Patents

Literature

375 results about "Material fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material fatigue is a phenomenon where structures fail when subjected to a cyclic load. This type of structural damage occurs even when the experienced stress range is far below the static material strength. Fatigue is the most common source behind failures of mechanical structures.

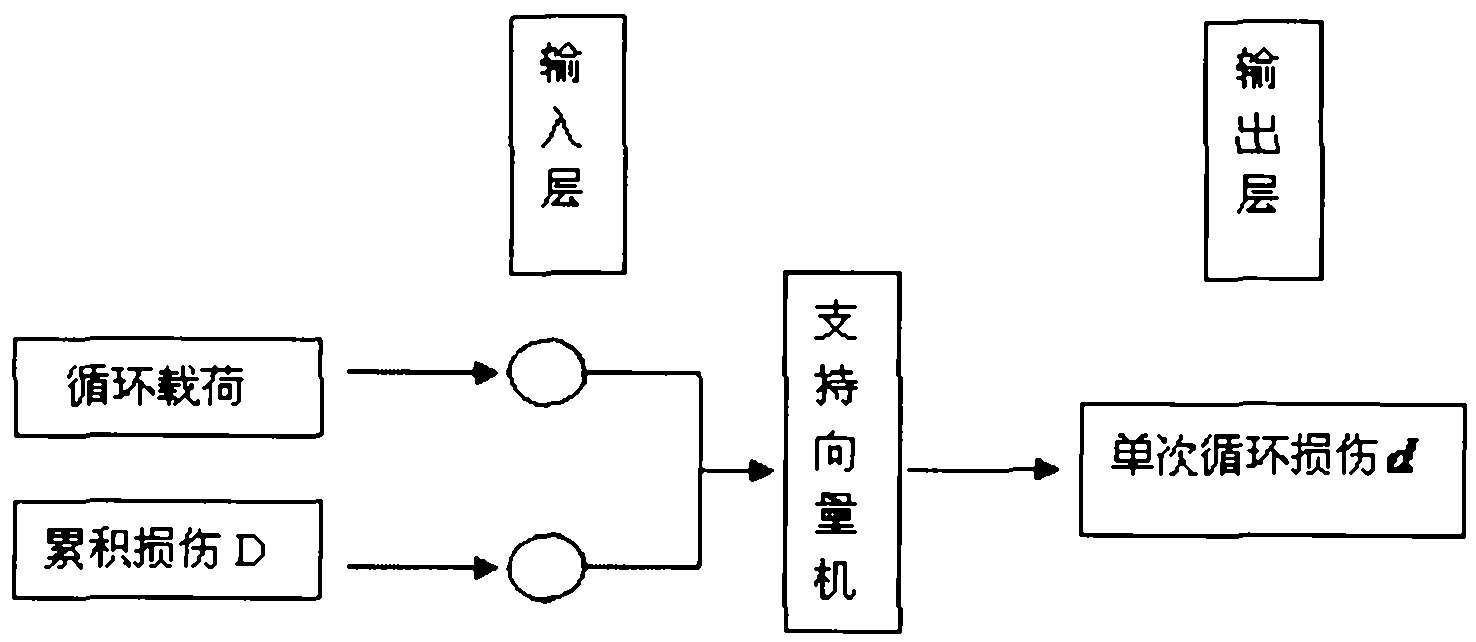

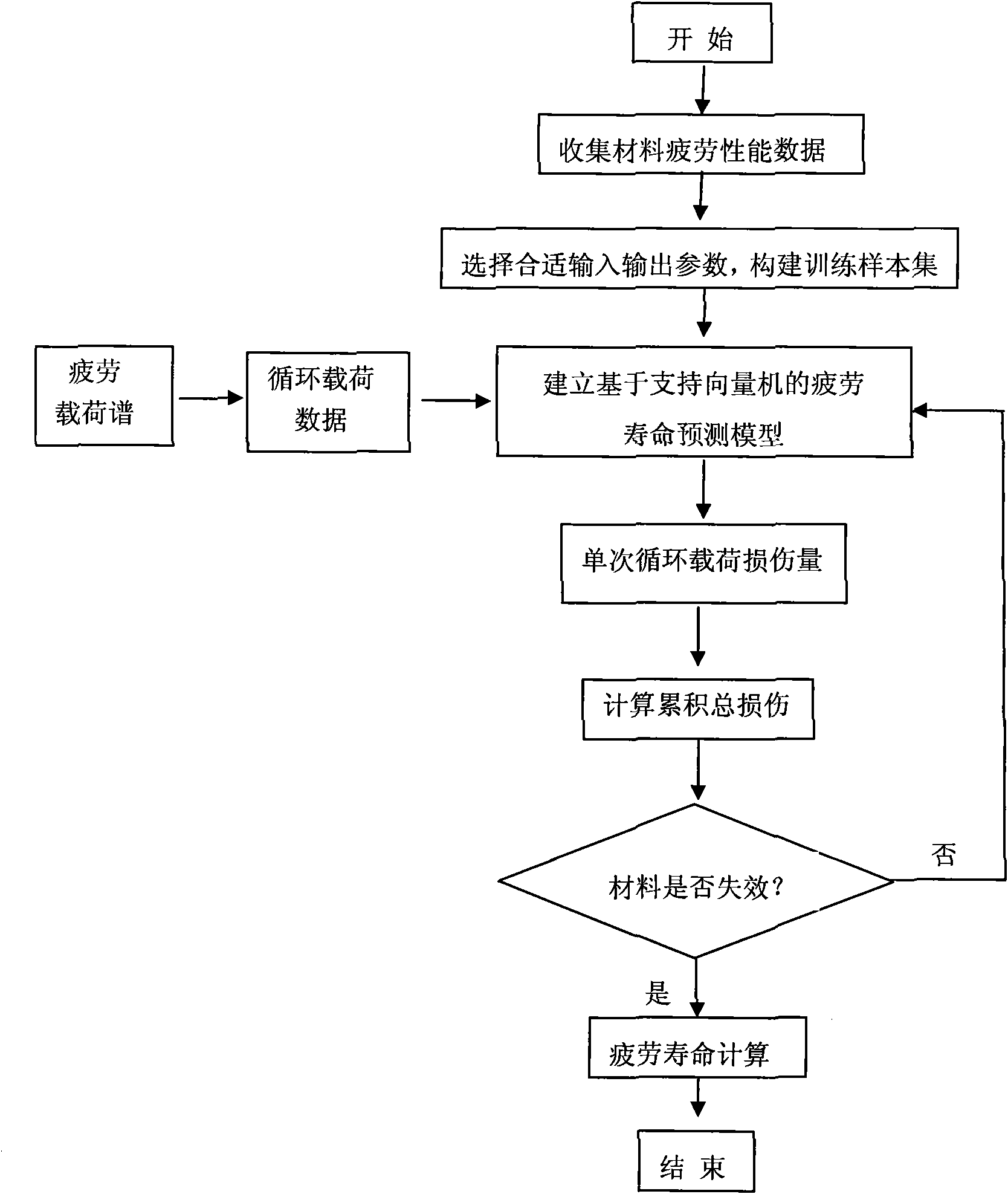

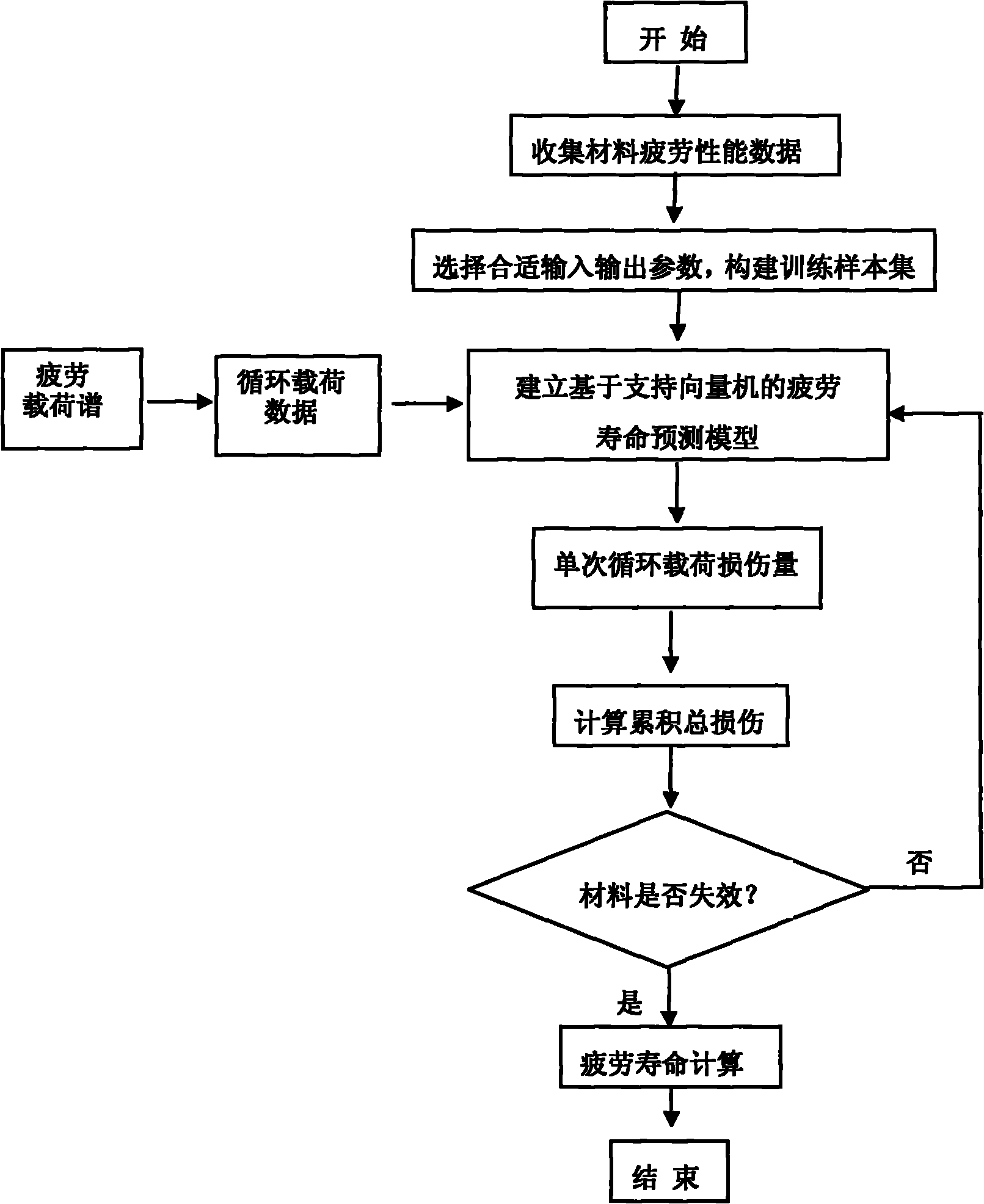

Material fatigue-life predicting method based on support vector machine

InactiveCN102081020ASave fatigue experimentsExtended service lifeStrength propertiesFatigue damageSupport vector machine

The invention relates to a material fatigue-life predicting method based on a support vector machine, and discloses a method for predicting the fatigue service life of a structural material, which comprises the steps of: obtaining material fatigue performance data, selecting a proper input and output parameter to construct a training sample set, establishing a fatigue-life predicting model based on the support vector machine, preprocessing a fatigue load, and calculating the fatigue life. The material fatigue-life predicting method has the advantages of realizing the nonlinear accumulation of fatigue damages by using less material fatigue performance data, and improving the accuracy of predicting the life. The method provided by the invention is suitable for the structural material fatigue life estimation and the life prolonging analysis, and has an important theoretical significance and an actual application value in formulating a reasonable maintenance plan for prolonging the service life of the material.

Owner:SHANGHAI MARITIME UNIVERSITY

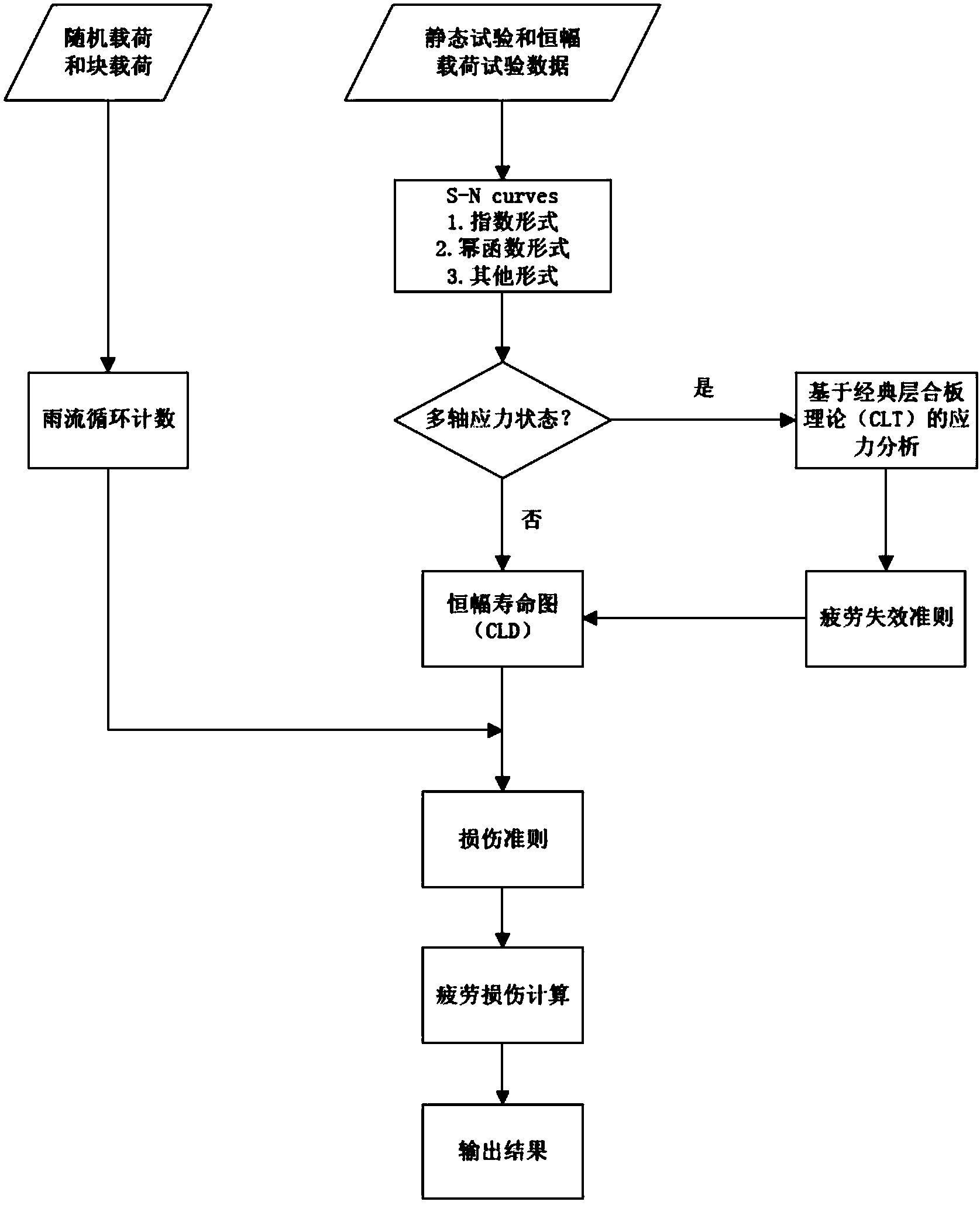

Carbon fiber composite material fatigue life estimating method based on stress ratio influences

InactiveCN103942441AAccurate lifeAccurate Damage AssessmentSpecial data processing applicationsStrength propertiesFinite element techniqueDispersity

The invention belongs to the technical field of composite materials, and discloses a carbon fiber composite material fatigue life estimating method based on stress ratio influences. Structural response calculation is carried out by means of a finite element technology. A finite element model is based on a classical laminate plate theory, and a umat subprogram taking tension and compression asymmetry into consideration is built. By carrying out constant-amplitude fatigue tests under different stress ratios, an equation of an influence mechanism of average stress on prediction of the service life of a carbon fiber composite material structure is built and is popularized to a block load and a spectrum load. A service life estimating model built through the method is based on the classical laminate plate theory and takes influences of the average stress and a variable-amplitude load into consideration, dispersity of a prediction result is little, accuracy is high, theoretical guidance is provided for reliability design of parts made of carbon fiber composite materials, and the technical problems that existing carbon fiber composite material structure fatigue life is only estimated through a test method, and accordingly cost is high and consumed time is long are solved.

Owner:SHANGHAI JIAO TONG UNIV

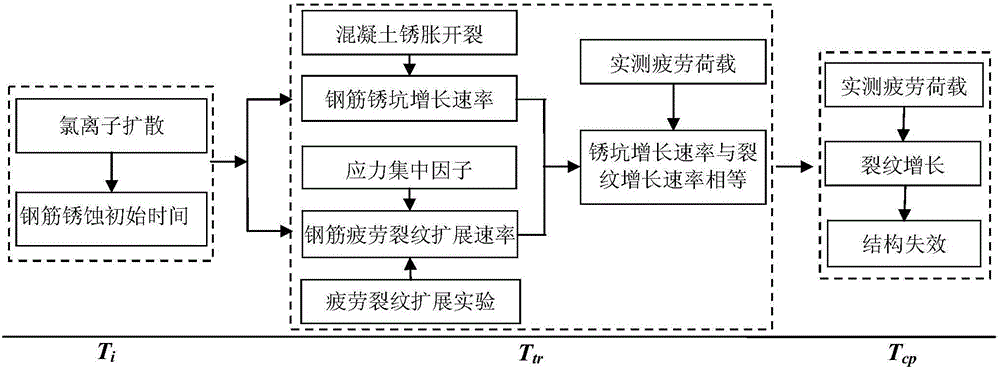

Method for evaluating fatigue life of aged reinforced concrete bridge

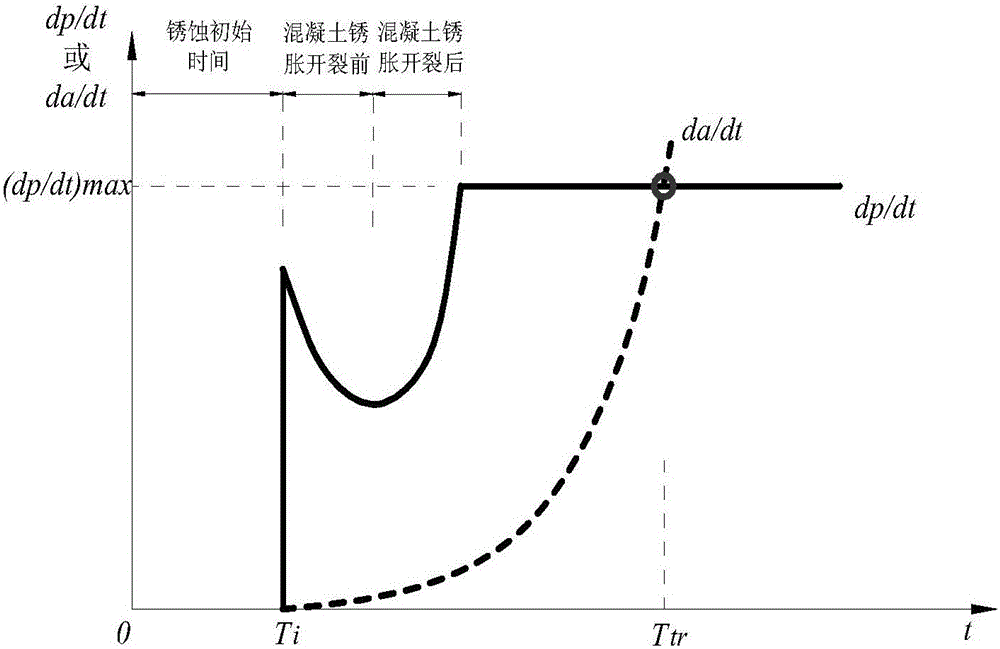

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

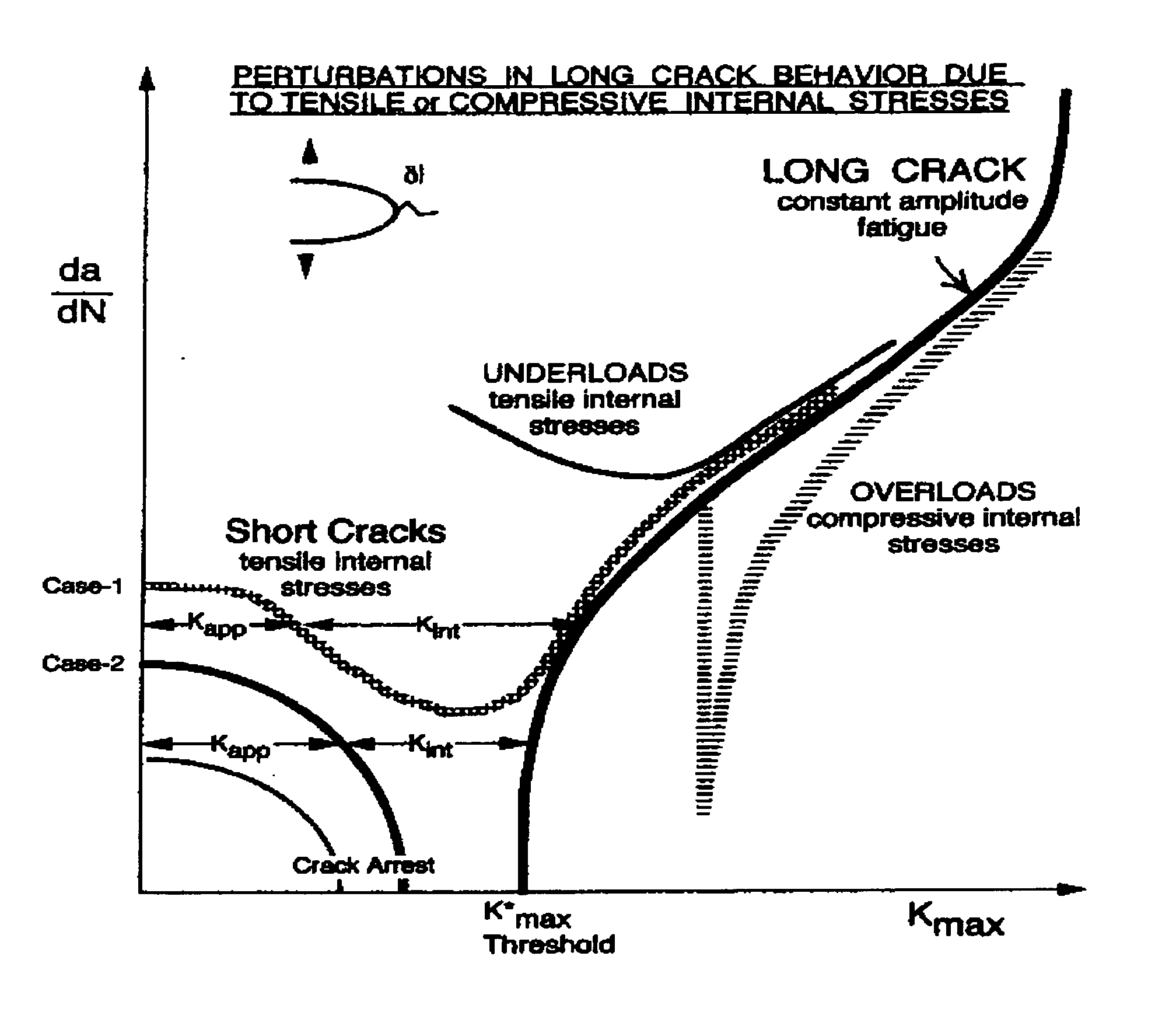

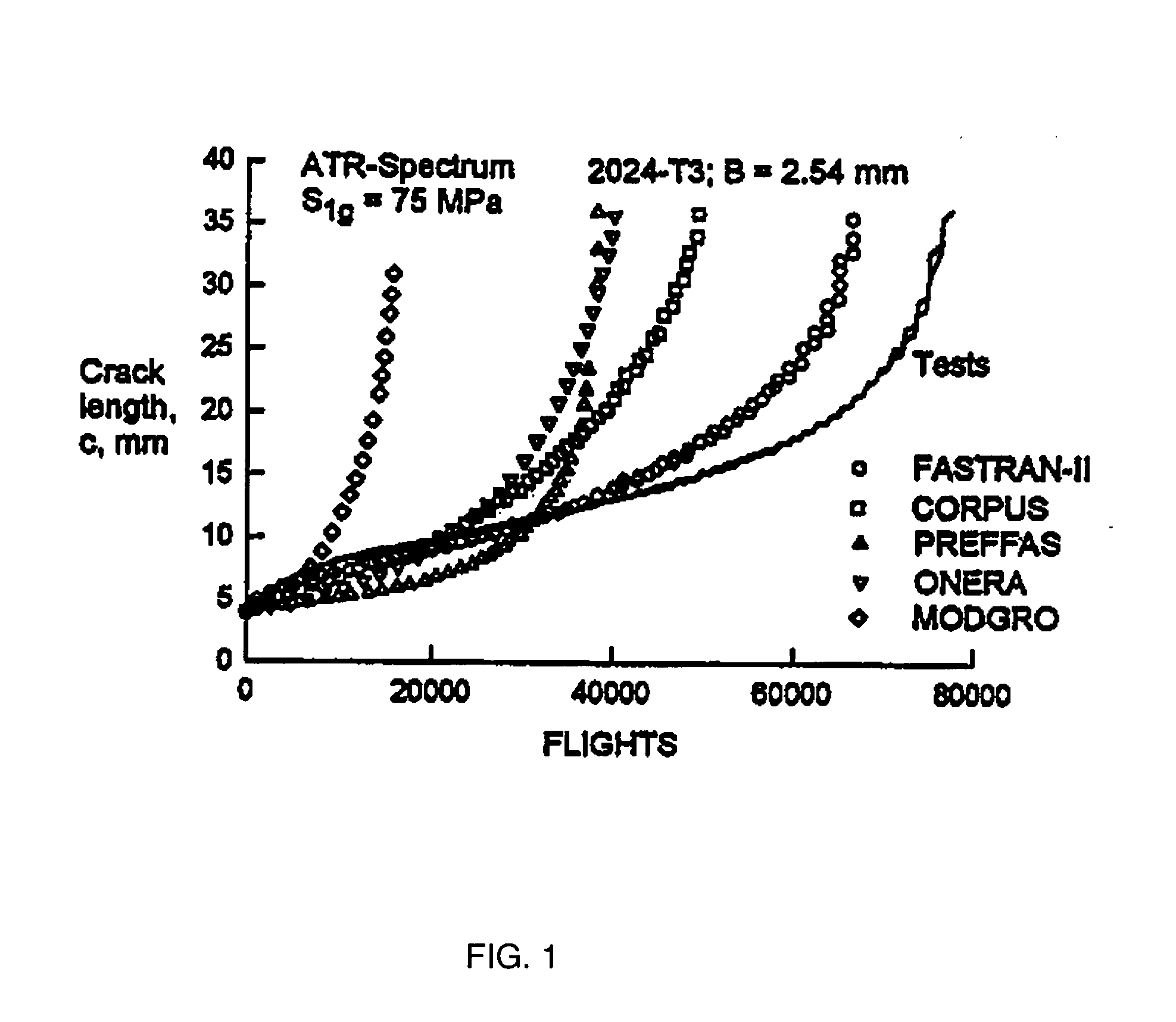

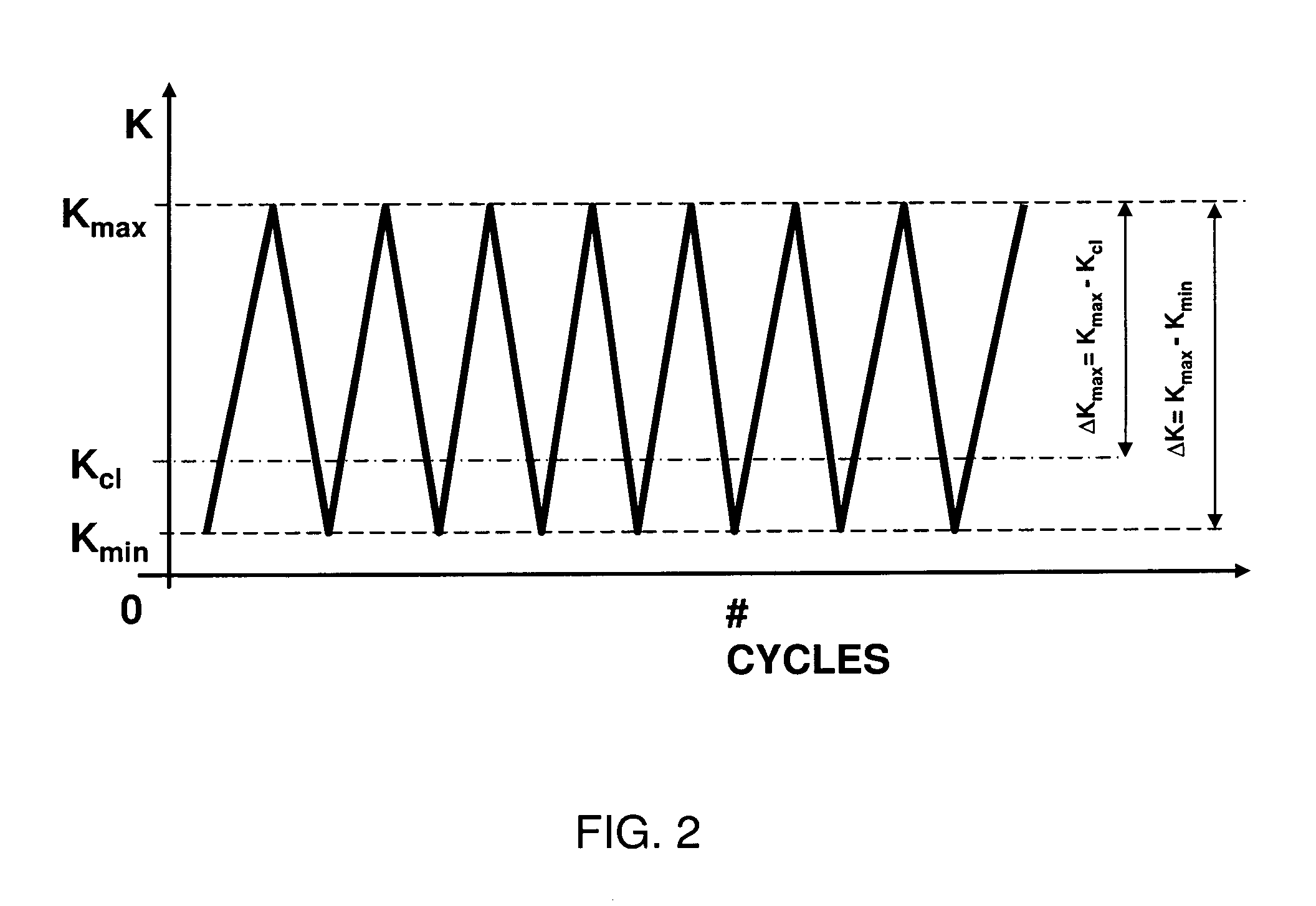

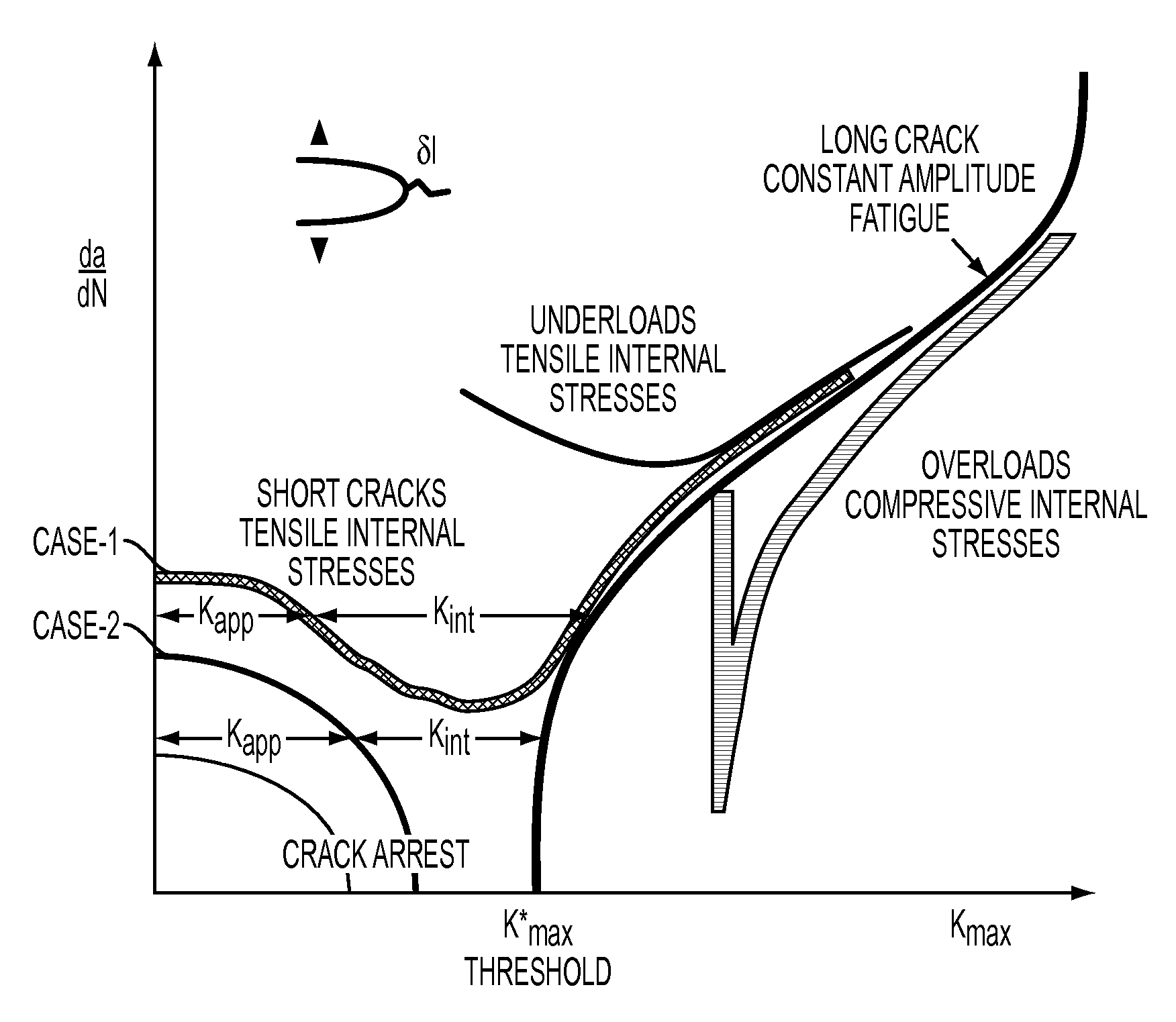

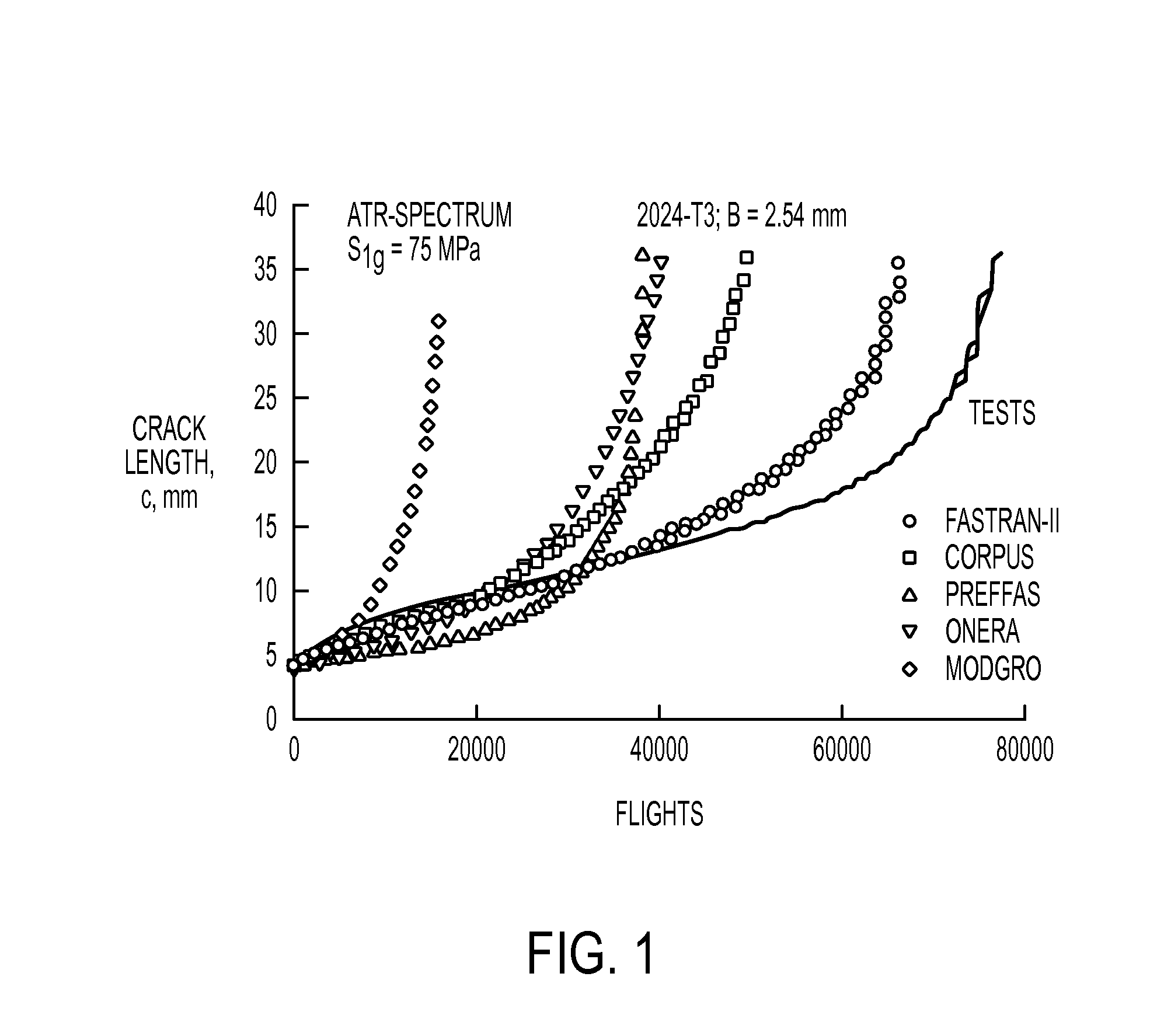

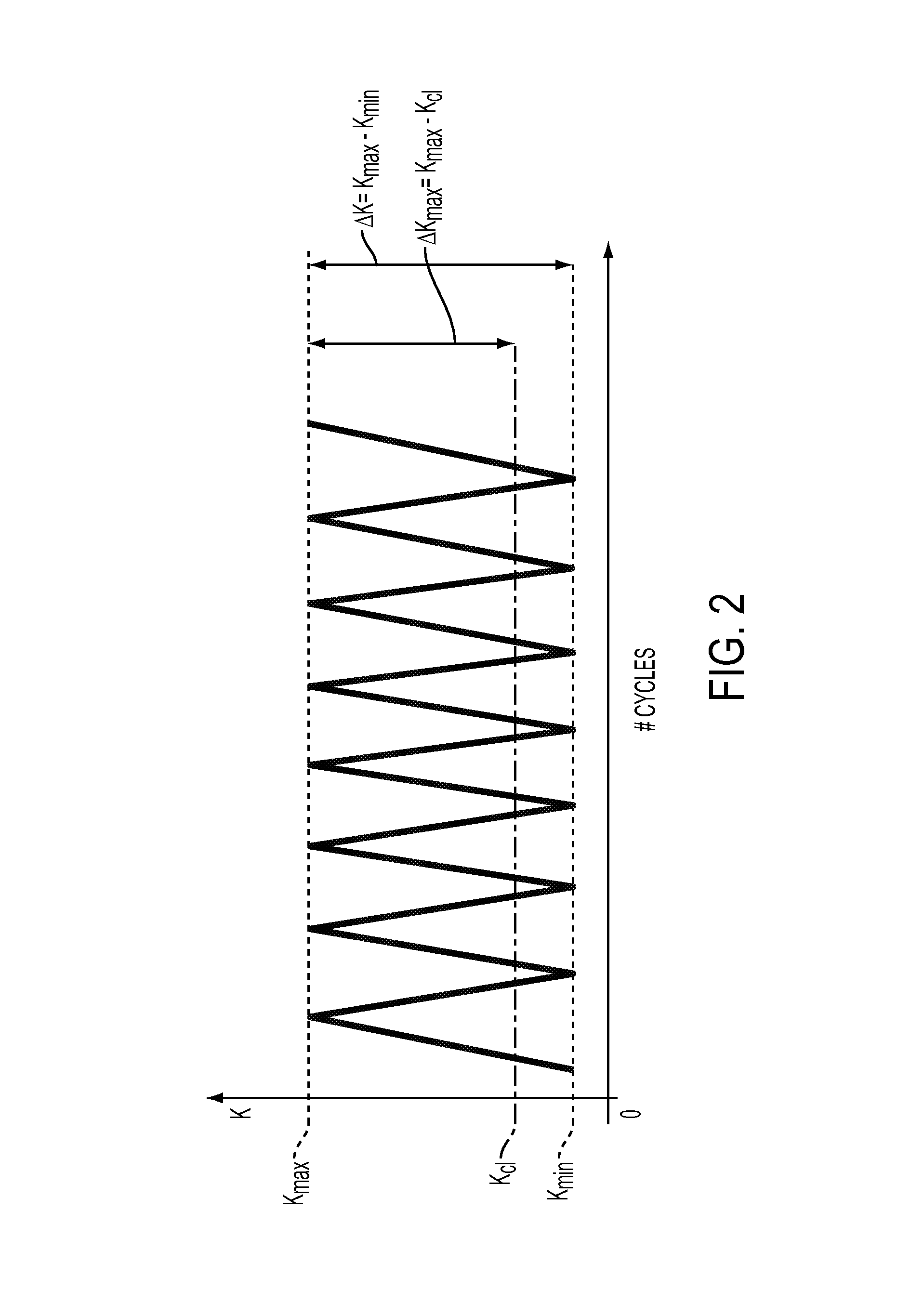

System and Method for predicting Material Fatigue and Damage

InactiveUS20080177516A1Registering/indicating quality control systemsDigital computer detailsReliability engineeringMaterial fatigue

A method and system for determining damage prediction of a component. The component may be critical component used in an aircraft or other vehicle experiencing cyclic loading. The method and system determines the ΔK, Kmax and Kinternal values for the component and utilizes these values in order to predict damage and / or failure of the component.

Owner:NAVY SEC OF THE THE USA AS REPRESENTED BY THE

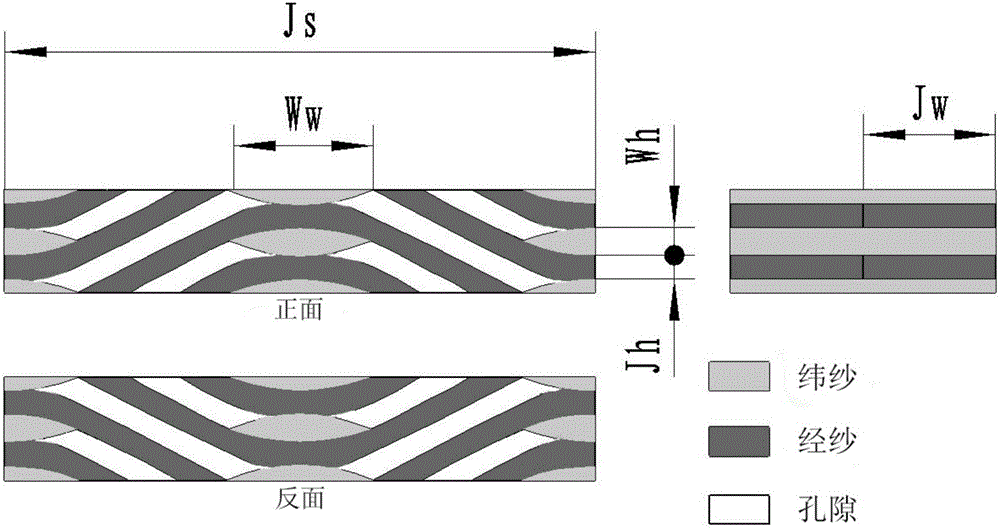

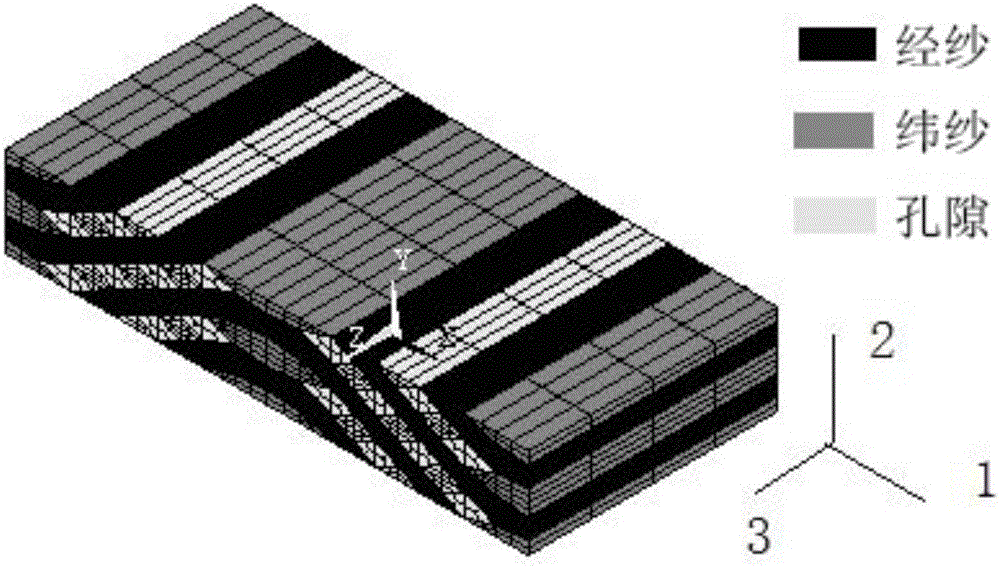

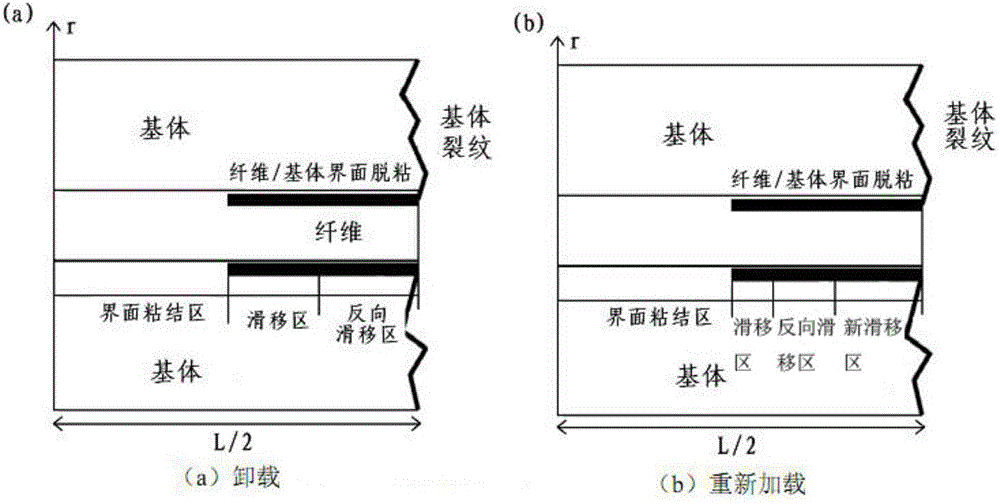

Prediction method for fatigue life of complex braided structure ceramic-based composite material

InactiveCN105760605APredict fatigue lifeDesign optimisation/simulationSpecial data processing applicationsFiberFailure strain

The invention discloses a prediction method for the fatigue life of a complex braided structure ceramic-based composite material.The prediction method comprises the steps that the fatigue performance under a cycle number and the fiber failure percentage under the cycle number are calculated; the relationship between the fiber failure percentage and a fiber failure critical value is determined; the unit-cell scale fatigue performance is calculated to obtain the maximum strain epsilon'max under the cycle; the relationship between the maximum strain epsilon'max and the maximum failure strain epsilonmax is determined; a fatigue life curve of the material is obtained.According to the prediction method, a microscale model taking account of fibers, a base body and pores and a unit-cell multi-scale prediction model taking account of warp yarn, weft yarn and holes are presented and overcome the defects that a micromechanical method cannot be directly applied to the braded material with the complex structure, and a macroscopic phenomenological method depends on a large quantity of tests and only can achieve prediction on the fatigue life of a special material, macromechanics and micromechanics are combined, a micromechanical stress strain field of a complex braided structure is supplied, and the application range of the material is widened while the fatigue life curve of the material is precisely predicted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

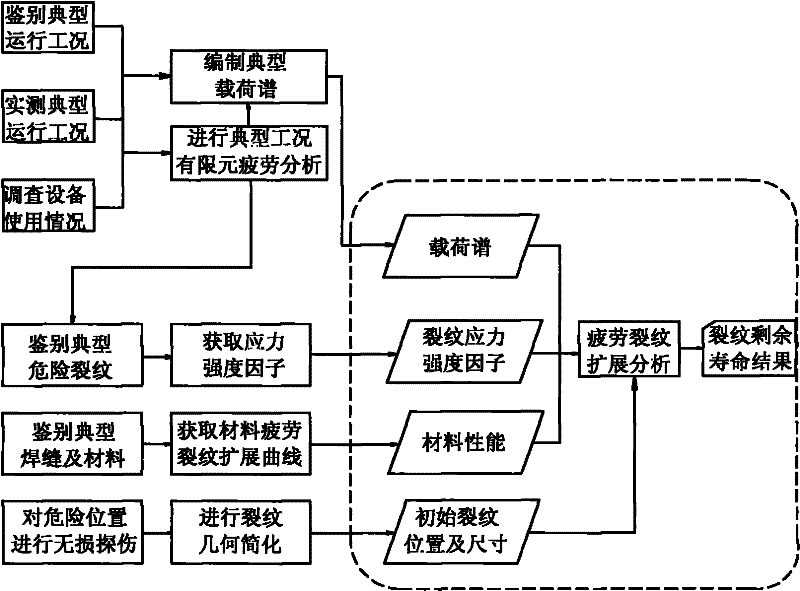

Method for estimating remaining fatigue life of main metal structure of crane

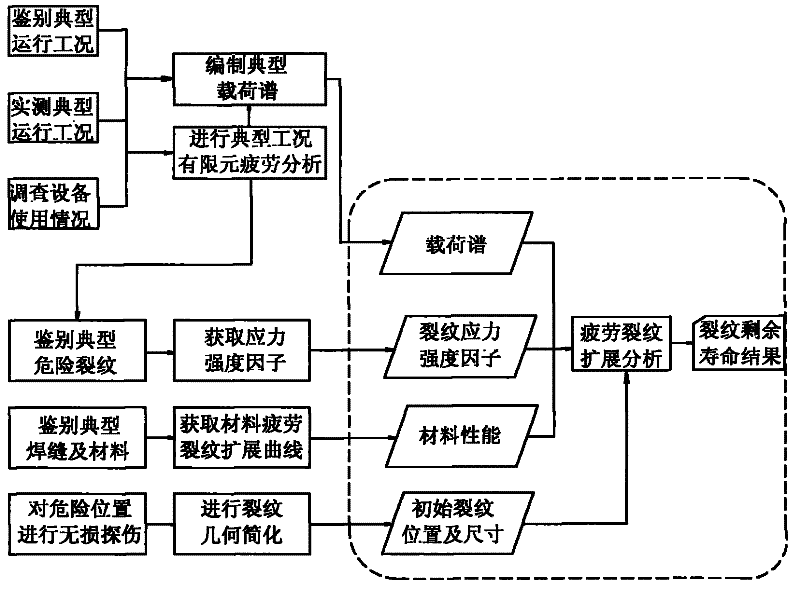

InactiveCN102221473AReflect duty cycleEstimating Fatigue LifeStructural/machines measurementUsing wave/particle radiation meansEstimation methodsEngineering

The invention relates to a method for estimating the remaining fatigue life of a main metal structure of a crane. The method is applied to the compiling of actually measured load spectrums, the measurement of material fatigue crack propagation curves, the nondestructive detection of hazardous locations and the estimation of the remaining fatigue life of the main metal structures of the large cranes at relatively higher working levels in shipyards, ports and the like, and is also applied to the estimation of the remaining fatigue life of the cranes of other types. The method comprises the following steps of: (1) acquisition of the load spectrum; (2) measurement of material performance; (3) detection of an initial crack location and an initial crack size; (4) acquisition of a crack stress intensity factor; and (5) estimation of the remaining fatigue life. In the method, factors such as the existence of a crack in the structure, the detection of the location and size of the actually crack, and the like are taken into account, and the nondestructive detection is performed on the hazardous location; therefore, the remaining fatigue life of the metal structure of the crane can be accurately estimated.

Owner:GUANGZHOU ACAD OF SPECIAL EQUIP INSPECTION& TESTING

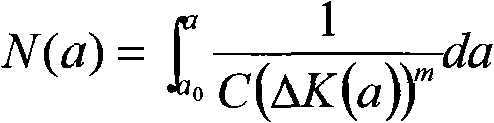

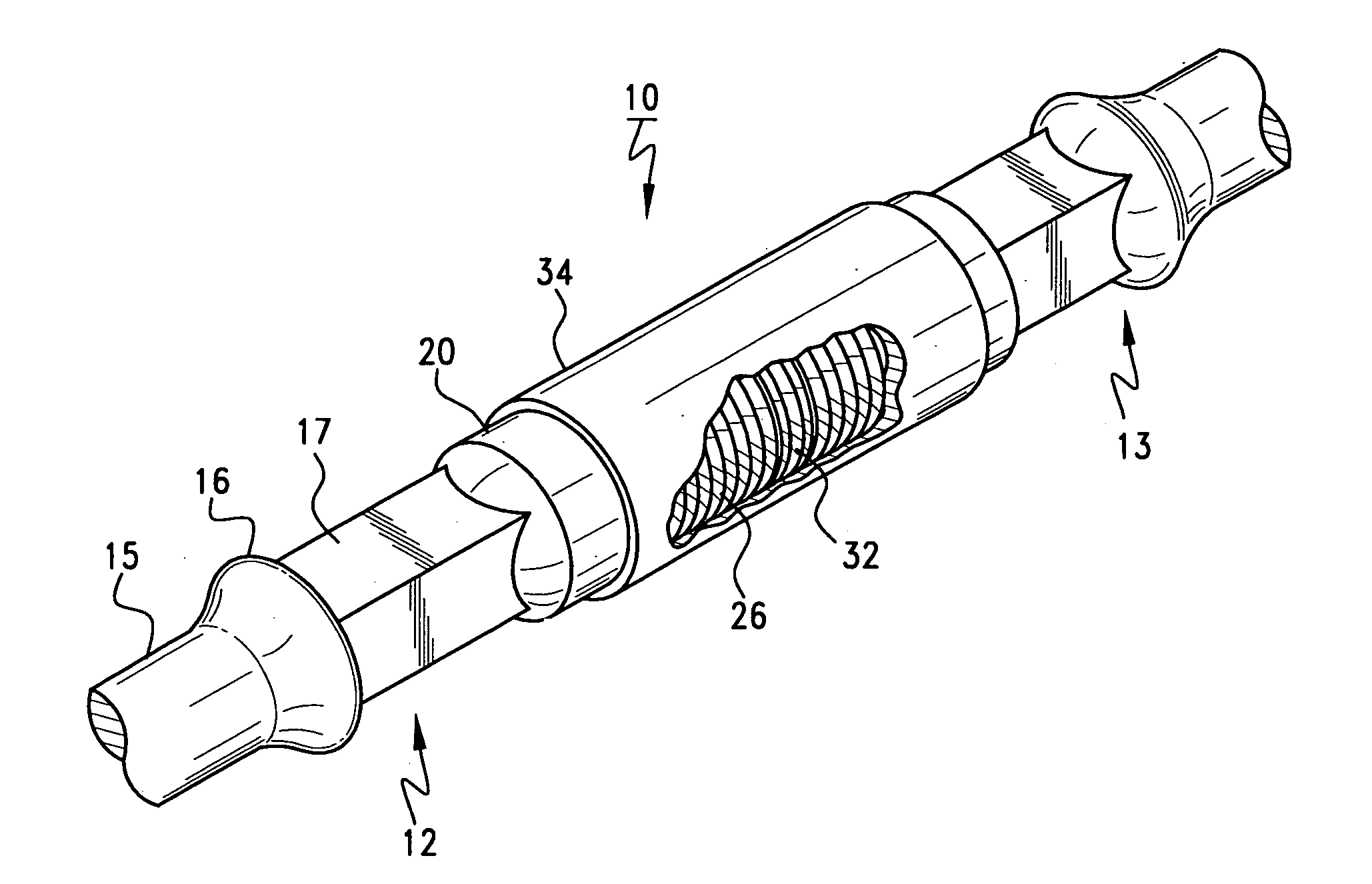

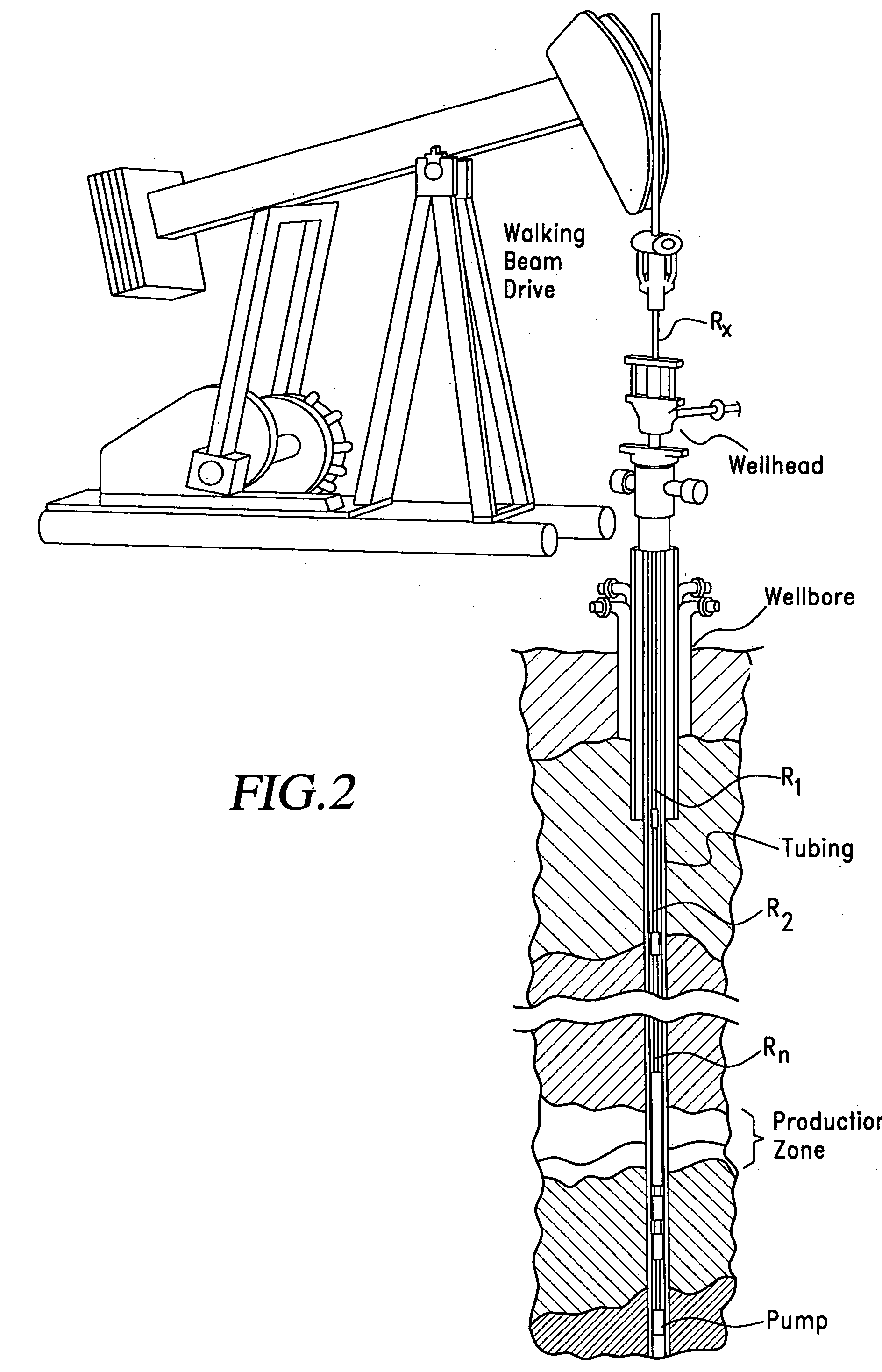

Connectable rod system for driving downhole pumps for oil field installations

InactiveUS20060273601A1Improve torque performanceUnique and useful tensionDrilling rodsDrilling casingsEngineeringAxial distance

Improved sucker rod joints for down hole petroleum pumping applications are provided within the form factor of standard API sucker rods, such that existing inventory in suitable condition is fully usable in more demanding applications. The pin ends are selected or processed such as to provide preselected axial distance between a flat pin end and at least one reference surface, such as a threaded region or reference shoulder or both. The coupler is dimensioned such that the pin ends are in abutment either with each other or with opposite sides of an intervening torque washer in the central region, when the connection is made to a selected level of thread engagement. Furthermore, the engagement is such as to put the pin ends in compression and the coextensive length of coupler in tension. This increases frictional restraints and locks the elements together to resist fatigue failure upon cycling and to insure together with an anaerobic adhesive sealant, against back threading. This arrangement enables standard quality sucker rods to be employed in a configuration which is mechanically secure and highly resistant to tensile, bending and torsional forces, thus assuring a greater strength at the joint than in the rod itself, and resisting the effects of material fatigue arising from long term and stressful cycling operations.

Owner:CARSTENSEN KENNETH J

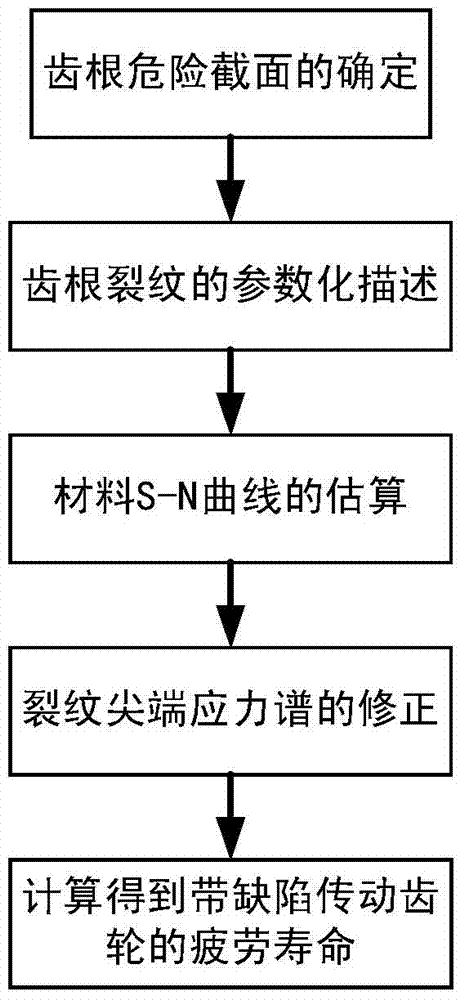

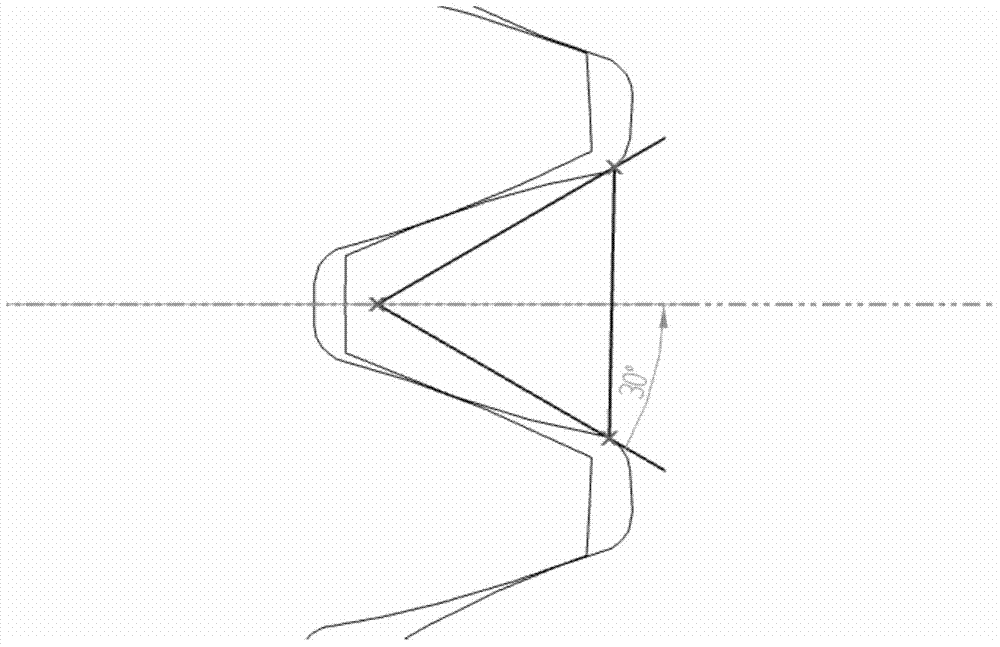

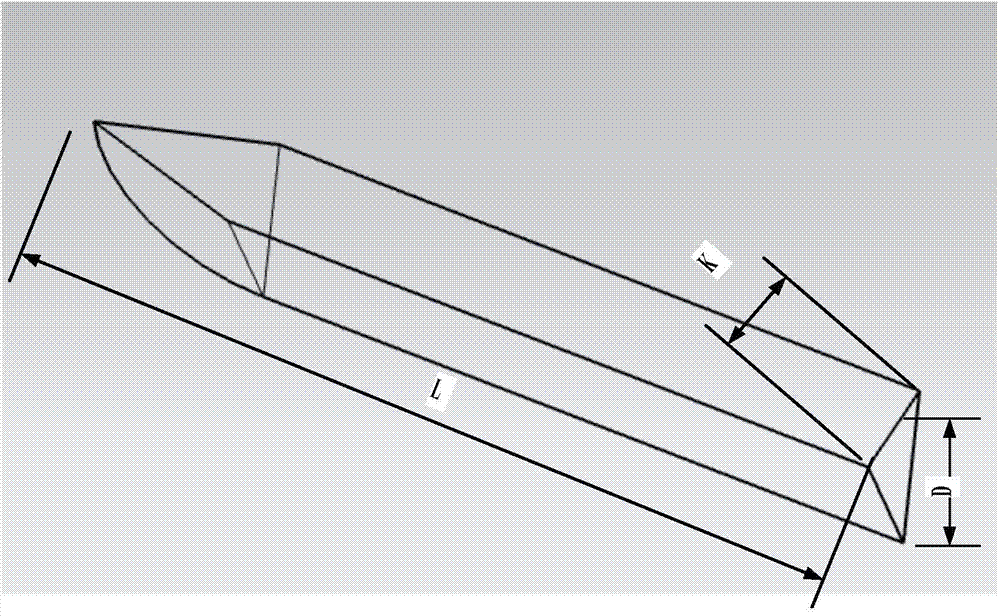

Transmission gear fatigue life assessment method based on defect modeling

InactiveCN103616179AImprove fatigue analysis efficiencyReduce fatigue life analysis complexityMachine gearing/transmission testingFatigue damageEstimation methods

The invention discloses a transmission gear fatigue life assessment method based on defect modeling. The method includes the following steps that (1), crack occurrence rules and reasonable crack forms are analyzed, and the method for introducing cracks into a gear model is researched; (2), material fatigue characteristic parameters are obtained through test data fitting or a numerical value estimation method; (3), a stress spectrum under the condition of working situations of a gear containing the cracks is calculated by using a finite element method, and the stress spectrum is corrected according to obtaining conditions of the material fatigue characteristic parameters; (4), fatigue life under the condition of working situations of a gear containing the cracks is calculated by using the reasonable fatigue damage accumulation theory. The fatigue life assessment method based on defect modeling is provided for the transmission gear, and an effective detection basis is provided for the remanufacturing process of a gear recycled part.

Owner:GUANGXI UNIV

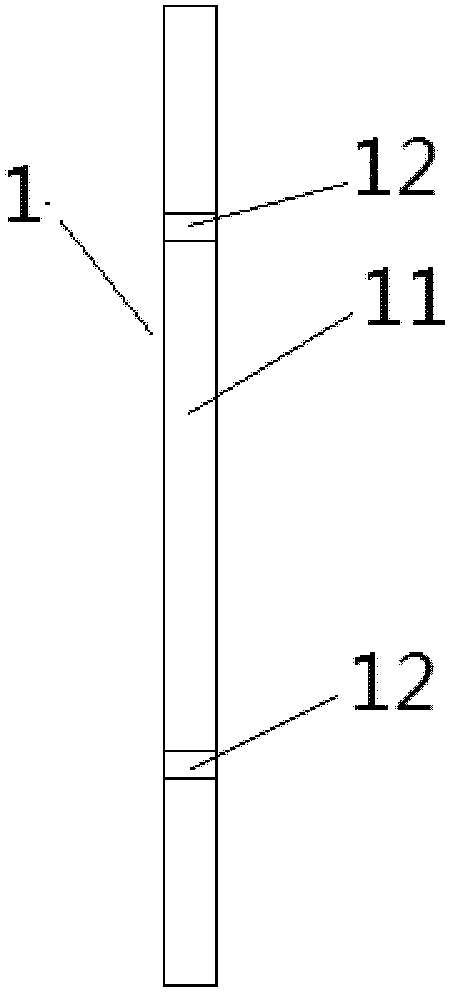

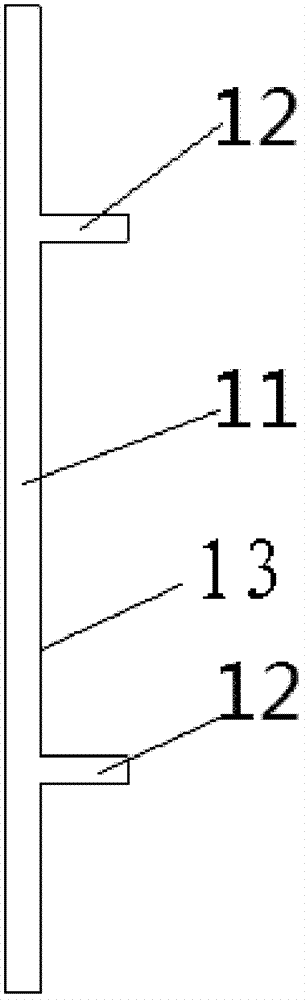

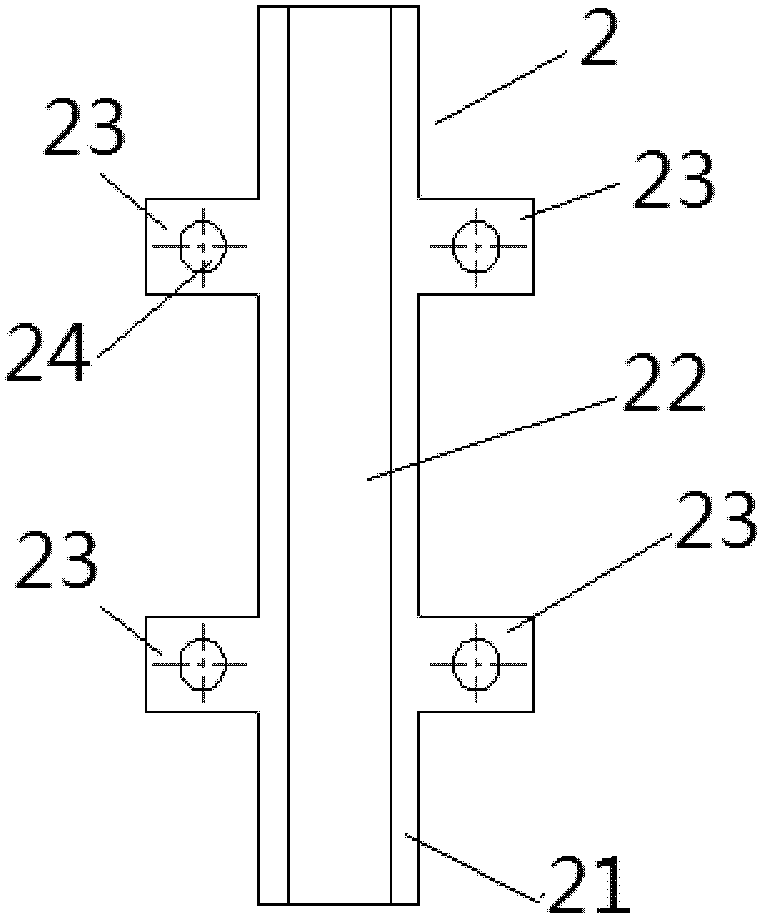

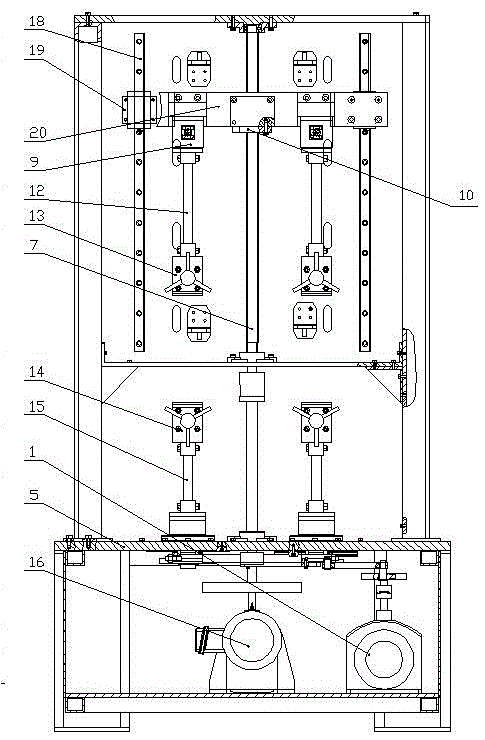

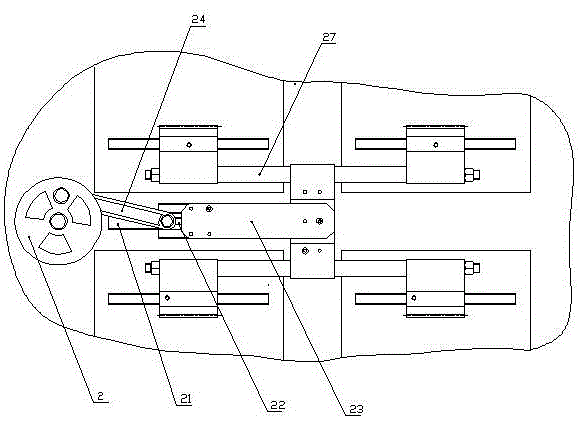

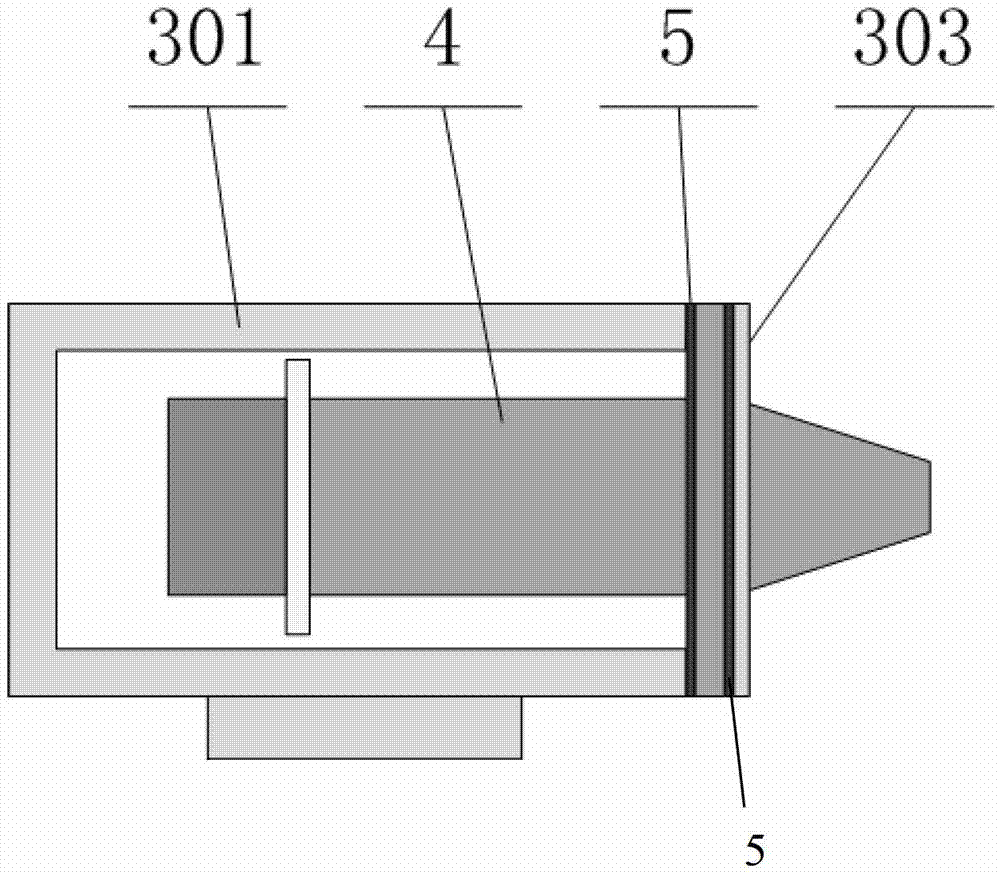

Fatigue test device for vehicle body thin plate, and test method thereof

ActiveCN102735557AEnsure consistencyAvoid influenceMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

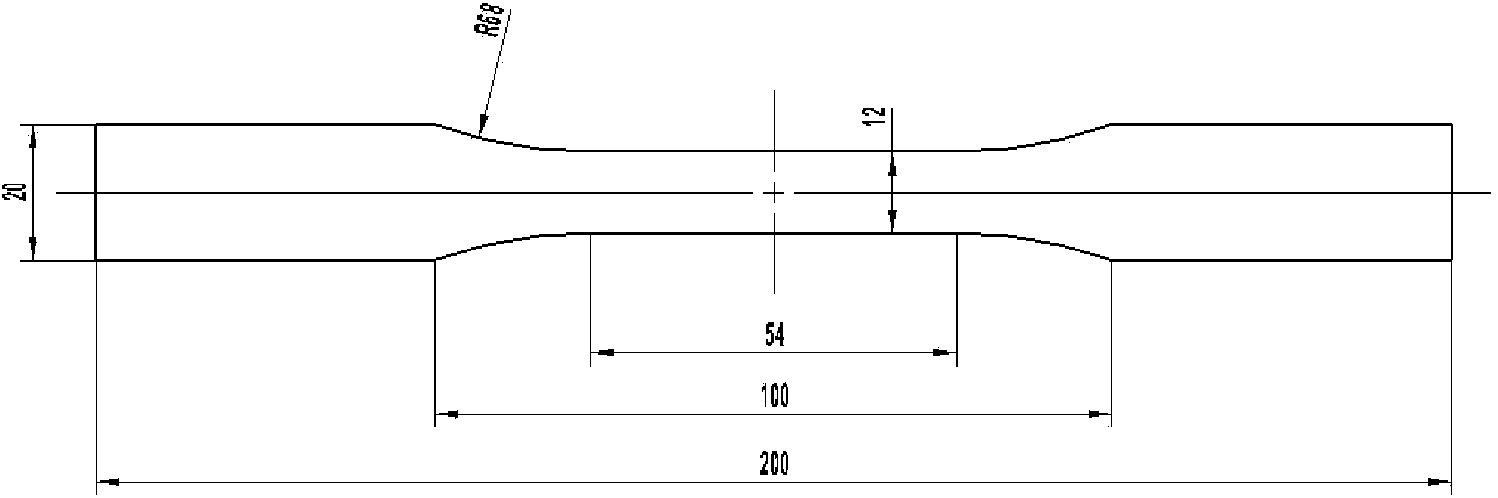

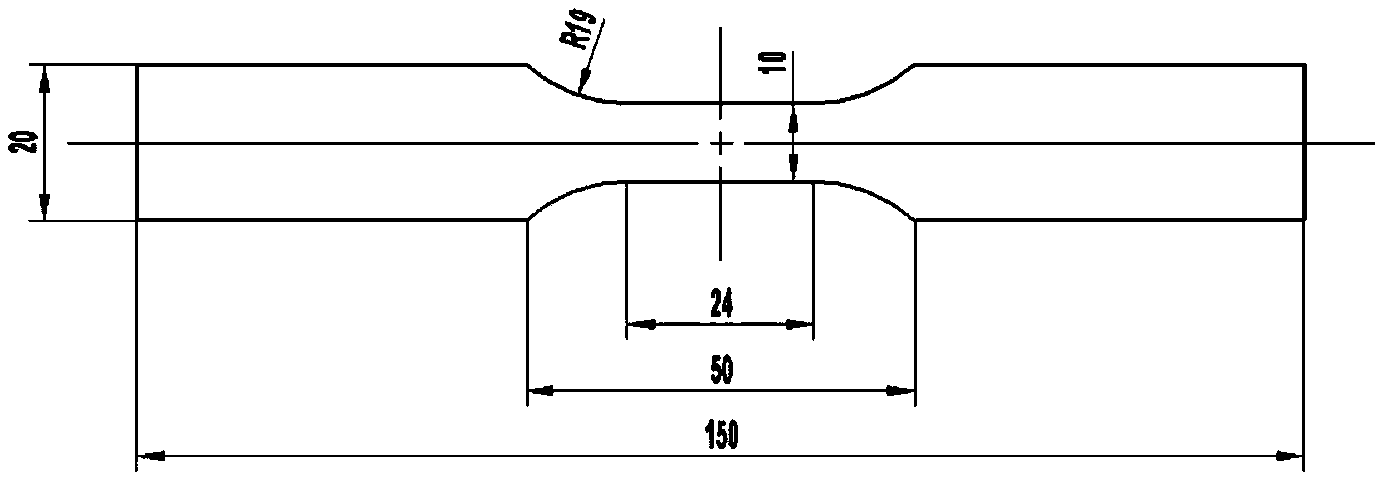

The present invention discloses a fatigue test device for a vehicle body thin plate, and a test method thereof, and belongs to the field of material fatigue test. The test device comprises: a centering apparatus and an anti-bending constraining apparatus. The centering apparatus comprises a vertical column and two centering clamping blocks, wherein the vertical column is provided with a reference plane correspondingly attaching to holding fixtures so as to make a center line of a fatigue specimen parallel to the reference plane, and the two centering clamping blocks are intervally and vertically arranged on the reference plane of the vertical column, such that the fatigue specimen is centered to a center line of test fixtures. The test method comprises: selecting a thin plate fatigue specimen and measuring a static tension curve; carrying out calibration on test force, selecting the initial test force, and setting a condition fatigue limit of the material; adopting the fatigue test device to carry out centering and anti-bending constraining on the fatigue specimen, and adopting a testing machine to carry out a fatigue test on the fatigue specimen. According to the present invention, uniformity of the test process is ensured and influence on the tested result due to additional factors is reduced by the centering apparatus and the anti-bending constraining apparatus, the test efficiency is improved, and the test cost is saved.

Owner:CHERY AUTOMOBILE CO LTD

System and method for predicting material fatigue and damage

InactiveUS7889840B2Registering/indicating quality control systemsDigital computer detailsReliability engineeringMaterial fatigue

A method and system for determining damage prediction of a component. The component may be critical component used in an aircraft or other vehicle experiencing cyclic loading. The method and system determines the ΔK, Kmax and Kinternal values for the component and utilizes these values in order to predict damage and / or failure of the component.

Owner:NAVY SEC OF THE THE USA AS REPRESENTED BY THE

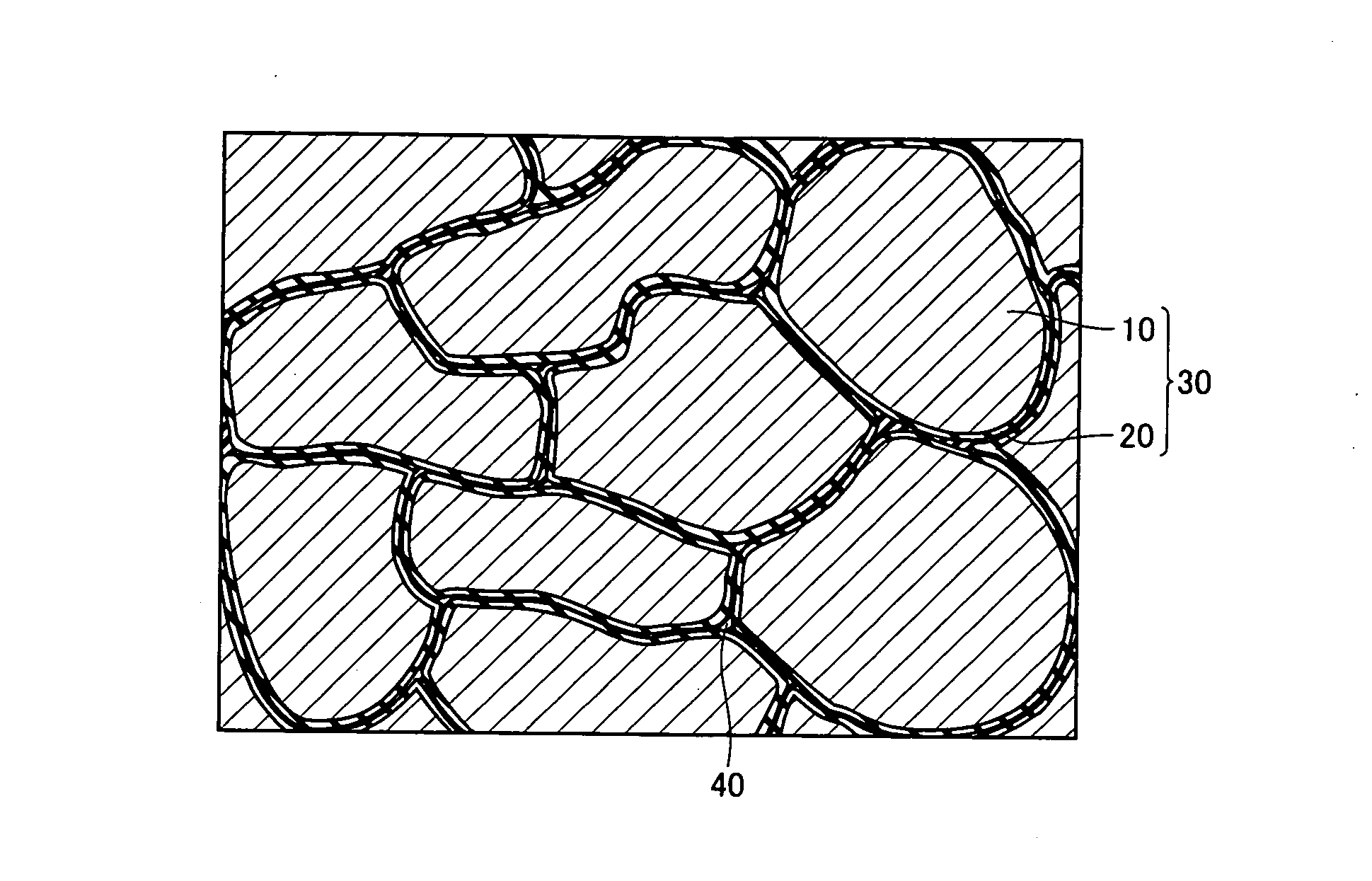

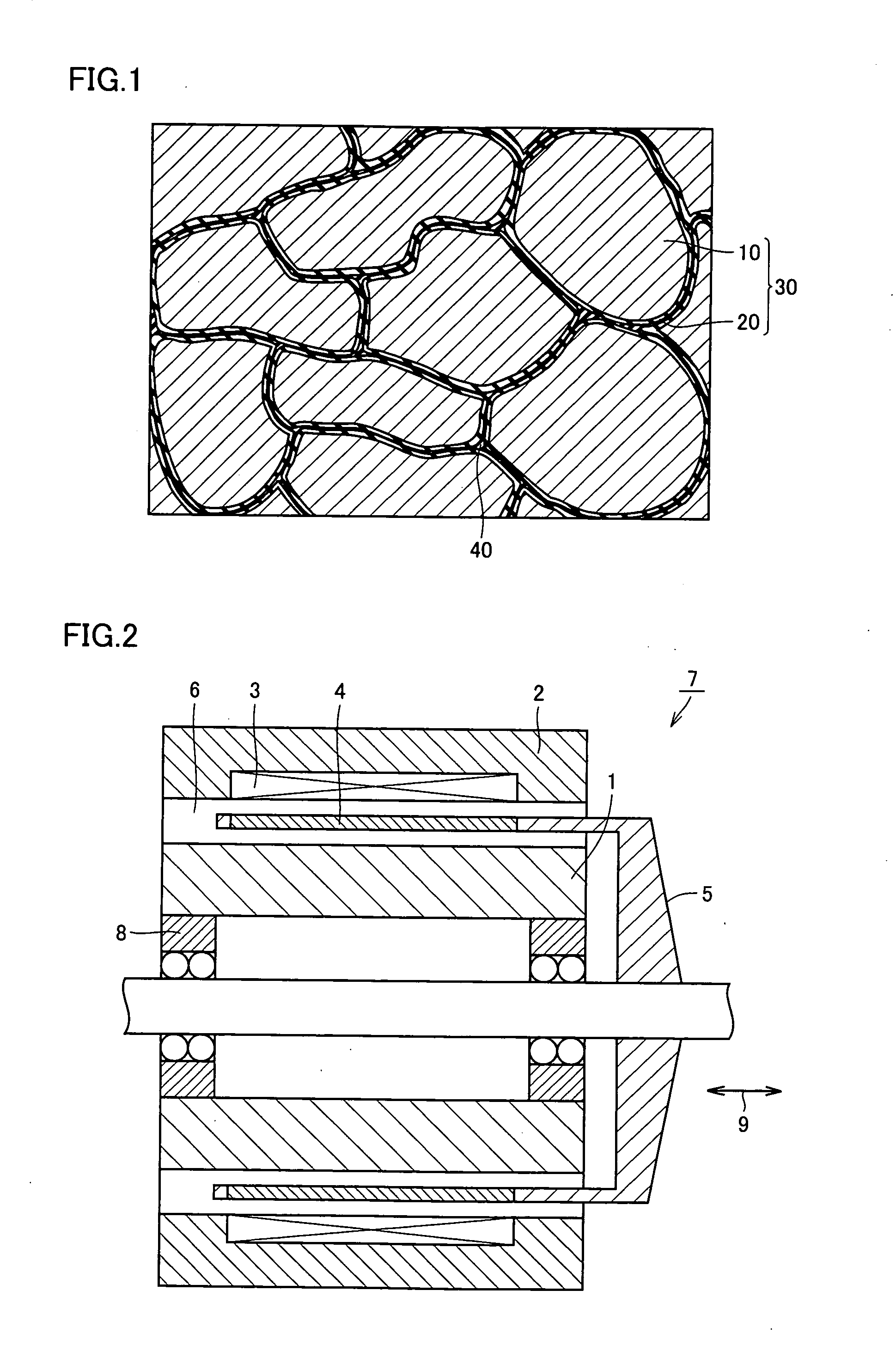

Soft magnetic material, motor core, transformer core, and method for manufacturing soft magnetic material

InactiveUS20110104476A1High resistivityIncreased durabilitySynthetic resin layered productsMetal-working apparatusTransformerOrganic matter

A soft magnetic material includes a composite magnetic particle and an organic substance. The composite magnetic particle has a metallic magnetic particle and a coating layer coating the metallic magnetic particle and containing an oxide therein. The organic substance is formed by adding at least one of a thermoplastic resin and a higher fatty acid having an effect of increasing resistivity of the material, to a non-thermoplastic resin having an effect of improving durability such as material fatigue limit. The organic substance is contained in the soft magnetic material by not less than 0.001% by mass and not more than 0.2% by mass. The present invention provides a soft magnetic material having high magnetic property and mechanical strength and also having fatigue property and resistivity satisfying durability enough for use as a motor core or the like, and a method for manufacturing the same. Further, the invention provides a motor core and a transformer core made of the soft magnetic material. A core loss can significantly be reduced in a motor core made of the soft magnetic material.

Owner:SHARP KK +1

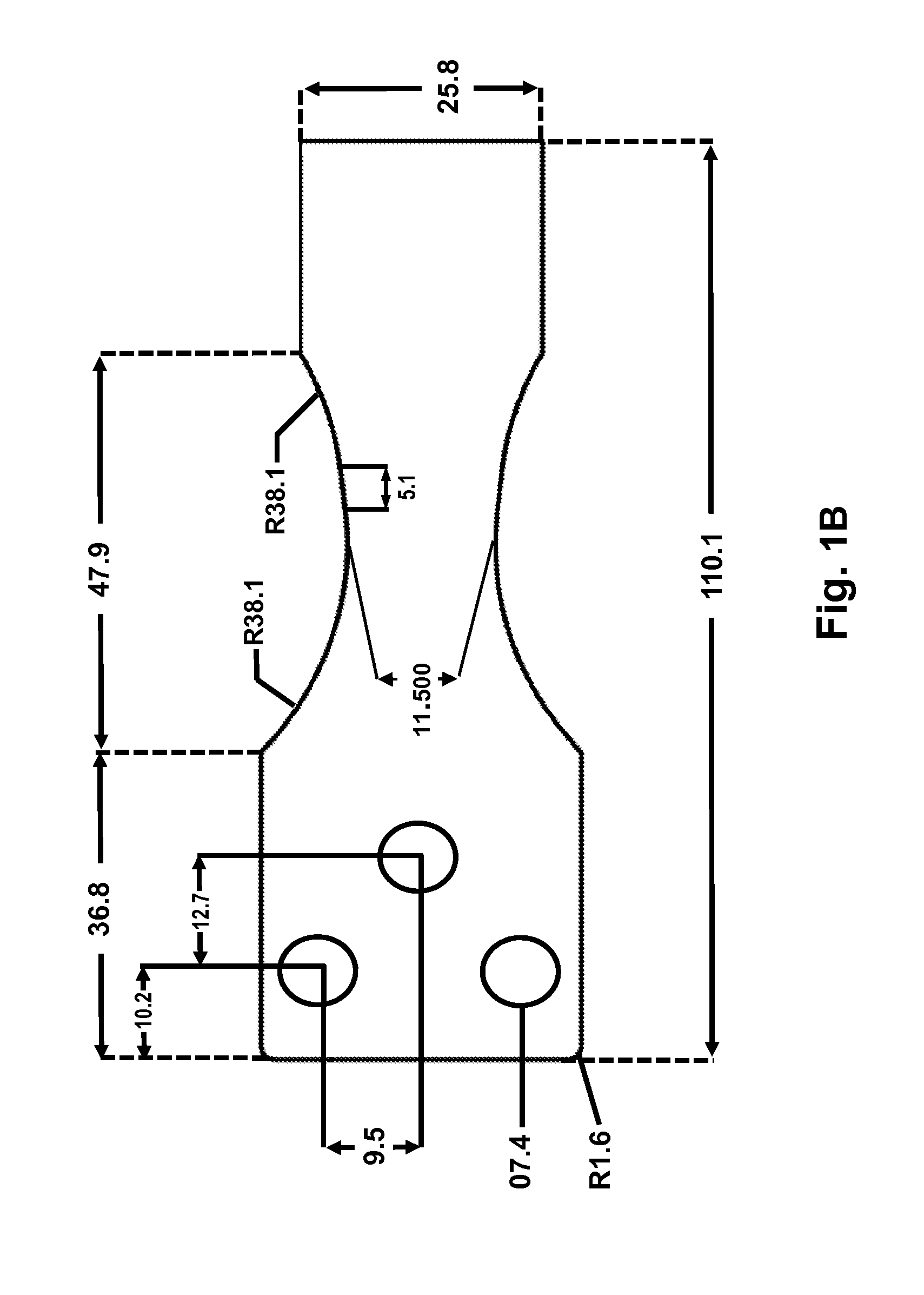

Method for detecting influence of different parameters on material fatigue crack expansion performance

InactiveCN102645385ATest accurateLow costPreparing sample for investigationMaterial strength using repeated/pulsating forcesMicrocomputerReliability engineering

The invention relates to a method for detecting the influence of different parameters on material fatigue crack expansion performance, which comprises the following steps of: firstly, processing a sample according to the standard and adopting a compact tensile sample; secondly, clamping the sample on a fatigue tester according to a standard test method, monitoring the crack length by using a microcomputer-aided potential method, and calculating and giving electric potential functions by using a boundary element method; thirdly, applying different test parameters according to different detection samples; and fourthly, treating the test data and comparing the test results. The method has the characteristics of high detection efficiency, low cost and accurate detection.

Owner:XI'AN PETROLEUM UNIVERSITY

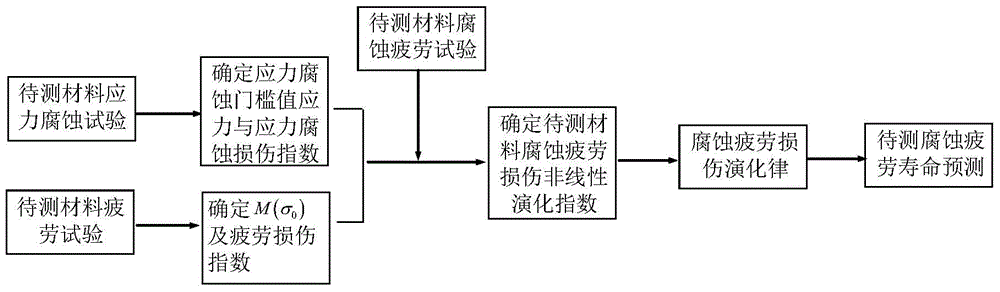

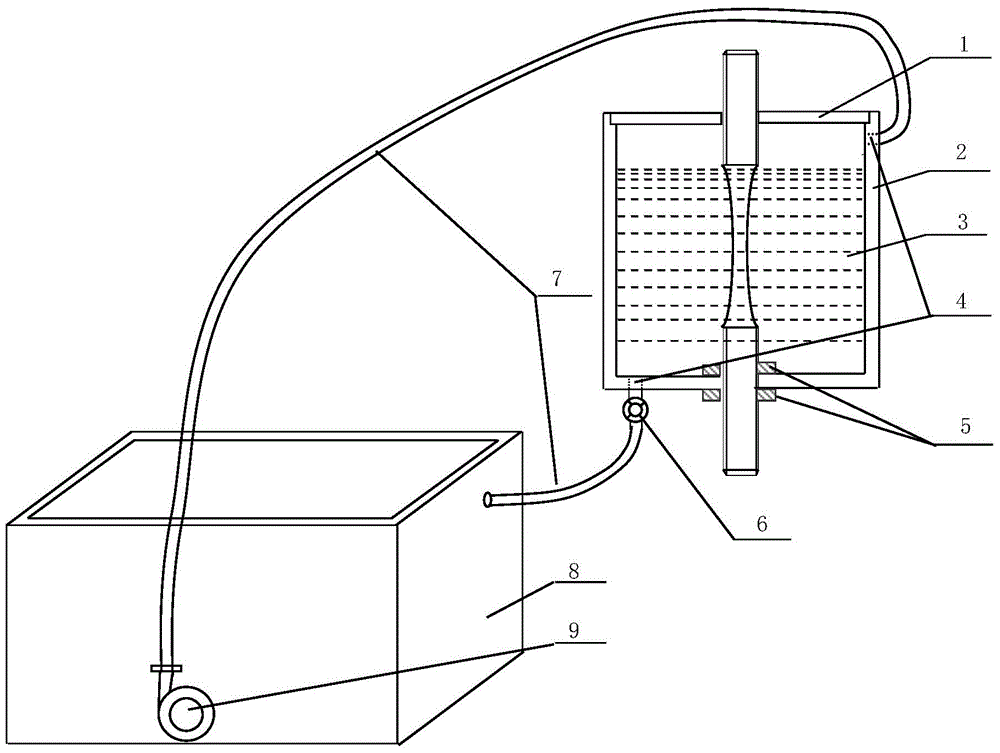

Corrosion fatigue life prediction method based on damage evolution

InactiveCN104062196ACycle simpleOvercome deficienciesWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFatigue damagePredictive methods

The invention belongs to technical field of metal material corrosion and particularly relates to a corrosion fatigue life prediction method based on damage evolution. The method includes following steps: carrying out a stress corrosion test to a to-be-tested material for determining a stress threshold value of the stress corrosion and a damage index; carrying out a fatigue test to the to-be-tested material for determining a fatigue damage parameter; determining a corrosion fatigue damage nonlinear evolution index of the to-be-tested material; and predicting a corrosion fatigue life of the to-be-tested material. A corrosion solution circulating device in the invention can achieve cyclic refreshing of a corrosion liquid in a metal material corrosion fatigue and stress corrosion test. The corrosion fatigue life is predicted through a method of combining theory with experimental investigation so that defects in an analytical method and a test method are overcome. The prediction method is reasonable and is accurate in result. The predicted result is free of any influence due to combination of environment and the material. The prediction method is simple in operation, is easy to carry out, is strong in popularizing performance and is convenient in engineering application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

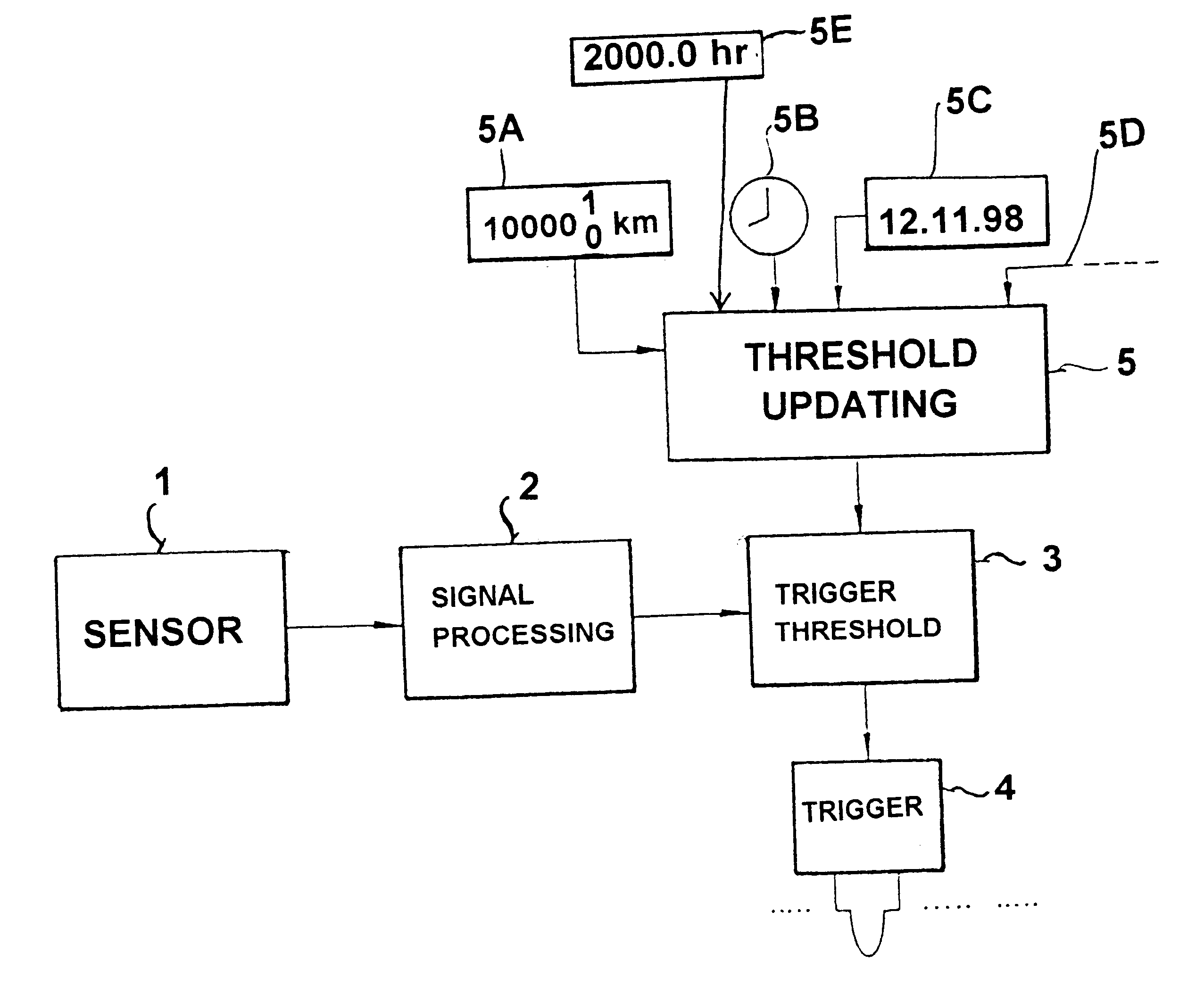

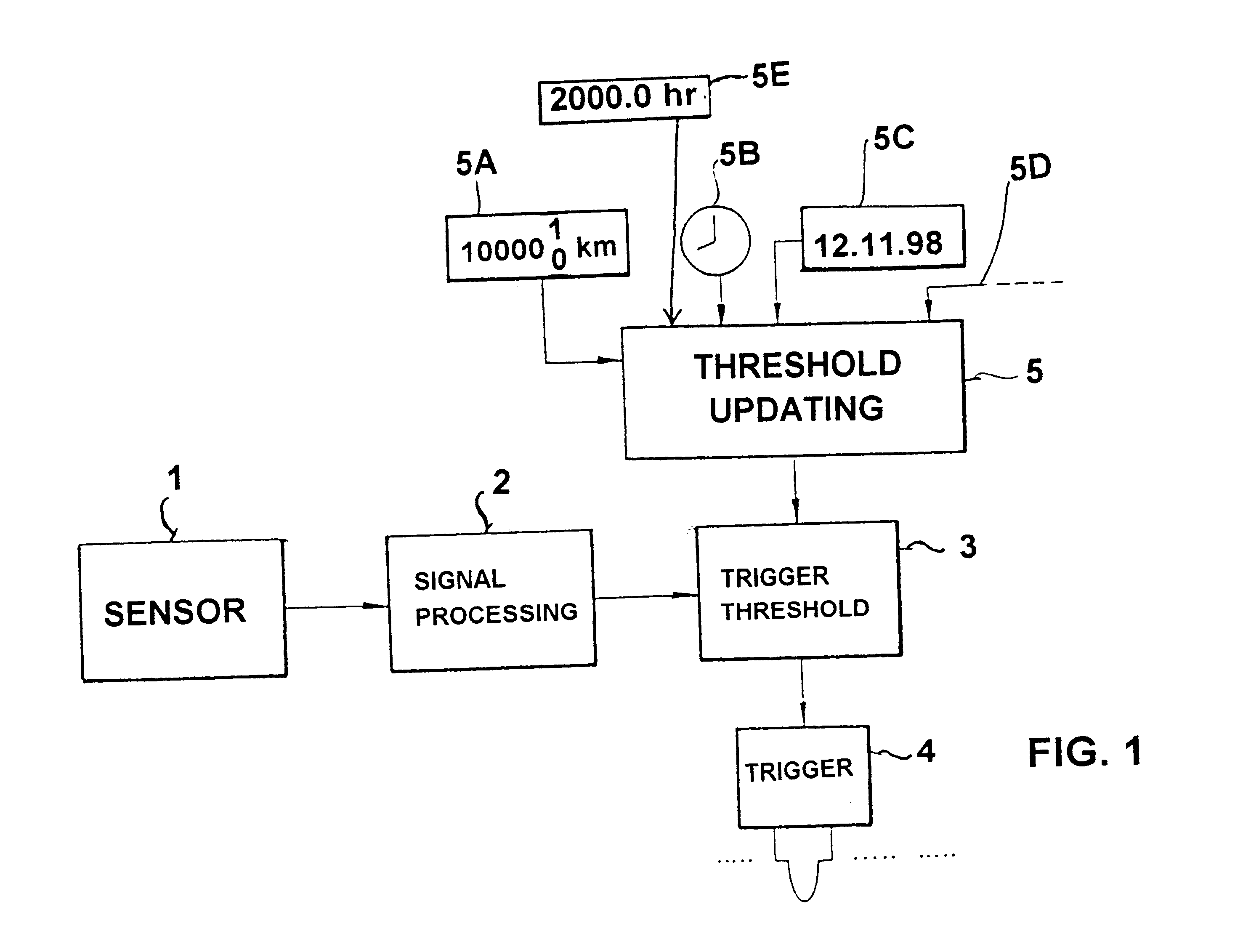

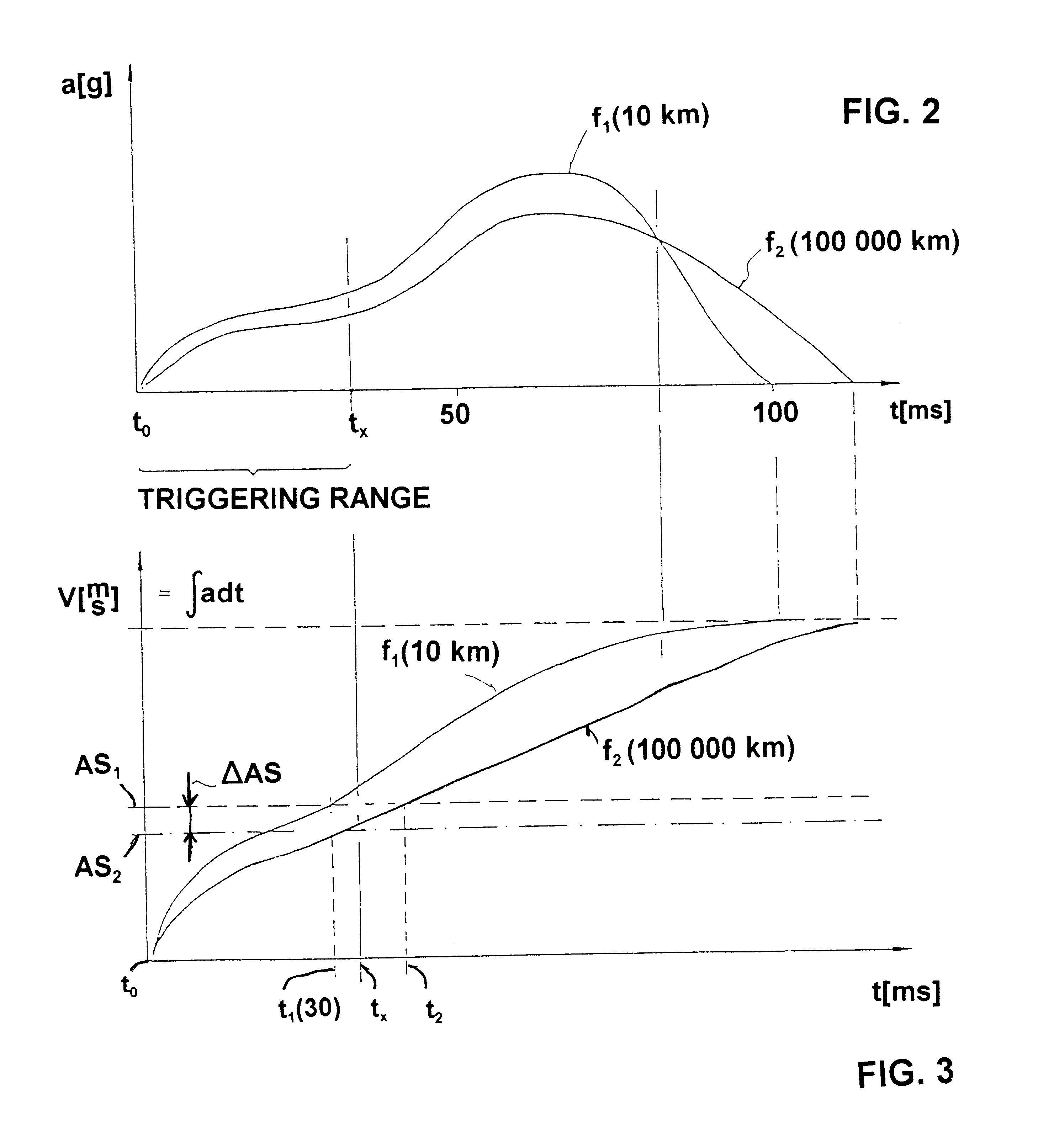

Method of updating the trigger threshold of a passive safety system

InactiveUS6312013B1Improve securityImprove reliabilityDigital data processing detailsPedestrian/occupant safety arrangementMobile vehicleAirbag deployment

In a method of operating a passive safety system, such as an airbag supplemental restraint system in a motor vehicle, the trigger threshold value for triggering the deployment of the airbag or the like is updated or changed over time as the vehicle deteriorates with age or operation. As a result of material fatigue, rust and the like, the vehicle chassis becomes less stiff with increased age and / or increased operation. Consequently, the crash behavior of a deteriorated vehicle differs from that of a new vehicle of the same type. Namely, the deceleration during a crash will be less abrupt. To achieve reliable, consistent and timely triggering of the airbag regardless of advancing deterioration of the vehicle, the trigger threshold value is reduced by pre-determined correction values responsive to an increase of one or more degradation-related parameters, such as the age of the vehicle as indicated by a clock, the cumulative operating time of the vehicle as indicated by an operating hour meter, and / or the cumulative distance traveled by the vehicle as indicated by an odometer.

Owner:DAIMLER AG

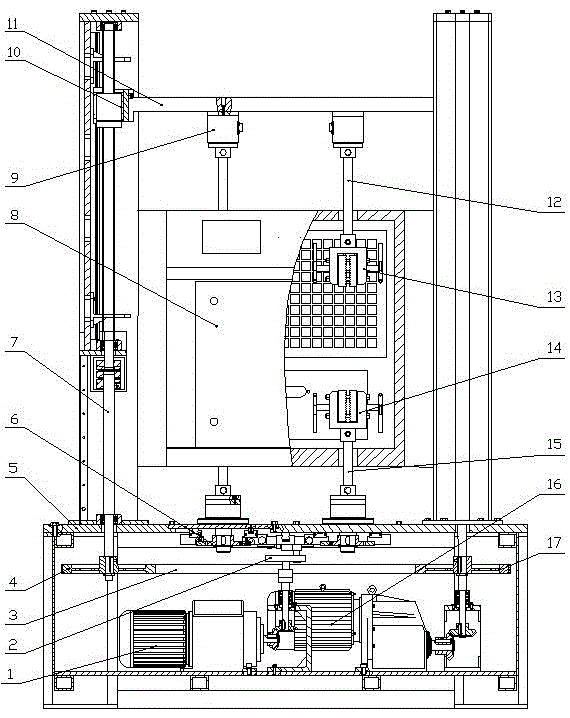

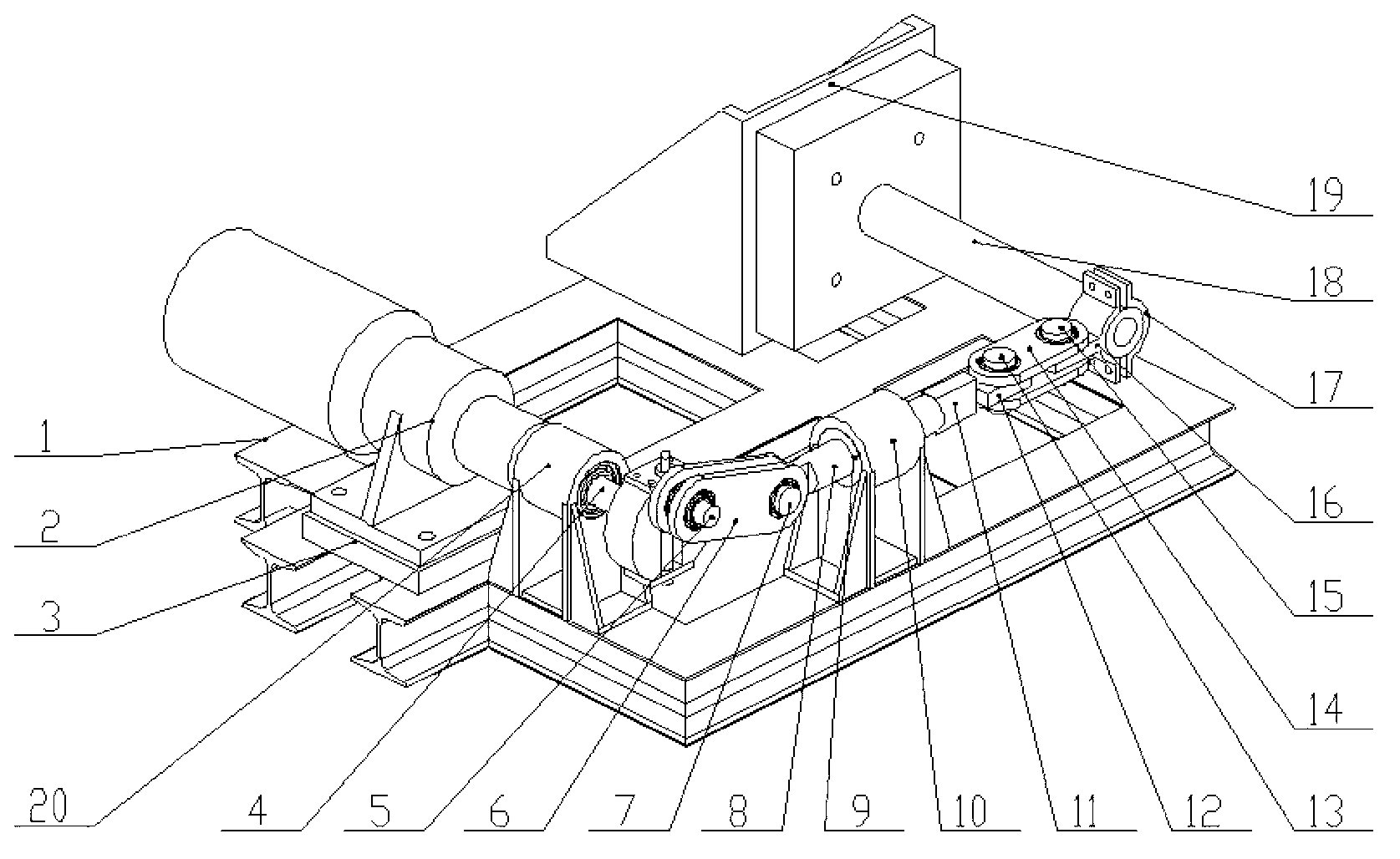

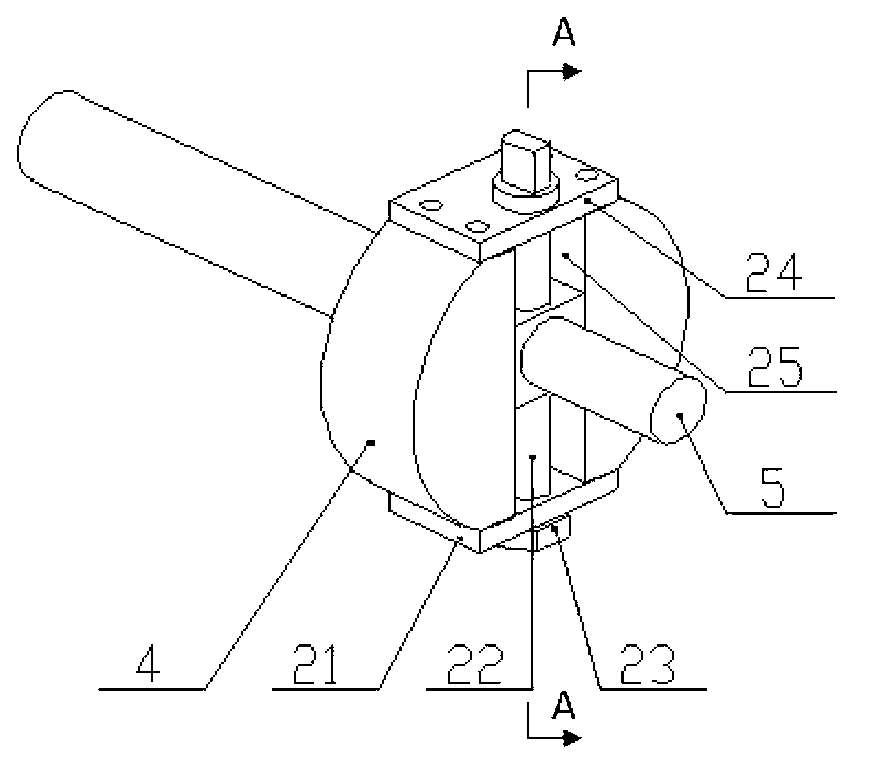

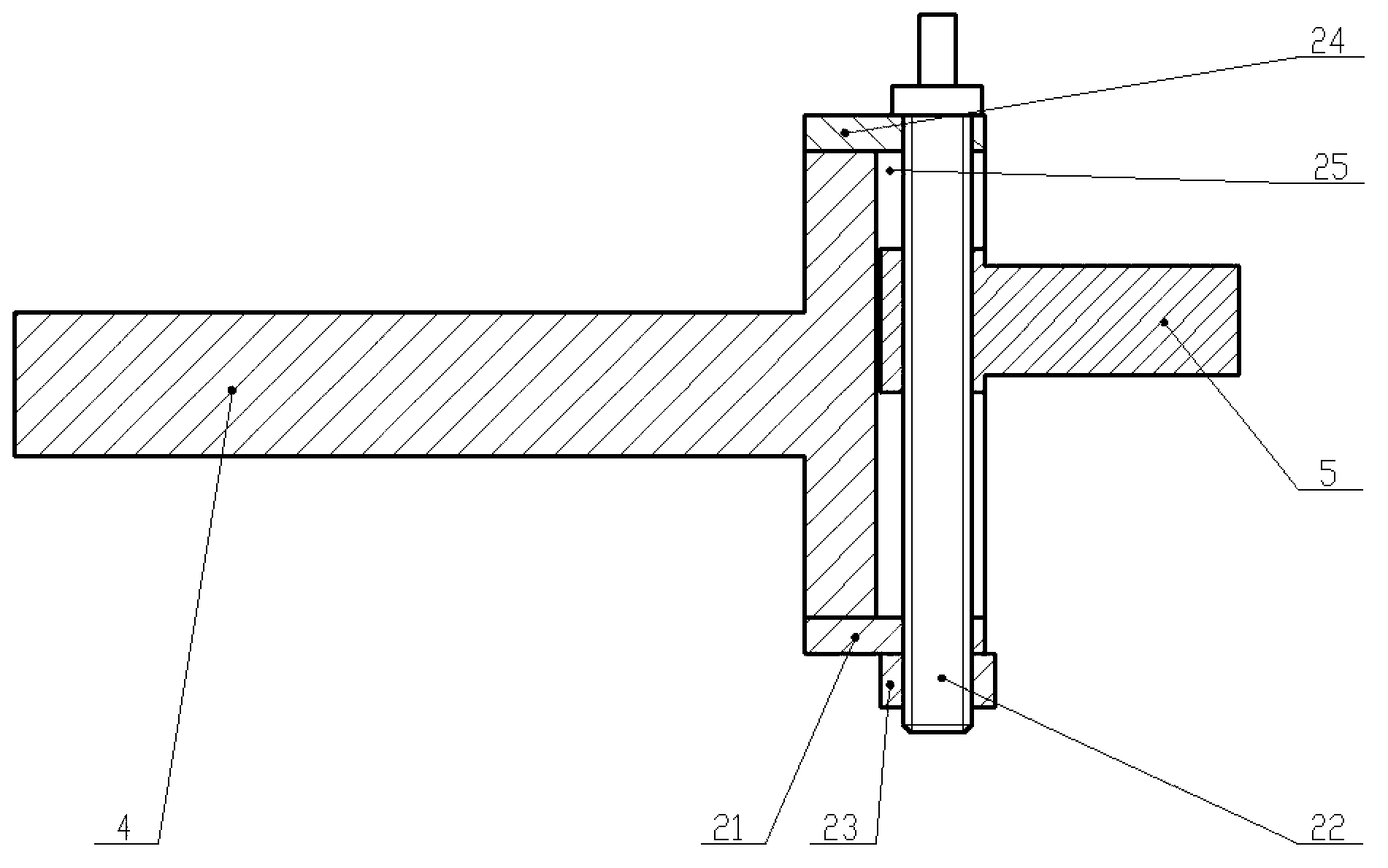

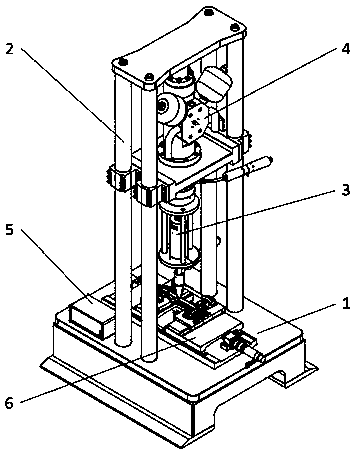

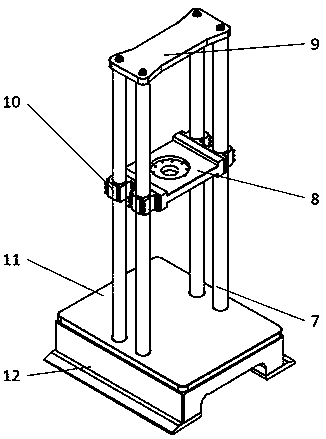

Rubber material tension-torsional fatigue combined testing machine

ActiveCN105486594AImplement twist testTrue reflection of actual performanceMaterial strength using tensile/compressive forcesMaterial fatigueHinge joint

The invention discloses a rubber material fatigue performance detection device, and specifically discloses a rubber material tension-torsional fatigue combined testing machine. The rubber material tension-torsional fatigue combined testing machine comprises an installing support; a stretch motor, a torsion motor, lifting guide rails, and a stretch screw rod are arranged in the installing support; each lifting guide rail is provided with a lifting slide seat; a driving cross beam is arranged between the lifting slide seats; an upper clamping head is arranged on the driving cross beam; the stretch screw rod is connected with the stretch motor and the driving cross beam; a transmission shaft is arranged on the lower part of the installing support; a lower clamping head is arranged on the upper end of the transmission shaft; a torsion driving gear is arranged on the lower side of the transmission shaft; a driving gear rack engaging with the torsion driving gear is arranged on the side part of the torsion driving gear; the torsion motor is provided with a crank rotary table; the crank rotary table is connected with one end of a connecting rod via hinge joint; the connecting rod is connected a reciprocating connection block connected with the driving gear rack with via hinge joint; and a tension-torsion compound strength sensor is arranged between the upper clamping head and the driving cross beam. The rubber material tension-torsional fatigue combined testing machine is simple in structure, is convenient to use, and can be used for real simulation of working environment and working mode of rubber parts; and measured data is accurate, and can be used for real reflecting of part practical performance.

Owner:王友善

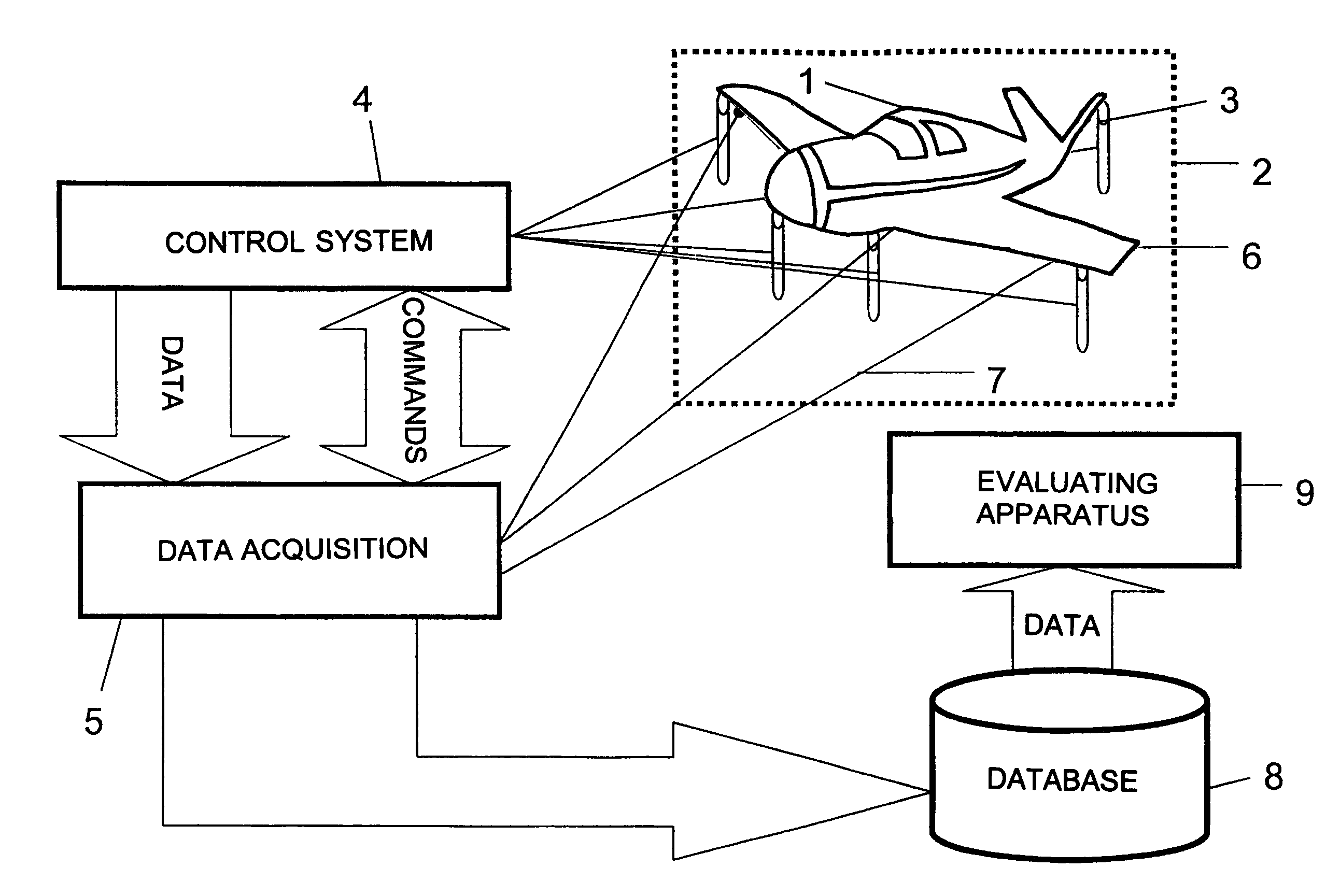

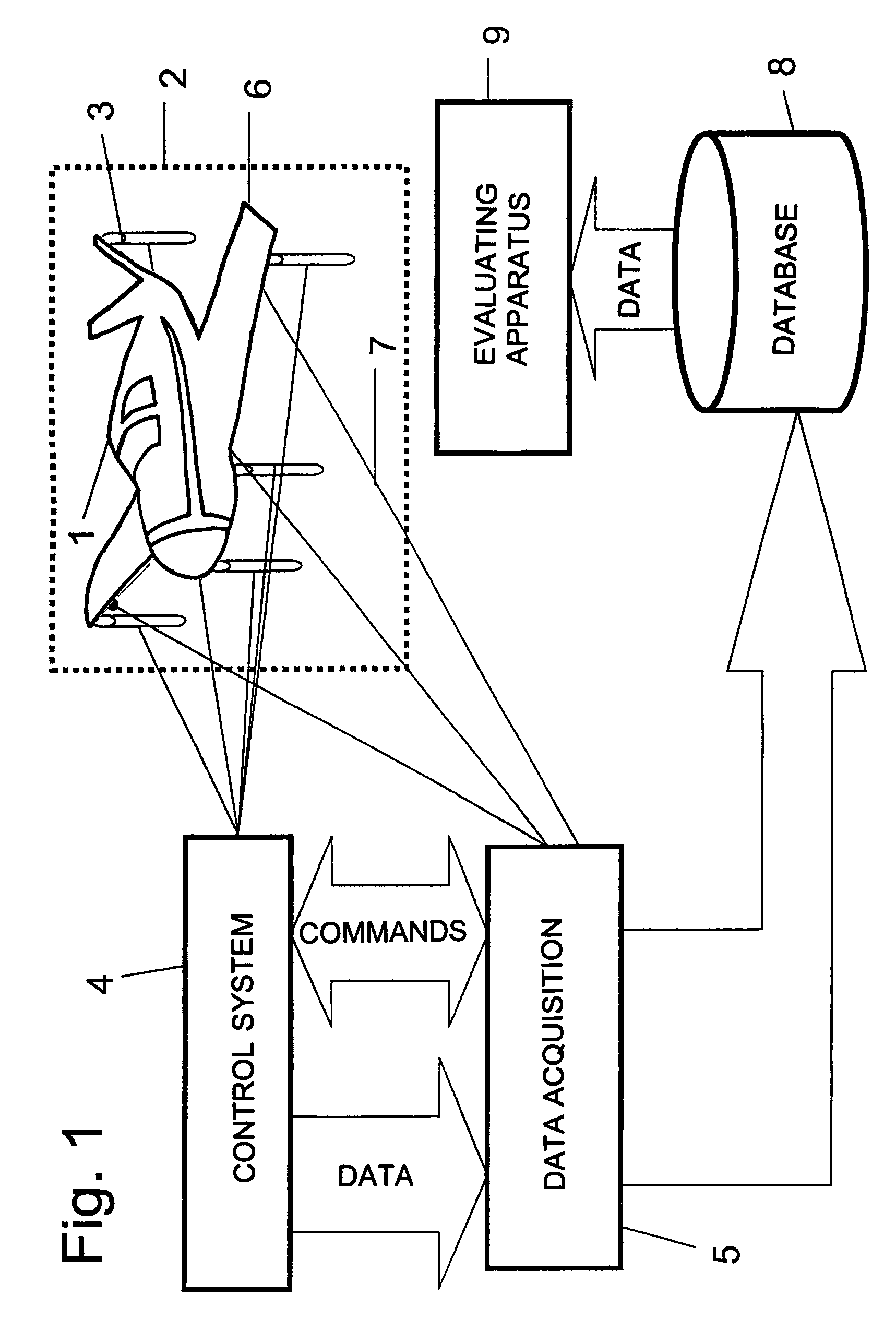

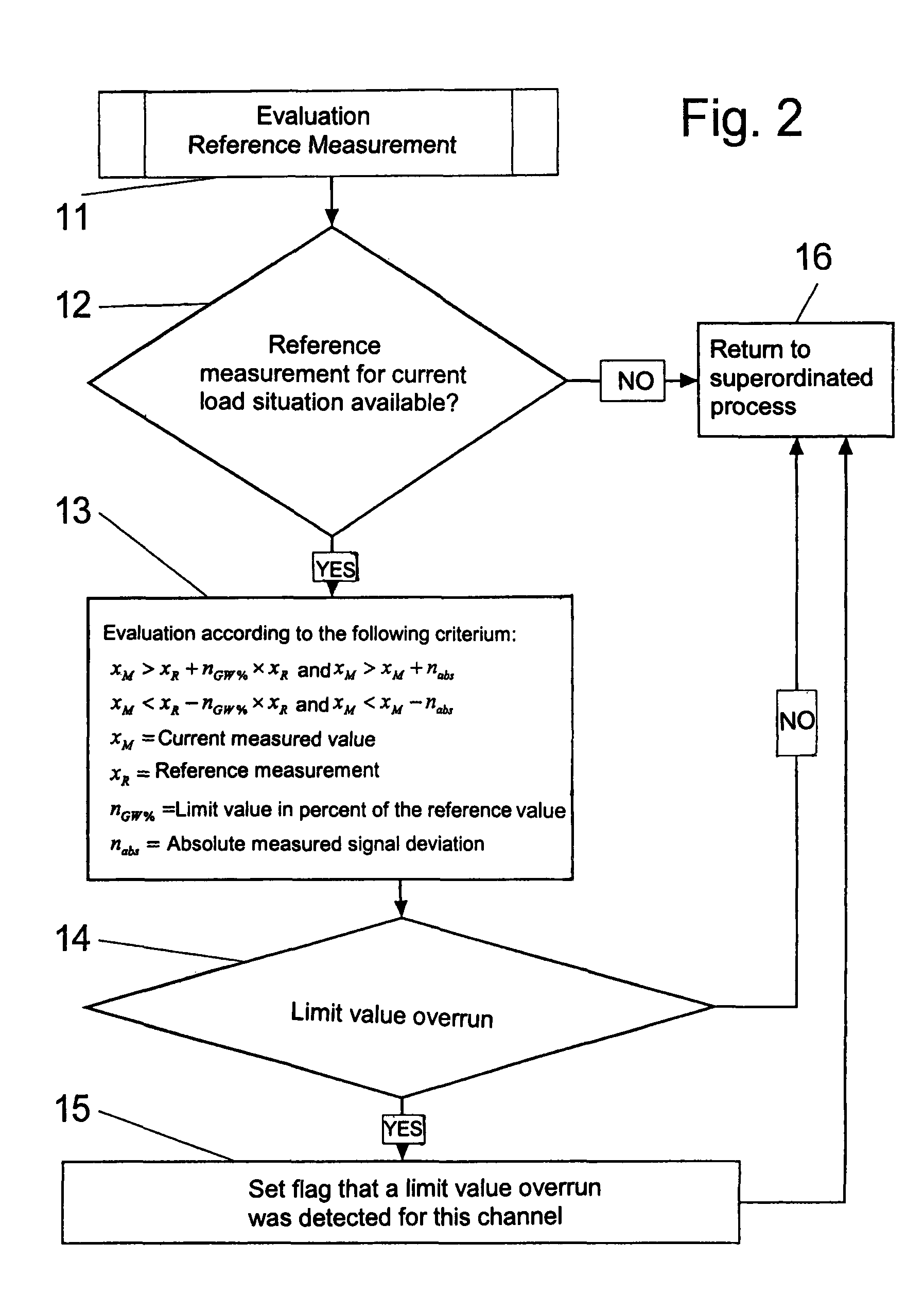

Method for evaluating measured values for identifying a material fatigue

InactiveUS7930112B2The process is fast and accurateAdvantageouslyPlug gaugesForce measurementEngineeringLimit value

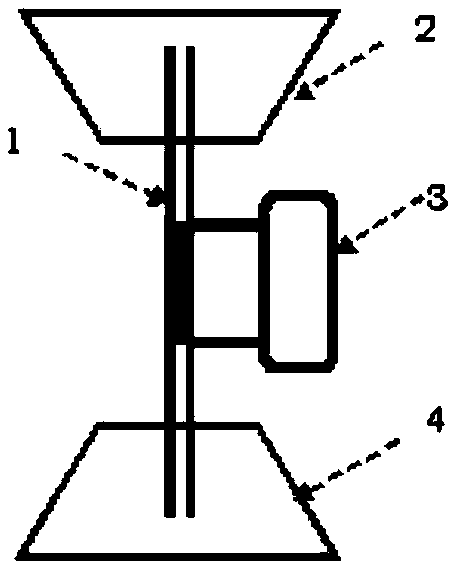

In a method of evaluating measured values for recognizing defect conditions due to material fatigue on aircraft parts, strain sensors (6) are applied on the critical locations of an aircraft (1) and measured values of outputs of the strain sensors are detected at different loading conditions, amplified and stored through several measuring circuits. An evaluating apparatus (9) derives, signals or indicates a material fatigue by comparison of current measured values with previous measured values. The critical aircraft parts (1) are impinged on with prescribed loading conditions by loading elements (3). The strain effect caused thereby is detected by measuring circuits. The evaluating apparatus (9) forms, for at least each loading condition and each measuring circuit, an allocated reference value and a permissible limit value range. If current measured values exceed the limit value range, this represents a material fatigue manifestation.

Owner:HOTTINGER BRUEL & KJAER GMBH

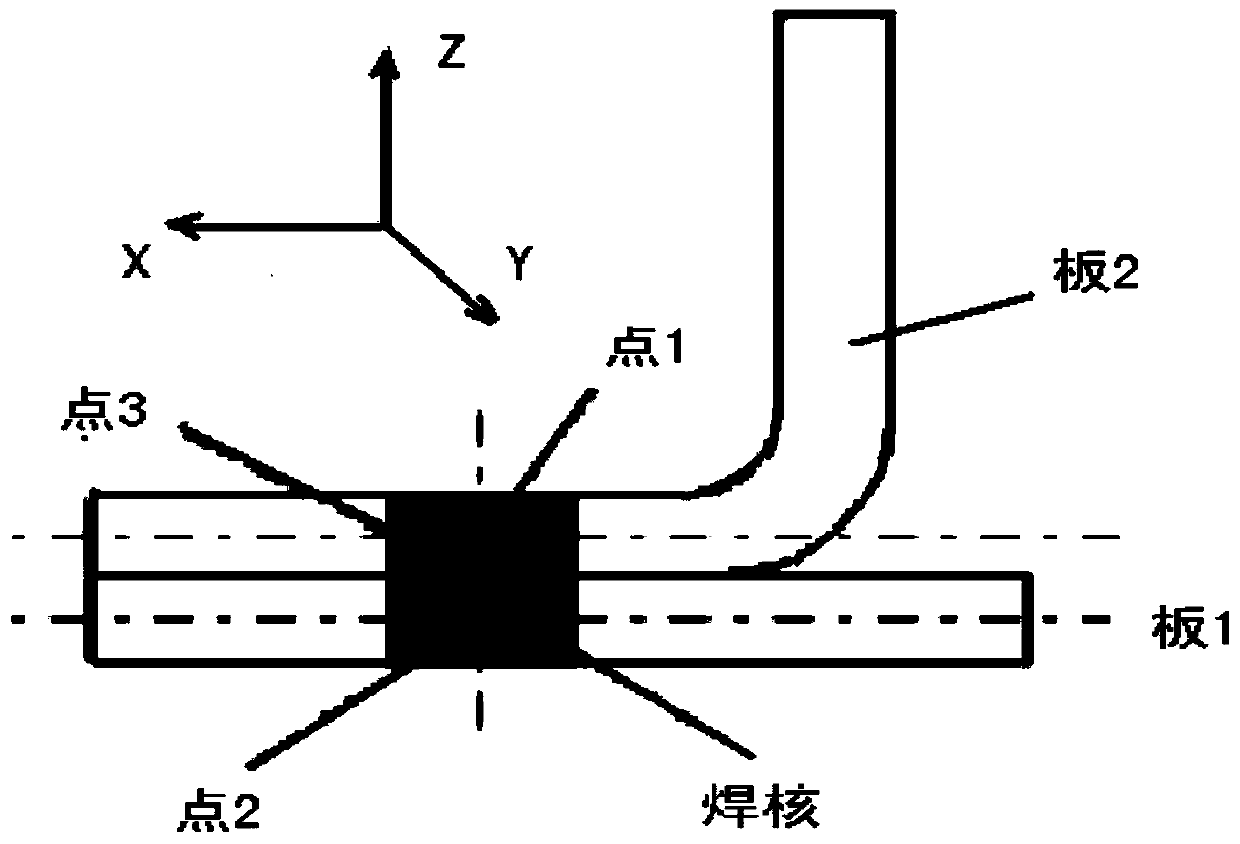

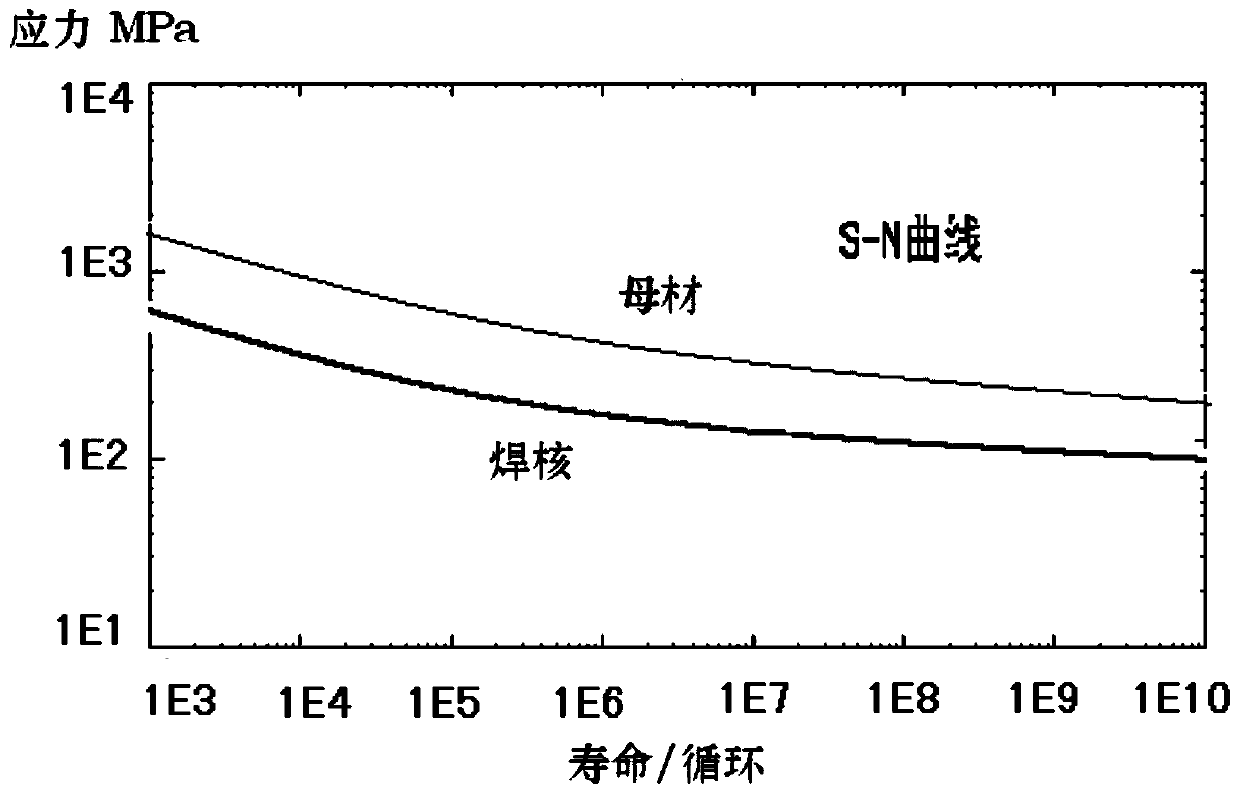

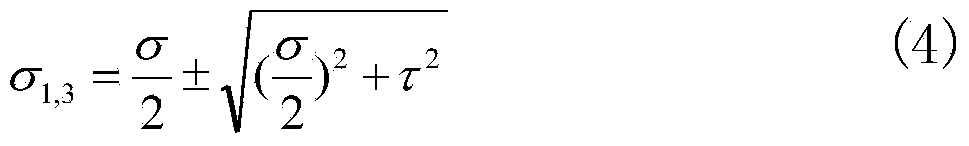

Method for calculating and analyzing fatigue life of airplane structure welding spots

InactiveCN103995919AHigh fatigueReduce manufacturing costSpecial data processing applicationsFatigue damagePrincipal stress

The invention belongs to the field of calculation and analysis of fatigue life of an airplane structure, and relates to a method for calculating and analyzing fatigue life of airplane structure welding spots. The method is characterized in including the following steps that structure stress of a weld nugget is calculated by means of an equivalent stiffening bar unit simulating the weld nugget, and principal stress with the largest absolute value serves as a damage parameter; by means of material fratigue performance tests, an S-N curve of the weld nugget and a parent material is obtained; the effective stress course of each calculation point is calculated through a quasi-steady-state solution, a stress spectrum is determined, fatigue damage is calculated in a damage accumulation method, and distribution situations of damage and service life of all weld spots are obtained. The method has the advantages that the fatigue life of the weld points can be predicted through calculation in the initial stage of design by putting forward to a weld spot fatigue life calculation model and an analysis method suitable for engineering application, the distribution situations of the weld spots of a whole structure are known, and the number and the distribution mode of the weld spots in the actual process can be guided to be reasonably adjusted.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

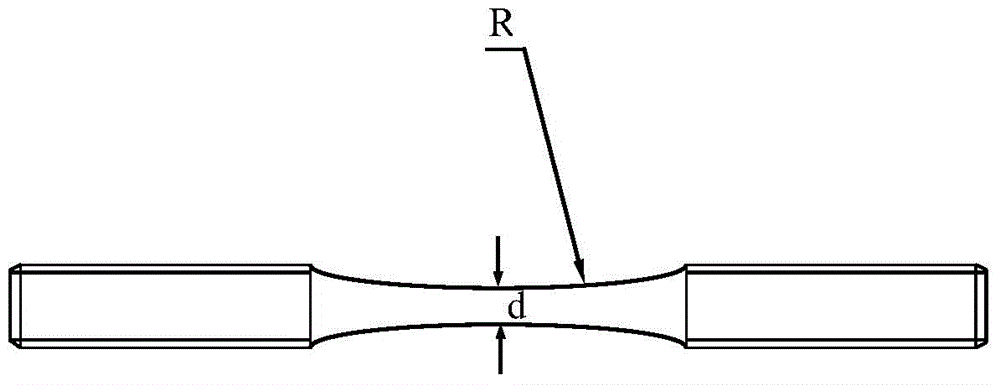

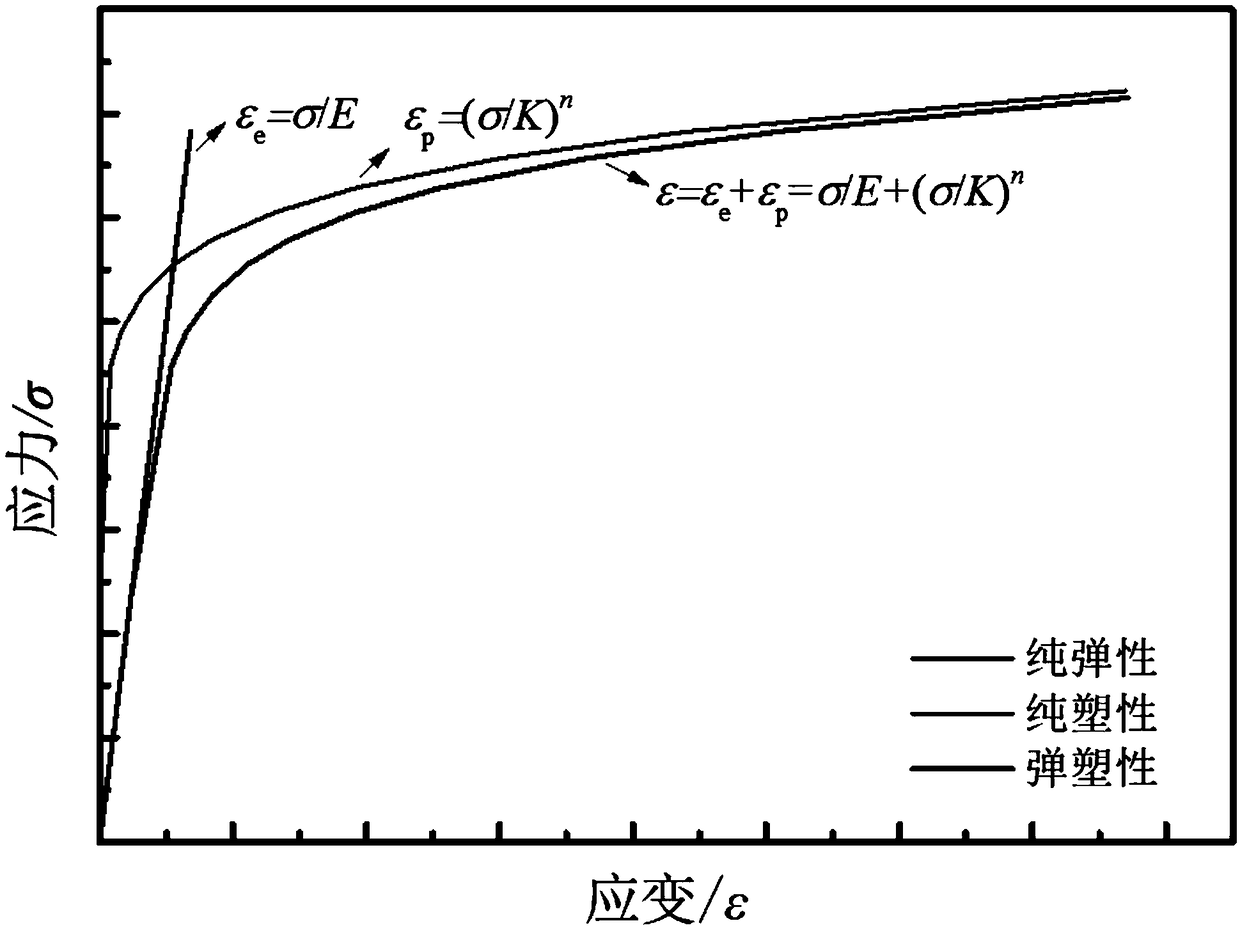

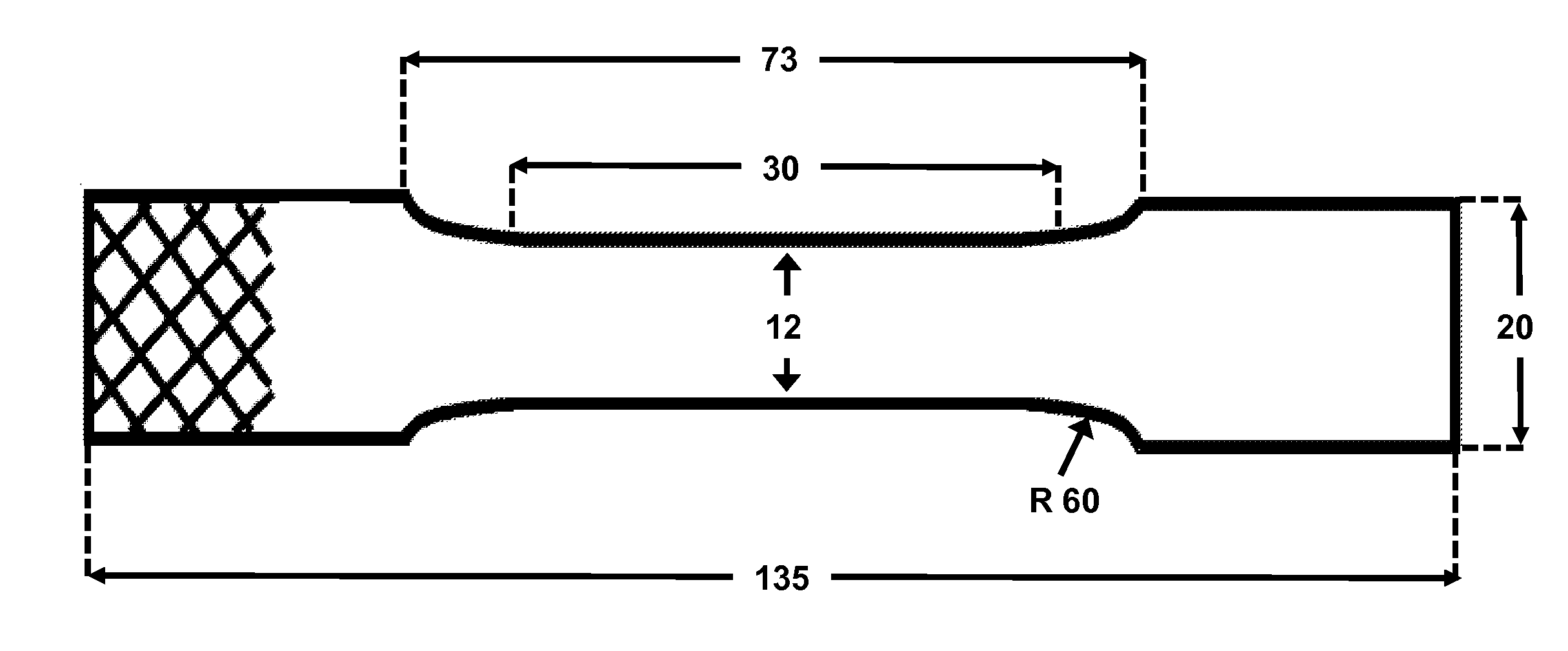

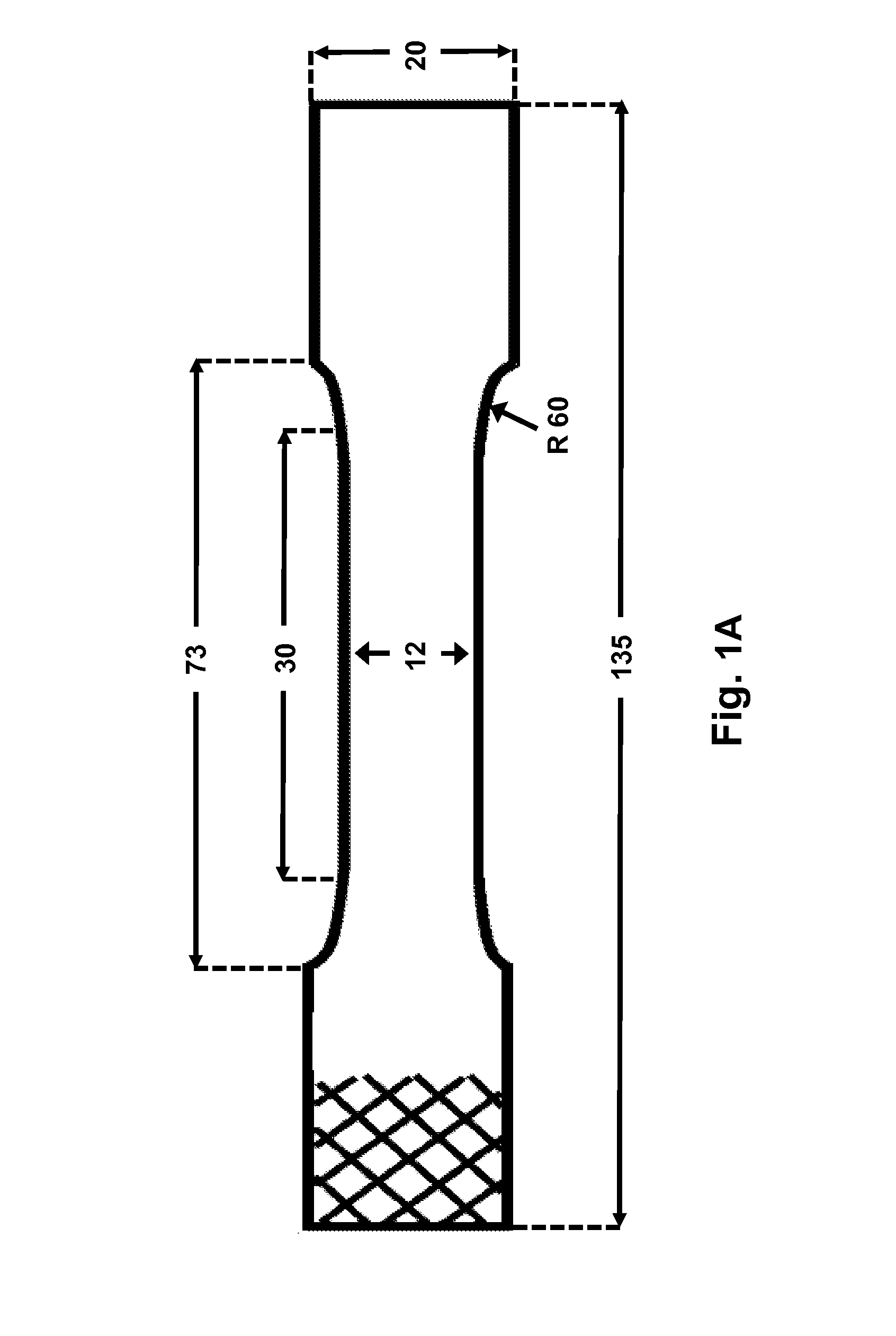

Material fatigue performance obtaining method for sheet sample

ActiveCN108693055AOvercome size limitationsMaterial strength using repeated/pulsating forcesHysteresisRamberg osgood

The invention discloses a material fatigue performance obtaining method for a sheet sample, which comprises the following steps: step 1: completing a tension-pressure symmetric cyclic loading test ofa multi-stage strain amplitude for the sheet sample under strain control to obtain a cyclic stable load-displacement curve; step 2: connecting load-displacement curve hysteresis loop tips as the cyclic load-displacement curve, and predicting a cyclic stress-strain relationship in accordance with a Ramberg-Osgood constitutive model with a cyclic load-displacement relationship; step 3: establishinga relationship between a true strain amplitude epsilon r, a stress amplitude sigma r and a measured and controlled strain amplitude epsilon eq of a fatigue source RVE by using the cyclic stress-strainrelationship as a material parameter; step 4: establishing a fatigue life estimation model according to epsilon r and sigma r to obtain the fatigue property of the material. According to the materialfatigue performance obtaining method, the material dimension limitations of the traditional fatigue performance test method are overcome, and the method does not rely on empirical formulas, and is applied to different materials and sample configurations.

Owner:SOUTHWEST JIAOTONG UNIV

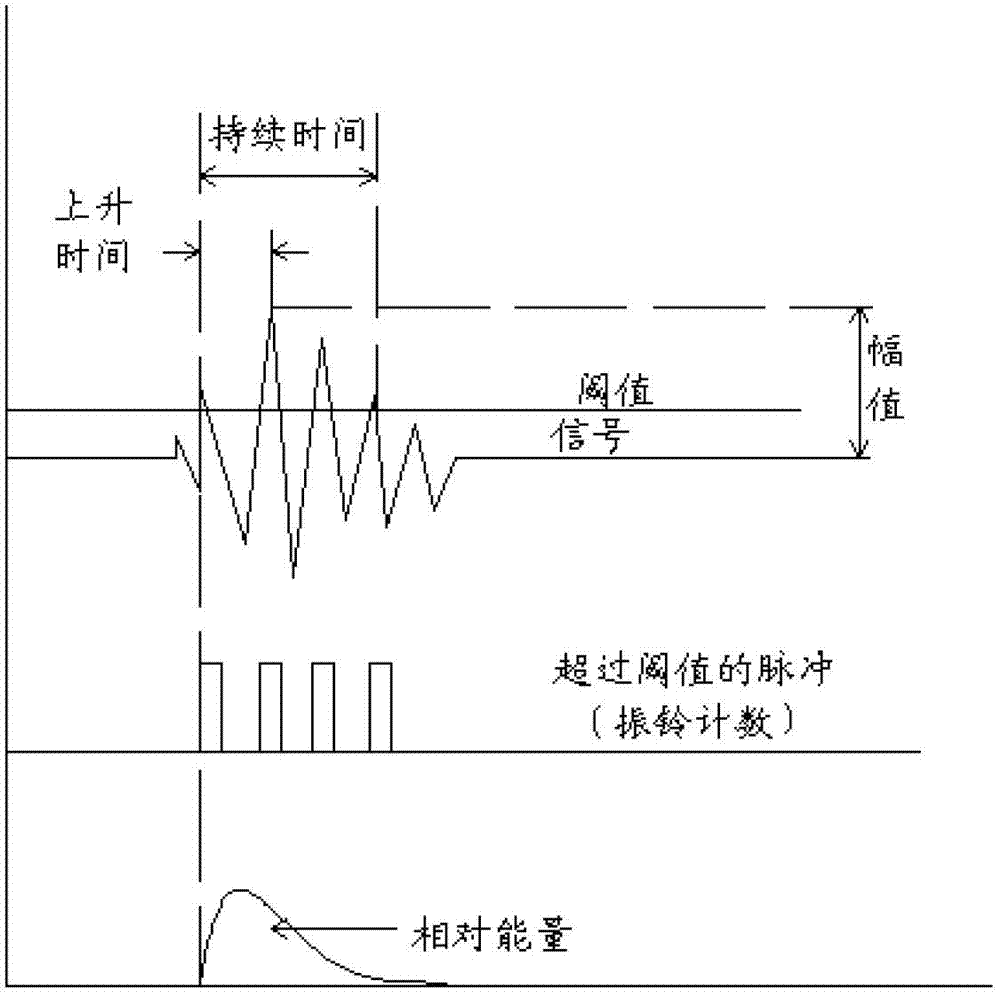

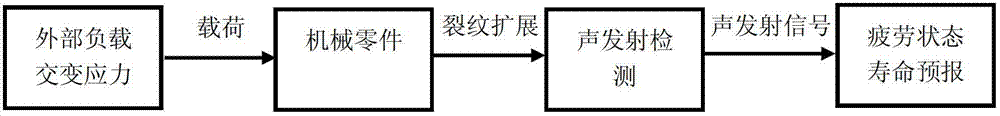

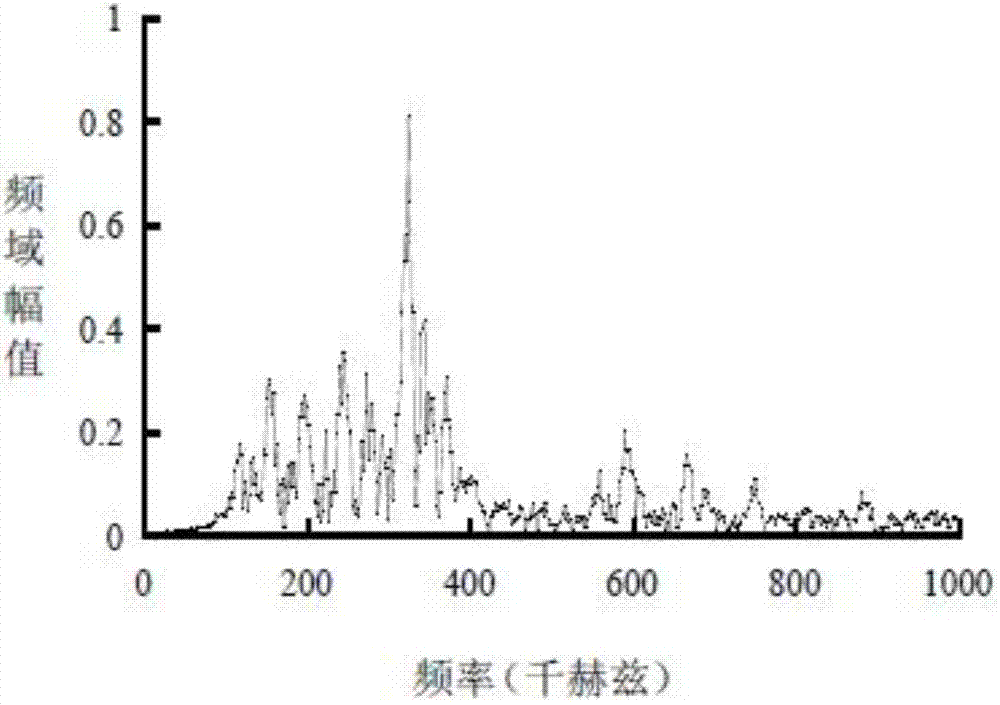

Method and system used for detecting metal material fatigue state

InactiveCN102854252AGuarantee personal safetyLow costMaterial analysis using acoustic emission techniquesAcoustic emissionEngineering

The invention provides a method and a system used for detecting a metal material fatigue state. According to the invention, an acoustic emission sensor is adopted; acoustic emission voltage signals released by fatigue metal material are acquired; acquired acoustic emission energy signals are converted into energy accumulation within a specific frequency range; a fatigue state is converted according to the energy accumulation within the specific frequency range; and service life forecast is obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

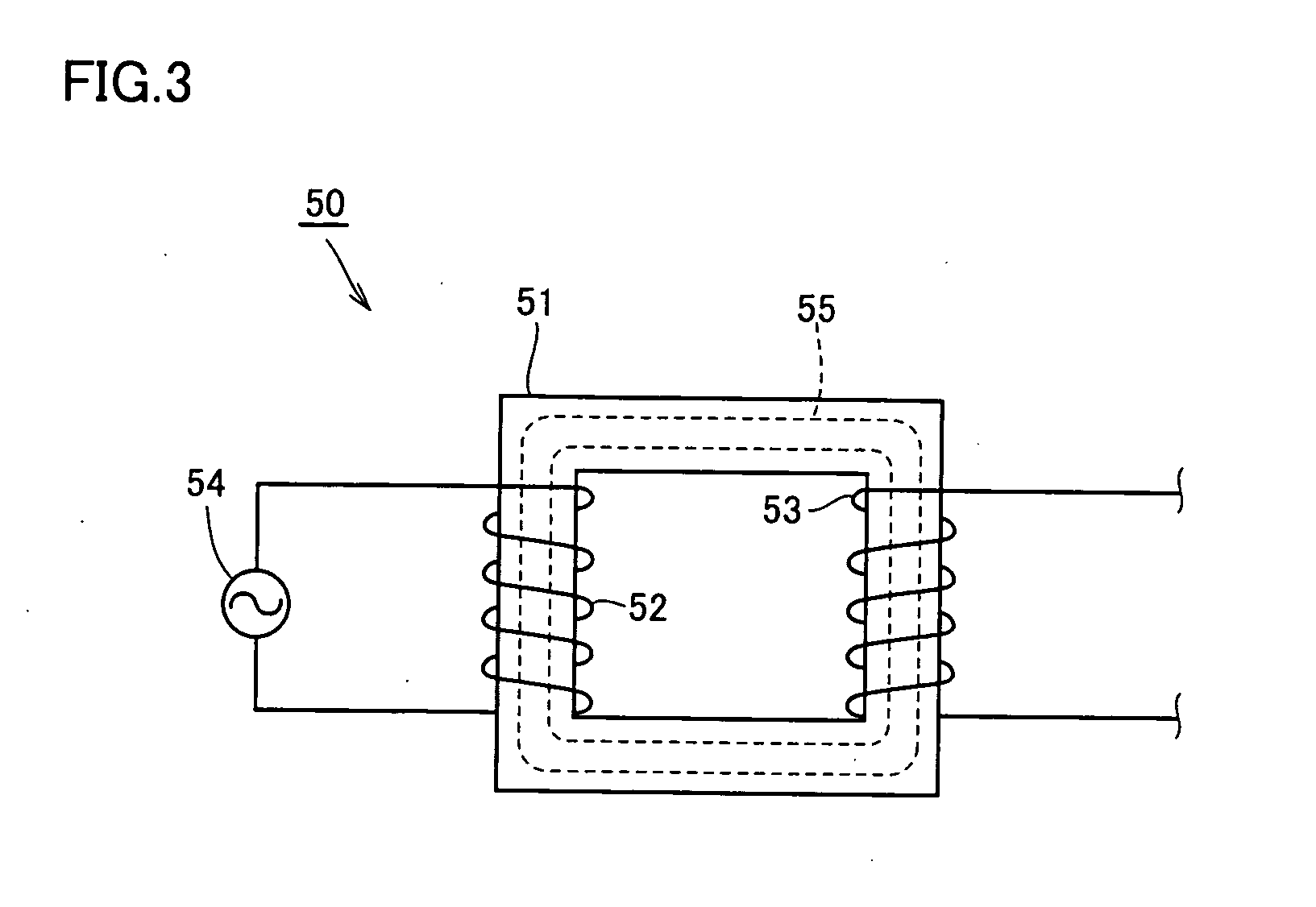

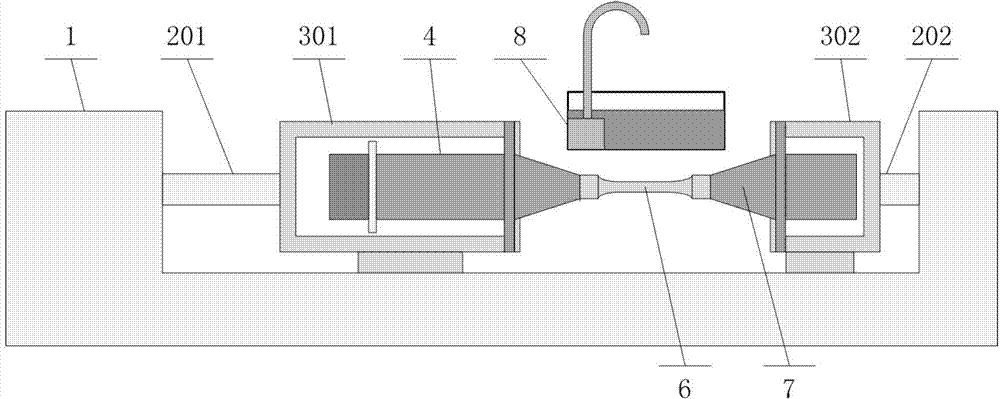

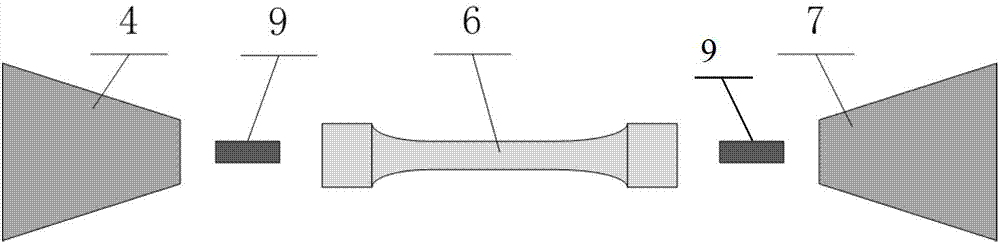

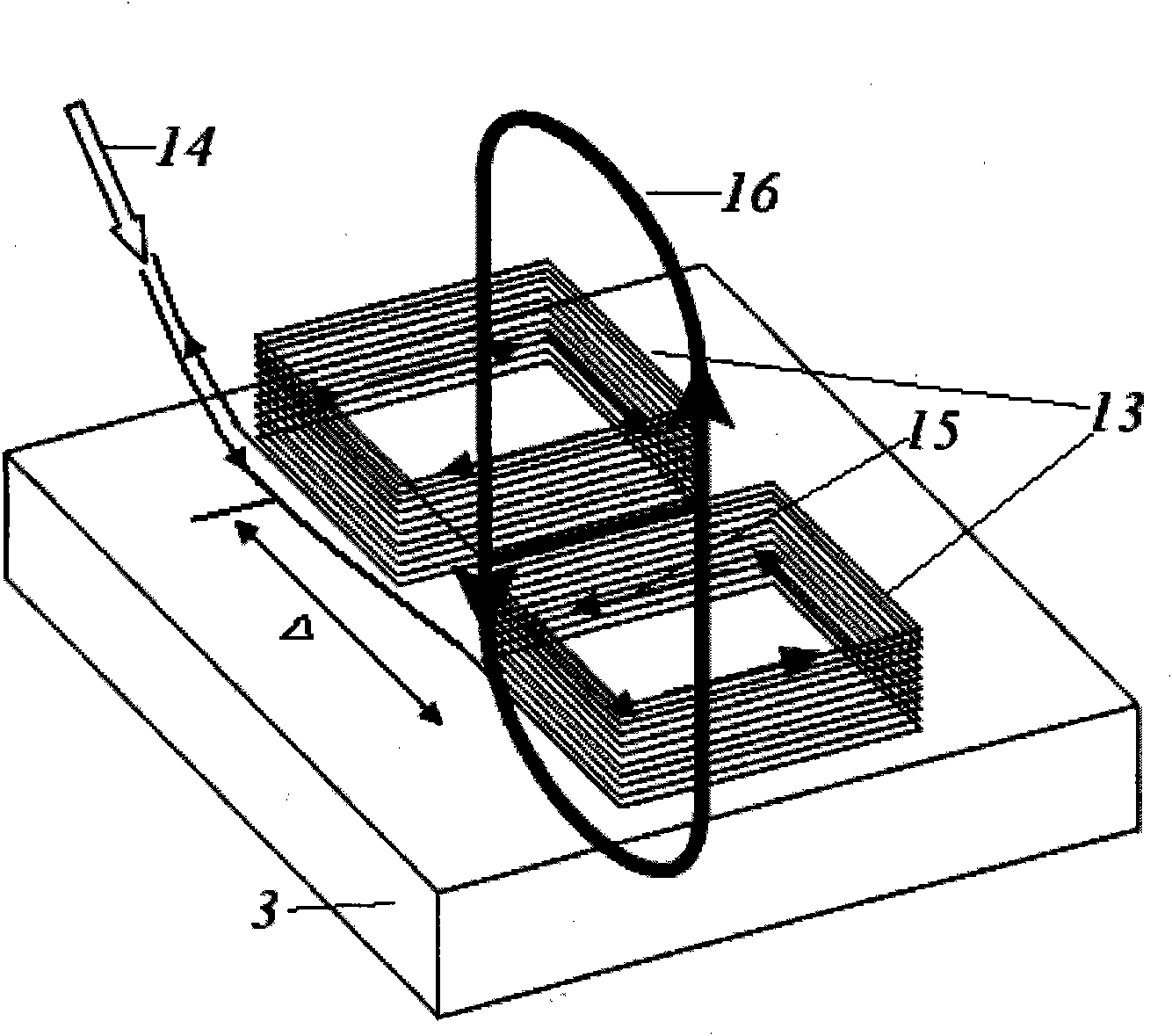

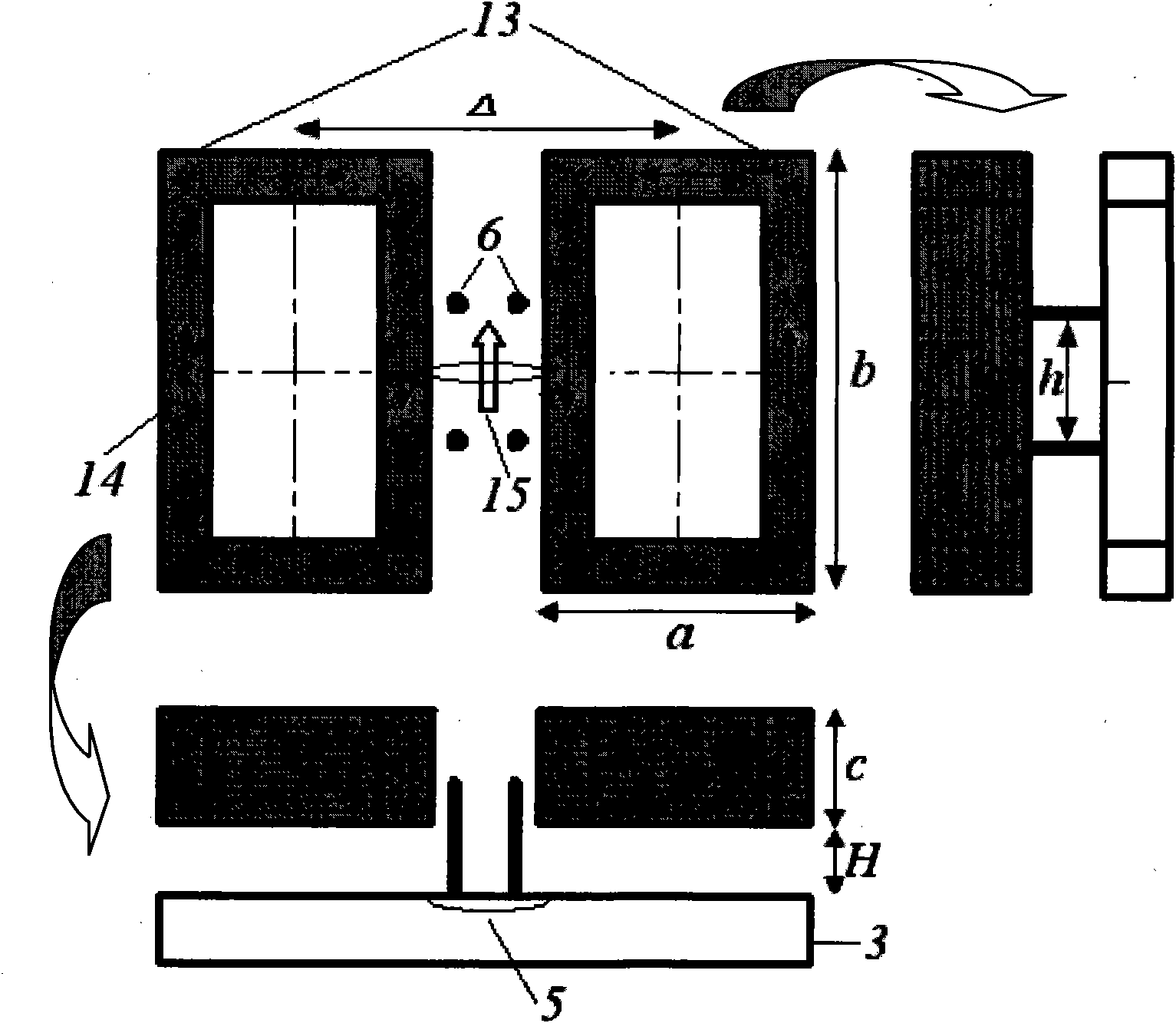

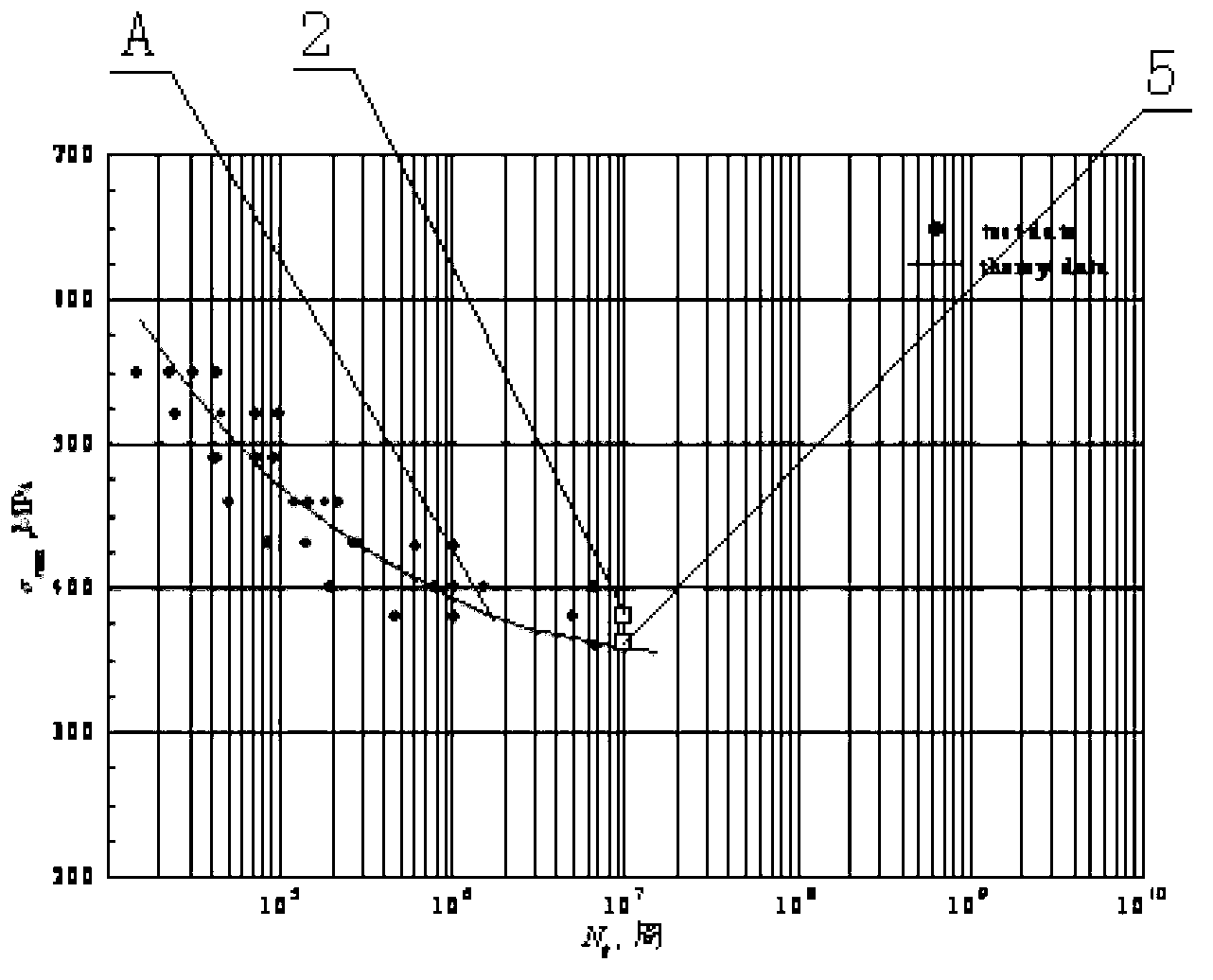

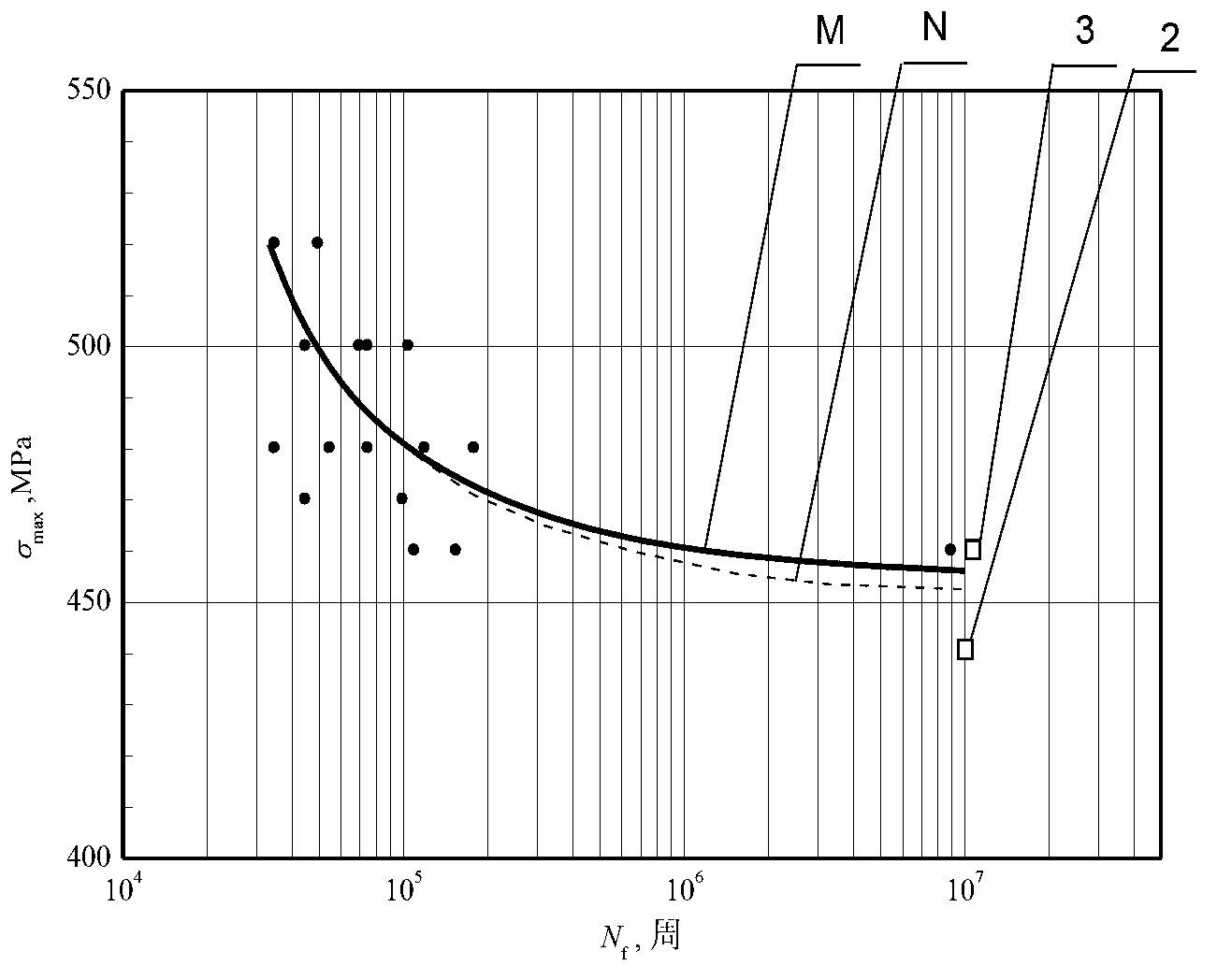

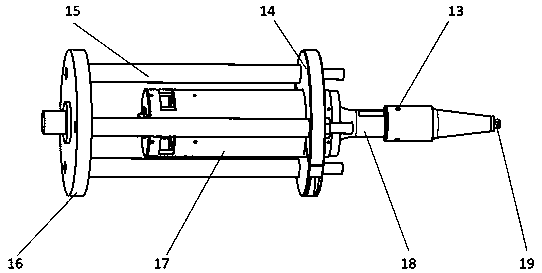

Sub-ultrasonic high-frequency fatigue testing machine

ActiveCN103091184AReduce frequencySmall sizeMaterial strength using repeated/pulsating forcesStress ratioTransformer

The invention discloses a sub-ultrasonic high-frequency fatigue testing machine. An energy converter used as a driving force source, the energy converter, a tested sample and a driven amplitude transformer form a resonance system, and a prearranged static loading mechanism provides static load for a test piece. The energy converter can be a full-wavelength energy converter or a half-wavelength energy converter. The energy converter converts an electric signal into mechanical vibration under the driving of an external alternating voltage, so the whole system is in a resonance state, and the tested sample has resonance vibration and a stress, thereby the fatigue detection can be realized. The energy converter can be a piezoelectric energy converter or a giant magnetostrictive energy converter. The sub-ultrasonic high-frequency fatigue testing machine allows the sub-ultrasonic high-frequency fatigue tests of the test piece under different stress ratios to be carried out according to the system prearrangement state; compared with traditional high-frequency fatigue testing machines, the sub-ultrasonic high-frequency fatigue testing machine has the advantages of simple structure, small volume, test period shortening, high efficiency and energy saving; and compared with present ultrasonic fatigue testing machines, the sub-ultrasonic high-frequency fatigue testing machine has the advantage of reduction of the frequency effect and the dimension effect to the material fatigue performances.

Owner:天津益普科技发展有限公司

Fatigue Monitoring for Composite Materials

ActiveUS20140067285A1Plug gaugesMaterial strength using repeated/pulsating forcesIrreversible processMaterials science

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

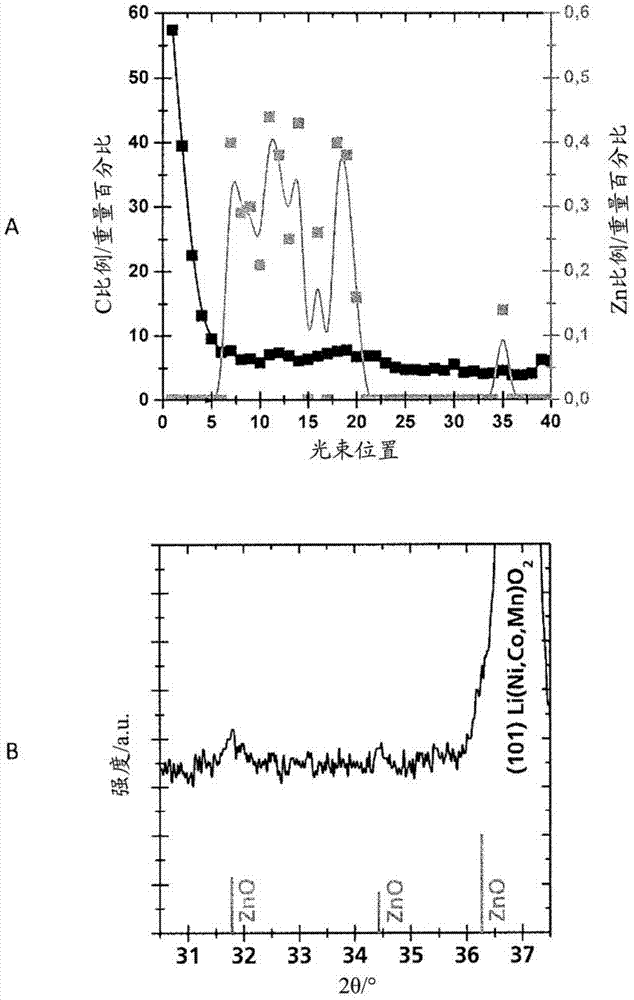

Particulate electrode material having coating made of crystalline inorganic material and/or inorganic-organic hybrid polymer and method for production thereof

InactiveCN104812485AHigh catalytic activityLarge specific surface areaPhysical/chemical process catalystsElectrode thermal treatmentParticulatesHigh energy

The invention relates to a particulate electrode material which has a high energy density, security and durability (stability against degradation and material fatigue). The electrode material is also characterized by having a high electric conductivity and also a high ionic conductivity and as a result reaches very low resistance values. Furthermore, the invention also relates to a method for coating particulate electrode material, according to which the claimed electrode material can be produced. The invention further relates to uses of the claimed electrode material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

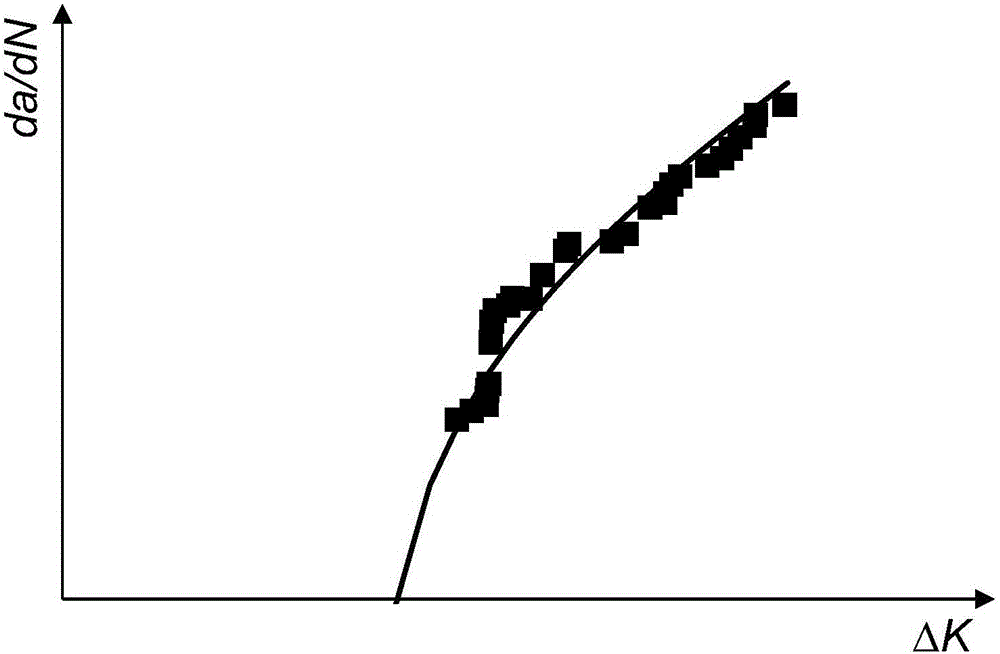

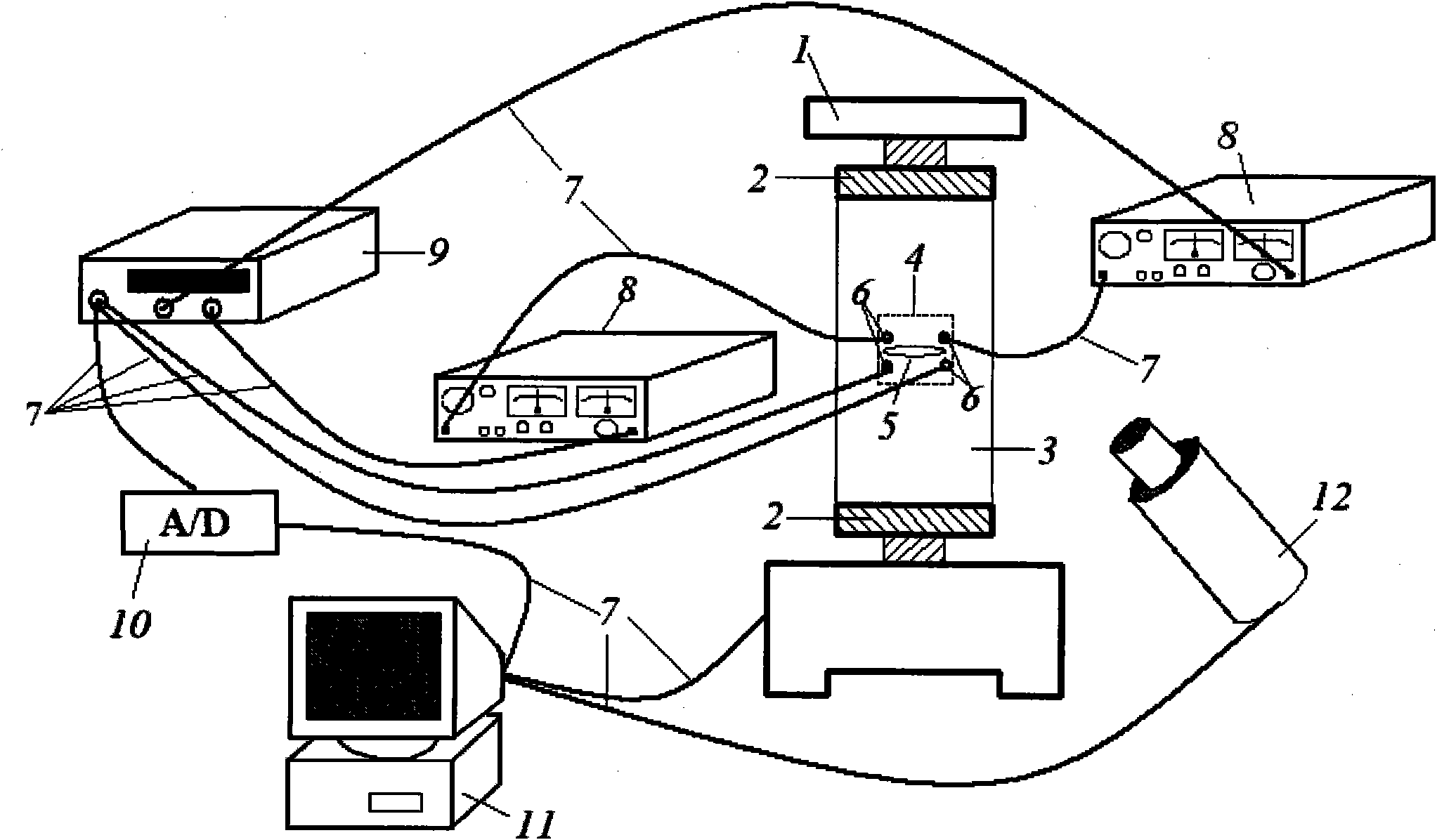

Device and method for reckoning fatigue crack propagation rate of flat alloy by AC potentiometry

InactiveCN101832970AImprove conductivityIsolation of high resistance interferenceMaterial magnetic variablesPotential measurementAlloy

The invention provides a device and a method for reckoning the fatigue crack propagation rate of a flat alloy by AC potentiometry, relating to the field of detecting material fatigue performance. The method comprises the following steps: in the process of a tension-tension fatigue test, two pairs of probes are arranged on the surface of a flat alloy sample, and the sample monitors electric potential change at the two sides of a crack in real time by an AC potentiometry sensor thereon when the fatigue crack propagates; the electric potential change is transmitted to a dual-trace oscilloscope by an amplifier; the dual-trace oscilloscope displays the electric potential oscillogram of the propagation of the two ends of the crack; and the electric potential oscillogram is input to a computer by an A / D converter, and is analyzed by a bundled software to obtain fatigue propagation rate such as the fatigue crack propagation rate and the like. The device of the invention mainly comprises a fatigue-testing machine, sample fixtures, the AC potentiometry sensor, potential measurement probes, lead wires, a signal amplifier, the dual-trace oscilloscope, the A / D converter, a CCD image acquisition system and the computer. The invention is applicable to research on the fatigue crack propagation behavior of the alloy.

Owner:JIANGSU UNIV

Method for processing material fatigue life test data

ActiveCN102798568AReasonable handlingFatigue life underestimationStrength propertiesRational methodMaterials science

The invention belongs to a material fatigue life test technology and relates to a method for processing material fatigue life test data. The method is characterized by comprising the following processing steps of: finding out the fatigue limit of a material; preprocessing the fatigue life data; and finding out an intercept B1 and a slope B2 in a fatigue life curve. The invention provides a quite rational method for processing the material fatigue life test data, thereby avoiding the waste of the data obtained at high cost and underestimation of the fatigue life of the material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Fatigue testing machine for lifetime measurement of cantilever parts

InactiveCN103018032AAccurately determine the number of fatigue cycles to failureNo stuckMachine part testingStructural fatigueReciprocating motion

A fatigue testing machine for lifetime measurement of cantilever parts comprises a base, a motor, an eccentric mechanism, a loading mechanism and a test piece clamping device. Rotation of the motor is converted into variable amplitude constant-amplitude reciprocating motion by the eccentric mechanism and the loading mechanism. The front end and bottom of a cantilever test piece to be tested are fixed by the test piece clamping device, so that the front end of the cantilever test piece is allowed to fatigue by reciprocating swing. The defect that commercially available instruments are not applicable to structural fatigue lifetime measurement of practical cantilever parts but applicable to material fatigue lifetime measurement of standard parts only is overcome, test conditions that existing commercial products cannot achieve can be achieved, serving actual lifetimes of the cantilever parts are predicted more accurately, and more reliable basis for structural design and modeling of the cantilever parts.

Owner:TSINGHUA UNIV

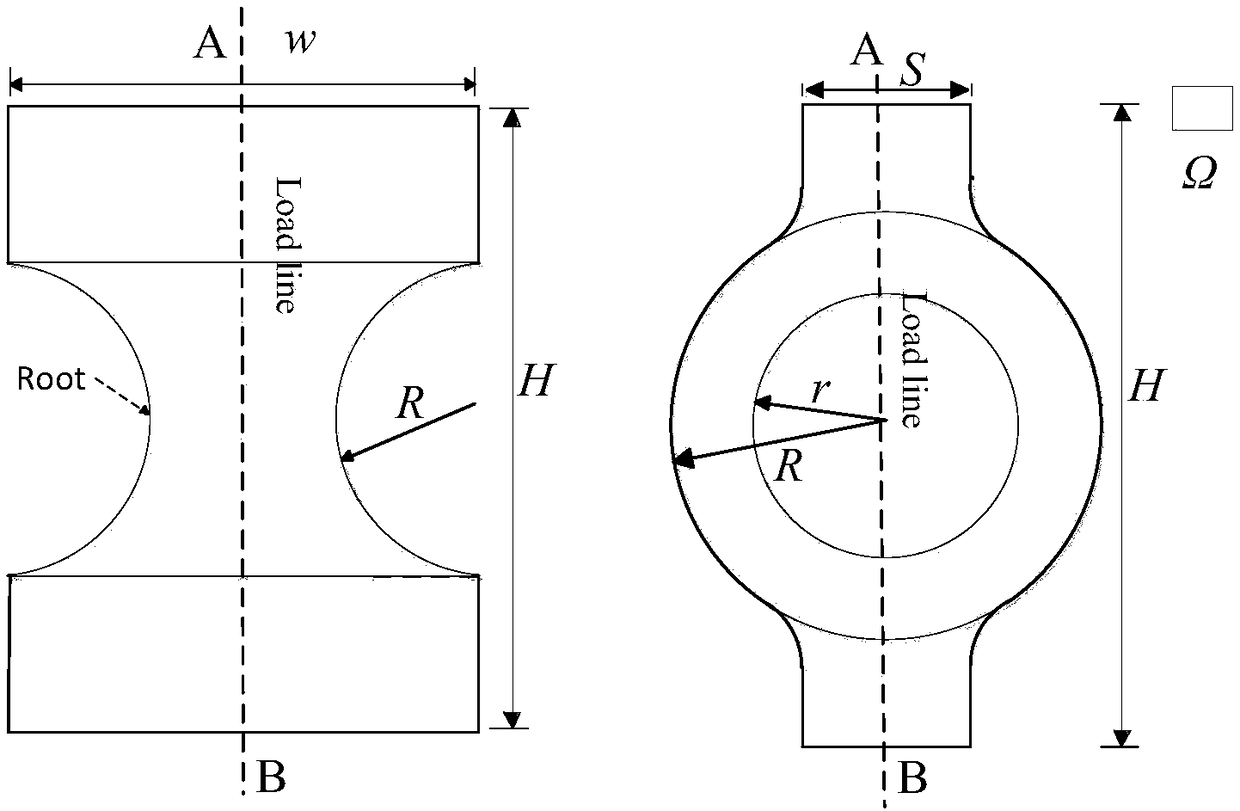

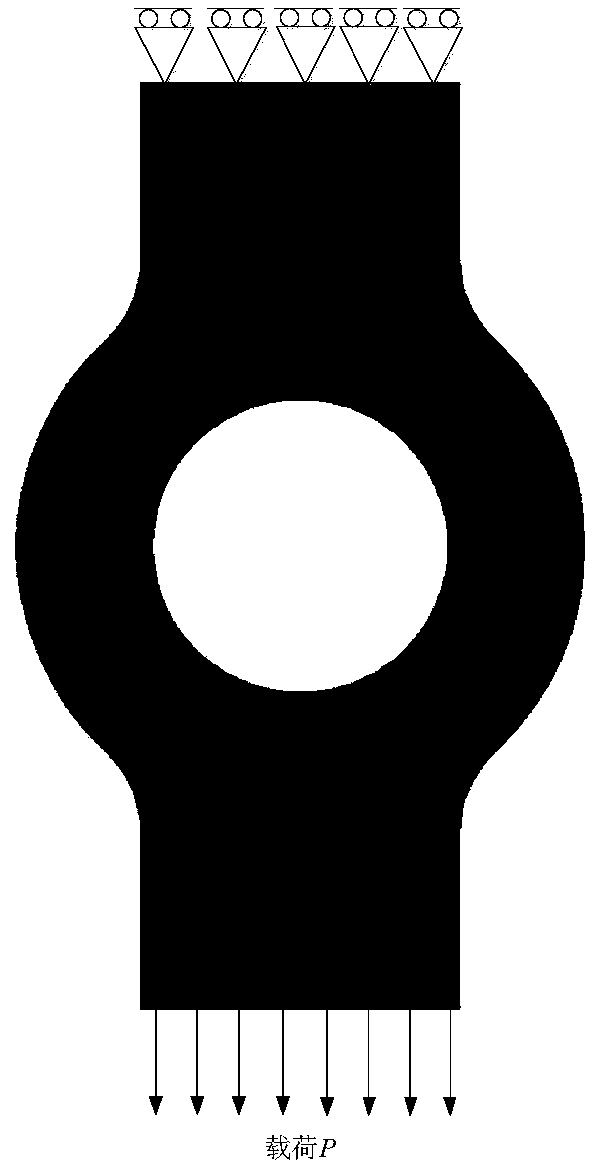

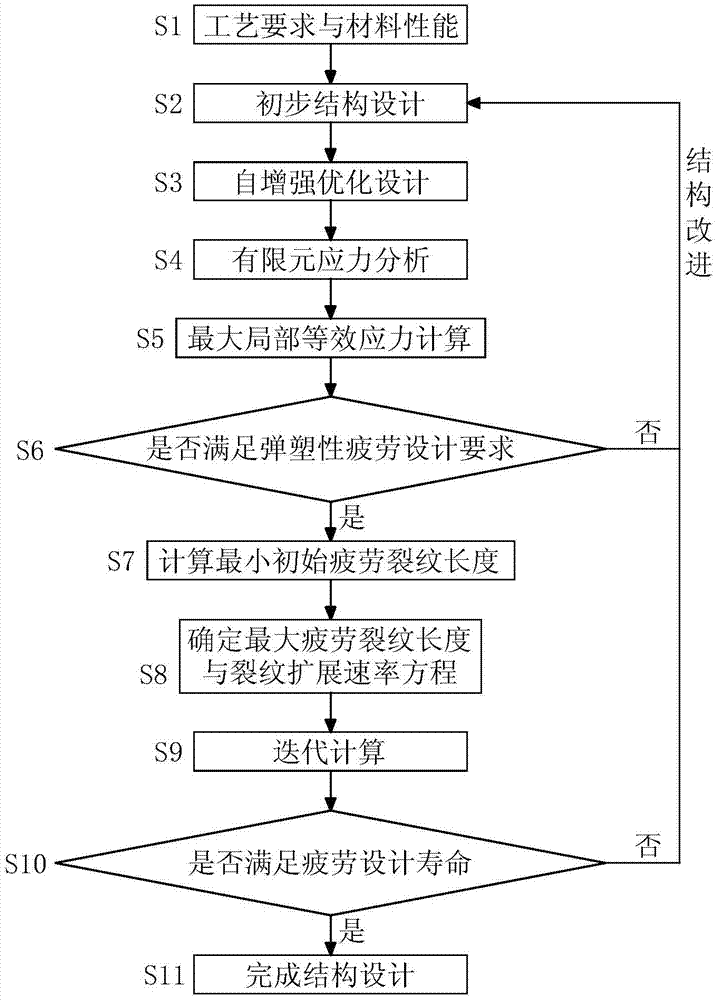

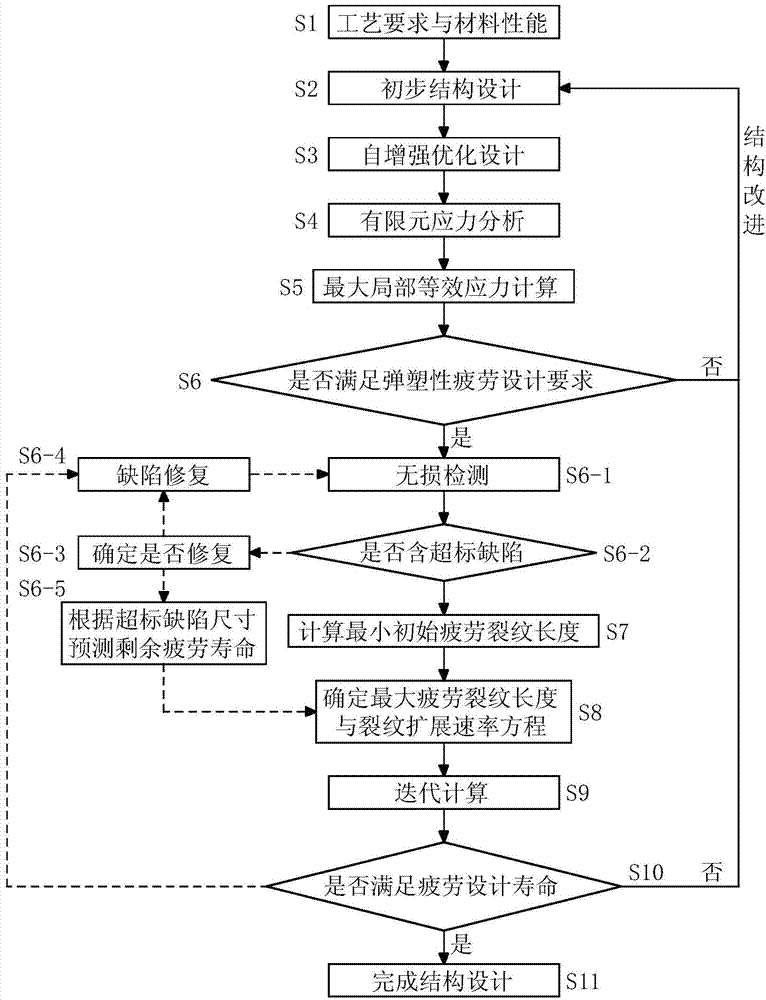

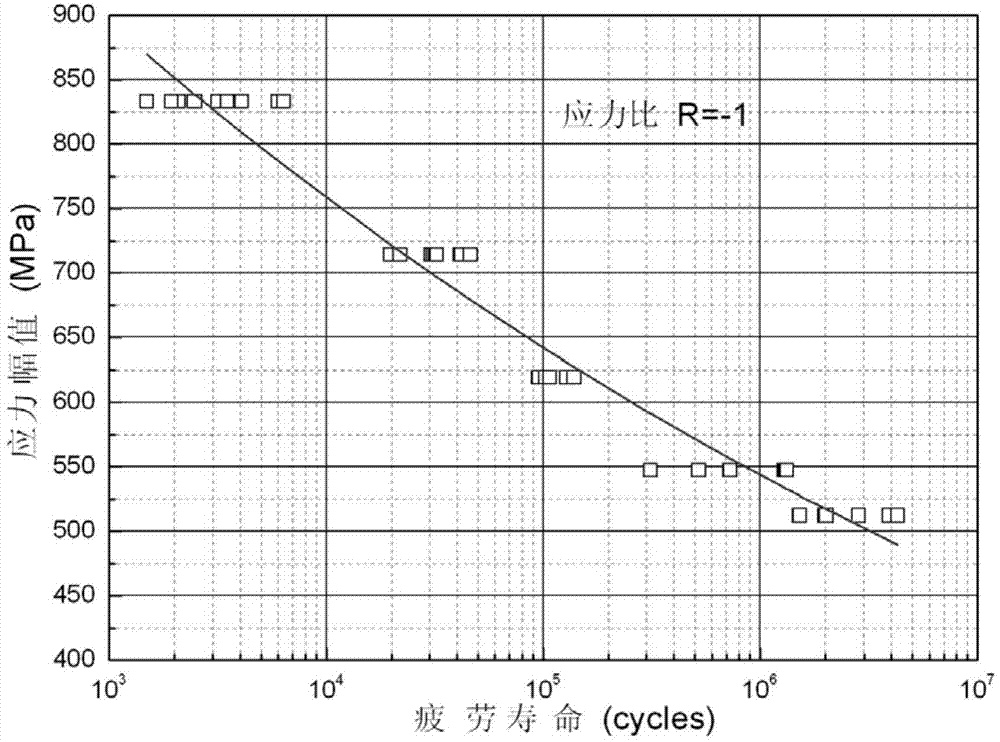

Life-based design method for fatigue strength of ultrahigh-pressure container

ActiveCN104122137AFully grasp the characteristics of the stress fieldIncreased fatigue riskMaterial strength using repeated/pulsating forcesDesign phaseFracture mechanics

The invention relates to a life-based design method for the fatigue strength of an ultrahigh-pressure container. The design method comprises the following steps: firstly carrying out primary structure designing; then carrying out an optimal design of self-enhanced treatment according to the principle of minimum shearing stress; then calculating by utilizing finite element software so as to obtain largest local equivalent stress, and comparing with the designed fatigue strength, if the designed fatigue strength is met, calculating the minimum initial fatigue crack length according to a design pressure and a threshold value of fatigue crack propagation of materials; determining the maximum fatigue crack length by utilizing the fracture toughness of the materials and establishing an accurate description equation on the basis of data of a fatigue crack propagation test; and carrying out iterative calculation on the basis, judging whether the fatigue design life is met, if so, finishing the structure design. The design method has the advantages that multiple risk factors in the process of manufacture and operation of the ultrahigh-pressure container are considered and controlled at a design phase, and the fatigue design life is given according to a modern numerical calculation technology; the designing method is safer compared with a conventional elastic-plastic design method and is more accurate and reasonable compared with the existing fracture-mechanics design method.

Owner:HEFEI GENERAL MACHINERY RES INST

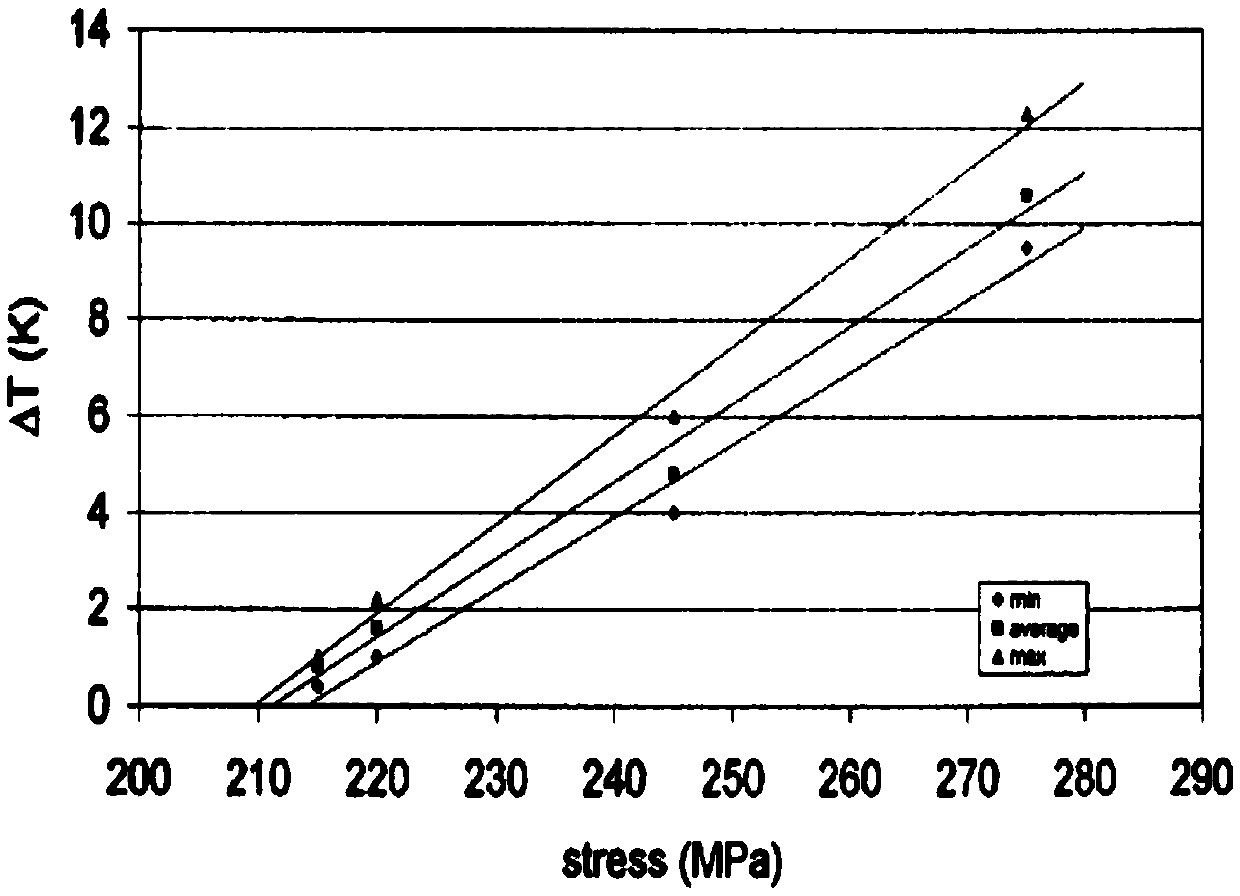

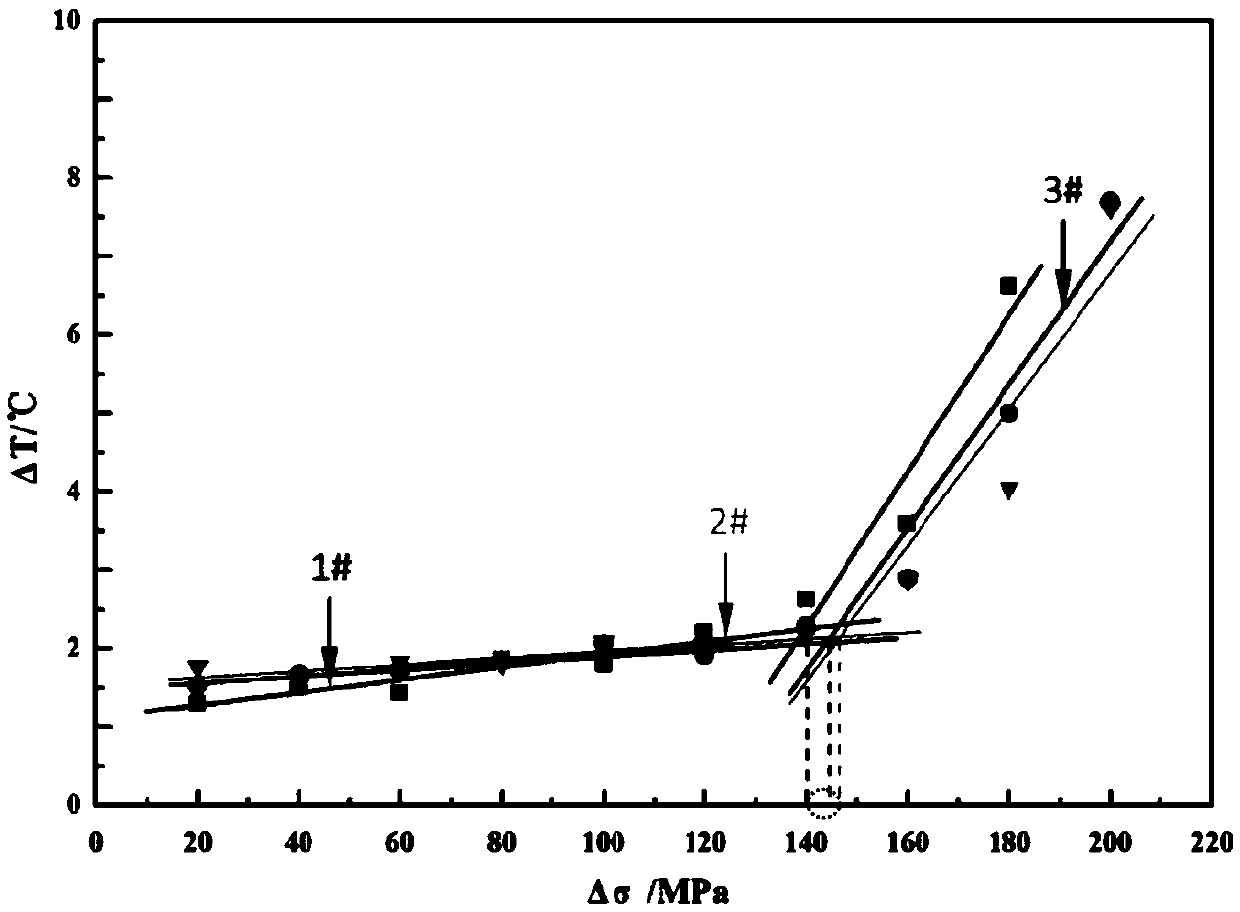

Fatigue limit rapid prediction method based on strain increment

ActiveCN105372136AMaterial strength using repeated/pulsating forcesPredictive methodsEconomic benefits

A fatigue limit rapid prediction method based on strain increment belongs to the field of rapid prediction of material fatigue limit. The invention discovers that under gradient stress load, the variation rule of strain capacity is very similar to the variation rule of temperature. Since the Luong method can use corresponding stable temperature rise value under gradient load to predict the fatigue limit, the strain capacity under gradient load can theoretically be used for rapid prediction of fatigue limit. The method utilizes a fatigue testing machine and an extensometer thereof (no dependence on expensive high-precision thermal infrared imager), and theoretically only uses one specimen to rapidly and economically predict a reliable fatigue limit of the material or a simple member in a day time according to variation rule of strain capacity under gradient load. The traditional lifting method and grouping method spend a few months and consume a large amount of human and financial resources, therefore the present invention has high engineering practical value and significant economic benefits.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

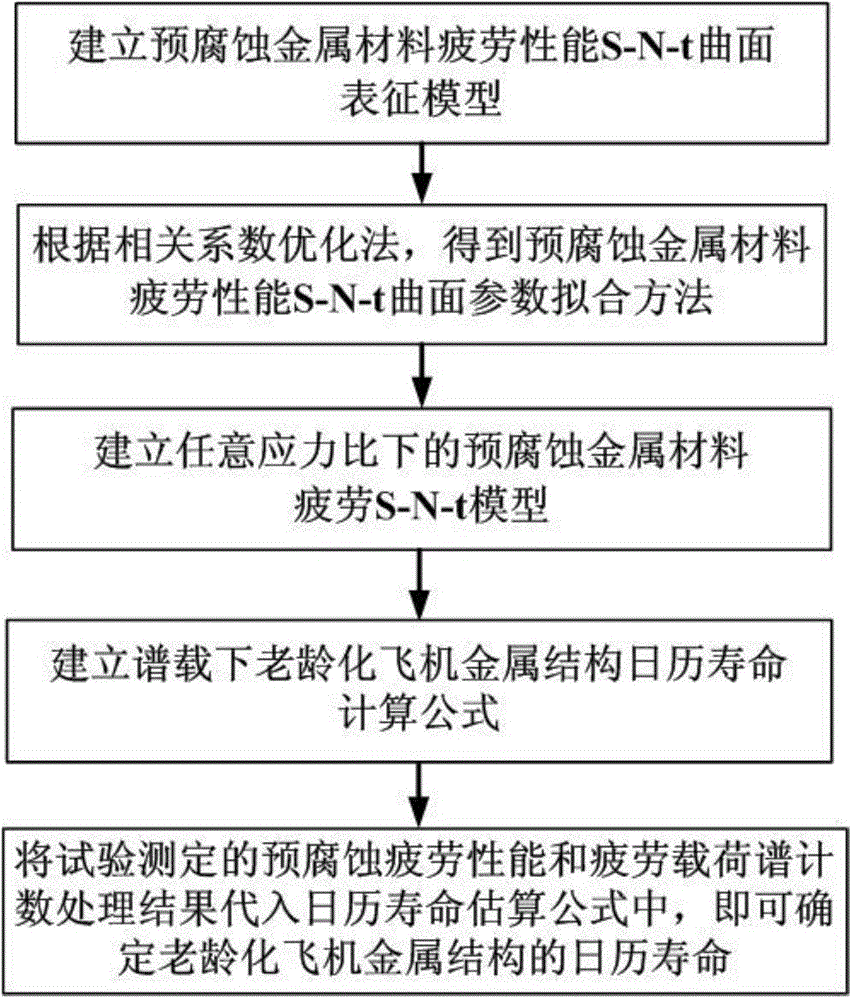

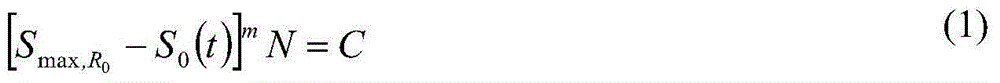

Novel method for forecasting calendar life of metal structure of aging aircraft

ActiveCN104978490ACalendar life getsFew parametersSpecial data processing applicationsFatigue loadingStress ratio

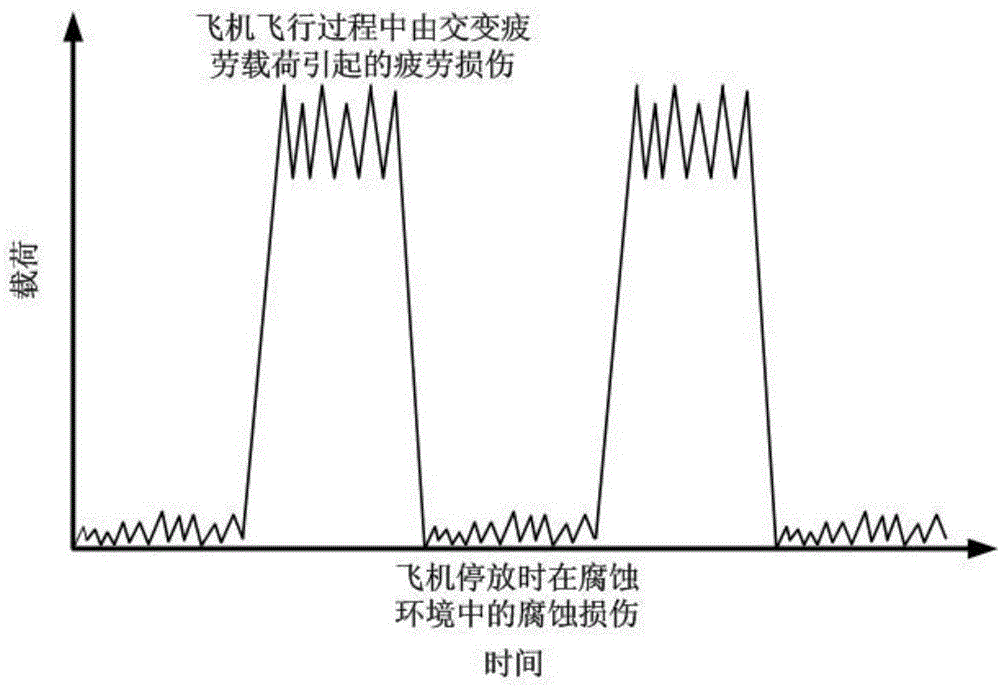

A novel method for forecasting a calendar life of a metal structure of an aging aircraft. The method comprises five steps of: S1, establishing a prior-corroded metal material fatigue property S-N-t curve surface representation model; S2, according to a relative coefficient optimization method, establishing a prior-corroded metal material fatigue property S-N-t curve surface parameter fitness method; S3, establishing a prior-corroded metal material fatigue S-N-t curve surface model in a random stress ratio; S4, establishing a calendar life calculating formula for the metal structure of the aging aircraft under a spectrum load; and S5, substituting material fatigue properties with different prior-corrosion life limits, which are measured by testing, and a fatigue load spectrum counting processing result into the calendar life calculating formula to determine the calendar life of the metal structure of the aging aircraft. The novel method is simple and practical; a small number of model parameters need to be measured by testing; and the calendar life of the metal structure of the aging aircraft can be determined only by substituting the material corrosion fatigue properties with different prior-corrosion life limits and fatigue load spectrum data into the calendar life calculating formula.

Owner:北京睦邦仁科技有限公司

Device and method for testing fatigue mechanical property of material under tensile-bending composite load

PendingCN109883833ARealize in-situ monitoringNovel structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesScientific instrumentEngineering

The invention relates to a device and a method for testing the fatigue mechanical property of a material under a tensile-bending composite load, and belongs to the field of precision scientific instruments and material testing. The device comprises a vibration isolation base, a supporting frame, an ultrasonic loading module, a hydraulic loading module, a tensile loading module and an ultrasonic flaw detection module; the supporting frame is connected with the vibration isolation base; the hydraulic loading module is connected with the supporting frame through a connecting flange; the ultrasonic loading module is connected with the hydraulic loading module through a thread; and the tensile loading module and the ultrasonic flaw detection module are arranged on the vibration isolation base.The device has the advantages as follows: high-frequency and high-load cross-range loading can be realized; ultrahigh-frequency bending fatigue loading and tensile-bending static dynamic composite load loading can be realized; and the tensile loading module can ensure accurate centering of tested material samples. The tested material samples made of different materials and having different sizes can be subjected to high-frequency fatigue testing under the static dynamic composite load; and a reliable means is provided for service performance analysis of key materials in aerospace and numerousfields.

Owner:JILIN UNIV

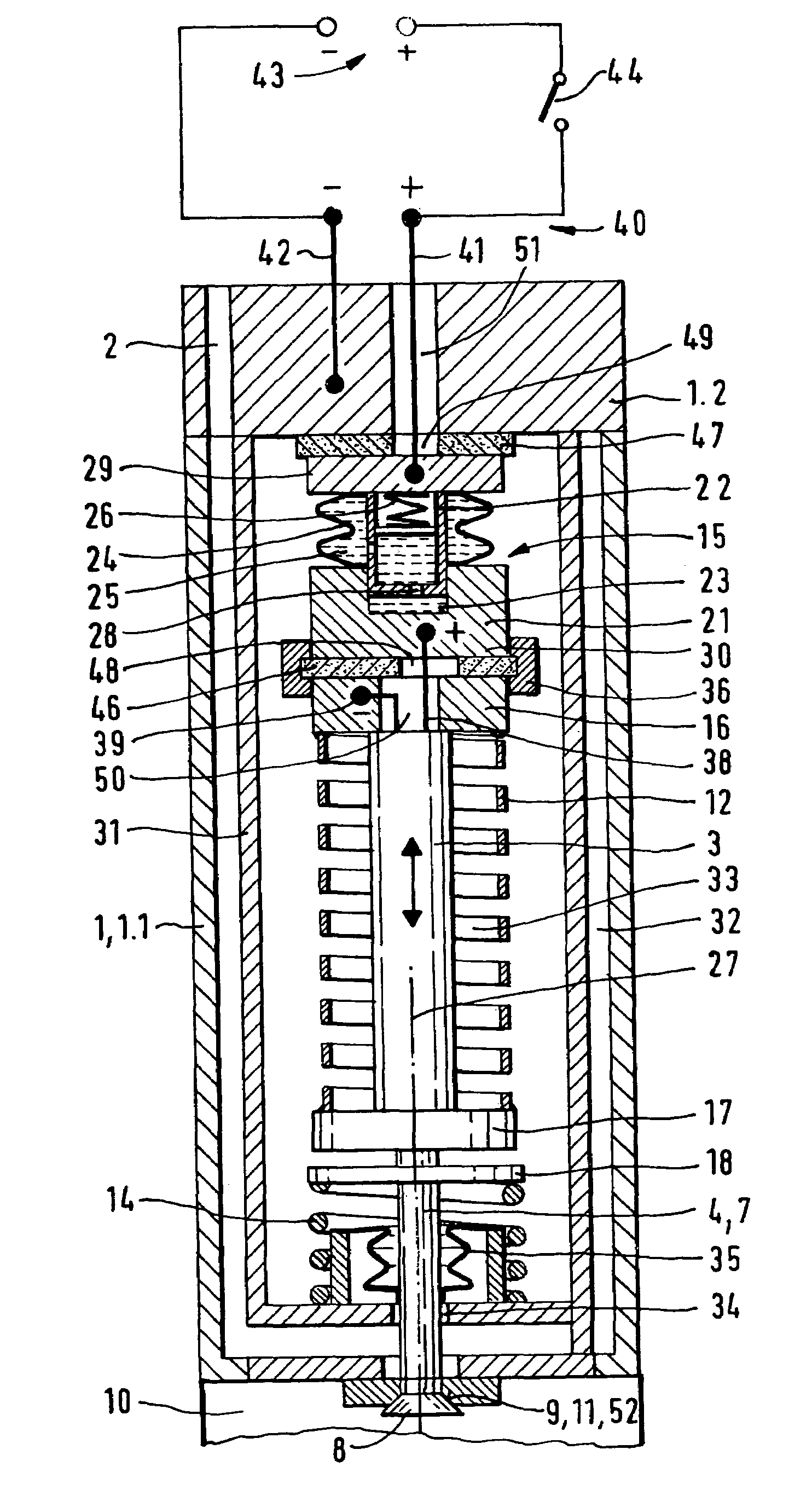

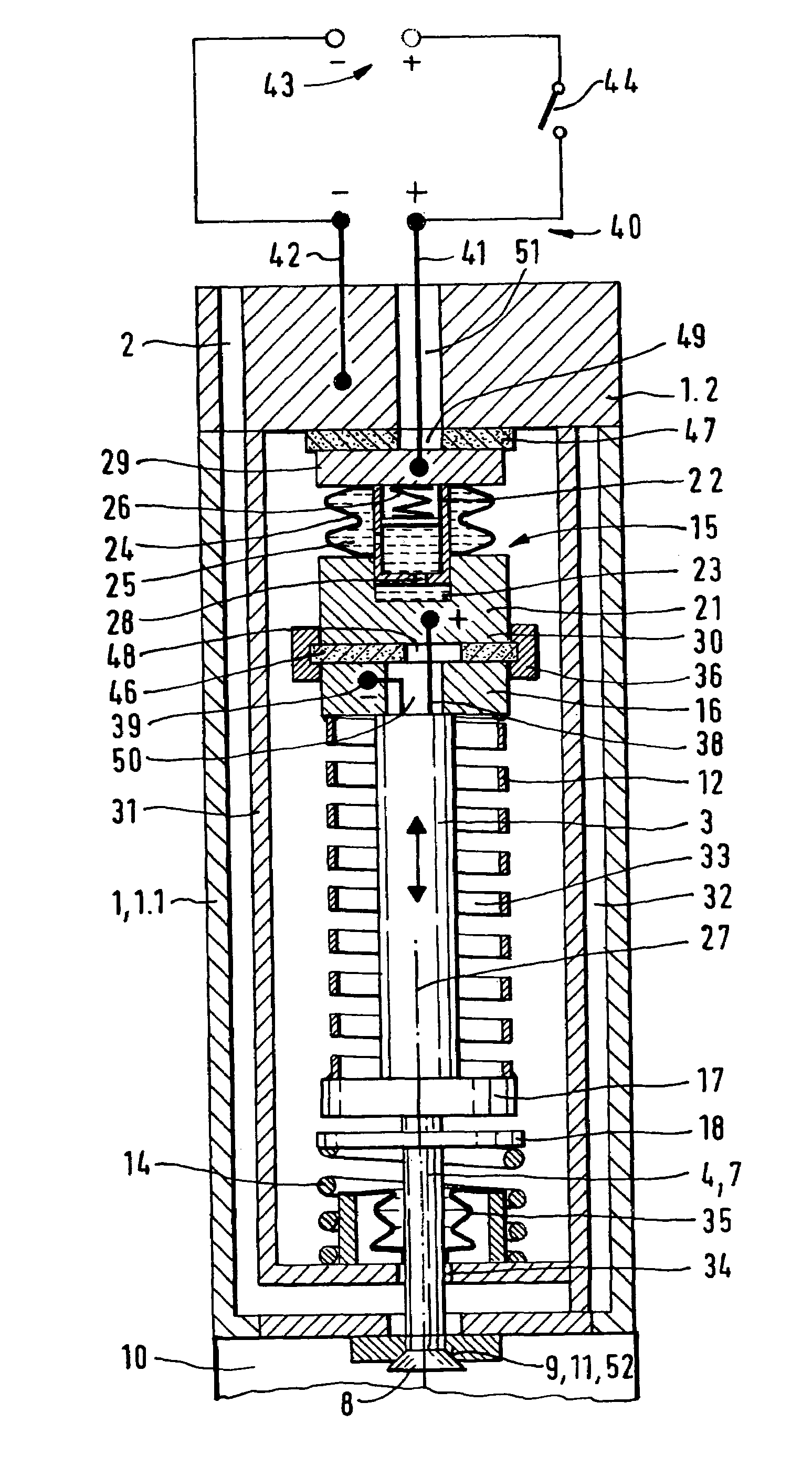

Fuel injector

InactiveUS7267111B2Small designExtended service lifeMovable spraying apparatusSpray nozzlesElectricityActuator

Owner:ROBERT BOSCH GMBH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com