Welder exercise and process evaluation device

A technology for evaluating devices and welders, which is applied in the field of welder training, can solve problems such as poor visualization, poor recording, and lack of tools, and achieve the effect of improving practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

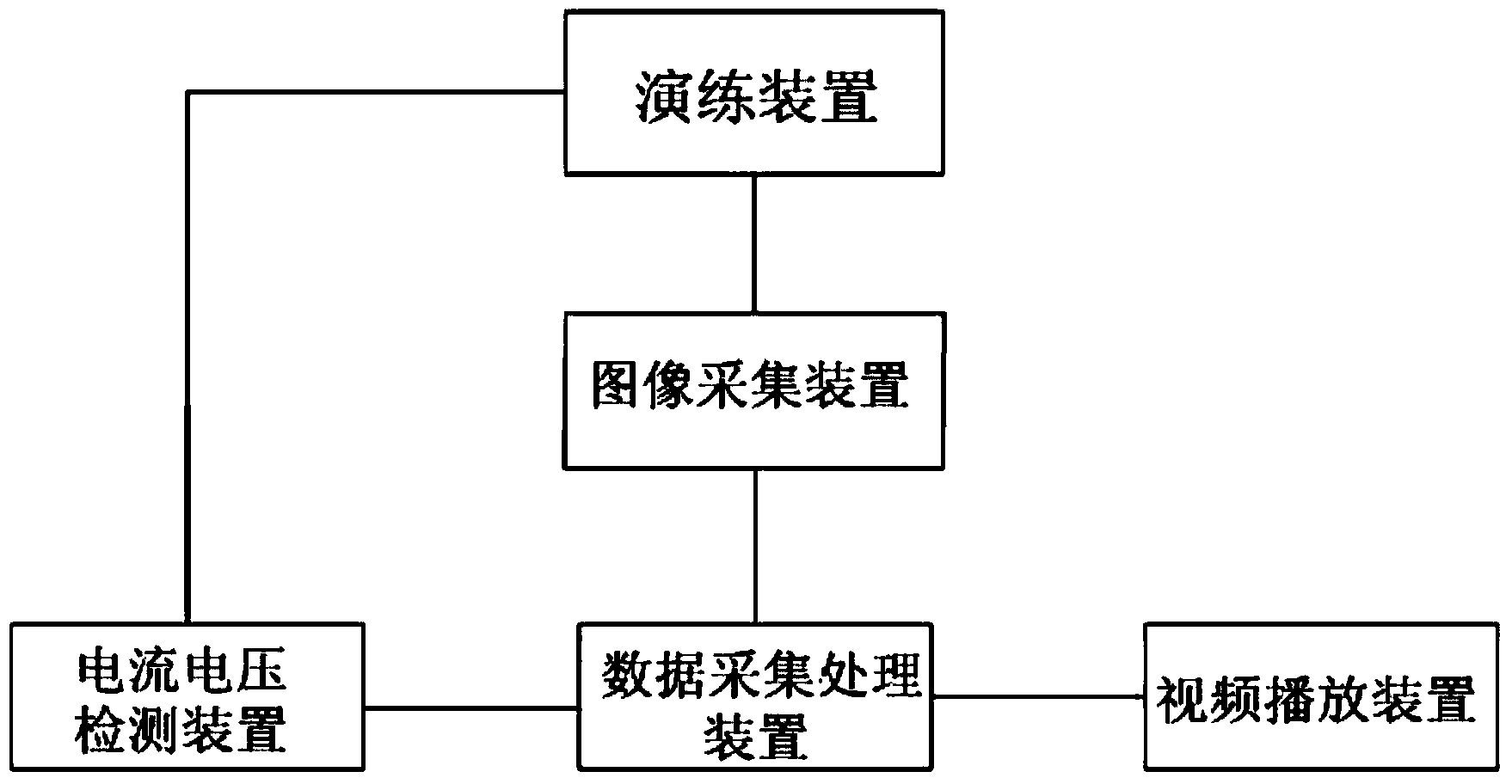

[0013] like figure 1 As shown, a welding drill and process evaluation device of the present invention includes a drill device, an image acquisition device, a current and voltage detection device, a data processing device, and a video playback device. The drill device includes a welder training platform, and the image acquisition device is a camera, the image acquisition device is connected to the data processing device, the data processing device is an industrial computer, and the camera is set on the welder training platform and connected to the industrial computer.

[0014] The current and voltage detection device includes a current detection device and a voltage monitoring device, the current detection device includes a current sensor, a current signal conditioner, and a current signal acquisition board, and the output terminal of the current sensor is connected to the input of the current signal conditioner terminals, and the output terminal of the current signal condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com