Automatic laminated wood board core processing method and device

A blockboard and automatic processing technology, which is applied to wood processing equipment, lamination devices, and the joining of wooden veneers, can solve problems such as production stagnation and affecting the quality of blockboard finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

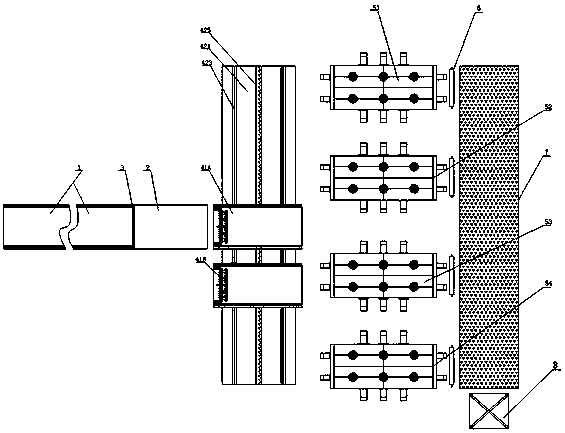

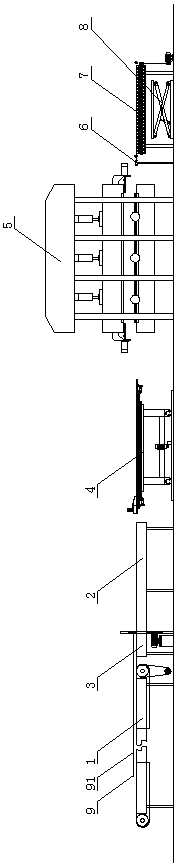

[0064] Joinery board core automatic processing device, including slab conveying assembly, displacement adjustment mechanism, hot press unit and finished board conveying mechanism; the end of the slab conveying assembly is provided with a displacement adjustment mechanism, and the end of the displacement adjustment mechanism is provided with a hot press The unit, the end of the hot press unit is equipped with a finished plate conveying mechanism;

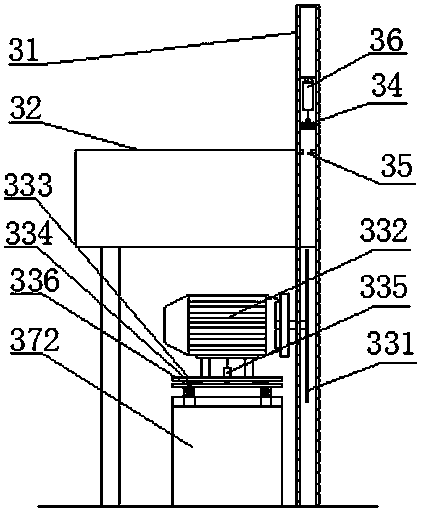

[0065] The slab conveying assembly includes a conveyor belt 1, a loading platform 2 and a cutting mechanism 3, the conveyor belt 1, the loading platform 2 and the cutting mechanism 3 are arranged on the same level, the conveyor belt 1 is along the conveying direction, and the end A loading platform 2 is configured, and a cutting mechanism 3 is provided at the junction of the loading platform 2 and the conveyor belt-1; the cutting mechanism includes a cutting bracket 31, a cutting platform 32, a cutting saw 33 and a pressing plate 34, ...

Embodiment 2

[0093] Joinery board core automatic processing device, including slab conveying assembly, displacement adjustment mechanism, hot press unit and finished board conveying mechanism; the end of the slab conveying assembly is provided with a displacement adjustment mechanism, and the end of the displacement adjustment mechanism is provided with a hot press The unit, the end of the hot press unit is equipped with a finished plate conveying mechanism;

[0094] The slab conveying assembly includes a conveyor belt 1, a loading platform 2 and a cutting mechanism 3, the conveyor belt 1, the loading platform 2 and the cutting mechanism 3 are arranged on the same level, the conveyor belt 1 is along the conveying direction, and the end A loading platform 2 is configured, and a cutting mechanism 3 is provided at the junction of the loading platform 2 and the conveyor belt-1; the cutting mechanism includes a cutting bracket 31, a cutting platform 32, a cutting saw 33 and a pressing plate 34, ...

Embodiment 3

[0121] Among them, the number of ferry cars is 2, and the number of hot presses is 10, among which, 10 hot press machines are arranged longitudinally and symmetrically at the end of the displacement adjustment mechanism with the conveyor belt 1 as the axis; each ferry car is responsible for 5 Slab transfer and loading work for a hot press. Other same as above.

[0122] The traditional slab production line, according to each set of units, is equipped with 10 skilled male workers as standard, 3 shifts for 24 hours, and the daily output is less than or equal to 400 sheets.

[0123] However, the blockboard core automatic processing device of the present invention has high operating precision, can accurately control the size index of the product, and produces no corner waste in the production process, which can maximize productivity;

[0124] At the same time, each production line saves 4-5 male laborers; all the action process is completed automatically, the program runs reliably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com