Positive electrode active material and secondary battery including the same

A material and positive electrode technology, applied in the field of positive active materials and secondary batteries containing them, can solve the problems of reduced battery performance, inability to uniformly coat, and reduced electrode surface smoothness, and achieve the effect of reducing residual lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-6

[0217] After putting 2.5 liters of distilled water into the co-precipitation reactor (capacity 16L, the power of the rotary motor is more than 80W), supply N2 gas to the reactor at a rate of 2 liters / minute, and keep the temperature of the reactor at 45°C and stir at 400rpm .

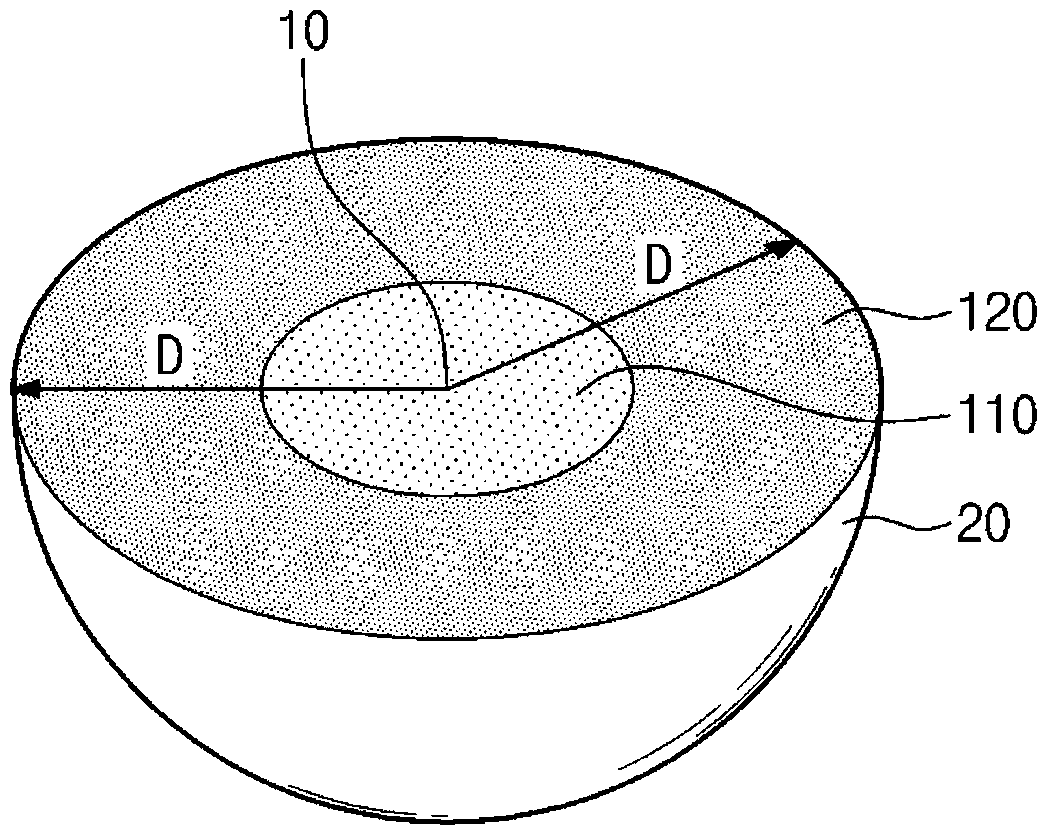

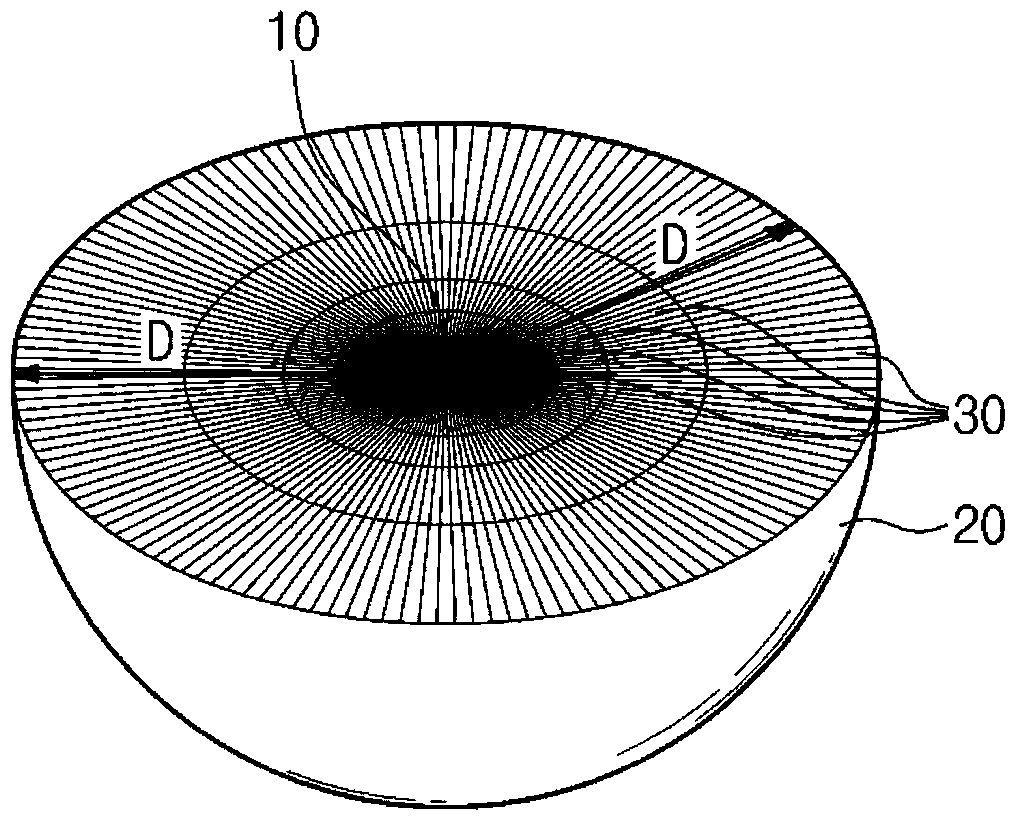

[0218] Mixing nickel sulfate, cobalt sulfate and manganese sulfate, the first metal aqueous solution consisting of NiX1Coy1Mnz1OH2 (x1, y1, z1) and the second metal aqueous solution of NiX2Coy2Mnz2OH2 (x2, y2, z2) were produced, and the first metal solution was replaced. While mixing the aqueous solution and the second metal aqueous solution at a rate of 0.7 liters / hour, the ammonia solution with a concentration of 25 mol was continuously fed into the reactor at 0.07 liters / hour to manufacture a chip part with a concentration gradient. and concentration gradient. And, in order to adjust the pH, a sodium hydroxide solution of 5 mol concentration was supplied so that the pH was maintained at 11.5. The i...

experiment example

[0228] EDX photograph measurement

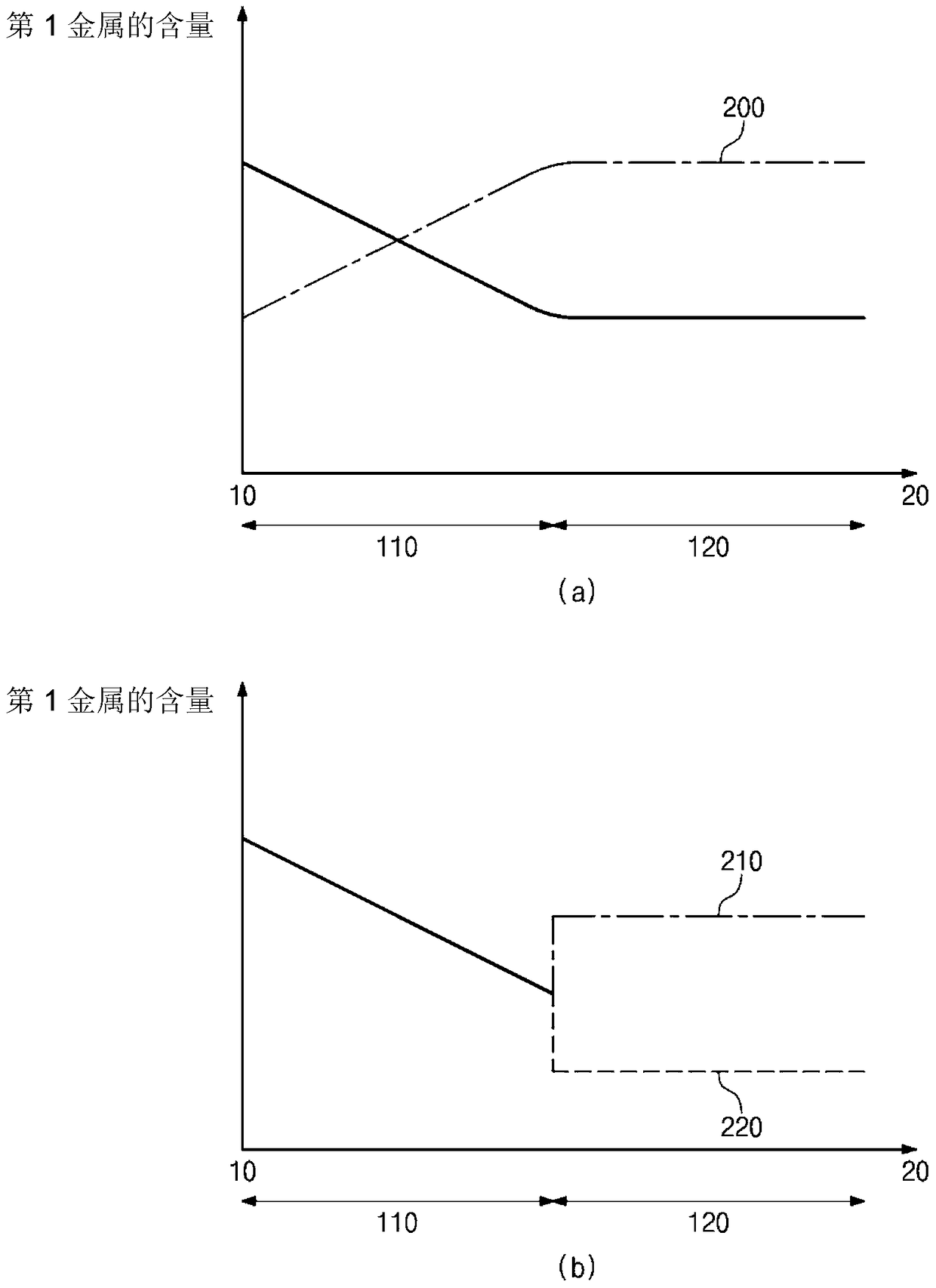

[0229] Measured by EDX according to the Ni of the distance from the center of the particle that manufactures in the above-mentioned embodiment 1-1 and comparative example 1-1, Mn, the concentration of Co, and its result is shown in Figure 23 . Figure 23It can be seen that, according to the particles of the embodiments of the present invention, the chip portion and the concentration gradient portion form a gradient, and include a shell portion that is continuous with the chip portion and the concentration gradient portion and has a fixed concentration of nickel, manganese, and cobalt, and, The function of the concentration according to the distance in the chip portion and the concentration gradient portion is displayed as a straight line, and the magnitude of the concentration gradient in the chip portion and the concentration gradient portion is constant.

[0230] SEM photo measurement

[0231] Measured the SEM photographs of the p...

Embodiment 1-7~1-10

[0241] After putting 2.5 liters of distilled water into the co-precipitation reactor (capacity 16L, the power of the rotary motor is more than 80W), supply N2 gas to the reactor at a rate of 2 liters / minute, and keep the temperature of the reactor at 45°C and stir at 400rpm .

[0242] Mix nickel sulfate, cobalt sulfate and manganese sulfate to make Ni X1 co y1 mn z1 Oh 2 (x1, y1, z1) of the first metal aqueous solution and Ni X2 co y2 mn z2 Oh 2 (x2, y2, z2) of the second metal aqueous solution, and while changing the mixing ratio of the second metal aqueous solution to the first metal aqueous solution, mix it at 0.7 liter / hour, and then at 0.07 liter / hour to the reaction. A 25mol ammonia solution was continuously fed into the device to manufacture a chip part and a concentration gradient part with a concentration gradient. And, in order to adjust the pH, a sodium hydroxide solution of 5 mol concentration was supplied so that the pH was maintained at 11.5. The impelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com