Patents

Literature

254 results about "Corrosion fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion fatigue is fatigue in a corrosive environment. It is the mechanical degradation of a material under the joint action of corrosion and cyclic loading. Nearly all engineering structures experience some form of alternating stress, and are exposed to harmful environments during their service life. The environment plays a significant role in the fatigue of high-strength structural materials like steel, aluminum alloys and titanium alloys. Materials with high specific strength are being developed to meet the requirements of advancing technology. However, their usefulness depends to a large extent on the degree to which they resist corrosion fatigue. The effects of corrosive environments on the fatigue behavior of metals were studied as early as 1930. The phenomenon should not be confused with stress corrosion cracking, where corrosion (such as pitting) leads to the development of brittle cracks, growth and failure. The only requirement for corrosion fatigue is that the sample be under tensile stress.

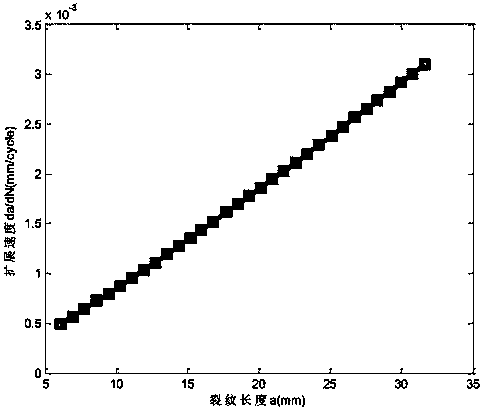

Method for evaluating fatigue life of aged reinforced concrete bridge

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

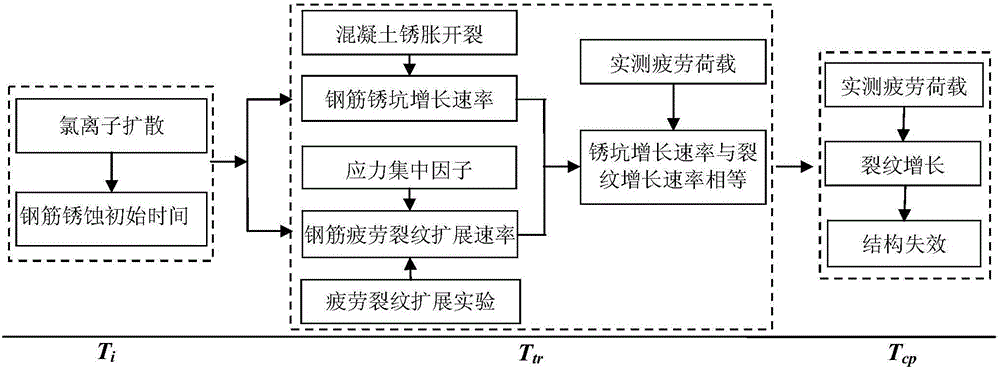

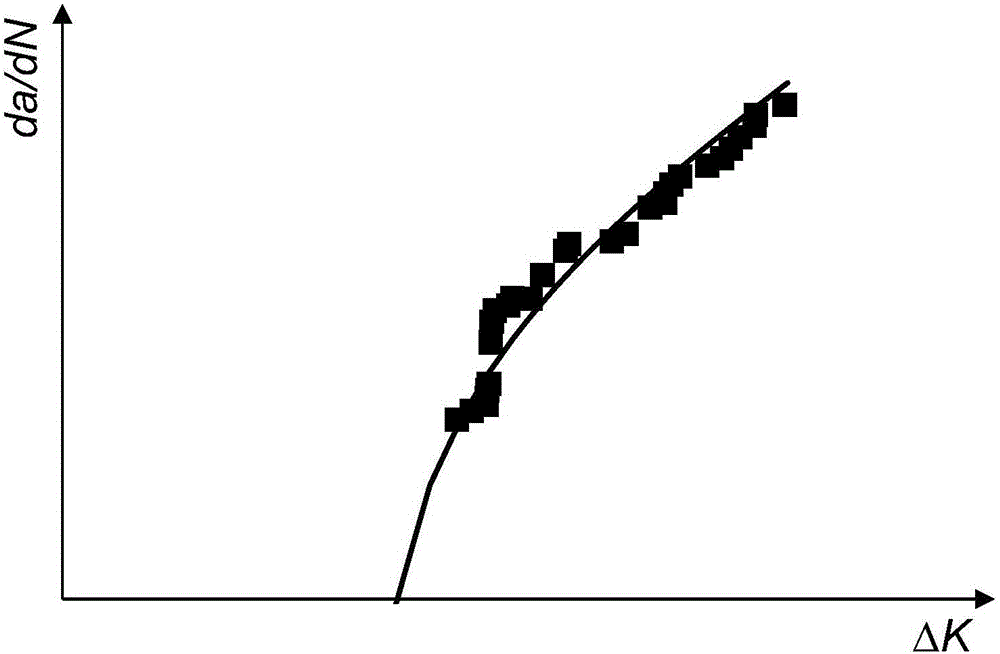

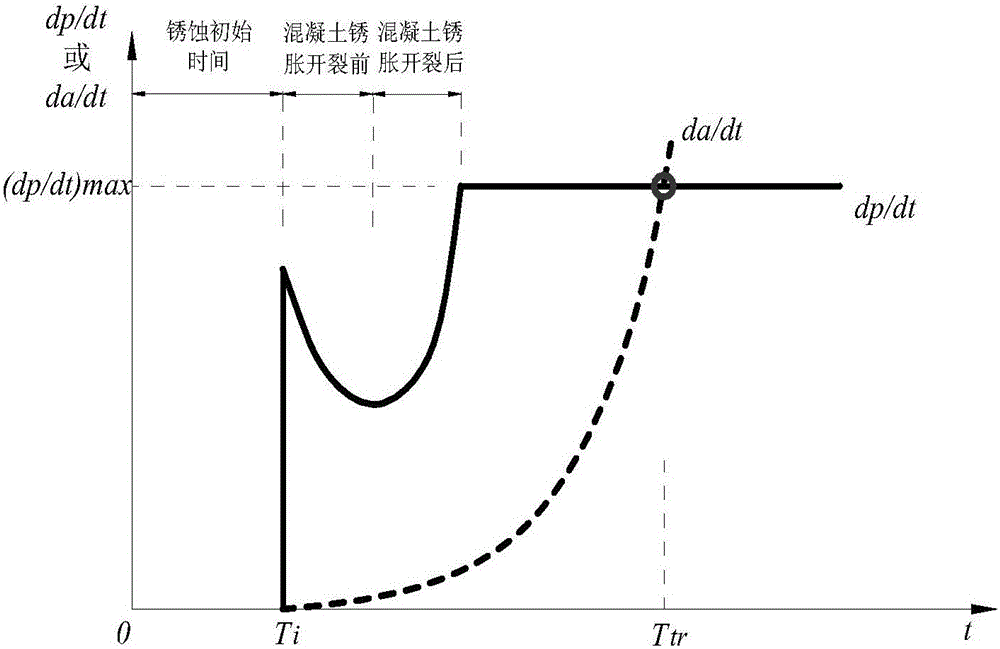

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

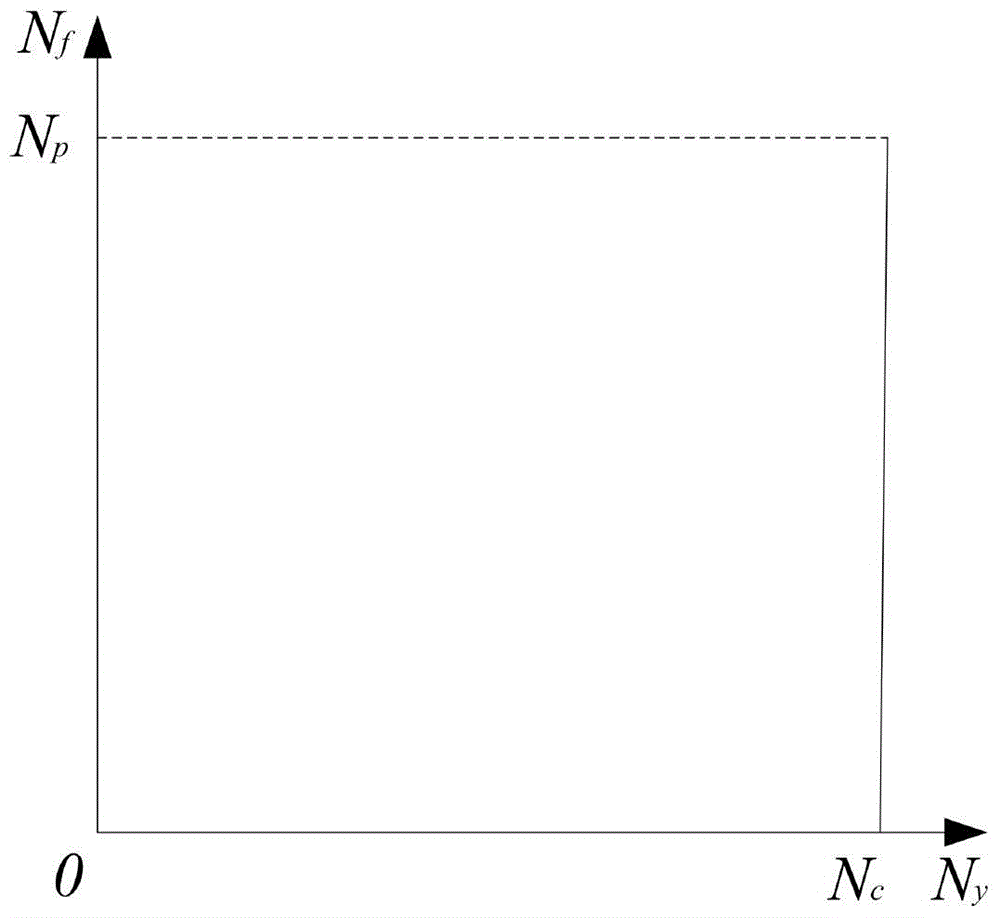

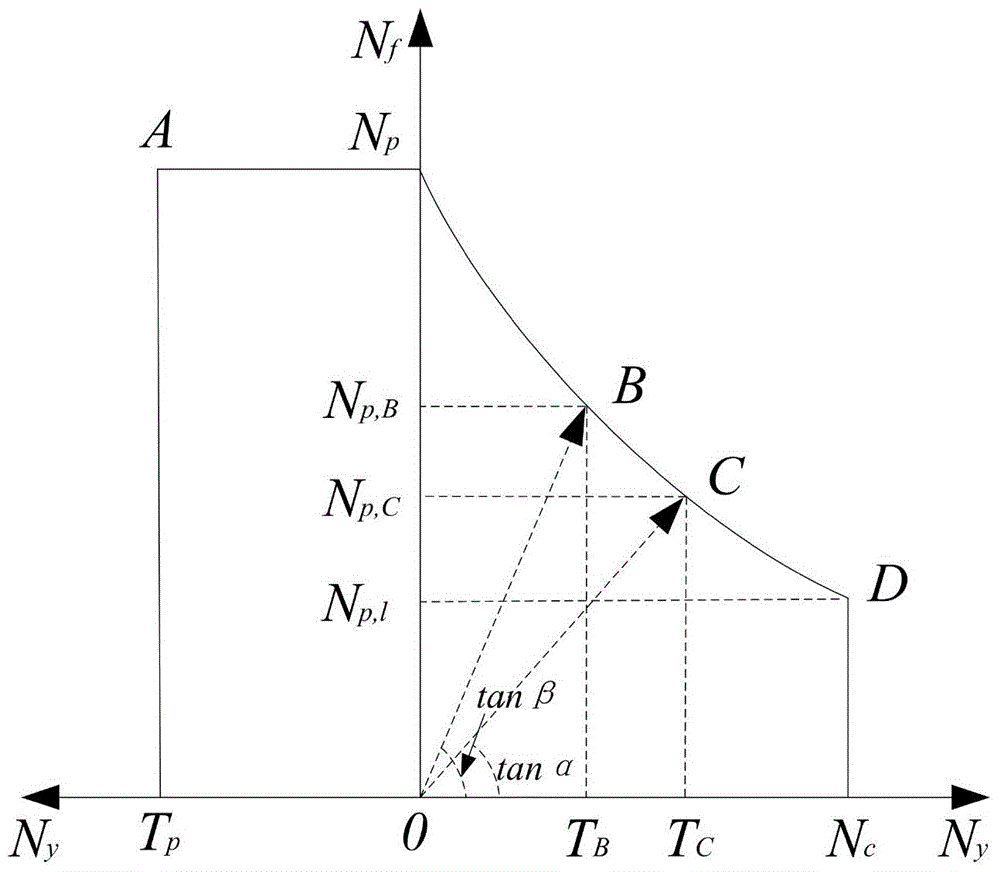

Method for predicting remaining lifetime of single airplane based on airplane structural life envelope principle

ActiveCN104537133AGuarantee the safety of useImprove service life efficiencySpecial data processing applicationsJet aeroplaneLife time

The present invention discloses a method for predicting remaining lifetime of a single airplane based on the irplane structural life envelope principle. The method is characterized by comprising a method for determining a fatigue key component life envelope and predicting a remaining life thereof, a method for determining a corrosion key component life envelope and predicting a remaining life and a method for determining a corrosion-fatigue key component life envelope and predicting a remaining life. The method of the present invention provides theoretical and methodological support for ensuring safe use of the structure of the airplane and improving the efficiency of the service life of the airplane structure.

Owner:AIR FORCE UNIV PLA

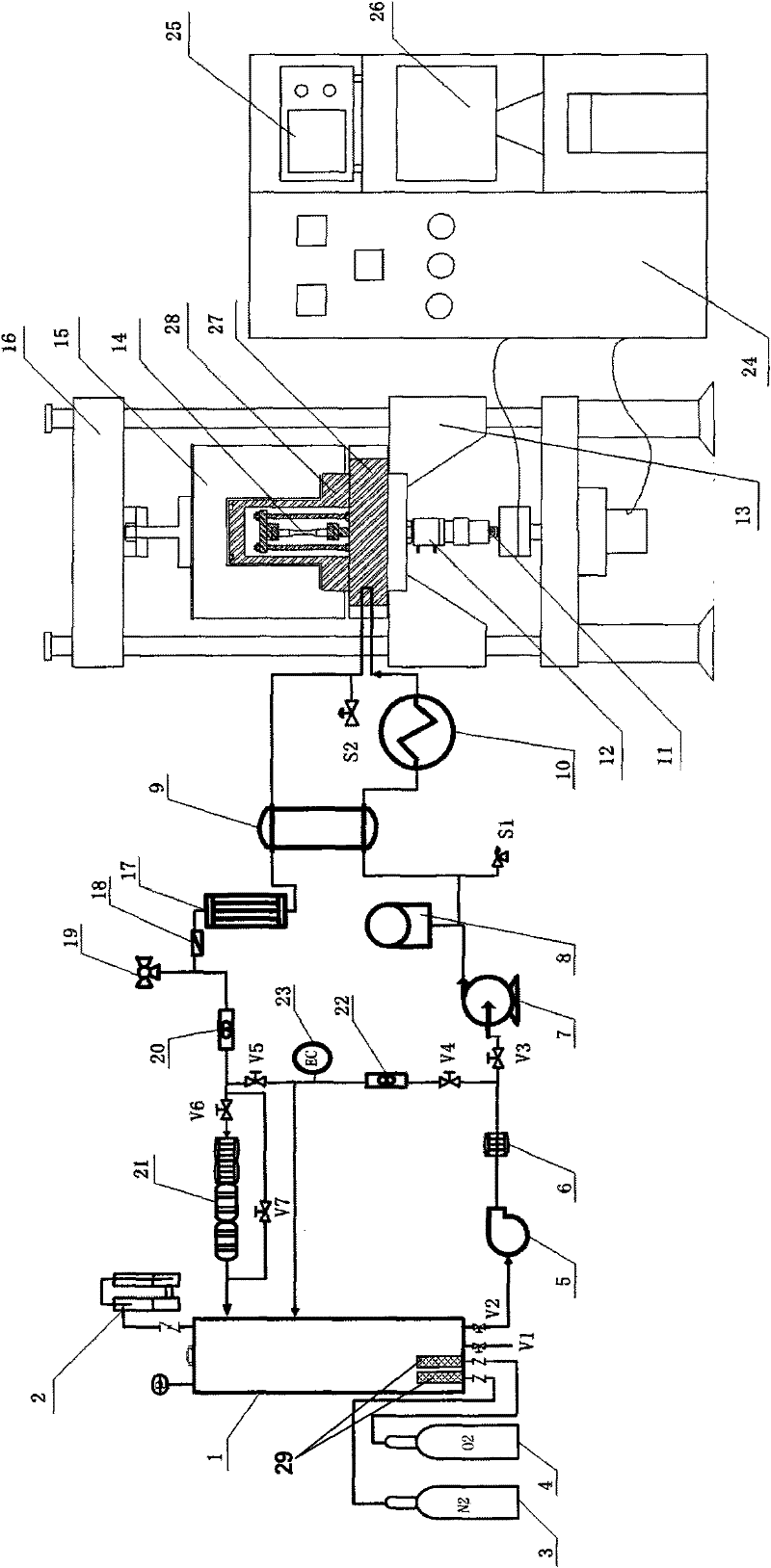

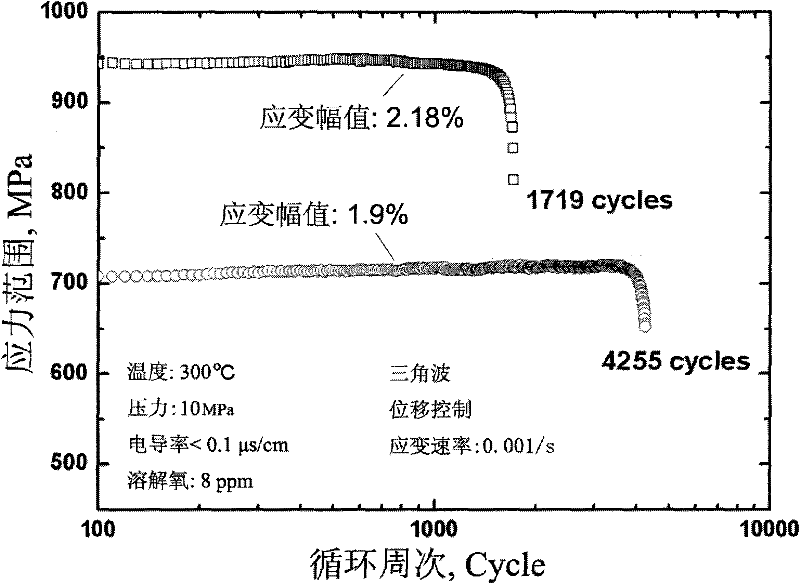

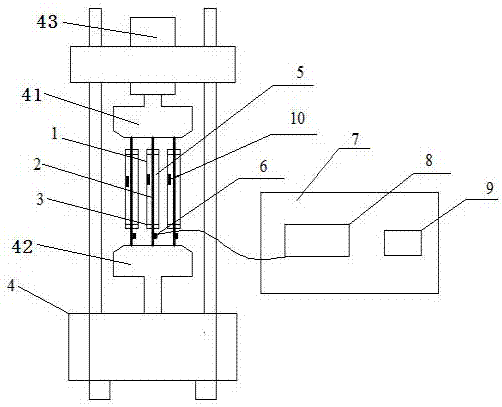

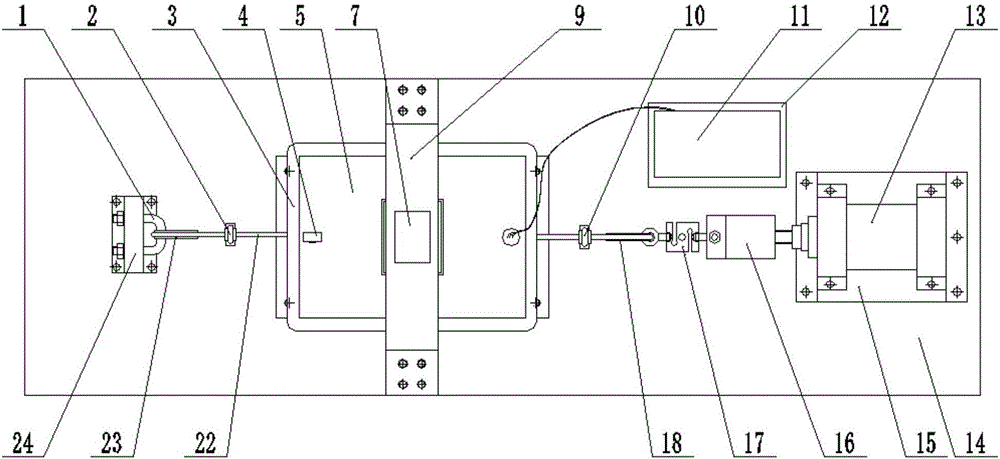

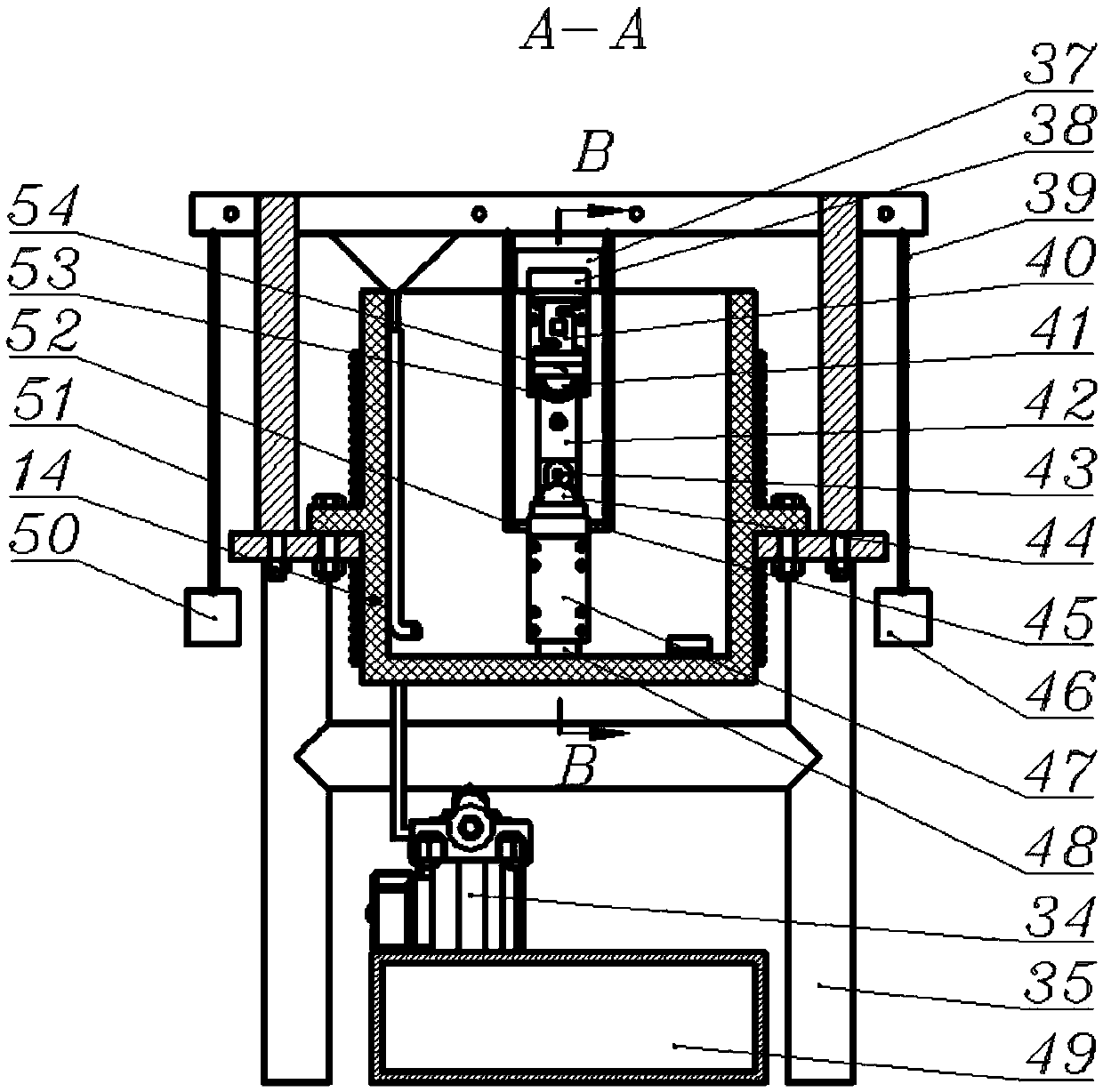

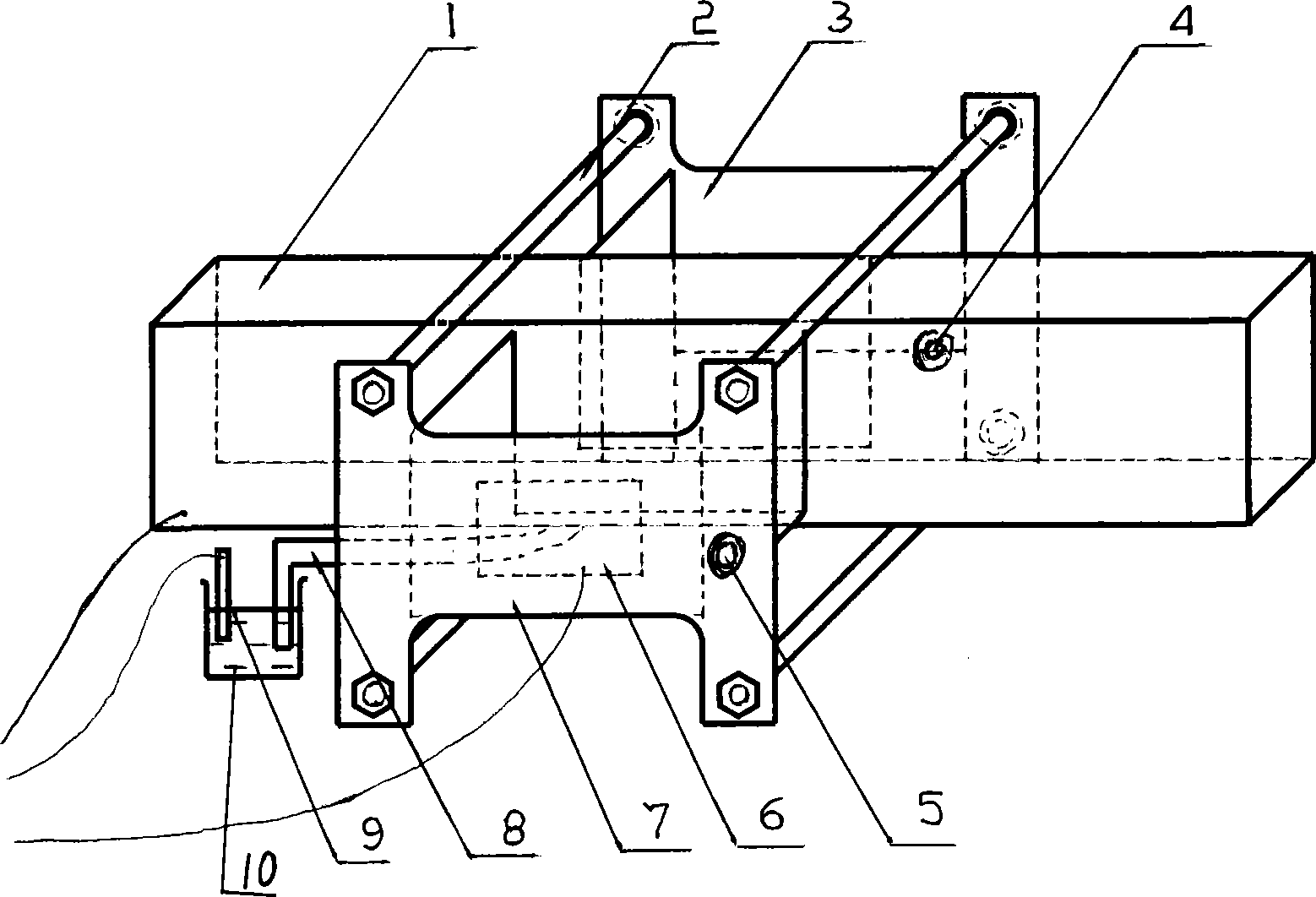

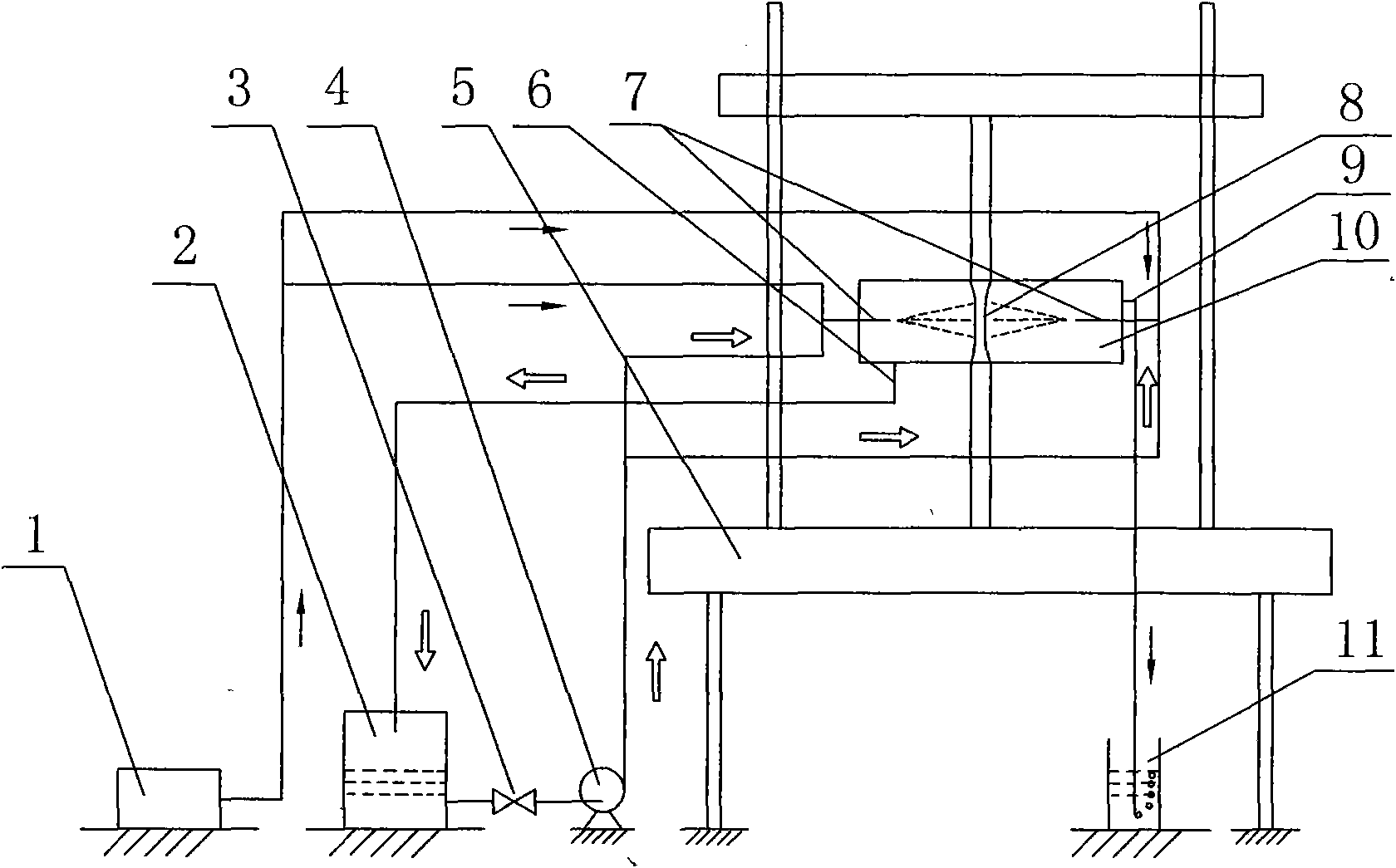

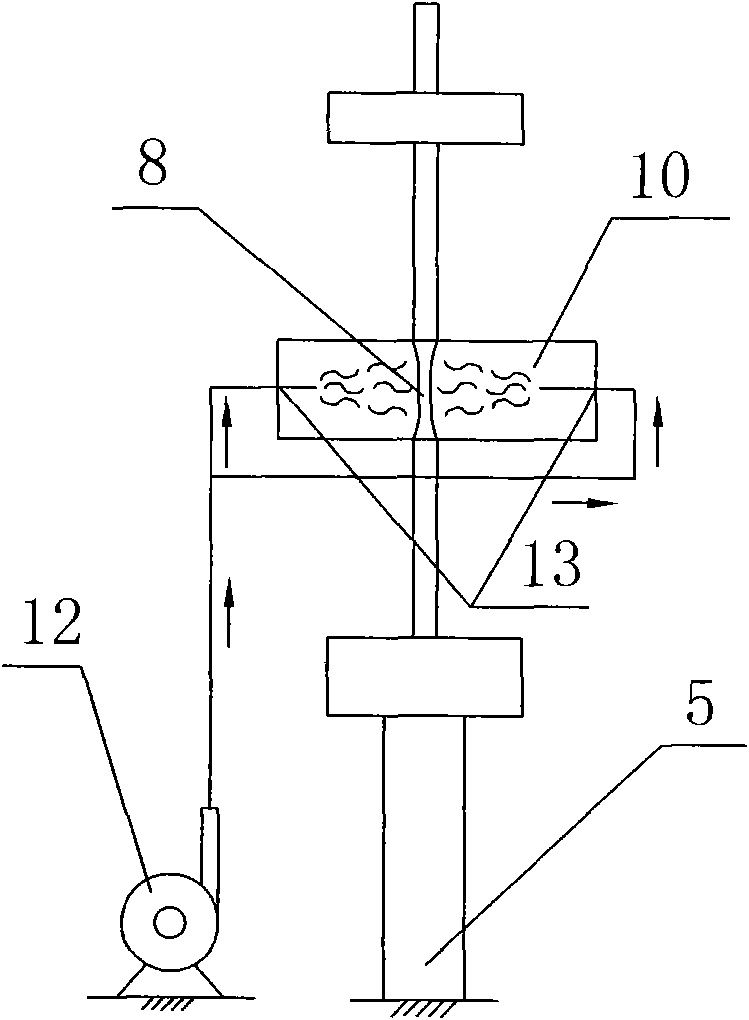

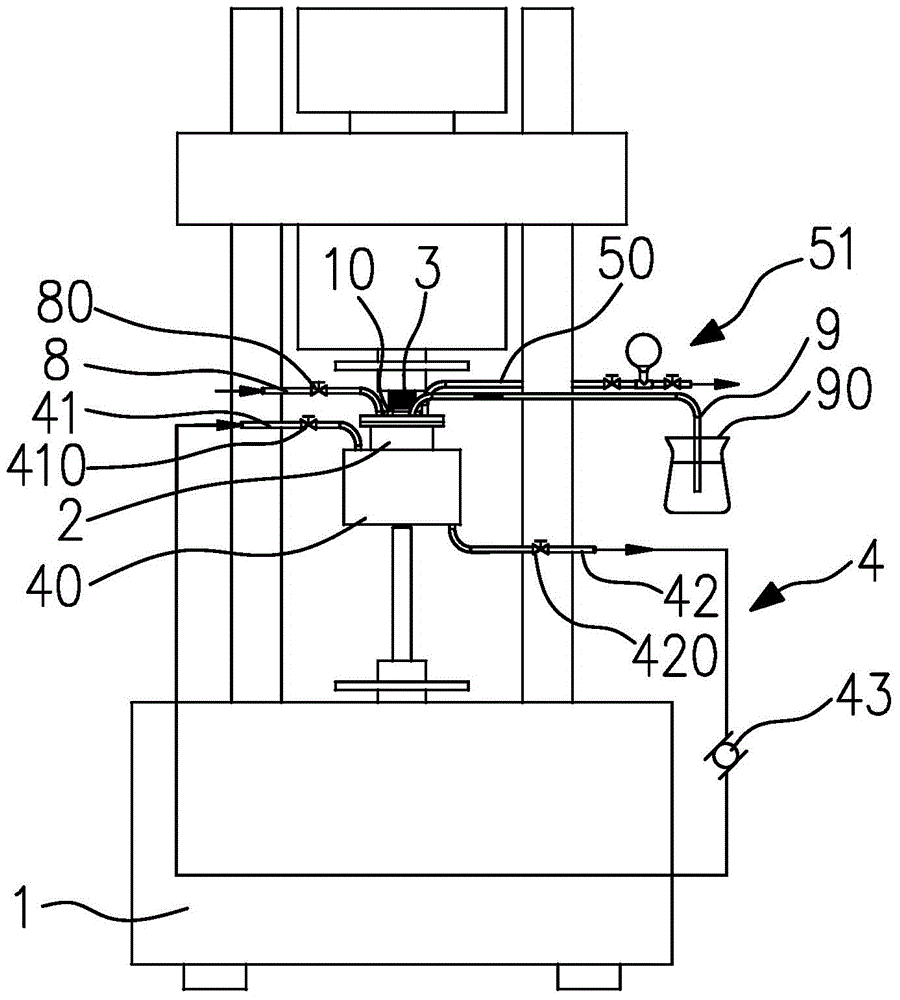

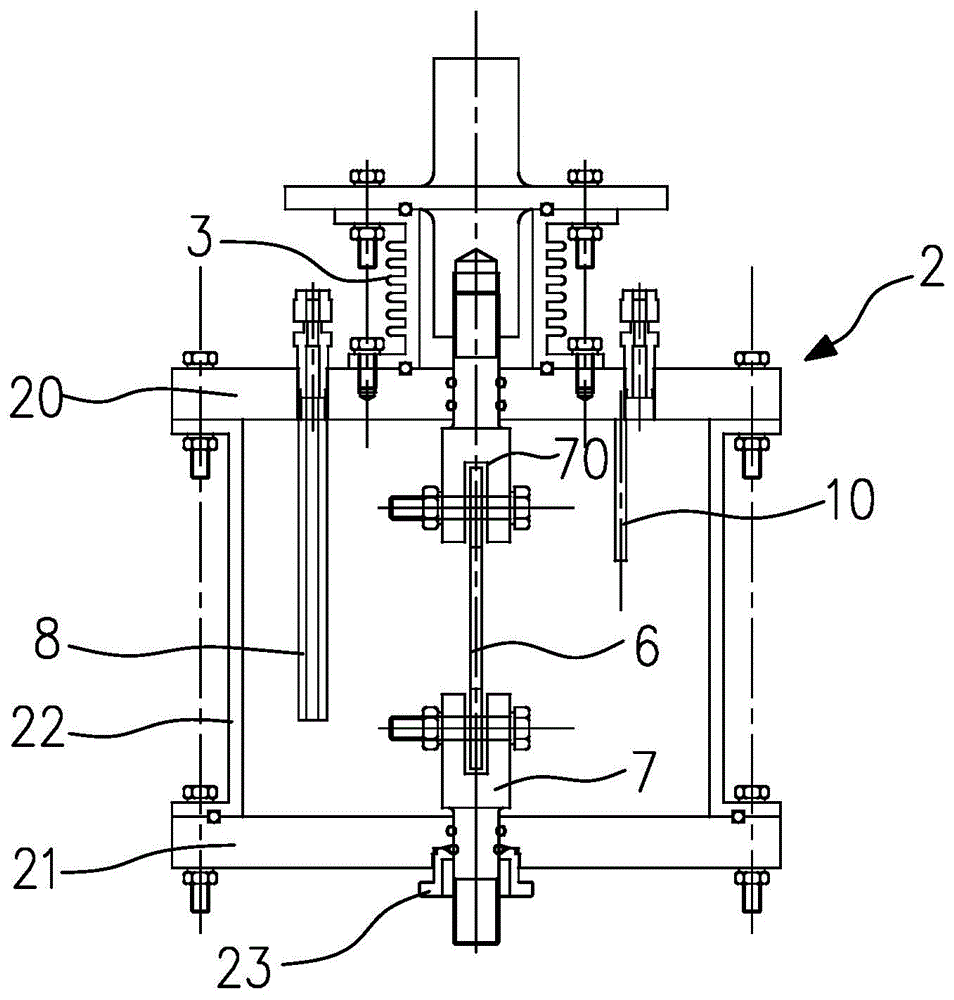

Corrosion fatigue test apparatus with high temperature and high pressure circulating water

ActiveCN102346114ATemperature controlControl pressureMaterial strength using tensile/compressive forcesFatigue loadingWater storage tank

The invention belongs to the field of material testing, specifically to a corrosion fatigue test apparatus with high temperature and high pressure circulating water. With the present invention, the problems of the complex structure and the cumbersome use and maintenance in the prior art are solved. The apparatus is provided with a high temperature and high pressure circulating water system, an autoclave and a fatigue machine. The high temperature and high pressure circulating water system is communicated with the autoclave. A test sample is placed in the autoclave, and is connected with a loading part of the fatigue machine. The high temperature and high pressure circulating water system comprises a water storage tank, a circulation pump, a high pressure pump, a buffer tank, a heat exchanger, a preheater, a condenser, a back pressure valve and an ion exchange resin. An inlet of the autoclave is connected with the heat exchanger through a pipeline. The pipeline is provided with the preheater. An outlet of the autoclave is connected with the heat exchanger through the pipeline. The high temperature and high pressure circulating water system is provided for providing high temperatureand high pressure water required by the test. The fatigue machine is provided for performing fatigue loading for the test sample in the autoclave. A control system controls the high temperature and high pressure circulating water system and the fatigue machine.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

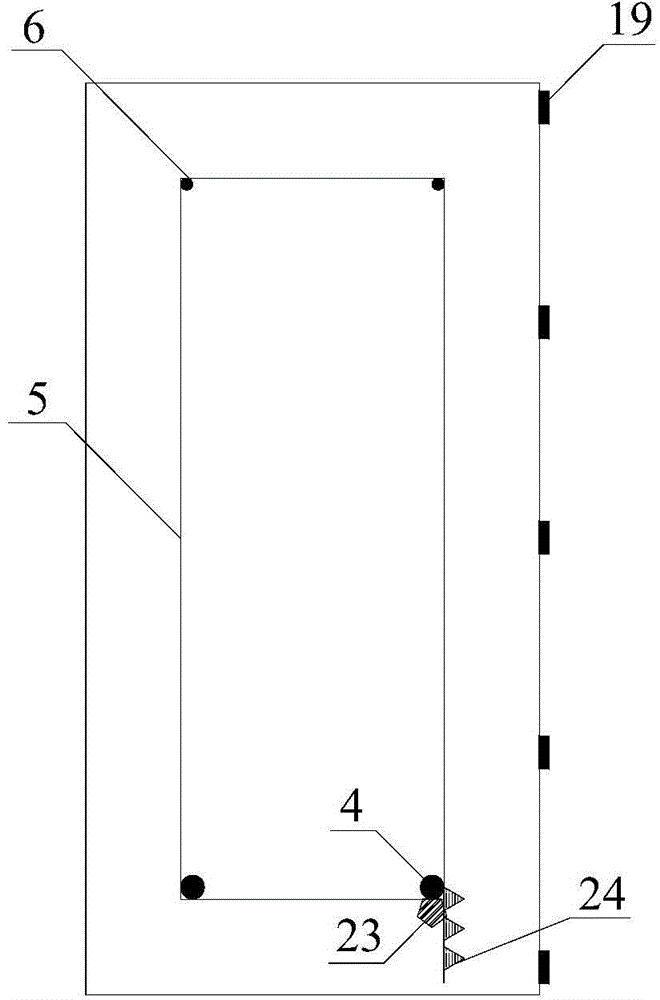

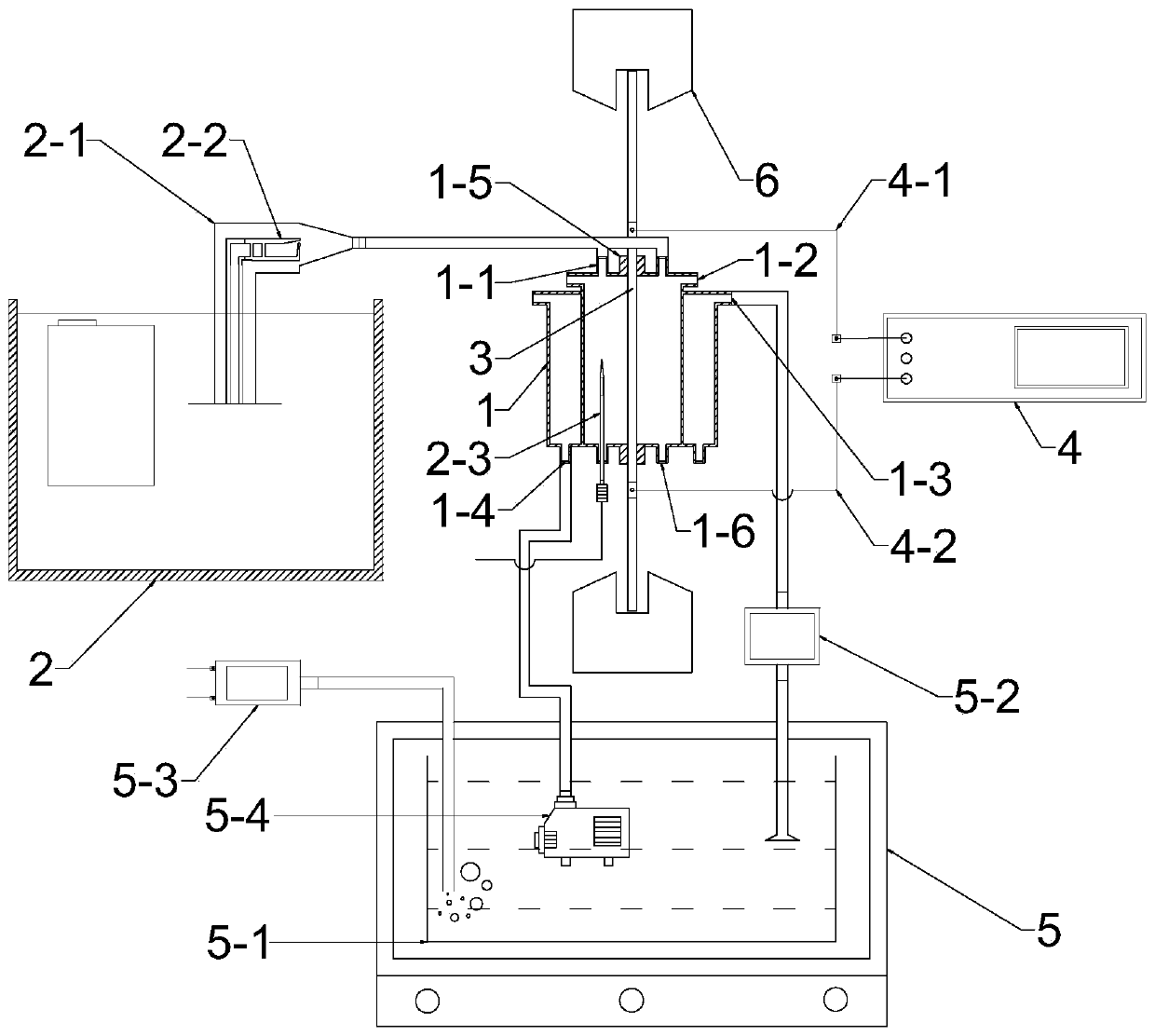

Corrosion-fatigue testing method for reinforced concrete on basis of optical-fiber sensing and device thereof

ActiveCN104483258AThe test data is accurate and reliableRealize real-time synchronous monitoringWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceReinforced concreteRebar

The invention discloses a corrosion-fatigue testing method for reinforced concrete on the basis of optical-fiber sensing and a device thereof. The corrosion-fatigue testing method comprises the following steps: (1) casting a reinforced concrete beam and arranging fiber grating sensors; (2) installing the reinforced concrete beams; (3) connecting with a power supply; (4) injecting electrolyte; and (5) acquiring test data. The device constructed according to the method comprises the reinforced concrete beam to be tested, a load distributing beam, a supporting device, a corrosion groove with an opened upper end, a hydraulic jack, a monitoring device and a direct-current voltage stabilizing power supply. The corrosion-fatigue testing method and the device disclosed by the invention have the advantages that the coupling action of a corrosion medium and alternating stress is fully considered, and the environment is closer to the use environment of the reinforced concrete structure in service, so that the test data is more effective and reliable.

Owner:ZHEJIANG UNIV

Drill rod and method for its manufacturer

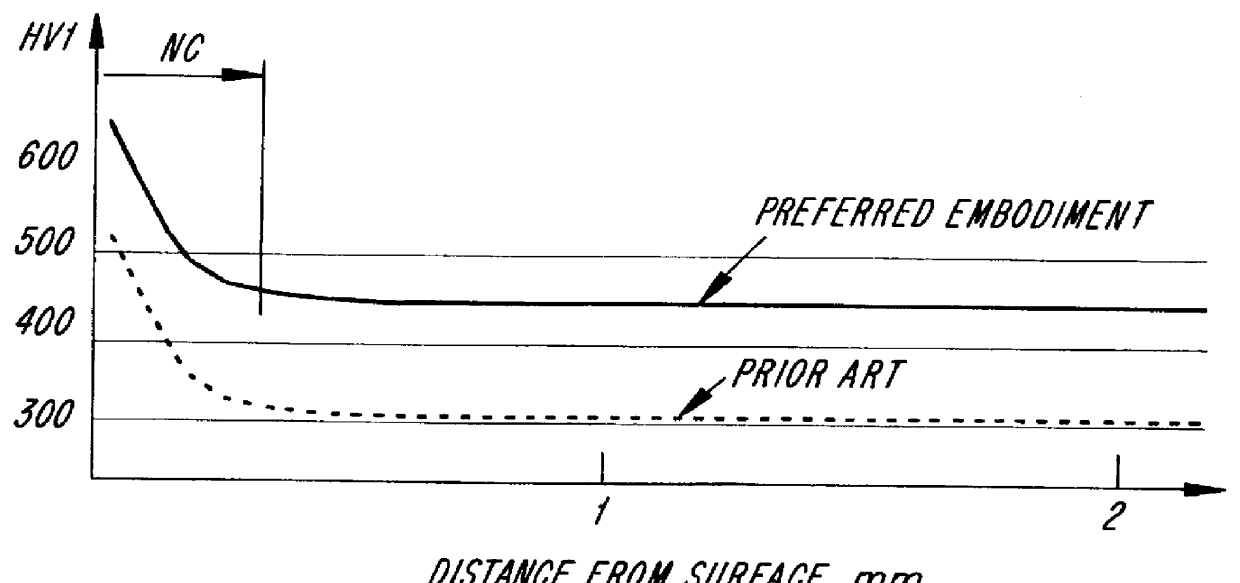

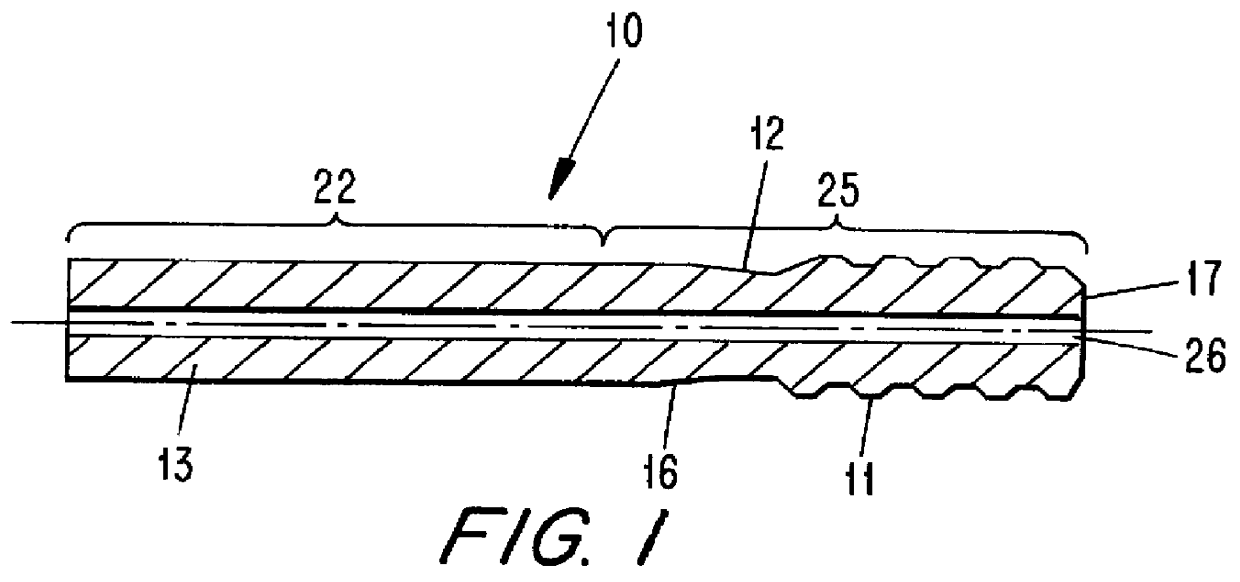

InactiveUS6095266AUnique resistance against corrosion fatigueAbility to withstand high impact loadDrill bitsDrilling rodsFriction weldingAbutment

A rock drilling rod is manufactured by placing free ends of first and second hollow rod components in abutment, and establishing relative rotation between the free ends to friction weld those free ends together. The first component comprises a thread and a clearance portion disposed adjacent the thread. The first component has a hot hardness value of at least about 170 HV1 at 600 DEG C. Prior to friction welding the components together, the thread, clearance portion and central passage of the first component are heat treated against corrosion fatigue. Then, the thread is high frequency hardened to a depth at least as great as the heat treated layer. Following the welding, the weld is cooled while keeping a core hardness of the respective portions of the first and second components disposed immediately adjacent the weld no lower than 390 HV1.

Owner:SANDVIK AB

Method for predicting residual life of storage tank

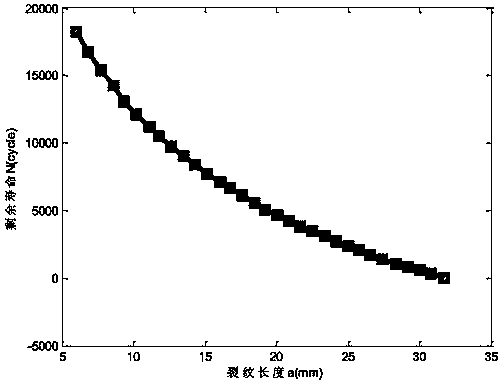

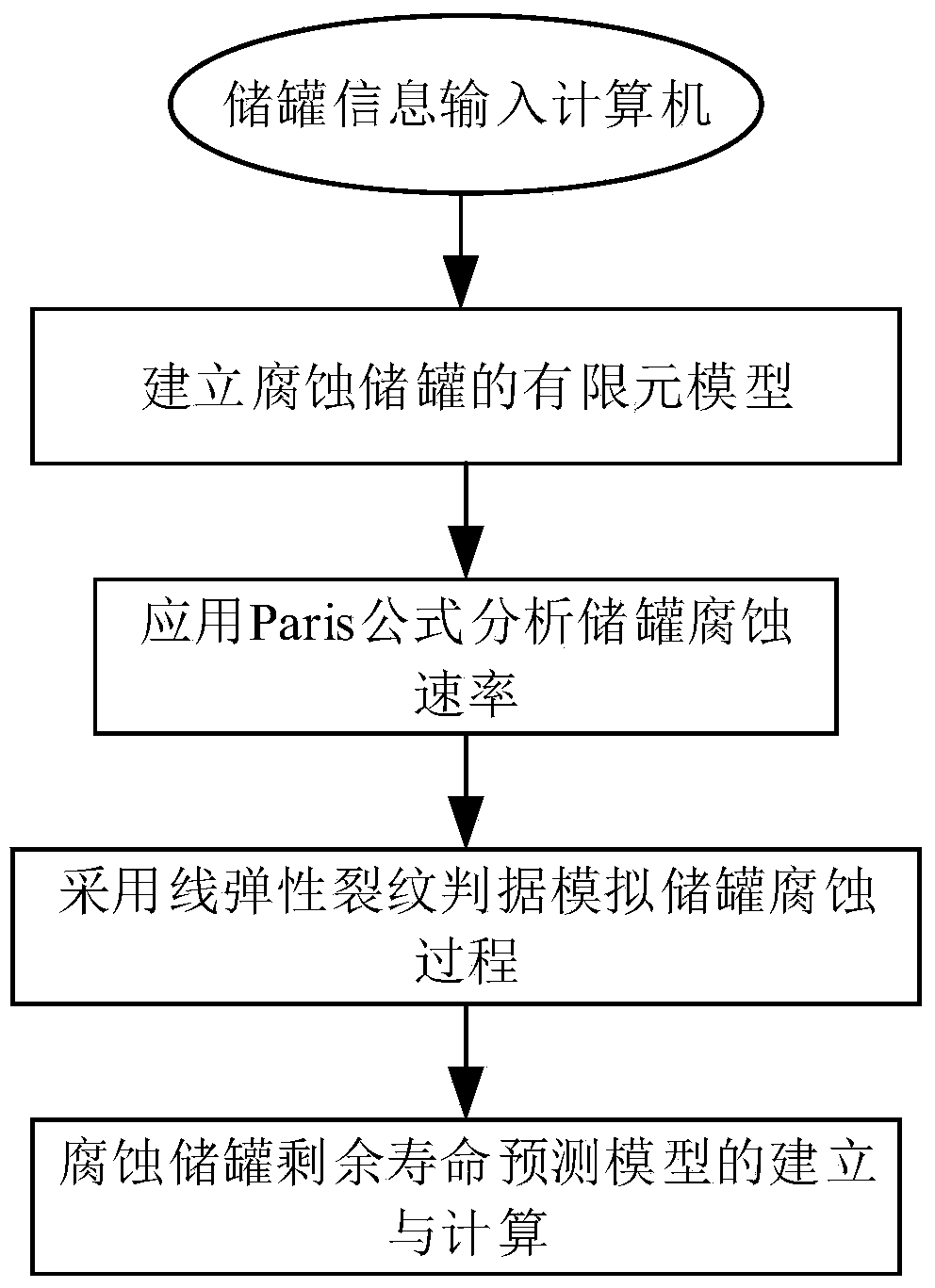

InactiveCN103870662AEfficient prediction of remaining lifeTimely maintenanceSpecial data processing applicationsElement modelComputer support

The invention relates to a method for analyzing the residual life of a storage tank through ANSYS software. The method mainly comprises the following steps that (1) a computer supporting ANSYS is used, collected storage tank data are input to the computer in the form of a database or a text, a finite element model of the corroded storage tank is established through the ANSYS software, and corresponding boundary conditions and an external load are applied to the finite element model according to the actual stress condition of the storage tank; (2) regression processing is conducted on experimental data points through a fatigue crack propagation law Paris formula, and a corrosion fatigue rate equation under the corresponding conditions is obtained; (3) the critical invalid wall thickness when the storage tank loses efficacy is determined according to a predicted value of the corrosion rate; (4) according to the critical invalid wall thickness when the storage tank loses efficacy due to corrosion, a storage tank residual life prediction model is established, and the approximate analysis method is used for calculating the residual life of the storage tank under the condition of uniform corrosion.

Owner:QINGDAO UNIV OF SCI & TECH

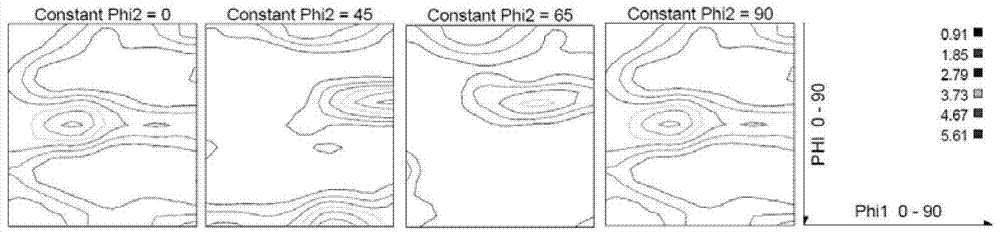

Steel for structural part of automobile and method for producing the same

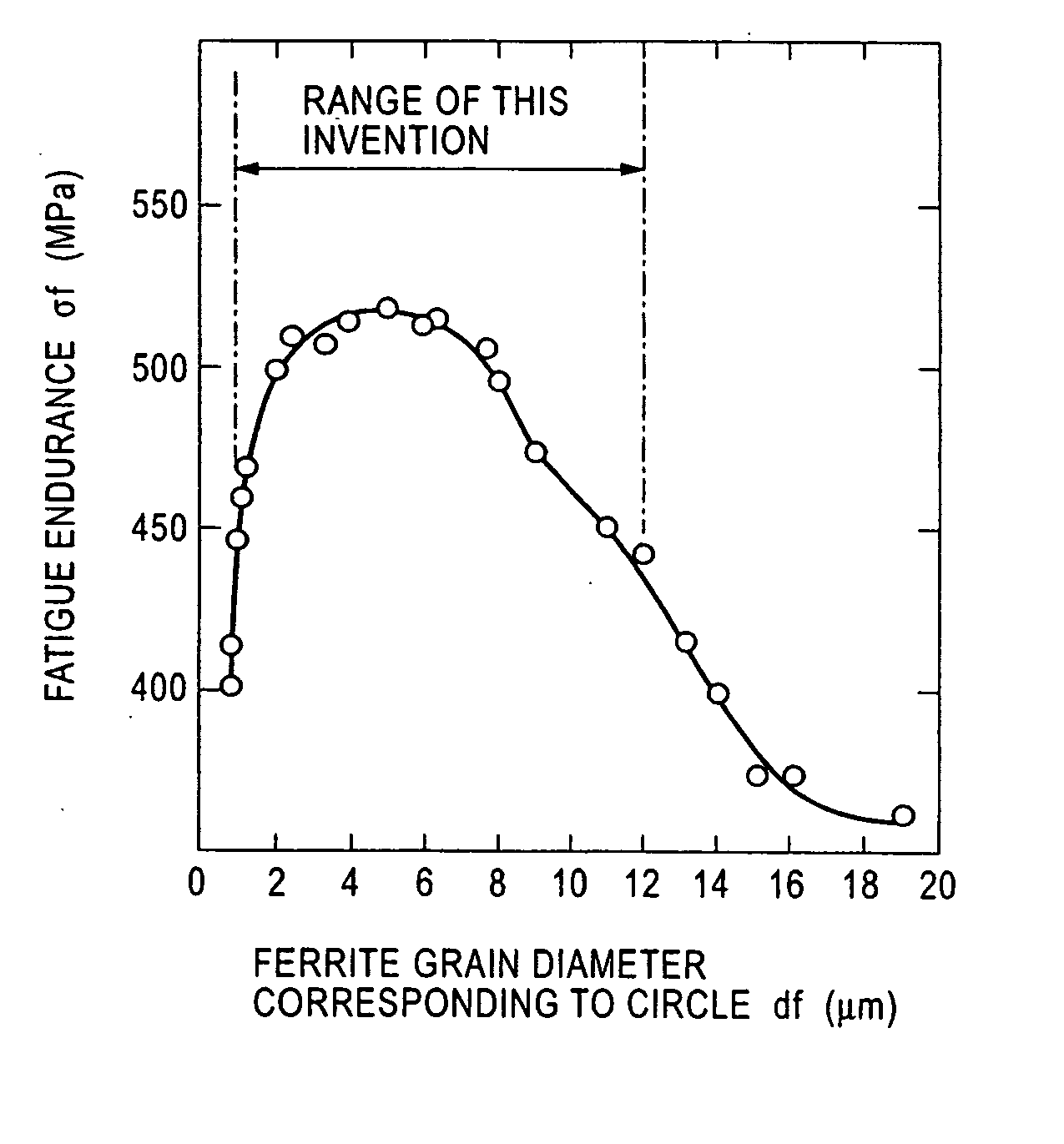

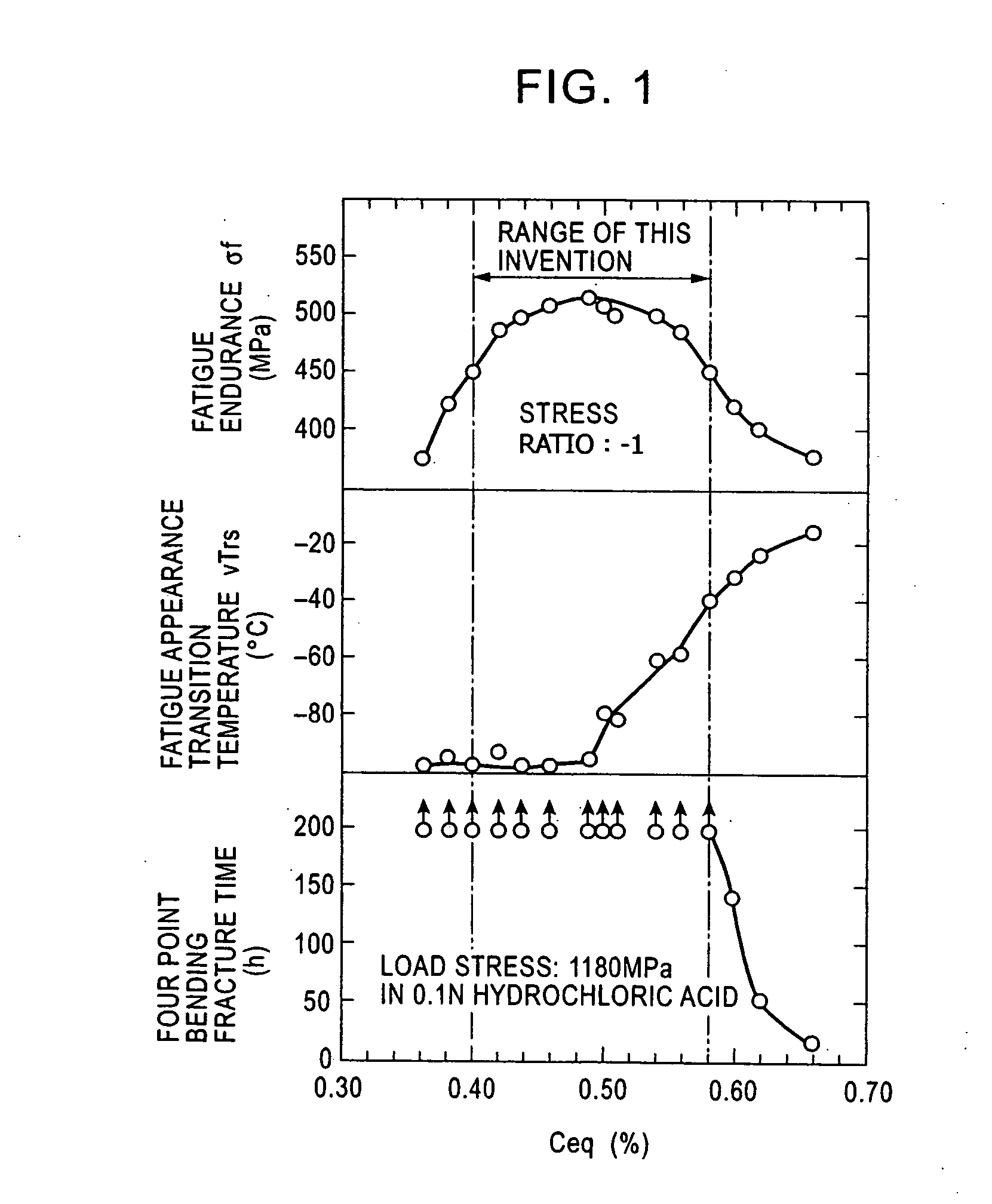

InactiveUS20070144632A1Improve fatigueGood formabilityFurnace typesIncreasing energy efficiencySlow coolingCorrosion fatigue

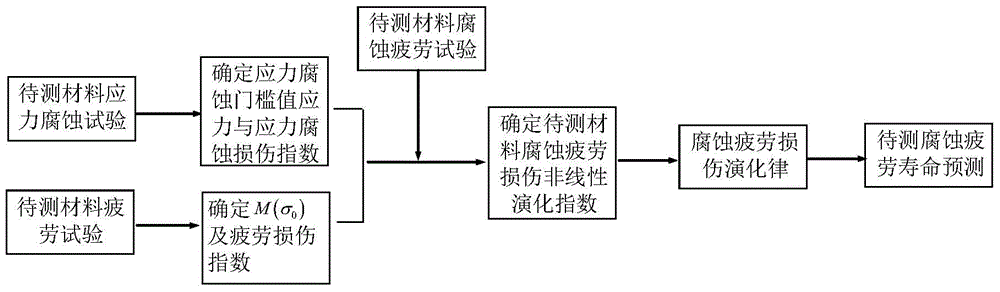

A steel having excellent formability, fatigue endurance after quenching, low temperature toughness, resistance for hydrogen embrittlement, and corrosion fatigue endurance. A method includes heating a steel slab at 1160° C. to 1320° C., hot-finish-rolling the steel slab at a finisher delivery temperature of 750° C. to 980° C., and then coiling the hot-rolled steel at a coiling temperature of 560° C. to 740° C. after slow cooling for a time of 2 seconds or more to produce a hot-rolled steel strip having a structure in which the ferrite grain diameter df corresponding to a circle is 1.1 μm to less than 1.2 μm and the ferrite volume fraction Vf is 30% to 98%, the steel slab containing 0.18 to 0.29% of C, 0.06 to 0.45% of Si, 0.91 to 1.85% of Mn, 0.019% or less of P, 0.0029% or less of S, 0.015 to 0.075% of sol. Al, 0.0049% or less of N, 0.0049% or less of O, 0.0001 to 0.0029% of B, 0.001 to 0.019% of Nb, 0.001 to 0.029% of Ti, 0.001 to 0.195% of Cr, and 0.001 to 0.195% of Mo so that the carbon equivalent Ceq satisfies a value of 0.4 to less than 0.58, and the total x of multiplying factors including that for B according to Grossmann satisfies a value of 1.2 to less than 1.7.

Owner:JFE STEEL CORP +1

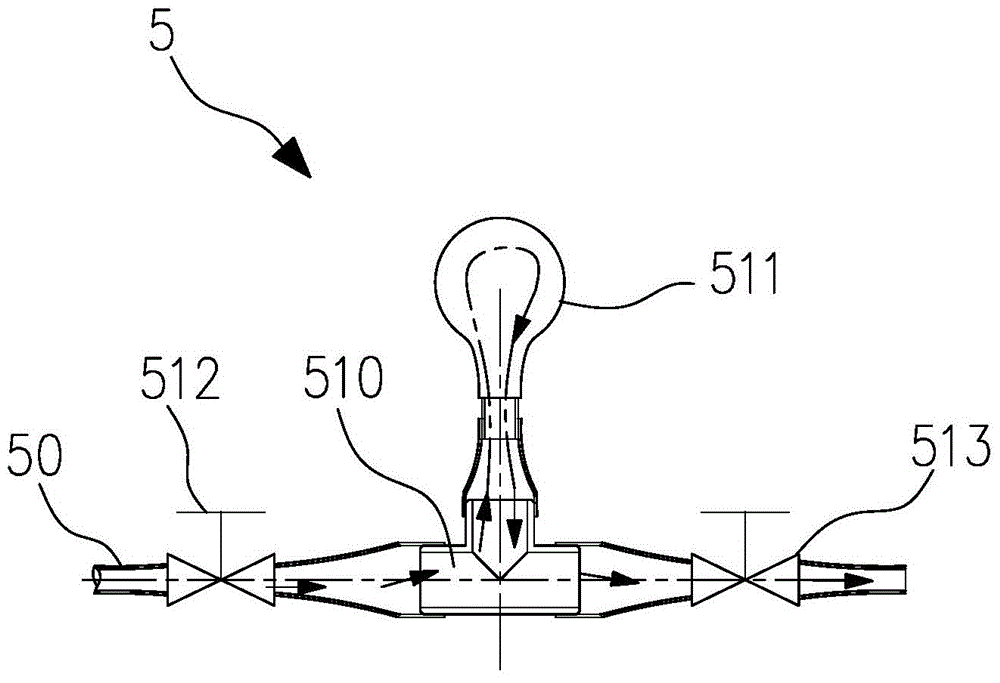

Corrosion fatigue life prediction method based on damage evolution

InactiveCN104062196ACycle simpleOvercome deficienciesWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFatigue damagePredictive methods

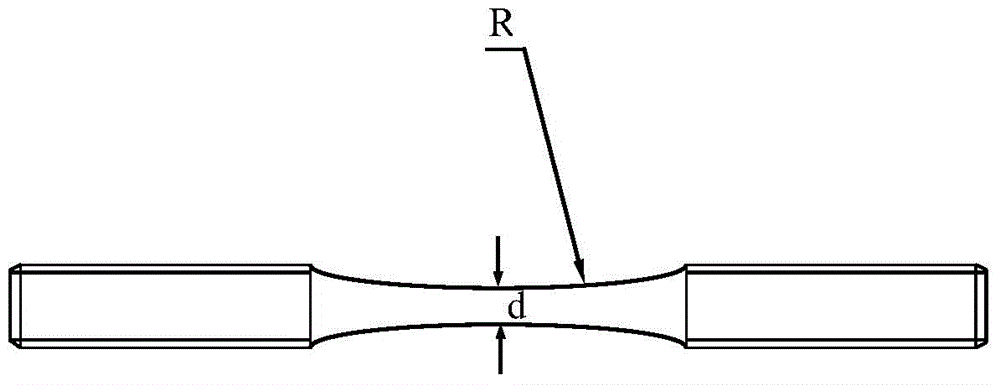

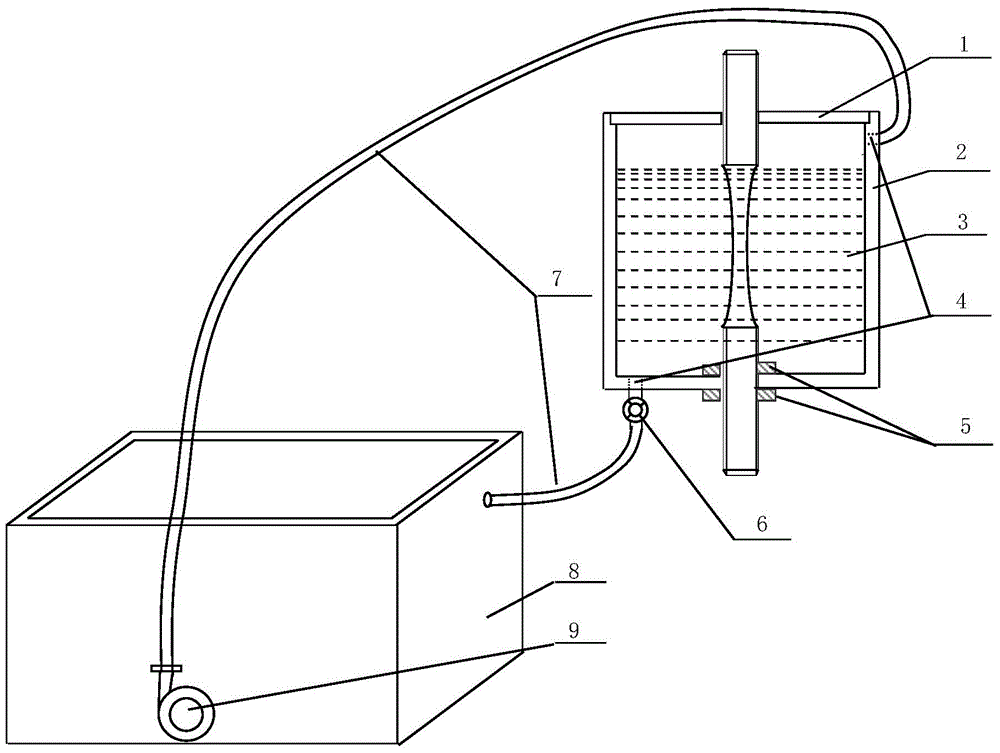

The invention belongs to technical field of metal material corrosion and particularly relates to a corrosion fatigue life prediction method based on damage evolution. The method includes following steps: carrying out a stress corrosion test to a to-be-tested material for determining a stress threshold value of the stress corrosion and a damage index; carrying out a fatigue test to the to-be-tested material for determining a fatigue damage parameter; determining a corrosion fatigue damage nonlinear evolution index of the to-be-tested material; and predicting a corrosion fatigue life of the to-be-tested material. A corrosion solution circulating device in the invention can achieve cyclic refreshing of a corrosion liquid in a metal material corrosion fatigue and stress corrosion test. The corrosion fatigue life is predicted through a method of combining theory with experimental investigation so that defects in an analytical method and a test method are overcome. The prediction method is reasonable and is accurate in result. The predicted result is free of any influence due to combination of environment and the material. The prediction method is simple in operation, is easy to carry out, is strong in popularizing performance and is convenient in engineering application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

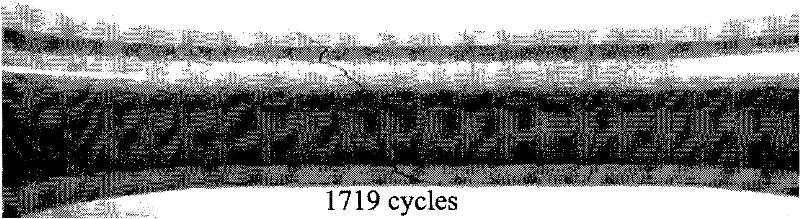

Test method for acoustic emission detection cable coating corrosion fatigue crack initiation and growth

ActiveCN107219119AOptimal critical thicknessMaterial analysis using acoustic emission techniquesMaterial strength using tensile/compressive forcesCrazingAcoustic emission

The invention relates to a test method for acoustic emission detection cable coating corrosion fatigue crack initiation and growth. The test method comprises the following steps of manufacturing a coating cable sample, searching for critical rupturing tensile force, configuring a corrosion medium, filling with the corrosion medium, clamping the coating cable sample, carrying out a fatigue test, recording a crack initiation moment, carrying out a crack growth test, evaluating a crack growth rate, drawing an S-N curve and searching for the optimal coating thickness. According to the test method provided by the invention, the crack initiation moment and the crack growth rate of the coating cable sample can be effectively monitored, the optimal coating thickness under different stress amplitudes can be found, the service life of the cable coating is prolonged, and the economic loss is reduced.

Owner:HOHAI UNIV

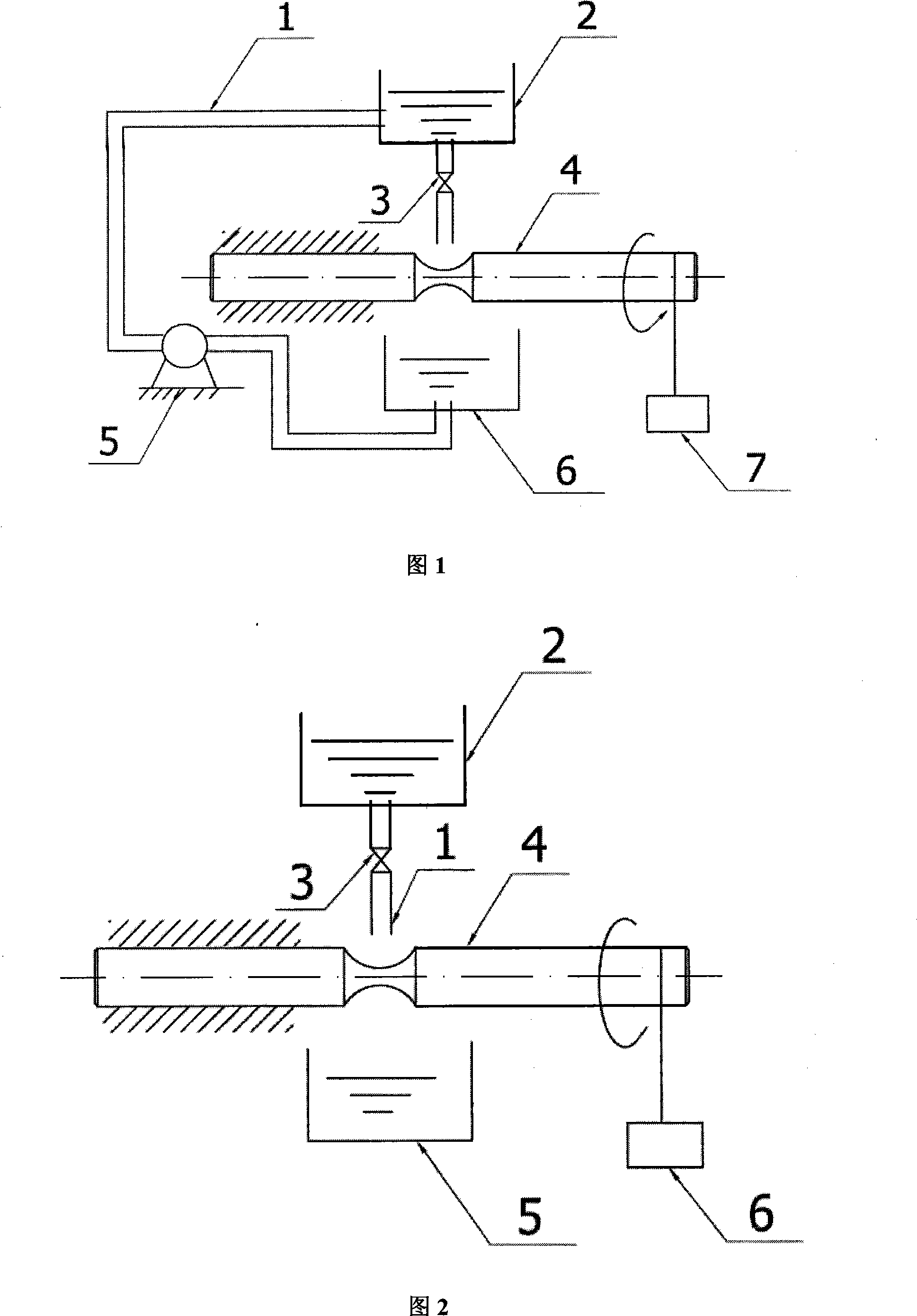

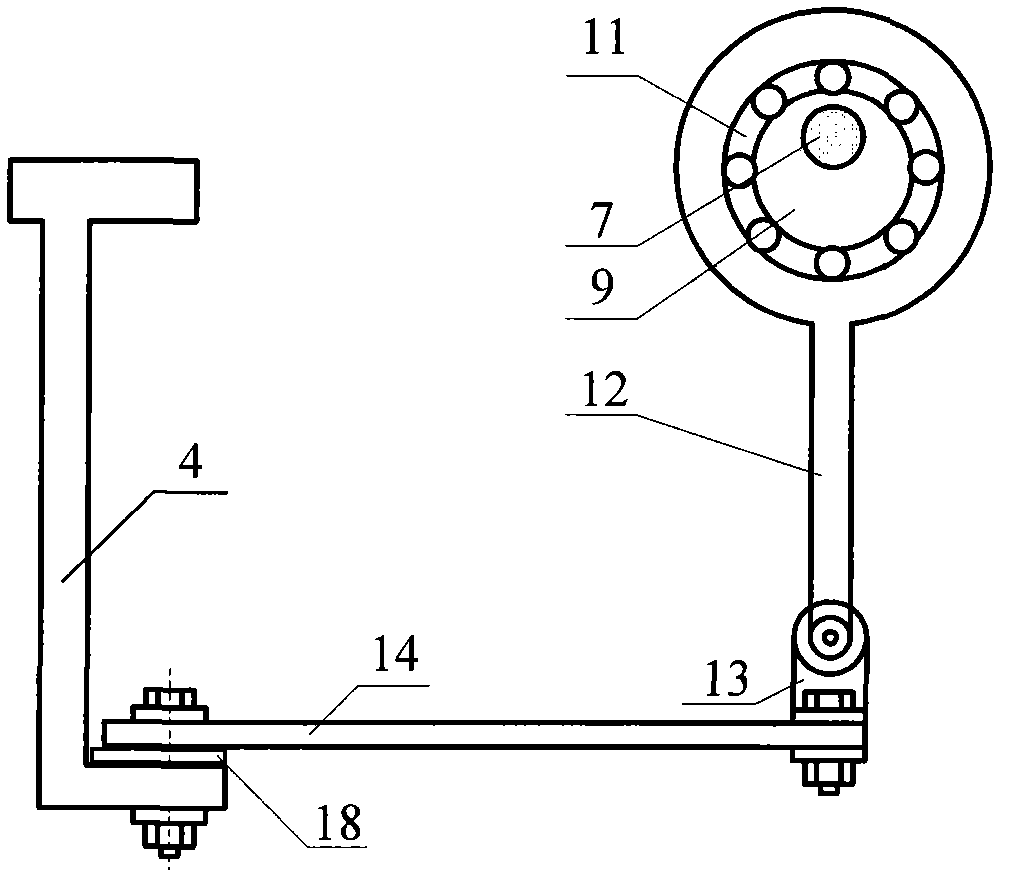

Rotating and bending corrosion fatigue testing device

InactiveCN101221108ASimple structureSimple and fast operationMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceBending fatigue testCorrosion fatigue

The invention discloses a rotary bending corrosion fatigue test device. The device includes a rotary bending fatigue test device and a corrosion liquor supplying system; wherein, the rotary bending fatigue test device is used for mounting a test piece and applies bending load on the test piece during the process of driving the test piece to rotate and realizes the test on the fatigue data of the test piece. The corrosion liquor supplying system includes a liquor storage tank, a transfusion pump, a flow adjusting valve and a connecting pipeline. The corrosion liquor supplying system feeds the corrosion liquor to the test piece during testing in real time from an output opening. The invention realizes the testing on the middle, high cycle and ultra-high cycle corrosion fatigue performance of the material by adding the corrosion liquor supplying system based on the existing rotary bending fatigue test device machine. As the design of the test device is approximate to an engineering design, the measured result by using the device has a greater reference value to the engineering design. The corrosion fatigue test device of the invention has the advantages of simple structure and convenient operation, and can get standardized test results.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

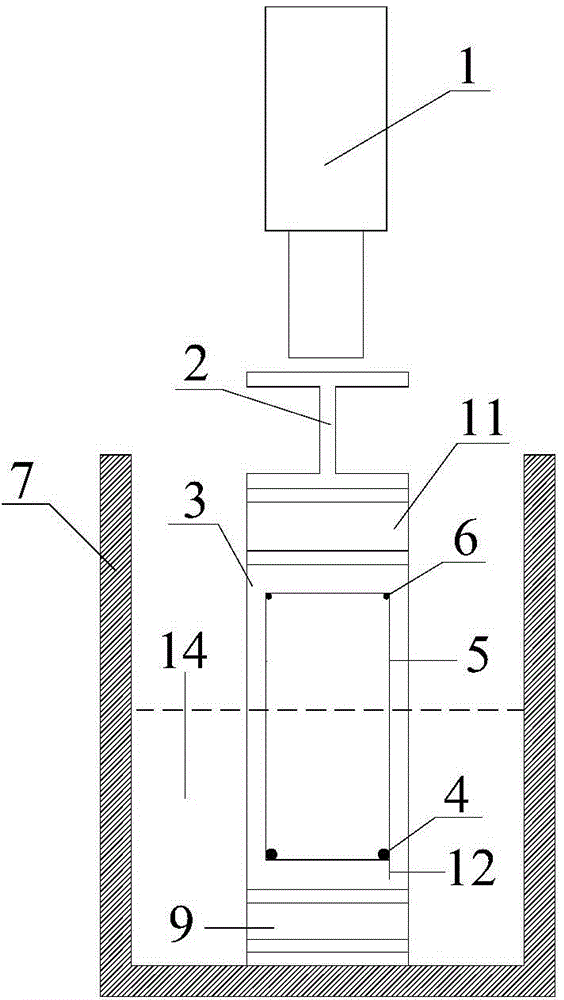

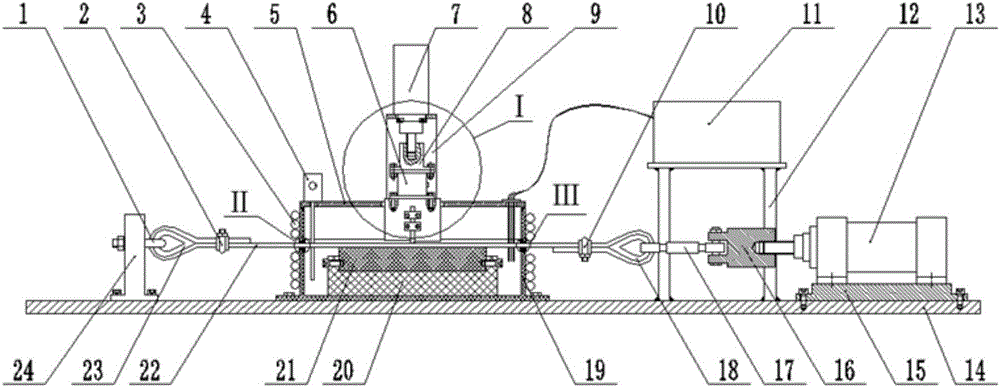

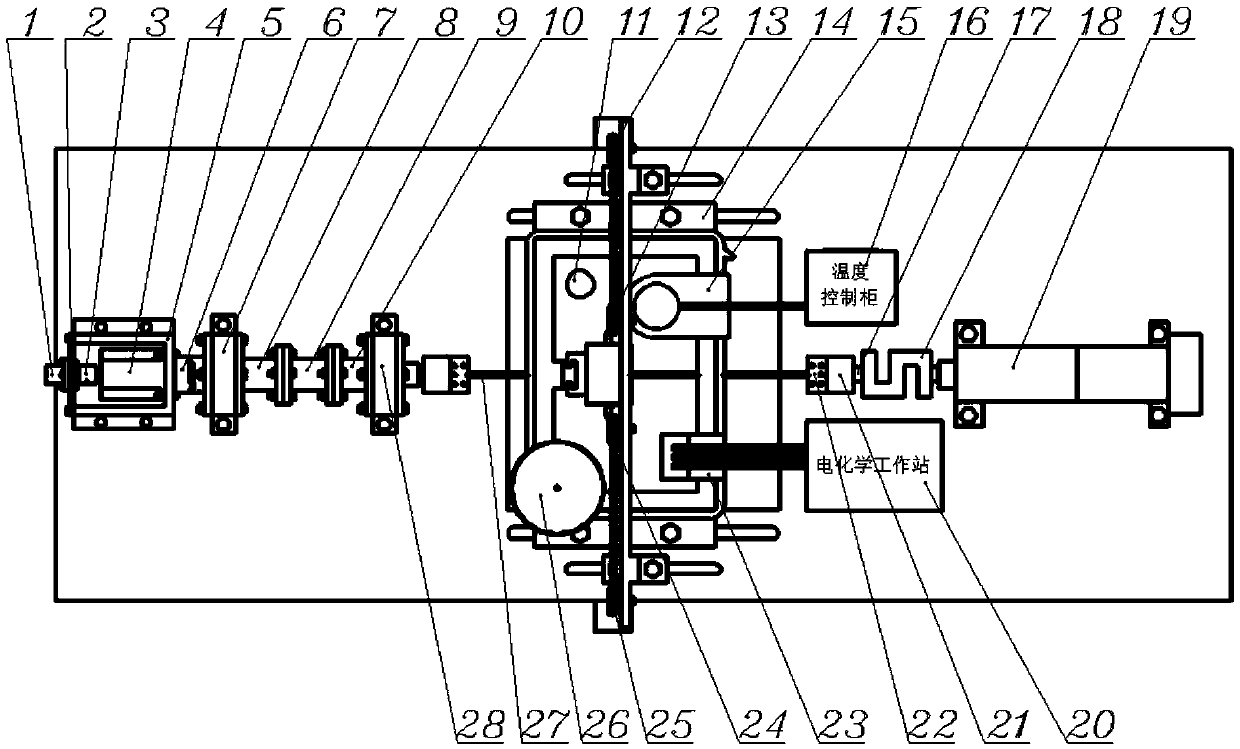

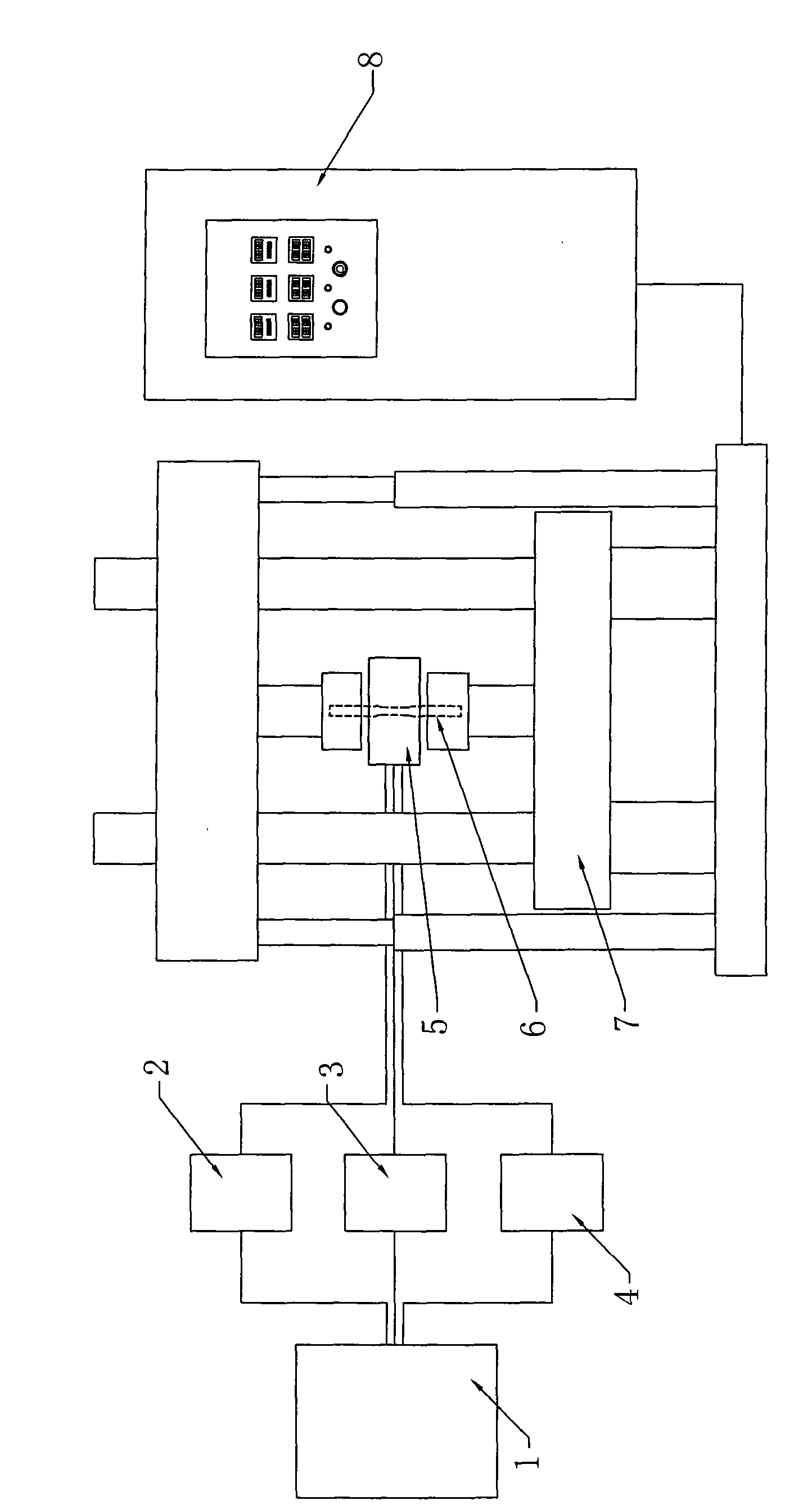

Device and method for monitoring friction and corrosion fatigue damage to twisted type lifting steel wire rope of super deep vertical shaft

ActiveCN106290035APredicted service lifeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceSupporting systemMonitoring system

The invention discloses a device for monitoring friction and corrosion fatigue damage to a twisted type lifting steel wire rope of a super deep vertical shaft. The device comprises a supporting system, a tension-tension fatigue system, a constant-temperature corrosion system, a dynamic loading system and a monitoring system, wherein the supporting system supplies supporting to the tension-tension fatigue system, the constant-temperature corrosion system, the dynamic loading system and the monitoring system; the fatigue steel wire rope to be monitored is provided with a fatigue load supplied by the tension-tension fatigue test system in the horizontal direction, a dynamic contact load supplied by the dynamic loading system in the vertical direction, and a constant-temperature corrosion environment supplied by the constant-temperature corrosion system respectively; the monitoring system monitors the fatigue load, the dynamic contact load and a change of friction force on the fatigue steel wire rope. The device can realize the friction and corrosion fatigue damage to steel wire ropes on adjacent twisted layers of a twisted type lifting machine of the super deep vertical shaft under different temperatures, corrosion solutions, different dynamic tensile loads and different dynamic contact load parameters and dynamically monitor the damage.

Owner:CHINA UNIV OF MINING & TECH

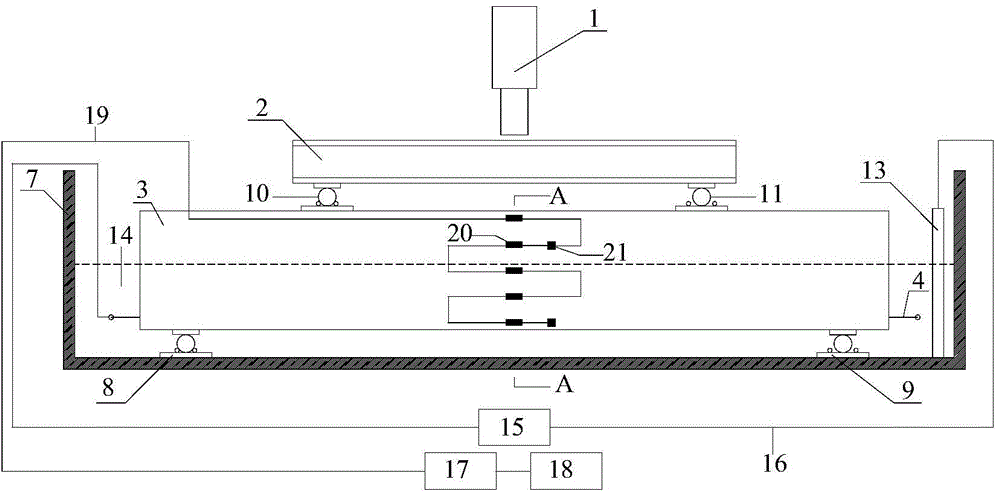

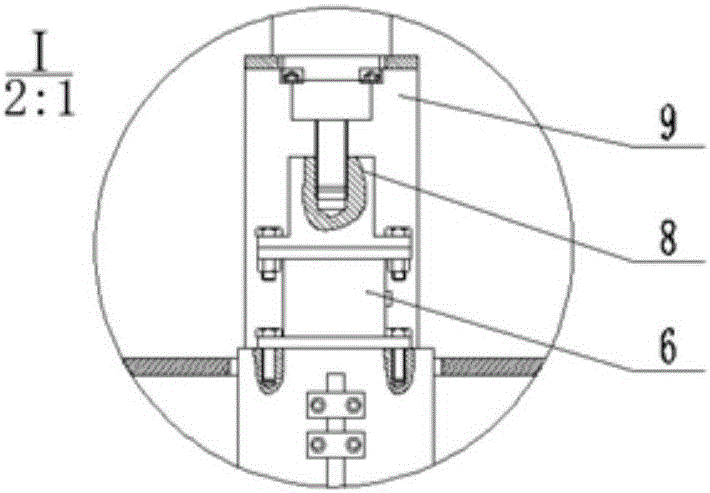

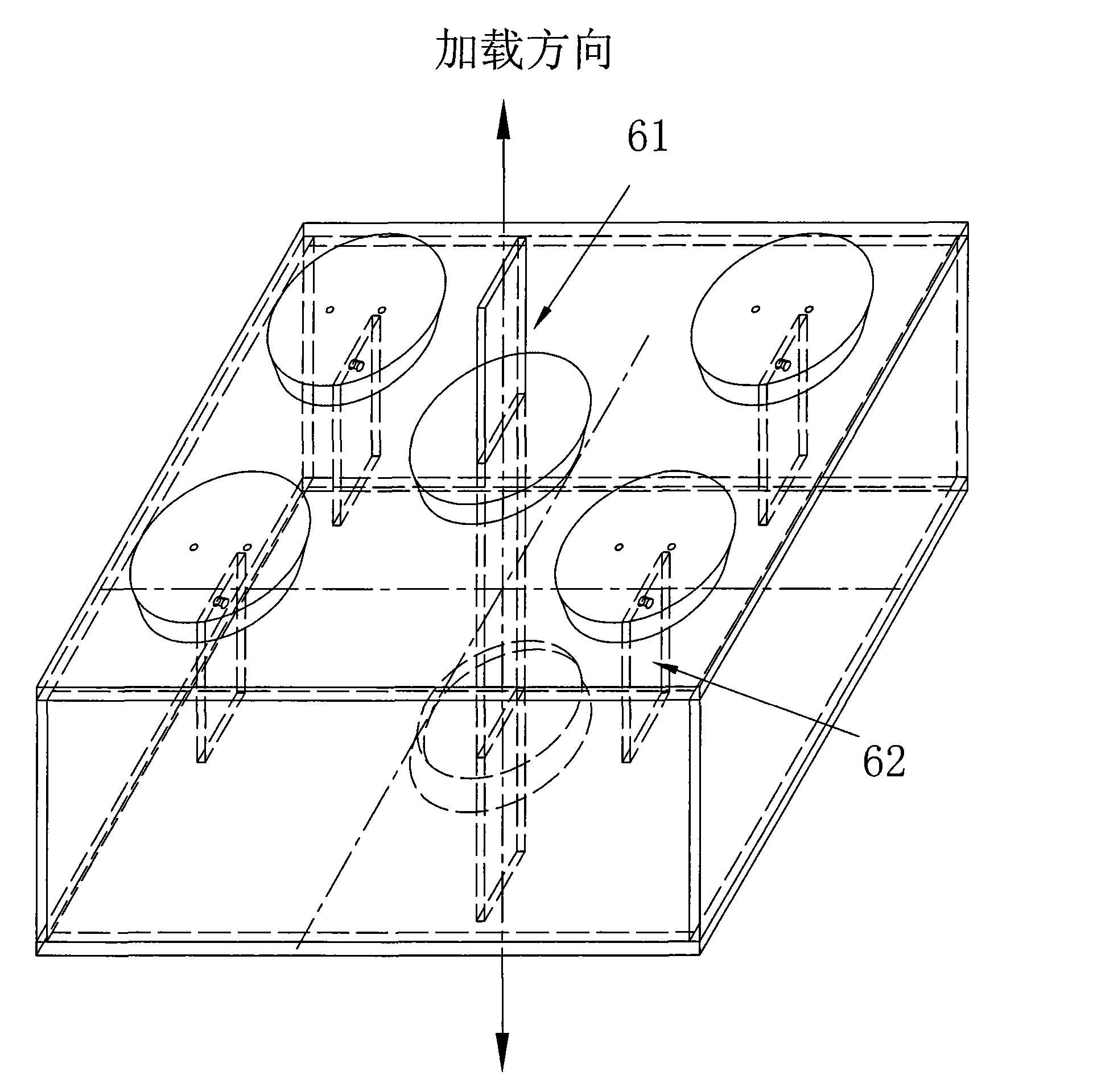

Multiaxis fretting corrosion fatigue damage monitoring device and multiaxis fretting corrosion fatigue damage monitoring method for kilometer deep shaft hoisting rope

The invention discloses a multiaxis fretting corrosion fatigue damage monitoring device and a multiaxis fretting corrosion fatigue damage monitoring method for a kilometer deep shaft hoisting rope. The device comprises a fretting system arranged on a base rack, a tension-torsional fatigue system and a constant-temperature corrosion system, wherein the constant-temperature corrosion system comprises an anti-corrosion tank, a constant-temperature control system, a cooling system and an electrochemical corrosion system; the fretting system comprises an upper loading unit, a lower loading unit and a fatigue steel wire; the upper loading unit comprises a clump weight, an anti-corrosion linear guide rail, a two-dimensional force sensor, an anti-corrosion loading steel wire clamp and a loading steel wire; the lower loading unit comprises a loading clump weight, an anti-corrosion fiber rope, a guide bracket, a guide pulley, an anti-corrosion linear guide rail and a friction gasket; the tension-torsional fatigue system comprises an angular displacement sensor, a double-shaft motor, a torque sensor, a fatigue steel wire clamp, a tension sensor and an electric cylinder. The device and the method are capable of realizing multiaxis fretting corrosion fatigue test for the kilometer deep shaft hoisting rope under different temperatures, different corrosion liquid PH values and multiaxis fretting fatigue parameters.

Owner:CHINA UNIV OF MINING & TECH

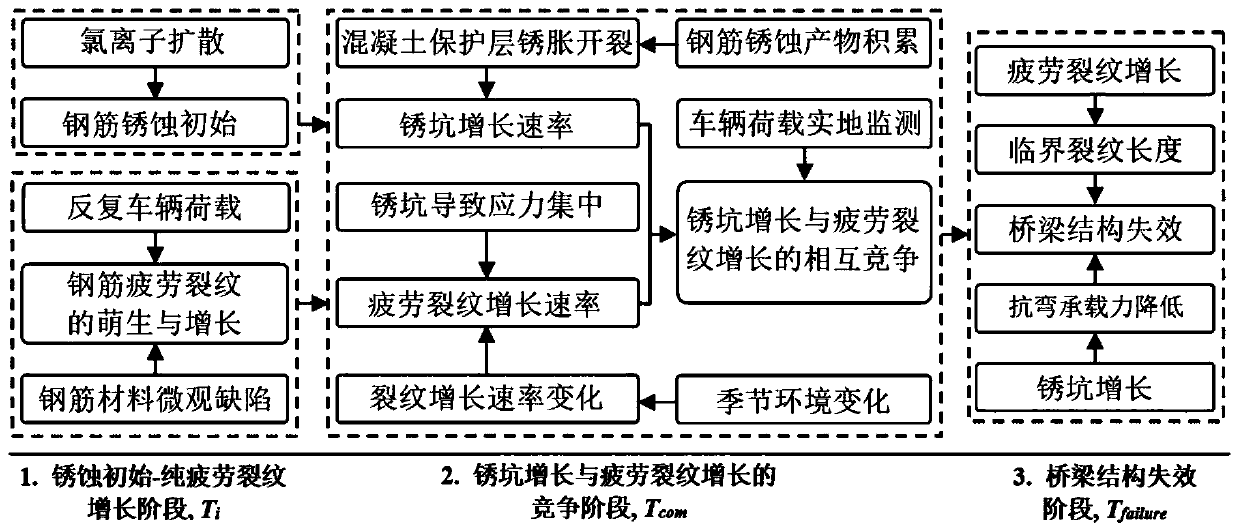

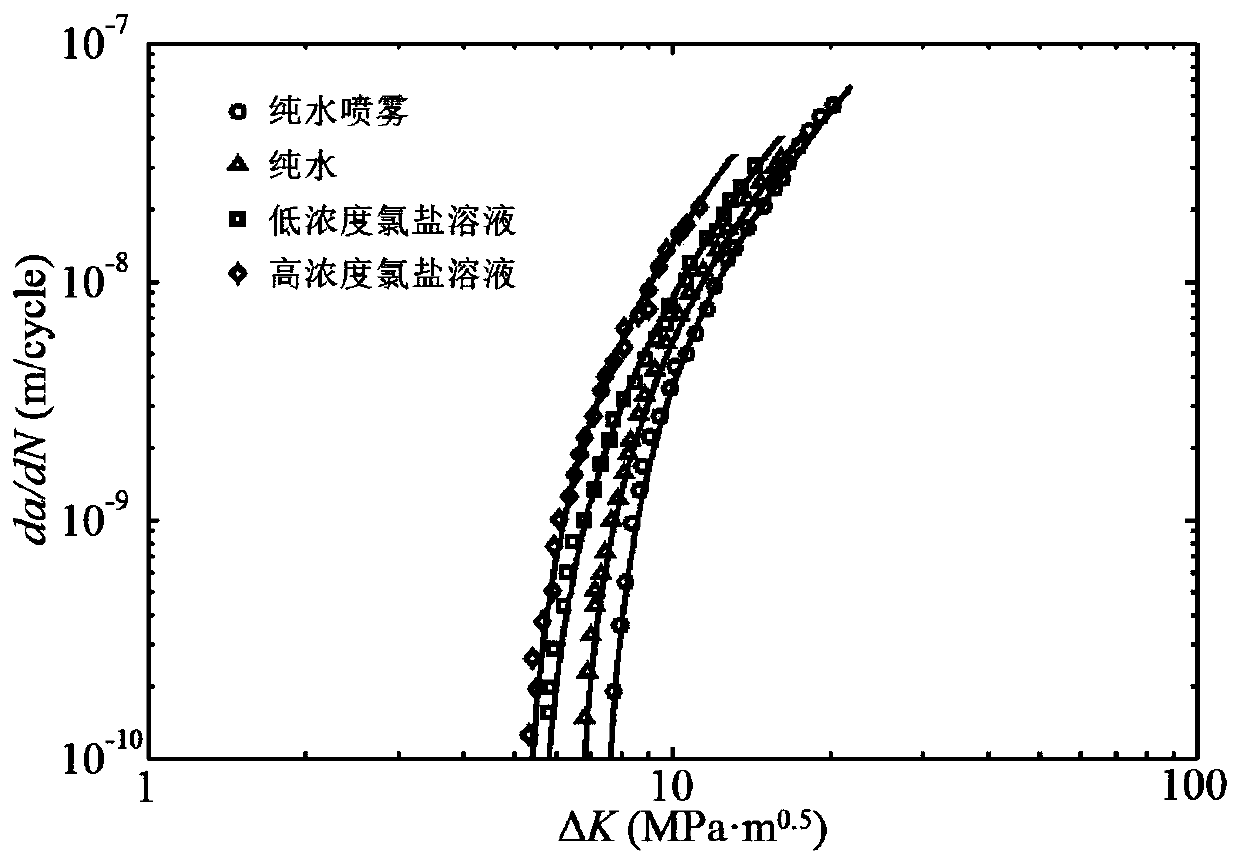

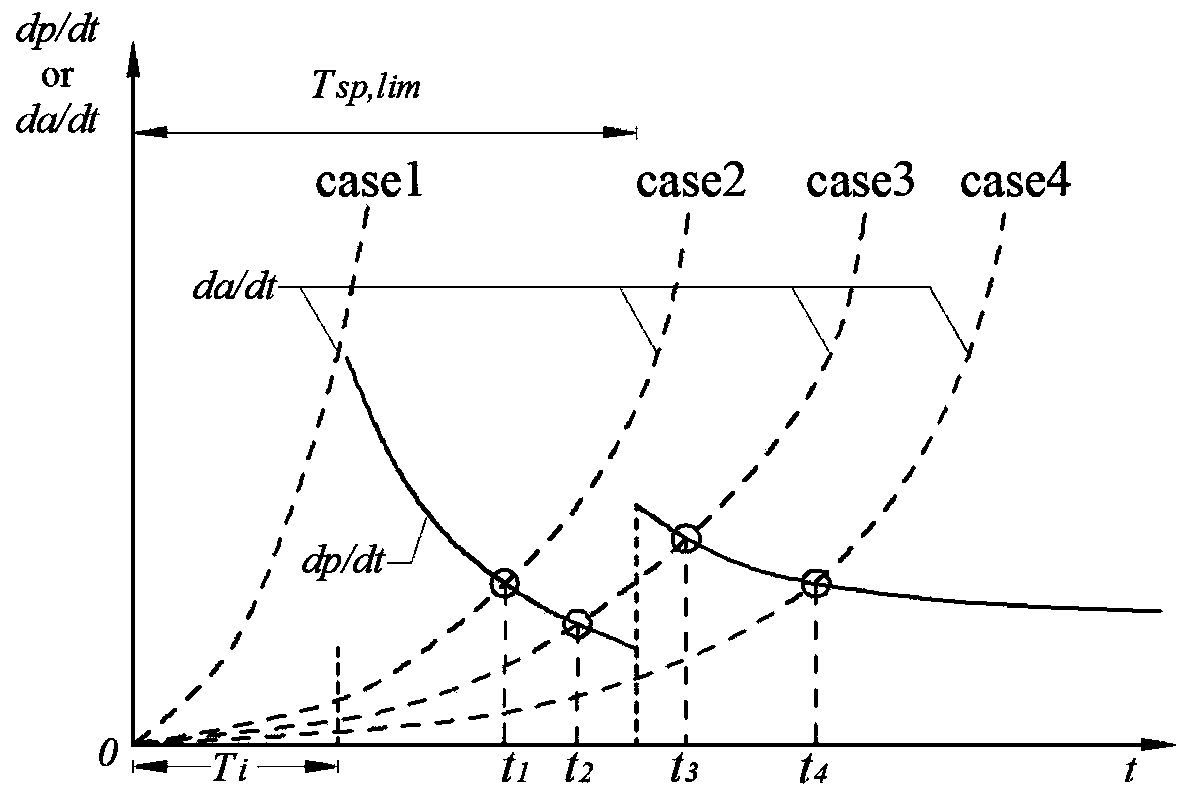

Method for predicting service life of reinforced concrete bridge under conditions of seasonal corrosion and fatigue coupling

ActiveCN109827855AEnables corrosion fatigue life assessmentNovel forecasting methodWeather/light/corrosion resistanceMaterial testing goodsStress concentrationRebar

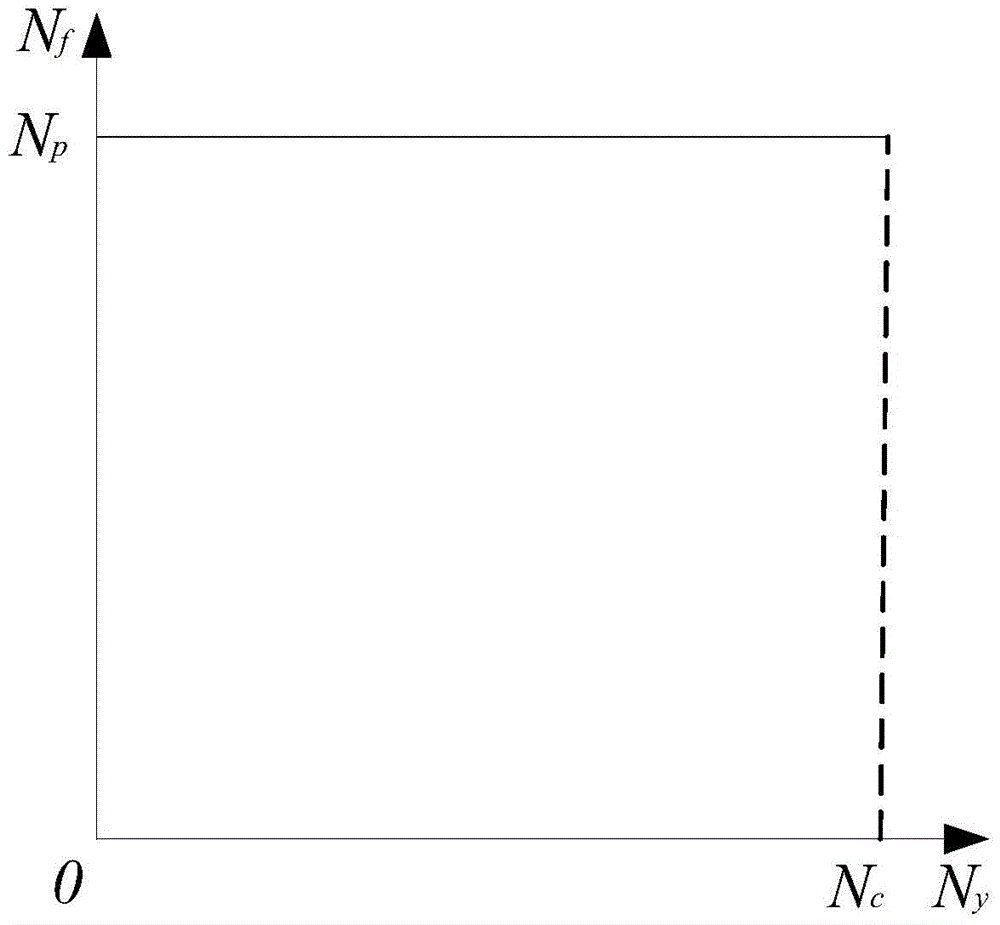

The invention discloses a method for predicting the service life of a reinforced concrete bridge under the conditions of seasonal corrosion and fatigue coupling. The method comprises the steps: dividing the service life of the reinforced concrete bridge into three stages: corrosion initiation-pure fatigue crack development stage, a rust pit and fatigue crack competing development stage and a structure failure stage; establishing an initial reinforcing steel bar corrosion model and a rust pit growth model based on the Fick second diffusion law and the consideration of the influence of concreterust expansion cracking damage; testing and simulating a reinforcing steel bar crack propagation rule under the influence of a four-season environment, and determining fatigue crack growth characterization parameters; constructing a stress intensity factor model considering the influence of stress concentration, and proposing a steel bar corrosion fatigue crack growth analysis method correspondingto a four-season environment; enabling the structural failure criterion to be clear, combining with the vehicle load observation information, performing the systematic consideration of the competitive coupling relation between rust pit growth and fatigue crack growth, judging a failure mode in real time, and achieving the prediction of the service life of the bridge. The method is novel and reasonable, and can provide technical support for safety assessment of the concrete bridge.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

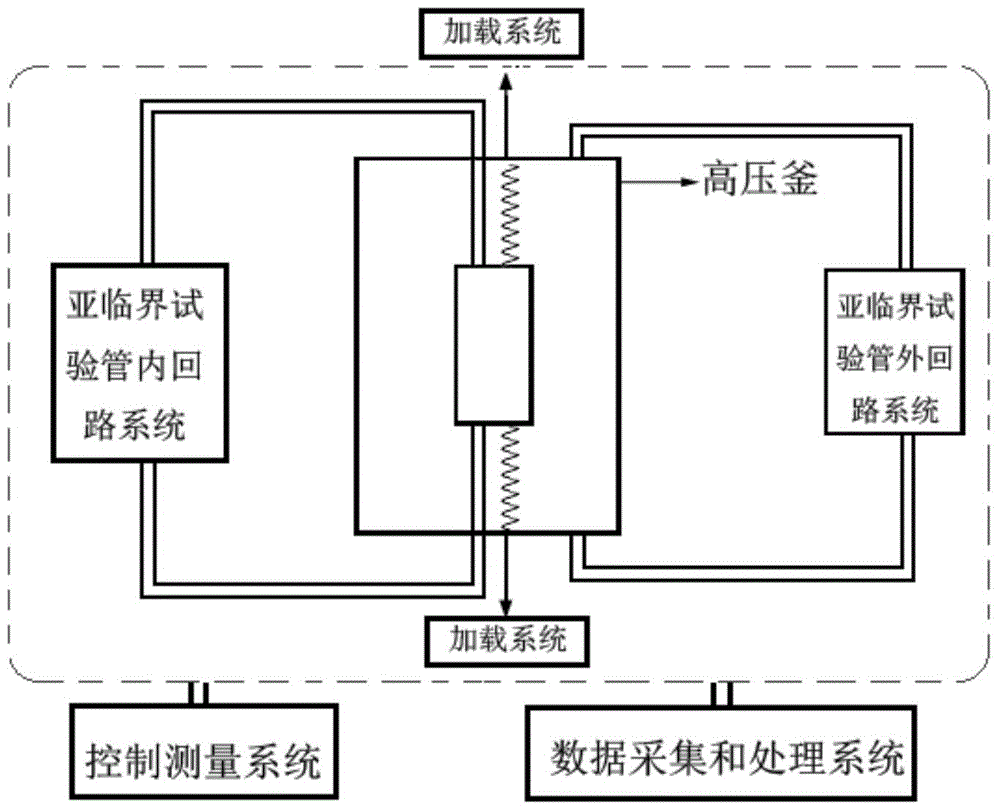

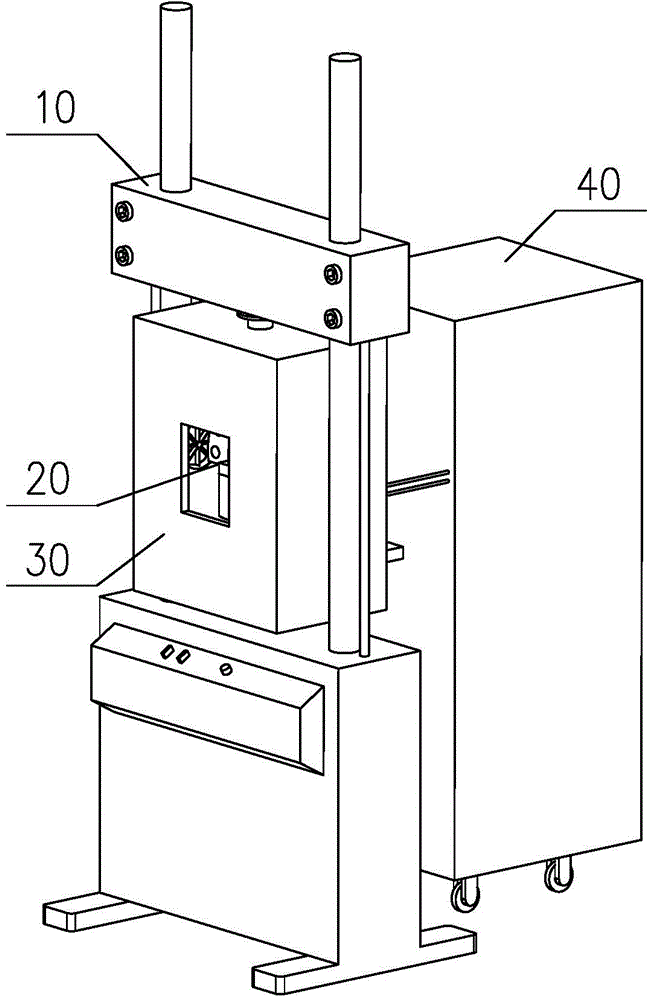

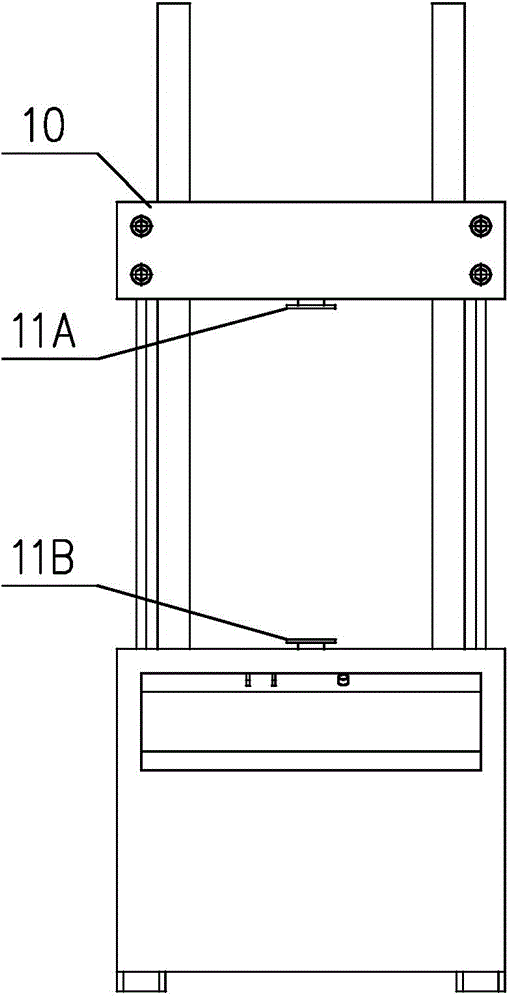

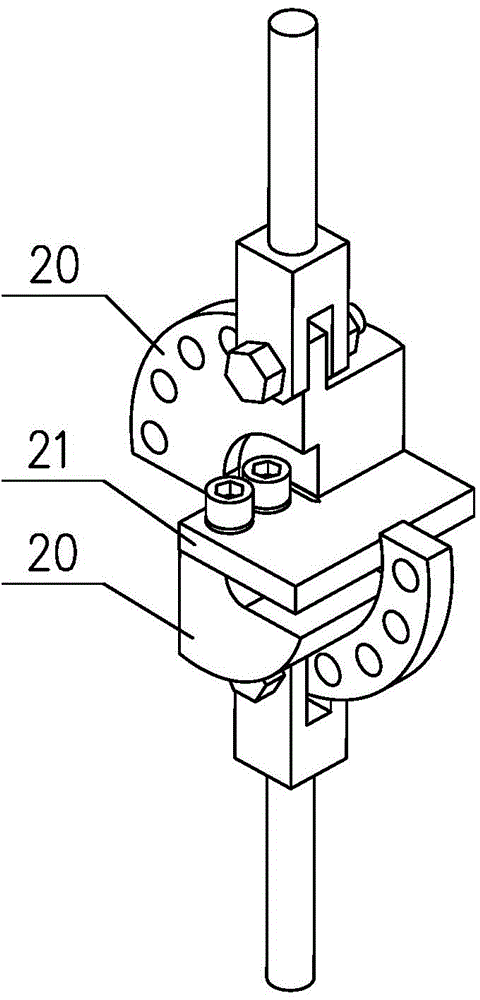

High-temperature and high-pressure water vapor environment structural material testing device

ActiveCN104458400AWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePressurized water reactorData acquisition

The invention discloses a high-temperature and high-pressure water vapor environment structural material testing device. The testing device is provided with a pipe, wherein high-temperature water flows inside and outside the pipe. The testing device comprises an autoclave, a test tube loading system, a loop system inside a test tube, a loop system outside the test tube, a controlling and measuring system and a data acquisition and processing system. The testing device which can be used for simulating the temperature, pressure, flow velocity, water chemical conditions, load and the like of a high-temperature and high-pressure water vapor environment structural material is applicable to tests in the aspects of corrosion, stress corrosion, corrosion fatigue, flow accelerated corrosion and the like of tubular specimens through complex flow and complex load coupling effect. Especially, the working conditions of different flow, different inner-side and outer-side temperatures, different pressures and different water chemistry in a heat exchange tube of a steam generator in a nuclear reaction pressurized-water reactor can be simulated to carry out related testing and research on the heat exchange tube.

Owner:UNIV OF SCI & TECH BEIJING

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

Test system for extension of multi-axis and salt-spray corrosion fatigue crack

ActiveCN104931407AContinuous, stable and reliable supplyFacilitated DiffusionWeather/light/corrosion resistanceStrength propertiesFatigue loadingFracture mechanics

The invention relates to a test system for the extension of a multi-axis and salt-spray corrosion fatigue crack. The test system comprises a fatigue tester for providing I-type, II-type, III-type and compound fatigue loads required by a test for a test sample through a pull-cut-twist multi-axis loading fixture, and further comprises a salt-spray corrosion environmental box, wherein the salt-spray corrosion environmental box comprises a salt-spray corrosion box body and a salt-spray pre-occurrence box body which are mutually communicated through a pipeline; the salt-spray pre-occurrence box body conveys air and salt water required by salt-spray forming to the salt-spray corrosion box body; the salt-spray corrosion box body provides a required salt-spray corrosion environment for the fatigue crack extension test; both the pull-cut-twist multi-axis loading fixture and the fatigue crack extension test sample are positioned in the salt-spray corrosion box body. Through the adoption of the test system, the fatigue crack extension rate and other fracture mechanics parameters under the combined action of multi-axis loads and the salt-spray corrosion environment can be measured relatively well, and thus the material selection design and the service life evaluation for marine engineering equipment serving in the salt-spray corrosion environment and under a complex stress state can be supported.

Owner:HEFEI GENERAL MACHINERY RES INST +1

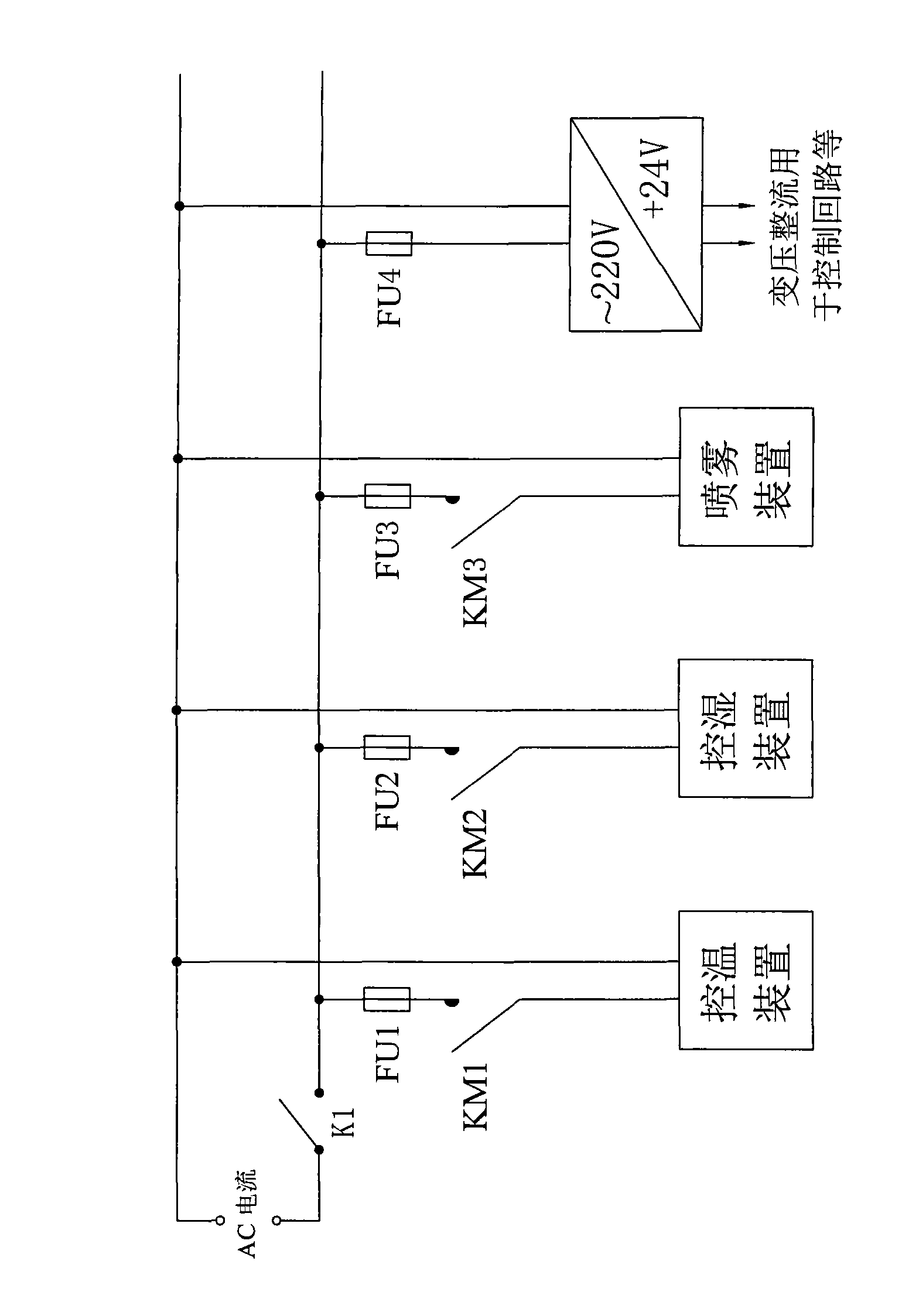

Equipment for implementing synchronous dry-wet alternate accelerated corrosion in loading process and application thereof

InactiveCN101660985ARealize temperature and humidity controlRealize wet and dry alternating corrosionPreparing sample for investigationStrength propertiesTemperature controlControl system

The invention relates to the fields of metal material accelerated corrosion and corrosion fatigue, in particular to equipment for implementing synchronous dry-wet alternate accelerated corrosion in aloading process and application thereof. In the equipment, a temperature control device and a humidity control device sense temperature and humidity in a corrosion fatigue tank, and transmit signals to a control system, and the control system sends an instruction for adjusting the temperature and humidity in the corrosion fatigue tank to implement temperature control and humidity control. Simultaneously, a loaded sample in the corrosion fatigue tank is regularly sprayed through the instruction of the control system so as to implement dry-wet alternate corrosion. The equipment can assist fatigue testers and slow strain equipment to implement the synchronous dry-wet alternate corrosion of the sample in the fatigue, tensile or slow strain process, also can be used for simulating temperature control and humidity control corrosion fatigue, tensile or slow strain tests under different weather conditions, and temperature control and humidity control dry-wet alternate corrosion tests, and implements the synchronous dry-wet alternate accelerated corrosion in the corrosion fatigue process and in the slow strain process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Determination method of cable steel wire corrosion fatigue damage law, application, device and fixture

ActiveCN110044740AAccurate service lifeEasy to operateWeather/light/corrosion resistanceMaterial strength using repeated/pulsating forcesElectrical resistance and conductanceMeasuring instrument

The invention discloses a determination method of a cable steel wire corrosion fatigue damage law, application, a device and a fixture. Four parts of specific content are involved, wherein the first part is the corrosion fatigue damage law acquisition method which comprises the steps that a corrosion fatigue test is performed by processing an environment spectrum and a load spectrum of service conditions, a resistance method is used to measure corrosion fatigue test general damage and stress corrosion damage, the difference value between the two types of damage is corrosion fatigue damage, andthe law of the damage is fitted by use of a formula; the second part is the application of the corrosion fatigue damage law, wherein after the test law is obtained, a high-precision resistance measuring instrument is used to test current resistance, and then residual life can be obtained; the third part is the device used for determining the damage law, wherein the device comprises a double-layercorrosion cavity, a salt mist box, the high-precision resistance measuring instrument, a constant-temperature box and a fatigue testing machine; and the fourth part is the insulated fixture used forpreventing interference of equipment on resistance testing. Through combined use of the four parts, reasonable residual life of a cable steel wire in a complicated environment can be given, and convenience is brought to engineering practice.

Owner:SOUTHEAST UNIV

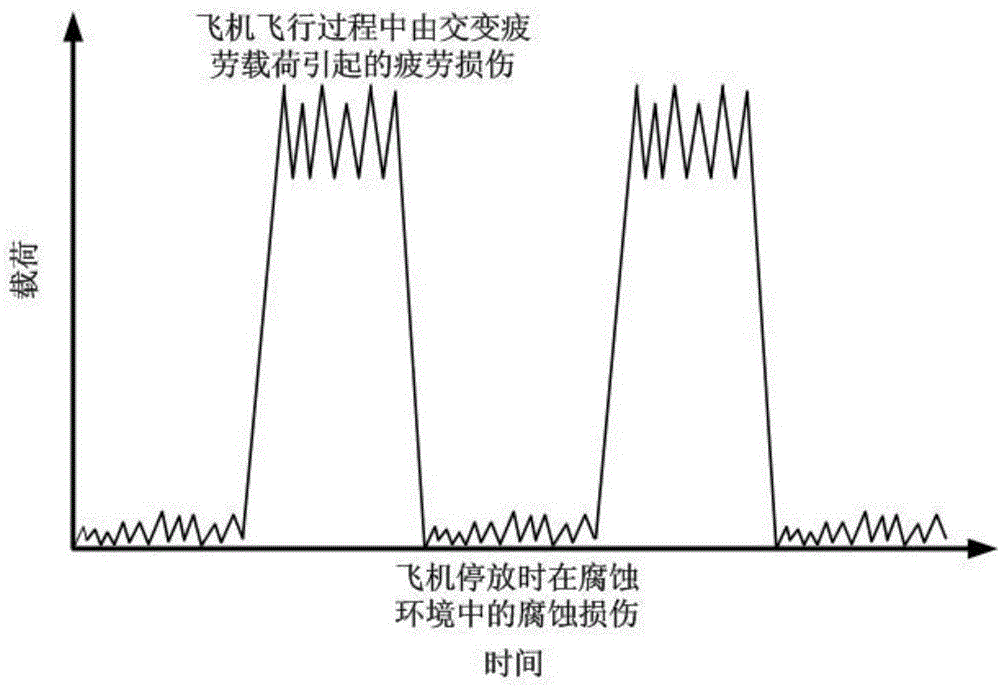

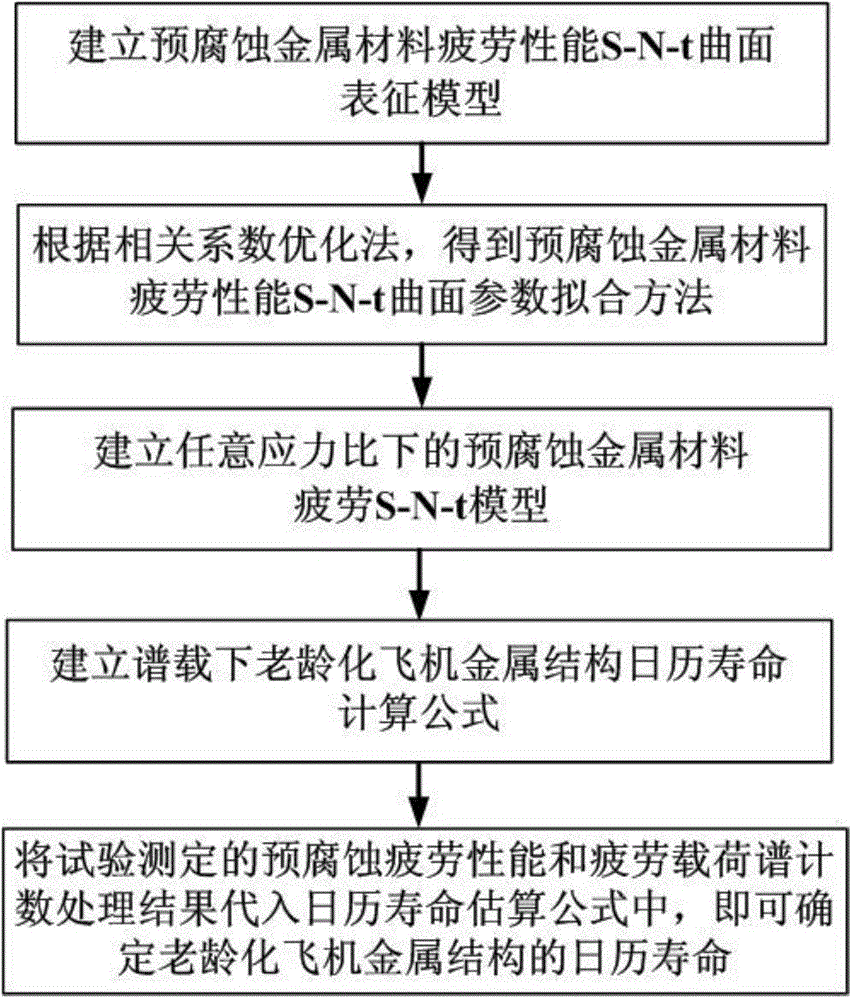

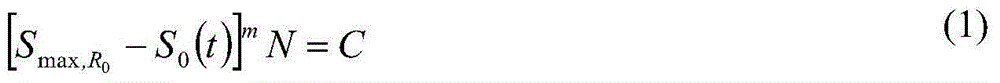

Novel method for forecasting calendar life of metal structure of aging aircraft

ActiveCN104978490ACalendar life getsFew parametersSpecial data processing applicationsFatigue loadingStress ratio

A novel method for forecasting a calendar life of a metal structure of an aging aircraft. The method comprises five steps of: S1, establishing a prior-corroded metal material fatigue property S-N-t curve surface representation model; S2, according to a relative coefficient optimization method, establishing a prior-corroded metal material fatigue property S-N-t curve surface parameter fitness method; S3, establishing a prior-corroded metal material fatigue S-N-t curve surface model in a random stress ratio; S4, establishing a calendar life calculating formula for the metal structure of the aging aircraft under a spectrum load; and S5, substituting material fatigue properties with different prior-corrosion life limits, which are measured by testing, and a fatigue load spectrum counting processing result into the calendar life calculating formula to determine the calendar life of the metal structure of the aging aircraft. The novel method is simple and practical; a small number of model parameters need to be measured by testing; and the calendar life of the metal structure of the aging aircraft can be determined only by substituting the material corrosion fatigue properties with different prior-corrosion life limits and fatigue load spectrum data into the calendar life calculating formula.

Owner:北京睦邦仁科技有限公司

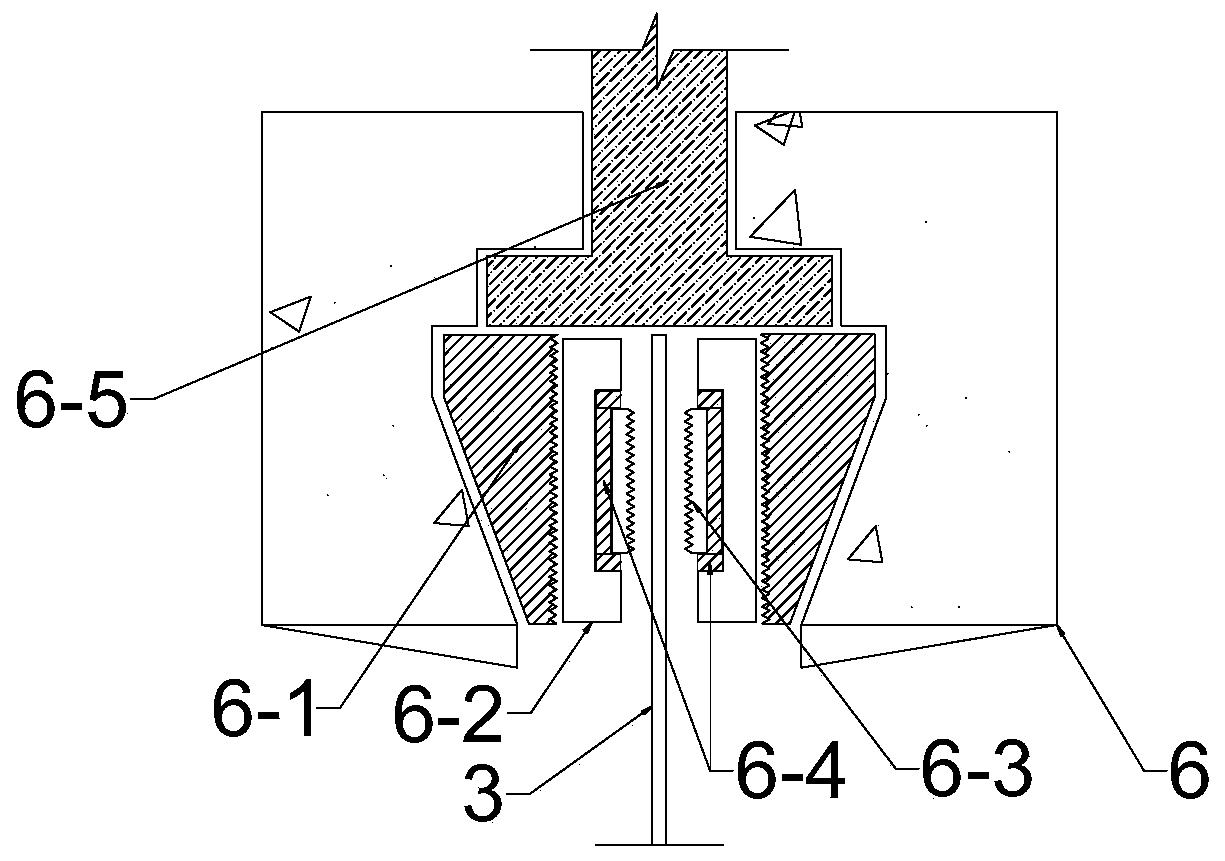

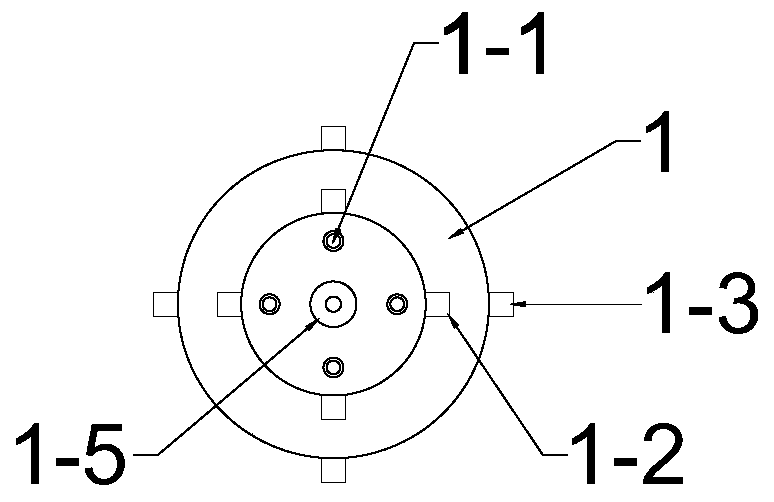

Electrochemical in-situ measurement electrolytic cell device

InactiveCN101451941AAvoid Galvanic CorrosionWon't interfereWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceSalt bridgeMetallic materials

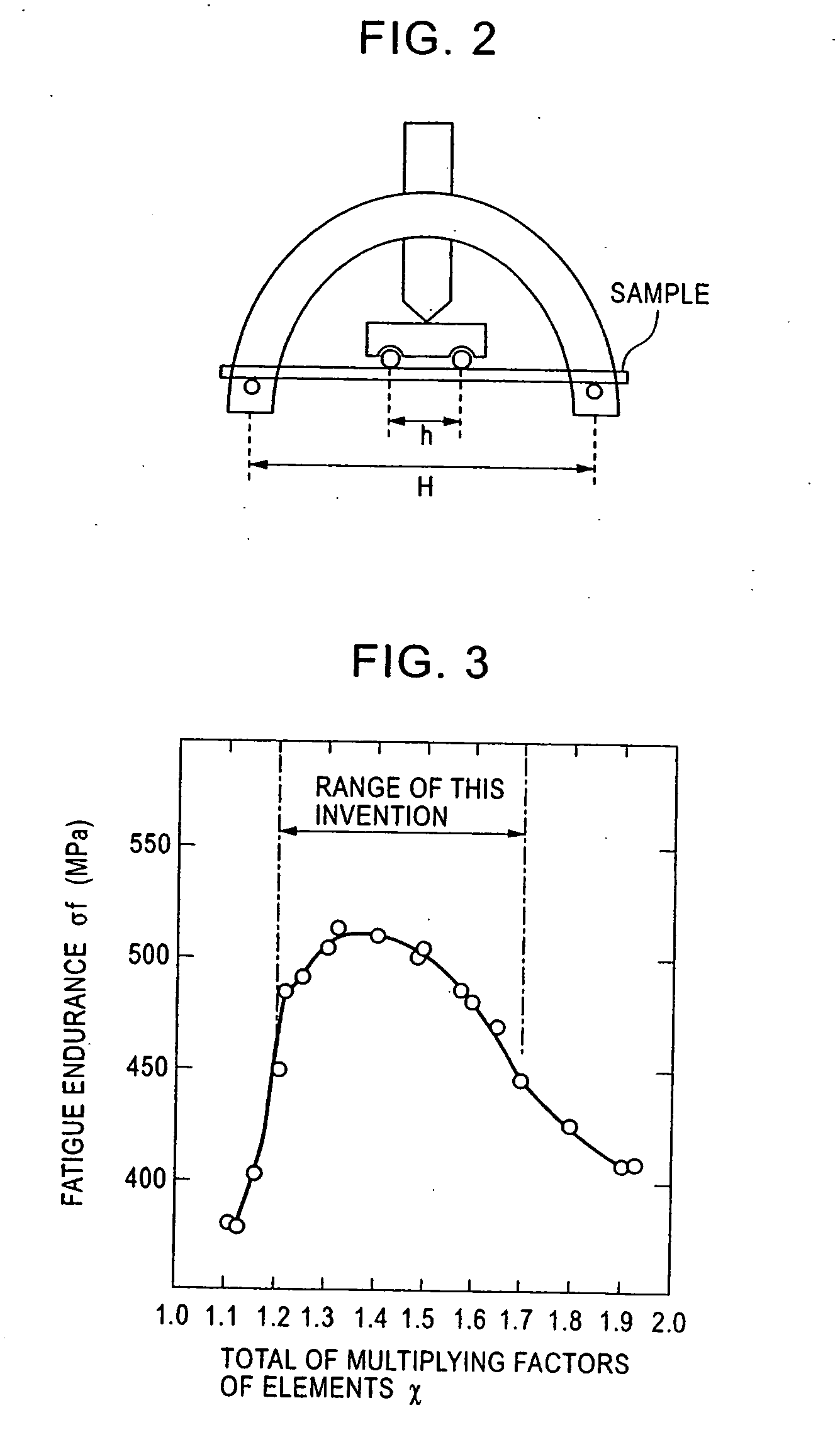

The invention relates to an electrolytic cell device of electrochemistry electrochemistry for performing corrosion fatigue crack propagation experiment on metal materials, belonging to the technical field of material corrosion research, mainly comprising a front trough solid, a rear trough solid, a three point bending specimen, a bolt, a water outlet, a water inlet, an auxiliary electrode, a salt bridge, a reference electrode and a conical flask; the front trough solid and the rear trough solid are symmetrical halfbody structures, which fix the electrolytic cell in a box shaped structure on two sides of the three point bending specimen through a thru bolt. A groove placing auxiliary electrode is arranged at the center of the front plate inner side of the front trough solid. One end of the salt bridge communicates with the auxiliary electrode and the work electrode through etching solution, and the other end is connected with the reference electrode through the conical flask full of saturated potassium chloride solution. A left posterior lateral plate and a right posterior lateral plate have the same height and the same width with a left front lateral plate and a right front lateral plate, which is a symmetrical shape and structure, having simple and practical structure, multiple measurable functions, long service life, high measuring precision and good accuracy.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

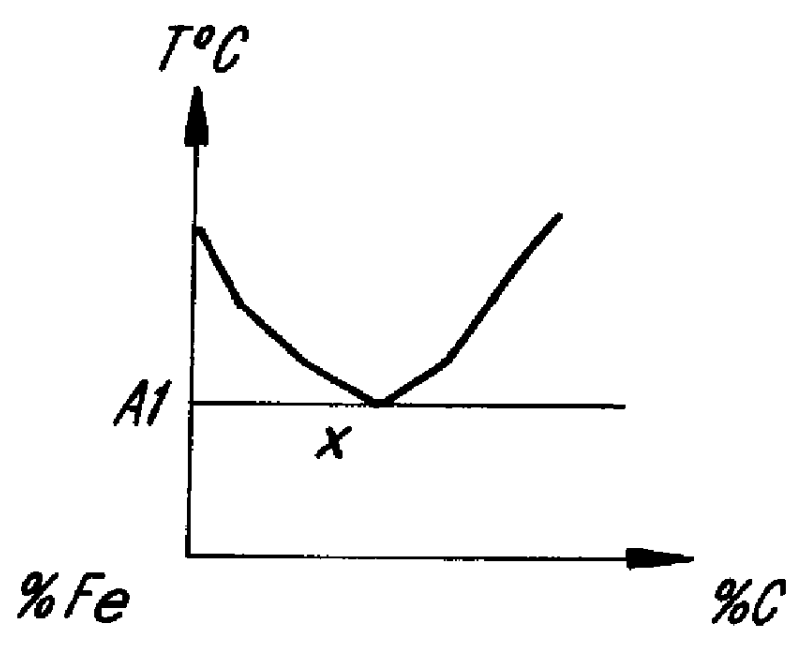

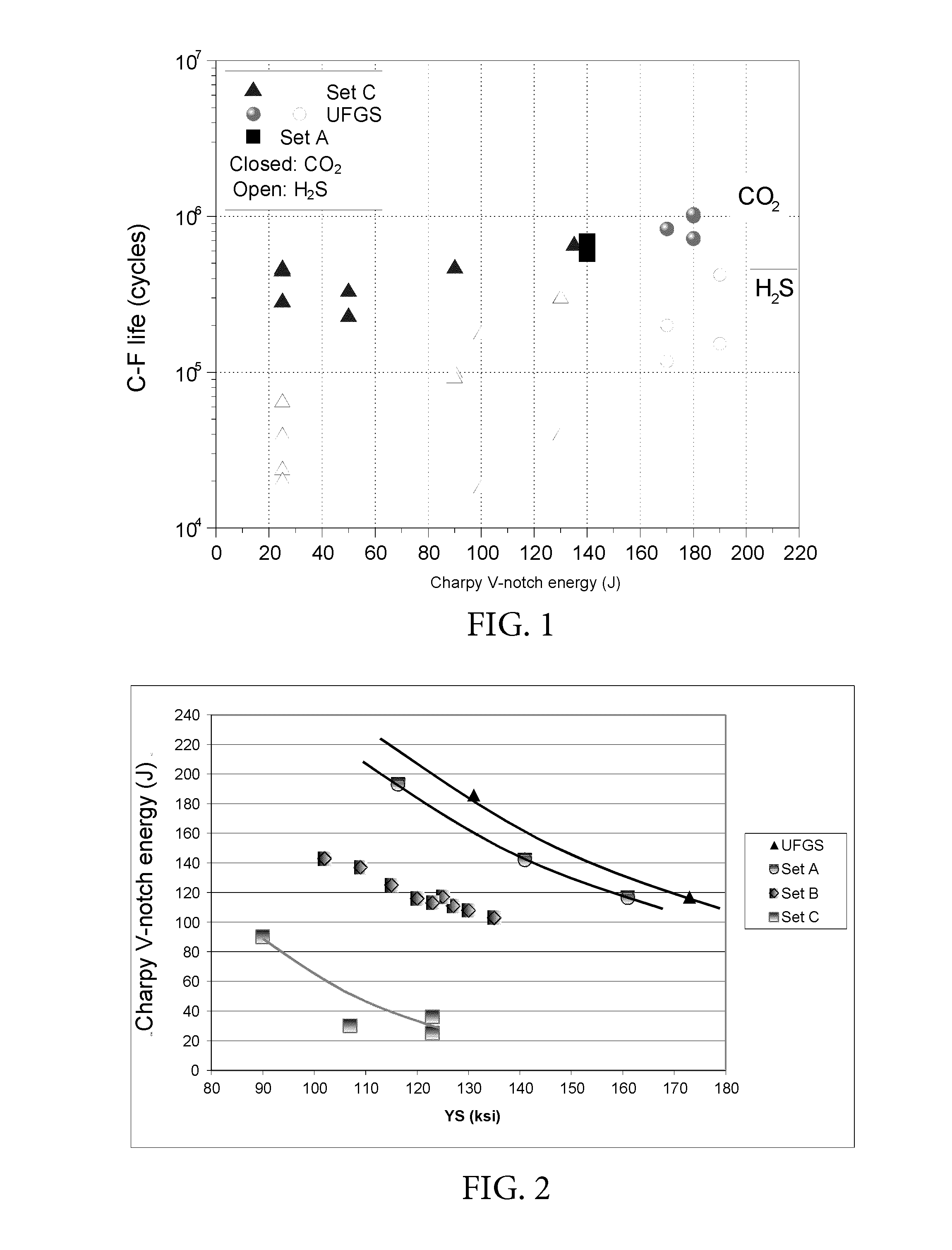

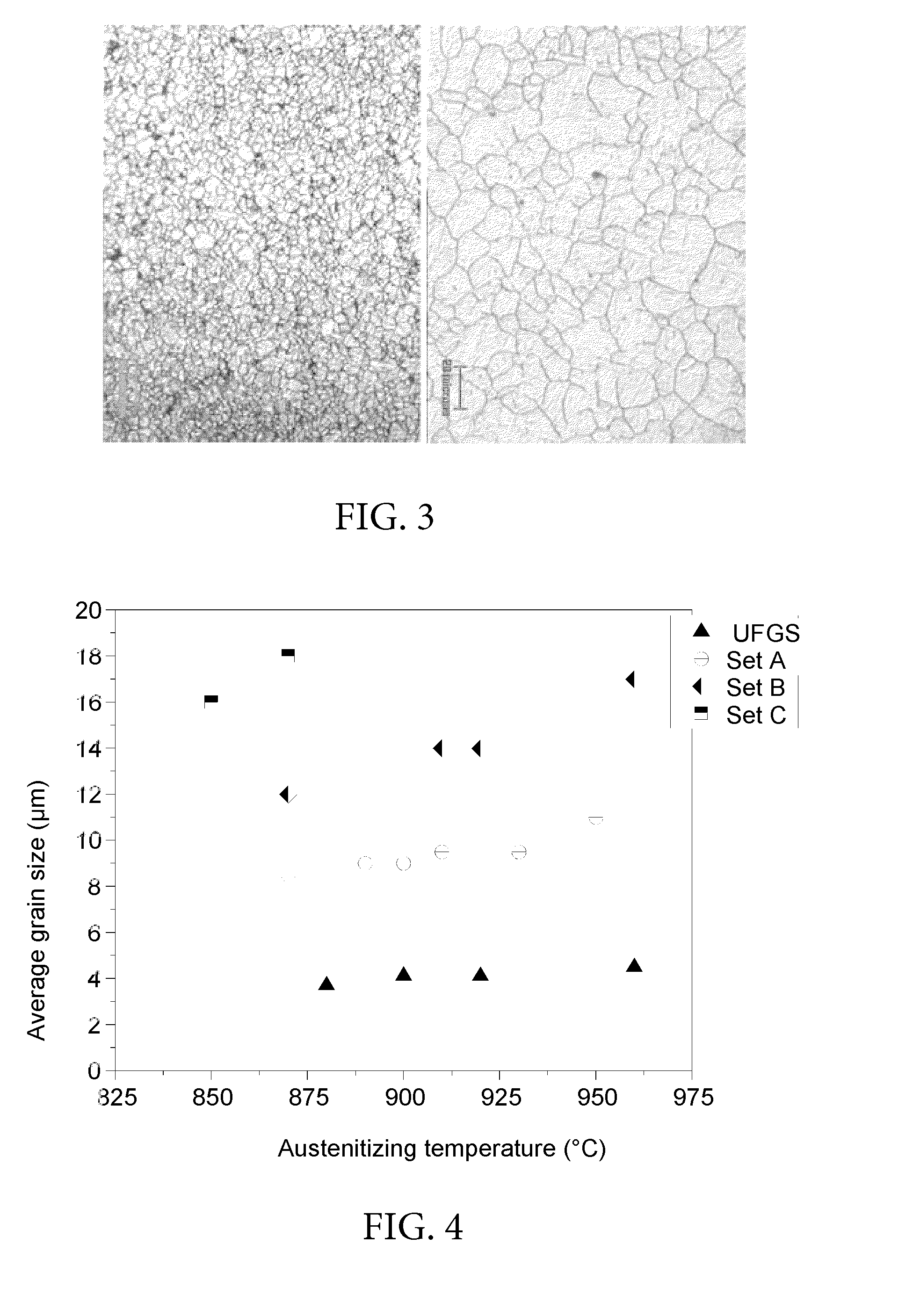

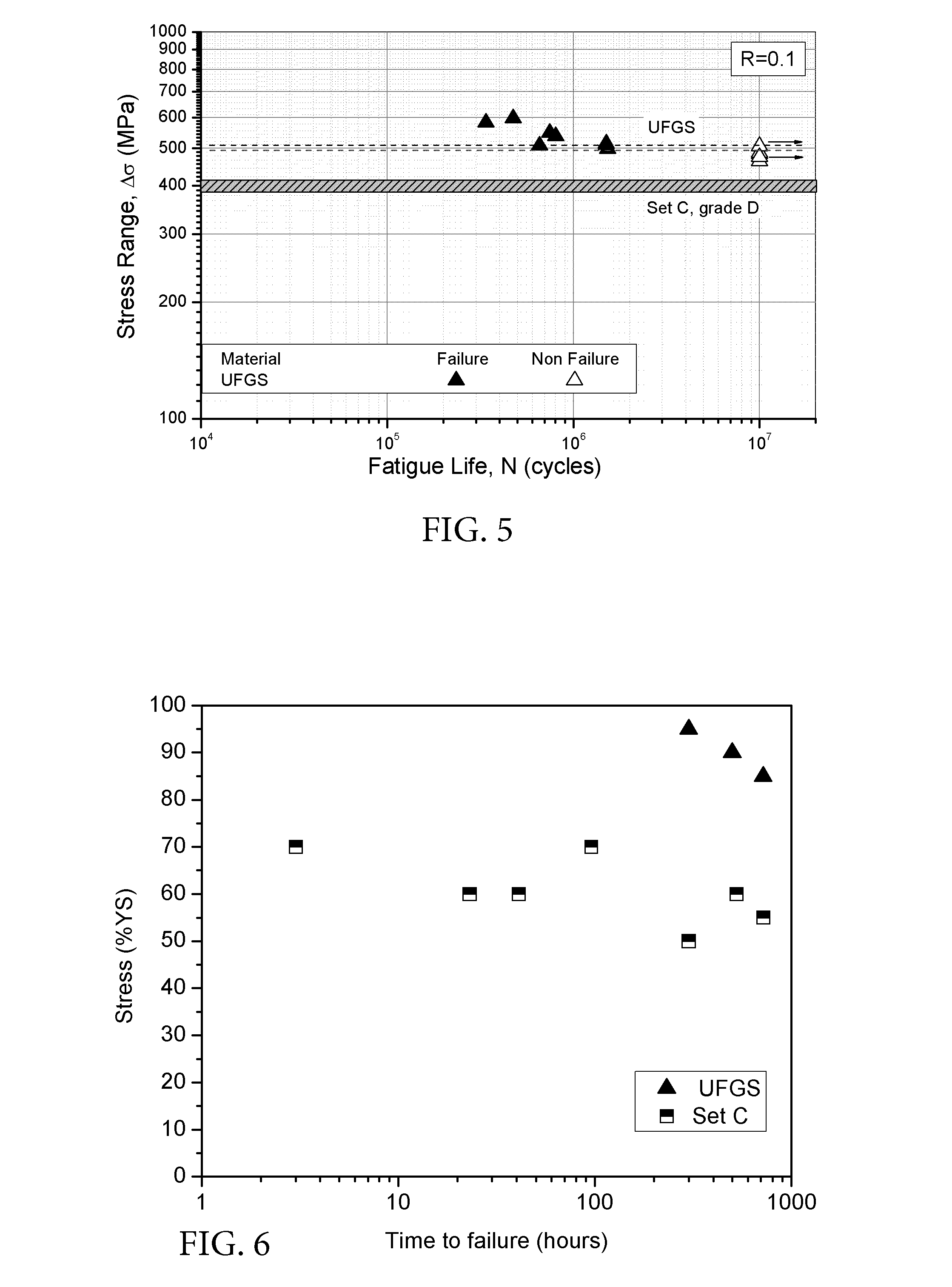

Ultra-fine grained steels having corrosion-fatigue resistance

Embodiments of an ultra-fine-grained, medium carbon steel are disclosed herein. In some embodiments, the ultra-fine grained steel can have high corrosion fatigue resistance, as well as high toughness and yield strength. The ultra-fine grained steels can be advantageous for use as sucker rods in oil wells having corrosive environments.

Owner:TENARIS CONNECTIONS

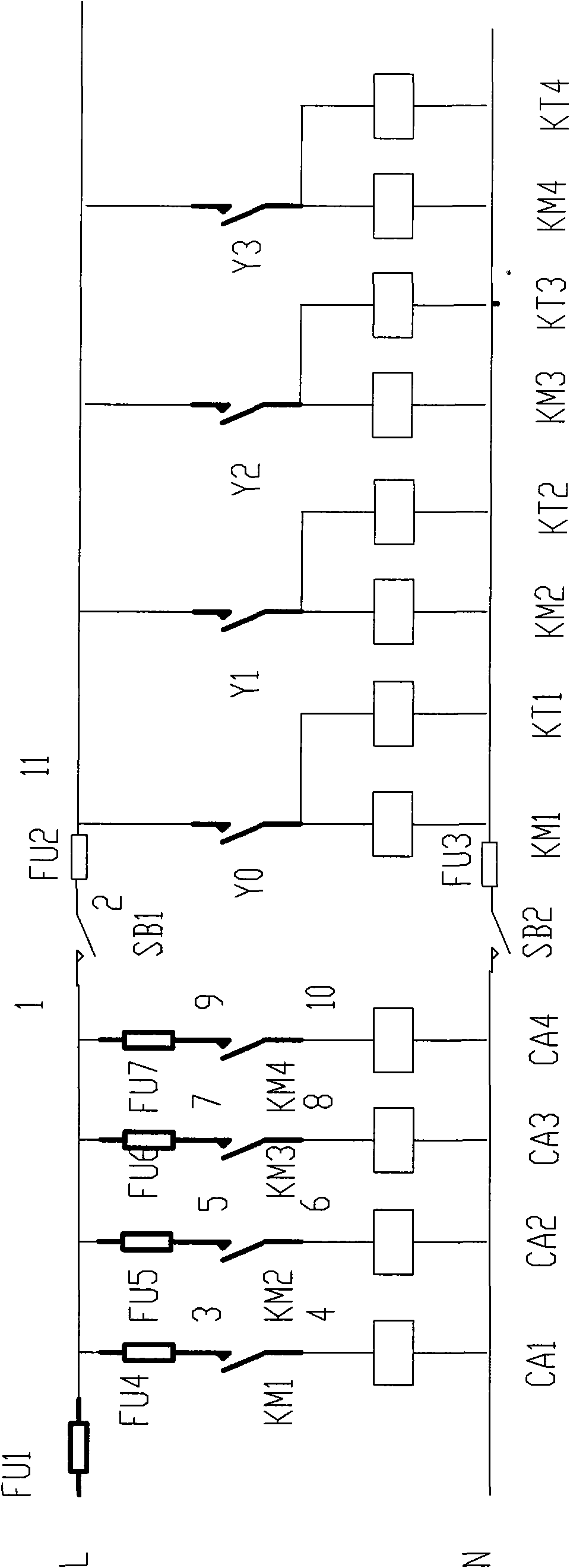

Control device for providing simulated marine environment for corrosion fatigue test

InactiveCN101986224ASimple and fast operationNo need for human on dutyWeather/light/corrosion resistanceProgramme control in sequence/logic controllersEngineeringDrying time

The invention belongs to the field of simulation of marine environment, in particular to a control device for providing a simulated marine environment for a corrosion fatigue test. The defects of time and labor waste, inaccurate control and the like in the prior art are overcome, and the control device is used for corrosion fatigue tests of a simulated tidal range area, a flowing seawater area, a sea splashing area and other environments. The device is provided with a control system and an environment simulation system, wherein a core of the control system adopts a programmable logic controller; and the environment simulation system is provided with an environmental cabinet, and an artificial seawater circulation loop, a compressed air channel and a hot air channel which are respectively connected with the environmental cabinet. The control system can perform programmable control on artificial seawater cycle interval contacted with tested samples and alternate wetting and drying time to the precision of a second; and the environment simulation system can simulate environmental modes of the seawater flowing area, the tidal range area and a spindrift splashing area. By matching with a fatigue test program, the device can realize the corrosion fatigue tests of materials under combination of any environmental spectrum and loading spectrum in the seawater flowing area, the tidal range area and a spindrift splashing area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

Corrosion fatigue test apparatus in wet hydrogen sulfide environment, and test method thereof

ActiveCN104964911AGuaranteed trafficHigh precisionWeather/light/corrosion resistanceTemperature controlBaseboard

The invention discloses a corrosion fatigue test apparatus in wet hydrogen sulfide environment, and a test method thereof. The apparatus comprises a fatigue test machine, and also comprises a closed corrosion environment box arranged in the working section of the fatigue test machine and having a corrugated expansion joint, a circulating water system arranged outside the closed corrosion environment box and used for heating a corrosion medium in the closed corrosion environment box, and an online liquid sampling device connected with the closed corrosion environment box and used for measuring and regulating the concentration of the corrosion medium in real time; and a sample in the closed corrosion environment box is clamped by a clamp adapting to the sample, and the clamp traverses through the upper cover board and the lower baseboard of the closed corrosion environment box, and is connected with the fatigue test machine. The apparatus has a simple structure and a good sealing performance, and can be used for carrying out corrosion fatigue performance test of fatigue samples with different shapes and dimensions in the wet hydrogen sulfide environment; and the test method of the apparatus has a temperature control function, can be used for online measurement of the concentration of hydrogen sulfide in a corrosion solution, and improves the accuracy of a test result.

Owner:HEFEI GENERAL MACHINERY RES INST

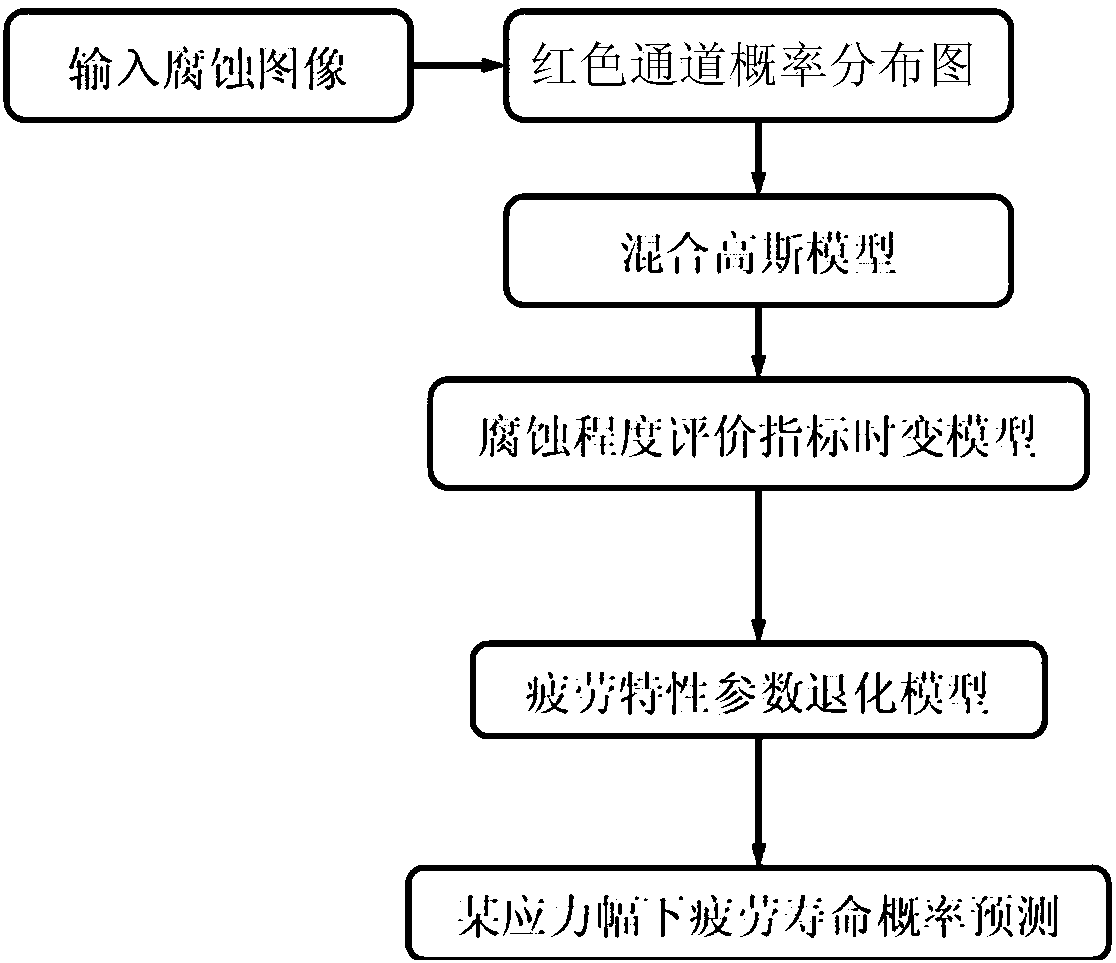

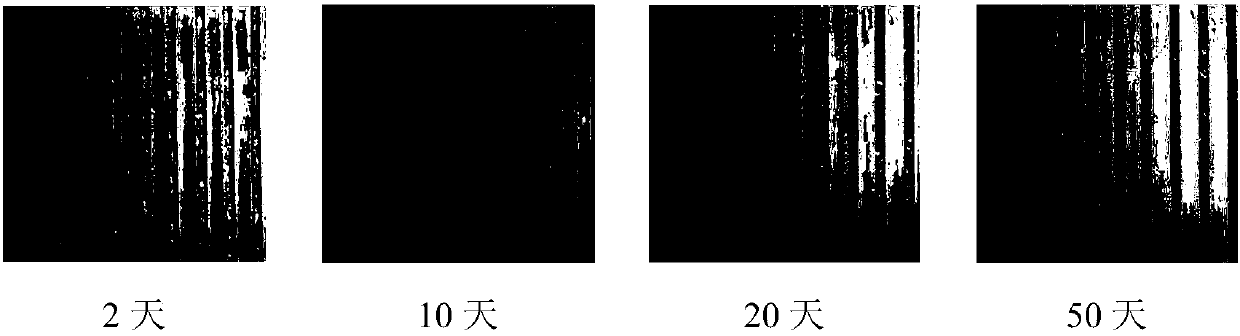

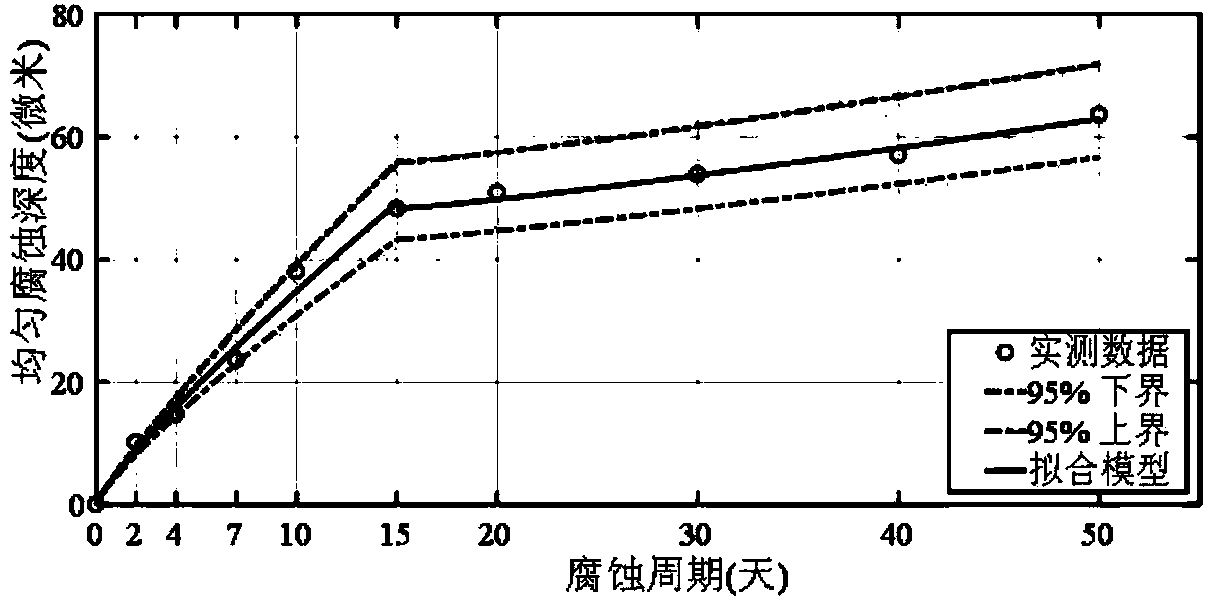

Method for monitoring and recognizing pulling rope corrosion and evaluating fatigue life on basis of computer vision

ActiveCN108225906AImprove accuracyImprove stabilityWeather/light/corrosion resistanceStrength propertiesPattern recognitionData set

The invention provides a method for monitoring and recognizing pulling rope corrosion and evaluating a fatigue life on the basis of computer vision. The method comprises the following steps: shootingan image of a corroded high-strength steel wire by a perspective inspection window at an anchoring end of a pulling rope, extracting image characteristics from the image, then building a corrosion-degree evaluation model, then building a fatigue-life characteristic energy number evaluation model, matching with a performance degrading state of the corrosion and the fatigue of the steel wire under an artificially accelerated corrosion test, and finally finishing the corrosion-state recognition and the fatigue-life evaluation of the in-service pulling rope. The method provided by the invention has the beneficial effects that the recognition accuracy is high, the speed is fast and the cost is low; the requirement for real-time data processing of online monitoring and early warning of corrosionand fatigue of the pulling rope also can be met, i.e., the image acquired by a consumer-grade ordinary camera is directly recognized without data-set updating; the automation, intelligentization, accuracy and robustness of corrosion monitoring and recognition and fatigue-life evaluation of the pulling rope are improved, and a solution is provided for automatic monitoring and recognition of the corrosion and the fatigue of the pulling rope of a bridge structure.

Owner:HARBIN INST OF TECH

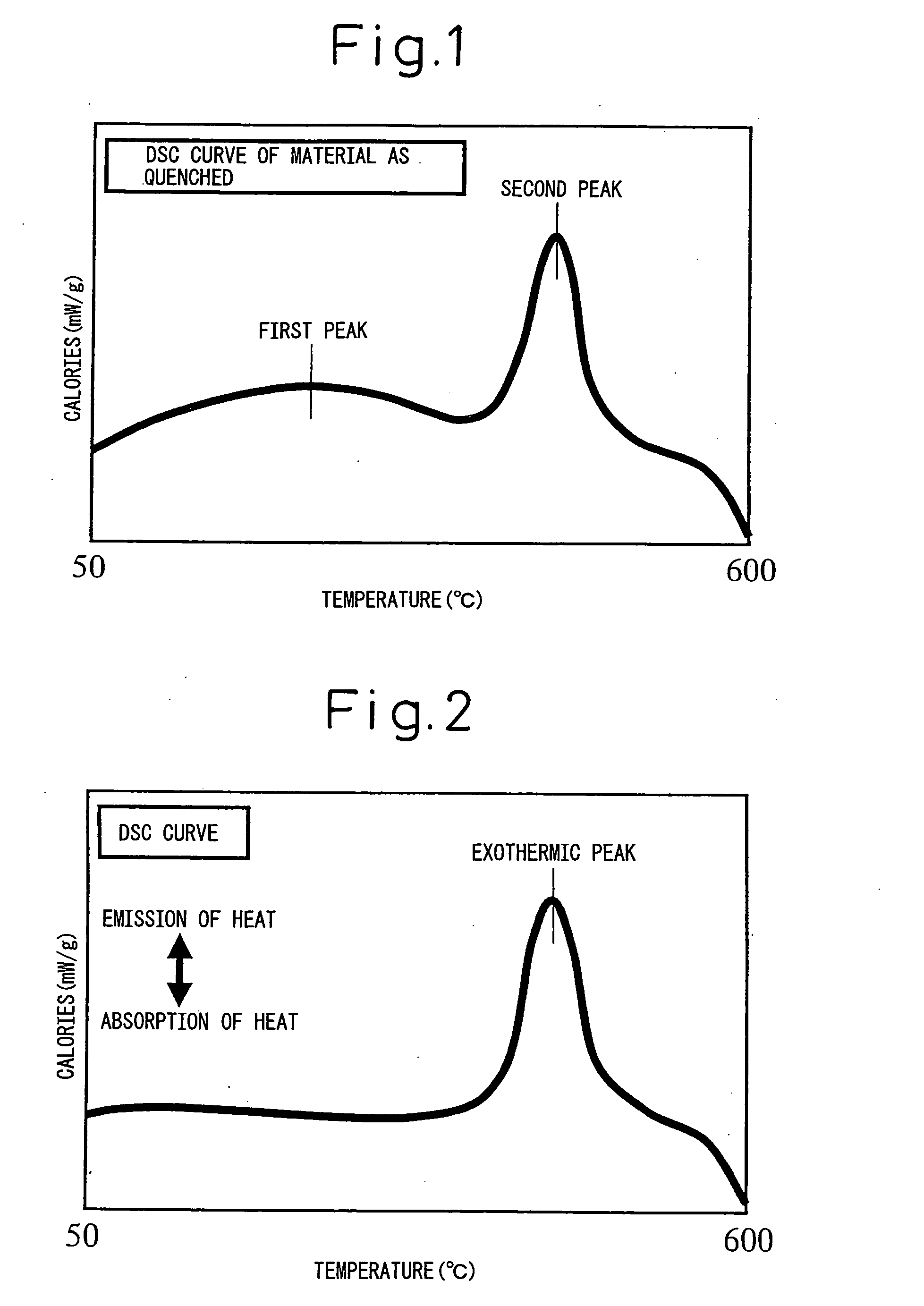

High Strength Spring Steel Wire and High Strength Spring and Methods of Production of the Same

InactiveUS20090020195A1Superior in corrosion fatigue characteristicHigh strengthIncreasing energy efficiencyFurnace typesHigh intensitySpring steel

The present invention provides high strength spring and high strength spring steel wire superior in corrosion fatigue characteristics and methods of production of the same, that is, a high strength spring steel wire and high strength spring containing, by mass %, C: 0.35 to 0.50%, Si: 1.00 to 3.00%, and Mn: 0.10 to 2.00%, restricting P to 0.015% or less and S to 0.015% or less, having a balance of Fe and unavoidable impurities, and, when raising the temperature in the range from 50° C. to 600° C. by 0.25° C. / s and measuring the differential scanning calories, having the only peak of the exothermic reaction present at 450° C. or more. A method of production of high strength spring characterized by tempering under conditions where the tempering temperature T[K], tempering time t[s], and content Si % [mass %] of Si satisfy the following:16000≦(T−40×[Si %])×(31.7+log t)≦23000.

Owner:NIPPON STEEL CORP

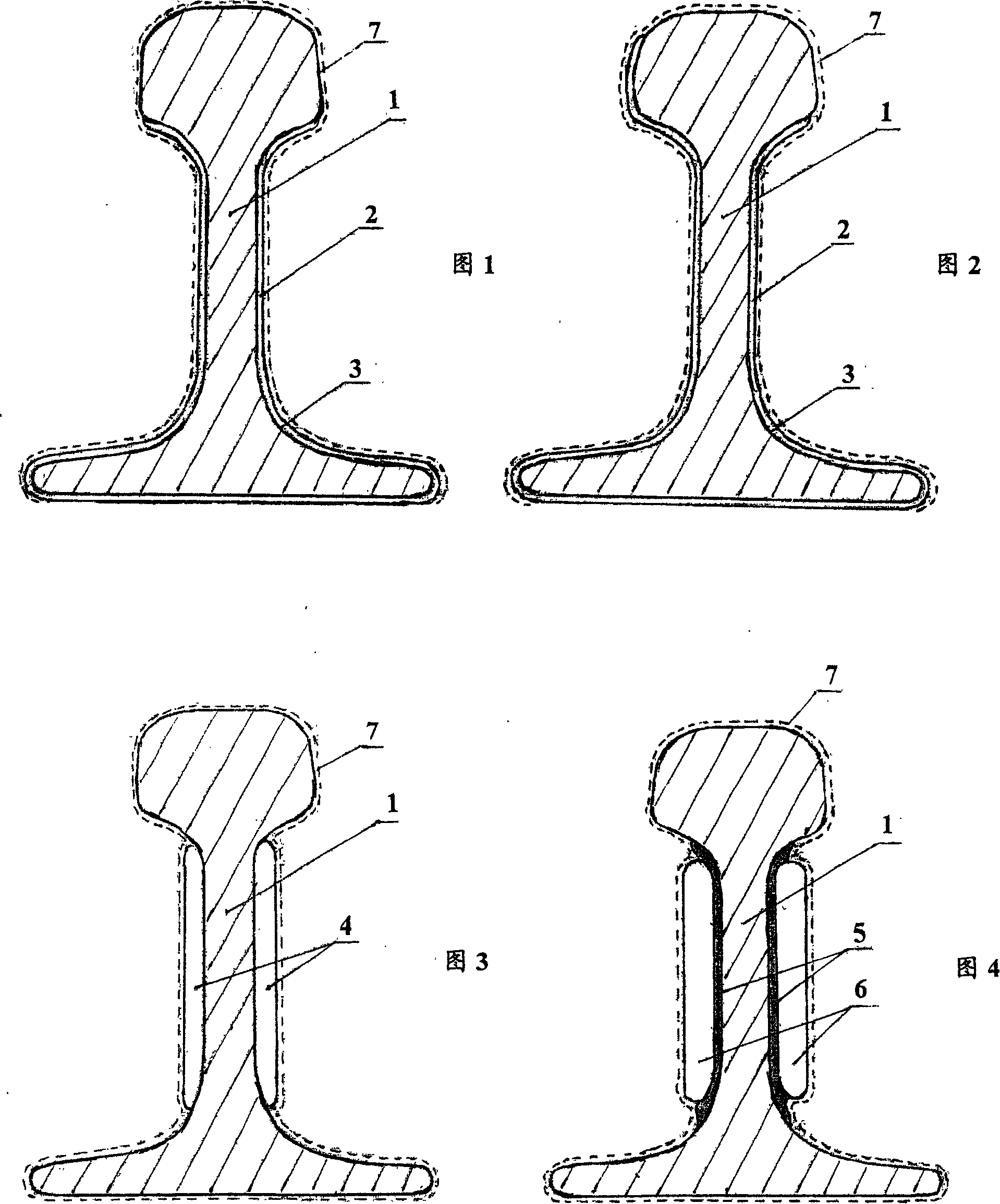

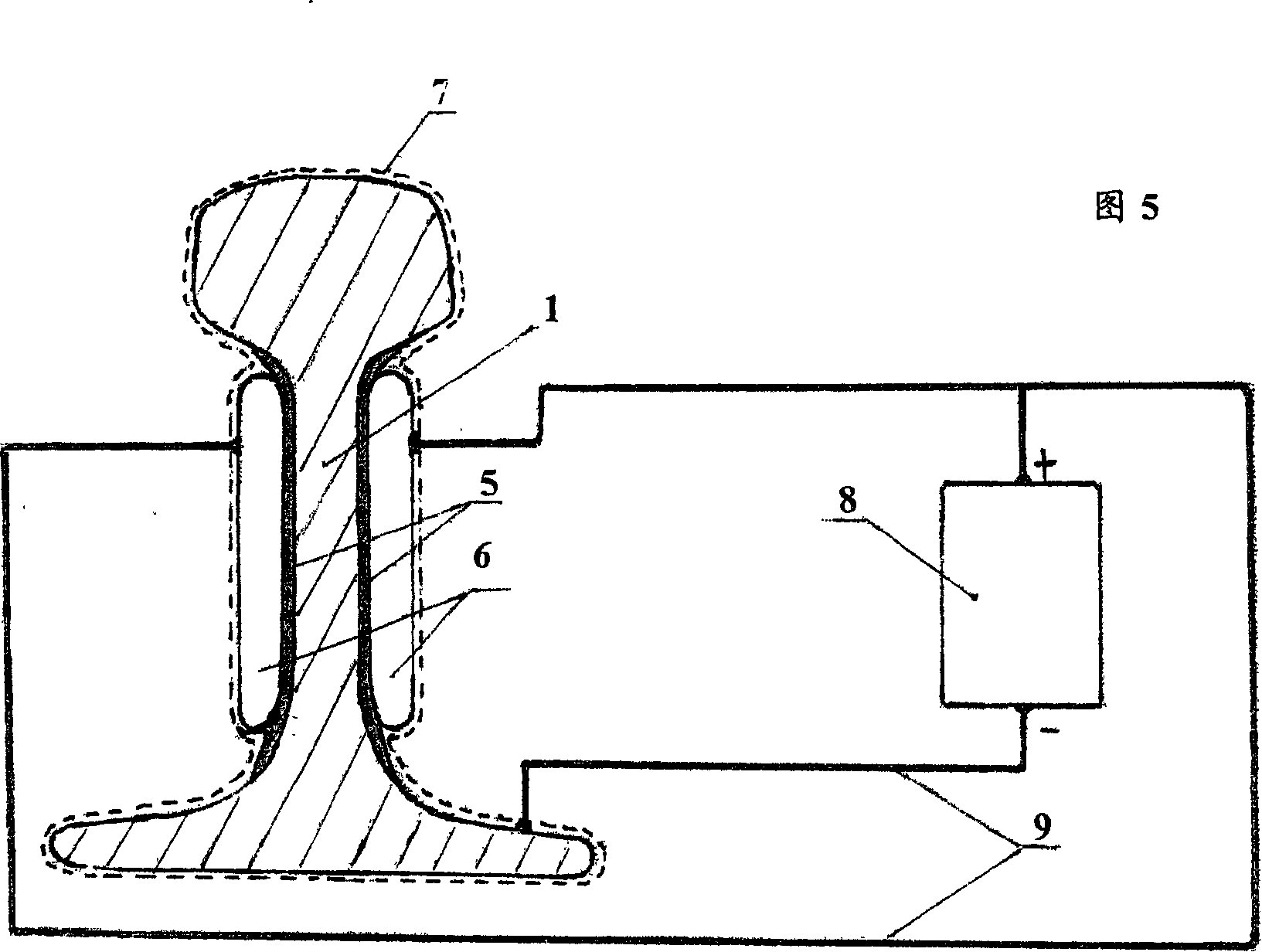

Corrosion-resistant break-resistant steel rail or steel wheel of train

InactiveCN101153398AAutomatic adjustment of cathodic polarization valuePlay a role in monitoring and finding broken railsRailsRail-engaging wheelsCrack resistanceWear resistant

The invention relates to a corrosion- and fracture-resistant rail or train rail, which aims to eliminate various failures caused by corrosion, the crack or fracture phenomenon of wear resistant rail-wheel (or ordinary rail-wheel) caused by stress corrosion or corrosion fatigue and the contradiction between wear resistance and crack resistance of rail (or wheel). Concretely, an anode is directly arranged on the non-working face of a rail or a wheel; moreover, the surface of the rail or the wheel is coated with a corrosion inhibition layer with ionic conduction and corrosion inhibition functions. Through sacrificing anode or external connection with a controllable DC source, the invention realizes the novel electrochemical protection which combines cathodic protection with corrosion inhibitor; therefore, the service life of the rail, the wheel and rail fittings are prolonged times to meet the pressing requirements of speed increase and increasing heavy load of railway transportation.

Owner:赵全玺

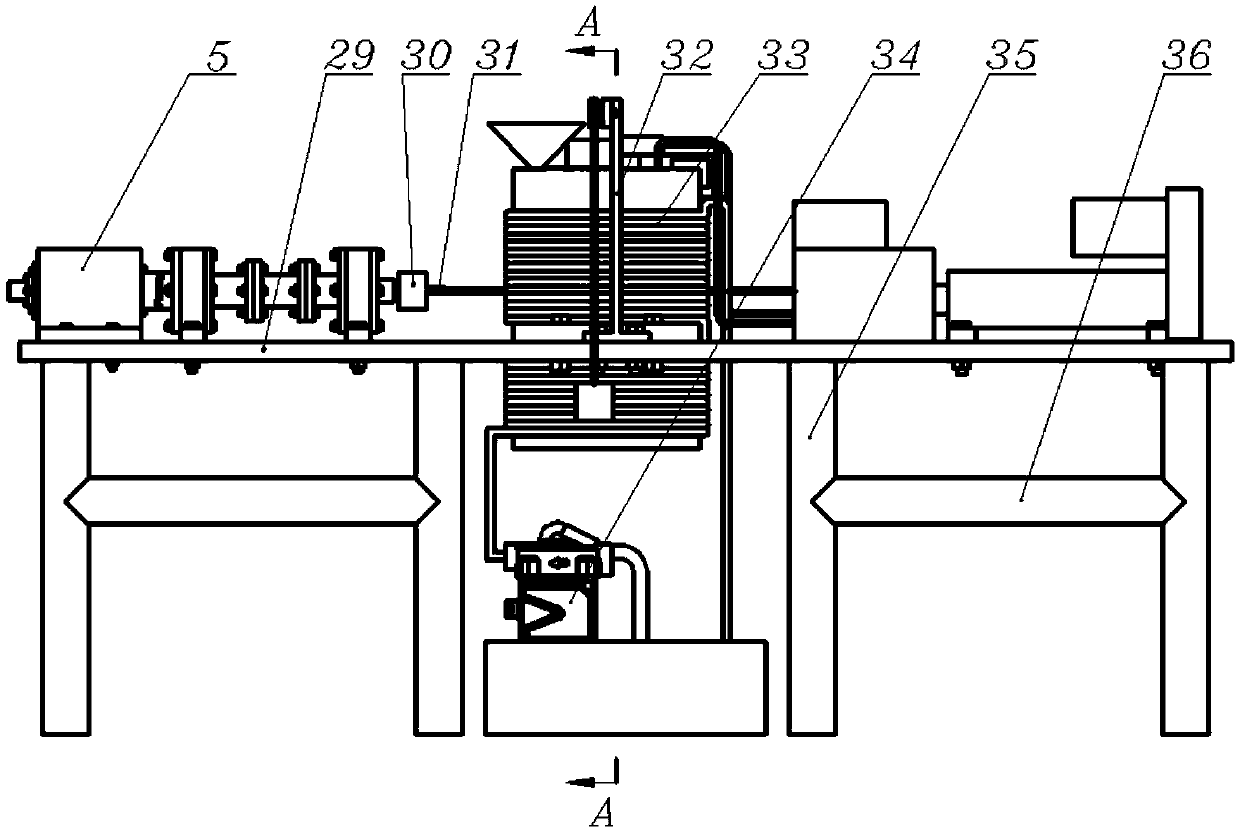

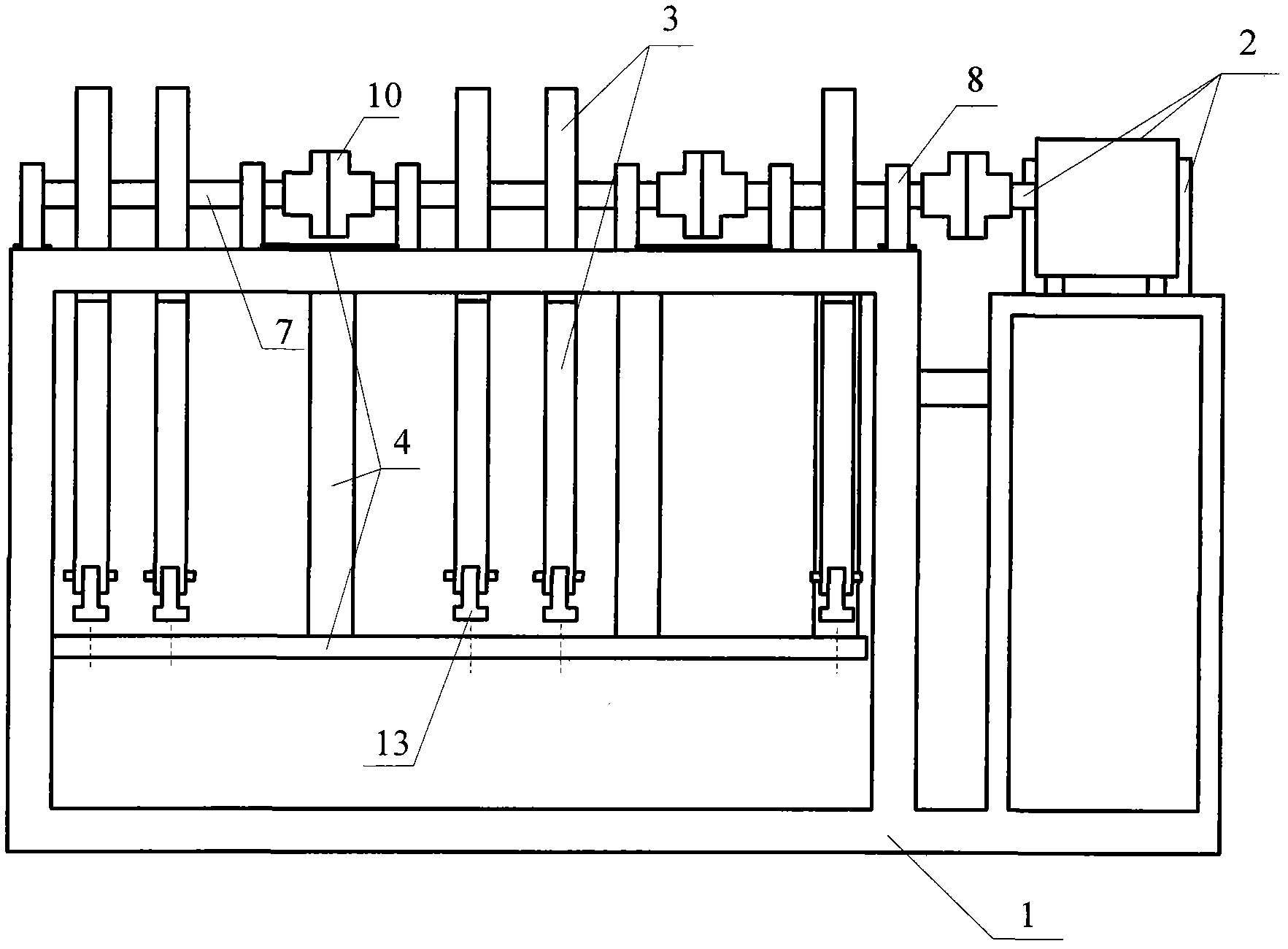

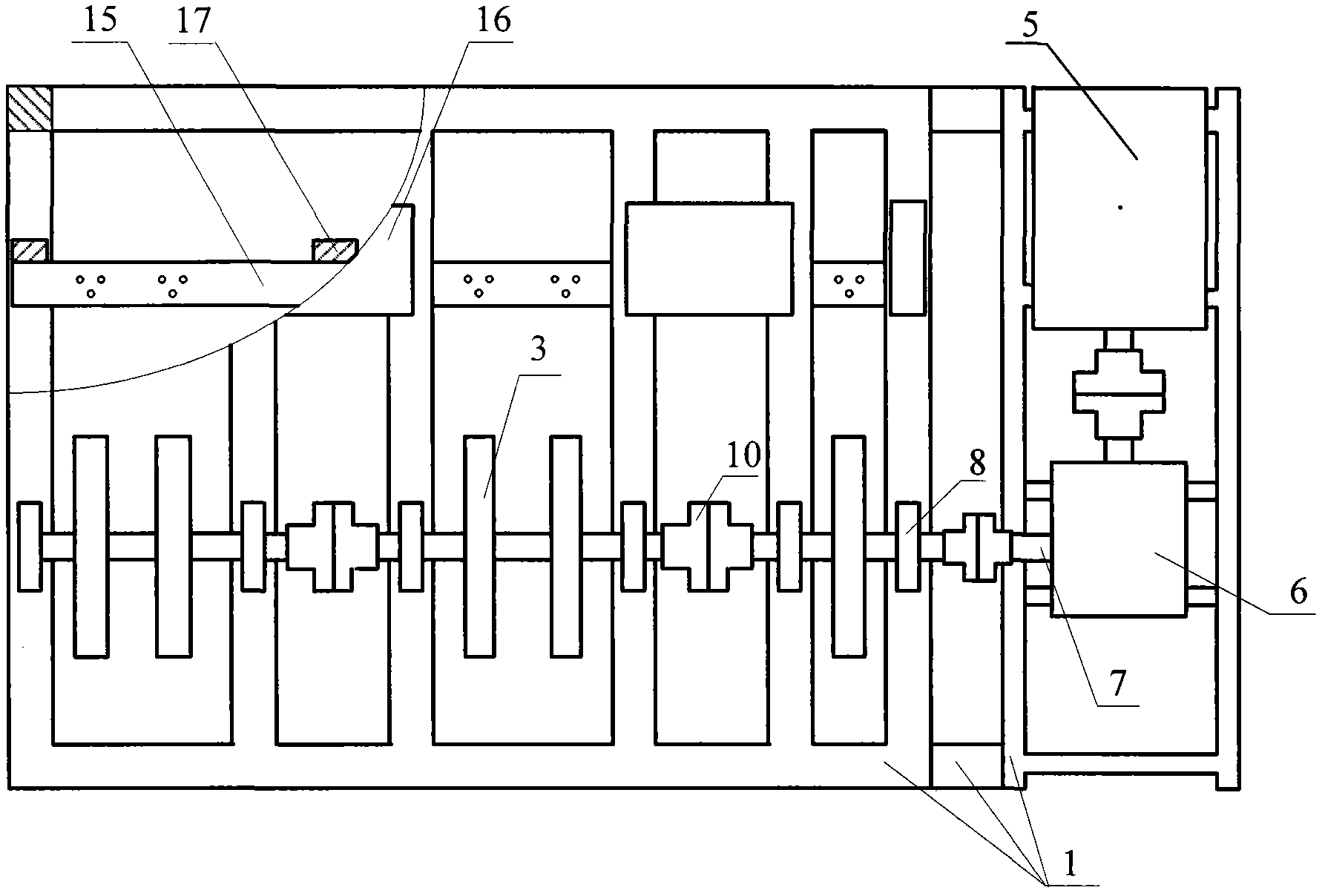

Reciprocating bending corrosion fatigue testing machine

InactiveCN102156077AImproving Experimental Efficiency for Low-Frequency Corrosion FatigueReduce labor intensityWeather/light/corrosion resistanceMaterial strength using steady bending forcesTemperature controlReduction drive

The invention discloses a reciprocating bending corrosion fatigue testing machine which manly comprises a steel frame, a power mechanism, eccentric wheel mechanisms and an adjusting bracket mechanism. An exciting motor with controllable rotation speed is connected with a speed reducer through a coupler; the speed reducer reverses by 90 degrees through the coupler to drive a rotation shaft to rotate; the rotation shaft is fixed in the length direction of the steel frame through a bearing pedestal; the five eccentric wheel mechanisms are arranged on the rotation shaft, and each eccentric wheel mechanism comprises an eccentric wheel as well as a bearing and a connecting rod which are sleeved outside; the stress of a sample can be adjusted through the eccentricity of the eccentric wheel; the connecting rod of each eccentric wheel mechanism is connected with one end of the sample through a T-shaped block, and the other end of the sample is fixed on a bottom plate of an adjusting bracket; the distance between the adjusting bracket and the rotation shaft can be adjusted to test the sample of different size; and the thickness of a gasket arranged between the sample and the bottom plate of the adjusting bracket can be adjusted to adjust the cyclic load stress ratio. The reciprocating bending corrosion fatigue testing machine has the functions of medium temperature control, motor start / stop control, automatic counting and remote alarm.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

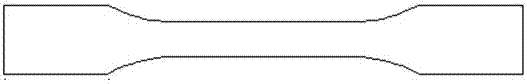

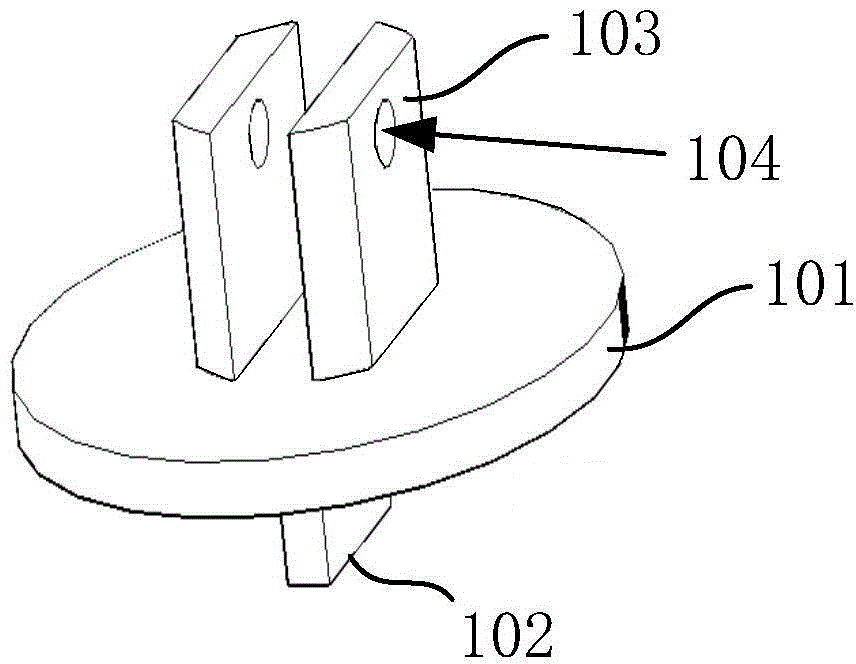

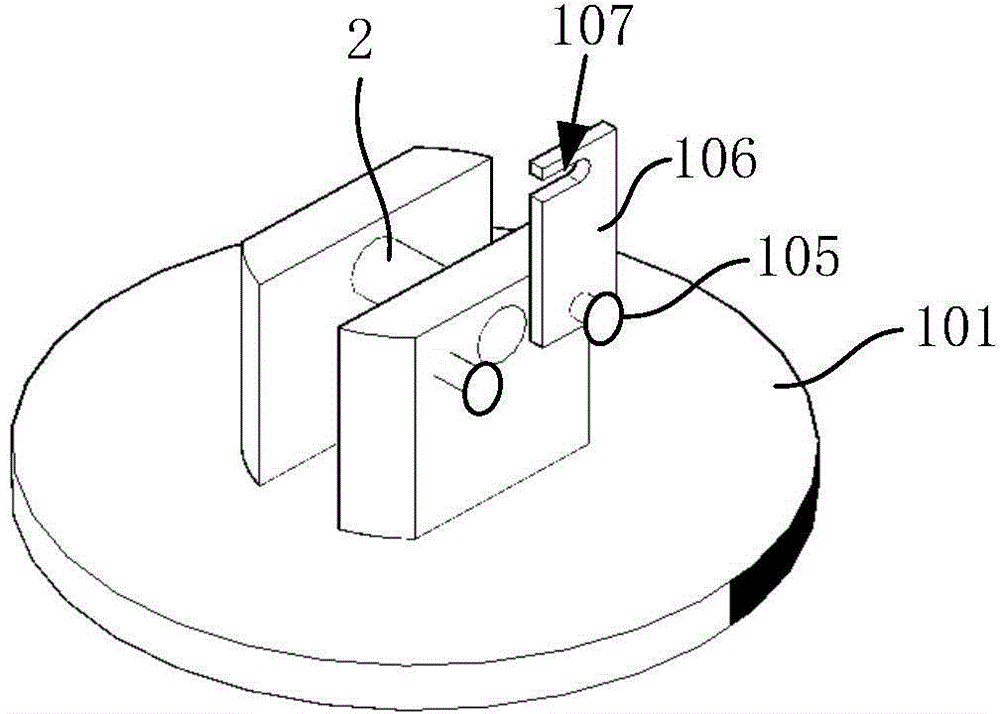

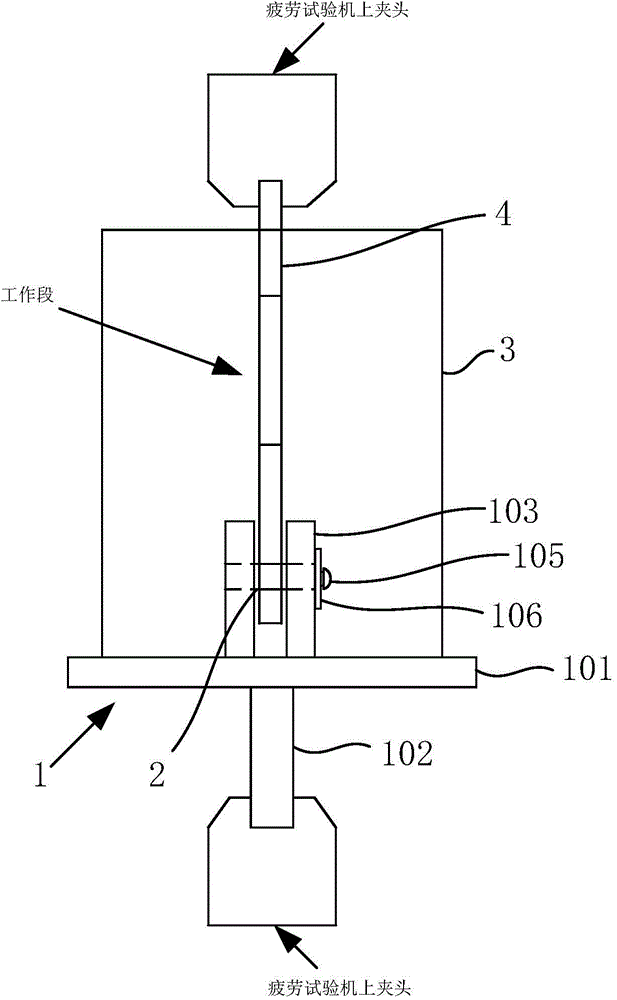

Device and method for testing metal corrosion fatigue crack extension

InactiveCN104792638ARealize measurementEasy to observeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMetallic materialsCorrosion fatigue

The invention discloses a device and a method for testing metal corrosion fatigue crack extension. The device comprises a pedestal and a corrosive medium accommodation container, wherein a fatigue machine clamping piece is designed on the lower surface of the pedestal and used for clamping the lower chuck of the fatigue machine; a testing specimen locking piece is designed on the upper surface of the pedestal and used for fixing the lower end of a fatigue testing specimen; the upper end of the fatigue testing specimen is clamped by a fatigue machine upper clamp; the alternating load of the fatigue machine can be transferred to the testing specimen through the fatigue machine clamping piece; the corrosive medium accommodation container adopts a cylindrical structure; the bottom end of the cylindrical structure is fixedly mounted on the upper surface of a circular table in the pedestal; the testing specimen locking piece in the pedestal is positioned in the corrosive medium accommodation container. The device is used for testing according to the test fatigue testing parameters until the working section of the fatigue testing specimen is broken; in the process, a microscope is utilized to record and shoot the producing-extending-fracturing process of the crack. The device disclosed by the invention has the advantage of realizing the corrosive fatigue performance test of the metal material in the corrosive medium under the standing state.

Owner:BEIHANG UNIV

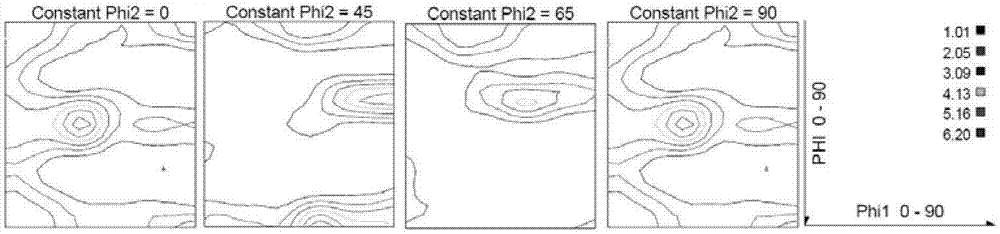

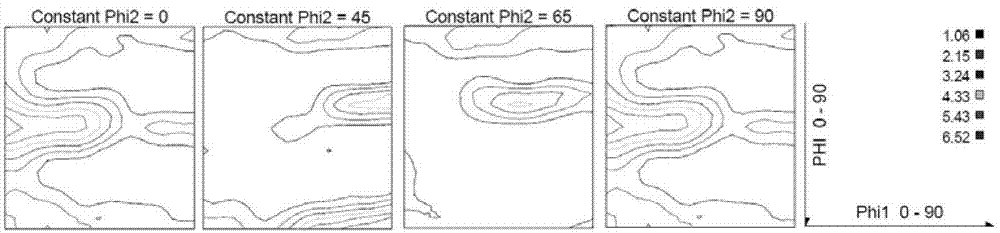

Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com