Composite high-efficiency high-flow servo valve

A composite, high-flow technology, applied in the field of servo valves, can solve the problems of large magnetic field excitation power, large positioning error, large output force of memory alloy deformation, etc., achieve high frequency response and high precision, compact structure, and large output force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

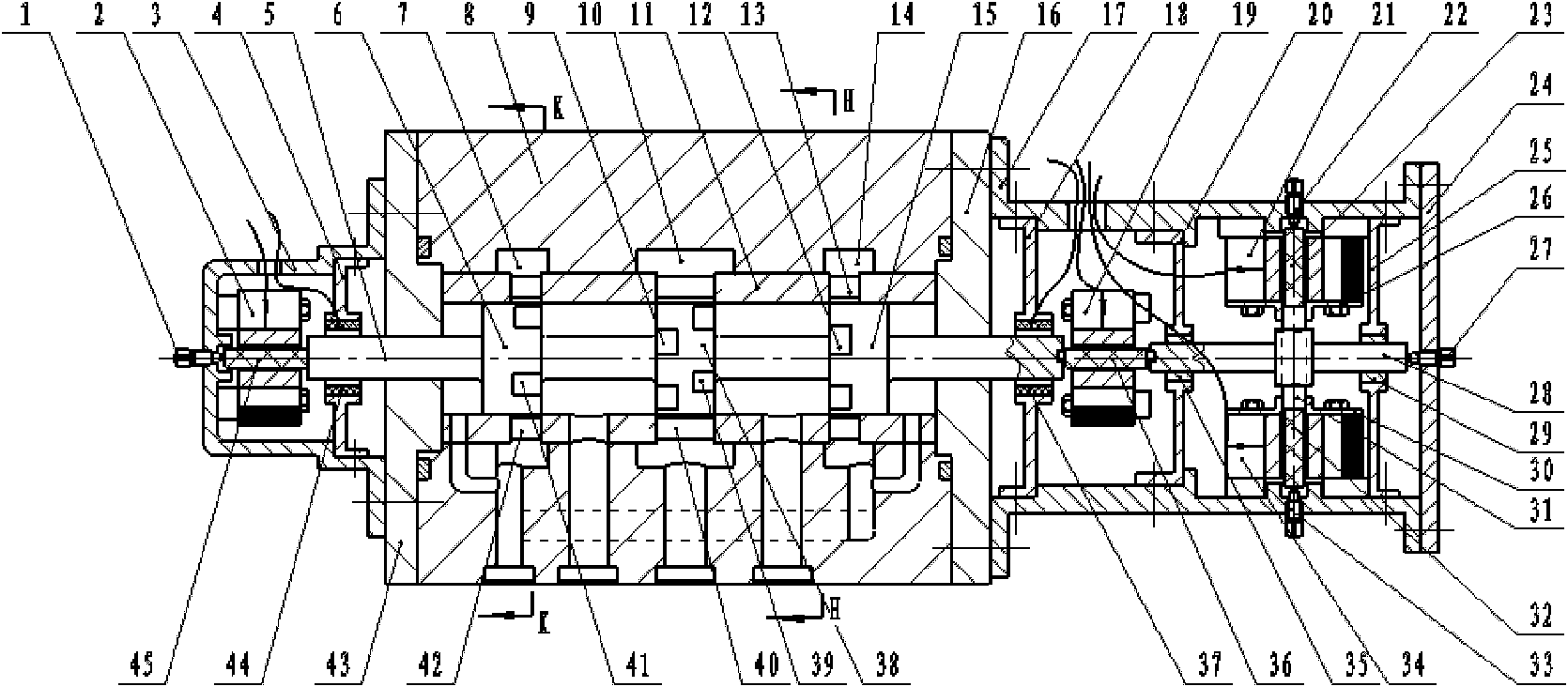

[0038] A composite high-frequency large-flow servo valve. The composite high-frequency large-flow servo valve such as figure 1 Shown: It consists of connecting the two ends of the compound flow valve with the left half of the compound magnetic control motor and the right half of the compound magnetic control motor respectively.

[0039] The structure of the left half of the composite magnetic control motor is: the first electromagnetic converter 2 and the displacement sensor 44 are arranged concentrically in the left housing 3 from left to right, and the first electromagnetic converter 2 is fixedly installed on the left housing. The inner wall of the body 3, the first magnetic memory alloy 45 passes through the central hole of the first electromagnetic converter 2, and the left zero adjustment screw contacts the left end face of the first magnetic memory alloy 45 through the left housing 3; the displacement sensor 44 passes through The first bracket 4 is fixedly installed on ...

Embodiment 2

[0057] A composite high-frequency large-flow servo valve. structured as figure 1 Shown: except following technical parameter, all the other are with embodiment 1.

[0058] The valve body 8 is evenly provided with a left annular groove 7, a middle annular groove 10 and a right annular groove 14, and 5 to 8 plain lines are evenly provided on the valve sleeve 11, and each plain line on the valve sleeve 11 is respectively provided with There are left window 42, middle window 40 and right window 13, and each left window 42, middle window 40 and right window 13 corresponds to left annular groove 7, middle annular groove 10 and right annular groove 14 respectively.

[0059]There are 5 to 8 left shoulder square grooves 41 evenly distributed on the right edge of the left shoulder 6 cylindrical surface, and 5 to 8 middle shoulder left square grooves are evenly distributed on the left edge of the middle shoulder 38 cylindrical surface. Groove 9, there are 5~8 middle shoulder square gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com