Medical nose department medicine powder grinding device

A grinding device and medical technology, which is applied in the field of medical equipment, can solve the problems of poor grinding effect and achieve the effect of grinding thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

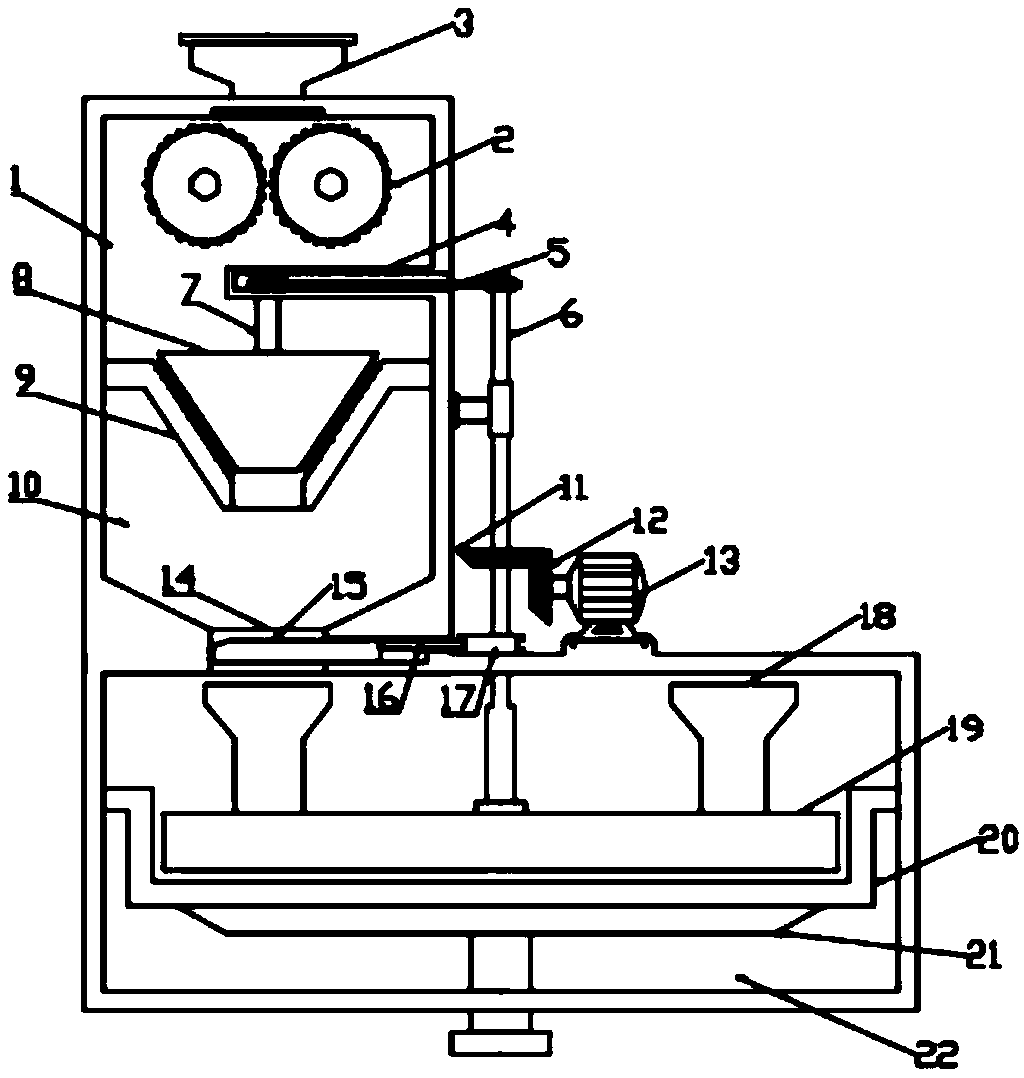

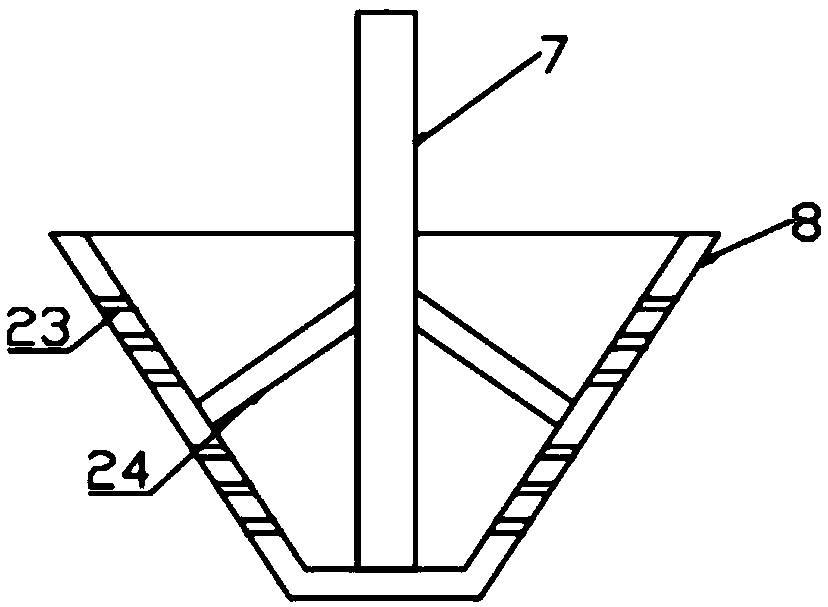

[0028] see figure 1 and 3 , in an embodiment of the present invention, a medical nasal drug powder grinding device includes a primary grinding chamber 1, a storage chamber 10 and a secondary grinding chamber 22; the primary grinding chamber 1 and the storage chamber 10 pass through a cylindrical grinding disc 9 apart, the inner side of the conical grinding disc 9 is provided with a conical grinding roller 8, the conical grinding roller 8 is a hollow structure, and its upper end is in the opening, the conical grinding roller 8 is fixed on its inner wall by a fixed The rod 24 is fixedly connected with the rotating rod 7. Preferably, the fixed rod 24 is arranged in multiples and arranged on the rotating rod 7 in a circumferential direction. The upper end of the rotating rod 7 runs through the transmission chamber 4 fixed on the inner wall of the primary grinding chamber 1. The lower wall of the lower wall is connected with the transmission chamber 4 in rotation. The rotation rod...

Embodiment 2

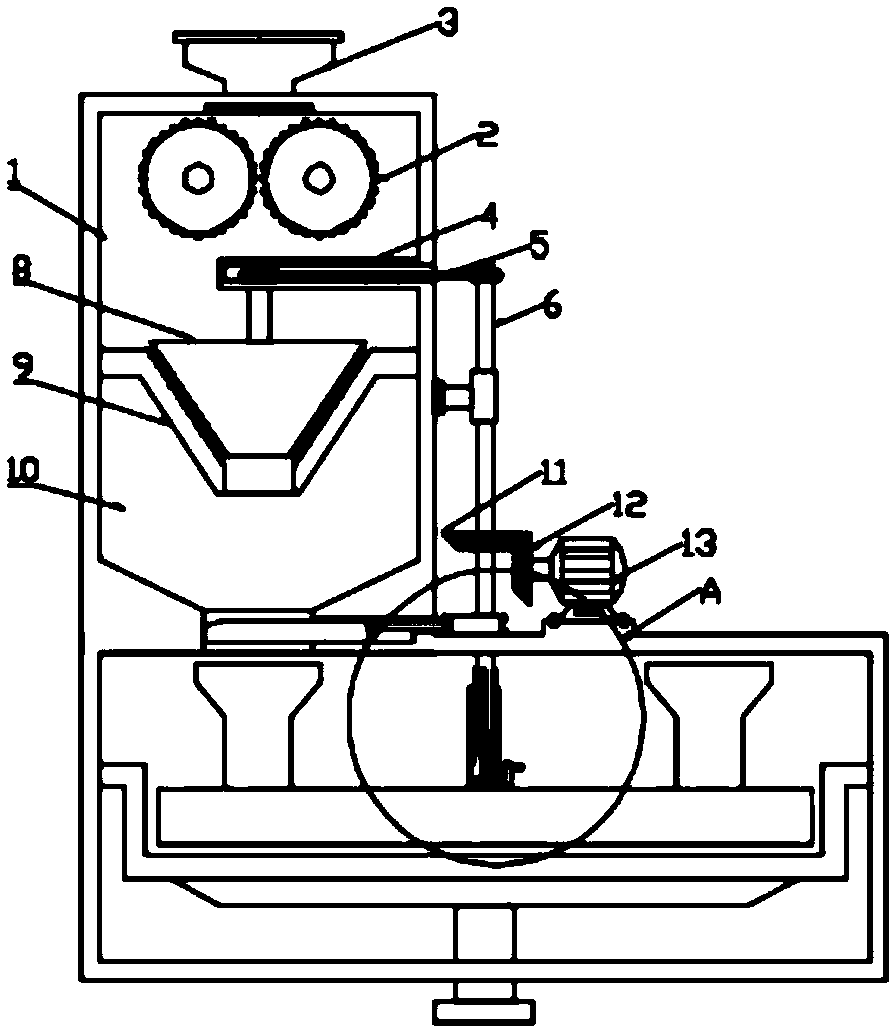

[0034] see Figure 2-4, In the embodiment of the present invention, a medical nasal medicine powder grinding device includes a primary grinding chamber 1, a storage chamber 10 and a secondary grinding chamber 22; the primary grinding chamber 1 and the storage chamber 10 pass through a cylindrical grinding disc 9, the inner side of the conical grinding disc 9 is provided with a conical grinding roller 8, the conical grinding roller 8 is a hollow structure, and its upper end is in the opening, and the conical grinding roller 8 is fixed on its inner wall by a fixed The rod 24 is fixedly connected with the rotating rod 7. Preferably, a plurality of the fixed rods 24 are provided and arranged on the rotating rod 7 in a circumferential direction. The upper end of the rotating rod 7 penetrates the transmission cavity 4 fixed on the inner wall of the primary grinding cavity 1. The lower wall of the shaft is connected to the transmission cavity 4 in rotation, and the rotating rod 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com