Reciprocating bending corrosion fatigue testing machine

A corrosion fatigue, testing machine technology, applied in the direction of applying stable bending force to test material strength, weather resistance/light resistance/corrosion resistance, test wear resistance, etc. The influence of medium temperature fatigue performance and other issues can reduce labor intensity and improve experimental efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

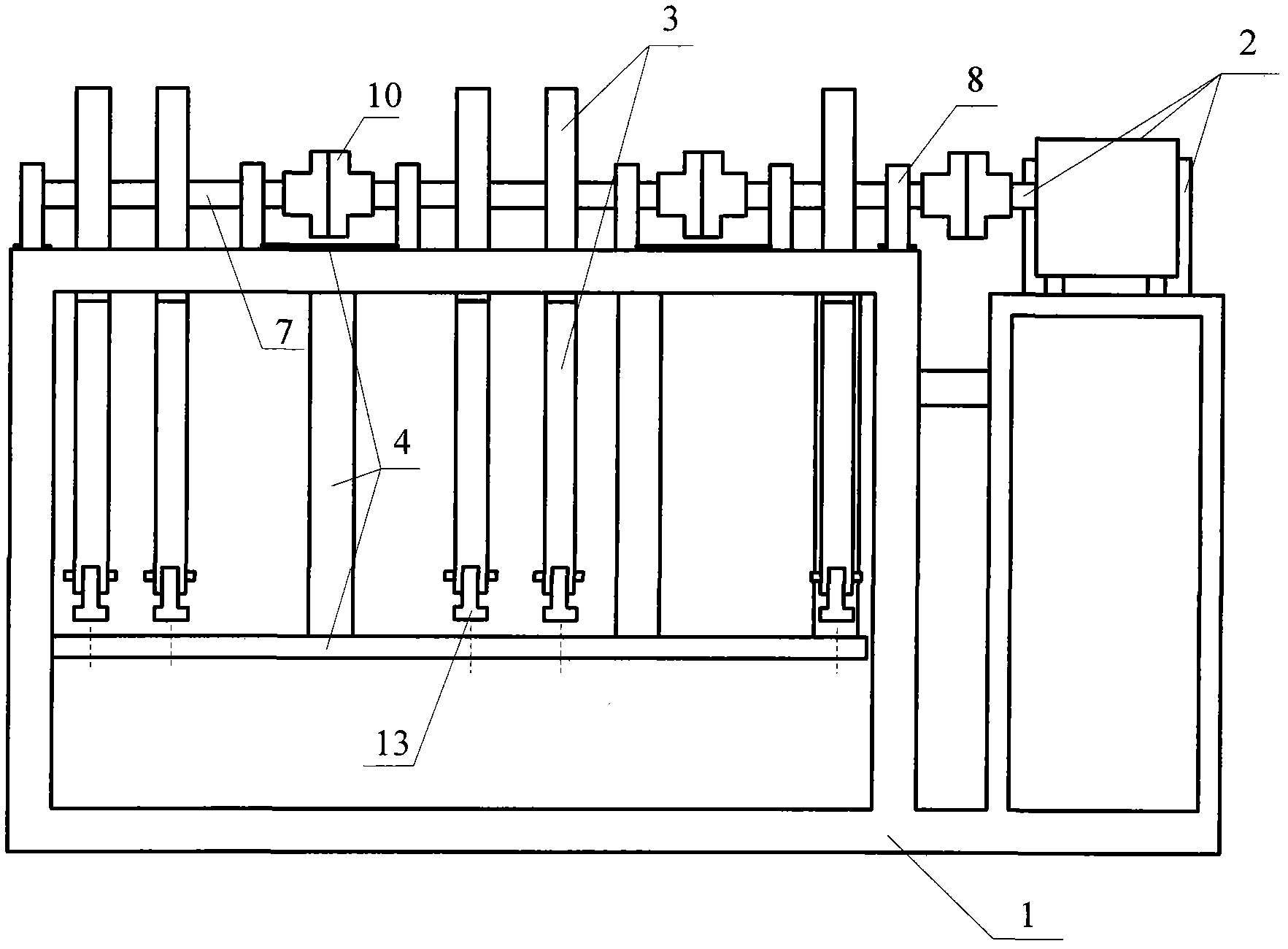

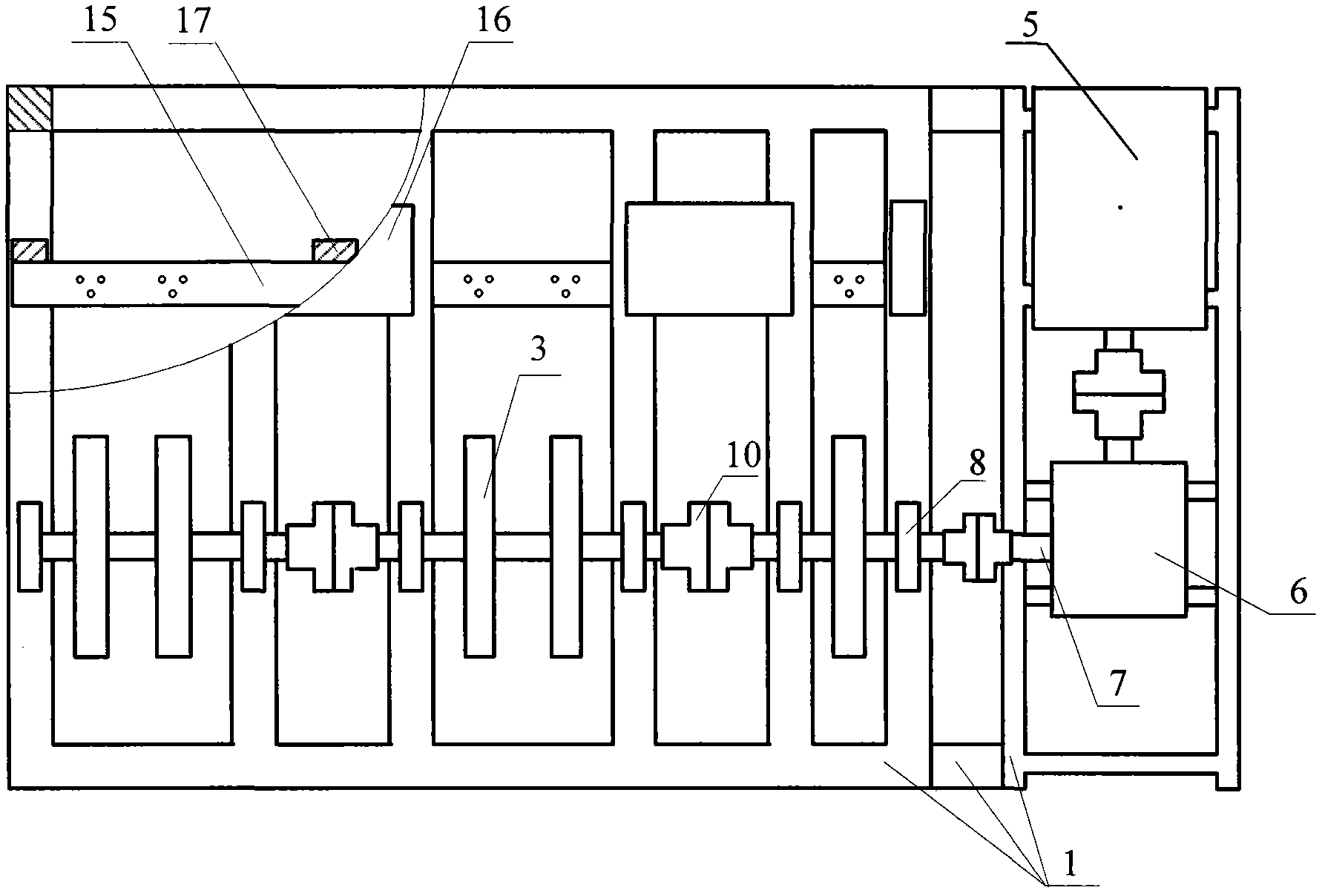

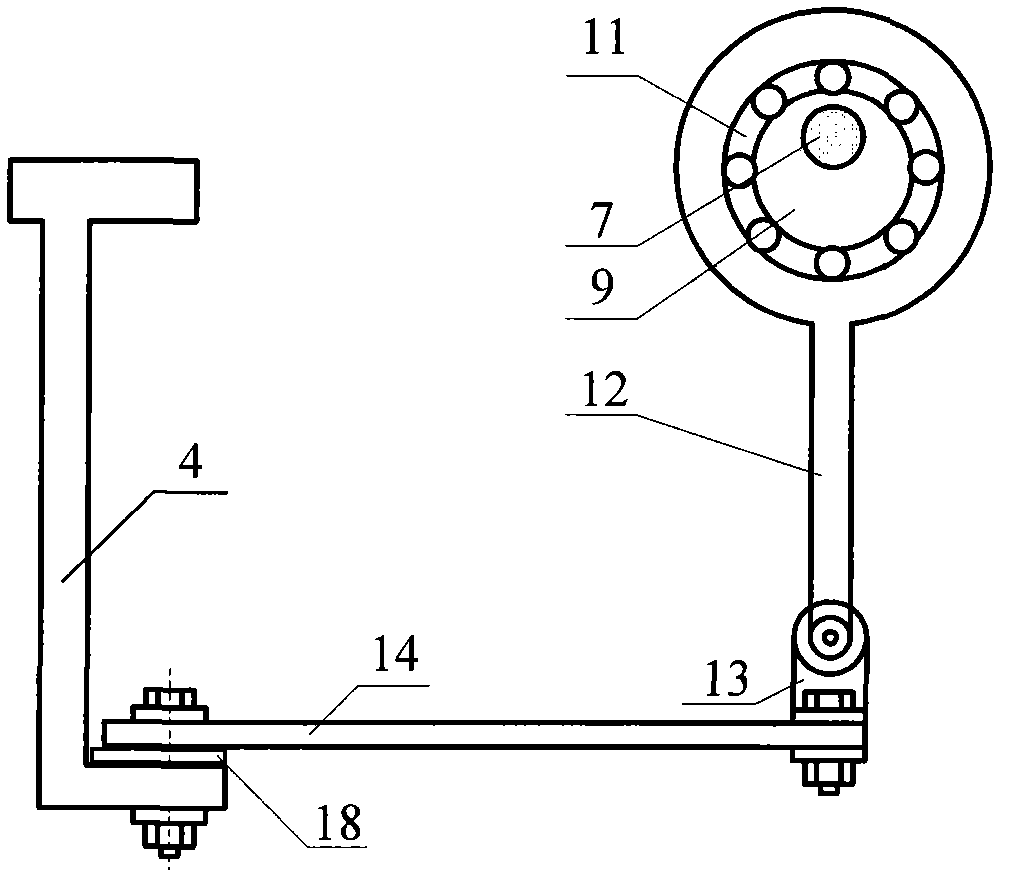

[0012] Such as figure 1 with figure 2 As shown, the testing machine proposed by the present invention is mainly composed of a steel frame 1, a power mechanism 2, an eccentric wheel mechanism 3 and an adjusting frame mechanism 4, wherein the steel frame 1 is the supporting body of the whole testing machine, and the power mechanism 2 is controlled by a rotating speed The excitation motor 5 is used as the power source, after being decelerated by the reducer 6, it is reversed to 90° and then drives the rotating shaft 7 to rotate. The outer bearing of the rotating shaft 7 is fixed on the length direction of the steel frame 1 through the bearing seat 8, and can be adjusted by adjusting the rotating speed of the rotating shaft 7. Cycle load frequency. Rotating shaft 7 is made up of three sections, adopts coupling 10 to join by bearing between every section rotating shaft. Five sets of eccentric wheel mechanisms 3 are installed on the rotating shaft 7, and each set of eccentric whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com