Patents

Literature

1280results about "Veneer presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

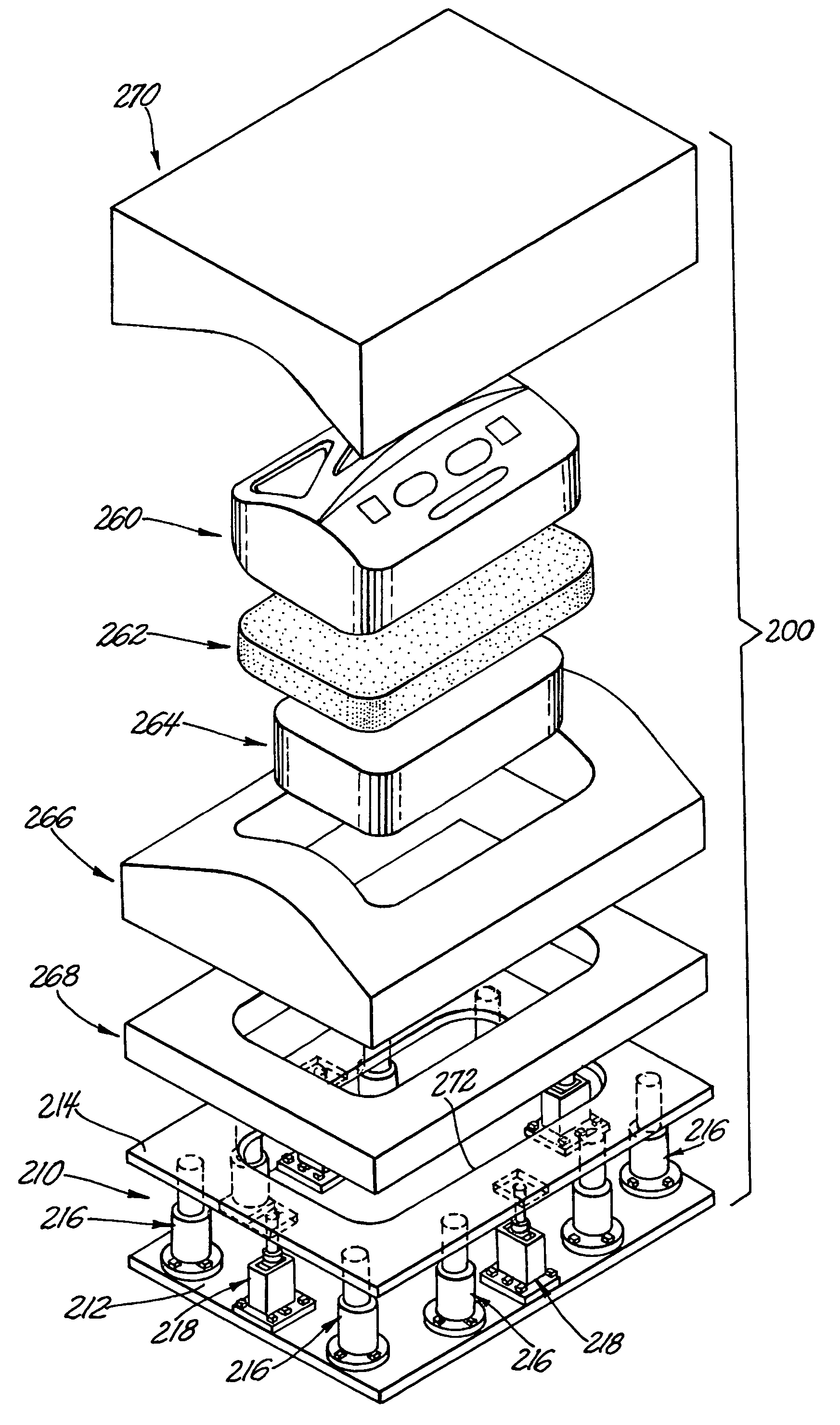

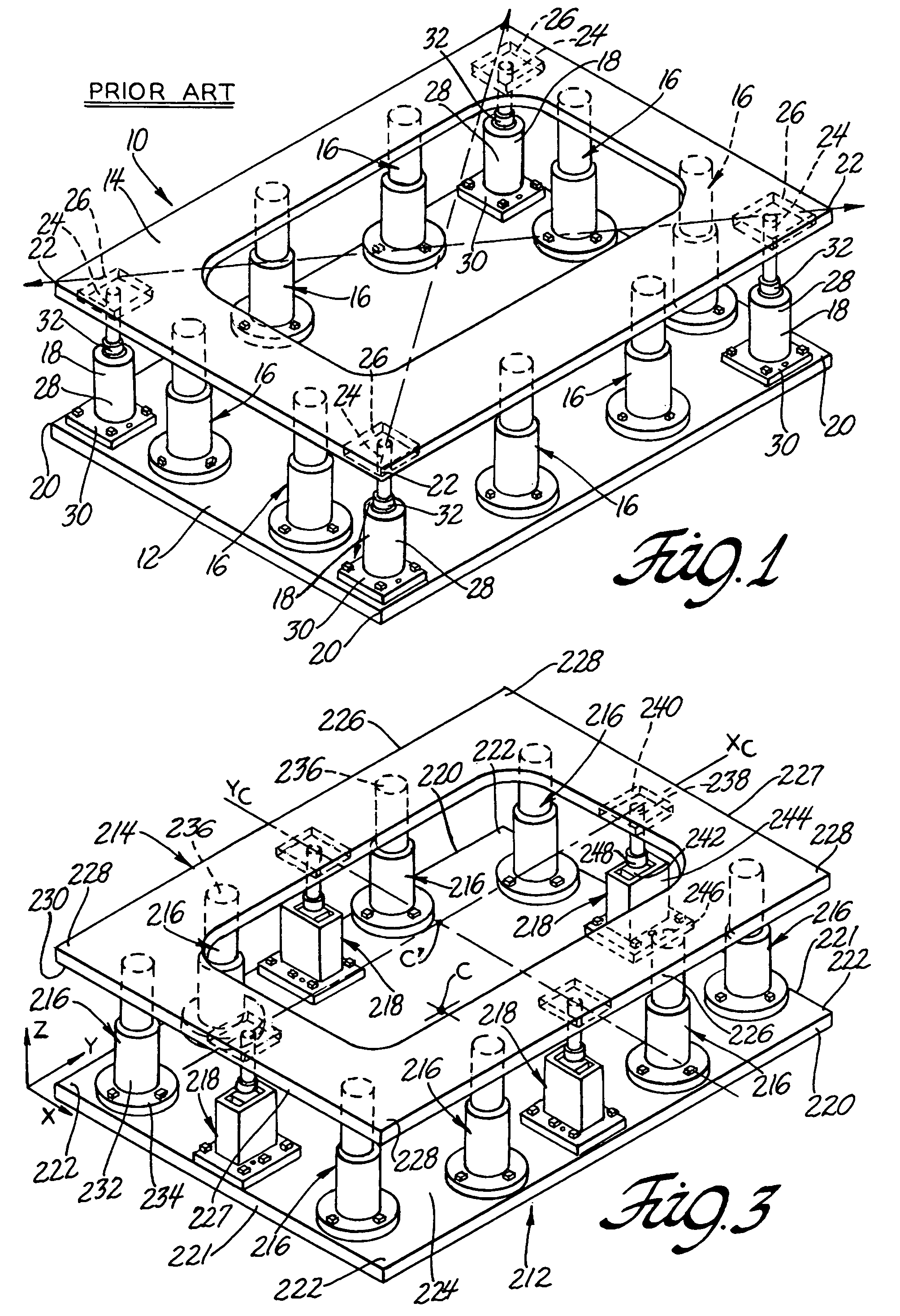

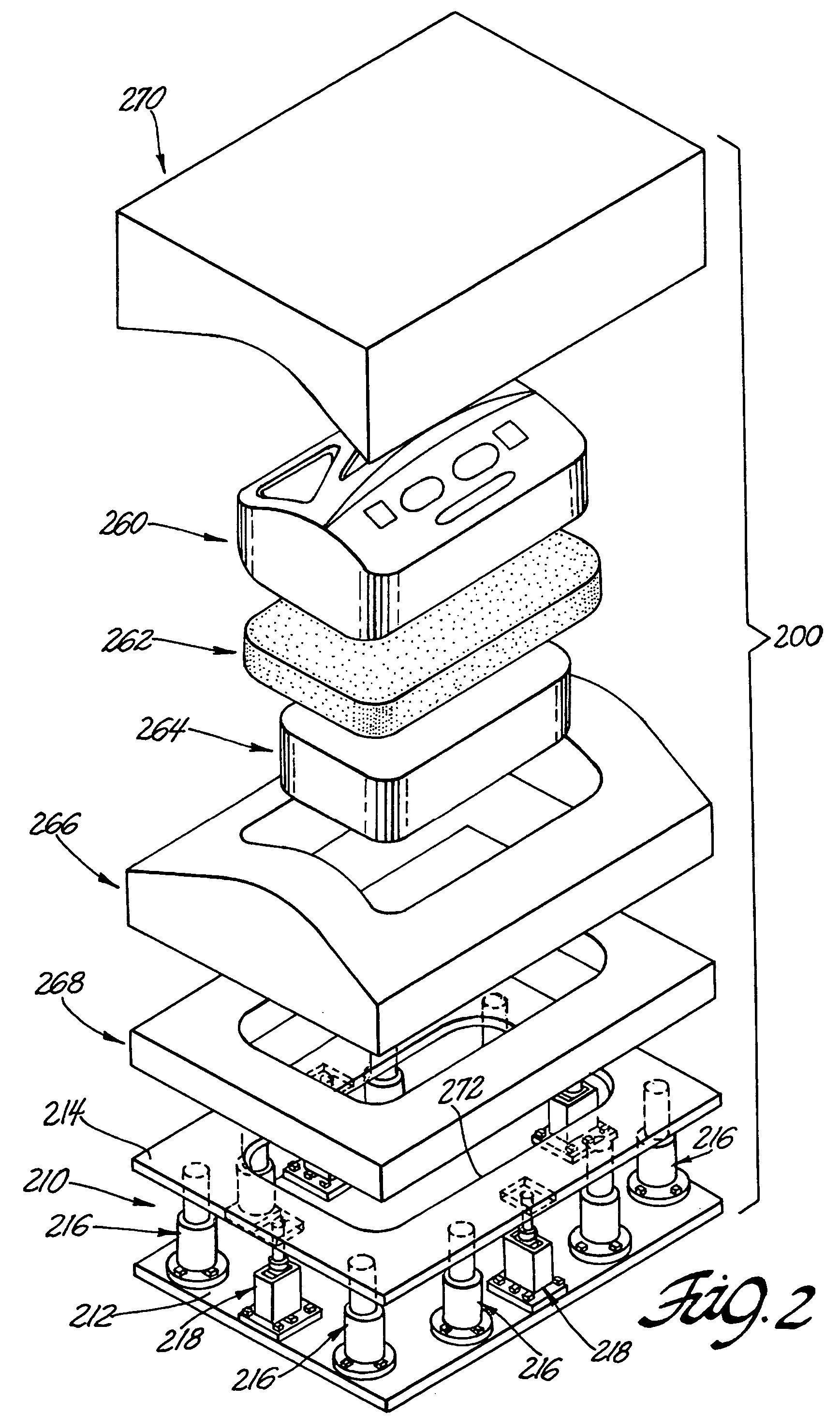

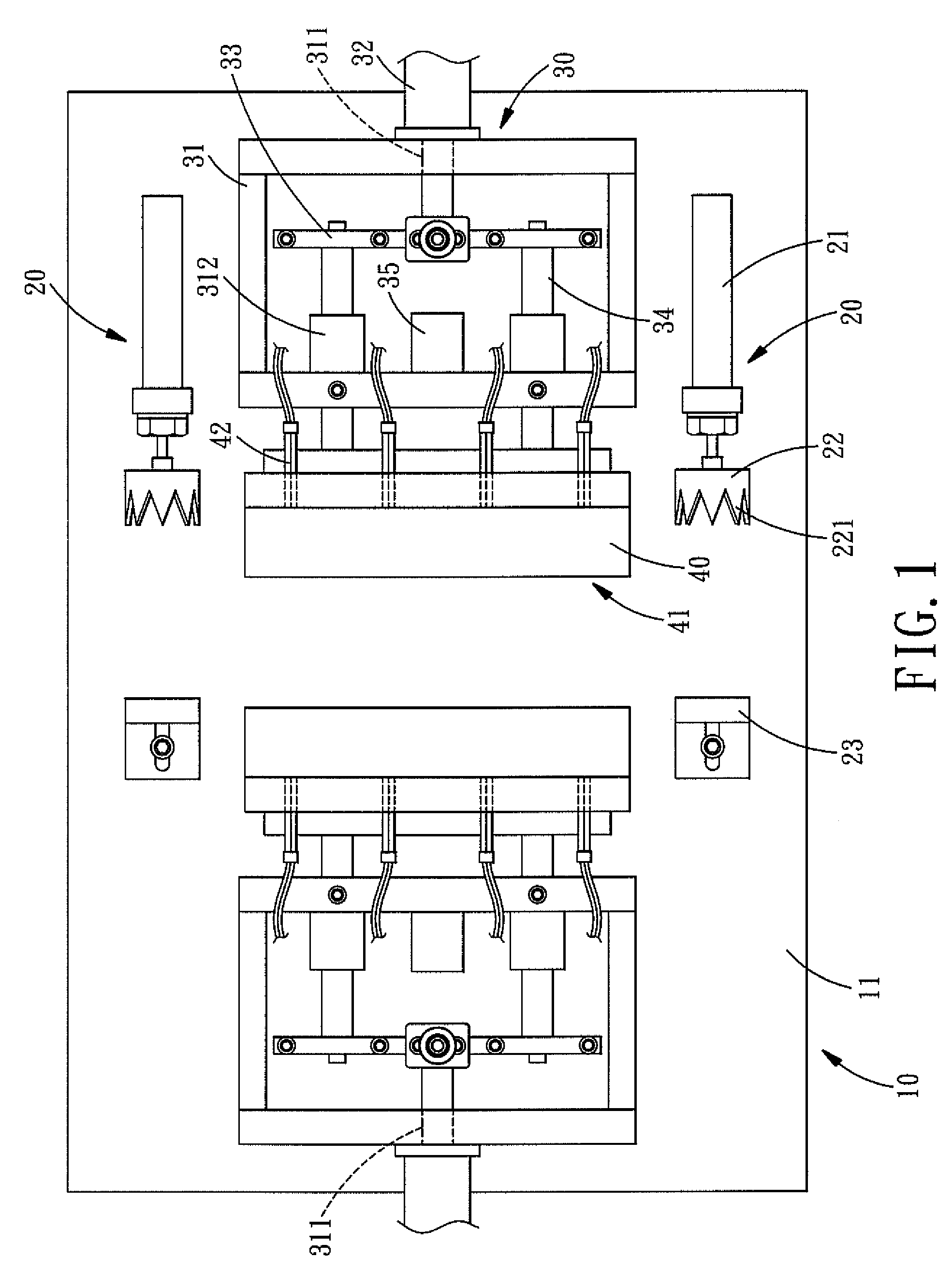

Die cushion apparatus for hot stretch-forming

ActiveUS7004007B2Accurate locationInhibit bindingShaping toolsPlywood pressesRelative displacementThermal expansion

A self-contained die cushion assembly for use in a stretch-forming process involving heated tooling. A lower plate is mounted below an upper plate that undergoes different thermal expansion than the lower plate. Guidance devices are mounted between the upper and lower plates and include a guide post, a bearing sleeve circumscribing the guide post, and a cylinder circumscribing the bearing sleeve. The guide post is mounted in fixed relation to the upper plate, and the cylinder is mounted in laterally translatable relation to the lower plate to accommodate lateral relative displacement between the upper and lower plates due to different thermal expansion thereof, thereby preventing binding of the guidance devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus for calendering paper

The invention relates to a method for operating a calender, comprising a cylindrical heated roll and a flexible belt surrounding a stationary support beam which supports at least one actuator which may urge a concave load shoe against the heated roll by means of said flexible belt to form an extended and heated nip through which a fiber web passes to be calendered and a separating mechanism for having at least one of the rolls movable into and away from the nip characterized in that said flexible belt is a flexible tubular jacket which forms a part of an enclosed shoe roll such that the ends of said jacket have end walls mounted thereto, which end walls are rotatably mounted in relation to said support beam, and in that at least one of said end walls is driven by means of a drive arrangement which drive arrangement may be activated to drive the end walls and thereby also the jacket independently of its position in relation to the fiber web or the heated roll.

Owner:VALMET TECH INC

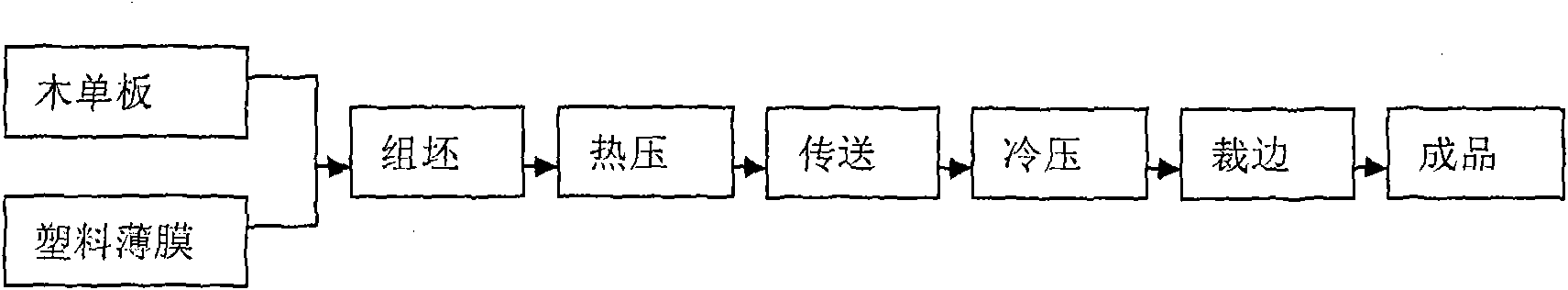

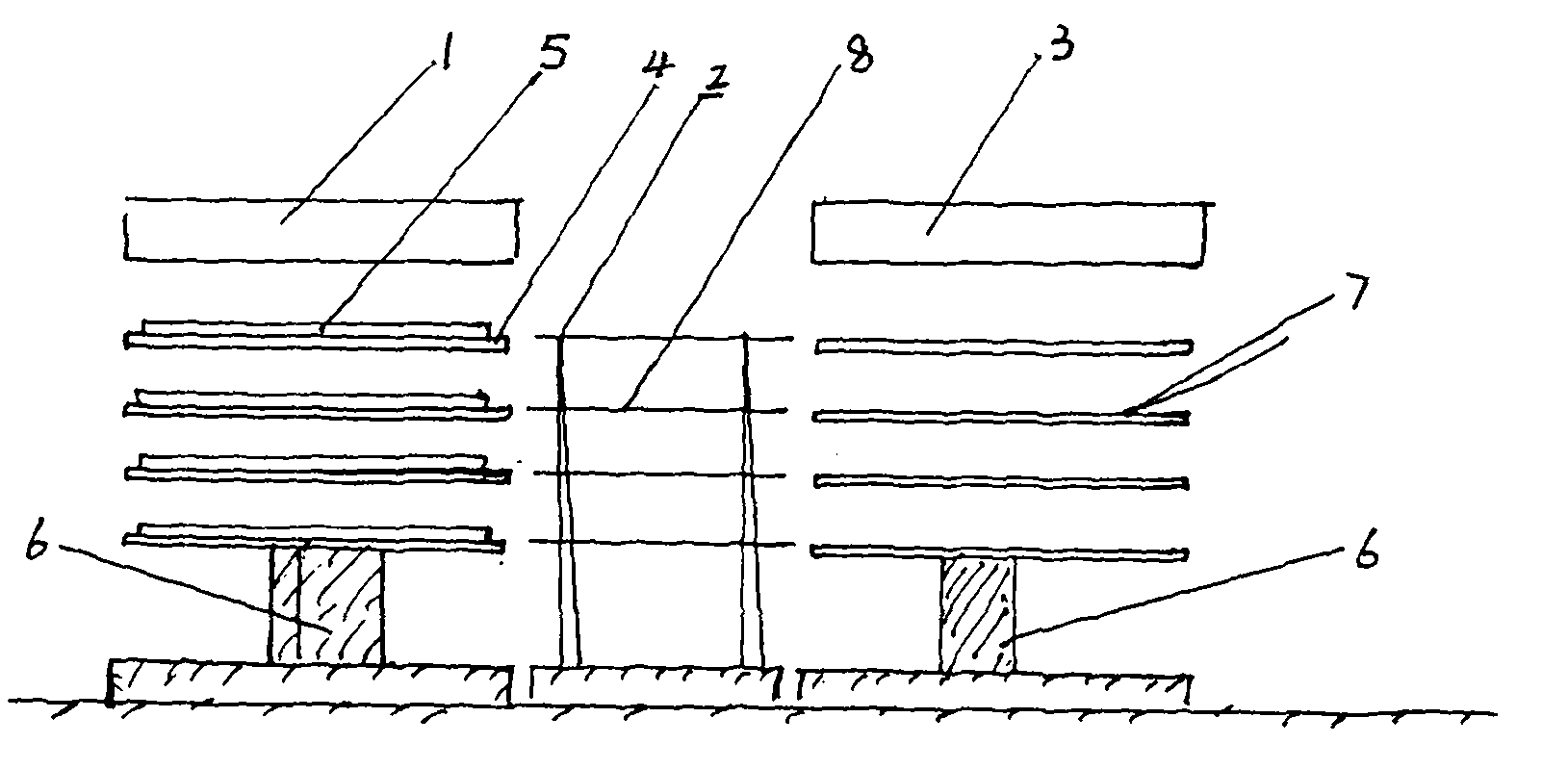

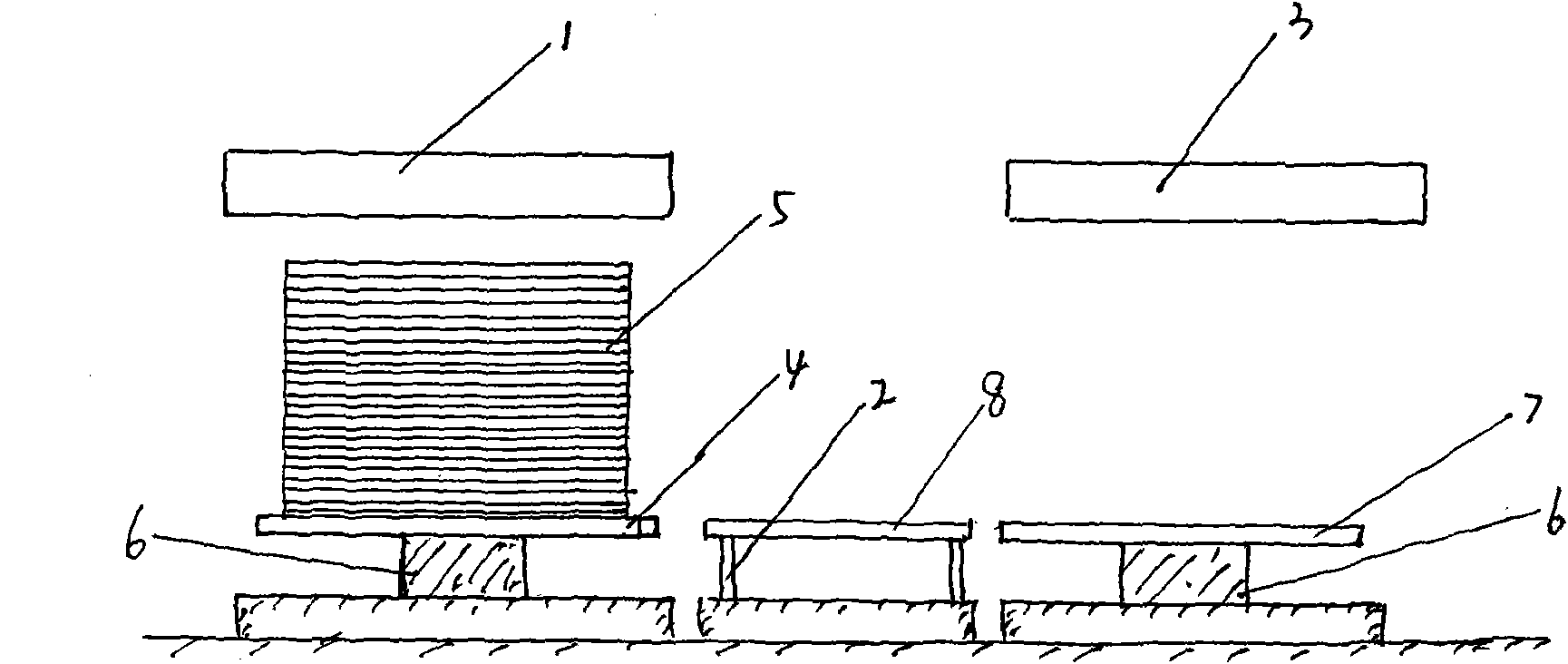

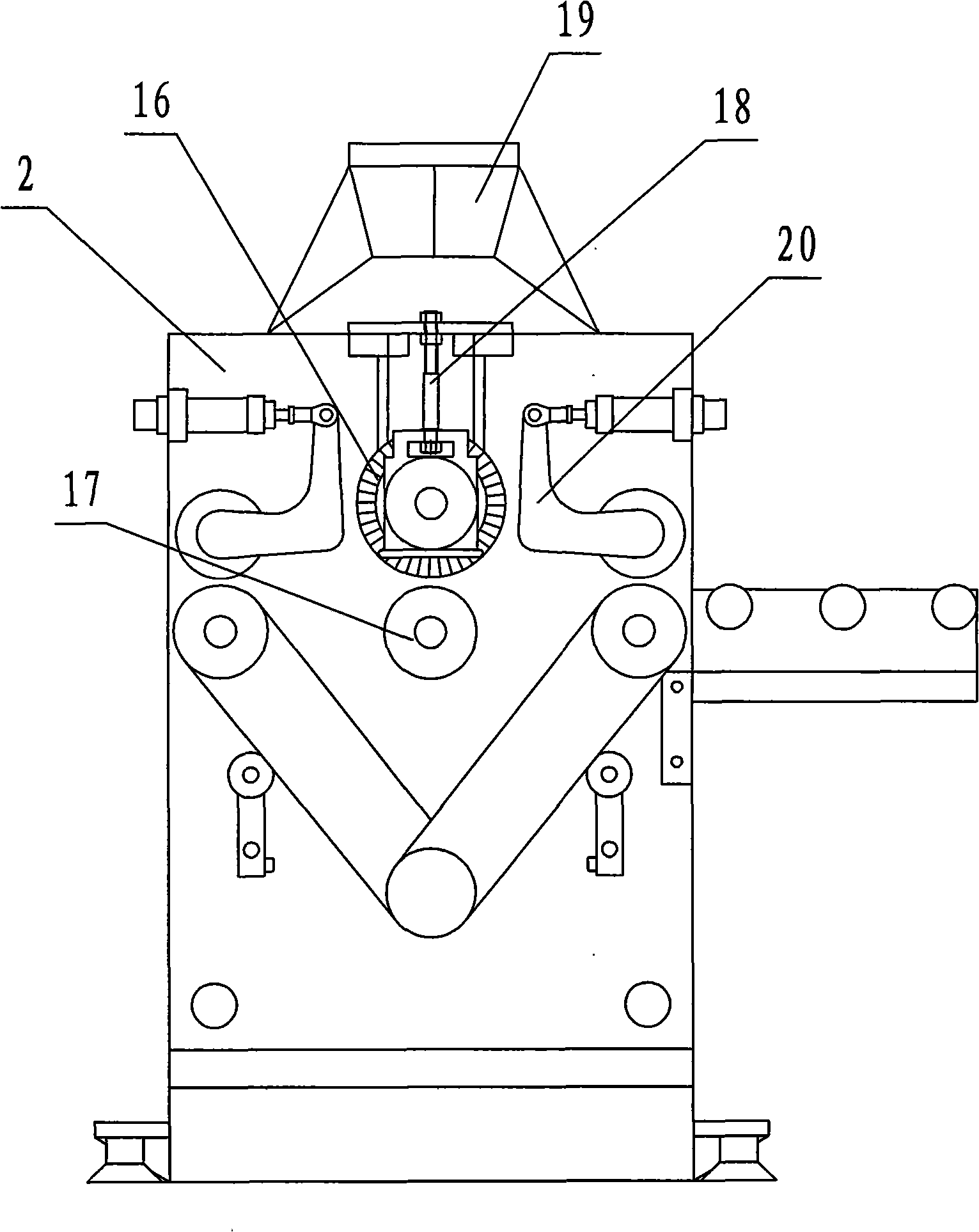

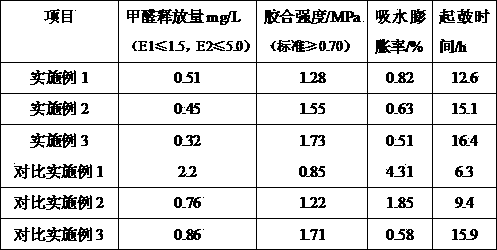

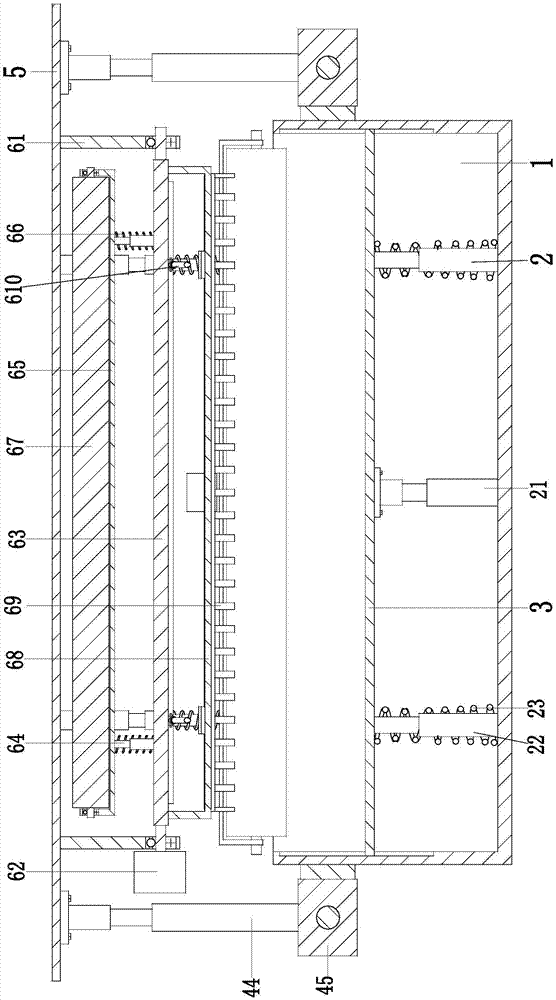

Manufacturing method of thermoplastic resin wood composite board and special equipment

InactiveCN101870127AMeet the use requirementsReasonable workmanshipPlywood pressesVeneer pressesBuilding renovationEngineering

The invention discloses a manufacturing method of thermoplastic resin wood composite board and special equipment. The bonding strength of the thermoplastic resin wood manufactured by the invention is more than 0.7 MPa, has the characteristics of low formaldehyde releasing amount and favourable waterproofness and humidity resistance, has peculiar application value and can be widely applied in the fields of building renovation, furniture, vehicles and ship decoration.

Owner:唐善学

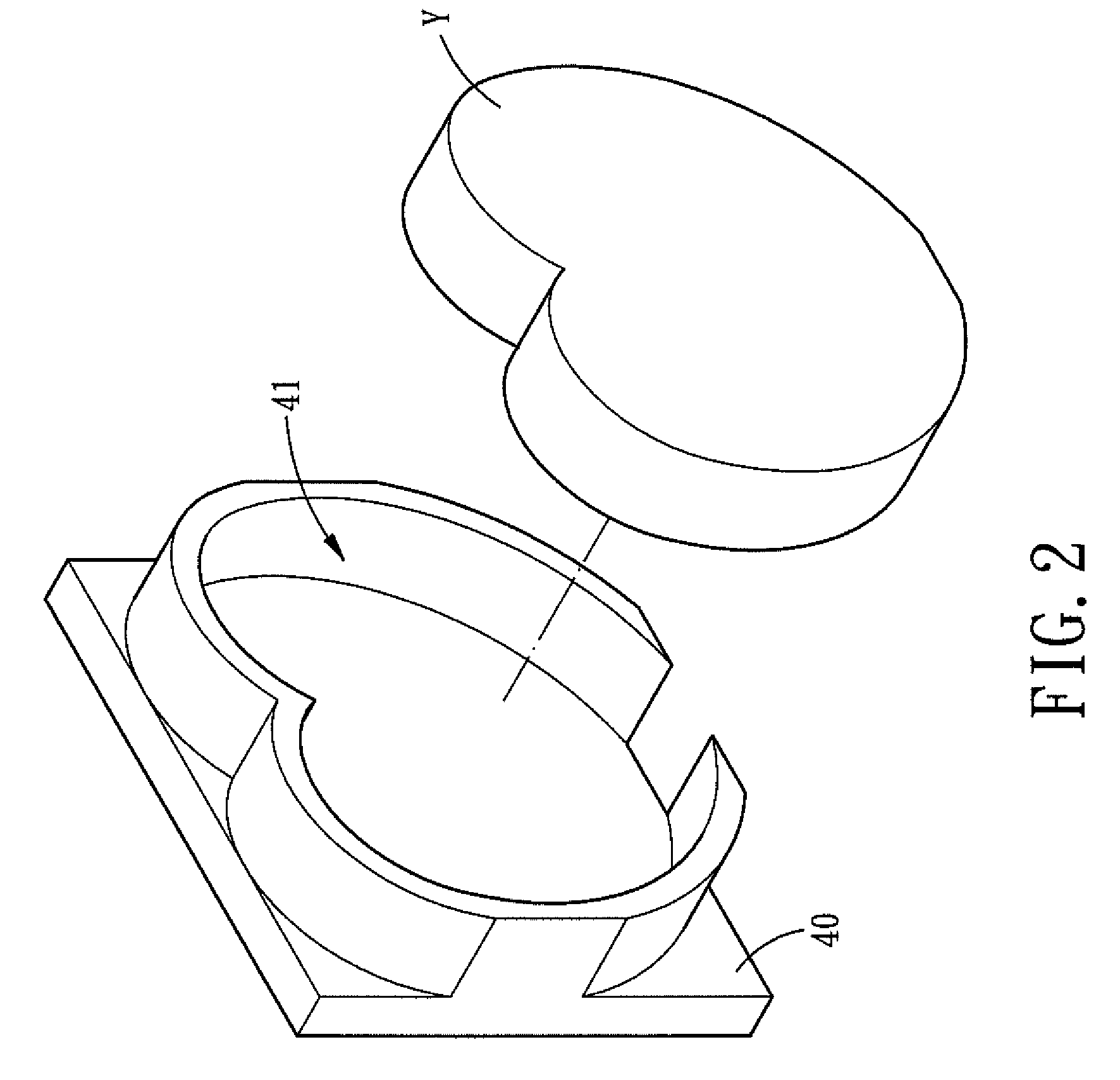

Ice-carving machine

An ice-carving machine comprises a framework, an ice block positioning system, at least one feeding system, and at least one heating mold. The ice block positioning system is fixed on the workbench of the framework for positioning the ice block to be processed. The feeding system drives the heating mold to heat and press the ice block in a mold cavity with a predetermined shape. By the pressure and heat of the heating mold, the ice block is made into the shape identical to the shape of the mold cavity, thus simplifying the process of carving ice blocks, and also saving carving time and cost, being especially suitable for a mass production of ice sculptures.

Owner:YANG WU CHANG

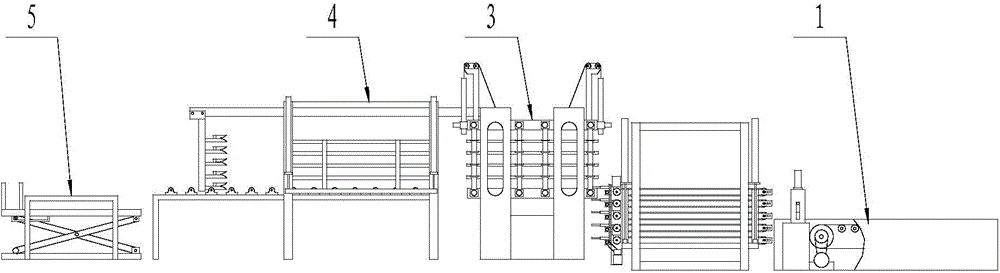

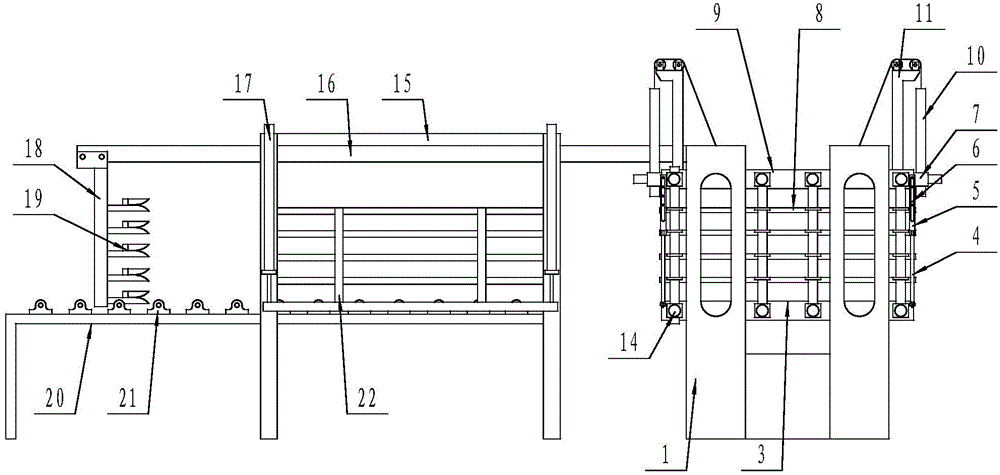

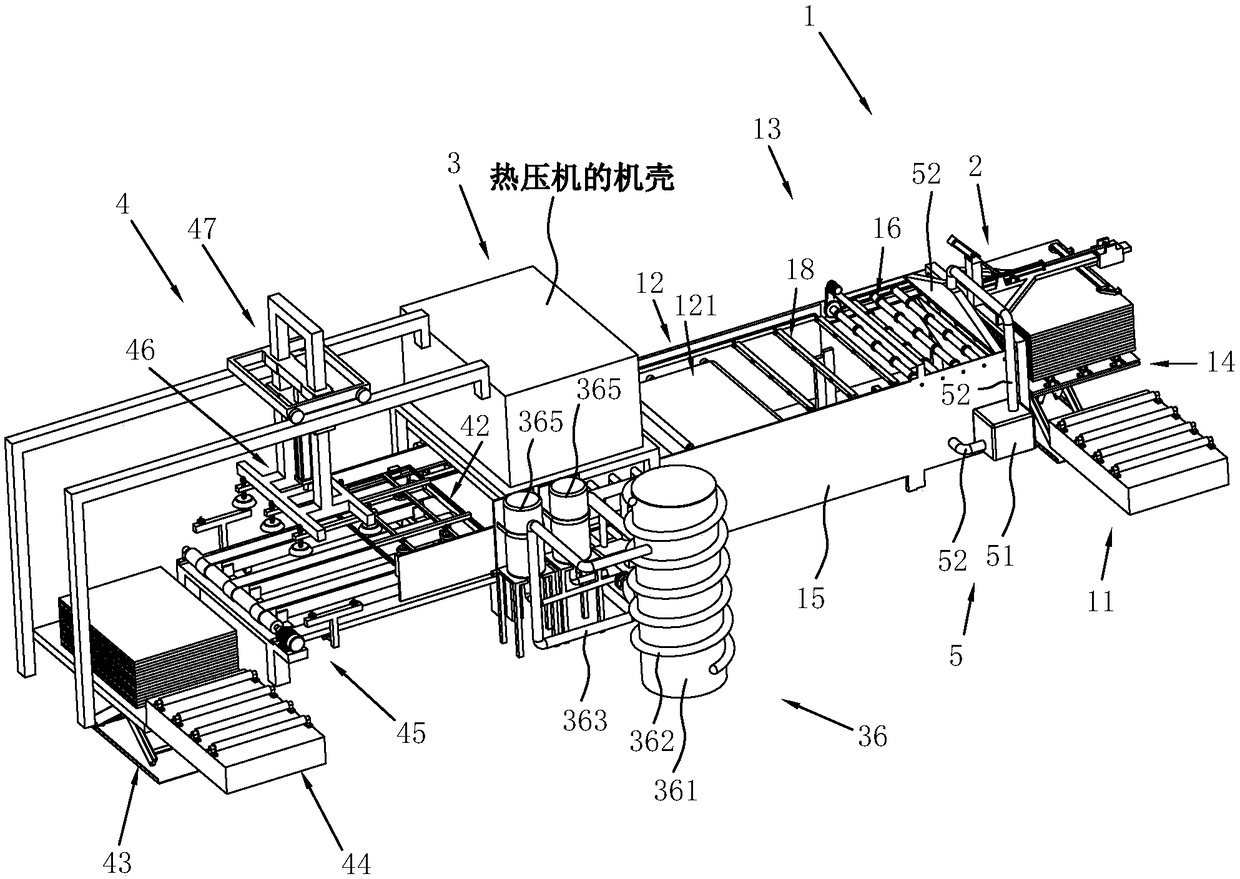

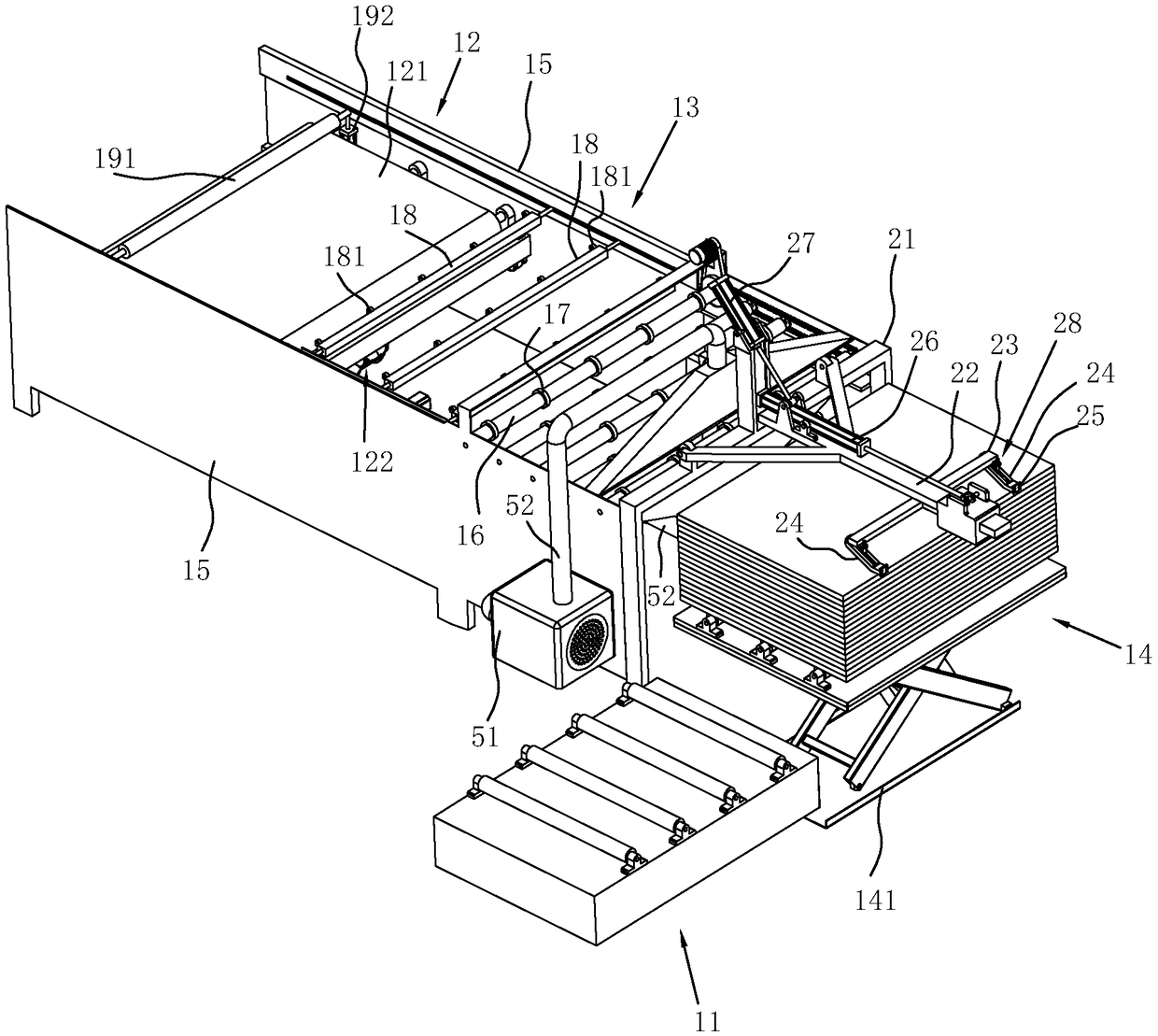

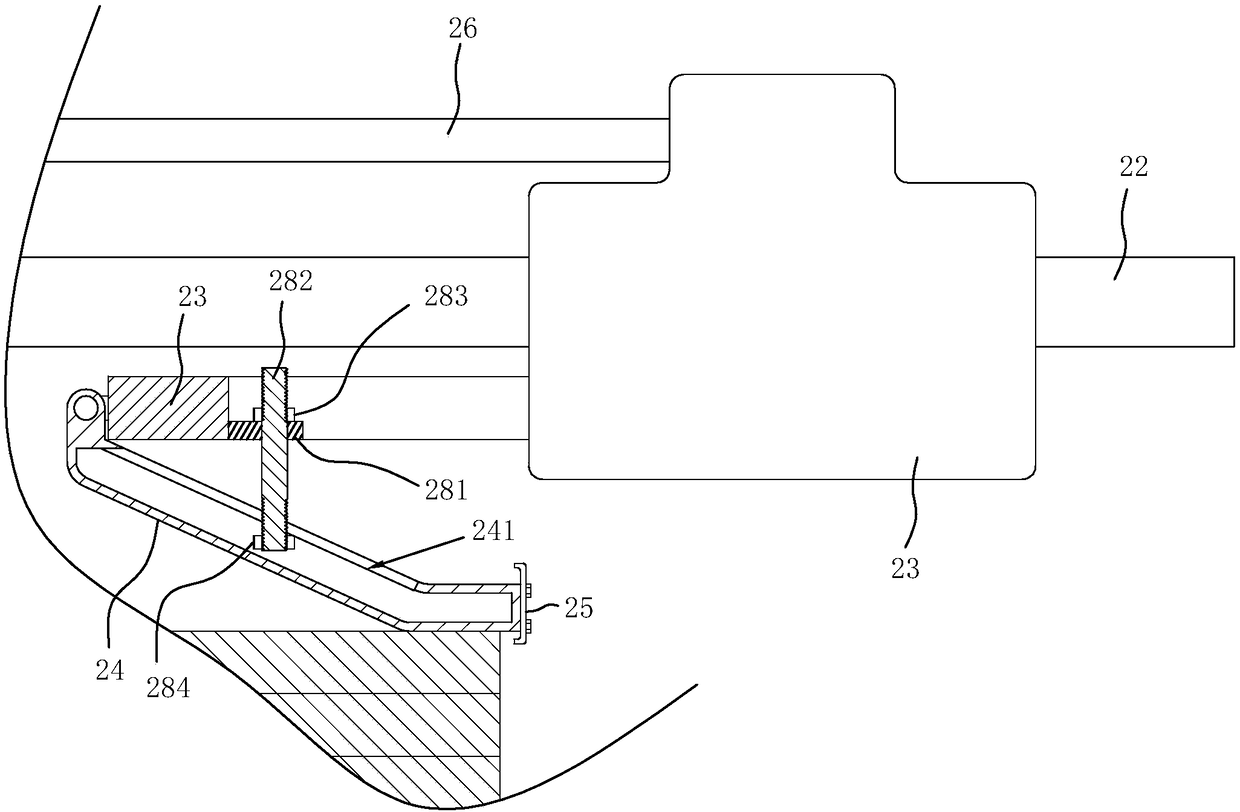

Woodworking plate paving-hot-pressing all-in-one machine

InactiveCN104526796AImprove processing qualityRise steadilyOther plywood/veneer working apparatusPlywood pressesControl systemSlide plate

The invention discloses a woodworking plate paving-hot-pressing all-in-one machine and belongs to the field of plate machining machinery. The woodworking plate paving-hot-pressing all-in-one machine comprises a jointed plate conveying platform, an automatic feeder, a multilayer thermal press, an automatic plate taking device, a plate stacker and a programming control system. The automatic feeder comprises a feeder frame, a lifting table, a lifting oil cylinder I connected with the lifting table and at least two plate storing platform layers arranged on the lifting table. Transmission devices and conveying sliding plates connected with the transmission devices are arranged on the plate storing platforms. The machine is used for woodworking plate production and machining, automatic conveying, automatic sawing, automatic multilayer thermal press placing in, automatic plate taking and automatic stacking can be achieved, following plate joining operation is not affected, the automatic degree and the production efficiency are high, and plate machining quality is high.

Owner:姜皓月

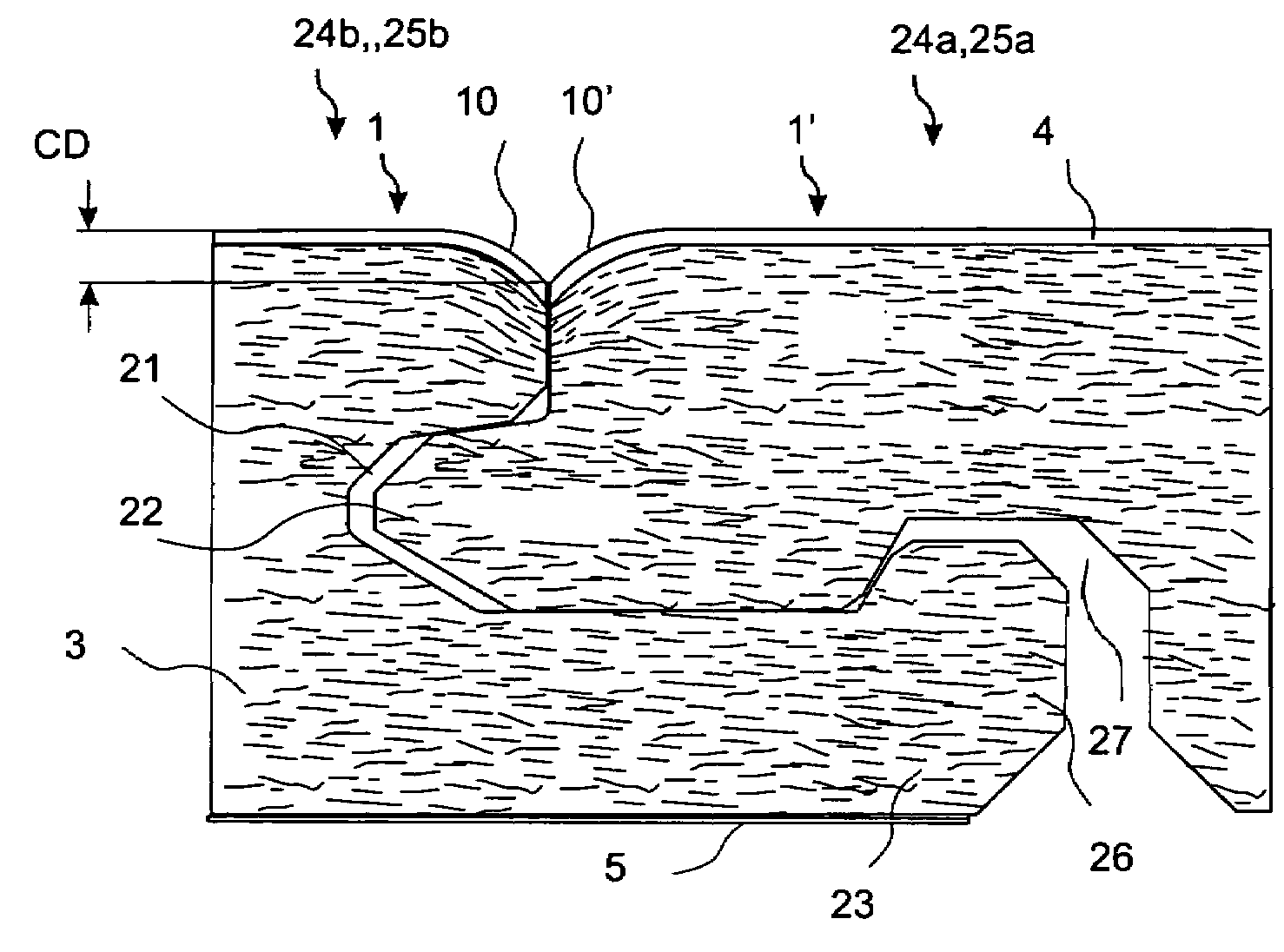

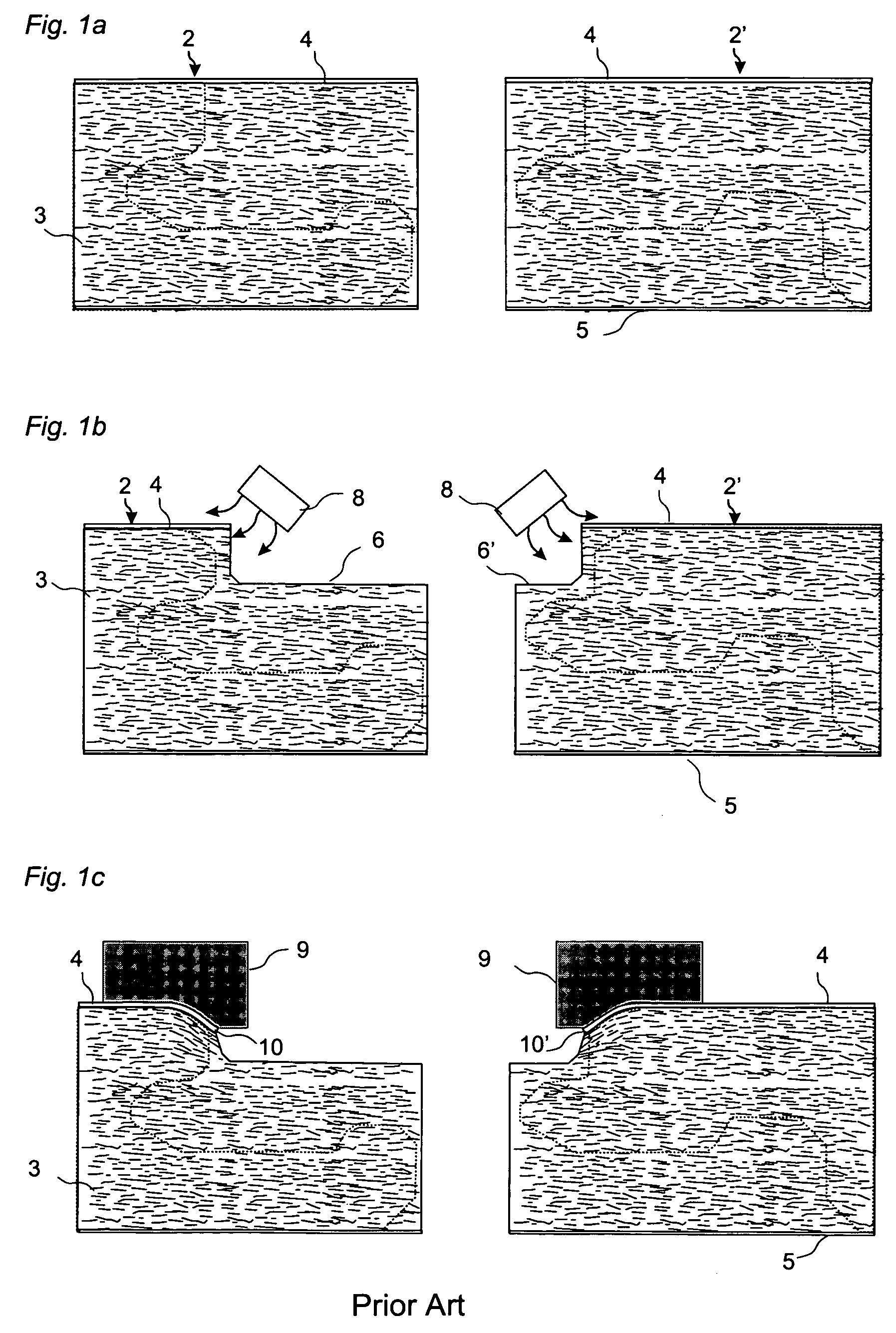

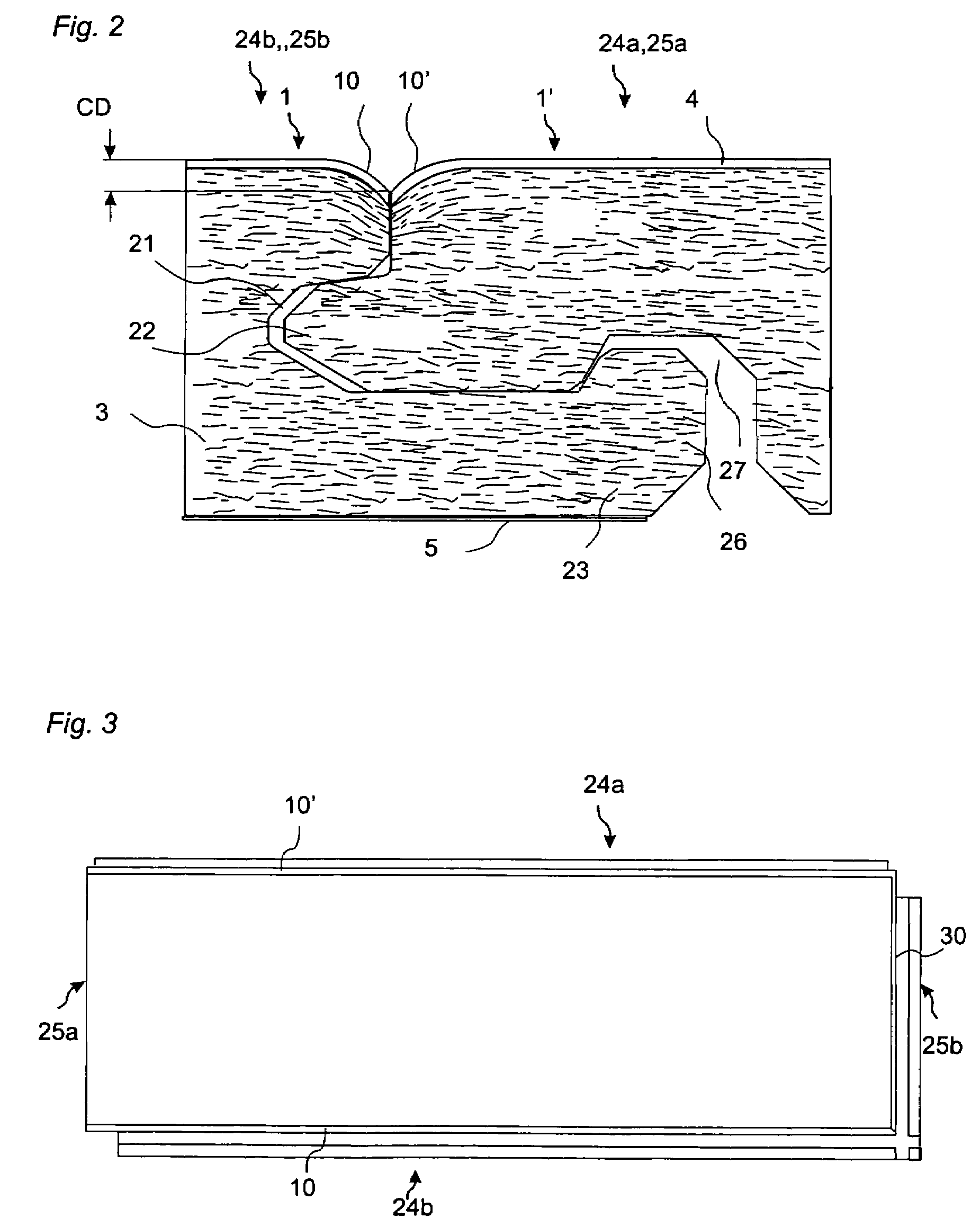

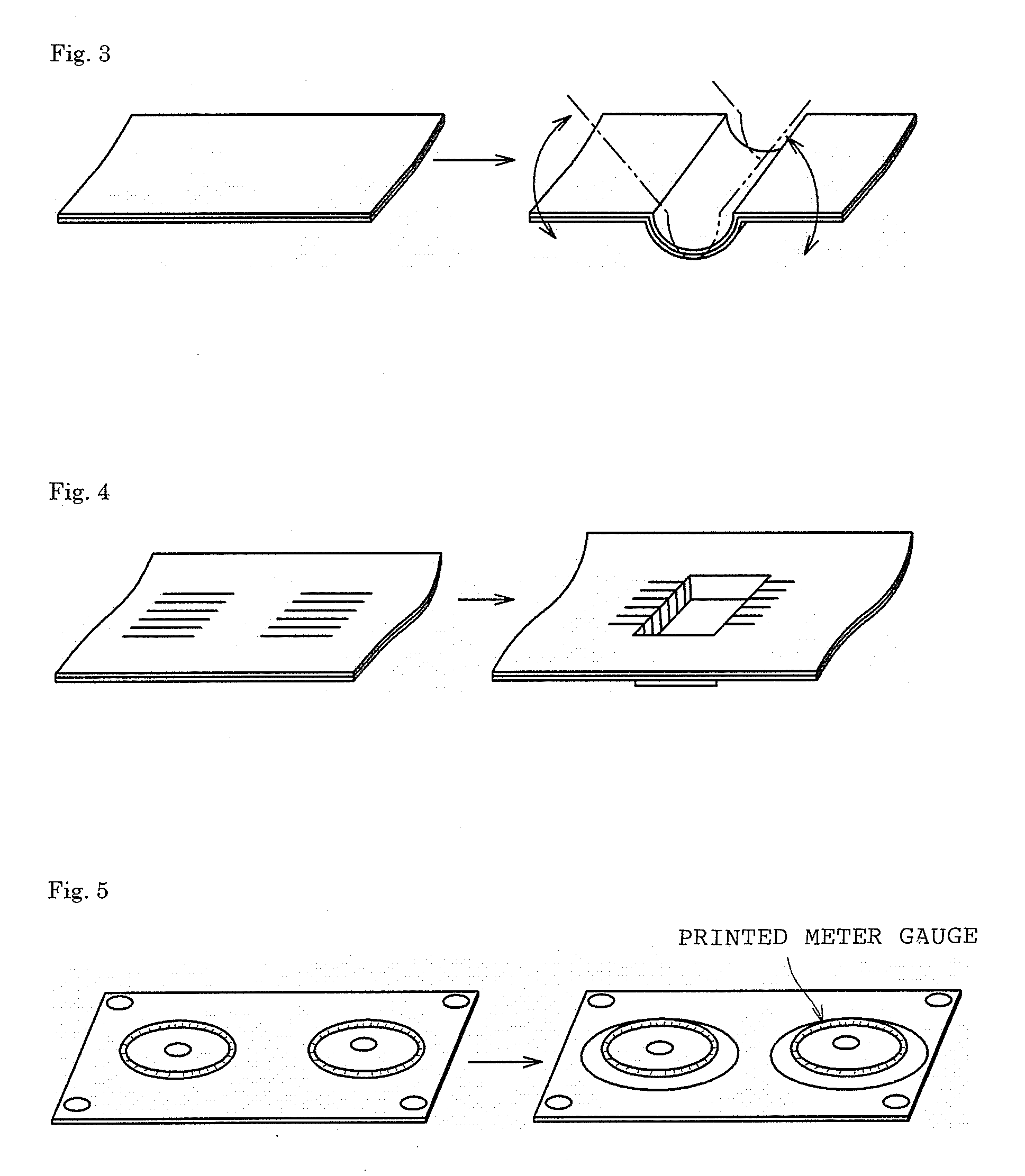

Device and method for compressing an edge of a building panel and a building panel with compressed edges

ActiveUS20080120938A1Increase speedDeeper curved edge portionPlywood pressesCovering/liningsArchitectural engineeringStructural engineering

Owner:VÄLINGE INNOVATION AB

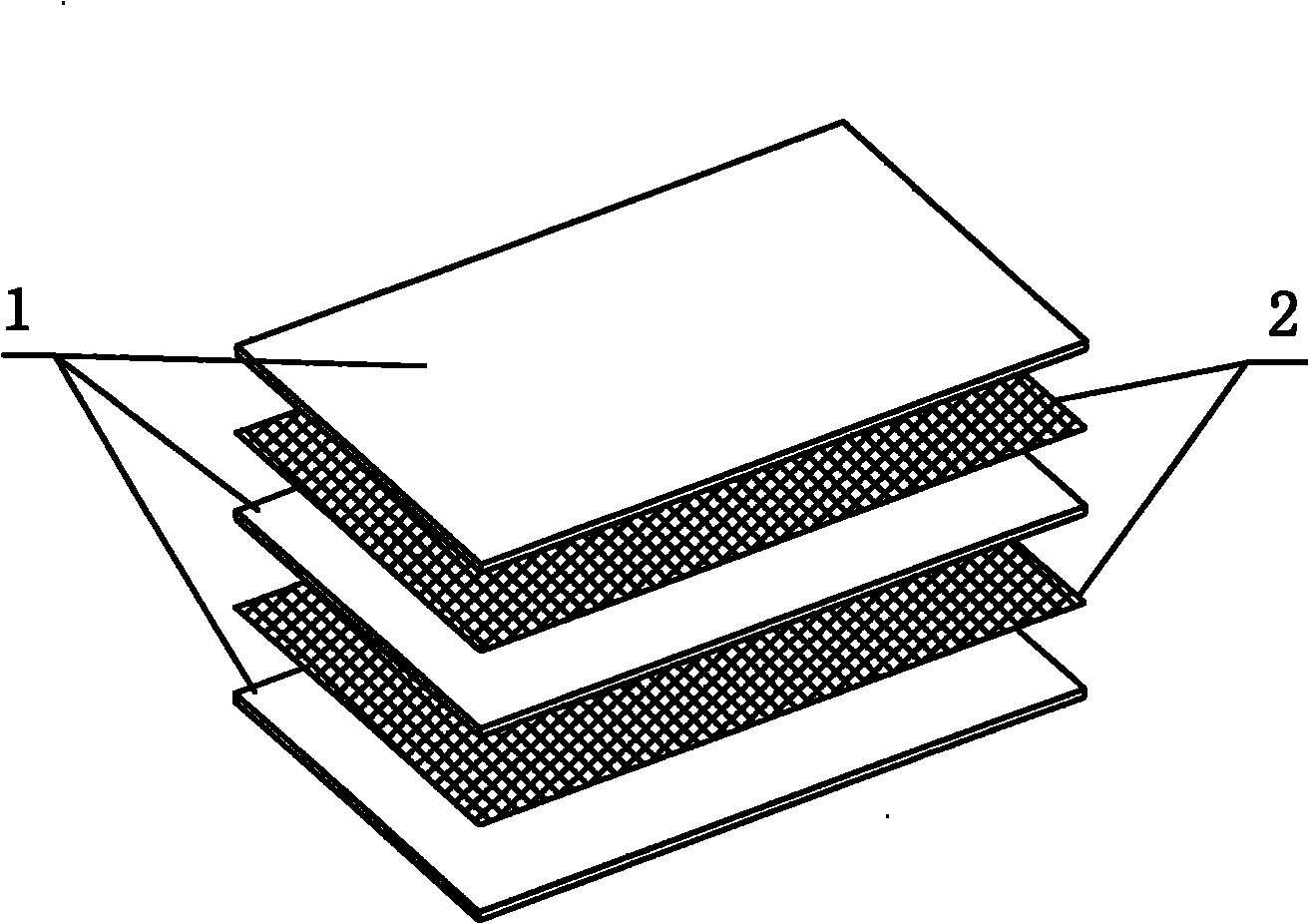

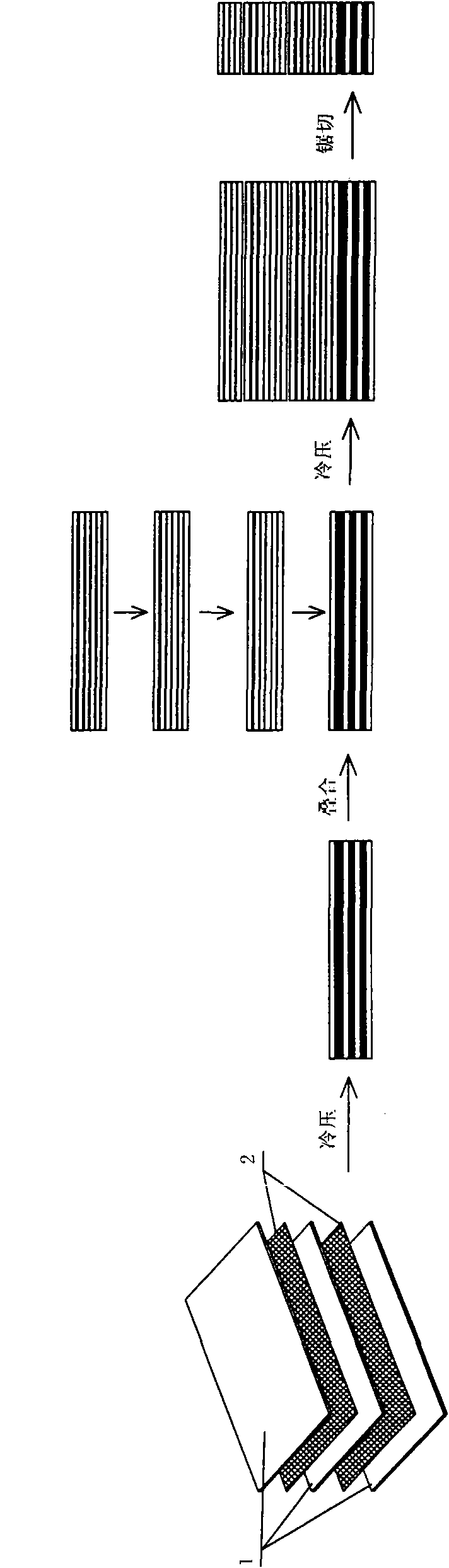

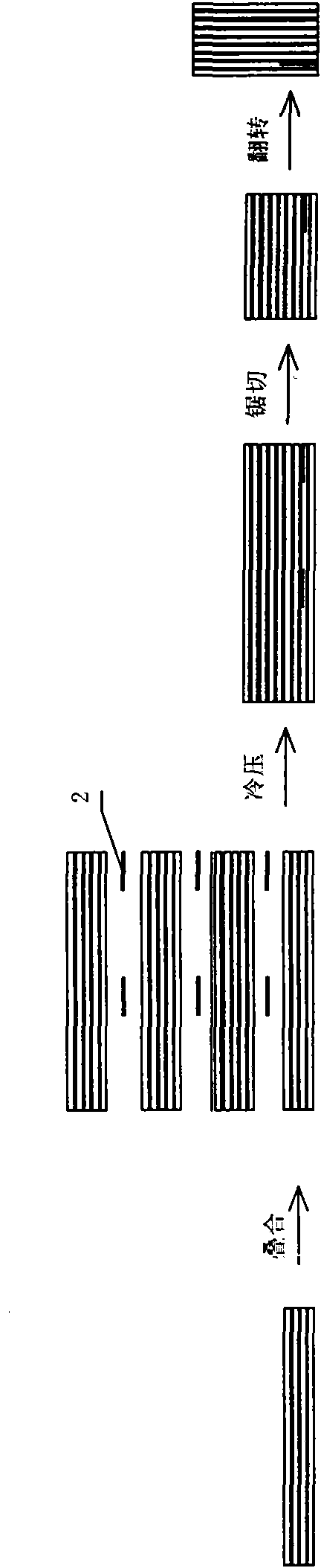

Carbon fiber fabric reinforced poplar laminated veneer lumber structural element and machining method thereof

The invention discloses a carbon fiber fabric reinforced poplar laminated veneer lumber structural element and a machining method thereof. The structural element is characterized in that the structural element is prepared by alternately laminating and bonding poplar rotary slices (1) and carbon fiber fabric (2), and the structural element fully exerts the advantages of carbon fiber fabric and Italian poplar laminated veneer lumber, greatly improves the mechanical property of an Italian poplar material and the added value and the technological content of poplar production, and greatly broadens the application of field of the Italian poplar through the control of the process flow. Moreover, the structural element can avoid the problems of common anchor failure, peeling breakage and the like when the carbon fiber fabric is adhered outside and exerts the strength of the carbon fiber fabric more fully, so that the structural element can be manufactured into a large-scale lumber structural element and solves the problem that the large-scale lumber structural element cannot be produced currently.

Owner:江苏省苏科建设技术发展有限公司

Continuous and stable hot-pressing equipment for furniture boards

InactiveCN106493806AEnsure safetyQuality assurancePlywood pressesVeneer pressesEngineeringWood panel

The invention discloses continuous and stable hot-pressing equipment for furniture boards. The equipment comprises a bottom plate, limiting plates, a supporting plate, a work table, connectors, grooves, buffering springs, sliding grooves and sliding blocks; supporting columns are installed at the upper end of the bottom plate, a crank shaft is arranged between the two supporting columns, a rod journal is arranged in the middle of the crank shaft and is provided with a shaft sleeve in a sleeved mode, the lower end of the shaft sleeve is connected to a lifting plate through a connecting rod, and a hot-pressing plate is arranged on the lower surface of the lifting plate; and guide holes are formed in the left end and the right end of the lifting plate, and guide rods penetrate into the guide holes. According to the equipment, the boards placed on the work table can be hot-pressed continuously, and the hot-pressing is higher relative to traditional hot-pressing; the supporting plate under the work table has the buffering function, the safety of the boards can be guaranteed in the process of continuous hot-pressing, damage caused by excessive hot-pressing force can be avoided, and the hot-pressing quality is guaranteed; and the overall base has the buffering performance, and therefore the hot-pressing equipment can be stable and safe and is suitable for being popularized and used.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

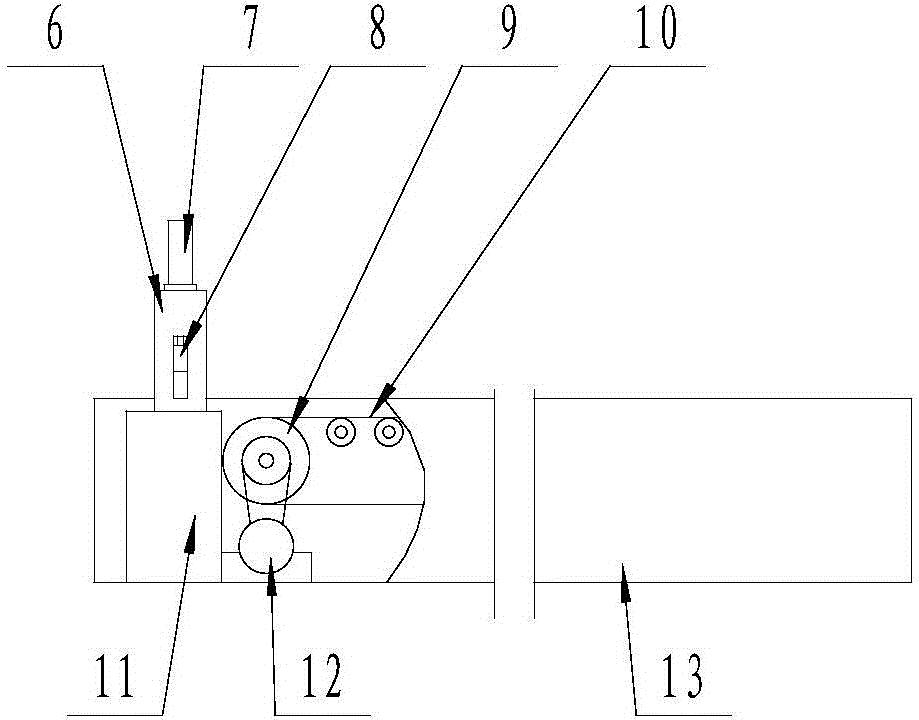

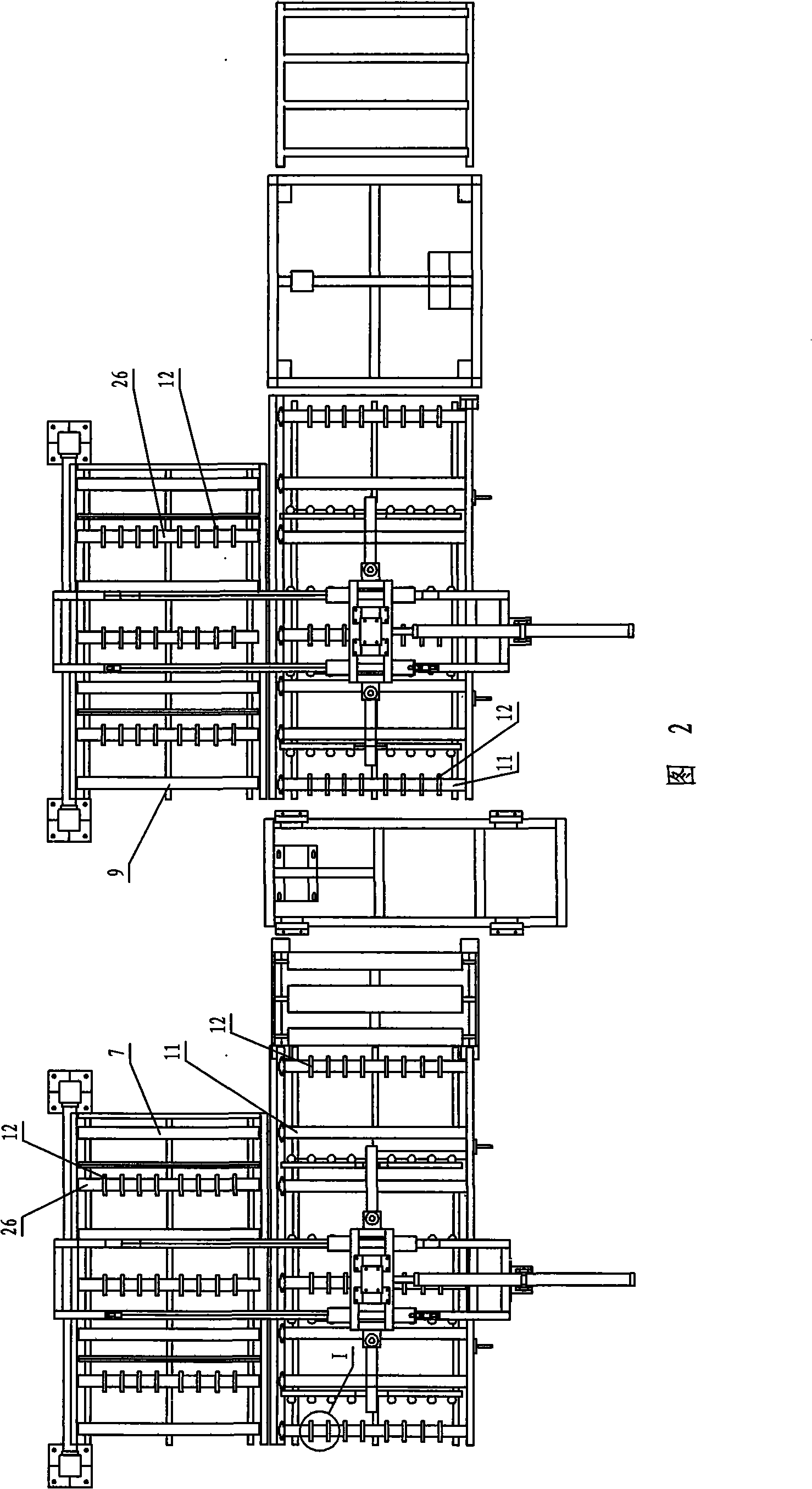

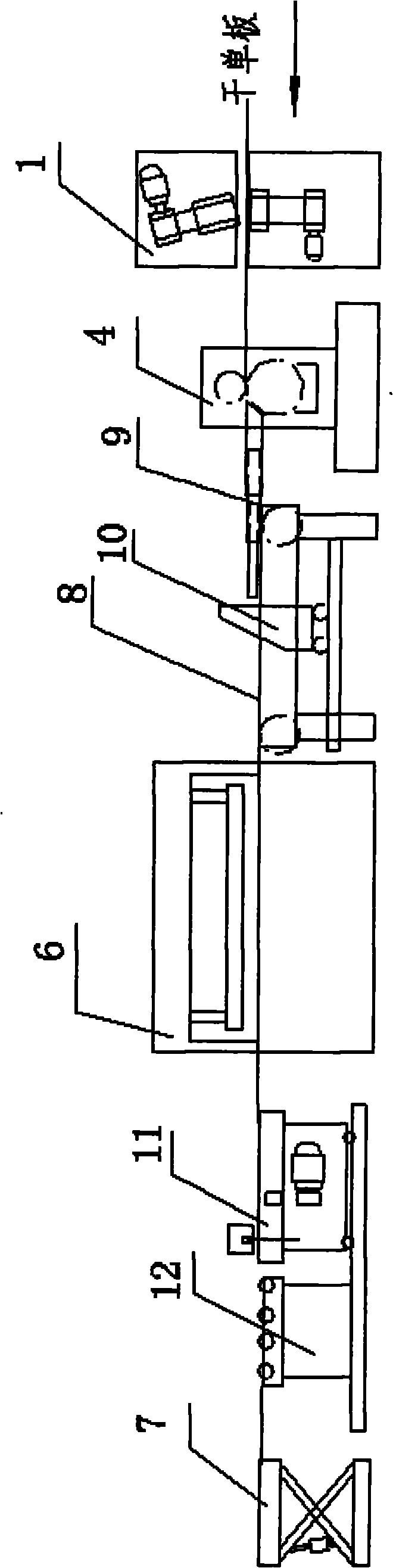

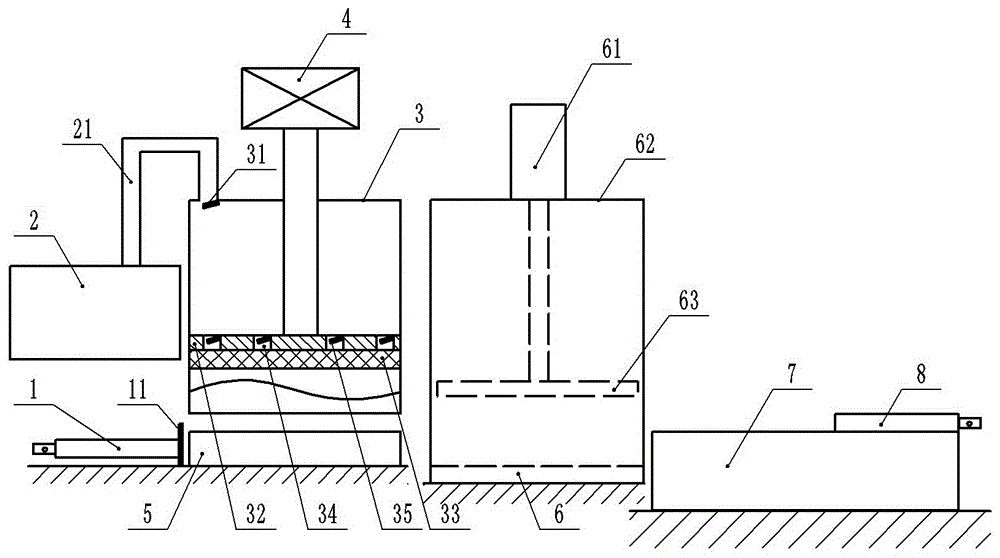

Composite board automatic production line

InactiveCN101306544AReduce labor intensityImprove ergonomicsOther plywood/veneer working apparatusPlywood pressesProduction lineSurface cleaning

The invention discloses an automatic production line of composite boards, which is used for attaching a base plate of a composite board to a faceplate of the composite board and comprises a roller conveyor device, a base plate surface cleaning device, an automatic glue spraying device, a conveying aligning and attaching device, an attaching pressing device and a board conveying device which are arranged in sequence. A base plate piling device is arranged at the side of the roller conveyor device; a base plate moving and carrying device arranged above the roller conveyor device and the base plate piling device; a face plate piling device is arranged at the side of the conveying aligning and attaching device; and a face plate moving and carrying device is arranged above the conveying aligning and attaching device and the face plate piling device. The production line can realize the automatic combination of a plurality of base plates and a plurality of face plates, thus achieving the purposes of improving production benefit, reducing labor intensity, and ensuring the stability and the reliability of the product.

Owner:JINGJIANG WEIYI INTPROP SERVICE

Automatic board drilling machine

The automatic drilling machine for wall anchoring decoration board includes one frame, one fixing and supporting top, one elevating roll supporting top and one eccentric reaming mechanism. The fixing and supporting top consists of main support boards in X direction and auxiliary support boards in Y direction to form one hollowed top; the elevating roll supporting top has one set of rolls supported with one skeleton and elevated with one elevating mechanism; and the eccentric reaming mechanism consists of one bit, one main shaft, one eccentric block, one shifting block and one reaming stroke acting unit. The present invention has high quality of drilled hole.

Owner:苏州工业园区科特建筑装饰有限公司

Formaldehyde-free decorative board and preparation method thereof

The invention discloses a formaldehyde-free decorative board and a preparation method thereof. The decorative board is formed by overlaying multiple layers of wood veneers with adhesive, wherein the adhesive is plastic film. The preparation method is as follows: the plastic film is evenly laid between every two adjacent wood veneers, and the use level of the plastic membranes is over 100g / m ; a veneer press is used for pressing, with the pressure over 100 tons, the veneer press performs heat pressing firstly and cold pressing later, the temperature of heat pressing is over 100 DEG C and the temperature of the cold pressing is 20 DEG C to 100 DEG C The decorative board contains no formaldehyde, causes no poison or pollution on human body and surrounding environment and truly realizes the environment protection. In addition, the invention adopts the cheap plastic film as the adhesive, the production cost is low, the technology is simple, and qualitative indexes of the product completely satisfy the national standards.

Owner:深圳伟伦嘉禾环保装饰材料有限公司

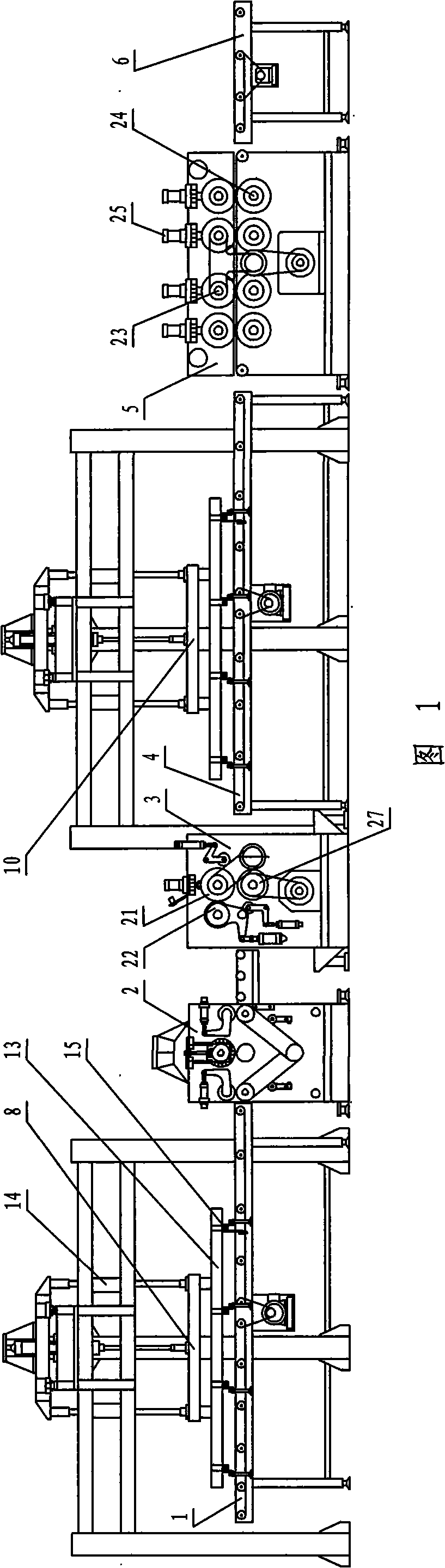

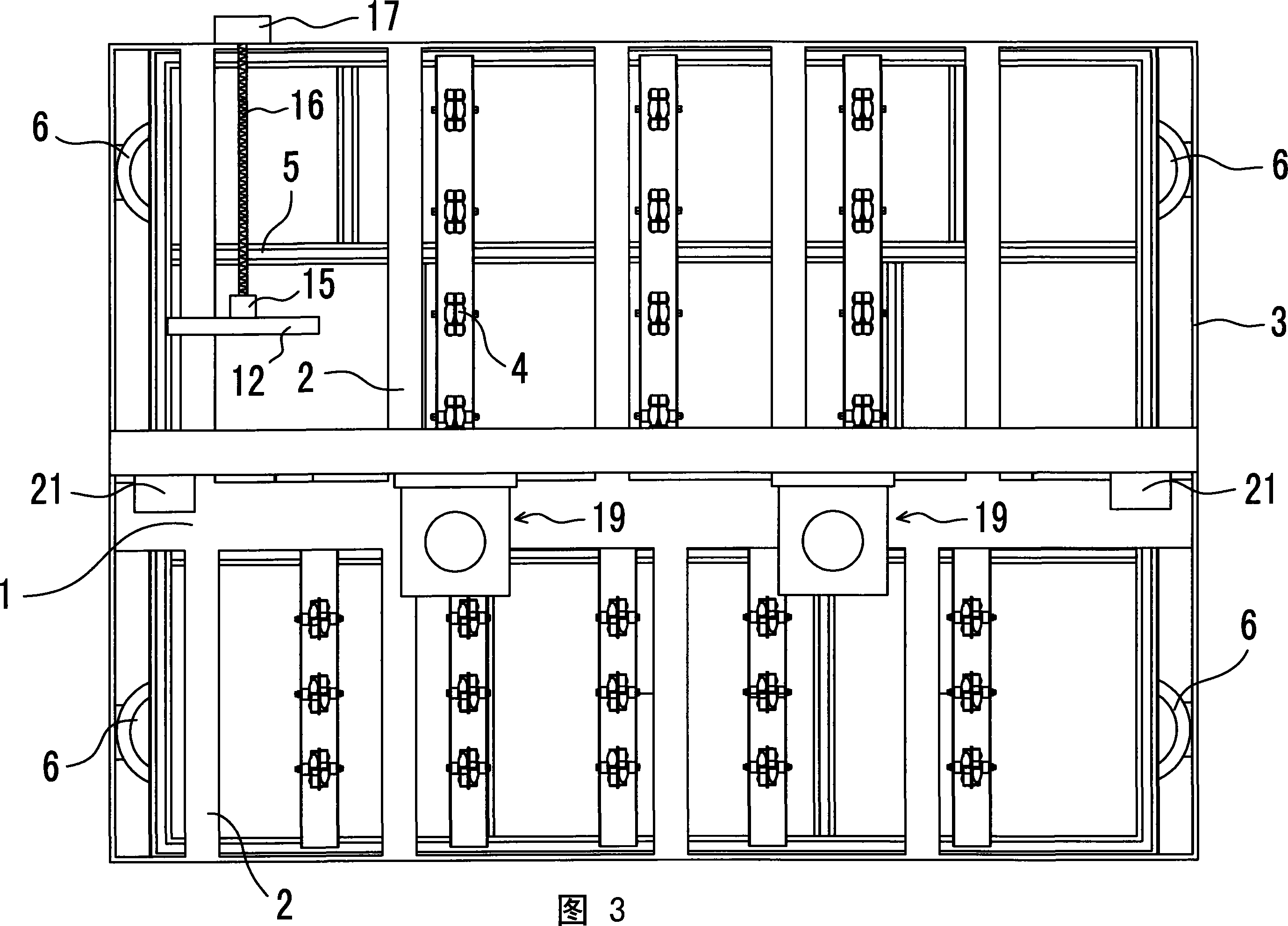

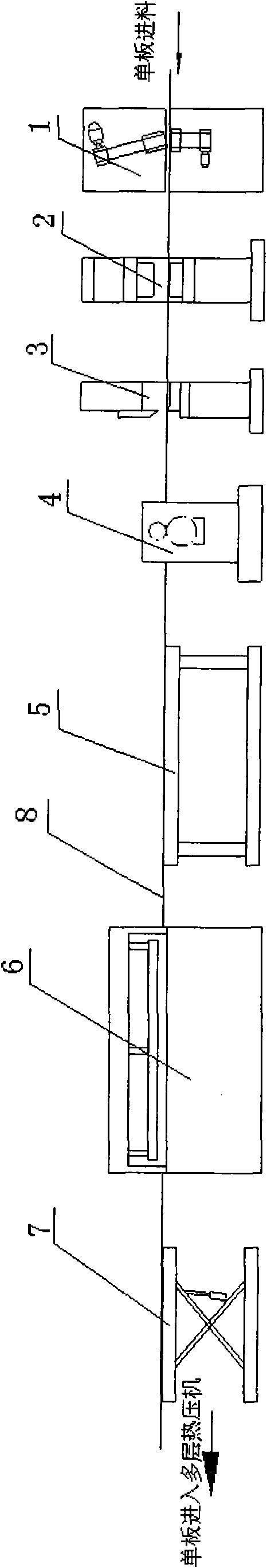

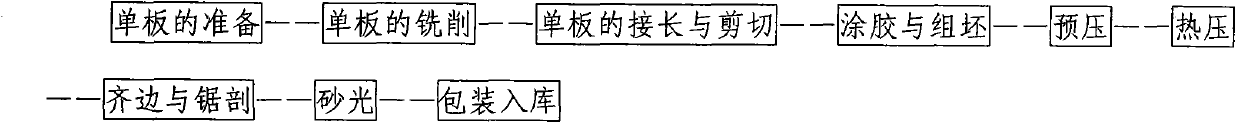

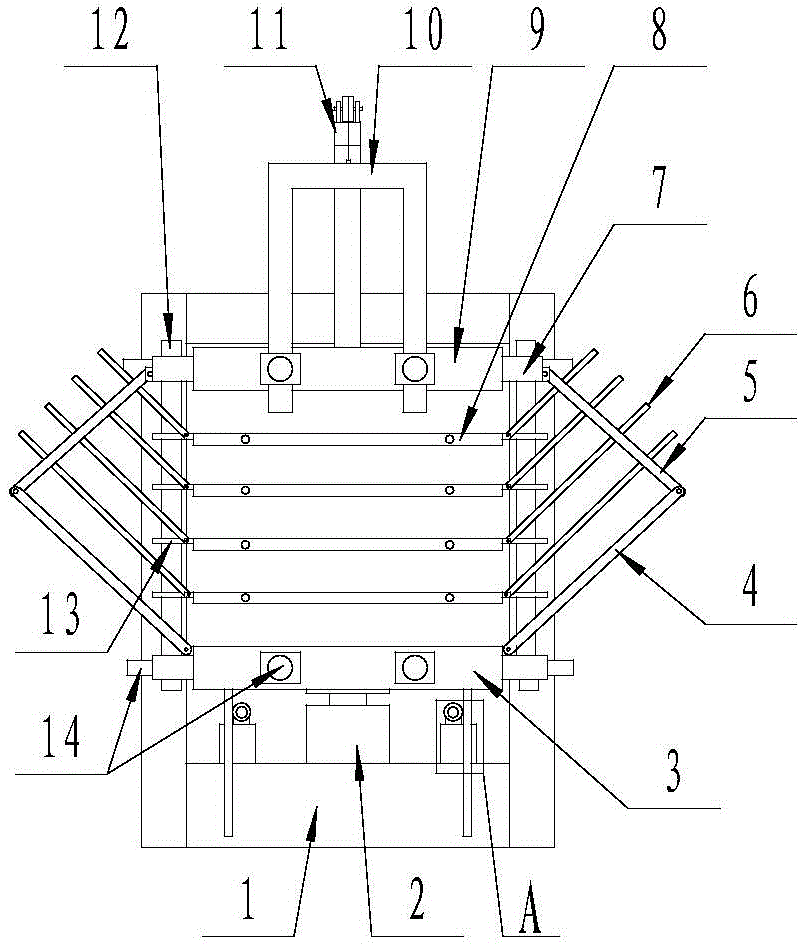

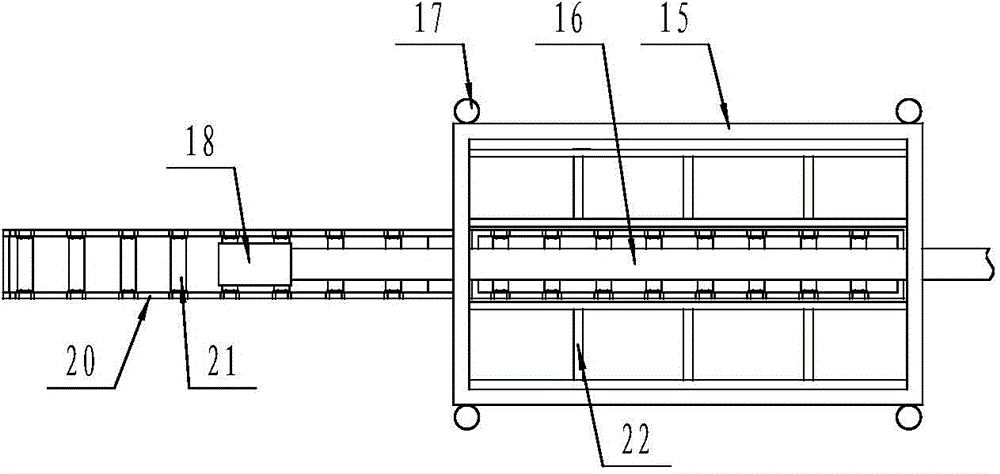

Complete production equipment for laminated veneer lumbers

InactiveCN101947801AReduce investmentPrecise positioningPlywood pressesVeneer pressesNumerical controlProduction line

The invention discloses complete production equipment for laminated veneer lumbers, which comprise an abrasive belt slant milling machine, a glue spreading machine, a veneer performing press, a material storing table and a multilayer thermal press. The complete production equipment is characterized by arranging a telescopic feeder and a numerical control locating assembly machine in sequence between the glue spreading machine and the veneer performing press, and a movable cutting saw and a conveying roller are arranged in sequence between the veneer performing press and the material storing table, wherein the abrasive belt slant milling machine, the glue spreading machine, the telescopic feeder, the numerical control locating assembly machine, the veneer performing press, the movable cutting saw, the conveying roller, the material storing table and the multilayer thermal press are connected in sequence to form a production line through an operating platform. Compared with the traditional complete production equipment for laminated veneer lumbers, the invention saves equipment investment, the location of the lumbers is very accurate due to the adoption of the numerical control locating assembly machine, production efficiency and product quality are obviously improved, assembled veneers can be infinitely prolonged, the production field of the laminated veneer lumbers is widened, and meanwhile, the degree of automation is also obviously increased.

Owner:NANJING FORESTRY UNIV

Panel compositing and pressing device

InactiveCN105856346AImprove efficiencyQuality improvementPlywood pressesLaminationHydraulic cylinderMechanical devices

The invention discloses a panel compositing and pressing device, and belongs to the field of building machining mechanical devices. The panel compositing and pressing device comprises a fixed support, panel bearing rollers, panel pressing rollers, pressing hydraulic cylinders and a panel guide support. The two sides of the fixed support are horizontally and rotationally connected with a panel input roller and a panel output roller respectively. The middle of the fixed support is horizontally, evenly and rotationally connected with the panel bearing rollers. The panel guide support is horizontally, evenly and rotationally connected with a plurality of panel guide rollers. Connecting rods are arranged between the two ends of the lower side of the panel guide support and the fixed support respectively. The two pressing hydraulic cylinders are vertically downwards arranged on the upper side of the fixed support. The output ends of the pressing hydraulic cylinders are horizontally provided with a lifting plate. The lower side of a pressing plate is horizontally, evenly and rotationally connected with the panel pressing rollers. Panel pressing springs are arranged on lifting guide rods between the lifting plate and the pressing plate. The panel compositing and pressing device is reasonable in structural design, firm pressing of composited panels can be rapidly and efficiently achieved, panel compositing efficiency and quality are improved, and requirements of machining and using are met.

Owner:晋正正

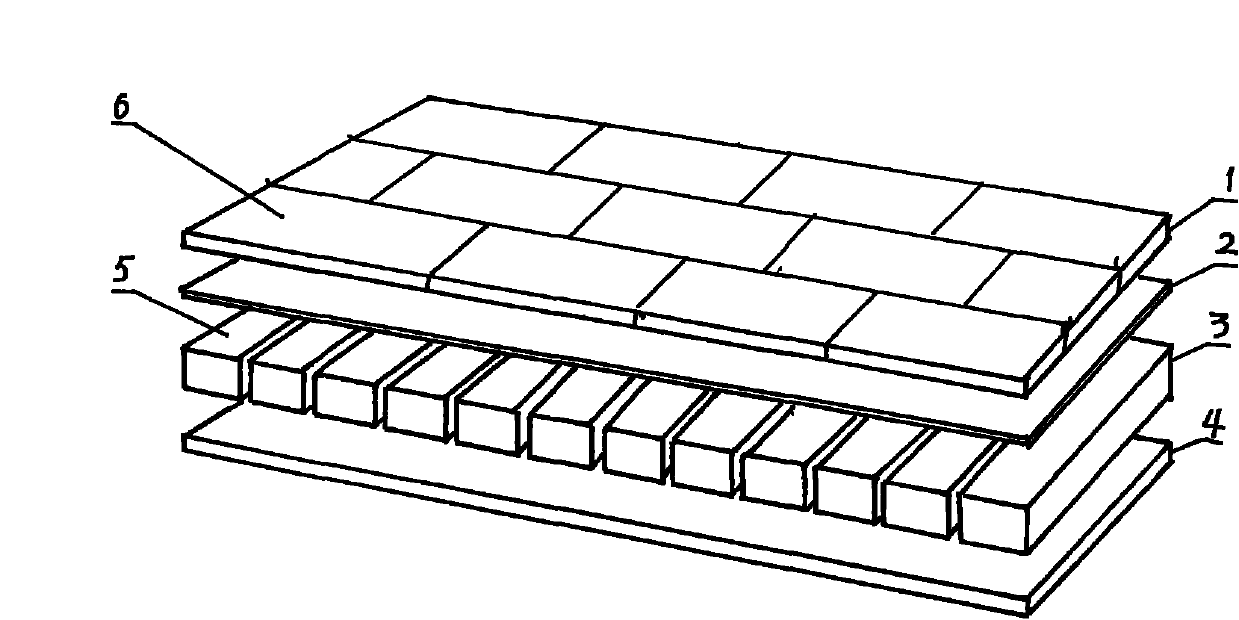

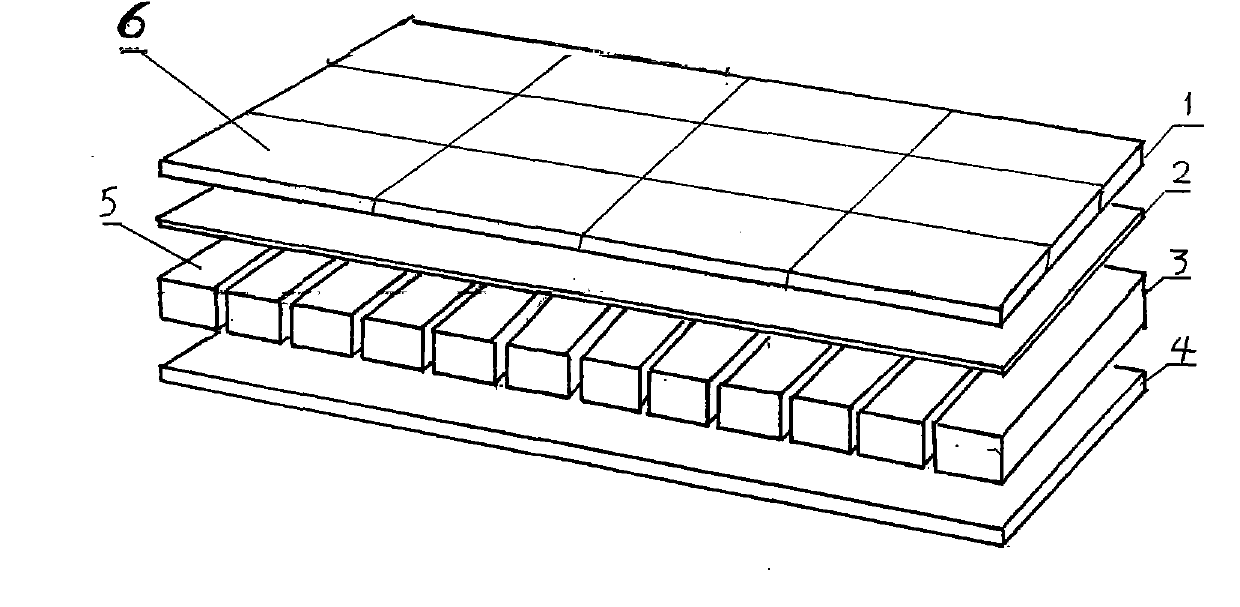

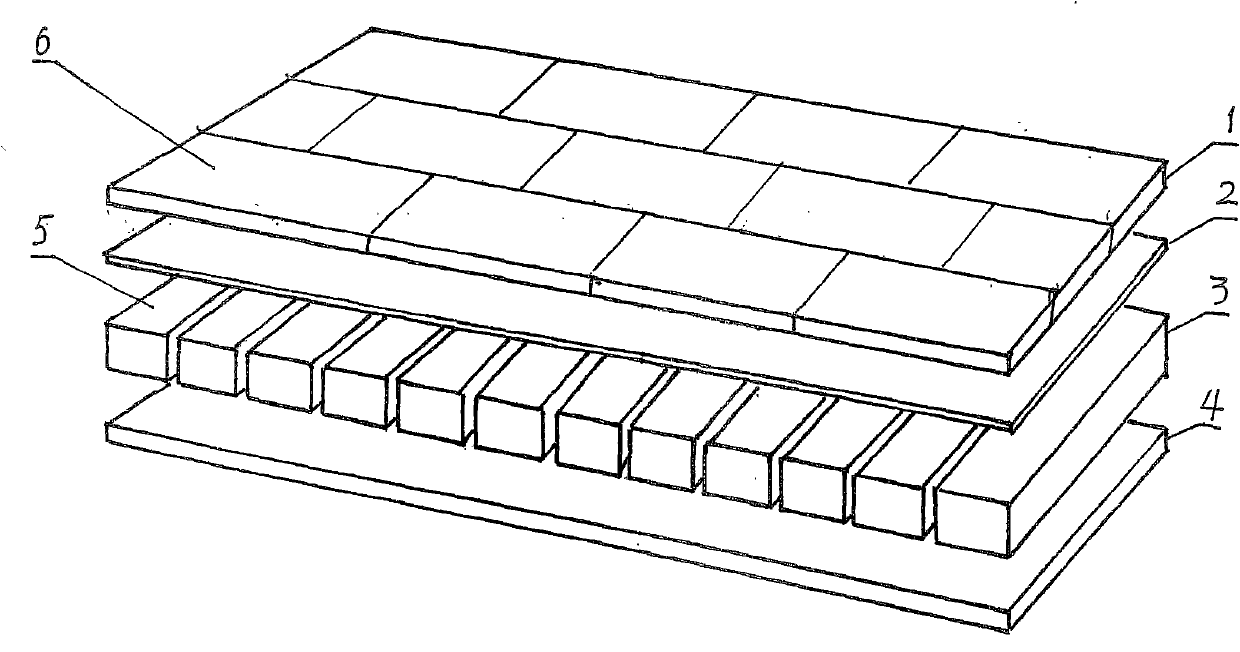

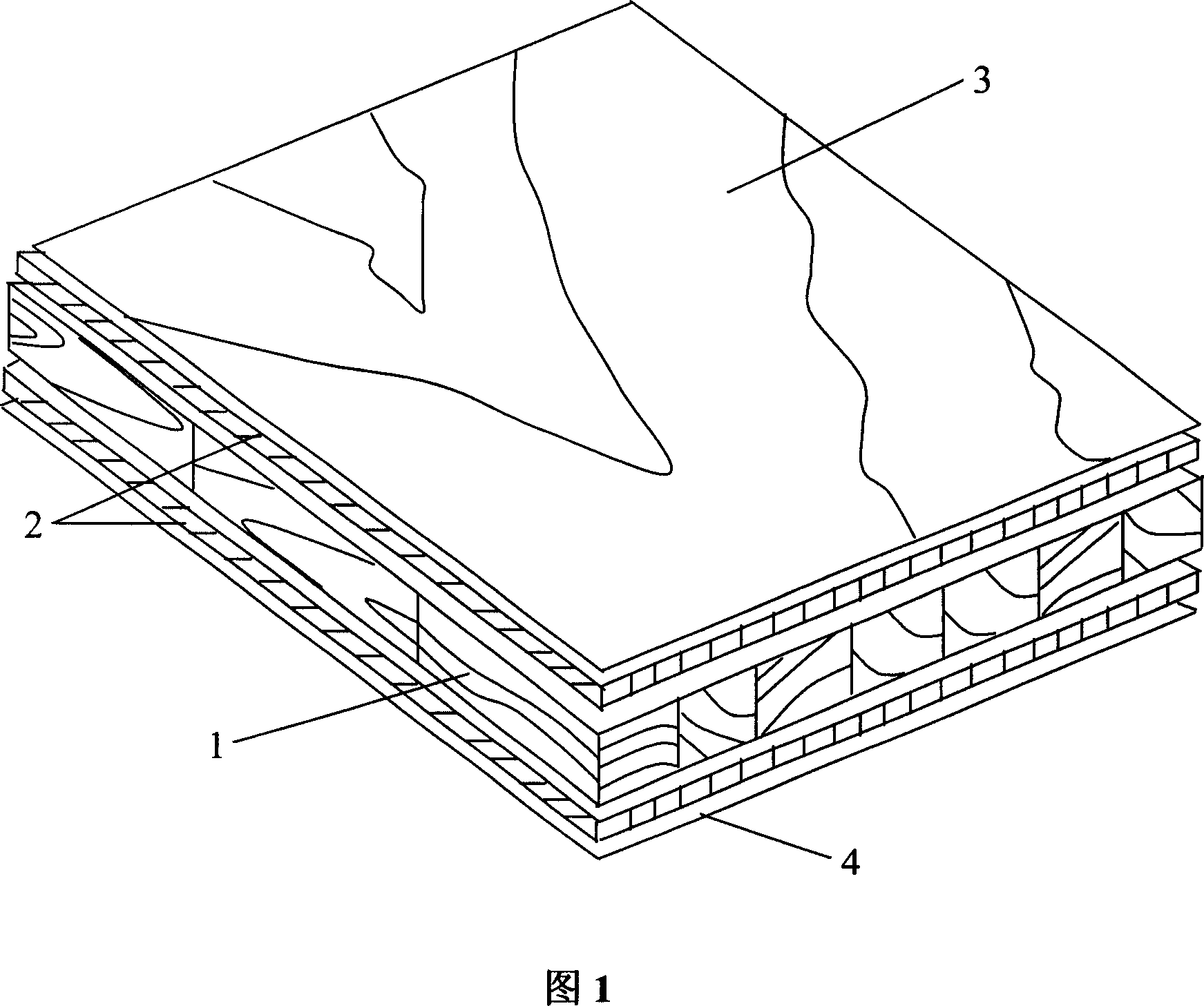

Production method of stabilized solid wood composite floor with buffer layer

InactiveCN102166775AImprove stabilityEasy to crackPlywood pressesVeneer pressesSolid woodSurface layer

The invention discloses a production method of a stabilized solid wood composite floor with a buffer layer, comprising four steps of preparing materials, gluing, preparing blanks and hot pressing. The composite floor comprises a surface layer (1), a core layer (3) and a base layer (4); the buffer layer (2) is arranged between the surface layer (1) and the core layer (3); the wood grains of three layers of the surface layer (1), the buffer layer (2) and the base layer (4) are all arranged longitudinally consistently; and only the wood grains of the core layer (3) which is formed by parallelly arranged rectangular battens (5) at intervals are laterally distributed. The composite floor produced by the method is specially used for the floor or the wall plate to decorate the house, compared with the general three-layer solid composite floor, because of adding the buffer layer, the cracking phenomena that wavy stripes and the surface-layer wood appear in the original three-layer solid composite plate are improved; a continuous binding interface is formed on the surface of the core layer; the surface-layer binding area is increased; the bonding strength is improved; and the deformation of the surface-layer wood is impeded, thus the stability of the floor is improved.

Owner:ZHEJIANG FUDELI WOOD IND +1

Production method for damp-proof full-eucalyptus laminated wood veneer

ActiveCN103406951AStress reliefReduce water exposurePlywood pressesVeneer pressesWood veneerAdhesive

The invention provides a production method for a damp-proof full-eucalyptus laminated wood veneer. The artificial board is formed by high-temperature pressing and pasting of a base material and melamine impregnated paper, wherein the base material is formed by bonding a plurality of layers of eucalyptus veneers through adhesives. The production method comprises the steps of veneer sorting, gluing, cold pressing, hot pressing, stacking maintenance and pasting of the melamine impregnated paper. The production method is characterized in that three times of cold pressing and hot pressing and two times of thermostatic chamber standing maintenance and cooling maintenance processes are adopted, the cold pressing is performed at the room temperature and under the pressure of 0.8-1.0MPa, the hot pressing is performed under the pressure of 1.5-2.0MPa, the first hot pressing is performed at the temperature of 120-125DEG C, the second hot pressing is performed at the temperature of 115-120DEG C, and the third hot pressing is performed at the temperature of 125-130DEG C; the thermostatic chamber standing maintenance is performed at the temperature of 80-90DEG C for 4-6h; the cooling maintenance is cooled to the room temperature from the temperature of a thermostatic chamber through natural ventilation for 3-4h.

Owner:莫明鑫

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

Automatic processing and manufacturing equipment for shaving boards

ActiveCN107283554AQuality will not affectSmall savings in qualityPlywood pressesVeneer pressesEngineeringMachining process

The invention relates to automatic processing and manufacturing equipment for shaving boards. The automatic processing and manufacturing equipment comprises a working box, wherein two supporting mechanisms are symmetrically mounted at the front end and the rear end of the bottom of the working box separately; a working plate is mounted at the upper ends of the two supporting mechanisms; two moving and lifting mechanisms are symmetrically mounted on the left side and the right side of the working box separately; a transverse plate is mounted at the upper ends of the two moving and lifting mechanisms; an auxiliary material rolling mechanism is mounted at the middle of the transverse plate; two vibration extrusion mechanisms are symmetrically mounted on the two sides of the transverse plate separately; and the supporting mechanisms, the moving and lifting mechanisms, the auxiliary material rolling mechanism and the vibration extrusion mechanisms well coordinate with each other to complete the automatic processing and manufacturing process of shaving boards. According to the automatic processing and manufacturing equipment for shaving boards, the problems that during the conventional processing process of shaving boards, the occupied space of the equipment is large, stirred materials are easy to cake after being fed into a die to affect the quality of shaving boards, the die needs to be manually adjusted when shaving boards with different thicknesses are processed, the labor intensity of working personnel is improved and the working efficiency is reduced are solved, and the function of automatically processing and manufacturing shaving boards is realized.

Owner:临沂兴滕人造板机械有限公司

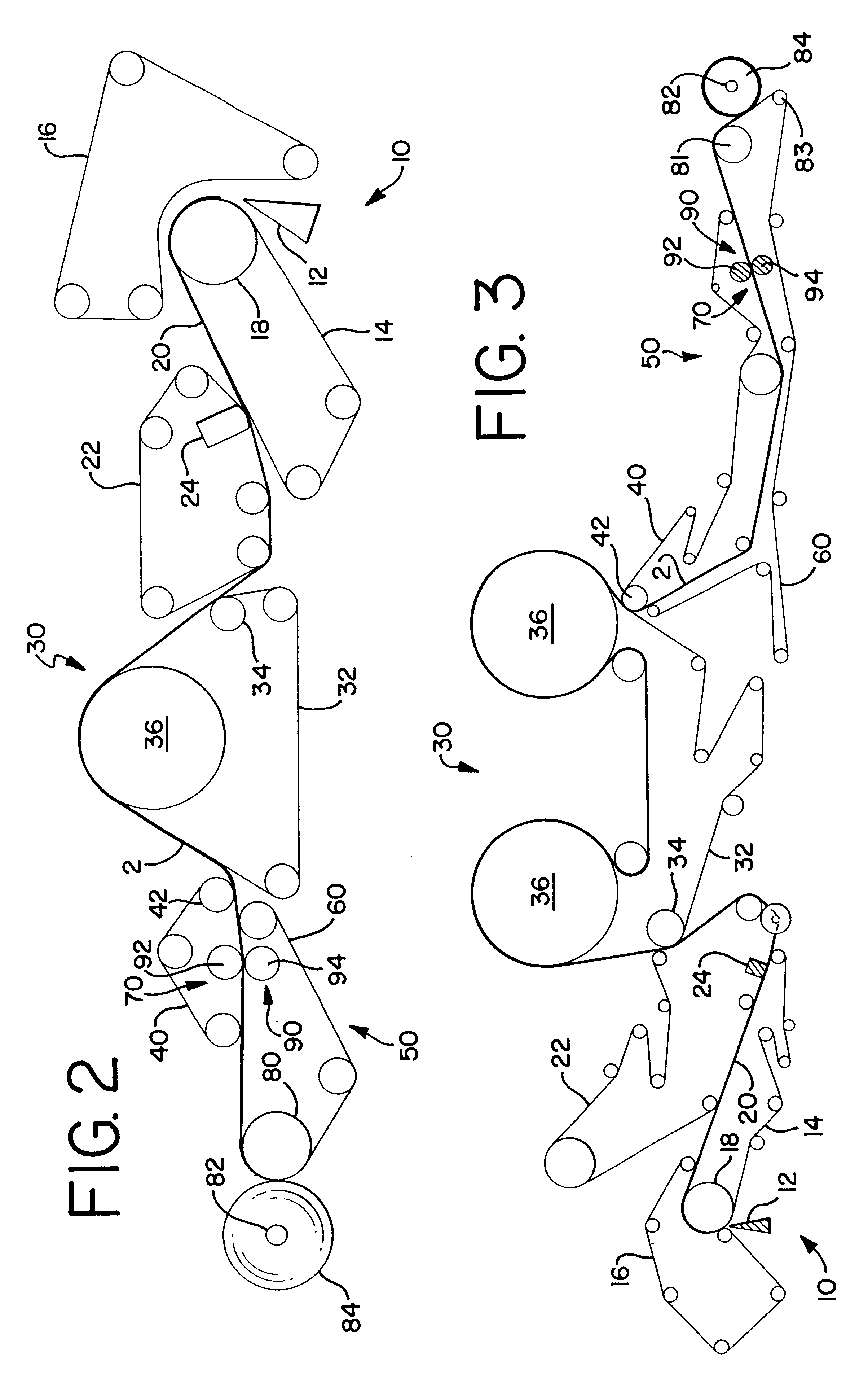

Apparatus for calendering a sheet material web carried by a fabric

An apparatus for calendering a sheet material web being carried on or between one or more carrier fabrics. In a preferred embodiment, the apparatus includes a calender section having first and second calender rolls forming a nip therebetween. At least one carrier fabric is disposed between the first and second calender rolls. The first and second calender rolls apply a load to the carrier fabric and sheet material web as they pass through the nip between the calender rolls so as to reduce the caliper, or thickness, of the sheet material web. A method for calendering the sheet material web includes carrying the sheet material web on one or more carrier fabrics through the calender nip formed by the first and second calender rolls and applying a load to the carrier fabric, and sheet material carried thereby, so as to reduce the thickness of the sheet material web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

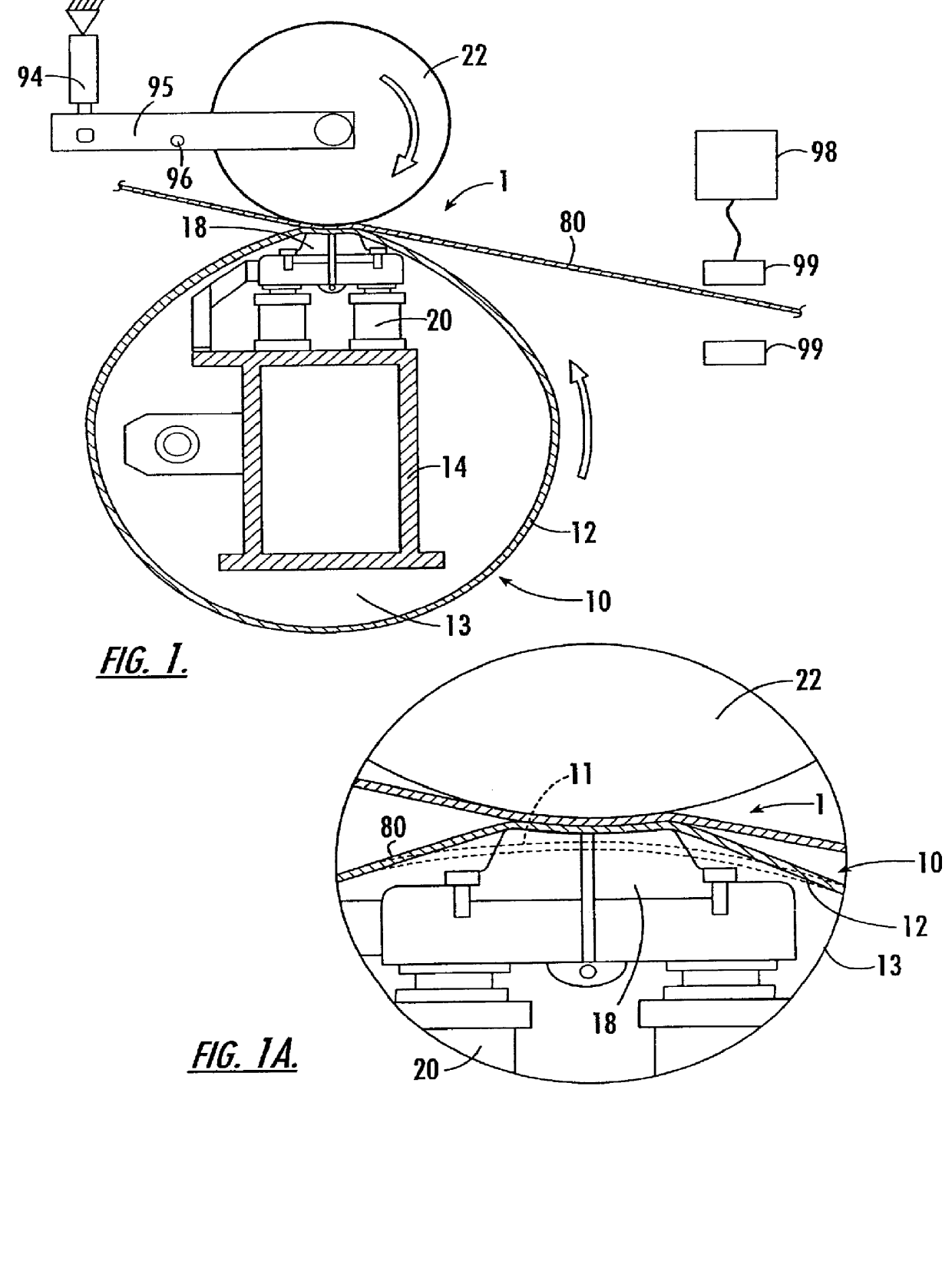

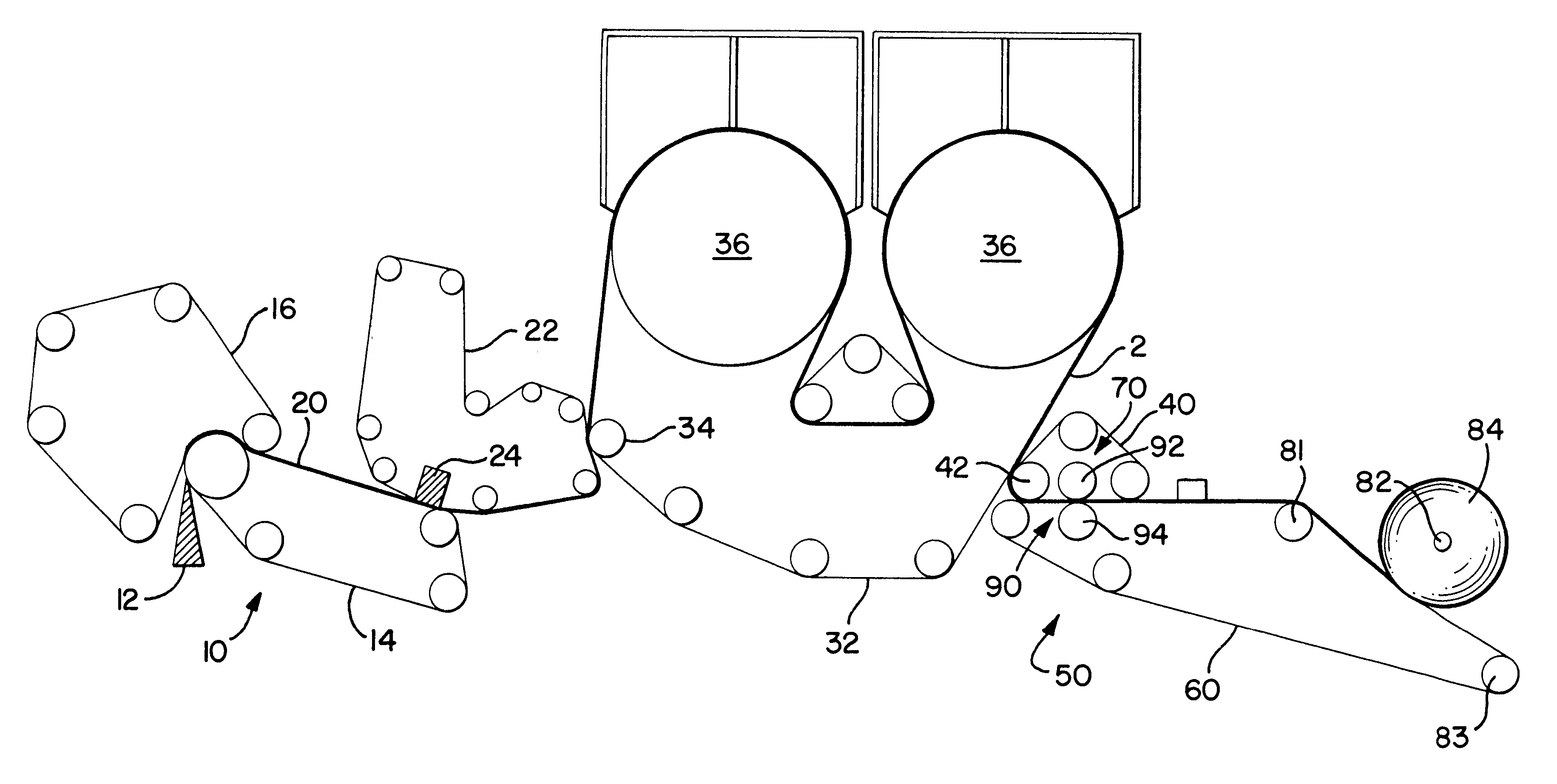

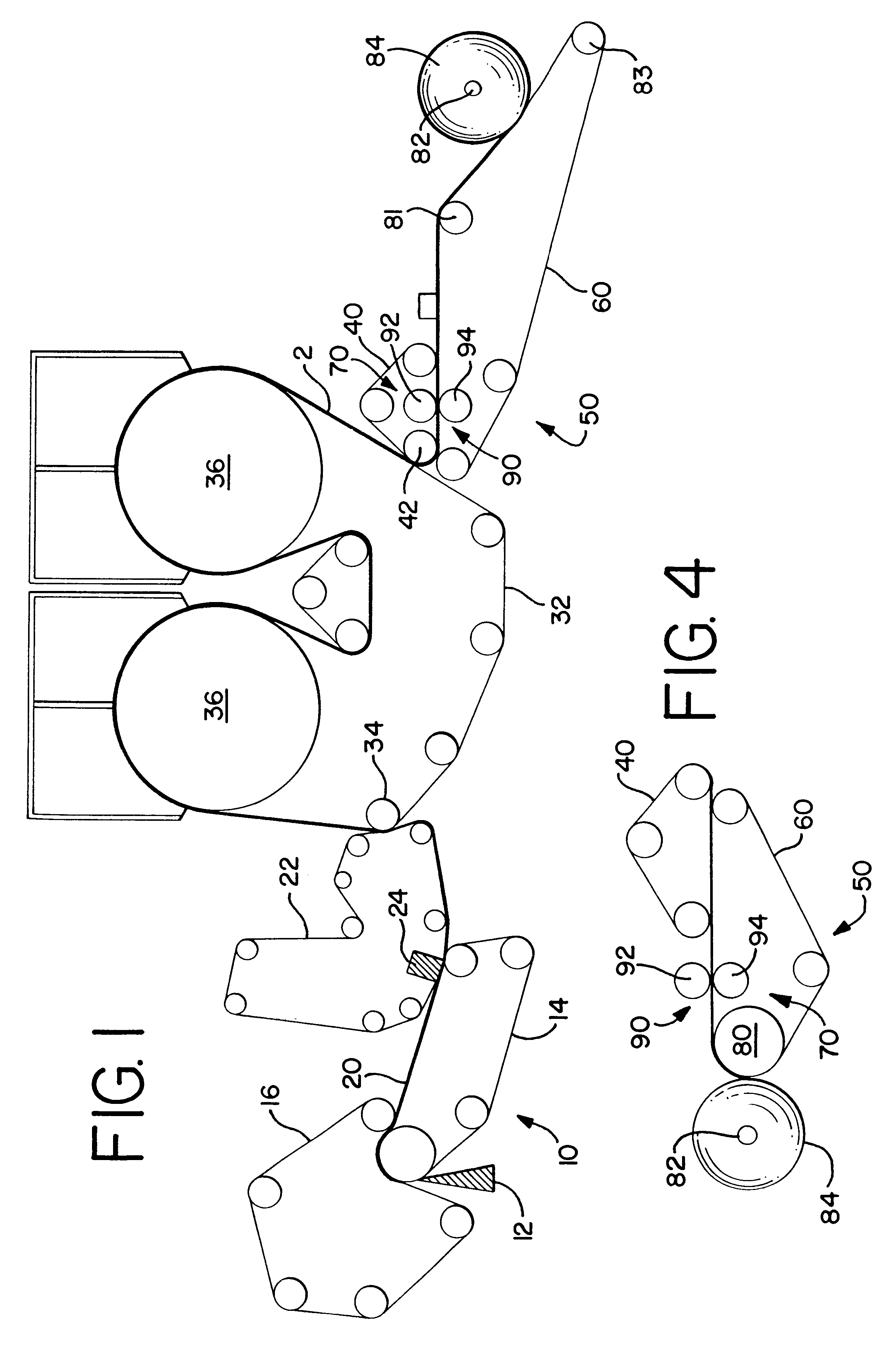

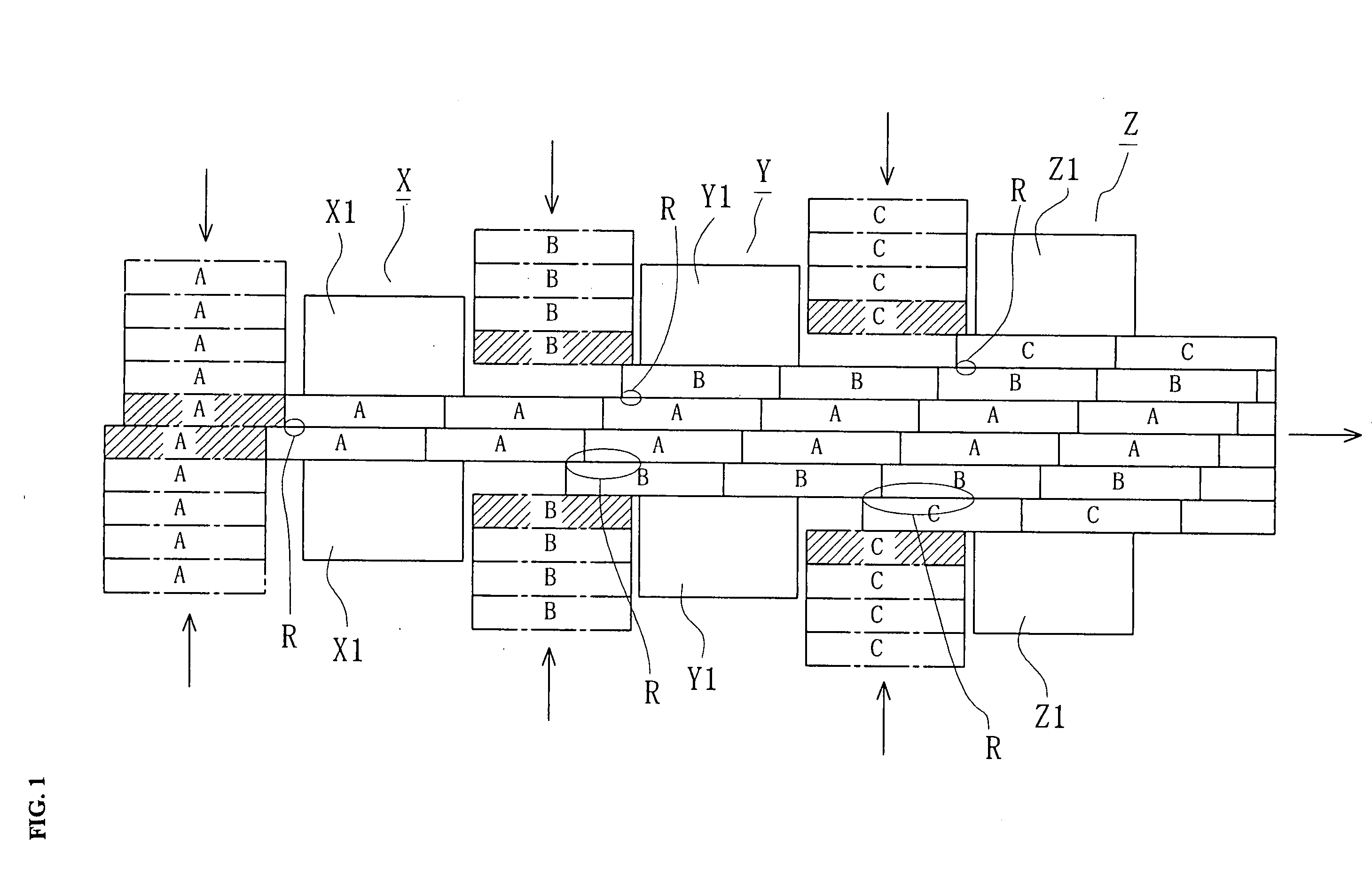

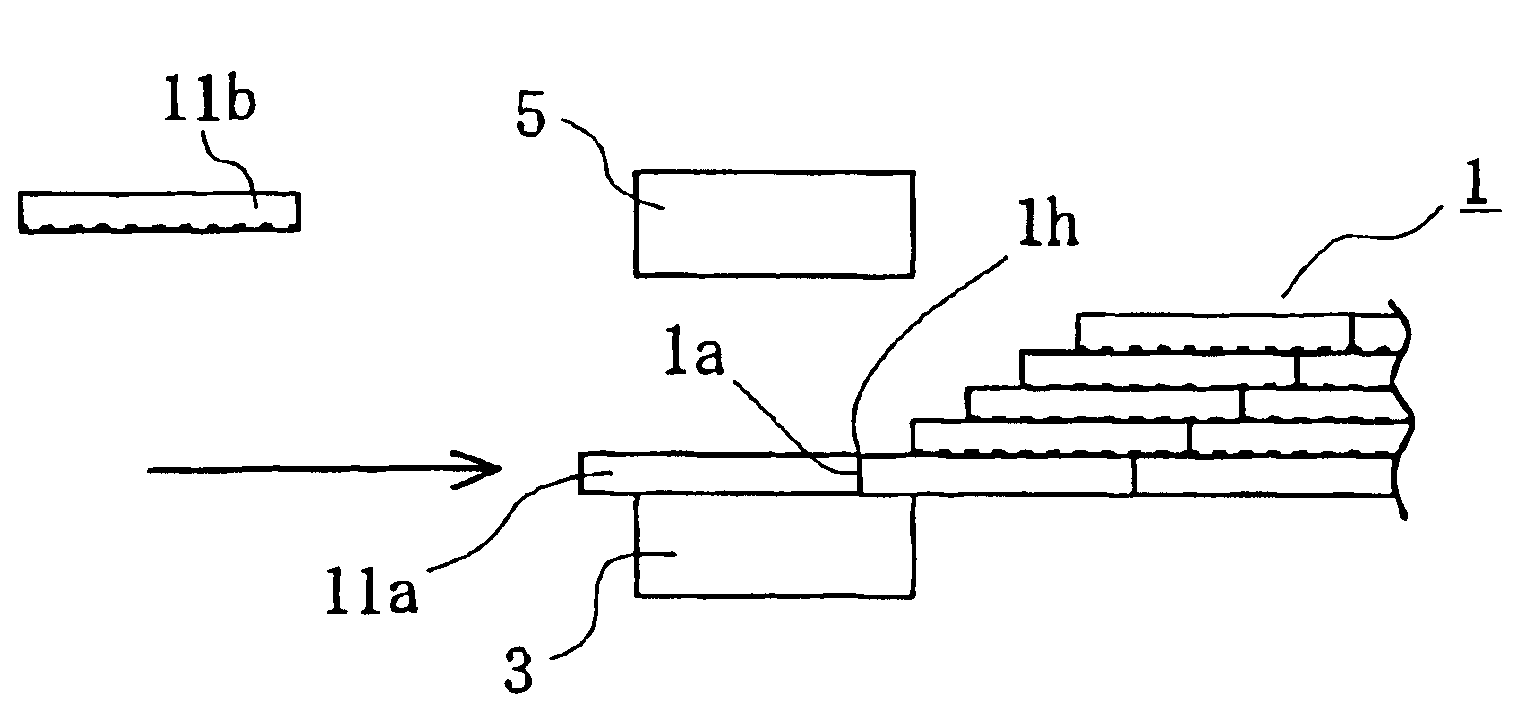

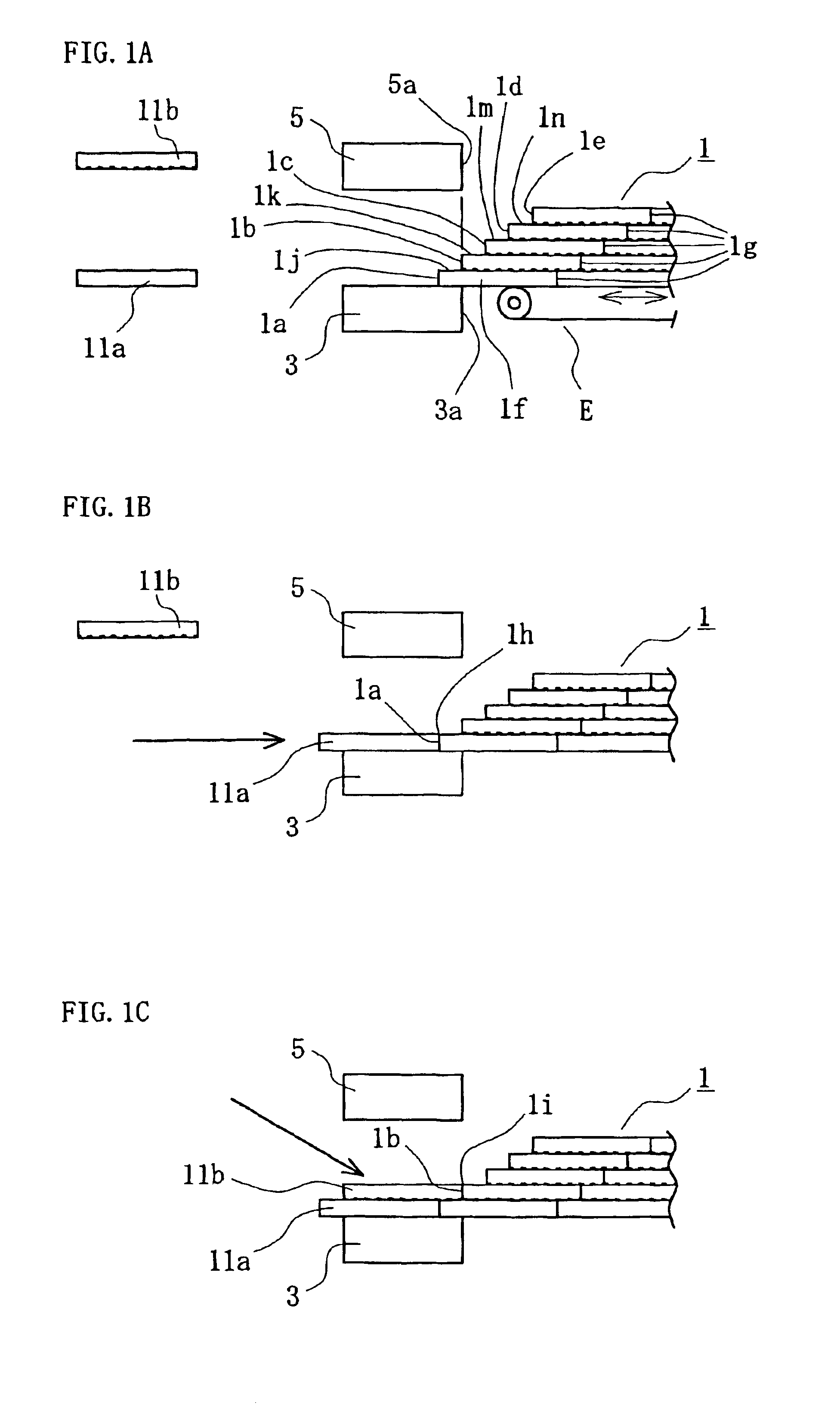

Method and apparatus of manufacturing glued laminated wood

A method and apparatus of manufacturing glued laminated wood such as laminated veneer lumber (LVL) are disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board of the glued laminated wood wherein wood sheets in each layer of the multiple-layered board are arranged in a staggered relation in the lengthwise direction of the board to wood sheets in an adjacent layer. The hot press has a pair of heating plates arranged substantially in facing relation to each other and an auxiliary heating plate disposed adjacent to one end of each heating plate. The auxiliary heating plate is adapted to press part of wood sheet which extends out beyond the above end of the heating plate.

Owner:MEINAN MASCH WORKS INC

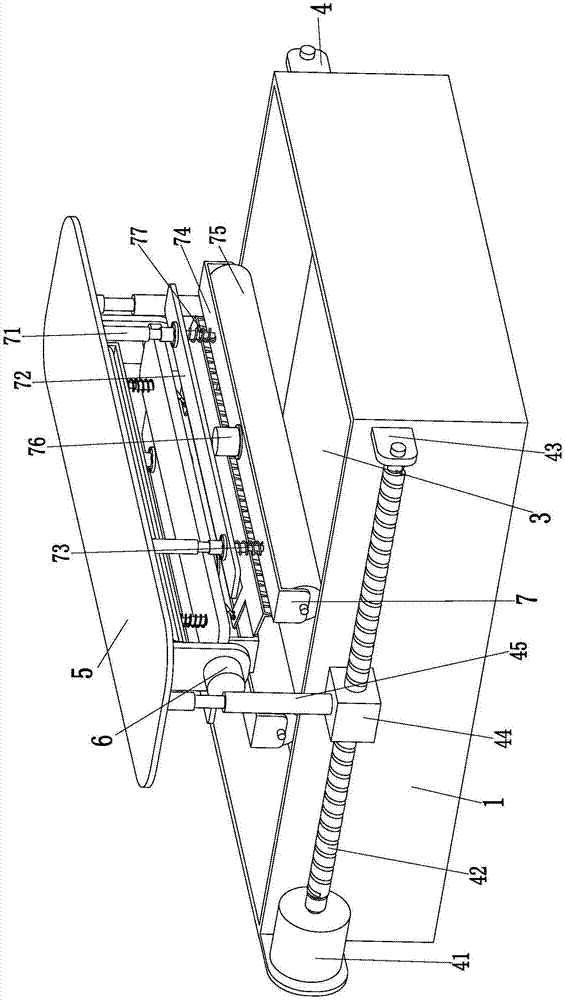

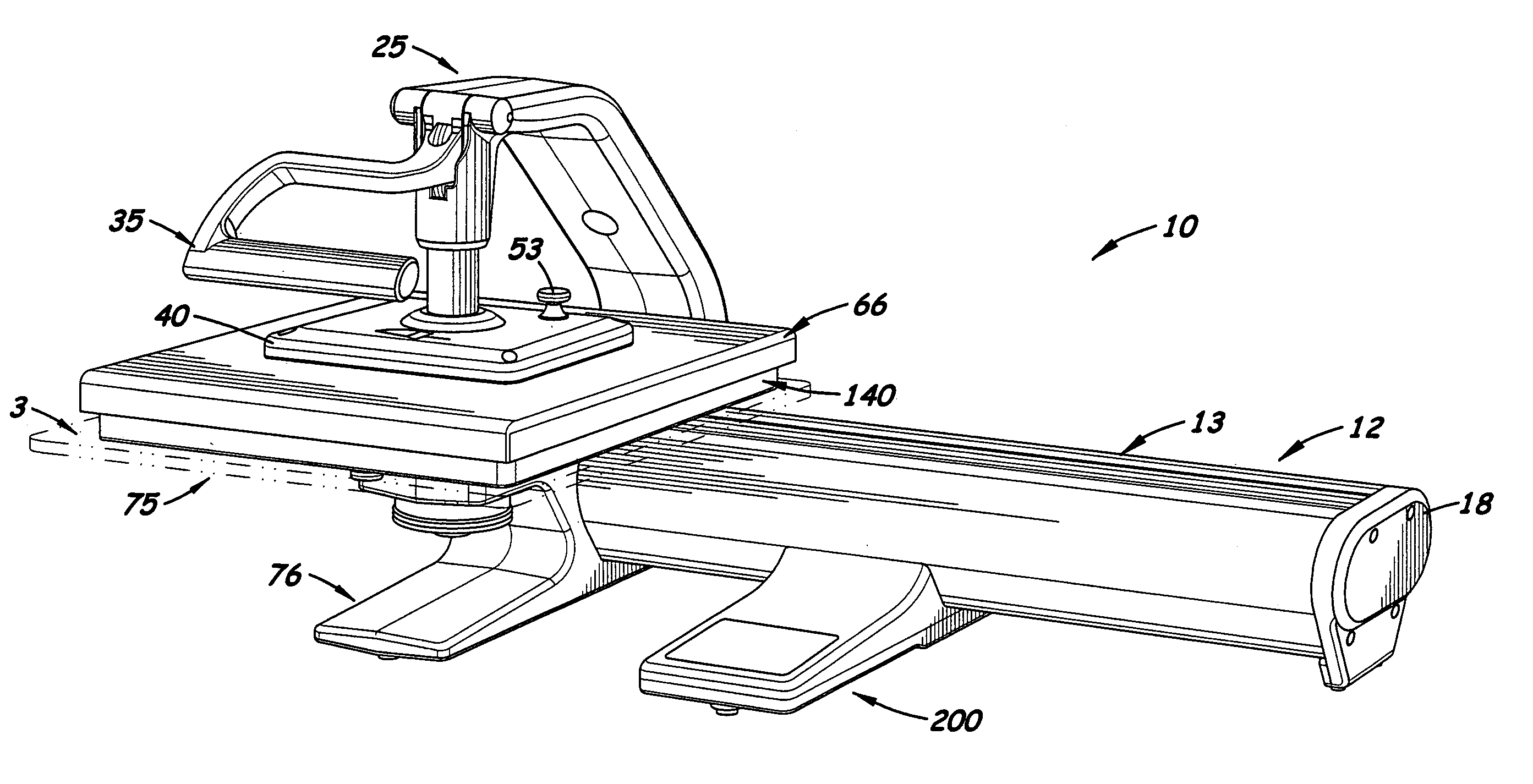

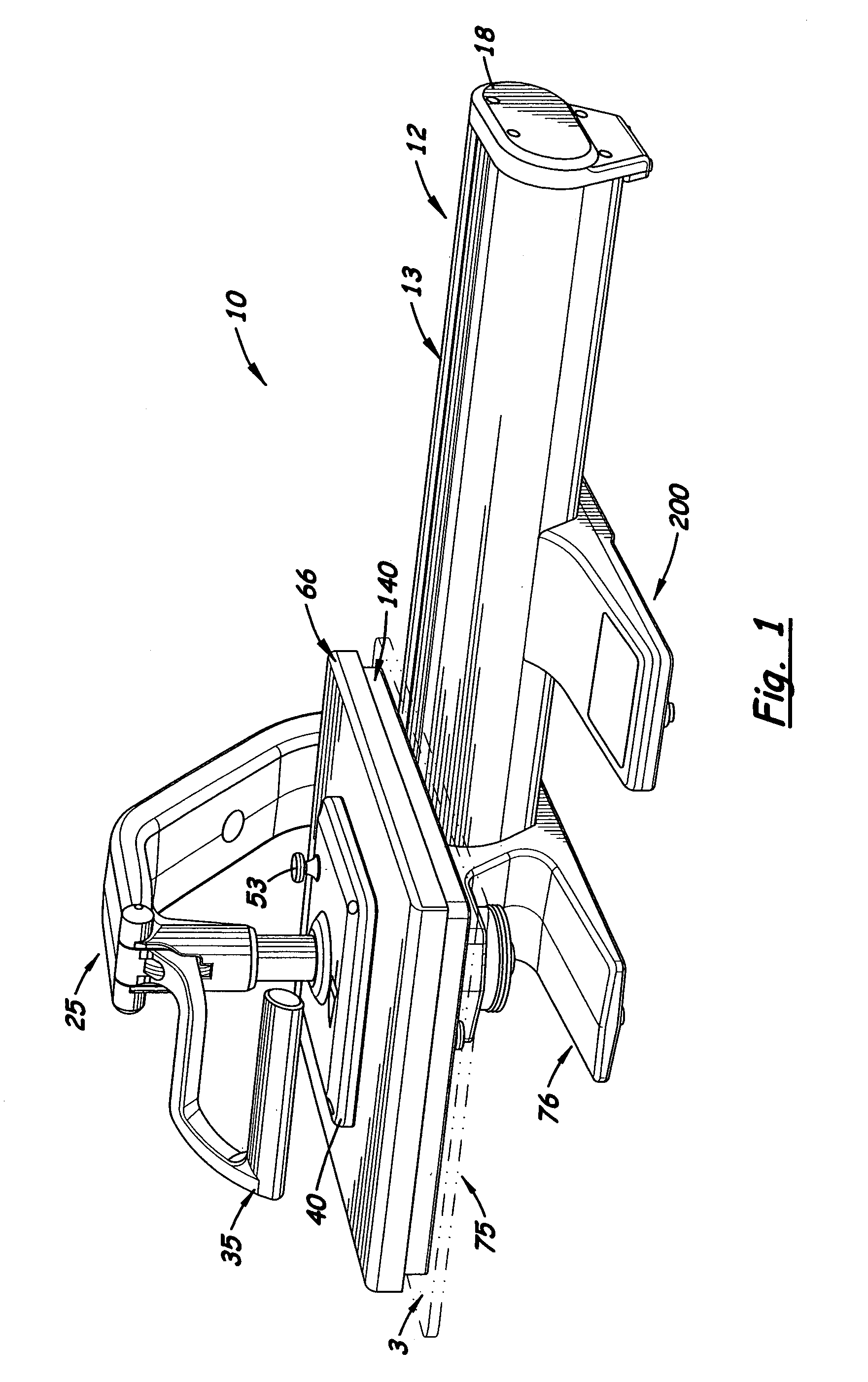

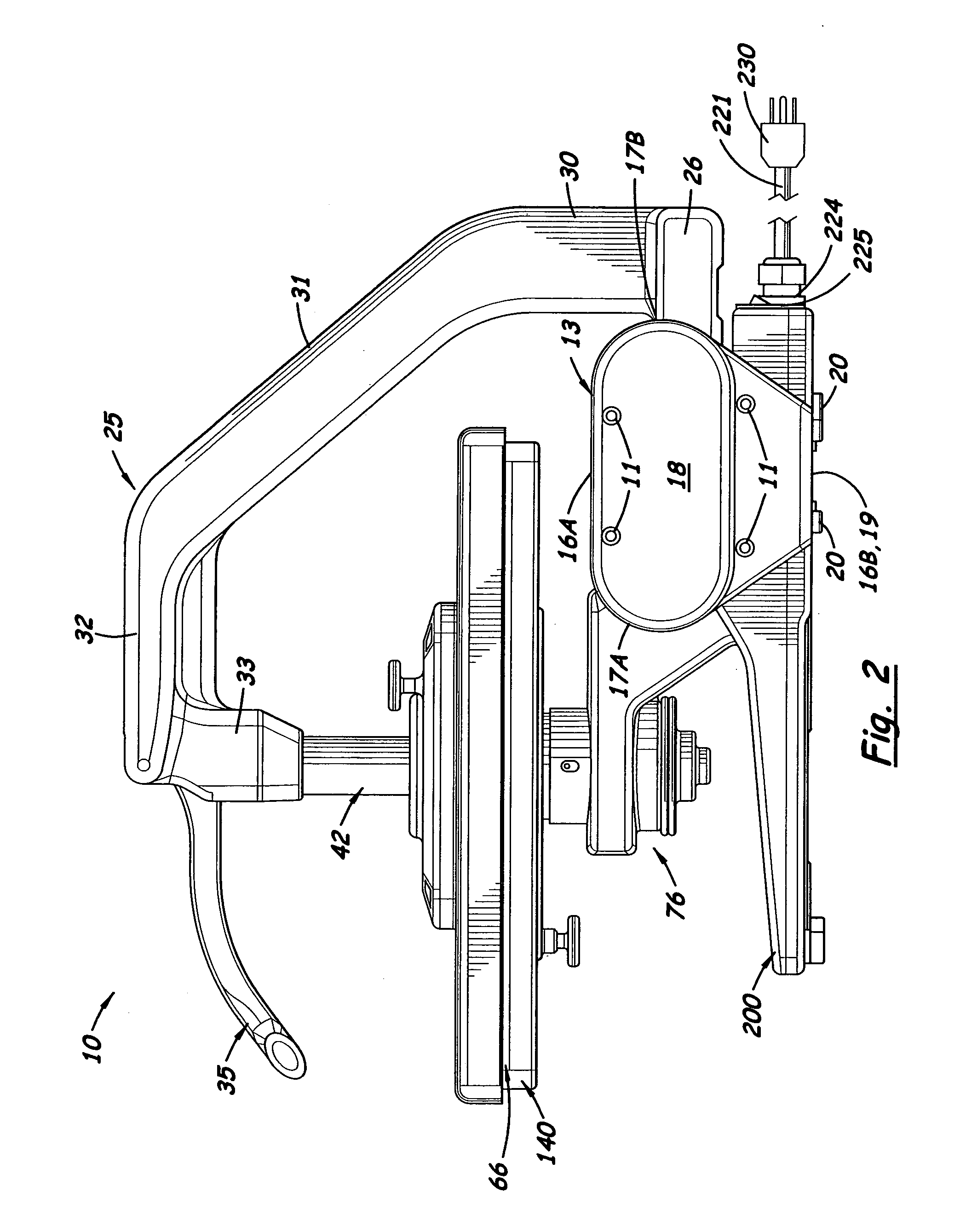

Modular lateral heat press machine

InactiveUS7185584B1Easy to useEasily and quickly exchangedTransfer printingPlywood pressesEngineeringWorkstation

A lightweight, portable lateral heat press machine that allows an operator to quickly and economically transfer graphic characters or images using an ink transfer paper process or a sublimation process, or vinyl onto the surface of a garment or an object. The device includes a vertical aligned sliding arm assembly perpendicularly aligned to a horizontally aligned chassis assembly. Attached to the chassis assembly is at least one workstation assembly and a console. The workstation assembly includes a pedestal with an exchangeable, horizontally aligned lower platen that may be selectively rotated and locked in portrait or landscape orientation and a height and pressure adjustment feature. The sliding arm assembly extends upward and forward and includes a heated, upper platen attached to a manually operated plunger. The console contains the controls for operating the heating element inside the upper platen and a timer. In a second embodiment, a second workstation assembly is provided which enables the operator to slide the arm assembly between workstations thereby enabling the operator to setup one workstation as the pressing procedure is being performed on the other.

Owner:PREMIUM INCENTIVES

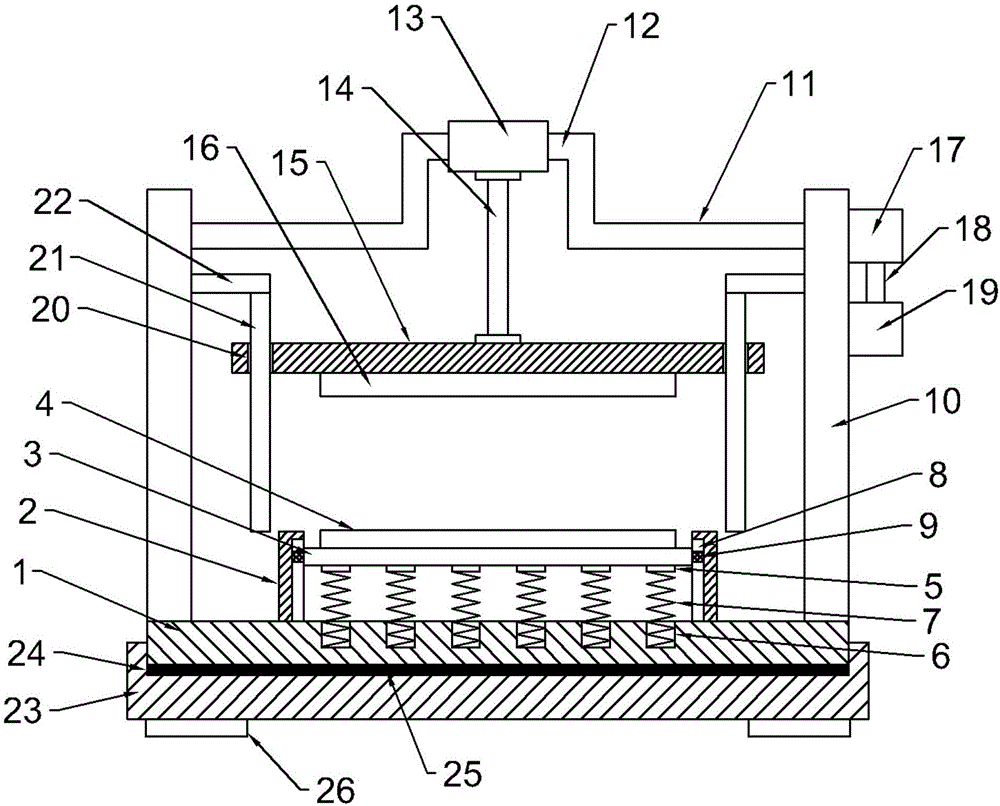

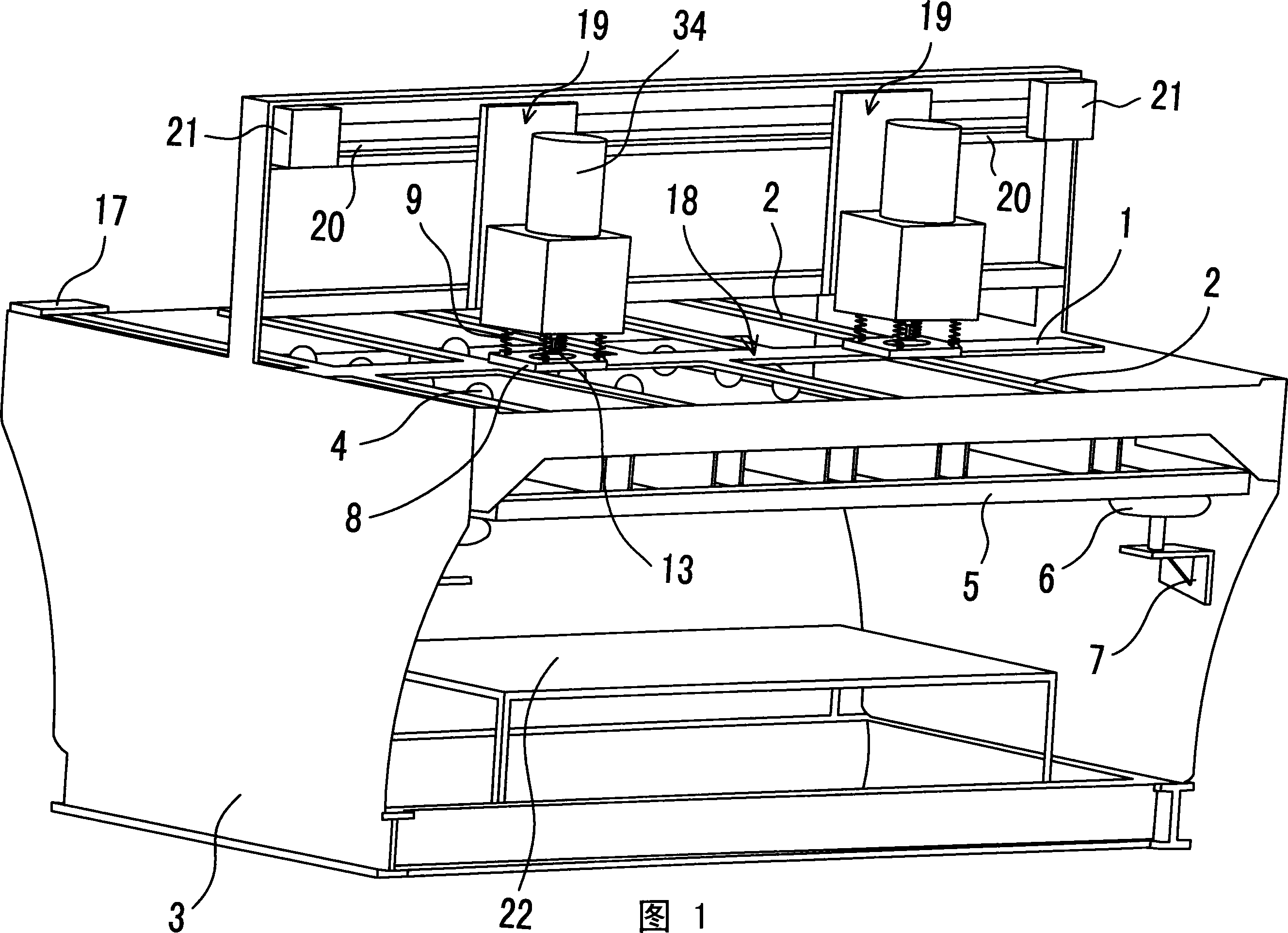

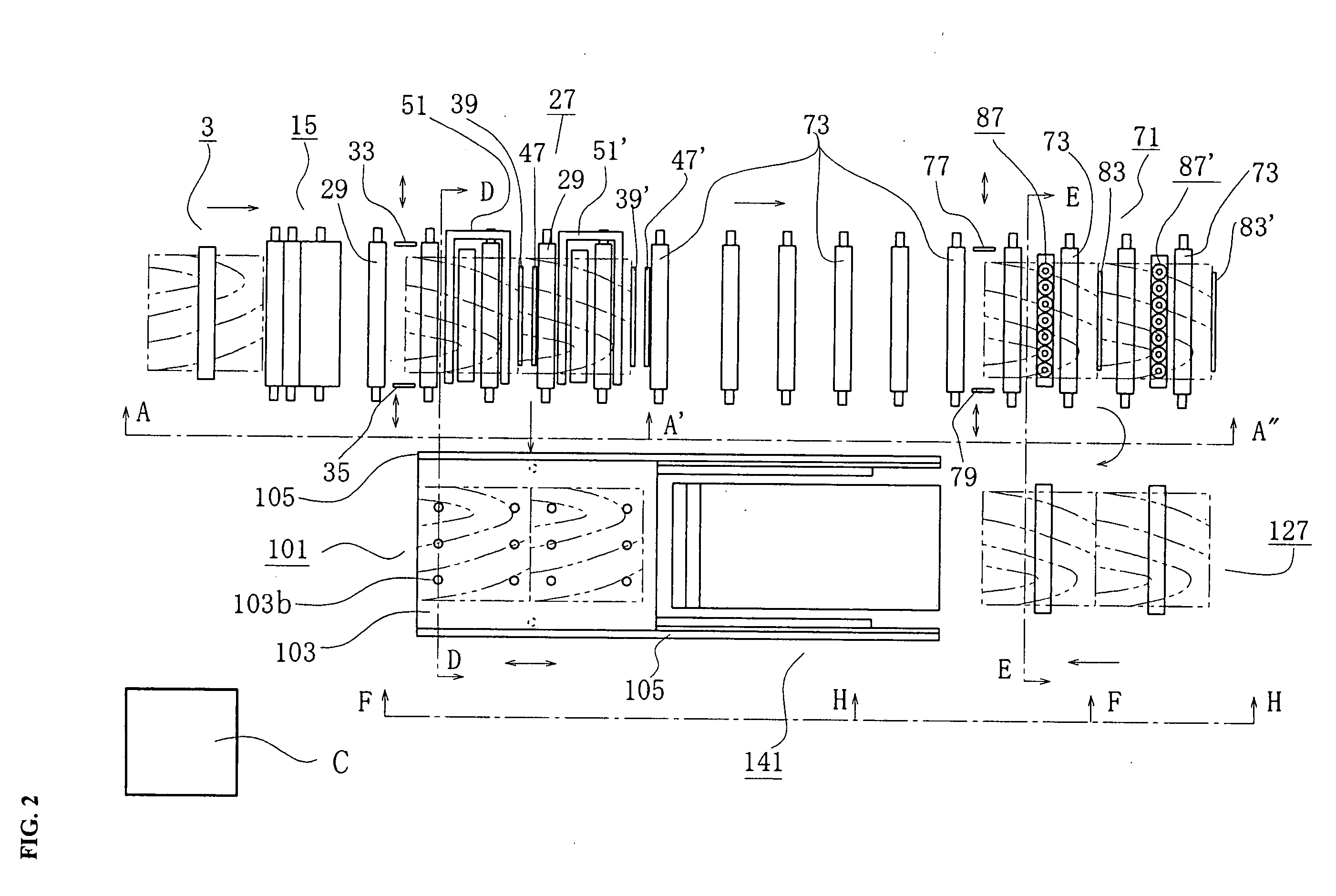

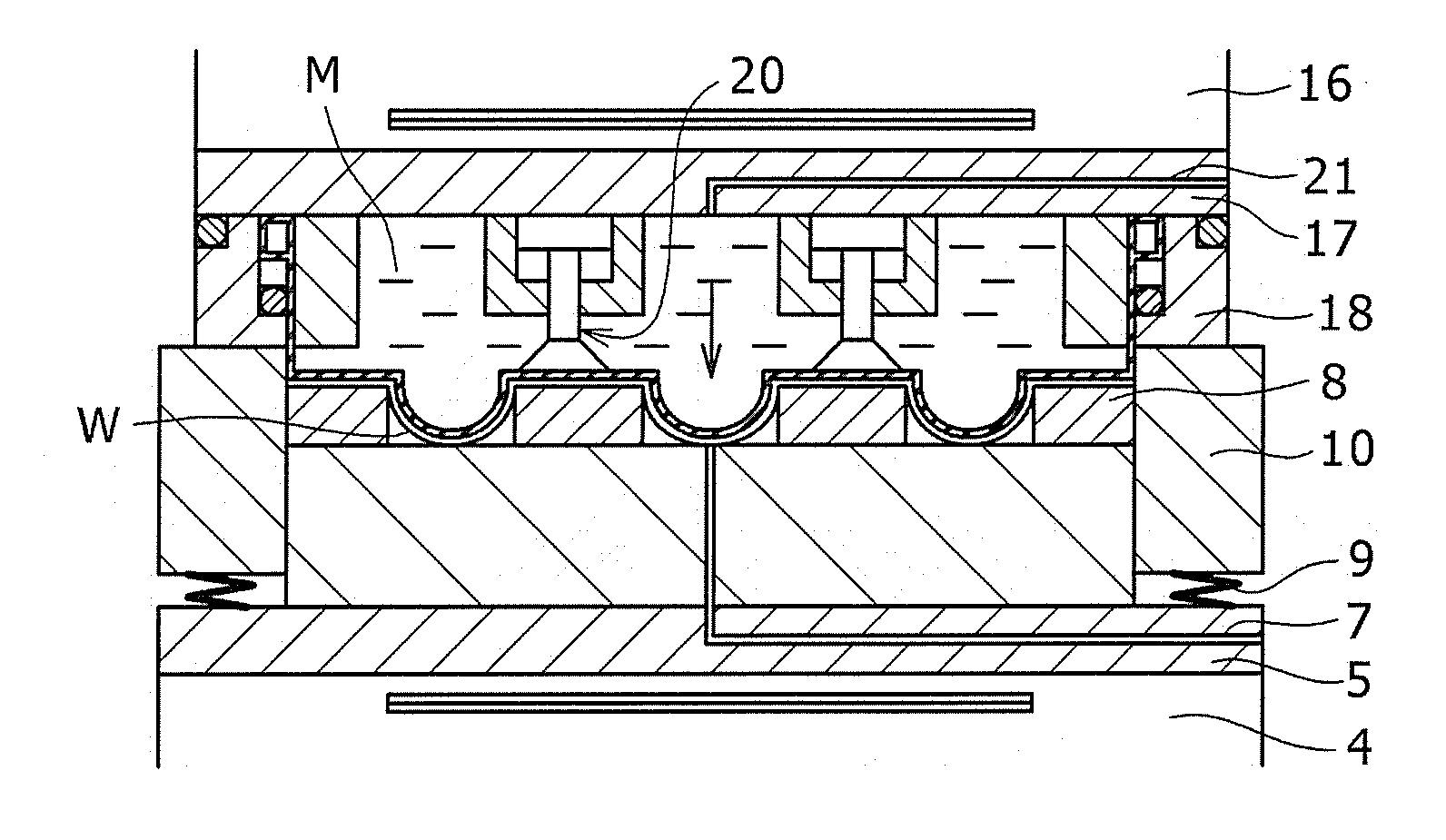

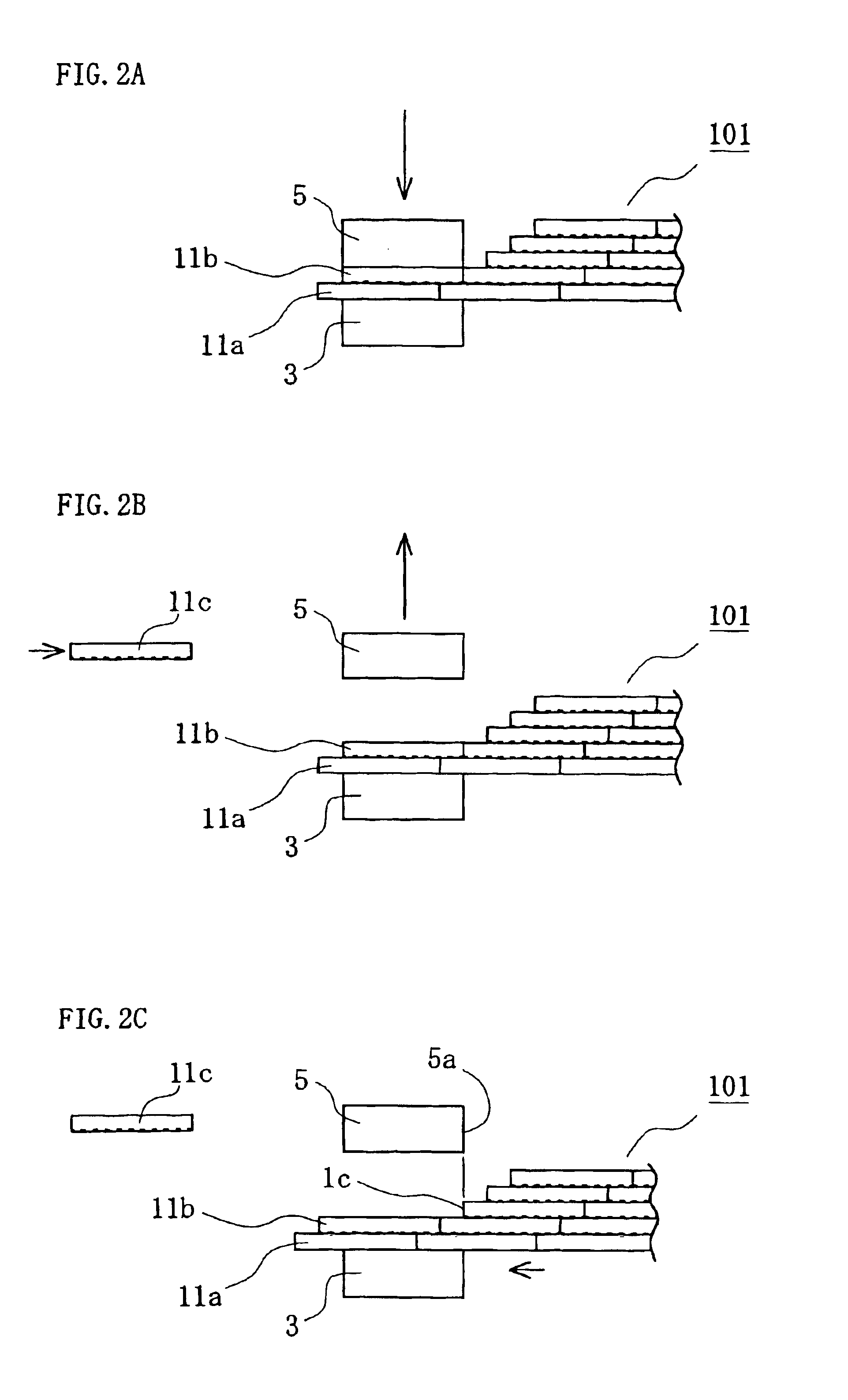

Hot press apparatus and a hot press method for thin plate-like workpieces

InactiveUS20090151576A1Stable positionPrevented from expandingPlywood pressesDryer sectionMechanical engineeringFlat panel

A hot press apparatus for hot pressing a thin plate-like workpiece, includes a base 1, lower and upper heating plates 4, 16, a flat lower mold member 8, lower and upper frame members 10, 18, a workpiece taking-out unit 7, an upper press plate 12, a heat-resistant and stretchable film member 19 covering the lower end portion of the upper frame member 18, a heat medium M filled in a heat medium-filling space above the film member, and a driving unit 13. A film member-horizontally holding member 20 substantially horizontally holds the film member while preventing the film member from hanging, while keeping it at a substantially constant position as viewed in a horizontal direction. The workpiece is hot pressed with the film member by applying pressure to the heat medium inside the heat medium-filling space while the film member is prevented from expanding radially outwardly at an outer periphery thereof.

Owner:MIKADO TECHNOS

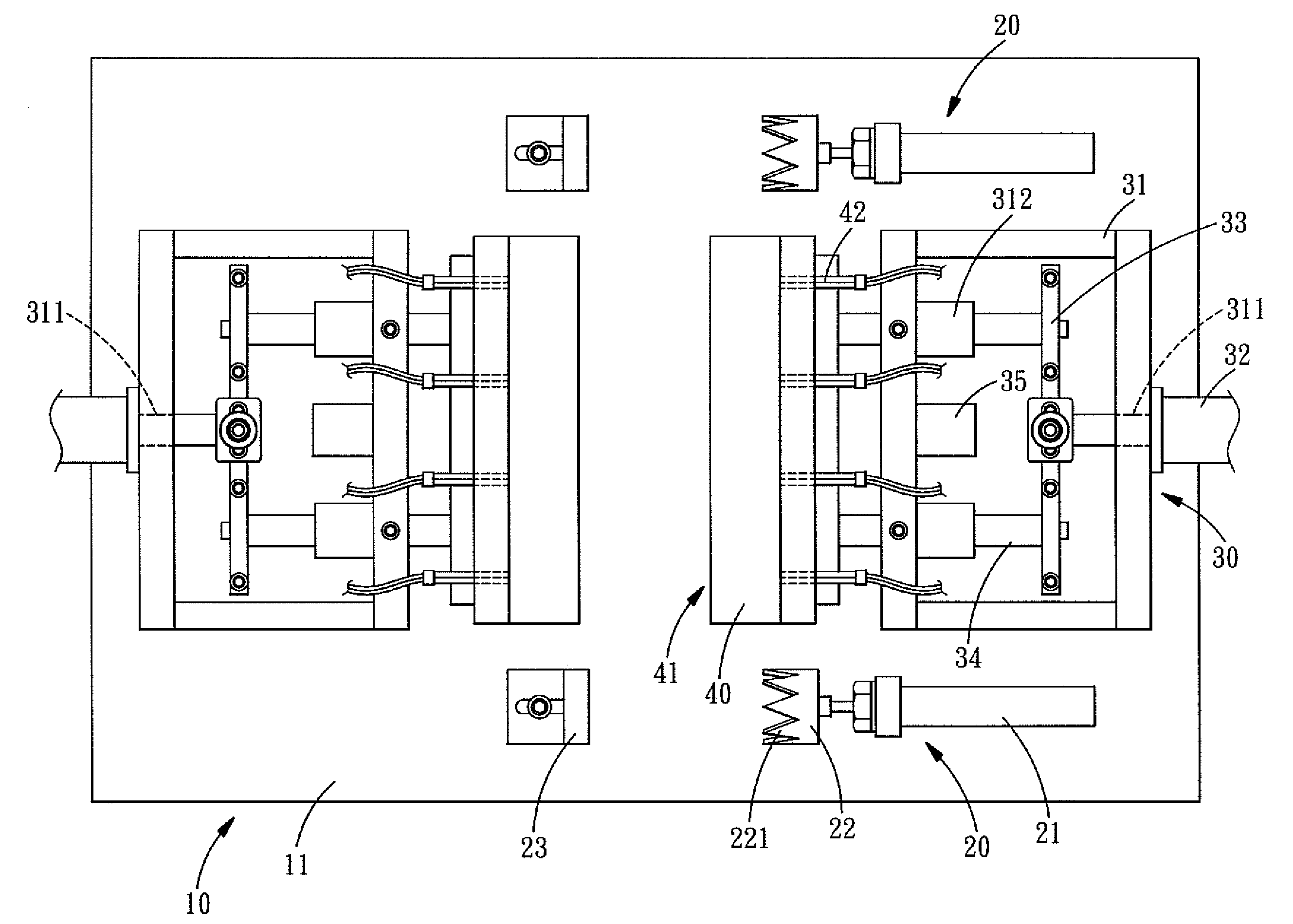

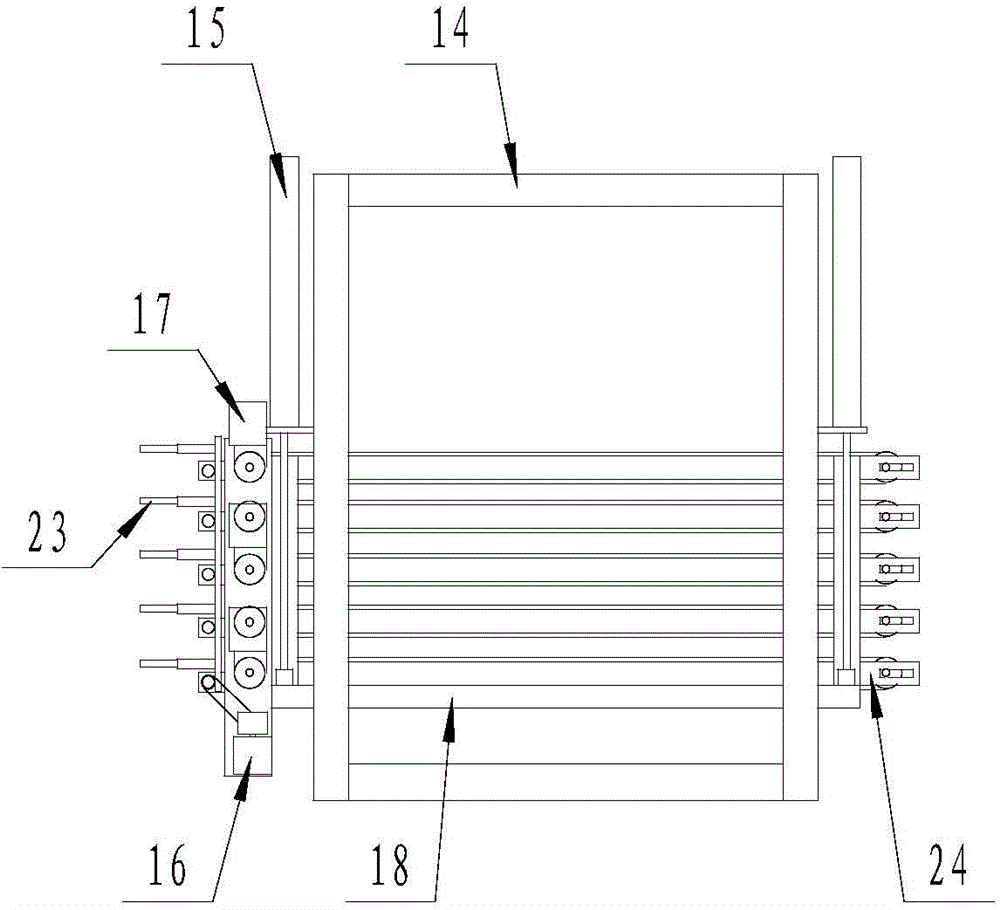

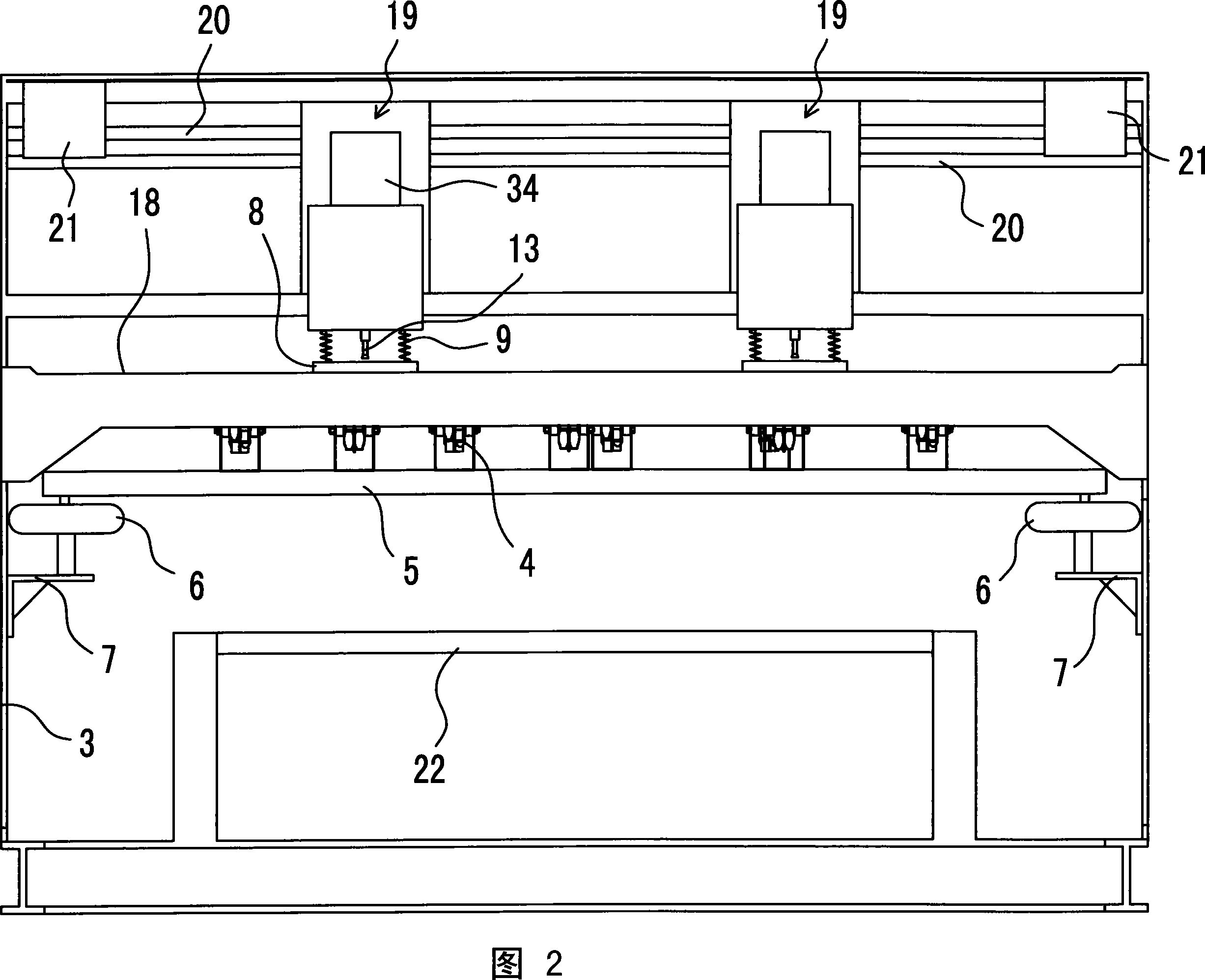

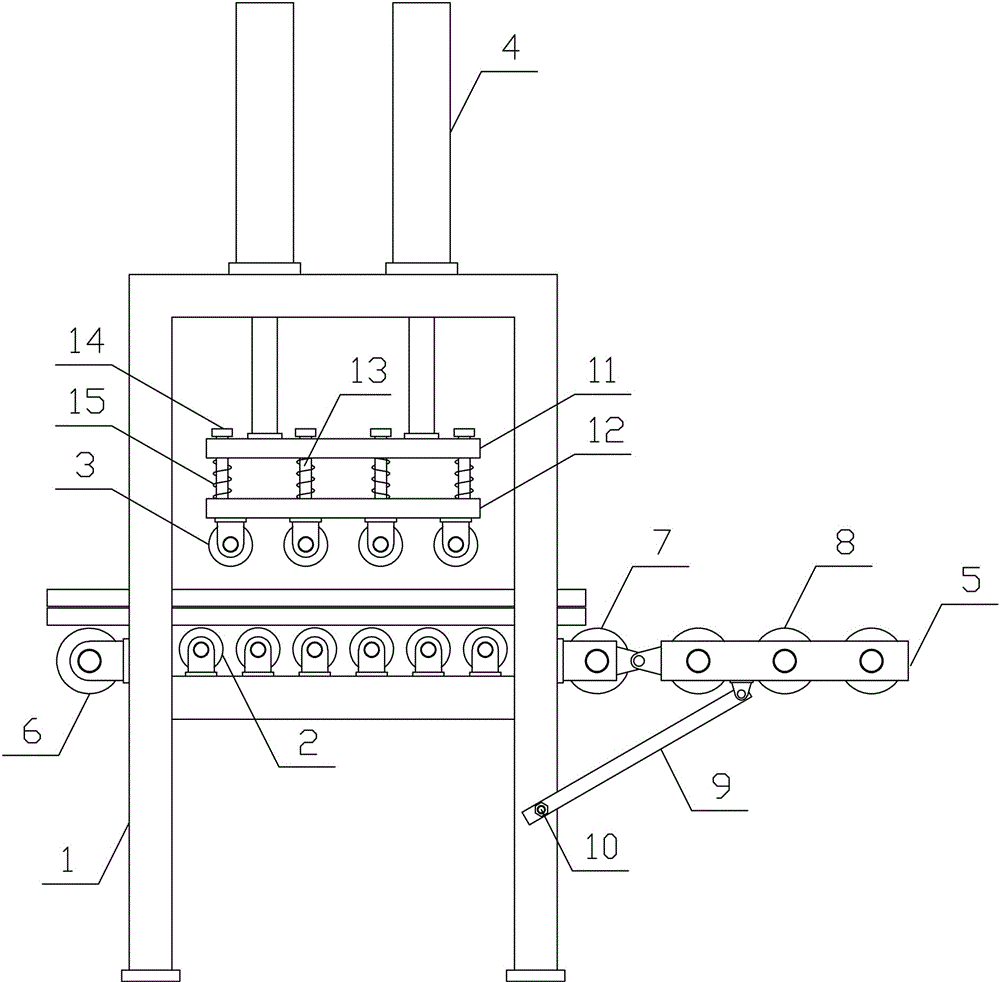

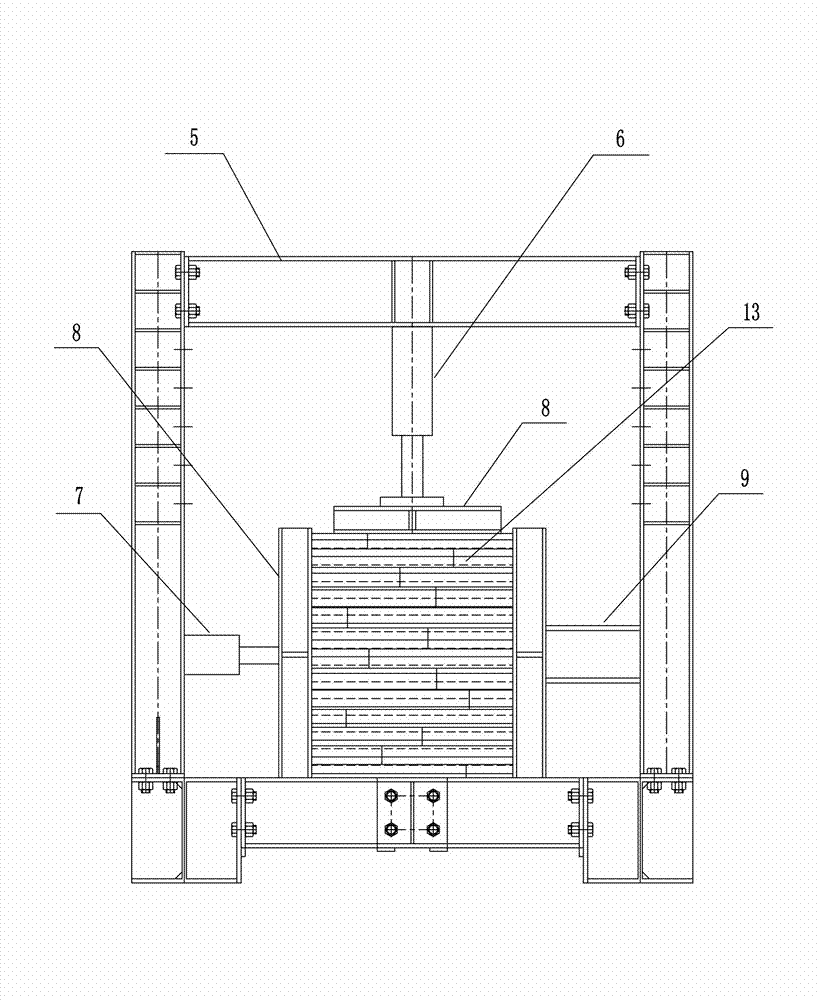

Multilayer thermal press for sheet material

InactiveCN104589432AIncrease productivityNo gapsPlywood pressesVeneer pressesThermal compressionEngineering

The invention discloses a multilayer thermal press for a sheet material and belongs to the field of sheet material machining. The multilayer thermal press comprises a rack, a press plate oil cylinder, an upper pressing plate, a plurality of carrier plates, a lower pressing plate, side locating rods, a suspending locating rod and a hot gas pipeline, wherein the press plate oil cylinder is connected with the lower pressing plate, and the carrier plates are arranged between the upper pressing plate and the lower pressing plate. The multilayer thermal press further comprises a synchronous closing device, wherein the synchronous closing device comprises two synchronous link mechanisms which are symmetrically distributed at the two sides of the rack, each synchronous link mechanism comprises an upper link, a lower link and a plurality of middle links, one end of each upper link is hinged to the upper pressing plate, a plurality of insertion holes are formed in each upper link, one end of each lower link is hinged to the lower pressing plate, the other end of each upper link is hinged to the other end of the corresponding lower link, one end of each middle link is hinged to the corresponding carrier plate, and the other end of each middle link is inserted into the corresponding insertion hole of the corresponding upper link and is always parallel to the corresponding lower link. The multilayer thermal press is applied to a thermal press procedure of a woodworking board machining process and has the advantages of high degree of automation, high production efficiency and high machined woodworking board quality.

Owner:王雨琪

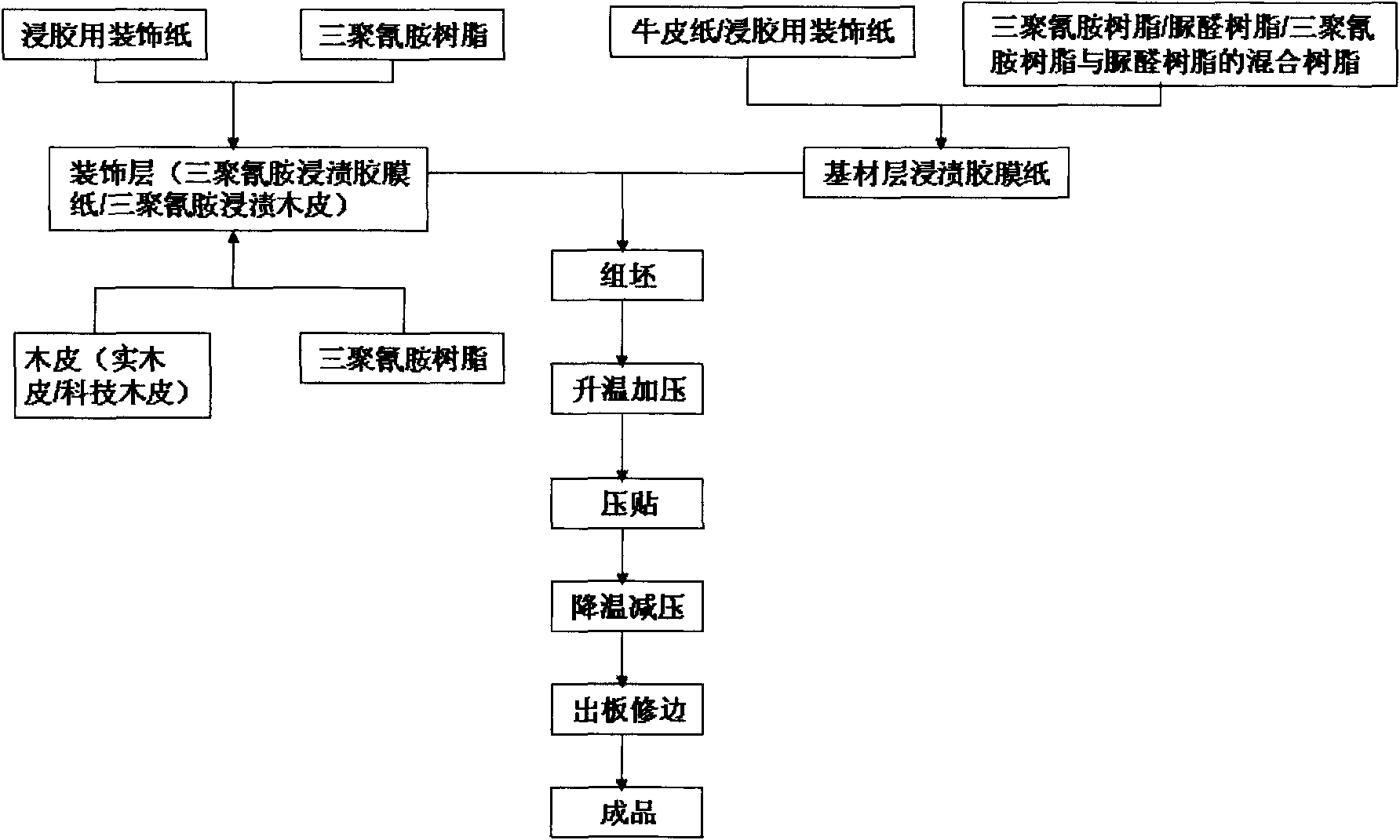

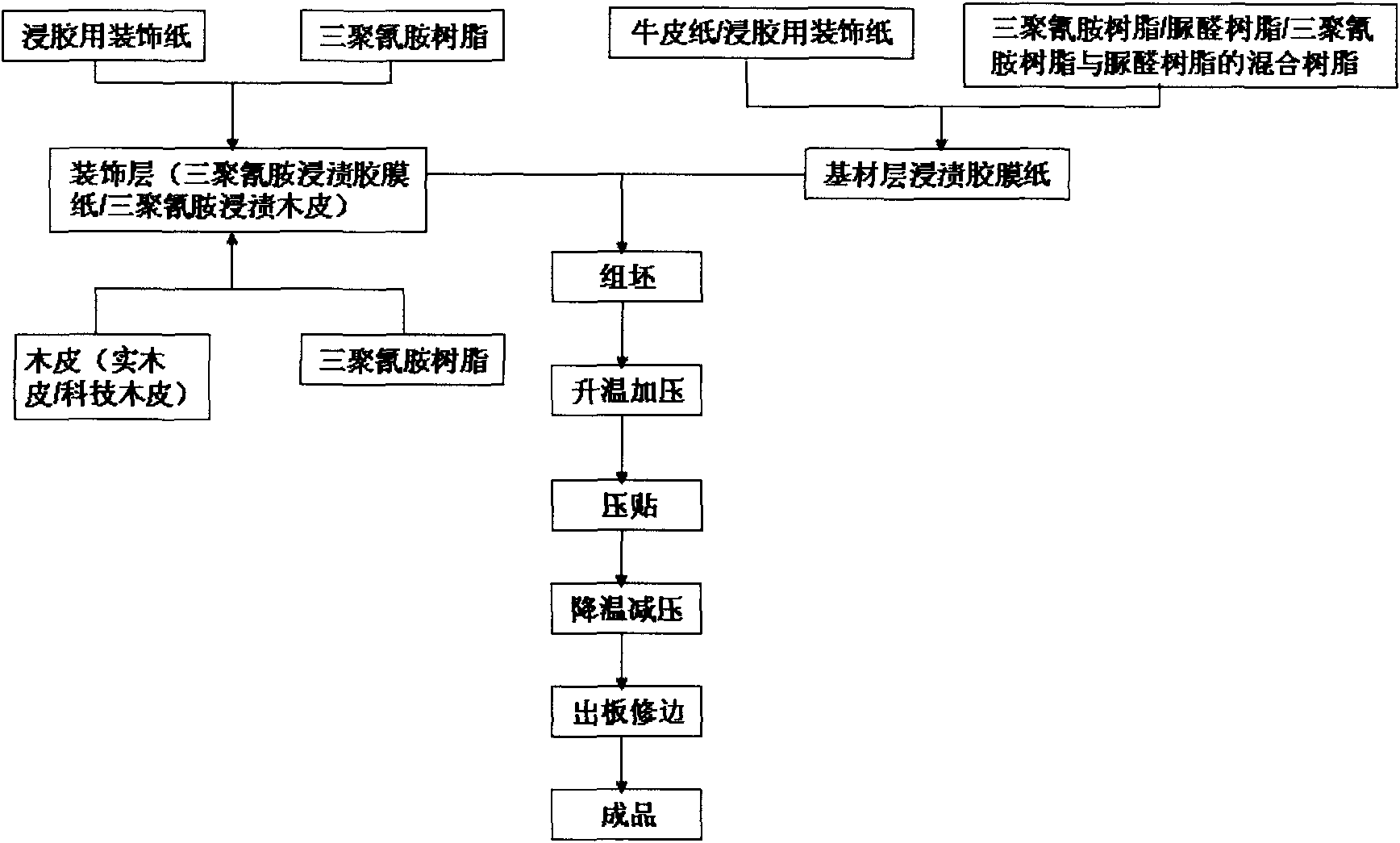

Melamine laminate and manufacturing process thereof

InactiveCN101987471AColorfulVibrant color saturationPlywood pressesVeneer pressesHeat conductingColor saturation

The invention relates to a melamine laminate and a manufacturing process thereof. The laminate comprises a decorative layer, wherein the decorative layer and a substrate layer are mutually laid and compressed. The laminate is characterized in that the decorative layer comprises melamine resin-impregnated paper and melamine impregnated veneer, wherein the substrate layer comprises a resin-impregnated material consisting of decorative paper and melamine resin or urea-formaldehyde resin, the resin-impregnated material consisting of kraft paper and the melamine resin or urea-formaldehyde resin, the resin-impregnated material formed by mixing the decorative paper and the melamine or formaldehyde and the resin-impregnated material formed by mixing the kraft paper and the melamine or formaldehyde. The finished product is obtained by the following steps of: assembling the substrates of the decorative layers and laminating by a multi-layer steam heat-conducting laminating machine and finally trimming. The process has the advantages of simple process, environment friendliness, high deformation resistance and low cost; and the performance of the product, from color saturation to brightness effect, is greatly improved.

Owner:吴根水

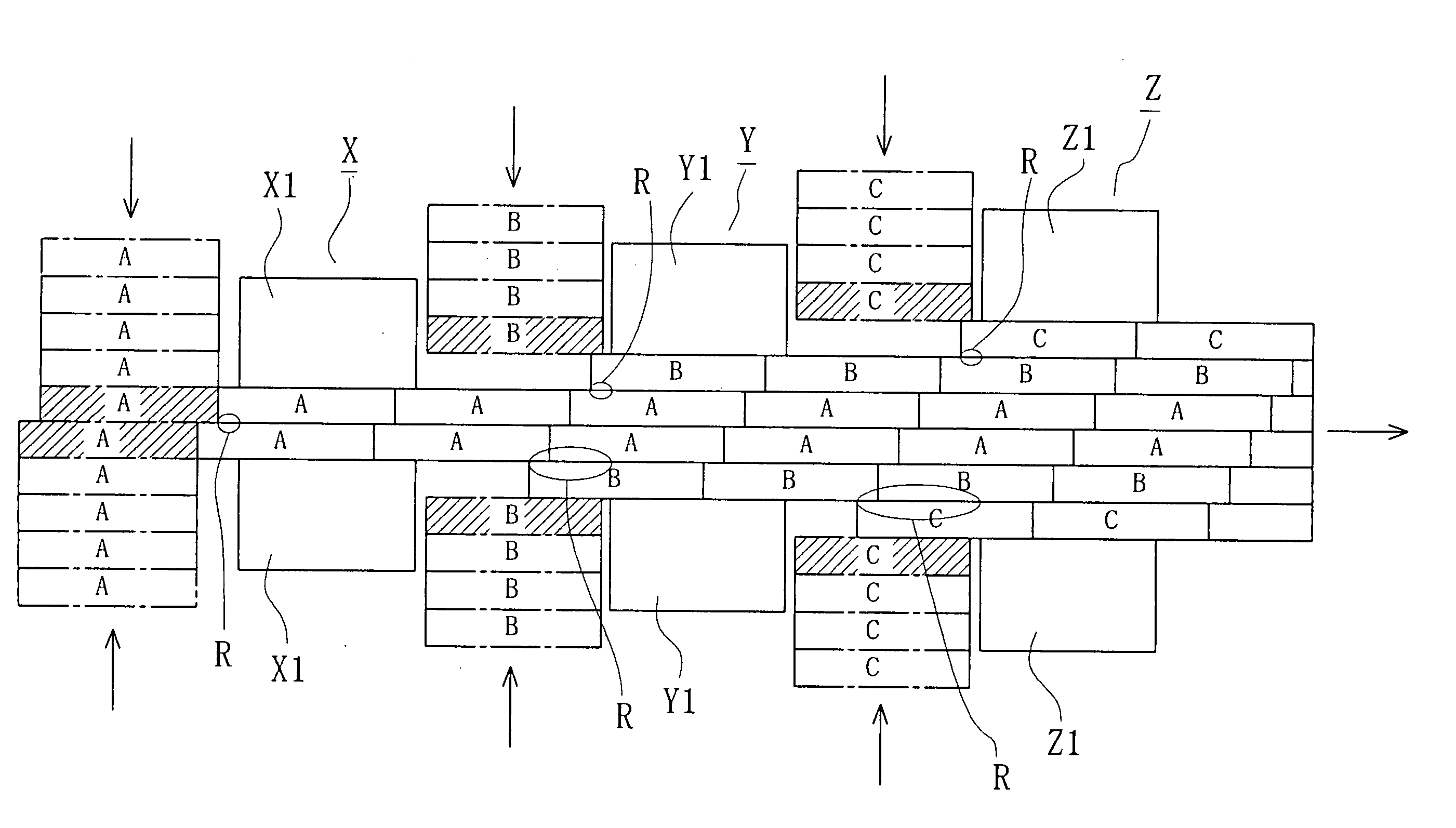

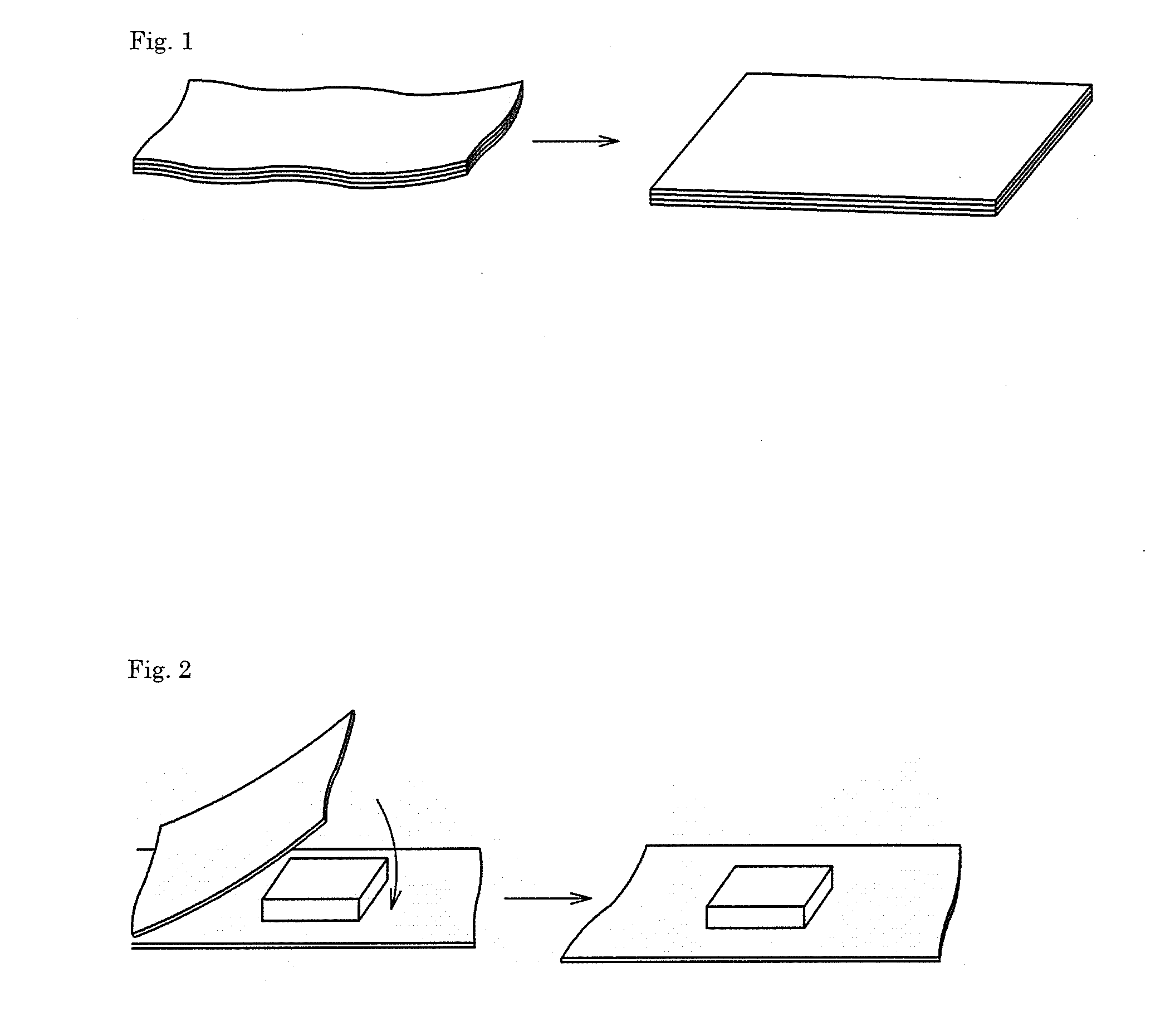

Method of manufacturing glued laminated wood

A method of manufacturing glued laminated wood such as laminated veneer lumber (LVL) is disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board wherein the end joints of the wood sheets are disposed in a staggered array. There is provided an initial base material having an end which is shaped in the form of a flight of steps including a series of alternate horizontal surface having a lengthwise dimension smaller than the length of the wood sheet and a vertical surface having a height corresponding to the wood sheet thickness, and the glued laminated wood board is formed extending from the end of such initial base material. The hot press includes a pair of heat plates each having an effective pressing area capable of covering the entire surface of the wood sheet. In hot pressing a wood sheet having on one surface thereof coated with adhesive, a board of the glued laminated wood in progress is placed and maintained for a predetermined length of time at a position where the entire top surface of the wood sheet is kept to be pressed from the top by one of the plates while the entire lower surface of the wood sheet is supported from the bottom by the other plate.

Owner:MEINAN MASCH WORKS INC

Formaldehyde-free decorative board and preparation method thereof

InactiveCN101554741BNo pollutionAchieve friendlyPlywood pressesFilm/foil adhesivesSolid woodWood veneer

The invention discloses a formaldehyde-free decorative board and a preparation method thereof. The decorative board is formed by overlaying multiple layers of wood veneers with adhesive, wherein the adhesive is plastic film. The preparation method is as follows: the plastic film is evenly laid between every two adjacent wood veneers, and the use level of the plastic membranes is over 100g / m <2>; a veneer press is used for pressing, with the pressure over 100 tons, the veneer press performs heat pressing firstly and cold pressing later, the temperature of heat pressing is over 100 DEG C and the temperature of the cold pressing is 20 DEG C to 100 DEG C The decorative board contains no formaldehyde, causes no poison or pollution on human body and surrounding environment and truly realizes the environment protection. In addition, the invention adopts the cheap plastic film as the adhesive, the production cost is low, the technology is simple, and qualitative indexes of the product completely satisfy the national standards.

Owner:深圳伟伦嘉禾环保装饰材料有限公司

Formaldehydeless fine wooden board and its preparing method

InactiveCN101058197AMoisture-proofWaterproofPlywood pressesVeneer pressesDouble coatingPulp and paper industry

The invention relates to processing technique for ornament material and building laminated fine wood board. It adjusts the glue and applies to the gluing machine, sending the wood chip to double coating machine then to the working platform and cold press on the cold forging machine. Putting the laminated wood board on the hot press, it forms into the blank made of wood chip and wooden jobbing sheet. It cut off its irregular parts, sanding both surface smooth, then coating the plate blank for double faces coating, spreading bottom and surface plates on the working platform, then cold and hot pressing, trimming and sanding to get the laminated wood board. The laminated wood board is moisture proof, water proof, durable and good in stability.

Owner:戴武兵 +1

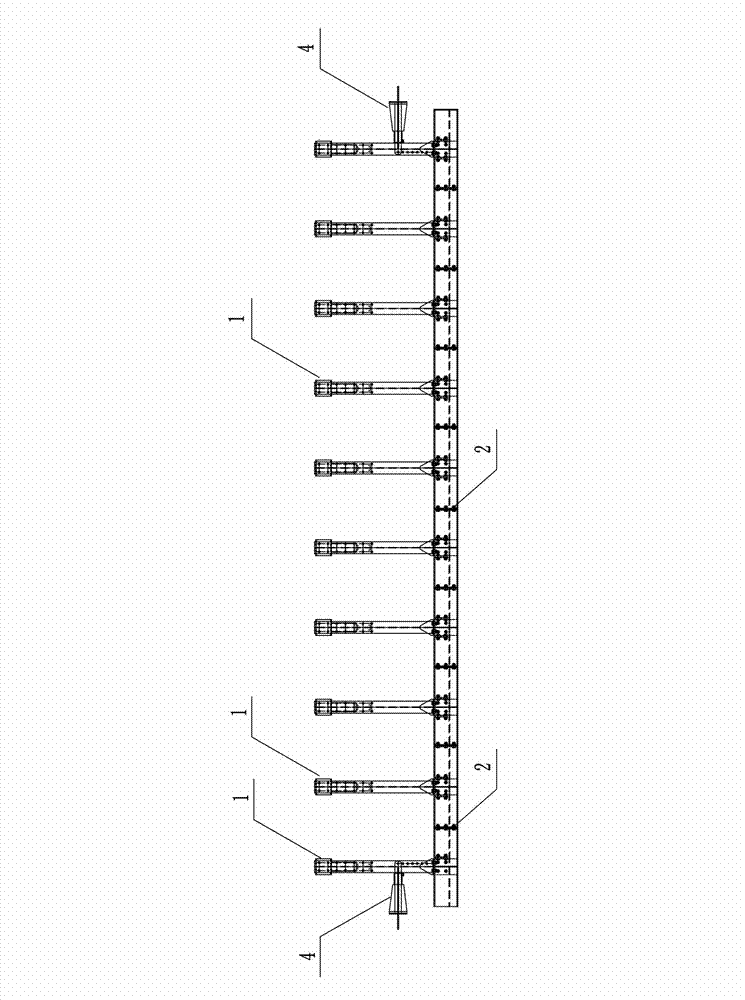

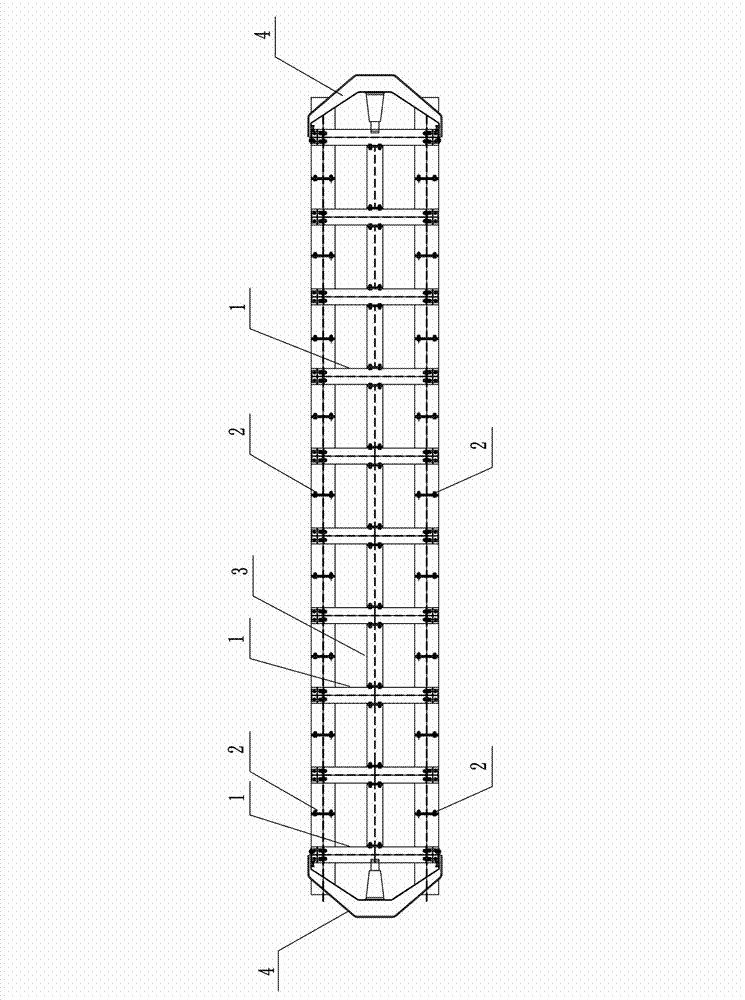

Cold press for glue-laminated bamboo member

ActiveCN102862196AImprove processing qualityImprove mechanical propertiesPlywood pressesVeneer pressesRack unitEngineering

The invention discloses a cold press for a glue-laminated bamboo member, comprising longitudinal pressurizing assemblies, a cold press integral set composed of more than one rack unit which is sequentially arrayed, as well as a lateral pressurizing element and a vertical pressurizing assembly which are arranged on the rack unit, wherein the longitudinal pressurizing assemblies are installed on the rack units which are located on the two end parts in the cold press integral set, and the force-applying ends of the longitudinal pressurizing assemblies generate a pressure along the longitudinal direction of the glue-laminated bamboo member. The cold press disclosed by the invention has the advantages of being simple and convenient in operation, wide in application range, capable of applying multidirectional pressures, capable of improving machining capacity and machining efficiency, and the like.

Owner:湖南博世安新技术有限公司

Laminated board hot-pressing device

The invention discloses a laminated board hot-pressing device. According to the technical scheme, the laminated board hot-pressing device is characterized by comprising a hot-pressing machine, a feeding device and a receiving device, the hot-pressing machine comprises a support, an upper hot-pressing table, a lower hot-pressing table, a lifting press fitting mechanism for driving the hot-pressingtable to move vertically and exerting pressure on an artificial board and an electric heating mechanism for heating the upper hot-pressing table and the lower hot-pressing table, wherein the side walls of the upper hot-pressing table and the lower hot-pressing table are both provided with a row of oil conducting through holes, the electric heating mechanism comprises a heating pipe for containingheat conducting oil, an electric heating wire spirally wound around the peripheral side of the heating pipe, oil conducting pipes for communicating two ends of the heating pipe with two ends of a heatconducting oil through hole, an oil pump for making heat conducting oil flowing among the heating pipe, the oil conducting pipes and the heat conducting oil through hole, and the outer side of the heating pipe is coated with a heat insulation material. The laminated board hot-pressing device has the advantages that the hot-pressing device heats heat conducting oil in an energy-saving and environment-friendly mode and is good in heating effect.

Owner:天津涵霖科技发展有限公司

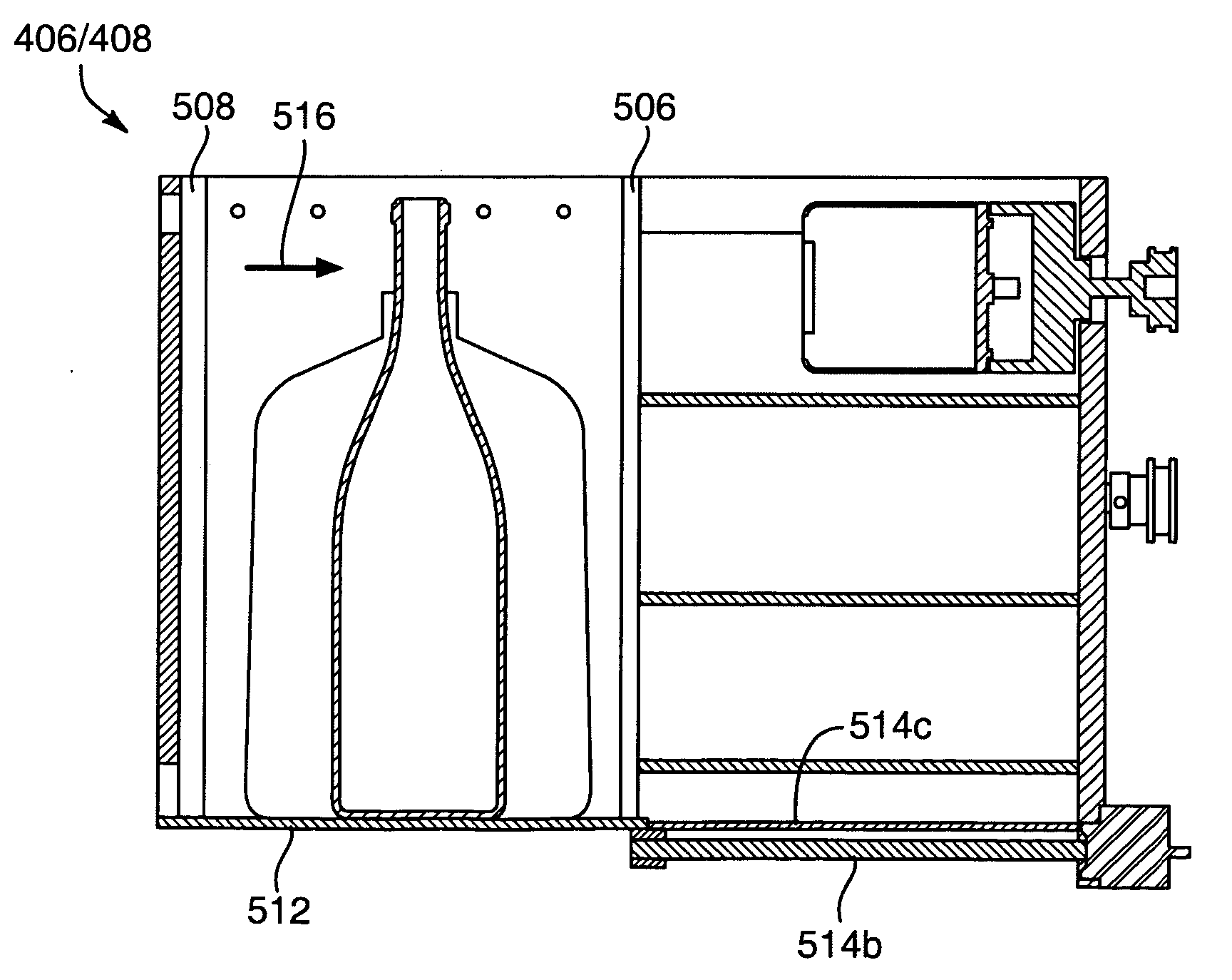

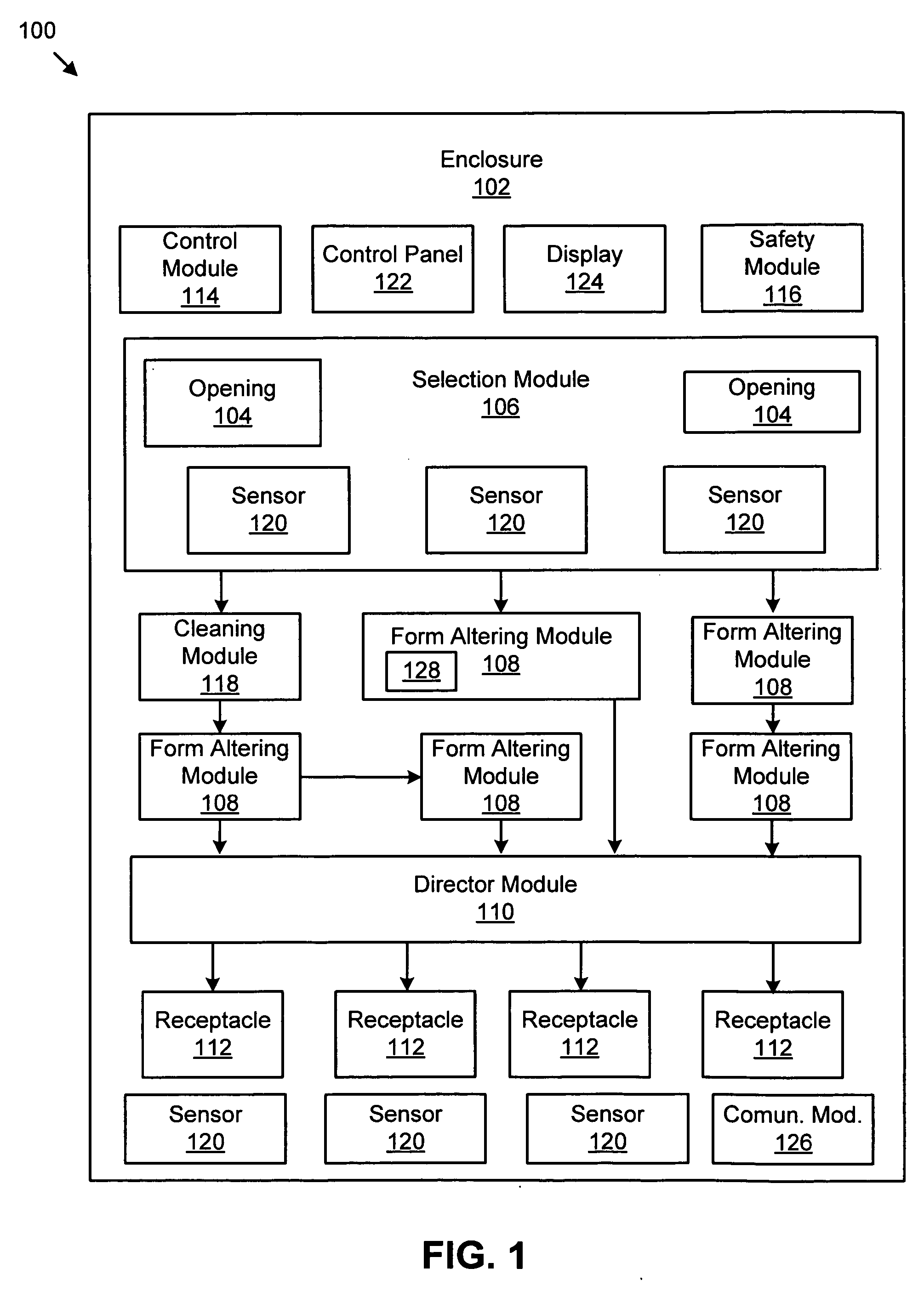

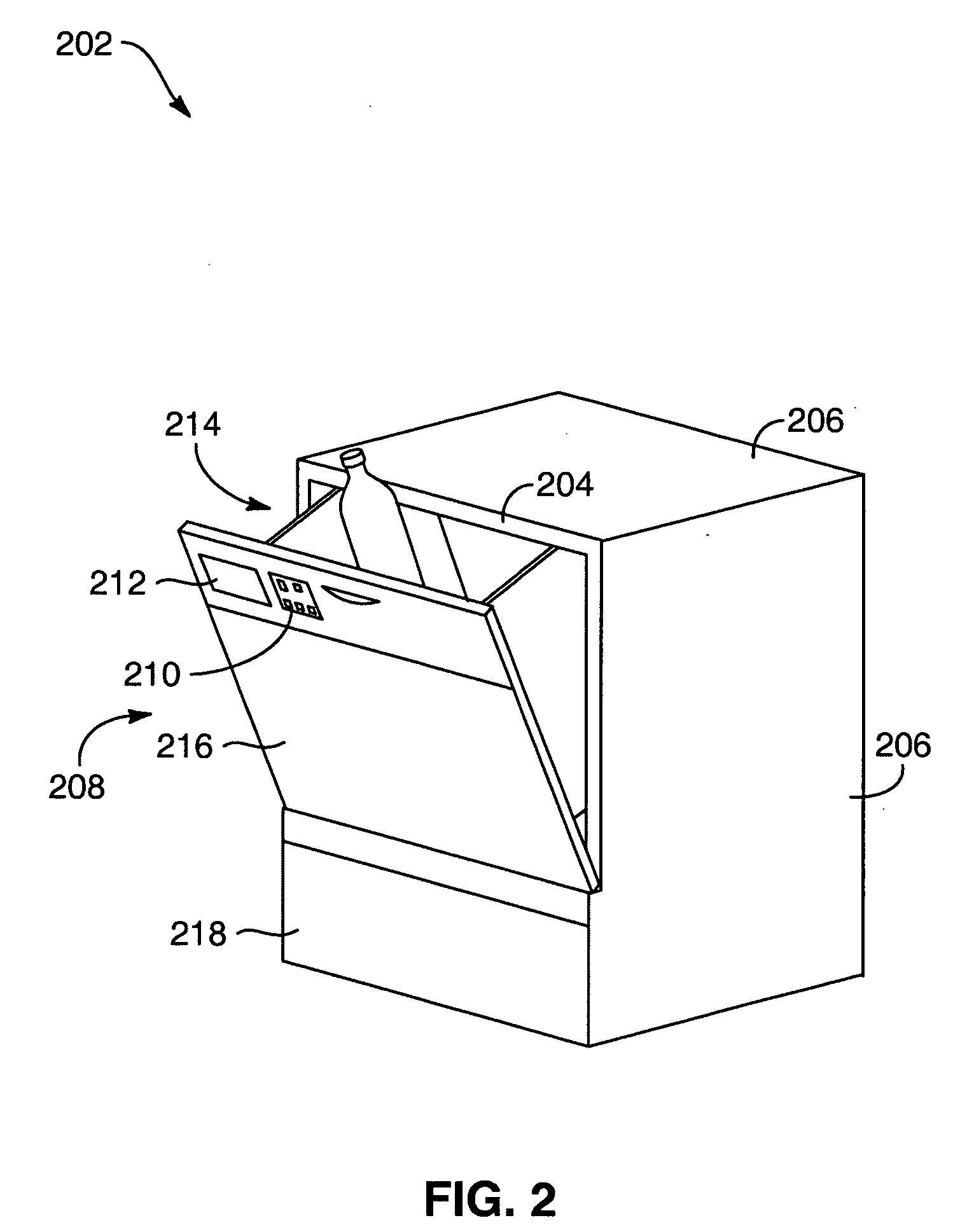

Apparatus, system, and method for condensing, separating and storing recyclable material

InactiveUS20060042197A1Easy to reprocessEasy to storePlywood pressesWaste collection and transferEngineeringWaste management

An apparatus, system, and method are disclosed for condensing, separating and storing recyclable materials. The apparatus, in one embodiment, selects a type of recyclable material, alters the recyclable material to a condensed form and stores the recyclable material in a designated receptacle. The apparatus may include an enclosure with one or more openings to receive an item made from a recyclable material, a selection module, a plurality of form altering modules, a plurality of receptacles, and a director module to automatically direct a recyclable material, responsive to a selection made with the selection module, to one of a plurality of receptacles according to the type of material selected. A system, in one embodiment, includes a recycling appliance and one or more modular form altering devices. The modular form altering devices may be interchangeable.

Owner:LANGSTON JODY

Wear-resistant composite wood plate working method

InactiveCN1935474AImprove flatnessUniform internal stressPlywood pressesVeneer pressesWear resistantFree cooling

The present invention relates to a production method of wear-resistant composite wooden plate. Said production method includes the following several steps: cutting log to obtain single plate, drying, water content of single plate is less than or equal to 7%, the thickness of top layer single plate is greater than that of lower portion single plate, gluing, prepressing at normal temperature by using 12MPa-18MPa, retaining pressure for 15 min-20 min, hot-pressing by using 14MPa-22MPa at 110-130 deg.C, retaining pressure for 3 min-12 min, placing wear-resistant decorative layer, hot-pressing by using 14-20MPa at 160-190 deg.C, retaining pressure for 30s-50s, cooling and cutting so as to obtain the invented finished product.

Owner:孙维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com