Patents

Literature

5035results about How to "Guarantee the construction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

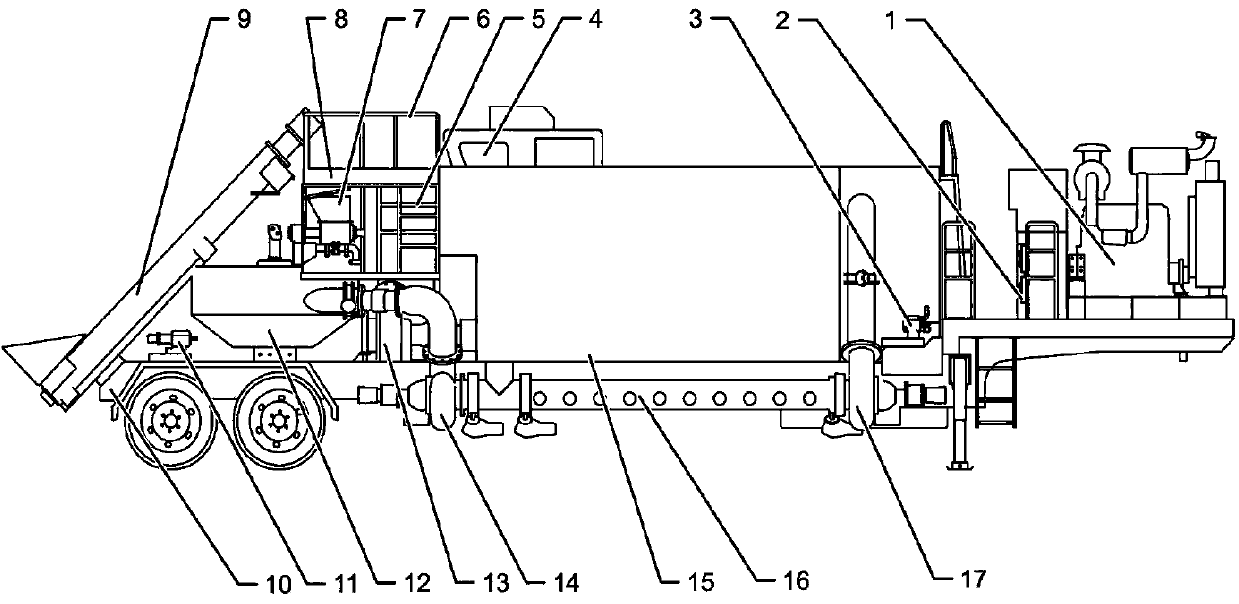

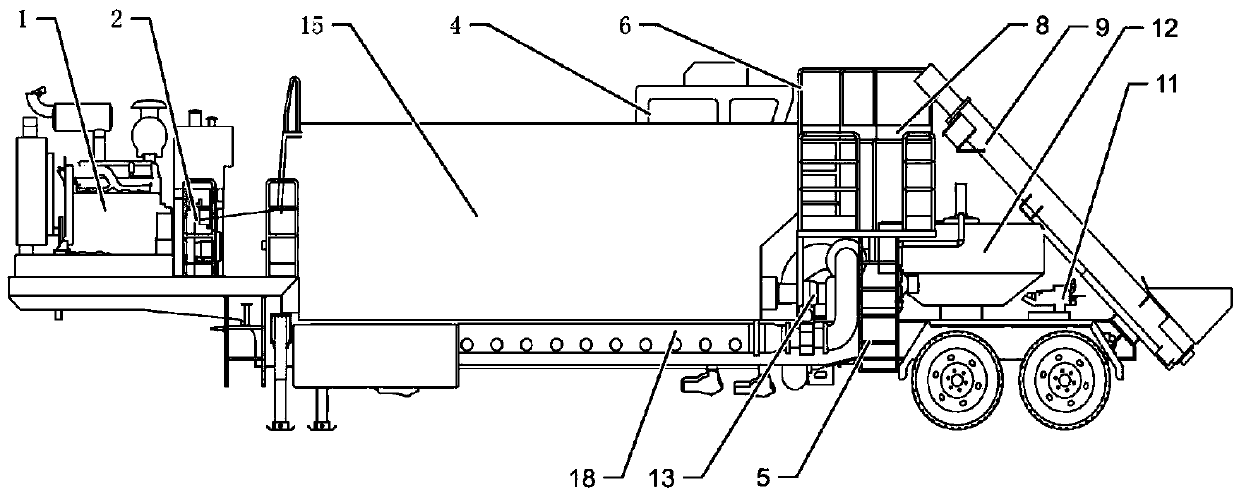

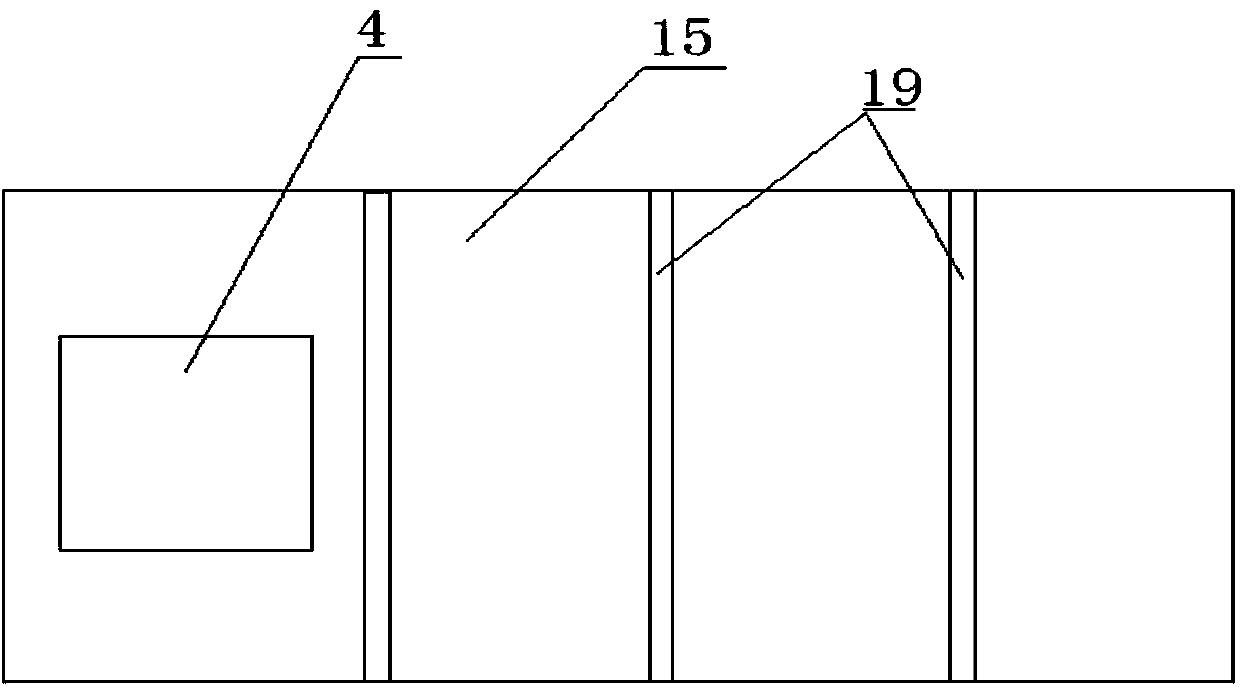

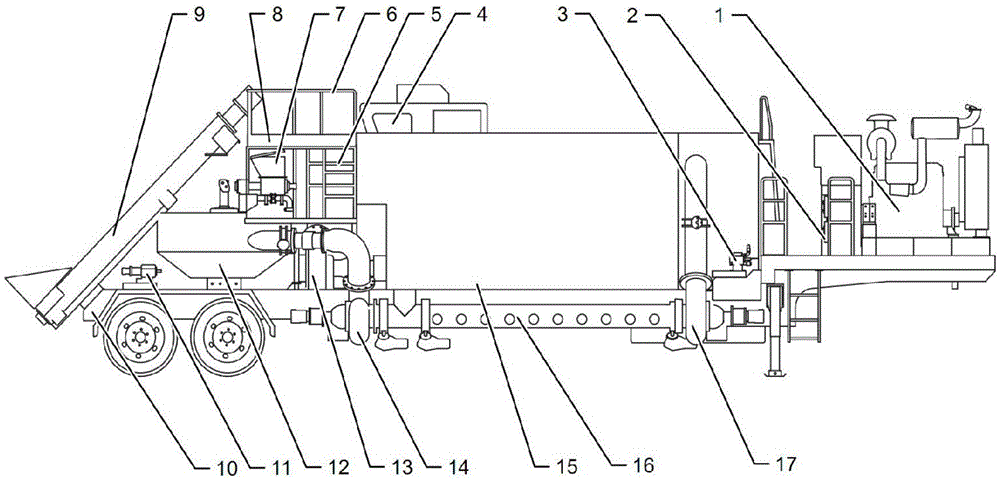

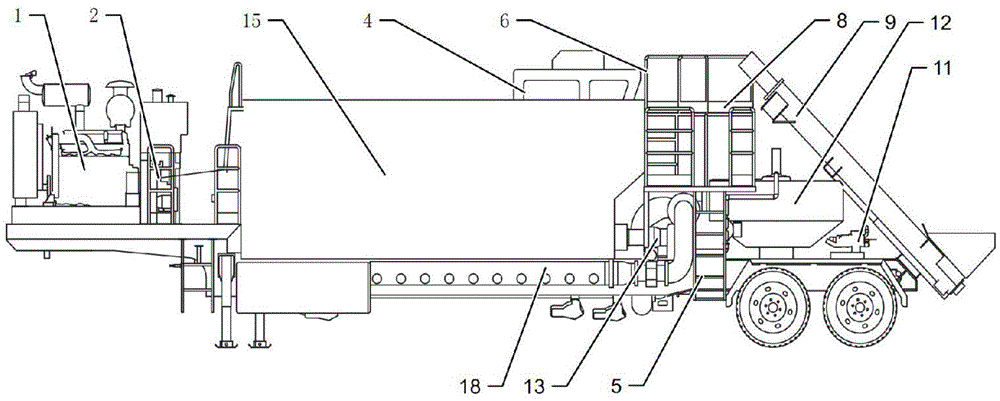

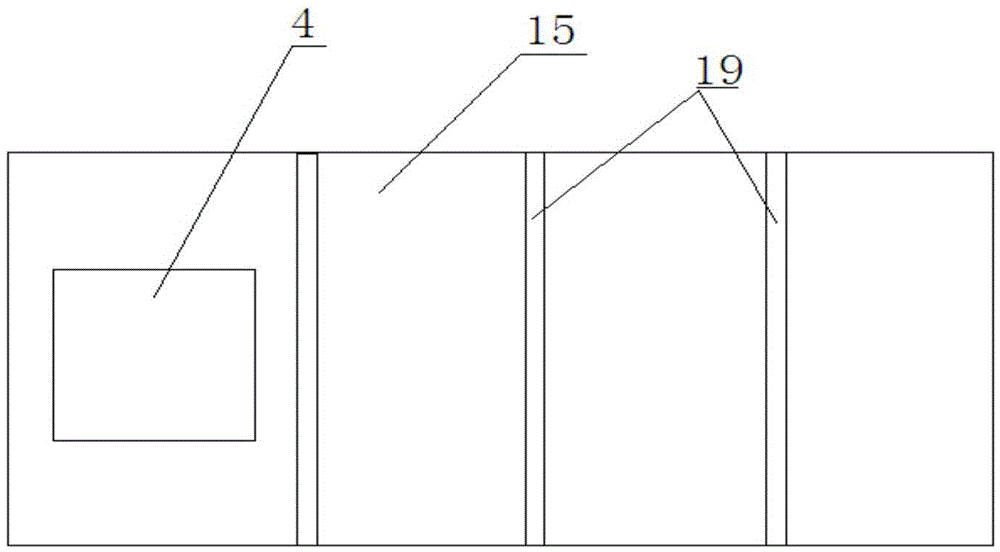

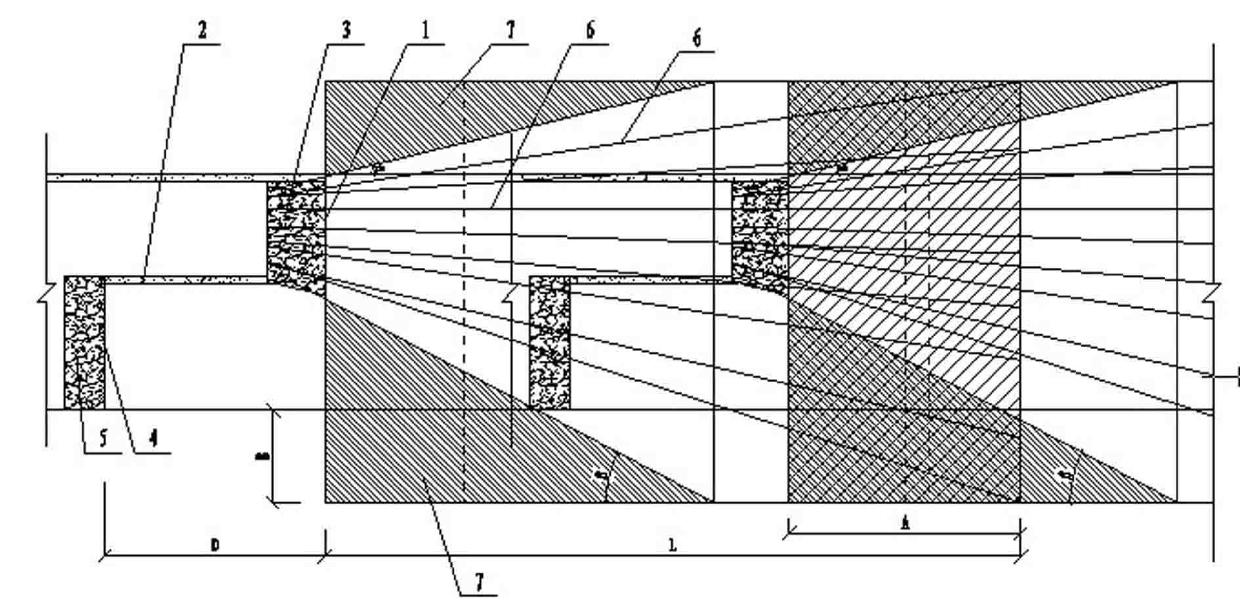

Fracturing fluid mixing and sand mixing semitrailer

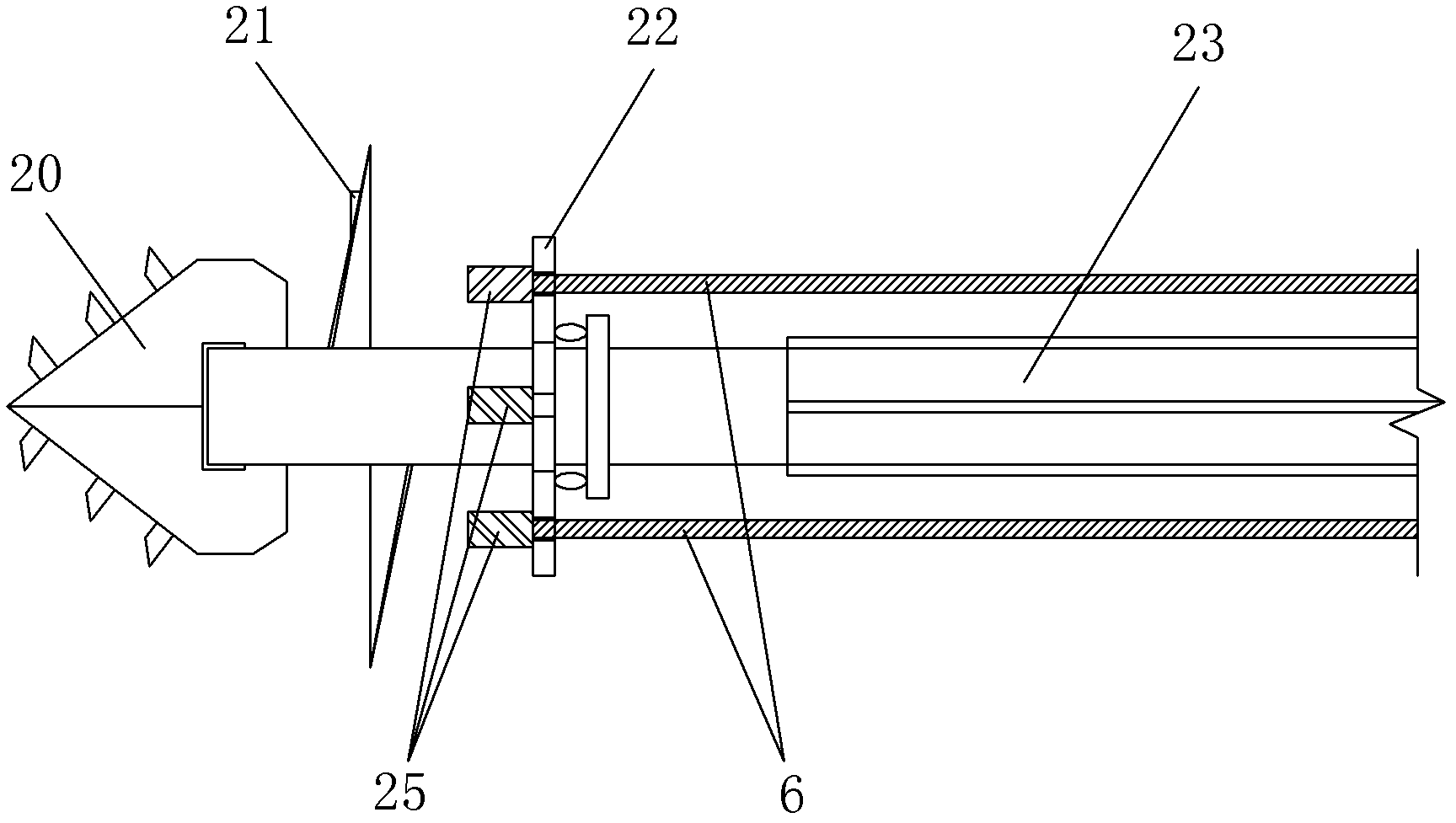

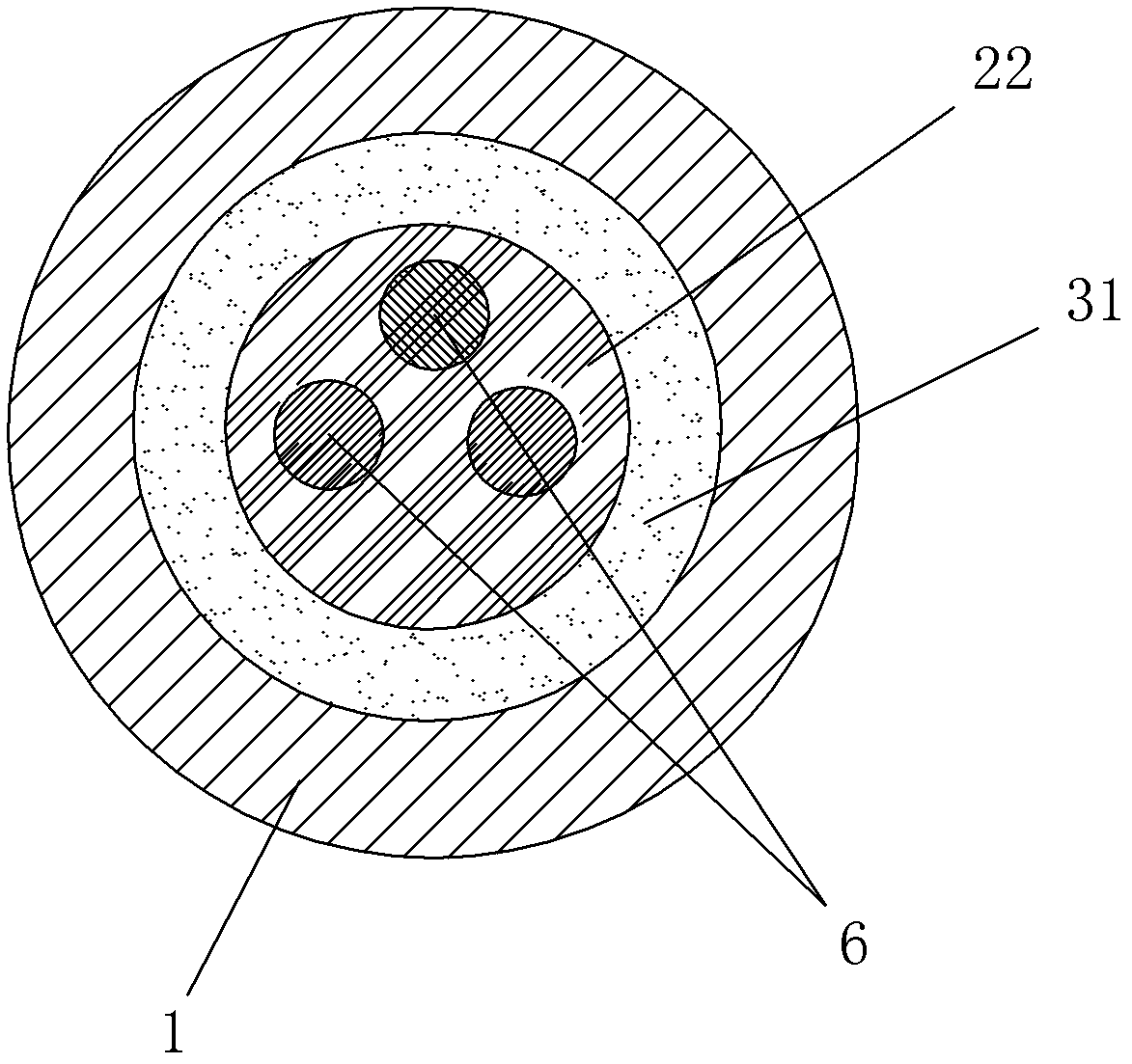

ActiveCN103993869ALess supporting equipmentReduce workloadFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

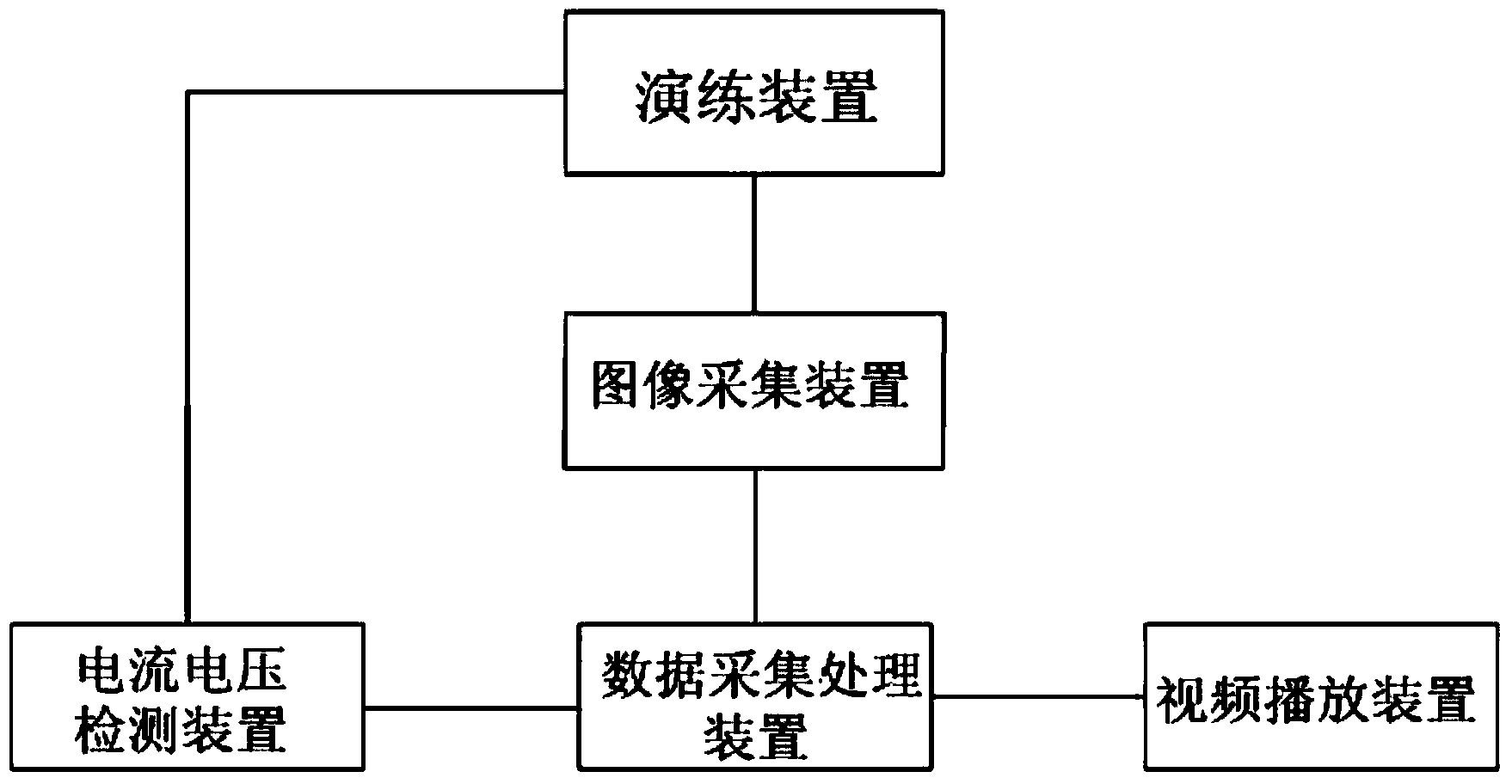

Welder exercise and process evaluation device

InactiveCN103871279AHigh practicalityGuarantee the construction qualityElectrical appliancesPhysical exerciseVoltage

The invention provides a welder exercise and process evaluation device. The welder exercise and process evaluation device comprises an exercise device, an image acquisition device, a current and voltage detecting device, a data processing device and a video playing device. The exercise device comprises a welder training platform and the image acquisition device arranged on the welder training platform, wherein the image acquisition device is connected with the data processing device. The current and voltage detecting device comprises a current detecting device and a voltage detecting device. An output circuit of a welding power source of the welder training platform is connected with the current detecting device in series and connected with the voltage detecting device in parallel, and the signal output ends of the current detecting device and the voltage detecting device are connected to the input end of the data processing device through a signal optical cable. The output end of the data processing device is connected with the video playing device. The welder exercise and process evaluation device has the advantages that multimedia is fully utilized for display and processing of training content so that training exercise can be implemented, the process can be looked back upon, and the actual significance of plan training and exercise is greatly improved.

Owner:TIANJIN BINFU ENTERPRISE MANAGEMENT CONSULTING

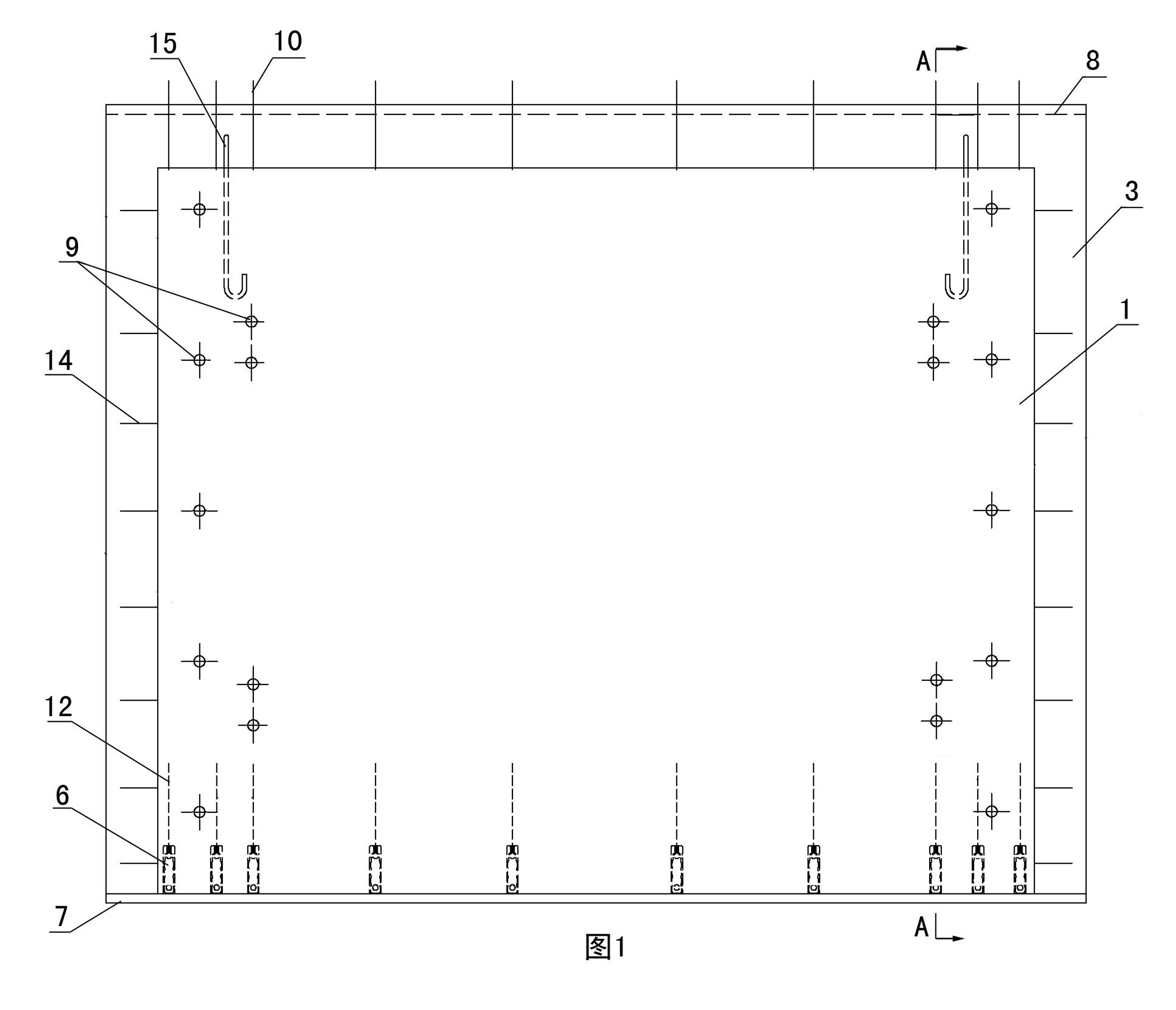

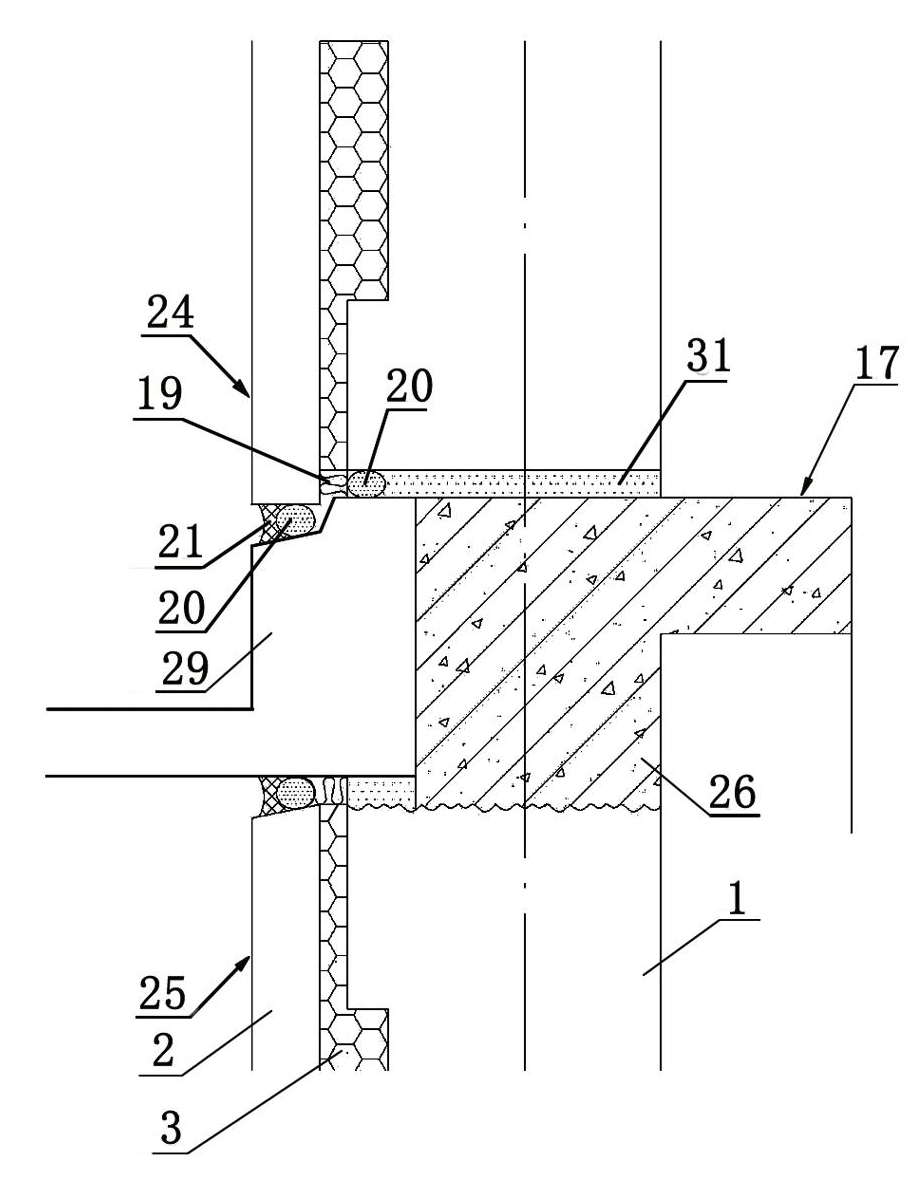

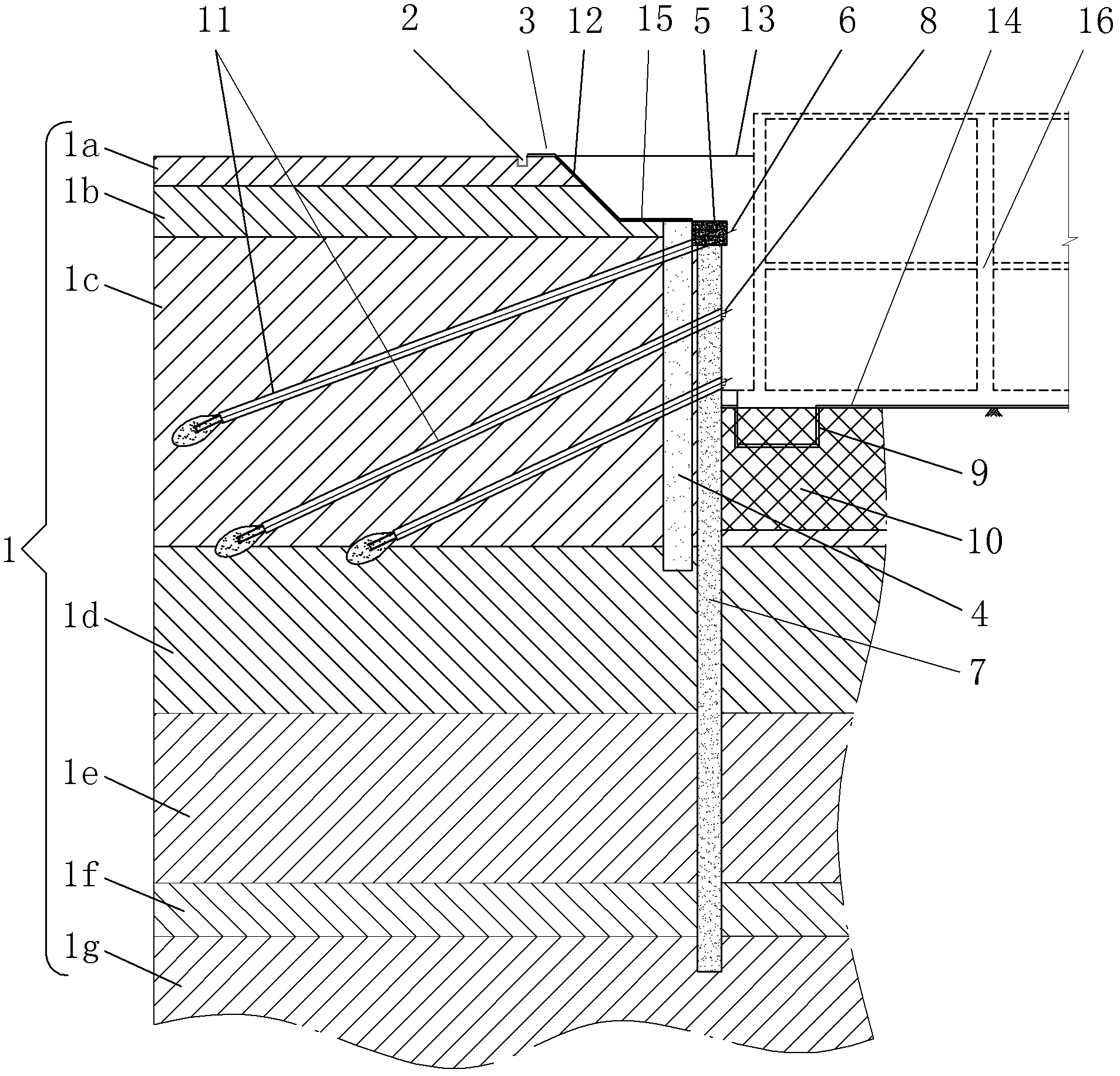

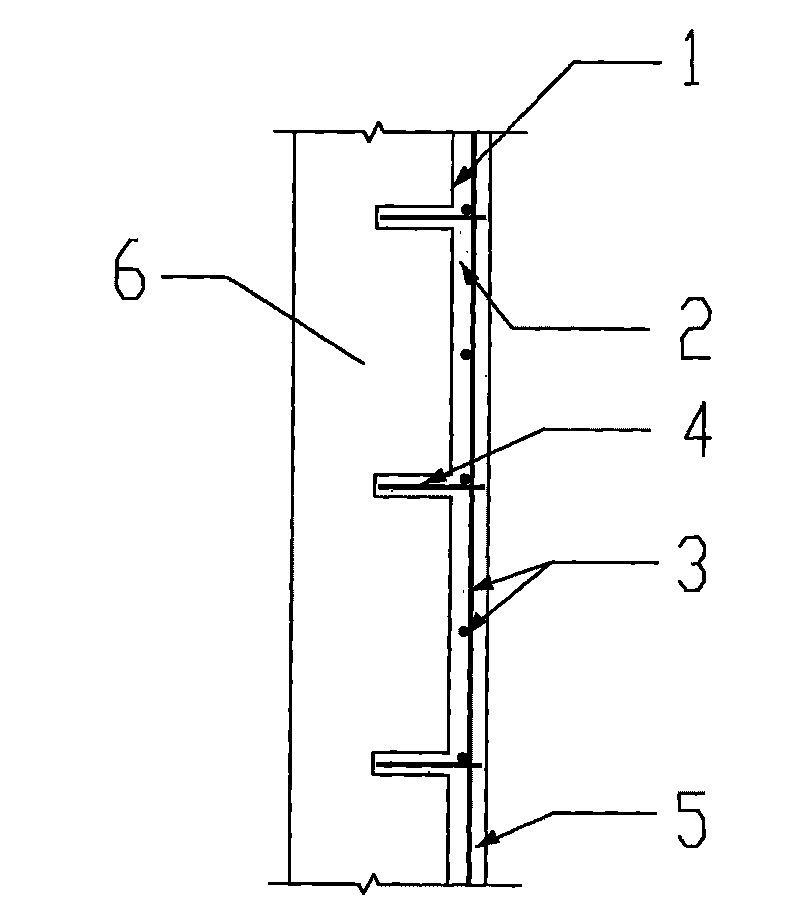

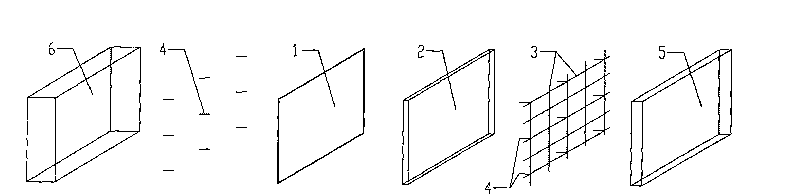

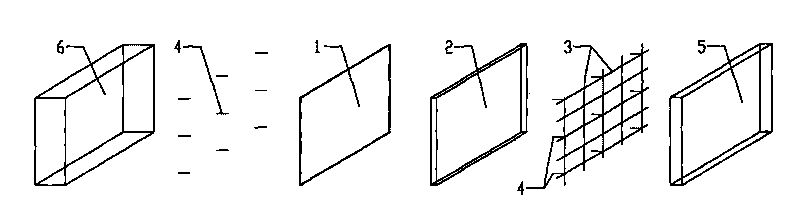

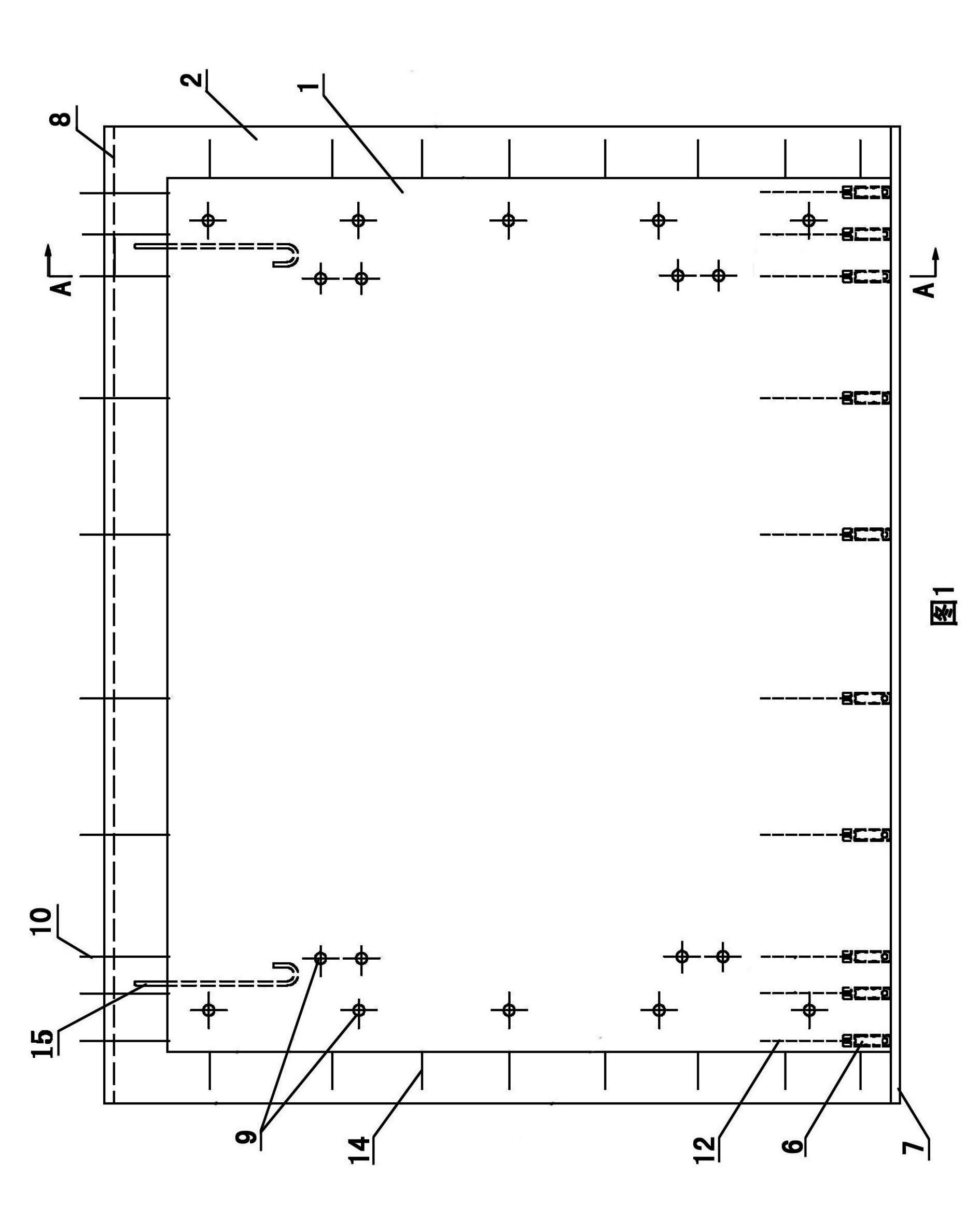

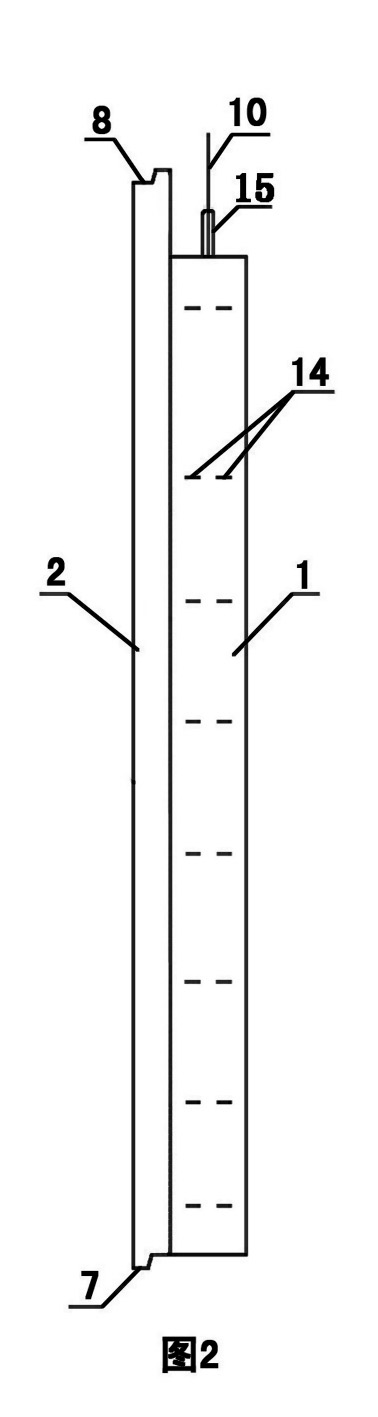

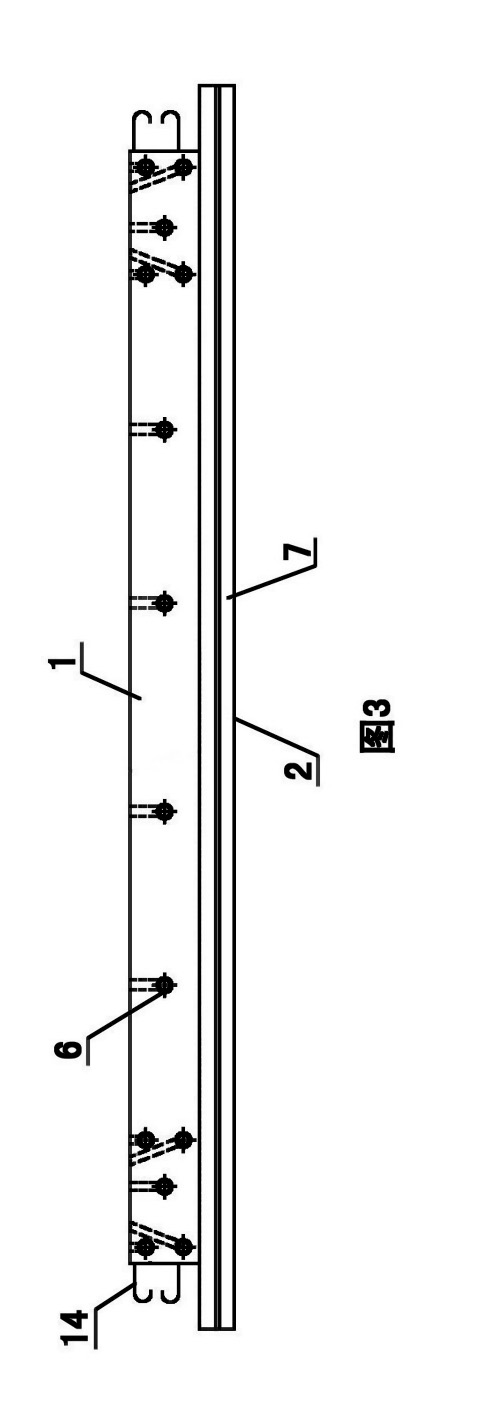

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

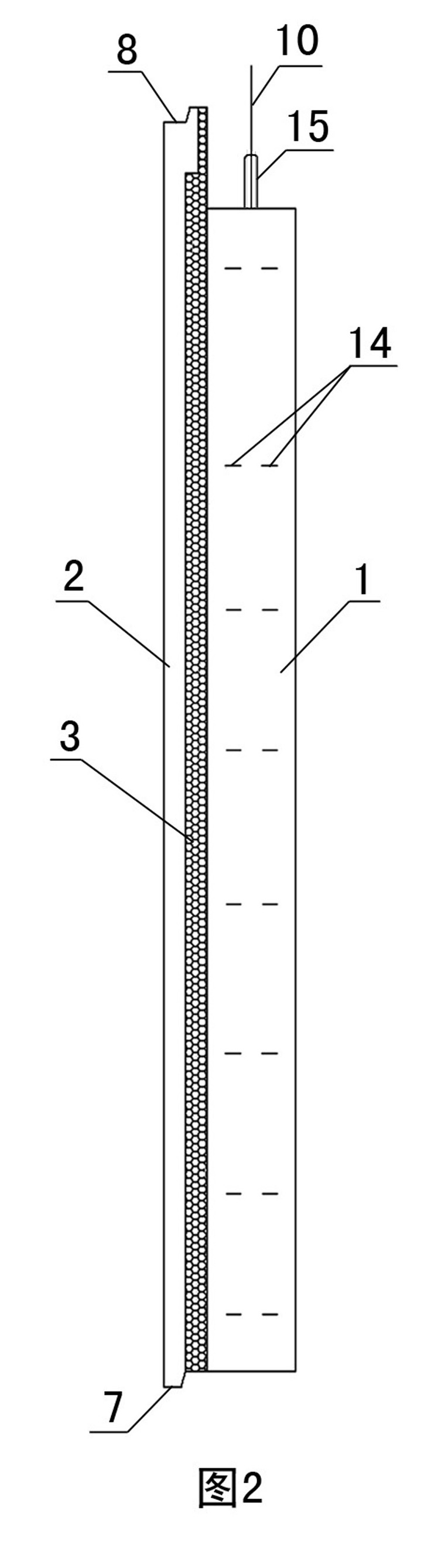

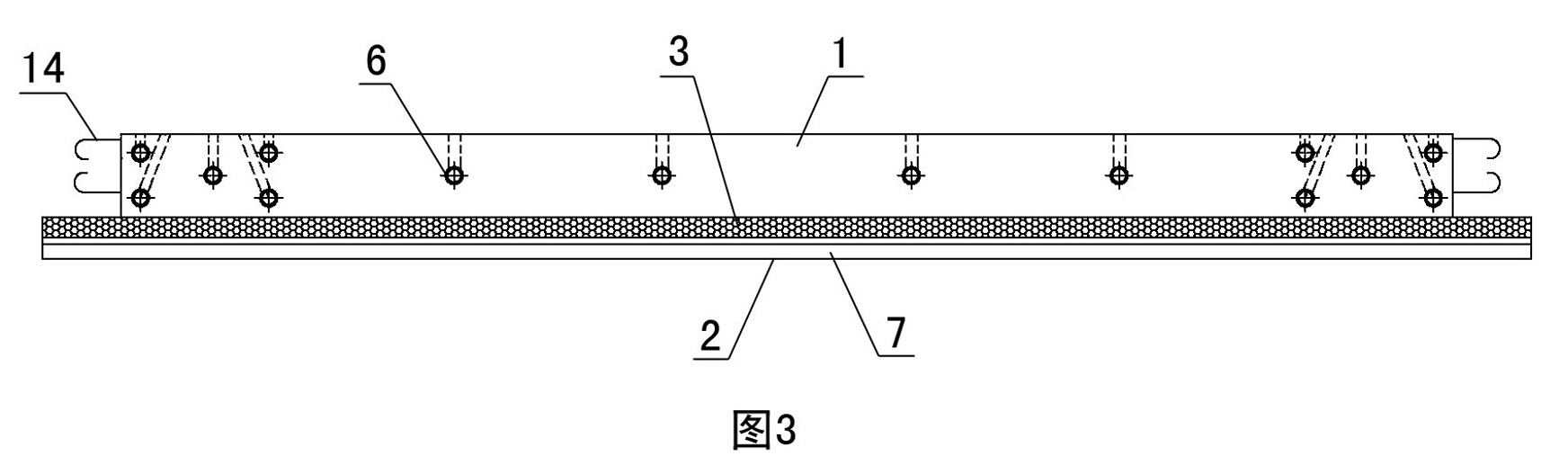

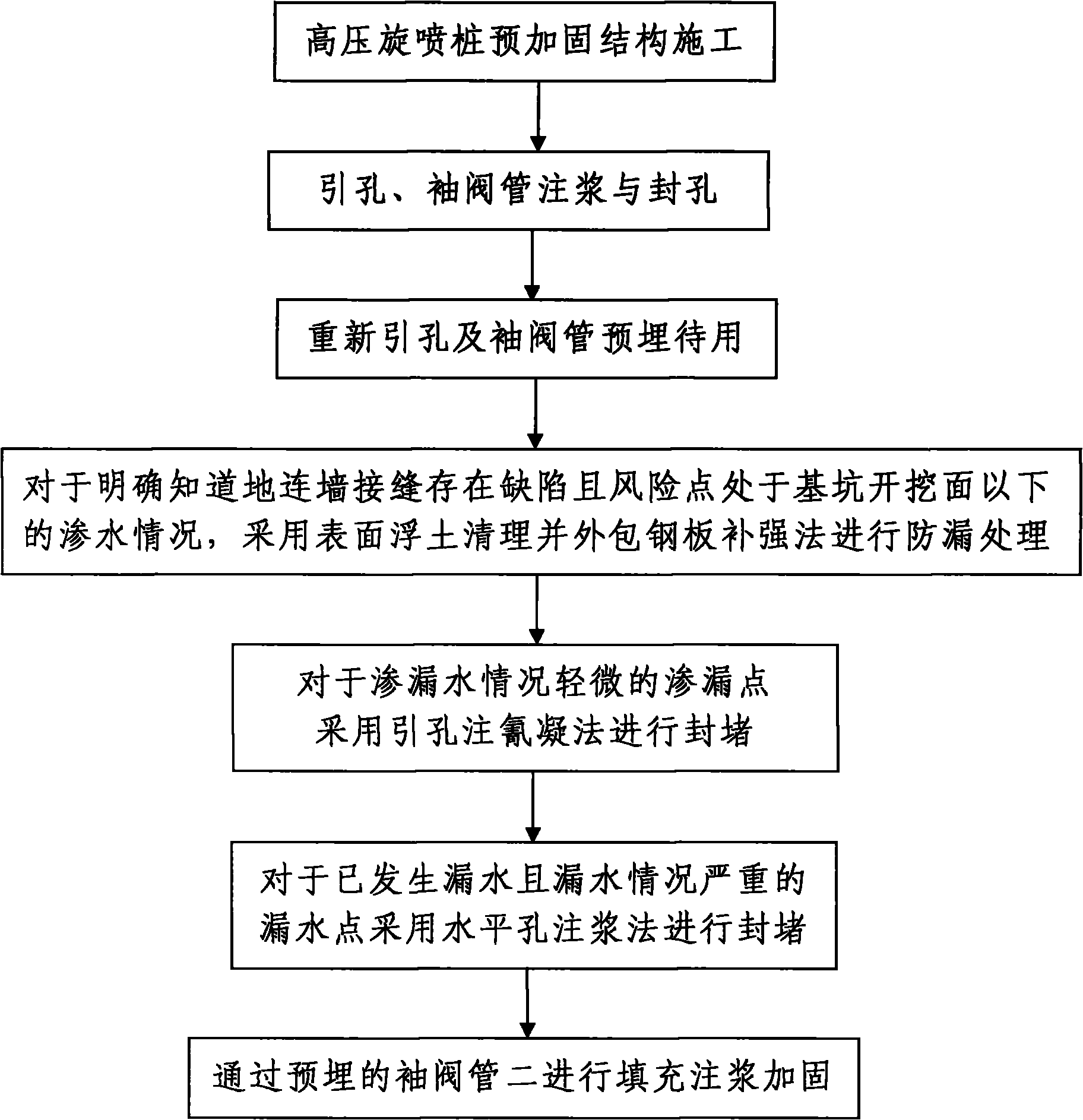

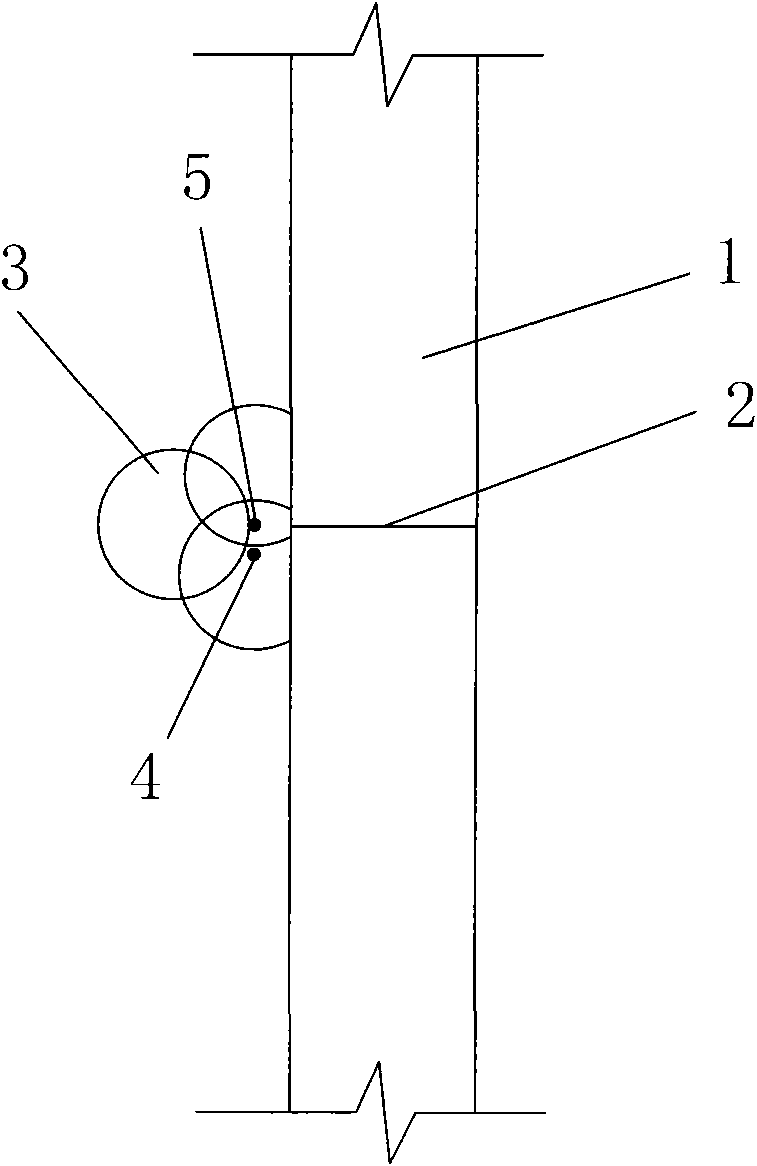

Anti-seepage and leak-blocking construction method for excavation of subway foundation pit in soft soil area

The invention discloses an anti-seepage and leak-blocking construction method for excavation of a subway foundation pit in a soft soil area, which comprises the following steps: 1) joint pre-reinforcement construction of an underground continuous wall: constructing a pre-reinforcement structure of a high-pressure rotary jet grouting pile, guiding holes, grouting by a sleeve valve pipe, sealing the holes, guiding the holes again and pre-burying the sleeve valve pipe for standby; and 2) the excavation of the foundation pit and the anti-seepage and leak-blocking construction: using surface floating earth for clearing and using the encased steel plate reinforcement method for anti-leak treatment for the situations that joints of the underground continuous wall have defects definitely and risk points are positioned below the excavation surface of the foundation pit, adopting the hole-guiding cyanogen injection condensing method for blocking of leak points with slight water leakage situation, adopting the horizontal hole grouting method for blocking for the water leak points with serious water leakage situation, and carrying out filling, grouting and reinforcement through the pre-buried sleeve valve pipe after completing the blocking. The method has reasonable design, convenient construction, comprehensive consideration, good anti-leak and leak-blocking effect, fast leak-blocking speed and can solve the problems of pipe blocking, poor anti-leak and leak-blocking effect, slow construction progress and the like in the existing anti-leak and leak-blocking construction.

Owner:TIANJIN CONSTR ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

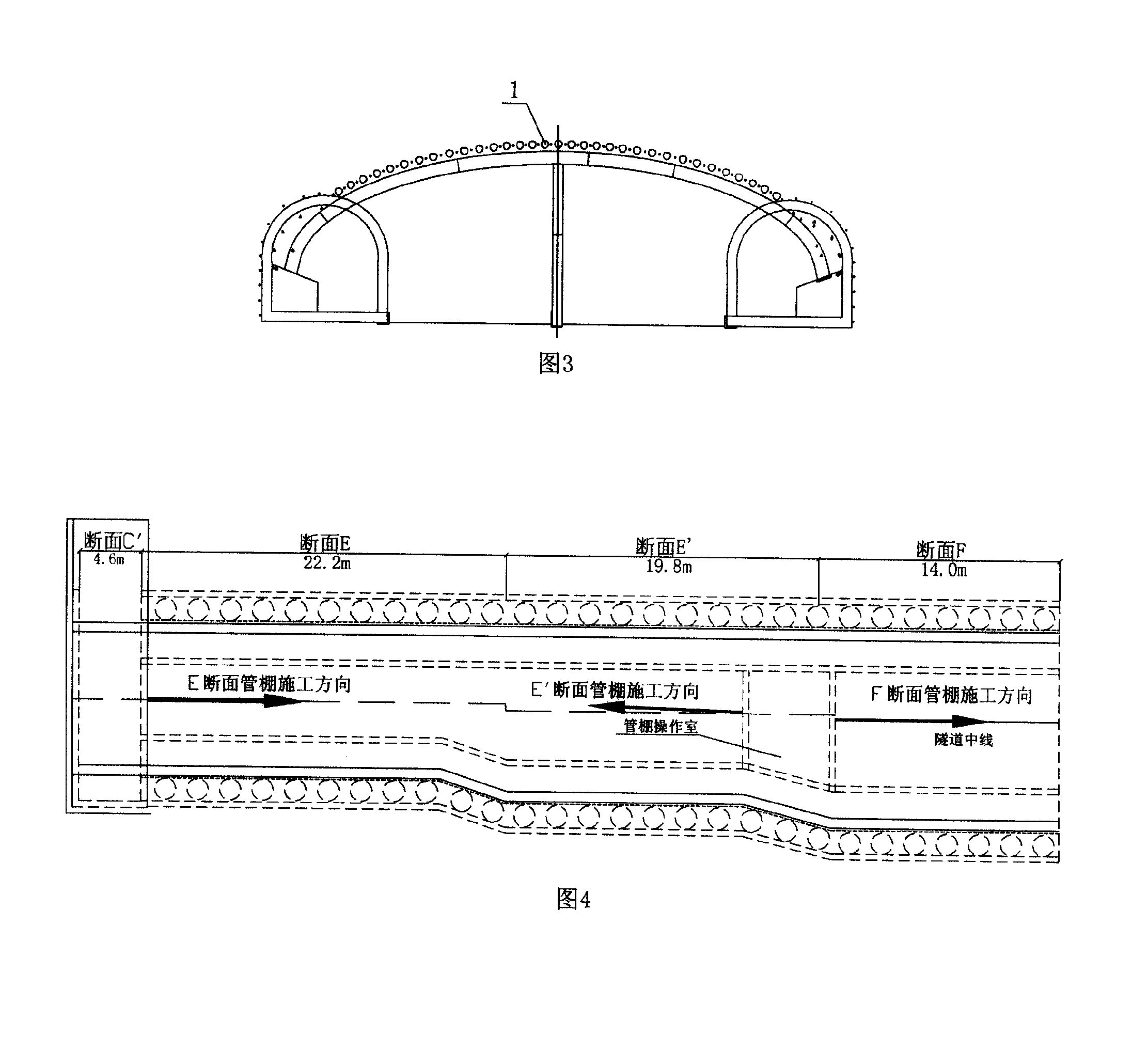

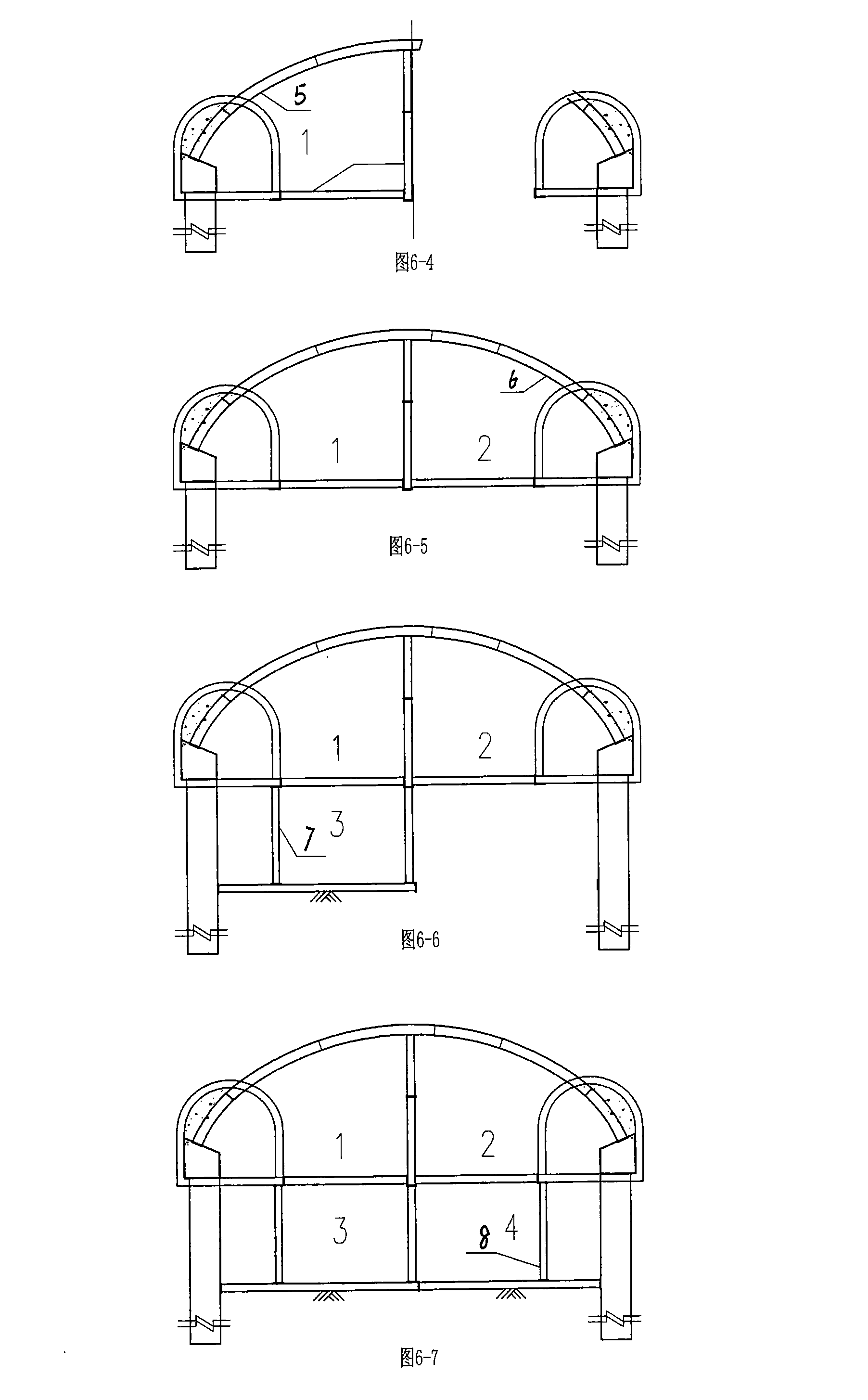

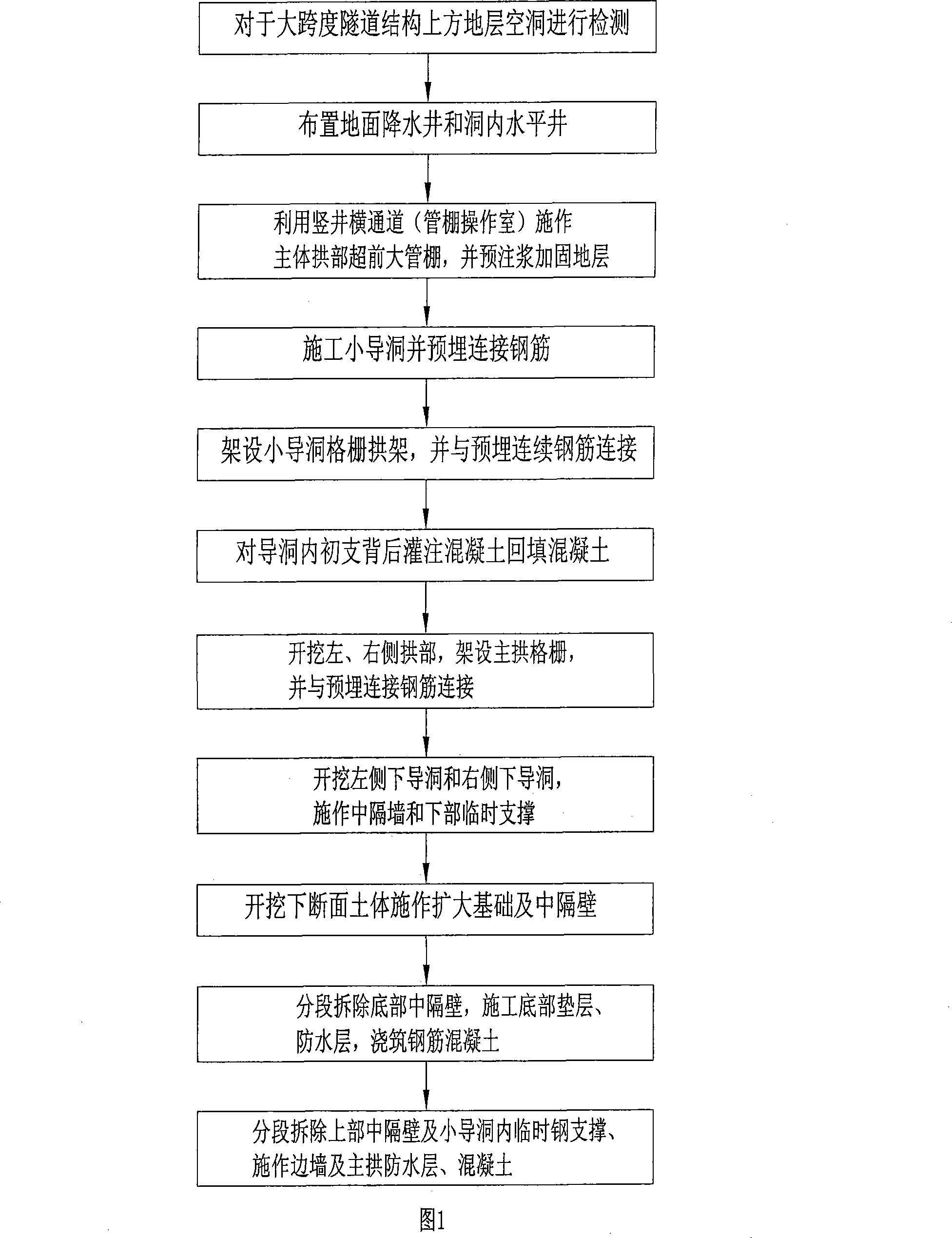

Construction method of shallow buried underground excavating tunnel super large section using PBA method

ActiveCN101225742ASolve comprehensive technical problemsSolve processing problemsUnderground chambersTunnel liningShotcreteTerrain

The invention relates to a method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel, comprising the following steps: 1. to detect the geologic cavity over the wide span tunnel structure; 2. to arrange the ground dewatering well and the tunnel horizontal well; 3. to take the horizontal channels of vertical well as the front large pipe shed on the arch part of the main body and to inject for strengthening the terrain formation; 4. to carry out the supporting arch construction on the side span of small pilot tunnel and the supporting major arch construction on the main body; 5. to excavate the soil mass of lower cross section as the extended foundation and the central partition wall; 6. to remove the bottom central partition wall section by section, construct bottom underlayer and waterproof layer, pour the reinforced concrete; 7. to remove the central partition wall of the upper part section by section and temporary steel shotcrete in the small pilot tunnel, construct the waterproof layer and concrete of the side wall and the main arch. The method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel has the advantages of guaranteeing the safety, quality and time limit of the construction, saving cost and enhancing work efficiency.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

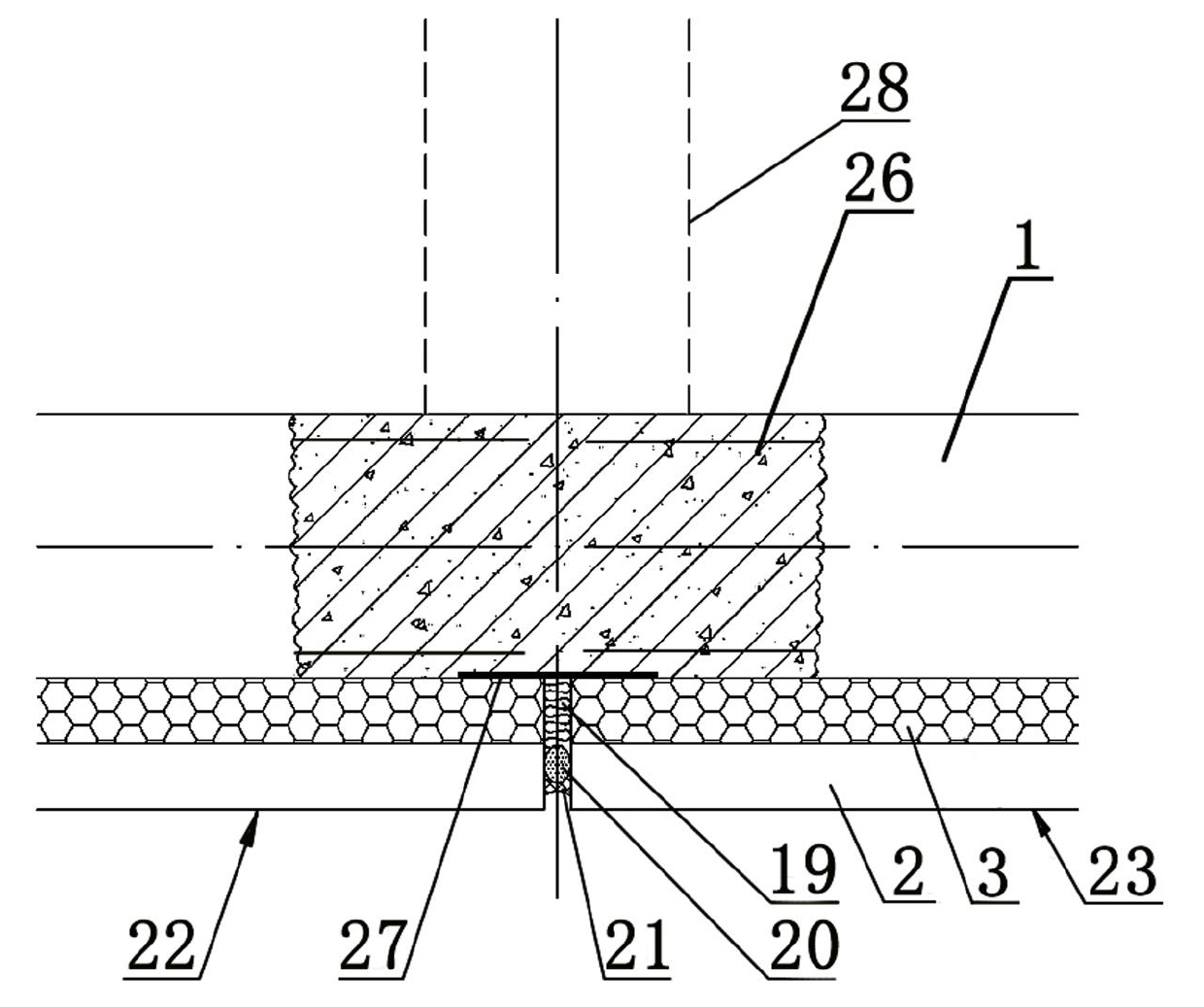

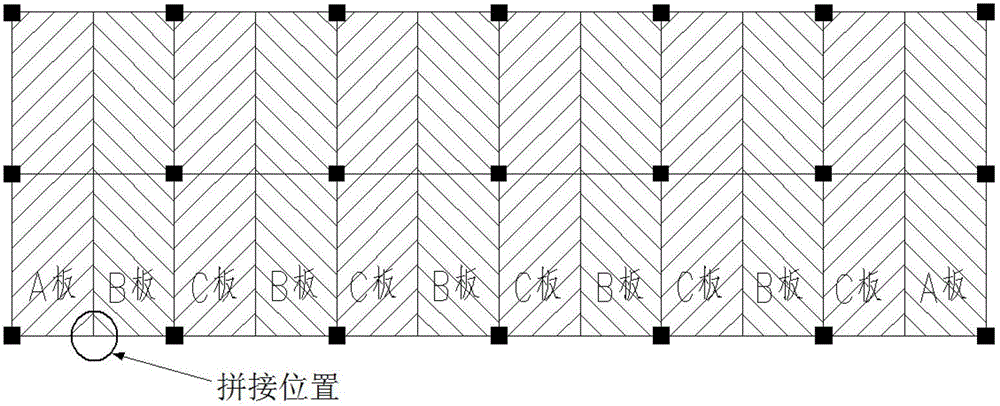

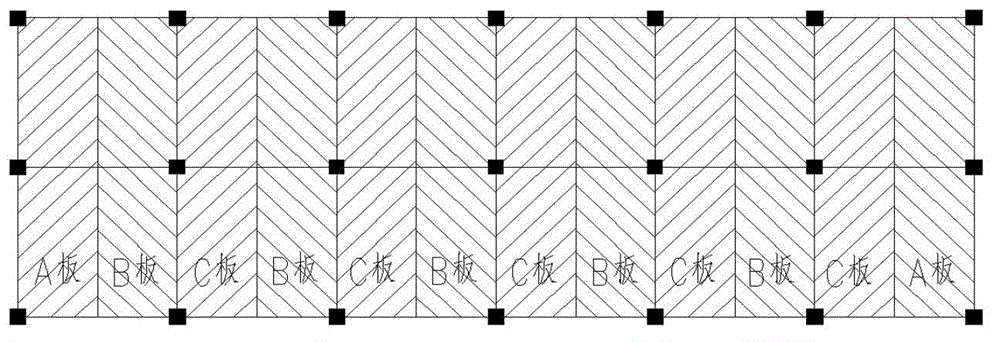

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

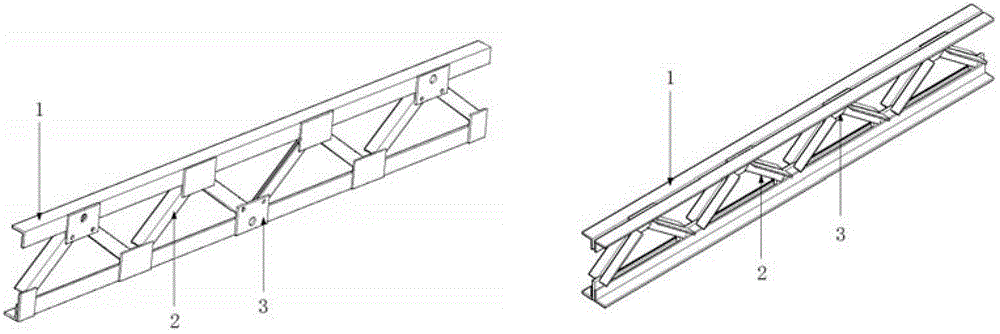

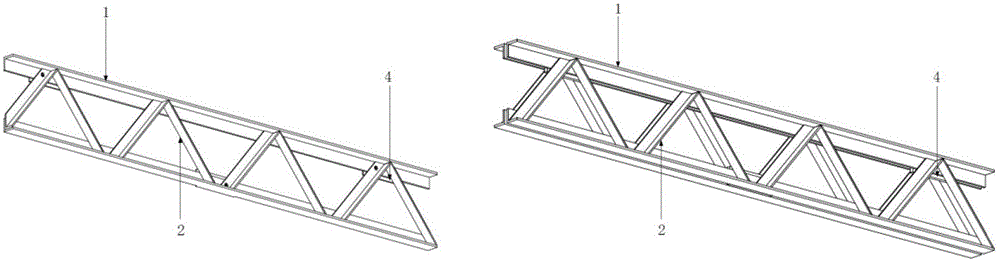

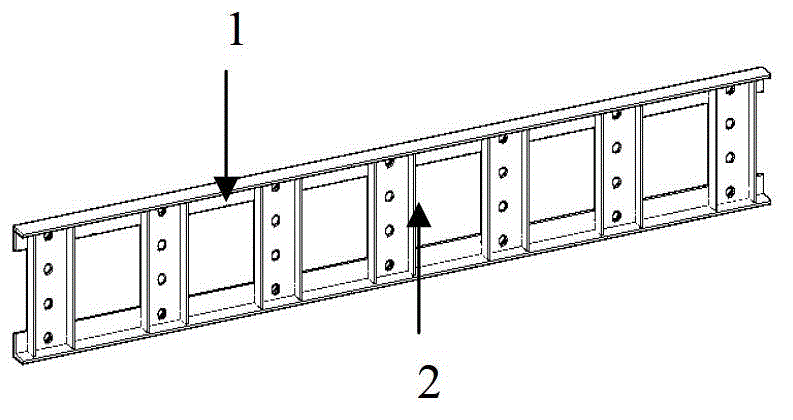

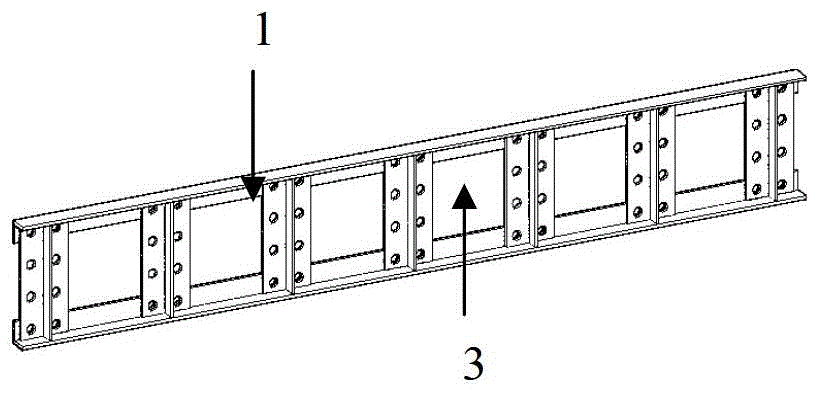

Industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system

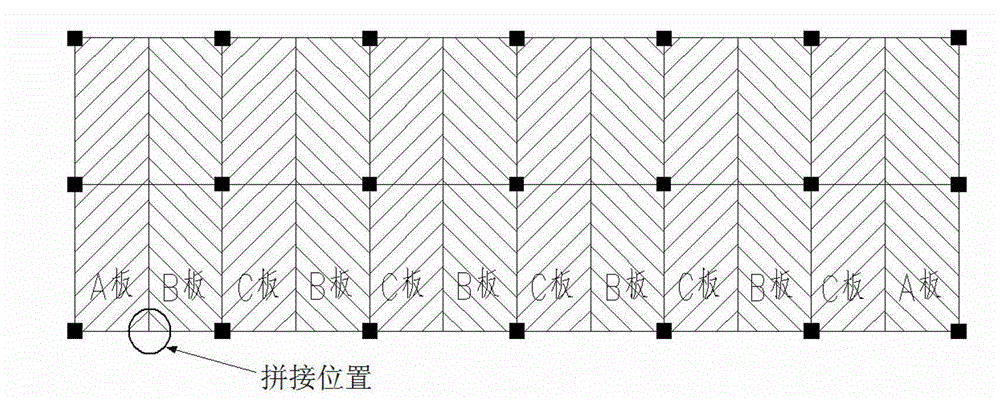

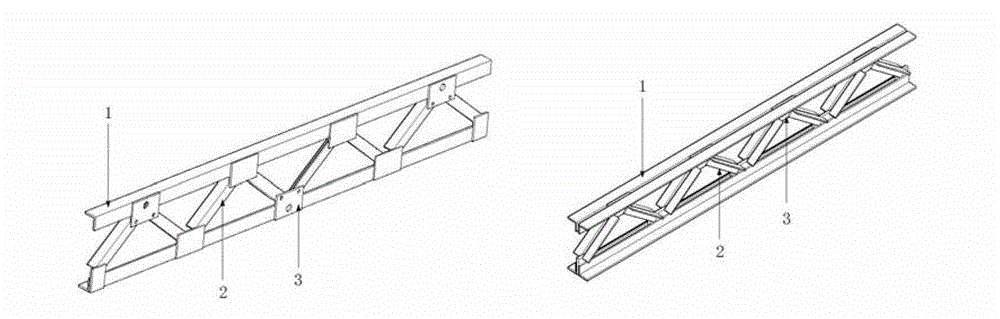

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled truss plates, assembled flange columns and eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

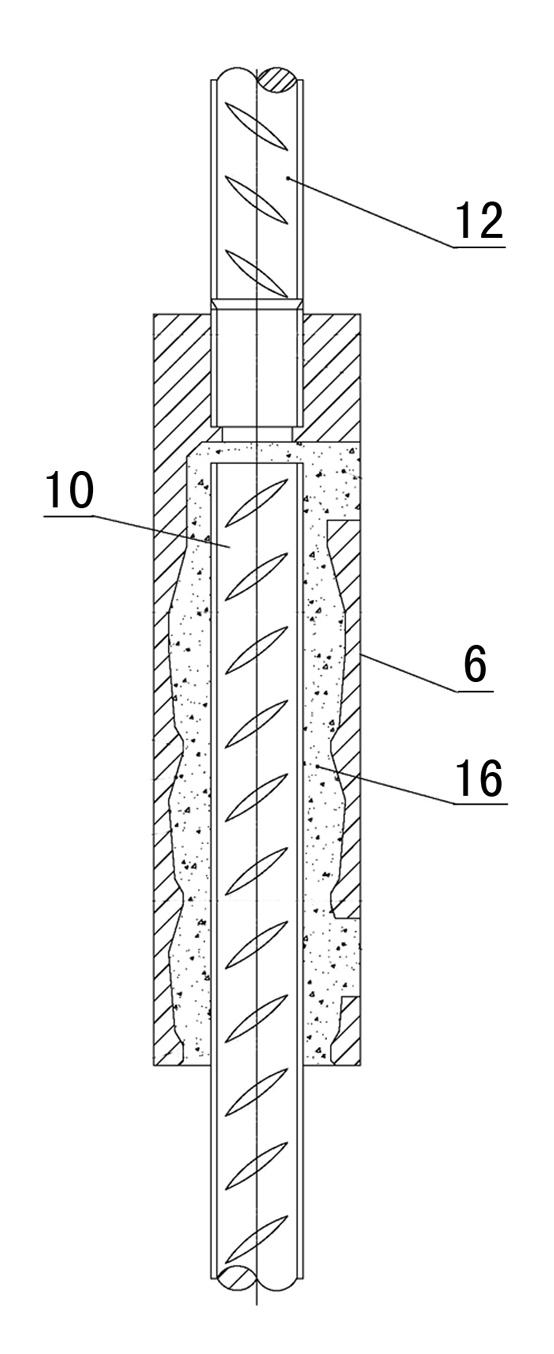

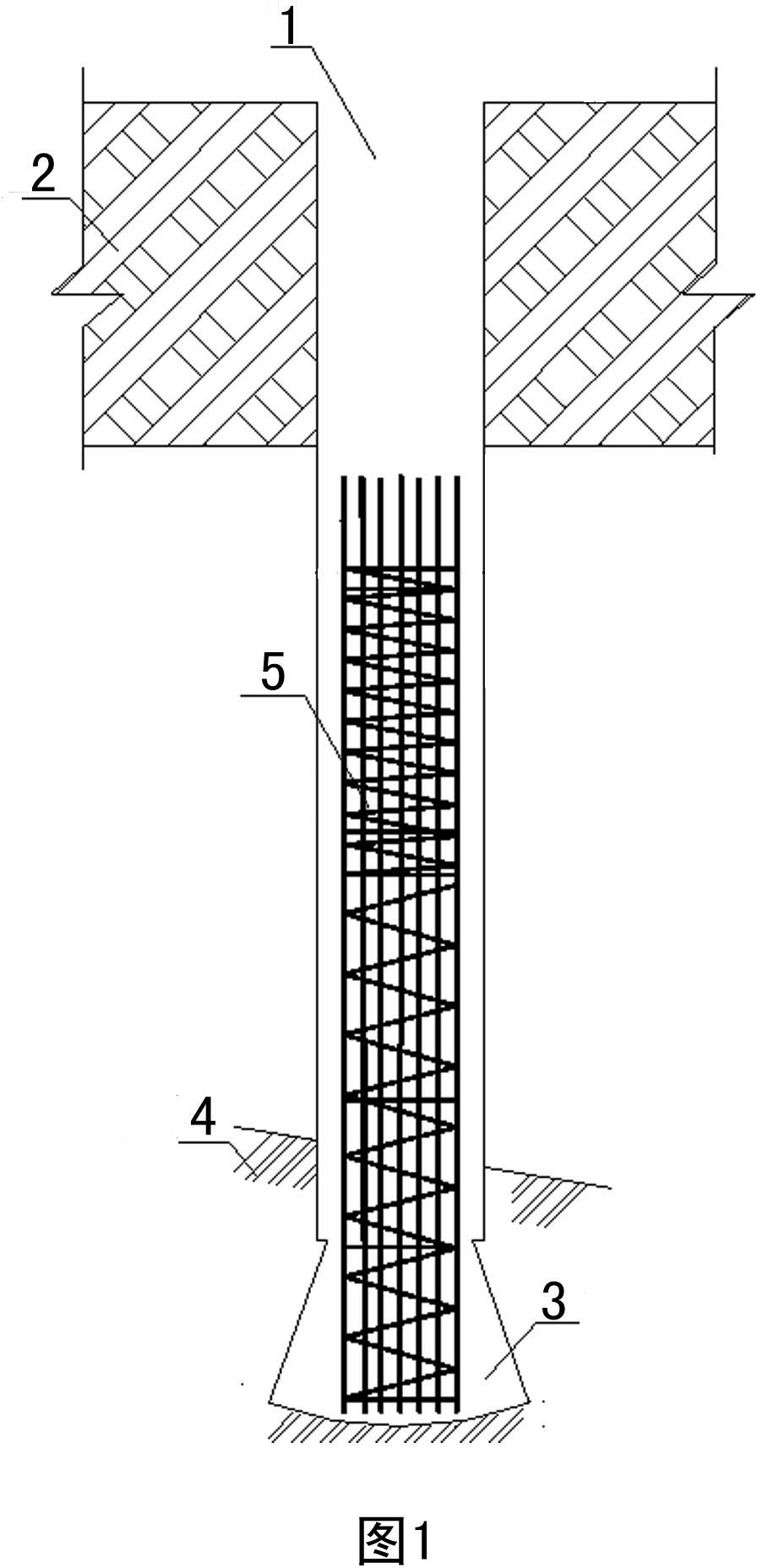

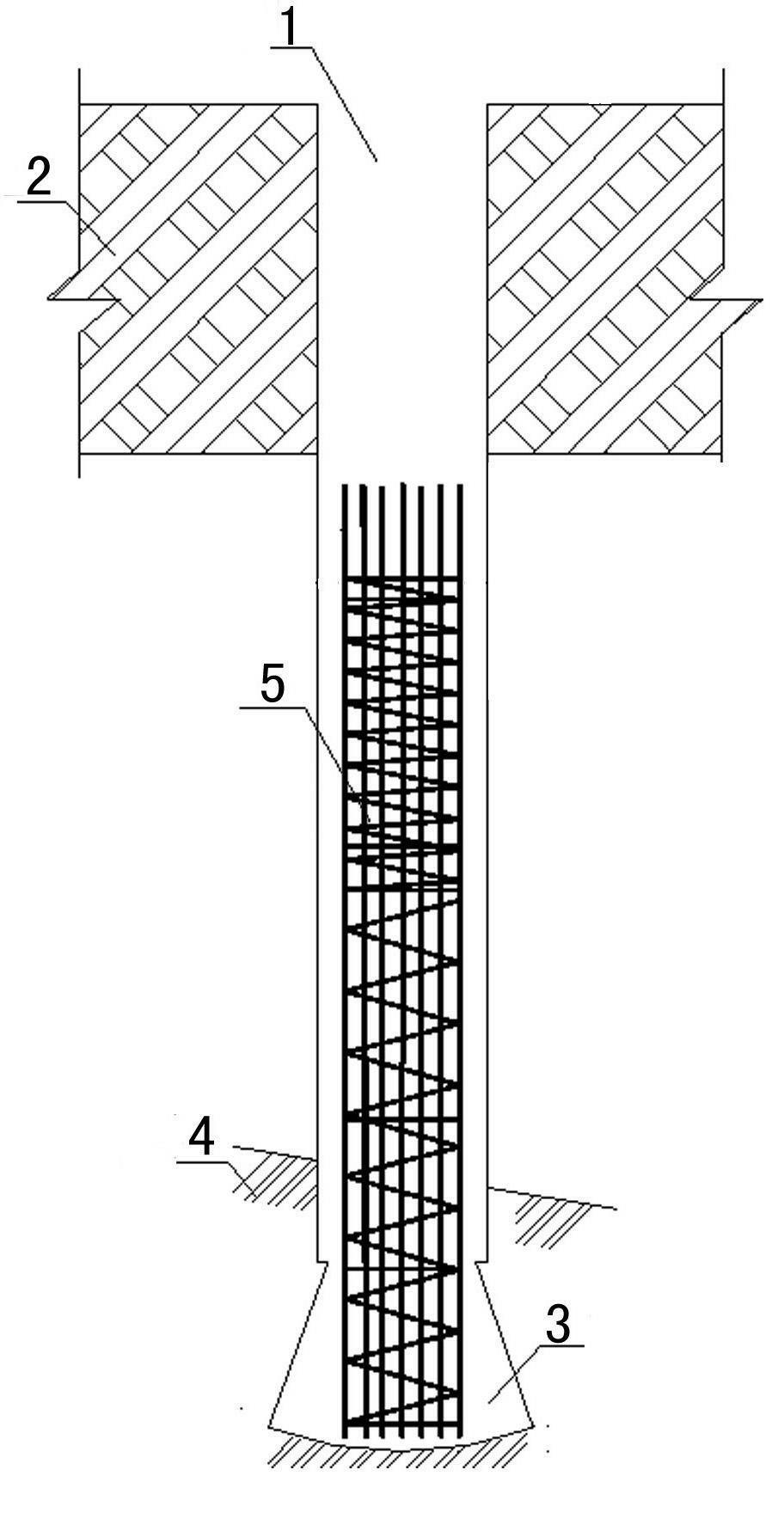

Method for constructing engineering pile by combining rotary drilling rig with manual pile base chambering

InactiveCN102425160AGuarantee the construction qualityImprove construction qualityBulkheads/pilesRebarDrill

The invention relates to a method for constructing an engineering pile by combining a rotary drilling rig with manual pile base chambering, which comprises the following steps: (1) preparation work before construction, including field leveling; (2) pile lofting; (3) pile casing embedding; (4) rig installation and rotary drilling; (5) manual pile base chambering; (6) rotary drilling drill quality detection; (7) reinforcement cage manufacturing; (8) reinforcement cage installation; (9) preparation before casting, mainly including hole cleaning, final hole acceptance check, and pump concrete casting quality safeguard measure; and (10) concrete casting, mainly including guide pipe installation, concrete casting and sampling for test and pile forming. In the method for constructing the engineering pile by combining the rotary drilling rig with the manual pile base chambering, the high efficiency of the rotary drilling rig is fully utilized, and the manual pile base chambering is utilized, the advantages of the rotary drilling rig and the manual pile base chambering are combined to make up the defects of the rotary drilling rig and the manual pile base chambering. The construction steps are detailed; the process flow is clear and definite; the construction quality of the engineering pile is ensured through an effective detail measure; the construction process of the rotary drilling rig and the process step of the manual pile base chambering are combined as a whole to realize the effective allocation of a construction field, a construction machine and construction time; and when the construction quality is ensured, the construction efficiency of a digging pile is greatly increased, thereby, the construction time of the engineering pile can be greatly saved, and the construction period requirement of the project is met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

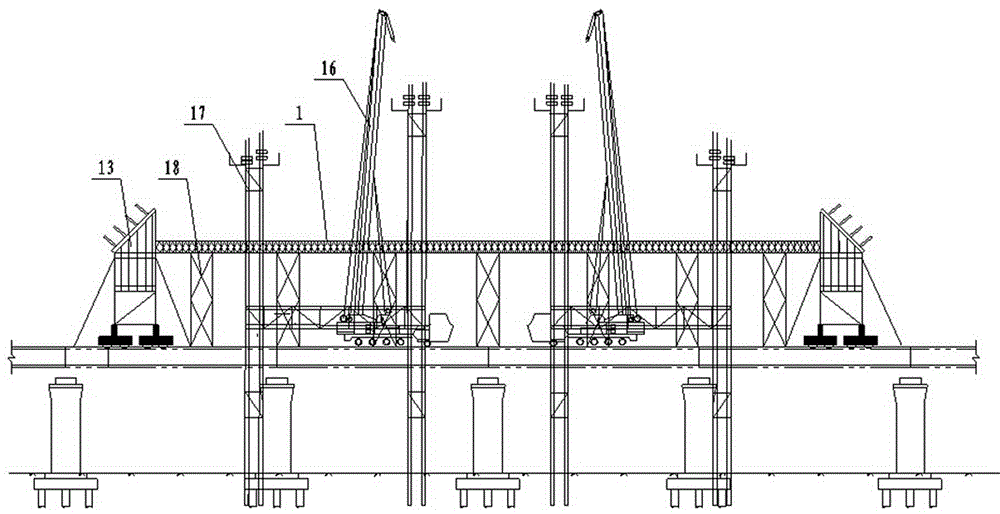

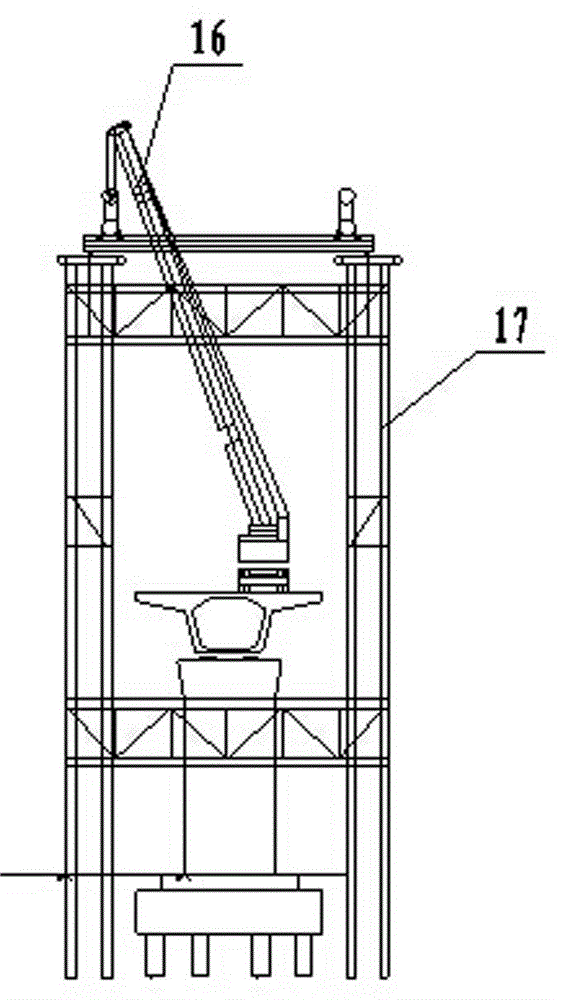

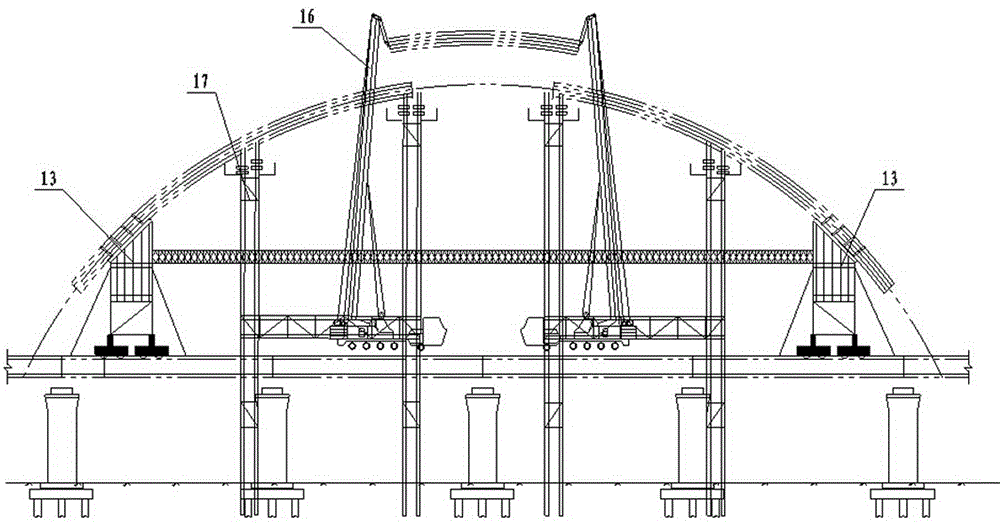

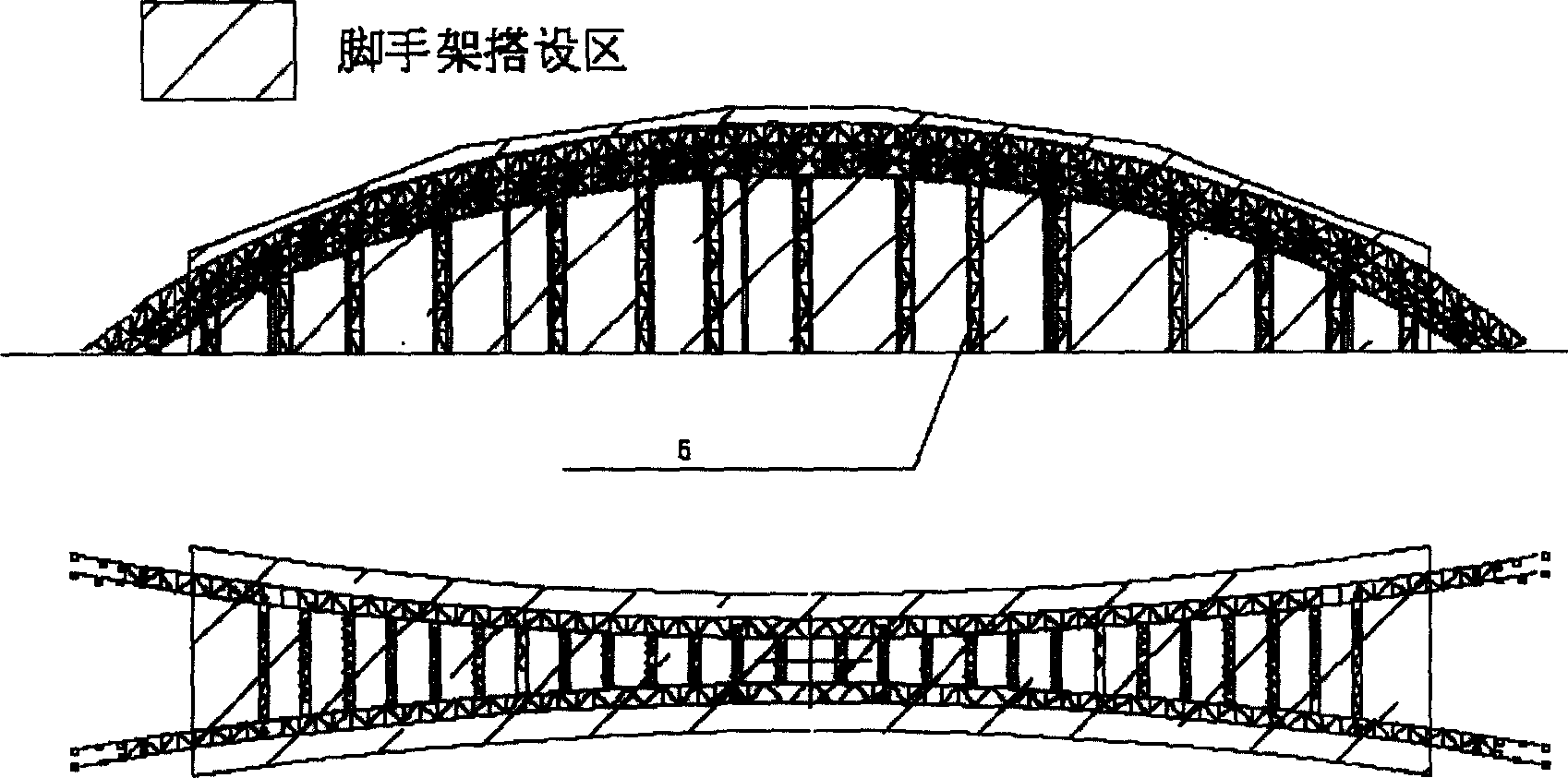

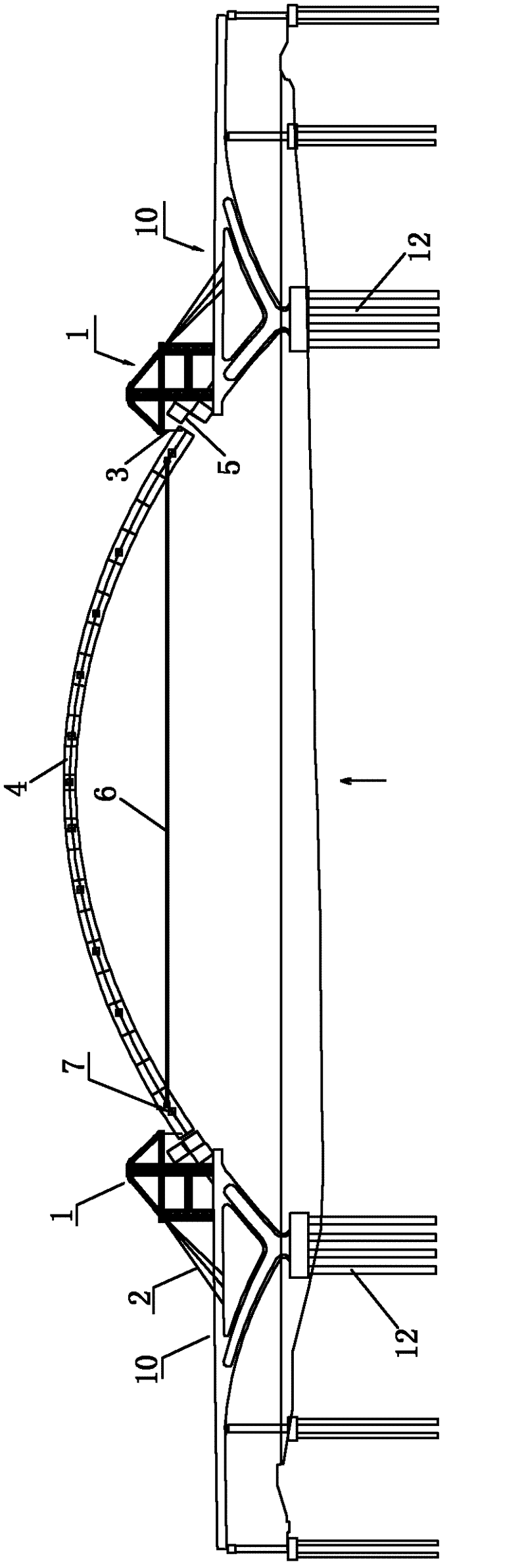

Construction method for continuous tie bar steel tube arch bridge

ActiveCN104562936AStress state is the sameSolving the Linear Control ChallengeBridge erection/assemblyArch-type bridgeEngineeringAbutment

The invention relates to a bridge construction method, in particular to a construction method for a continuous tie bar steel tube arch bridge; the construction method aims at solving the problems that the construction cycle is long, the potential safety hazard is big, the construction difficulty is big, and the like by adopting the existing support method. The construction method comprises the following steps of performing construction on assembling supports for a steel tube arch; processing the steel tube arch by stages, and hoisting the steel tube arch onto the assembling supports; installing temporary abutment supports and opposite-pull steel stranded wires to enable the steel tube arch to form a bowstring whole bearing structure; supporting the steel tube arch by the temporary abutment supports instead of the assembling supports, and removing the whole assembling supports; installing a longitudinal movement pushing system for the steel tube arch to enable the steel tube arch to move forward; welding the steel tube arch after the steel tube arch are pushed in place. Firstly, The difficult problem that the safety risk is big due to the fact that the pushing distance is far and the steel tube arch needs to cross the existing railways and highways after the steel tube arch is assembled is solved; secondly, the problem that arch feet are low in installation accuracy is solved, so that the linearity and design linearity of the whole steel tube arch are enabled to be consistent, and the stress state and the design state of the steel tube arch are finally enabled to be consistent; thirdly, the stress state and the design state of a beam body are consistent, so the construction quality is finally guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

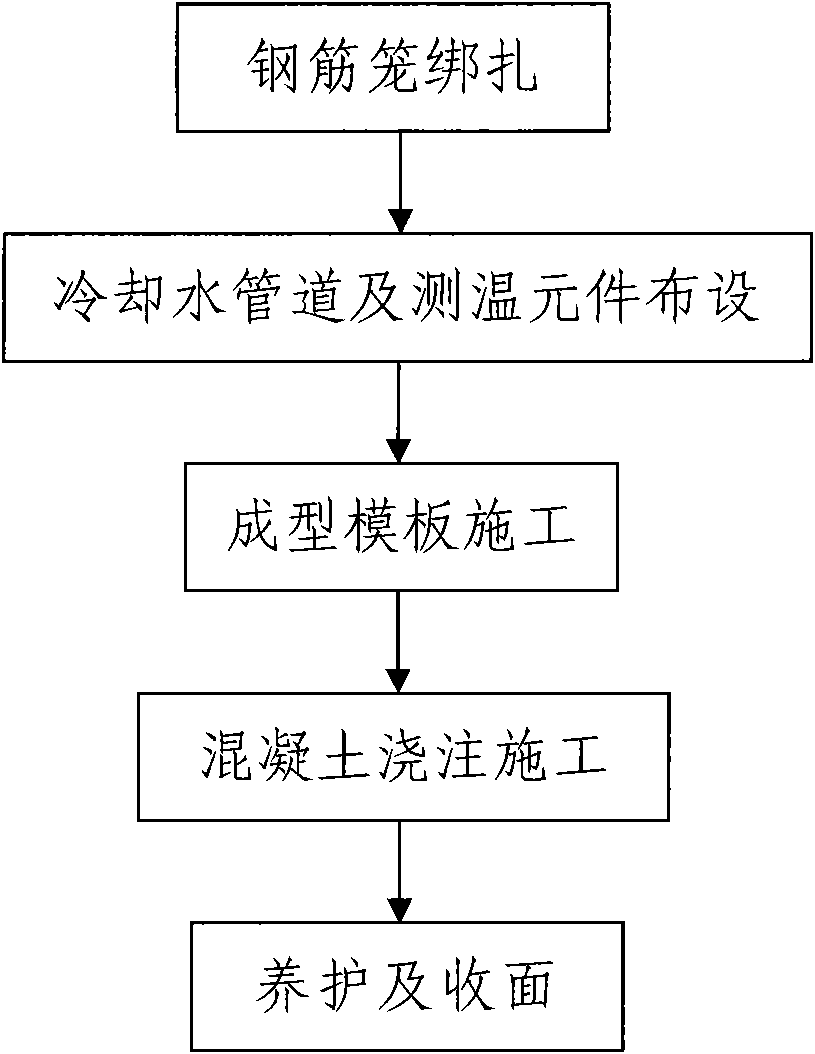

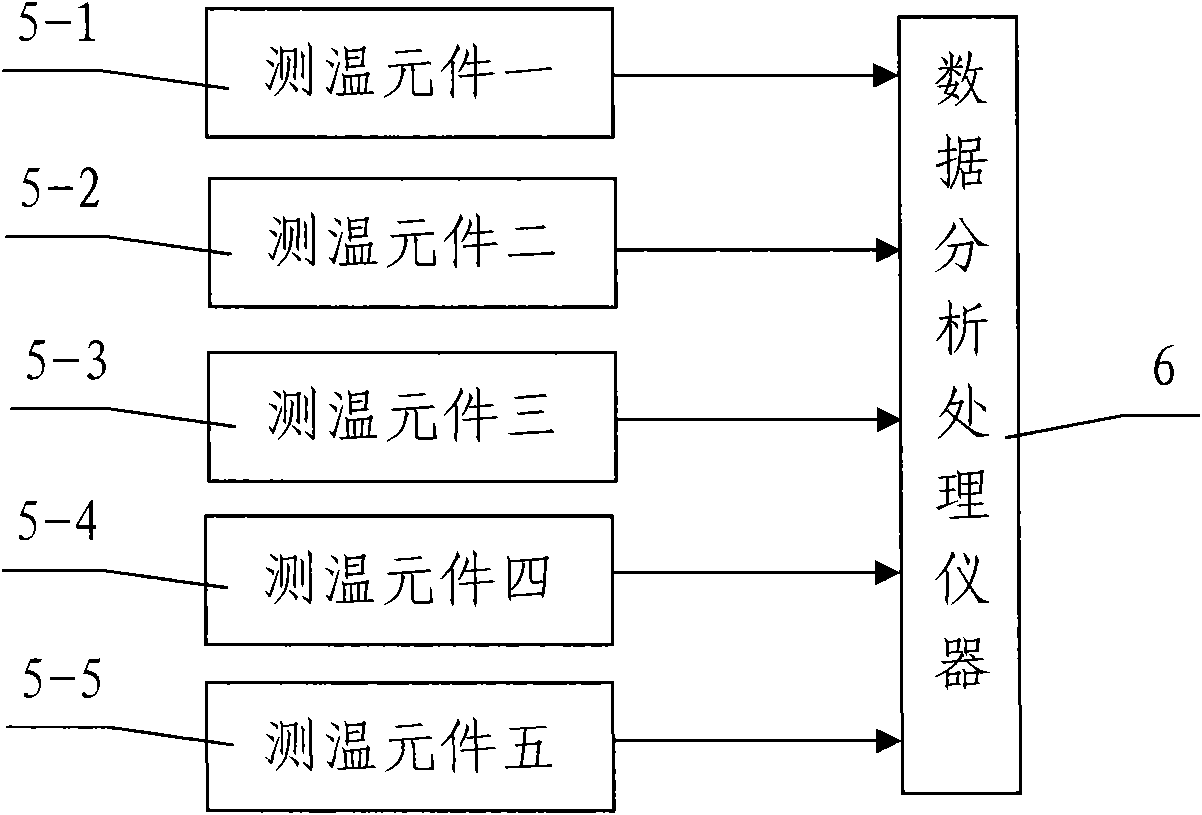

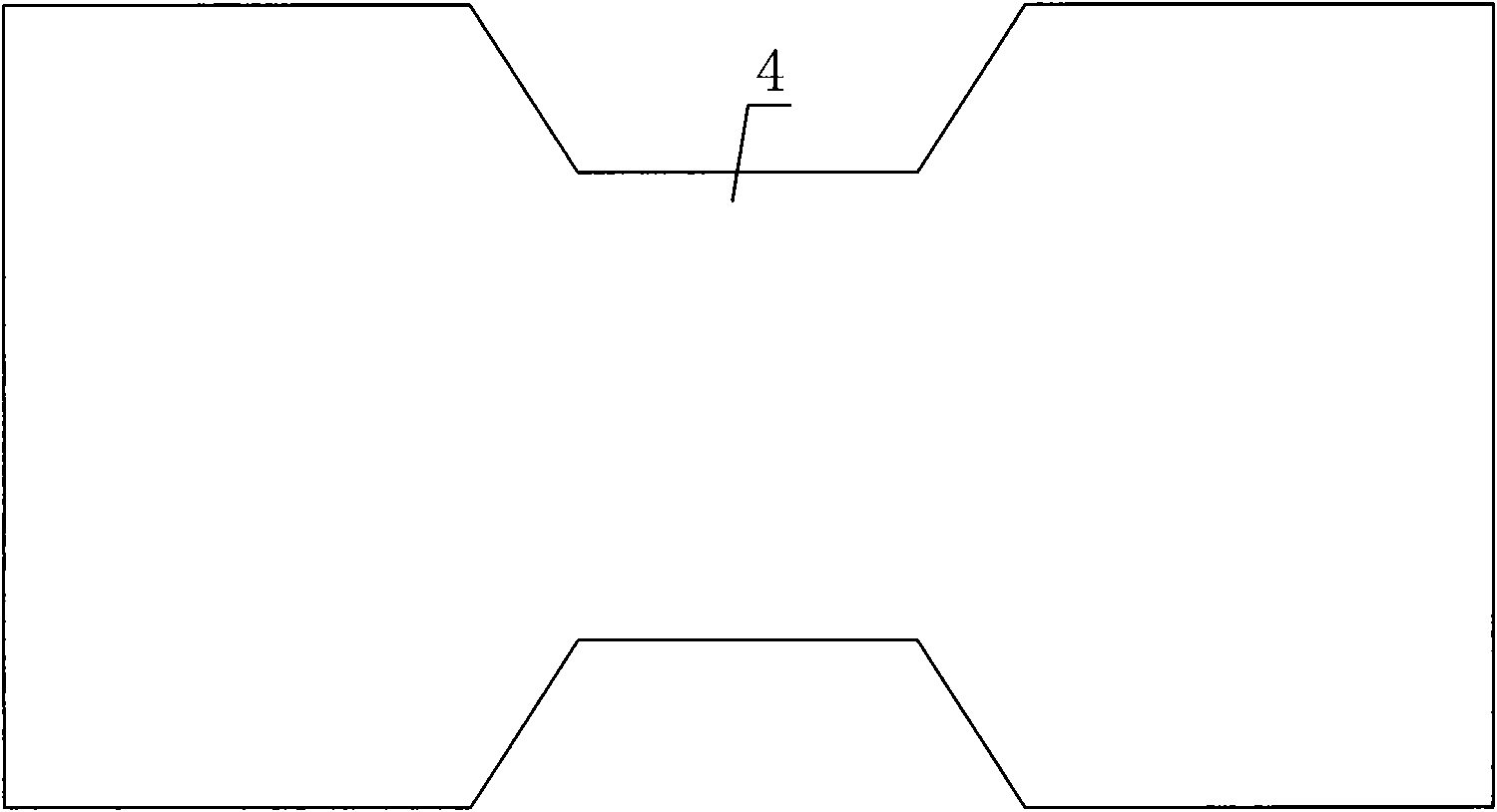

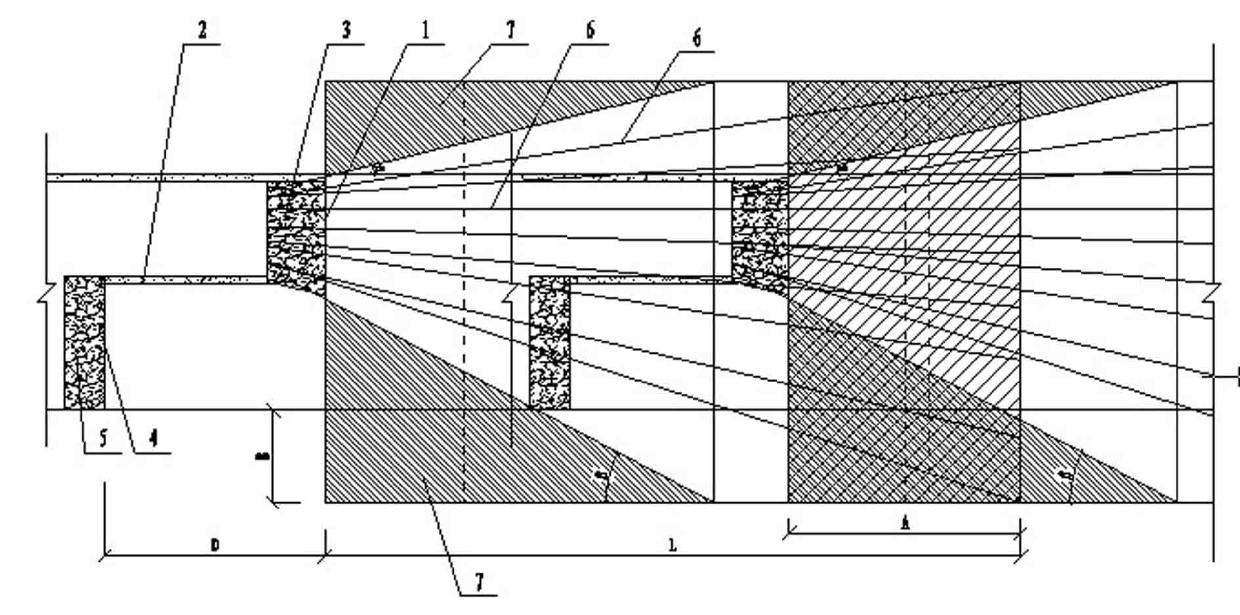

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Method for constructing tunnel by finishing full section curtain grouting from upper-half section

ActiveCN101994513AReduce construction difficultyShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringGeological section

The invention relates to the field of tunnel construction, in particular to a method for constructing a tunnel by finishing full section curtain grouting from an upper-half section, which solves the problems of long construction period, difficult construction, high construction safety risk and the like during full section curtain grouting construction of a complex geological section. The method comprises the following steps of: firstly, excavating the upper-half section, and strengthening the support of a tunnel face; secondly, constructing a temporary inverted arch and a grout-stopping wall of the upper-half section; thirdly, excavating the lower-half section in place, and strengthening the support of the tunnel face; fourthly, constructing a grout-stopping wall of the lower-half section; fifthly, forming grouting holes on the upper-half section, wherein the maximum elevation angle alpha is between 25 and 45 degrees, the maximum depression angle beta is between 30 and 70 degrees, andthe longitudinal strengthening length is between 15 and 30 m; sixth, performing grouting operation; seventh, constructing a large-scale lead pipe roof; eighth, excavating a grout-stopping wall; ninth, excavating a tunnel trunk; and finally, continuously cycling by taking an area of 15 to 30 m as a grouting strengthening cycling section to realize the construction of the tunnel by curtain groutingfrom the upper-half section. The method can greatly reduce the construction difficulty, shorten the construction period, and ensure the construction quality, and the construction is safe, quick and economic, so the method can be widely used in the field of tunnel construction.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP

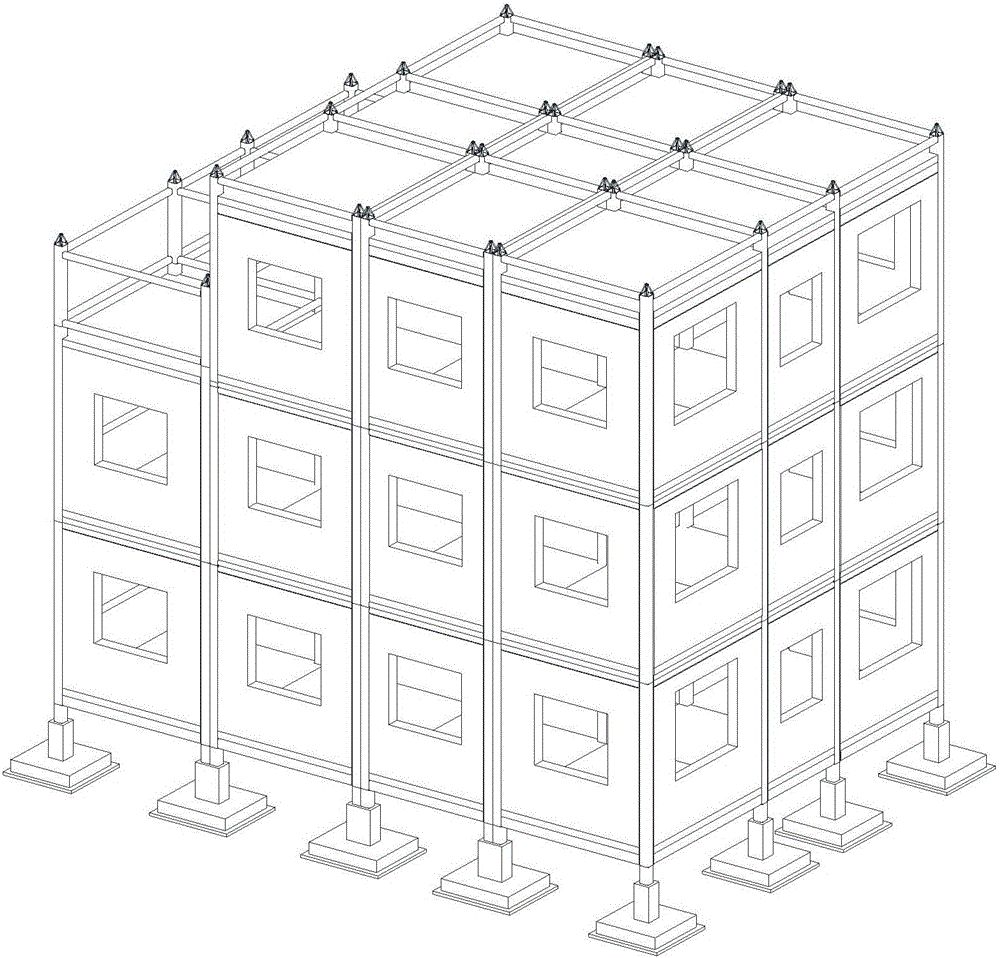

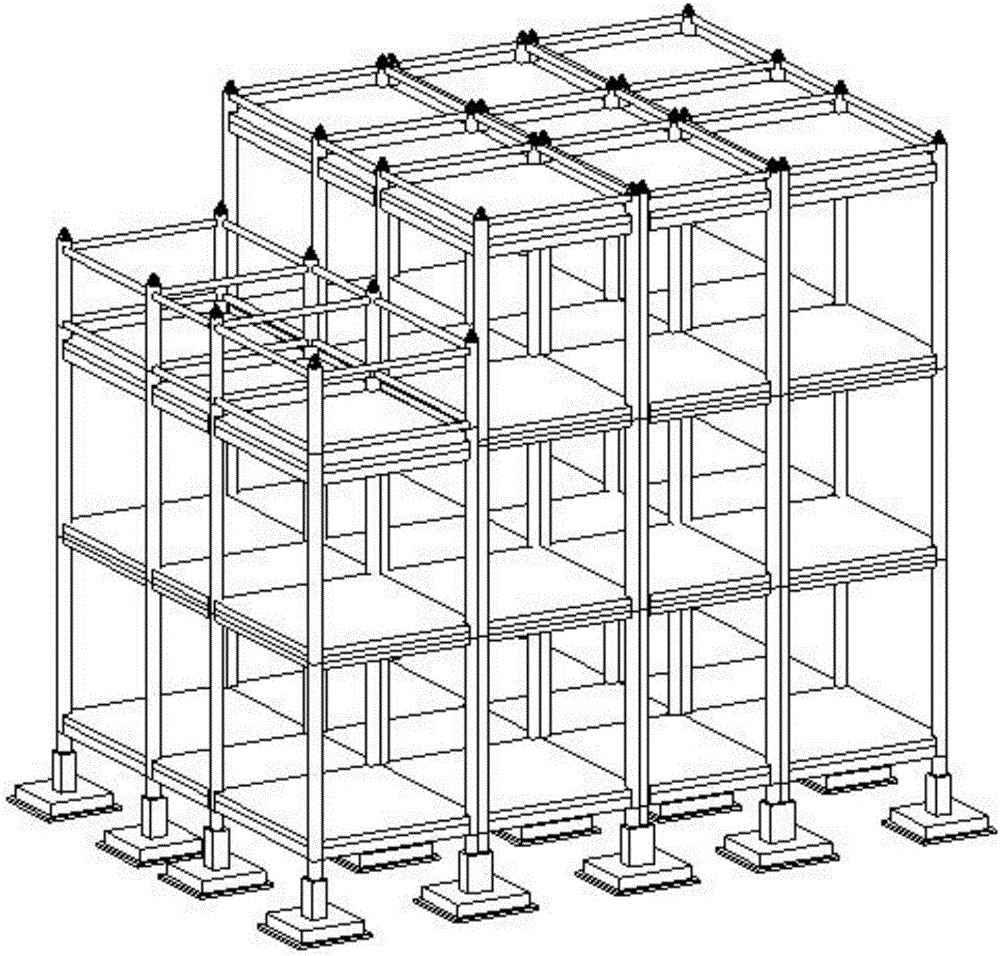

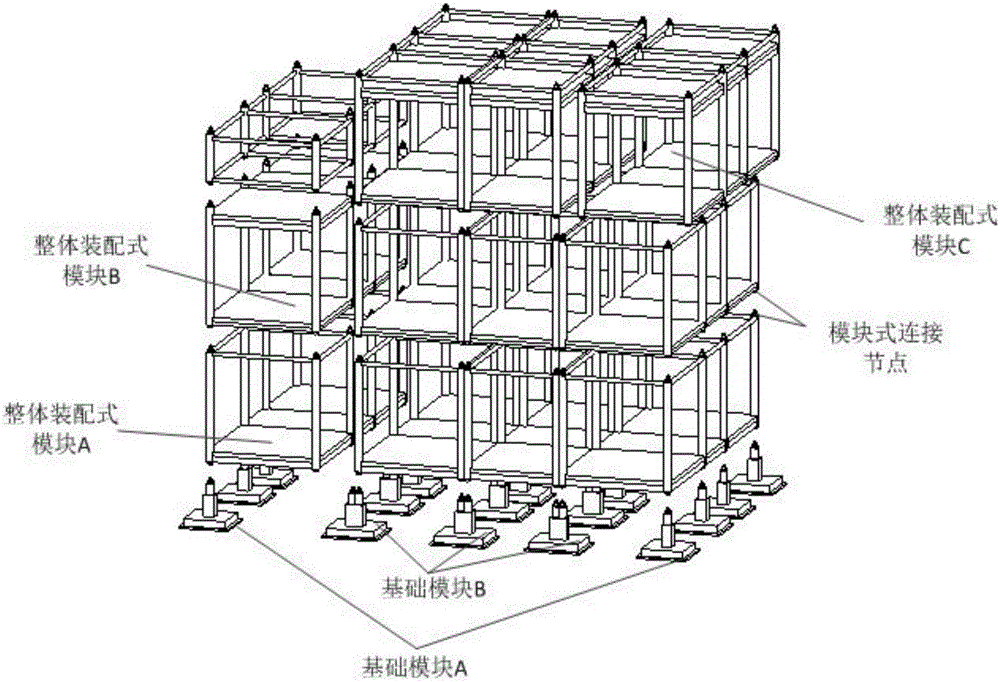

Modular multi-storeyed overall assembly type steel structural house structure system

The invention discloses a modular multi-storeyed overall assembly type steel structural house structure system, and belongs to the technical field of structural engineering. The steel structural house structure system comprises an assembling house module, a foundation module, a hanging hook between modules and a bend plate connector; various modules of the assembling house module are processed and manufactured in a factory, and every module is plugged on construction site through the hanging hook and the bending plate, and then the column is internally poured with concrete or welded, thus the structure building is completed; the hanging plate and the bending plate can plug and guide the module to the place, and anchor with concrete, and enhance the node connection; a dual-column structure is formed between the overall house modules, thus the overall structure performance of the house is strengthened. The house modules can complete the installation of inside and outside wall bodies, floor slabs, doors and windows in the factory, thus all or a part of inside decoration and outside decoration can be completed; thereby significantly reducing the work load on site and improving the construction speed.

Owner:BEIJING UNIV OF TECH

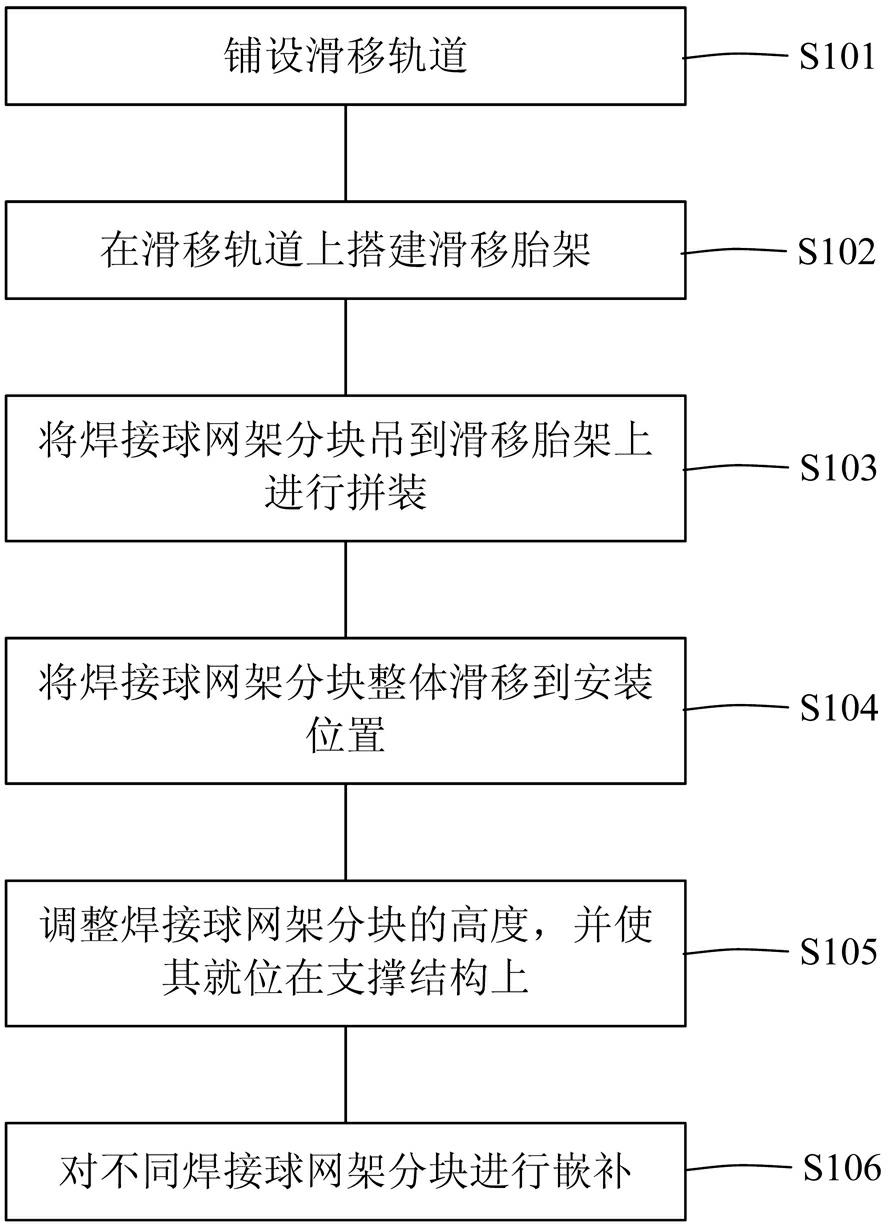

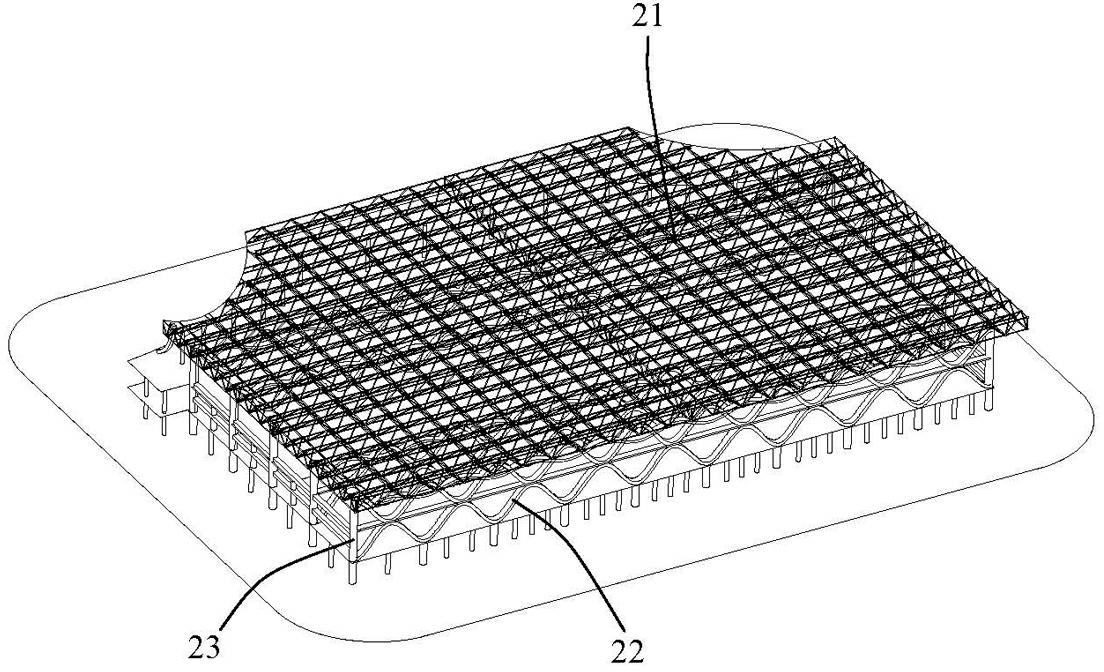

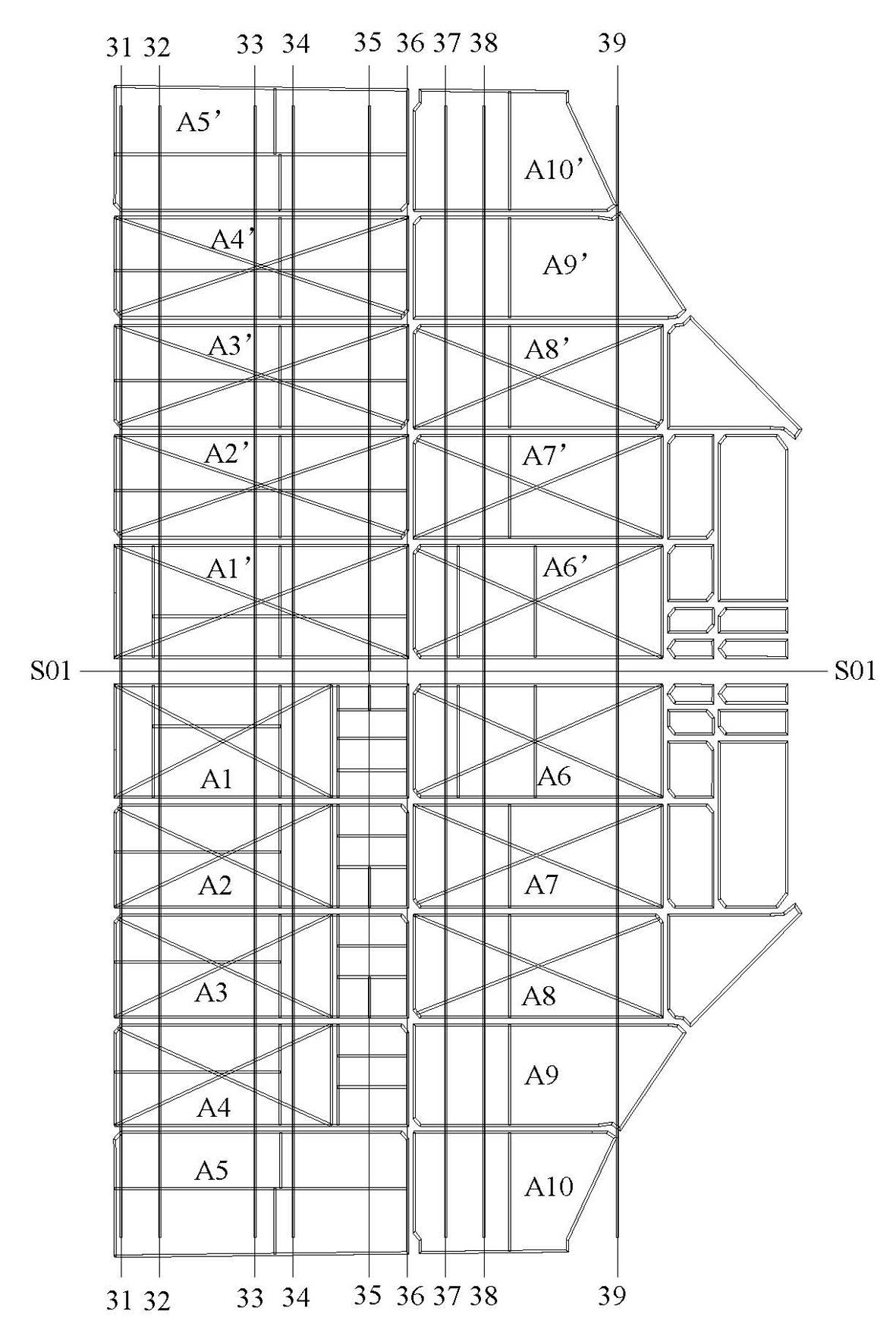

Extra-large-area hyperboloid welding ball network frame sliding construction method

ActiveCN102146732ASolve construction difficultiesEasy constructionBuilding material handlingHyperboloidEngineering

The invention provides an extra-large-area hyperboloid welding ball network frame sliding construction method, which comprises the following steps of: (1) laying a sliding rail; (2) building a sliding jig frame on the sliding rail; (3) hoisting welding ball network frame blocks to the sliding jig frame; (4) wholly sliding the welding ball network frame blocks to a mounting position; (5) adjustingthe heights of the welding ball network frame blocks and positioning the welding ball network frame blocks on a supporting structure; and (6) inlaying different welding ball network frame blocks to form an extra-large-area welding ball network frame. The invention has the advantages that: the method solves the problem that the extra-large welding ball network frame structure is difficult to construct, the construction is convenient and the safety is high.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

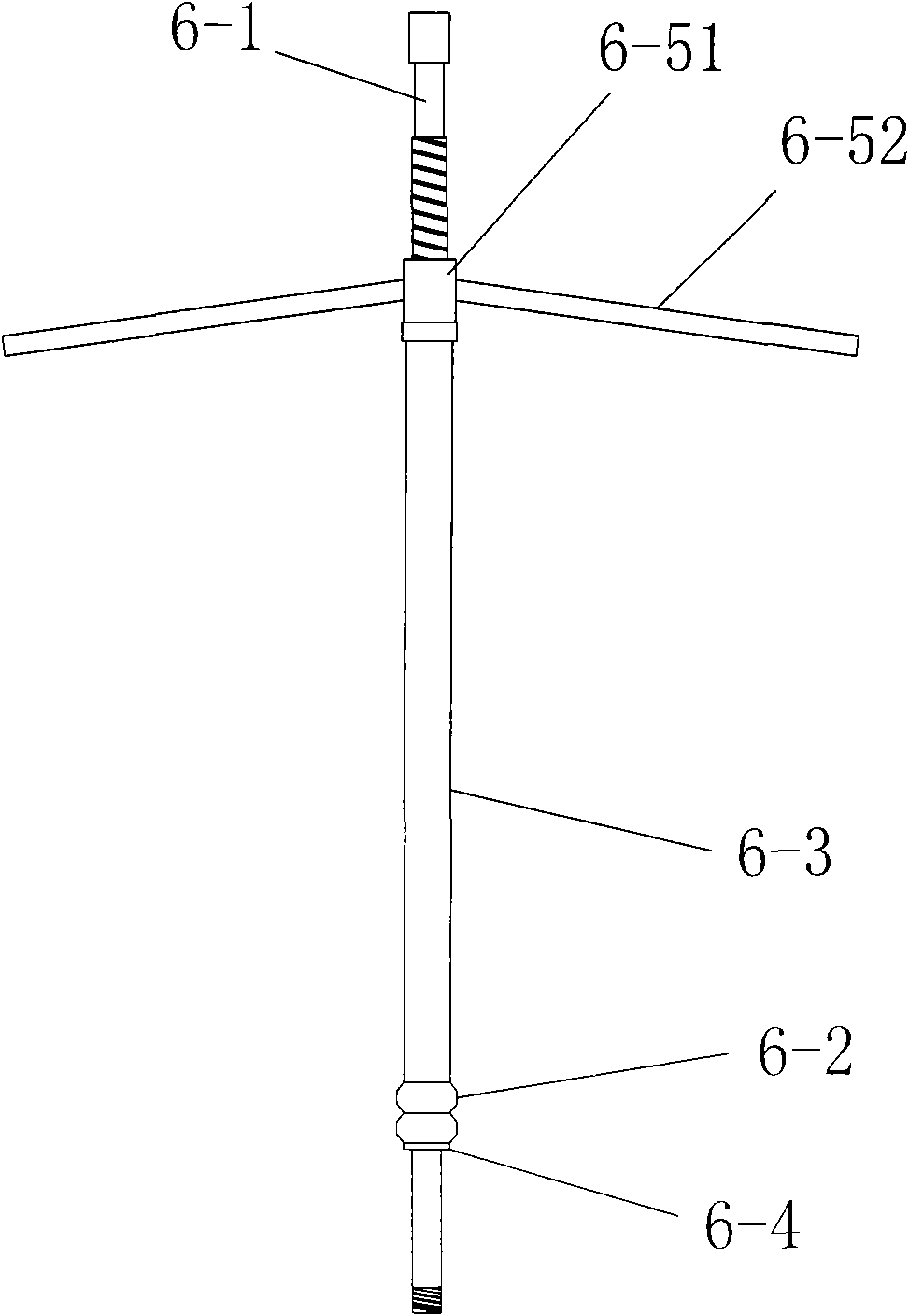

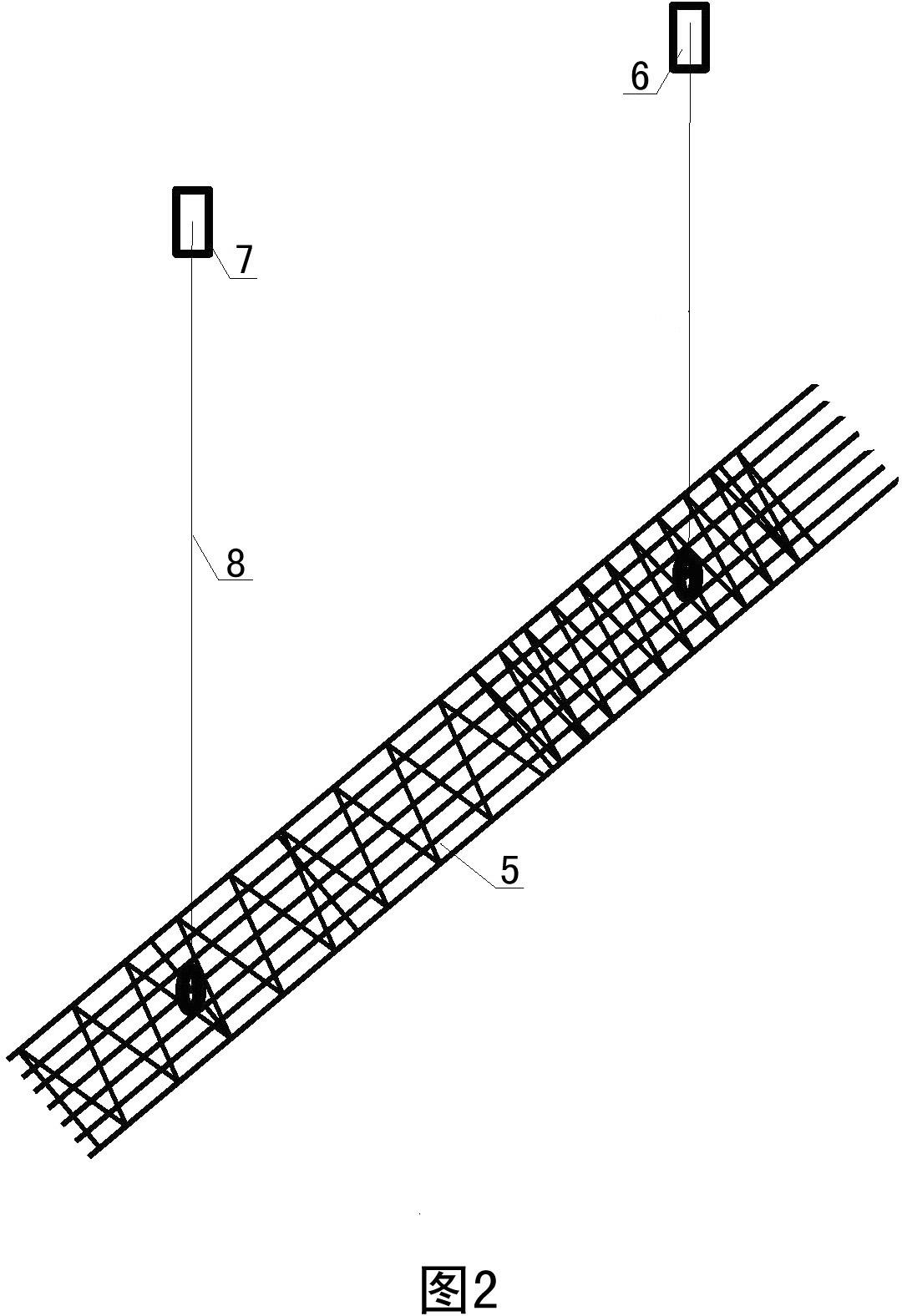

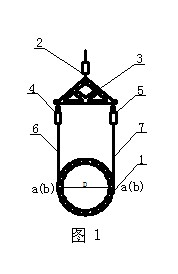

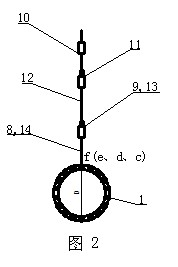

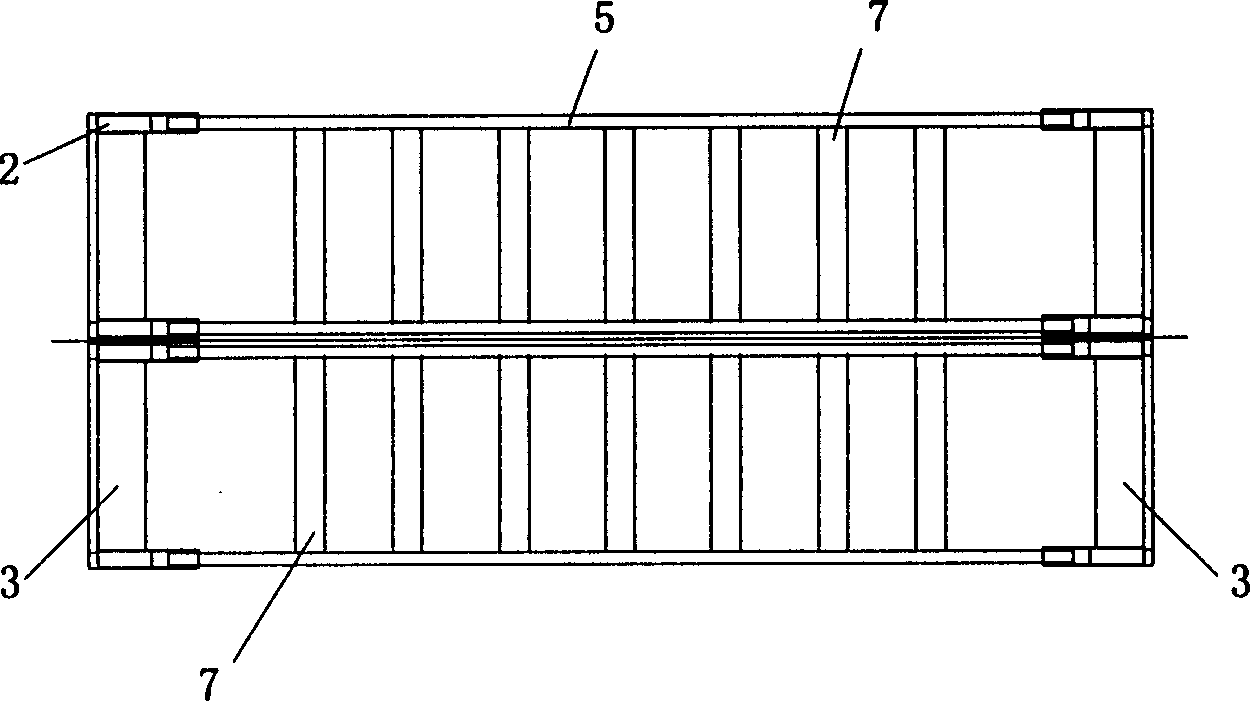

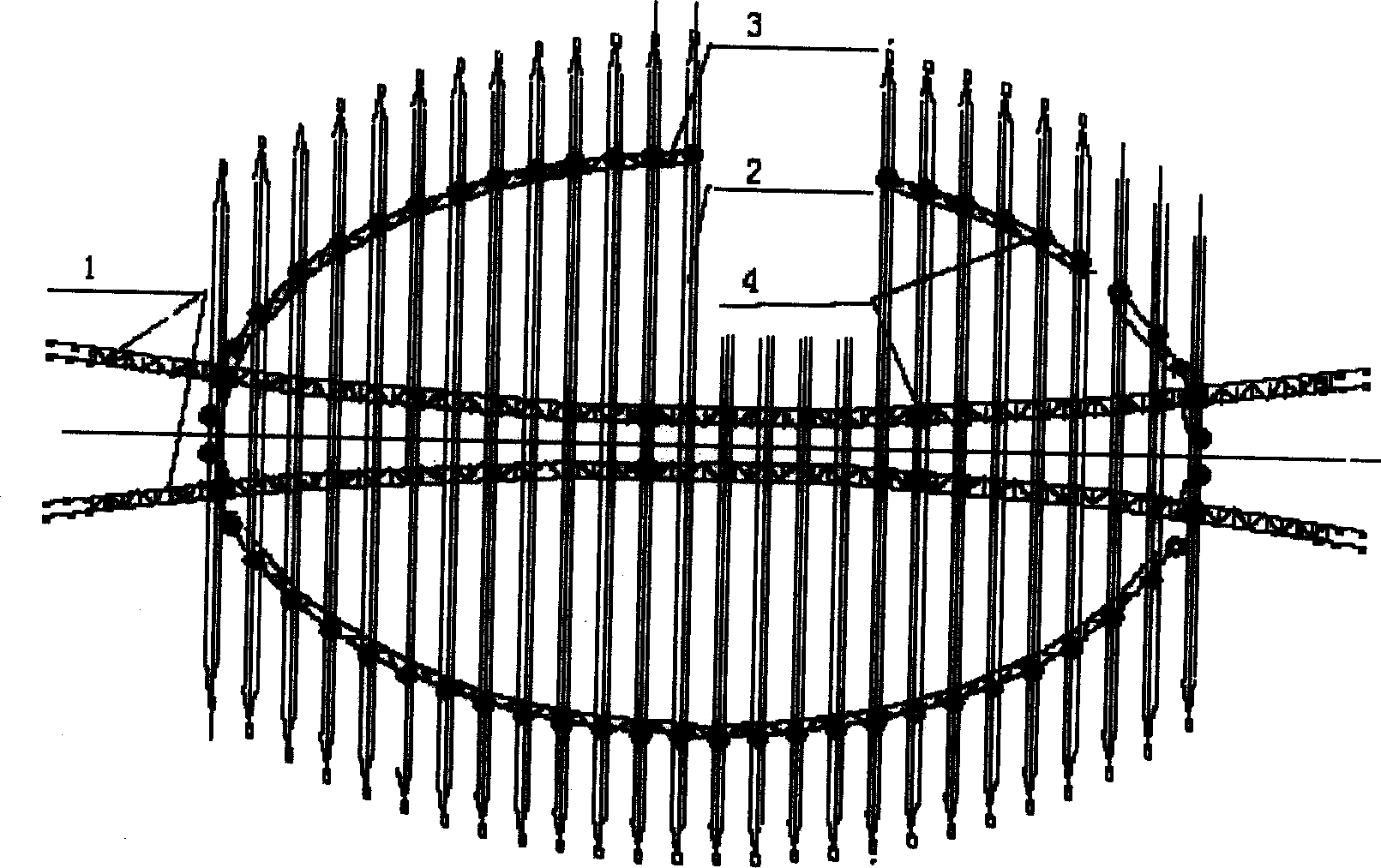

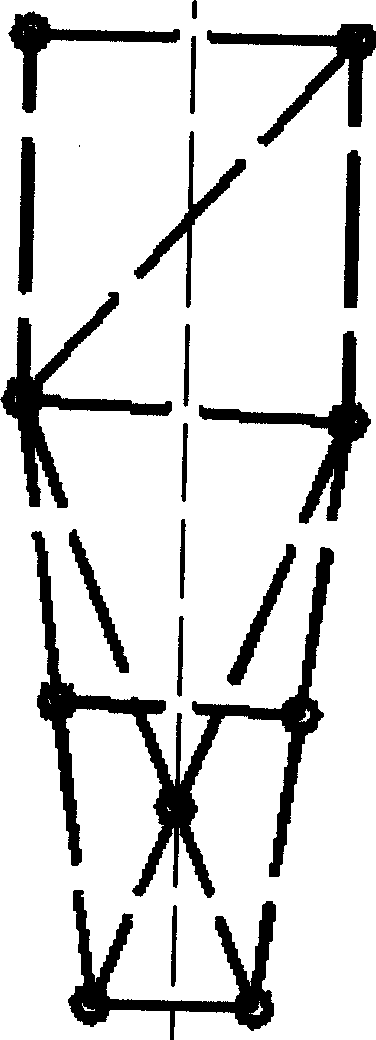

Hoisting method of steel reinforcement cage

ActiveCN102070071AAvoid deformationGuaranteed design strengthLoad-engaging elementsBulkheads/pilesRebarMechanical engineering

The invention relates to a hoisting method of a steel reinforcement cage. The method comprises the following steps of: 1) preparing for hoisting, namely preparing a hoisting machine which is provided with a main hoisting hook and an auxiliary hoisting hook and manufacturing a main hoisting component, an auxiliary hoisting component and the like; 2) setting hoisting points, namely setting main hoisting points at the two ends of the horizontal diameter of a horizontal steel reinforcement cage and setting an auxiliary hoisting point on a steel reinforcement cage at the upper end of the vertical diameter of the horizontal steel reinforcement cage, and connecting the main and auxiliary hoisting components with corresponding main and auxiliary hoisting points; and 3) hoisting, namely hoisting the main and auxiliary hoisting hooks at the same time, always keeping the distance of between 0.5 and 1.0 meter between the steel reinforcement cage and the ground by using the auxiliary hoisting hookafter the steel reinforcement cage leaves the ground, continually hoisting the main hoisting hook upwards, gradually erecting the steel reinforcement cage until the steel reinforcement cage is vertical to the ground, rotating the hoisting machine, aligning the steel reinforcement cage with a drill hole and putting the steel reinforcement cage into the drill hole. The hoisting method has the advantages that: the steel reinforcement cage is not deformed easily, reinforcement is not required during hoisting and working efficiency is high; construction cost is low; and design intensity of the steel reinforcement cage is ensured, potential safety hazard is not left easily and construction quality is ensured.

Owner:CHEM IND GEOTECHN ENG

First-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete

InactiveCN1811070AFast constructionLow costBridge erection/assemblyArch-type bridgePre stressPre stressing

The first-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete includes the following steps: A. tensing permanent horizontal pre-stressed steel cable at the end cross beam; B. assembling steel pipe arch rib, floating and conveying the steel pipe arch rib and hoisting with floating crane to the site; C. controlling the displacement of abutment by using the permanent pre-stressed steel cable temporarily as the constructing pulling cable and regulating the tensing stress of the horizontal pre-stressed steel cable to bear the horizontal pushing force of the steel pipe concrete arch bridge; and D. hoisting bridge surface pre-stressed beam to site with the steel pipe concrete arch rib and suspender. Compared with conventional construction process, the present invention has fast construction speed, low cost, reduced overhead welding work load and high construction quality.

Owner:SHANGHAI NO 7 CONSTR

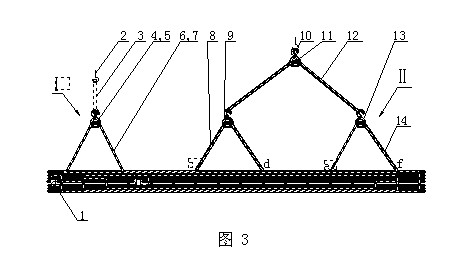

Building truss integral lifting method and equipment thereof

The integral building truss lifting method features that the lifting process includes assembling the main truss on ground in two units; manufacturing and installing corresponding lifting frame; setting cable system on the elevating frame and installing hydraulic elevator in corresponding position; installing the truss ground end shifting units; lifting the two elevated ends of the truss units with the hydraulic elevator synchronously while ensuring the horizontal shift of the ground ends of the truss units under the control of main computer; dismantling the ground end shifting units after the overhead butt joints are in place; elevating and fixing the ground ends; and assembling the overhead butt joints.

Owner:中国机械工业建设总公司

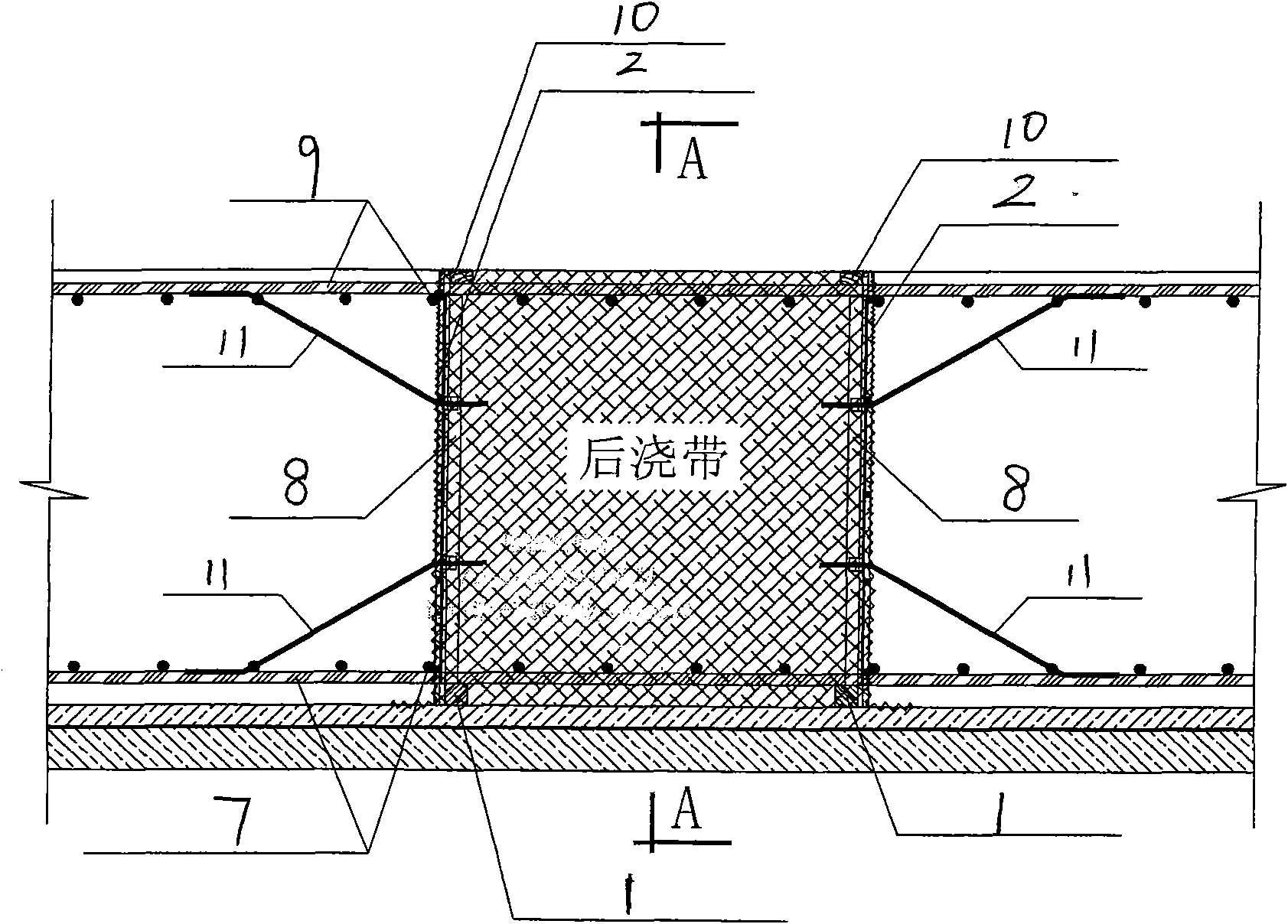

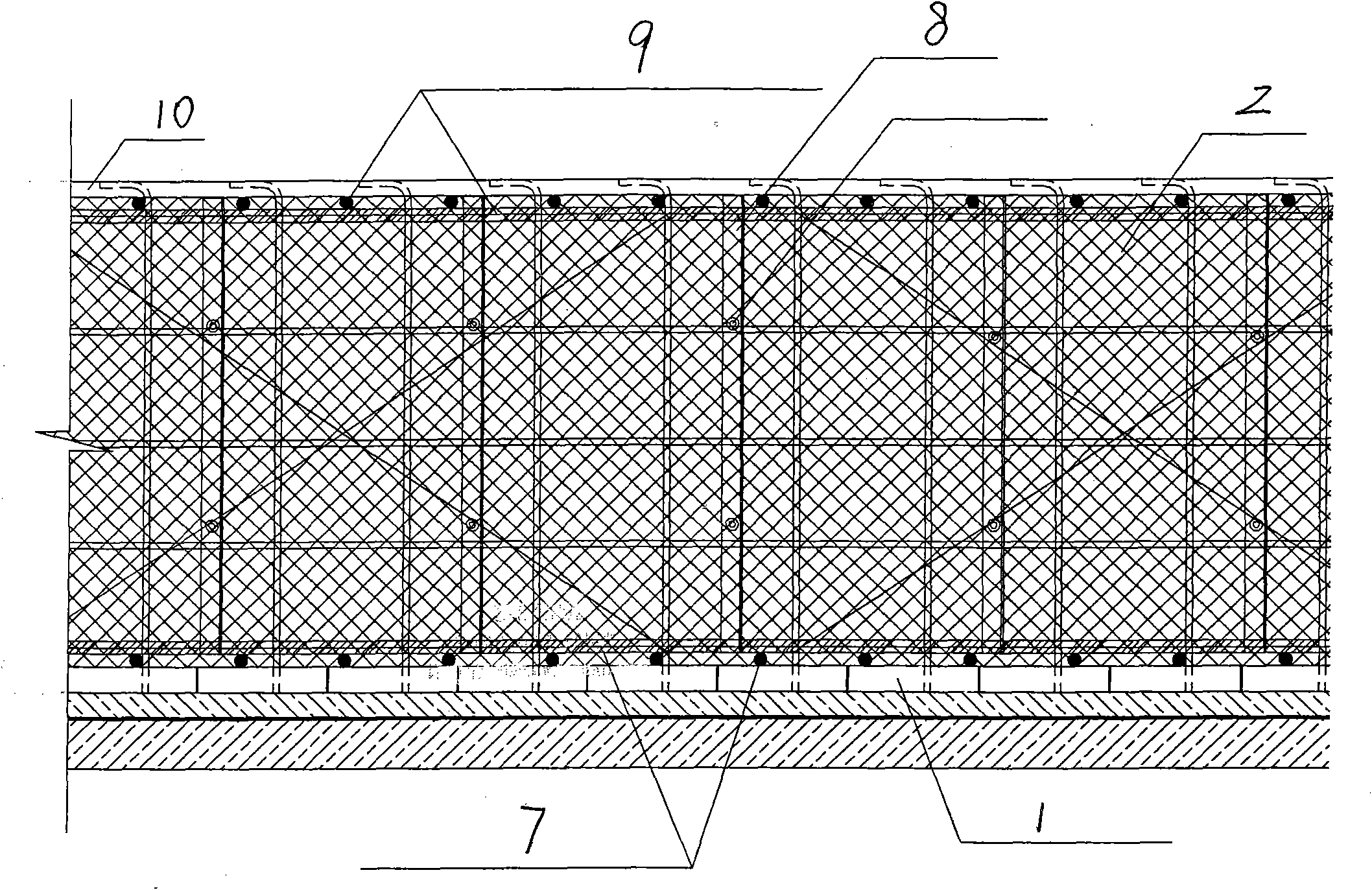

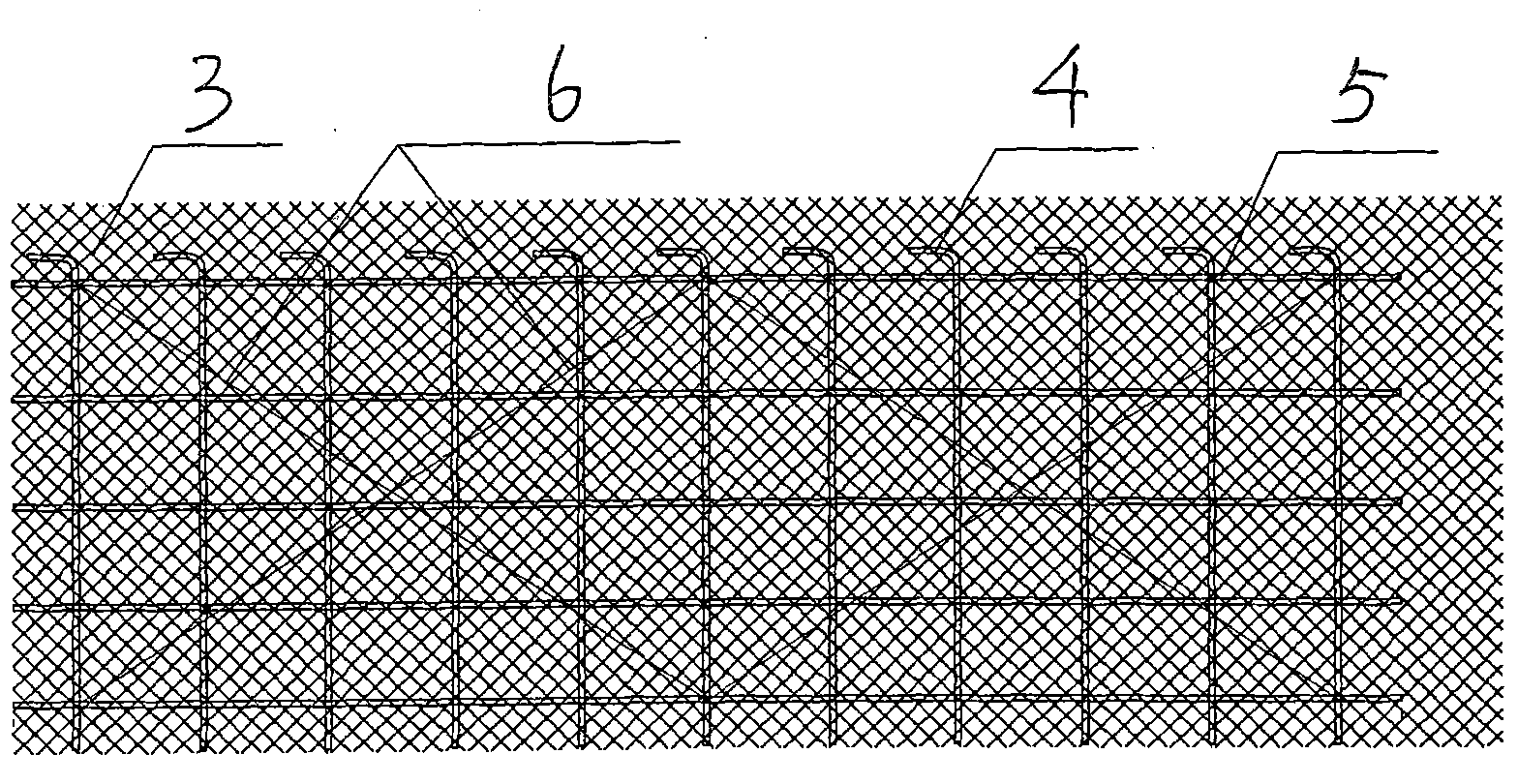

Construction method of sole plate post-poured strip form bracing system

ActiveCN101832026AGuarantee the construction qualityEasy constructionBuilding material handlingForm treatmentRebarSheet steel

The invention discloses a sole plate post-poured strip form bracing system, applicable to sole plate post-poured strip form bracing of basement in constructional engineering. The form bracing system is mainly composed of components of a steel screen mould, a cable-stayed bolt and structural steel back plank, a precast slurry baffle concrete strick and a slurry baffle wood block. The invention utilizes a sole plate reinforcing mattress as a main bracing body, side pressure of concrete at the two sides of the post-poured strip can be effectively braced, the cavity of the formed post-poured strip is clean, tidy and clear and has no concrete pouring oozing or laitance pollution, most materials in the post-poured strip form bracing system are available and can be dismantled and recycled, and design function of post-poured strip can be effectively realized.

Owner:南通建工集团股份有限公司

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

Full house decoration personalized customization method

ActiveCN103255884AAddressing Incompleteness RegretsScientific and efficient house decorationCovering/liningsThree-dimensional spaceDisplay device

The invention provides a full house decoration personalized customization method and relates to a decoration management method. At present, more and more conditions that home decoration is repeated and family resources are wasted appear. The full house decoration personalized customization method includes the following steps that 1) setting up a general database of decorating elements, 2) obtaining positions and areas of all functional areas, 3) setting up a plurality of sub-modules, 4) setting up a corresponding three-dimensional space model, and pending a database, 5) displaying the three-dimensional space model though a display, and automatically generating a new three-dimensional space model when a user selects elements of a replaceable module to replace elements of each standard module in the three-dimensional space model, 6) according to the three-dimensional model selected by the user, generating an implementation database and a price sheet, and enabling the construction side to conduct standard decoration construction according to the implementation database and the price sheet. According to the technical scheme, the full house decoration personalized customization method effectively improves design efficiency and prevents repeated labor. The design effect and the price are clear at a glance. The full house decoration personalized customization method improves decoration transparency and is convenient to supervise.

Owner:BEIJING JUST EASY BEST RESIDENTIAL FULL DECORATION

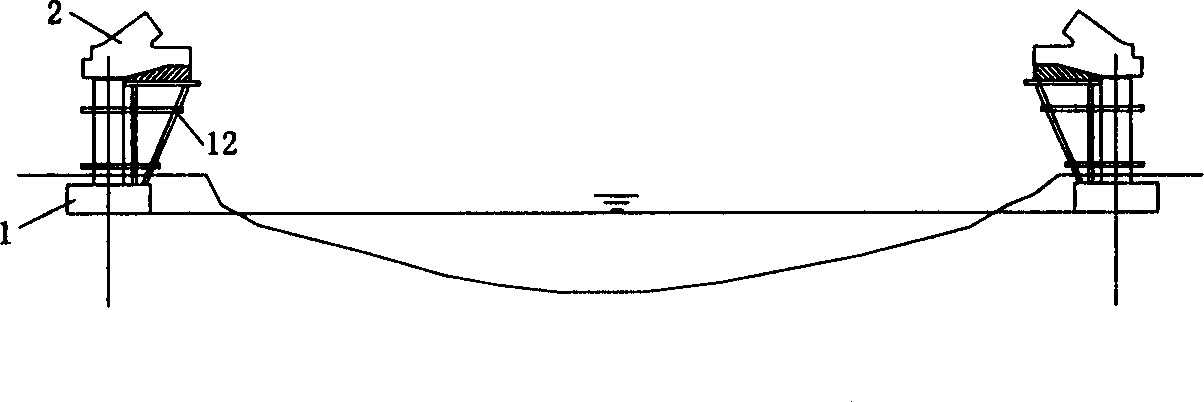

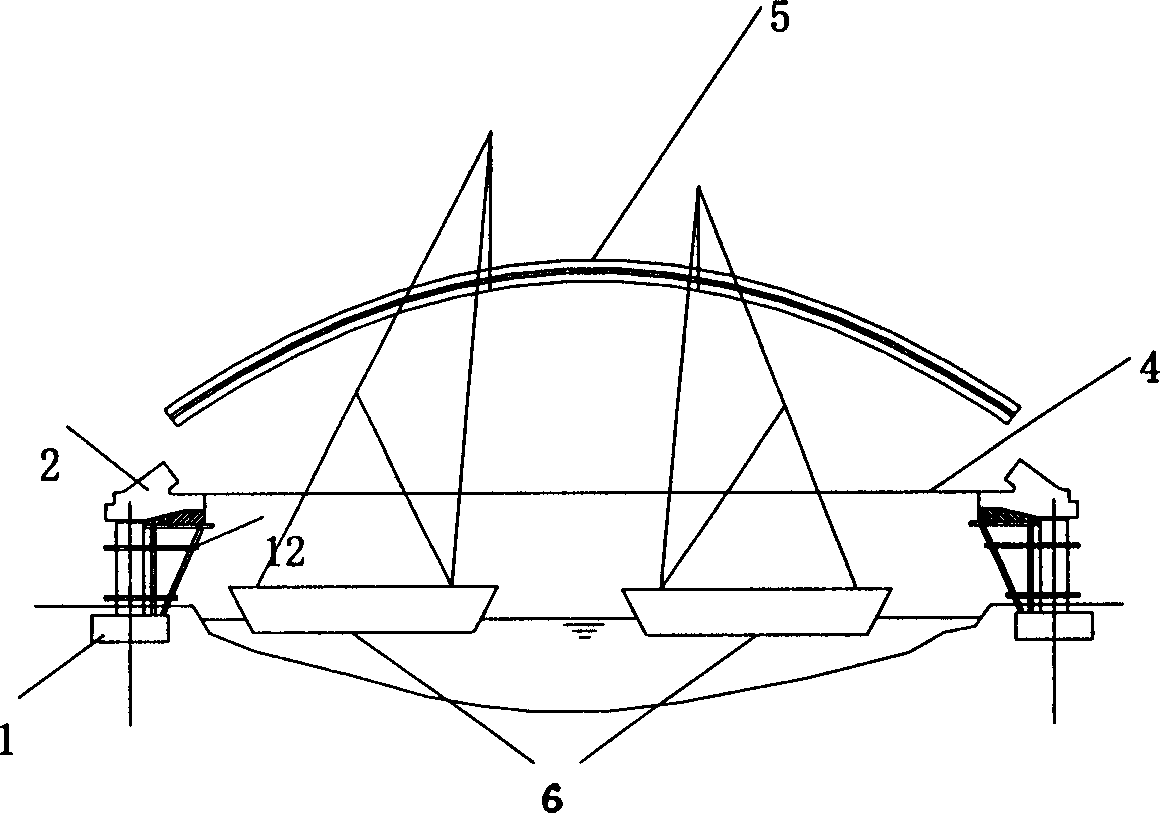

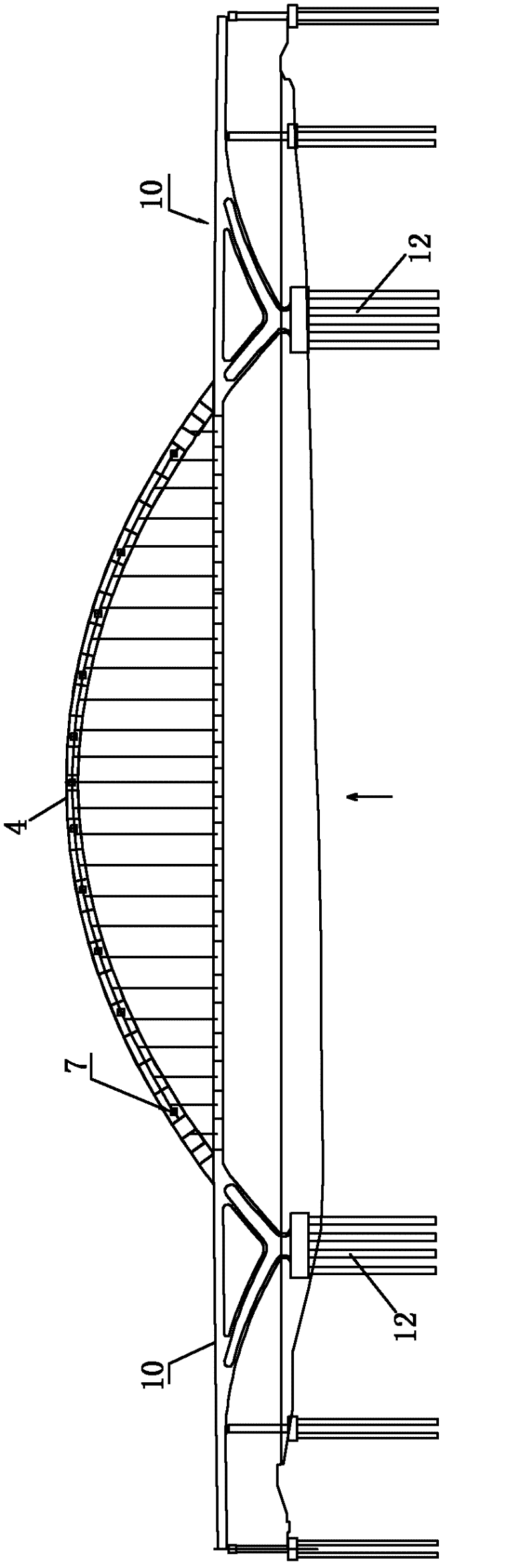

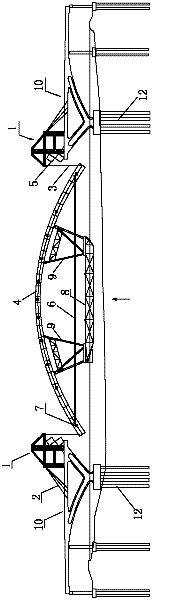

Integral lifting system and construction method for arch bridge ribs

InactiveCN102561191AReduce difficultyReduce working at heightsBridge erection/assemblySteel frameArch bridge

The invention discloses an integral lifting system and a construction method for arch bridge ribs. The integral lifting system comprises a pair of triangular steel frames, two lifting stations, arch rib brackets and an integral arch rib of an arch bridge, and a barge for conveying the integral arch rib. The triangular steel frames are fixedly rested on bridge piers and symmetrically disposed on two sides of main span of the arch bridge, an arch rib closure section in closure with the integral arch rib is disposed on the inner side of the arch bridge main span and close to the corresponding triangular steel frame, the lifting stations are disposed on the triangular frames respectively, the arch rib brackets are rested on the barge and support the integral arch rib, the lifting stations are connected with the integral arch rib through lifting steel stranded wires, the integral arch rib which is lifted up is in fixed closure with the arch rib closure sections, and accordingly the integral arch bridge is formed. The integral lifting system is adaptable to severe construction environments, and accordingly construction progress is quickened. The invention further provides the construction method for integral lifting of the arch bridge rib.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Multi-story high-rise assembled steel structure frame - prestressed centrally-braced system

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed centrally-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed centrally-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed sway braces are arranged on the basis of the steel frame, so as to improve the lateral rigidness of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled truss plates, assembled flange columns and prestressed eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the prestressed eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

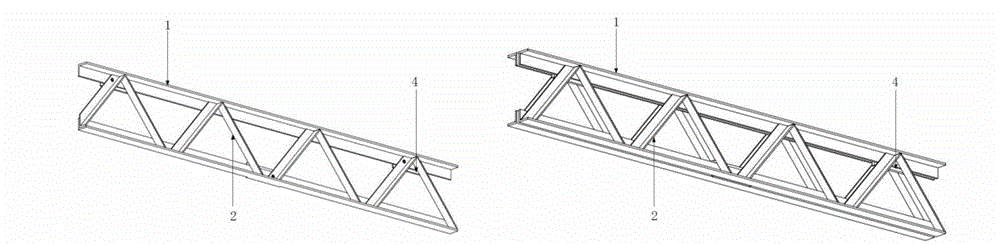

Rotary drilling rig coordinated with percussion drill hole-forming construction method

InactiveCN103088814AGuarantee the construction qualityFoundation testingBulkheads/pilesDrill holeEngineering

The invention relates to a rotary drilling rig coordinated with percussion drill hole-forming construction method which comprises forming field, locating and paying off, measuring elevation, calculating rotary digging depth and installing a plurality of temperature sensors in a permanent steel protective cylinder; rechecking a pile position; rotationally digging and drilling into a tundra layer; burying a temporary steel protective cylinder; measuring the depth of a hole and checking the formed hole; burying the permanent steel protective cylinder into a non-tundra layer; pulling out the temporary steel protective cylinder and moving a machine to conduct next construction of forming the hole rotationally; secondarily locating and sampling; locating a percussion drill; punching the hole; meanwhile digging a mud pit, producing mud and pouring the mud into the hole; secondarily measuring the depth of the hole and checking the formed hole; cleaning the hole; processing a reinforcing cage and hanging the reinforcing cage; installing a guide tube and conducting a water sealing test on the guide tube; measuring sediment and pouring concrete underwater; and curing the concrete. The rotary drilling rig coordinated with percussion drill hole-forming construction method offers a feasible technical measure for socketed pile construction and road repairing on frozen earth on island shape frozen earth area at high altitude in China and has notable economic benefit.

Owner:路桥华祥国际工程有限公司

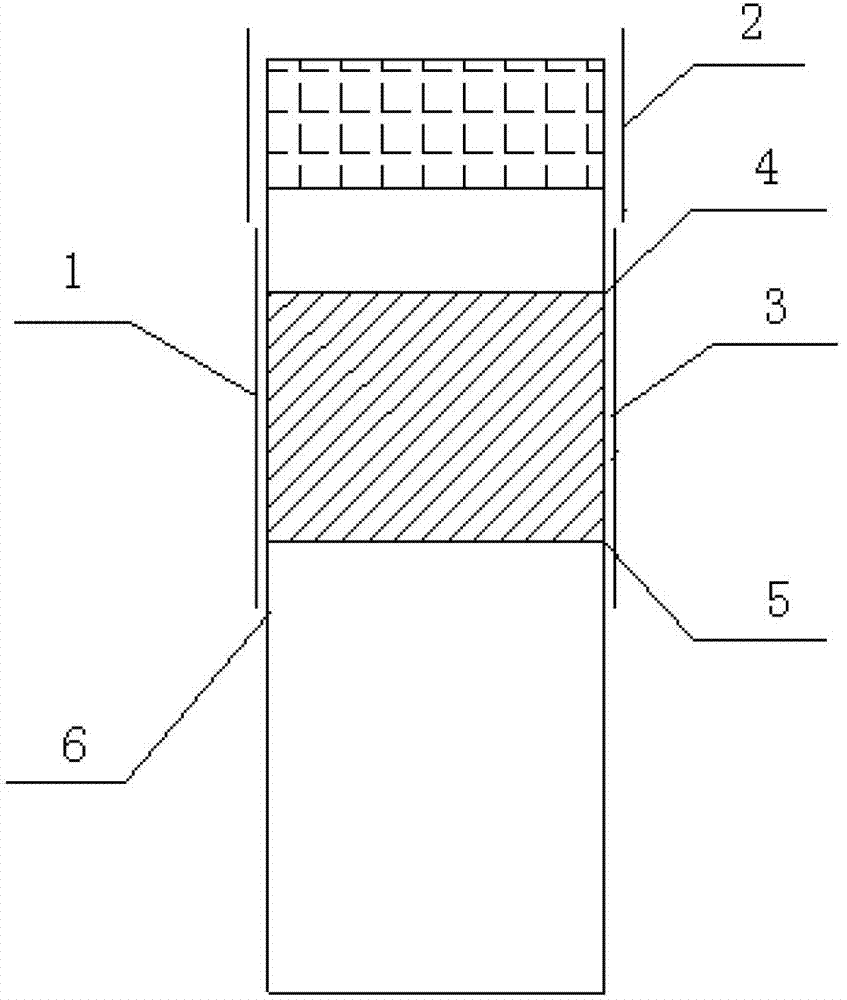

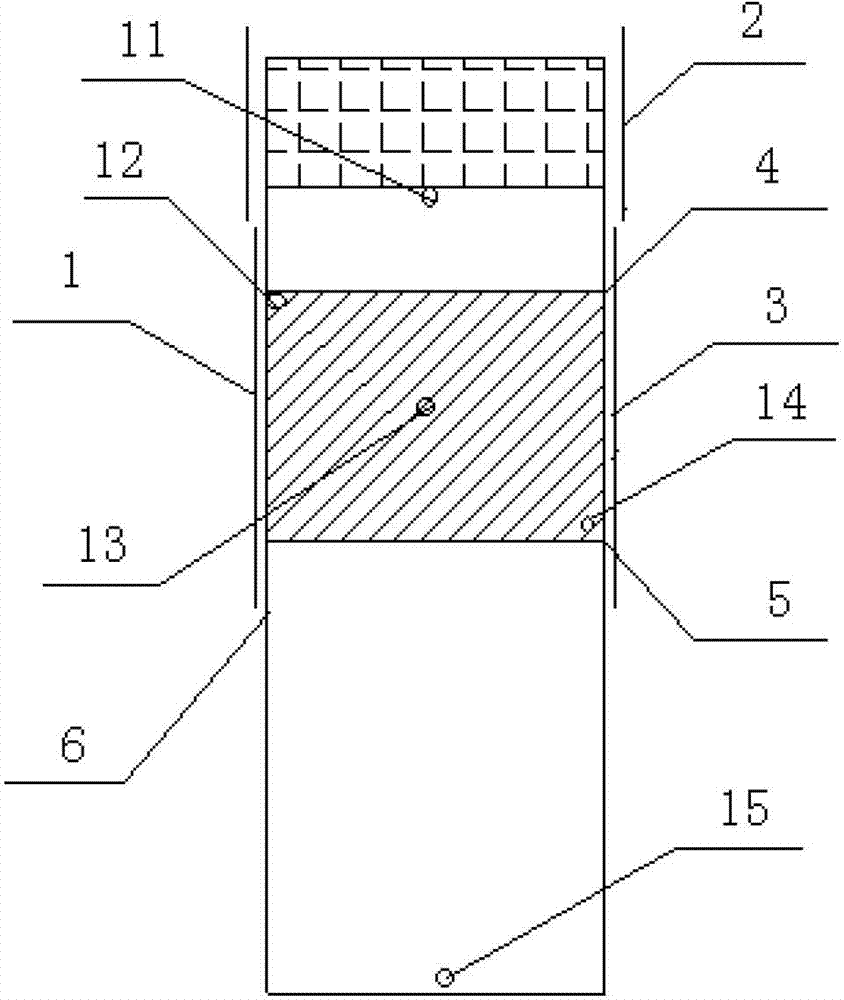

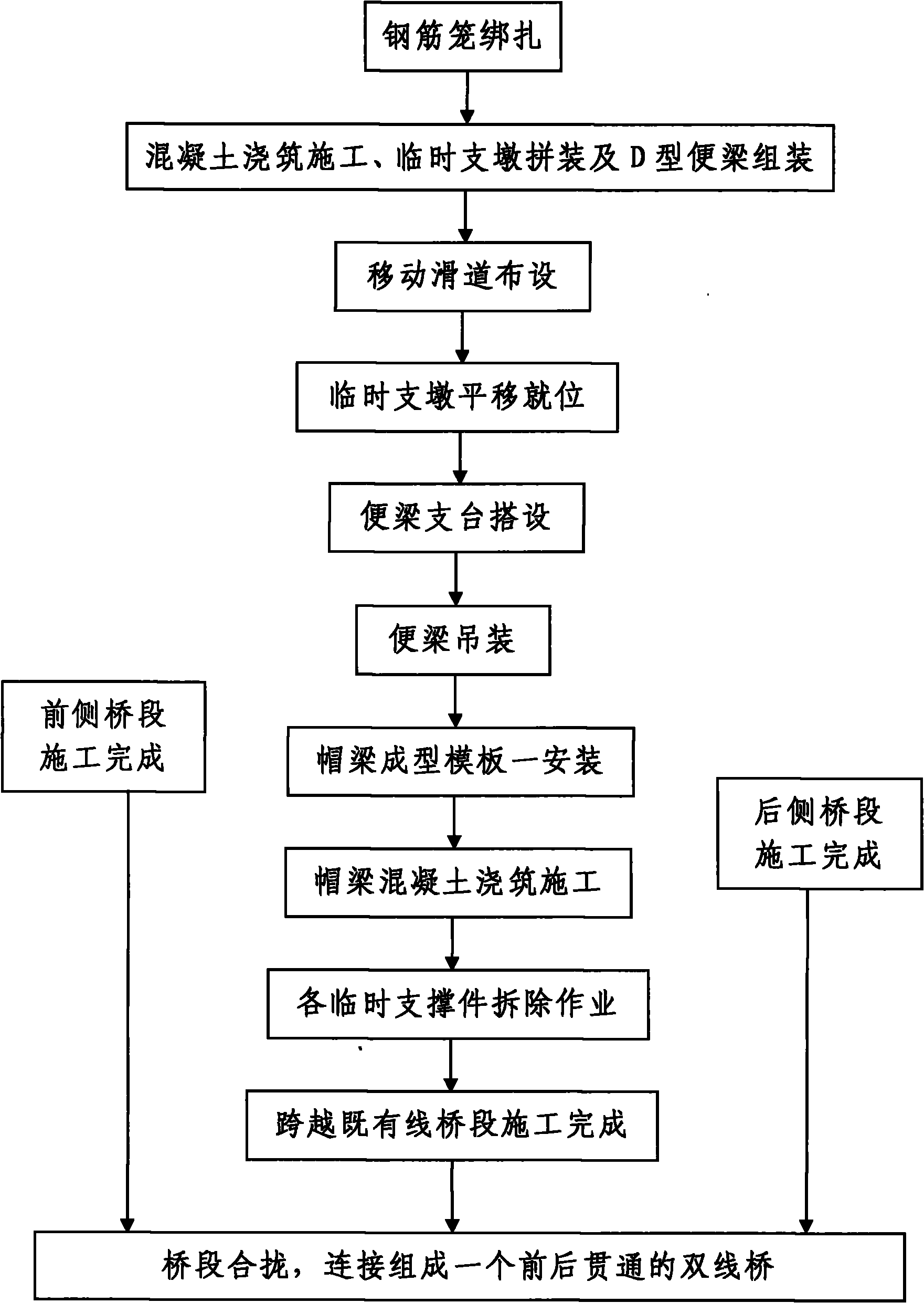

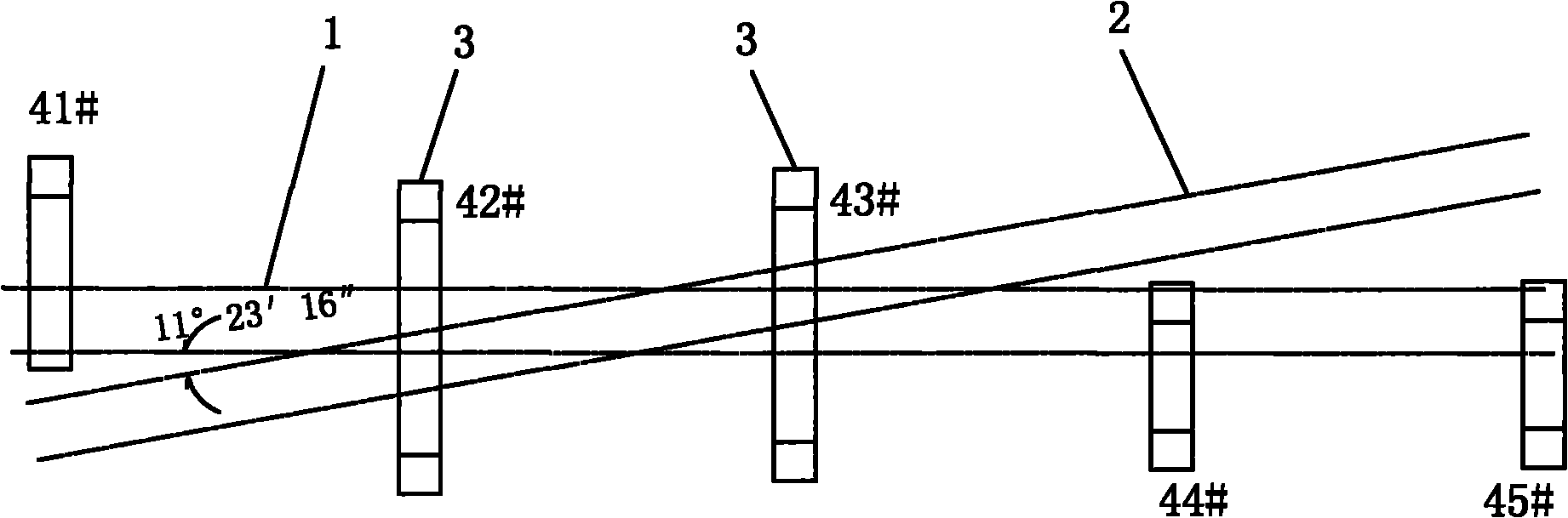

Double track bridge construction process crossing existing railway operational lines

ActiveCN101838968AReduce distractionsImprove construction progressBridge erection/assemblyButtressSafety risk

The invention discloses a double track bridge construction process crossing existing railway operational lines, and the constructed double track bridge comprises a front side bridge section, a crossed existing line bridge section with mutually connected front and rear ends and a rear side bridge section. The process comprises the following steps: 1) synchronously constructing the front side bridge section, the crossed existing line bridge section and the rear side bridge section, wherein the crossed existing line bridge section is constructed as follows: binding reinforcement cages, concreting, assembling temporary buttresses and D-shaped temporary beams, arranging movable slide rails, carrying out translation insertion on the temporary buttresses, setting up temporary beam supporters, hoisting the temporary beams, installing cap beam forming templates, concreting cap beams and removing all temporary strut members; and 2) folding the bridge sections. The invention has the advantages of reasonable design, convenient construction, low investment cost, good use effect, high construction efficiency, short construction period and low safety risk, and can effectively solve the actual problems such as large construction difficulty, long construction period, high investment cost, high safety risk and the like in the construction process of the crossed existing line gate piers.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Construction method of edge top arch and bottom arch of concrete pouring tunnel

ActiveCN102937027AReduce construction costsImprove construction efficiencyUnderground chambersTunnel liningRebarMovable type

The invention provides a construction method of an edge top arch and a bottom arch of a concrete pouring tunnel and relates to a construction method of the concrete pouring tunnel. The construction method is invented for mainly solving the problems of the existing concrete pouring tunnel that the construction cost is high and the like. With regard to the tunnel needing to be constructed, the bottom arch is firstly constructed and the pouring of the edge top arch is secondly constructed. The bottom arch is plastered by overturning a die; and the edge top arch adopts an integrally movable type steel pipe scaffold to be configured with a steel template to carry out a process of construction. A construction method of pouring the bottom arch of the tunnel comprises the following steps of: cleaning a rock surface and checking a foundation; measuring and setting out; mounting a steel bar; mounting the template; pre-burying a slurry filling pipe and mounting water-sealing and grounding flat irons; mounting a drain plug template; cleaning a cabin and checking; pouring concrete; and overturning the die and plastering; and maintaining. A construction method of pouring the edge top arch of the tunnel comprises the following steps of: cleaning the foundation, processing a construction seam and flushing; erecting an integrally movable bearing frame, measuring, setting out and mounting a steel arch frame; splicing the template; mounting the steel bar and a pre-buried piece; cleaning the cabin and checking; pouring the concrete; removing the template, the arch frame and the like; and maintaining. The construction method has the advantage of low construction cost.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD

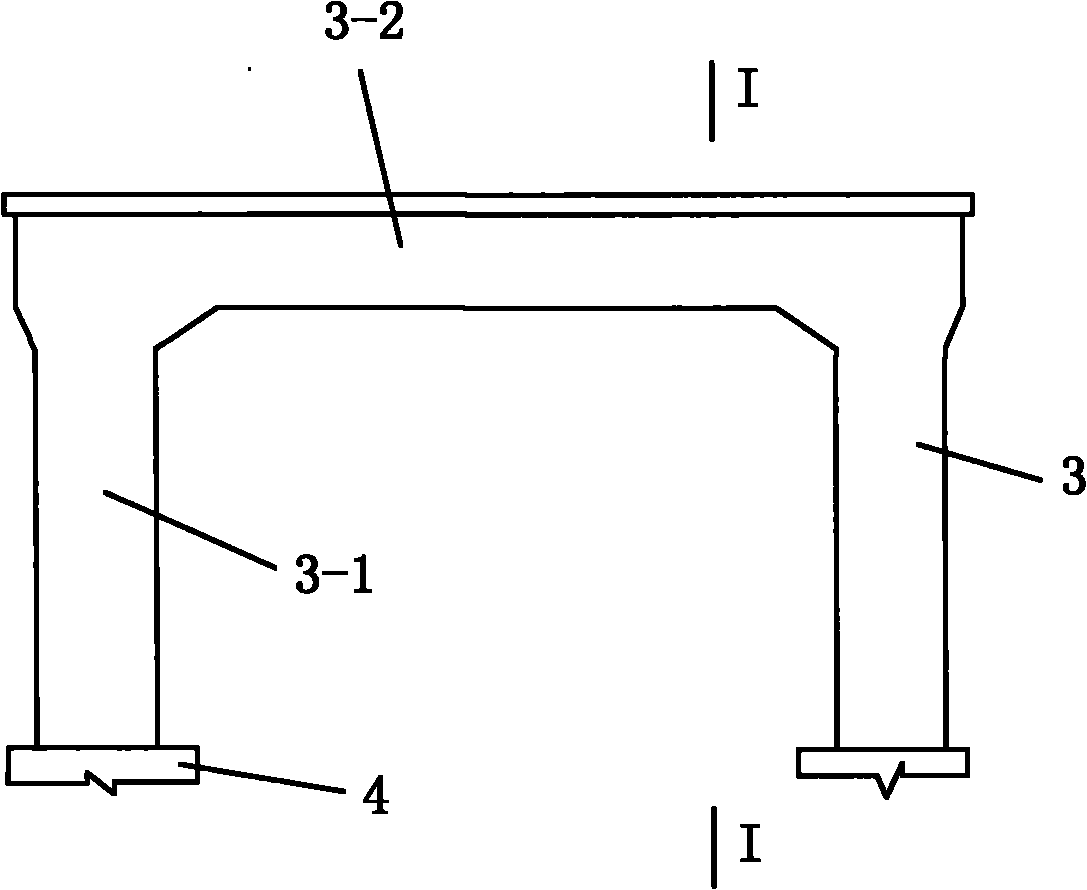

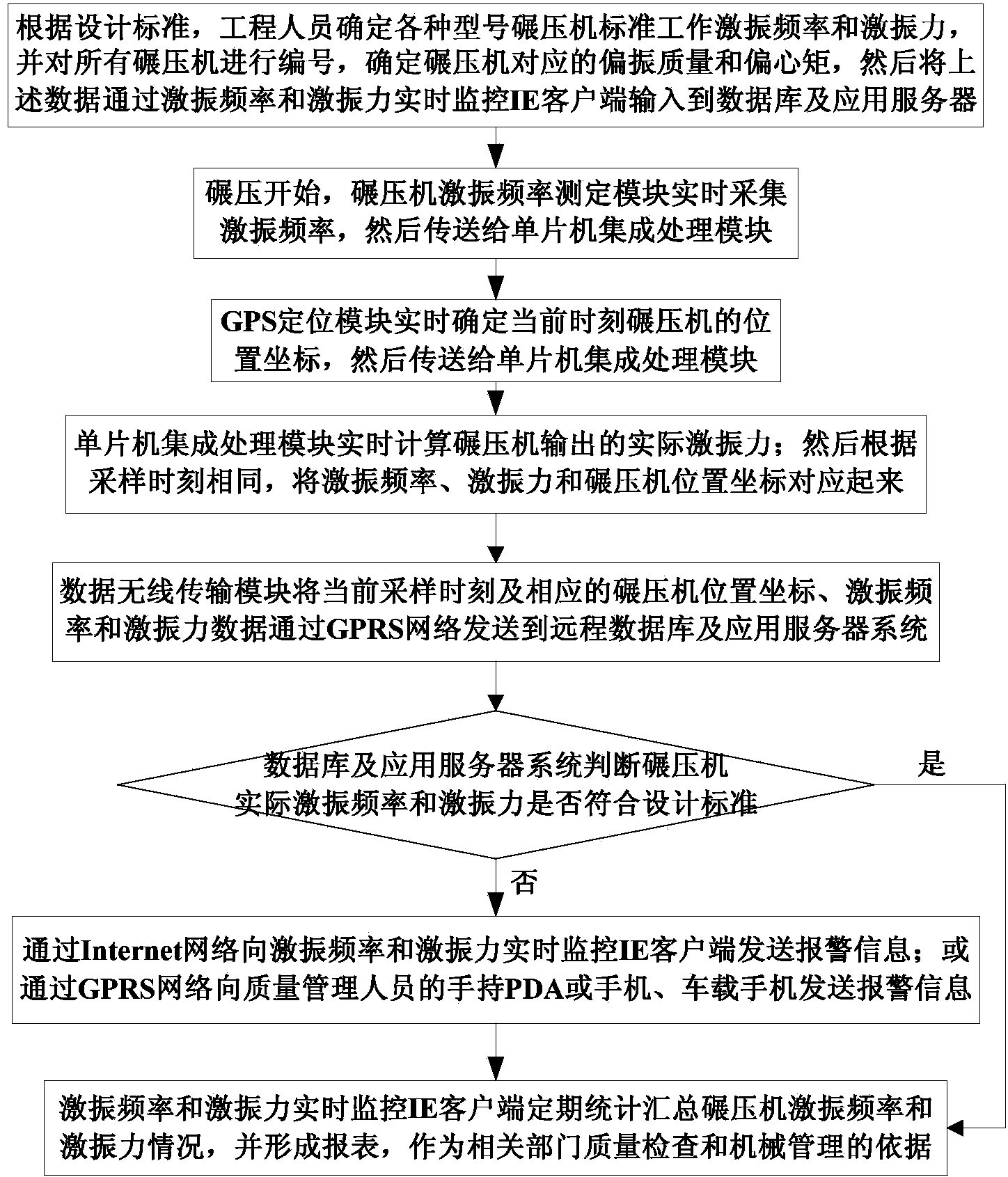

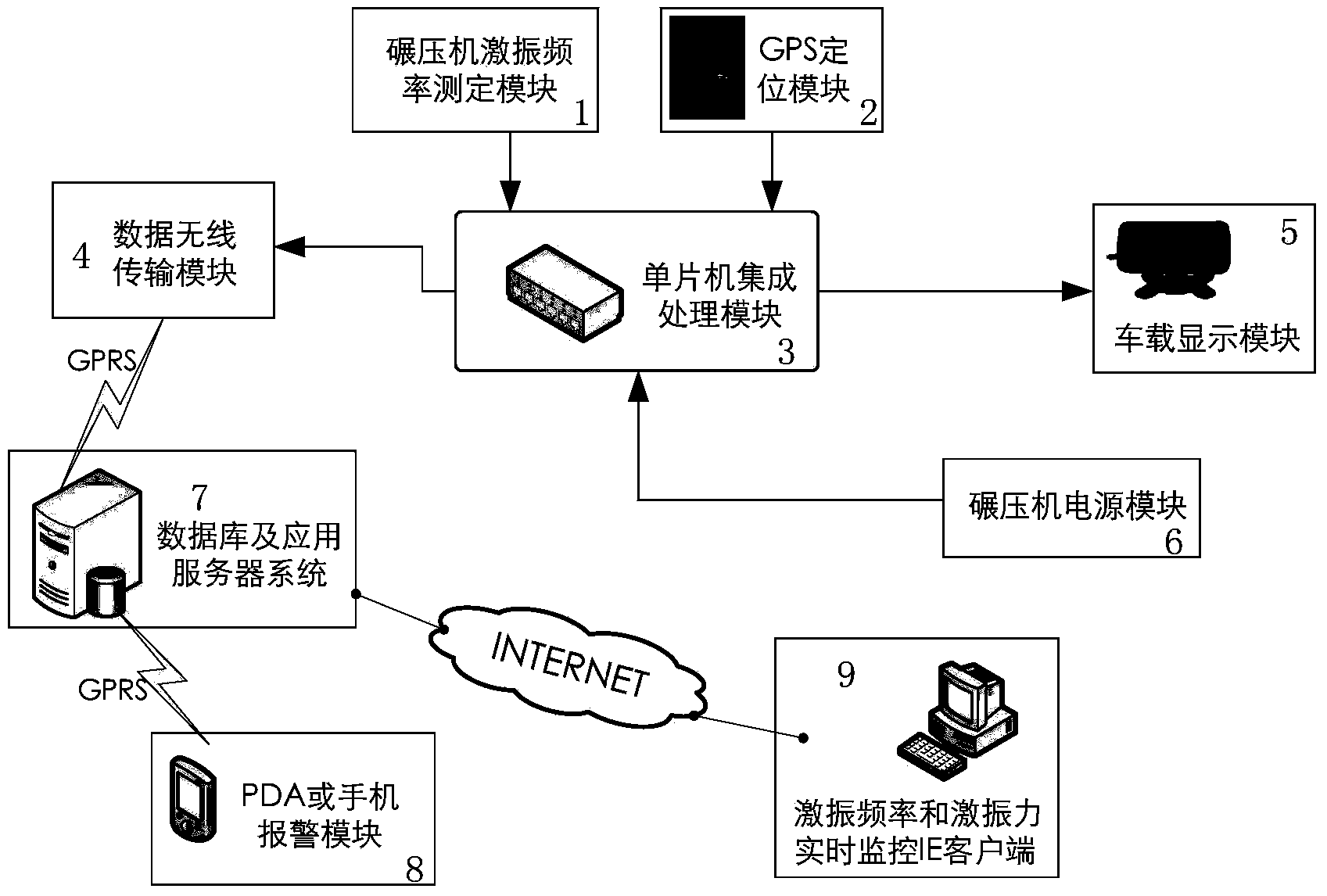

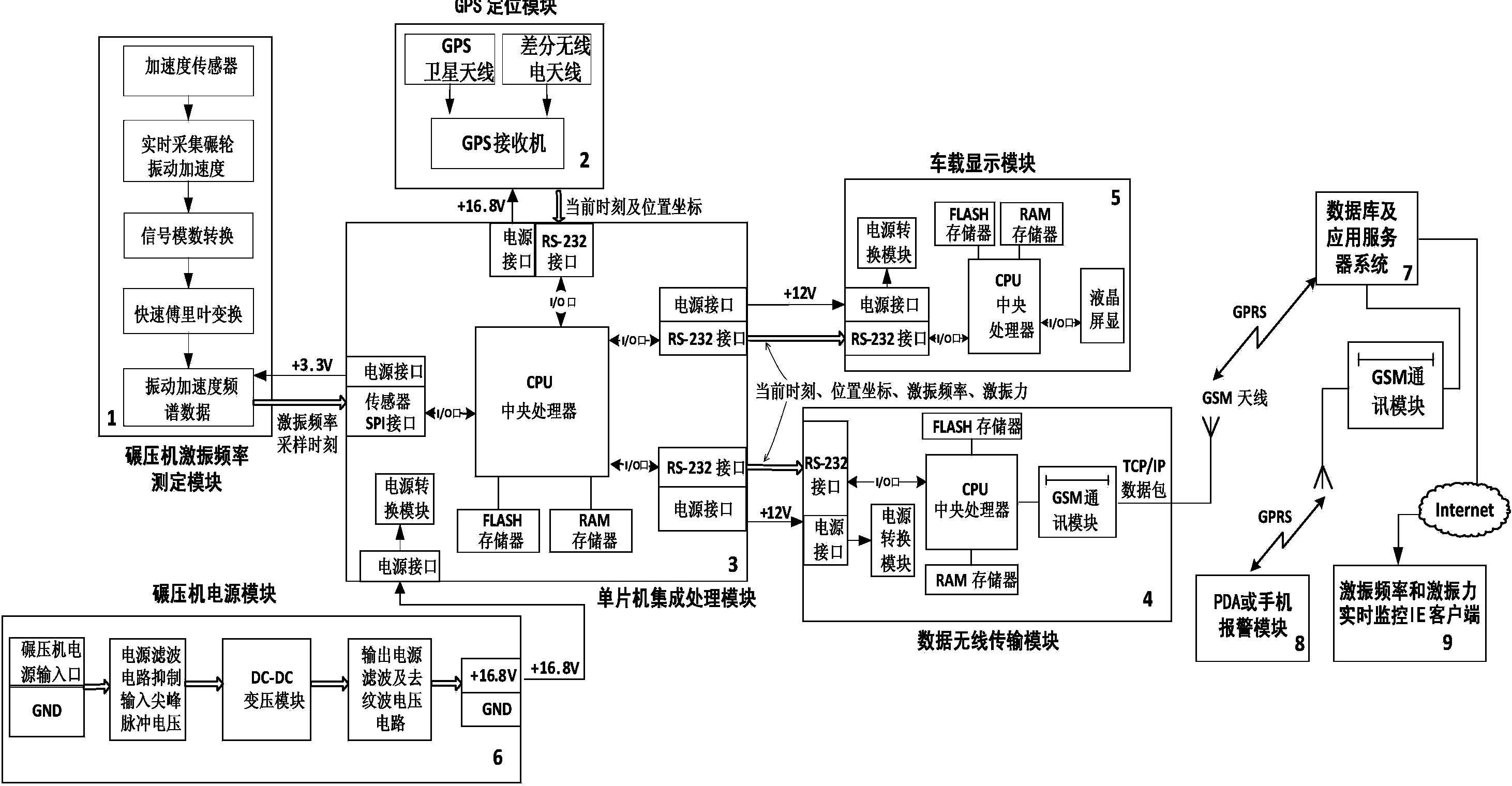

Earth and rockfill dam milling excitation frequency and excitation force real-time monitoring system and monitoring method

ActiveCN103850241AAvoid human interferenceGuarantee the construction qualityTransmission systemsSoil preservationVibration accelerationReal time acquisition

The invention belongs to the field of earth and rockfill dam construction quality control, and belongs to a method for carrying out remote real-time monitoring and subsequent quality assessment on the milling machine excitation frequency and the excitation force. Therefore the method adopts the technical scheme that an earth and rockfill dam milling excitation frequency and excitation force real-time monitoring system and monitoring method comprises he following steps that vibration acceleration signals in the vertical direction of a milling wheel are collected in real time in the process of milling earth and rockfill dam materials by using a milling machine excitation frequency testing module arranged on a part which is arranged on a milling machine vibration wheel and does not rotate along with the vibration wheel, the frequency spectrum data of the vibration acceleration of the milling wheel is obtained through signal analog-to-digital conversion and fast Fourier transformation (FFT), a corresponding relationship among the excitation frequency, the excitation force and the milling machine position coordinates is built according to the same sampling moment, whether the excitation frequency and the excitation force of a milling machine at the current moment conform to the design standard or not is judged, and if the excitation frequency and the excitation force do not reach the standard, warning is sent. The method provided by the invention is mainly applied to the earth and rockfill dam construction quality control.

Owner:TIANJIN UNIV

Building strengthening method

InactiveCN101691818AGood reinforcing effectWork together wellBuilding repairsPolymer modifiedFireproofing

The invention discloses a building strengthening method, which comprises the following steps of: 1) clearing the surface of a structure to be strengthened to expose a hard part; 2) carrying out water spray wetting on the structure to be strengthened; 3) implanting pins connecting a reinforcing steel bar net and the structure to be strengthened, and bonding the reinforcing steel bar net; 4) spraying an interface agent coating on the surface of the structure to be strengthened; and 5) spraying a polymer modified cement mortar bond layer and a polymer modified cement mortar protective layer by layers on the interface agent coating. The method can effectively improve the bearing capacity of the structure to be strengthened, improves the rigidity of the structure to be strengthened, and has less occupied space; a molded surface strengthening structure and the structure to be strengthened have the advantages of reliable bond, compactness, no crack, waterproofing, permeability resistance, fireproofing, high-temperature resistance, Cl-corrosion resistance, carbonization prevention, rust resistance and good durability; and a construction process is simple, formworks are not needed to be built, the speed of improving the strength of polymer modified cement mortar is high, and a construction period is greatly shortened. The method can be simultaneously applied to repairing and strengthening of the existing concrete structures and masonry structures, and solves the problems of breakage and aging of materials and insufficient structural strength of an old building.

Owner:上海维固工程实业有限公司

Precast concrete wallboard and preparation method thereof

ActiveCN101831985ALow costGuarantee the construction qualityConstruction materialForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention relates to a precast concrete wallboard and a preparation method thereof. A wall body has a structural layer and a protection layer from inside to outside, wherein the structural layer is internally provided with a reinforcement cage, and a reinforcement fabric is arranged in the concrete of the protection layer; the protection layer is connected with the structural layer through a transverse connecting reinforcement connected to the reinforcement fabric; the left edge and the right edge of the protection layer protrude out of the structural layer; the lower edge of the protection layer downwards extends out of a protruded port; and the top of the protection layer upwards protrudes out of the structural layer; the upper edge of the protection layer has a dent corresponding to the protruded port of the adjacent precast concrete wallboard on the upper layer; and the two ends of a transverse bar of the reinforcement cage protrudes out of the left side surface and the right side surface of the structural layer of the wall body and form two rows of transverse steel ties bending inwards. The wallboard has the advantages that the construction process is simplified, the construction speed is accelerated, and the construction cost is reduced. Meanwhile, products precast by a factory have uniform specification and quality, and thus, the construction quality of a building structure can be guaranteed sufficiently. The precast concrete wallboard can be widely applied to construction of concrete steel buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com