Patents

Literature

4980results about "Investigating abrasion/wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

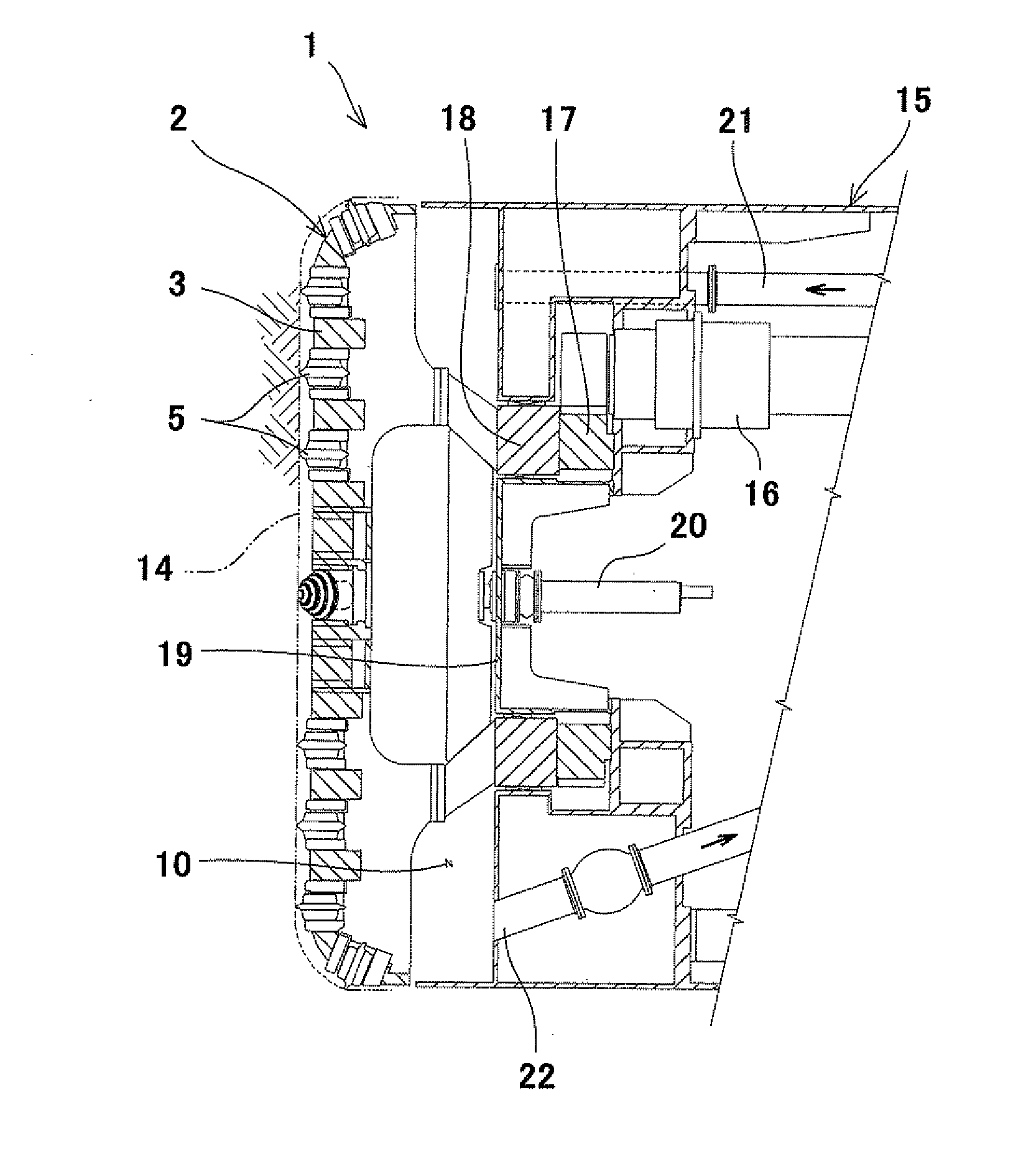

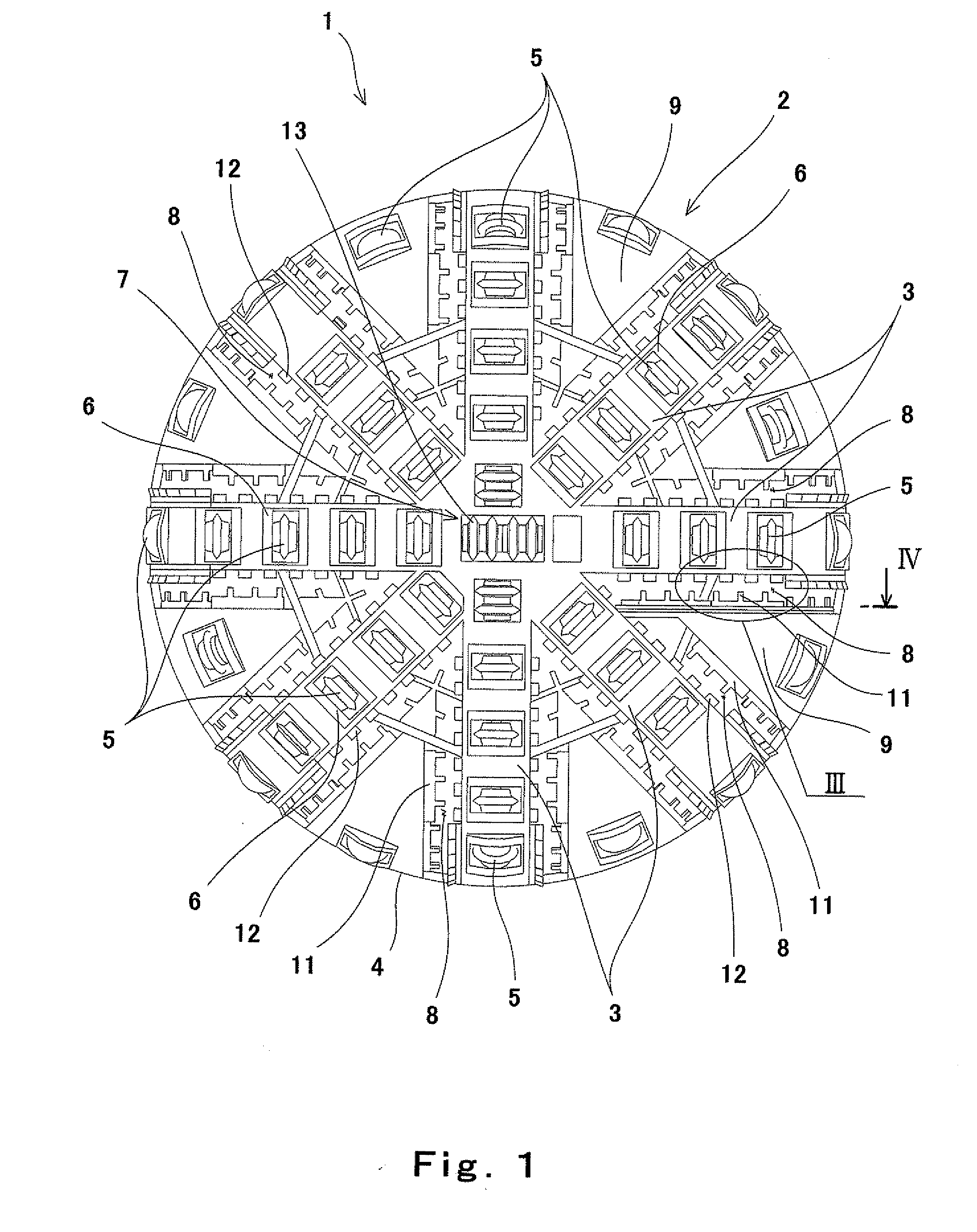

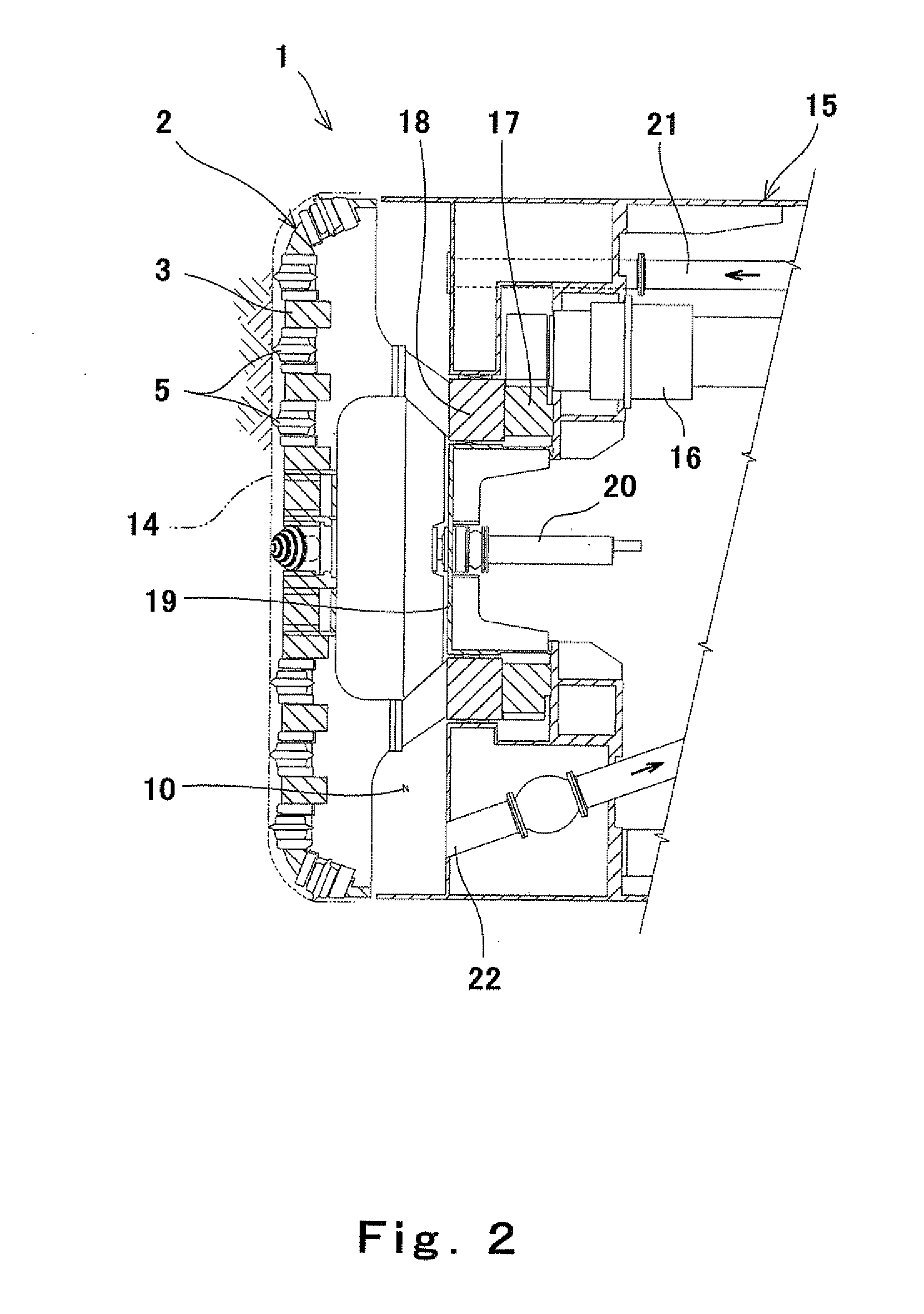

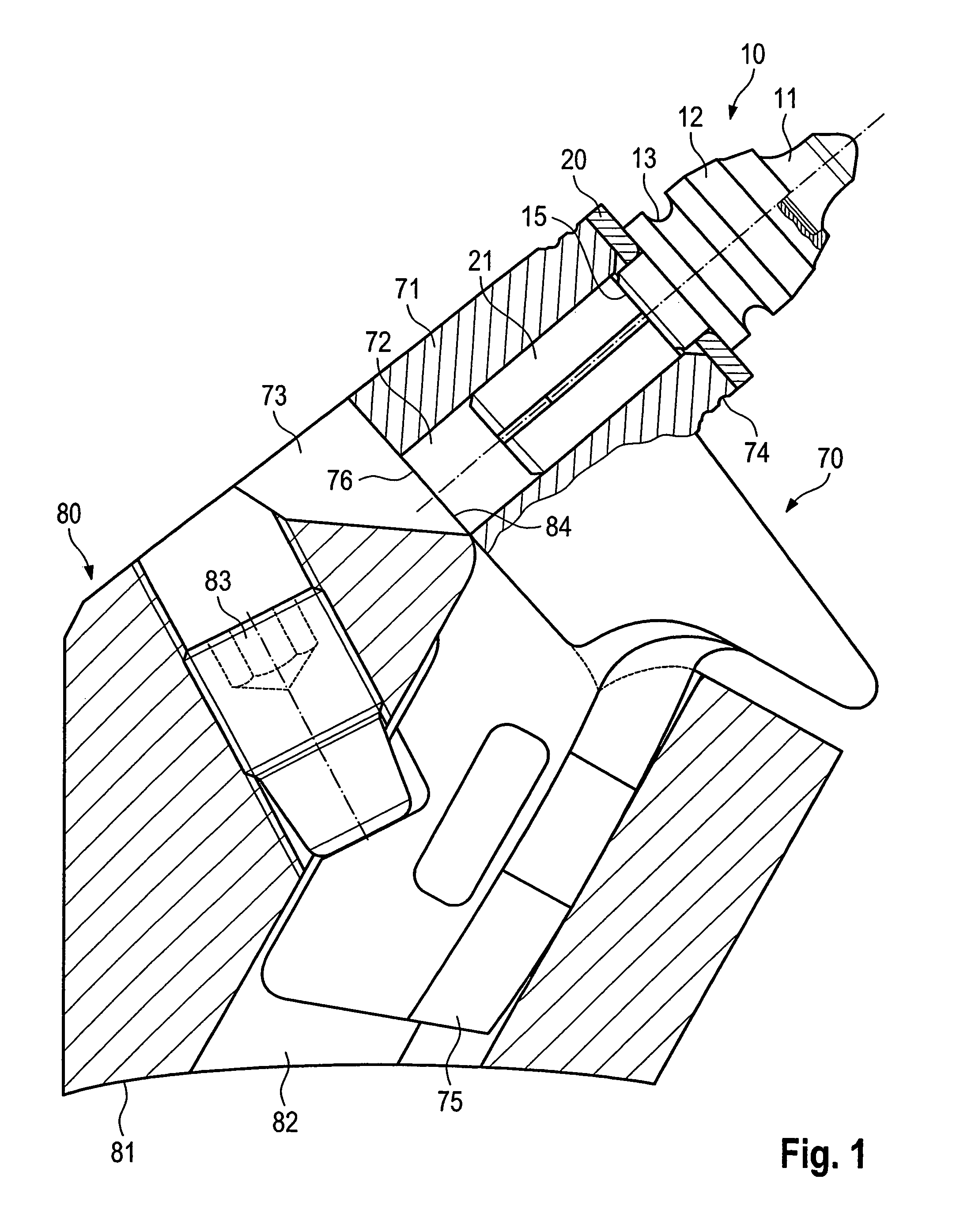

Abrasion detecting apparatus detecting abrasion of component of cutter head and tunnel boring machine including abrasion detecting apparatus

ActiveUS20110031017A1Efficient executionLabor savingEarth drilling toolsSurveyTunnel boring machineEngineering

An abrasion detecting apparatus is configured to detect an abrasion of a component of a cutter head of a tunnel boring machine configured to excavate a ground using a cutter to bore a tunnel, the abrasion detecting apparatus including: an abrasion detection probe located rearward of a front end of the cutter by a certain distance and located forward or rearward of a front end of a component, whose abrasion needs to be detected, of the cutter head by a certain distance, the abrasion detection probe including an abrasion detecting portion at a front end portion thereof, the abrasion detecting portion abrading away by contact with the ground to be excavated; and a detecting device configured to detect an abrasion of the abrasion detecting portion.

Owner:UNDERGROUND INFRASTRUCTURE TECH CORP

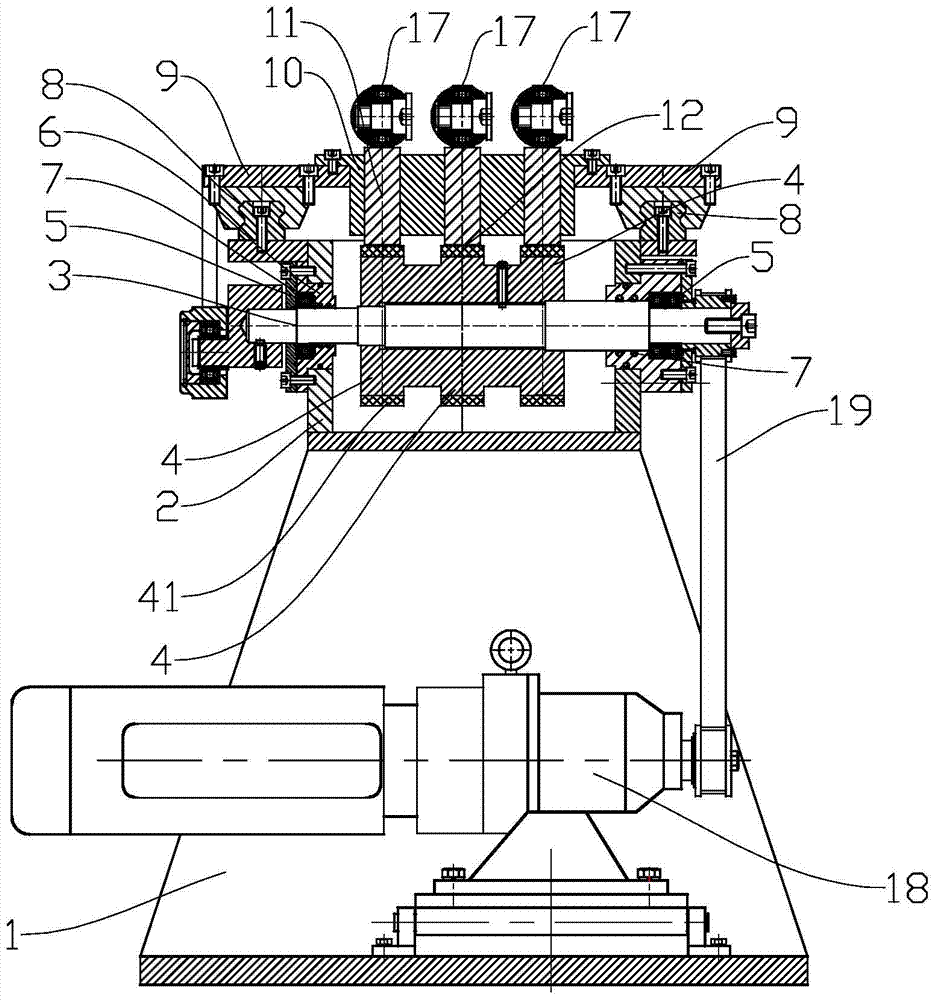

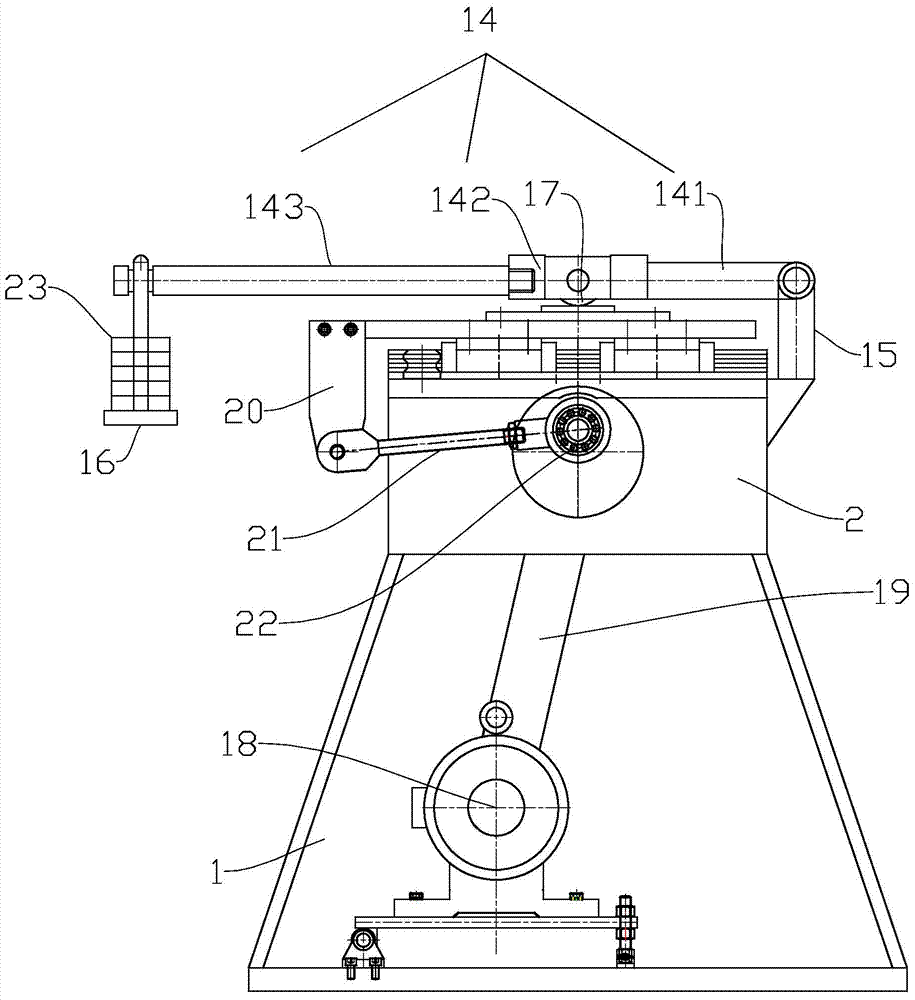

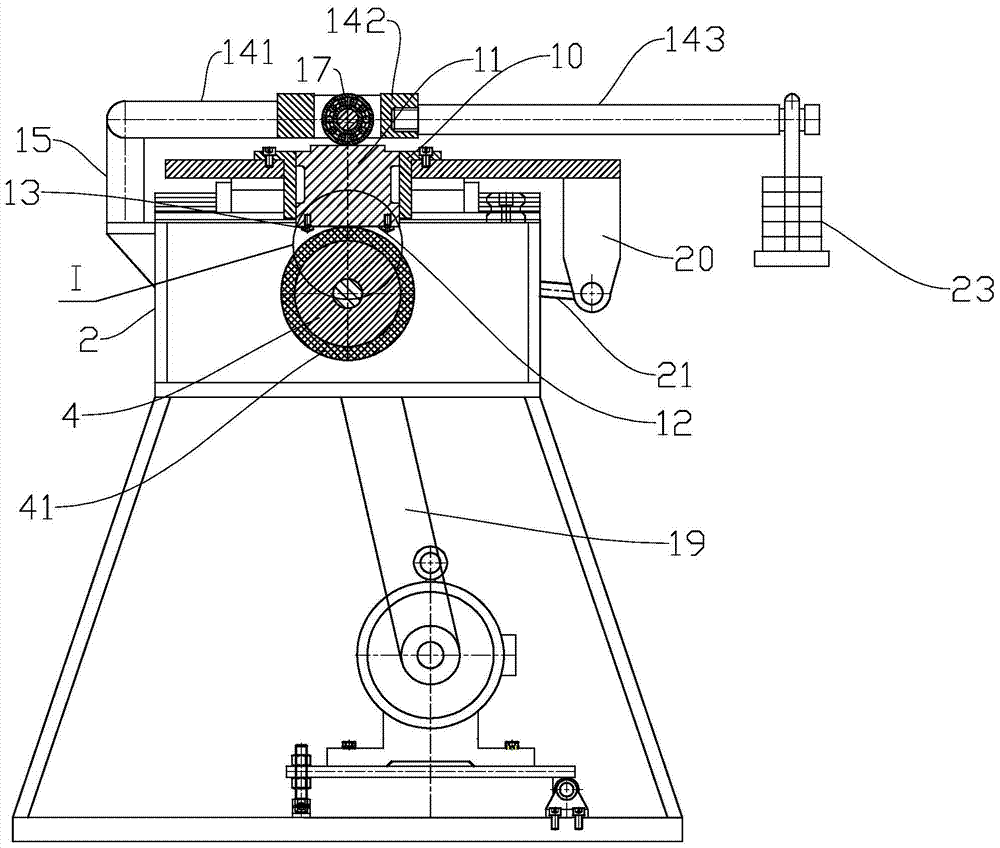

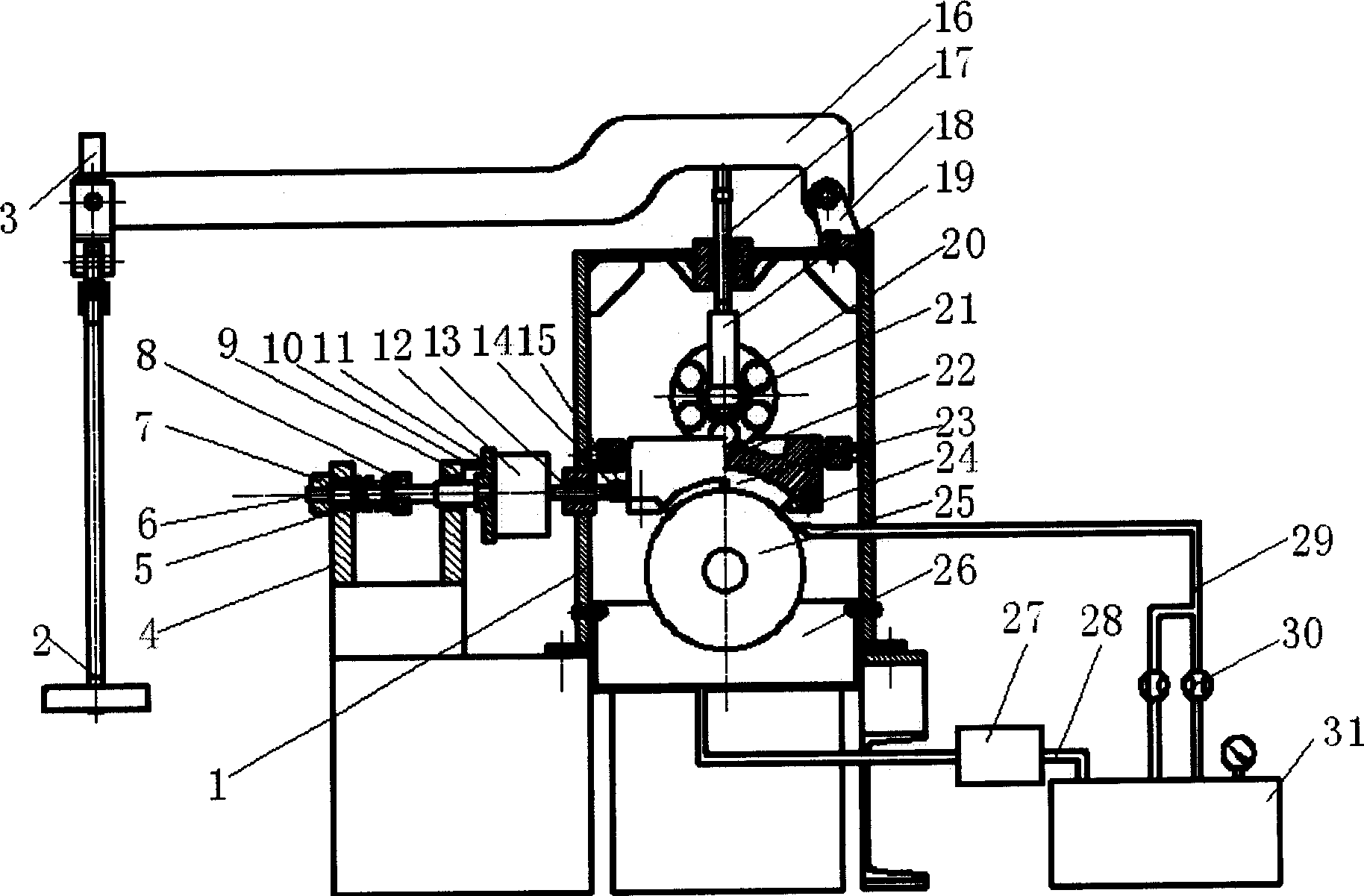

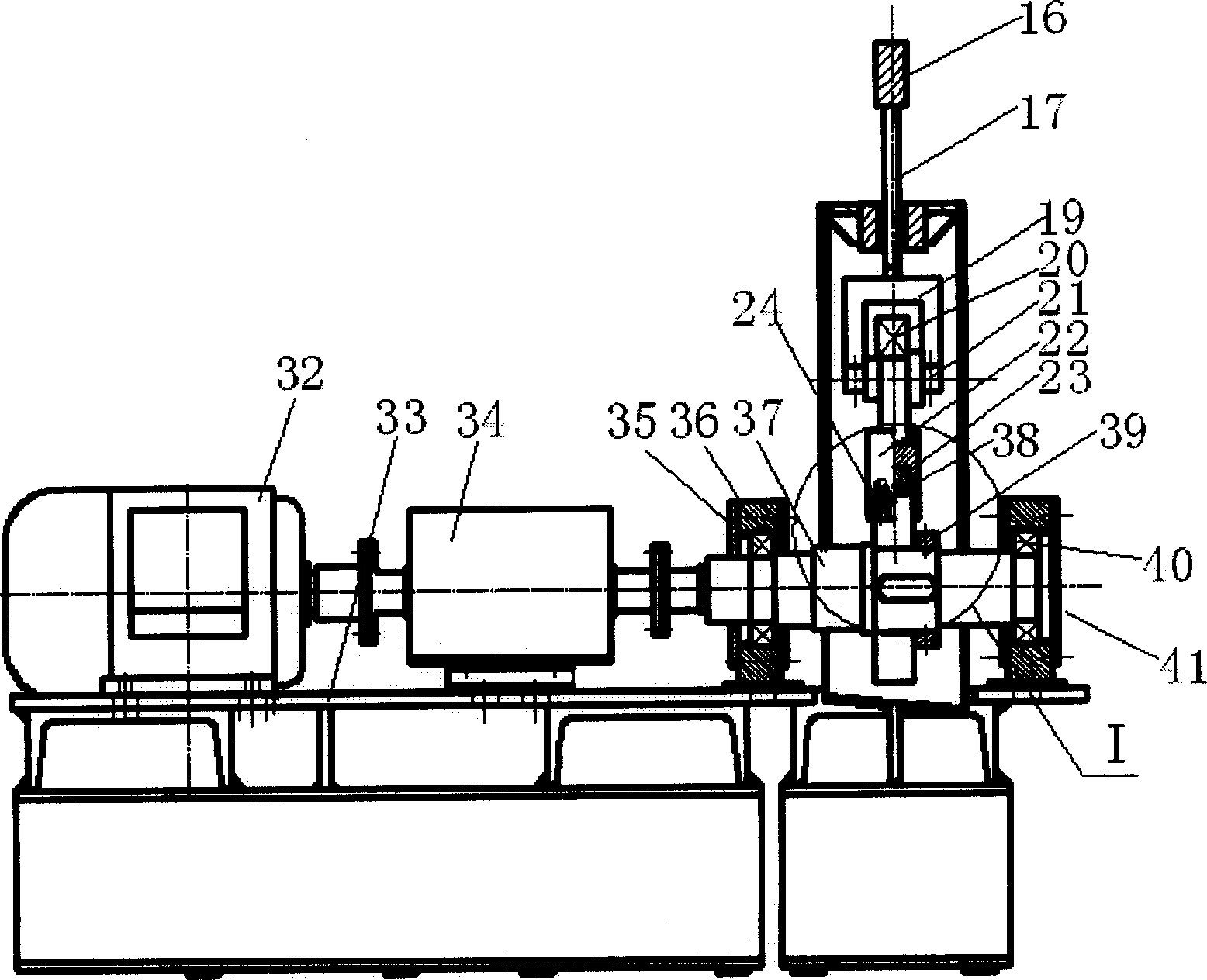

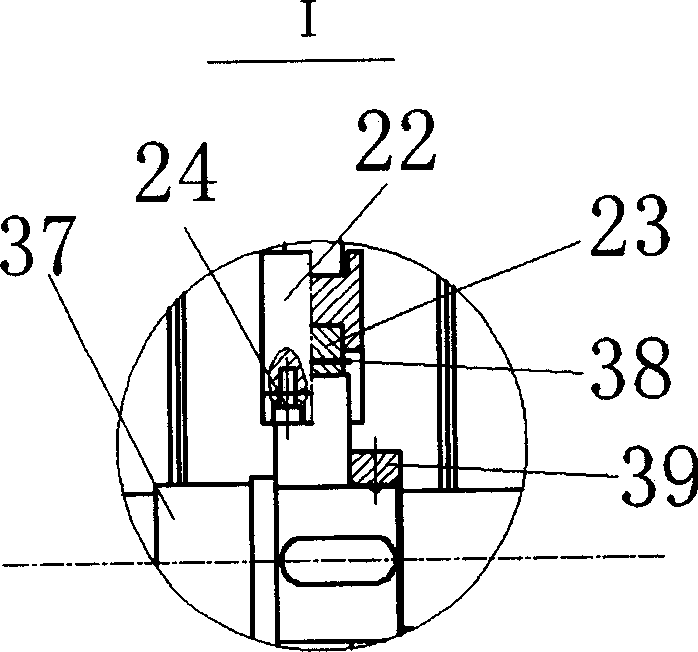

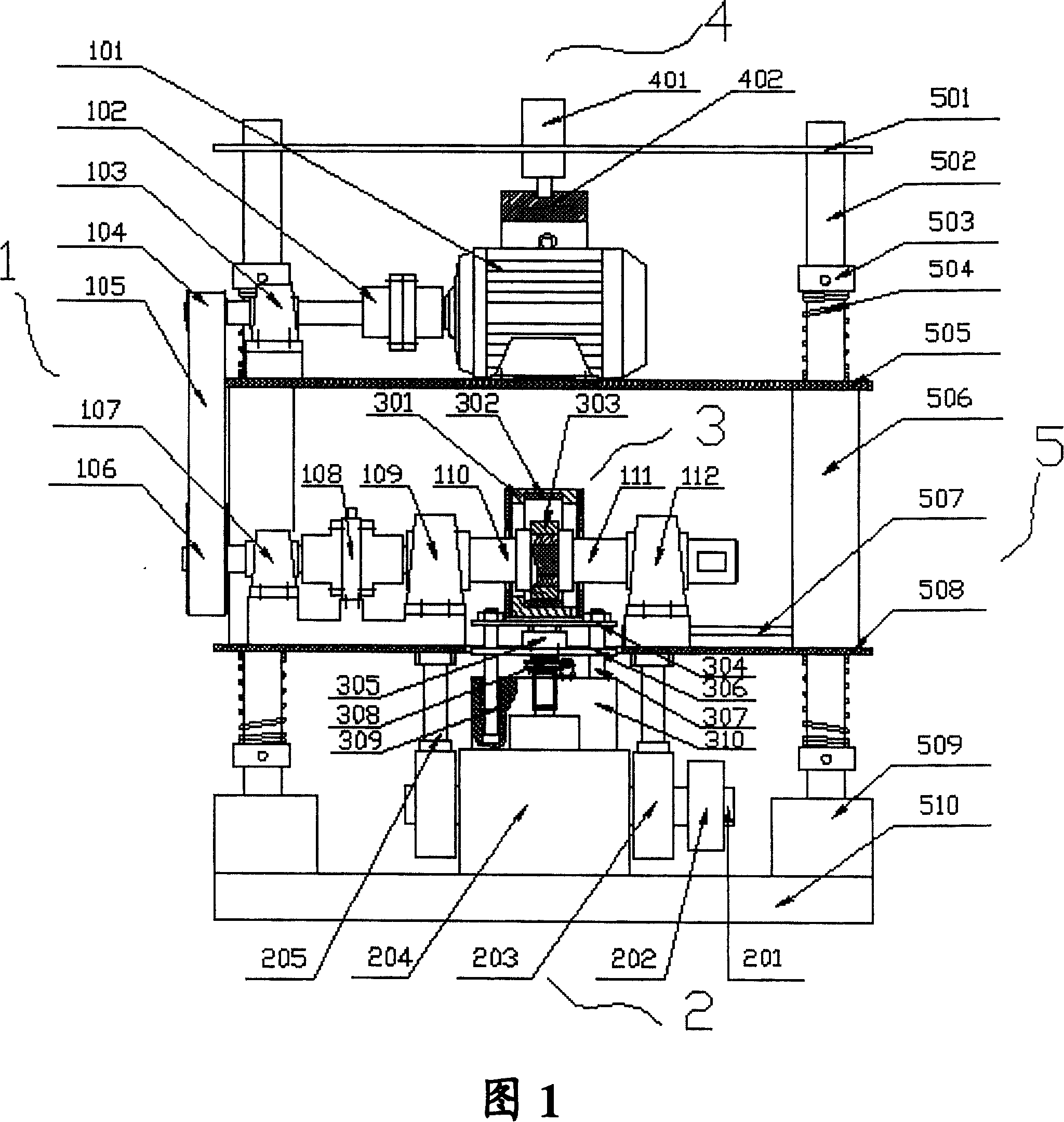

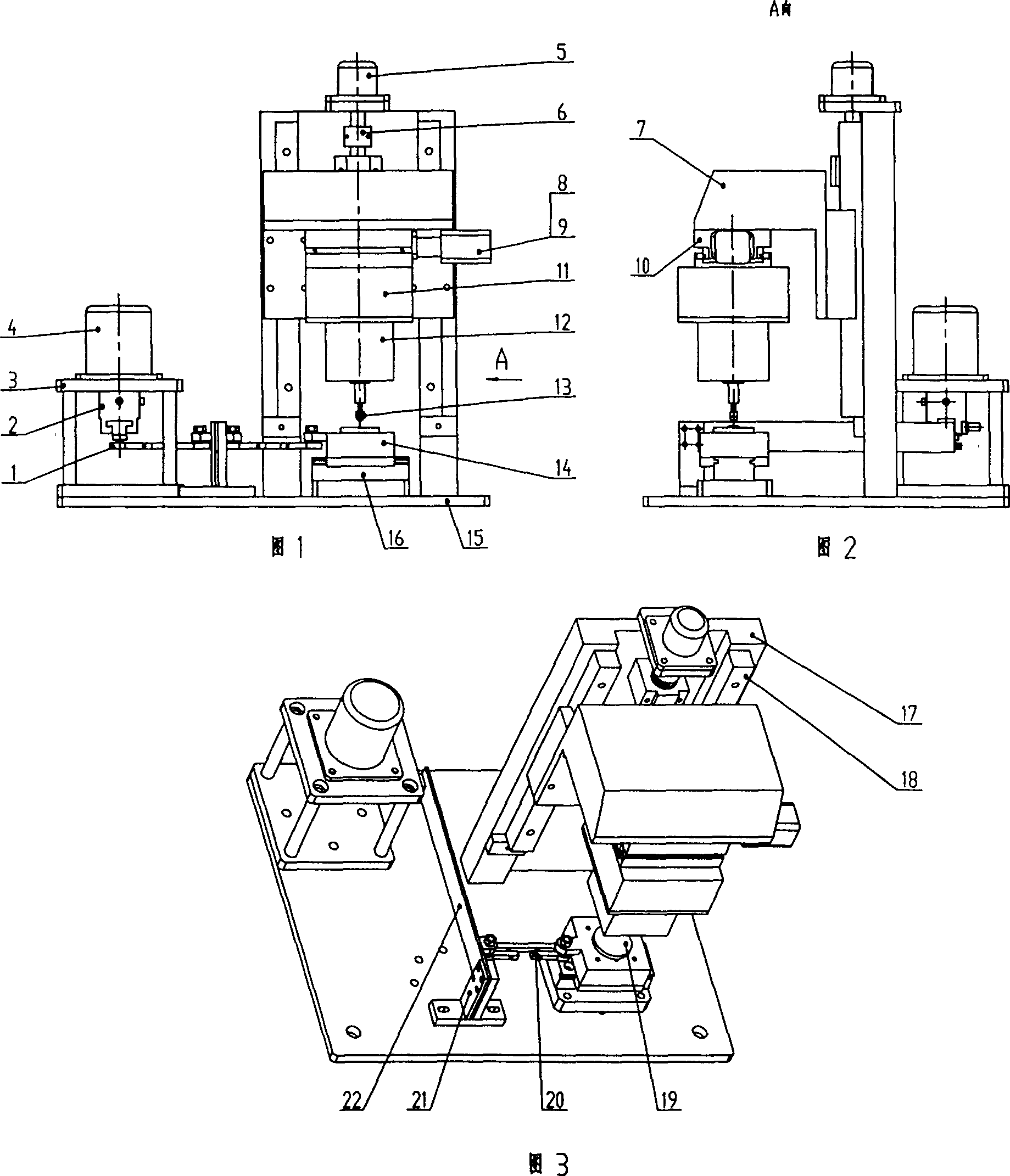

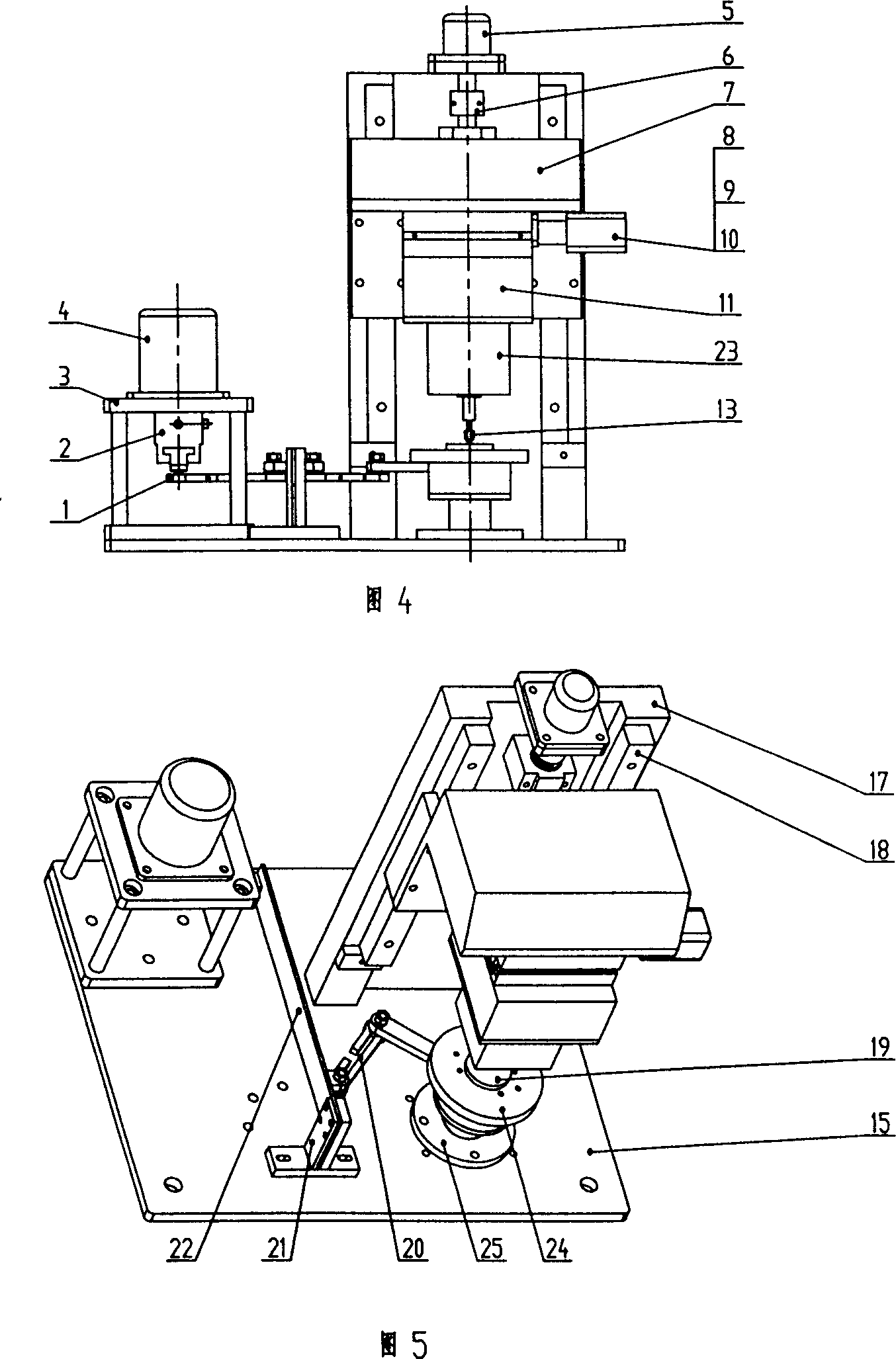

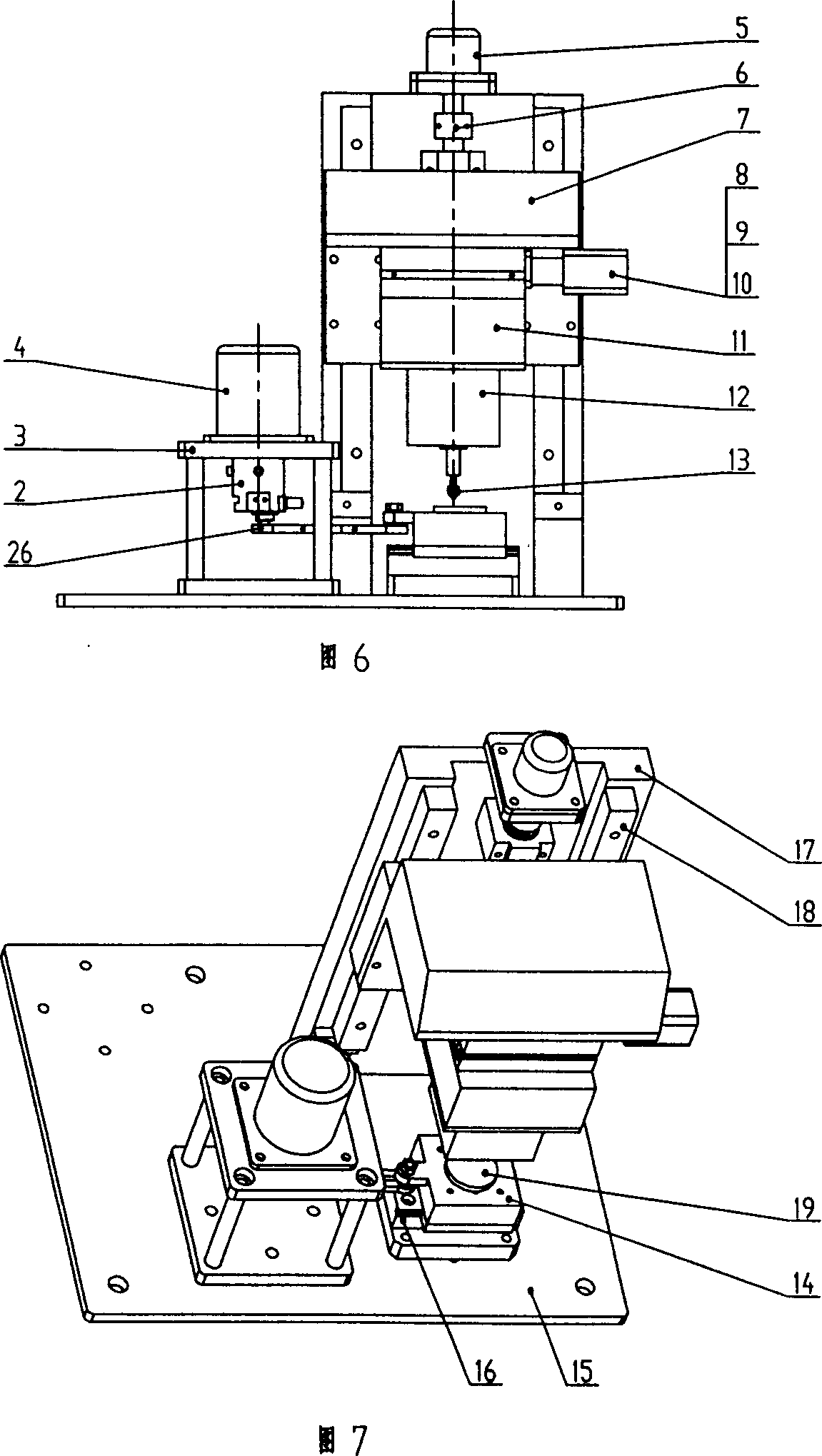

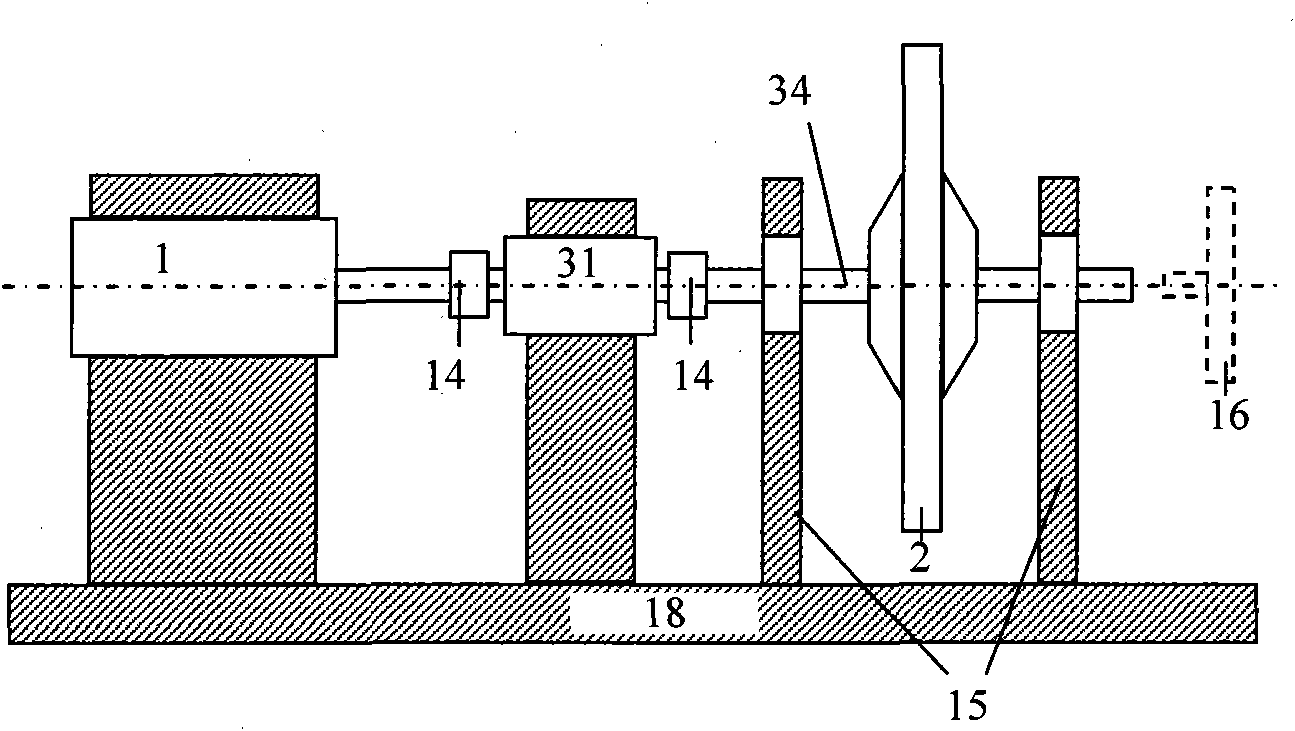

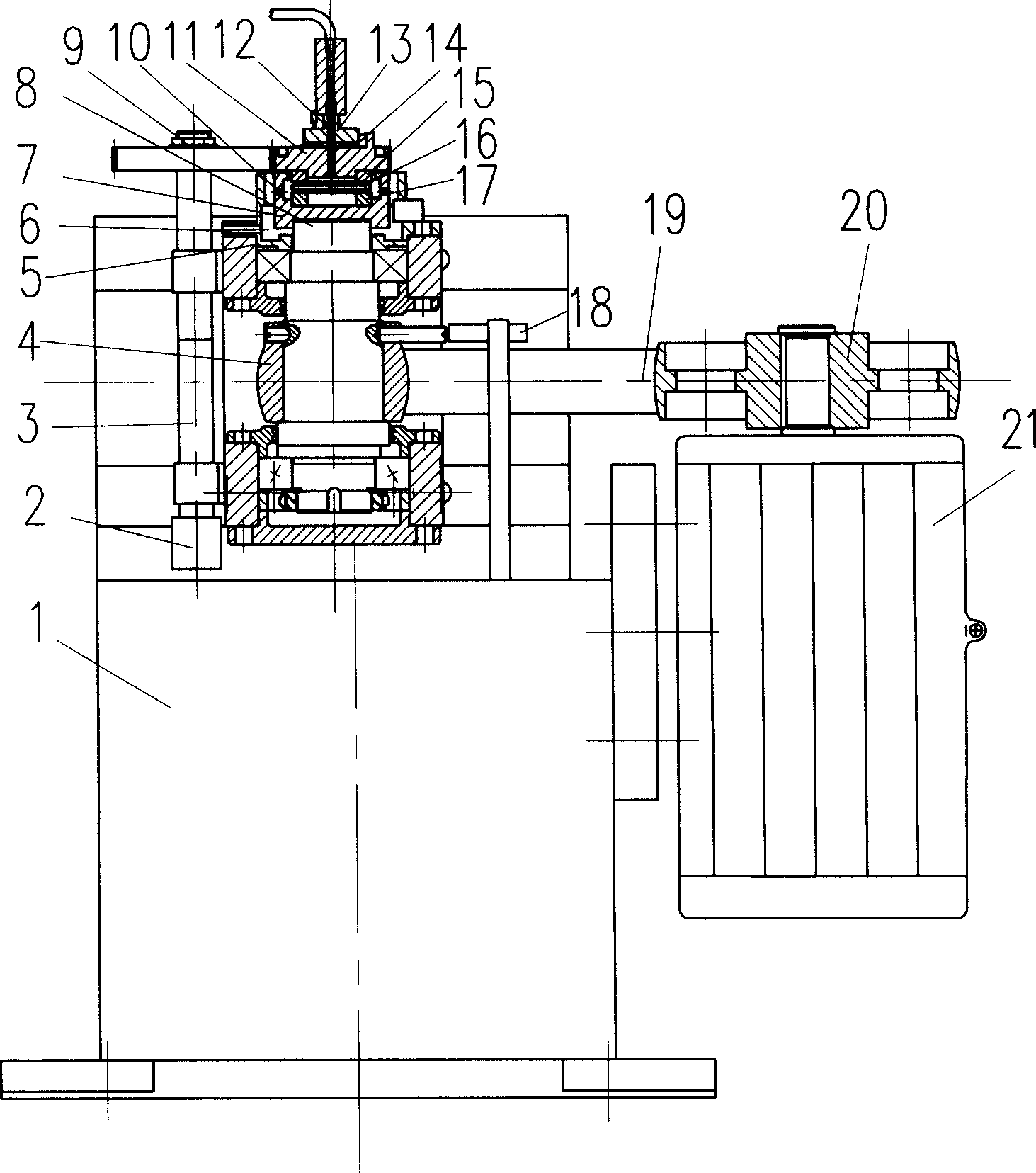

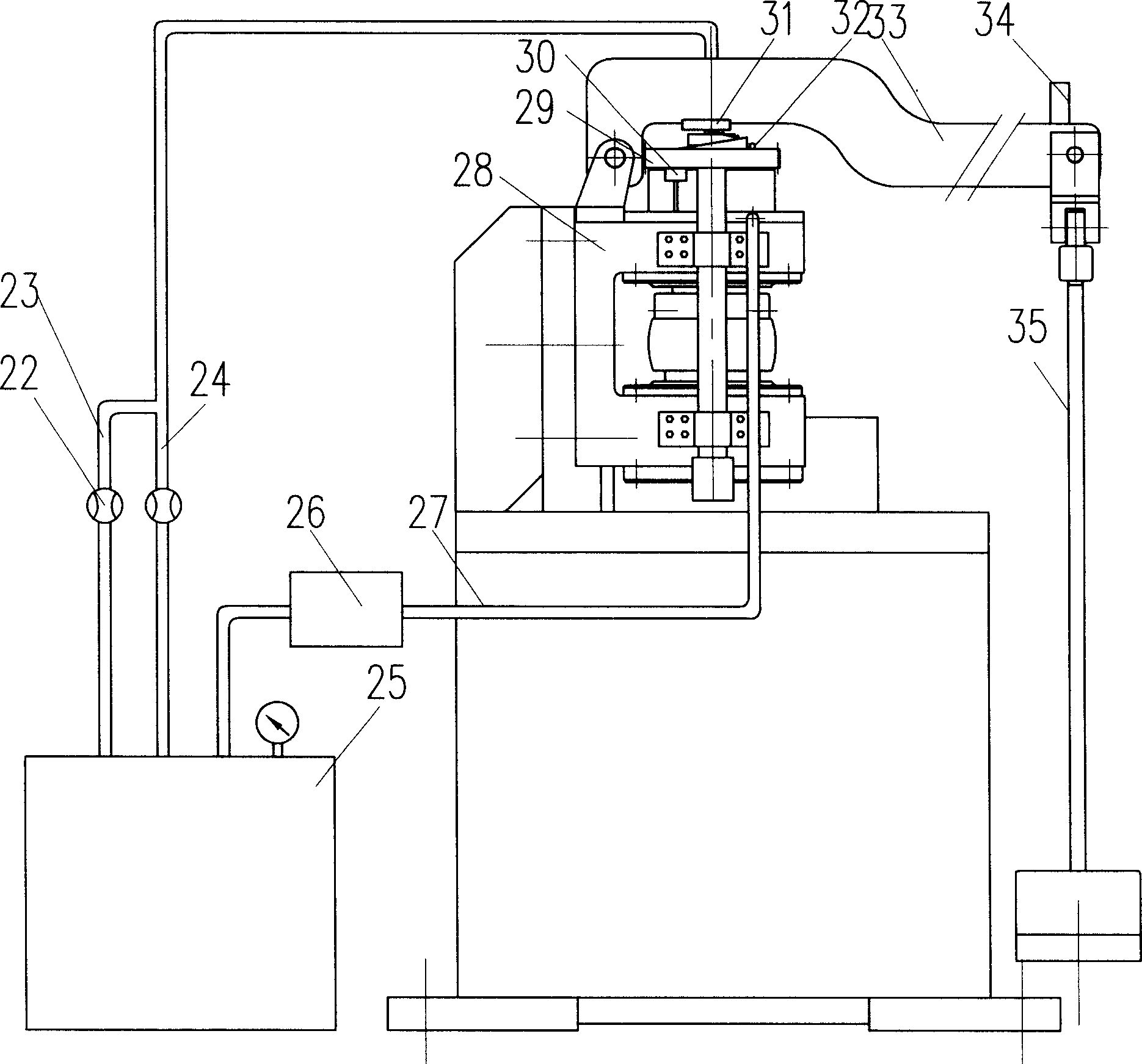

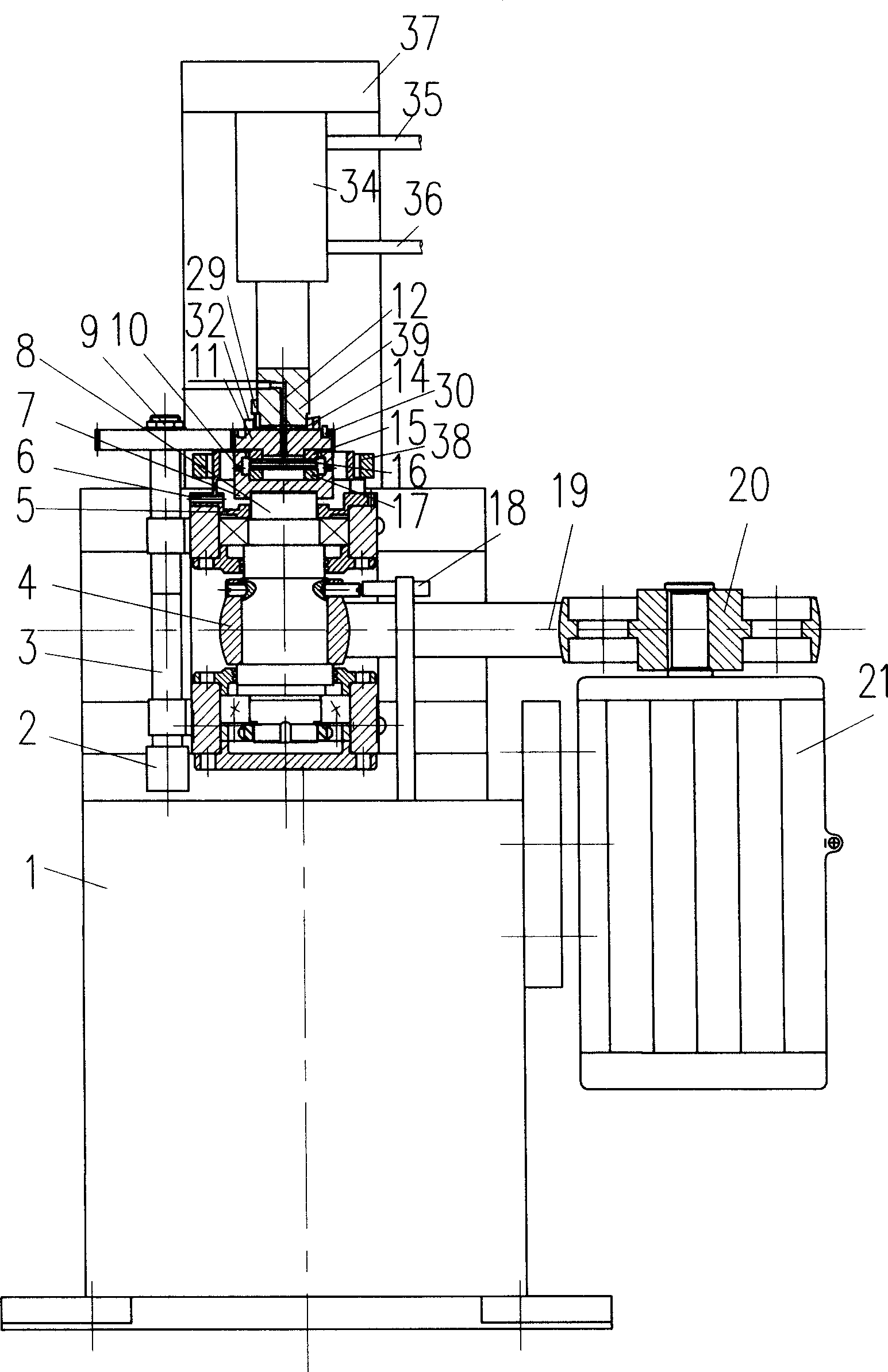

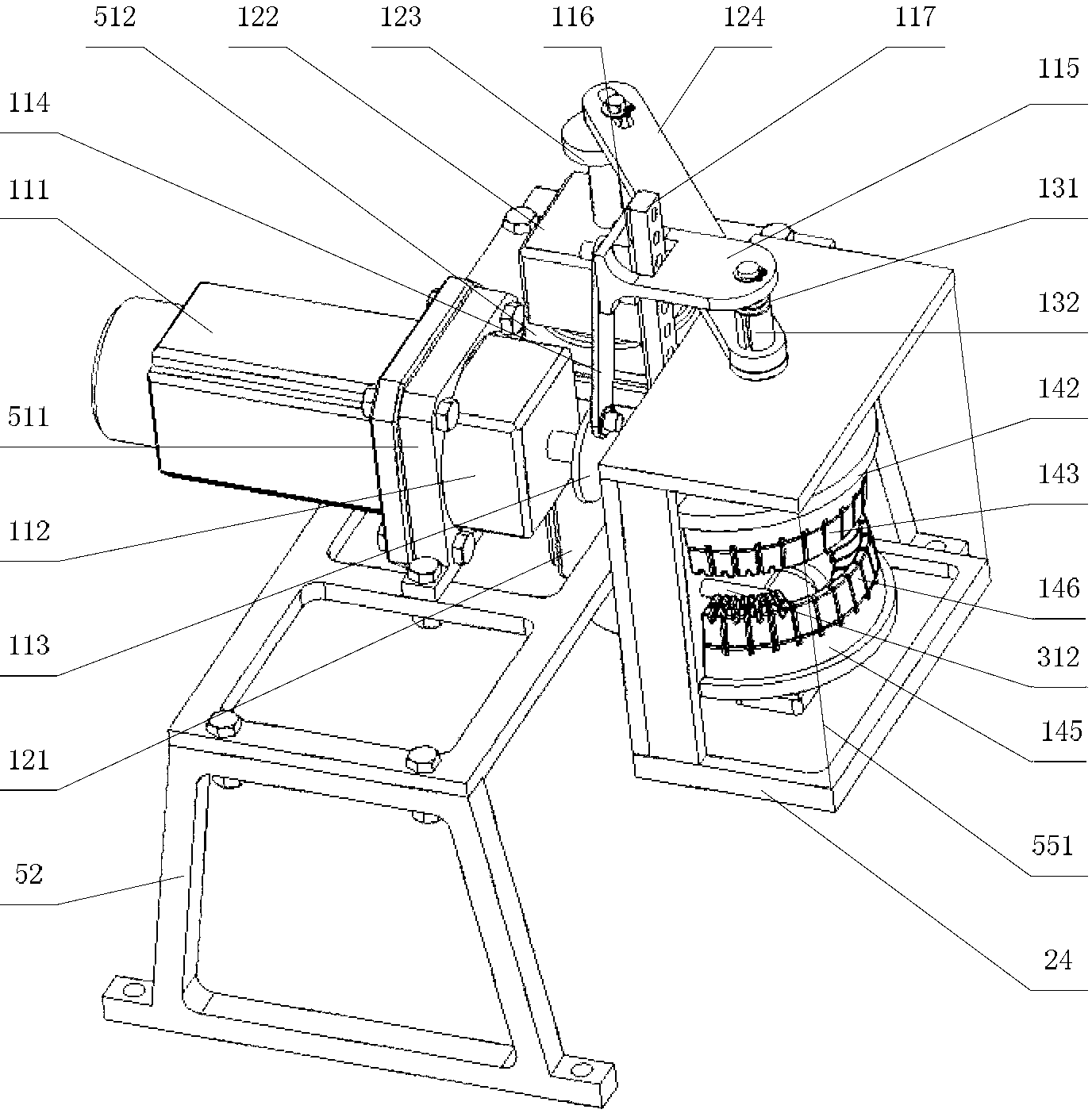

A friction test device and test method for screw drilling tool rotor coating

ActiveCN105092401BTest data availableAccurate data supportInvestigating abrasion/wear resistanceElectric machineEngineering

The invention discloses a screw rd drilling tool rotor cladding layer friction test device and a screw rod drilling tool rotor cladding layer friction test method. The device comprises a rack, a box, a grinding wheel assembly, a linear rail assembly, a rectilinear motion assembly, a pressurizing assembly, a speed reducing machine with a motor, and a rectilinear motion assembly driving mechanism. Mud liquid is added in the box; a main shaft of the grinding wheel assembly penetrates through the box; a plurality of grinding wheels are fixedly arranged on the main shaft; at least lower parts of the grinding wheels are positioned in the box; two linear rails of the linear rail assembly are fixed at two sides of the box and are vertical to the main shaft; a base part of the rectilinear motion assembly runs on the linear rails; a pressing block limiting device is arranged on the base part; pressing blocks in the pressurizing assembly are arranged in pressing block installation holes in the pressing block limiting device; the bottom surface of each pressing block clamps a test piece; each pressing block is loaded by a lever mechanism and a pressure applying roller; the speed reducing machine drives the main shaft to rotate by a belt transmission mechanism; the main shaft rotates to drive the rectilinear motion assembly to run by a cam mechanism and a connection rod. Test data are relatively desirable, so that a relatively accurate data support is provided for study on a wear-resisting property of a cladding layer.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

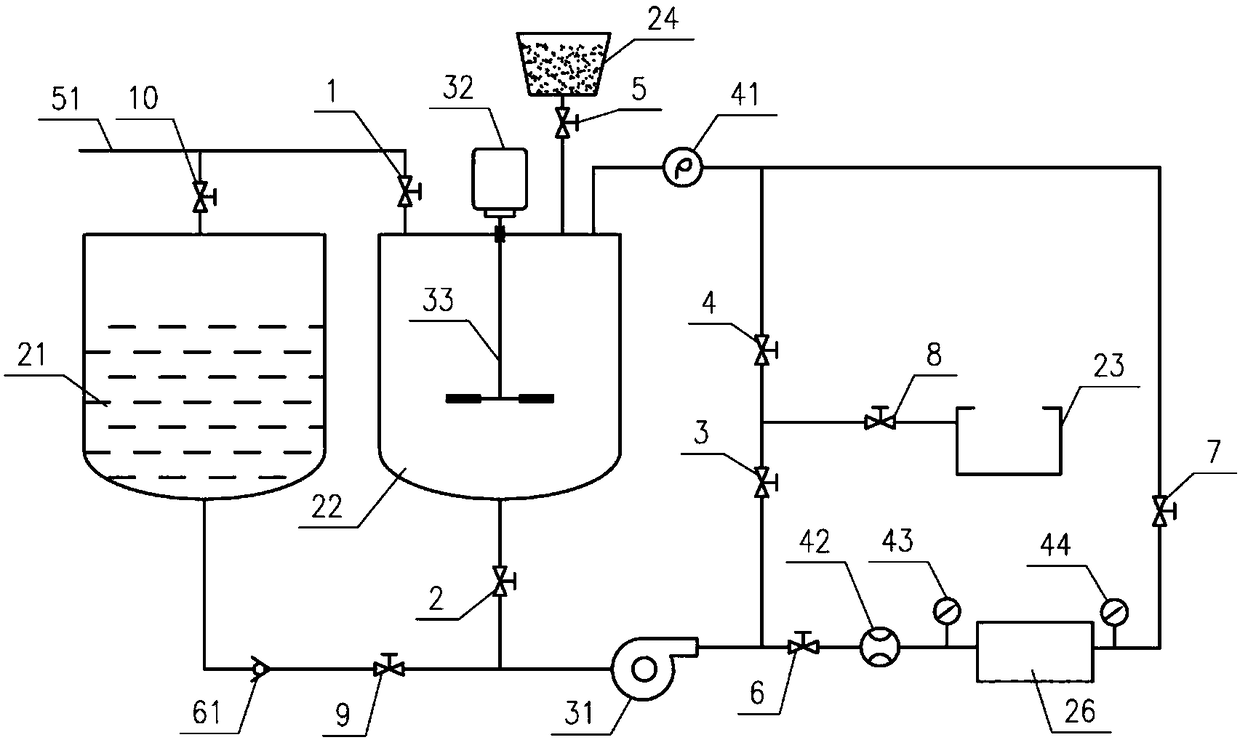

Fluid product service life testing device and testing method

PendingCN108254276AImprove work efficiencyPrevent sinkingInvestigating abrasion/wear resistanceProduct testingBiomedical engineering

The invention provides a fluid product service life testing device. The fluid product service life testing device comprises a fluid generation device, a fluid product testing region and a washing device, wherein a fluid circulating pipeline is formed between the fluid generation device and the fluid product testing region; fluid flows into the fluid product testing region from the fluid generationdevice and then continually flows back into the fluid generation device; the washing device is communicated with the fluid circulating pipeline; the washing device is communicated with the fluid product testing region and then is communicated with the fluid generation device through the fluid circulating pipeline; the fluid generation device is connected with a sediment recycling device. The fluid product service life testing device can be used for testing the service life of a product through simulating fluid flowing of production conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

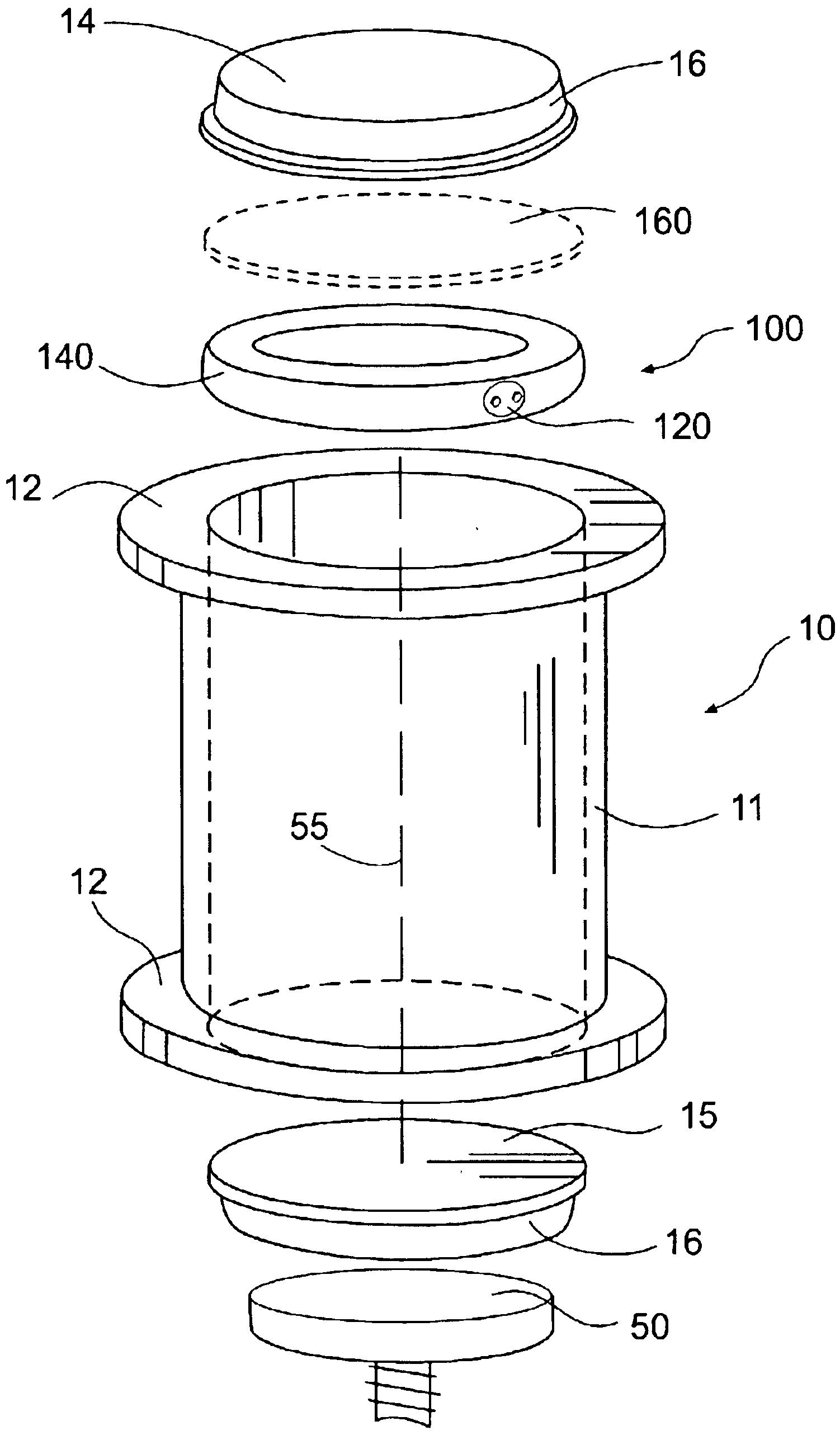

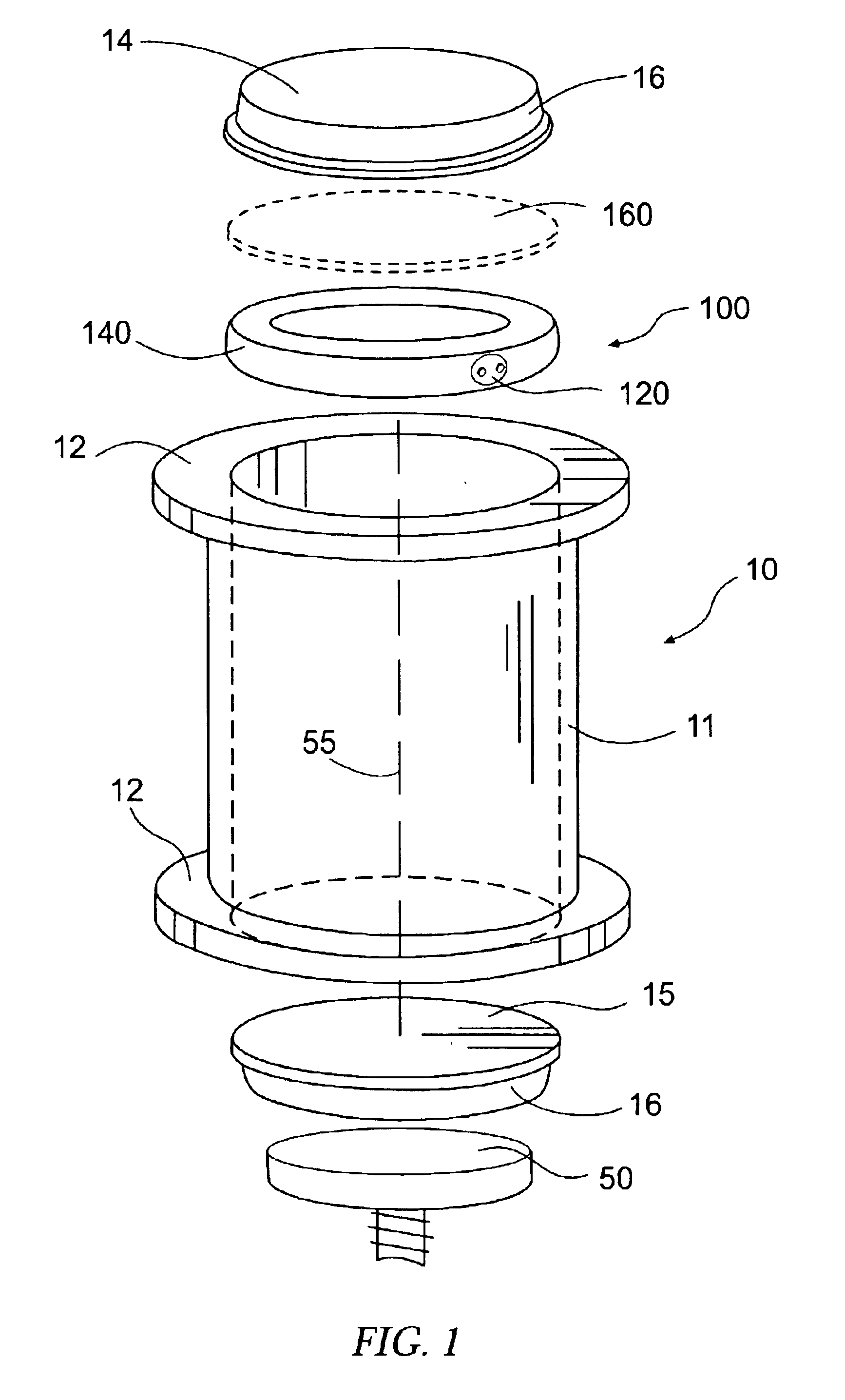

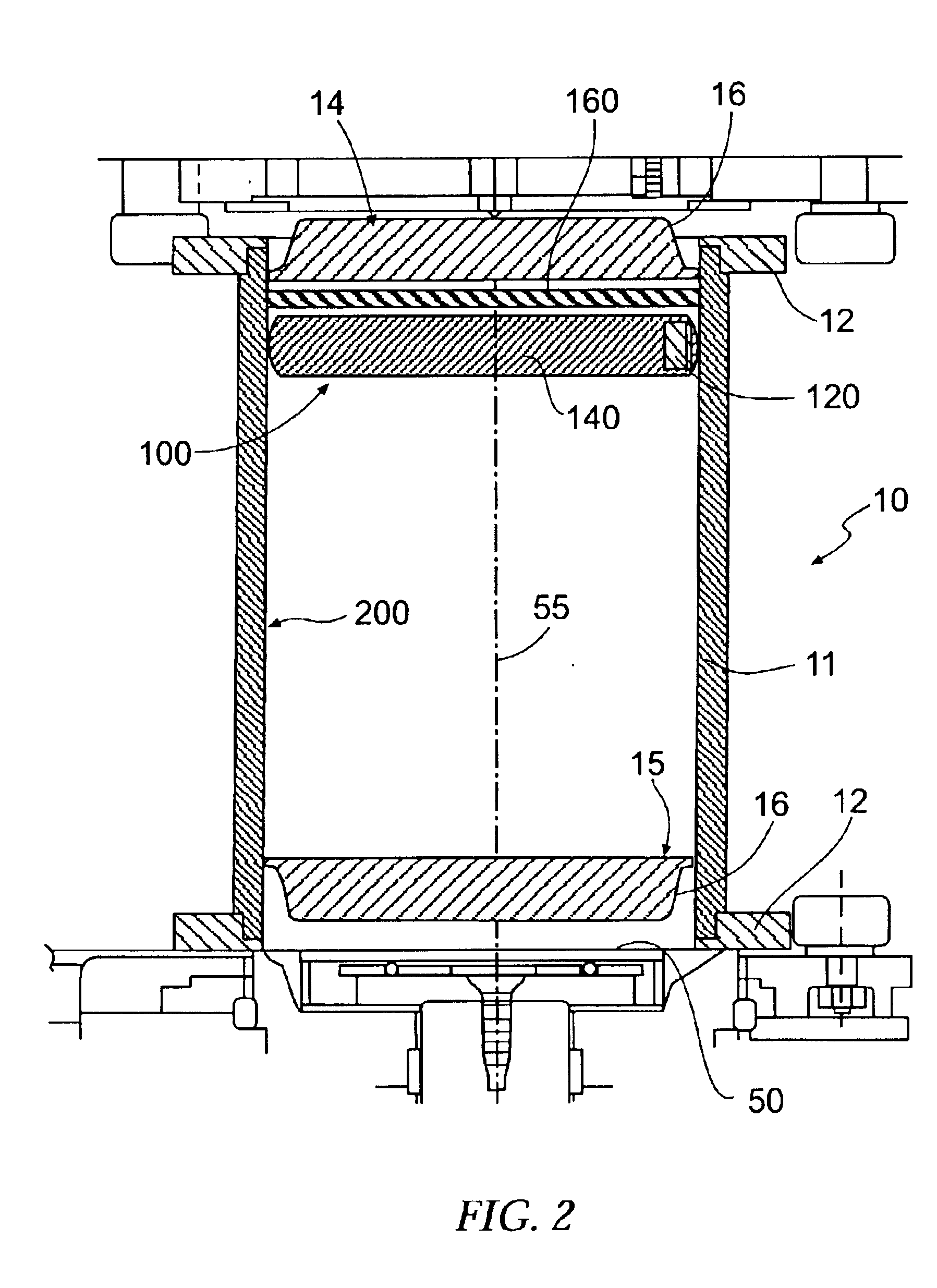

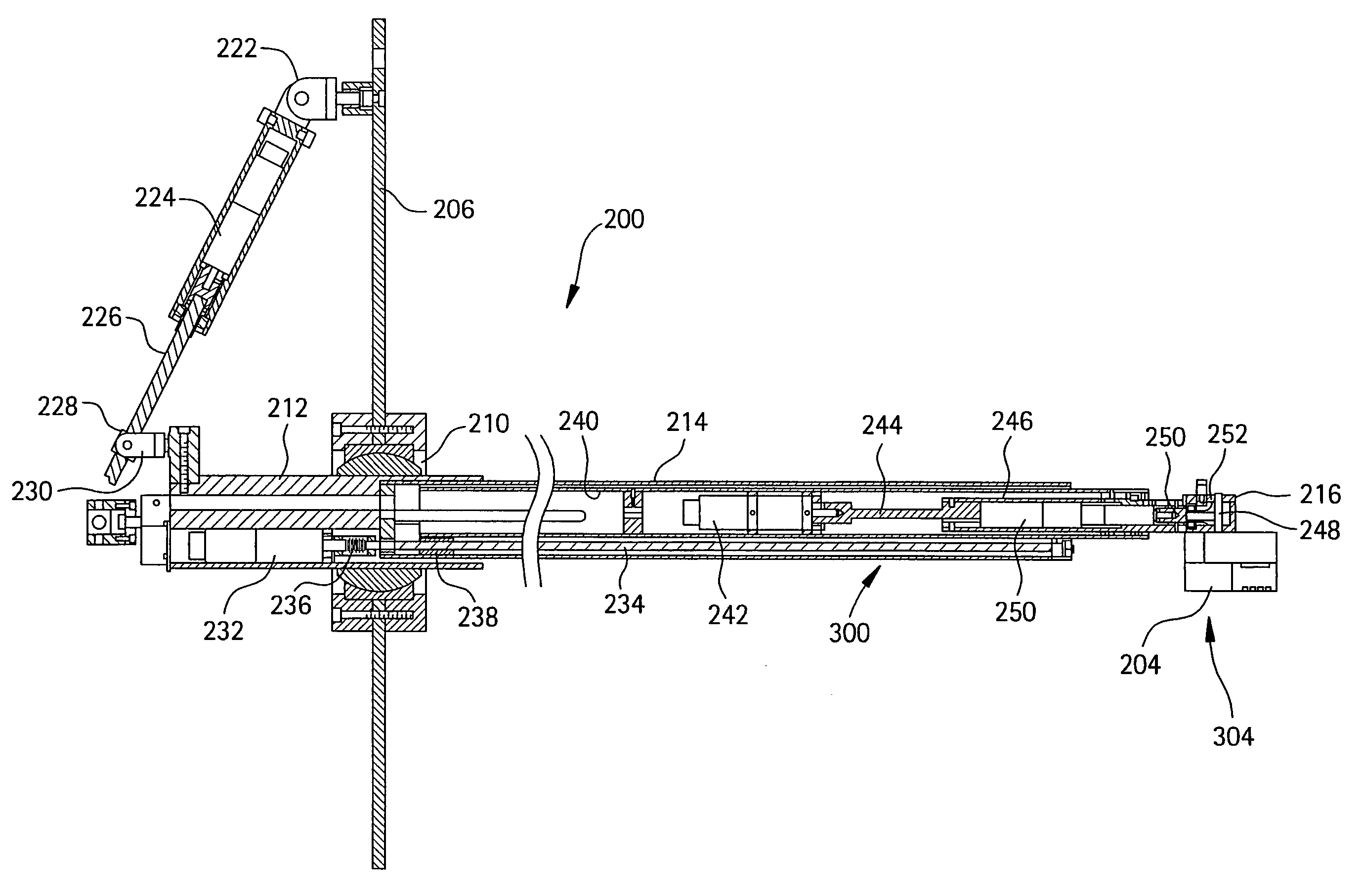

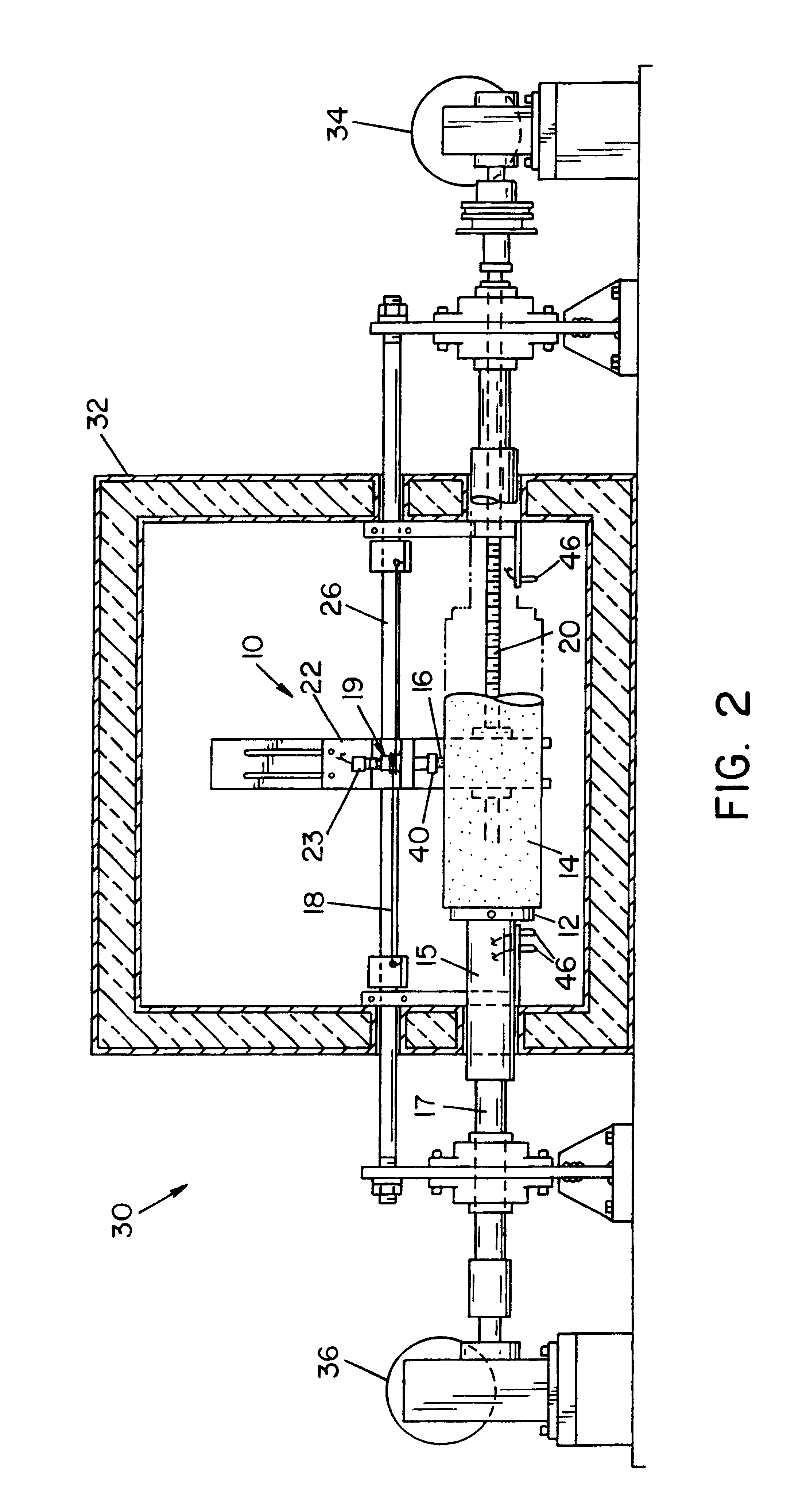

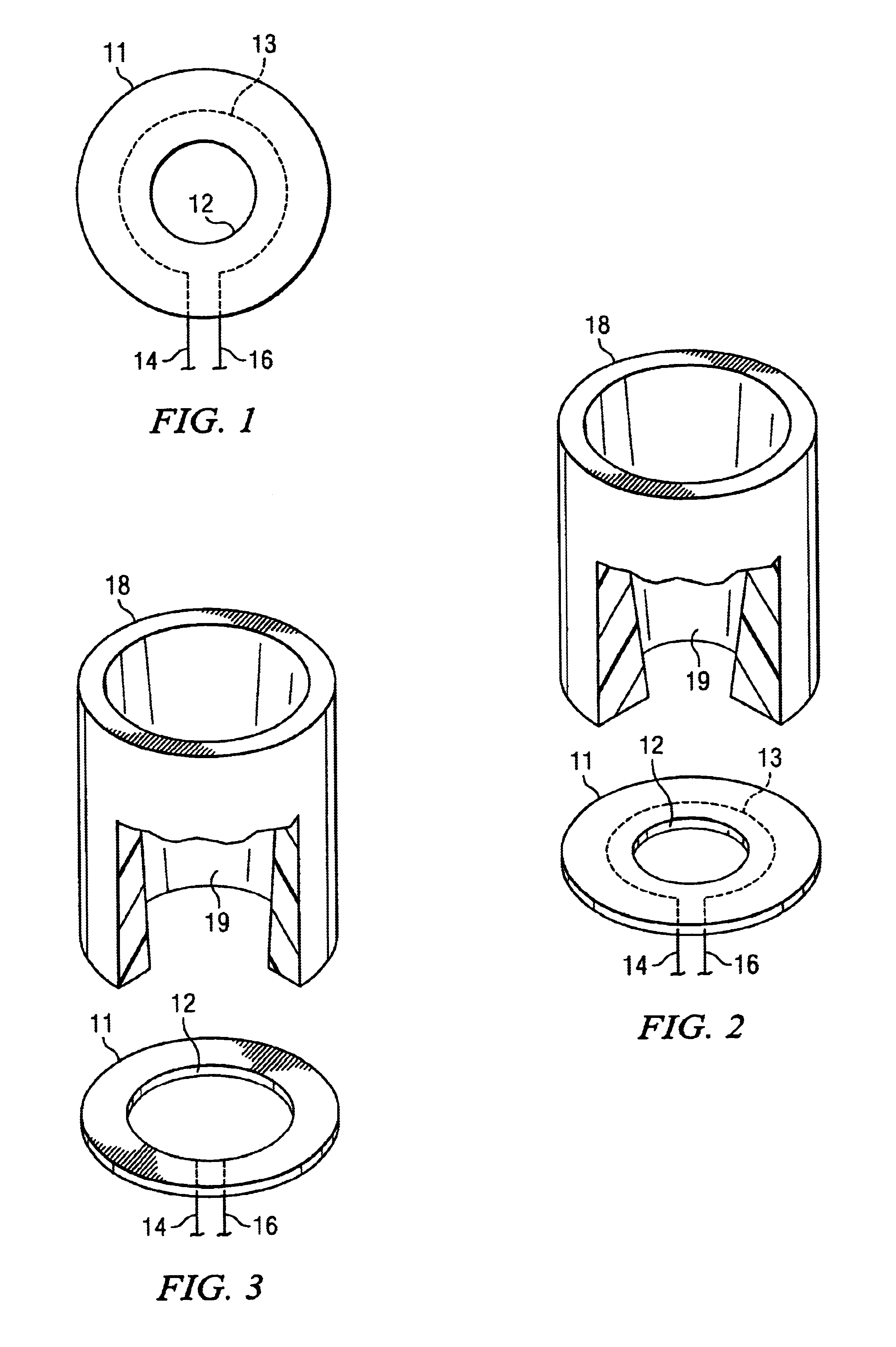

Method and apparatus for determining the angle of gyration and/or the pressure in a gyratory compactor

InactiveUS6868738B2Preparing sample for investigationMaterial strength using tensile/compressive forcesEngineering

An apparatus adapted to interact with a cylindrical mold for a gyratory compactor so as to determine a property of the gyratory compactor is provided, wherein the mold is adapted to contain a sample therein. Such an apparatus comprises a rigid disk-shaped plate defining an axis and a periphery, with the plate being adapted to be disposed within the mold. At least one sensing device is operably engaged with the plate, wherein the at least one sensing device is configured to measure a proximity of the at least one sensing device with respect to a reference member and to produce a corresponding signal indicative of the property of the gyratory compactor. In one embodiment, the apparatus is configured to determine the gyration angle of the mold, while in another embodiment, the apparatus is configured to determine the pressure exerted on the sample within the mold. The property of the mold may be determined either statically or dynamically. Associated apparatuses, devices, systems, and methods are also provided.

Owner:TROXLER ELECTRONICS LAB INC

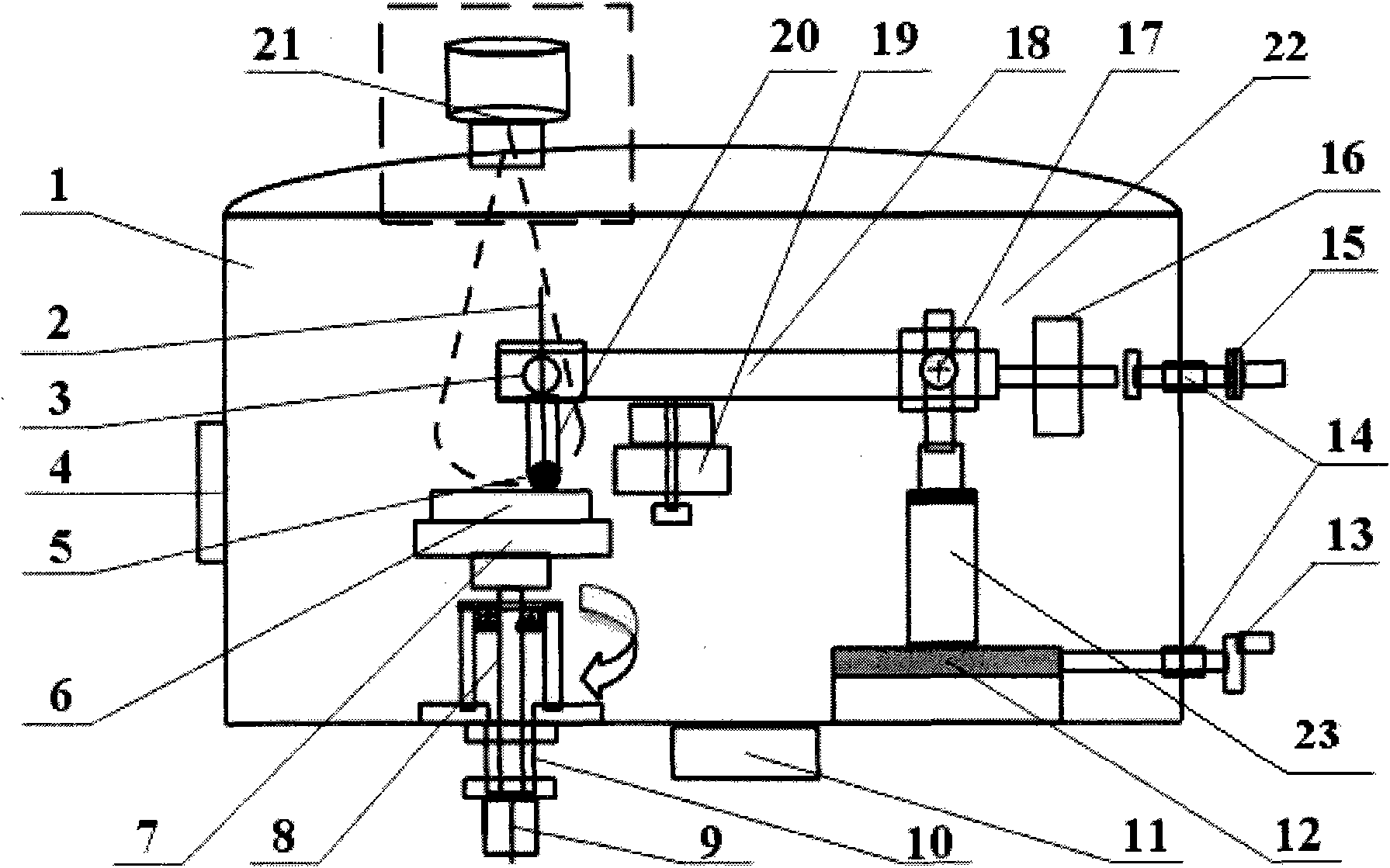

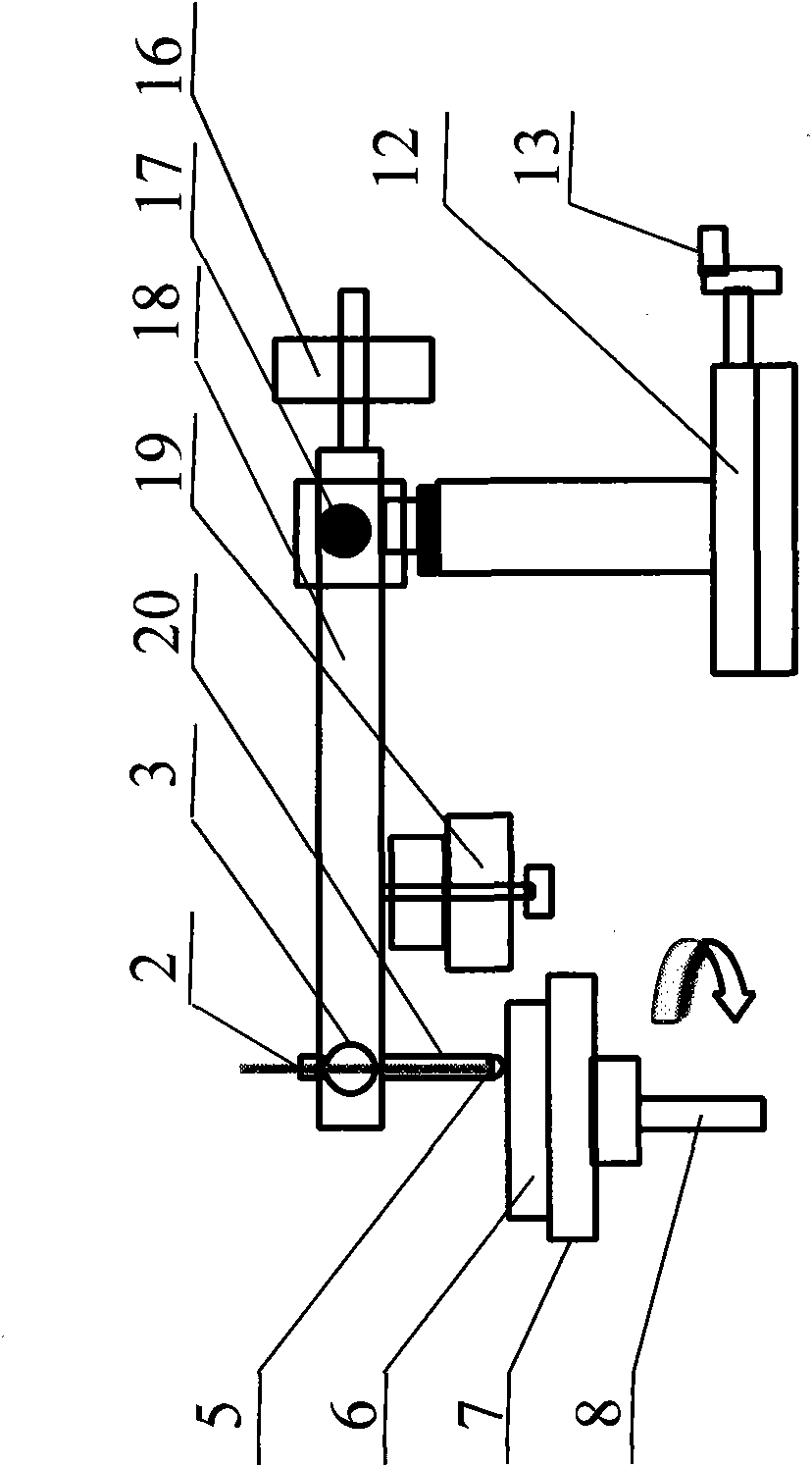

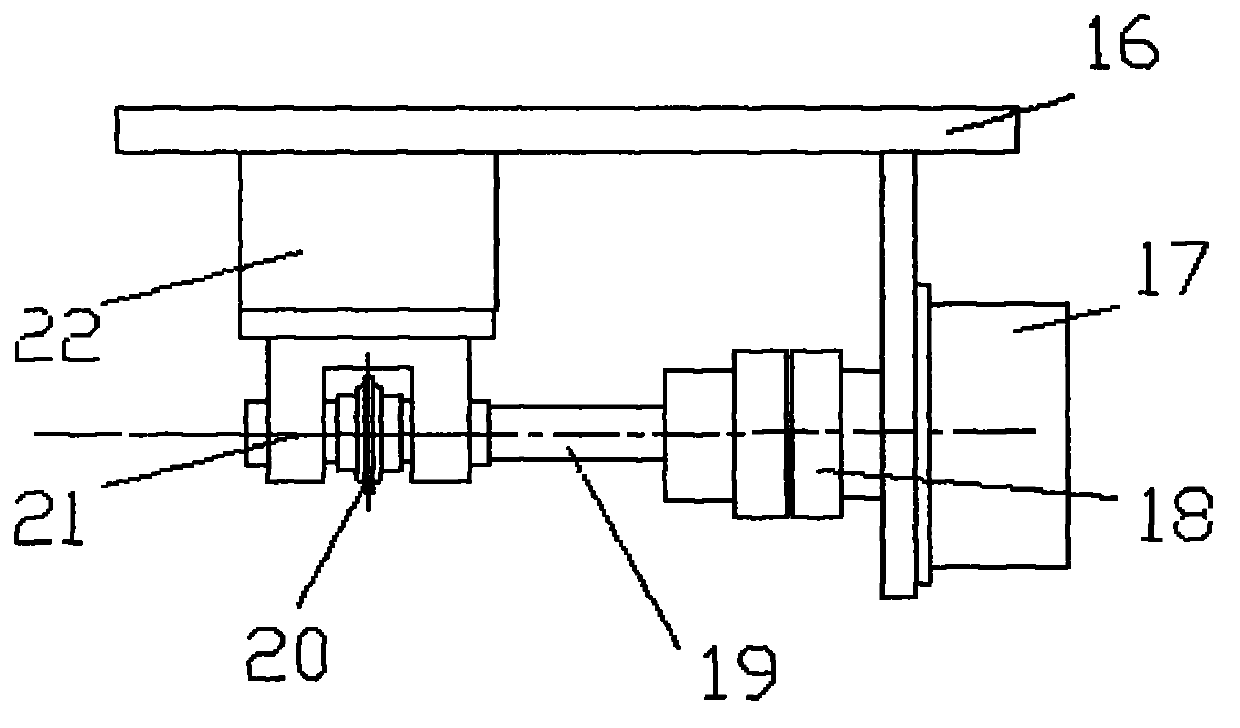

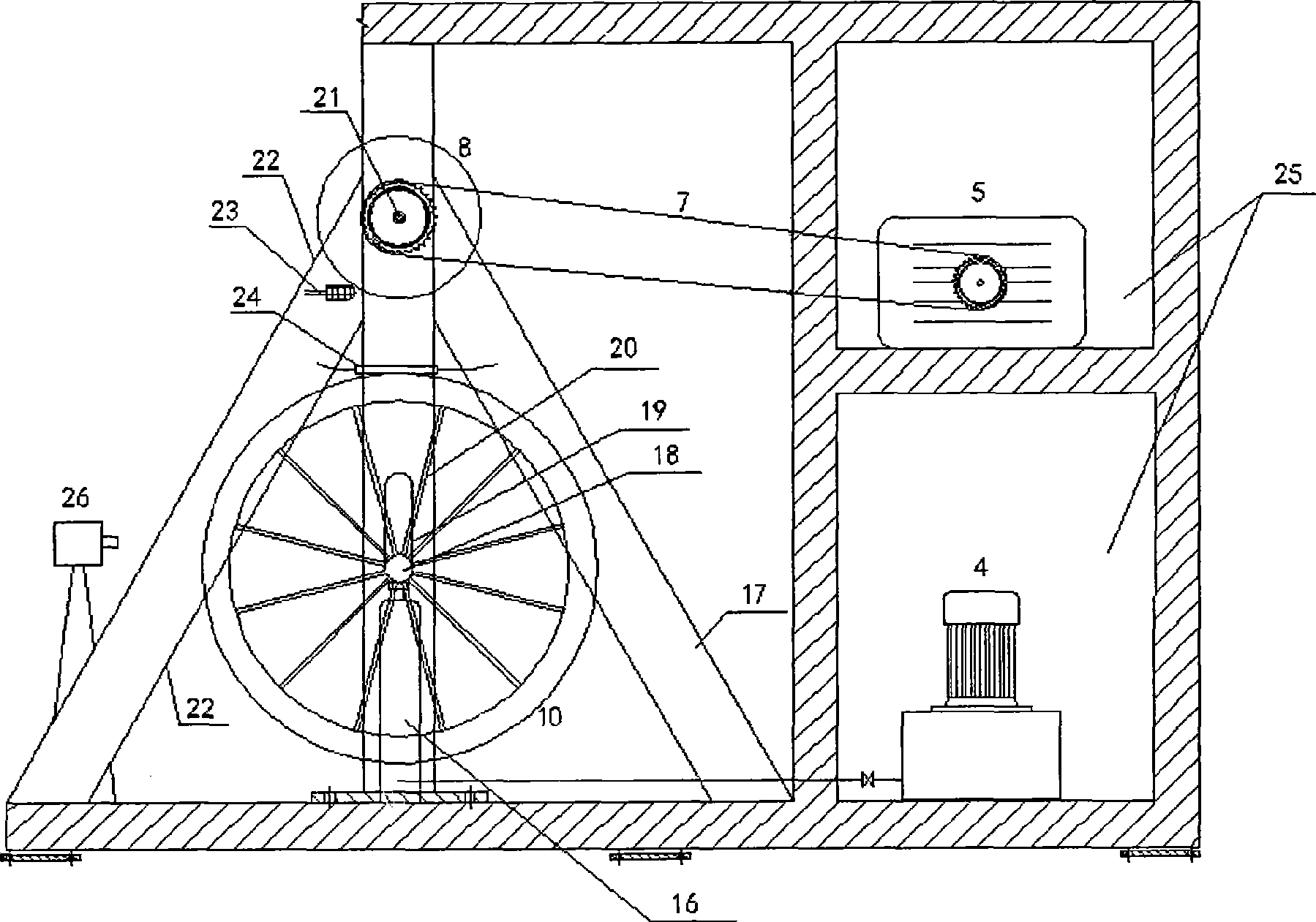

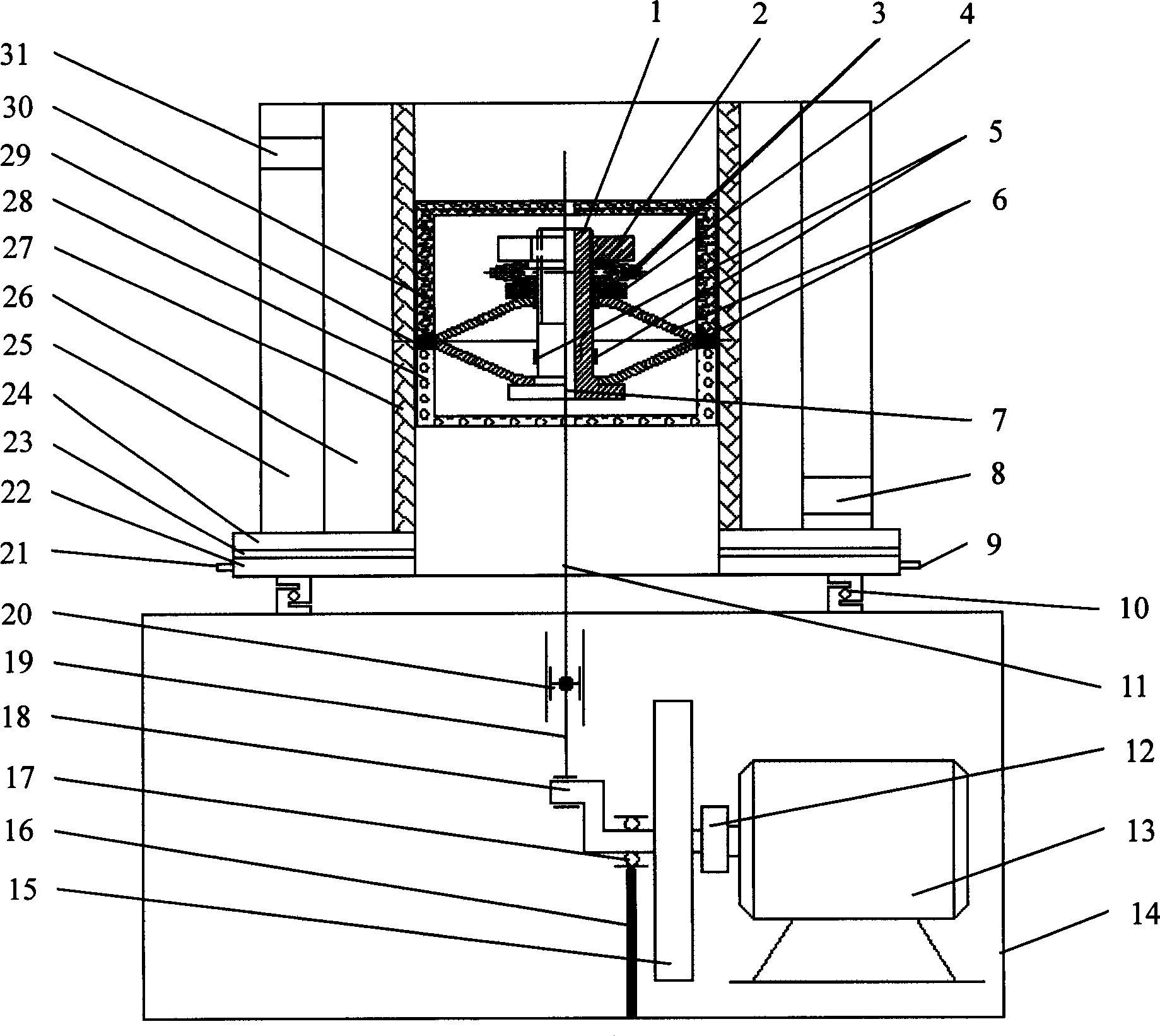

Multifunctional vacuum friction and wear testing machine

ActiveCN102759489APrecise position adjustmentAvoid time costInvestigating abrasion/wear resistanceDrivetrainEngineering

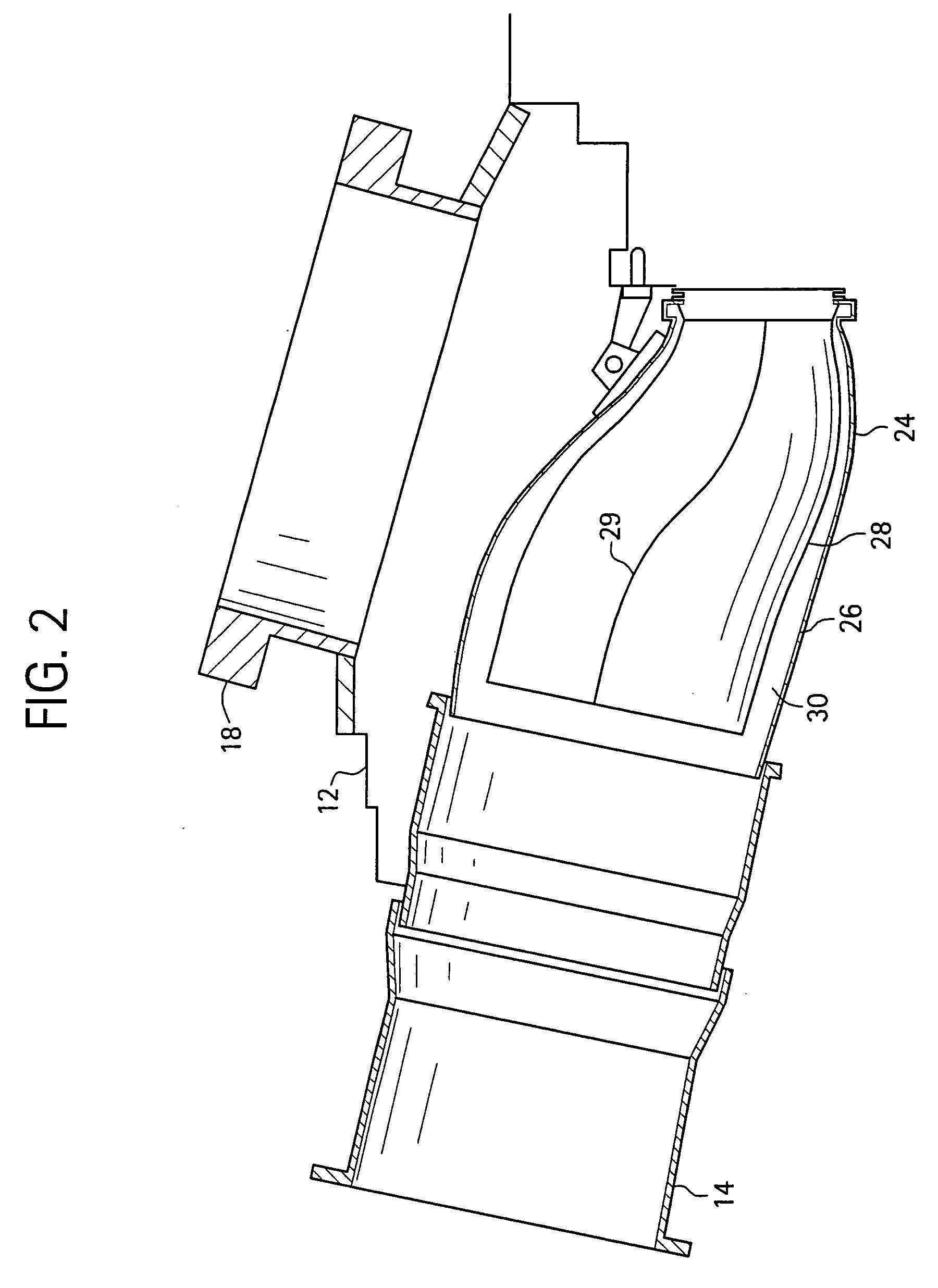

The invention provides a multifunctional vacuum friction and wear testing machine, which not only can simulate special environmental atmospheres such as vacuum, radiation and corrosion, but also can conduct tribology tests in a relatively wide speed and load range by using various contact manners (ball-disc and pin-disc). The multifunctional vacuum friction and wear testing machine mainly comprises a vacuum system, a friction and wear system, a power transmission system, a control system, and the like, wherein the friction and wear system comprises a lever structure (22) used for fixing a test sample fixture (20) and capable of freely rotating in a horizontal direction and a vertical direction; the lever structure (22) comprises a cantilever beam (18) and a vertical arm (23) which are arranged in a perpendicular manner; the cantilever beam (18) is connected with the vertical arm (23) through a two degree of freedom bearing structure (17); positions of the cantilever beam (18) and the vertical arm (23) can be adjusted in the horizontal direction and the vertical direction through the control of a manipulator (15) and a hand wheel structure (13), so that the test sample fixture (20) can accurately move within two degrees of freedom; and a temperature sensor (2) and a pressure sensor (3) are mounted on the test sample fixture (20), so as to detect / monitor friction coefficients and temperature variations during the tribology tests.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

On-line measuring and testing machine for radial sliding bearing friction and wearing

InactiveCN1828264AProtection of transient contact surface statesMachine bearings testingUsing mechanical meansTested timeEngineering

The tester comprises: a clamp (22) to fix the upper sample (23) on its arc groove above the lower sample (25) connected to the middle of supporting shaft (37) by a flat key, a oil bath (26) to accommodate part (25), and a pressure bearing (20) with outside circle contacted to the upper arc surface of (22). This invention can protect the failure condition, and cuts wear test time.

Owner:YANSHAN UNIV

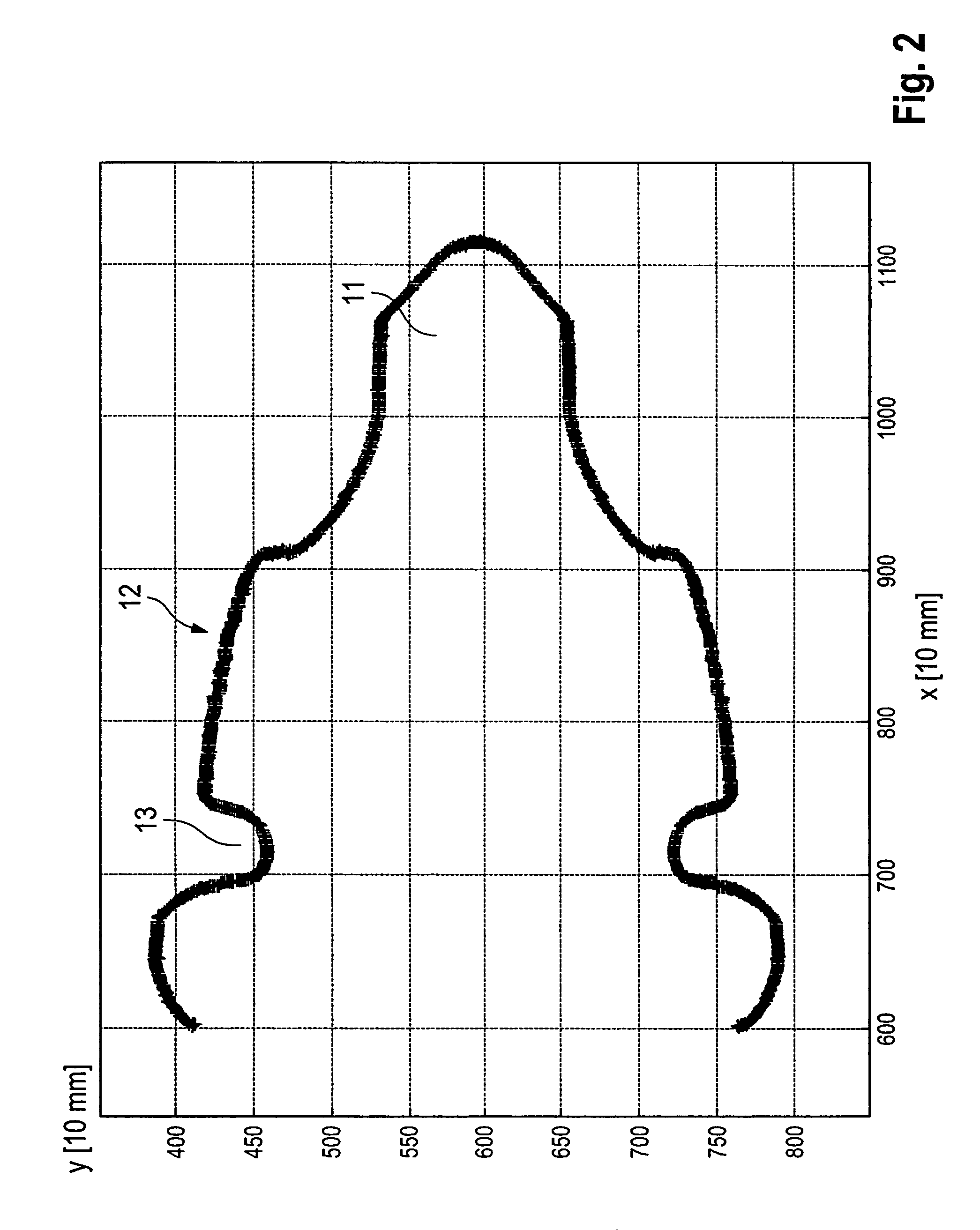

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

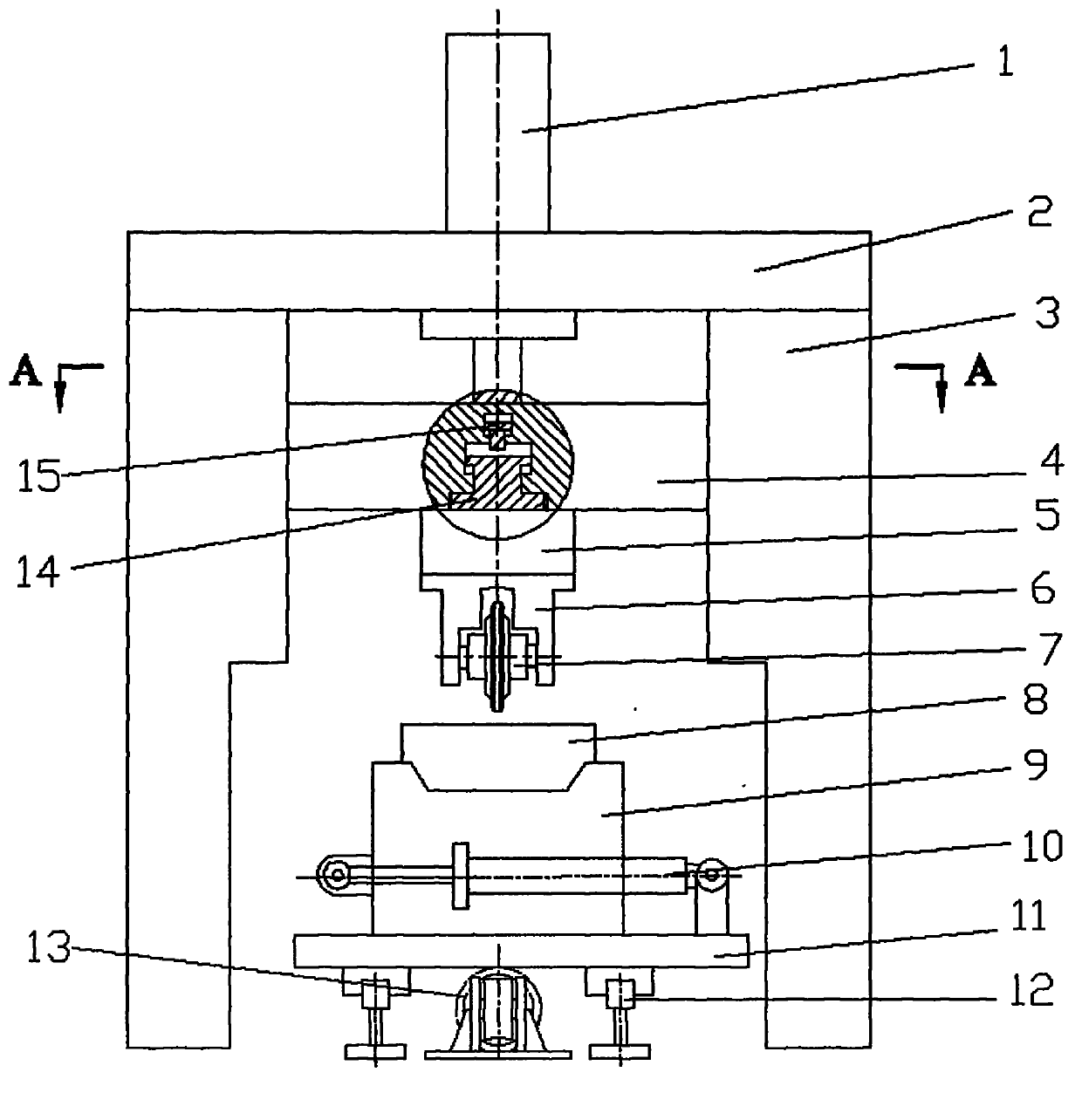

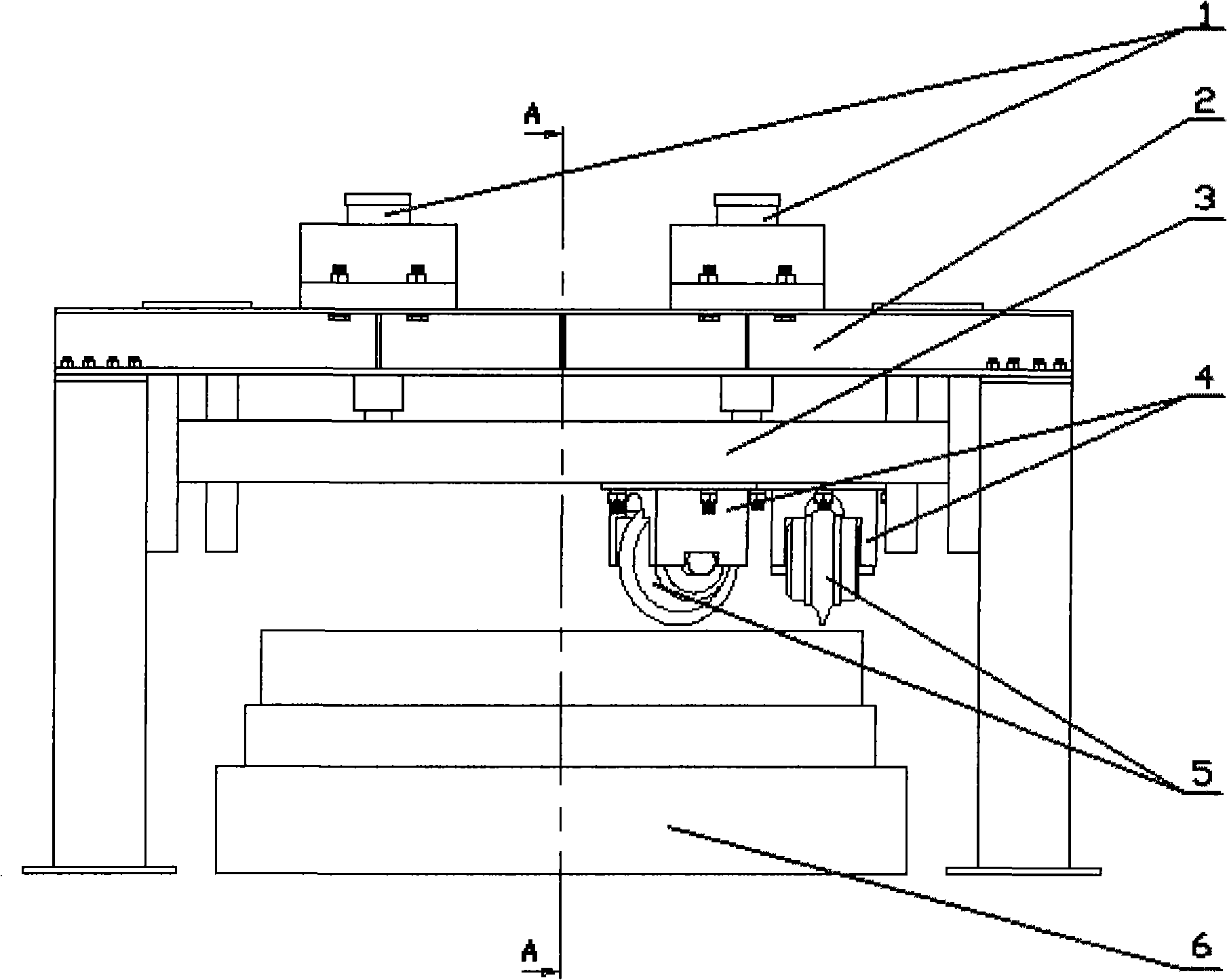

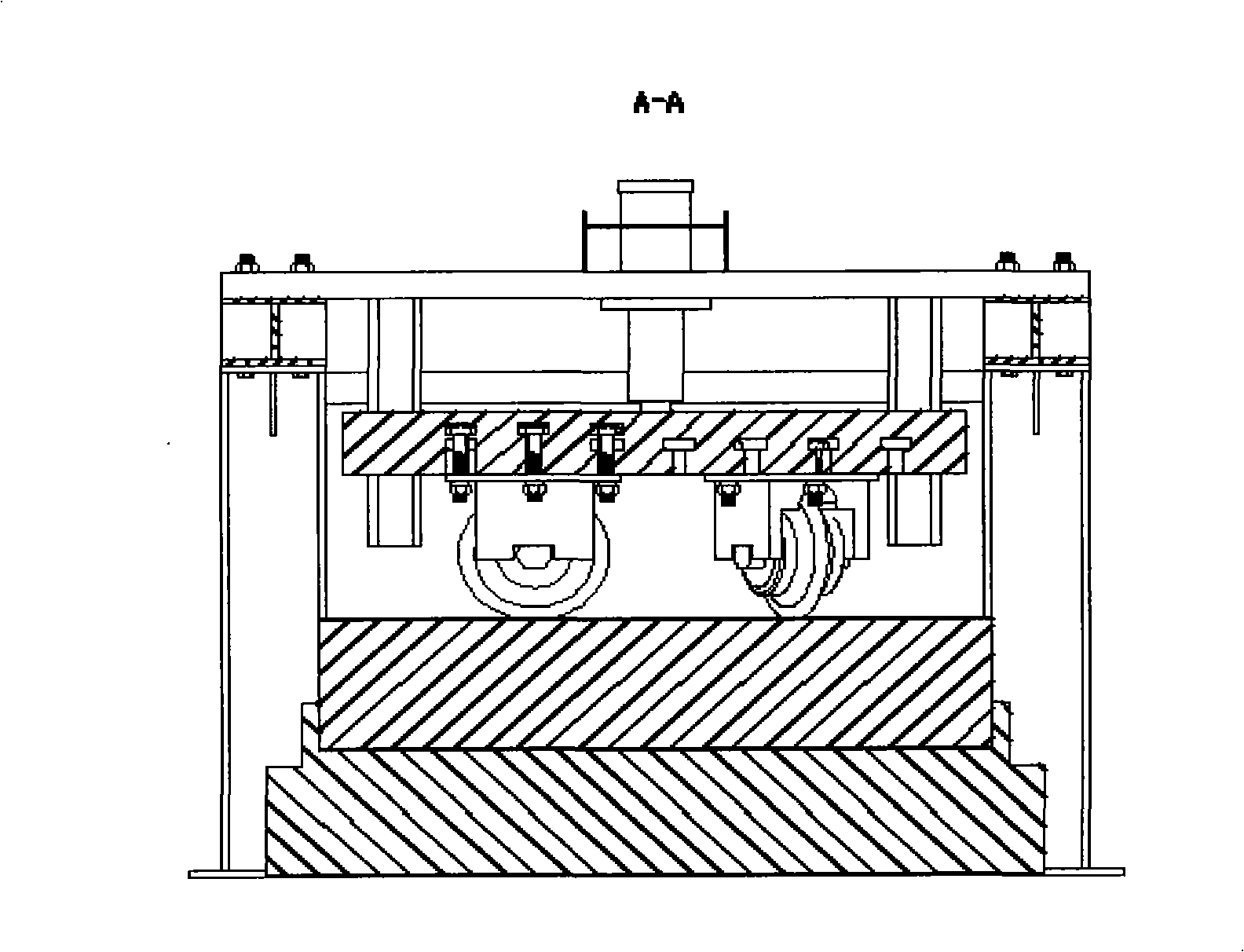

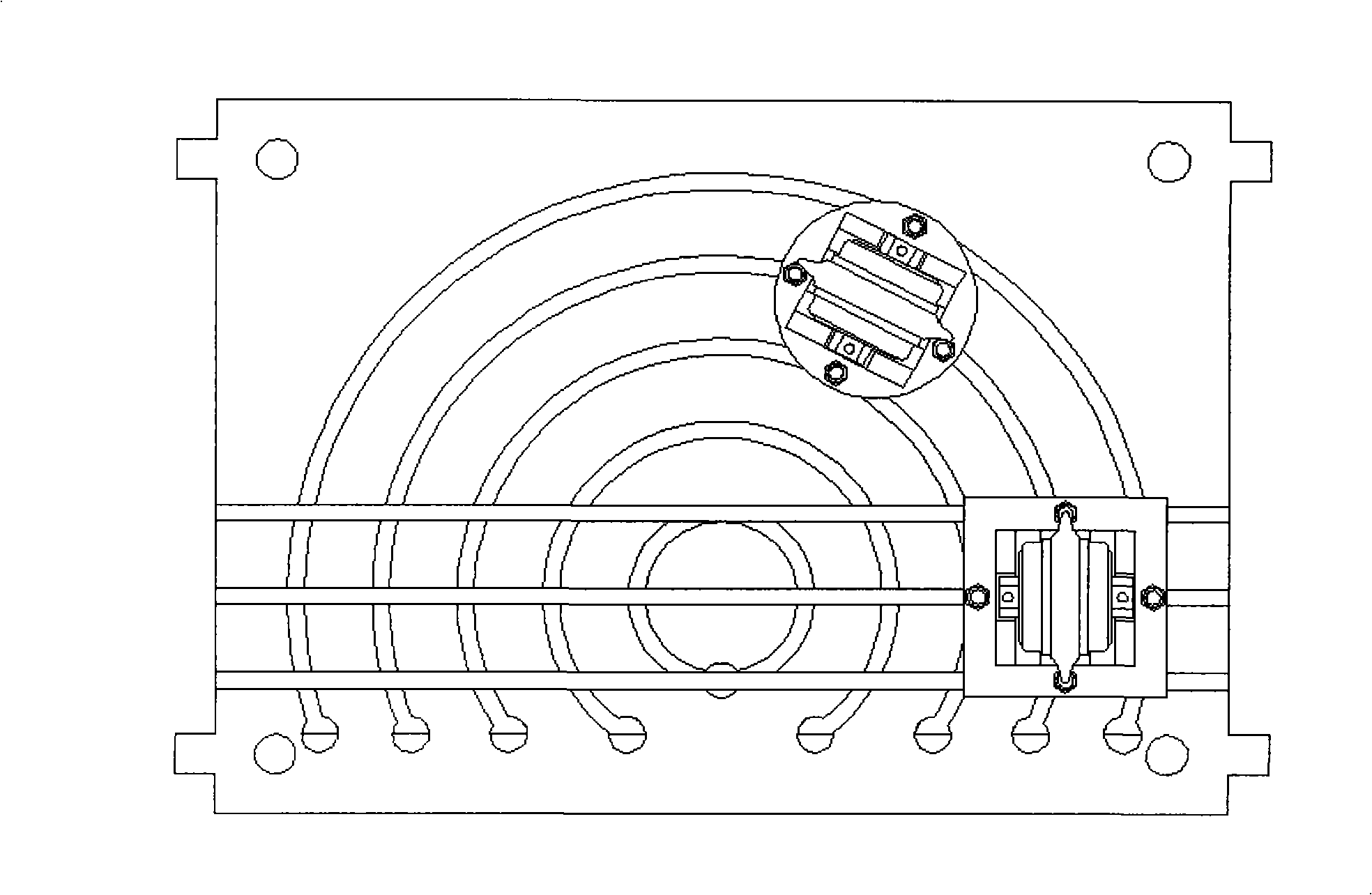

A hard rock hobbing cutter rock breaking characteristic testing device

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

Methods of use of substrate having properties of keratinous tissue

ActiveUS20070288186A1Easy to produceEasy to storeComponent separationAnalogue computers for chemical processesZeta potentialCoated surface

Method of product evaluation comprising the steps of applying at least one substance to a surface of an artificial substrate to form a substance-coated surface, wherein the substrate surface demonstrates at least one physical property selected from the group consisting of a total surface energy of from about 15 mJ / m2 to about 50 mJ / m2, a polar component of the total surface energy of from about 0 mJ / m2 to about 15 mJ / m2, a zeta-potential at a pH of about 5.0 of from about −30 mV to about 30 mV, and combinations thereof, and performing at least one analysis of the substance-coated surface.

Owner:THE PROCTER & GAMBLE COMPANY

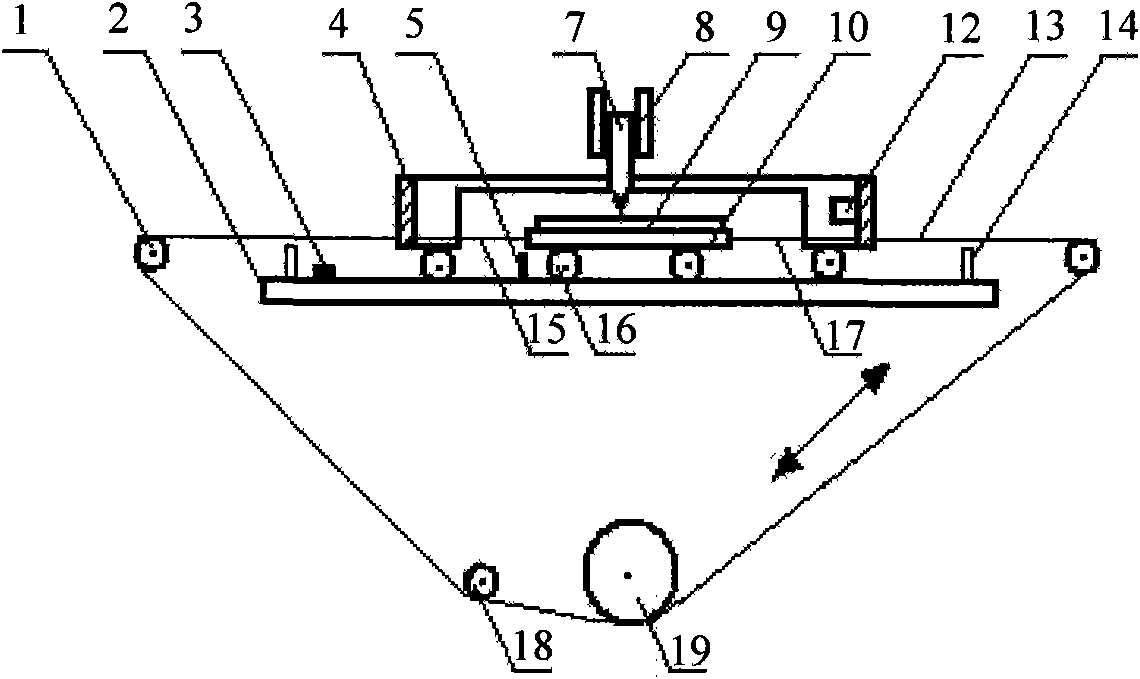

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

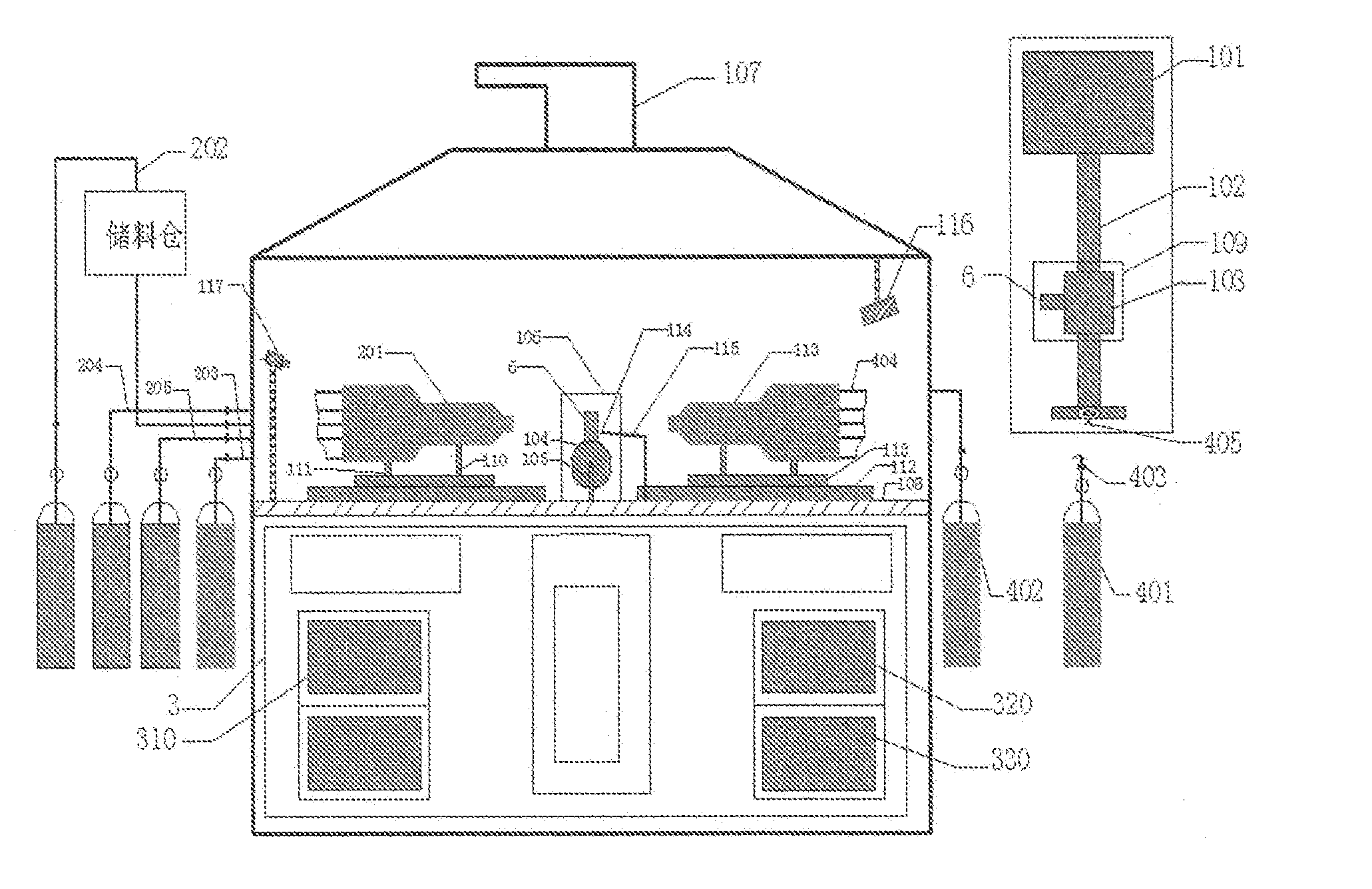

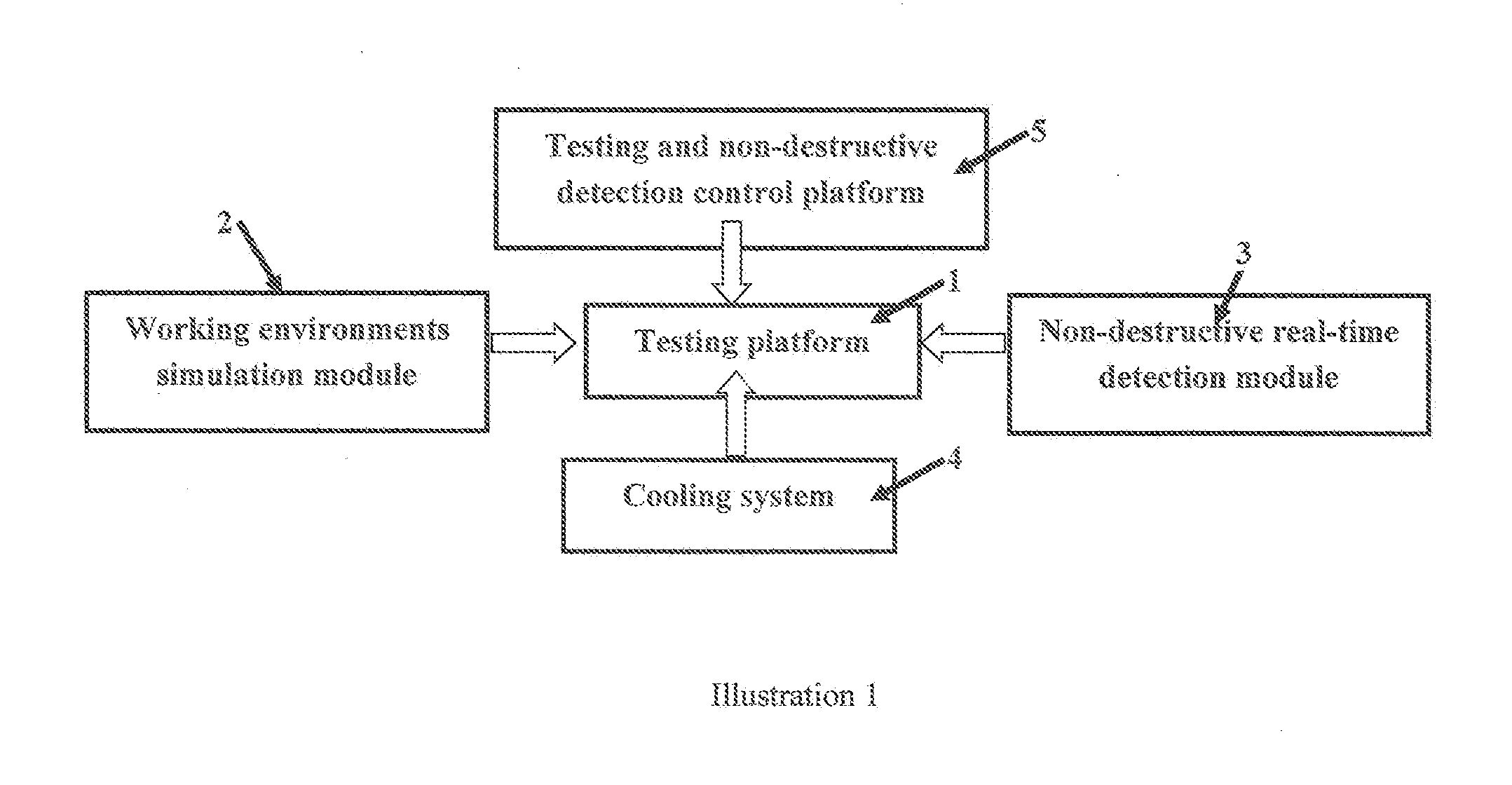

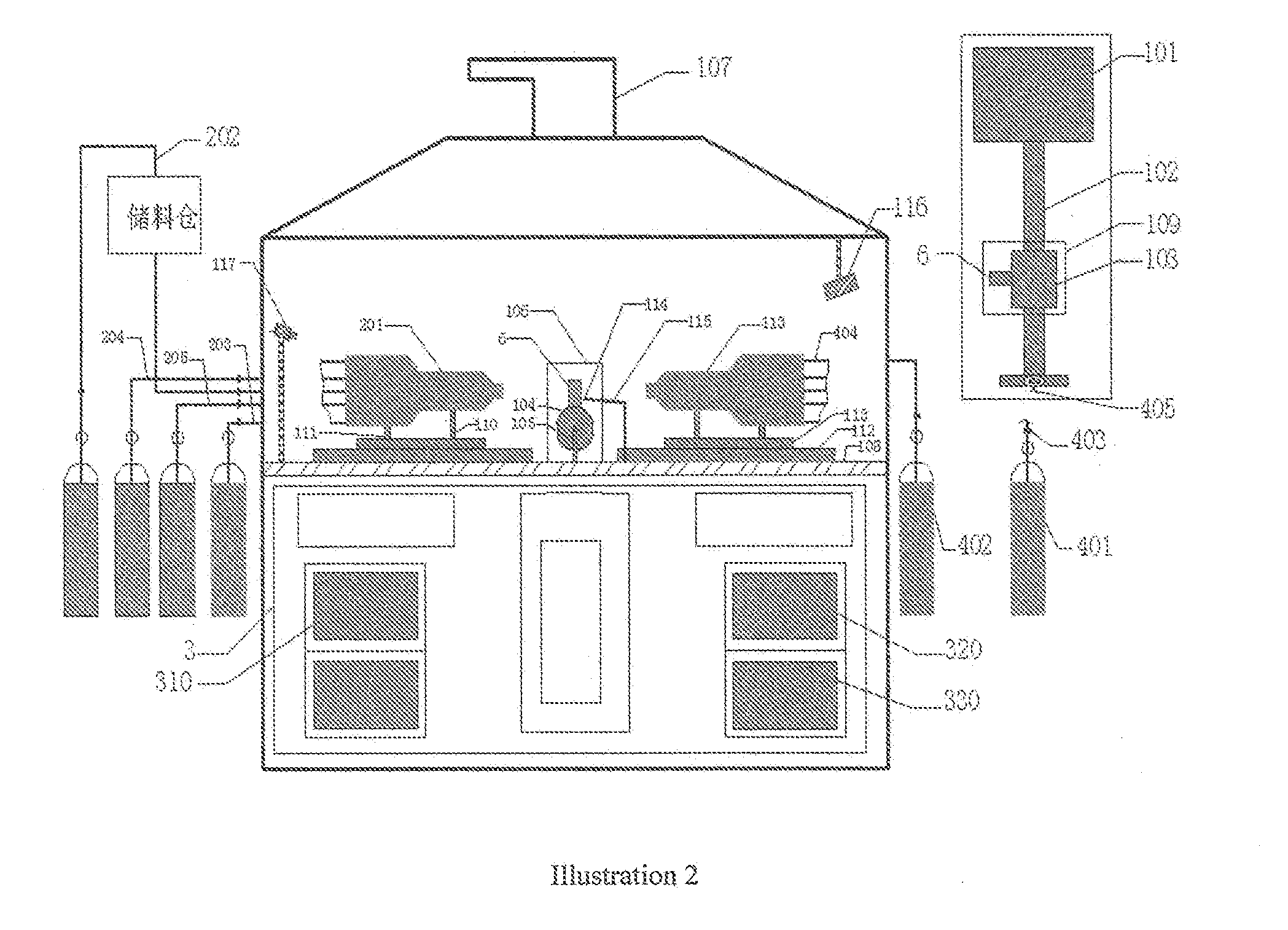

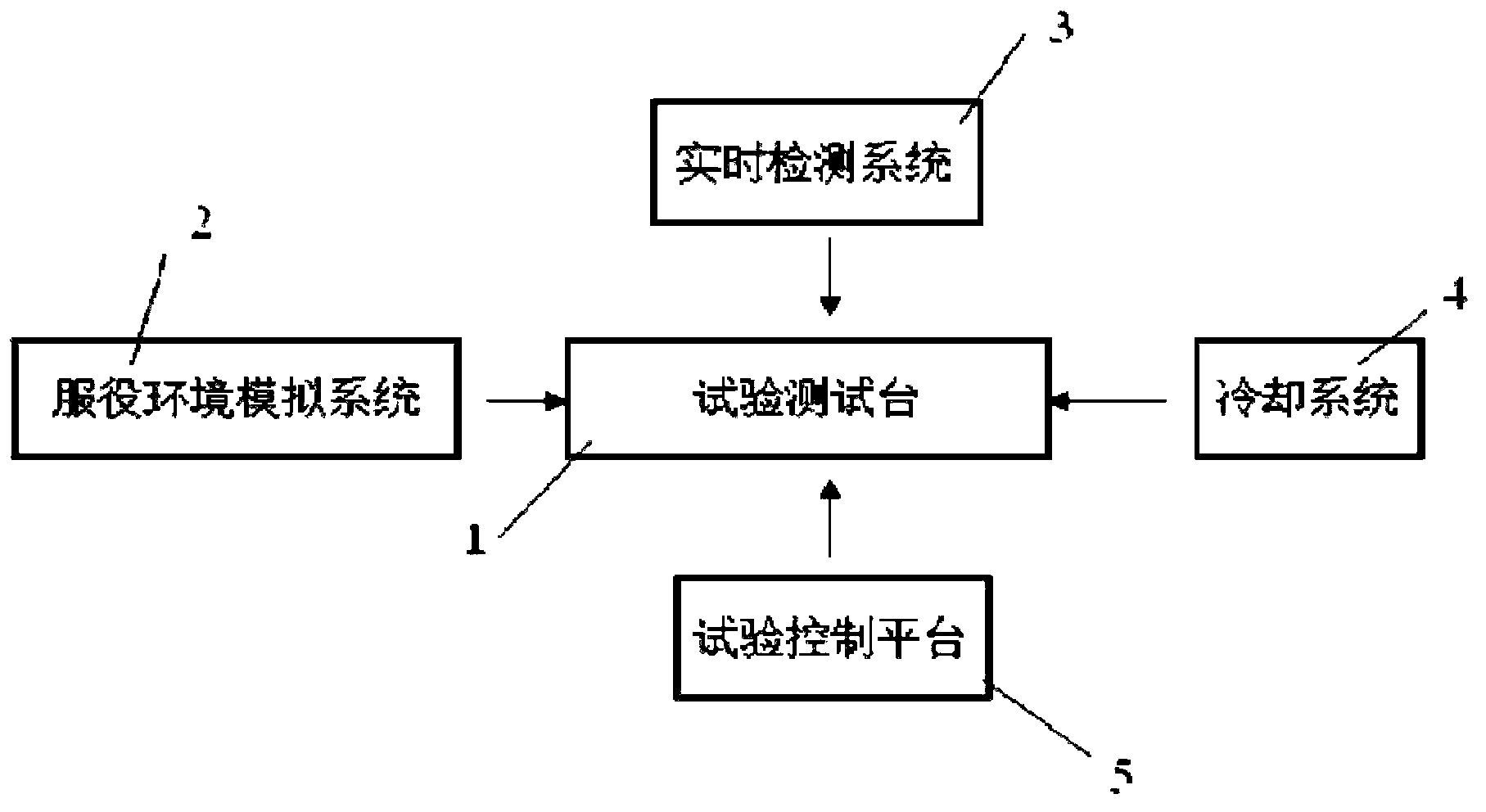

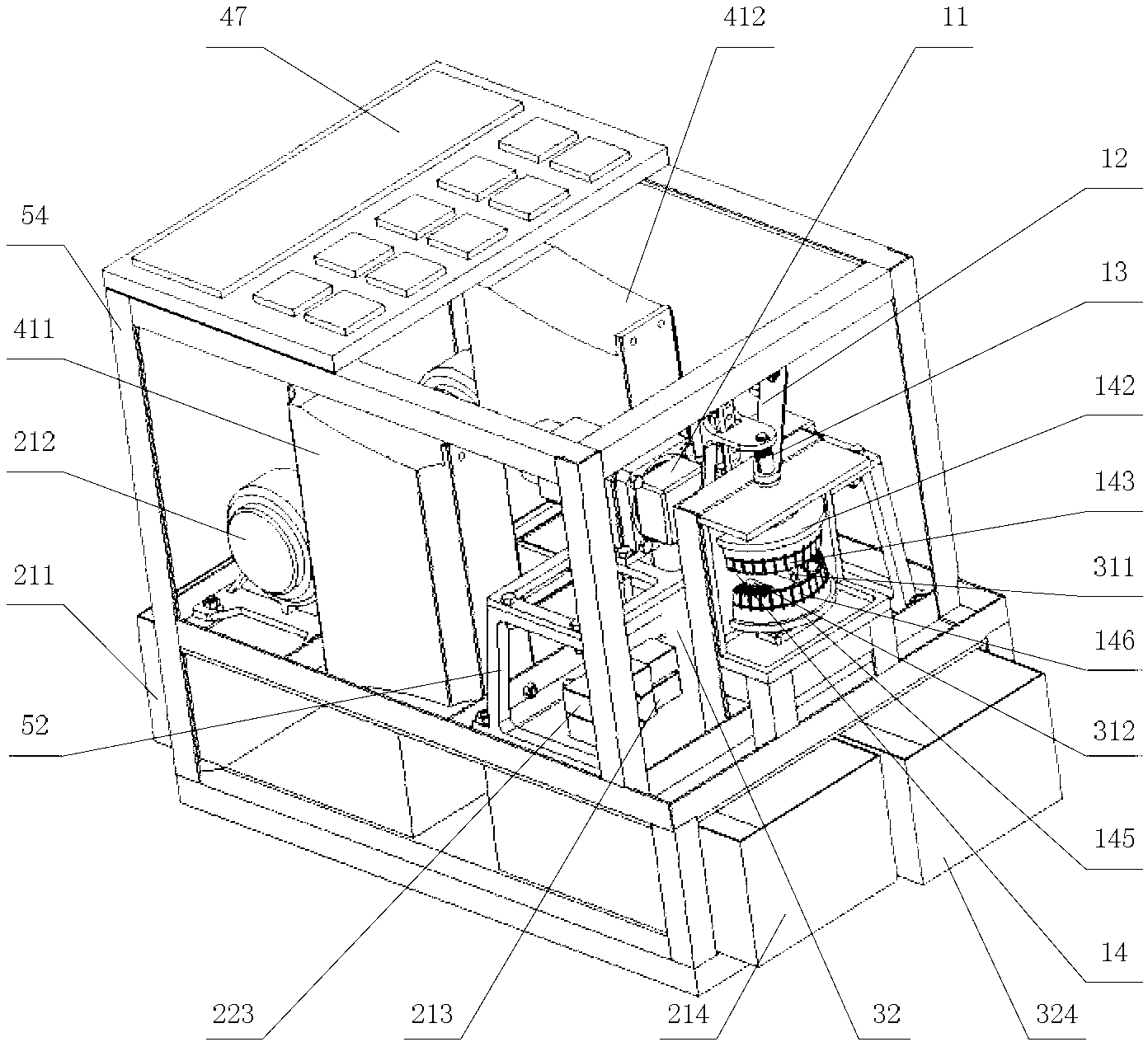

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

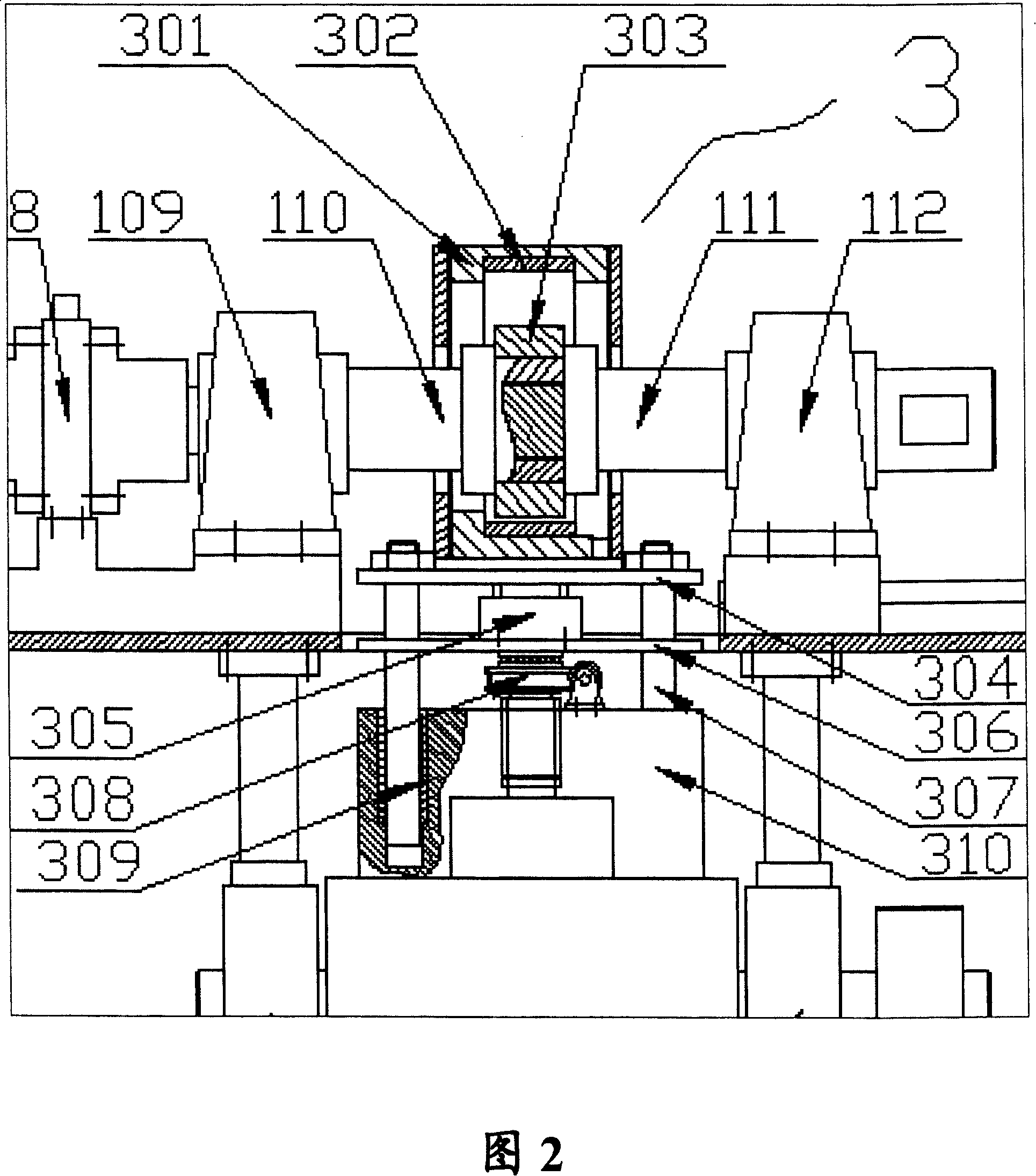

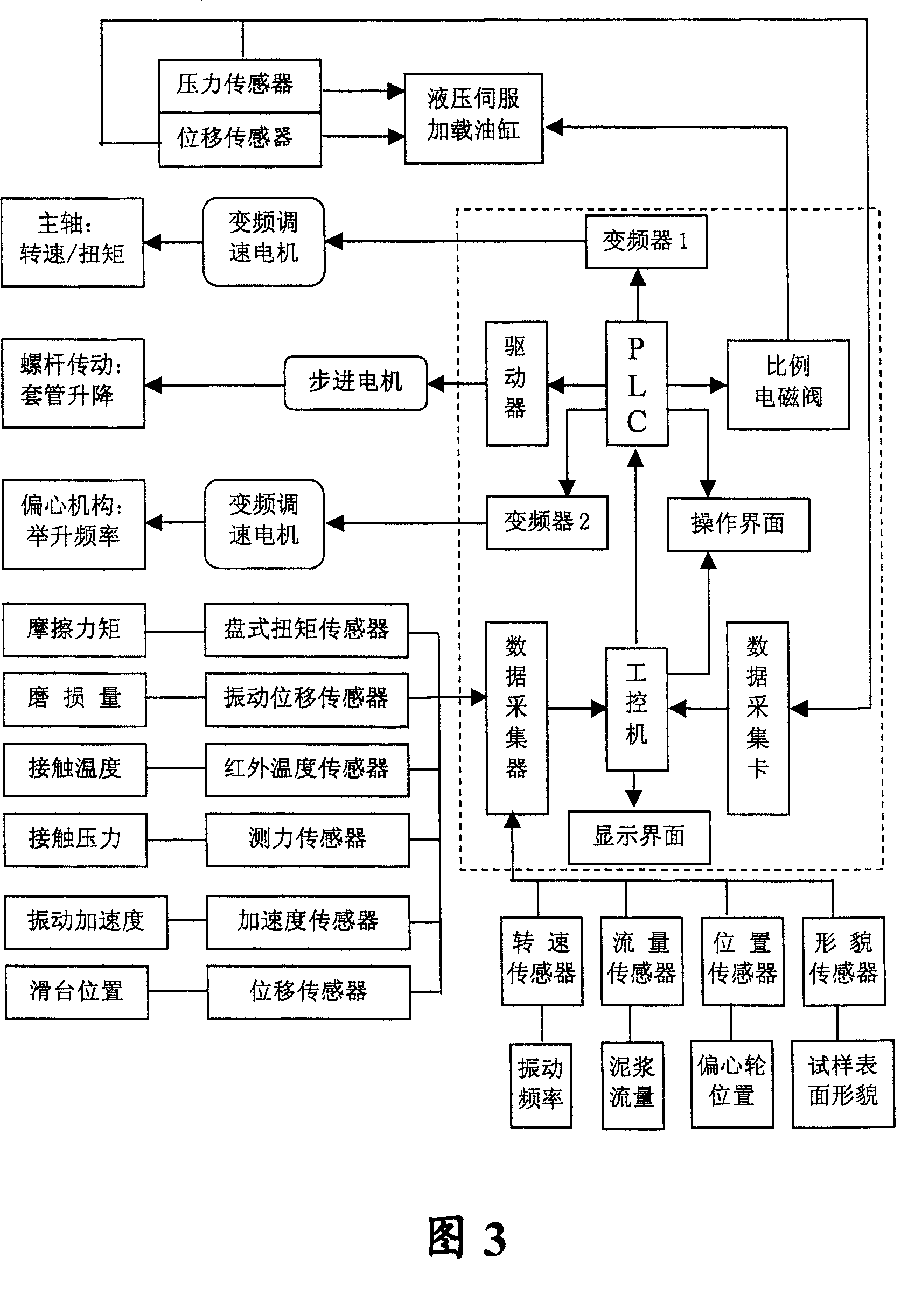

Sliding desk type casing tube abrasion testing machine

InactiveCN101153835AAchieve frictionEnable wear studiesStructural/machines measurementInvestigating abrasion/wear resistanceDrive shaftPetroleum

The invention is a sliding way sleeve abrasion testing machine, which comprises a transmission system, an excitation system, a clamping system and a rack. A first test piece is fixed and clamped on a rotating transmission shaft of the transmission system; a second test piece is arranged corresponding to the first test piece on the clamping system and the transmission system drives the first test piece to rotate around the axis. The rack is provided with at least one sliding platform and the transmission system is arranged on the sliding platform. The excitation system can drive the sliding platform to vibrate up and down to drive the first test piece to impulse the second test piece while rotating. The testing machine overcomes the disadvantage of the prior abrasion testing machine which is incapable of satisfying the requirement on studying the impulse and sliding composite abrasion test between petroleum the drilling rod and the sleeve under the conditions of circulating medium and can perform systematic investigation on the impulse and sliding composite abrasion of various materials of large dimension between the petroleum the drilling rod and the sleeve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

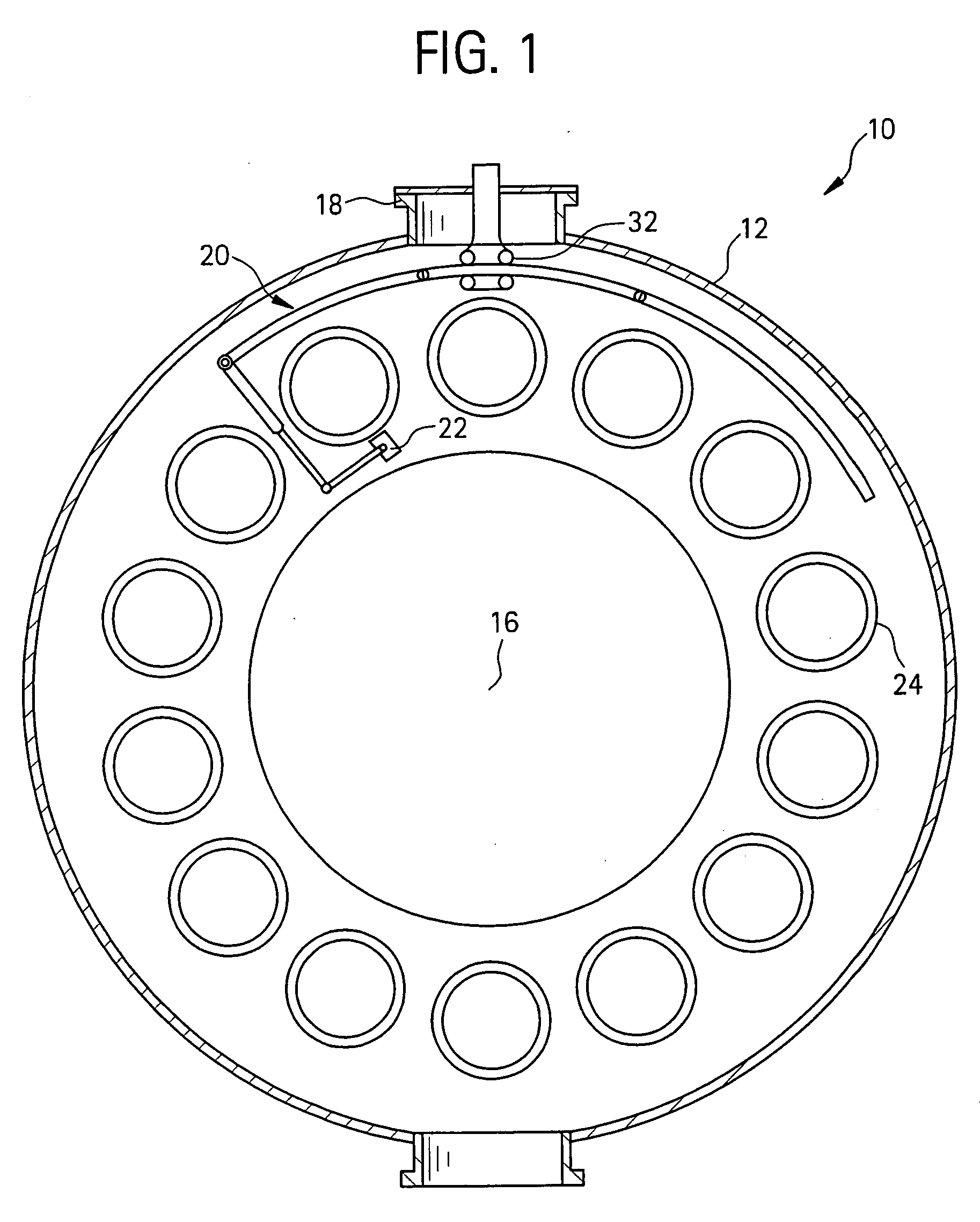

Imaging system for robotically inspecting gas turbine combustion components

A system for in situ inspection of a surface of a hot gas component of a turbine includes a robot having an elongated inspection arm extending toward the surface of the hot gas component; and an inspection head carried adjacent an end of the inspection arm remote from controls for the robot. The inspection head is manipulated by the inspection arm to locate the inspection head adjacent interior wall portions defining the hot gas component including by displacing the inspection head in a generally axial direction and generally radially toward a wall portion of the hot gas component being inspected. The inspection head is configured with a UV system to excite and detect fluorescence from a taggant material disposed in a coating on the hot gas component.

Owner:GENERAL ELECTRIC CO

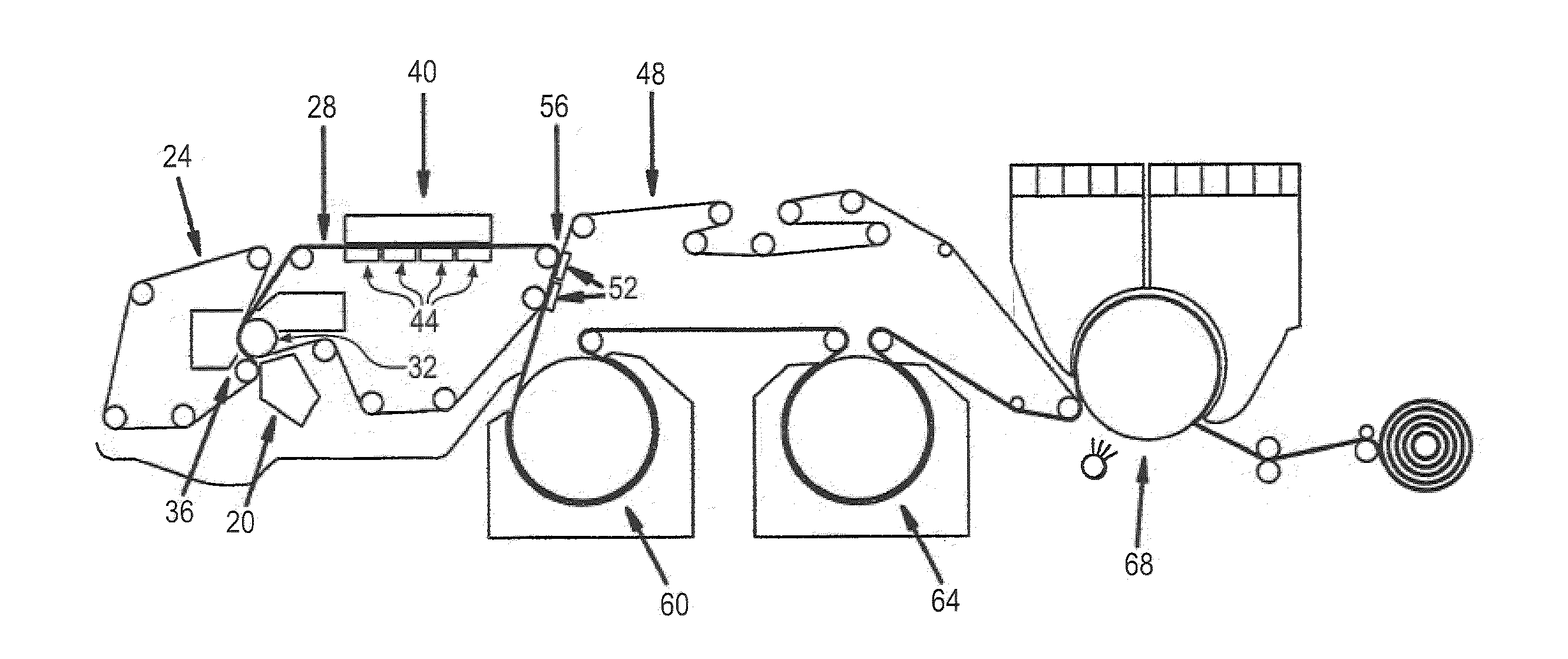

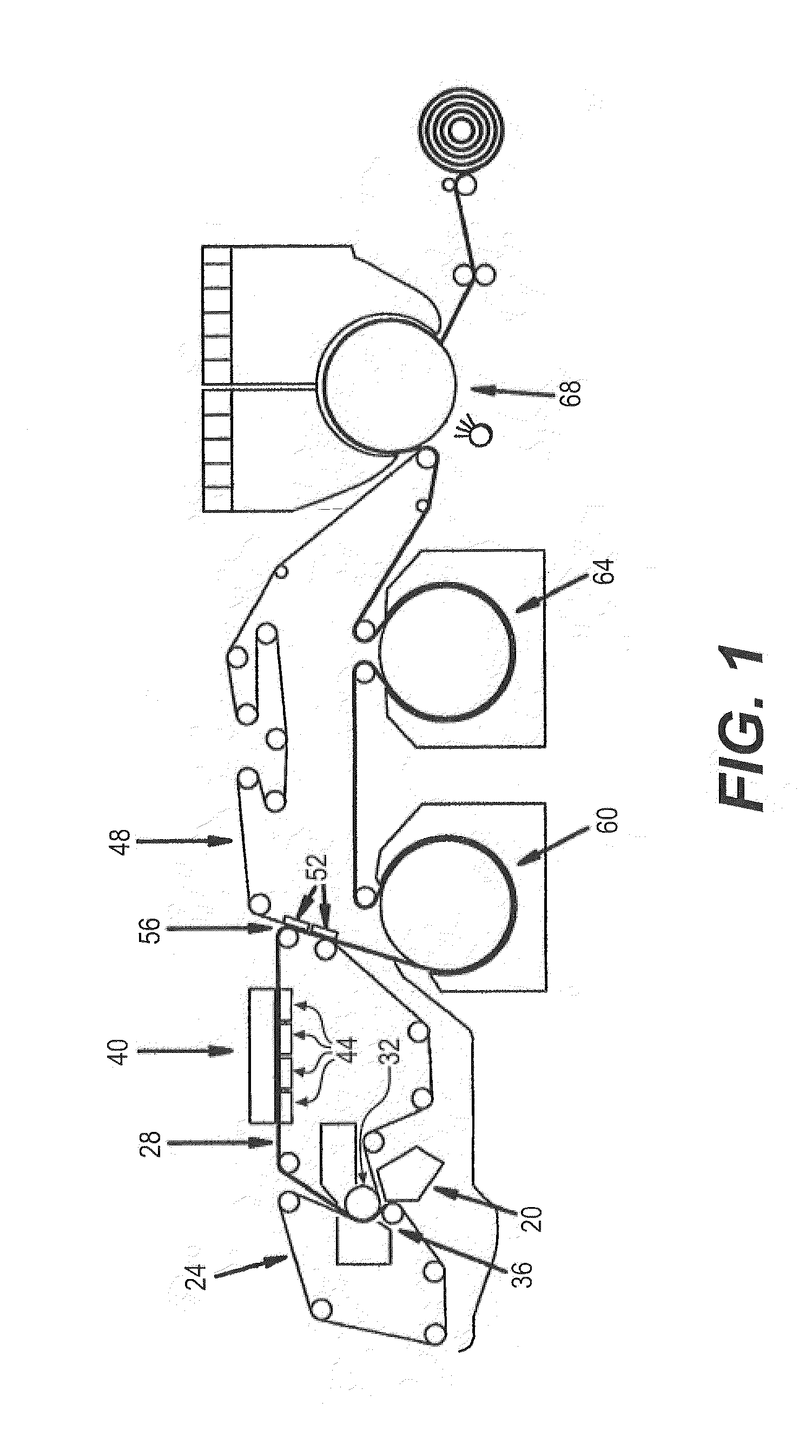

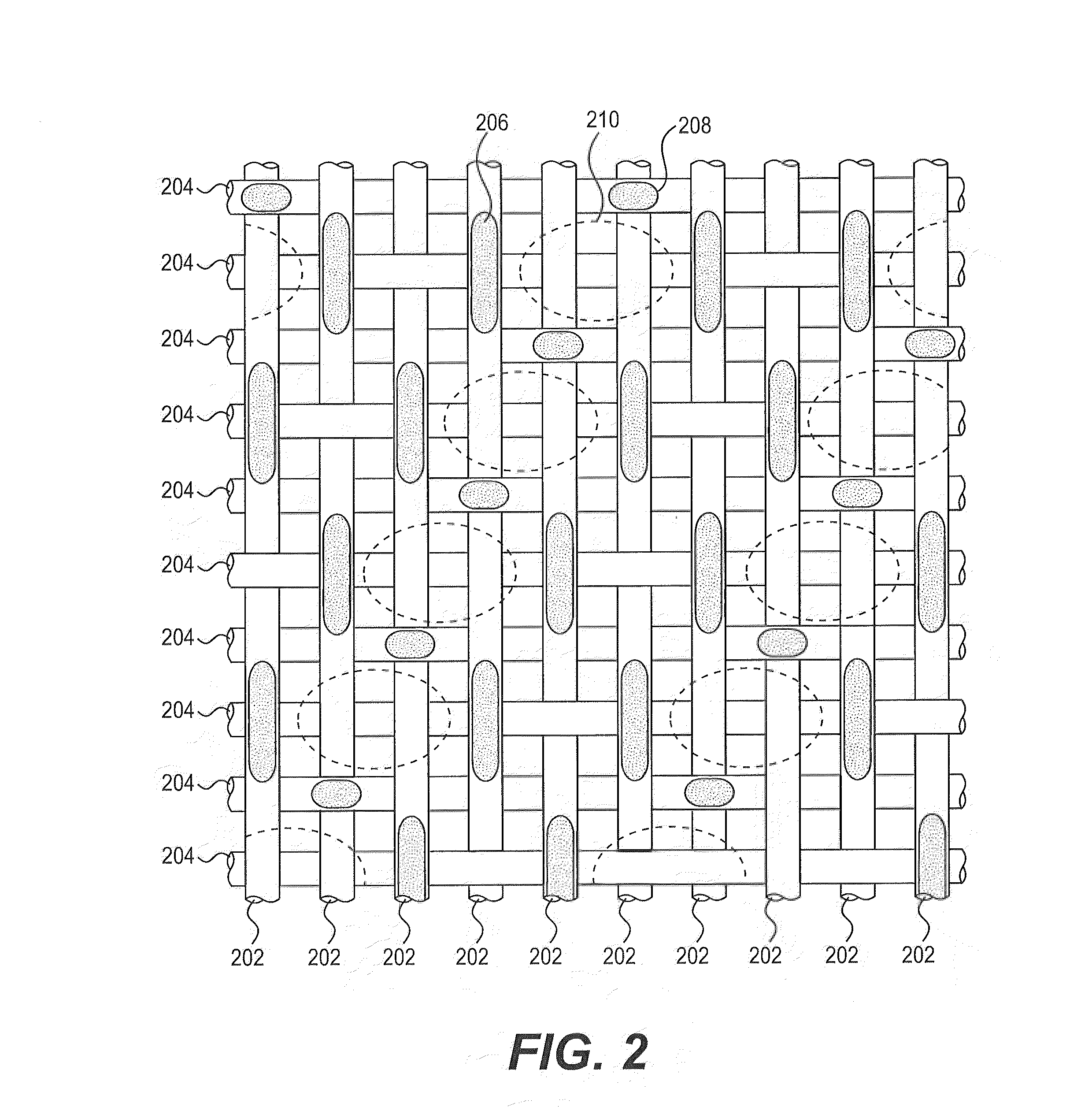

Apparatus, system, and process for determining characteristics of a surface of a papermaking fabric

Apparatuses, processes, and systems for implementing techniques for determining characteristics of a papermaking fabric. The techniques include forming a representation of a portion of the surface of the fabric, with the representation showing the knuckles and pockets in the surface. The representation can be formed, for example, in pressure measurement film, in wax paper, or as a photograph. An image is generated from the representation, and the image is analyzed to determine characteristics of the surface of the fabric, such as knuckle sizes and pocket sizes. The depth of pockets in the fabric can also be determined. The techniques can be used in processes for analyzing wear of a fabric, and for obtaining a fabric for making a paper product with a particular three-dimensional structure.

Owner:GPCP IP HLDG LLC

Multifunctional micro friction wear testing machine

InactiveCN101017129AGreat driving forceLess exerciseUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceWear testing

This invention relates to one multi-function micro friction test machine, which comprises drive device, move device connected to the drive one and load and measurement device on the move device and lift bench of the measurement device, wherein, it uses hanging spring board and connection bar are hinged with drive device and move device to make the slide bench generate one small range reverse line move under bar push with constant vibration range and small error; it uses motor to drive connection bar push slide to generate large vibration reverse line move.

Owner:CHINA UNIV OF MINING & TECH

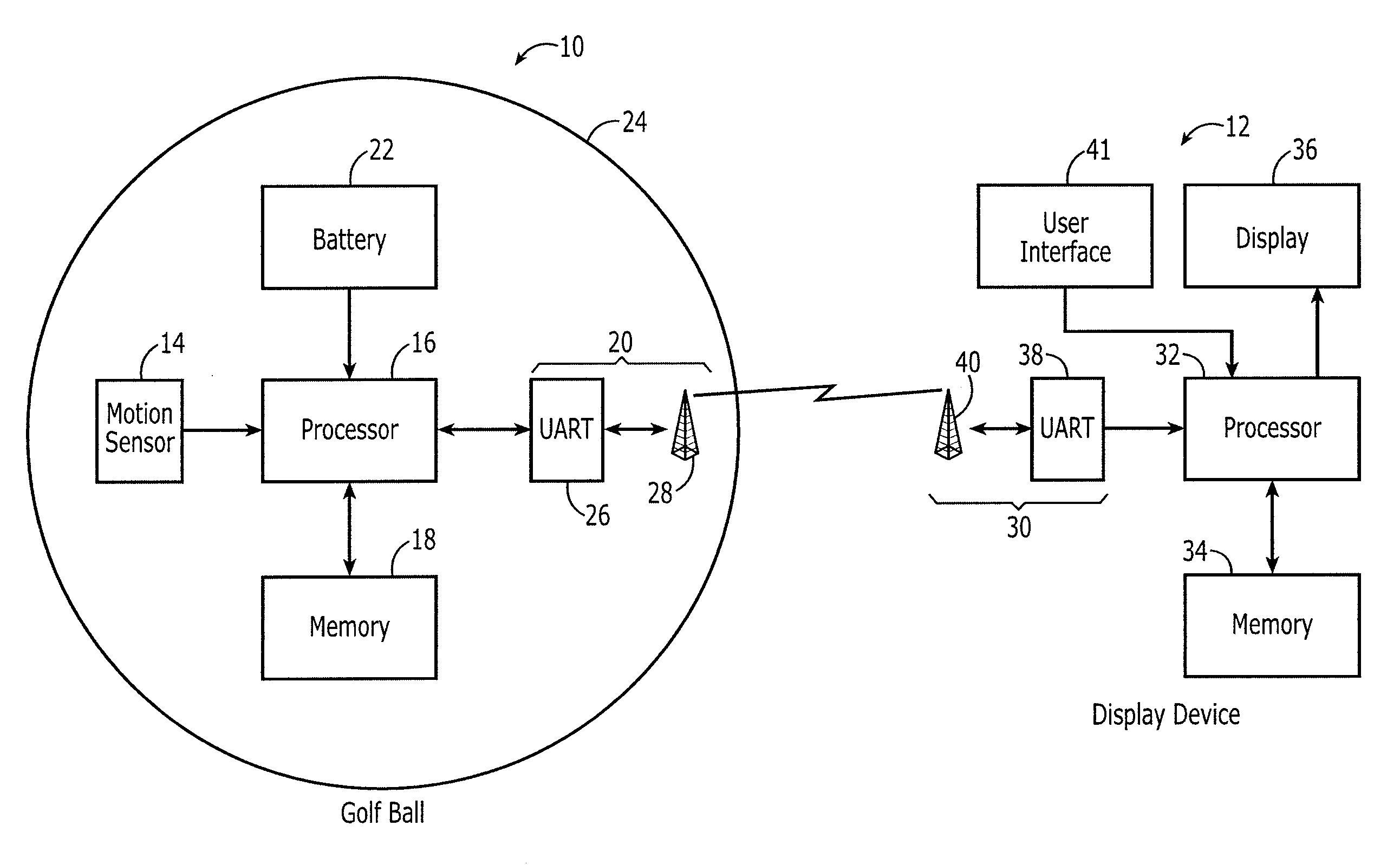

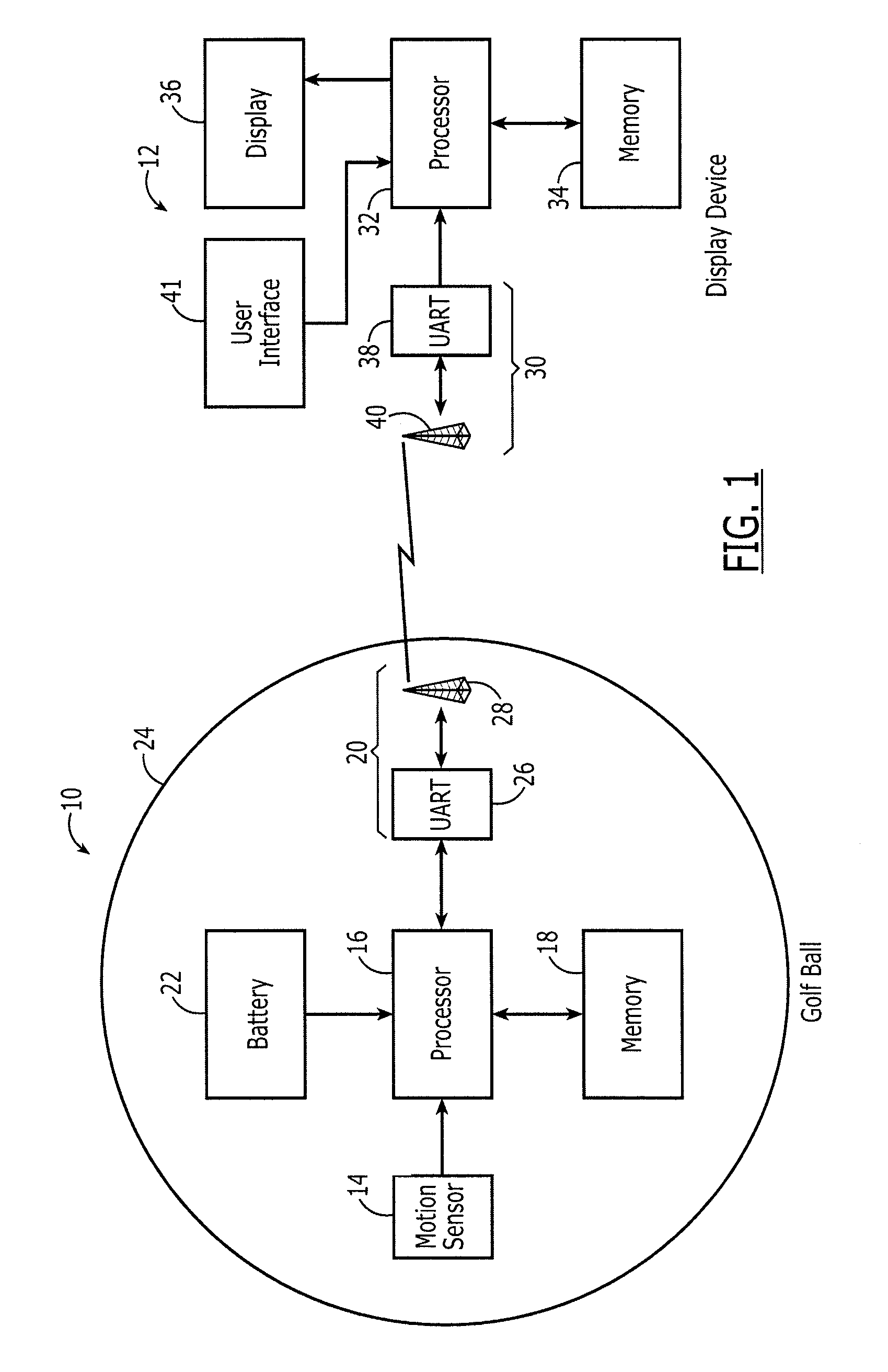

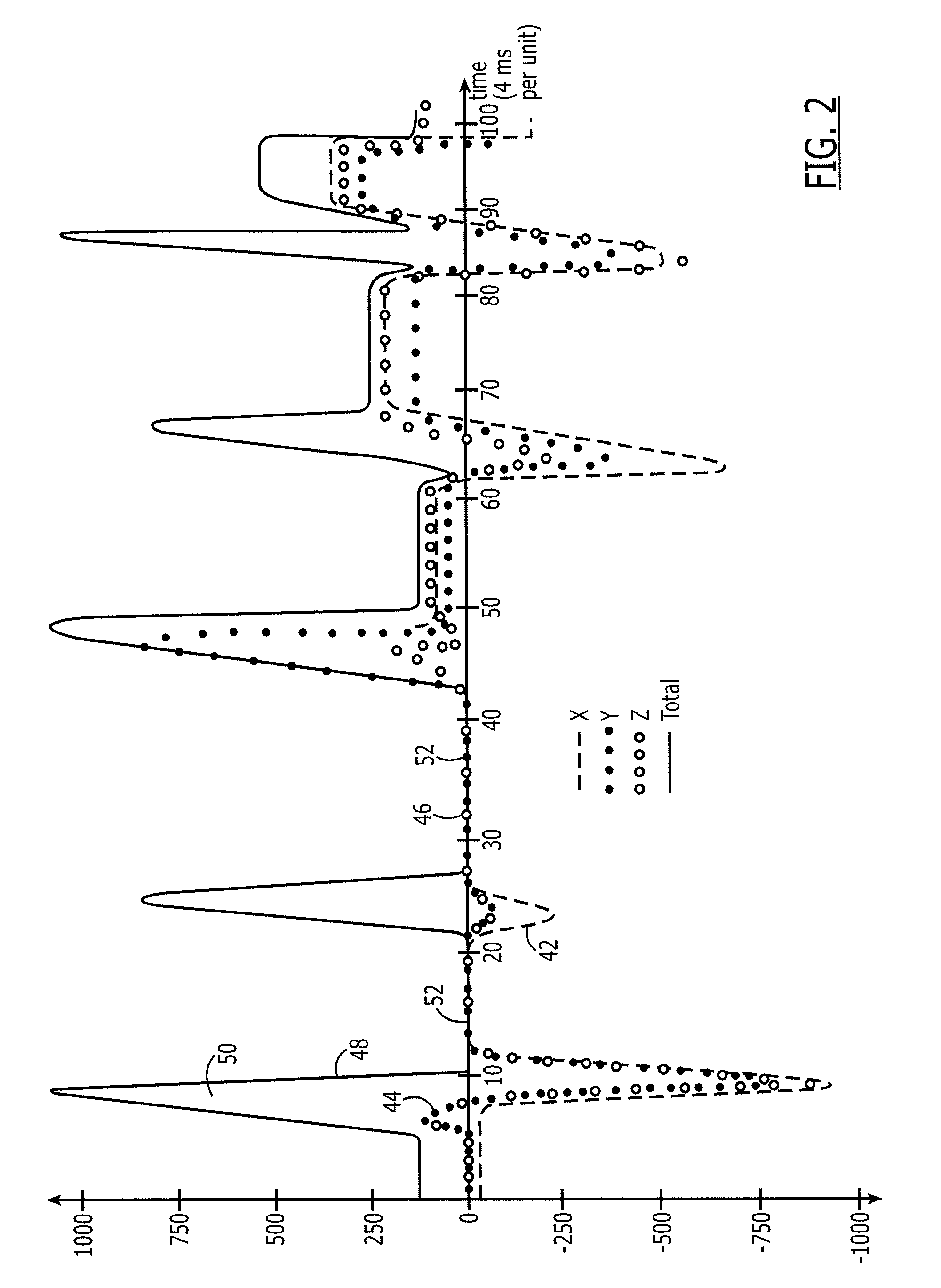

Method and apparatus for measuring golf green speeds

A method, system and golf ball are provided to determine the deceleration of a golf ball and, in turn, the speed of a green. The system may include a golf ball and an offboard display device. The golf ball may include a golf ball body, a motion sensor disposed within the golf ball body to measure acceleration of the golf ball along each of three mutually perpendicular axes, and a transmitter disposed within the golf ball body to transmit data representative of deceleration. The display device may include a receiver to receive data representative of the deceleration of the golf ball from transmitter and a display to provide a representation of the deceleration of the golf ball. At least one of the golf ball and the display device may include a processor to determine deceleration of the golf ball based upon the acceleration measured by the motion sensor.

Owner:TOPGOLF CALLAWAY BRANDS CORP

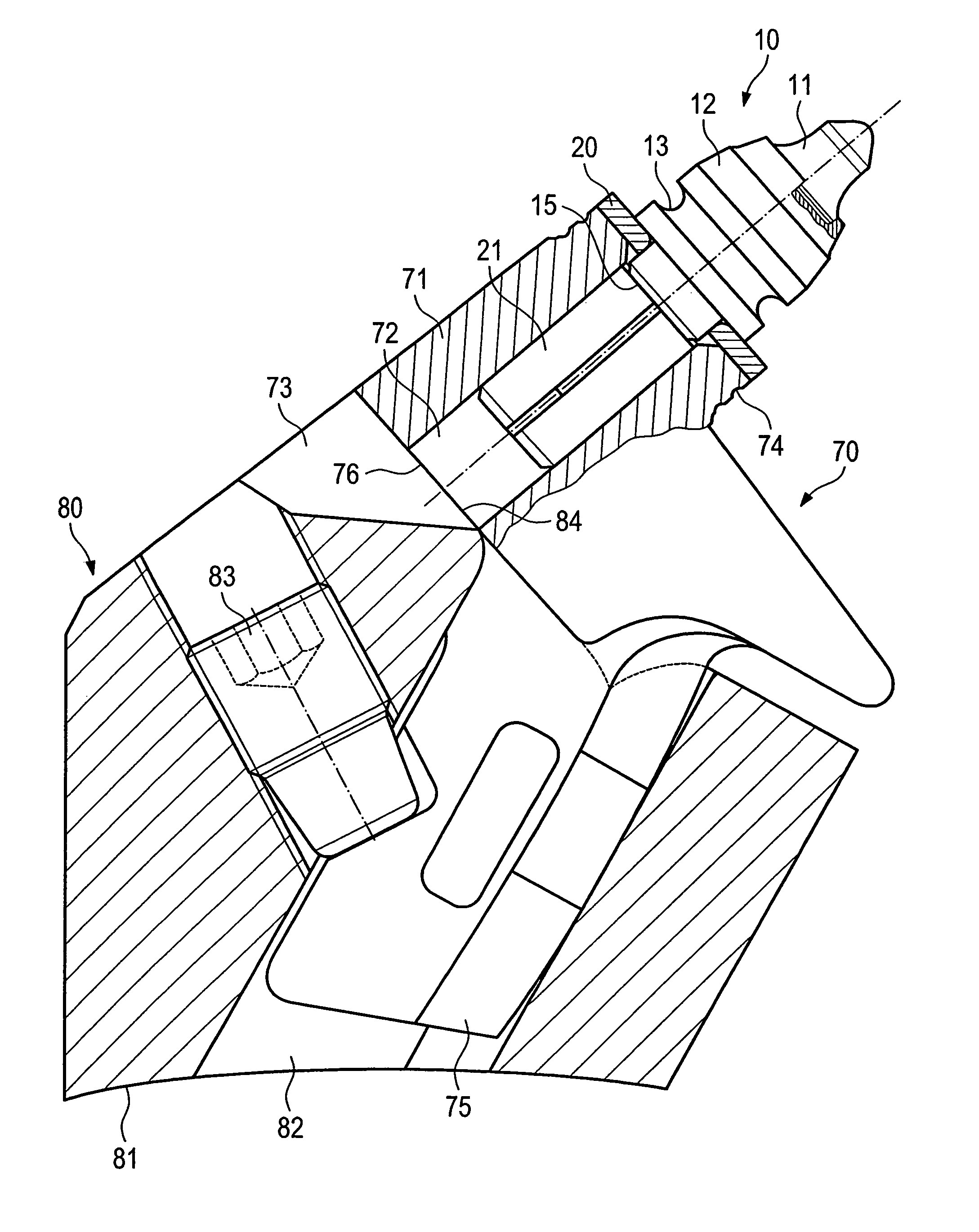

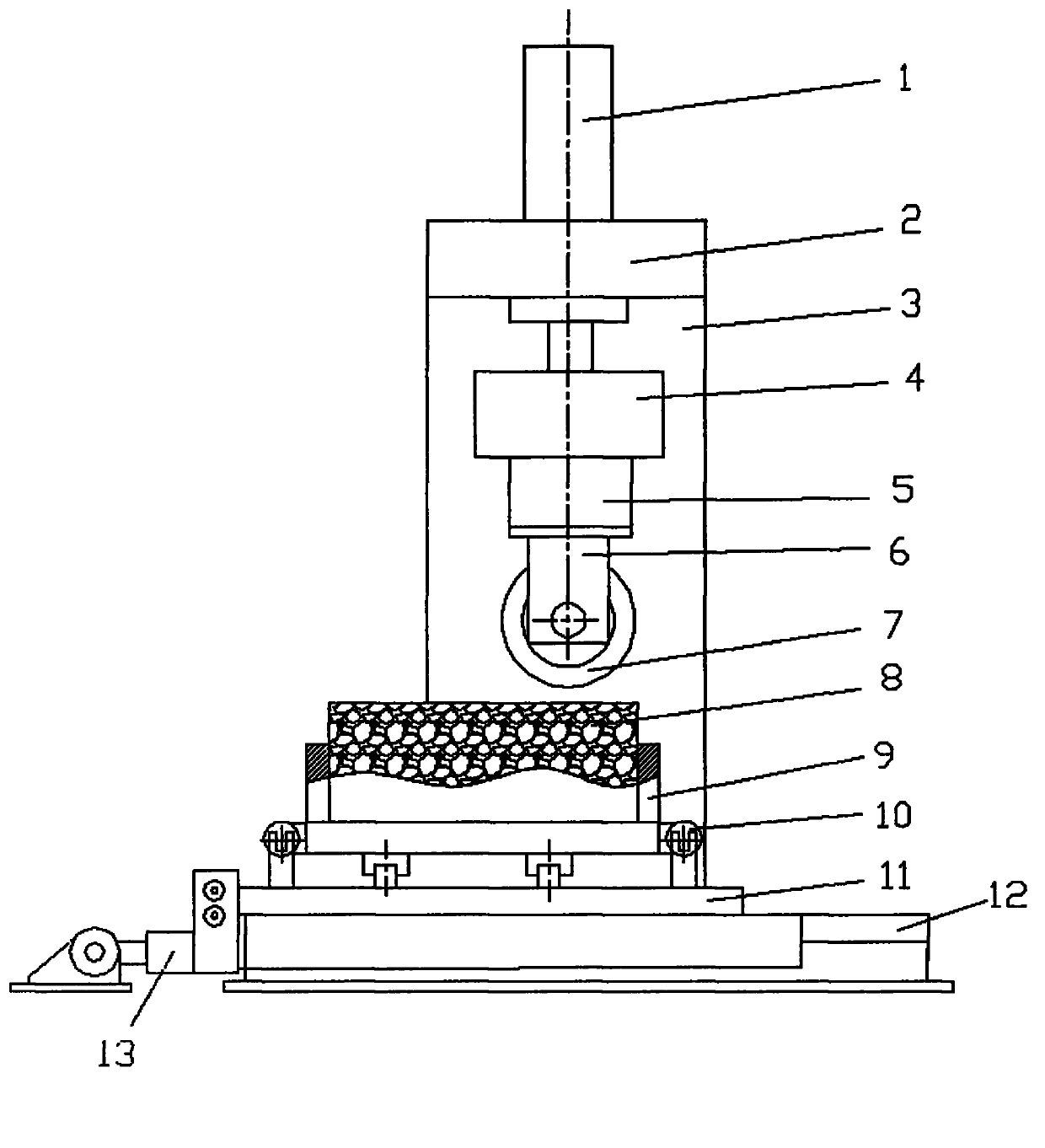

Tool bit rock breaking mechanism and abrasion tester

InactiveCN101299013AIdea novel scienceFunction increaseInvestigating abrasion/wear resistanceInvestigating machinabilityTool bitHydraulic cylinder

The present invention provides a cutter rock-breaking mechanism which is applied in the technical field of the cutter experiment and an abrasion resistant tester thereof. The abrasion resistant tester comprises a hydraulic cylinder, a structural frame, a bearing plate, a cutter support, a disc-shaped hob and a rotation worktable. When the cutter rock-breaking mechanism and the abrasion resistant tester work, the disc-shaped hob is connected with the cutter support through a bolt. The cutter support is jointed and fixed on the bearing plate through the bolts. The hydraulic cylinder exerts a certain load to impact the disc-shaped hob to the rock sample on the worktable and generate a certain penetration. Afterwards the worktable is rotated through a power system to execute cutting test to the rock passively. The cutter rock-breaking mechanism and the abrasion resistant tester execute cutting with a single cutter to do the abrasion resistance test of the cutter. The bearing plate is provided with a groove. The regulation to the cutter space and the phase angle is realized through the variation of the jointing position of the cutter support on the bearing plate. The regulation to the inner deflection angle of the cutter is realized by changing the cutter supports with different angles. The positioning and rotation of the rock are realized through the rotating worktable. The designing of the device is novel and scientific. The knife angle, phase angle and inner deflection angle which affect larger to the rock breaking and abrasion of cutter are researched. The device settles the problem that two hob cutters simultaneously cut the rock.

Owner:NORTHERN HEAVY IND GRP CO LTD

Method of detecting wear on a substrate using a fluorescent indicator

InactiveUS6864489B2Quickly and easily determineEasy to implementRadiation pyrometrySpectrum investigationCoated surfaceFluorescence

A method of detecting wear on a substrate including coating a composition that includes a fluorescent compound on the surface of a first substrate, exposing the coated surface to wear, exposing the coated surface to radiation capable of exciting the fluorescent compound, and detecting the presence or absence of fluorescence.

Owner:3M INNOVATIVE PROPERTIES CO

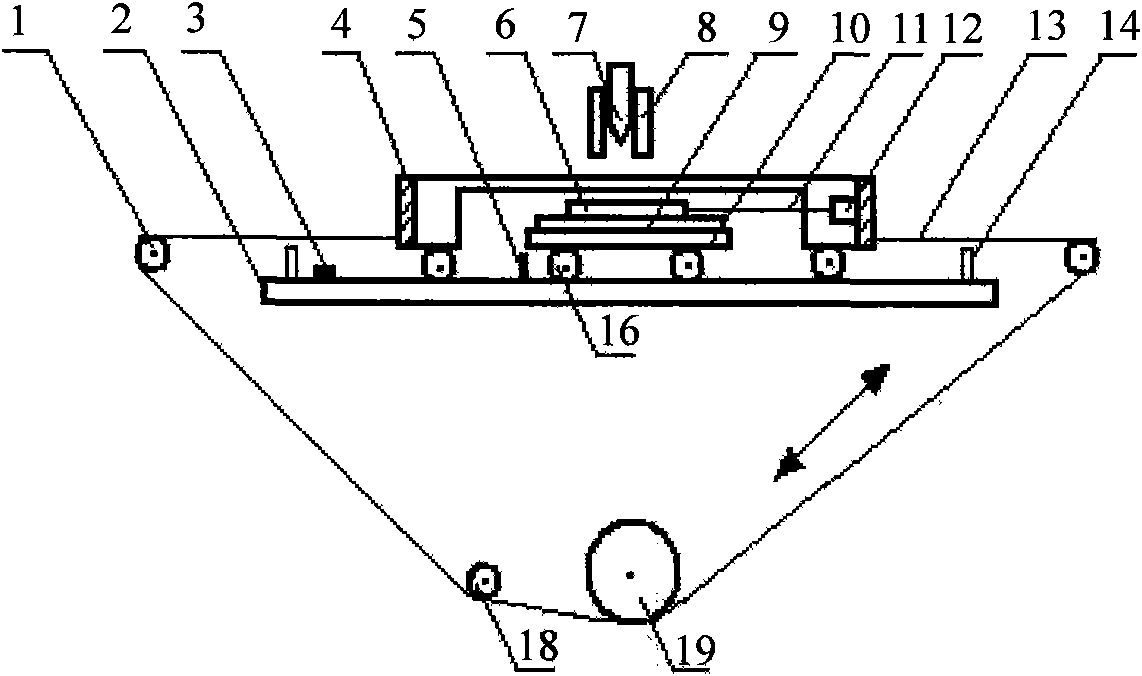

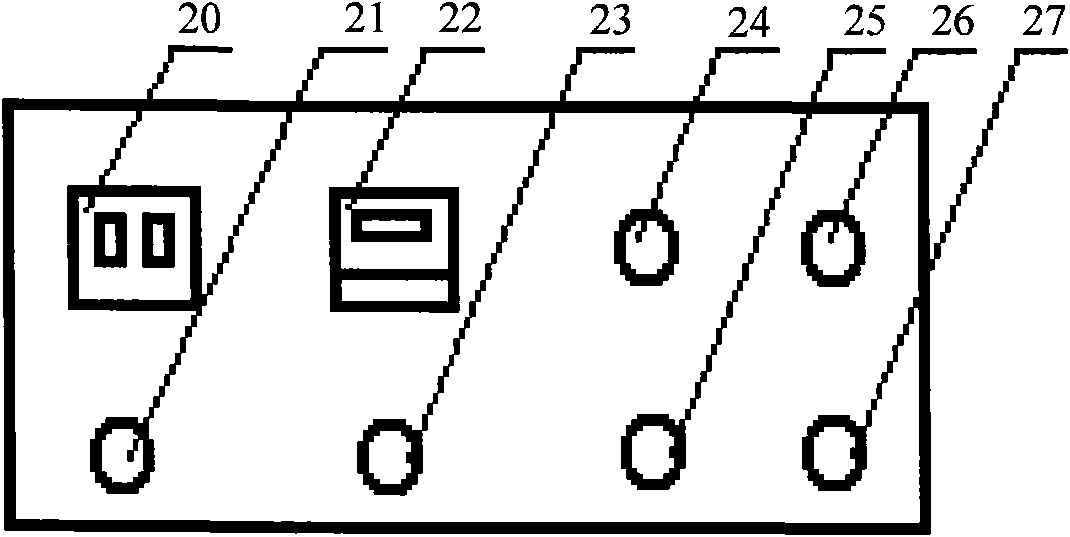

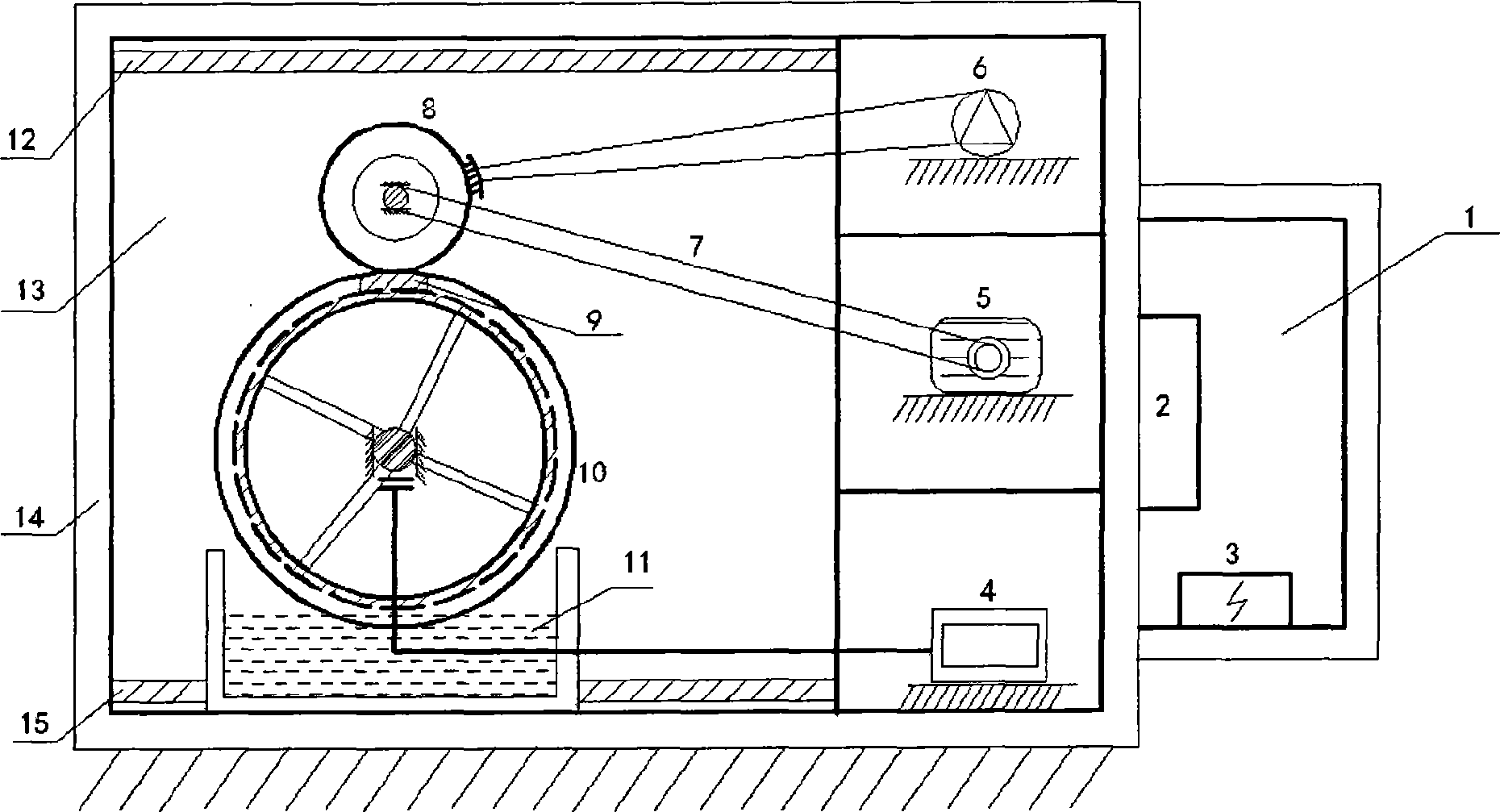

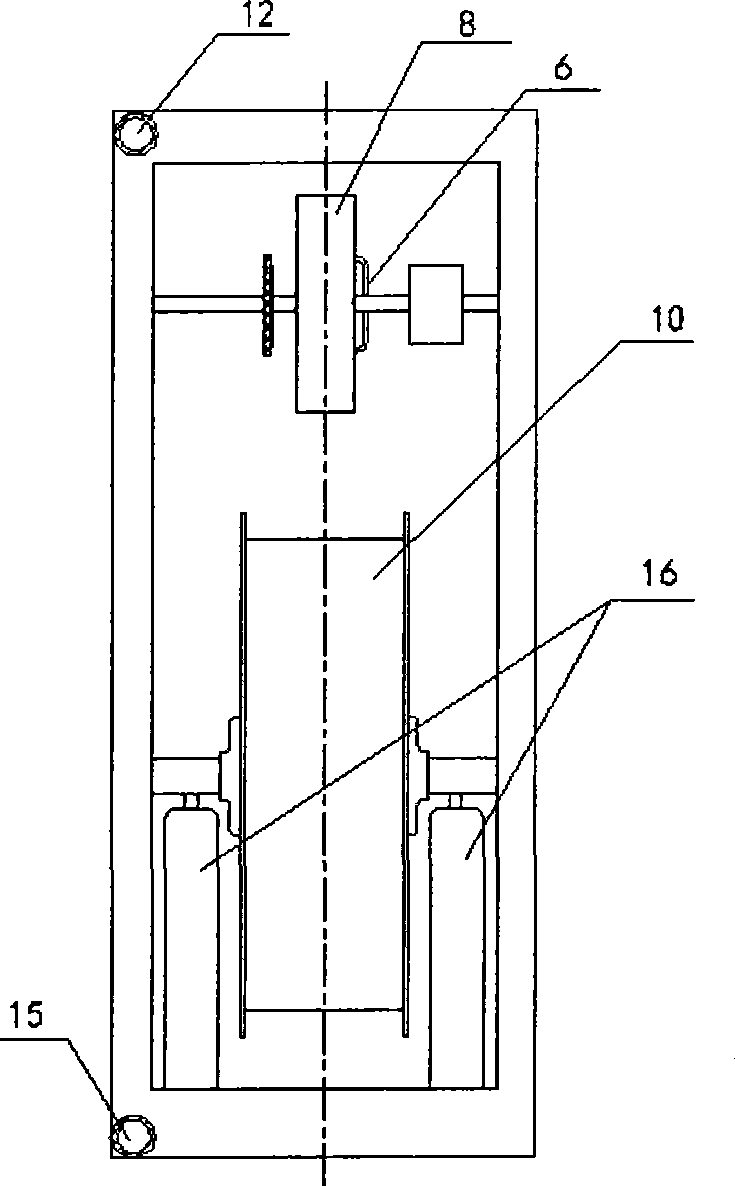

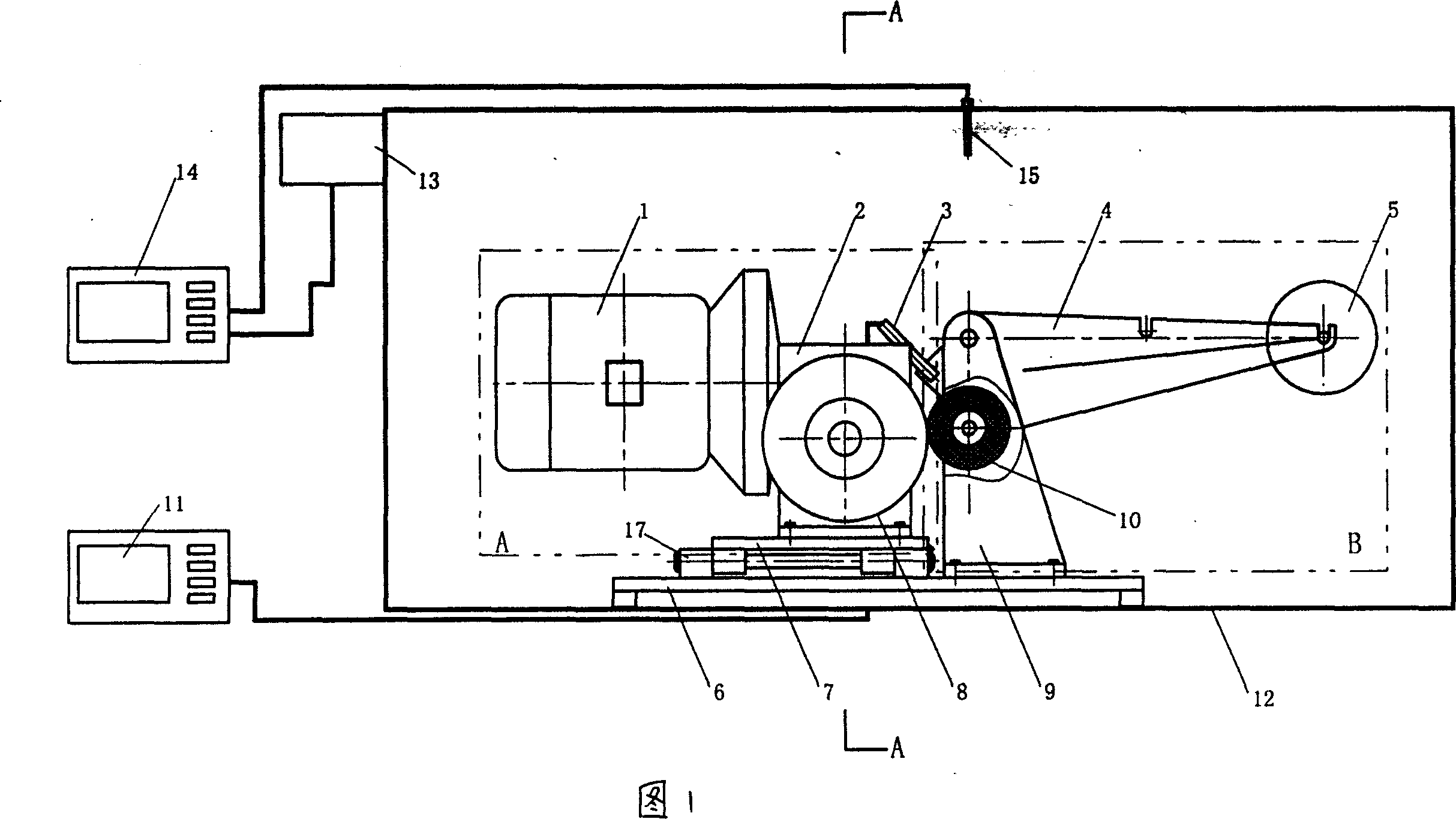

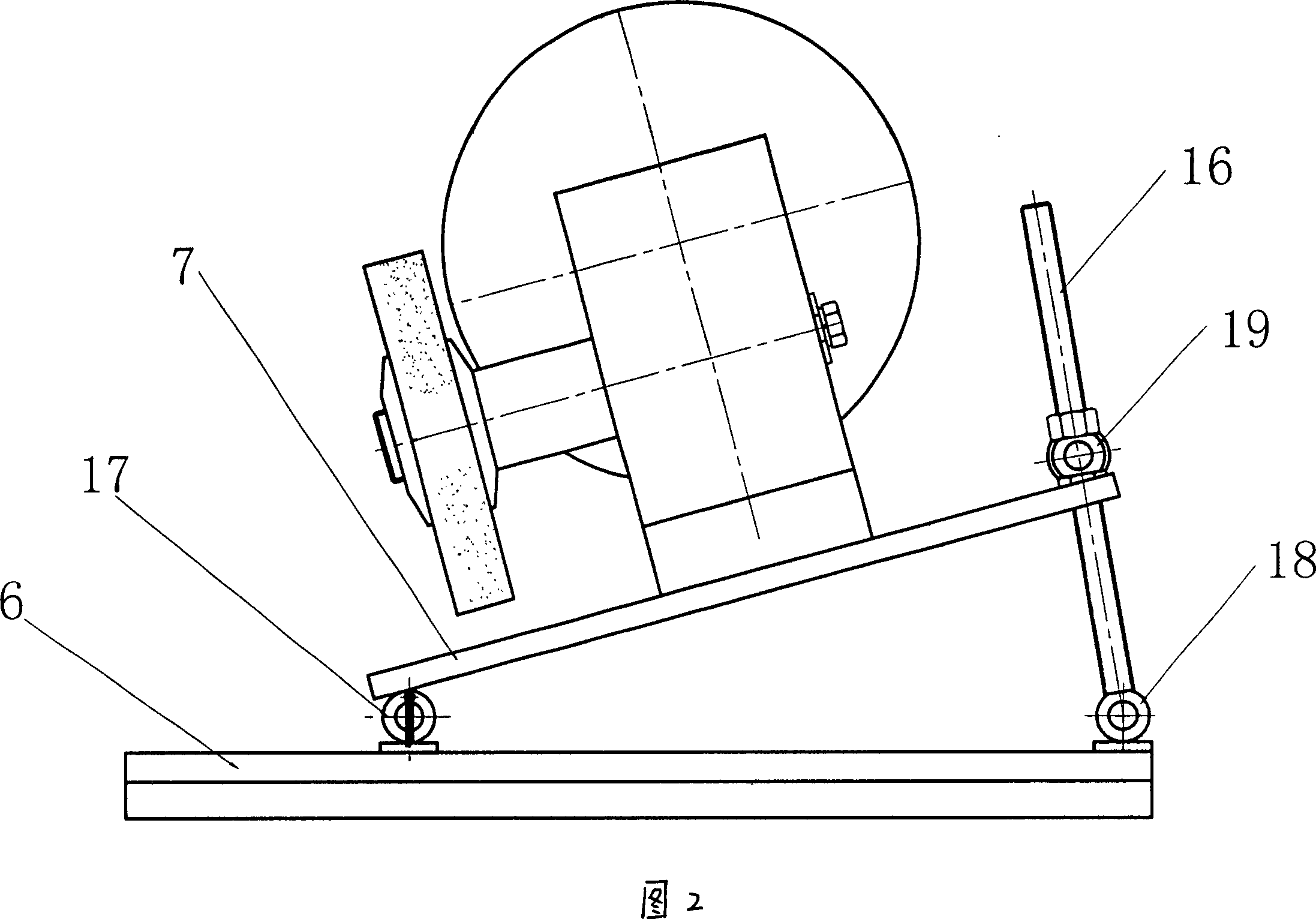

Method for testing accelerating and loading of main drive wheel type pavement materials and device

InactiveCN101532934AImprove guidanceImprove applicabilityMaterial strength using tensile/compressive forcesUsing mechanical meansWater bathsDrive wheel

The invention discloses a method for testing accelerating and loading of main drive wheel type pavement materials and a device thereof. The device comprises a control console, a PLC control box, an electronic box, a hydraulic device, a motor, a brake, a driving chain and chain wheel, a drive wheel, a driven wheel, a water bath tank, a circulated air inlet duct, a thermostatic chamber, a test cabinet and a circulated air outlet duct; the control console is positioned on the outside of the test cabinet; the hydraulic device is connected with the driven wheel; the motor is connected with the drive wheel via the driving chain and chain wheel; the drive wheel is fixed on a bracket; the driven wheel is positioned in a guide slot; the water bath tank is arranged right below the driven wheel; a ranging laser is positioned on one side of the driven wheel; one end of the drive wheel is provided with a microphone and the bottom thereof is provided with a torque sensor; the contact surface of the drive wheel and a test piece is provided with a pressure sensor; two tachometers are fixed on the bracket and are respectively positioned on the outsides of the drive wheel and the driven wheel. The device has simple structure, low prices, flexible use and good reliability.

Owner:SOUTH CHINA UNIV OF TECH

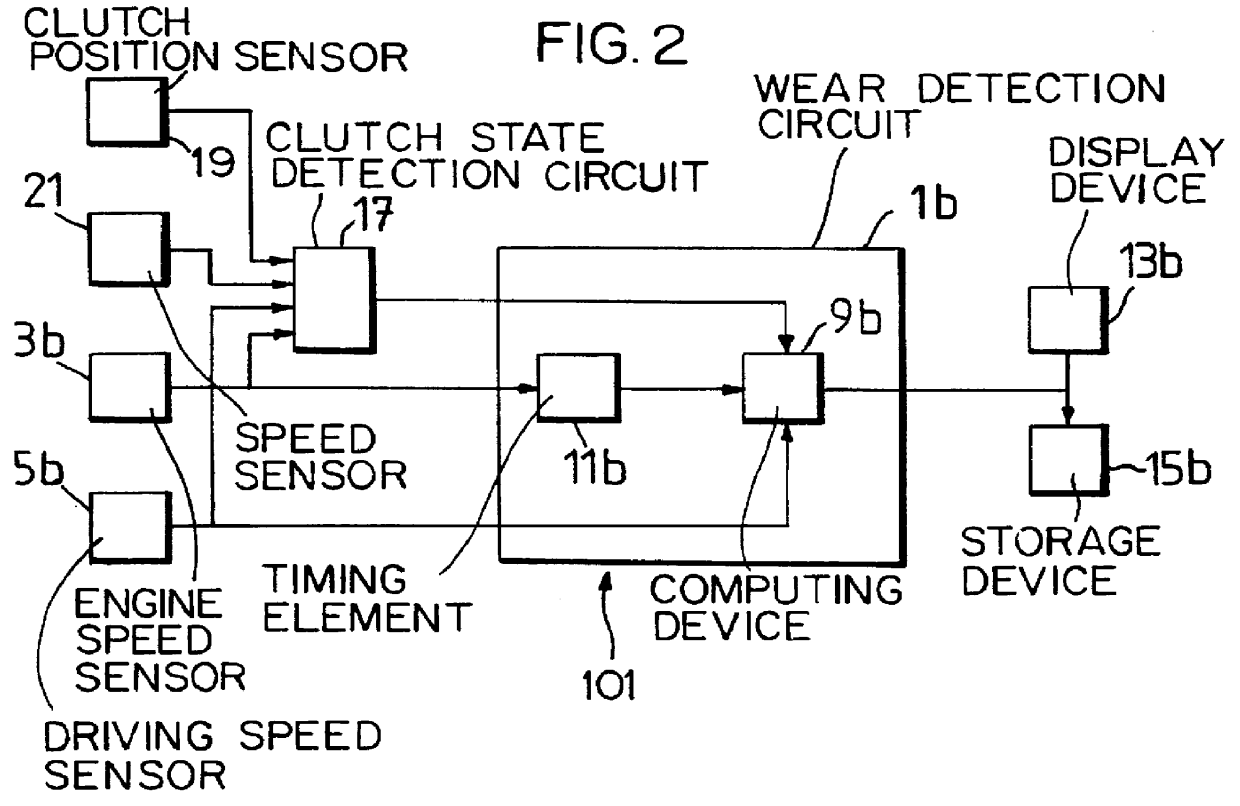

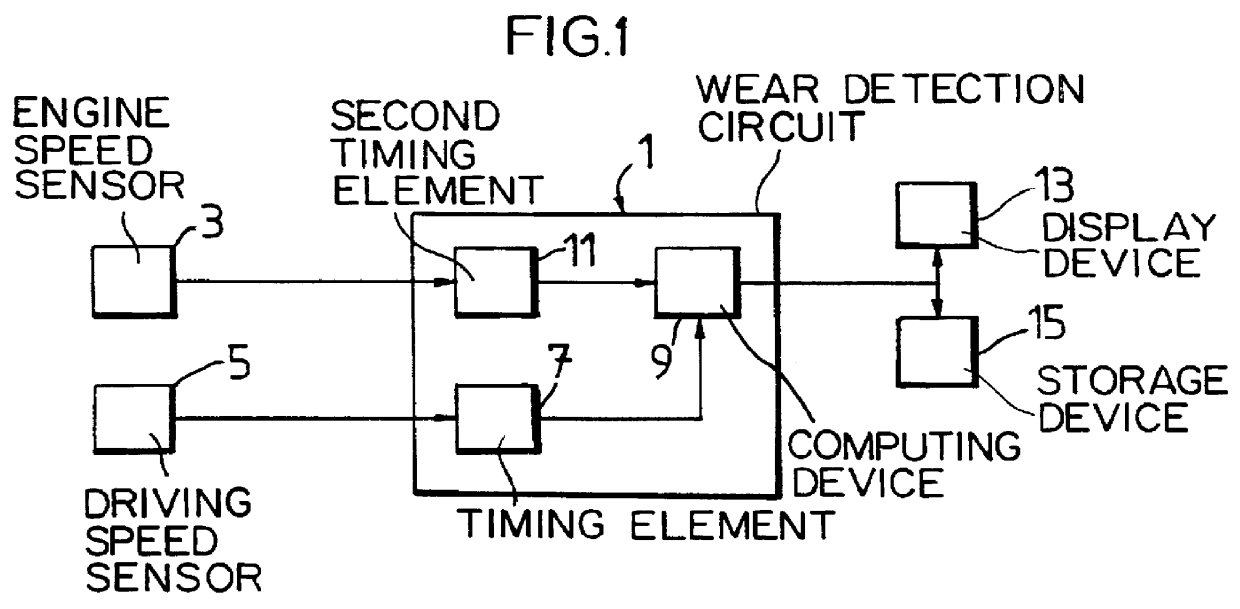

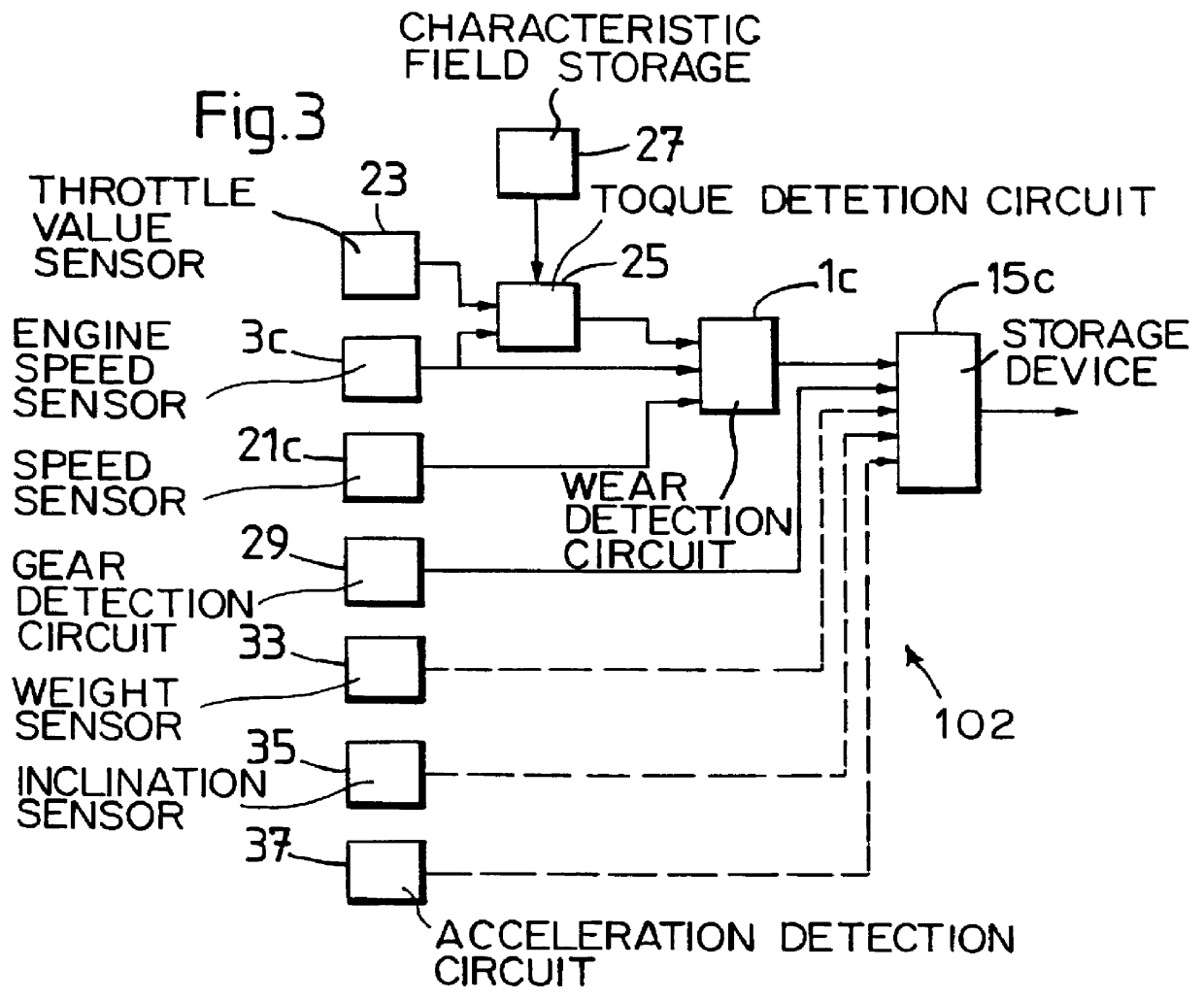

Arrangement for monitoring the wear status of a friction clutch

An arrangement for monitoring the wear status of a friction clutch in the drivetrain of a motor vehicle driven by an internal combustion engine includes a wear detection circuit that responds to speed information representing the instantaneous input speed of the friction clutch supplied by a first speed sensor and to information supplied by a movement sensor representing the beginning of a starting process. The wear detection circuit supplies, as a measurement for the loading of the friction clutch during a starting process, load information which is a predetermined monotonic function of a value of the first speed information following the beginning of movement after a predetermined time interval. The monotonic function could also be of a mean value from a plurality of values of the first speed information succeeding one another at predetermined time intervals following the beginning of movement.

Owner:ZF FRIEDRICHSHAFEN AG

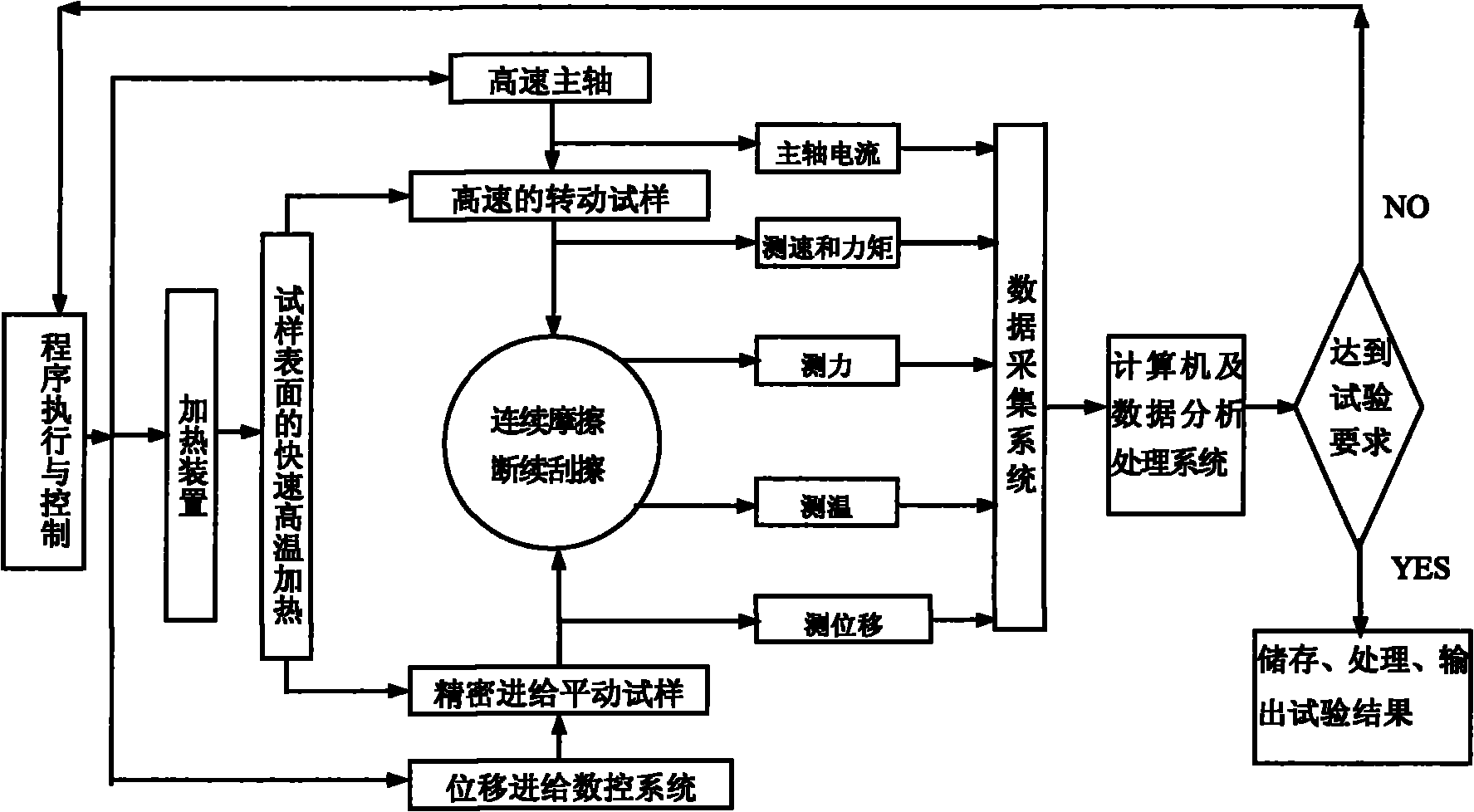

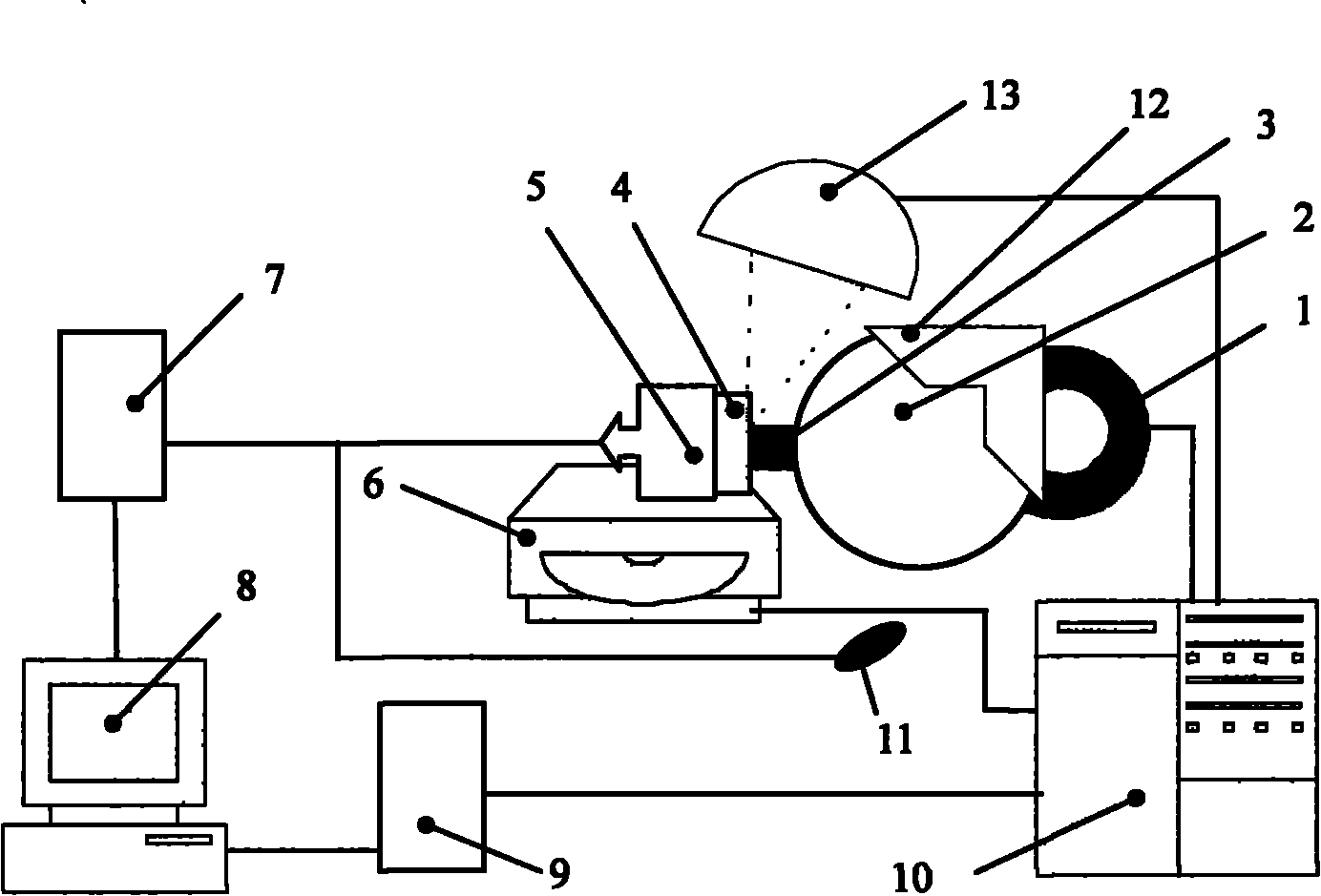

High-speed high-temperature multifunctional friction and abrasion tester

InactiveCN102116722AHeating fastMeasured lossInvestigating abrasion/wear resistanceNumerical controlPaired samples

The invention relates to a high-speed high-temperature multifunctional friction and abrasion tester which is especially applicable to simulating the service conditions of the sealed pairs of turbojet engines and solves the problems that the friction pairs in the prior art can not meet the needs of high speed (over 100m / s) and high temperature (up to 1200DEG C) in the aspects of motion line speed and experiment temperature and can not simulate the high-speed high-temperature friction and abrasion conditions of the gas path sealing of the turbojet engines and the like. The tester is provided with a rotation main shaft, a rotation disc, a numerical control sliding table and heating devices, wherein the rotation disc is arranged on the rotation main shaft, a rotation sample is arranged on therotation disc, the numerical control sliding table is arranged at one side of the rotation main shaft, a translation sample is arranged on the numerical control sliding table and is opposite to the rotation sample to form a friction pair; and the heating devices are arranged at the side of the rotation sample and at the side of the translation sample. By adopting the invention, the high-speed stable rotation of the rotation main shaft of the tester and the rapid heating of surface of the friction pair sample can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

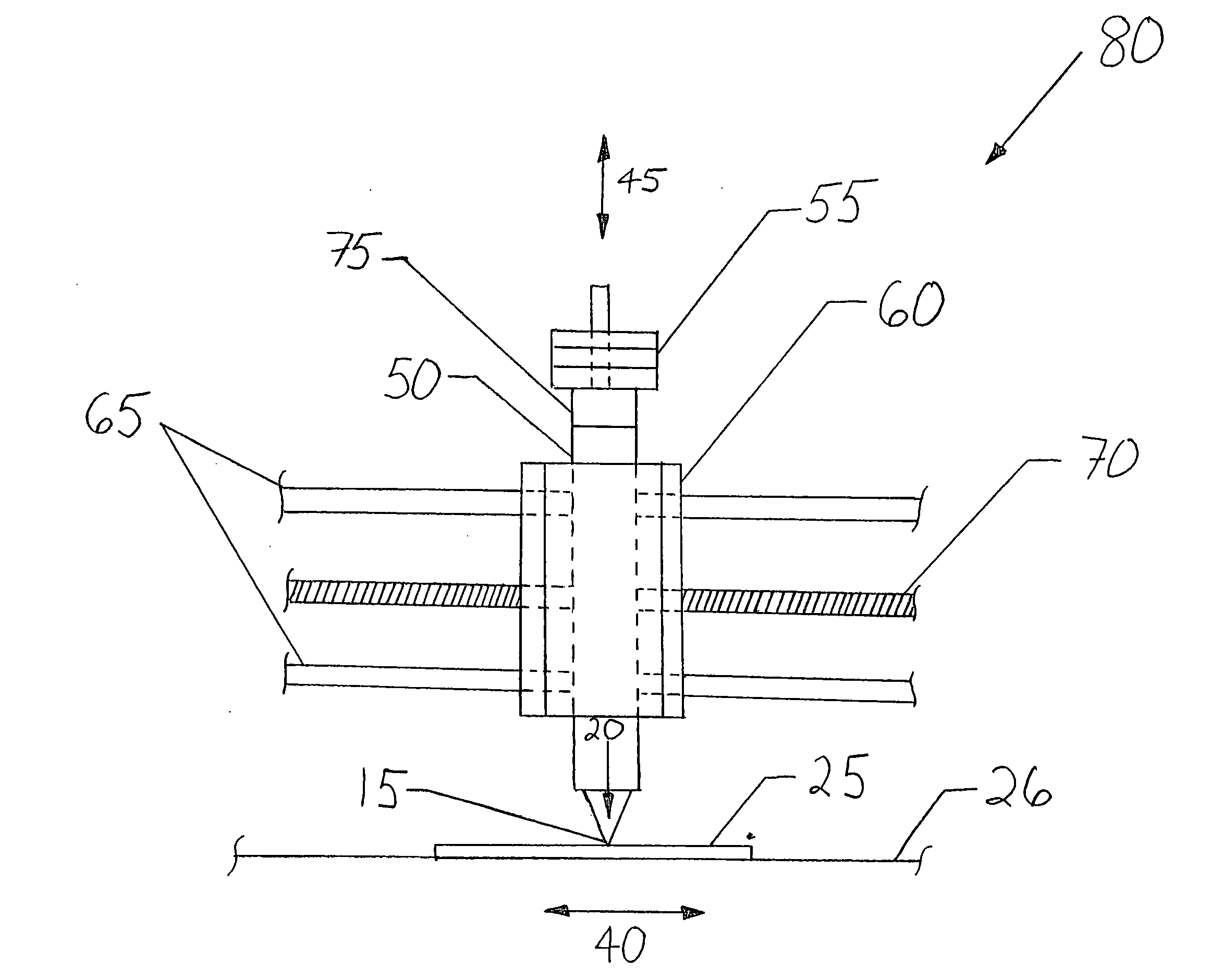

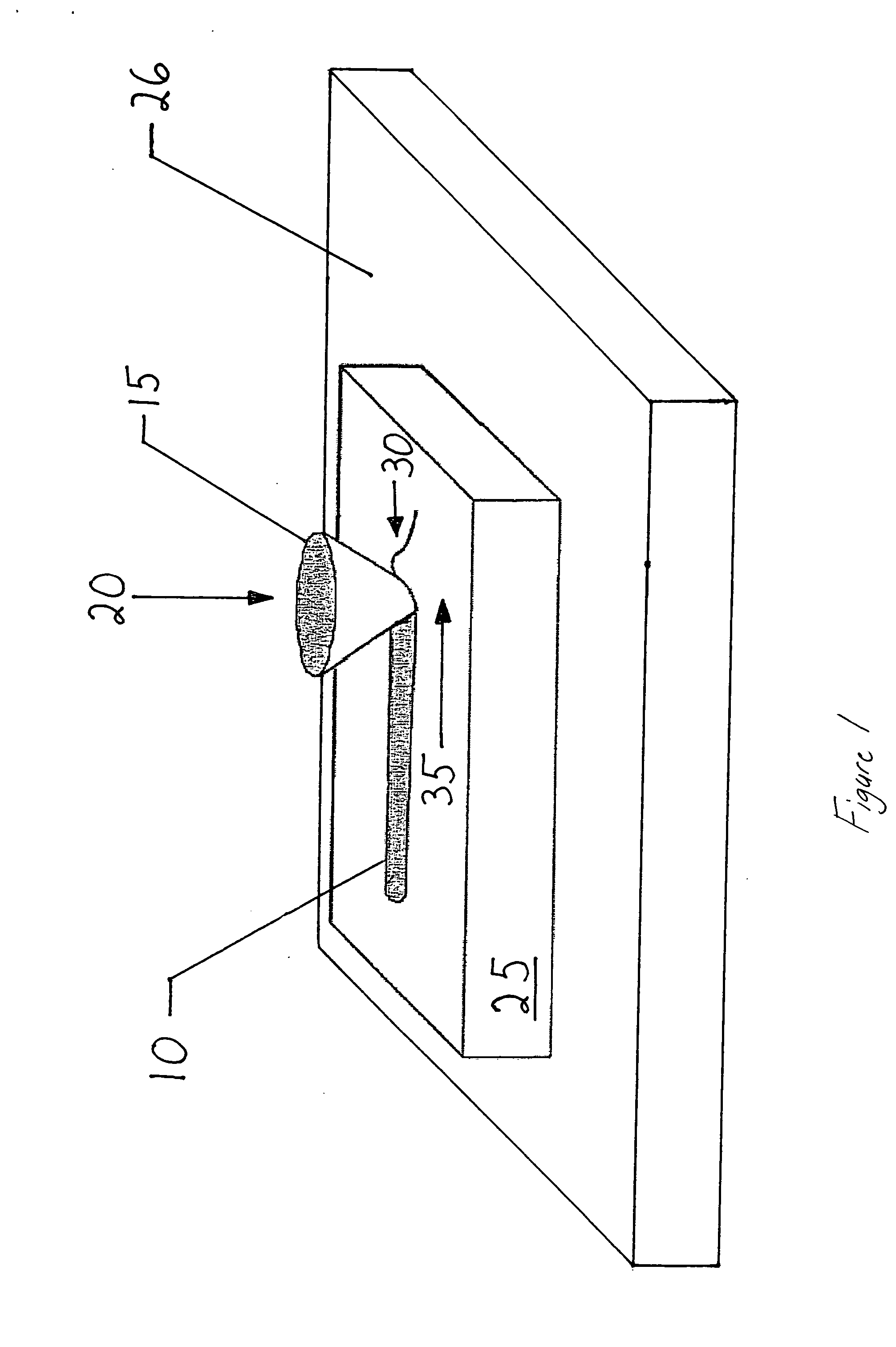

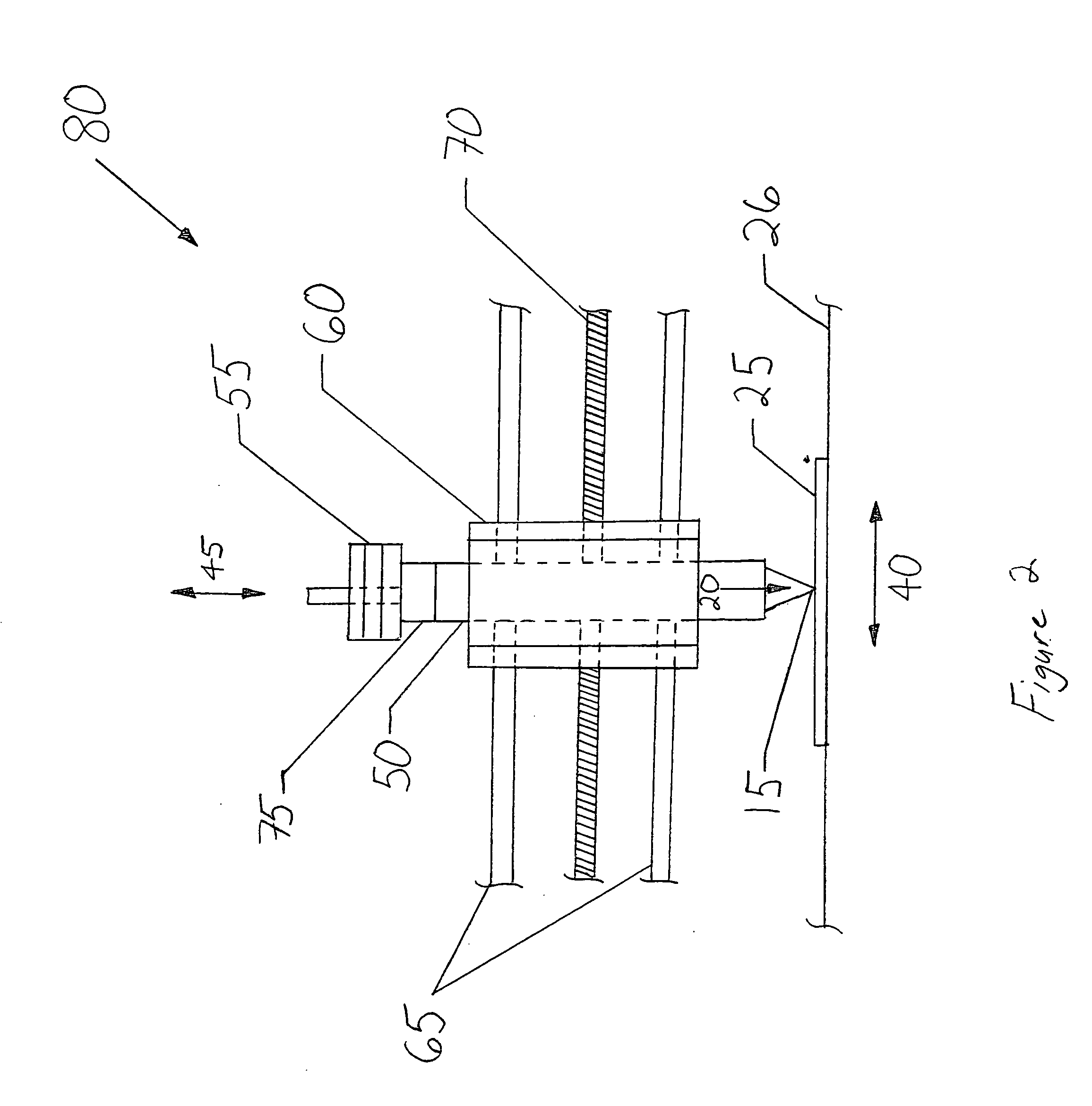

Scratch testing device

ActiveUS20060150710A1Using mechanical meansInvestigating material hardnessEngineeringEmbedded system

A device and method for scratch and / or mar testing the surface of a material specimen. In an embodiment, the scratch testing device comprises a scratching member. In addition, the scratch testing device comprises a carriage operable to move the scratching member. Further, the scratch testing device comprises a load mechanism, wherein the load mechanism applies a load to the scratching member.

Owner:MOYSE ALLAN H +1

Rubber abrasion test equipment

InactiveCN101013074AReflects real wear resistanceFacilitates continuous batch testingUsing mechanical meansVehicle tyre testingWear testingElectric machinery

The invention discloses a rubber wear test equipment, which includes the wear machine main-body, thermo-regulating device, speed-regulating device, angle-regulating device and temperature measurement device, in which the wear machine main-body is divided into driven system A and follower system B, the driven system A installed in the motor seat, the follower system B directly installed on the base through the bolts, and the driven system A includes a speed regulating motor, a speed controller and the wheel, the follower system B including a load lever, a weight, a frame and a sample rubber tire. In the wear testing of this invention, temperature, speed, load, wear angle are all adjustable to achieve different speed, different load, different angle wear testing, and it can fully simulate the tire different practical using conditions. It overcomes the defects of Akron wear machine that the test temperature, load and speed are all constant value and less than the tire actual value, and the experimental results show that the invention can better reflect the real wear resistance of rubber tires in different environmental conditions.

Owner:SOUTH CHINA UNIV OF TECH

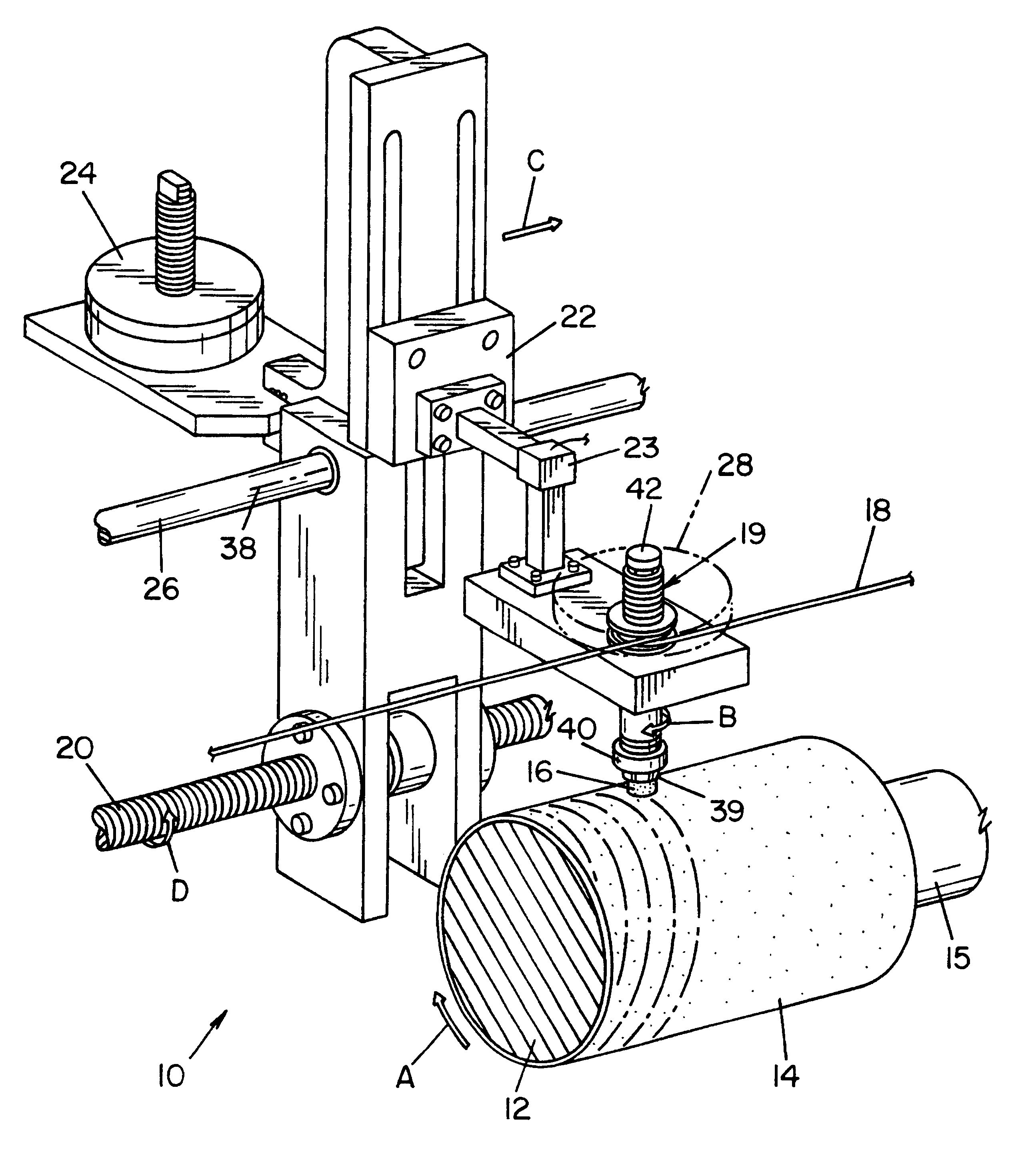

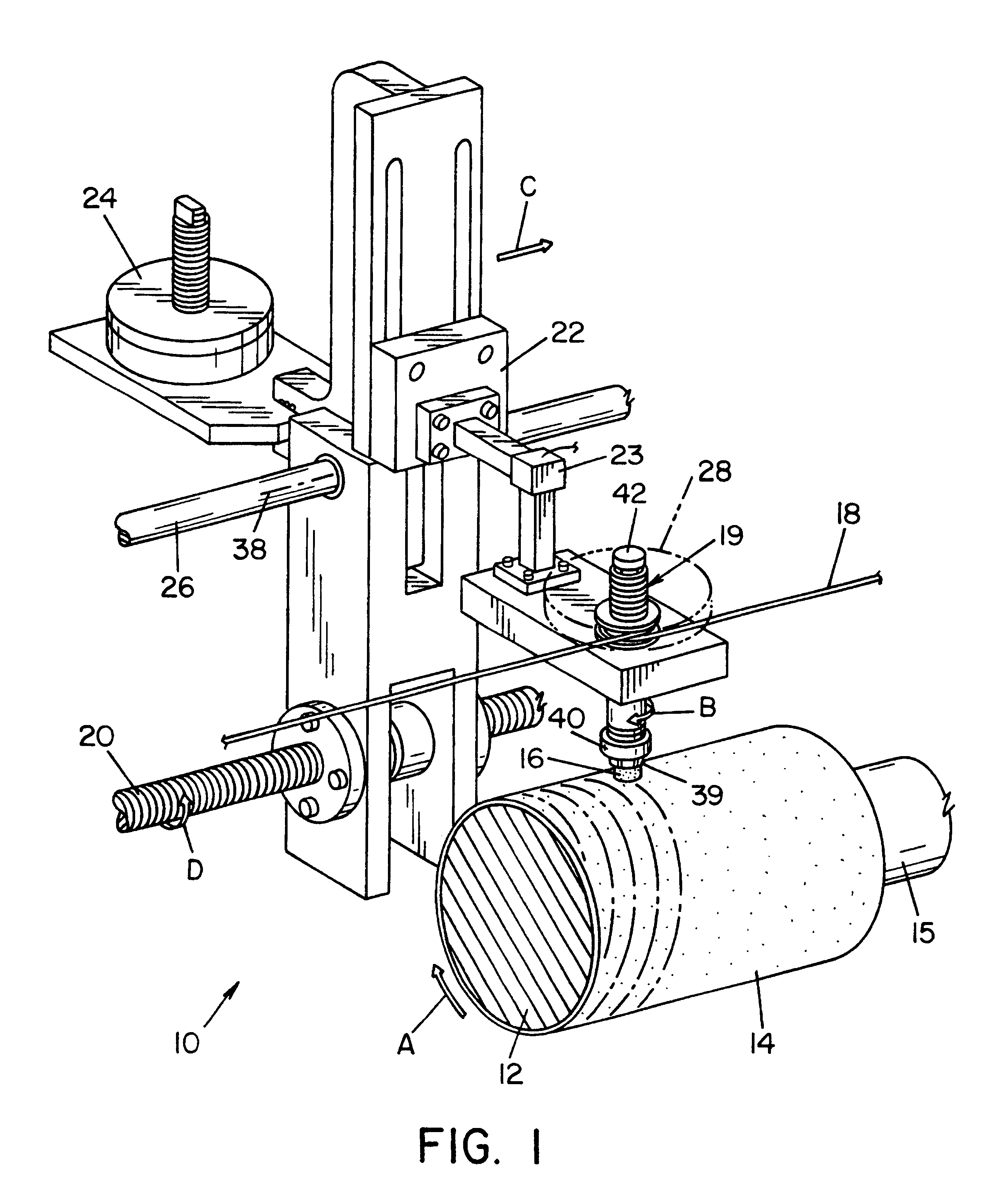

Abrasion tester

InactiveUS6412330B1Drag minimizationMinimal frictionUsing mechanical meansMaterial testing goodsRough surfaceWear testing

An apparatus for measuring abradability of a sample comprises a rotating drum with a rough surface and a means for contacting a sample with the rough surface while the drum is rotating. The sample may be caused to rotate relative to the drum, and to translate across the drum while the drum is rotating. Environmental controls may be used to control the temperature and the atmospheric conditions of the test. In the method of the invention, energy consumed by contact between the sample and the drum, as well as the weight loss of the sample, may be measured.

Owner:THE GOODYEAR TIRE & RUBBER CO

Work condition analogue rolling contact fatigue tester

InactiveCN1715869AReduce the numberReduce fatigue test timeMachine bearings testingUsing mechanical meansTemperature controlInterference fit

The on-line work condition simulating rolling contact fatigue tester includes driving device, loading device, testing device and signal collecting device, and has temperature controlling cavity sleeved on the driving shaft, lower test cavity end interference fitted to the end of the driving shaft and set inside the temperature controlling cavity, test cavity with upper test sample, rolling part, lower test sample, abruptly stopping cam on the upper test sample, and rolling pin thrust bearing on the abruptly stopping cam and matching the pressure block below the loading lever. The present invention can simulate the contact fatigue, friction and wear process of friction pair with or without surface coating for relevant detection, and the instantaneous failure state may be kept by means of abrupt stopping unit.

Owner:YANSHAN UNIV

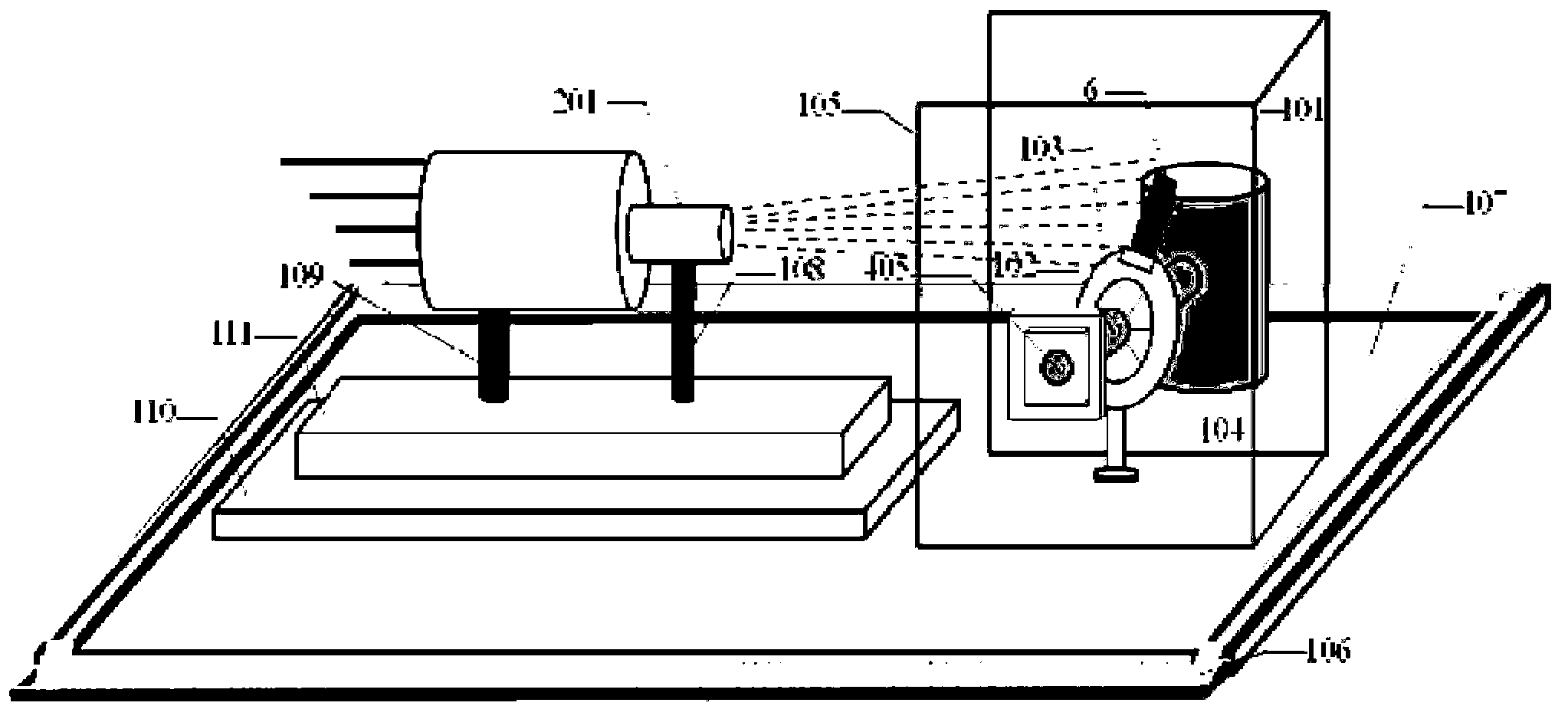

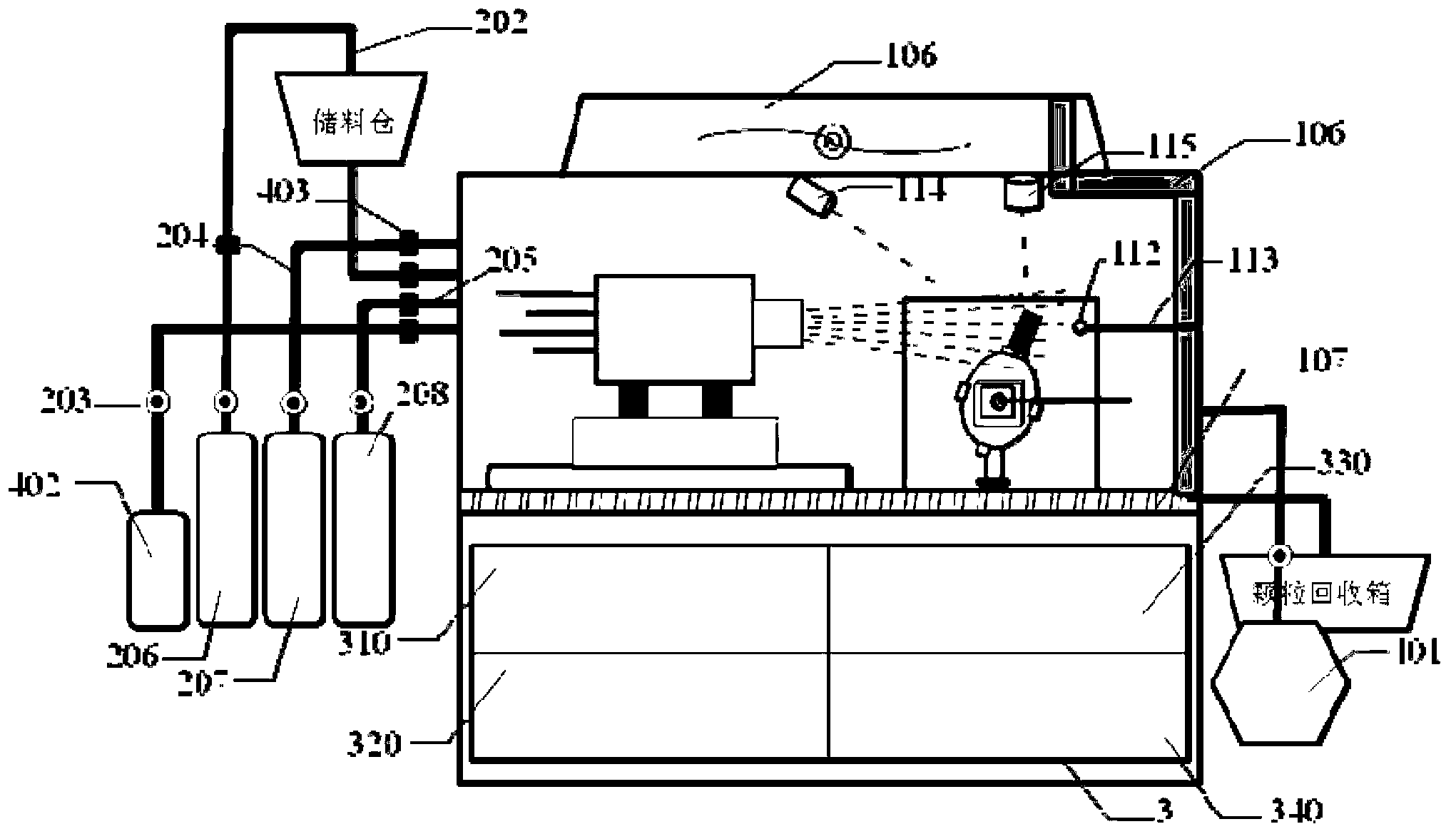

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

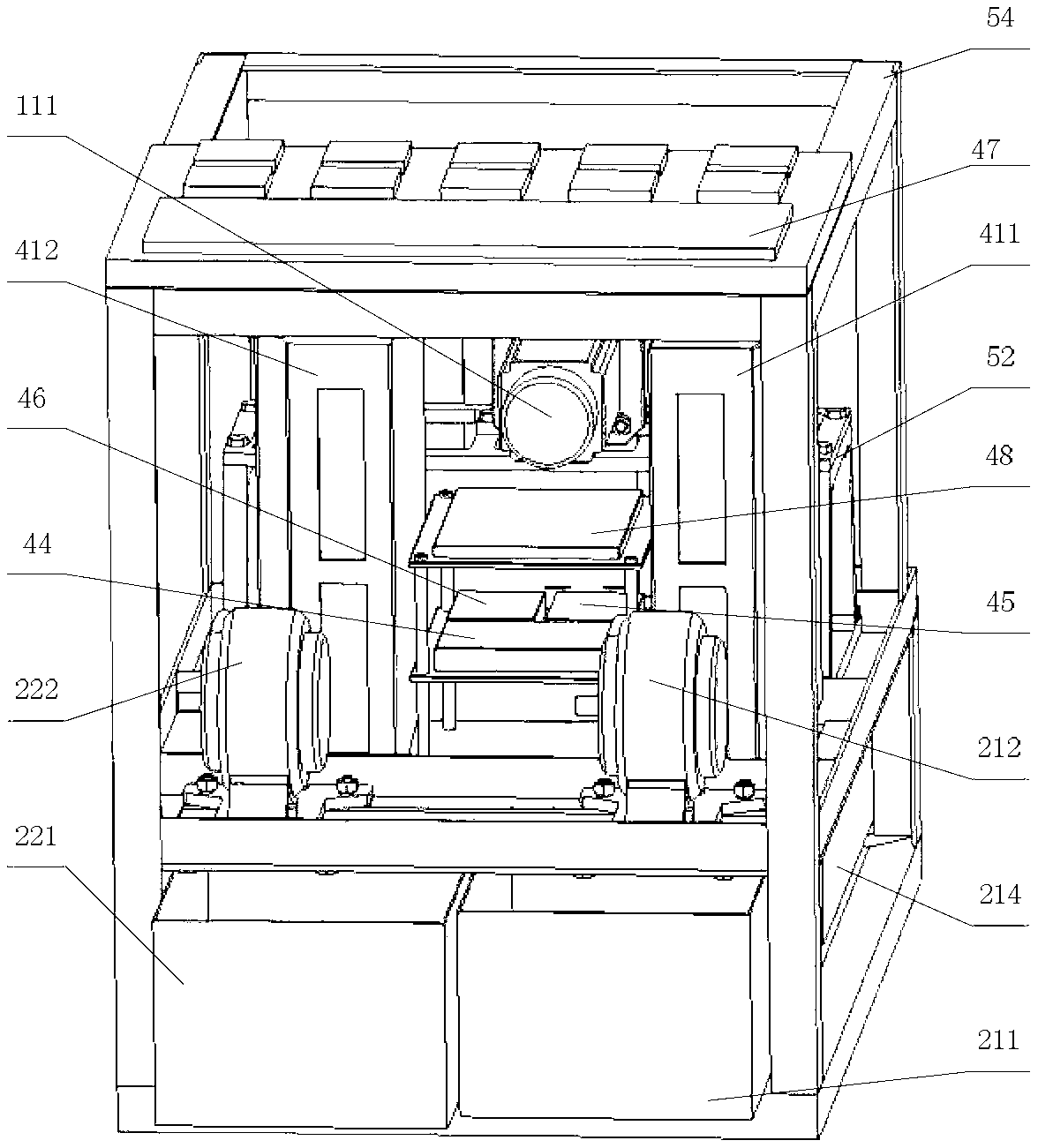

Oral environment simulation test machine

InactiveCN102841028AAvoid complex processHigh degree of automationMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceNatural toothDentures

The invention discloses an oral environment simulation test machine comprising a stomatognathic two-free-degree motion unit, intraoral liquid spouting units, an intraoral temperature adjusting unit and a control unit. The stomatognathic two-free-degree motion unit, the intraoral liquid spouting units and the intraoral temperature adjusting unit are respectively connected with the control unit and arranged in an integral framework of the test machine. The stomatognathic two-free-degree motion unit is arranged at the front end of the integral framework of the test machine for observers to observe simulation states of stomatognathic two-free-degree chewing movements in a window form. The intraoral liquid spouting units are arranged on the rear end and the lower end of the integral framework of the test machine. The intraoral temperature adjusting unit is arranged on the front end of the integral framework of the test machine. The control unit is arranged between the stomatognathic two-free-degree motion unit and the intraoral liquid spouting unit. The oral environment simulation test machine achieves frictional wear and fatigue test between extra-oral dentures and natural teeth, and oral environment simulation of a service life forecast experiment under a simulate real oral environment.

Owner:NANJING UNIV OF SCI & TECH

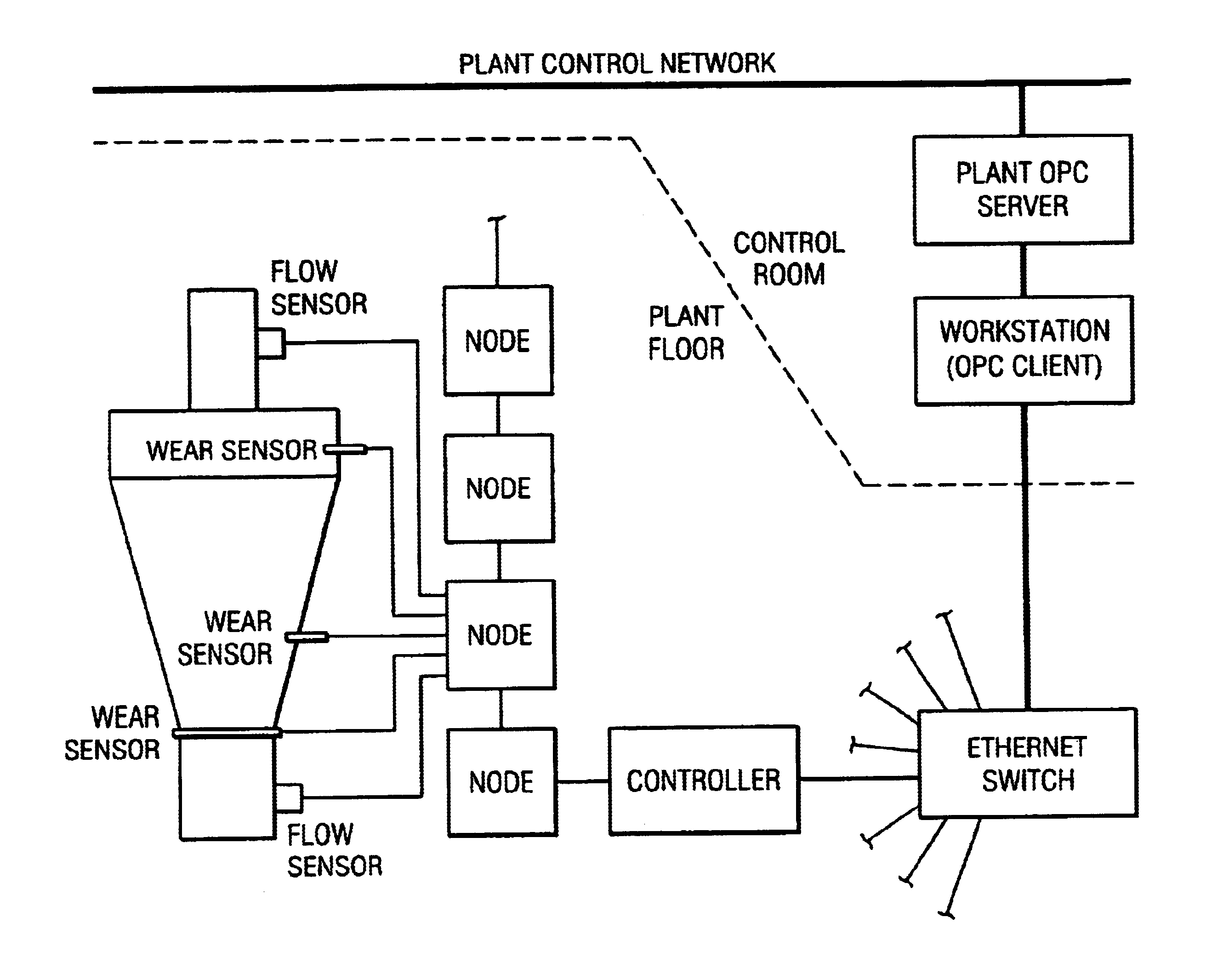

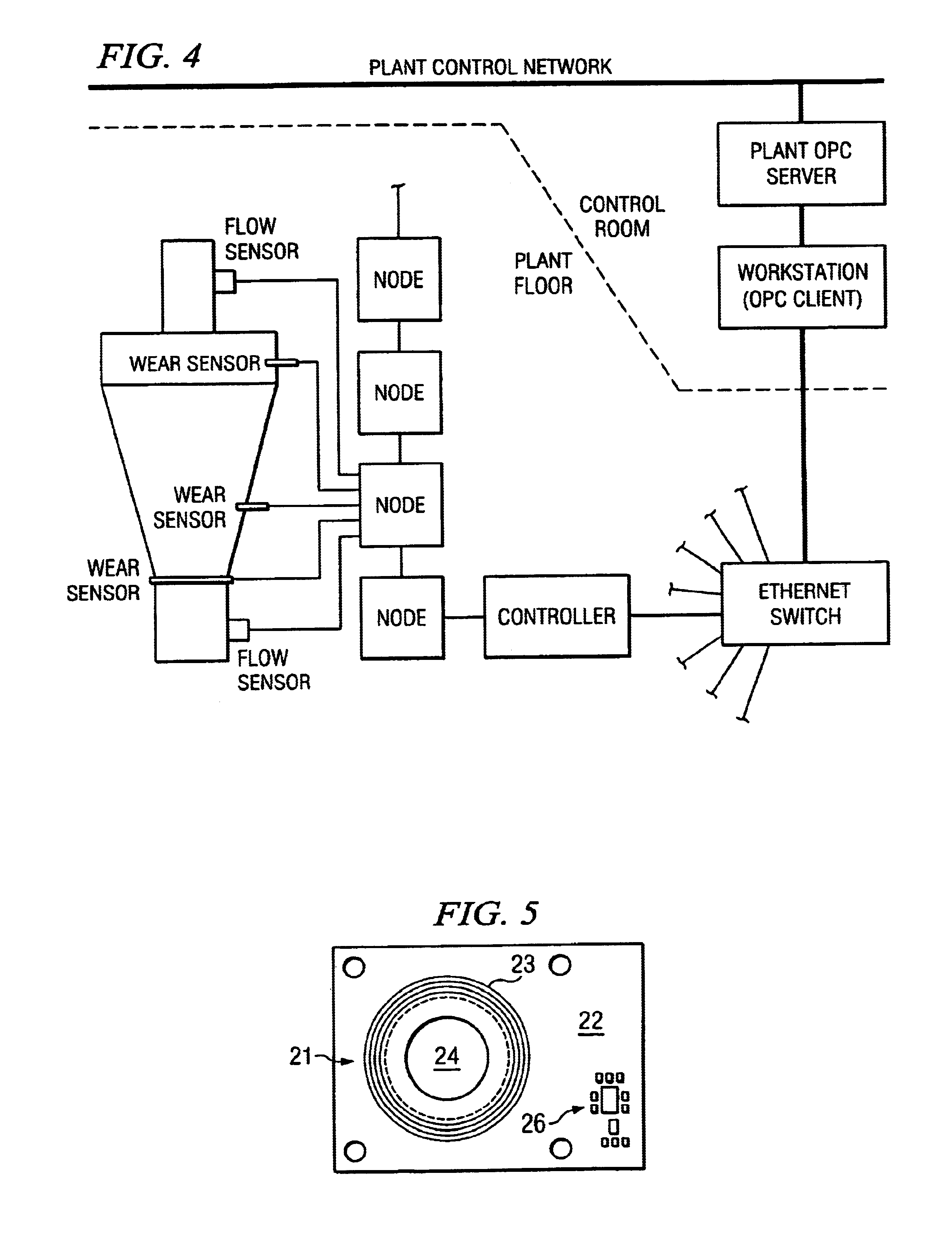

Hydrocyclone wear-detection sensor

Wear-detection sensor has a body of electrically insulating material with an opening through which a flowable substance can pass, and one or more electrical conductors surrounding the opening and adapted to undergo a discernable change in conductivity as the insulating material is worn away by the flowable substance.

Owner:KREBS ENGINEERS CORP +1

Friction wear test method and apparatus for cylinder liner piston ring component

InactiveCN1789963AEliminate the effects ofPrecise frictionMachine part testingInvestigating abrasion/wear resistanceThermal insulationPiston ring

The invention discloses a friction and abrasion testing method and equipment of cylinder piston ring element in the friction and abrasion testing technique domain, which is characterized by the following: adapting mechanic radial loading construction method and equipment to test the cylinder and piston ring element; adding liquid through heating the cylinder cavity to keep thermal; fixing the friction force sensor on the test machine rack directly; eliminating the measuring result influence of friction force by inertia force of moving component to gain more precise friction force; segregating the friction force sensor and cylinder through thermal-insulation material; setting the cooler to prevent the rack temperature from elevating and the temperature of friction force sensor from exceeding the highest working temperature. The invention is used as the rapid assessment method in the lab developing procedure of cylinder piston ring.

Owner:DALIAN MARITIME UNIVERSITY

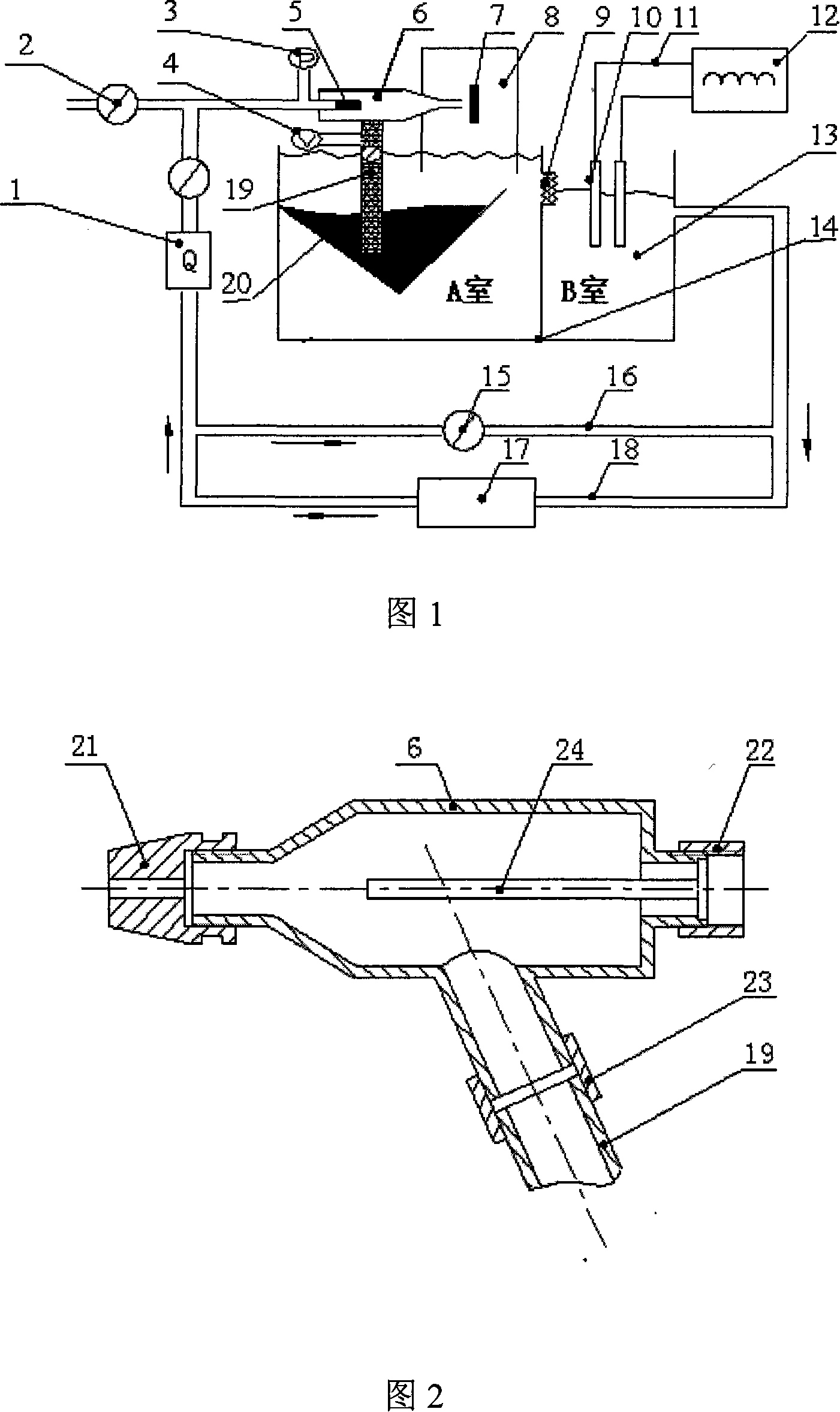

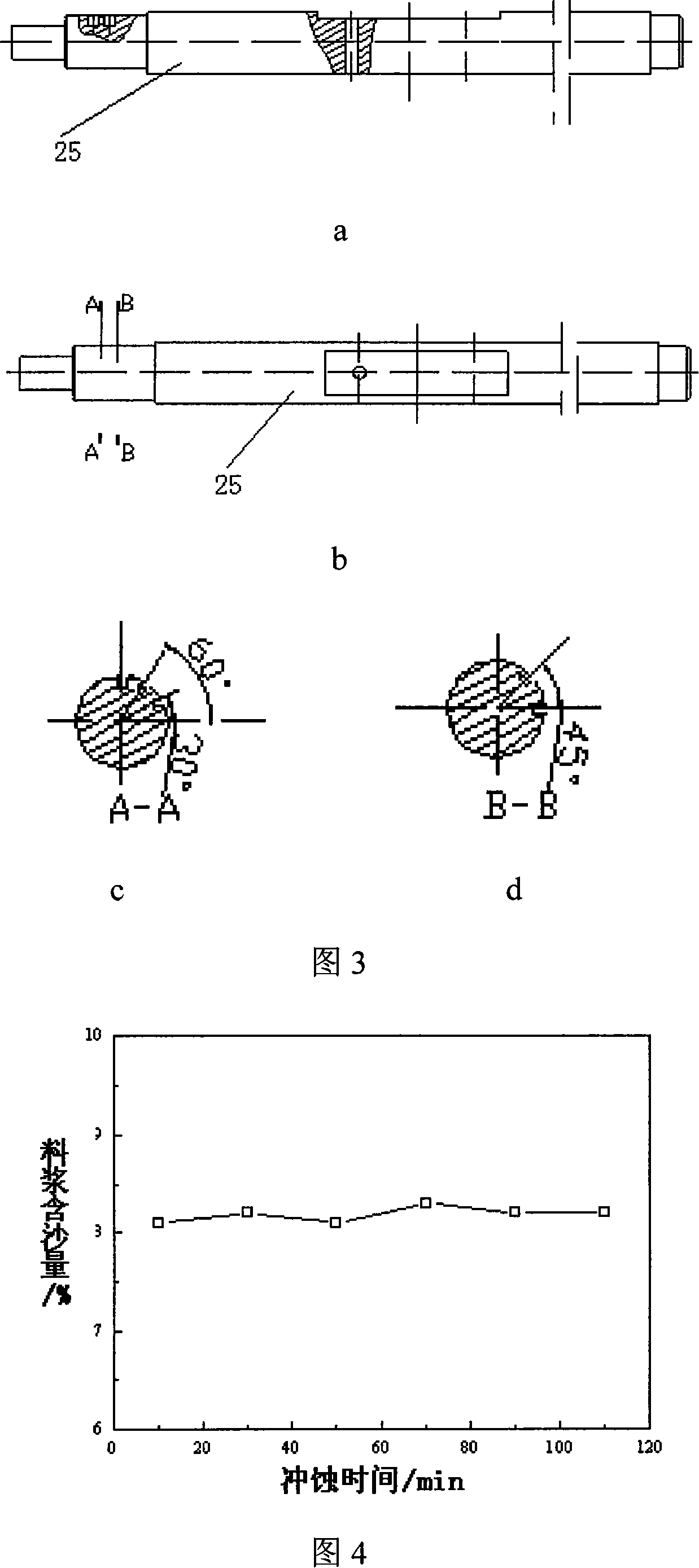

Jet stream type erosion abrasion test device

InactiveCN101140209AThe principle is simpleEasy to operateWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceEngineeringElectric potential

The invention discloses a jet type erosive wear test device which comprises a centrifugal pump and a connecting pipeline, wherein one end of the pipeline is firmly connected with a nozzle, the front end of the nozzle is corresponding with the position of a sample, the lower part of the nozzle and the sample is provided with a storage hopper, the storage hopper is leftwards and rightwards partitioned into an A chamber and a B chamber by a layer of filter screen, the interior of the storage hopper A chamber relative to the nozzle and the sample is provided with a sand hopper, the nozzle stretches into the sand hopper through a liquid lifting pipe, the interior of the storage hopper B chamber is provided with a pair of electrodes stretching into the interior, the electrode is connected with an external electric potential testing meter through a lead wire, and the other end of the pipeline is communicated with the storage hopper B chamber. The device provided in the invention can simulate the requirements of actual working conditions, which not only can implement the test study for the selection of wearable materials, but also can be suitable for the study of erosive wear mechanism.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com