Patents

Literature

479 results about "T-beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

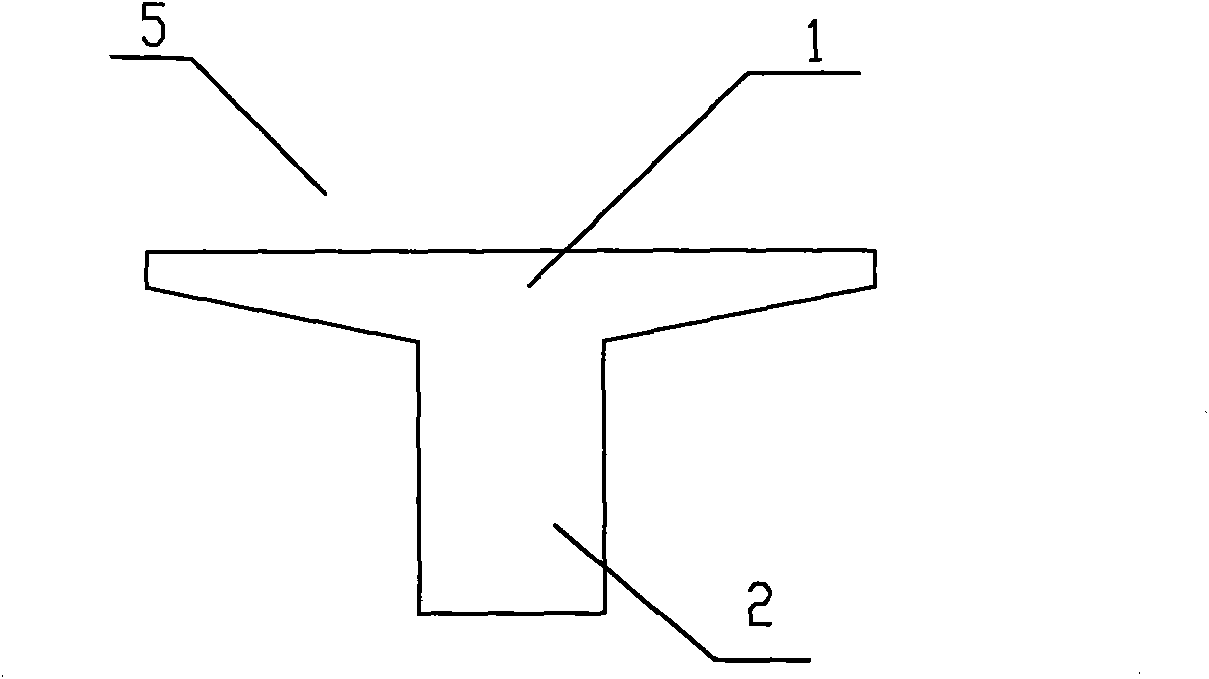

A T-beam (or tee beam), used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a t-shaped cross section. The top of the t-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web (vertical section) of the beam below the compression flange serves to resist shear stress and to provide greater separation for the coupled forces of bending.

Method for mounting box arch bridge

ActiveCN101519864ASimplified installation procedureReduce engineering costsBridge erection/assemblyArch-type bridgeT-beamAbutment

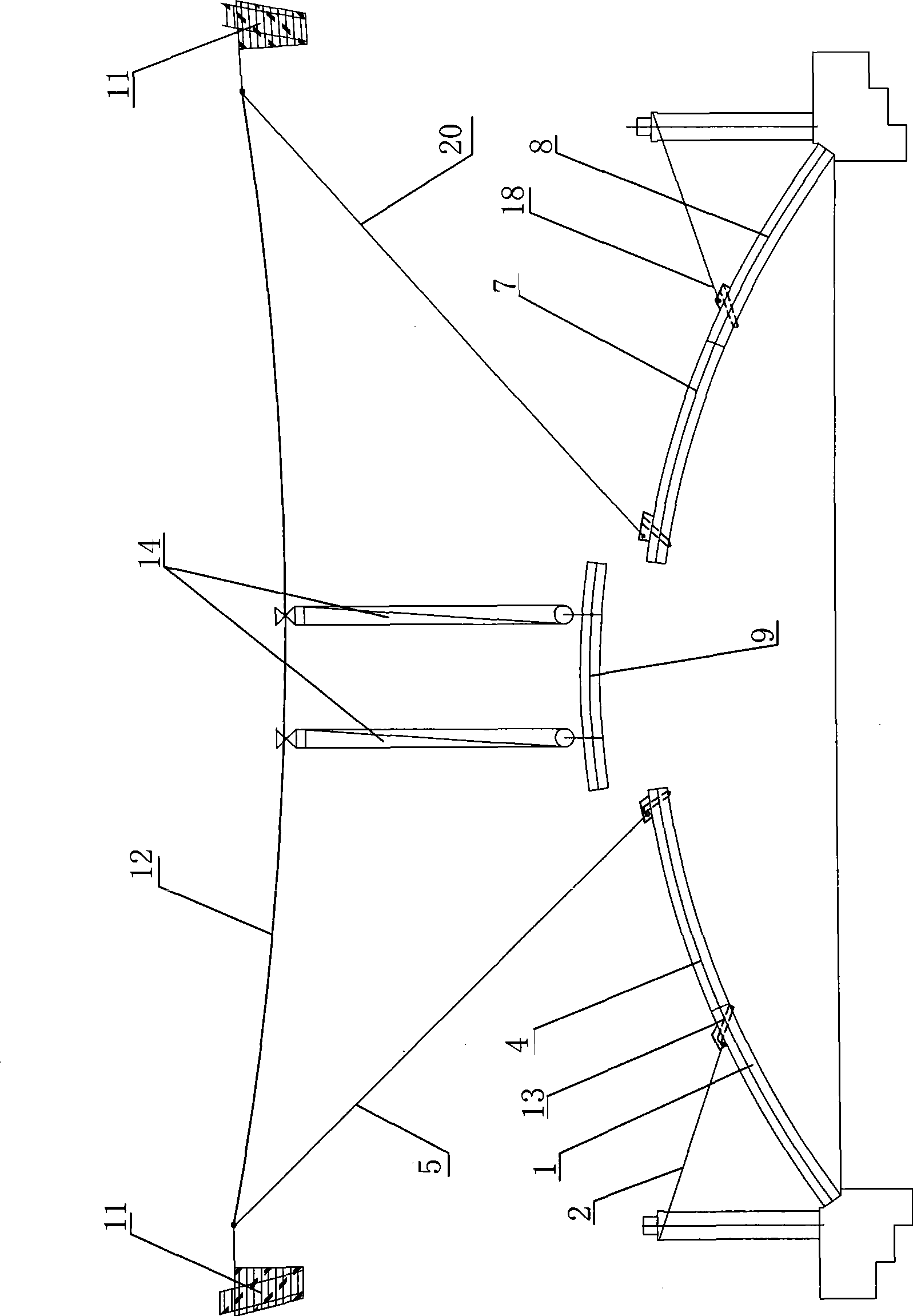

The invention discloses a method for mounting a box arch bridge. The method comprises the following steps: (1) excavating earth and stone work of a main arch abutment, and mounting a cable system; (2) pouring concrete of the main arch abutment and haunch; (3) hoisting the haunch; (4) mounting a bent on the arch; (5) mounting a T beam; and (6) constructing a bridge floor system. In haunch hoisting, after a first arch rib is mounted, a knotted rope used for stabilizing the haunch is detached, and the knotted rope is used for mounting a second haunch, and the like, so that all haunches can be mounted by the first knotted rope. The method simplifies mounting program of the box arch bridge, and greatly saves construction cost.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

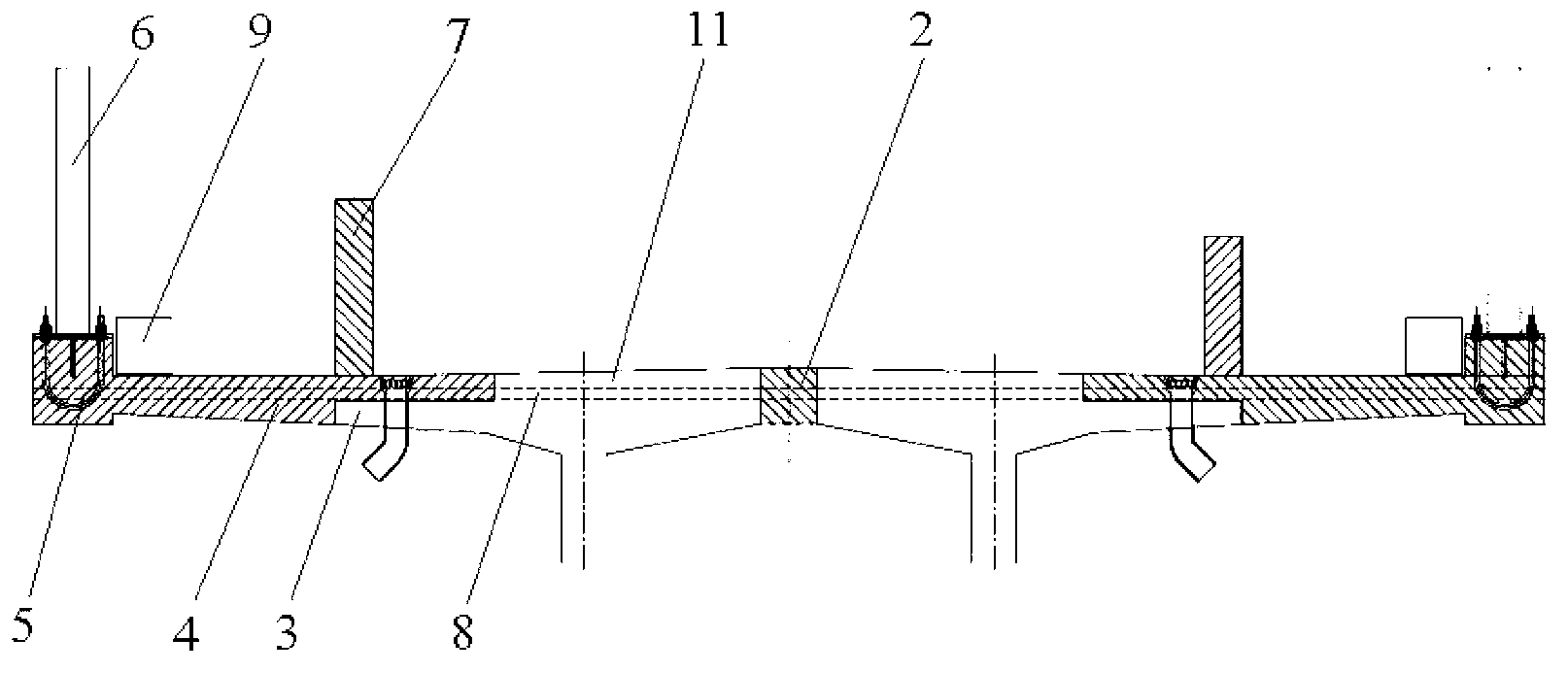

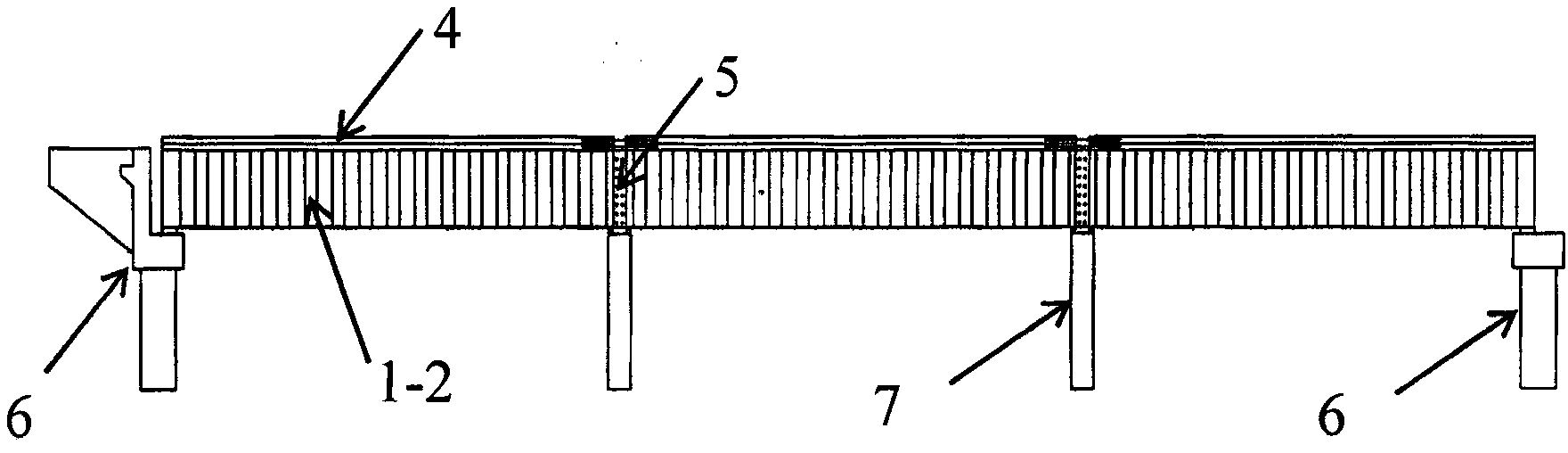

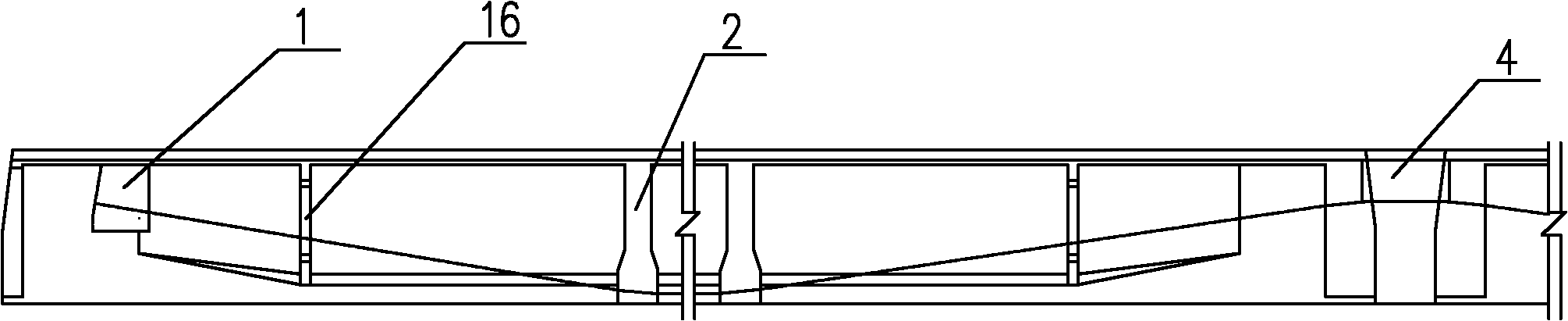

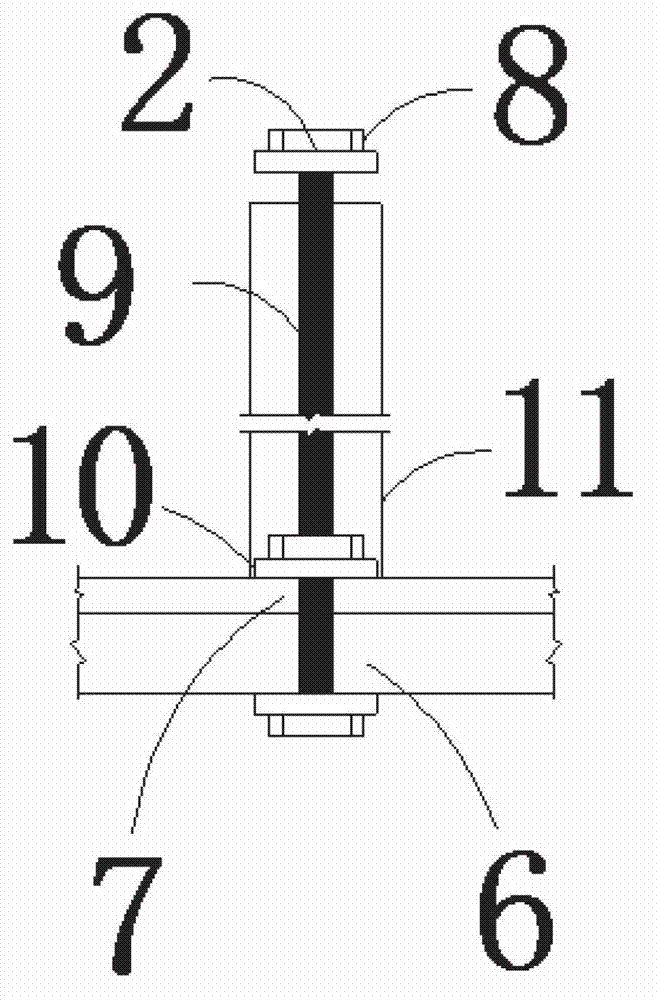

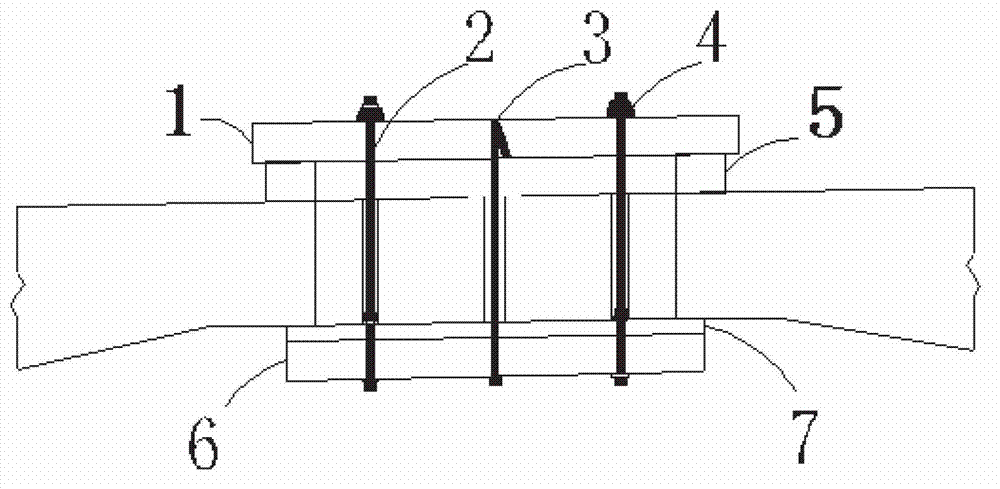

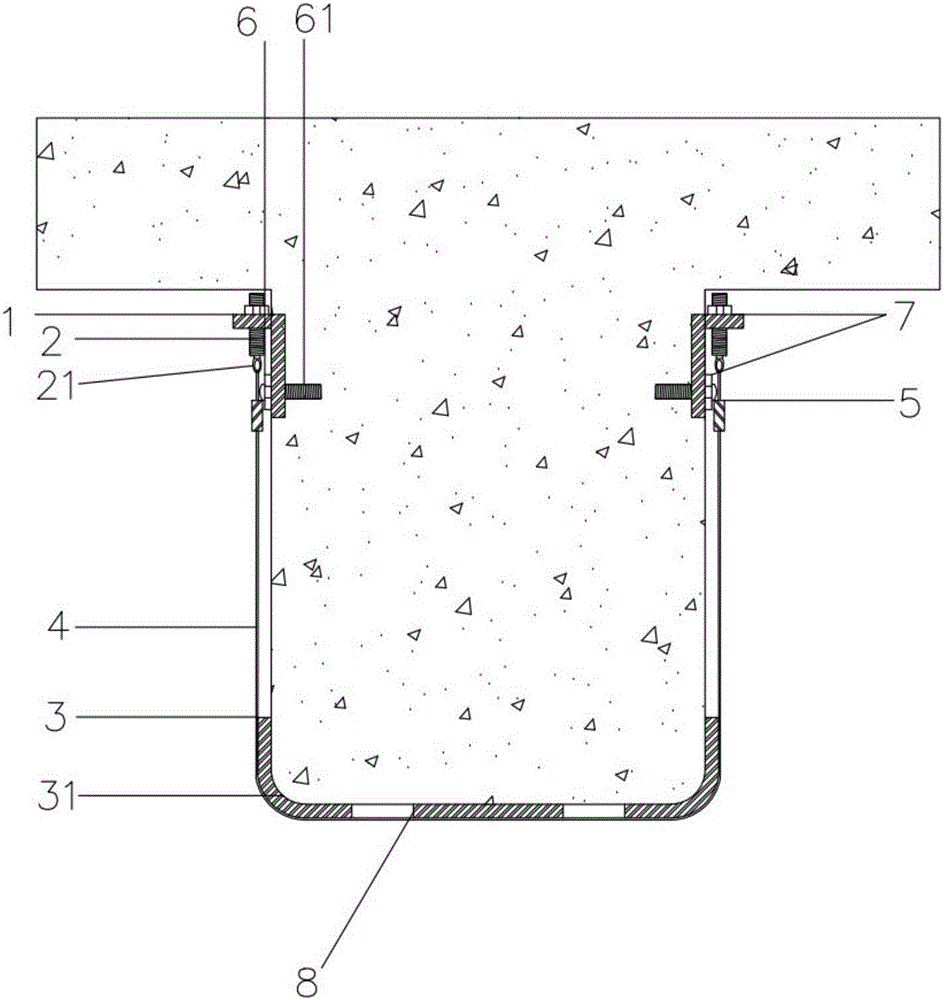

Self-balancing external prestressing strengthening method for bridge structure

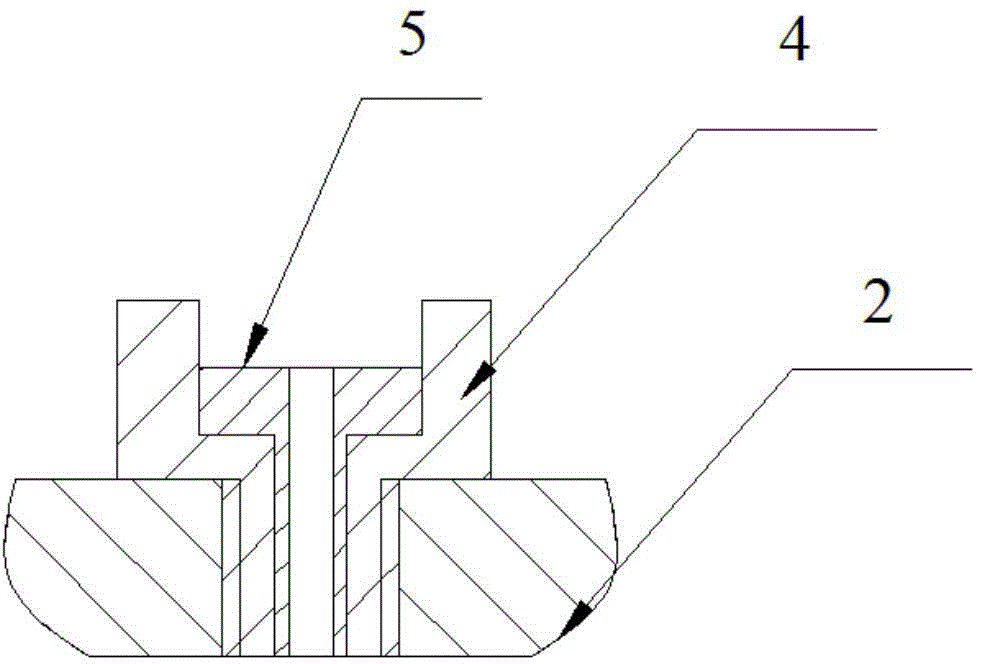

ActiveCN102587296AReduce the burden onGive full play to the role of reinforcementBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

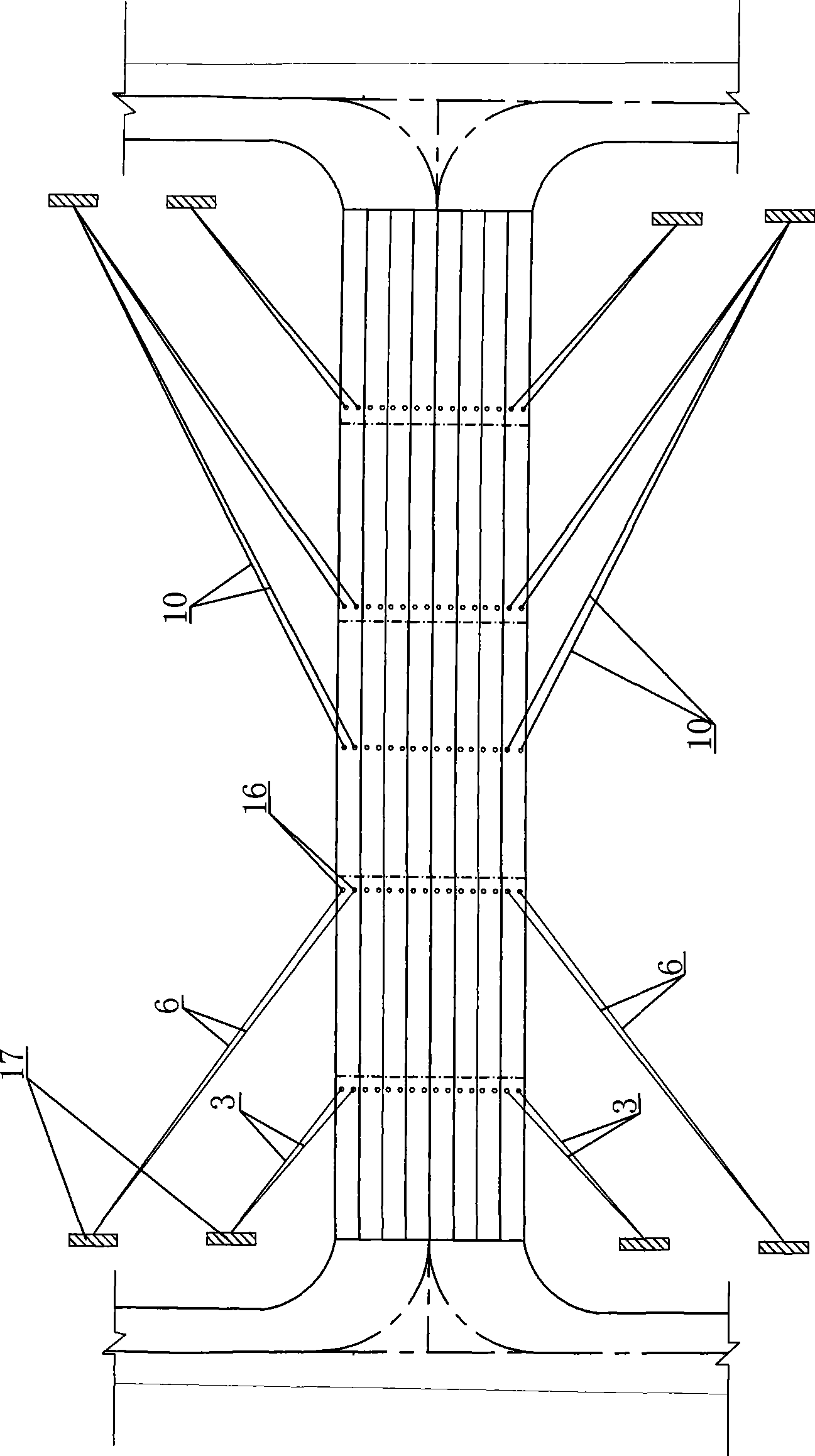

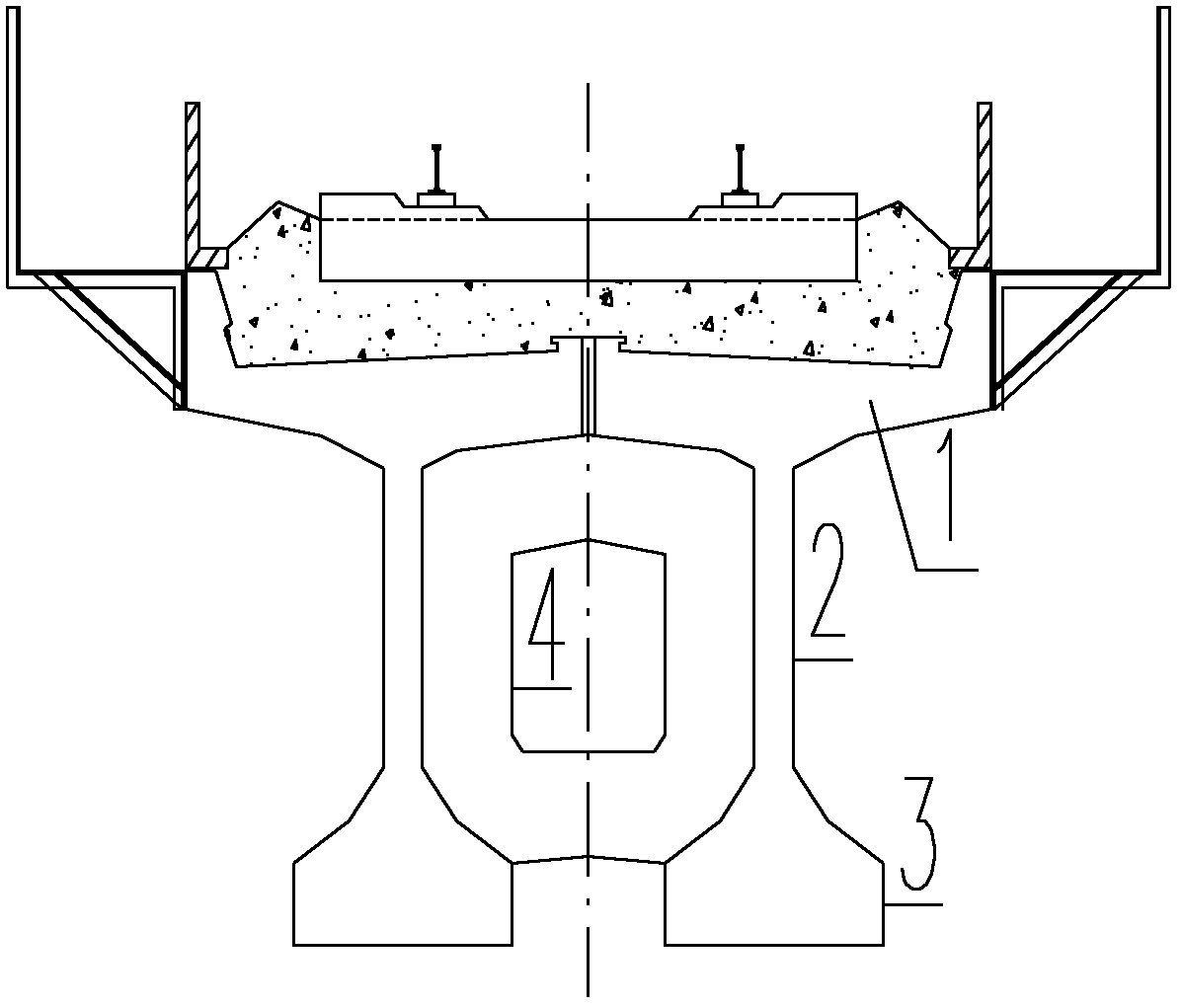

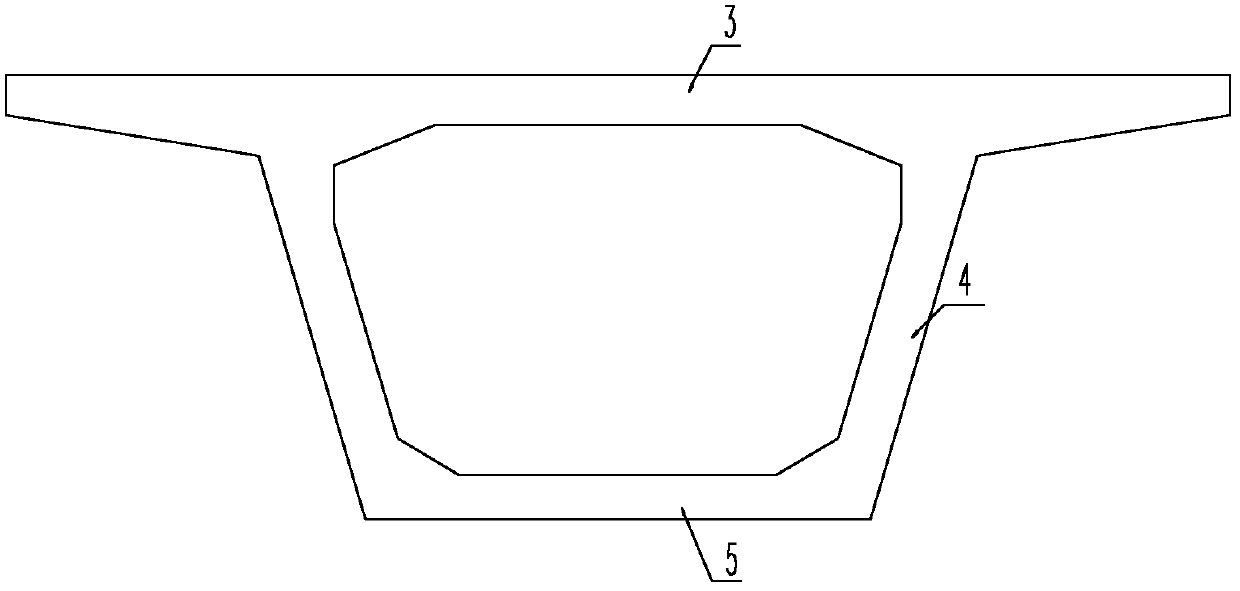

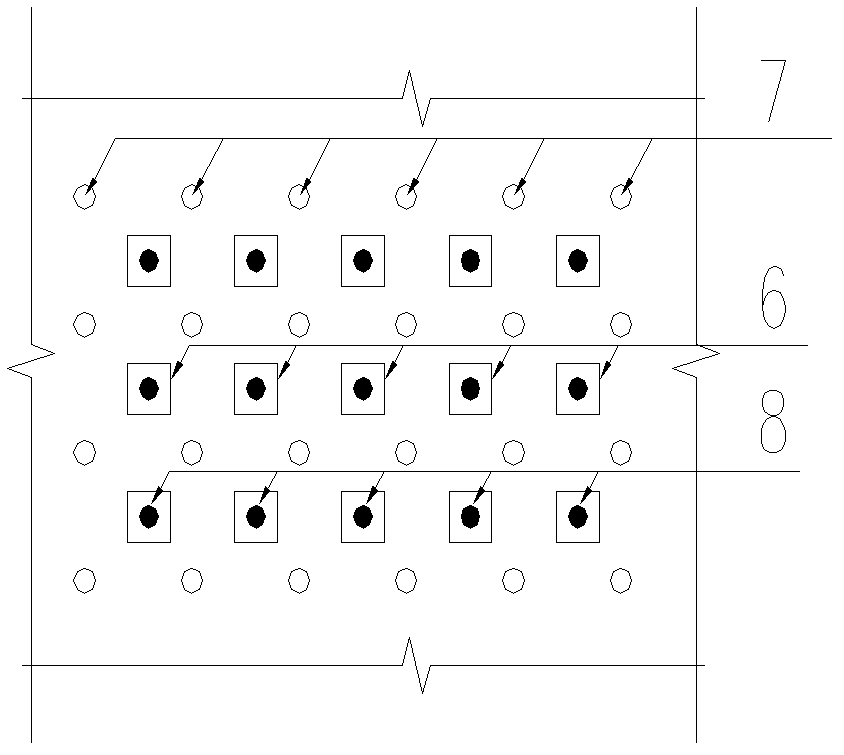

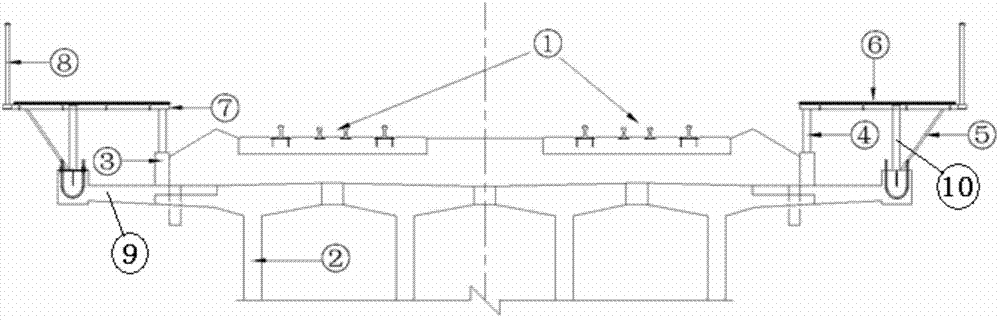

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

Steel plate-concrete composite structure reinforcement method of structural negative moment region

ActiveCN102561213AEnhanced interface connection reliabilityImprove connection reliabilityBridge erection/assemblyBridge strengtheningPrestressed concrete beamT-beam

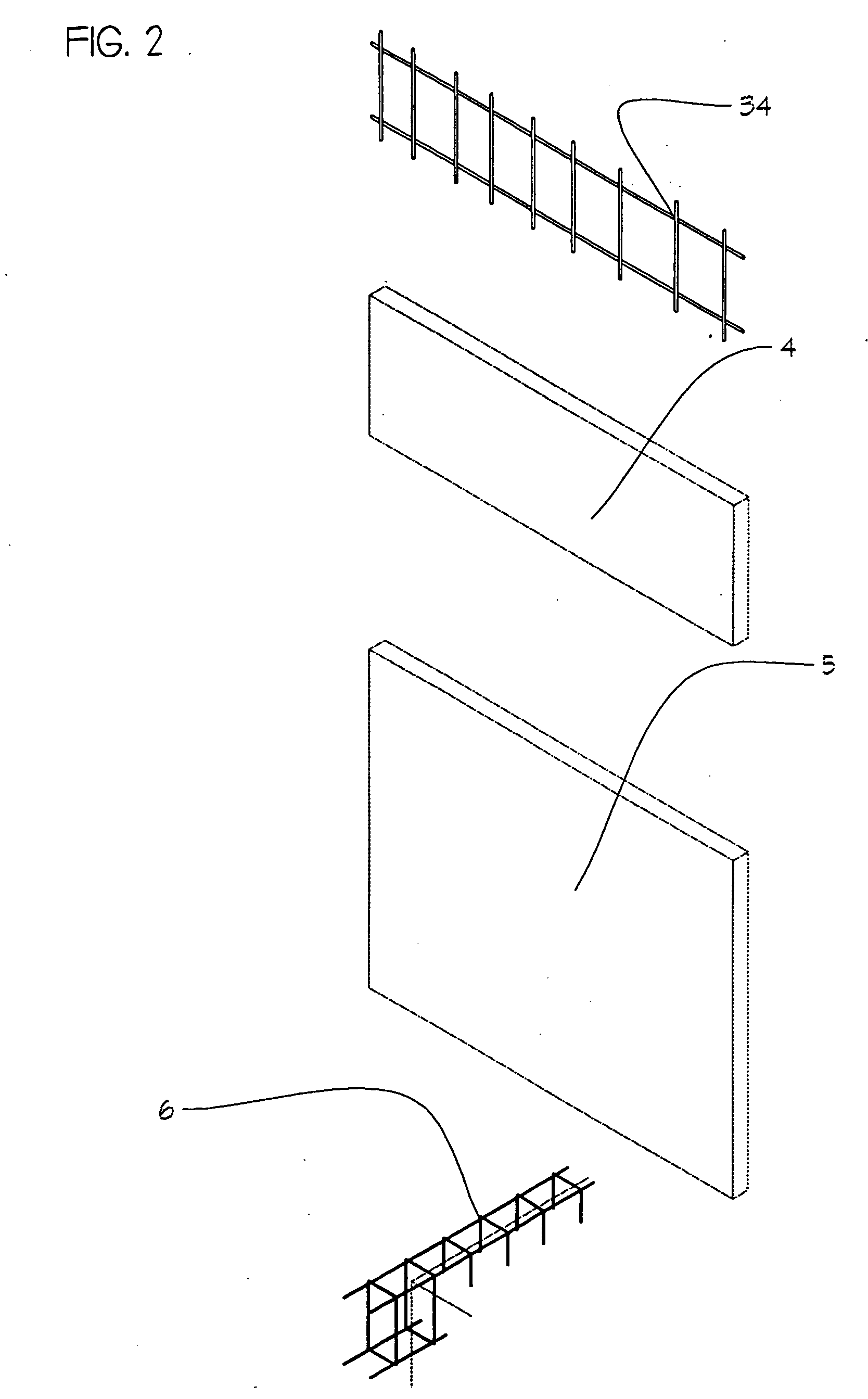

A steel plate-concrete composite structure reinforcement method of a structural negative moment region is characterized in that the method comprises the steps of: (1) carrying out interface treatment of a negative moment region of a concrete box girder top plate 3; (2) planting bars on the surface of the negative moment region of the concrete box girder top plate 3; (3) manufacturing a steel plate 9, a welding stud 8 and a corrugated steel plate 14: (4) forming a self-compacting concrete pouring hole 13 and a location leveling hole 17 on the steel plate 9; (5) erecting a reverse ejection support 2 and unloading reverse ejection; (6) binding a reinforcing mesh 10 and installing in position; (7) applying a structural adhesive on the steel plate 9 and spreading fine sands; (8) installing and leveling the steel plate 9 to the design position, applying a pre-stress to the top of the steel plate 9 through a pre-installed apparatus; (9) mixing and pouring self-compacting concrete; and (10) releasing the pre-stress, removing the corrugated steel plate 14, curing concrete, constructing a pavement layer, and removing the reverse ejection support 2. The novel steel plate-concrete composite structure negative moment region reinforcement method can be widely used for negative moment region reinforcement of concrete box girder, T-beam, hollow plate girder, common reinforced concrete beam, and pre-stressed concrete beam, and can be used in the bridge reinforcement with the advantages of almost no reduction of the headroom below the bridge, no requirement for surface levelness of the original structure, low cost, no influences on the appearance, and so on. The steel plate-concrete composite structure reinforcement method is economic, safe, and practical, is easy to ensure the project quality and has wide application prospect.

Owner:CENT SOUTH UNIV +2

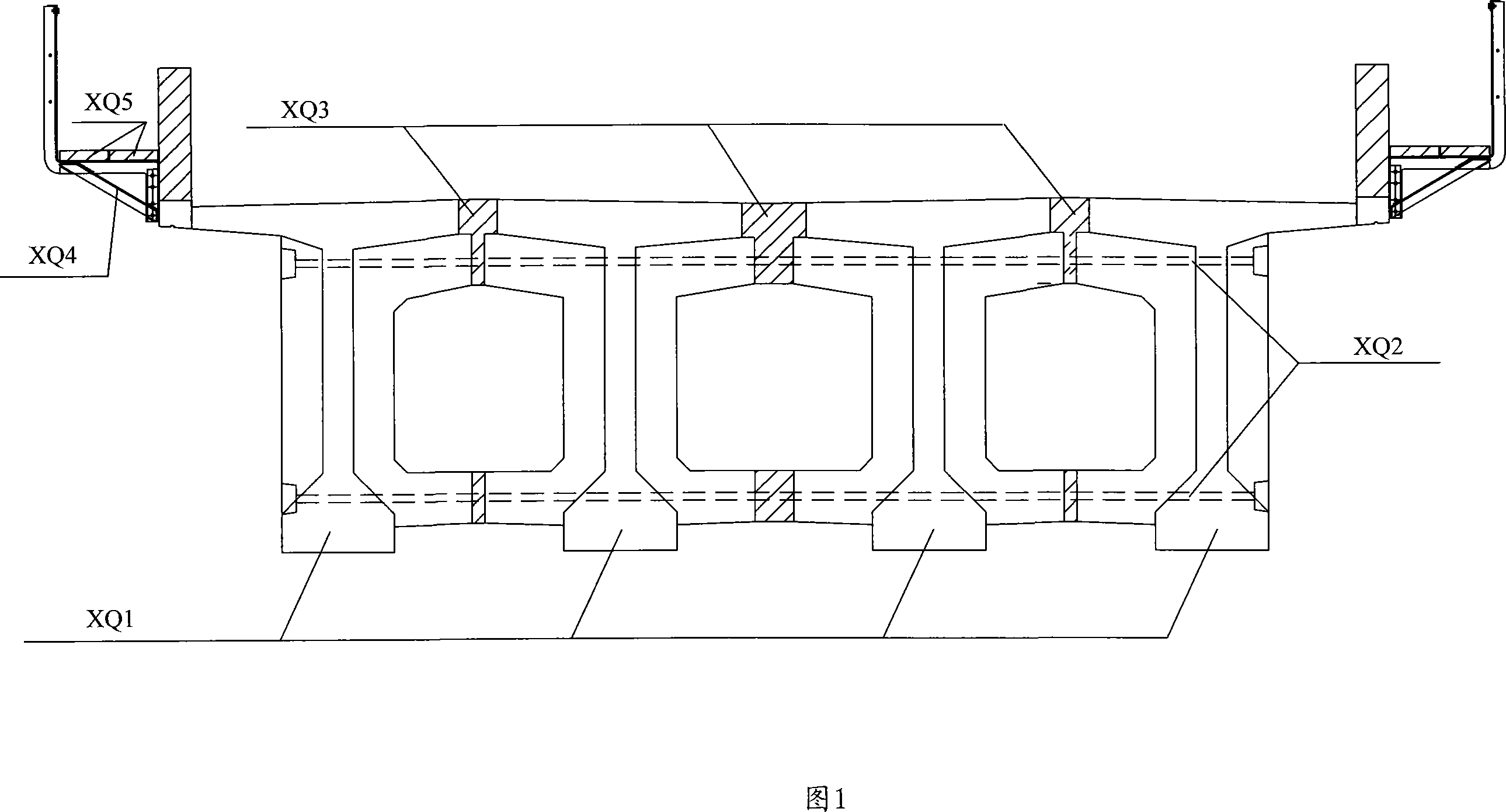

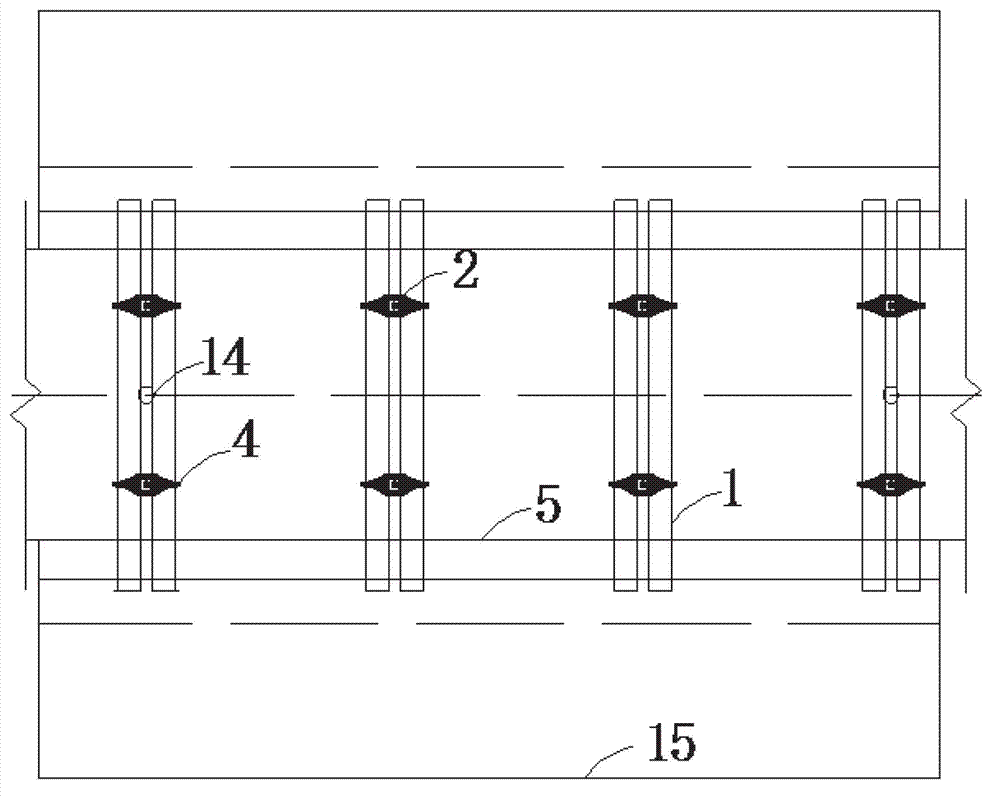

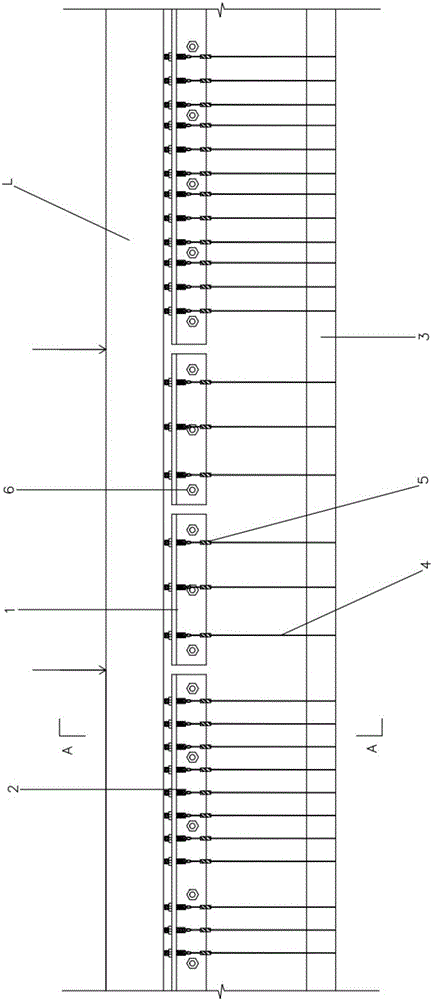

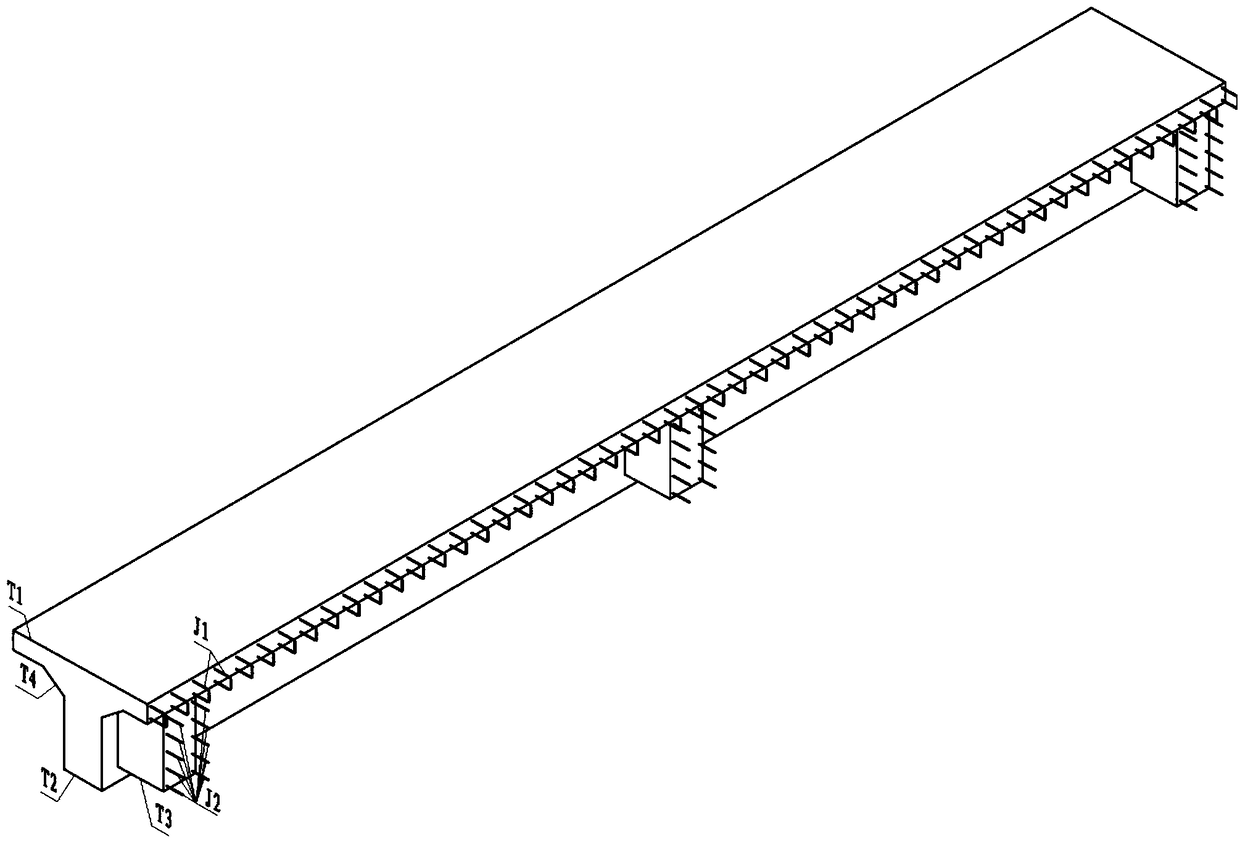

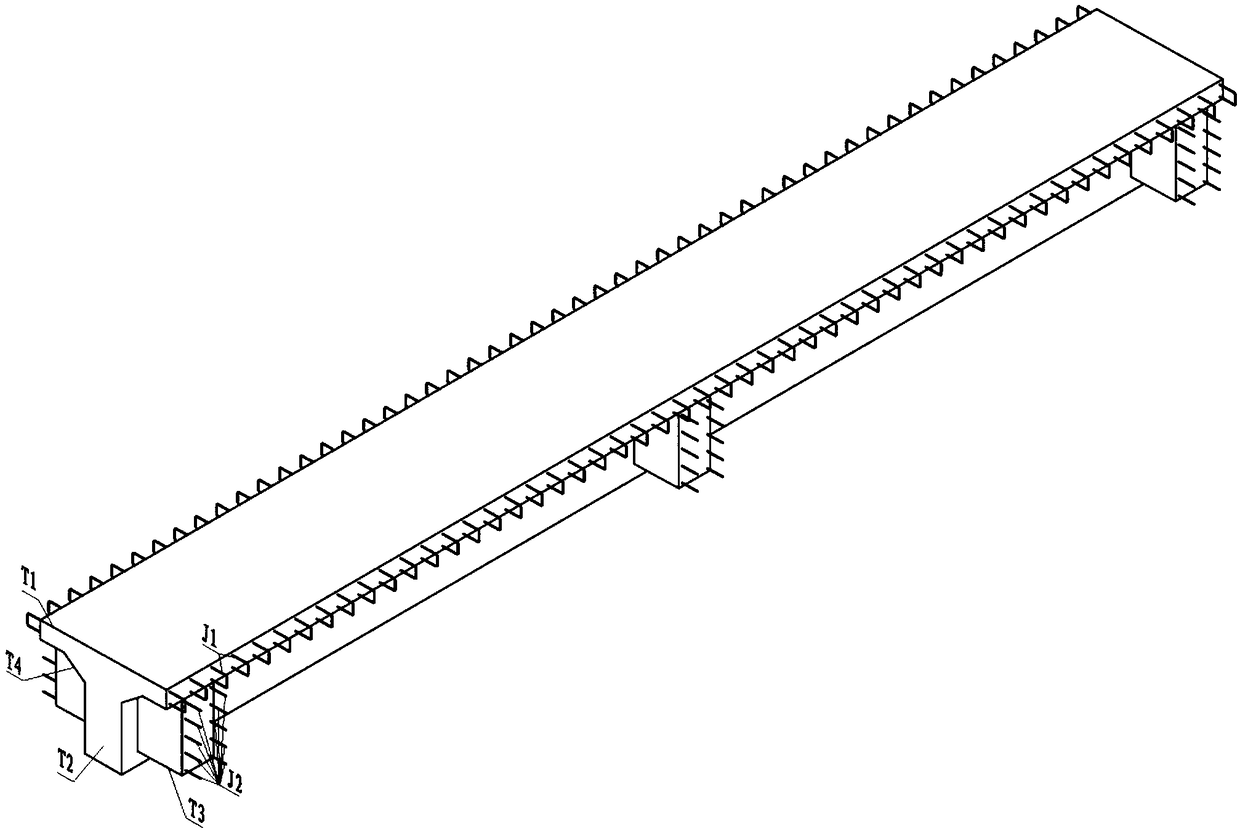

Sound-barrier simply-supported T-beam bridge

ActiveCN103061242AImprove integrityReduce workloadNoise reduction constructionBridge structural detailsSound barrierT-beam

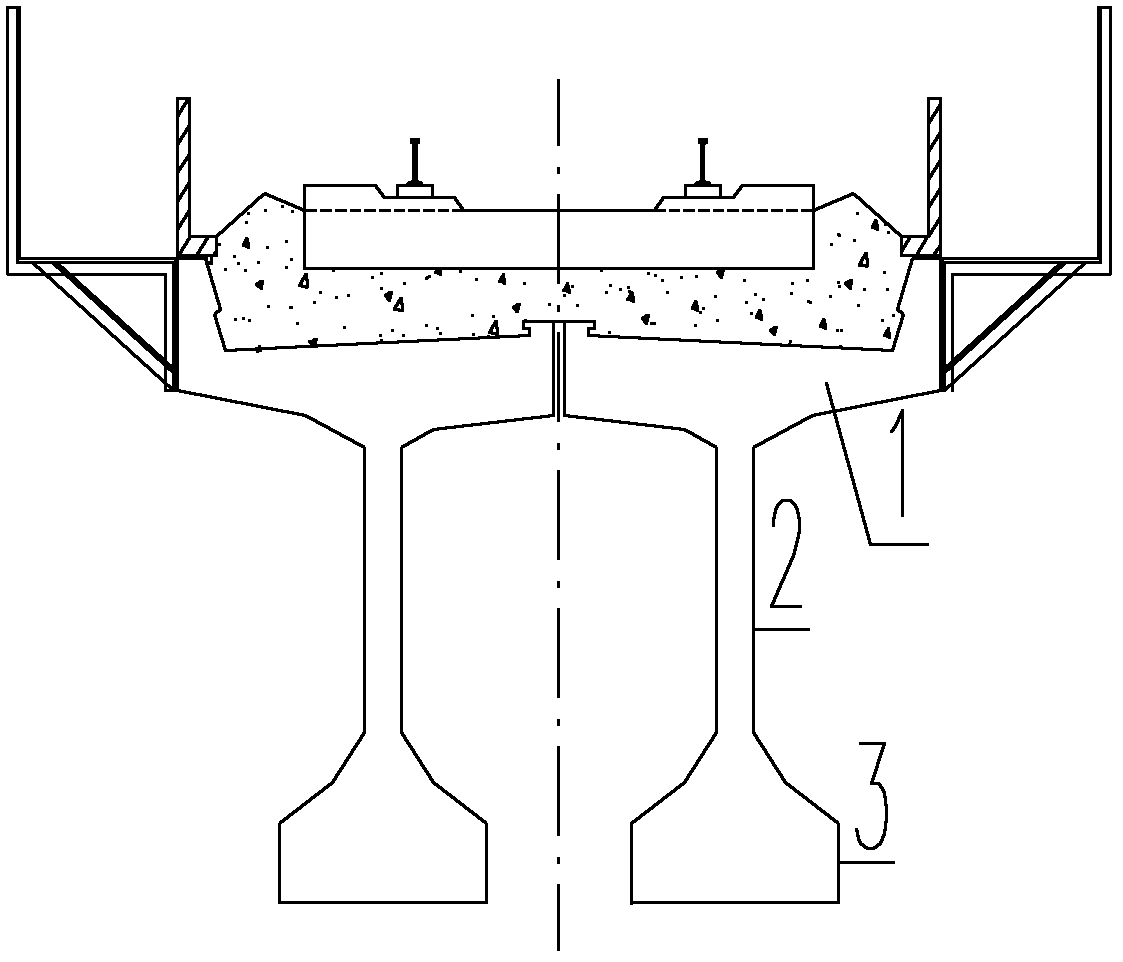

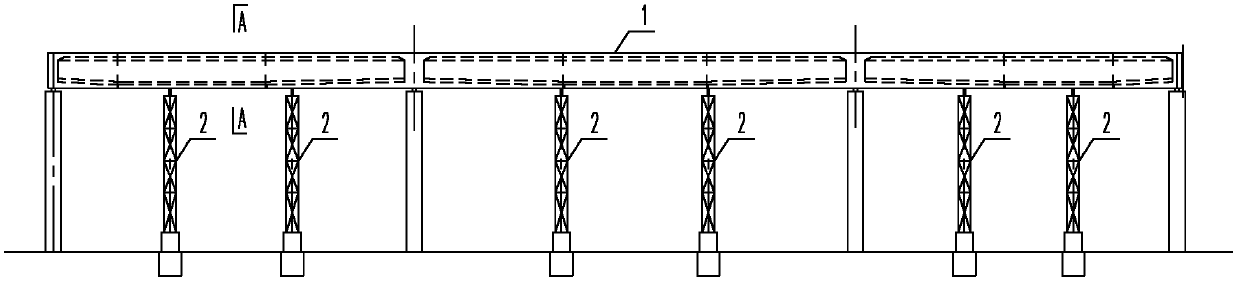

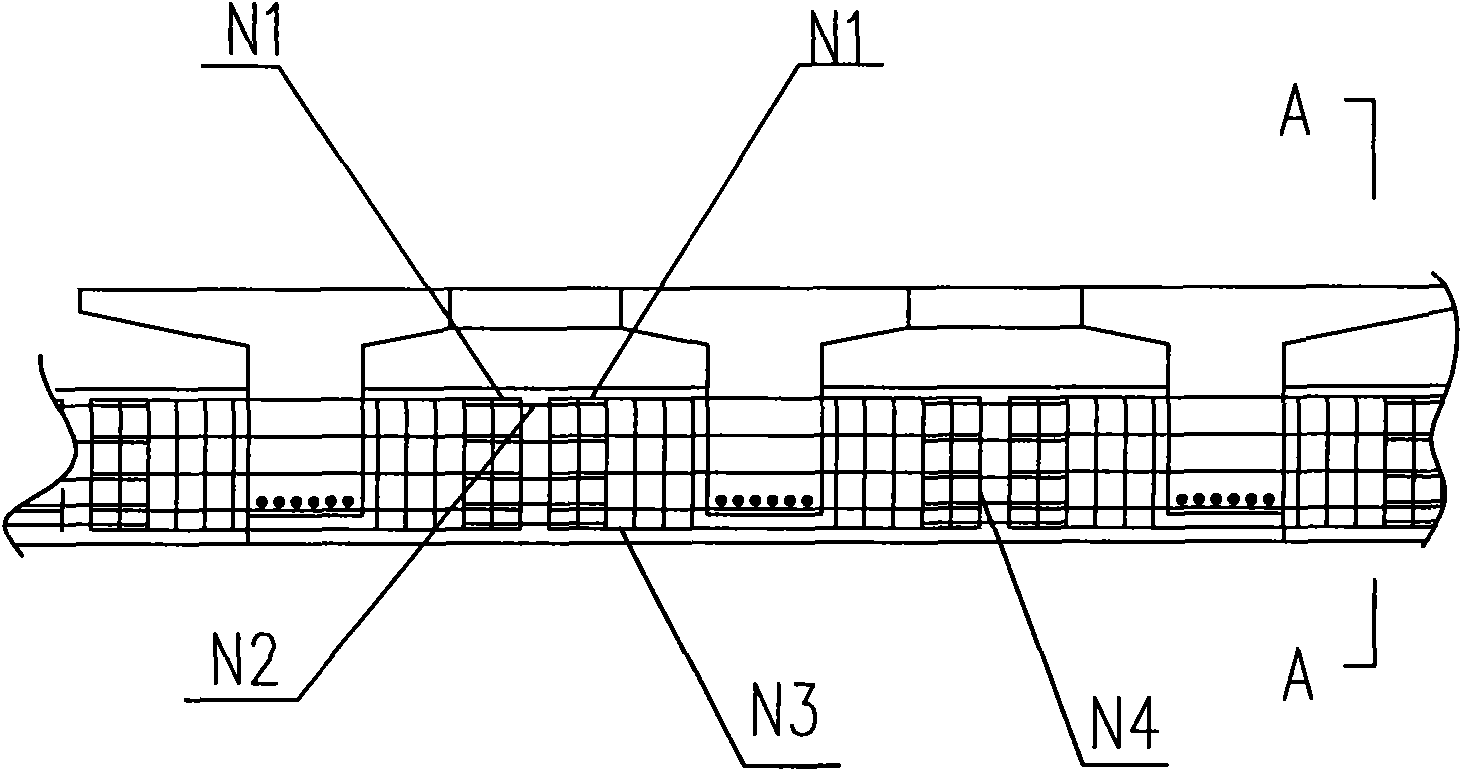

The invention relates to the technical field of railway bridges and particularly discloses a sound-barrier simply-supported T-beam bridge which comprises a plurality of simply supported T-beams. Each simply supported T-beam is formed by connecting a plurality of simply supported T-beam units end to end. The simply supported T-beams are transversely connected through transverse partitions, wet joints and concrete. Concrete cast-in-place decks are arranged outside the simply supported T-beams on two sides. The upper surfaces of the simply supported T-beams, the upper surfaces of concrete connections and the upper surfaces of the concrete cast-in-place decks form an integral bridge deck. The whole integral bridge deck is provided with transverse prestressed bars. Sound-barrier column foundations are arranged outside the concrete cast-in-place decks, and sound-barrier columns are arranged at the sound-barrier column foundations. A sound barrier is arranged between each two adjacent columns. The performance of the railway bridge is improved, the railway bridge meets the requirement of providing the sound barrier by the aid of the integral bridge deck, sound barrier absorbs or isolates noise generated in running process of trains and the influence of the trains upon lives of nearby residents is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

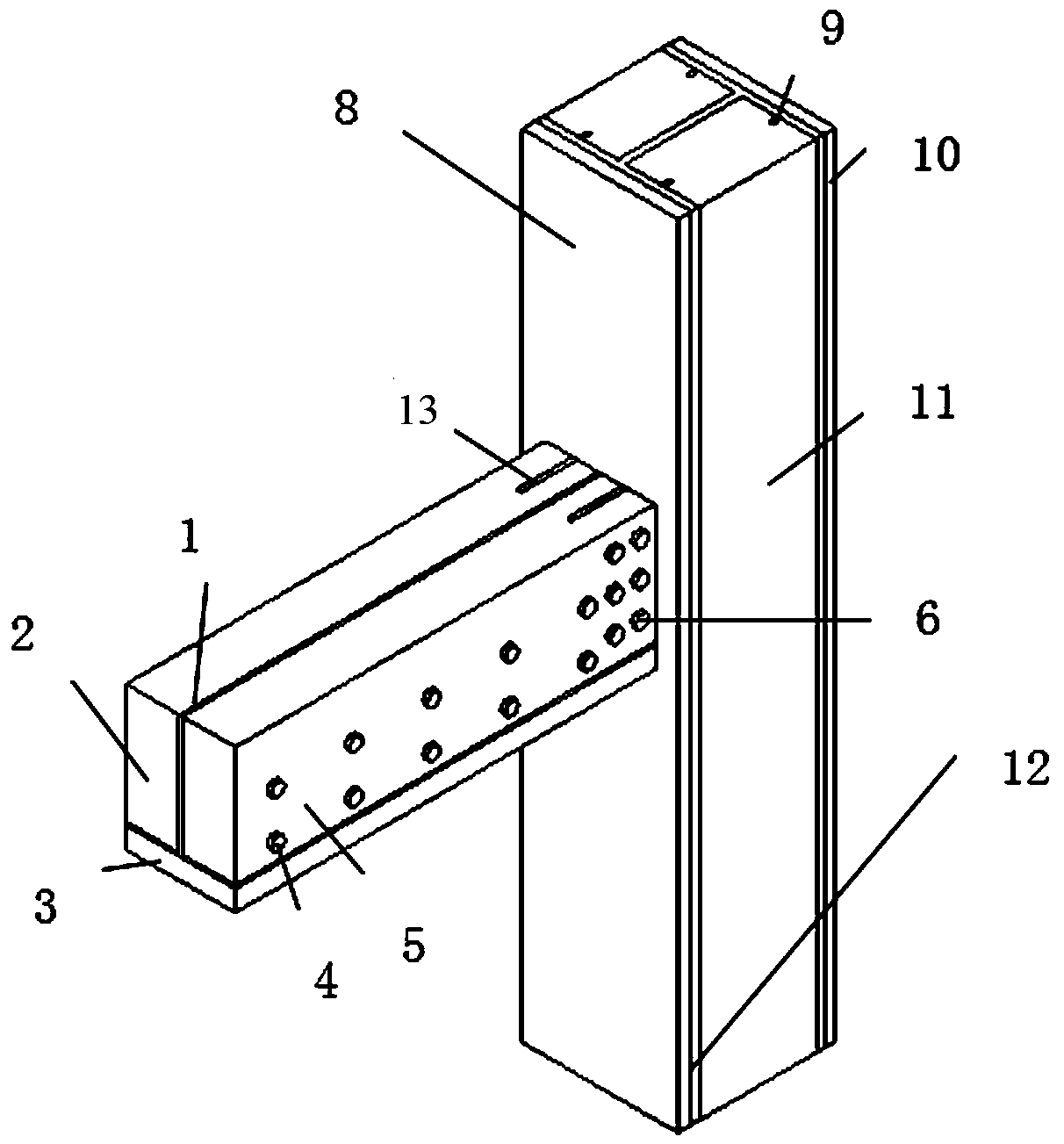

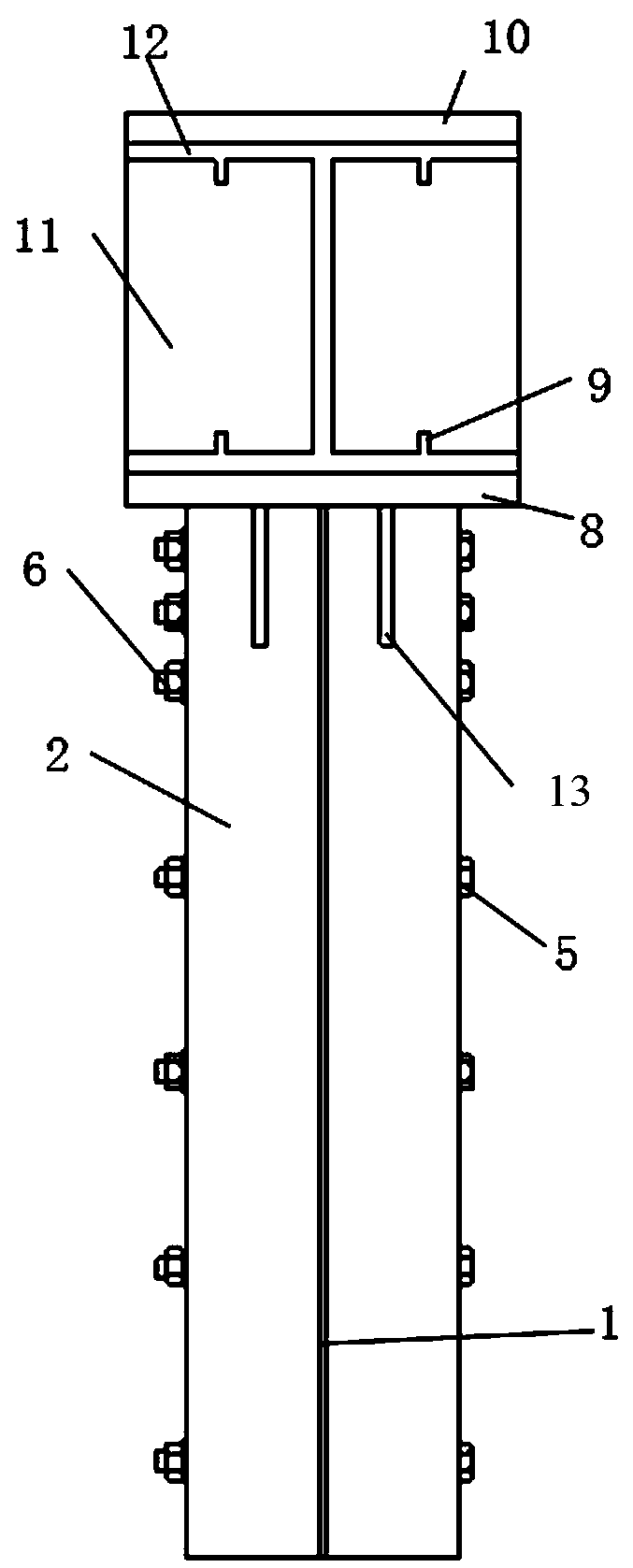

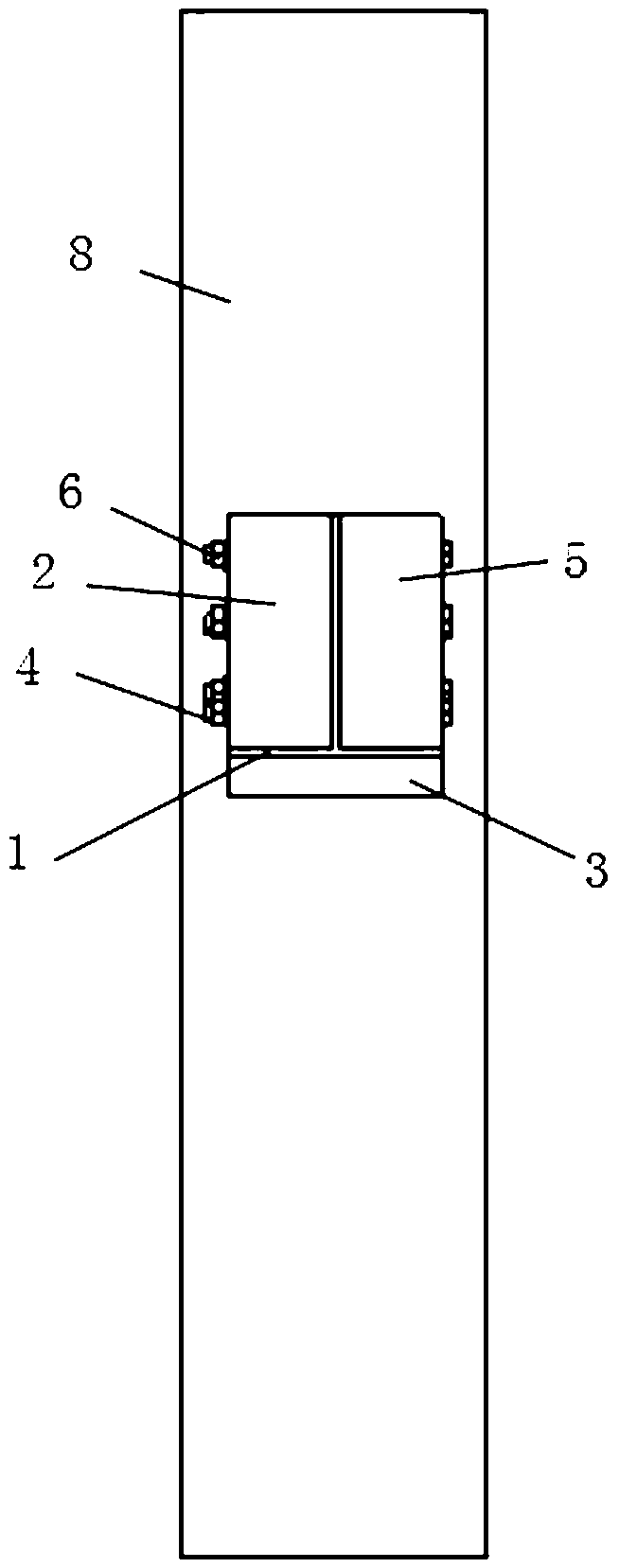

Assembly-type steel-wood combined beam column joint structure and construction method thereof

PendingCN108978869AReduce dosageImprove bearing capacityBuilding constructionsClimate change adaptationShaped beamT-beam

Provided are an assembly-type steel-wood combined beam column joint structure and a construction method thereof. The joint structure comprises a steel-wood combination beam, a steel-wood combination column and a connector fixing the steel-wood combination beam and the steel-wood combination column. The steel-wood combination beam and the steel-wood combination column are vertical to each other. The steel-wood combination beam comprises an inverted T-shaped beam, left and right wood boards connected to two sides of an inverted T-shaped web board and a lower wood board connected to the bottom surface of an inverted T-shaped beam flange. The steel-wood combination column comprises an I-shaped column, wed wood boards connected between two flanges of the I-shaped column and front and back flange wood boards connected outside the two flanges of the I-shaped column. The connector comprises a bottom board and inserting boards connected to the right side of the bottom board. During construction, the inserting boards are inserted into inserting grooves of left and right wood boards in order to be fixedly connected with the steel-wood combination beam. The bottom board is fixedly connected tothe outer surface of the flange board of the steel-wood combination beam in order to achieve joint connection of a steel-wood combined beam column. Material stress characteristics of a steel-wood structure are fully leveraged in order to reduce self weight of the structure and save steel material. Due to design of joints, high operationality is obtained so that construction time is saved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

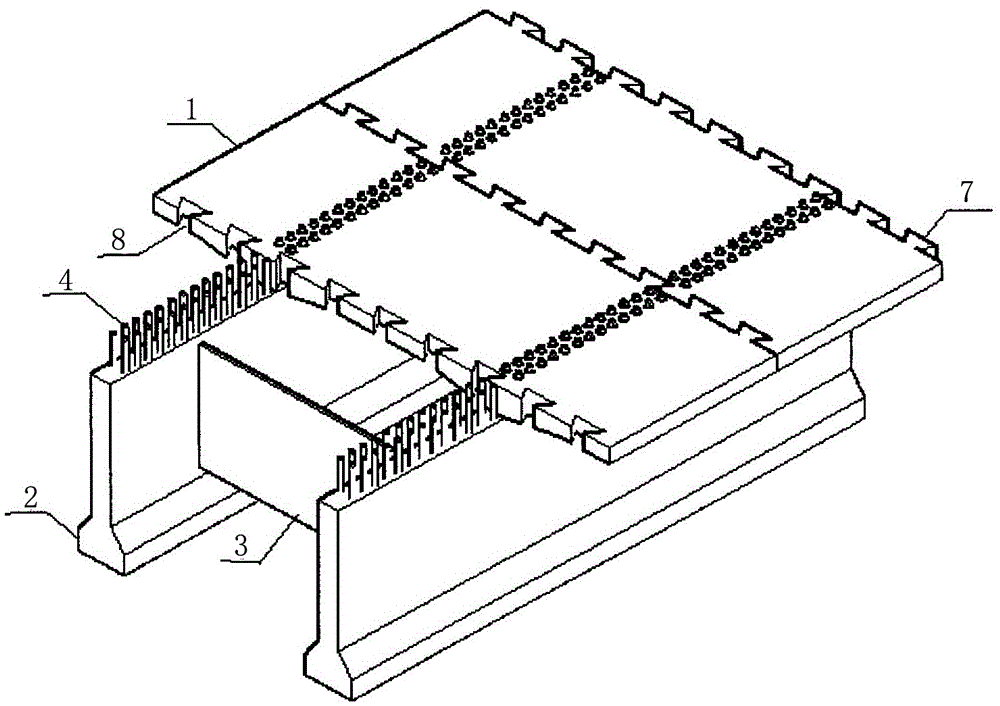

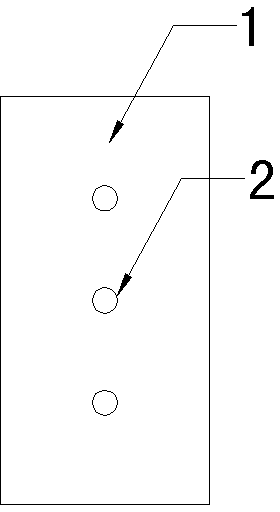

Prefabricated T beam and construction method

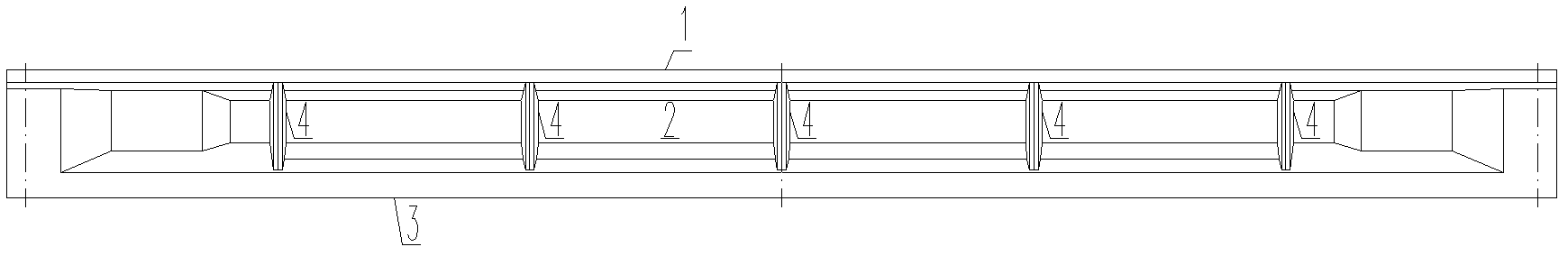

The invention discloses a prefabricated T beam and a construction method. The prefabricated T beam comprises bridge panels, a longitudinal beam and a steel transverse partition plate. The bridge panels and the longitudinal beam are prefabricated parts. The adjacent bridge panels are connected in an embedded mode. The portions, at the upper end of the longitudinal beam, of the bridge panels are evenly provided with preformed holes. Pre-buried deformed steel bars are arranged inside a bridge beam of the longitudinal beam. A pre-buried steel plate is arranged on the side face of the longitudinal beam. The pre-buried deformed steel bars need to stretch out of the upper edges of the spliced bridge panels on the basis of the length. The steel transverse partition plate is fixedly connected with the pre-buried steel plate on the longitudinal beam. The construction method comprises the steps of prefabricating the bridge panels and the longitudinal beam; connecting the steel transverse partition plate with the longitudinal beam after the longitudinal beam is suspended to a bridge pier and abutment; placing the bridge panels on the longitudinal beam, and connecting the adjacent bridge panels in the embedded mode; pouring epoxy mortar concrete into the preformed holes. The bridge panels and the longitudinal beam of the T beam are partially prefabricated separately, and therefore the wet joint problem existing in concrete T beam splicing is effectively solved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

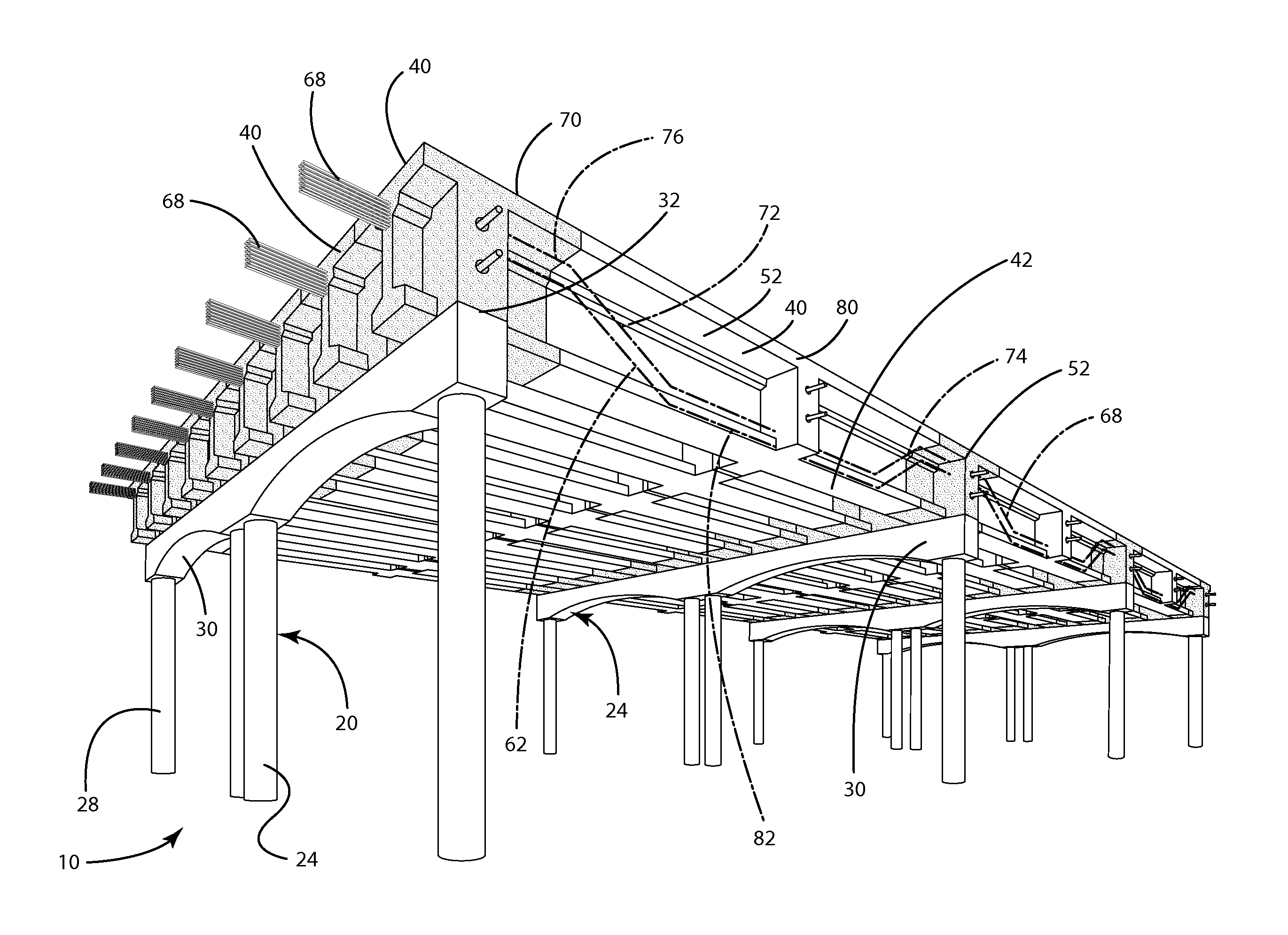

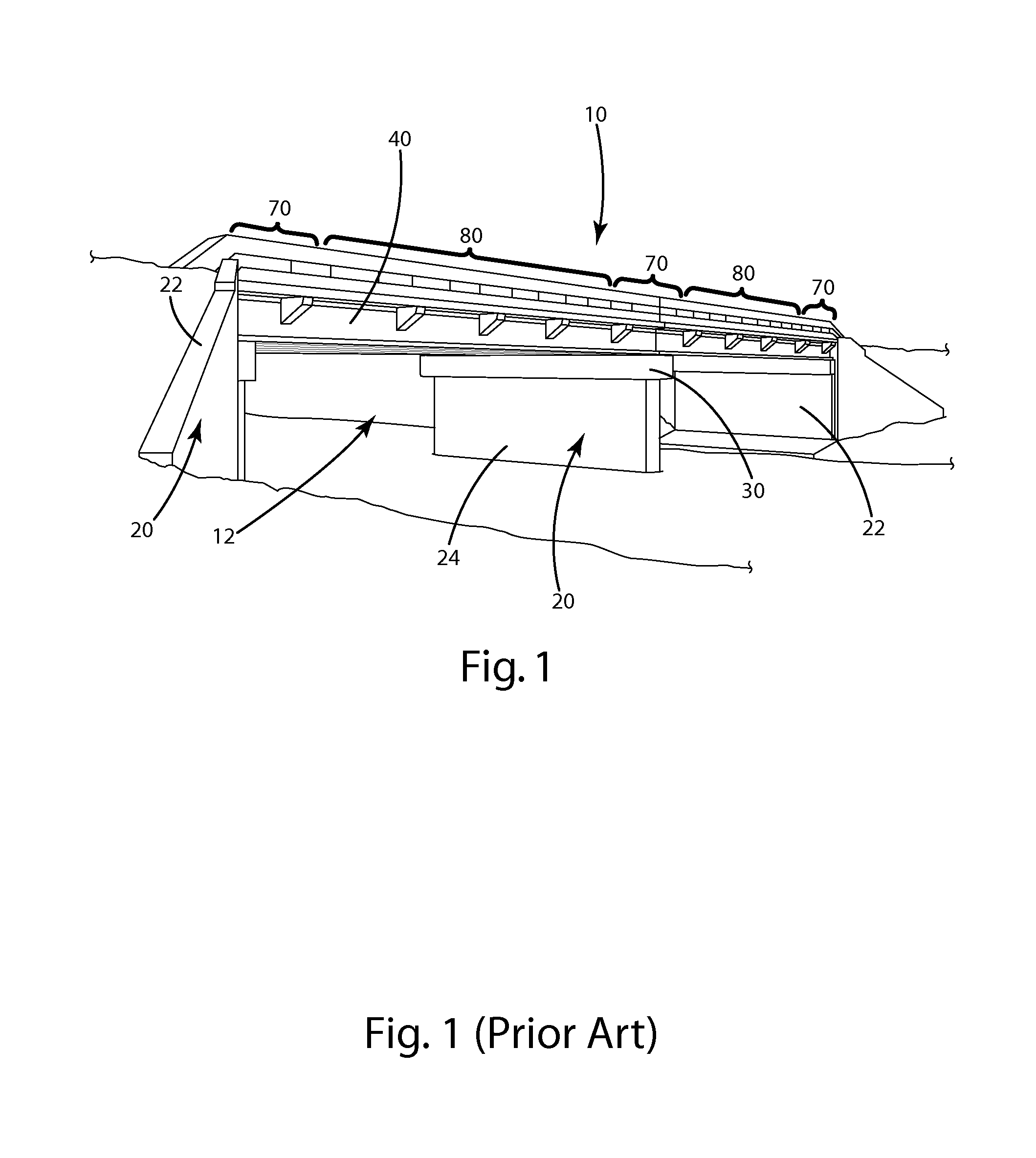

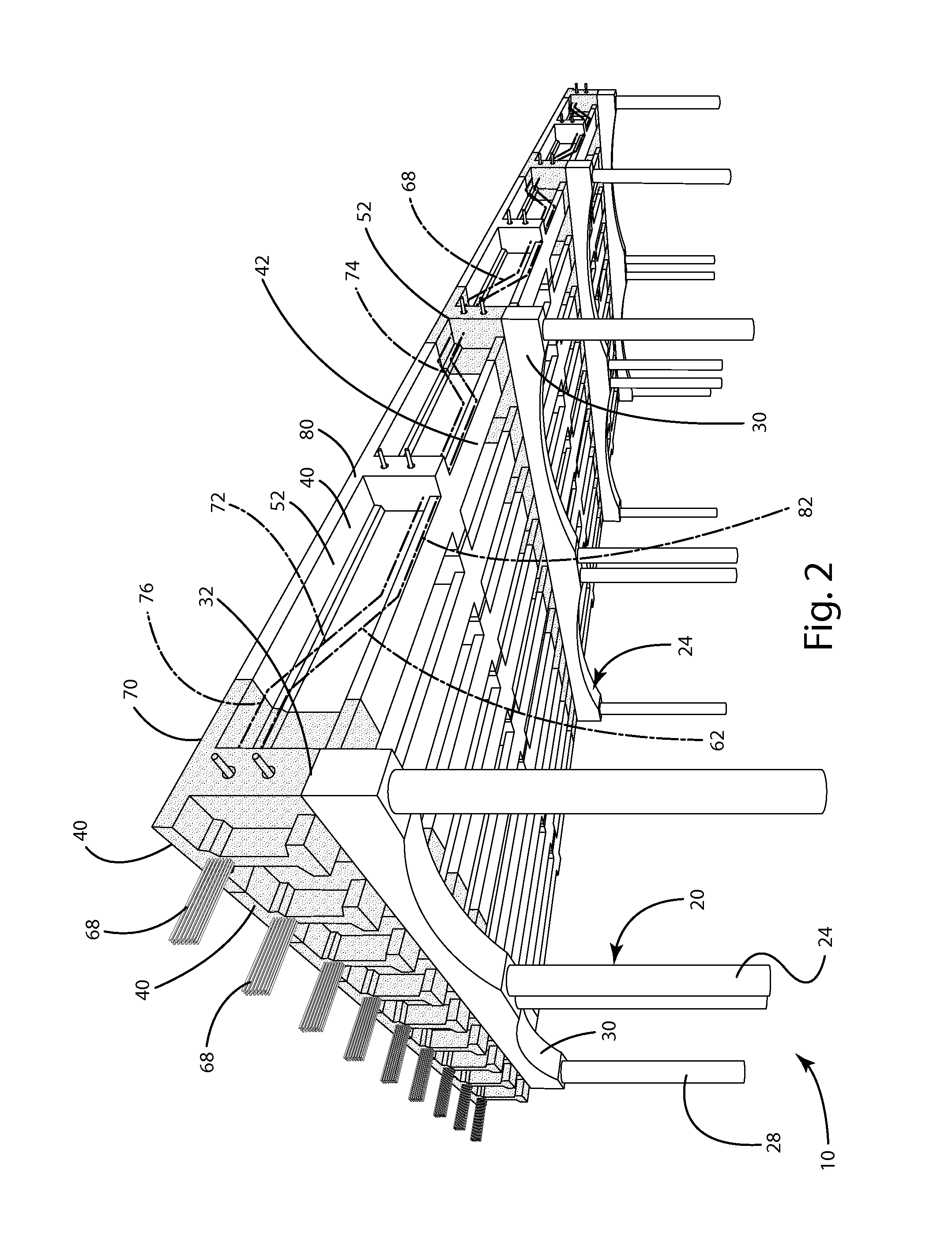

Continuous CFRP Decked Bulb T Beam Bridges For Accelerated Bridge Construction

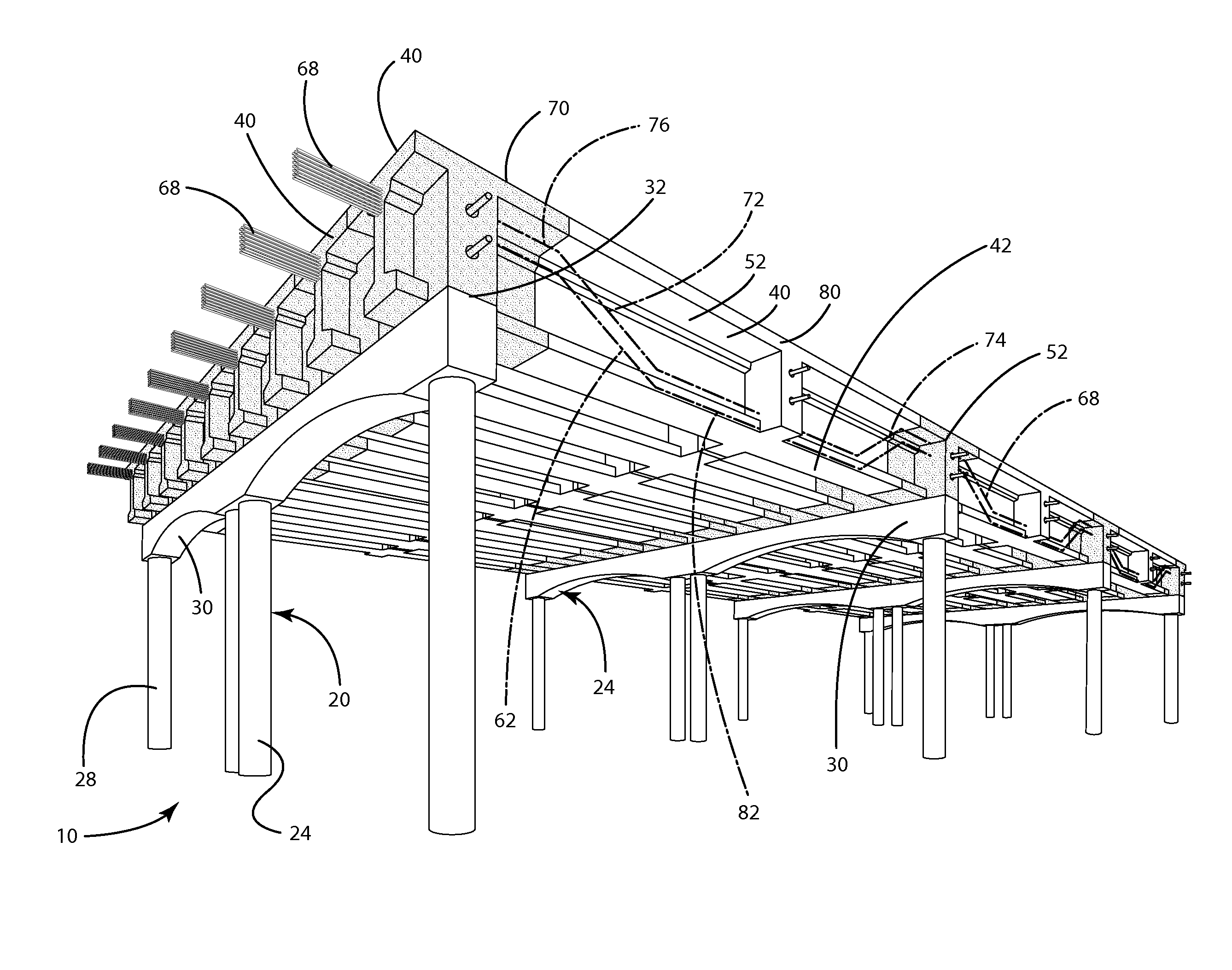

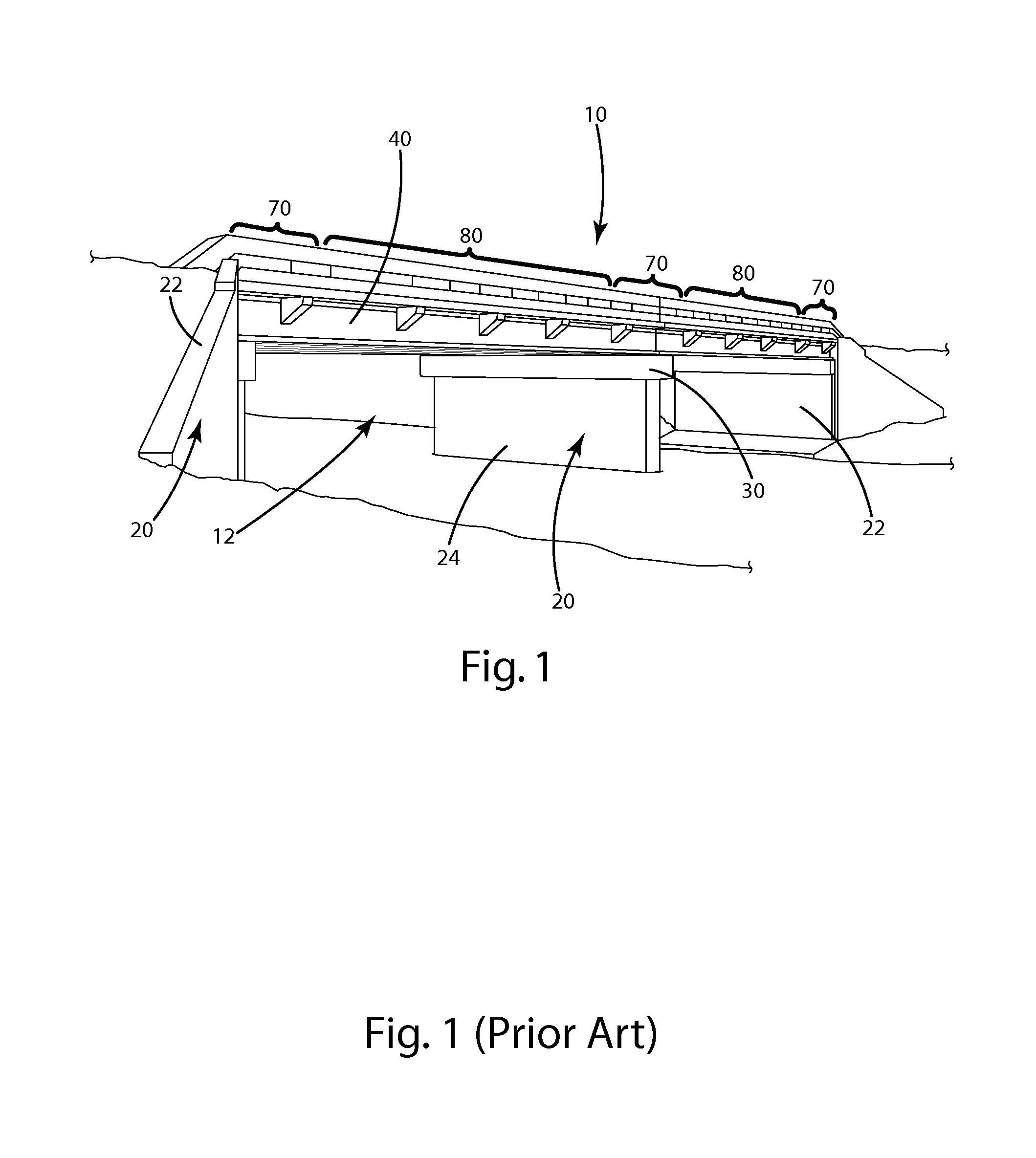

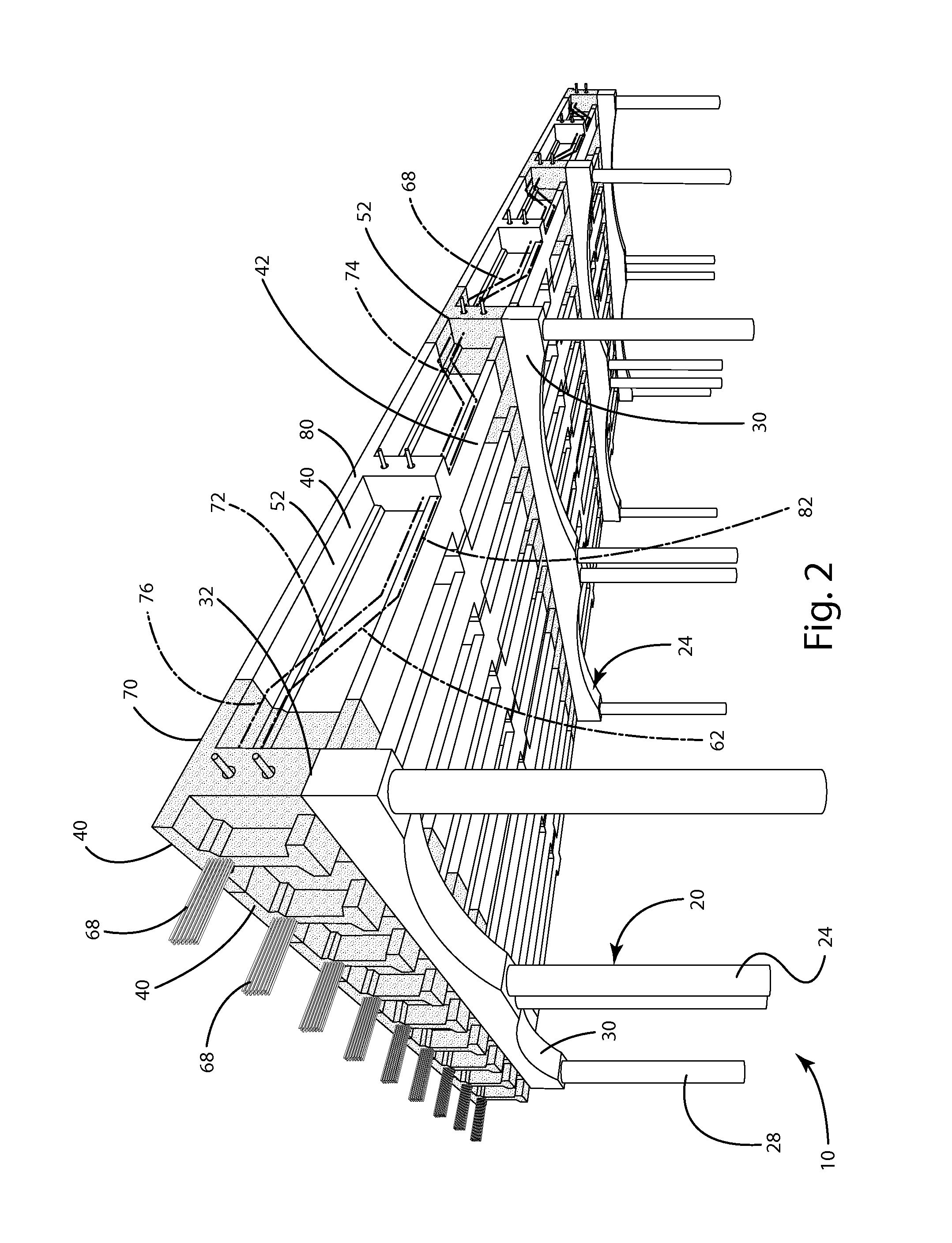

A pre-stressed concrete bridge using longitudinal load members of a single continuous beam including at least two types of concrete, one of which is ultra-high-performance concrete (UHPC) mix with a compressive strength exceeding 20 ksi and tensile strength exceeding 1.5 ksi in a region proximate to the support structure.

Owner:LAWRENCE TECHNOLOGICAL UNIV

Prefabricated steel-concrete combination T beam with corrugated steel web and construction method

ActiveCN103924505AReduce the amount of pouringImprove stabilityBridge structural detailsBridge erection/assemblyWave shapeT-beam

The invention discloses a prefabricated steel-concrete combination T beam with a corrugated steel web and a construction method. A plurality of prefabricated steel-concrete combination T beam section units (4) formed by combination of H-shaped wave-shaped steel web steel beams (1) and concrete bridge face plates (3) are included. Adjacent combination T beam section units (4) form a whole through a longitudinal connecting section (5) and a beam end wet joint horizontal beam (11). The advantages of a traditional steel-concrete combination beam structure with a flat steel plate are achieved, the stability of the web and be improved, influence of concrete shrinkage and creep is avoided, meanwhile, the shortcoming of a current construction method of the steel-concrete combination beam can be effectively overcome, and the prefabricated steel-concrete combination T beam has the advantages of being convenient to convey, easy to assemble, small in site welding amount, small in concrete placing amount, high in construction speed, small in influence on ground traffic and the like.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

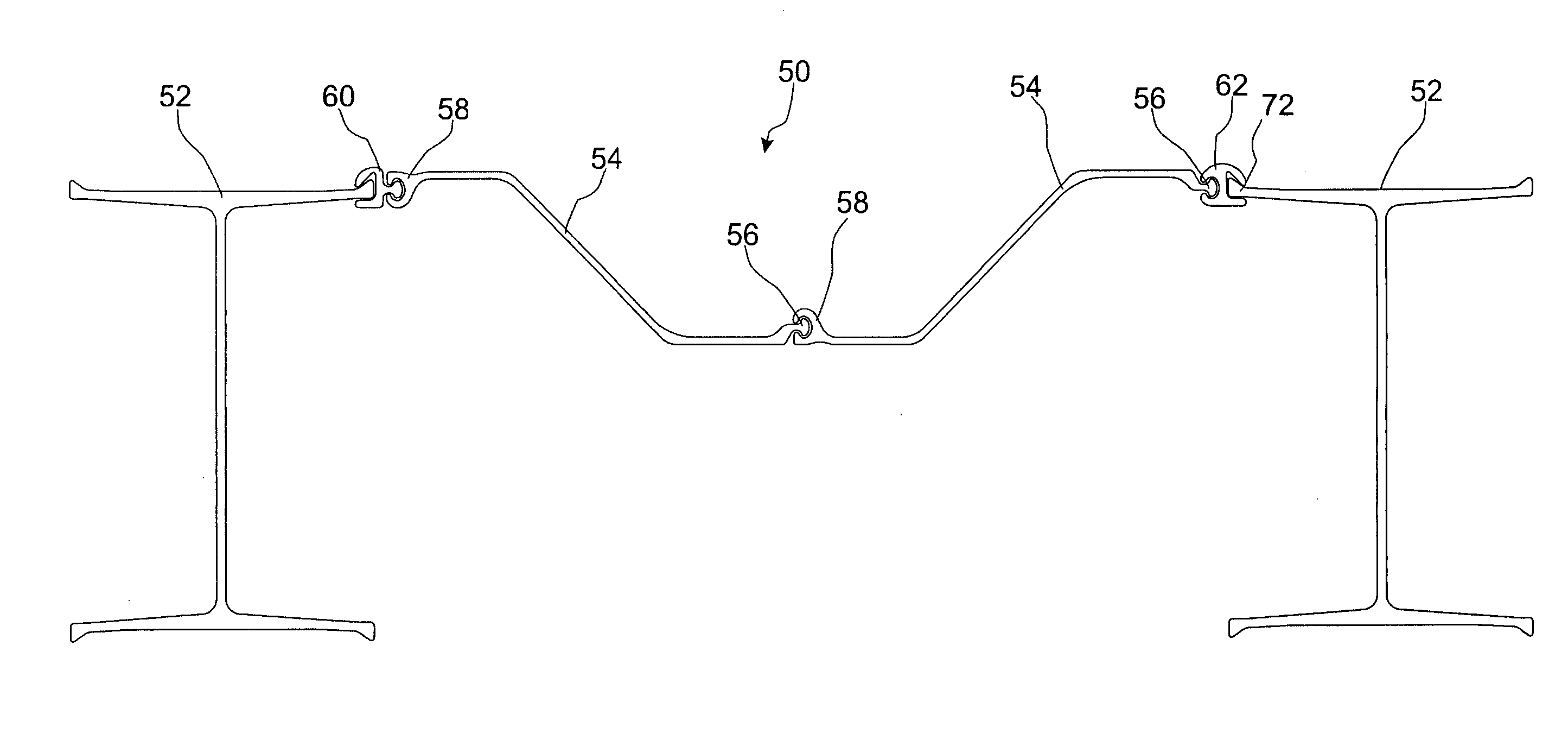

Combination pile wall

InactiveUS20060179771A1Adequate characteristicsImprove stabilityArtificial islandsWallsT-beamEngineering

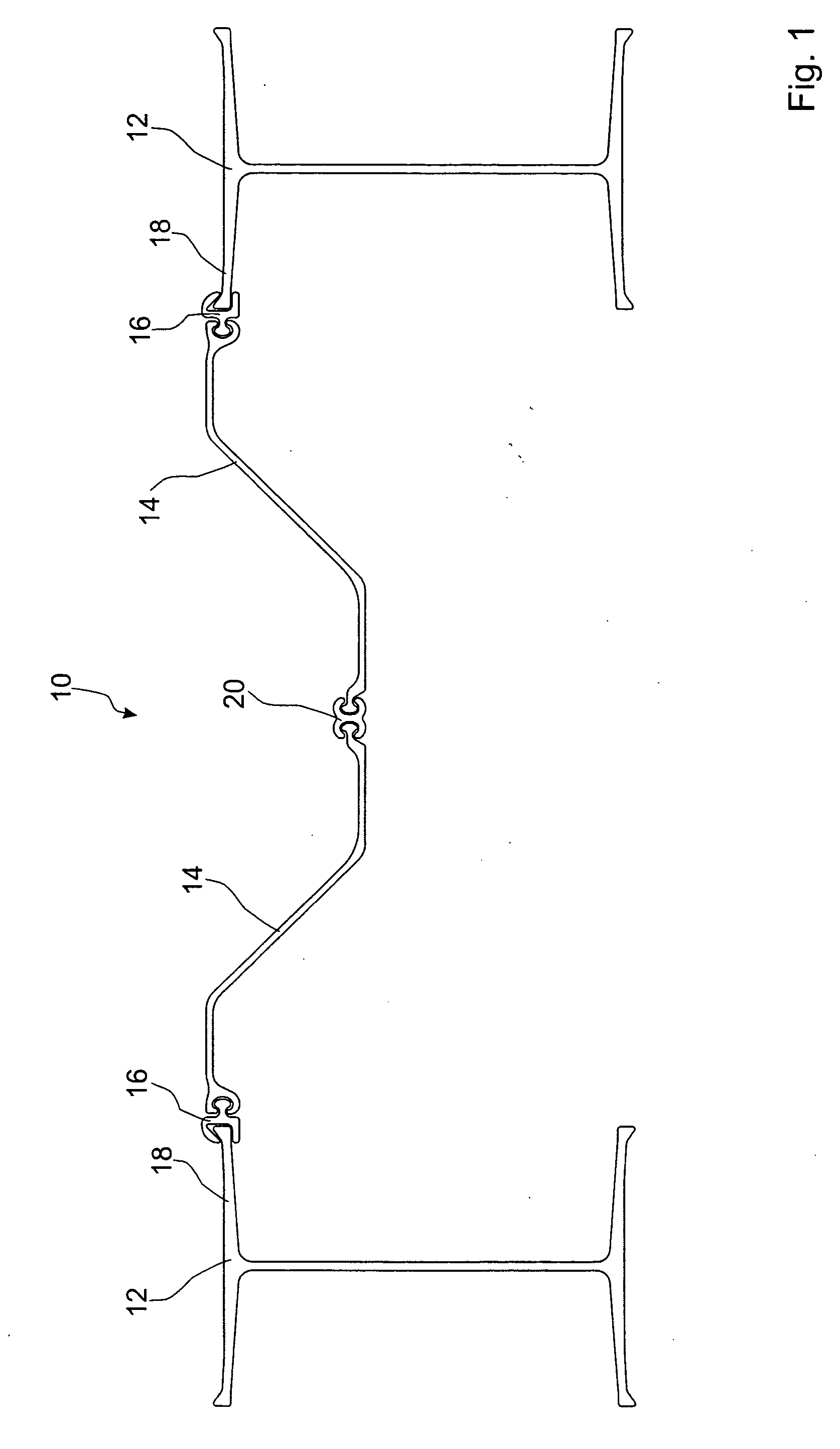

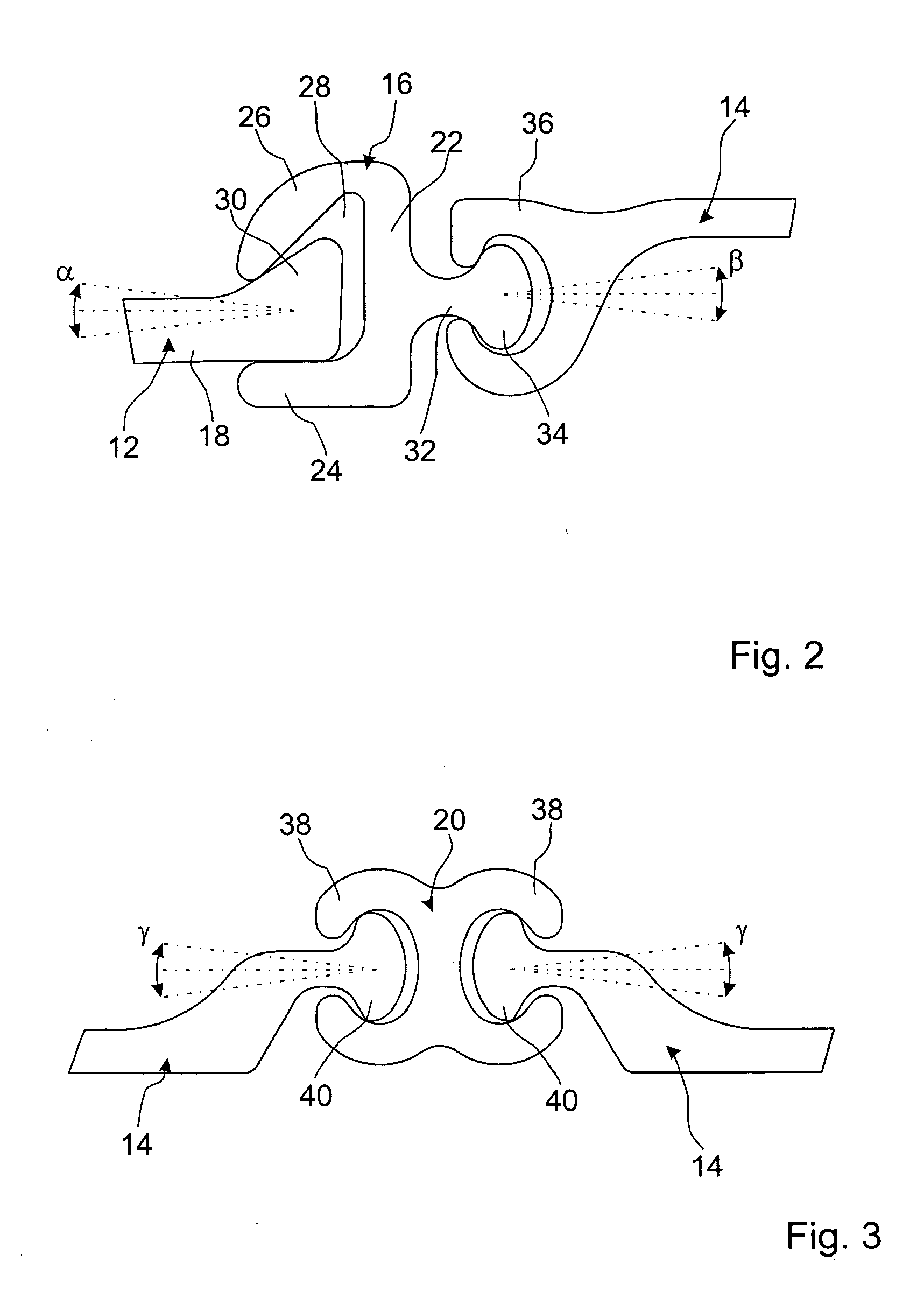

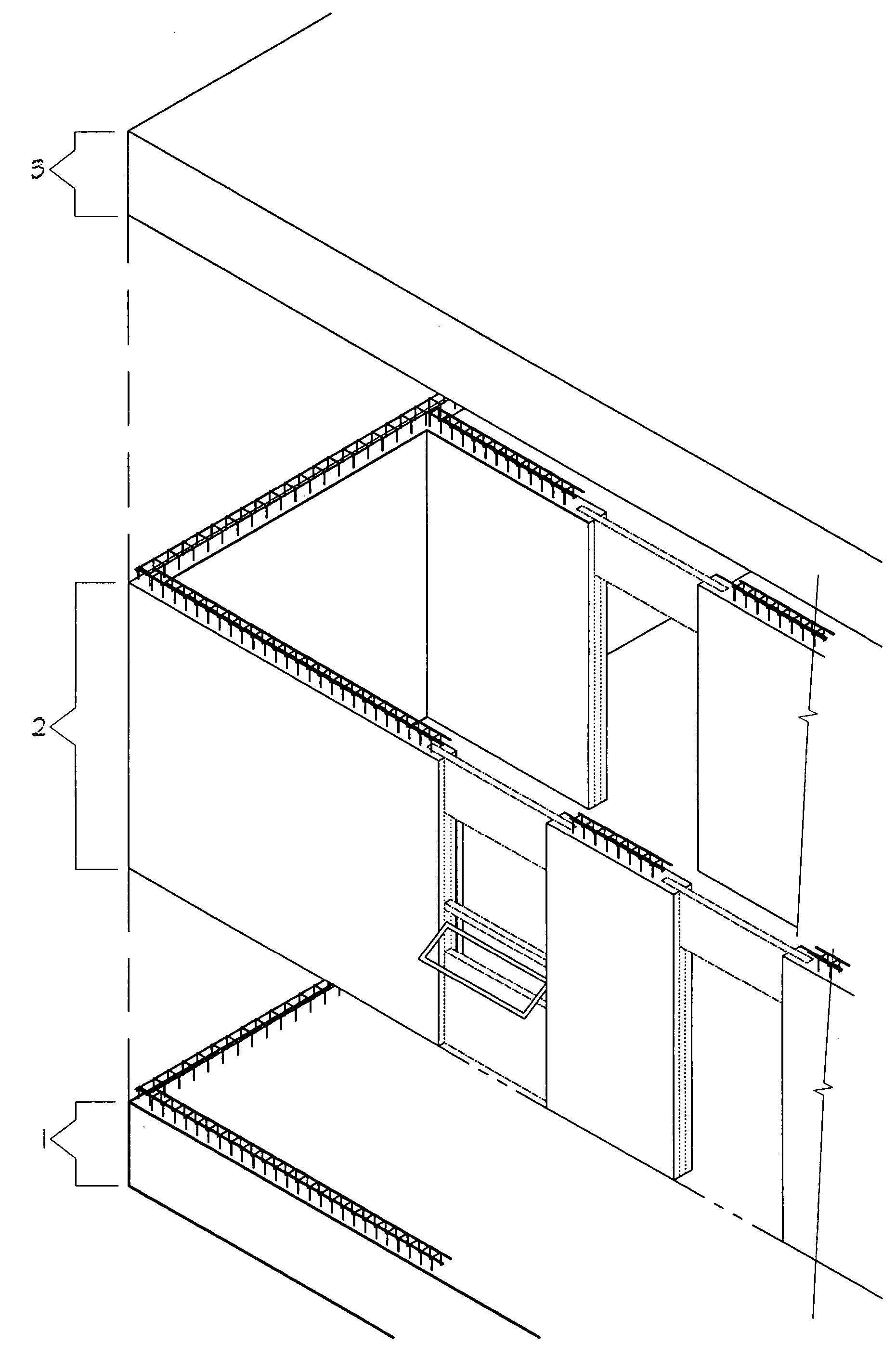

A combination pile wall is formed of beam elements (12), particularly T-beams and double-T-beams (I-beams), and shaped connection strips (16) directly or indirectly connecting the beam elements (12), whereby each shaped connection strip (16) that is coupled directly with one of the beam elements (12) is engaged with one of the locking elements (30) formed on the respective beam element (12). The two mutually-engaged locking elements (24, 26) of the shaped connection strip (16) and of the beam element (12) are configured with a cross section such that the two locking elements (24, 26) may pivot with respect to each other through an angular range of a minimum ±3° to a maximum ±10°.

Owner:SHEET PILE LLC

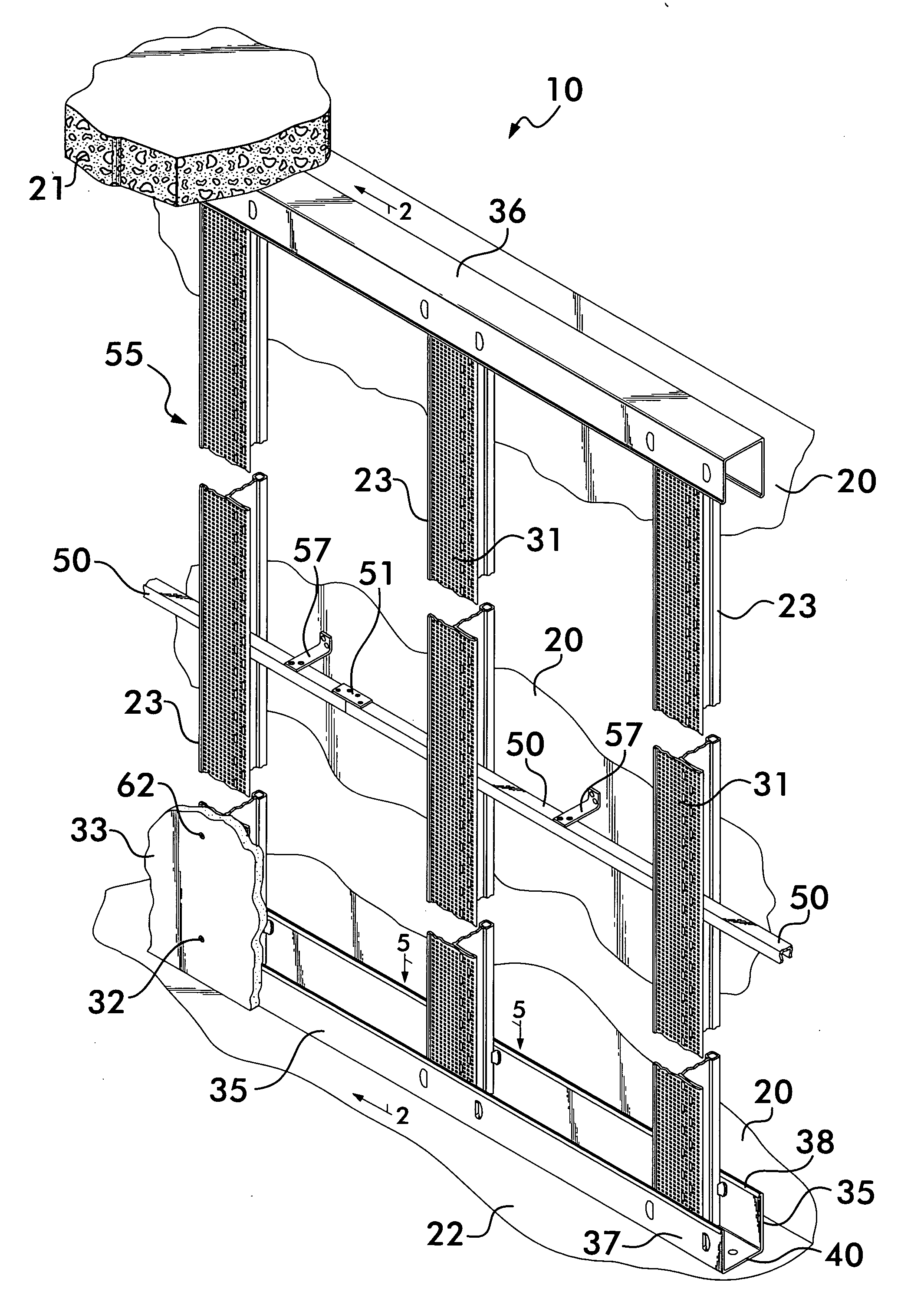

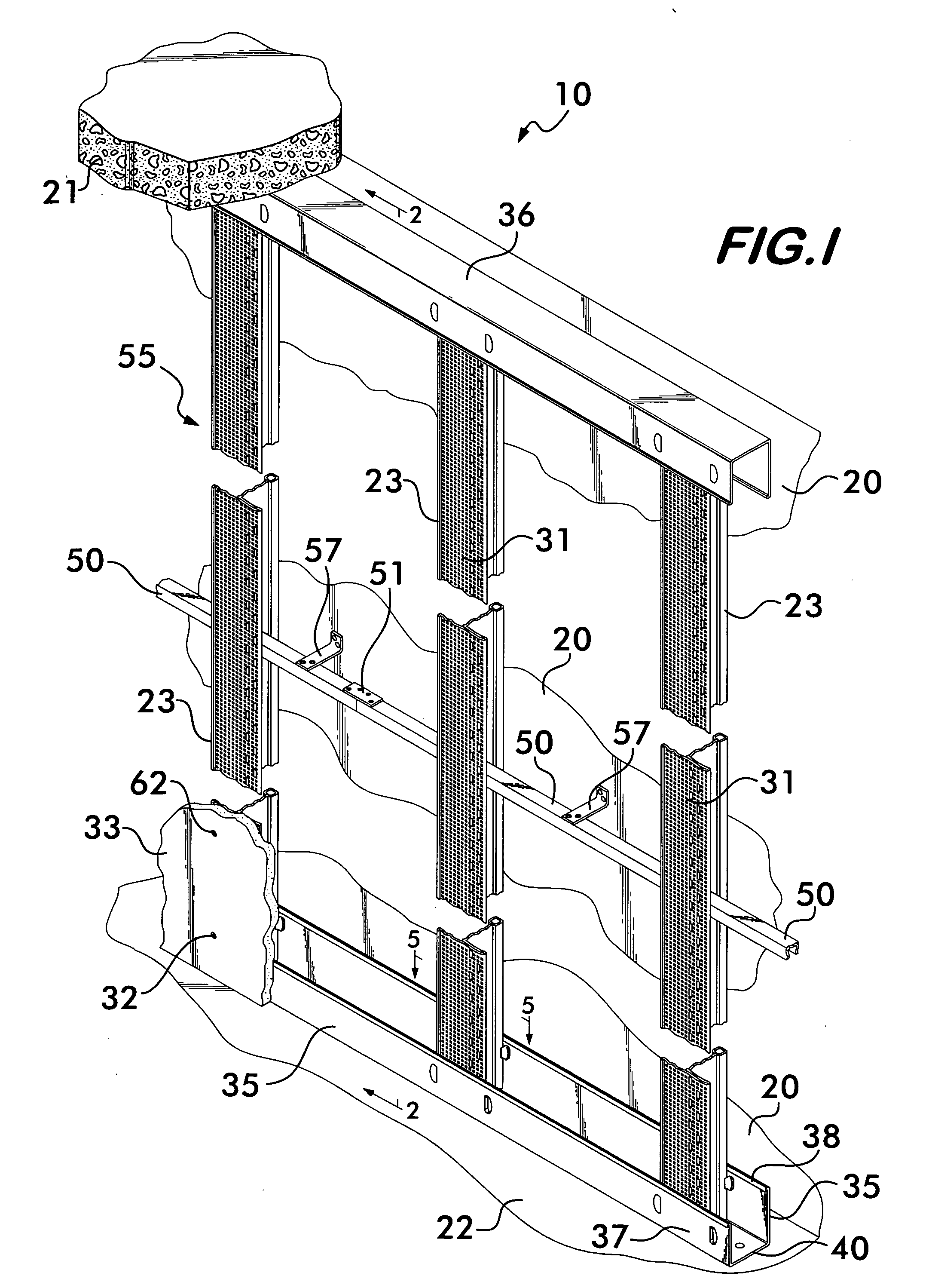

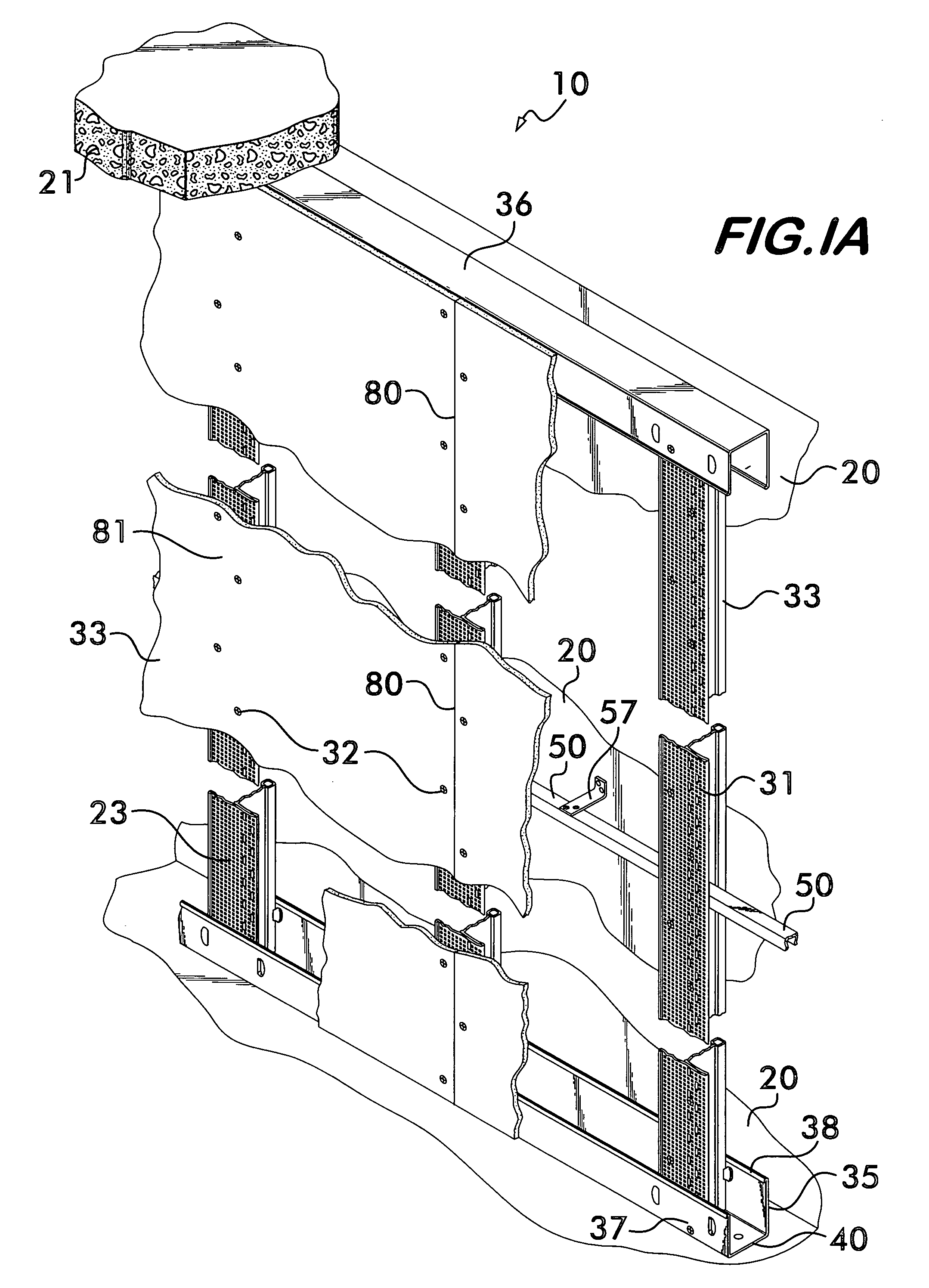

Massive construction system using rock masonry

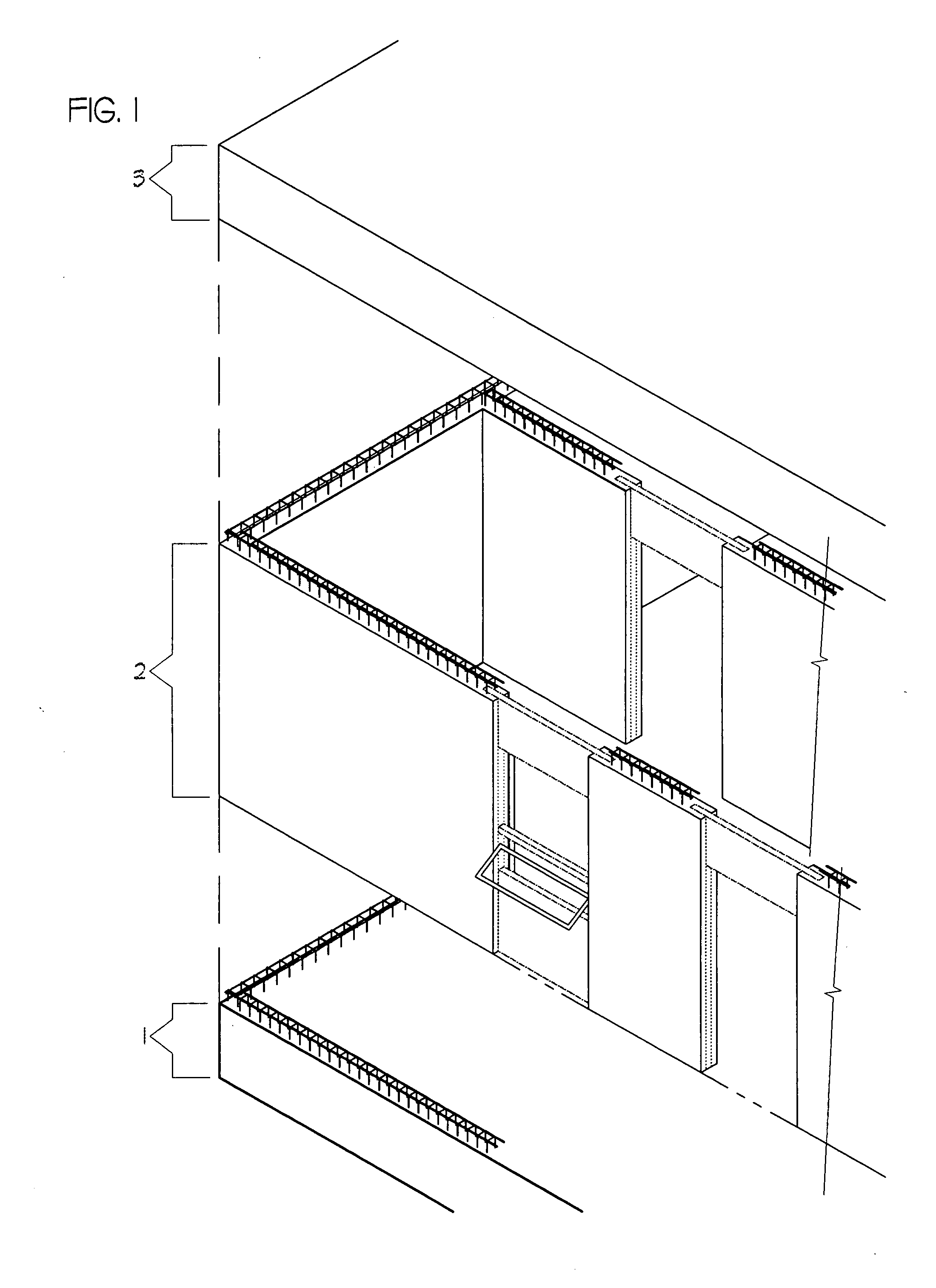

InactiveUS20050155297A1Improve the environmentLow costPublic buildingsSpecial buildingT-beamEngineering

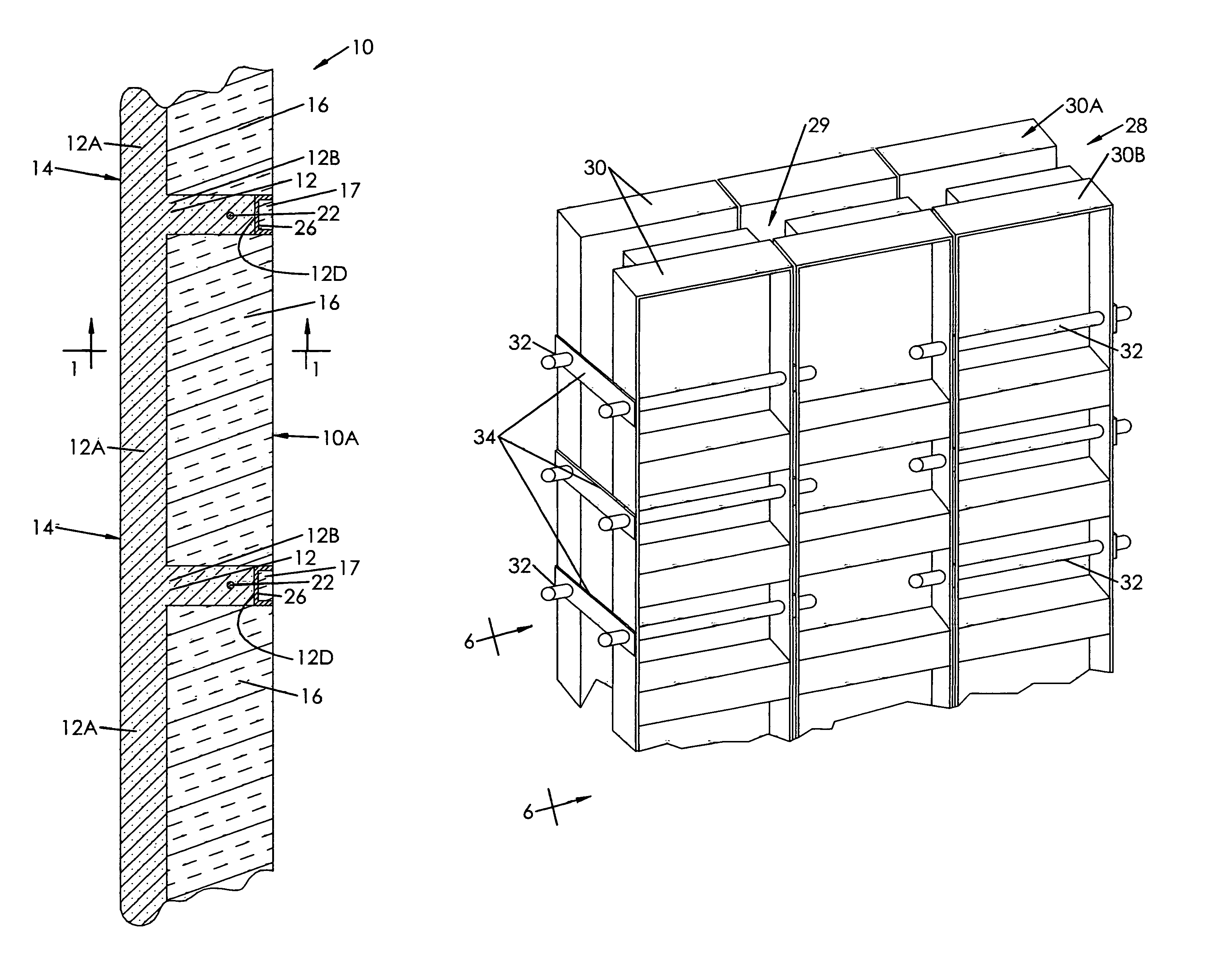

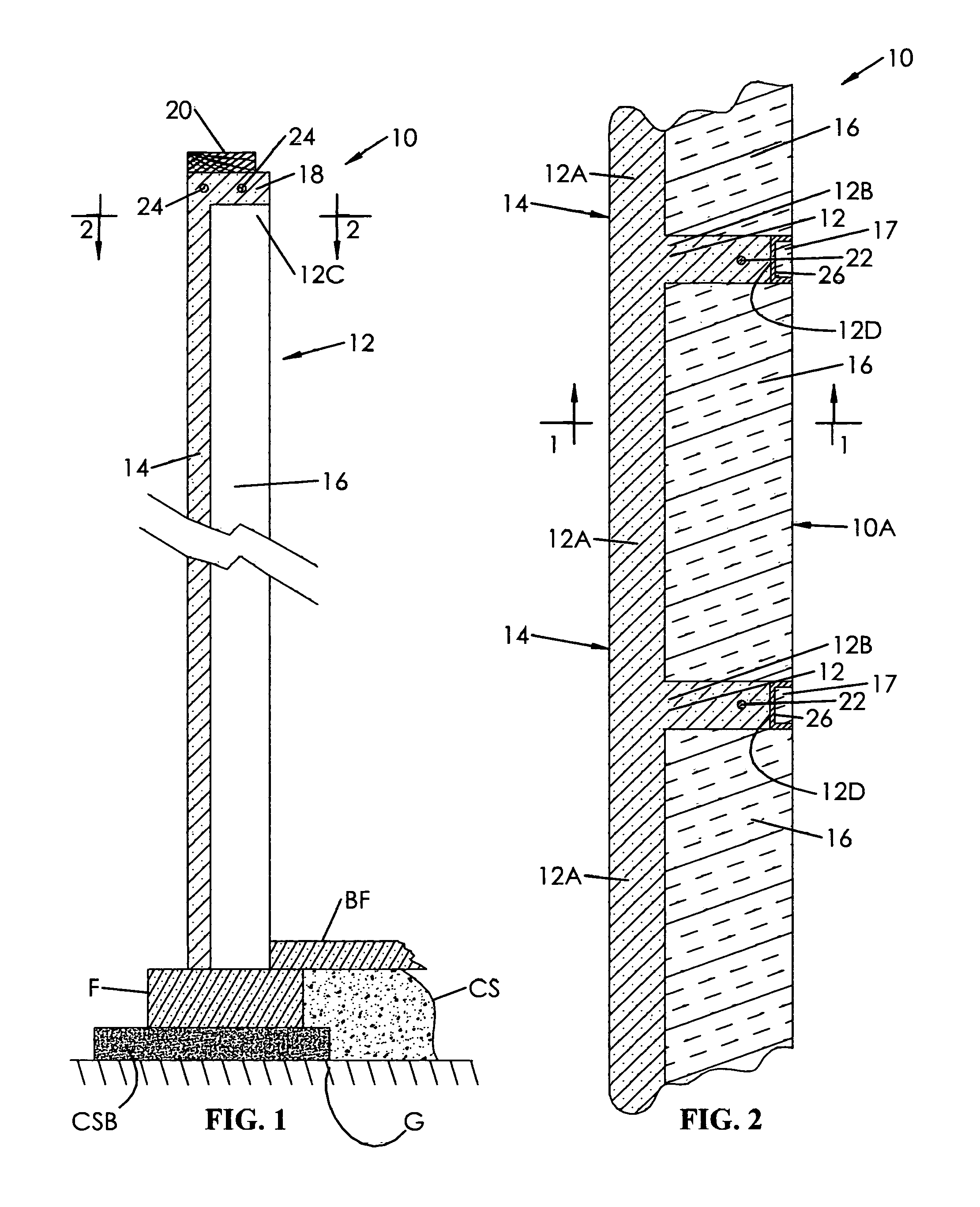

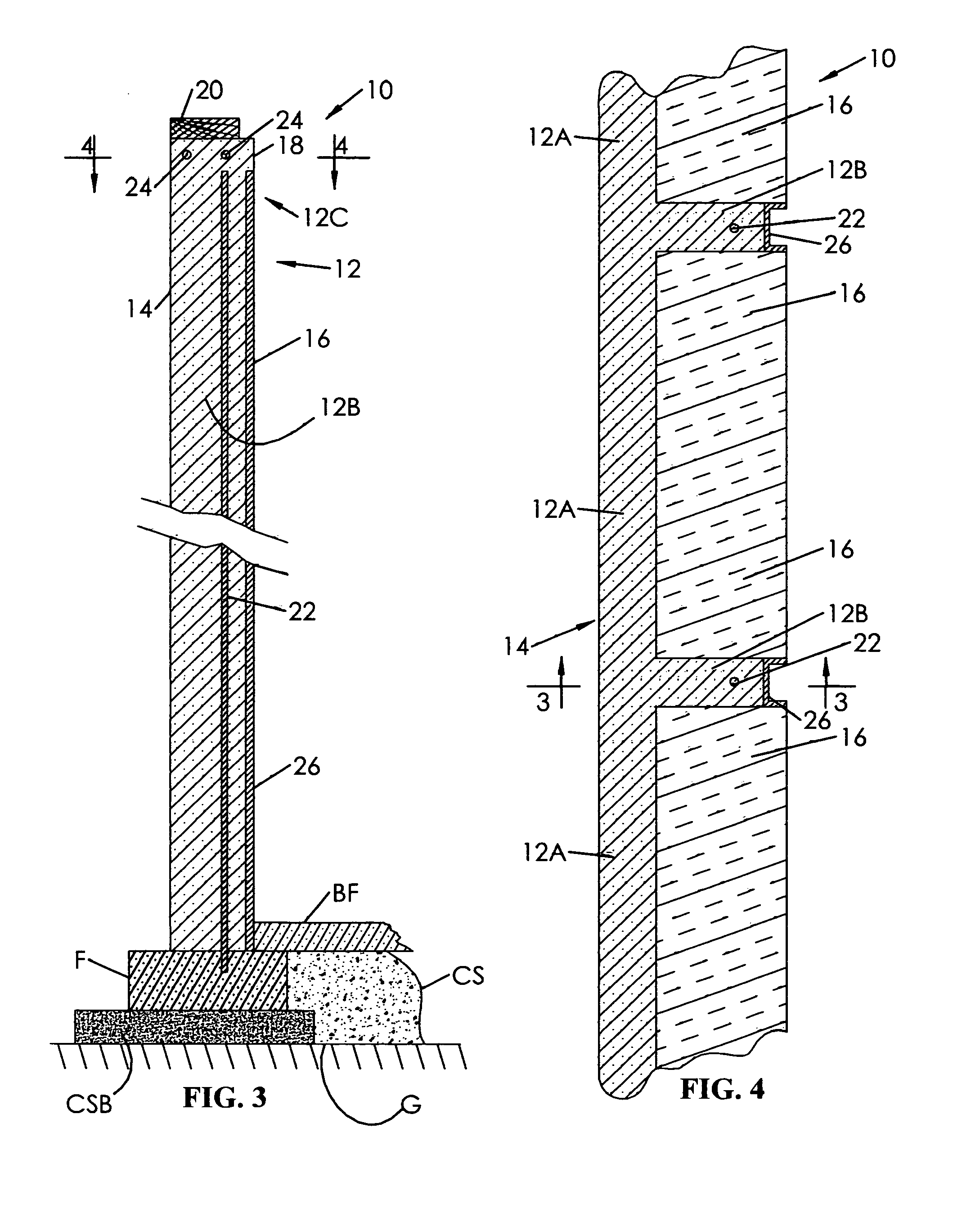

A construction system for massive dwellings or alike; a unit shall be built in 5 days after preliminary work. First, shall be prepared precast items: sills and headers, using templates and reinforcing them to resist shear and diagonal stresses; and exterior and interior wall molds to use numerous times. Then foundation shall be set to have a slab floor with pipes inside a steel structure, and wall molds erected on each side of it, following a predetermined color and graphic code. Afterwards, shall be inserted precasts and all openings of building to pour concrete masonry and form a monolithic structure. A steel structure shall be embedded on top of walls for anchoring concrete T-beams. A material to insulate and form a stem of said T-beams shall be put on platform surface, and then a metallic mesh for reinforcing said T-beams, and for setting pipes, lastly, concrete shall be poured over.

Owner:ABURTO PONCE EUGENIO

Insulated poured concrete wall structure with integal T-beam supports and method of making same

Owner:WEILER NEAL RAY

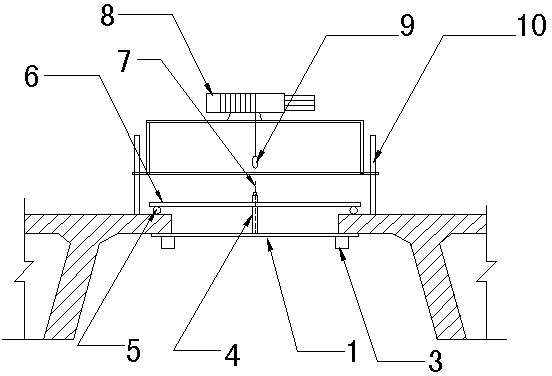

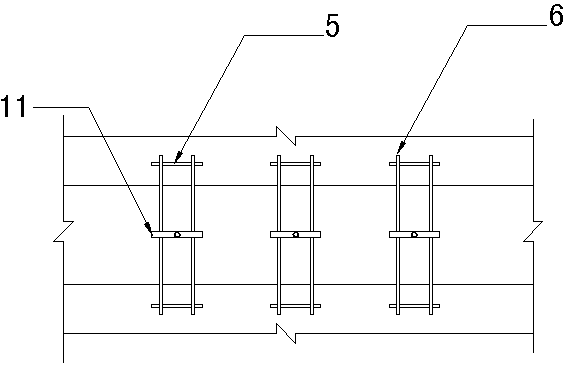

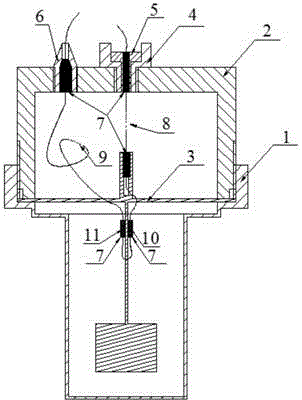

Construction method of longitudinal wet joint formwork of prefabricated T beam or box beam

InactiveCN103306205AEasy to install and removeEasy constructionBridge erection/assemblyVehicle frameT-beam

The invention discloses a construction method of a longitudinal wet joint formwork of a prefabricated T beam or a box beam. A trolley, which can move along the upper surface of a wet joint, comprises a frame and wheels; the wet joint is clamped between the trolley and a bottom formwork; a motor hoist and a steel wire rope are arranged on the frame; the steel wire rope is positioned in the center position of the wet joint; the smooth lifting mounting of the die plate and the dismantling and falling of the die plate are realized through the connection of the steel wire rope, passing through the wet joint, with a screw rod and the bottom die and the lifting by a small hoist; and after the hoisted bottom die is in contact with the lower surface of a beam plate, a PVC (polyvinyl chloride) pipe is sheathed outside a pull rod, and then the bottom die is firmly mounted on the lower surface of the beam plate by an adjustable spanner through a bearing reinforcement, a bridging reinforcement, a hill-shaped buckle and a nut. The construction method facilitates the avoidance of working aloft, the die plate is convenient to assemble and disassemble, the operational safety is improved, the labor intensity is reduced, the mounting and falling working efficiency of the die plate is improved effectively, and each set of die plate can be recycled, so that the cost is lowered.

Owner:CHINA MCC17 GRP

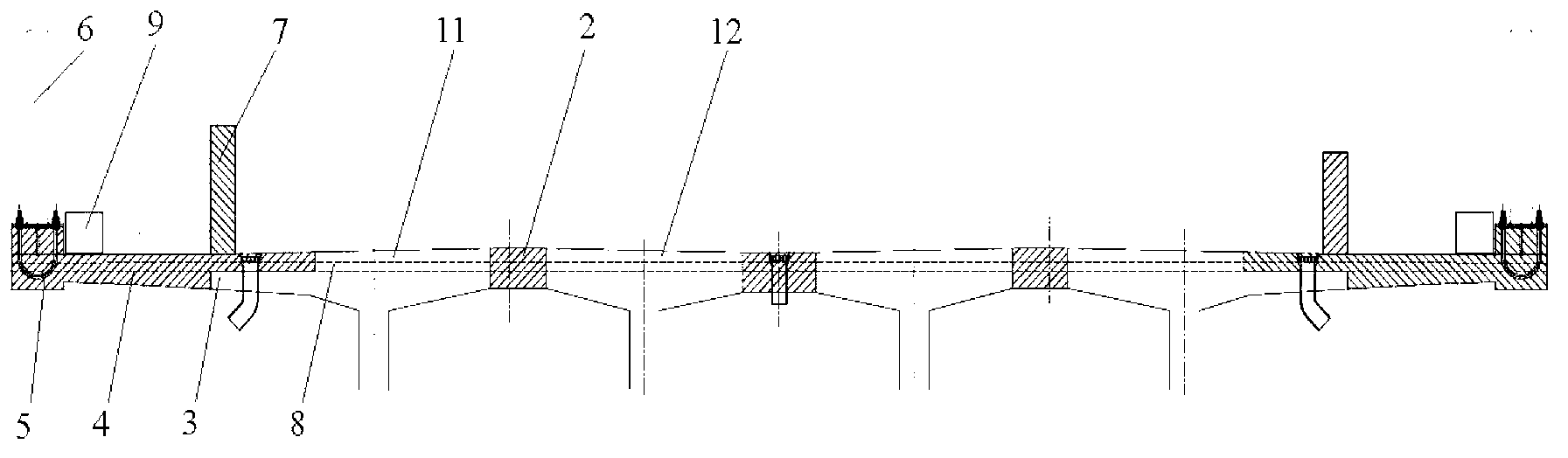

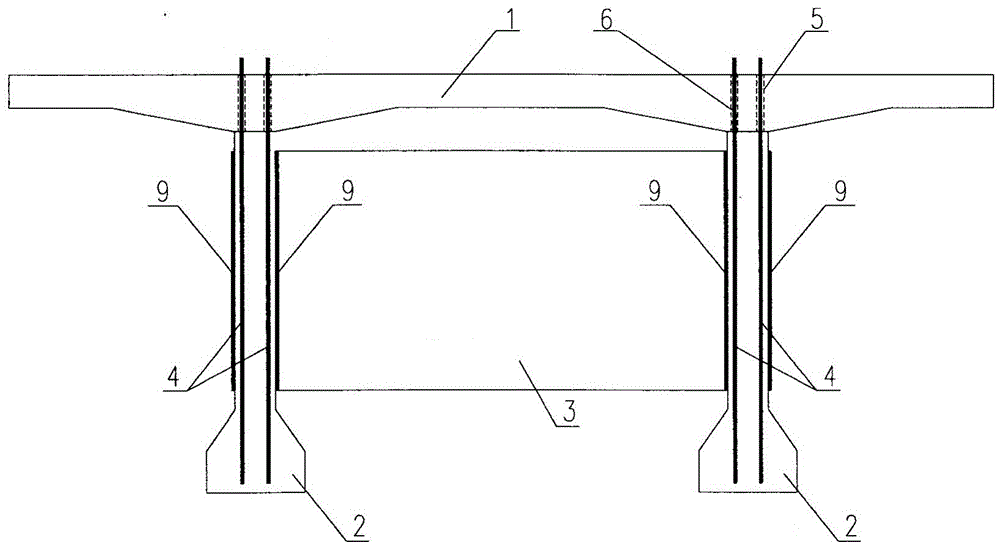

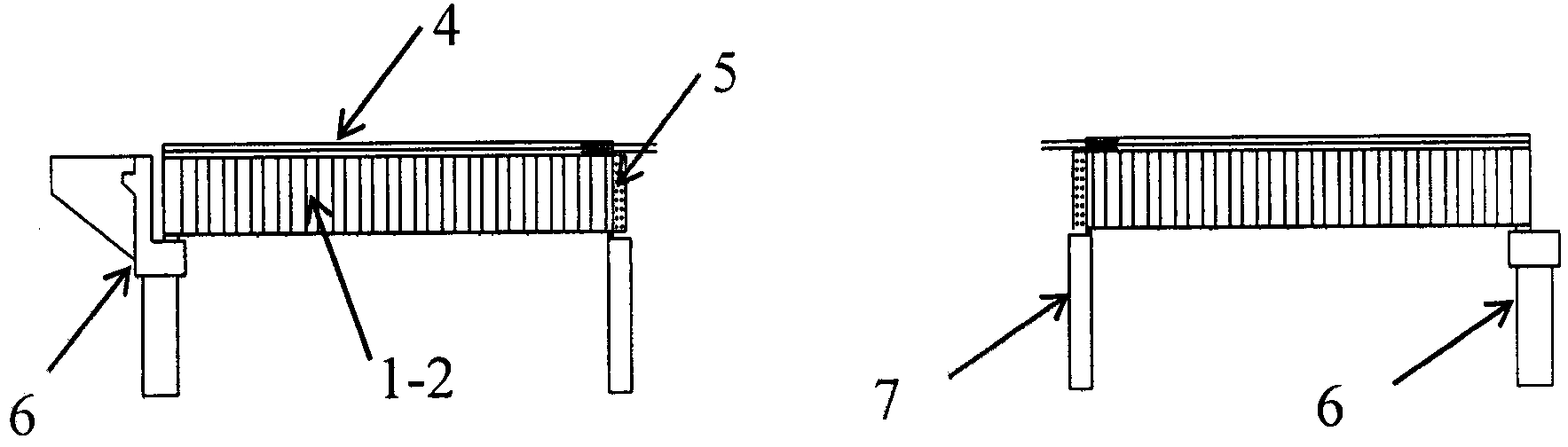

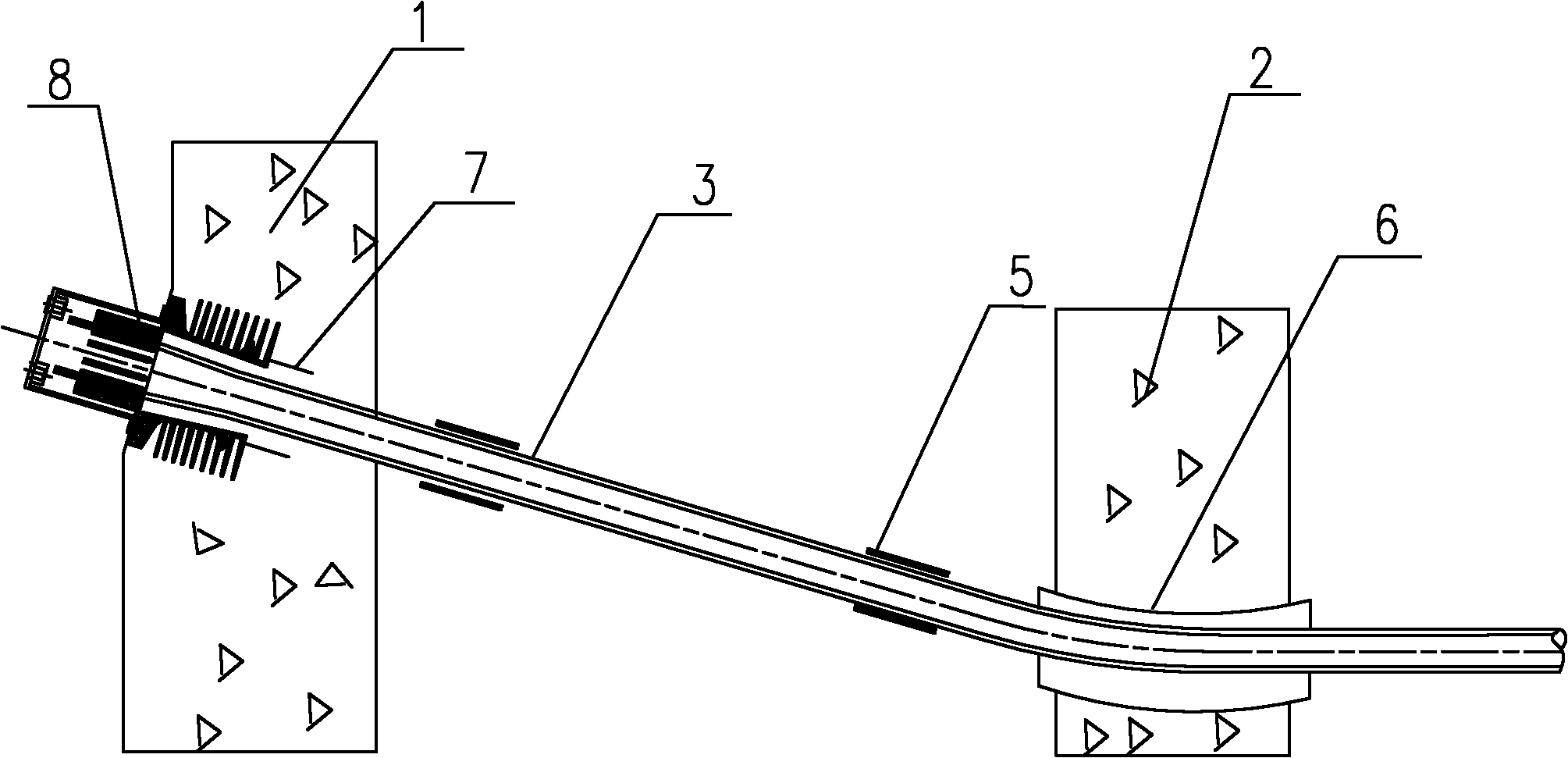

Construction technology for simply supported and continuously supported external prestressed continuous beam bridge T-shaped section

InactiveCN101942808ALose weightImprove leaping abilityBridge erection/assemblyBridge materialsT-beamPre stress

The invention discloses construction technology for a simply supported and continuously supported external prestressed continuous beam bridge T-shaped section, which comprises the following steps of: a, prefabricating a concrete T-beam, and tensioning an internal prestressing tendon; 2, setting up the concrete T-beam, namely setting up the concrete T-beam hole by hole, and inserting an external prestressing tendon; c, pouring the concrete T-beam, namely pouring wet joints of the beam end on the top of piers to longitudinally form a continuous structure, transversely connecting cast-in-place wet joint transversely passing between wing plates and transverse clapboards into a whole, and tensioning the external prestressing tendon for the first time; and d, constructing a bridge floor system, and tensioning the external prestressing tendon again. The construction technology has the characteristics of convenient exchange of prestressing tendon, low friction loss, light hoisting weight of the beam body, easy assembly and construction, and thin thickness of bridge floor pavement.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fastening method of T-shaped beam bridge

InactiveCN101570960AIncrease stiffnessImprove rigidityBridge erection/assemblyBridge strengtheningShaped beamT-beam

The invention relates to a fastening method of a T-shaped beam bridge. The T- shaped beam bridge comprises a plurality of T-shaped beams with the sections being T-shaped; the T-shaped beams comprise a wing plate positioned in a horizontal part and a ventral shield positioned in a vertical part; the fastening method comprises the following steps: reinforcing steel bars are embedded between the ventral shields of the adjacent T- shaped beams and concrete is poured thereinto so that the at least one concrete cross beam along the T-shaped beam span direction is arranged between the ventral shields of the adjacent T- shaped beams. The fastening method of the T-shaped beam bridge solves the problems existing in the prior art fastening the hinge T- shaped beam that the articulation connection is lacking; the jointing position of the articulation seam is easy to weaken and even fails; the whole rigidity of the bridge is not high.

Owner:BEIJING MUNICIPAL ENG PROFESSIONAL DESIGNINST

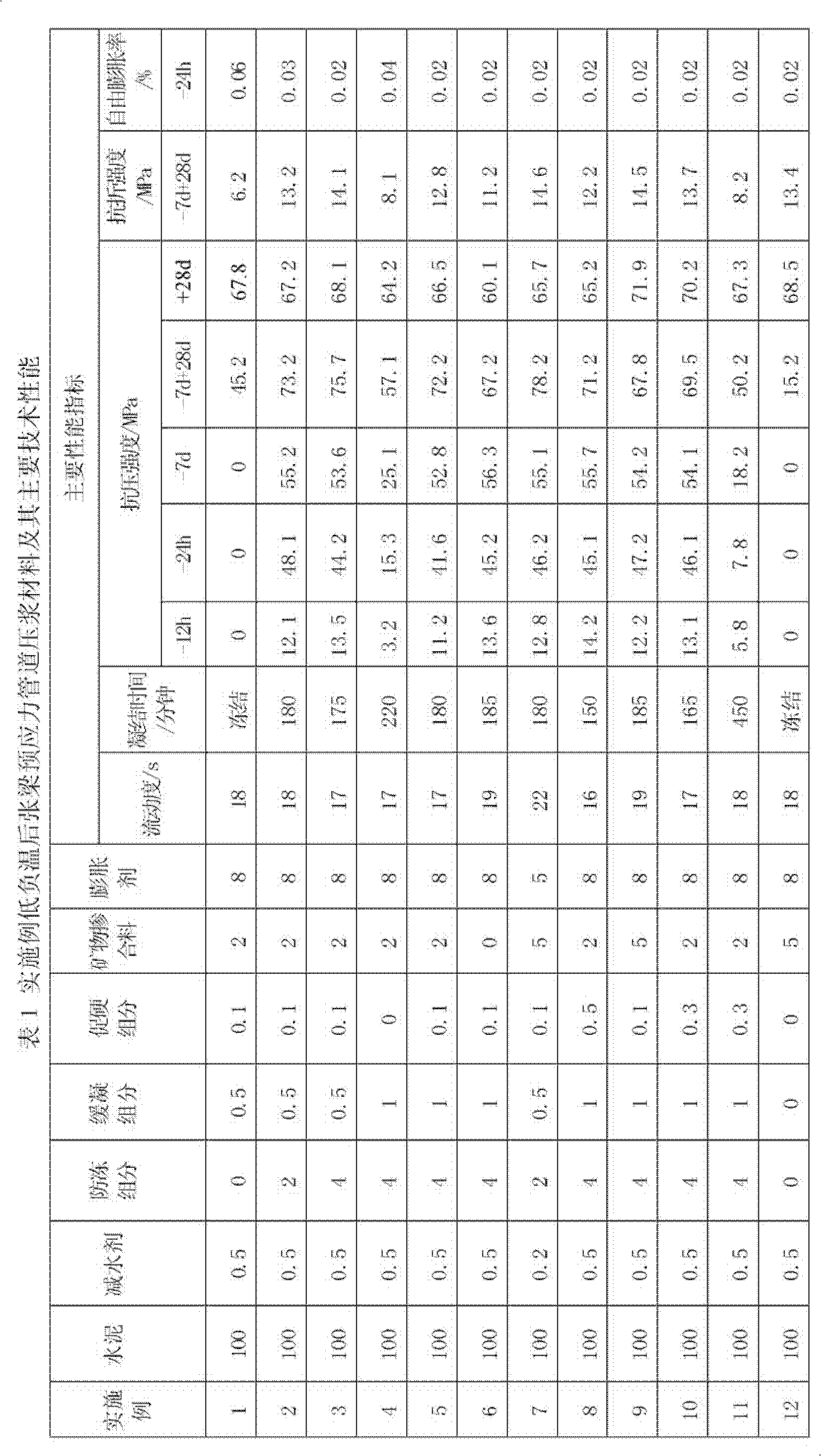

A low negative temperature post-tensioned beam prestressed pipeline grouting material

The invention belongs to the technical field of building materials, and in particular relates to a low negative temperature post-tensioned beam prestress pipeline mudjacking material. The material disclosed by the invention is prepared from cement, a poly-carboxylate water reducer, an anti-freezing component, a retardant component, a harness promoting component, mineral admixtures and an expanding agent through mixing and stirring; the material can be used for the construction of pipe mudjacking of a post-tensioned prestressing T beam and a continuous beam in the construction condition not lower than minus 10 DEG C; and the effect of the material is more obvious in the environment condition of shifts between positive and negative temperatures day and night. The strength of hardened mortarcan develop continuously in the conditions of low temperature and negative temperature, the maintenance time can be shortened greatly, the construction efficiency can be improved, and large energy consumption required by low and negative temperature construction can be reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

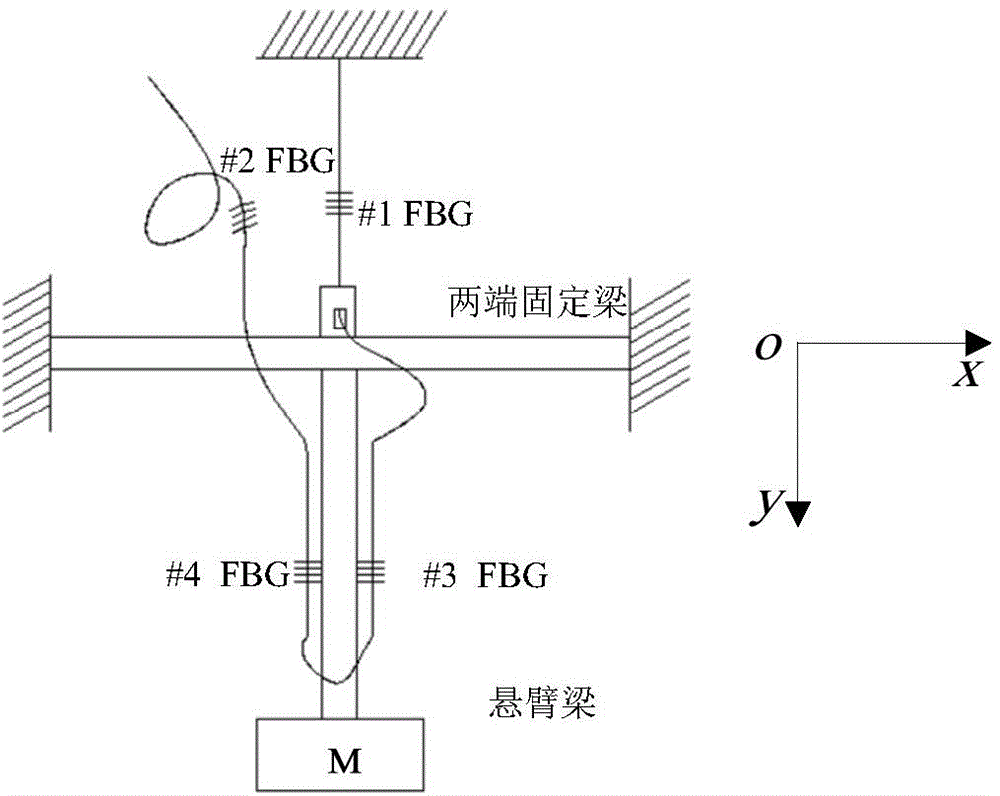

Fiber Bragg grating two-dimensional vibration sensor with temperature compensation

ActiveCN104807536ARaise the resonant frequencyHigh sensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberElastomer

The invention discloses a fiber Bragg grating two-dimensional vibration sensor with temperature compensation, which comprises an upper end cover, a T-shaped beam, a lower end cover and four fiber Bragg gratings, wherein the T-shaped beam comprises a cross beam and a vertical beam, the third fiber Bragg grating and the fourth fiber Bragg grating along the direction of the cross beam are connected through the first fiber Bragg grating arranged along the direction of the vertical beam, vibration acceleration parameters in the two mutually vertical directions can be measured in real time, temperature compensation is carried out on the first fiber Bragg grating through the second fiber Bragg grating, the T-shaped beam is adopted to act as an elastic body to realize vibration measurement, and the resonant frequency and the sensitivity of the sensor are effectively improved. Meanwhile, a pretightening force of the first fiber Bragg grating is changed through adjusting a pretightening screw, and the vibration measurement range along the direction of the vertical beam can be enlarged. According to the invention, the fiber Bragg grating two-dimensional vibration sensor transmits optical signals through optical fibers and has a higher anti-electromagnetic interference ability. In addition, multi-parameter distributed vibration dynamic measurement can be realized through connecting a plurality of the fiber Bragg grating two-dimensional vibration sensors with temperature compensation in series.

Owner:WUHAN UNIV OF TECH

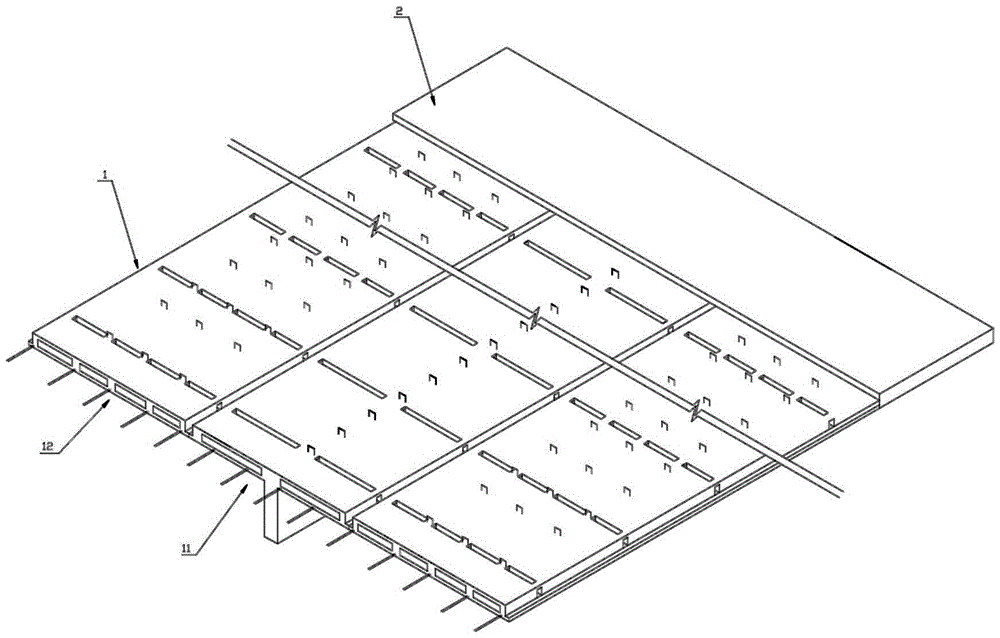

Overlapped floor

The invention discloses an overlapped floor which comprises a plurality of prefabricated reinforced concrete panels and T beam plates. At least one panel is spliced between every two adjacent T beam plates, and the prefabricated reinforced concrete panels and the T beam plates form the integral overlapped floor through post-poured reinforced concrete overlapped layers. According to the overlapped floor, due to the prestress technology and a bidirectional dense rib sandwiching structure form, the use amount of concrete is reduced, dead load is reduced, cost is reduced, and the rigidity and the bearing force of the overlapped floor are improved. Longitudinal rib belts and transverse rib belts are poured through lightweight aggregate structure heat insulation concrete so that the thermal bridge influences on the longitudinal rib belts and the transverse rib belts can be reduced, and meanwhile light filling blocks are matched for improving the heat insulation capability of the overlapped floor. When the overlapped floor is used, the T beam plates and the panels are arranged on a pre-pouring frame beam, and then the integral overlapped floor is formed after post-pouring of the reinforced concrete overlapped layers. The dead load is not increased, the bearing force is ensured, the shearing resisting capability of connecting points is ensured, and meanwhile heat preservation and heat insulation can be achieved; under the premise that the integrity and safety of the overlapped floor are ensured, the construction cost is reduced, and construction is simplified.

Owner:HUNAN DONGFANGHONG CONSTR GRP

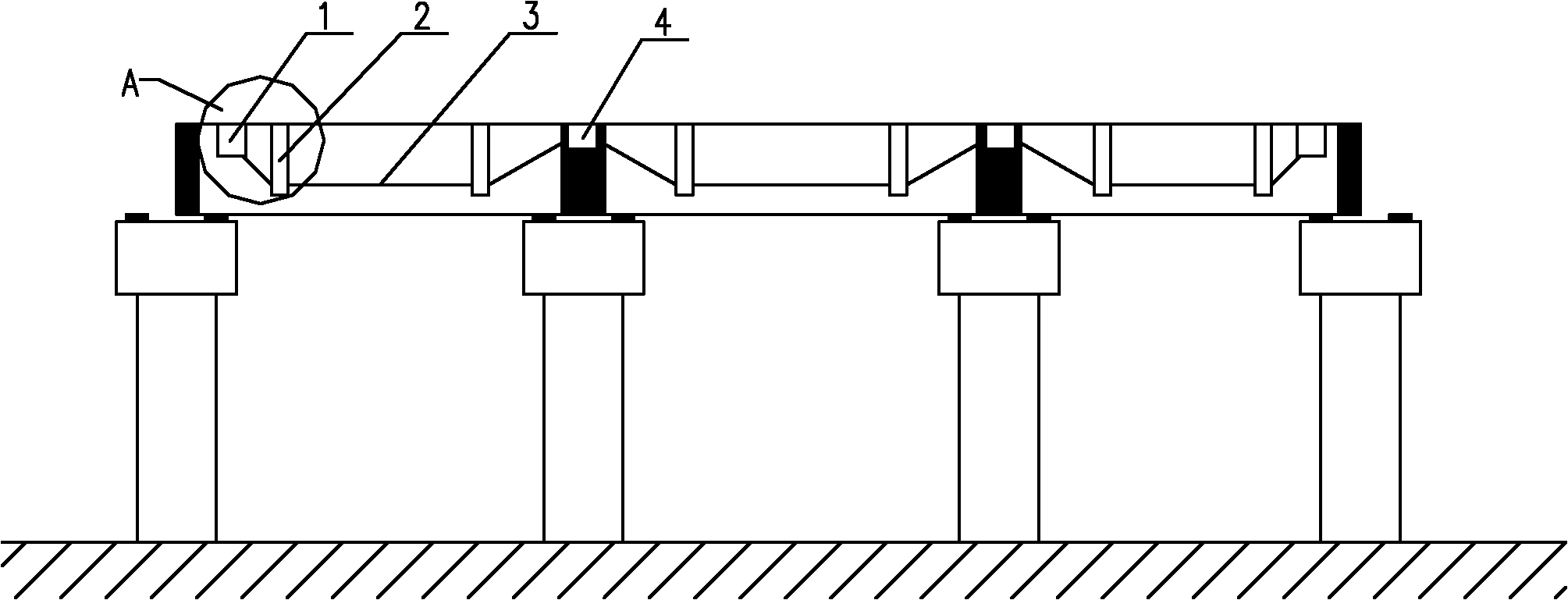

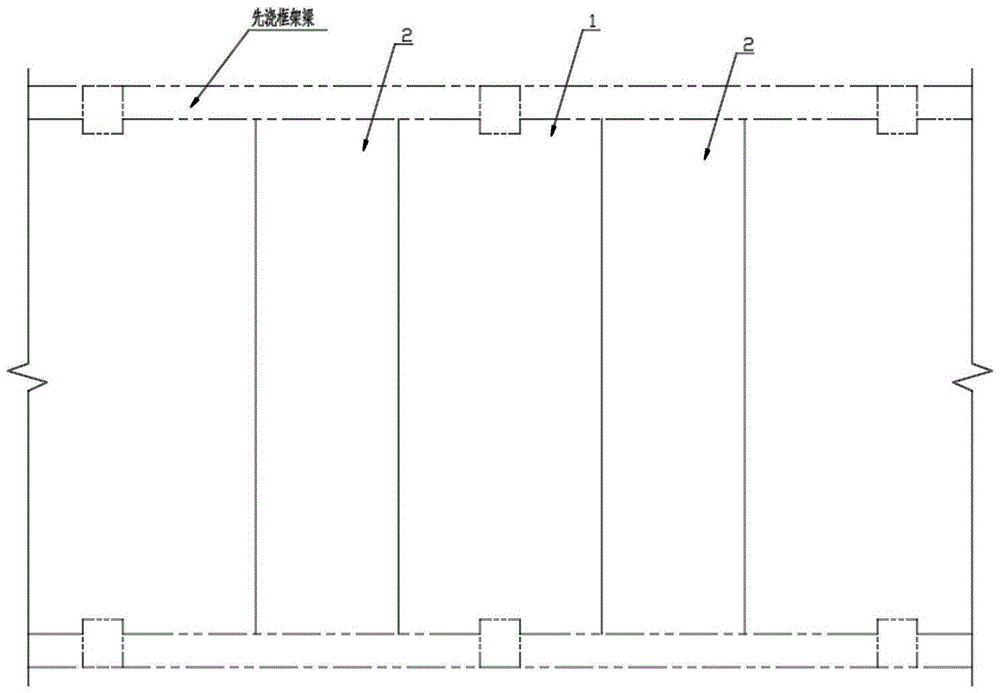

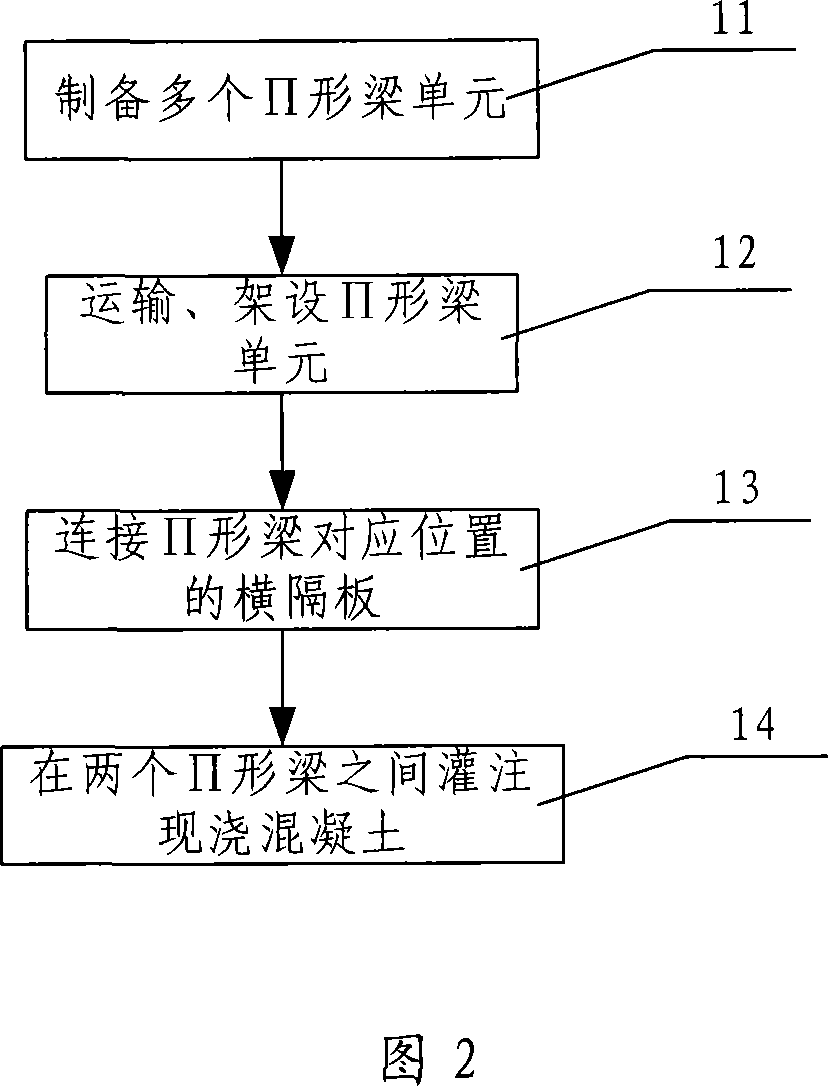

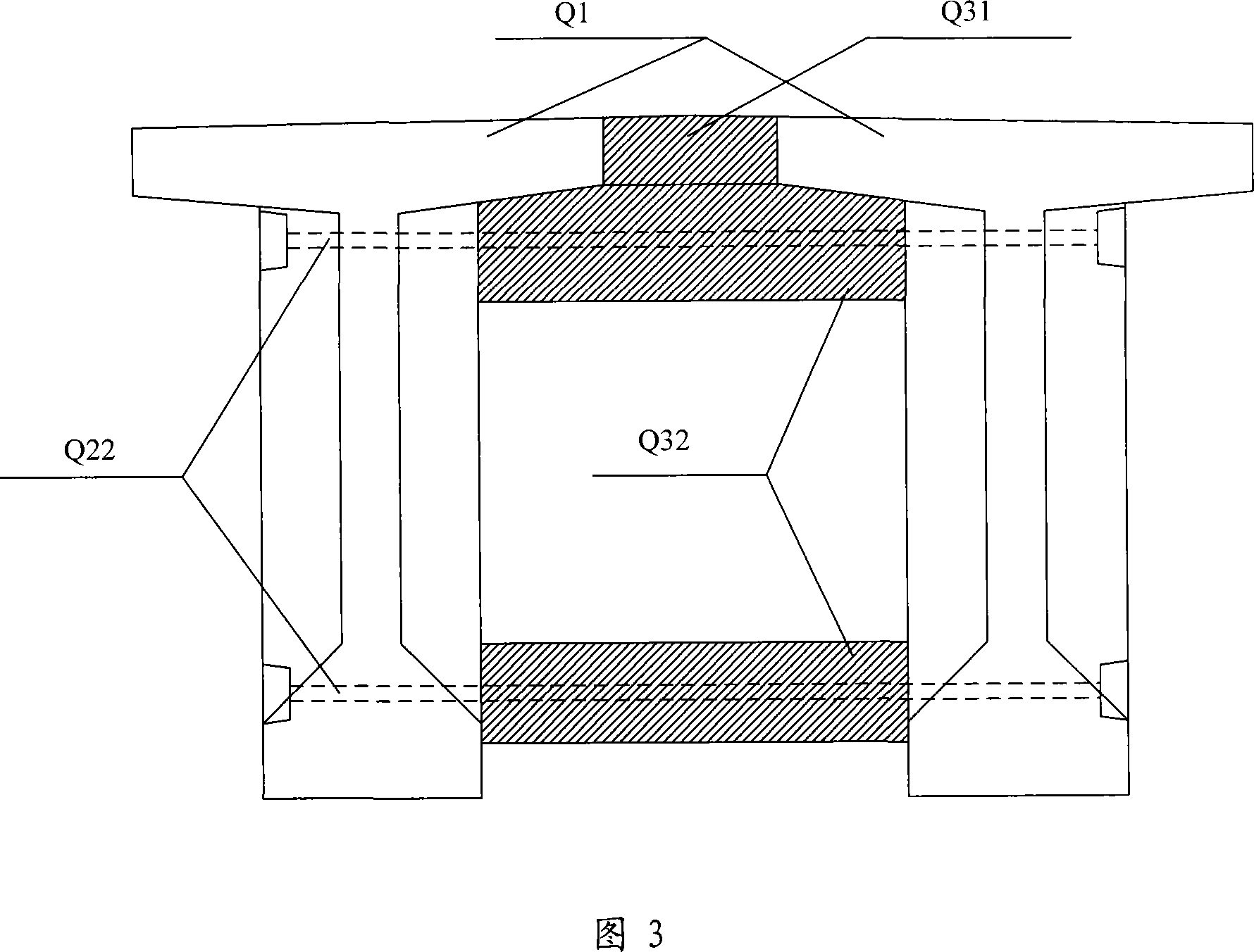

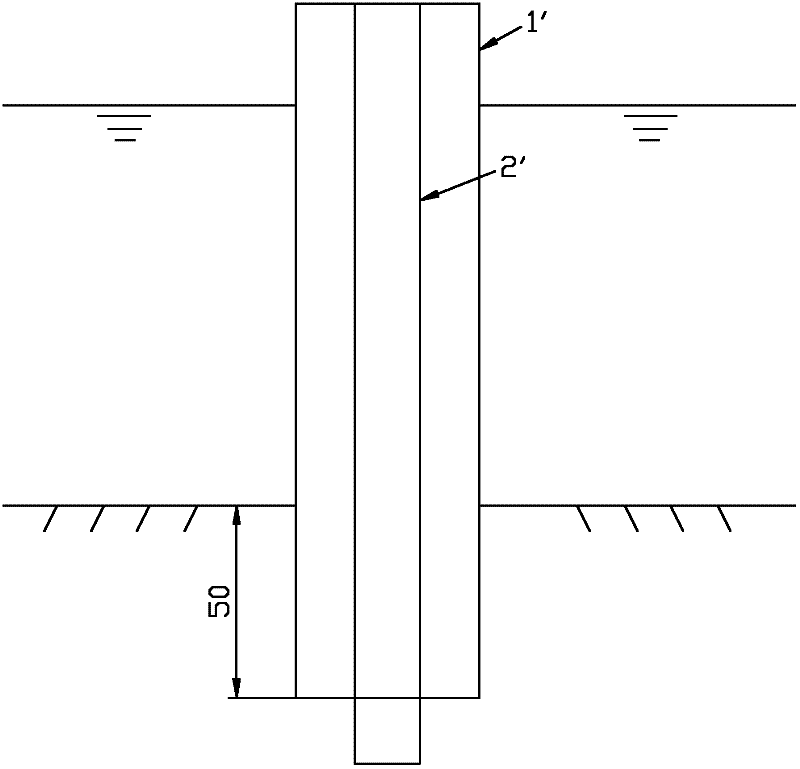

Method for building railway bridge and simple support T beam bridge

ActiveCN101050622AFast erectionMeet the needs of setting up bridge ancillary facilitiesBridge materialsShaped beamT-beam

The present invention relates to a method for erecting railway bridge and a simply-supported T-beam bridge. Said erection method includes the following steps: preparing inverted 'U'-shaped beam unit under the bridge, then transporting and placing all the inverted 'U'-shaped beam units, and transverse connecting all the inverted 'U'-shaped beam units so as to implement erection of simply-supported T-beam bridge.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

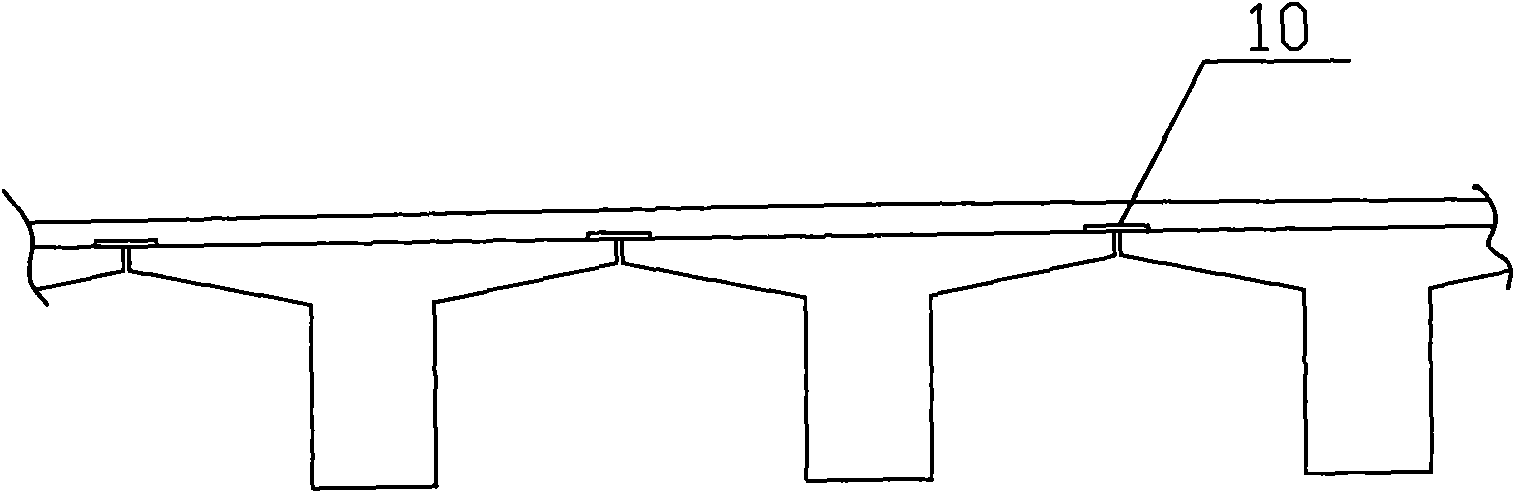

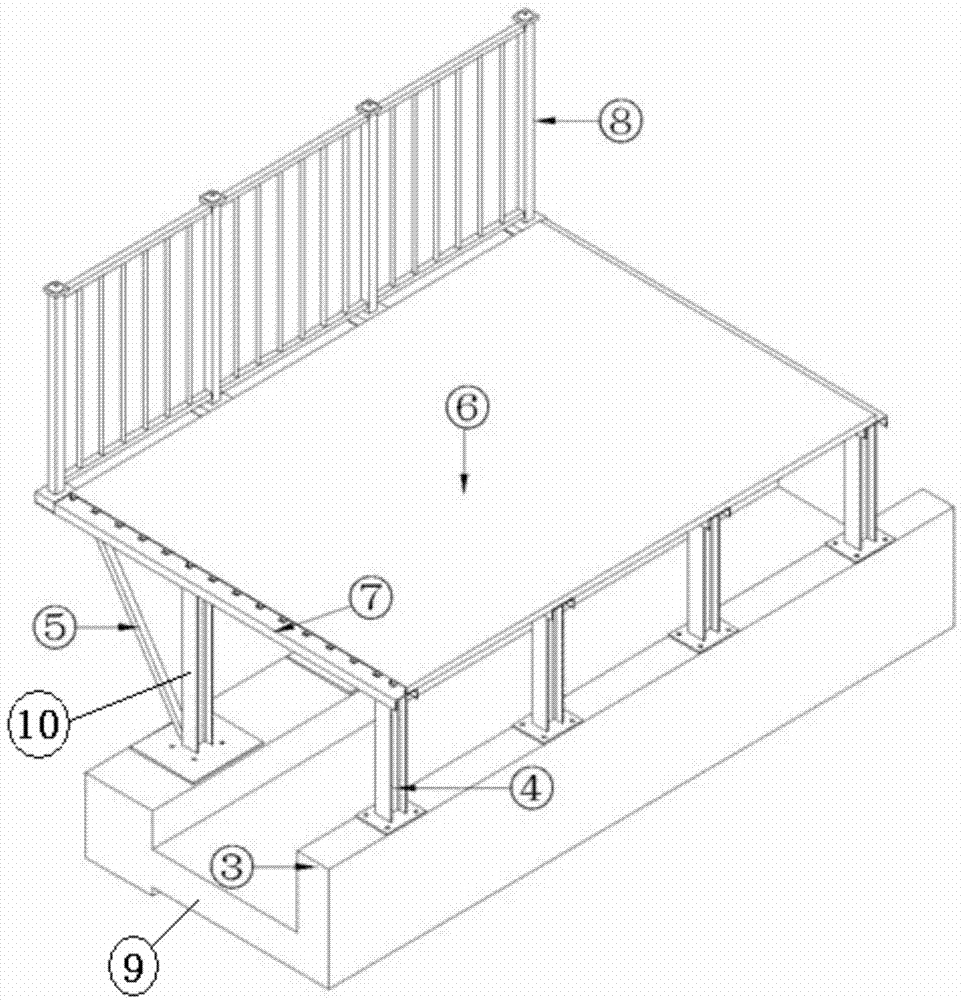

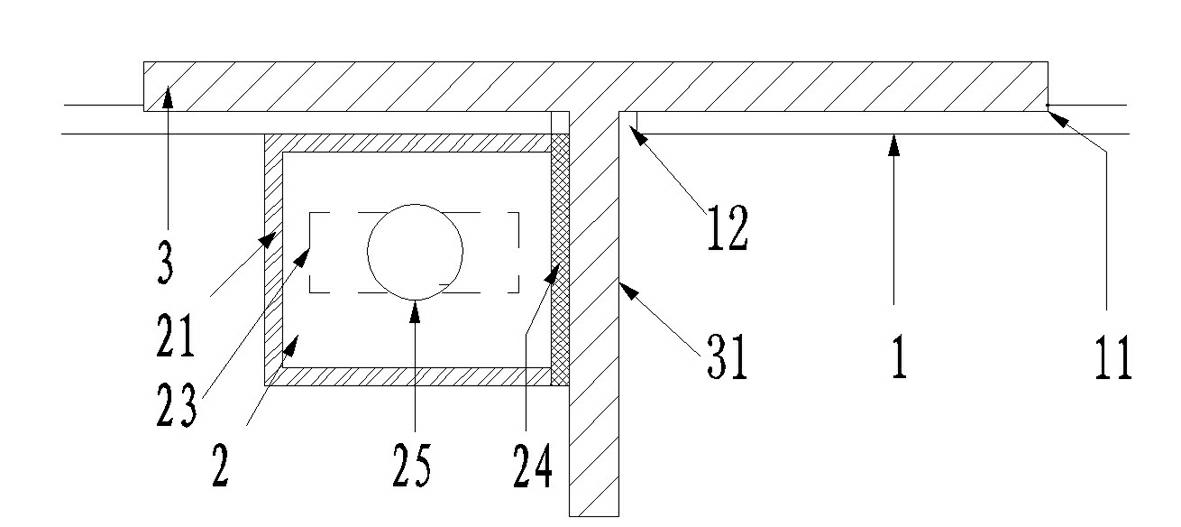

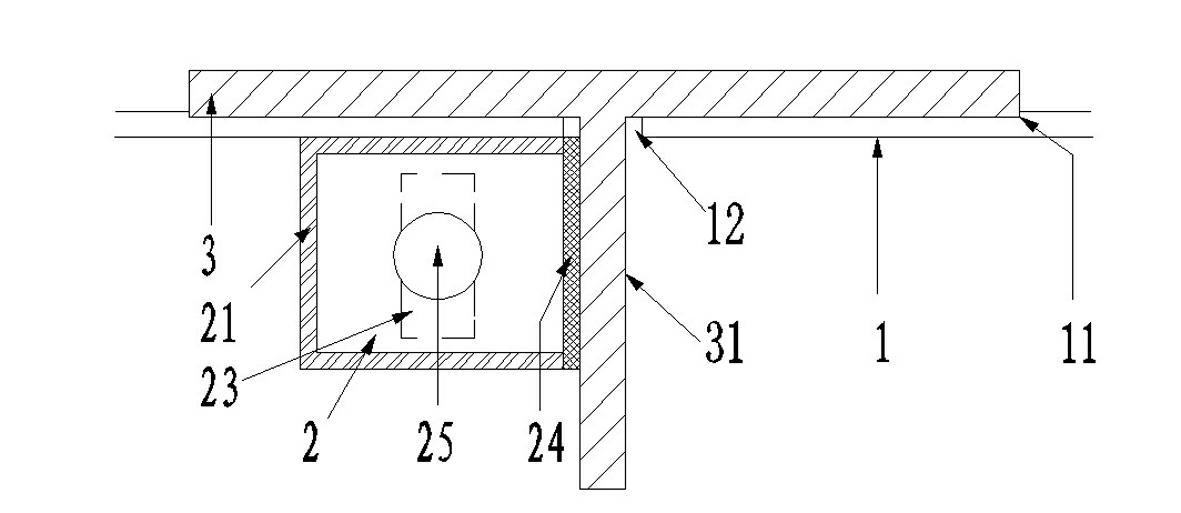

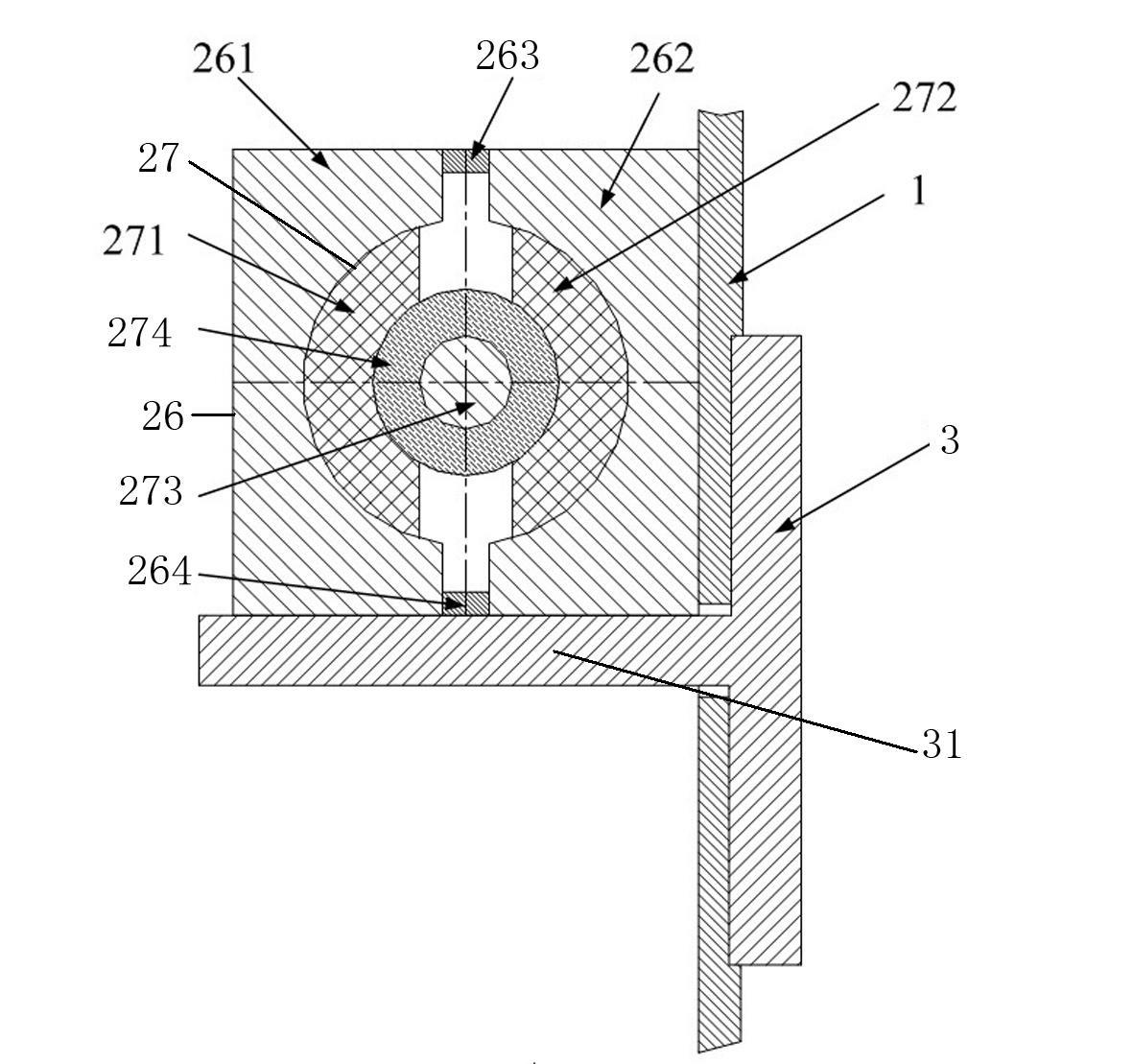

Railroad bridge evacuation platform

ActiveCN103938538AImprove securityDead load improvementBridge structural detailsBridge erection/assemblyT-beamBridge deck

The invention provides a railroad bridge evacuation platform and belongs to the technical field of railroad traffic engineering. The problem that beam sheets can not be widened easily through an existing railroad T-beam evacuation platform is solved. The railroad bridge evacuation platform comprises a cantilever beam installed at the top of a T-beam and extending outwards. A ballast stop wall is installed in the middle of the cantilever beam. Multiple front uprights are longitudinally installed at the top of the ballast stop wall. The transverse outer side of each front upright is provided with a rear upright. A beam is installed at the top of each front upright and the top of the corresponding adjacent rear upright. The top of each beam is provided with a flier. The edges of the transverse outer sides of the fliers are provided with handrails. According to the railroad bridge evacuation platform, the number of beam sheets of the T-beam can be obviously reduced, the size of piers and the size of foundations do not need to be increased, the dead load above a bridge floor is remarkably improved, and structural safety is enhanced.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

Continuous CFRP decked bulb T beam bridges for accelerated bridge construction

A pre-stressed concrete bridge using longitudinal load members of a single continuous beam including at least two types of concrete, one of which is ultra-high-performance concrete (UHPC) mix with a compressive strength exceeding 137.9 Mpa (20 ksi) and tensile strength exceeding 10.34 Mpa (1.5 ksi) in a region proximate to the support structure.

Owner:LAWRENCE TECHNOLOGICAL UNIV

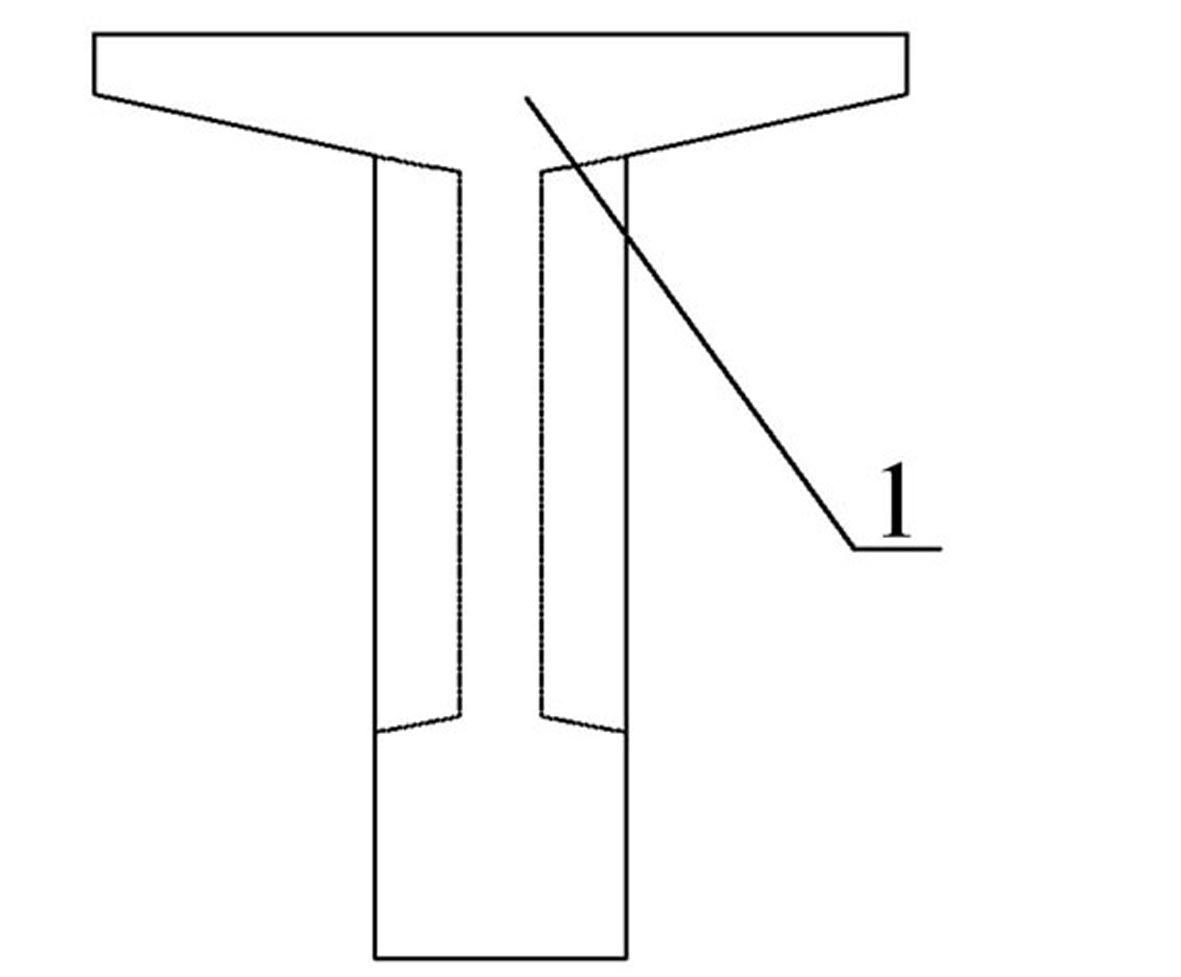

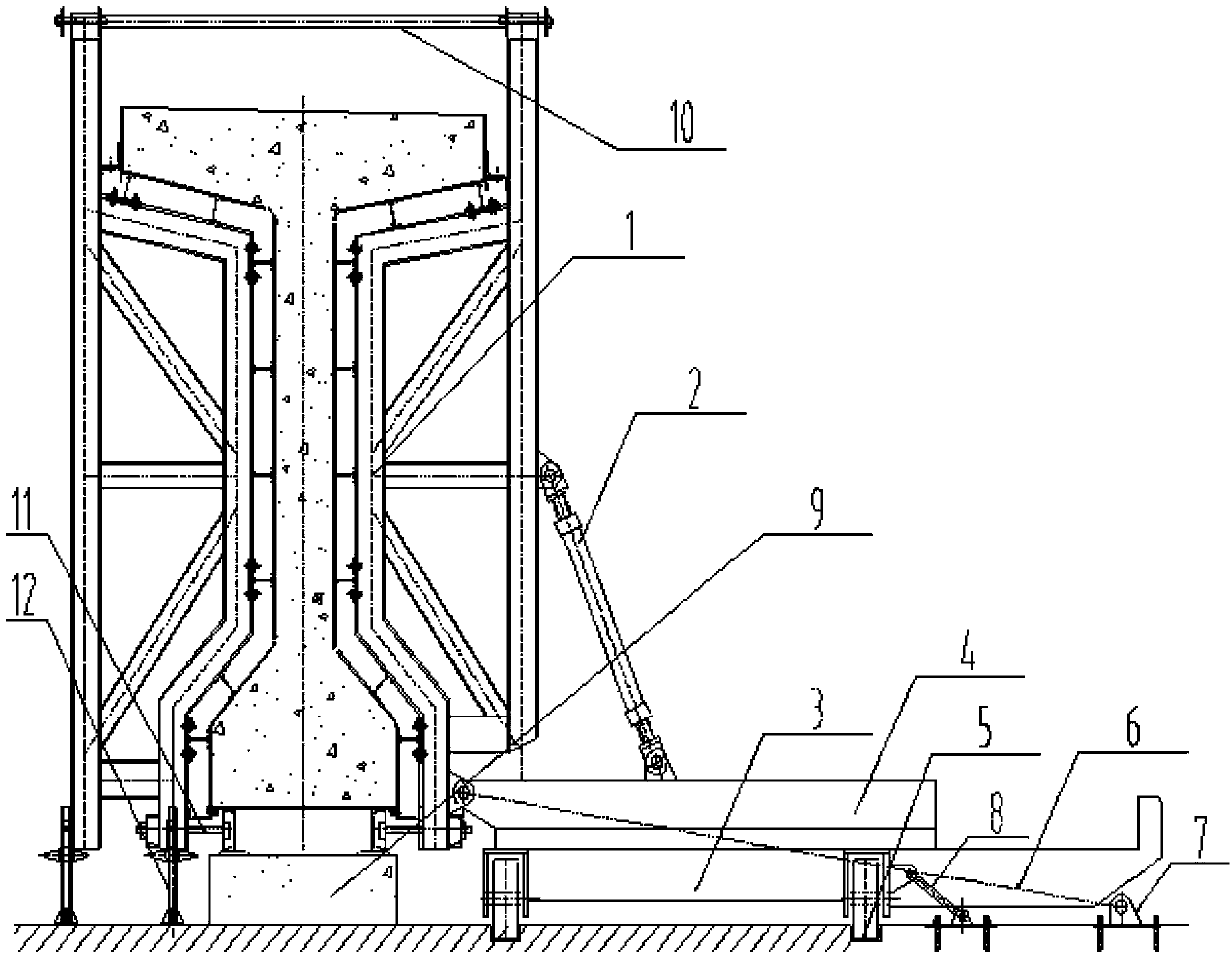

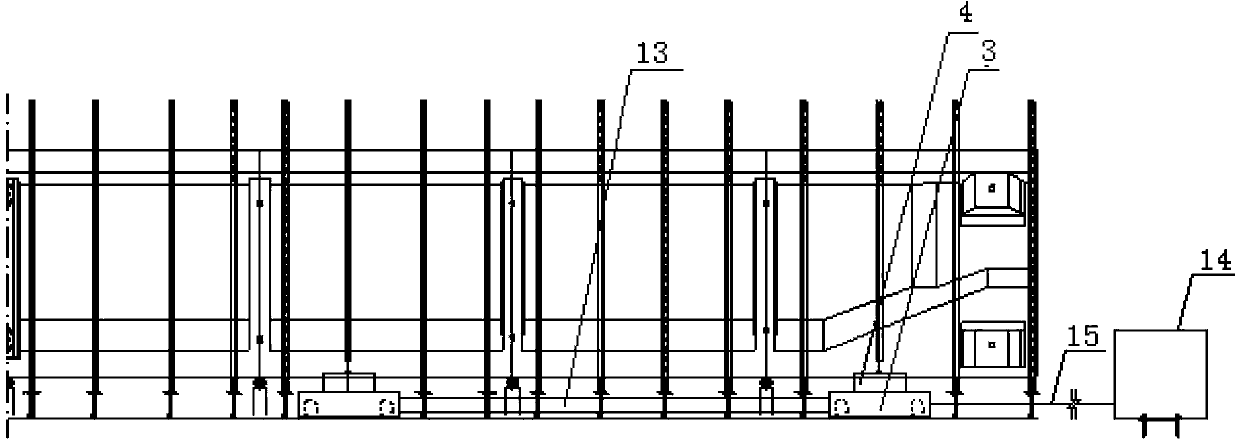

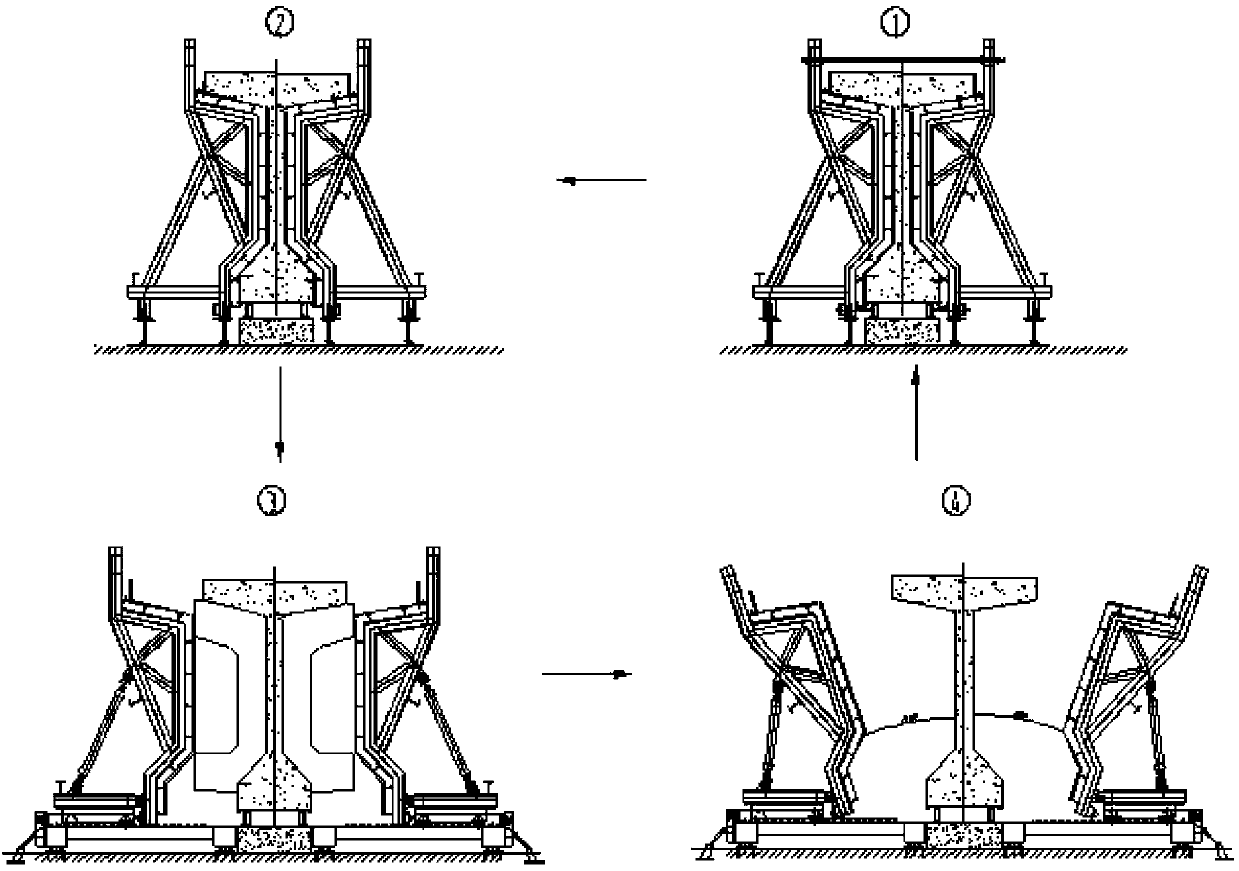

T-shaped beam casting special mold and using method thereof

PendingCN109968499AQuality improvementHigh quality, high market application prospectsDischarging arrangementMouldsShaped beamT-beam

The invention discloses a T-shaped beam casting special mold and a using method thereof, and relates to the technical field of T-shaped beam manufacturing. The T-shaped beam casting special die comprises a guide rail, wherein a walking trolley is arranged on the sliding rail in a sliding mode, a left mold and a right mold are symmetrically arranged on the walking trolley, the left mold comprises frames and panels connected to the inner side of the frames, the walking trolley is provided with mold guide devices which are positioned at the outer side ends of the two frames and provided with high-stroke spaces, the outer side ends of the two frames are provided with overturning type demolding mechanisms, an automatic slope adjusting mechanism and a locking mechanism are arranged on each frame, the tops of the automatic slope adjusting mechanisms and the tops of the locking mechanisms are hinged to the bottom of rotatable parts of the panels, combined adjusting mechanisms for adjusting theheight of the left mold and the bottom of the right mold are arranged at the bottom of the left mold and the bottom of the right mold, and supporting columns which are convenient to assemble and disassemble are arranged on the outer sides of the tops of the two frames, and during use, the supporting columns are subjected to mold closing and grouting, demoulding. The T-shaped beam casting specialmold has the advantages of being complete in function and good in T-shaped beam forming quality.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

Wall liner

Owner:WORTHINGTON ARMSTRONG VENTURE

Split mounting type bridge wet joint construction method

Owner:THE FIRST ENG CO LTD OF CTCE GRP

Prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam and reinforcing method thereof

InactiveCN105937307AEasy constructionImprove construction efficiencyBuilding repairsBuilding material handlingHysteresisT-beam

The invention discloses a prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam. The prestress-steel-wire-rope-bending-shearing-reinforced concrete T beam comprises a reinforcing system arranged on the concrete T beam. The reinforcing system comprises steel wire ropes, a plurality of bending-resistant reinforcing steel plates arranged at the bottom of the concrete T beam and a plurality of angle steels horizontally fixed to the two sides of a web plate of the concrete T beam; a plurality of bolt holes are formed in the other edges of all the angle steels in the length direction of the angle steels, adjustable bolts are arranged in all the bolt holes, circular rings are arranged at one ends of the adjustable bolts, and after the steel wire ropes are wound around the beam bottom, the two ends penetrate through corresponding circular rings respectively and are tensioned; a protection system is further arranged on the outer side of the reinforcing system. In the reinforcing process, prestress is applied to the steel wire ropes through the adjustable bolts, a specially-made tensioning apparatus does not need to be adopted, construction is convenient and fast, construction efficiency is greatly improved, the prestress is applied to the steel wire ropes, the stress hysteresis effect is avoided, and the reinforcing effect and the whole bearing capacity are improved; construction cost is low, construction is easy and convenient, the influence on structure weight is small, and the excellent structural performance and economic benefits are achieved.

Owner:JIANGXI GANYUE EXPRESSWAY +2

Assembly construction process of prefabricated 40m T-beam in intertidal zone of open sea

The invention discloses an assembly construction process of a prefabricated 40m T-beam in an intertidal zone of an open sea. The intertidal zone is a critical construction region of a coastal construction, and is a construction which does not adapt to water or land construction process; and construction of the intertidal zone is a technical problem at home and abroad. The process comprises the following steps: a prestress T beam is shipped to the construction field after the 40m prestress T beam is prefabricated by a post-tensioning method; the T beam is hoisted to a beam transporting trolley through a cross-mound gantry crane on a switching platform, and transported to the erection field by the beam transporting trolley, and is spanned to a designated position through a bridge girder erection machine. The particular assembly sequence is that the beams are spanned from the sea side to the coach side, and the erection sequence of each T beam is side, center, side and center. According to the assembly construction process, the typical intertidal zone construction problems that prefabricated T beams are adopted in the upper structure of an approach bridge with a designed length of over 3km and bent spacing of 40m, the single T beam with maximum weight of over 180 tons is positioned between high and low tide levels of a spring tide and is submerged and exposed along with tiding can be solved successfully.

Owner:NO 3 ENG CO LTD OF CCCC THIRD HARBOR ENG CO LTD +1

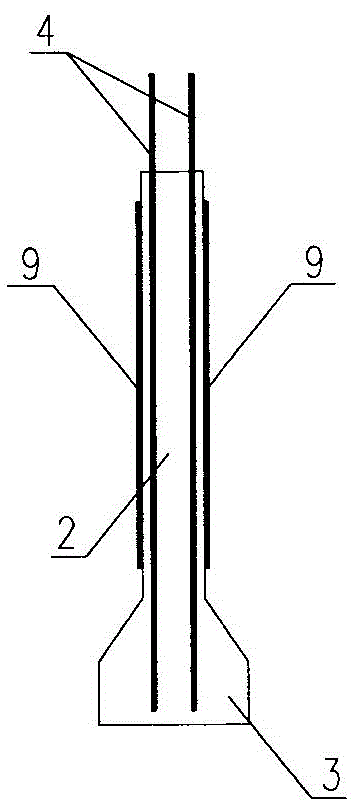

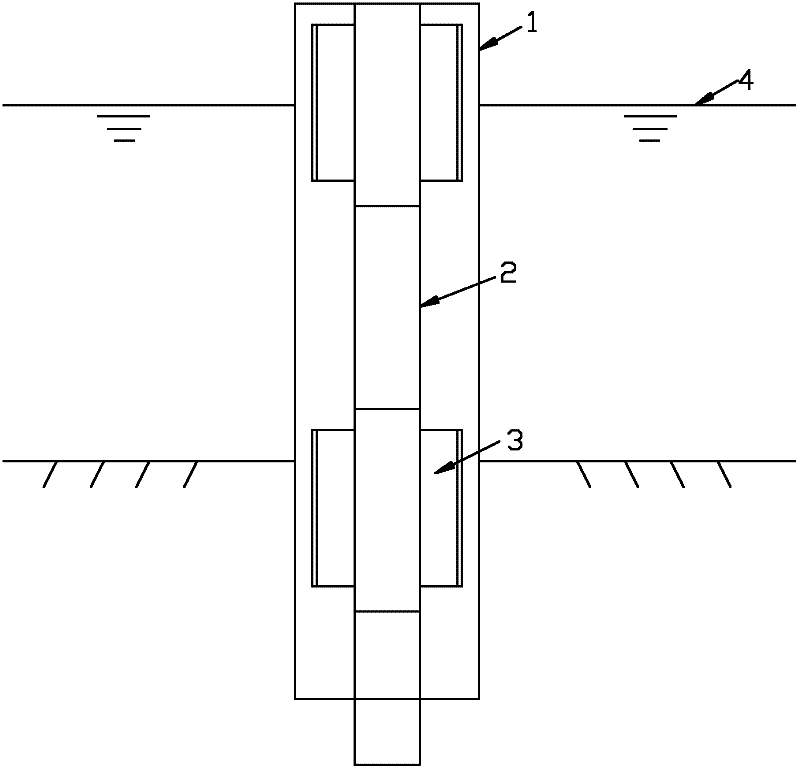

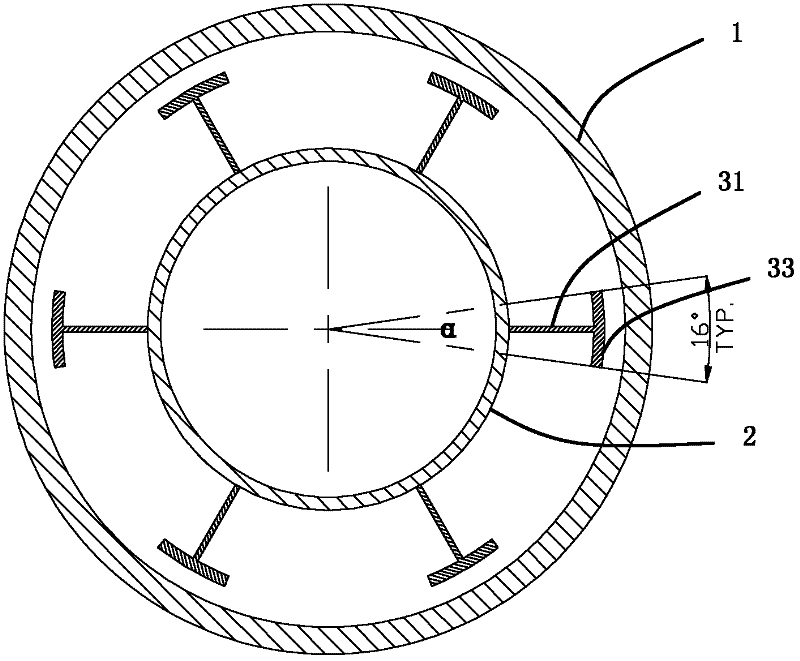

Reinforced riser pipe combined structure and construction method thereof

ActiveCN102226378AIncreasing the thicknessIncreased stiffness against lateral stressDrilling rodsUnderwater drillingWell drillingT-beam

The invention discloses a reinforced riser pipe combined structure and a construction method thereof, and the reinforced riser pipe combined structure comprises an inner-layer sleeve and a riser pipe, wherein a T-like beam structure is welded on the outer surface of the inner-layer sleeve; and the inner-layer sleeve which is of the T-like beam structure is arranged at a position which is 5-10m below a mud line and 3-10m above the sea level, and an annular space part between the riser pipe and the inner-layer sleeve is poured and consolidated through cement. The T-like beam structure is welded on the outer surface of the inner-layer sleeve and simultaneously set along with the inner-layer sleeve, thereby facilitating the construction. By adopting the reinforced riser pipe combined structure and the construction method thereof, the size of the riser pipe can be reduced while the safe construction of well drilling is ensured, the use amount of steel can be greatly reduced while the same mechanical properties of the large-size riser pipe are ensured, and the engineering cost can be greatly saved on the premise of not affecting the construction period of well drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

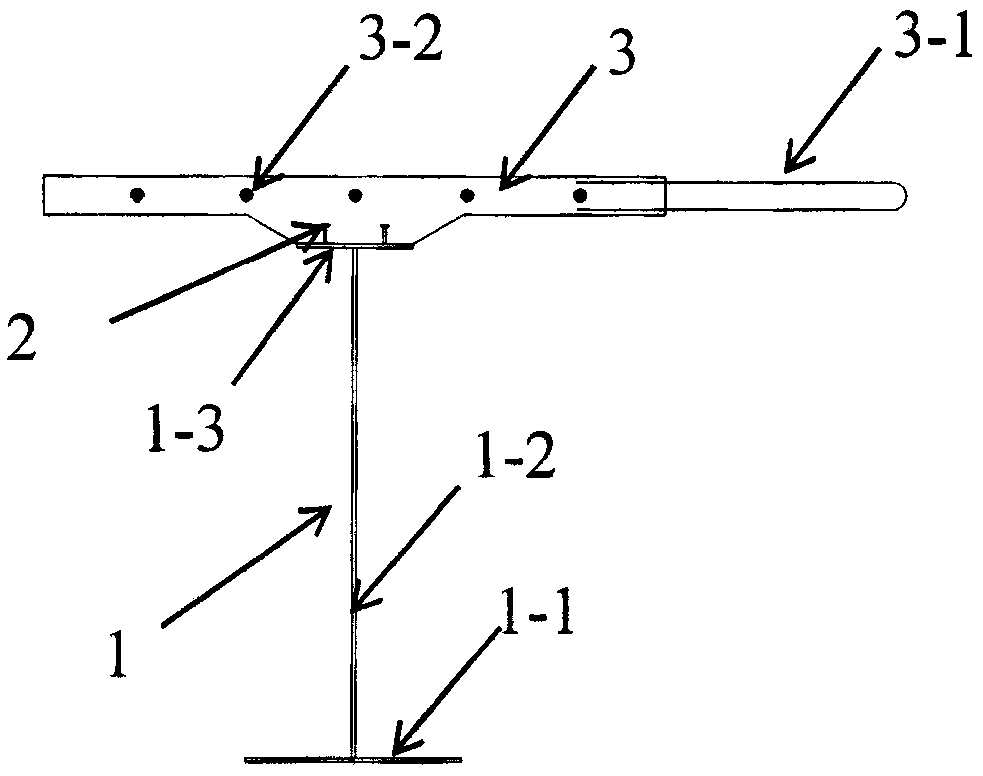

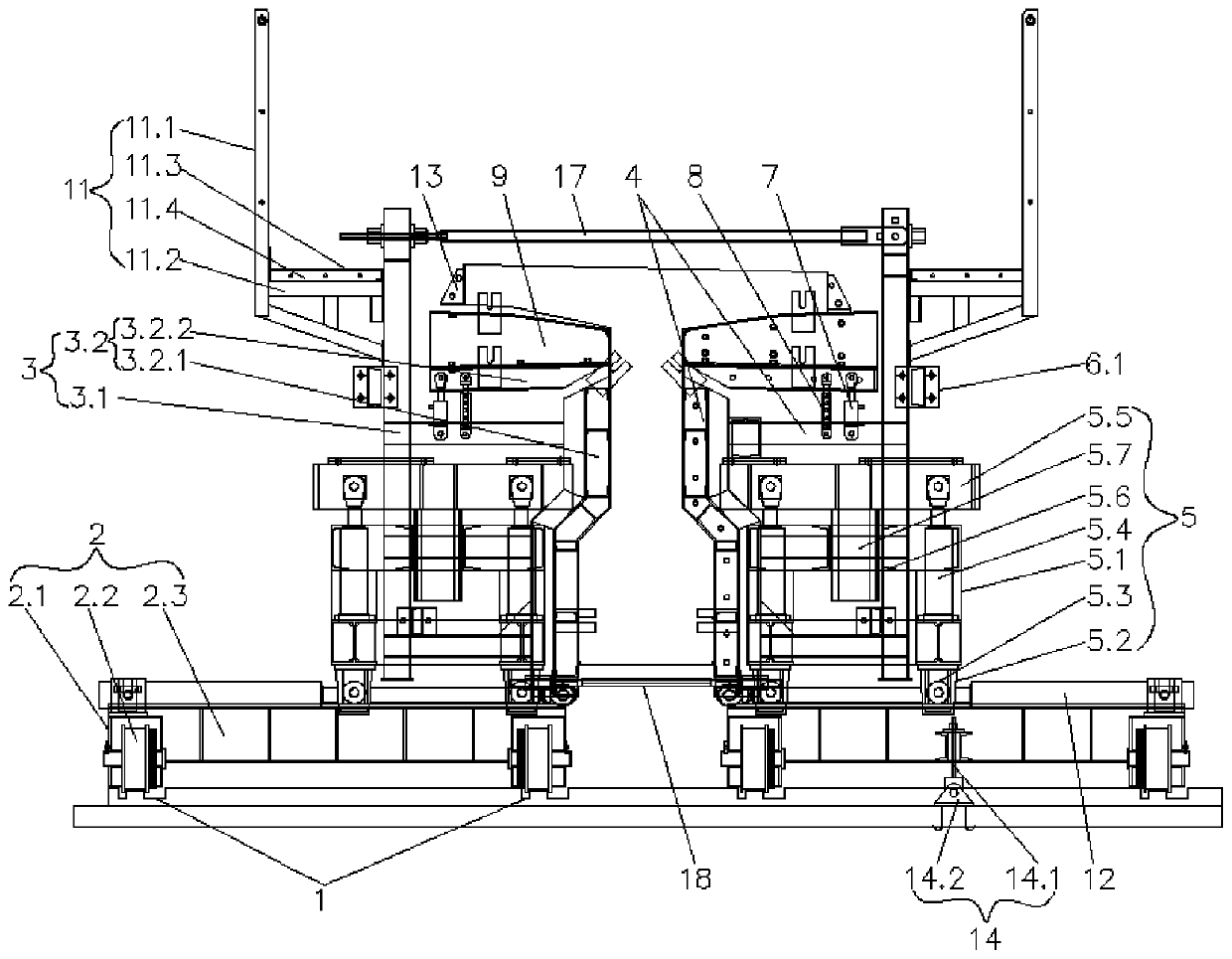

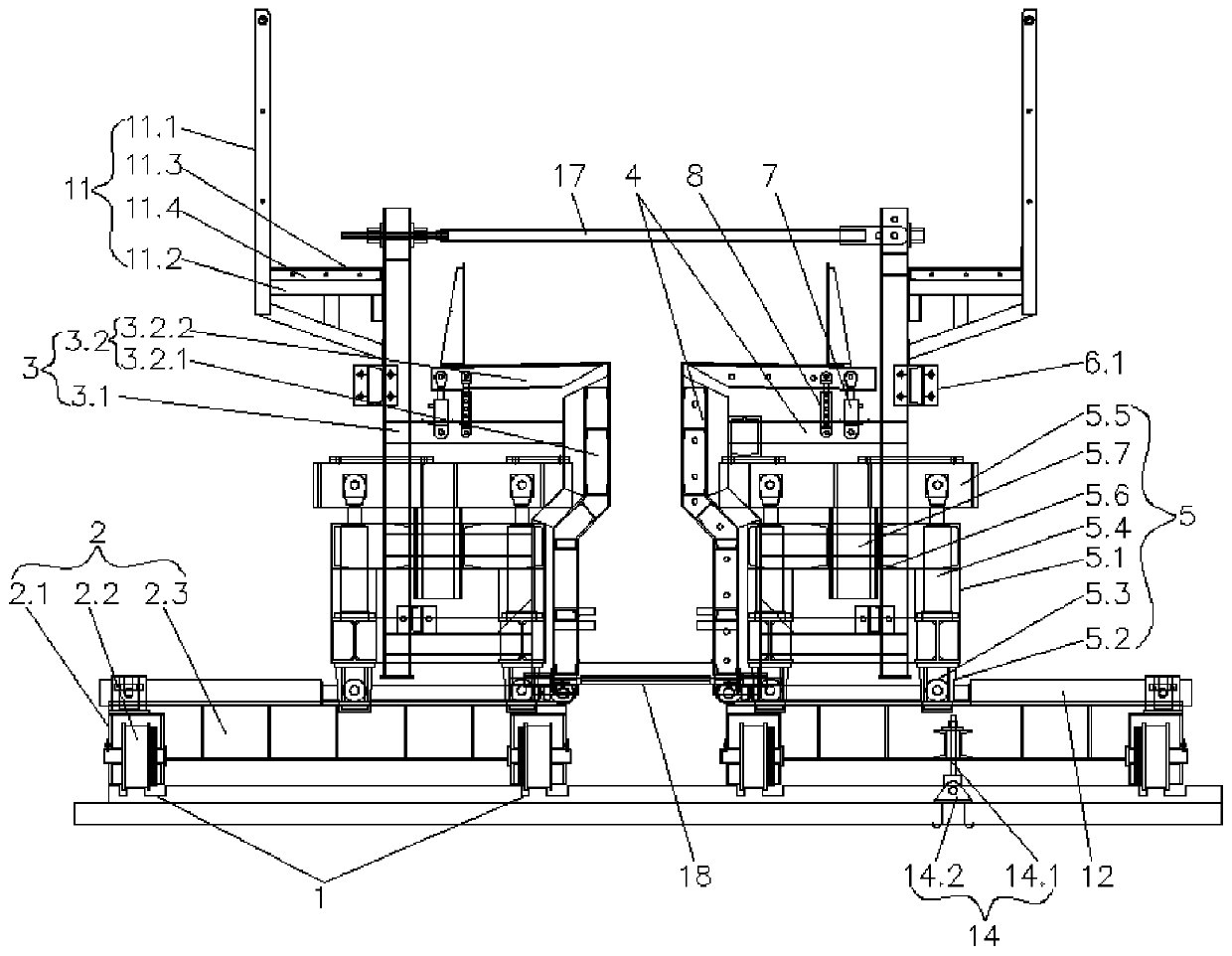

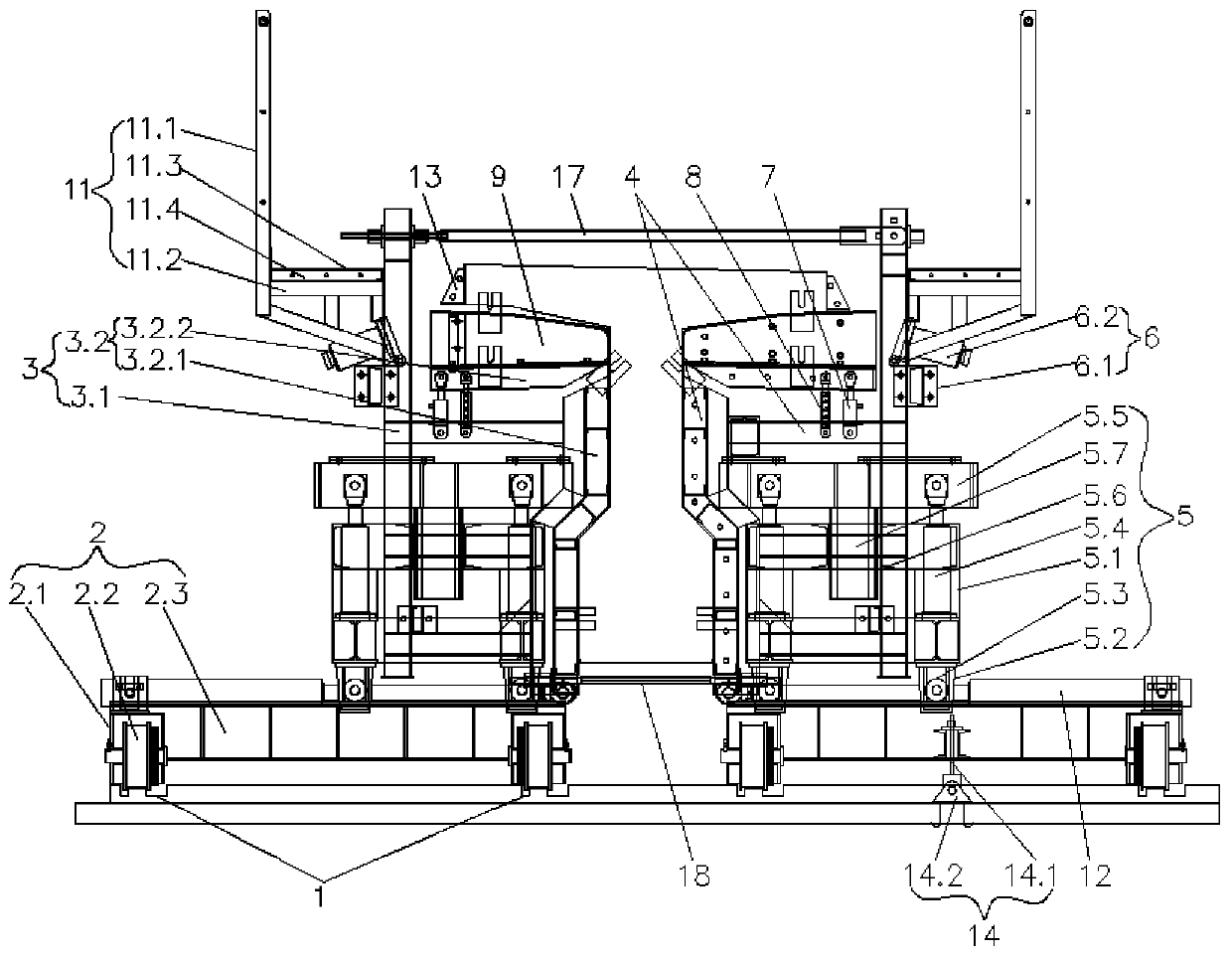

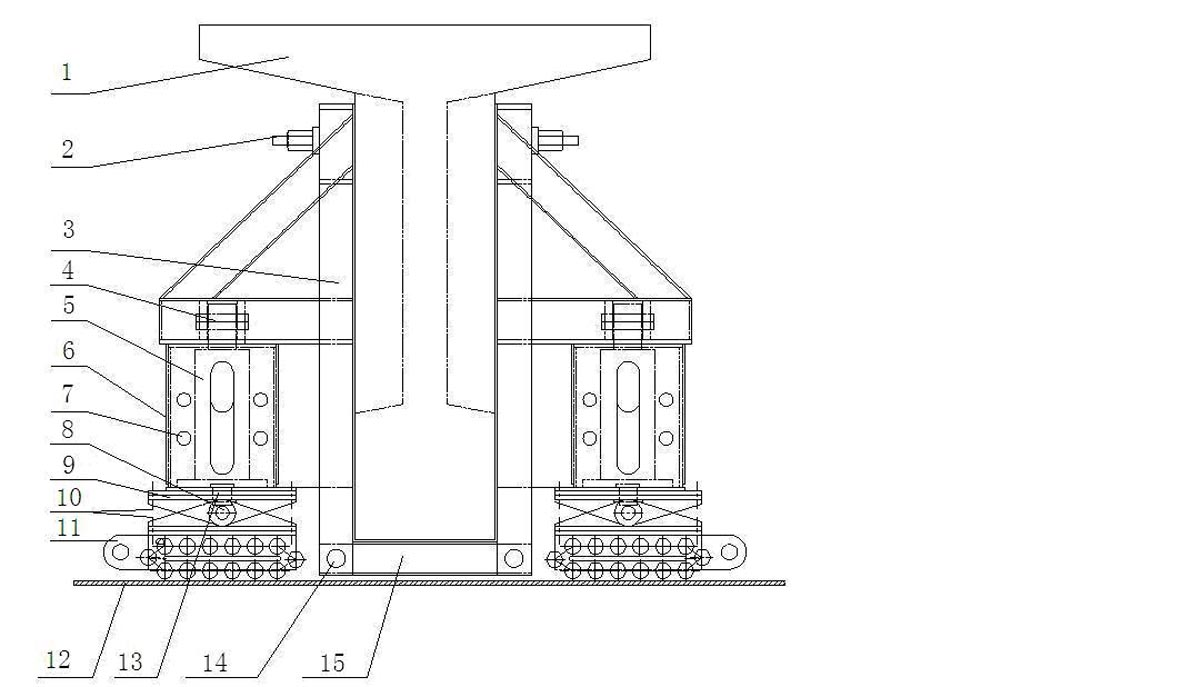

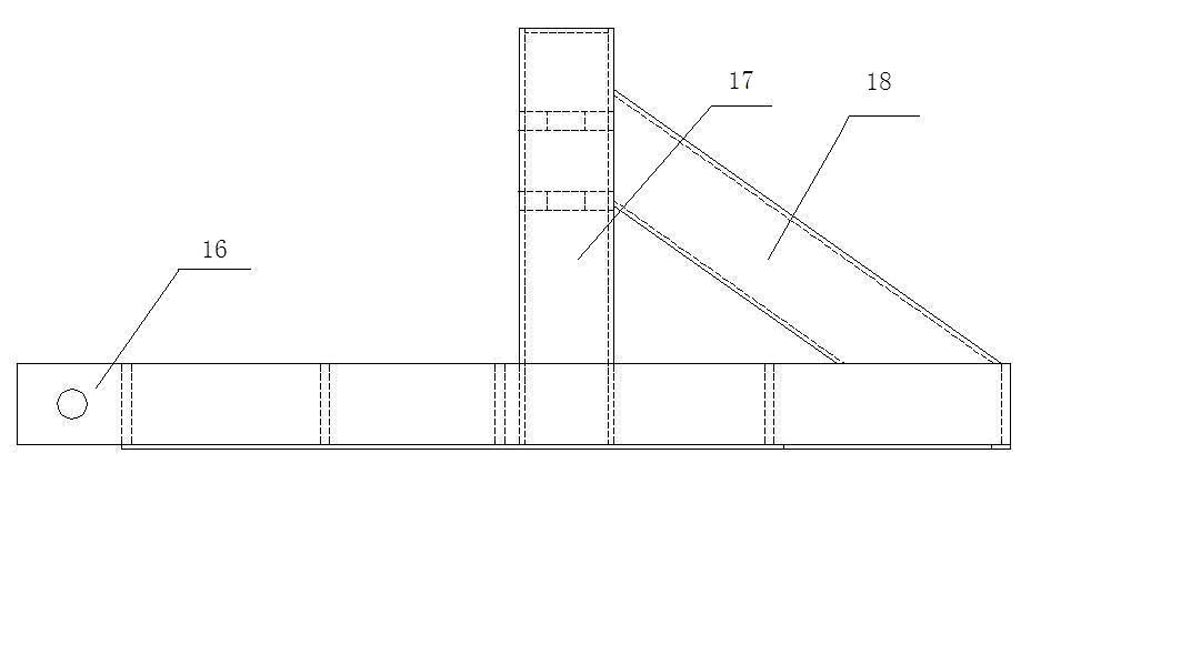

Prefabricated T beam transferring trolley

ActiveCN102002913AEasy to fixAdaptableMouldsBridge erection/assemblyChinese charactersField conditions

The invention relates to building construction equipment, in particular to an omnidirectional chain wheel type beam transferring trolley and a construction method of a prefabricated T beam. The beam transferring trolley comprises a walking mechanism, a jacking mechanism arranged on the walking mechanism, and a T beam clamping device connected with the jacking mechanism and used for clamping the prefabricated T beam, wherein the cross section of the T beam clamping device is shaped as a Chinese character ao, the T beam clamping device mainly comprises a trimming beam bottom plate and two trolley brackets symmetrically arranged at two sides of the trimming beam bottom plate, the prefabricated T beam is fixed in a groove of the T beam clamping device, the trolley brackets comprise a verticalsupporting rod and a triangular bracket fixedly connected with the outer side of the vertical supporting rod, and the triangular bracket is supported on the jacking mechanism. The invention has the advantages that the prefabricated T beam is reliably fixed through a special T beam clamping device, which avoids inclining or turning during the transferring; and the beam rising action is stable, theadaptability is strong, the requirements on the foundation and the base are low, and the adaptability to the field conditions is strong.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

Positioning method for fixing T steel through magnetic force

ActiveCN102140843ANo damage to the rigidityDoes not damage appearanceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksMagnetic tension forceT-beam

The invention relates to the technical field of dies in T beam pouring construction, in particular to a positioning method for fixing T steel through magnetic force. The method is characterized by comprising the following steps of: pre-welding a magnetic force device on one side of a long hole outside a steel die; after a web of the T steel is inserted into the long hole, generating a magnetic field by using the magnetic force device or changing the direction of the magnetic field to adsorb the exposed part of the T steel web so as to fix and position the T steel; and making the magnetic field of the magnetic force device disappeared or changing the direction of the magnetic field to separate the T steel from the steel die. The method has the advantages that: by arranging the magnetic force device and using a principle that a magnet magnetically attracts ferric materials, a hole is not required to be punched, and the T steel and the steel die can be positioned and fixed through the magnetic force, so that slurry leakage can be effectively prevented, and the stiffness and appearance of the steel die are not damaged simultaneously; and the method is easy to operate, and the die is convenient to disassemble.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

Overall dismantling and longitudinal slipping construction method of T beam formwork

The invention discloses an overall dismantling and longitudinal slipping construction method of a T beam formwork. The method is characterized in that integrality of unilateral formworks is kept in formwork installation and dismantling of formworks and moving and transportation between beam manufacturing pedestals, and all segments do not need disconnecting; each unilateral formwork is provided with four sets of transverse slipping and longitudinal slipping bogies used for supporting the formworks in overall transverse slipping and longitudinal slipping processes of the T beam formwork; each unilateral formwork is provided with four sets of thorn wheels used for transversely slipping and is provided with formwork inclination angle regulation screw rods; the T beam formwork is provided with longitudinal slipping rails in a longitudinal moving mode and is pulled through a winch. The overall dismantling and longitudinal slipping construction method of the T beam formwork has the advantages of being strong in formwork integrality, easily guaranteeing the size of a beam body, not needing large-scale hoisting equipment in coordination for construction, saving labor force and lightening labor intensity.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

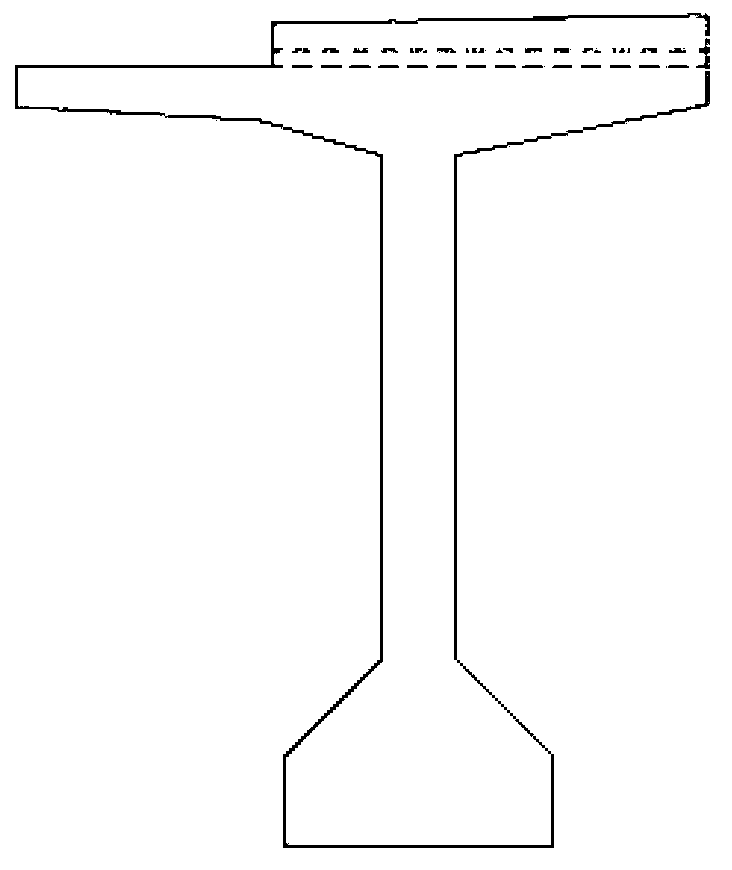

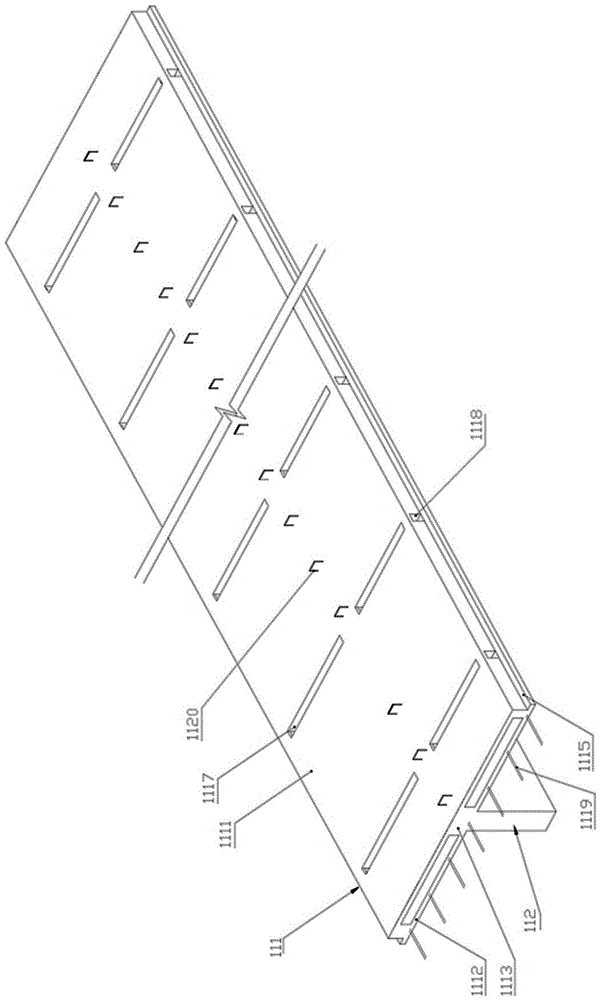

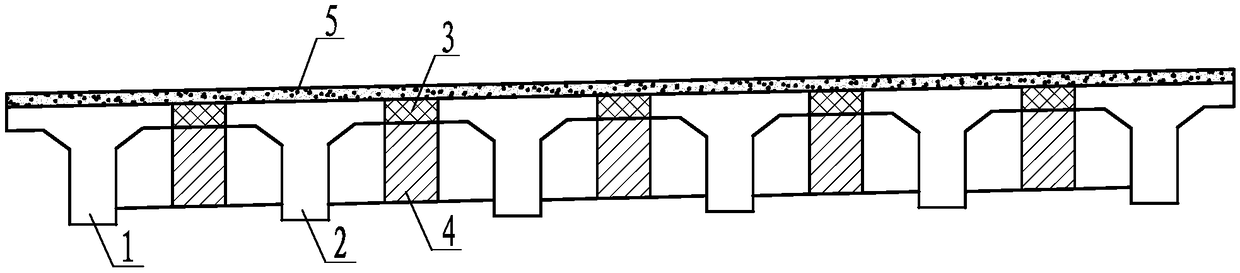

Pre-tensioning prestressed concrete short rib T-beam bridge and construction method thereof

The invention discloses a pre-tensioning prestressed concrete short rib T-beam bridge and a construction method thereof. Each pre-tensioning prestressed concrete short rib T-beam is composed of a flange plate, a web and a horizontal partition plate. Common construction reinforcements are arranged in the flange plates, the webs and the horizontal partition plates, and linear prestressed ribs are arranged on the portions close to the bottom edges of the webs; concrete cast-in-situ seams are arranged among the adjacent short rib T-beams, a reinforced concrete bridge deck cast-in-situ layer is laid on the top faces of the short rib T-beams, and all the short rib T-beams are connected into an entirety through the cast-in-situ seams and the bridge deck cast-in-situ layer; the pre-tensioning prestressed concrete short rib T-beam bridge is prefabricated and constructed on an assembly-type steel mold pedestal. The pre-tensioning prestressed concrete short rib T-beam bridge is suitable for an upper bridge structure in a span range of 10-20 cm and comprises a simple support and a simple support rotation continuous bridge structure, the oblique crossing angle of the bridge is within 0-45 degrees, and the assembly-type steel mold pedestal can be recycled. By means of the bridge, the construction design is simple, the construction operation is convenient, the construction quality is improved, the production cost is lowered, and the durability of the bridge is improved.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com