Sound-barrier simply-supported T-beam bridge

A sound barrier and simply supported technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of not considering the load of the sound barrier, inconvenient installation of the sound barrier, and unsuitability of the sound barrier, so as to reduce the workload of maintenance and repair , Guarantee the effect of construction organization and arrangement, and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

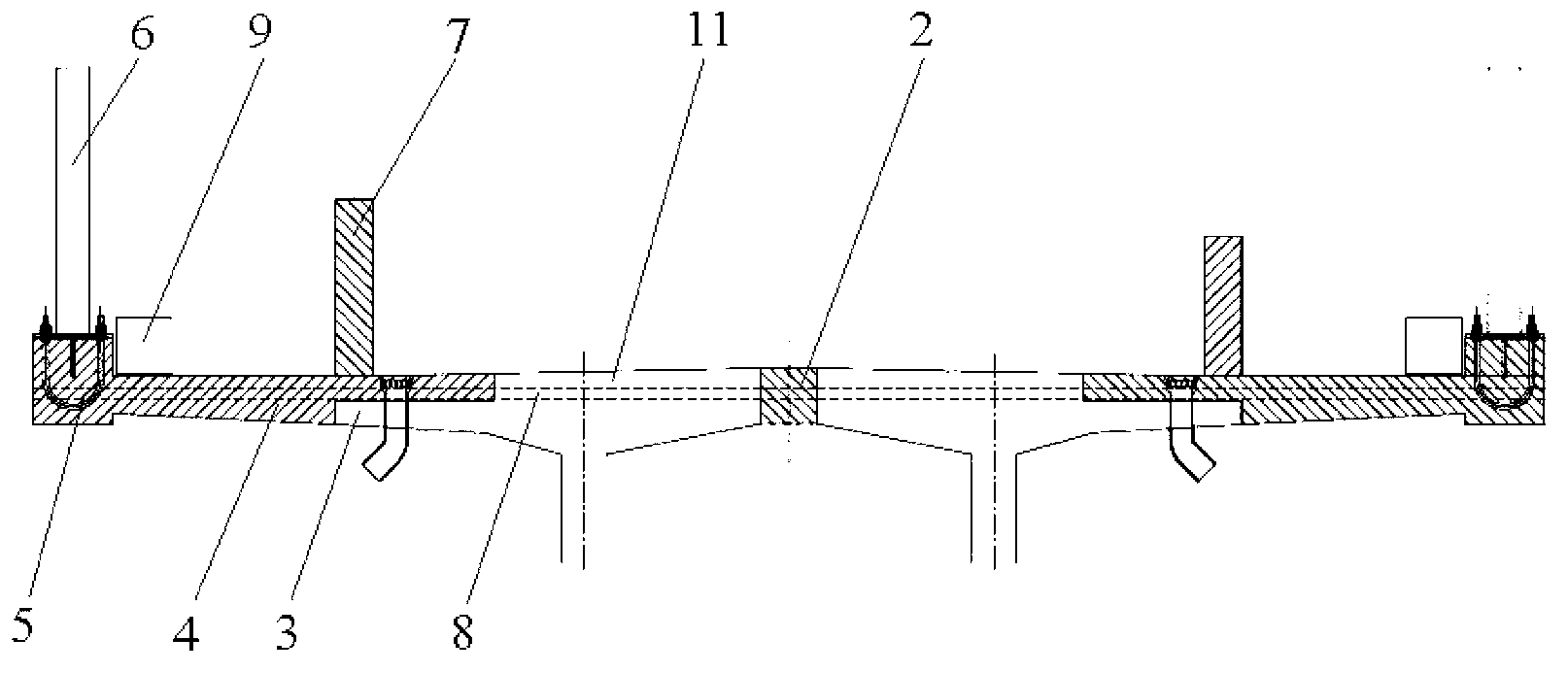

[0031] Such as figure 1 , 5 , 6, the simply supported T-beam bridge with sound barrier of the present embodiment is a single-track railway bridge, including two simply supported T-beams, and the simply supported T-beams are prefabricated beams.

[0032] Each simply supported T-beam is composed of multiple simply supported T-beam units connected end to end. The weight of a simply supported T-beam unit is less than 148 tons. The weight of a single piece of this simply supported T-beam unit meets the requirements of centralized prefabrication and railway transportation. It is beneficial to ensure the construction quality and construction organization arrangement, and the joints of each simply supported T beam unit are located on the pier 20; two simply supported T beams are horizontally connected together through the wet joint concrete of the diaphragm, and the two simply supported T beams A section of platform 3 protrudes from the outside of the beam, and the height of the plat...

Embodiment 2

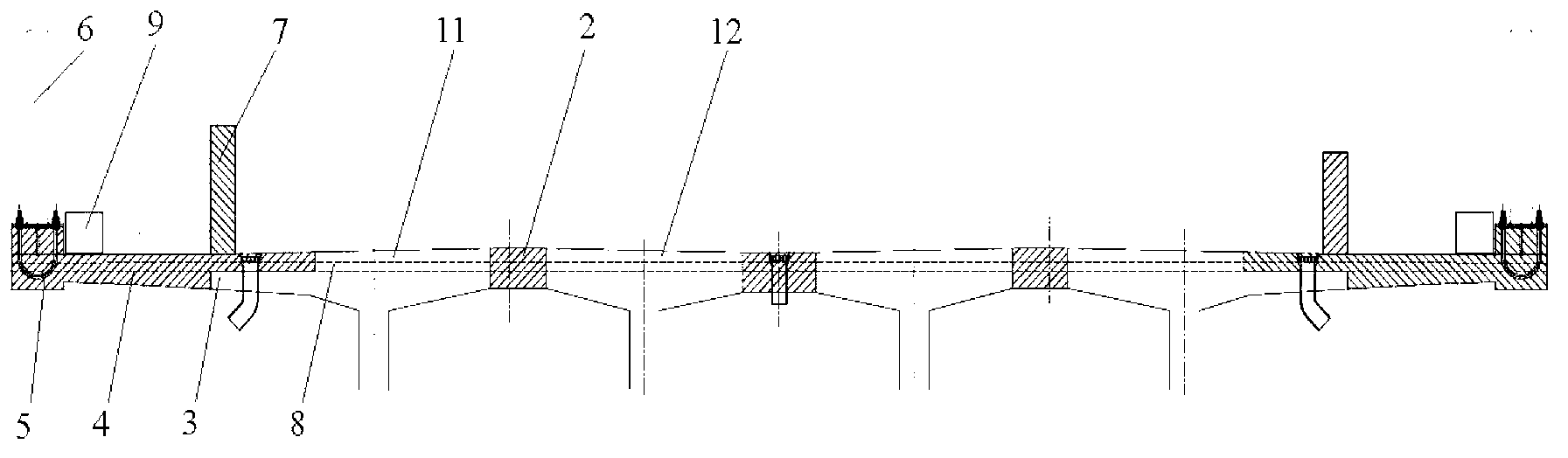

[0037] Such as figure 2 , 6 As shown, the simply supported T-beam bridge with sound barrier in this embodiment is a passenger-cargo double-track railway bridge, including four simply supported T-beams, and the simply supported T-beams are prefabricated beams.

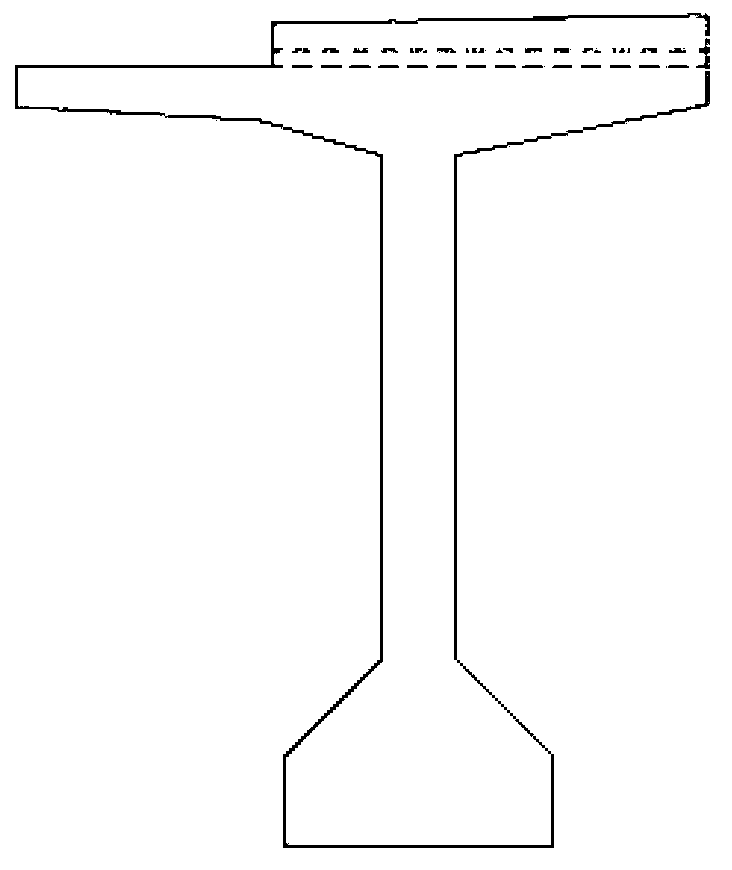

[0038] Each simply supported T-beam is composed of multiple simply supported T-beam units connected end to end. The weight of a simply supported T-beam unit is less than 148 tons. The weight of a single piece of this simply supported T-beam unit meets the requirements of centralized prefabrication and railway transportation. It is beneficial to ensure the construction quality and construction organization arrangement, and the joints of each simply supported T-beam unit are located on the pier 20; the four simply supported T-beams are horizontally connected together through the wet joint concrete of the diaphragm, and the simply supported T-beam units on both sides T beams are side beams (such as image 3 ), the simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com