Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

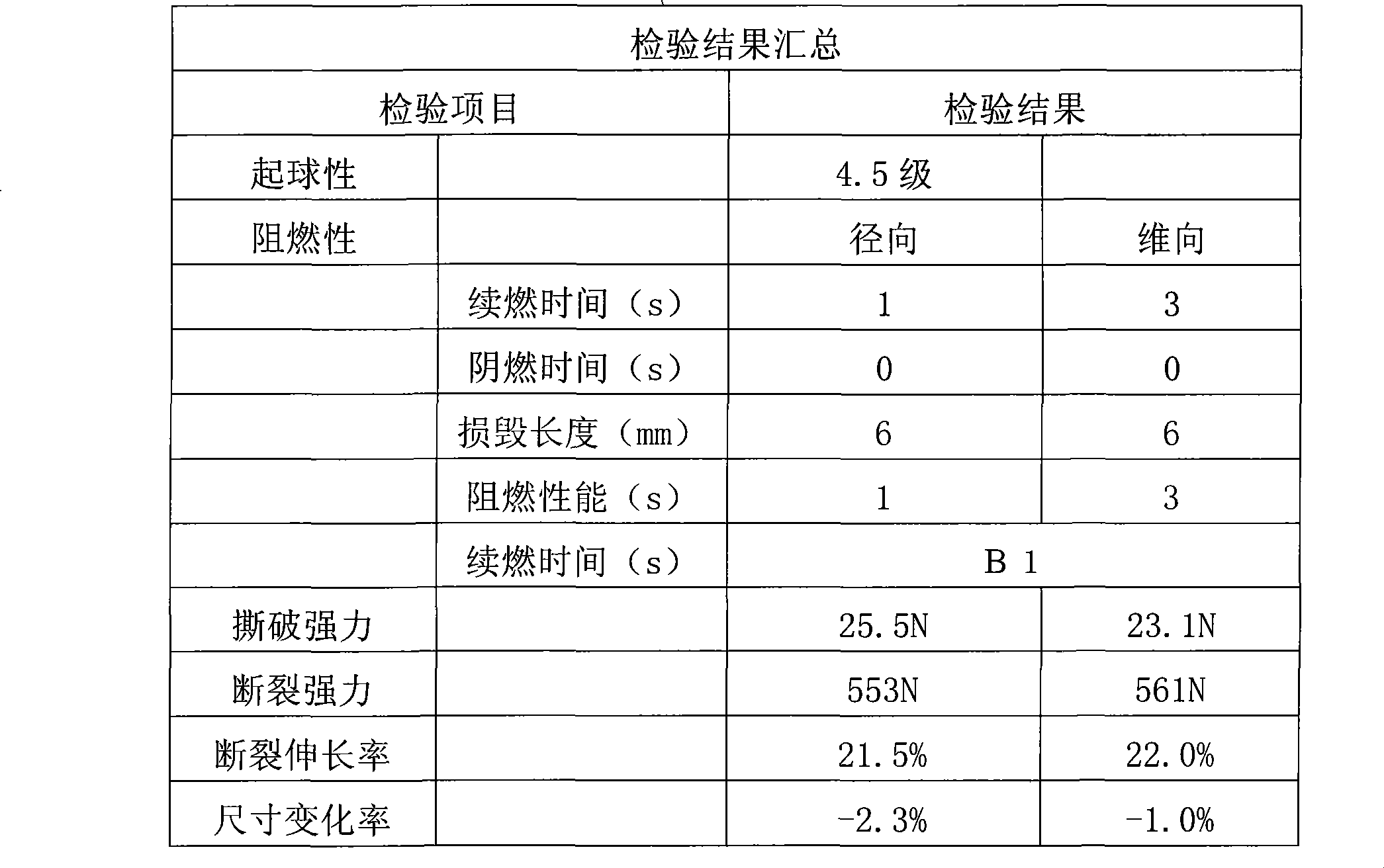

A manufacturing method and technology of protective clothing, applied in the direction of fabrics, protective clothing, textiles and papermaking, can solve the problems of difficult to achieve high temperature resistance, insufficient softness and comfort, high cost, etc., and achieve the effect of good breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

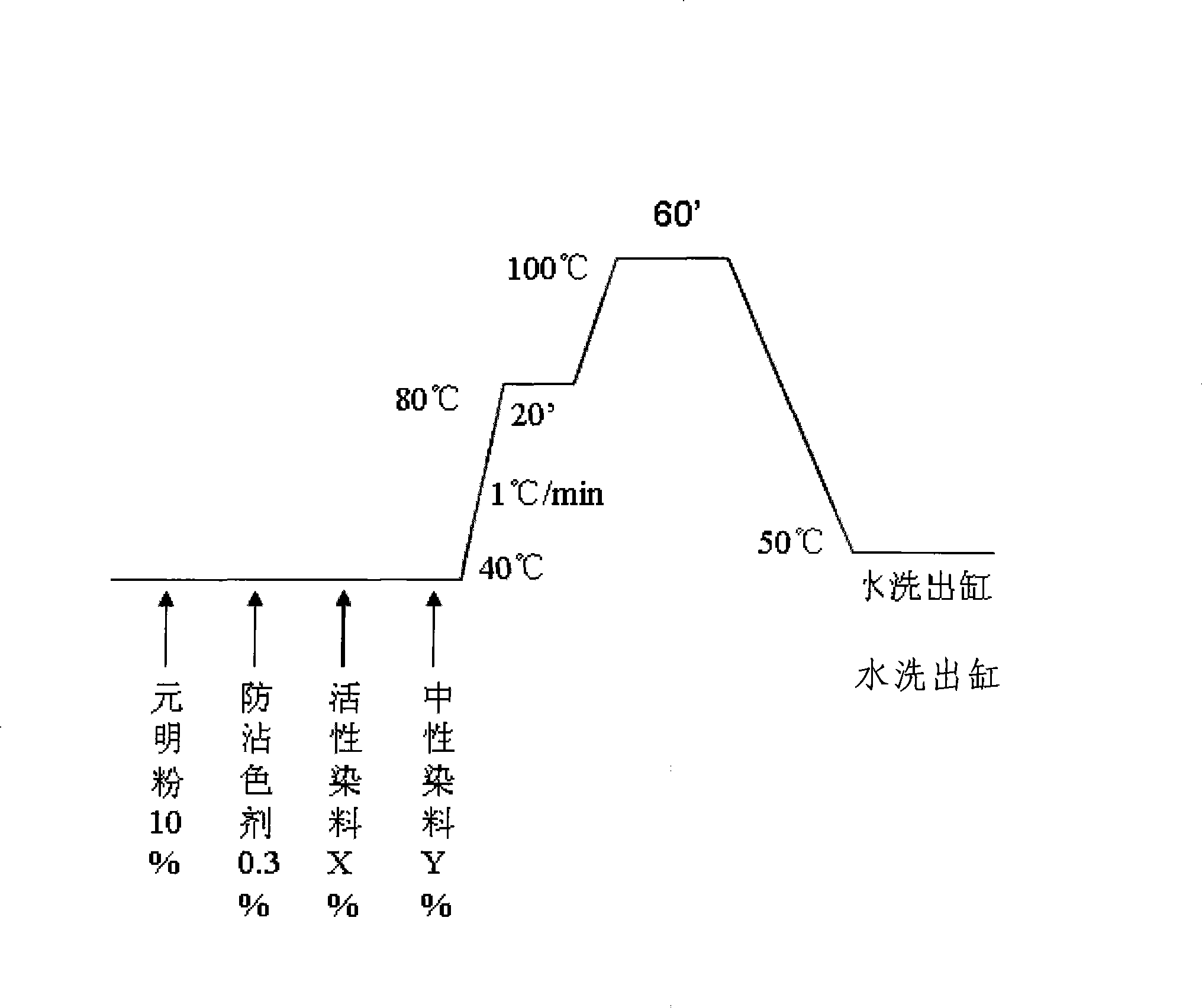

Embodiment 1

[0073] The industrial flame-retardant protective clothing fabric of the present invention. The yarn used for the fabric fabric of the industrial flame-retardant protective clothing is made of flame-retardant viscose Lenzing FR (produced in Italy), and the flame-retardant viscose is retarded by a flame-retardant particle size<1um. Burning agent treatment, the fiber fineness is 1.5-1.7DTEX, and the wool fiber count is 64-66.

[0074] The wool fibers can be treated with a flame retardant finish. The nylon is aromatic polyamide fiber PA, the fiber denier range is 2-3D, and the blending proportions (weight) of the flame-retardant viscose, wool fiber and nylon fiber are 50%, 40% and 10% respectively.

[0075] When blending, the count of the flame-retardant viscose, wool fiber and nylon fiber blended yarn is single yarn Nm40 / 1 twist 750t / mS, ply yarn Nm40 / 2 twist 500t / mZ. The flame retardant viscose, wool fiber and nylon fiber blended yarn is steamed.

[0076] The steamed yarn proc...

Embodiment 2

[0108] Except following process, other is the same as embodiment 1, makes three flame-retardant protective clothing fabrics of the present invention.

[0109] Weaving process:

[0110] 271g / m 2 319g / m 2 364g / m 2

[0111] Composition PA6%

[0112] Gross 66s 39%

[0113] Lenzing FR55%

[0114] Single yarn Nm38 / 1 twist 760t / m S

[0115] Ply yarn Nm38 / 2 twist 520t / m Z

[0116] Warp (finished product) 312 / 10cm 312 / 10cm 375 / 10cm

[0117] Woven Twill 2 / 1 2 / 1 2 / 1

[0118] Reed 95 / 10cm 95 / 10cm 85 / 10cm

[0119] Reed width 167, 47 167, 47 168, 74

[0120] Reeding 3 / 1 3 / 1 4 / 1

[0121] Weft yarn (finished product) 200 / 10cm 255 / 10cm 275 / 10cm

[0122] Width (finished product) 153cm 153cm 153cm

[0123] In the dyeing process, after the cloth is fully soaked, add 8% sodium sulfate, and add anti-staining agent 15g / l after running for 10 minutes. In the post-finishing process, the anti-wrinkle and anti-shrinkage resin finishing agent: 42g / L double d...

Embodiment 3

[0125] Except following process, other is the same as embodiment 1, makes three flame-retardant protective clothing fabrics of the present invention.

[0126] Weaving process:

[0127] 271g / m 2 3201g / m 2 364g / m 2

[0128] Composition PA12%

[0129] Gross 64s 36%

[0130] Lenzing FR52%

[0131] Single yarn Nm42 / 1 twist 740t / m S

[0132] Ply yarn Nm42 / 2 twist 510t / m Z

[0133] Warp (finished product) 312 / 10cm 312 / 10cm 375 / 10cm

[0134] Woven Twill 2 / 1 2 / 1 2 / 1

[0135] Reed 95 / 10cm 95 / 10cm 85 / 10cm

[0136] Reed width 167, 47 167, 47 168, 74

[0137] Reeding 3 / 1 3 / 1 4 / 1

[0138] Weft yarn (finished product) 200 / 10cm 255 / 10cm 275 / 10cm

[0139] Width (finished product) 153cm 153cm 153cm

[0140] In the dyeing process, after the cloth is fully soaked, add 5% sodium sulfate, and add anti-staining agent 11g / l after running for 10 minutes. In the post-finishing process, the anti-wrinkle and anti-shrinkage resin finishing agent: 42g / L d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com