L-shaped supporting frame for mounting bridge anticollision guardrail formwork

An anti-collision guardrail and installation technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of formwork deformation and installation deviation, formwork self-heavy, single connection form, etc., to achieve fast fixing, fast construction operation, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

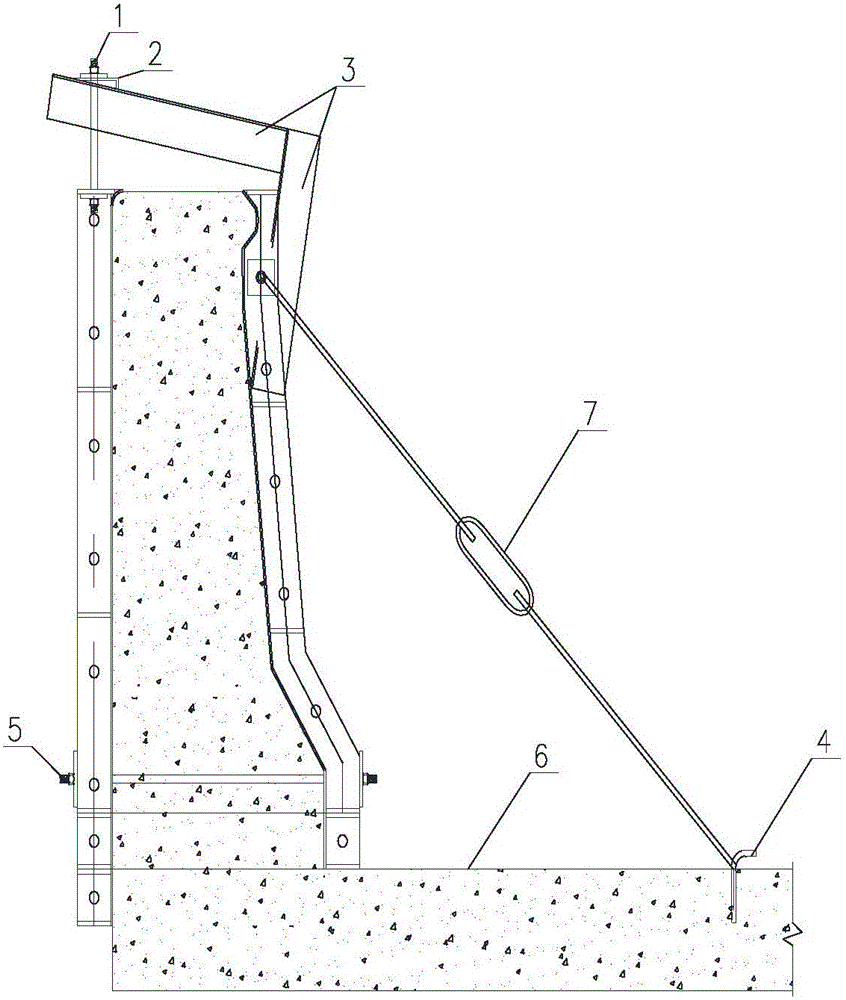

[0012] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

[0013] The "L"-shaped support frame used for the installation of the bridge anti-collision guardrail formwork includes two T-beam flange plates 6, the two T-beam flange plates 6 are perpendicular to each other, one is placed horizontally, and the other is placed vertically;

[0014] The top of the vertically placed T beam flange plate 6 is provided with 10# equilateral angle steel 3, and one end of 10# equilateral angle steel 3 is welded on one side of the vertically placed T beam flange plate 6, and 10# equilateral angle steel 3 The other end is fixed on the top of the vertically placed T beam flange plate 6 by an upper screw mandrel 1, and the upper screw mandrel 1 can be adjusted up and down; an angle steel welding leveling device 2 is arranged between the upper screw mandrel 1 and 10# equilateral angle steel 3 ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com