Process for constructing shield rapid inspection shaft

A construction technology and maintenance well technology, which is applied in the direction of sinking, shaft equipment, shaft lining, etc., can solve problems such as high risk, and achieve the effects of safe and stable structure, fast construction speed and convenient construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

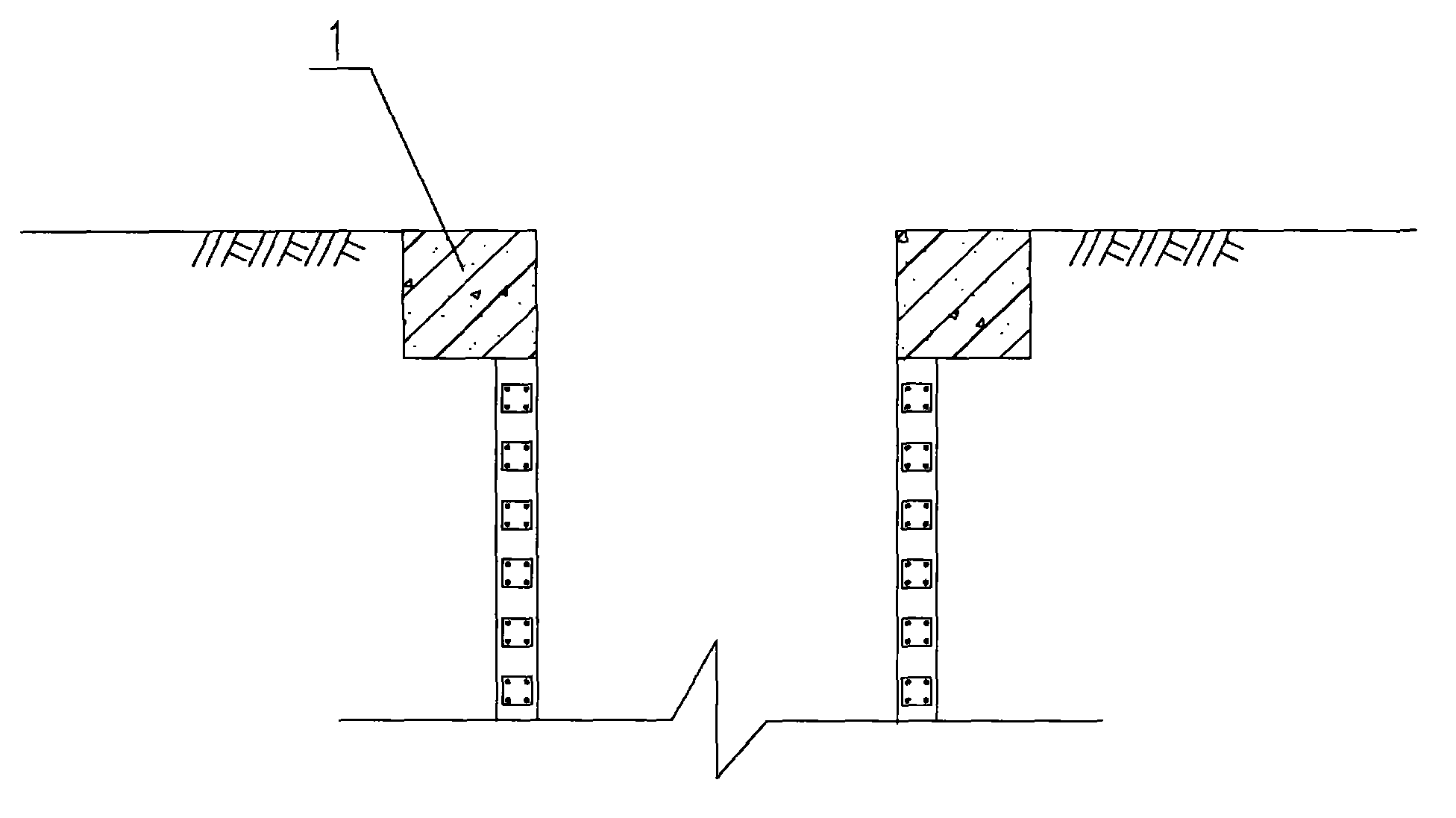

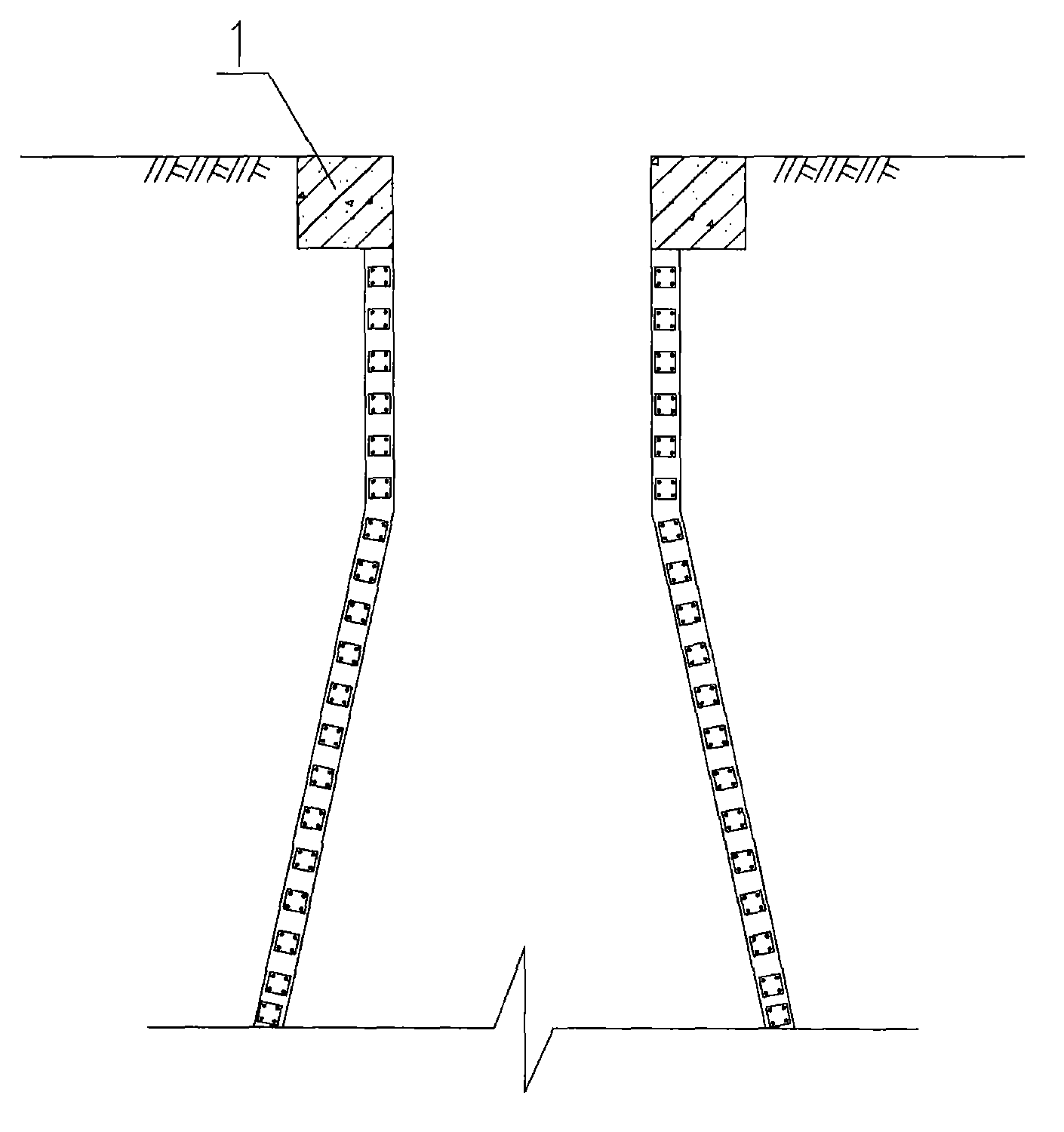

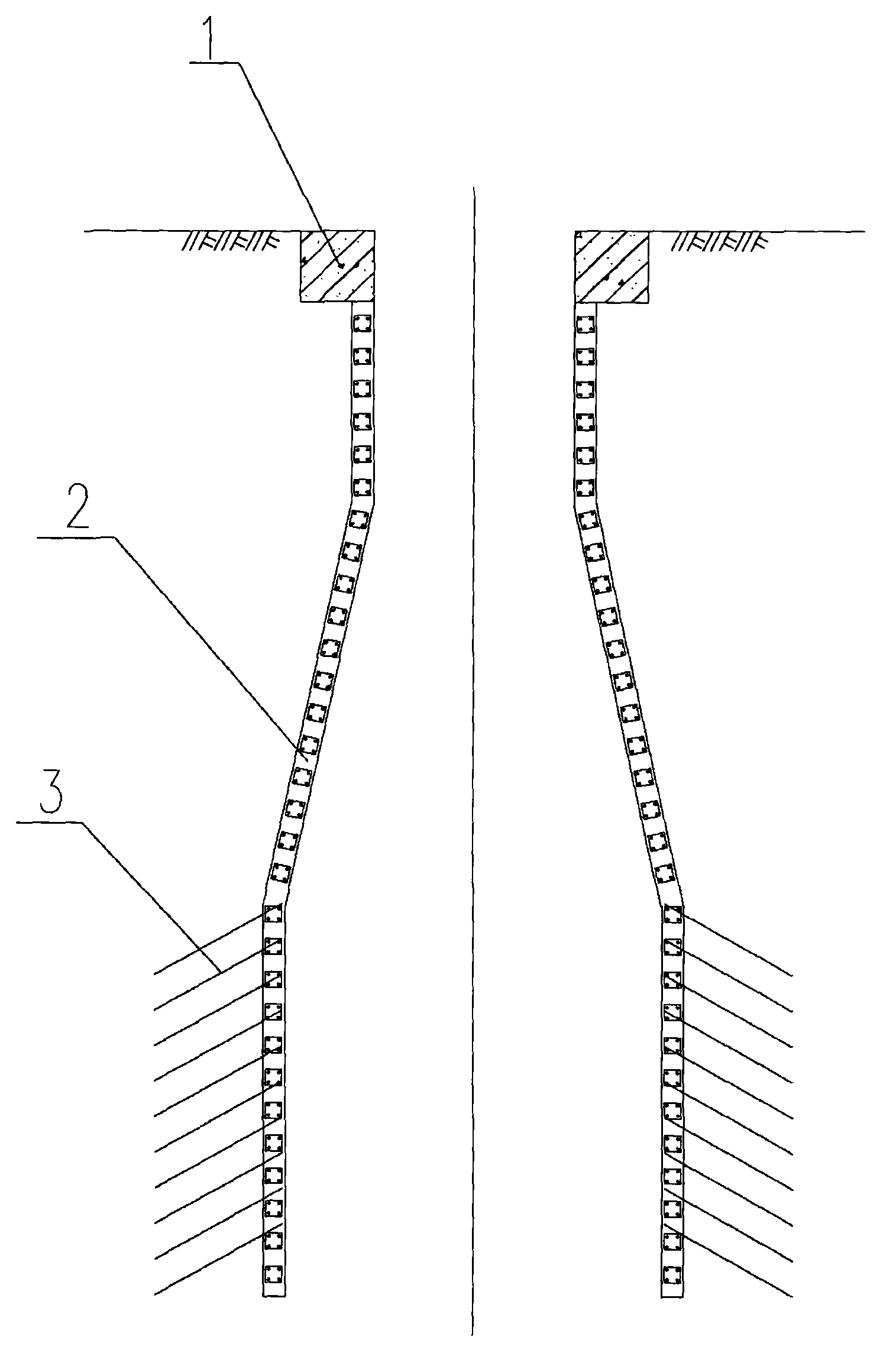

[0017] Please refer to the attached figure 1 to attach Figure 4 Shown, the present invention is a kind of construction technique of shield tunneling rapid maintenance well, and it comprises following process steps:

[0018] 1) For the construction of the locking ring beam 1, steel bars are reserved at the bottom of the locking ring beam 1 (not shown);

[0019] 2), shaft expansion: the expansion is carried out with the standard that the vertical angle of the expansion surface is not greater than 45°;

[0020] 3), construction of the shaft body 2: the retaining wall of the shaft adopts steel bar grid 3 plus concrete anchor shotcrete, and the thickness of the retaining wall is 300mm; for welding;

[0021] 4) Matou gate construction in the shaft: construct a vault gate type Matou gate 4 on the shaft side wall of the shield tunneling axis;

[0022] 5), Shaft back cover 5: use a steel frame to cover the bottom of the shaft to control the uplift of the bottom of the shaft.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com