Patents

Literature

315results about How to "Safe and stable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

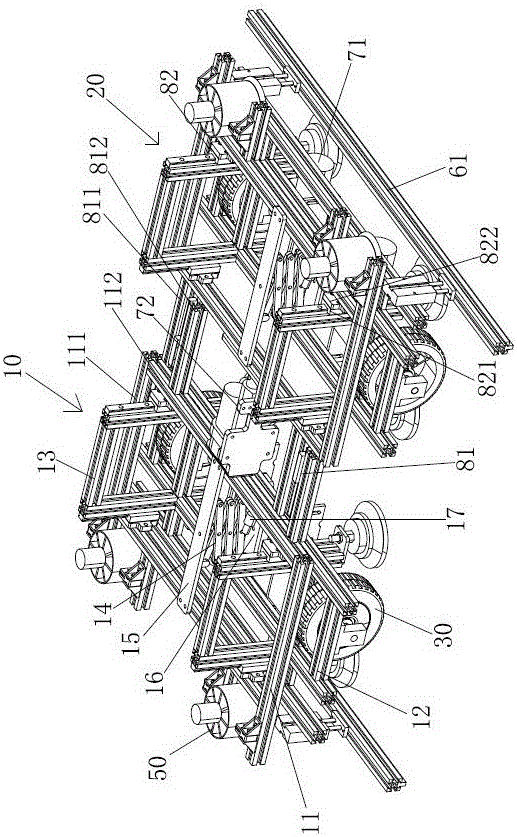

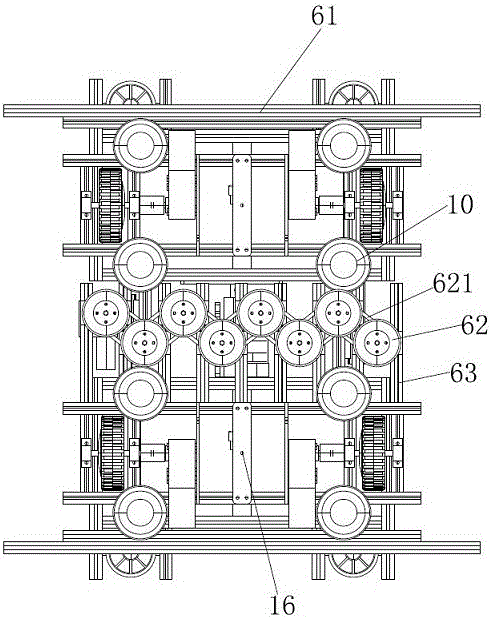

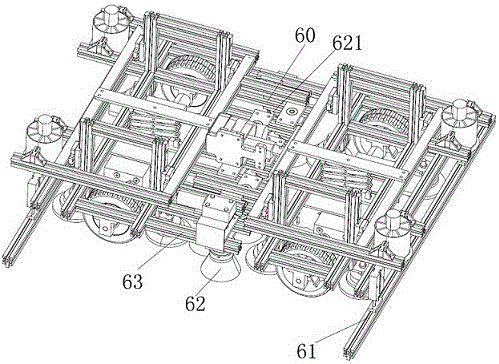

Wall robot capable of surmounting and tramping obstacles

ActiveCN106388725ARealize lifting functionSafe and stable structureAutomatic obstacle detectionTravelling automatic controlVertical planeDrive wheel

The invention provides a wall robot capable of surmounting and tramping obstacles. The wall robot comprises a first bracket and a second bracket which are symmetrically arranged, and driving wheels arranged on the first bracket and the second bracket respectively, a sucker, a draught fan, a first driving device and a control device, the first bracket and the second bracket is connected with a first guide rail mechanism through a second driving device, and the first bracket comprises a fixing bracket, a driving frame and a driven frame; a shear type lifting structure is arranged between the fixing bracket and the driving frame; the driving frame is fixedly connected with the driven frame through a second guide rail mechanism; the driven frame is connected to the fixing bracket through the fixing bracket; the driving wheel, the sucker, and the first driving device is arranged on the driving frame. With such a structure, the wall robot capable of surmounting and tramping obstacle achieves extending on the horizontal plane and lifting on the vertical plane, thus the function of surmounting and tramping obstacles is further achieved.

Owner:HUAWAY IOT TECH

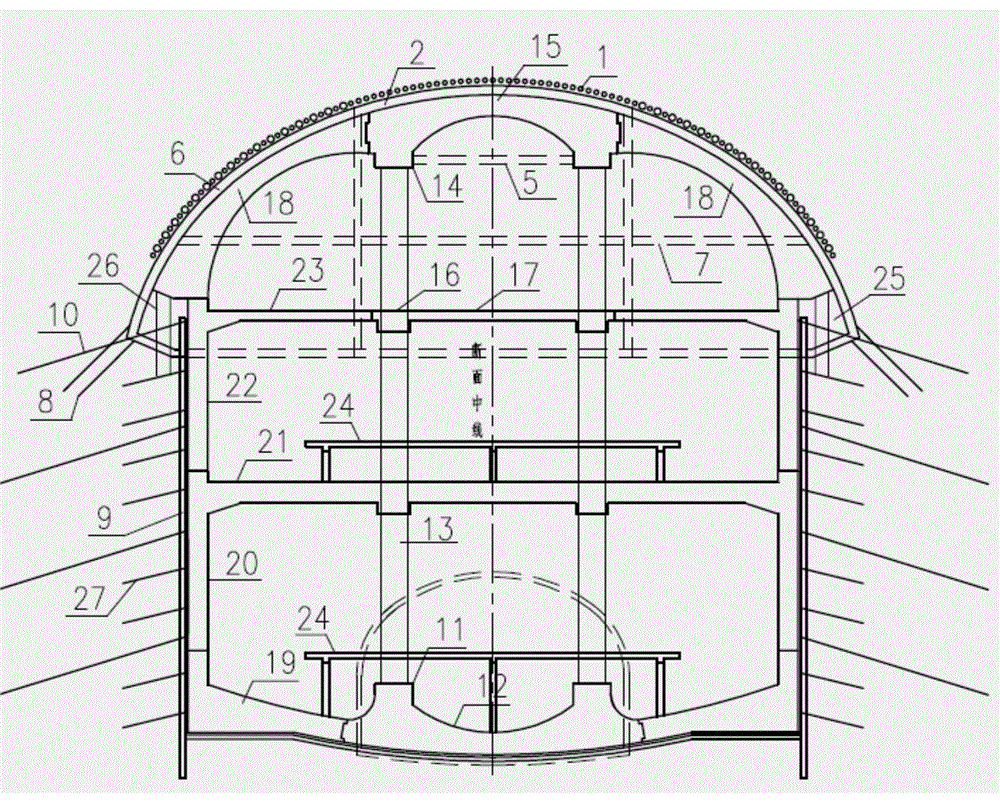

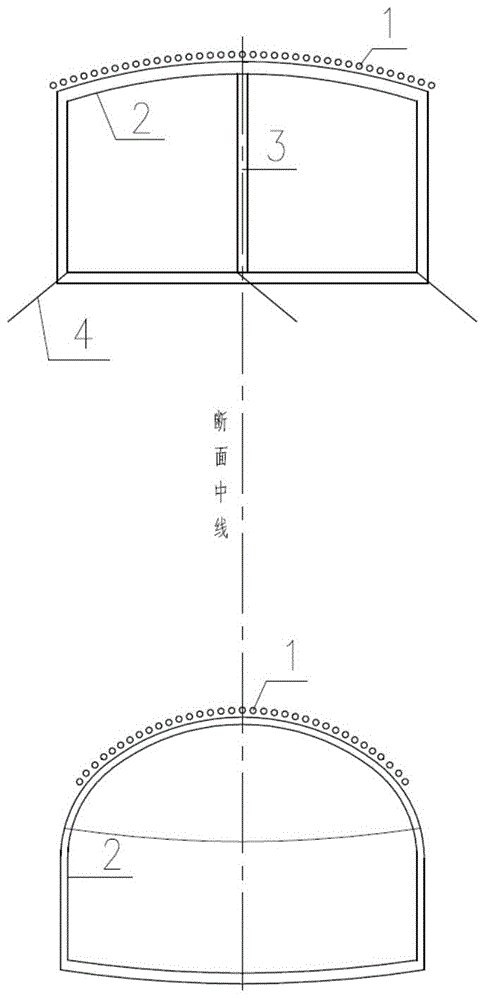

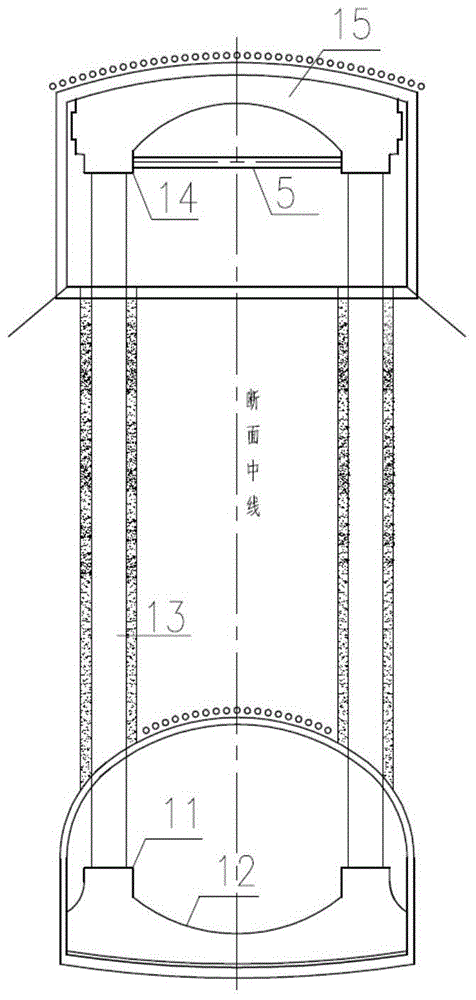

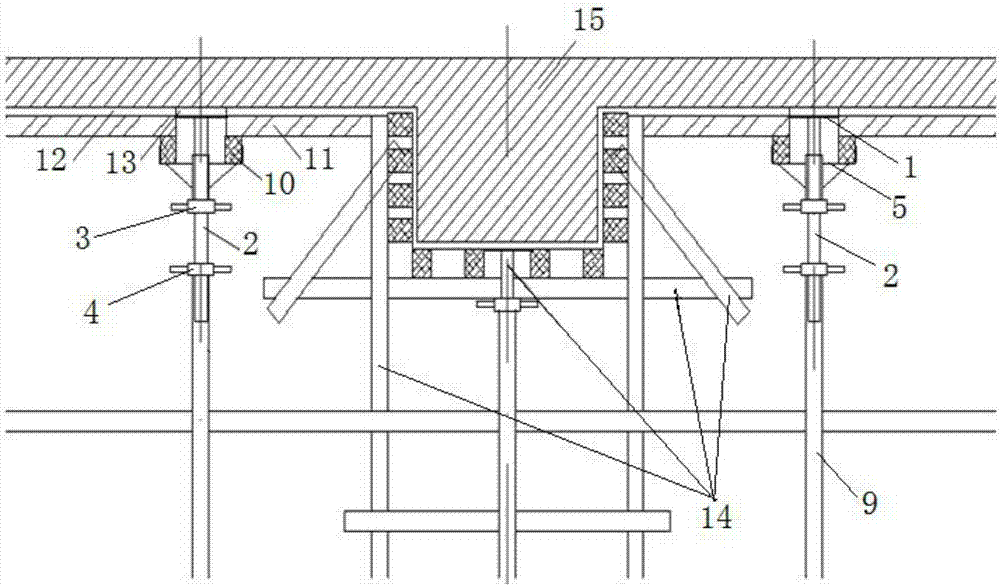

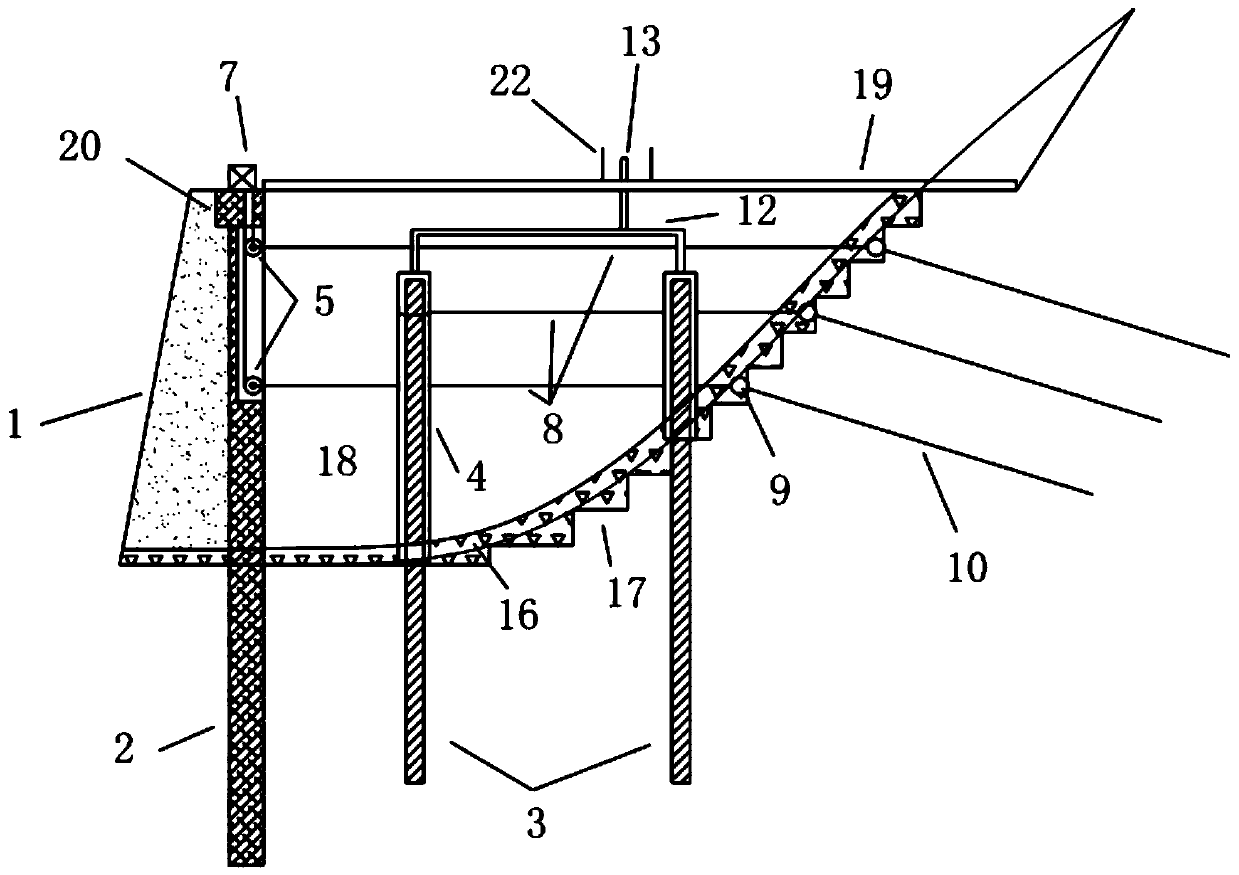

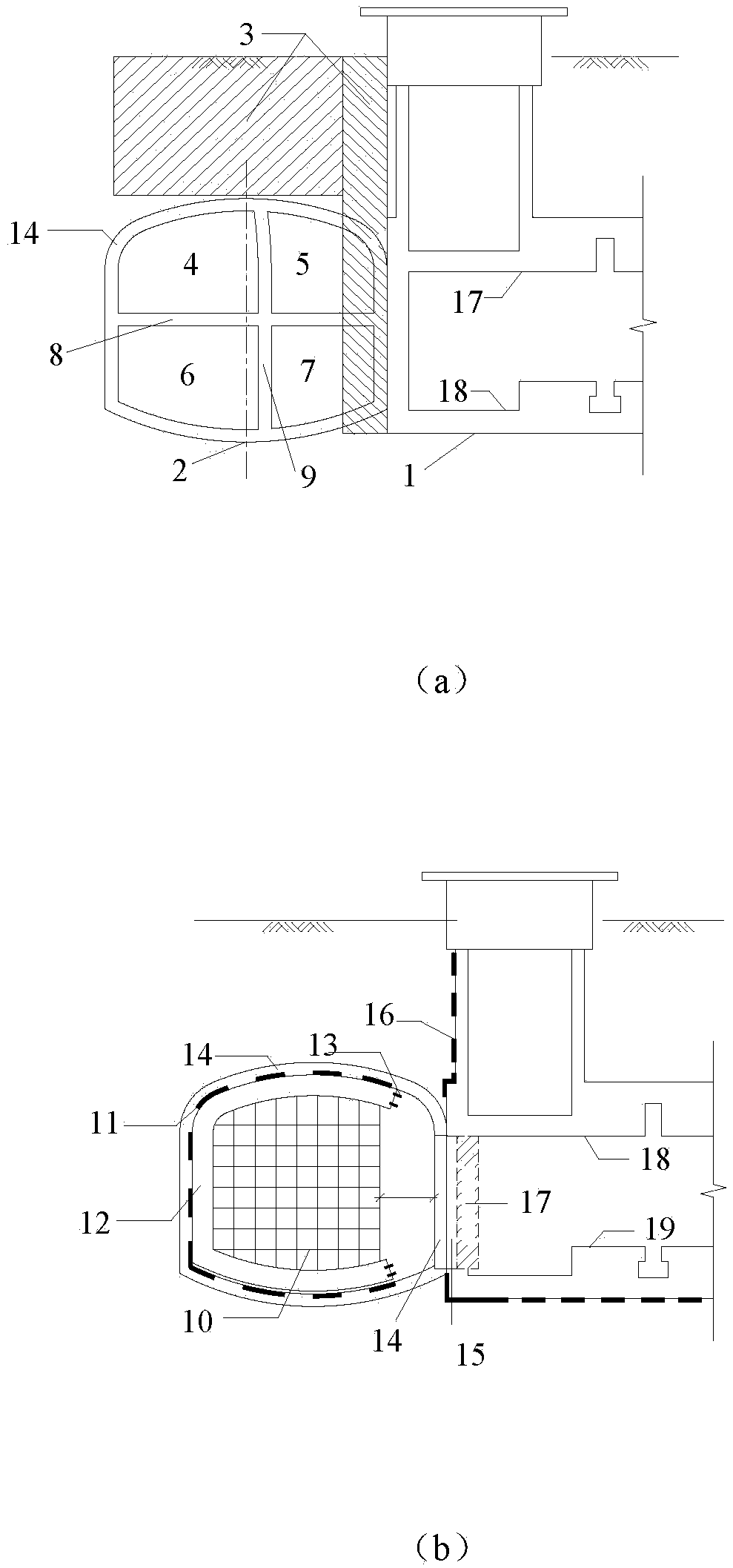

Rock stratum underground excavation three-story subway station umbrella cover structure and construction method thereof

ActiveCN106337686AReasonable structural designImprove stabilityUnderground chambersTunnel liningReinforced concreteSubway station

The invention belongs to the technical field of design and construction of tunnel and underground engineering and especially relates to a rock stratum underground excavation three-story subway station umbrella cover structure and a construction method thereof. The structure comprises a main arc structure and a reinforced concrete inverted arch. an underground two-story side wall and an underground three-story side wall are installed between the main arc structure and the reinforced concrete inverted arch. The main arc structure comprises an arch portion second lining middle segment and arch portion second lining side segments; the arch portion second lining side segments are positioned at two sides of the arch portion second lining middle segment; the reinforced concrete inverted arch comprises an inverted arch second lining middle segment and inverted arch second lining side segments; the top of the inverted arch second lining middle segment is provided with two bottom girders; the bottom of the arch portion second lining middle segment is provided with two top girders; steel-pipe columns are installed between the top girders and the bottom girders. The structure and the method of the invention is suitable for supporting structure and construction of weak rock stratum dug three-story subway station and large sections of underground space; the structure has good stability and increased construction efficiency.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

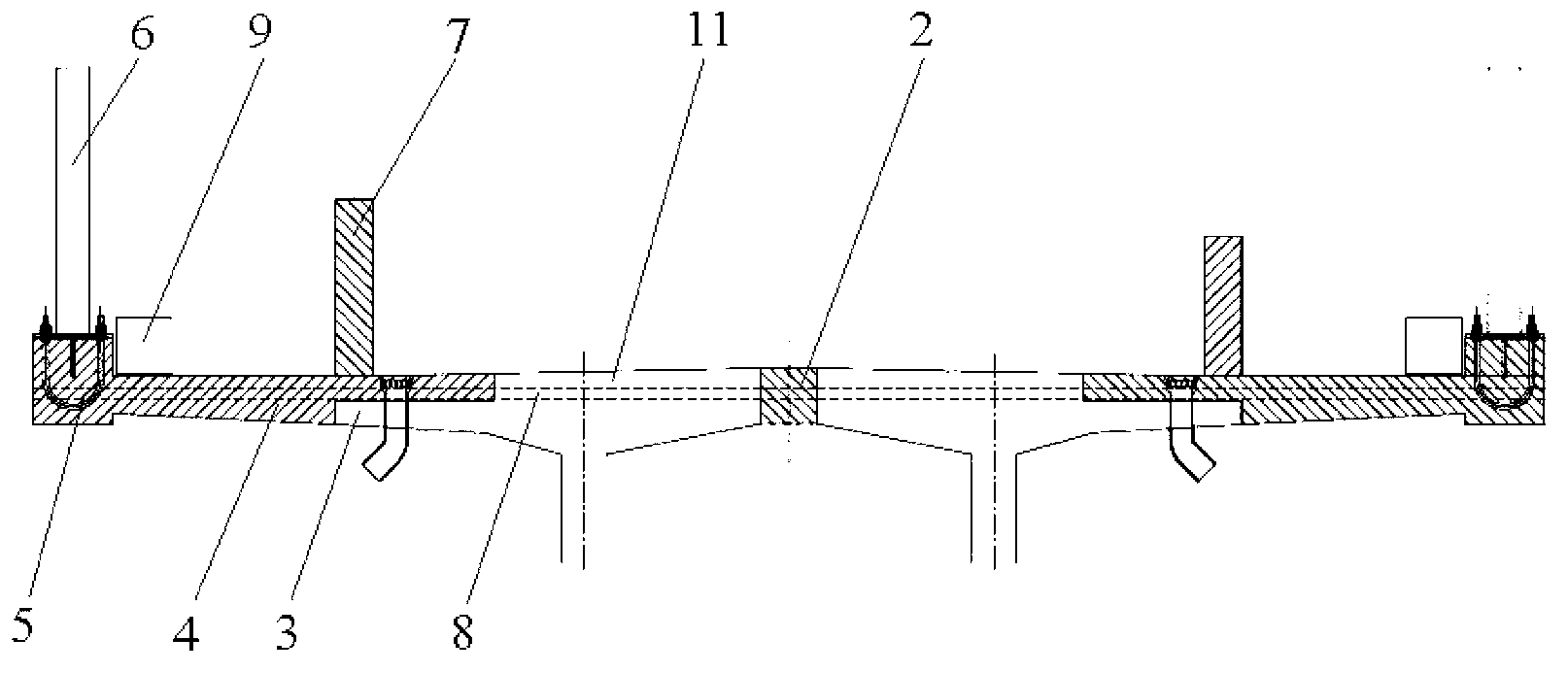

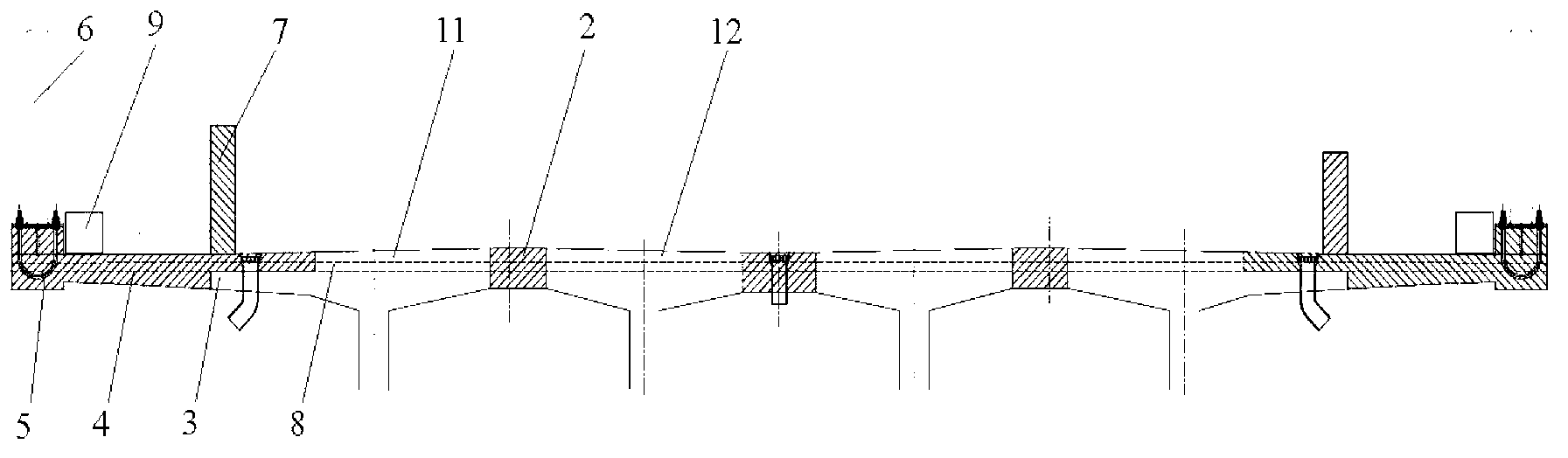

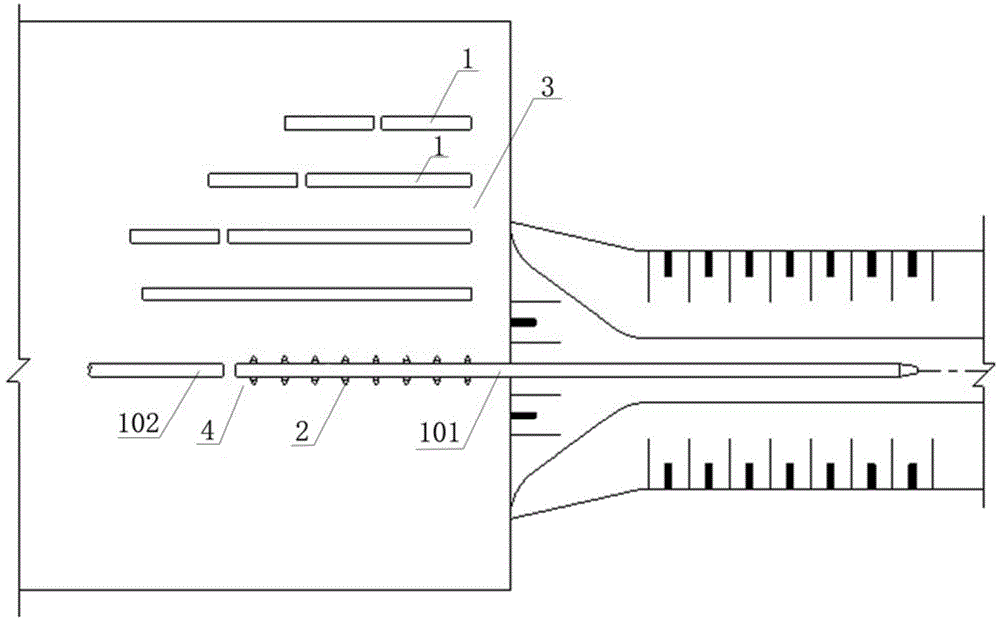

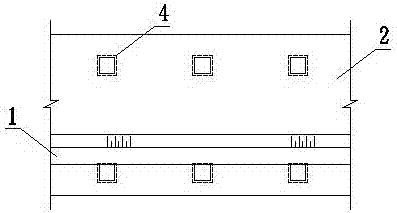

Sound-barrier simply-supported T-beam bridge

ActiveCN103061242AImprove integrityReduce workloadNoise reduction constructionBridge structural detailsSound barrierT-beam

The invention relates to the technical field of railway bridges and particularly discloses a sound-barrier simply-supported T-beam bridge which comprises a plurality of simply supported T-beams. Each simply supported T-beam is formed by connecting a plurality of simply supported T-beam units end to end. The simply supported T-beams are transversely connected through transverse partitions, wet joints and concrete. Concrete cast-in-place decks are arranged outside the simply supported T-beams on two sides. The upper surfaces of the simply supported T-beams, the upper surfaces of concrete connections and the upper surfaces of the concrete cast-in-place decks form an integral bridge deck. The whole integral bridge deck is provided with transverse prestressed bars. Sound-barrier column foundations are arranged outside the concrete cast-in-place decks, and sound-barrier columns are arranged at the sound-barrier column foundations. A sound barrier is arranged between each two adjacent columns. The performance of the railway bridge is improved, the railway bridge meets the requirement of providing the sound barrier by the aid of the integral bridge deck, sound barrier absorbs or isolates noise generated in running process of trains and the influence of the trains upon lives of nearby residents is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

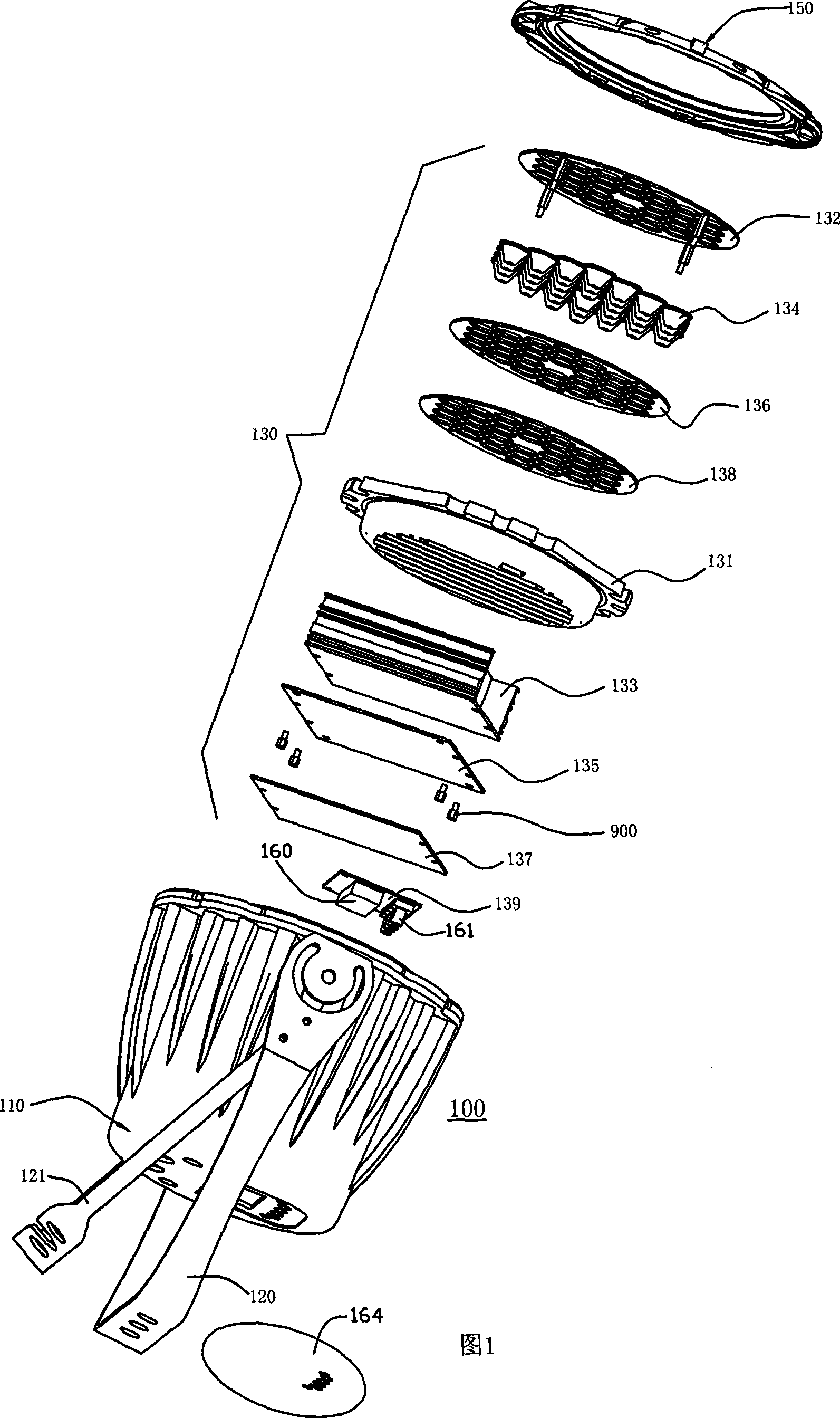

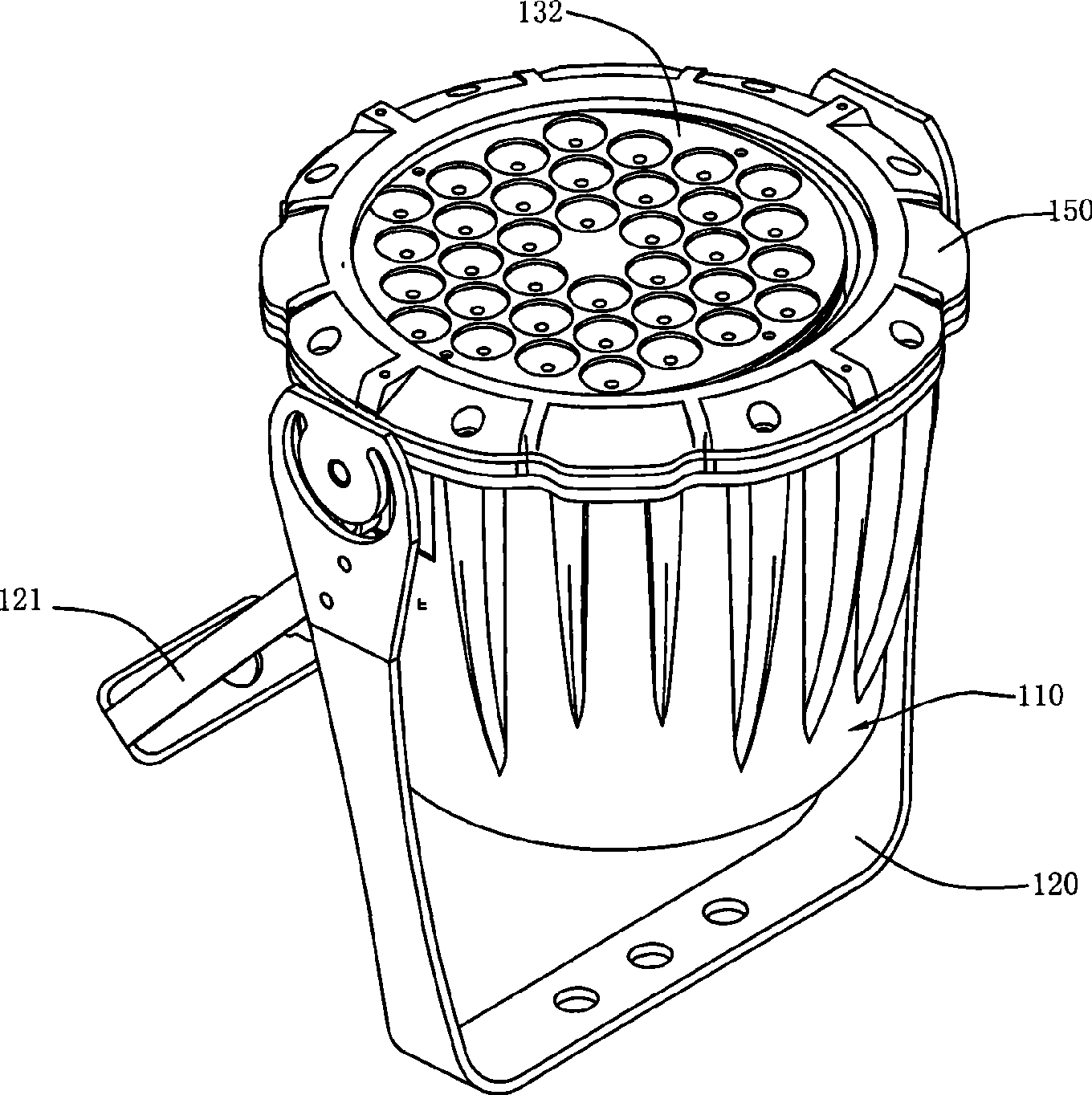

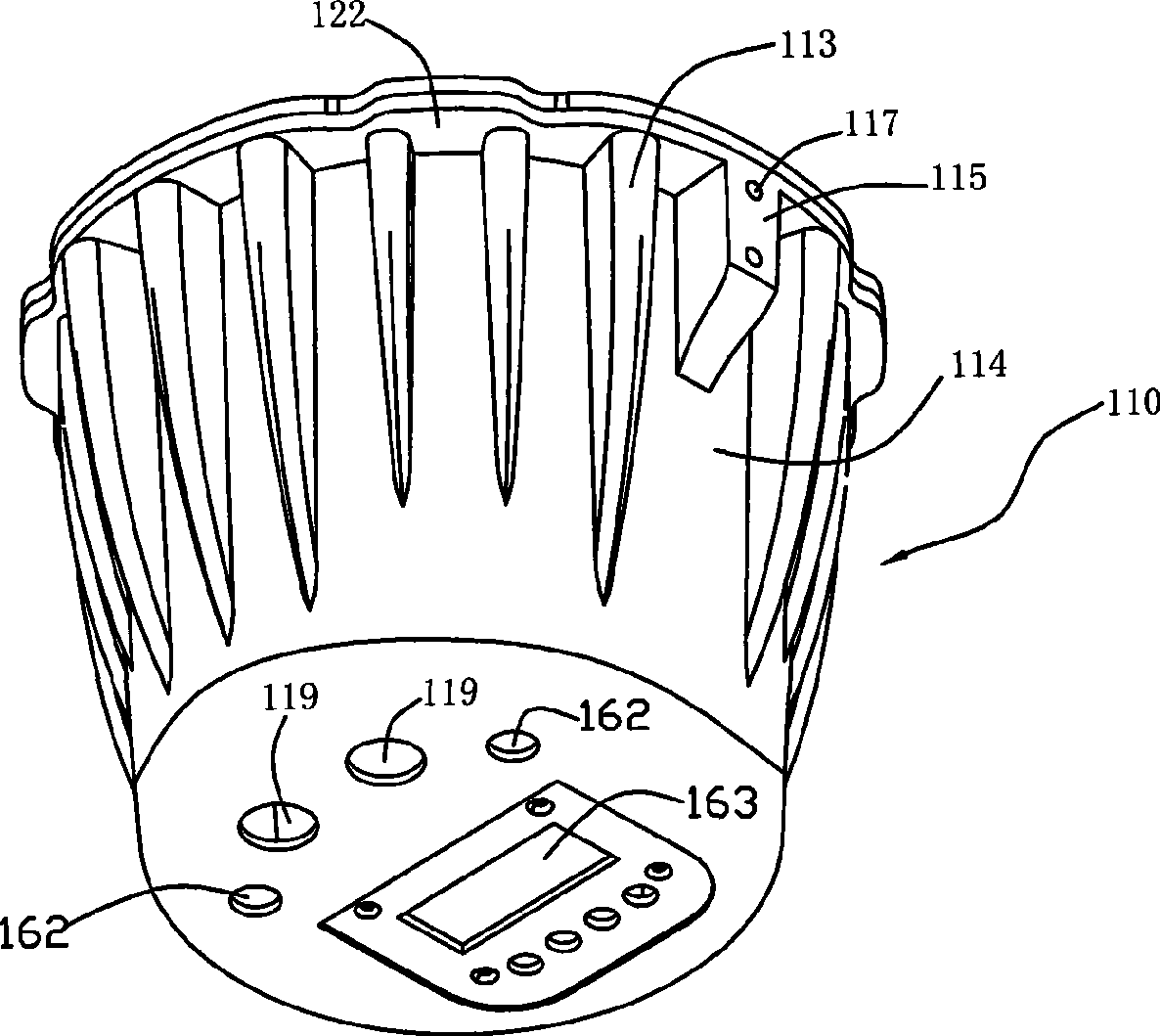

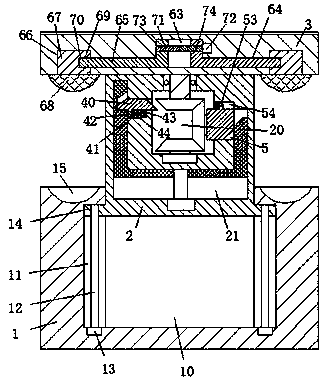

Projector

ActiveCN101398162ASafe and stable structureImprove cooling effectLighting applicationsPlanar light sourcesEngineeringHeat sink

The invention provides a spot lamp which comprises a base seat, a light emitting module installed in the base seat and an upper cover which is connected with the base seat to provide convenience for installing the light emitting module in the base seat, wherein, the base seat comprises a bottom part and annular side walls which are bended and extended from the bottom part; the light emitting module is held in a holding space defined by the bottom part and the annular side walls and at least comprises a lamp bead tray and a lamp bead plate which is supported in the lamp bead tray; reinforcing ribs used for increasing the strength of the base seat are arranged on external walls of the annular side walls; and the periphery of the bottom part takes the shape of a ring with round angles and a heat sink strip used for dissipating heat is arranged on the lamp bead tray. The spot lamp has good performance of heat dissipation and firm and safe structure.

Owner:广州市德晟光电科技股份有限公司

Foundation pit supporting structure with oblique support and pre-stress surrounding purlin

The invention provides a foundation pit supporting structure with an oblique support and a pre-stress surrounding purlin. An enclosure wall and an oblique steel support are arranged inside the foundation pit supporting structure; the enclosure wall is connected with the pre-stress surrounding purlin which is connected with one end of the oblique steel support; and the other end of the oblique steel support is connected with a base plate of a foundation pit. The foundation pit supporting structure with the oblique support and the pre-stress surrounding purlin has the advantages of substantially reducing the length and number of supports, saving materials and construction costs and being short in construction period and large in construction space.

Owner:SHANGHAI STRONG FOUND ENG

Girder-exchange construction method for existing railway bridge by successively incremeantal launching framework process

ActiveCN101200881AReduce the impact of operationsReduce investmentBridge erection/assemblyBridge strengtheningEngineeringBallast

The invention relates to a girder replacement construction method of the existing railway line bridges, which applies a method of incremental launching framework. The girder replacement construction method is fulfilled according to seven steps: (1) A split slideway is respectively arranged on one side of the existing line and a framework is respectively prefabricated on the split type slideway; (2) Temporary rest piers are arranged under the existing line bridge and used to upbear a track skeleton, and the locking of seamless lines and the installation of a crossarm track are carried out on the two sections of a grider-replaced section; (3) The temporary rest piers are used to upbear the girder body of the existing line, and the bearings under the existing girder are disassembled; (4) the prefabricated framework is connected with the existing girder by a steel stranded wire; (5) A continuous jack is utilized to tow the steel stranded wire to haul the cascaded framework and the existing girder to the position required by the design; (6) The bearing side under the bottom plate of the prefabricated framework is grouted and reinforced; (7) After dropping the track and replenishing ballast, the line is resumed. The present invention has the advantages that the construction is safe and stable, the cost is reduced, the construction procedures are simplified, the construction period is shortened and the engineering cost is saved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

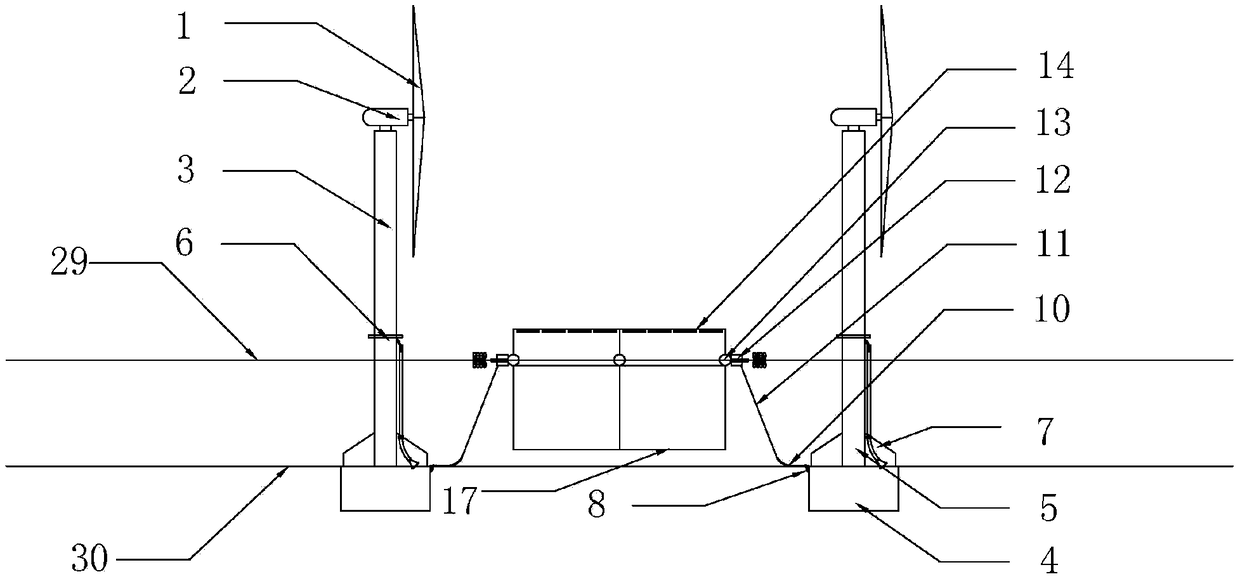

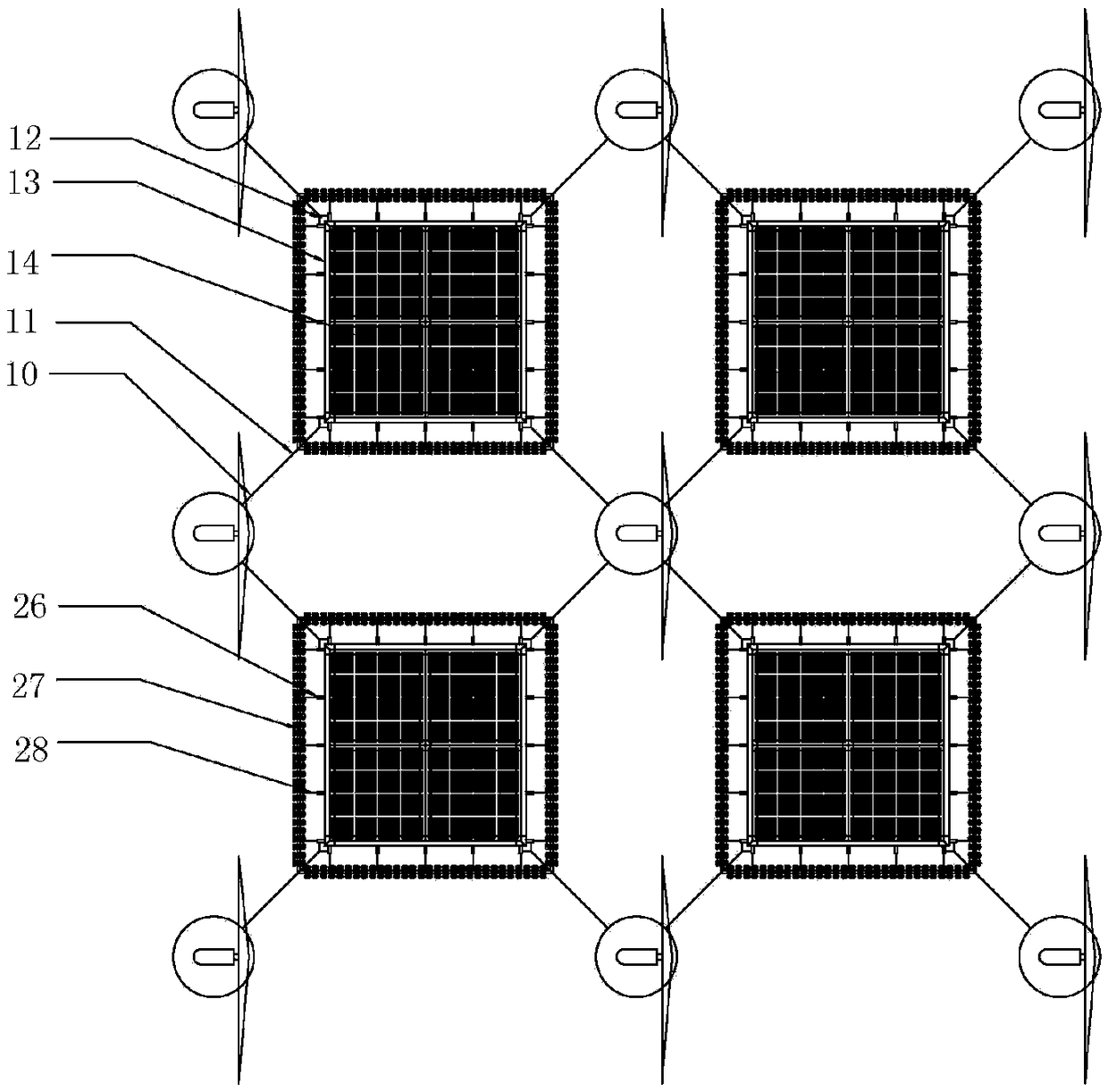

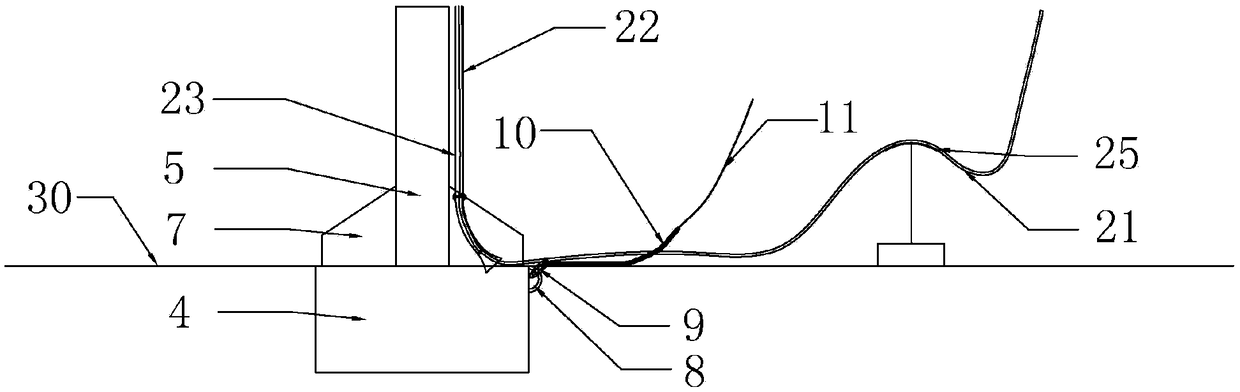

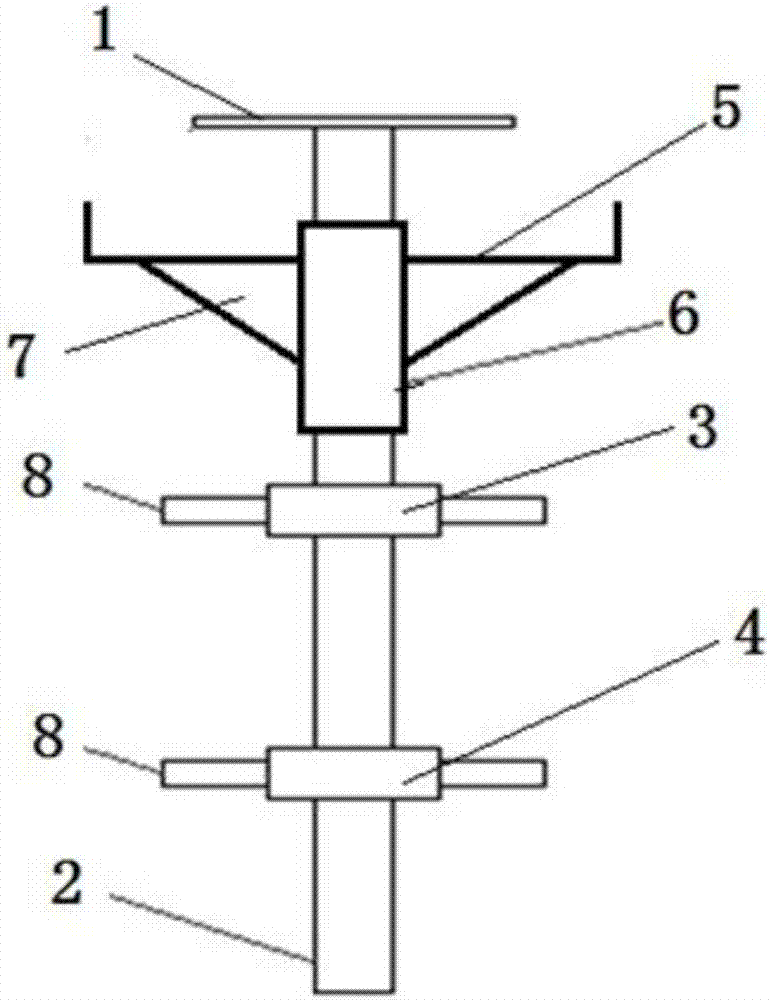

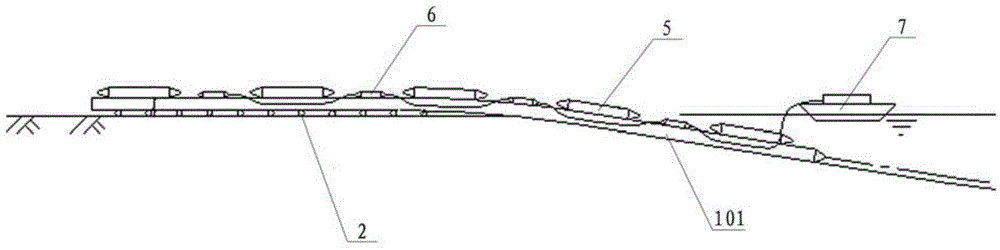

Integrated system of offshore wind, photovoltaic power generation and cage farming

PendingCN109263819ALow costEasy to salvageClimate change adaptationAgricultural fishingElectricityNacelle

The invention provides an integrated system for offshore wind power generation, photovoltaic power generation and cage farming in order to overcome the problem of high cost of developing and constructing offshore wind power generation equipment, offshore photovoltaic equipment and cage farming equipment separately in the prior art. The system includes a plurality of wind power generation devices including blades, nacelle, tower drum and anchoring foundation. The invention is characterized in that a buoy structure is arranged between the wind power generation devices, a photovoltaic power generation device is arranged above the buoy structure, and an aquaculture cage device is arranged below the buoy structure. The invention combines offshore wind power with photovoltaic power generation and aquaculture, and reduces the total cost of construction, production and operation of photovoltaic power generation project and aquaculture cage project; the photovoltaic power generation device andthe aquaculture cage device can move up and down freely with the sea surface, resist the sea waves to a certain extent, and ensure the safety and stability of the structure.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

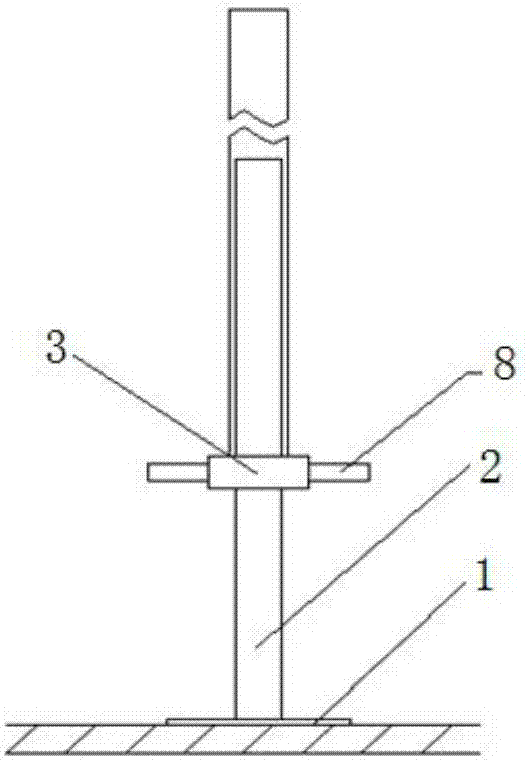

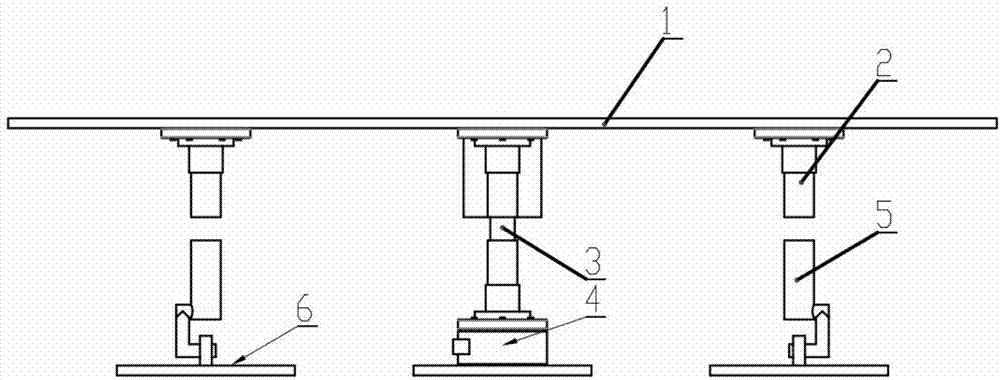

Wood formwork early-dismantling supporting device and construction application method

PendingCN107355073AAvoid deformationFlexible installationForms/shuttering/falseworksArchitectural engineeringStructural safety

The invention provides a wood formwork early-dismantling supporting device and construction application method. The wood formwork early-dismantling supporting device comprises a jacking part and an adjustable supporting plate part; the jacking part is composed of a steel top plate (1), a screw rod (2), an upper adjusting nut (3) and a lower adjusting nut (4), wherein the screw rod (2) is welded to the bottom of the steel top plate, and the upper adjusting nut (3) is installed on the screw rod in a sleeving mode; handles (8) are correspondingly welded to the two sides of the upper adjusting nut and the lower adjusting nut; the adjustable supporting plate part is composed of a tray (5) and a casing pipe (6) which penetrates through the center of the tray; the casing pipe is installed on the screw rod in a sleeving mode and is located between the upper adjusting nut and a top plate. According to the wood formwork early-dismantling supporting device, through finalized design, the structure is safe and reliable, installing and disassembling turnover is convenient, universality is high, formwork early dismantling can be implemented in formwork construction, and the problem that a formwork in the key position cannot be dismantled in advance during top plate formwork construction is solved.

Owner:YUNNAN CONSTR ENG GENERAL CONTRACTING

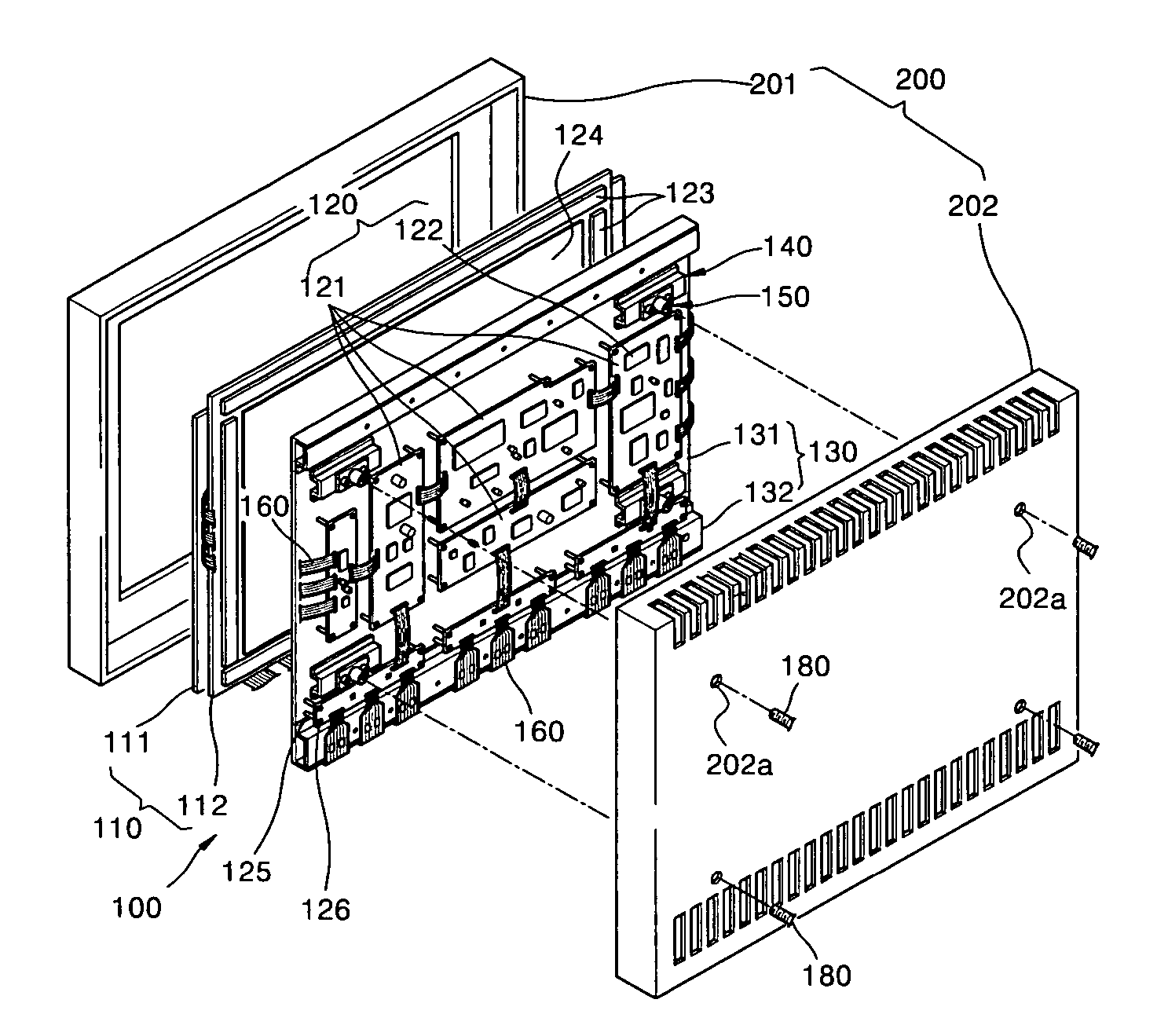

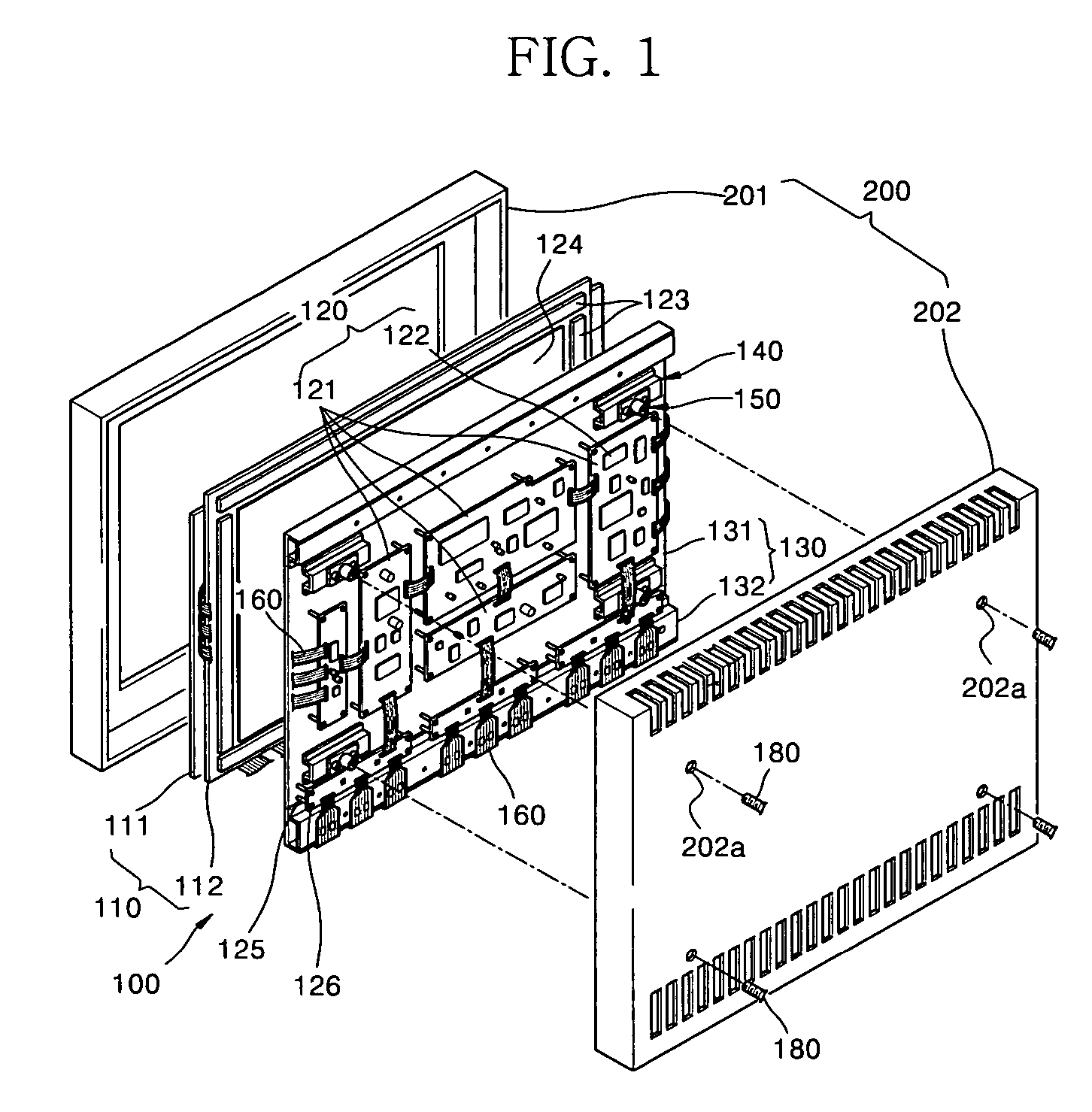

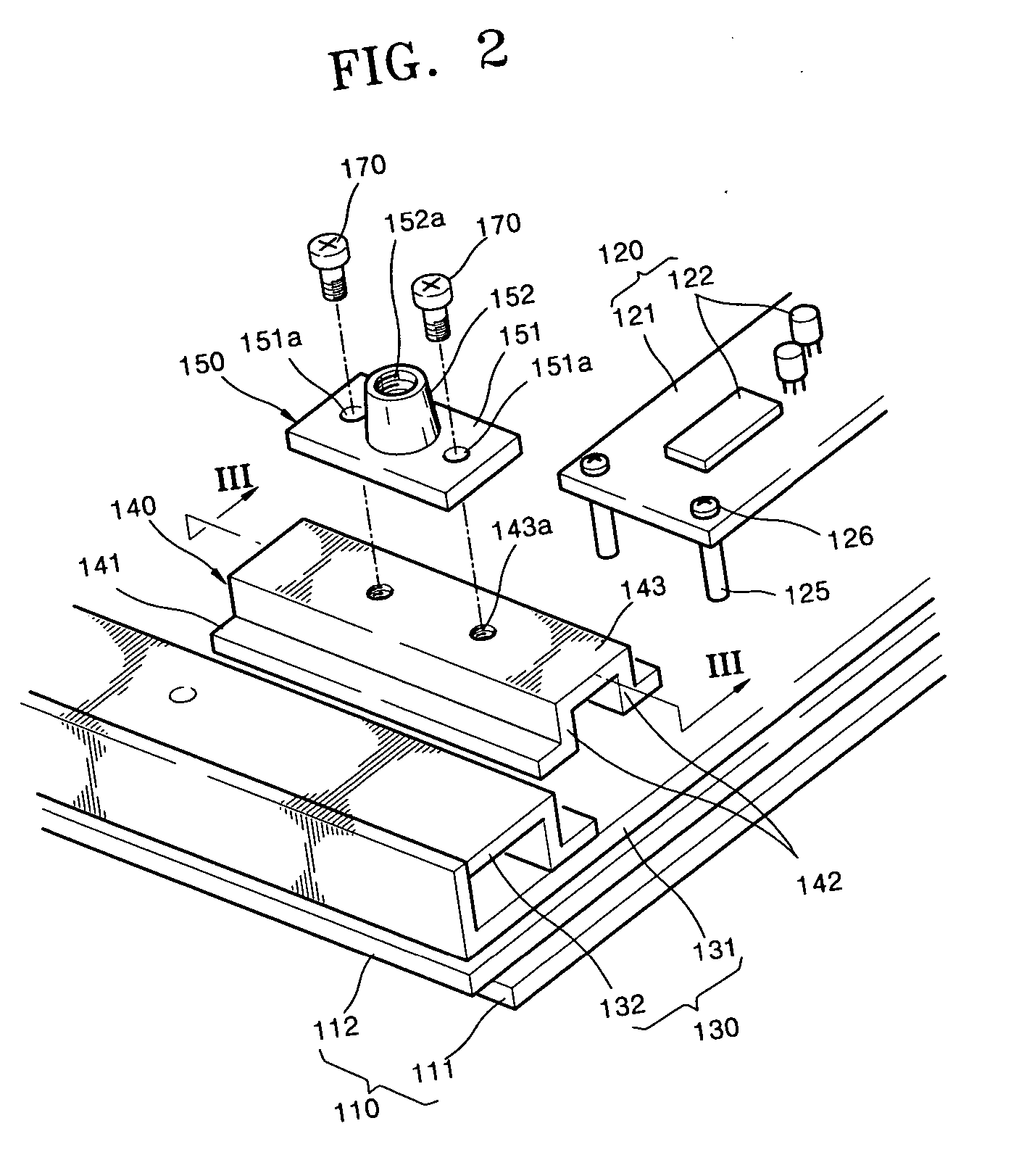

Mounting structure of flat panel display module and flat panel display module including the same

InactiveUS20060244875A1Safer and firmer mounting structureSafe and stable structureTelevision system detailsAnti-theft devicesDisplay deviceEngineering

A mounting structure to a flat panel display (FPD) module which can safely and firmly mount a FPD module in a case or on a surface such as a wall, ceiling, accoutrement, furniture, or window, and a FPD module including the same. The mounting structure includes: a chassis including a chassis base; a bracket disposed on the chassis base; and a connecting member disposed on the bracket and separated from the chassis base by a predetermined gap.

Owner:SAMSUNG SDI CO LTD

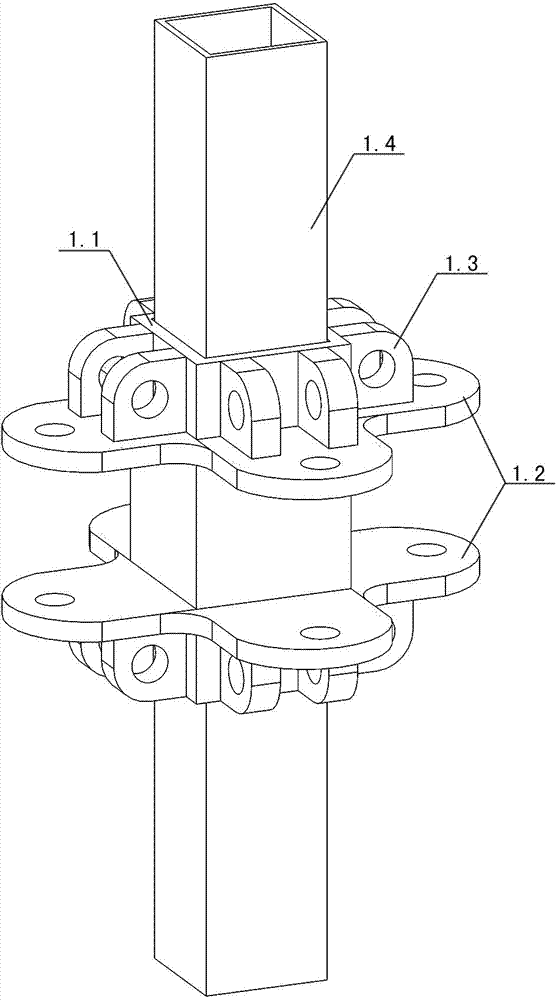

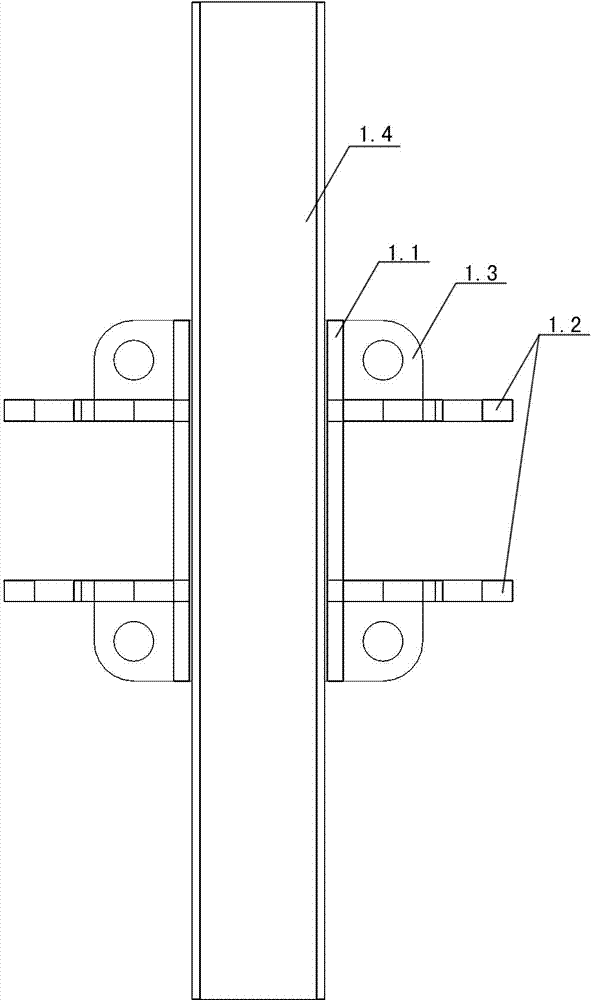

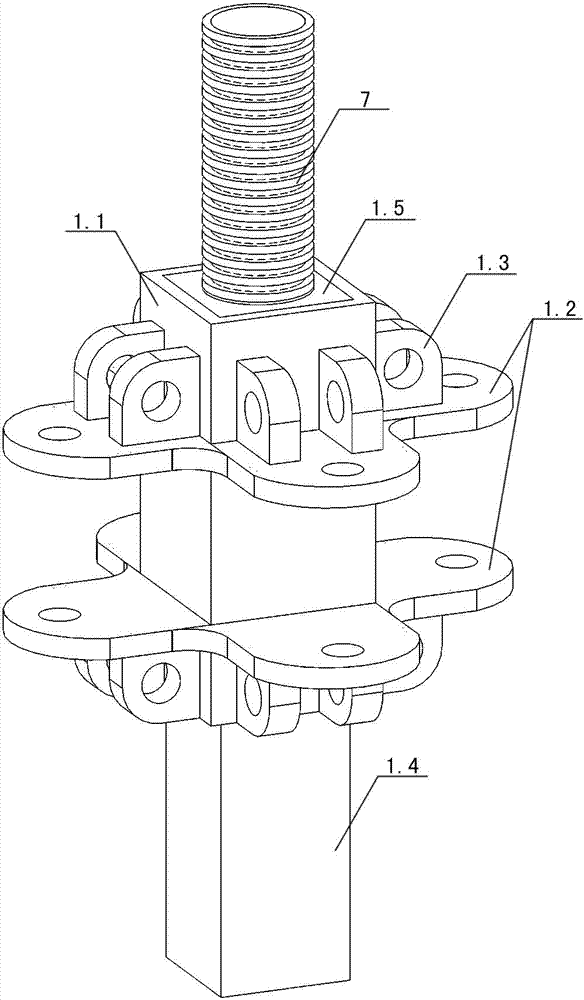

Positively-biased multidirectional three-dimensional connected clamp plate link, quick-release frame, application and method of positively-biased multidirectional three-dimensional connected clamp plate link and quick-release frame

ActiveCN104763717AForce relationship is clearSimple design and constructionScaffold connectionsRod connectionsMechanical engineeringMulti directional

The invention discloses a positively-biased multidirectional three-dimensional connected clamp plate link, a quick-release frame, an application and a method of the positively-biased multidirectional three-dimensional connected clamp plate link and the quick-release frame. The clamp plate link comprises a knob core, a clamp plate, a clamp ring and a knob pin, and is an independent connecting piece capable of simultaneously realizing forwardly, obliquely and multidirectional connecting or concentrically connecting in a same point way; the quick-release frame is a planar frame or a three-dimensional frame formed by mutually assembling an upright bar, a flat bar and an oblique bar; the clamp plate link and the quick-release frame can be applied to a carrying frame, a bailey frame, a bridge frame, a storage rack, a frame, a crane carriage, an elevator frame, a suspension frame, a lifting frame and a carrying frame to be quickly dismounted, especially a scaffold, a template support and the like in the engineering construction field; the independent nodes and independent rod pieces of the quick-release frame can be realized in a solderless manufacturing and pin fixed connection way, the same-point, same-node, coplanar and concentric connection can be realized, the multi-directional bearing, flexibility and diversity and variation can be realized; in addition, the clamp plate link is safe and convenient, firm and durable, accurate and quick.

Owner:朱宏宇

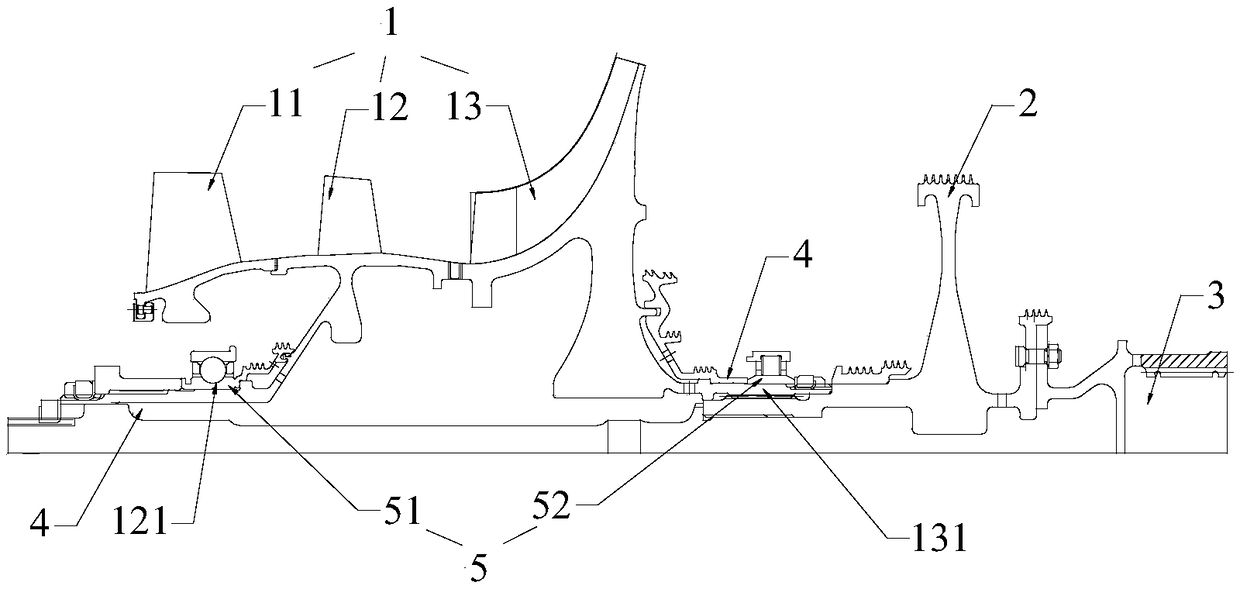

Rotor assembly of gas compressor test part and gas compressor test part

ActiveCN109322848AShorten the distance of the spanImprove rigidityPump componentsGas turbine plantsAxial forceEngineering

The invention discloses a rotor assembly of a gas compressor test part and the gas compressor test part. The rotor assembly comprises a gas compressor blade disc used for increasing the gas flow speedand gas pressure, a balance disc used for balancing axial acting force and arranged coaxially with the gas compressor blade disc, a center pull rod used for tensioning the rotor assembly and transmitting axial force, a power input shaft used for transmitting axial force of torque and fixedly connected with the balance disc and a supporting structure used for supporting the rotor assembly on a casing. The center pull rod penetrates through and locks the gas compressor blade disc and the balance disc. The supporting structure comprises a first supporting part and a second supporting part, the first supporting part and the second supporting part are arranged at the front end and the rear end of the gas compressor blade disc correspondingly, and the balance disc is arranged behind the secondsupporting part. By means of the structural design of the rotor assembly, the supporting span of a rotor is obviously reduced, bending deflection generated when the rotor assembly rotates is reduced,the rigidity and strength of the rotor assembly are increased, and the critical rotation speed margin of the rotor assembly is improved.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

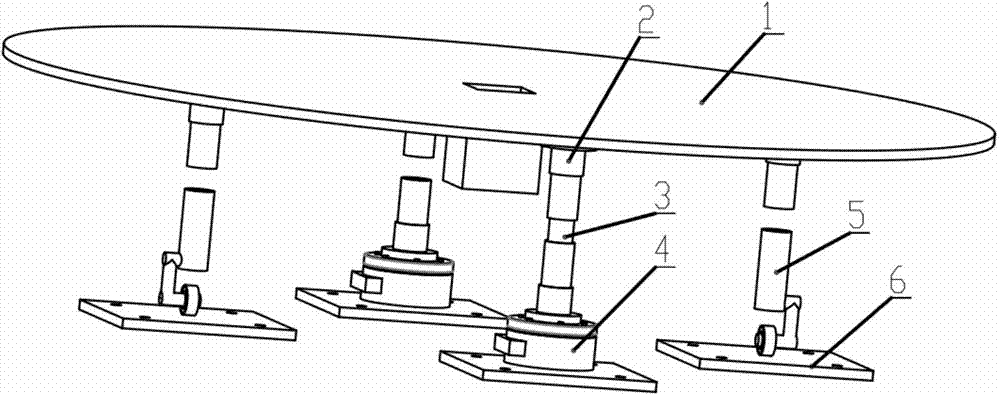

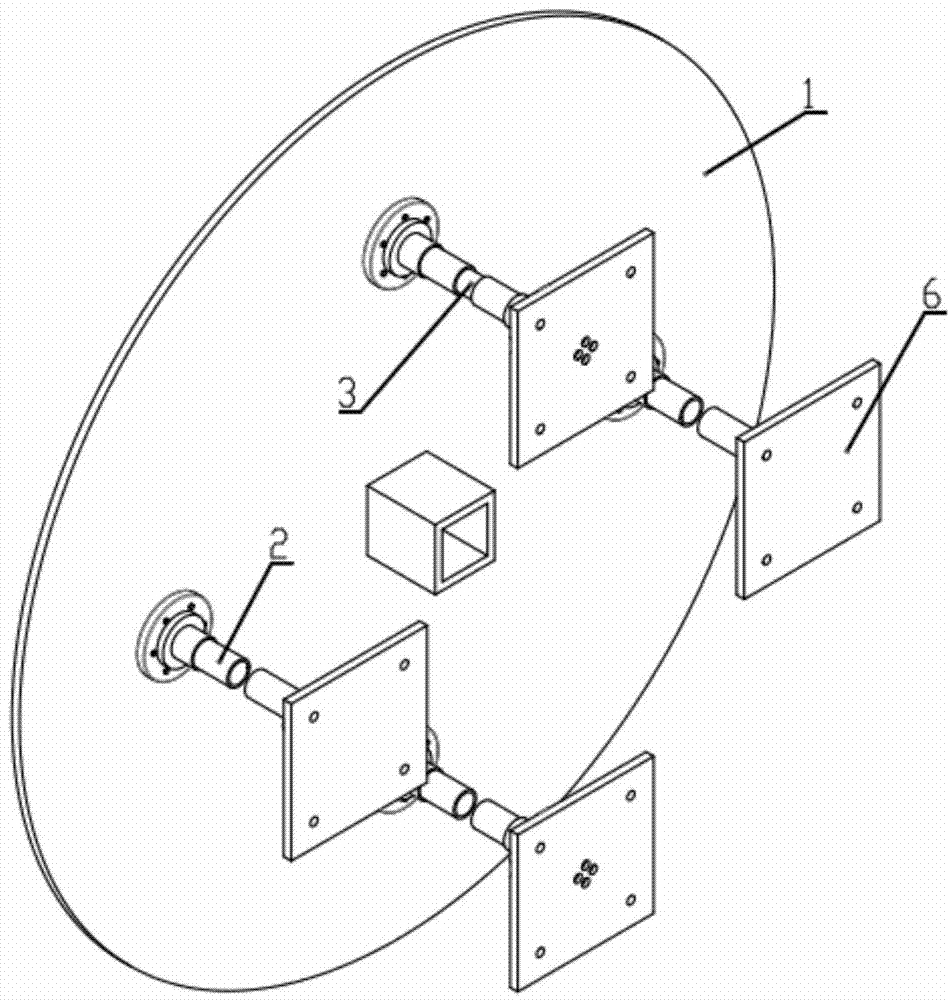

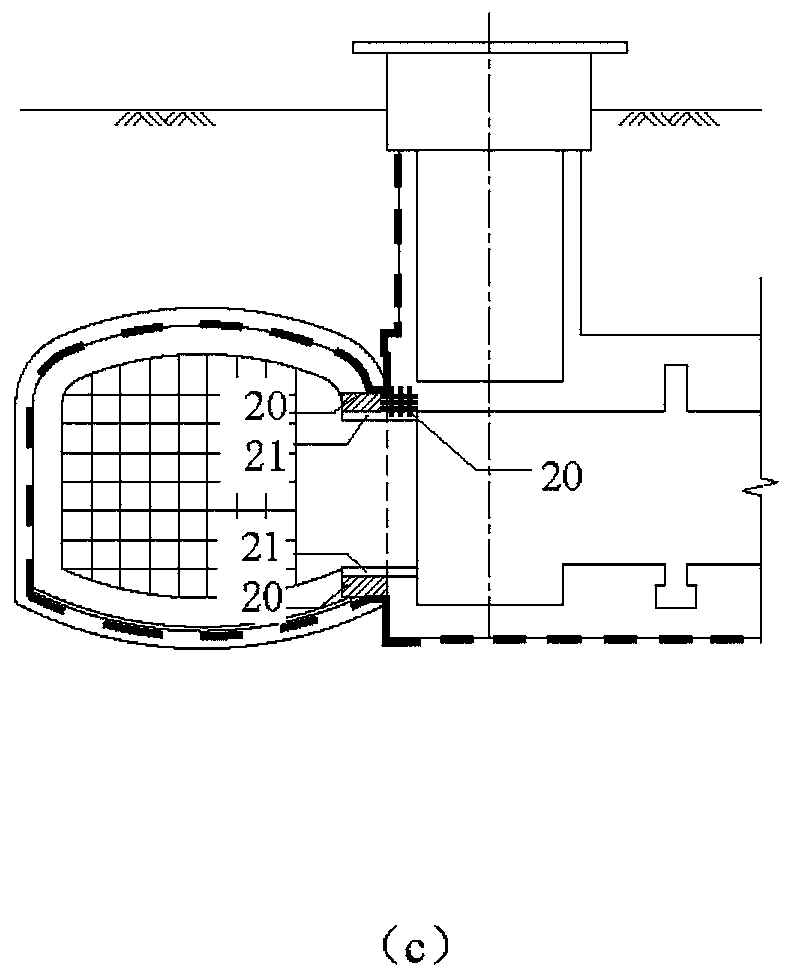

Multi-freedom-degree force measuring device for vibration test of ocean platform model

ActiveCN103759872AMeet force measurement needsMeet the force measurement requirements of six degrees of freedomHydrodynamic testingApparatus for force/torque/work measurementEngineeringForce sensor

The invention discloses a multi-freedom-degree force measuring device for a vibration test of an ocean platform model. The multi-freedom-degree force measuring device comprises a movement transmission disc, connecting rod supports, connecting rod pieces, three-component sensors, sliding wheel supports and fixed square plates. The movement transmission disc is connected with a forced movement mechanism and is a base disc of the whole device, the connecting rod supports are fixed to the movement transmission disc or the three-component sensors, the connecting rod pieces are connected with two connecting rod supports or connected with the connecting rod supports and the sliding wheel supports, the upper end faces and the lower end faces of the three-component sensors are connected with the connecting rod supports and the fixed square plates respectively, the sliding wheel supports are connected with the connecting rod pieces and support the fixed square plates, and the fixed square plates are fixed to the ocean platform model, or connected with the three-component sensor, or supported by the sliding wheel supports. The multi-freedom-degree force measuring device is simple in structure, clear in function and capable of being used repeatedly, and the force measurement requirements of the forced vibration test of the ocean platform model under the test work conditions of different freedom degrees and different freeboard heights are met.

Owner:SHANGHAI JIAO TONG UNIV

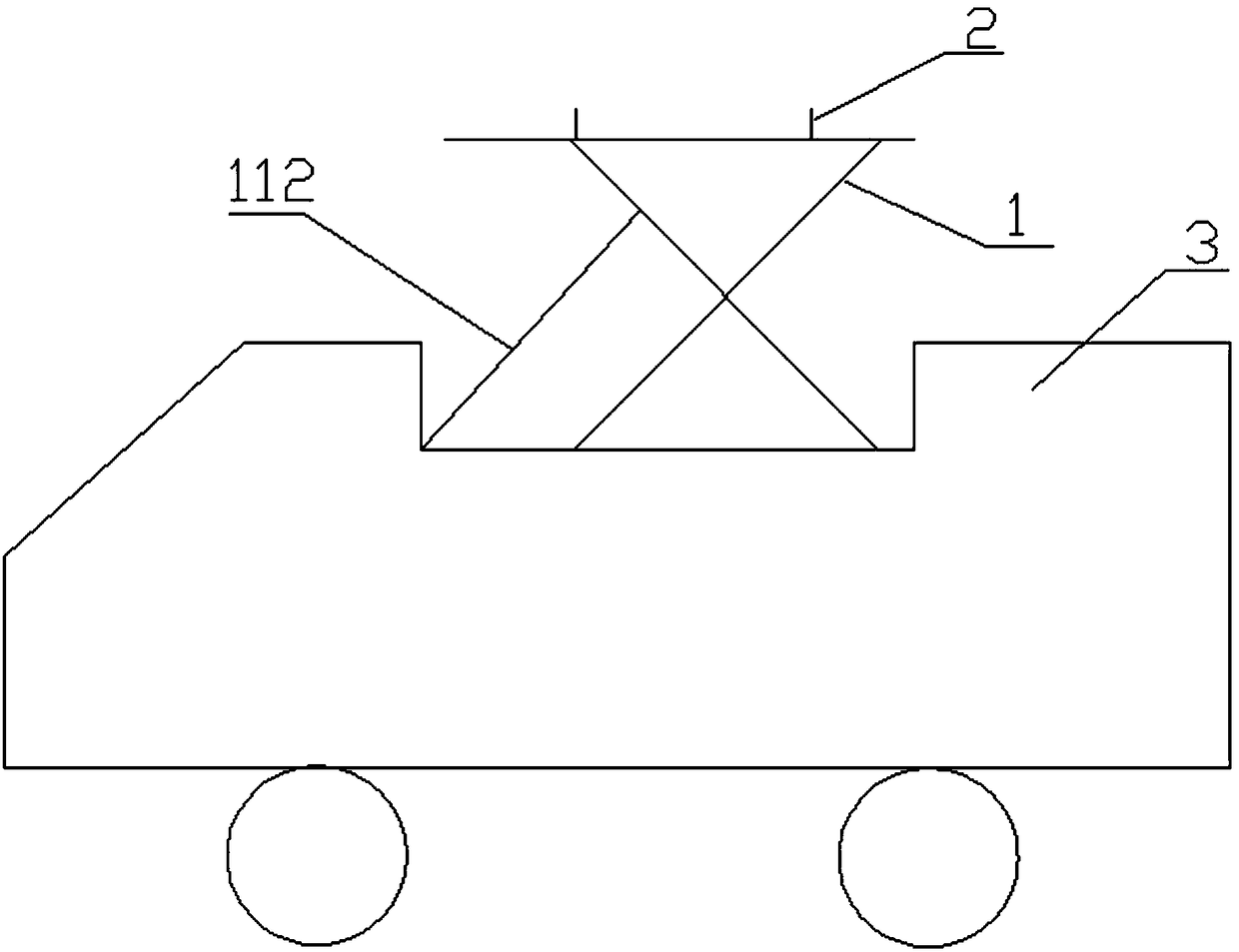

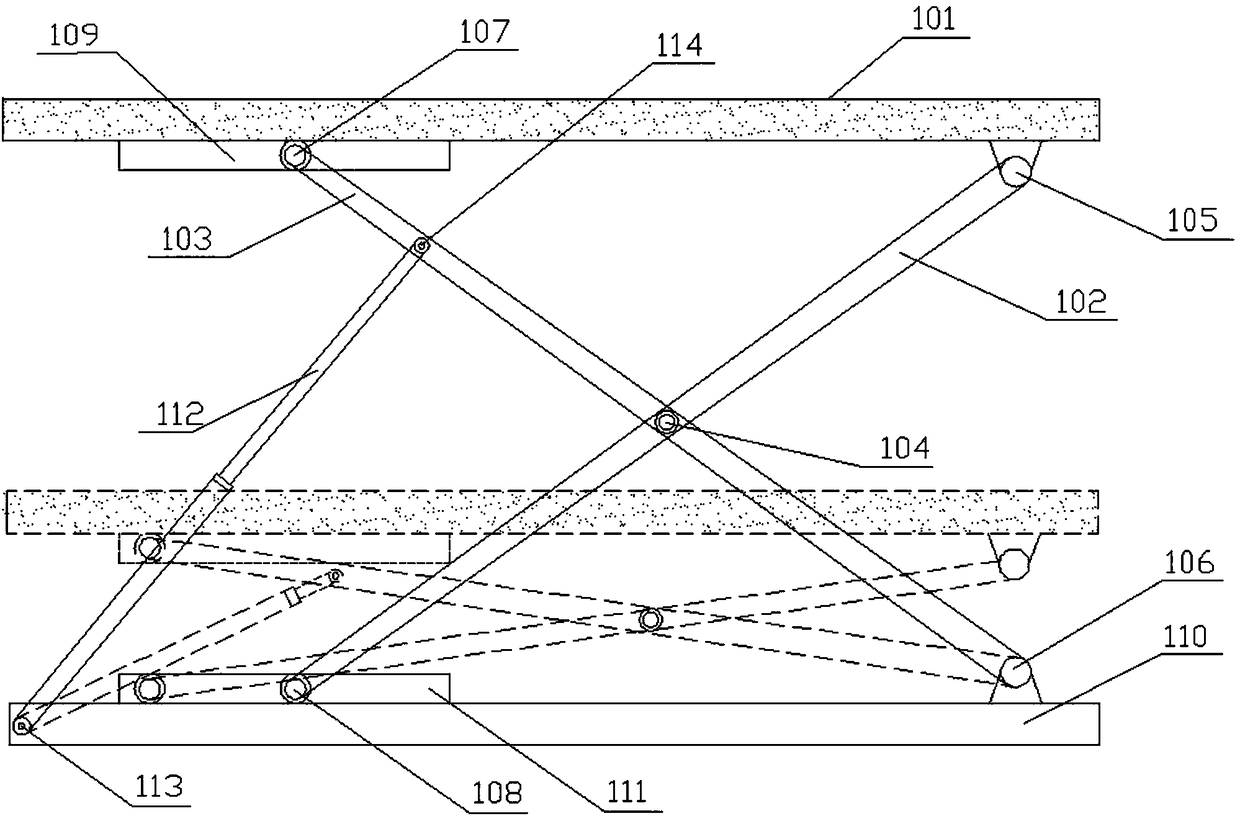

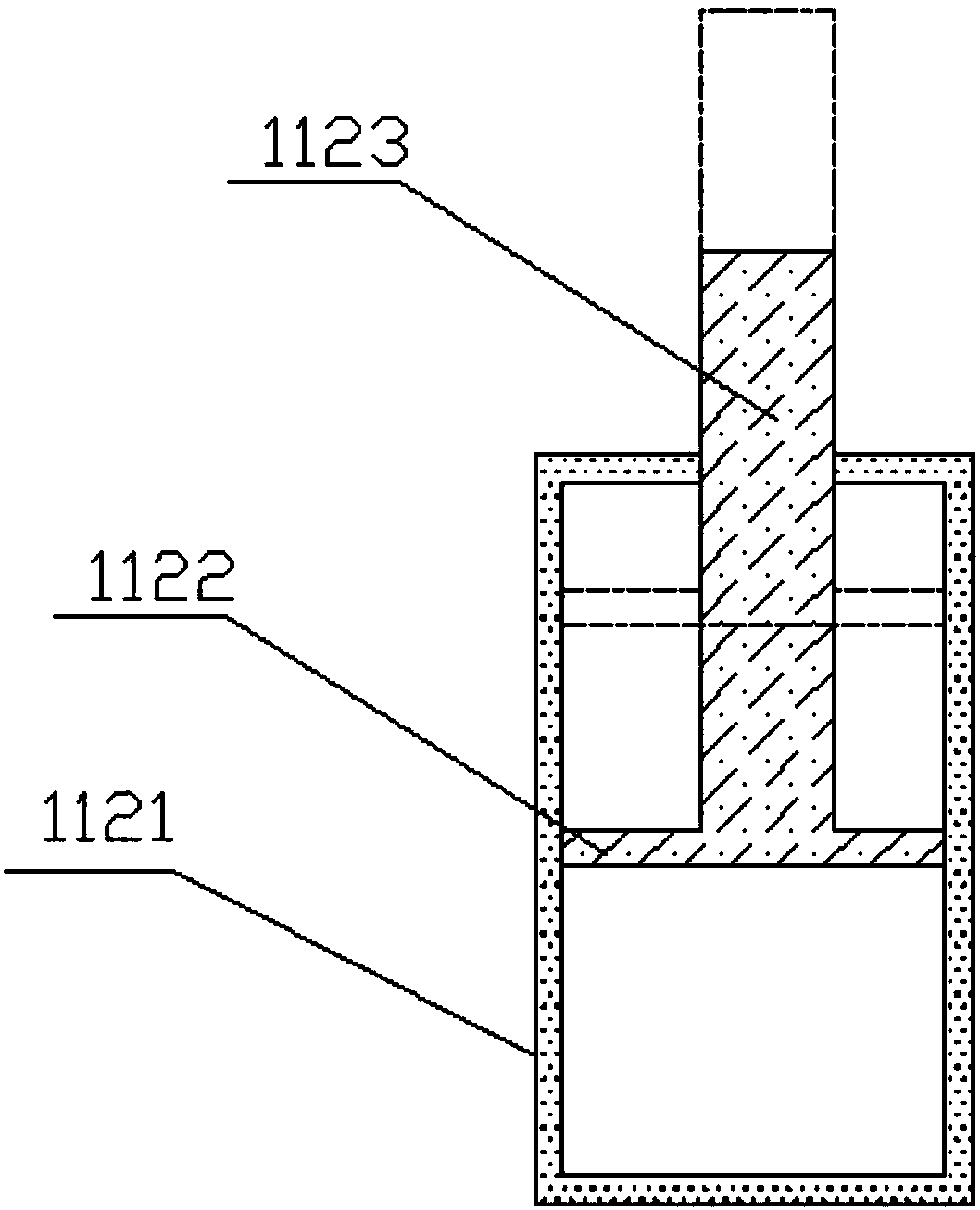

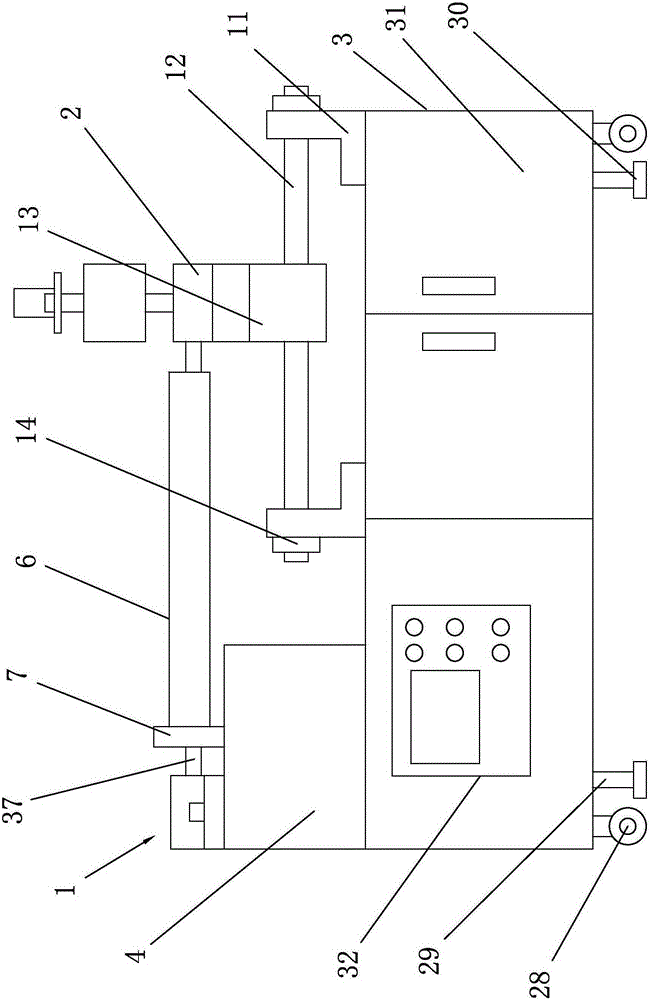

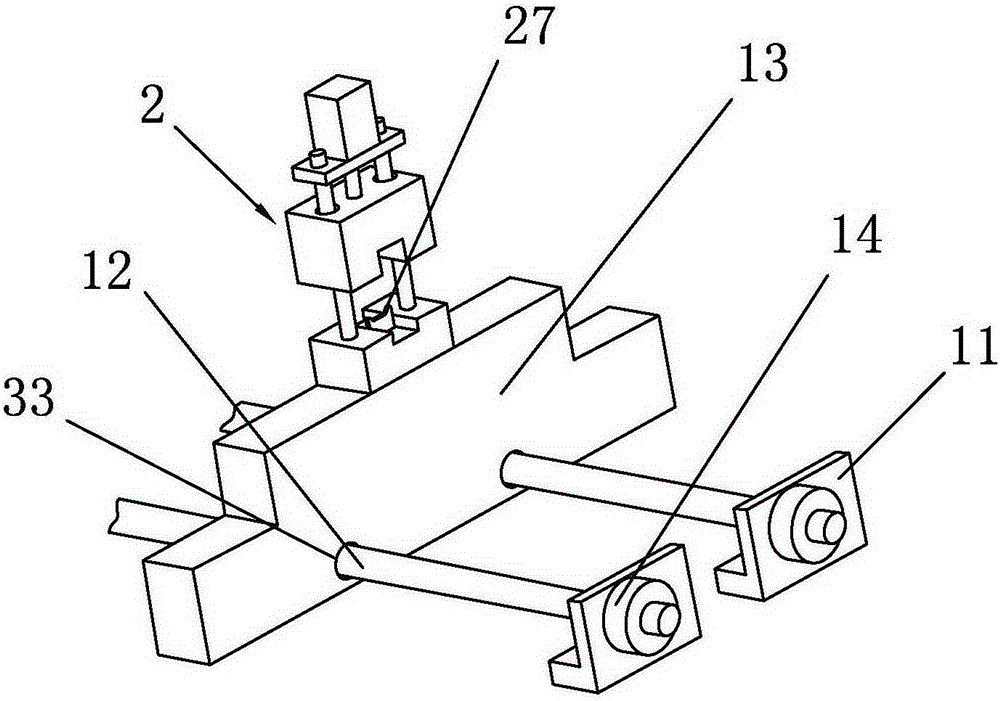

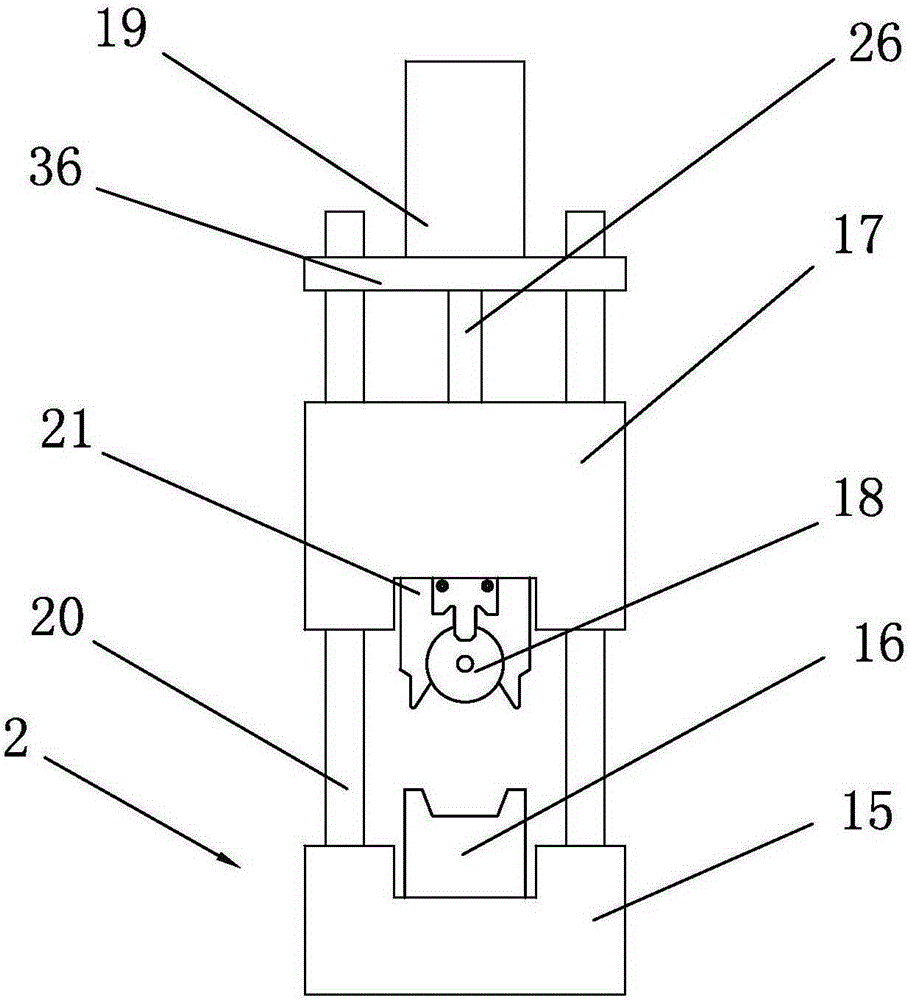

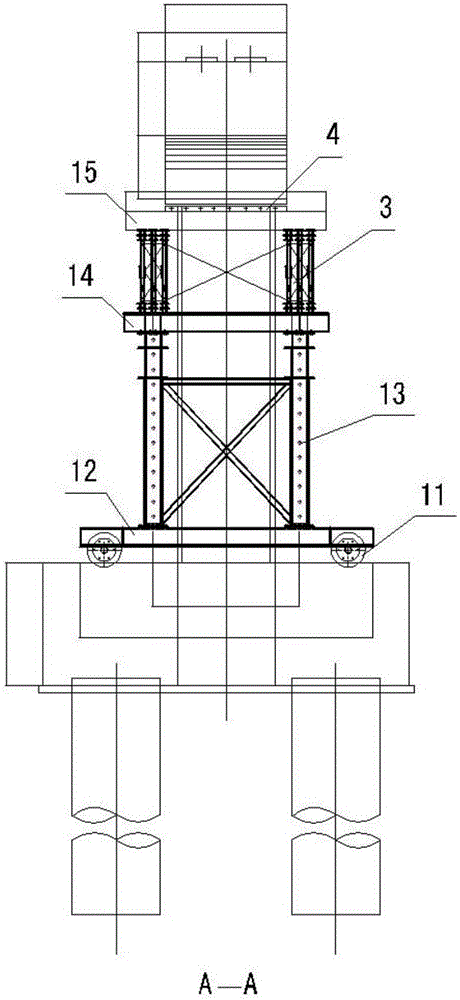

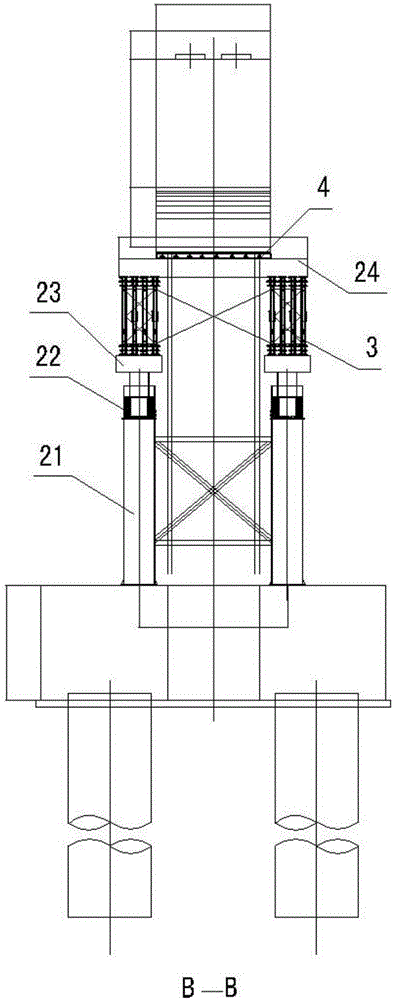

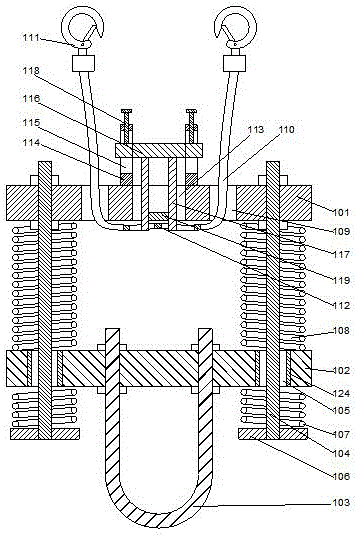

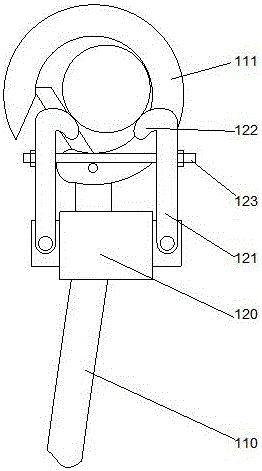

Unmanned aerial vehicle recovery device and method based on hydraulic lifting and mechanical hand locking structure

PendingCN108501797AEasy to operateRealize the voltage supplyPortable landing padsVehicle carriersControl systemManipulator

The invention provides an unmanned aerial vehicle recovery device and method based on a hydraulic lifting and mechanical hand locking structure and belongs to the technical field of unmanned aerial vehicle recovery. The device comprises a lifting device, locking devices, a recovery vehicle and a control system. The lifting device and the locking devices are all connected with the control system, meanwhile, the control system is in communication connection with an unmanned aerial vehicle, the lifting device is installed on the recovery vehicle, is of a scissors fork type lifting structure and achieves stretch and retraction through hydraulic transmission so as to achieve a lifting function, and the locking devices are installed at the top of the lifting device and used for fixing the unmanned aerial vehicle. The method includes the steps that when the unmanned aerial vehicle finishes a task or encounters an emergency and needs to land forcibly, the lifting device drives the locking devices to ascend, after the unmanned aerial vehicle lands, the locking devices start to work, a mechanical hand is closed tightly, and the unmanned aerial vehicle is fixed through the locking devices. Compared with the prior art, the recovery efficiency of the unmanned aerial vehicle is improved, and the unmanned aerial vehicle is recovered more conveniently and quickly.

Owner:JILIN UNIV

High embankment slope stabilizing structure and construction method thereof

ActiveCN111501796AReduce landslide riskPerfect drainage systemArtificial islandsRoadwaysSteel tubeRock bolt

The invention discloses a high embankment slope stabilizing structure. The high embankment slope stabilizing structure comprises a retaining wall, steel pipe piles and anchor rods; the retaining wallis arranged at the foot of a high embankment slope, concrete-filled steel pipe piles are arranged on the inner surface of the retaining wall, an excavation step and a gravel drainage zone are arrangedat a filling and excavation interface, the bottoms of the concrete-filled steel pipe piles and the steel pipe piles penetrate through the gravel drainage zone, and the upper sections of the steel tube piles are sleeved with grouting sleeves correspondingly; the lower end of the grouting sleeves extend to the gravel drainage zone, the upper end of each grouting sleeve is connected with a groutingopening through a grouting pipe, a fixed pulley and a pipeline channel are arranged inside each concrete-filled steel pipe pile, the anchor rods are is fixed in a rock stratum behind the excavation step, the exposed parts of the tops of the anchor rods are connected with steel strands, and the steel strands are connected to the fixed pulleys or the steel pipe piles at the same height; the steel strands connected to the fixed pulleys are led out of crown beam through the pipeline channel and connected with a steel strand tensioning device. The high embankment slope stabilizing structure is suitable for reinforcing and active control of embankment deformation in the embankment construction and operation process, and is particularly suitable for embankment projects with high requirements forembankment stability and later operation safety.

Owner:ZHEJIANG UNIV CITY COLLEGE

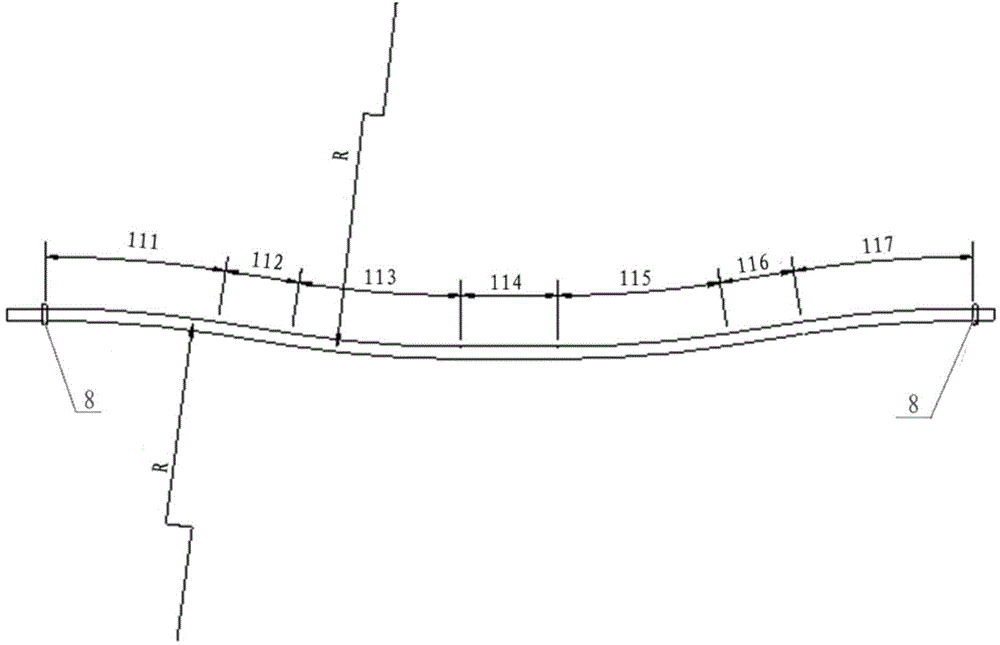

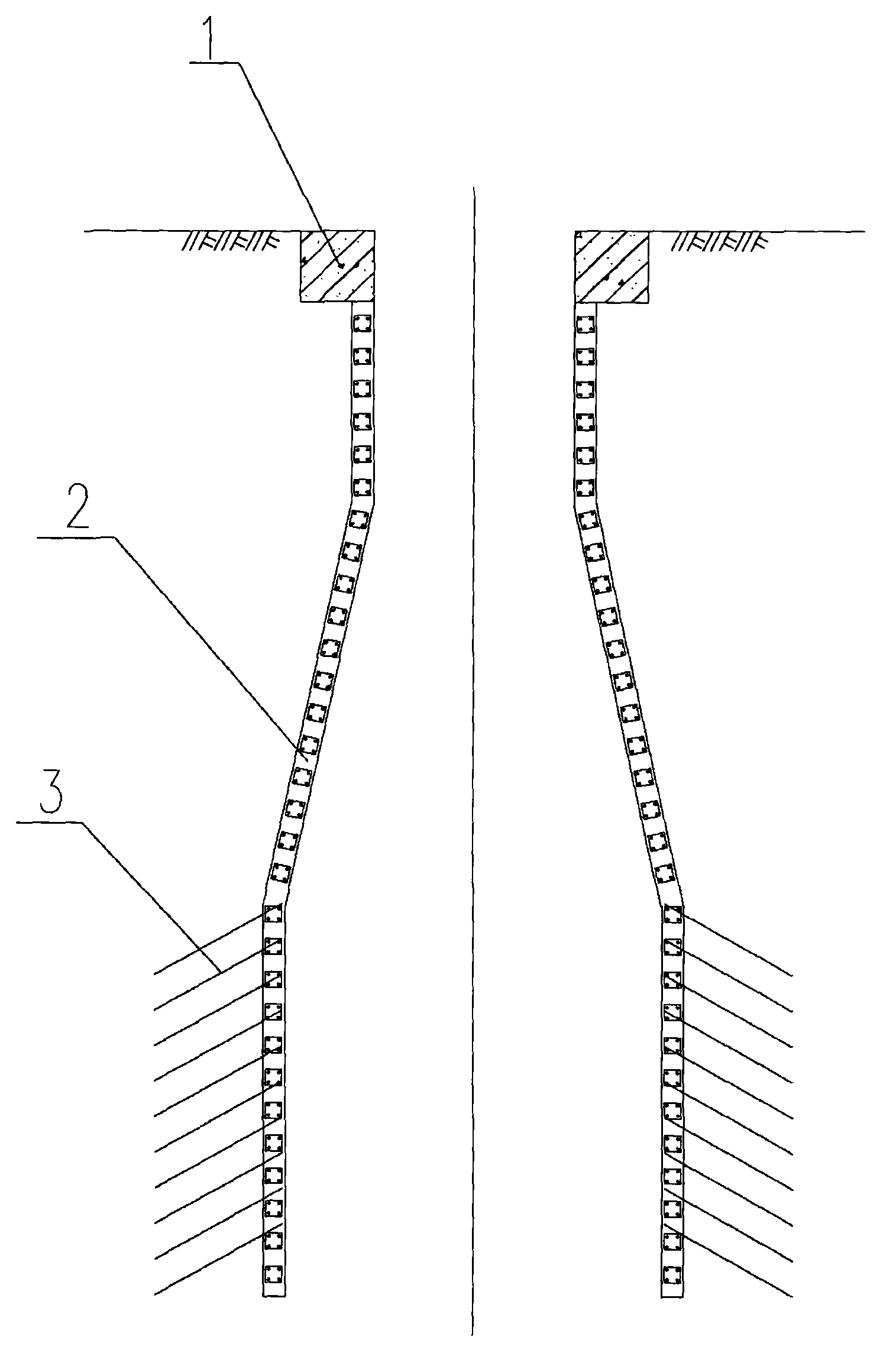

Designing method for sea-crossing steel sinking pipeline

The invention discloses a designing method for a sea-crossing steel sinking pipeline. The designing method for the sea-crossing steel sinking pipeline comprises the following steps: (1) determining the arrangement of a pipeline route according to the terrain of a seabed, wherein the sea-crossing steel sinking pipeline comprises two upwards-bent sections and two downwards-bent sections, which are on the same plane and have the same curvature radius; (2) calculating a design curvature radius: calculating the design curvature radius according to the strength and the stress characteristics of a pipeline material and a specification, and determining the arc lengths of the upwards-bent and downwards-bent sections according to the arrangement of the pipeline route and the design curvature radius; (3) digging a foundation trench matched with the pipeline route in the seabed on the basis of the arrangement of the pipeline route and the design curvature radius; (4) constructing and dragging the pipeline, and ensuring that the curvature radius of the sinking pipeline is equal to the design curvature radius. According to the designing method for the sea-crossing steel sinking pipeline, the shortcomings of a conventional bottom towing method are overcome, and the designing method for the sea-crossing steel sinking pipeline is safer and more suitable.

Owner:广东省水利电力勘测设计研究院有限公司

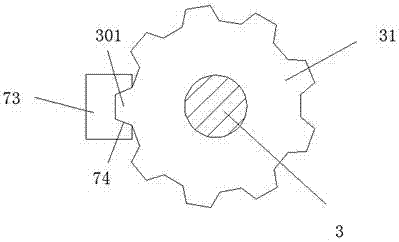

Novel energy vehicle charging pile

ActiveCN106926735AImprove carrying capacityAvoid offsetCharging stationsElectric vehicle charging technologyAutomatic controlEngineering

The invention discloses a novel energy vehicle charging pile. The novel energy vehicle charging pile comprises a base body and an operating chamber arranged in the base body, a rotary shaft which is operably connected with the base body is arranged at the rear end of the operating chamber, the upper end of the rotary shaft extends outside the base body and is fixedly connected with a pile body, a power charging port is formed in the pile body, a rotary dial is arranged on the top end surface of the base body, a shaft hole used for the rotary shaft passing is formed in the midpoint of the rotary dial, and a first toothed wheel is arranged, in the position of the top of the operating chamber, on the rotary shaft. According to the novel energy vehicle charging pile, the overall structure is simple, manufacturing cost is low, the structure is safe and stable, automatic adjustment and locking of the direction of the power charging port of the pile body can be realized, automatic control to adjust the direction of the power charging port of the pile body can be realized, the existing requirement of people to adjust the direction of the power charging port of the pile body is met, operation is simple and convenient, the direction of the power charging port of the pile body can be adjusted precisely through the arranged rotary dial, and adjustment accuracy is increased.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

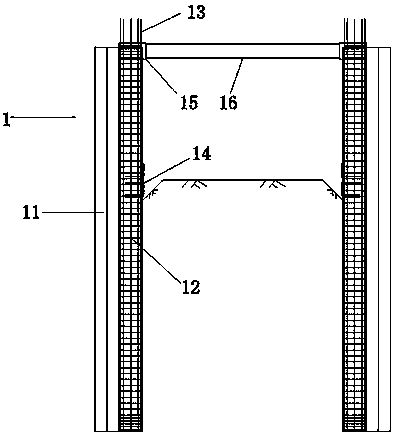

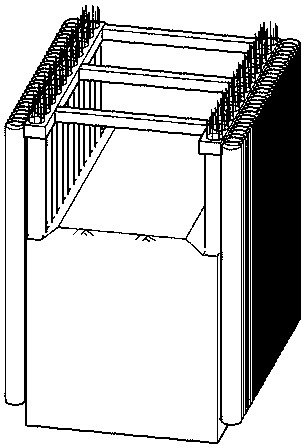

Assembly type utility tunnel for building envelop bearing strength and construction method thereof

ActiveCN108252329AImprove anti-floating performanceSafe and stable structureArtificial islandsProtective foundationRebarDrill hole

The invention discloses an assembly type utility tunnel for building envelop bearing strength and a construction method thereof. The structure is formed by two parts of a building envelop and a prefabricated utility tunnel by casting in place and connecting, the building envelop comprises a triaxial soil-cement stirring pile and a drill hole cast-in-place pile, the top of the drill hole cast-in-place pile is reserved with longitudinal reinforcements, the inner side, near the bottom of a foundation pit, of the drill hole cast-in-place pile is reserved with pre-embedded reinforcements; the top of the prefabricated utility tunnel is provided with a set of structural beams at intervals, the top of each structural beam is provided with a lap plate, the two ends of each lap plate are reserved with lap plate reserved reinforcements extending outward, the two sides of the bottom of the prefabricated utility tunnel are reserved with bottom plate reserved reinforcements extending outward, pile top reserved reinforcements are connected with the lap plate reserved reinforcements, and the pre-embedded reinforcements are connected with the bottom plate reserved reinforcements. According to the assembly type utility tunnel for building envelop bearing strength and the construction method thereof, nodes of the prefabricated utility tunnel are all in cast-in-place connection with the reinforcements of the drill hole cast-in-place pile, the damage of uneven settlement caused by foundation subsidence is prevented, the construction period is shortened, and the assembly type utility tunnel is economic and environmental.

Owner:ZHEJIANG XINSHENG CONSTR GROUP

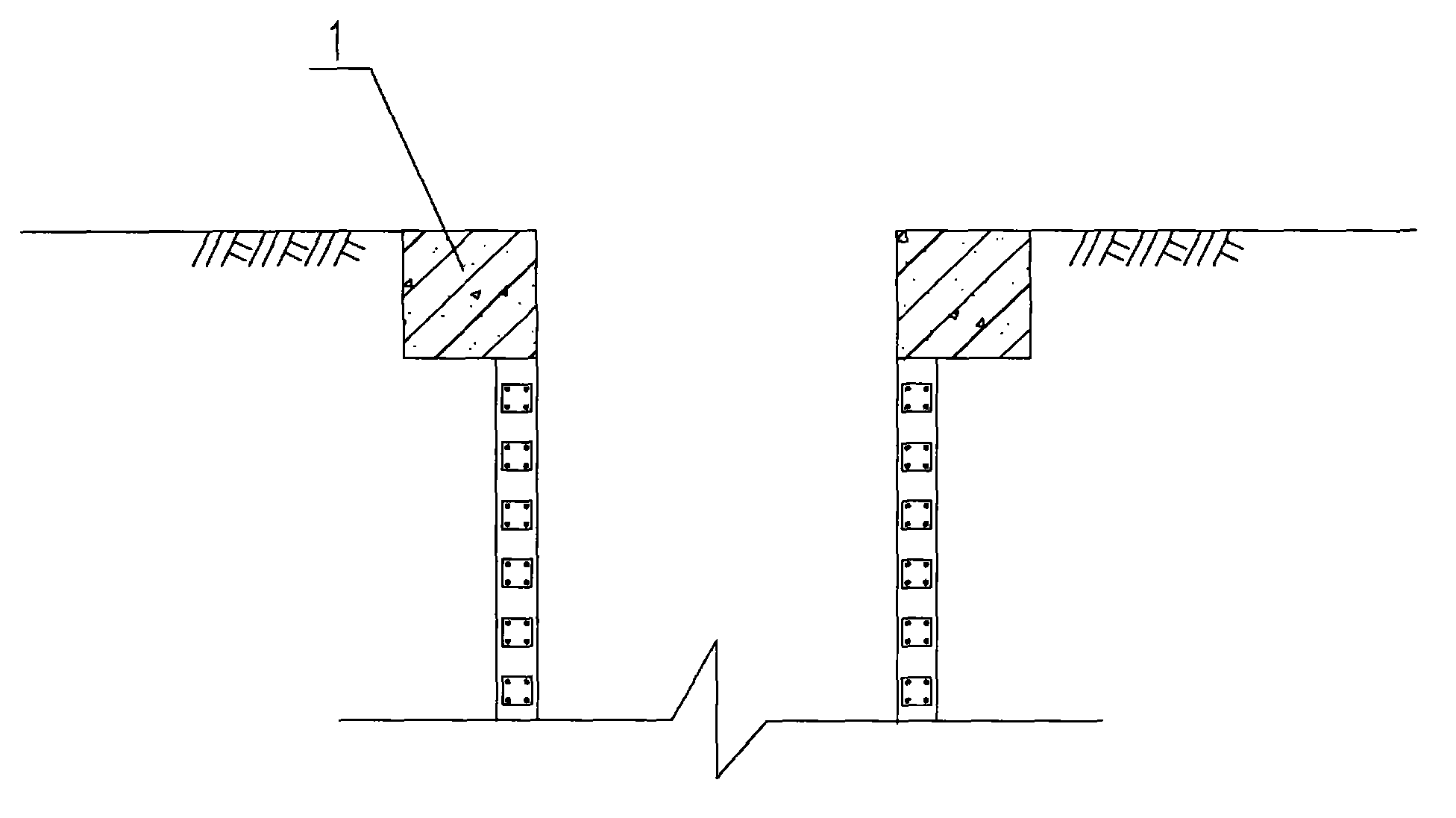

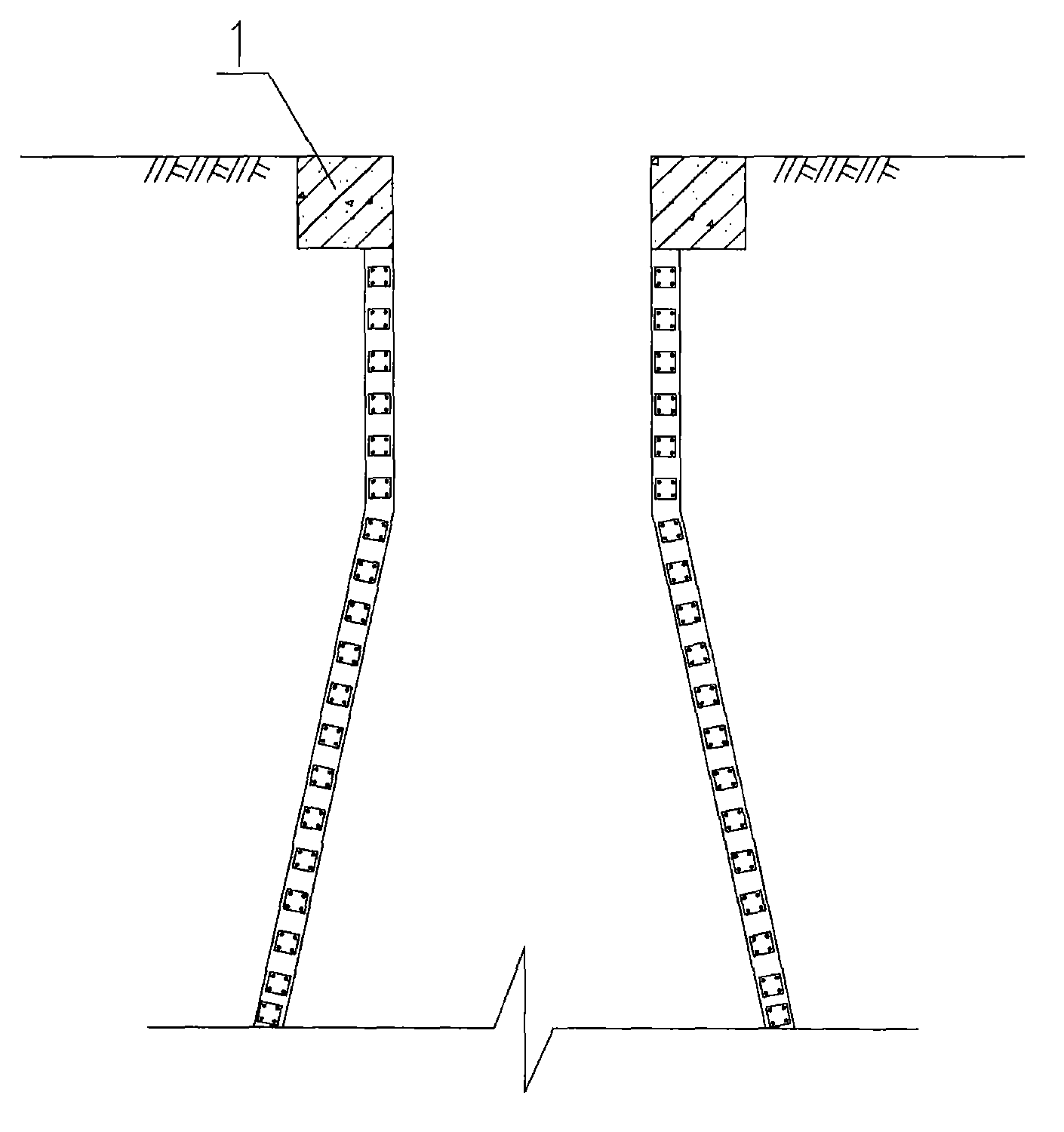

Process for constructing shield rapid inspection shaft

InactiveCN103806916ASafe and stable structureFlexible space controlShaft sinkingShaft liningGratingRebar

The invention relates to a process for constructing a shield rapid inspection shaft. The process includes the following steps that firstly, a lock catch ring beam with steel bars reserved at the bottom is constructed; secondly, expanding excavation of a vertical shaft is carried out according to the standard that the vertical included angle of expanding excavation surfaces is smaller than or equal to 45 degrees; thirdly, the shaft body of the vertical shaft is constructed, wherein the retaining wall of the vertical shaft is formed by steel bar gratings and concrete in an anchoring and shotcreting mode and is 300 mm in thickness, and the steel bar gratings are connected with the reserved steel bars of the lock catch ring beam; fourthly, an ingate is constructed in the vertical shaft, wherein the arch-crown-gate-type ingate is constructed on the vertical shaft side wall along the tunneling axis of a shield; fifthly, the bottom of the vertical shaft is sealed through a steel bar truss to be prevented from hunching. The process for constructing the shield rapid inspection shaft is suitable for shield inspection shaft construction under various geological and hydrologic conditions, thereby bringing convenience to inspection of the shield under the shaft. The shield inspection shaft has the advantages of being safe and stable in structure, flexible in space layout, convenient to construct and operate, high in construction speed, small in occupied area and the like.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG

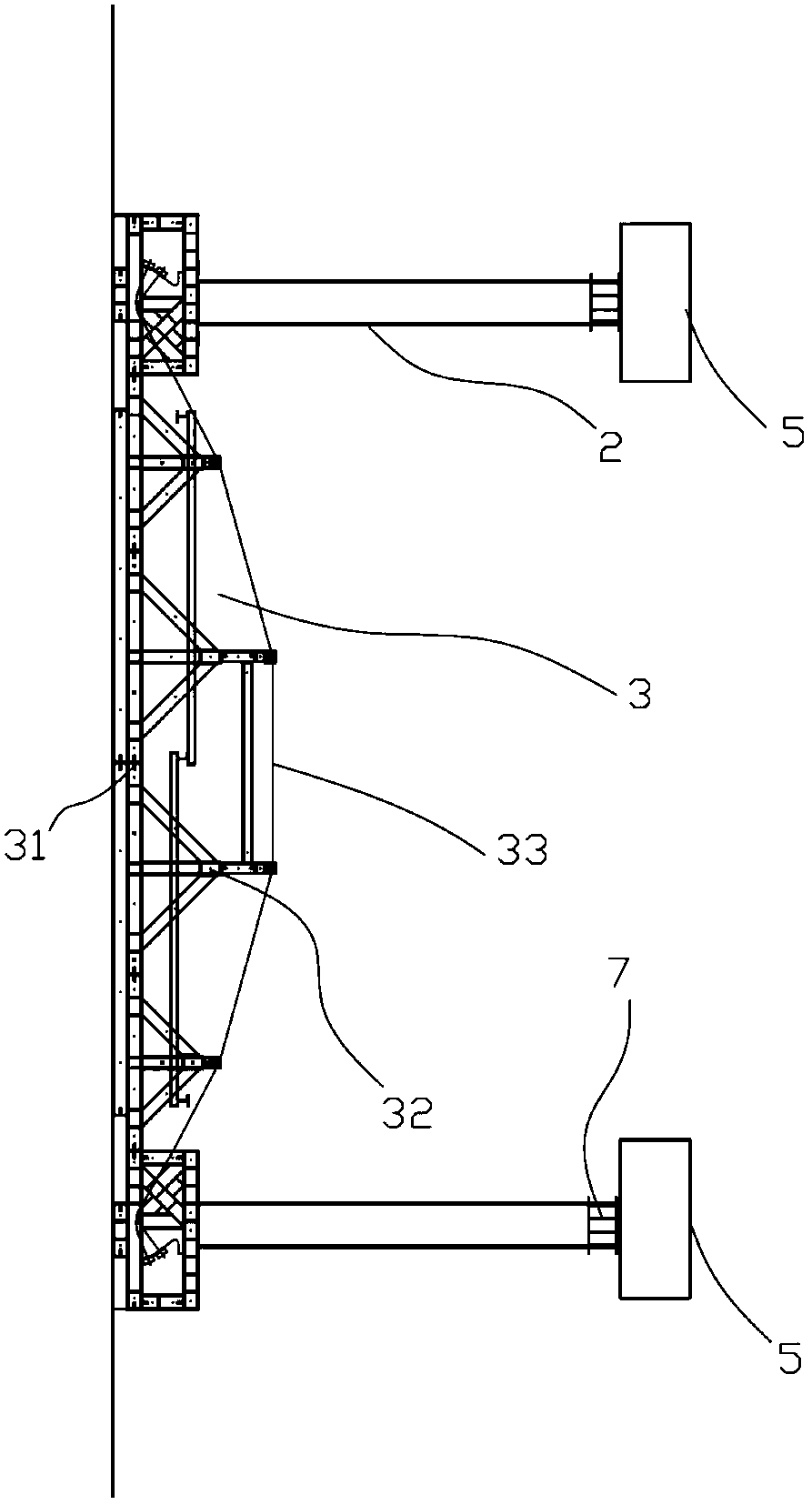

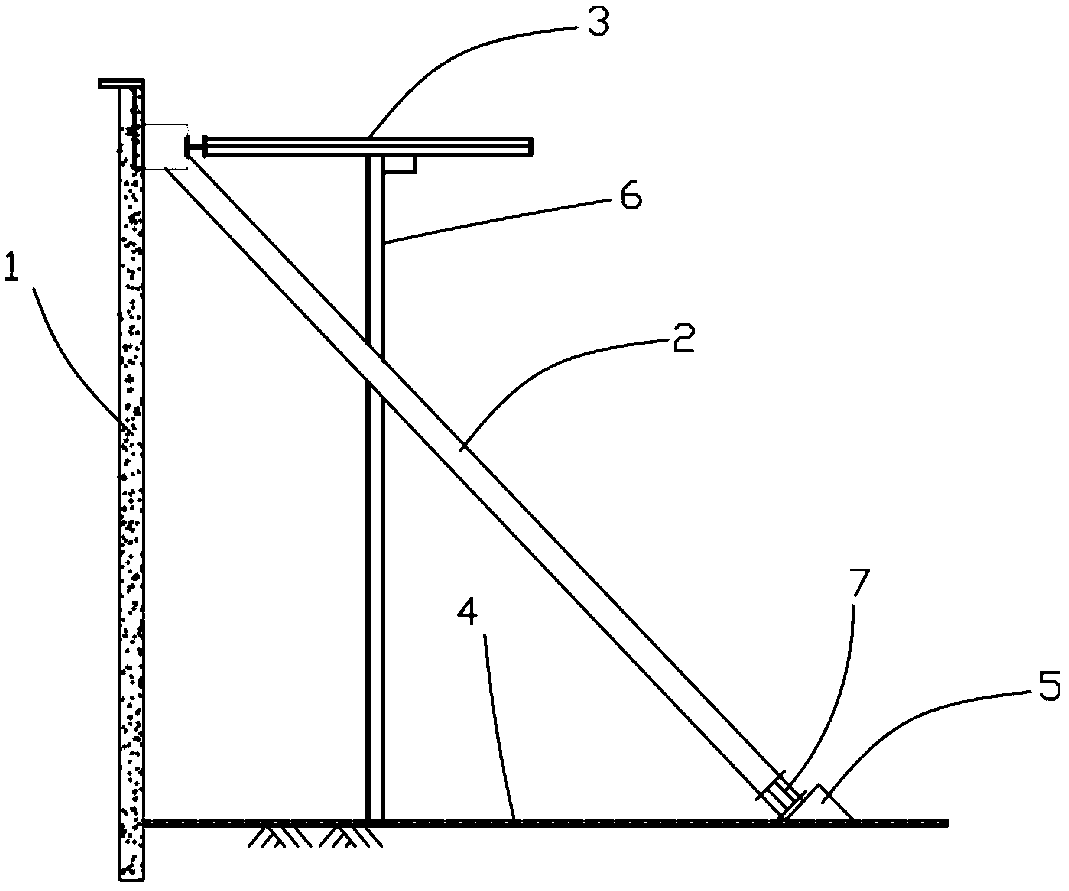

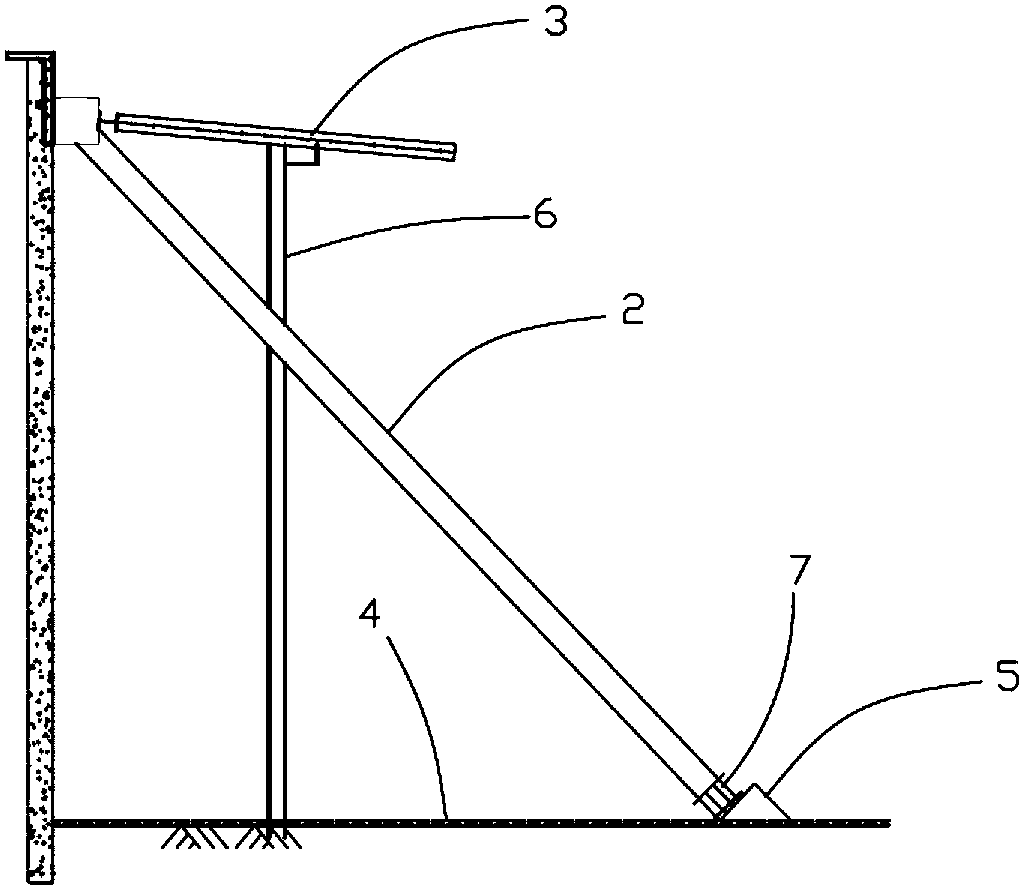

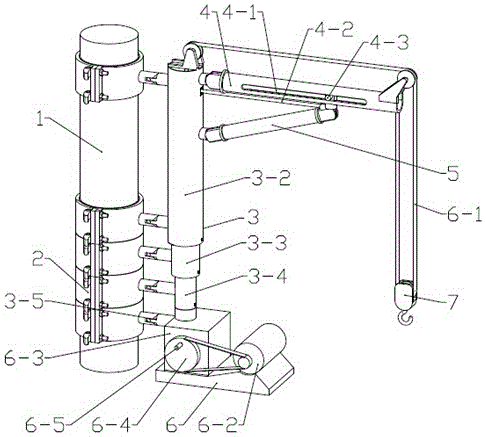

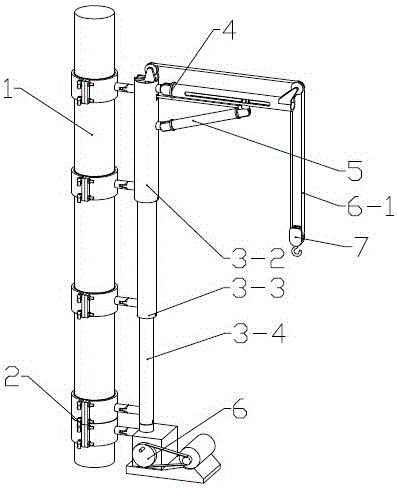

Folding type suspension arm device supported by electric pole

The invention relates to a folding type suspension arm device supported by an electric pole. The folding type suspension arm device comprises a telescopic supporting rod body connected with the electric pole through a fixing seat, a horizontal suspension arm hinged to the upper end of the supporting rod body, an inclined supporting rod connecting the supporting rod body and the horizontal suspension arm and a driving mechanism arranged on the lower portion of the supporting rod body. A first traction rope set of the driving mechanism winds across a pulley at the upper end of the supporting rod body and a pulley at the moving end of the horizontal suspension arm and then is connected with a hoisting hook. The folding type suspension arm device supported by the electric pole has the characteristics of being safe and stable in structure, simple in erection process and the like; the existing electric pole is used for supporting the device, the device structure is thus simplified, and safety of the construction process is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

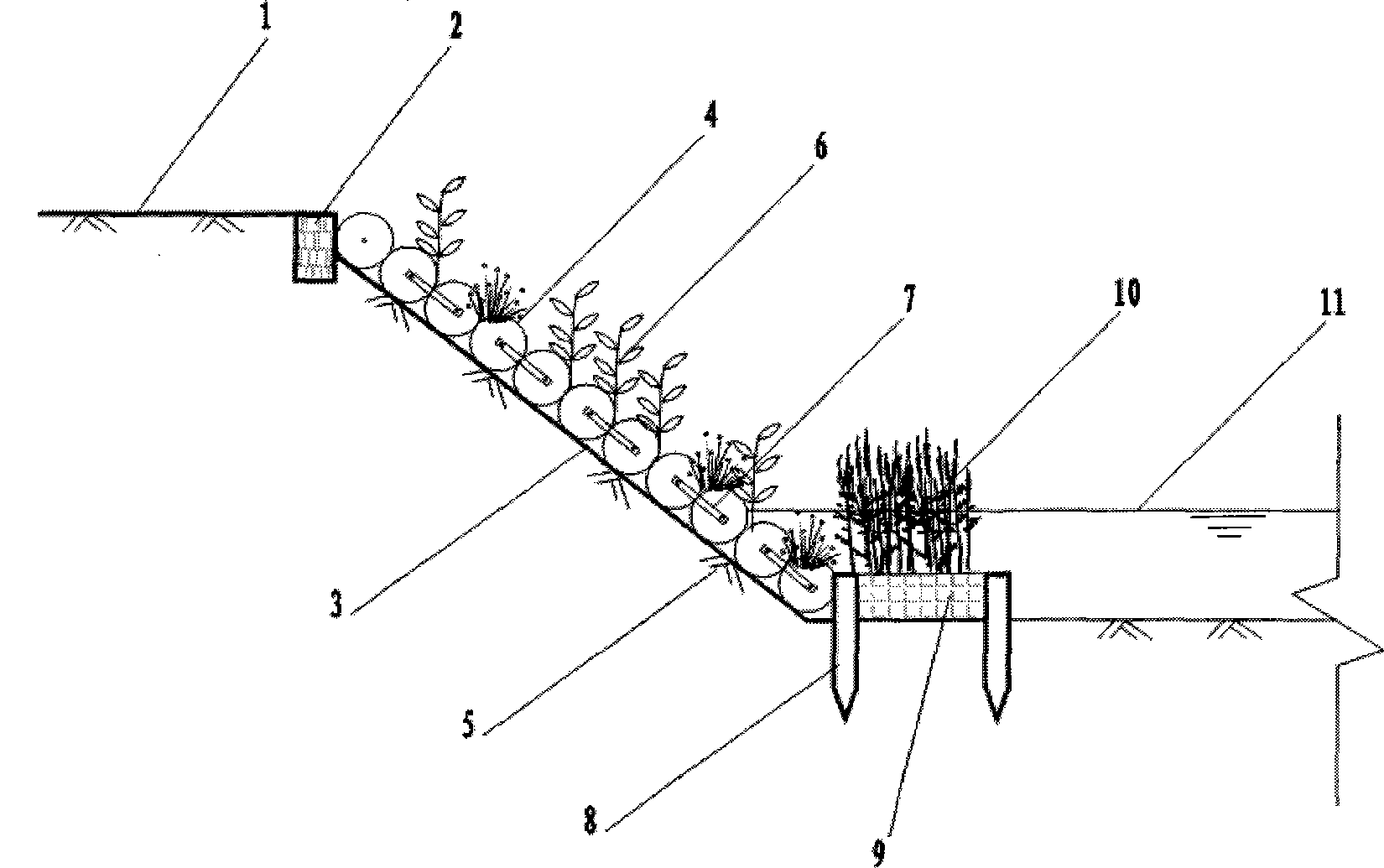

Slope-type ecological embankment

InactiveCN102839633ASafe and stable structureCoastlines protectionHorticultureWater qualityEngineering

The invention discloses a slope-type ecological embankment. The slope-type ecological embankment is formed by arranging a geotextile inverted layer (3), a porous concrete revetment, a plant planting tank foot protection and a hygrophyte in sequence on the basis of the original stable structure slope surface (5), wherein the stable structure slope surface (5) is of undisturbed soil with a stable structure; the geotextile inverted layer (3) is a layer of water permeability non-woven geotextile; the porous concrete revetment is paved by a single layer globular complex made of porous concrete materials; the plant planting tank foot protection is set at the position where a slope toe is connected with a river bottom; the hygrophyte is a plant planted in the porous concrete revetment and the plant planting tank. The slope-type ecological embankment is stable and safe in structure, and simultaneously has functions of purifying water quality of river and constructing a river wall ecosystem.

Owner:金丹越 +2

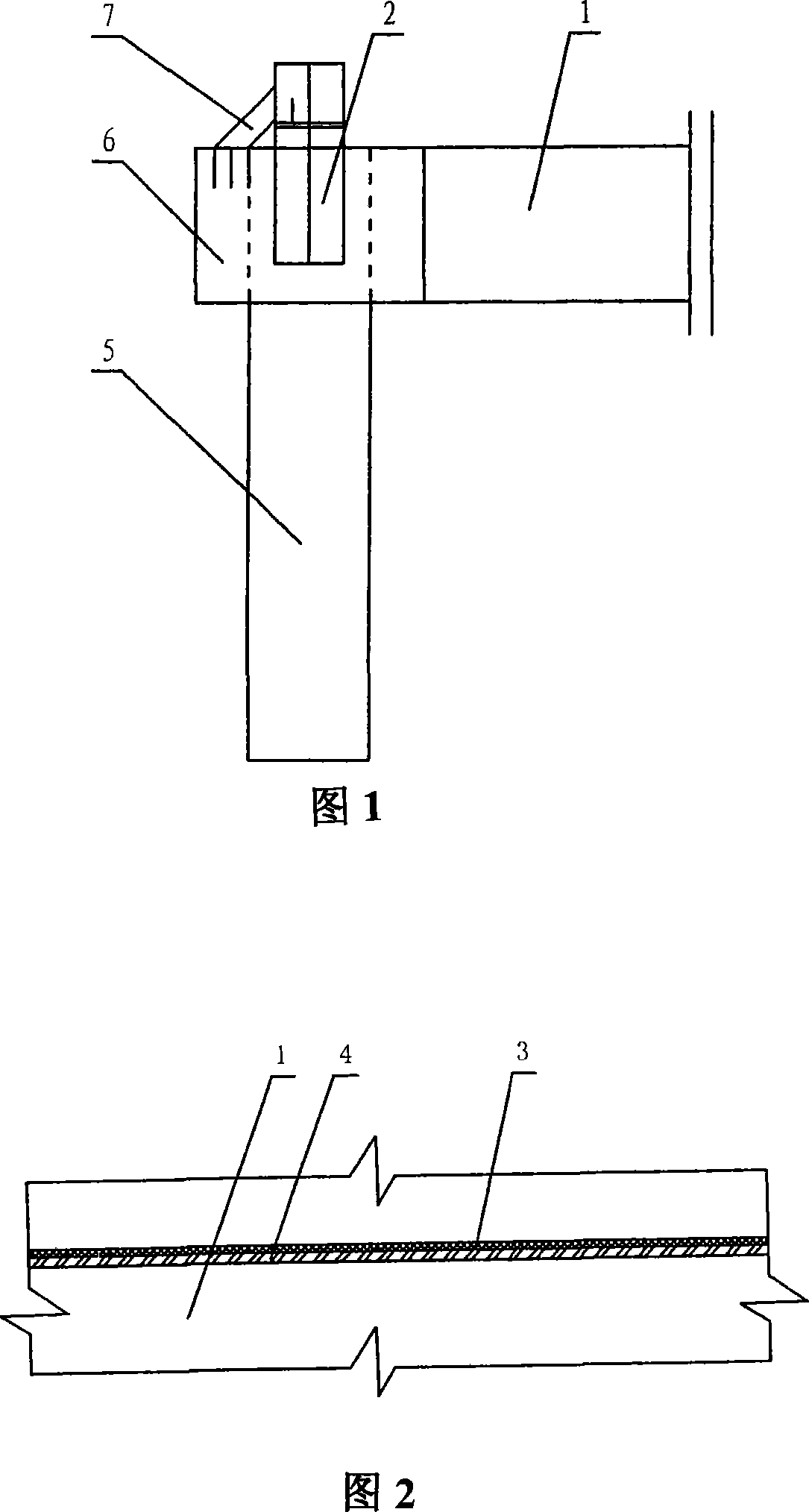

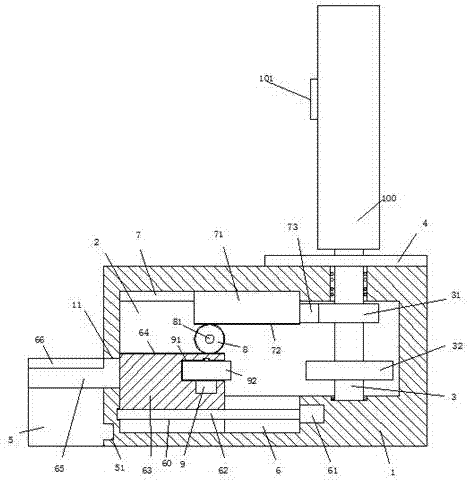

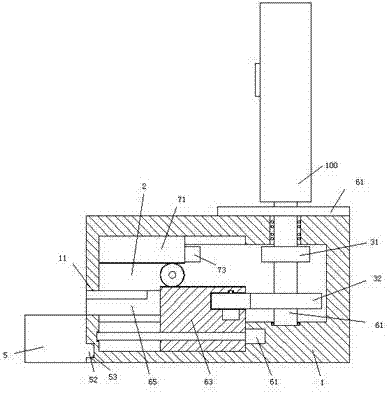

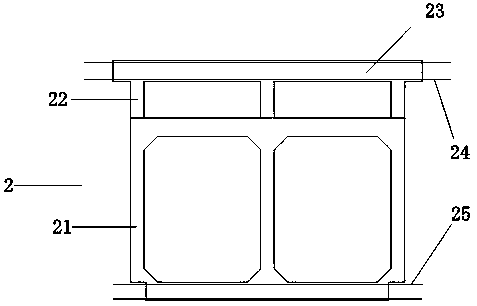

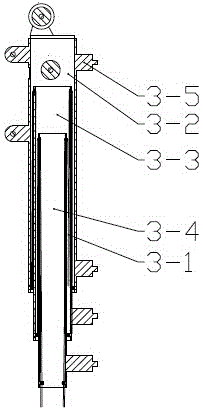

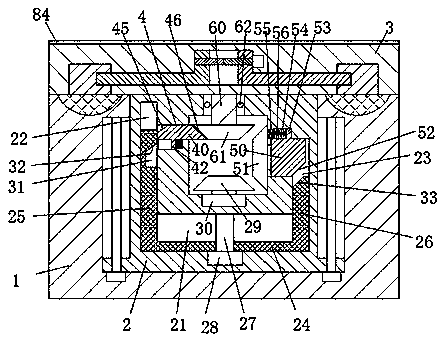

Car frame for economical passenger elevator

InactiveCN102951523ALow costMeet structural strength requirementsBuilding liftsUltimate tensile strengthLinkage concept

The invention relates to a car frame for an economical passenger elevator. The car frame for the economical passenger elevator comprises an upper beam component (1), a vertical beam component (2), stay bolt components (3), a safety clamp device (4) and a bolt linkage component (5). The safety clamp device (4) is fixed to the bottom end of the vertical beam component (2), one end of the stay bolt component (3) is fixed onto the vertical beam component (2) while the other end of the stay bolt component (3) is fixed onto a car supporting frame, and the stay bolt components (3) in two pairs are arranged in the middle of the vertical beam component (2) and can meet the integral structural strength requirements by means of obliquely staying. The car frame for the economical passenger elevator has the advantages that the car frame is simple and firm in structure, production cost can be reduced while stability in performance and safety in operation of the elevator are guaranteed, and product competitiveness can be improved effectively.

Owner:CANNY ELEVATOR

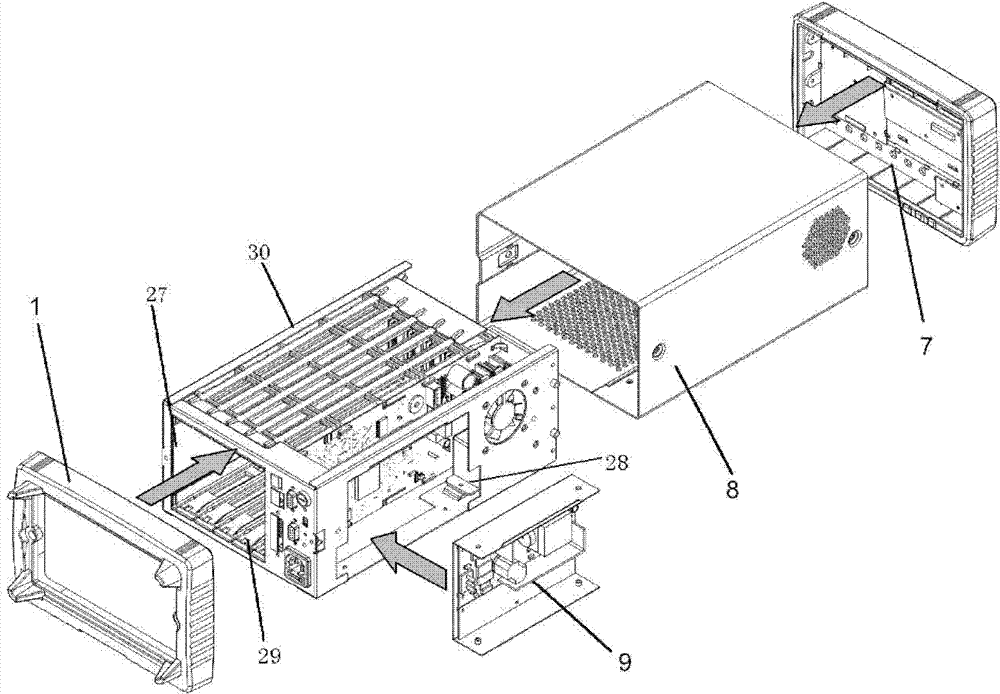

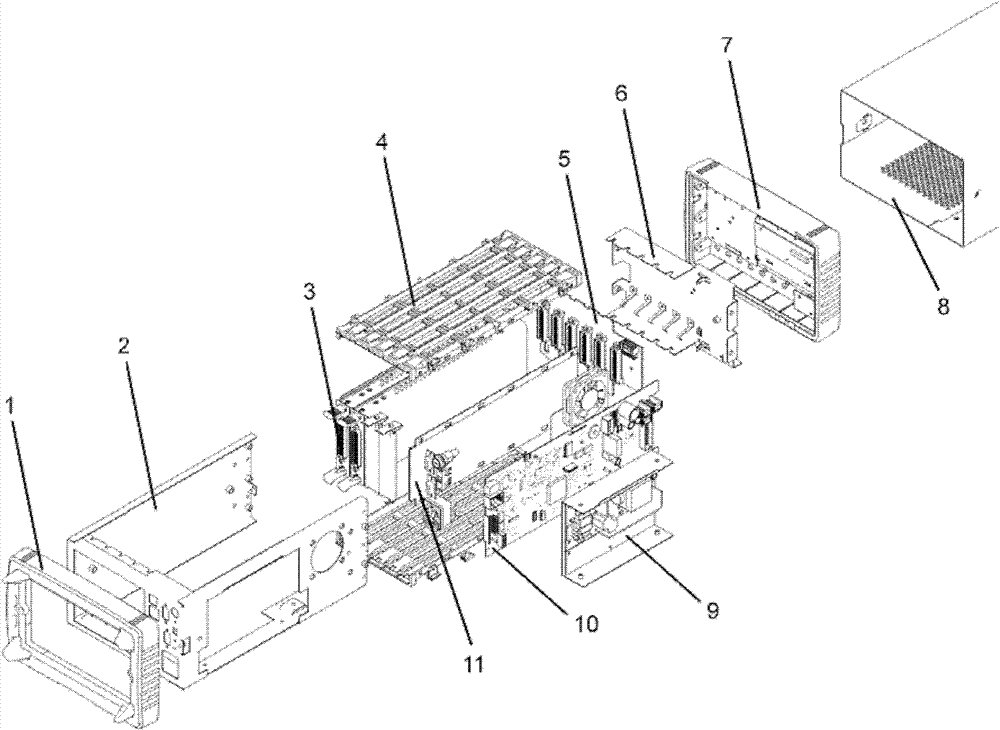

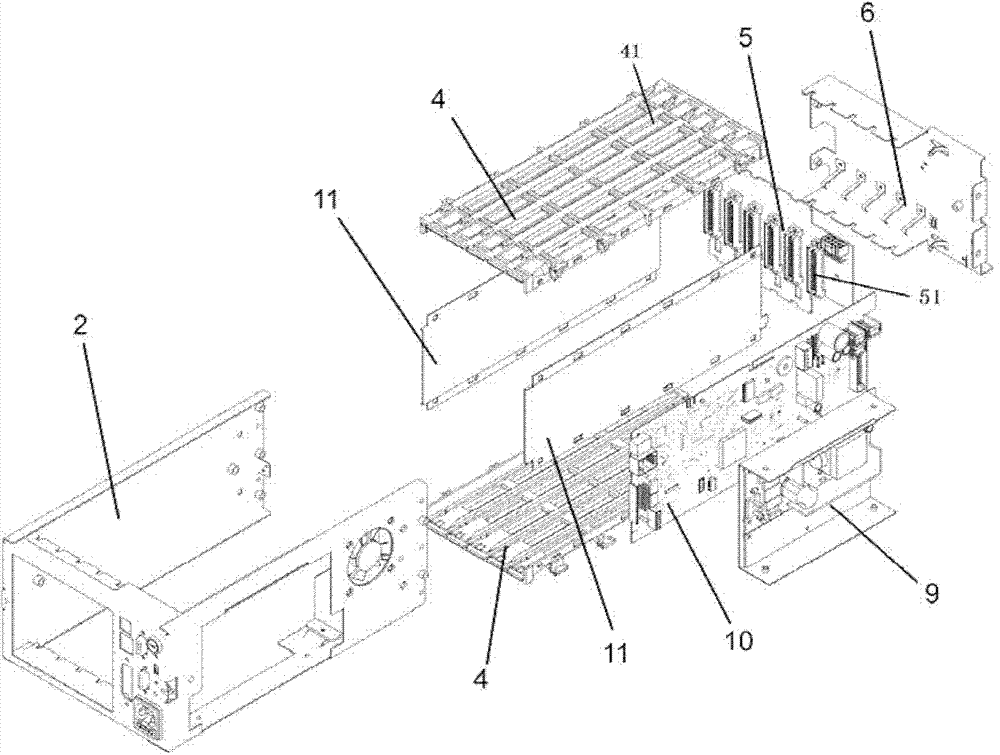

Chassis with bus structure

ActiveCN102770002AAvoid assemblyAvoid connectivitySupport structure mountingSelf lockingEmbedded system

The invention relates to a chassis with a bus structure. The chassis comprises a sleeve, an instrument frame and a main control panel, wherein the instrument frame is arranged in the sleeve; a module card entrance is arranged at the rear end wall of the instrument frame; a power-supply module socket is arranged on the side wall of the instrument frame; a module card guide rail and the main control panel are arranged in the instrument frame; the main control panel is arranged on the side wall of the module card guide rail and is connected with the power-supply module which is arranged on the power-supply module socket; the instrument frame is fixedly connected by inserting a front frame and a rear frame; a bus rear panel is longitudinally arranged in the front frame; the module card is inserted into the module card guide rail through the module card entrance and is socketed with the bus rear panel; and the module card guide rail is connected with the rear frame and the front frame respectively in a clamping and hooking way. According to the chassis with the bus structure, the design difficult point of an instrument in a compact space is solved, as the internal main structures and the main control panel are all assembled by self-locking structure assembles such as plugging, clamping and hooking, the chassis is high in assembling efficiency, compact in structure and high in installation reliability.

Owner:RIGOL

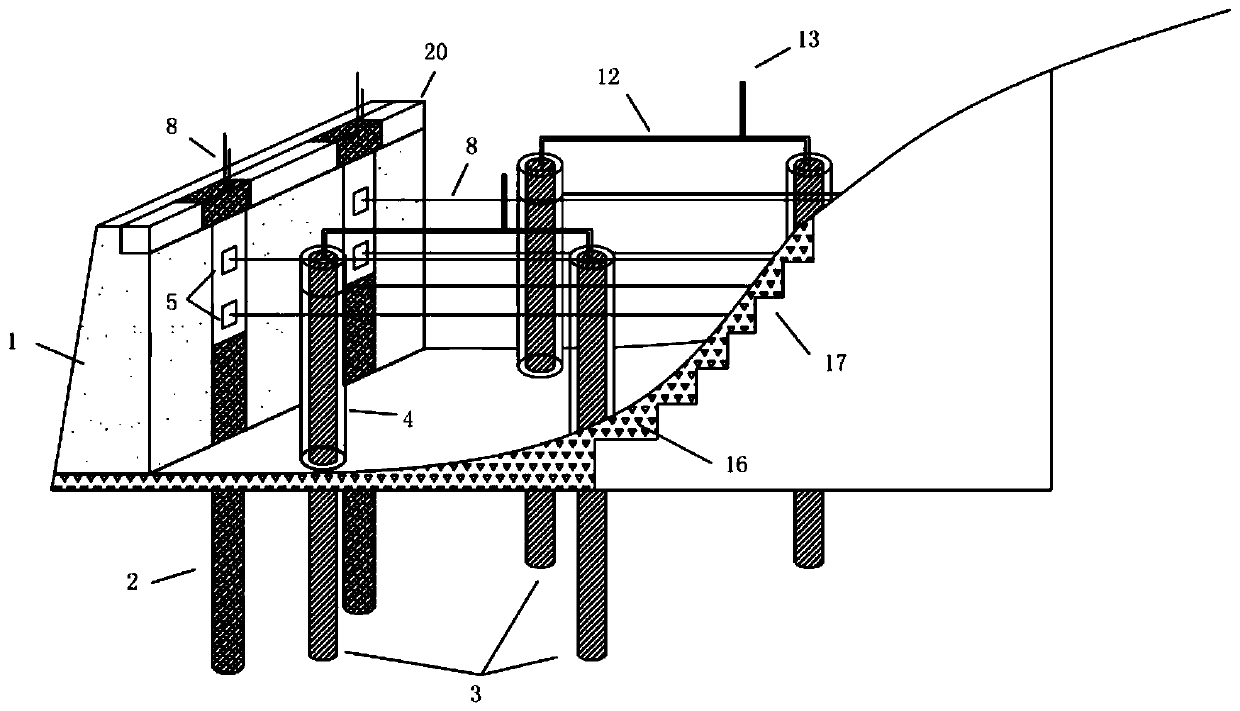

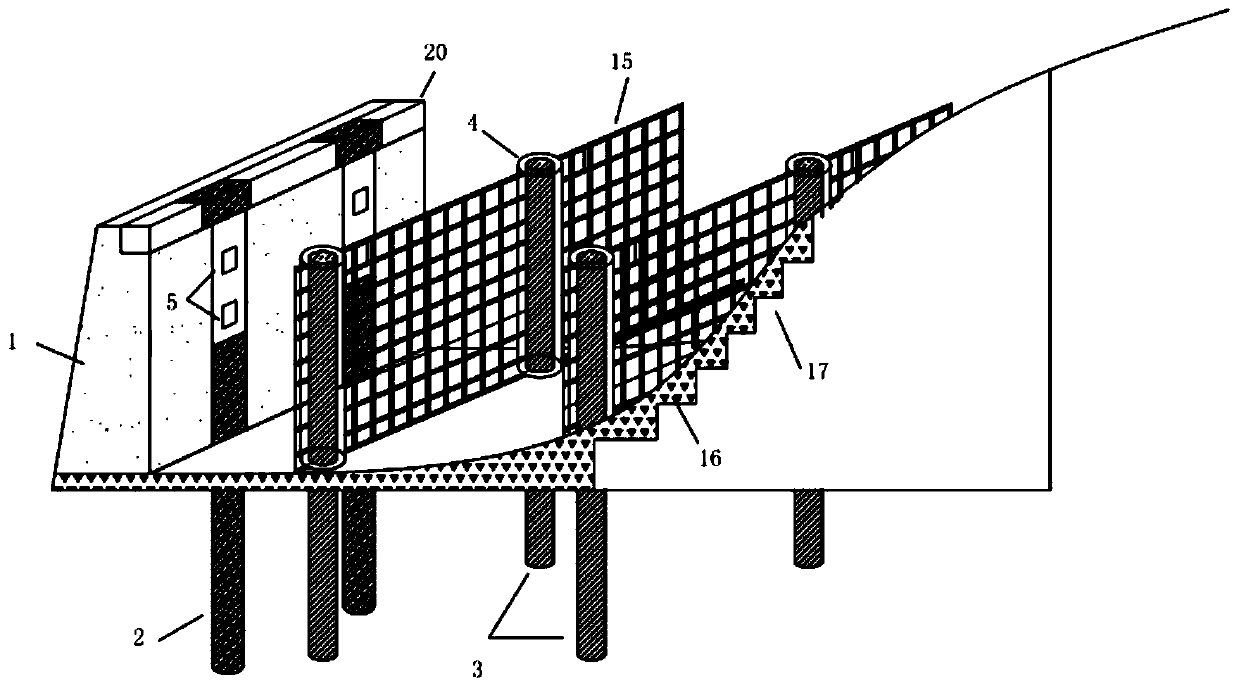

Fabricated integral-type revetment structure on soft soil foundation and construction method thereof

PendingCN107059773ASafe and stable structureStable structureBreakwatersQuaysHorizontal forcePile cap

The invention discloses a fabricated integral-type revetment structure on a soft soil foundation. The fabricated integral-type revetment structure comprises a prefabricated vertical plate, a prefabricated base plate and a prefabricated pile foundation. The prefabricated vertical plate is arranged at the top end of the prefabricated base plate, and the prefabricated pile foundation is arranged at the bottom end of the prefabricated base plate. The prefabricated vertical plate and the prefabricated base plate are formed in an integrated casting mode. The prefabricated pile foundation comprises a plurality of prefabricated piles. The top of each prefabricated pile stretches into the prefabricated base plate. A plurality of prefabricated pile holes are evenly formed in the prefabricated base plate, and each prefabricated pile hole and the corresponding prefabricated pile are in one-to-one correspondence. The prefabricated pile holes are located over the corresponding prefabricated piles. The invention further discloses a construction method of the fabricated integral-type revetment structure on the soft soil foundation. According to the fabricated integral-type revetment structure on the soft soil foundation, the prefabricated pile foundation, the prefabricated vertical plate and the prefabricated base plate are adopted to be integrally assembled, a low-pile cap revetment structure is formed together, horizontal force equipollent loads behind a wall are borne by the revetment structure so that the effect of being safe, stable and reliable in structure can be achieved, and the purposes of high efficiency, energy saving, greening and environmental protection can further be realized.

Owner:CCCC THIRD HARBOR CONSULTANTS

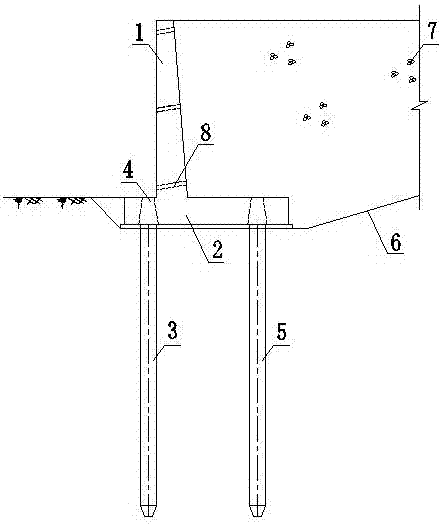

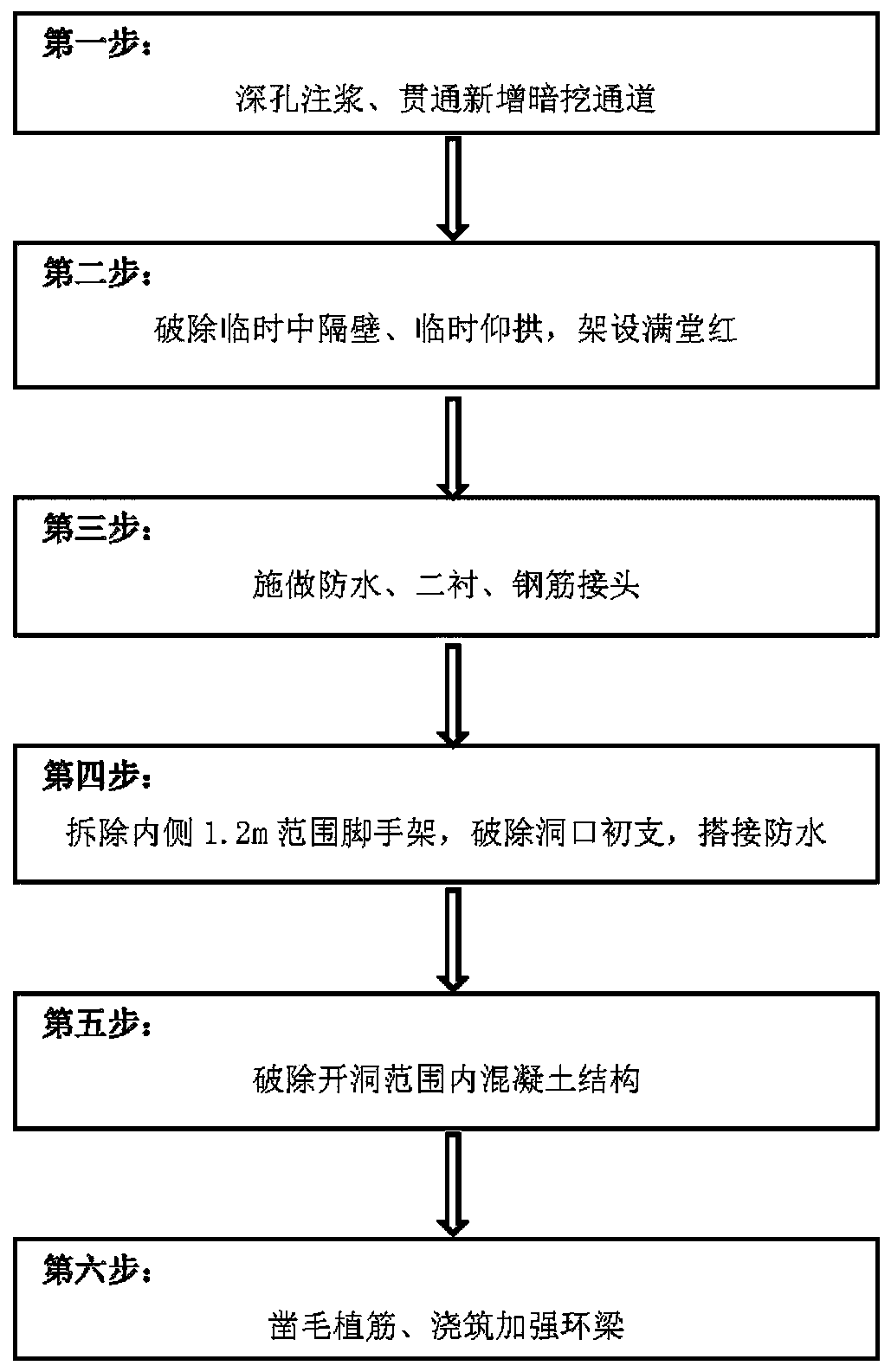

Communication and connection construction method of newly-added underground excavation channel and existing station hall layer

ActiveCN111594181AReduce transfer experienceAvoid pollutionUnderground chambersTunnel liningArchitectural engineeringStructural safety

The invention discloses a communication and connection construction method of a newly-added underground excavation channel and an existing station hall layer. By means of the method, a side wall of the existing station hall layer is broken, and therefore the construction method adopted when the existing station hall layer and the newly-added underground excavation channel are in communication andconnection is achieved. In order to guarantee structure safety and stability, the side wall of the existing station hall layer is broken under the condition of erecting in the full house, the side wall of the existing station hall layer is cut in a rope saw cutting manner through partitioning step by step, and cut blocks are broken on the principle of achieving dismounting and supporting at the same time. By means of the adopted connection side wall breaking method, construction structure stability and construction safety are guaranteed from multiple angles, and the influence on existing raillines is reduced to the lowest degree.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Civil aviation air traffic control monitoring data treatment device

InactiveCN109000119AEasy to install and replaceThe overall structure is safe and stableBatteries circuit arrangementsClosed circuit television systemsAir traffic controlSurveillance camera

The invention discloses a civil aviation air traffic control monitoring data treatment device. The data treatment device comprises a supporting seat, a lifting seat and a monitoring device, wherein the lifting seat can be slidably arranged in the supporting seat in an up-and-down mode, the monitoring device can be rotationally arranged at the top of the lifting seat. According to the data treatment device, the angle of shooting and monitoring of a monitoring camera can be automatically controlled and adjusted so that all-directional real-time monitoring and shooting can be achieved, the lifting seat can also be contracted in a lifting sliding groove, the monitoring camera is stored in a containing cavity, then a good protection effect on the monitoring camera is achieved, the height of shooting and monitoring of the monitoring camera can be adjusted, the installation and replacement of two monitoring cameras can be controlled through one motor, the installation and replacement operation is simple and convenient, the overall structure is safe and stable, and the operation is convenient and rapid.

Owner:张晓彬

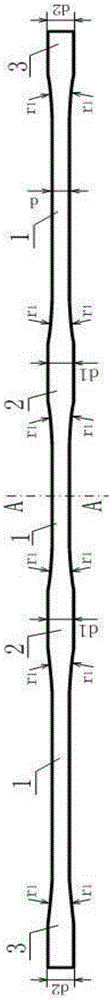

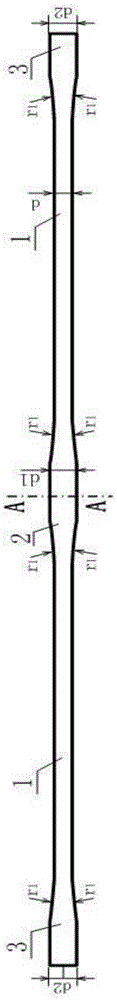

Special-shaped-cross-section hot-rolled steel plate coil and manufacturing method thereof

InactiveCN105605404ASolution areaSolve the problem of frequent crackingSheets/panelsRollsSheet steelUltimate tensile strength

The invention provides a special-shaped-cross-section hot-rolled steel plate coil and a manufacturing method thereof. The cross section of the special-shaped-cross-section hot-rolled steel plate coil is composed of a base plate (1), a middle double-side thickening region (2), an end double-side thickening region (3) and an inner arc r1, wherein the lengthwise strength of the special-shaped-cross-section hot-rolled steel plate coil can reach 6-600 meters; the middle double-side thickening region (2) and the end double-side thickening region (3) are horizontally connected by the base plate (1) to form an integral body; and the middle double-side thickening region (2) and the end double-side thickening region (3) transit to the base plate (1) through the inner arc r1. The special-shaped-cross-section hot-rolled steel plate coil is prepared by finish rolling by using four-roller composite-orifice rollers and a matched technique. The special-shaped-cross-section hot-rolled steel plate coil is used for producing cold-roll-formed U rib steel, solves the technical problems of welding spot cracking and irrational structural strength caused by insufficient welding thickness on the two ends of the existing uniform-thickness U rib and reduced thickness of the bent angle part, enhances the stability and safety of the bridge, and lowers the manufacturing and maintenance cost of the bridge.

Owner:莱芜美澳冶金科技有限公司

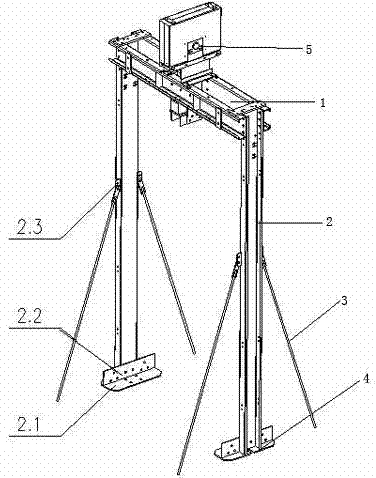

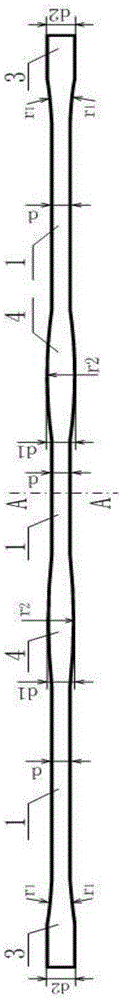

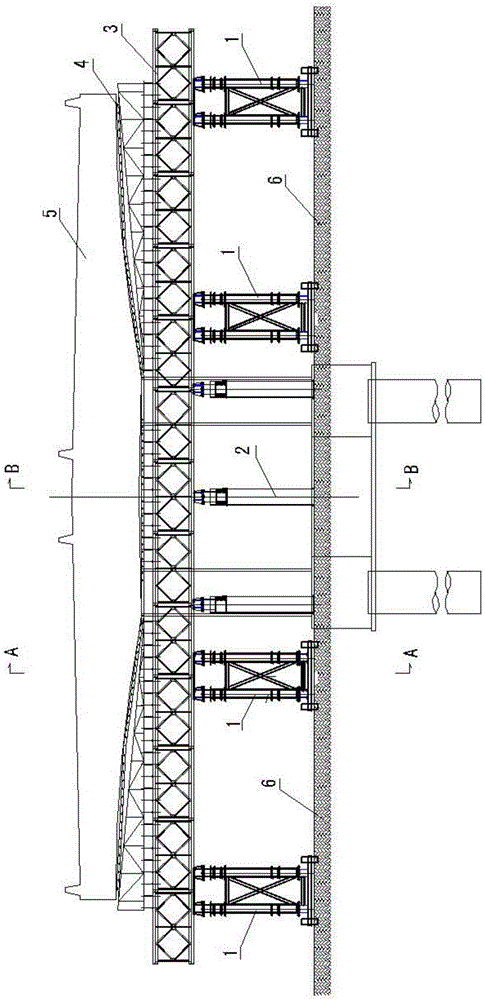

Construction method of movable gantry in construction of big cantilever bent cap

ActiveCN106638312AShort laying timeSafe and stable structureBridge erection/assemblyVehicle drivingCantilever

The invention discloses a construction method of a movable gantry in a construction of a big cantilever bent cap. The construction method is characterized in that aiming at the construction of the big cantilever bent cap, a movable gantry system is set, wherein the movable gantry system comprises three units of a left side unit, a middle unit and a right side unit respectively, the left side unit and the right side unit have symmetrical structural forms and are composed of two groups of independently set movable gantries respectively, and the distance between the two groups of the movable gantries is the width of a motor way which maintains normal traffic; movable universal wheels are adopted as trundles of the movable gantries, a helix tube is adopted by the middle unit as a bearing stand column, the top of the helix tube is provided with a sand box, a distributive girder is arranged on the sand box, and a Bailey girder which is used for paving bent cap bottom board is supported on the movable gantry system. The construction method is applied to the construction of the bent cap on an existing road, erection time can be effectively shortened, and vehicle driving on the road is guaranteed.

Owner:SHANGHAI CIVIL ENG GRP CO LTD OF CREC +1

Anti-falling device for power test climbing

InactiveCN106549335AAvoid injuryReduce forceSafety beltsApparatus for overhead lines/cablesAerial cableEngineering

The invention discloses an anti-falling device for power test climbing. The device comprises an upper support plate and a lower support plate, wherein a hanging ring is arranged on the lower end of the lower support plate; at least two connecting rods are arranged on the lower support plate; the upper end of each connecting rod penetrates the upper support plate and is fixed through a nut; a cambered strip-shaped hole is formed on the lower support plate; the lower end of each connecting rod penetrates the strip-shaped hole; a spacing plate is arranged at the end part of the lower end of each connecting rod; a high-strength spring is sleeved on each connecting rod; the lower end of the high-strength spring is propped against the upper end surface of the spacing plate; the upper end of the high-strength spring is propped against the lower end surface of the lower support plate; and a buffer spring is arranged on each connecting rod between the upper plate and the lower plate. Through the adoption of the device disclosed by the invention, the whole structure can be hung on an aerial cable; the structure is stable, safer and more reliable.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

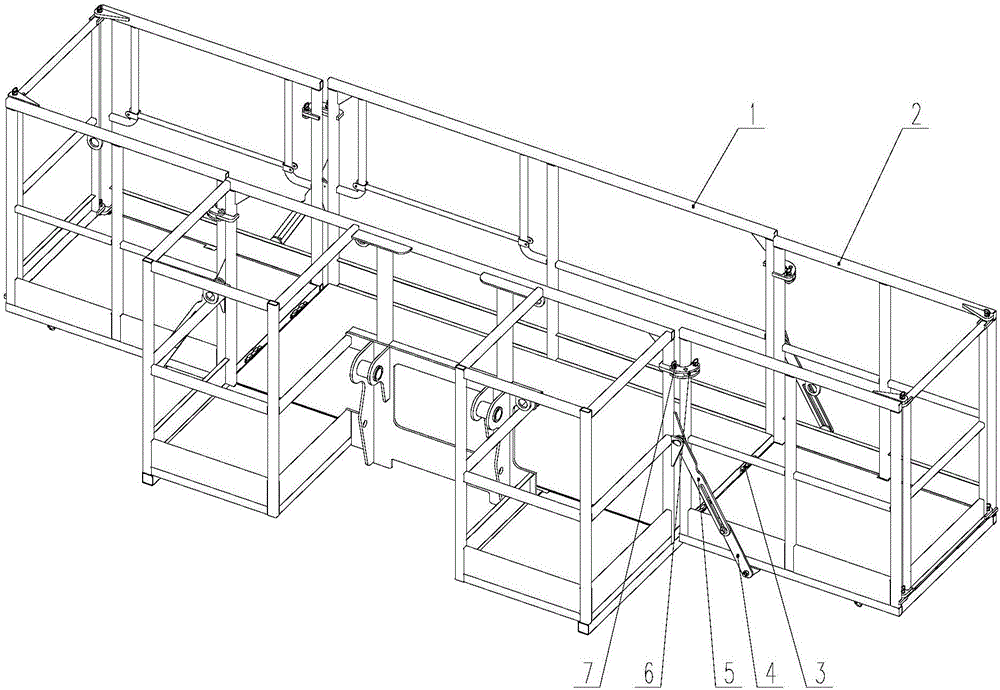

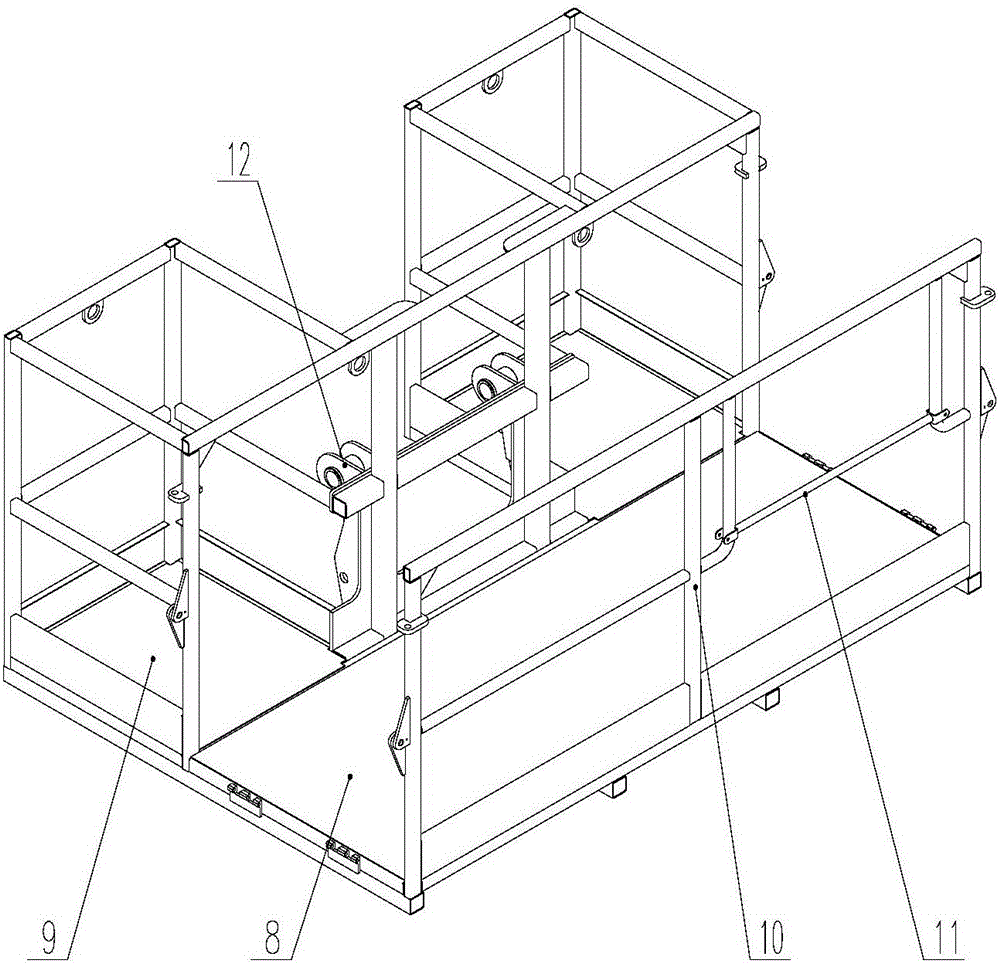

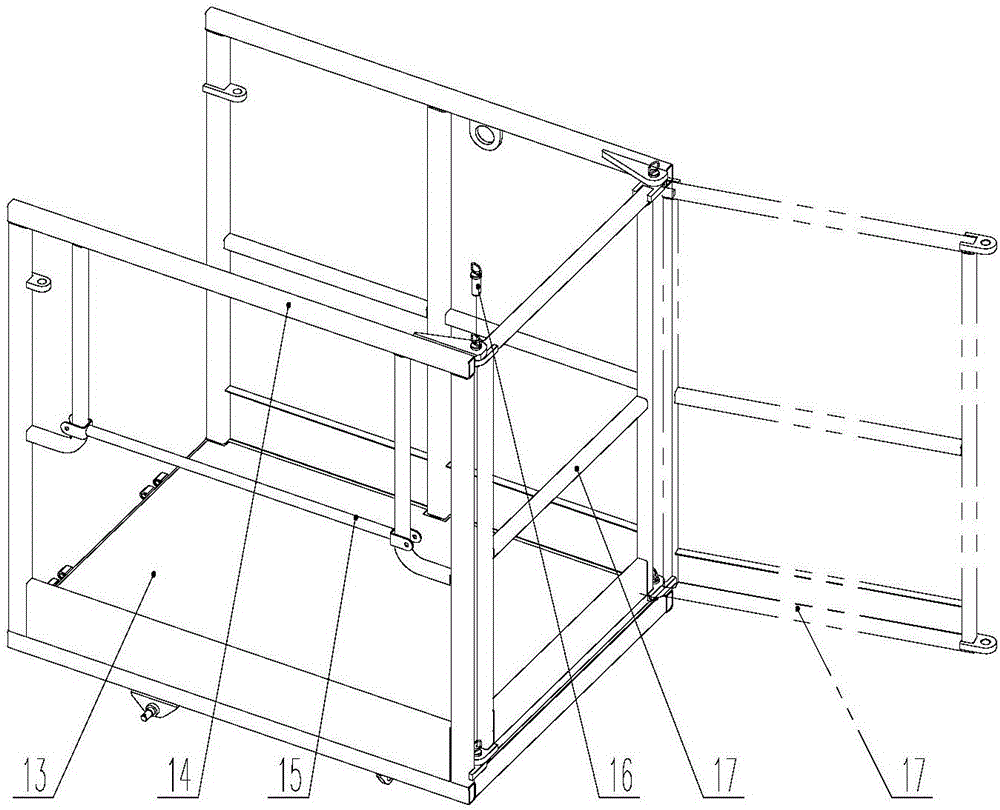

Extendable multi-purpose high altitude platform

InactiveCN106639286ASafe and stable structureFlexible and convenient operationScaffold accessoriesBuilding support scaffoldsMarine engineeringBuilding construction

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com