Patents

Literature

35results about How to "Content adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-silicon series deforming alloy and manufacturing method thereof

The present invention discloses aluminum silicon deformable aluminum alloy and the preparation method thereof. According to the weight percentages, the alloy contains 9.0-12.6 percent of silicon, 1.5-4.0 percent of copper, 0.3-0.6 percent of magnesium, 0.1-3.5 percent of bismuth, less than 0.30 percent of iron, less than 0.20 percent of zinc, less than or equal to 0.15 percent of impurity, and aluminum as the residual. The raw material is molten and fined in a reflecting smelting furnace, after Al-Sr intermediate alloy modification to the alloy liquid, cast rods are obtained through semi continuous casting, and after hot extrusion and deformation to the cast rods, the aluminum silicon deformable aluminum alloy is produced through forging and T6 heat treatment. After adding the element bismuth into the alloy, the present invention greatly enhances the wear-resisting performance of the alloy, leads the alloy to have self lubricating property, prolongs the service life of the product produced with the alloy, reduces the use cost, and leads the alloy to have the tensile strength of above 390 MPa, the elongation rate after breaking of 6 percent, and the hardness degree of 136-141 HB. The present invention is mainly used for producing vehicle components of wheels, pistons, bearings, and two-side swash plates of vehicles and motorcycles which have high demands on the intensity, the toughness and the abrasion resistance.

Owner:李贞宽 +1

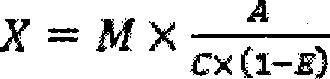

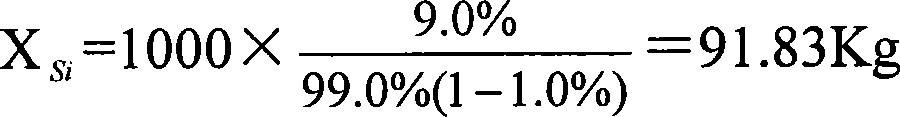

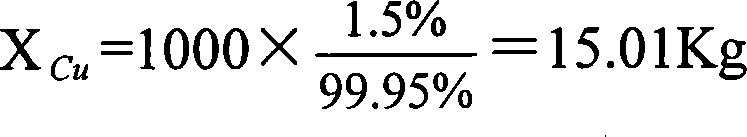

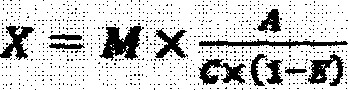

Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

The invention discloses an Al-Si-Cu-Mg series distortion aluminum alloy and the manufacturing method. The alloy is made up from 9.0-12.0wt% Si, 3.0-4.0wt% Cu, 0.3-0.6wt% Mg, <0.30% Fe, <0.20% Zn, and other impurity <=0.15wt%, and the rest is Al. The method includes the following steps: smelting and refining the raw materials in reflecting smelter, after processing the allow liquation by Al-Sr intermediate alloy, gaining cast rod through hemicontinuous casting, extruding the cast rod and after forging and T6 thermal treatment to gain the product. The tensile strength of the alloy is over 397MPa, and broken tensile stretch is 6%, and rigidity is 136-141HB. It is mainly used to make wheel for vehicle and motorcycle, piston, bearing, bidirectional sloping cam plate, etc.

Owner:SHANDONG UNIV

Feed composite for anthony pig weaned at early stage

ActiveCN101411406AImprove digestibilityImprove survival rateFood processingAnimal feeding stuffAntigenAnimal science

The invention discloses combined feedstuff for a weanling anthony pig in the early stage. The combined feedstuff comprises the following four stages of feedstuff: the feedstuff used in the first 3 days after weaning, the feedstuff used in the 4th to 11th days, the feedstuff used in the 12th to 24th days, and the feedstuff used in the 25th to 50th days. According to the number of weaning days and the physiologic tendency of the weanling anthony pig in the early stage, the feedstuff with different components is prepared so as to ensure the reasonable nutrition of the anthony pig. The combined feedstuff has high nutrient concentration, good palatability, easy digestion and absorption, low cost and a high conversion rate. In addition, the combined feedstuff has the low content of antigen component and the high content of immunity component, and uses a proper amount of acidifier so as to reduce the weaning stress and improve the survival rate of the anthony pig.

Owner:MUYUAN FOODS CO LTD

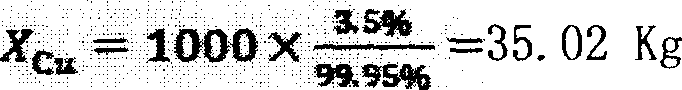

Nickel-based alloy of nuclear power steam generator

The invention relates to a nickel-based alloy of a nuclear power steam generator. The invention can maintain or increase the alloy performance while reducing the alloy cost. The specific scheme of the invention is as follows: 1. a defined amount of rare earth elements are added in steel to have purification and metamorphism functions of deoxidizing, desulfurizing, changing the shape of inclusion and the like, have microalloy function in the alloy and finally increase the oxidation resistance, high temperature strength and plasticity, fatigue life, corrosion resistance, crack resistance and the like of the steel; 2. in view of the production cost, the content of the precious element nickel is needed to be as low as the lower limit under the premise of ensuring the processability and ensuring that the alloy can form the desired metallographic structure; 3. the content of chromium element is increased properly so as to increase the high temperature oxidation resistance and corrosion resistance of alloy; 4. the content of silicon element is adjusted so as to increase the tensile strength and corrosion resistance of alloy while the plasticity of alloy is ensured; and 5. the content of carbon is controlled and titanium element is added at the same time so as to further increase the oxidation resistance and corrosion resistance of steel.

Owner:江苏龙鑫特殊钢实业总公司

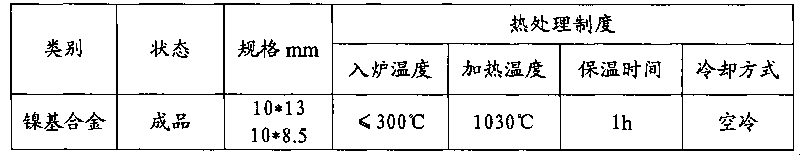

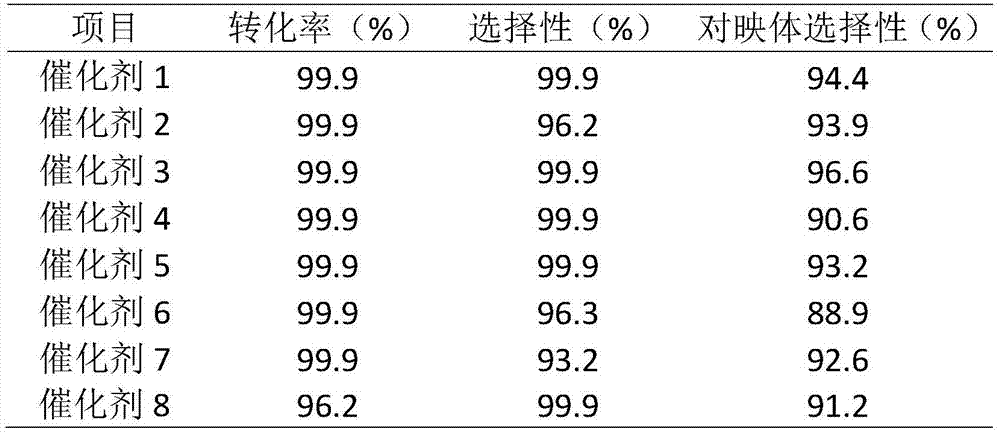

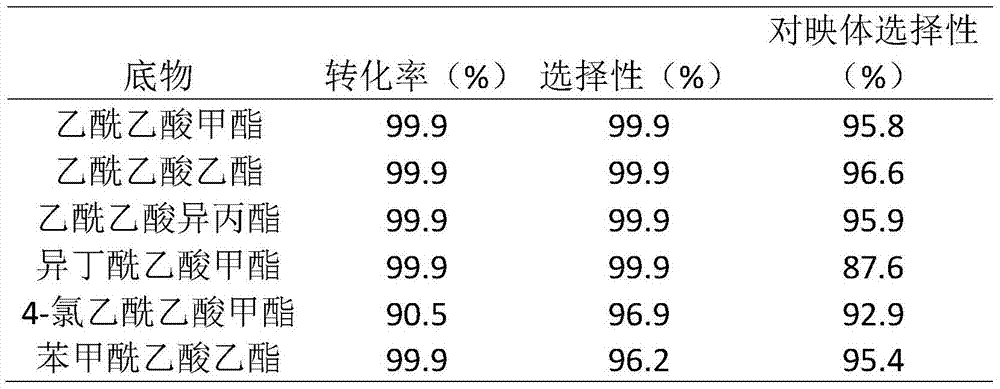

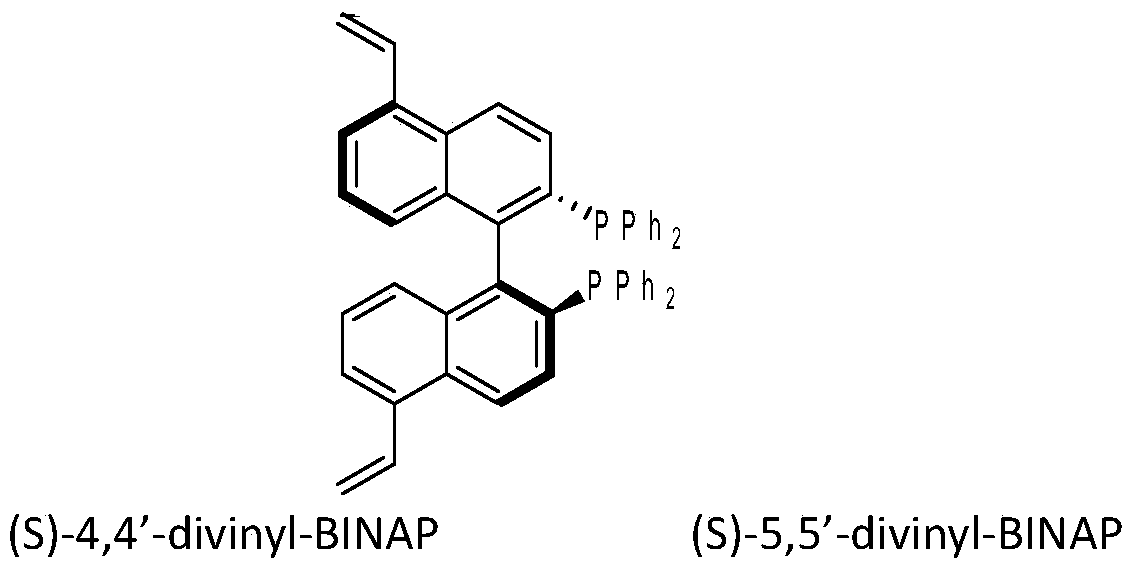

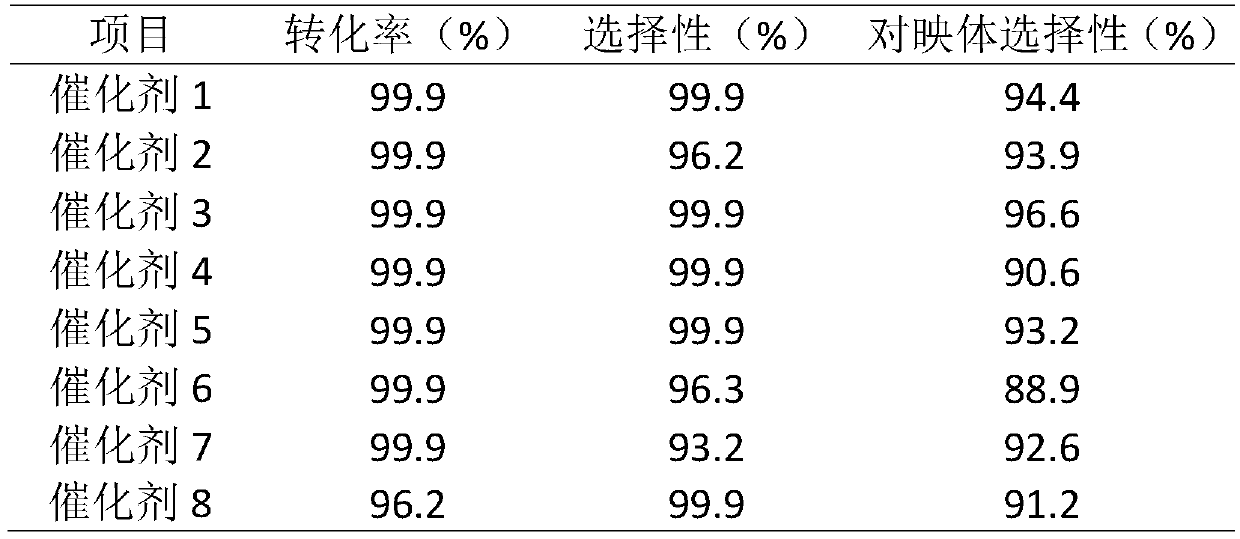

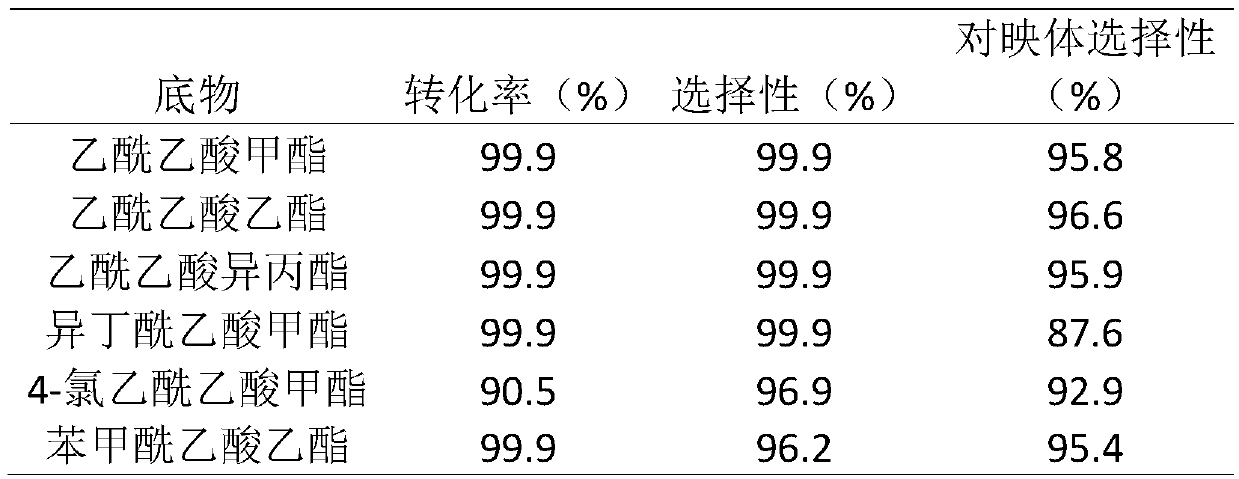

Applications of chiral polymer catalyst in asymmetric reaction

ActiveCN106853380AThe synthesis method is simpleShort reaction timeOrganic compound preparationOrganic chemistry methodsDispersityPorosity

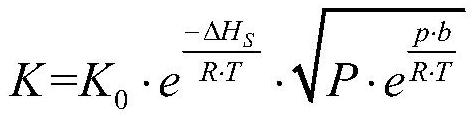

The invention discloses applications of a chiral polymer catalyst in asymmetric reaction, and belongs to the field of material synthesis and application. The phosphine-containing polymer is obtained via mixed polymerization of vinyl-containing chiral bidentate phosphine ligand BINAP (2,2'-bis(diphenylphosphino)-1,1'-binaphthyl) and derivative of vinyl-containing chiral bidentate phosphine ligand BINAP (2,2'-bis(diphenylphosphino)-1,1'-binaphthyl) with other vinyl comonomers. The vinyl polymer possesses relatively large specific surface area and porosity, and excellent thermal stability and chemical stability. In the heterogeneous catalyst, one or a plurality of elements selected from Ru, Rh, Ir, Pa, Au, and Cu are taken as active ingredients. The chiral ligand is uniformly embedded into and highly dispersed in a polymer skeleton, so that metal dispersion degree on the catalyst is relatively high, and relatively high catalytic activity is achieved. The heterogeneous catalyst is suitable for a plurality of reaction technology including intermittent still reaction, continuous fixed bed reaction, and trickle bed reaction. When the heterogeneous catalyst is used in catalytic kettle-type asymmetric hydrogenation, high target product yield is achieved, and enantioselectivity is higher than 96%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

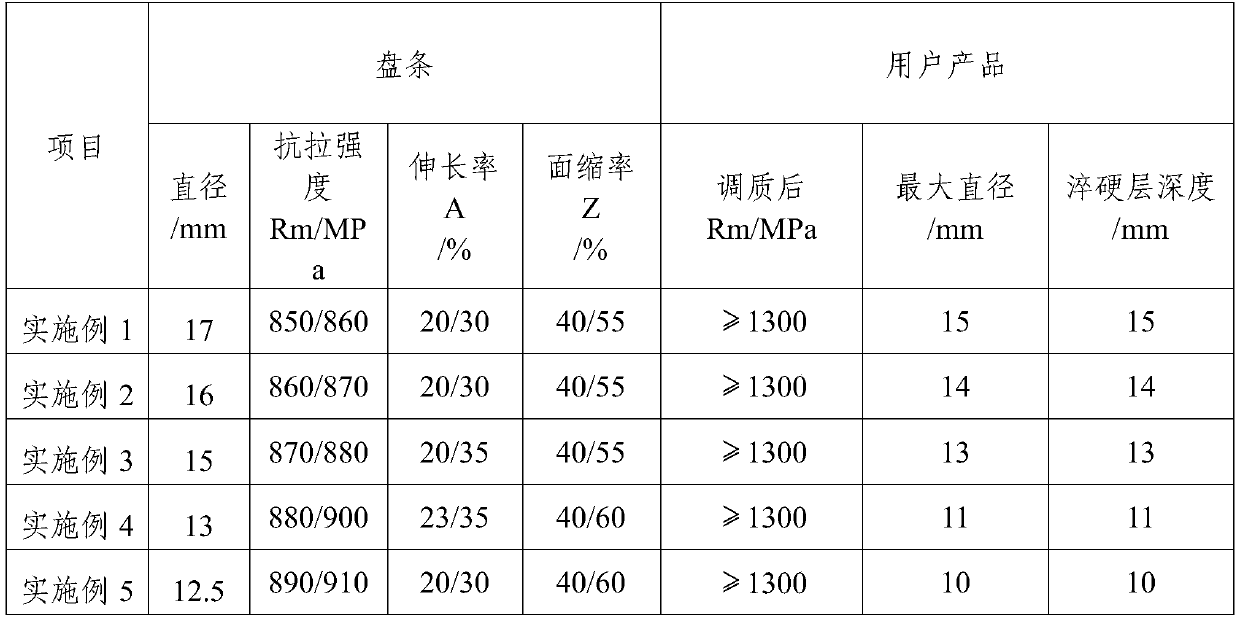

Extra large high strength steel for fastening part and production method

The invention belongs to the field of alloy steel smelting of iron and steel industries, and particularly provides an extra large high strength steel for a fastening part and a production method. The steel for the fastening part comprises, by mass, 0.43-0.47% of C, no more than 0.10% of Si, 0.60-0.90% of Mn, no more than 0.020% of P, no more than 0.010% of S, 0.02-0.06% of Als, 0.90-1.20% of Cr, 0.30-0.60% of Mo, 0.20-0.50% of V, 0.02-0.06% of Nb, 0.001-0.003% of B, and the balance Fe and unavoidable impurities. The production method of the steel comprises the following steps of molten iron desulfurization, converter smelting, deoxidation alloying, argon blowing, LF furnace treatment, continuous casting, casting blank heating, high line or bar rolling and stelmor control cooling. Steel inclusion produced through the method is low in grade, the extra large high strength steel is uniform in texture, good in cold heading property and hardenability and good in delayed fracture resistance, the tensile strength of wire rods reaches above 850 MPa, the depth of hardening layers of produced products reaches above 10 mm, the problem that the diameter of the large-scale fastening part needs to be increased to meet the tolerance requirements is solved to a certain extent, and the method is suitable for manufacturing the large-scale high strength fastening part.

Owner:武汉钢铁有限公司

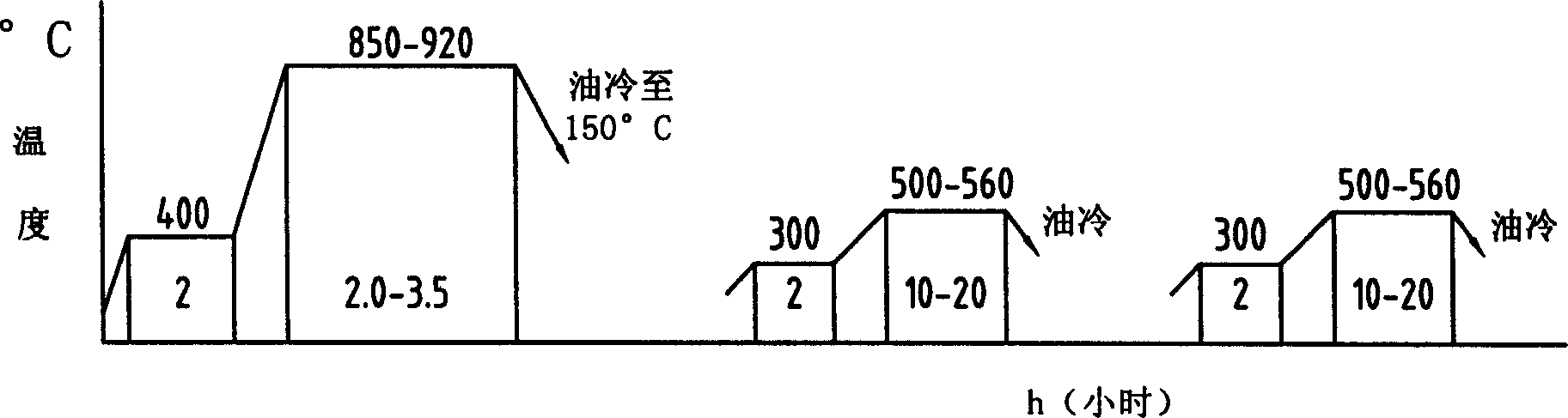

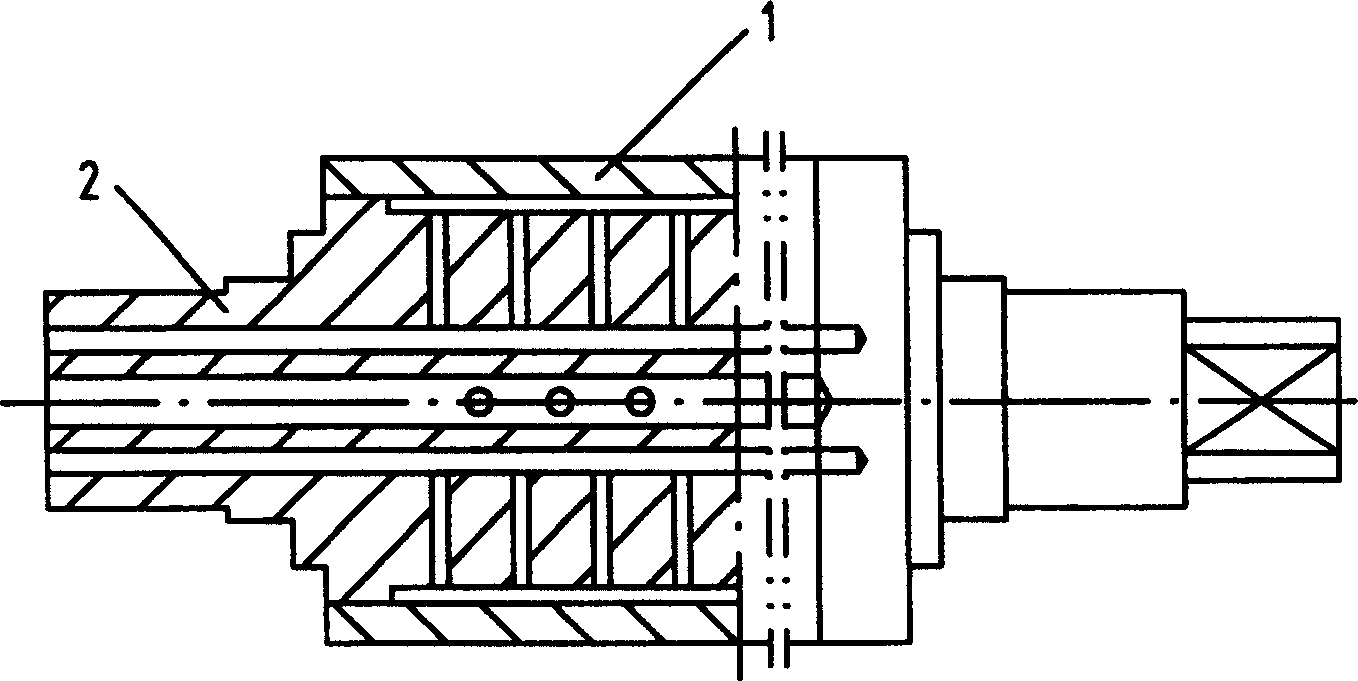

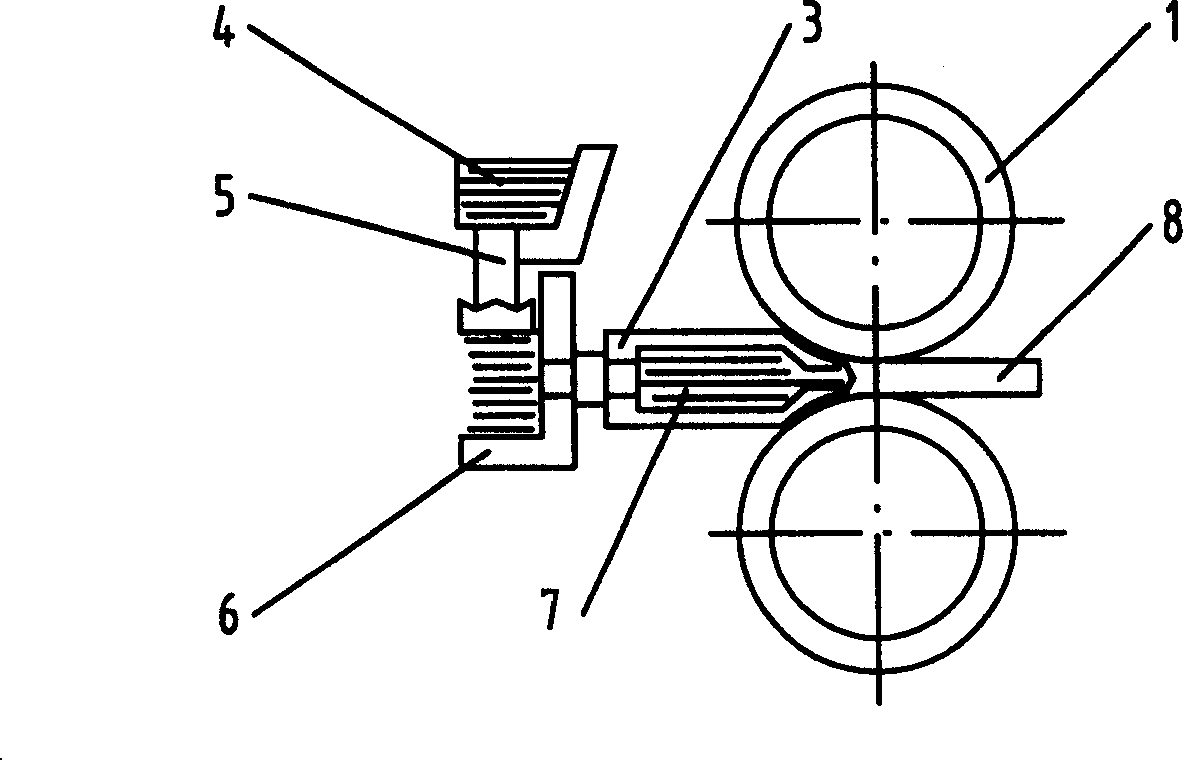

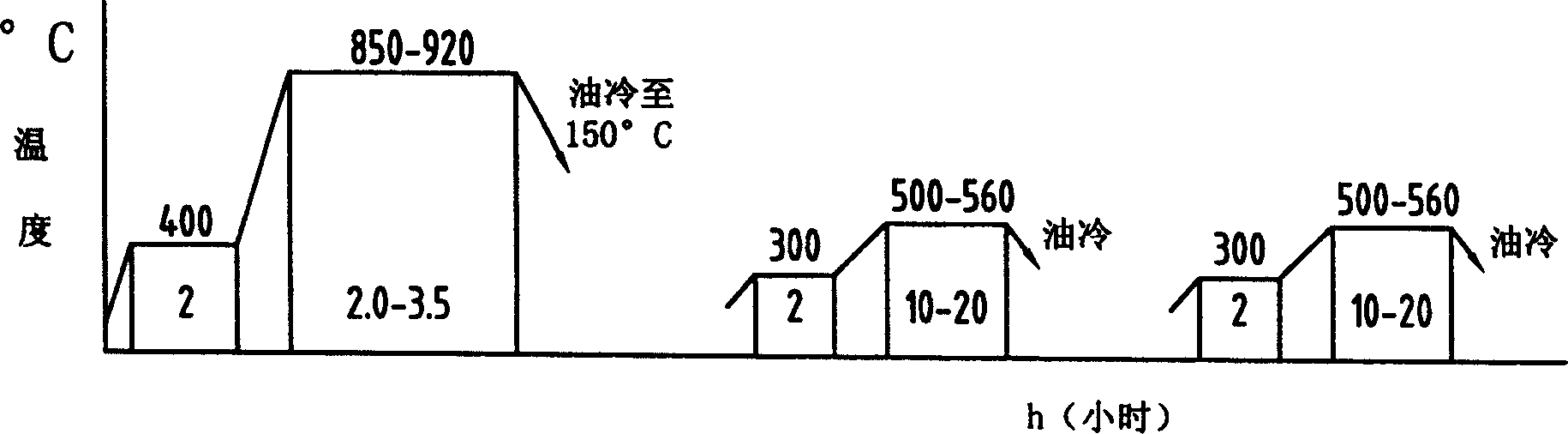

Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

InactiveCN1594636AImproved resistance to thermal fatigue cracksExtended service lifeFurnace typesHeat treatment furnacesStrip millAluminium casting

The invention relates to a roll ring steel for aluminum casting rolling mill and its heat treatment method. Chemical ingredient weight percentage of roll ring steel for aluminum casting rolling mill are : C 0.30-0.45, Mn 0.60-0.80, Si 0.20-0.40, P <=0.025, S <=0.025, Cr 2.00-3.00, Ni 0.50-1.00, Mo 0.80-1.20, V 0.10-0.20, Al <=0.012, surplus being ferrum and other impurity. The final heat treatment method of roll ring steel adopt second tempering after quenching. Quenching temperature is 850-920 DEG C , and proceeding in engine oil after heat preservation. In first tempering, roll ring is heated to 500-560 DEG C , insulated 10-20 hours, cooled in engine oil. The second tempering parameters are same with that of first tempering. The invention promotes anti heat fatigue crack capability of roll ring, so promotes the life of roll ring.

Owner:李春治

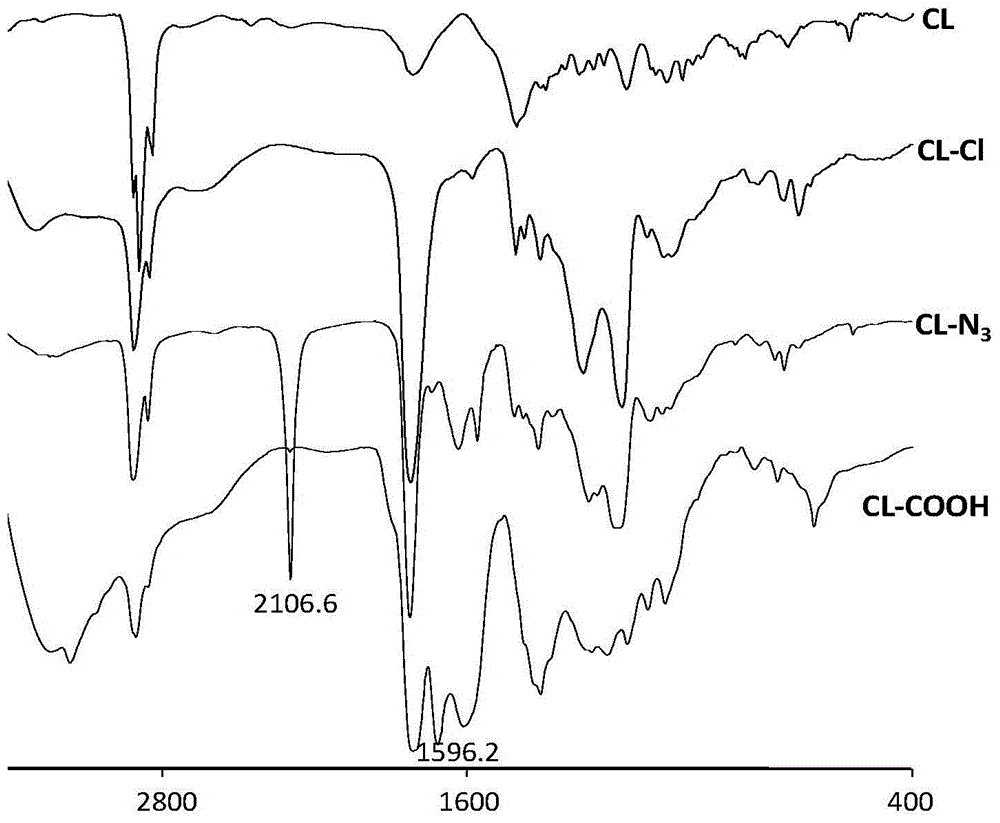

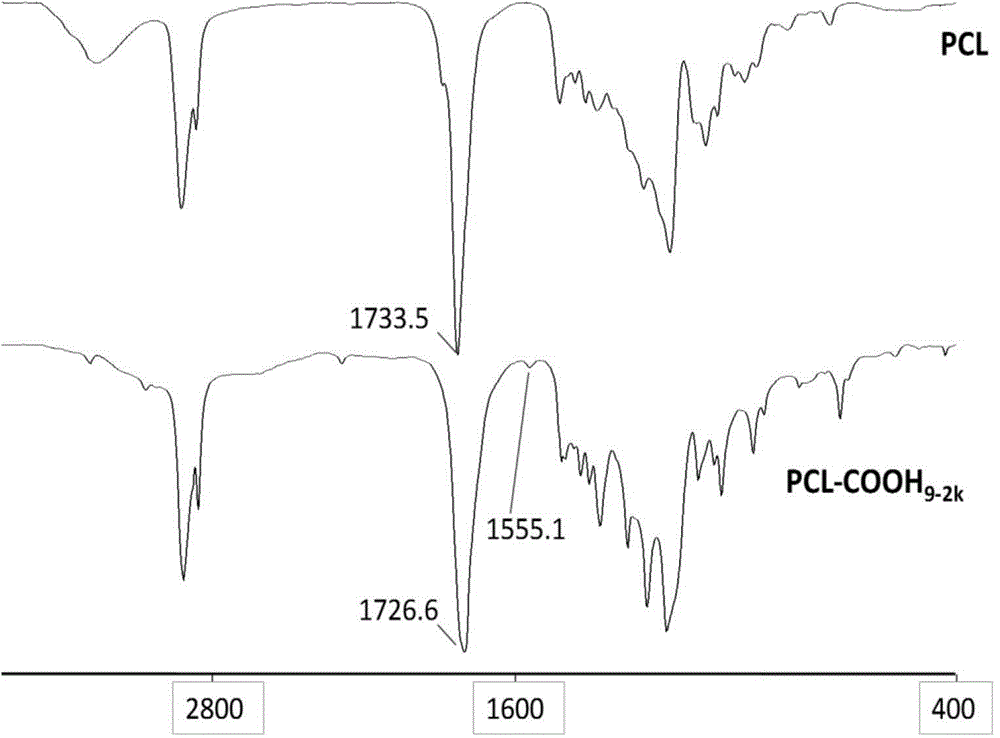

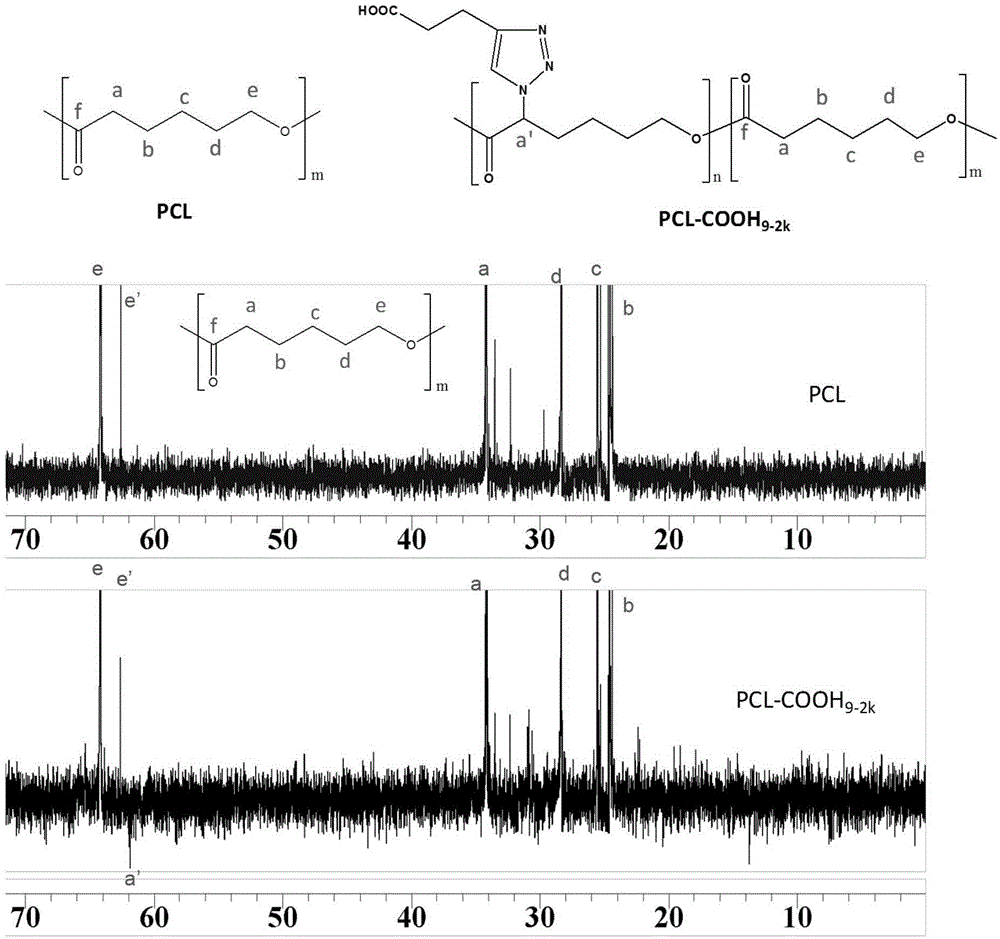

Polycaprolactone with reactive group on side chain and preparation method of polycaprolactone

The invention discloses polycaprolactone with a reactive group on a side chain and a preparation method of the polycaprolactone. The side chain of the reactive polycaprolactone contains -COOH, the hydrophilic-hydrophobic property of the reactive polycaprolactone can be adjusted by adjusting the content of the -COOH, the -COOH on the side chain has a reaction property and can be used for chemically fixing bioactive molecules, the bioactivity of the polycaprolactone is achieved, and the application range of the polycaprolactone can be enlarged.

Owner:CHONGQING UNIV

Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

The invention discloses an Al-Si-Cu-Mg series distortion aluminum alloy and the manufacturing method. The alloy is made up from 9.0-12.0wt% Si, 3.0-4.0wt% Cu, 0.3-0.6wt% Mg, <0.30% Fe, <0.20% Zn, and other impurity <=0.15wt%, and the rest is Al. The method includes the following steps: smelting and refining the raw materials in reflecting smelter, after processing the allow liquation by Al-Sr intermediate alloy, gaining cast rod through hemicontinuous casting, extruding the cast rod and after forging and T6 thermal treatment to gain the product. The tensile strength of the alloy is over 397MPa, and broken tensile stretch is 6%, and rigidity is 136-141HB. It is mainly used to make wheel for vehicle and motorcycle, piston, bearing, bidirectional sloping cam plate, etc.

Owner:SHANDONG UNIV

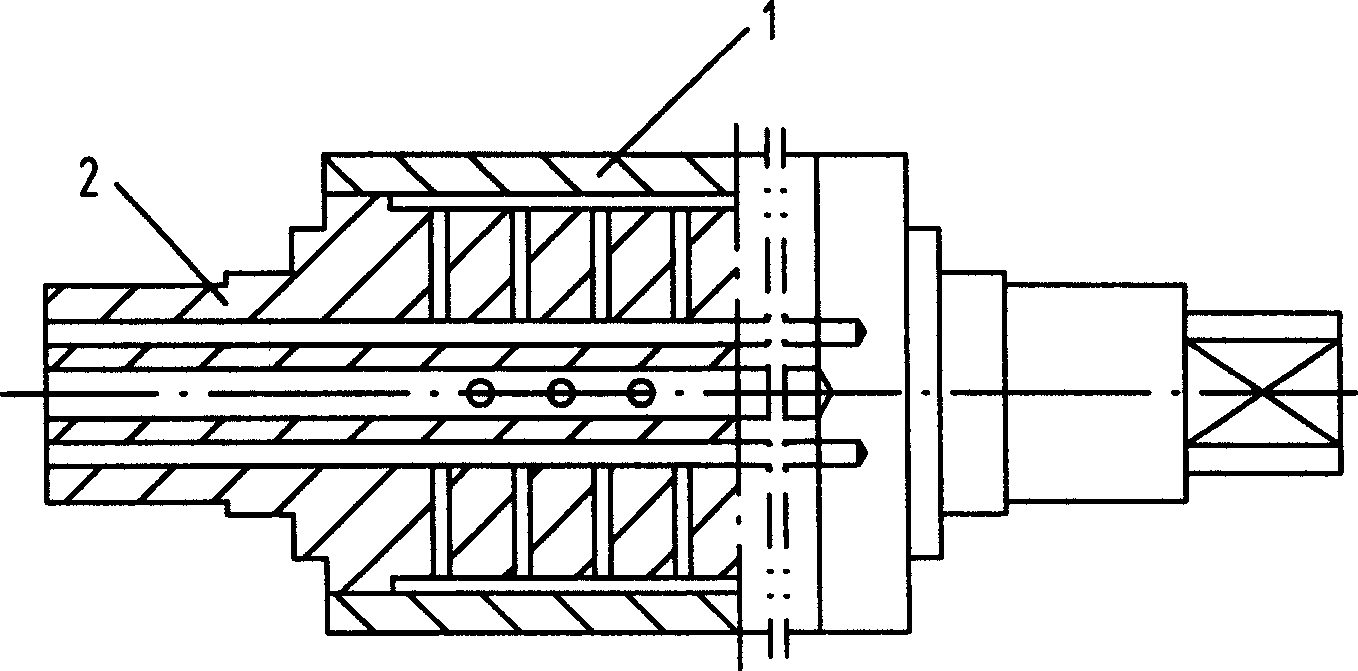

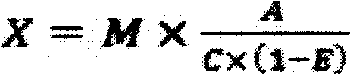

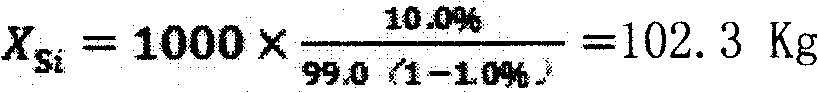

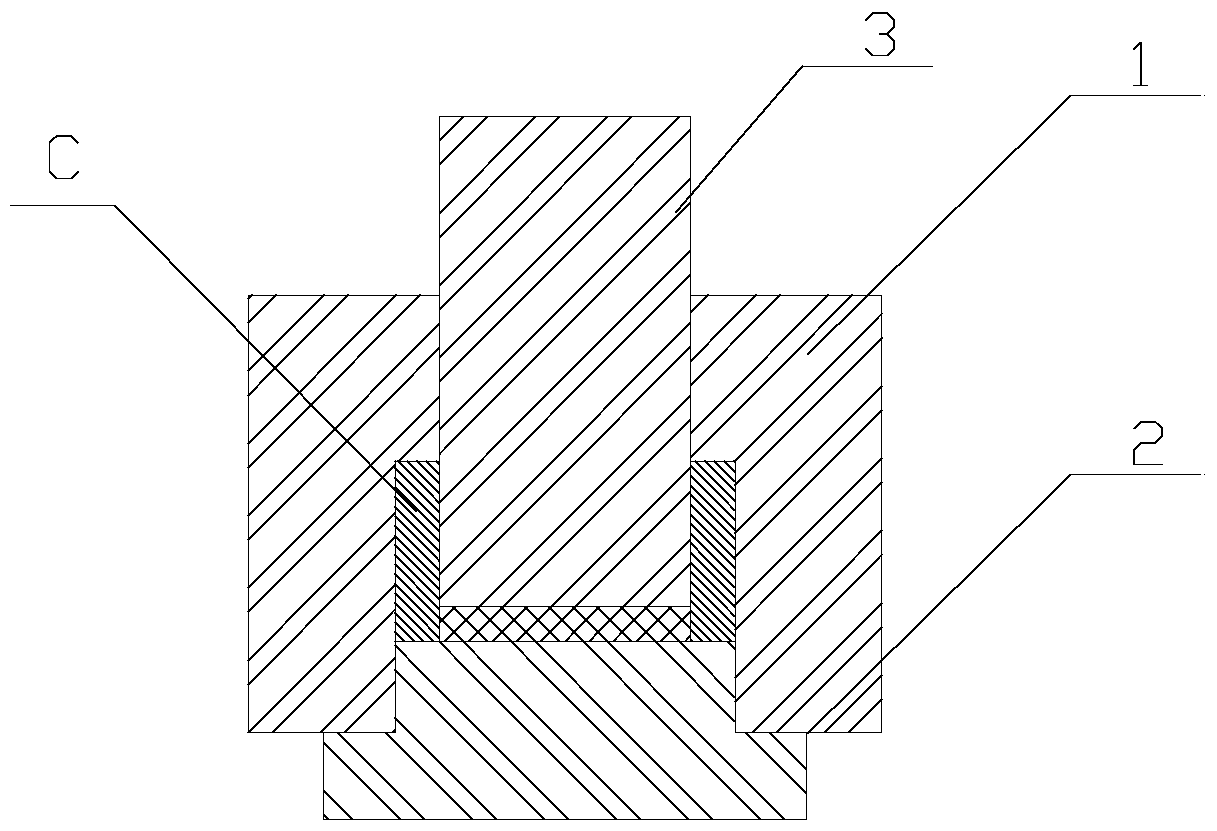

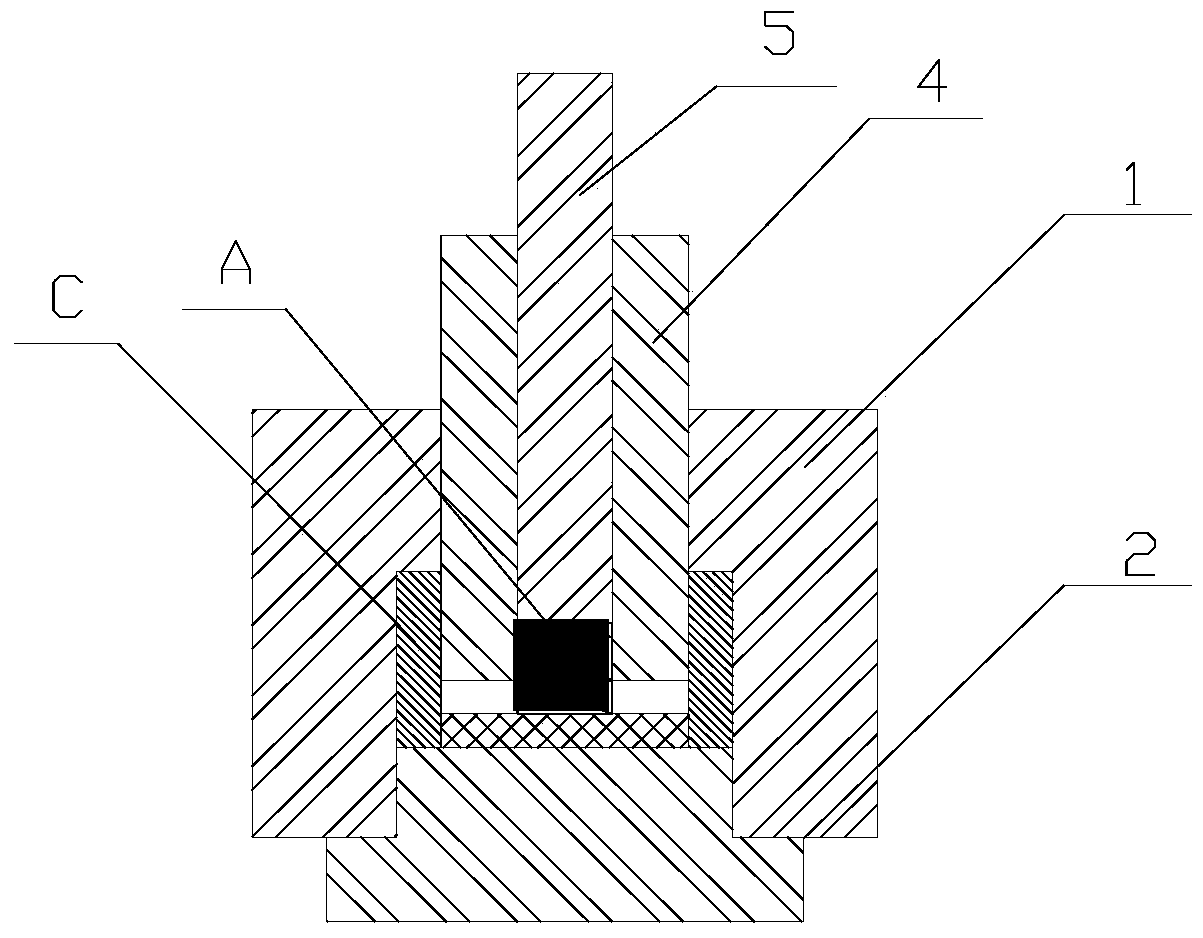

Spark plasma sintering manufacturing technology for high-rigidity polycrystalline diamond drawing die

The invention discloses a spark plasma sintering manufacturing technology for a high-rigidity polycrystalline diamond drawing die. A bushing is obtained by carrying out spark plasma sintering on metal powder, the vacuum degree is 2-8 Pa, the initial pressure is 20-30 MPa, after the temperature is increased to 300-350 DEG C with the rate of 80-100 DEG C / min, the pressure is reduced to 10-20 MPa, after the temperature is increased to 420-450 DEG C with the rate of 50-80 DEG C / min, the pressure is reduced to 8-10 MPa, after the temperature is increased to 500-520 DEG C with the rate of 30-50 DEG C / min, the temperature is increased to 550-570 DEG C with the rate of 20 DEG C / min, the temperature and the pressure are kept for 30-50 seconds, and the drawing die is obtained through cooling. In the spark plasma sintering process, shock waves, electrons and ions generated by pulse discharge can purify and activate powder, particles can be subjected to the comprehensive action of ion discharge, electric conduction heating and pressurizing at the same time, the activation energy is reduced, the sintering time is shortened, and the growth of grains is restrained; the nucleation energy can be reduced through pulse current, the nucleation rate is increased, and fine tissue is obtained. According to the spark plasma sintering manufacturing technology, a novel metal powder formula for the bushing and the spark plasma sintering technology are adopted, and therefore the high-strength, high-rigidity and high-density die is obtained.

Owner:天长市天屹模具科技发展有限公司

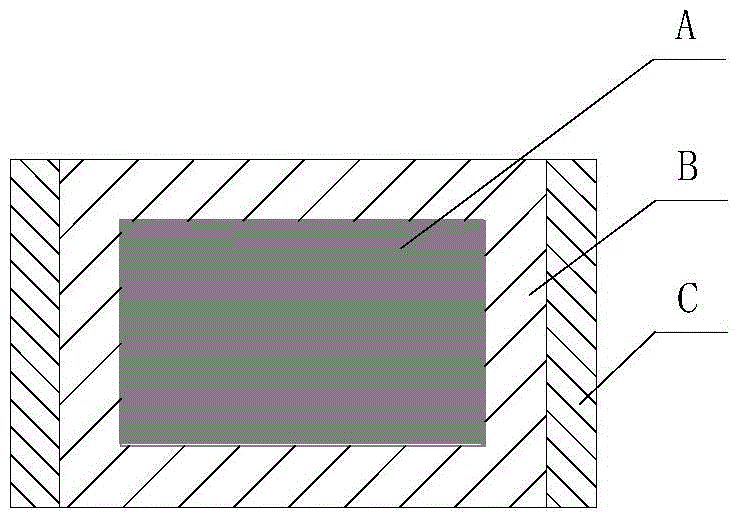

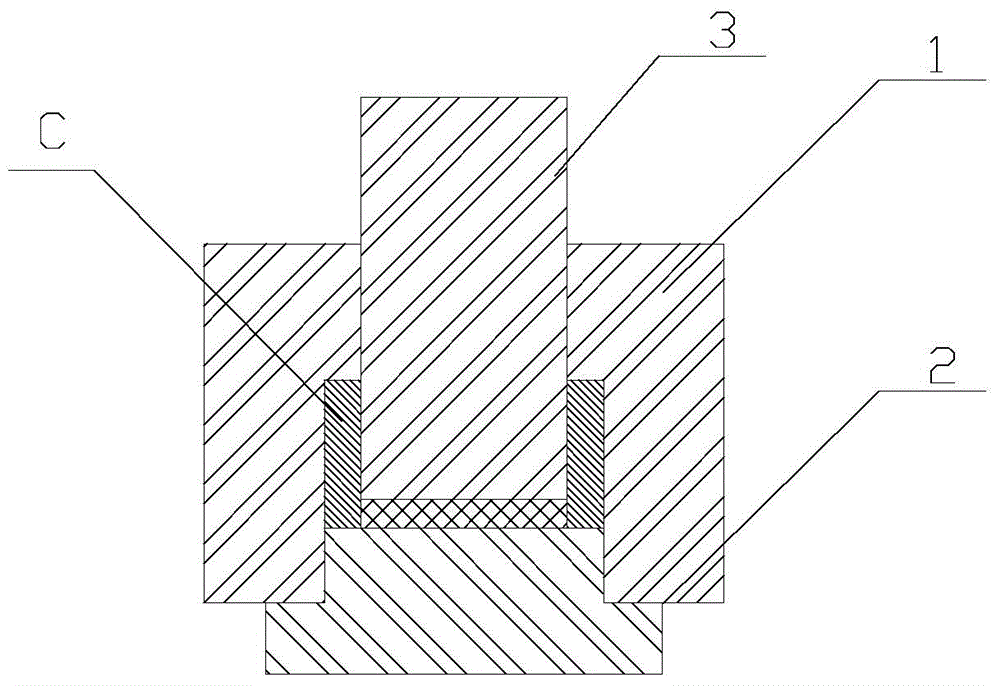

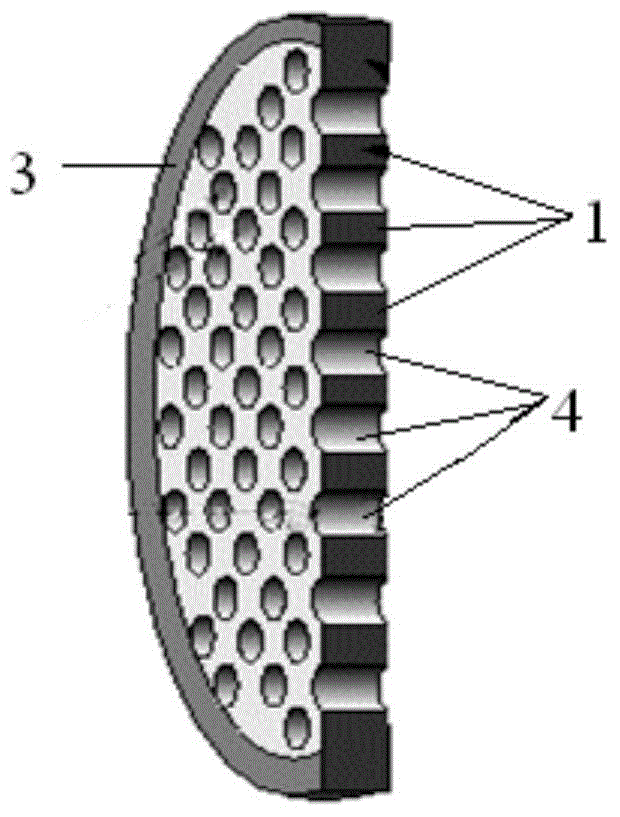

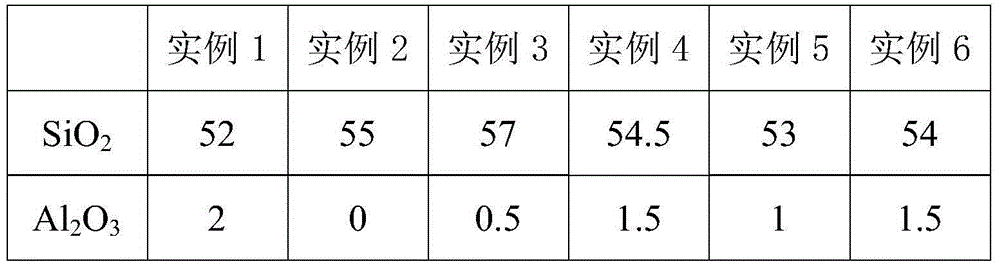

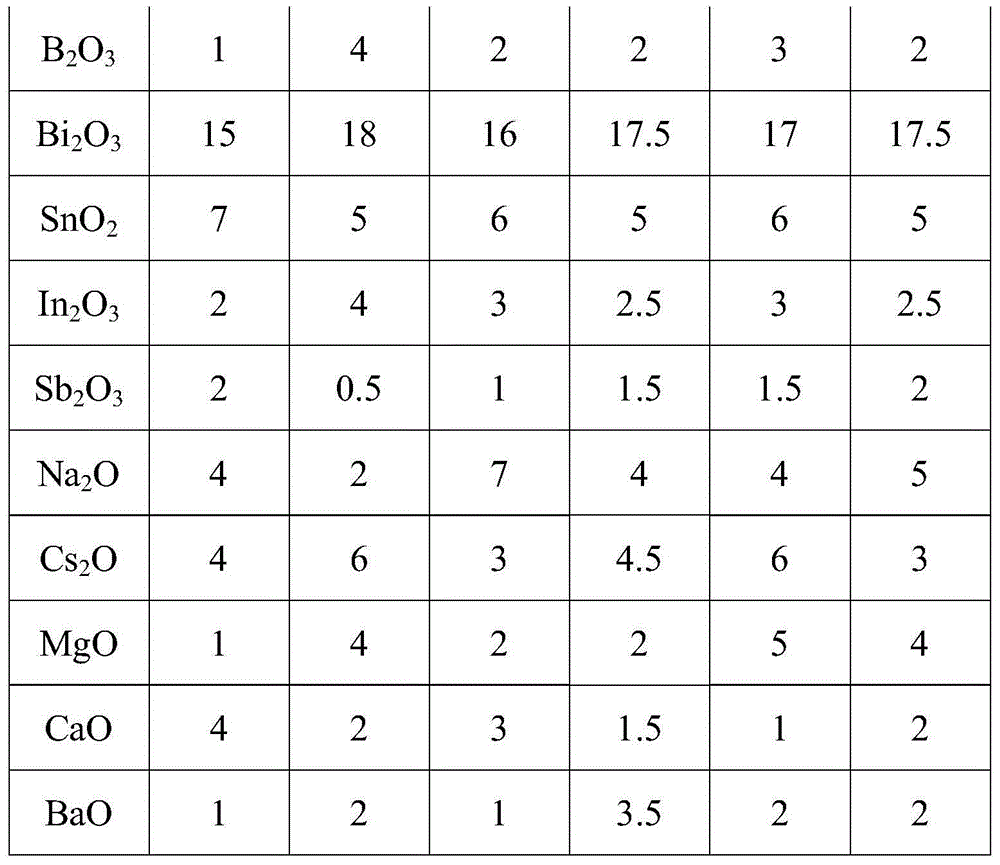

Micro-channel plate cladding glass and preparation method thereof

The invention relates to a micro-channel plate cladding glass, a micro-channel plate, and a preparation method thereof. The micro-channel plate cladding glass comprises the following components in parts by weight: 52 to 57 parts of SiO2, 0 to 2 parts of Al2O3, 1 to 4 parts of B2O3, 15 to 18 parts of Bi2O3, 5 to 7 parts of SnO2, 2 to 4 parts of In2O3, 0.5 to 2 parts of Sb2O3, 8 to 10 parts of Na2O and Cs2O, and 6 to 8 parts of MgO, CaO, and BaO. The micro-channel plate cladding glass and micro-channel plate prepared therefrom have the characteristics of non-toxicity, innocuousness, and environment-friendliness.

Owner:CHINA BUILDING MATERIALS ACAD

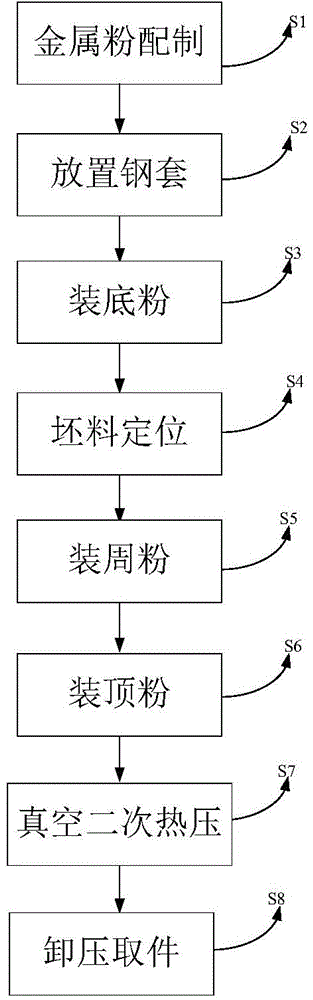

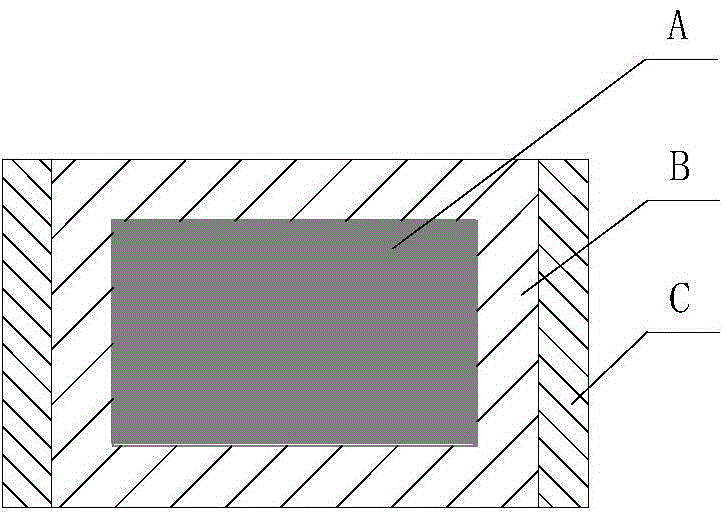

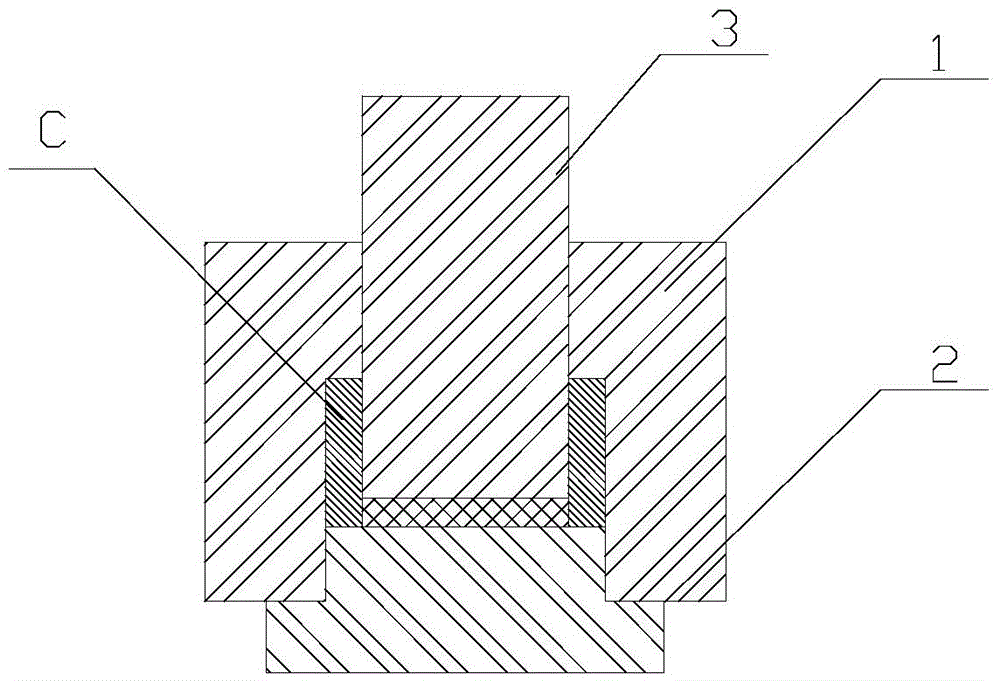

Vacuum secondary hot pressing manufacturing technology for high-strength polycrystalline diamond drawing die

The invention discloses a vacuum secondary hot pressing manufacturing technology for a high-strength polycrystalline diamond drawing die. A bushing is obtained by metal powder through vacuum secondary hot pressing, the vacuum degree is 2*10-3-8*10-3 Pa, the pressing pressure is 20-45 MPa, the temperature is increased to 500-550 DEG with the rate of 20-30 DEG C / min, the temperature and the pressure are kept for 10-20min, the temperature is increased to 600-650 DEG C with the rate of 10-15 DEG C / min, the temperature is kept for 10-15 min, the pressure is kept for 15-20 min, and the drawing die is obtained through cooling. The method of vacuum secondary hot pressing is adopted, particles can be scattered and slide through the surface energy and the external pressure, pores in a sintered body are removed, and the compactness of materials is improved; elastic strain in the cold pressing process can be removed, the density of the sintered body can be increased, the elastic failure does not exist, and the adverse influences generated by size increasing after demolding are reduced; the vacuum sintering is neutral sintering of anaerobic and non-reducing gas, combination of interfaces can be improved, and the obtained drawing die bushing is closely attached to a die core and a steel bushing; the gaps of the sintered body can be fully filled with the particles through secondary hot pressing, obtained material cracks are few, and the utilization rate of the die is increased.

Owner:天长市天屹模具科技发展有限公司

Tea tree planting method

The invention belongs to the technical field of planting, and specifically relates to a tea tree planting method. The method comprises the following steps: selecting a planting field, establishing a tea garden, transplanting tea seedlings, planting shade trees, establishing grassland, managing saplings, and managing after picking tea. Grass seeds are uniformly sown in the field, to cultivate the grassland. Thus, vapor content in a ground proximity section where tea trees live is increased, proportion of scattered light in the section is improved, proportion of nutrient substances in tea is adjusted, content of pigment is reduced, and quality of tea is improved. After the grassland is harvested, grass can be used as a fodder or a raw material of an organic fertilizer, so that land resourcesare rationally used. Firs are planted in the tea garden as the shade trees of the tea garden. Growing conditions of the tea trees in natural environment are artificially created, so buds and leaves sprout early, round seals late, buds and leaves are stout and strong, leaf texture is soft, and yield and quality are improved. The firs have drought control and water retention effects.

Owner:贵州省普定县德胜茶叶专业合作社

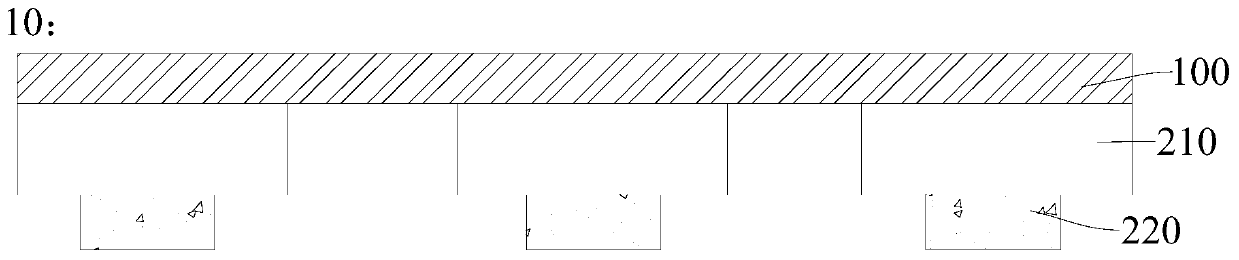

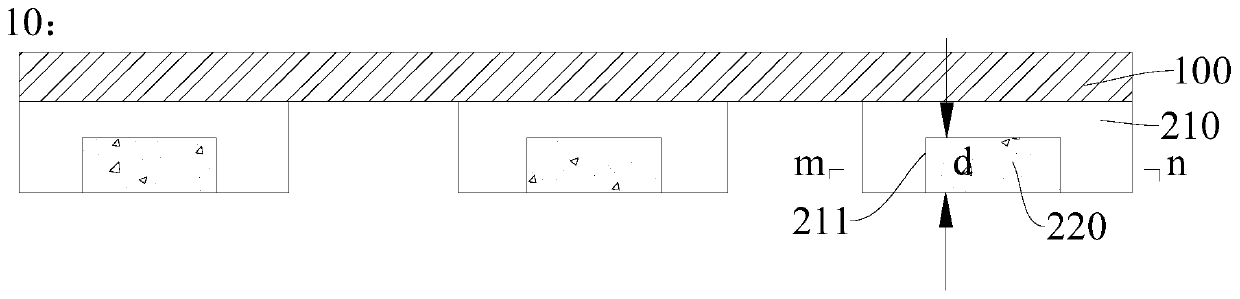

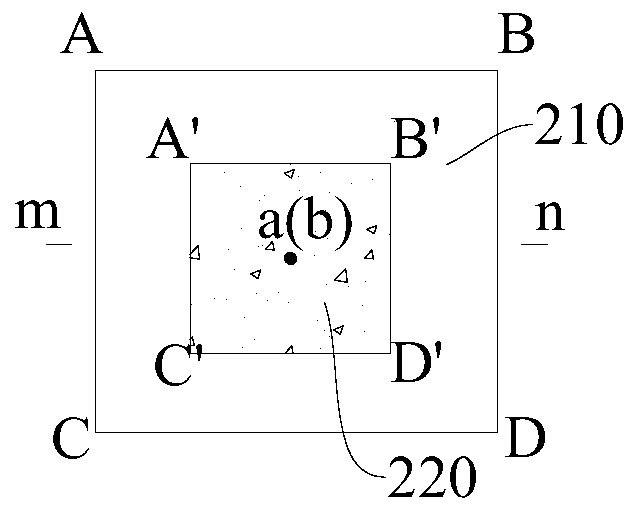

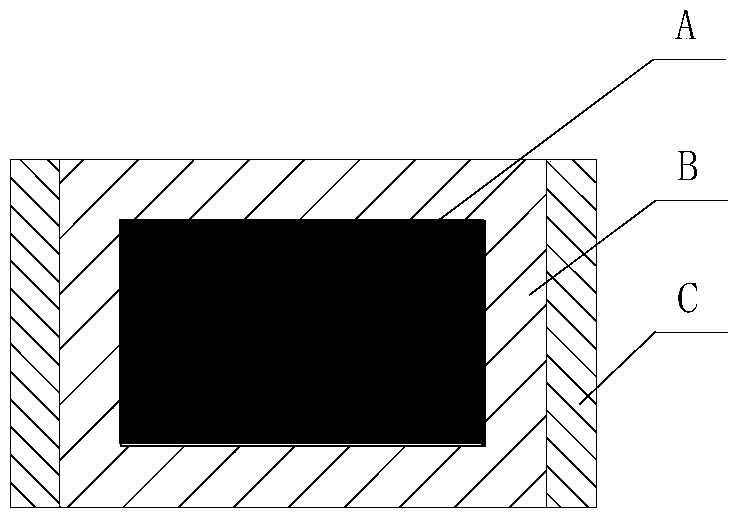

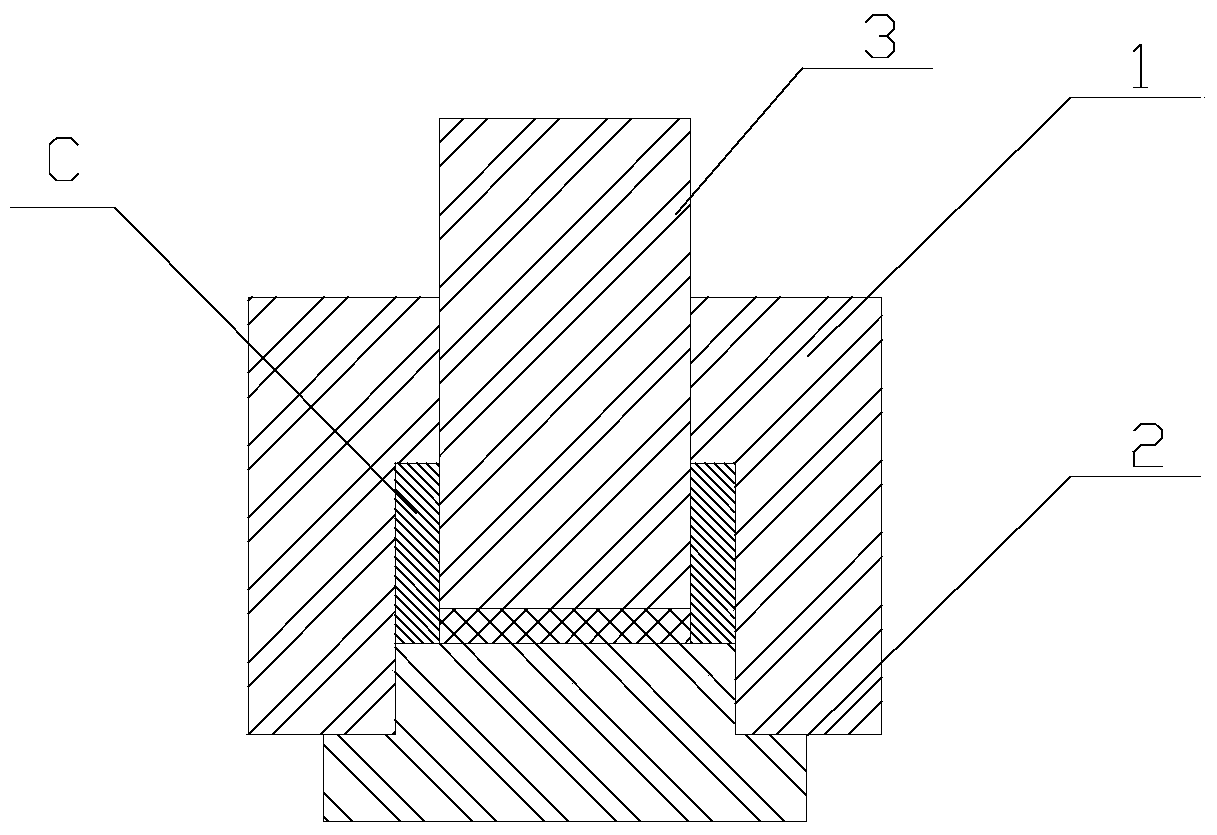

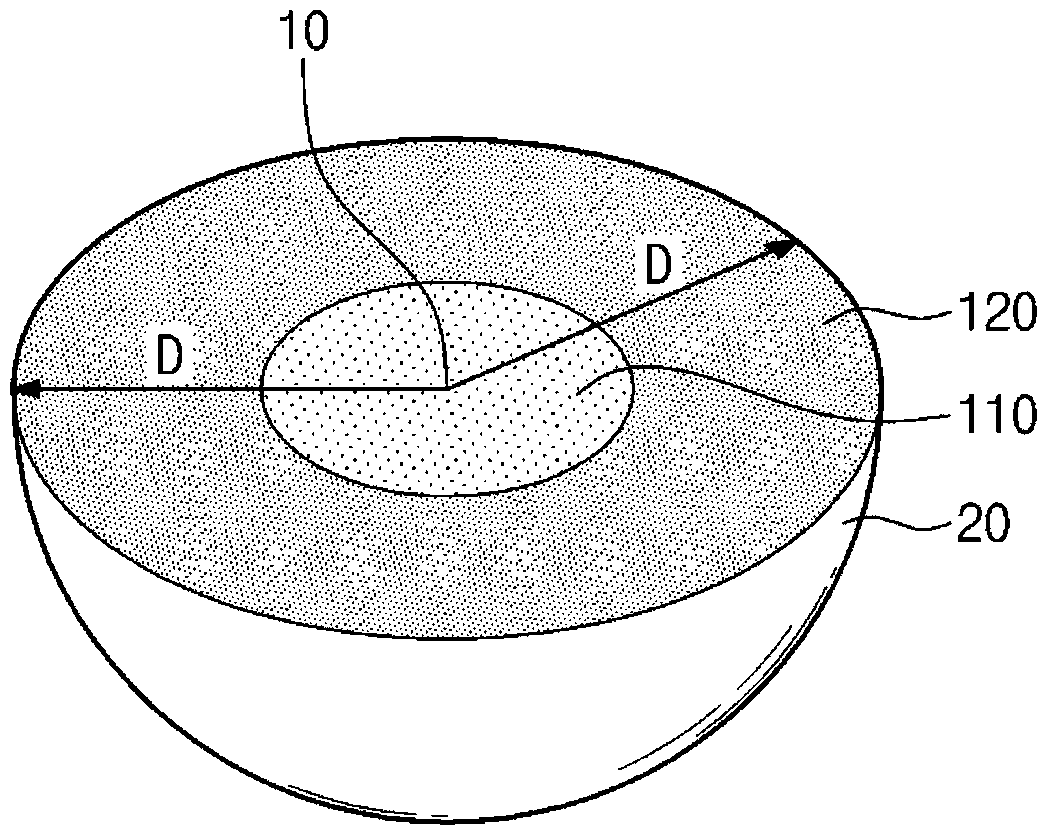

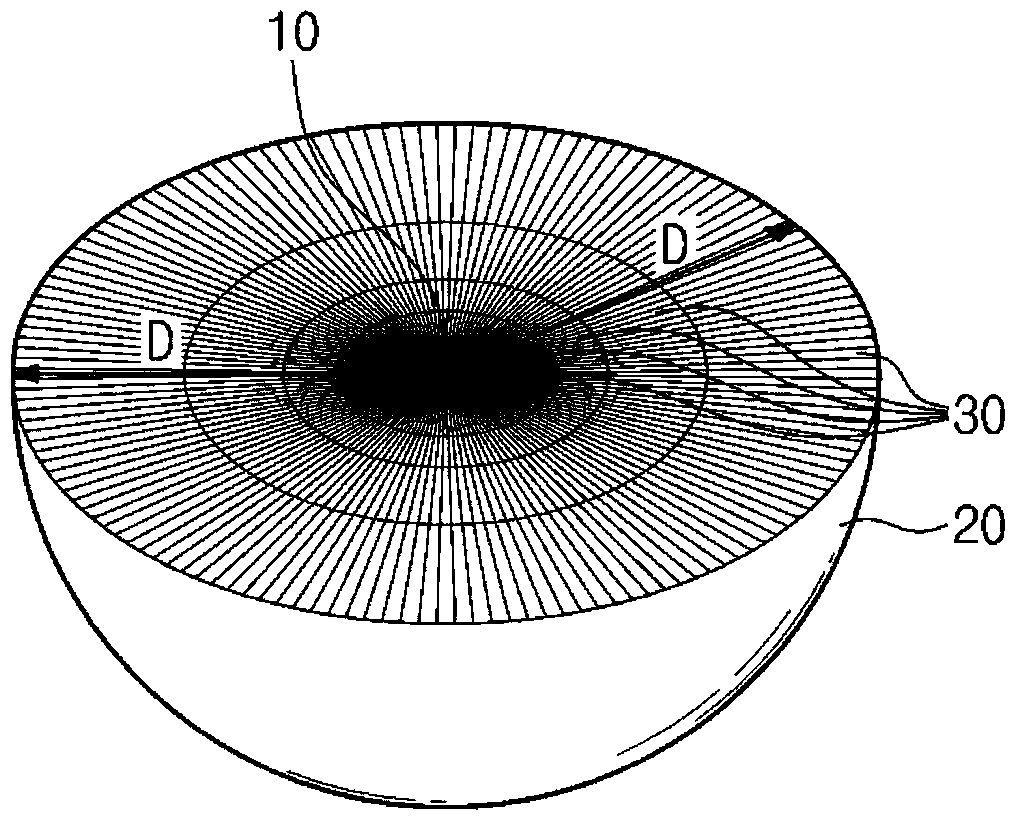

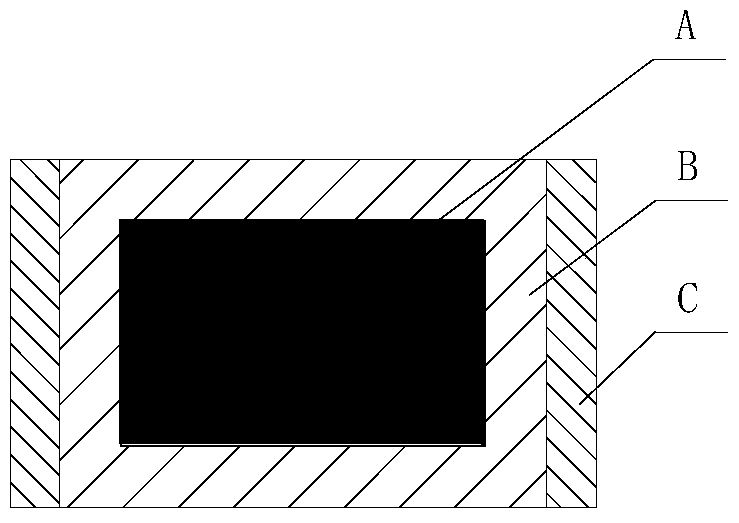

Color film substrate for OLED and preparation method thereof, and OLED display device

ActiveCN110400888AAlleviate uneven display brightnessImprove color gamutSolid-state devicesSemiconductor/solid-state device manufacturingResistColor film

The invention discloses a color film substrate for an OLED and a preparation method thereof, and an OLED display device. The color film substrate includes a substrate and multiple color resist blocks,wherein the multiple color resist blocks are located on the substrate, colors of the multiple color resist blocks are not completely the same, the multiple color resist blocks respectively includes afirst color resistance portion and a second color resistance portion, the orthographic projection of the second color resistance portion on the substrate is located at the center of the orthographicprojection of the color resistance block on the substrate, and the transmittance of a material forming the second color resist portion to the light emitted by the OLED is lower than the transmittanceof a material forming the first color resist portion to the light emitted by the OLED. The color film substrate is advantaged in that the structure is simple, the OLED display device is made to be less prone to a pixel edge darkening phenomenon, uniformity of display brightness is strong, and the display effect is good.

Owner:BOE TECH GRP CO LTD

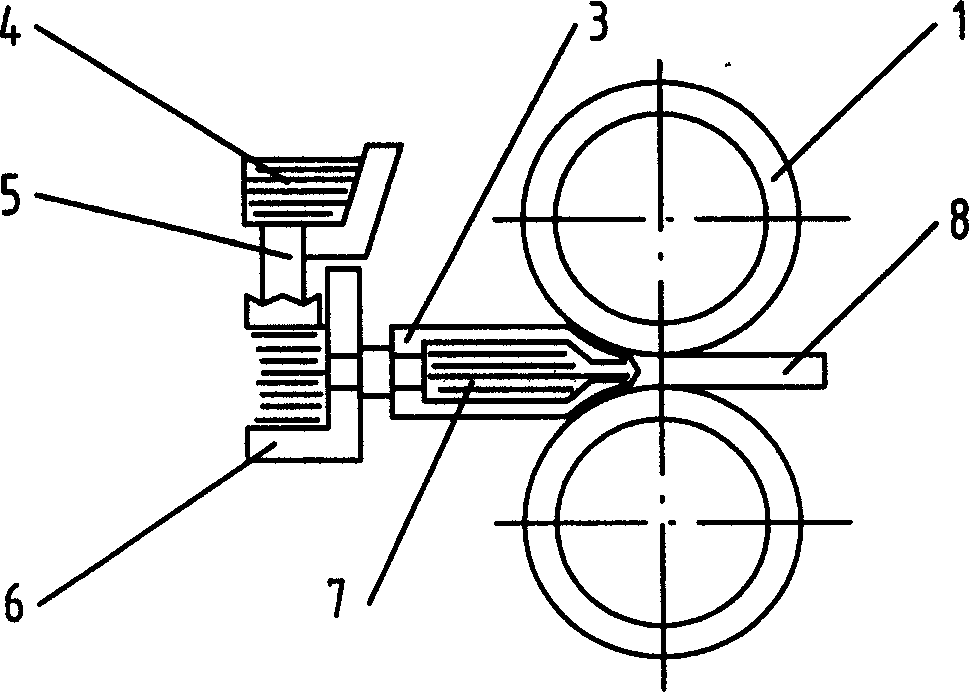

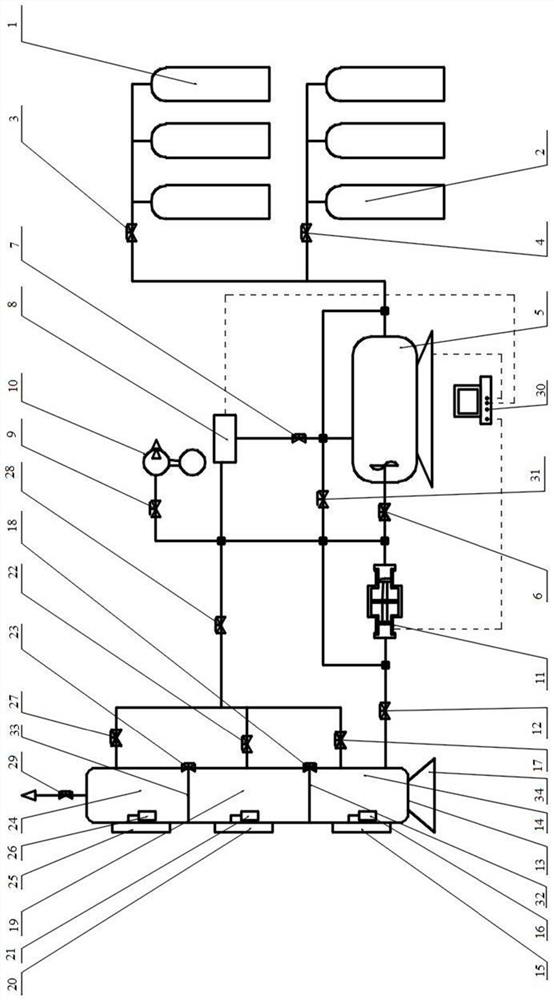

Device and method for testing gas component distribution in hydrogen-doped natural gas

ActiveCN113804854APrecise ratioGuaranteed accuracyComponent separationFuel testingElectric machineryDrive motor

The invention relates to a hydrogen-doped natural gas technology, and aims to provide a device and a method for testing gas component distribution in hydrogen-doped natural gas. The device comprises: a stirring kettle internally provided with a stirring paddle, wherein the inlet of the stirring kettle is respectively connected with a natural gas cylinder group and a hydrogen cylinder group through pipelines; a vertical gas cylinder, wherein at least three layers of partition plates are arranged in the vertical gas cylinder, and can be controlled by valves to be opened and closed so as to form mutually independent internal partitions; a pneumatic booster pump respectively connected with the stirring kettle and the vertical gas cylinder; a plurality of gas outlets formed in the wall of the vertical gas cylinder and connected with a chromatographic analyzer through pipelines, wherein each gas outlet corresponds to one internal partition; and a control system connected to the chromatographic analyzer, the stirring paddle and the driving motor of the pneumatic booster pump through signal lines. According to the testing device and the testing method provided by the invention, the gas component distribution of hydrogen-doped natural gas in a high-pressure gas cylinder in a station yard after long-term standing layering can be conveniently and accurately measured.

Owner:ZHEJIANG UNIV

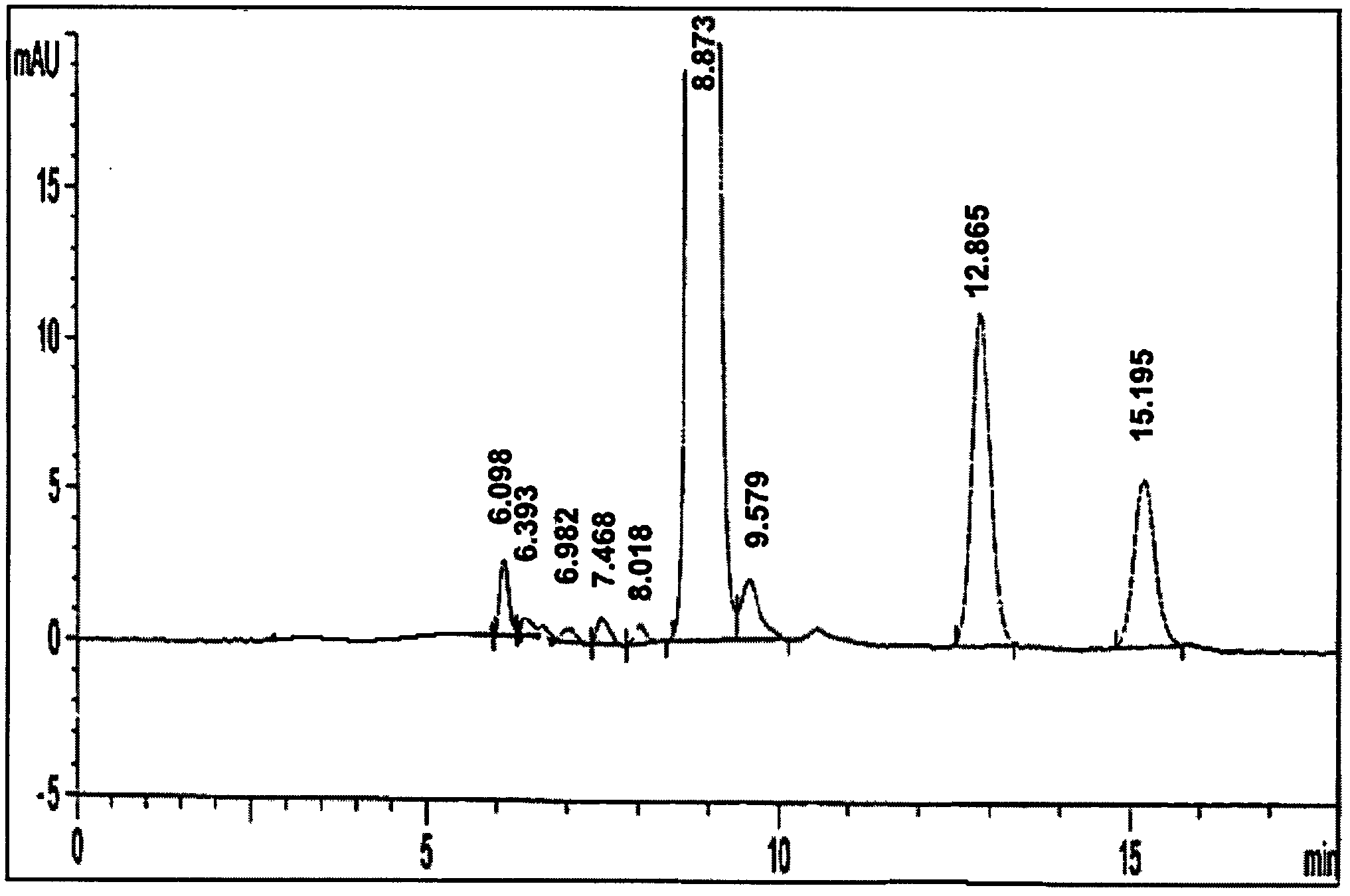

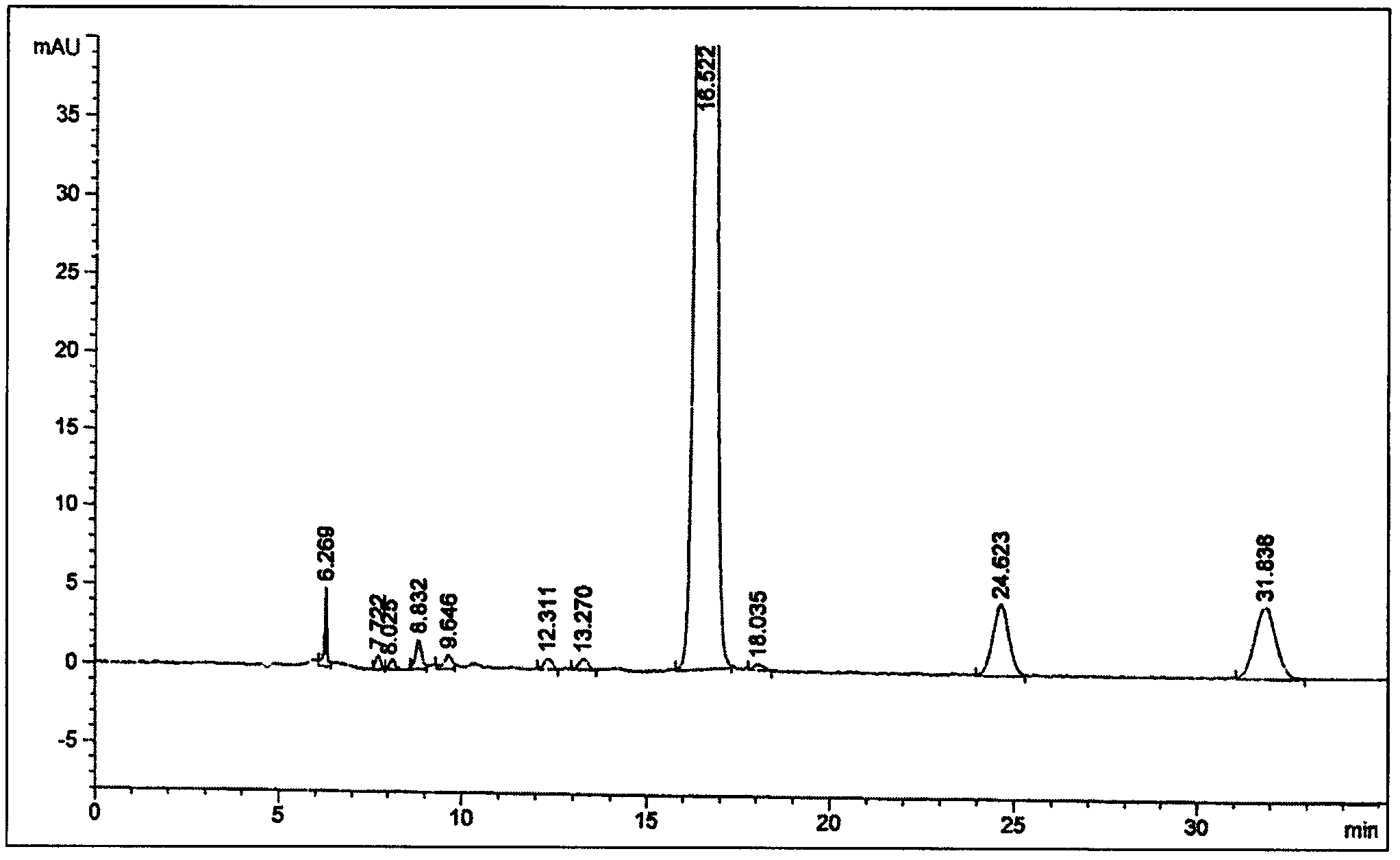

Detection method of methylprednisolone sodium succinate freeze-dried powder injection related substance

A detection method of methylprednisolone sodium succinate freeze-dried powder injection related substances adopts a high performance liquid chromatography method, and is characterized in that the chromatographic conditions are that: silica gel is selected as a stationary phase of a chromatographic column; n-butyl chloride - water-saturated n-butyl chloride - tetrahydrofuran - methanol - glacial acetic acid with a volume ratio of 130:130:14:7:6 is selected as a mobile phase; and the detection wavelength is 254 nm.

Owner:TIANJIN JINYAO GRP

026Cr18Ni12Mo2N stainless steel forging for nuclear power station and manufacturing method thereof

The invention discloses a 026Cr18Ni12Mo2N stainless steel forging for a nuclear power station. The 026Cr18Ni12Mo2N stainless steel forging for nuclear power station comprises the following chemical components: 0.015-0.035% of C, not greater than 1%of Si, not greater than 2% of Mn, not greater than 0.03% of P, not greater than 0.015% of S, 2-18.2% of Cr, 11.6-12.5% of Ni, 2.25-2.75% of Mo, 0.05-0.08% of N, not greater than 1% of Cu, and the balance pig iron. The invention also discloses method of manufacture. The method comprises the steps of refining raw materials; forging: forging the obtained stainless steel ingot into a stainless steel forging, wherein the stainless steel forging is subjected to main deformation at the temperature of 1000 + / -20 DEG C; and heat treatment, namely, heatingthe forged stainless steel forging to 1050-1120 DEG C, preserving heat, and then cooling with water; and detecting. According to the method adopting the abovementioned mode, the content of C and N isincreased in chemical components, the content of Cr and Ni is adjusted, and the strength of the forging is increased in material components. In the aspect of the manufacturing method, the internal stress generated in the finish forging process can also generate static recrystallization in the heat treatment process, so that the material grains are effectively refined, and the refined grains can increase the material strength.

Owner:无锡市法兰锻造有限公司

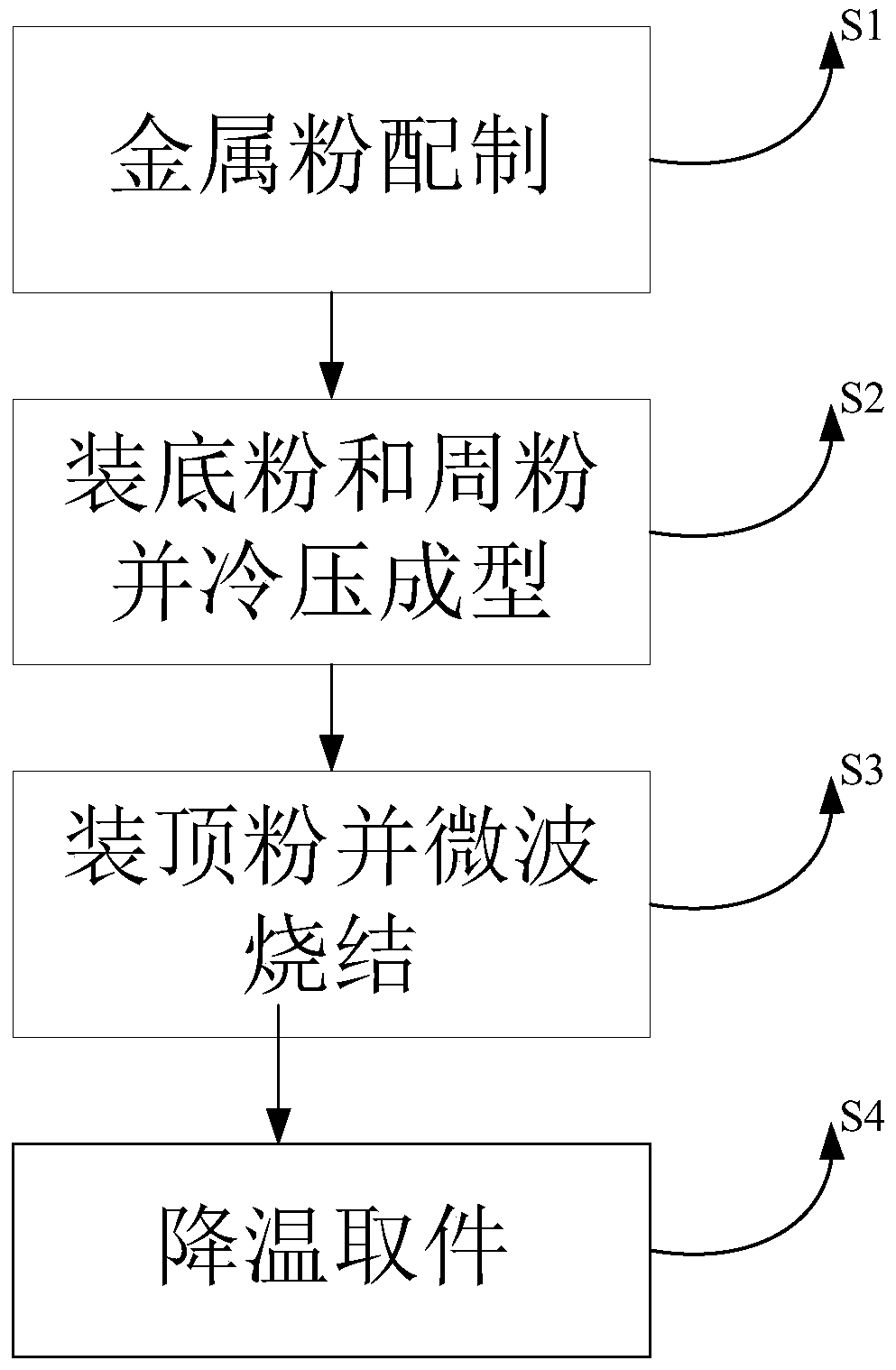

Microwave sintering manufacturing process of a high-density polycrystalline diamond wire drawing die

The invention discloses a microwave sintering manufacturing process of a high-density polycrystalline diamond wire drawing die. A microwave sintering method is used to form an insert. The sleeve, the polycrystalline diamond core and the steel sleeve are microwave sintered to form a polycrystalline diamond wire drawing die; the sintering atmosphere is N2+H2, the initial input power is 300-320W, and the temperature rises to 380-400°C, and the input power is adjusted to 380 ‑400W, the temperature rises to 450‑480°C and the input power is adjusted to 300‑320W, the temperature rises to 520‑540°C and keeps warm at this temperature. Using microwave sintering, the grains lack the growth time to obtain fine grain structure, so as to obtain more excellent performance; at the same time, in the sintering process, set a reasonable initial input power, so that the incubation period of the material during the sintering process is reasonable, At the same time, the input power is adjusted according to the temperature change.

Owner:天长市天屹模具科技发展有限公司

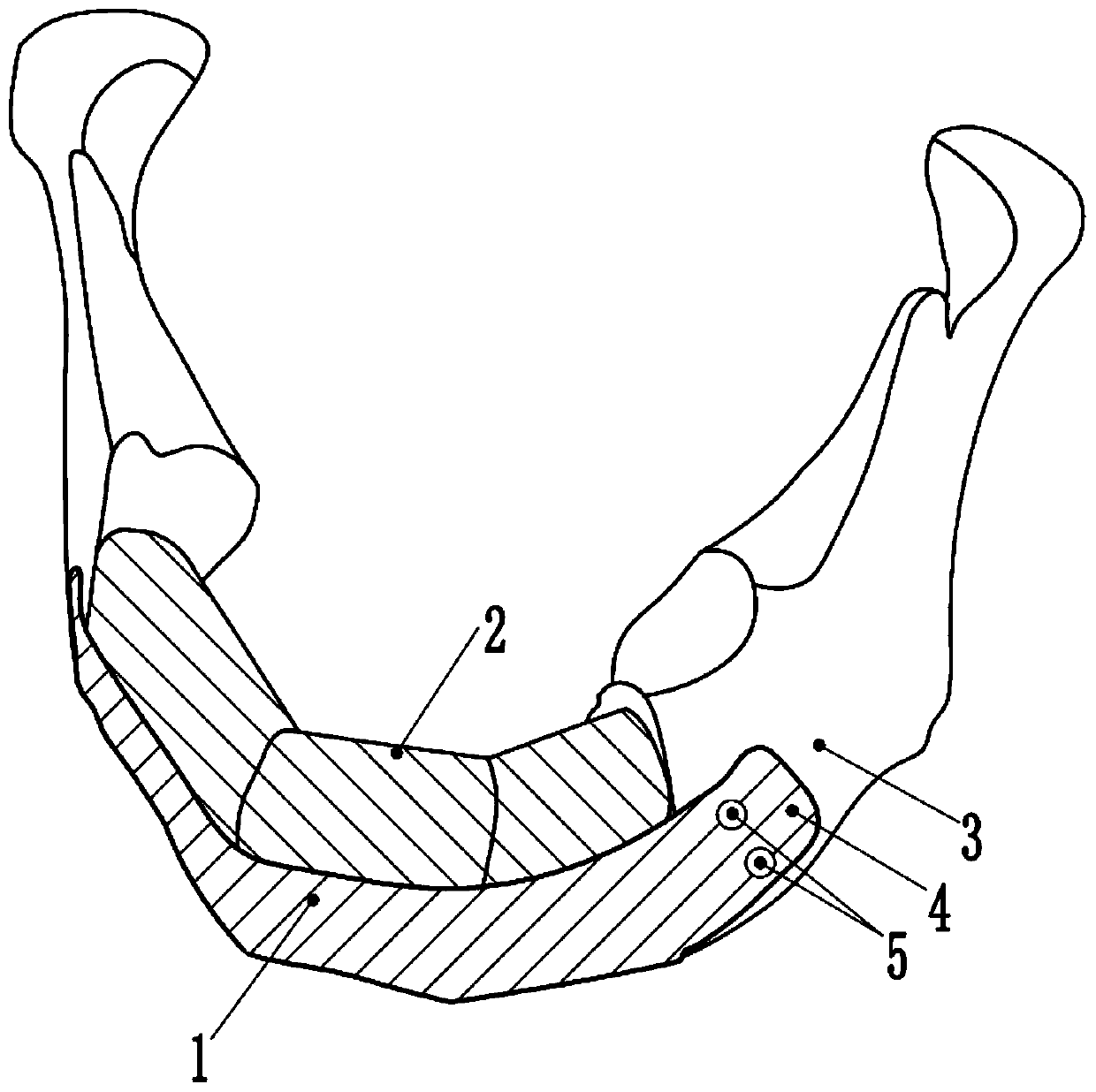

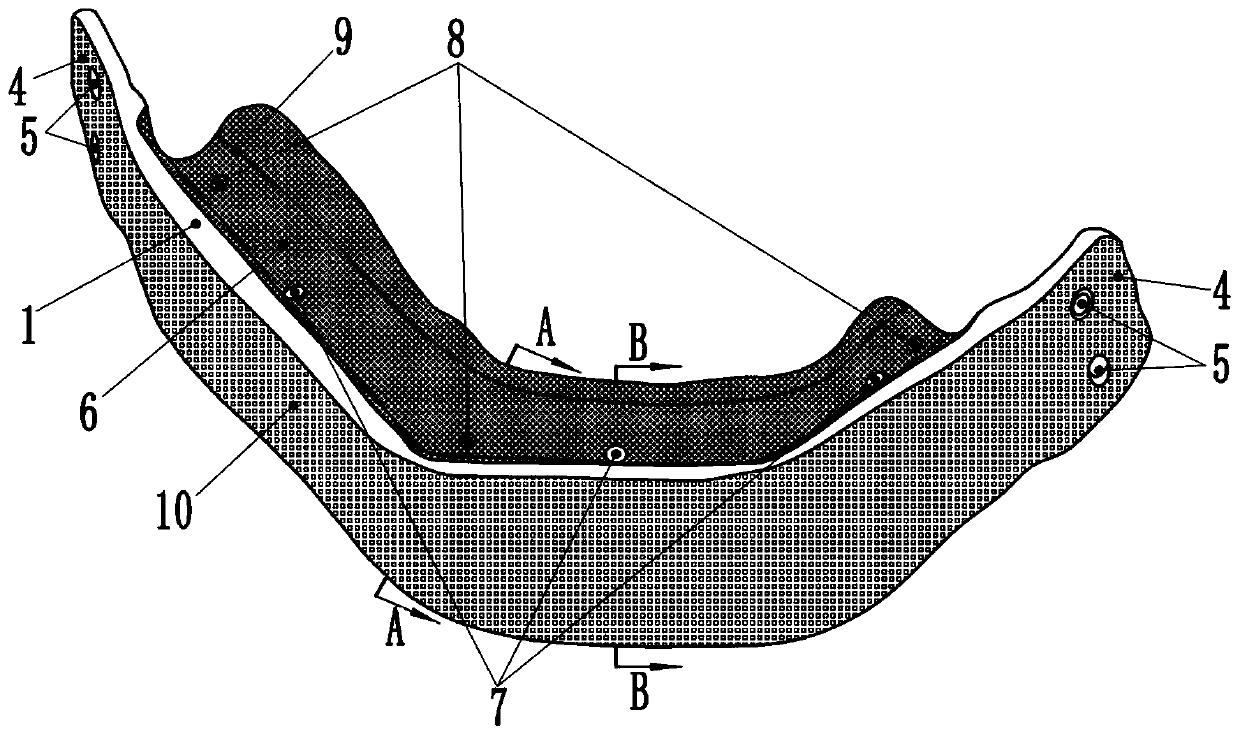

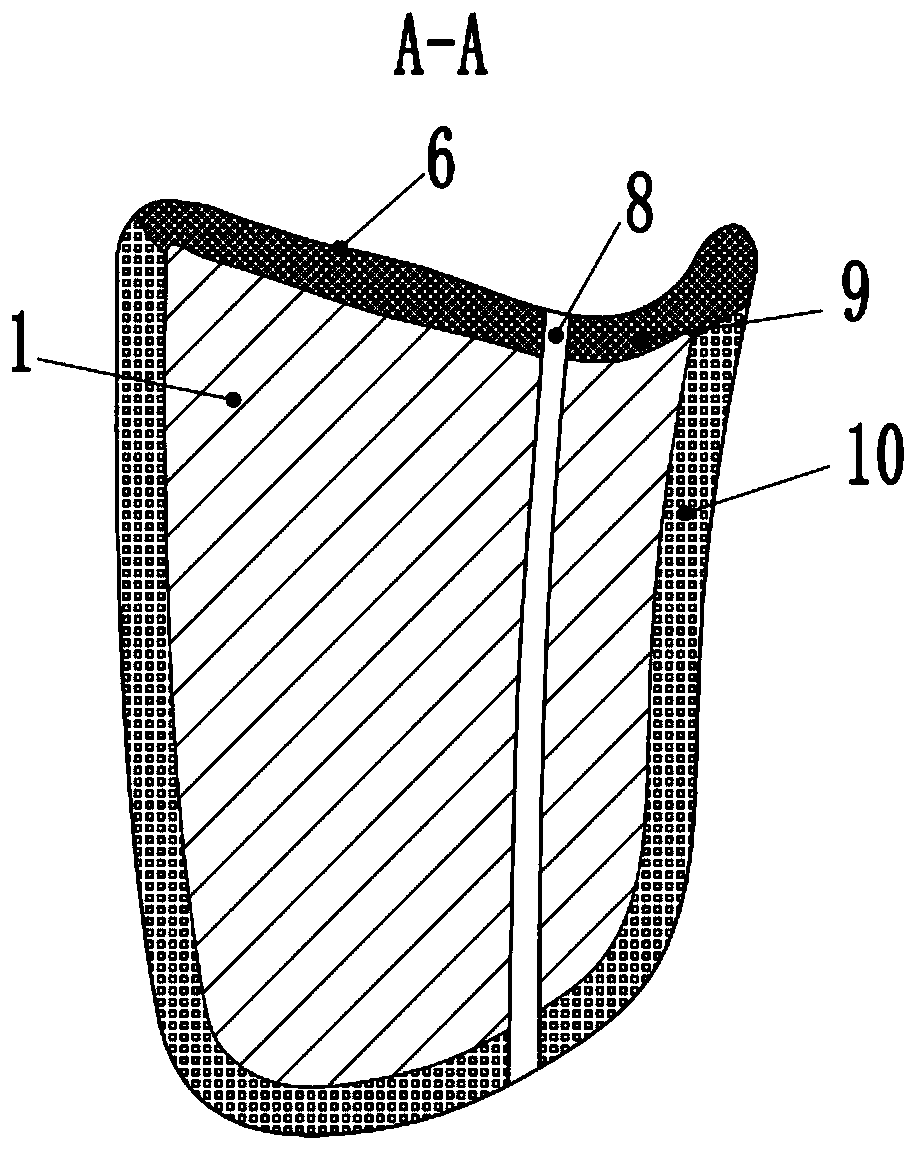

Personalized mandible substitute compounded with autologous bone

PendingCN111494061AImprove long-term stabilityImprove the quality of lifeBone implantJoint implantsBiomechanicsEngineering

The invention discloses a personalized mandible substitute compounded with an autologous bone. Two ends of a substitute are respectively provided with a fixing wing plate to realize connection with anatural mandible, and the upper part of the substitute is provided with a fixing groove for fixing an autologous bone; bone fusion areas are arranged in contact areas of two ends of substitute and natural mandible, the contact area of the fixing wing plate and natural mandible and the contact area between the substitute and autogenous bone and a soft tissue fusion area is arranged in the area, making contact with the surrounding soft tissue, of the substitute so as to promote fusion of the substitute and the surrounding tissue, improve the biocompatibility of the substitute and enhance the biomechanical strength of the substitute; and the rest is a mandible body supporting area. According to the invention, a problems of autogenous bone shortage, difficult shaping, poor fusion of a thermoplastic material as a mandible implant with natural bone tissues and surrounding soft tissues and the like can be solved, so that the fusion of the mandible substitute and the surrounding tissues is promoted, the healing of a wound after the substitute is implanted is accelerated, and the living quality of a patient is further improved.

Owner:XI AN JIAOTONG UNIV +1

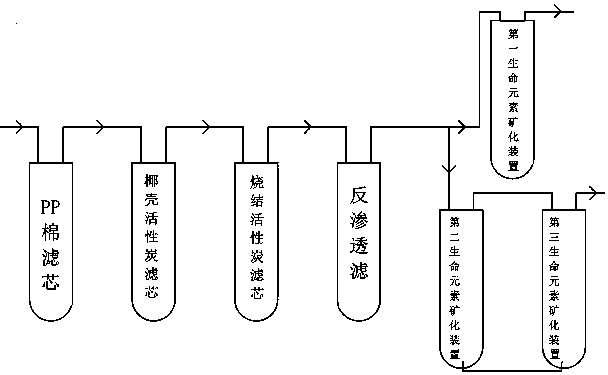

Life element mineralization apparatus

PendingCN108689518AReduce contentContent adjustmentTreatment involving filtrationMultistage water/sewage treatmentProcess engineeringWater soluble

The invention discloses a life element mineralization apparatus used for drinking water. The life element mineralization apparatus comprises a purified water processing apparatus, and comprises a first life element mineralization apparatus and a second life element mineralization apparatus, the first life element mineralization apparatus and the purified water processing apparatus are connected inseries, the second life element mineralization apparatus and the purified water processing apparatus are connected in series, and is connected with the first life element mineralization apparatus inseries, and the second life element mineralization apparatus is filled with a mixture of water-soluble life element crystal particles and coconut shell active carbon particles. The apparatus can simultaneously mineralize a soluble silicon element and other life necessary elements, the concentration control effect of the added element is good, and the apparatus is convenient for drinking for people.

Owner:郑进

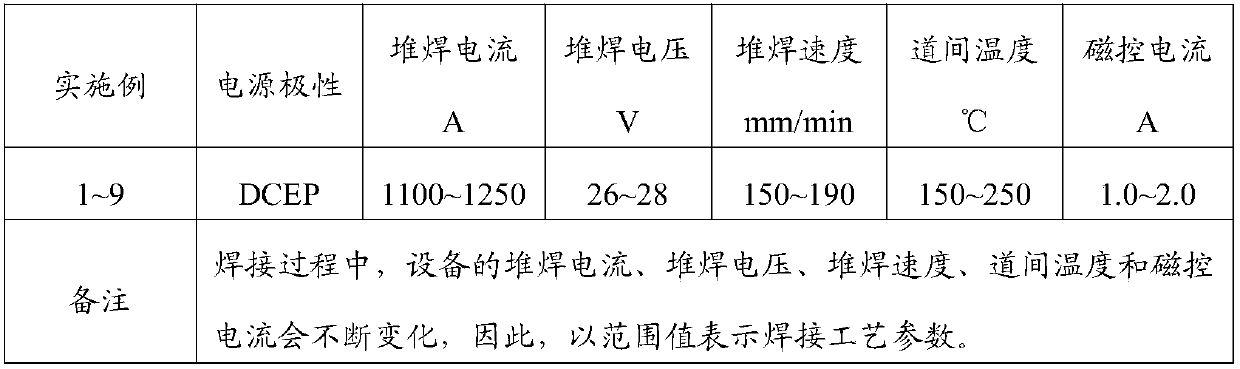

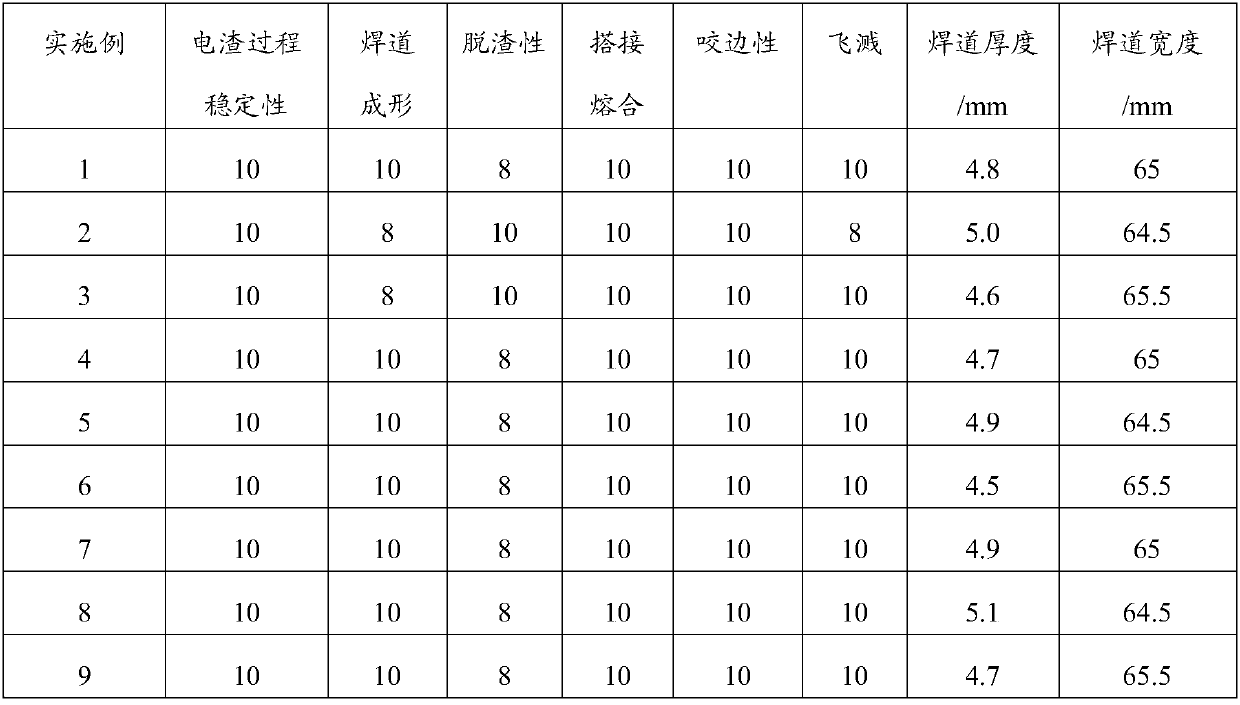

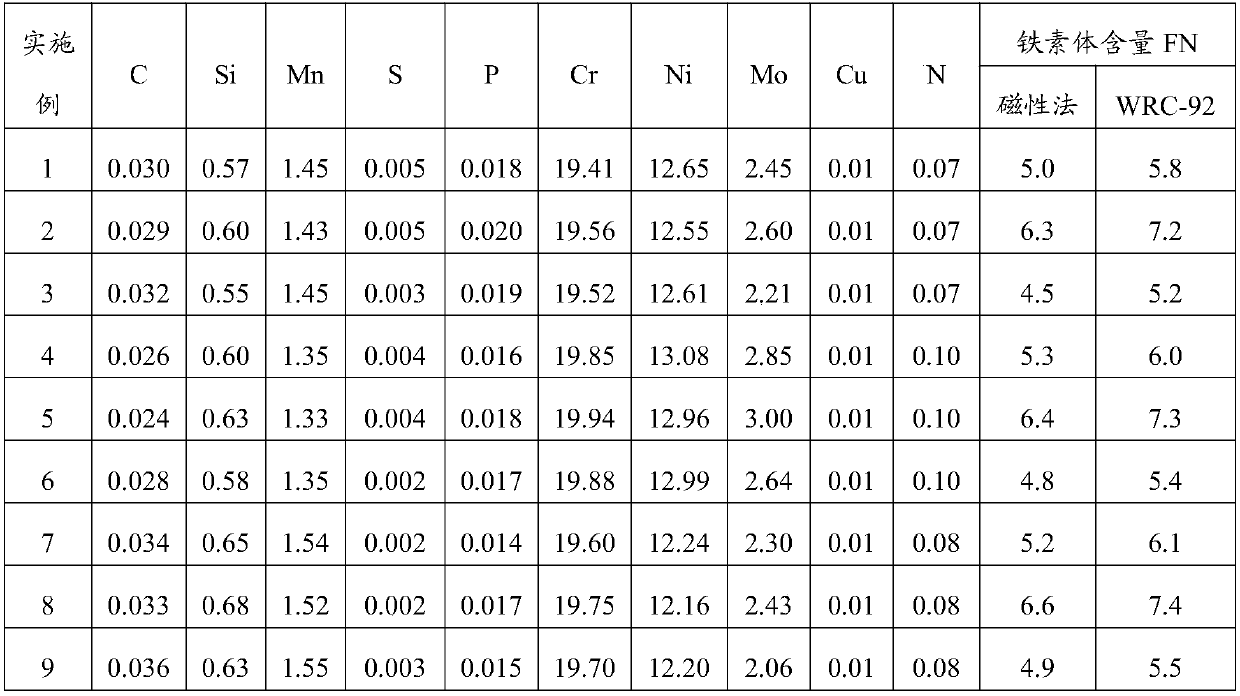

Mo-contained stainless steel welding strip, preparation method thereof, sintered flux, preparation method thereof and single-layer electrode electroslag surfacing method

InactiveCN109514126AIncrease contentReduce contentWelding/cutting media/materialsSoldering mediaChemical IngredientsStainless steel welding

The invention provides a Mo-contained stainless steel welding strip, a sintered flux and a single-layer electrode electroslag surfacing method, and belongs to the technical field of welding. By meansof the Mo-contained stainless steel welding strip, chemical ingredients are reasonable, the ferrite content in a single-layer electrode electroslag surfacing layer can be reduced, and the problems oflateral bending and cracking of welded parts can be reduced.

Owner:HARBIN WELL WELDING CO LTD +1

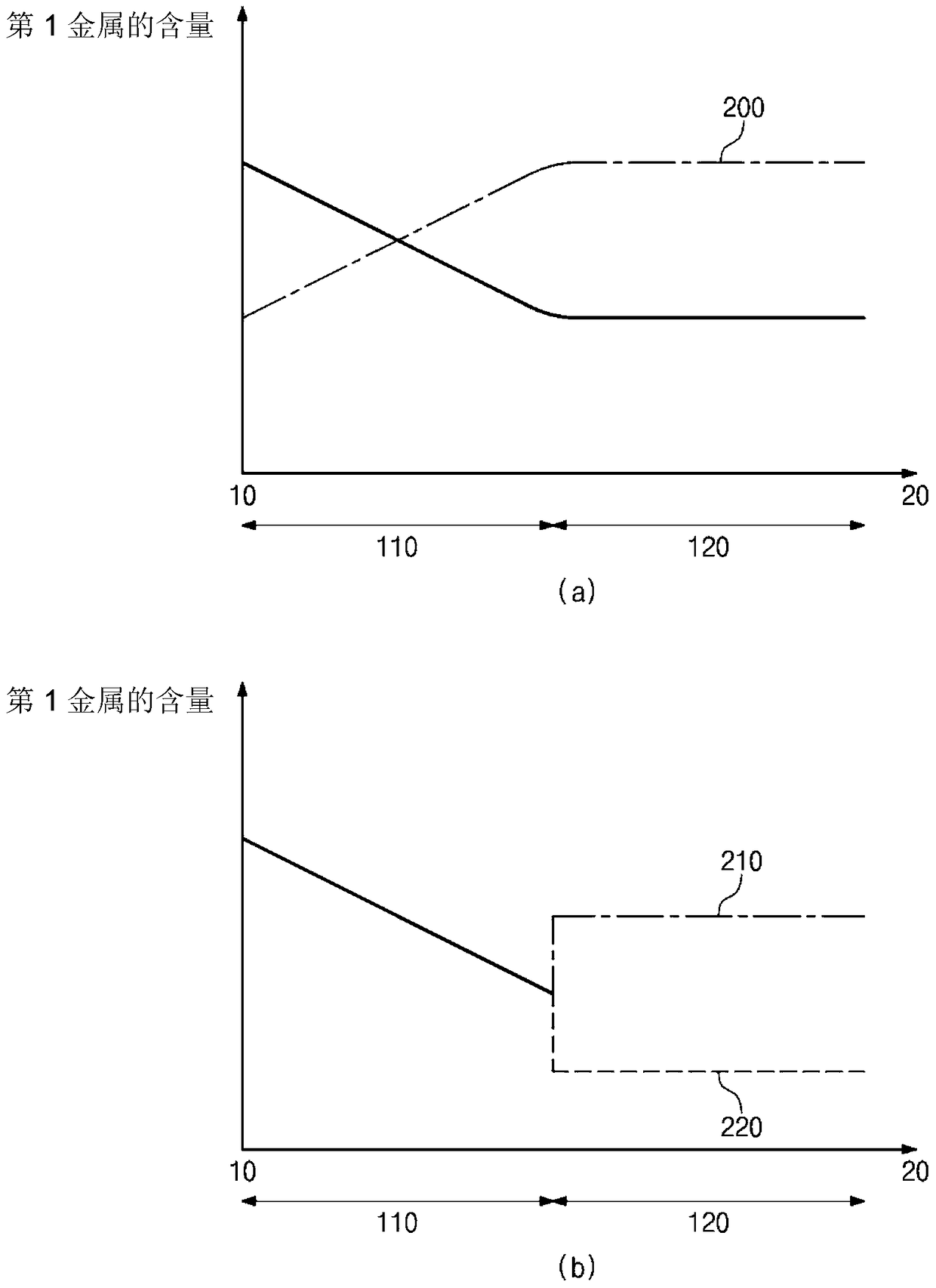

Positive electrode active material and secondary battery including the same

ActiveCN105576226BStable structureImprove life characteristicsActive material electrodesLi-accumulatorsLithiumManganese

According to the positive electrode active material of the present invention, the concentration of nickel is high, but the residual lithium can be reduced, so that the life characteristics and charge-discharge characteristics are excellent, and the crystal structure is stable while exhibiting high capacity, and the structure can also be expressed when used at a high voltage. stability. And, according to the positive electrode active material of the present invention, nickel, manganese, cobalt form the surface of the chip part of concentration gradient, the concentration of nickel is adjusted to a fixed range, and the shell part of the concentration of remaining metal is fixed, thereby, the concentration of nickel is high, Residual lithium can also be reduced, so that the life characteristics and charge-discharge characteristics are excellent, while exhibiting a high capacity, the crystal structure is also stable, and when used at a high voltage, it is possible to exhibit structural stability.

Owner:LG CHEM LTD

Feed composite for anthony pig weaned at early stage

ActiveCN101411406BImprove digestibilityImprove survival rateFood processingAnimal feeding stuffAntigenAnimal science

The invention discloses combined feedstuff for a weanling anthony pig in the early stage. The combined feedstuff comprises the following four stages of feedstuff: the feedstuff used in the first 3 days after weaning, the feedstuff used in the 4th to 11th days, the feedstuff used in the 12th to 24th days, and the feedstuff used in the 25th to 50th days. According to the number of weaning days and the physiologic tendency of the weanling anthony pig in the early stage, the feedstuff with different components is prepared so as to ensure the reasonable nutrition of the anthony pig. The combined feedstuff has high nutrient concentration, good palatability, easy digestion and absorption, low cost and a high conversion rate. In addition, the combined feedstuff has the low content of antigen component and the high content of immunity component, and uses a proper amount of acidifier so as to reduce the weaning stress and improve the survival rate of the anthony pig.

Owner:MUYUAN FOODS CO LTD

A kind of 026cr18ni12mo2n stainless steel forging for nuclear power plant and its manufacturing method

The invention discloses a 026Cr18Ni12Mo2N stainless steel forging for nuclear power plants. The stainless steel forging contains the following chemical components: 0.015%≤C≤0.035%, Si≤1%, Mn≤2%, P≤0.03%, S≤0.015%, 17.2%≤Cr≤18.2%, 11.6%≤Ni≤12.5%, 2.25%≤Mo≤2.75%, 0.05%≤N≤0.08%, Cu≤1%, and the rest is pig iron. A manufacturing method is also disclosed, comprising the following steps: raw material refining; forging: forging the obtained stainless steel ingot into a stainless steel forging, and the stainless steel forging undergoes main deformation at a temperature of 1000°C±20°C; heat treatment: heating the forged stainless steel forging To 1050 ℃ ~ 1120 ℃ and heat preservation, and then water cooling; detection. Through the above method, the present invention increases the content of C and N in terms of chemical composition, adjusts the content of Cr and Ni, and improves the strength of the forging in terms of material composition. In terms of manufacturing methods, the internal stress generated during final forging can also produce static recrystallization during heat treatment, so that the grains of the material can be effectively refined, and the grain refinement can increase the strength of the material.

Owner:无锡市法兰锻造有限公司

Roll ring steel for aluminium casting rolling mill and heat treatment method thereof

InactiveCN1285749CImproved resistance to thermal fatigue cracksExtended service lifeFurnace typesHeat treatment furnacesManganeseQuenching

The invention relates to a roll sleeve steel for aluminum casting and rolling mills and a heat treatment method thereof. A roll sleeve steel for aluminum casting and rolling mills, the chemical composition weight percent (%) is: carbon (C) 0.30-0.45, manganese (Mn) 0.60-0.80, silicon (Si) 0.20-0.40, phosphorus (P) ≤ 0.025 , sulfur (S) ≤ 0.025, chromium (Cr) 2.00 ~ 3.00, nickel (Ni) 0.50 ~ 1.00, molybdenum (Mo) 0.80 ~ 1.20, vanadium (V) 0.10 ~ 0.20, aluminum (Al) ≤ 0.012, the rest is iron and other impurities. The final heat treatment method of the roller sleeve steel is secondary tempering after quenching, the quenching heating temperature is 850-920°C, and quenching in engine oil after heat preservation; the first tempering roller sleeve is heated to 500-560°C, and the heat preservation is 10-20 hours. Cool in oil; the second tempering parameters are the same as the first tempering parameters. The invention improves the ability of the roller sleeve to resist thermal fatigue cracks, thereby increasing the service life of the roller sleeve, reducing production failures and reducing production costs.

Owner:李春治

A hot pressing and sintering manufacturing process of polycrystalline diamond wire drawing die

Owner:天长市天屹模具科技发展有限公司

Application of a Chiral Polymer Catalyst in Asymmetric Reaction

ActiveCN106853380BThe synthesis method is simpleShort reaction timeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDispersityPorosity

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hot-work die steel for aluminum die-casting mould

Owner:柳州福臻车体实业有限公司

Aluminum-copper-magnesium alloy wire rod and manufacturing technique thereof

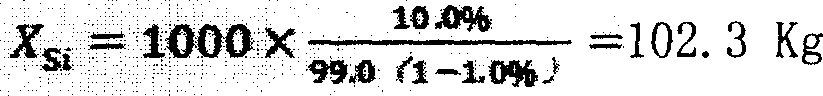

The invention relates to an aluminum-copper-magnesium alloy wire rod and a manufacturing technique of the aluminum-copper-magnesium alloy wire rod. The aluminum-copper-magnesium alloy wire rod is formed by the following raw materials in percentage by weight: 0.2-2.5% of copper, 0.2-2.8% of magnesium, 0.1-0.6% of silicon, 0.2-0.7% of iron, 0.03-0.5% of boron, 0.03% of manganese, 0.03% of zinc, 0.03% of chrome, 0.01% of titanium, and 96%-98% of aluminum. The manufacturing technique comprises the following steps: (1), smelting of aluminum alloy, (2), online treatment of aluminum alloy, (3), casting of aluminum alloy, (4), rolling of aluminum alloy wire rod, and (5), carrying out online aging treatment on the rolled aluminum alloy wire rod to obtain the wire rod, wherein the drawing out temperature is not higher than 60 DEG C. The aluminum-copper-magnesium alloy wire rod meets the performance requirements on the raw material aluminum alloy wire rod in copper clad aluminum alloy in the cable industry field, in particular the requirements on the performances in the aspects of tensile strength, percentage elongation and compressive creep, and the like.

Owner:庆毅 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com