Patents

Literature

1208 results about "Nylon fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon Fiber: Nylon is a manufactured fiber in which the fiber forming substance is a long-chain synthetic polyamide in which less than 85% of the amide-linkages are attached directly (-CO-NH-) to two aliphatic groups.

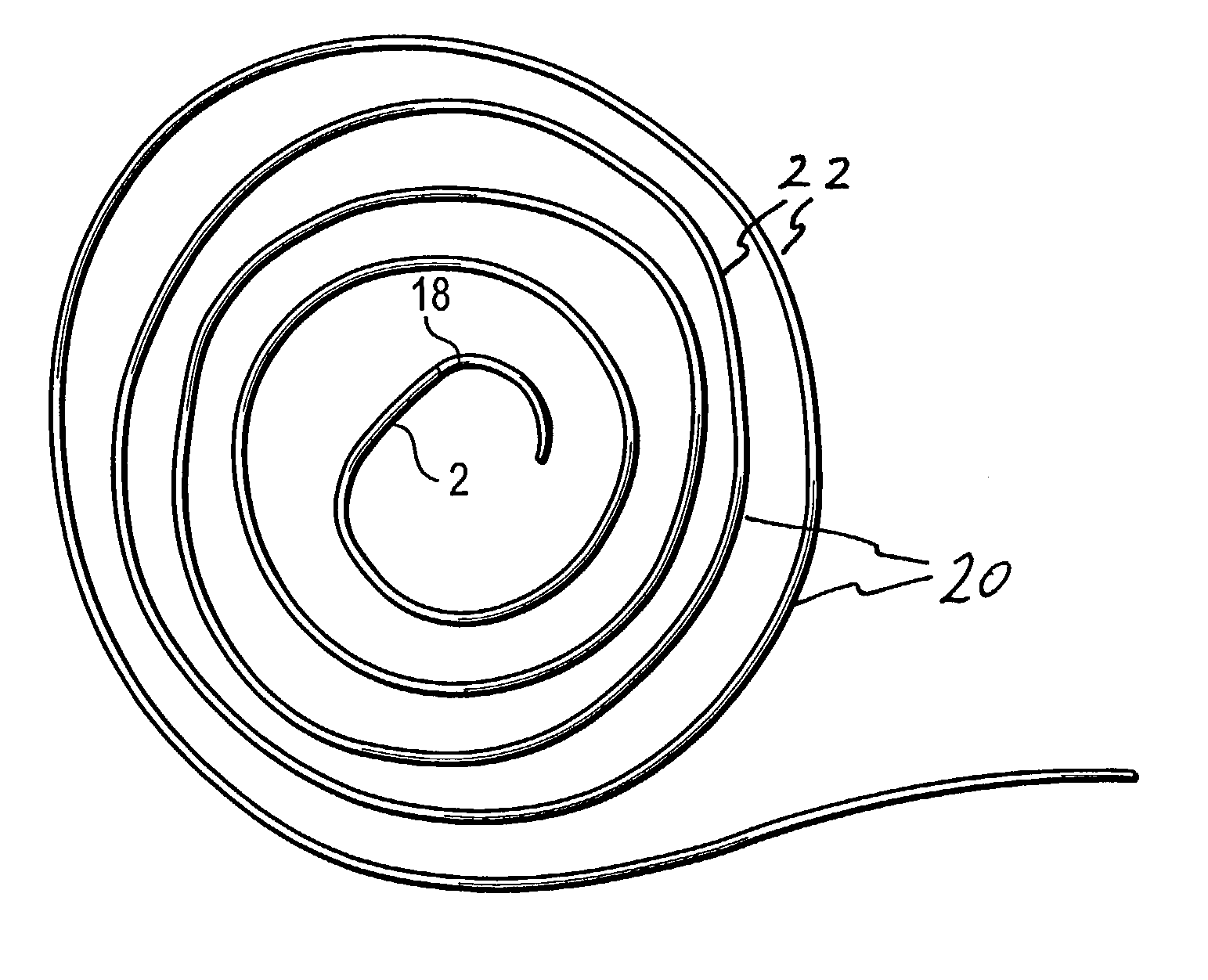

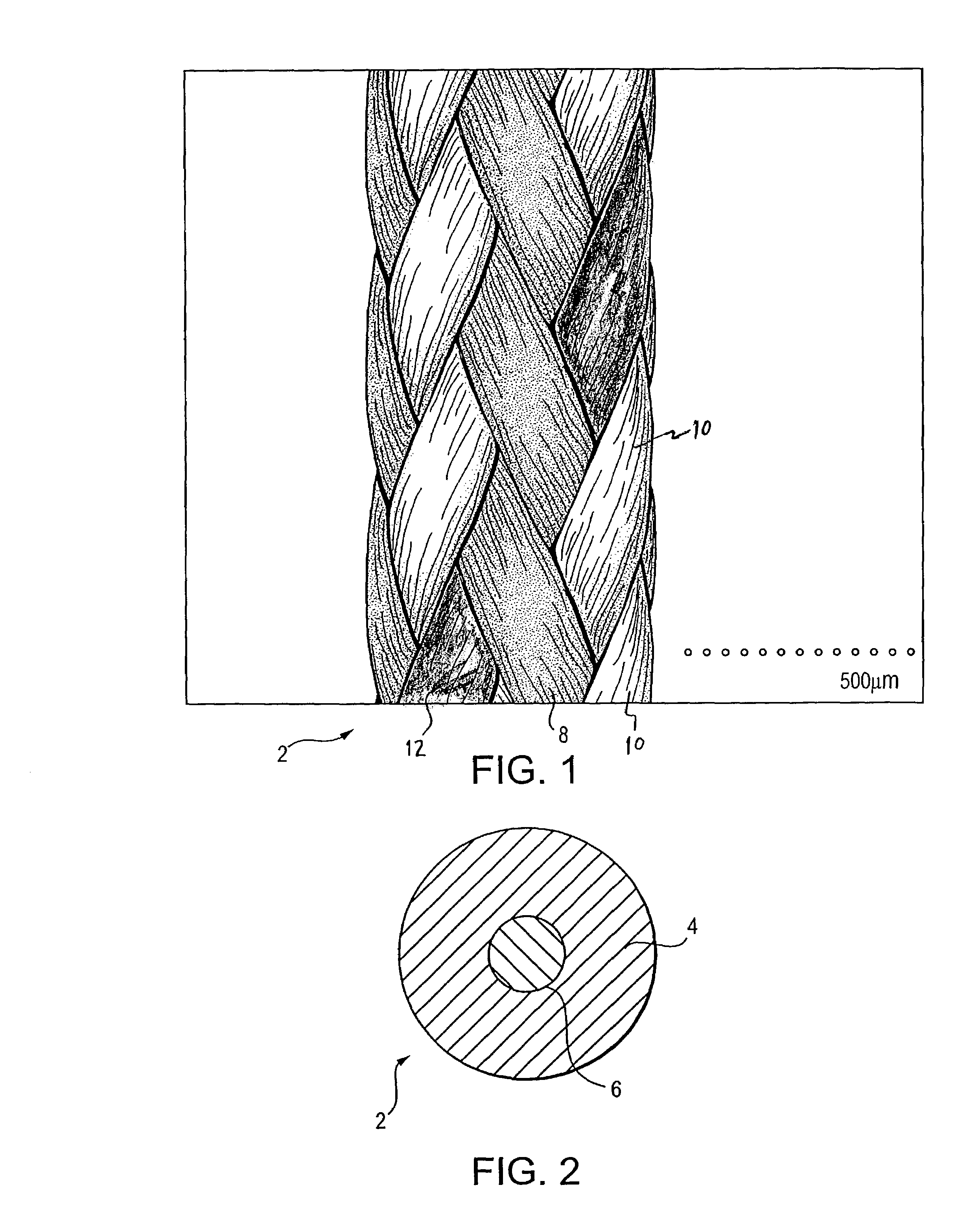

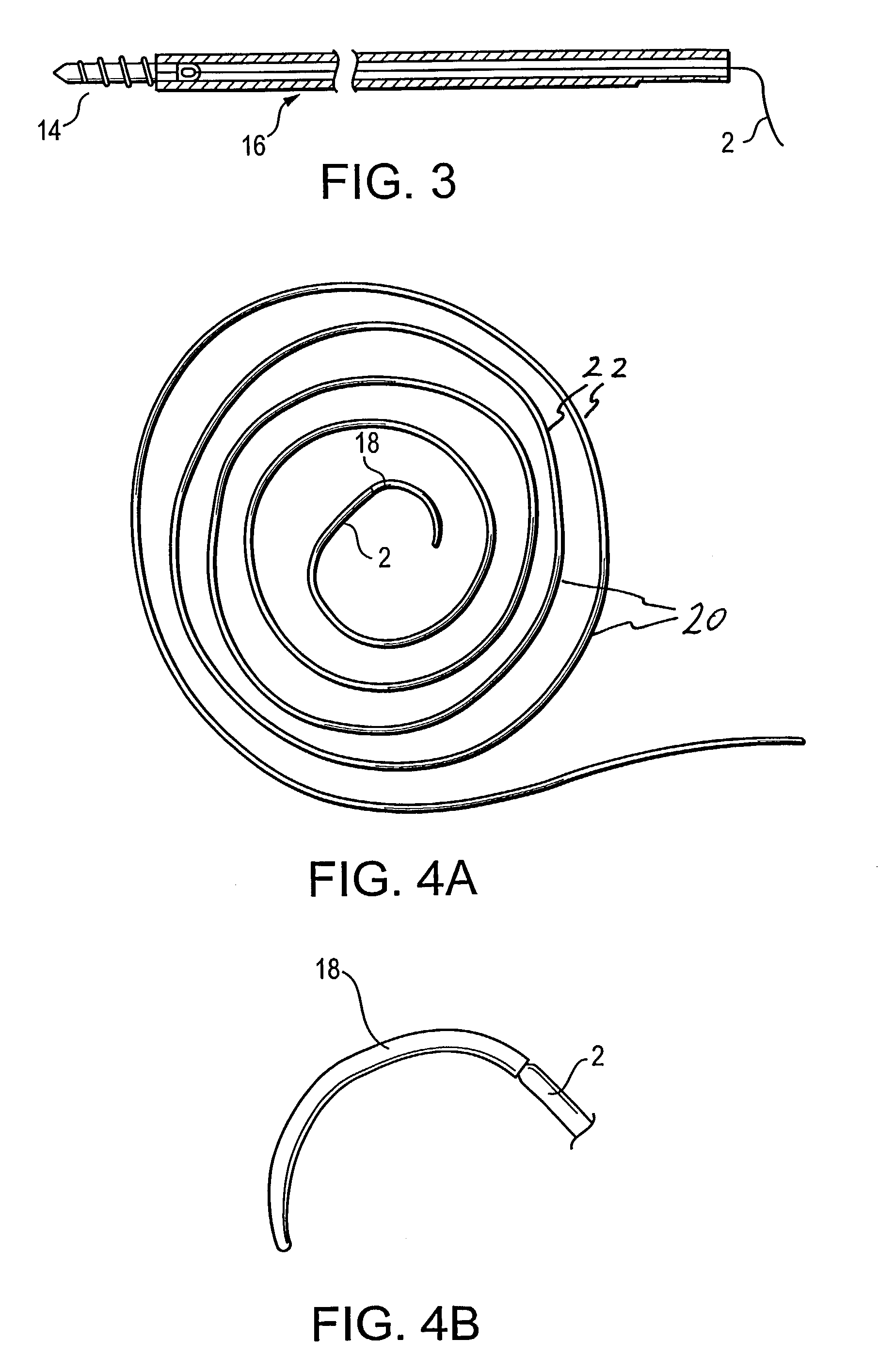

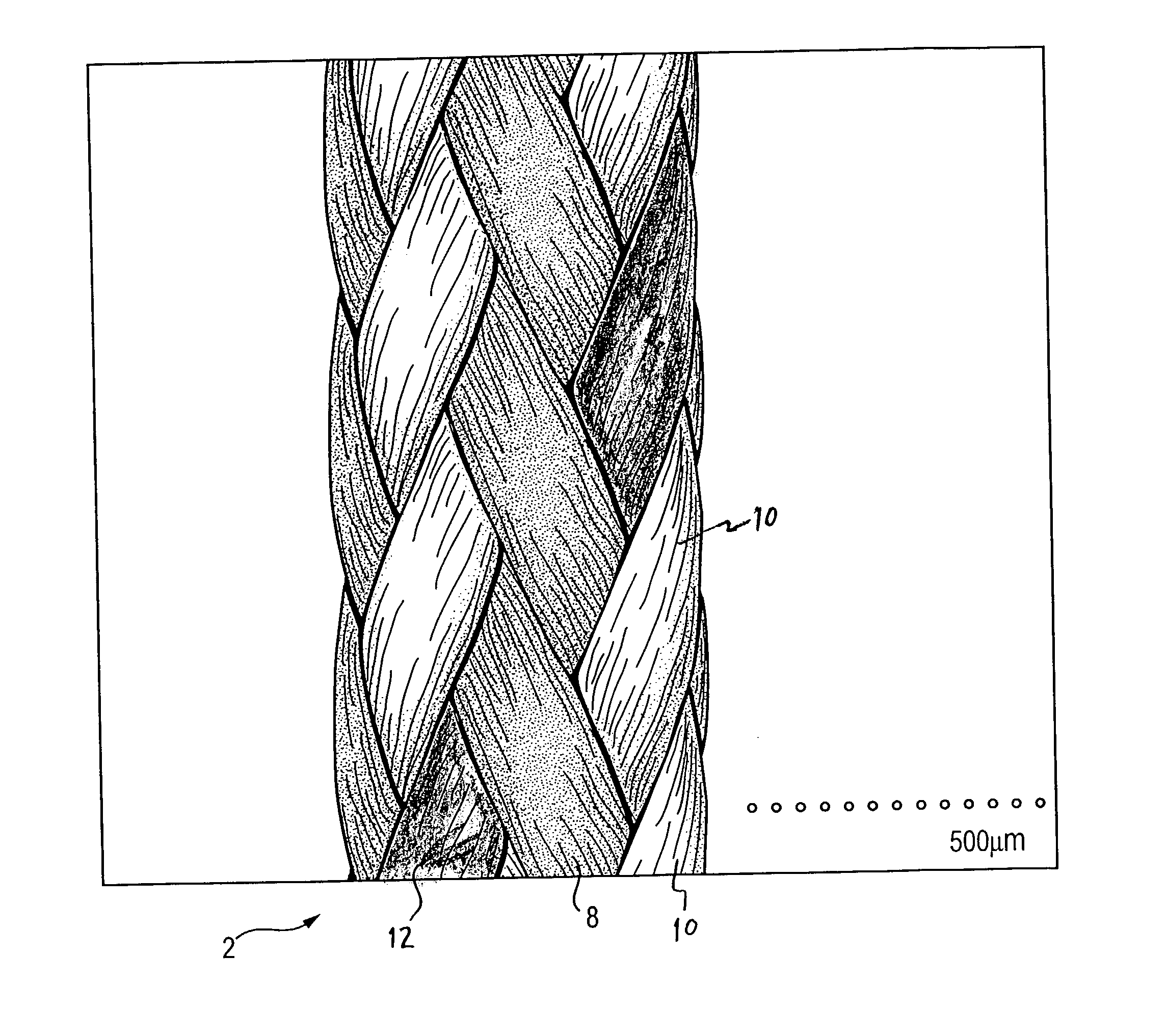

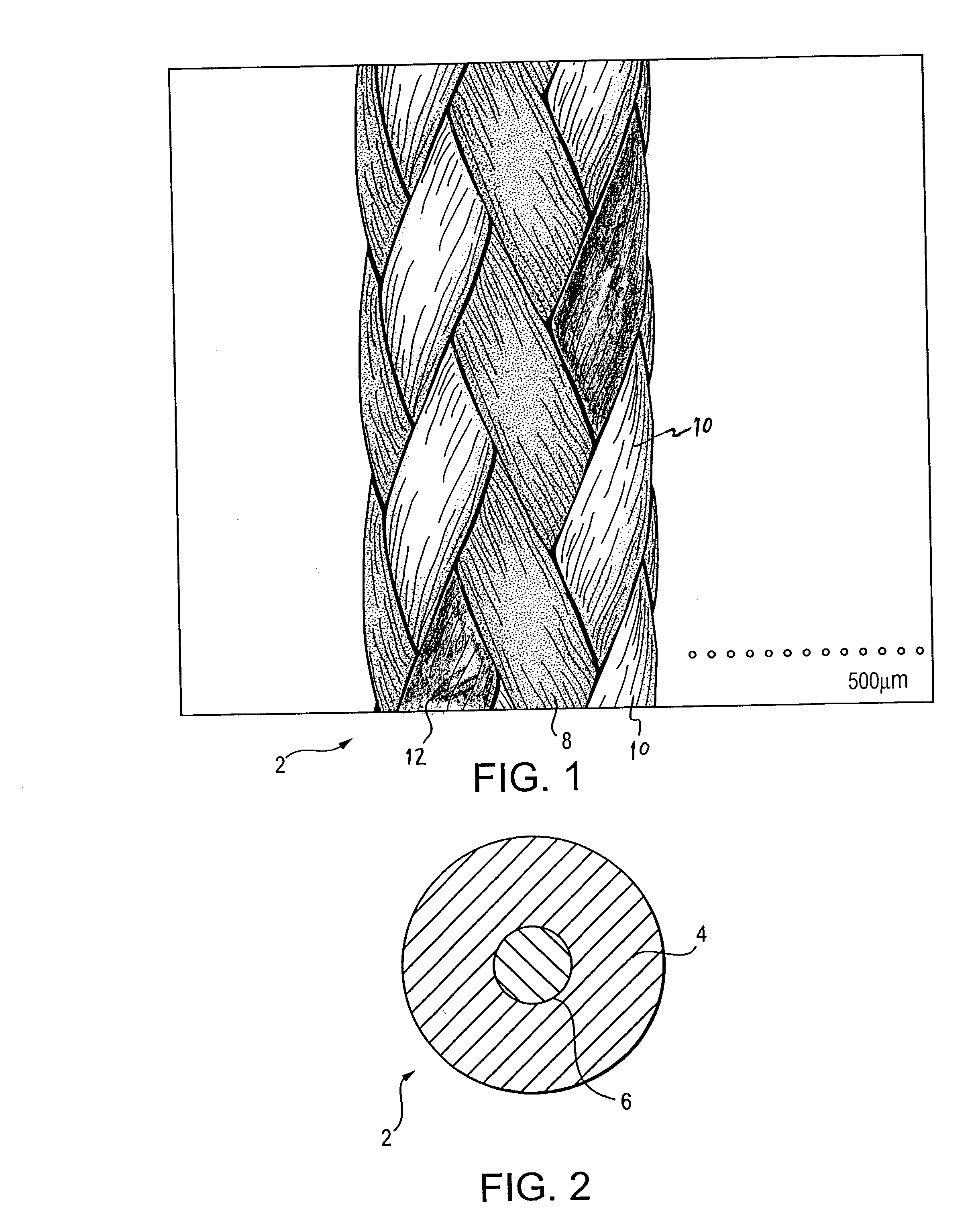

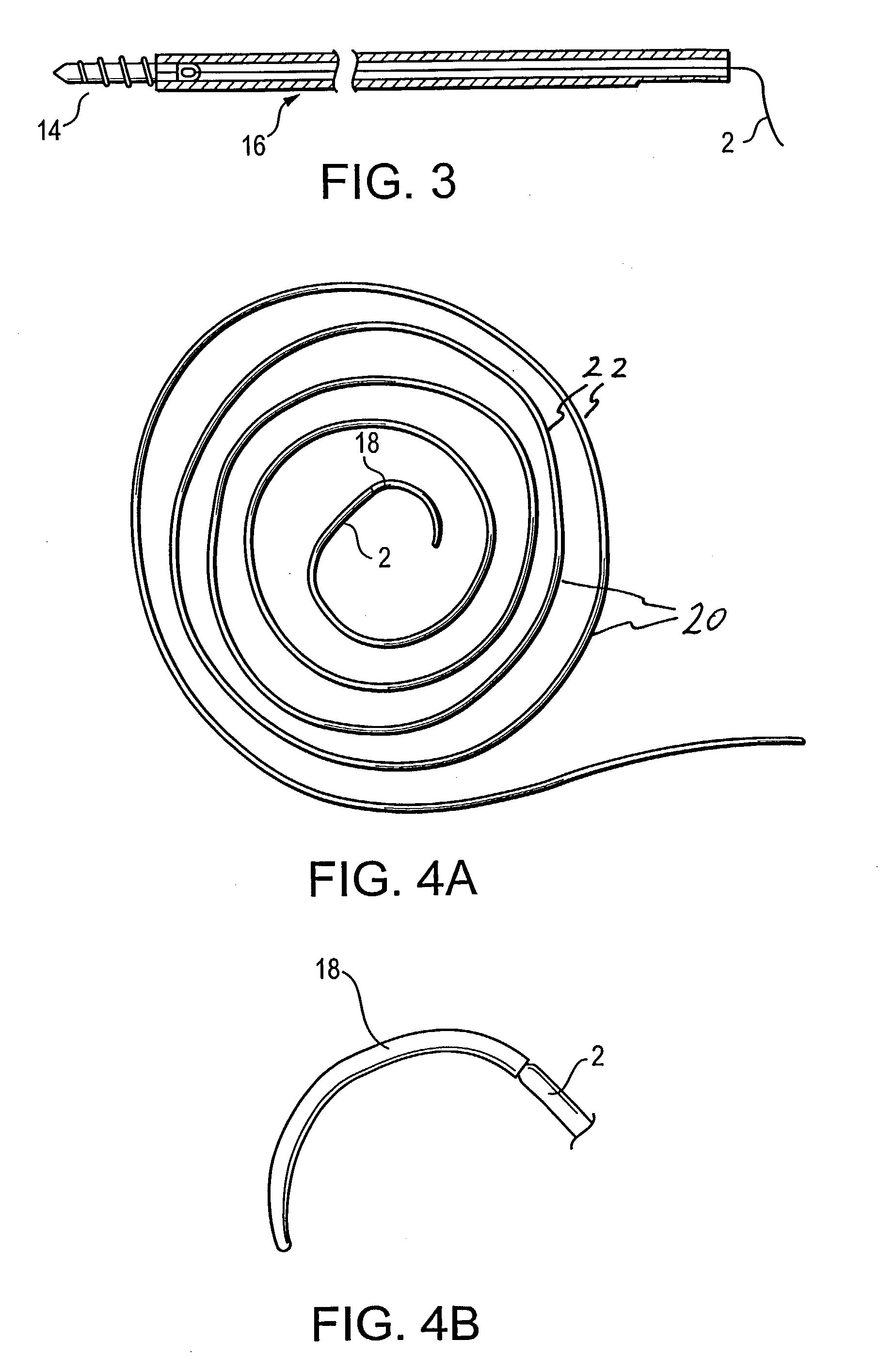

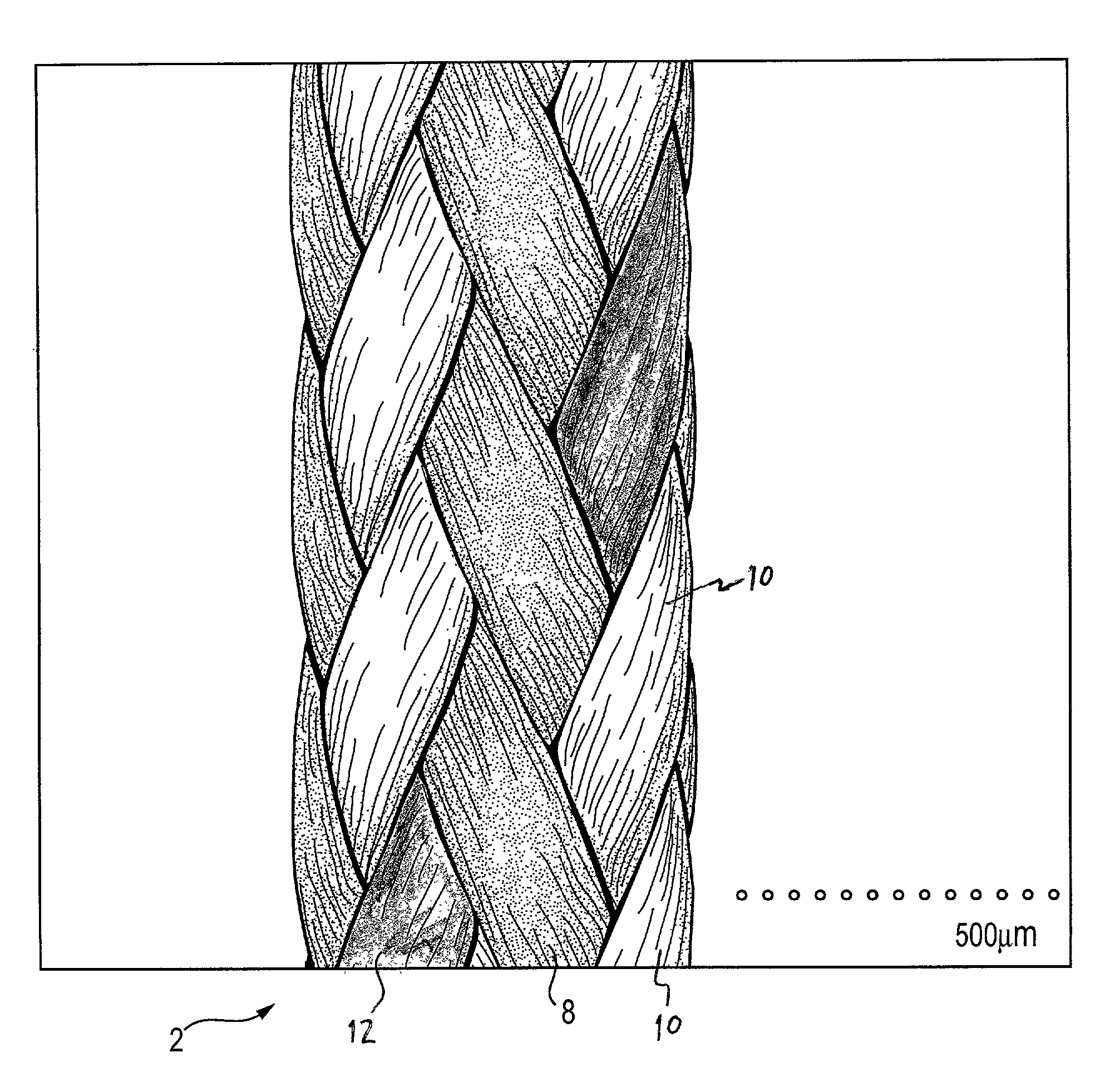

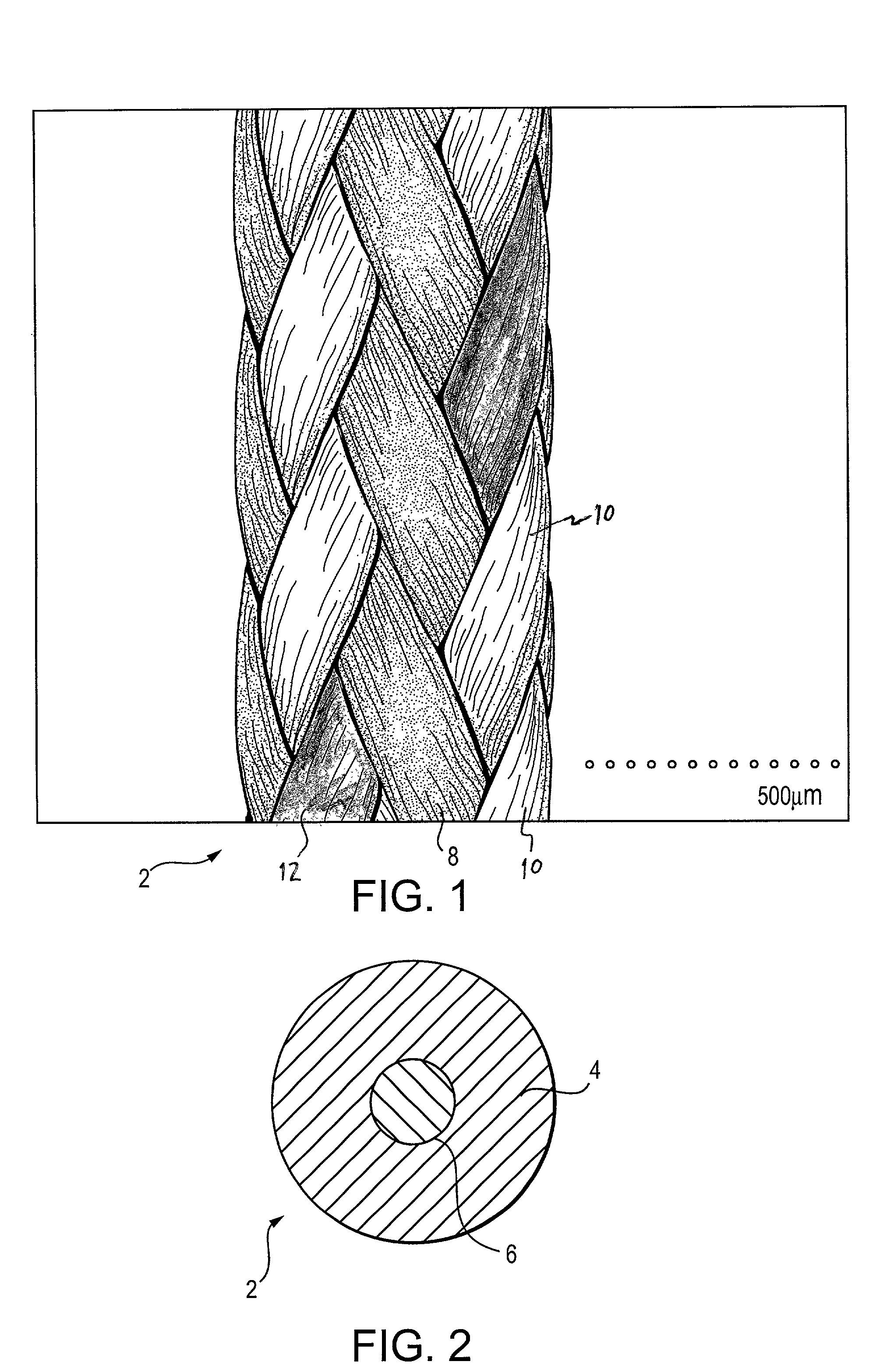

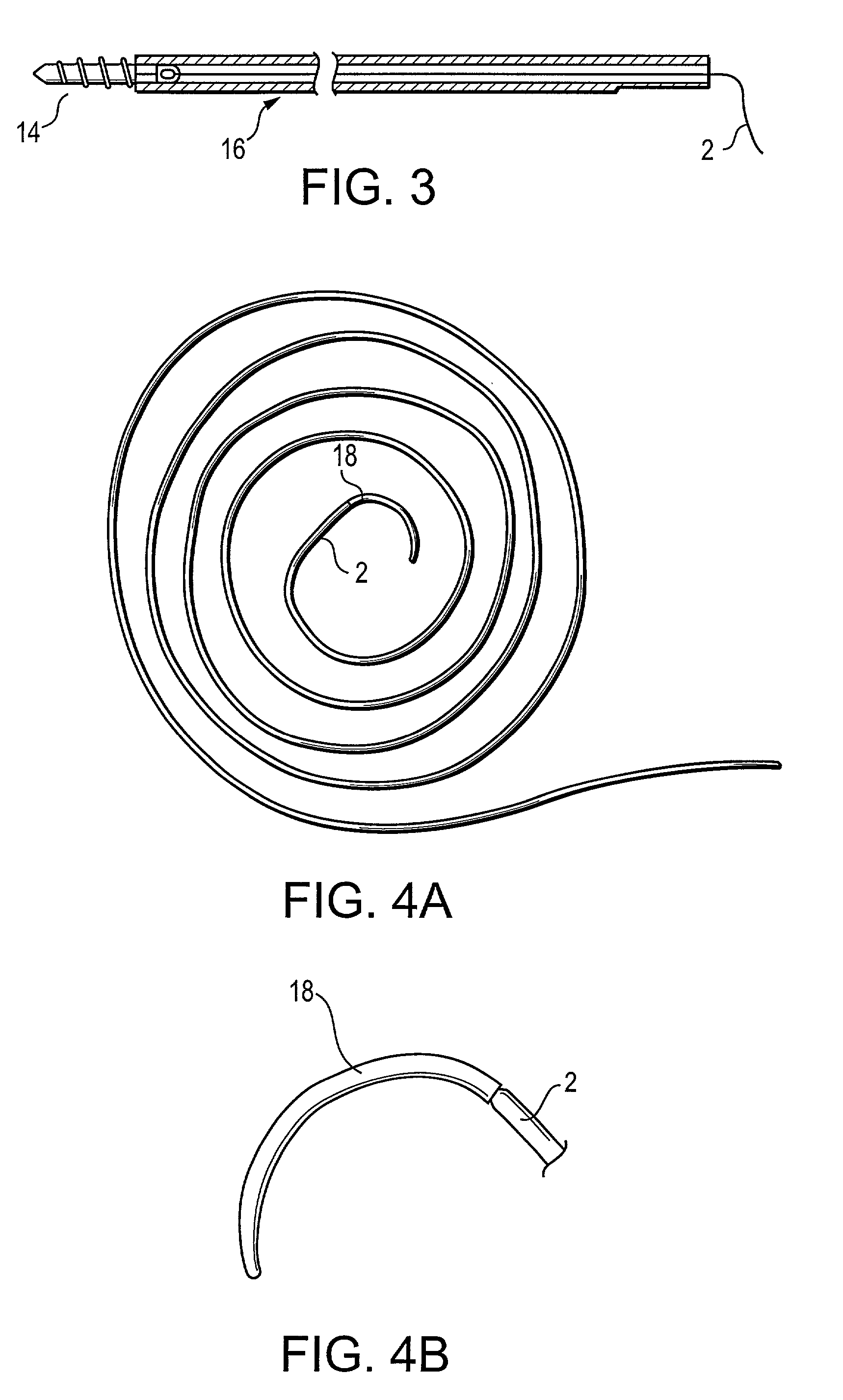

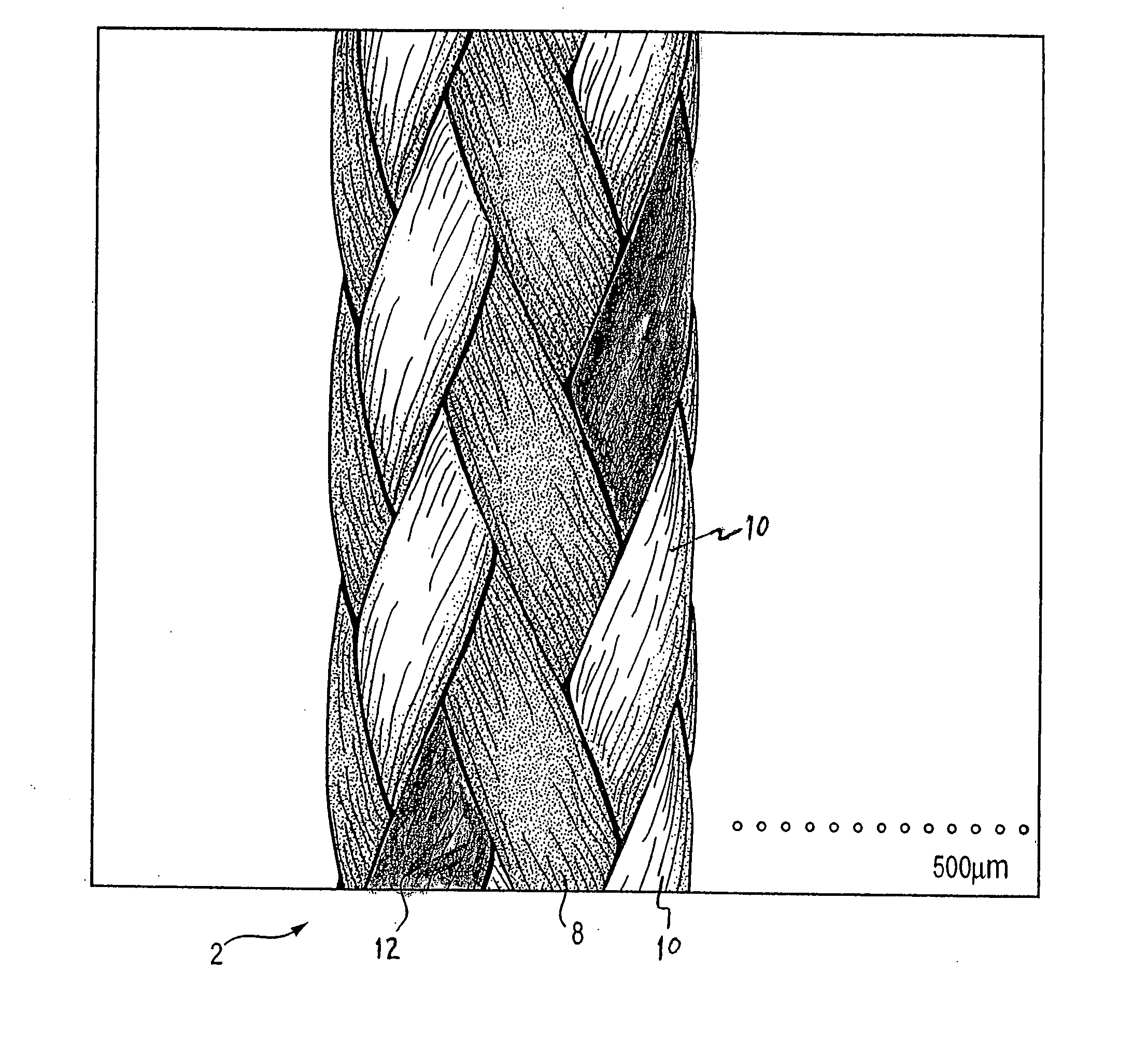

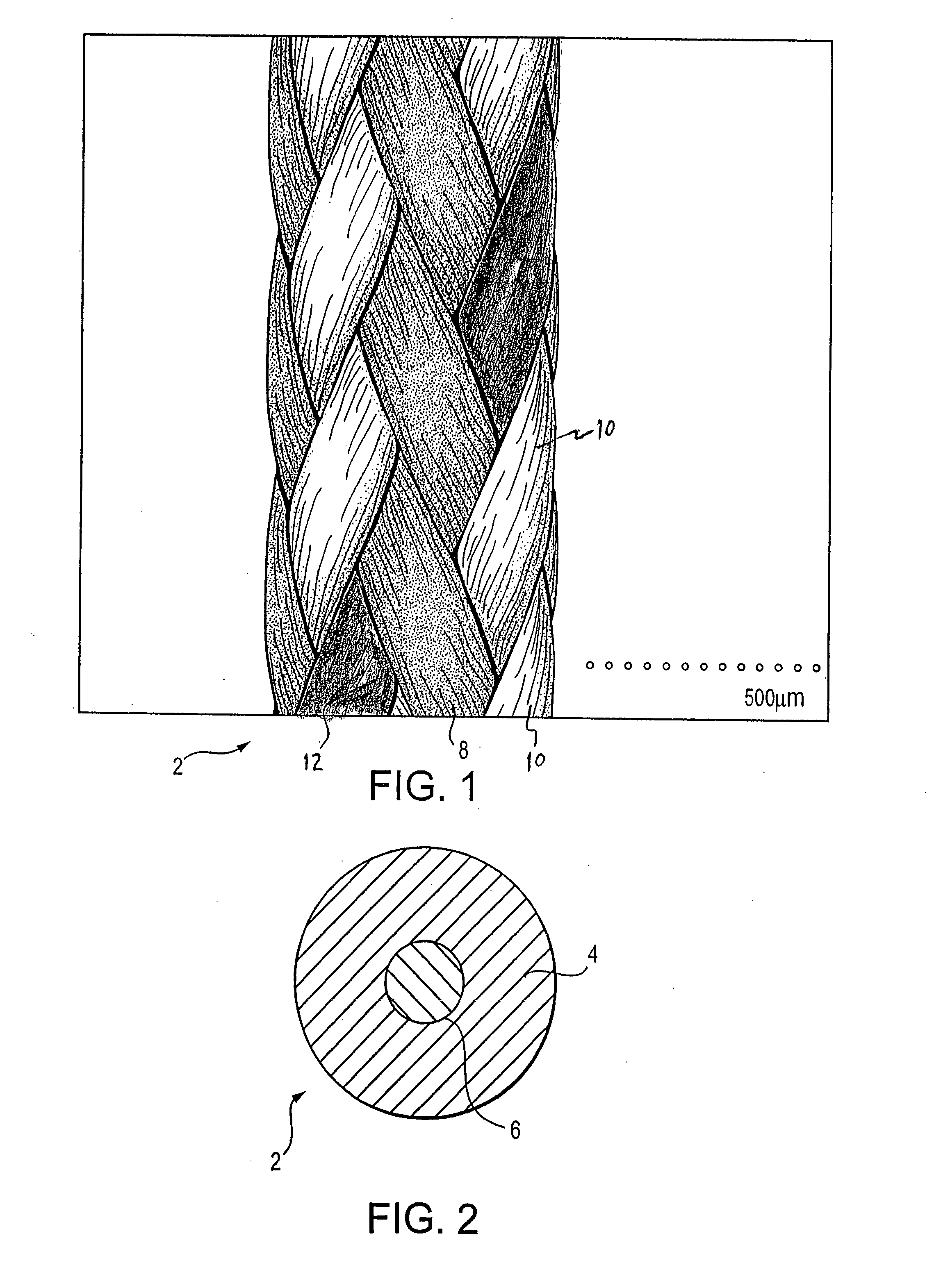

High strength suture with colored trace at one end

InactiveUS6994719B2High strengthImproved tie down characteristicSuture equipmentsDiagnosticsPolyesterEngineering

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable trace preferably is provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily identified.

Owner:ARTHREX INC

High strength suture with colored trace at one end

Owner:ARTHREX

High strength suture with coating and colored trace

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

Flame-resistant fiber blend, yarn, and fabric, and method for making same

InactiveUS20060292953A1Improve flame retardant performanceReduce weightWarp knittingWoven fabricsYarnAramid

A fiber blend, a yarn spun from the fiber blend, and a fabric made from the yarn, wherein the fiber blend comprises: (a) about 40 wt.% to about 65 wt.% modacrylic fibers containing antimony, or FR acrylic fibers; (b) about 10 wt.% to about 50 wt.% cotton fibers or FR cotton fibers; (c) up to about 25 wt.% nylon fibers; and (d) greater than about 3 wt.% and less than 10 wt.% para-aramid fibers. The fabric is over 90 percent dyeable and is capable of achieving ASTM F1506 certification with an Arc Thermal Performance Value greater than 8.0 cal / cm2. The fabric is woven or knitted, and has a weight of about 4.0 oz. / yd.2 to about 10.5 oz. / yd.2. The fabric is suitable for garments worn during activities in which there is potential for exposure to flame and / or electrical arc.

Owner:SPRINGFIELD

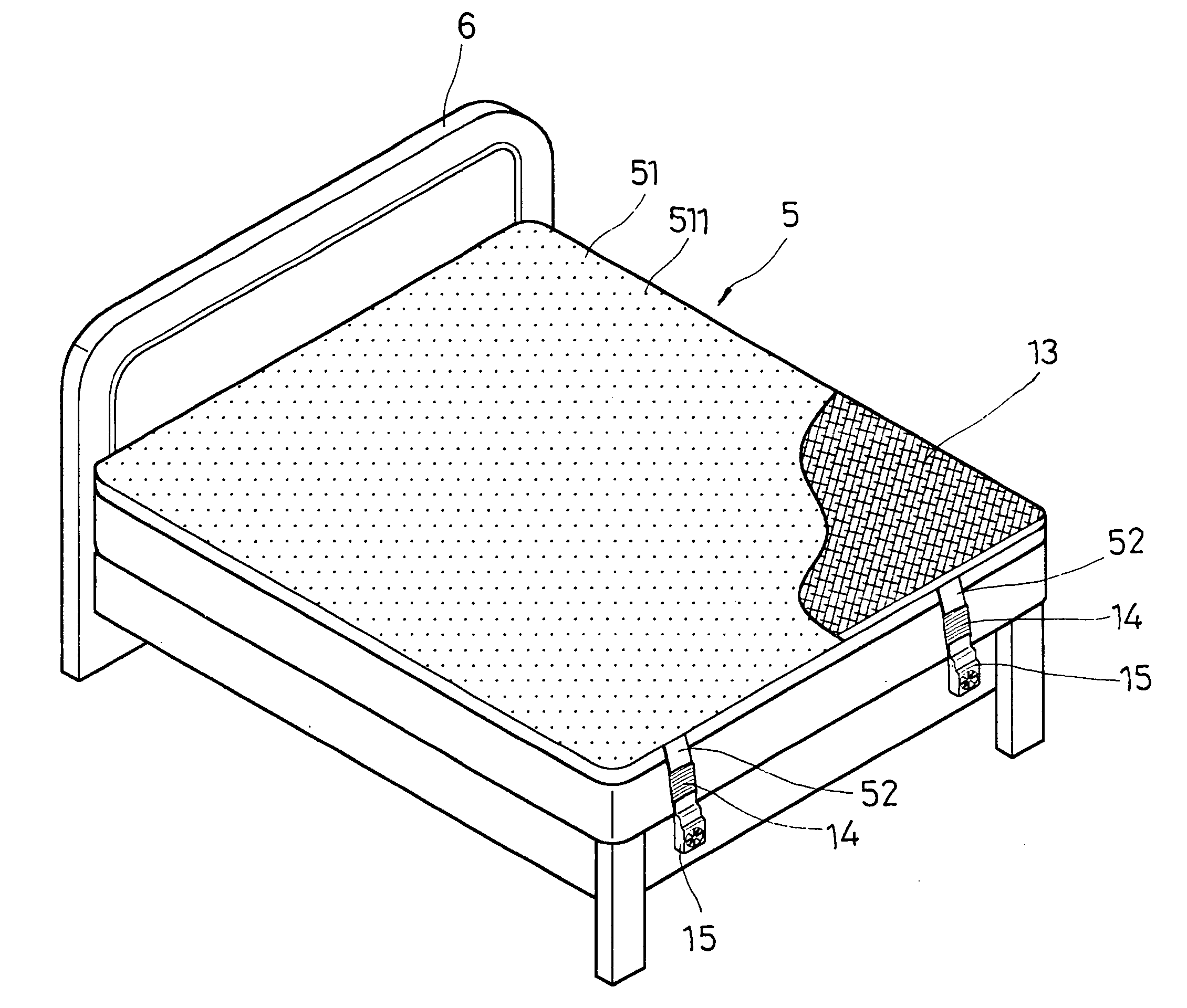

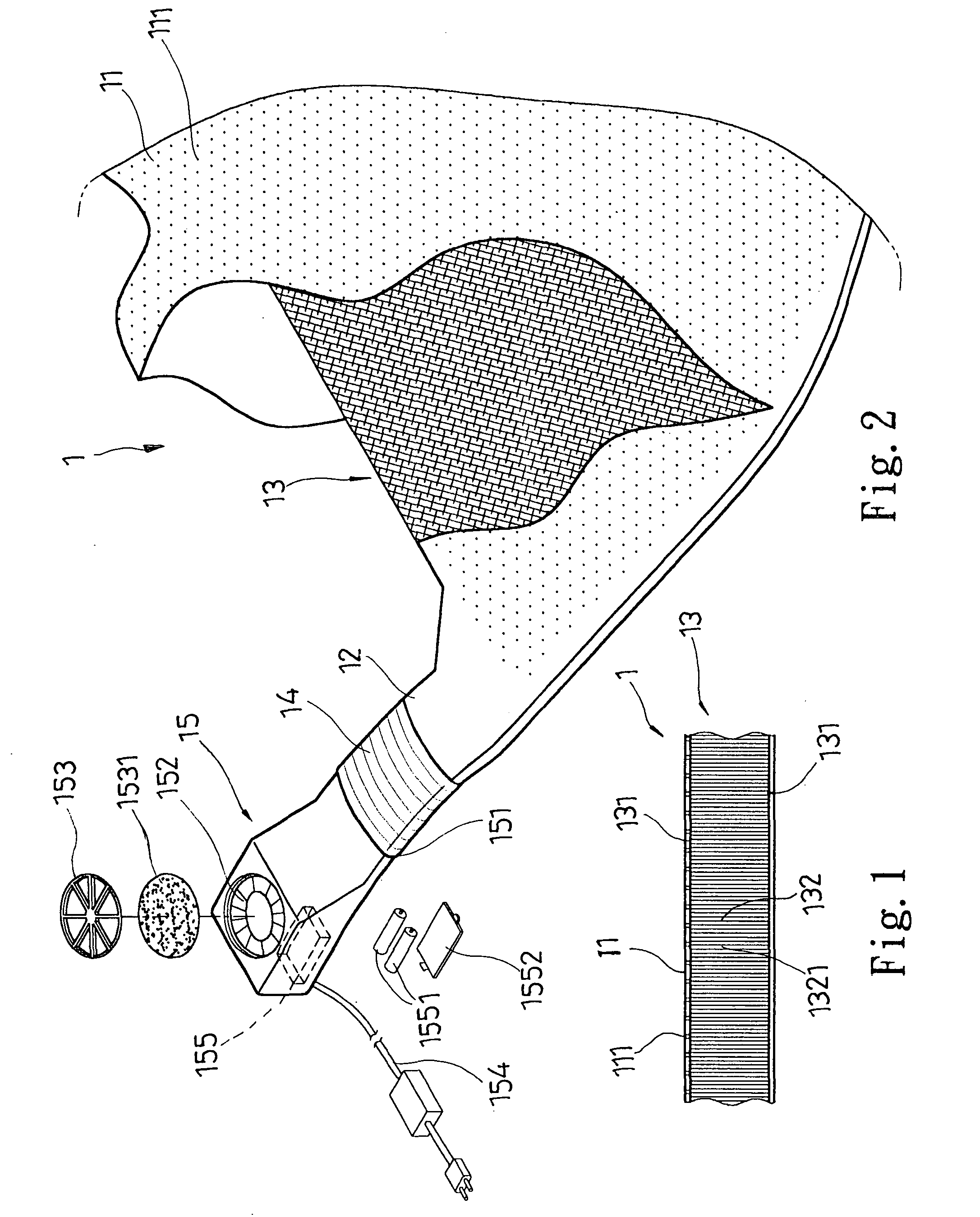

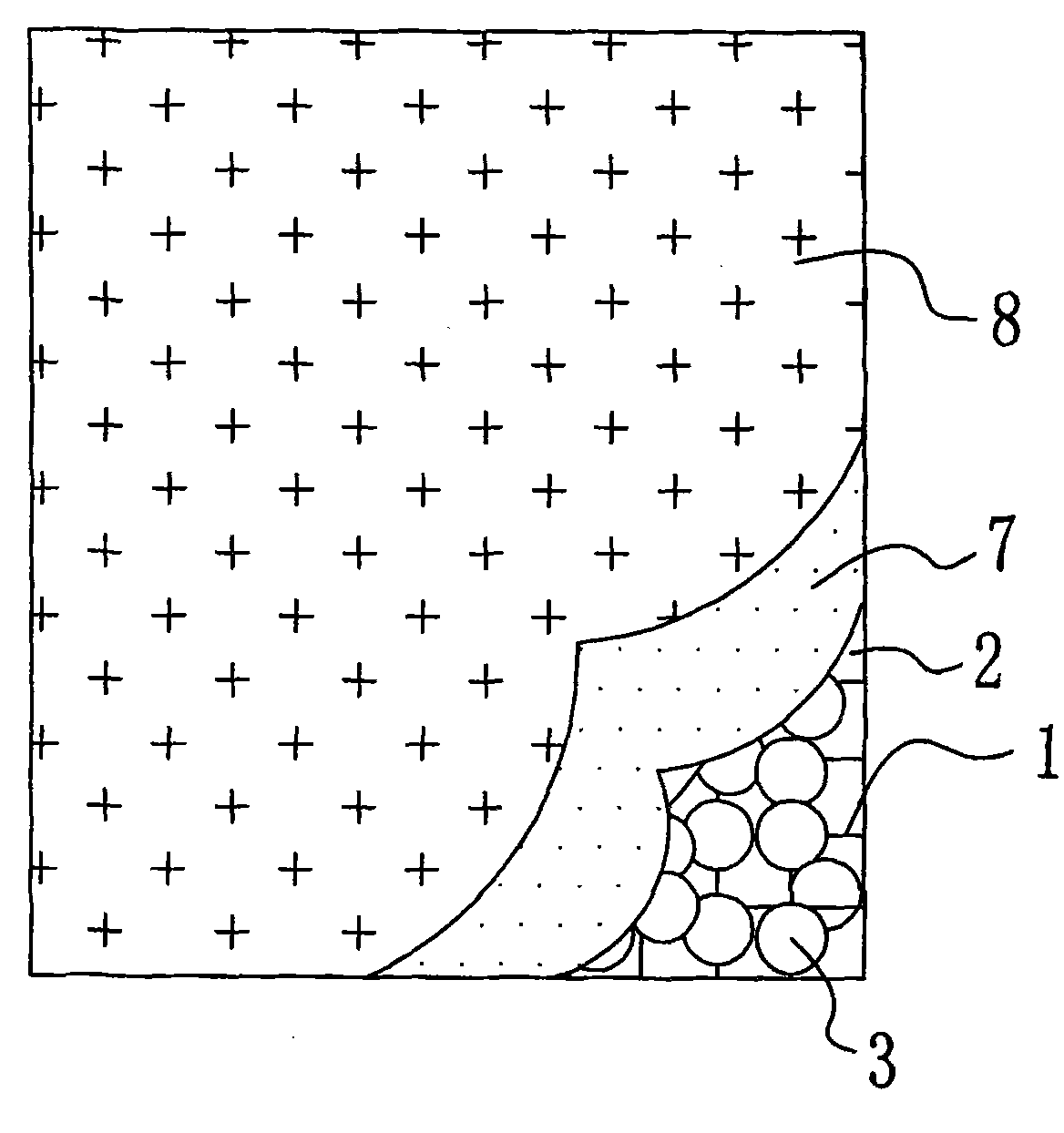

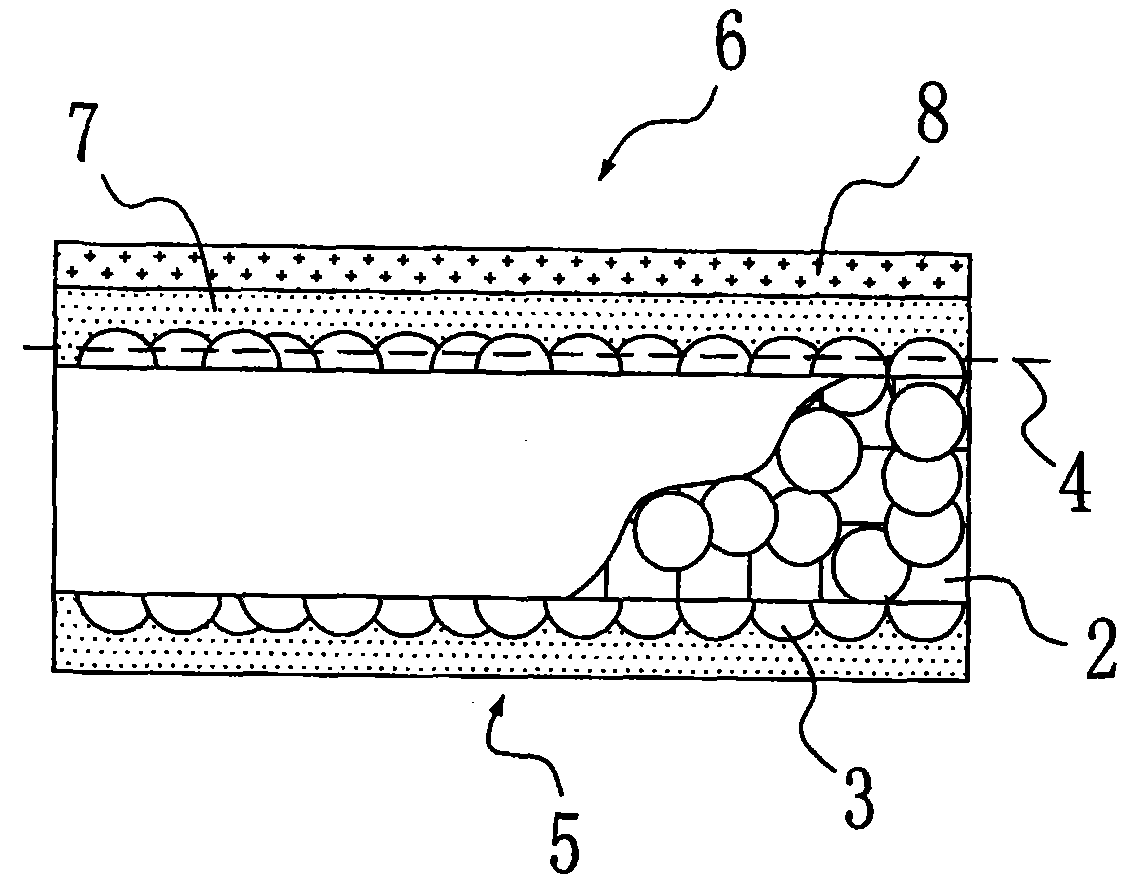

Ventilation mattress

InactiveUS20050011009A1Easy to adjustHighly compressibleStuffed mattressesSpring mattressesNylon fiberAirflow

Owner:WU HSIANG LING

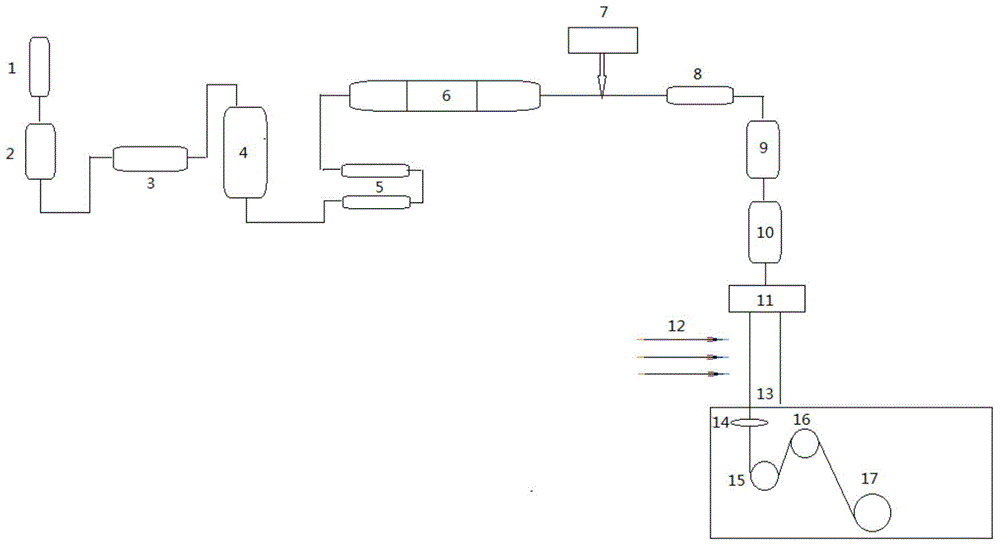

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

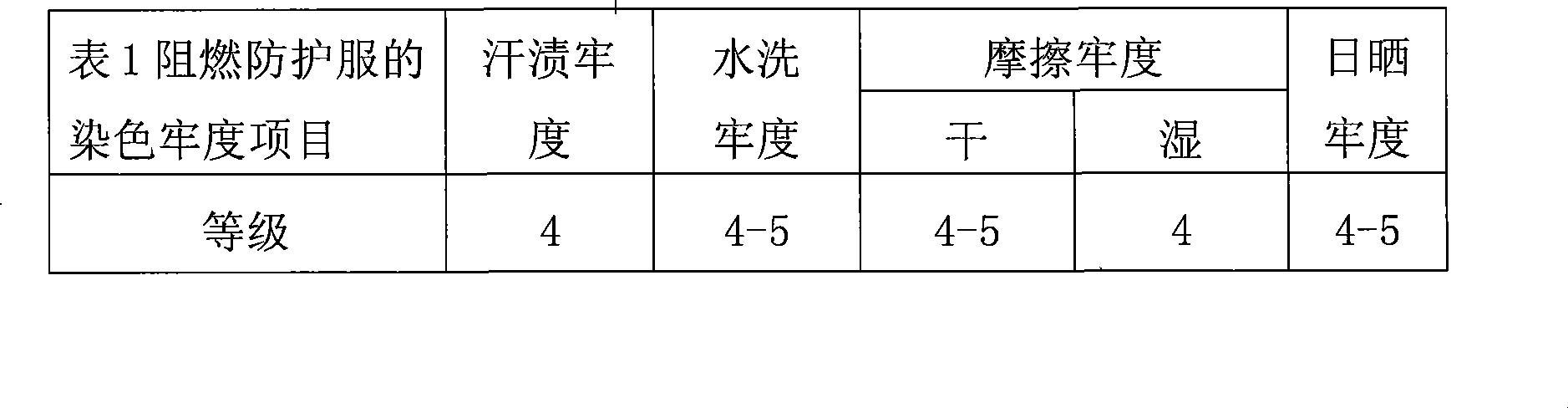

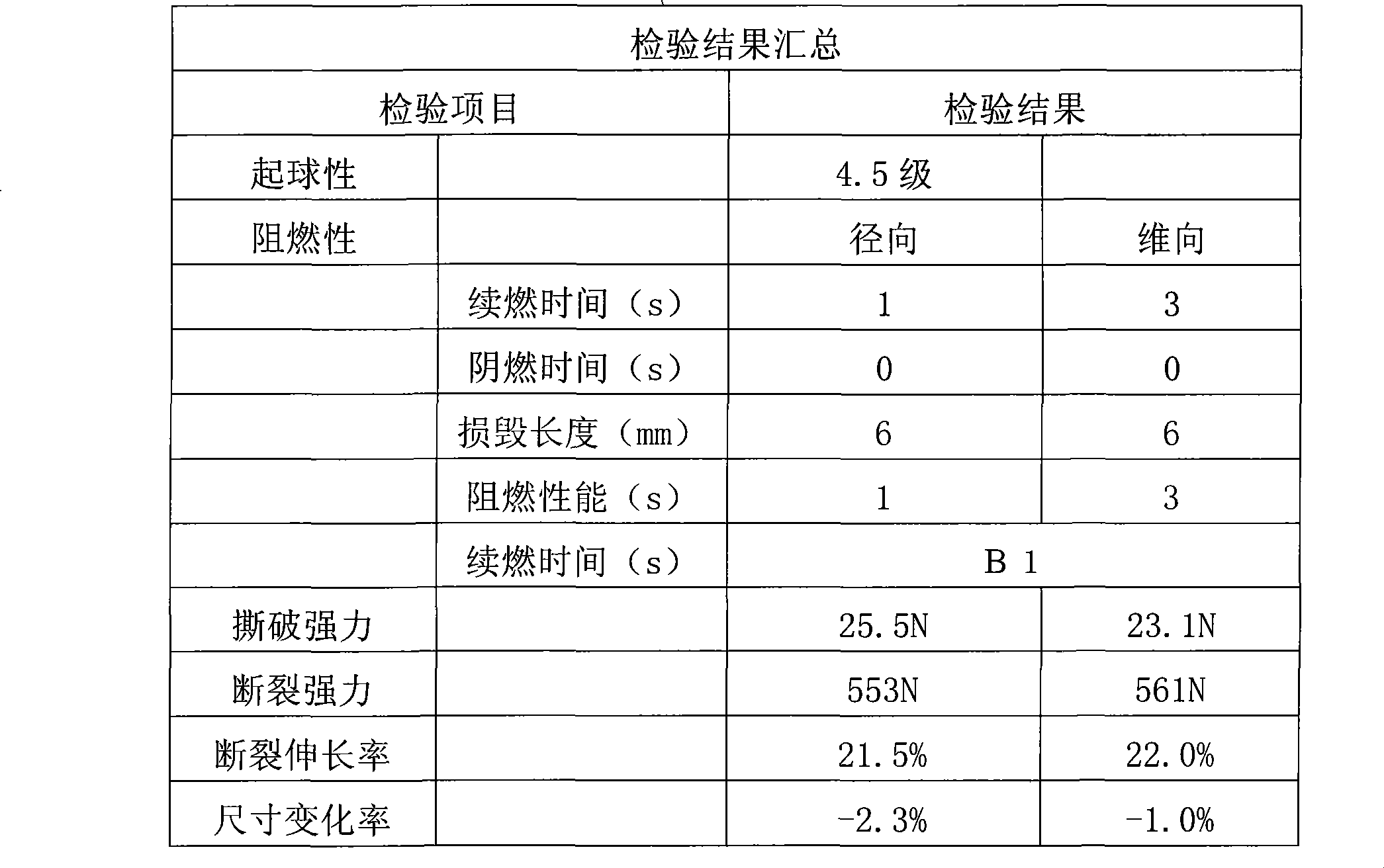

Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

The invention relates to an industrial anti-flaming exposure suit fabric and a manufacturing method and an exposure suit thereof. Yarns used in the industrial anti-flaming exposure suit fabric are formed by the blending of anti-flaming viscose, wool fibers and nylon fibers. The blending proportions (weight percentage) of the anti-flaming viscose, the wool fibers and the nylon fibers are respectively 45 percent to 55 percent, 35 percent to 45 percent and 5 percent to 15 percent. The industrial anti-flaming exposure suit fabric used in front of electric welding and metallurgy smelting furnaces has the functions of permanent anti-flaming performance, high temperature resistance, heat convection resistance, molten metal splashing resistance, and the like. The fabric is not only suitable for firefighter uniforms, flying protective clothing, and the like, realizes permanent anti-flaming performance and high temperature resistance, but also meets the requirements of the anti-flaming exposure suit fabric used in front of the electric welding and metallurgy smelting furnaces for the functions of heat convection resistance, molten metal splashing resistance, and the like.

Owner:SHANGHAI IBENA TEXTILE PROD

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

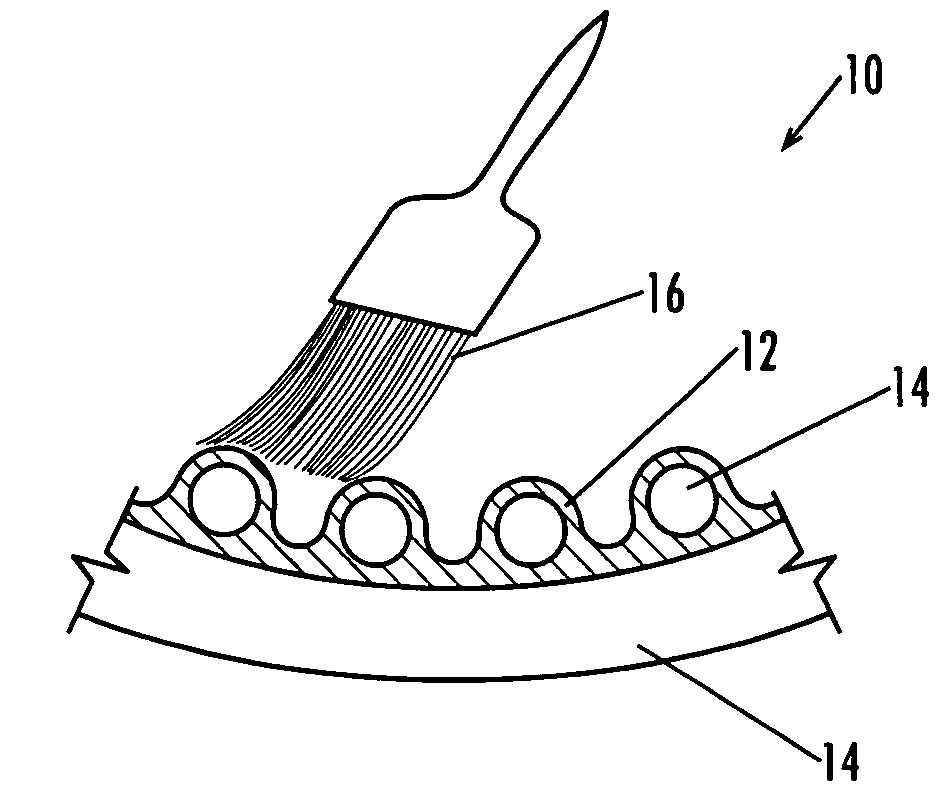

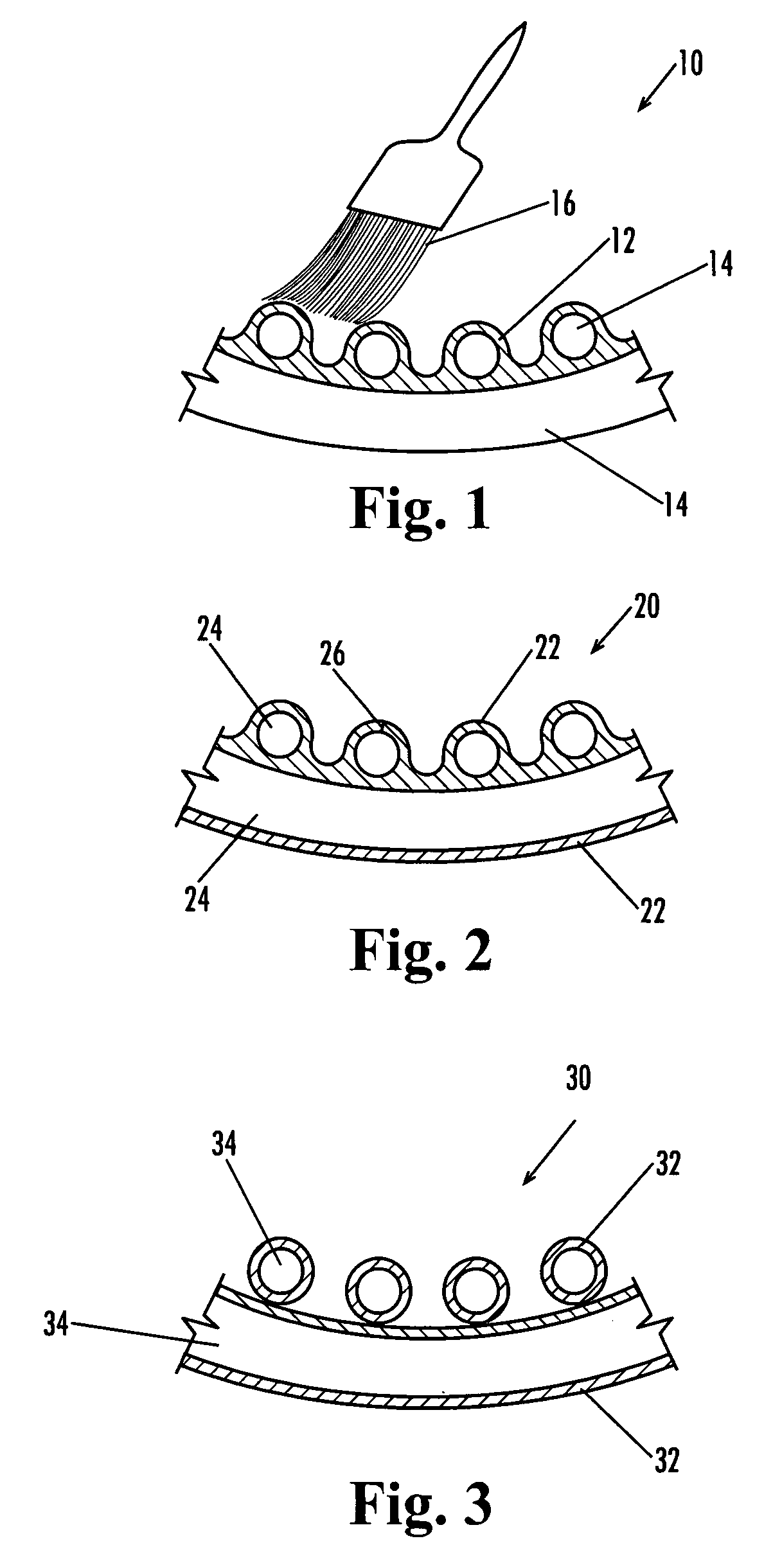

Lacrosse net

InactiveUS20080146385A1Improve adhesionImprove integrityThrow gamesCoatingsElastomerThermoplastic elastomer

A modified form of a lacrosse net provides increased adherence, integrity, and “give” as a result of a coating applied to the fibers. In one form, the fibers are manually coated by brushing them with a natural latex mixture followed by evaporation of the volatile components, which gives the coated fibers a tacky and energy absorbent nature. The soft nature of the coating may also aid in dissipating energy during impact with the ball, and this could contribute to the sense of increased “feel.” There are many natural and synthetic polymers that might be capable of delivering similar benefits, including conventional synthetic elastomers, e.g., butyl rubber. Thermoplastic elastomers are a growing field of interest in coating technologies, and with the appropriate tuning, they can be made with all of the same properties as the natural rubber coating. A brush-on method delivers the desired coating thickness and properties, but other methods, such as dip coating and spray coating, may increase feasibility for scaling-up the process. In one arrangement, the entire fiber is composed of a rubbery material. The resulting properties may not be exactly what is desired, however, because the underlying integrity of the nylon fiber would be absent, and this might result in netting with a “springy” feel.

Owner:LUNDBERG STEPHEN F

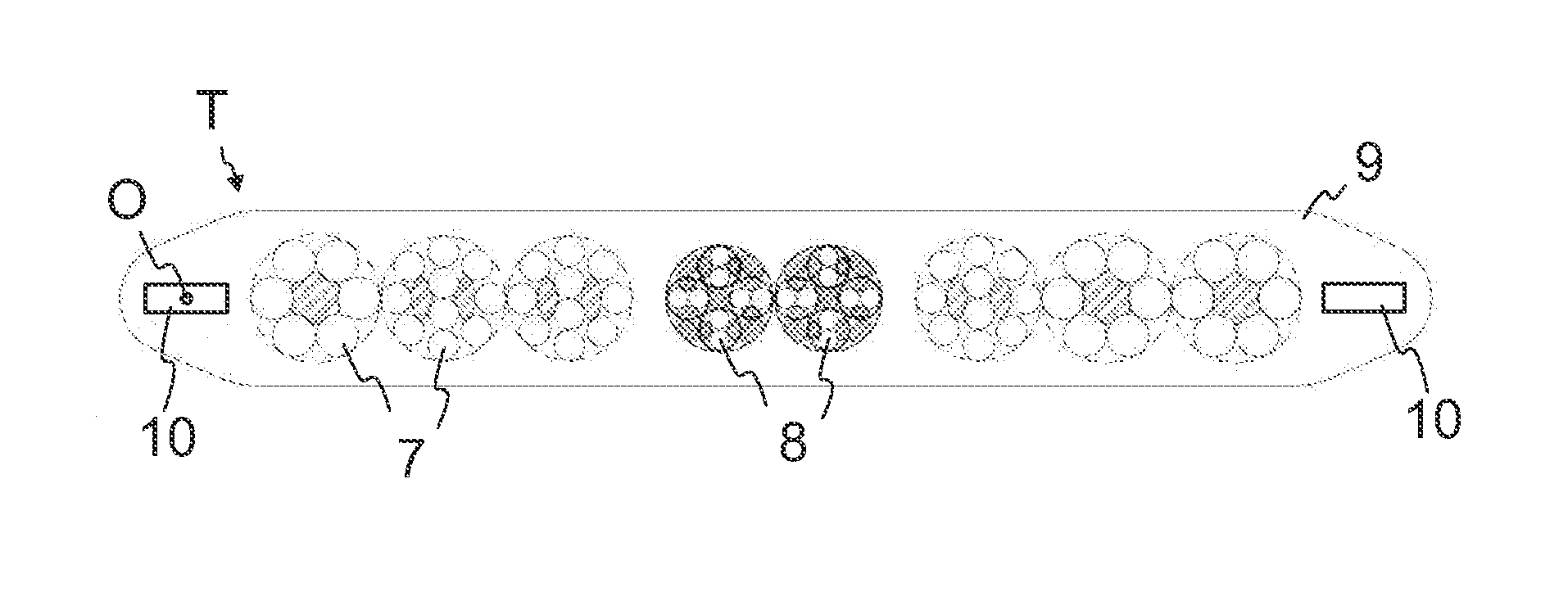

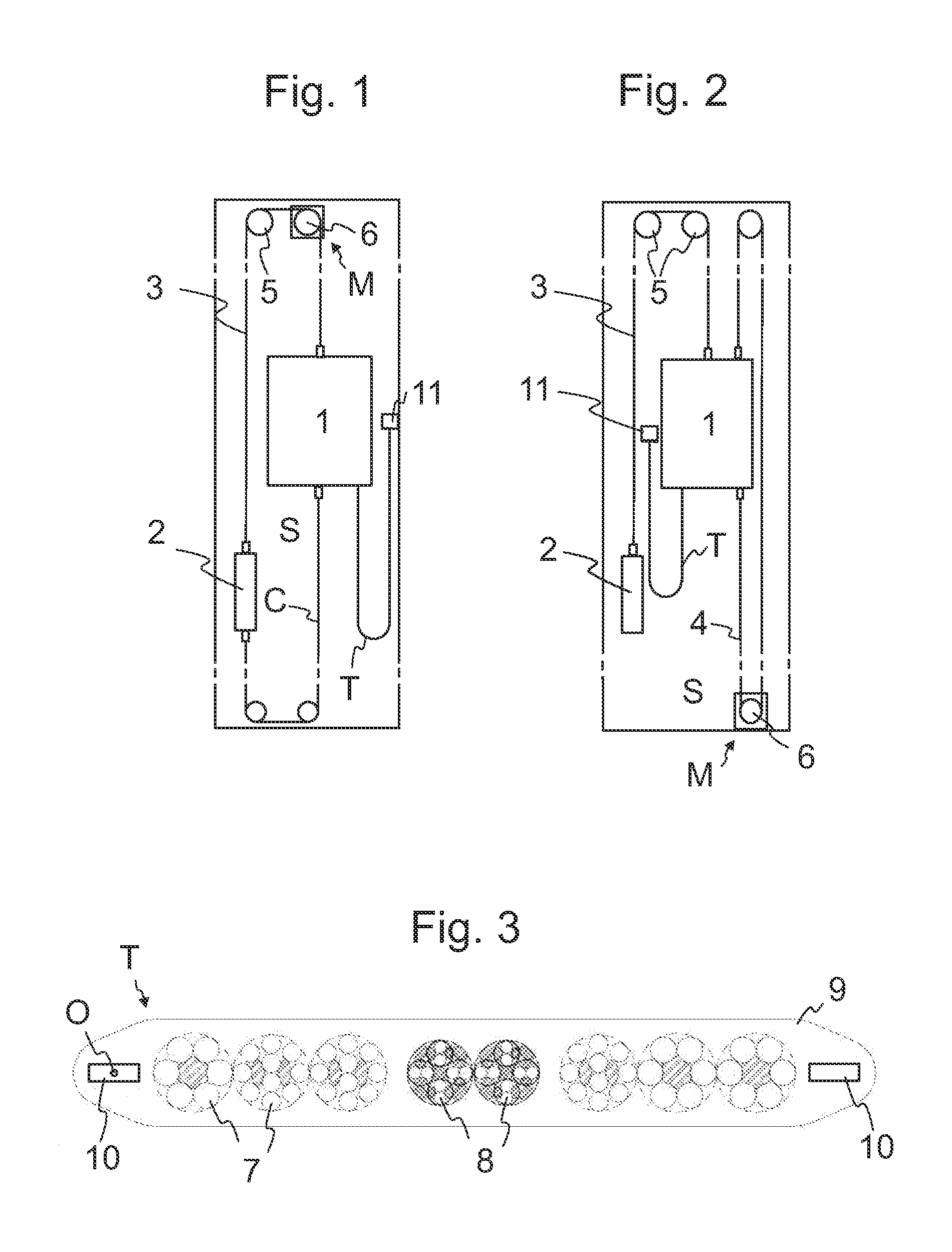

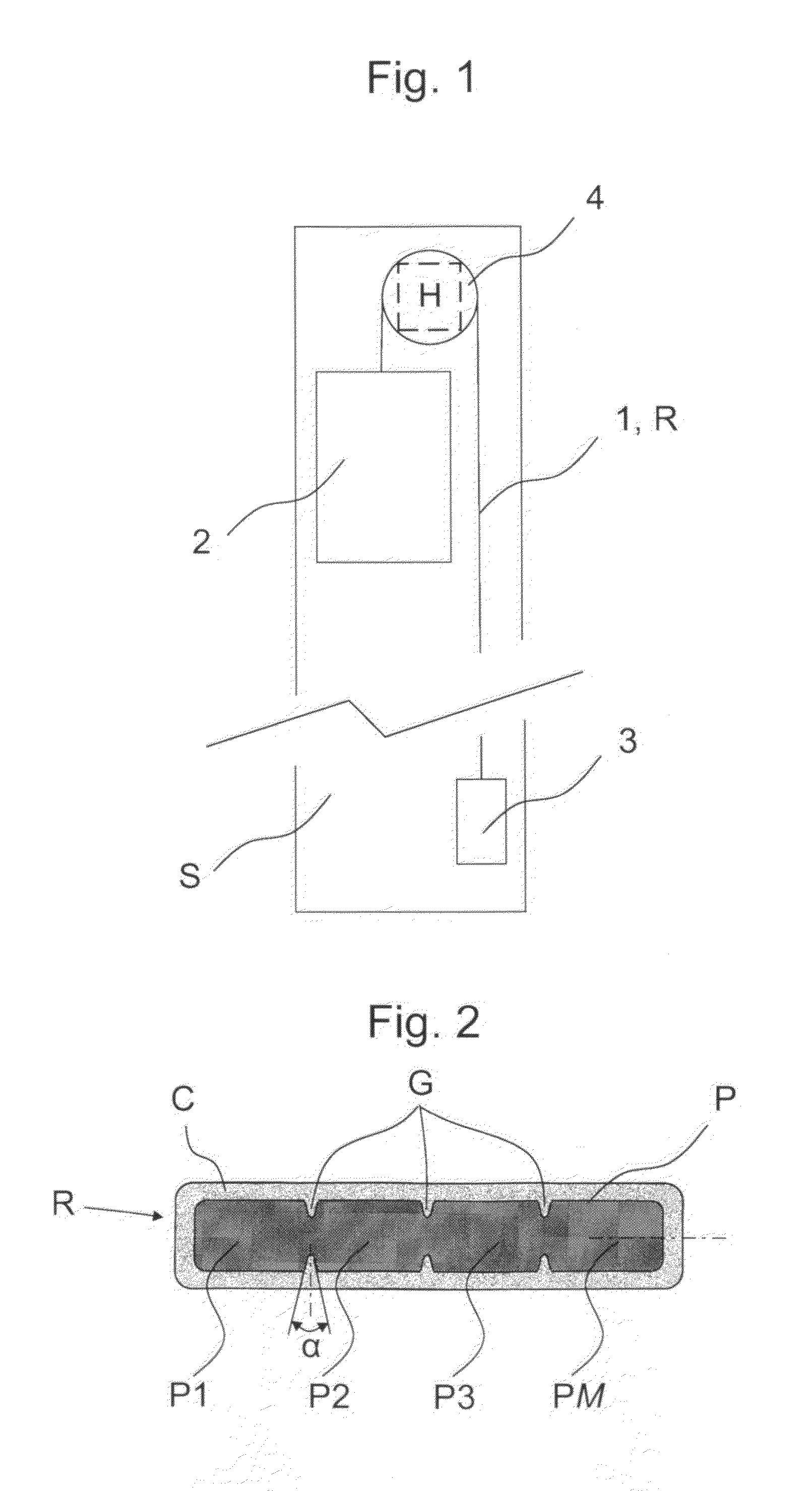

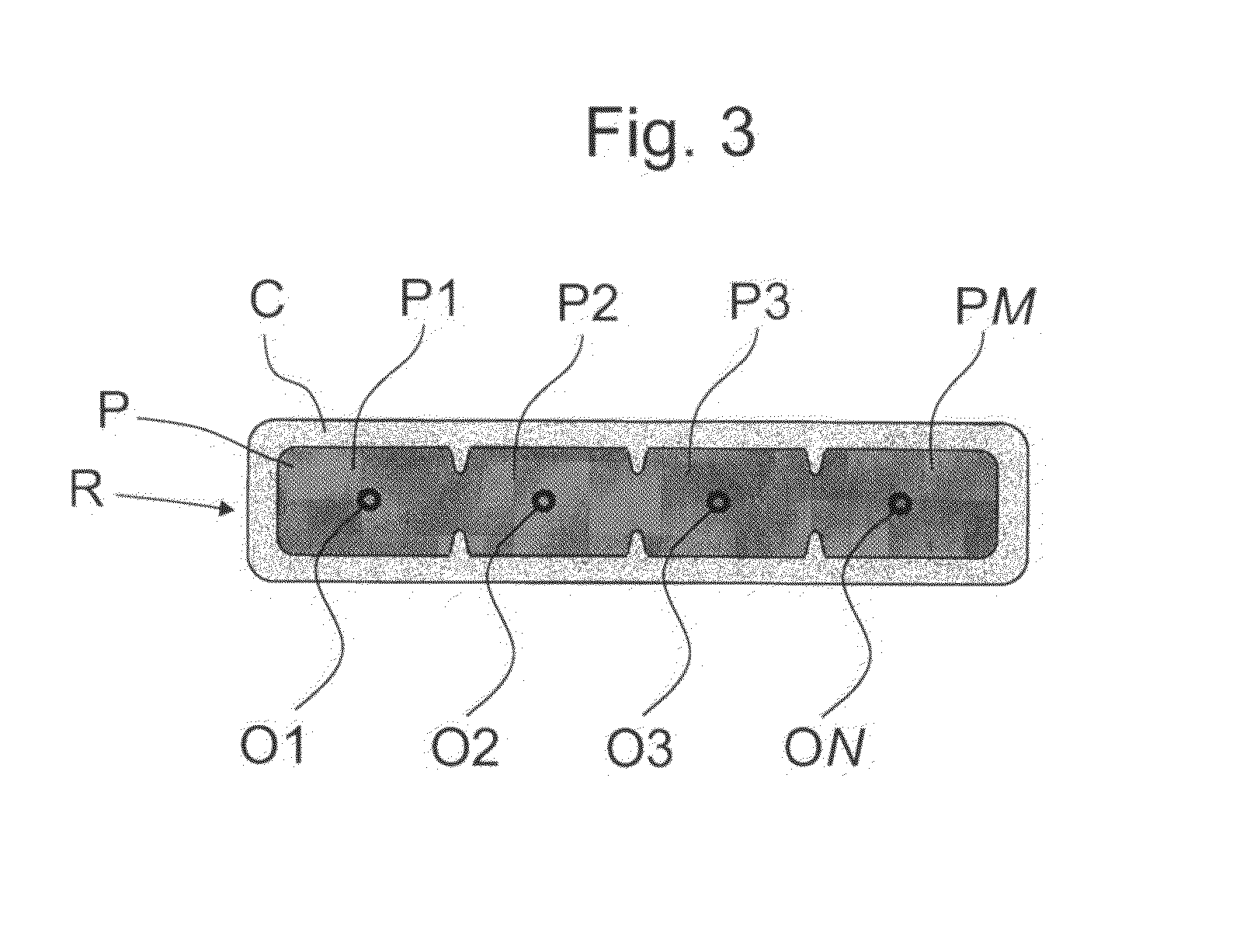

Travelling cable of an elevator, and an elevator

ActiveUS20140345978A1Saving can be considerableImprove energy efficiencyPower cables including communication wiresInsulated cablesGlass fiberElectrical conductor

A travelling cable of an elevator, more particularly of a passenger transport elevator and / or freight transport elevator, includes a protective envelope, conductors for transmitting electrical energy and data between the elevator car and the elevator hoistway, and one or more load-bearing bearer parts of essentially the length of the travelling cable for fixing the travelling cable at its first end to the elevator car and at its second end to the elevator hoistway, and which bearer part includes glass-fiber reinforcements and / or aramid-fiber reinforcements and / or carbon-fiber reinforcements and / or polybenzoxazole-fiber reinforcements and / or polyethylene-fiber reinforcements and / or nylon-fiber reinforcements in a polymer matrix material. An elevator includes the travelling cable.

Owner:KONE CORP

Low temperature producing method for nylon fiber

InactiveCN101054739AImprove securityLower spinning temperatureMelt spinning methodsArtifical filament manufactureAntistatic agentChemical compound

The present invention discloses a technology field relating to the preparation method of textile materials, especially to a process for for low temperature production of nylon fibre. Said process comprises the steps of adding a chemical compound of transient metal during or before nylon melting course and then spinning the obtained molten mass at a low temperature of 160-250 DEG C.Adding auxiliaries of oxidation preventives, ultraviolet absorbents, light-stability agents and anstatic agents therein before the melting course or during the melting course will result in more excellent effects. The method has a lower energy consumption and a lower cost, and its industry operations are more convenient and safe, will find wide use in industries such as garments and intertexture.

Owner:HANGZHOU NORMAL UNIVERSITY +1

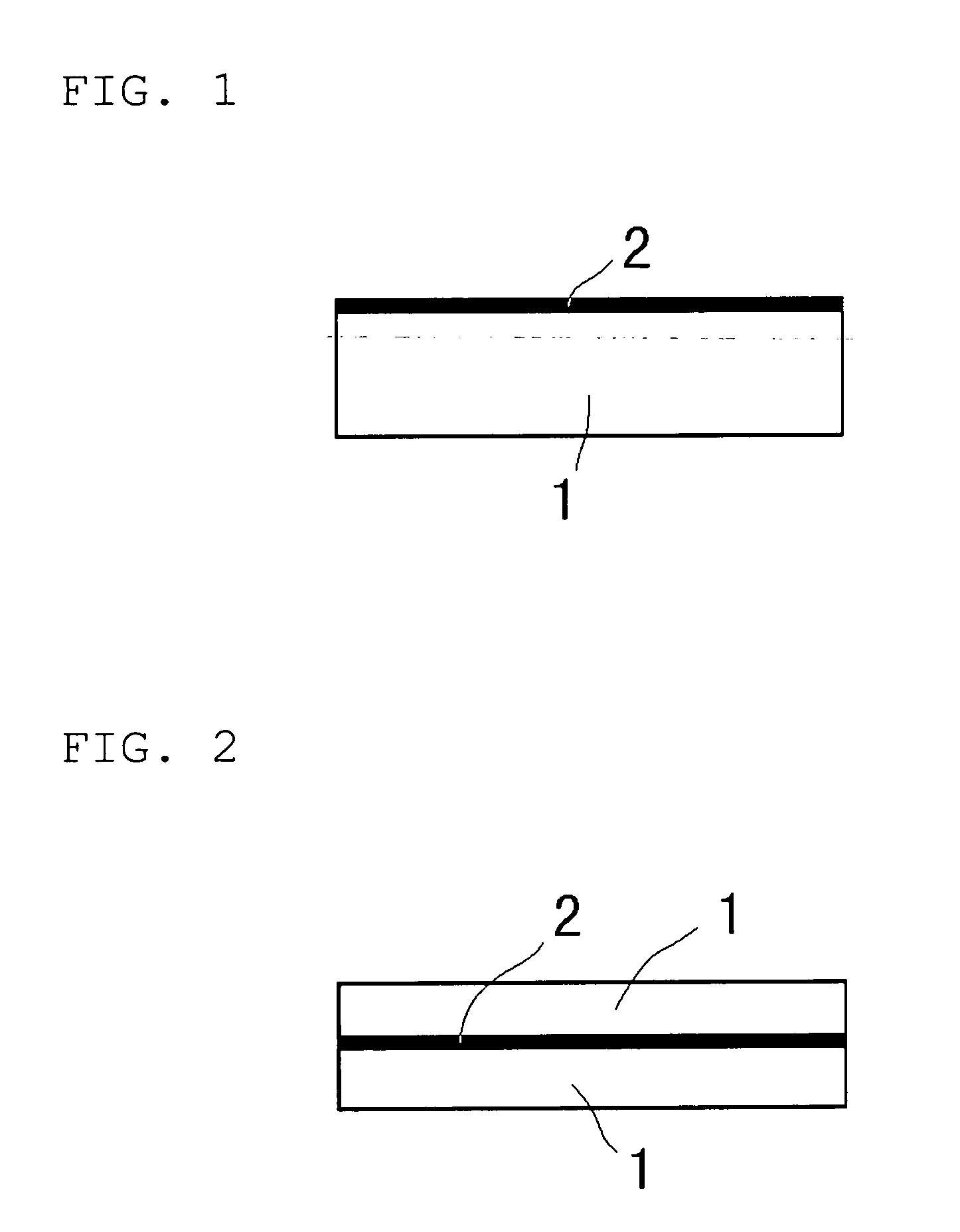

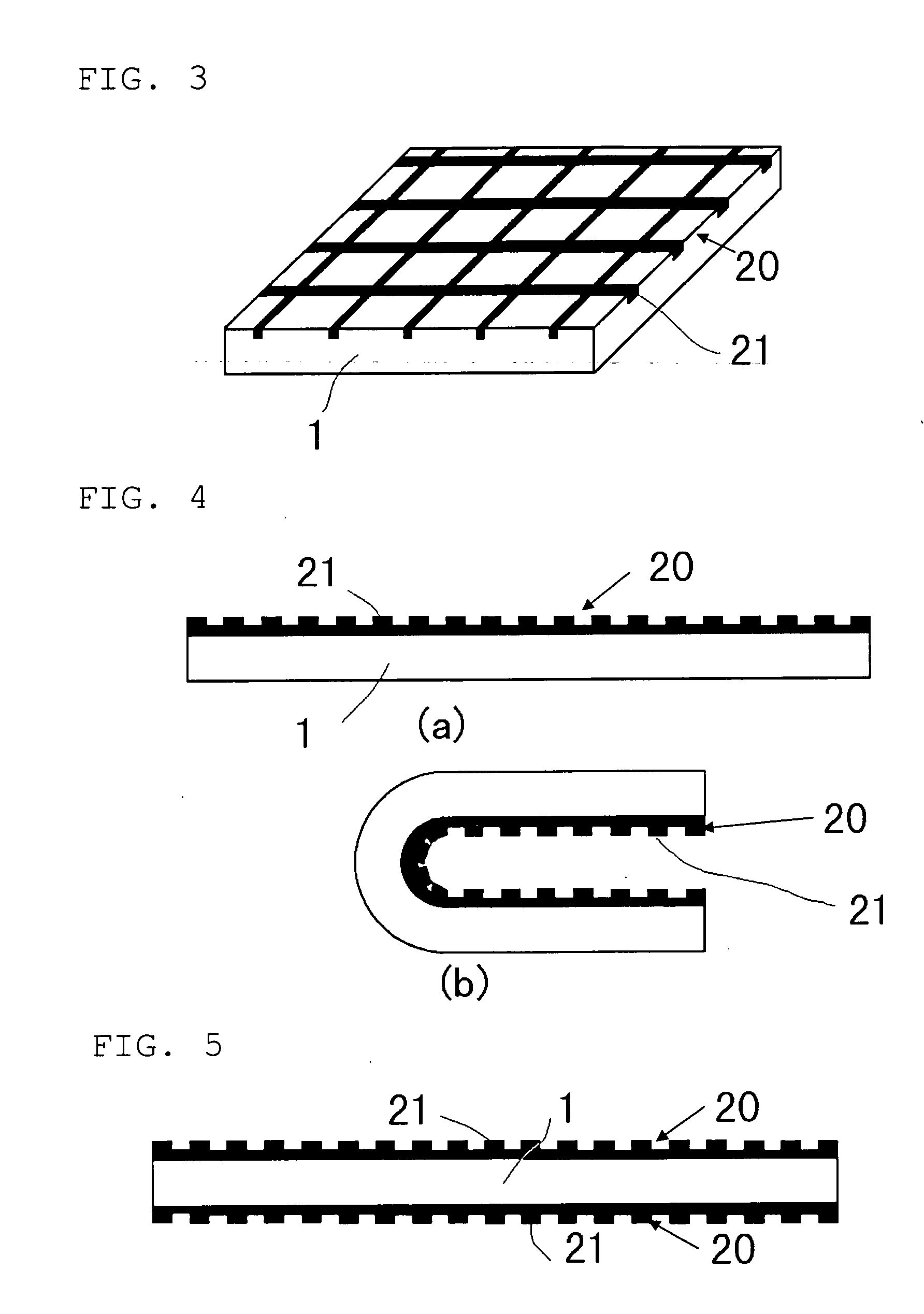

Shield material

InactiveUS20060251203A1Improve the immunityHigh densityElectrode and associated part arrangementsDischarge tube/lamp detailsPolyesterCarbon fibers

Disclosed is a fire-resistant lead-free shield material having high shielding ability against nuclear or electromagnetic radiation, and excellent bending workability and handling performance. The shield material comprises a composite material consisting of an organic material and a metal or metal compound having a nuclear or electromagnetic radiation-shielding ability. The composite material is formed into a given shape, such as a plate shape, and wrapped with a cloth-like sheet formed of glass fibers, metal fibers or carbon fibers. Alternatively, the shield material comprises a shielding element consisting of an elastic polymeric organic compound and a particle having a nuclear or electromagnetic radiation-shielding ability, such a heavy metal or ferrite. The shield material also includes either one of a film made of polyethylene, nylon, polyester or metal, a wire mesh formed of nylon fiber or metal fiber, and a plate- or rod-shaped member having a surface formed with a protrusion, which is compression-bonded onto or in the vicinity of a surface of the shielding element, or inside the shielding element.

Owner:NIPPON TUNGSTEN CORP

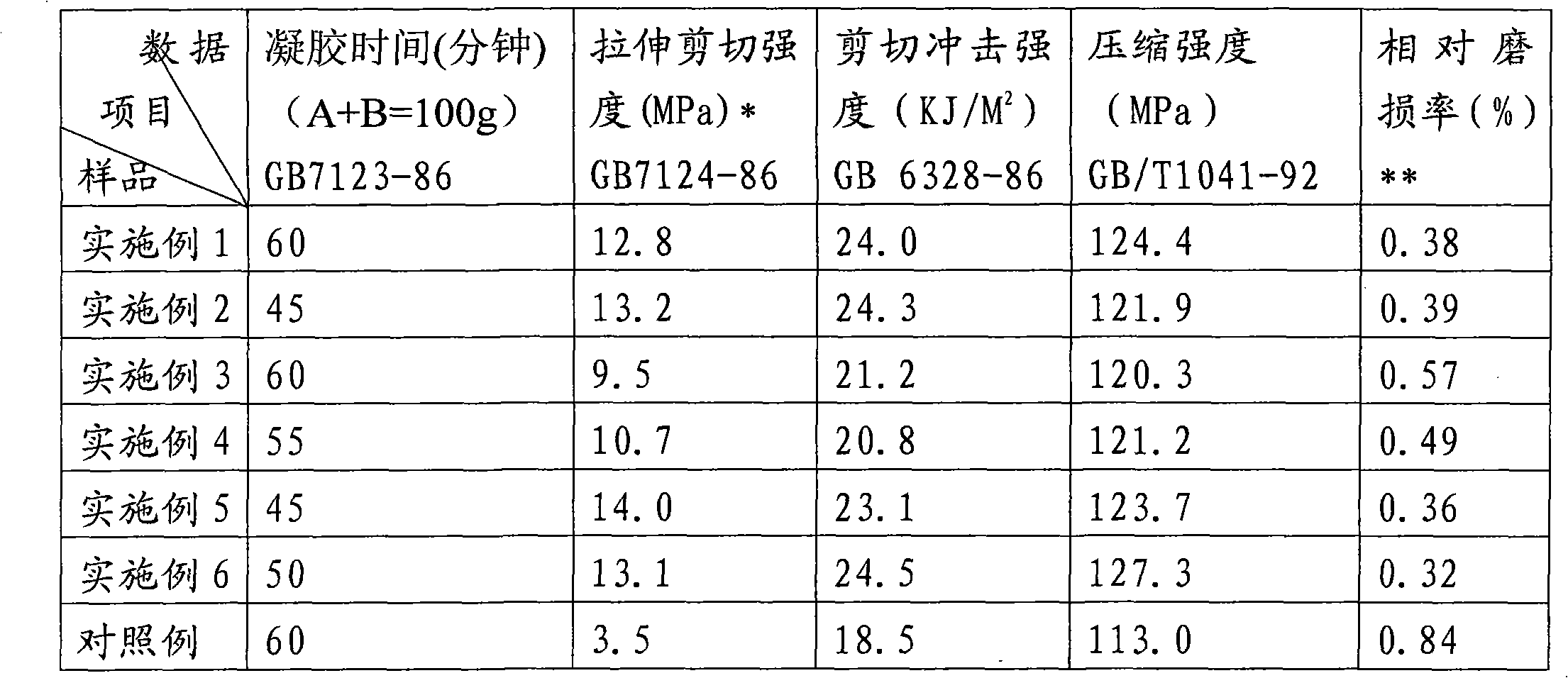

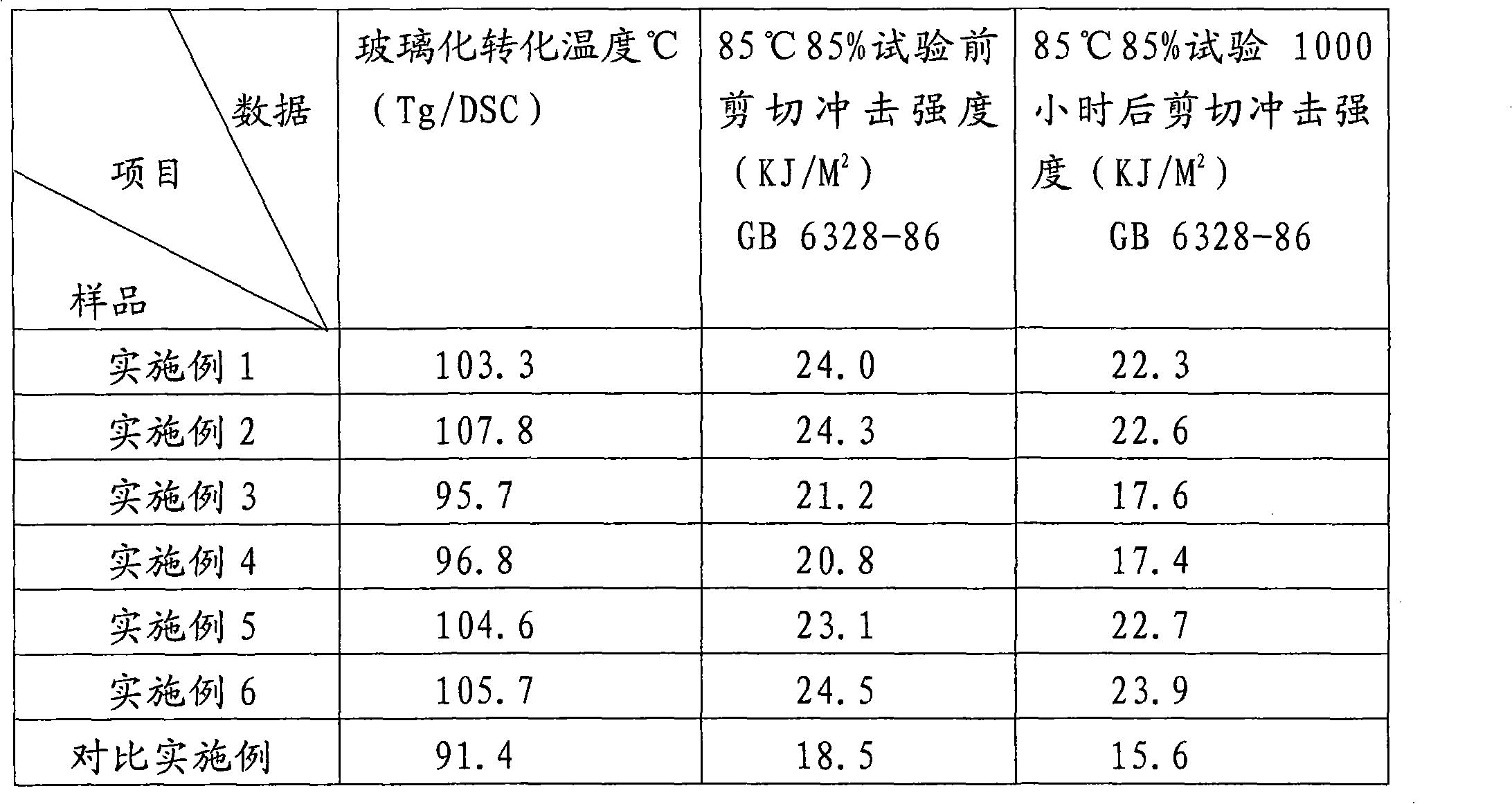

Wear-resistant epoxy glue and preparation method thereof

InactiveCN102040933AIncrease elasticityImprove wear resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phaseMicrosphere

The invention relates to wear-resistant epoxy glue and a preparation method thereof. The epoxy glue is prepared by mixing a component A and a component B based on a weight ratio of (100:11.1)-(100:13.3), wherein the component A comprises the following raw materials in parts by weight: 10-20 parts of liquid epoxy resin, 10-20 parts of bisphenol F epoxy resin with modified nano rubber particles, 2.5-5 parts of epoxy resin activity diluent, 0.5-1.0 part of coupling agent, 53-61 parts of aluminum oxide ceramic microsphere, 4-6 parts of white alundum powder, 3-5 parts of glass fiber powder, 0.5-1.2 parts of chopped nylon fiber and 1-2 parts of gas-phase silicon dioxide; and the component B comprises the following raw materials in percentage by weight: 55-65 parts of polyamide, 12-18 parts of isophorone diamine, 4-7.5 parts of AEPHP (N-Aminoethylpiperazine), 1-2 parts of solidification accelerating agent, 8-10 parts of kaolin, 3-6 parts of glass fiber powder and 3-5 parts of gas-phase silicon dioxide. The preparation method comprises the following steps: preparing the bisphenol F epoxy resin with modified nano rubber particles; respectively preparing the component A and the component B;and mixing the component A and the component B in proportion when the epoxy glue is used.

Owner:YANTAI DARBOND TECH

Preparation method of highly-spinnable halogen-free flame-retardant nylon fiber

ActiveCN102653890AGood dispersionImprove spinnabilityFlame-proof filament manufactureMonocomponent polyamides artificial filamentAntioxidantMelamine

The invention relates to a preparation method of highly-spinnable halogen-free flame-retardant nylon fibers, which comprises the following steps: performing blending and granulation of nylon slices, cyclic phosphates, melamine compounds, nanometer inorganic substances, and antioxidants in a double screw extruder to obtain a halogen-free flame-retardant nylon master batch, spinning the halogen-free flame-retardant nylon master batch with nylon slices into halogen-free flame-retardant nylon fibers through a melt spinning method. Compared with the prior art, the invention improves the dispersibility of the fire retardants and the compatibility of the polymers, and thus the product has good flame retardance; the spinnability of the nylon fibers is improved to a great extent; the invention has low cost, is industrialized; both halogen-free flame-retardant nylon aircraft seat covers and aviation carpet lines spun by the method of the invention pass FAR 25.853 cabin internal material flammability tests.

Owner:上海安凸塑料添加剂有限公司

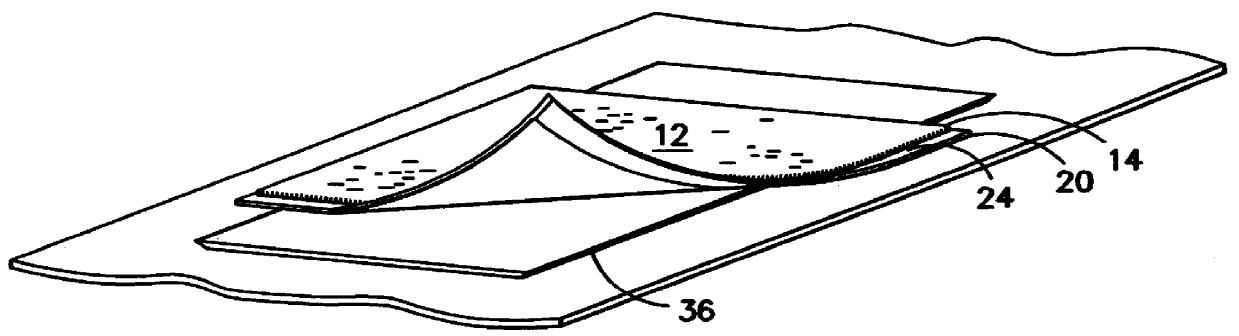

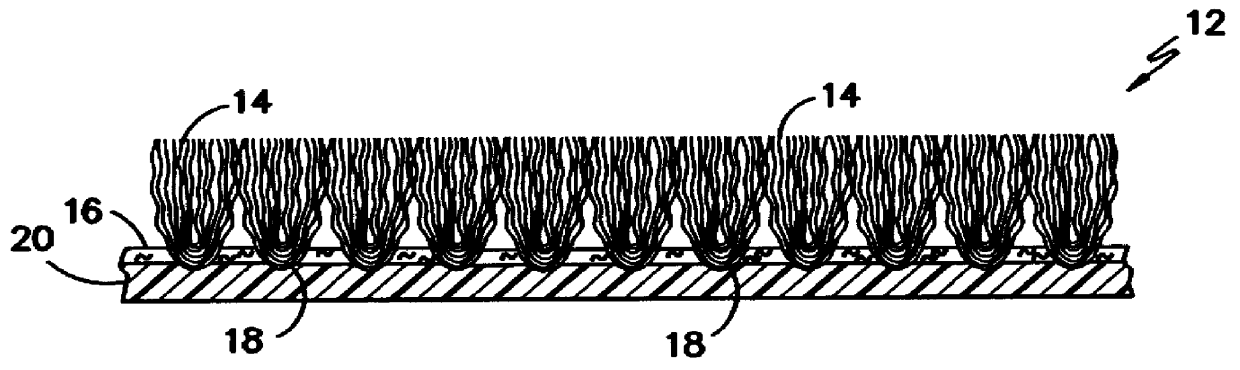

Floor mat solely comprised of monofilament nylon fiber and having an ozone resistant, non-staining rubber backing sheet

This invention relates to a floor mat primarily for use in an outdoor environment wherein the mat includes a tufted carpet solely comprised of nylon monofilament fibers. Furthermore, this mat comprises a foam rubber backing which possesses a high level of ozone resistance and simultaneously will not appreciably stain a handler's skin or a floor's surface with carbon particles. The utilization of all monofilament nylon fibers provides for the extreme effective removal of moisture, dirt, and debris from the footwear of pedestrians and also permits easy cleaning and effective drying of the overall article. The utilization of a foam rubber backing also allows for heavy duty industrial-scale laundering in such standard washing machines without appreciably damaging either the washing machines or inventive floor mats themselves.

Owner:MILLIKEN & CO

Process for producing fine denier or superfine denier nylon fibre composition and fine denier or superfine denier nylon fibre

InactiveCN101311389AElectroconductive/antistatic filament manufactureMelt spinning methodsRare earth metal compoundsNylon fiber

The invention discloses a method for producing a compound of fine denier nylon fiber or super fine denier nylon fiber or producing fine denier nylon fiber or super fine denier nylon fiber. The compound comprises nylon and a lanthanide rare-earth metal compound; wherein the weight of the rare-earth metal in the rare-earth metal compound is between 50ppm to 10 percent based on the weight of nylon used. The method for producing the fine denier nylon fiber or super fine denier nylon fiber is a melt-spinning method, which includes the step of adding a rare-earth metal compound during the process of nylon melt-spinning. Fine denier nylon fiber or super fine denier nylon fiber, the denier of which is smaller than 1, can be obtained by the method.

Owner:PEKING UNIV +1

Silver coated nylon fibers and associated methods of manufacture and use

InactiveUS20100166832A1Heat dissipationWear safeBiocideInorganic active ingredientsYarnAntimicrobial surface

Silver coated nylon fibers are disclosed that can be used to make fabrics that are silver coated on one side of the fabric. Silver coated nylon fabrics provide an antimicrobial surface which remains on the surface and retains its antimicrobial characteristic until destroyed. The methods of adherence of the silver to the nylon fabric may be performed in a number of ways. The creation of a single fabric with one side silver coated and the other side being dyed or left natural is encompassed within this invention. In addition there can be more than two yarns creating the fabric such as the use of spandex to provide a more elastic garment.

Owner:BRAND SOLUTION

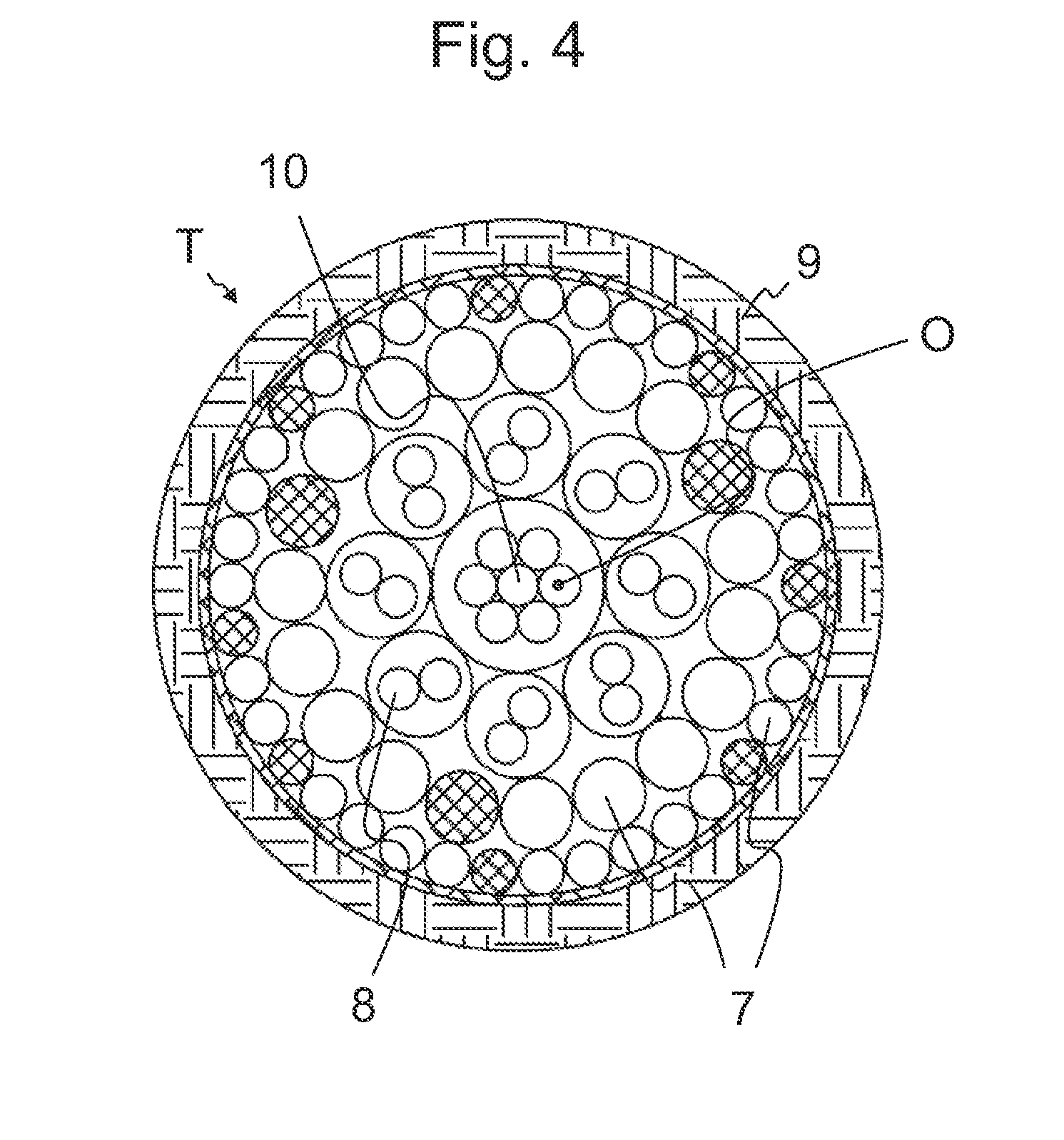

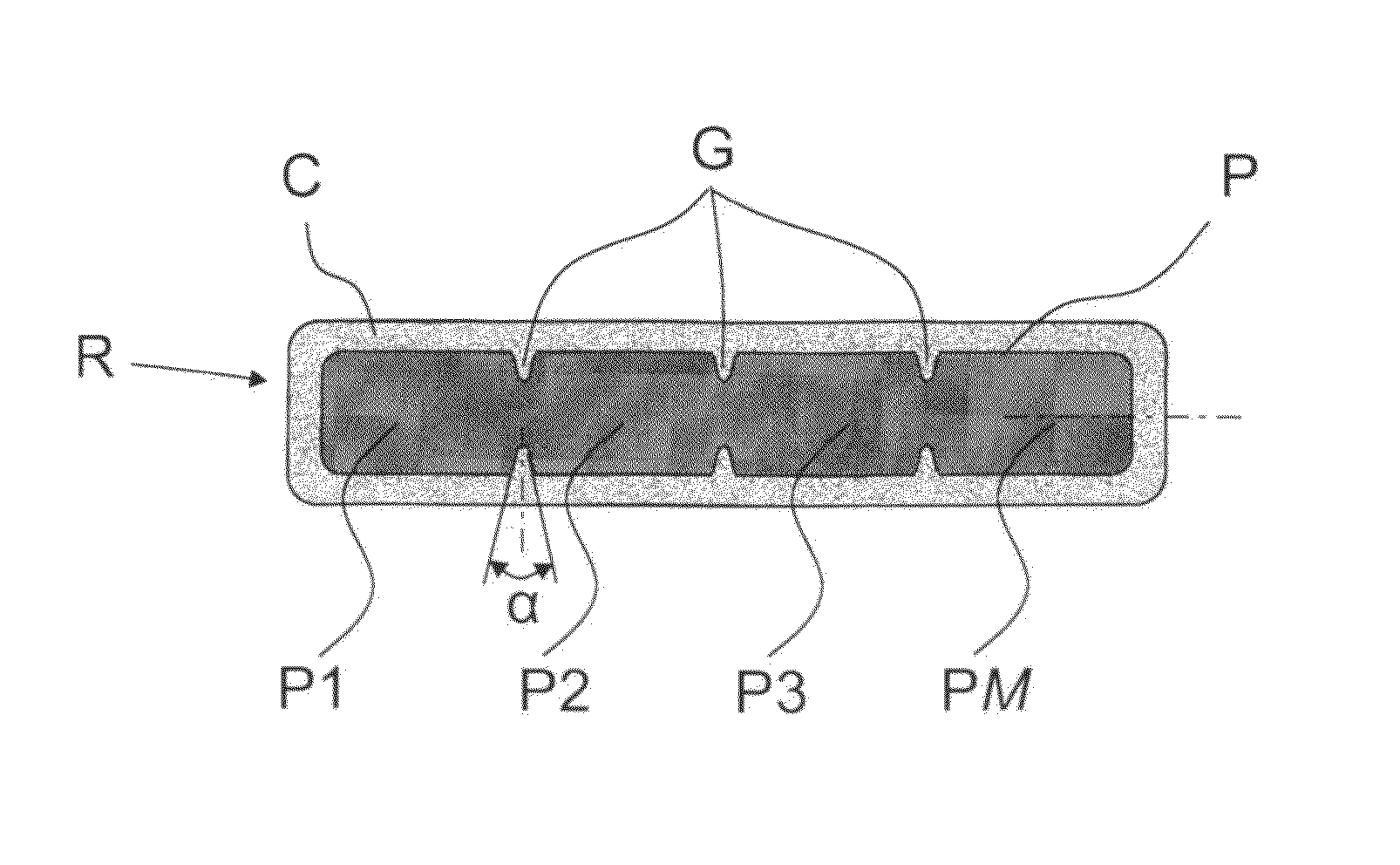

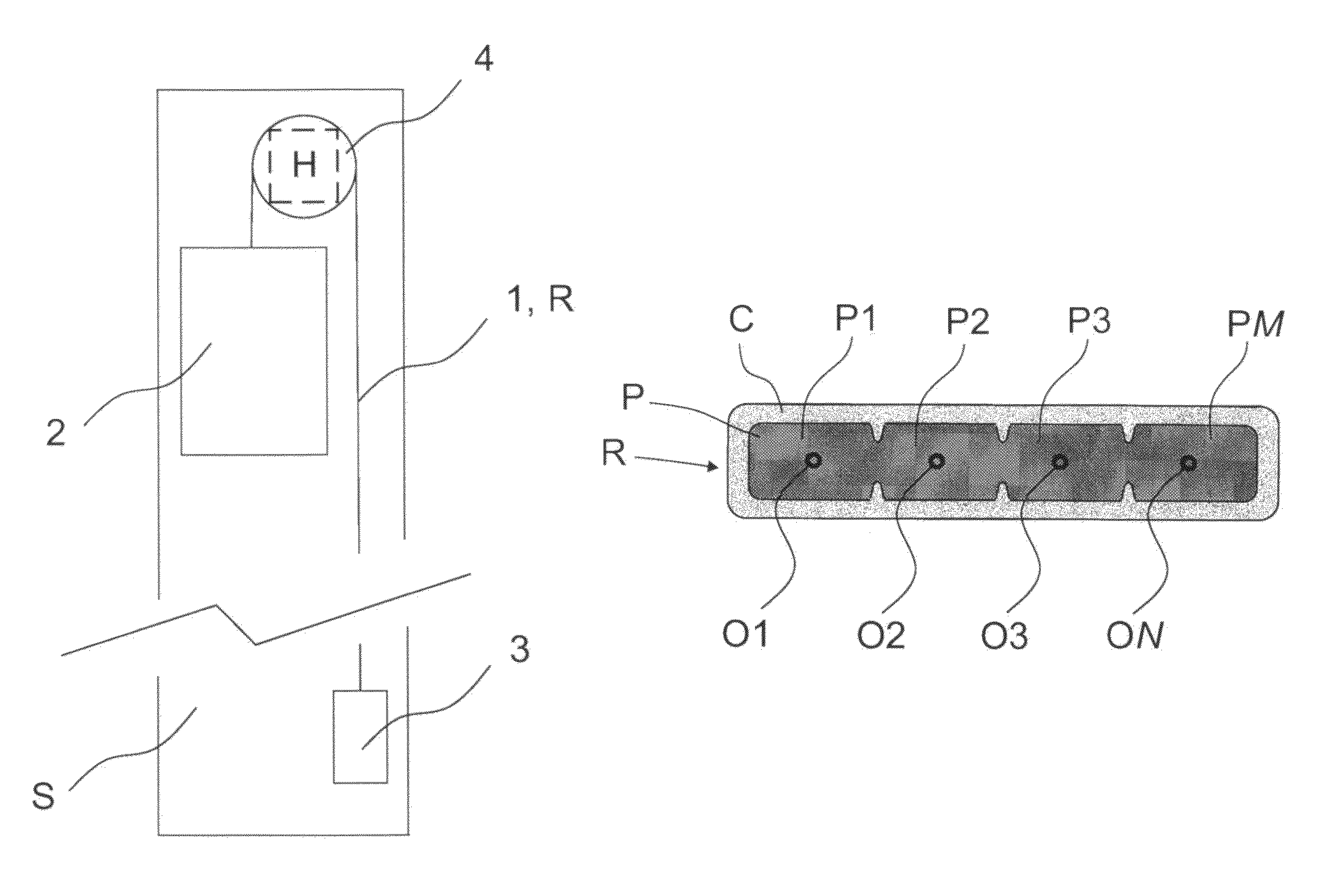

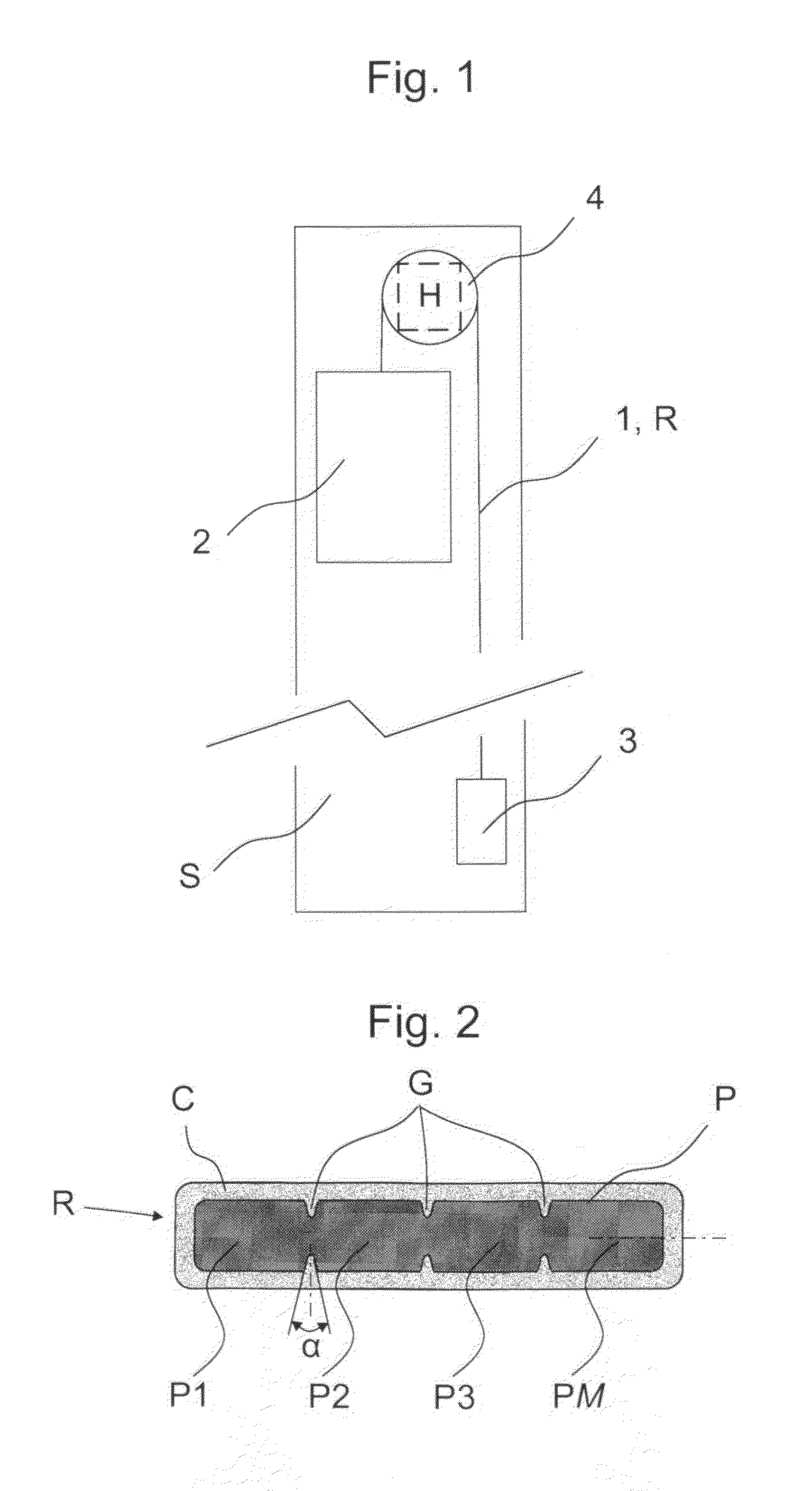

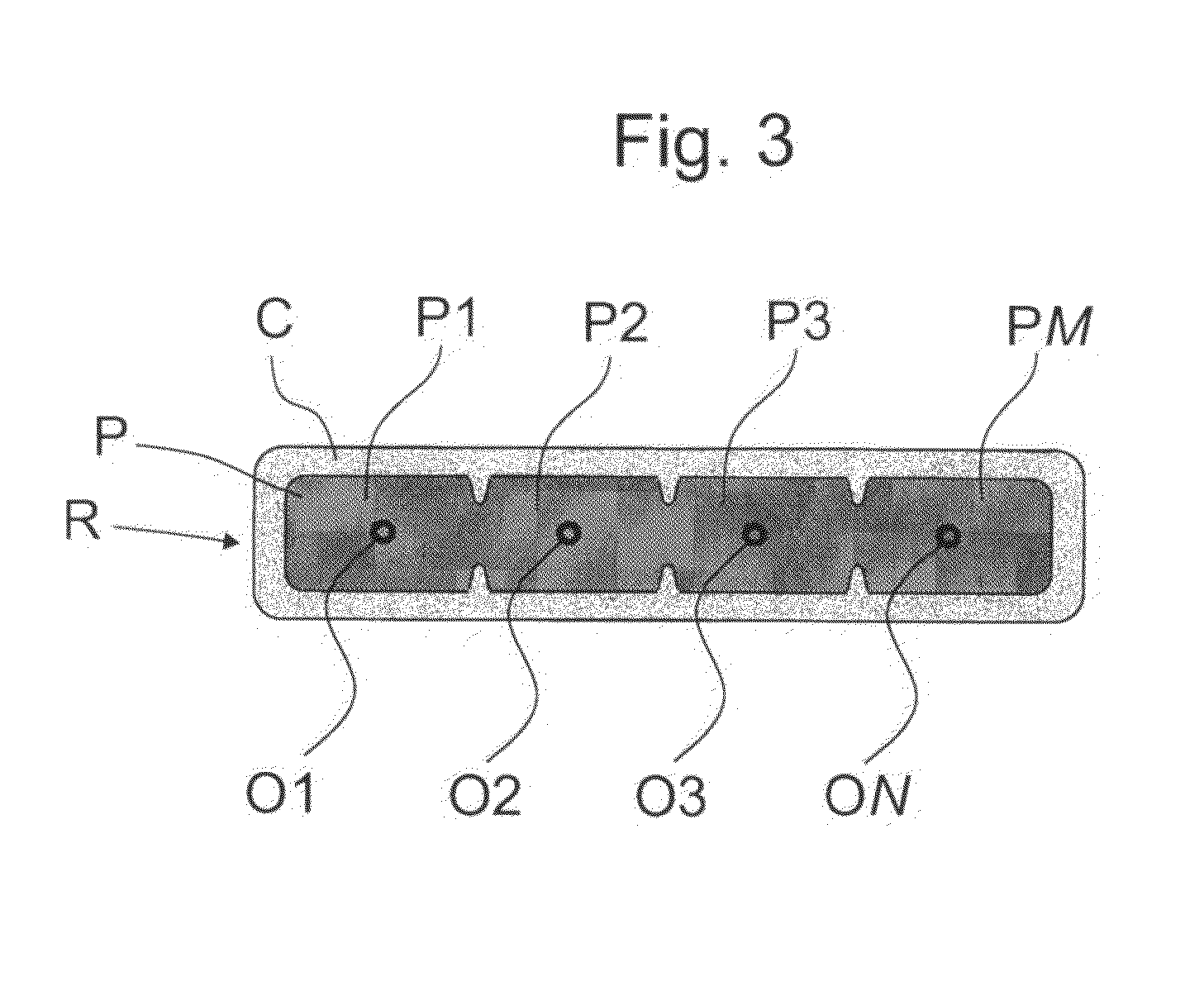

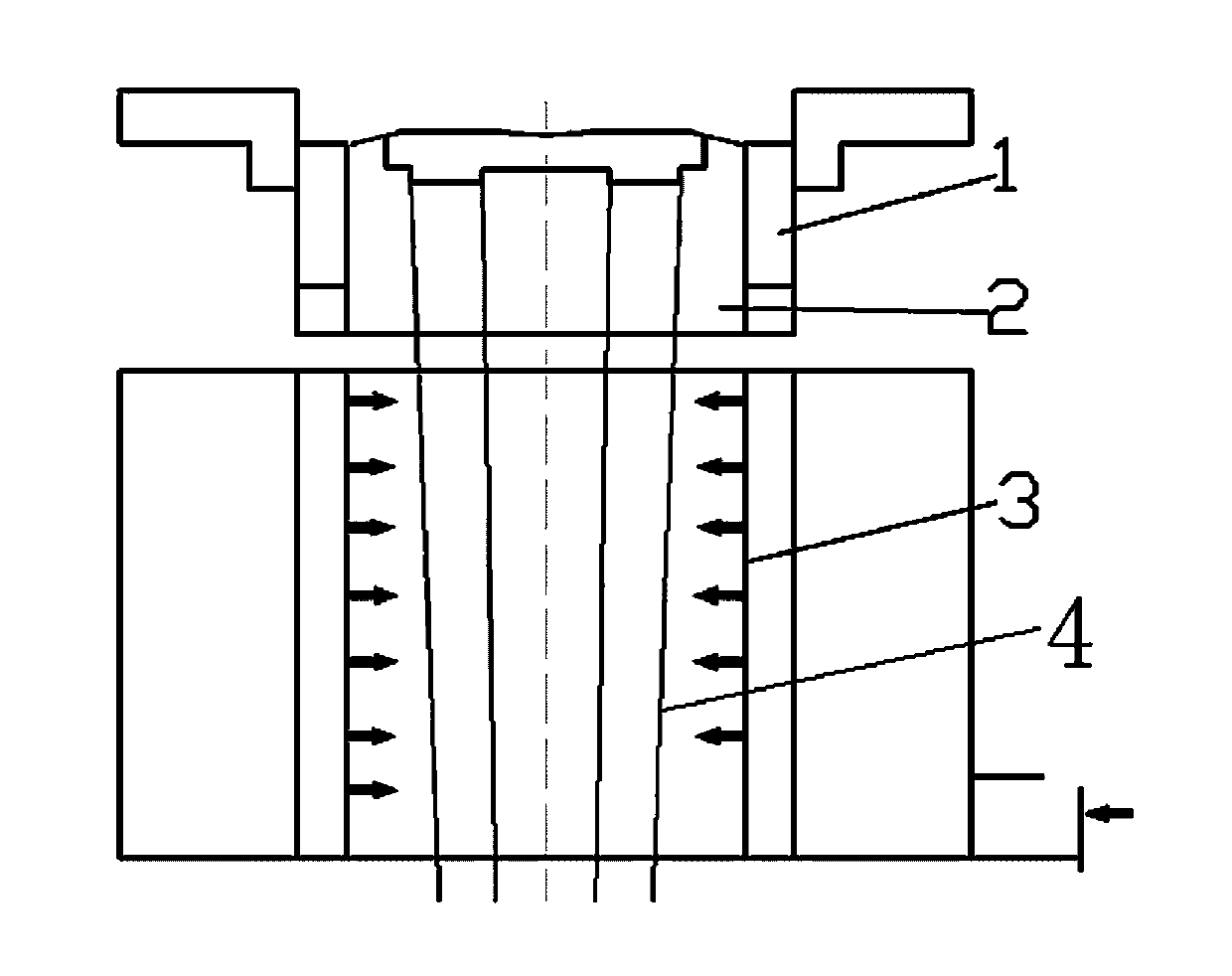

Rope of a lifting device, an elevator and a method for manufacturing the rope

ActiveUS20130206516A1Drawback can be obviatedControlRopes and cables for vehicles/pulleyGlass fiberCarbon fibers

A rope of a lifting device, more particularly of a passenger transport elevator and / or freight transport elevator, an elevator, and a method for manufacturing the rope are disclosed. The rope includes an unbroken load-bearing part, the profile of which is essentially of rectangular shape, and the width of the cross-section is greater than the thickness and which load-bearing part comprises glass fiber reinforcements and / or aramid fiber reinforcements and / or carbon fiber reinforcements and / or polybenzoxazole fiber reinforcements and / or polyethylene fiber reinforcements and / or nylon fiber reinforcements in a polymer matrix material. The long sides of the cross-section of the load-bearing part include one or more grooves symmetrically or asymmetrically in the longitudinal direction of the rope, which grooves divide the load-bearing part into smaller parts.

Owner:KONE CORP

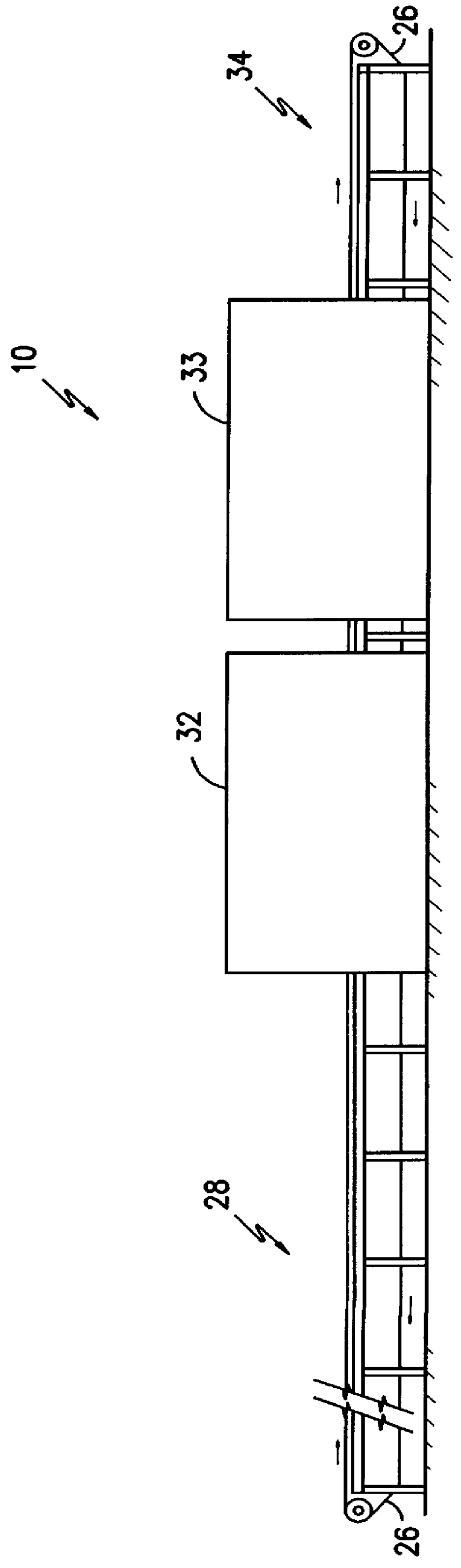

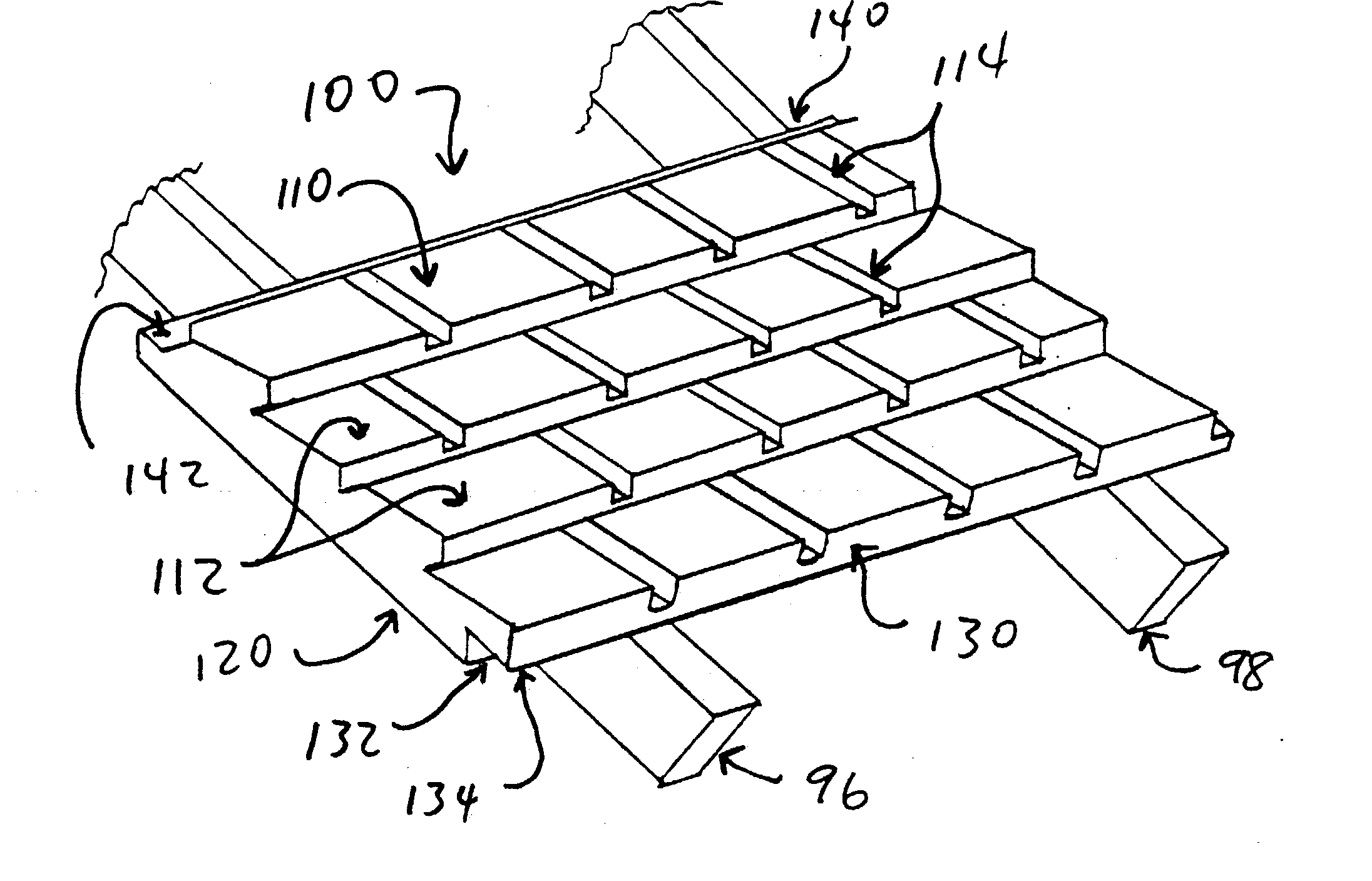

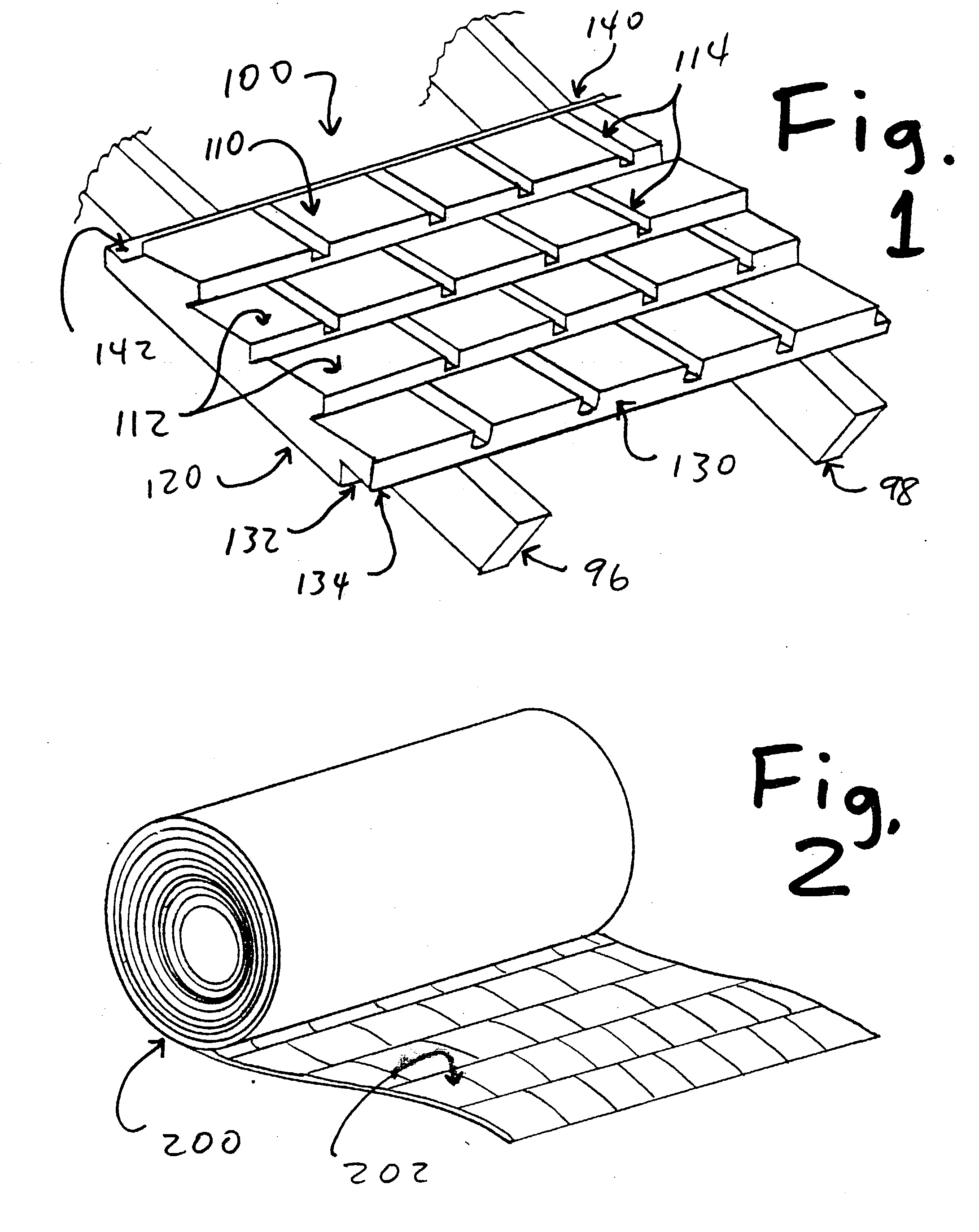

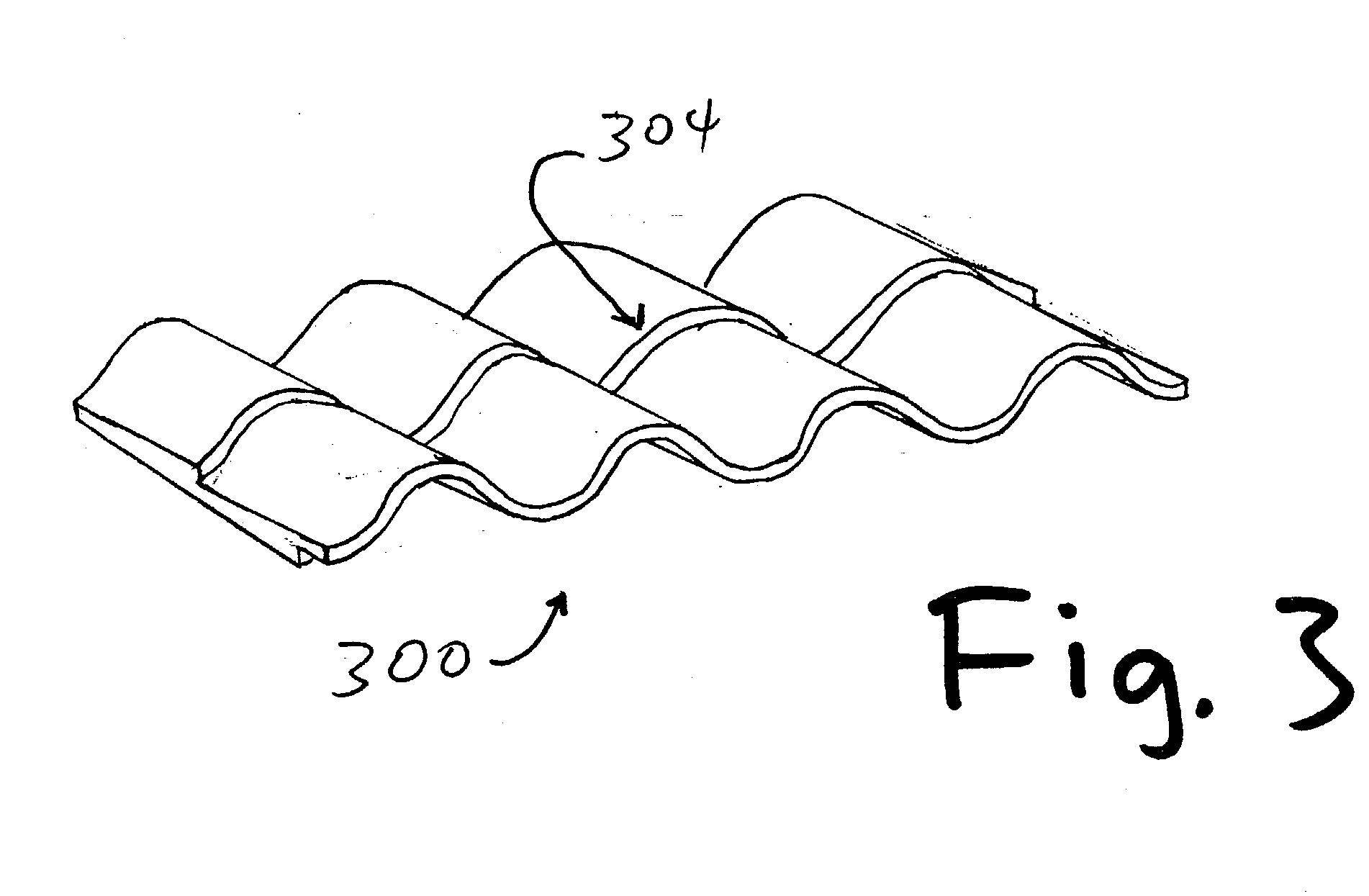

Roofing materials made with nylon fiber composites

InactiveUS20050170141A1Avoid insufficient thicknessSolve the lack of stiffnessLayered productsRecord information storageManufacturing technologyRoof tile

Synthetic nylon fiber composite materials having embossed or molded surfaces that emulate shingles or roofing tiles are disclosed, for providing waterproof, high-strength, durable substitute for shingles or roofing tiles. In one embodiment, these materials can be relatively thin, and designed to rest on supporting sheets of plywood, oriented strand board (OSB), or nylon fiber composite board that have been nailed to rafters. In an alternate embodiment, these materials can be manufactured in sheets with sufficient thickness, stiffness, and strength to allow them to be nailed directly to rafters, thereby eliminating the need for a supporting layer of plywood or OSB. In a third embodiment, these materials can be molded or embossed to emulate Spanish tiles, or to provide enhanced drainage or other useful traits. For improved waterproofing, the lower edge of each segment can be provided with an overhang that will overlap the upper edge of an adjacent sheet on the next lower horizontal row, to provide overlapping material at each juncture between these composite segments. These materials also can be coated or embedded with chemicals that provide increased resistance to water, fire, and ultraviolet damage. They provide excellent thermal insulation, and can reduce heating and air conditioning costs. A preferred manufacturing process uses needle-punched fiber mats, and any combination of nylon-6 and nylon-6,6 fibers can be used.

Owner:BACON FORREST C +2

High strength suture with UHMWPE and polybutester

InactiveUS20080021501A1High strengthImproved tie down characteristicSuture equipmentsSynthetic resin layered productsMedicineSuture anchors

A high strength abrasion resistant surgical suture material with improved tie down characteristics. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polybutester. Selected nylon fibers in the cover may be provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

Fine denier or ultra-fine denier nylon fibre and producing method thereof

InactiveCN101122053AImprove mechanical propertiesHigh strengthMelt spinning methodsArtifical filament manufactureChemical compoundUltra fine

The invention relates to a micro or super micro nylon fiber and a method of making the fiber. The technical problems the invention needs to solve is to provide a micro or super micro nylon fiber with the fiber number which can be fewer than 1 denier and the method of making the fiber. The fiber of the invention is characterized in that the fiber contains nylon, a first main group metal chemical compound in an effective amount and an auxiliary agent-antioxidizing agent also in an effective amount. The making method of the invention is characterized in that the first main group metal chemical compound and the nylon are melted in advance, mixed together, extruded and shaped, and an additive in agglomerate shape is obtained, wherein, the first main group metal chemical compound accounts for 5 to 50percent of the total weight of the additive; and then the additive agglomerates and the nylon are melted and spinned, and the consumption of the additive agglomerates must make the ration of the weight of the first main group metal element to that of the nylon is consistent.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Modified asphalt and preparation method thereof

The invention discloses modified asphalt which comprises the following components in parts by weight: 75-95 parts of matrix asphalt, 1-10 parts of star-shaped SBS, 1-5 parts of waste rubber powder, 1-5 parts of waste plastic, 1-4 parts of a cross-linking agent, 0.8-1.5 parts of a compatilizer, 0.5-1.2 parts of kieselguhr, 0.5-0.8 part of nylon fiber, 0.3-0.7 part of carbon black, 0.3-0.5 part of talcum powder, 0.1-0.3 part of a stabilizer, 0.2-0.1 part of zinc oxide and 0.01-0.04 part of an ester solvent. The invention further provides a preparation method of the modified asphalt. The modified asphalt which is prepared by using the preparation method that different components are matched is good in high-temperature stability, low-temperature anti-cracking property and anti-fatigue property, relatively high in softening point and relatively good in adhesion property.

Owner:JIANGXI PROVINCIAL TRANSPORTATION ENG GRP

Rope of an elevator and a method for manufacturing the rope

ActiveUS9126805B2Drawback can be obviatedControlRopes and cables for vehicles/pulleyGlass fiberCarbon fibers

A rope of a lifting device, more particularly of a passenger transport elevator and / or freight transport elevator, an elevator, and a method for manufacturing the rope are disclosed. The rope includes an unbroken load-bearing part, the profile of which is essentially of rectangular shape, and the width of the cross-section is greater than the thickness and which load-bearing part comprises glass fiber reinforcements and / or aramid fiber reinforcements and / or carbon fiber reinforcements and / or polybenzoxazole fiber reinforcements and / or polyethylene fiber reinforcements and / or nylon fiber reinforcements in a polymer matrix material. The long sides of the cross-section of the load-bearing part include one or more grooves symmetrically or asymmetrically in the longitudinal direction of the rope, which grooves divide the load-bearing part into smaller parts.

Owner:KONE CORP

Production method of fine-denier hollow nylon 6FDY filament

InactiveCN101768789ARealize fine denier spinningEnhanced melt tensile strengthHollow filament manufactureMonocomponent polyamides artificial filamentNylon materialFree zone

The invention relates to a production method of a fine-denier hollow nylon 6FDY filament. The technical problem to be solved is as follows: the denier of the produced nylon fiber is lower than 1.0dtex. The weight ratio of the nylon chips with specific viscosity requirements and fine-denier nylon master batch adopted by the invention is 1:20 50. in the process route, 1) a spinning pack keeps steady pressure: 12 - 18MPa; 2) metal sand filter of 40 - 100 meshes is adopted; 3) the bore diameter of the hollow spinneret plate is 0.15 - 0.30mm, the aspect ratio is 2 - 4; 4) a slow-cooling device (1) is arranged at the back of the spinning pack, the slow-cooling device is a ring-shaped heating cap with temperature of 160 - 180 degrees C., and a wind-free zone (2) with height of 20-40 cm is formed between the slow-cooling device (1) and a ring-shaped air-blowing device (3); 5) the location of the cluster point is uplifted; 6) the winding speed of spinning is 3000-5000m / min.

Owner:HANGZHOU NORMAL UNIVERSITY

Fire-retardant fiber blended yarn, preparation method of fire-retardant fiber blended yarn and fabrics of fire-retardant fiber blended yarn

ActiveCN103255521AImprove spinnabilityImprove flame retardant performanceFibre typesYarnYarnPolymer science

The invention relates to fire-retardant fiber blended yarn, a preparation method of the fire-retardant fiber blended yarn and fabrics of the fire-retardant fiber blended yarn. Double-layer fibers are used in the fire-retardant fiber blended yarn which comprises a surface layer and a core layer, the surface layer is composed of, by weight percentage, 20-30% of phenolic fibers, 20-25% of fire-retardant acrylic fibers, 30-40% of copolyamide fibers, 20-30% of antistatic synthetic fibers in a blending mode, the characteristics of the fibers can be sufficiently utilized, the problem existing in single fibers is solved, the spinnability of the fibers is improved, and a fire-retardant effect is improved. The core layer is composed of, by weight percentage, 10-20% of wool fibers, 30-40% of nylon fibers and 40-50% of polyester fibers, cost is lowered, and the air permeability of the fibers is improved. Fire retardant soaking treatment is conducted on the fibers of the core layer, and the core layer is made to have the fire-retardant capacity. The fire-retardant fiber blended yarn can be applied to clothing, home textiles, sports products, health care products, and fire-proof fabrics.

Owner:北京邦维普泰防护纺织有限公司

Anti-algae anti-aging fishing net

InactiveCN105442086ASimple processing technologyImprove toughnessStain/soil resistant fibresConjugated synthetic polymer artificial filamentsEpoxyPolystyrene

The invention discloses an anti-algae anti-aging fishing net prepared from the following components: polystyrene, polyethylene fibers, nylon fibers, MBS resin, an epoxy resin adhesive film, ethylene glycol dimethacrylate, a calcium carbonate powder, an attapulgite powder, dibutyl phthalate and calcium stearate. The prepared fishing net has simple processing technology; ultraviolet intermittent irradiation treatment is carried out in a process of polyethylene fiber treatment, and the prepared fishing net can be allowed to have extremely strong performance of preventing algae attachment; the nylon fibers have the defects that the nylon fibers have poor optical rotation resistance, are prone to yellowing and have the strength decreased when illuminated for a long time by the sun outdoor, so a hexamethylene diamine and maleic anhydride mixture is adopted for treating the nylon fibers, the problems are solved, and the anti-aging ability of the prepared fishing net is greatly improved; and through addition of the treated attapulgite powder, mechanical properties of the fishing net are improved, and the toughness is enhanced.

Owner:CHAOHU TIANYU FISHING TACKLE CO LTD

Anti-static dust-free wiping cloth and preparation method thereof

The invention relates to antistatic dustless wiping cloth and a method for preparing the same, in particular to wiping cloth. The invention provides the antistatic dustless wiping cloth which has the advantages of stronger dust absorbing and decontaminating capabilities, strong abrasion resistance, better softness, more remarkable static electricity clearing effect, lower cost, difficult fuzz falling in use, and the method for preparing the same. The antistatic dustless wiping cloth is made of polyester filaments and nylon fibers through continuous weaving, and an antistatic dustless cloth detergent is added to a cloth material. The method for preparing the antistatic dustless wiping cloth comprises the following steps: cutting dustless cloth longitudinally and then transversely, wherein the transverse cutting of the dustless cloth is subjected to ultrasonic transverse cutting optimally; using purified water to wash the dustless cloth for the first time; dehydrating the dustless cloth for the first time; using the purified water to wash the dustless cloth for the second time; dehydrating the dustless cloth for the second time; using the purified water to wash the dustless cloth for the third time; dehydrating the dustless cloth for the third time; using the purified water to wash the dustless cloth for the fourth time; dehydrating the dustless cloth for the fourth time; performing drying and dust absorption on the dustless cloth after the dehydration for the fourth time; and performing vacuum packaging on the dustless cloth after the dust absorption in a dust free room to obtain the antistatic dustless wiping cloth.

Owner:厦门市捷瑞静电设备有限公司

Low temperature producing method for nylon fiber

InactiveCN101054740AImprove securityLower spinning temperatureMelt spinning methodsArtifical filament manufactureAntistatic agentUv absorber

The present invention discloses a technology field relating to the preparation method of textile materials, especially to a process for for low temperature production of nylon fibre. Said process comprises the steps of adding a mixture of metallic compounds during or before nylon melting course and then spinning the obtained molten mass at a low temperature of 160-250 DEG C. Adding auxiliaries of oxidation preventives, ultraviolet absorbents, light-stability agents and anstatic agents therein before the melting course or during the melting course will result in more excellent effects. The method has a lower energy consumption and a lower cost, and its industry operations are more convenient and safe, will find wide use in industries such as garments and intertexture.

Owner:HANGZHOU NORMAL UNIVERSITY +1

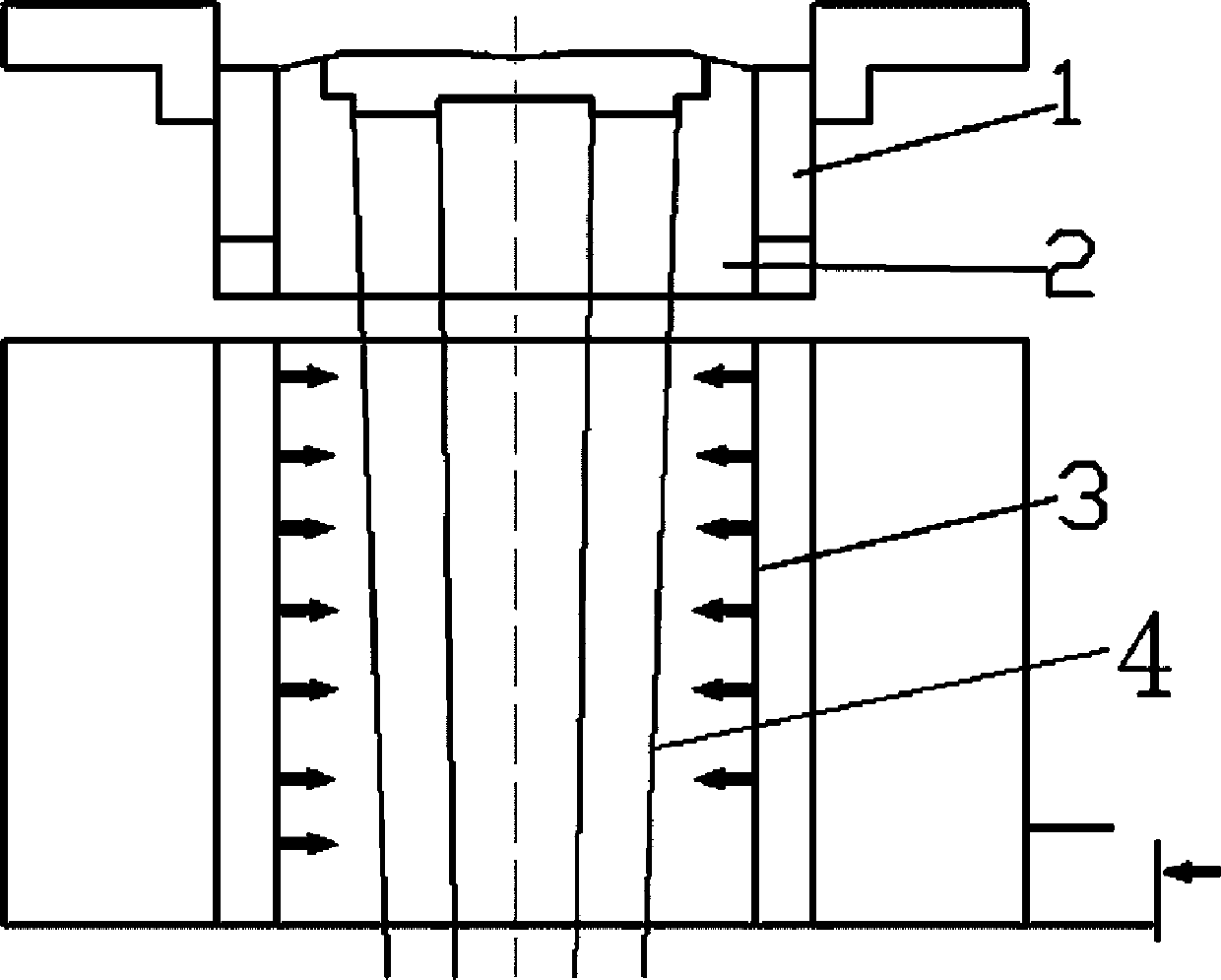

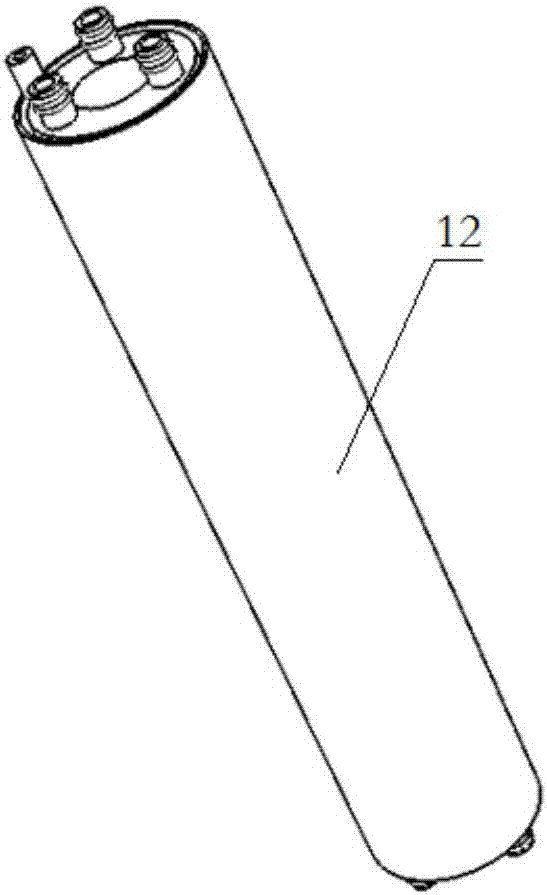

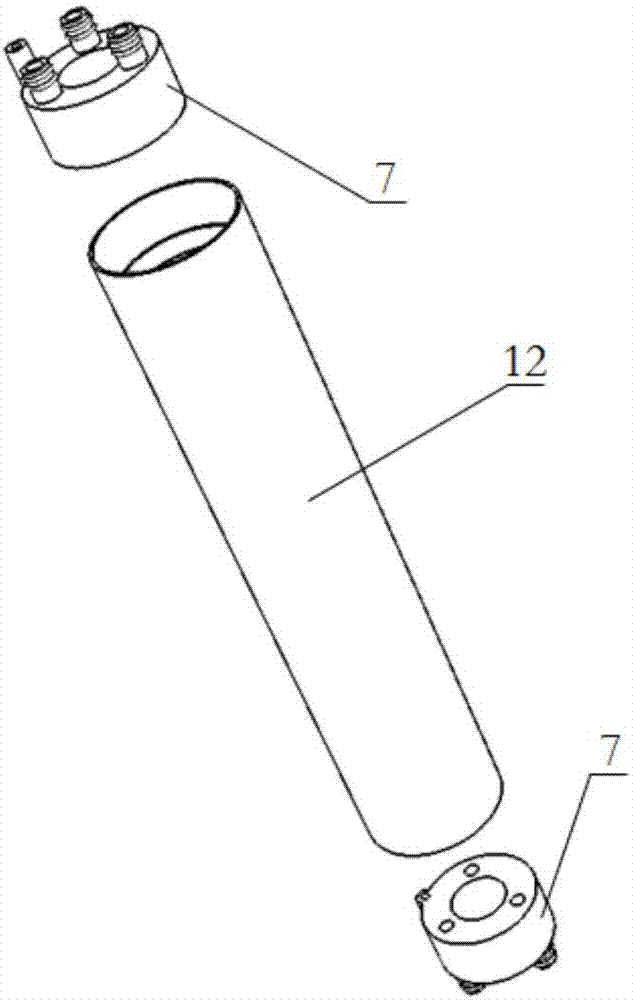

Multi-degree-of-freedom stiffness variable pneumatic operation operating arm and manufacturing method

The invention discloses a multi-degree-of-freedom stiffness variable pneumatic operation operating arm and a manufacturing method. The operation operating arm is formed by connecting multiple sections of identical pneumatic driver units. Each pneumatic driver unit comprises a cylindrical driver, the two ends of the driver are connected to bases, the driver comprises an outside stiffness adjusting layer, and the stiffness adjusting layer is internally provided with a driving layer. The driving layer comprises a cylindrical silicone rubber layer with through holes, multiple cavities are formed in the silicone rubber layer, the inner surface of the silicone rubber layer is covered with a PDMS layer, and the outer surface of the silicone rubber layer is covered with double helix nylon fiber. The bases are provided with air holes corresponding to the cavities and vacuum orifices corresponding to the stiffness adjusting layer. The multi-degree-of-freedom stiffness variable pneumatic operation operating arm has the advantages of being highly flexible in motion capability, variable in stiffness, small in size and light in weight, causing little damage to a human body rigidity, and having less gas circuits, which facilitates control.

Owner:XI AN JIAOTONG UNIV

Silver-plated electromagnetic shielding lining cloth and production process thereof

InactiveCN103898740AImprove antioxidant capacityImprove performancePhysical treatmentFibre typesProduction lineSilver plate

The invention discloses silver-plated electromagnetic shielding lining cloth and a production process thereof. The silver-plated electromagnetic shielding lining cloth comprises nylon fiber grey cloth woven by base layer nylon fiber, wherein a layer of uniform and close silver particles are plated on the nylon fiber grey cloth; a silver particle layer covering on the nylon fiber grey cloth is formed by a plurality of silver particles; both the inner and outer surface layers of the nylon fiber grey cloth are coated with a protective layer which is used for covering the silver particle layer on the nylon fiber grey cloth and preventing the silver particle layer from oxidizing. The silver-plated electromagnetic shielding lining cloth is prepared through the steps of weaving of the nylon fiber grey cloth, the production of silver-plated electromagnetic shielding base cloth, sizing and coating of a hot melt adhesive, powder dusting, powder sucking, infrared sintering, drying and cooling coiling. According to the production process, a silver-plated fabric is used as the base cloth; through the production of a double-point lining cloth production line, the clothes are suspended, elegant or stiff and have favorable electromagnetic shielding function; through special postprocessing procedure, the silver-plated lining cloth has better oxidation resistance than the common silver-plated fabrics.

Owner:QINGDAO UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com