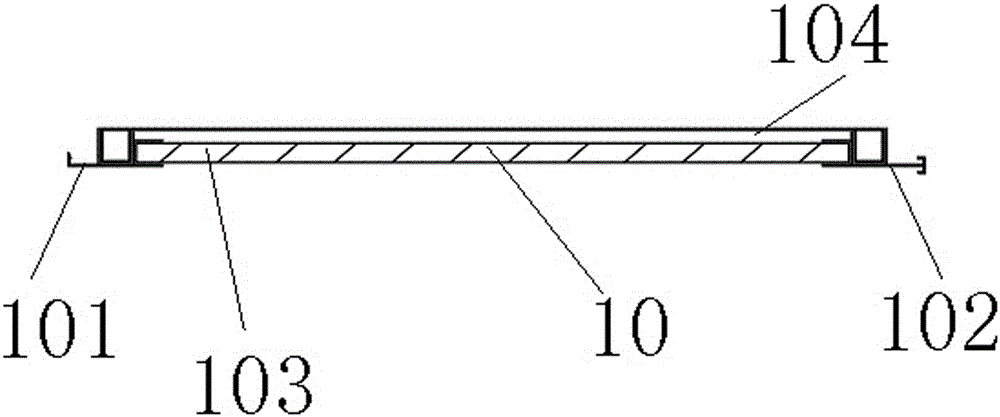

Bridge maintenance vehicle and method for avoiding bridge pier by maintenance platform

ActiveCN110820555AAvoid damageEasy to operateBridge structural detailsArchitectural engineeringUncrewed vehicle

The invention provides a bridge maintenance vehicle and a method for avoiding a bridge pier by a maintenance platform, and belongs to the field of bridge detection and maintenance construction. Cantilever hoisting devices (5) are arranged at a plurality of points on the two sides of a bridge floor, wherein a guide rope (3) connected with the maintenance platform (1) is pulled by an unmanned aerialvehicle (4) to transversely penetrate through the lower part of the bottom face of a bridge; hoisting ropes (2) are pulled to the cantilever hoisting devices (5); the operation of avoiding the bridgepier is achieved through the cooperative operation mode that a plurality of hoisting ropes (2) are pulled and rotated to be positioned on the maintenance platform (1) on the bottom face of the bridge; the movement of the maintenance platform (1) can be monitored by the unmanned aerial vehicle (4); the operation is visual and convenient, the multiple devices are cooperatively operated; the construction efficiency is high; the auxiliary time is short; the construction time for avoiding the bridge pier can be greatly shortened; the number of constructors is small; and the construction cost is reduced. The method is particularly suitable for conducting bridge pier avoiding construction operation on the bridge maintenance vehicle and the maintenance platform on the bridge with the large bridgefloor height, the large bridge bottom slope, the severe river channel condition, the poor bridge bottom construction environment and the poor condition.

Owner:陈雨羲

L-shaped supporting frame for mounting bridge anticollision guardrail formwork

PendingCN105887675AQuick fixEasy to useBridge structural detailsBridge erection/assemblyT-beamArchitectural engineering

The invention discloses an L-shaped supporting frame for mounting a bridge anticollision guardrail formwork. The L-shaped supporting frame comprises two T beam flange plates which are perpendicular to each other, one of the T beam flange plates is placed horizontally while the other one is placed vertically, 10# equilateral angle steel is arranged at the top of the T beam flange plate which is placed vertically, one end of the 10# equilateral angle steel is welded on one side of the T beam flange plate which is placed vertically while the other end of the same is fixed at the top of the T beam flange plate which is placed vertically through an upper-portion screw, and the upper screw can be adjusted up and down, an angle steel welding leveling device is arranged between the upper screw and the 10# equilateral angle steel, and a lower screw is penetratingly inserted into the bottom of the left side of the T beam flange plate which is placed vertically from left to bottom. The L-shaped supporting frame is welded on the upper portion of the formwork inside an anticollision guardrail to achieve the objective of quickly fixing an outside formwork, and construction operation is quicker.

Owner:CCCC FIRST HARBOR ENG +1

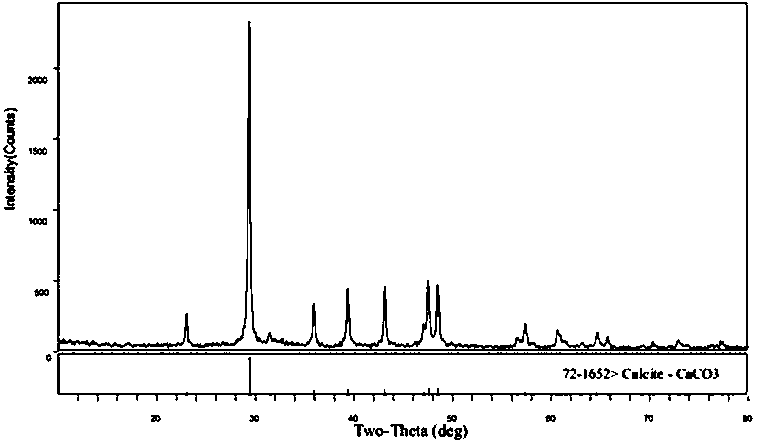

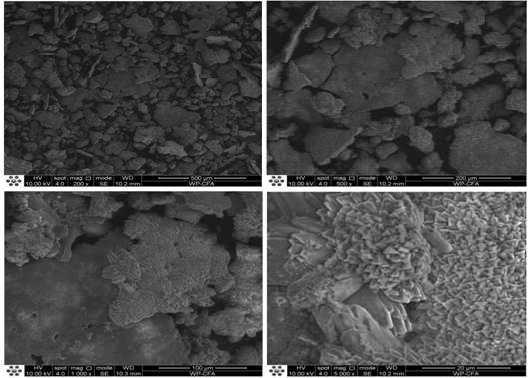

Method for mineralizing and reinforcing clay roadbed by using carbon fixation bacteria

ActiveCN109629360AEasy to operateFast construction operationRoadwaysBuilding constructionsQuartzMaterials science

The invention discloses a method for mineralizing and reinforcing a clay roadbed by using carbon fixation bacteria. The method comprises the following steps that A, streptomyces microflavus is cultured, and a bacteria solution is obtained; B, quartz sand is poured into clay for forming a roadbed, stirring for mixing is conducted, and then a mixture of the streptomyces microflavus bacteria solution, slaked lime and foam carbon dioxide is poured into the mixture of the clay and the quartz sand for sufficient stirring; C, standing is conducted to form a carbonized coagulum. The method for reinforcing the clay roadbed is more environmentally friendly, the operation is more convenient and faster, and the reinforcing effect is better.

Owner:WENZHOU UNIVERSITY

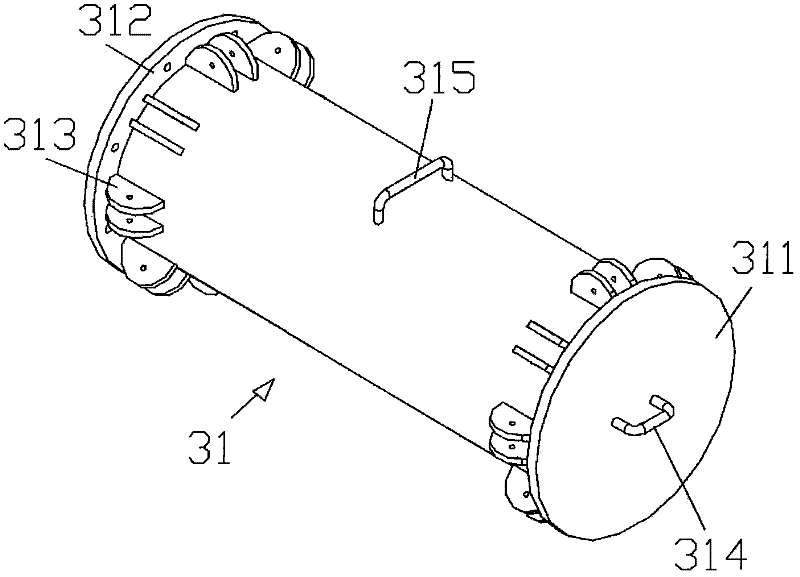

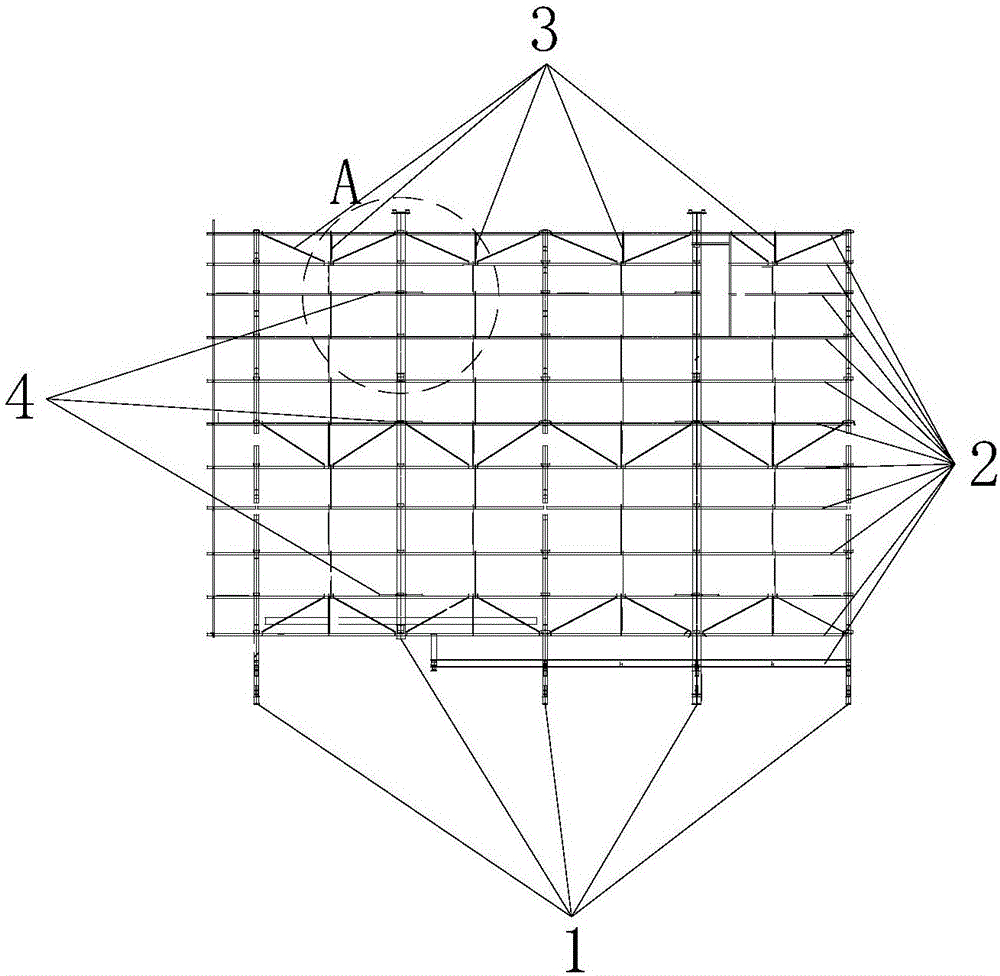

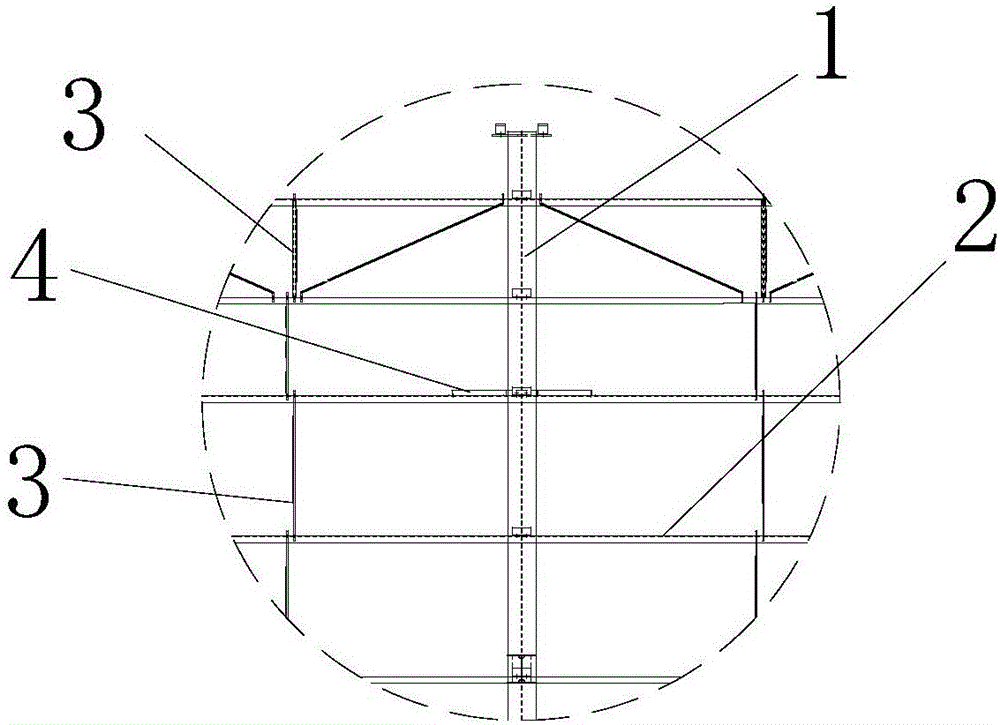

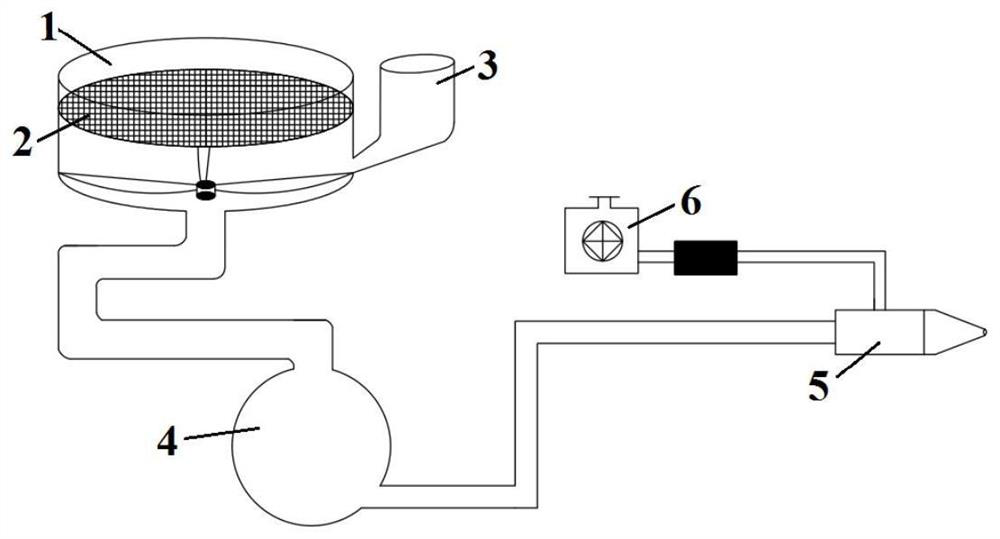

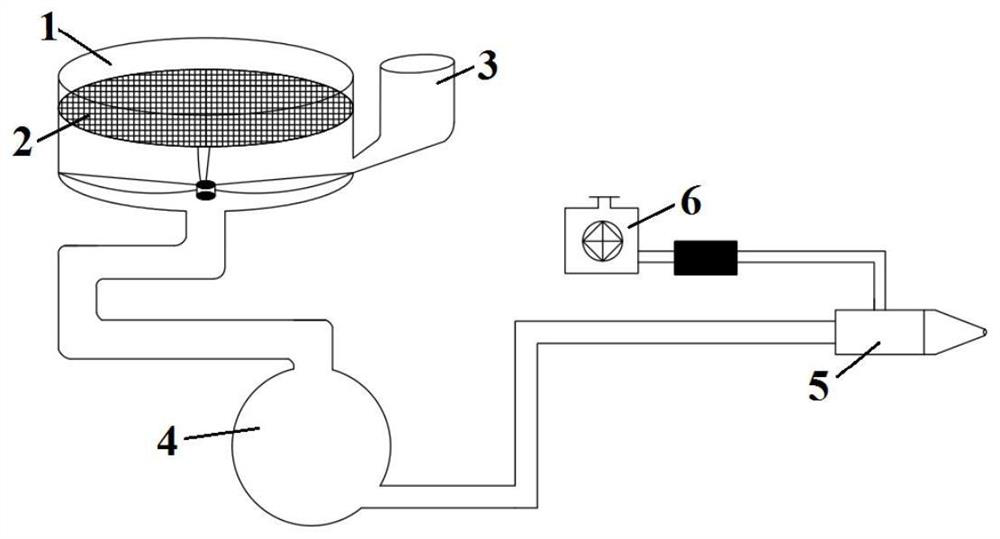

Pile foundation static loading test device

InactiveCN102392463AReduce steel beam sizeSolve the collapseFoundation testingArchitectural engineeringCounterforce

The invention discloses a pile foundation static loading test device. The device is characterized in that an ejector rod is composed of a base section ejector rod and linkage section ejector rods, the base section ejector rod is a cylinder with a base section head cover, and the lower part of the base section ejector rod is provided with a base section flange plate; the linkage section ejector rods are hollow cylinders and the two ends of the linkage section ejector rod are provided with linkage section flange plates, and the base section flange plate and the linkage section flange plates are fixed together through a bolt; the linkage section flange plates of two linkage section ejector rods are fixed together through the bolt, and the base section ejector rod and linkage section ejector rods are sleeved on a pile to be tested; a connecting rod is composed of an outer ring connecting rod and an inner ring connecting rod, one end of the outer ring connecting rod is articulated on the base section ejector rod, and the other end of the outer ring connecting rod is articulated on a soil-bearing base; and one end of the inner ring connecting rod is articulated on the linkage section ejector rods, and the other end of the inner ring connecting rod is articulated on the soil-bearing base. The test device provided by the invention has the advantages that steel beam size of a counterforce device is decreased, the assembling is convenient and rapid, the applicability is larger, the construction operation is more rapid, the waste is not generated in a testing process, thus the device is energy-saving, is environmentally-friendly, and the experimental cost is low.

Owner:ZHEJIANG BAOYE CONSTR GROUP CO LTD

Wall installing method for blast furnace casting house plant

InactiveCN106245808ARealize hoistingAchieve installationWallsBuilding material handlingStructural engineeringErosion

The invention discloses a wall installing method for a blast furnace casting house plant, a wall system can be integrally installed, aloft work is reduced, and installing efficiency is improved. The installing method comprises the steps that (1) an assembling site is determined according to the installing design size of a wall; (2) wall columns are placed in the assembling site, and it is ensured that the wall columns are on the same horizontal plane; (3) wall purlines, wall tension bars and a purline angle brace structure are installed sequentially; (4) after the wall system is installed, wall levelness and the straightness of the wall purlines are uniformly adjusted to ensure that requirements of a drawing and standards are met; (5) after assembly is completed, welding, accepting and supplementary brushing of an erosion resistant coating on welded portions are conducted sequentially; and (6) the assembled wall is hoisted and installed through a hoisting device. The wall installing method for the blast furnace casting house plant is few in aloft work procedure, safe, reliable, high in installing precision, good in welding quality, short in overall installing time, short in project schedule and low in cost.

Owner:CHINA 19TH METALLURGICAL CORP

Novel offshore pile anti-stormy-wave device

A novel offshore pile anti-stormy-wave device comprises a rubber plate body, a plate body internal inflation matched device, a circular thin-walled steel sleeve and a screw. The rubber plate body comprises a rubber upper plate and a rubber lower plate. The lower surface of the circular edge of the rubber upper plate and the upper surface of the circular edge of the rubber lower plate are connectedinto a whole. The rubber plate body air cavity inflation matched device comprises an inflation nozzle, an eight-square screw nut, an air guide pipe, an air valve switch, an air pressure gauge and aninflation air pump. The novel offshore pile anti-stormy-wave device has the advantages that when a pile body generates great displacement and deformation under the action of horizontal loads, the lower surface of the plate body makes contact with silt and a vacuum negative pressure effect is generated, the anti-stormy-wave device has a stabilizing effect for allowing a high-pile marine building toresist horizontal loads, horizontal displacement is reduced, and compared with other methods, construction operation is rapid and construction cost is low.

Owner:HEBEI UNIV OF ENG

Method of Consolidating Clay Subgrade Using Carbon-fixing Bacteria Mineralization

ActiveCN109629360BEasy to operateFast construction operationRoadwaysBuilding constructionsPhysical chemistryCarbonization

The invention discloses a method for mineralizing and reinforcing clay roadbeds by using carbon-fixing bacteria, which comprises the following steps: A. cultivating Streptomyces luteus bacteria to obtain bacterial liquid; B. first pouring quartz sand into the clay constituting the roadbed and stirring , then pour the mixture of Streptomyces luteus bacterial liquid, slaked lime and foamy carbon dioxide into the mixture of clay and quartz sand and fully stir; The method for reinforcing the clay subgrade provided by the invention is more environmentally friendly, more convenient and faster to operate, and has better reinforcing effect.

Owner:WENZHOU UNIV

Novel framework connecting piece

PendingCN113931325AFast construction operationSimple and efficient operationBuilding constructionsPhysicsBending moment

The invention relates to a novel framework connecting piece. The novel framework connecting piece structurally comprises a node connecting piece and connectors used in cooperation with the node connecting piece. One end of a connector is provided with a spherical end part, and the other end of the connector is provided with a connecting part for connecting beams and columns; and the node connecting piece comprises a main body and connector inserting grooves formed in the bottom and the side face of the main body, the spherical ends of the connectors are inserted into the connector inserting grooves in a matched mode, and clamping heads used for clamping the connectors are arranged in the connector inserting grooves. According to the framework connecting piece, on-site construction operation of a framework is faster, operation is easy and convenient, the assembling efficiency of the framework is improved, the framework connecting piece can be suitable for framework structure materials such as steel and wood, and the connecting piece can transmit axial force, shearing force and bending moment at the same time; and the node connecting piece can be designed into a corresponding polygon according to different numbers of framework beams connected with the node connecting piece, and can also be designed into connecting surfaces in different shapes according to different shapes of framework beams and columns connected with the node connecting piece, so that the connecting nodes of the framework are more fit.

Owner:SHANGHAI LANDSCAPE ARCHITECTURE DESIGN INST

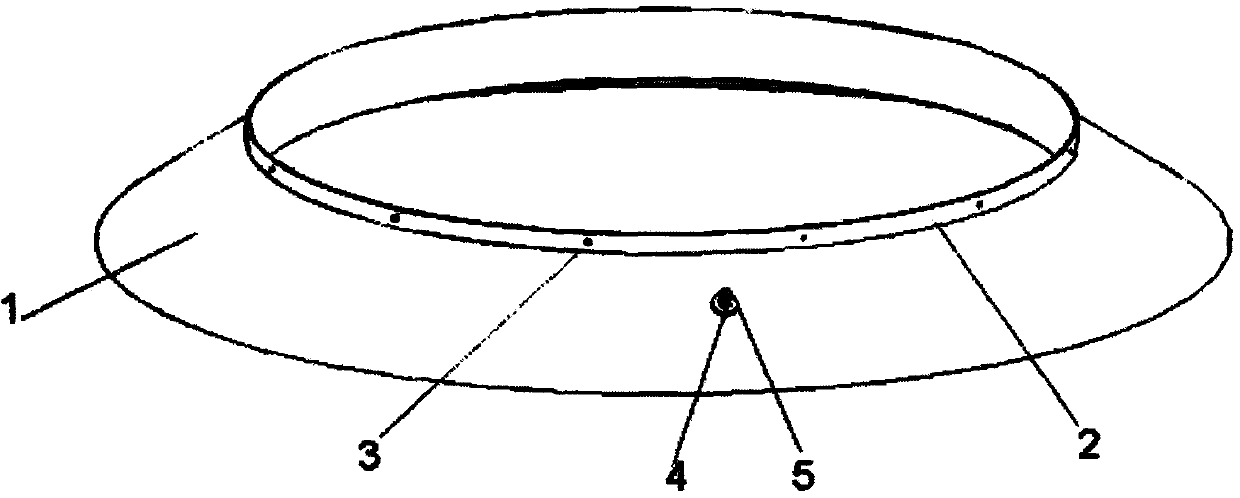

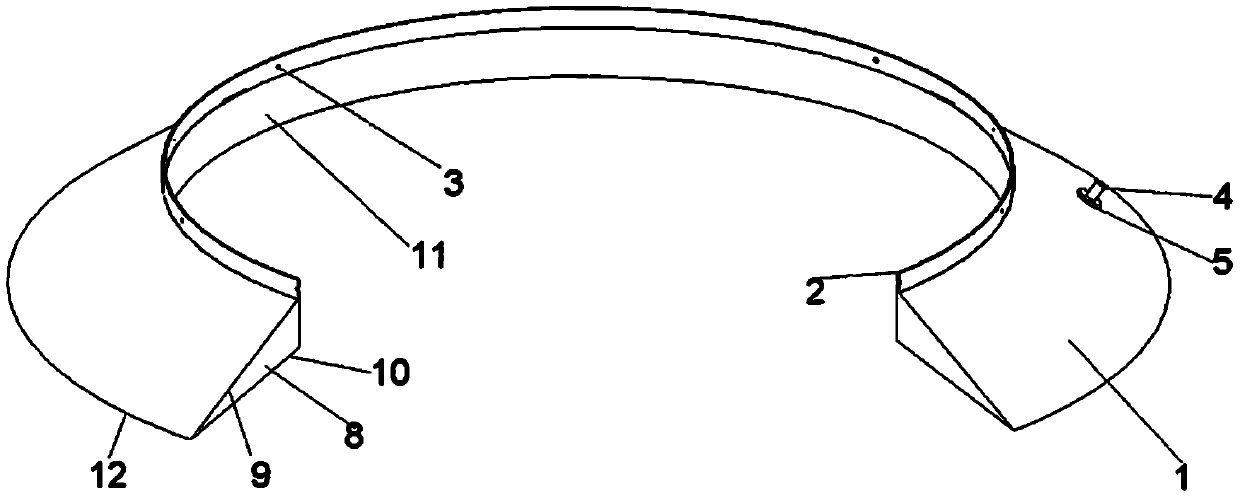

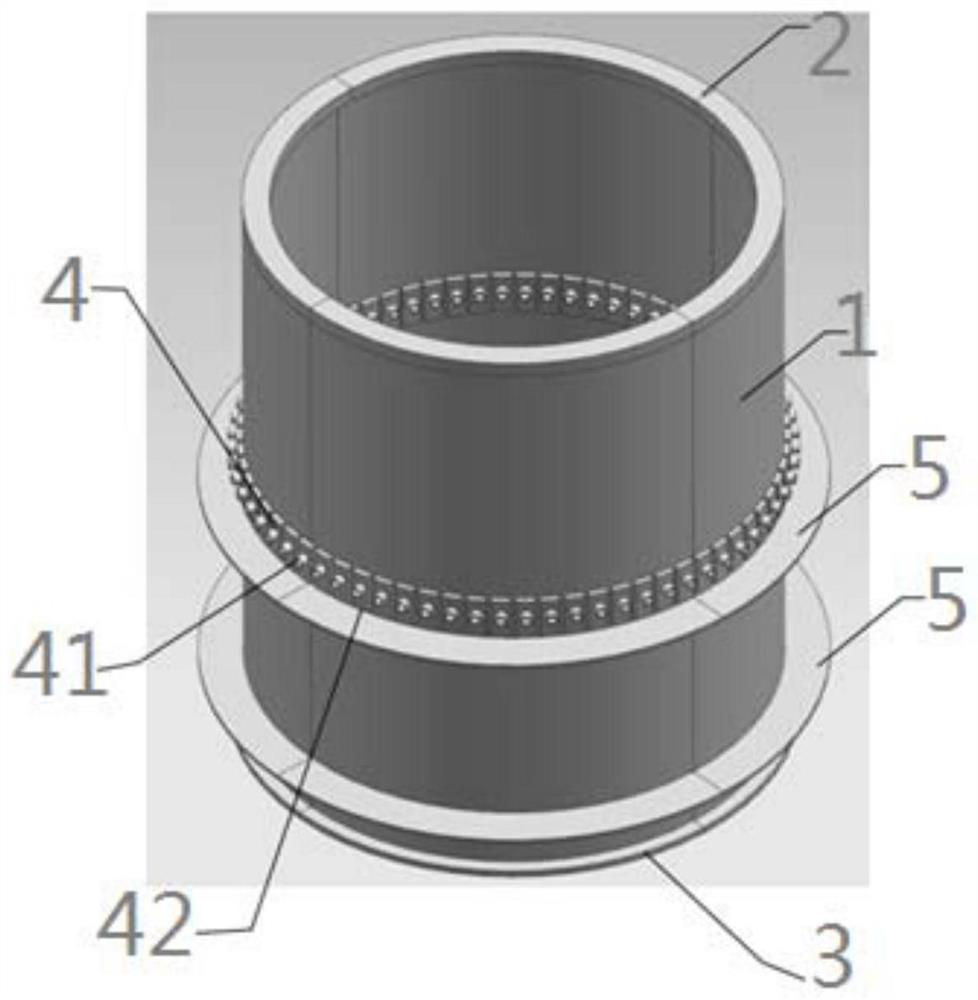

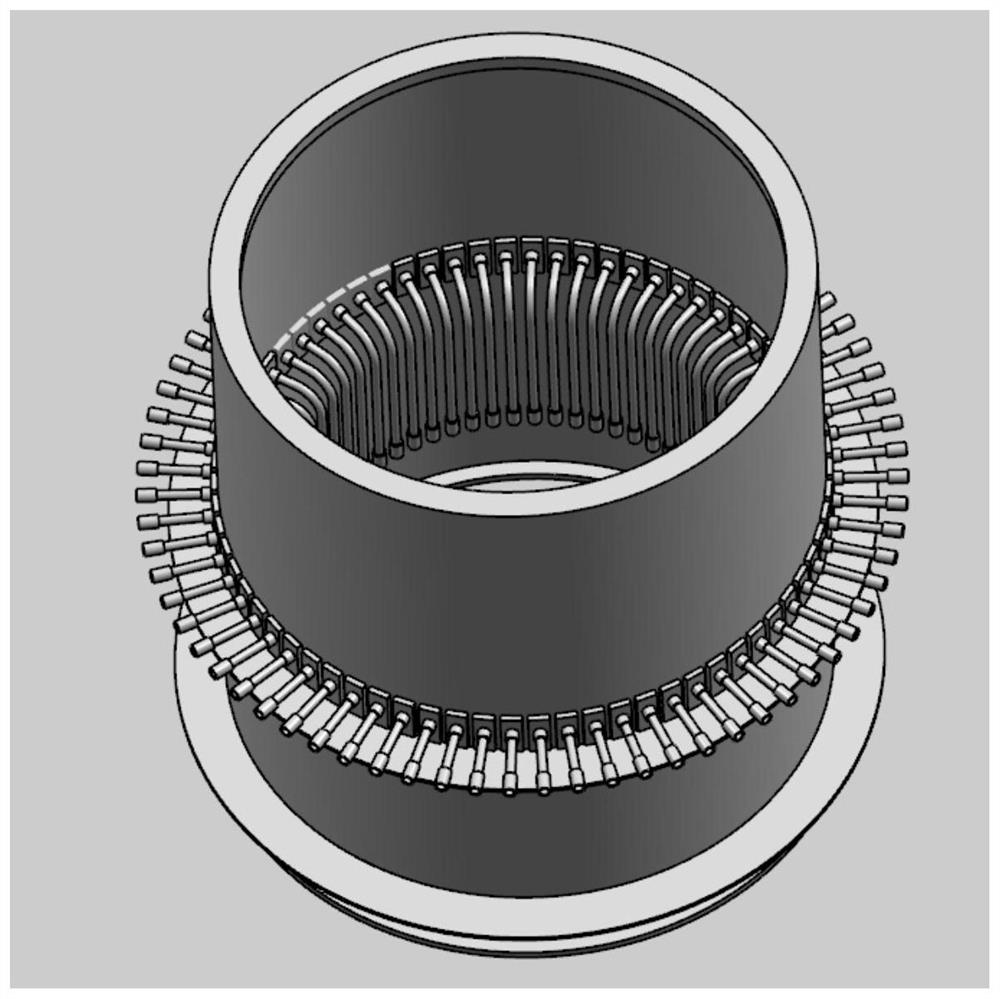

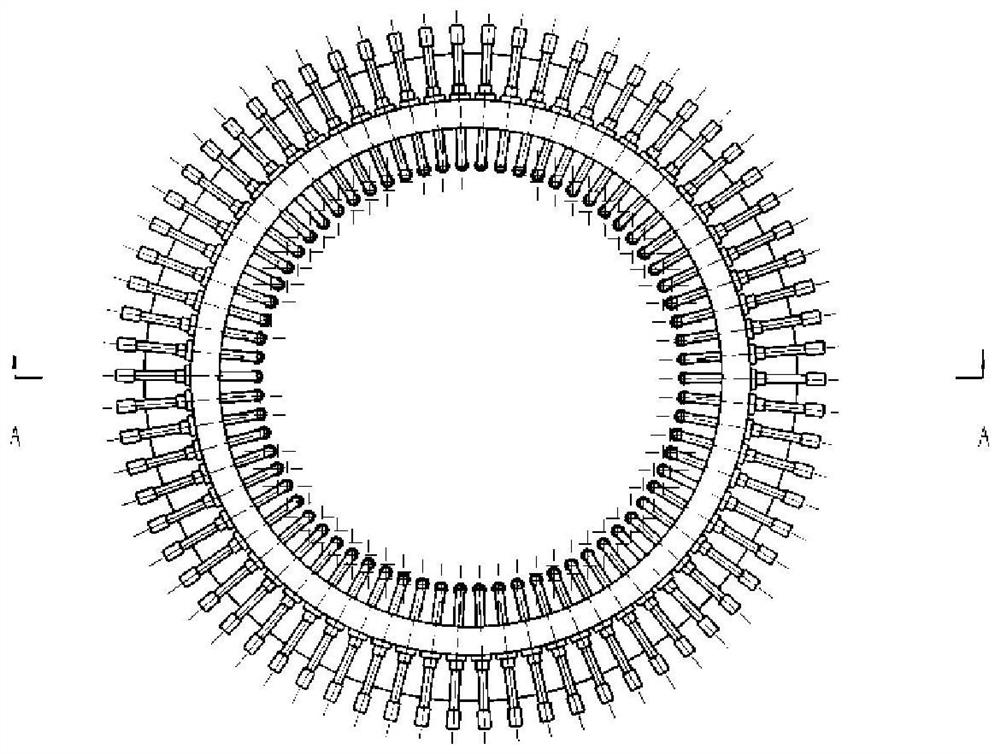

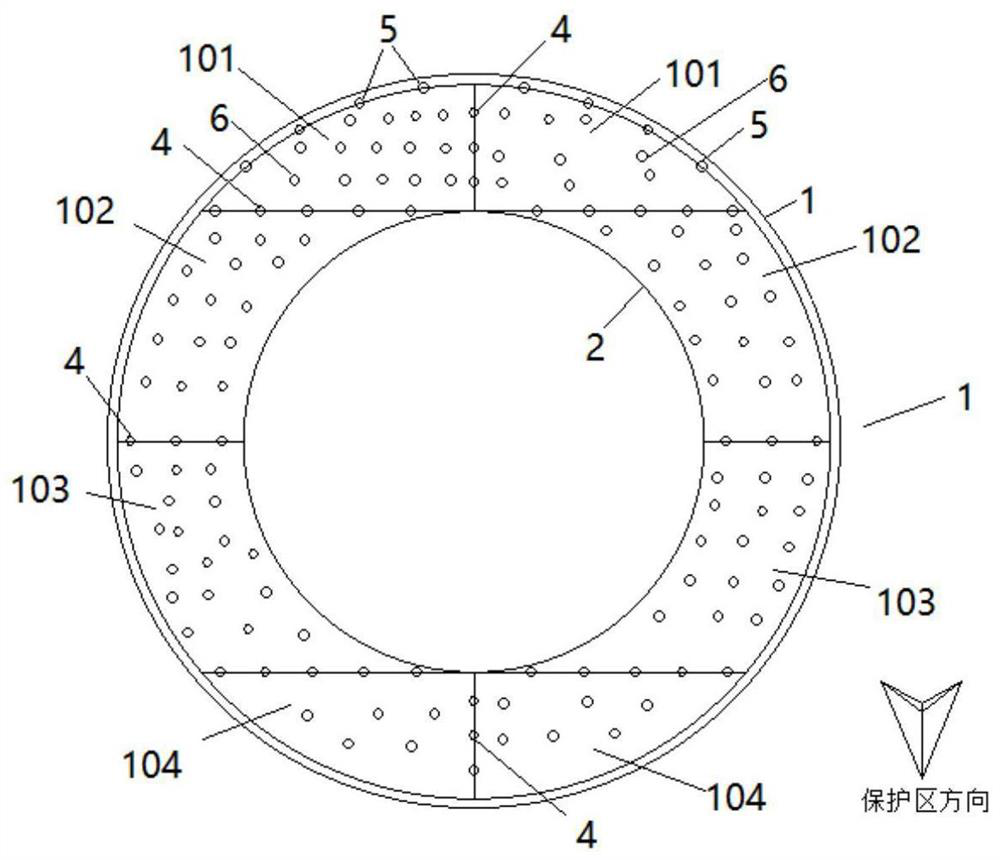

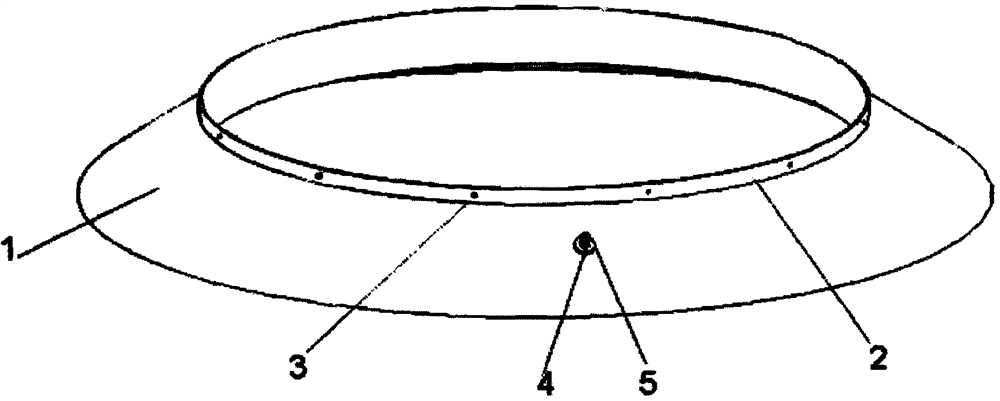

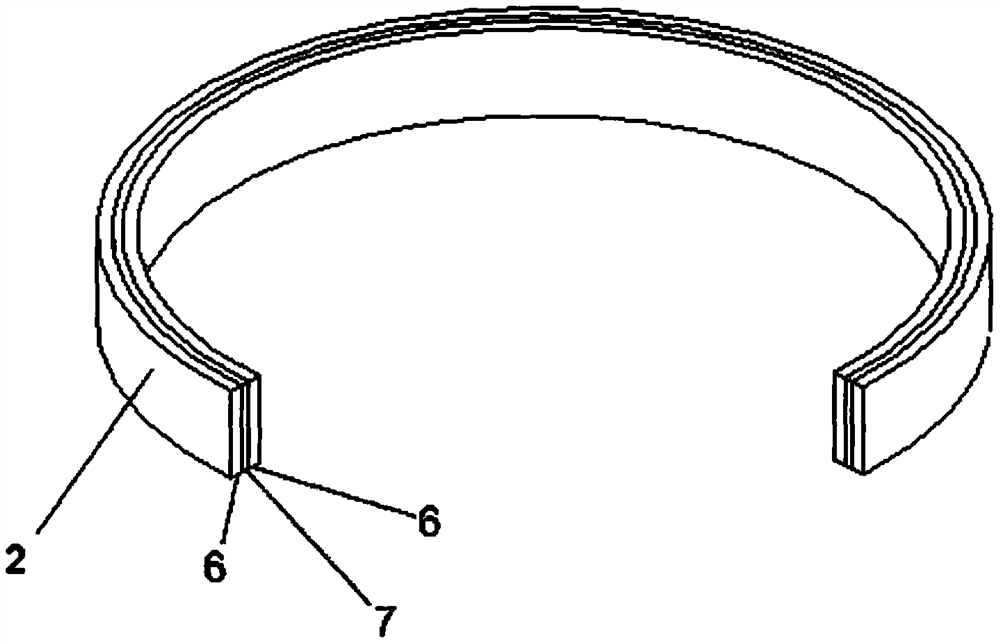

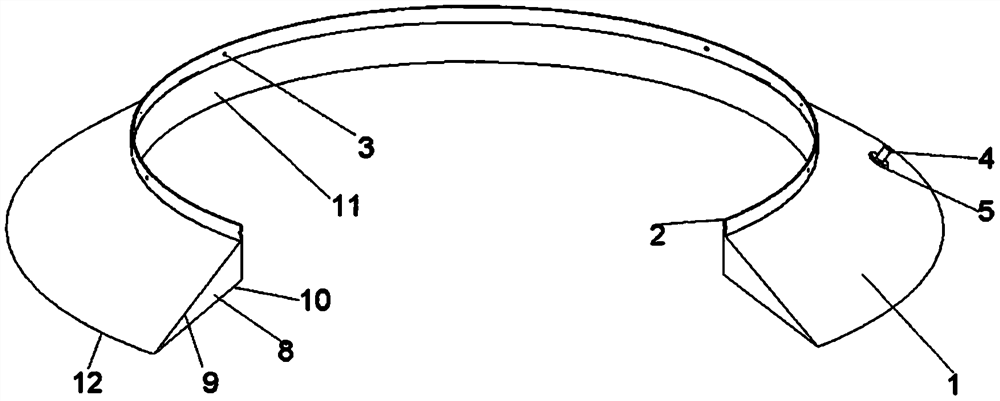

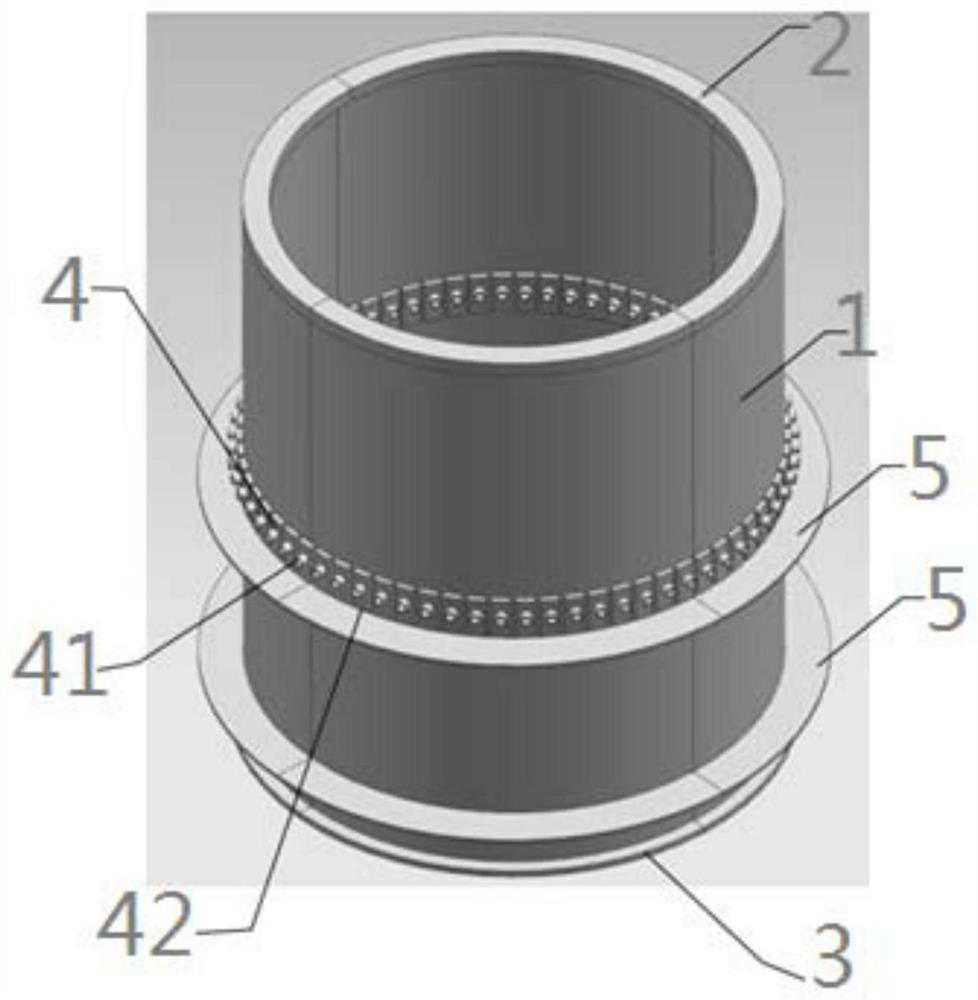

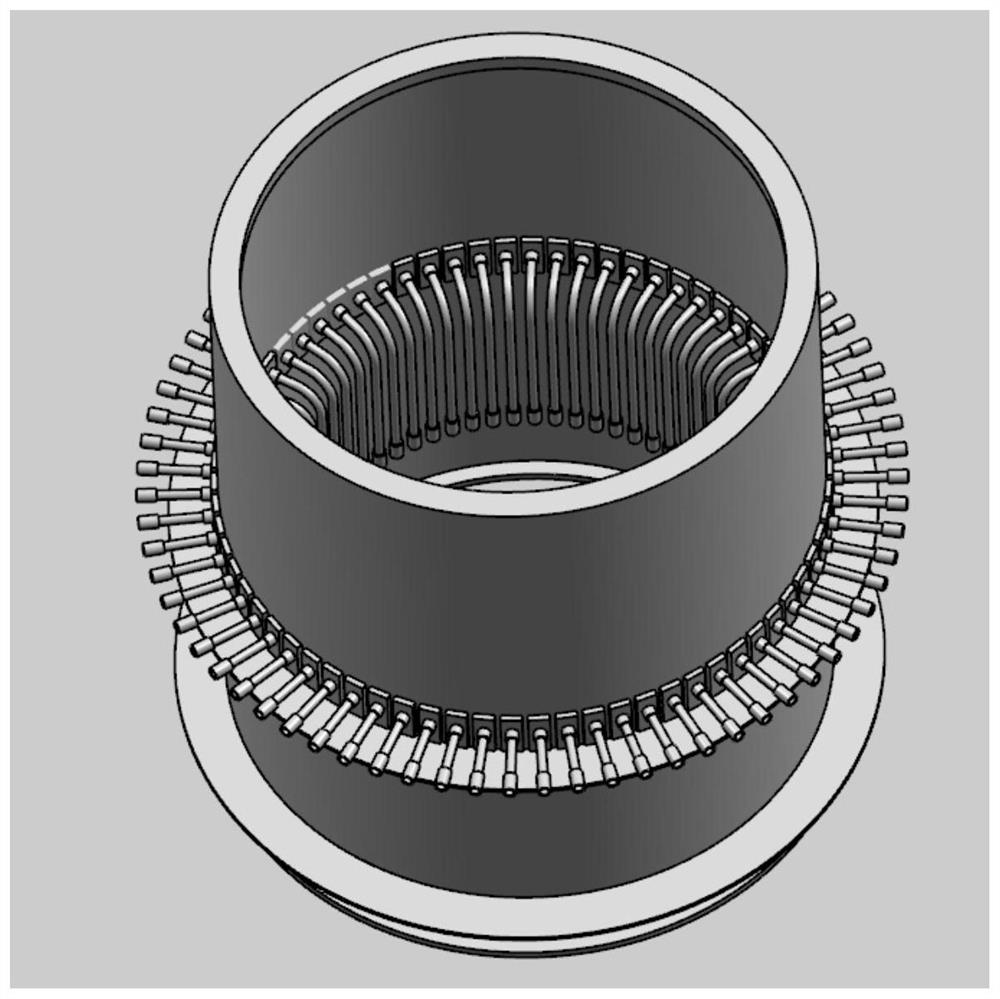

Foundation ring, and processing and construction method thereof

ActiveCN111963383AAvoid opening holes to damage the ring structureWeaken the strength of the ringWind motor supports/mountsFoundation engineeringRebarFlange

The invention discloses a foundation ring and a processing and construction method thereof. The foundation ring is used for connecting a tower tube with a foundation and comprises a ring body, a top flange, a bottom flange and a plurality of steel bar connectors. The upper end of the ring body is fixedly connected with the top flange. The tower tube is fixedly mounted through the top flange. The lower end of the ring body is fixedly connected with the bottom flange. The plurality of steel bar connectors. Are fixed to the wall of the ring body and used for being in screwed connection with and being fixed to steel bars. During foundation pouring, the bottom flange, the ring body connected with the bottom flange, the steel bar connectors on the ring body and the steel bars connected with thesteel bar connectors are buried in concrete and finally integrated with a foundation, connection of the foundation ring and the foundation is realized, and the foundation ring is anchored. Through thefoundation ring provided by the invention, there is no need to form holes in the ring body, so that connection operation between the ring body and the steel bars is easy and efficient, and the foundation ring and the foundation are convenient to repair and maintain.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

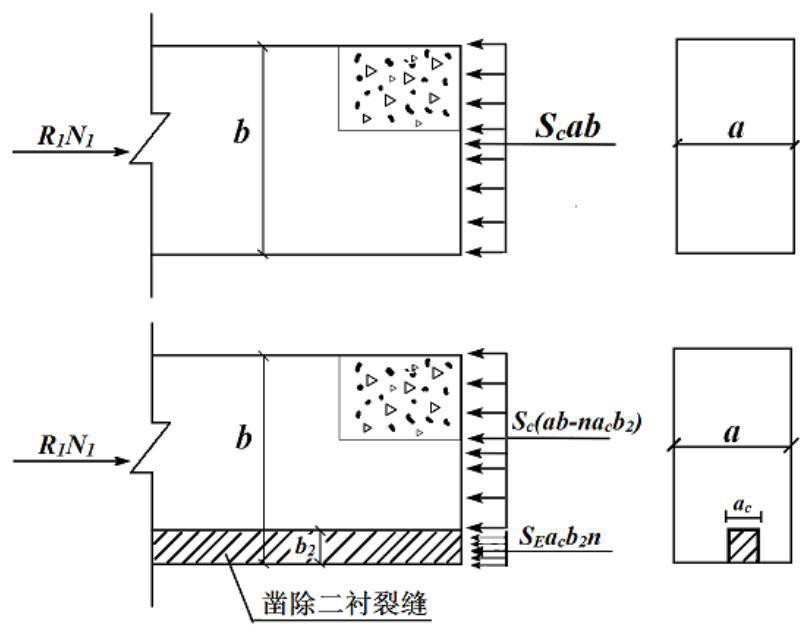

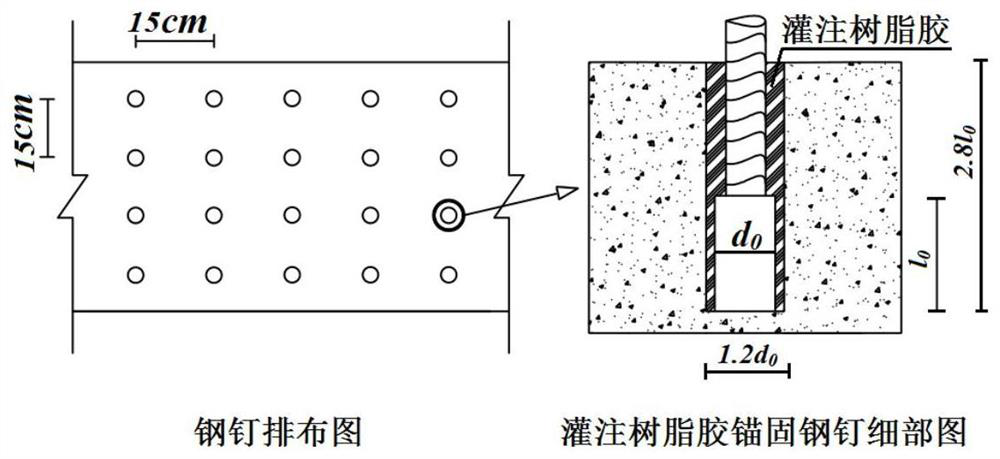

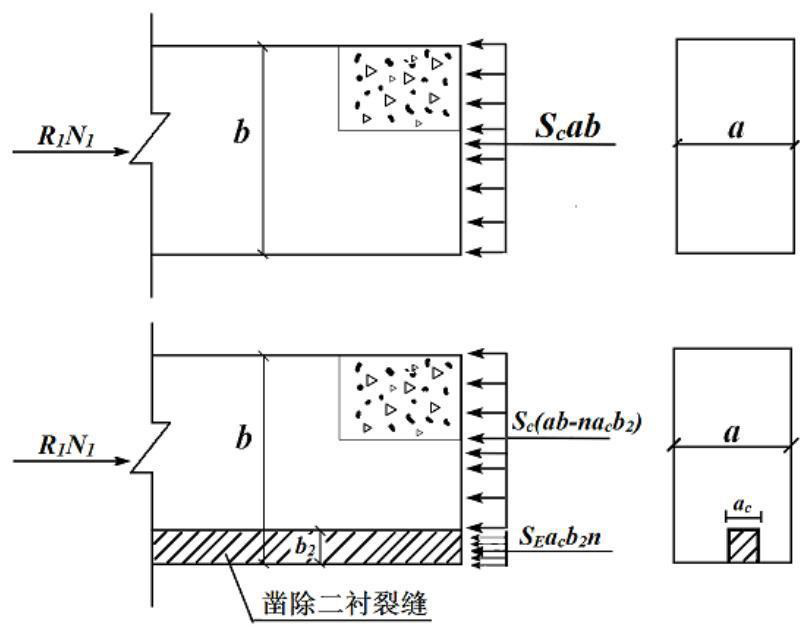

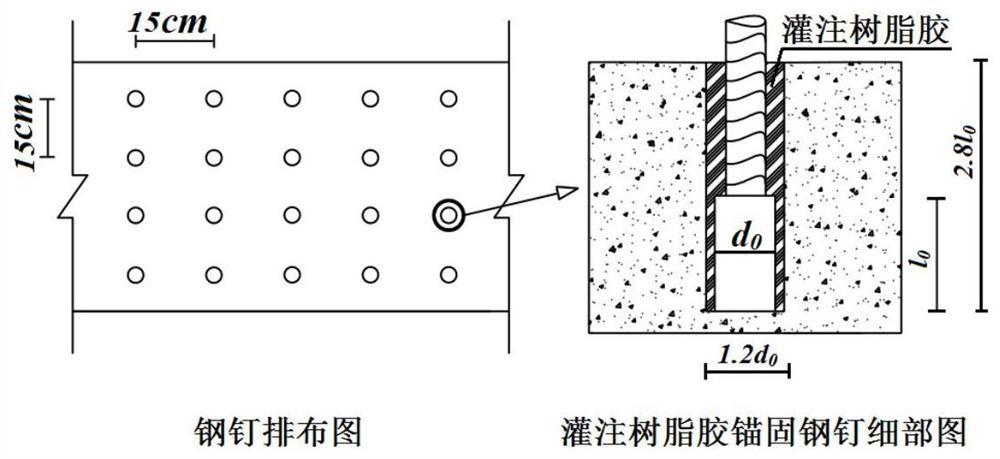

A kind of tunnel cracked secondary lining reinforcement method and device based on sprayed cement-based composite material

ActiveCN112012767BGuaranteed normal operationAvoid the problem of repeated crackingUnderground chambersTunnel liningStructural engineeringCement based composites

The invention discloses a method and a device for reinforcing a cracked secondary lining of a tunnel based on a spray-type cement-based composite material, belonging to the technical field of underground engineering. The present invention carries out the pretreatment of reinforcement technology for the cracked secondary lining of the tunnel and the reinforcement spraying construction for the secondary lining of the cracked tunnel. The treated surface of the secondary lining of the tunnel is subjected to inclined drilling treatment; then, drill holes again on the surface of the secondary lining of the tunnel after chiseling treatment and lay high-strength anchoring steel nails in it; finally, the cement-based composite material is sprayed onto the treated secondary lining of the tunnel. Reinforce the lining surface. The reinforcement method has little disturbance to the original structure, ensures the stability, safety and durability of the structure, reduces the impact on the operation of the tunnel, and ensures the integrity of the tunnel lining. The use of an integrated device for stirring and spraying construction with screening function can improve construction efficiency and ensure that the freshly mixed mixture has good working performance.

Owner:KUNMING UNIV OF SCI & TECH

A modern arched bamboo bridge and its construction method

InactiveCN104594175BStable, reliable and long-lasting supportImprove power transmissionBridge erection/assemblyArch-type bridgeAbutmentUltimate tensile strength

The invention discloses a modern arch type bamboo bridge. The modern arch type bamboo bridge is characterized by comprising bamboo arch ribs, bamboo beams, diagonal bracings, bamboo panels and steel shoes, wherein the bamboo arch ribs, the bamboo beams, the diagonal bracings and the bamboo panels are made of reconsolidated bamboo materials; the steel shoes are made of steel materials. The invention further discloses a construction method of the modern arch type bamboo bridge. The construction method of the modern arch type bamboo bridge is characterized in that the bamboo arch ribs, the bamboo beams, the diagonal bracings, the bamboo panels and the steel shoes are prefabricated, installation of the steel shoes and a bridge abutment skewback is finished, then installation of the bamboo arch ribs and the steel shoes is finished, the bridge abutment skewback is poured, and finally the bamboo beams, the diagonal bracings and the bamboo panels are installed. The construction method of the modern arch type bamboo bridge has the advantages that the manufacturing process is simple, the cost is low, factorization and standardization of structural components are good, the assembly degree is high, the building time is short, the structural intensity is high, rigidity is large, ductility is good, and the seismic performance is good, and the obtained arch type bamboo bridge has the effects of being environmentally friendly and low in carbon.

Owner:CHONGQING JIAOTONG UNIVERSITY

Multifunctional furring brick

InactiveCN101294440BWith building energy efficiencyWaterproofFireproof paintsCovering/liningsPolyesterVegetable oil

The invention discloses a multifunctional furring brick which consists of a finishing coat, a multifunctional layer, and a bonding layer. The multifunctional layer is manufactured and molded at a time with multifunctional liquid and foaming equipment. The finishing coat and the bonding layer are manufactured on the upper face and the lower face of the multifunctional layer respectively. The multifunctional liquid adopts polyfunctionality polyether glycol, polyester polyol prepolymer, vegetable oil polyhydric alcohol and hydramine as initiators, and polyether glycol, a fire retardant, a foam uniformizing agent, a foaming agent, postassium acetate, triethylenediamine, acetal mixture, a delaying catalyst, an ultraviolet absorbent and isocyanate as raw materials. The finishing coat can be an ordinary finishing coat, a fashionable finishing coat, a luxurious finishing coat or a fireproof finishing coat as required. The multifunctional furring brick has the characteristics of energy conservation, water resistance, decoration and portability. Wet land construction with the multifunctional furring brick can be carried out as the construction with ceramic mosaic and porcelain facing bricks, and the multifunctional furring brick can also be cast with concrete in a molding board. In addition, the multifunctional furring brick can also be bonded with an adhesive. The process is simple andoperation is quick. The multifunctional furring brick integrates a plurality of functions, such as decoration, thermal insulation, water resistance and imperviousness, antisepsis, sound insulation, light weight, hardness and so on.

Owner:刘建永

Pre-splitting Blasting Method of Negative Excavation Ring Corridor in Nuclear Island

ActiveCN101368812BFast construction operationQuality Construction OperationsBlastingEngineeringPre cracking

The invention relates to a pre-splitting blasting method for a nuclear island negative excavation ring gallery, and belongs to the technical field of earthwork construction methods. The steps of the method are: digging down at the selected location according to the elevation of the center of the nuclear island, and reserving a reserved layer; drilling holes at equal intervals along the inner and outer circumferences of the ring corridor; installing flexible materials at the bottom of the holes as a buffer Cushion layer; in the hole where the cushion layer is installed and the hole is left with a blockage depth, the charge is divided into three sections, the bottom is the reinforced charge section, the top is the weakened charge section, and the middle is the normal charge section; after the explosive is loaded , the orifice plugging depth is filled with conventional materials; detonation forms cracks along the inner and outer circumferences of the ring corridor. The invention can form ideal inner and outer circumferential cracks in the ring corridor at the predetermined position of the rock foundation, and then can carry out the main explosion for the purpose of removing the rock in the ring corridor. Therefore, the construction operation of the negative excavation ring corridor of the nuclear island can be completed quickly and with high quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

A support method and device for preventing mudstone landslides

The invention discloses a support method and device for preventing mud rock landslides. A design excavation line is set at the position away from a slope top building outer wall by 2 M or above; during construction, excavation is conducted according to the sloping slope ratio required by the design from top to bottom, excavation is paused every time when excavation is downwards conducted by 1.5 m, temporary anchor rod support is conducted on the layer, and a drainage pipe is driven into a slope body to conduct drainage treatment; downward excavation is conducted while support and drainage are conducted layer by layer till the slope bottom is reached; a foundation trench is dug in the slope bottom, the outer wall of the foundation trench is a concrete pouring body, the foundation trench is filled with mud rock materials obtained after excavation to be compacted; then, a concrete cavity is constructed above the foundation trench in a layering pouring manner, and the cavity is filled with the mud rock materials to be compacted till the slope top is reached; and finally, anchor rods, the drainage pipes and the outer side of the concrete cavity are fixed. According to the support method and device, the structure is simple, the cost is low, little waste slag exists, the safety performance is high, and construction and operation are fast.

Owner:贵州建工第八建设集团有限公司

Tunnel crack secondary lining reinforcing method and device based on jet type cement-based composite material

ActiveCN112012767AGuaranteed normal operationAvoid the problem of repeated crackingUnderground chambersTunnel liningStructural engineeringCement based composites

The invention discloses a tunnel crack secondary lining reinforcing method and device based on a jet type cement-based composite material, and belongs to the technical field of underground engineering. According to the method, reinforcement technology pretreatment for a cracked tunnel secondary lining and reinforcement spraying construction for the cracked tunnel secondary lining are conducted, and specifically, concrete on the surface of the cracked tunnel secondary lining is chiseled away in a segmented mode; inclined drilling treatment is conducted on the surface of the tunnel secondary lining which is obtained after chiseling treatment is accomplished; drilling is conducted on the surface of the tunnel secondary lining subjected to chiseling treatment again, and high-strength anchoringsteel nails are laid in holes; and finally, the cement-based composite material is sprayed to the surface of the treated tunnel secondary lining to conduct reinforcement. According to the reinforcingmethod, the disturbance to an original structure is small, the stability, the safety and the durability of the structure are guaranteed, the influence on tunnel operation is reduced, and the integrity of the tunnel lining is guaranteed. A stirring and spraying construction integration device with a screening function is adopted, and therefore the construction efficiency can be improved, and the situation that a newly-mixed mixture has the good working performance is guaranteed.

Owner:KUNMING UNIV OF SCI & TECH

Method for bridge maintenance vehicle and maintenance platform avoiding bridge piers

ActiveCN110820555BAvoid damageEasy to operateBridge structural detailsArchitectural engineeringUncrewed vehicle

The invention provides a bridge maintenance vehicle and a method for avoiding a bridge pier by a maintenance platform, and belongs to the field of bridge detection and maintenance construction. Cantilever hoisting devices (5) are arranged at a plurality of points on the two sides of a bridge floor, wherein a guide rope (3) connected with the maintenance platform (1) is pulled by an unmanned aerialvehicle (4) to transversely penetrate through the lower part of the bottom face of a bridge; hoisting ropes (2) are pulled to the cantilever hoisting devices (5); the operation of avoiding the bridgepier is achieved through the cooperative operation mode that a plurality of hoisting ropes (2) are pulled and rotated to be positioned on the maintenance platform (1) on the bottom face of the bridge; the movement of the maintenance platform (1) can be monitored by the unmanned aerial vehicle (4); the operation is visual and convenient, the multiple devices are cooperatively operated; the construction efficiency is high; the auxiliary time is short; the construction time for avoiding the bridge pier can be greatly shortened; the number of constructors is small; and the construction cost is reduced. The method is particularly suitable for conducting bridge pier avoiding construction operation on the bridge maintenance vehicle and the maintenance platform on the bridge with the large bridgefloor height, the large bridge bottom slope, the severe river channel condition, the poor bridge bottom construction environment and the poor condition.

Owner:陈雨羲

Negative excavation blasting structure and method for nuclear island corridor foundation pit

ActiveCN114018112AFast construction operationQuality Construction OperationsBlastingArchitectural engineeringStructural engineering

Owner:CHINA NUCLEAR IND 22ND CONSTR

An anti-wind and wave device for offshore piles

ActiveCN110820736BLow costPlay a stabilizing roleBulkheads/pilesMarine architectureMarine engineering

Owner:HEBEI UNIV OF ENG

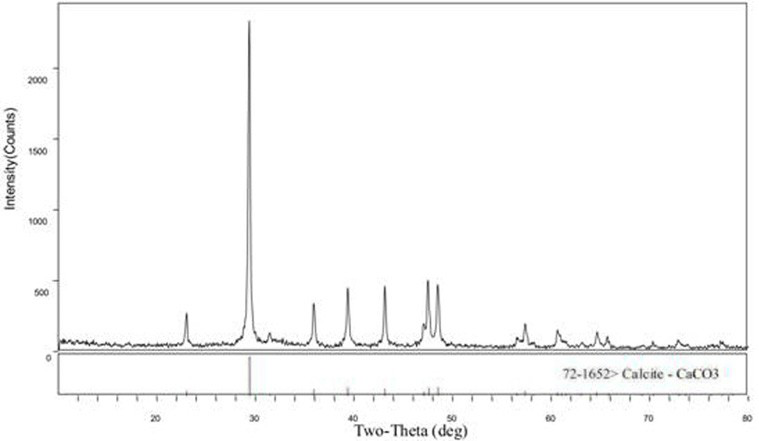

High-content fly ash-based secant pile building method for water blocking curtain

InactiveCN111778968ASimple processEasy to operateMeasurement devicesBulkheads/pilesStructural engineeringSlurry

The invention discloses a high-content fly ash-based secant pile building method for a water blocking curtain. Secant pile construction is performed by the aid of a rotary drilling rig, secant piles are held by each other and enter a waterproof clay layer or a mudstone layer, high-content fly ash-based grouting materials are poured into the secant piles, I-beams are inserted intermittently, and acontinuous secant pile wall used as the anti-seepage water blocking curtain is formed. According to the method, the problems of low secant pile hole forming speed, tedious and complex pouring procedures, slurry sedimentation, high concrete pouring cost and high construction site requirements can be solved effectively, and the continuity and the anti-seepage performance of the water blocking curtain can be improved while the problems of low construction efficiency, high cost, large construction site and the like can be solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Hook-or-buckle fine assembled combined vertex angle line

InactiveCN105089252AGuaranteed assembly accuracyAssembly precisionBuilding constructionsEngineeringStructural engineering

The invention discloses a hook-or-buckle fine assembled combined vertex angle line, and belongs to the technical field of decorative building materials. The vertex angle line comprises an assembling support and angular lines, the assembling support comprises a general assembling support body in the horizontal direction, the inner side of the general assembling support body is directly or indirectly fixed on the vertical wall face, the upper end of the general assembling support body is fixed on the indoor top, multiple opened special-shaped assembly tubes are arranged on the surface, facing the interior, of the general assembling support body, tube-shaped assembly stripes with handles are arranged to be matched with the opened special-shaped assembly tubes, hooks or buckles are arranged on the handles of the tube-shaped assembly stripes with the handles, and partial or all angular lines are assembled on the tube-shaped assembly stripes with the handles through the corresponding hooks or buckles. According to the hook-or-buckle fine assembled combined vertex angle line, the assembling precision is higher, and the construction operation is easier, more convenient and faster.

Owner:宋明群

A foundation ring and its processing and construction method

ActiveCN111963383BReduce intensityReduce stress concentrationWind motor supports/mountsFoundation engineeringArchitectural engineeringRebar

The invention discloses a basic ring and its processing and construction methods. The foundation ring is used to connect the tower and the foundation, and includes a ring body, a top flange, a bottom flange, and several steel bar connectors. The upper end of the ring body is fixedly connected to the top flange, and the tower is fixedly installed through the top flange; the lower end of the ring body is fixedly connected to the bottom flange, and a number of steel bar connectors are fixed on the ring body wall of the ring body for connecting with the Reinforcement screw connection is fixed. During the foundation pouring process, the bottom flange, the ring body connected to the bottom flange, the steel bar connector on the ring body, and the steel bars connected by the steel bar connector are buried in the concrete, and finally become a whole with the foundation, realizing the foundation Connection of the ring to the foundation, anchoring the foundation ring. The foundation ring provided by the invention avoids the opening of the ring body, makes the connection operation between the ring body and the steel bar simple and efficient, and facilitates the repair and maintenance of the foundation ring and the foundation.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Construction joints and construction methods of concrete structures with large height difference and variable cross-section

ActiveCN103628575BEasy to set upSolve the relative slip problemBuilding constructionsMarine site engineeringEngineeringSubstructure

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com