Preparation method of polyvinylidene fluoride mixed matrix membrane

A polyvinylidene fluoride and mixed matrix membrane technology, which is applied in the field of membrane separation, can solve the problems of low retention rate and poor anti-pollution ability of the vinylidene fluoride mixed matrix membrane, and achieves easy control of preparation process conditions and excellent anti-pollution. The effect of mild performance and preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

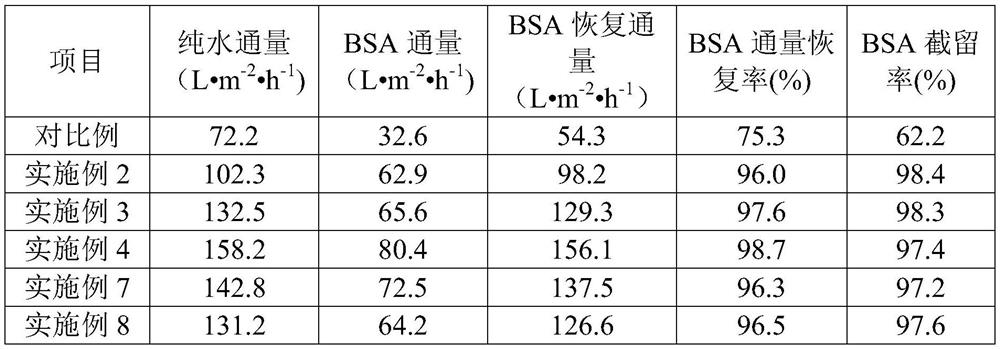

[0033] A method for preparing a uniform sponge-like polyvinylidene fluoride mixed matrix membrane with high rejection rate and strong anti-pollution property. In this method, nano-SnO 2 It is compounded with graphene oxide and added to the polyvinylidene fluoride casting solution, and the polyvinylidene fluoride casting solution is made into the polyvinylidene fluoride mixed matrix membrane by using a non-solvent-induced phase separation method (NIPS). The specific steps of the method include the following steps:

[0034] (1) Nano-SnO 2 - Preparation of graphene oxide composites

[0035] Dissolve 0.1-0.5g of graphene oxide in 60-180ml of ethanol aqueous solution with a volume ratio of ethanol and water of 1-4:0.5-2, sonicate, and then add 0.1-1g of nano-SnO 2 , and then stirred and sonicated to make nano-SnO 2 React with graphene oxide. The reaction conditions are to react at normal temperature and pressure for 100-150 minutes to obtain a suspension; the suspension is centr...

Embodiment 1

[0042] This example is for the preparation of SnO 2 -GO composite material, the specific preparation method is as follows:

[0043] (1) 0.2 g GO was dissolved in a mixed solution containing 50 mL ethanol and 40 mL deionized water, and sonicated for 1 h to completely disperse GO.

[0044] (2) 0.6g SnO 2 Add to the dispersion obtained in step (1), and continue to stir for 30min and sonicate for 1h to form a uniform suspension.

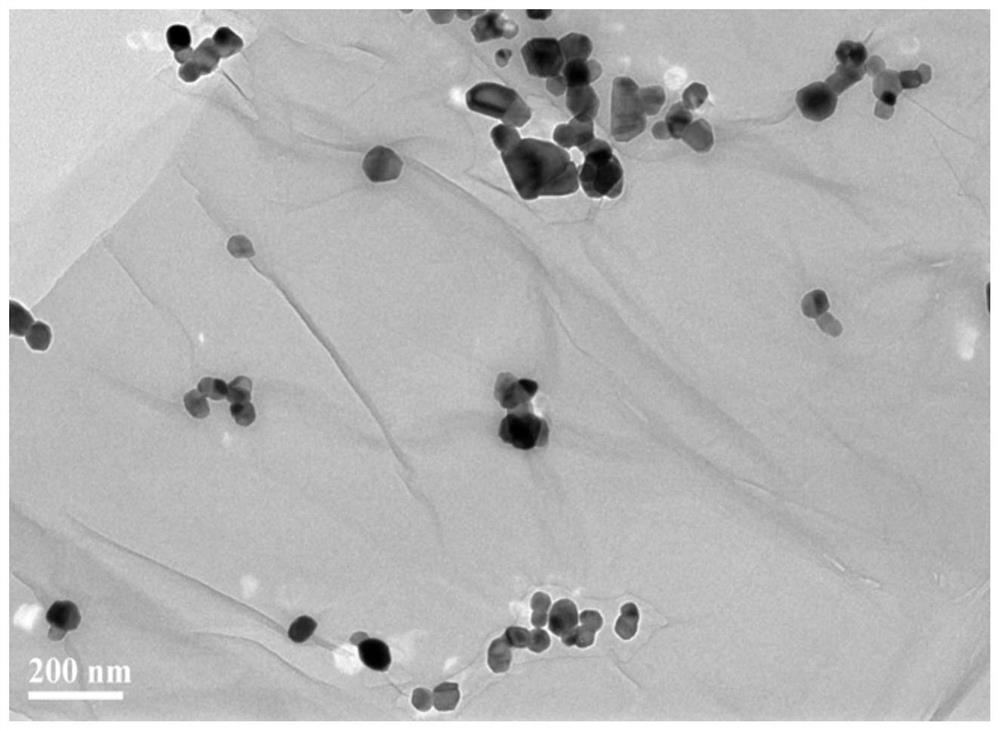

[0045] (3) Then, the resulting product was recovered by centrifugation by rinsing with deionized water, and vacuum-dried at 50°C. For the obtained SnO 2 -GO composites were characterized to obtain SnO 2 -TEM images of GO composites, such as figure 1 As shown, it can be seen from the electron microscope photos that this embodiment has obtained uniformly dispersed SnO 2 -GO composites.

Embodiment 2

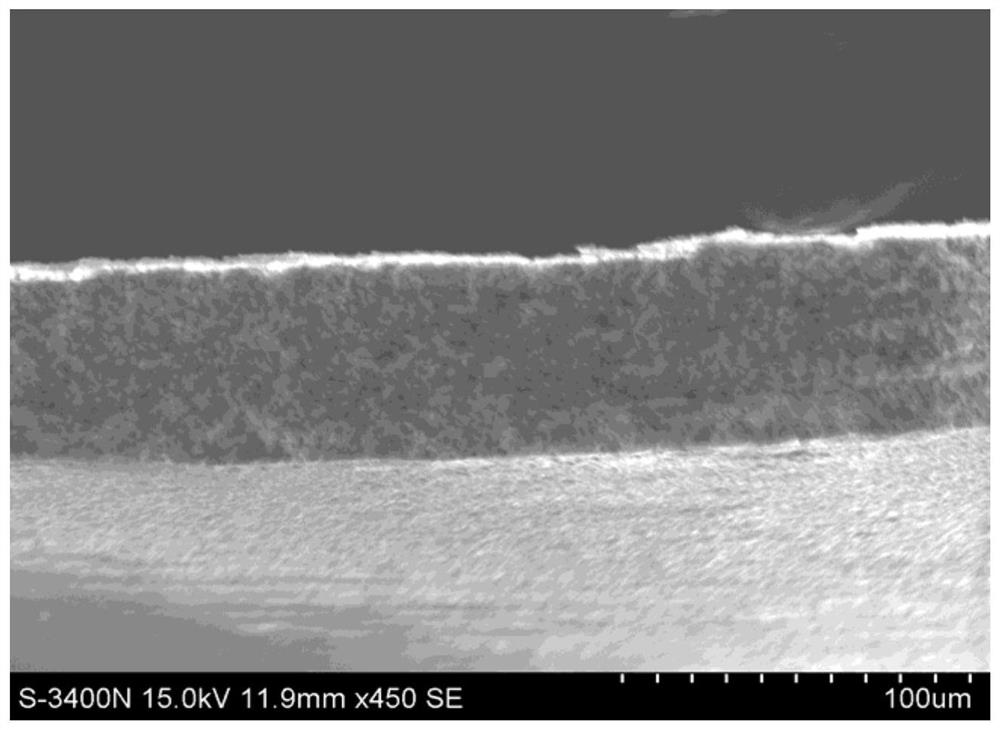

[0047] This embodiment is to utilize the SnO in embodiment 1 2 -GO composite material to further prepare polyvinylidene fluoride mixed matrix membrane, the specific preparation method is as follows:

[0048] (1) The composite material SnO 2 -GO, PVP, PVDF are dissolved in DMF, the composition ratio is: SnO 2 -GO:PVP:PVDF=0.3:2:20, stir at 80°C to fully dissolve, then let it stand for 24 hours for defoaming;

[0049] (2) Scrape the casting solution of step (1) on a glass plate to a film with a thickness of 250 μm;

[0050] (3) Immerse the glass plate with the film solution in step (2) in a mixture of ethanol and deionized water at a volume ratio of 1:1 at 15°C for phase separation;

[0051] (4) Transfer the film after phase separation in step (3) to deionized water and soak for 8 days to remove excess solvent, and then put it into clean deionized water for preservation to obtain a polyvinylidene fluoride mixed matrix film, which is denoted as SnO 2 - GO / PVDF ultrafiltration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com