Carbon fiber fabric reinforced poplar laminated veneer lumber structural element and machining method thereof

A carbon fiber cloth and poplar veneer technology, which is applied in wood processing appliances, wood veneer bonding, veneer presses, etc. The problem of low tensile strength is to improve the added value of production and technological content, solve the inability to produce large-scale wooden structural components, and expand the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

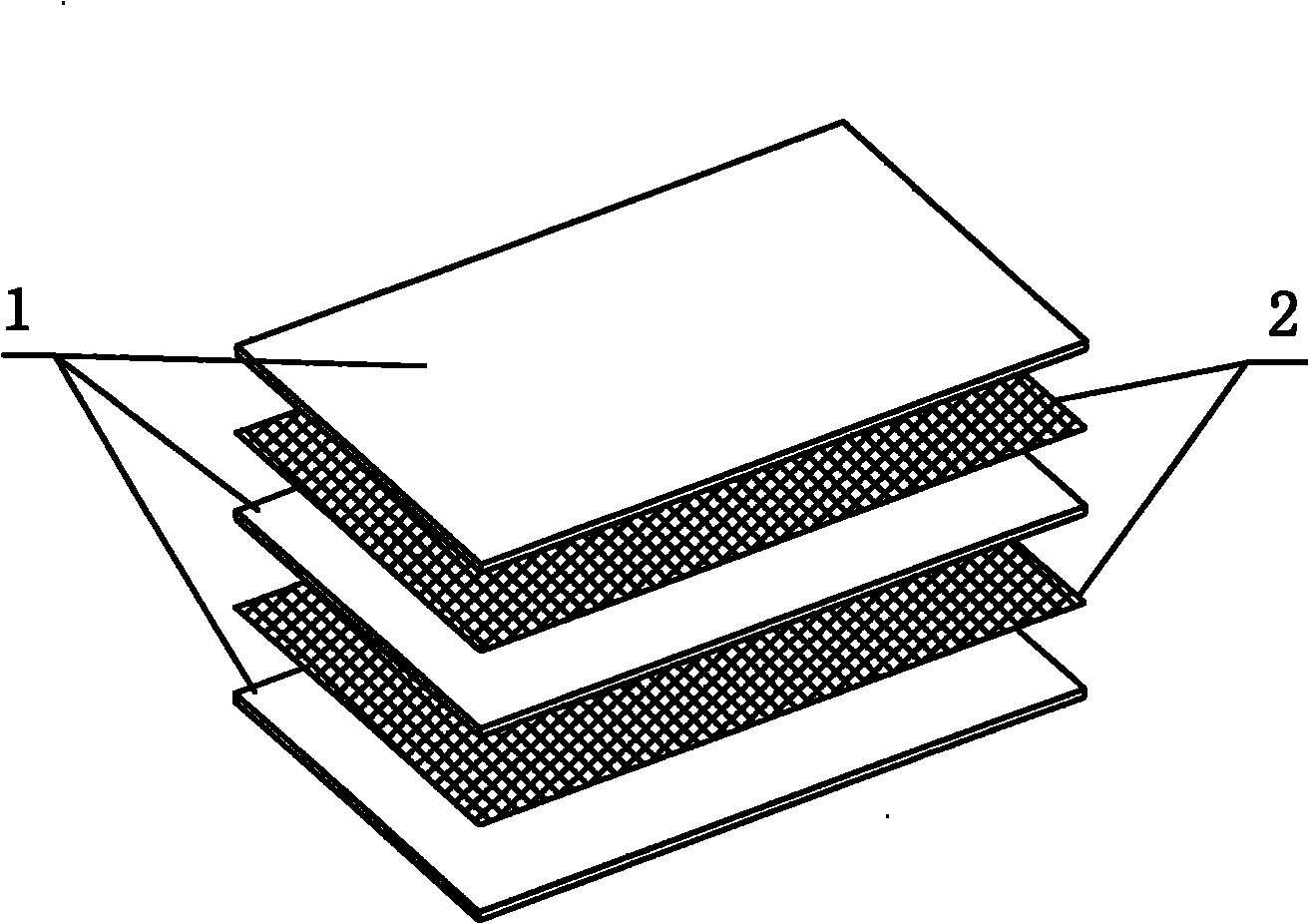

[0028] Such as figure 1 As shown, the present invention is that carbon fiber cloth and poplar wood rotary slices can be formed by laying up method, and processed and manufactured by cold pressing forming technology, and poplar wood rotary slices 1 and carbon fiber cloth 2 are laminated and glued together. Through their combination, greatly improved The mechanical properties of poplar materials. The thickness of the poplar rotary slice 1 is less than 2mm, and the poplar rotary slice 1 and the carbon fiber cloth 2 are bonded by epoxy resin.

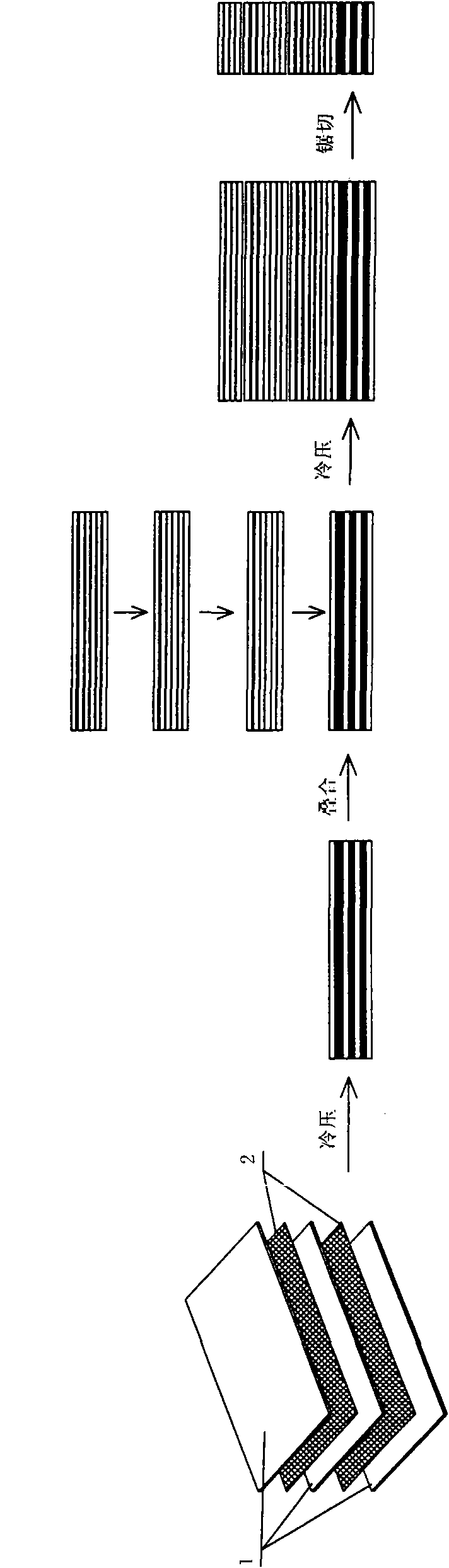

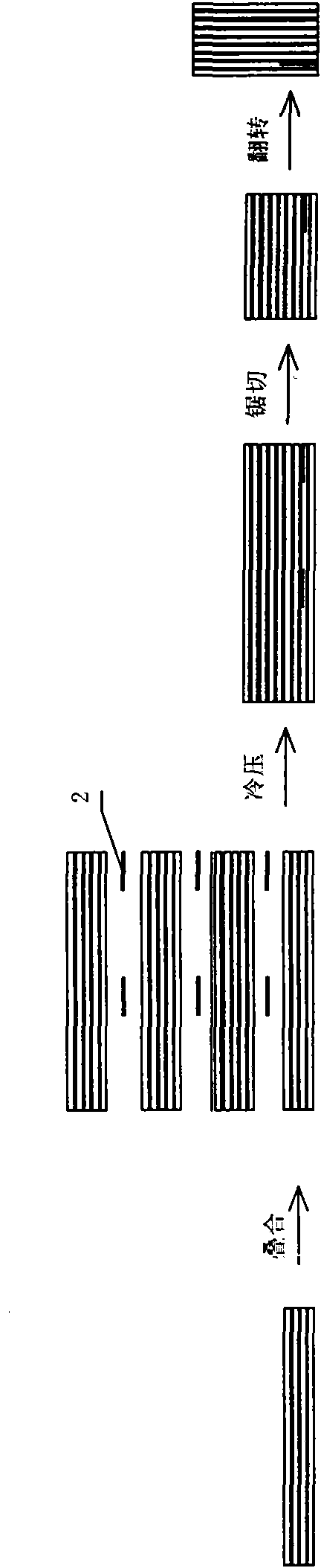

[0029] Carbon fiber cloth is used to reinforce LVL. During production, the LVL sheet is first produced according to the LVL production process, and then sawn into LVL sheets of corresponding length and width according to the size of the structural member, and then The thickness problem is solved by laminating the laminated veneer lumbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com