Patents

Literature

1438results about "Threaded caps application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

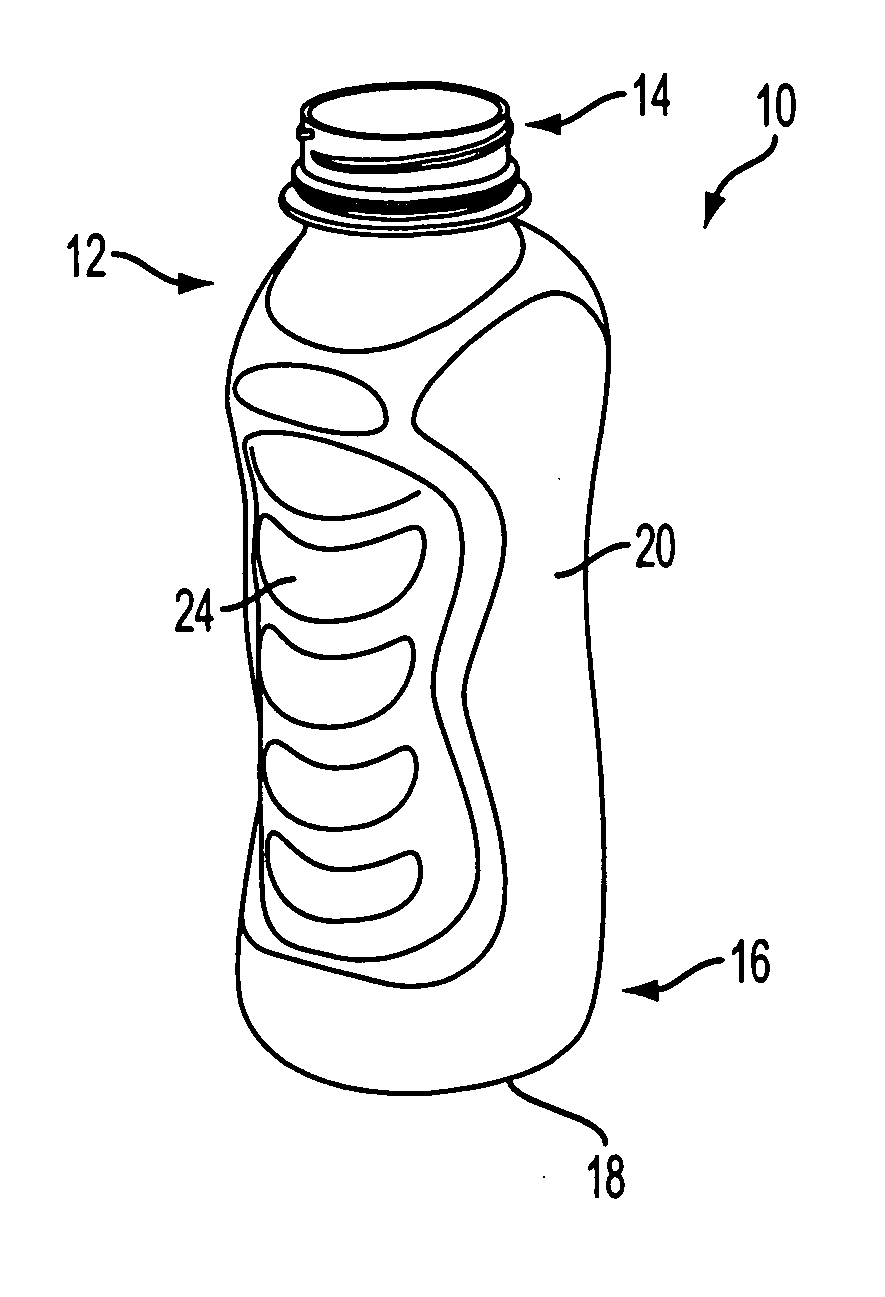

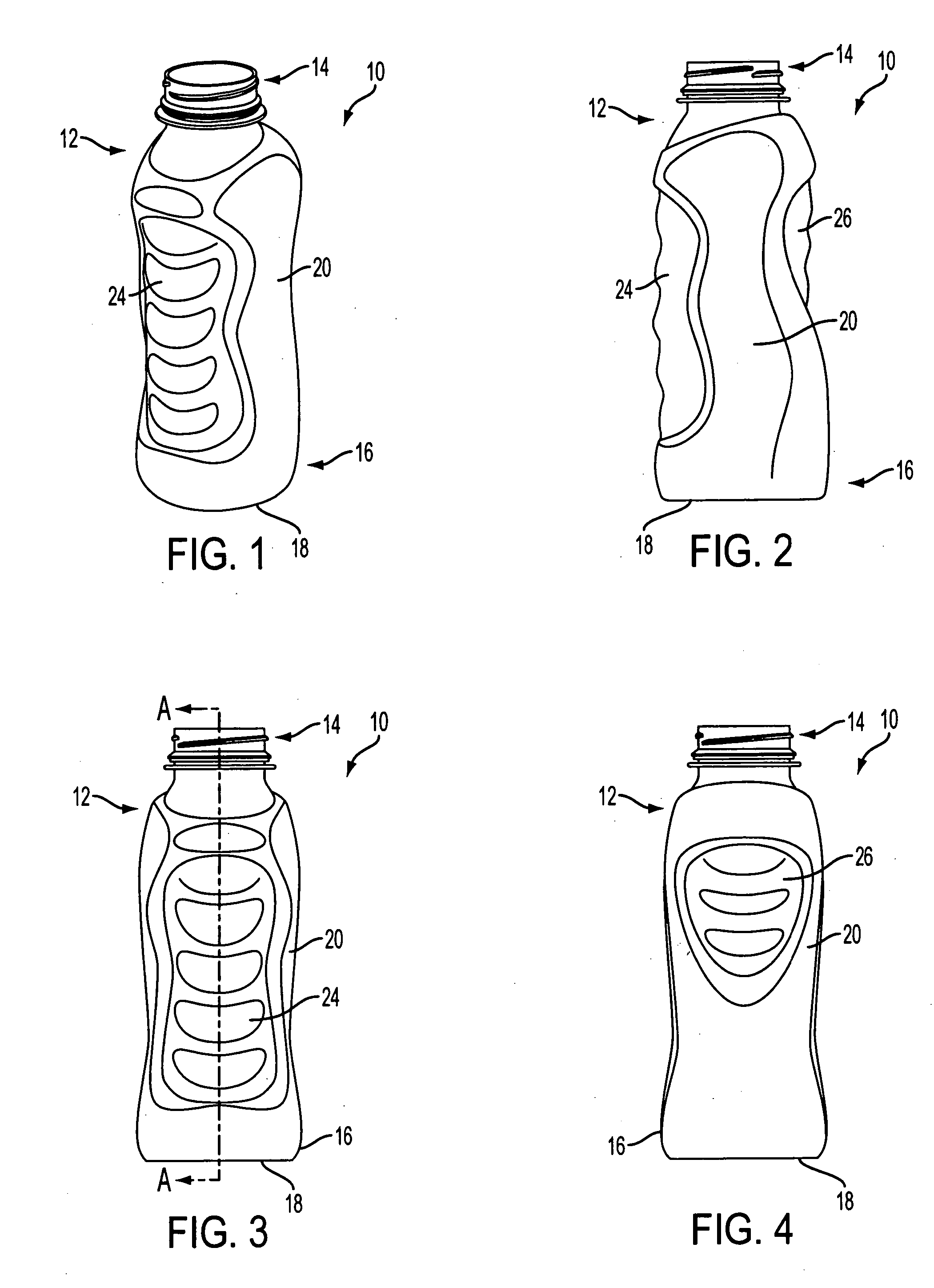

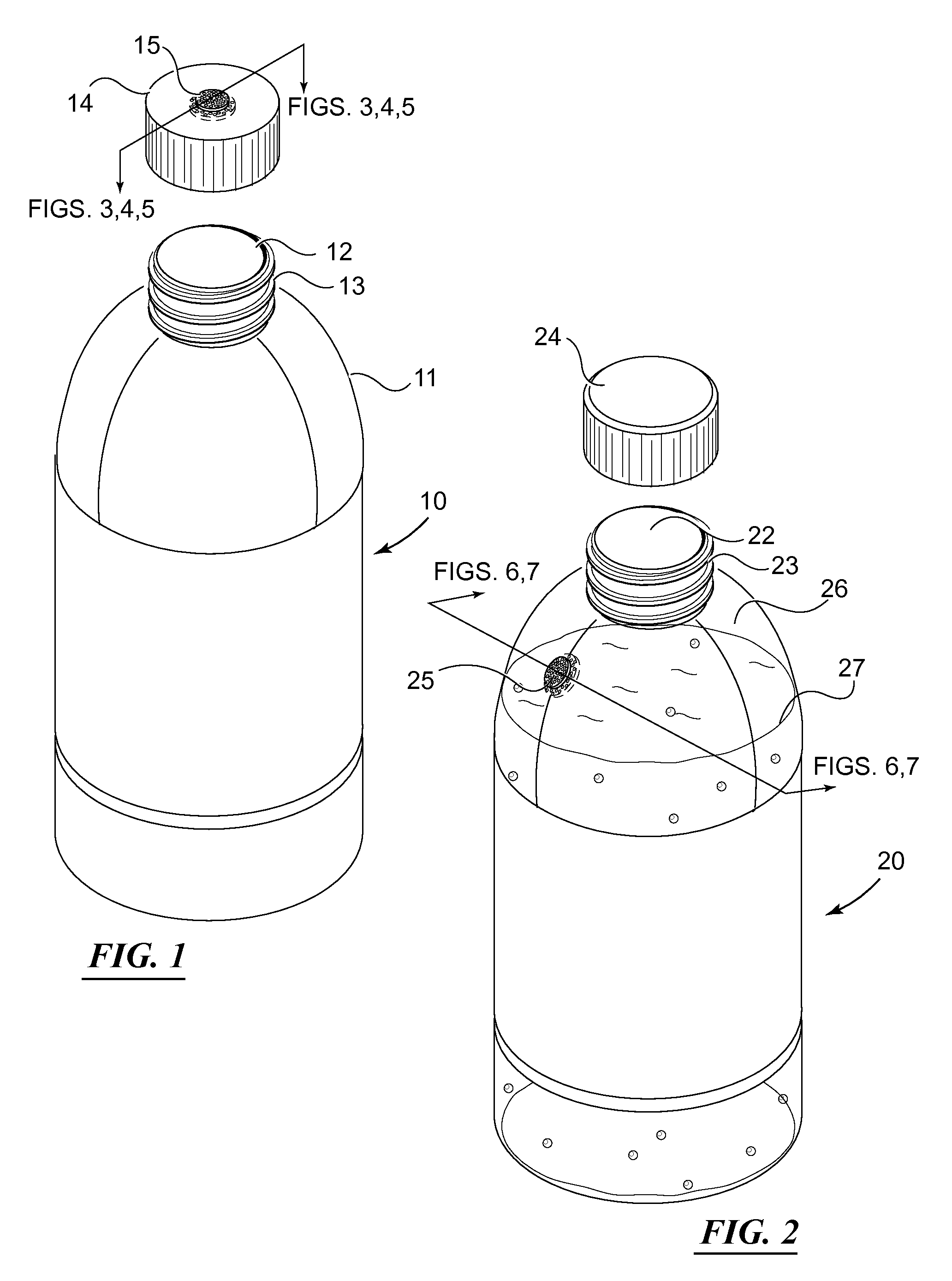

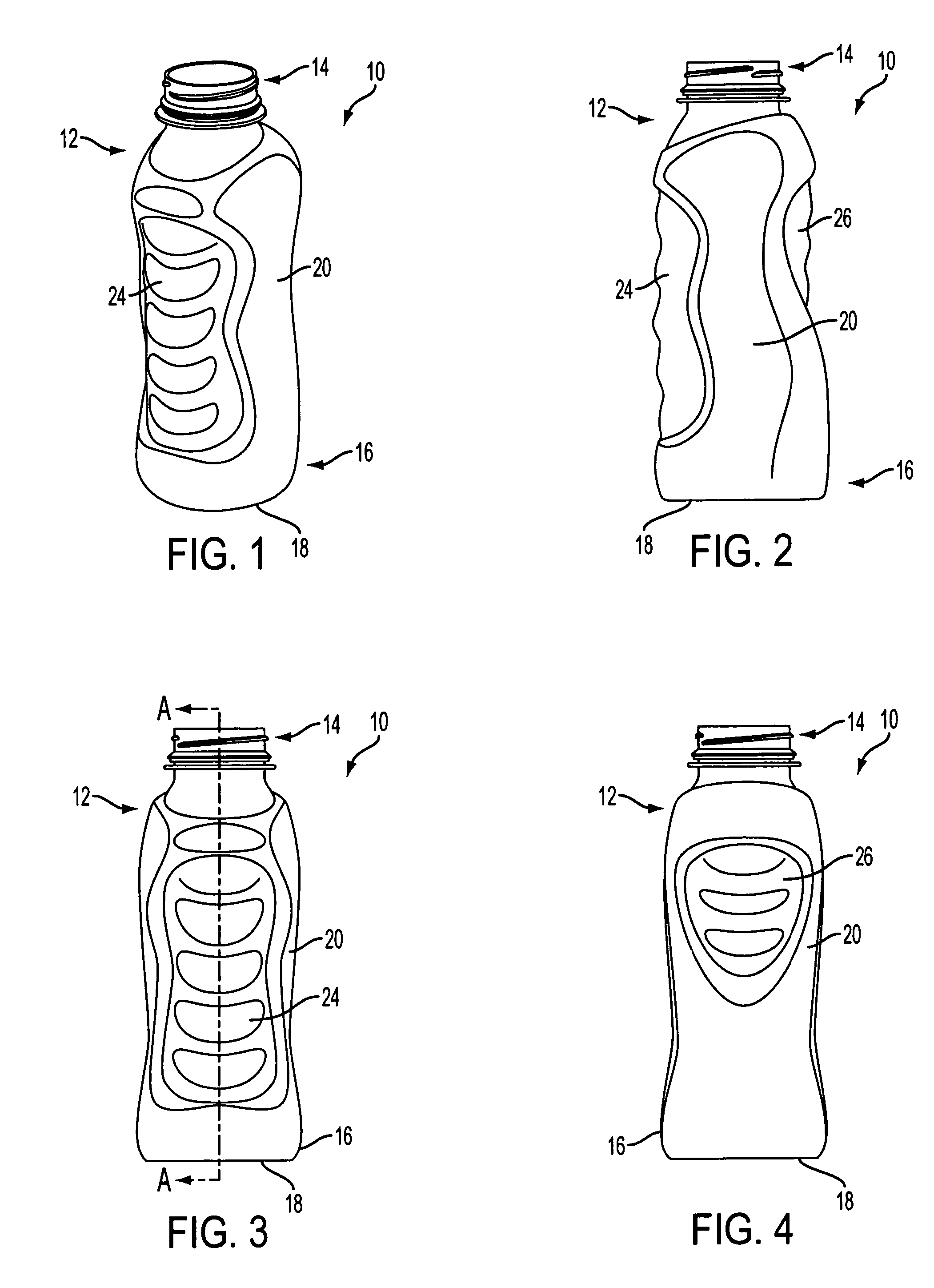

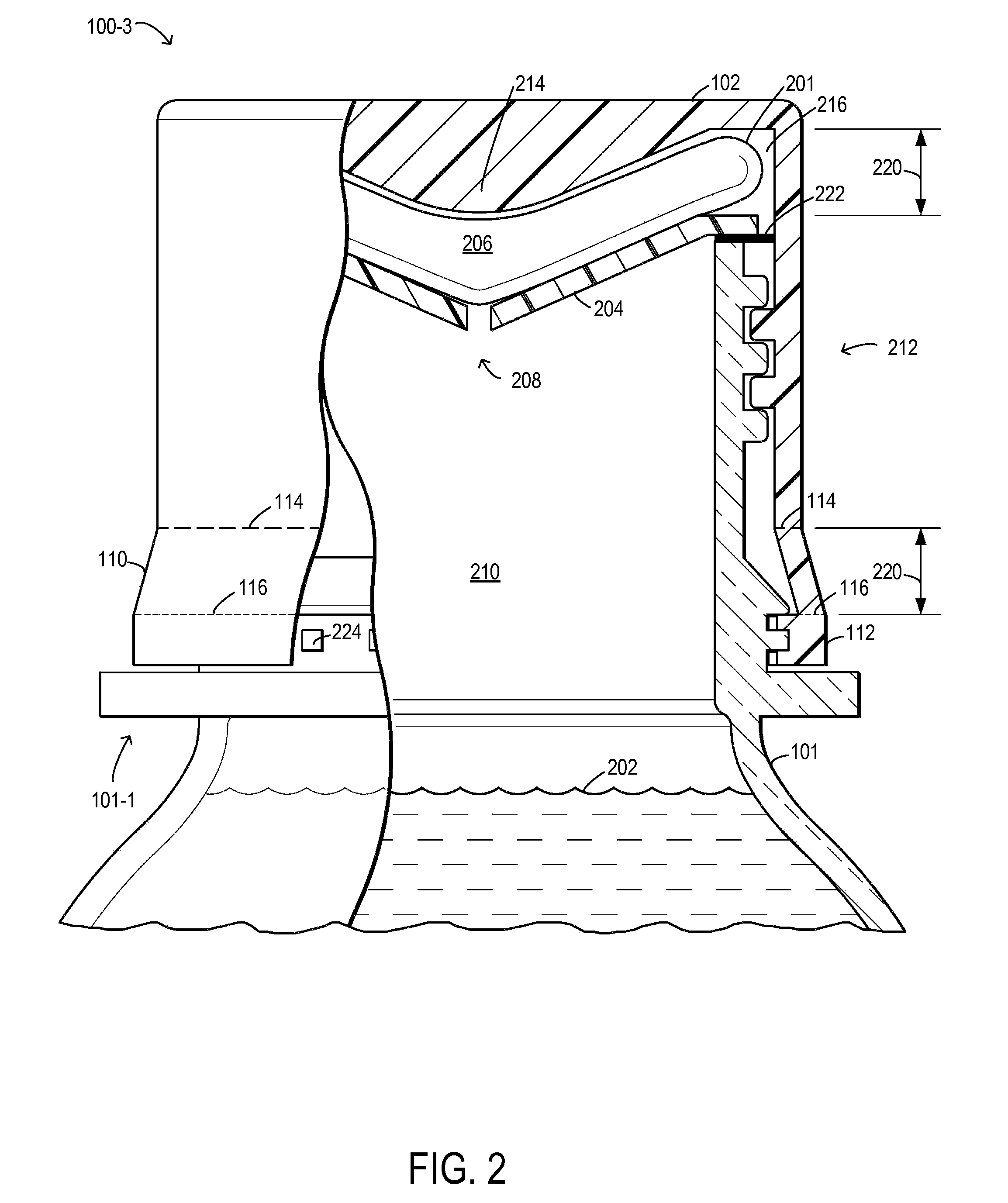

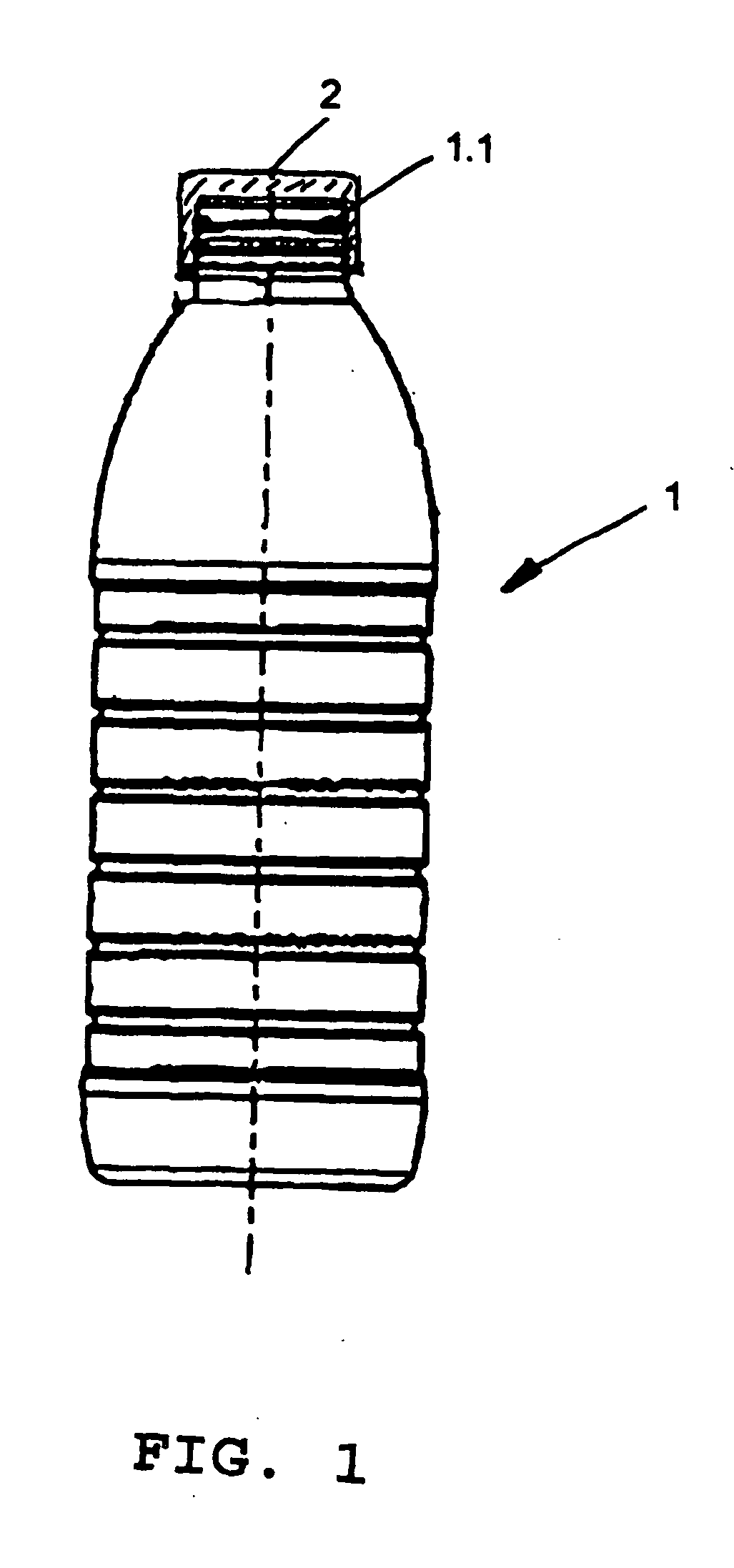

Pressure reinforced plastic container and related method of processing a plastic container

InactiveUS20060255005A1Reduce internal volumeReduce needCapsThreaded caps applicationPositive pressureEngineering

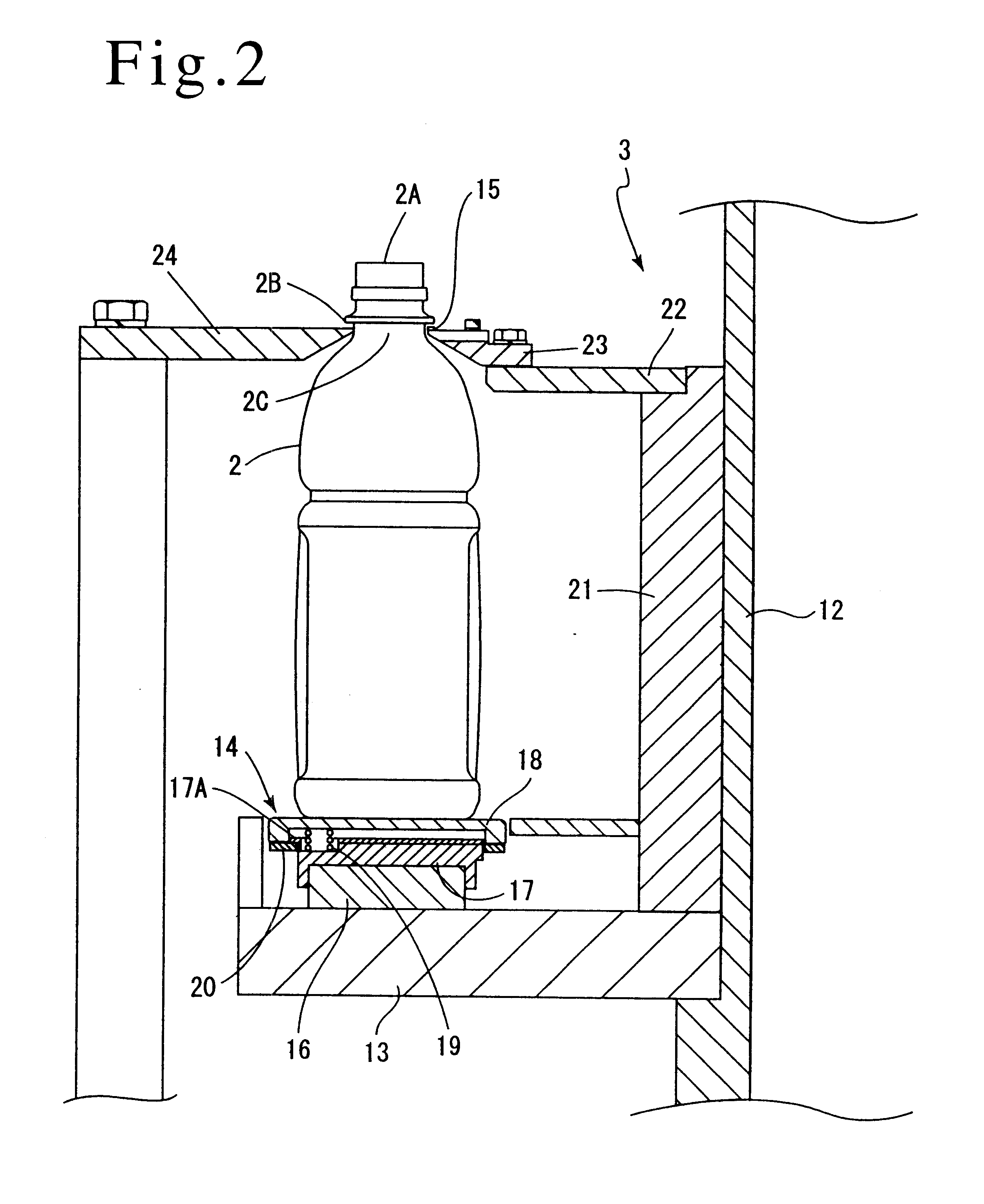

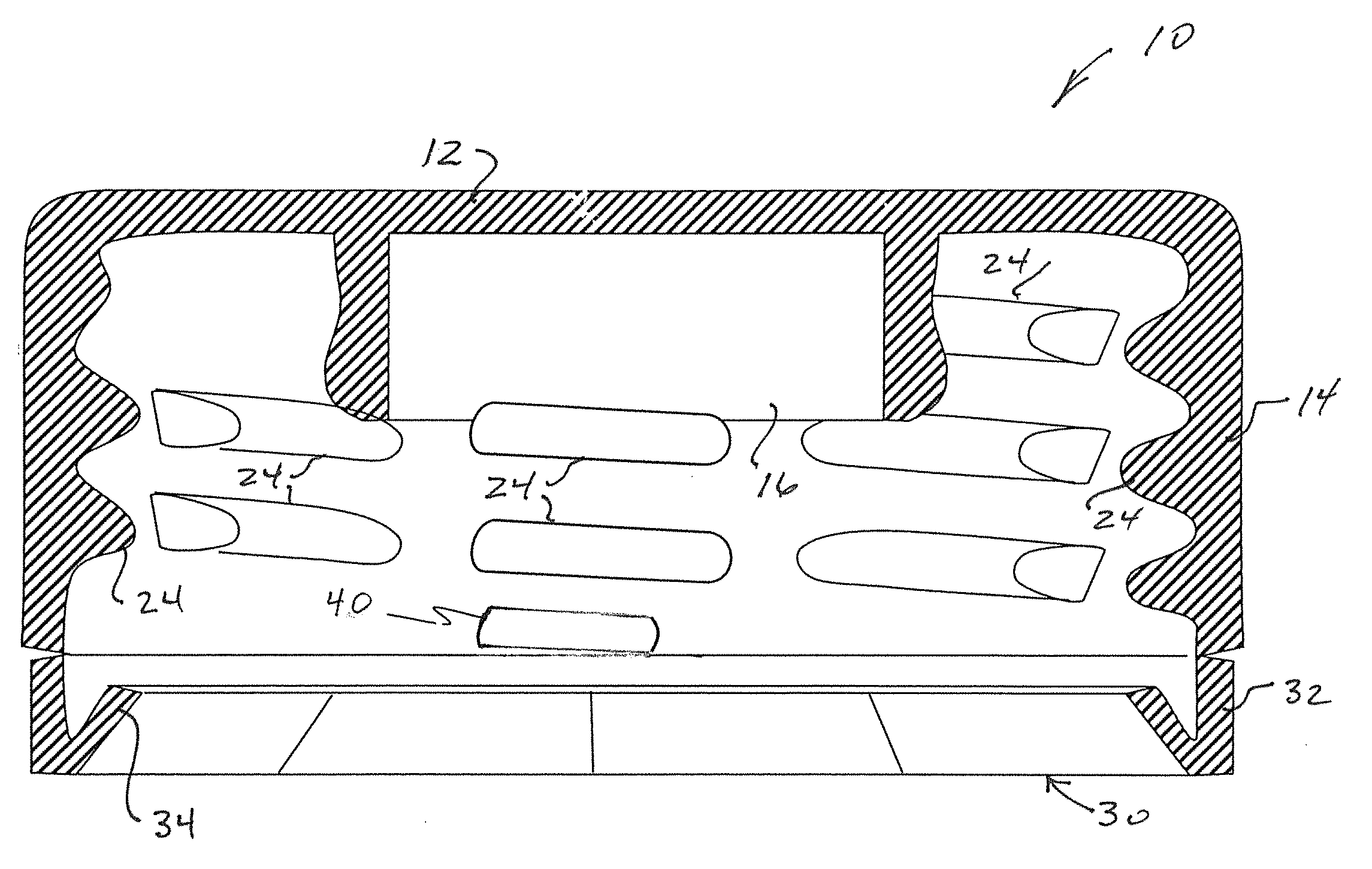

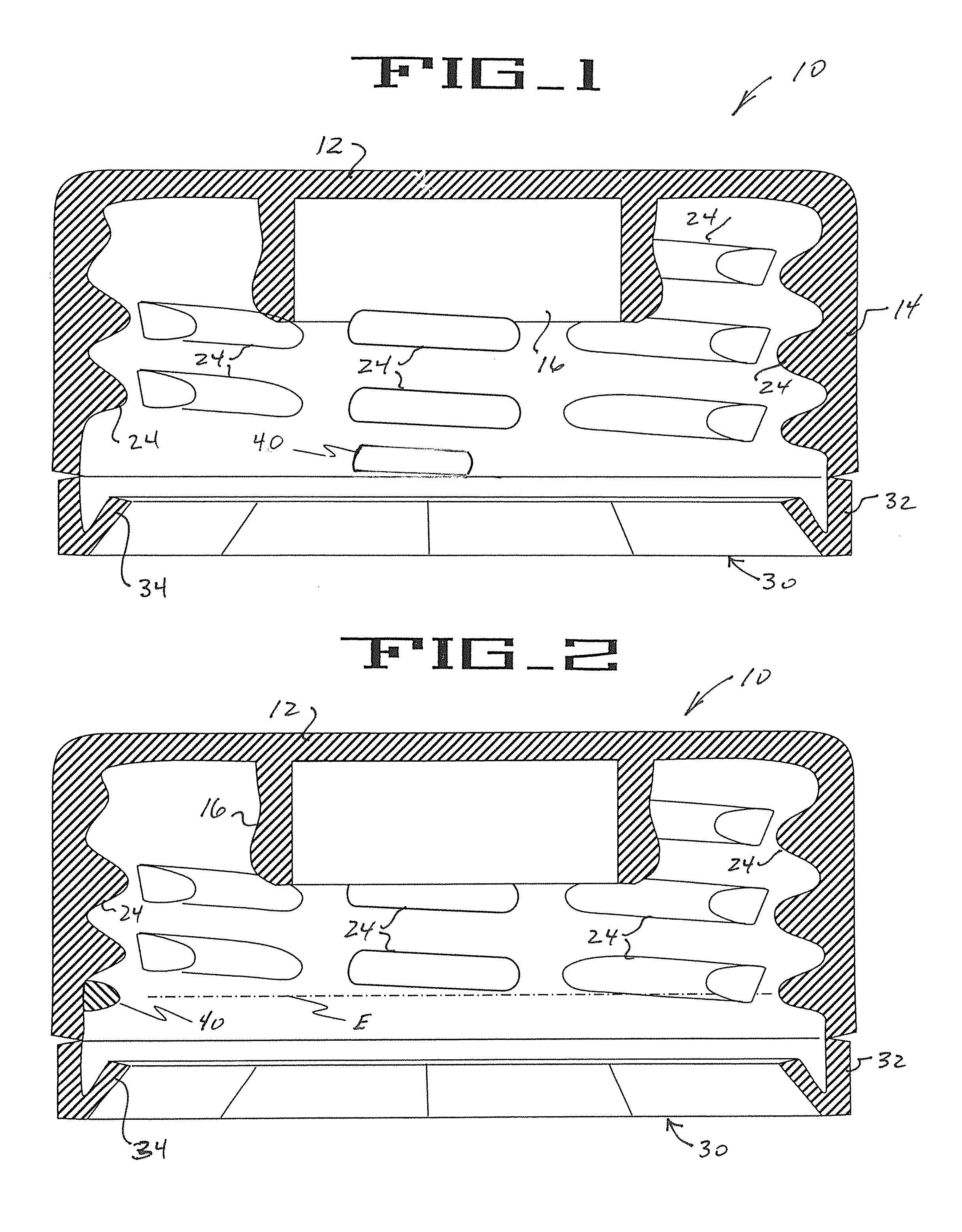

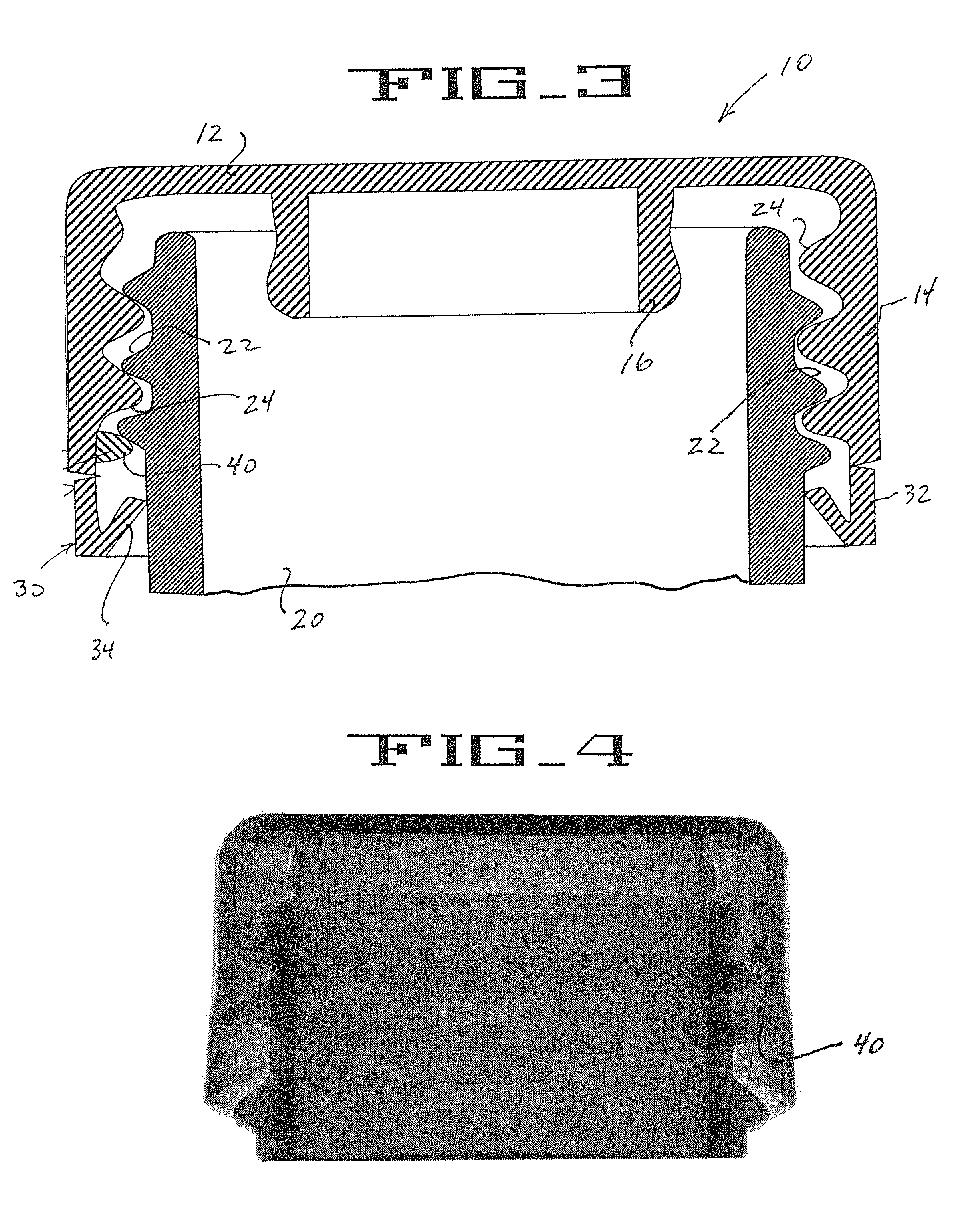

A plastic container comprises an upper portion including a finish adapted to receive a closure, a lower portion including a base, and a sidewall extending between the upper portion and the lower portion. The upper portion, the lower portion, and the sidewall define an interior volume for storing liquid contents. The plastic container further comprises a pressure panel located on the container and moveable between an initial position and an activated position. The pressure panel is located in the initial position prior to filling the container, and is moved to the activated position after filling and sealing the container. Moving the pressure panel from the initial position to the activated position reduces the internal volume of the container and creates a positive pressure inside the container. The positive pressure reinforces the sidewall. A method of processing a container is also disclosed.

Owner:CO2 PAC

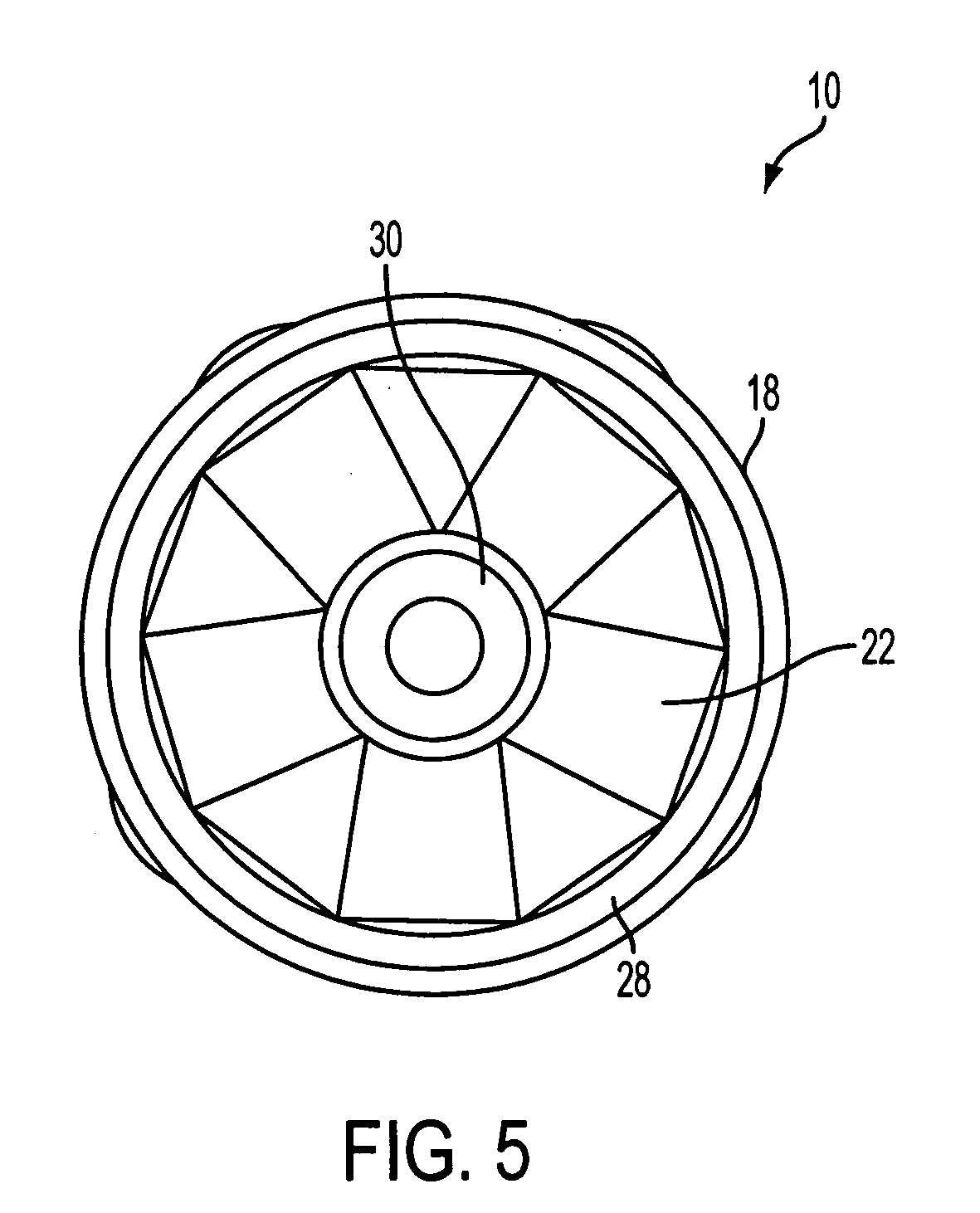

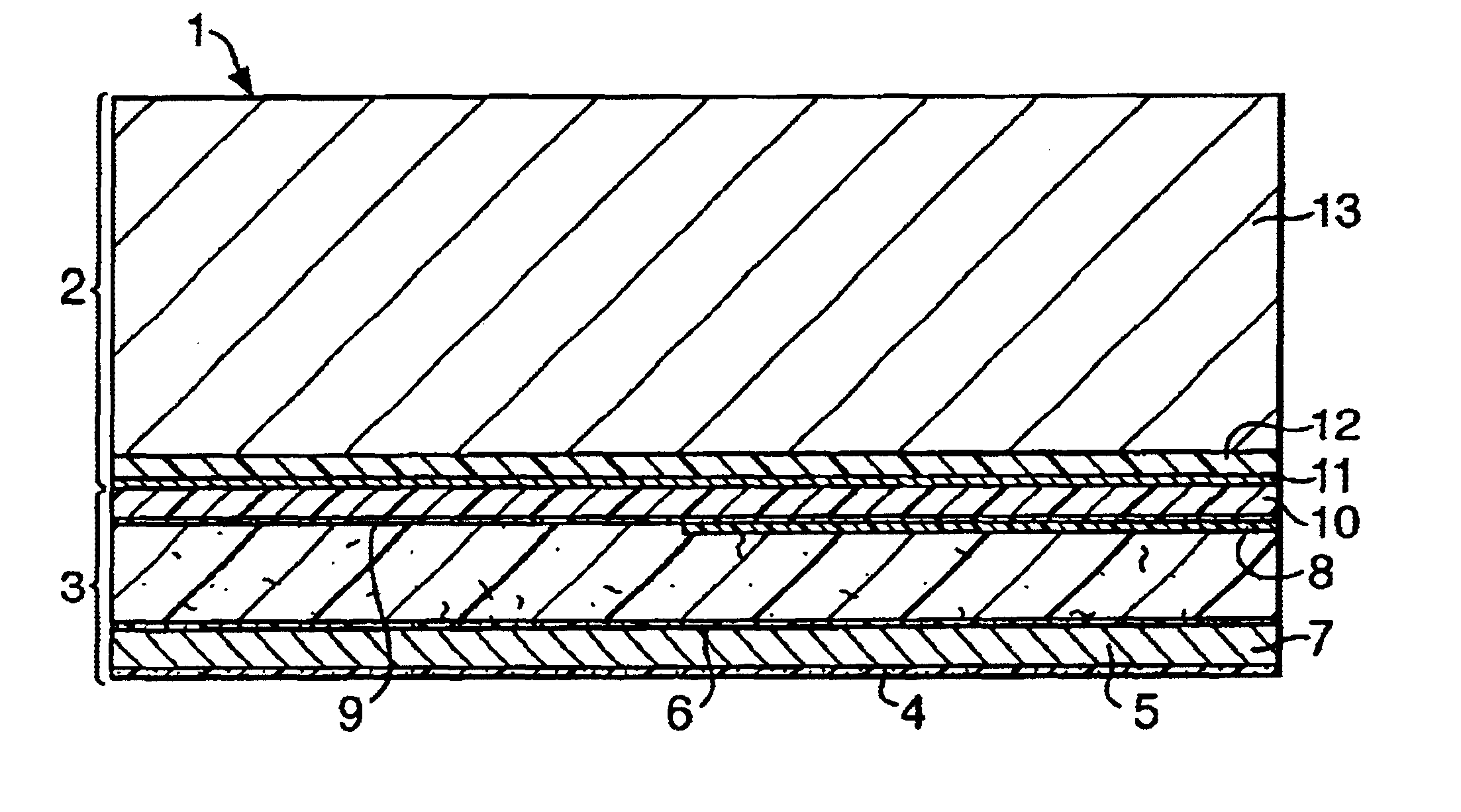

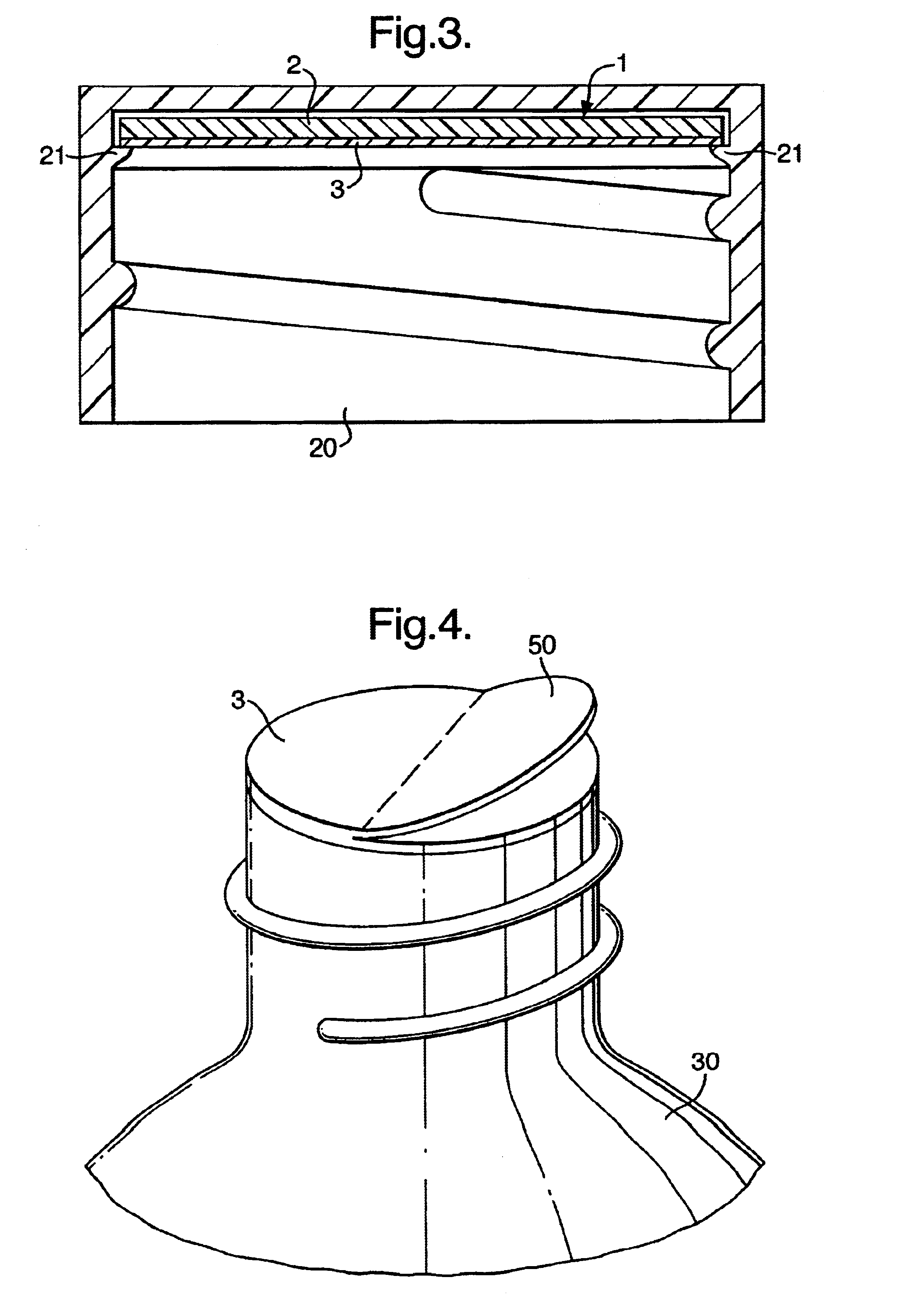

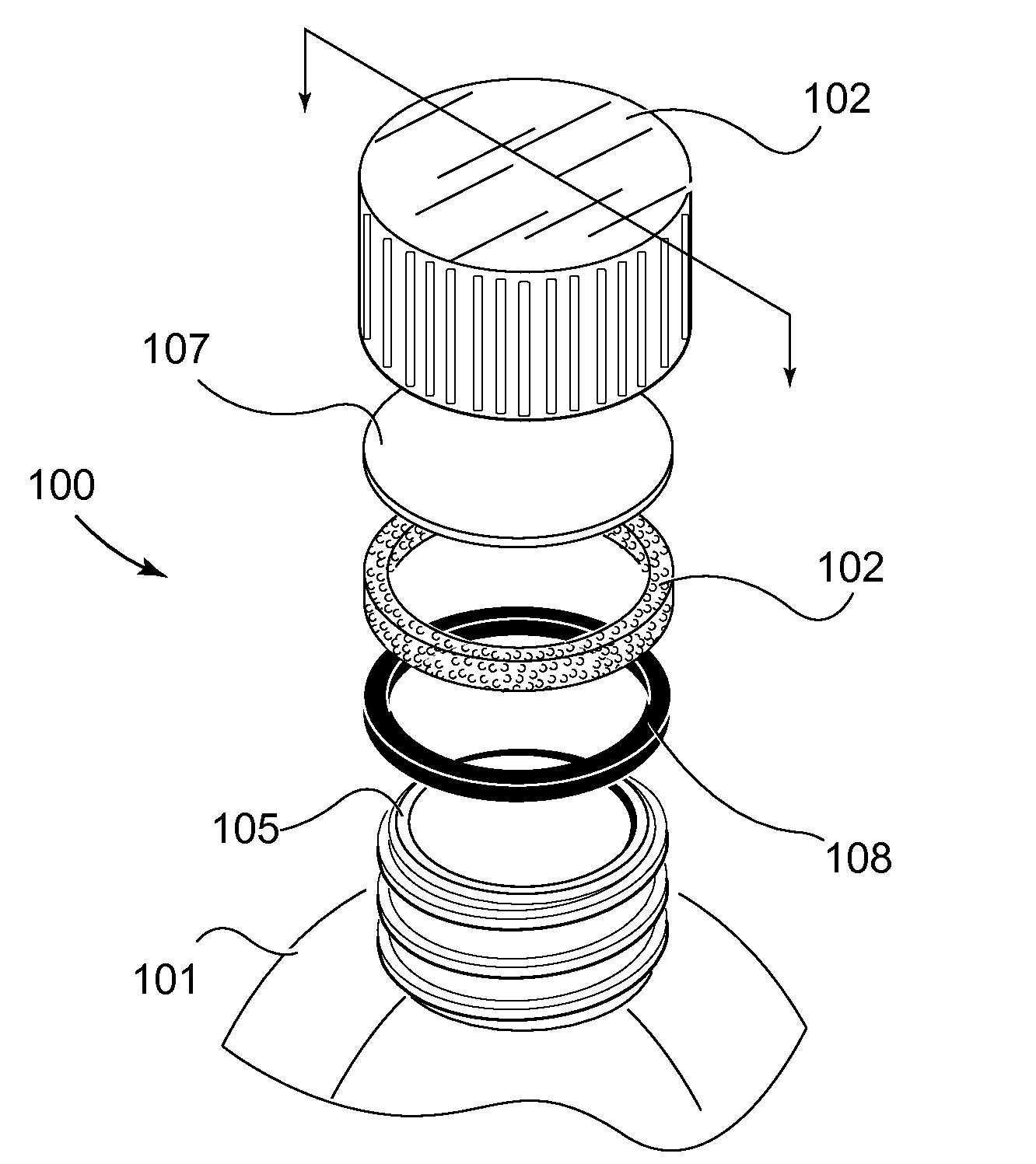

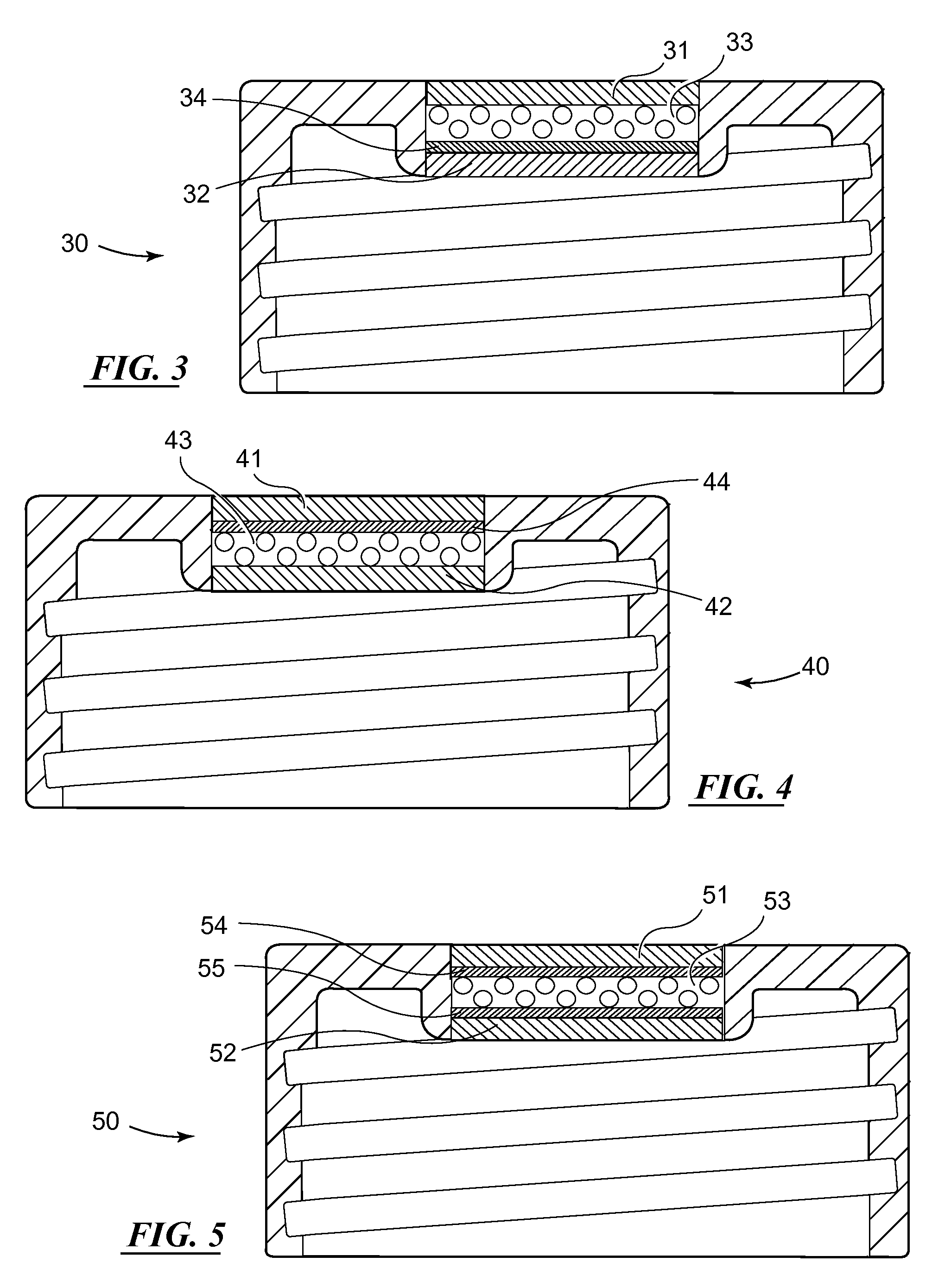

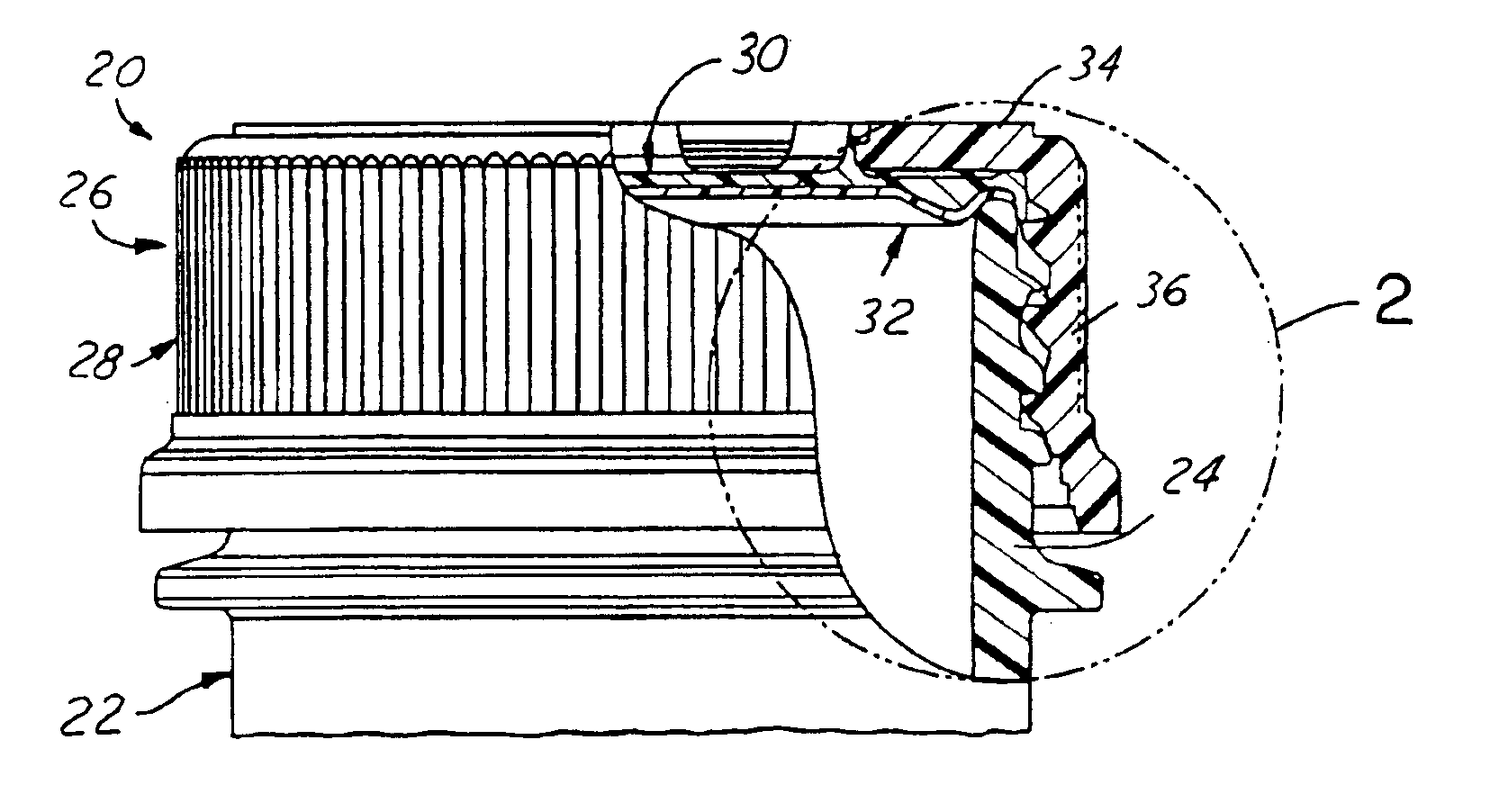

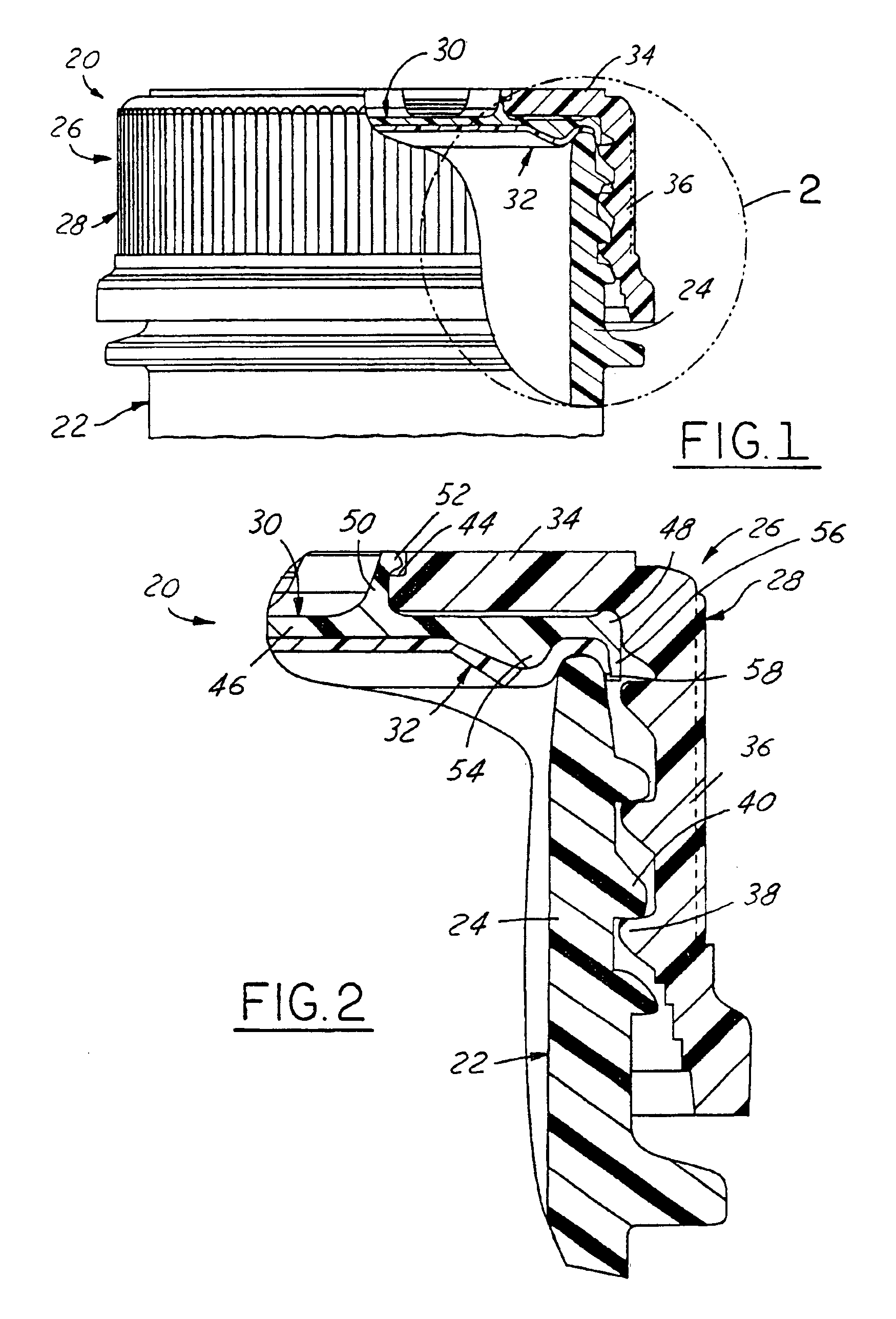

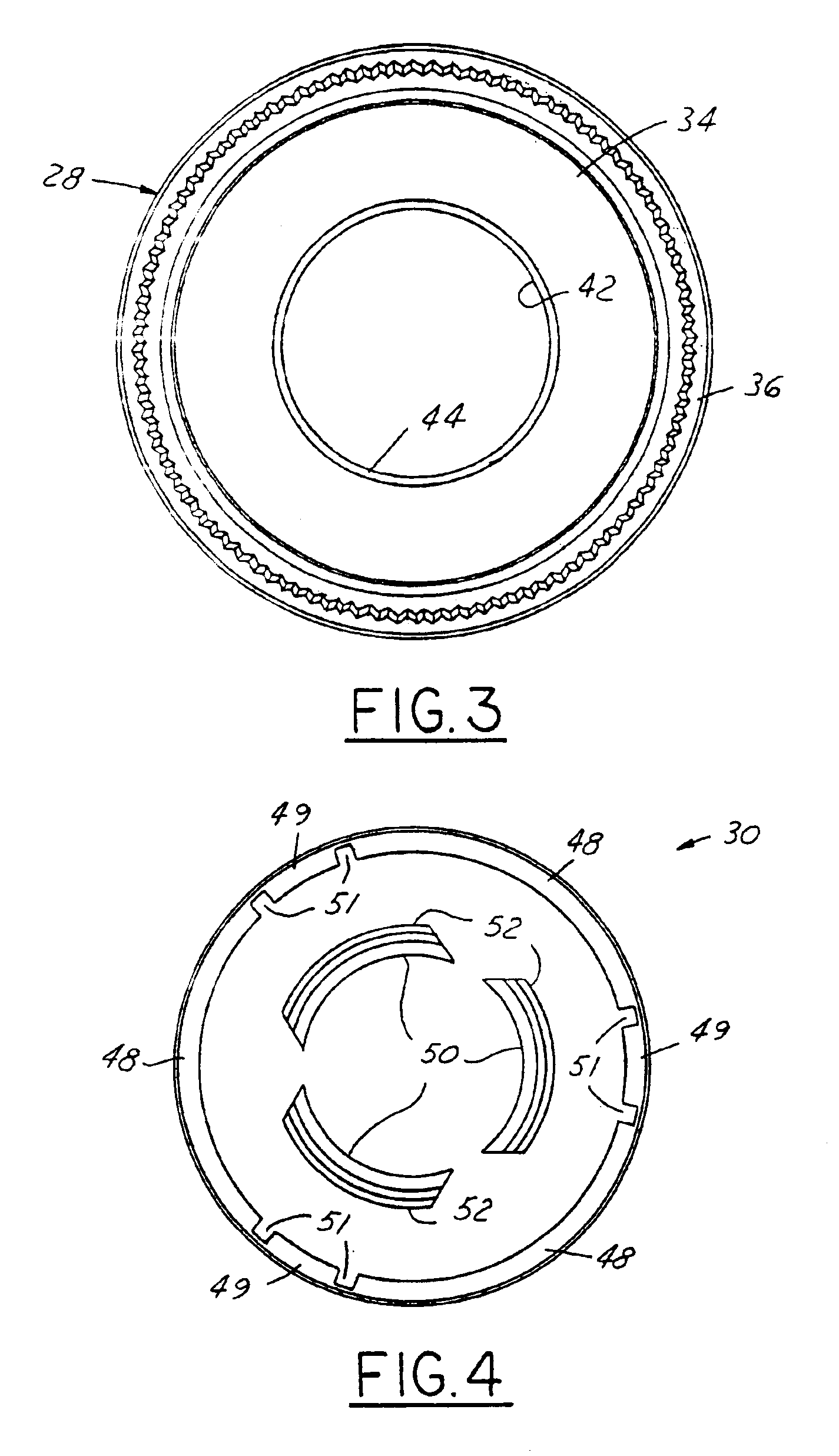

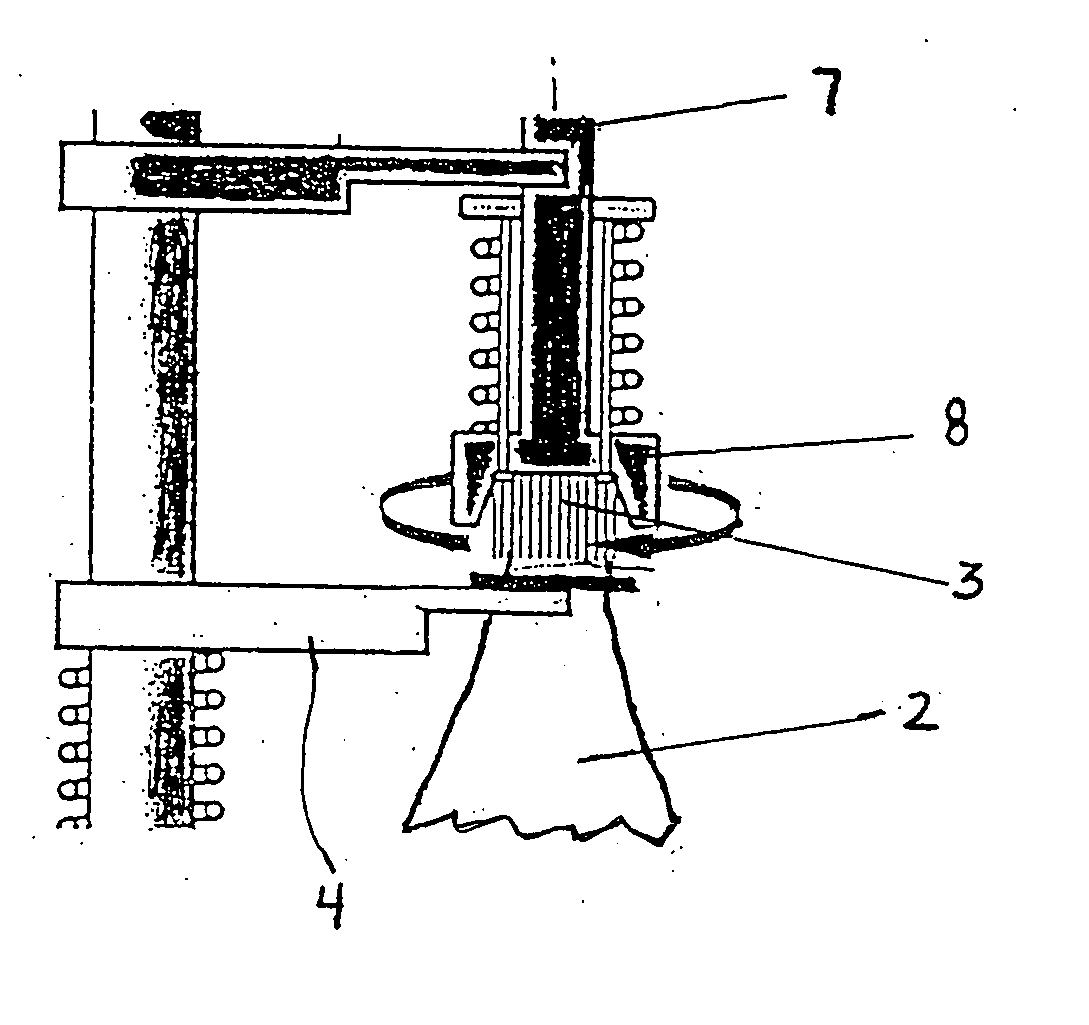

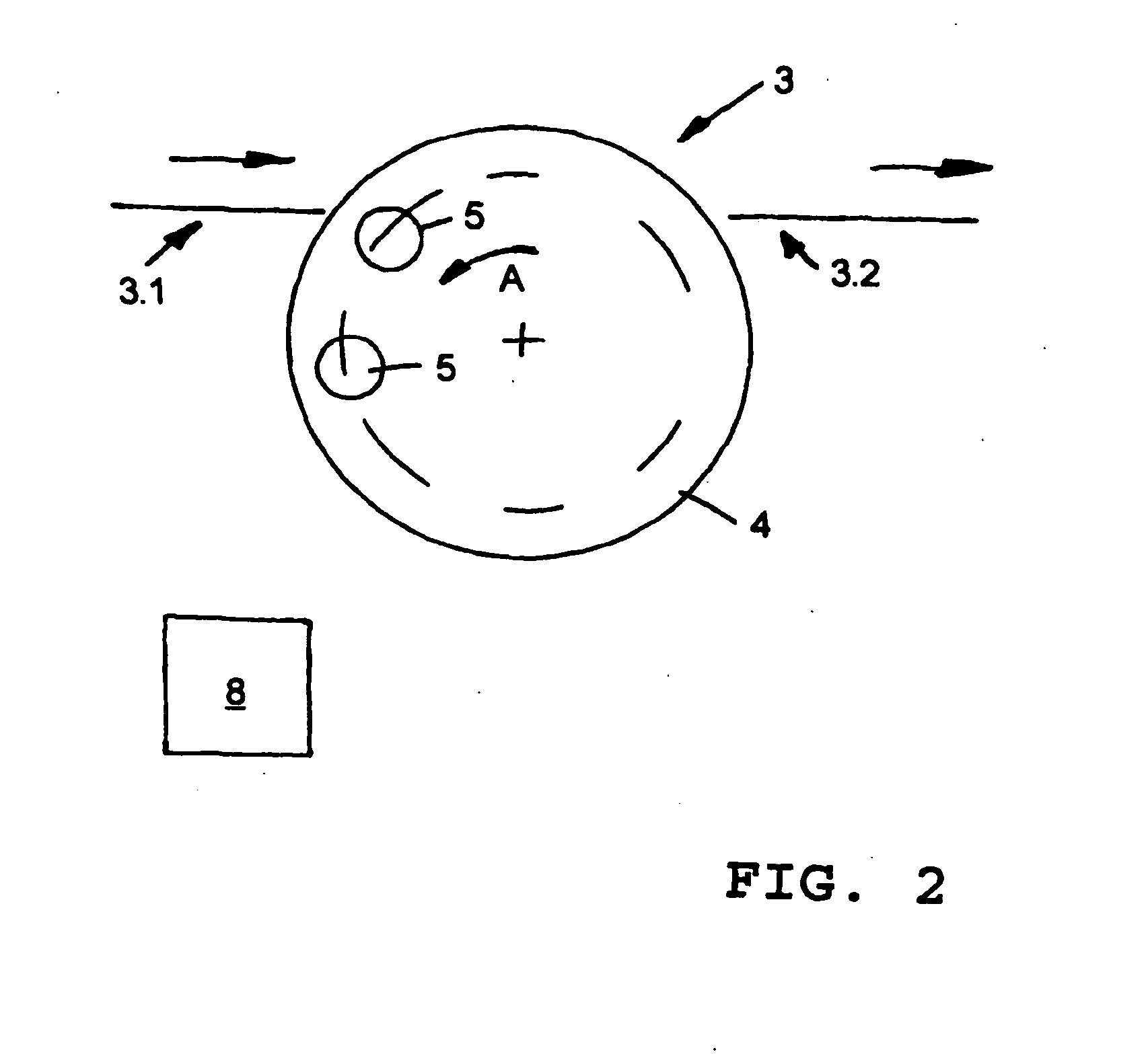

Container closure

InactiveUS6902075B2Achieve stabilizationHigh elongationCapsThreaded caps applicationWaddingEngineering

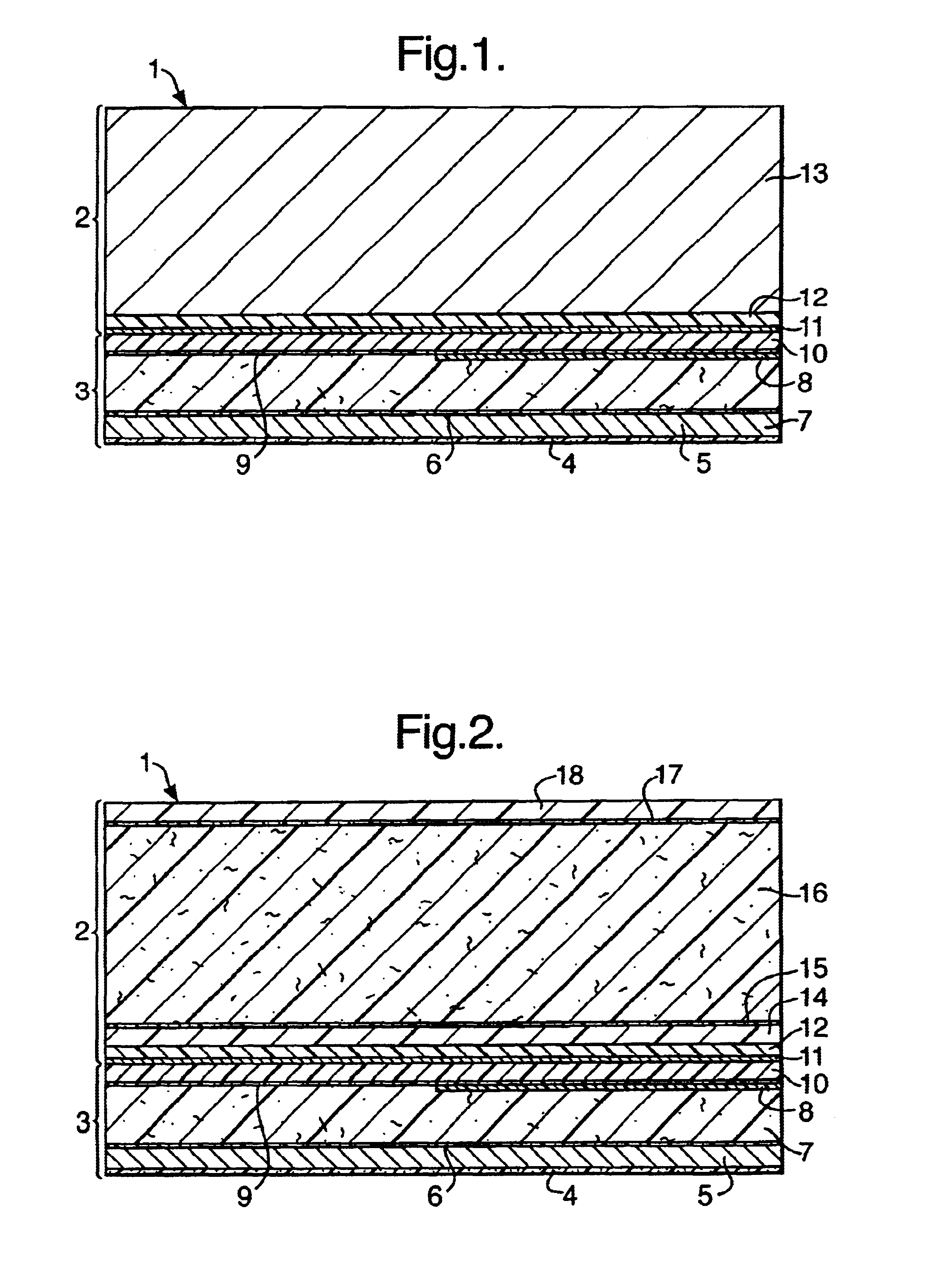

A one-component seal and wadding system (1) for a screw-cap includes a seal (3) having lower layers (4,5) forming an induction heating sealable system for attaching the seal (3) to the neck of a container, a seal substrate (6) including a free tab (50) lying wholly within the circumference of the seal, a layer of liner (2), and an attachment element (10,11,12) including a release layer (11) for attaching the seal substrate (7) including the tab (50) to the wadding (2).

Owner:SELIG SEALING PROD INC

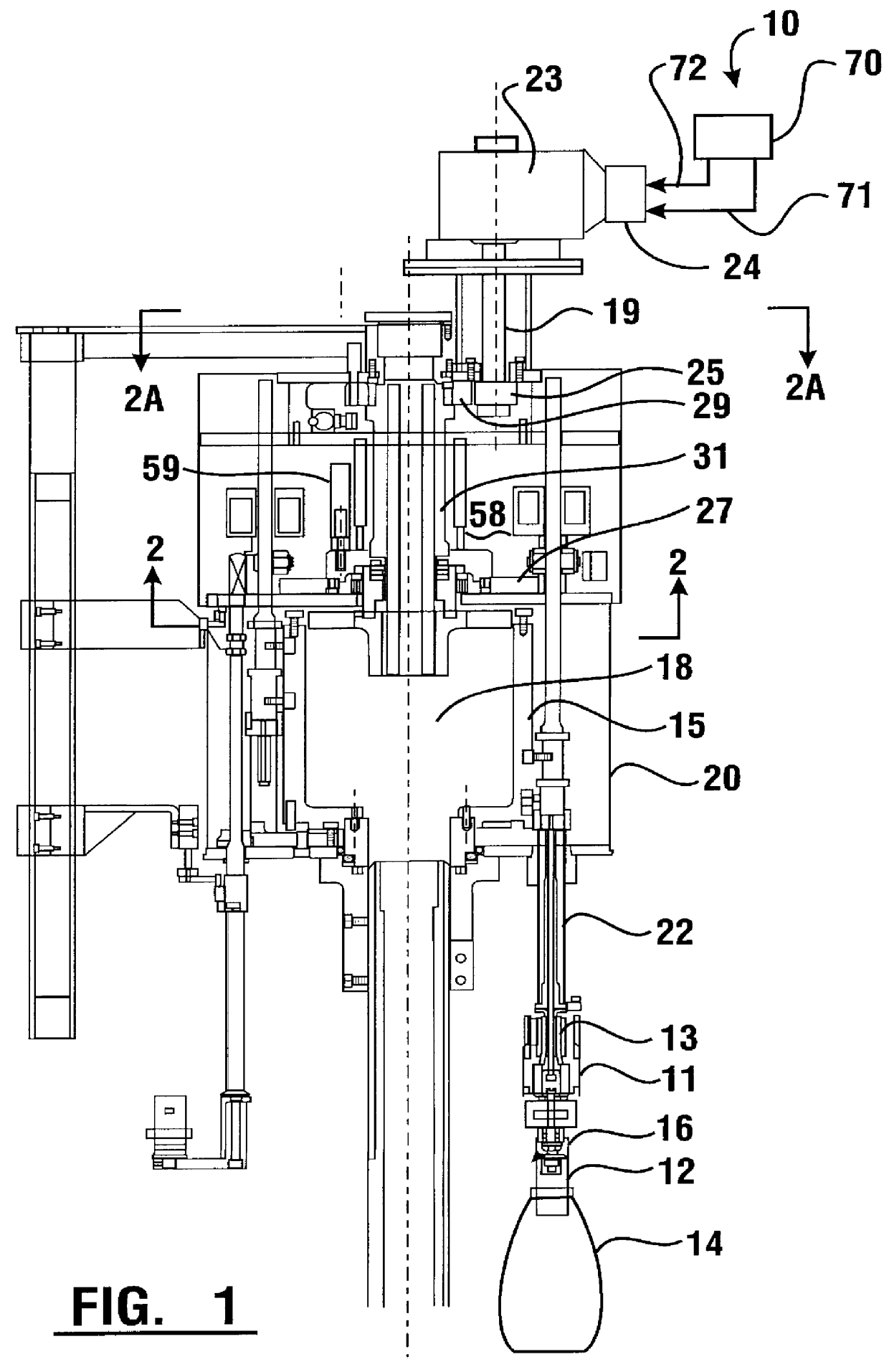

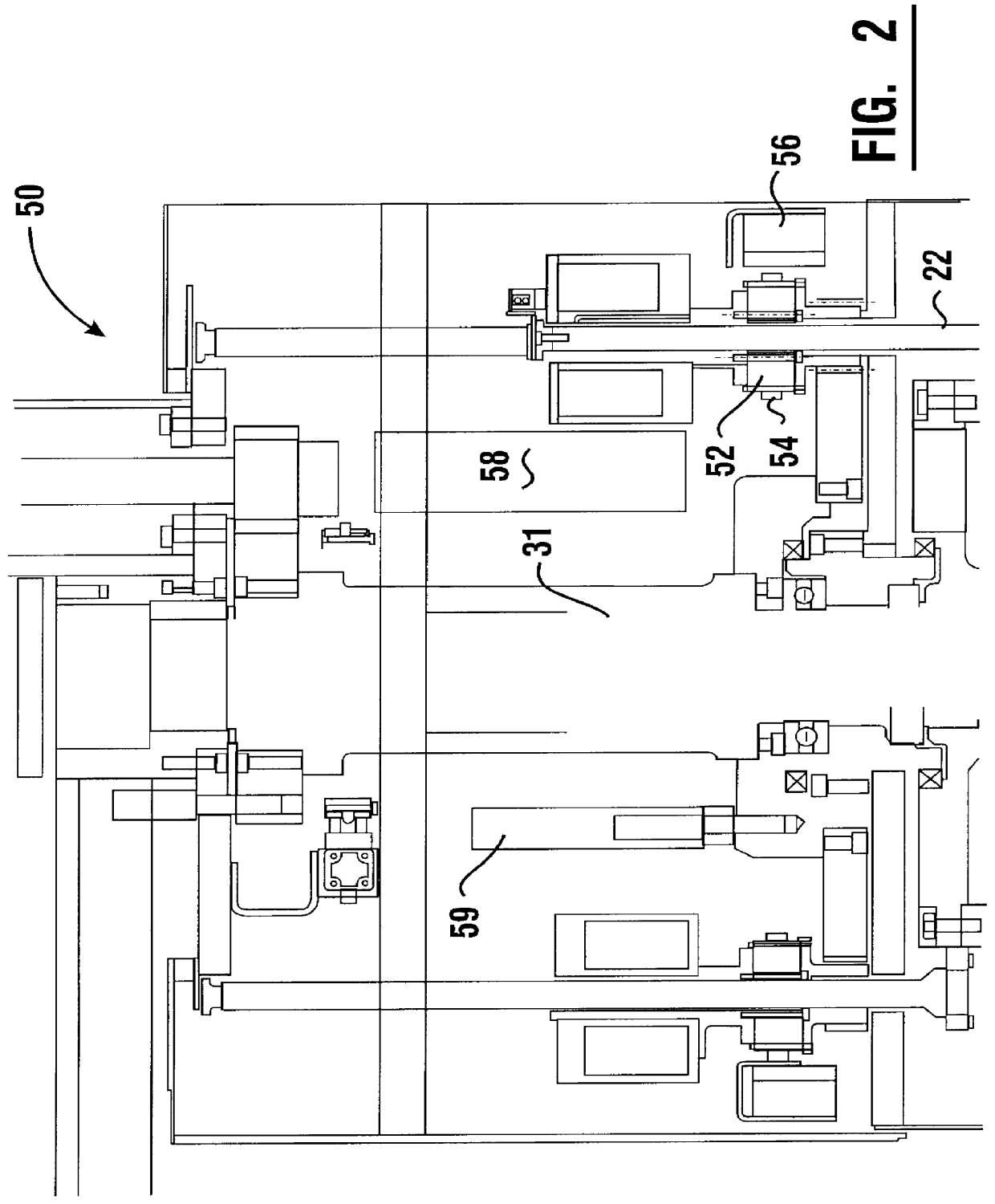

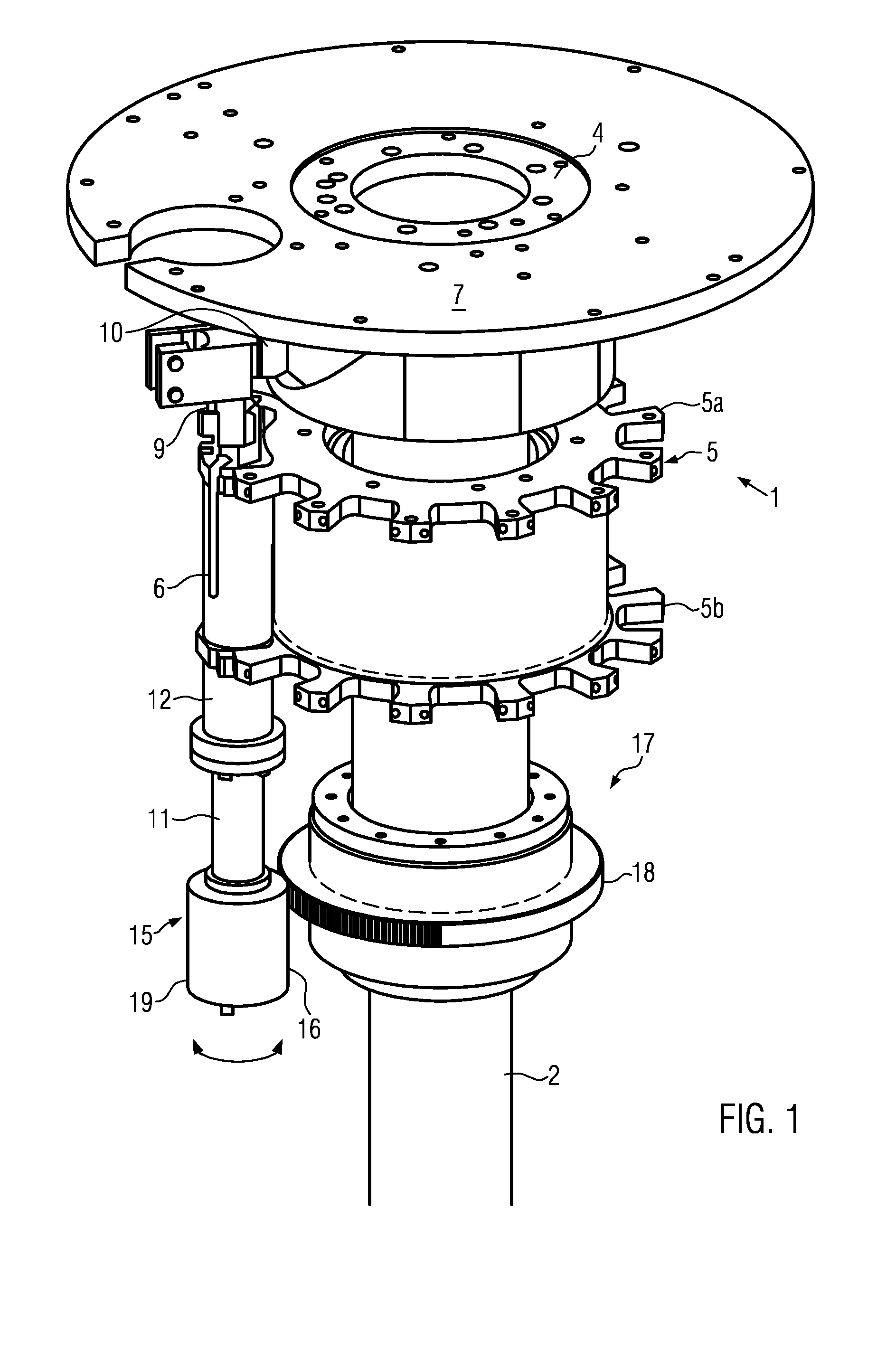

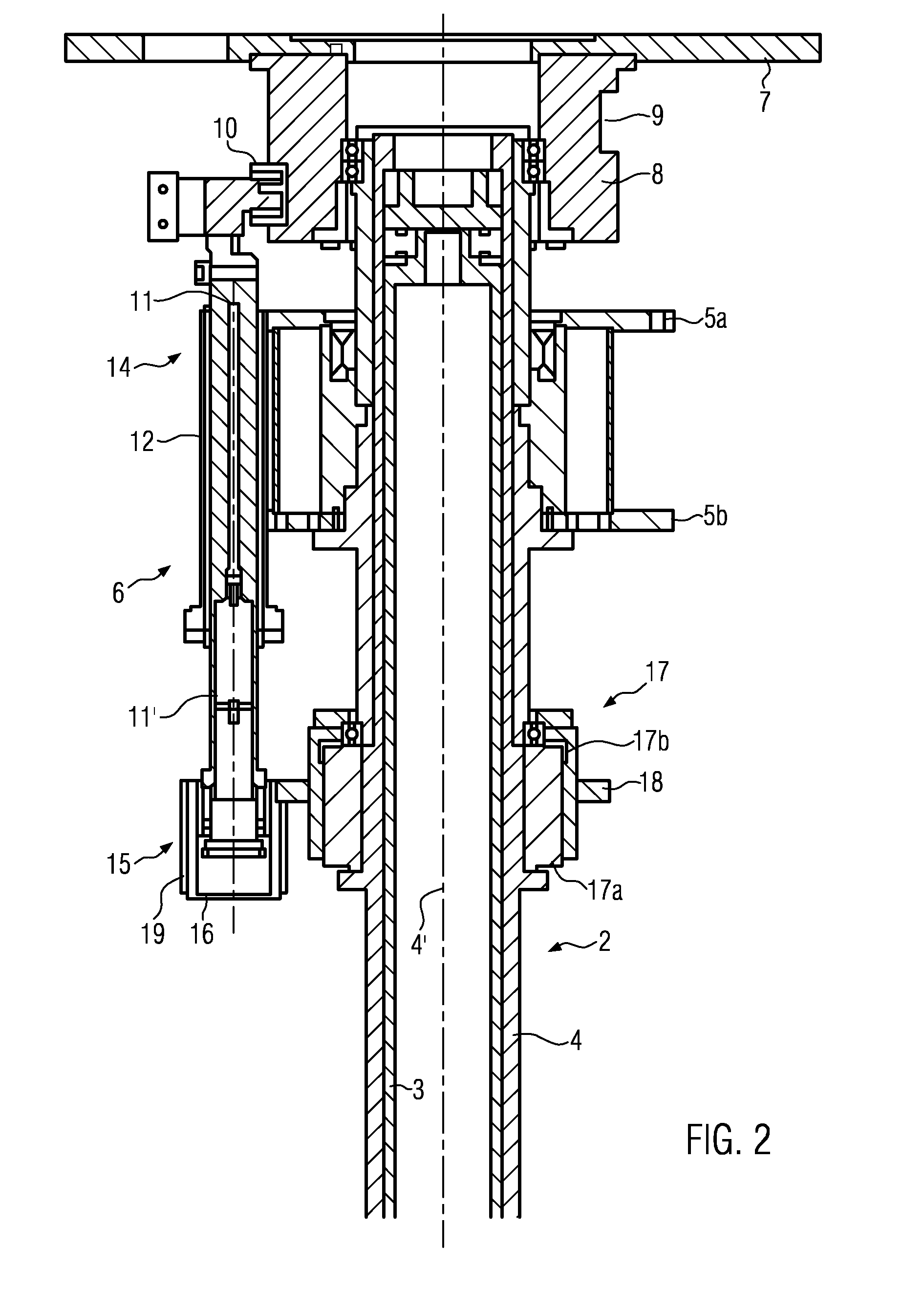

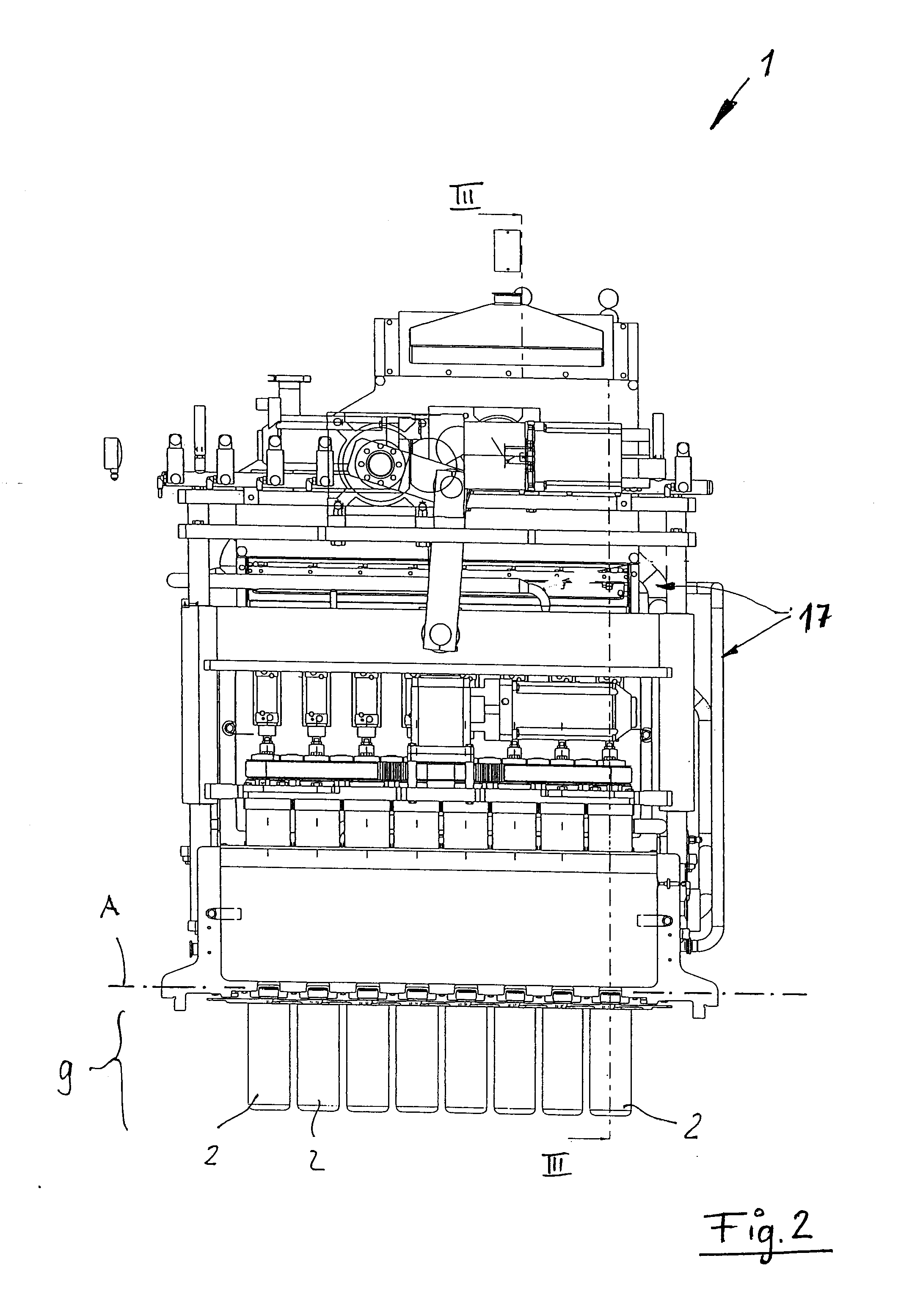

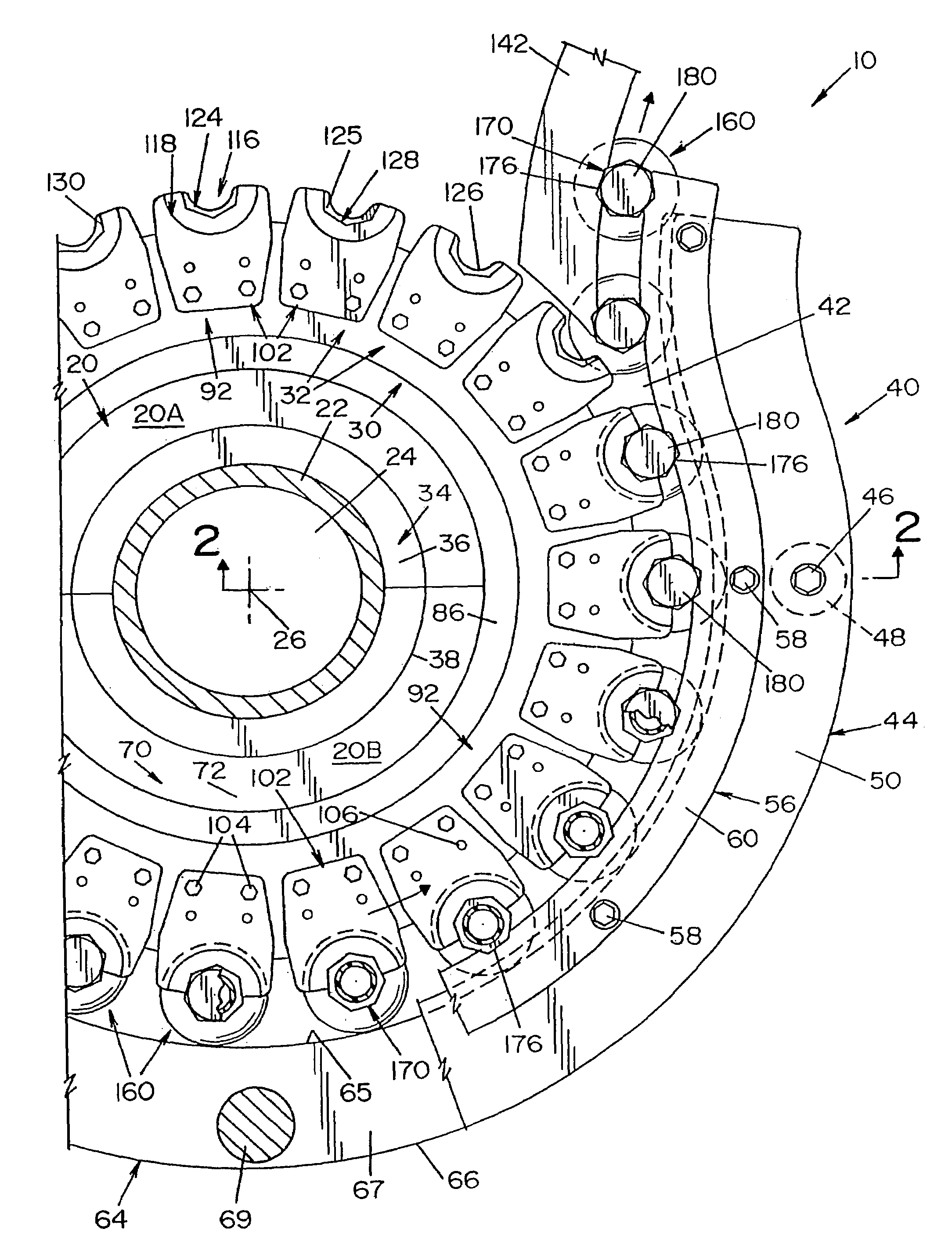

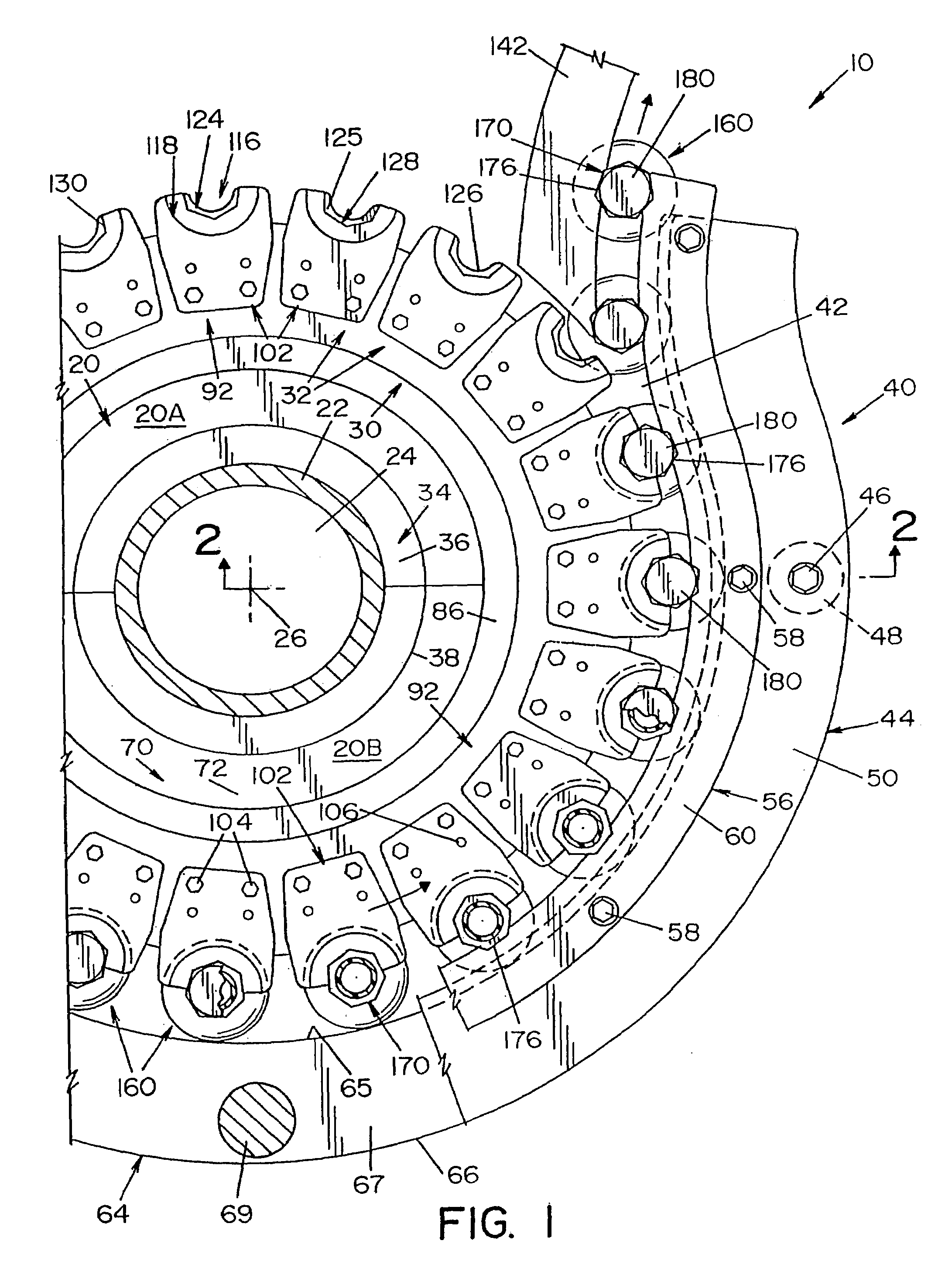

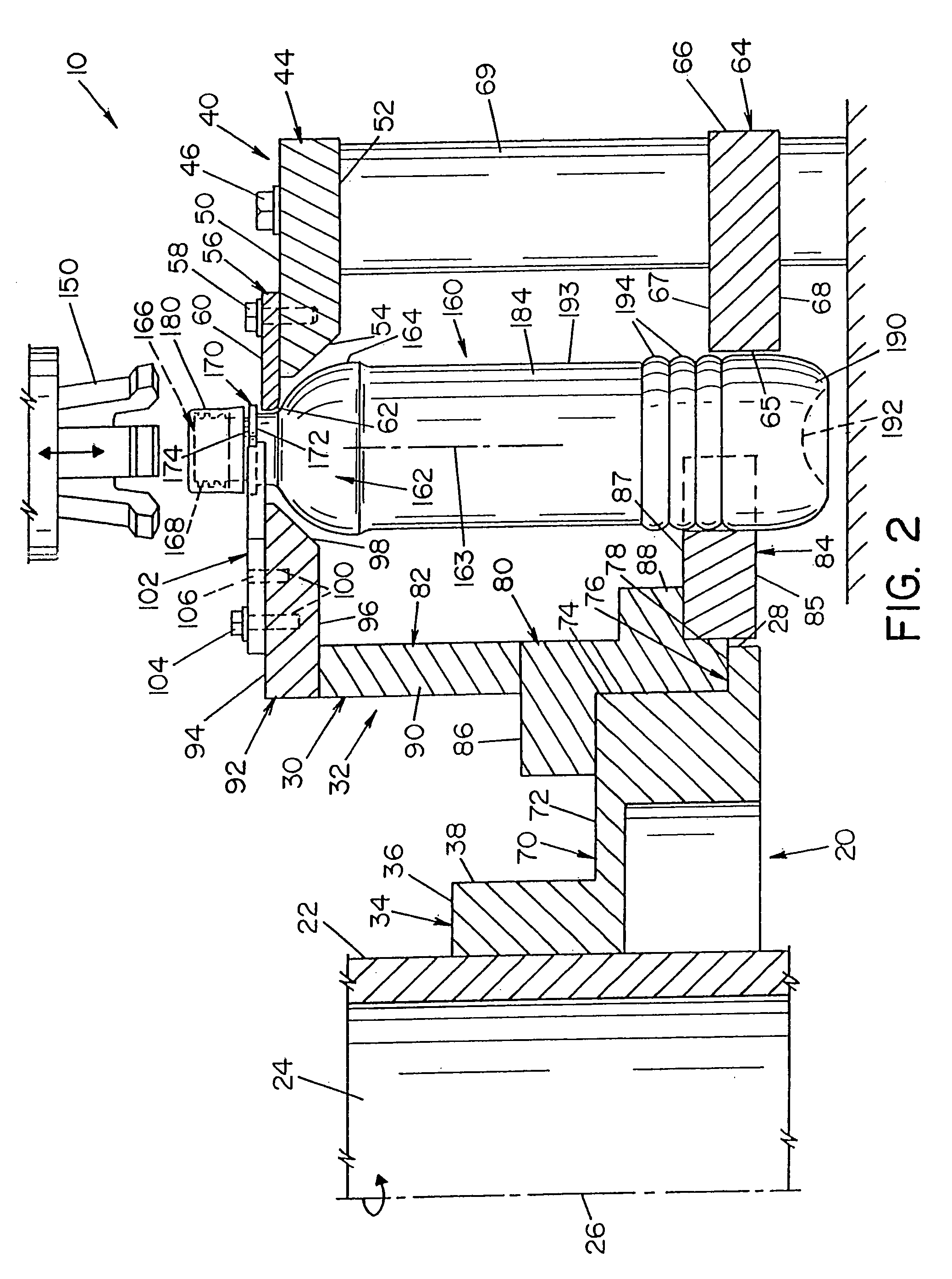

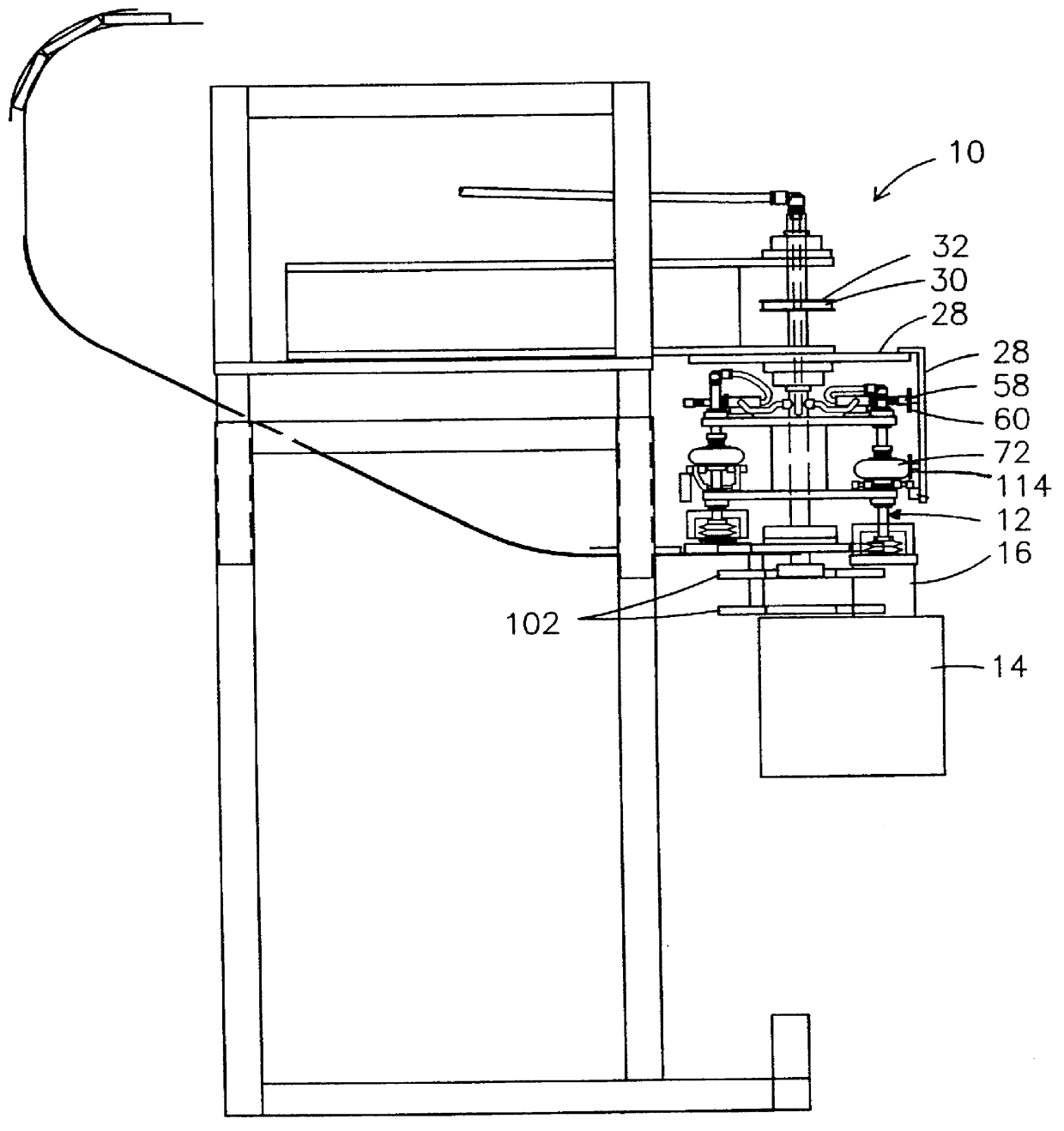

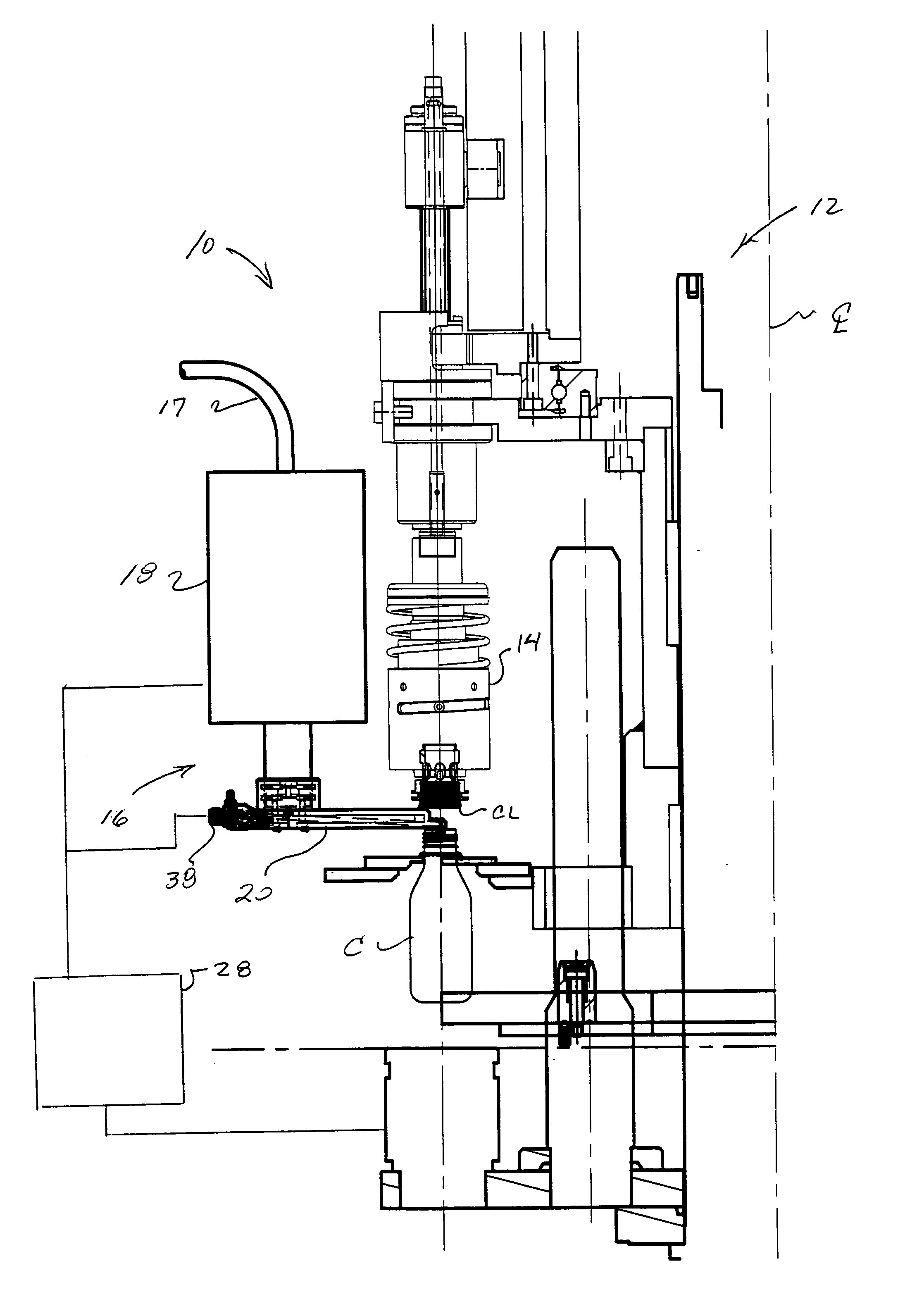

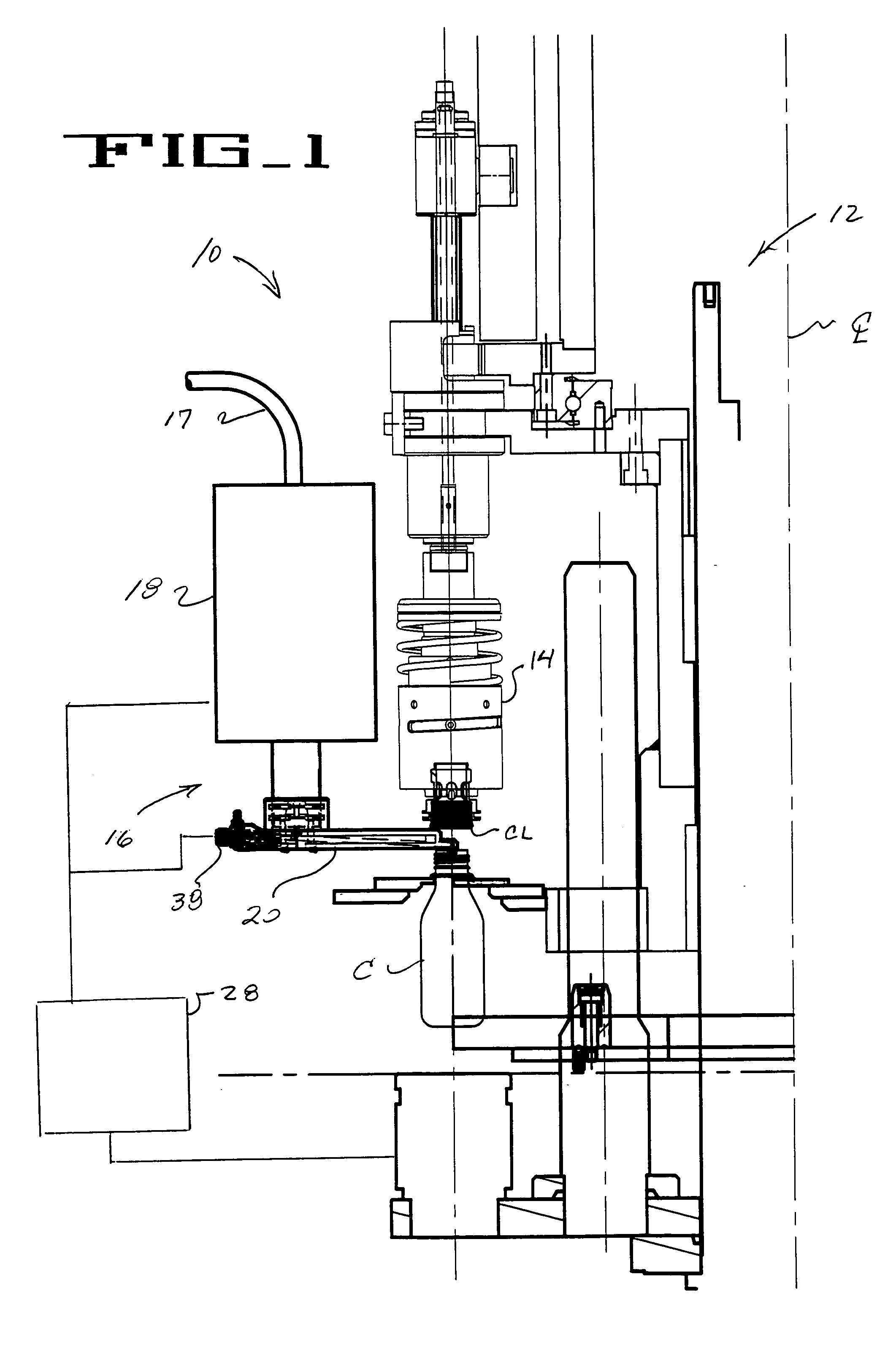

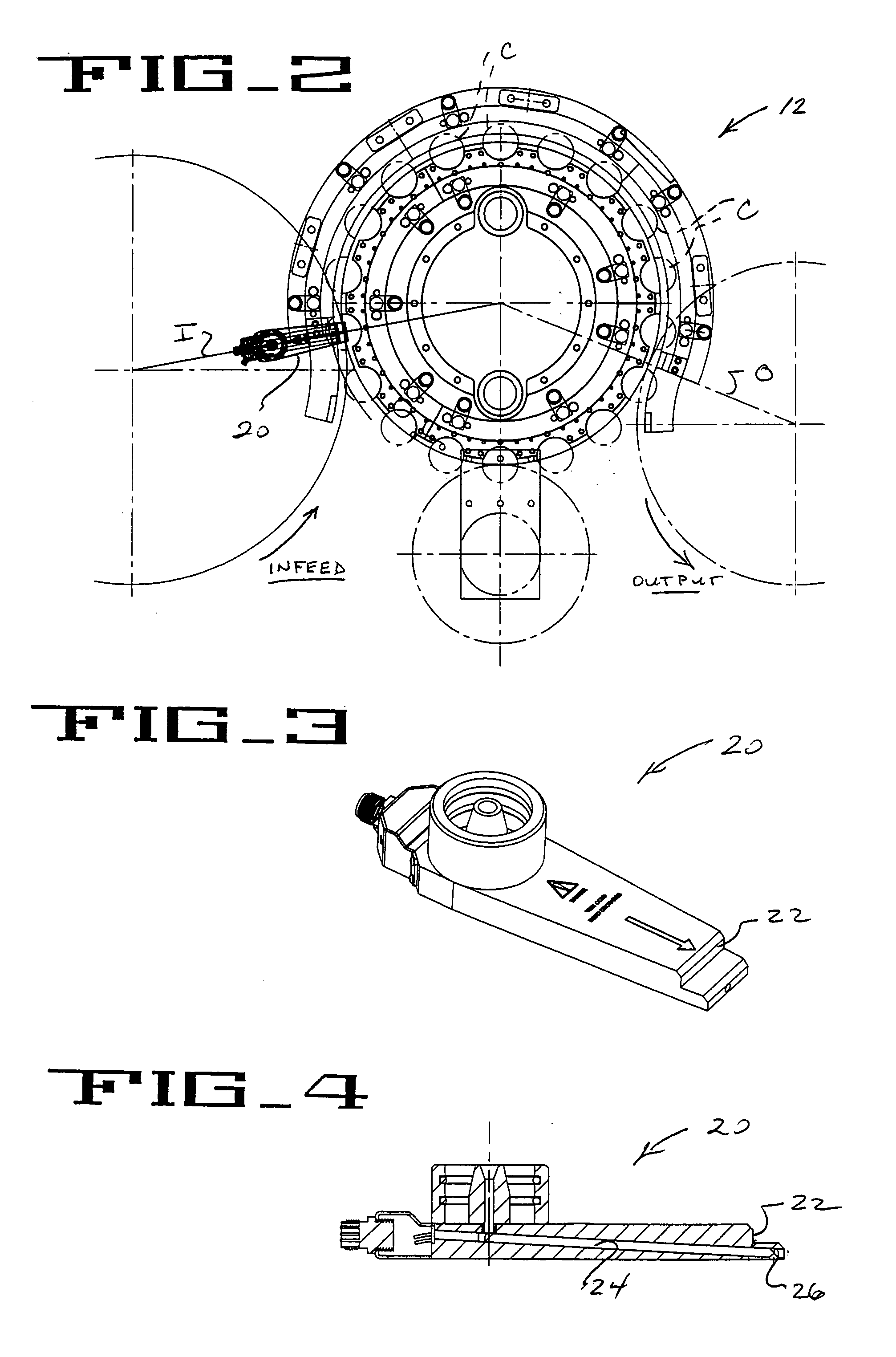

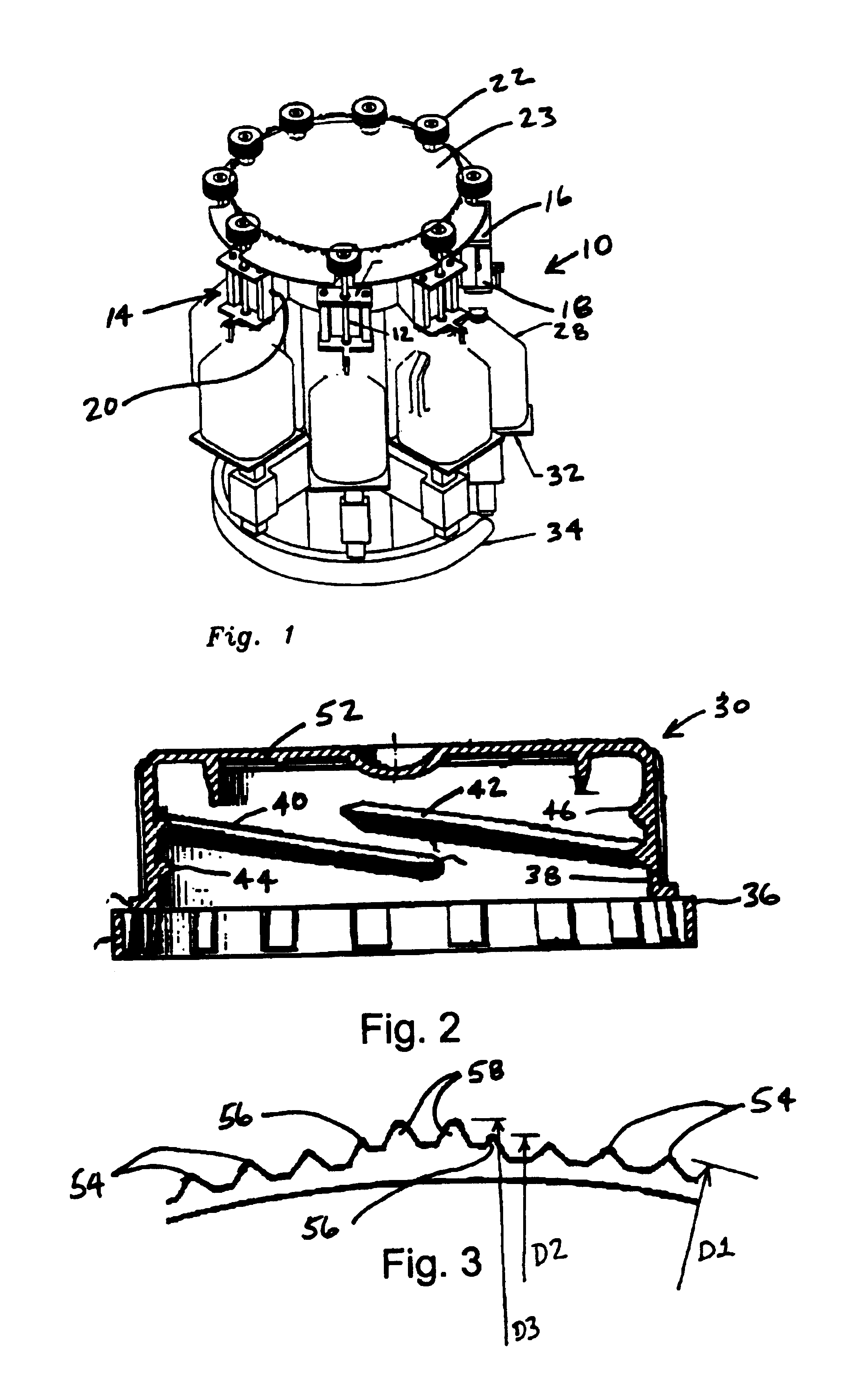

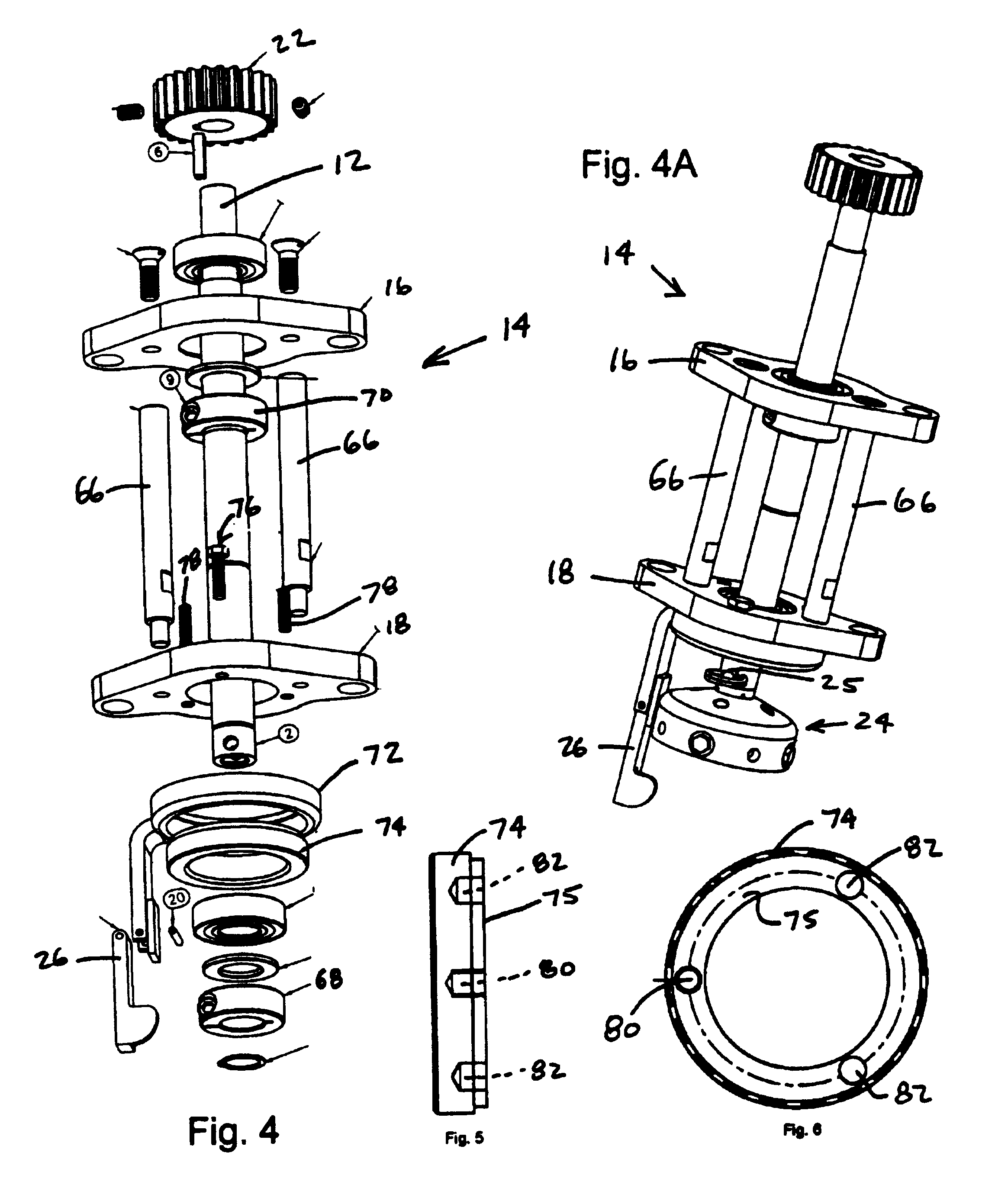

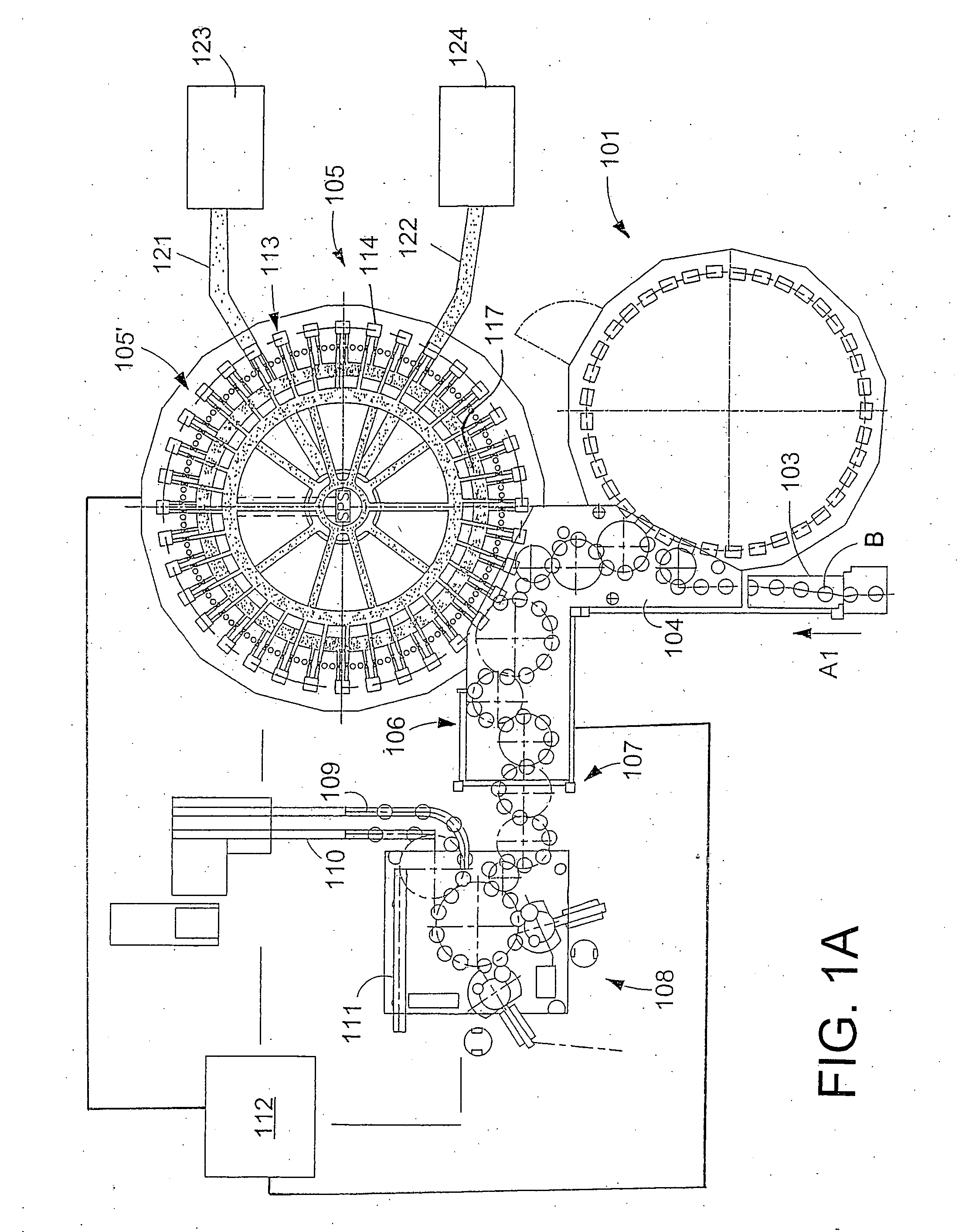

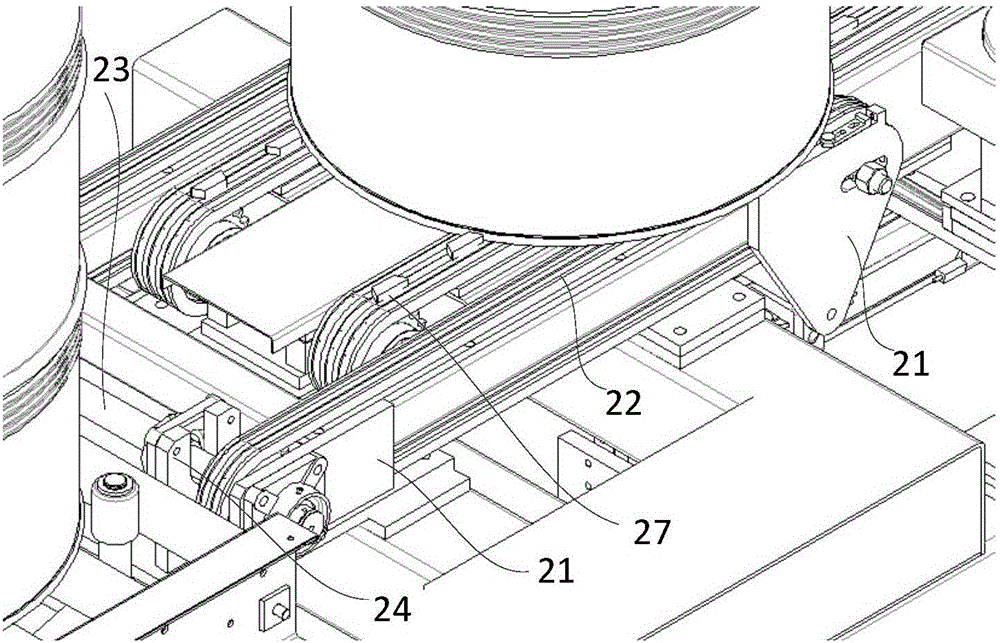

Apparatus and method for a capping machine

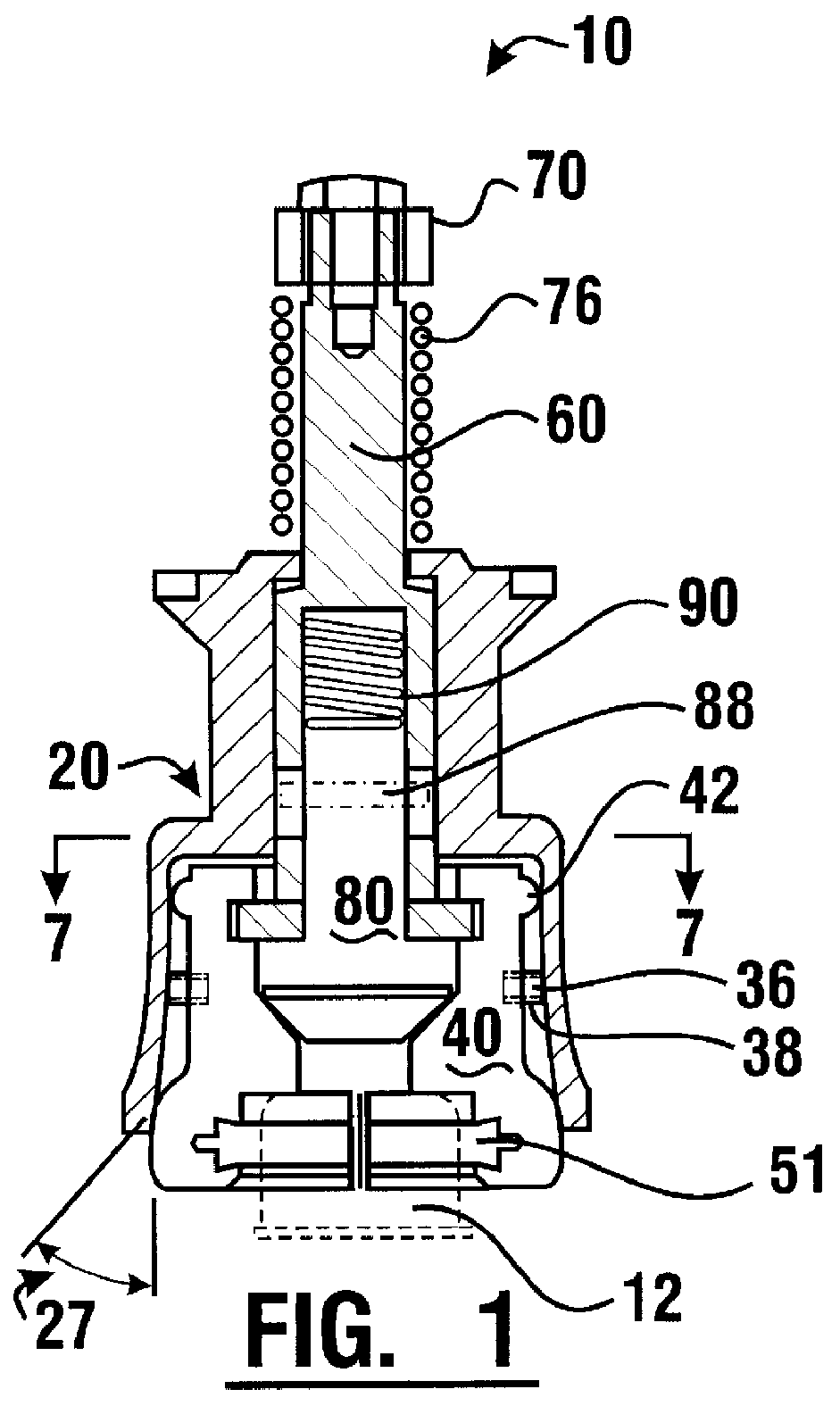

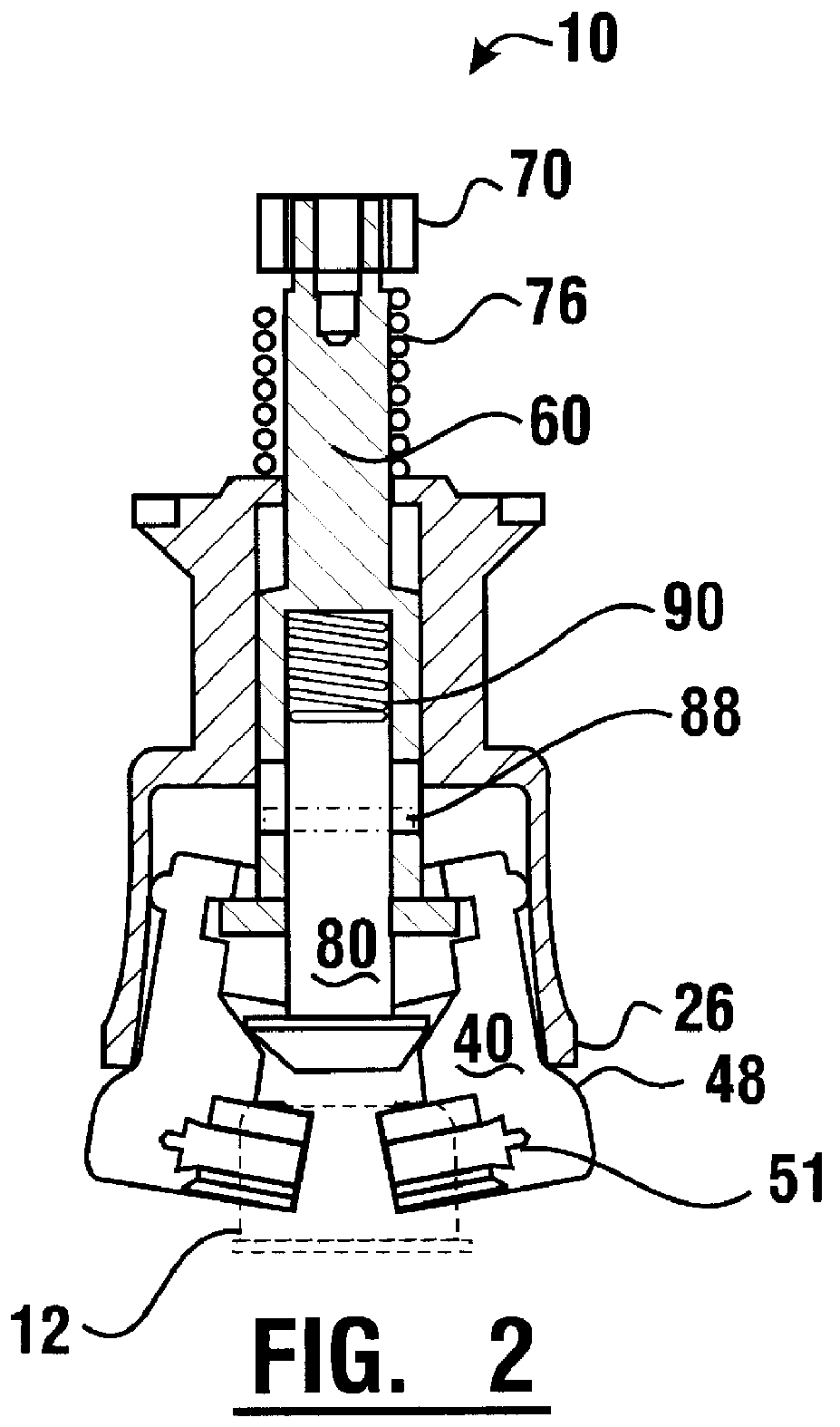

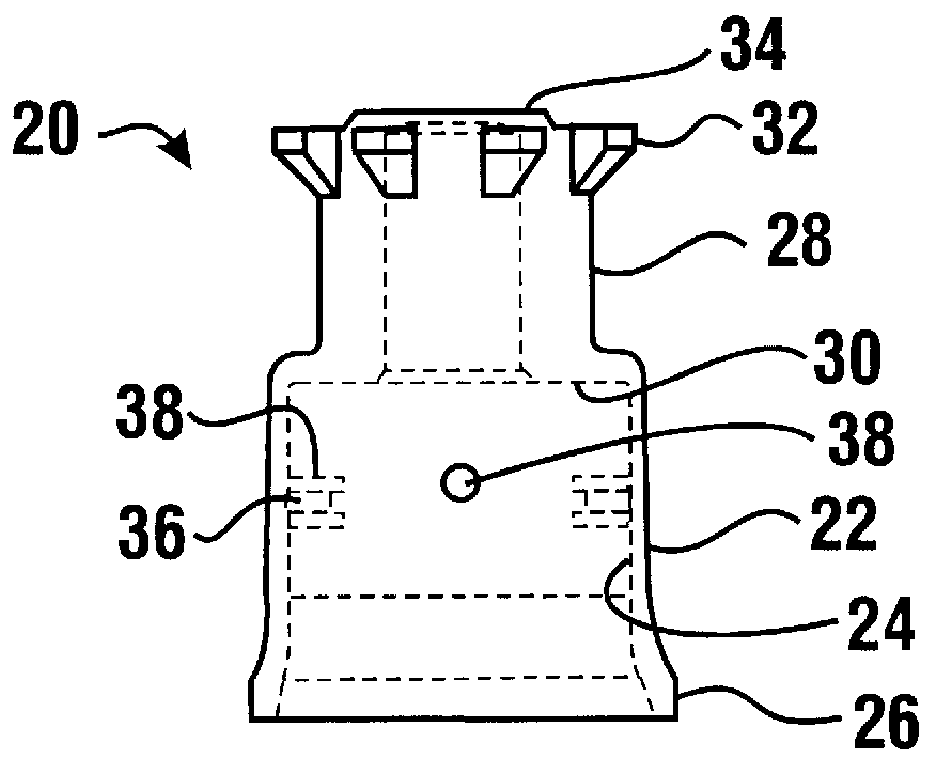

A capping machine (10) and method for installing a cap (12) having a threaded portion onto a container (14) having a threaded portion, the threaded portion of the cap corresponding to the threaded portion of the container, the capping machine having a rotatable turret (20) and a rotatable cap chuck (16) which grips the cap and positions the cap on the container. The cap chuck is rotated by a spindle (22) driven by a servo motor (24) at adjustable and reversible rotational velocities independent of the rotational velocity of the turret. The number of rotations of the cap is determined by monitoring the number of rotations of the servo motor compared to the number of rotations of the turret and is transmitted to a spindle drive control(70). The torque imparted to the cap is monitored by a torque monitor (50) and is transmitted to the spindle drive control. The rotational velocity of the cap is adjustable in response to the compared monitored number of rotations and monitored torque. The capped container is released from the cap chuck after a selected number of rotations of the cap onto the container has been made. Caps applied outside a selected range of monitored torques and number of rotations are tracked and rejected.

Owner:PNEUMATIC SCALE CORP

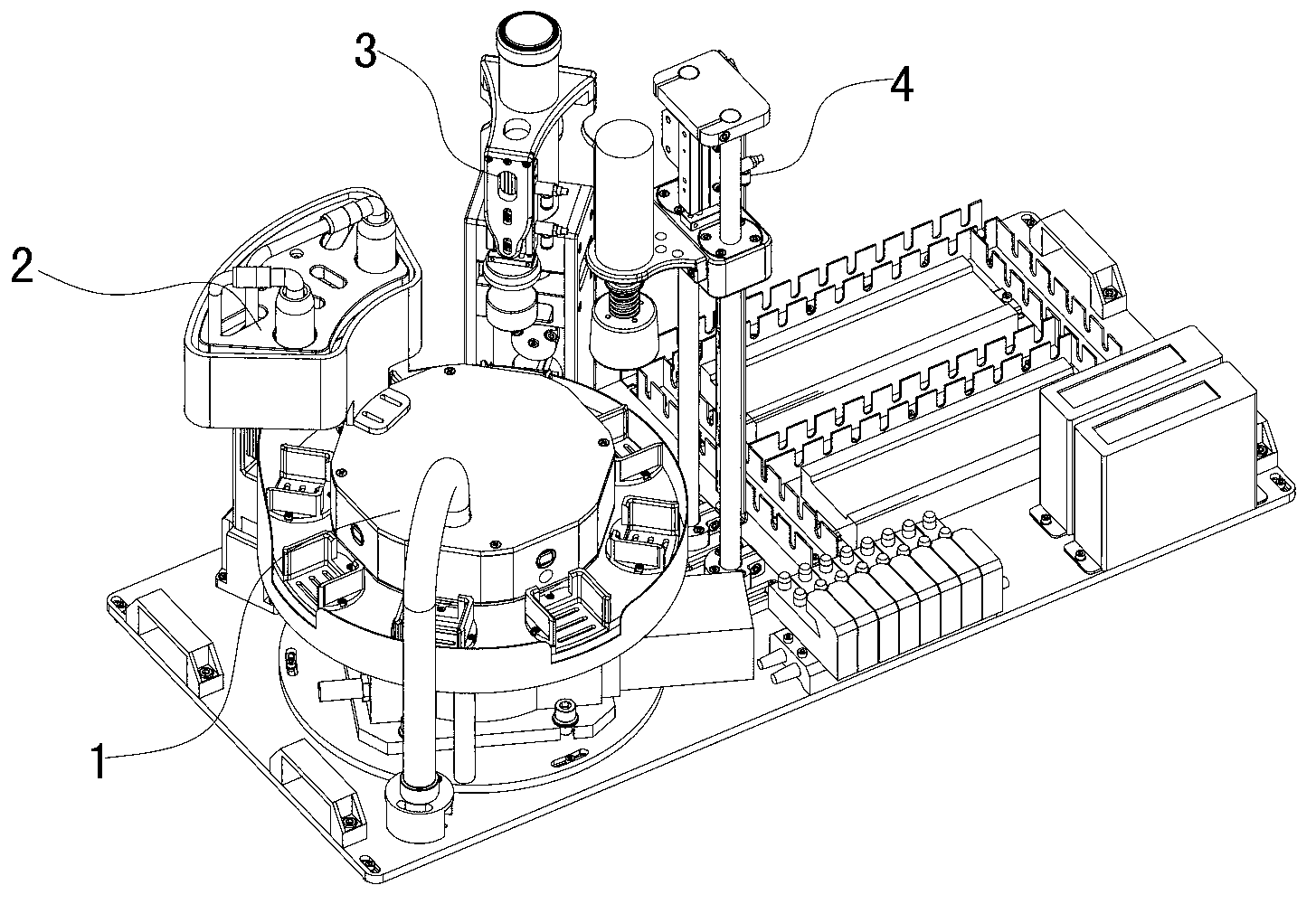

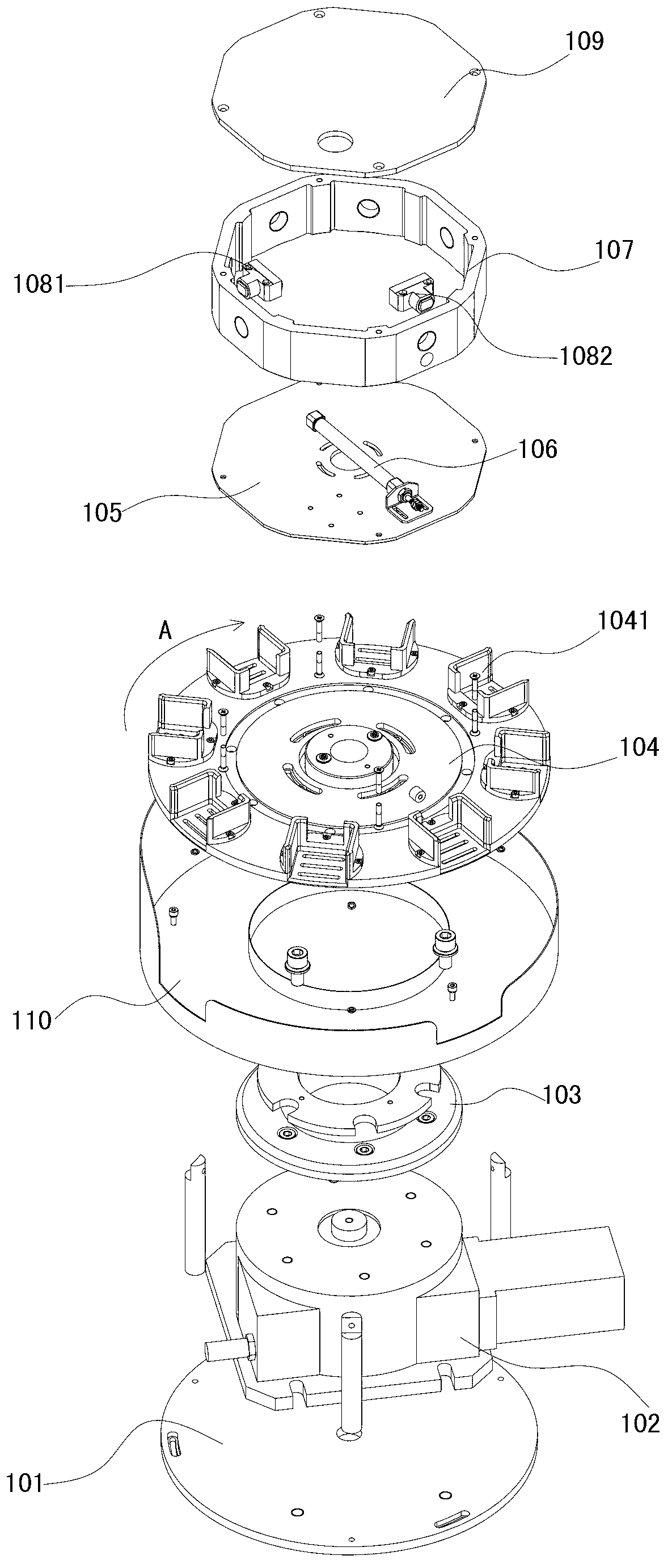

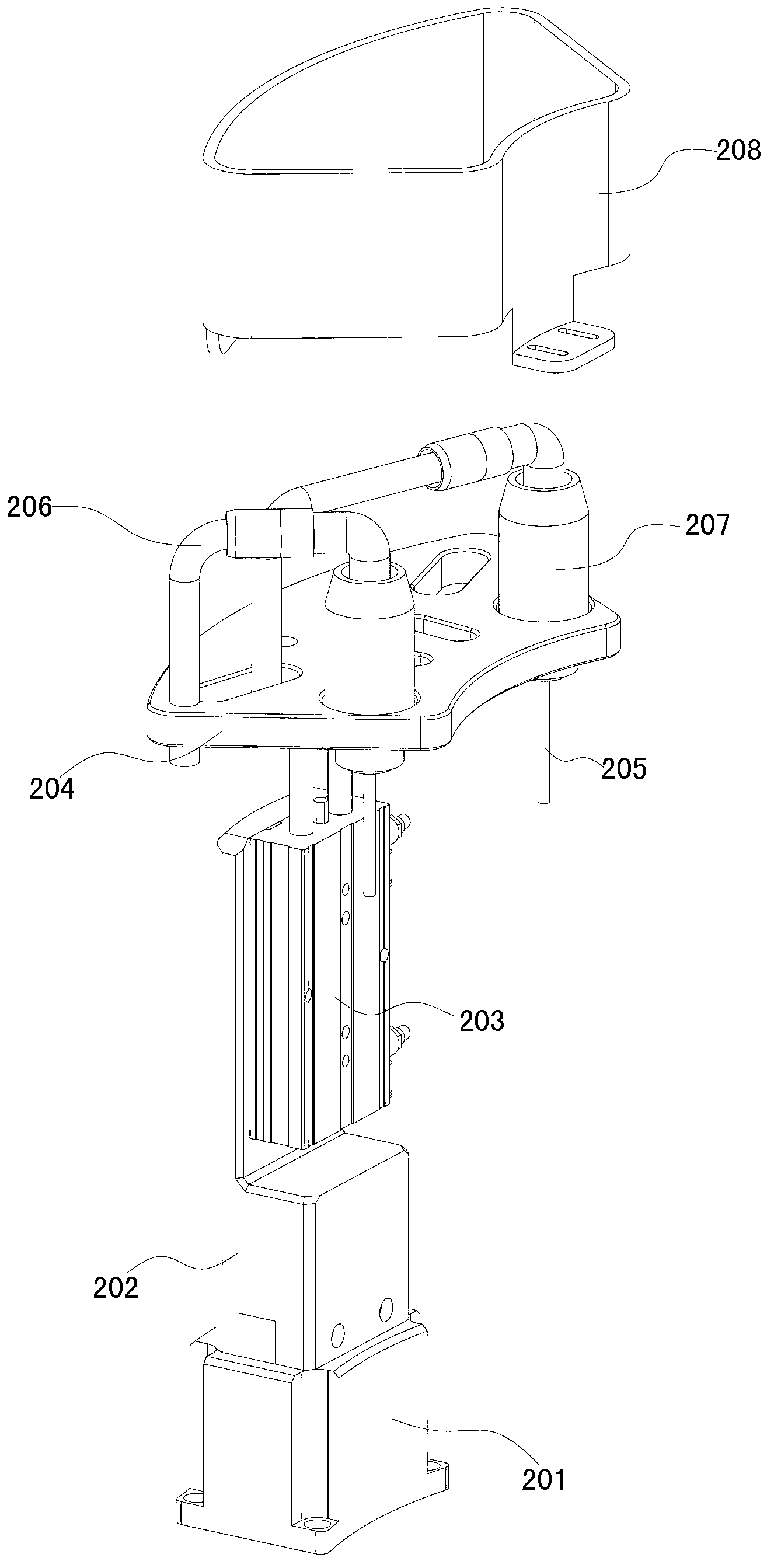

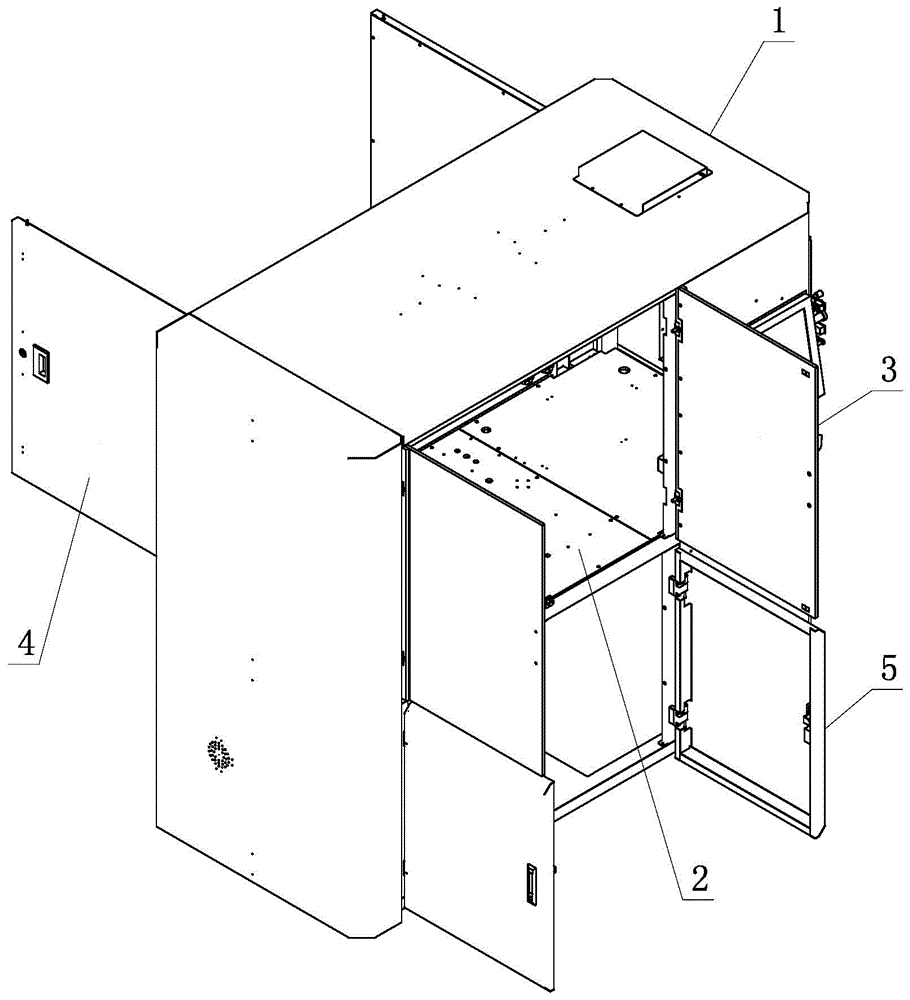

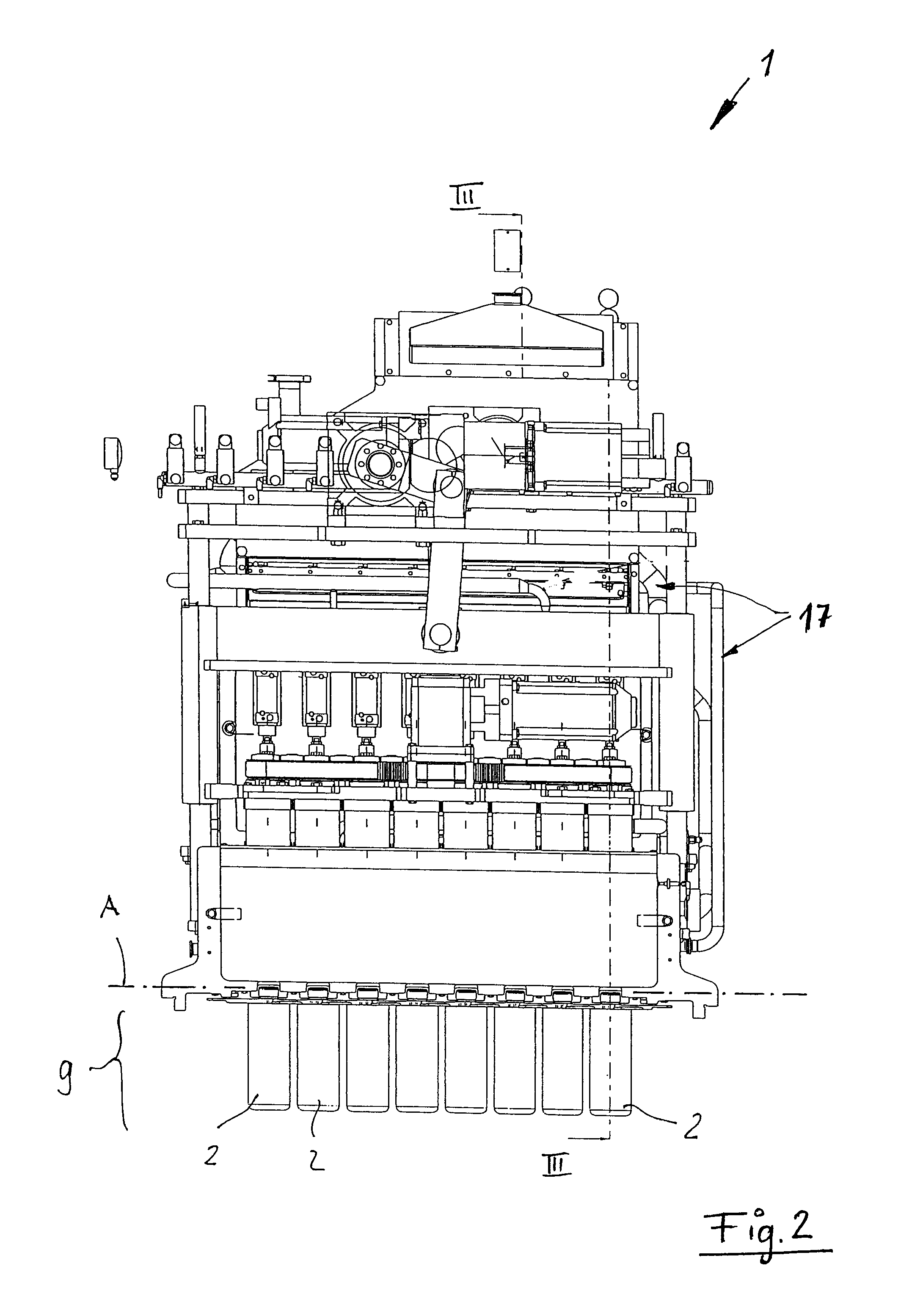

Filling capping device

ActiveCN102701127ALow costImprove space utilizationThreaded caps applicationLiquid fillingElectric machineryBottle cap

The invention discloses a filling capping device comprising a rotary disk component, a filling component, a cap pressing component and a screw capping component. The rotary disk component comprises a rotary disk and a pneumatic division plate which is used for driving the rotary disk to intermittently rotate; the filling component comprises a liquid injection needle, a liquid feeding pipe and a liquid injection lifting cylinder for driving the liquid injection needle to move up and down; the cap pressing component comprises a storage barrel, a transverse push cylinder and a cap pressing cylinder for pushing downwards a bottle cap to be added pushed by the transverse push cylinder; and the screw capping component comprises a screw capping motor, a screw capping lifting cylinder for driving the screw capping motor to move up and down and a rotating sleeve arranged at the free end of the screw capping motor, and a screw capping core arranged in the rotating sleeve. The filling capping device has a simple structure and is low in equipment cost; as the rotary disk is adopted to convey bottles, the volume of the entire device is reduced and subsequently the occupied area of the device is reduced; the filling capping device can be used for teaching demonstration; and furthermore, the space utilization rate of a workshop is improved.

Owner:广东三向智能科技股份有限公司

Closing means

InactiveUS20120186194A1Increase flexibilityImprove controllabilityCapsThreaded caps applicationLinear motionGear wheel

A closing means for containers including a transport means for the containers having a drive and at least one closing unit for applying a closure by a linear motion along a central line and a rotary motion about the central line, wherein the rotary motion is applied by rolling off two gear members. To achieve a structurally simple and flexible embodiment the first one of the gear members is connected with a separate drive independent of the drive of the transport means.

Owner:KRONES AG

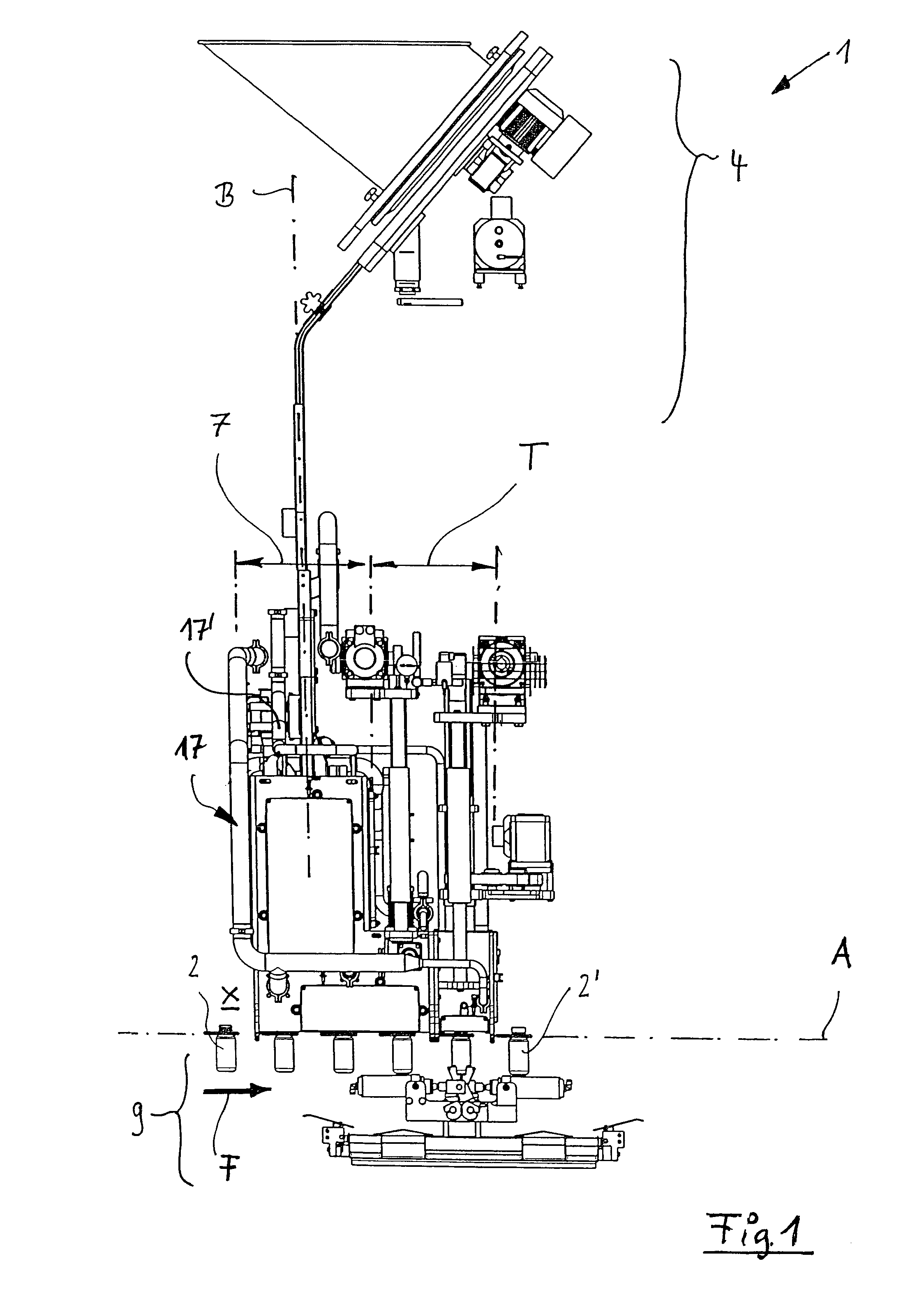

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

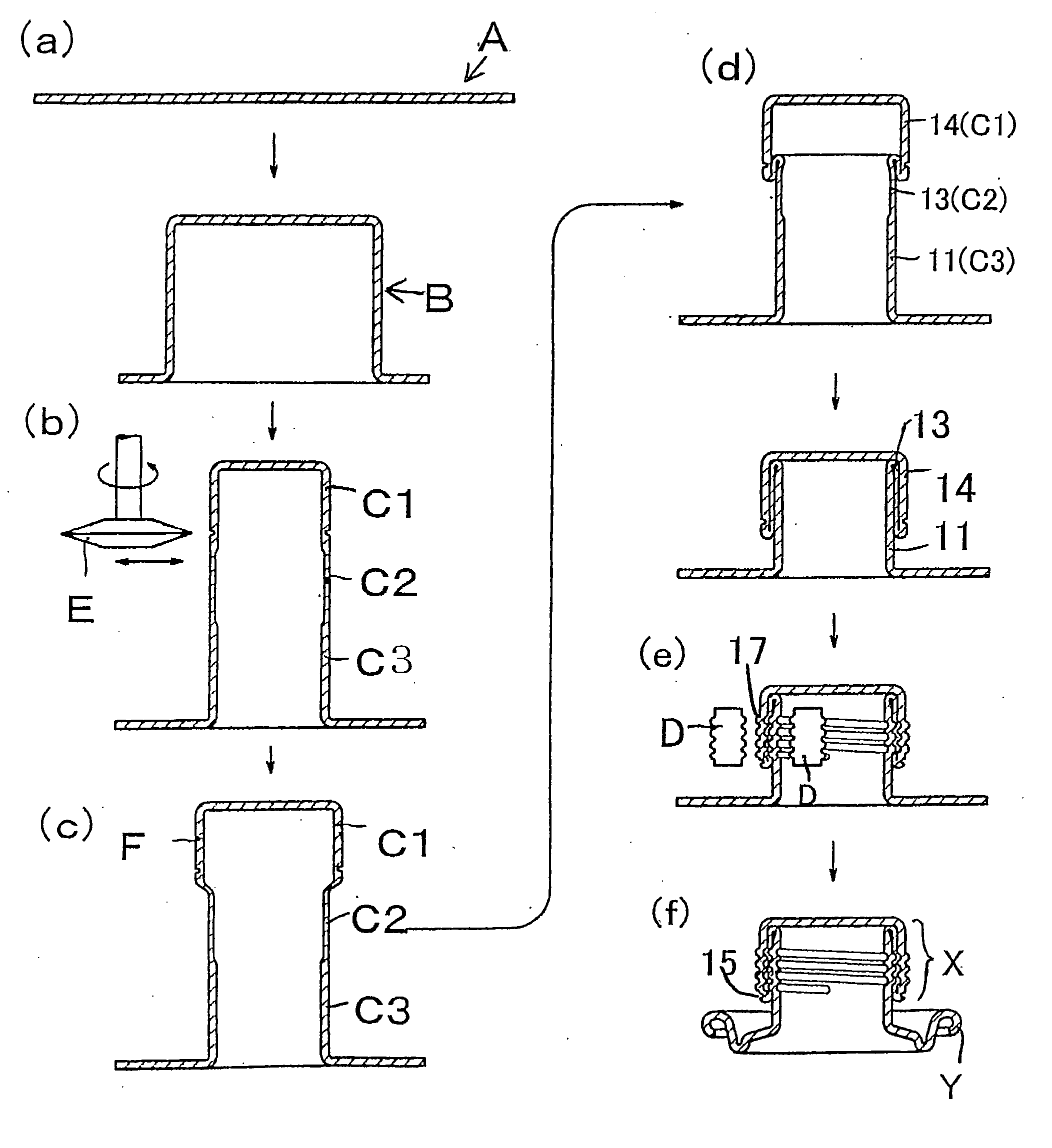

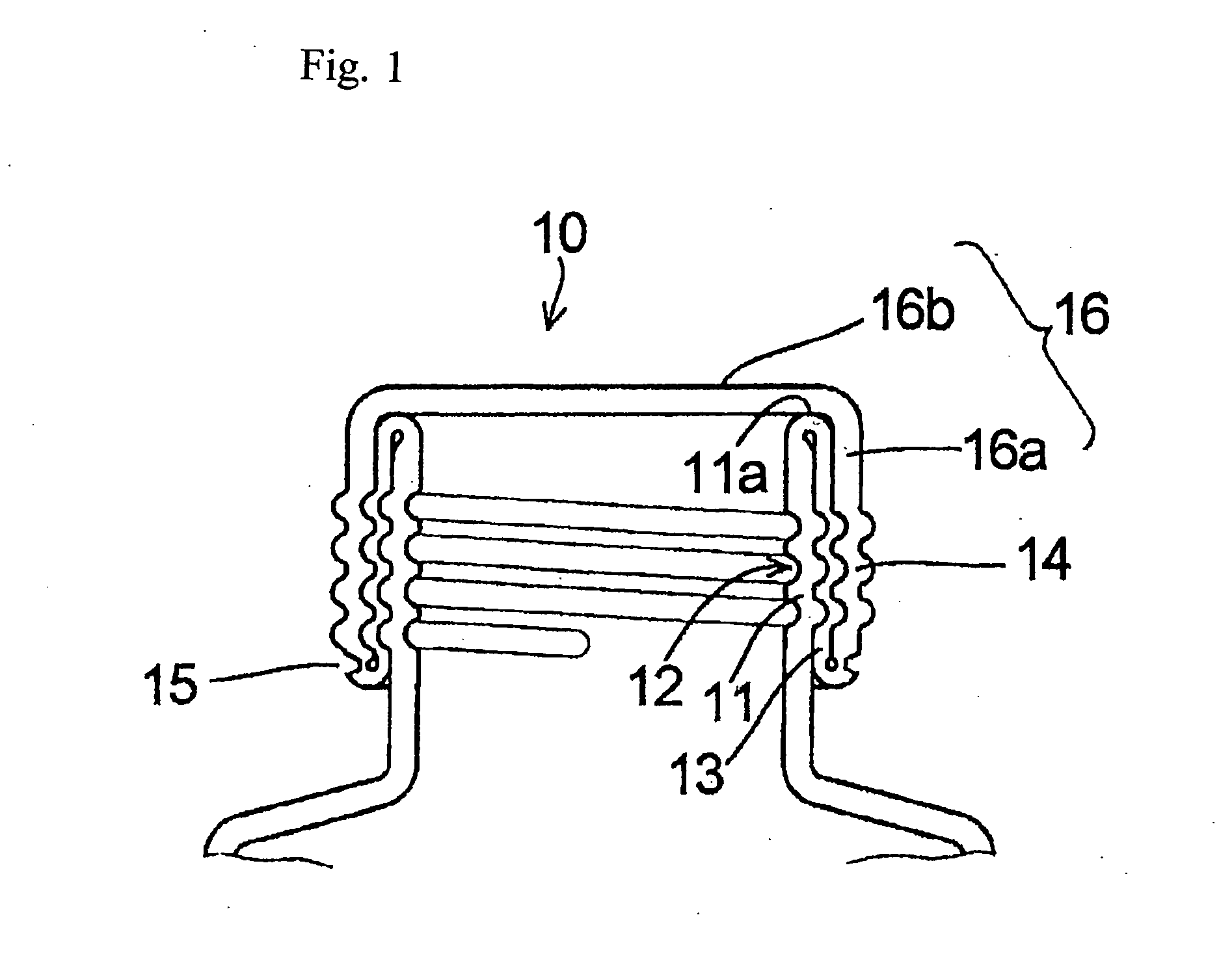

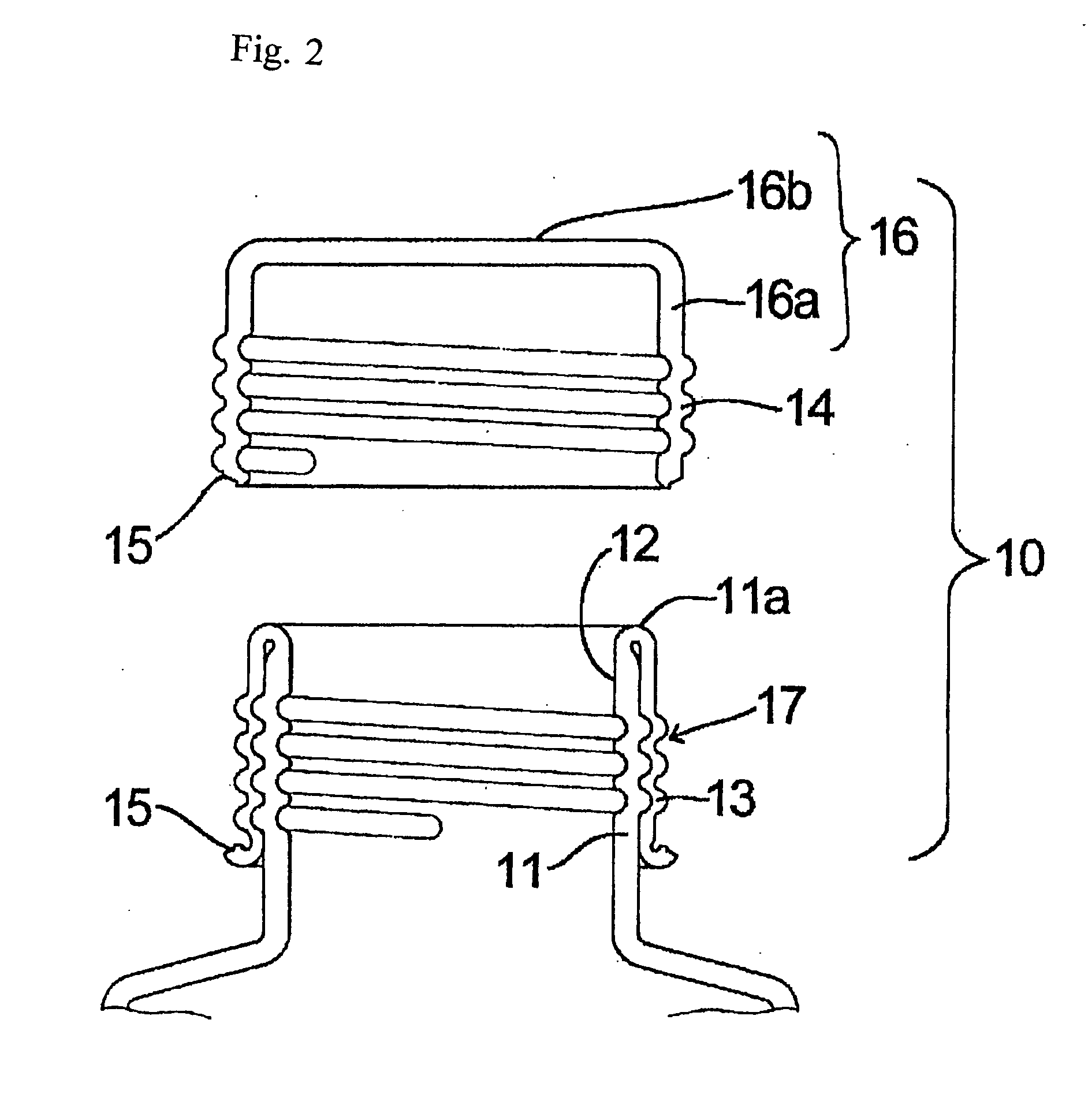

Container sealing structure, container with the sealing structure, and method of manufacturing the sealing structure

InactiveUS20050205575A1Easily breakableImprove tamper resistanceCapsThreaded caps applicationMechanical engineering

Owner:TOYO SEIKAN KAISHA LTD

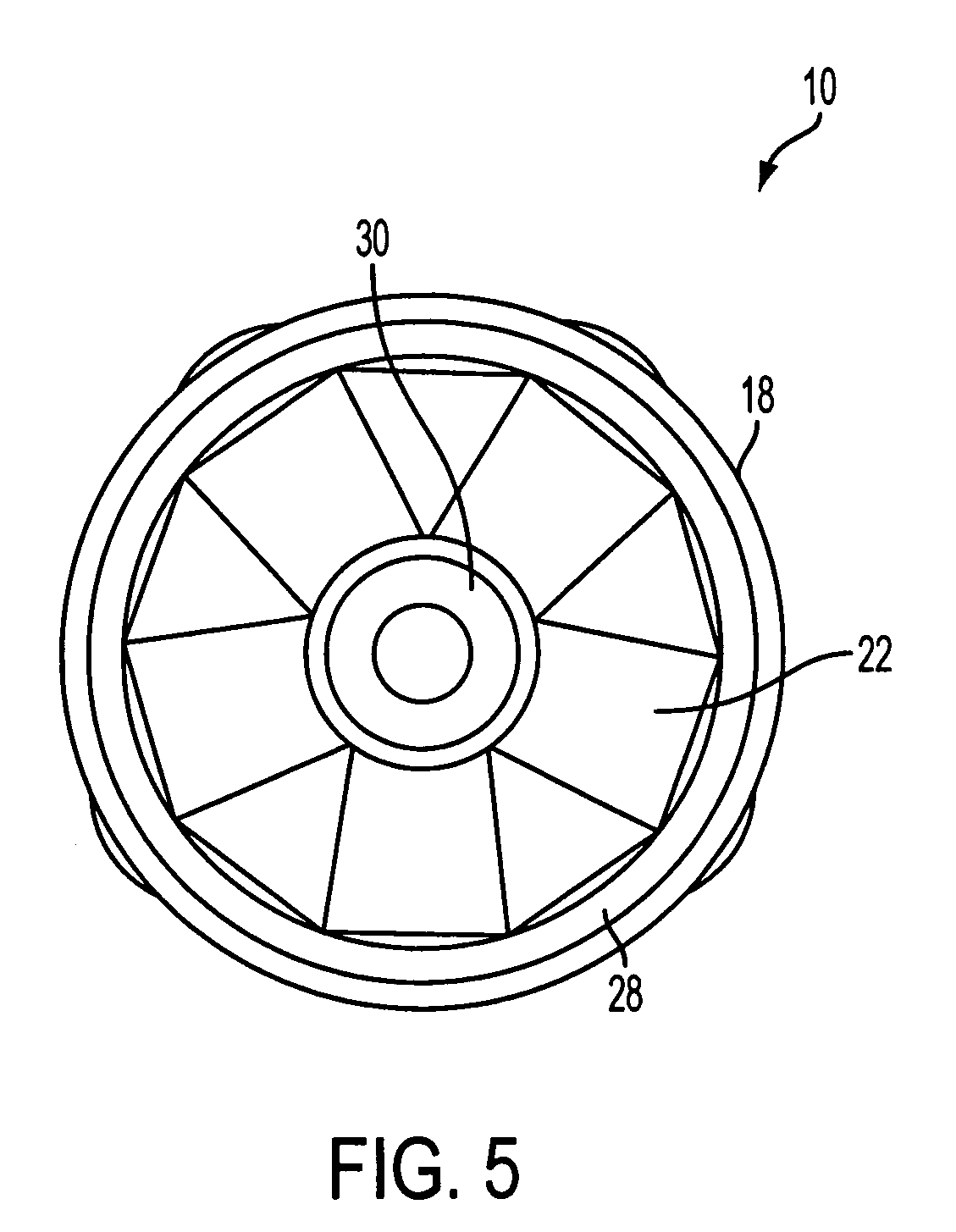

Plastic water bottle and apparatus and method to convey the bottle and prevent bottle rotation

A plastic container for beverages to replace a container having a round flange with a round flange diameter and which is adapted to be conveyed by air along a track with inwardly extending track rails spaced from one another a set distance. The plastic container replacing the replaced container without significant modifications to the conveying system including the inwardly extending track rails of the track. The container including a central axis, an upper mouth portion, a neck portion coaxial to the axis with a diameter, a cylindrical sidewall, a lower base and an anti-rotation flange below the upper mouth portion having a polygonal peripheral edge with a shape including a plurality of flats and a plurality of apexes each located between adjacent flats. Each apex being diametrically opposite one of the flats. The peripheral edge having a diametrical distance between each of the apexes and the flat opposite the apex. The diametrical distance being at most only slightly less than the round flange diameter of the replaced container.

Owner:BEVCORP

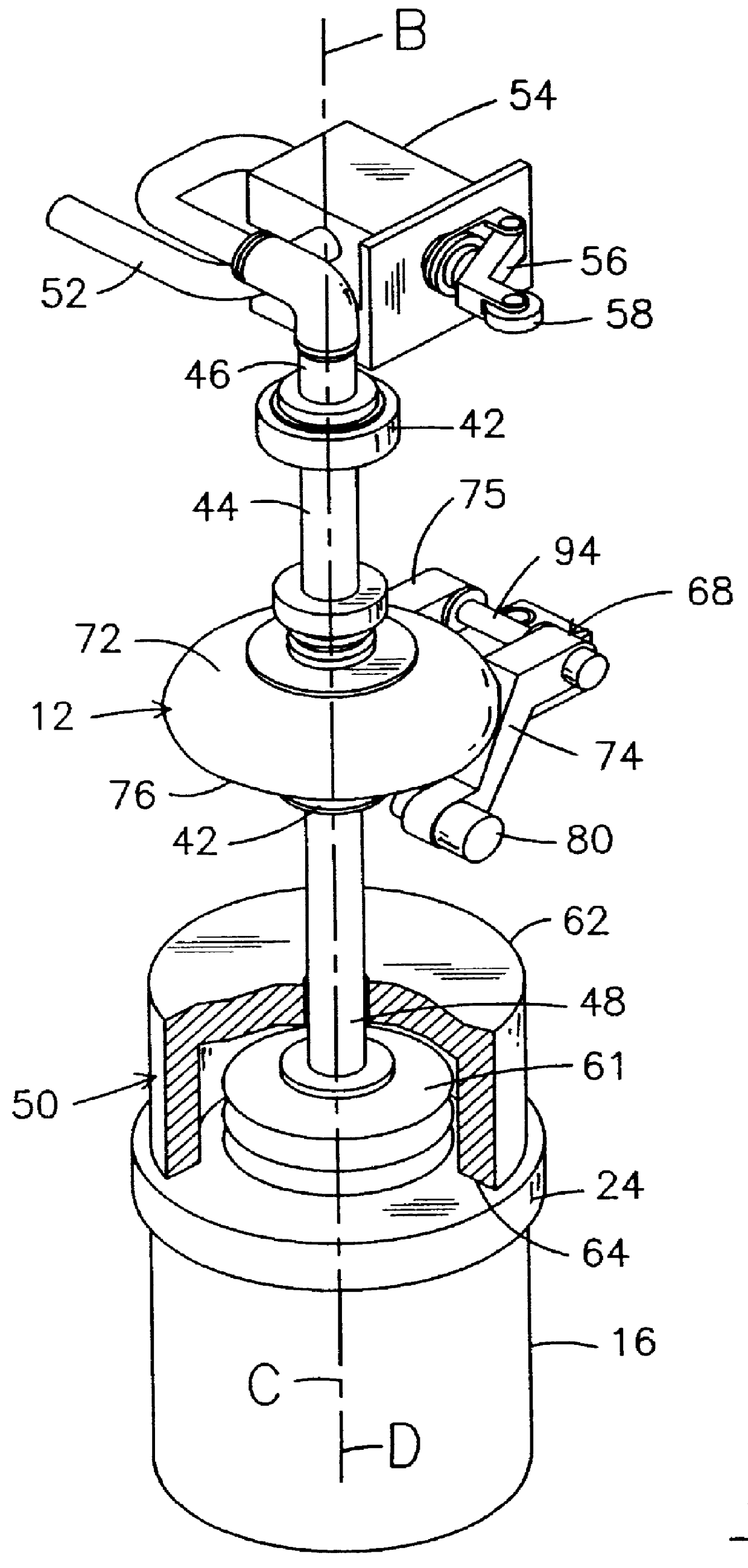

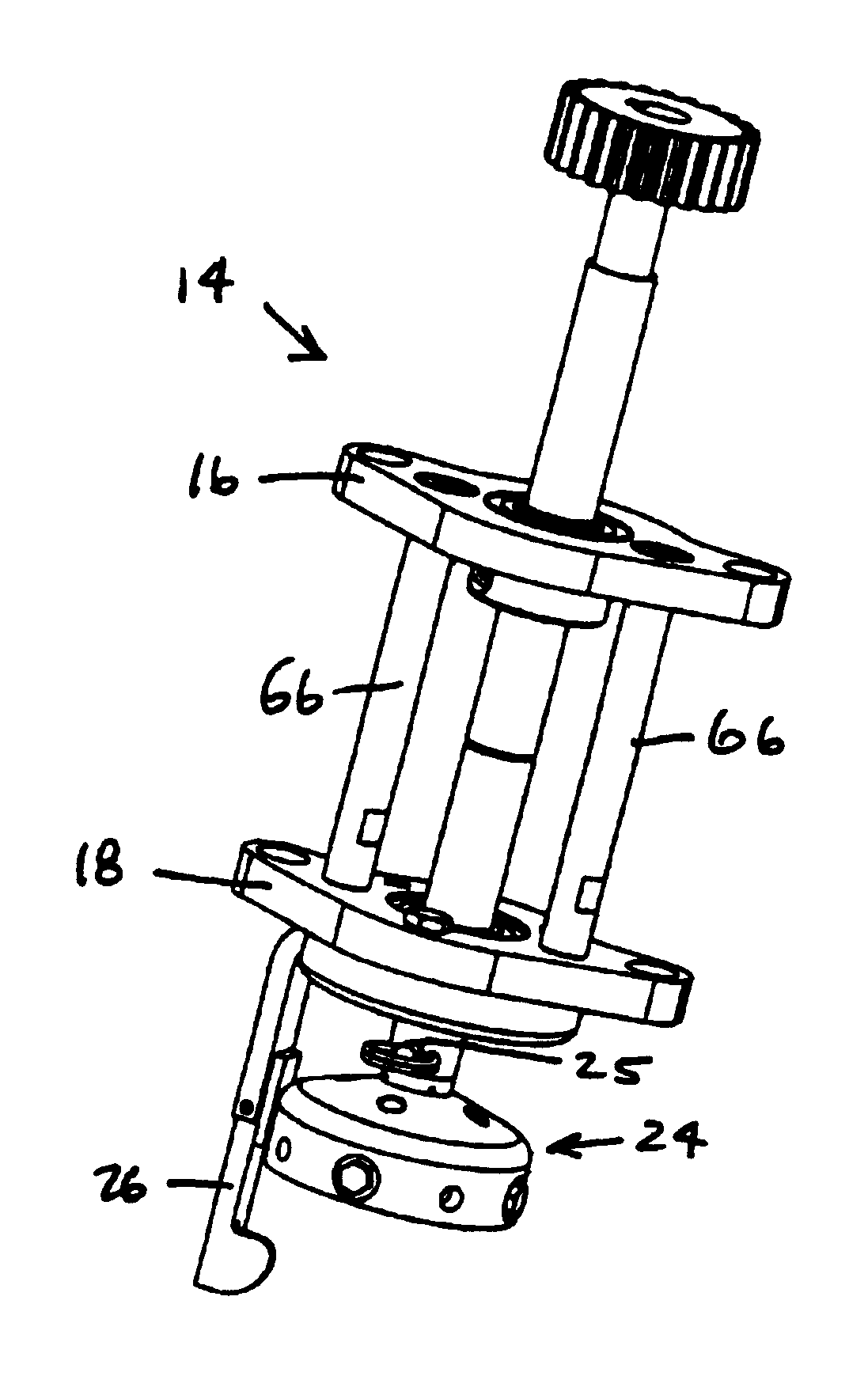

Apparatus and method for pre-capping containers

An improved pre-capping machine and method for pre-capping containers that are advanced along a predetermined path by standard conveyor systems. The present invention pretightens caps, plugs, overcaps and other fitments to ensure that they are squarely placed on the containers, without damage to the containers, in preparation for their final closure. The apparatus comprises a spindle assembly, having a longitudinal spindle axis, that is connected to a frame for movement of the spindle assembly along the spindle axis. The spindle assembly comprises a cap gripper that is configured to hold a cap centered over the open end of a container so that axes through the cap, the open end of the container and the spindle assembly generally coincide. To place a cap on the container, the spindle is released for free movement along the spindle axis.

Owner:NEW ENGLAND MACHINERY

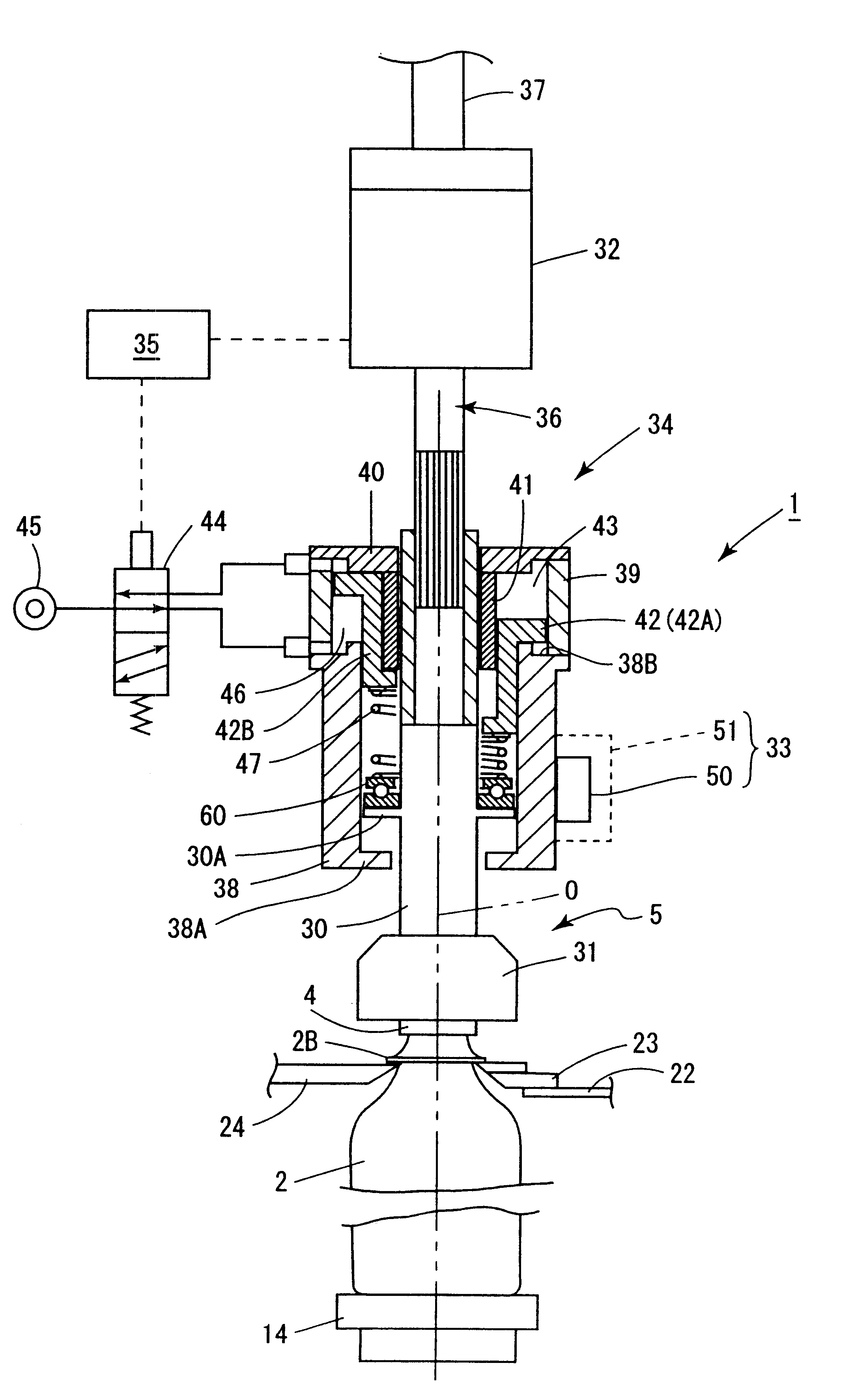

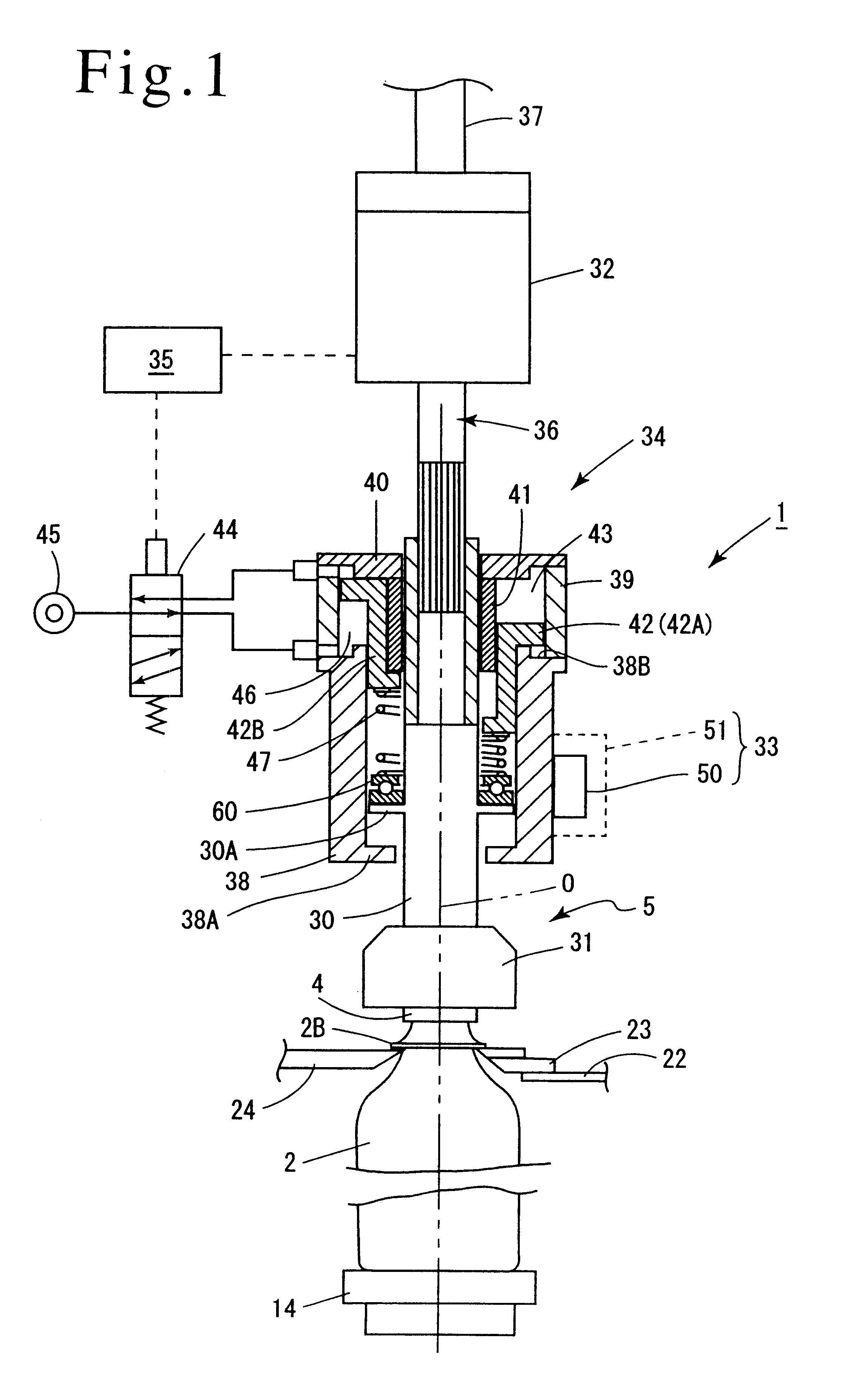

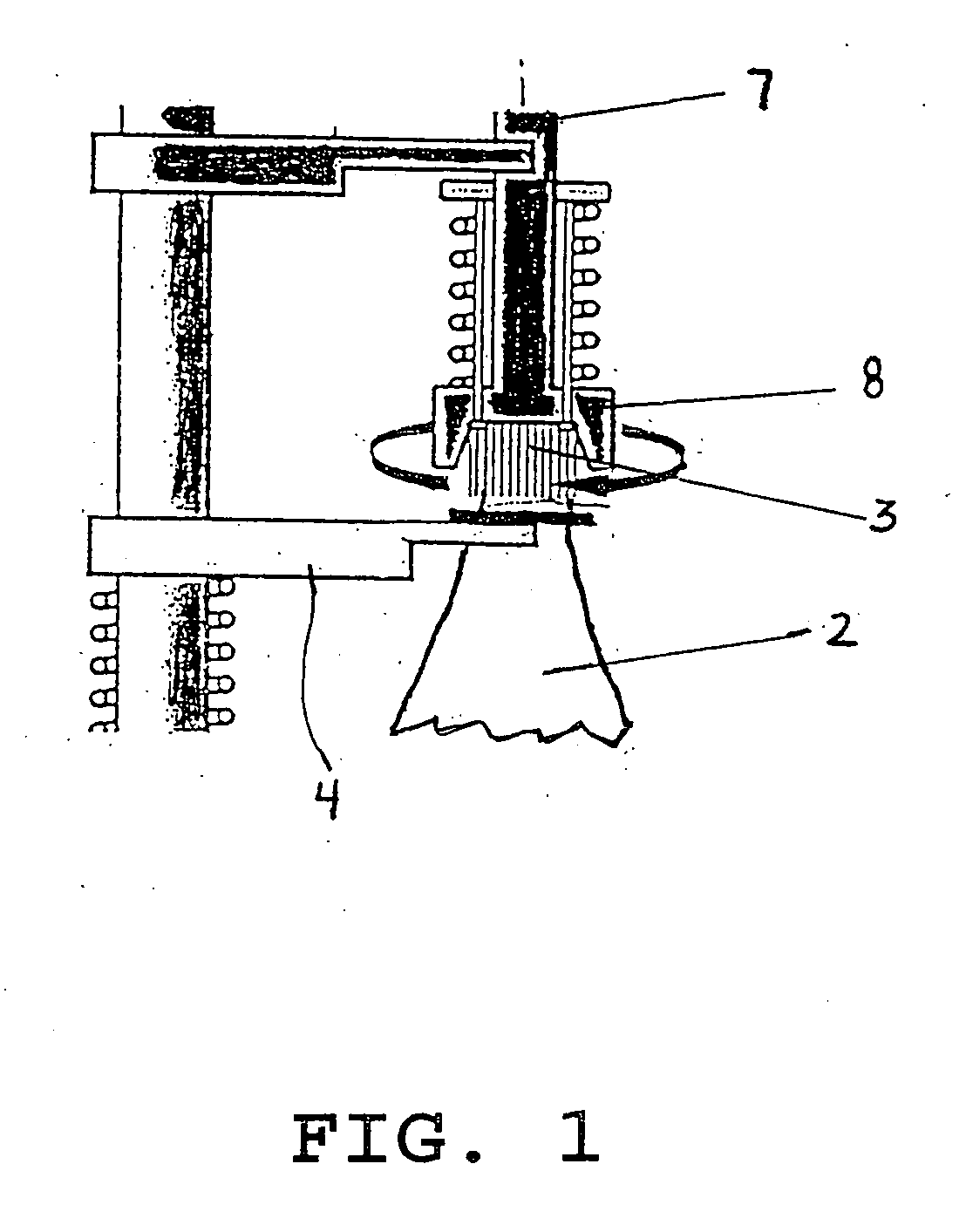

Screw capper

A screw capper includes a capping head which comprises a chuck for holding a cap, a motor for driving the chuck for rotation, a cam mechanism for elevating the chuck, and an air cylinder for imparting a load to the chuck. A load imparted by the air cylinder is controlled by a controller to be zero from the beginning of a screwing and tightening operation until an angle of rotation of the chuck exceeds a specific angle where the load is changed, and is controlled to a higher value upon detection of an angle of rotation of the chuck which exceeds the specific angle in the course of the screwing and tightening operation. The arrangement allows a reliable screwing and tightening to be achieved as compared with the prior art while preventing a damage to threads or the occurrence of a cocked cap.

Owner:SHIBUYA IND CO LTD

Chuck for capping machine

Owner:PNEUMATIC SCALE CORP

Sealable Containers

Owner:PROCUREMENT TECH

Capping and nitrogen dosing apparatus

InactiveUS20050028487A1Operation efficiency can be improvedFacilitate consistent operationCapsThreaded caps applicationNitrogenNitrogen gas

A capping and nitrogen dosing apparatus for containers includes a rotary capping machine which is configured to serially receive filled containers, and apply closures to respective ones of the containers. The present apparatus includes a dosing system for injecting an inert gas, typically nitrogen in liquid form, into the head space of each container to enhance the integrity and rigidity of the package, and to improve the freshness and flavor of the container's contents. Notably, the dosing system is configured to effect nitrogen injection close to or at the so-called transfer point of the capping machine, thus desirably abating nitrogen dissipation, and enhancing consistent and efficient product dosing.

Owner:CREDIT SUISSE SYDNEY BRANCH

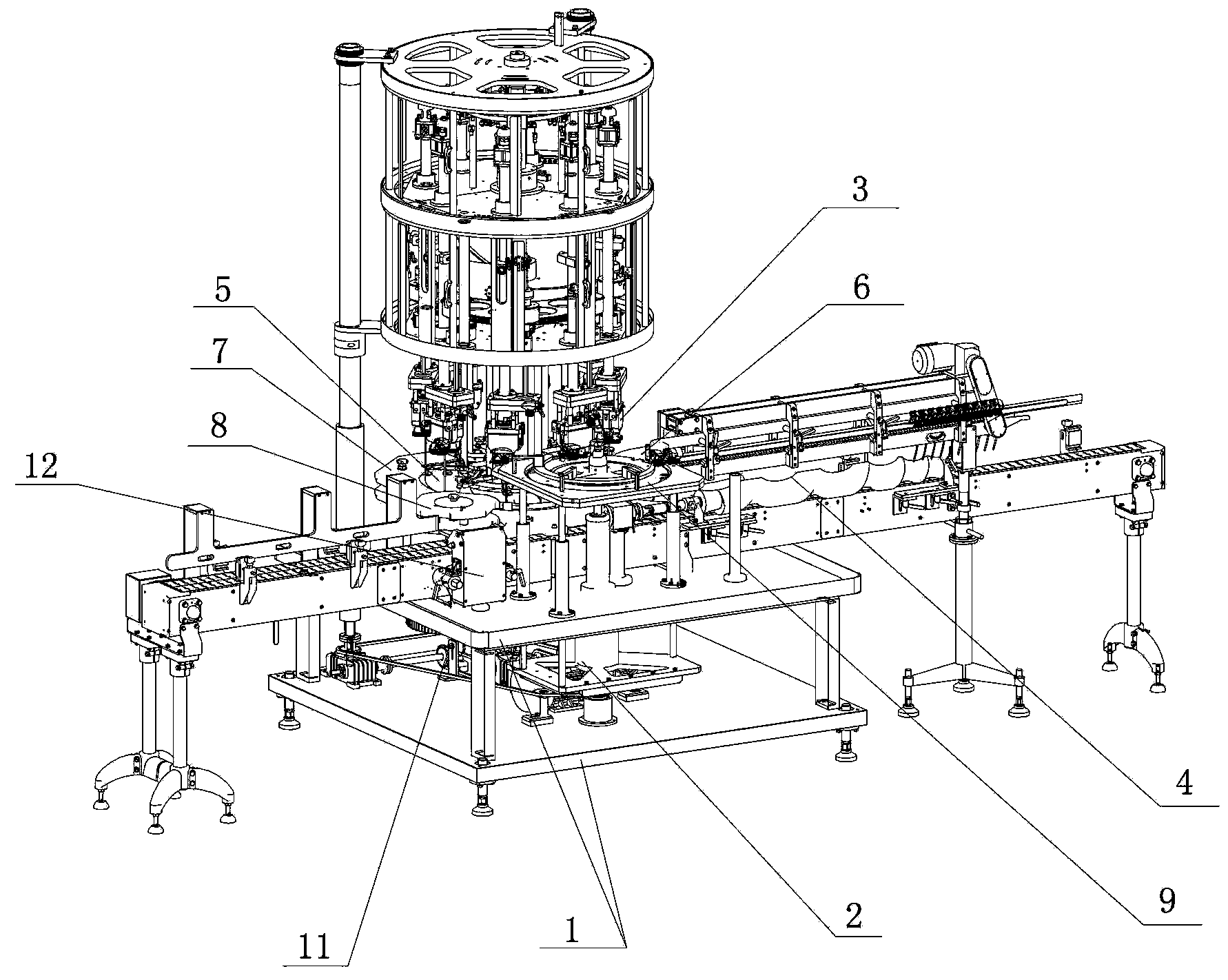

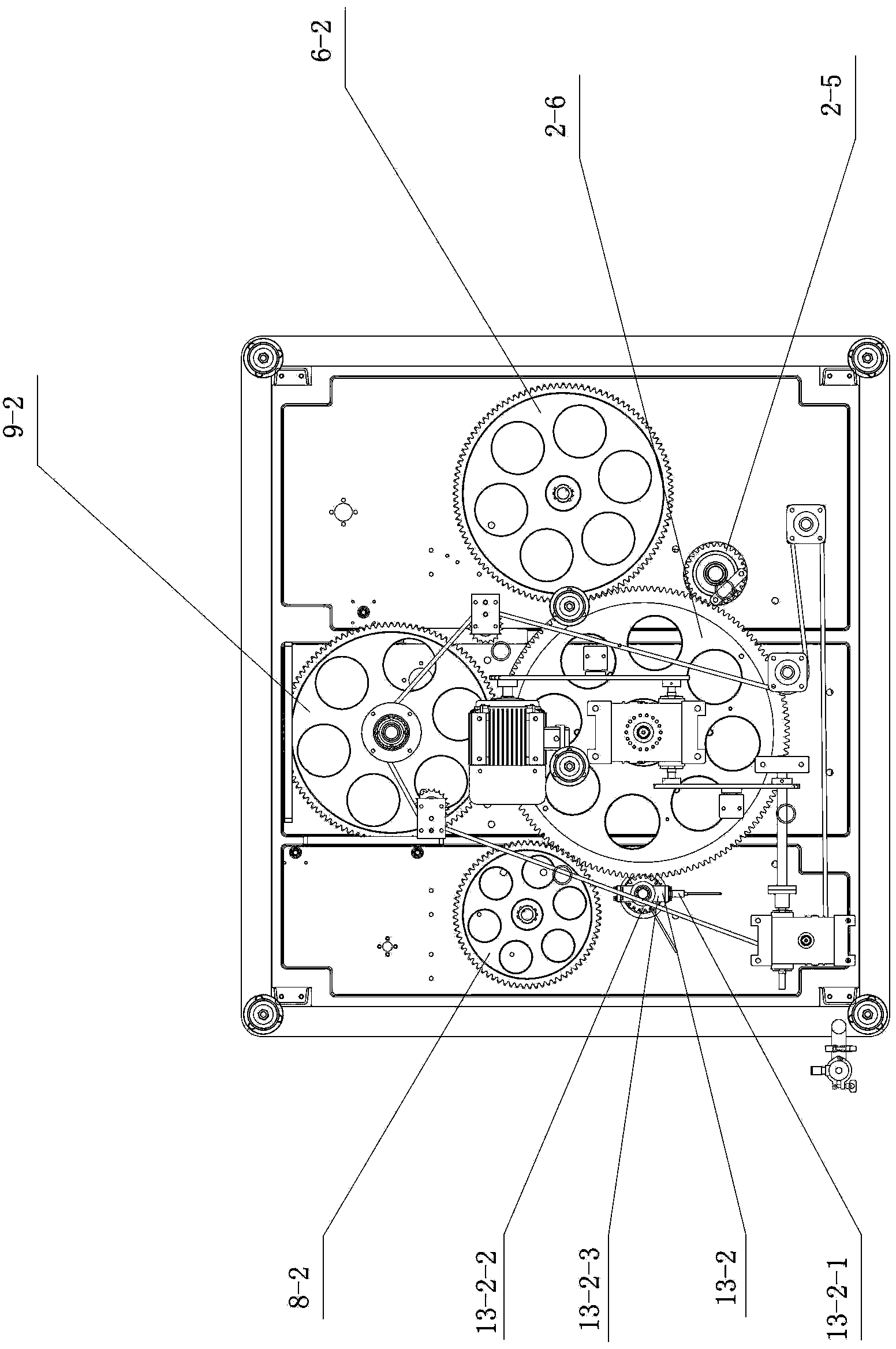

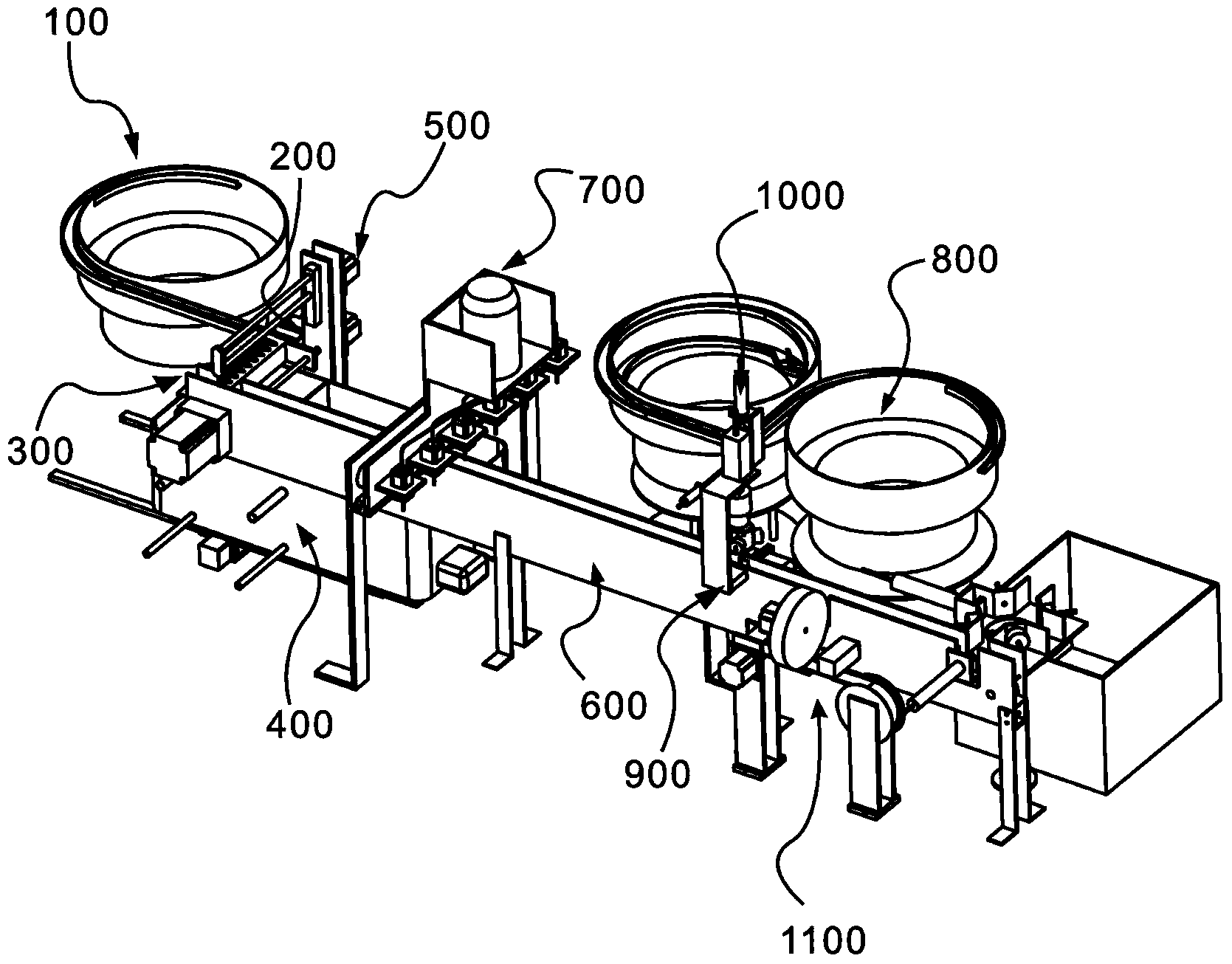

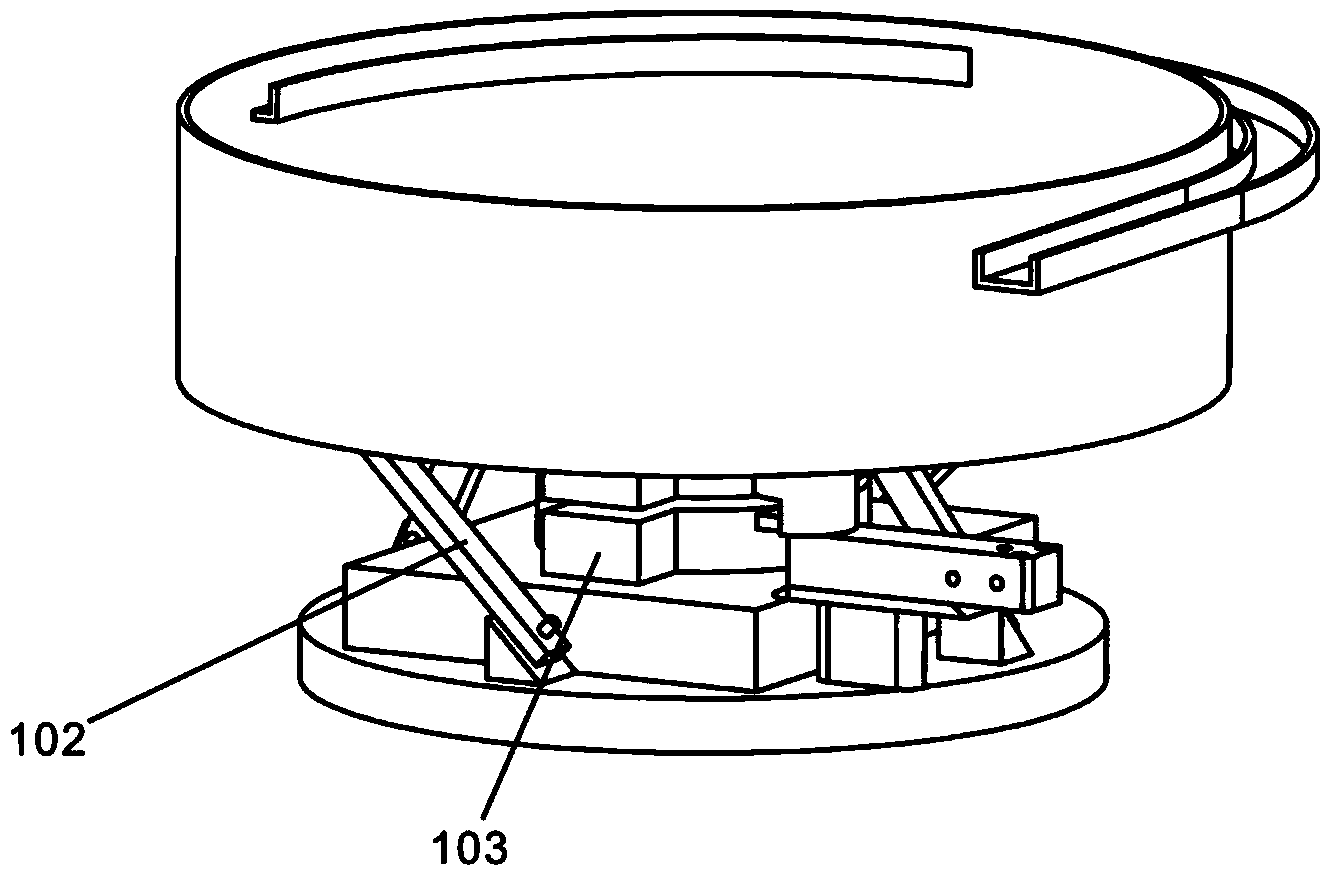

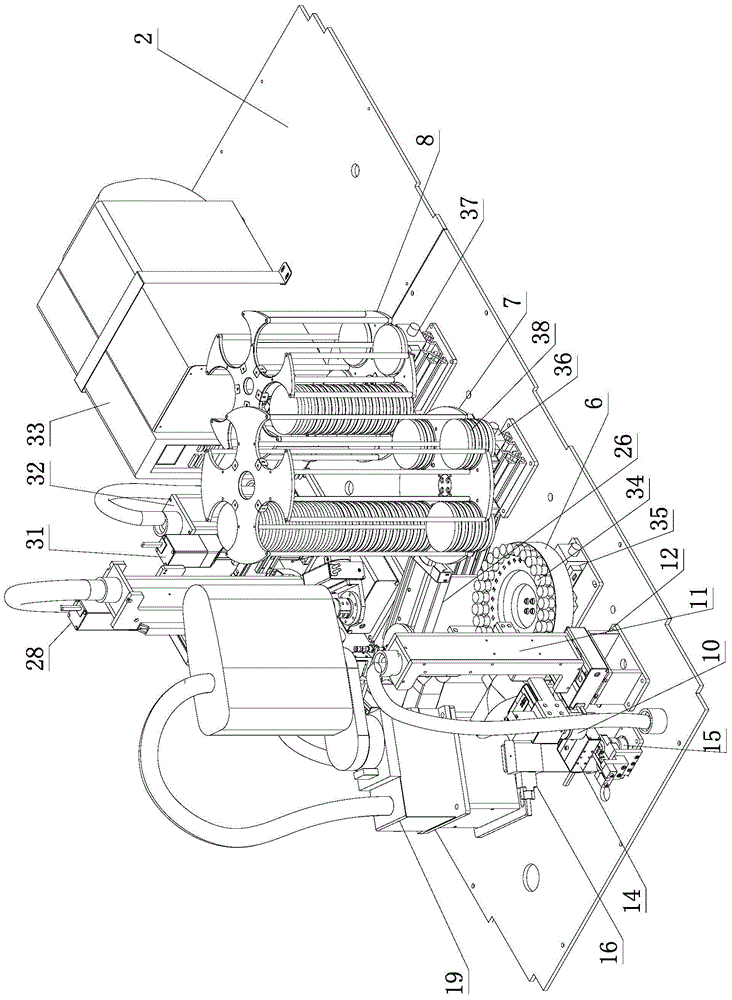

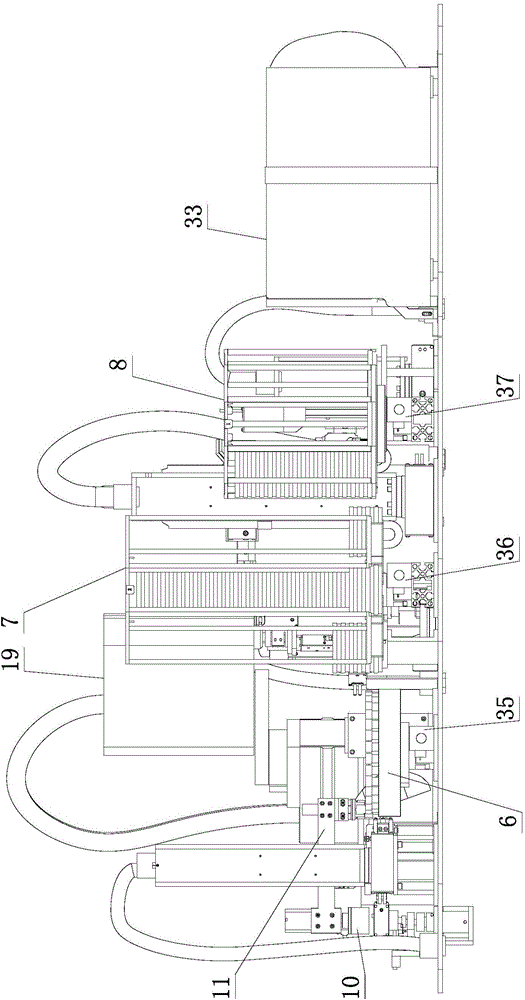

Full-automatic multifunctional cap screwing machine

ActiveCN103754807ARealize automatic positioningAdjustable tightening forceThreaded caps applicationCapping machinery safety/controlElectrical controlEngineering

The invention provides a full-automatic multifunctional cap screwing machine. A power transmission device, a cap screwing assembly, a bottle supply device, a bottle guide device, a bottle feeding star wheel device, a bottle stopping device, a bottle discharge star wheel device, a cap supply device, a bottle output device, a lifting adjusting device and a removing mechanism are included and are arranged on a rack, and the cap screwing assembly comprises a main shaft, a hollow shaft sleeve, an upper shaft sleeve, a first lead screw, a bearing pedestal, a bottle supporting plate, a bottle driving plate, a bottom flower plate, a middle flower plate, a top flower plate, a supporting plate, a lifting portion, a cap grabbing and screwing portion, a transmission portion, a pipe clamping portion, a main gear, a cam, a lower fixing ring, a middle fixing ring and a stand column. PLC electrical control is adopted in the full-automatic multifunctional cap screwing machine, and cap supply, cap grabbing and cap screwing are completed at one step. Bottle caps are automatically located, the screwing force of the bottle caps is adjustable, and the full-automatic multifunctional cap screwing machine has the advantages of being high in automation degree, wide in product application range and the like.

Owner:CHANGZHOU HUITUO TECH

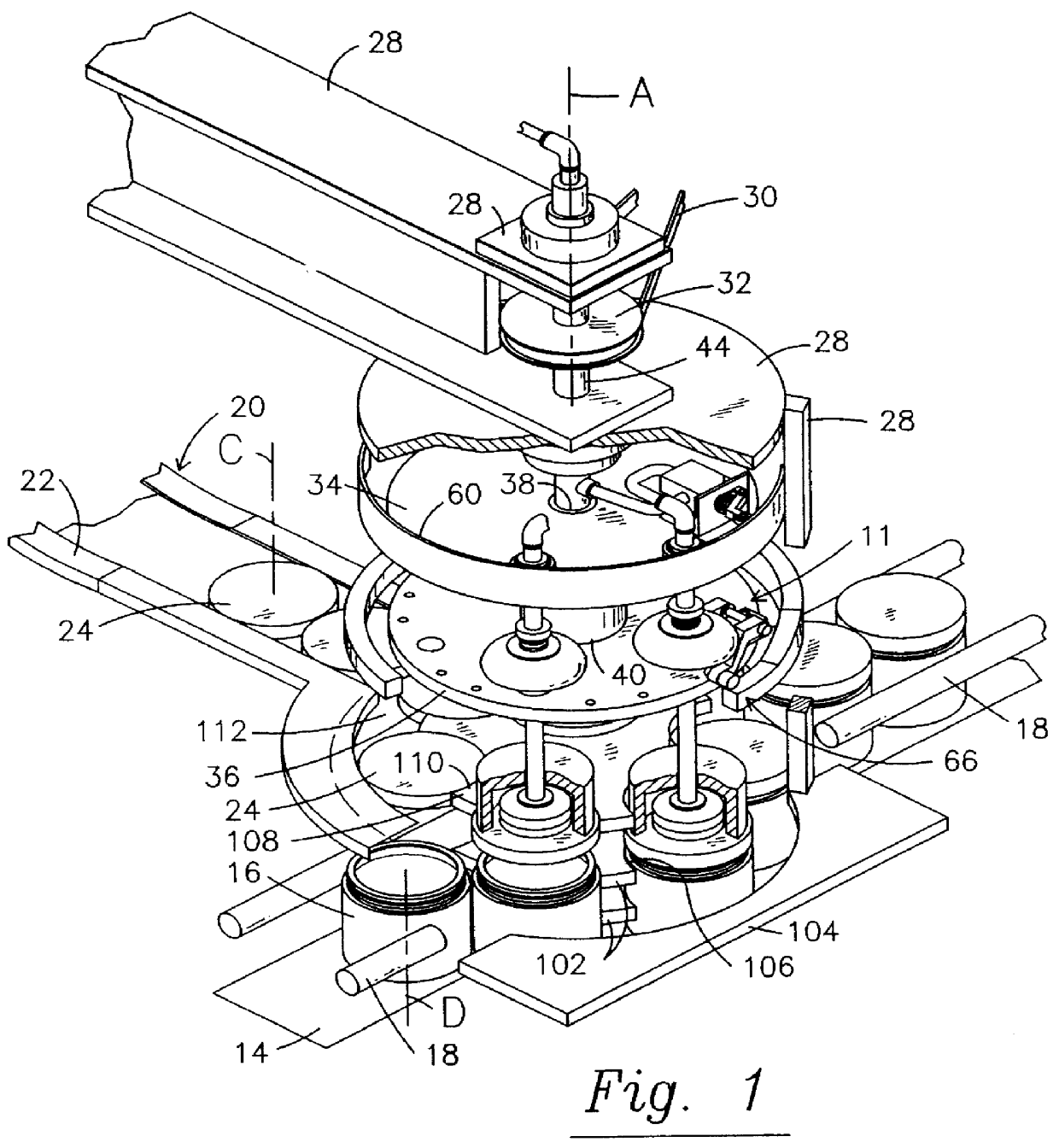

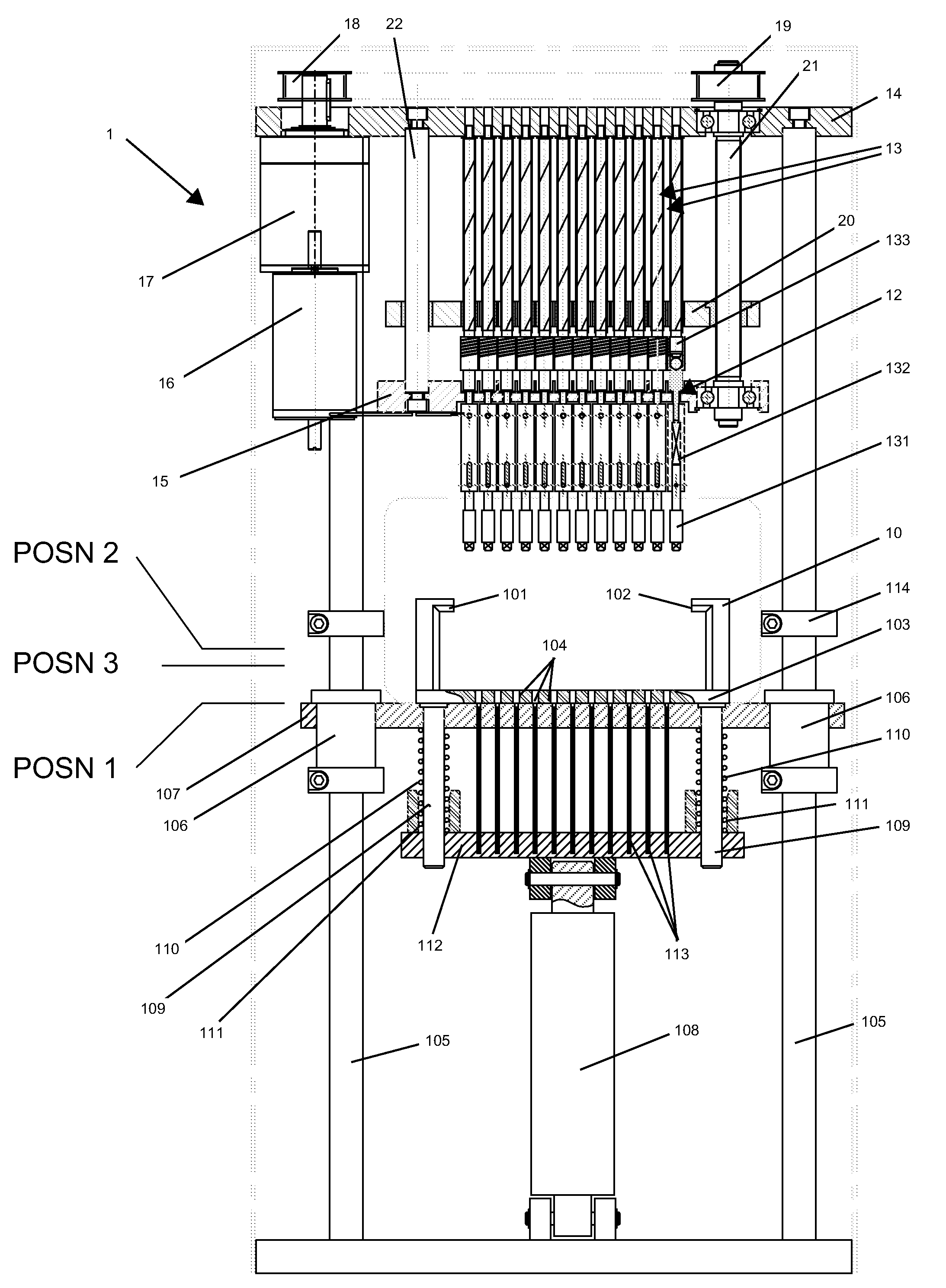

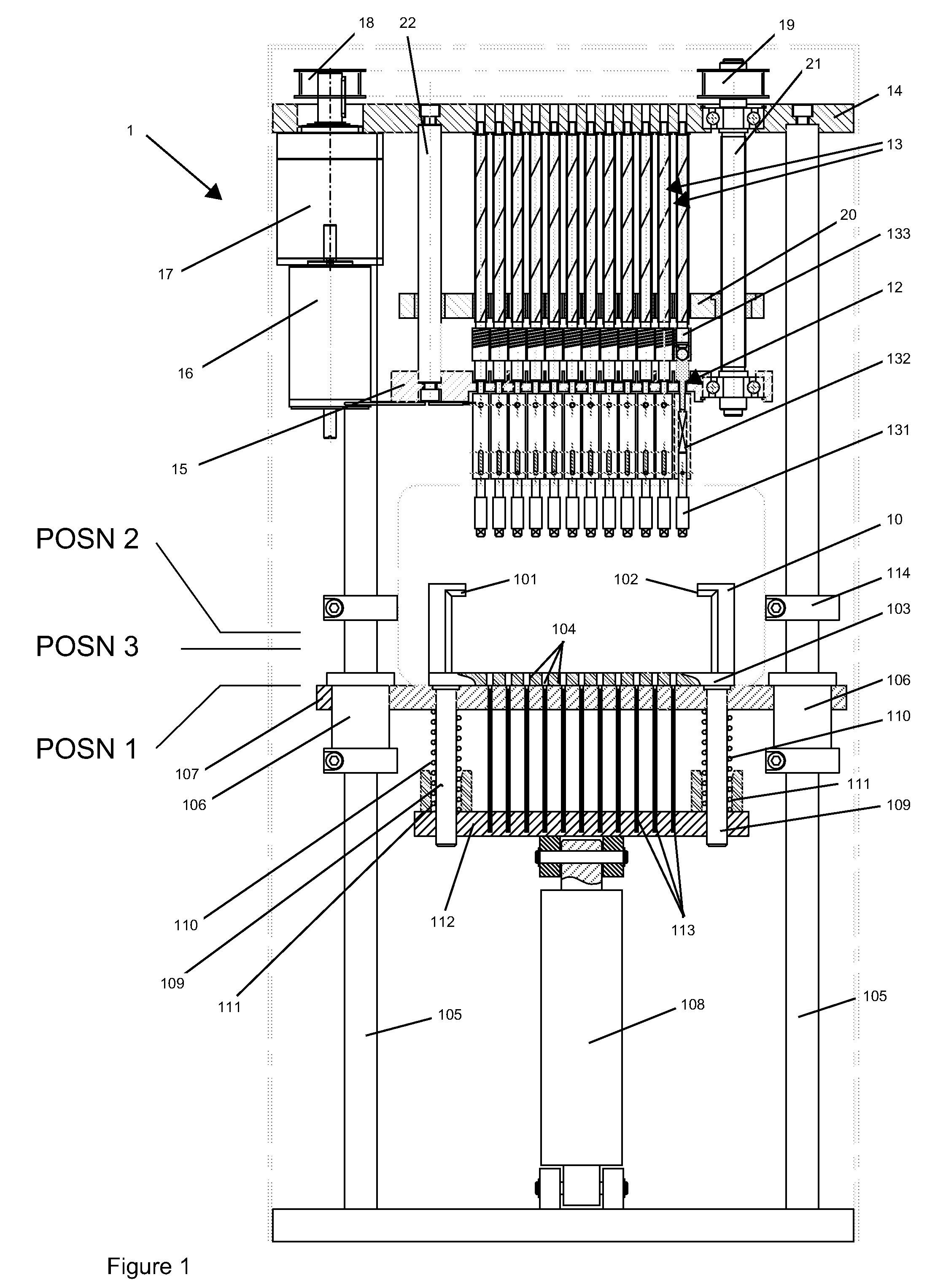

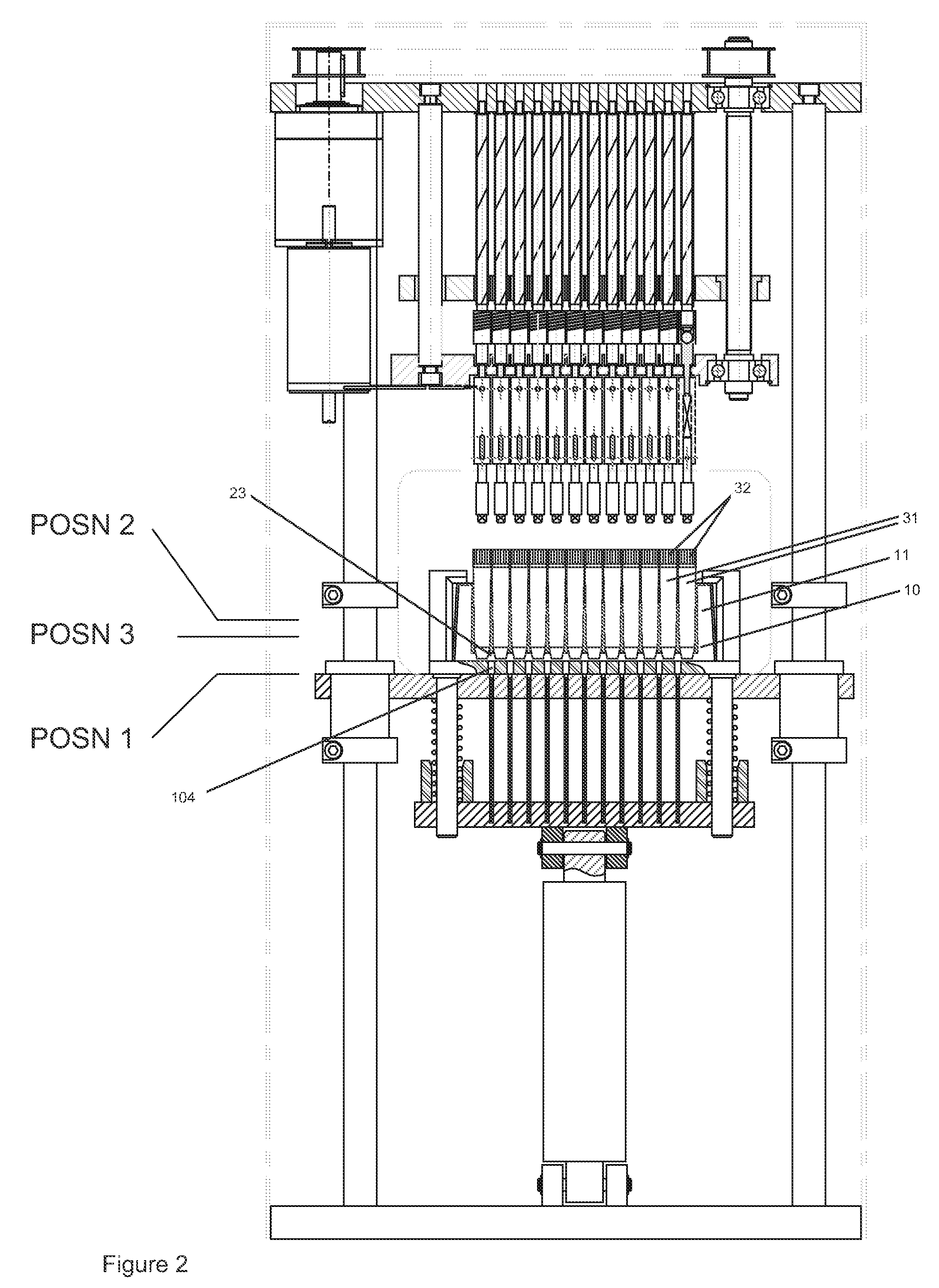

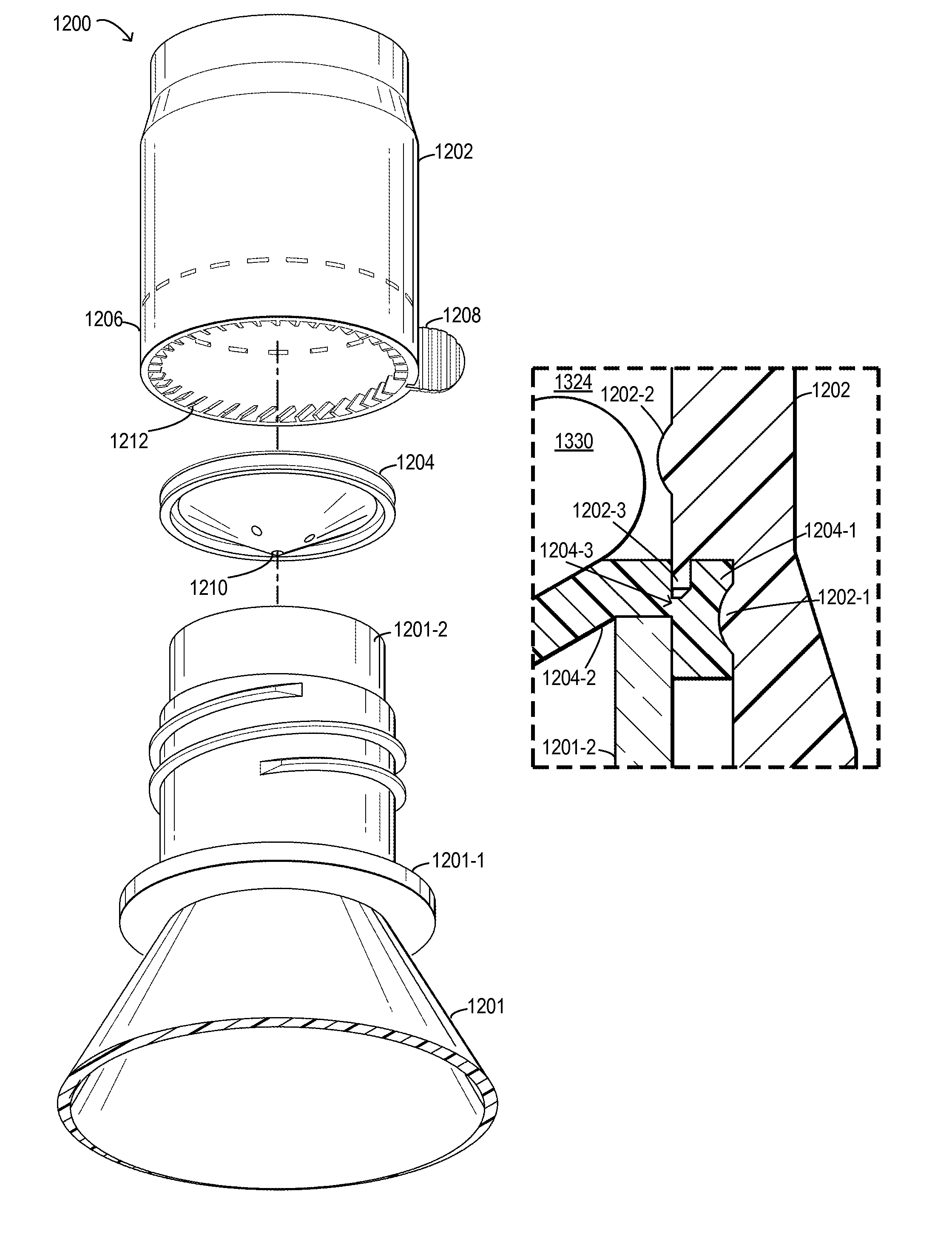

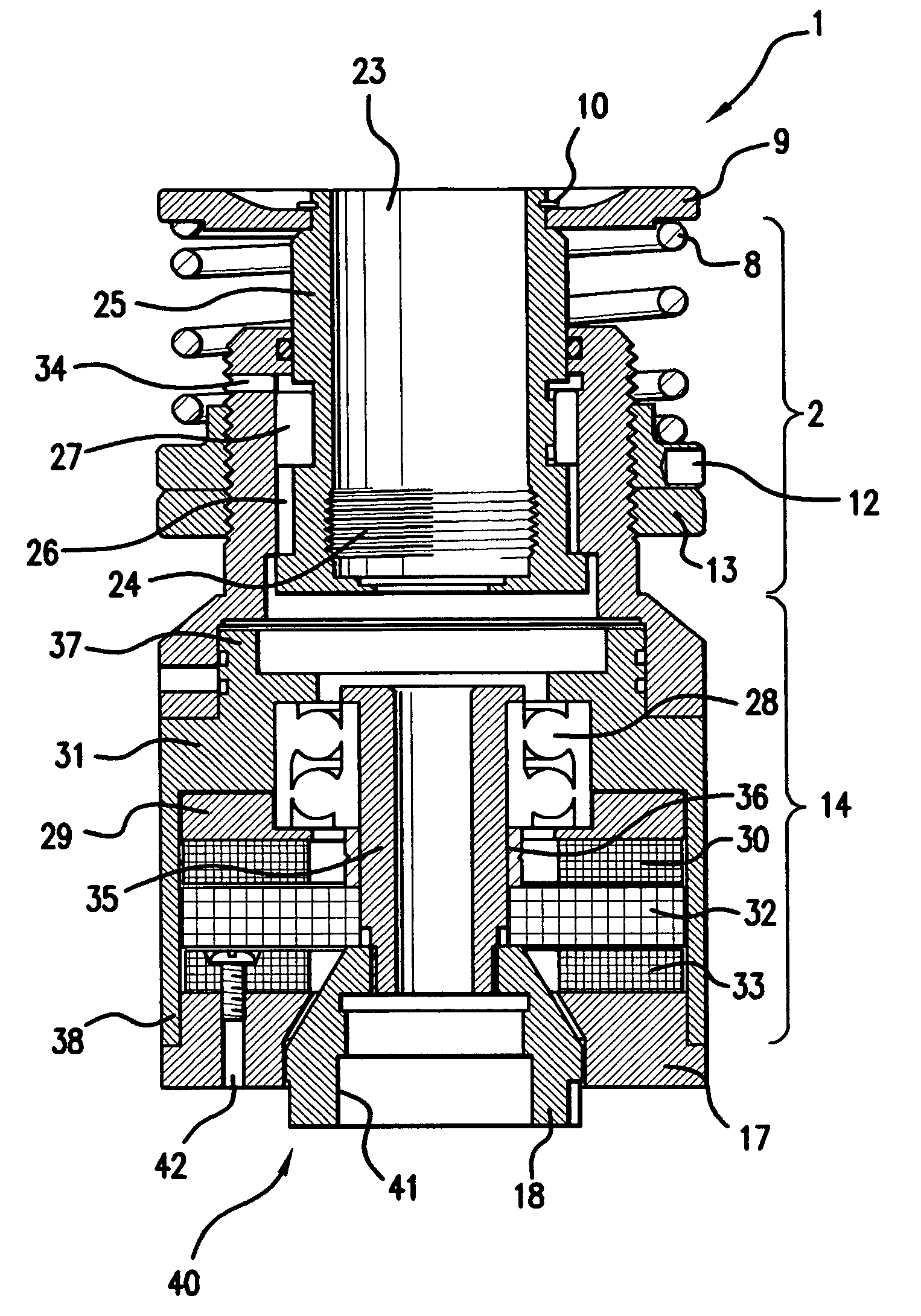

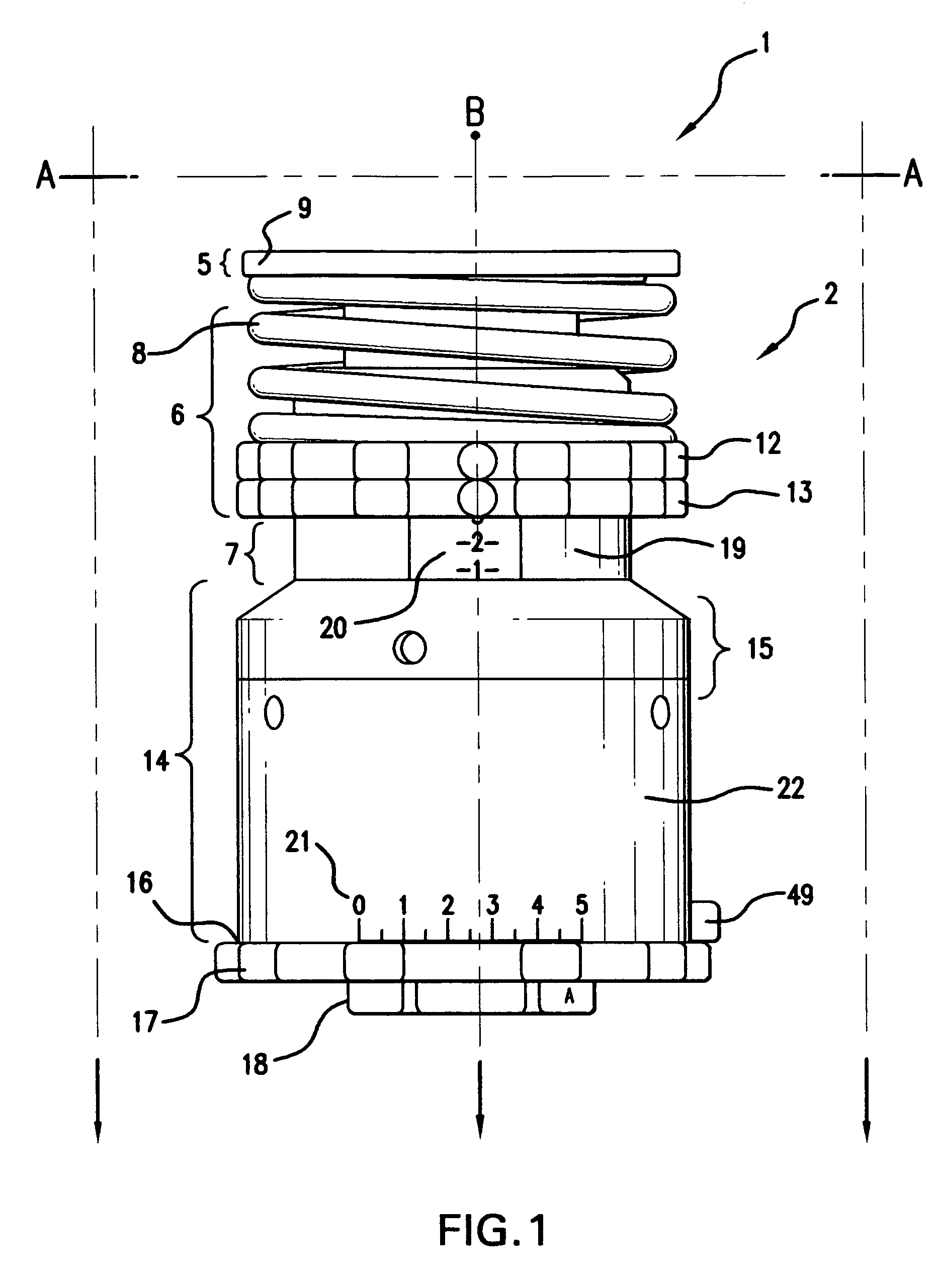

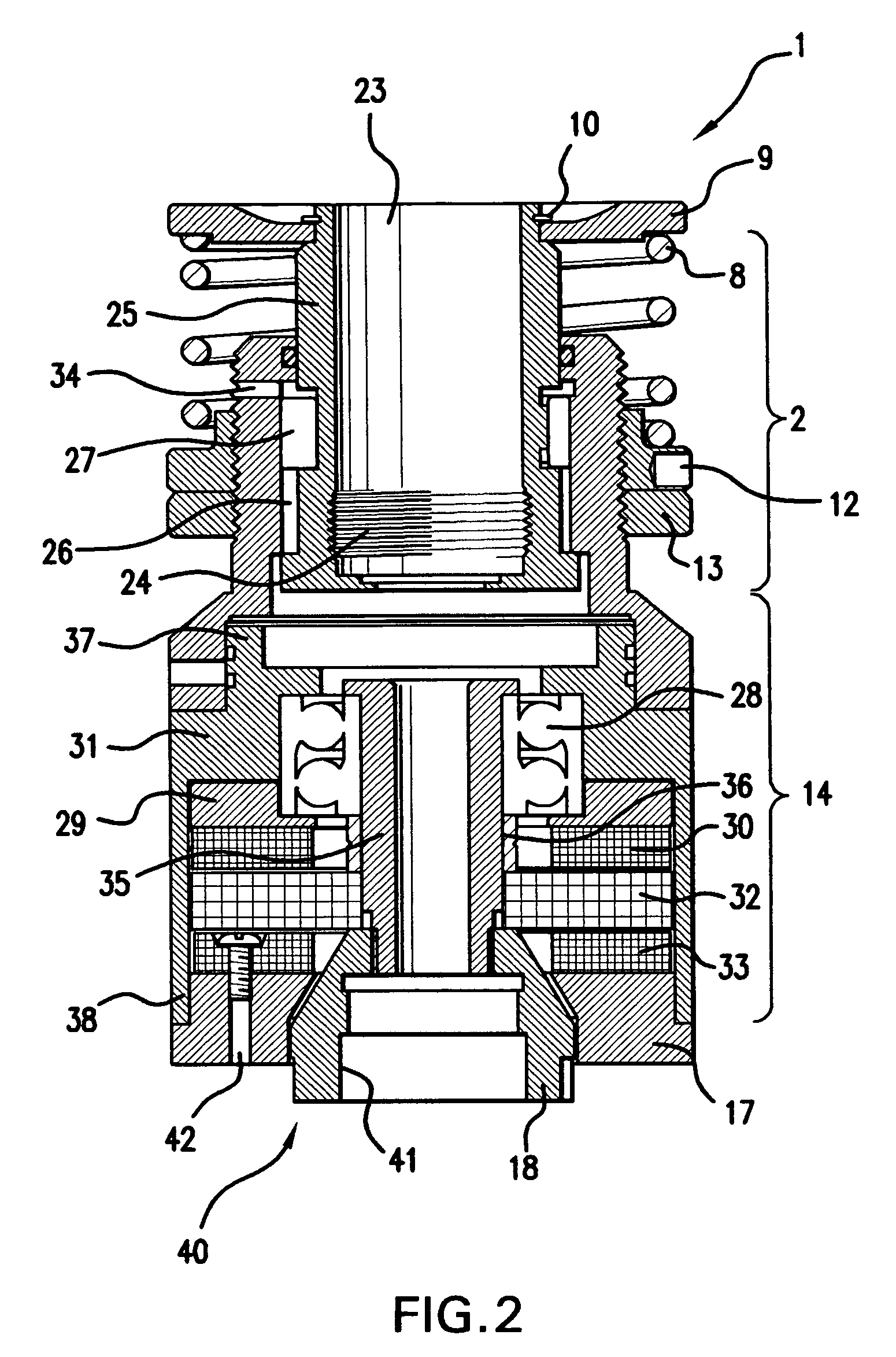

Tube capper/decapper

A capper / de-capper system 1 has a rack support 10 for supporting a rack 11 containing a plurality of capped tubes 31 in a given position. A head unit 12 supports a two-dimensional array of capping / de-capping spindles 13, each of which includes a clutch 133 and a capping / de-capping spigot 131 or socket, the spindles being aligned with the tube positions defined in the rack. A drive mechanism 108 moves the tubes and the head unit relatively towards and away from one another in use, when a rack containing capped tubes is disposed in the rack support, causing engagement and disengagement of the capping / de-capping spigots or sockets with and from the tube caps 32. A spindle drive system 15-22 provides simultaneous rotation of the capping / de-capping spigots or sockets together after engagement with the caps, either to detach caps from the tubes or attach caps to the tubes.

Owner:THE AUTOMATION PARTNERSHIP CAMBRIDGE

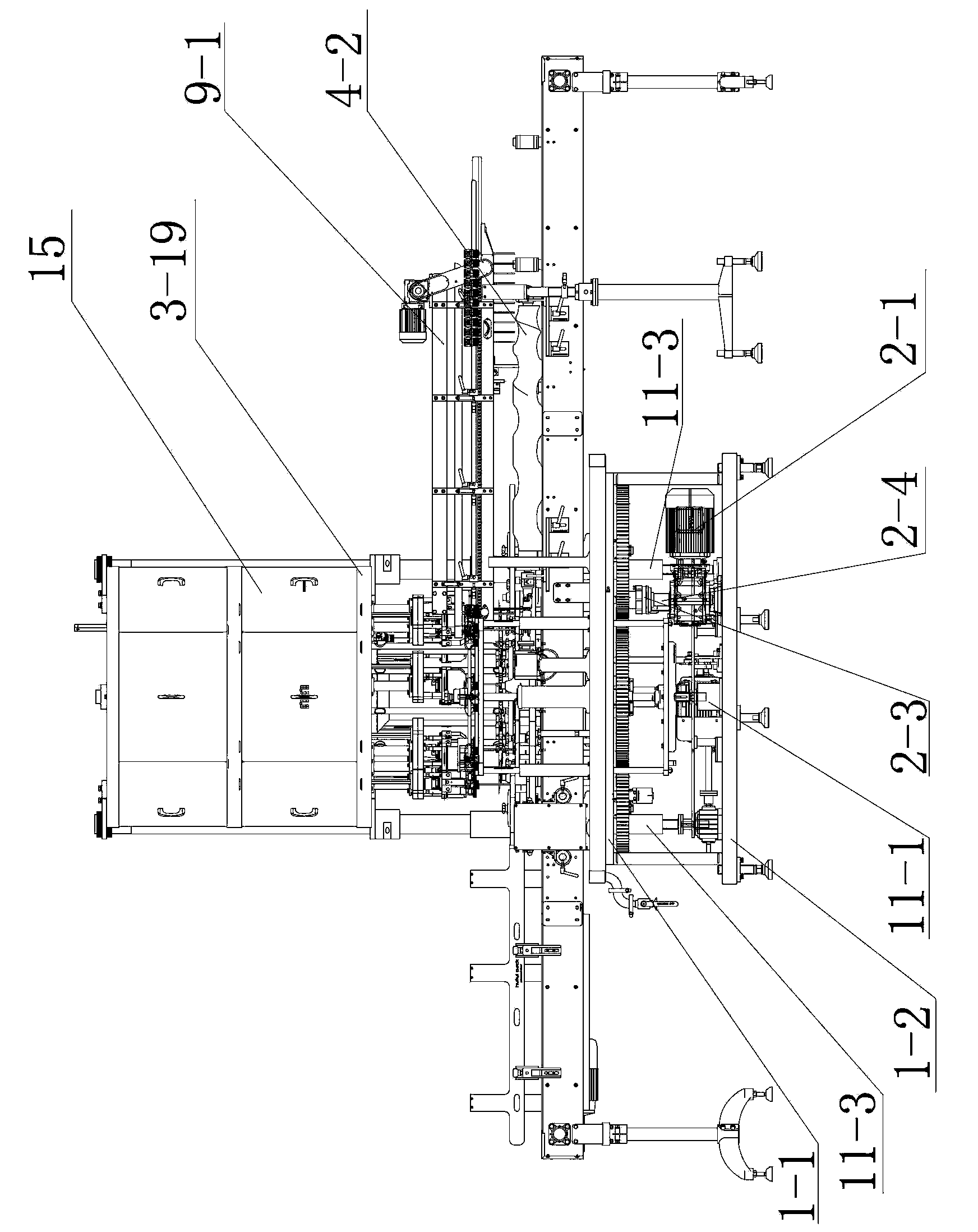

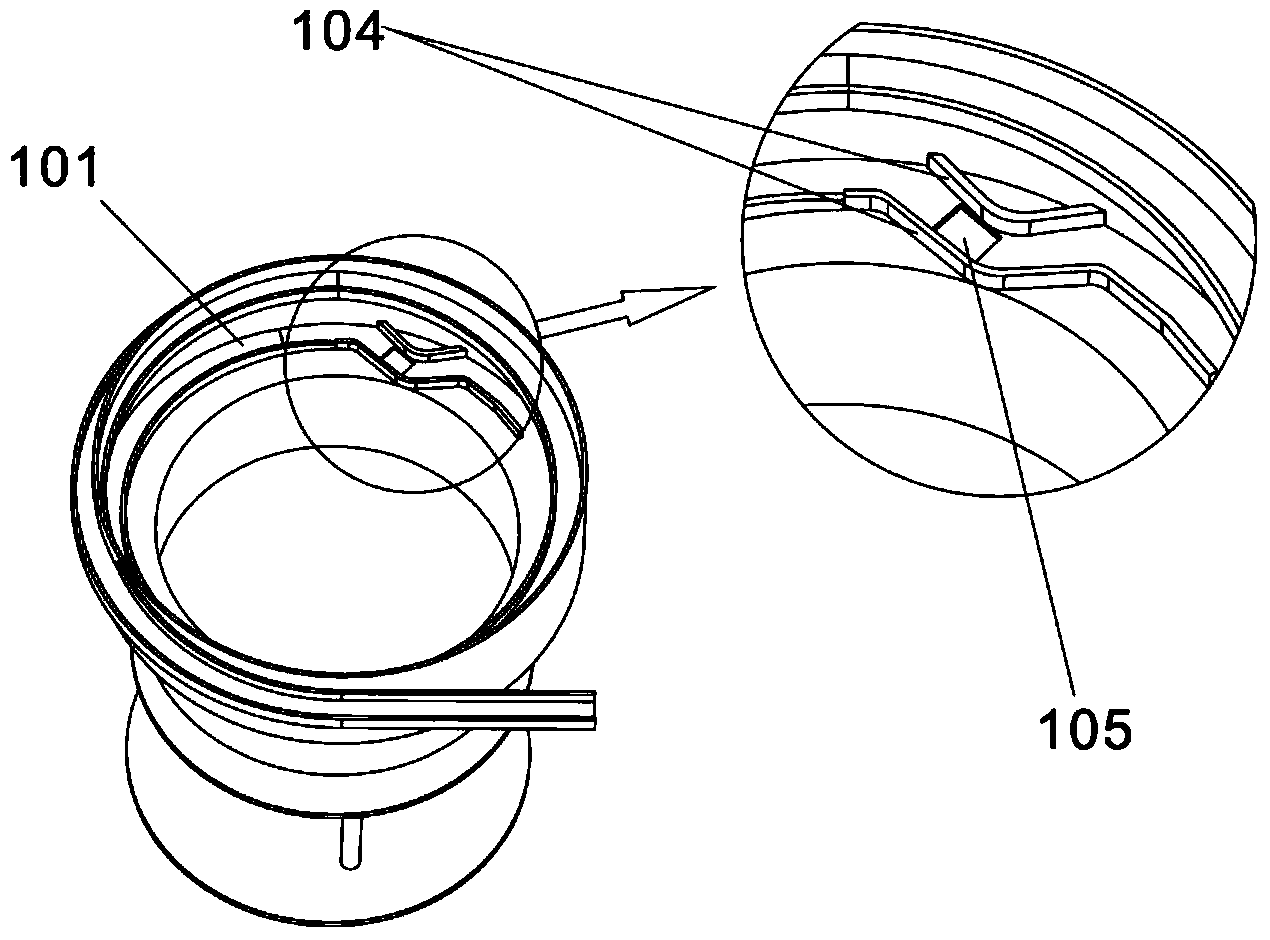

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

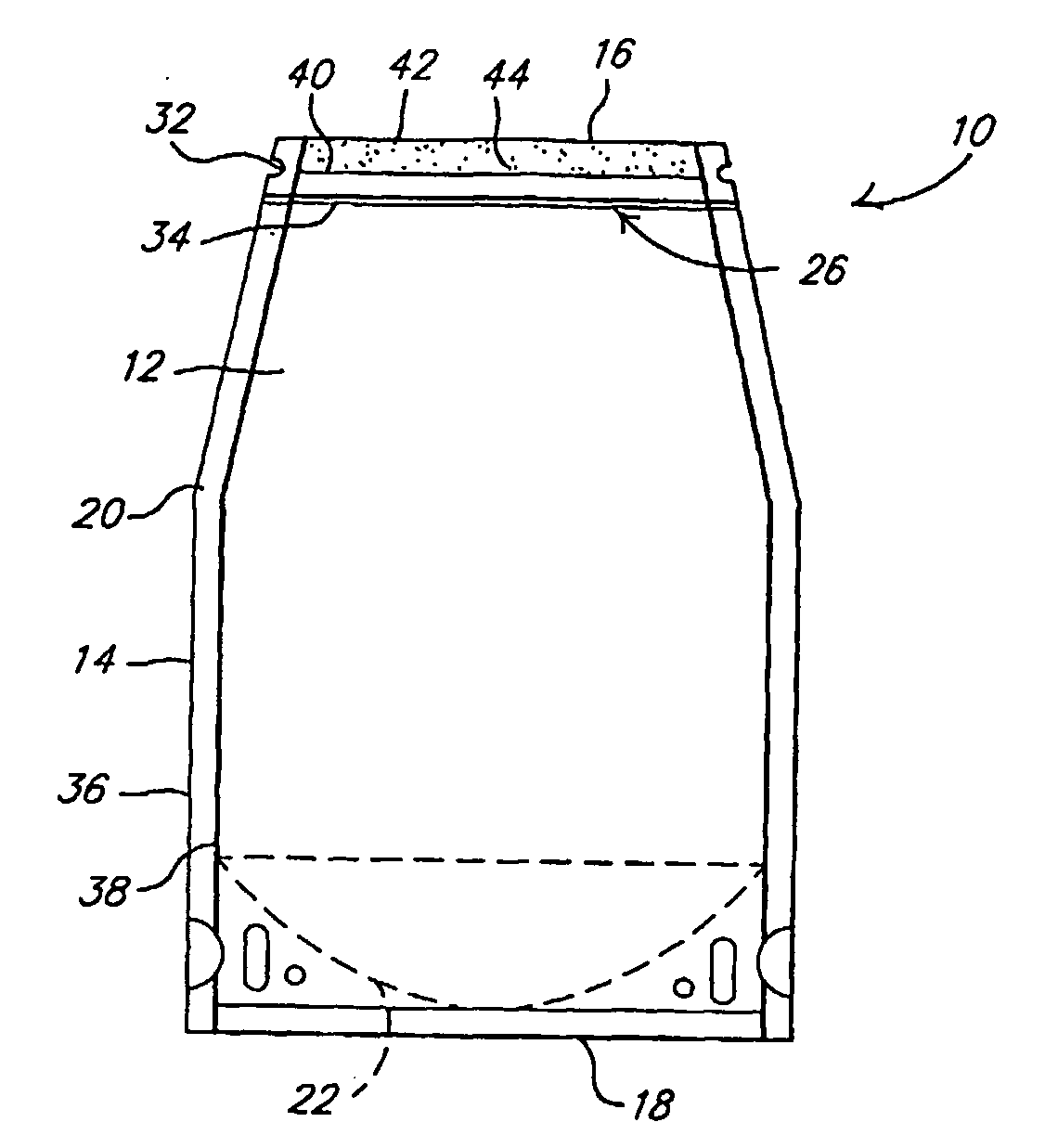

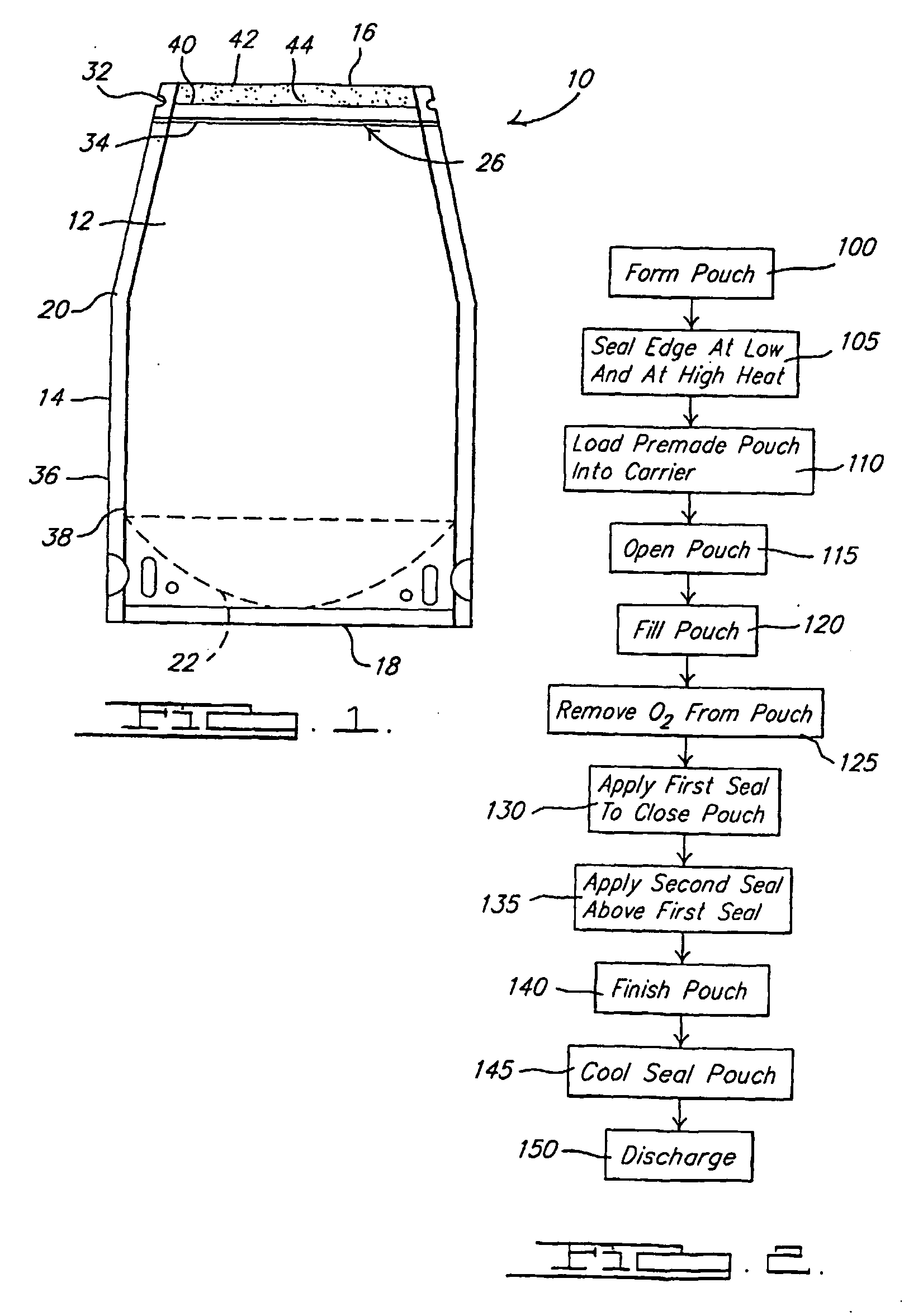

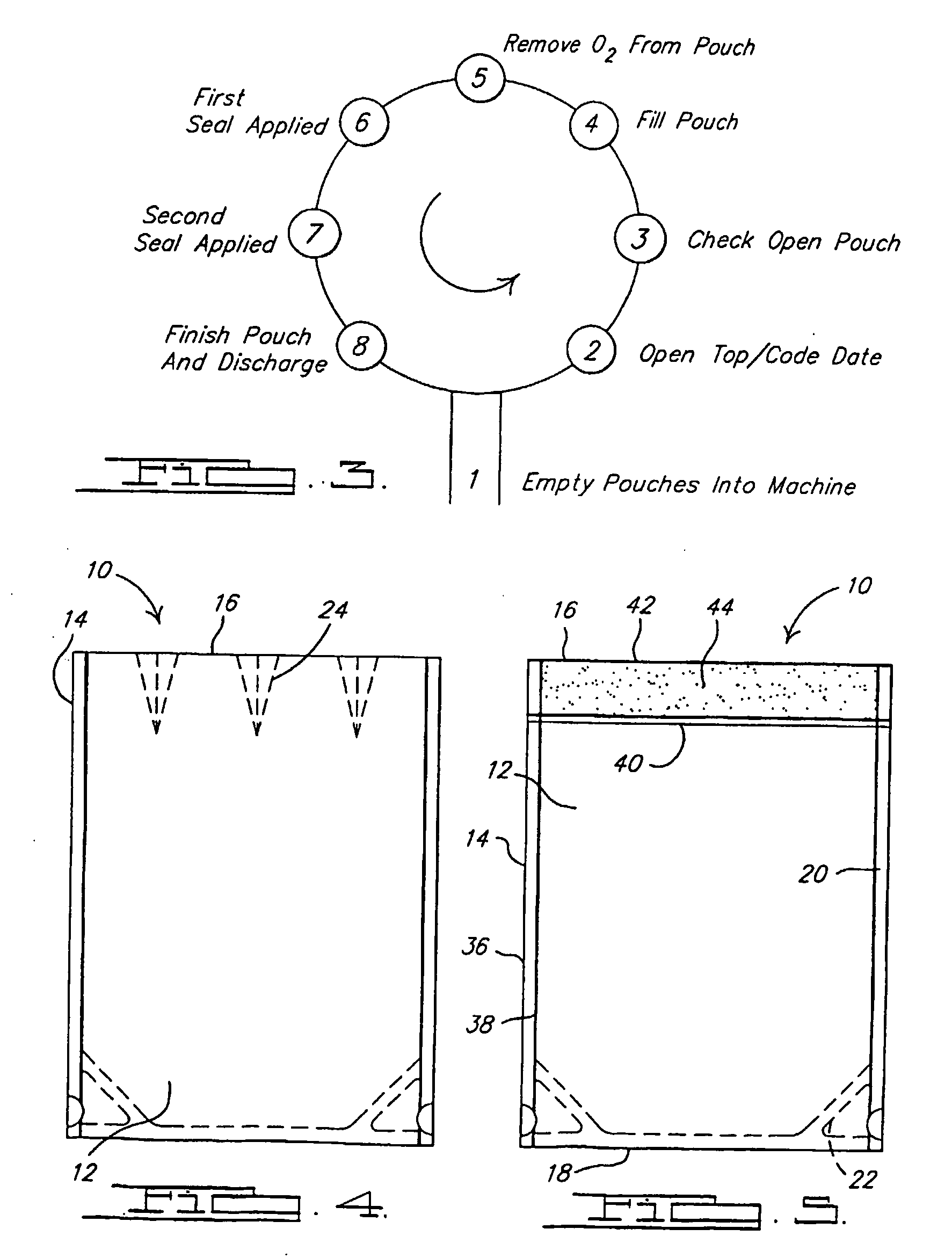

Flexible pouch and method of forming a flexible pouch

InactiveUS20050271306A1Cost-effective manufacturingReduce heatCapsThreaded caps applicationEngineeringFront panel

A flexible pouch for packaging a product, such as a carbonated beverage, is provided that includes a front panel and a back panel each having an upper edge, a lower edge opposite the upper edge, and side edges extending therebetween the upper and lower edges. The pouch includes a first closing seal extending along an upper edge of the joined front and back panel formed a predetermined length from the open edge so that there is no dead space inside the pouch between the product and the first closing seal and a second closing seal outside the first closing seal, to form a pocket trapping some of the product between the first closing seal and the second closing seal. A method of forming and filling the pouch includes the steps of forming each panel and joining two panels by scaling together the side edges and lower edge. The method also includes the steps of opening the pouch and filling the pouch with the product. The method further includes the steps of closing the filled pouch by forming a first closing seal extending along an upper edge of the pouch a predetermined length from the upper edge, such that there is no dead space inside the pouch between the product and the first closing seal, and forming a second seal between the first closing seal and the upper edge thereby trapping the product between the first closing seal and the second closing seal, and finishing the pouch.

Owner:POUCH PAC INNOVATIONS

Plastic closure, closure and container package, and method of manufacture

Owner:BERRY PLASTICS CORP

Automatic cover opening or closing and carrying device for sample test tube

ActiveCN104444983AImprove work efficiencyLow costClosing machinesThreaded caps applicationMicrobial inoculationElectric machinery

The invention relates to an automatic cover opening or closing and carrying device for a sample test tube, and solves the technical problems of low efficiency, high cost, easy bacterial infection of operators and negative influence caused by artificial and environmental factors during manual operation of an existing microorganism sample test tube. The device comprises a machine table, a test tube clamping vertical movement electric cylinder, a test tube top rotary motor, a test tube clamping bottom rotary electric cylinder, a test tube clamping electric cylinder and a test tube cover opening clamping electric cylinder, wherein the test tube clamping bottom rotary electric cylinder is connected with the machine table; the test tube clamping vertical movement electric cylinder is connected with the test tube clamping bottom rotary electric cylinder; the test tube clamping electric cylinder and the test tube top rotary motor are connected with the test tube clamping vertical movement electric cylinder respectively; the test tube clamping electric cylinder is provided with two clamping jaws; the test tube top rotary motor is connected with a cover screwer; the test tube cover opening clamping electric cylinder is connected with the machine table and provided with two clamping jaws. The device is widely applied to the technical fields of microorganism inoculation, clinics, chemicals, environments and the like.

Owner:WEIHAI SHILI ELECTRONICS TECH

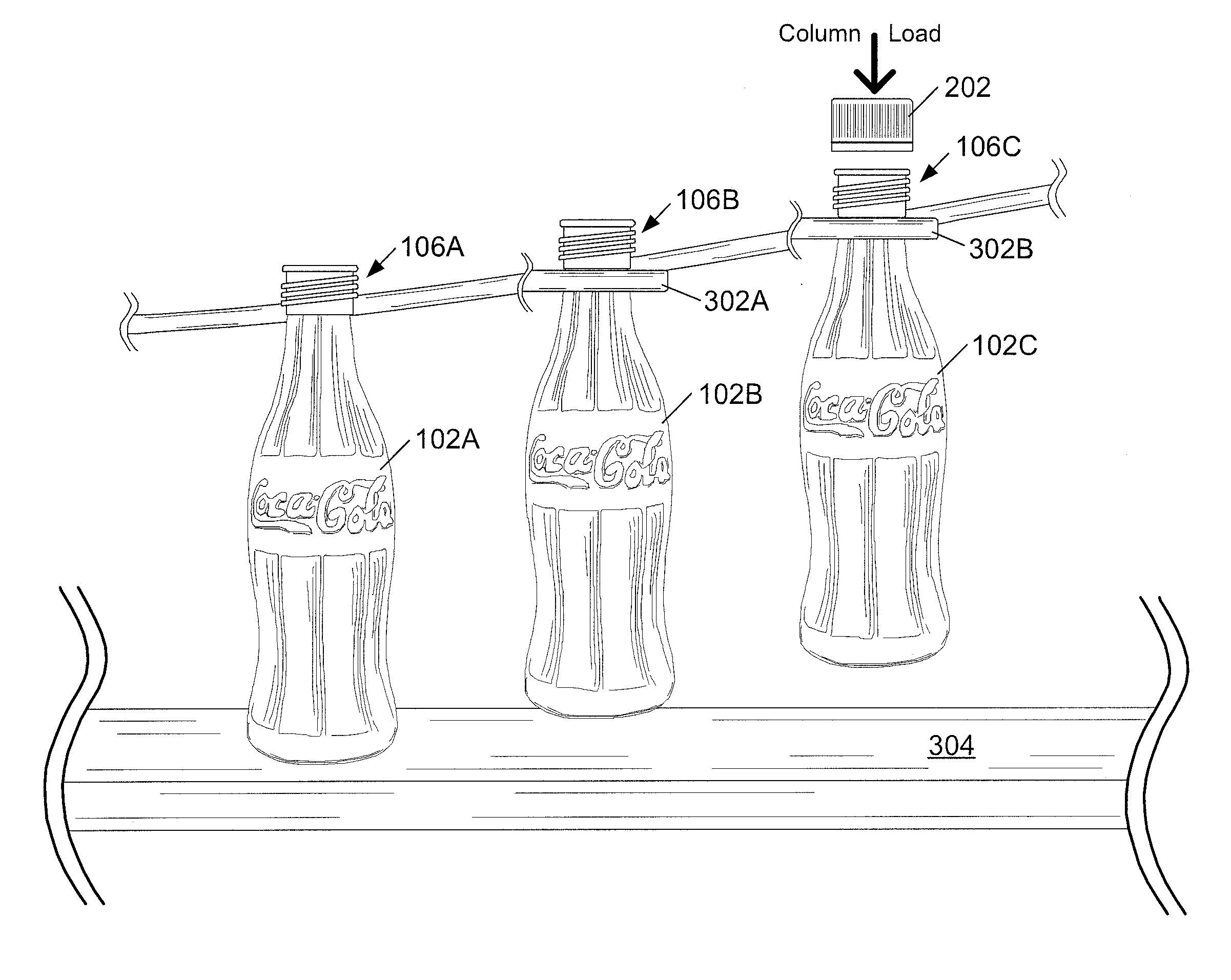

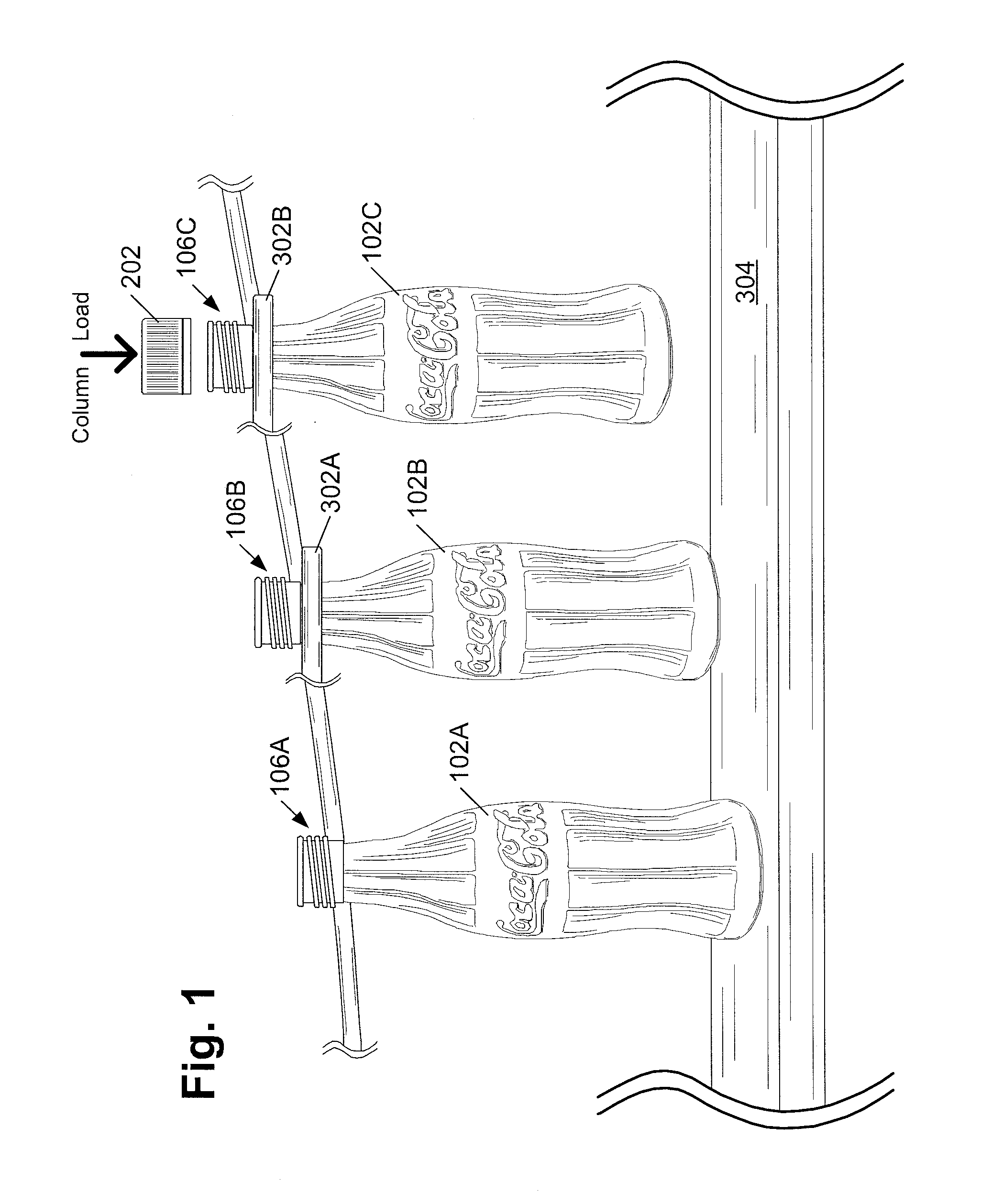

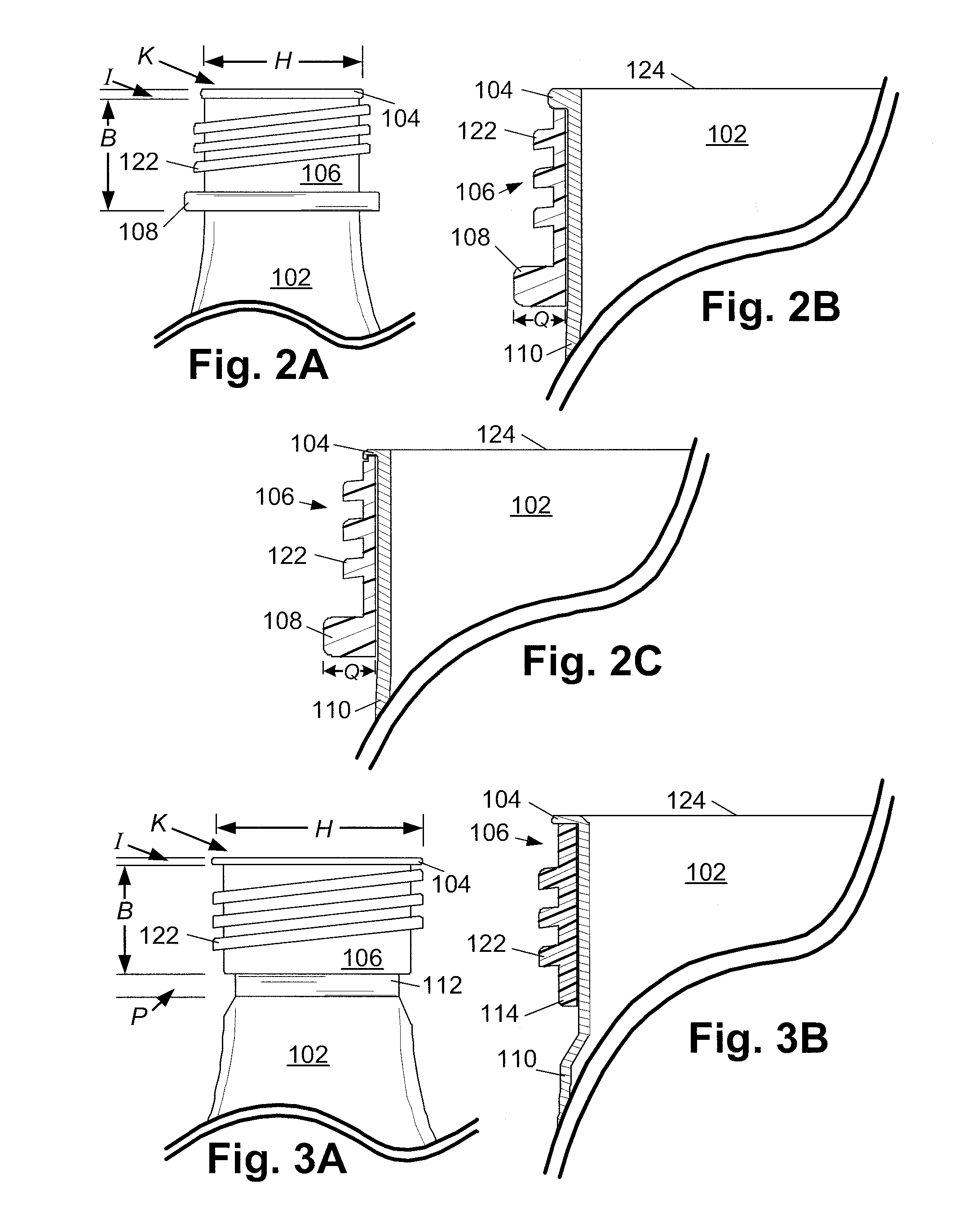

Method of isolating column loading and mitigating deformation of shaped metal vessels

InactiveUS20110113732A1Overcomes shortcomingReduce distortionThreaded caps applicationBottlesEngineeringMetal

The present invention relates to a method of isolating column loading and mitigating deformation of shaped metal vessels, the method comprising forming a cylindrical metal tube into a shaped metal vessel, the shaped metal vessel comprising a sealed end, an open end, and an integral carry ring proximate the open end. Column load is isolated between the open end and the carry ring by supporting the shaped metal vessel by the carry ring. The shaped metal vessel is sealed with a closure, wherein deformation of the shaped metal vessel between the sealed end and the carry ring due to column load is minimized during application of the closure.

Owner:THE COCA-COLA CO

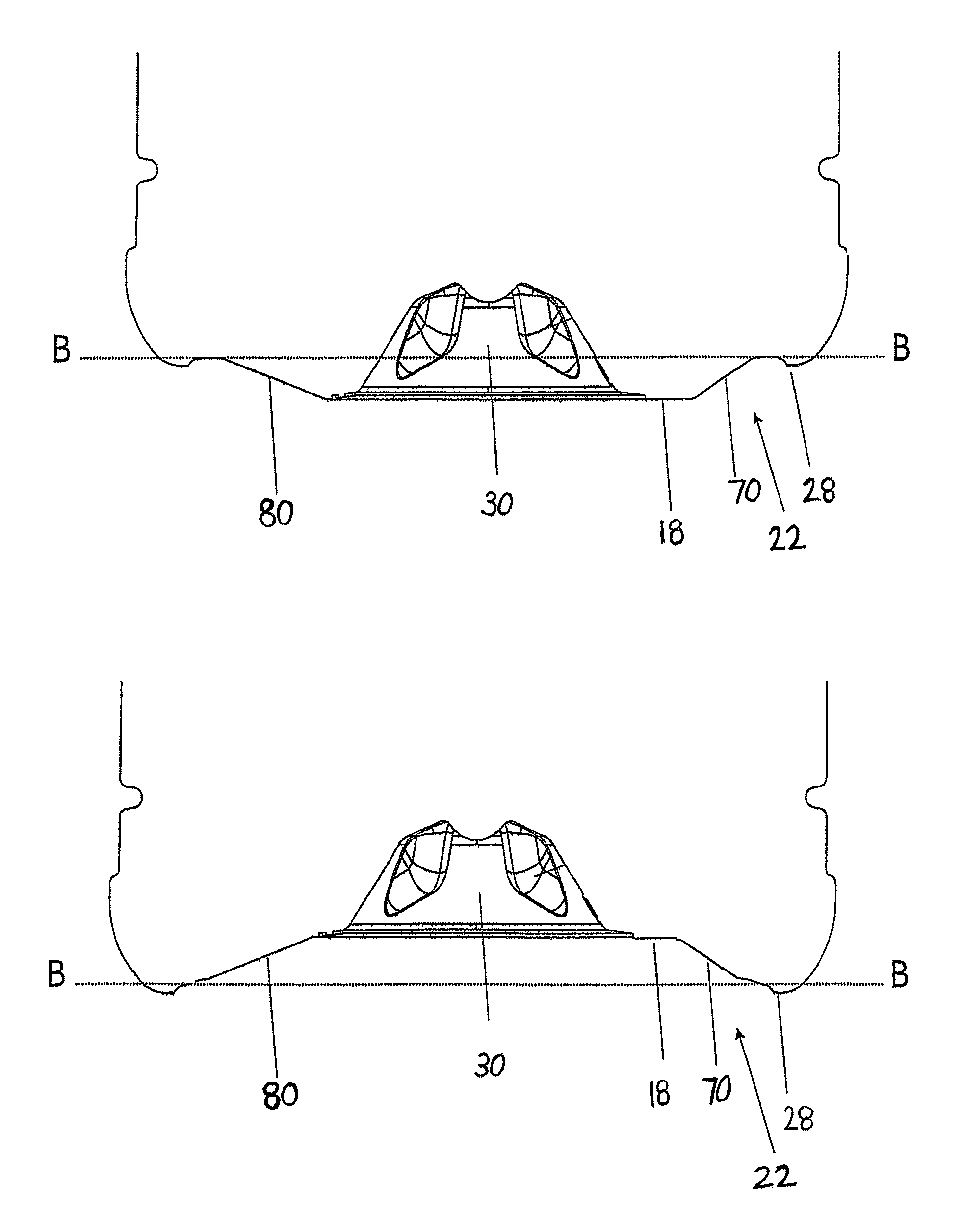

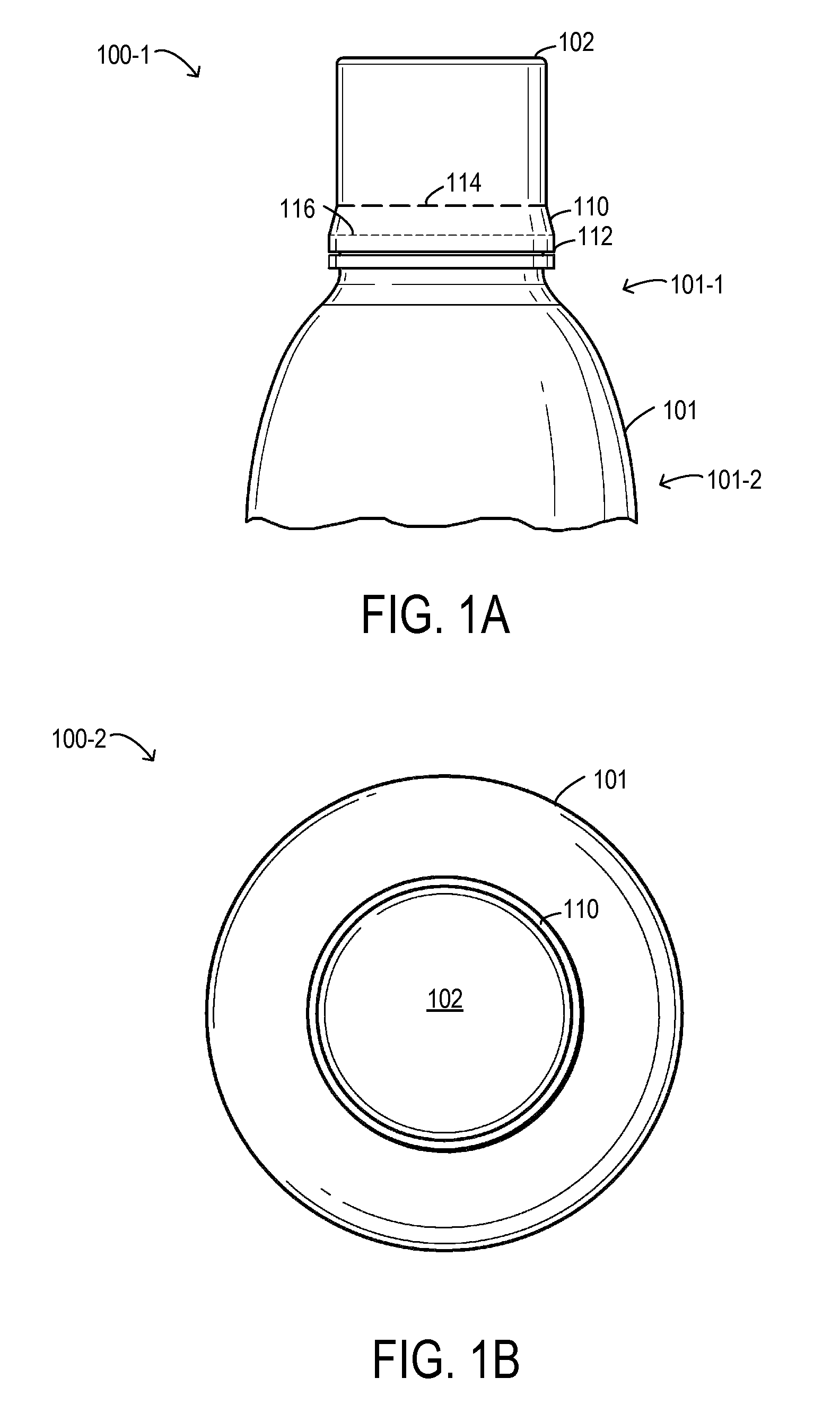

Pressure reinforced plastic container having a moveable pressure panel and related method of processing a plastic container

InactiveUS8381940B2Reduce internal volumeReduce needCapsThreaded caps applicationPositive pressureEngineering

A plastic container comprises an upper portion including a finish adapted to receive a closure, a lower portion including a base, and a sidewall extending between the upper portion and the lower portion. The upper portion, the lower portion, and the sidewall define an interior volume for storing liquid contents. The plastic container further comprises a pressure panel located on the container and moveable between an initial position and an activated position. The pressure panel is located in the initial position prior to filling the container, and is moved to the activated position after filling and sealing the container. Moving the pressure panel from the initial position to the activated position reduces the internal volume of the container and creates a positive pressure inside the container. The positive pressure reinforces the sidewall. A method of processing a container is also disclosed.

Owner:CO2 PAC

Method and machine for closing bottle with sterile caps

ActiveUS7536839B2Easy to operateImprove throughputCapsDecorative coversSterile environmentLinear machine

Owner:KHS CORPOPLAST GMBH & CO KG

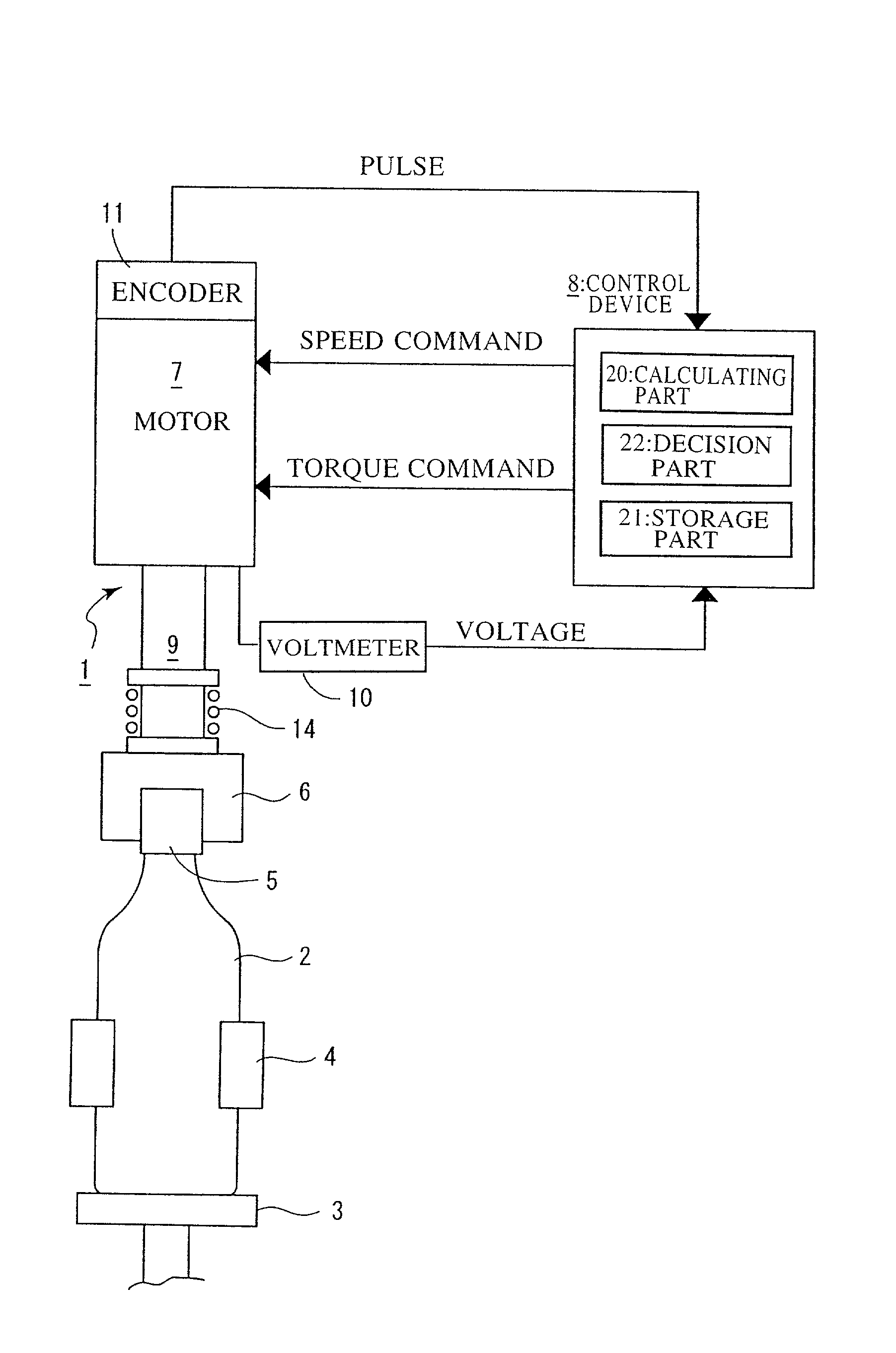

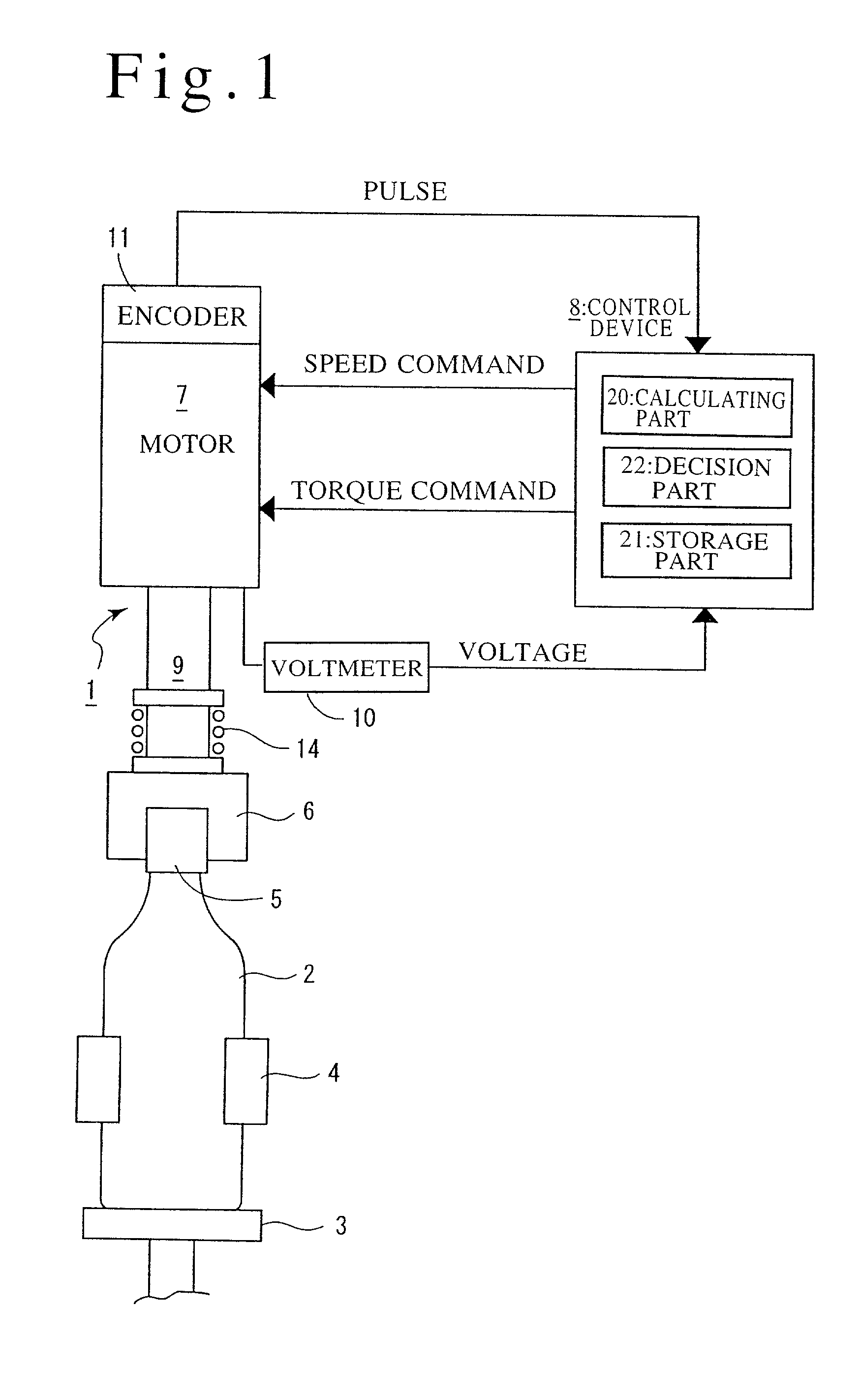

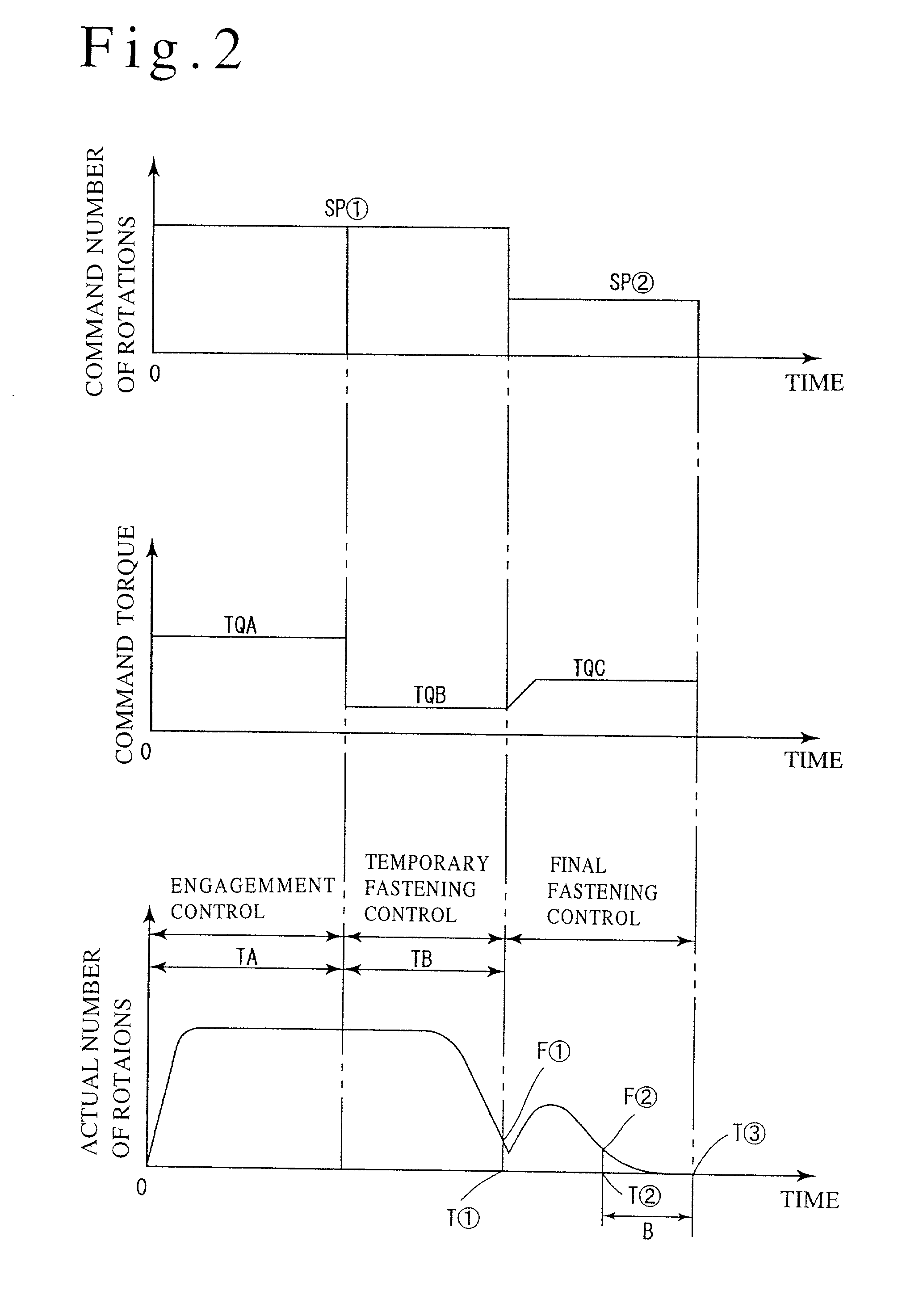

Capping method and capping apparatus

A screw capper 1 includes a capping head 6 which grips a cap 5, a servo motor 7 which rotates the capping head, a voltmeter 10 which measures the torque of the capping head, an encoder 11 which detects the rotational angle of the capping head, and a control device 8 which controls the servo motor. In the screw capper, when whether rotational fastening is acceptable is to be determined during the rotational fastening, the measured value of the encoder is measured from a predetermined measurement starting point until a rotational fastening completion point, and if the measured rotational angle is in the range of an acceptable decision angle which is set in advance, it is determined that the rotational fastening has been acceptably performed, whereas if the measured rotational angle is not in the range of the acceptable decision angle, it is determined that the rotational fastening is unacceptable. In the screw capper, defective rotational fastening can be detected, and reductions in costs can be realized compared to a case where a device for detecting such defective rotational fastening is separately provided.

Owner:SHIBUYA IND CO LTD +1

Container closure system

InactiveUS6945011B2Prevent peelingSimplify and facilitate applicationCapsThreaded caps applicationFast releaseEngineering

A system for sealing threaded containers. The system includes a clutch-free spindle assembly which is easily disassembled and cleaned. The special interface between the exterior surface of the cap an the gripping jaws of the chuck allow the system to operate without the moving parts and complications that attend the use of clutch. The spindle assembly features an easily adjustable stop arm and a quick release pin for removing and cleaning the chuck. The chuck has several passageways for the rapid infusion of cleaning fluid.

Owner:BLACKHAWK MOLDING

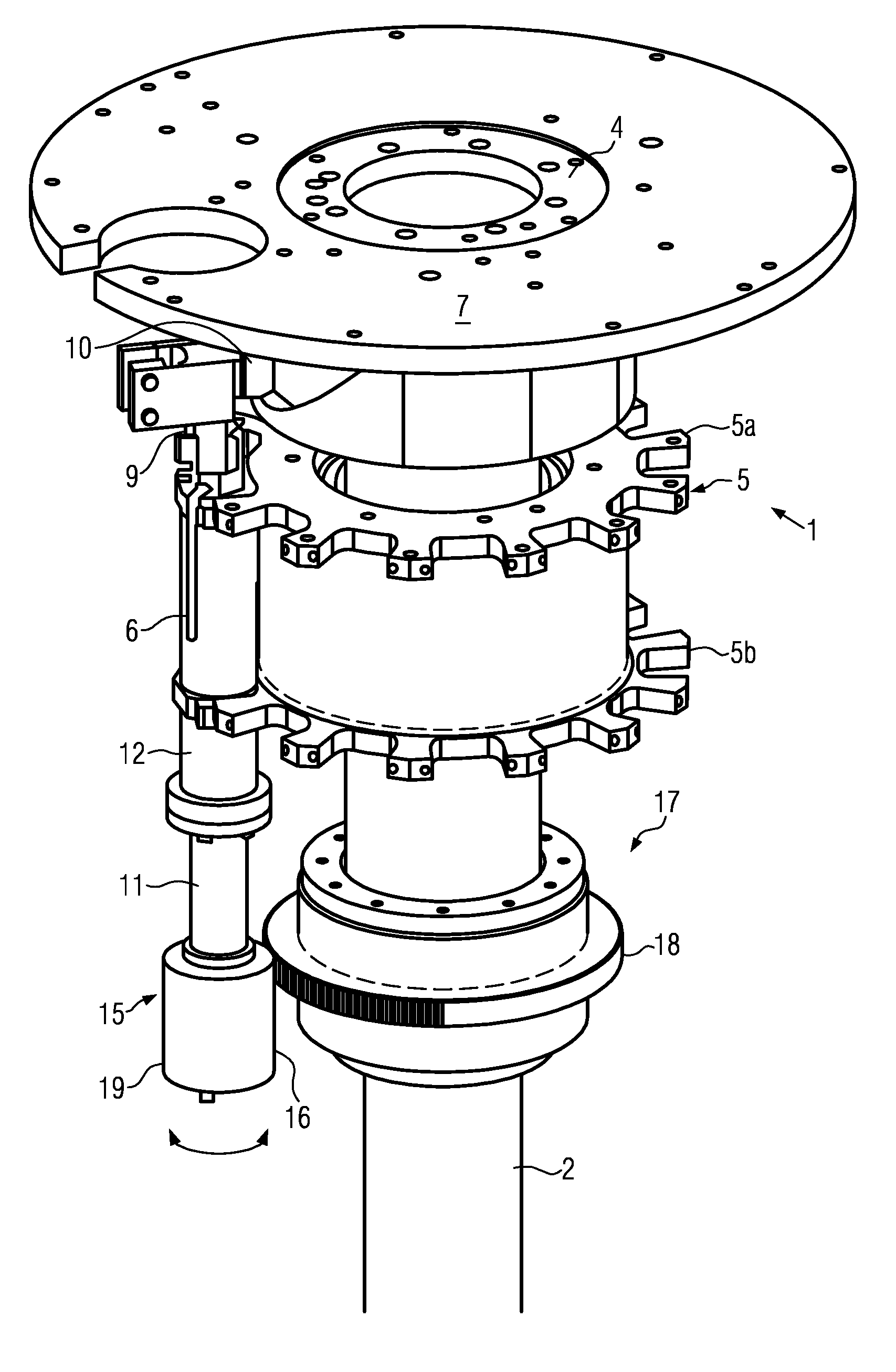

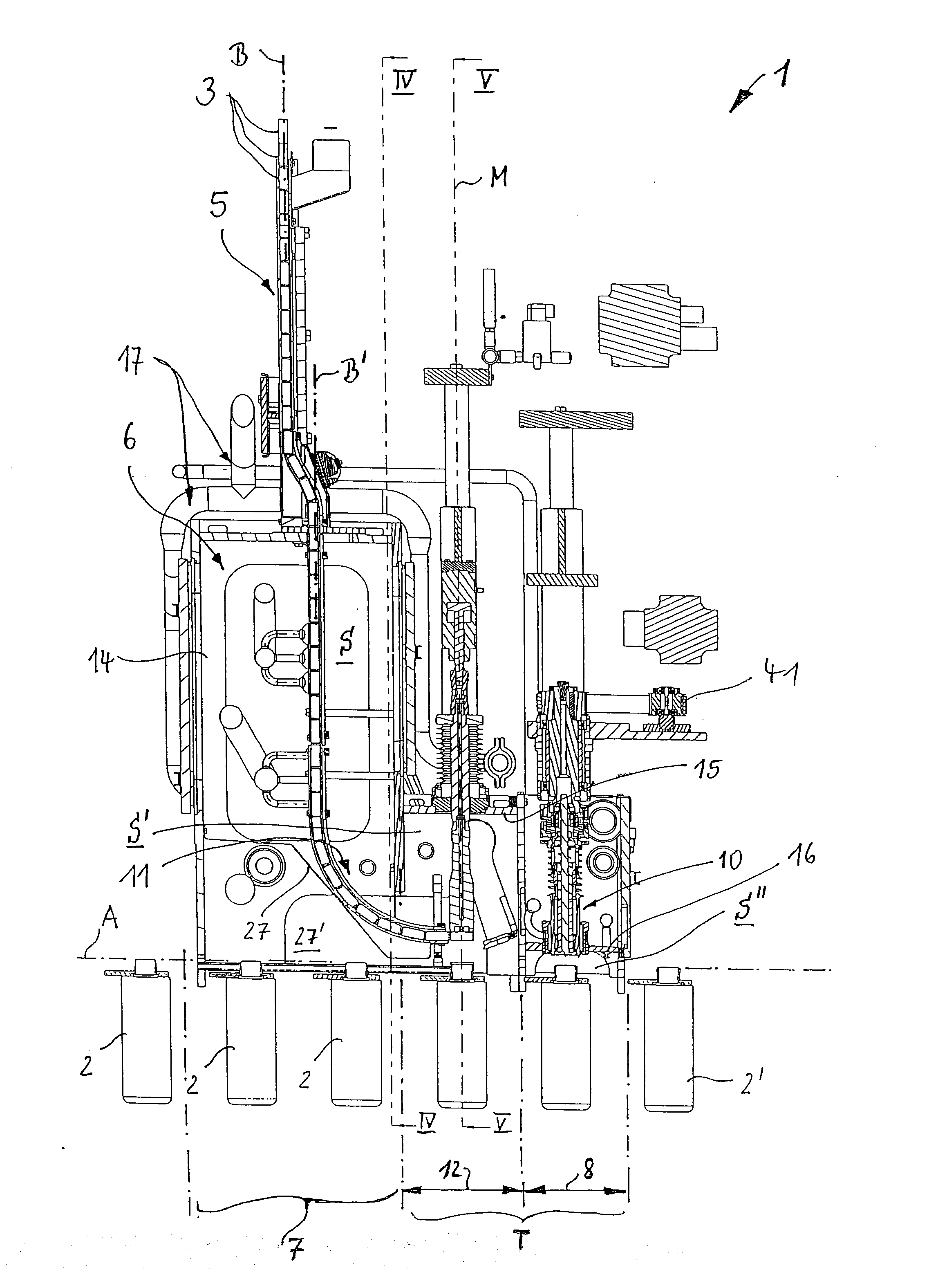

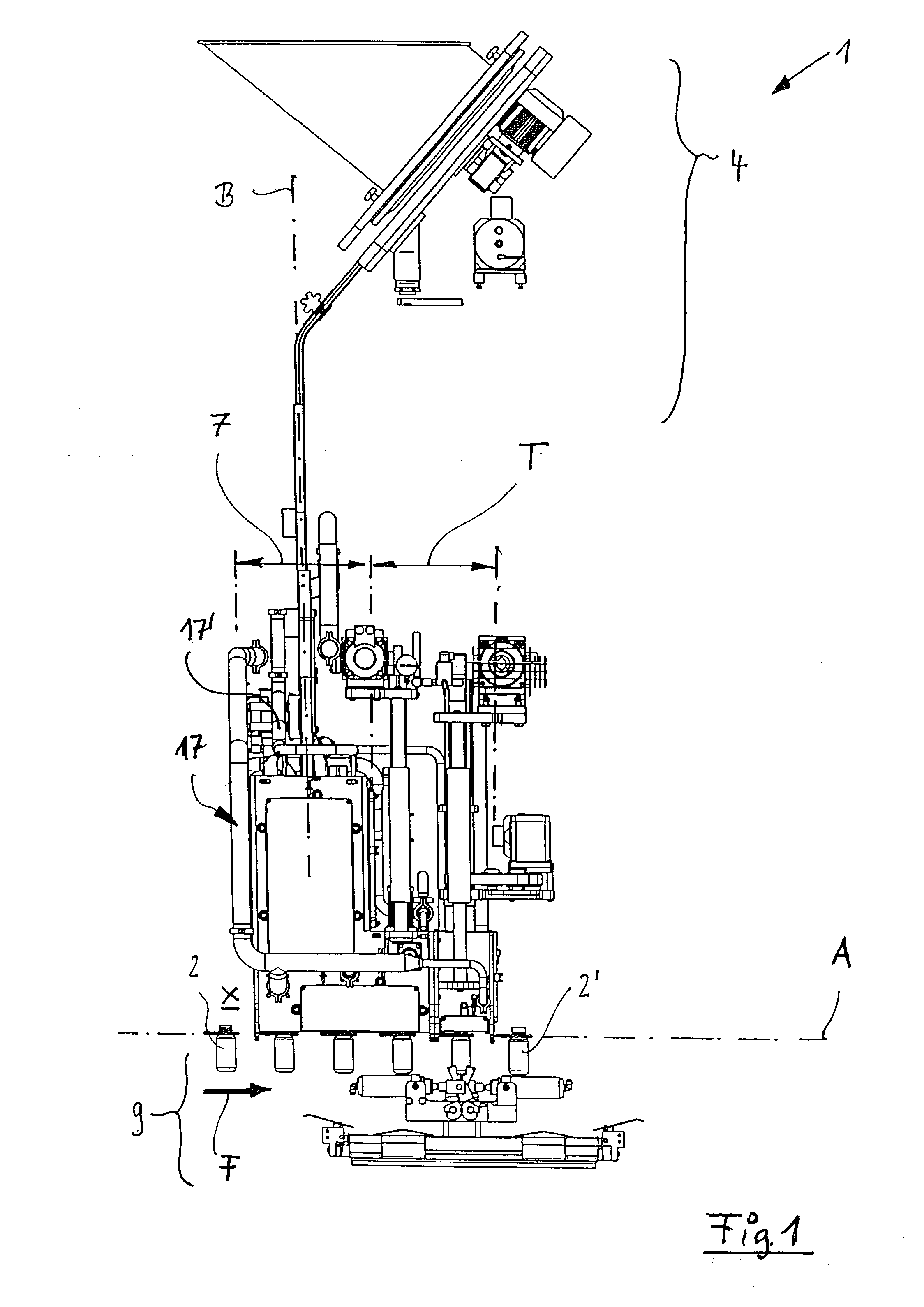

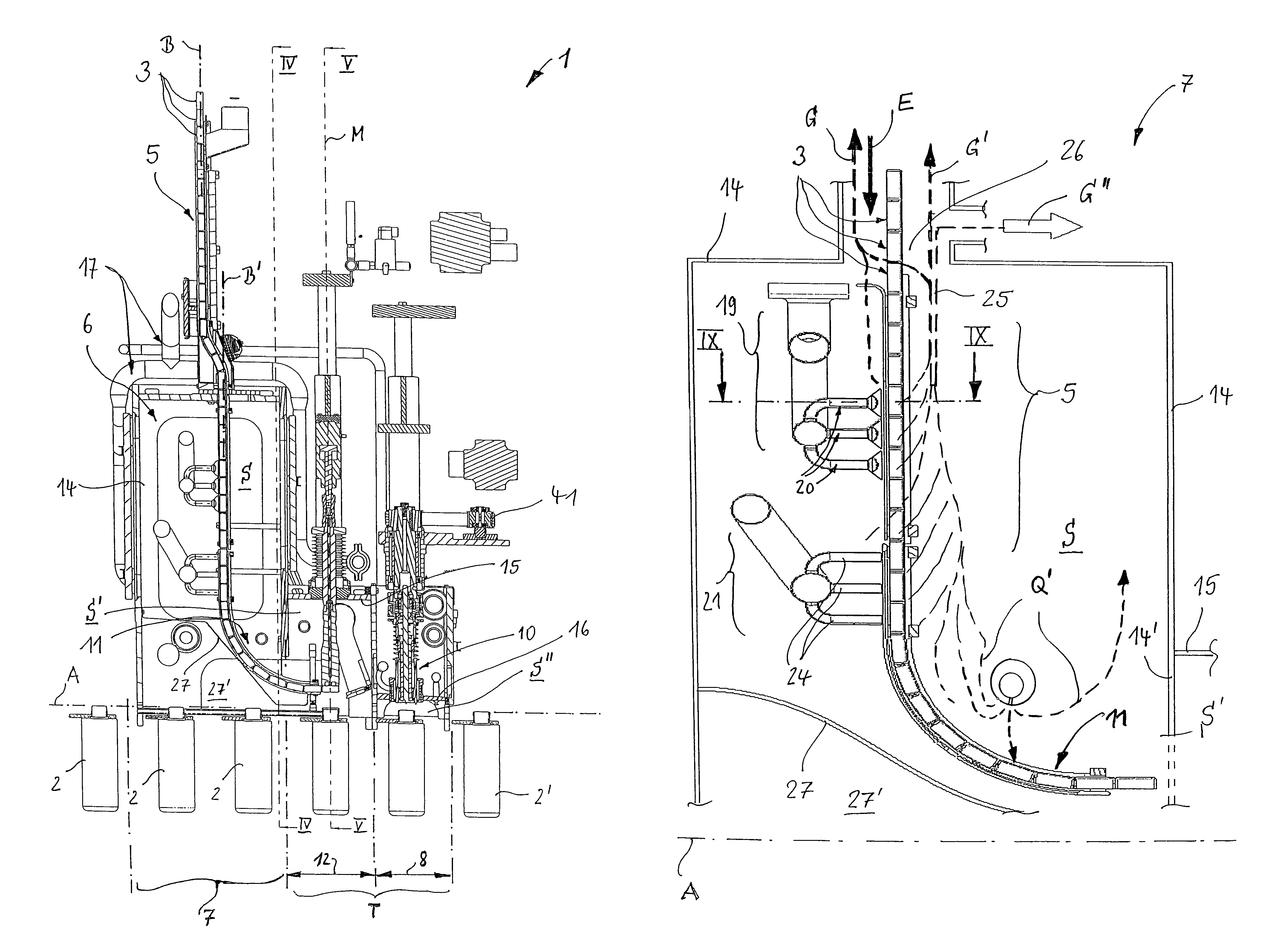

Beverage bottling plant for filling bottles with a liquid beverage filling material having a closing machine for closing containers

InactiveUS20050150193A1Improve reliabilityImprove securityClosing machinesCapsFilling materialsTrademark

A beverage bottling plant for filling bottles with a liquid beverage filling material, and a method for the operation of a closing machine and a closing machine for the closing of bottles or similar containers with closures or screw caps by screwing on the closure or cap, with a plurality of closing positions formed on the periphery of a rotor that circulates around a vertical machine axis, to which positions the containers to be closed are transferred at a container inlet and the closed containers are removed at a container outlet, whereby each closing position has a container carrier and a screw shaft that is provided on its lower end with a screw head and is mounted so that it can rotate around an axis, whereby each of these screw shafts can be driven by its own drive motor, whereby above the closing positions a mounting space (13) is formed which rotates together with the main column. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

System and method for dispensing additives to a container

A method and system for liquid dispensing provides an additive to a base liquid in a container. The additive may be enclosed by an additive bladder that is contained in a container cap and supported by a retaining element having an additive dispensing hole. When the cap is screwed down, a convex element in the cap may press the additive bladder and dispense the additive. The cap may then be removed and may be configured to internally retain the retaining element and the emptied additive bladder. In certain instances, the additive bladder may be omitted from the method and system.

Owner:LIDQUIDS

Capping head with a magnetic clutch

Owner:PRECISION TORQUE CONTROL

Closure with application guide

InactiveUS9126726B2Prevent closure tilting or cockingFacilitate threaded applicationCapsThreaded caps applicationEngineeringScrew thread

Owner:CLOSURE SYST INT INC

Method of testing, determining, and adjusting a final closing torque of a beverage bottle or container closing machine and an apparatus for performing the method

Method of testing, determining, and adjusting a final closing torque of a beverage bottle or container closing machine and an apparatus for performing the method. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

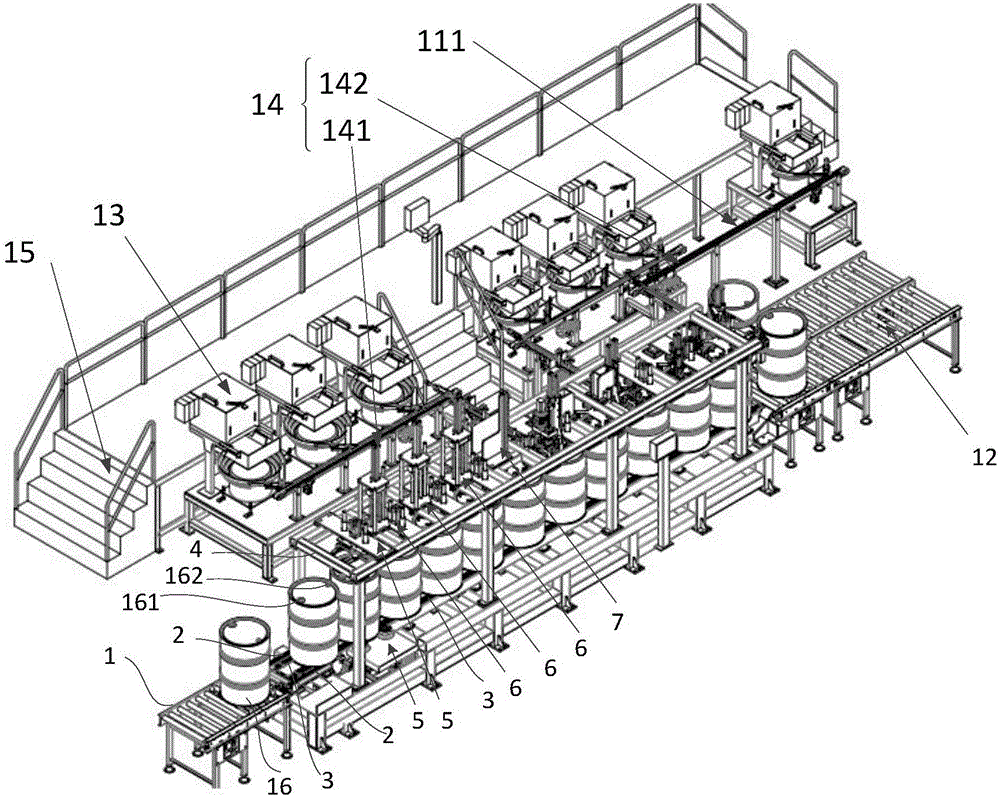

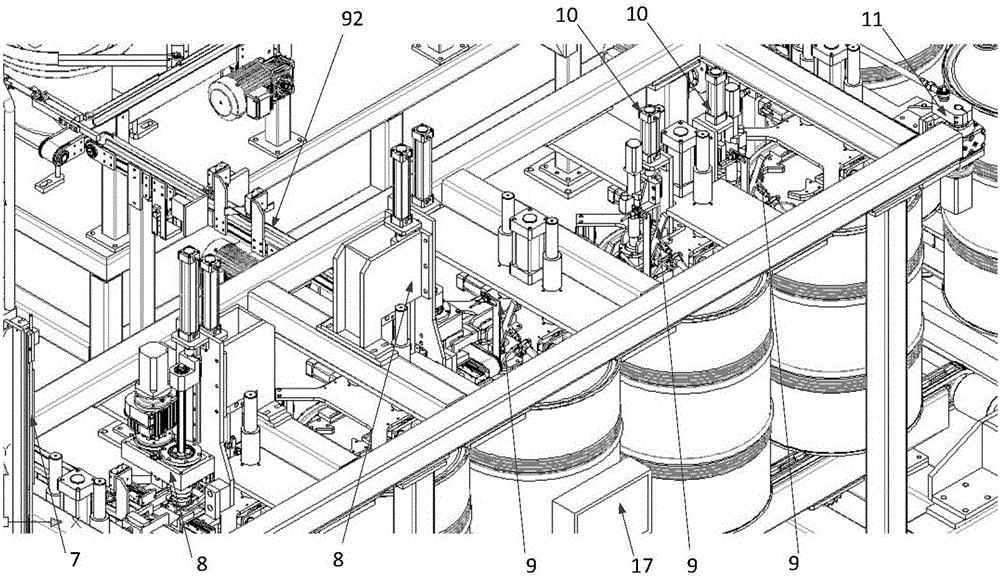

Automatic inflation cover tightening system

ActiveCN105836686ARealize automatic fillingEasy to installClosing machinesCapsControl systemEngineering

The invention provides an automatic inflation cover tightening system. The automatic inflation cover tightening system comprises a barrel body conveying system for conveying barrel bodies, a main machine frame and a control system connected with the barrel body conveying system, and further comprises large opening and small opening positioning devices, dry air injection devices, an inert gas injection device, a barrel cover conveying device, barrel cover pre-tightening devices, barrel cover tightening mechanisms, a sealing cover mechanism and an outlet conveyor. Each dry air injection device comprises a first injection device body and a second lifting pressing device used for pressing barrel bodies downwards. The barrel cover pre-tightening devices are used for pre-tightening barrel covers. The barrel cover tightening mechanisms are used for tightening barrel covers and each comprise a tightening gun unit for tightening barrel covers and a second vertical lifting mechanism for driving the tightening gun unit to move. The sealing cover mechanism comprises a sealing cover taking mechanism, a sealing cover conveyor connected with the control system, and a second lifting pressing device. The outlet conveyor is connected with the control system and arranged at an outlet of the automatic inflation cover tightening system. The automatic inflation cover tightening system provided by the invention relieves the manual labor intensity, improves production efficiency and can lower production cost and management cost for enterprises.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com