Automatic inflation cover tightening system

A technology for automatically inflating and driving cylinders, applied in screw caps, bottle/container caps, container filling methods, etc., can solve the problems of high labor cost, high production cost, low production efficiency, etc., to reduce labor intensity of workers, save money Production cost and management cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

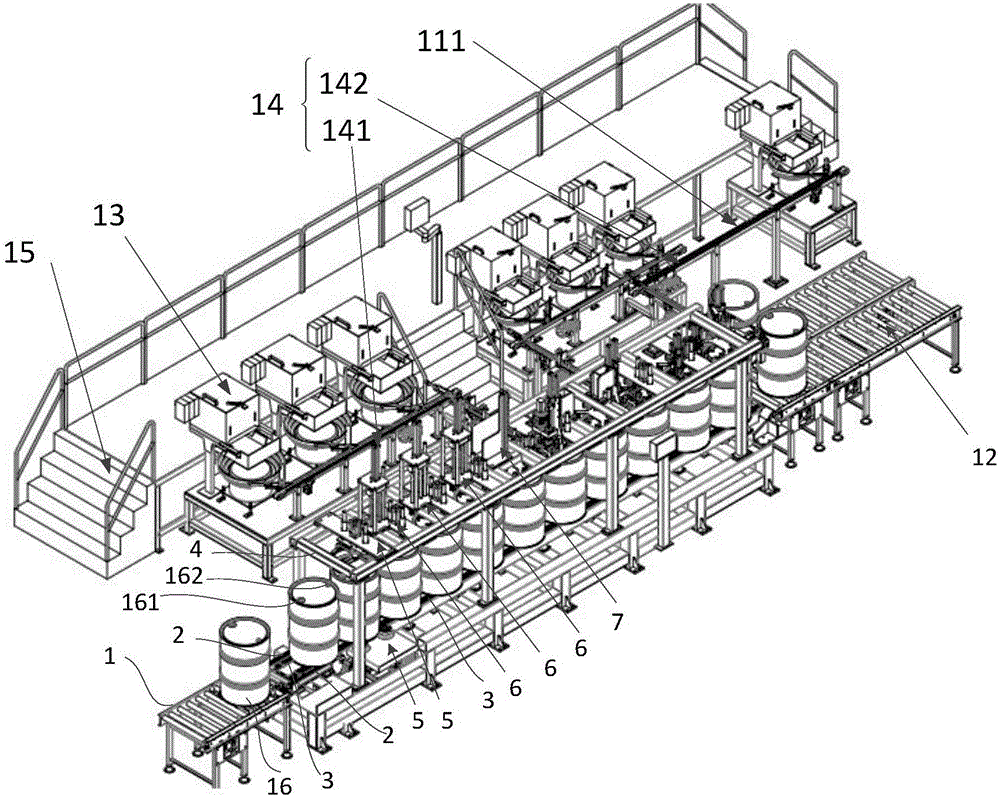

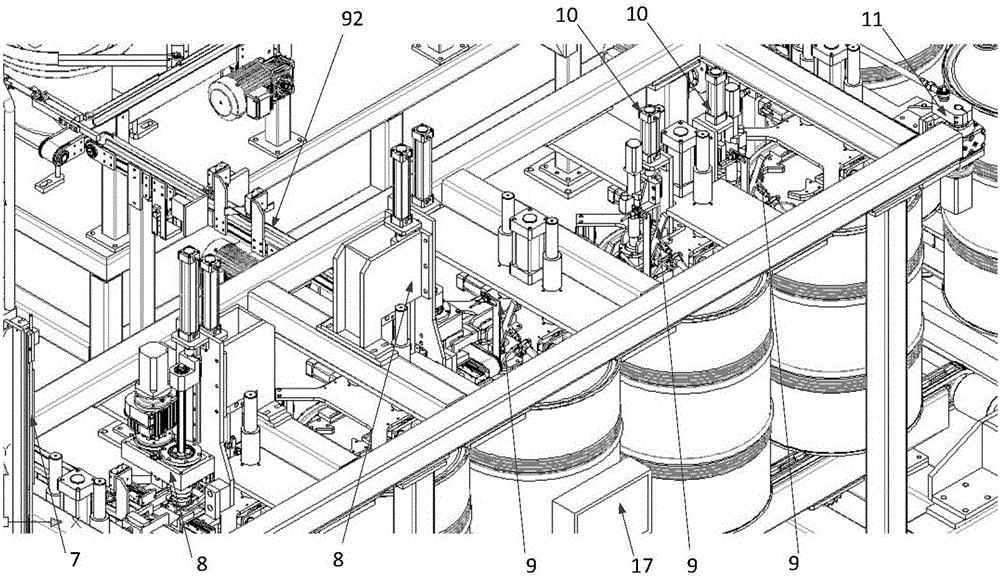

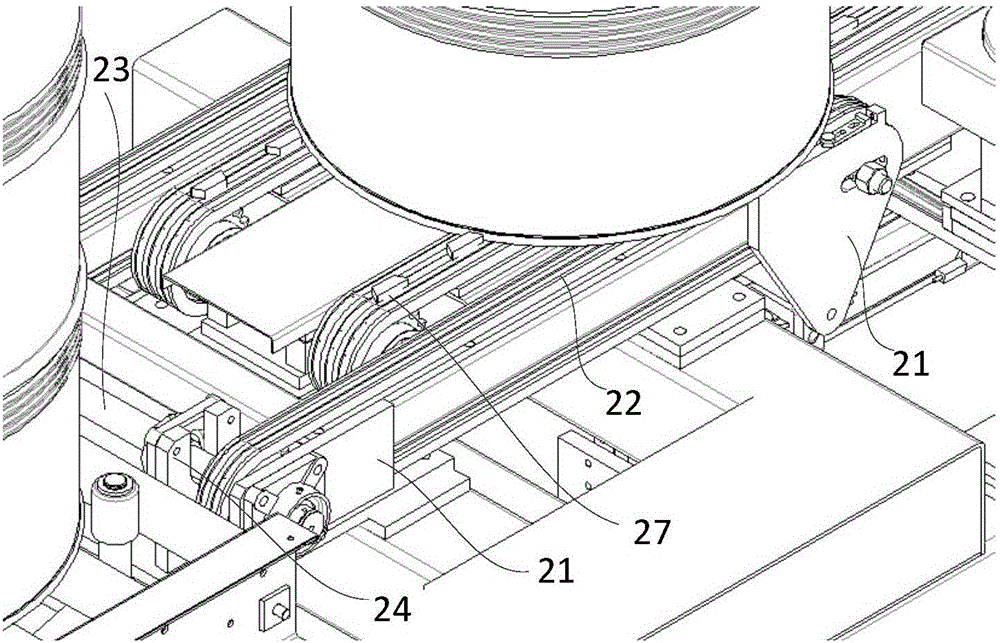

[0029] Such as Figure 1~2 As shown, this embodiment provides an automatic inflatable cap screwing system, which includes an inlet conveyor 1, a connecting conveyor 2, a barrel conveying system 3, a main frame 4, a large and small opening positioning device 5, and a dry air injection device 6 , an inert gas injection device 7, a bung pre-twist device 8, a bung detection module 9, a bung tightening mechanism 10, a capping mechanism 11, an outlet conveyor 12, a bung conveying device 14 (in this embodiment, including a bung Large lid conveying device 141 and bucket small lid conveying device 142), bung finishing device 13, step platform 15, are respectively connected with described inlet conveyor 1, connecting conveyor 2, bucket body conveying system 3 and bung conveying device 14 The control system and the control panel 17 connected with the control system.

[0030]In this embodiment, the automatic inflating cap screwing system is applied to a drum, and the material of the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com