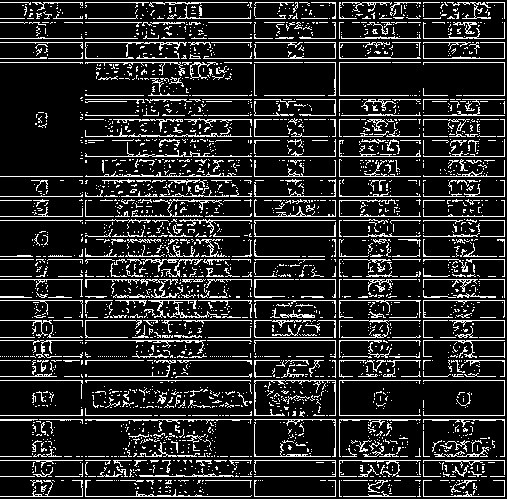

Patents

Literature

113results about How to "Fast demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hypoeutectic aluminum-silicon alloy with excellent thermal conductivity, preparation method and application thereof

ActiveCN104630576AReduce burning lossMeet the needs of casting long-term productionConductive materialMetal/alloy conductorsSilicon alloyCastability

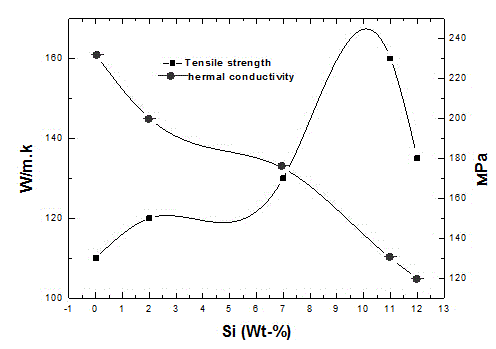

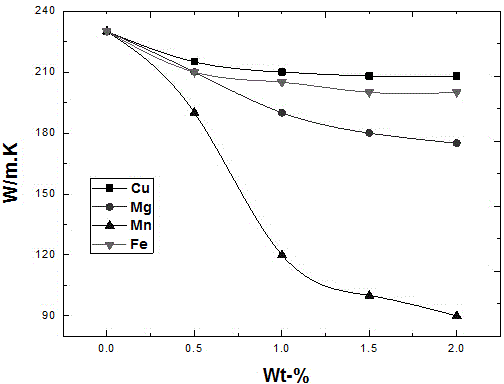

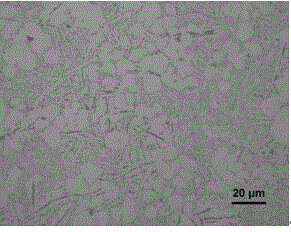

The invention discloses a hypoeutectic aluminum-silicon alloy with excellent thermal conductivity. The alloy comprises the following chemical components: 5-9 wt% of Si, smaller than 0.5 wt% of Mg, smaller than 0.5 wt% of Cu, smaller than 0.7 wt% of Fe, smaller than 0.3 wt% of Mn, inevitable impurity elements and the balance of Al, a single inevitable impurity element is not less than 0.05 wt%, and the total amount of the inevitable impurity elements is lower than 0.25 wt%. The hypoeutectic aluminum-silicon alloy with thermal conductivity of 170-200 W / (m.K) can be obtained in a preparation process by such technical means as controlling the chemical components of the alloy and casting, and thermal treatment and the like. Good castability and mechanical properties of the aluminum-silicon alloy are guaranteed, and excellent thermal conductivity of the aluminum-silicon alloy is guaranteed at the same time.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

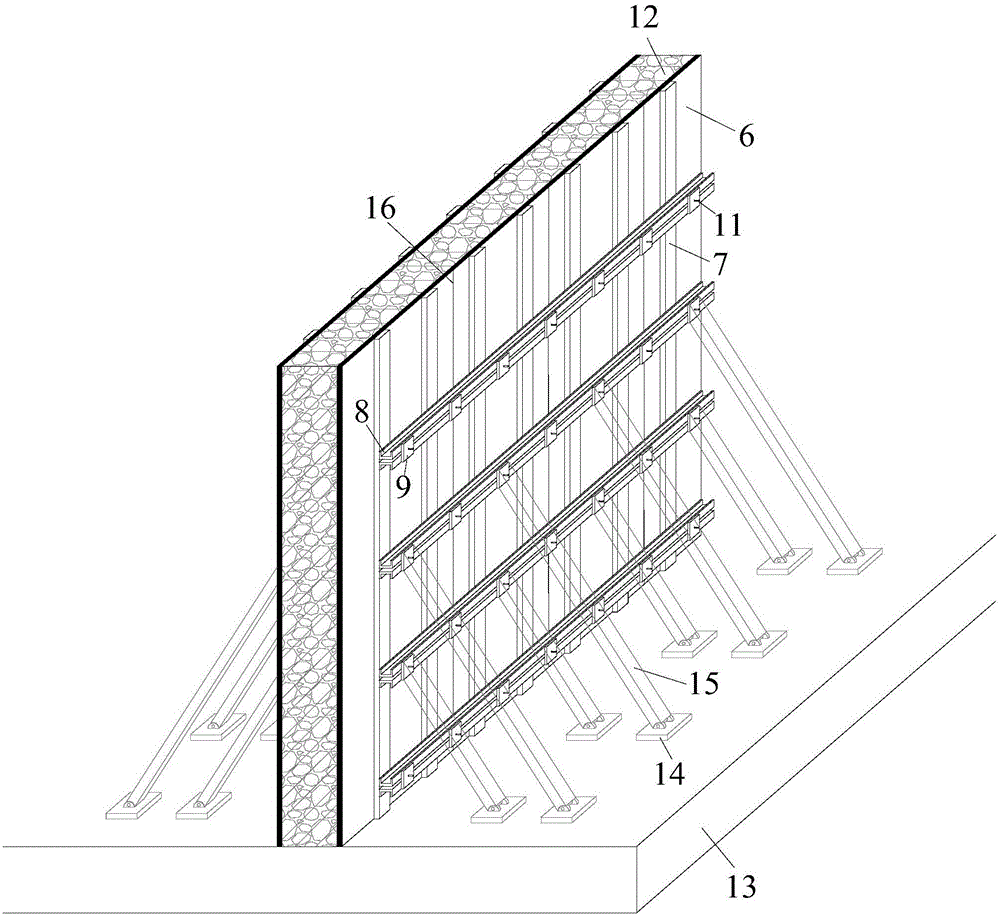

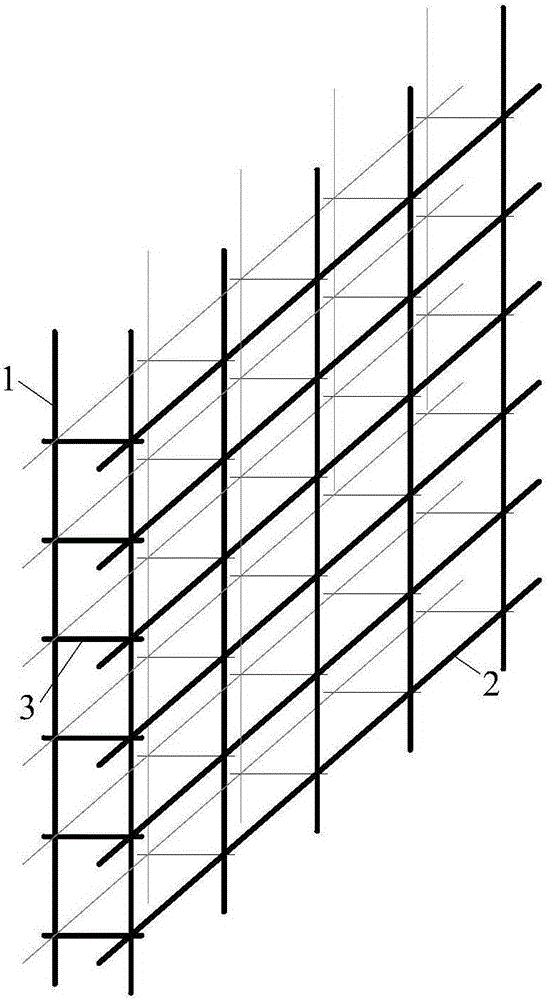

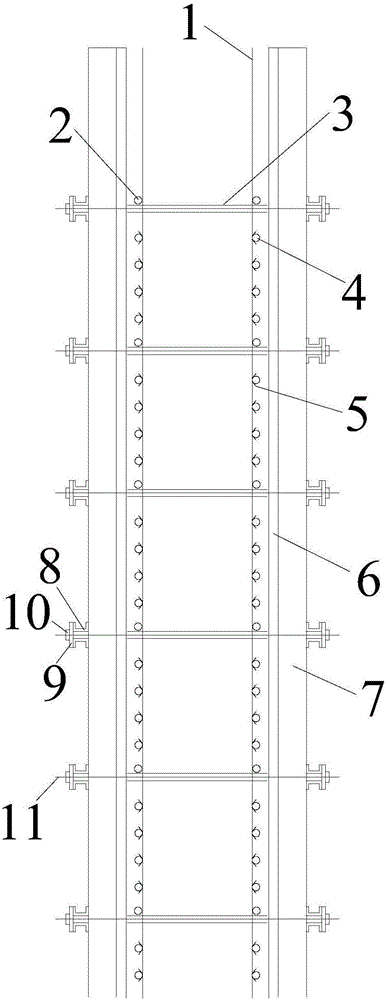

Reinforced concrete shear wall with positioning prefabricated member inside and construction method of reinforced concrete shear wall

ActiveCN105888108AEasy to install and combineFast demouldingWallsMouldsFloor slabReinforced concrete

The invention relates to a reinforced concrete shear wall with a positioning prefabricated member inside and a construction method of the reinforced concrete shear wall. The construction method includes: manufacturing the prefabricated member; arranging the prefabricated member on a floor slab structure; making positioning ladder rebars; binding rebars; mounting the prefabricated member; mounting steel formworks; setting up a steel formwork inclined strut. During constructing the reinforced concrete shear wall, vertical ladder rebars and horizontal ladder rebars are adopted as a positioning supporting frame for rebar binding, and the positioning prefabricated member is clamped in horizontally-vertically-distributed rebars, so that thickness of a protection layer is guaranteed and connection of rebar nets is enhanced; the assembly steel formworks are arranged on two sides of the rebar nets, oppositely-puling threaded rods penetrate connecting steel pipes to be fastened on embedded members of the steel formwork inclined strut and the floor slab structure through screws, and concrete is poured to form a shear wall structure. By using the construction method, construction site order and construction efficiency are improved, related measures guarantee construction quality of the shear wall, rebar positioning accuracy and thickness accuracy of the protection layer are improved remarkably, and the construction method has good technical and economic benefit.

Owner:ZHONGDA CONSTR

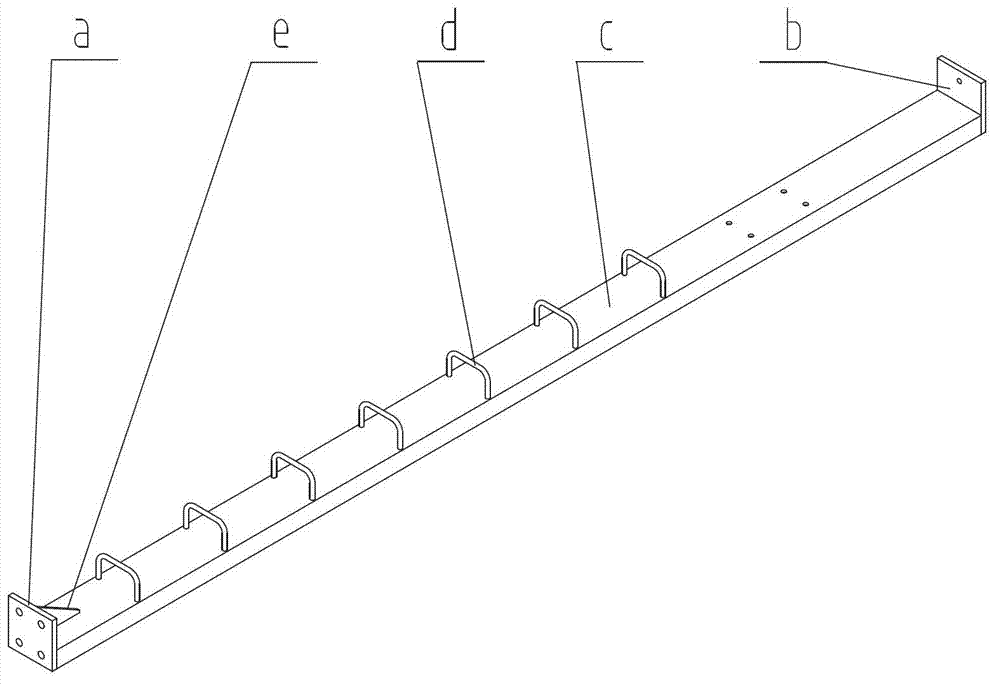

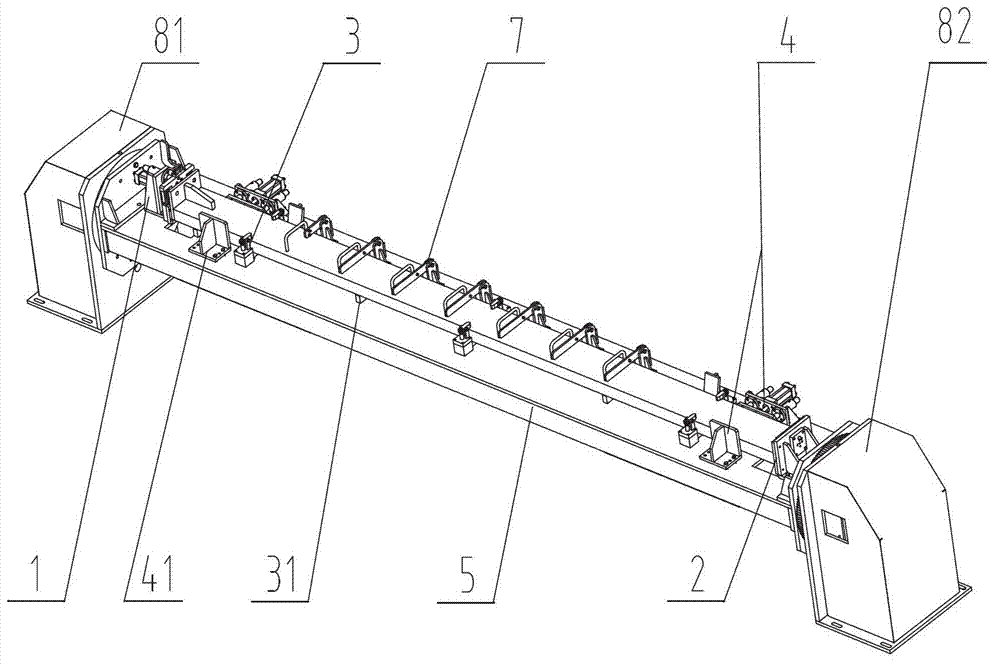

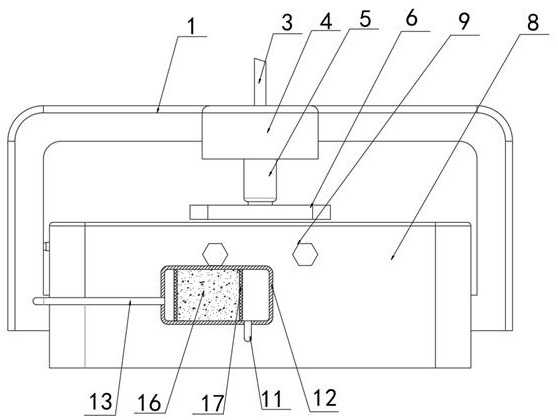

Standing column assembly welding tool

InactiveCN102825408AFast demouldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention provides a standing column assembly welding tool for welding a standing column of a mixing plant. The standing column assembly welding tool comprises a left and right limit mechanism, an up and down limit mechanism and side limit mechanisms. The left and right limit mechanism comprises a first end and a second end. A first connecting plate of the standing column is limited at the first end. A second connecting plate of the standing column is limited at the second end. The up and down limit mechanism is used for limiting fluctuation of a standing column body. The side limit mechanisms are disposed on sides of the standing column body and are used for limiting the forward and backward motions of the standing column body. By the aid of the limit mechanisms, all parts of the standing column can be limited. The standing column assembly welding tool has the advantages of high work efficiency, low labor intensity, high assembly precision.

Owner:SANY HEAVY IND CO LTD (CN)

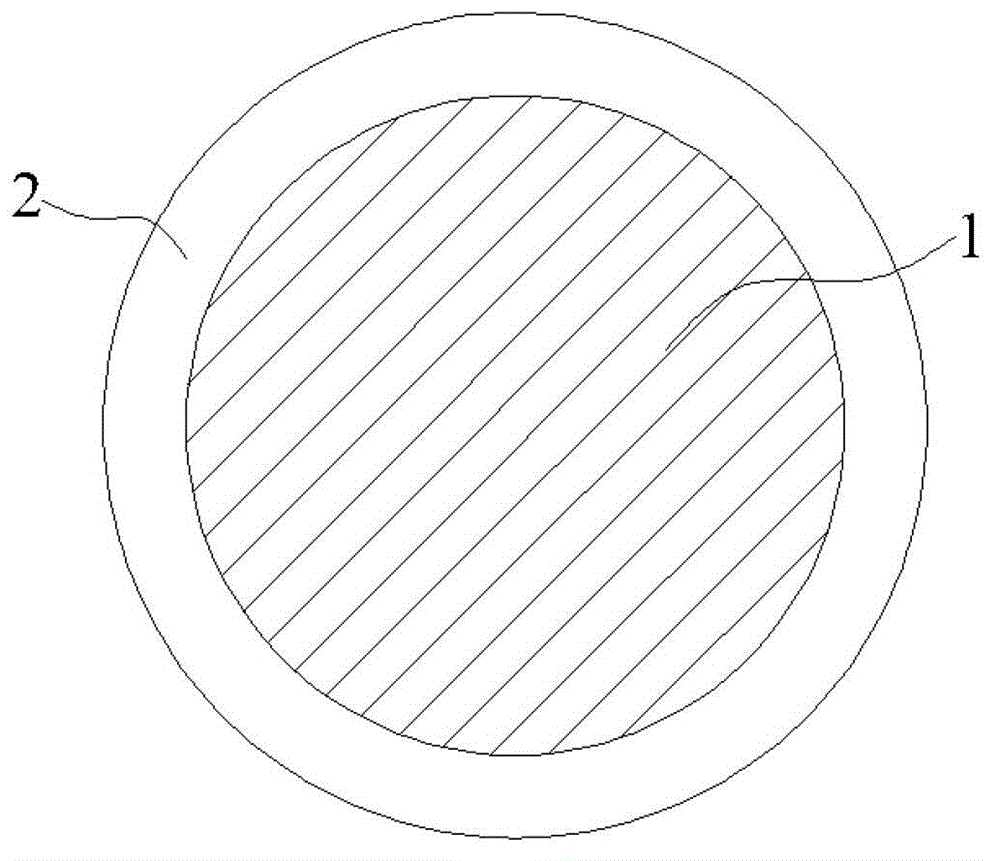

Low smoke zero halogen flame retardant sheath layer for optical cable

ActiveCN102977451ASolve the technical problem of outer diameter fluctuationReduced filling capacityFibre mechanical structuresAluminium hydroxideCarvacryl acetate

The invention discloses a low smoke zero halogen flame retardant sheath layer for an optical cable, wherein the optical cable comprises an optical cable core and a low smoke zero halogen flame retardant sheath layer covering the outer surface of the optical cable, and the low smoke zero halogen flame retardant sheath layer is composed of the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high-pressure metallocene polyethylene, 10-20 parts of special modified polyethylene, 70-110 parts of aluminium hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 parts of antioxidant and 2-5 parts of black master batch. The low smoke zero halogen flame retardant sheath layer for the optical cable enables the outer diameter of the optical cable to be even, thereby guaranteeing the shrinkage integrity of the optical cable core; as a result, signals can not be greatly attenuated in the transmission process in the cable; and simultaneously, the tensile strength of the cable is greater than or equal to 13 MPa, while the elongation at break is greater than or equal to 250% and the oxygen index is greater than or equal to 34%; and the cable has excellent mechanical properties.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

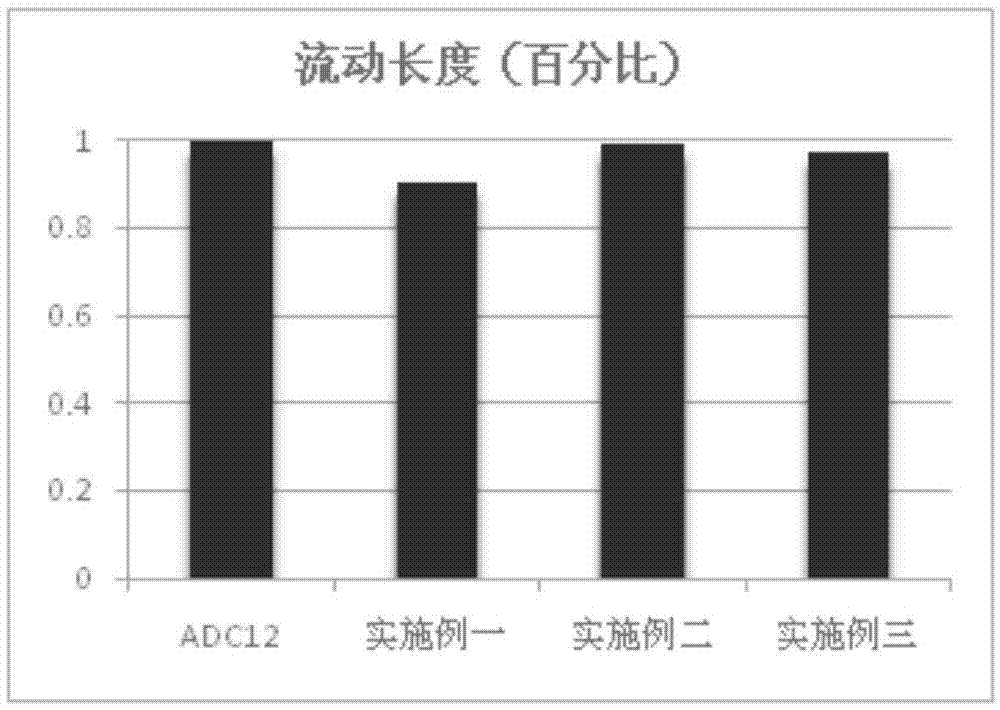

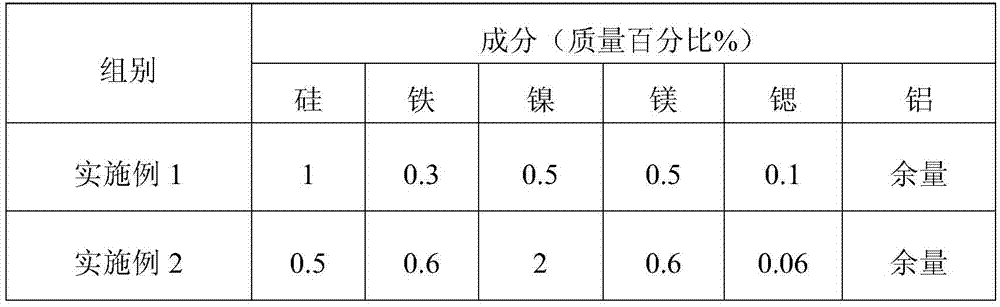

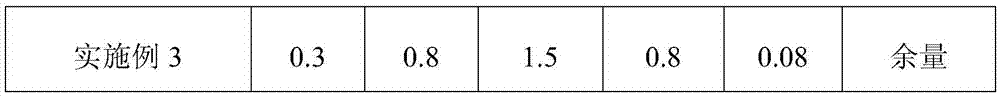

High-thermal-conductivity die-casting aluminum alloy and preparing method thereof

The invention provides a high-thermal-conductivity die-casting aluminum alloy. The high-thermal-conductivity die-casting aluminum alloy comprises, by mass percentage, 0.05%-1.0% of silicon, 0.3%-1. 3% of iron, 0.2%-2.0% of nickel, 0.1%-1.2% of magnesium, 0.001%-0.15% of strontium and the balance aluminum and inevitable impurities, wherein the mass percentage of the impurities is smaller than 0.2%. The invention further provides a preparing method of the high-thermal-conductivity die-casting aluminum alloy. The preparing method comprises the steps that at different heating temperatures, the aluminum and magnesium, an aluminum silicon intermediate alloy, a ferro-aluminium intermediate alloy, a nickel-aluminum intermediate alloy and an aluminum strontium intermediate alloy are sequentially fused to obtain aluminum, silicon, iron, nickel, magnesium and strontium fusion; then refined treatment and slag removal treatment are carried out to obtain an aluminum alloy solution; and the temperature of the aluminum alloy solution is adjusted to be 680 DEG C to 720 DEG C, and then casting can be carried out. The high-thermal-conductivity die-casting aluminum alloy has the excellent casting performance and has the higher heat conductivity coefficient.

Owner:ZTE CORP

Anti-blocking low smoke zero halogen flame-retardant cable material for optical cable

ActiveCN103849063AFast demouldingGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesMelt flow indexCarvacryl acetate

The invention discloses an anti-blocking low smoke zero halogen flame-retardant cable material for an optical cable. The anti-blocking low smoke zero halogen flame-retardant cable material comprises the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high pressure metallocene polyethylene, 10-20 parts of modified polyethylene, 70-110 parts of aluminum hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 part of antioxidant, and 2-5 parts of black master batch, wherein the content of VA in the ethylene-vinyl acetate copolymer is 20-28%, the melt index of 2.16Kg of high pressure metallocene polyethylene at 190DEG C is less than or equal to 3g / 10min, the density is less than 0.92g / cm<3>. By adopting the anti-blocking low smoke zero halogen flame-retardant cable material, the outer diameter of the optical cable is uniform, so that the shrinkage integrity of the core of the optical cable is guaranteed, the signal transmitted in the optical cable is not attenuated sharply; and in addition, the tensile strength of the cable is greater than or equal to 13MPa, the elongation at break is greater than or equal to 250%, the oxygen index is greater than or equal to 34%, and the cable has excellent mechanical property.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

High-thermal-conductivity and high-strength aluminum alloy material and preparation method thereof

The invention discloses a high-thermal-conductivity and high-strength aluminum alloy material and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 1.0 to 2.0 percent of silicon, 0.3 to 1.2 percent of iron, 0.1 to 0.9 percent of copper, 0.1 to 0.9 percent of magnesium, less than or equal to 1.5 percent of nickel and the balance ofaluminum. The preparation method comprises the following steps: mixing a pure metal material or an intermediate alloy material and the required elements according to the proportion, heating the mixedaluminum alloy material to 700 to 800 DEG C and performing heating and melting treatment; introducing nitrogen gas into a container with the aluminum alloy material, adding a refining agent and refining; scraping out scum after refining, performing standing treatment on the aluminum alloy material and removing included slag; and controlling the temperature range of the aluminum alloy material to660 to 700 DEG C and casting a forming part. Al-Si-Fe alloy serves as basis and Cu and Mg strengthening elements and other alloy elements are added, so that high thermal conductivity and excellent mechanical property requirement are achieved.

Owner:SHANGHAI INST OF TECH

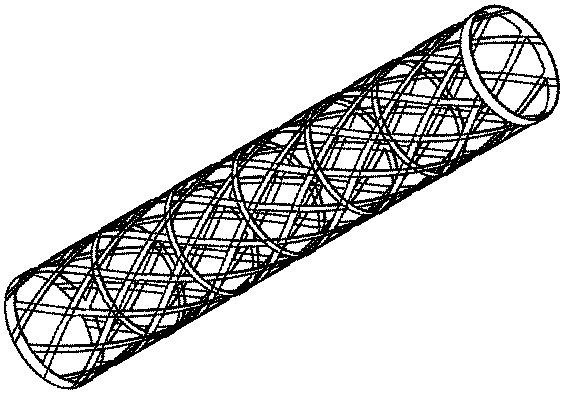

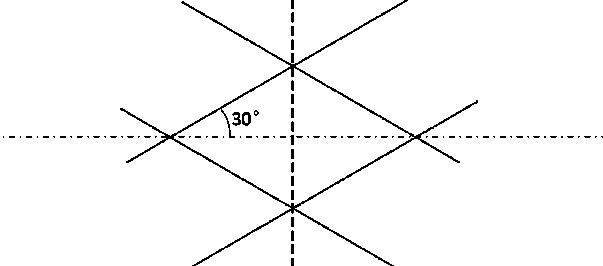

Simple composite material grid workpiece forming method

The invention provides a simple composite material grid workpiece forming method. The forming structure is a thin-wall structure. A simple cylinder die is adopted for forming. The forming method comprises the following steps that 1, a die is installed and located; 2, grid winding is carried out; 3, thin film winding is carried out; 4, curing is carried out; and 5, demoulding is carried out. According to the forming method, the die design is simple, the demoulding manner is simple, the requirement for winding equipment is low, the workpiece appearance is better, the method can be used for batchproduction, the production efficiency is high, and the cost is low.

Owner:HENGSHEN

Concrete additive and preparation method thereof

The invention provides a concrete additive and a preparation method thereof, relating to the technical field of concrete. The additive is prepared from the following raw materials: cement, kaolin, limestone, latex powder, mineral slag, polyacrylamide, butoxy polyalkaneneglycol ether, dodecathiol, glycerol, organic water-soluble polysaccharides, an initiator, a waterproofing agent, an antifreezing agent and an anticorrosive agent. The concrete additive can greatly reduce the quantity of water for mixing, improves the rheological properties of the concrete mixture, promotes the setting and demolding of the concrete, and accelerates the construction progress. The concrete additive improves the concrete strength and enhances the engineering quality.

Owner:萧县良宇混凝土有限责任公司

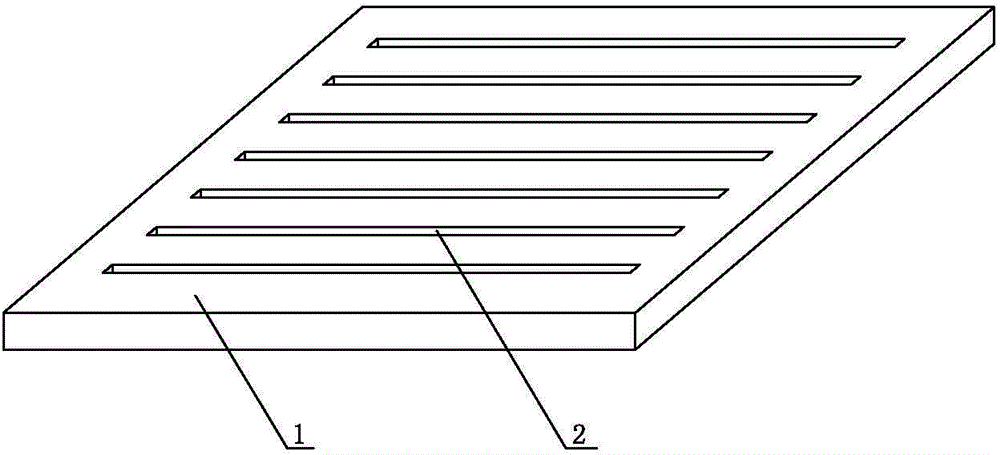

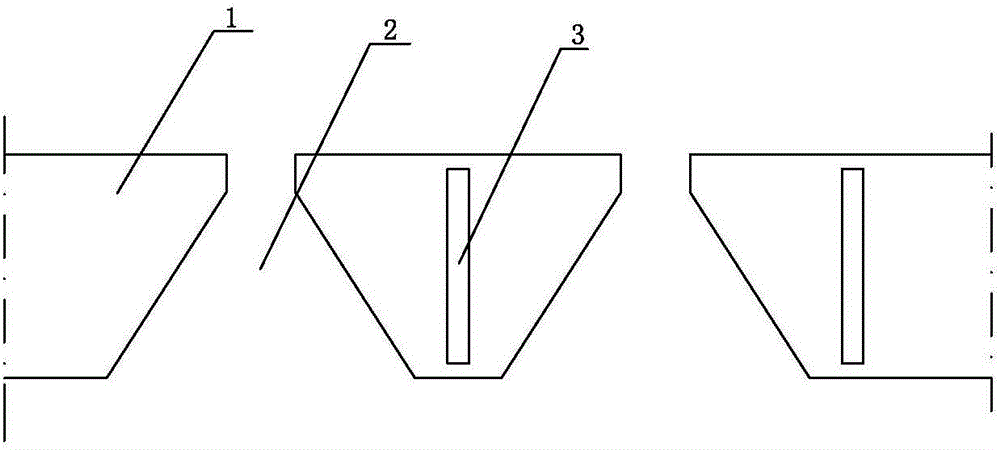

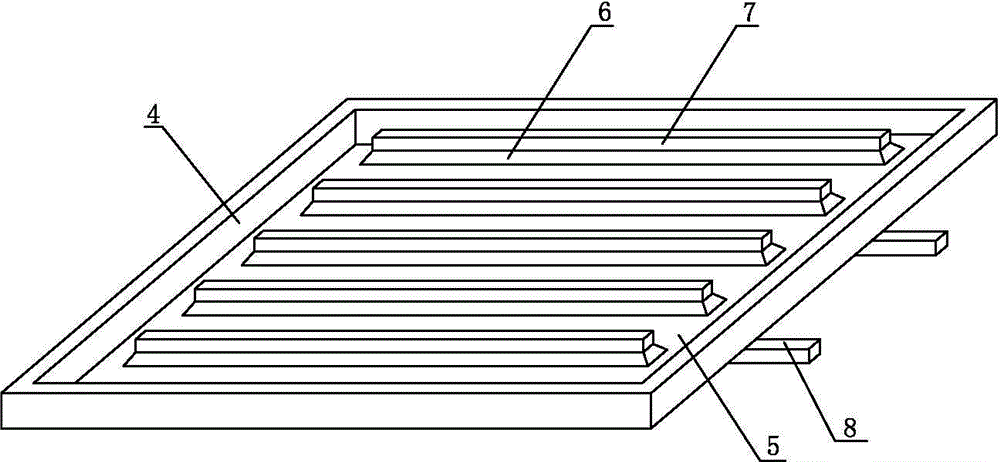

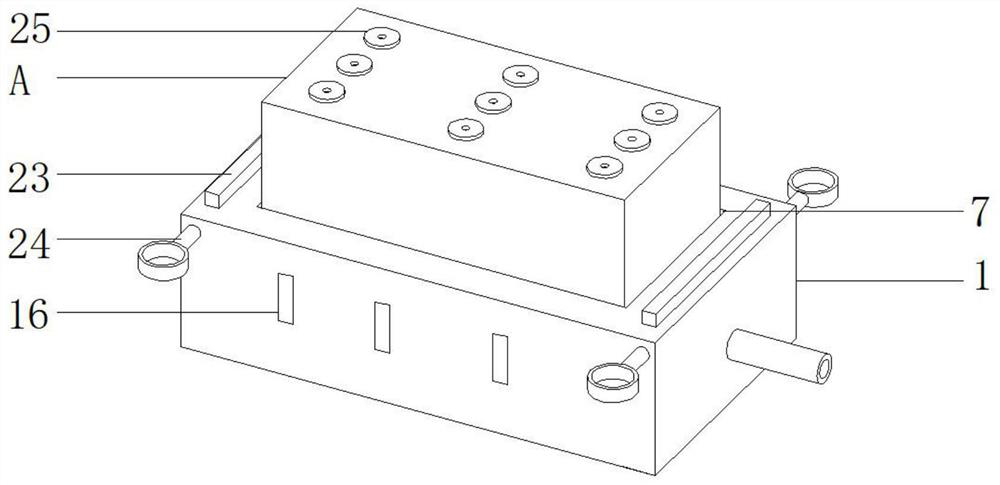

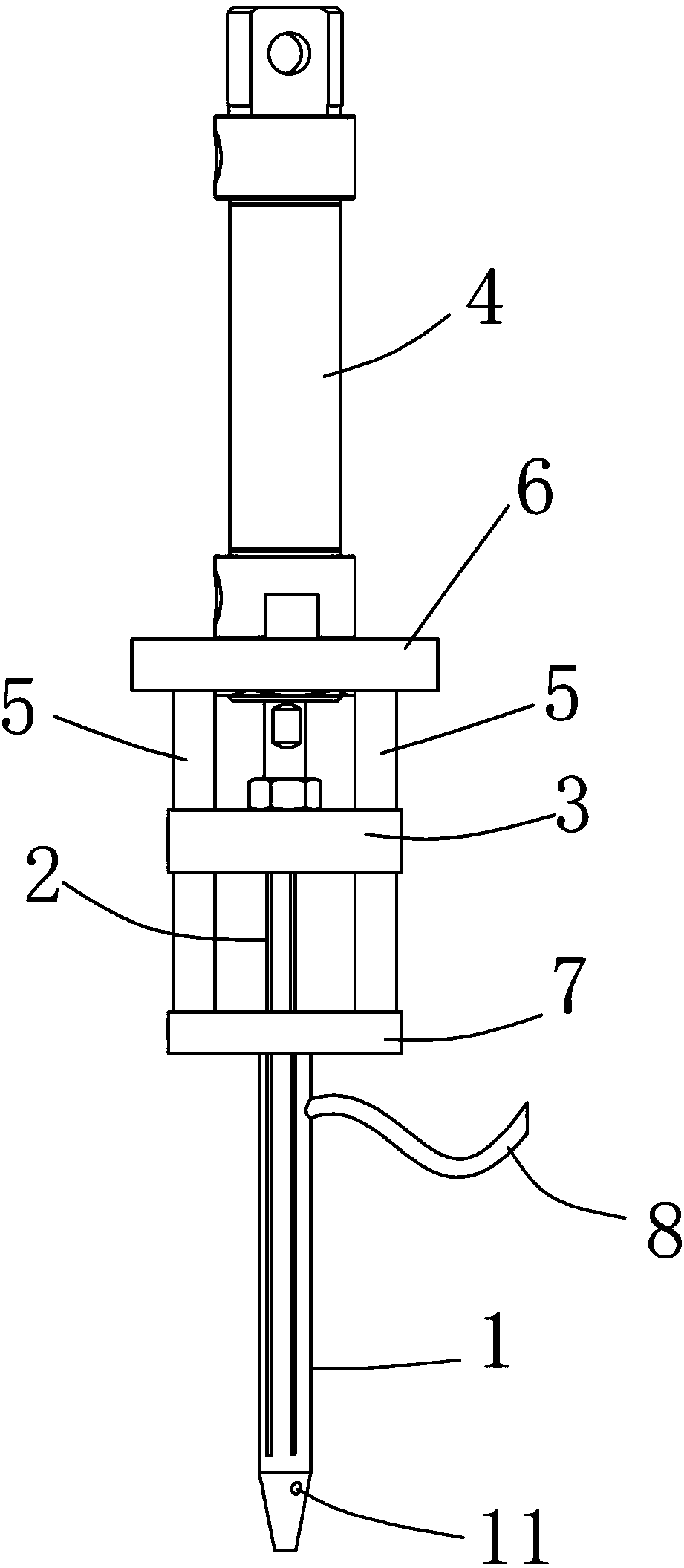

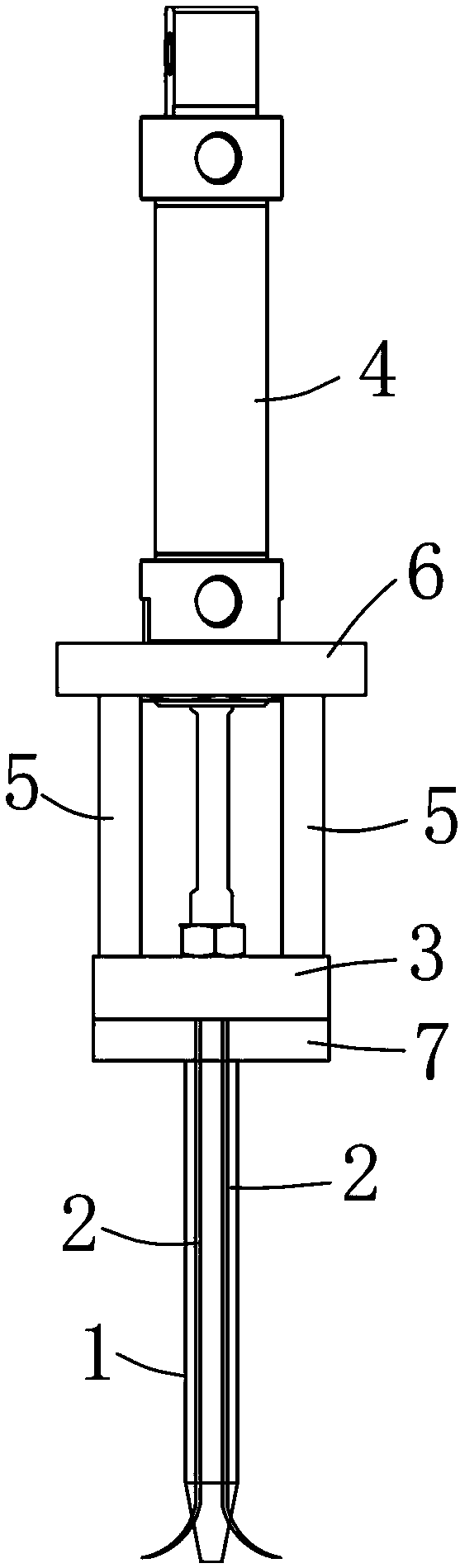

Trapezoid manure leaking floor and manufacturing mold assembly thereof

ActiveCN105104214ADesign scienceReasonable structureDischarging arrangementMouldsUltimate tensile strengthManure

The invention discloses a trapezoid manure leaking floor and a manufacturing mold assembly thereof, and relates to a pig house. The trapezoid manure leaking floor and the manufacturing mold assembly are characterized in that a plurality of manure leaking seams are formed in the trapezoid manure leaking floor at equal intervals, the cross section of each manure leaking seam is in a trapezoid shape with a small upper opening and a big lower opening, and a reinforcing steel bar frame is arranged in the portion, between every two adjacent manure leaking seams, of the manure leaking floor and buried vertically so that the strength of the manure leaking floor can be improved. The manufacturing mold assembly comprises a manure leaking floor mold and a demolding tool. The trapezoid manure leaking floor is manufactured through the manure leaking floor mold, and the demolding procedure is rapidly completed through the demolding tool. By means of the trapezoid manure leaking floor and the manufacturing mold assembly, concrete is directly poured into the mold, the manure leaking floor with the trapezoid seams is manufactured through the mold with trapezoid protrusions, the demolding tool is used in cooperation with a forklift, and demolding work can be rapidly conducted.

Owner:YUNNAN SHENNONG AGRI IND GROUP

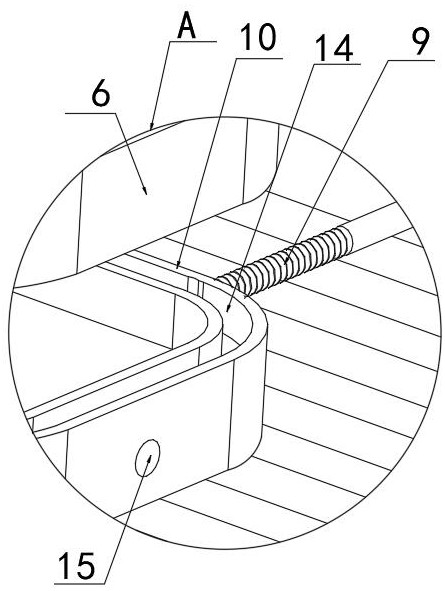

Box container plastic uptake mould capable of conveniently de-moulding

InactiveCN111823551AEasy to demouldGood release effectDomestic articlesEngineeringMechanical engineering

The invention discloses a box container plastic uptake mould capable of conveniently de-moulding. The box container plastic uptake mould capable of conveniently de-moulding comprises a power frame anda mould arranged on the top of the power frame, wherein the middle part inside the power frame is provided with a storage cavity, and the center position of the power frame is provided with an oil cylinder; a movable sealing plug is arranged inside the oil cylinder; the left side of the oil cylinder horizontally communicates with an oil passing tube; a movable load-bearing column is connected above the sealing plug; the bottom end of the mould is welded with a stainless steel cushion plate which is connected to the load-bearing column; the middle of the cushion plate on the top of the power frame is provided with a slot hole which corresponds to the mould; the cushion plate and the mould on the top of the cushion plate can move up and down; and the mould comprises a top plate and side plates formed by side corners of the top plate. The mould is controlled to move, so that an external workpiece is in contact and extrusion with the power frame on the bottom, and therefore, de-moulding is promoted; and a column hole can be additionally formed in the top plate of the mould for exhausting gas outwards; and cooling structures on inner walls of the side plates of the mould can quicken cooling and assist de-moulding, so that de-moulding efficiency is high.

Owner:滁州新佳诚模具制造有限公司

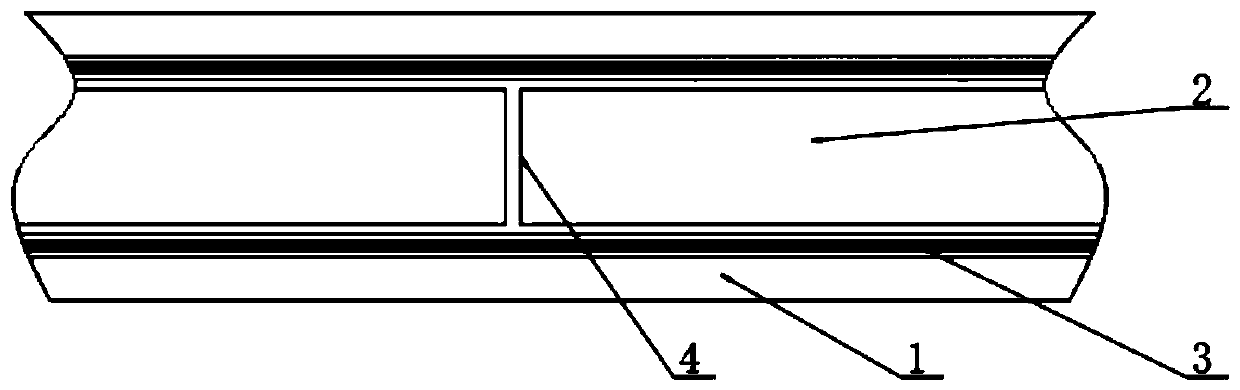

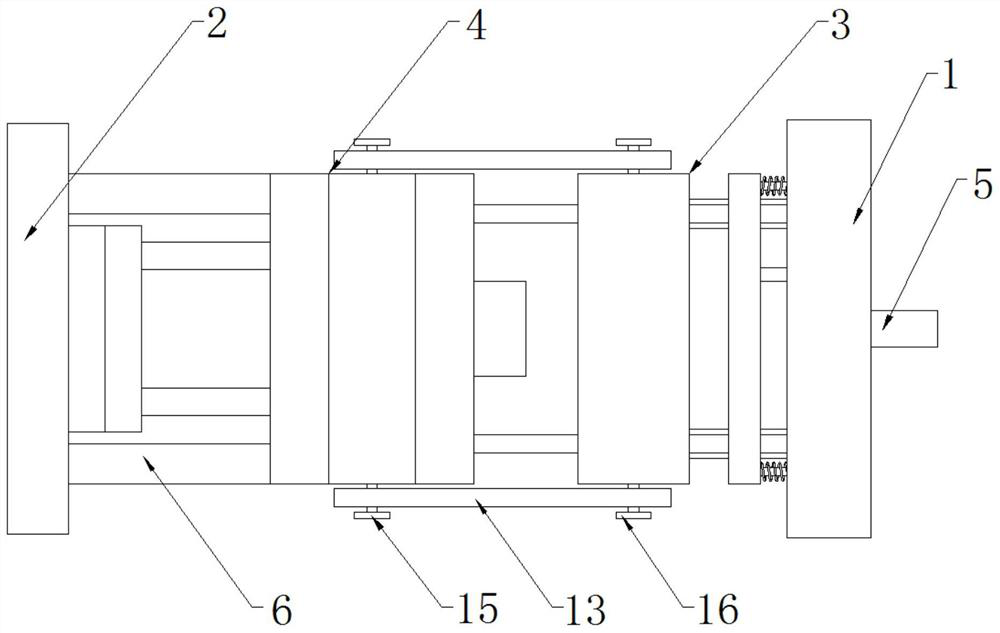

Continuous casting machine

InactiveCN105855527AGet rid of manual crushingReduce labor costsMolten metal conveying equipmentsEconomic benefitsSprocket

The invention provides a continuous casting machine, and belongs to metallurgical equipment. The continuous casting machine comprises a machine head frame, a machine body frame, a machine tail frame, a die, machine head transmission chain wheels, a machine head transmission main shaft, a machine tail transmission chain wheel, a machine tail transmission shaft, a motor, a speed reducer, a transmission chain, cooling devices, a die releasing agent spraying device, a die releasing device and a casting port, wherein the machine head frame, the machine body frame and the machine tail frame are all of rectangular steel frame structures and are sequentially integrally fixedly connected; bearing blocks which are assembled to the machine head transmission main shaft are mounted at two sides of the machine head frame; the machine head transmission chain wheels are mounted at two ends of the machine head transmission main shaft. The continuous casting machine is simple in structure; all components can be independently dismounted and replaced, so that the convenience of maintenance is ensued, a plurality of problems caused by manual breaking can be completely solved, and as a result, huge economic benefits can be brought to metallurgical enterprises.

Owner:宁夏铸源机械制造有限公司

Pier stud template for road and bridge construction

ActiveCN111395175ANot easy to break awayFixed way is firmBridge structural detailsBridge erection/assemblyArchitectural engineeringWood plank

The invention discloses a pier stud template for road and bridge construction. The template comprises two half templates; T-shaped clamping grooves are formed in the ends, close to each other, of thetwo half templates. An I-shaped plate is inserted between the two adjacent clamping grooves; a top plate is fixed to the ends, away from the inner sides of the half templates, of the I-shaped plate, the end of the top plate extends to the outer sides of the outer walls of the half templates, two arc-shaped plates attached to the outer walls of the half templates are fixed to the outer side of eachhalf template, an inserting opening is formed in each arc-shaped plate in a communicating mode, and a U-shaped rod is arranged on the outer side of the joint of the two half templates. According to the invention, the I-shaped plate is inserted to connect and fix the half templates, so that a problem that loosening is likely to happen when an outer hoop is adopted for fixing traditionally is solved; separation of concrete from the joint of the baffle and the half template is achieved through continuous contact and impact between the impact ball and the half template and upward movement of thetop plate, so that rapid demolding is achieved, and damage to a wood plate or a pier stud is avoided.

Owner:宁波谦屹节能科技有限公司

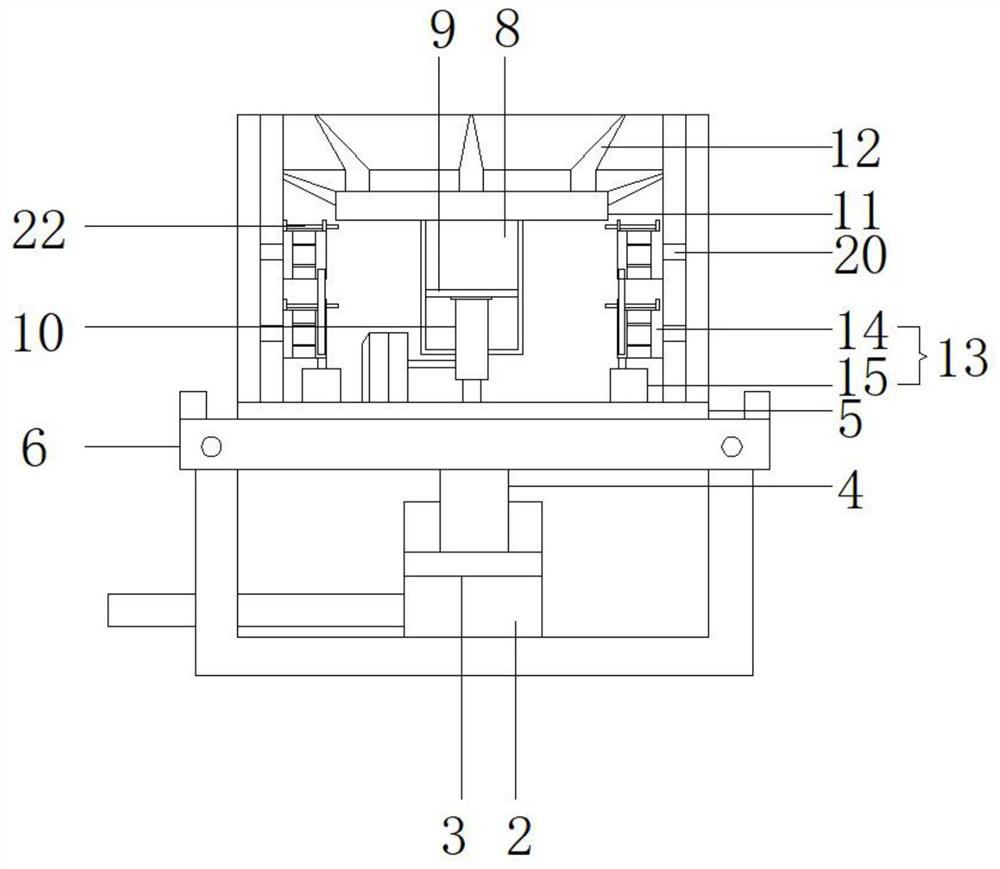

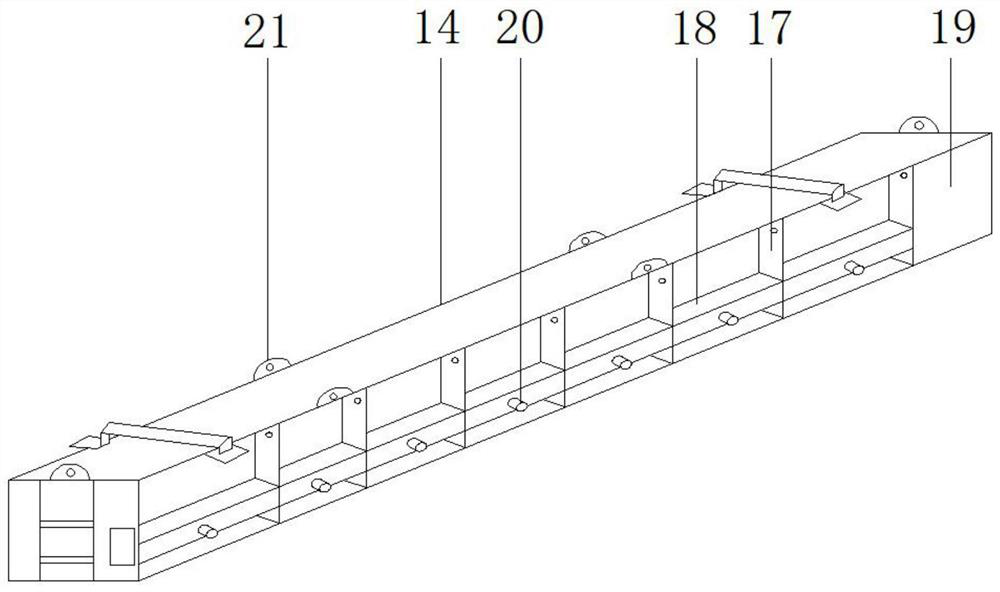

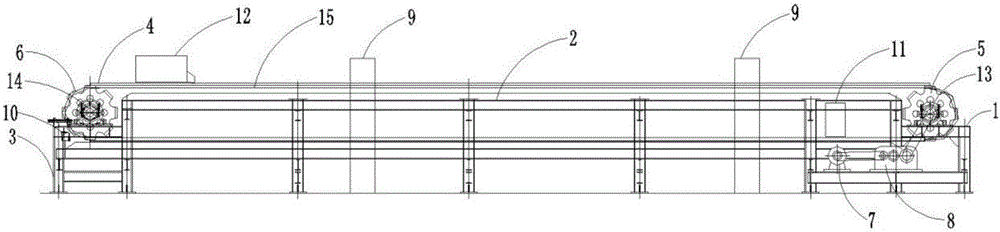

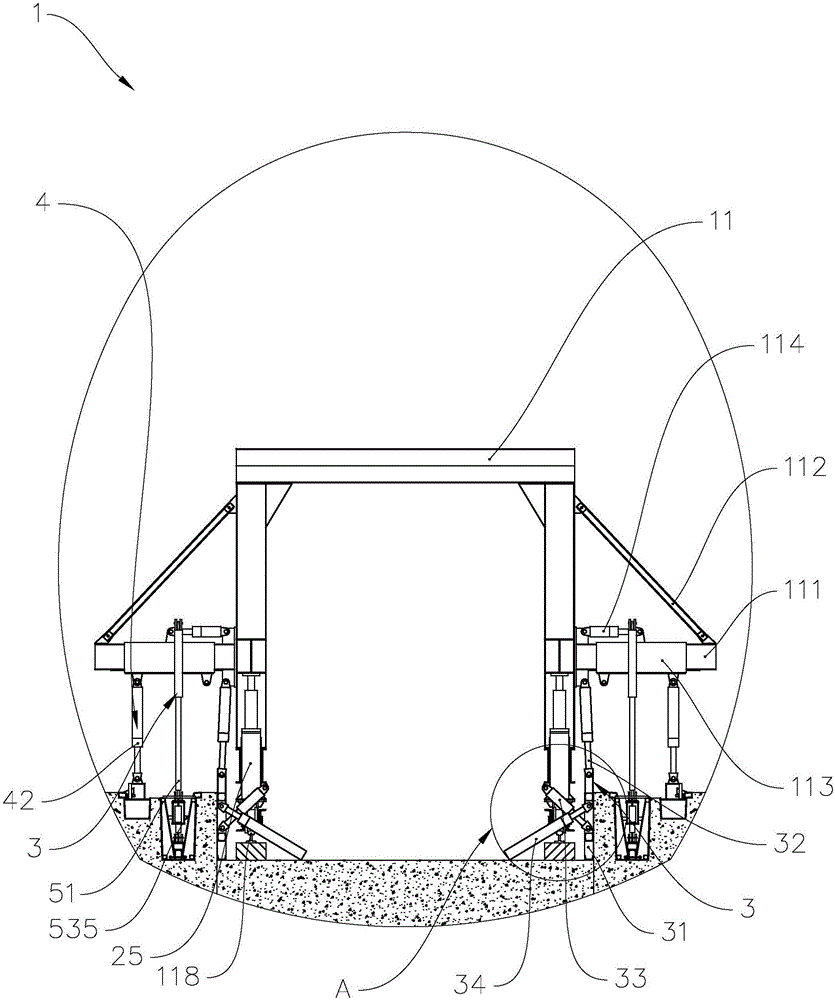

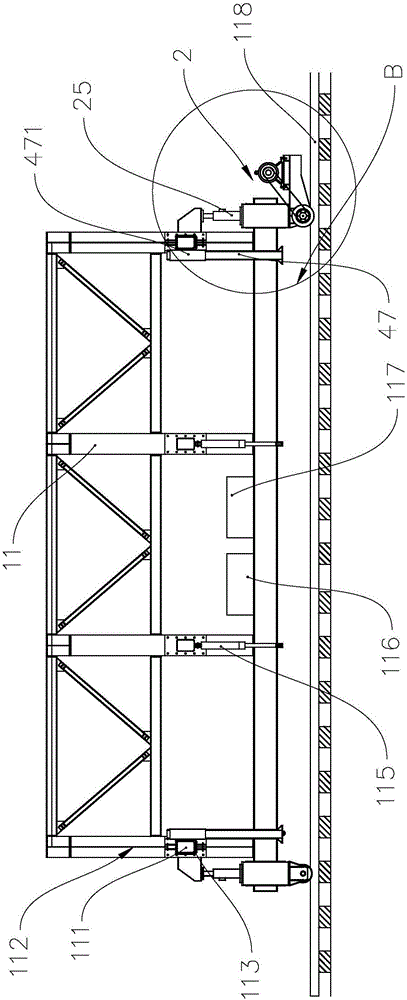

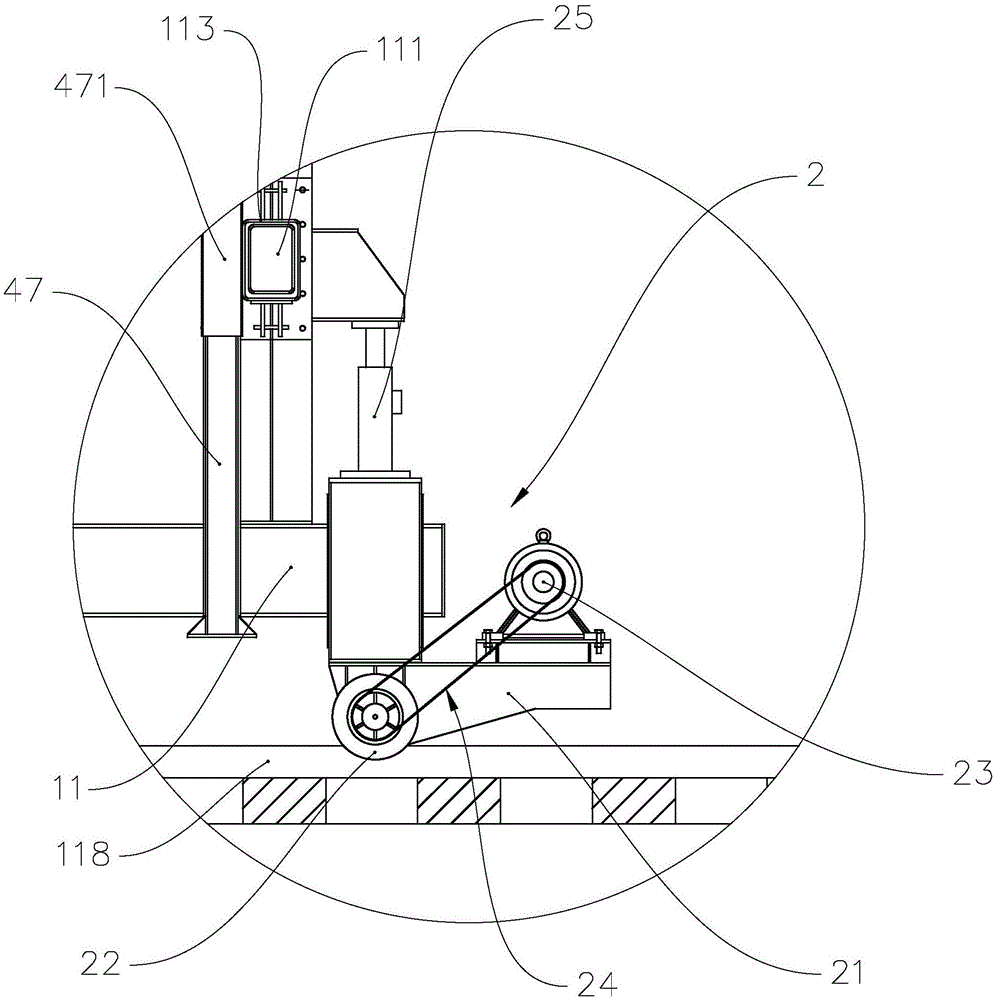

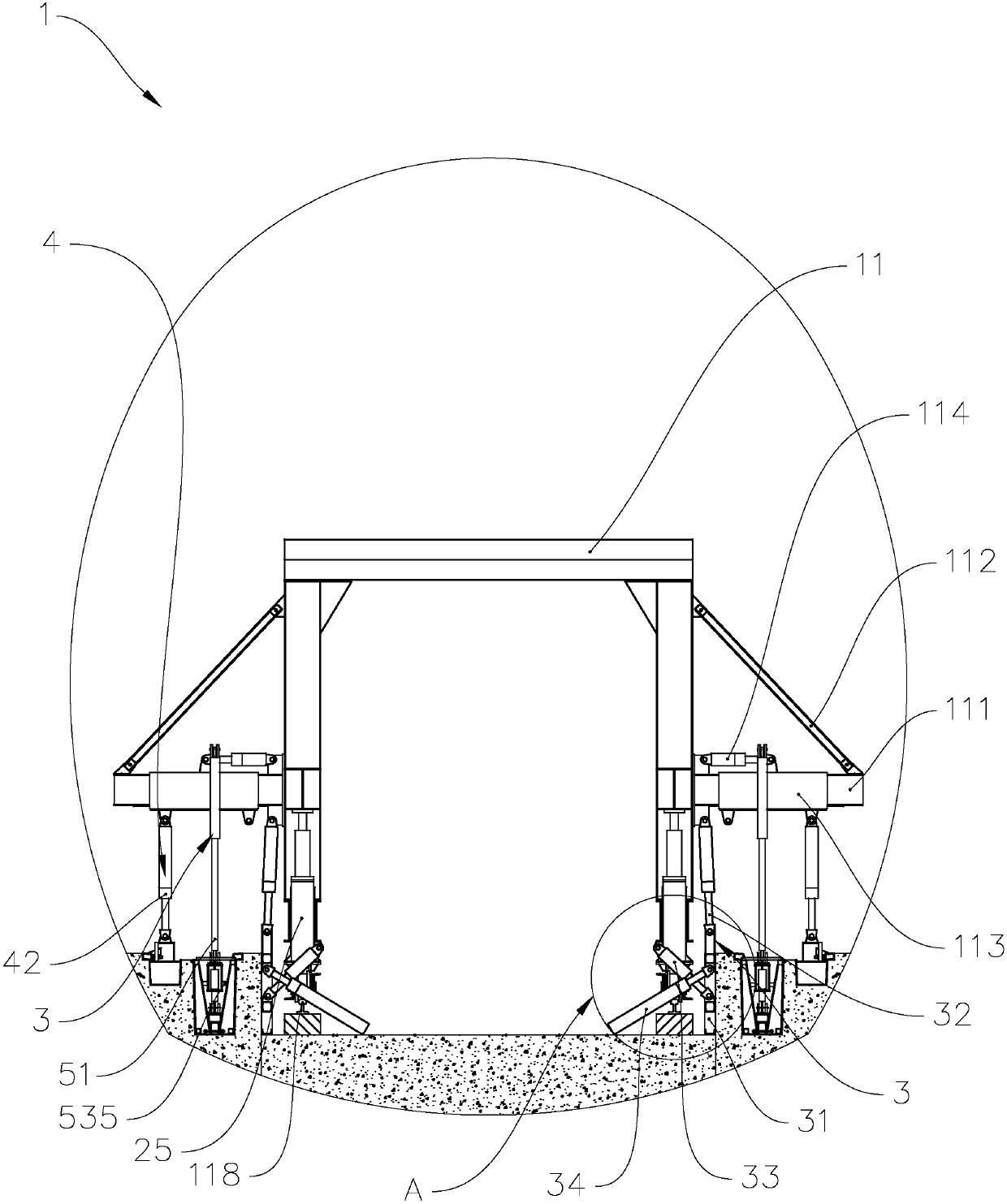

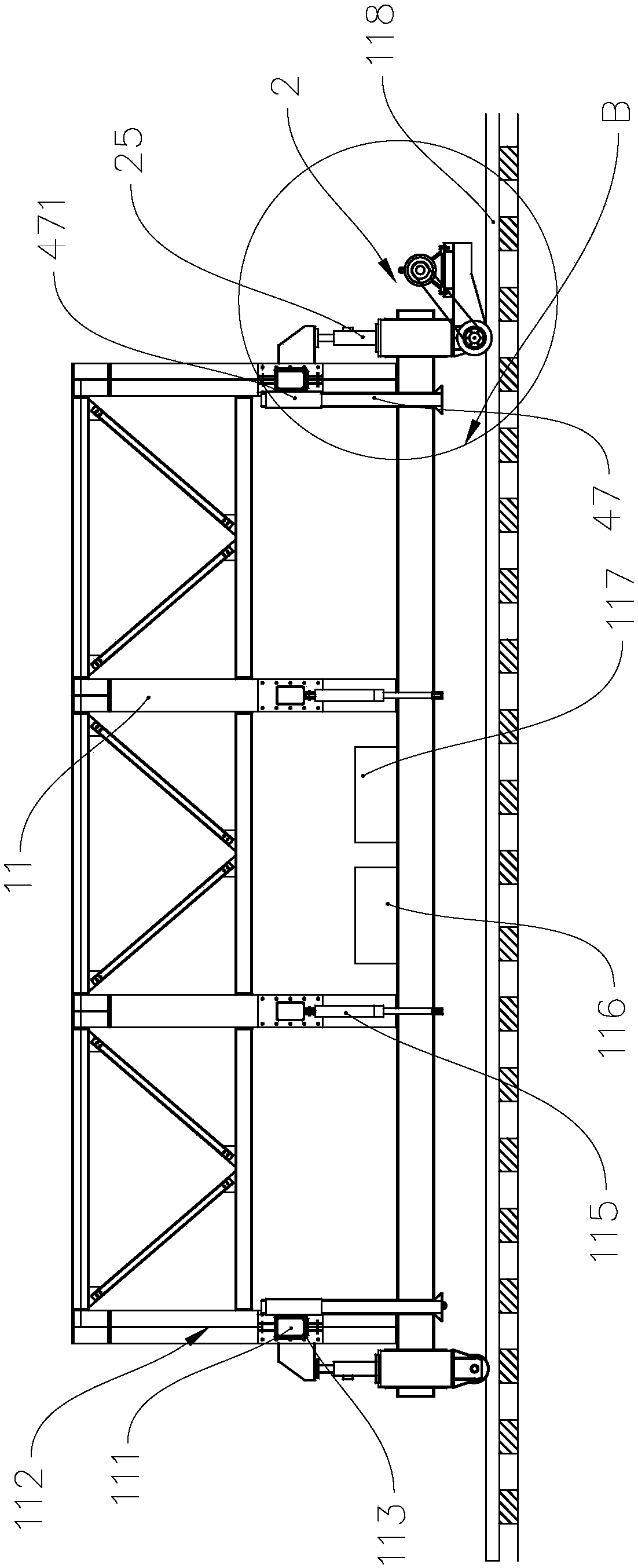

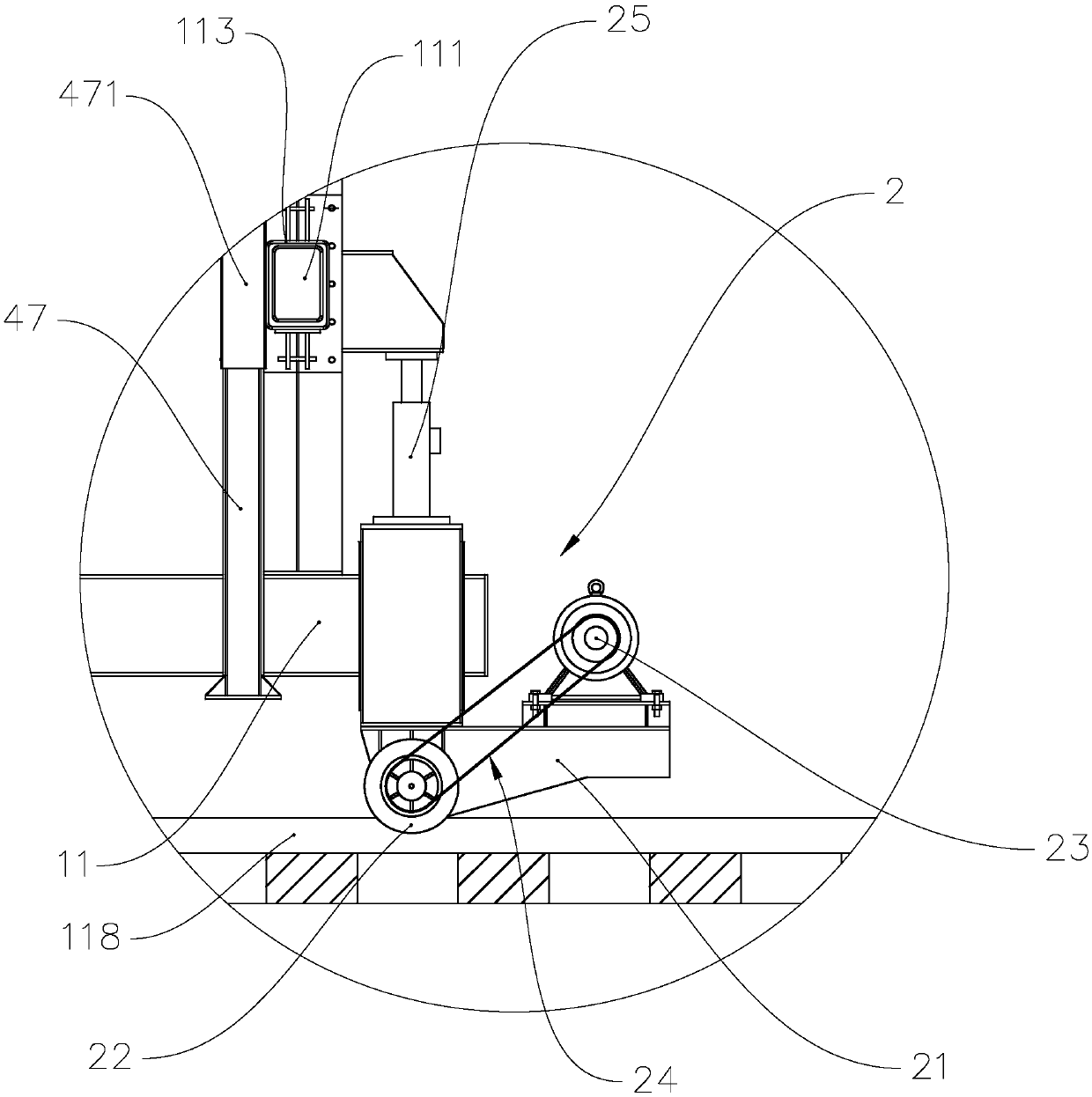

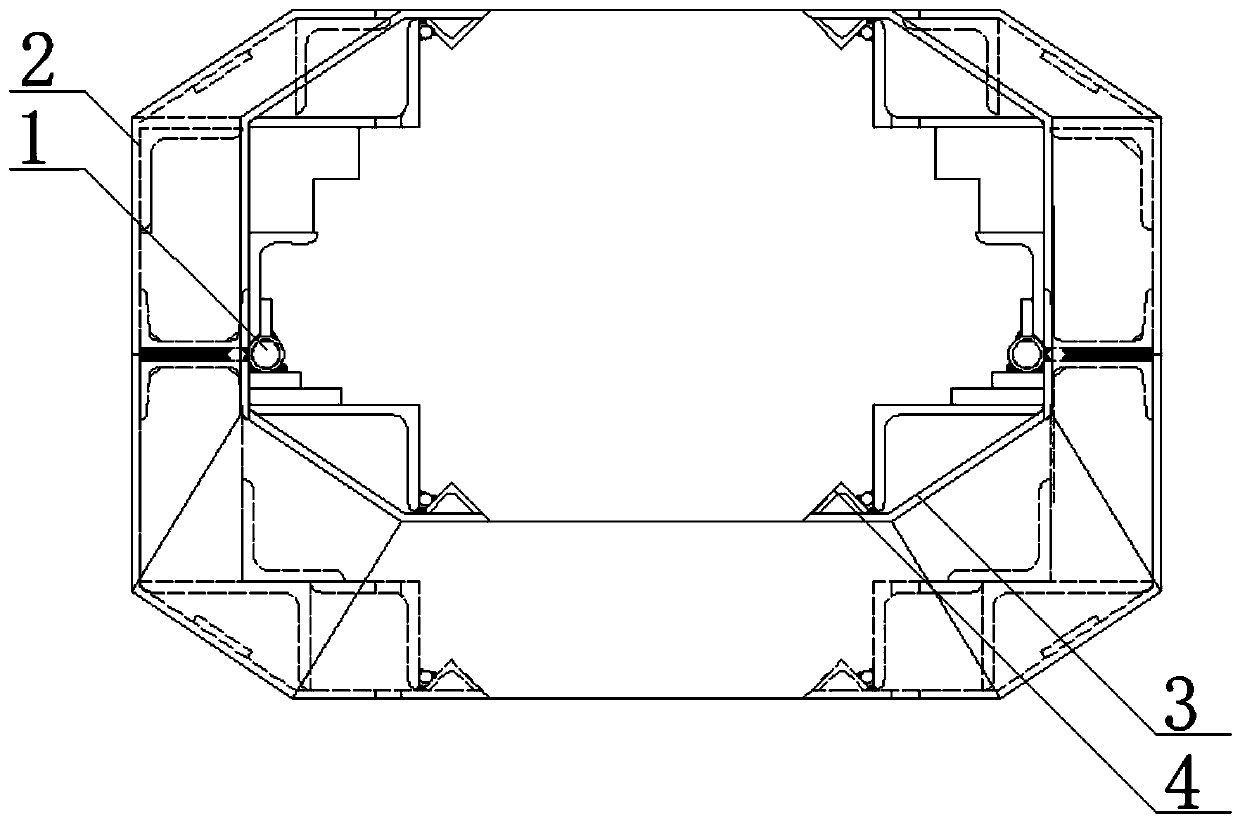

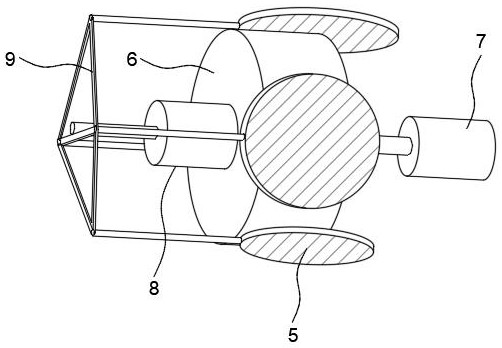

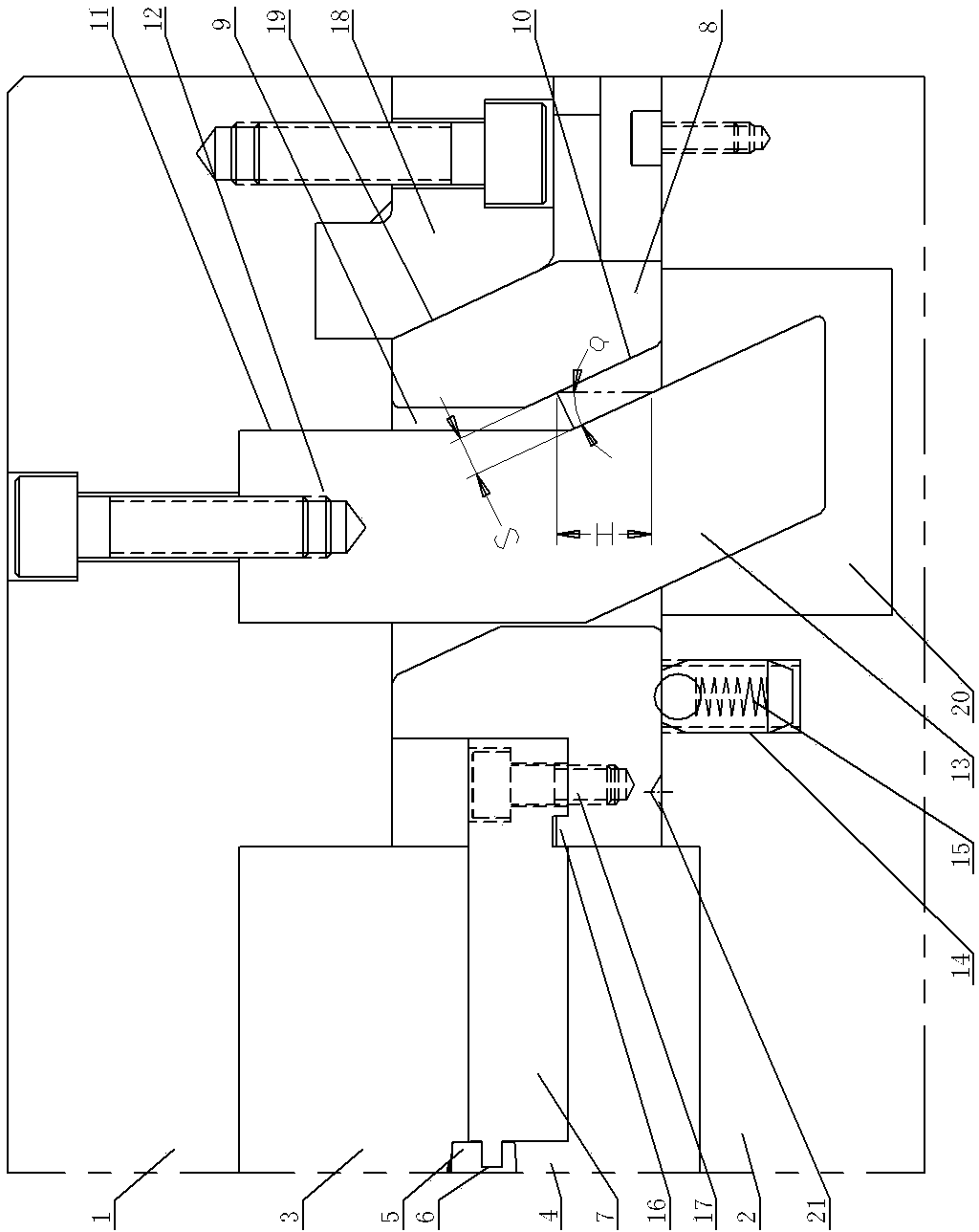

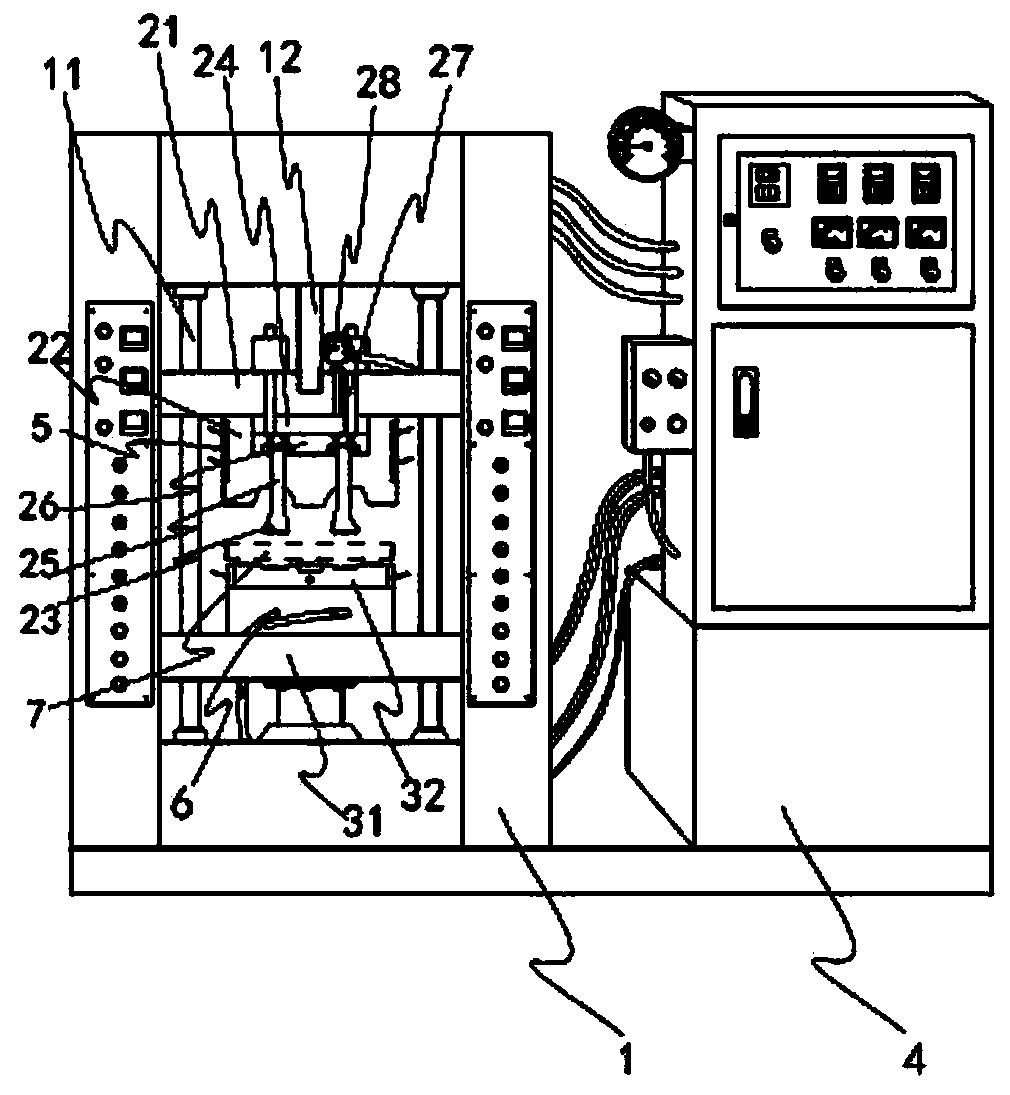

Tunnel ditch cable trough construction trolley

InactiveCN106089257AImprove construction qualityShort demoulding timeUnderground chambersDrainageDitchThreaded rod

The invention provides a tunnel ditch cable trough construction trolley which comprises a truss and a traveling system installed below the truss. The tunnel ditch cable trough construction trolley further comprises side wall die set devices, cable die set devices and ditch die set devices. Each side wall die set device comprises a side wall die set, a first oil cylinder and a second oil cylinder, wherein the two ends of the first oil cylinder are hinged to the side wall die set and the truss correspondingly, and the two ends of the second oil cylinder are hinged to the side wall die set and the truss correspondingly. Each cable die set device comprises a cable die set and a third oil cylinder, and the two ends of the third oil cylinder are hinged to the cable die set and the truss correspondingly. Each ditch die set device comprises a fourth oil cylinder, two oppositely arranged wedge-shaped die sets and an adjusting unit, wherein the adjusting unit comprises a bearing beam, an adjusting hand wheel and two oppositely arranged threaded rods, the two ends of the fourth oil cylinder are hinged to the truss and the bearing beam correspondingly, the adjusting hand wheel is arranged on the bearing beam, and each threaded rod is connected between the adjusting hand wheel and the corresponding wedge-shaped die set. The construction trolley has the advantages that the construction quality is high, and the demolding time is short.

Owner:NO 7 ENG CO LTD OF CHINA RAILWAY 19 BUREAU GRP +1

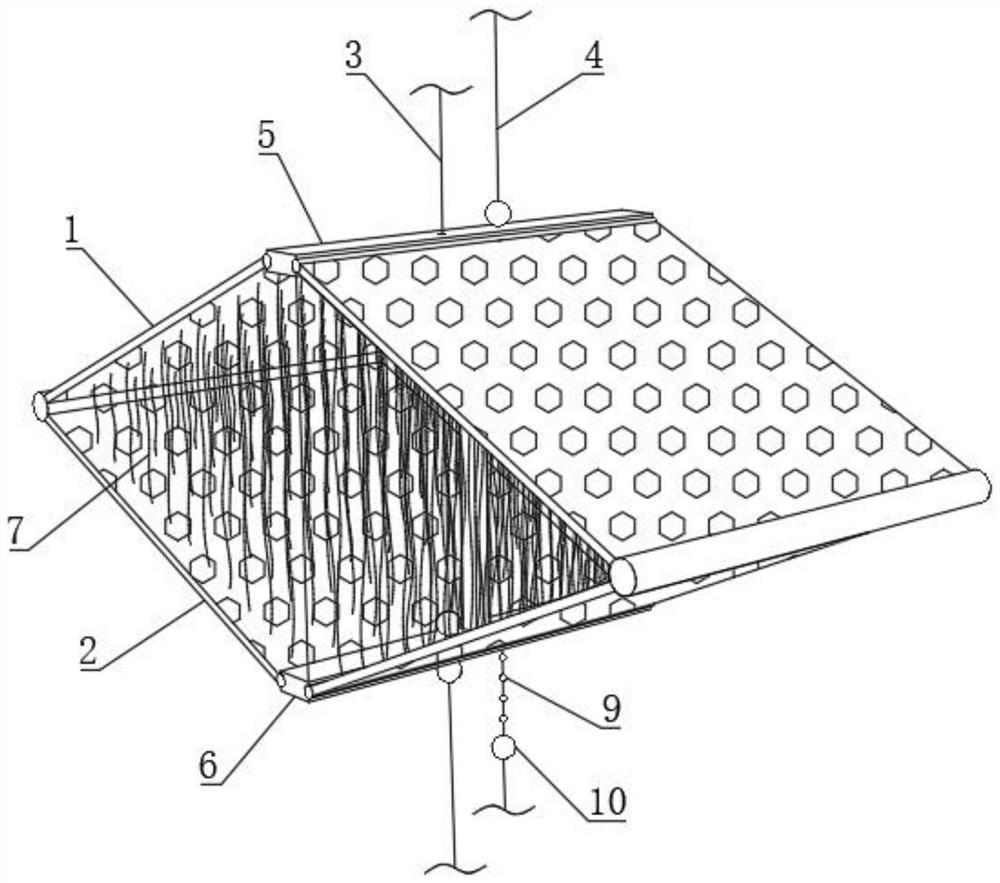

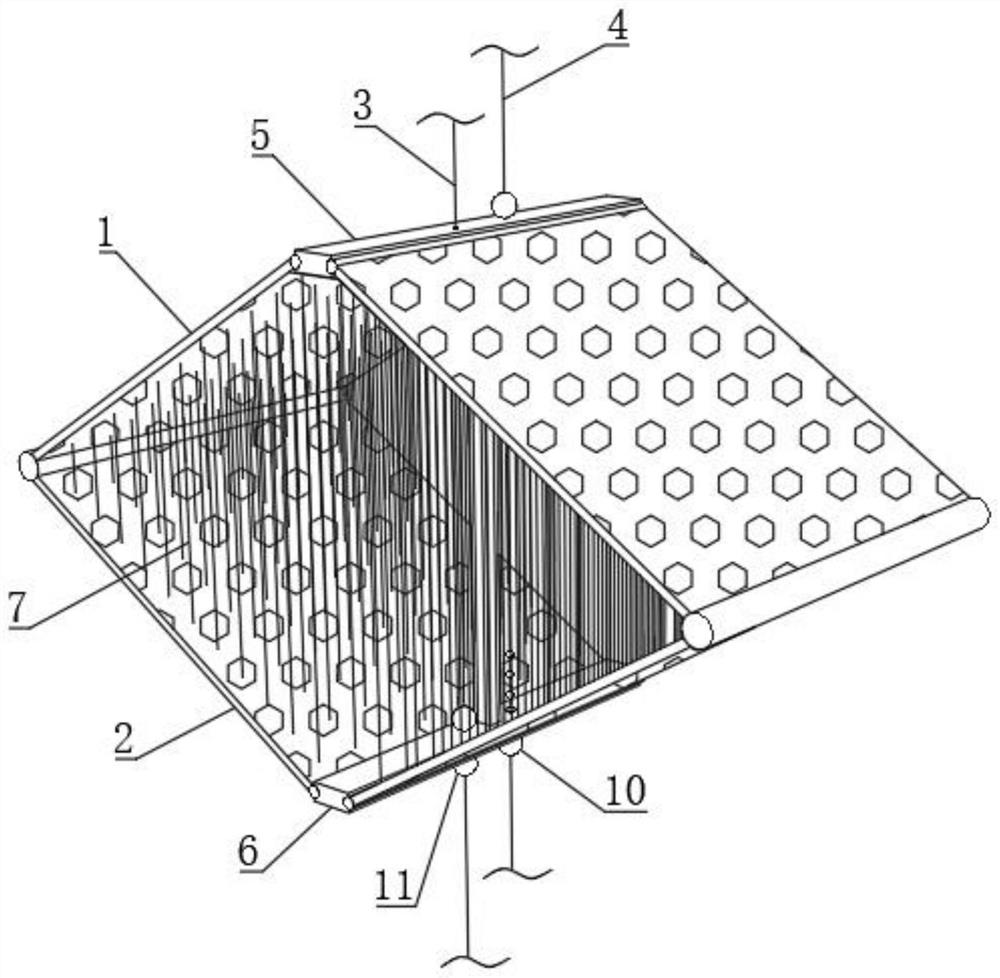

Wire-drawing gathering-scattering type combined filler for sewage treatment

InactiveCN113072194AChange densityIncrease internal porosityBiological treatment apparatusChemistryComposite material

The invention discloses a wire-drawing gathering-scattering type combined filler for sewage treatment, and belongs to the field of combined fillers. The wire-drawing gathering-scattering type combined filler for sewage treatment comprises a fixed rope, a semi-elastic movable rope and a plurality of uniformly distributed rhombic filler bodies, wherein the fixed rope and the semi-elastic movable rope sequentially penetrate through the rhombic filler bodies and are connected with the rhombic filler bodies, and the rhombic filler body comprises a pair of upper net plates and a pair of lower net plates. According to the invention, the shape change of the rhombic filler body is controlled, so that the loose state and the dense degree of the biofilm hanging silk are changed, the integrity of a biofilm is damaged, the internal pores of the biofilm are enlarged, the dense degree of the biofilm can be quantitatively and uniformly adjusted according to the actual situation, on the basis of not influencing the normal use of the biofilm, the internal porosity of the biofilm is improved, the adhesion capacity of the biofilm is reduced, and the separation of the aged biofilm is promoted so as to provide the combined filler which is easy to adjust, promotes demolding and has efficient degradation capacity for sewage treatment.

Owner:刘日山

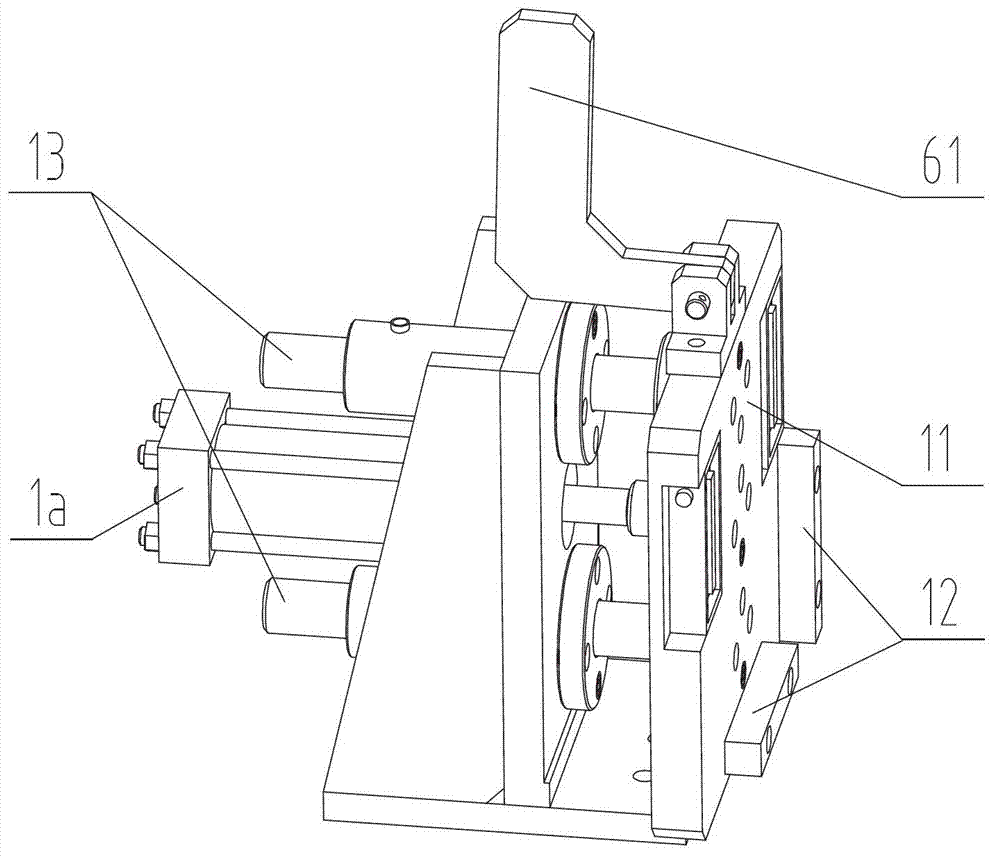

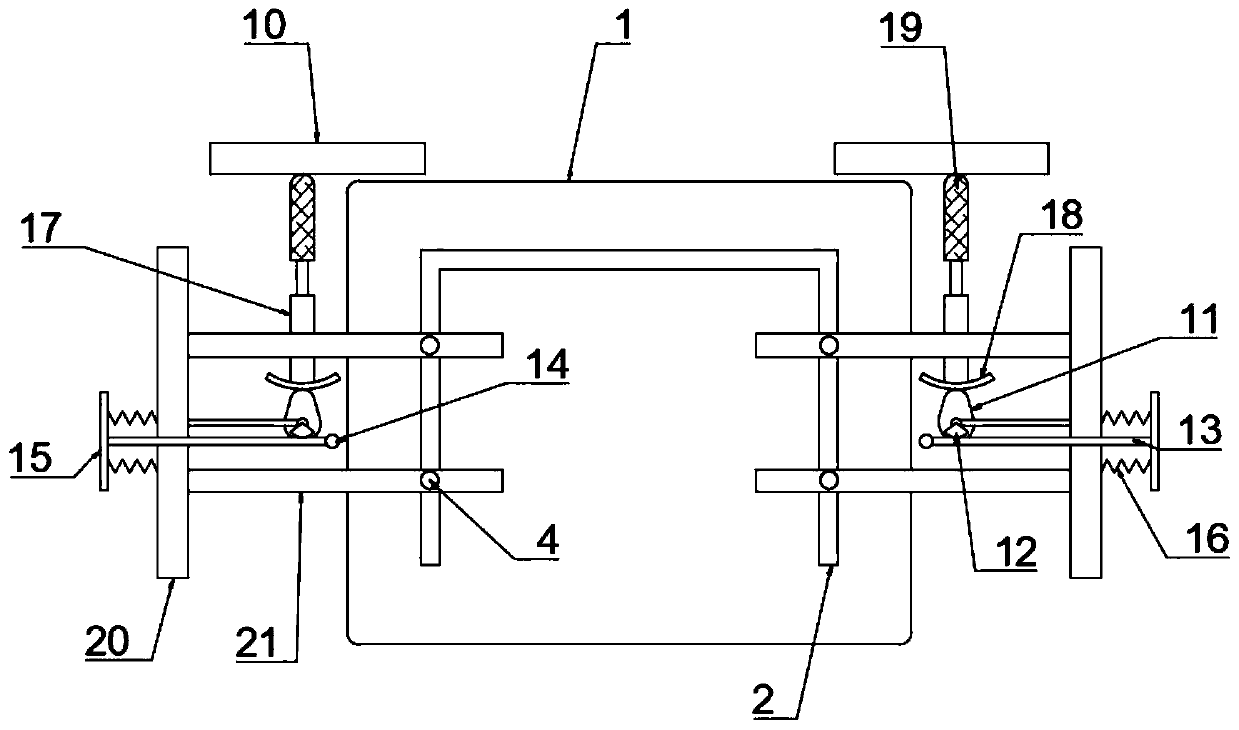

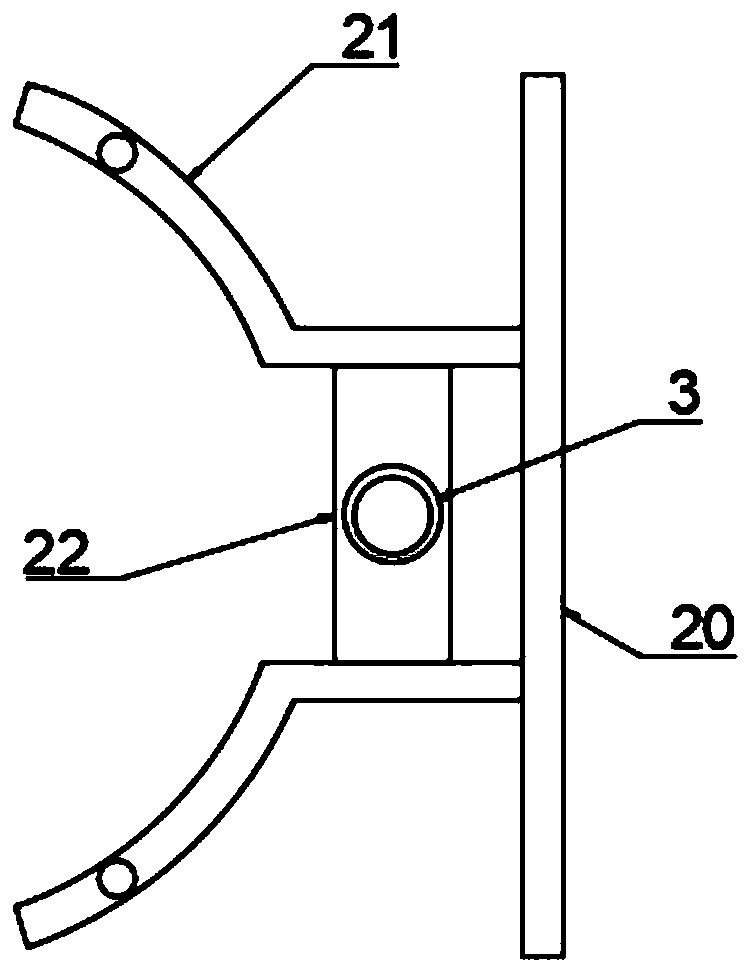

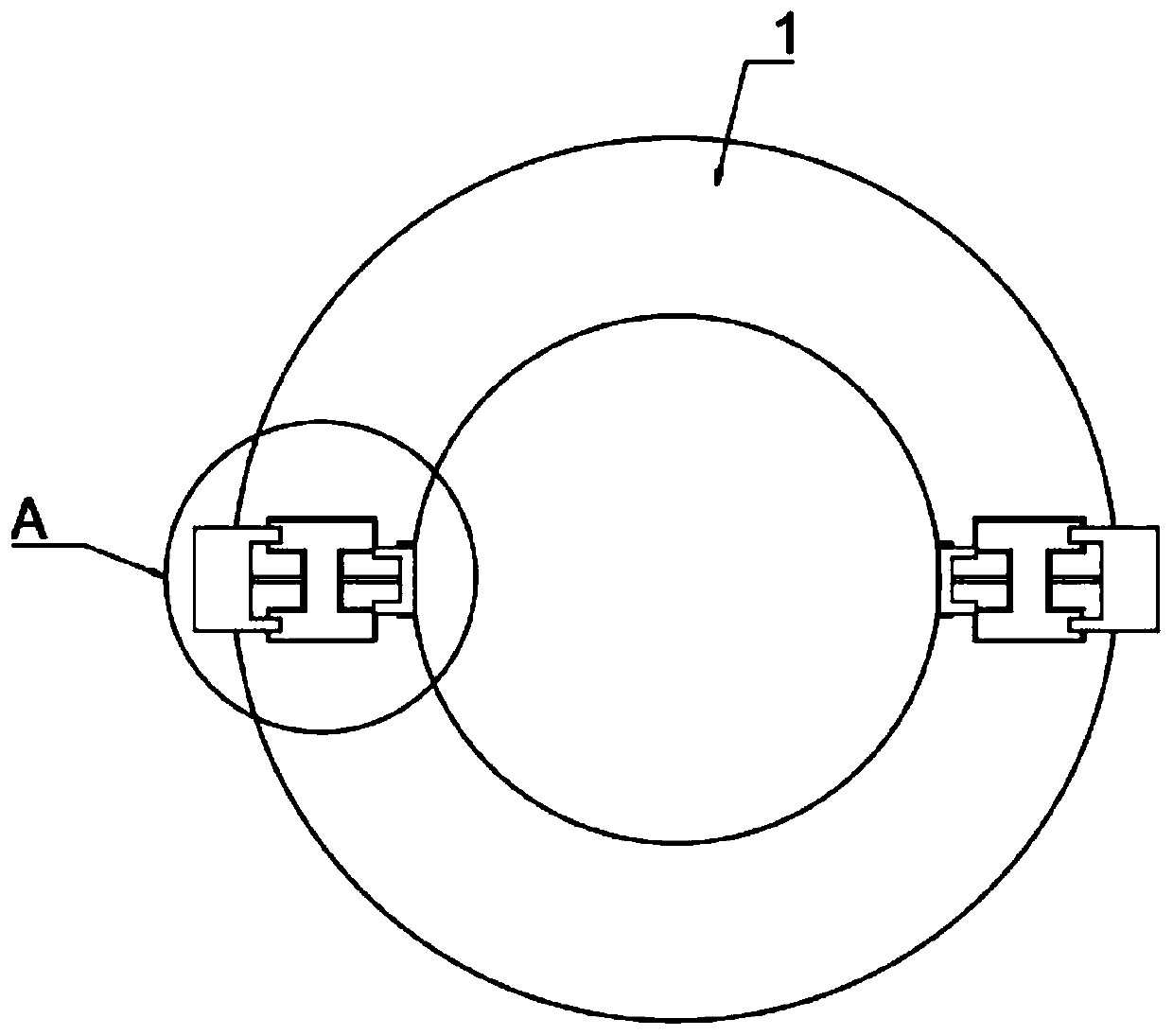

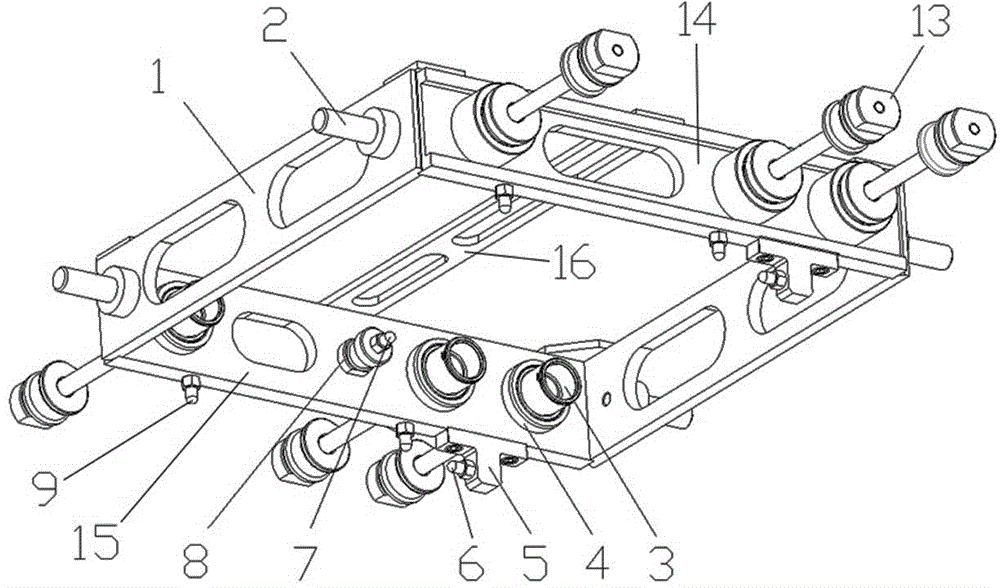

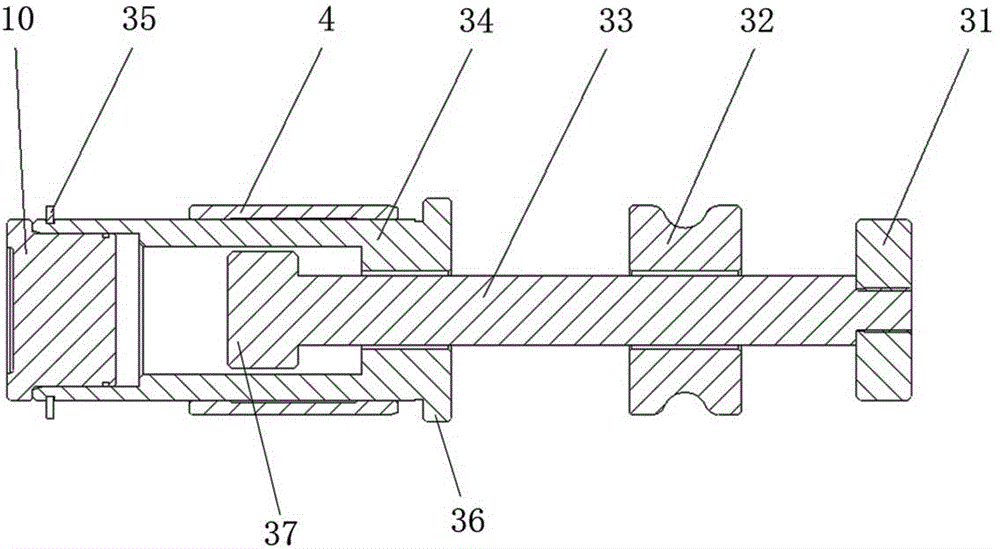

Jig for assembling main roller shafts of fork carrier of forklift

ActiveCN104625540AHigh precisionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringForklift truck

A jig for assembling main roller shafts of a fork carrier of a forklift is characterized in that a frame is rectangular and is made by splicing four side plates; two opposing side plates of the frame are provided with more than two first positioning mechanisms and more than two second positioning mechanisms, respectively; the first positioning mechanisms are disposed on the same horizontal plane, correspond to the second positioning mechanisms and are symmetrical to the second positioning mechanisms; the first positioning mechanisms and the second positioning mechanisms are identical in structure; each first positioning mechanism is composed of a bushing, a sleeve, a sliding rod, a second stopper, a slider and a first retainer ring, the inner surface of the first side plate is provided with an adjusting base which is parallel to the sleeve and which faces the middle of the frame, and the end of the adjusting base is provided with a first positioning pin; the bottom of the first side plate and the bottom of the second side plate are symmetrically provided with pin components; each pin component comprises a step base, a second positioning pin and a third positioning pin. The jig is simple in structure and convenient to use.

Owner:ANHUI HELI CO LTD

Synthetic resin workpiece demolding device and demolding method thereof

The invention discloses a synthetic resin workpiece demolding device and a demolding method thereof, belongs to the technical field of demolding devices, and aims to solve the problems that in the prior art, a synthetic resin workpiece is mostly poked through a clamp, so that the synthetic resin workpiece is separated from a mold disc and clamped out, and demolding of the synthetic resin workpiece is troublesome. The mold comprises a mold base, and a groove hole is formed in the surface of the mold base; a threaded rod is rotated, the threaded rod drives a third guide block to slide, the third guide block pushes an arc-shaped push plate through a push rod, the arc-shaped push plate pushes a synthetic resin workpiece on the surface of a lifting disc, the synthetic resin workpiece is pushed to the upper surface of a material conveying belt, a rotating shaft is driven to rotate, and the rotating shaft enables the material conveying belt to convey through a material conveying roller. And the material conveying belt conveys the synthetic resin workpiece, so that the conveying of the demolded synthetic resin workpiece is conveniently completed, and the phenomenon that the molded synthetic resin workpiece is scalded due to manual taking is effectively avoided.

Owner:徐州宏马塑业有限公司

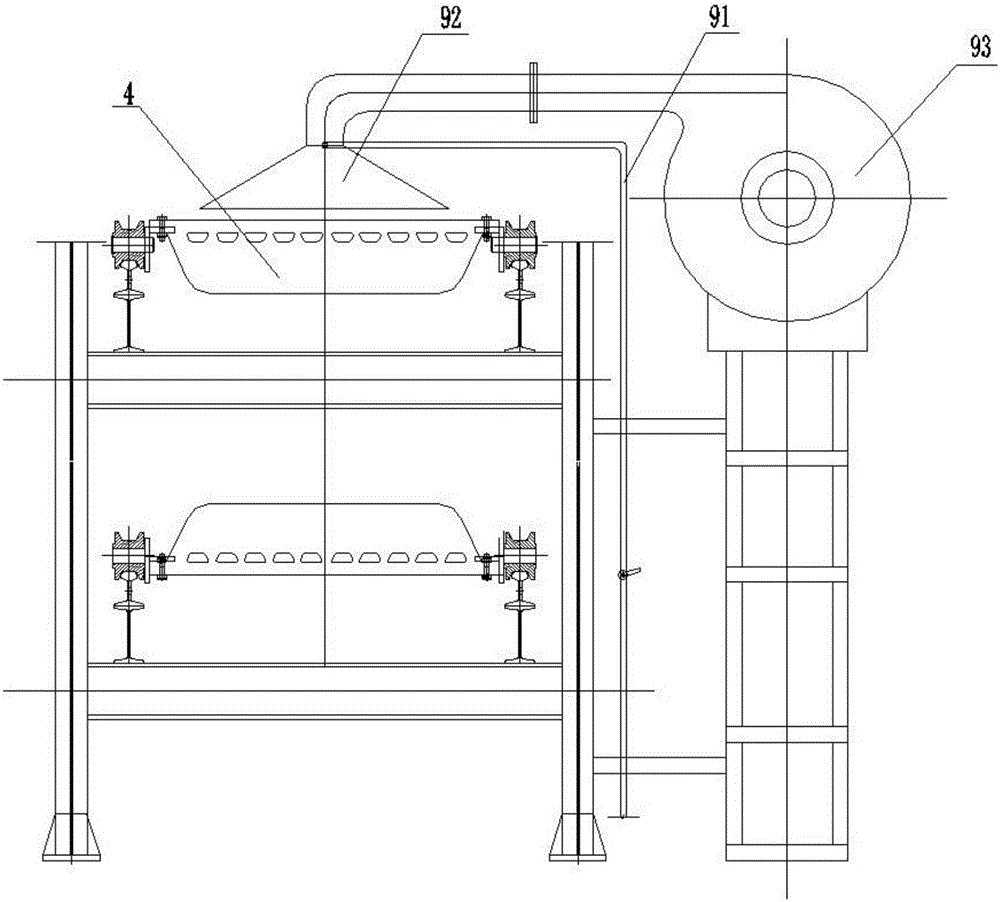

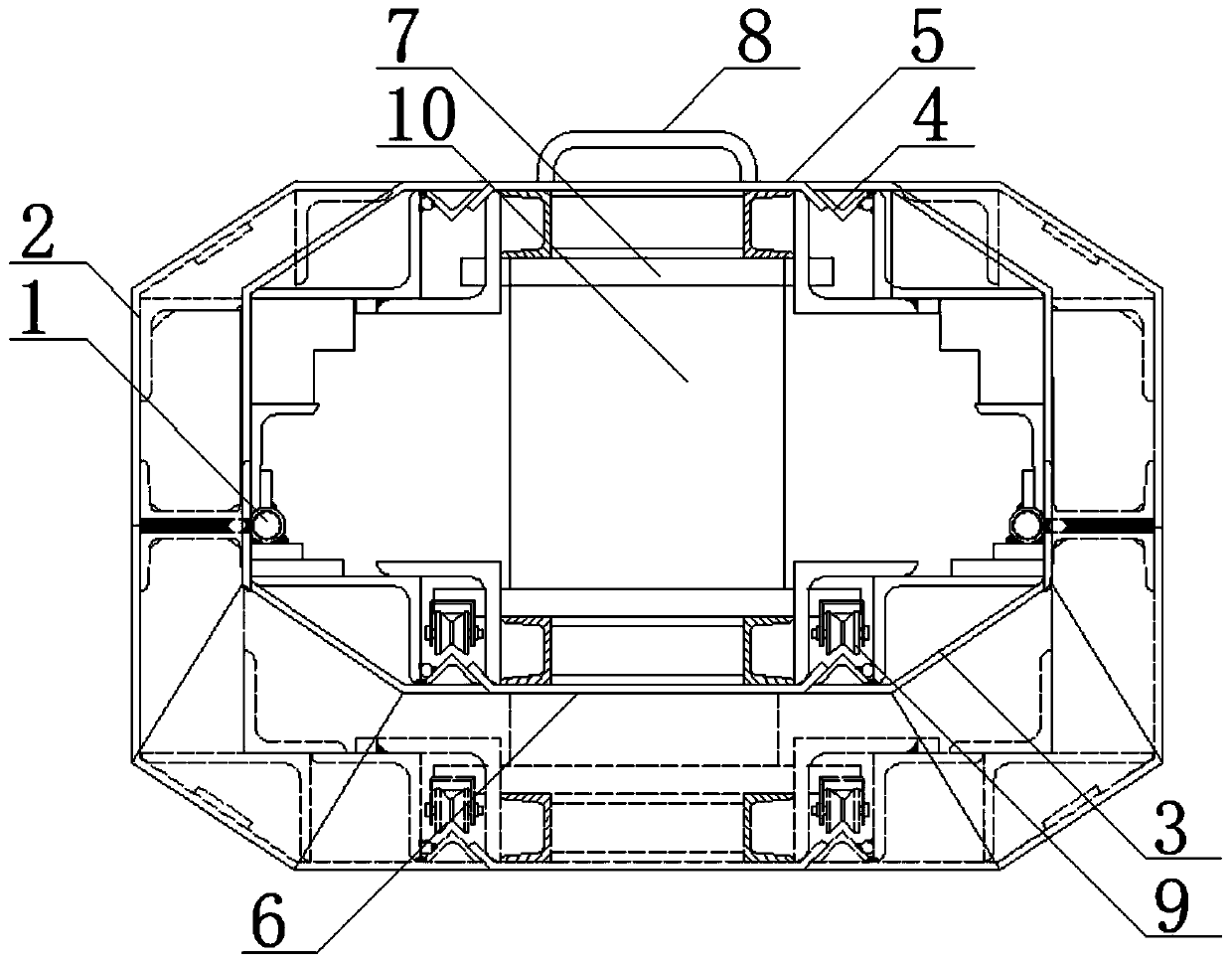

Formwork device and construction method for tunnel water ditch

InactiveCN106050271BEasy to demouldFast demouldingUnderground chambersDrainageWedge shapeBuilding construction

The invention provides a ditch formwork device for a tunnel. The ditch formwork device comprises a first oil cylinder and further comprises an adjusting unit, two oppositely-arranged wedge-shaped formworks and a supporting shaft, the adjusting unit comprises a load bearing beam, an adjusting hand wheel and two oppositely-arranged screws, the adjusting hand wheel is arranged on the load bearing beam which is connected with one end of the first oil cylinder, each screw is mounted between the adjusting hand wheel and one wedge-shaped formwork, and the supporting shaft penetrates the load bearing beam to be connected with the wedge-shaped formworks respectively. The invention further provides a construction method of the ditch formwork device. Compared with the prior art, the ditch formwork device and the construction method thereof have the advantages that construction quality and construction accuracy are high, formwork stripping time is short, and construction period can be shortened effectively.

Owner:NO 7 ENG CO LTD OF CHINA RAILWAY 19 BUREAU GRP

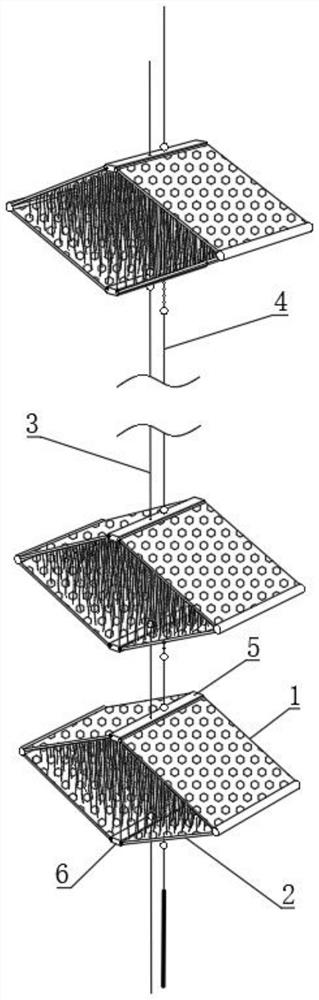

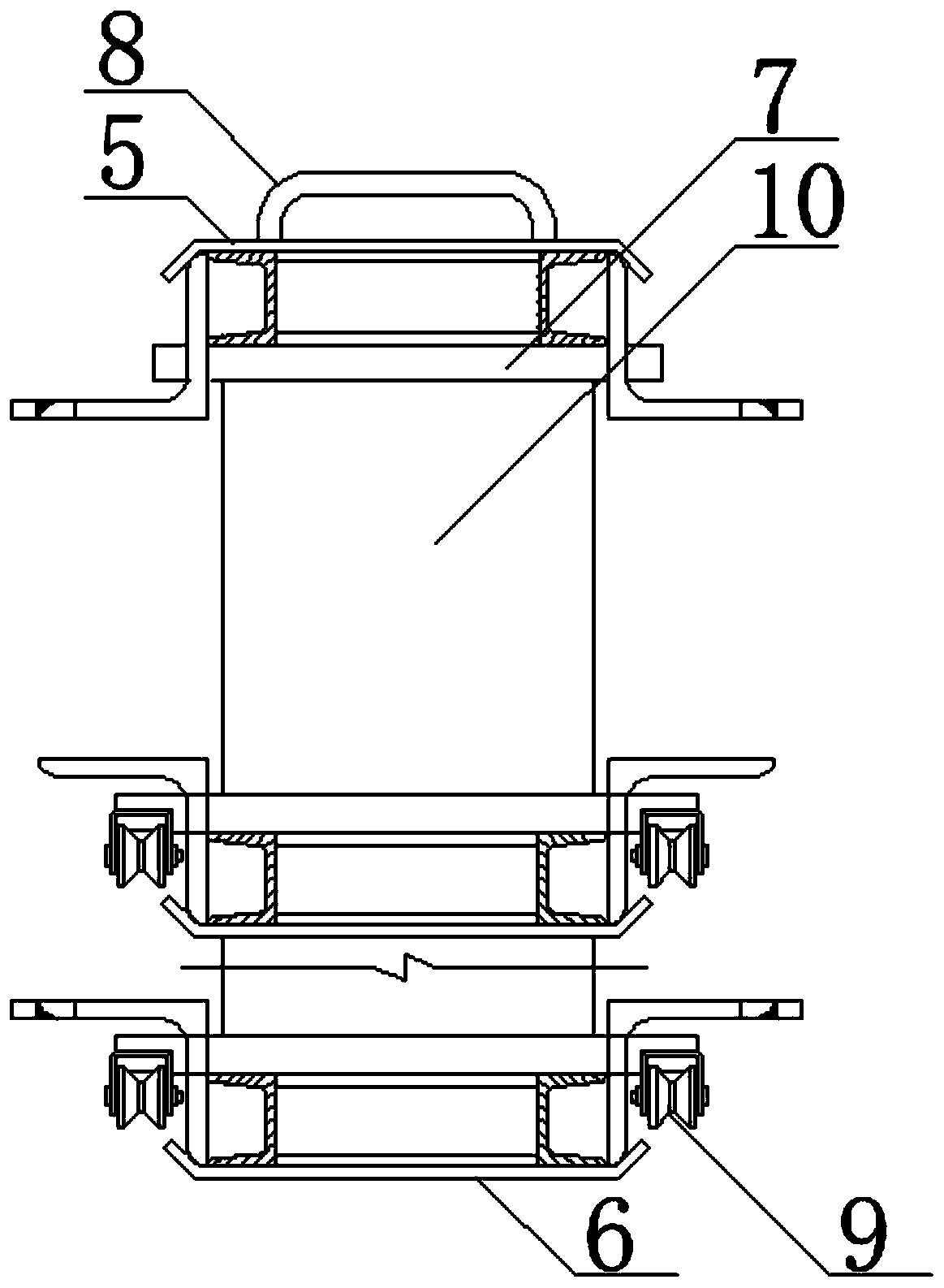

Novel pulling-type internal mold for prefabricated concrete board beam of expressway

PendingCN111195978AImprove accuracy and stabilityGood workmanshipDischarging arrangementCeramic shaping mandrelsStructural engineeringIndustrial engineering

The invention discloses a novel pulling-type internal mold for a prefabricated concrete board beam of an expressway. The novel pulling-type internal mold comprises four first rotation shafts. Upper supporting mold plates and lower supporting mold plates are rotatably connected to the first rotation shafts, and every two first rotation shafts are used as a set. The novel pulling-type internal moldis divided into three parts, during demolding, the middle part is removed first, a second rotation shaft is passively rotated, then idler wheels fall on slide rails, a lower mold plate is separated from bottom concrete according to the principle of lever prizing, after the middle part is removed, the huge space of the middle is released, conditions are created for rotation folding and removal of the mold plates of the two sides, and the novel pulling-type internal mold is suitable for large and small blocks and good in technology capability and provides convenience for processing manufacture and construction application. An internal-external line is designed as the overlapping axis of the two sides, that is to say, the axis of the large-diameter part and the axis of a port are designed atthe same axis, the problems of structural defects and inconvenient operation caused by different internal and external axes are solved, internal and external rotation of the two sides keeps uniform, folding is smoothly performed, and demolding is quickly performed.

Owner:宁夏桥多美路桥钢模板科技有限公司

Hip joint bone cement interval blister mould

InactiveCN114474688ARadian size changesReduce magnetismDomestic articlesPhysical medicine and rehabilitationElectric machinery

The invention relates to the technical field of cement interval forming, and discloses a hip joint bone cement interval blister blister mold which comprises a lower mold body, a cavity is formed in the lower mold body, a sliding opening is formed in the inner wall of the cavity, a radian adjusting mechanism is arranged in the lower mold body, and the radian adjusting mechanism comprises a cavity formed in the lower mold body. The cavity is communicated with the sliding opening, a motor is fixed in the cavity, a cylinder is fixed to the driving end of the motor, a telescopic rod is fixed to the end, away from the motor, of the cylinder, a frame is fixed to the driving end of the telescopic rod, and a plurality of connecting rods are fixed to the outer wall of the frame. The circular plate is replaced according to the requirement for the radian of the hip joint, the radian of the formed cement interval is changed, the applicability is higher, meanwhile, after the circular plate is replaced, self-adaptive change of the moving distance of the sealing plate is automatically conducted, the sealing performance between the sliding opening and the circular plate is guaranteed, and the sealing effect is better. Swing of the swing rods accelerates demolding of the cement intervals.

Owner:源利腾达(西安)科技有限公司 +1

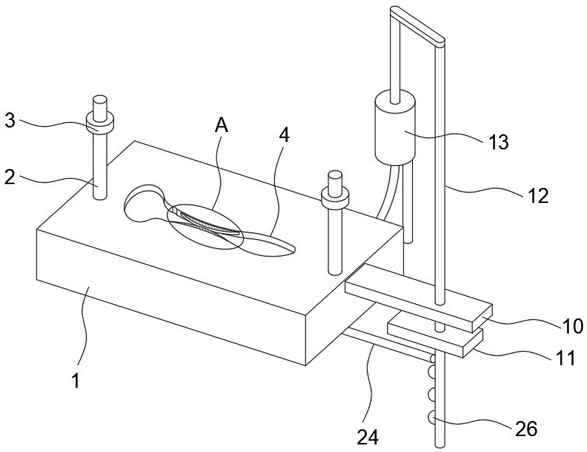

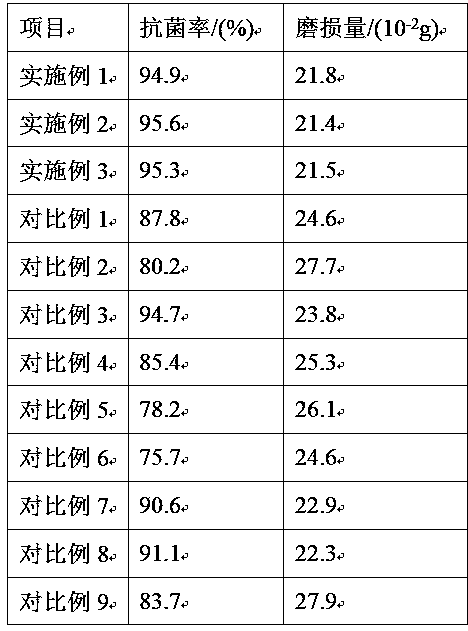

Antibacterial and wear-resistant invisible brace

InactiveCN109718117ASimple methodHigh strengthImpression capsDentistry preparationsCelluloseMedical equipment

The invention mainly relates to the technical field of medical equipment processing and discloses an antibacterial and wear-resistant invisible brace. The antibacterial and wear-resistant invisible brace is prepared from raw materials as follows: 87-91 parts of modified gum dammar, 65-67 parts of polyurethane resin, 14-16 parts of stearic acid, 11-13 parts of Ag-tricalcium phosphate, 8-10 parts ofsodium carboxymethyl cellulose, 3-4 parts of nano-zinc oxide, 2-3 parts of nano-titania and 2-3 parts of polyhexamethylene guanidine. According to the antibacterial and wear-resistant invisible braceprovided by the invention, a method is simple, the raw materials are easy to obtain, the cost is low, and the brace is white, does not affect image during wearing, has high strength and wear resistance, is not required to be taken off during eating and can effectively inhibit germ breeding, so that the brace is simpler and more convenient to use and wear; and after the modified gum dammar and thepolyurethane resin are mixed and molten, the stearic acid is added, the fluidity and smoothness of the material can be improved, and the brace is easy to mold, has higher similarity to real teeth andis attractive and comfortable to wear.

Owner:安徽一升医疗设备有限公司

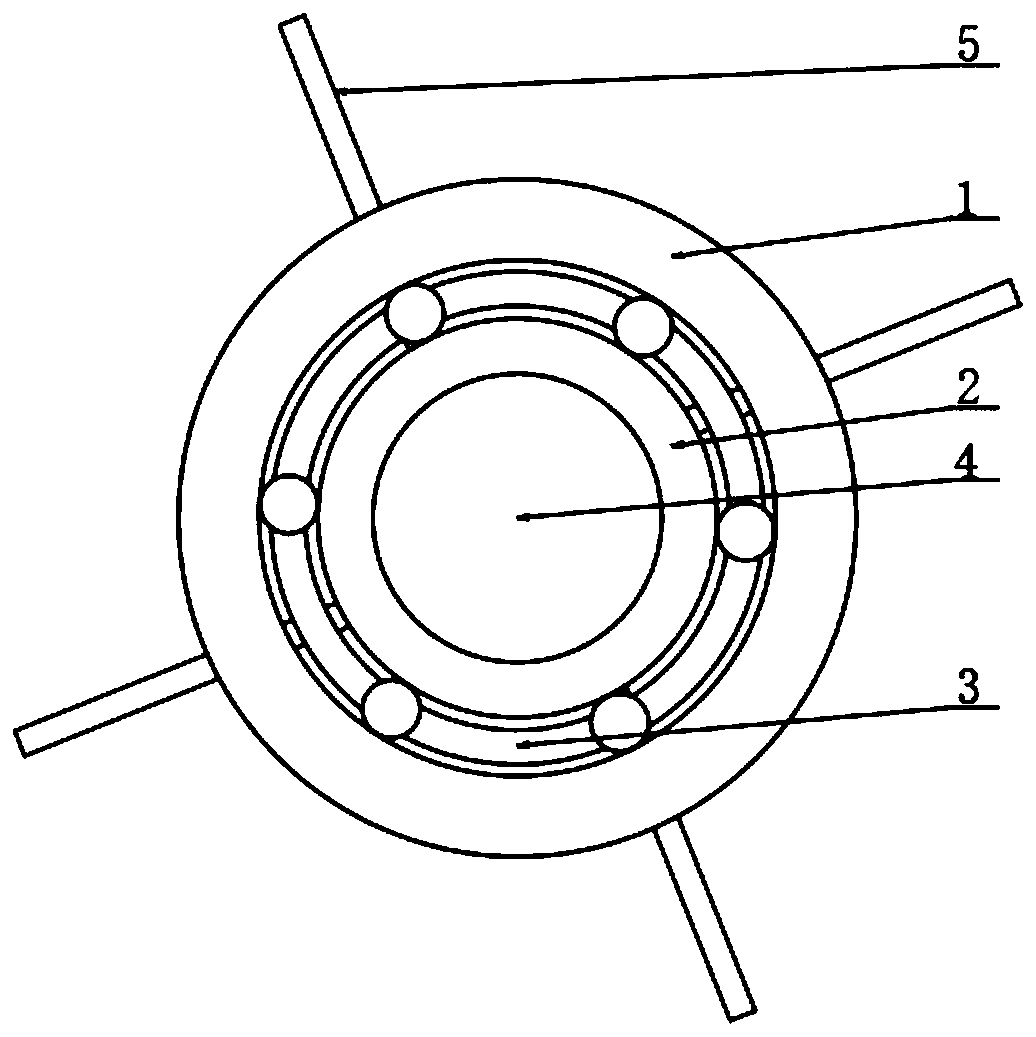

Partial solid prestressed pile produced through centrifuge method, and production process

InactiveCN110625780AImprove corrosion resistanceImprove work efficiencyMouldsShaping reinforcementsPre stressEngineering

The invention discloses a partial solid prestressed pile produced through a centrifuge method, and a production process, and belongs to the technical field of partial solid prestressed piles. The production process comprises the following steps of a, sorting; b, manufacturing concrete; c, manufacturing a cage frame; d, assembling a mold; e, filling the mold; f, carrying out a centrifugal molding method; g, standing; and h, demolding. An outer mold and an inner mold are adopted, and an obstruction plate is arranged in the inner mold at the same time; in the concrete feeding process, the concrete is fed into one side of an inner cavity of the inner mold, so that one half of a molded prestressed pile is solid, the other half of the molded prestress pile is hollow, the working efficiency is improved, and the molding quality is ensured; and meanwhile, the centrifugal molding method is further adopted, the concrete between the outer mold and the inner mold before centrifugal molding and theconcrete filled in one side of the inner cavity of the inner mold are filled densely, and the concrete is gathered toward a pile corner part under the effect of a centrifugal force, so that the denseness is improved, the overall strength is high, the service life is long, the quickness in demoulding is realized, and the production time is greatly reduced.

Owner:江苏瀚龙建材科技有限公司

Injection mold convenient to overhaul

The invention discloses an injection mold convenient to overhaul. An anti-damage demolding assembly is installed on the top face of a bottom plate, a uniform forming assembly is installed at the top end of the anti-damage demolding assembly, an upper mold plate is installed at the top end of a lower mold plate, a supporting ring is fixedly connected to the top end of an upper rotating cover in a sleeving mode, and butt joint grooves are evenly formed in the edge of the top face of a lower rotating ring; a rotating pipe is installed at the top end of a demolding frame in a penetrating mode, demolding air holes are formed in the positions, close to the butt joint plane, of the two sides of a jacking box, a guide lubricating assembly is installed on the top face of the bottom plate, a heating connecting assembly is installed between the upper mold plate and the top plate, and an auxiliary connecting assembly is installed between the lower mold plate and the upper mold plate. The injection molding effect is improved through the uniform forming assembly, bubbles are reduced, the heating connecting assembly is used in cooperation with the uniform forming assembly, raw materials are prevented from being solidified in the feeding process, the raw materials conveniently enter the forming assembly to be formed, and the damage-prevention demolding assembly prevents the situation that a mold core and a product are damaged due to the fact that the jacking amplitude is too large.

Owner:栾飞

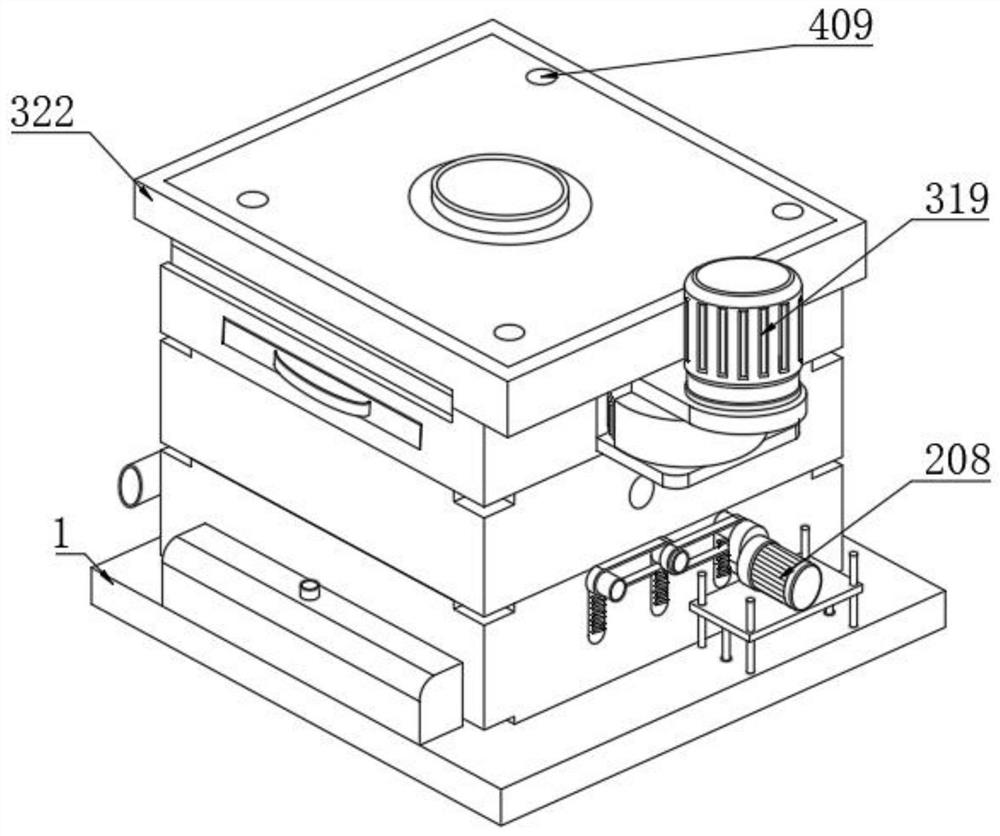

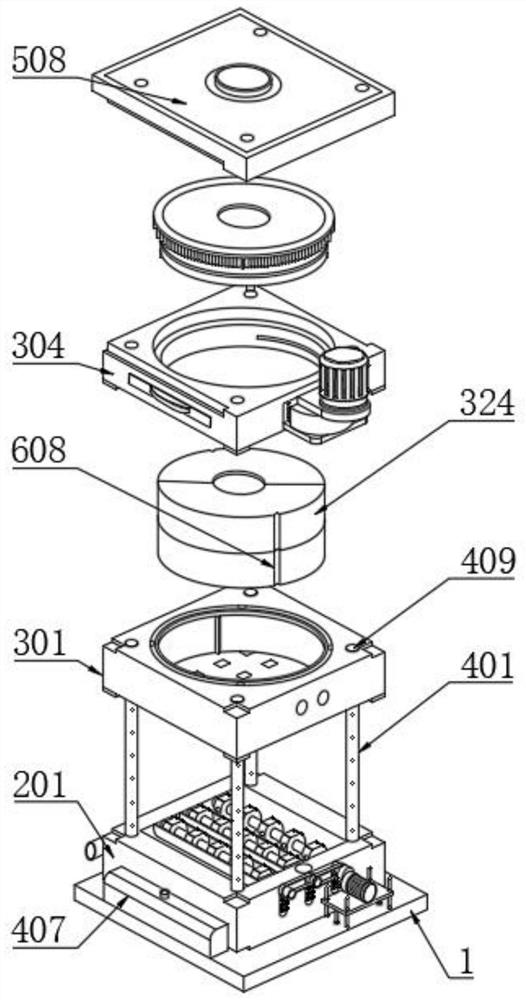

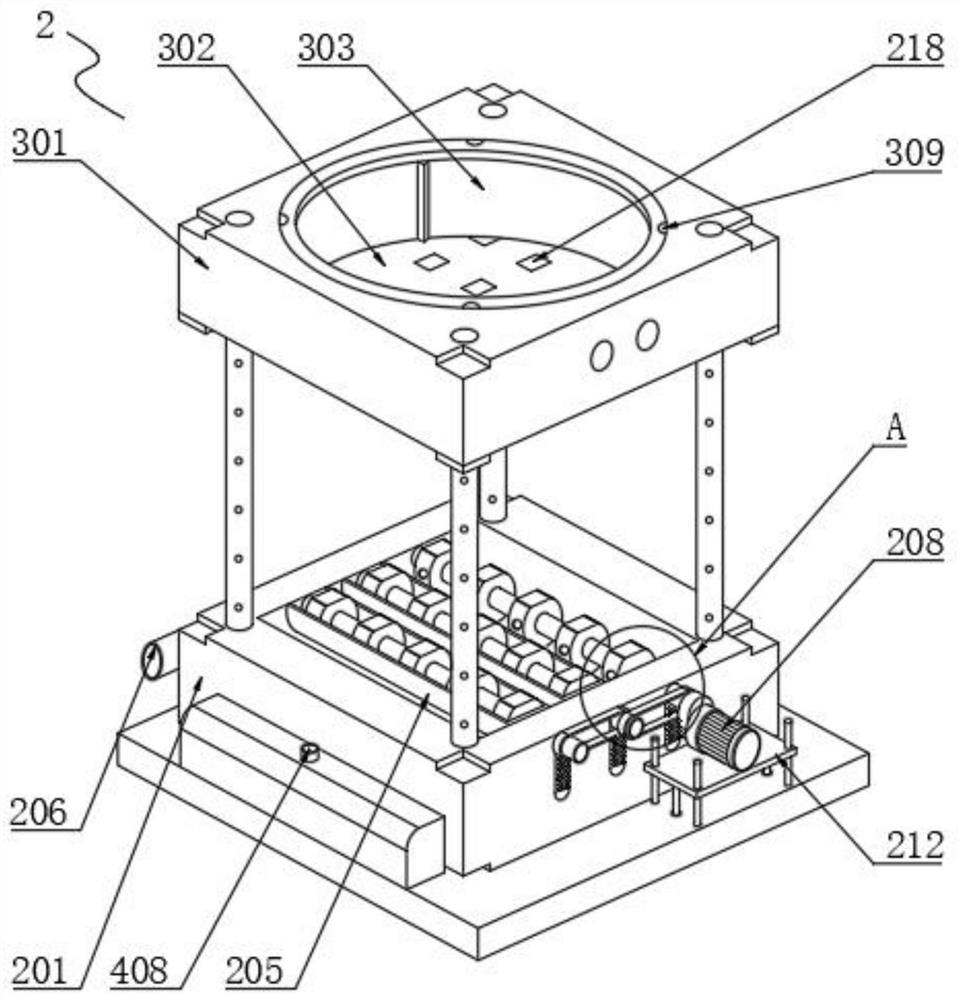

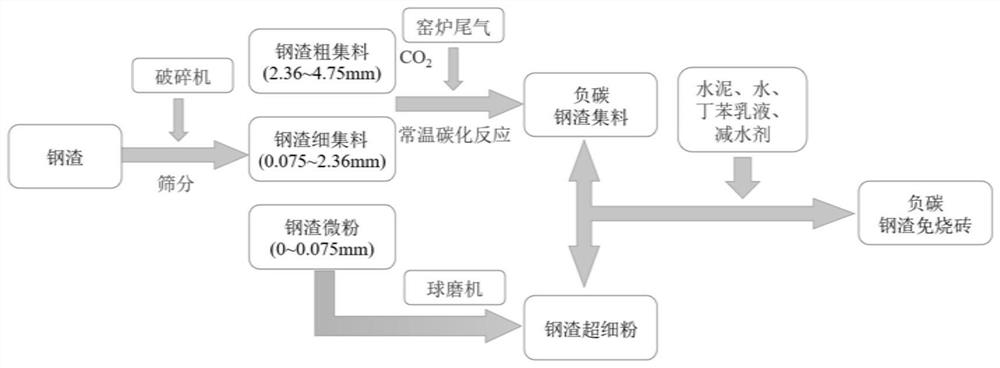

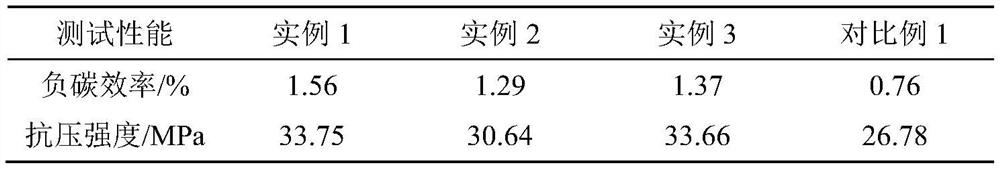

Negative carbon steel slag baking-free brick as well as preparation method and application thereof

The invention discloses a negative carbon steel slag baking-free brick as well as a preparation method and application thereof. The steel slag with the particle size smaller than 0.075 mm is subjected to ball milling to obtain steel slag superfine powder; the method comprises the following steps: carrying out carbonization treatment on steel slag with the particle size of 0.075-4.75 mm to obtain a carbonized product; the carbonized product, a cementing material, steel slag ultrafine powder and an auxiliary cementing material are mixed and stirred uniformly, a mixture is obtained, and the carbonized product accounts for 57 wt%-63 wt% in the mixture; the binding material accounts for 13 wt%-18 wt%; the superfine steel slag powder accounts for 15.5 wt%-20.0 wt%, and the auxiliary cementing material accounts for 6 wt%-8 wt%; the auxiliary cementing material comprises water, a binder and a water reducing agent; and carrying out compression molding on the mixture, and then carrying out maintenance treatment to obtain the negative carbon steel slag baking-free brick. The negative carbon steel slag baking-free brick disclosed by the invention is short in forming period and high in strength; the steel slag contains free calcium oxide, so that CO2 in the atmosphere can be absorbed, carbon reduction and carbon loading are achieved, and a certain positive influence on the environment is achieved.

Owner:武汉理工大学重庆研究院

Rear-die slide block time-lapse core pulling mould structure

InactiveCN103522461AGuaranteed production efficiencyThere will be no phenomenon of sticking to the front moldMechanical engineering

Owner:VANGUARD TECH WUXI

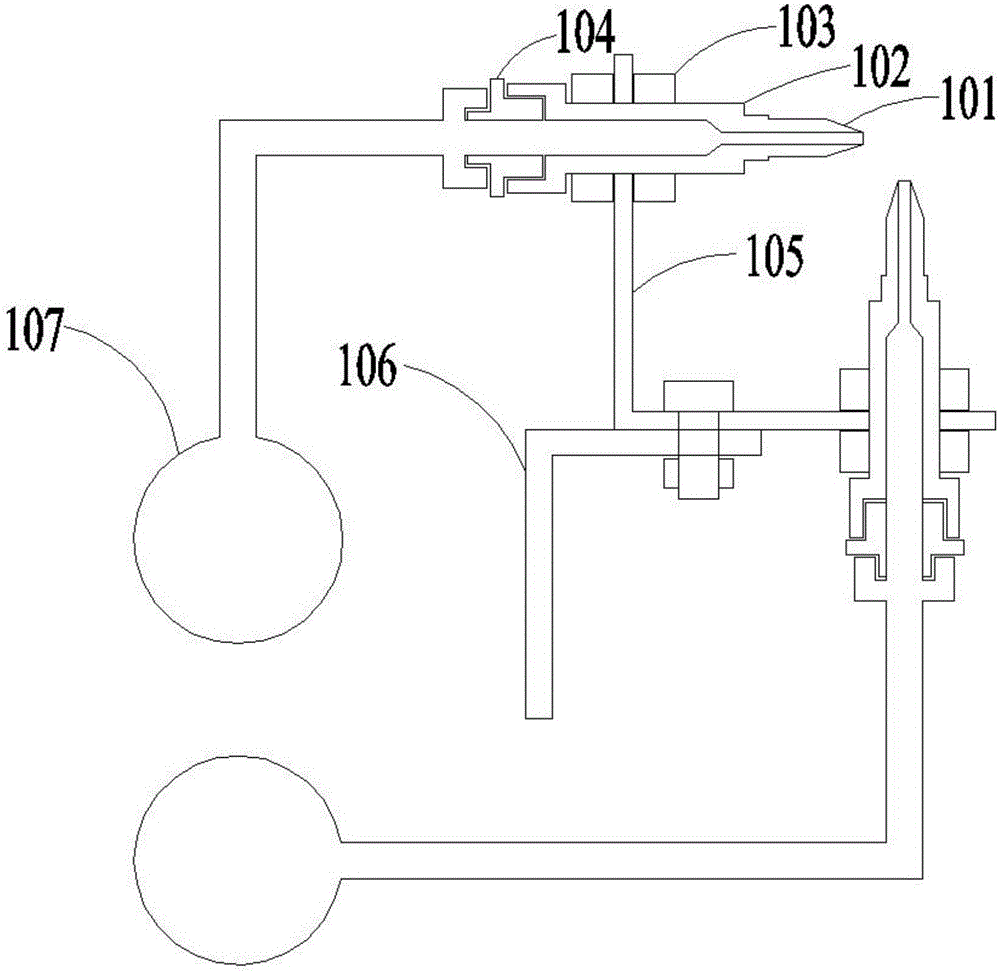

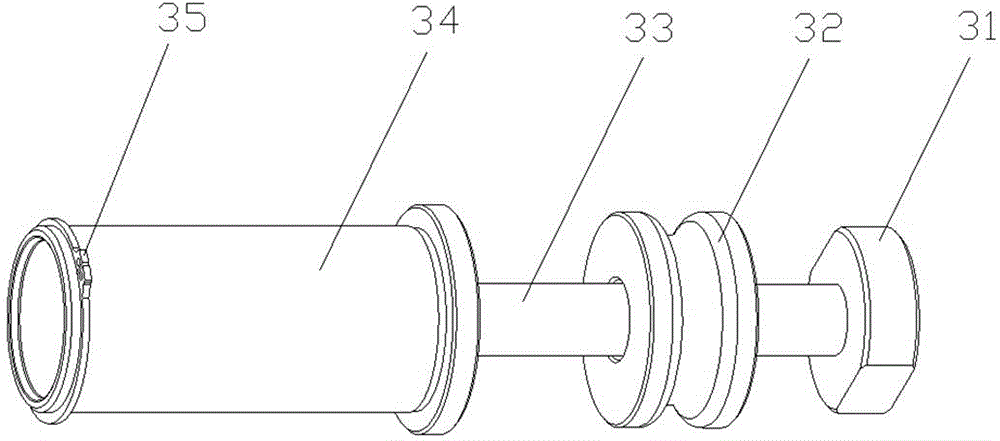

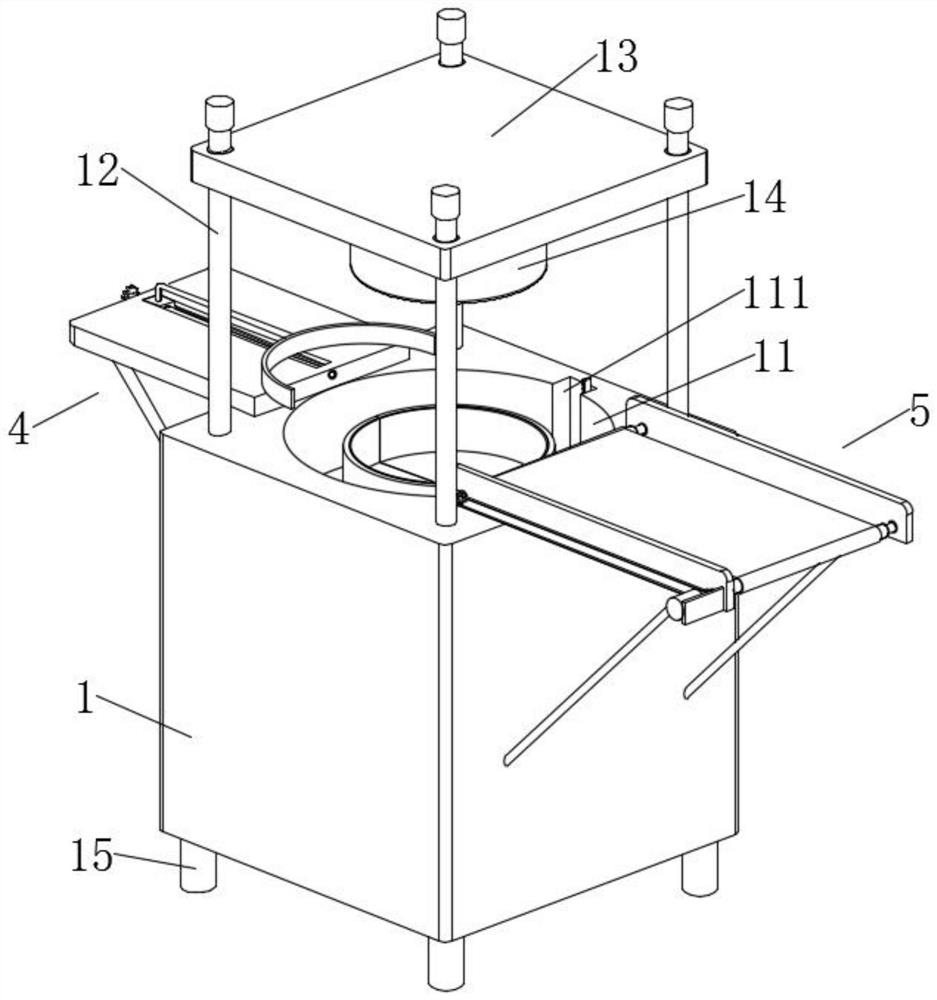

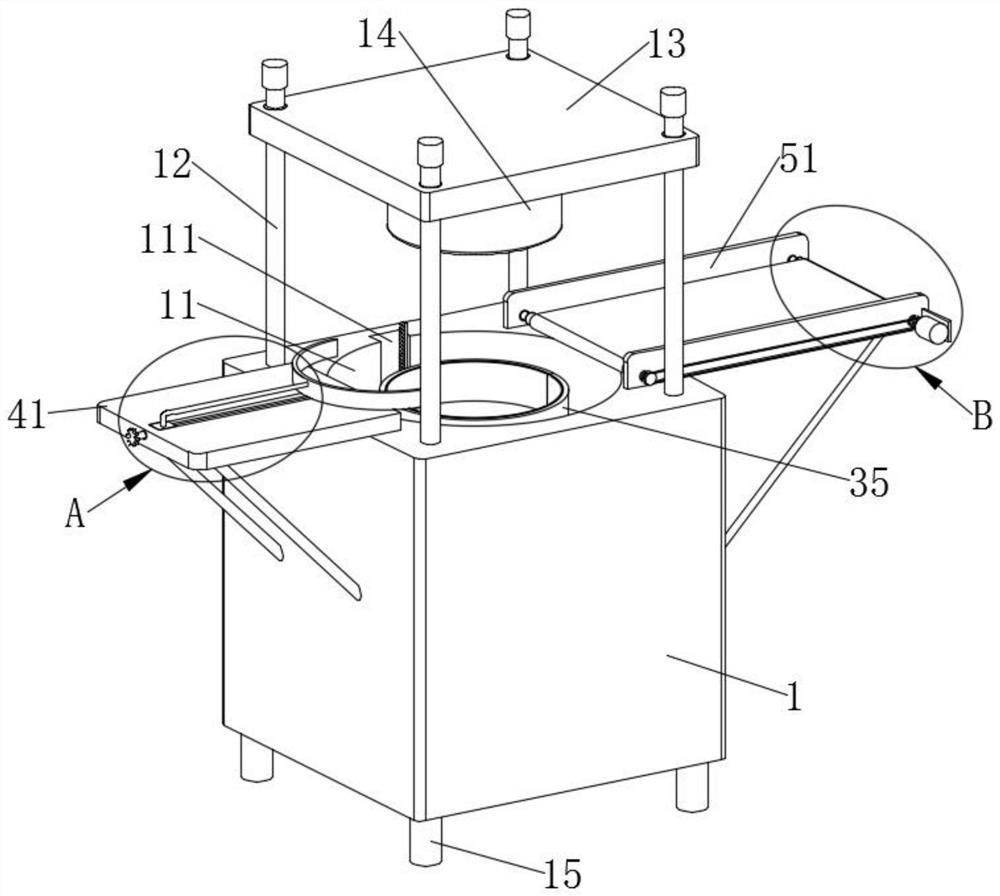

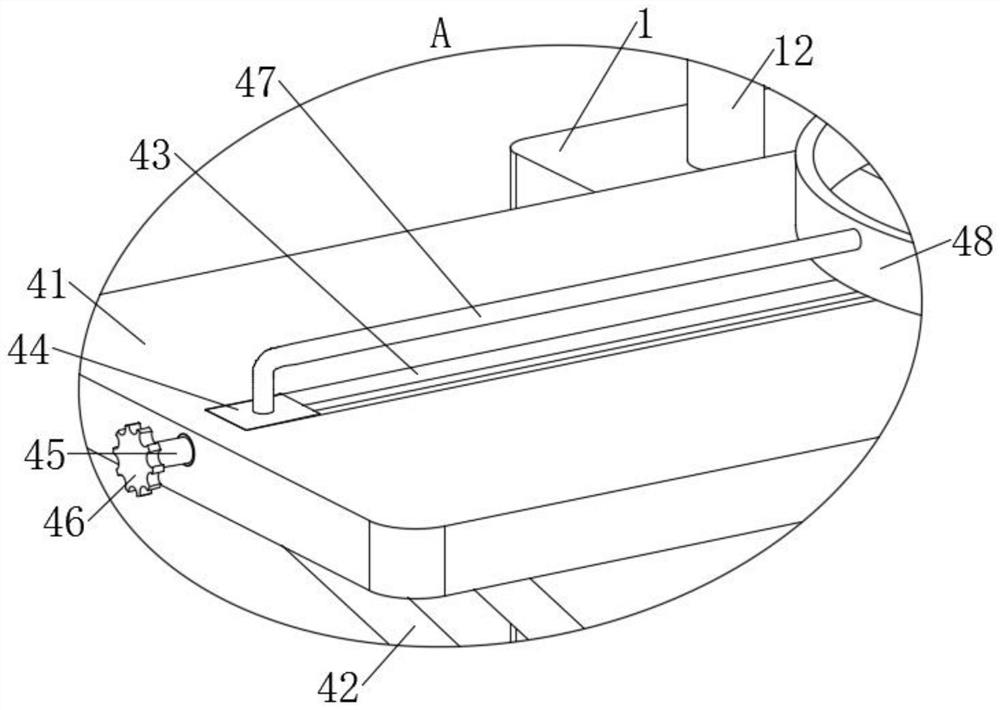

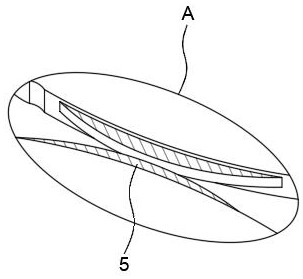

Filling injecting pastry demolding needle

InactiveCN107594599AImprove efficiencyImprove automationFood coatingBiomedical engineeringFood processing

The invention relates to the technical field of food processing equipment, in particular to a filling injecting pastry demolding needle. The filling injecting pastry demolding needle comprises a filling injecting syringe, wherein the filling injecting syringe is provided with a mounting end and a filling injecting end; the filling injecting end of the filling injecting syringe is provided with a filling injecting opening which communicates with a feeding pipe; a telescopic demolding pin is assembled on the filling injecting syringe, is of a deformable strip shape, and extends and contracts inthe filling injecting syringe; a bending guide hole is formed in the filling injecting end of the filling injecting syringe; and an end head of the demolding pin penetrates through the bending guide hole and conveniently forms a bending mold for demolding. According to the filling injecting pastry demolding needle disclosed by the invention, the filling injecting structure and the demolding structure can be integrated; the filling injecting pastry demolding needle is simple in structure and easy to operate; after filling injecting, demolding operation can be performed through the demolding pin; the demolding is convenient and quick, so that the making efficiency and the automation degree of pastry processing are effectively improved; the demolding pin extends out and forms the bending moldfor demolding, so that a pastry is supported, demolding is realized, the shape of the pastry can also be kept, the quality of the food is improved, and the yield of finished products is increased.

Owner:汕头市煜丰机械有限公司

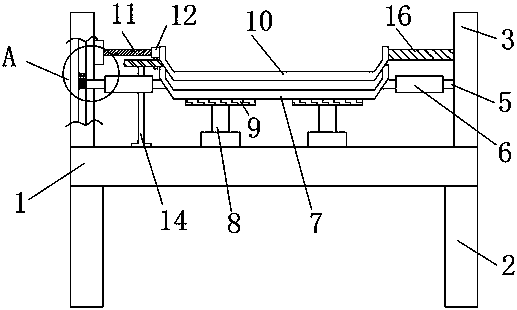

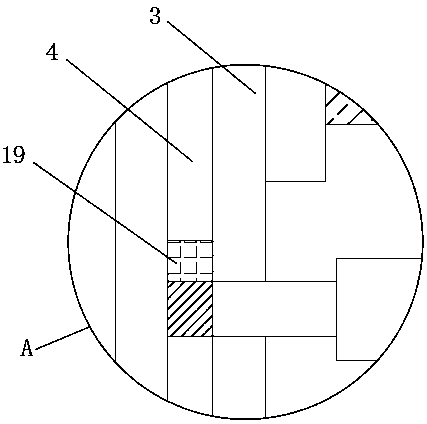

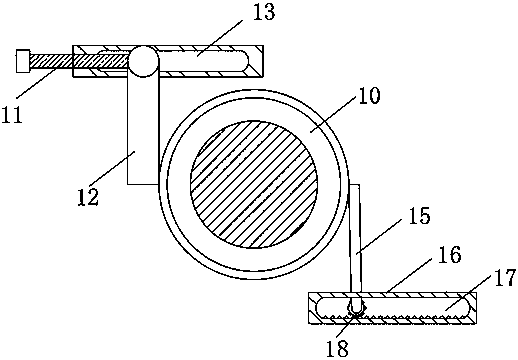

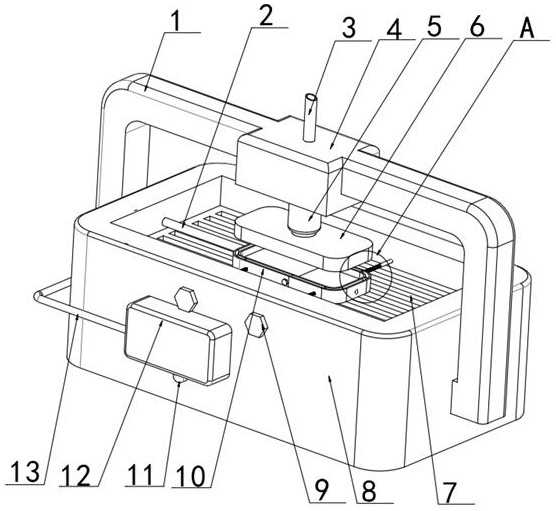

Quick positioning demoulding device for casting iron pan pressure casting production

The invention discloses a quick positioning demoulding device for casting iron pan pressure casting production. The quick positioning demoulding device comprises a working table and landing legs, thelower end of the working table is fixedly connected with the landing legs, the upper surface of the working table is fixedly provided with two sets of fixing plates, a damping sliding groove is formedin the middle portion of each fixing plate and is fixedly connected with a first fixing rod through a sliding block, and an insulation cover is arranged on the outer surface of each first fixing rod.The quick positioning demoulding device is provided with the damping sliding grooves and the sliding blocks, a lower mold can be driven to move up and down quickly, limiting blocks limit the slidingblocks, and the lower mold can move to the same position each time; and a hydraulic lifting device and a support plate apply pressure to the lower mold to promote quick molding of a casting iron pan.A linear actuator is arranged to push a sliding rod to slide horizontally, an upper mold is further driven to rotate clockwise, a driven rod is stressed to drive a gear to move along a toothed groove,the upper mold rotates back and forth to quickly separate from the casting iron pan through reciprocating motion, and demoulding is accelerated.

Owner:HENAN ZHONGSHUAI METAL PROD CO LTD

Forming mold with positioning structure for wallboard production

InactiveCN111873124AImprove protectionAvoid damageMouldsDispersed particle separationAir pumpWall plate

The invention provides a forming mold with a positioning structure for wallboard production, and relates to the technical field of wallboards. The forming mold with the positioning structure for wallboard production comprises a base, a transverse frame is fixedly connected to the outer side of the top of the base, injection molding equipment is fixedly connected to the bottom of the transverse frame, an electric push rod is fixedly connected to the bottom of the injection molding equipment, and an upper mold body is fixedly connected to the bottom of the electric push rod. According to the forming mold with the positioning structure for wallboard production, a lower mold body is composed of two combination blocks, the two combination blocks are fixed through a threaded hole and a fixing bolt, and then the lower mold body is fixed into the base through multiple locking bolts and fixed to the top of a screen plate; and then the electric push rod, the upper mold body and a feeding pipe are used for injection molding. According to the forming mold, local replacement can be conducted, then an air pump is started, air in the base can be exhausted after injection molding is conducted, andtherefore harmful gas cannot be blown out.

Owner:孟远航

Mold device easy to demold

The invention relates to a shoe-making mold, and discloses a mold device easy to demold. The mold device has a simple structure and is quickly demolded, and yield and production efficiency of injection molding is effectively improved, and the mold device is suitable for mass production and use. a telescopic cavity is arranged on an upper die core positioned above an upper mold cavity of the mold device; a brake rod is arranged on a shoe tree and can move up and down and penetrate into the telescopic cavity; a brake plate is fixedly connected to the end of the brake rod in the telescopic cavity; a telescopic base is arranged on the upper mold base, a telescopic rod capable of moving up and down penetrates through the telescopic base, and one end of the telescopic rod penetrates into the telescopic cavity and is connected with the brake plate; a pressurizing device is also arranged on the upper mold base, and a pressurizing end of the pressurizing device communicates with the telescopiccavity; and an exhaust valve is also arranged on the telescopic cavity.

Owner:MAOTAI FUJIAN SOLES CO LTD

Rapid demolding injection mold for automobile lampshade

The invention discloses a rapid demolding injection mold for an automobile lampshade, and relates to the technical field of automobile machining equipment. The injection mold comprises an upper mold installing plate, a lower mold installing plate, an upper mold mechanism and a lower mold mechanism, wherein a feed nozzle is inserted into the upper mold installing plate, penetrates through the uppermold installing plate and then is inserted into a mold cavity in the upper mold mechanism; the upper mold mechanism further comprises an upper mold pushing plate, a spring, a demolding hook and a connecting bolt; the lower mold mechanism is arranged at the other side of the upper mold mechanism; foot pads are fixed to the four corners of one side wall of a first fixing plate in the lower mold mechanism correspondingly; the foot pads are fixed to one side wall of the lower mold installing plate; and the lower mold mechanism further comprises a second fixing plate, a lower mold core, a lower mold pushing plate, a first top plate, a second top plate and an ejector rod. After injection molding is completed, the formed raw materials and waste materials can be easily taken down without manual demolding, then the effect of rapid demolding is achieved, and the injection mold has the beneficial effects of being reasonable in arrangement, low in manufacturing cost and the like.

Owner:常州赛达电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com