Patents

Literature

2909results about How to "Ensure construction safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

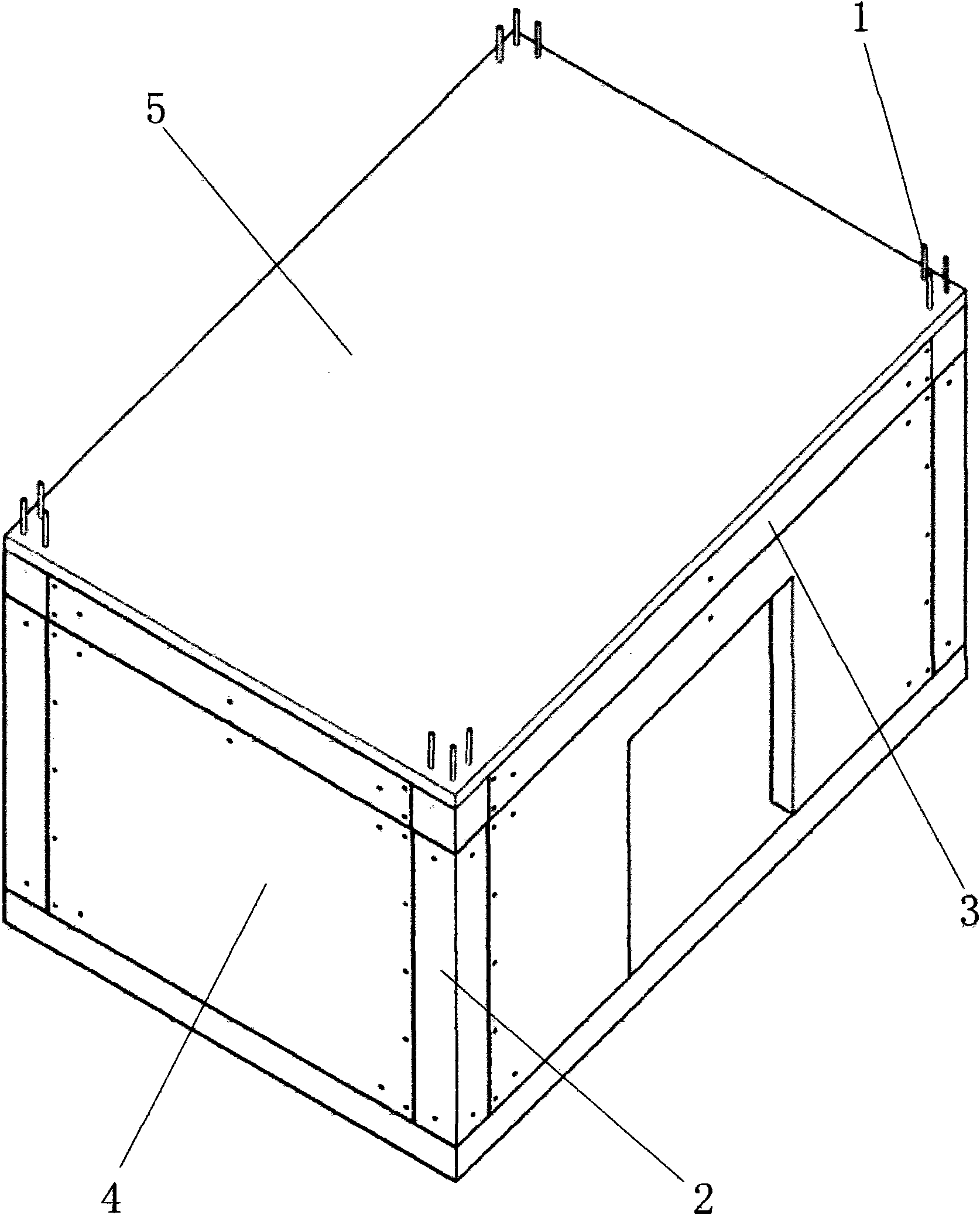

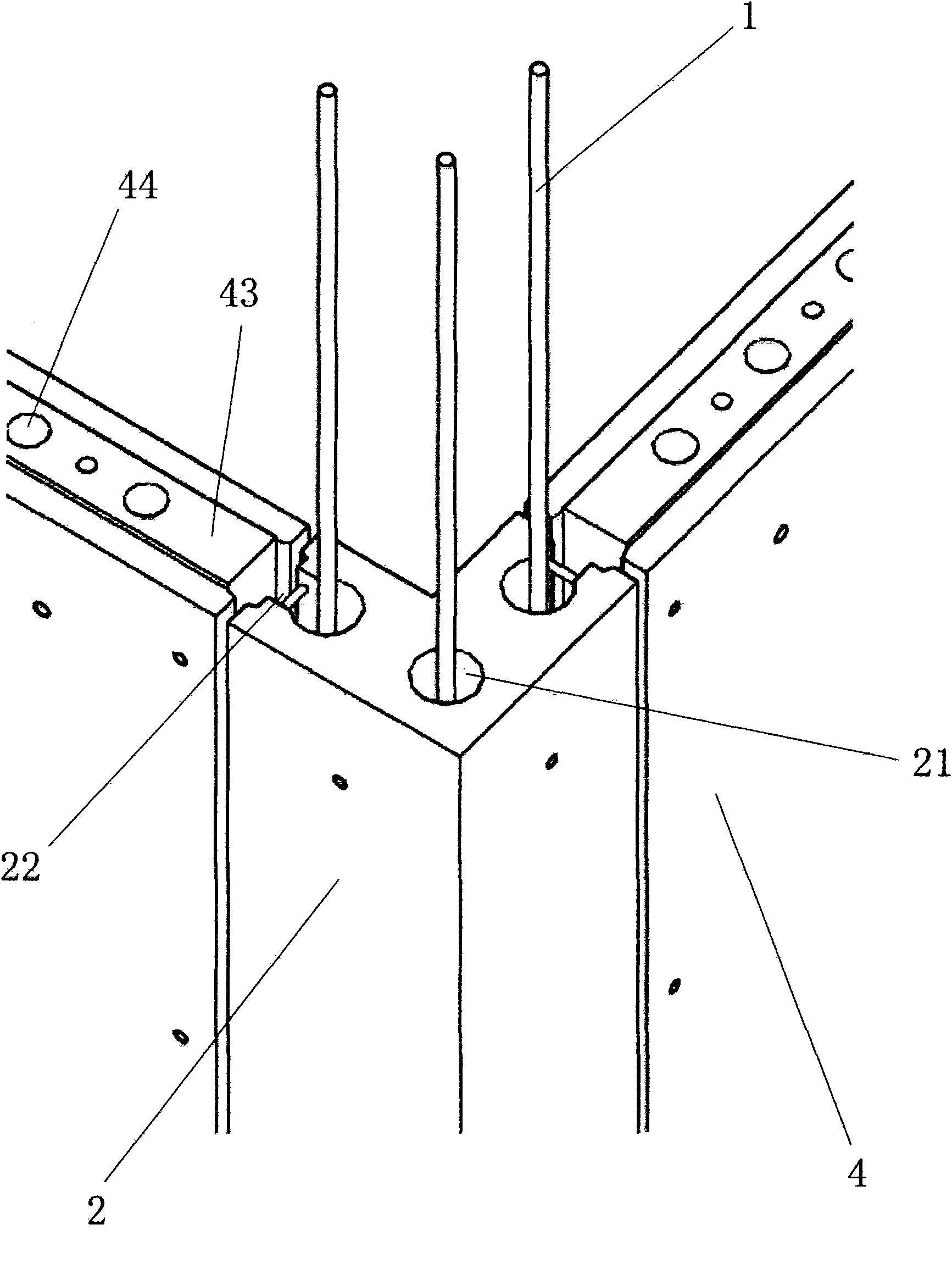

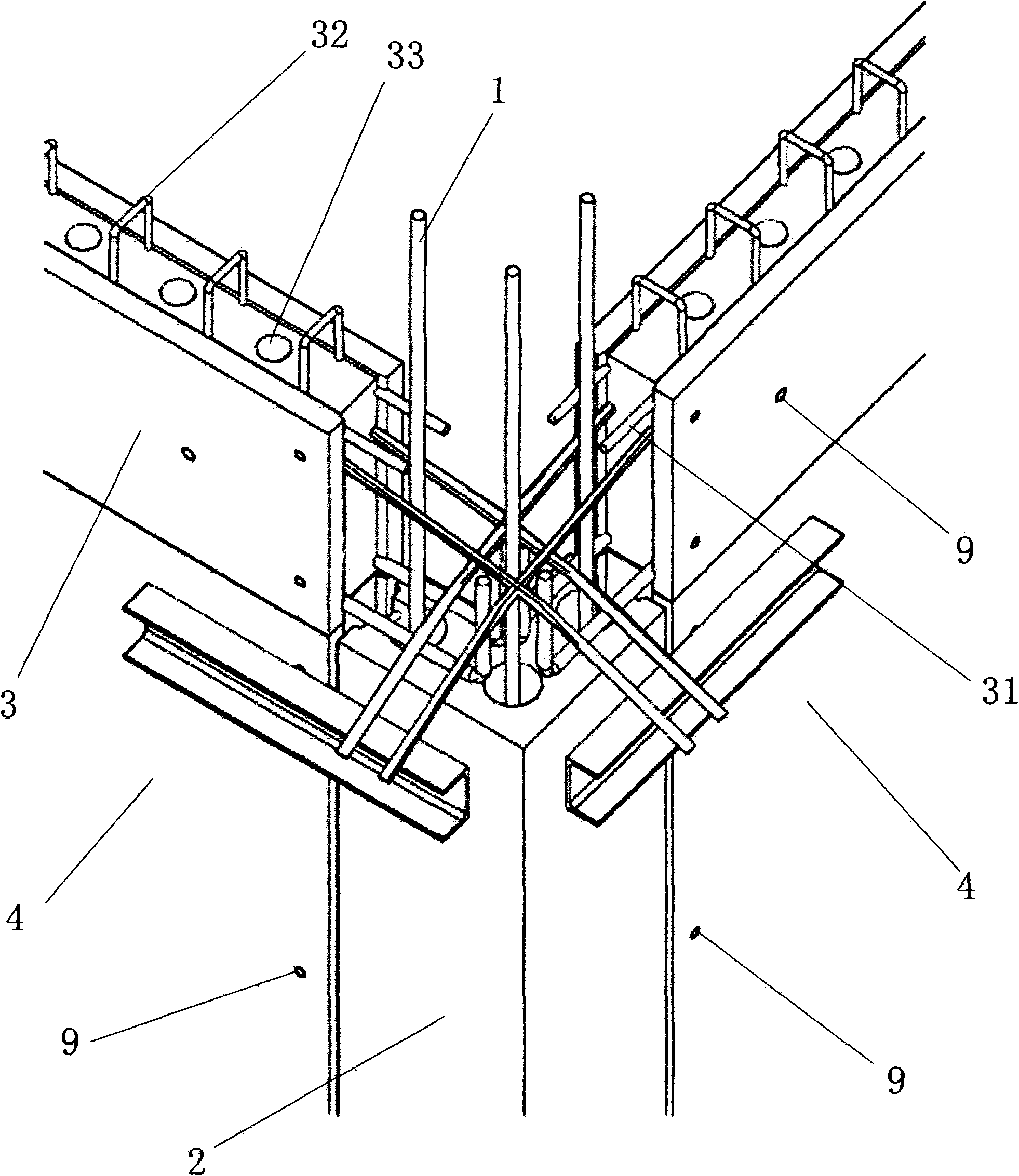

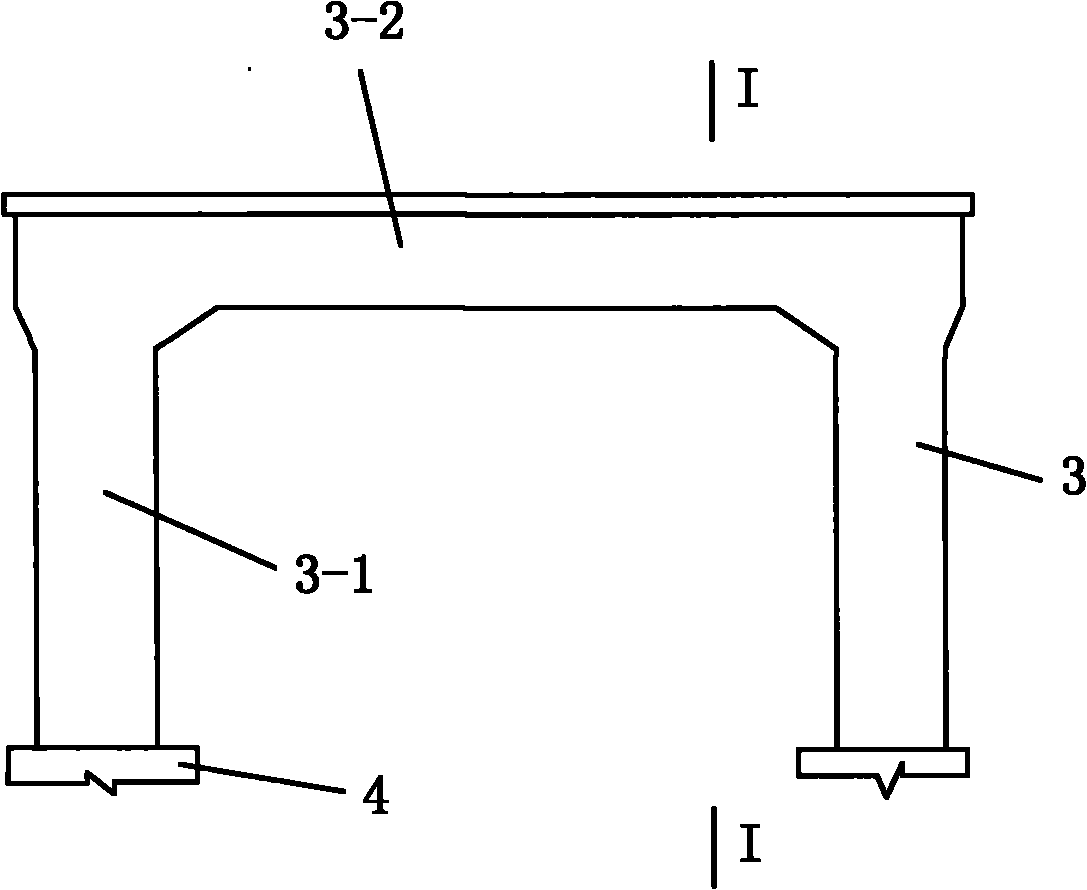

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

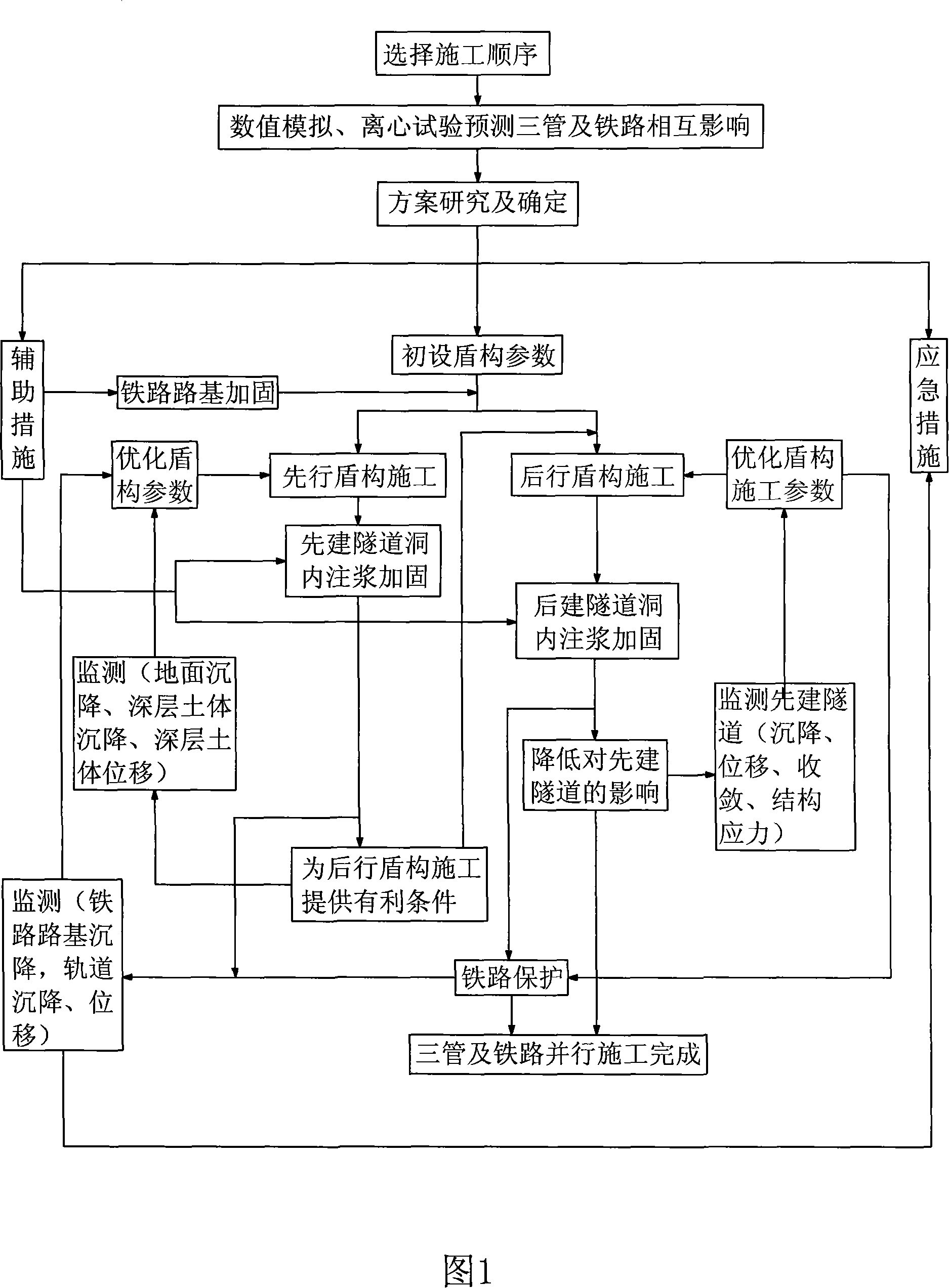

Shield construction method for three-line parallel under-passing trunk railway tunnel

ActiveCN101126318AEffective control of deformationEffective control of displacementUnderground chambersTunnel liningRailway tunnelEconomic benefits

The invention discloses a shield construction method of digging three parallel tunnels under a trunk railway, which belongs to the field of tunnel construction technology. The construction method of the invention comprises the procedure that: the model analysis on each construction sequence and method is made by a three-dimensional finite element and the shield construction sequence is selected; to select the reinforcement project of the railway bed is selected according to the influence degree of the dynamic stress, the load-carrying structural model is adopted to calculate and decide the shield area reinforcing bars enhancement project under the dynamic load of the railway train; the construction parameters are selected according to the test results and the performance of the shield machine, the front earth pressure is reasonably set , the synchronizing mortar injection is enhanced, the forward digging speed and the axis deviation are strictly controlled, the secondary mortar injection is made, the foam or mud is filled by utilizing a pre-embedded injection hole; the strict monitoring measures to monitor the shield construction process is adopted so that the construction unit can adjust the construction parameters in time and guarantee the construction safety. The invention not only guarantees the construction quality and the construction safety of the project but also creates good economic benefit.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

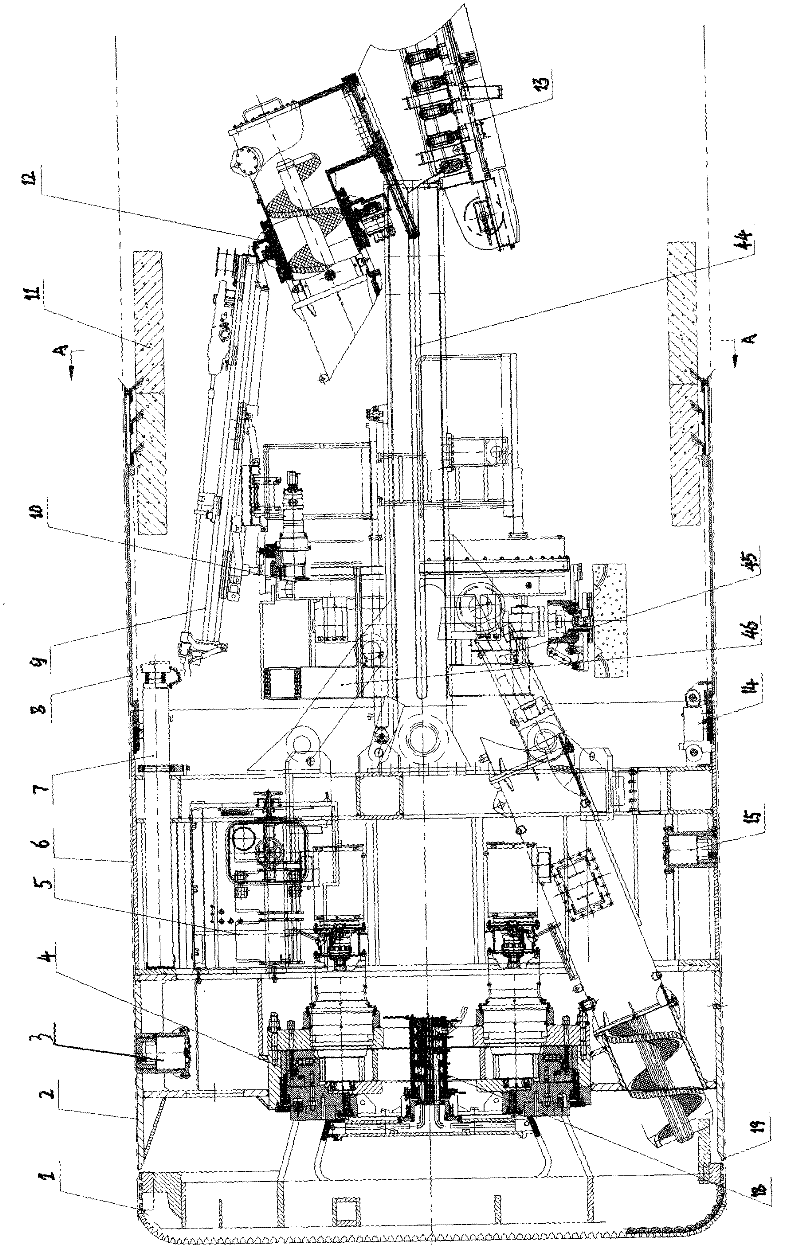

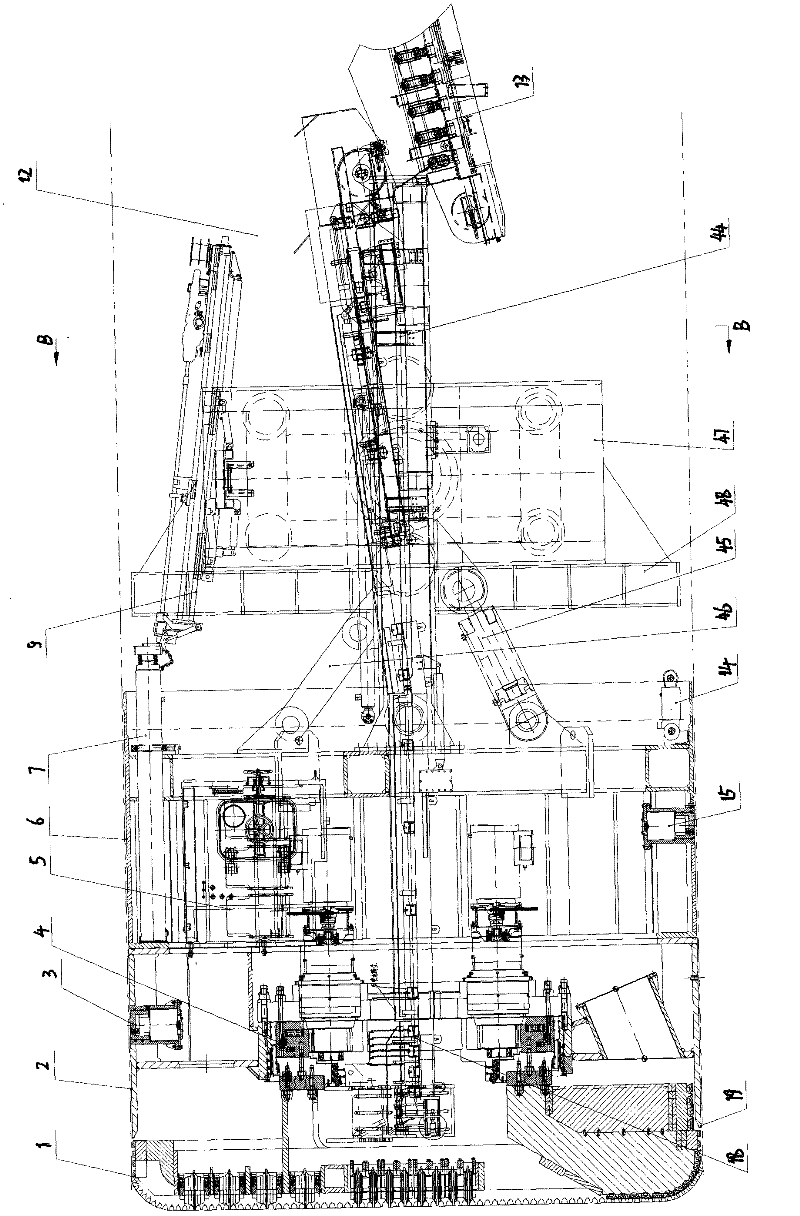

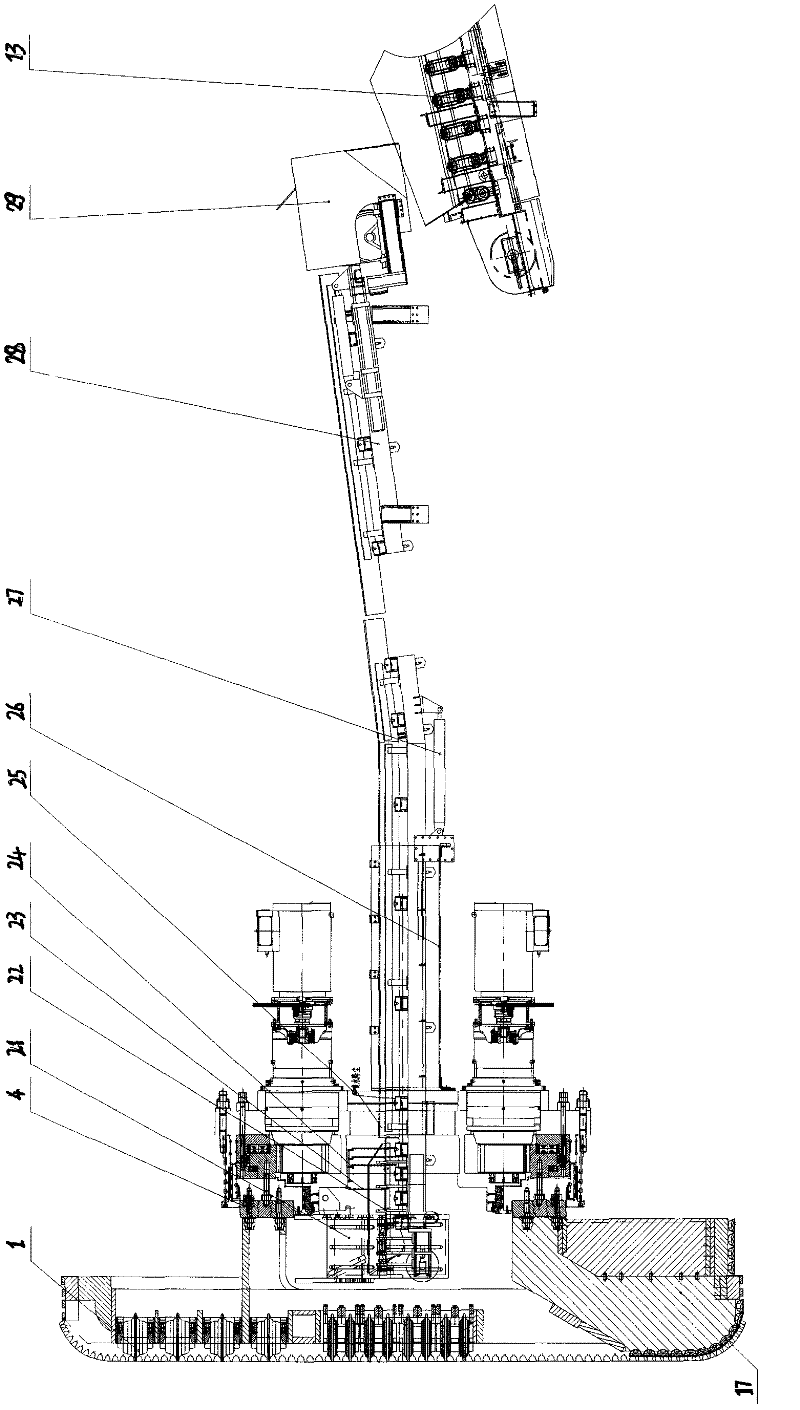

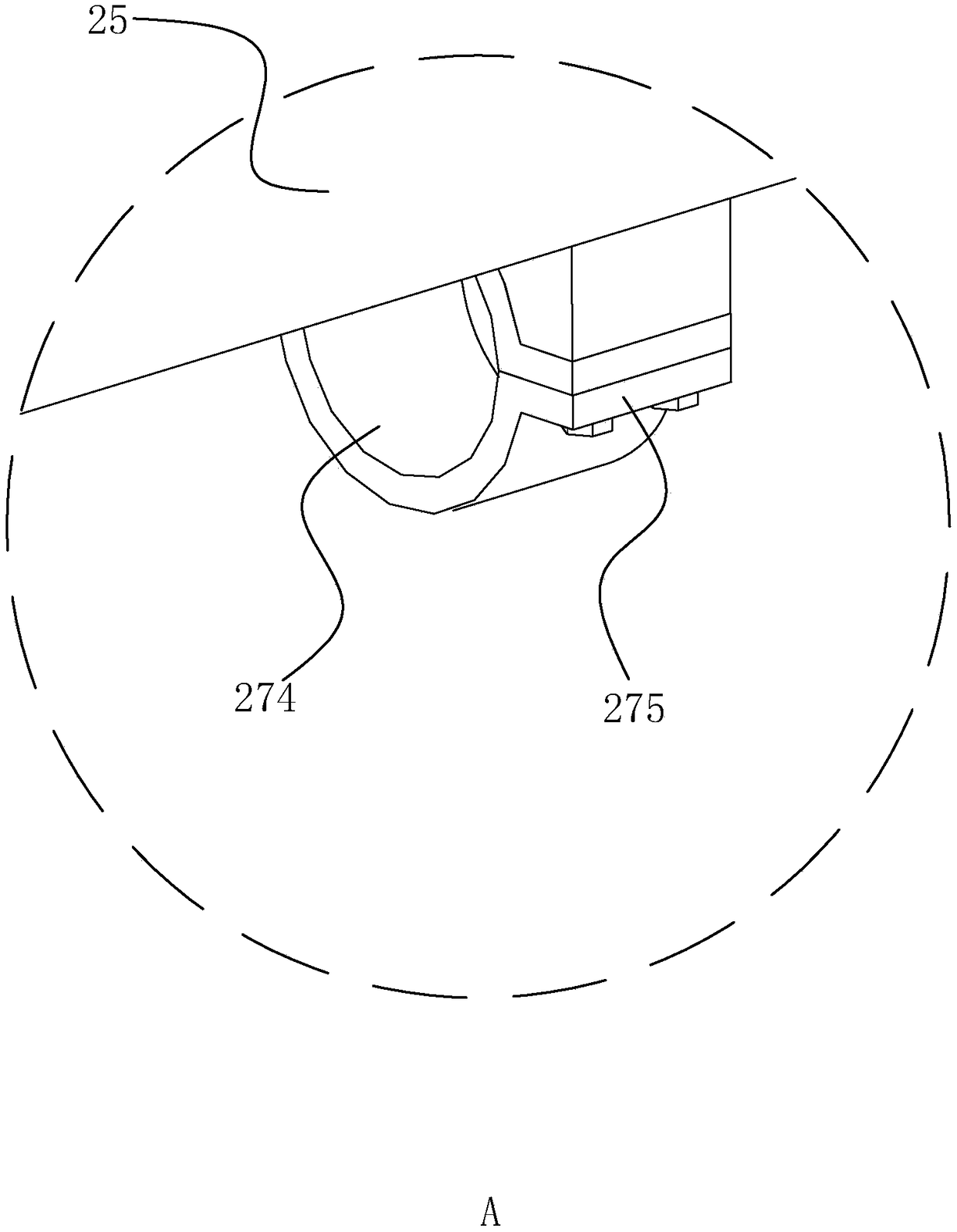

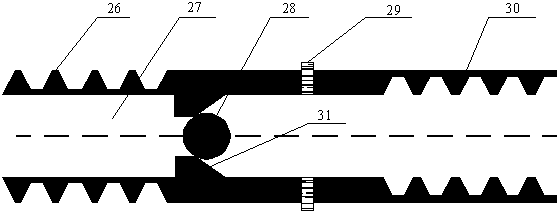

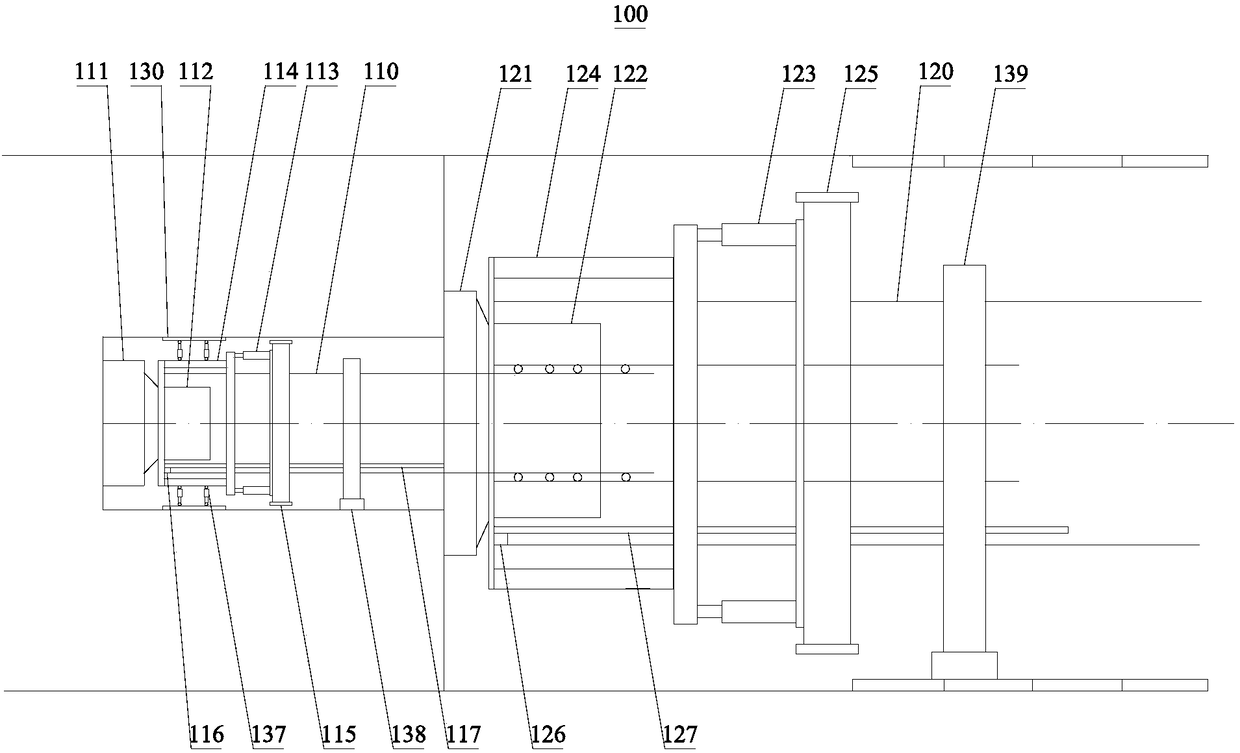

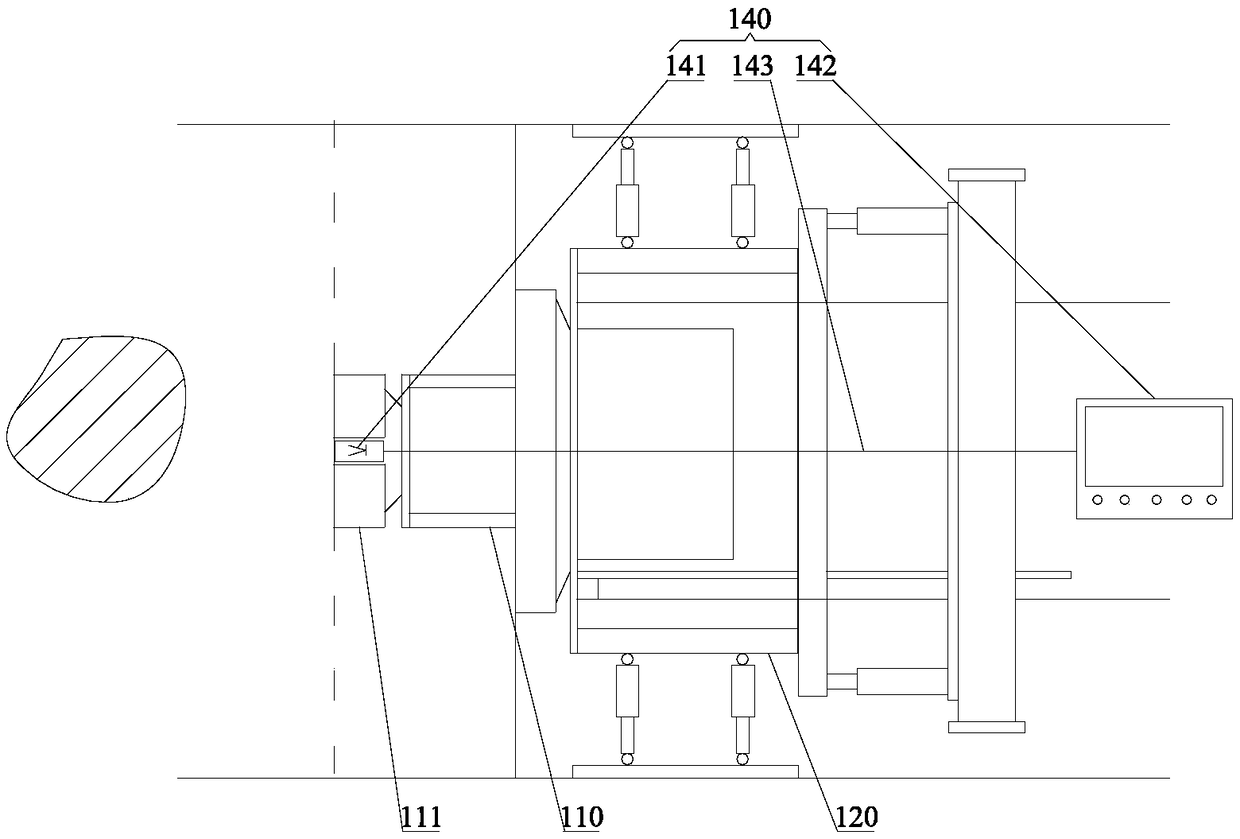

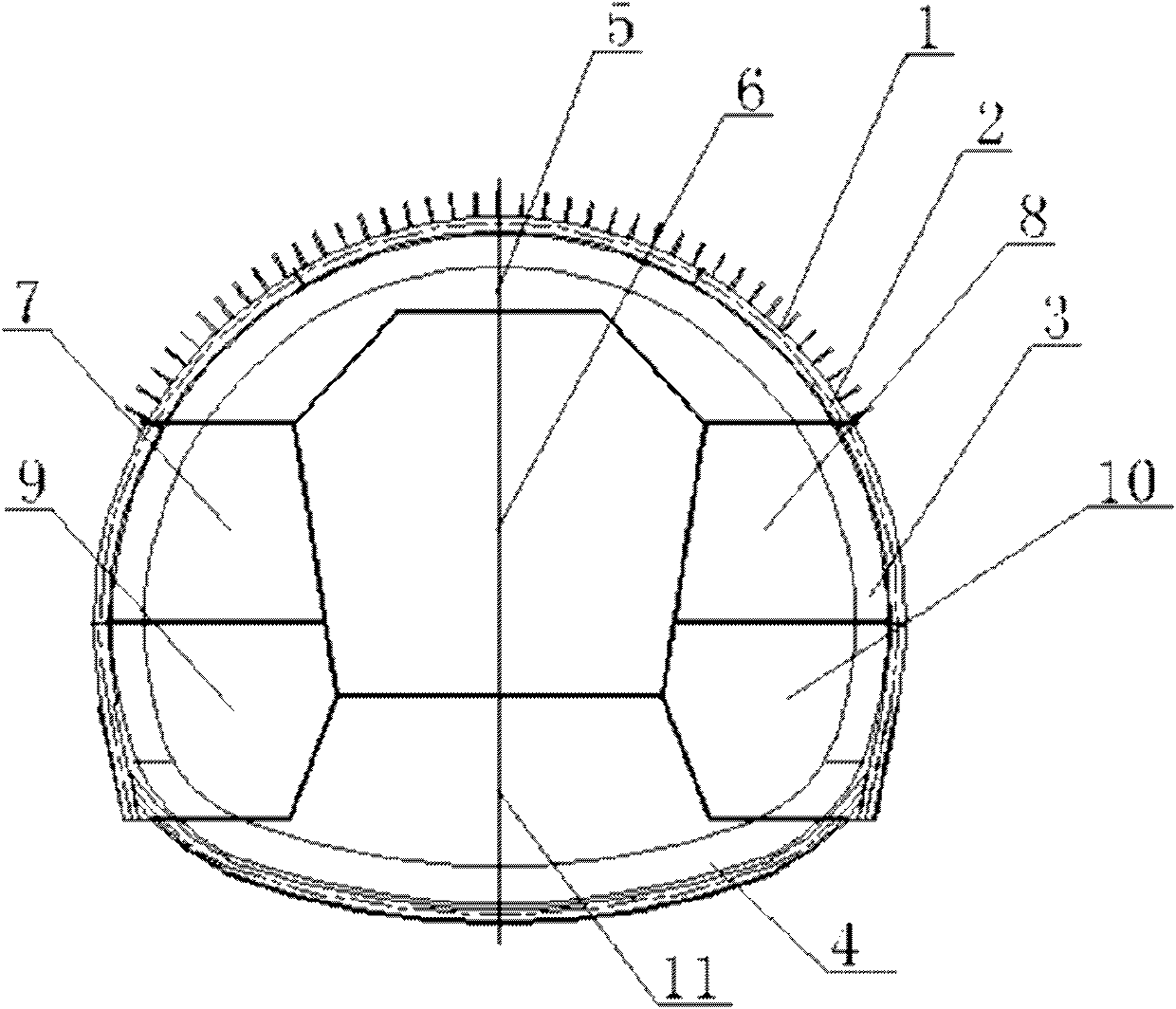

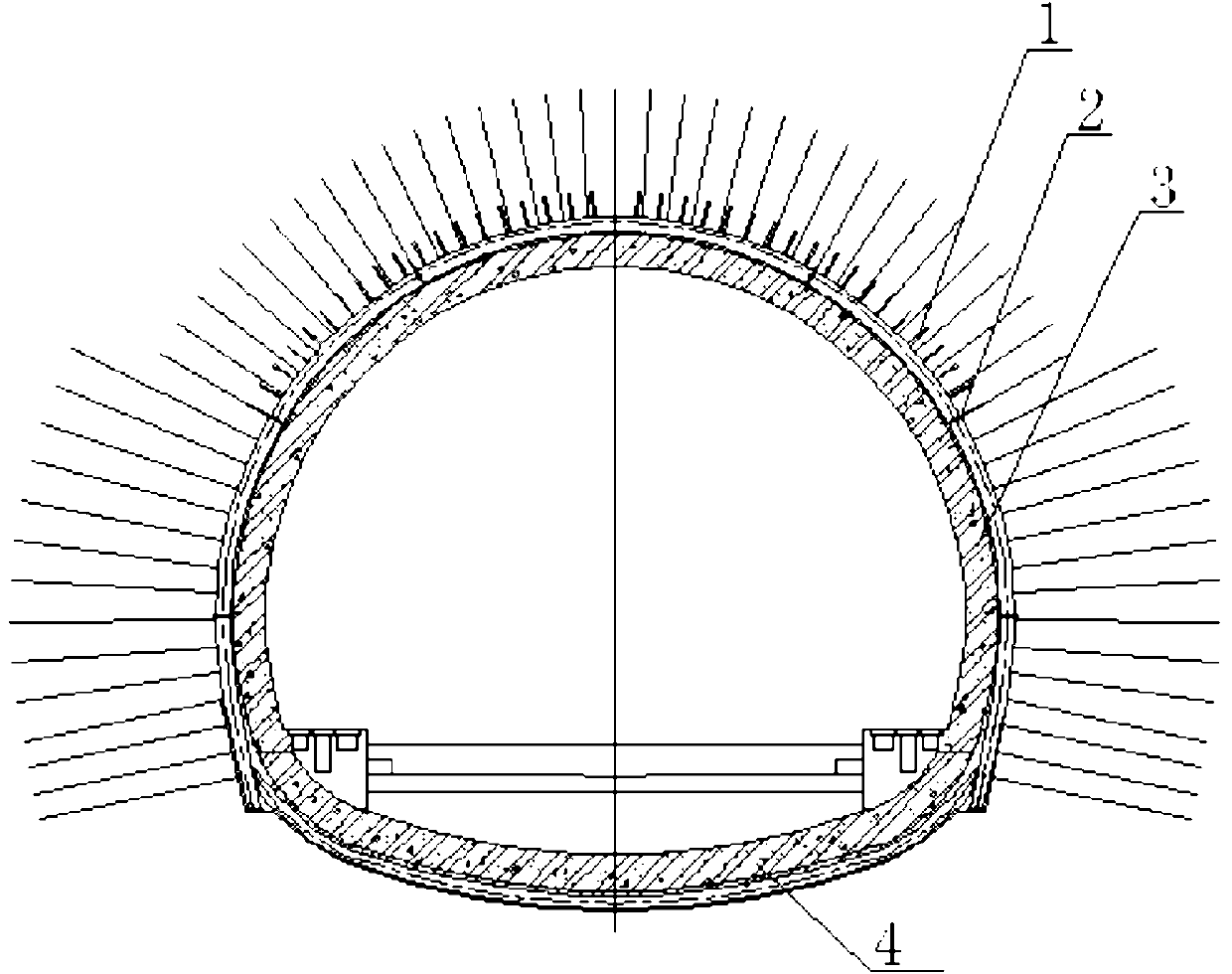

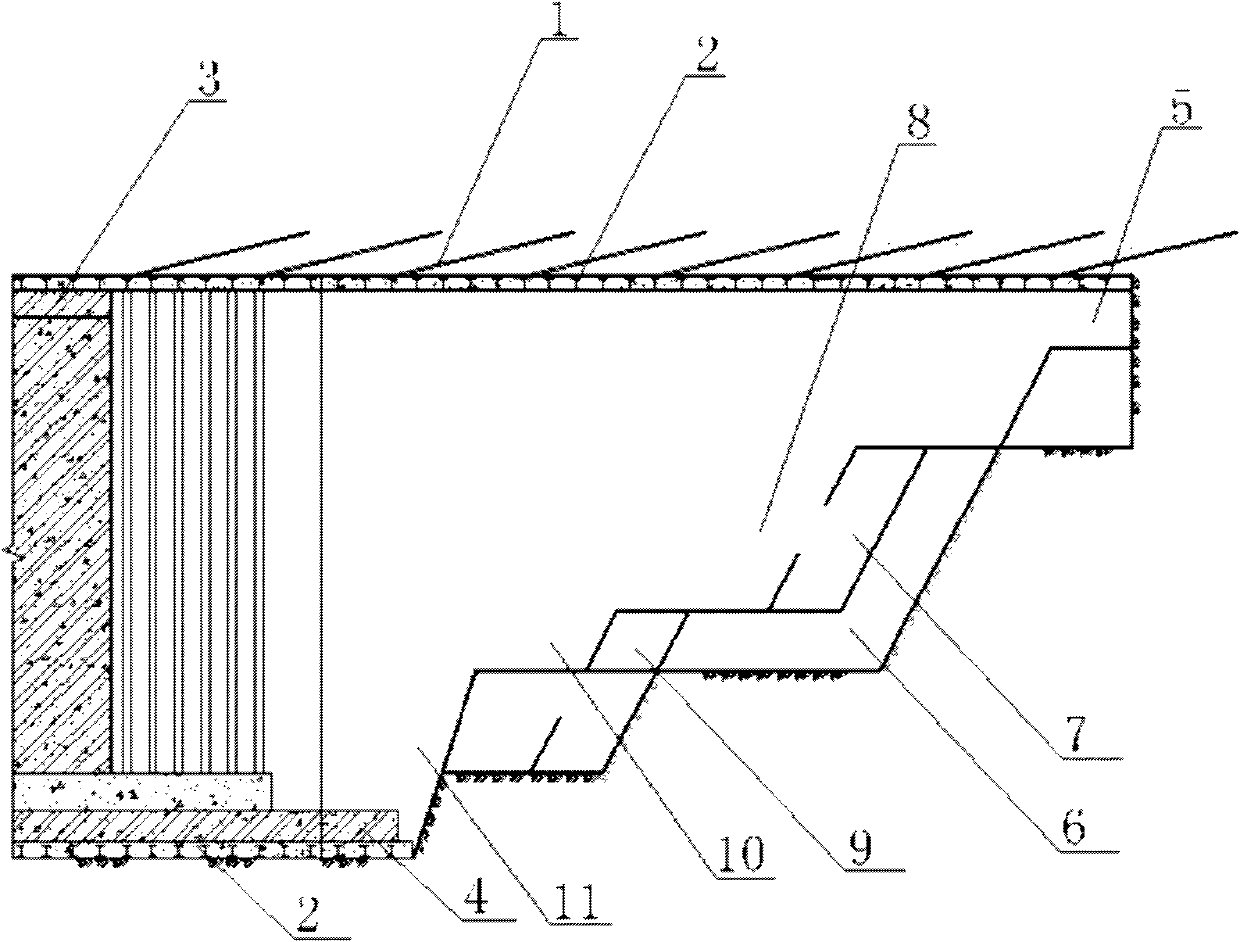

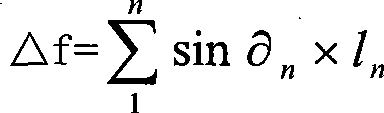

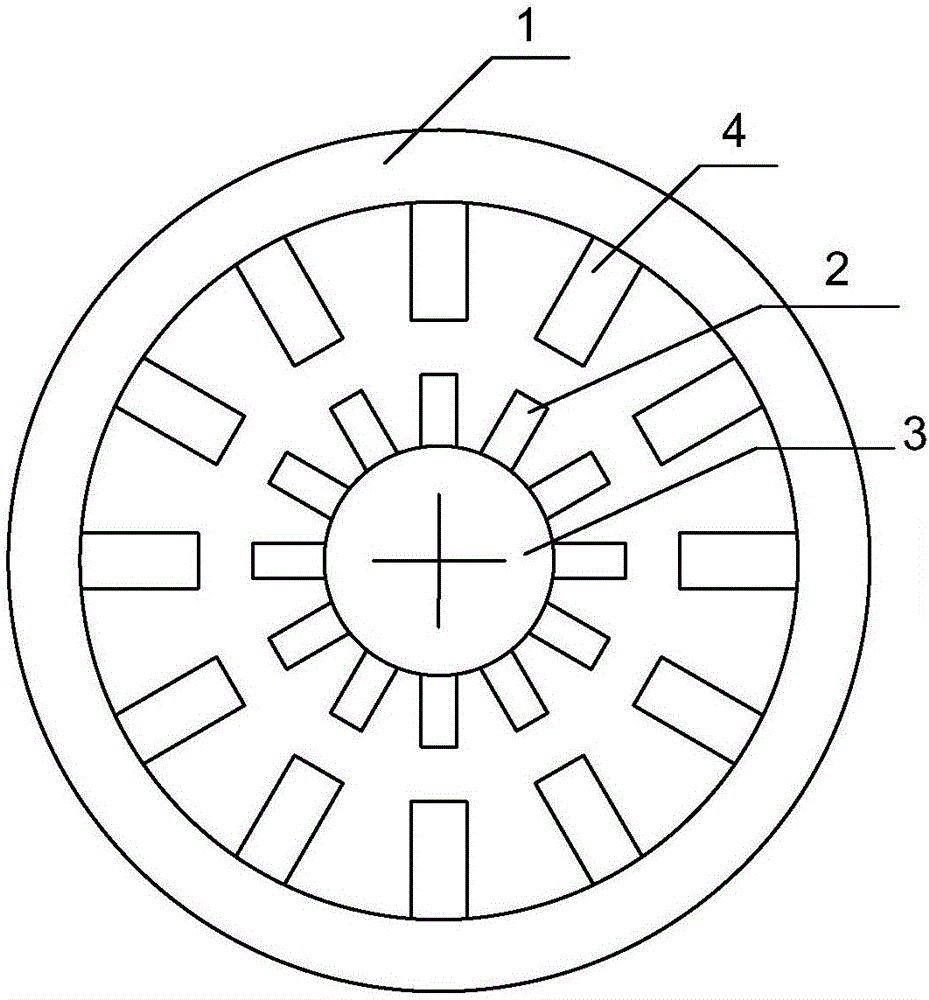

Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

ActiveCN102383805AControl face stabilityEnsure construction safetyTunnelsSludgeTunnel boring machine

The invention discloses tunnel construction equipment, in particular a mixed TBM (Tunnel Boring Machine) with a multiple-boring mode, which is suitable for sludge, clay, sand, grit, decomposed rock, hard rock and composite transition stratum. According to the invention, three modes of an earth pressure balance mode, a shield open mode and a TBM mode are adopted for construction according to different stratum geological conditions and construction tunnel supporting requirements; a deslagging mode is that a spiral conveyer or a TBM belt conveyor is adopted for deslagging; and simultaneously, a supporting mode can adopt a finned-tube lining or flexible post-supporting mode. The mixed TBM disclosed by the invention has very strong geological adaptability, is especially suitable for soft, hard and complex stratal construction of a mains underground engineering, and simultaneously, has the advantages that the whole machine has low manufacture cost, the mode conversion is relatively simple, the interference to mating construction is small, the control is convenient, the equipment manufacture cost is low, the economic property and practicability are achieved, and the use requirements of the flexible supporting mode of the construction can be met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

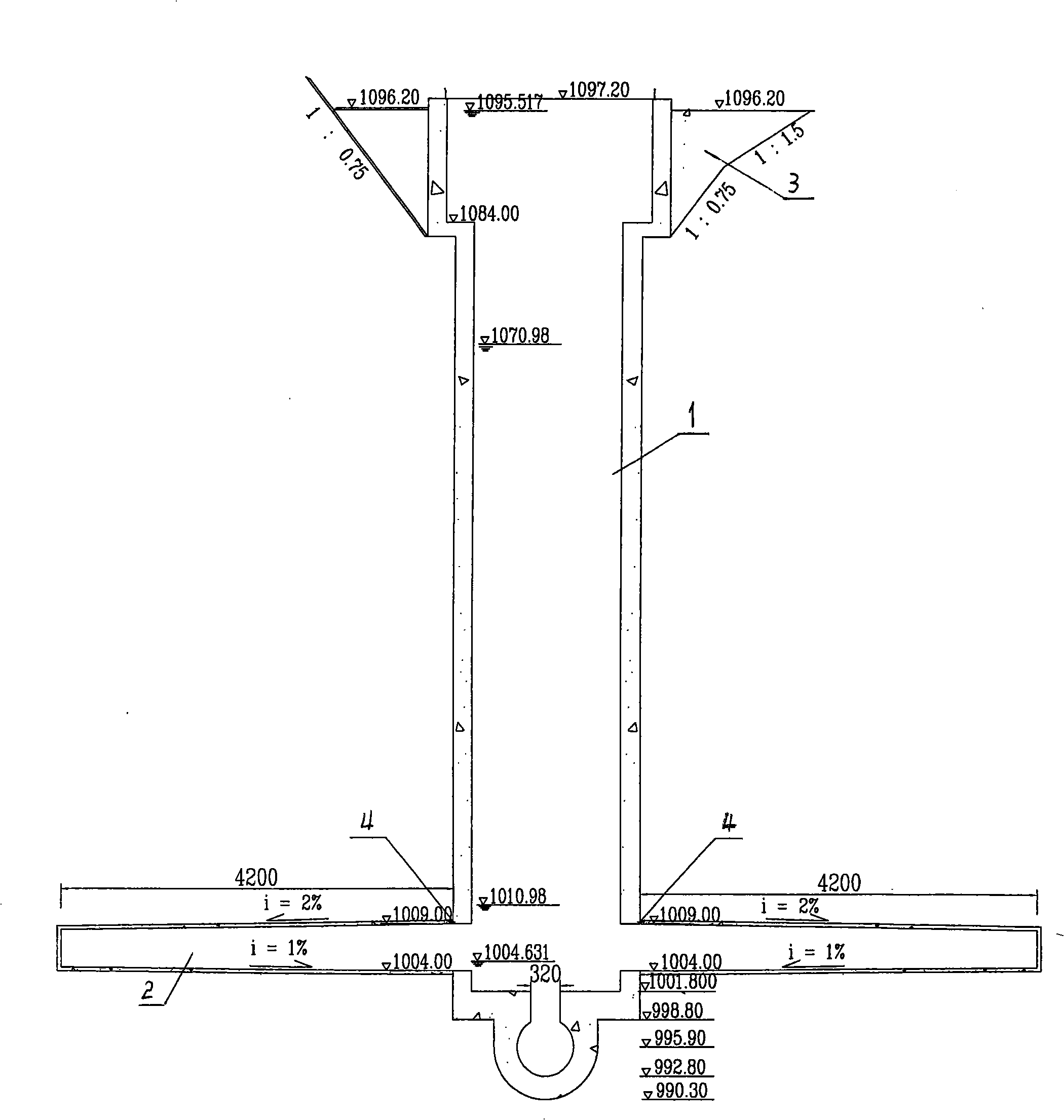

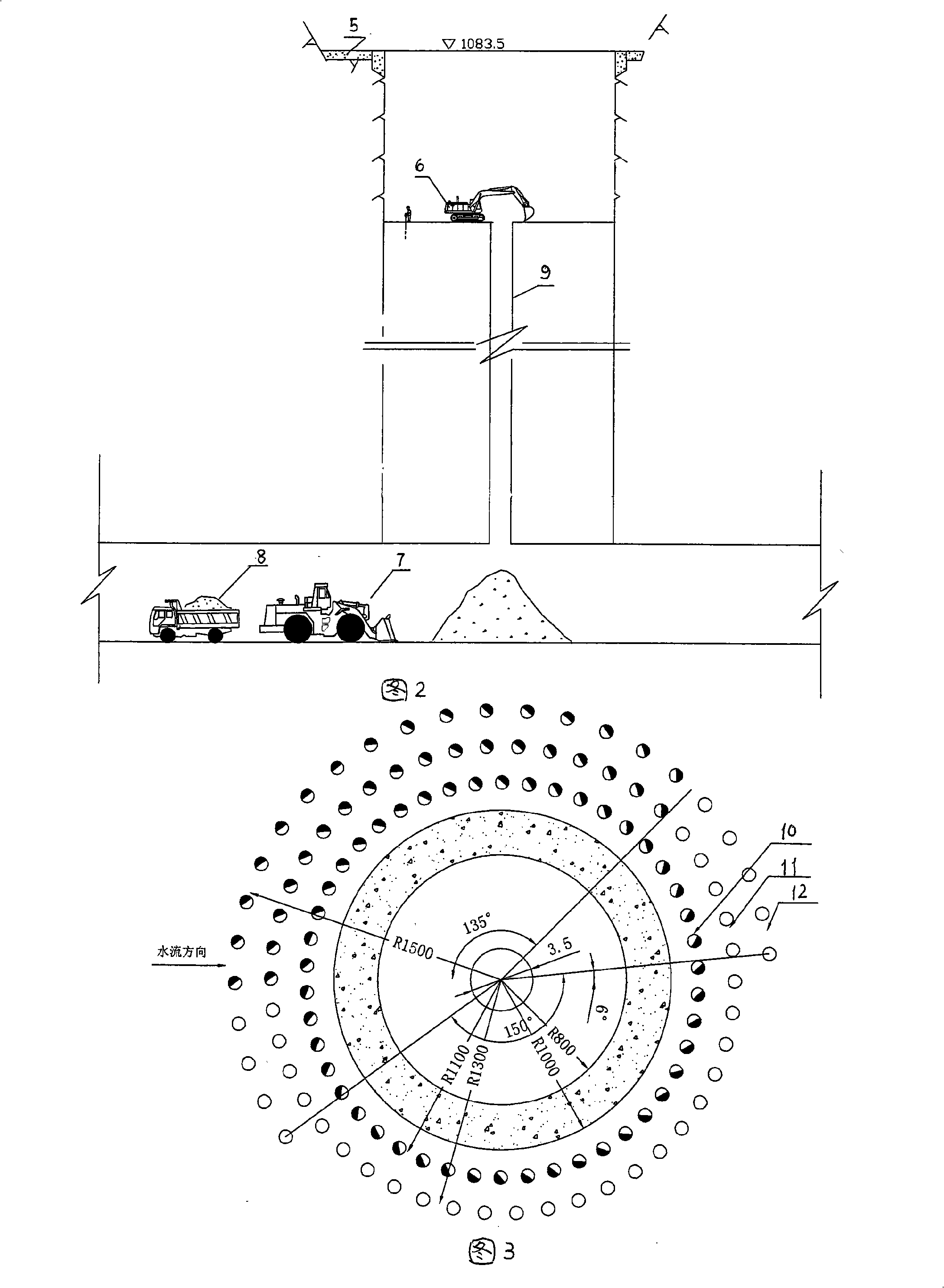

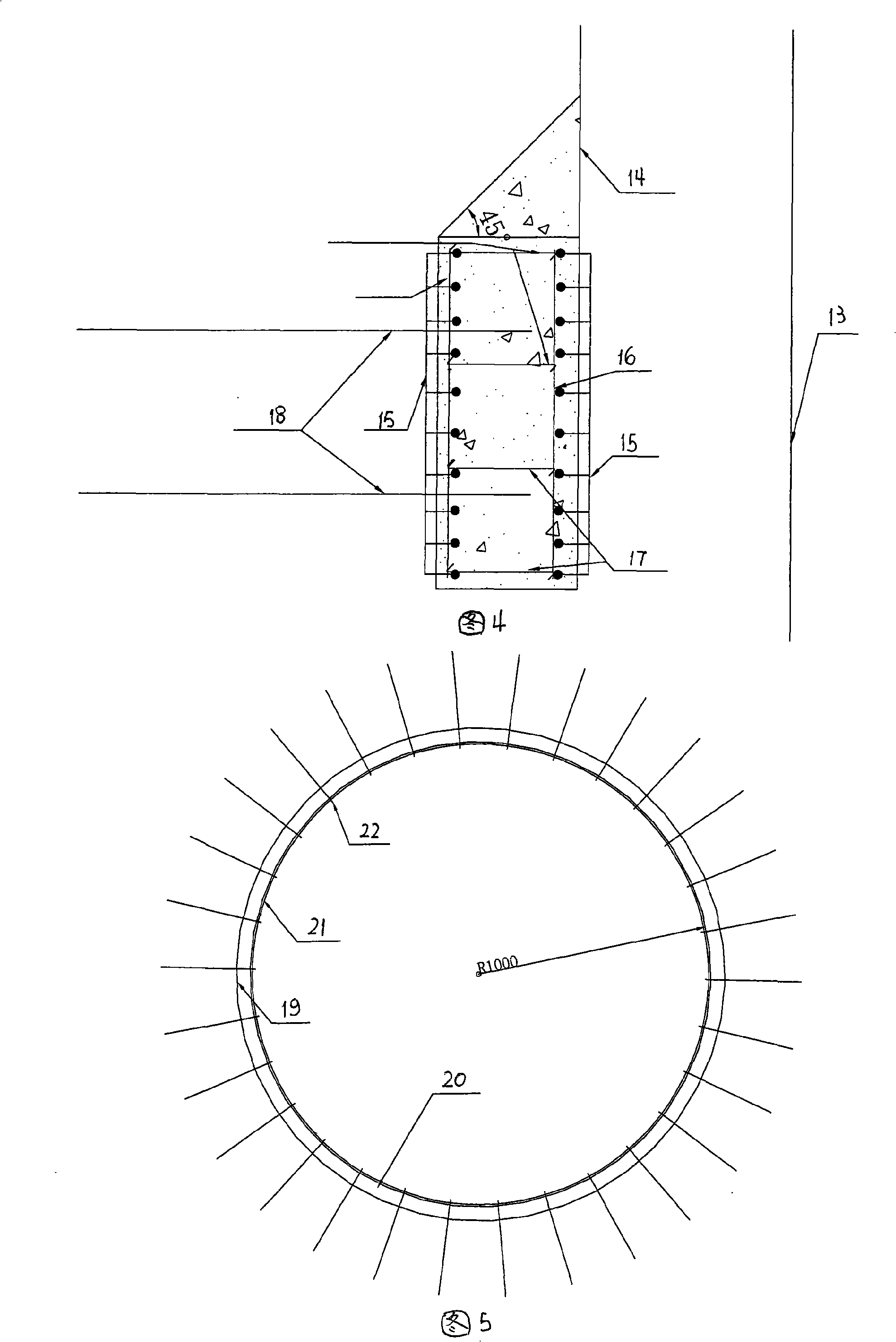

Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

ActiveCN101349064ASimple designEnsure safetyArtificial islandsUnderwater structuresSteam-electric power stationGeomorphology

The invention relates to a method for constructing a drilled shaft of a surge chamber in a hydropower station under the condition of weak rock geology; the excavation diameter of the drilled shaft is more than or equal to 20 meters; and the depth of the drilled shaft is more than or equal to 50 meters. The method comprises the following steps: firstly, a safe prestress reinforcing measure is adopted; a prestress anchor rope is arranged in a side slope of the drilled shaft; the deep rock holes in the periphery of the drilled shaft are subjected to consolidation and grouting; the periphery of the drilled shaft is cast with reinforced concrete for locking a mouth, etc; the construction sequence of excavating the drilled shaft comprises that: a raise-boring machine drills a guide hole of phi 216 millimeters from top to bottom; the raise-boring machine enlarges and excavates a small guide well of phi 1, 400 millimeters; a slag slipping guide well of phi 2, 500 millimeters is enlarged and excavated manually from bottom to top; and the slag slipping guide well is enlarged and excavated from top to bottom. The slag slipping guide well is excavated by manual drilling and blasting; slag is naturally slipped and mechanically loaded in the bottom of the well; a large well is enlarged and excavated through drilling and blasting by a manual air drill; and the skimmed slag in a hydraulic backhoe well slips to the bottom of a passage through the slag slipping guide well and is mechanically loaded in the bottom of the well. The construction method has the characteristics of having reasonable construction arrangement, alternately and simultaneously carrying out a plurality of construction types and saving the construction period.

Owner:SINOHYDRO BUREAU 5 +1

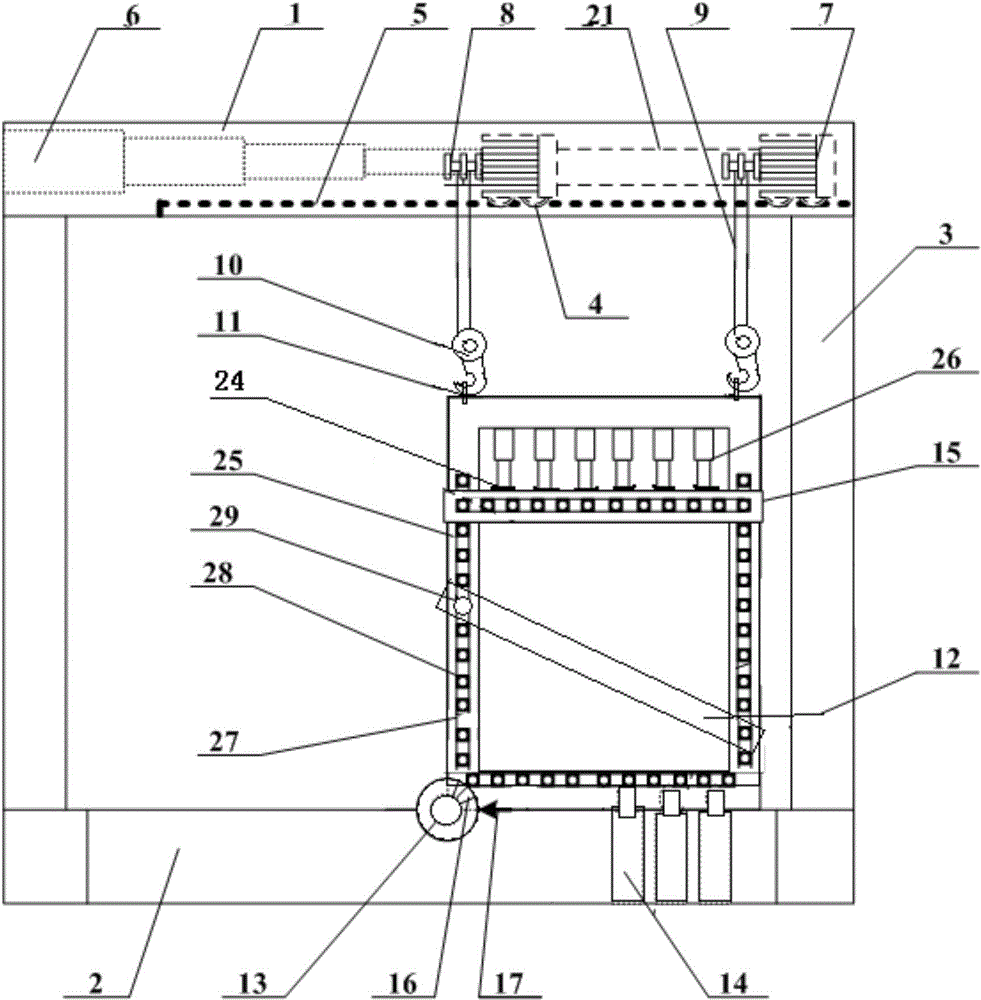

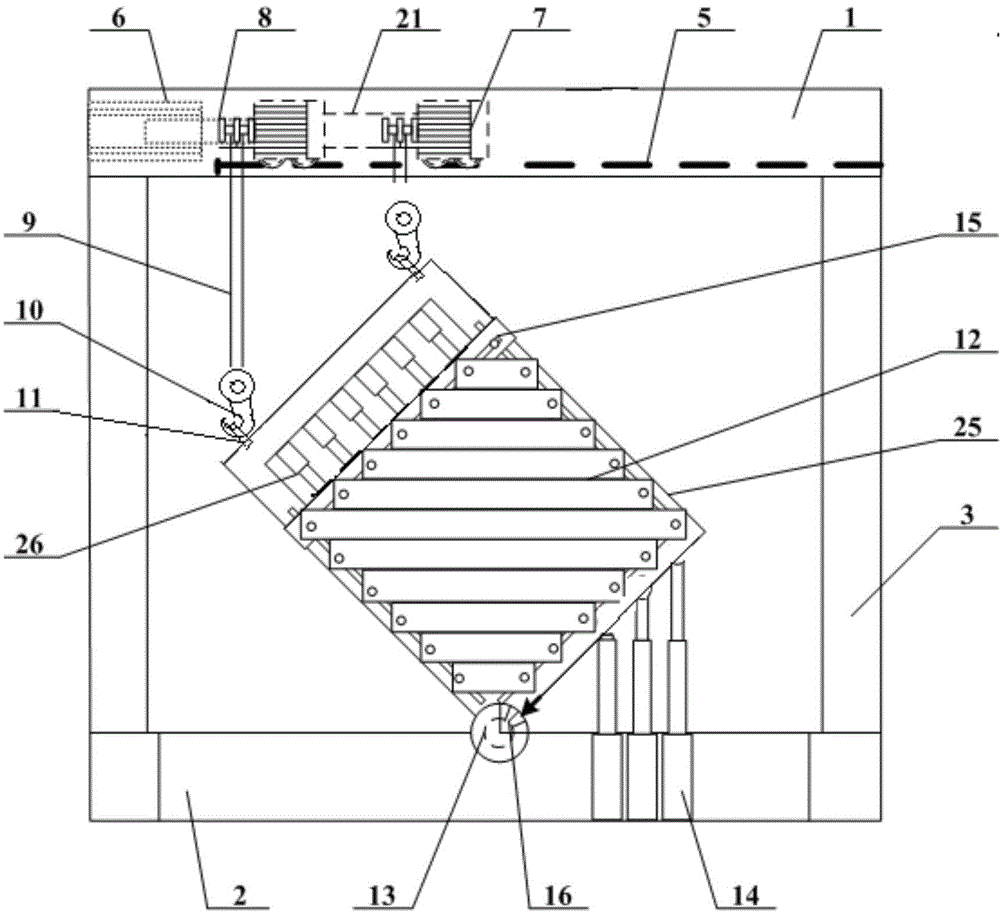

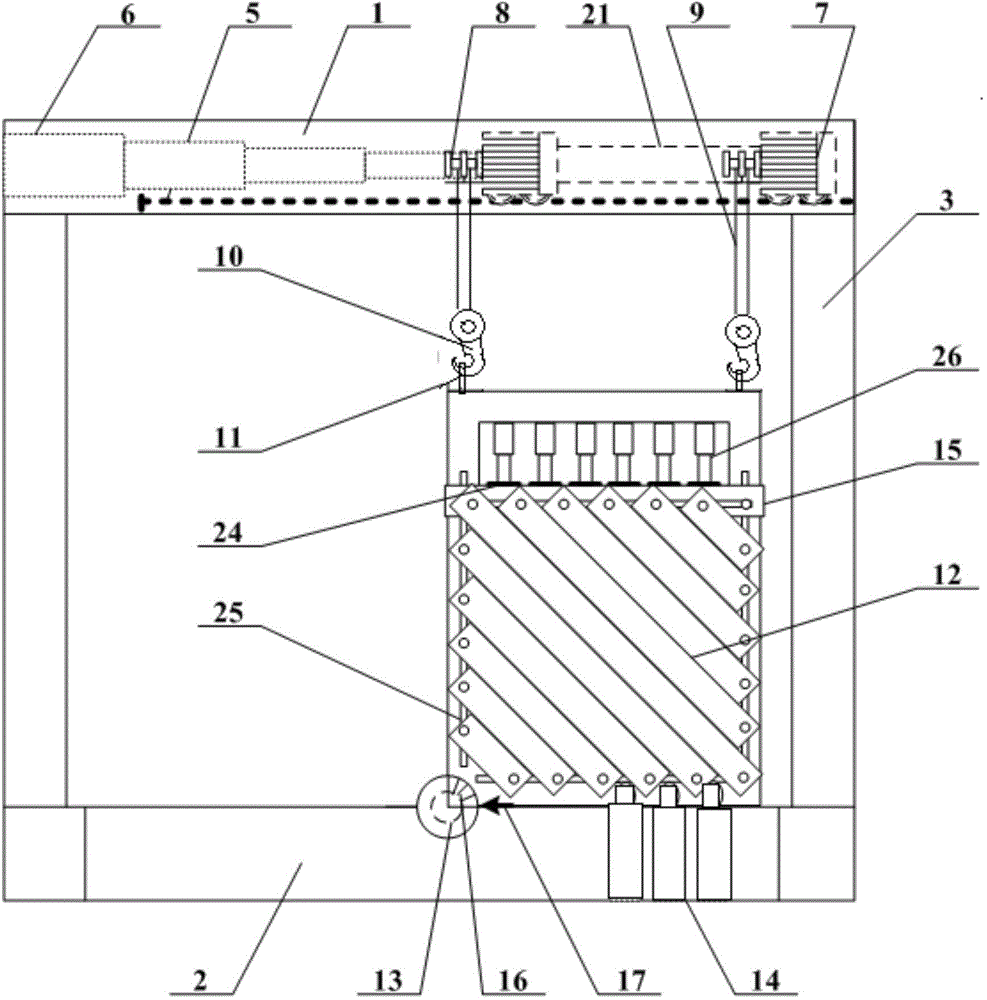

Physical similar simulation test device and physical similar simulation test method for tilted stratums

ActiveCN104596855AGuaranteed balance and stabilityEliminate potential safety hazardsMaterial strength using tensile/compressive forcesUsing optical meansStress distributionComputer science

The invention discloses a physical similar simulation test device and a physical similar simulation test method for tilted stratums. The physical similar simulation test device comprises an external framework, a tiltable rack, a front baffle, a rear baffle, a hydraulic supporting device and a hanging hoisting device, a similar simulation test is performed on stratums with different tilt angles by adopting the device and the method, physical mechanical performances of stress distribution, displacement change and the like inside the stratums under the action of external disturbance, ground stress, external force application and the like can be measured to obtain related technical indexes and parameters so as to research the rule of the true stratums in the process, and the effective struts can be facilitated during the construction of the stratums, thus providing a guarantee for the safety construction of the stratums.

Owner:SHANDONG UNIV OF SCI & TECH

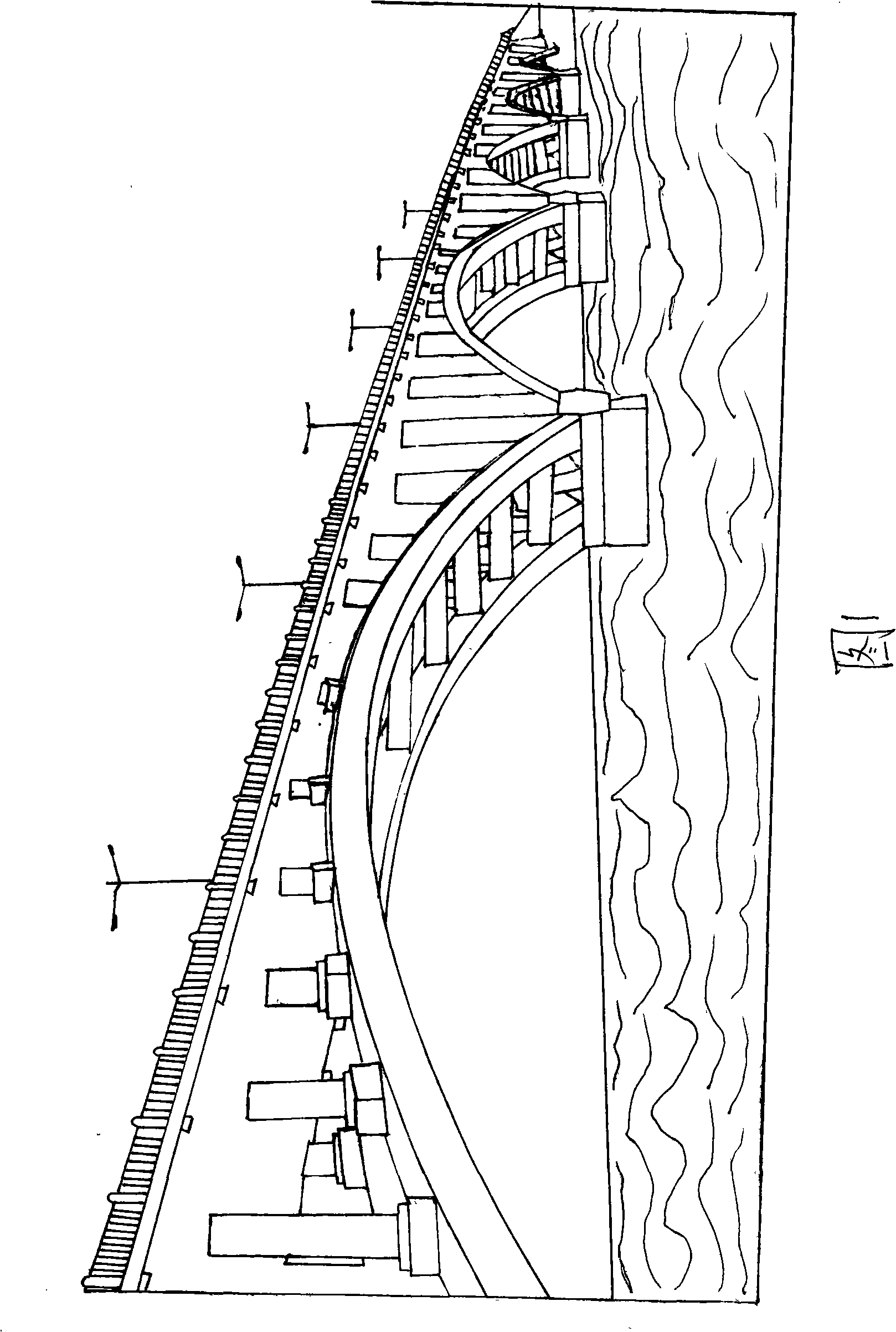

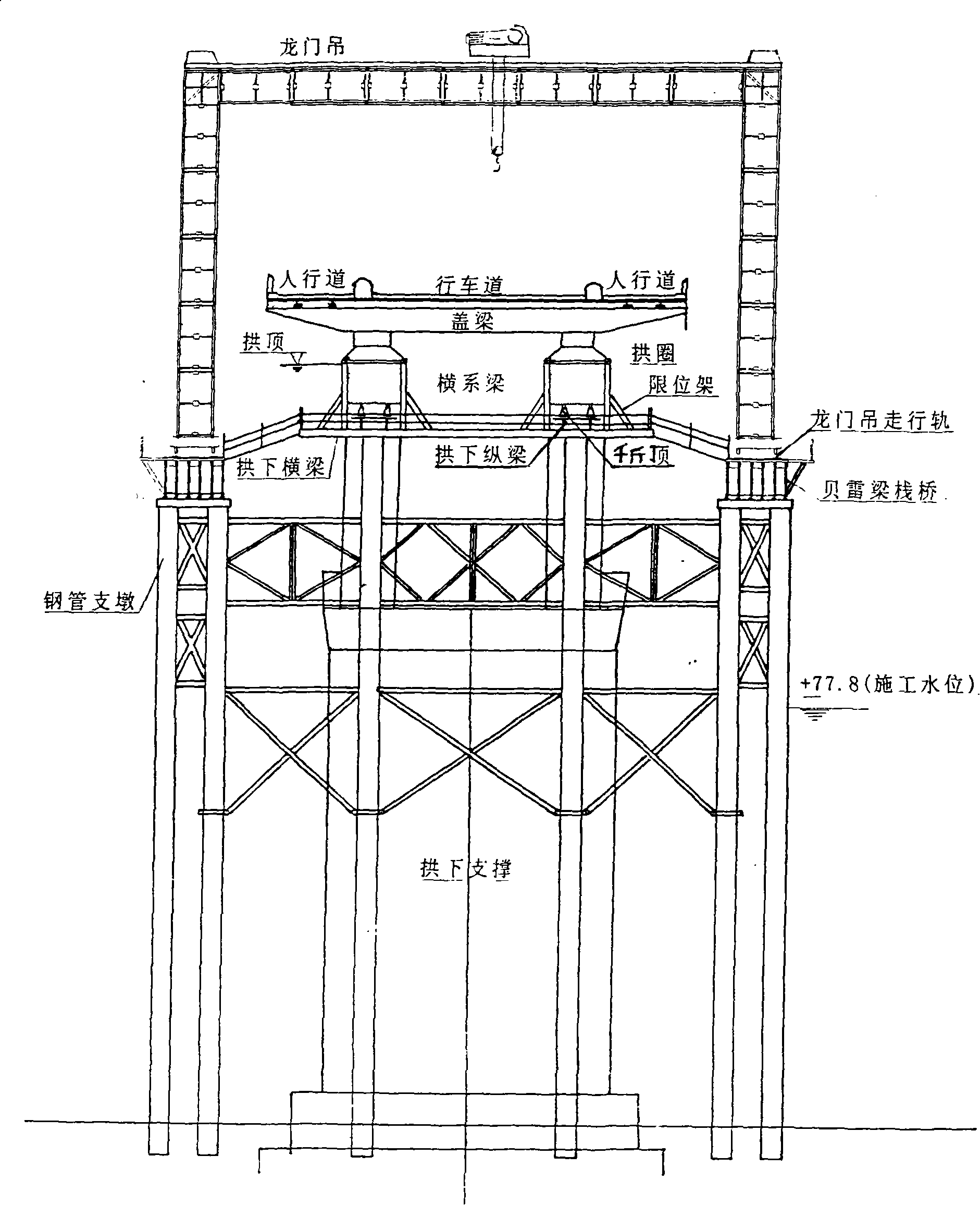

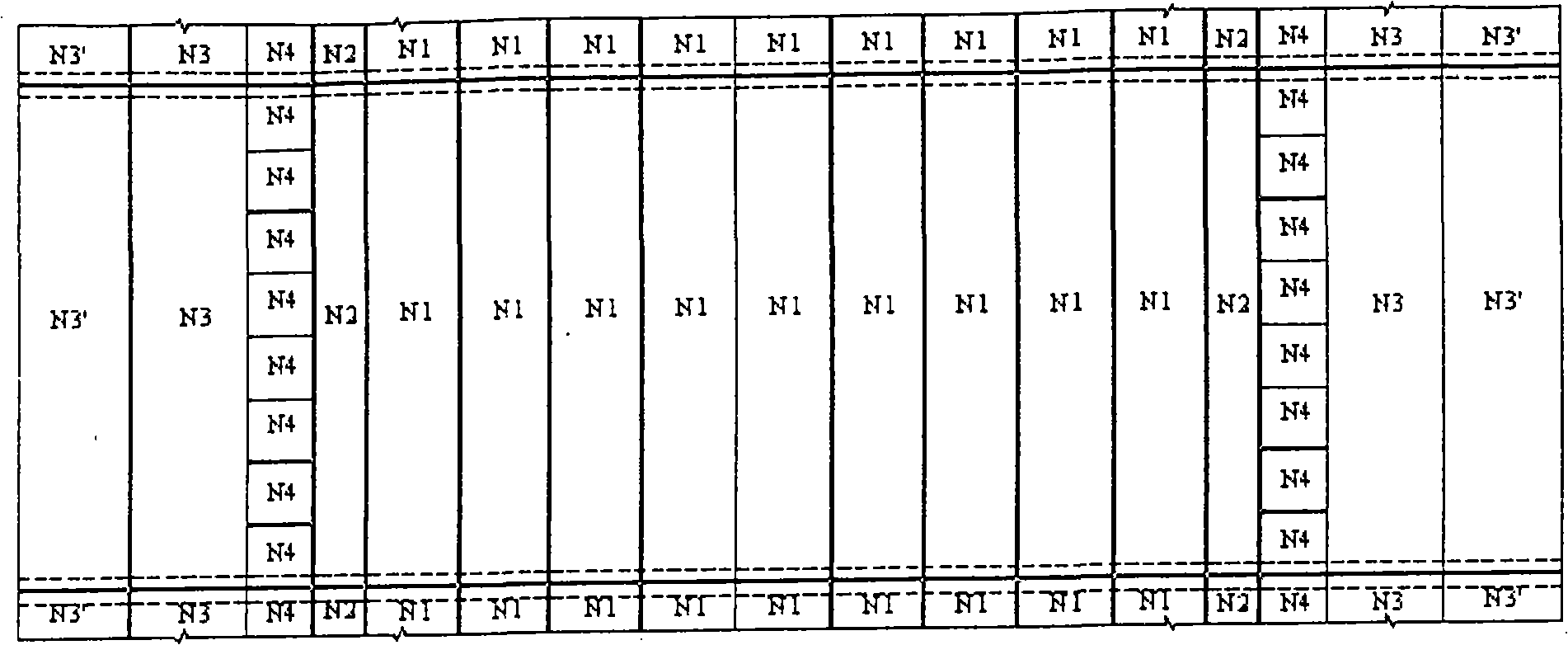

Method for dismantling arch bridge for protection

InactiveCN101265690AShort construction periodEnsure construction safetyBuilding repairsSocial benefitsReverse order

The invention provides a protective method for removing an arch bridge, which belongs to the technology field of bridge removal. The method aims to provide a protective bridge removal method with safety, high efficiency and no pollution. The technical points include: building up a new trestle, erecting a gantry crane, carrying out the bridge removal in a reverse order of the bridge building including bridge decking, coping, column, beam, arch rib and arch support in sequence. The removal stage of the arch rib especially includes removing by adopting methods of top-supporting under the arch, arch box transverse stop and horizontal restraining rope, which better solves the difficult problem of the protective bridge removal with safety, high efficiency and no pollution in a complex construction environment of guaranteeing under-arch navigation, high security level, short construction period and various unpredictable elements, manages to meet the design requirements of the removal safety factor in the protective bridge removal process and the limit control under various removal working conditions and guarantees the removal quality and the construction safety. The removal method has low cost and remarkable social benefit reflected in the direct economic analysis, which is a protective removal method of large-span bridges with safety, high efficiency and practicability.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

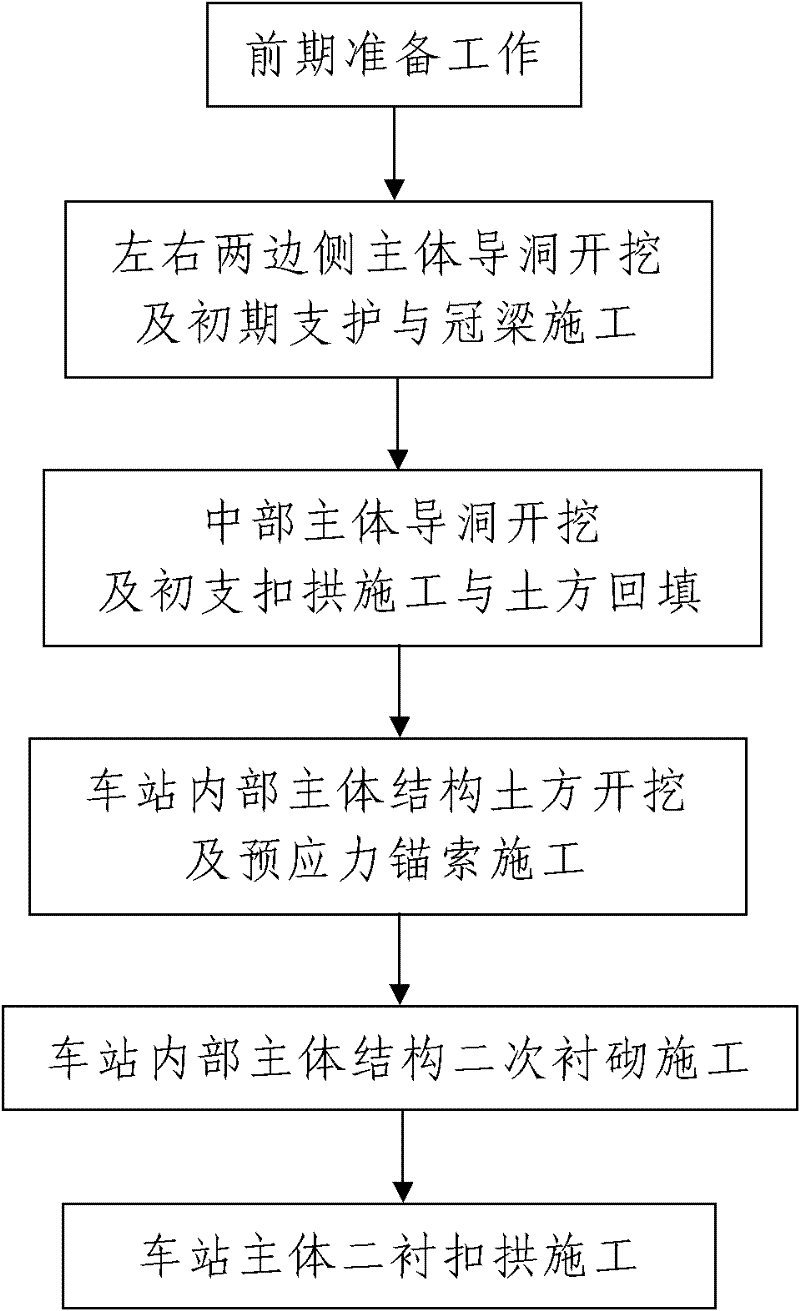

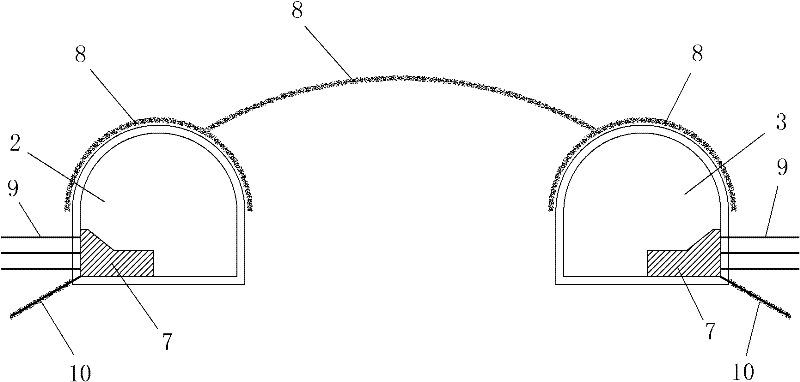

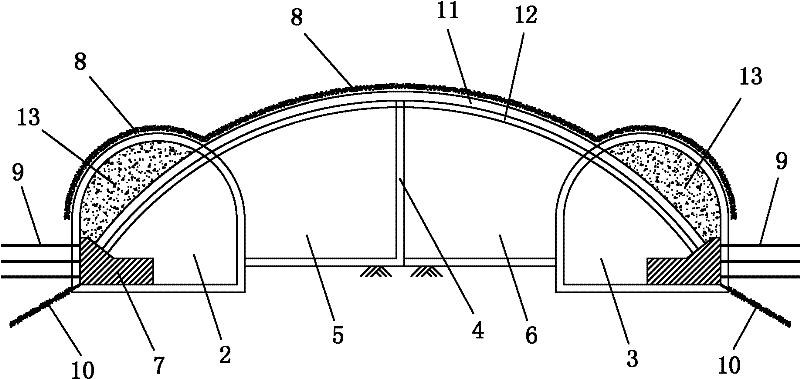

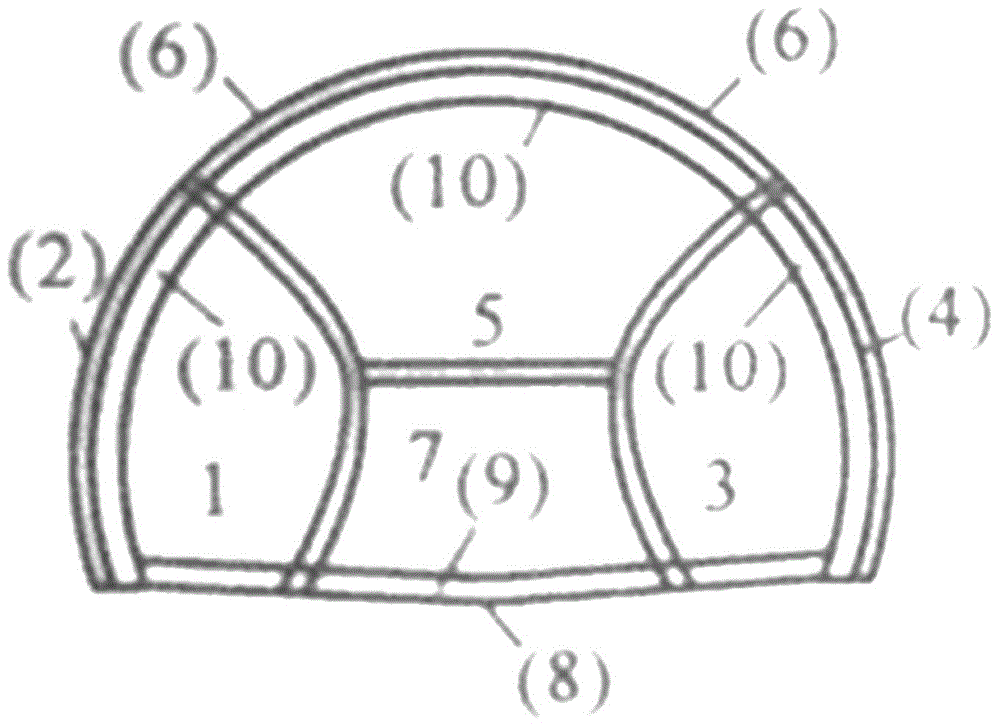

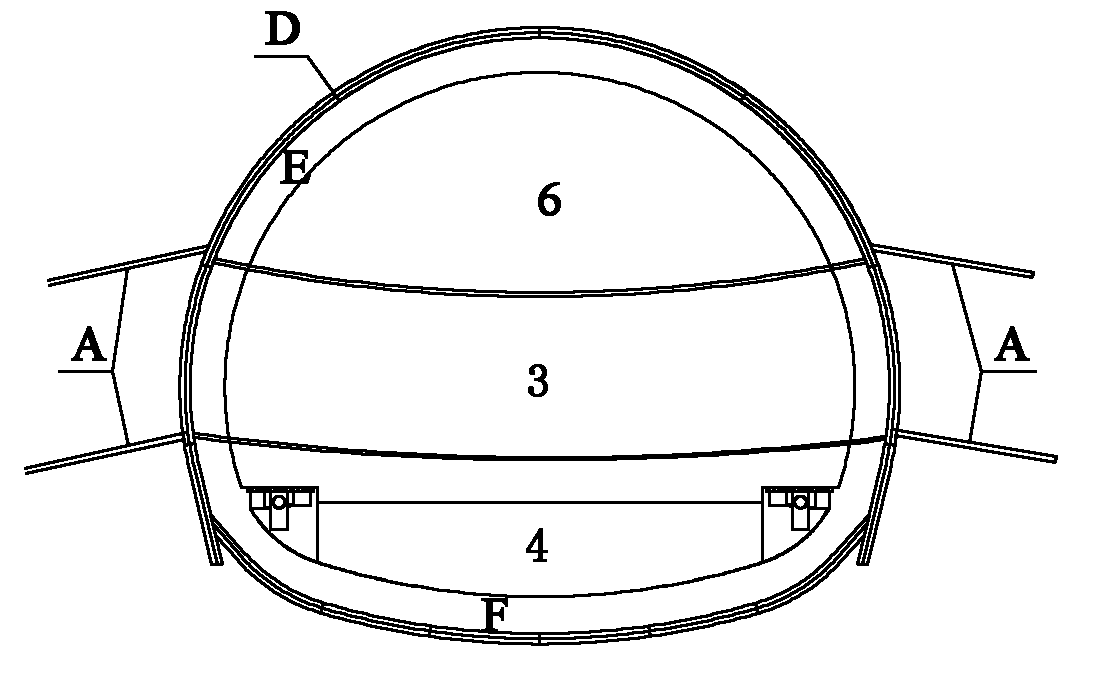

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

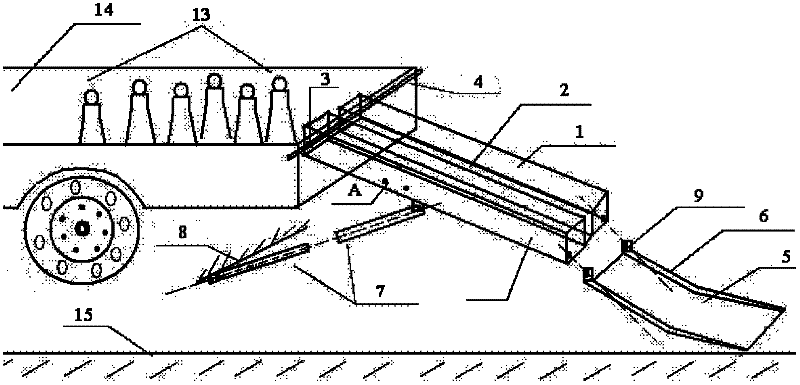

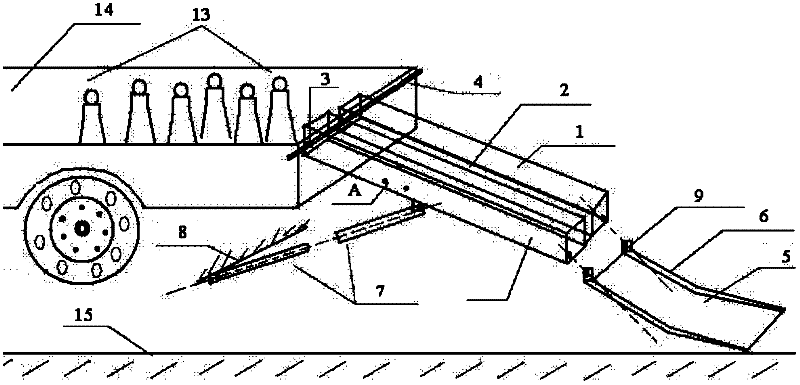

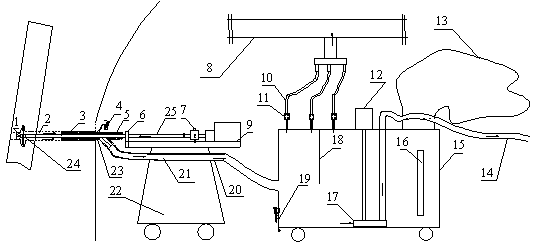

Automatic traffic cone putting device

InactiveCN102400444AIncrease placement speedEnsure safetyTraffic signalsRoad signsMonitoring systemSimulation

The invention relates to an automatic traffic cone putting device, which belongs to the field of traffic machinery, and comprises a cone putting device, a suspension device, a guiding device and a supporting device, wherein the suspension device and the guiding device are arranged at the two ends of the cone putting device, and the supporting device is arranged at the bottom of the cone putting device. Compared with the prior art, the automatic traffic cone putting device provided by the invention has a novel structure and a reasonable design, is simple and convenient to install and maintain, is easy to operate, is flexible to move, and is convenient to regulate and control, a large number of labor can be saved, the speed for putting traffic cones can be obviously improved, the safety of workers can be effectively guaranteed, simultaneously, the putting effect is ensured, stable and accurate putting of the traffic cones can be realized, the consistency in putting intervals of the traffic cones is ensured, the putting intervals can be regulated according to the need, an operator can know running conditions of devices constantly through a monitoring system, the construction safety is fully ensured, and the automatic traffic cone putting device is suitable to be promoted and applied in traffic-related engineer operation requiring putting the traffic cones and similar facilities.

Owner:北京公联洁达公路养护工程有限公司

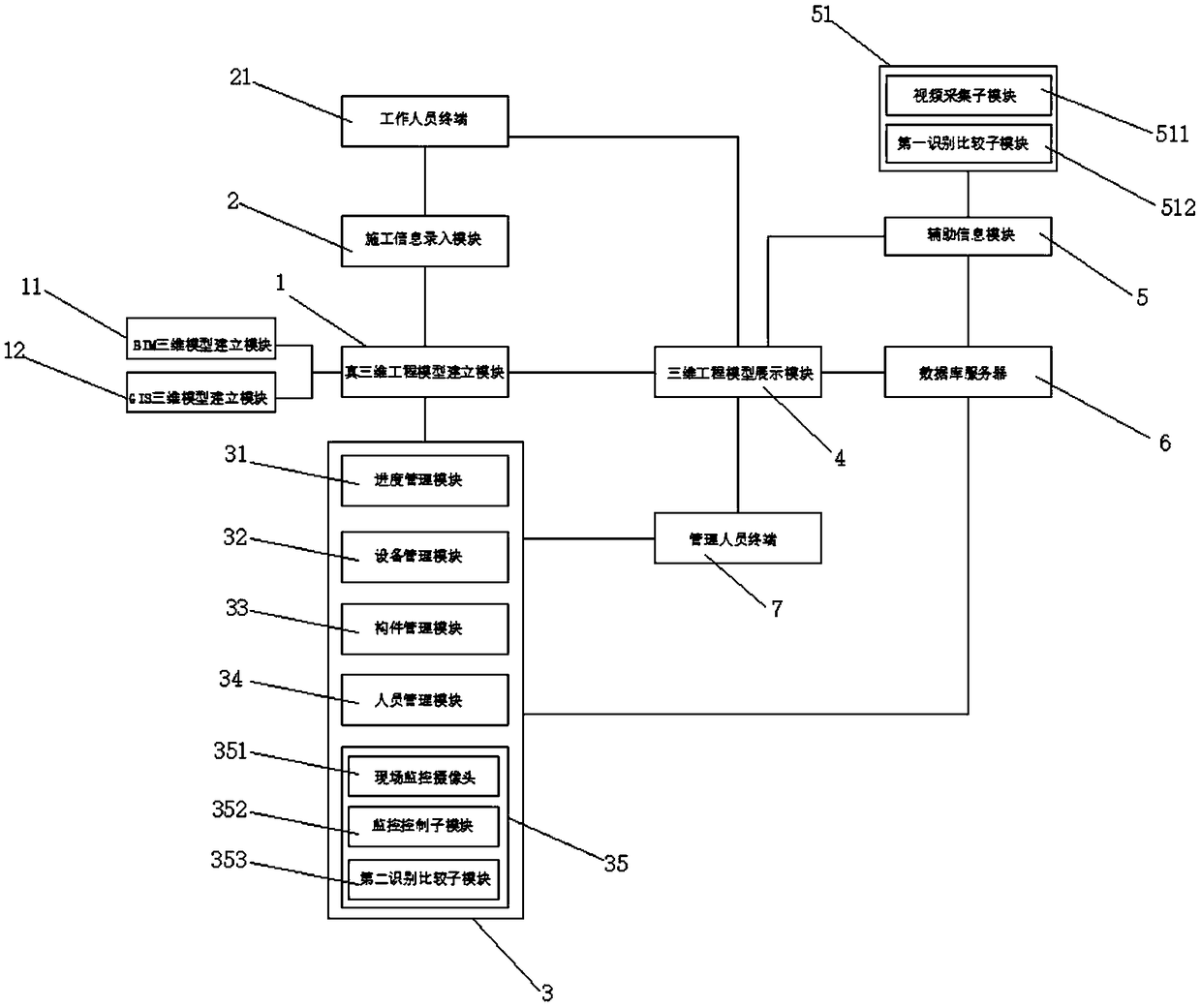

A project management system based on three-dimensional visualization

ActiveCN109447479AEasy to understandEasy to manageOffice automationResourcesDatabase serverTopographic map

The invention relates to the technical field of engineering management, in particular to a project management system based on three-dimensional visualization, including a BIM three-dimensional model building module; a GIS three-dimensional topographic map establishment module; a true three-dimensional engineering model building module which is used for combining the BIM three-dimensional model building module and the GIS three-dimensional topographic map building module to generate a true three-dimensional engineering model; a construction information input module used for construction progress and construction process records input; a project management platform used for managing a project through a manager terminal; a three-dimensional engineering model display module which is used for combining the data of the construction information input module and the data of the engineering management platform with the true three-dimensional engineering model establishment module, and realizingthe sharing of the engineering component information; and a database server used for storing and sending data. The system of the invention can facilitate the management and planning of the project bythe management personnel, and is convenient for the staff to report the construction information of the project.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

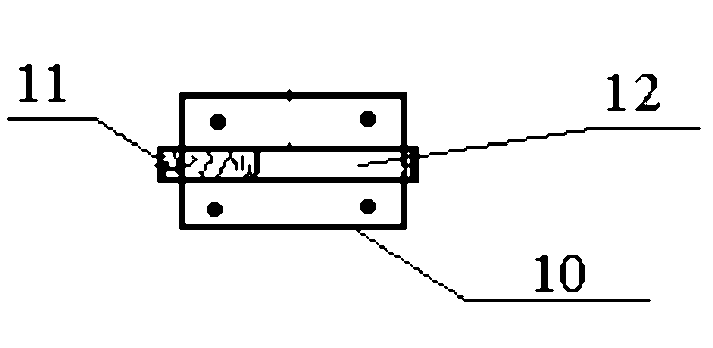

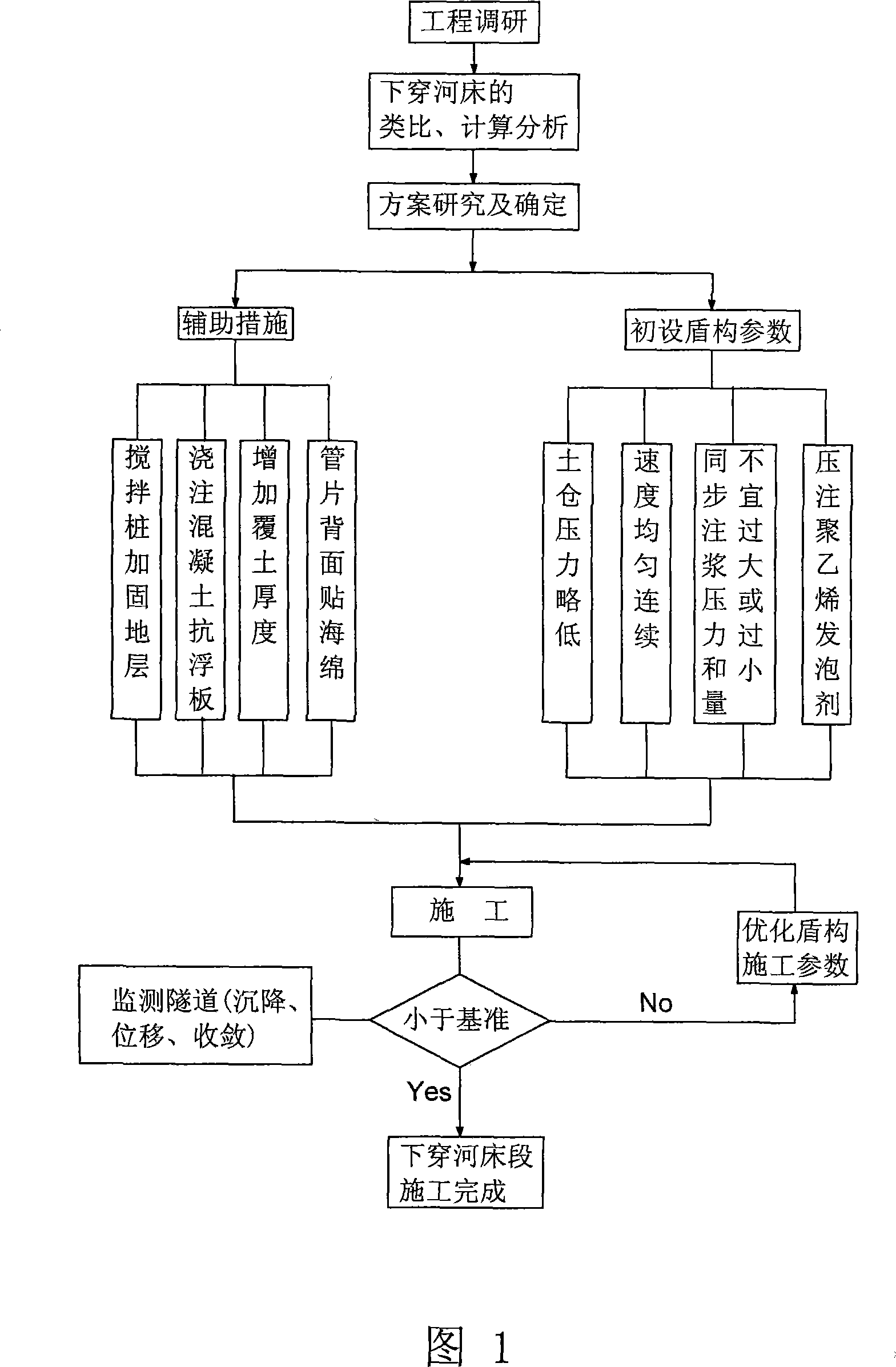

Construction method for shallow soil-covered river bed under shield tunnel

The construction process for shielded tunnel to penetrate through river bed with shallow covered soil layer includes the following steps: engineering investigation, river bed analogy, calculation and analysis, research and determination of technological scheme, determining auxiliary measures and setting the initial shielding parameters, river bed penetrating construction, etc. The auxiliary measures include foundation consolidation, setting anti-floating plate, surface blasting weight, etc. The initial shielding parameters include earth pressure, earth output amount, propulsion speed, grouting amount, etc. During the construction, one computerized real-time monitoring system is adopted for comprehensive monitoring on tunnel sedimentation, displacement and other conditions. The construction process can ensure safety and avoid water inrush, collapse and other accidents.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Walking type multipoint pushing construction method and walking type multipoint pushing construction system for steel box girder

ActiveCN102587291ASolve the shortcomings of conventional processesReduce stress valueBridge erection/assemblyHorizontal forceSteel box girder

The invention discloses a walking type multipoint pushing construction method for a steel box girder, which is an improved optimized scheme for improving the disadvantages of a pulling type pushing method. The optimized scheme comprises the steps of installing pushing devices at assembly platforms, temporary mounds, main mounds and other points, firstly jacking the steel box girder with a vertical jack to separate the steel box girder from a girder laying frame, then pushing the steel box girder for a stroke in the longitudinal direction by a pushing jack, lowering the steel box girder to the girder laying frame, retracting the pushing jack for a next stroke of pushing, and keeping the circulation of the work until the installation of the steel box girder is finished. The pushing construction method for the steel box girder provided by the invention adopts a multipoint walking type pushing system, which not only can avoid disadvantages in the process in prior arts, but also has the advantages that the horizontal force at the mound top is greatly reduced; the structure of the temporary mound is simplified; the damage to the steel box girder is small; the construction cost is low and the like.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

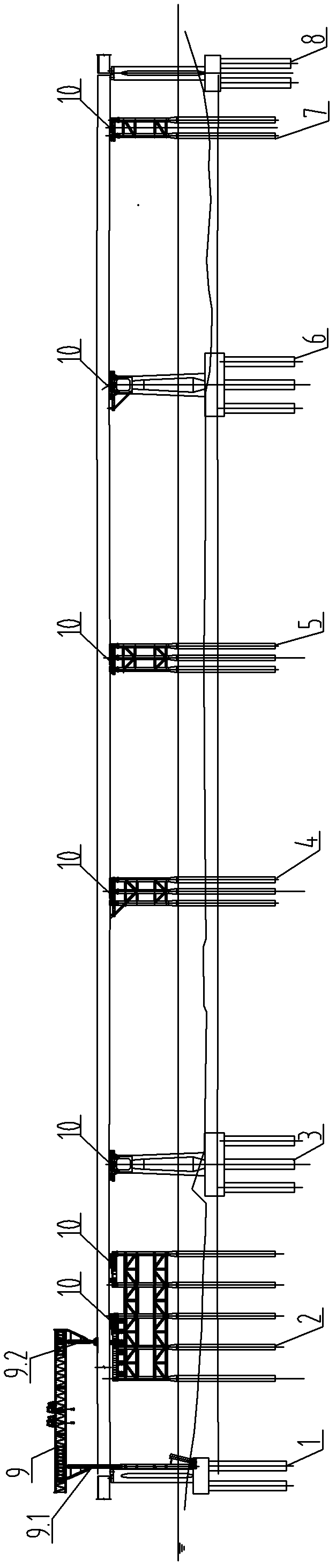

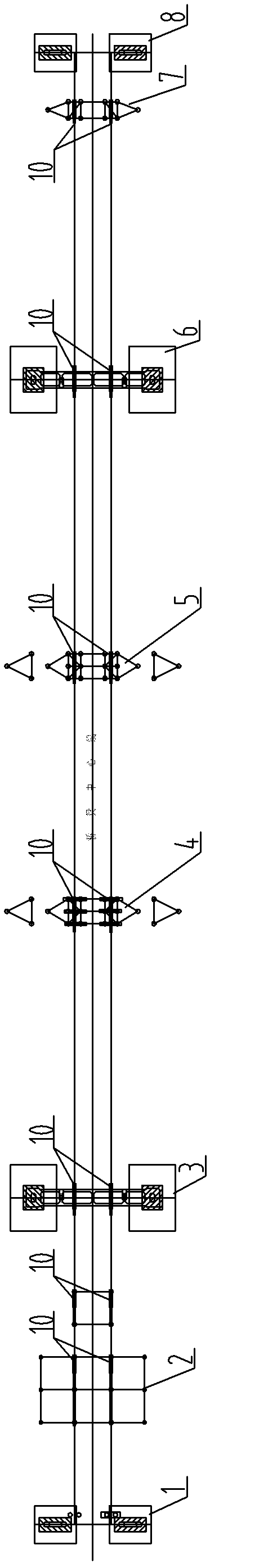

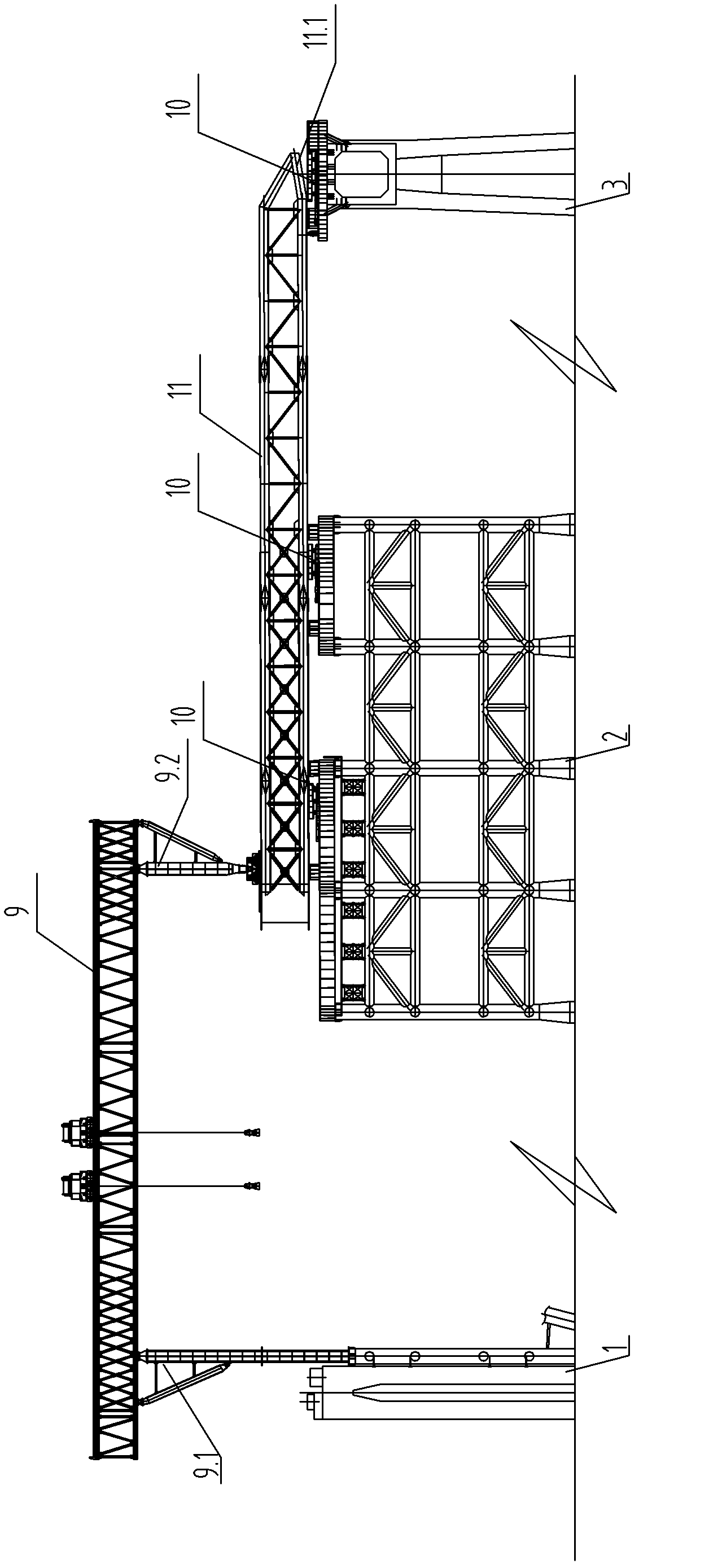

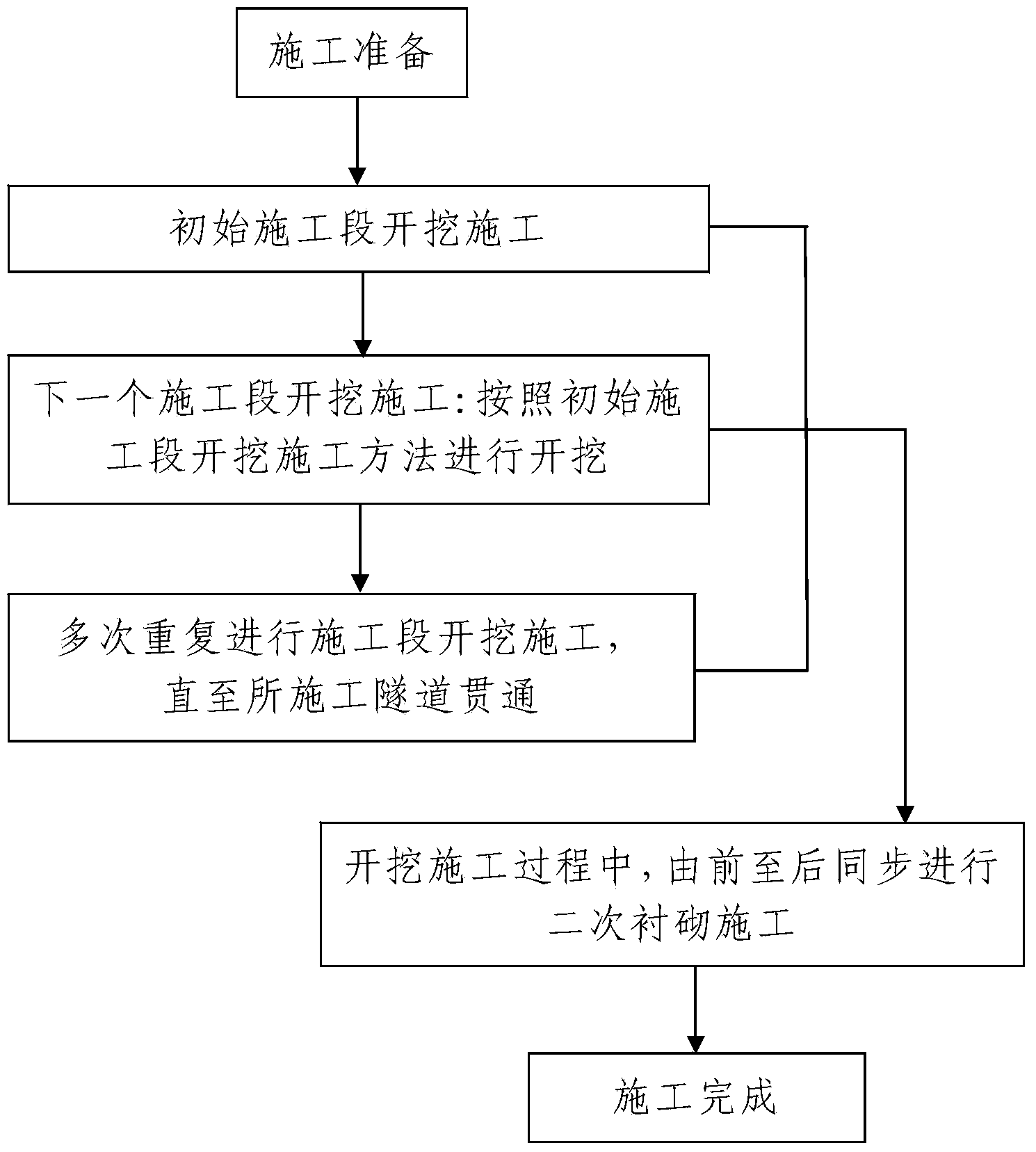

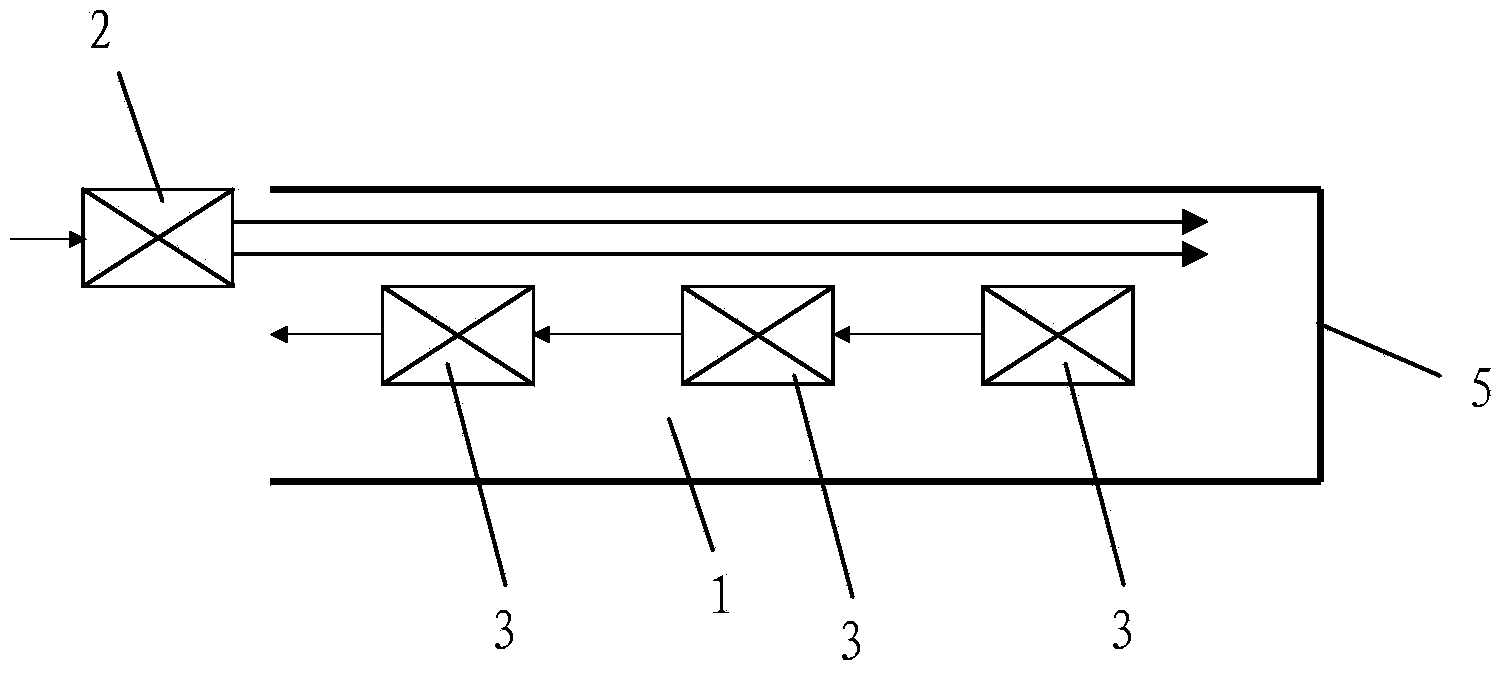

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

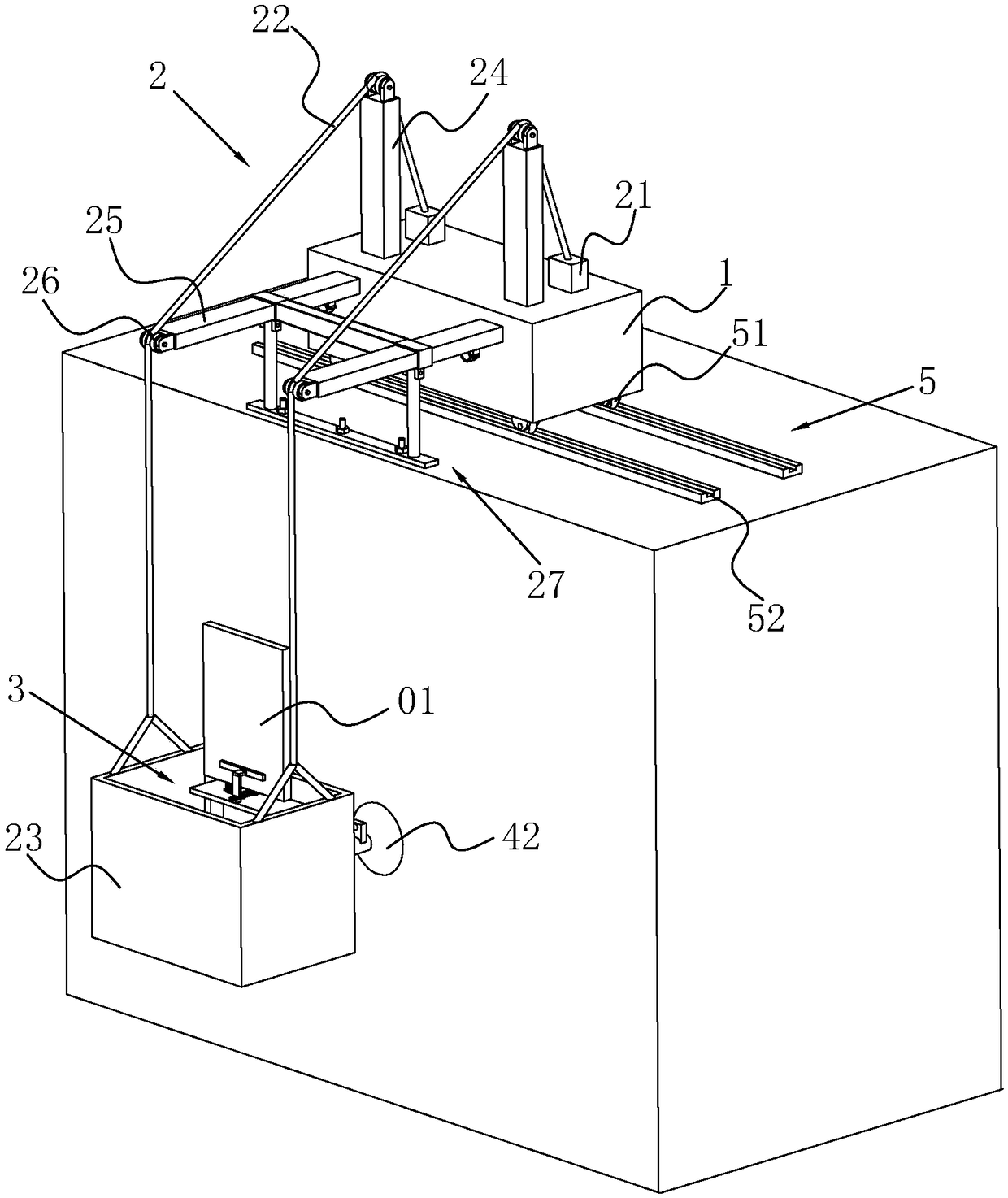

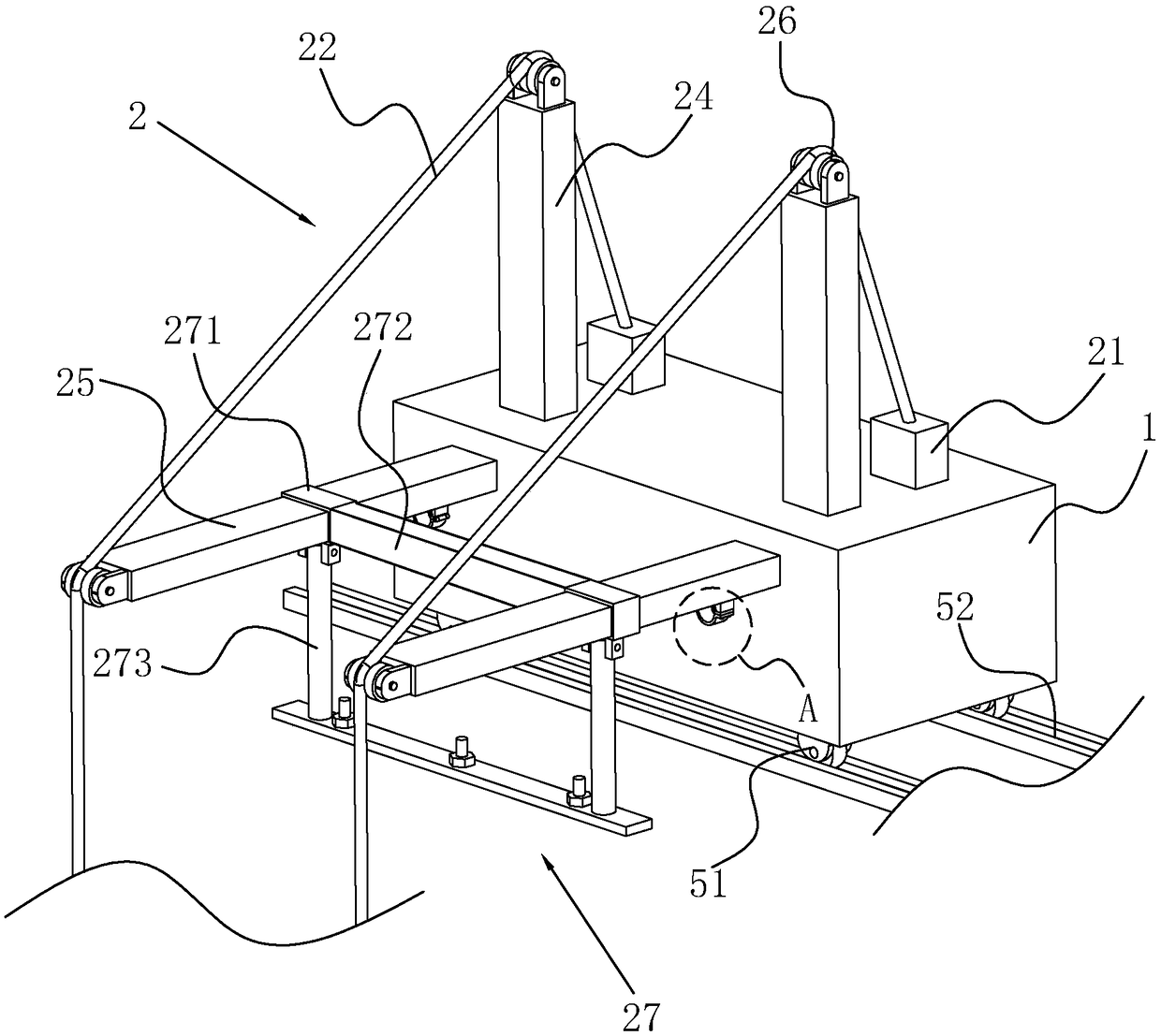

Fabricated architectural decoration stone artificial board curtain wall mounting frame

InactiveCN108952184AImprove conveniencePlay a supporting roleWallsBuilding material handlingEngineeringHanging basket

The invention discloses a fabricated architectural decoration stone artificial board curtain wall mounting frame and relates to the technical field of curtain wall mounting. The problems that in the prior art, the overall weight of a mounting frame is difficult to support by a guide rail attached to a wall, a large quantity of areas around the roof surface are occupied, consequently the strength is low, stability is poor, and curtain wall mounting is inconvenient are solved. The fabricated architectural decoration stone artificial board curtain wall mounting frame is characterized in that thefabricated architectural decoration stone artificial board curtain wall mounting frame comprises a base, a hoisting support facing the outer side of a roof is arranged on the base, and a winch is mounted on one side of the hoisting support; the winch is connected with a hanging basket through a steel rope which is arranged along the hoisting support in a penetrating mode, and the hoisting supportcomprises two spaced supporting rods which are longitudinally arranged on the base, and two spaced cantilevers which are transversely arranged on the base; the distance between the supporting rods isequal to the distance between the cantilevers and equal to the length of the hanging basket, and fixed pulleys are arranged at the ends, away from the base, of the supporting rods as well as the ends,away from the supporting rods, of the cantilevers correspondingly; and the ends, close to the fixed pulleys, of the cantilevers are provided with roof surface steel trusses. The fabricated architectural decoration stone artificial board curtain wall mounting frame has the advantages that the strength is high, the stability is good, and curtain wall mounting is convenient.

Owner:江苏华欣装饰集团有限公司

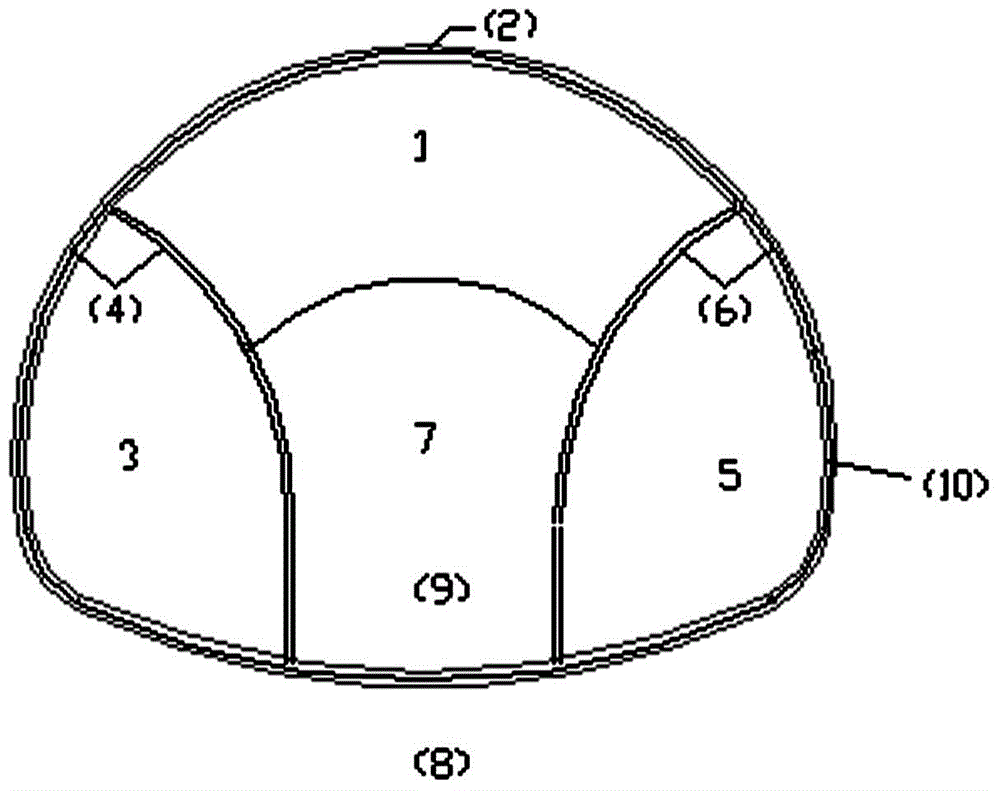

Method for constructing branch guide pits of tunnels

InactiveCN104929648AAvoid accidentsAccurate measurement dataUnderground chambersTunnel liningEngineeringBuilding construction

The invention discloses a method for constructing branch guide pits of tunnels. The method includes steps of (1), carrying out preparation work; (2), constructing advanced pipe sheds and small guide pipes; (3), carrying out ring-type excavation on arches; (4), primarily supporting and temporarily supporting the arches; (5), excavating and supporting left and right guide pits; (6), excavating core soil and inverted arches; (7), primarily supporting the bottoms of the tunnels; (8), pouring and filling the inverted arches; (9), secondarily lining the tunnels. Compared with the prior art, the method for constructing the branch guide pits of the tunnels has the advantages that the arches of the large-span shallow-buried tunnels with fractured surrounding rock can be prevented from collapsing, and full construction procedures are in safe, stable and quick controllable states; the good rate of the engineering quality can reach 95% at least, and safety production accidents can be assuredly prevented.

Owner:XIHUA UNIV

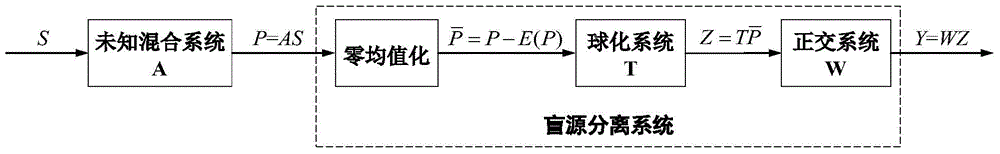

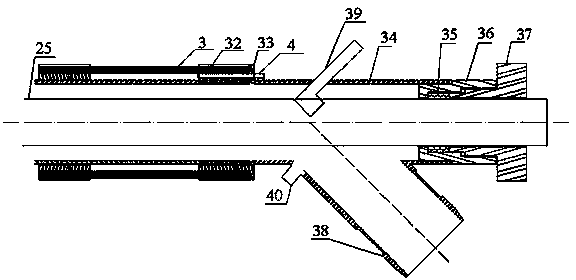

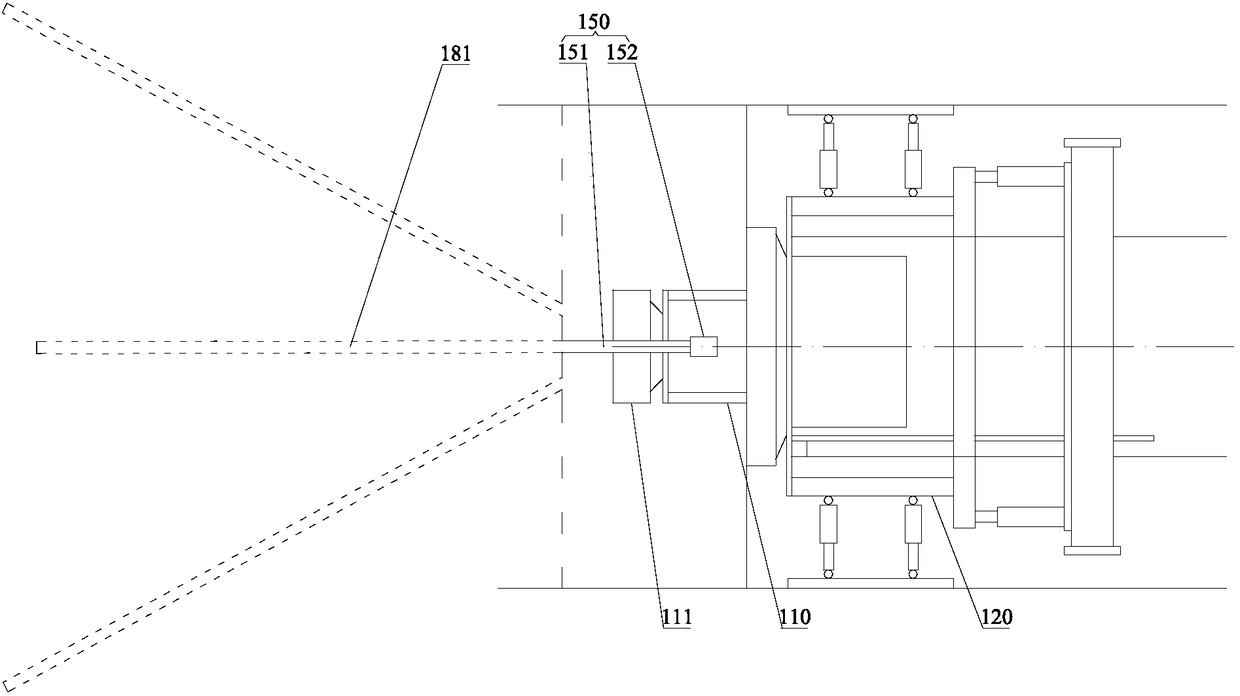

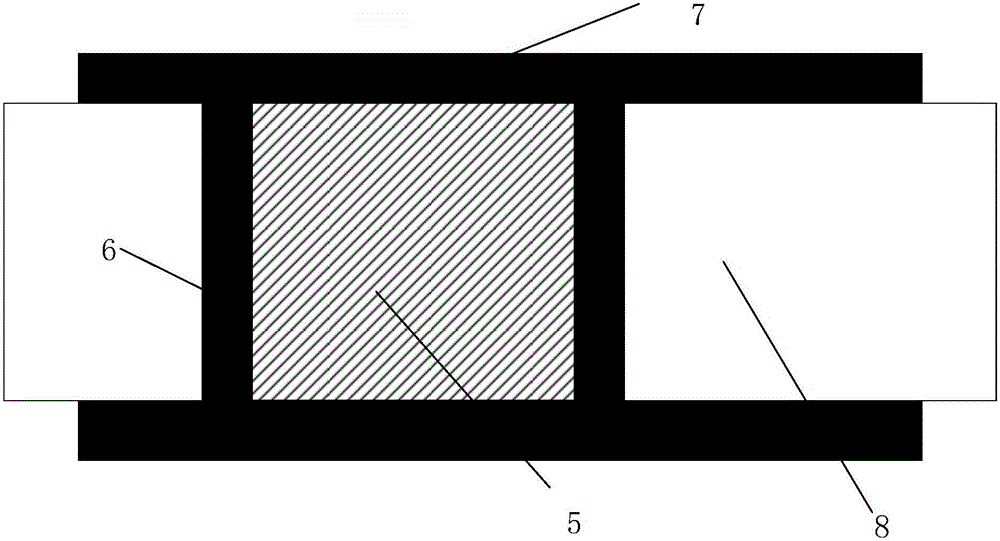

Tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method

ActiveCN104678427ADoes not affect normal workflowQuick layoutSeismologySensor arrayIndependent component analysis

The invention discloses a tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method. The device comprises a seismic source sensor array, a receiving sensor and a supporting device thereof, a noise sensor, and a multichannel seismic wave data collecting instrument, wherein the multichannel seismic wave data collecting instrument is connected with the seismic source sensor array, the receiving sensor and the noise sensor and receives seismic wave signals and noise signals of a noise source. Aiming at the special situation of the construction tunnel of a tunnel boring machine, the device adopts a seismic source signal blind source separation method based on an independent component analysis theory, a seismic source signal reconstruction method and a method for performing powerful interference signal degeneration on receiving sensor signals to finally obtain geological conditions in front of a working surface of the tunnel boring machine and the surrounding rock mass of a tunnel and corresponding mechanical parameters, can realize the advanced prediction of geological anomalous bodies, can further be used for evaluating the quality of surrounding rocks of a region to be excavated, and provides reference for the optimization of tunnel boring machine operating parameters and guarantee of construction safety.

Owner:山东百廿慧通工程科技有限公司

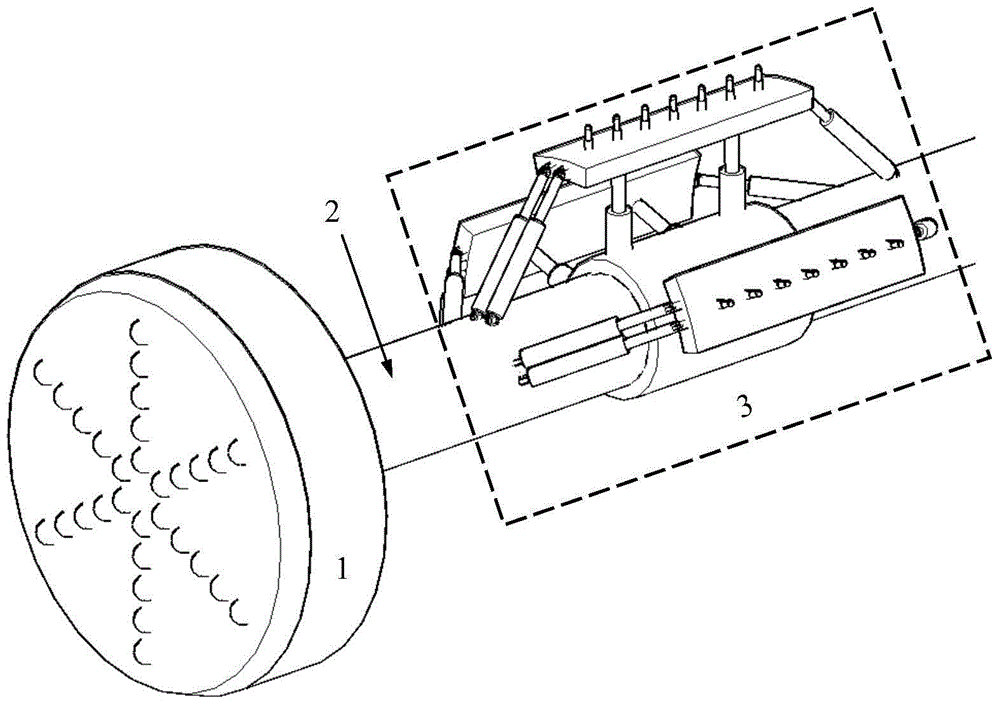

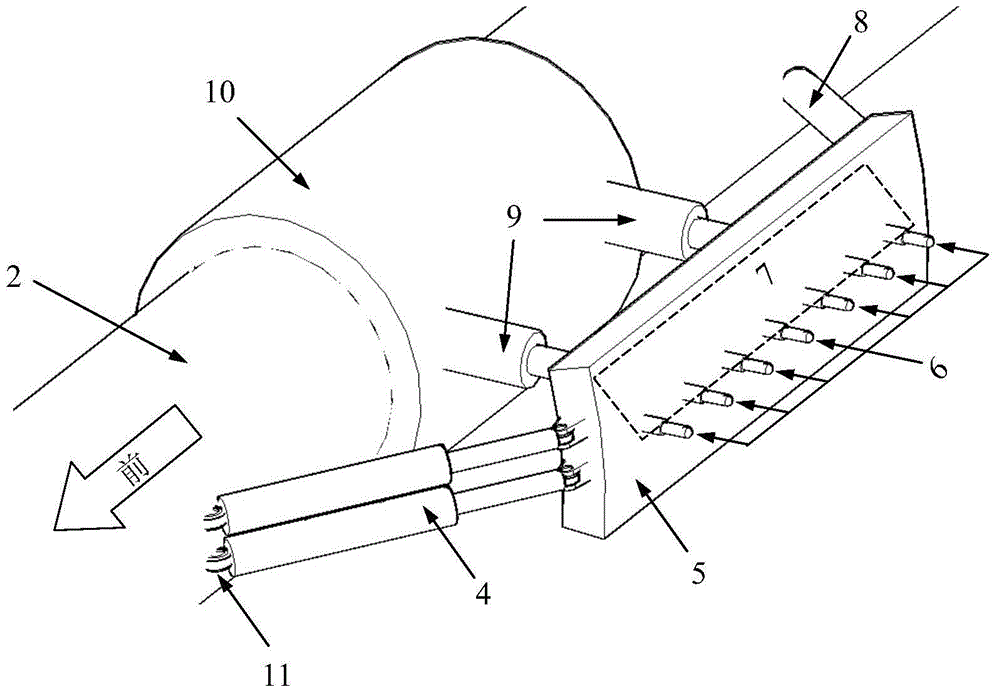

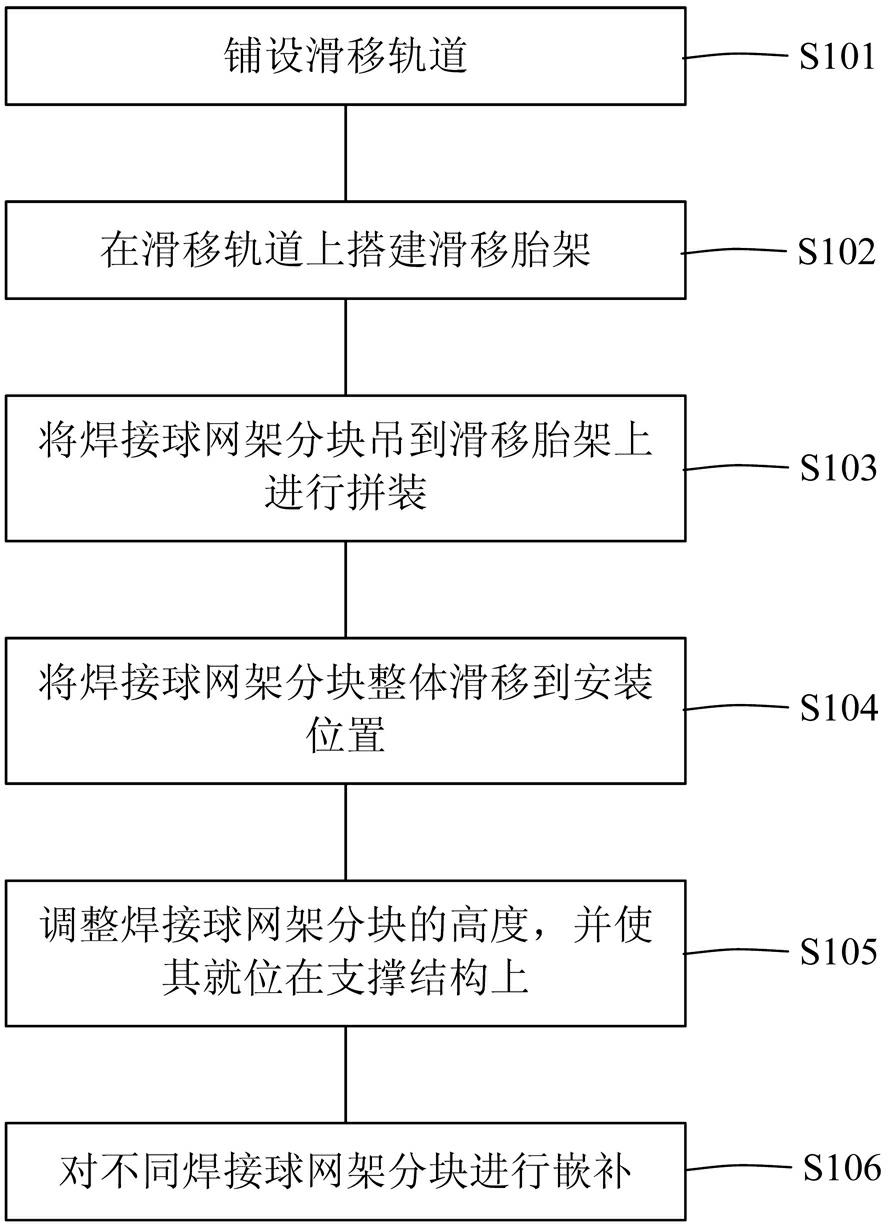

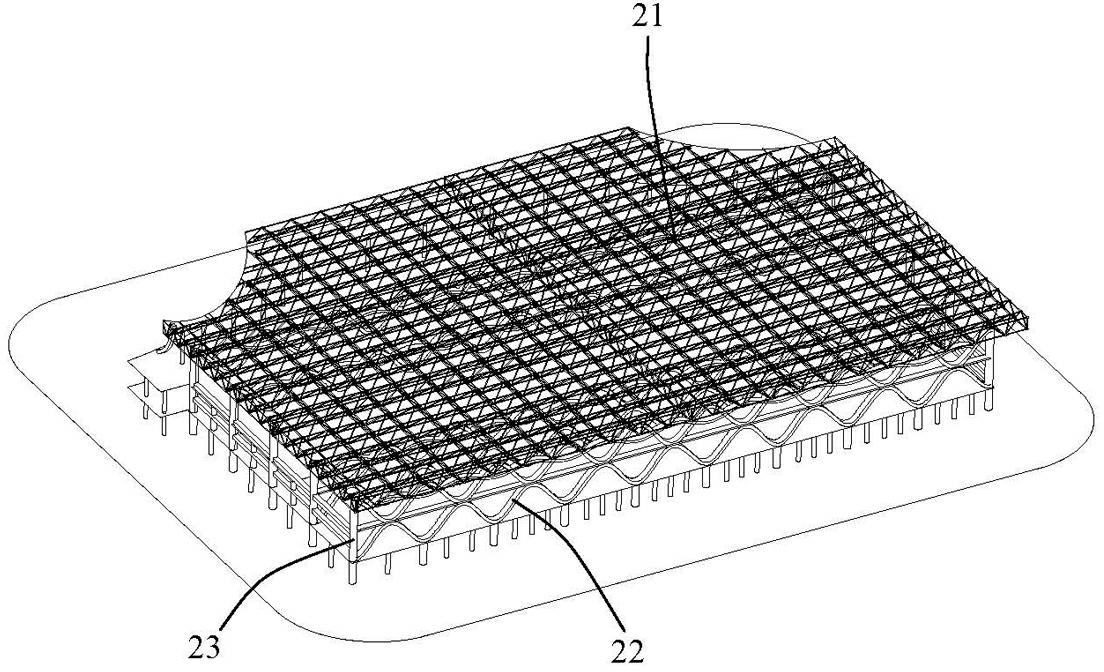

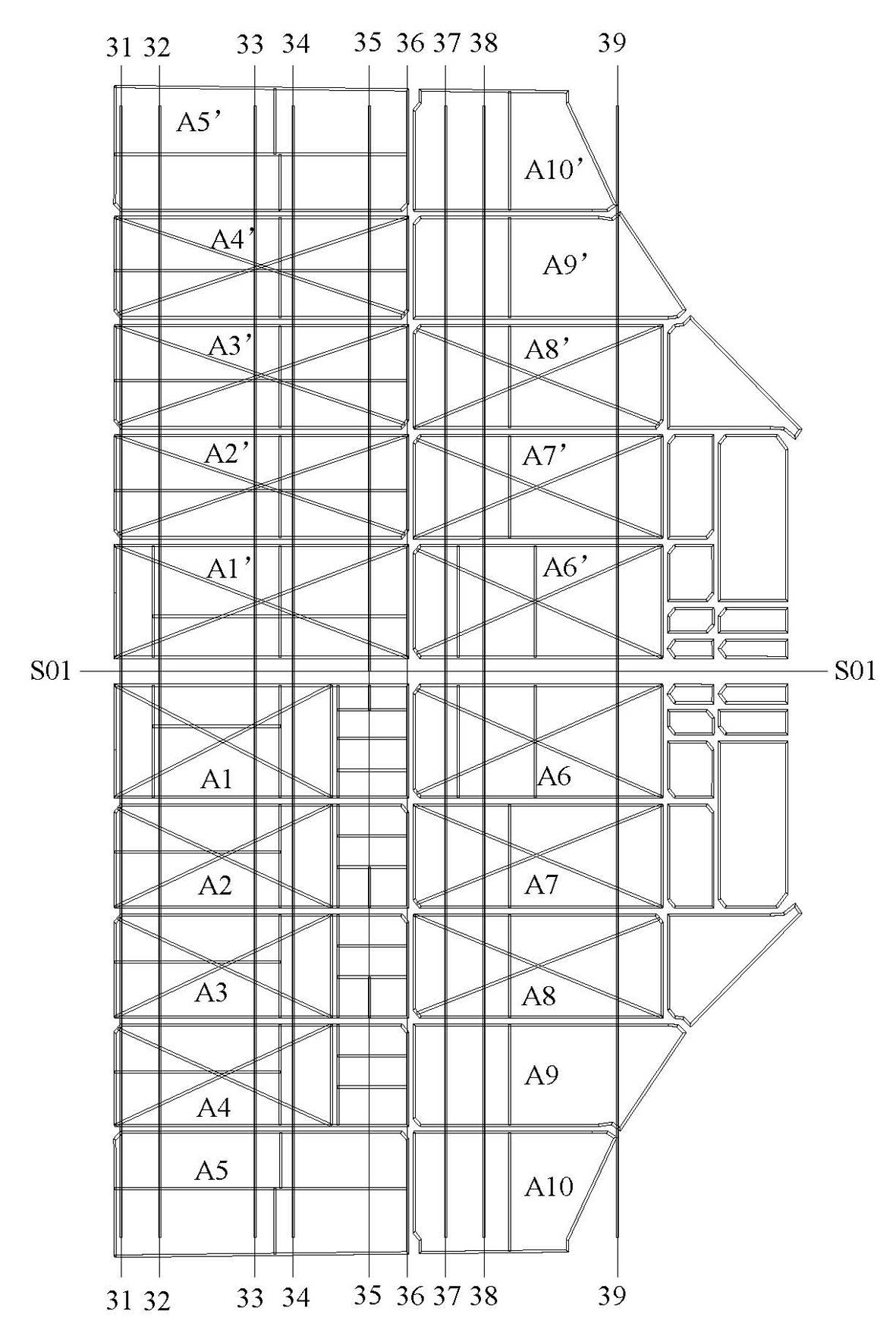

Extra-large-area hyperboloid welding ball network frame sliding construction method

ActiveCN102146732ASolve construction difficultiesEasy constructionBuilding material handlingHyperboloidEngineering

The invention provides an extra-large-area hyperboloid welding ball network frame sliding construction method, which comprises the following steps of: (1) laying a sliding rail; (2) building a sliding jig frame on the sliding rail; (3) hoisting welding ball network frame blocks to the sliding jig frame; (4) wholly sliding the welding ball network frame blocks to a mounting position; (5) adjustingthe heights of the welding ball network frame blocks and positioning the welding ball network frame blocks on a supporting structure; and (6) inlaying different welding ball network frame blocks to form an extra-large-area welding ball network frame. The invention has the advantages that: the method solves the problem that the extra-large welding ball network frame structure is difficult to construct, the construction is convenient and the safety is high.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

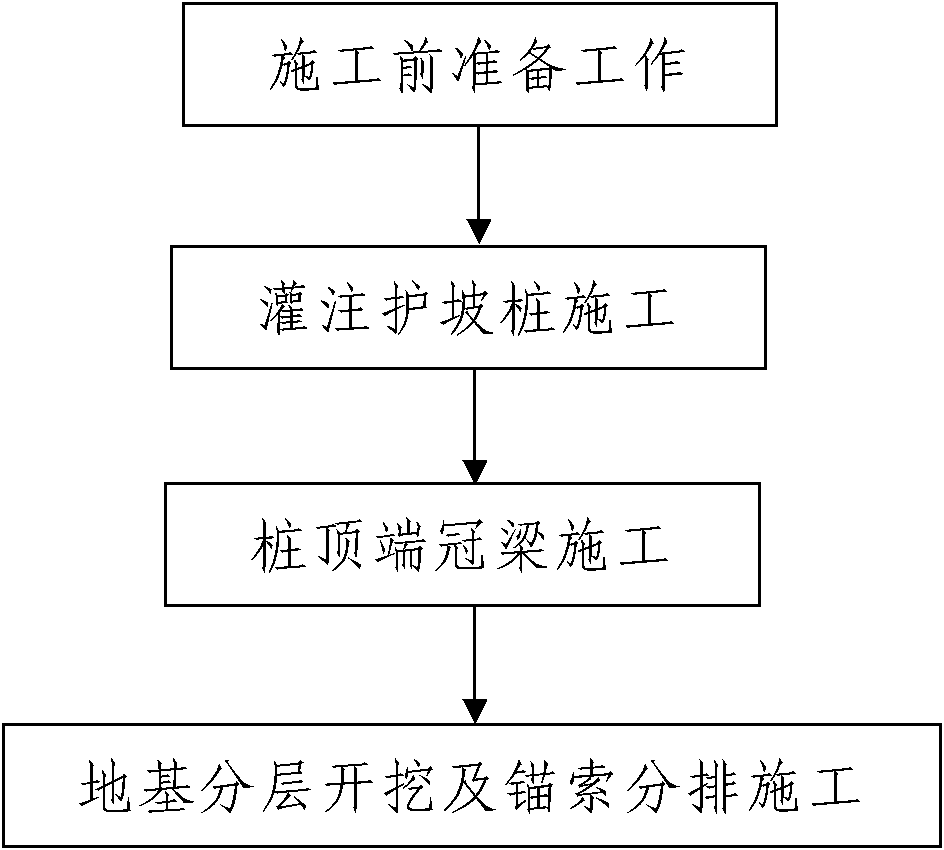

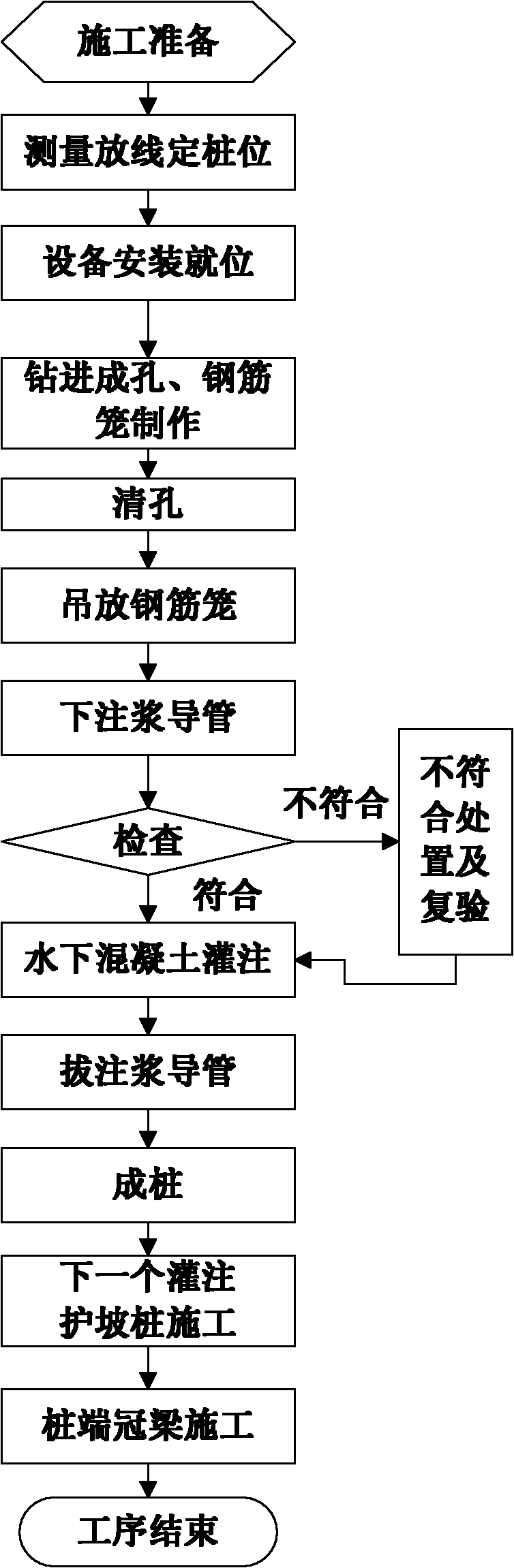

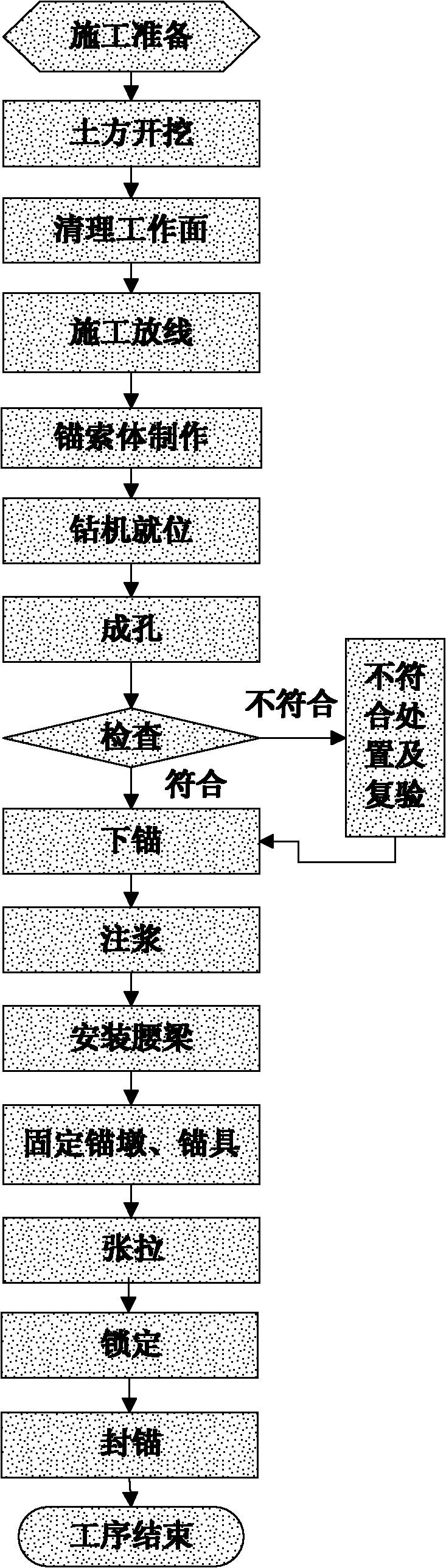

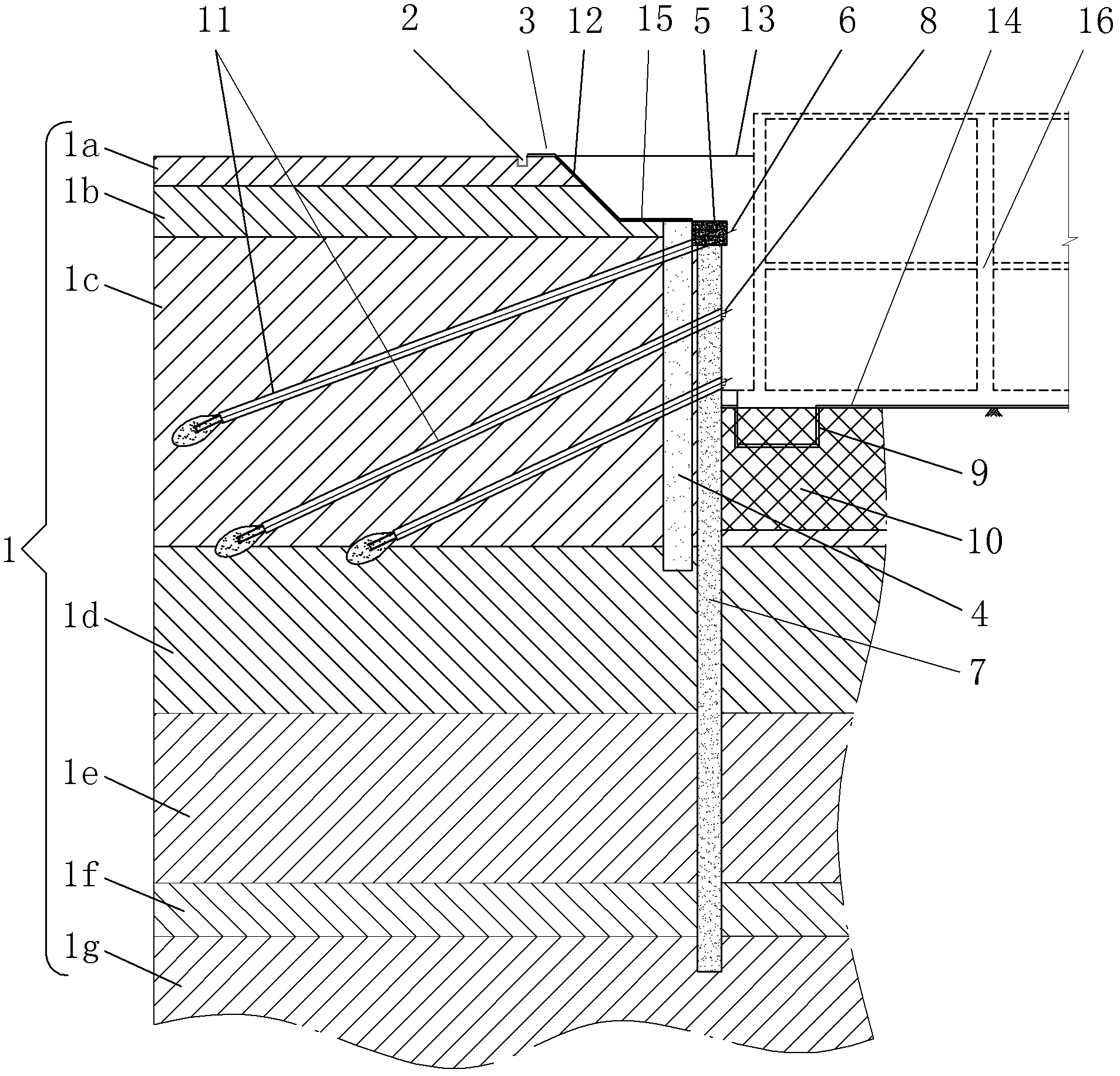

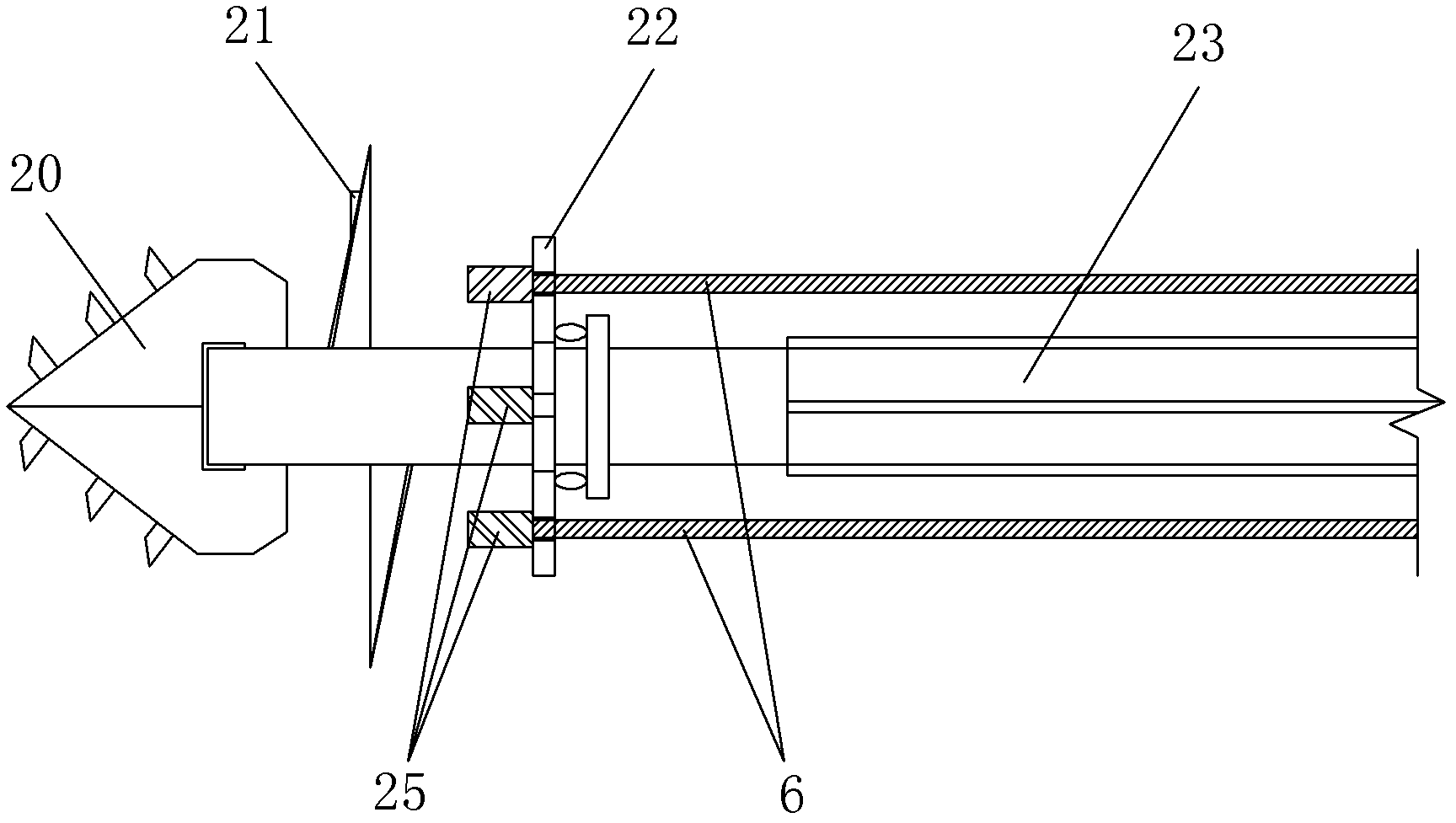

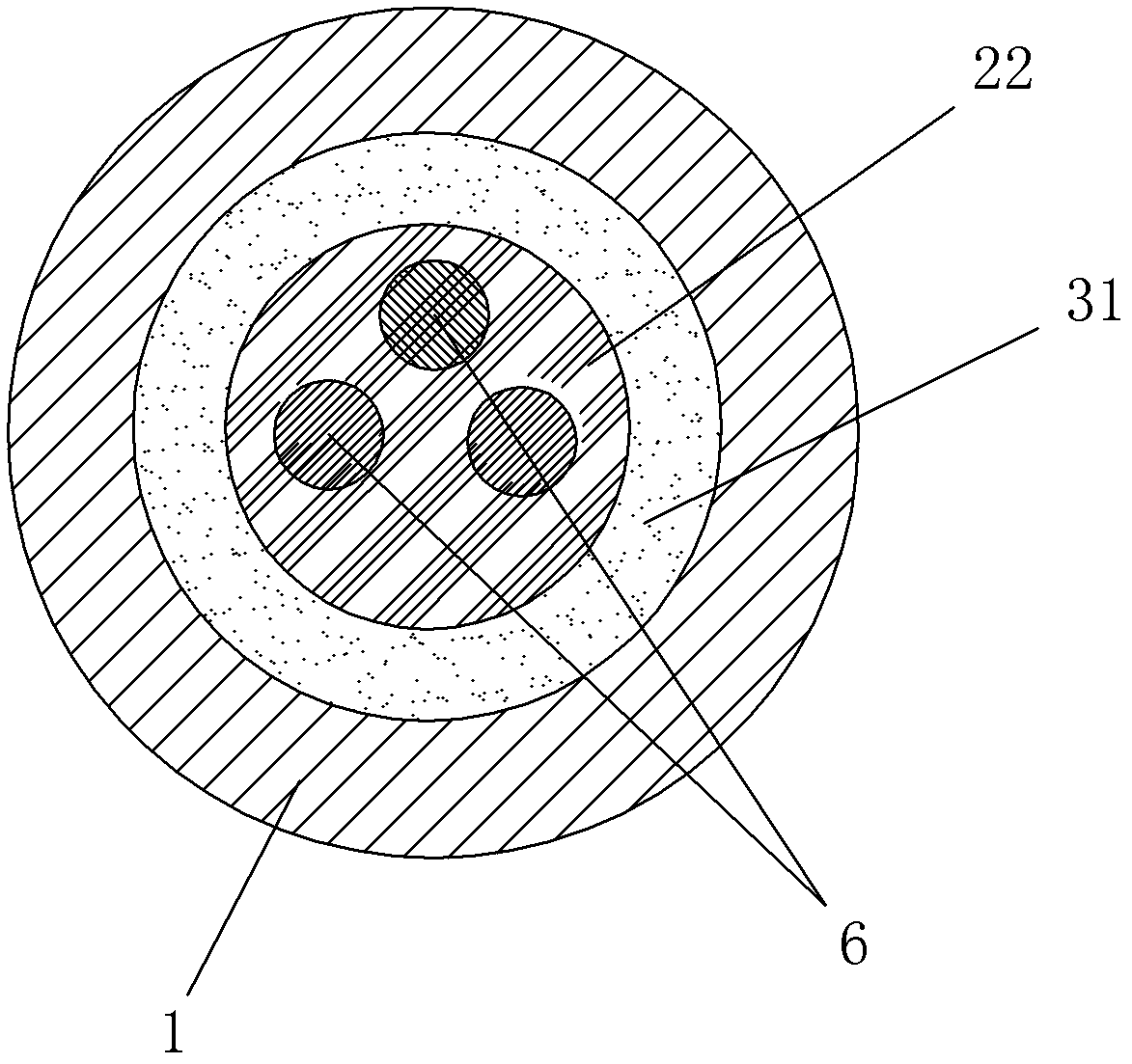

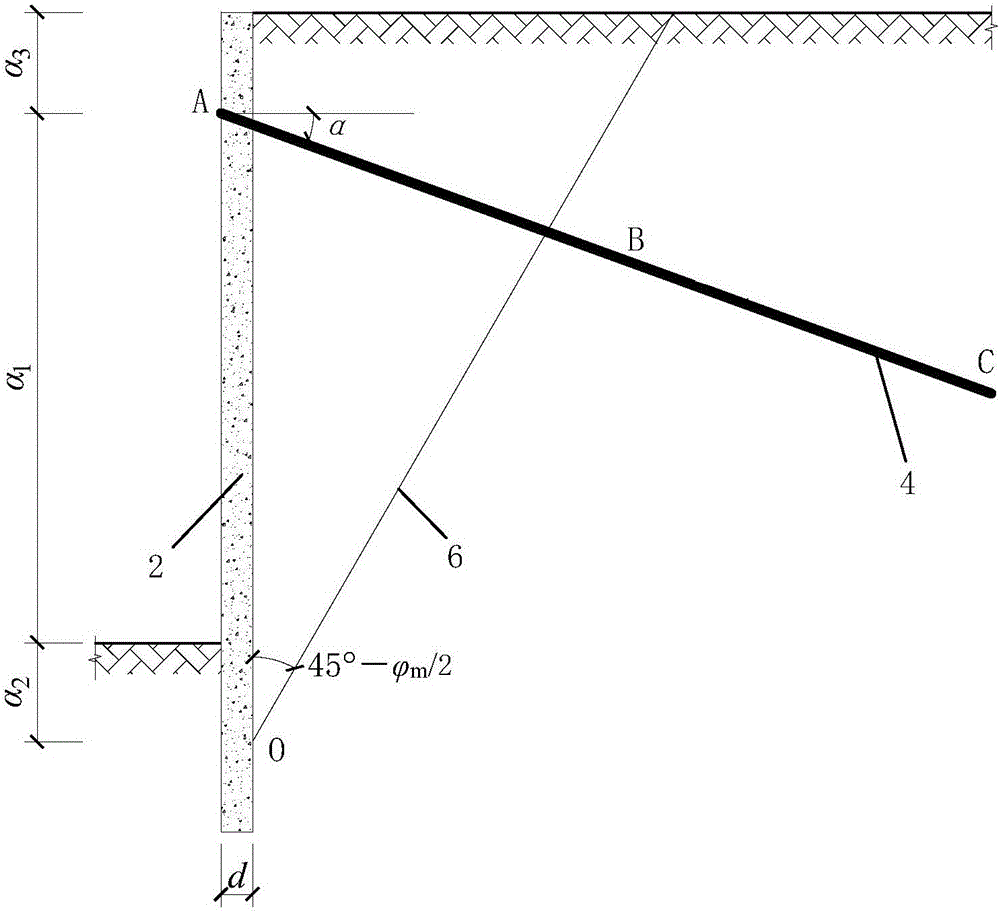

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

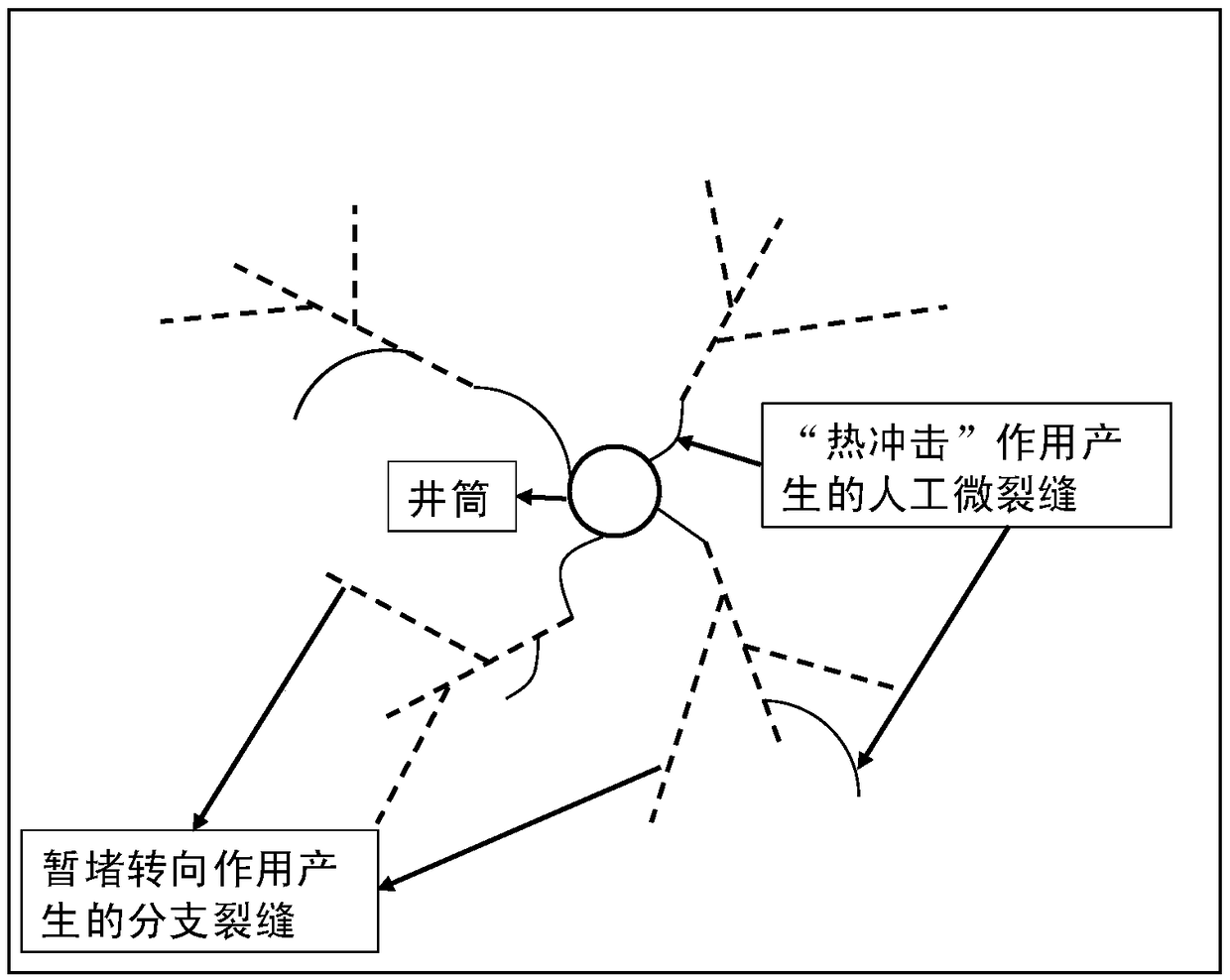

Fracturing method for increasing complexity of high-temperature stratum artificial crack net

ActiveCN108661617AReduce construction pressureIncrease the complexity of artificial fracturesFluid removalHorizontal wellsFracturing fluid

The invention discloses a fracturing method for increasing the complexity of a high-temperature stratum artificial crack net and belongs to the technical field of petroleum and natural gas engineeringexploitation. The method comprises the following steps that low-temperature work liquid is injected into a high-temperature stratum, a strong cold-hot stress impacting effect is generated through thehigh-temperature difference between the low-temperature work liquid and the high-temperature stratum, rock around a well is induced to generate micro cracks, then fracturing liquid is injected to enable the micro cracks to continue to expand forwards, finally temporary plugging steering liquid is injected to conduct bridge plugging on the artificial cracks to force the cracks to steer to form multi-branch cracks, and the steps are executed at least once. Through the fracturing method, the multiple artificial cracks can be formed, the seepage area is enlarged, the single-well yield and economic benefits are increased, the bursting pressure can be lowered, the fracturing construction risk caused by high temporary plugging steering pressure in the high-temperature stratum is avoided, and safe construction is ensured. The fracturing method is suitable for the high-temperature strata such as hot dry rock, deep-layer shale gas and deep-layer compact oil gas, can be used for vertical well fracturing construction and can also be applied to fracturing construction of horizontal wells, oblique wells and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

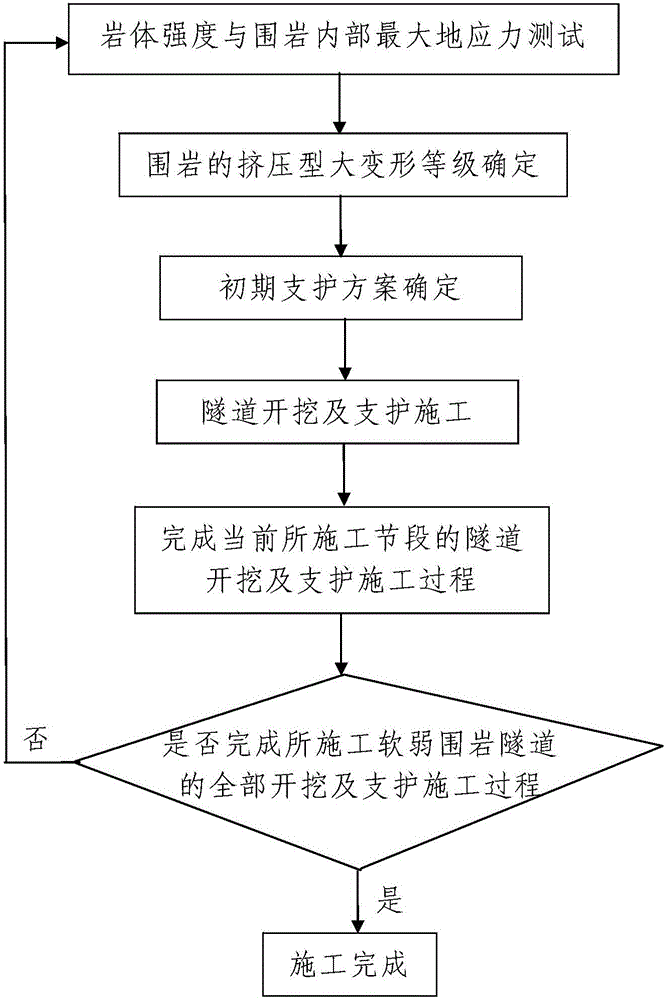

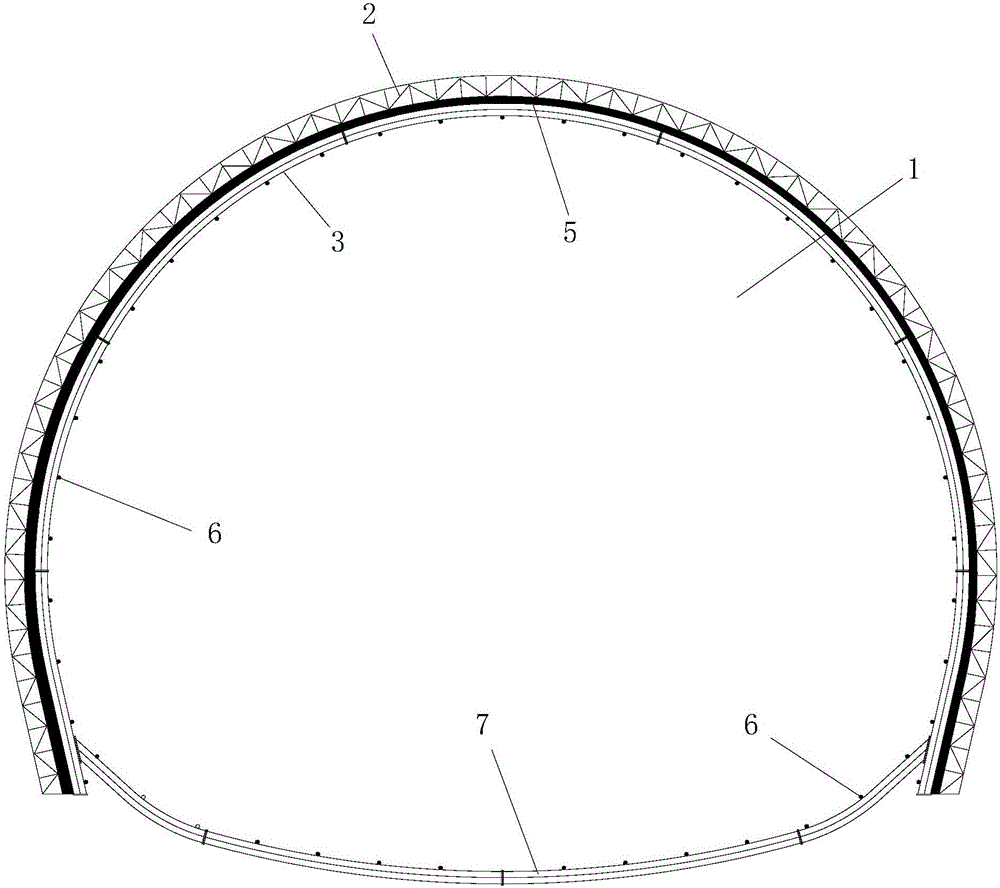

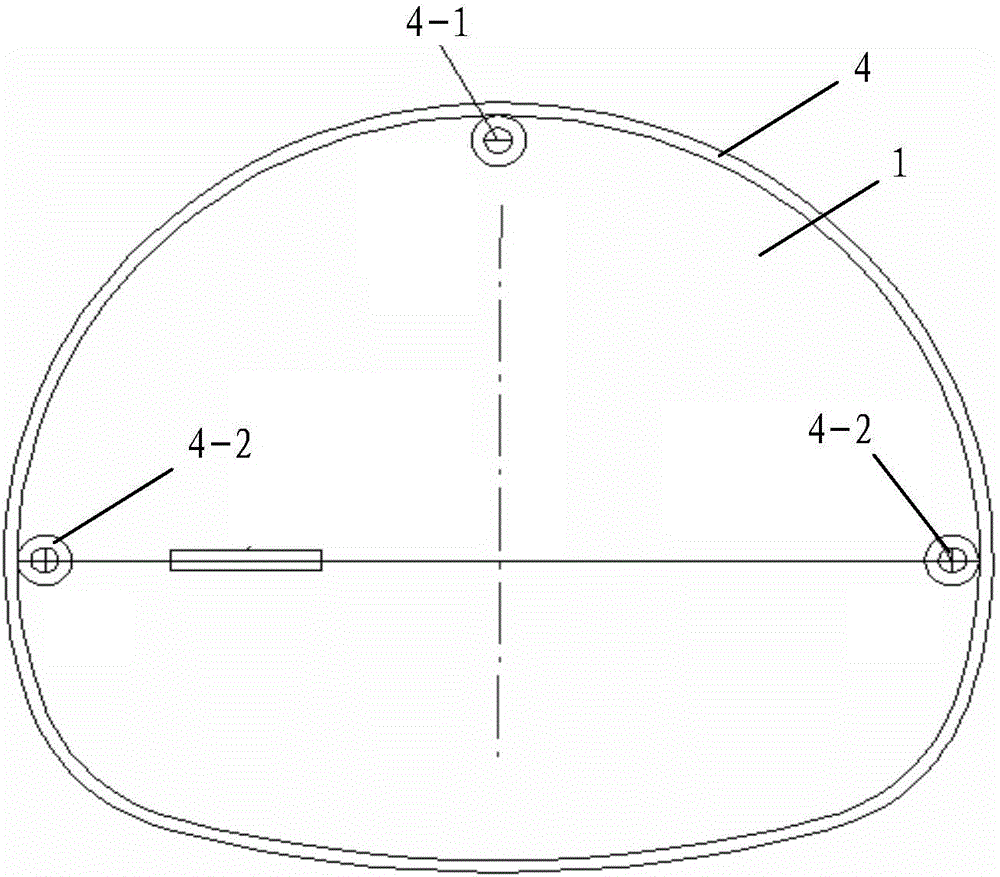

High ground stress weak surrounding rock tunnel excavation and support construction method

ActiveCN105156118AThe method steps are simpleReasonable designUnderground chambersTunnel liningSteel frameRock tunnel

The invention discloses a high ground stress weak surrounding rock tunnel excavation and support construction method. Excavation and support construction are conducted on a weak surrounding rock tunnel to be constructed in multiple sections from rear to front in the longitudinal extension direction of the tunnel. The method comprises the steps that 1, rock body strength and the maximum ground stress inside surrounding rock are tested; 2, the extrusion-type large-deformation level of the surrounding rock is determined; 3, a primary support scheme is determined, wherein the primary support scheme is determined according to the determined extrusion-type large-deformation level, and the primary support scheme is a profile steel frame support scheme or a grid steel frame and cover arch combined support scheme; 4, tunnel excavation and support construction are conducted; 5, excavation and support construction of the next section are conducted; 6, the fifth step is repeated for many times till the whole excavation and support construction process of the weak surrounding rock tunnel to be constructed is completed. According to the high ground stress weak surrounding rock tunnel excavation and support construction method, the steps are simple, the design is reasonable, construction is convenient, the use effect is good, the tunnel excavation and support construction process of the high ground stress weak rock tunnel can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

Drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device and using method thereof

InactiveCN103470297APrevent overrunningPrevent overrun accidentsDrainageGas removalThermodynamicsSlag

The invention discloses a drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device and a using method thereof. The drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device comprises a water jet high and low pressure switching device, a blowout control hole guide device and a gas and slag separation discharge device. The water jet high and low pressure switching device is positioned between a drill bit and a drill stem and can achieve flexible switching between low-pressure drilling and high-pressure water jet slotting and punching. The blowout control hole guide device is positioned between the drill stem and a drill hole and used for guiding water coal slag and gas sprayed out of the drill hole into the gas and slag separation discharge device. The gas and slag separation discharge device is connected with the blowout control hole guide device through a pipeline and used for separating and discharging the coal slag and the gas in a sealed environment. The complete drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device can achieve flexible switching of high and low pressure drilling, timely collects, separates and discharges the gas and slag, and is simple, reliable, easy to assemble and disassemble, capable of being used for multiple times conveniently and especially suitable for performing multiple drill hole operation at the same workplace.

Owner:HUNAN COAL SCI INST

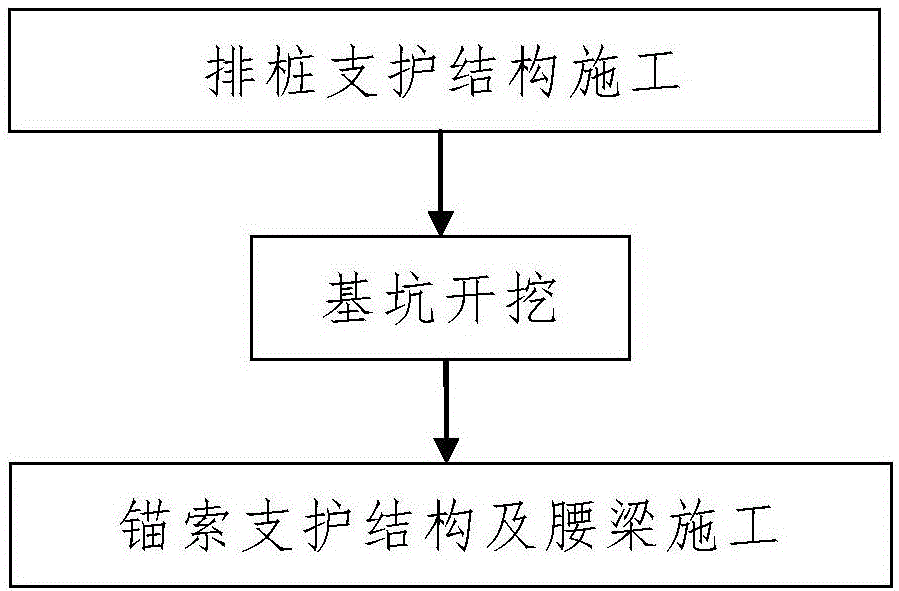

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

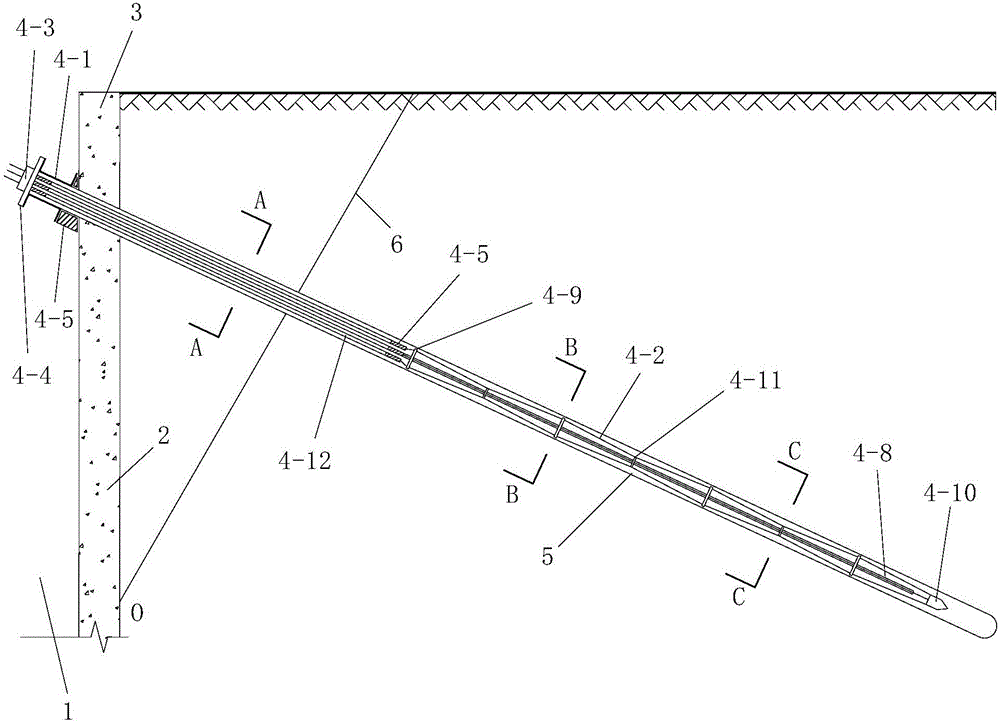

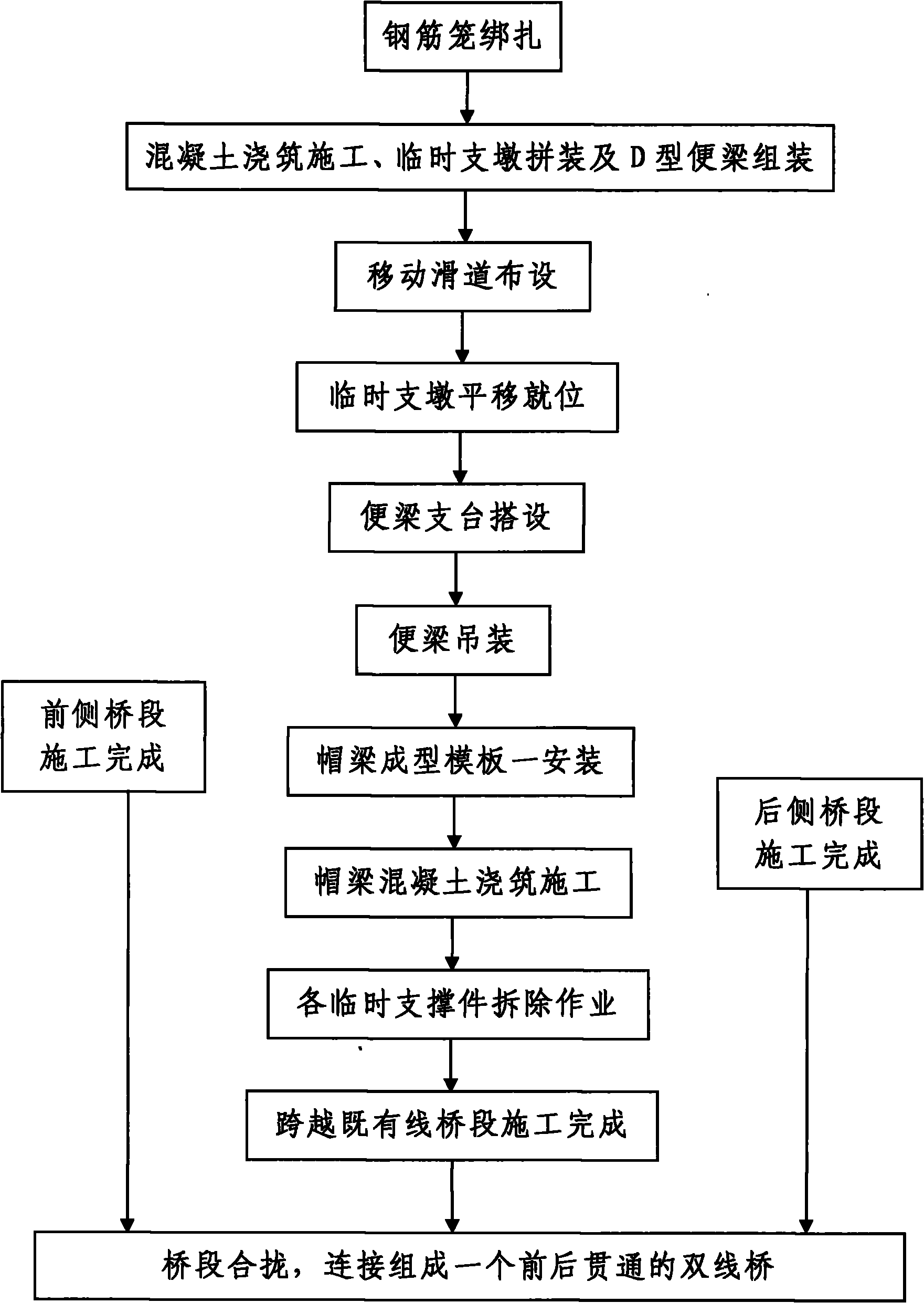

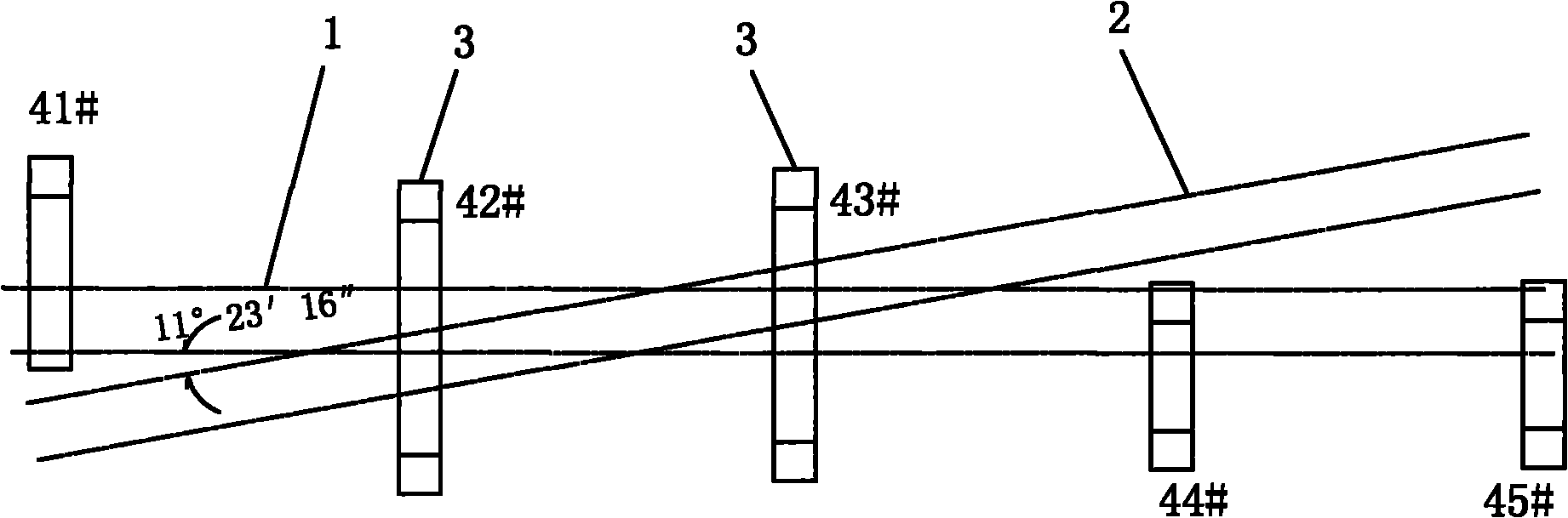

Double track bridge construction process crossing existing railway operational lines

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

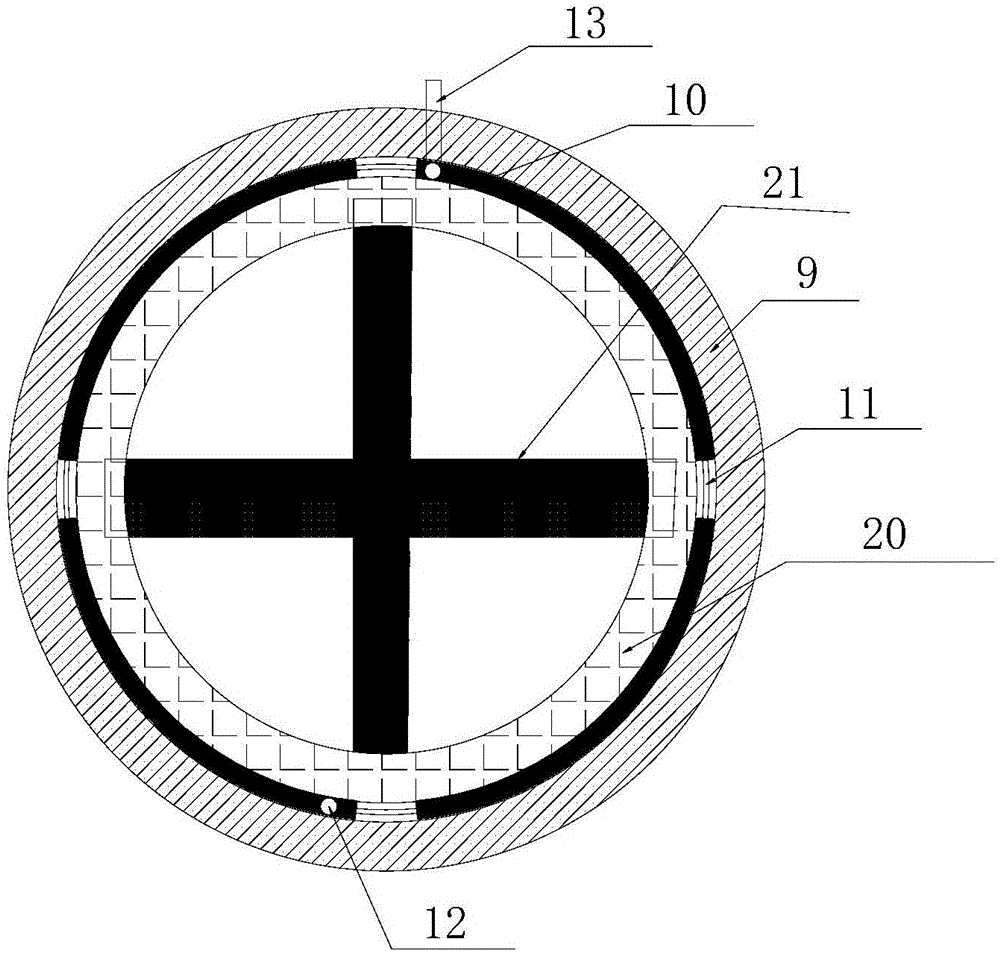

Combined-type tunnel boring machine (TBM) for achieving geological exploration, and geological exploration tunneling method

ActiveCN108798690AAvoid geological disastersEnsure construction safetySeismic signal processingTunnelsGeological structureGeomorphology

The invention discloses a combined-type tunnel boring machine (TBM) for achieving geological exploration, and a geological exploration tunneling method, and relates to the field of tunnel and underground engineering construction. The combined-type TBM for achieving geological exploration comprises an advance TBM body and an expanding excavation TBM body; the expanding excavation TBM body surroundsthe outer side of the advance TBM body; the advance TBM body is carried with a ground-penetrating radar device, a geological drilling rig, an acoustic exploration device and a micro-seismic monitoring device; through excavation of the advance TBM body, the geological situation in front of the tunnel face can be directly exposed; and the advance TBM body can be carried with various advance geological exploration devices, the geological situation in front of the tunnel face of the advance TBM body can be forecasted, and the geological environment in front of the tunnel face of the expanding excavation TBM body can also be forecasted. According to the geological exploration tunneling method, various advance geological exploration is conducted during excavation, the engineering geological andhydrology geological structures in front of and around the tunnel face are accurately forecasted, thus geological disasters of TBM construction engineering are effectively avoided, the construction safety is guaranteed, the progress is accelerated, and the cost is saved.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

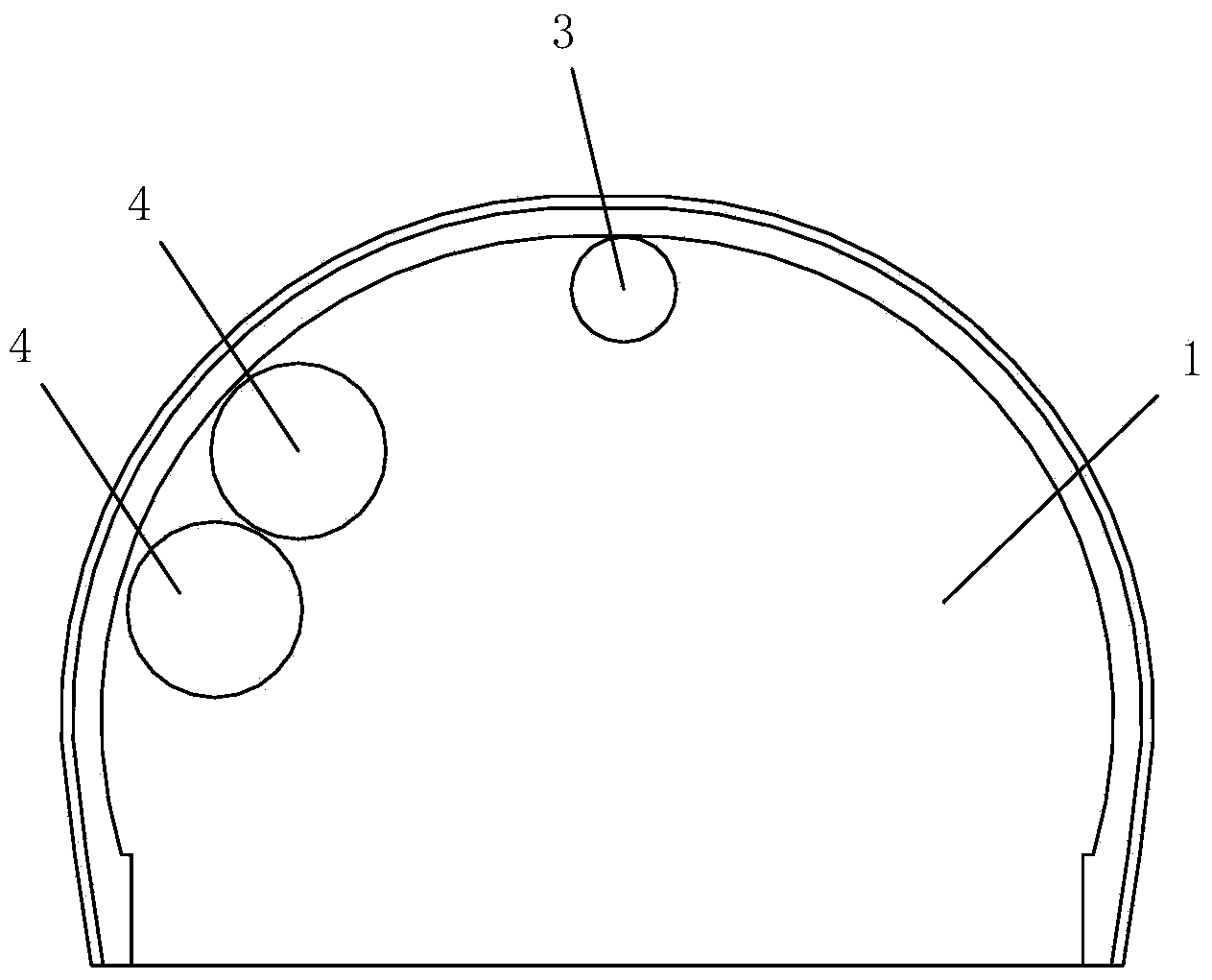

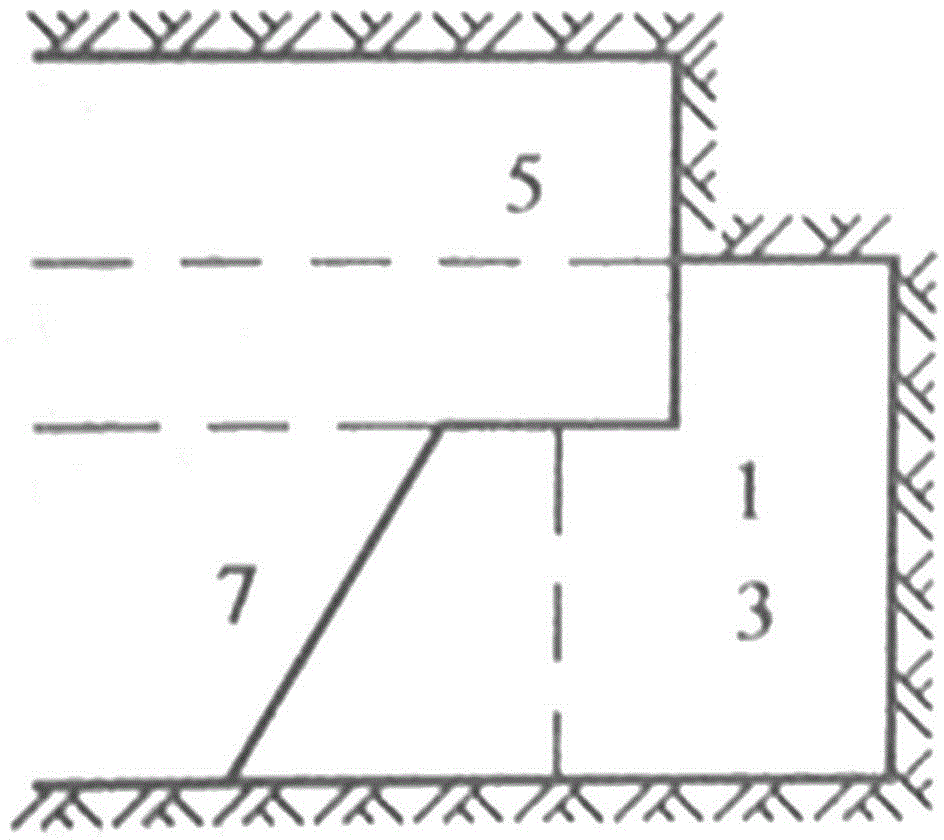

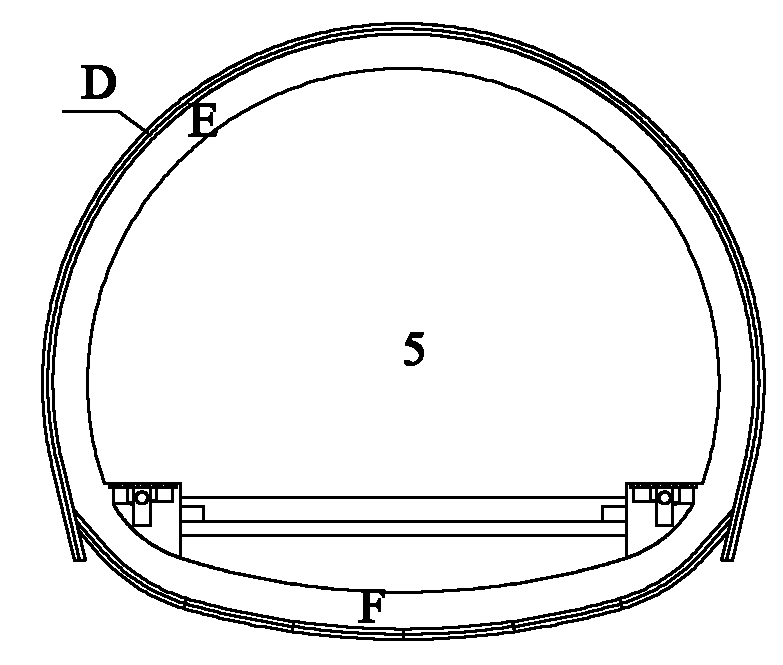

Supporting structure of extra-large cross-section loess tunnel and construction method thereof

InactiveCN101906974AEnsure construction safetyImprove construction progressUnderground chambersTunnel liningLarge deformationLarge size

The invention relates to a supporting structure of an extra-large cross-section loess tunnel and a construction method thereof. Larger deformation and even collapse accidents occur in the construction process of the loess tunnel easily. At present, aiming at the large cross-section loess tunnels, the construction of the large cross-section loess tunnel with the excavating area of 140 m<2> is realized by a reserved core soil short step method successfully; the construction of a new loess tunnel with the burial depth of 25 m and the excavating area of 120 m<2> under-passing the existing railway is realized by a CRD method; and the difficulty and the risk of the construction increase gradually along with further increment of the excavated cross-section of the loess tunnel. The supporting structure comprises an initial support, an archwall secondary lining and an inverted arch, wherein a small conduit leading support is arranged along the contour line of the tunnel arch part; and a waterproof layer is arranged between the initial support and the archwall secondary lining. The supporting structure and the construction method thereof have the advantages of effective guarantee of construction safety of the extra-large cross-section loess tunnel, simple construction process, large excavating space, convenient operation for a large-size machine and fast tunnel construction progress.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Construction method for super-long high-precision horizontal drilling

ActiveCN101158268AImprove stabilityImprove airtightnessDirectional drillingTunnelsConstruction planSlurry pump

The invention discloses a super-long and high-accurate horizontal boring construction plan. The plan is that a proper horizontal borer is used for driving a bit connected with a bore rod to turn to take cores and cut holes; a guiding device is used for controlling a decline rate; a slurry pump is used for pumping out the bore scraps generated in a boring process, so as to form a set-caliber super-long and high-accurate horizontal boring. The invention adopts a compound connection measure of combining a screw connection and a welding connection to connect the bore rod, guaranteeing the concentricity and sealing of the bore rod. When in a horizontal boring process, a freezing cut sealing and a freezer sealing are adopted. An area ranging from 8cm to 10cm is preserved as a safety layer in a tube-boring process on a concrete wall. And a strict deviation measuring and a deviation controlling are adopted to guarantee the construction safety. The form and improvement of the construction plan of the invention experiences many tests, researches and improvements, and a horizontal frozen boring bored through the construction plan of the invention can be provided with a high accuracy even when a construction horizontal length is too long.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

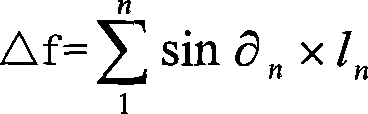

Fast large-cross-section tunnel construction method adapting to complicated and variable geological conditions

InactiveCN102312672AImprove construction progressReduce settlementTunnelsWork periodField monitoring

The invention discloses a fast large-cross-section tunnel construction method adapting to complicated and variable geological conditions. Middle walls and steps are combined, whether the arrangement of temporary inverted arches of each steps and middle partition walls of upper, middle and lower steps is needed or not is determined according to actual geological condition change conditions and field monitoring information in the tunnel construction process, when the rock surrounding condition becomes poor in the tunnel construction process, temporary support and protection of each excavated parts are respectively implemented, when the rock surrounding condition becomes good, a plurality of small excavated parts can be combined into a large excavated part until the full cross-section one-step excavation forming method is adopted, and division positions of each excavated parts in the construction process is not changed. The method has the advantages that in the construction, the conversion problem of the construction method does not exist when the geological conditions are changed, the construction speed of large-cross-section tunnels under the complicated and variable geological conditions is greatly accelerated, the construction work period is shortened, and the construction cost can be properly reduced.

Owner:CENT SOUTH UNIV

Test device and test method capable of simulating water pressure in tunnel

ActiveCN106353120AFlexible operationImprove controllabilityStructural/machines measurementGratingPre stress

The invention provides a test device and a test method capable of simulating water pressure in a tunnel. The test device comprises a load loading mechanism, a monitoring system and a counter-force mechanism. The load loading mechanism comprises a plurality of flexible cells and a liquid filling pump, wherein every two adjacent flexible cells are communicated with each other to form a closed structure body fitting a lining ring section, and a liquid filling pipe on one of the flexible cells is connected with a liquid outlet of the liquid filling pump. The monitoring system comprises stressometers, steel bar meters, fiber grating sensors, multi-point displacement indicators, osmometers and joint meters, wherein the stressometers and the steel bar meters are embedded into a lining, the fiber grating sensors are arranged on the inner and outer surfaces of the lining, the multi-point displacement indicators, the osmometers and the joint meters are embedded into a surrounding rock, and the signal output end of each sensor is connected with a data acquisition unit. The counter-force mechanism comprises a counter-force H-steel piece and a counter-force supporting piece which are fixedly connected with each other, one side of each flexible cell is arranged correspondingly to the lining ring section, and the counter-force supporting piece supports the other side of each flexible cell. The test device is capable of simulating detection of the concrete lining construction quality and prestress applying effect during operation of the tunnel filled with water.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Assembly type overhead construction process

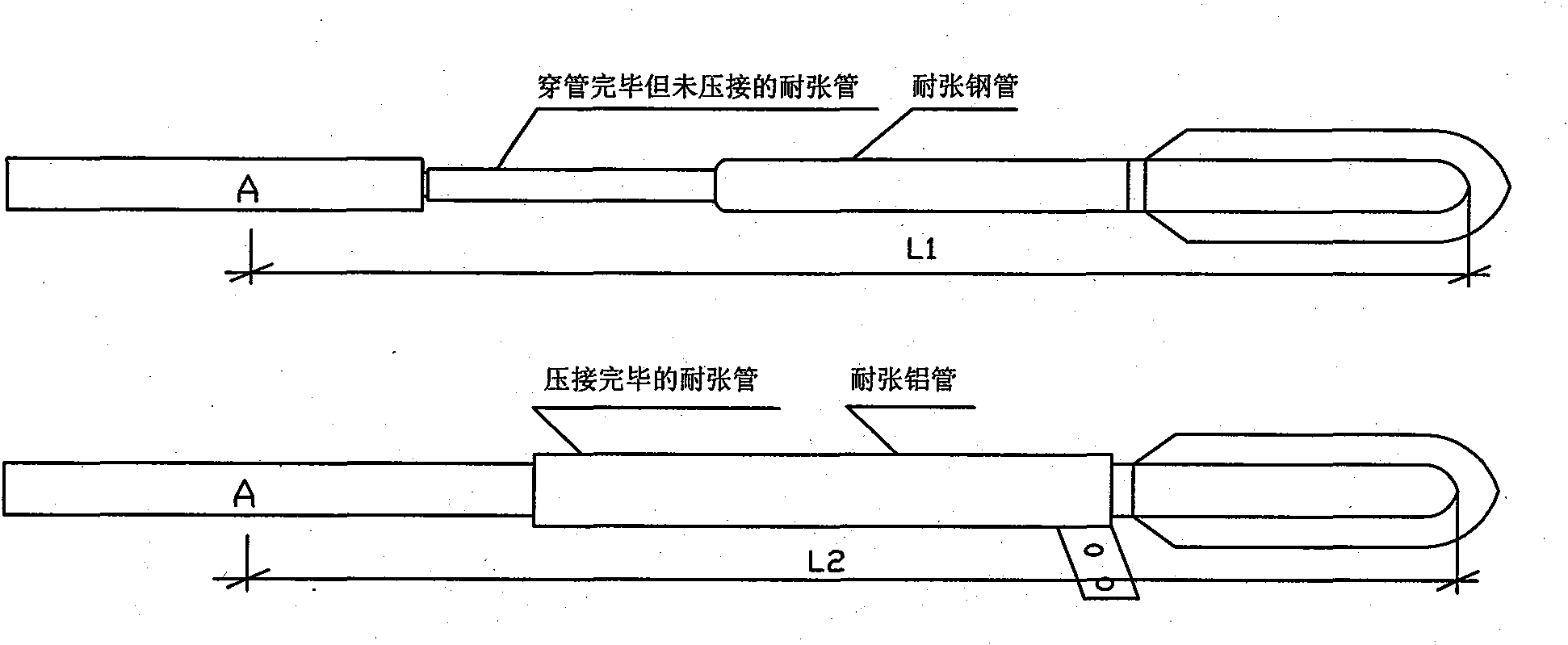

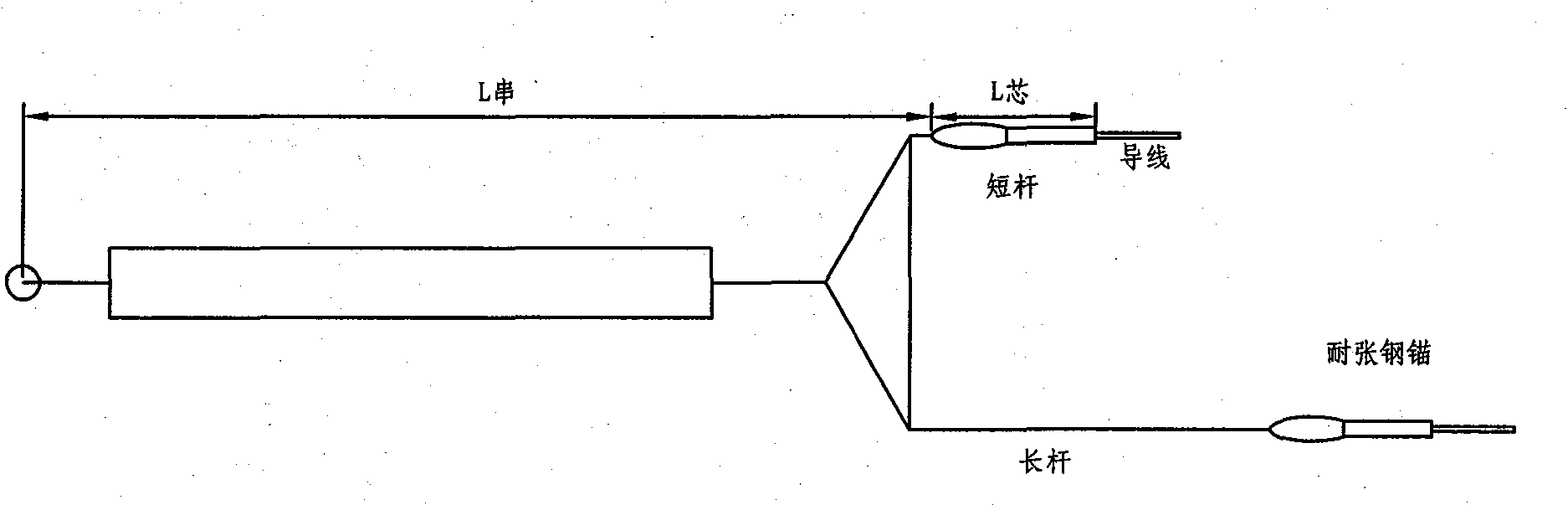

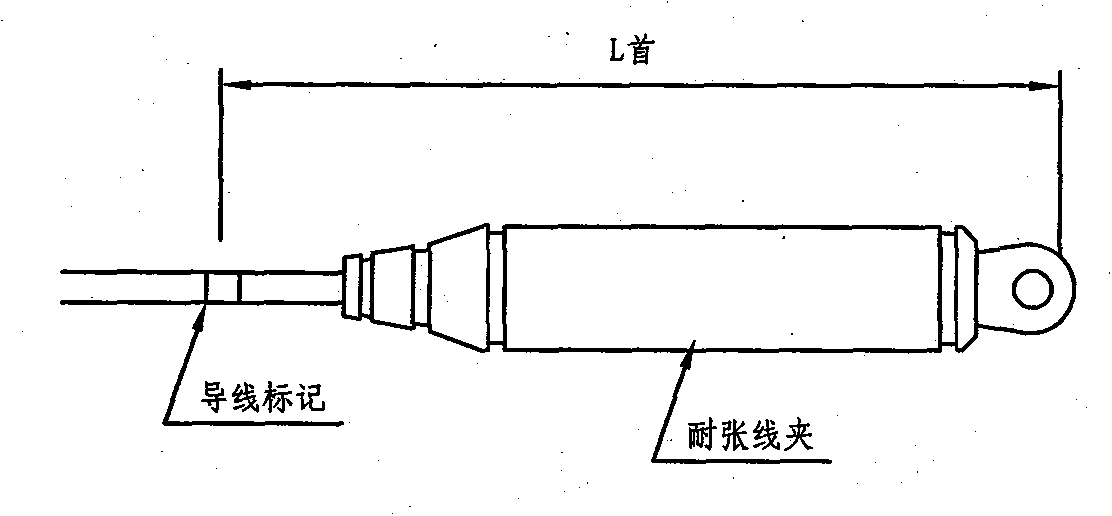

ActiveCN101859988AExemption from adjustmentAdvanced technologyApparatus for overhead lines/cablesQuality levelField data

The invention provides an overhead construction process, which comprises the following steps of measuring data and calculating the wire length, wherein field data and the influencing quantity of the pressure welding length of a strain clamp are collected and the length of a strain insulator-string is measured; and calculating the wire length according to a formula, wherein L is the wire length; H is the conductor tension; omega is the weight of the conductor per unit length; l is the horizontal distance between the hanging points of the conductor; h is the altitude difference between the hanging points of the conductor; performing fixed-length manufacturing and machining wires, wherein the length of each conductor is calculated according to a wire length calculation formula, the conductor allocation is performed based on the control of the longest conductor of each phase, and the length of the conductor of each coil to be machined is determined; releasing the wires; and tightly hanging the wires. In the overhead construction process, the length of the required wire of each span can be measured directly on the ground, the installation position of a suspension clamp is demarcated, and thus the wires are suspended to achieve the preset completion sag without wire sag observation. Meanwhile, the overhead construction process and the quality level are improved, while the construction quality and the safety are ensured.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

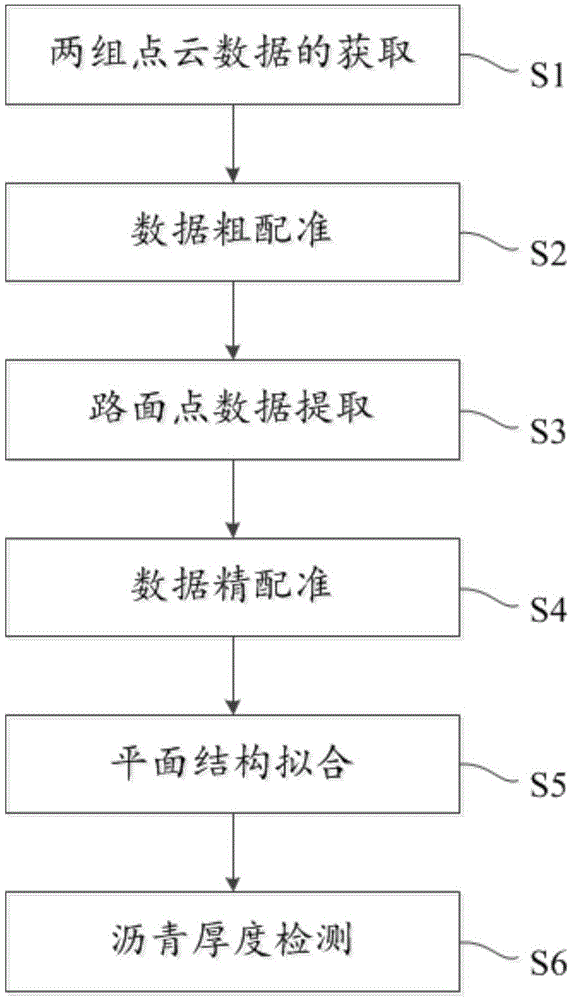

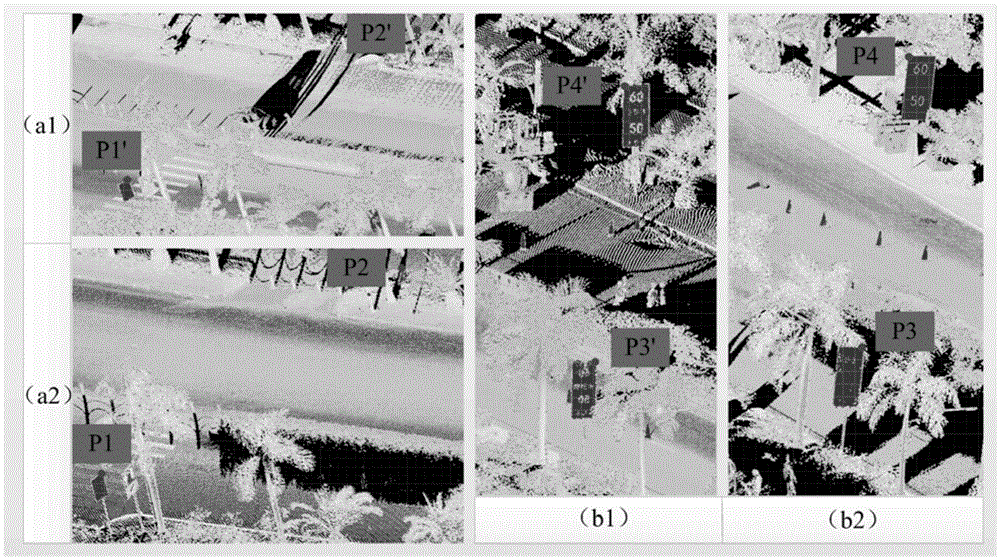

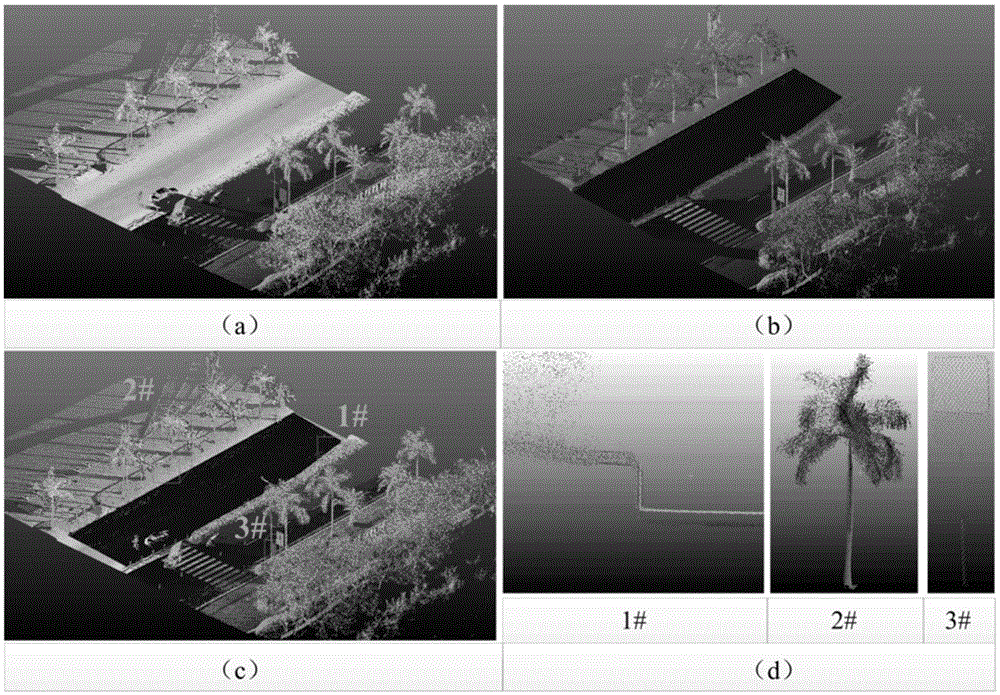

Pavement asphalt thickness detection method based on vehicle-mounted laser scanning spot cloud

InactiveCN105627938AImprove inspection time and costGuaranteed quality and safetyImage analysisUsing optical meansLaser scanningAsphalt

The invention discloses a pavement asphalt thickness detection method based on vehicle-mounted laser scanning spot cloud, comprising steps of obtaining spot cloud data, performing data rough registration through choosing a fixed object, using a pavement extraction algorithm based on the road shoulder to respectively detect two sets of the pavement points of the point cloud data, using the road shoulder point to perform precise registration on the data in the block, performing plane structure fitting on the pavement inside the grid, and detecting the asphalt thickness. The invention can fast and accurately detect and modify the thickness of the road asphalt, greatly reduces the processing time and the labor cost, effectively guarantees the road reconstruction quality and provides important data support to the civil traffic safety.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com