Patents

Literature

68results about How to "Easy to blend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filler for Porous Film and Porous Film Containing the Same

InactiveUS20080182933A1Good dispersionPoor adhesionSemi-permeable membranesGranular deliveryLiquid-crystal displayInorganic particle

A filler for porous films is provided which is easy to be mixed with a resin, has good dispersibility in a resin, and provides a porous film useful for a light reflector of, for example, a liquid crystal display and a lighting apparatus and a porous film useful for a diaphragm (separator) between electrodes of a battery.A filler comprises inorganic particles surface treated with a surfactant (A) and a compound (B) having a chelating function to an alkaline earth metal.

Owner:MARUO CALCIUM COMPANY

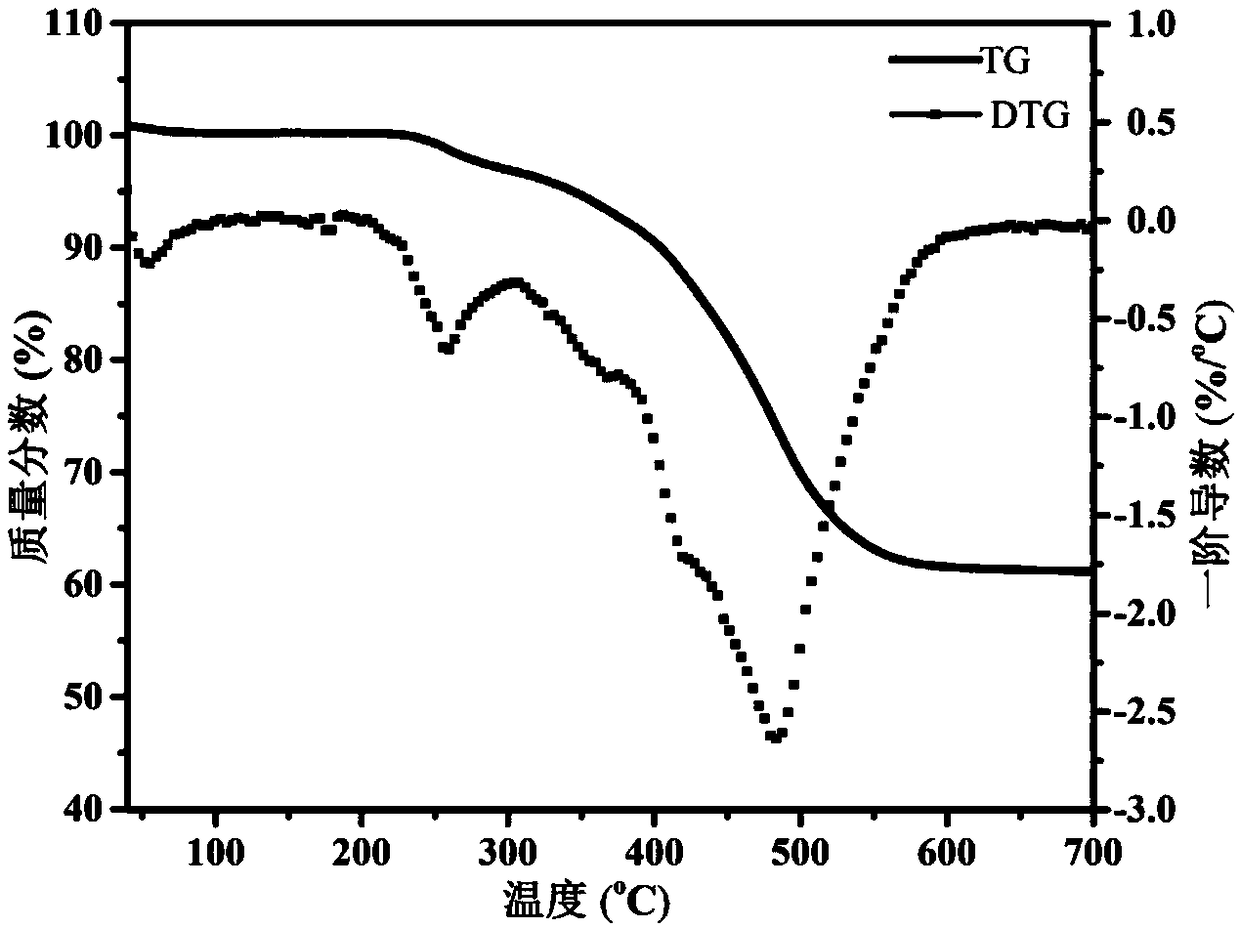

Ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, preparation method of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent, and application of ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent to flame retarding polymer

The invention discloses a ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent and a preparation method of the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The preparation method of the polymer is as follows: putting 10-(2,5-dyhydroxyl phenyl)-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reactor, adding a solvent,stirring for 5-10 minutes, adding an acid-binding agent; taking R1,R2'-ferrocene oxalyl chloride, adding the solvent, mixing, adding into the reactor dropwise, thermally insulating, stirring and reacting for 1-15 hours at the temperature of 0-50 DEG C under the protection of nitrogen after finishing adding dropwise; pouring a liquid obtained after the reaction into a precipitator while stirring, wherein the volume of the precipitator is 5-10 times that of the liquid, precipitating a yellow solid, carrying out suction filtration, washing a filter cake by using the precipitator, and drying to obtain the ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent. The ferrocene-DOPO biradical polyester type flame retarding and smoke suppressing agent can be used to retard flame and suppress smoke of high polymer materials like polyolefins and epoxy resins.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Disposable diaper construction and adhesive

A novel spray-on adhesive composition is made from a high melt index polymer and a rosin ester tackifier that interact to produce a composition that can form a low VOC, non-tacky, hot melt adhesive material that can be used in disposable article manufacture. The adhesive provides surprisingly high initial adhesion. Additionally, the adhesive is thermally stable at hot melt application conditions, low in cost, easily applied, and produces high quality disposable articles.

Owner:ADHERENT LAB

Preparation method for high-toughness monofilament blended cotton yarn

ActiveCN104651998AGood flexibilityIncrease elasticityDry-cleaning apparatus for textilesBleaching apparatusYarnCarding

The invention discloses a preparation method for high-toughness monofilament blended cotton yarn. The preparation method comprises the following steps of carrying out cotton feeding, rolling, cotton carding and drawing to obtain rough yarn after carrying out cotton opening and scutching on long staple cotton, fine staple cotton, prefabricated monofilament materials and mixed cotton, and obtaining the high-toughness monofilament blended cotton yarn through spinning and spooling, wherein the prefabricated monofilament materials are obtained through draining and drying after carrying out primary boiling and dehydrating, primary steaming, secondary boiling and dehydrating, secondary steaming, standing, bleaching and washing. The high-toughness monofilament blended cotton yarn prepared by the preparation method has the characteristics of high toughness, low cost and the like, meanwhile, the air permeability is good, and the comfort is strong.

Owner:福建新同兴针纺织有限公司

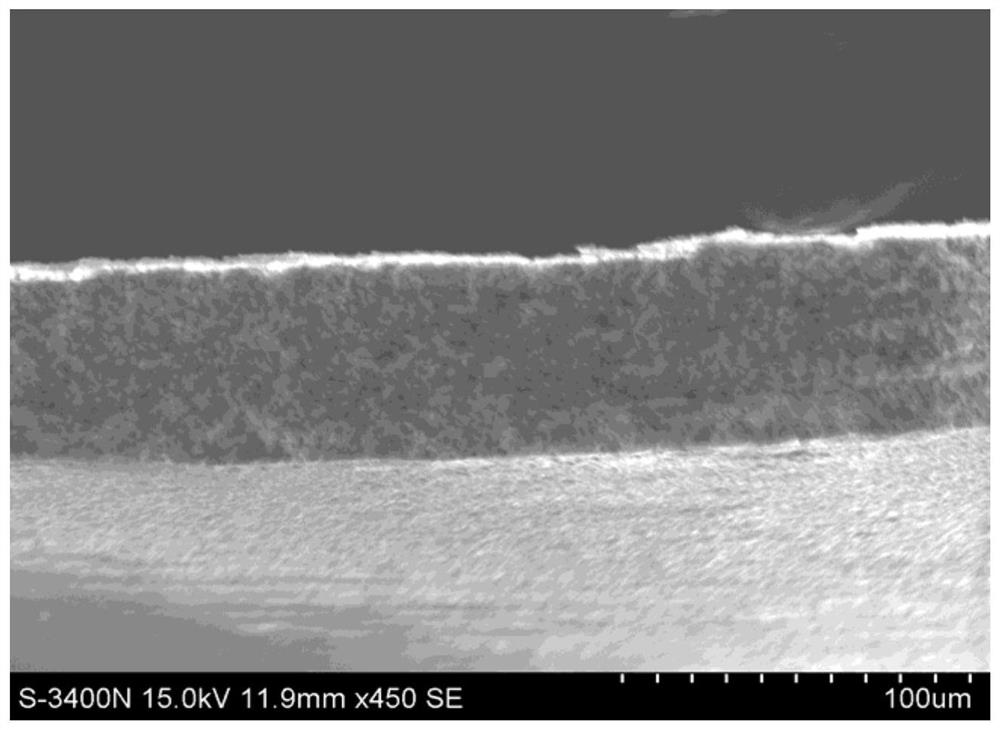

Anti-pollution aromatic polyamide composite reverse osmosis membrane and preparation method thereof

InactiveCN110038446AWater molecule mass transfer resistance is lowReduce mass transfer resistanceMembranesReverse osmosisUltrafiltrationPolyamide

The invention relates to an anti-pollution aromatic polyamide composite reverse osmosis membrane and a preparation method thereof. The preparation method of the reverse osmosis membrane comprises thefollowing steps of: soaking a cleaned polysulfone ultrafiltration membrane in a water phase monomer solution, taking out the polysulfone ultrafiltration membrane, airing the polysulfone ultrafiltration membrane, soaking one side of the polysulfone ultrafiltration membrane in an oil phase monomer solution, reacting for a period of time, taking out the polysulfone ultrafiltration membrane to completely volatilize an organic solvent to obtain a nascent state reverse osmosis membrane; coating the surface of nascent state reverse osmosis membrane with a layer of anti-pollution functional layer precursor solution, and performing heat treatment and rinsing to obtain the anti-pollution aromatic polyamide composite reverse osmosis membrane. A mixed matrix anti-pollution functional layer is constructed by a one-step method, the permeability of the functional layer is improved based on the design of the mixed matrix membrane, covalent bond fixation of the mixed matrix functional layer on the surface of the membrane is realized through chemical grafting and chemical crosslinking, and finally the anti-pollution reverse osmosis membrane with excellent long-term stability is obtained.

Owner:自然资源部天津海水淡化与综合利用研究所

Production method of polylactic-acid-fiber-containing spun wool fabric

InactiveCN103898765AEasy to blendGood water absorption and heat preservation performanceCarbon fibresBiochemical fibre treatmentYarnPolymer science

The invention discloses a production method of a polylactic-acid-fiber-containing spun wool fabric. The fabric is spun from wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers. The production method comprises the following steps: respectively carrying out anti-pilling treatment, enzyme treatment and softening treatment on the wool fibers and cashmere fibers; spinning the wool fibers, cashmere fibers, bamboo charcoal terylene fibers, superfine poly(butylene succinate) yarns and polylactic acid fibers in a weight ratio of (55-75):(12-18):(18-28):(12-15):(5-8) into a fabric; and finally, carrying out after-treatment on the fabric by using a water-soluble polyurethane wool anti-shrinking agent. The method can greatly reduce the damage of the wool fiber product and reduce pilling; and the fabric has the advantages of softer feeling, greatly lower felting shrinkage and better quality.

Owner:汤丽娟

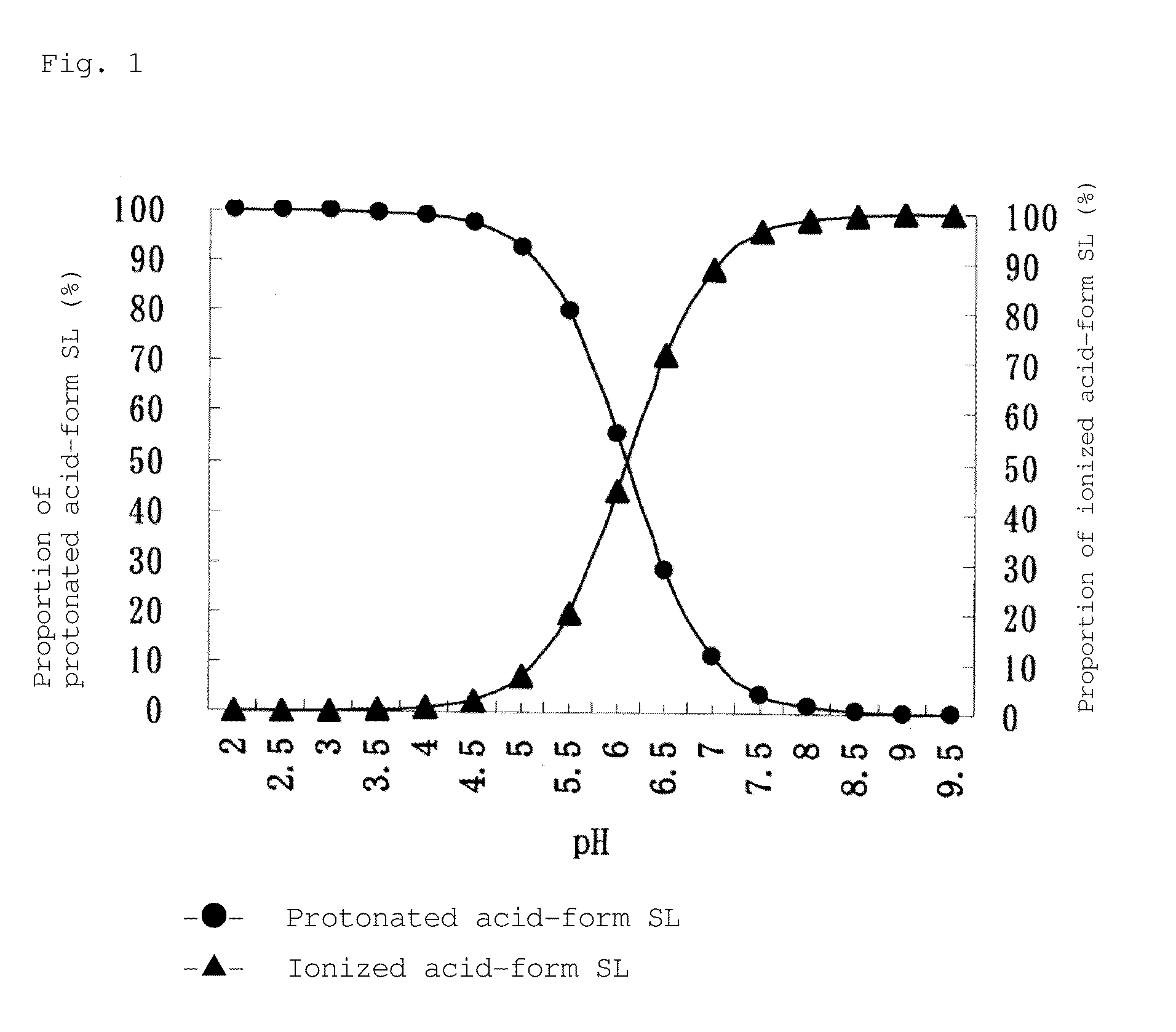

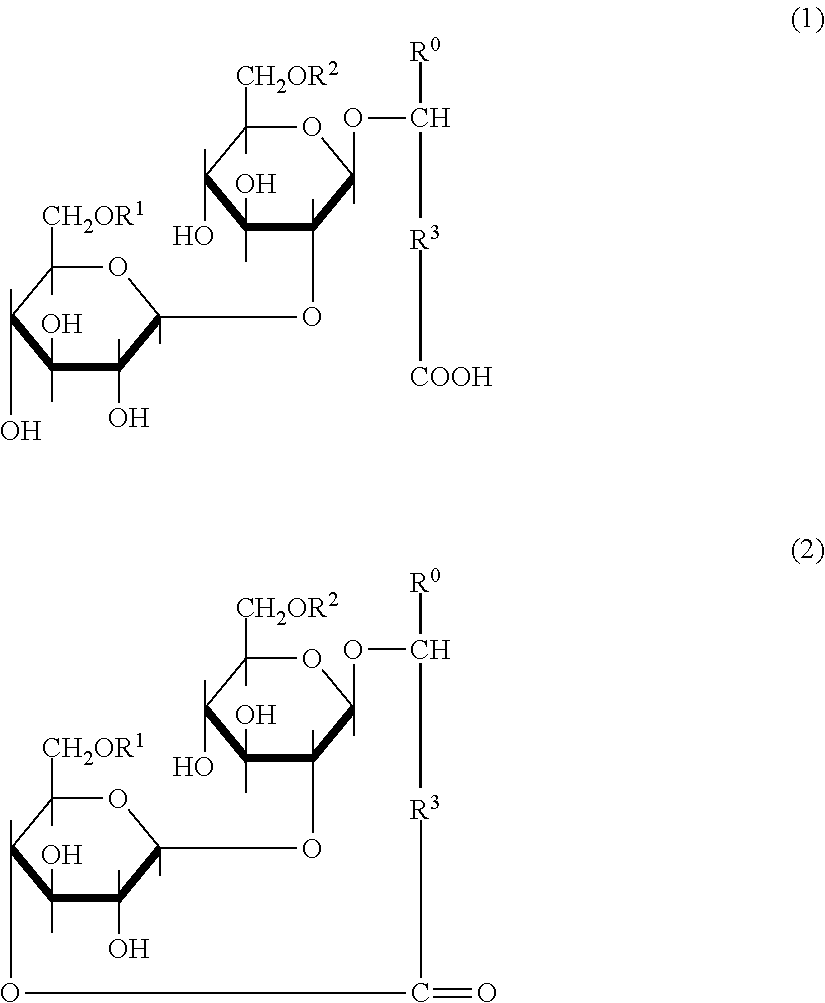

High-purity acid-form sophorolipid (SL) containing composition and process for preparing same

ActiveUS20150112049A1Less energyPurified safelyCosmetic preparationsSugar derivativesAcetic acidSophorolipid

The present invention provides a high-purity acid-form sophorolipid (SL)-containing composition characterized by substantially not containing acetic acid. The high-purity acid-form SL-containing composition can be produced, for example, by the following method:(i) adjusting the pH of a partially purified acid-form SL-containing composition to an acidic range; and(ii-a) subjecting an acidified partially purified acid-form SL-containing composition obtained in step (i) to chromatography to acquire a fraction containing an acid-form SL, or(ii-b) leaving the acidified partially purified acid-form SL-containing composition obtained in step (i) to stand under a low-temperature condition to acquire a resulting gelled object.

Owner:SARAYA CO LTD

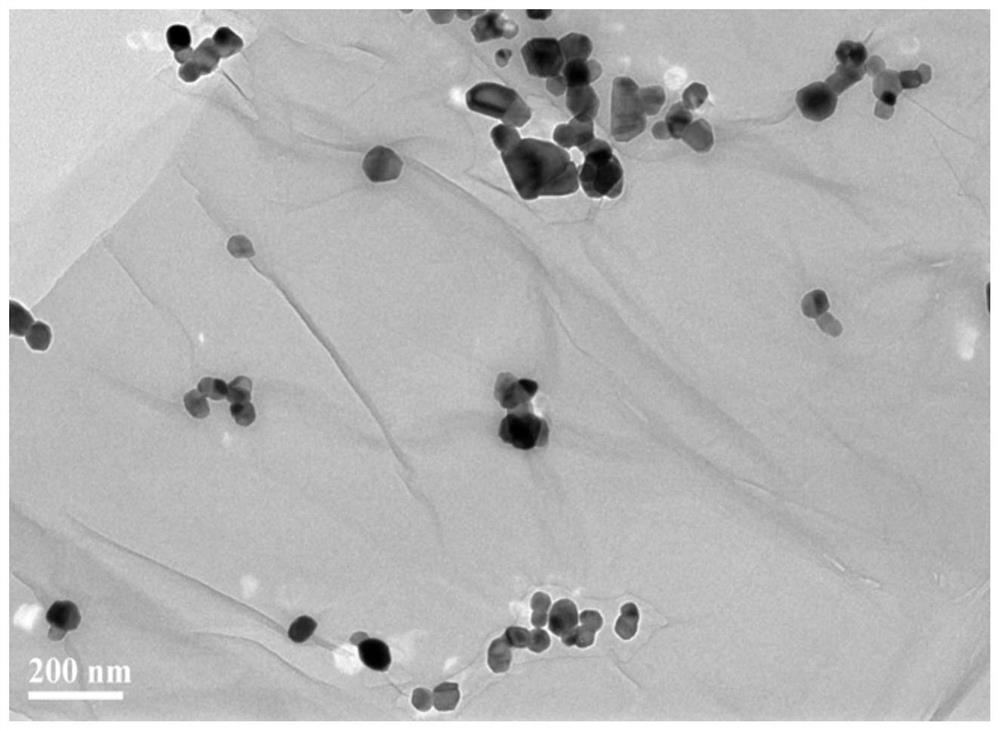

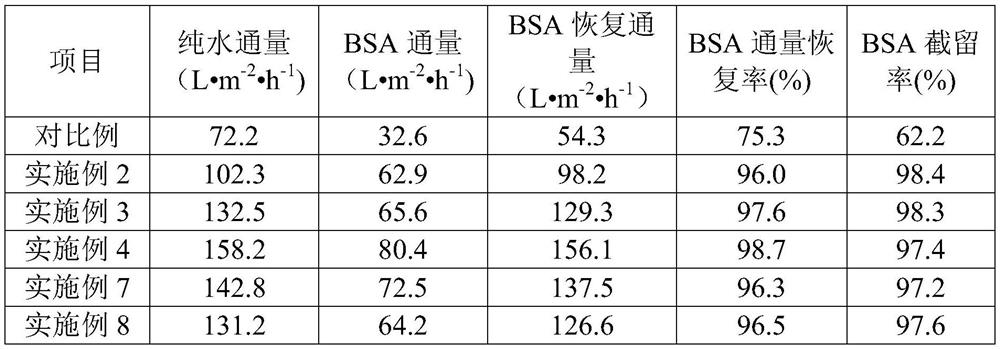

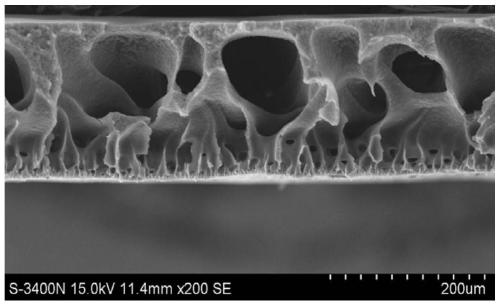

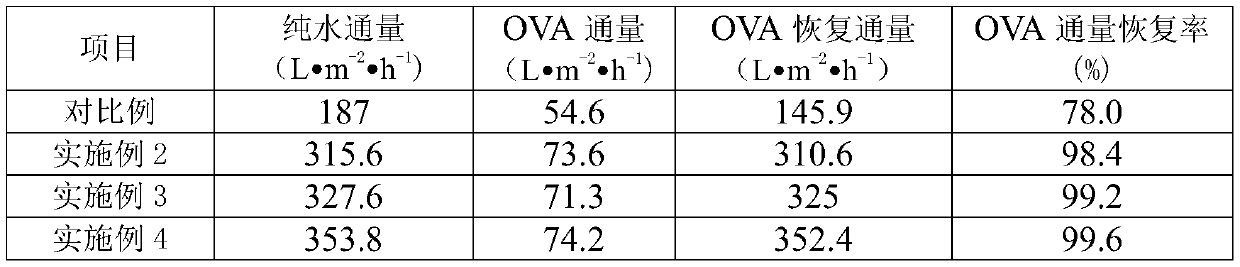

Preparation method of polyvinylidene fluoride mixed matrix membrane

ActiveCN111760461AStrong anti-pollutionHigh retention rateMembranesSemi-permeable membranesOxide compositePhysical chemistry

The invention relates to a preparation method of a uniform sponge porous polyvinylidene fluoride mixed matrix membrane with high rejection rate and strong pollution resistance. The preparation methodcomprises the following steps: preparing a polyvinylidene fluoride membrane casting solution containing a nano SnO2-graphene oxide composite material, and preparing the polyvinylidene fluoride mixed matrix membrane from the polyvinylidene fluoride membrane casting solution by using a non-solvent induced phase separation method. Compared with like membranes in the prior art, the ultrafiltration membrane prepared by the preparation method has the advantages of excellent anti-pollution performance, high rejection rate, simple preparation method and the like.

Owner:SHANGHAI INST OF TECH

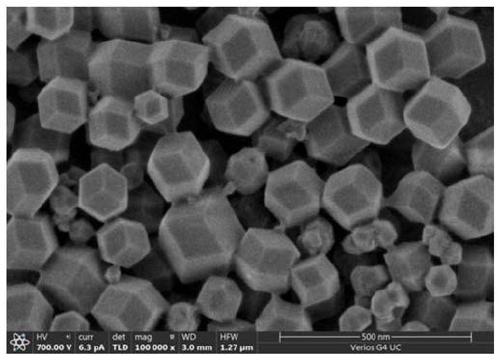

Preparation method of polyvinylidene fluoride mixed matrix membrane with high flux and strong pollution resistance

ActiveCN110479109AIncreased pure water fluxImprove permeabilitySemi-permeable membranesMembranesNon solventUltrafiltration

The invention relates to a preparation method of a polyvinylidene fluoride mixed matrix membrane with high flux and strong pollution resistance. The method comprises the following steps: adding a zeolite imidazate skeleton-8 material prepared by a solvothermal method into a polyvinylidene fluoride membrane casting solution, and preparing the polyvinylidene fluoride mixed matrix membrane from the polyvinylidene fluoride membrane casting solution by a non-solvent induced phase separation method. Compared with the prior art, the method has the advantages that the prepared ultrafiltration membraneis excellent in anti-pollution performance, high in water flux, simple in preparation method and the like.

Owner:SHANGHAI INST OF TECH

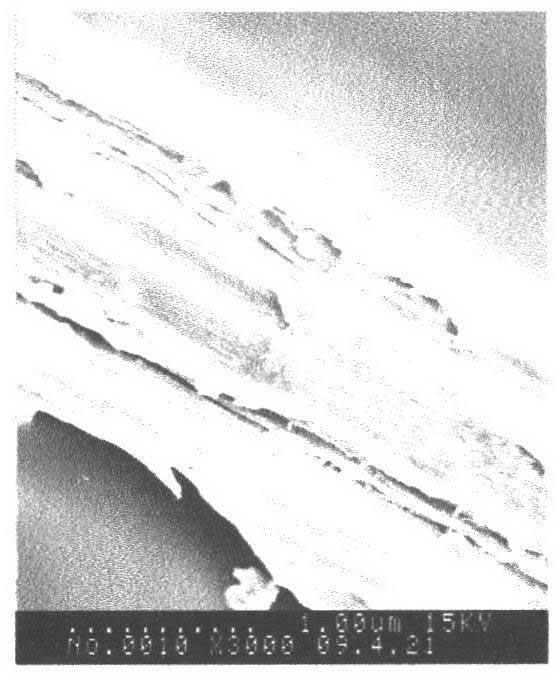

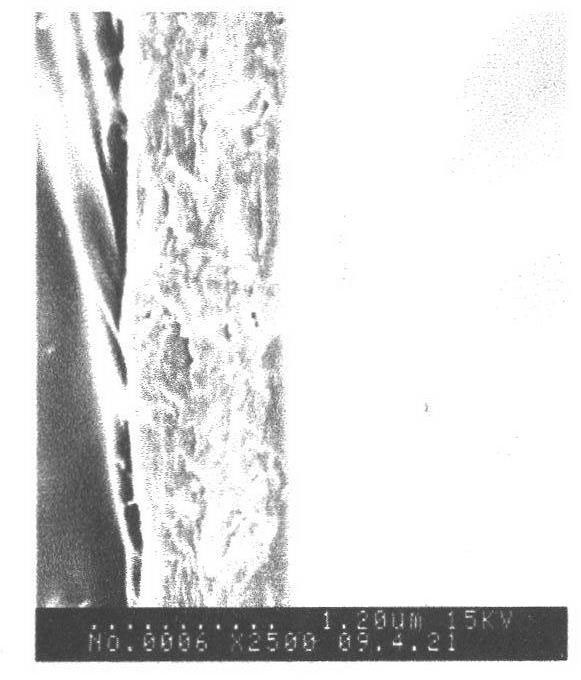

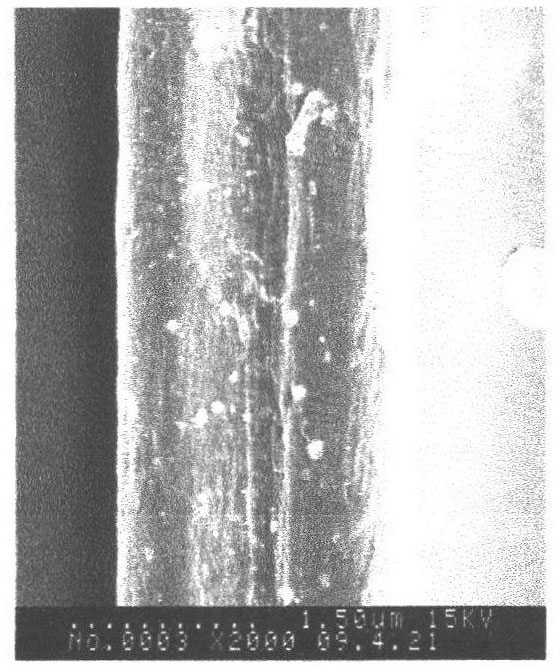

Flame retardant anti-dripping blended fabric and preparation method thereof

InactiveCN102634896AImprove cohesionImprove flame retardant performanceFibre treatmentYarnYarnTemperature control

The invention discloses a flame retardant anti-dripping blended fabric and a preparation method of the blended fabric. The blended fabric is formed by blending aramid fiber and flame retardant terylene according to the mass ratio of (8-20): (80-92). The preparation method comprises the pretreatment process of aramid staple fiber and the blending process of the flame retardant terylene, wherein before blending, polar solvent is used for treating the aramid fiber for 60-90min at the temperature controlled within the range of 60-90 DEG C, and the flame retardant terylene is treated by 4-8g / L alkali for 30-90min at the temperature controlled within the range of 50-80 DEG C. Surface treatment is carried out on the aramid fiber and the flame retardant terylene, so that the fiber surface becomes appropriately rough, and blending can be better carried out. The prepared fabric woven by mixed yarn not only has good flame retardant property, but also has good dripping resistance.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Preparation method of prefabricated palm fiber material for cotton/palm fiber blending

ActiveCN104651955AGood flexibilityImprove breathabilityDry-cleaning apparatus for textilesBleaching apparatusKerosenePalm fiber

The invention discloses a preparation method of a prefabricated palm fiber material for cotton / palm fiber blending. The preparation method comprises the following steps: performing primary boiling-off and primary steaming to water, palm fibers, sodium hydroxide solution, kerosene, camellia oil, refining agent MRN and JFC to obtain primarily steamed palm fibers; then performing secondary boiling-off and secondary steaming to the water, sodium hydroxide solution, refining agent MOL-201, new synthetic fiber refining agent AV-SCOUR-81, chelating agent EDTA, kerosene, camellia oil and the primarily steamed palm fibers to obtain secondarily steamed palm fibers; standing the secondarily steamed palm fibers; mixing with the sodium hydroxide, hydrogen peroxide, stabilizer LTP-S128 and water to obtain bleached palm fibers; and then washing and bleaching the palm fibers twice with water at different temperatures, draining off and drying to obtain the prefabricated palm fiber material for cotton / palm fiber blending.

Owner:崇夕山

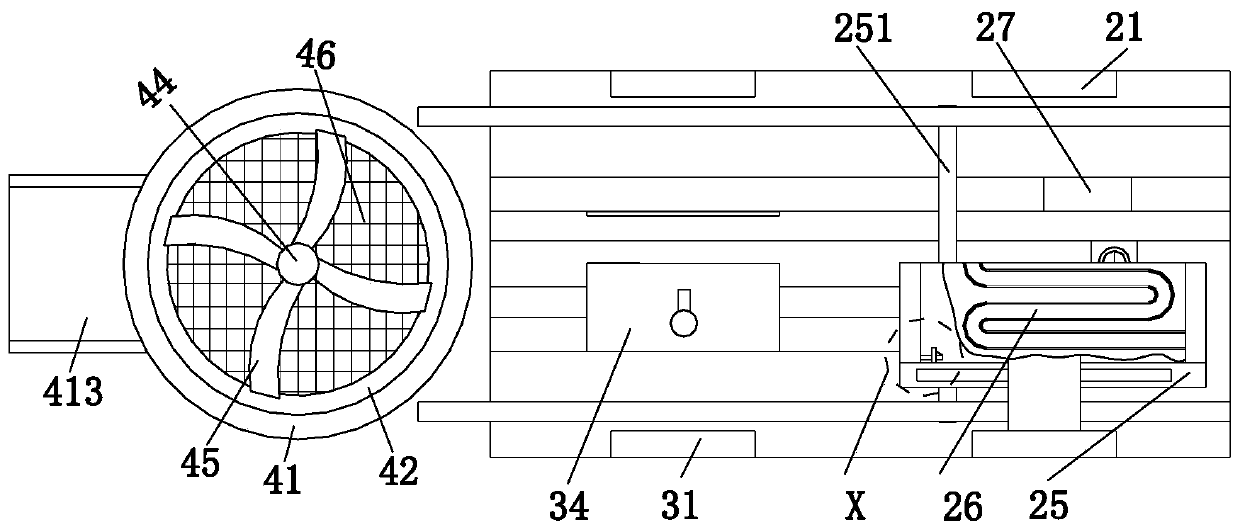

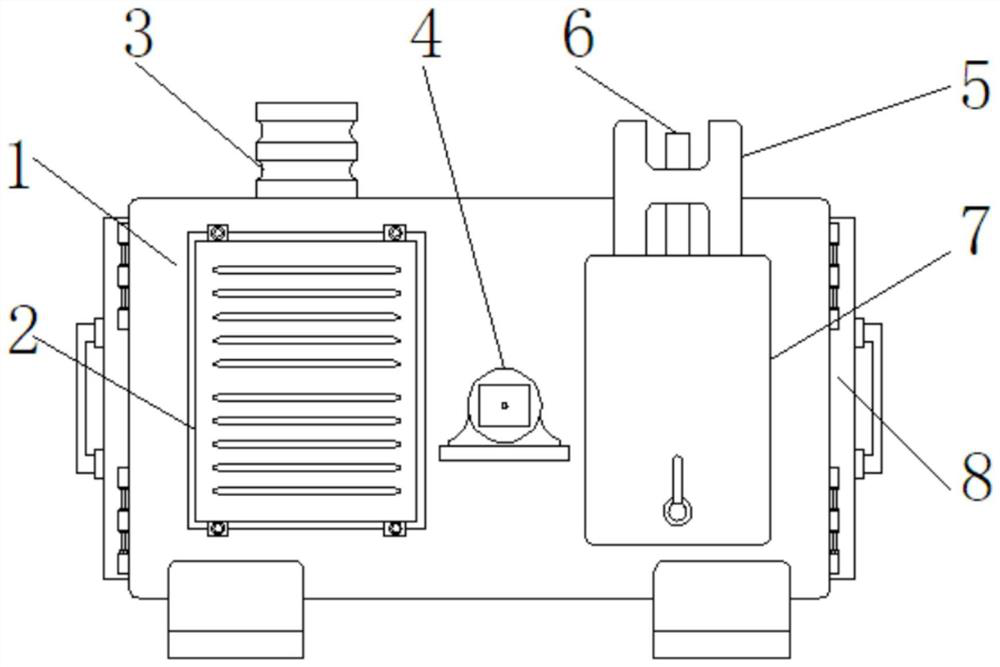

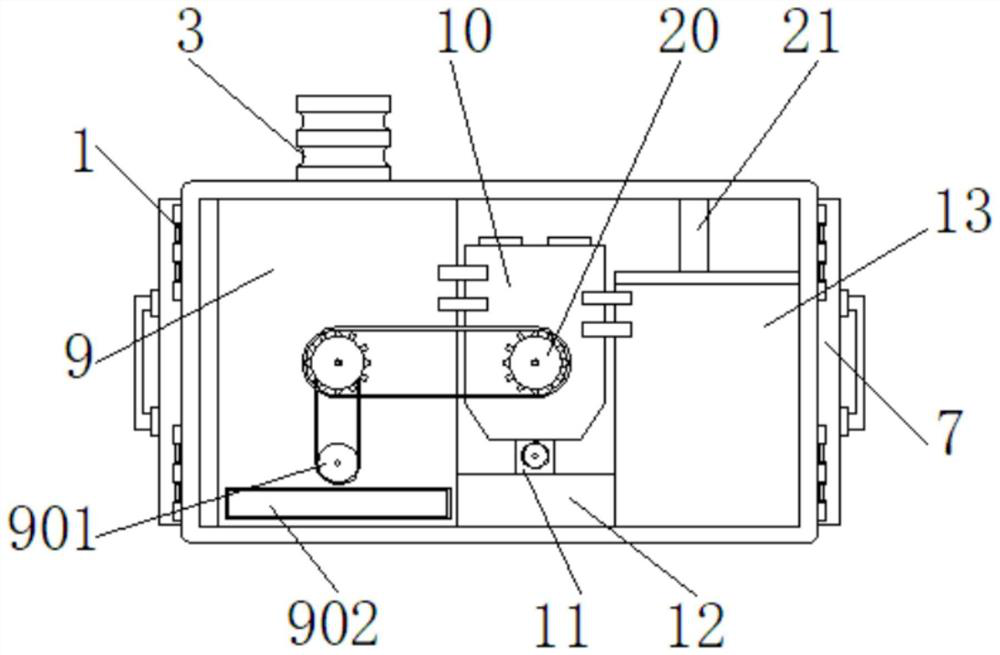

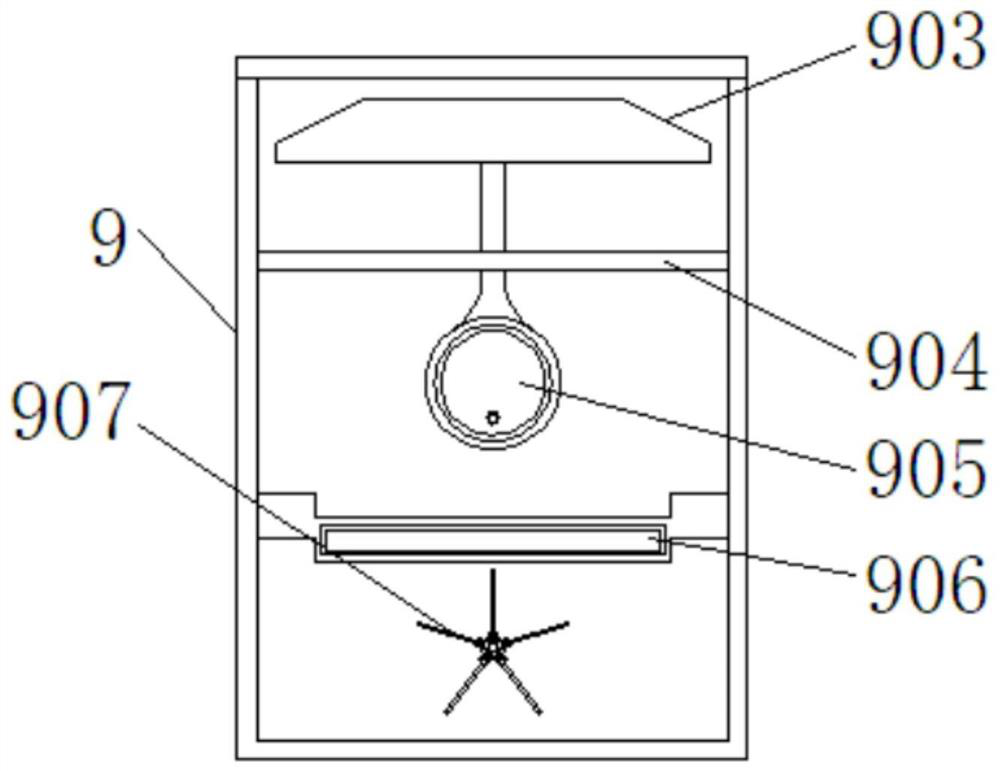

Vertical sludge cleaning treatment machine for river channel dredging

InactiveCN110698024AIncrease profitImprove formabilitySievingSludge treatment by de-watering/drying/thickeningEngineeringEnvironmental geology

The invention relates to a vertical sludge cleaning treatment machine for river channel dredging. The vertical sludge cleaning treatment machine comprises a workbench, a drying device, a block cuttingdevice and a crushing device, wherein the drying device is installed at the right end of the upper end face of the workbench in a sliding fit mode; the block cutting device is arranged on the left side of the drying device and is connected with the upper end face of the workbench in a sliding fit mode; and the crushing device is arranged on the left side of the workbench. According to the vertical sludge cleaning treatment machine for river channel dredging, river sludge is cleaned and reutilized by adopting the design concept of multi-stage treatment, so the waste is turned into the valuable, and the utilization rate and the forming degree of sludge are improved; and dried sludge blocks are crushed and refined by adopting the crushing device, so the crushed sludge blocks can be easily mixed with other substances during subsequent use.

Owner:谢诚浩

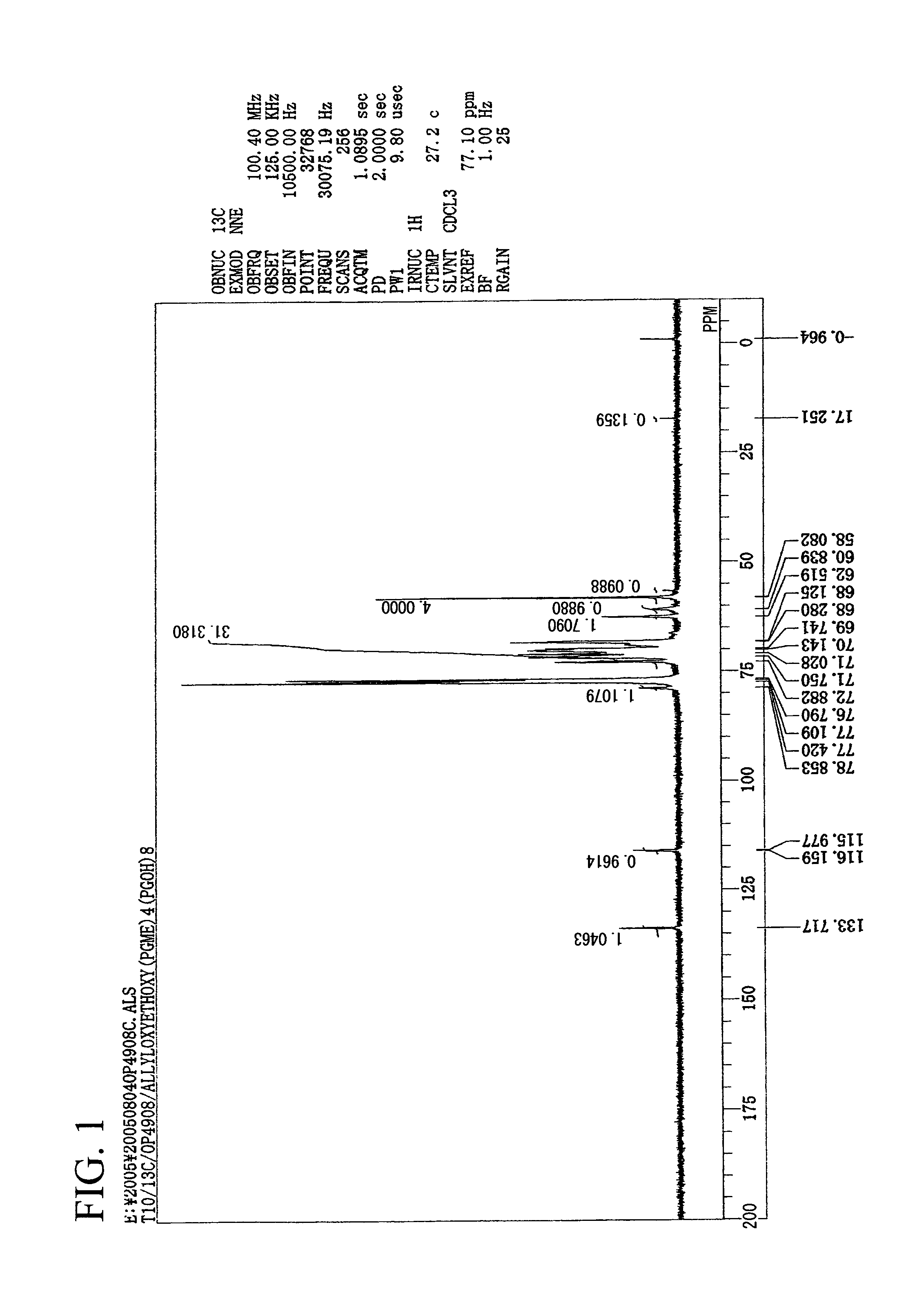

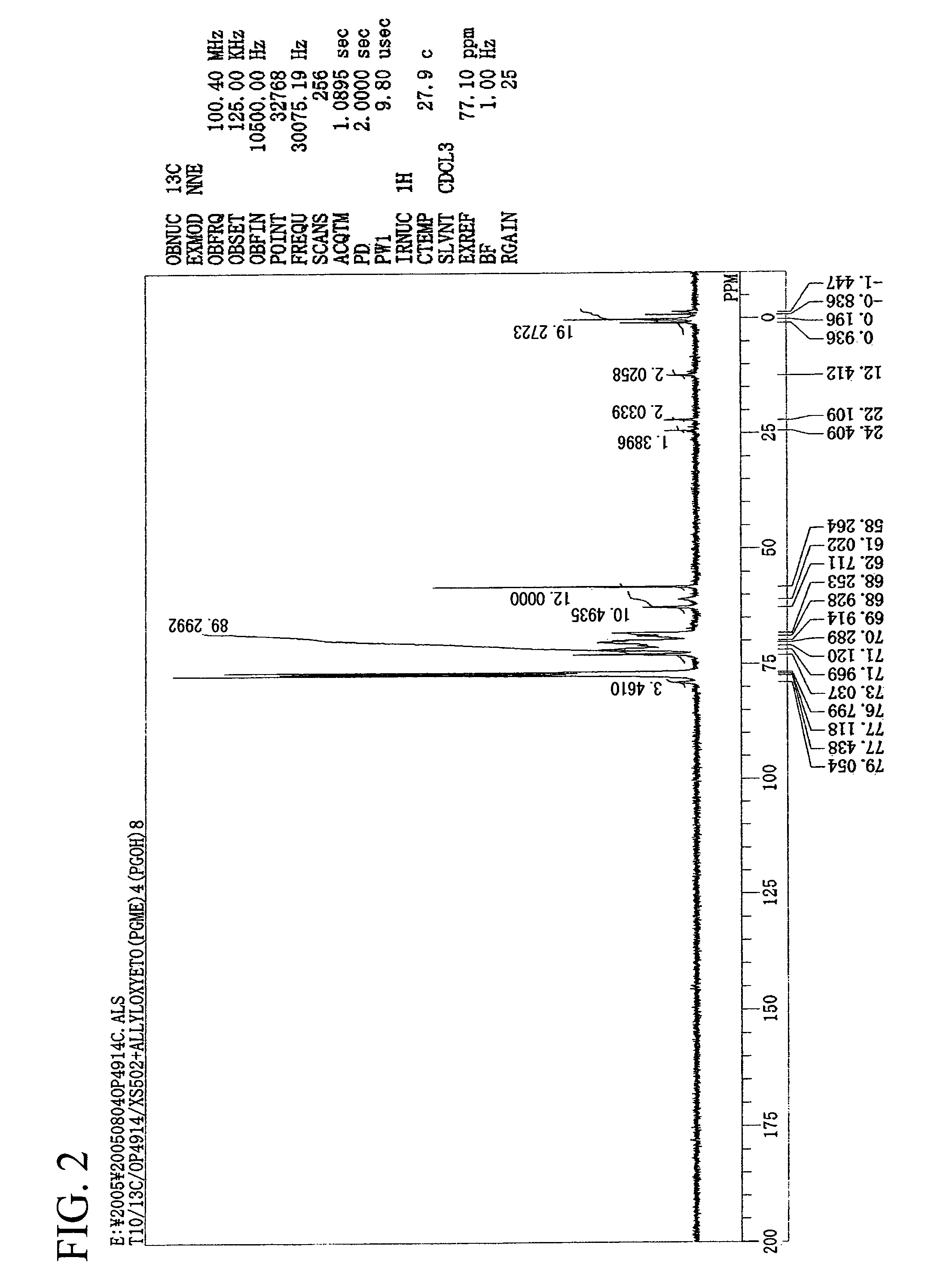

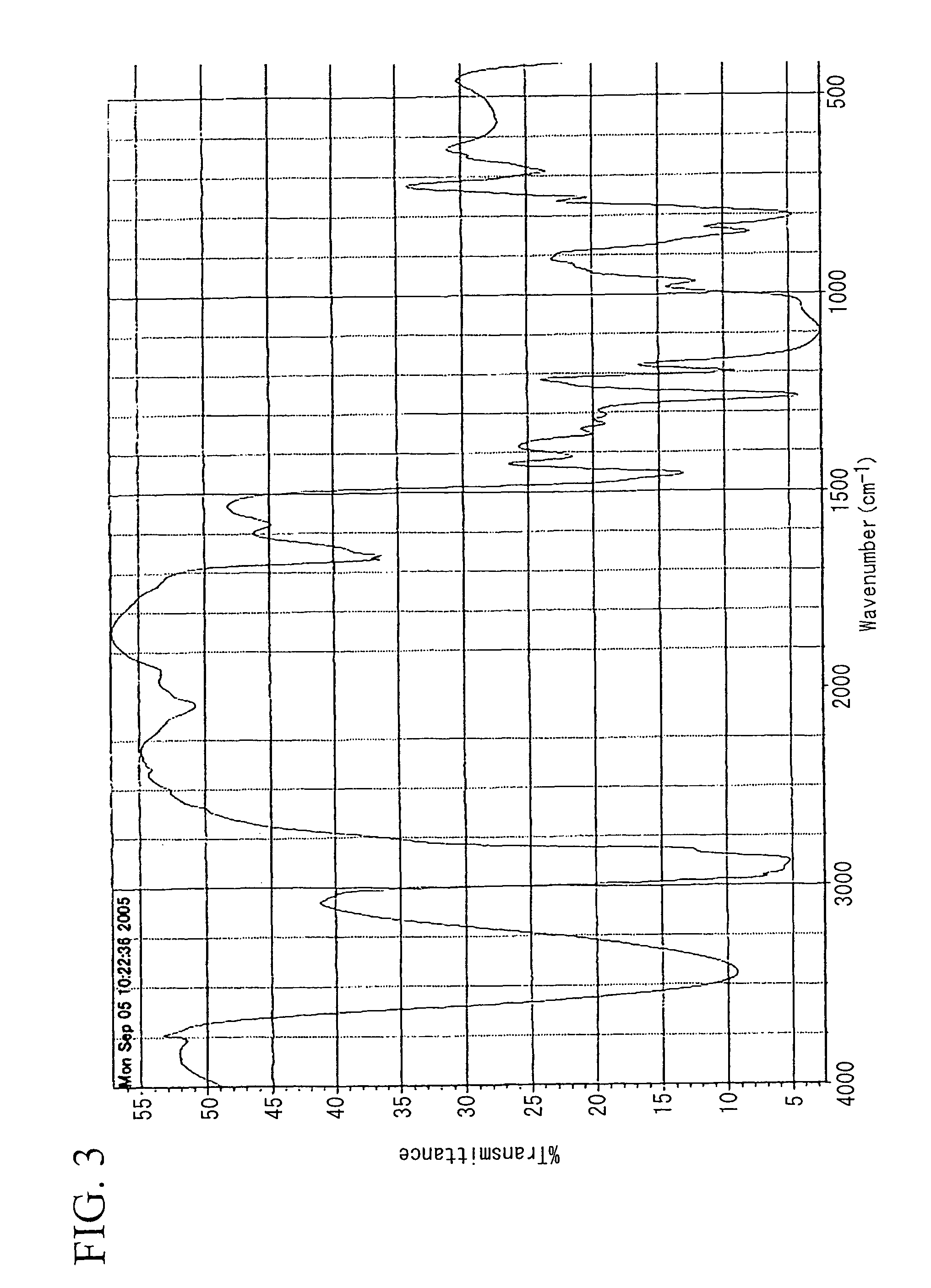

Partially hydrocarbon group-blocked (poly)glycerol-modified polysiloxane, method for producing the same, and cosmetic composition containing the same

ActiveUS8686174B2Well mixedLow viscosityCosmetic preparationsSilicon organic compoundsChemical compoundFormate

The present invention provides a novel modified-polysiloxane, method for producing the same, and a cosmetic containing the same. The aforementioned modified-polysiloxane exhibits a reduced viscosity and superior operationability as compared with conventional polyoxyalkylene-modified polysiloxanes and polyglycerol-modified polysiloxanes. In addition, since the modified-polysiloxane is hardly oxidized in air, hardly produce allergenic compounds such as formates, and aldehydes such as formaldehyde, during storage over time, an increased environmental compatibility can be exhibited. In addition, the modified-polysiloxane of the present invention exhibits a reduced hydrolysis property and is stable. In the modified-polysiloxane of the present invention, the terminal hydroxyl groups of a polyglycerol-modified polysiloxane are partially blocked with hydrocarbon groups.

Owner:DOW TORAY CO LTD

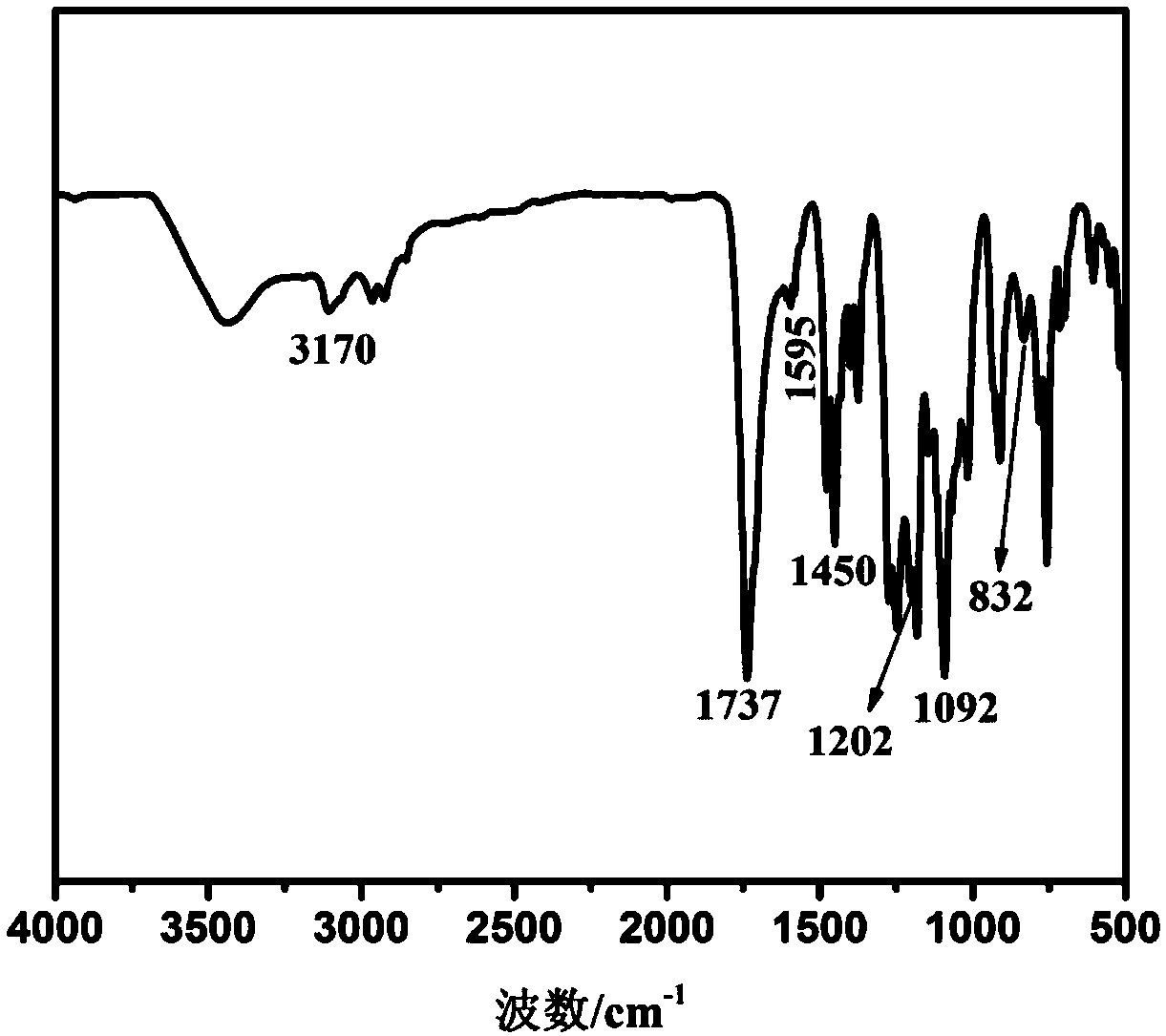

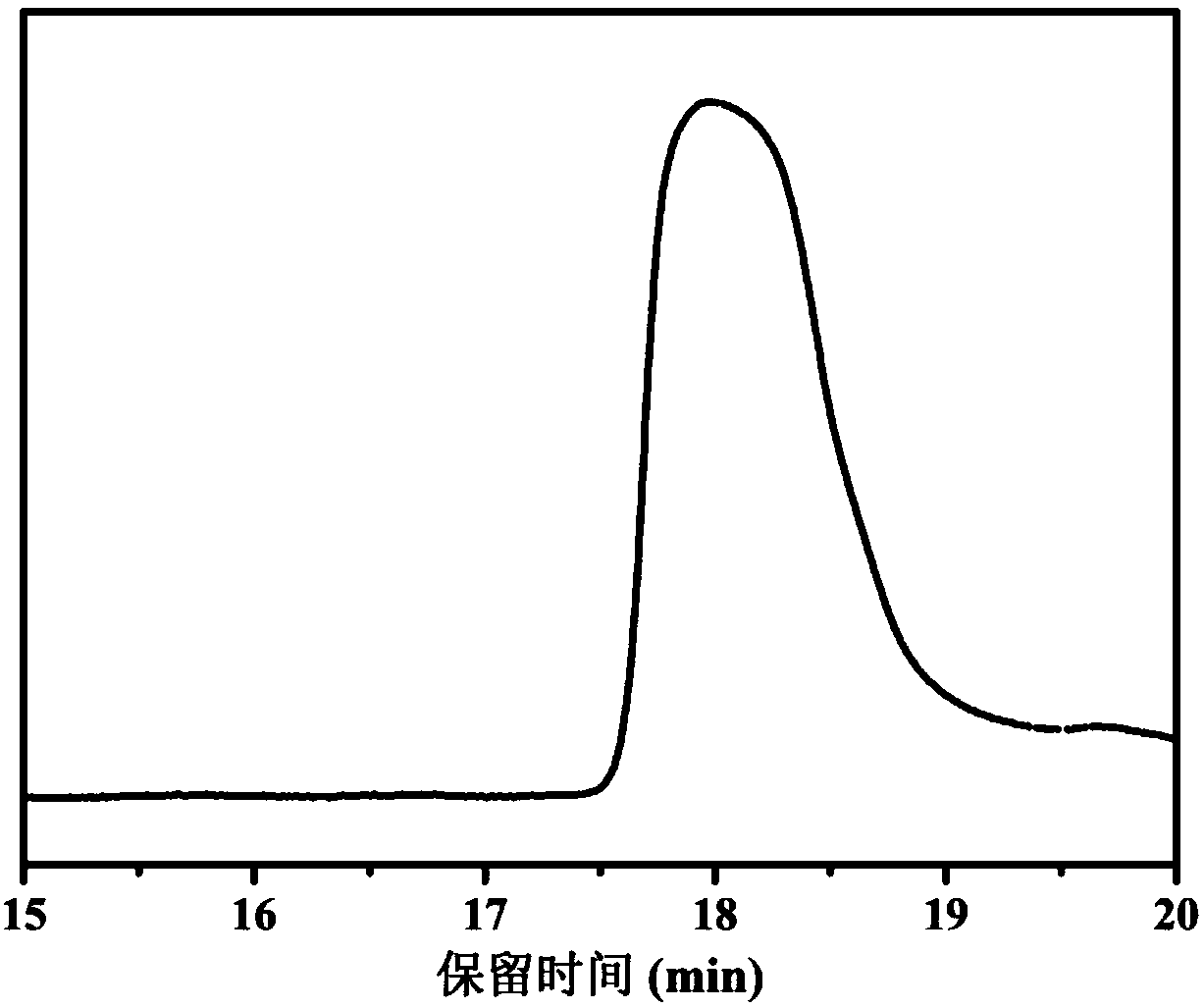

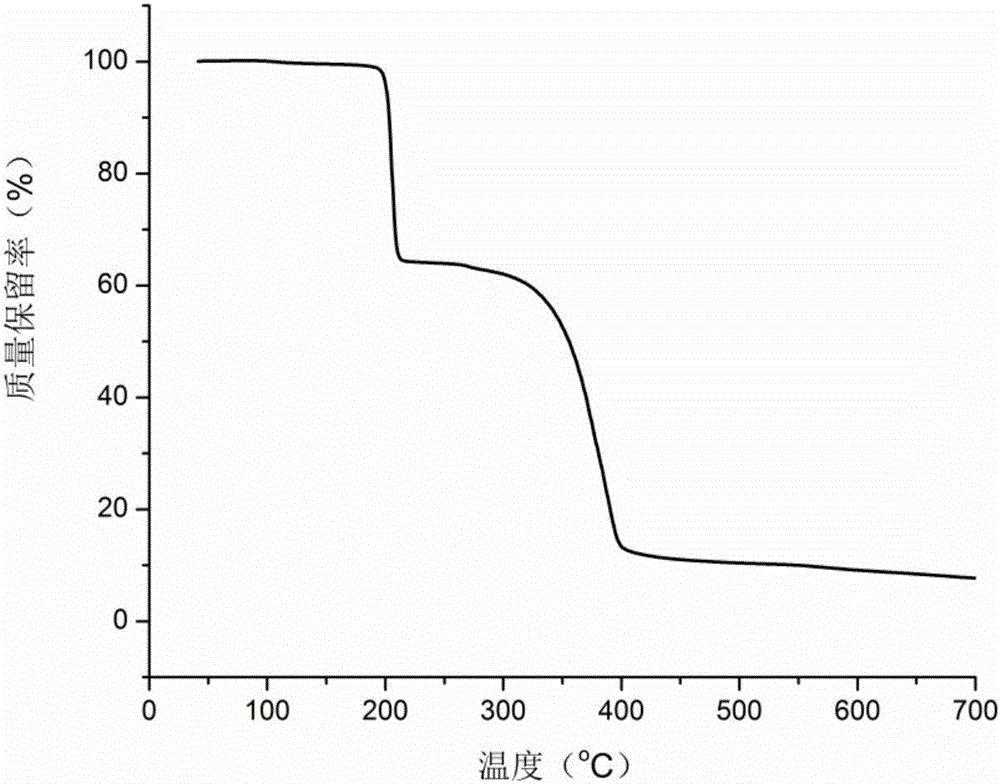

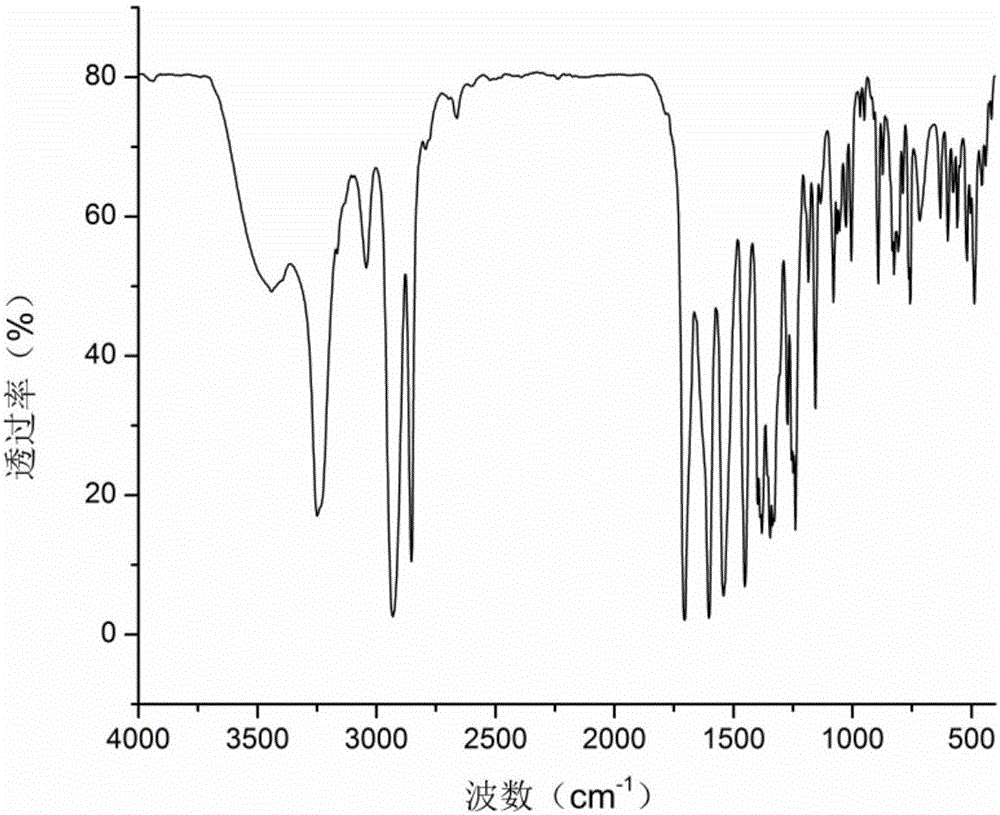

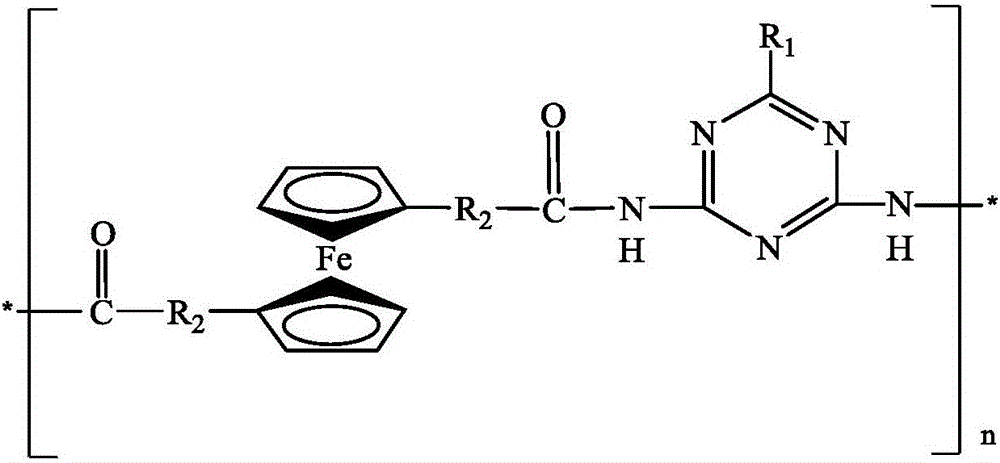

Ferrocene-thiotriazinone biradical polyamide synergistic charring agent and preparation method and application thereof

The invention discloses a ferrocene-thiotriazinone biradical polyamide synergistic charring agent shown in the formula (I) and a preparation method thereof.The preparation method of the polymer includes the steps that phenol, distilled water, an acid-binding agent I, cyanuric chloride, an organic solvent I and the like serve as raw materials and are prepared into an intermediate I through chemical reaction, the intermediate I, an acid-binding agent II, ammonia water, an organic solvent II and the like are prepared into an intermediate II through chemical reaction, and then the intermediate II, a raw material I, a dehydration agent, organic alkali, an organic solvent III and the like are prepared into the ferrocene-thiotriazinone biradical polyamide synergistic charring agent through chemical reaction.The polyamide synergistic charring agent is a polymerization type flame-retardant agent, can be used for flame retardance of plastic and other organic high polymer materials, can effectively improve heat stability and increase the residual carbon amount of a system, promotes matrix degradation cross-linking charring and compact carbon layer forming, and reduces release of smoke.The preparation method is simple and easy to control, and the polyamide synergistic charring agent is easy to obtain, good in performance and high in practicality.The formula (I) is as shown in the description.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Production method of roving woolen fabric with health care function

The invention relates to a production method of a roving woolen fabric with a health care function. The production method of the roving woolen fabric with the health care function adopts a light and thin roving high-count flat-coated tweed woven by roving yarns with the count number of 25 / 1 metric count; the light and thin roving high-count flat-coated tweed has good fiber cohesive property and antistatic property, the roving high-count wool yarns have the advantages of uniform yarn levelness and high strength, the fabric is light, thin, soft, full in hand feeling, smooth and bony. A polylactic acid fiber also has the characteristic of being easy to blend, so that advantage complementing and disadvantage reduction of all fibers are well realized, the fabric prepared by the fibers has the advantages of better strength, and better water adsorption and thermal insulation properties, is more stiff and smooth, and also has good benefits to human body health and environmental protection.

Owner:JIANGSU SUNSHINE GRP CO LTD

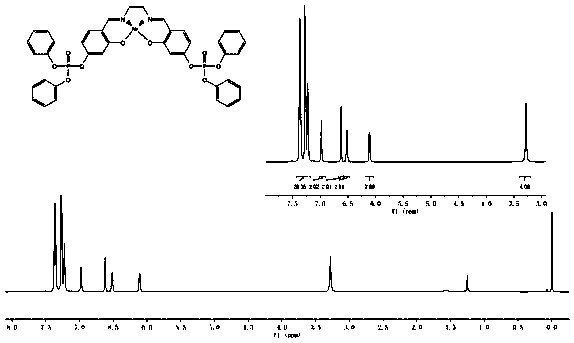

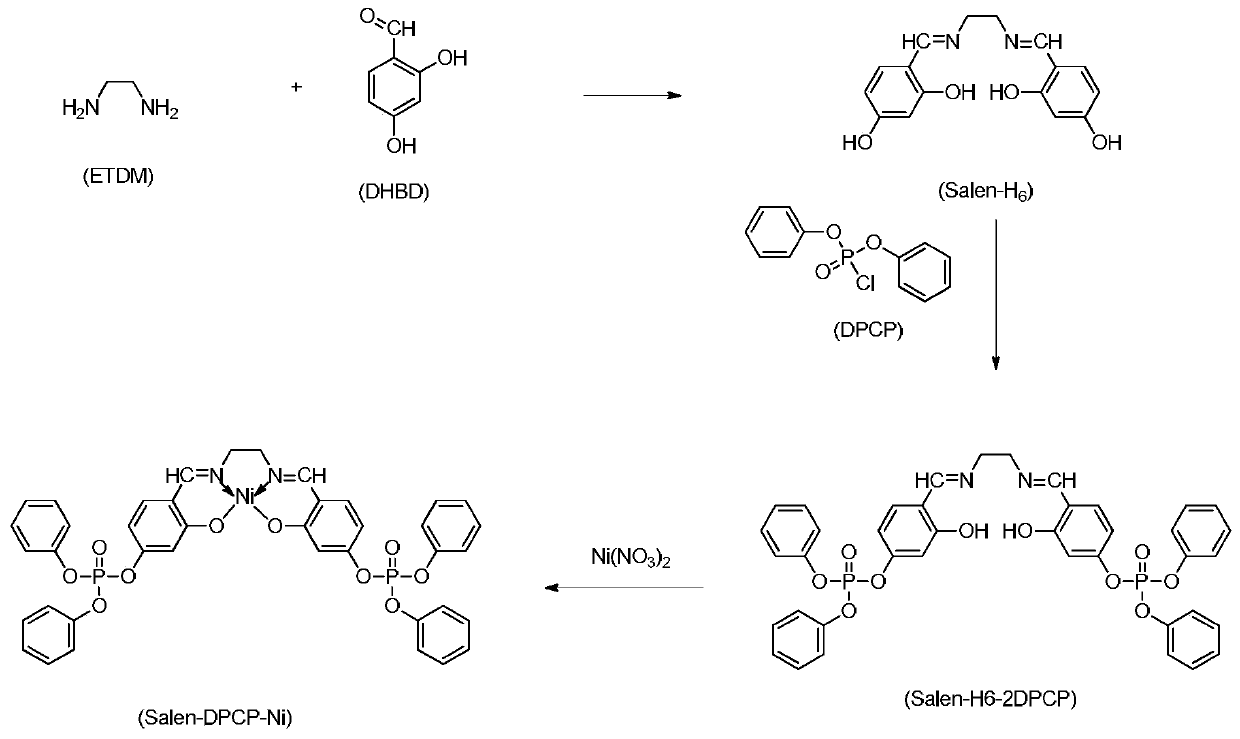

Metal ion flame retardant complex having Schiff base structure, and preparation method thereof

ActiveCN110467747AHas cross-linked anti-dripping propertiesHalogen freeGroup 5/15 element organic compoundsGas phaseFire retardant

The invention discloses a metal ion flame retardant complex having a Schiff base structure, and a preparation method thereof, and mainly relates to the field of reactive flame retardants, wherein thestructural formula is defined in the specification, and R is defined in the specification. According to the present invention, a series of flame retardant complexes Salen-DPCP-M are formed by complexing Salen-H6-2DCP and metals, wherein the phosphorus-containing organic fragments can provide gas phase flame retardant effect during the combustion of polymer materials, and the Schiff base and the metal respectively provide the cross-linking and catalytic carbon formation condensed phase flame retardant effect during the combustion.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Combed polyester cotton and mudar floss blended yarn and preparing method thereof

ActiveCN107523913AHigh modulus of elasticityReduce smoothnessYarnVegetal fibresEngineeringMoisture absorption

The invention discloses combed polyester cotton and mudar floss blended yarn and a preparing method thereof, and belongs to the technical field of spinning. The combed polyester cotton and mudar floss blended yarn is prepared by blending combed polyester cotton, mudar floss and bamboo charcoal fiber, the combed polyester cotton, the mudar floss and the bamboo charcoal fiber are processed into fiber rods through the spinning technological processes respectively and then blended into yarn on a drawing frame. The combed polyester cotton and mudar floss blended yarn integrates the advantages of the combed polyester cotton, the mudar floss and the bamboo charcoal fiber, has the advantages of excellent moisture absorption, heat preservation, dyeing property, soft hand feel and the like, and also has excellent bacteria resistance and bacteriostasis effects. The preparing method is simple and easy to operate and has wide application value.

Owner:阜阳恒泰纺织有限公司

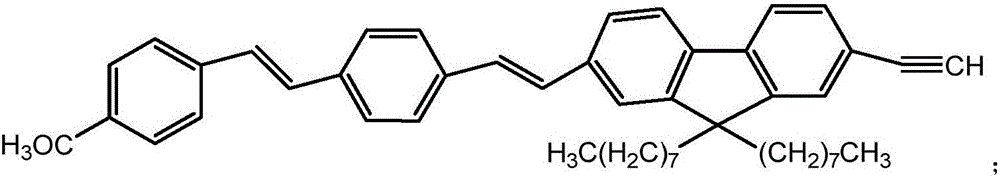

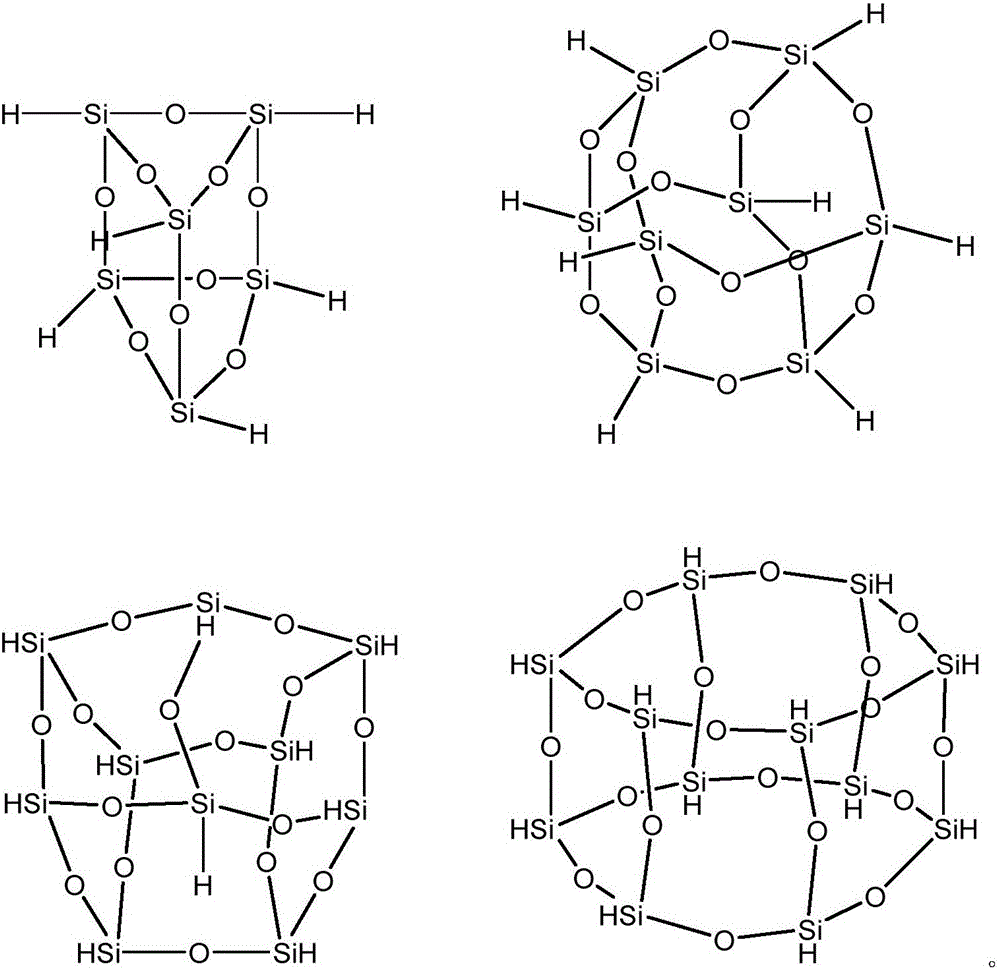

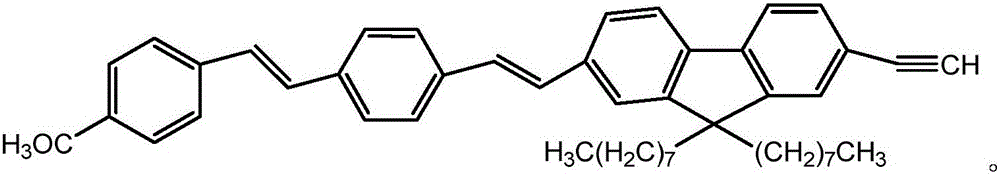

Preparation method of fluorescent polyhedral oligomeric silsesquioxane/polymethyl methacrylate

InactiveCN106589382AHigh fluorescence quantum yieldImprove luminous performanceLuminescent compositionsQuantum yieldAlkyne formation

The invention relates to a preparation method of novel fluorescent polyhedral oligomeric silsesquioxane / polymethyl methacrylate (POSS / PMMA). The method comprises the following steps: introducing a long-conjugate fluorine derivative EMOF with high fluorescence quantum yield to POSS by using an addition reaction of a Si-H bond and end alkyne through molecular design to prepare a dendritic organic / inorganic hybrid luminescent material EMOF-POSS with the POSS as a core and a fluorescence chromophore as an arm; and preparing an inorganic / organic composite nanomaterial from the EMOF-POSS and the PMMA through a solution blending technology. Combination of the POSS and the EMOF effectively reduces aggregation of the fluorescence chromophore in the PMMA matrix, so the luminescence properties of the material are obviously improved, and the composite material has good heat stability.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Adhesive

ActiveUS20120302686A1Improve breathabilityFine colloidMaterial nanotechnologyInksAdhesiveUnsaturated polyester

An adhesive including at least 100 weight parts of an unsaturated polyester resin suitable for air-drying, between 0 and 5 weight parts of hydrogenated castor oil, between 1 and 20 weight parts of a nano powder, between 10 and 250 weight parts of a filler, and between 1 and 15 weight parts of an anti-shrinking agent.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

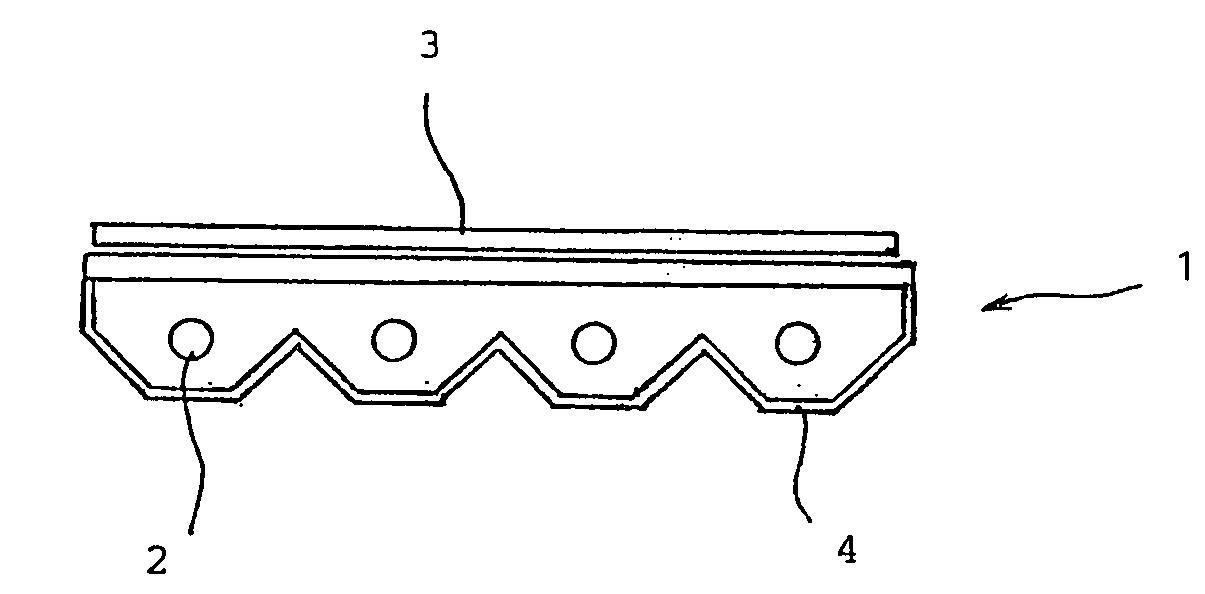

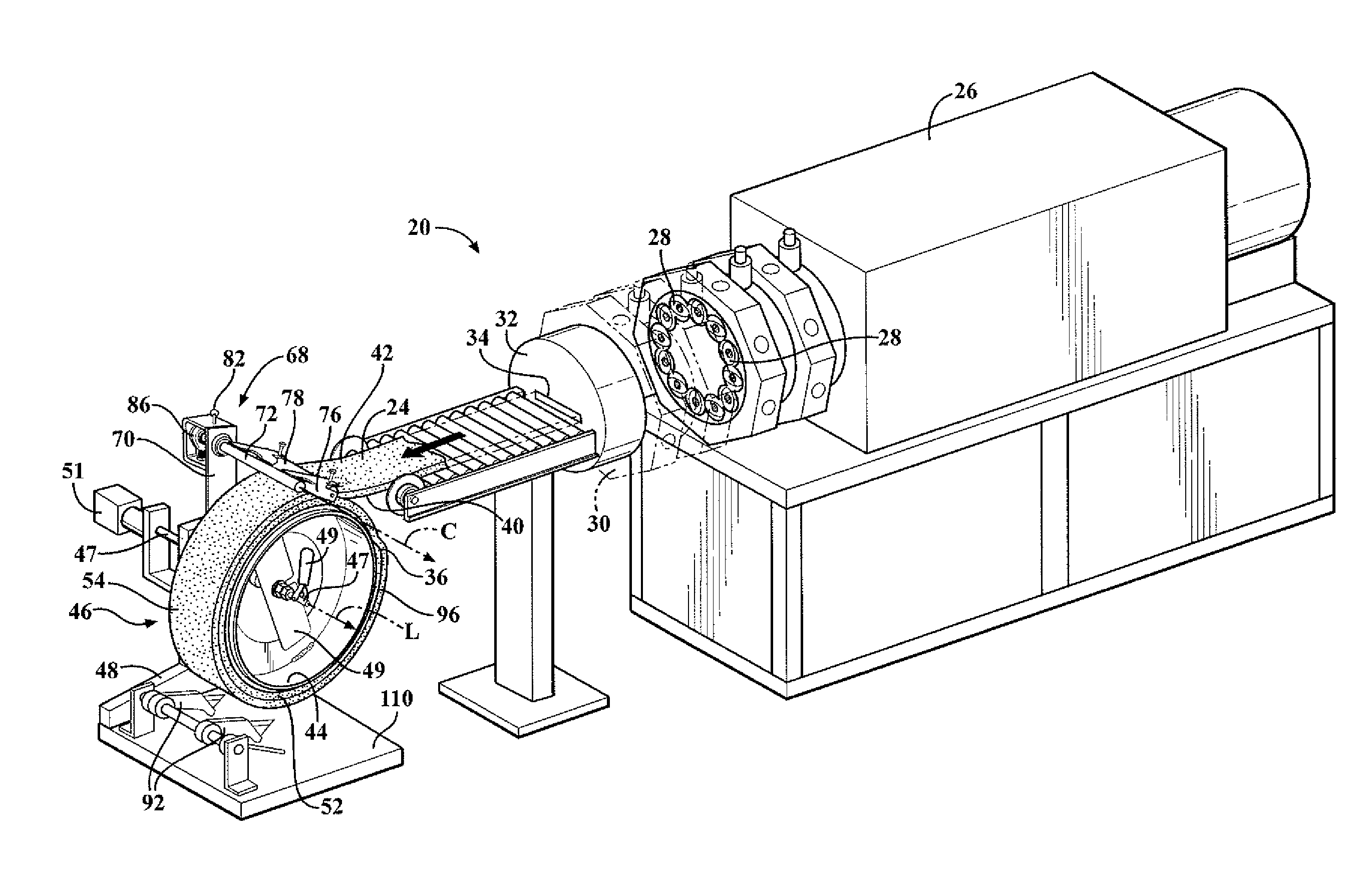

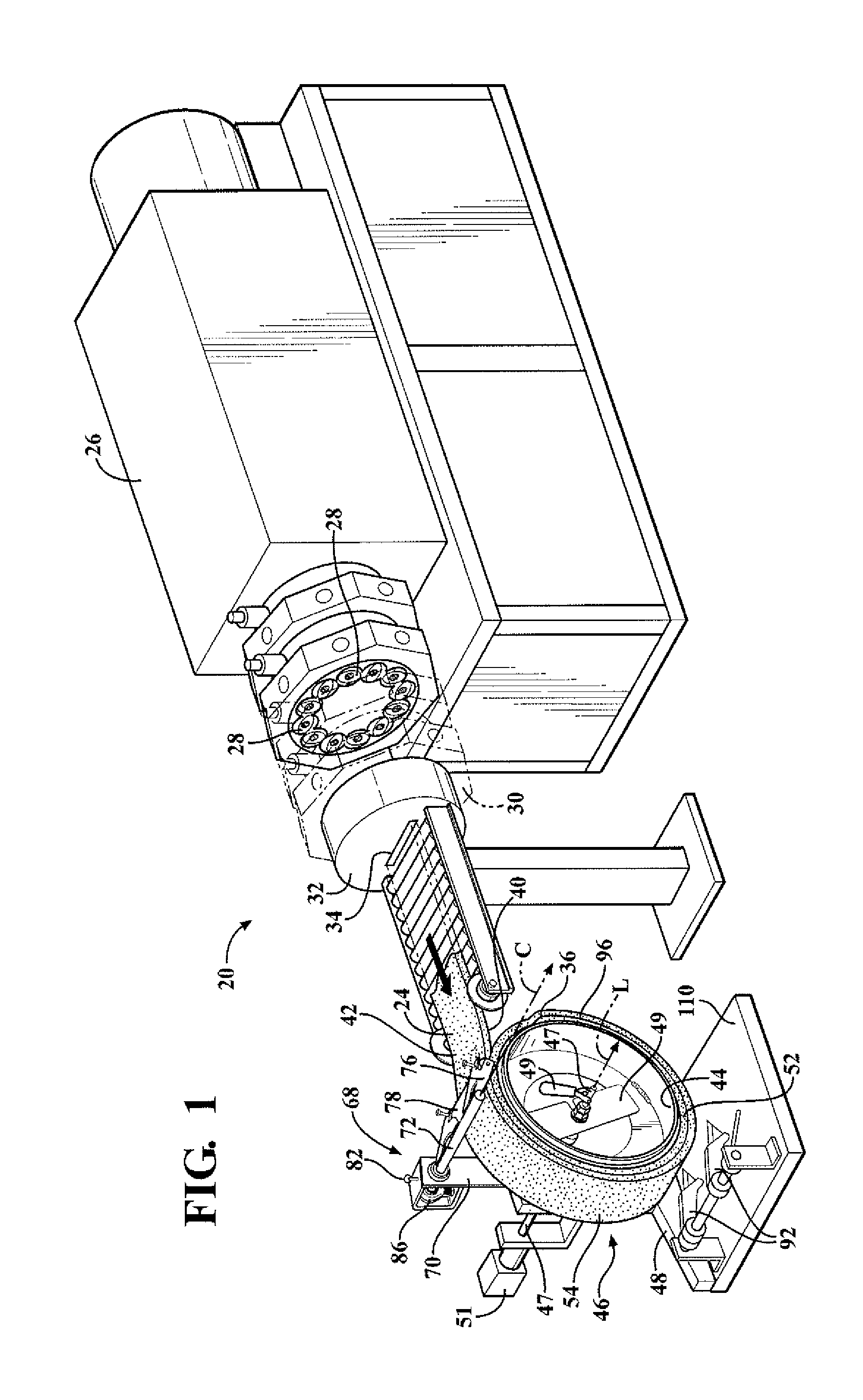

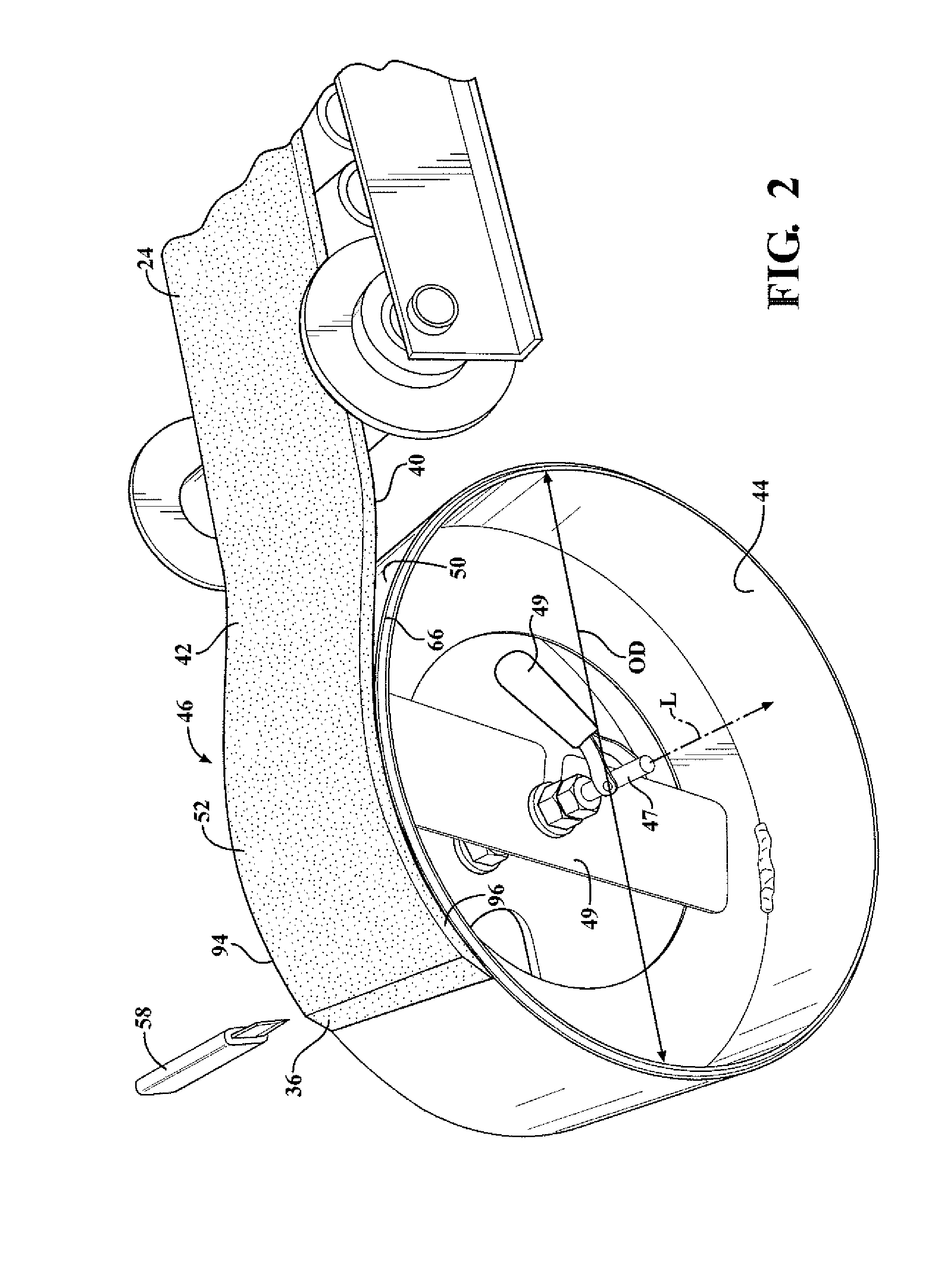

Manufacturing Apparatus And Method Of Forming A Preform

ActiveUS20120183707A1Well formedResistance to crackingMechanical working/deformationMouldsMaterials science

The present invention provides for a manufacturing apparatus for forming a ceramic preform from an extrudate having a first end and a second end. A cutter forms the first and second ends of the extrudate complementary to each other such that the first and second ends of the extrudate align with each other in a spaced relationship to define a preform having a substantially uniform exterior surface and a substantially uniform thickness. The present invention provides for a method of forming the preform from the extrudate having the first and second ends utilizing a mandrel. The method includes the step of aligning the second end complementary to the first end of the first layer in a spaced relationship to define the preform having the substantially uniform exterior surface and the substantially uniform thickness.

Owner:ROYAL BANK OF CANADA

Formula and preparation technology of ultralight once-moulded composite sole

The invention discloses a formula and a preparation technology of an ultralight once-moulded composite sole. Through use of thermoplastic styrene-butadiene rubber, which particularly refers to thermoplastic styrene-butadiene rubber 1475 and thermoplastic styrene-butadiene rubber 3411, a styrenic thermoplastic elastomer and ethylene-vinyl acetate copolymer as raw materials, not only is the cost reduced, but also the tensile strength of a material is improved, so that the material has small deformation and good flexibility and resilience; the oil content of the formula and other performance areextended; in addition, the viscosity is reduced during mixing, so that the blending operation of a mixture is facilitated; the folding resistance of a product is improved; by the preparation technology, a single-color or multi-color composite sole can be moulded once and additional manual pasting is not required; the ultralight once-moulded composite sole produced according to the formula is lightin weight, comfortable, wearable and low in cost.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

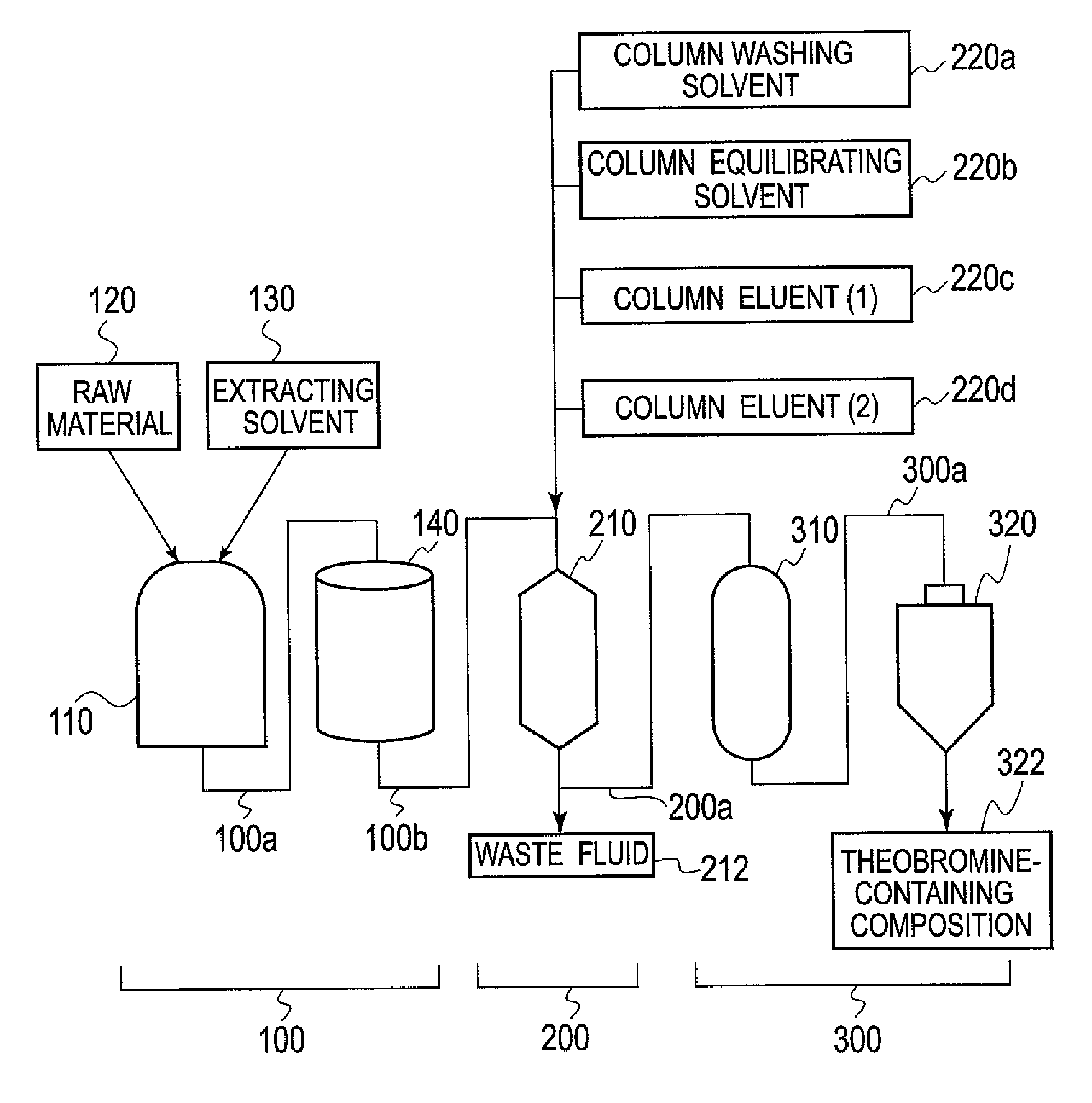

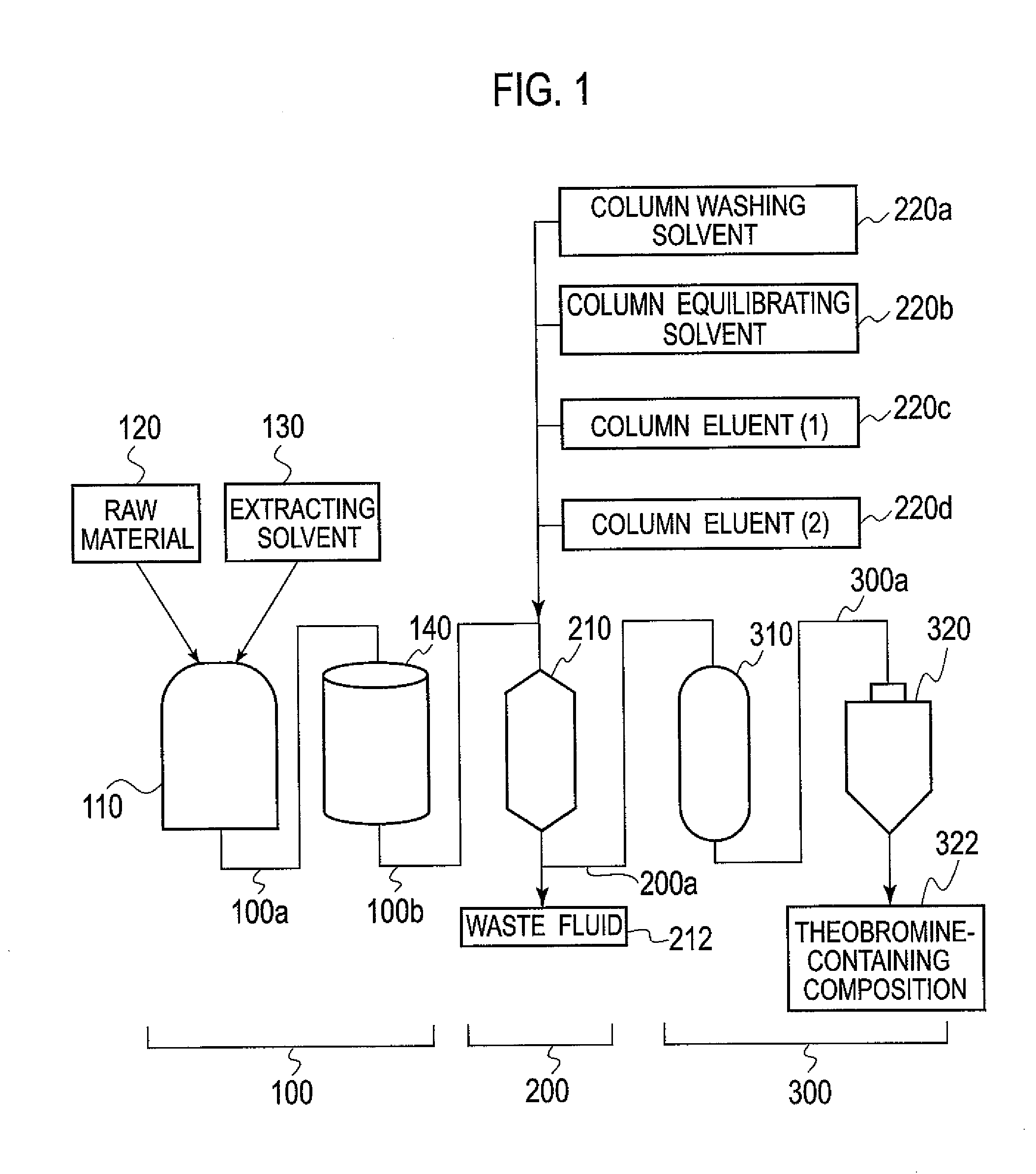

Production method and production apparatus for a high theobromine-containing composition

InactiveUS20110003834A1Efficient productionImprovement ingredientsBiocideNervous disorderTheobromineSolvent

An object is to provide a method for producing a high theobromine-containing composition effectively in a simple way. The method for producing a theobromine-containing composition comprises: (a) performing an extraction of a theobromine-containing plant or a processed product thereof with a solvent, to obtain a crude theobromine extract; (b) applying the crude theobromine extract to a cation exchange resin subjected in advance to hydrogen ion substitution, to allow an adsorption of theobromine onto the cation exchange resin; and (c) passing a solvent containing no ionic substance through the cation exchange resin subsequently to the step (b), to obtain a theobromine eluate.

Owner:MEIJI CO LTD

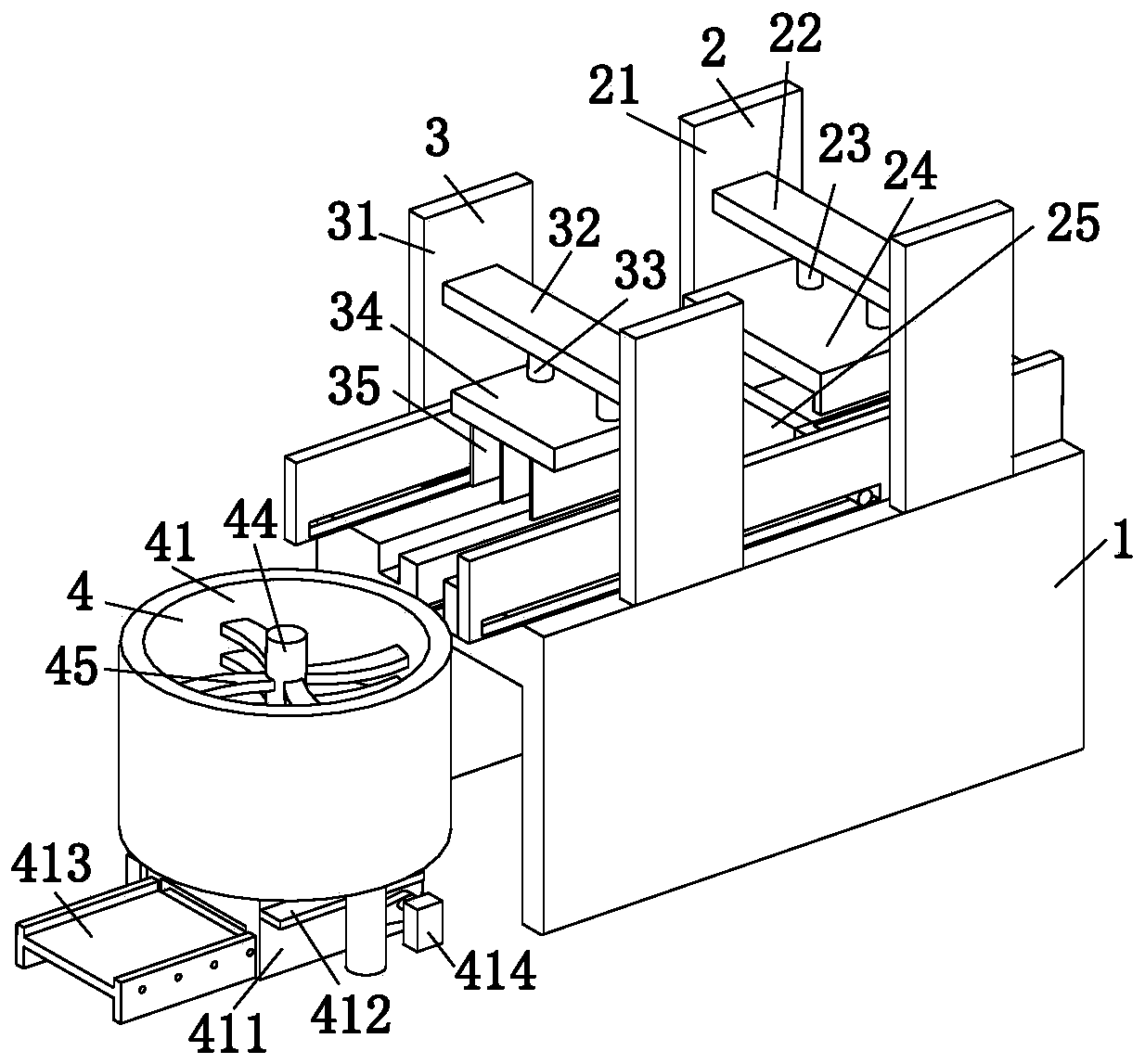

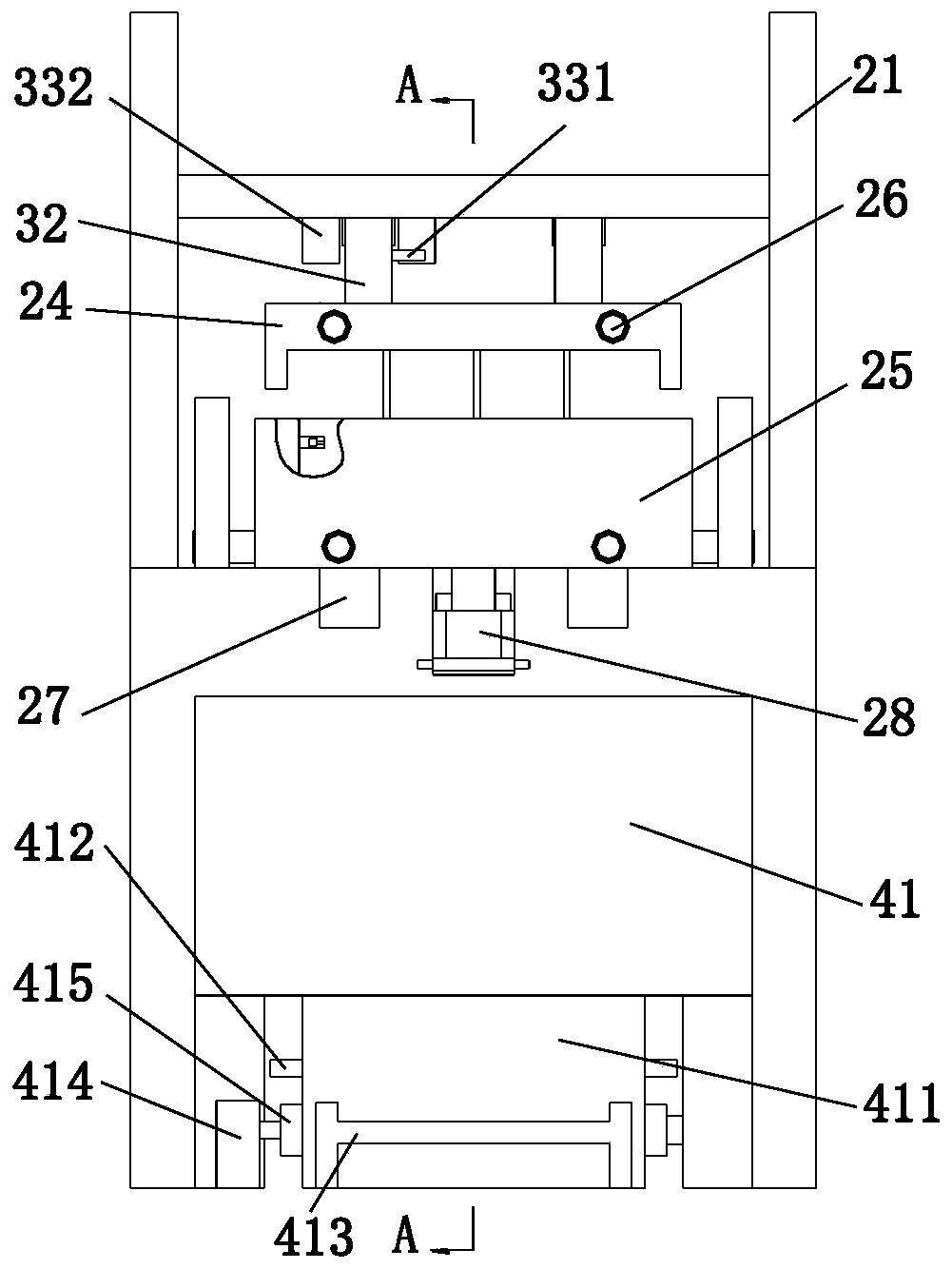

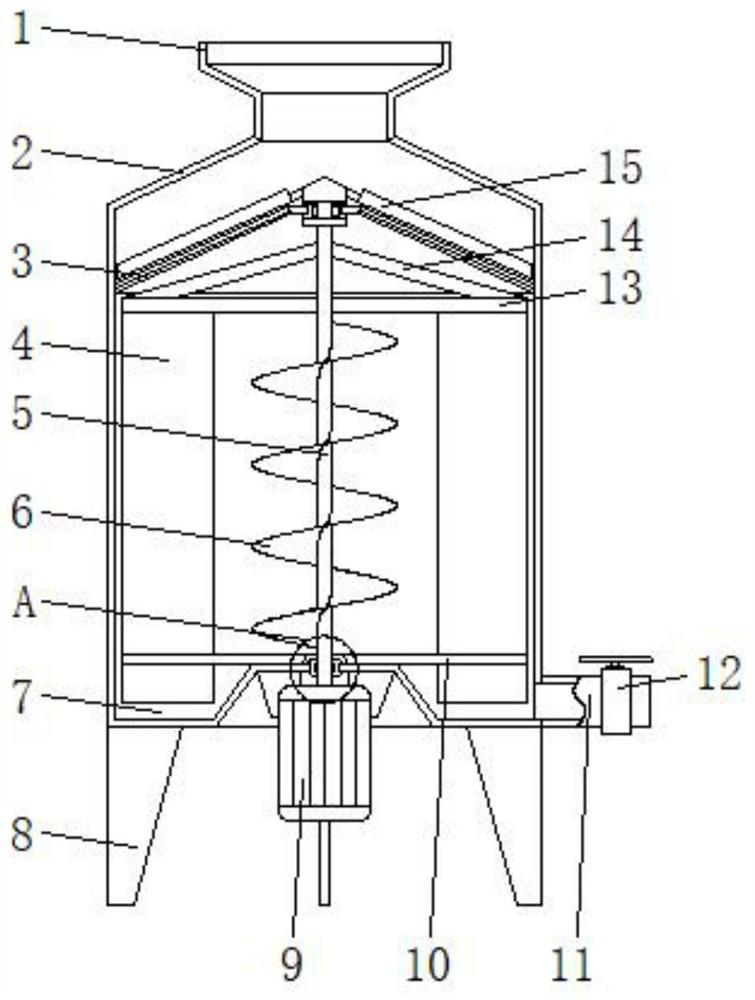

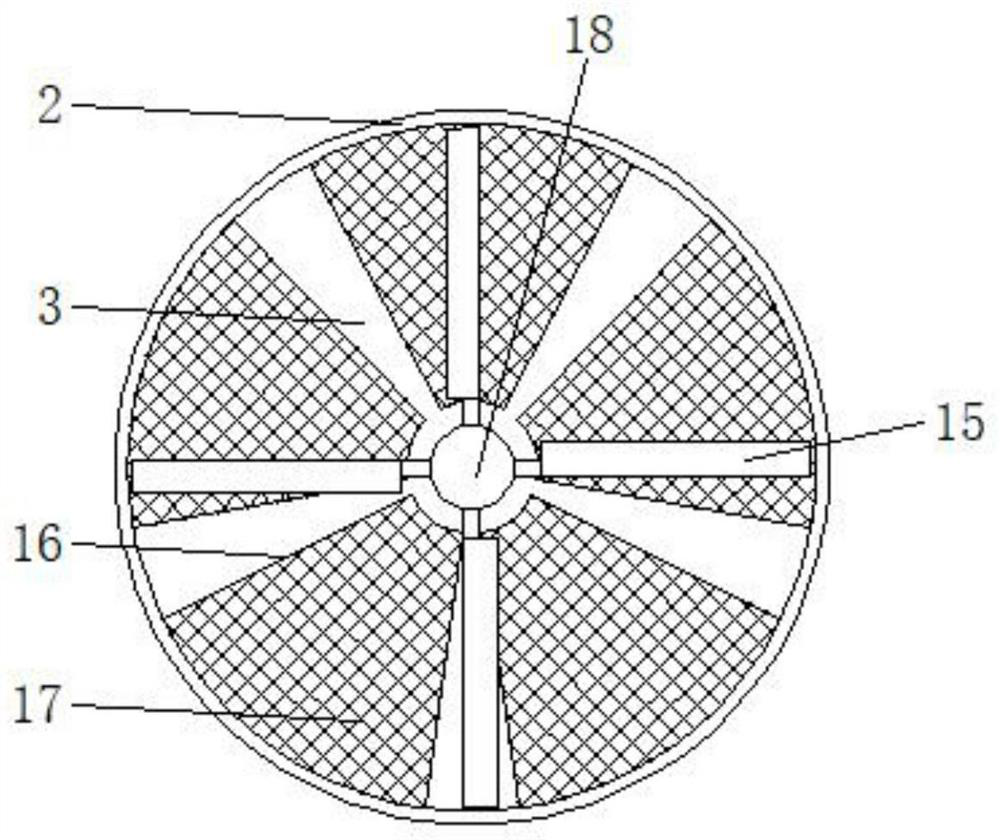

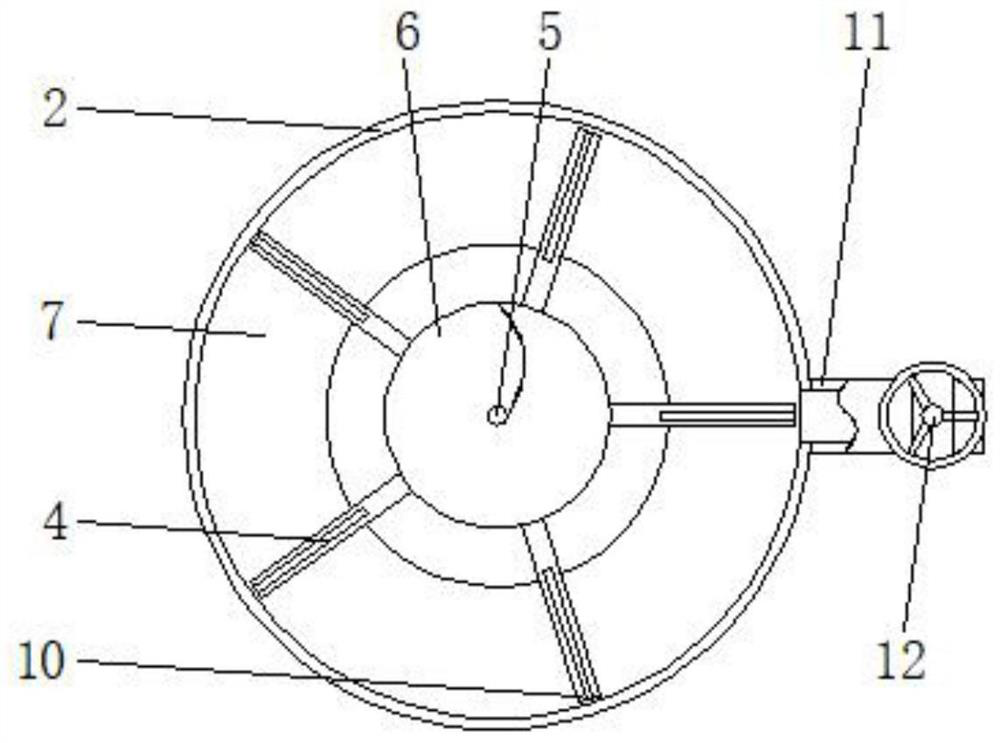

Efficient and energy-saving concrete water reducing agent blending device

PendingCN113209861AEasy to blendReduce electricity costsTransportation and packagingRotary stirring mixersElectric machineDrive shaft

The invention discloses an efficient and energy-saving concrete water reducing agent blending device which comprises a tank body, a grinding plate, a transmission shaft, a twisting piece, a deposition tank, a first shaft sleeve and a second shaft sleeve; the grinding plate is arranged in the upper end of the tank body, the deposition tank is arranged in the lower end of the tank body, and a motor is arranged on the lower surface of the tank body; the transmission shaft penetrating through the lower end of the tank body is arranged on the upper surface of the motor, the upper end of the transmission shaft penetrates through the grinding plate and is connected with a first limiting block, a stirring rod is welded to the outer wall of the first limiting block, the twisting piece is arranged on the surface of the transmission shaft, and first connecting rods and second connecting rods are arranged at the two ends of the transmission shaft; and mixing plates are embedded between the first connecting rods and the second connecting rods, and screens distributed in a circular array are embedded in the surface of the grinding plate. The stirring rod, the twisting piece and the material mixing plate are synchronously driven to rotate through the transmission shaft, so that fed raw materials can be synchronously ground, the blending uniformity can be improved, and the actual use effect is better.

Owner:山东华伟银凯建材科技股份有限公司

Ramie abrasive base cloth

InactiveCN102587002AHeat dissipation fastAvoid accumulationWoven fabricsYarnFiber elongationElectrical conductor

The invention relates to grinding and polishing equipment, particularly relates to ramie abrasive base cloth for grinding and polishing various types of electronic devices, and provides the ramie abrasive base cloth to overcome the technical defects that fabric fibers in the prior art are high in elongation and tend to elongate continuously when tensioned in grinding, the fabric fibers are low in strength and non-abrasion-resistant, the fabric fibers low in friction coefficient tend to emit light from the surfaces after used for a period of time, the friction coefficient is lowered so that the fabric fibers are unavailable, the service life of the fabric fibers is short, two types of insulators tend to generate static electricity in abrading, and the like. The ramie abrasive base cloth comprises, in mass percentage, 80-99% of ramie fibers, and 1-20% of conductive fibers. The ramie abrasive base cloth is simple in structure, high in friction coefficient, less apt to rupture and deform, less apt to generate static electricity, high in durability, stable in physical and chemical properties, and capable of meeting industrial production requirements.

Owner:益阳滔溪竹麻林纺科技发展有限公司

Adhesive

ActiveUS20120302687A1Improve breathabilityFine colloidMaterial nanotechnologyInksAdhesiveUnsaturated polyester

An adhesive, including: at least 100 weight parts of an unsaturated polyester resin suitable for air-drying, between 0 and 5 weight parts of hydrogenated castor oil, between 1 and 20 weight parts of nano powder, between 0 and 100 weight parts of a filler, and between 1 and 15 weight parts of an anti-shrinking agent.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

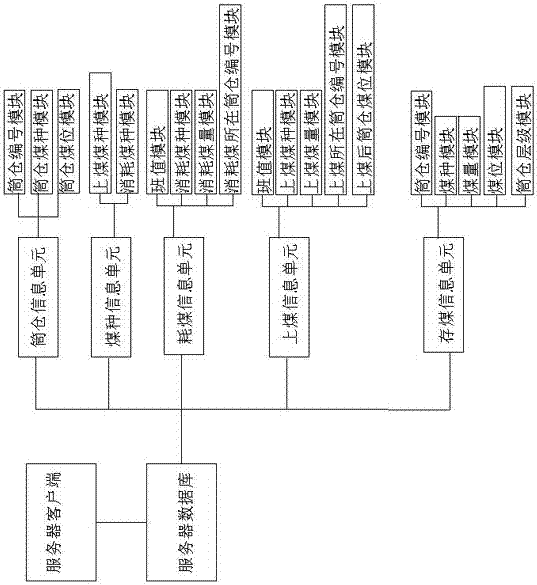

Silo coal level counting-monitoring system and method

ActiveCN107512504ASimple structureEasy to operateData processing applicationsLarge containersRelevant informationMonitoring system

The invention provides a silo coal level counting-monitoring system which comprises a server, and further comprises a coal level gauge used for the actual monitoring operation, wherein the server comprises a server database and a server client; the server database is used for acquiring and saving silo coal information, and comprises a calculating unit, a silo information unit, a coal type information unit, a coal consumption information unit, a coal loading information unit and a coal storage information unit; and through the server client, the operation-related information is recorded by working personnel. The silo coal level counting-monitoring system is simple in structure and convenient to operate; the coal types at any points of various silos, the heat of each coal type and the quantity of the coal types can be conveniently and visually checked, and coal can be conveniently blended from the various silos to a coal bunker; accordingly, operators on each duty can specifically understand and master the working conditions of both operators on the current duty and operators on the previous duty, handle the silo coal level and other information more clearly and skillfully, count and monitor the silo coal level, the coal types and other related information in time, and complete the visual coal blending operation; and the error is slight and the efficiency is high.

Owner:河北大唐国际丰润热电有限责任公司

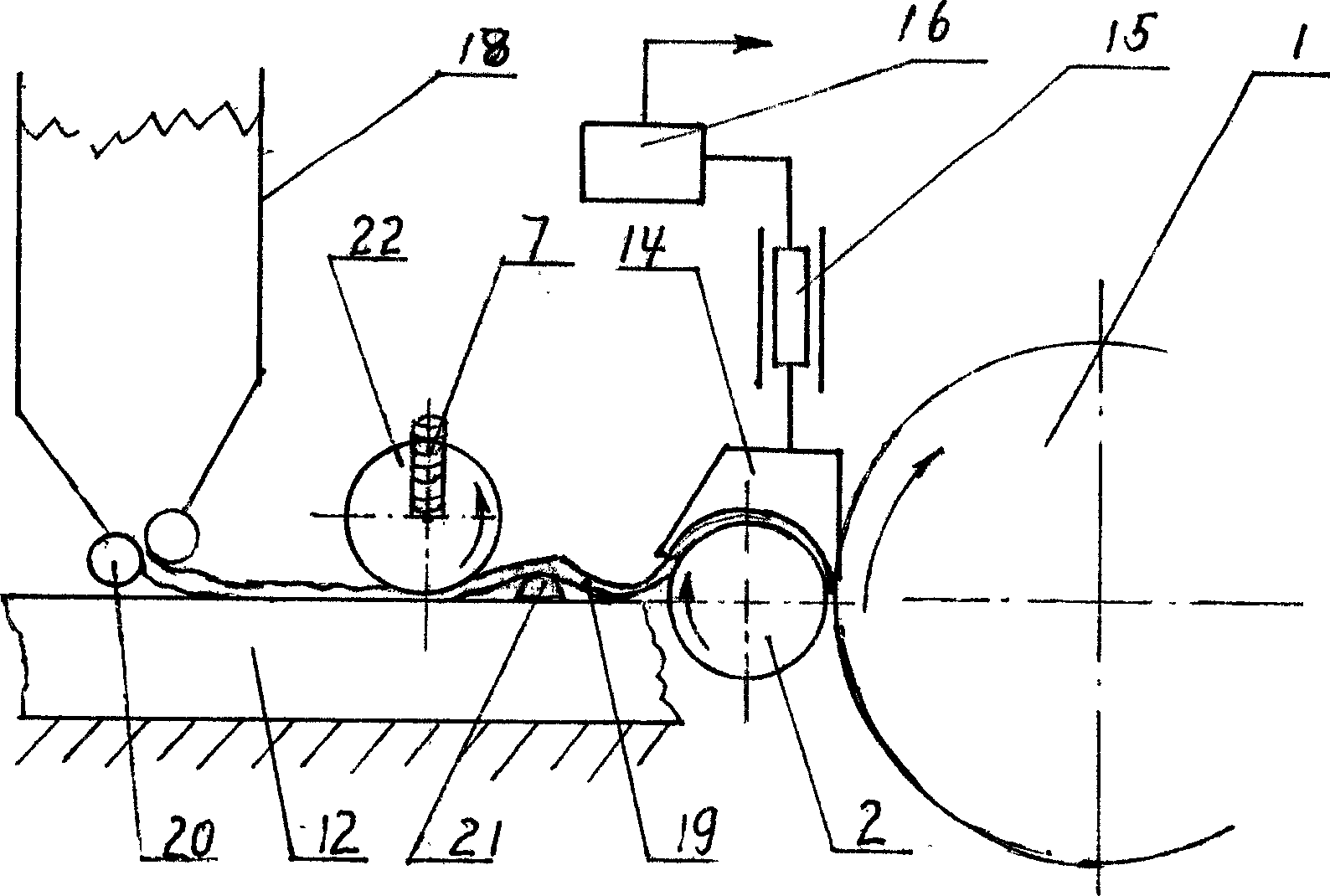

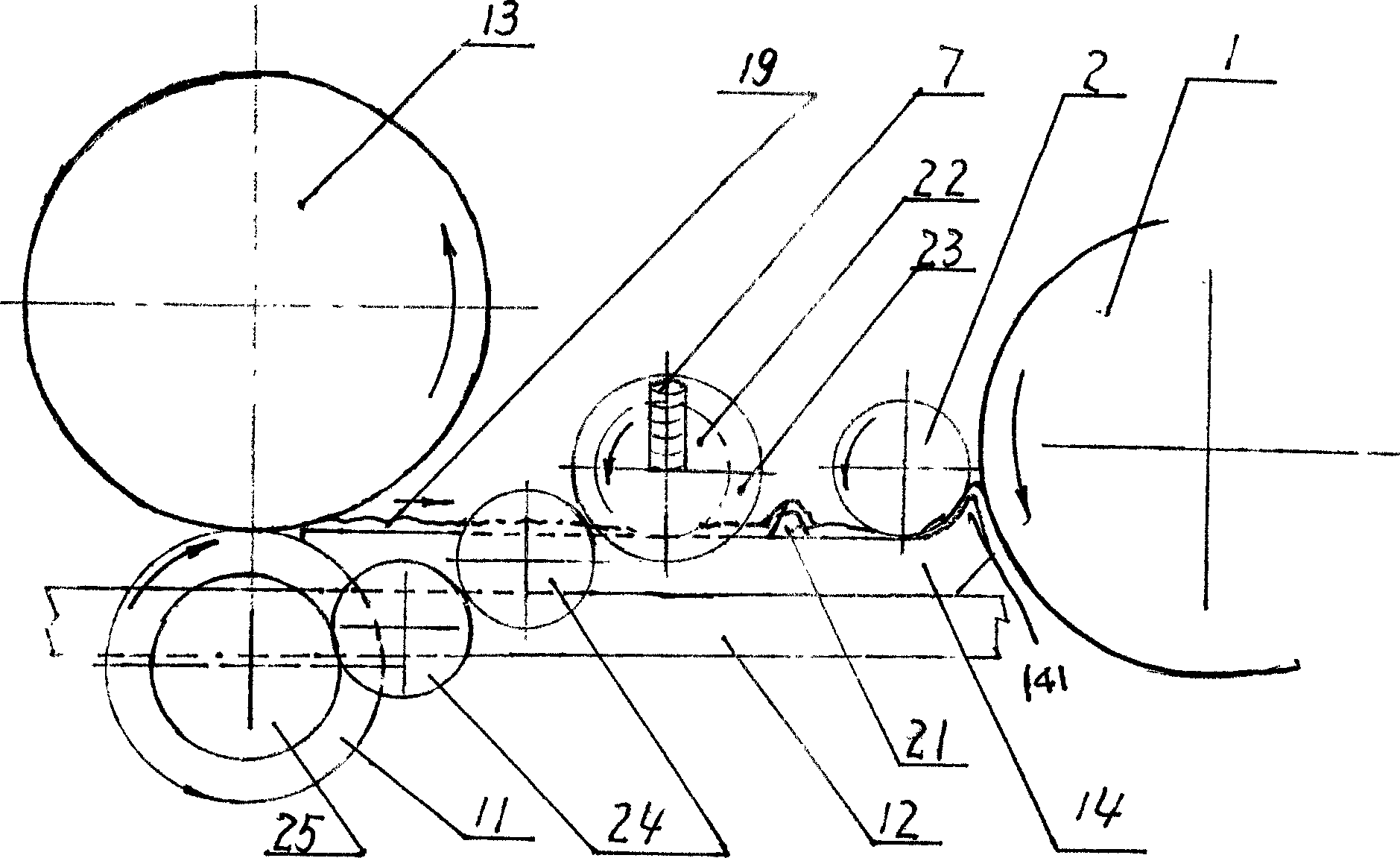

Feeder of carding machine

InactiveCN1779005AOptimize structural configurationIncrease projection lengthCarding machinesFiberEngineering

A receiver device of the cotton opener includes the rack, the driver, the roller of the cotton feeding and the cotton output part, which are the cotton box and the output roller. The cotton feeding bed is installed on the feeding roller, which is installed into the rack; the cotton feeding bed and the feeding roller form the feeding jaw; the friction roller is installed on the friction roller device, which is between the feeding roller and the output roller. The device can be used to all kinds of the cotton opener.

Owner:天津天鼎纺织集团有限公司 +1

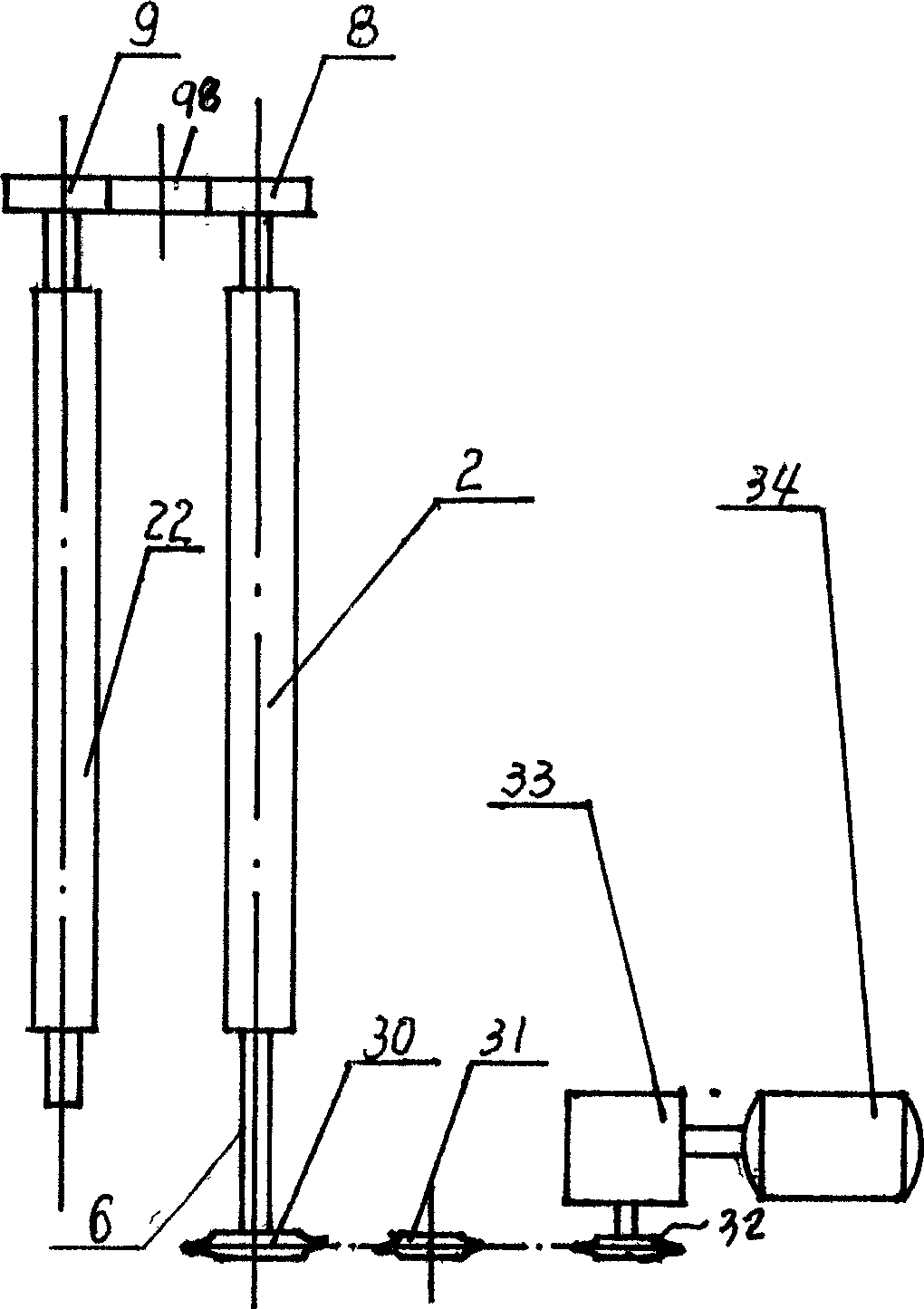

Preparation method of artemisia apiacea essential oil for pet skin health care and device thereof

PendingCN112940845AEasy to addEasy to mix and filterFatty-oils/fats refiningPharmaceutical delivery mechanismThreaded pipeDrive motor

The invention discloses a preparation method of an artemisia apiacea essential oil for pet skin health care and a device thereof, the device comprises a device box body, a supporting force arm, an inner threaded pipe, an instrument box body, a threaded rod, a bevel gear and a driving water pump, an equipment cover plate is fixed to the outer side of the device box body through bolts, and a feeding pipeline is welded and fixed to the position over the device box body; a driving motor is connected to the outer side of the device box body in a nested mode, the instrument box body is welded and fixed to the outer side of the device box body, an equipment box door is hinged and fixed to the outer side of the device box body, a squeezing box body and a liquid mixing tank body are installed in the device box body at the same time, and a control valve is welded and fixed to the lower portion of the liquid mixing tank body. According to the preparation method of the artemisia apiacea essential oil for pet skin health care and the device, an eccentric wheel and a belt pulley are arranged; and the eccentric wheel is arranged and drives a point pressing mechanism to vertically lift and roll, so that the cleaned artemisia apiacea raw material can be manually and continuously added, and the artemisia apiacea raw material can be automatically rolled and filtered.

Owner:HENAN HEIMA ANIMAL PHARM CO LTD

Adhesive

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

Dacron conductive wool top production technology

ActiveCN104562248AImprove anti-static effectIncreased durabilityNew-spun product collectionFilament manufactureEngineeringWater cooling

The invention discloses a Dacron conductive wool top production technology. The Dacron conductive wool top production technology comprises the following steps of filament clustering, finished product tows, cutting of filament clusters to form into tops, gilling for the first time, gilling for the second time and balling gilling; Dacron conductive fiber filaments are served as raw materials during the filament clustering procedure and single-strand conducting tows are obtained after gilling for the first time and gilling for the second time; during the finished product tow procedure, a plurality of single-strand Dacron conductive filament tows pass a tension roller set and are tensioned and clustered on tension rollers, then Dacron conductive tows are obtained, then the Dacron conductive tows are subjected to normal temperature water cooling, a first drafting roller set, oil bath for the first time, a second drafting roller set, oil bath for the second time, a third drafting roller set, preheating, curling and heat shaping, and the finished product tows which are obtained after heat shaping are collected inside a bucket. Dacron conductive wool tops obtained through the production technology are good in anti-radiation performance, good in durability, good in the performance of cohering with other common fibers and easy to blend or interweave.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com