Method and device for measuring thickness of semiconductor film

A thin film thickness, semiconductor technology, applied in the direction of mechanical thickness measurement, etc., can solve the problem of large amount of data, to achieve the effect of improving efficiency, improving fitting efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

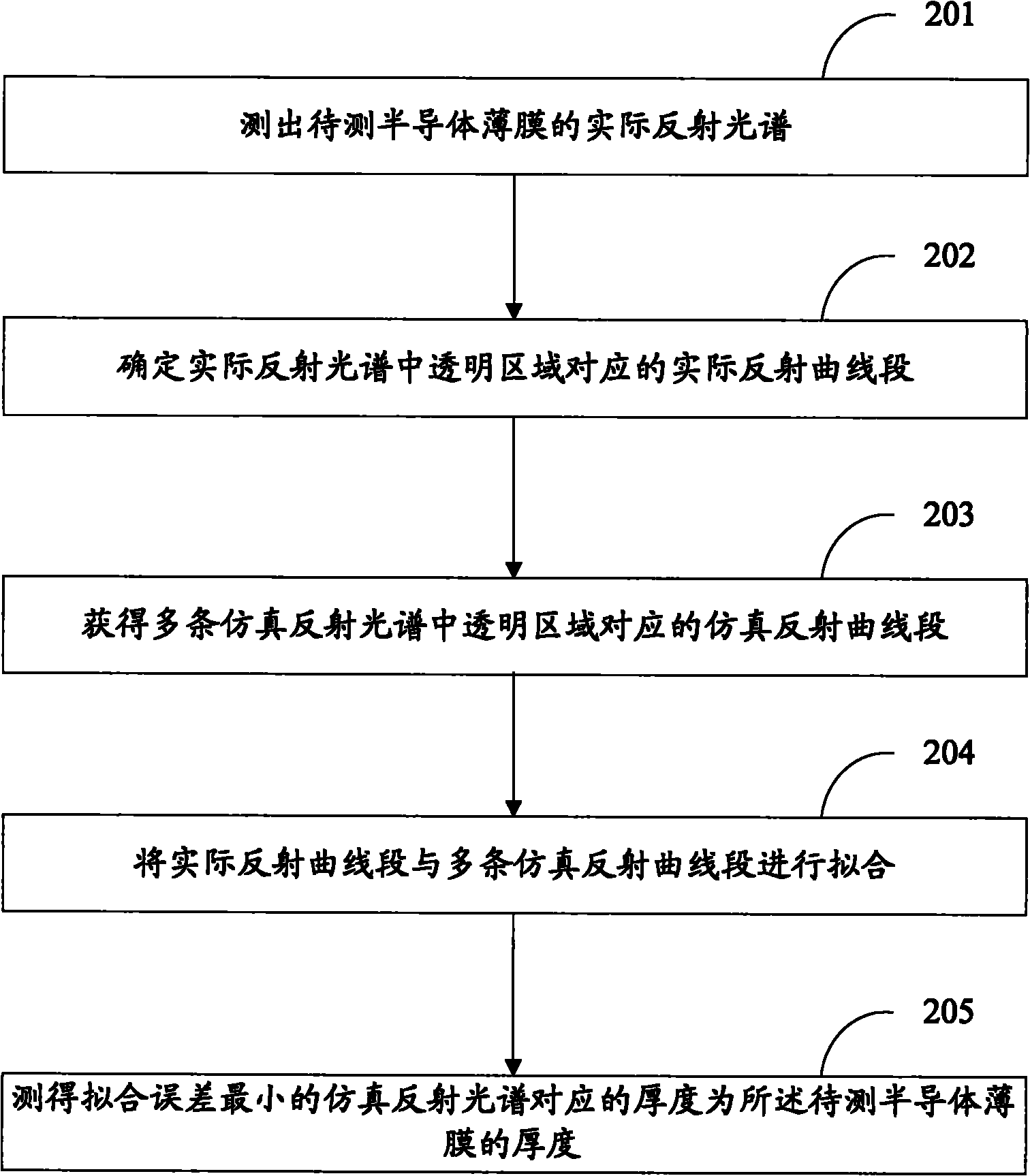

[0041] In the embodiment of the present invention, the transparent area of the actual reflection spectrum is fitted with the transparent areas of multiple simulated reflection spectra, and then the thickness corresponding to the simulated reflection spectrum with the smallest fitting error is measured as the thickness of the semiconductor film to be tested. In this way, in the embodiment of the present invention, the influence of the absorption region of the reflection spectrum on the fitting result is reduced, the accuracy of the fitting result is improved, and a more accurate film thickness is obtained. And because the partial reflection spectrum is used for fitting instead of the complete reflection spectrum, the fitting efficiency is improved, thereby improving the efficiency of obtaining the film thickness.

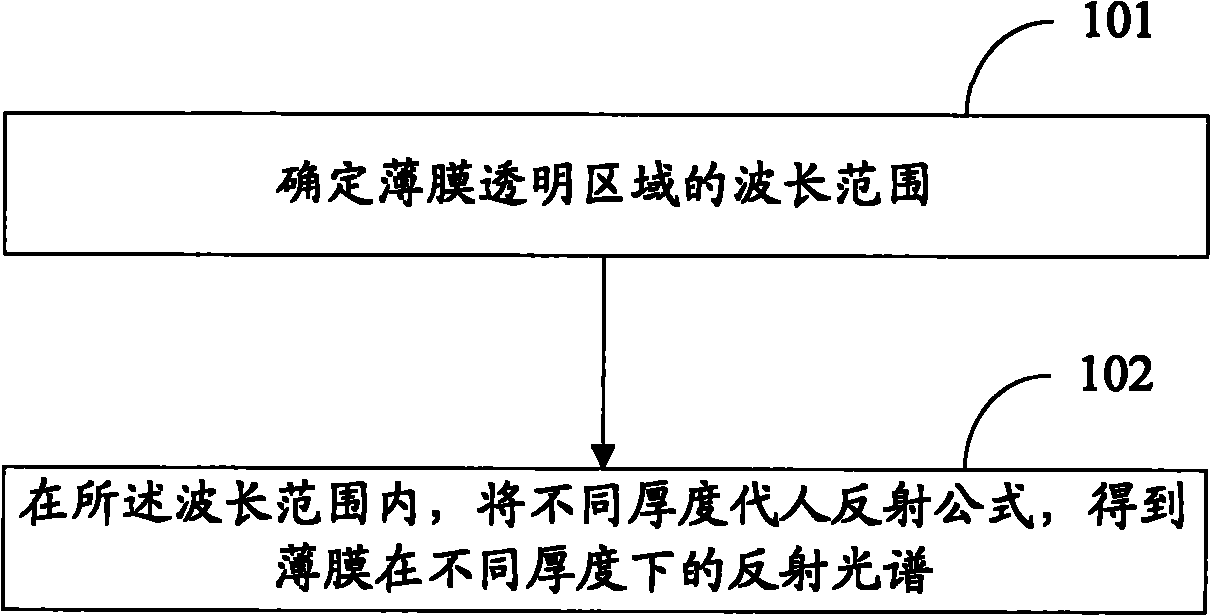

[0042] See figure 1 The process of the method for obtaining the simulated reflection spectrum of the film in this embodiment is as follows:

[0043] Step 101: Determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com