Patents

Literature

2221results about "Mechanical thickness measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

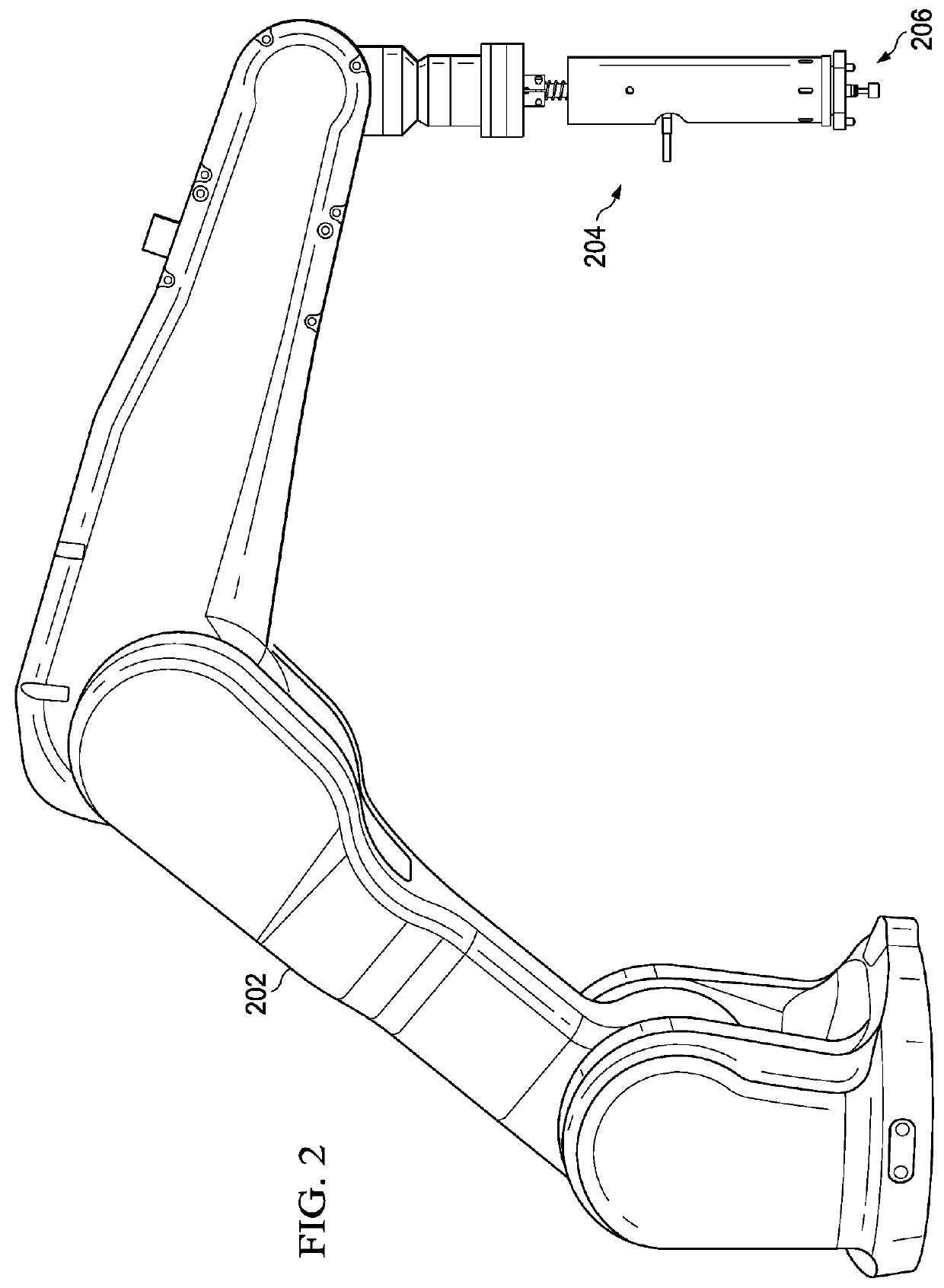

Hole Measurement Apparatuses

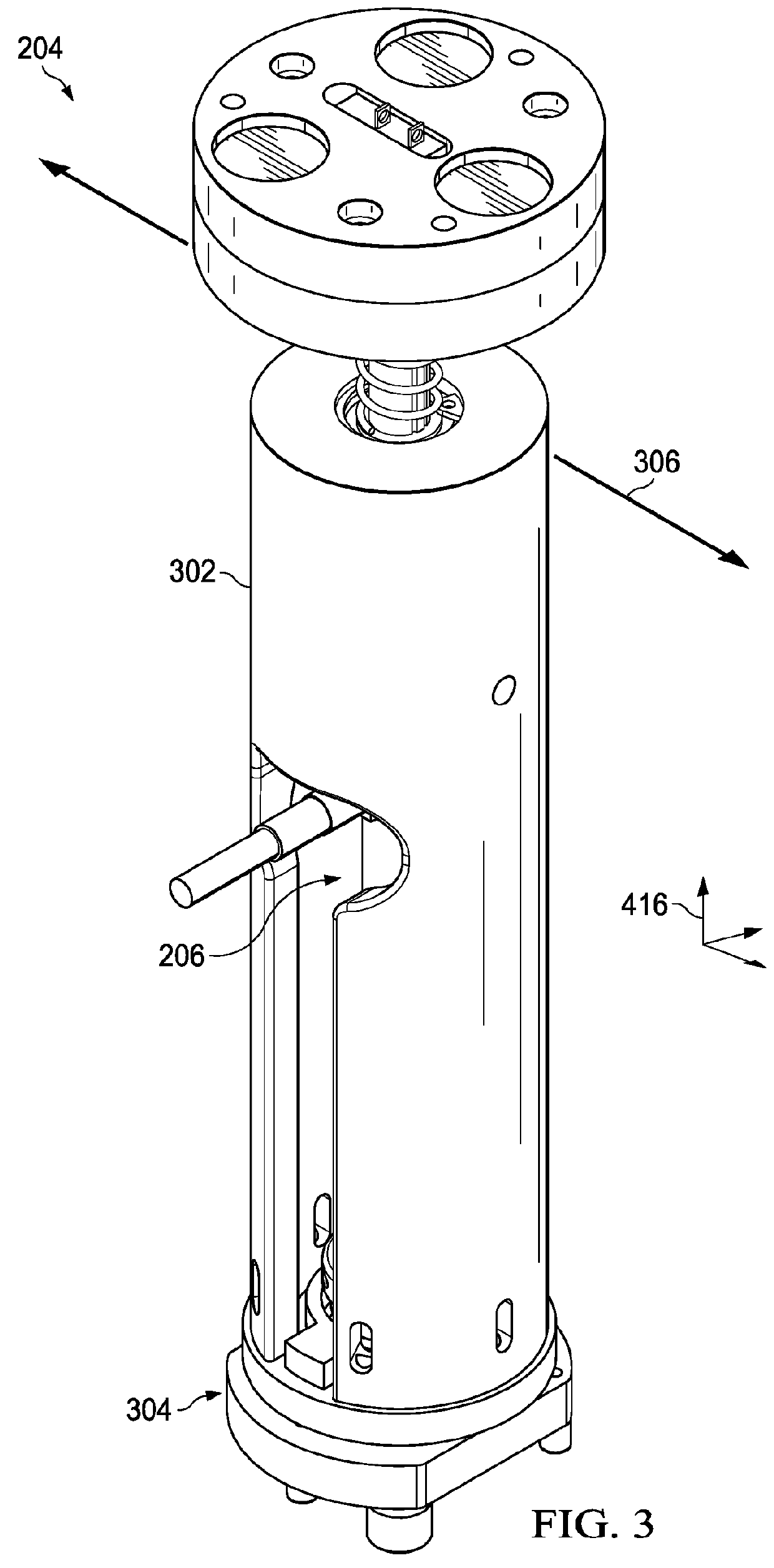

ActiveUS20110166824A1Increase productionIncrease workforceElectric/magnetic depth measurementElectrical/magnetic diameter measurementsEngineeringDiameter measurement

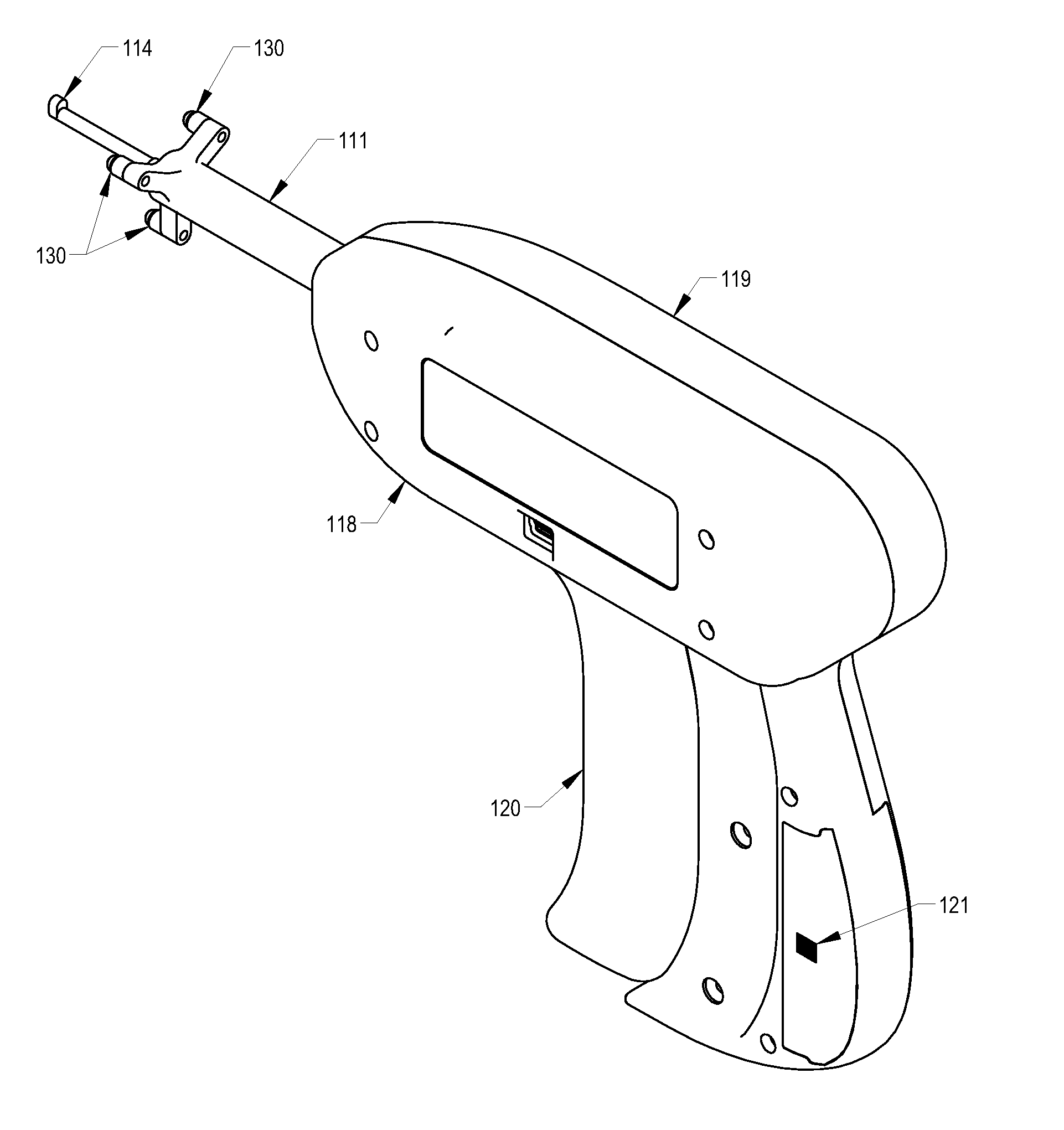

The present invention is directed to automated apparatuses and methods for measuring fastener hole depth, fastener length, countersink depth and / or hole diameters in a workpiece (or other object) in an automated and extremely rapid, efficient and accurate manner. The apparatuses may be operably connected with a power source and with one or a plurality of computers or other data collection devices to transmit fastener hole depth, countersink depth and / or hole diameter measurement data and / or information to them each time that a fastener hole is measured, while the apparatus is continuously measuring fastener holes (i.e., with no interruptions). Extremely advantageously, using only one hand, and by only squeezing a trigger only one time, an operator of such an apparatus may successfully and very rapidly and accurately perform more than one, or all three, of the following functions: (i) normalize the apparatus relative to one or a plurality of fastener holes and / or workpiece surfaces; (ii) make one or a plurality of accurate measurements; and (iii) transmit the one or more measurements from the apparatus to one or a plurality of computers and / or other data collection devices for, for example, recordation, storage, manipulation, other use and / or the like.

Owner:DELTA SIGMA

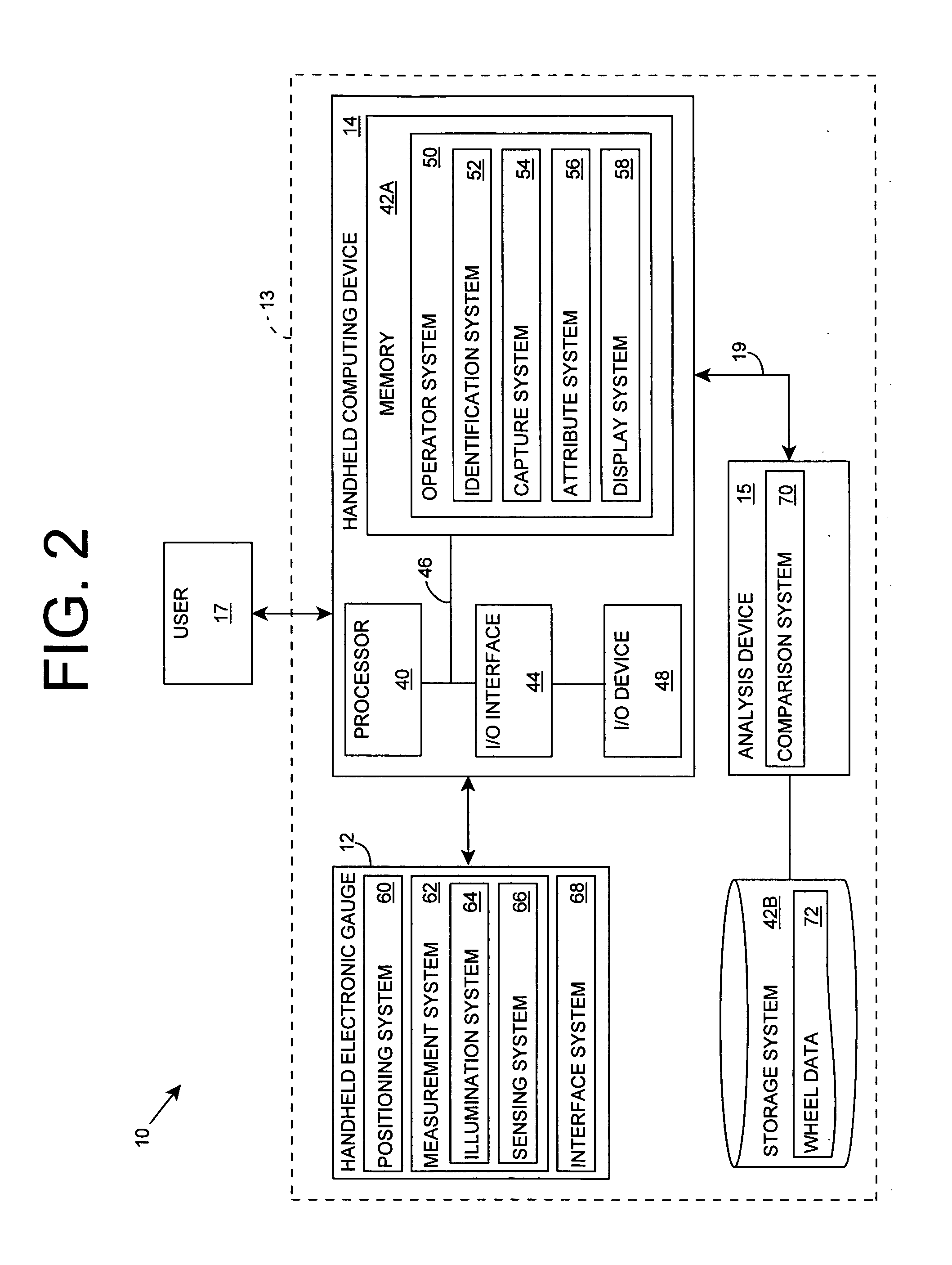

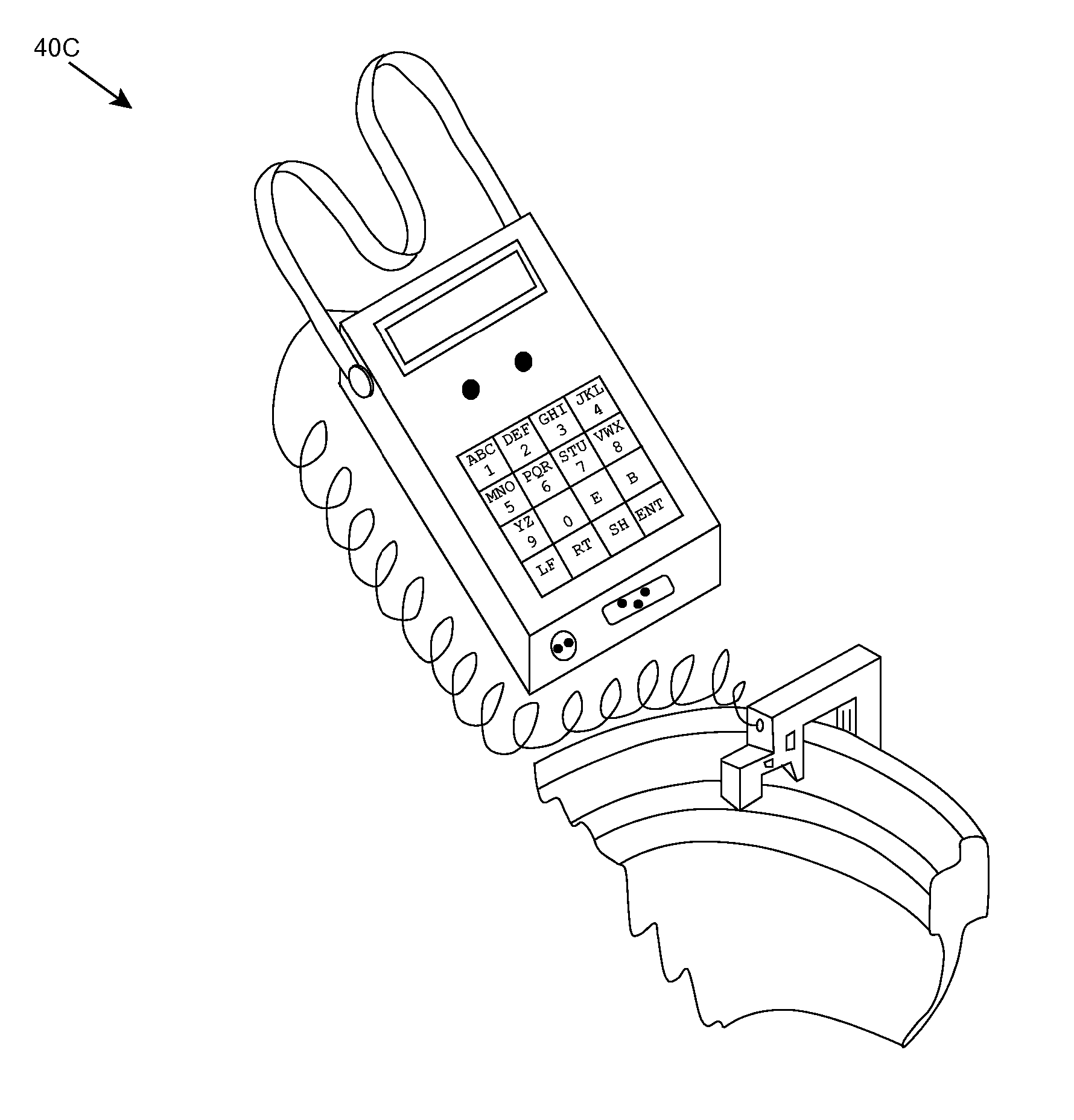

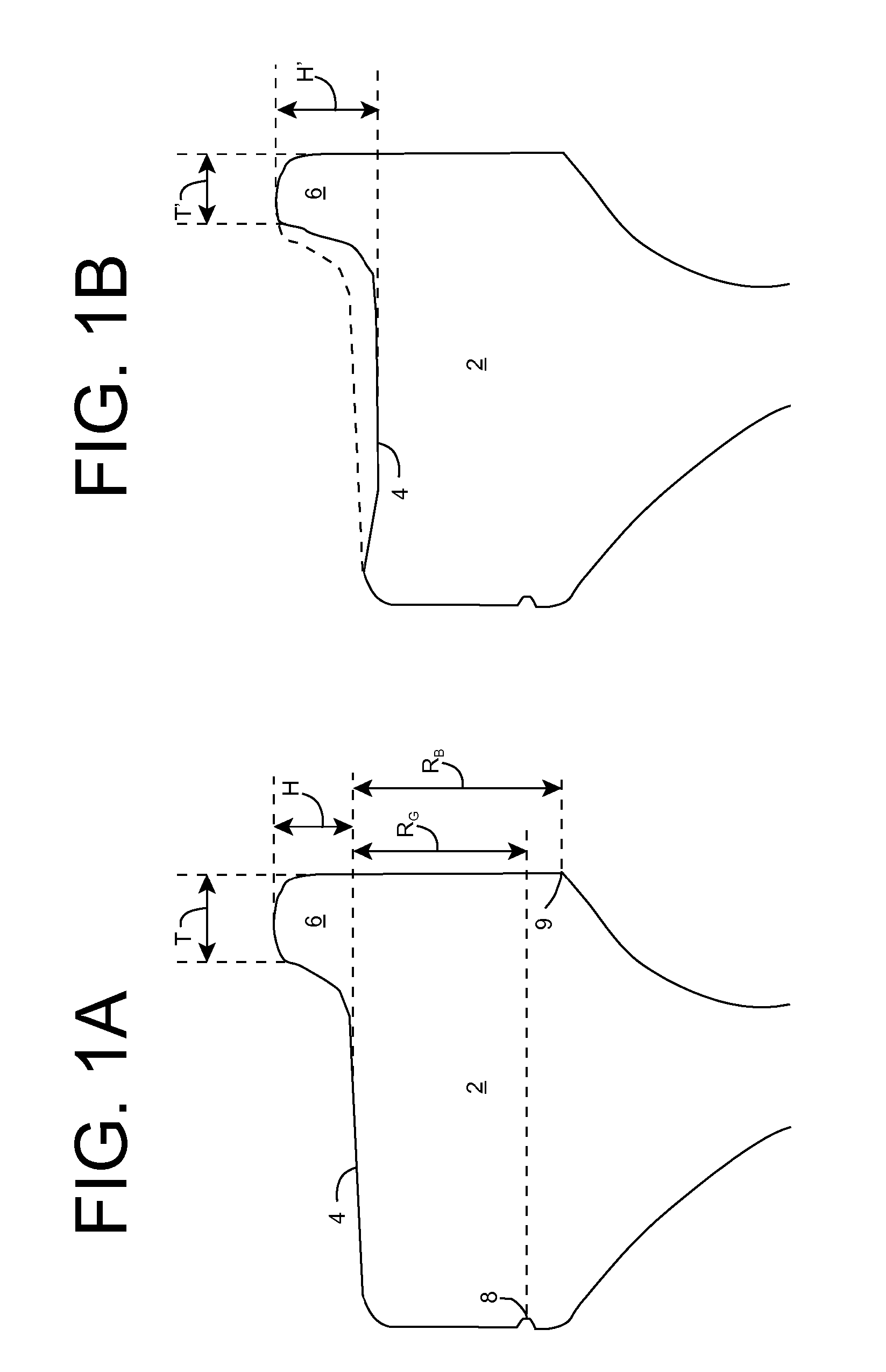

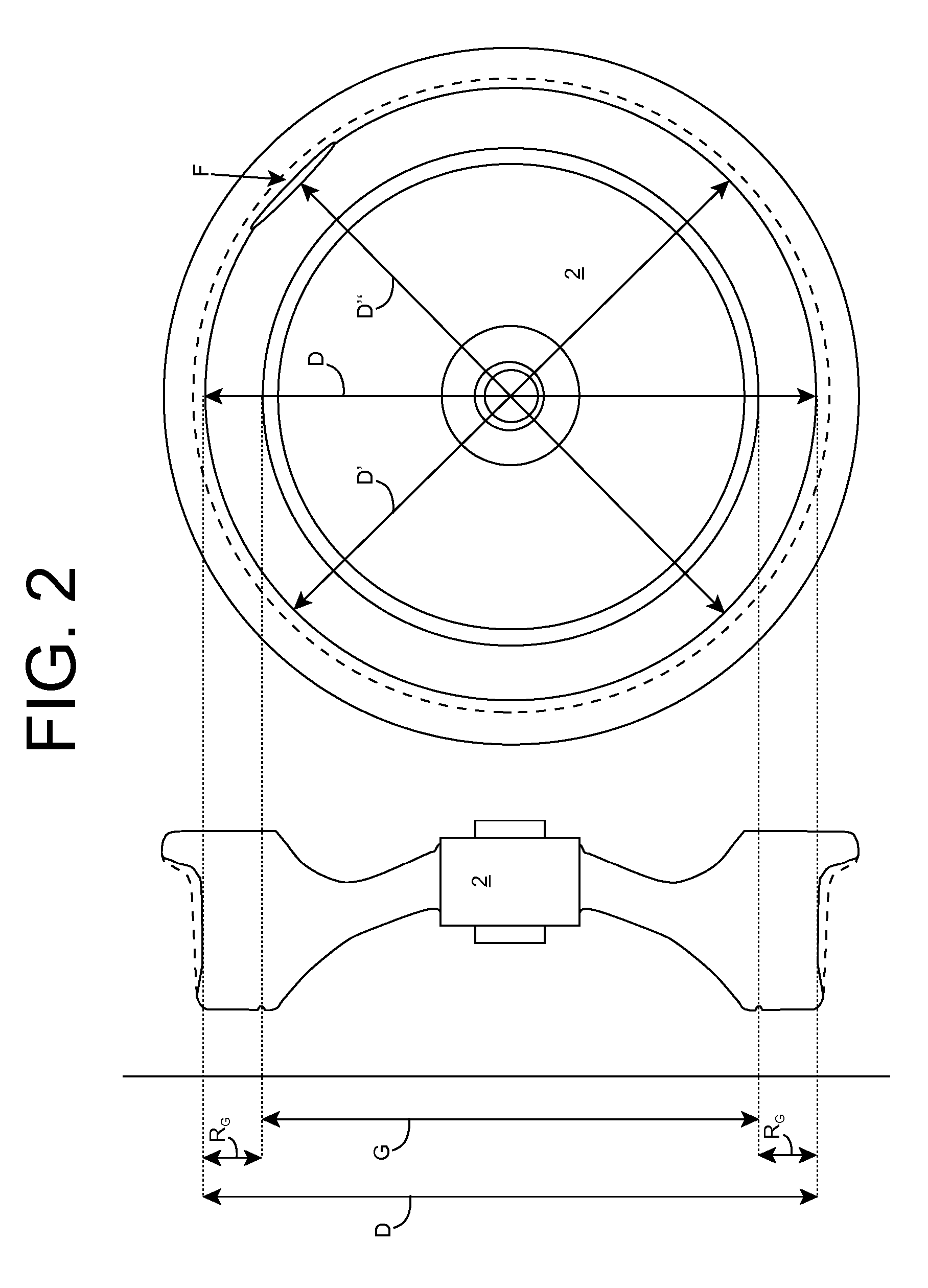

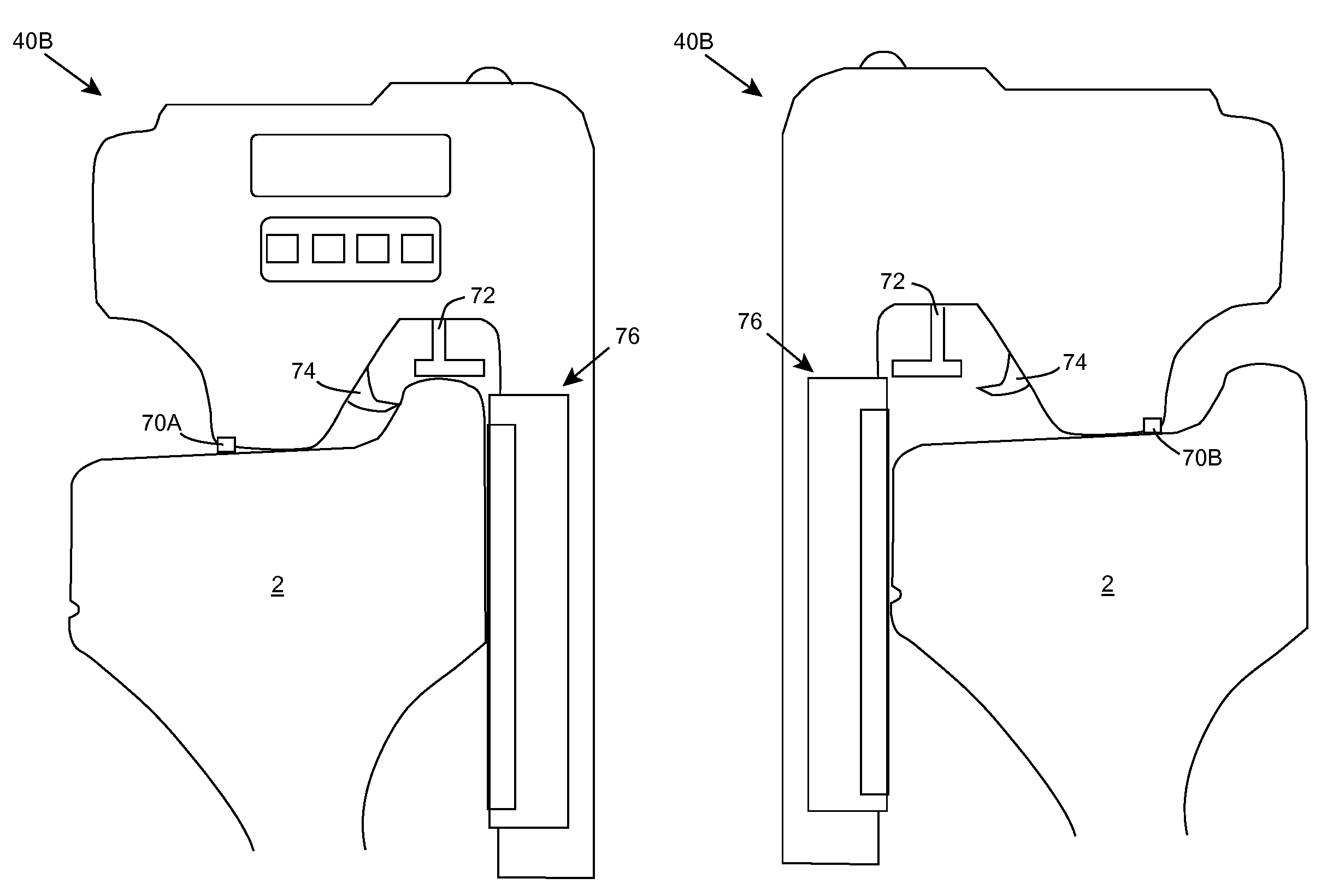

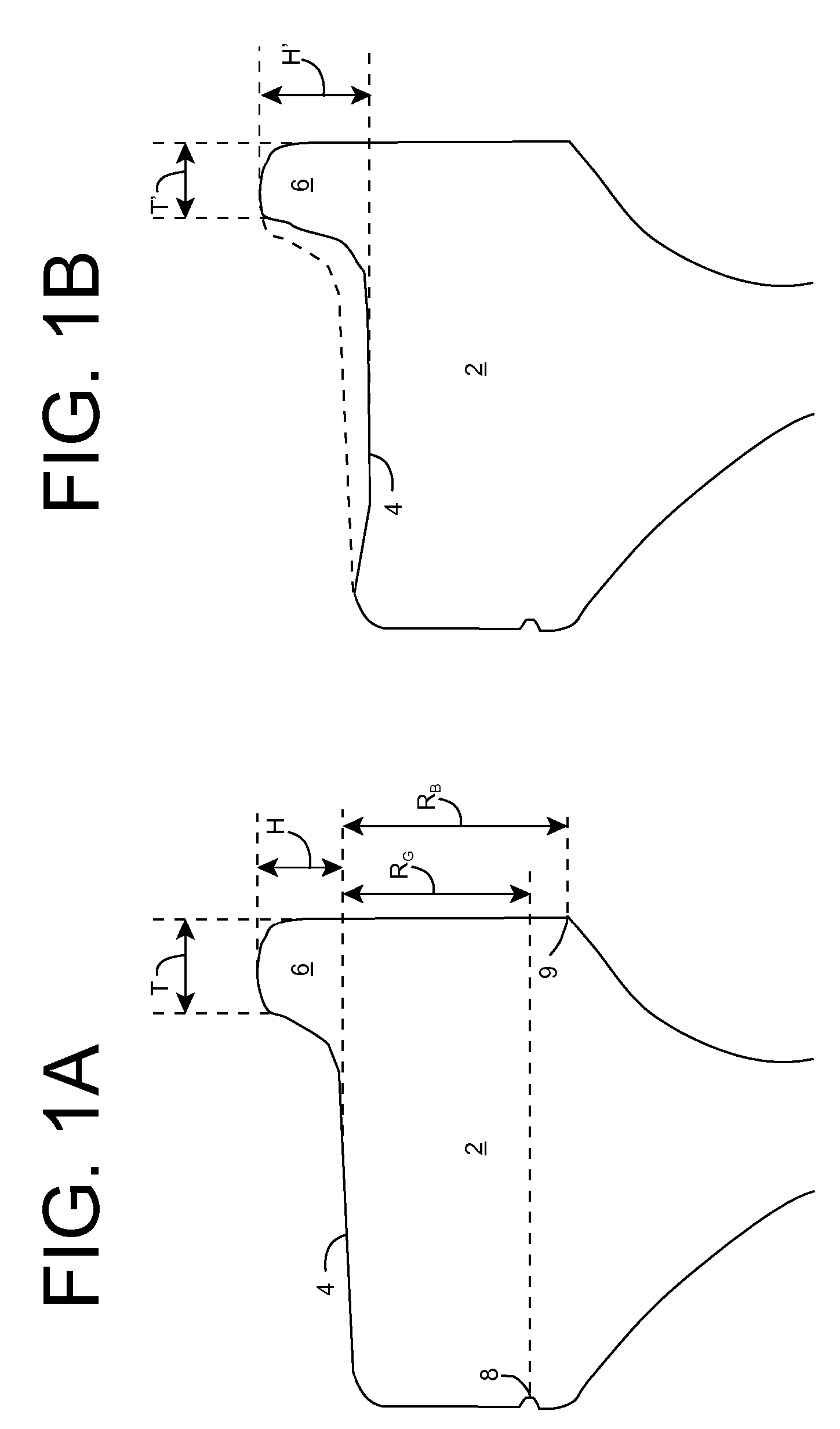

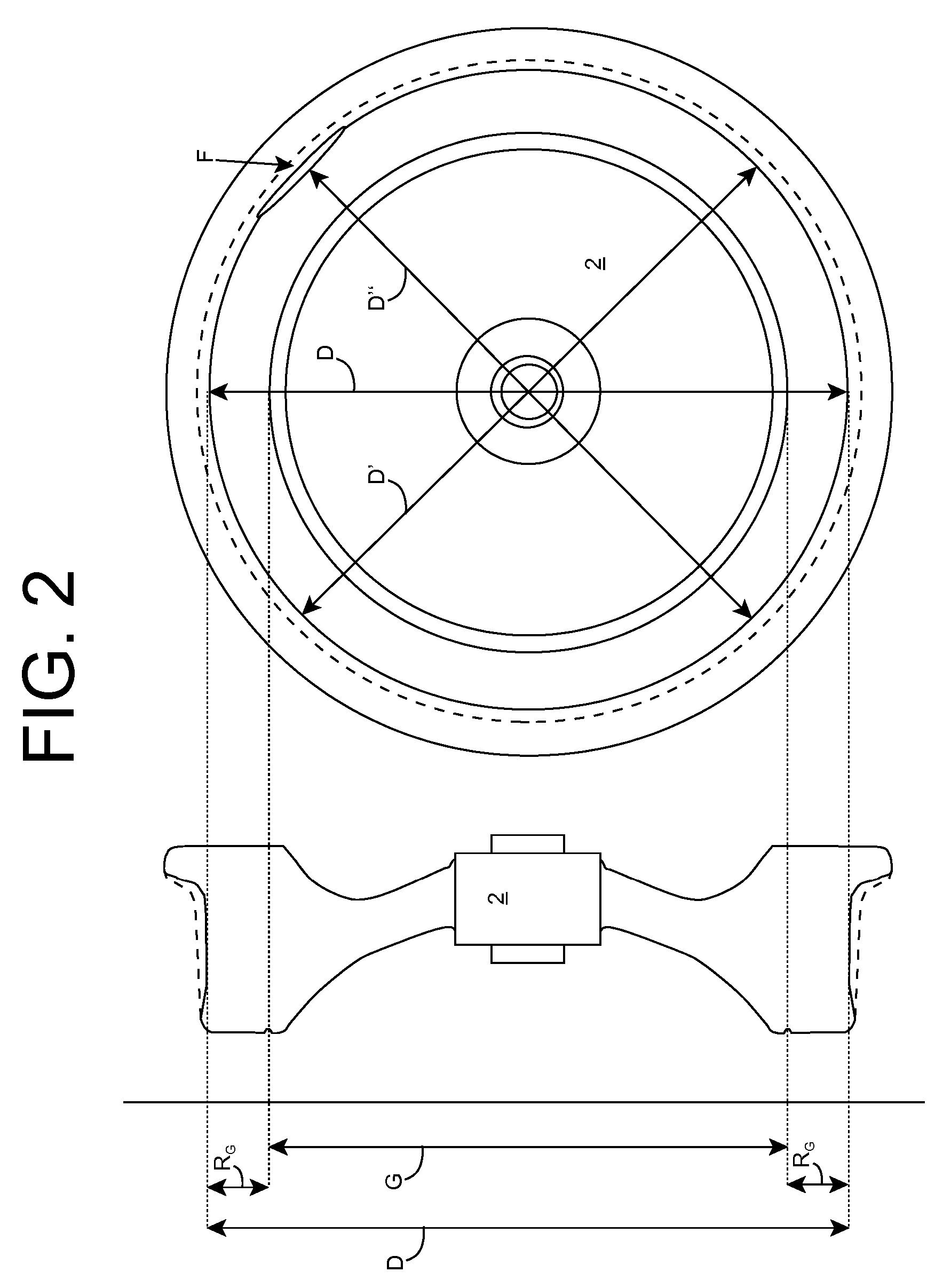

Portable electronic measurement

ActiveUS20050259273A1Angles/taper measurementsWheel-rims surveying/measuringHand heldComputer science

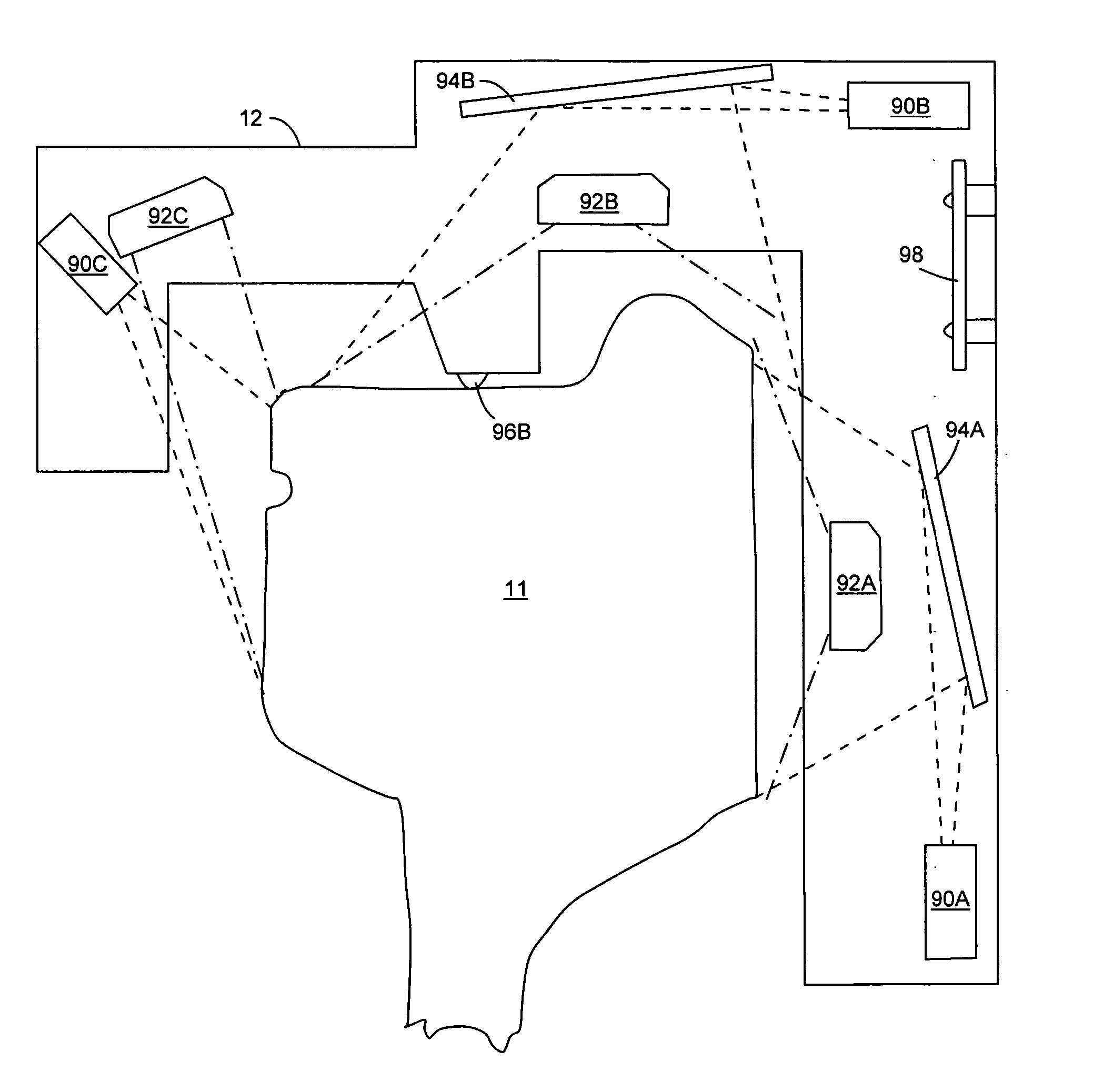

The invention provides a handheld electronic gauge that is configured to obtain measurement data for an object, such as a wheel, rail, axle, or the like. The gauge includes one or more position sensors that automatically determine when the gauge is in a measurement position. The invention also provides a handheld computing device that can automatically determine when a gauge is in the measurement position and automatically obtain measurement data using the gauge. As a result, the invention provides a solution for measuring an object, such as a railway wheel, that is portable and capable of repeatedly providing various desired measurements, irrespective of the operator.

Owner:INT ELECTRONICS MACHINES

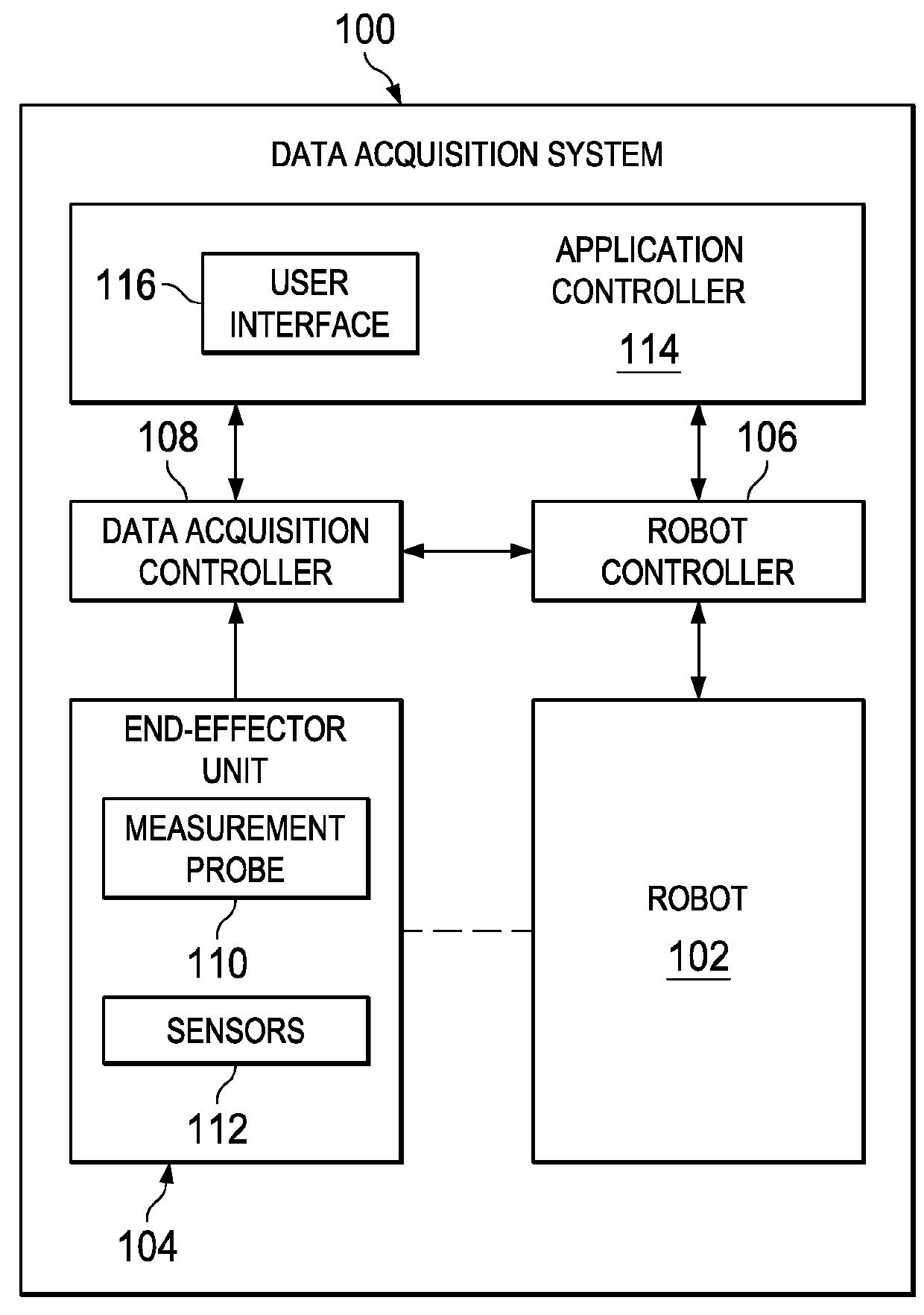

Method and Apparatus for Compliant Robotic End-Effector

A method and apparatus for performing an operation on a workpiece using a multi-axis compliant end-effector for attachment to a robotic device. The end-effector is positioned at a nominal location of a workpiece feature on which the operation is to be performed. The end-effector is passively aligned with the workpiece feature by contacting the end-effector with the workpiece feature. The operation is performed on the workpiece feature in response to aligning the end effector with the workpiece feature.

Owner:THE BOEING CO

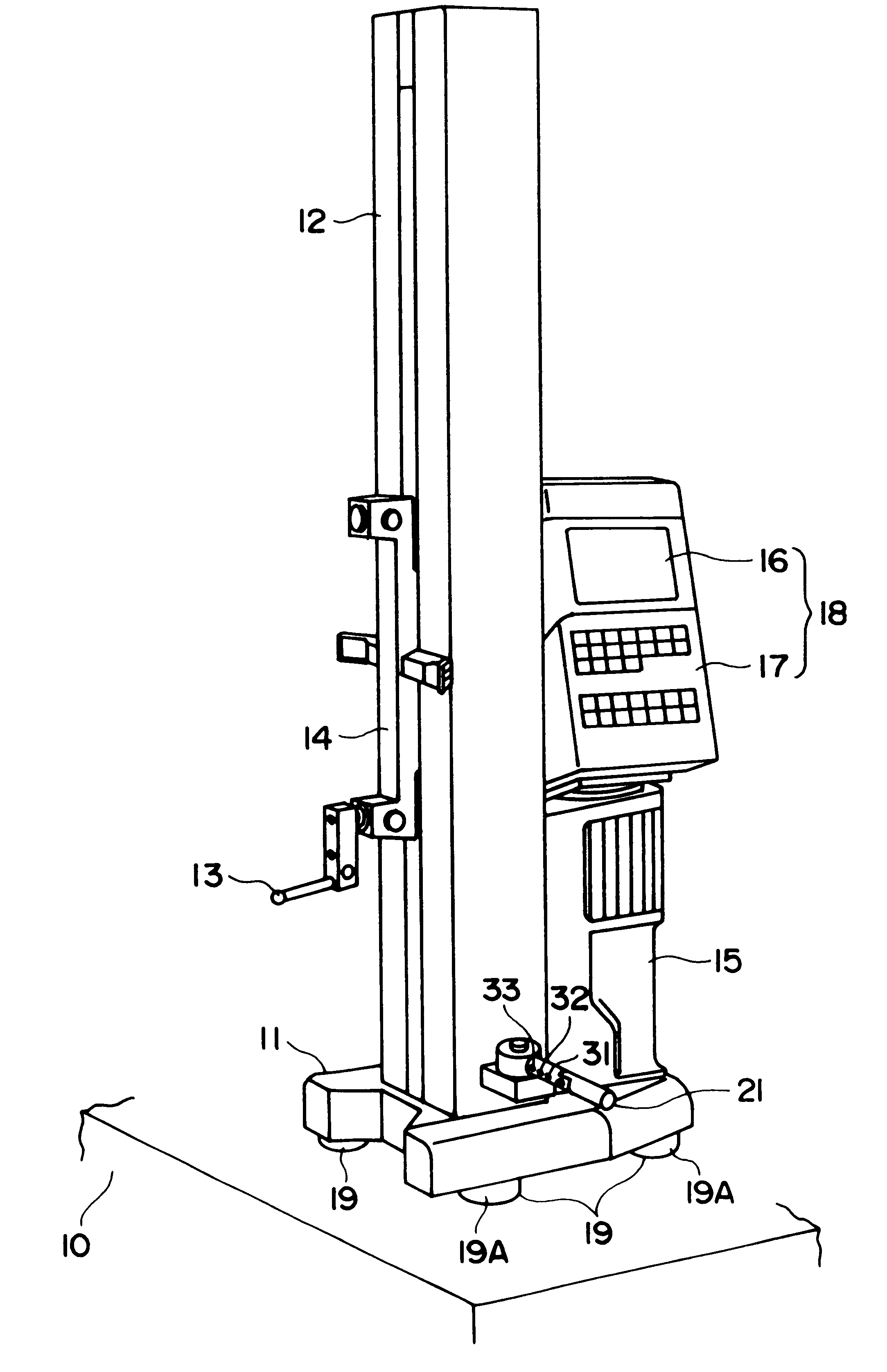

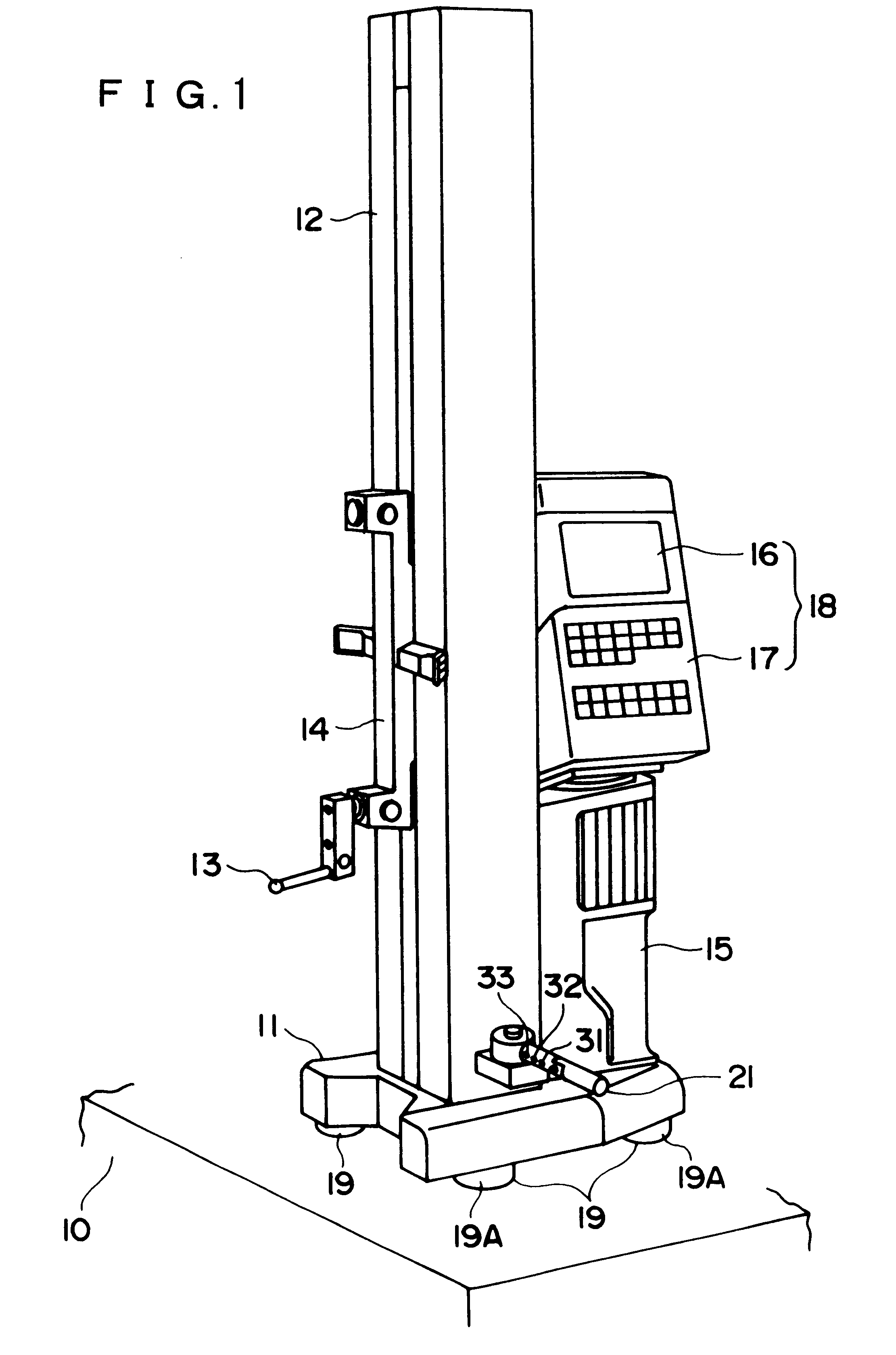

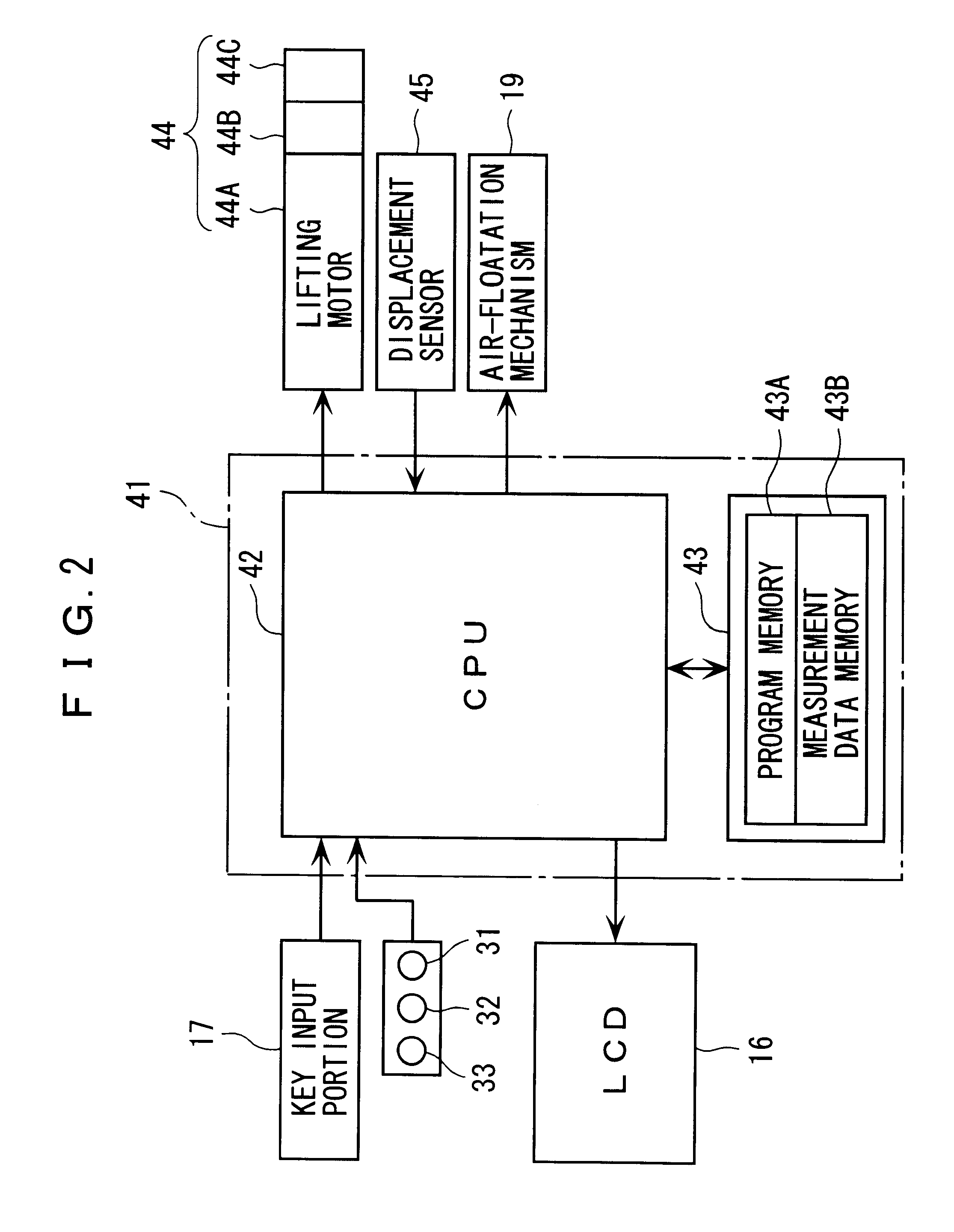

Linear measuring machine

InactiveUS6446351B1Not scarredImprove measurement efficiencyMechanical depth measurementsFeeler-pin gaugesElectric machineEngineering

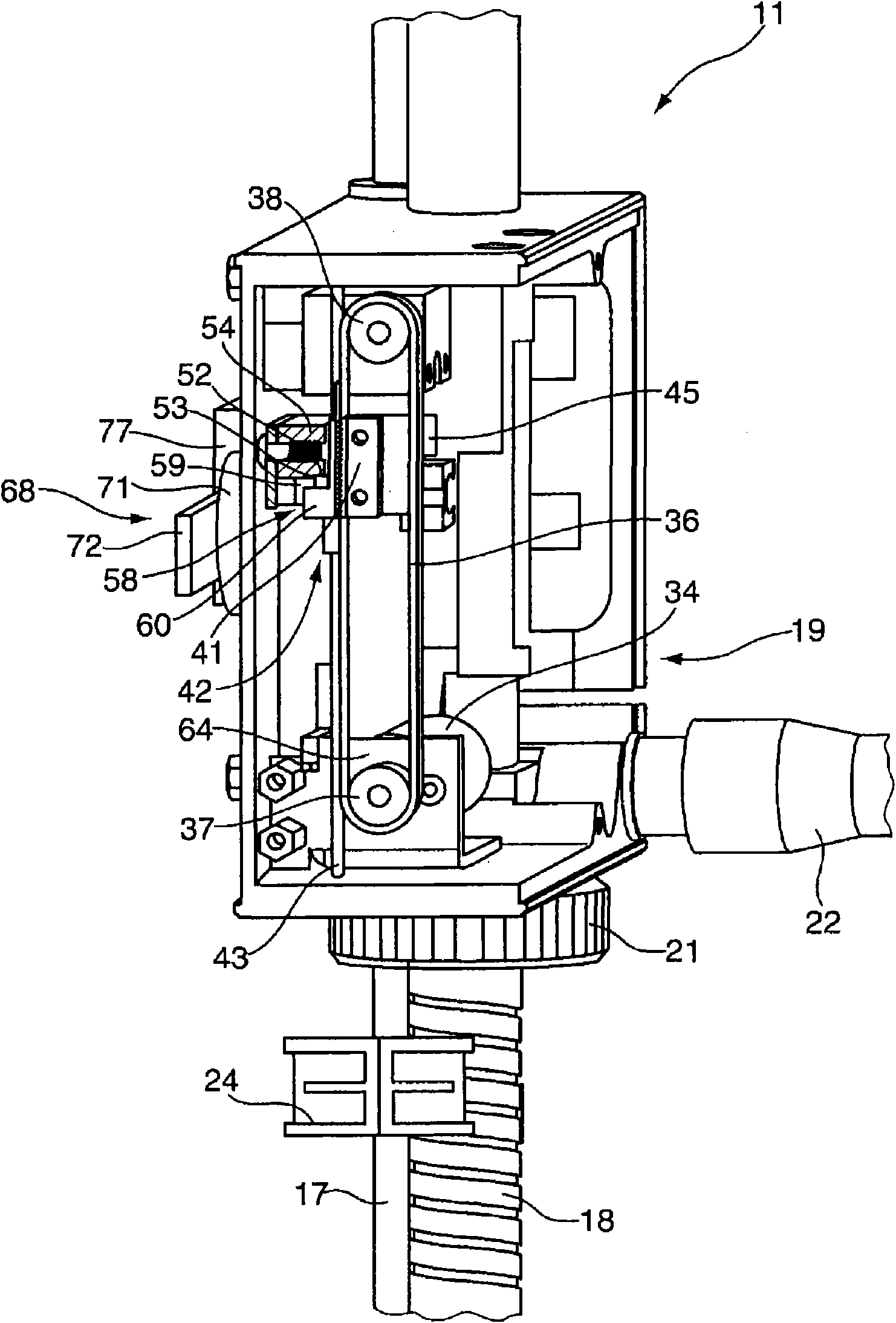

A linear measuring machine is provided, the linear measuring machine having a base (11), a column (12) disposed on the base, a slider (14) elevatable along the column and an elevation driving mechanism (44) including a motor for lifting and lowering the slider. The linear measuring machine further includes a touch-and-back mechanism for driving the elevation driving mechanism in a direction for a probe (13) to move away from a measurement surface of the workpiece after fetching a detection value of a displacement sensor (45) when the probe touches the measurement surface of the workpiece and for stopping the elevation driving mechanism.

Owner:MITUTOYO CORP

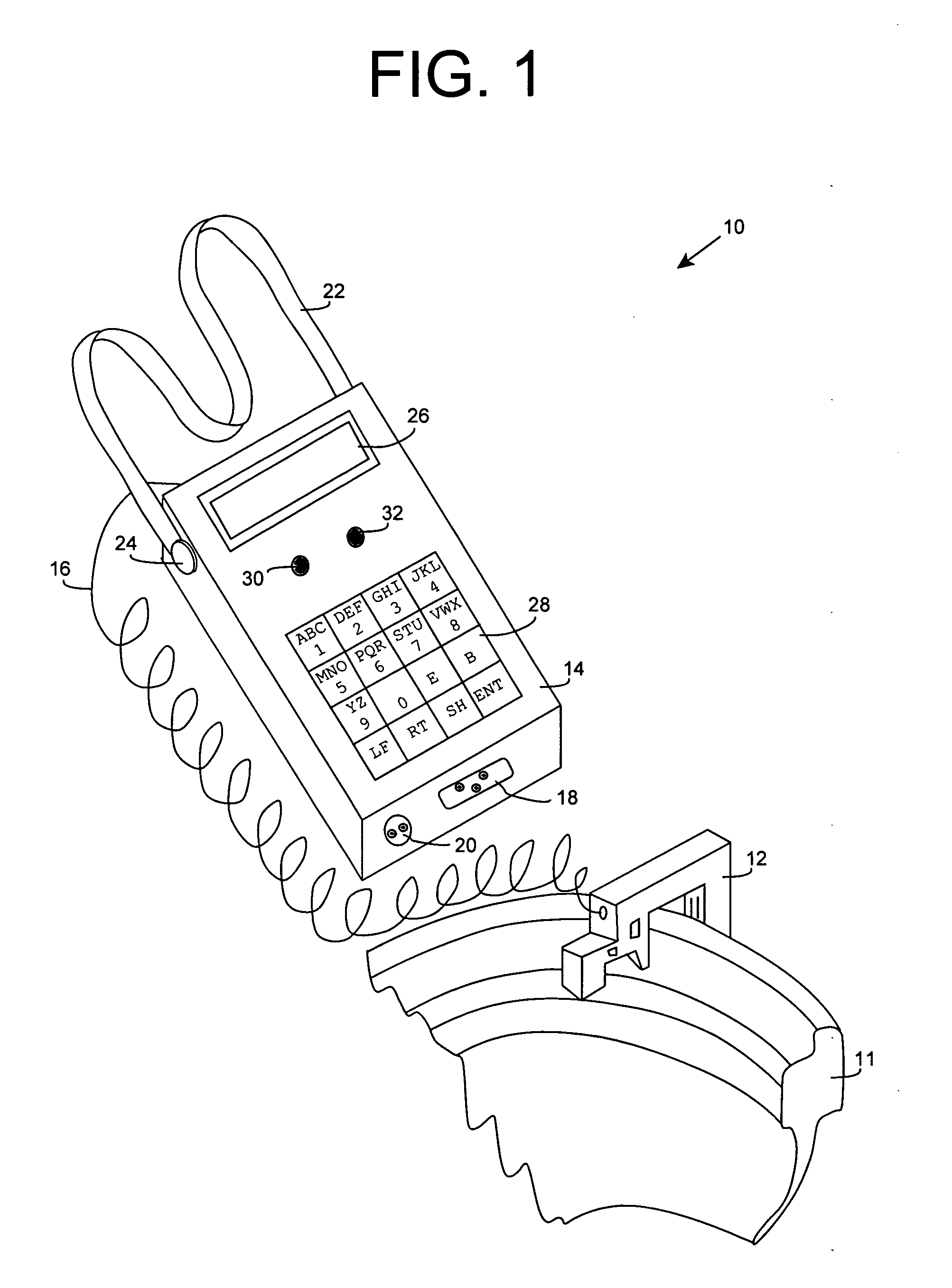

Wheel measurement systems and methods

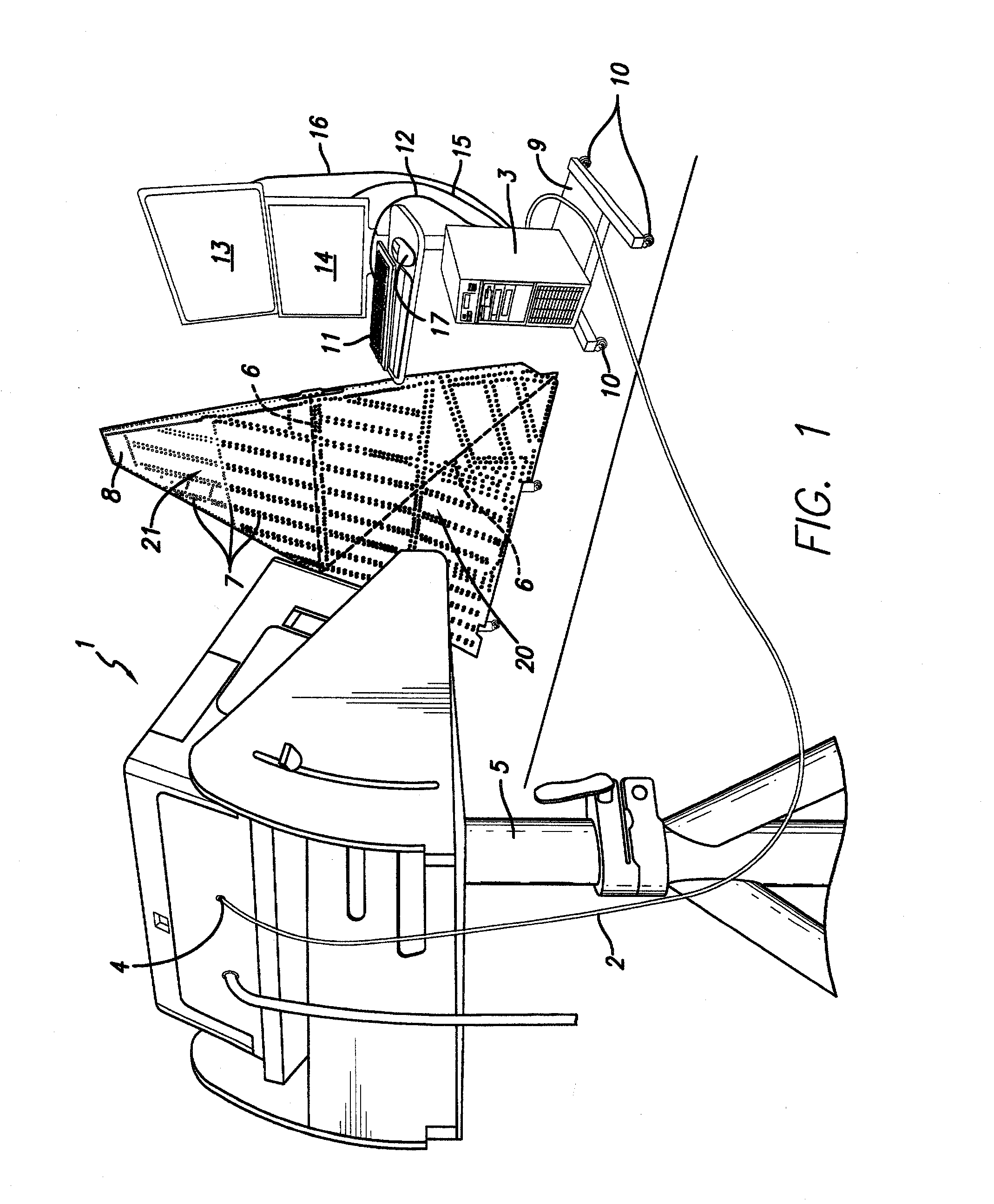

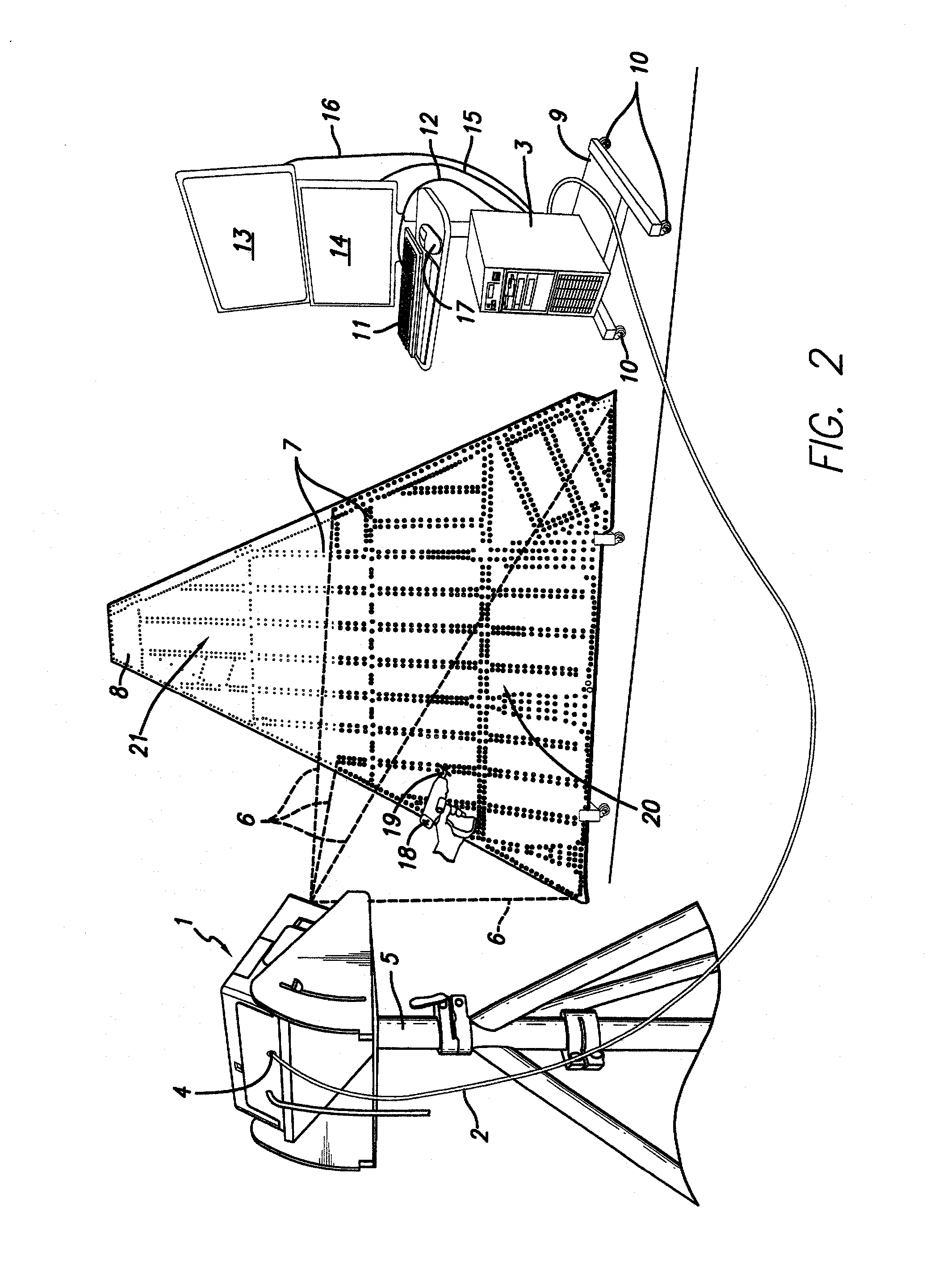

ActiveUS20070075192A1Improve efficiencyImprove reliabilityElectric devicesWheel-rims surveying/measuringGraphicsMeasurement device

An improved maintenance, inspection, and / or measurement solution is provided. An embodiment of the invention includes a handheld measurement device for measuring an object, such as a railway wheel on a train. The handheld measurement device can comprise a single unit to provide one handed operation and can include various features, such as onboard evaluation, a graphical user interface, and / or a self-health monitor. Additionally, aspects of the invention provide an inspection environment that incorporates preliminary measurement data, wireless communications, and / or historical data into the measurement and evaluation process.

Owner:INT ELECTRONICS MACHINES

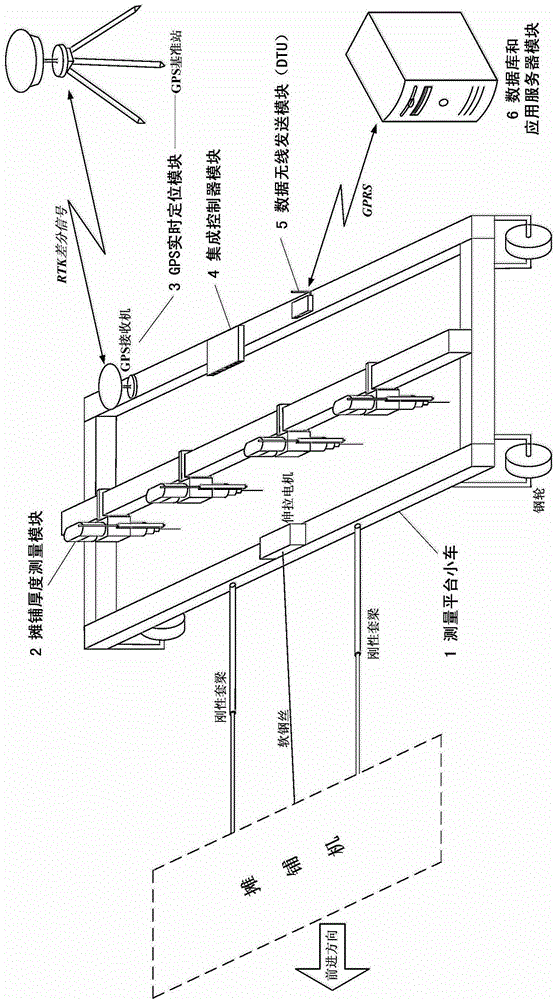

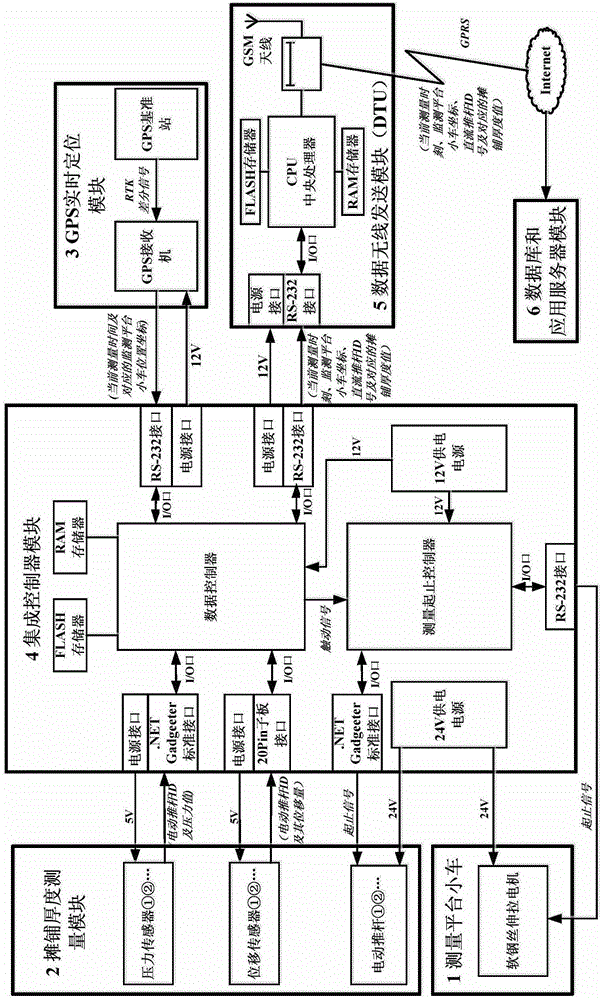

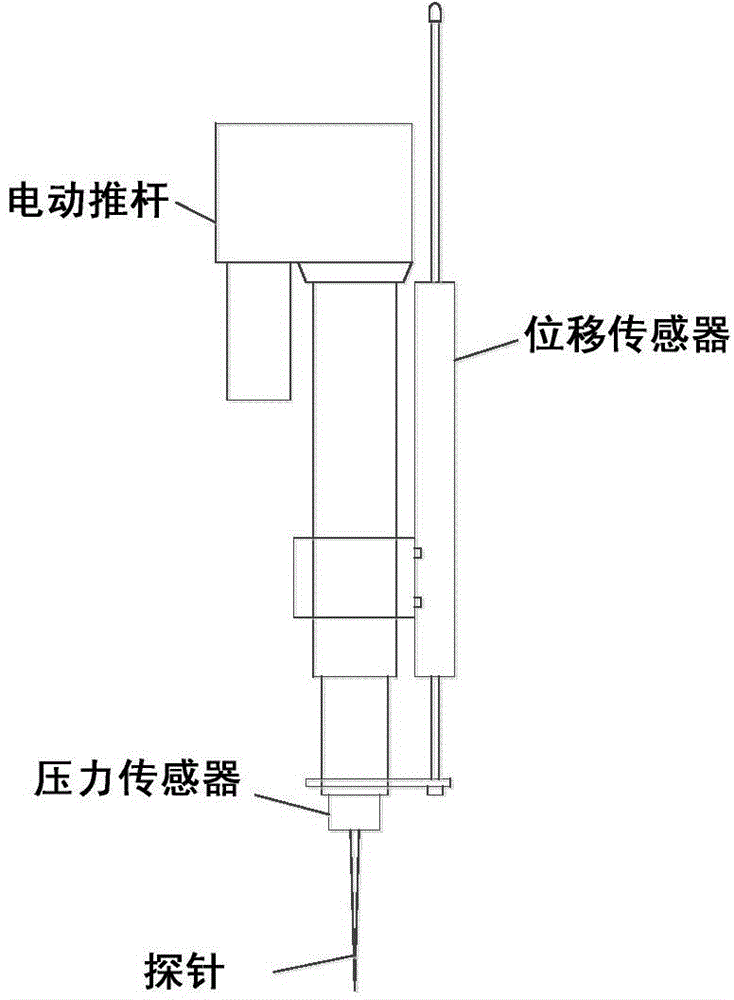

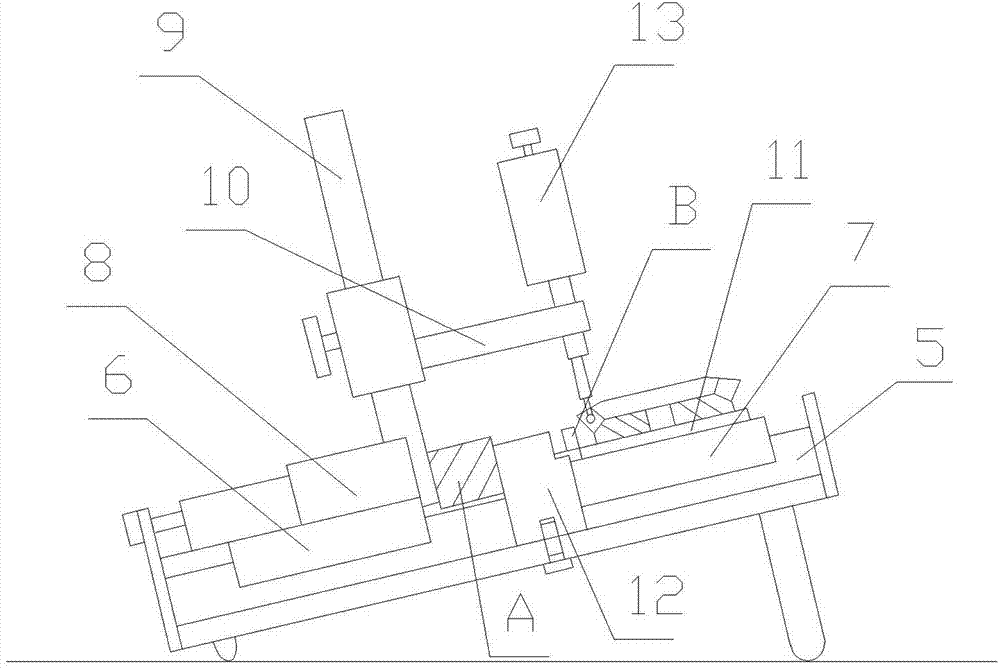

Highway pavement paving thickness plug-in automatic measuring device

ActiveCN104634224AHigh precisionReal-time acquisitionMechanical thickness measurementsRoads maintainenceMeasurement deviceQuality control

The invention belongs to the field of road construction quality control, and provides a device capable of realizing the automatic high-precision and real-time measurement on the highway pavement paving thickness. The real-time measurement of the pavement paving thickness can be realized, and measurement information can also be sent to a database in a remote way for subsequent quality assessment application and is used as the basis for relevant departments to realize paving quality management. Therefore, the invention has the technical scheme that a highway pavement paving thickness plug-in automatic measuring device comprises a measurement platform trolley, a paving thickness measuring module, GPS real-time positioning module, an integrated controller module, a DTU (date transfer unit), a database and a server module. The automatic measuring device is mainly applied to road construction quality control.

Owner:TIANJIN UNIV

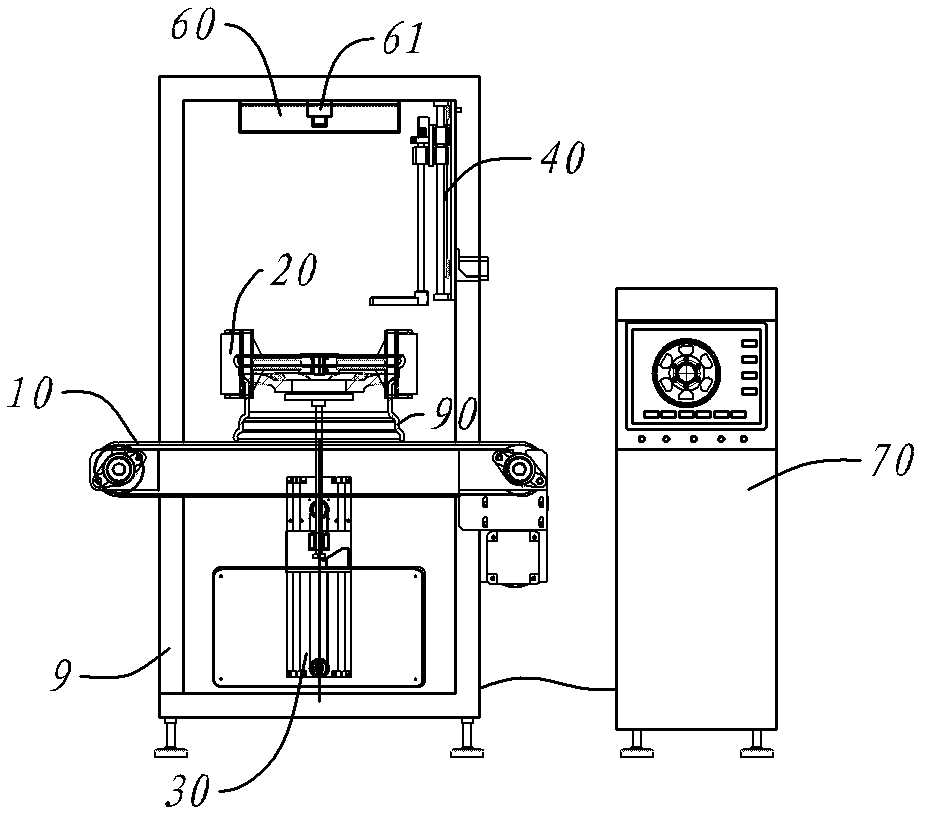

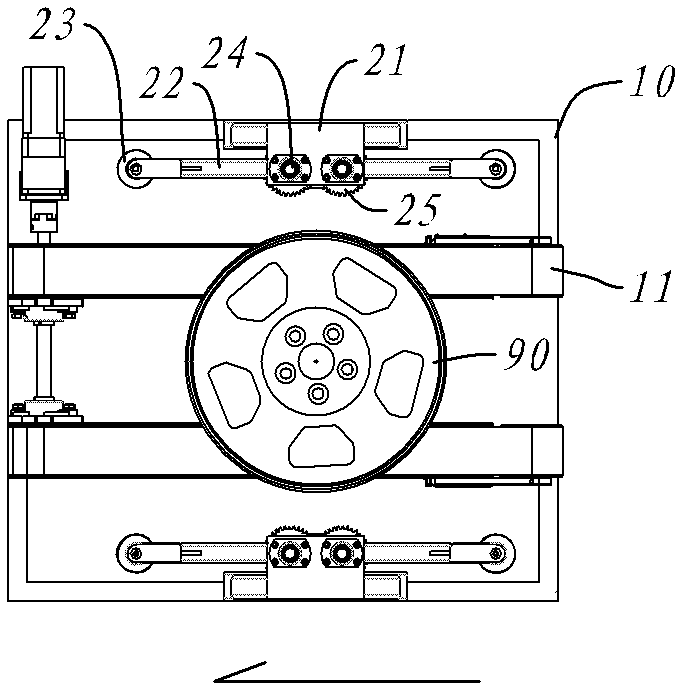

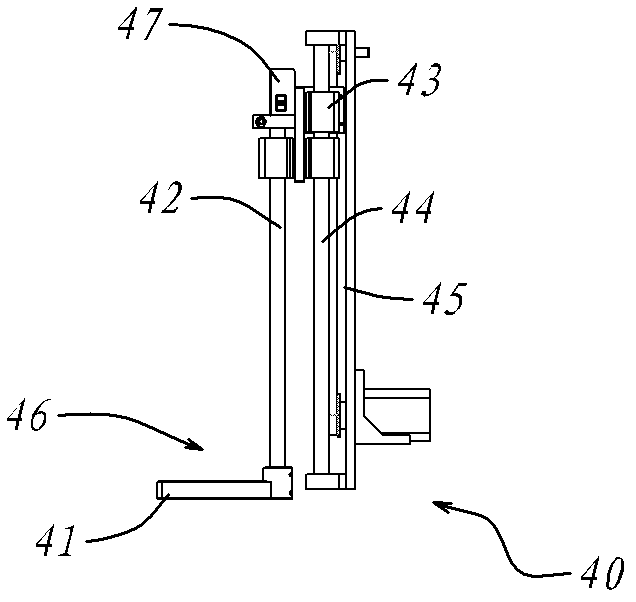

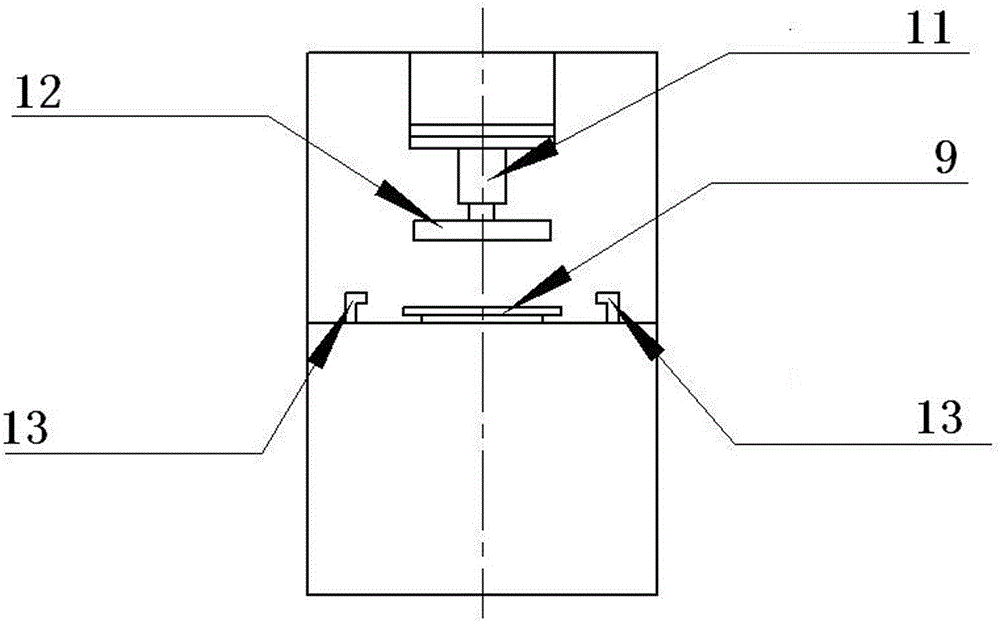

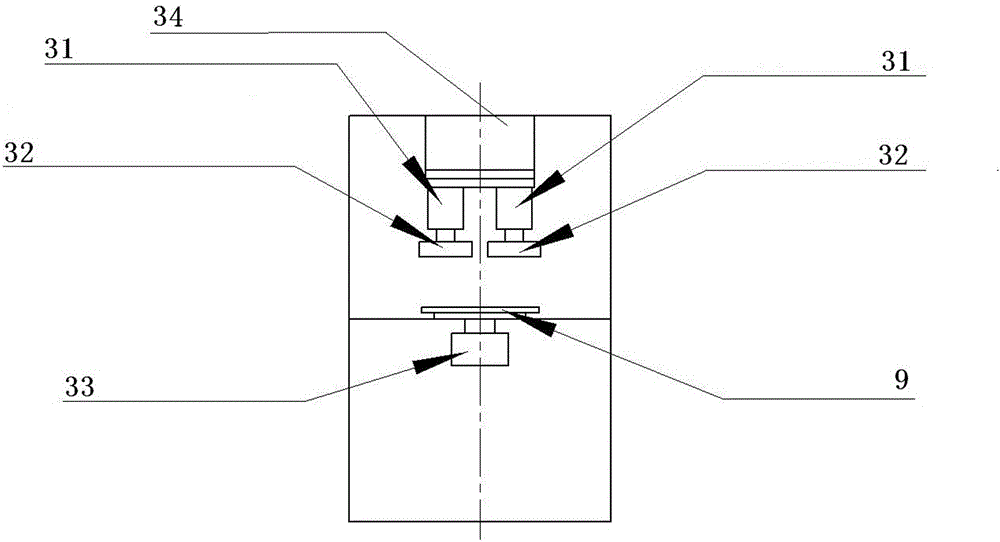

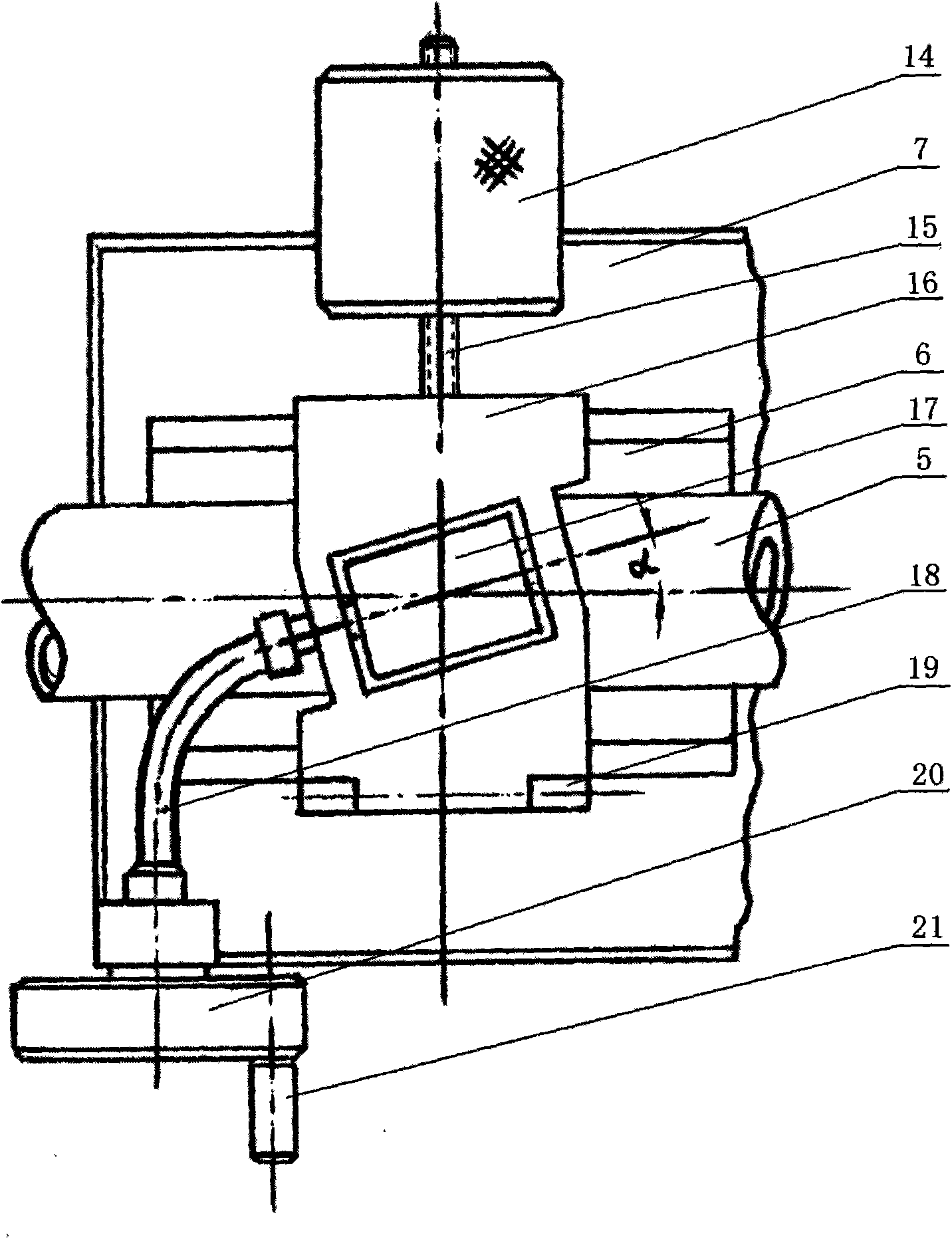

Hub characteristic detecting device for production line

InactiveCN102636093ASimple and reliable stepsNo additional displacementMechanical thickness measurementsUsing optical meansProduction lineHorizontal transmission

The invention discloses a hub characteristic detecting device for a production line. The hub characteristic detecting device is characterized by comprising a horizontal transmission mechanism, a positioning mechanism, an offset detecting mechanism, a thickness detecting mechanism and an imaging mechanism, wherein a rotating shaft of a hub is vertically arranged at one end of the horizontal transmission mechanism, moves to the position of the positioning mechanism horizontally and stands on a conveying belt naturally after being horizontally positioned; in the standing process, the offset detecting mechanism and the thickness detecting mechanism are controlled to acquire hub offset and thickness data, and carries out imaging processing from the top surface of the hub by the imaging mechanism; and finally, the hub is conveyed out by the horizontal transmission mechanism in a same posture. The posture of the hub is constant in the detecting process, the hub keeps standing after being horizontally positioned by the positioning mechanism once till being output finally, so that the step is simple and reliable, no additional displacement is caused. The hub characteristic detecting device disclosed by the invention has the advantages that low efficiency and worse consistency of manual operation are avoided, the detecting speed is high, the period is very short and the detecting consistency is good.

Owner:厦门宣凯精密制造有限公司

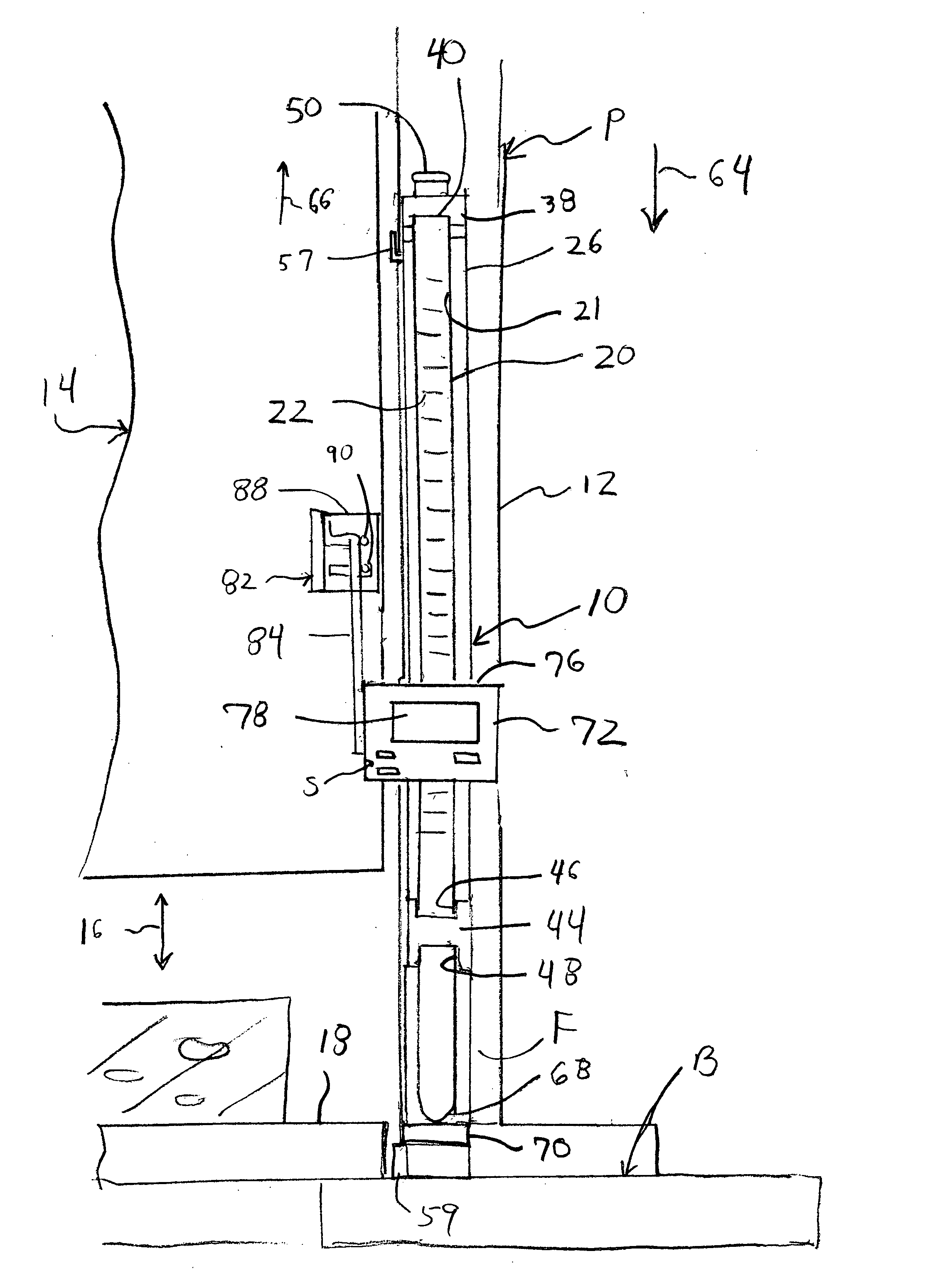

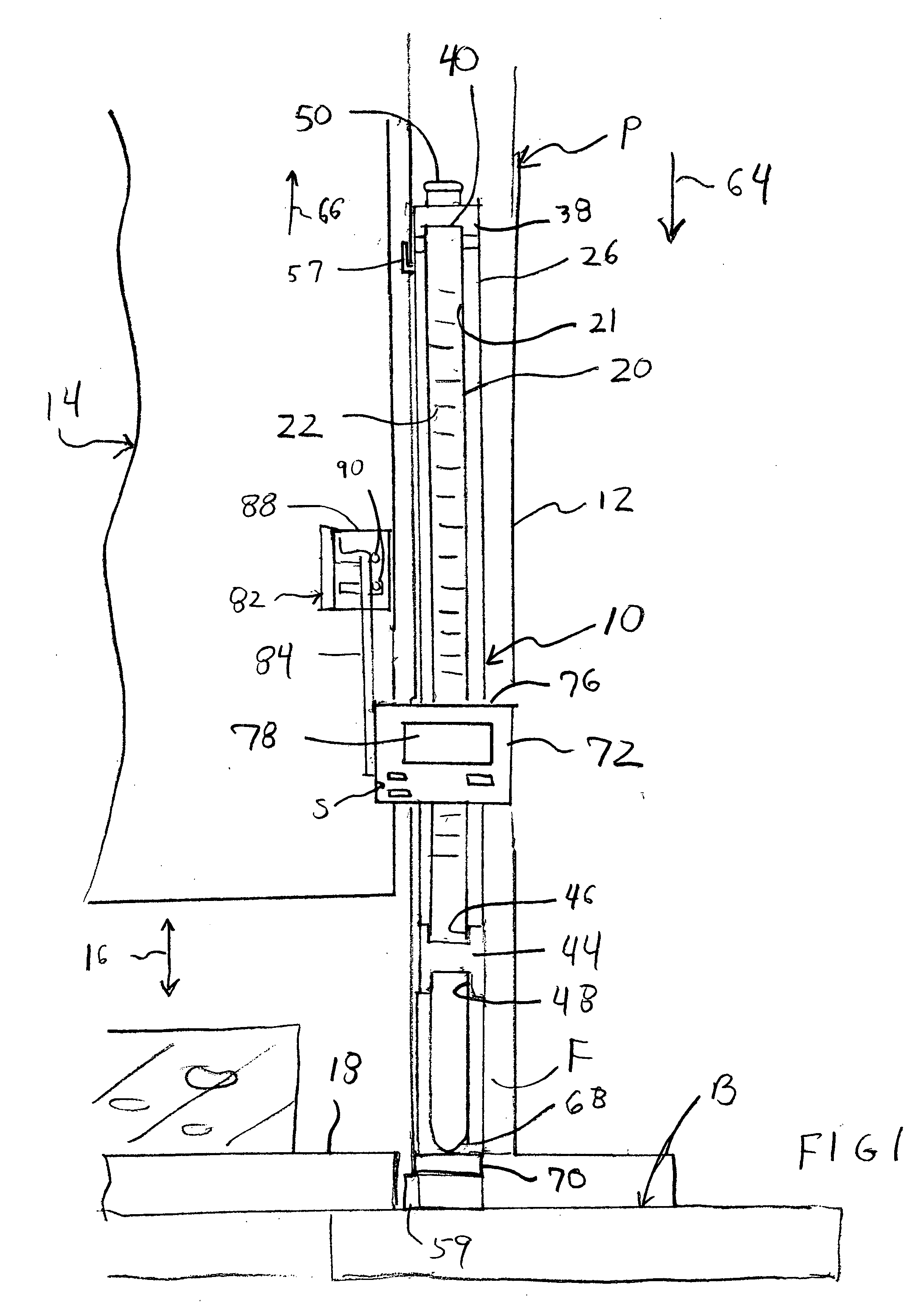

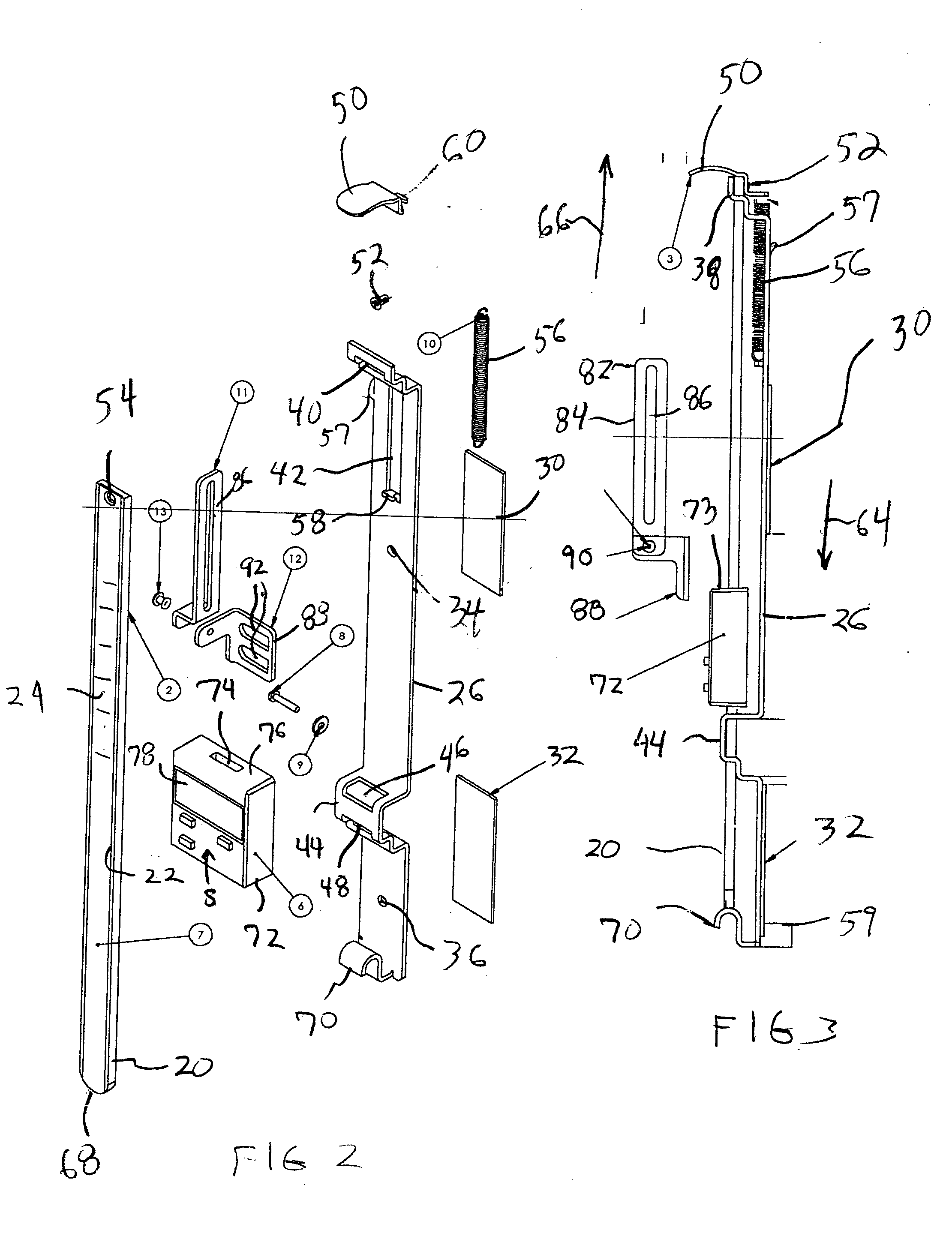

Digital measurement system

ActiveUS20050005468A1Highly accurate and calibrated measurementAccurate measurementDrilling/boring measurement devicesMeasurement/indication equipmentsEngineeringHead parts

A digital measurement system is provided for an apparatus including first and second parts that are positionally adjustable relative to one another, the first part having a base surface and the second part being selectively adjustable toward and away from the base surface. The measurement system includes an elongate reference element mounted for longitudinal movement on the first part such that a first end of the reference element is positionable to be substantially even with the base surface of the first part. A digital reader head is attachable to the second part. The reader head is operable is operably engaged with and moveable along the reference element for measuring relative movement of the reader head along the reference element. The readout further includes a digital display for indicating a measurement corresponding to the relative movement of the reader head along the reference element.

Owner:WIXEY BARRY

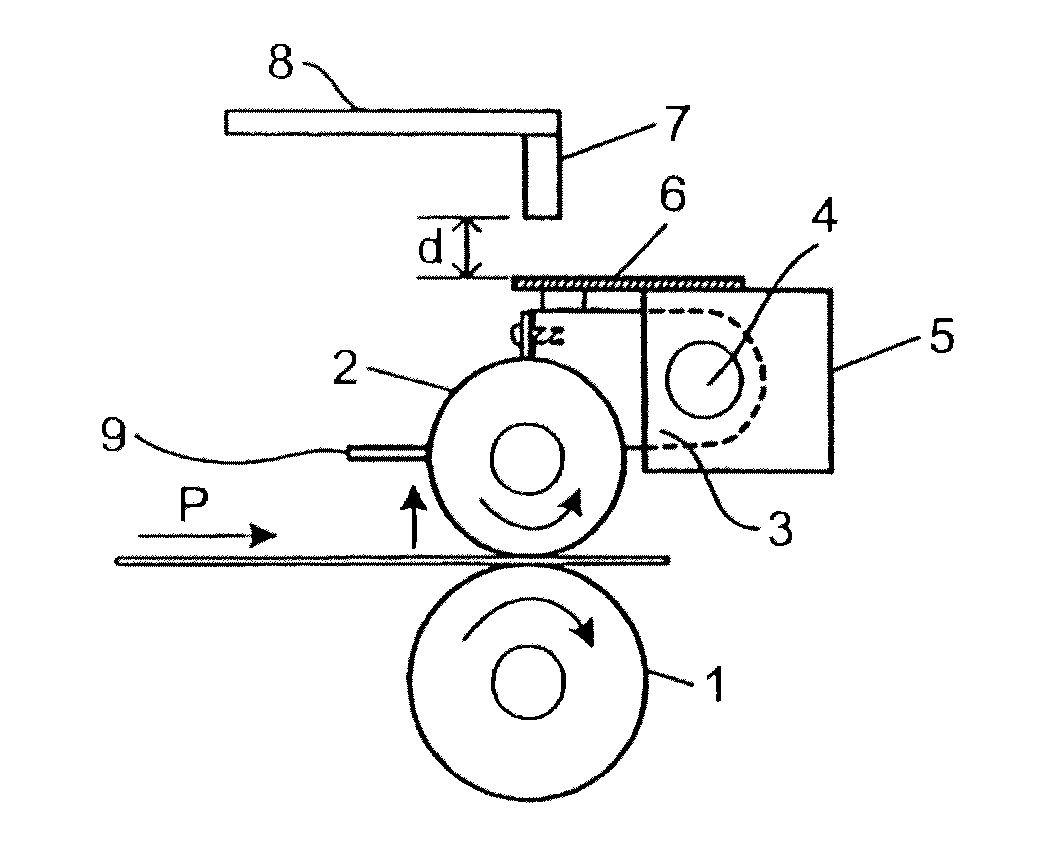

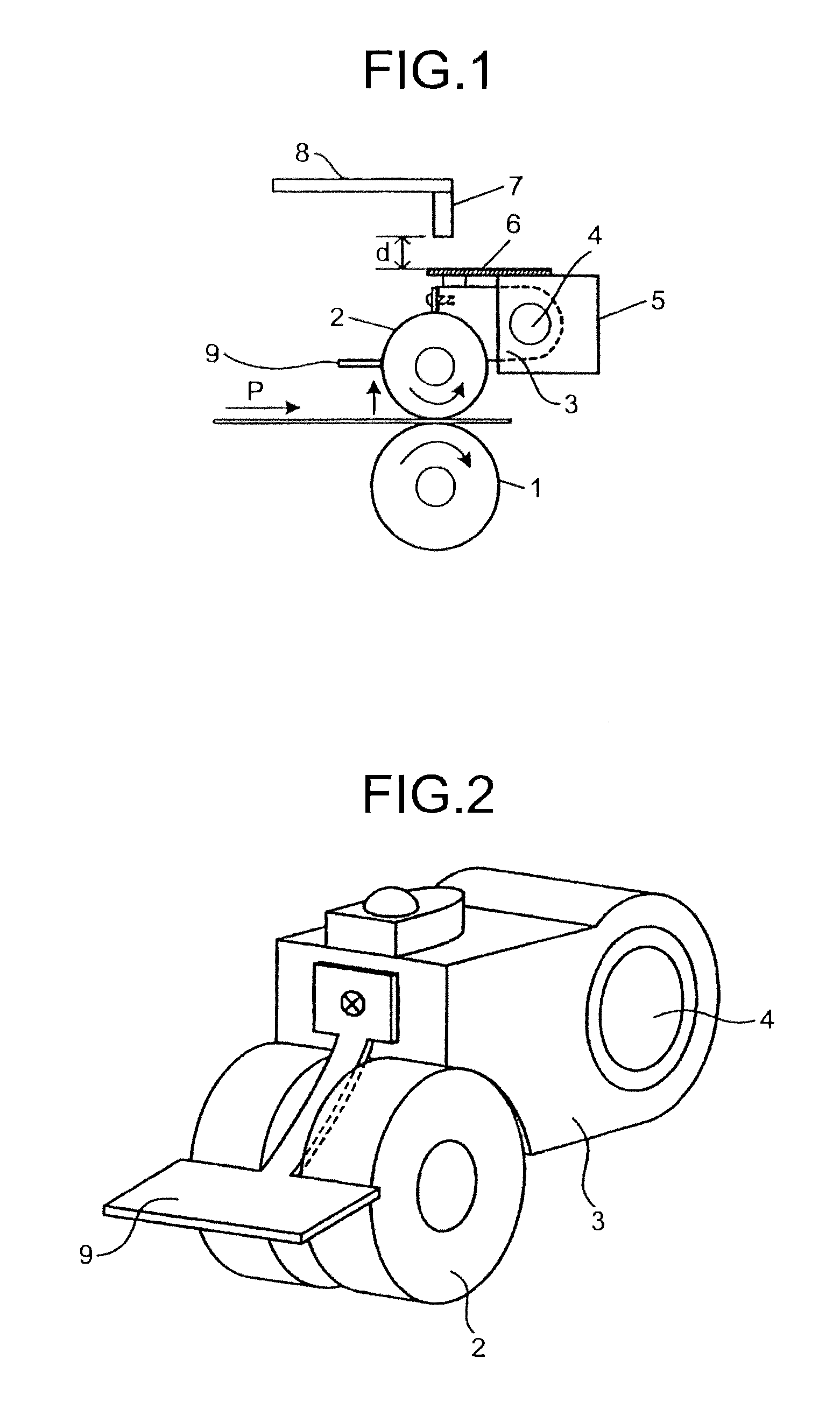

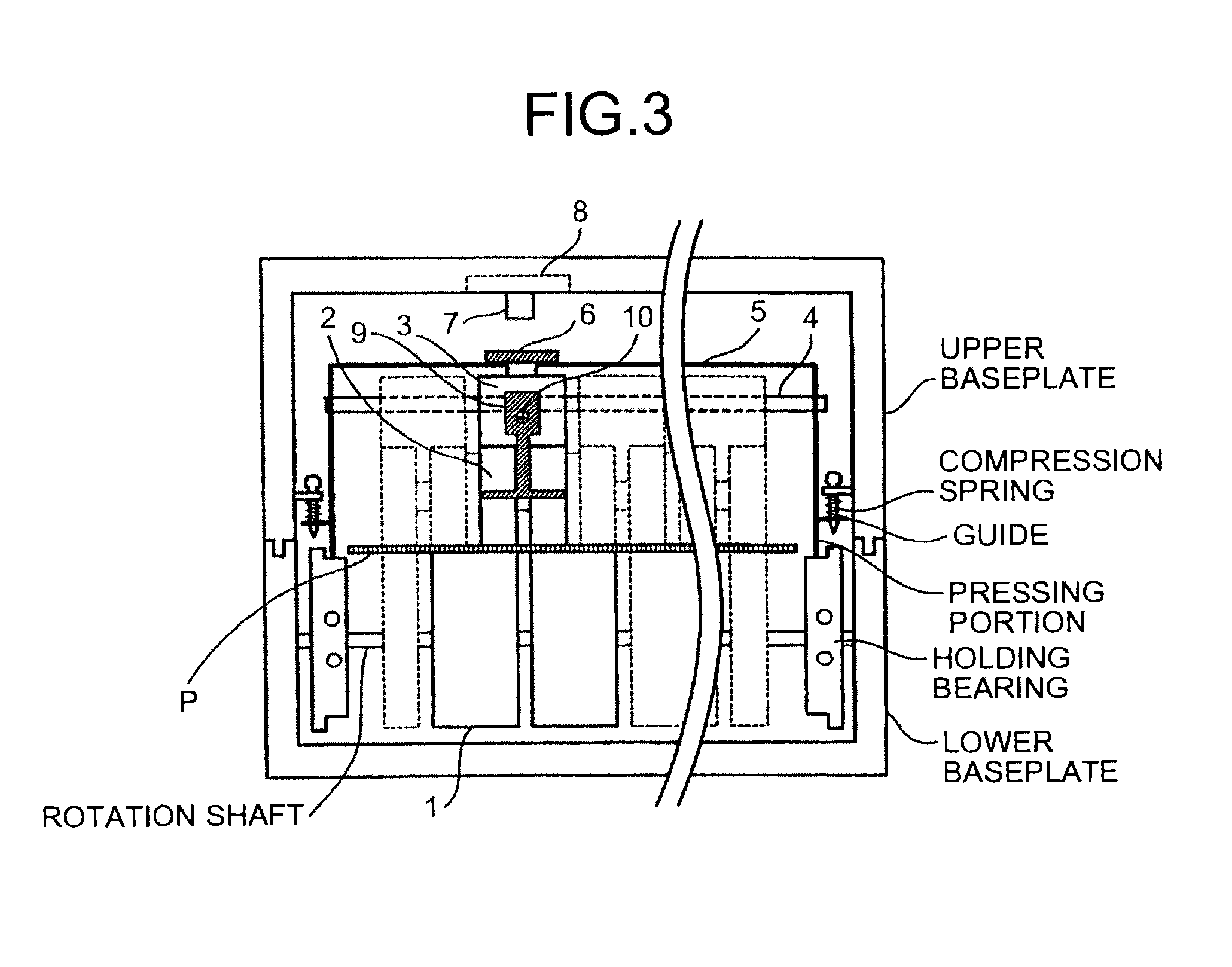

Thickness detector of paper

ActiveUS20120137533A1Decrease in kickPaper-money testing devicesFeeler-pin gaugesEngineeringPaper sheet

A paper-sheet-thickness detecting device includes a reference roller provided on a fixed rotation shaft; a detection roller provided to face and come into contact with the reference roller; a detection block in which the detection roller is provided at one end and the other end is rotatably fixed around a fulcrum shaft so that the detection block is turned and displaced according to a thickness of a paper sheet passing through between the reference and detection rollers; a holding block that holds the fulcrum shaft; a first pressing member fixed to the holding block to maintain contact between the detection and reference rollers by pressing the detection block, the first pressing member being displaced according to rotation and displacement of the detection block when the paper sheet passes through between the reference and detection rollers; and a displacement detector that detects a displacement amount of the first pressing member.

Owner:GLORY KOGYO KK

Device for measuring wall thickness

InactiveCN109341484ARealize line scan measurementImprove measurement efficiencyMechanical thickness measurementsEngineeringLine scanning

The invention discloses a device for measuring wall thickness. A part to be measured is placed on a turntable, and one scanning measurement is completed after the turntable rotates one circle. Thus, the measurement efficiency is greatly improved. The height of a vertical rod can be adjusted by rotating a rotary base, and the operation is very convenient. In addition, a measuring rod is set to onlymove in the axial direction in the shell, so that there is no radial offset between the measuring rod and the shell. The change of wall thickness is directly converted into the amount of travel of the measuring rod in the axial direction, and the amount of travel of the measuring rod is directly displayed through a display element, so that the measuring accuracy is ensured. Moreover, a first elastic piece is arranged between the measuring rod and the shell. Because of the automatic rebound of the first elastic piece, two contacts can always be close to the inner and outer walls of the part tobe measured during measurement. Therefore, line scanning measurement of the part to be measured can be realized, and all surfaces with wall thickness requirement can be covered. The measurement efficiency is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Clamping equipment for part machining

InactiveCN109397152AGuaranteed normal processingAvoid excessive extrusionMechanical diameter measurementsWork holdersSlide plateSteel tube

The invention relates to the technical field of clamping devices, in particular to clamping equipment for part machining. The clamping equipment comprises a fixing platform; a fixing mechanism and a driving mechanism are arranged below the fixing platform; the fixing mechanism comprises two fixing seats; a transversely-arranged bidirectional screw rod is rotationally connected between the two fixing seats; a sliding plate is in threaded connection to each of two threaded parts of the bidirectional screw rod; two sliding blocks are arranged between the two sliding plates; fixing blocks for fixing steel pipes are arranged on the two sliding blocks; compression springs are fixedly connected between the fixing blocks and the sliding blocks; first measuring mechanisms are connected between thefixing blocks and the sliding blocks; and a second measuring mechanism is further fixed to the upper end of the fixing platform. The first measuring mechanisms are used for measuring the pre-tightening force on the clamped steel pipes in real time, the bidirectional screw rod is rotated, the pre-tightening force on the steel pipes is close to the reference pre-tightening force, and thus the pre-tightening force for clamping the steel pipes is measured, regulated and controlled.

Owner:重庆亿普机电有限公司

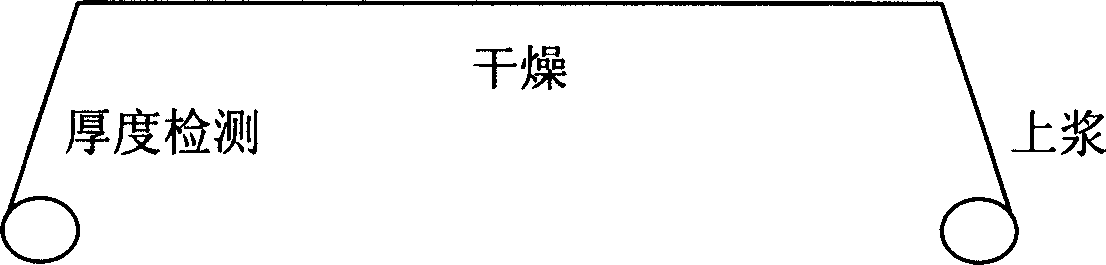

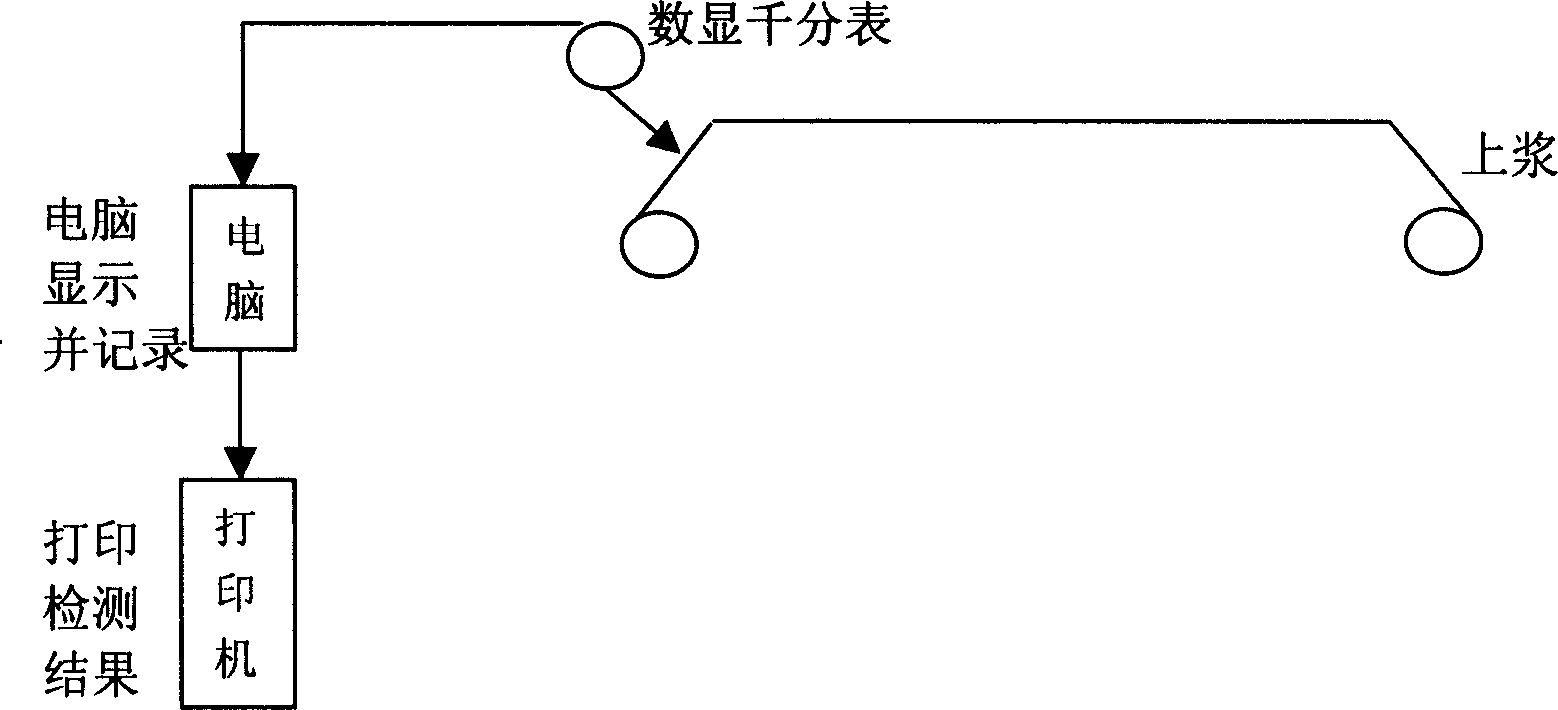

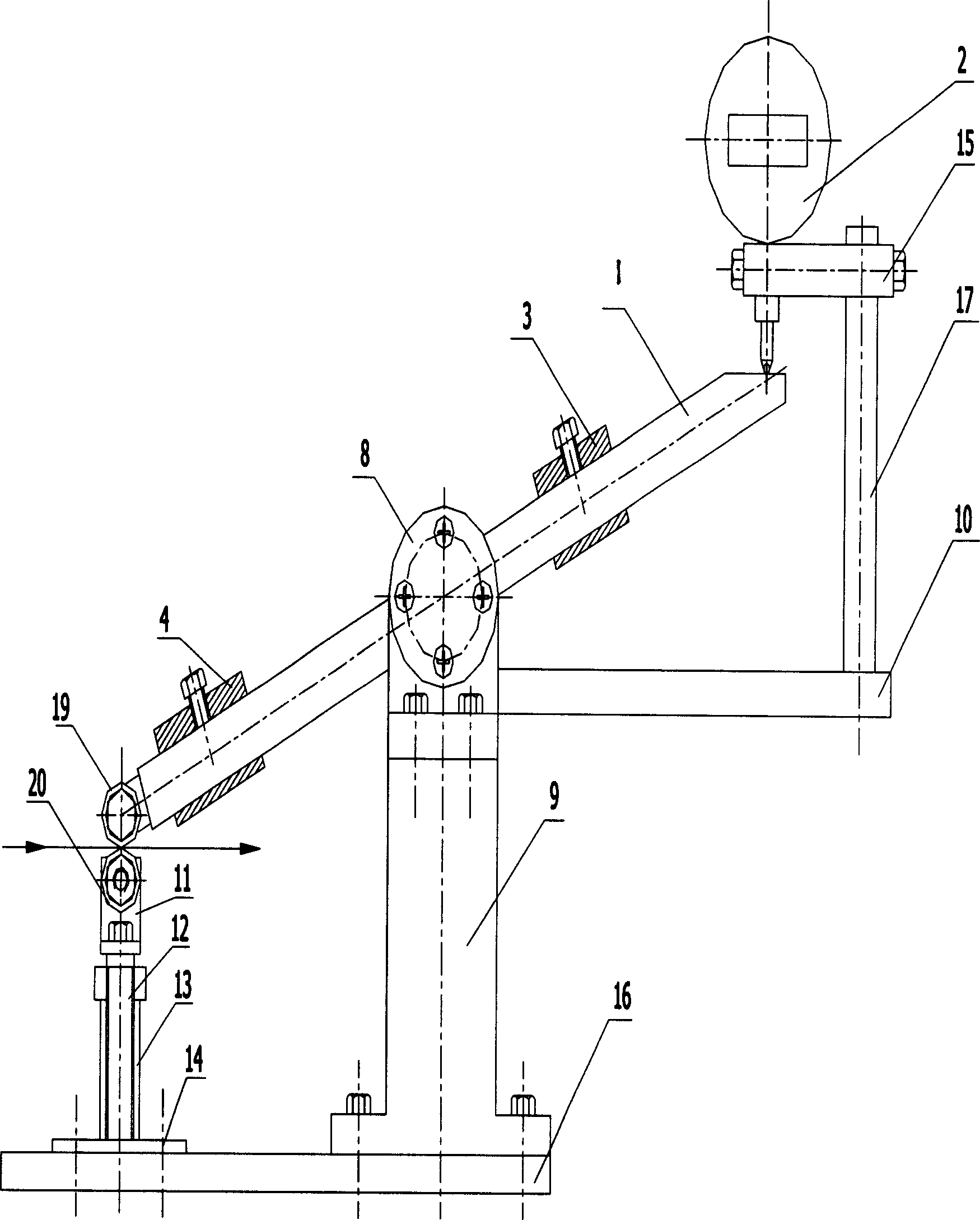

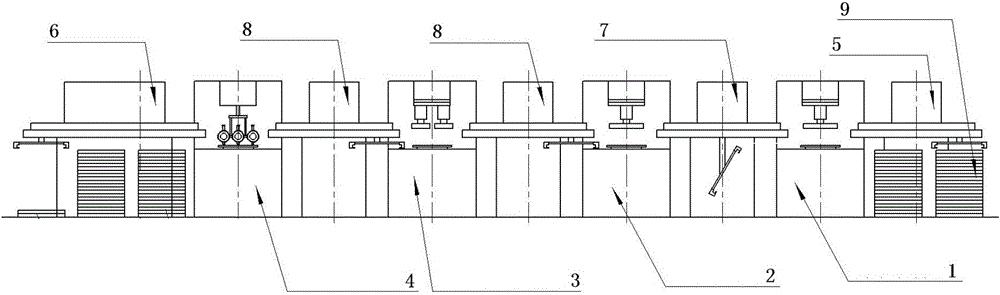

Lever type dynamic pachymeter

InactiveCN1743788AMeasurement results are free from human influenceHigh measurement accuracyFeeler-pin gaugesMechanical thickness measurementsPachymetersEngineering

A lever type dynamic thickness measuring meter for thickness of battery electrode piece, which contains base, support, lever, digital display dial gauge and balance block, one end of lever connected with the upper bearing, when the object to be measured passes the upper and lower bearings, the upper bearing is lifted, the height change transmitted to another end of lever by said lever, this end contacted with rod of digital display dial gauge and generating a numerical reading which is the height of the object to be measured, the balance block in upper bearing and lever can be adjusted according to hardness of measured object. Said invention raises measurement precision and avoids the error duo to manual measurement and the difference of hardness of objects.

Owner:HYB BATTERY

Quality testing system for friction discs

ActiveCN105784716AReduce false detection rateReduce manufacturing costOptically investigating flaws/contaminationMechanical thickness measurementsForeign matterDistance detection

The invention discloses a quality testing system for friction discs. The quality testing system consists of a first defect detection device, a second defect detection device, an internal tooth stick distance detection device, a thickness and flatness detection device, and a controlling and managing machine, wherein the first defect detection device, the second defect detection device, the internal tooth stick distance detection device and the thickness and flatness detection device are sequentially arranged, and the controlling and managing machine is used for controlling the whole testing system to work; a feeding manipulator is arranged at the front end of the first defect detection device; a discharging manipulator is arranged at the tail end of the thickness and flatness detection device; a moving and overturning manipulator which is used for completing the overturning operation of the friction discs in a moving process is arranged between the first defect detection device and the second defect detection device; moving manipulators are arranged between the second defect detection device and the internal tooth stick distance detection device, and between the internal tooth stick distance detection device and the thickness and flatness detection device. The detection of the friction plates on scratches, patches, foreign matters in grooves, broken blocks, grooving traces, center distances of internal tooth sticks, flatness and thickness can be completed at the same time; unmanned automated operation can be realized, a false detection rate generated due to the weariness of staff is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:SUZHOU JIUDIAN INTELLIGENT TECH CO LTD

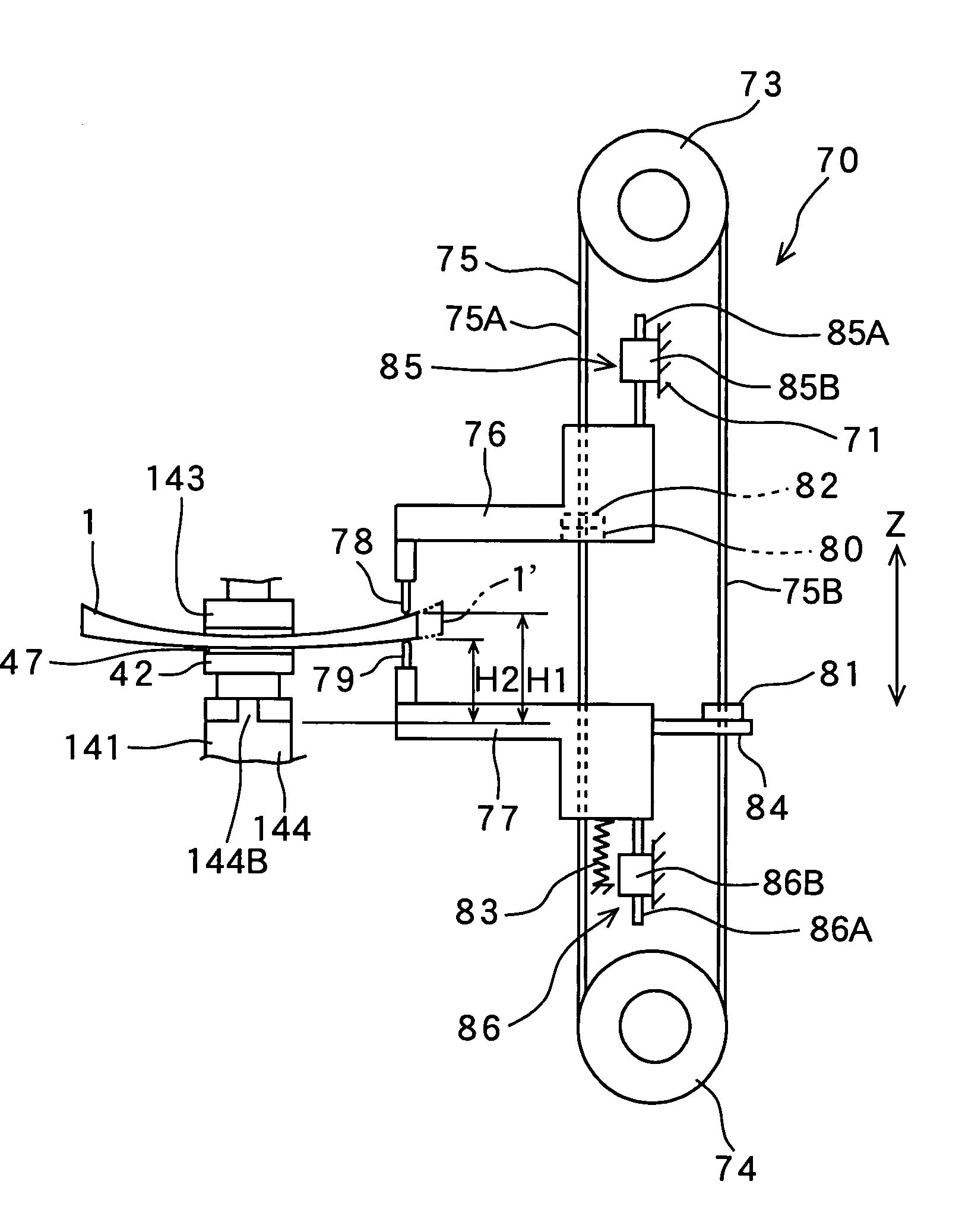

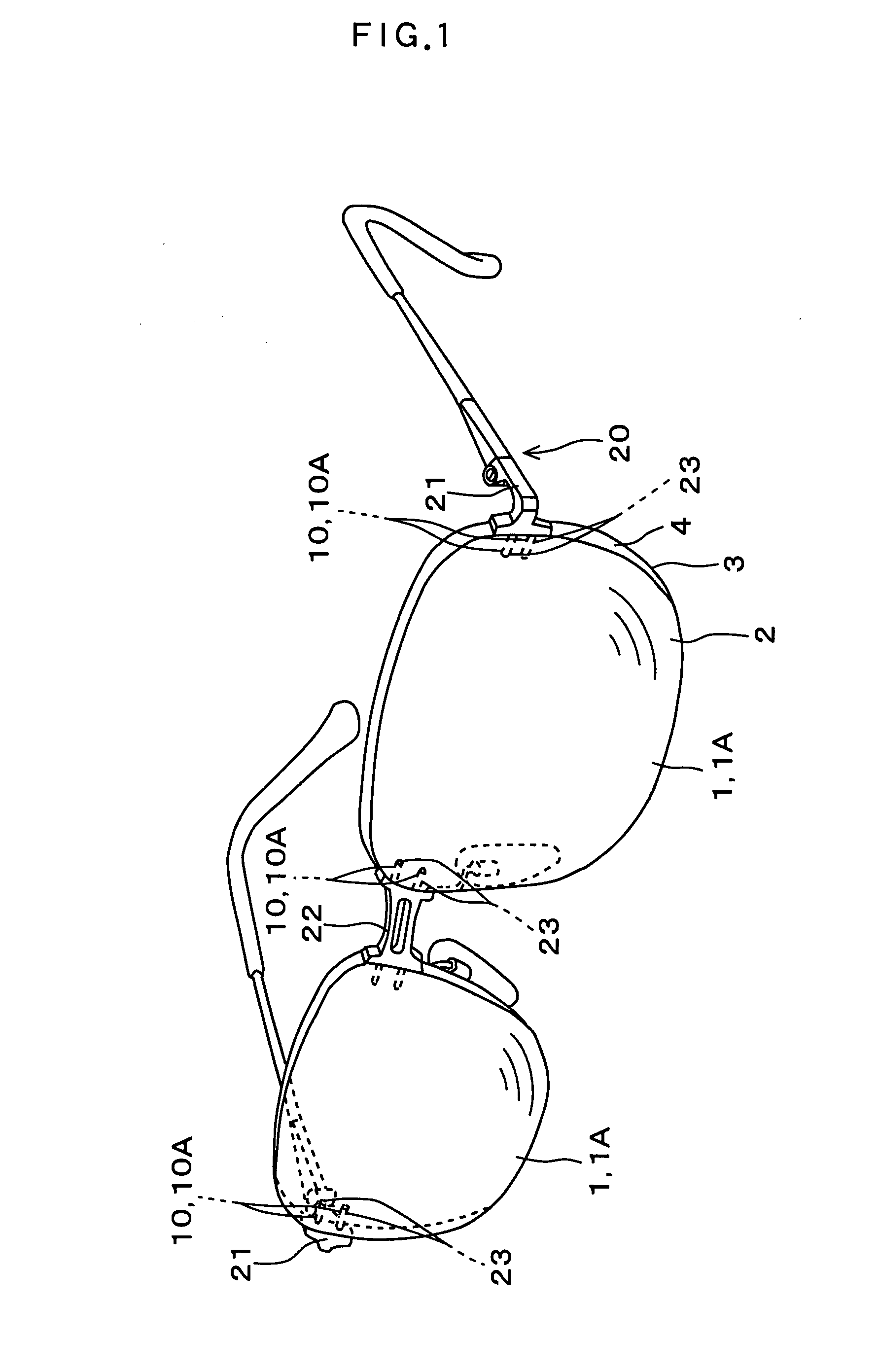

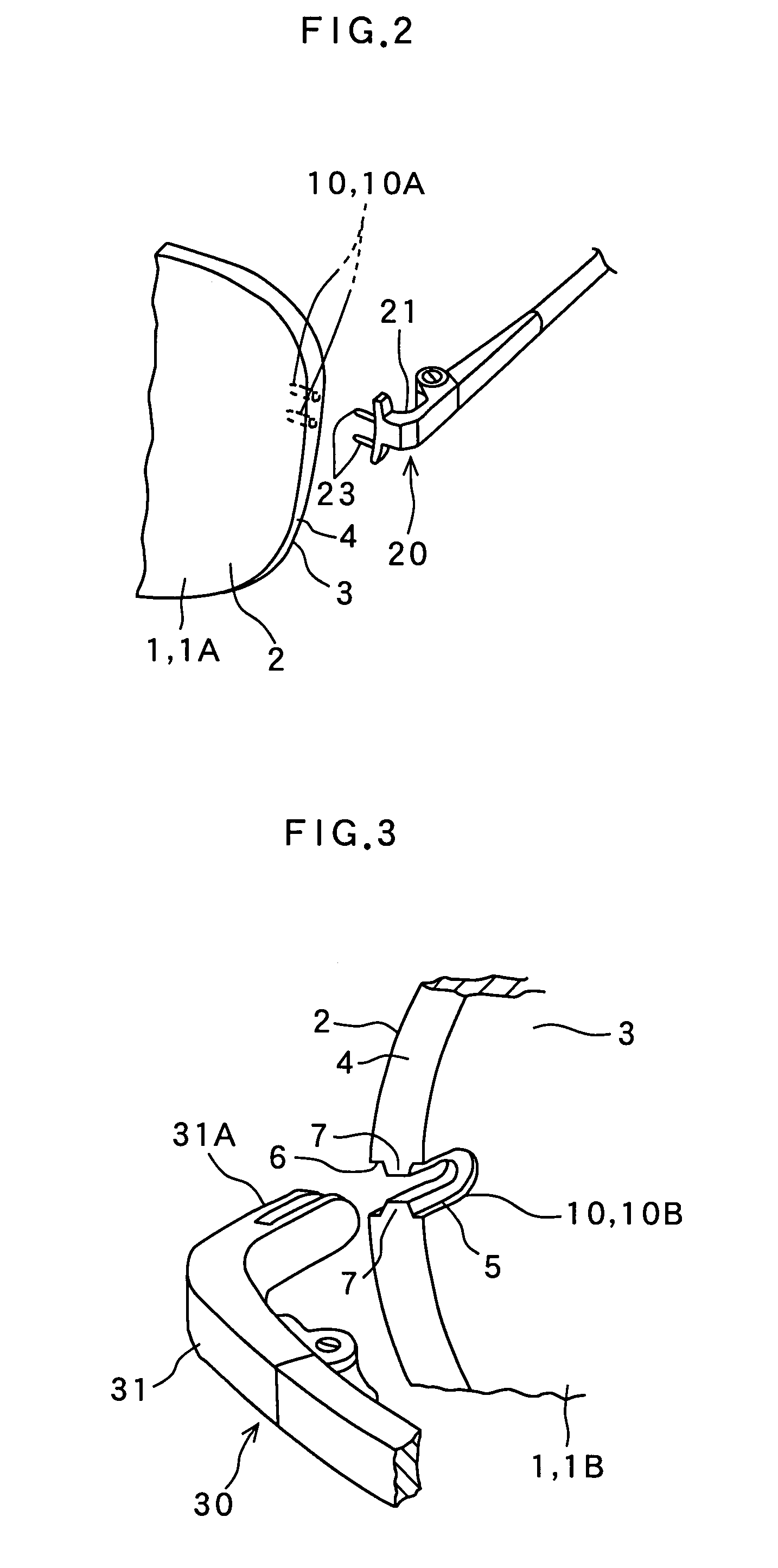

Device and method for measuring and machining spectacle lens, spectacle lens manufacturing method, and spectacles manufacturing method

A mounting part for mounting spectacle frame components such as lugs can be machined after confirming that a lens thickness at a mounting part-machined portion where the mounting part is machined is equal to or larger than the specified value, and can be installed the spectacle lens components on the spectacle lens with a requested strength. The device, the method for the above, a spectacle lens manufacturing method, and a spectacles manufacturing method are given. The spectacle lens (1) is fed to a lens thickness measuring device (70) by a lens feeder. The fed amount of the spectacle lens in this feeding is based on the measured results of a distance between a frame center forming a block center by a lens holder in an edging for manufacturing the spectacle lens (1) from a raw material lens and the edge face of the spectacle lens (1) where the mounting part is to be machined. The thickness of the lens at the mounting part-machined portion can be accurately measured by the measuring device (70) even if an error produced in the edging is included in the distance.

Owner:HOYA CORP

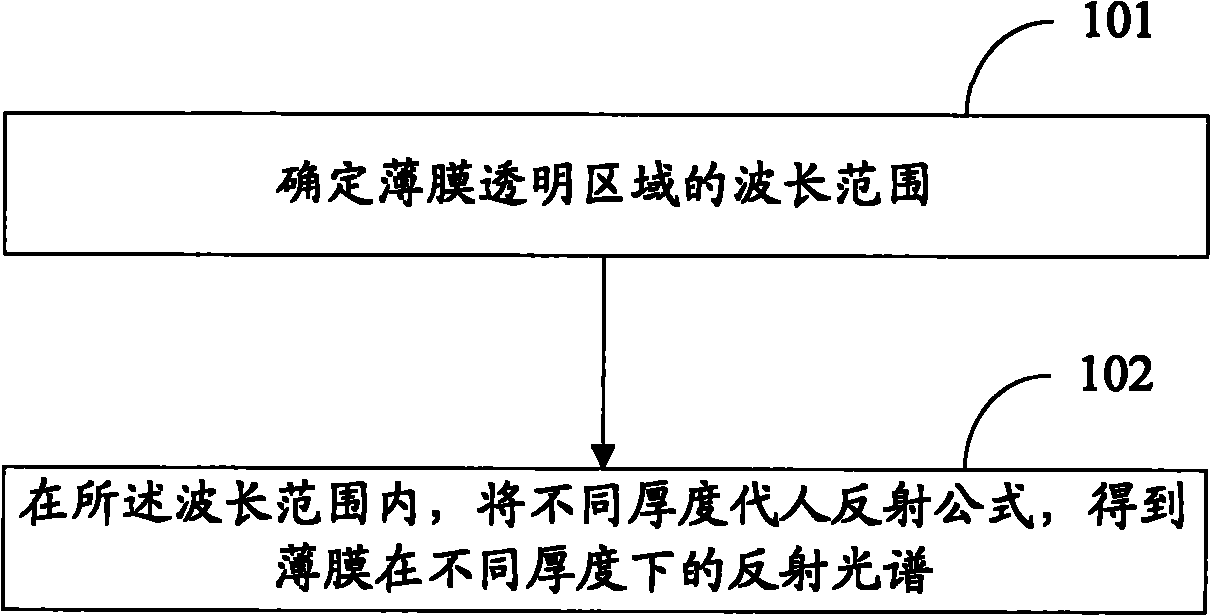

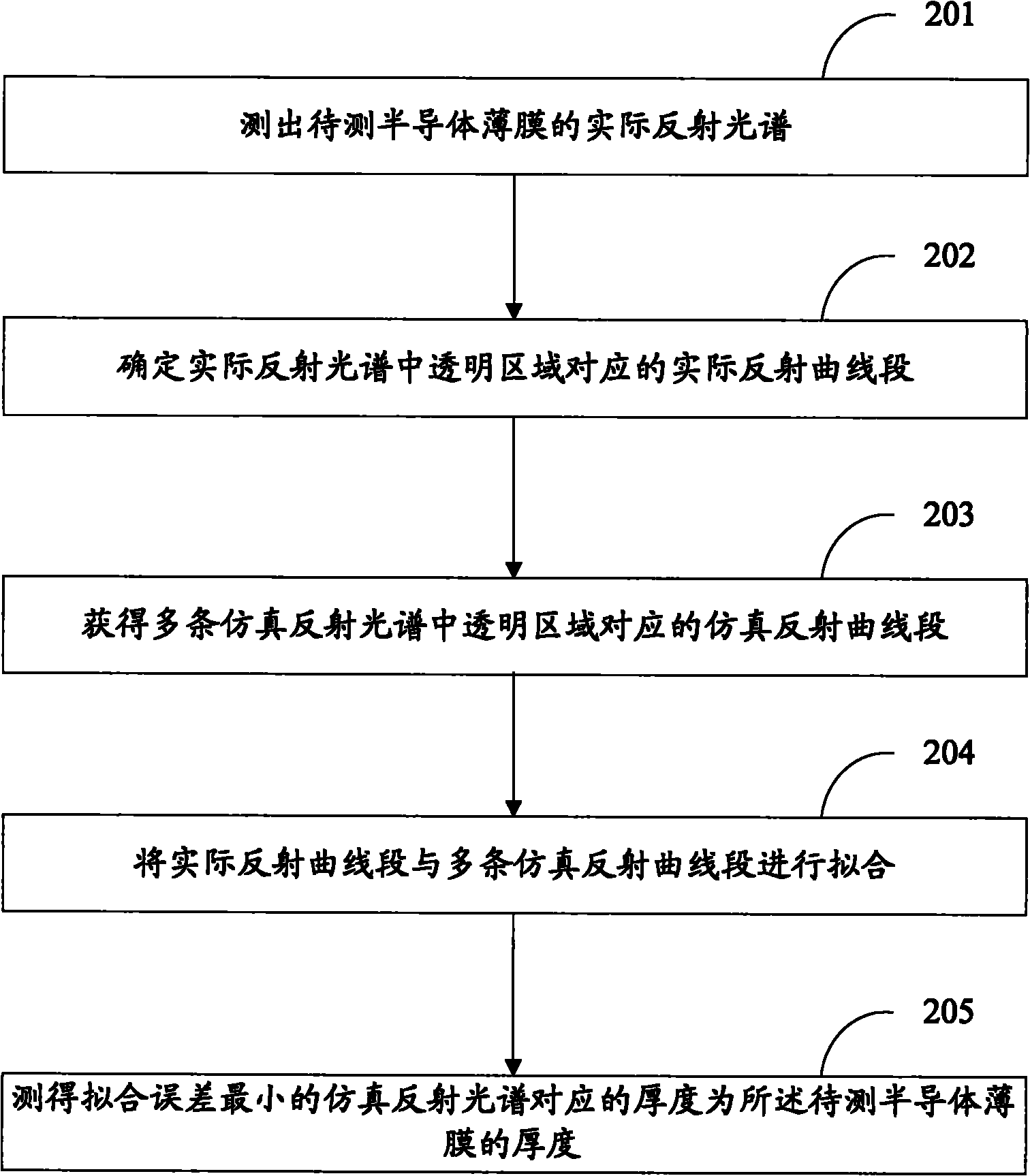

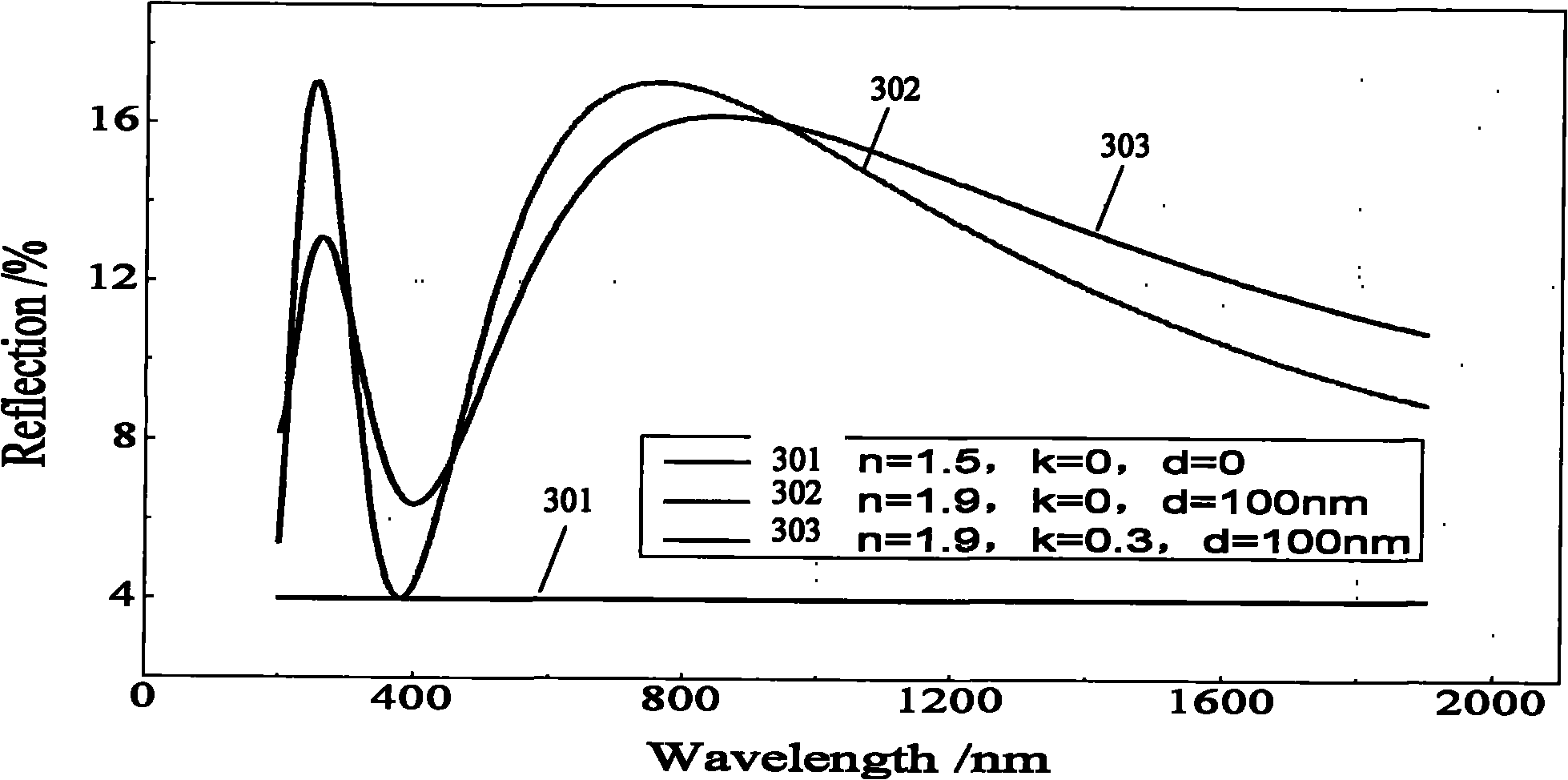

Method and device for measuring thickness of semiconductor film

ActiveCN101865641AAccurate thicknessReduce the impactMechanical thickness measurementsRefractive indexSemiconductor

The invention discloses a method for measuring the thickness of a semiconductor film, which is used for improving the efficiency of calculating film thickness and obtaining more accurate film thickness. The method comprises the following steps: measuring an actual reflection spectrum of the semiconductor film to be measured; determining an actual curve section corresponding to a transparent region in the actual reflection spectrum; obtaining simulated reflection curve sections corresponding to transparent regions in a plurality of simulated reflection spectra, wherein the plurality of simulated reflection spectra comprise reflection spectra of different thicknesses of film samples with the same reflective index as the semiconductor film to be measured; fitting the actual reflection curve sections and the plurality of simulated reflection curve sections; and measuring the thickness corresponding to the simulated reflection spectrum with the minimum error of fitting to be used as the thickness of the semiconductor film to be measured. The invention also discloses a device for realizing the method.

Owner:ENN SOLAR ENERGY

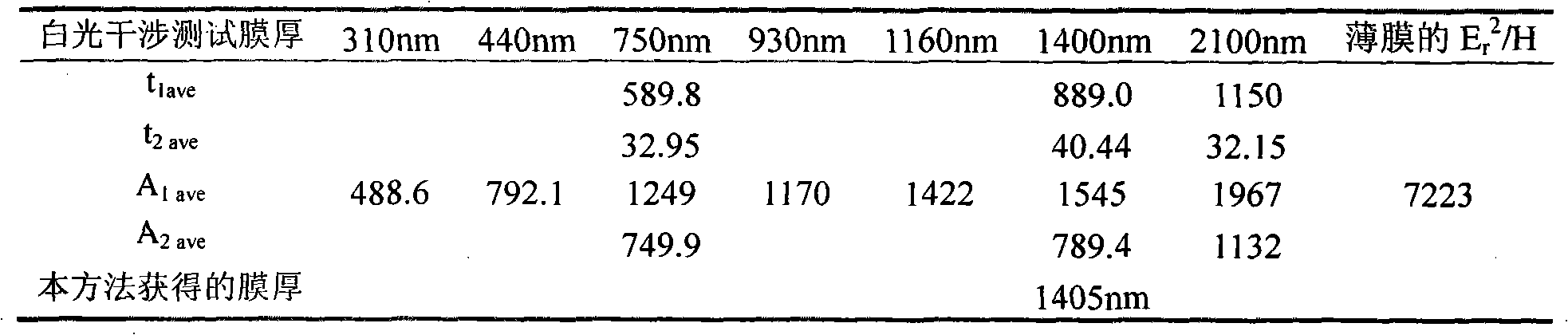

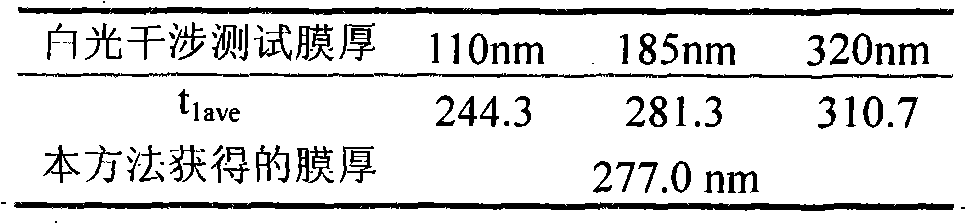

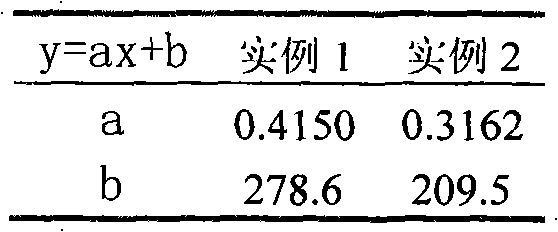

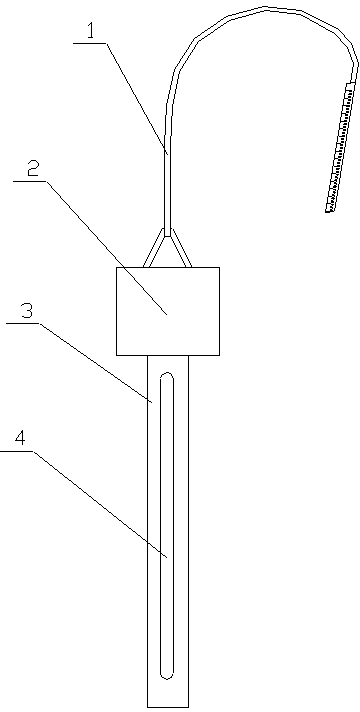

Method for testing physical performances of film and film-substrate interface based on nanometer indentation continuous stiffness curve

InactiveCN101806690AMechanical thickness measurementsInvestigating material hardnessInterface layerEngineering

The invention relates to a a method for testing physical performances of a solid film and a film-substrate interface and belongs to the technical fields of analytic instruments and material performance testing. The method is based on a nanometer indentation continuous stiffness curve and takes the ratio of elastic modulus square of a film-substrate system to the hardness as the ordinate and the indentation depth as the abscissa, a curve is fitted in a iteration screening least square method, and fitted parameters are analyzed and demarcated, thus measuring the physical performances of the film which includes the thickness and the ratio of the elastic modulus square to the hardness and representing parameters related to the thickness of an interface layer and parameters related to the ratio of the elastic modulus square of the interface layer to the hardness and the like. In the method, all tests of the physical performances of the film and the film-substrate interface are based on the nanometer indentation technology, the method can be carried out under the condition of not exposing the substrate surface, the existing equipment does not need to be altered, only the analytic method needs to be change, the application range is wide, and any film material with the film thickness less than the maximum indentation depth of a nanometer indenter can use the method.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

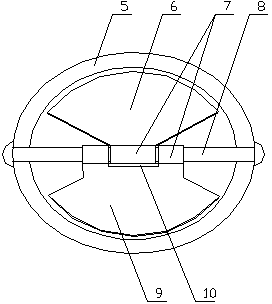

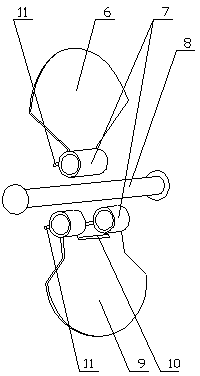

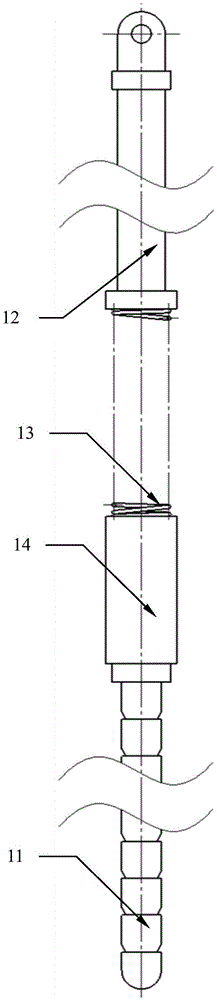

Excessive concrete pouring detector for underwater cast-in-place piles and method for using excessive concrete pouring detector

ActiveCN103195066ANot to be missedReduce wasteMechanical thickness measurementsFoundation engineeringStructural engineeringFan blade

The invention provides an excessive concrete pouring detector for underwater cast-in-place piles and a method for using the excessive concrete pouring detector. The excessive concrete pouring detector for the underwater cast-in-place piles comprises a measuring rope, a counterweight ring, a coring barrel and a leakage stop valve; the lower end of the measuring rope is fixedly connected with the counterweight ring, the lower end of the counterweight ring is fixedly connected with the coring barrel, a transparent observation window is arranged on a side wall of the coring barrel, and the leakage stop valve is arranged inside the lower end of the coring barrel; and a rotary shaft is arranged in the middle of the leakage stop valve, an upper fan blade and a lower fan blade penetrate through the rotary shaft via connected lantern rings, and two ends of the rotary shaft are fixedly connected with a fixing ring. Compared with the prior art, the excessive concrete pouring detector and the method have the advantages that concrete pouring heights of the underwater cast-in-place piles can be accurately detected, conditions of surfaces of the underwater cast-in-place piles or thicknesses of sediments at bottoms of the piles and the like can be known, the problem that bottoms of pile holes are not thoroughly cleaned or elevations of underwater concrete poured surfaces are inaccurate is effectively solved, the underwater cast-in-place piles can meet design requirements by the aid of the detector, waste of concrete is reduced, and the probability of potential safety hazards is reduced.

Owner:CHINA CONSTR EIGHTH ENG DIV

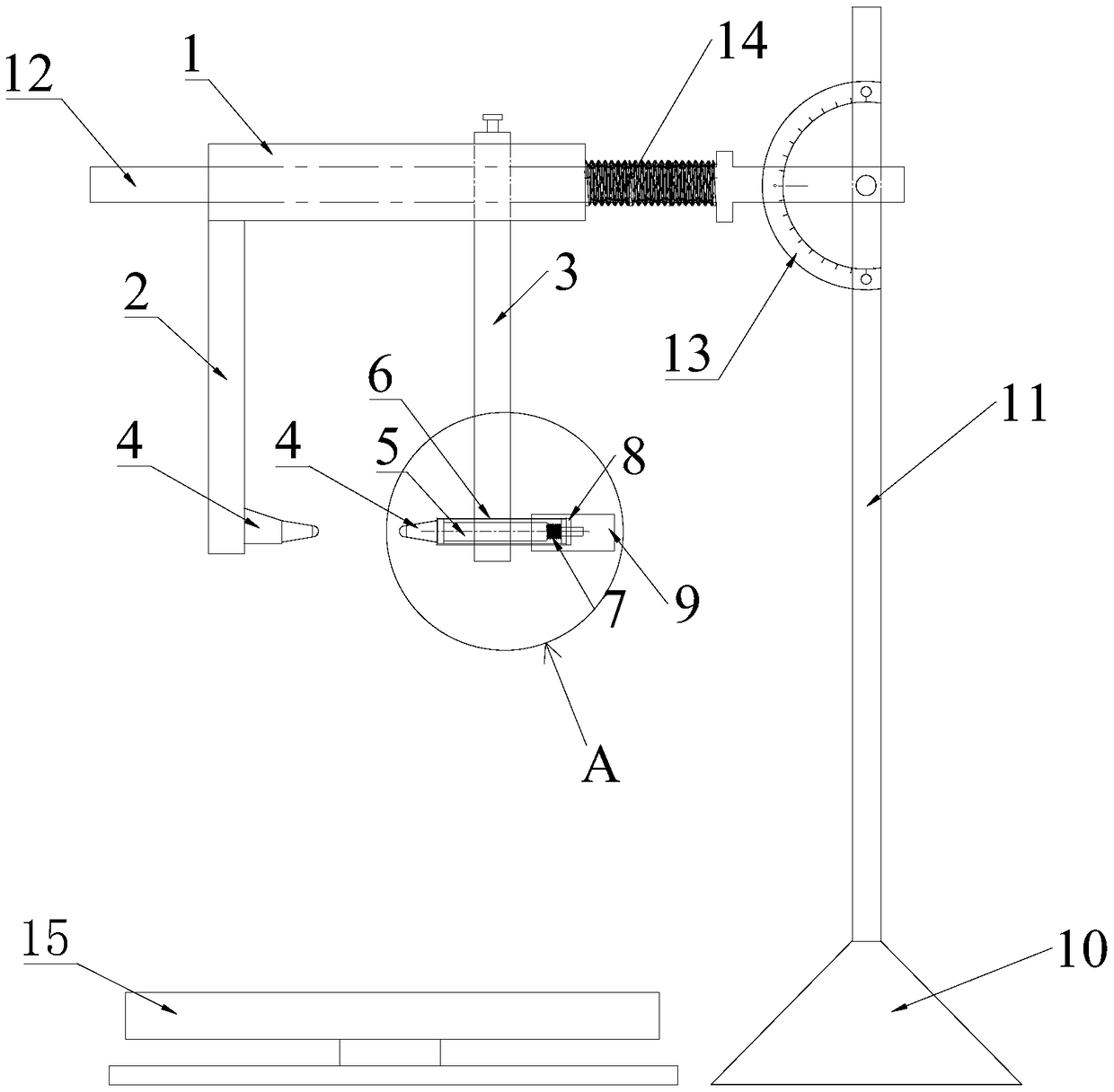

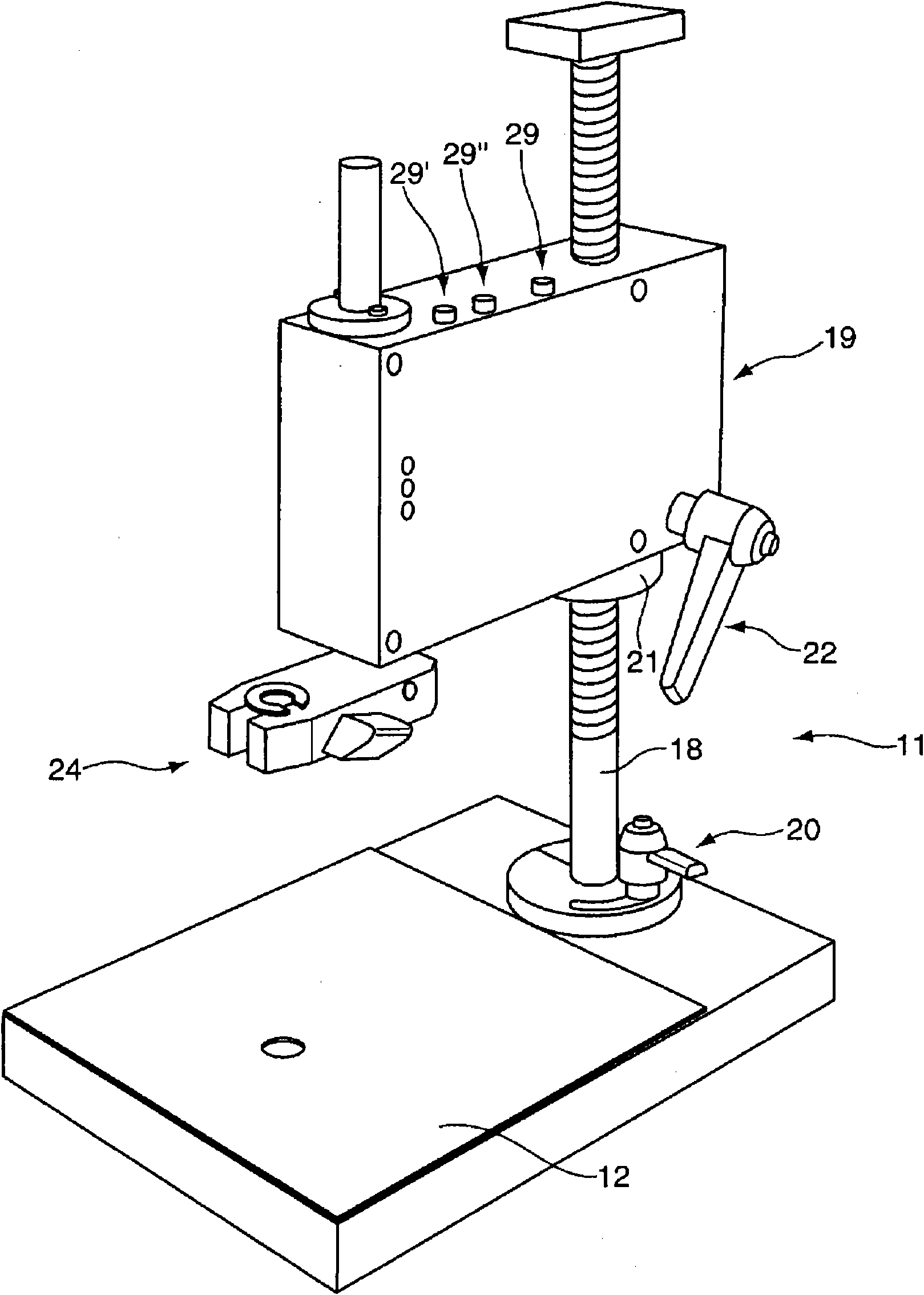

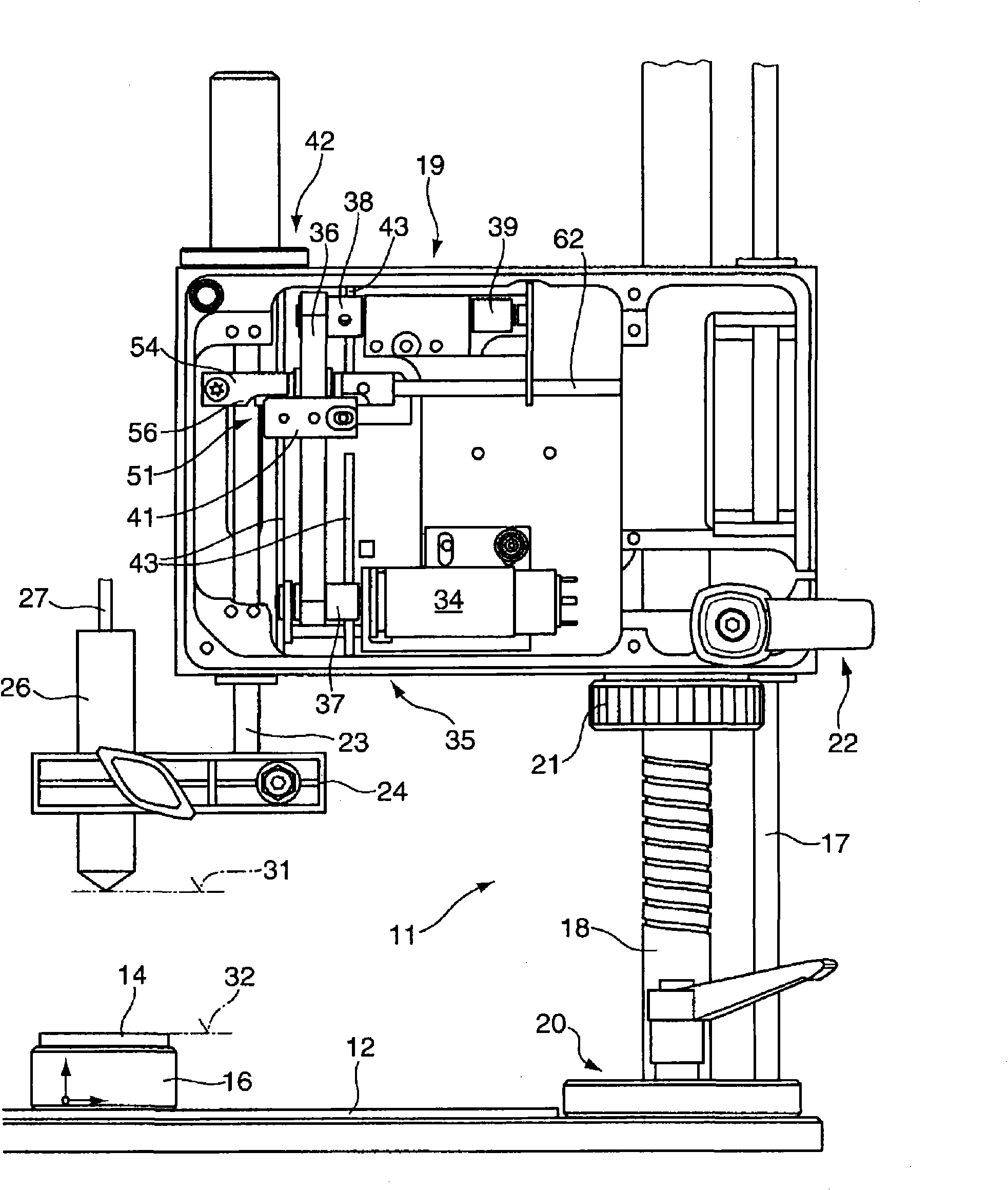

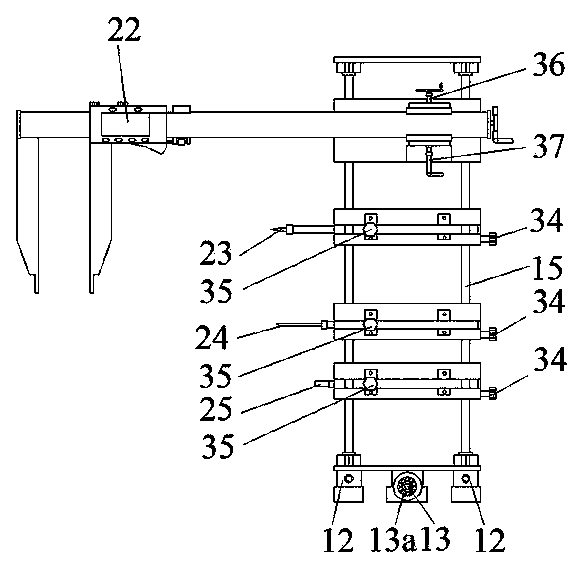

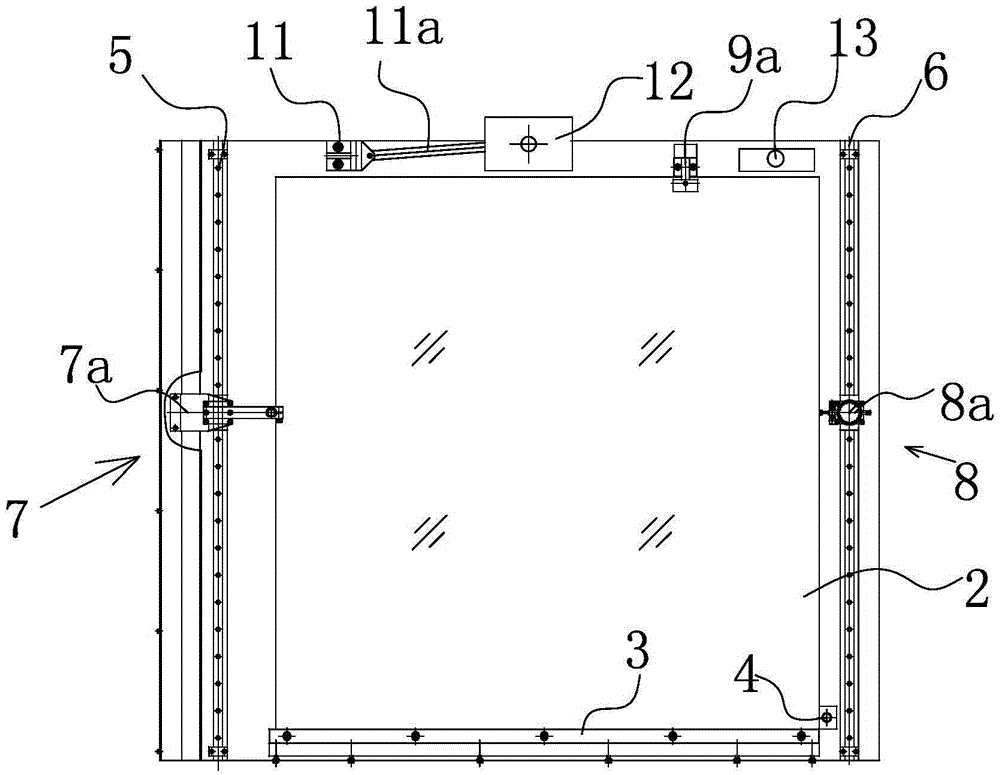

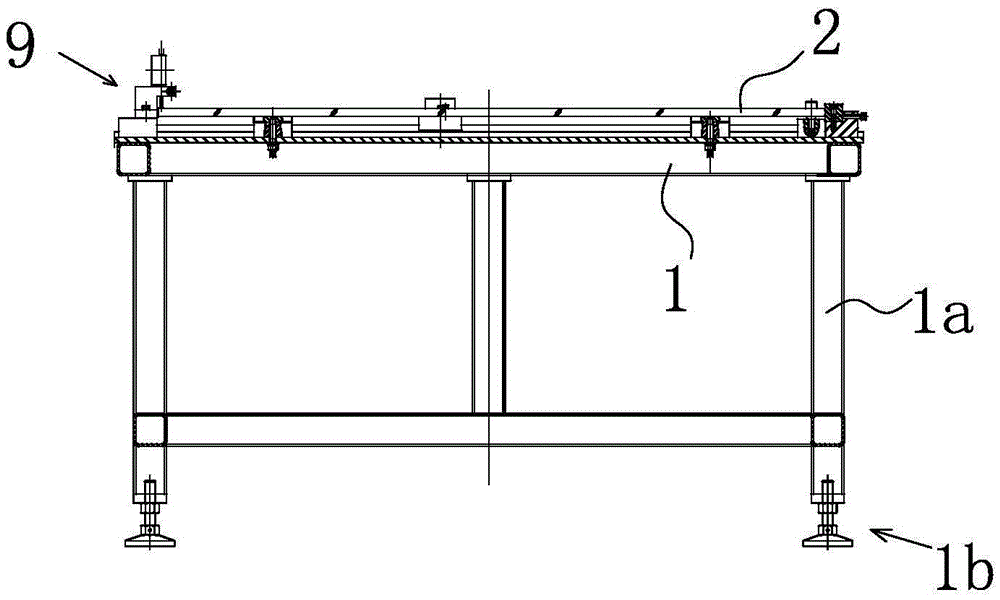

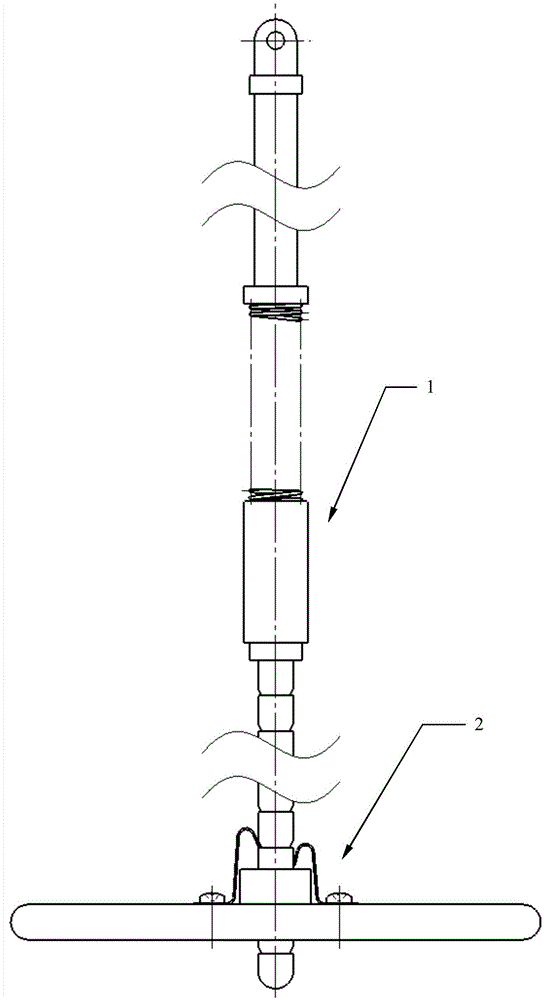

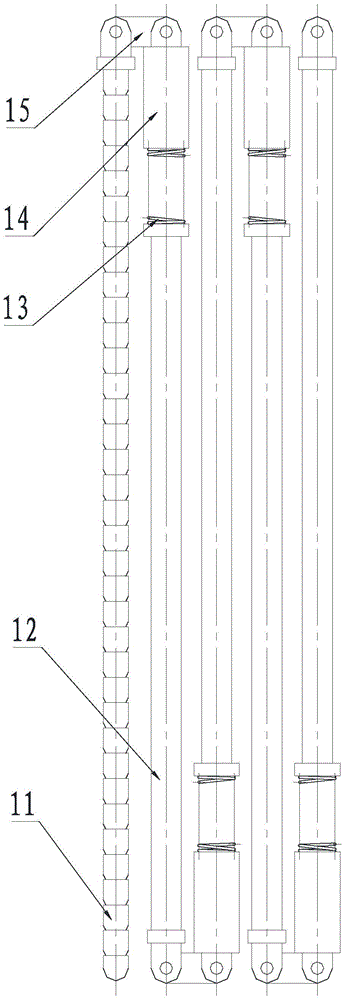

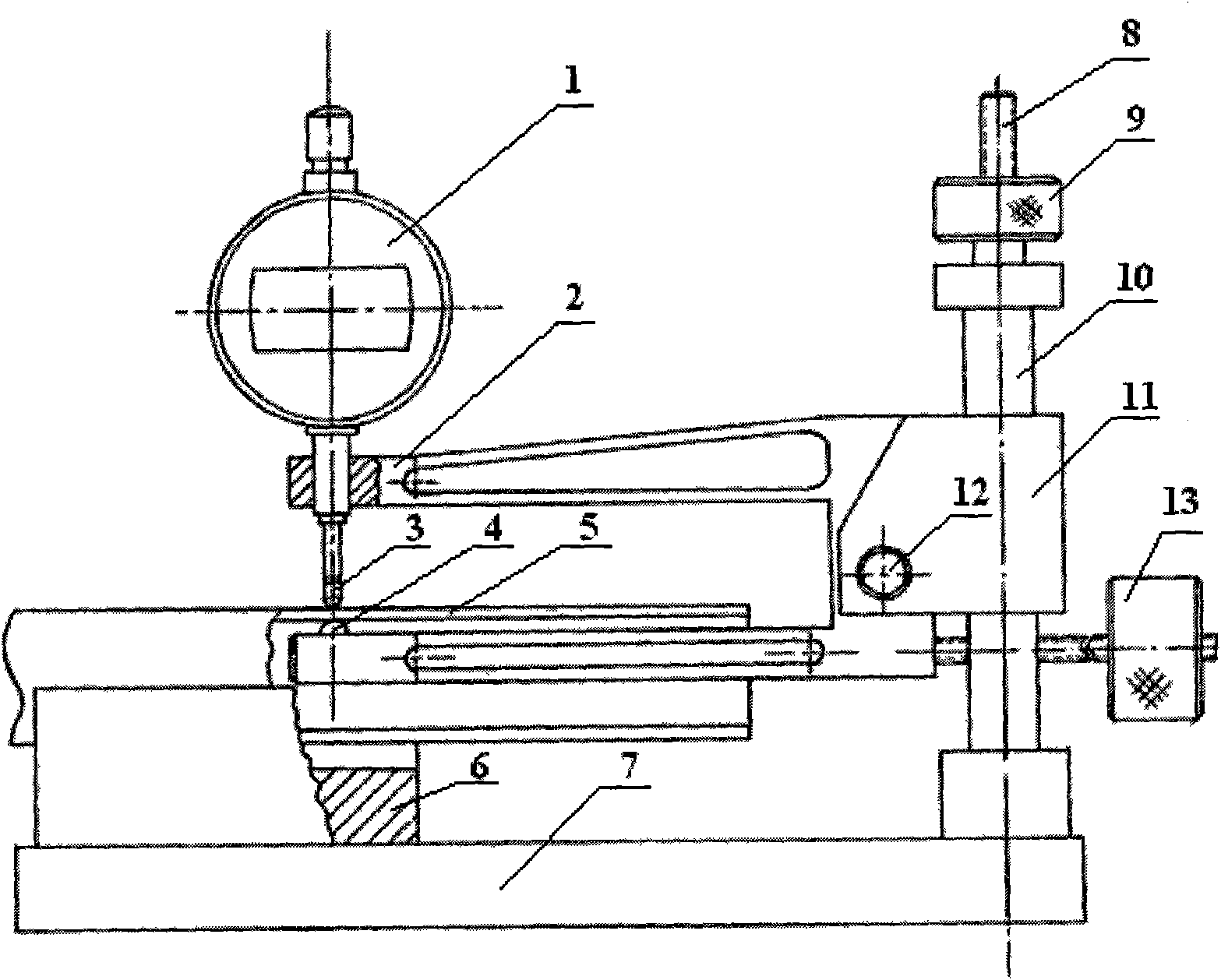

Measurement stand and method of its electrical control

InactiveCN101839681AEliminate mechanical playExact travel distanceProgramme controlUsing electrical meansElectrical controlThin layer

The invention relates to a measurement stand for holding a measuring probe intended in particular for measuring the thickness of thin layers, and to a method for controlling the measurement stand.

Owner:HELMUT FISCHER & INSTITUT FUR ELECTRONIK & MESSTECHN

Method and apparatus for pipe testing

ActiveUS20100212405A1Accurate locationLow costDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesTest chamberEngineering

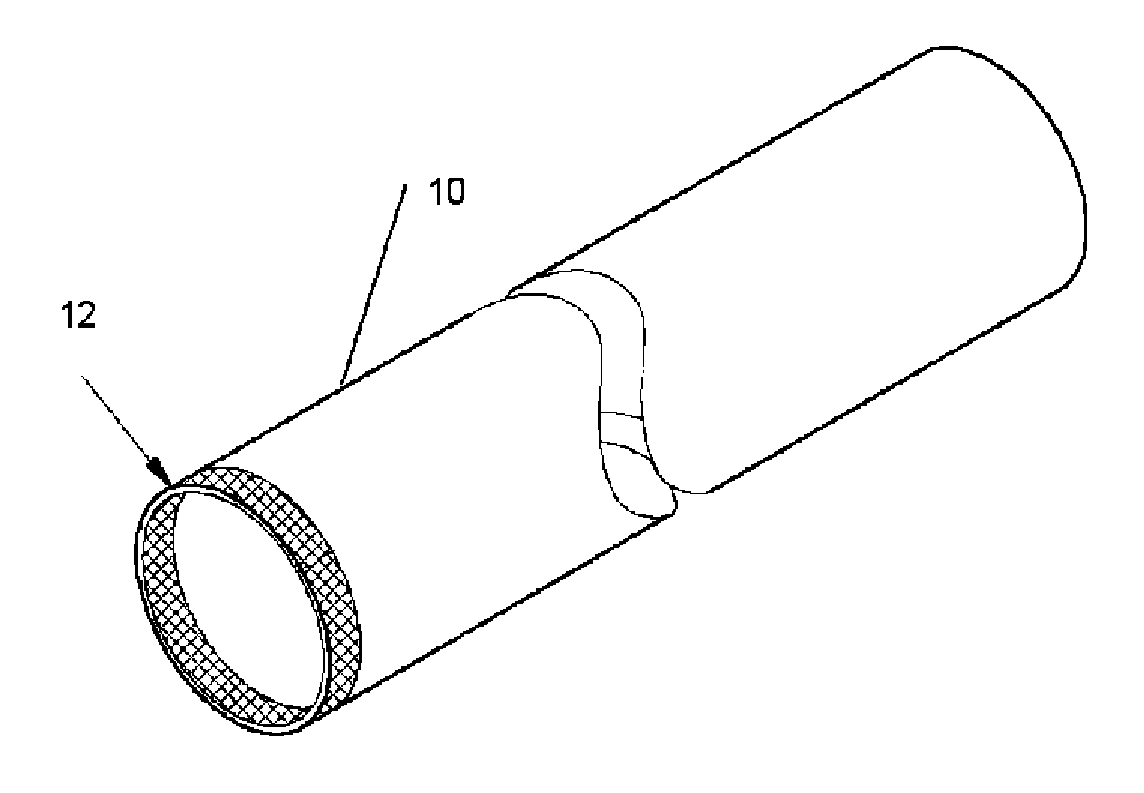

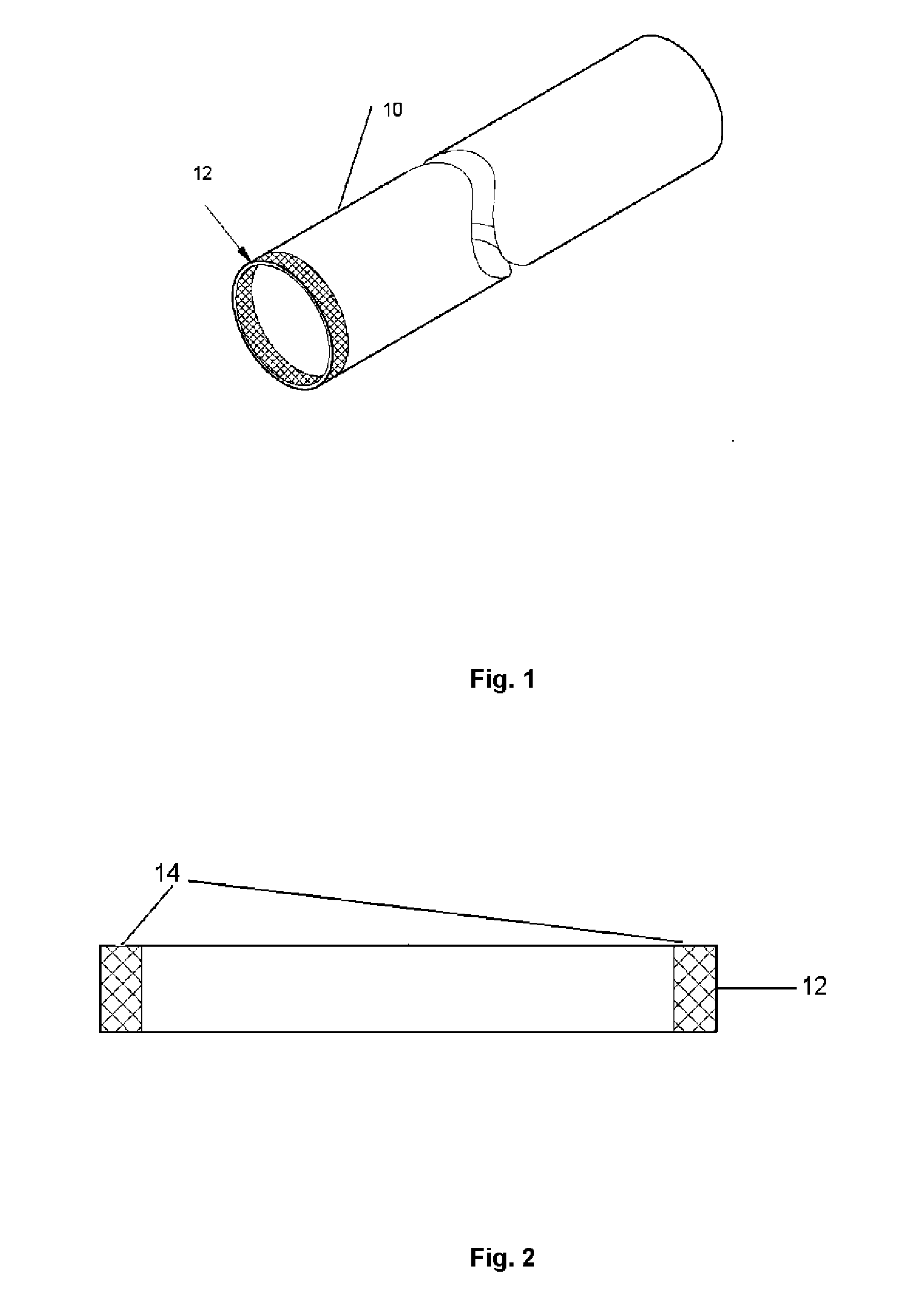

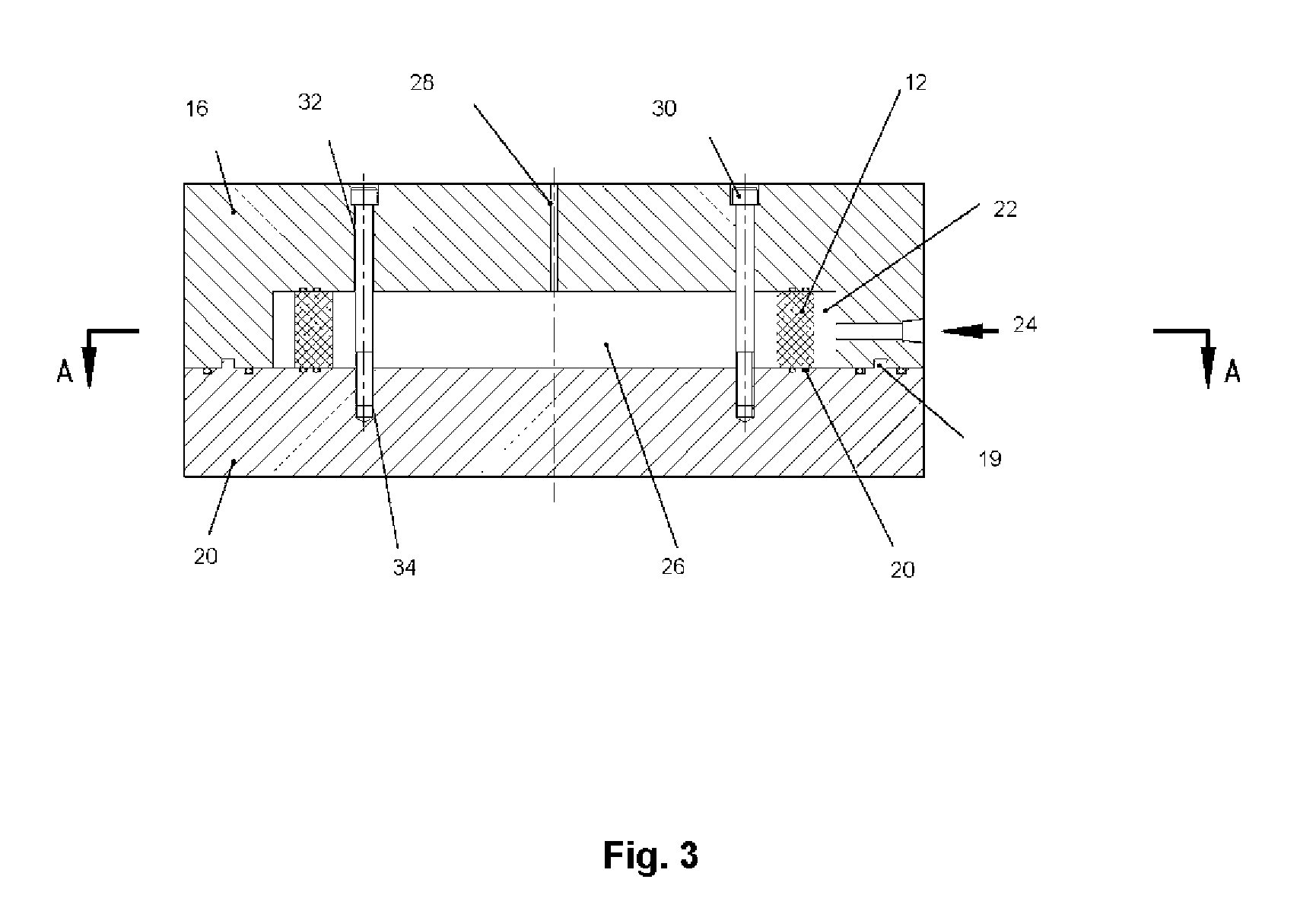

A method of testing pipes for use in making subsea pipelines comprises cutting a ring from one or more pipes of the type used to make the pipeline; forming flat, substantially parallel surfaces on the ends of the ring; providing means for measuring strain and deformation of the ring; mounting the ring in a pressure chamber such that the ends of the ring form seals with opposing walls of the chamber to isolate the inside of the ring from the outside; increasing the pressure outside the ring and measuring the strain and deformation on the ring as the pressure increases; and using the deformation and strain measurements to determine a wall thickness for pipes to be used for the pipeline. An apparatus for testing rings cut from pipes for use in making subsea pipelines, comprises first and second test chamber sections which, when placed together define a test chamber for receiving the ring to be tested; one or more sensors for measuring strain and deformation of the ring; sealing means located in the chamber for forming a seal against the ring when received in the chamber; means for clamping the first and second sections together to form the chamber and engage the sealing means against the ring when received in the chamber to form a pressure resistant seal between the inside and outside of the ring; and a fluid inlet port in one of the chamber sections to allow a pressurised fluid to be admitted to the chamber outside the ring when received in the chamber.

Owner:VERDERG PIPE TECH LTD

Gasket measuring and matching check tool

InactiveCN101915533AFast measurement optionsMatching fastMechanical thickness measurementsEngineeringInverted u

The invention discloses a gasket measuring and matching check tool. The check tool comprises an air cylinder and a check tool base plate, wherein the check tool base plate is fixed at the upper end of the air cylinder and is arranged horizontally; a push rod of the air cylinder vertically passes through the check tool base plate and is fixed with a check tool moveable plate which is arranged horizontally; two vertical upward check tool guide posts are arranged on the two sides of the check tool base plate; check tool top plates which are arranged horizontally are arranged at the upper ends of the check tool guide posts; the check tool top plates are provided with through holes; inverted U-shaped check tool measuring blocks are fixed on the lower side faces; two check tool positioning sleeves which pass through the inverted U-shaped check tool measuring blocks and the through holes on the check tool top plates at the same time are fixed on the upper side of the inverted U-shaped check tool measuring blocks; and height measurement and display mechanisms are fixed in the check tool positioning sleeves. The gasket measuring and matching check tool of the invention has the characteristics of simple structure and easy operation, realizes rapid measurement and matching of gaskets, eliminates a free gap between assemblies in a spring loaded way, and fulfills the aim of selecting a proper gasket effectively and accurately.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

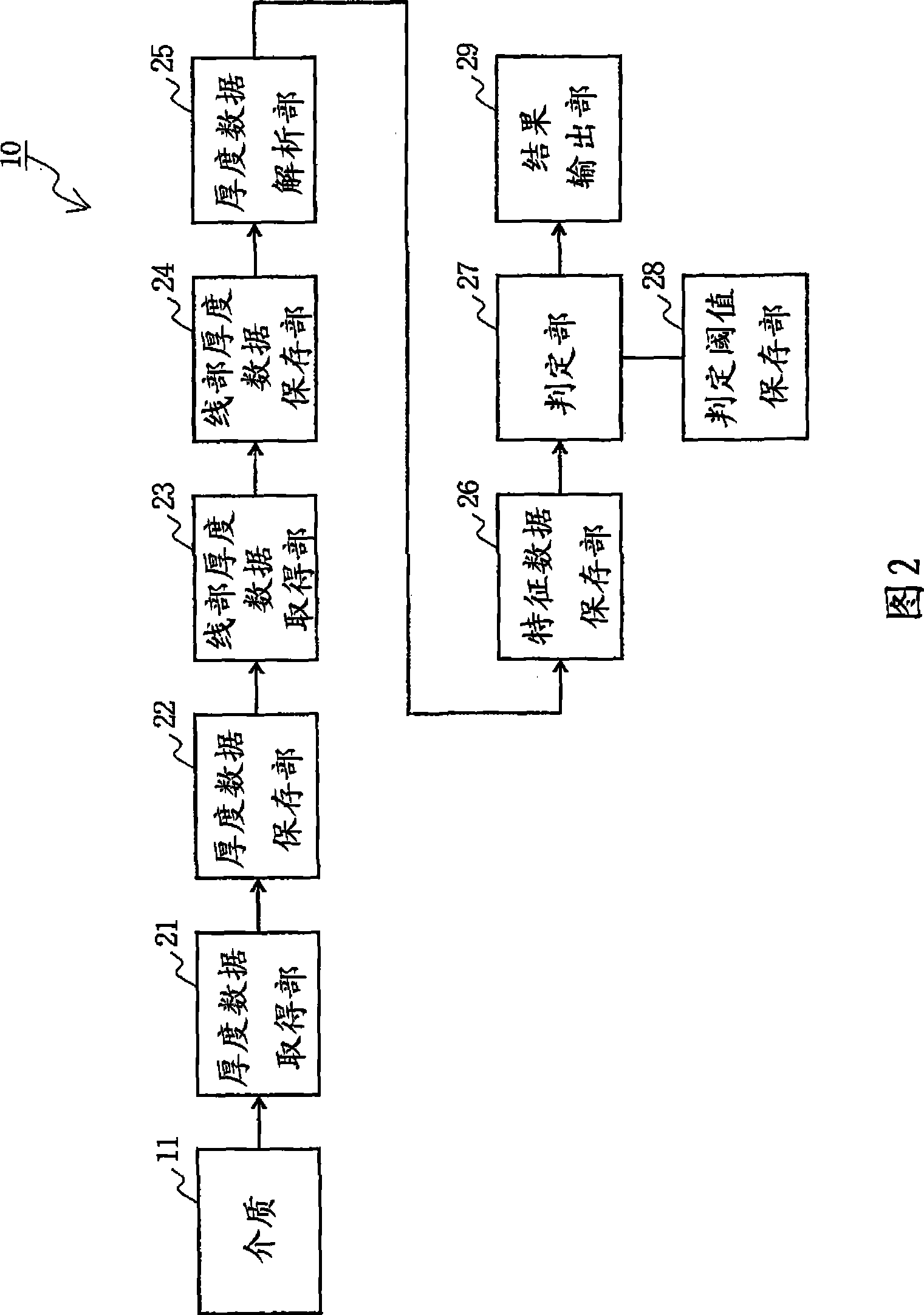

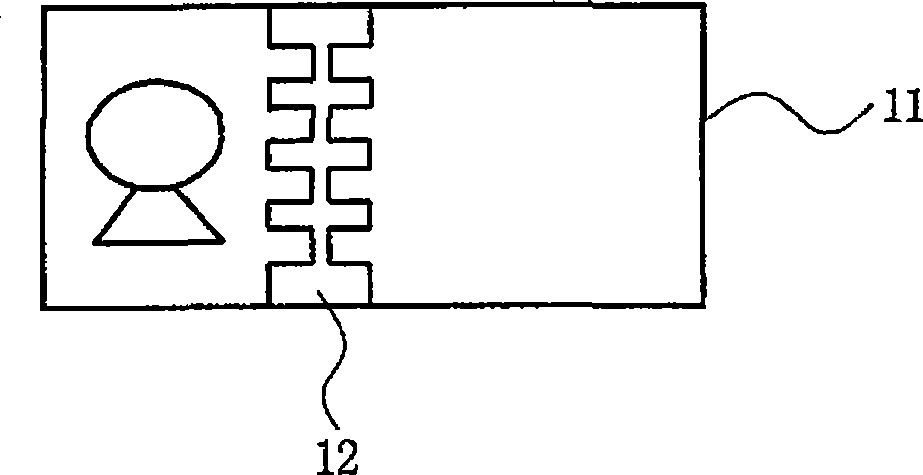

Medium recognization device

The present invention provides a medium recognization device, capable of recognizing whether an application ticket pasted with an adhesive tape based on thickness data corresponding medium safety line part, and capable of recognizing whether the safety line part is pasted with the adhesive tape or not reliably even though the medium with a line window pattern being formed on the safety line. The medium recognization device includes a thickness data obtainment part, for obtaining thickness data detected by a thickness detection sensor of each channel corresponding to each part of the medium; a line part thickness data obtainment part, for obtaining the line part thickness data corresponding to the safety line part of the medium from the thickness data; a thickness data analysis part, for calculating the variance of the line part thickness data; and a judgment part, for judging whether the safety line part is pasted with the adhesive tape or not by comparing the calculated avariance with a prescribed decision threshold.

Owner:OKI ELECTRIC IND CO LTD

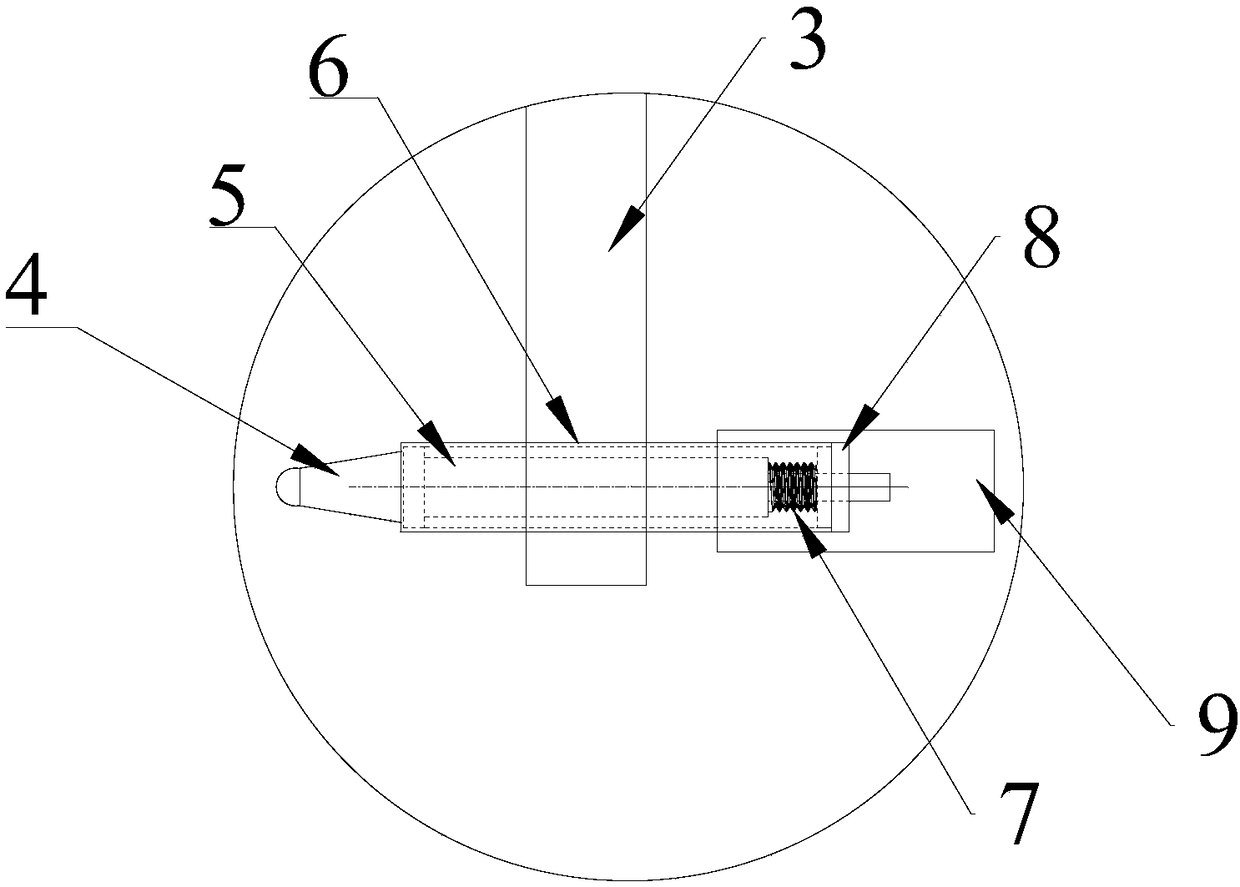

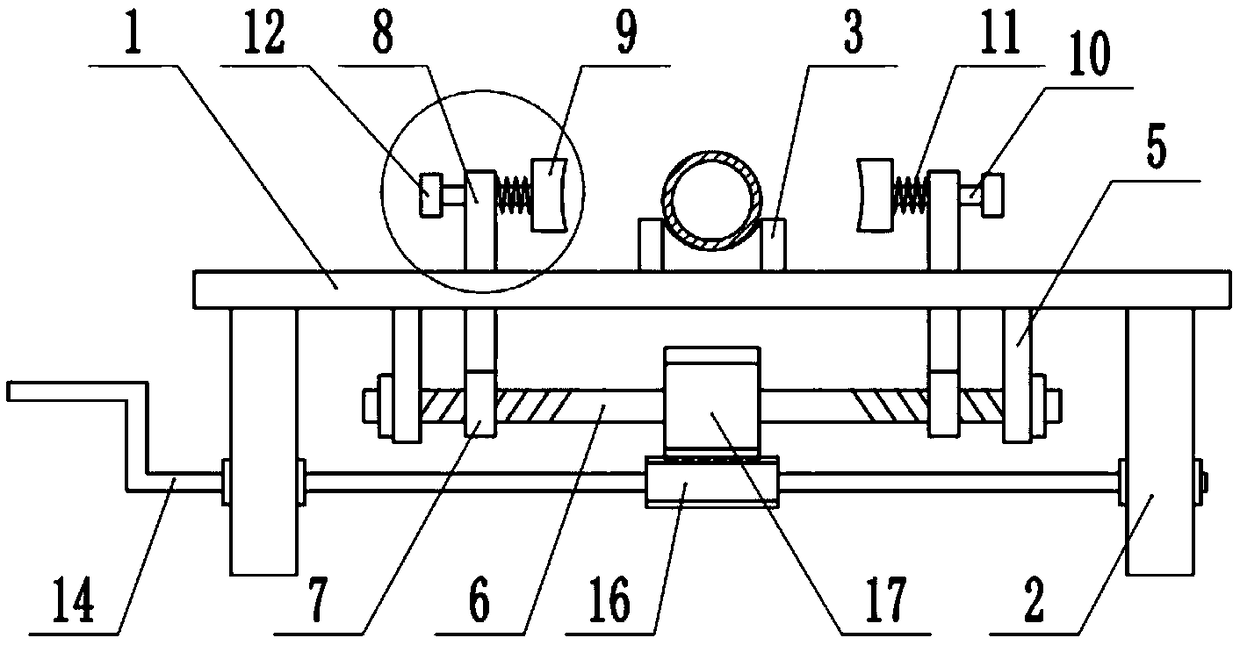

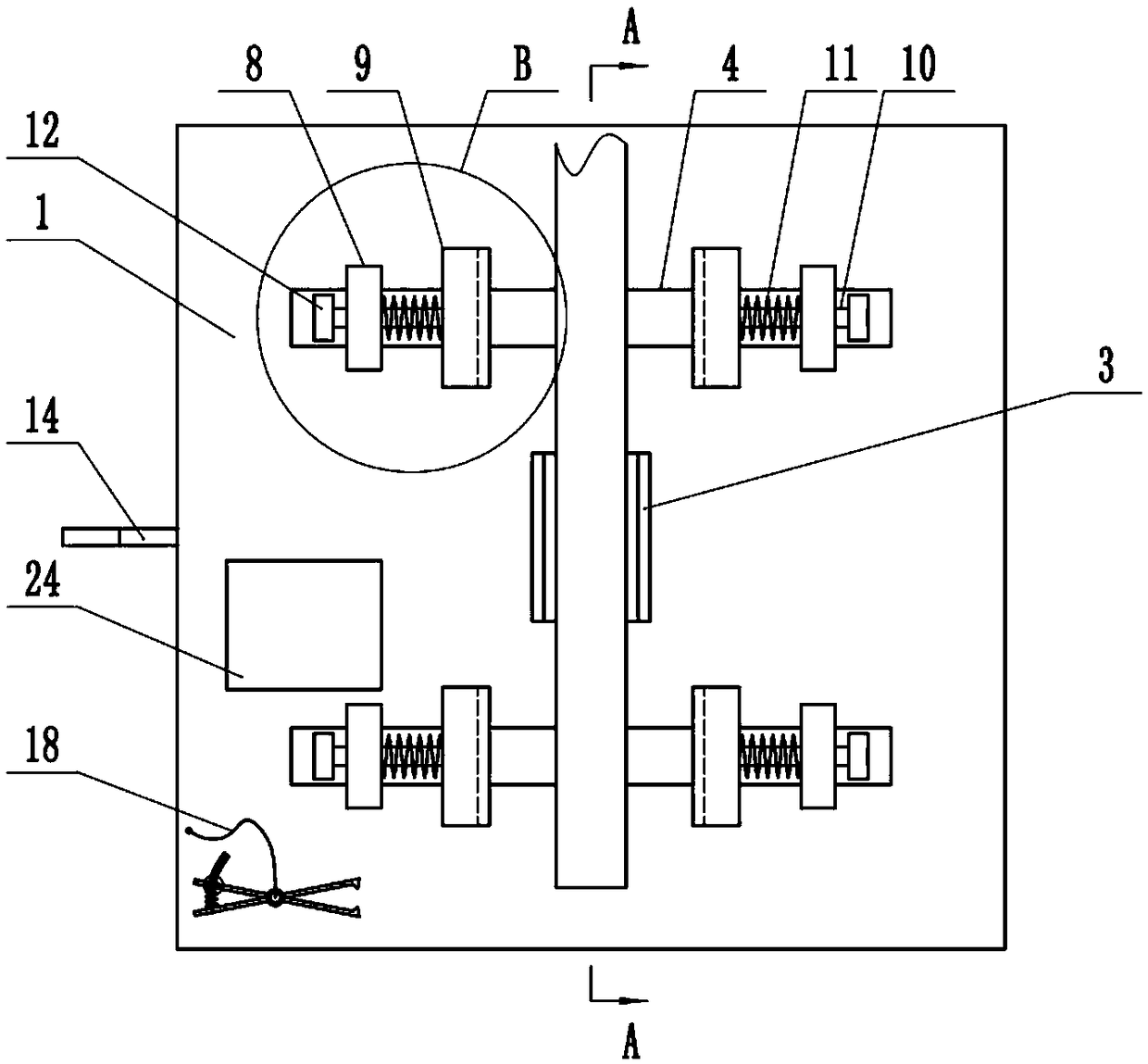

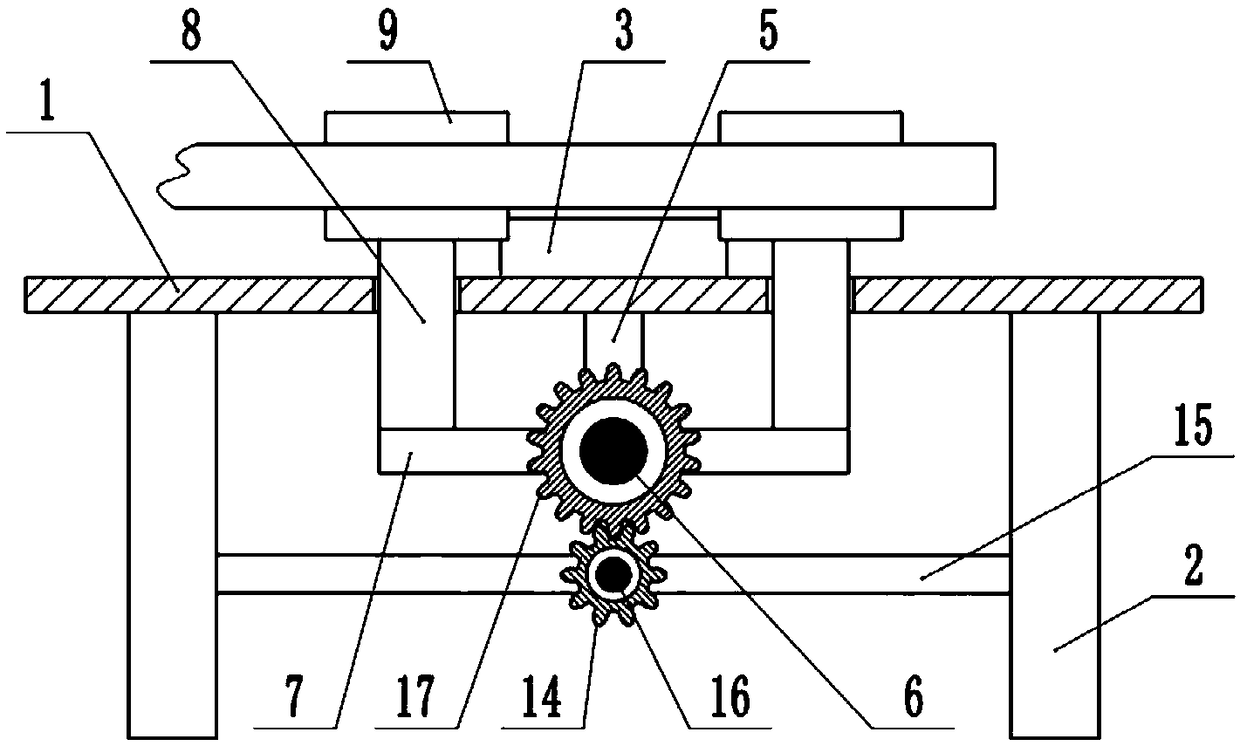

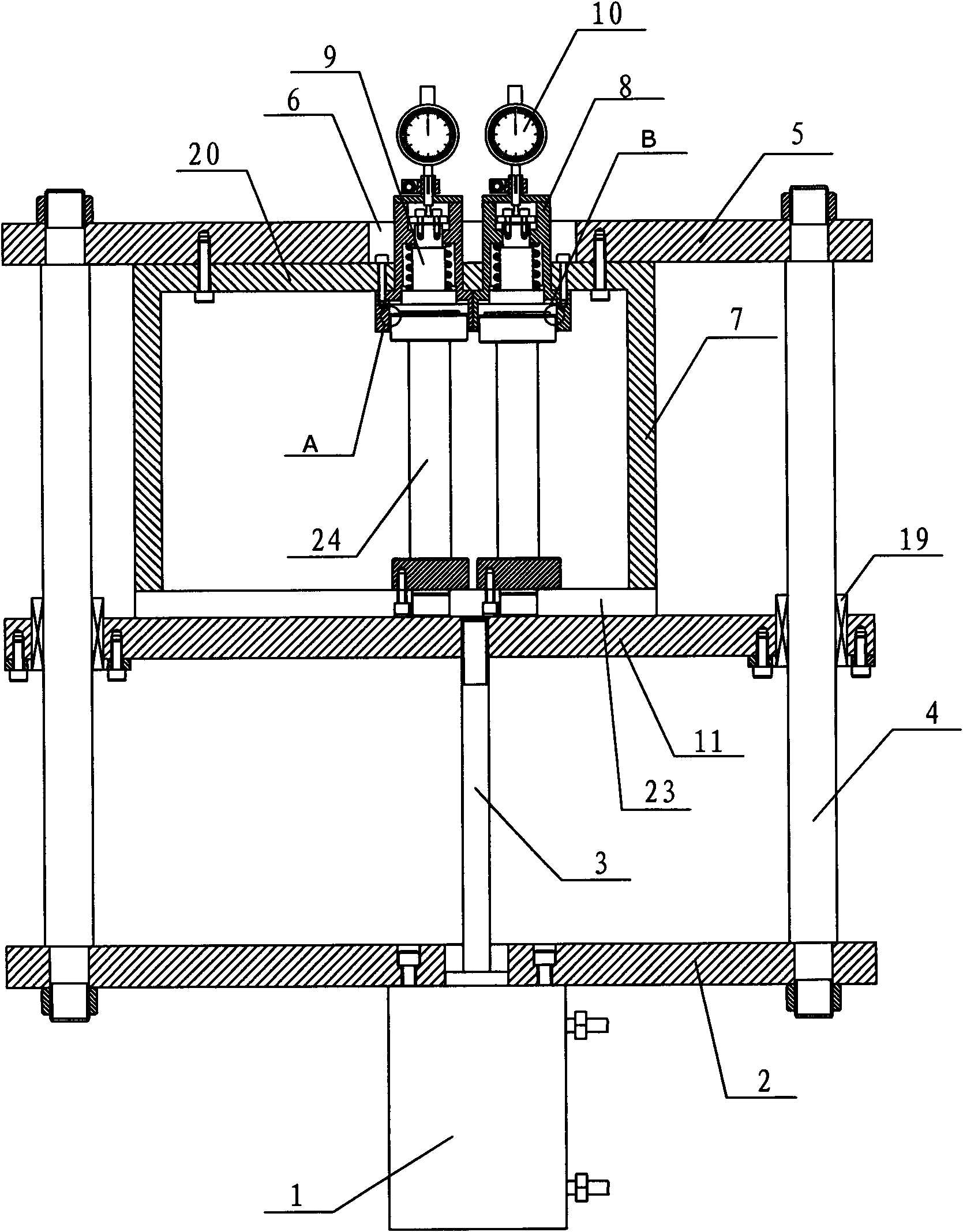

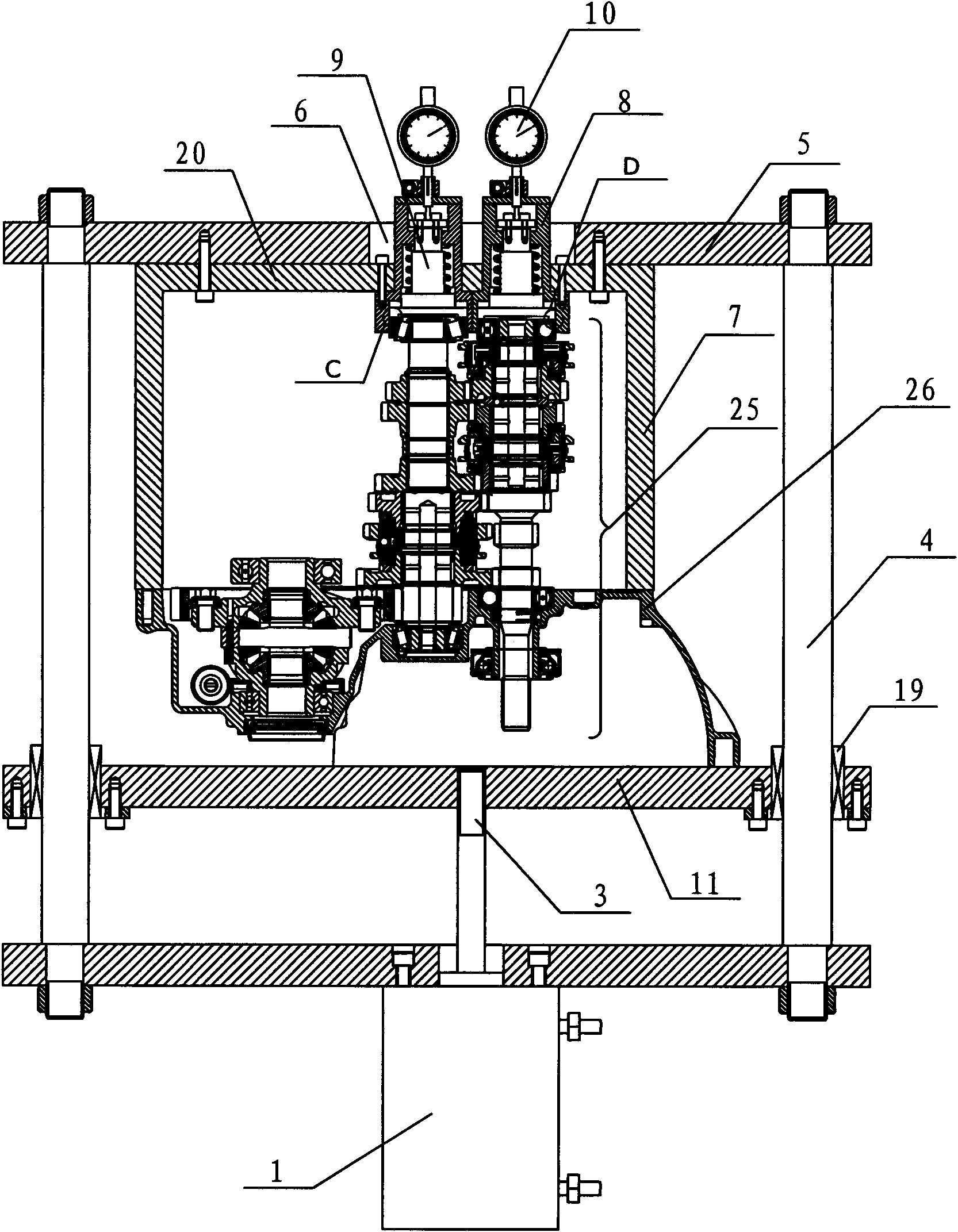

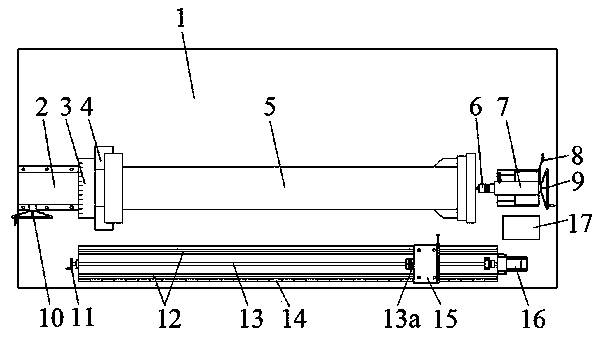

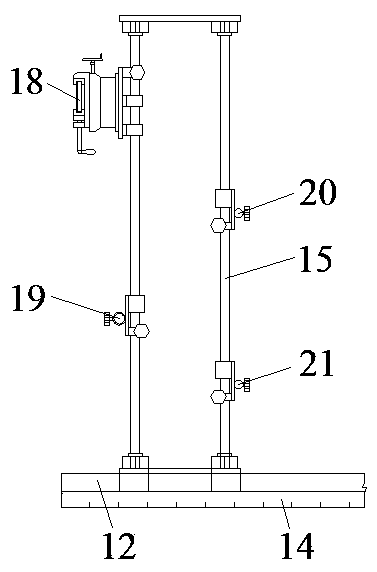

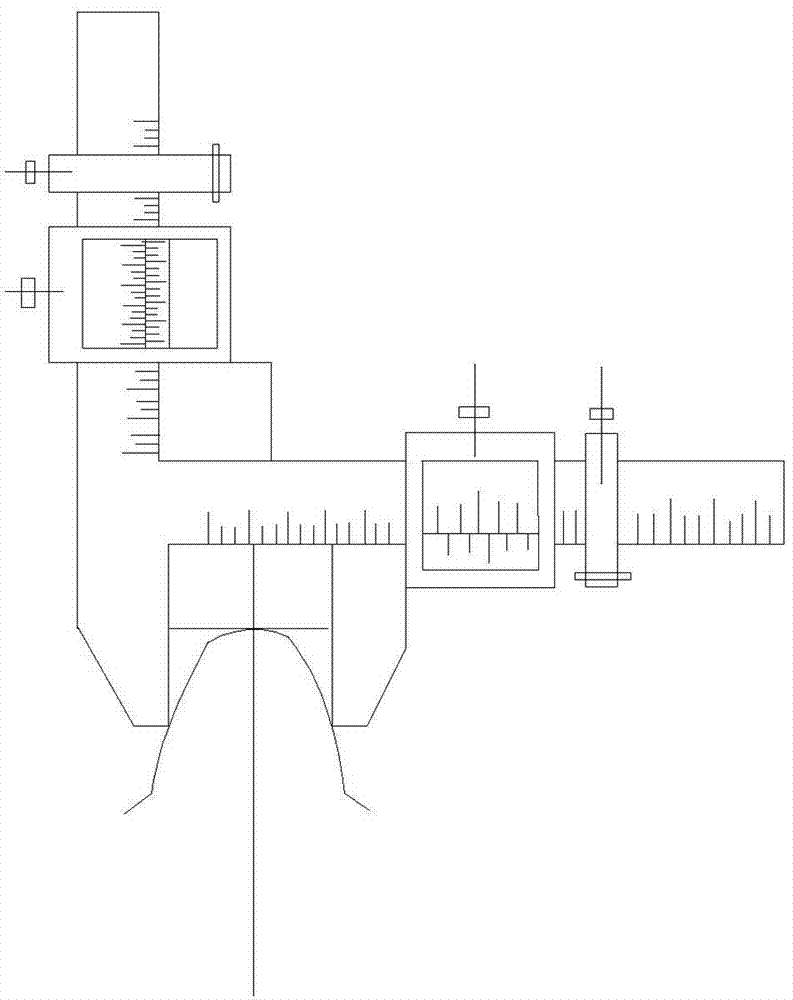

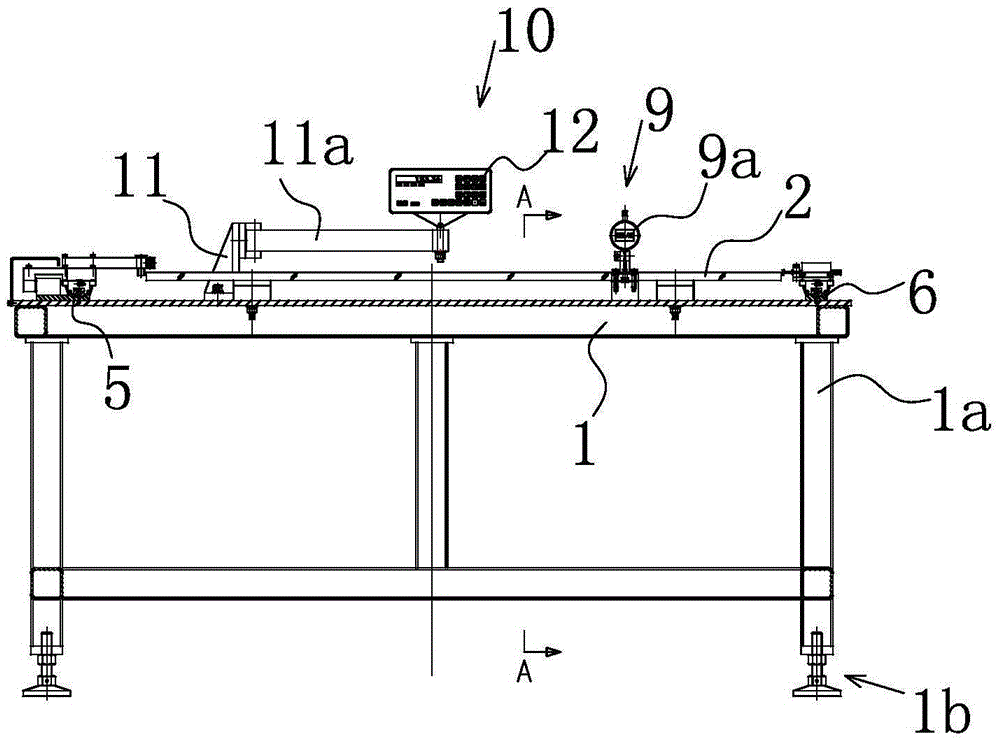

Pipeline geometric size measuring machine

InactiveCN103453823AHigh working reliabilityEasy to operateMechanical counters/curvatures measurementsMechanical diameter measurementsVernier scaleMarking out

The invention discloses a pipeline geometric size measuring machine and belongs to the technical field of measuring equipment. The pipeline geometric size measuring machine comprises a pipeline clamping device, a measuring device and a control box, and the pipeline clamping device, the measuring device and the control box are arranged on an operating platform. The pipeline clamping device is used for supporting a pipeline to be measured through a spindle box mechanism and a tail bracket mechanism. The measuring device is provided with two guide rails on the operating platform, the two guide rails are parallel to the axis of the pipeline clamping device, a measuring framework is driven by a measuring framework driving mechanism to move on the guide rails, and a vernier caliper clamp, an LVDT displacement meter clamp, a hatching pen clamp and a thickness gauge clamp are arranged on the measuring framework. When the pipeline geometric size measuring machine works, the position of the pipeline to be measured and the position of the measuring framework are adjusted electrically or manually, the geometric size of each portion of the pipeline to be measured is measured, or, marking-out is carried out. The pipeline geometric size measuring machine can complete the four operations of marking-out calibration of the pipeline, diameter measurement on any section, thickness measurement on any portion and ellipticity measurement on pipeline sections comprehensively. The pipeline geometric size measuring machine is high in working reliability and convenient to operate, and can improve locating accuracy, enhance measuring effects and improve work efficiency.

Owner:DALIAN UNIV OF TECH

Wheel measurement systems and methods

ActiveUS7478570B2Improve efficiencyImprove reliabilityWheel-rims surveying/measuringMechanical thickness measurementsGraphical user interfaceMeasurement device

Owner:INT ELECTRONICS MACHINES

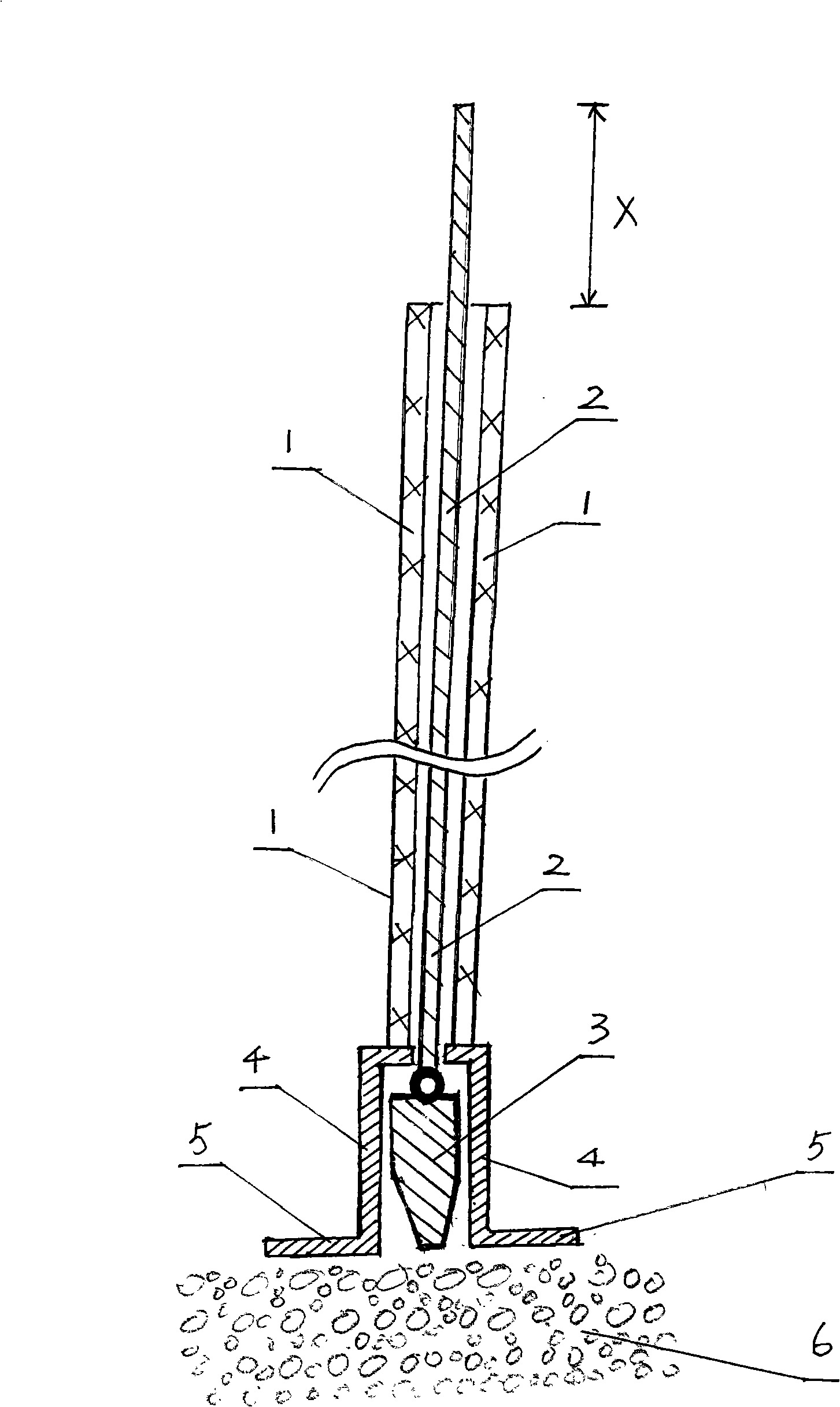

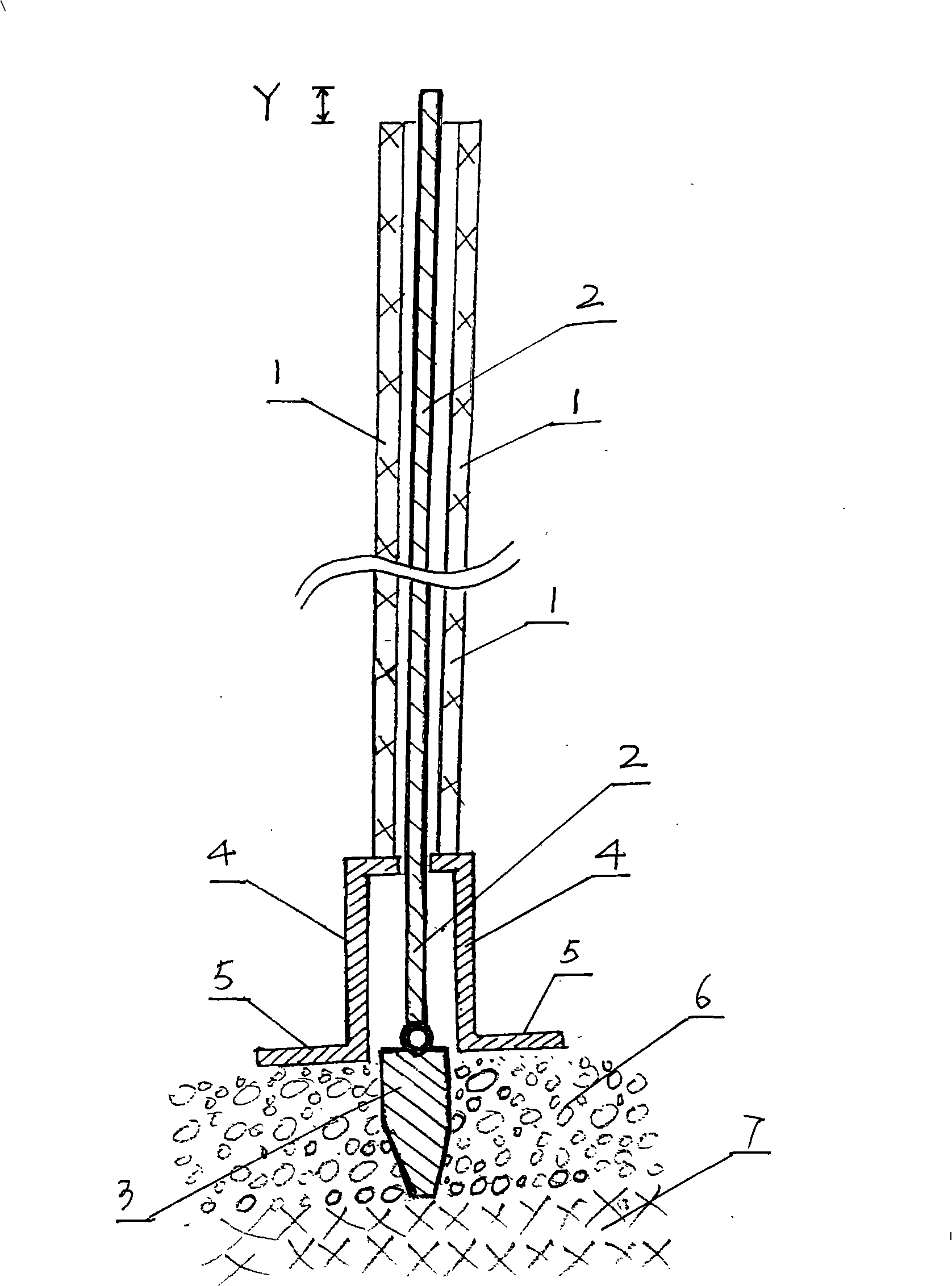

Tools and method for measuring thickness of drill pile hole bottom grain stillage

InactiveCN101324415AMeasure objectivelyMechanical depth measurementsMechanical thickness measurementsSlagEngineering

A tool for measuring the thickness of sinking slag on hole bottom of a bored pile comprises a measurement rope, and a metal measurement hammer fastened to the bottommost end of the measurement rope, wherein the measurement rope is composed of a sheath layer and a core layer; the sheath layer is sheathed on the outer side of the core layer in a loose fit manner; the metal hammer is fastened to the lower end of the core layer; a vertical sleeve is connected with the lower end of the sheath layer; a horizontal bottom sheet is arranged at the lower end of the vertical sleeve and is fixedly connected with the vertical sleeve as a whole; the metal measurement hammer is sheathed in the vertical sleeve in a loose fit manner; the upper end of the core layer is exposed out of the sheath layer; and length scales are formed the upper end of the core layer. The tool can objectively measure the thickness of sinking slag on the hole bottom of the bored pile without the need of the subjective determination of engineers based on experience and hand feeling. The invention also provides a method for measuring the thickness of sinking slag on the hole bottom of the bored pile.

Owner:黄建龙

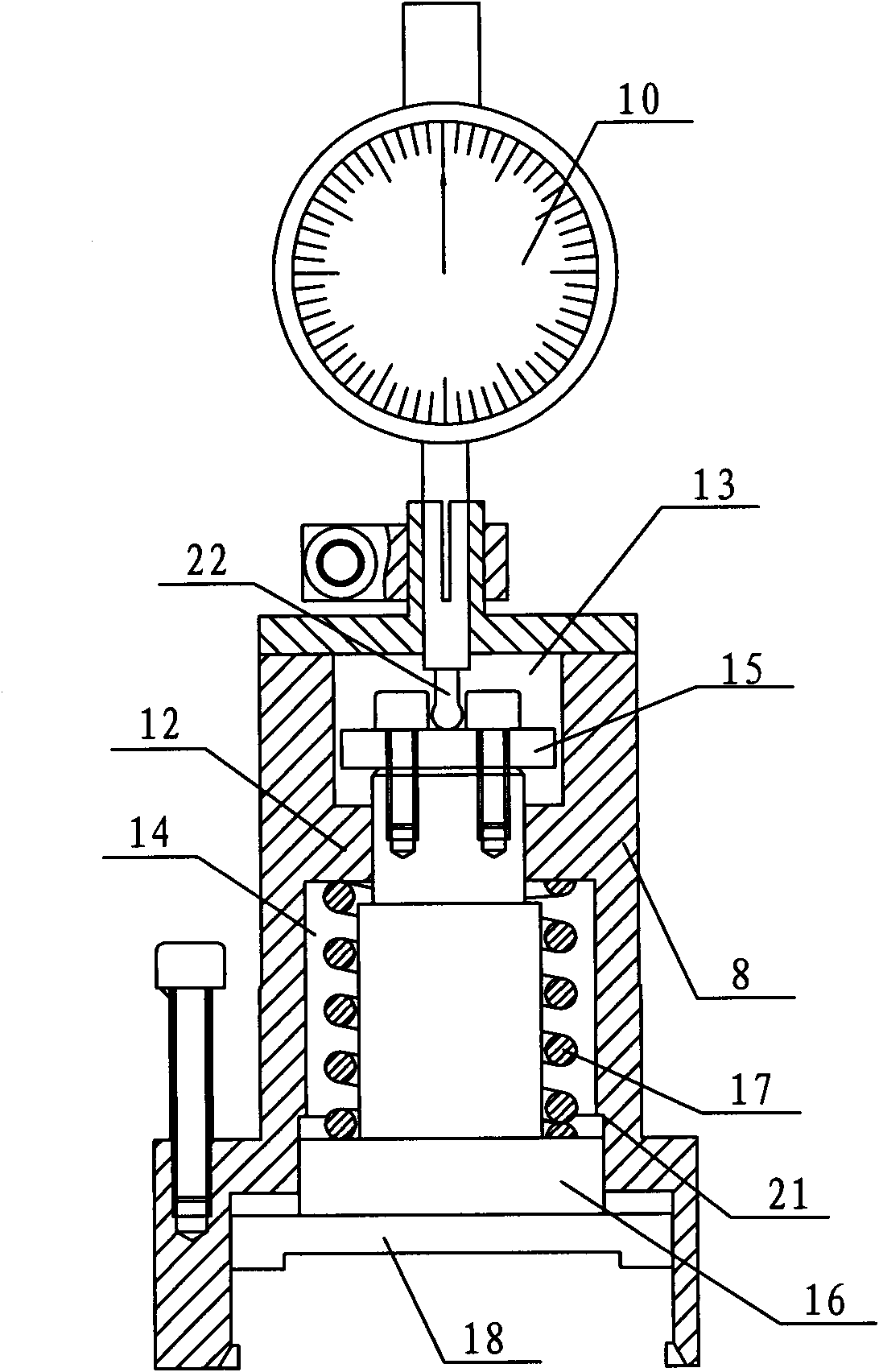

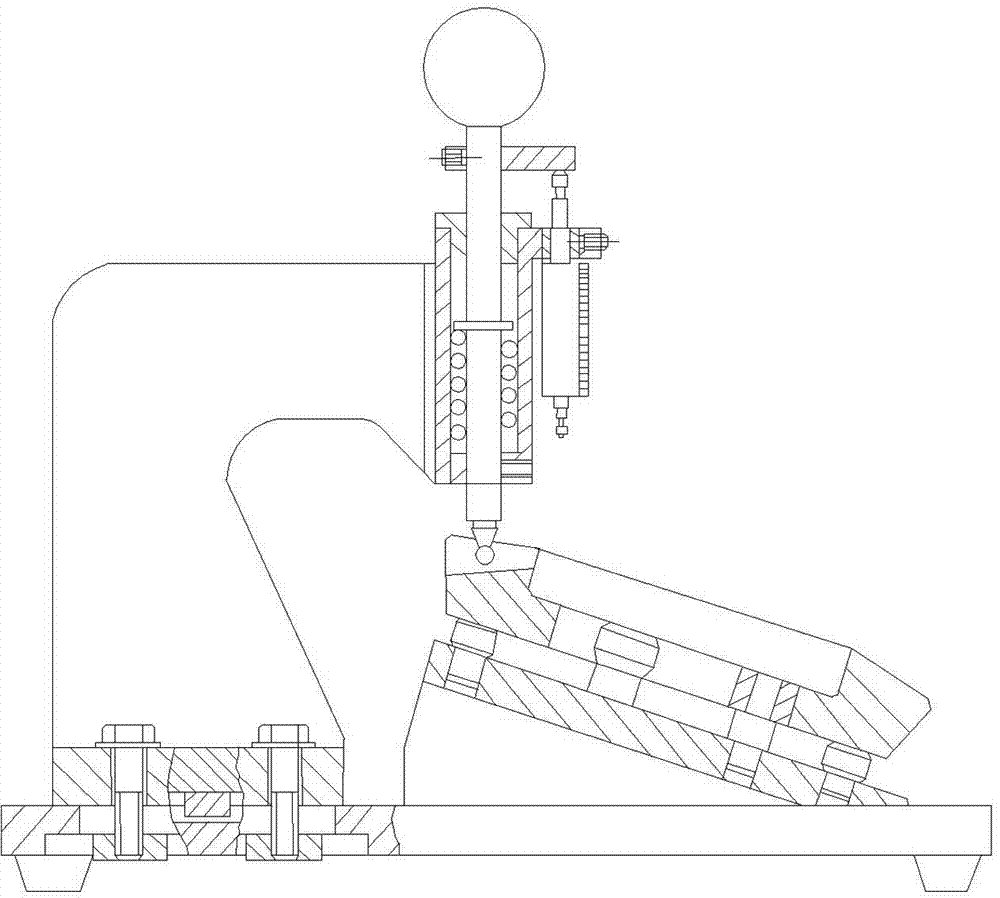

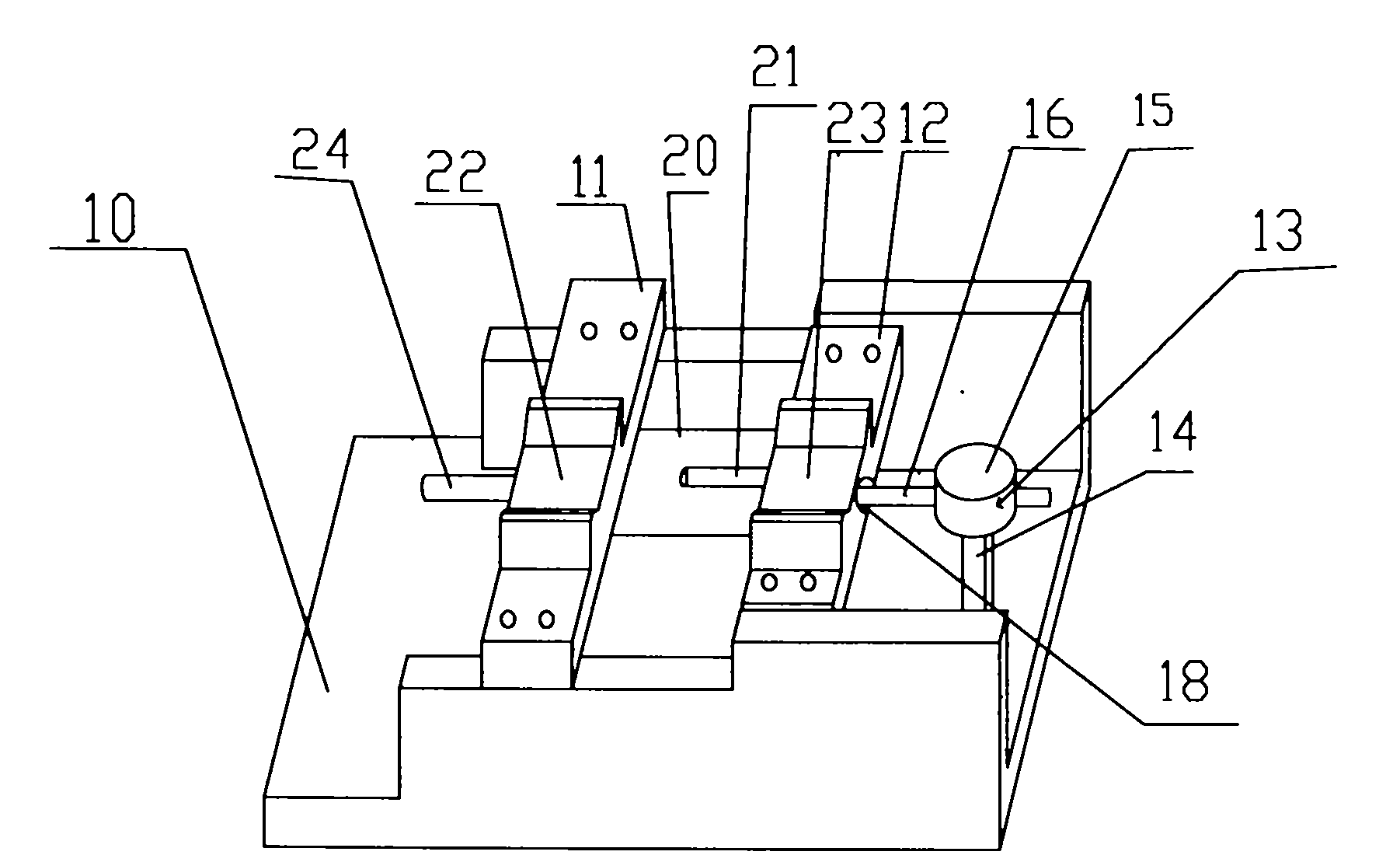

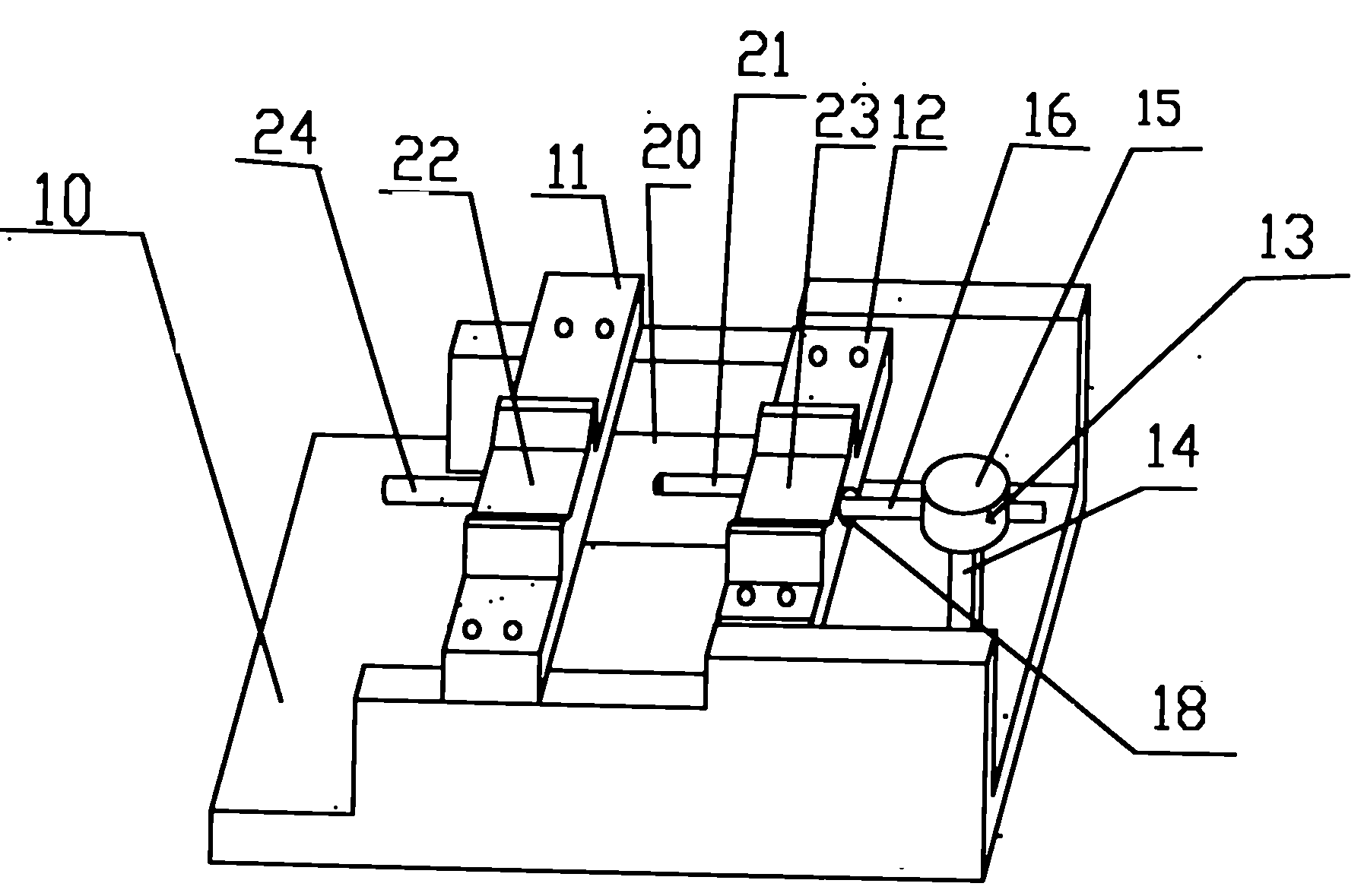

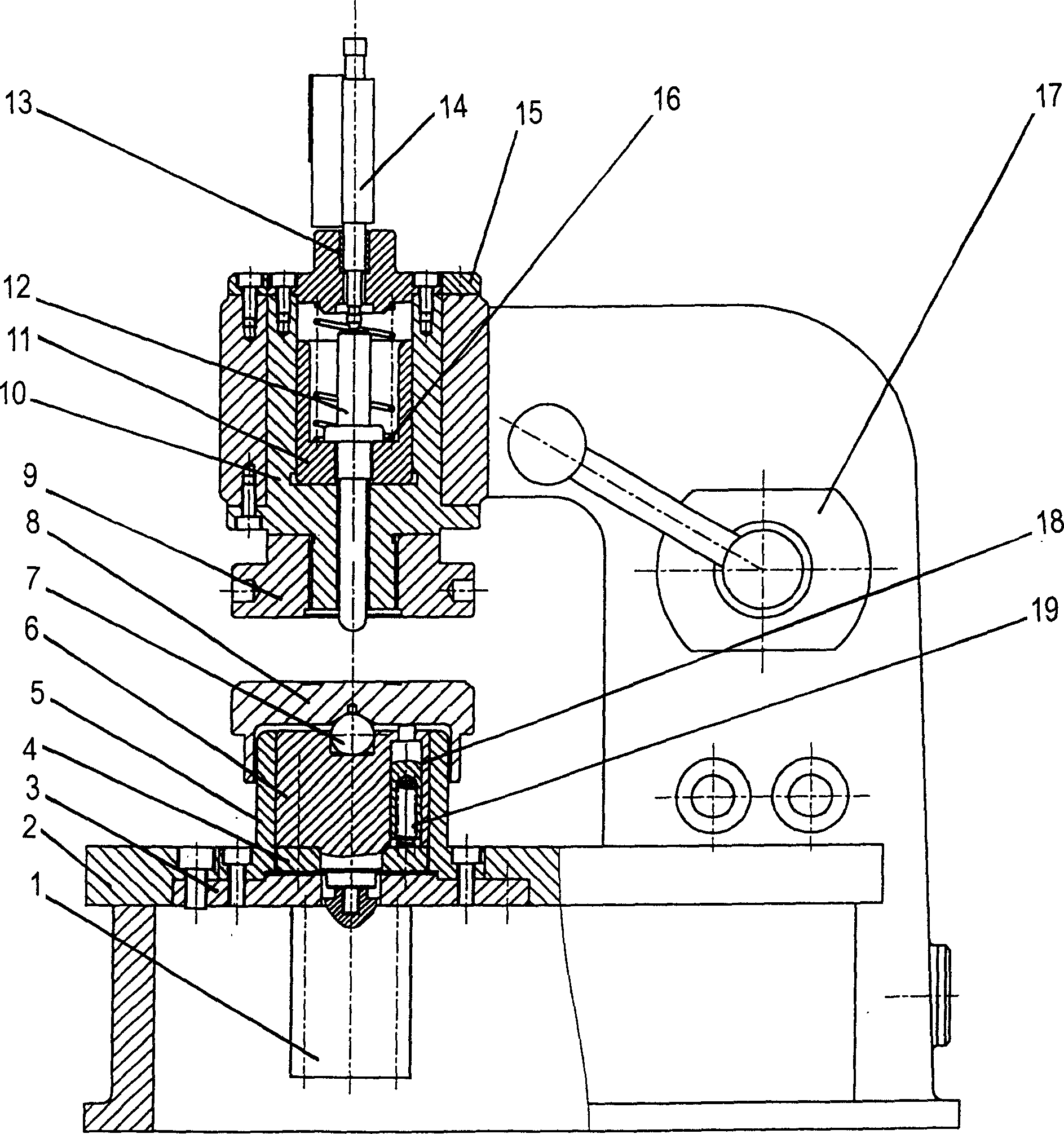

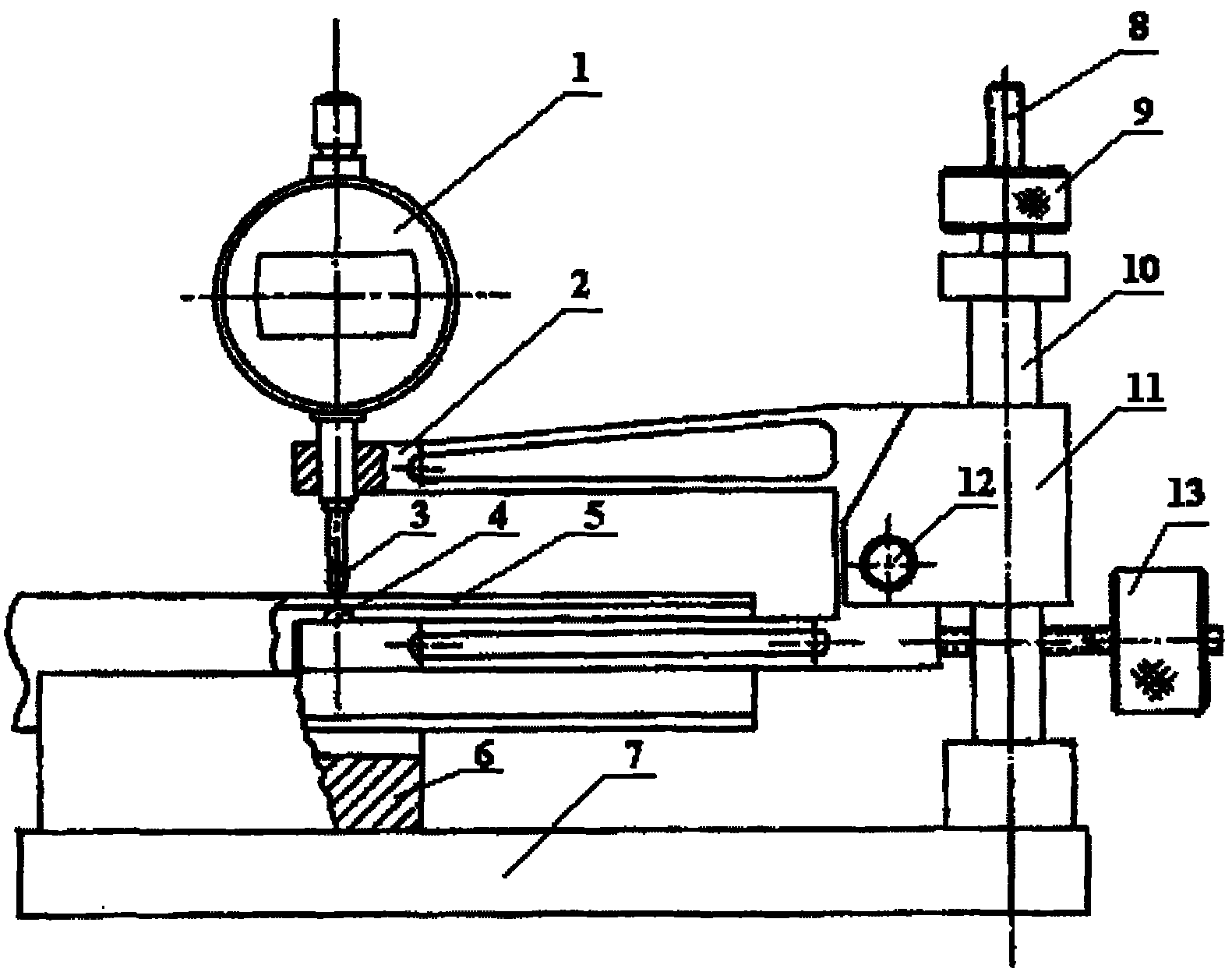

Device and method for measuring tooth thickness of medium and small modulus bevel gear

ActiveCN102901428AEasy to measureHigh measurement accuracyMechanical thickness measurementsMeasurement deviceEngineering

The invention provides a device for measuring tooth thickness of a medium and small modulus bevel gear. The device comprises a guide rail, a block gauge A and a block gauge B, wherein a guide rail sliding block I and a guide rail sliding block II, which can move forwards and backwards, are arranged on the guide rail, and are respectively connected with a dial indictor and a measuring worktable; the block gauge A and the block gauge B are matched with a measured gear in dimension; and the tooth thickness of the gear can be measured by lifting the dial indicator and replacing a measuring ball which is connected with the dial indicator; and the dimension of the measuring ball is in match with the tooth thickness of the measured gear. The device is convenient for measurement and high in measurement precision and is efficient and reliable. According to the device, the actual value of the tooth thickness can be obtained by calculating according to diameter data of the block gauge A, the block gauge B and the measuring ball and under the condition that the measuring ball can be replaced. The invention also provides an efficient and reliable measuring method adopting the measuring device. According to the method, a mounting base surface of the measured gear serves as a measuring reference surface, and the measuring method controls the tooth thickness to ensure the consistency between the tooth thickness on the mounting base surface and the mounting distance of the measured gear.

Owner:ZHEJIANG FENGLI INTELLIGENT TECH CO LTD

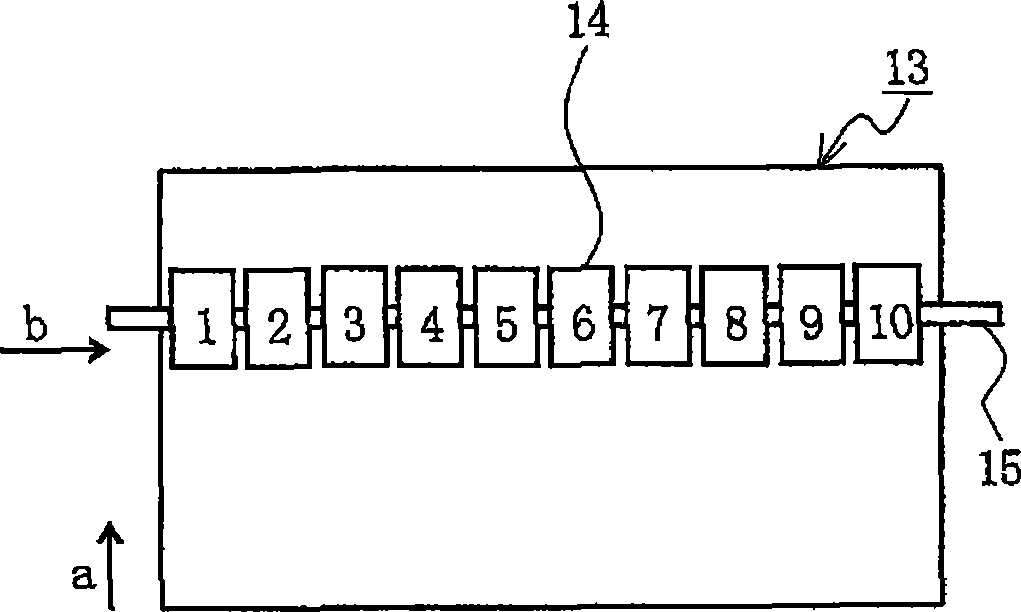

Gear tooth thickness detector

ActiveCN101865642ASimple structureReduce manufacturing costMechanical thickness measurementsMeasurement deviceGear wheel

The invention discloses a gear tooth thickness detector which comprises a pedestal, a guide rail and a measuring device, wherein the guide rail and the measuring device are arranged on the pedestal; the invention is characterized in that a first supporting seat and a second supporting seat are movably arranged on the guide rail, the first supporting seat and the second supporting seat are oppositely arranged, the measuring device comprises a dial indicator and a bracket, one end of the bracket is fixed on the pedestal, and the other end of the bracket is fixedly connected with the dial indicator. The gear tooth thickness detector has simple structure, convenient operation, lower use cost, convenient popularization and high detection precision.

Owner:TATUNG GEAR KUNSHAN

Sheet material detection method

ActiveCN105674885AReasonable designEasy to measureMechanical thickness measurementsUsing optical meansEngineeringSheet material

The invention belongs to the technical field of measurement and especially relates to a sheet material detection method which solves the technical problems including bad design in the prior art. The method comprises steps of loading and detection. In the step of loading, a to-be-detected sheet material (2a) is placed on a detection platform (2). The step of detection includes length detection, parallel degree detection, vertical degree detection, thickness detection, and flatness detection. The method has the advantages of more reasonable design, convenient, complete and accurate measurement process, and low manufacturing cost.

Owner:HANGZHOU HENGLI CUTTING EQUIP

Waste oil tank bottom sludge thickness measurer

The invention discloses a waste oil tank bottom sludge thickness measurer. The problem that the existing sludge thickness measuring method is neither safe nor accurate is solved. The measurer comprises a measuring mechanism and a positioning mechanism. The measuring mechanism is a length-adjustable straight rod, and a pawl structure is arranged axially under the straight rod. The positioning mechanism comprises a positioning plate and a positioning clamp spring. The bottom of the straight rod is inserted into the center of the positioning plate. The body of the positioning clamp spring is a strip-shaped elastic sheet. One end of the clamp spring is fixed on the positioning plate, and the other end of the clamp spring is bent into a hook. The clamp spring is hooked to an inter-pawl joint part of the pawl structure of the straight rod through the hook part to implement positioning. The measurer is of a foldable structure, and is convenient to carry and place; the measurer is self-locked through the one-way sliding function of the positioning clamp spring, and is accurate and reliable in measurement; and the measurer has a simple mechanical structure, and is easy to operate.

Owner:大庆市云泰石化产品有限公司

Spacer thickness measuring instrument

InactiveCN1624415ASimple structureHigh measurement accuracyMechanical thickness measurementsMeasuring instrumentEngineering

Owner:HEFEI UNIV OF TECH

Device for measuring wall thickness of pipe

ActiveCN102052885AFast "carpet" continuous wall thickness measurementFast continuous wall thickness measurementMechanical thickness measurementsObservational errorMeasurement device

The invention provides a device for measuring the wall thickness of a pipe. The device comprises a micrometer gauge (1), a measuring rocker arm (2) and a base (7), wherein the measuring rocker arm (2) comprises an upper arm and a lower arm, which are parallel to each other; a fixed measuring head (4) is arranged on the lower arm; the micrometer gauge (1) is fixed on the upper arm; a micrometer gauge measuring head (3) is aligned to the fixed measuring head (4) that is arranged on the lower arm; a heavy hammer is arranged at the rear end of the lower arm of the measuring rocker arm (2); a V-shaped support (6) and a guide column (10) are arranged on the base (7); and a sliding block (11) drives the measuring rocker arm (2) to slide on the guide column (10). During the measurement, a pipe tobe measured (5) is put inside the V-shaped support (6), and the lower arm of the measuring rocker arm (2) is put inside the pipe to be measured (5). The device achieves the tracking measurement of the wall thickness of the pipe, eliminates the measurement error due to the shape error of the pipe, and is easy and convenient to operate. In the combination with a pipe combined motion driving system,the device can rapidly and continuously measure the wall thickness of the pipe.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com