High-thermal-conductivity die-casting aluminum alloy and preparing method thereof

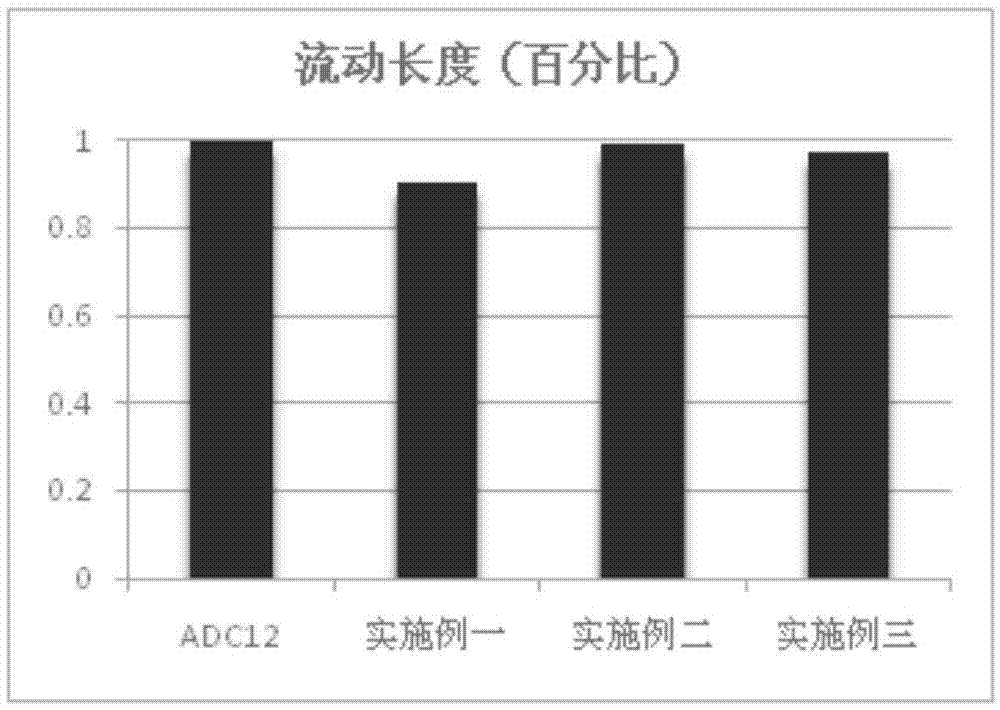

A technology of casting aluminum alloy with high thermal conductivity, which is applied in the field of high thermal conductivity die-casting aluminum alloy. It can solve the problems of low thermal conductivity, low hardness, and inability to improve thermal conductivity, and achieve the effect of uniform color and excellent fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

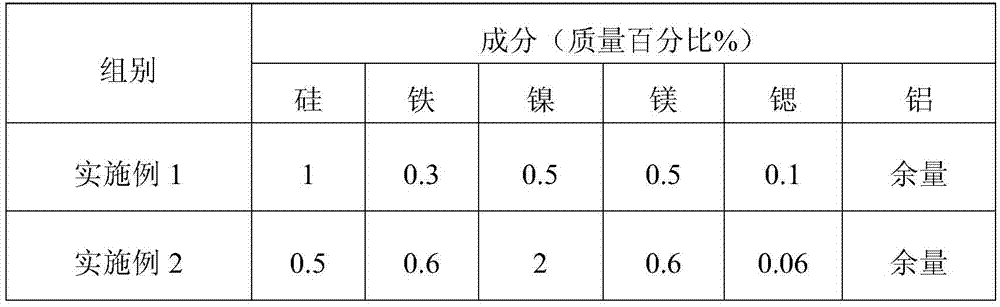

Embodiment 1

[0038] 1. Weigh the ingredients according to the total weight of 8Kg, prepare 6.84Kg aluminum block, 0.04Kg magnesium block, 0.4Kg aluminum-silicon alloy AlSi20, 0.48Kg aluminum-iron alloy AlFe10, 0.4Kg aluminum-nickel alloy AlNi10, 0.08Kg aluminum-strontium alloy AlSr10.

[0039] 2. Preheat the crucible. When the temperature reaches above 300°C, add aluminum block and magnesium block to melt in sequence. When the temperature rises above 780°C, add aluminum-silicon alloy, aluminum-iron alloy, and aluminum-nickel alloy to keep the temperature at 680-850°C. Within ℃, adjust the temperature of the solution to within 680-700 ℃ after the added material melts, then add Al-10Sr master alloy, and refine with general-purpose aluminum alloy refining agent for 15 minutes. After refining, remove the solvent and scum on the liquid surface. Then stand still for 10 minutes to make the inclusions fully float or sink, and remove the slag.

[0040] 3. After adjusting the solution to 680-720°C,...

Embodiment 2

[0042] 1. Weigh the ingredients according to the total weight of 8Kg, prepare 5.864Kg aluminum block, 0.096Kg magnesium block, 0.2Kg aluminum-silicon alloy AlSi20, 0.24Kg aluminum-iron alloy AlFe10, 1.6Kg aluminum-nickel alloy AlNi10, 0.048Kg aluminum-strontium alloy AlSr10.

[0043] 2. Preheat the crucible. When the temperature reaches above 300°C, add aluminum block and magnesium block to melt in sequence. When the temperature rises above 780°C, add aluminum-silicon alloy, aluminum-iron alloy, and aluminum-nickel alloy to keep the temperature at 680-850°C. Within ℃, adjust the temperature of the solution to within 680-700 ℃ after the added material melts, then add Al-10Sr master alloy, and refine with general aluminum alloy refining agent for 12min. After refining, remove the solvent and scum on the liquid surface. Then stand still for 8 minutes to make the inclusions fully float or sink, and remove the slag.

[0044] 3. After adjusting the solution to 680-720°C, pour the mol...

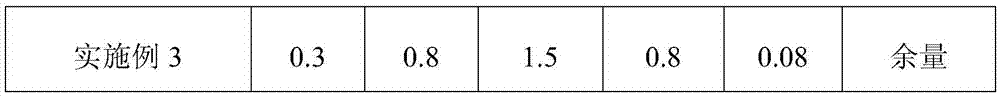

Embodiment 3

[0046] Step 1 Weigh the ingredients according to the total weight of 8Kg, and prepare 6.312Kg of aluminum block, 0.064Kg of magnesium block, 0.12Kg of aluminum-silicon alloy AlSi20, 0.64Kg of aluminum-iron alloy AlFe10, 0.8Kg of aluminum-nickel alloy AlNi10, and 0.064Kg of aluminum-strontium alloy AlSr10.

[0047] Step 2: Preheat the crucible. When the temperature reaches above 300°C, add aluminum block and magnesium block to melt in turn. When the temperature rises above 780°C, add aluminum-silicon alloy, aluminum-iron alloy, and aluminum-nickel alloy to keep the temperature at 680~ Within 850°C, adjust the temperature of the solution to within 680-700°C after the added material is melted, then add Al-10Sr master alloy, and refine with general aluminum alloy refining agent for 20min. After refining, remove the solvent and scum on the liquid surface. Then stand still for 15 minutes to make the inclusions fully float or sink, and remove the slag.

[0048] Step 3: After adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com