Extra-large-area hyperboloid welding ball network frame sliding construction method

A super-large-area, construction-method technology, which is applied in construction, building structure, and building material processing, can solve problems such as the difficulty of super-large-area hyperboloid welded ball net truss construction, to ensure flatness and construction quality, and to ensure The effect of sliding speed and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

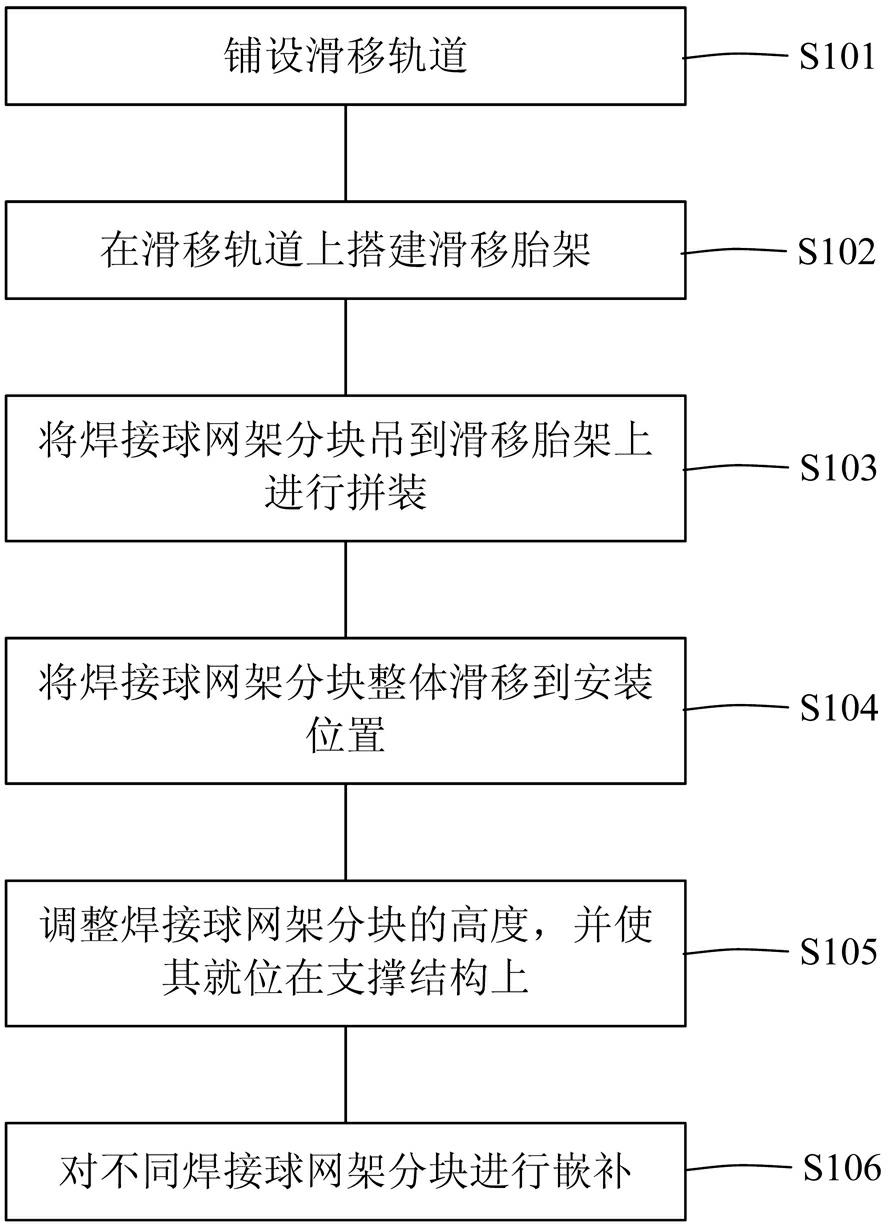

[0033] See figure 1 , which is a flow chart of an embodiment of the sliding construction method of the ultra-large-area hyperboloid welded ball net frame of the present invention, which includes the following steps:

[0034] S101, laying the sliding track.

[0035] S102, building a skid tire frame on the skid track.

[0036] S103, hoisting the welded ball grid frame into pieces on the skid tire frame for assembly.

[0037] S104, sliding the welded ball grid frame block to the installation position as a whole.

[0038] S105, adjust the height of the welded ball grid frame block, and make it in place on the supporting structure.

[0039] S106, embedding different welded ball net frames into blocks to form super large-area welded ball net frames.

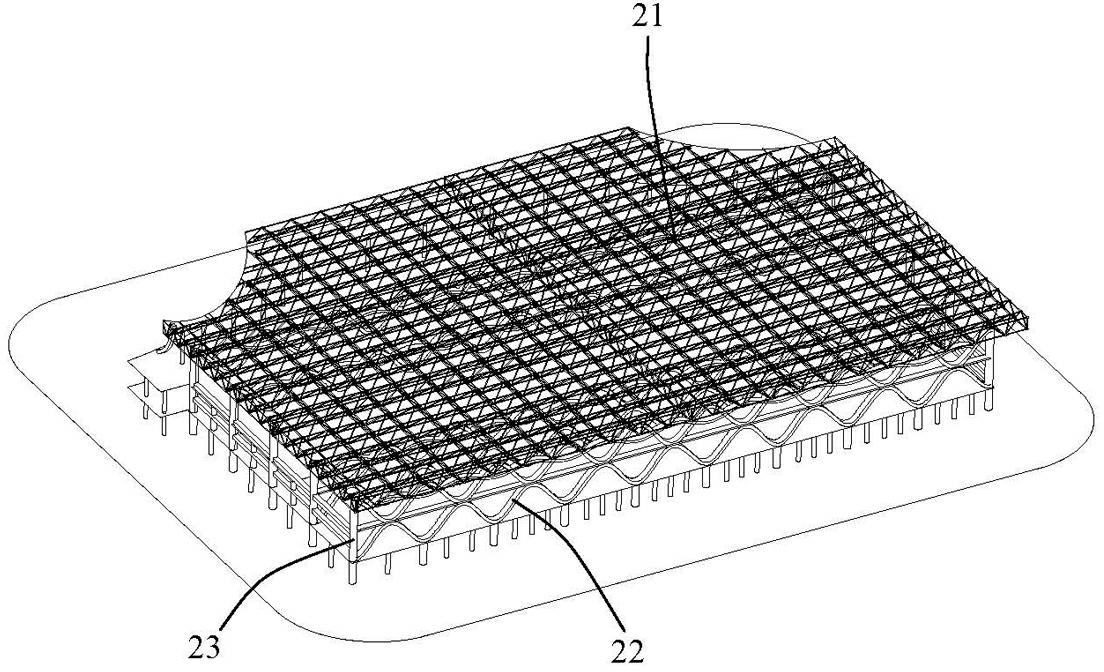

[0040] See figure 2 , which is a schematic diagram of a super-large roof grid structure system. The roof 21 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com