Patents

Literature

674results about How to "Good casting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

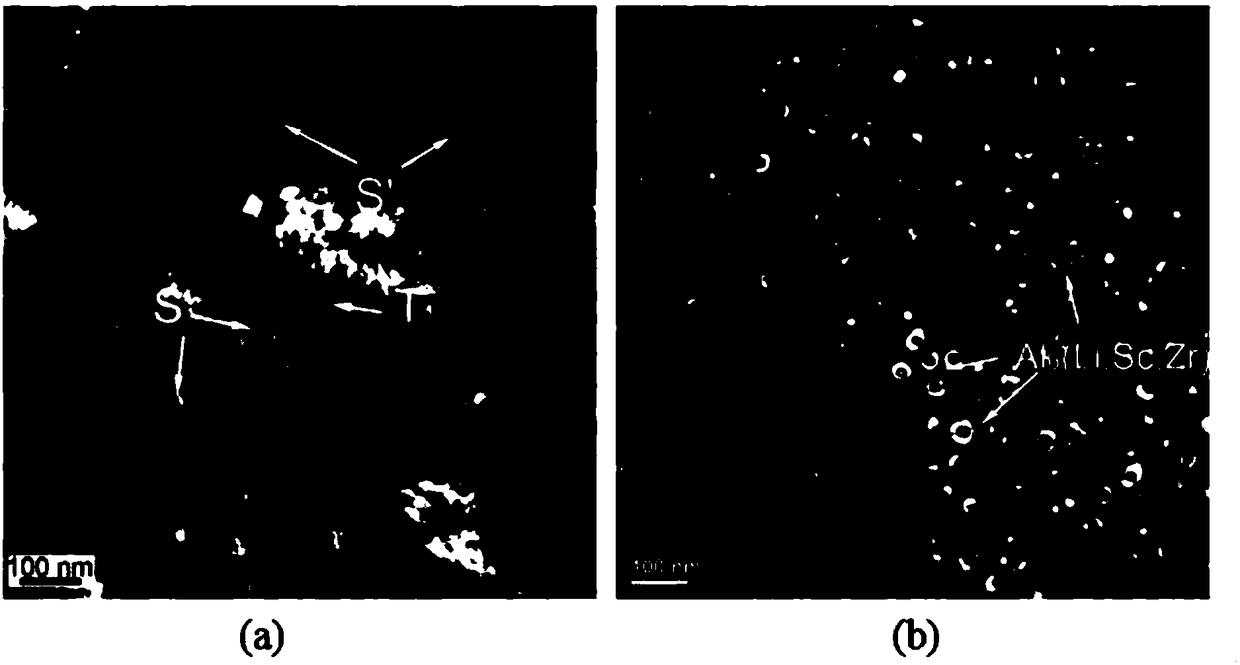

Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as ultrahigh-strength cast aluminum alloy and preparation method thereof

ActiveCN102127665AChange the solidification methodReduced hot cracking tendencyRare-earth elementSolid solution

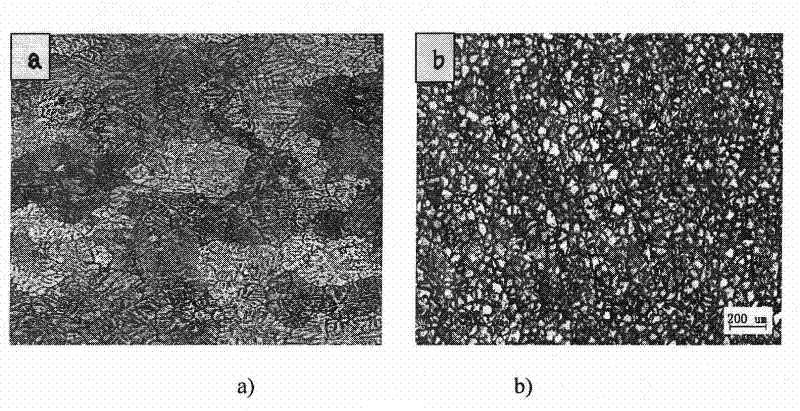

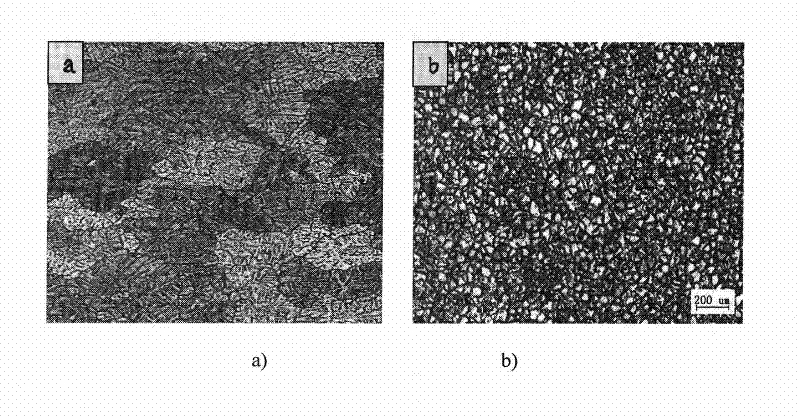

The invention discloses an Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as an ultrahigh-strength cast aluminum alloy and a preparation method thereof. In the alloy, Zn and Mg with higher content are adopted, Sc and Zr are compositely microalloyed, and trace rare earth elements Er and / or Yb are added, so that the aims of increasing an eutectic phase proportion, thinning a grain structure, suppressing dendritic crystal growth and changing an alloy solidification mode are fulfilled to reduce the heat cracking tendency of the alloy and obviously improve the casting performance of the alloy. The alloy comprises the following components in percentage by weight: 7.0 to 8.0 percent of Zn, 1.5 to 2.5 percent of Mg, 1.4 to 2.0 percent of Cu, 0.2 to 0.5 percent of Mn, 0.15 to 0.25 percent of Sc,0.10 to 0.20 percent of Zr, 0.1 to 0.3 percent of Er and / or Yb and the balance of Al. The as-cast alloy can achieve high toughness performance through long-time variable-temperature homogenization, enhanced solid solution treatment and aging treatment, can be used for producing an aluminum alloy casting with the yield strength of more than 500MPa and the elongation rate of more than 5 percent andcan be used as an alternate material for the ultrahigh-strength wrought aluminum alloy.

Owner:有研金属复材技术有限公司

Silver alloy wire and preparation method thereof

The invention relates to a silver alloy wire and a preparation method thereof. The silver alloy wire is prepared from the following components of 0.5-10 percent of Au, 0-1 percent of Pt, 1-6 percent of Pd, 0-1 percent of Rh, 0-1 percent of Cu, 0-500ppm of Ln, 0-200ppm of Ce, 0-0.5 percent of Al, 0.7-3 percent of Ti, 0-0.2 percent of Si, 0-0.3 percent of Zn, 0-1 percent of Sn, 0-10 percent of Be and the balance of Ag. A directional continuous casting process is adopted. The prepared silver alloy wire overcomes the problem that the bonded silver wire is easily subjected to sulfur corrosion in the prior art, and has a series of other excellent characteristics.

Owner:YANTAI YINUO SEMICON MATERIAL CO LTD

Aluminum-silicon series deforming alloy and manufacturing method thereof

The present invention discloses aluminum silicon deformable aluminum alloy and the preparation method thereof. According to the weight percentages, the alloy contains 9.0-12.6 percent of silicon, 1.5-4.0 percent of copper, 0.3-0.6 percent of magnesium, 0.1-3.5 percent of bismuth, less than 0.30 percent of iron, less than 0.20 percent of zinc, less than or equal to 0.15 percent of impurity, and aluminum as the residual. The raw material is molten and fined in a reflecting smelting furnace, after Al-Sr intermediate alloy modification to the alloy liquid, cast rods are obtained through semi continuous casting, and after hot extrusion and deformation to the cast rods, the aluminum silicon deformable aluminum alloy is produced through forging and T6 heat treatment. After adding the element bismuth into the alloy, the present invention greatly enhances the wear-resisting performance of the alloy, leads the alloy to have self lubricating property, prolongs the service life of the product produced with the alloy, reduces the use cost, and leads the alloy to have the tensile strength of above 390 MPa, the elongation rate after breaking of 6 percent, and the hardness degree of 136-141 HB. The present invention is mainly used for producing vehicle components of wheels, pistons, bearings, and two-side swash plates of vehicles and motorcycles which have high demands on the intensity, the toughness and the abrasion resistance.

Owner:李贞宽 +1

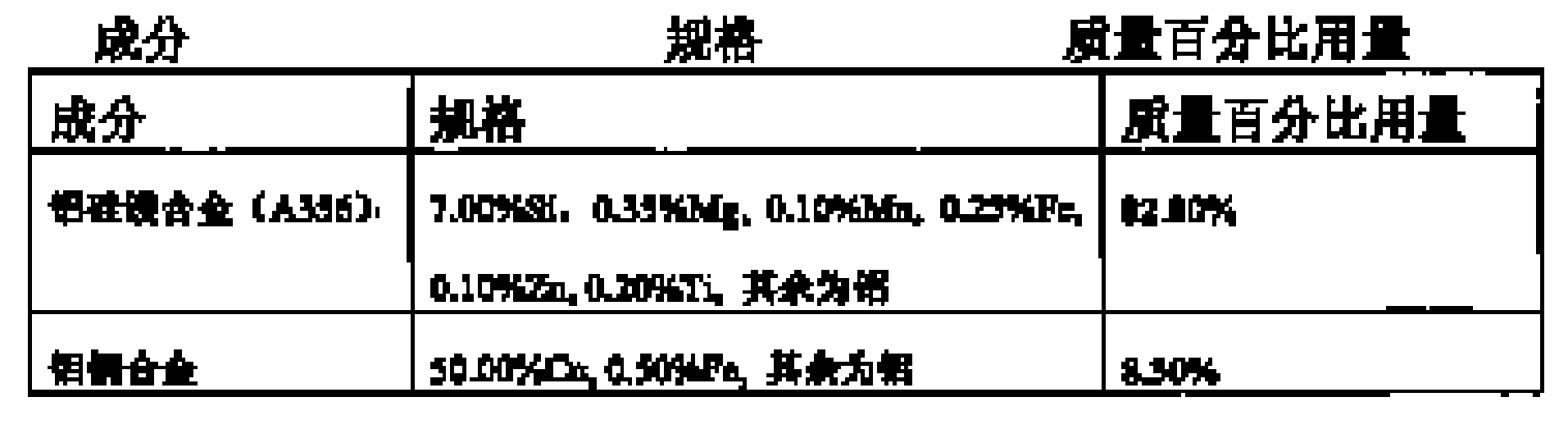

Aluminum-silicon-magnesium casted aluminum alloy and casting process thereof

The invention relates to aluminum-silicon-magnesium casted aluminum alloy and a casting process thereof. The aluminum alloy contains the following elements by mass: silicon 6.5 to 7.5, magnesium 0.40 to 0.60, titanium 0.10 to 0.30, strontium 0.01 to 0.03, iron no more than 0.20, copper no more than 0.10, zinc no more than 0.20, manganese no more than 0.10, beryllium no more than 0.01 and vanadium no more than 0.20, with the balance being aluminum. The casting process for the aluminum alloy comprises the following steps: putting A356.2 aluminum ingots in a furnace for melting; adding a modification material for refining; standing the product obtained in the previous step for a predetermined time and carrying out casting; sequentially carrying out solid solution, cooling, transfer and aging treatment. The invention enables the problems of low strength and elongation percentage of aluminum-silicon alloy and poor casting performance and corrosion resistance of aluminum-copper alloy and aluminum-zinc alloy to be overcome and tensile strength, toughness and casting performance of the aluminum alloy to be improved, and enables the aluminum alloy to have the advantages of low cost and good corrosion resistance.

Owner:ZTE KANGXUN TELECOM COMPANY

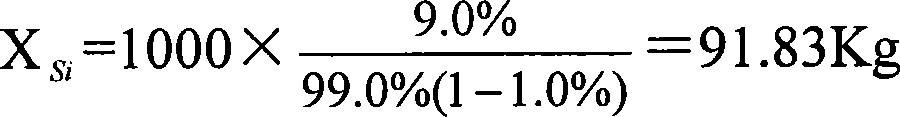

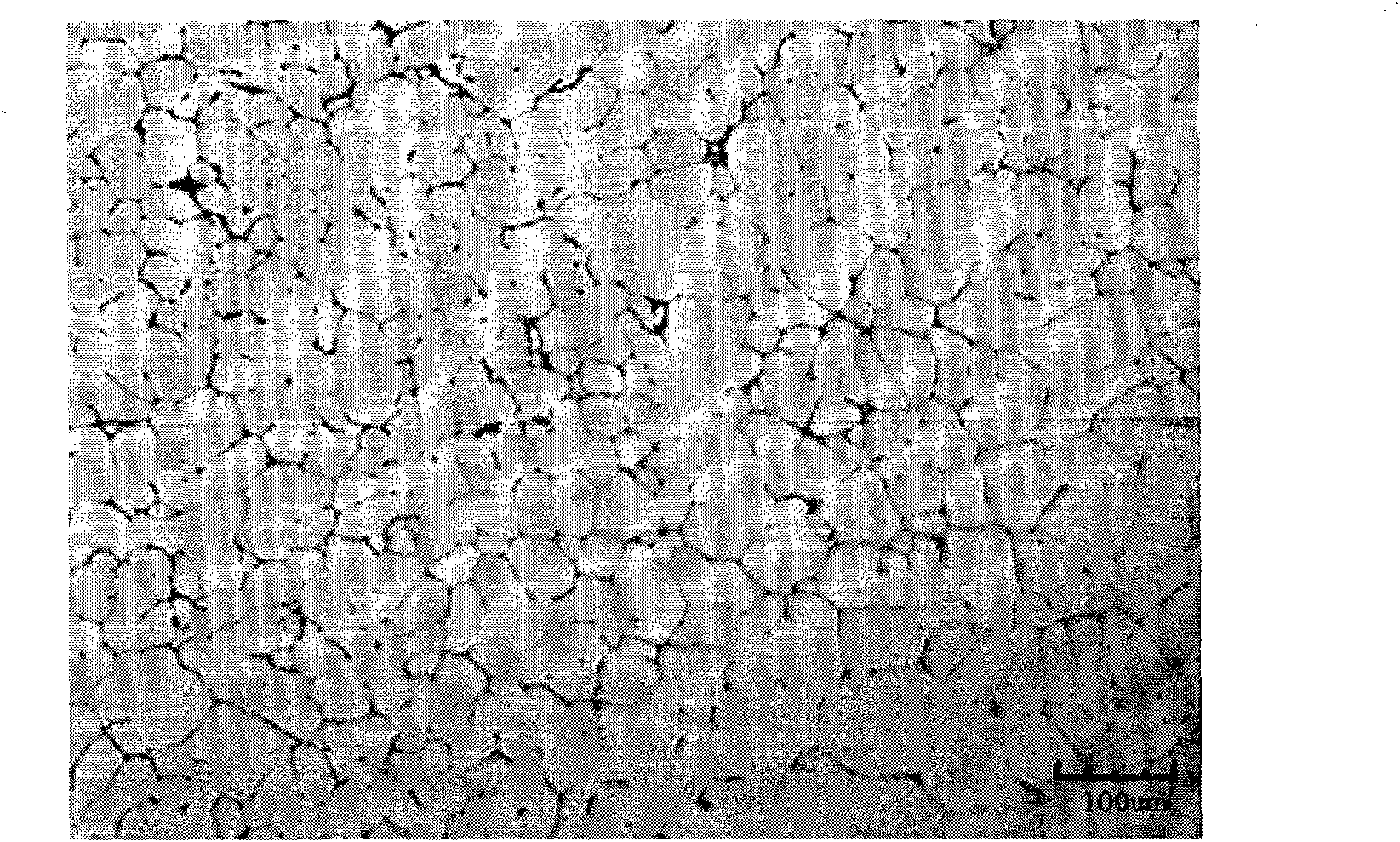

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Nickel base superalloys and turbine components fabricated therefrom

InactiveUS6908518B2Reduce incidenceReduce morbidityBlade accessoriesGas turbine plantsTungstenAluminium

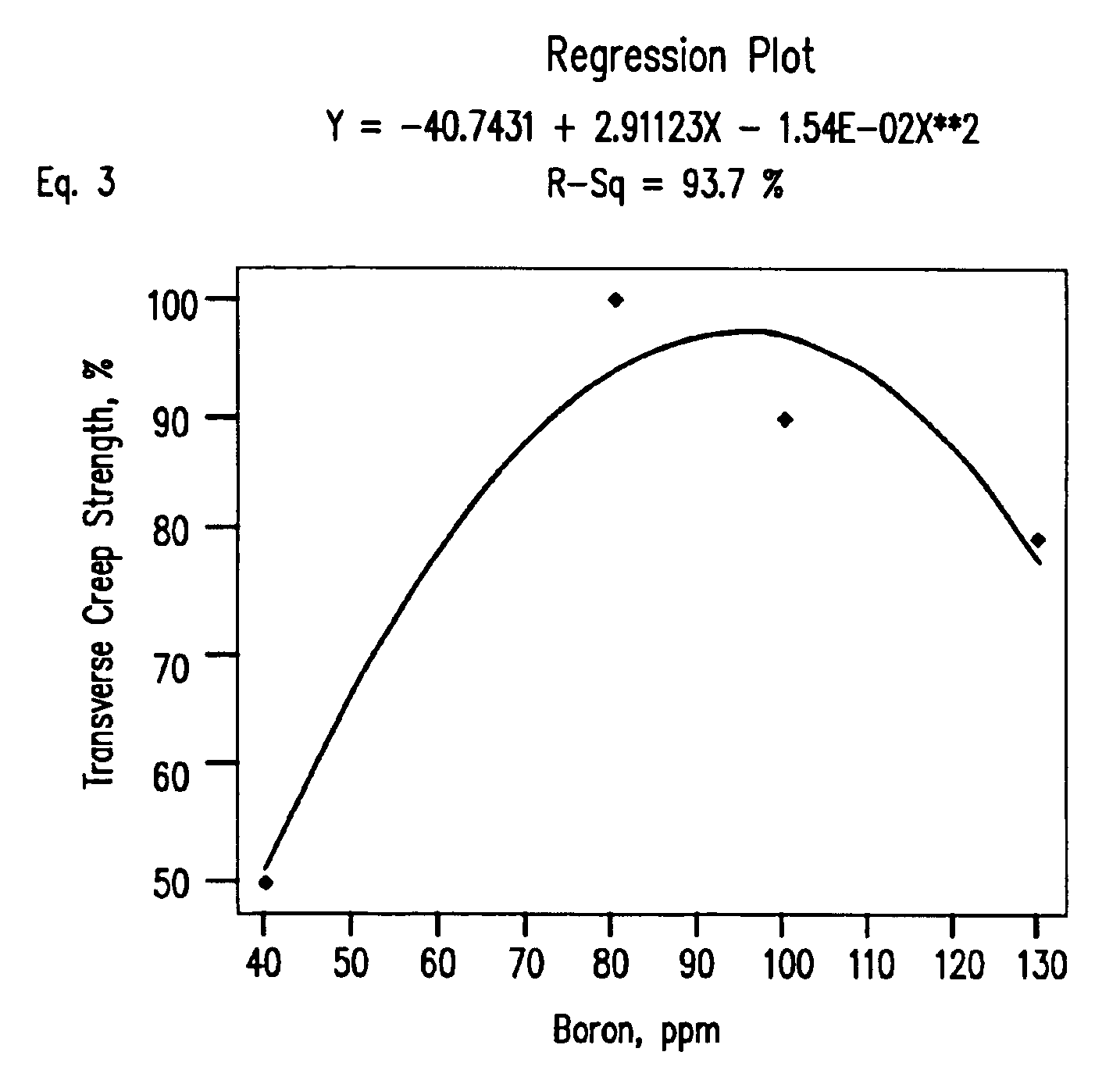

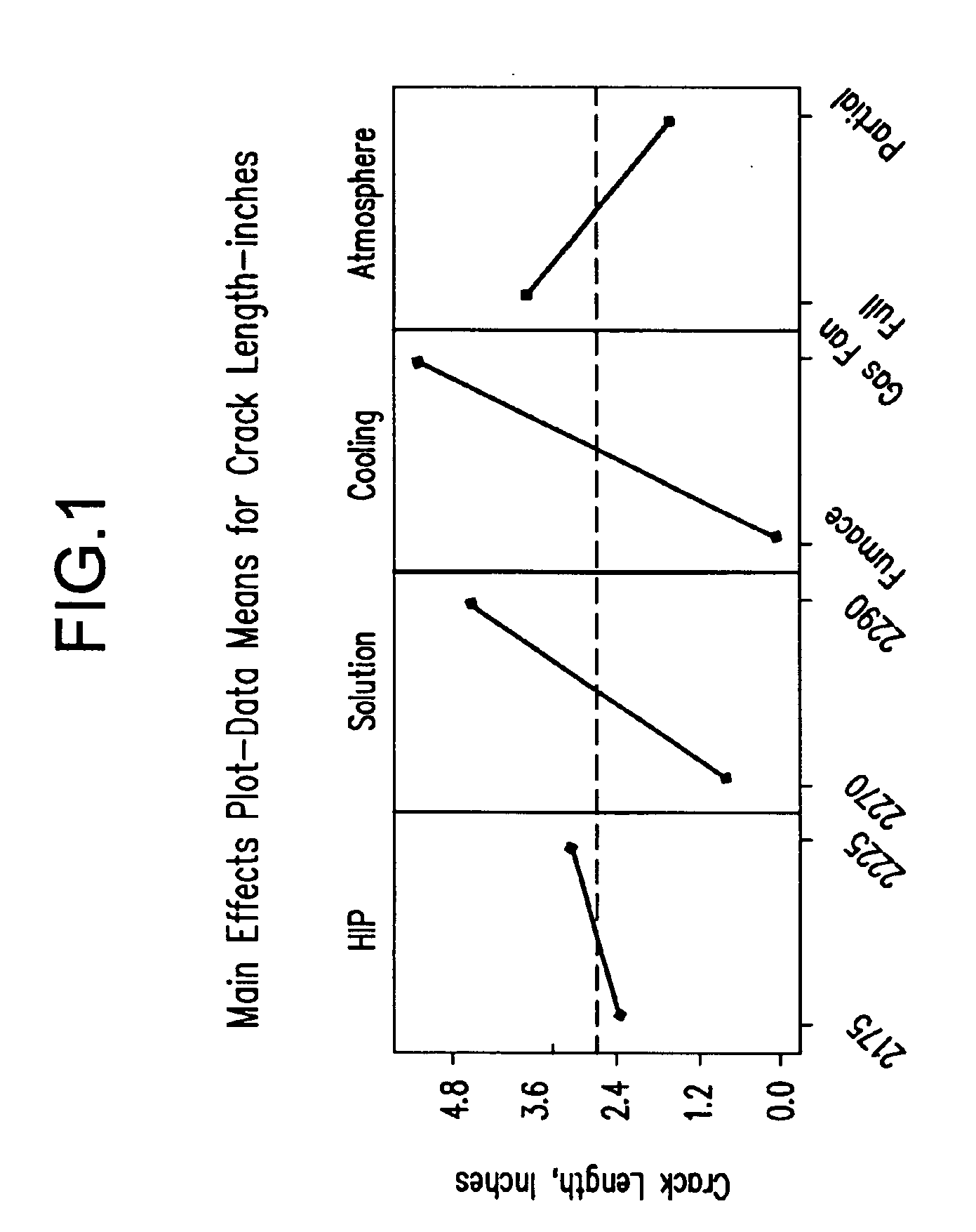

A nickel base superalloy suitable for the production of a large, crack-free nickel-base superalloy gas turbine bucket suitable for use in a large land-based utility gas turbine engine, comprising, by weight percents:Chromium 7.0 to 12.0Carbon 0.06 to 0.10Cobalt 5.0 to 15.0Titanium 3.0 to 5.0Aluminum 3.0 to 5.0Tungsten 3.0 to 12.0Molybdenum 1.0 to 5.0Boron 0.0080 to 0.01Rhenium 0 to 10.0Tantalum 2.0 to 6.0Columbium 0 to 2.0Vanadium 0 to 3.0Hafnium 0 to 2.0 andremainder nickel and incidental impurities.

Owner:GENERAL ELECTRIC CO

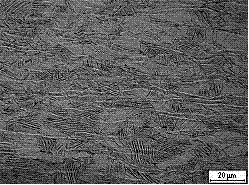

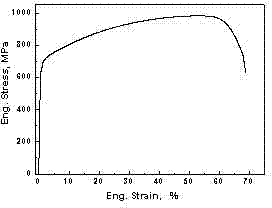

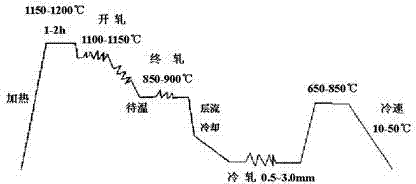

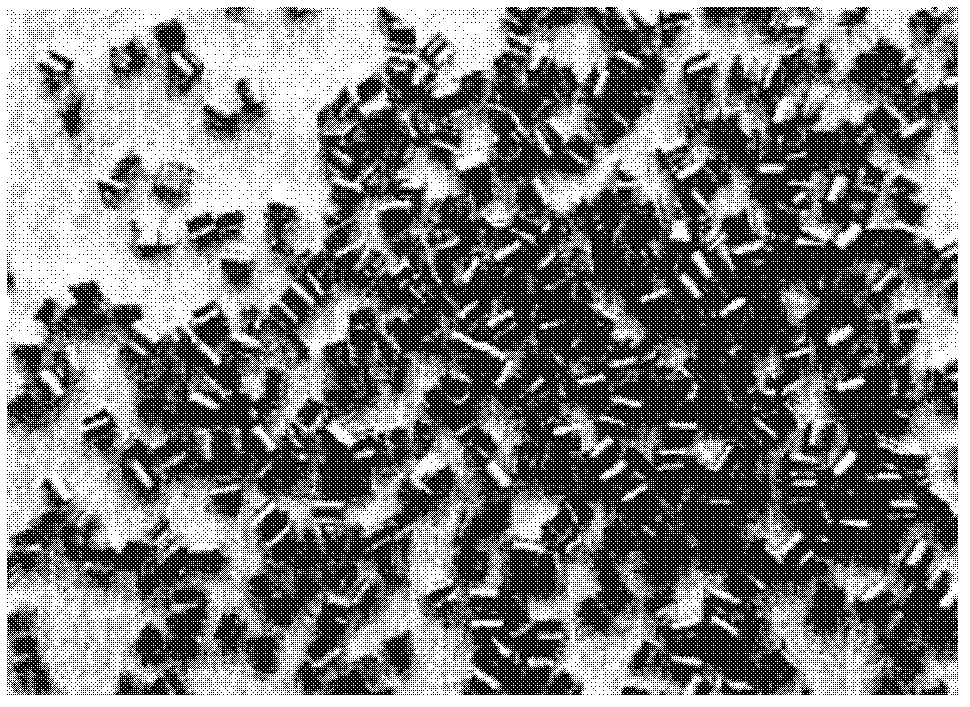

Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

ActiveCN102312158AExcellent overall performanceBroad application prospectsSteel platesManufacturing sector

The invention, belonging to the field of high-intensity alloy steel, relates to a preparation method of a Nb, Ti alloyed low-carbon high-intensity high-plasticity twinning induced plasticity (TWIP) steel. The steel comprises the following ingredients: 0.05-0.10 wt% C, 23.5-27 wt% of Mn, 0.01-0.03wt% of Si, at most 1.0 wt% of Al, at most 0.01 wt% of P, at most 0.02 wt% of S, 1.0-2.5 wt% of Nb, 0.5-1.25 wt% of Ti, 0.02 -0.08 wt% of N, and the balance consisting of Fe and inevitable impurities. The preparation method comprises the following steps: melting the ingredients and then casting into a casting blank, heating the casting blank and then carrying out hot rolling at the opening rolling temperature of 1100-1150 DEG C with multiple passes and small press quantity to obtain the accumulated deformation degree of more than 60 % at the temperature of more than 950 DEG C, processing the casting blank in a finishing rolling mode at the temperature of 850-900 DEG C, after the hot rolling, rapidly cooling to 400-550 DEG C for reeling, carrying out cold rolling on the steel plate processed by hot rolling with the thickness of 0.5-3.0 mm, preserving the steel plate processed by cold rolling at the temperature of 650-850 DEG C for 3-30 min, and then rapidly cooling to room temperature with the cooling rate of 10-50 DEG C / s. The material prepared by the method can be applied in automobile manufacturing industry. The material has the yield strength of more than 550 MPa and the elongation rate of no less than 60 %, thereby obviously improving the ability of anti-collision and impact of automobile for the first time and greatly increasing the crashworthiness indexes.

Owner:SHANGHAI JIAO TONG UNIV

Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

The invention discloses an Al-Si-Cu-Mg series distortion aluminum alloy and the manufacturing method. The alloy is made up from 9.0-12.0wt% Si, 3.0-4.0wt% Cu, 0.3-0.6wt% Mg, <0.30% Fe, <0.20% Zn, and other impurity <=0.15wt%, and the rest is Al. The method includes the following steps: smelting and refining the raw materials in reflecting smelter, after processing the allow liquation by Al-Sr intermediate alloy, gaining cast rod through hemicontinuous casting, extruding the cast rod and after forging and T6 thermal treatment to gain the product. The tensile strength of the alloy is over 397MPa, and broken tensile stretch is 6%, and rigidity is 136-141HB. It is mainly used to make wheel for vehicle and motorcycle, piston, bearing, bidirectional sloping cam plate, etc.

Owner:SHANDONG UNIV

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots and solving the problems of easy cracking and difficult forming during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO.1 flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials in the smelting furnace are smelted; adding magnesium ingots and then smelting; then refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the prepared ingot is 500-600mm, the width is 600mm, and the length is 2,000-3,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 90.5 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Leadless and free-cutting phosphorus-brass alloy and manufacturing method thereof

The invention provides a lead-free cutting-free alloy and a preparation method thereof. The components (weight percentage) of the alloy are: more than 97.0 but not equal to 99.5 of (copper + zinc), more than 35.0 of zinc, 0.4-1.6 of phosphor and 0.005-0.6 of at least two other elements selected from aluminum, silicon, antimony, stannum, lanthanon, titanium and boron, the balance being zinc and impurities, wherein, the zinc content is more than 35.0 (weight percentage). The invention also provides a preparation method for the lead-free cutting-free high phosphor brass alloy. The alloy of the invention has excellent machinability, castibility, welding property, dezincification corrosion resisting property, formability and mechanical property, and is particularly suitable for forged pieces and low-pressure cast castings needing cutting processing, grinding processing (polish), welding and plating, such as hydrants, valve bodies and bushings in a water supply system.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

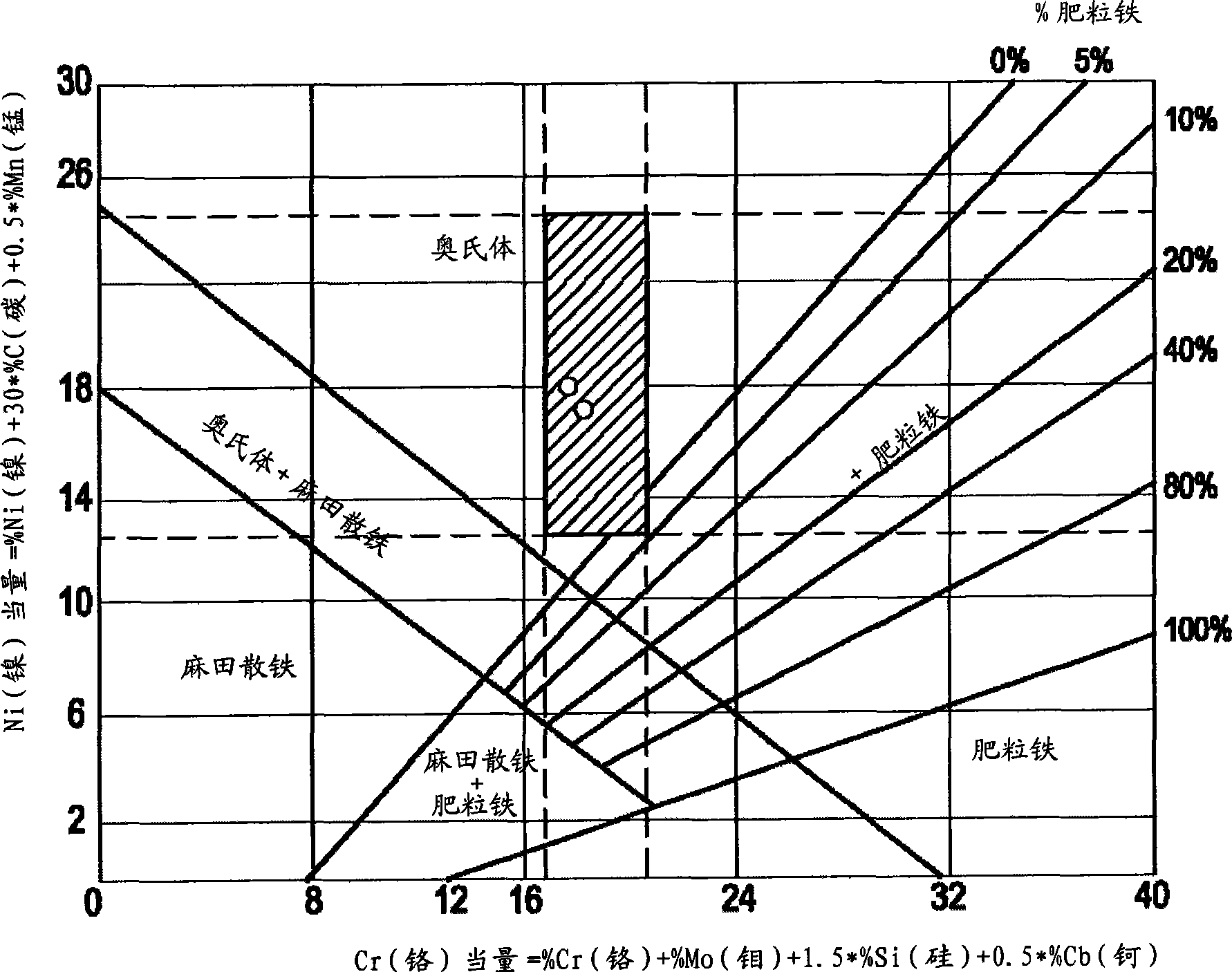

Chromium-manganese-nitrogen austenitic stainless steel

The invention relates to Cr-Mn-N austenite stainless steel. A proper amount of Mn and N are used to substitute expensive nickel to produce a novel Cr-Mn-N steel grade for reducing the cost for materials and maintaining the prior physical property and mechanical property. The Cr-Mn-N austenite stainless steel comprises the following composing elements in percentage by weight: 0.005 to 0.08 percent of carbon element, 0.3 to 0.9 percent of silicon element, 12.1 to 14.8 percent of manganese element, 0.001 to 0.04 percent of phosphorus element, 0.001 to 0.03 percent of sulfur element, 16 to 19 percent of chromium element, 0.5 to 1.8 percent of nickel element, 0.2 to 0.45 percent of nitrogen element, 0.001 to 0.3 percent of molybdenum element, 0.001 to 0.3 percent of copper element, and unavoidable trace elements during most manufacturing processes. The corrosion resistance, the strength and the elongation percentage of the Cr-Mn-N austenite stainless steel in marine atmosphere and acid atmosphere are the same as those of a 304 stainless steel material or are better than those of the 304 stainless steel material, and the Cr-Mn-N austenite stainless steel can reduce the cost for the materials. The Cr-Mn-N austenite stainless steel has the advantages of high elongation percentage, strong corrosion resistance, excellent casting formability and good high-temperature oxidation resistance.

Owner:ADVANCED INT MULTITECH CO LTD

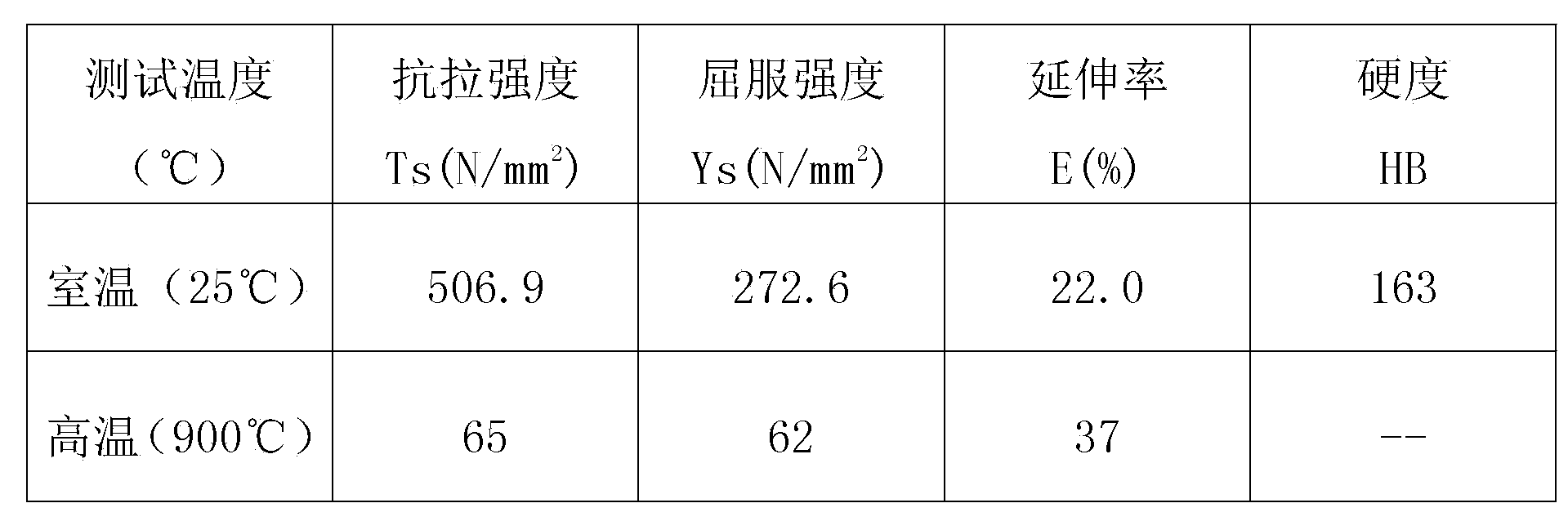

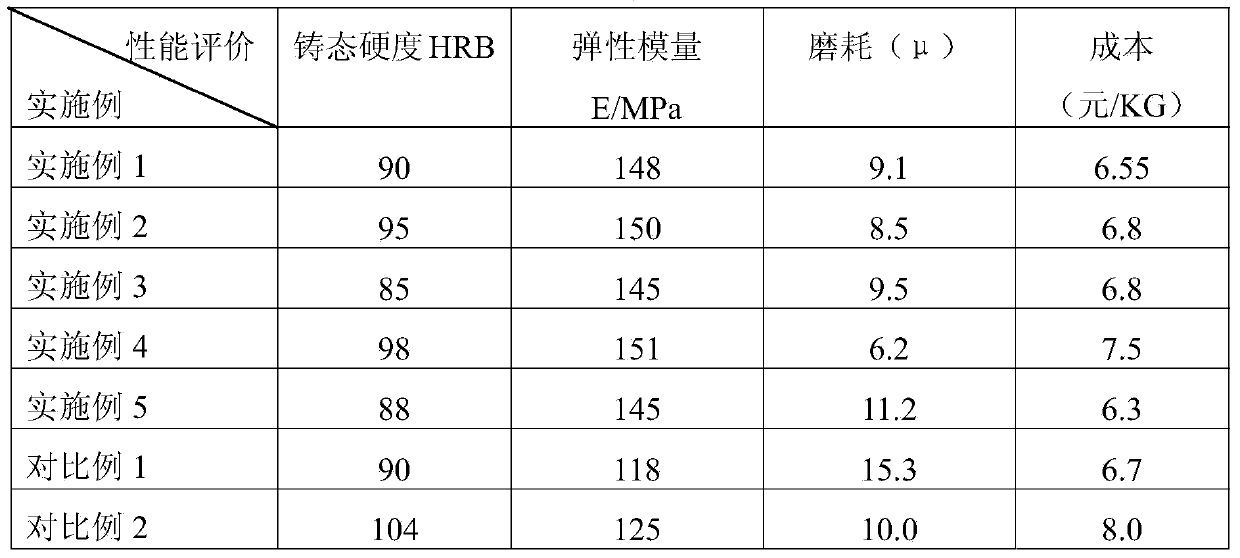

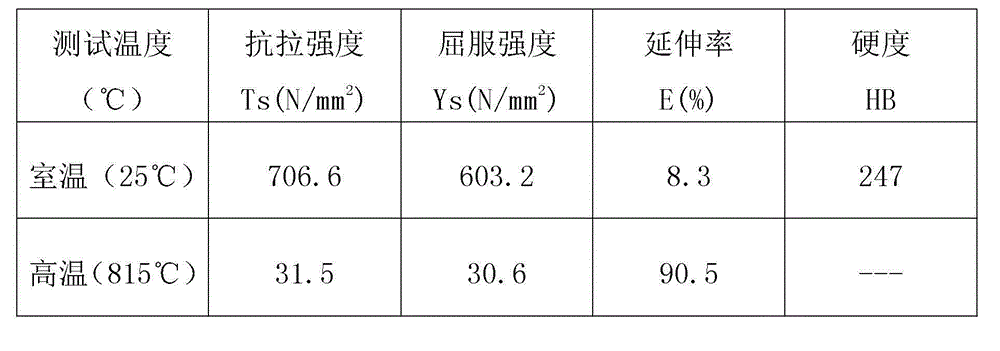

High-nickel austenitic nodular cast iron material for automobile turbine housing and preparation method for high-nickel austenitic nodular cast iron material

ActiveCN103820704AGood casting performanceEasy to processProcess efficiency improvementSlagFerrosilicon

The invention discloses a high-nickel austenitic nodular cast iron material for an automobile turbine housing and a preparation method for the high-nickel austenitic nodular cast iron material. The high-nickel austenitic nodular cast iron material comprises the following components in percentage by weight: 1.70 to 1.90 percent of carbon, 4.90 to 5.50 percent of silicon, 0.50 to 0.80 percent of manganese, less than 0.05 percent of phosphorus, less than 0.02 percent of sulfur, 0.06 to 0.09 percent of magnesium, 34.0 to 36.0 percent of nickel, 1.75 to 2.00 percent of chromium and the balance of iron. The preparation method comprises the following steps of sequentially throwing silicon carbide, cast iron, a recycled material, waste steel and pure nickel into melting equipment for melting; adding ferro-manganese, ferrochromium, ferrosilicon and a low-sulfur carburant after the materials in the melting equipment are molten; extracting the molten materials for spectral analysis; raising the temperature of the melting equipment to 1,560 to 1,620 DEG C for nodularizing treatment after the molten materials are qualified; pouring the heated materials into a nodularizing ladle for wire feeding nodularizing treatment; pouring the nodularized materials into a casting ladle for secondary inoculation, removing oxidizing slag, and performing standing and cooling; cooling and casting material liquid, and performing sand shakeout cleaning; performing heat treatment on a casting after the sand shakeout cleaning, and annealing the casting to obtain a finished product. The high-nickel austenitic nodular cast iron material is high in casting and machining performance and low in cost, and process conditions are reasonable, easy to control and favorable for casting production.

Owner:TIANJIN NEW WEISAN INDS

High-Ni-Cu alloy glass mold and method for manufacturing same

The invention discloses a high-Ni-Cu alloy glass mold and a method for manufacturing the same. The high-nickel-copper alloy glass mold is prepared from the following components by mass ratio: 8.5-10.5% of Al, 14.0-16.0% of Ni, 7.5-9.5% of Zn, 0.8-1.2% of Si, 0.8-1.2% of Fe, 0.08-0.15% of Mn and the balance of Cu. The method for preparing the high-Ni-Cu alloy glass mold comprises the following steps: preparing a Zn-Cu alloy, wherein the mass ratio of Zn and Cu is 45:55, determining the use amount of the raw materials for preparing the high-Ni-Cu alloy glass mold, the Zn-Cu alloy and the electrolytic copper according to the mass ratio of the components for preparing the high-Ni-Cu alloy glass mold, smelting the raw materials and the electrolytic copper in an intermediate-frequency furnace until the temperature reaches 1,200-1,240 DEG C, adding the Zn-Cu alloy, heating until the smelting temperature reaches 1,280-1,300 DEG C, preserving temperature and casting at 1,260-1,280 DEG C, and carrying out stress-relief annealing. The high-Ni-Cu alloy glass mold disclosed by the invention has the advantages of high heat conductivity and heat resistance and good corrosion resistance and can adapt to the high-speed production requirements of the high-speed bottle making machine.

Owner:CHANGSHU JINNUO JINGGONG MOLD MFG

Squeeze casting Al-Si-Cu alloy material

The invention relates to an aluminum alloy material, in particular to an extrusion casting Al-Si-Cu alloy prepared by solution heat treatment (T4 heat treatment) and solution heat treatment plus full artificial aging (T6 heat treatment) processes; the main components and the mass percentage thereof are as follows: 5.30 percent to 6.20 percent of silicon, 3.80 percent to 4.30 percent of copper, 0.60 percent to 0.91 percent of trace alloy strengthened element, 0.20 percent to 0.30 percent of impurity element iron, and the rest are aluminum and inevitable trace impurities. The material not only has quite high strength and good plasticity, but also has good casting shaping performance, low raw material cost and convenient sources, is in particular applicable in manufacturing parts with light weight and less weight requirements, and has very broad application prospect in automobile, aviation and other industries.

Owner:SOUTH CHINA UNIV OF TECH

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

Lost foam-shell mold casting vibration and solidification method based on foam mold

InactiveCN102744367ARefine the grain sizeGrain size stabilityFoundry mouldsFoundry coresDry sandPlastic film

The invention relates to a lost foam-shell mold casting vibration and solidification method based on a foam mold, comprising the following steps of: (1) manufacturing the foam mold with a ceramic shell on a surface thereof; (2) after the foam mold is subjected to lost foam mold and baking, putting the foam mold into a bottom-drawing sandbox, filling scattered molded dry sand into the bottom-drying sandbox, closing a vibrating table after vibrating and compacting the scattered dry sand pass through the vibrating table, coating a layer of plastic film on the upper part of the bottom-drawing sandbox, and placing a pouring cup on the upper part of the bottom-drawing sandbox to be poured; and (3) opening a vacuum device and the vibrating table, injecting metal liquid into a ceramic shell through the pouring cup, vibrating and solidifying, closing the vibrating table and the vacuum device after the metal liquid is solidified into a cast completely, and opening the sandbox to perform cleaning. The lost foam-shell mold casting vibration and solidification method based on the foam mold is simple, lower in cost, convenient to operate and environmental-friendly. An effective method with the characteristics of convenience, quickness, low cost, environmental-friendly grain size of refined casts and enhanced performances of the casts is provided for lost foam-shell mold casting enterprises.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

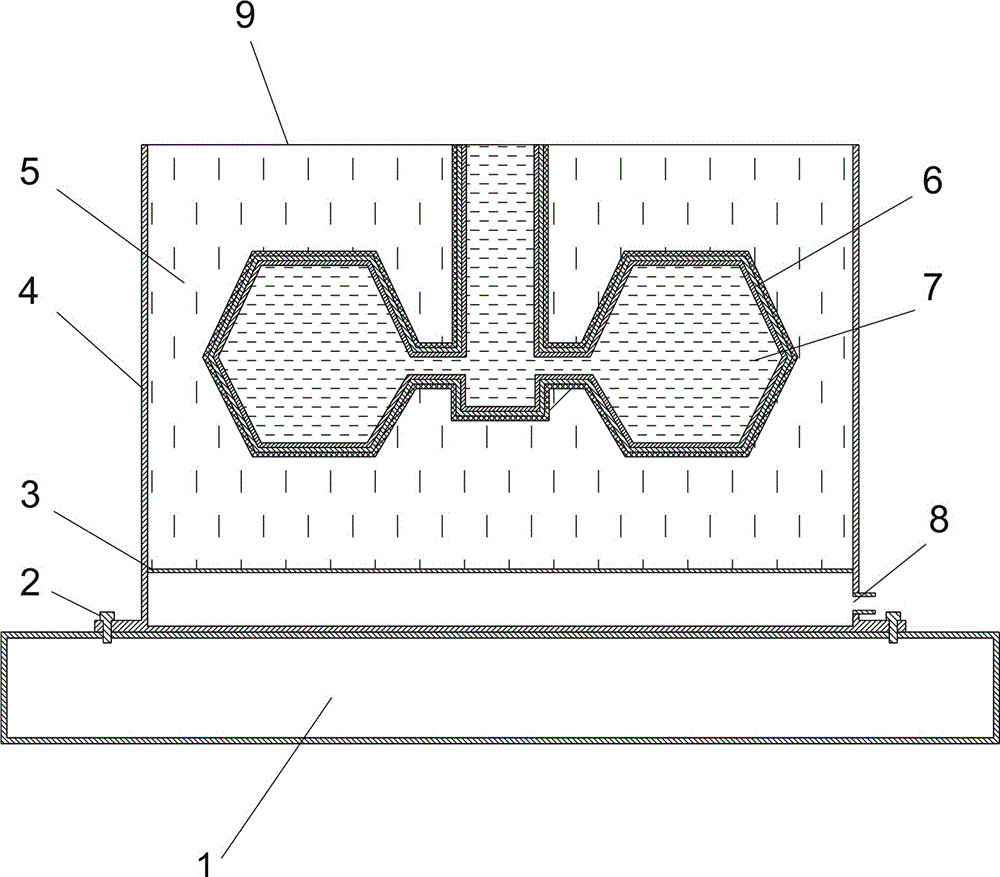

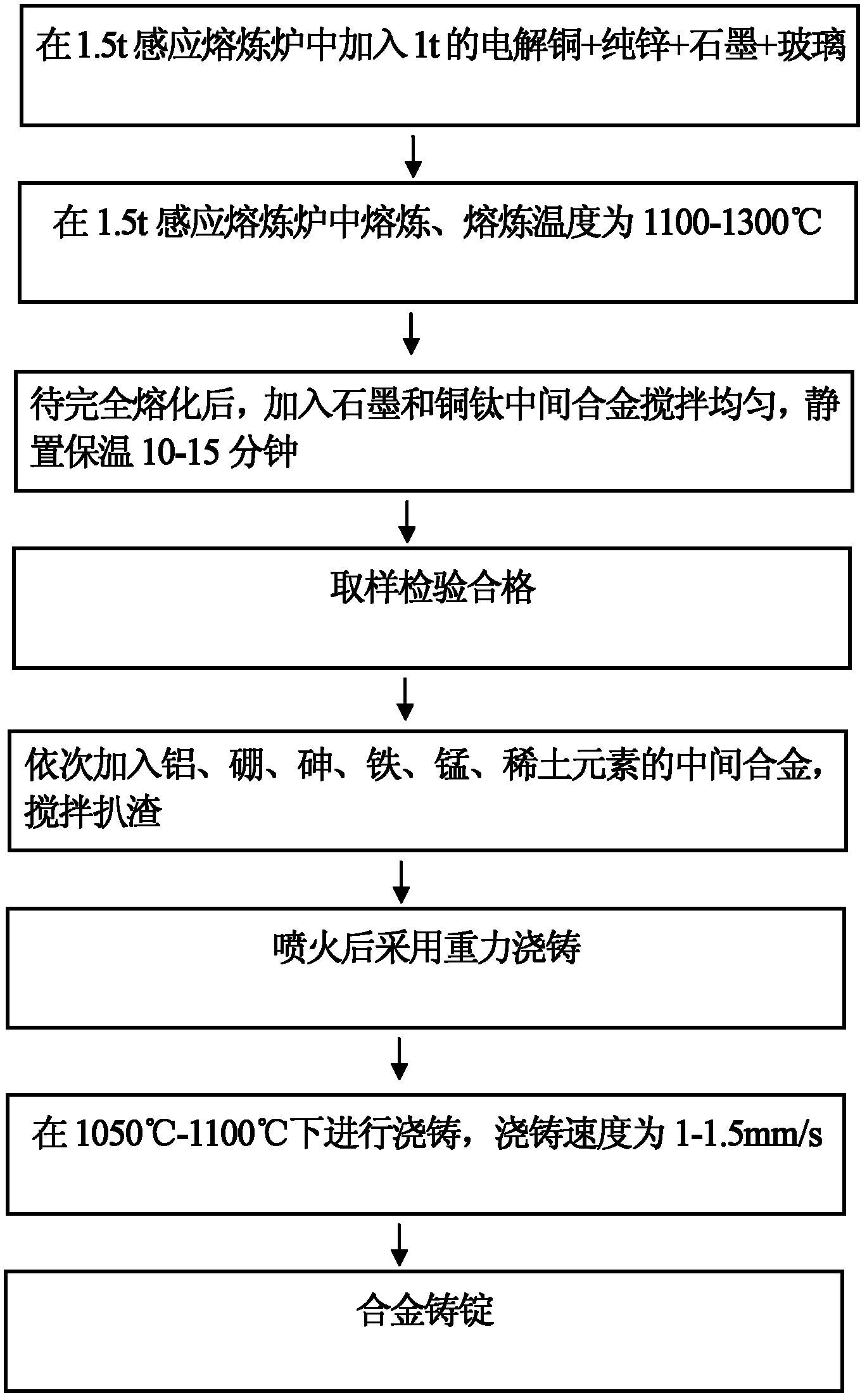

High-zinc leadless brass alloy and preparation method thereof

The invention relates to the field of leadless brass alloy and especially to an easily-cuttable corrosion-resistant high-zinc leadless brass alloy and a preparation method thereof. The alloy can be used to substitute machined lead brass alloy and is an excellent environment-friendly green metal material. The alloy comprises 57 to 63% of copper, 1 to 1 .5% of graphite, 0.05 to 2% of titanium, 0.001 to 0 .05% of aluminum, 0.001 to 0 .05% of boron, 0.02 to 0.06% of arsenic, 0.2 to 0.5% of iron, 0.1 to 0 .2% manganese and 0.001 to 0.07% of a rare earth element RE, with the balance being zinc. During melting, copper zinc alloy is melted at first, graphite and copper titanium intermediate alloy are added after copper zinc alloy is completely molten and are uniformly mixed with molten copper zinc alloy under stirring, then intermediate alloy of aluminum, boron, arsenic, iron, manganese and the rare earth element are sequentially added, stirring and slag removal are carried out, and gravity casting is carried out on an obtained mixture after flaming so as to prepare alloy cast ingots. According to the invention, graphite is added into the high-zinc leadless brass alloy to substitute lead,which enables the high-zinc leadless brass alloy to cost less compared to bismuth brass, the disadvantages of cracks, inclusion and the like of castings to be reduced, brass crystal grains to be refined and the high-zinc leadless brass alloy to have excellent hot and cold processing performances.

Owner:江西九星铜业有限公司

Scuff resistant aluminum piston and aluminum cylinder bore combination and method of making

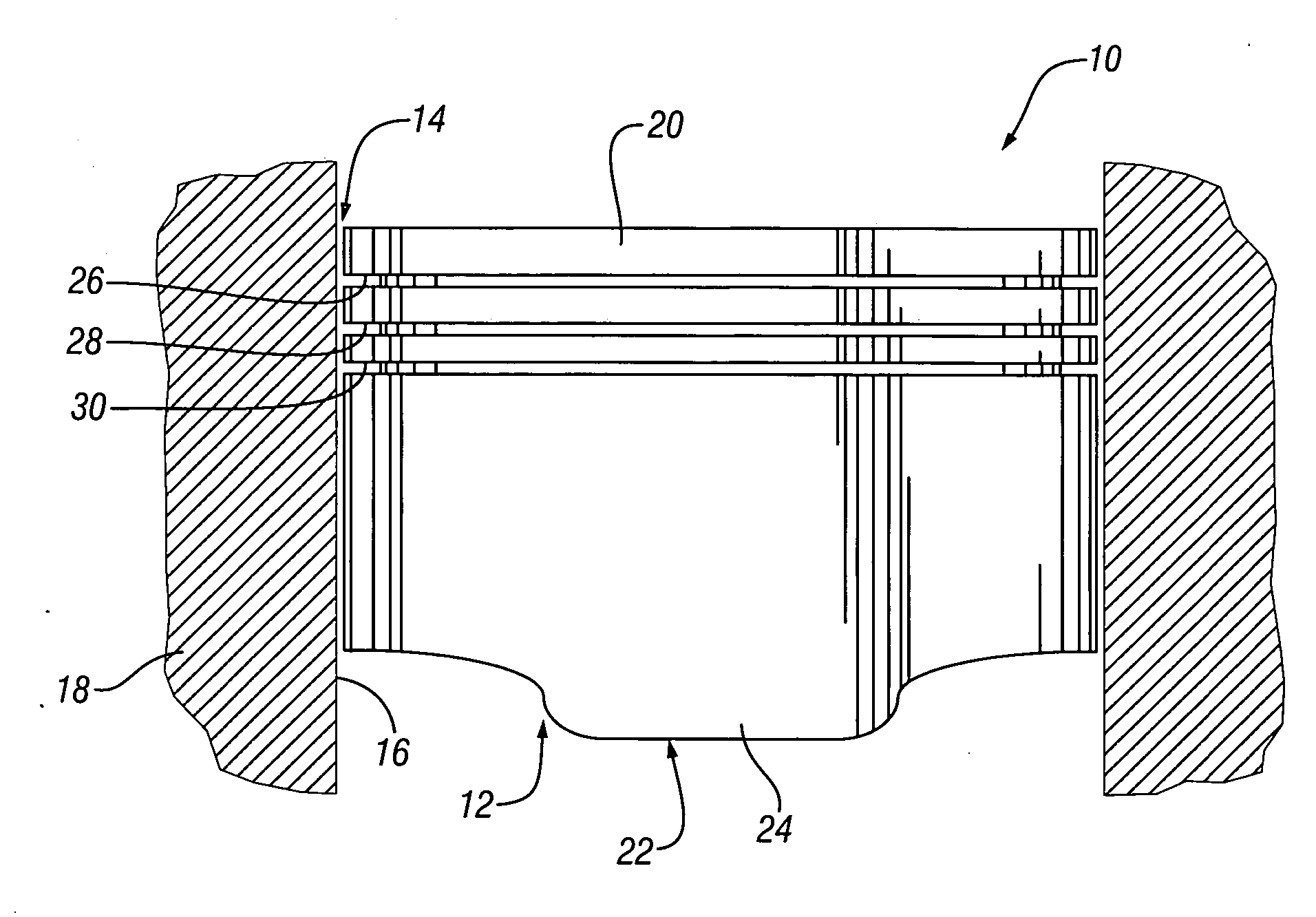

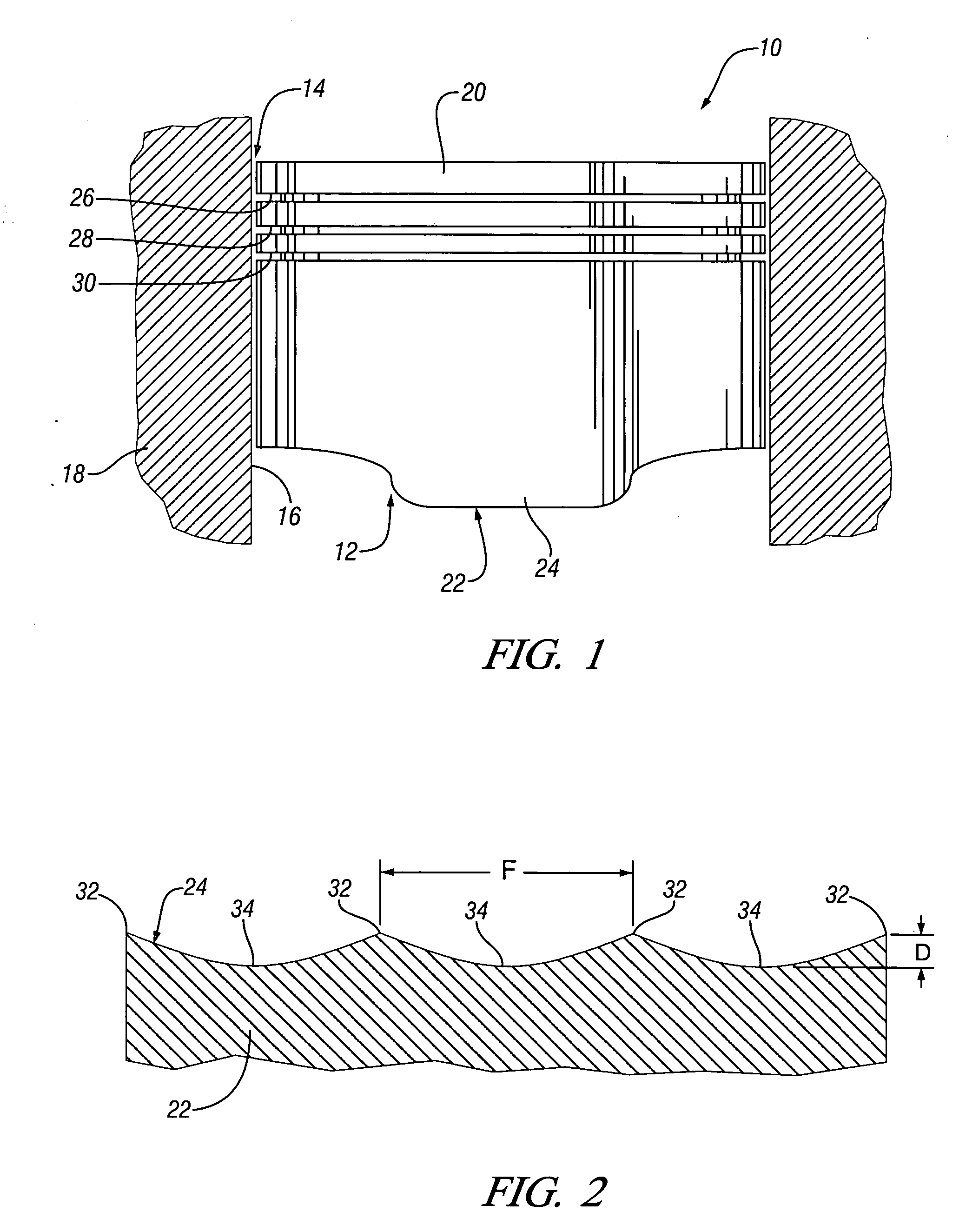

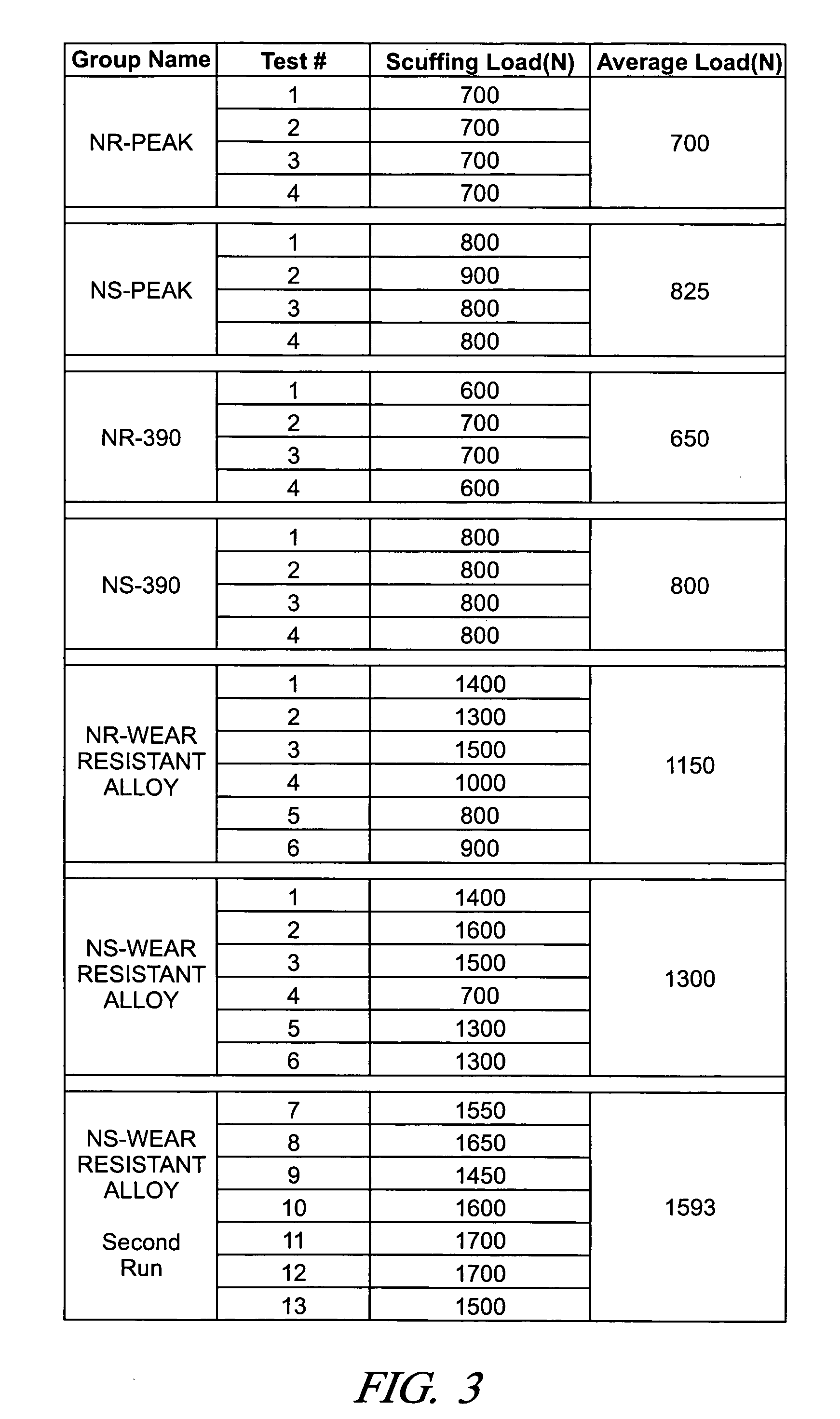

InactiveUS20070234994A1Good castabilityMaximize resistancePlungersCylinder headsMicrometerCylinder block

A piston and cylinder assembly for an engine is disclosed. The assembly includes a piston including an aluminum alloy piston body having a crown and a skirt extending from the crown. The skirt has an exterior surface having a surface finish in a wave form with peaks and valleys, and having a roughness total between approximately 6 and 12 micrometers, the roughness total (Rt) being defined as the difference between the highest peak and lowest valley within an assessment length. The surface finish has an approximate peak-to-peak distance between 0.17 and 0.25 millimeters within the assessment length. The exterior surface is coated with a nickel ceramic composite coating. An aluminum alloy cylinder bore is disposed in an engine block and is configured to receive the piston body. The cylinder bore has a bore surface having a roughness average (Ra) between approximately 0.09 and 0.25 micrometers. The cylinder bore may be made of a eutectic Al—Si alloy including other alloying elements.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-strength and high-toughness heat-treatment-free aluminum alloy material and preparation method thereof

PendingCN113755722AReasonably control the range of elementsGood mechanical propertiesMold fillingUltimate tensile strength

The invention discloses a high-strength and high-toughness heat-treatment-free aluminum alloy material and a preparation method, and belongs to the technical field of aluminum alloy casting. The high-strength and high-toughness heat-treatment-free aluminum alloy material comprises the following components in percentage by mass: 8.0-10.5% of Si, less than or equal to 0.15% of Fe, 0.05-0.3% of Mg, 0.05-0.3% of Zn, 0.3-0.6% of Mn, less than or equal to 0.1% of Cu, 0.05-0.15% of Ti, less than or equal to 0.005% of Ca, 0.005-0.030% of Sr, 0.1-0.3% of Zr, 0.01-0.1% of Mo, 0.01-0.3% of V, less than or equal to 0.02% of Cr, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.01% of Cd, less than or equal to 0.001% of Li, less than or equal to 0.0025% of B, less than or equal to 0.05% of Ga, and the balance Al and inevitable impurities. The alloy does not need to be subjected to heat treatment, and has excellent casting performance and mold filling capacity and good tensile strength, yield strength and toughness.

Owner:隆达铝业(顺平)有限公司 +2

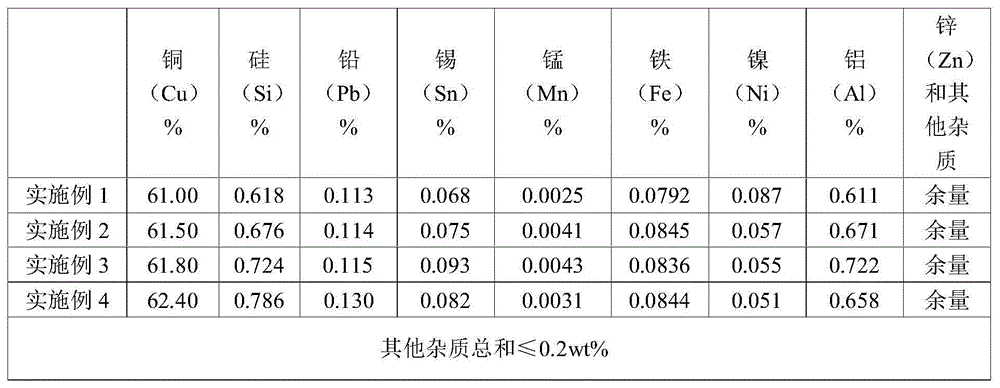

Easily processed silicon brass alloy and preparation method thereof

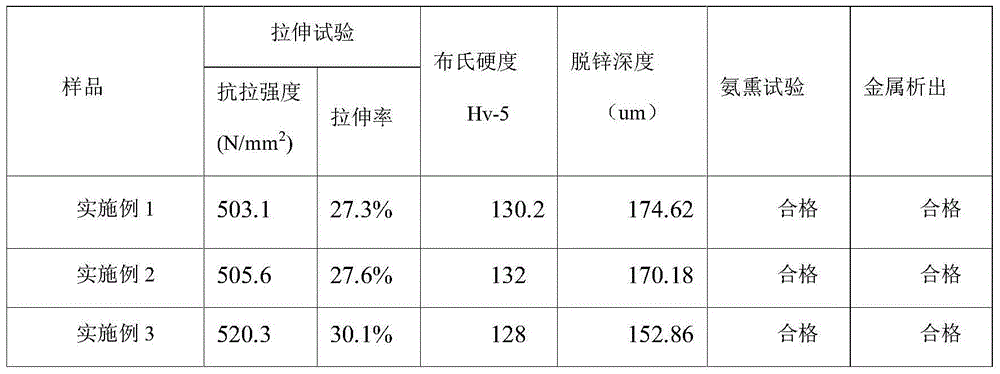

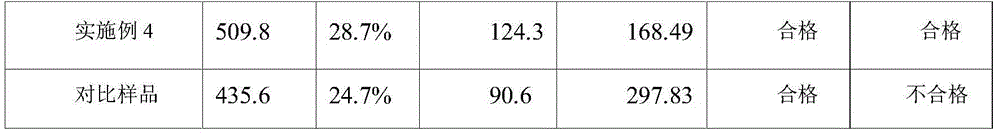

The invention discloses an easily processed silicon brass alloy. The alloy comprises the following components in percentage by weight: 60-63% of copper (Cu), 0.50-0.90% of silicon (Si), 0.50-0.80% of aluminum (Al), 0.10-0.20% of lead (Pb), less than 0.3% of other elements, and the balance of zinc (Zn) and inevitable impurities, wherein the sum of copper, silicon, aluminum and zinc is more than 99.60%, and other elements are a combination of tin (Sn), manganese (Mn), ferrum (Fe) and nickel (Ni). The invention further comprises a preparation method of the silicon brass alloy. The prepared silicon brass alloy is obviously higher than common lead brass in the performances of tensile strength, elongation rate, hardness and anti-zinc removal, the casting processability is good, practical production and application demands can be met, the precipitation of metals can meet the standard requirements, and the easily processed silicon brass alloy can be widely applied to water heating, valves and other various industries having limit on the precipitation of metal pollutants.

Owner:JOMOO KITCHEN & BATHROOM

Plunger for compressor pump body, production method thereof as well as compressor and refrigeration equipment

InactiveCN103993216AImprove liquidityExcellent machinabilityPositive displacement pump componentsPositive-displacement liquid enginesGraphiteRefrigeration

The invention discloses a plunger for a compressor pump body, a production method thereof as well as a compressor and refrigeration equipment. The plunger for the compressor pump body is made from vermicular graphite cast iron, wherein the vermicular graphite cast iron contains the following components in percentage by weight: 3.2%-3.8% of C, 2.0%-3.0% of Si, 0.5%-1% of Mn, not higher than 1.0% of Cu, not higher than 0.3% of P, not higher than 0.06% of S and the balance of iron.

Owner:GUANGDONG MEIZHI PRECISION MFG

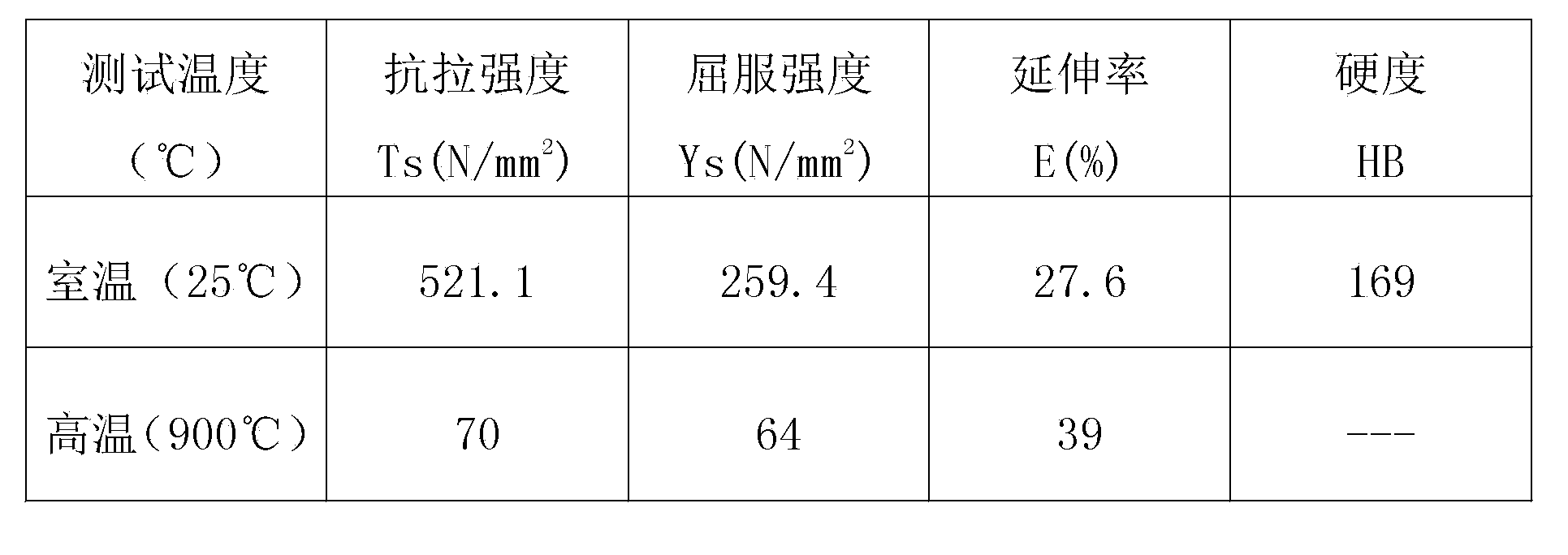

High-silicon-molybdenum-chromium spheroidal graphite cast iron material for automobile turbine housings and preparation method thereof

The invention discloses a high-silicon-molybdenum-chromium spheroidal graphite cast iron material for automobile turbine housings and a preparation method thereof. The material comprises the following compositions in percentage by weight: 2.90-3.10% of carbon, 4.40-4.80% of silicon, less than 0.30% of manganese, less than 0.05% of phosphorus, less than 0.02% of sulfur, 0.03-0.05% of magnesium, less than 0.50% of nickel, 0.70-0.80% of chrome, 0.50-0.65% of molybdenum, less than 0.03% of aluminum, less than 0.10% of copper, less than 0.035% of titanium, and the balance of iron (Fe). The preparation method comprises the following steps: putting silicon carbide, pig iron, return materials and scrap steel into a smelting device; after the materials are melted, adding silicon iron, molybdenum iron and chromium iron into the smelting device to carry out refining; carrying out pouring and spectrum analysis on a taken melted material; continuing to heat up the smelting device, adding a low-sulphur recarburizer in the smelting device, and preparing a spheroidizing treatment; putting the obtained material into a spheroidizing bag to carry out wire feeding spheroidizing treatment; putting the spheroidized material into a pouring ladle to carry out inoculation treatment, removing oxidizing slags, and cooling the material; carrying out temperature-drop pouring and cleaning shakeout treatment on material liquid; and carrying out heat treatment on the obtained casting subjected to shakeout, carrying out annealing on the casting until the casting is at room temperature, thereby obtaining a finished product. The material is reasonable in formulation, the preparation process is simple and easy to implement, the prepared material is good in casting and machining performances, low in cost, and ideal in application effect.

Owner:TIANJIN NEW WEISAN INDS

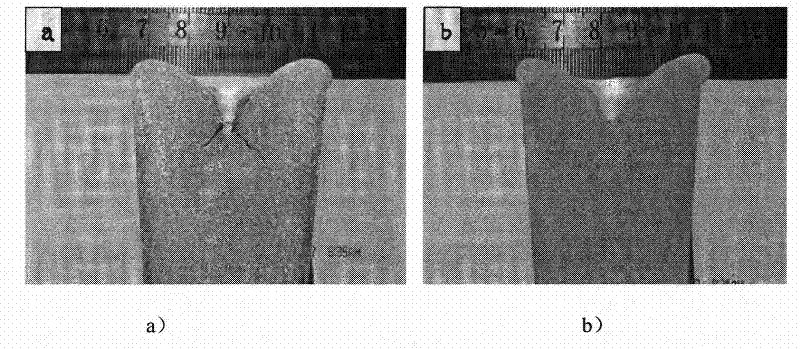

Manufacture method of extra super duralumin alloy cast ingots

InactiveCN102021447ANarrow downIncreased resistance to thermal crackingStructural elementDural material

The invention discloses a manufacture method of extra super duralumin alloy cast ingots, relating to a manufacture method of cast ingots. The invention aims at solving the problem of low yield due to the inner wall crack of the cast ingots manufactured by the existing casting method. The manufacture method of the extra super duralumin alloy cast ingots comprises the following steps: weighting raw materials, feeding the argon to refine after smelting, and manufacturing the extra super duralumin alloy cast ingots through the semi-continuous casting method. By using the casting method disclosed by the invention, the brittlement region of the aluminum alloy cast ingots is reduced, the heating crack resistance of the alloy is enhanced, the casting stress is reduced, and the casting performance of the extra super duralumin alloy is improved. The molding rate of the cast ingot reaches 62.3% and is enhanced by 7.3%, and the yield reaches 74.1% and is enhanced by 11.8% compared with that of the prior art. The manufacture method disclosed by the invention can be used in the field of manufacturing important structural elements.

Owner:NORTHEAST LIGHT ALLOY CO LTD

New stomalogical titanium alloy

InactiveCN1421536AGood mechanical properties and biocompatibilityGood casting performanceImpression capsDentistry preparationsBiocompatibility TestingHardness

The present invention is one kind titanium alloy suitable for making false tooth. The alloy consists of Fe 1-3 wt% Mo 14-18 wt%, Mn 8-13 wt%, Nb 12-22, Zr 6-16 wt% and Ce 0.01-0.3 and the rest is Ti.Compared with available titanium alloy for stomalogical use, the titanium alloy of the present invention has improved biocompatibility, higher compression strength, higher hardness and higher wear resistance.

Owner:JILIN UNIV

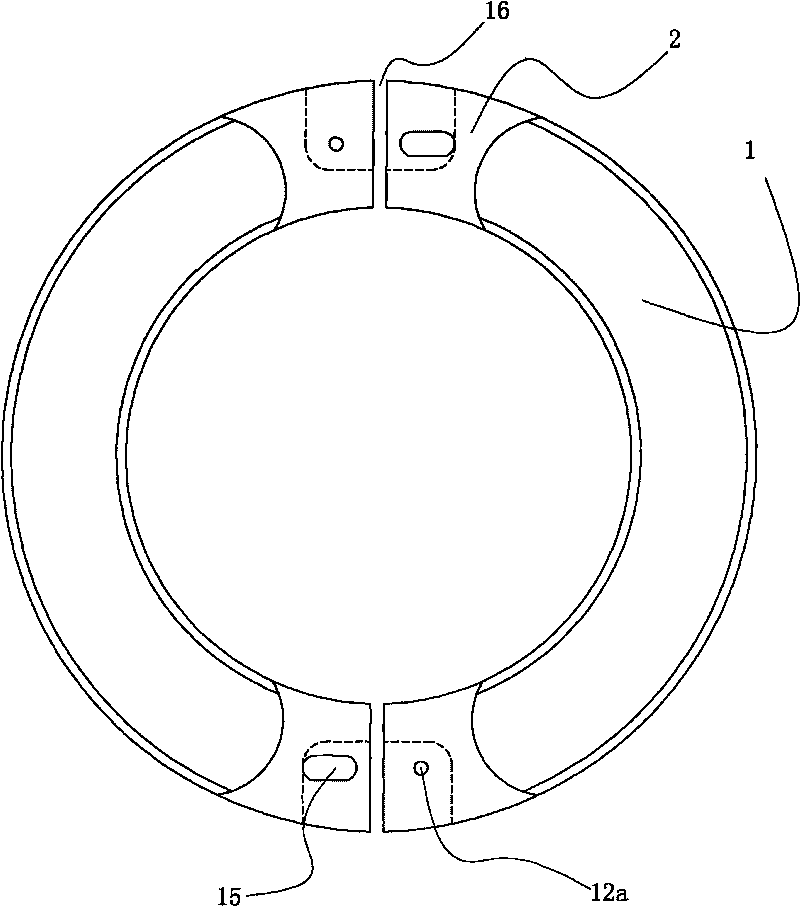

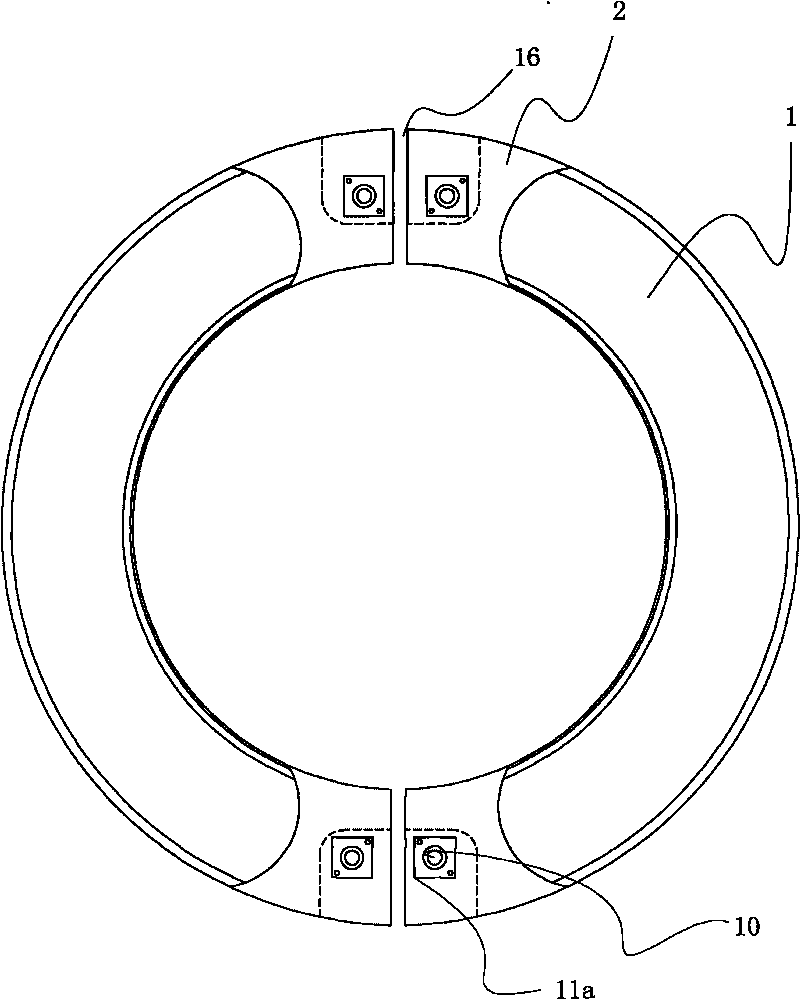

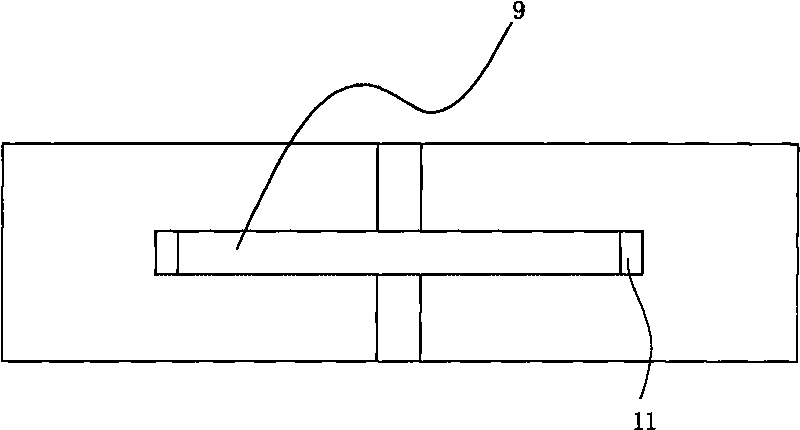

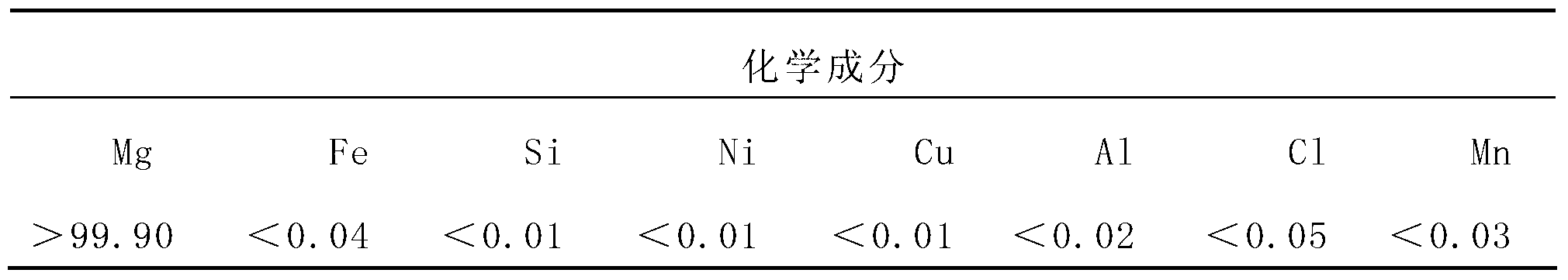

Inner supporting body for run-flat tire

The invention discloses an inner supporting body for a run-flat tire, which is characterized in that: the inner supporting body is made of a magnesium alloy serving as a raw material, and adopts a two-block split structure; the split parts comprise a main body and a joint respectively; and the joints between the split parts are connected by a connection piece. The inner supporting body has the advantages of high rigidity, good heat stability and light weight, and the inner supporting body adopts the magnesium alloy to improve the radiating condition fundamentally, prevent rubber and engineering plastics from softening due to quick and massive deformation, eliminate the ,thermal explosion, phenomenon in the process of using the inner supporting body, improve the safe driving distance after a vehicle has a flat tire, and prolong the service life.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Raw material composition for producing high-performance nodular cast iron valve and production method thereof

The invention discloses a raw material composition for producing a high-performance nodular cast iron valve and a production method thereof. The raw material composition comprises the following components in percentage by weight: 50-60% of Q10 pig iron, 15-20% of waste machine parts, 5-10% of scrap steel, 20-25% of scrap iron, 0.5-0.8% of ferronickel, 0.3-0.6% of scrap copper, 0.2-0.3% of scrap tin, 1-1.3% of nodulizer and 1-1.5% of inoculant. By adopting the composition to produce the high-performance nodular cast iron valve, the formula and process are simple, and the industrial production is easy to achieve; the cast part directly obtained from a cast state form has greatly improved performance, and truly belongs to high-performance nodular cast iron; and by adopting common scrap steel, waste machine parts and scrap iron, the raw material cost of high-performance cast part production can be lowered by times.

Owner:QINGDAO HEDELONG MACHINERY

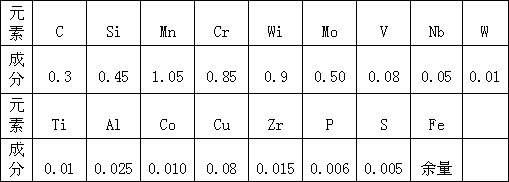

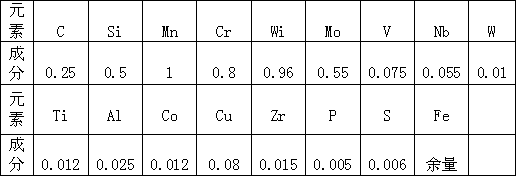

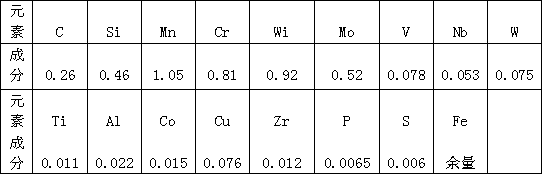

High-speed train alloy cast steel brake disc material and smelting process thereof

The invention relates to a high-speed train alloy cast steel brake disc material and a smelting process thereof. The material is composed of iron, carbon, silicon, manganese, chromium, nickel, molybdenum, vanadium, niobium, tungsten, titanium, aluminum, copper, zirconium, phosphorus, sulfur, and the like. The components are mixed according to a certain formula, and smelting is carried out with an acidic high-frequency or medium-frequency induction furnace. The production process provided by the invention is simple. A workpiece obtained after heat treatment has hardness of RC39-45, tensile strength of 1100-1200MPa, yield strength of 1000-1100MPa, and an elongation rate of 7%. The material has good impact strength, good wear resistance, low production cost, and good casting performance.

Owner:SHANDONG HAOAN GOLDTECH NEW MATERIALS

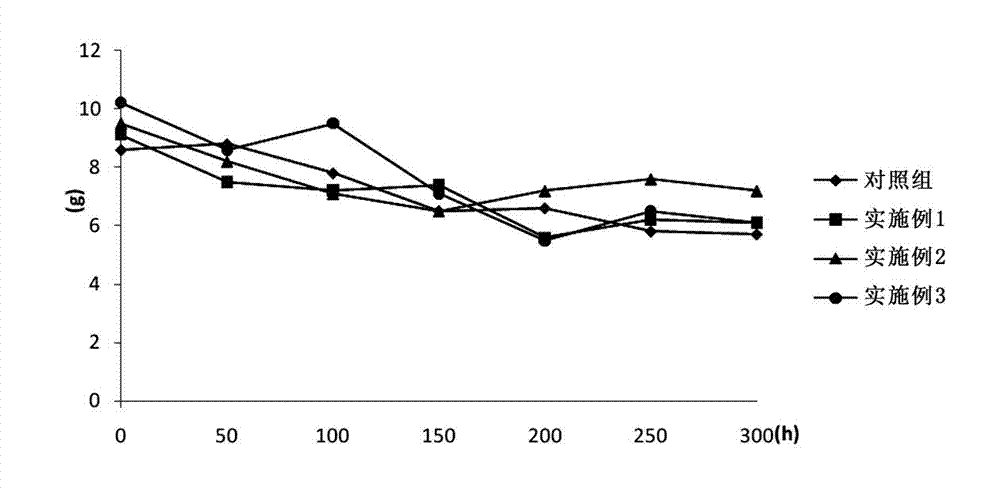

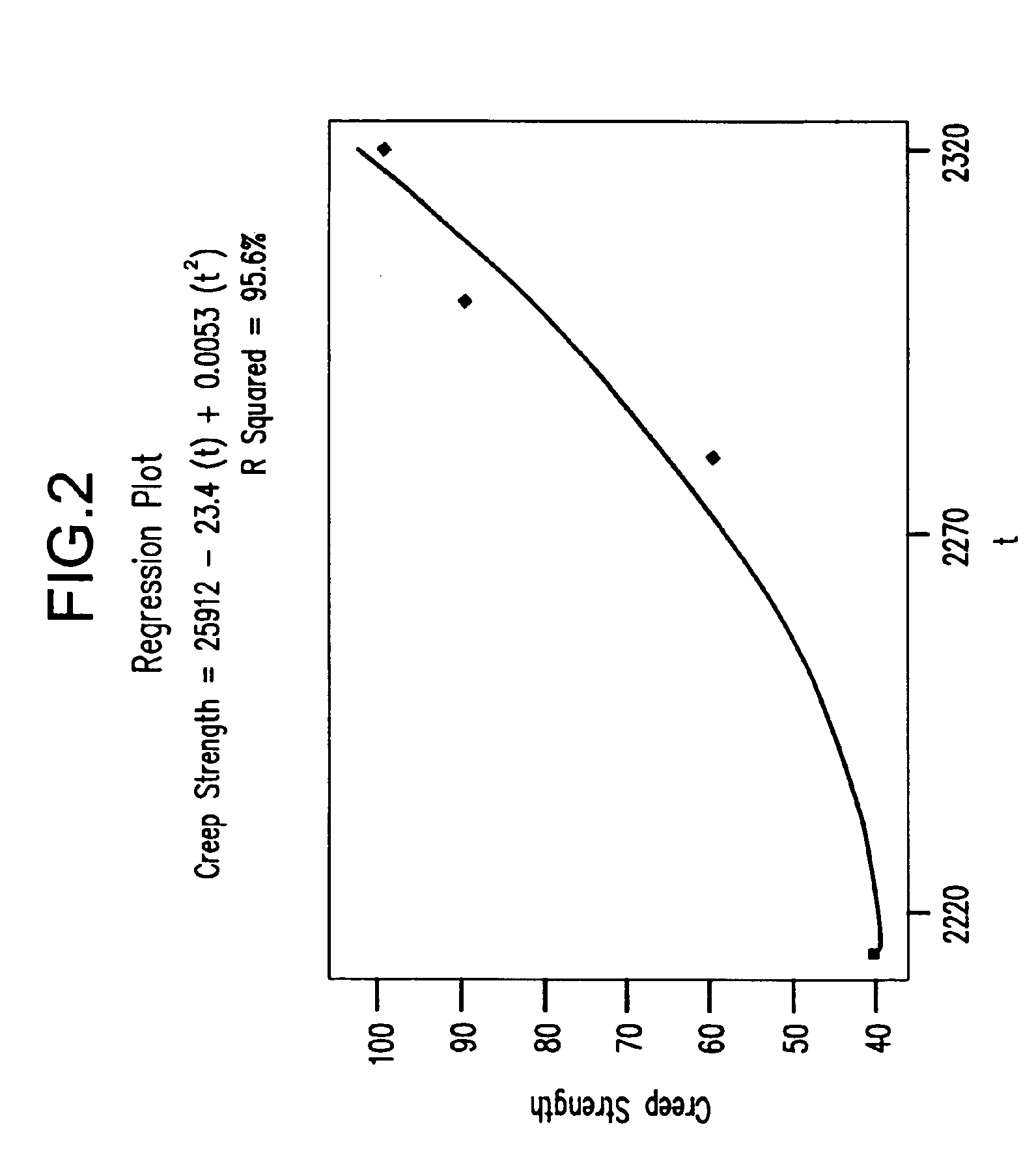

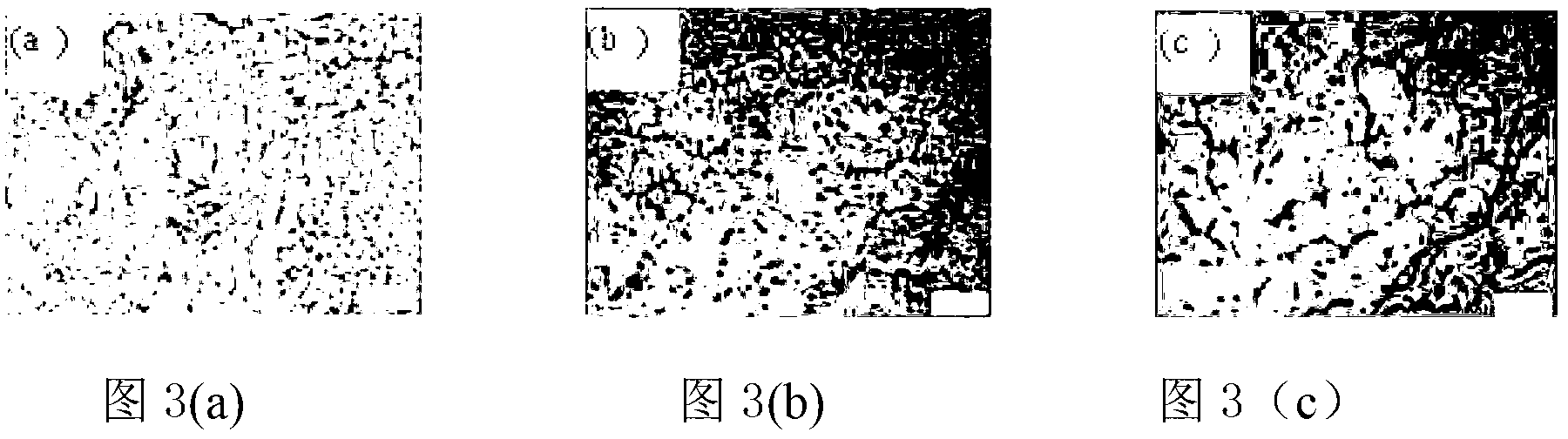

Magnesium alloy and smelting and heat treatment processes thereof

The invention provides a magnesium alloy, which comprises the following components in percentage by weight: 0.5-1.5% of calcium, 0.5-2.5% of zinc, and the balance of magnesium, wherein the sum of weight percentages is 100%. The invention also provides a melting process of the magnesium alloy, which comprises the following steps: (1) slicing magnesium ingots and removing impurities, and weighing zinc and calcium for standby; (2) preheating a crucible and a die; (3) putting the magnesium slices into the crucible, putting the crucible in a furnace, and after an operation of vacuumizing is completed, feeding mixed gas into the furnace; (4) heating the furnace until the magnesium slices are completely molten, and heating and stirring the obtained product; (5) wrapping metal calcium with an aluminum foil, adding the obtained object in the bottom of molten magnesium, then adding zinc slices, carrying out stirring and slag removal on the obtained mixture, and after the obtained product is heated, carrying out heat preservation on the obtained product; and (6) cooling molten liquid, carrying out heat preservation on the molten liquid, opening the furnace, taking the die, pouring the molten liquid into the die, and waiting. The invention also provides a heat treatment process of the magnesium alloy, which comprises the following steps of (1) homogenized annealing; and (2) solid solution treatment. The magnesium alloy disclosed by the invention has the advantages that the mechanical properties of the alloy are improved, the casting performance is improved, and the creep resistance of the alloy is increased.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

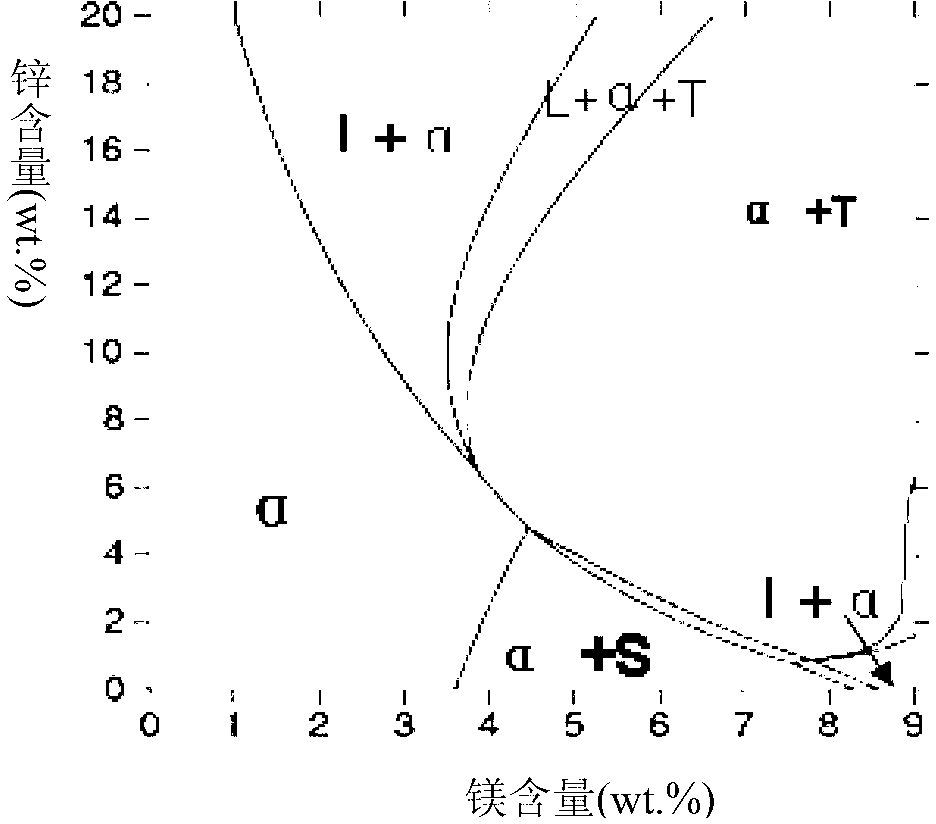

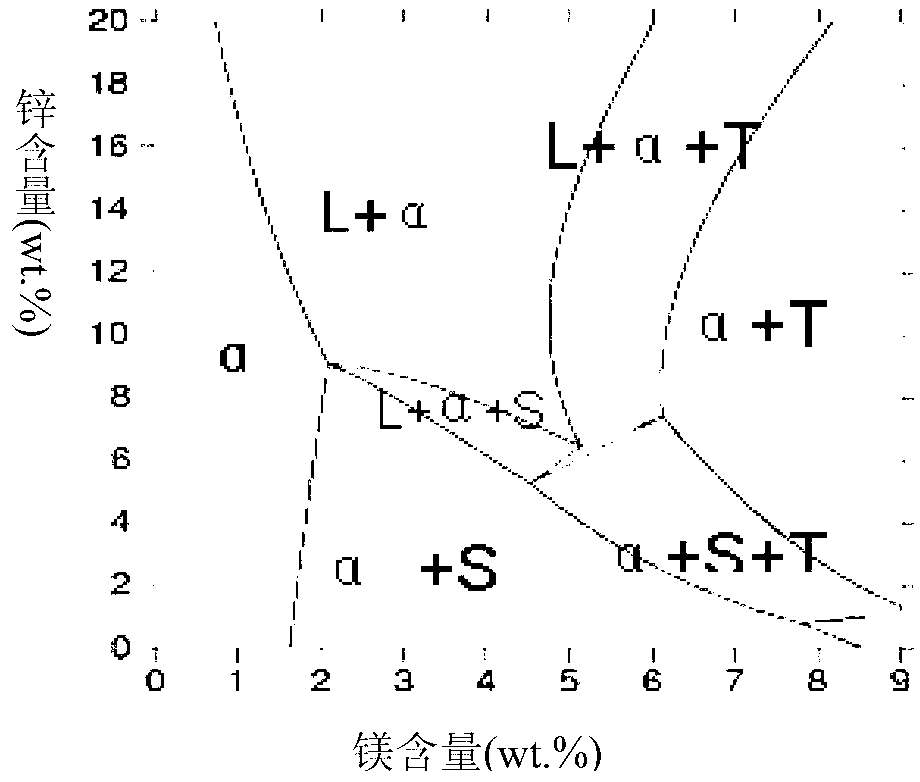

High-alumina magnesium alloy

The invention relates to a high aluminum-magnesium alloy and the weight percentages of the components are as follows: 10.5 to 11.5 percent of Al, 0.17 to 0.40 percent of Mn, 0.45 to 0.90 percent of Zn, less than or equal to 0.08 percent of Si, less than or equal to 0.004 percent of Fe, less than or equal to 0.025 percent of Cu, less than or equal to 0.001 percent of Ni, 0 to 0.0015 percent of Be and the allowance is Mg. Compared with the existing AZ91D magnesium alloy, the high aluminum-magnesium alloy has the advantages of improving the fluidity and at the same time decreasing the melting points of the alloy and then relatively reducing the cost.

Owner:南京云天镁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com