Patents

Literature

893 results about "Tribology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary. It draws on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. People who work in the field of tribology are referred to as tribologists.

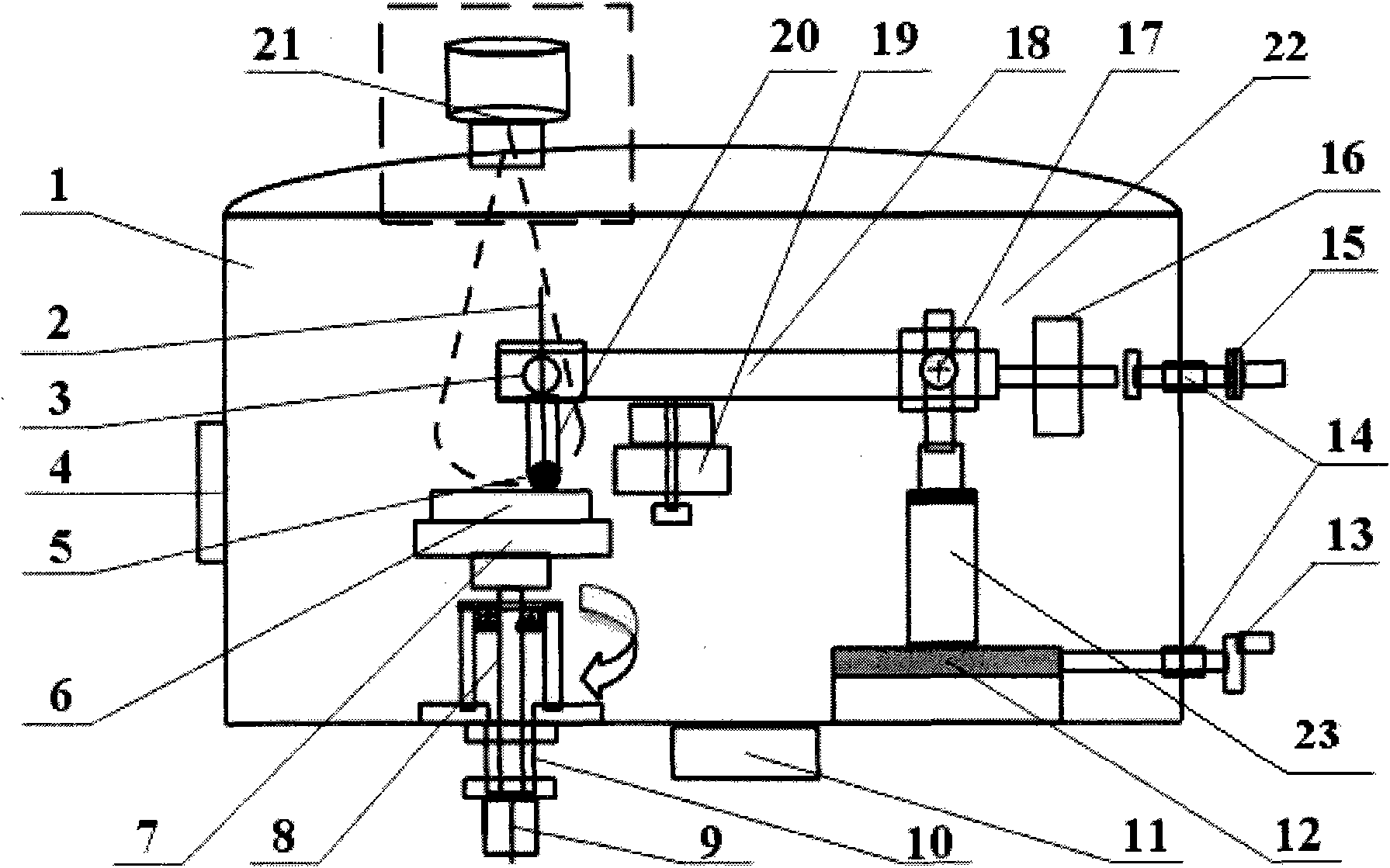

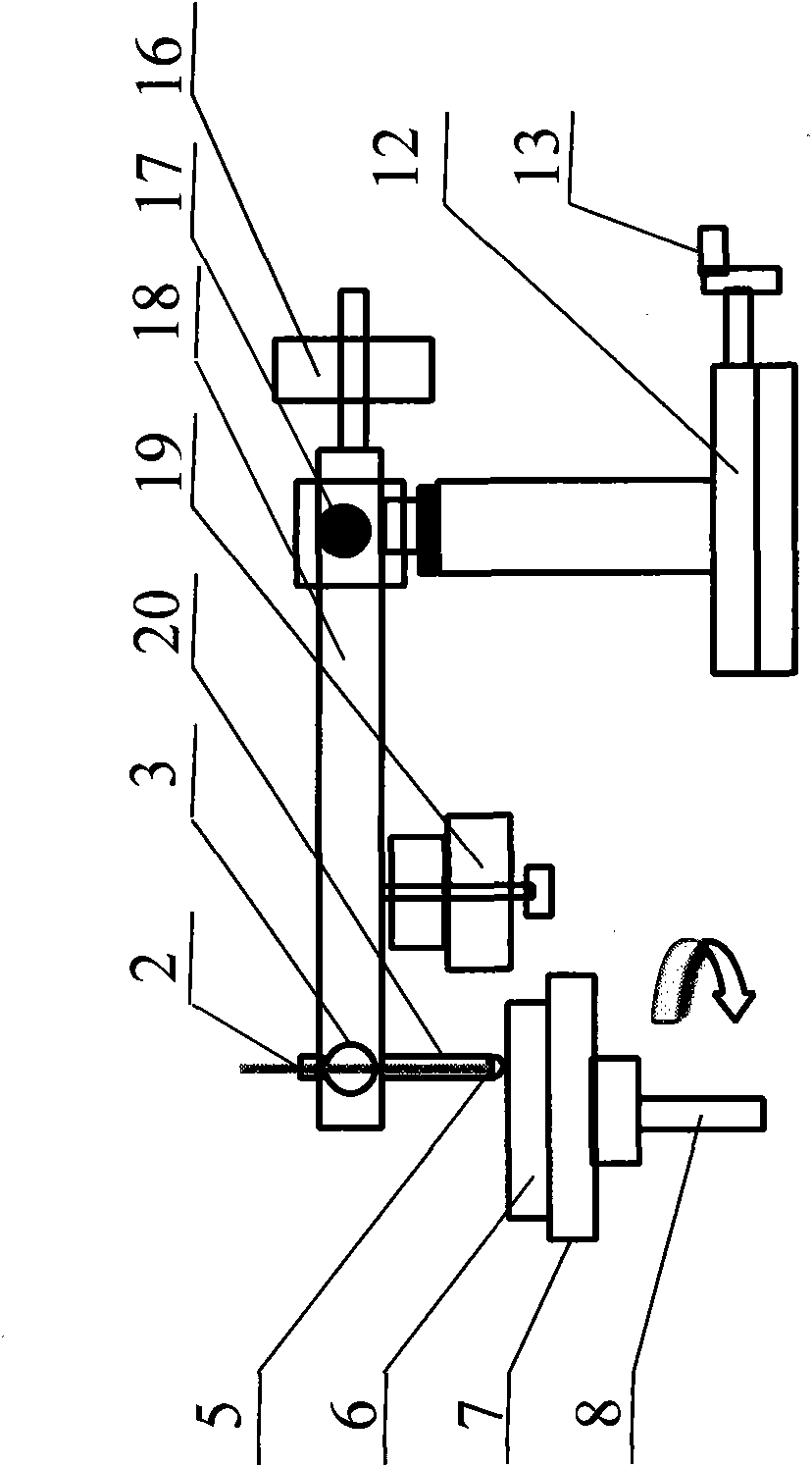

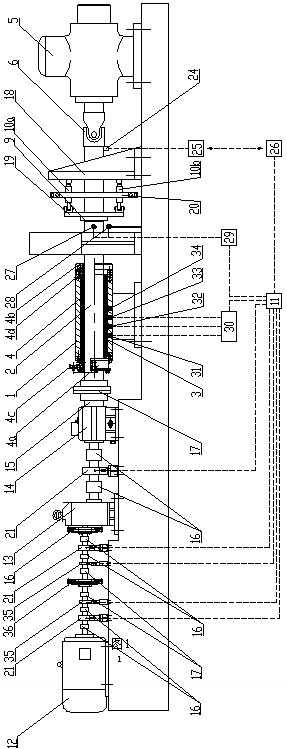

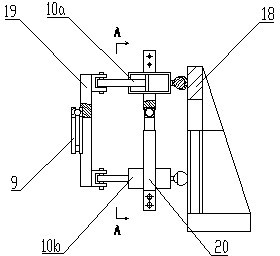

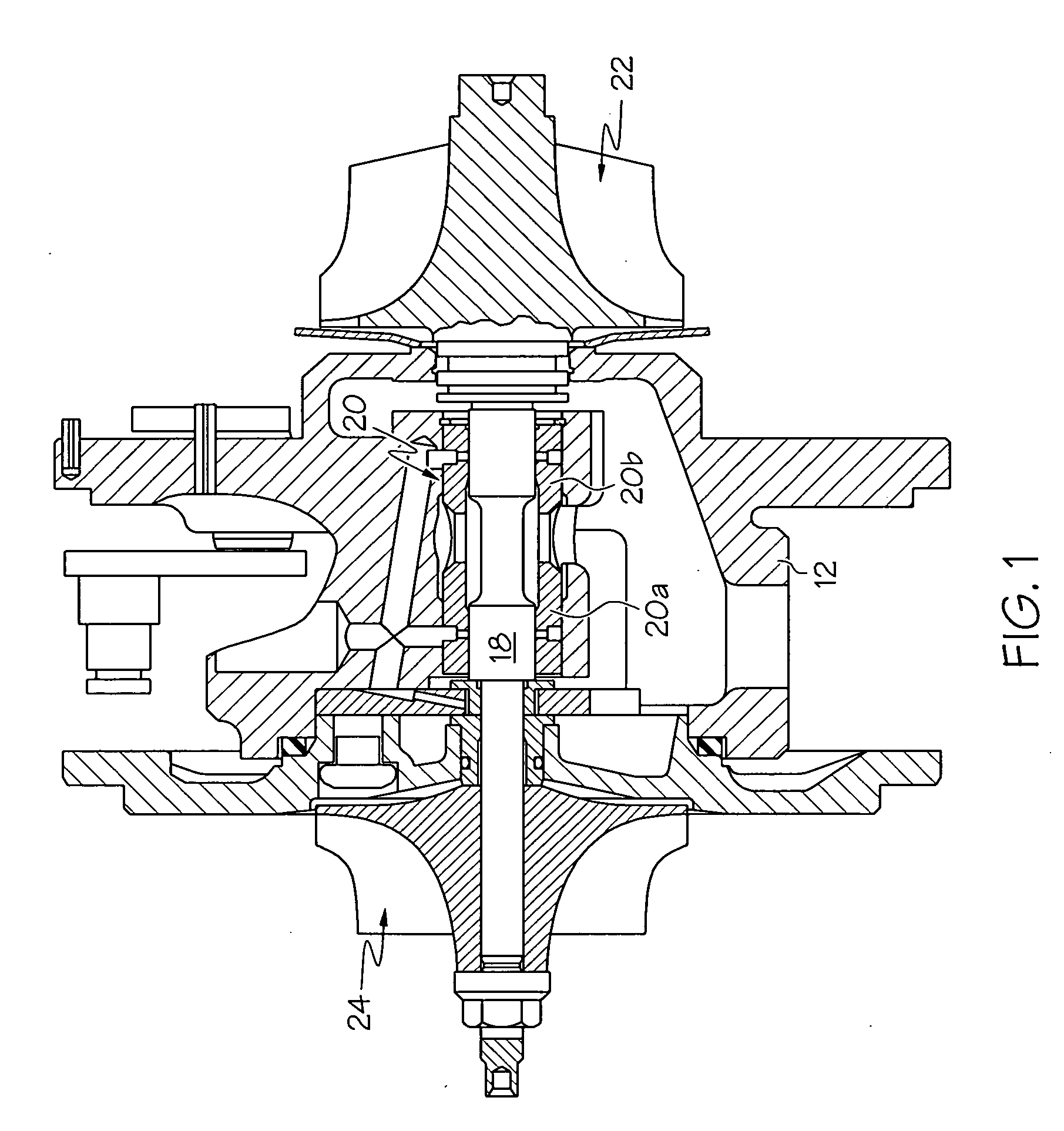

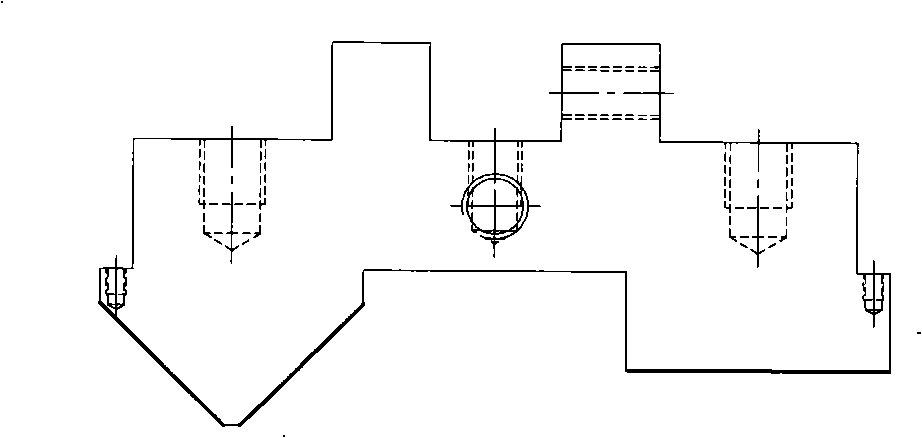

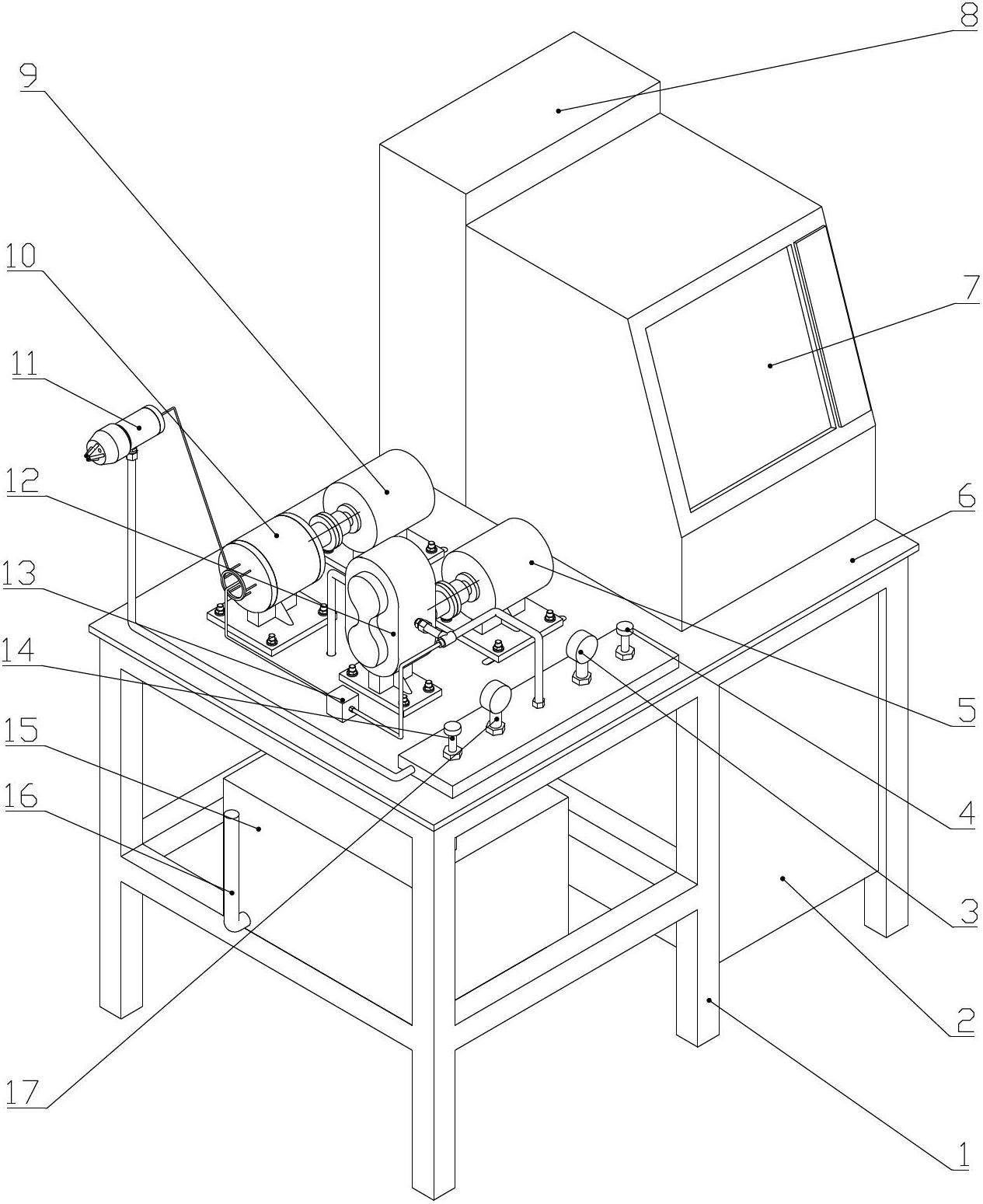

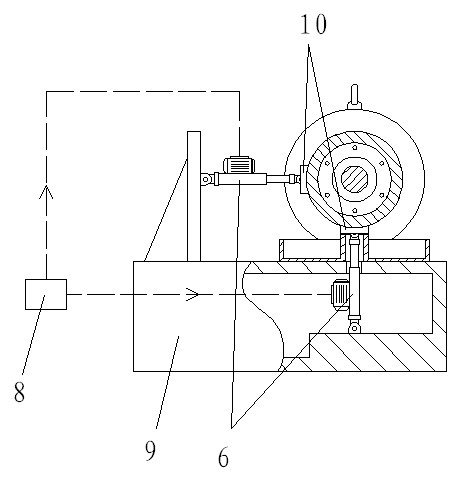

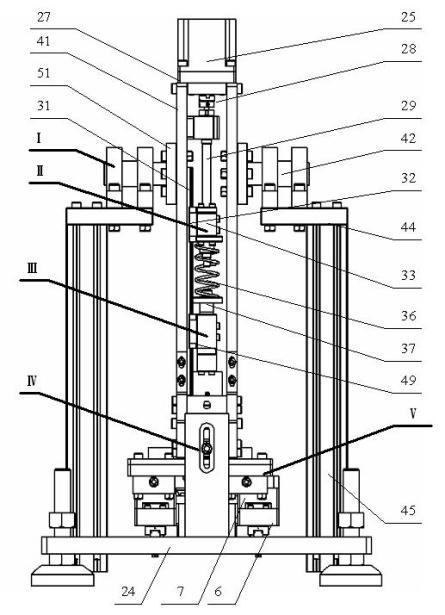

Multifunctional vacuum friction and wear testing machine

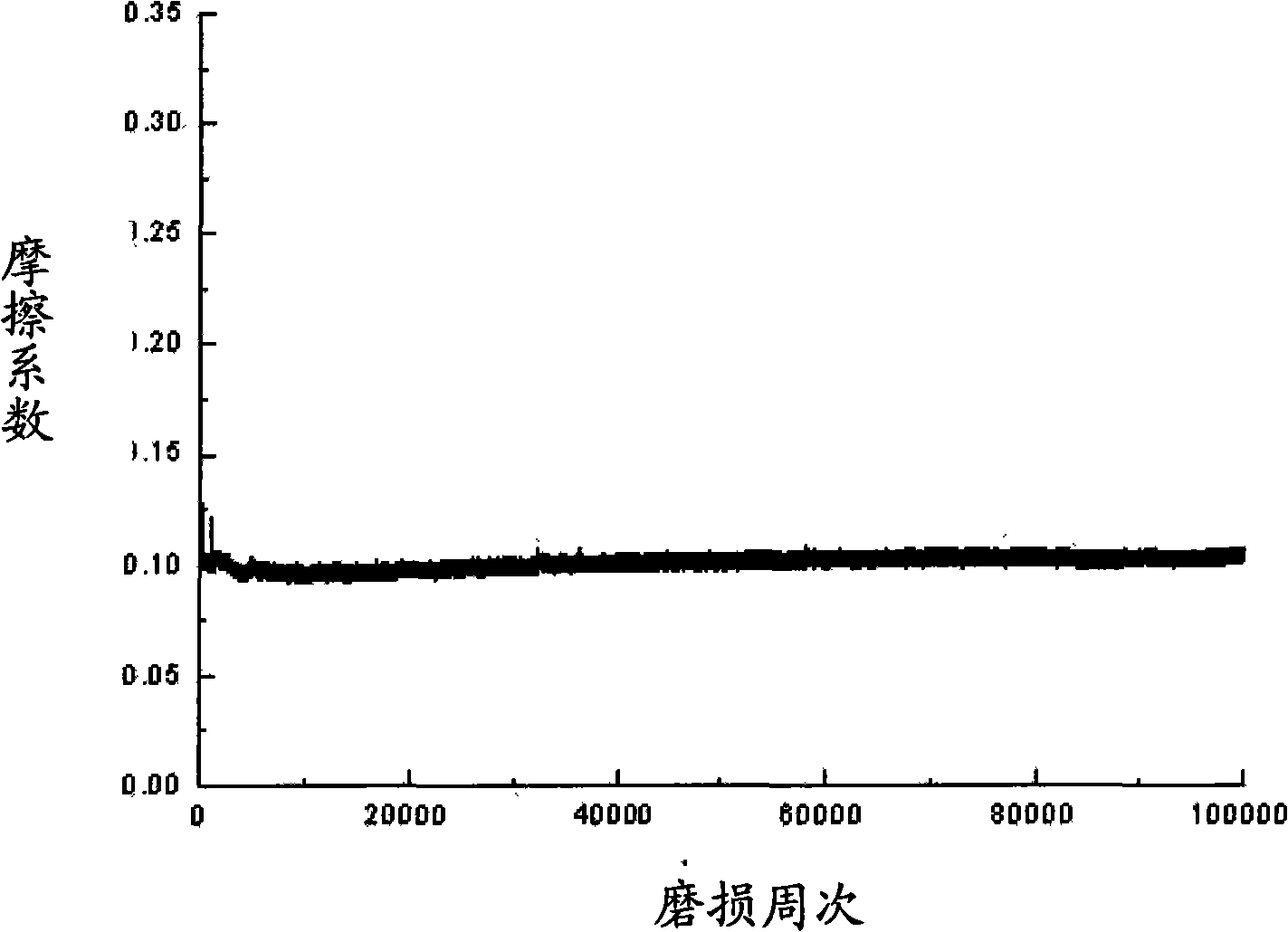

ActiveCN102759489APrecise position adjustmentAvoid time costInvestigating abrasion/wear resistanceDrivetrainEngineering

The invention provides a multifunctional vacuum friction and wear testing machine, which not only can simulate special environmental atmospheres such as vacuum, radiation and corrosion, but also can conduct tribology tests in a relatively wide speed and load range by using various contact manners (ball-disc and pin-disc). The multifunctional vacuum friction and wear testing machine mainly comprises a vacuum system, a friction and wear system, a power transmission system, a control system, and the like, wherein the friction and wear system comprises a lever structure (22) used for fixing a test sample fixture (20) and capable of freely rotating in a horizontal direction and a vertical direction; the lever structure (22) comprises a cantilever beam (18) and a vertical arm (23) which are arranged in a perpendicular manner; the cantilever beam (18) is connected with the vertical arm (23) through a two degree of freedom bearing structure (17); positions of the cantilever beam (18) and the vertical arm (23) can be adjusted in the horizontal direction and the vertical direction through the control of a manipulator (15) and a hand wheel structure (13), so that the test sample fixture (20) can accurately move within two degrees of freedom; and a temperature sensor (2) and a pressure sensor (3) are mounted on the test sample fixture (20), so as to detect / monitor friction coefficients and temperature variations during the tribology tests.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Lubricating oil

InactiveUS20070027038A1Low vapor pressureImprove heat resistanceOrganic chemistryProtective coatings for layersHeat resistanceBase oil

The invention provides a lube oil which exhibits low vapor pressure despite having low viscosity, is non-flammable, exhibits excellent heat resistance, has tribological characteristics equivalent to those of conventional hydrocarbon-based lube oils, and can be used for a long time under very severe conditions such as high temperature and vacuum. The lube oil contains, as a base oil, an ionic liquid formed of a cation and an anion and having an ion concentration of 1 mol / dm3 or more.

Owner:IDEMITSU KOSAN CO LTD +1

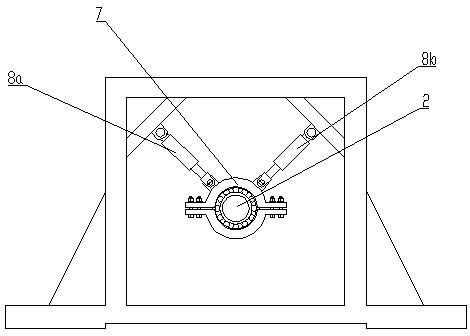

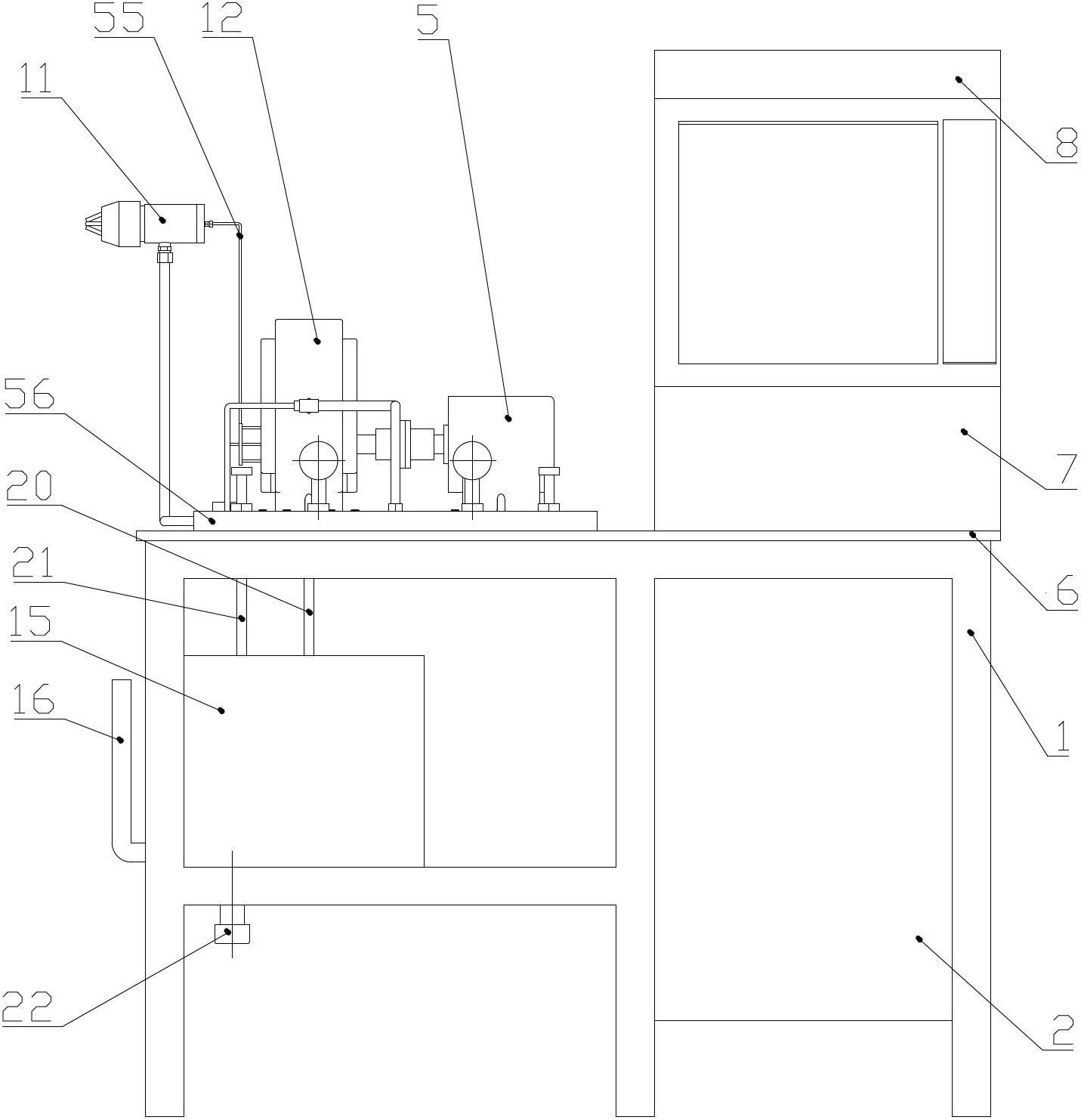

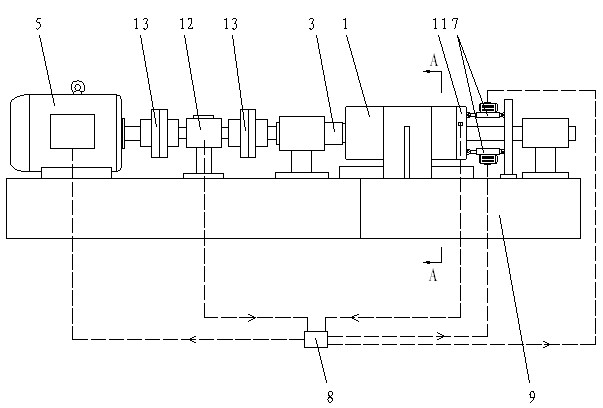

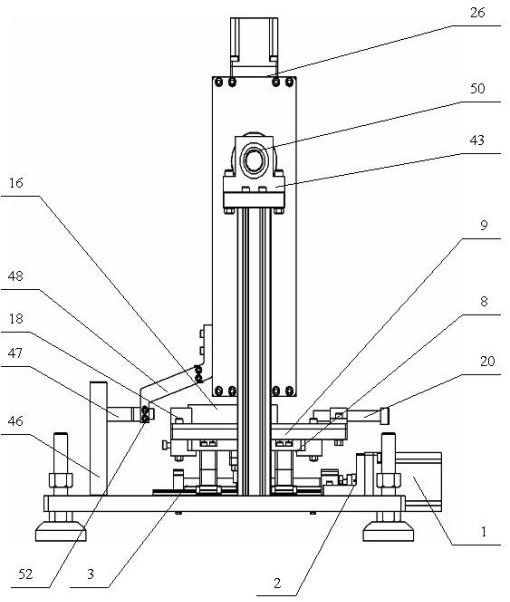

Comprehensive performance experiment platform for water-lubricated bearings and transmission systems

ActiveCN102269654AReal performance testPerformance testing is completeMachine gearing/transmission testingMachine bearings testingLow noiseDrive motor

The invention discloses a water lubricated bearing and transmission system comprehensive performance testing platform, which comprises a water lubricated bearing, a dynamic seal device, an elastic coupling, a gearbox, a water circulating system, a driving motor, an intermediate bearing, a bearing block, a loading and testing device and other parts. The loading device loads a test shaft in the circumferential direction, axial direction and radial direction so as to simulate complicated working conditions of the water lubricated bearing and the transmission system thereof; the testing system can detect various parameters of the water lubricated bearing, such as working speed, torque, temperature, frictional characteristics, water film pressure distribution, interface deformation distribution, shaft centerline orbit, noise and dynamic characteristics, and comprehensive performance of the dynamic seal, the elastic coupling and the transmission system on line; and the testing platform can be applied to research of scientific problems such as the loading bearing of a water lubricated friction pair, failure mechanism and evolution law, tribological performance and dynamic service behaviors, and provides a key scientific and technological basis for developing a pollution-free, low-noise, high-reliability, long-life, high-efficiency and energy-saving water lubricated bearing and a transmission system thereof.

Owner:CHONGQING UNIV

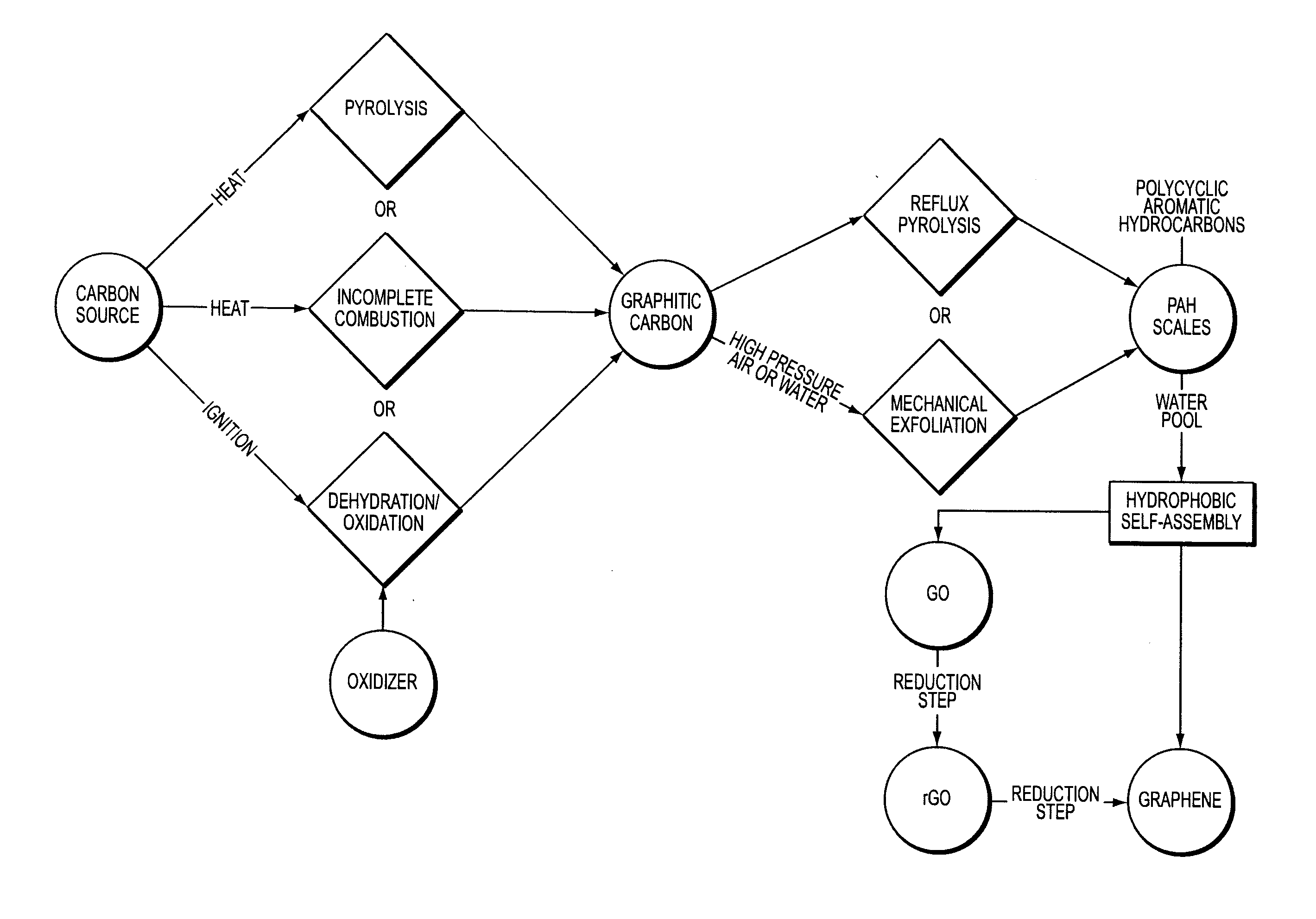

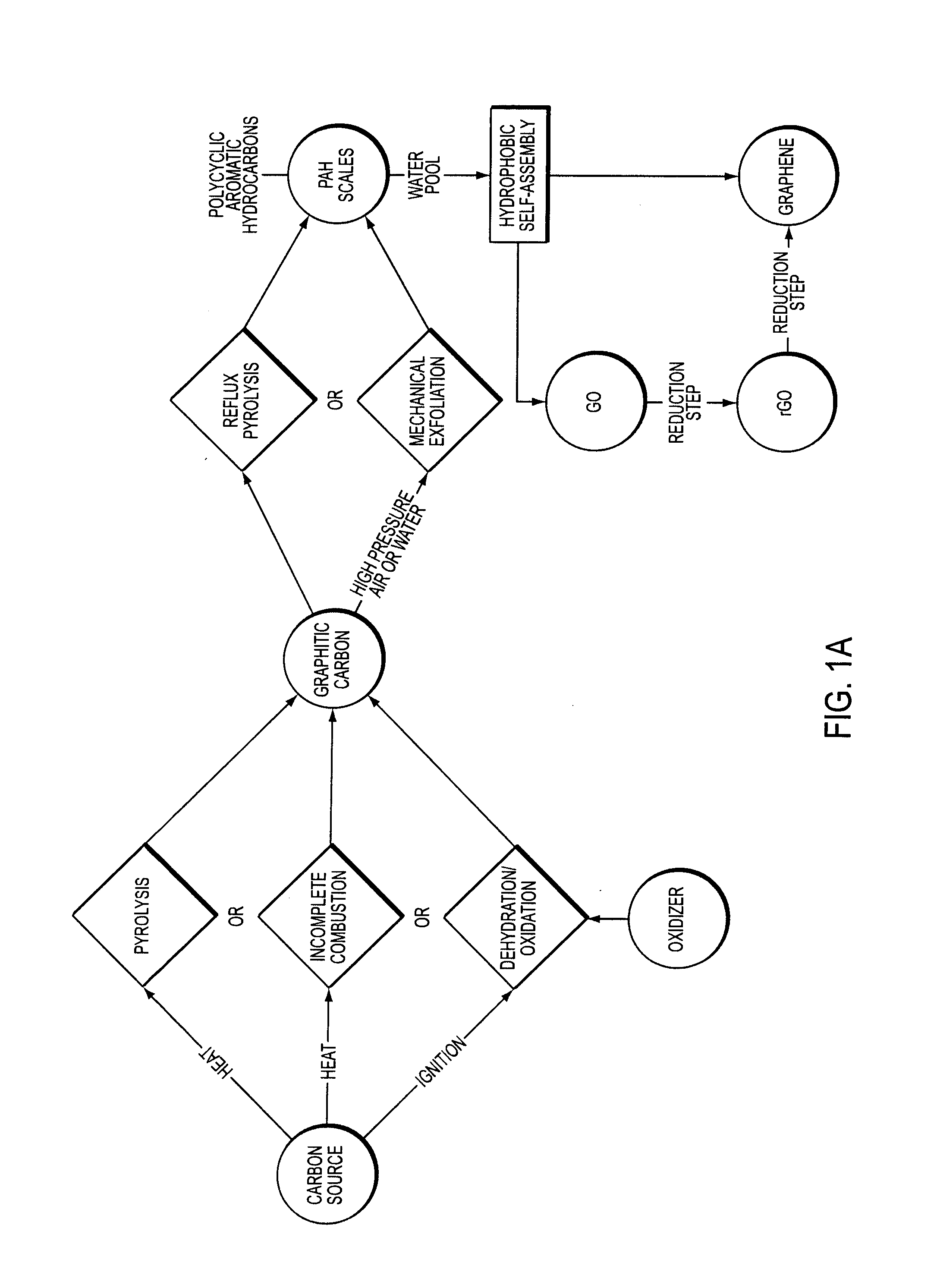

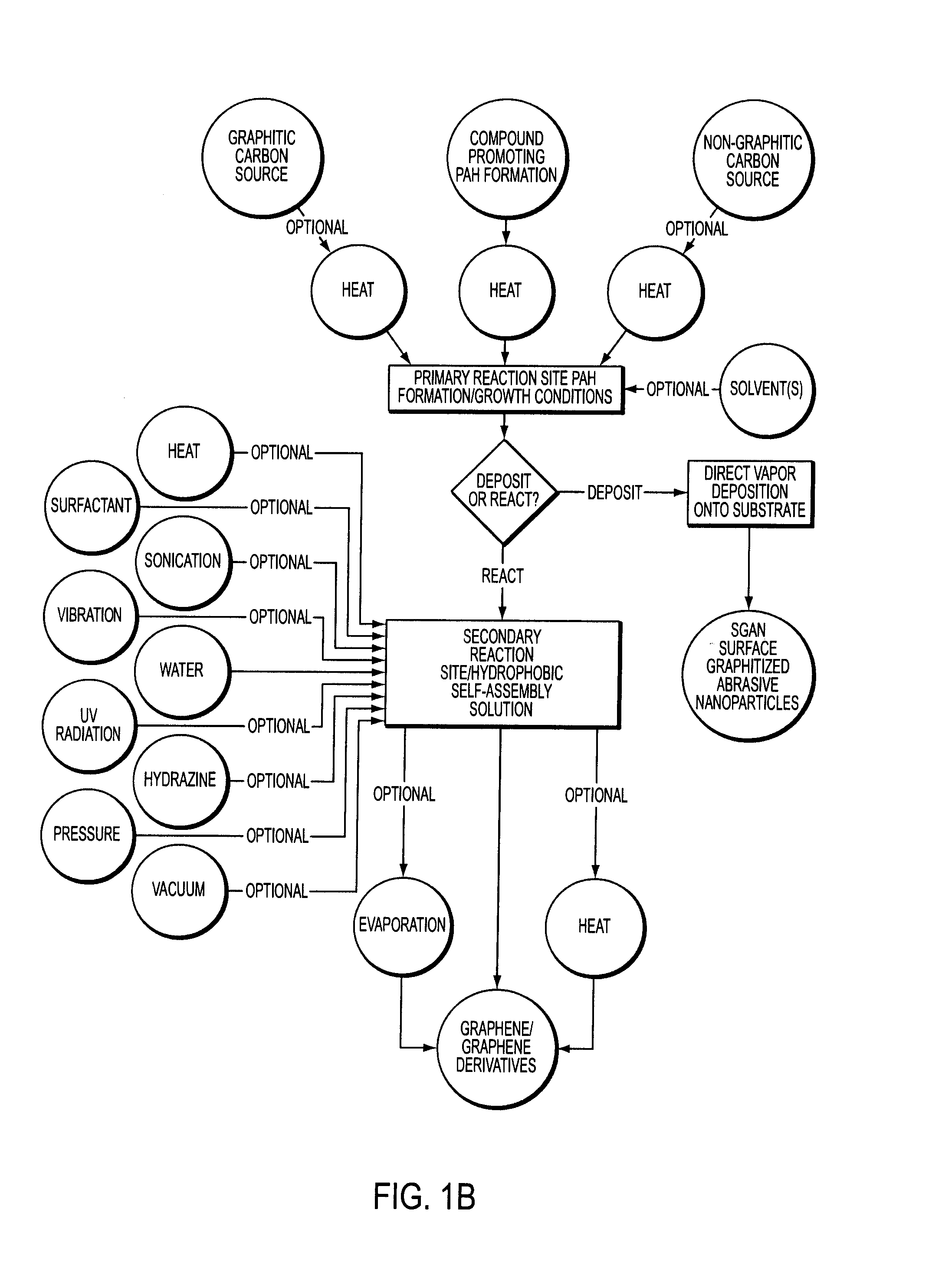

Facile synthesis of graphene, graphene derivatives and abrasive nanoparticles and their various uses, including as tribologically-beneficial lubricant additives

ActiveUS20140134092A1Reduce frictionImprove smoothnessMaterial nanotechnologyCosmetic preparationsNanoparticleGraphene derivatives

Owner:PEERLESS WORLDWIDE

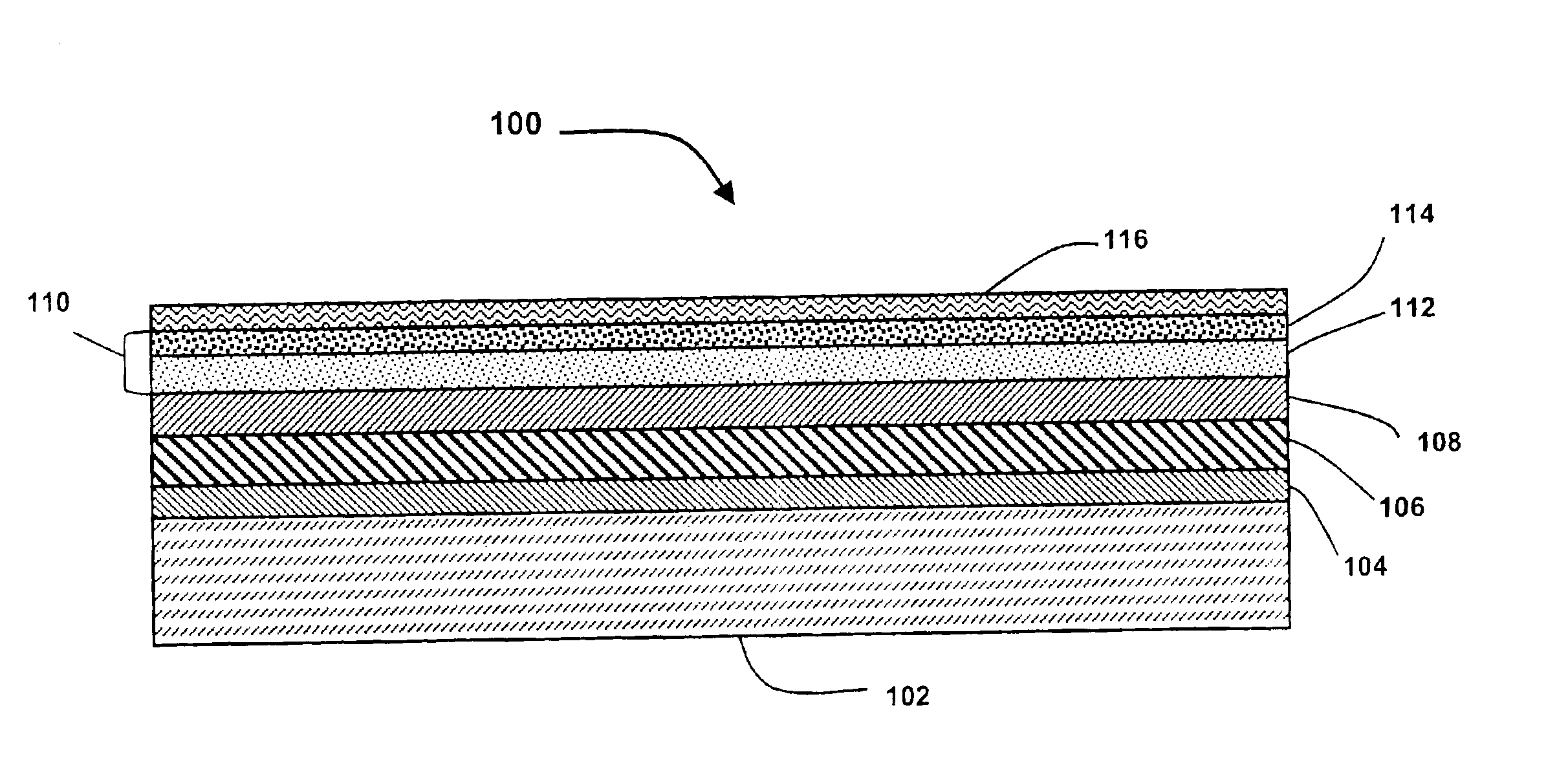

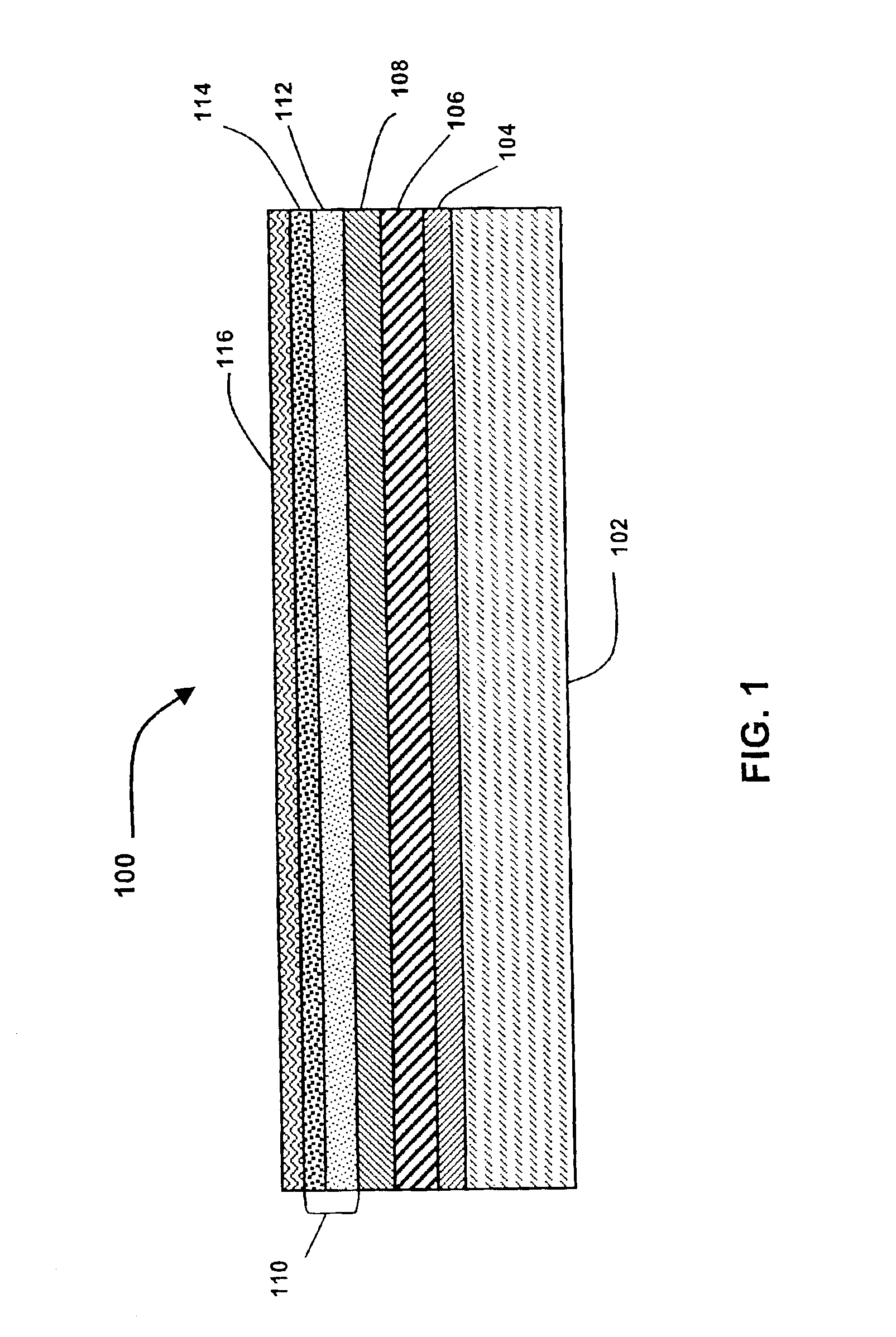

Carbon overcoat for magnetic recording medium

InactiveUS6875492B1Thin carbon overcoatImprove tribological propertiesProtective coatings for layersLayered productsRecording layerMaterials science

Magnetic recording media having a protective carbon overcoat adapted to protect the magnetic recording layer from surface contact events and corrosion. The carbon overcoat includes at least two layers. A first layer is adapted to protect the magnetic recording layer from surface contact events and corrosion. The second layer is disposed on the first layer and is adapted to enhance the bonding of a lubricant to the carbon overcoat and to minimize head degradation. The magnetic recording media of the present invention advantageously enables the use of thin carbon overcoats, enhancing areal density, while maintaining good tribological properties.

Owner:MAXTOR

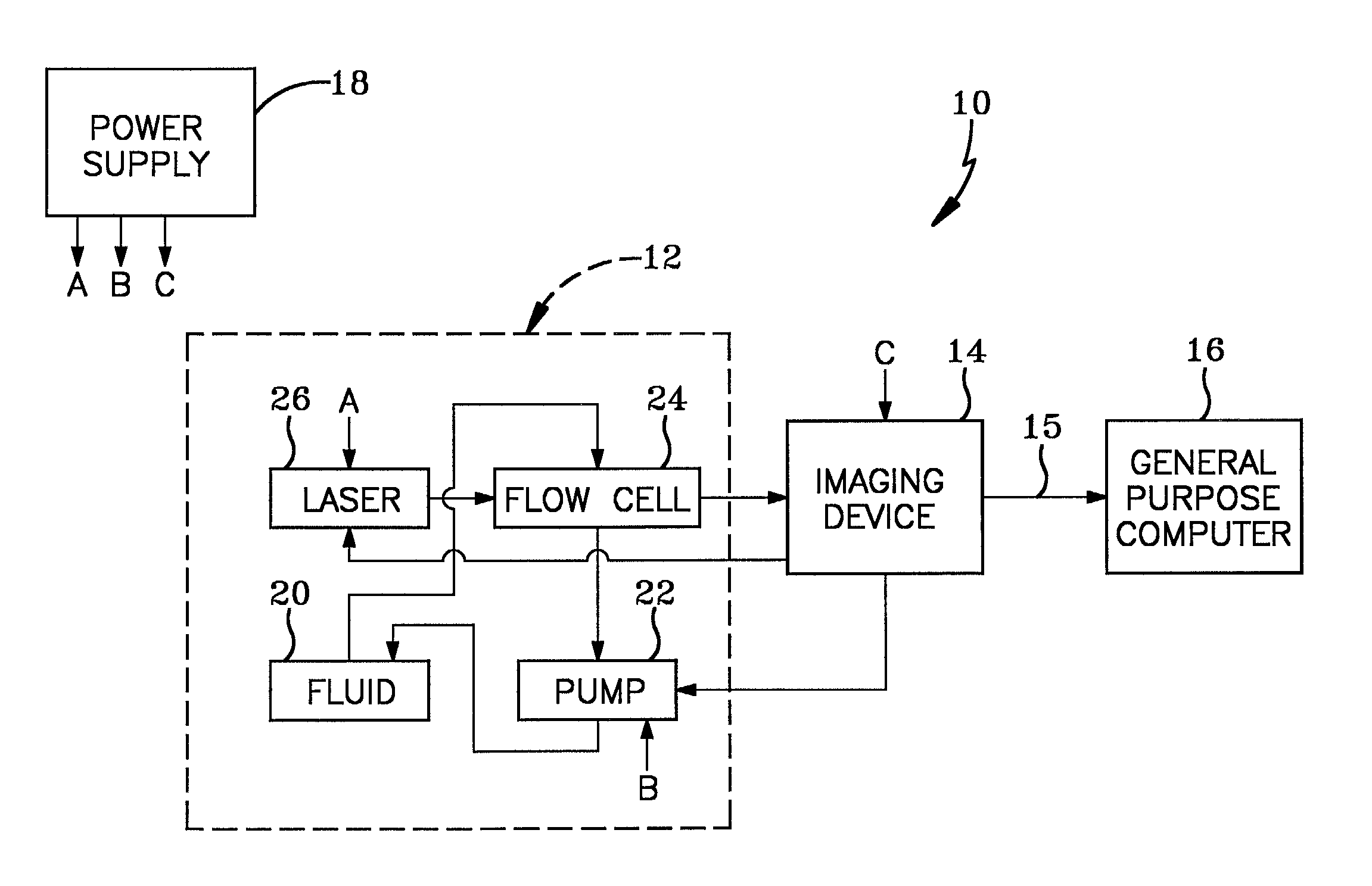

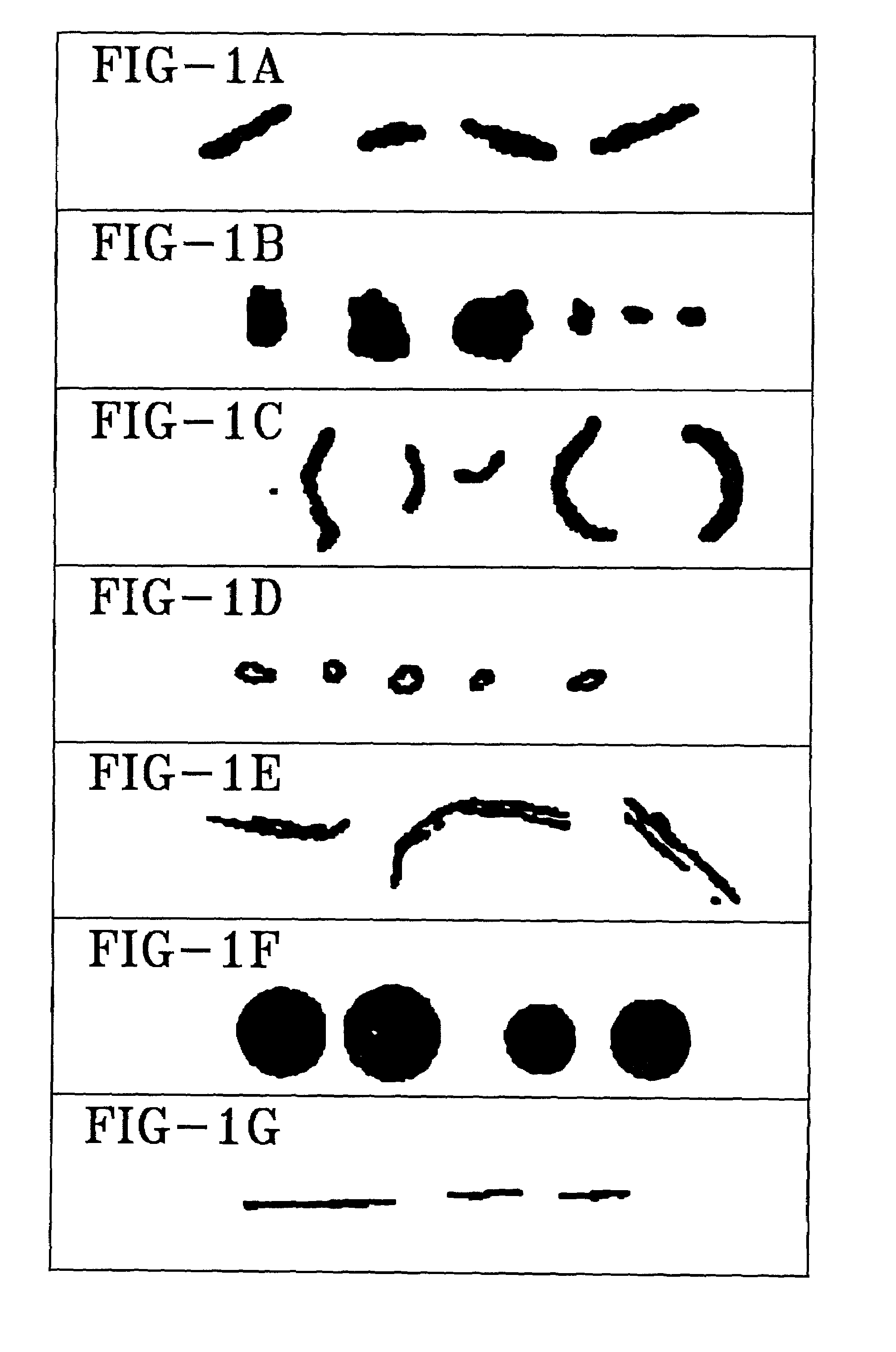

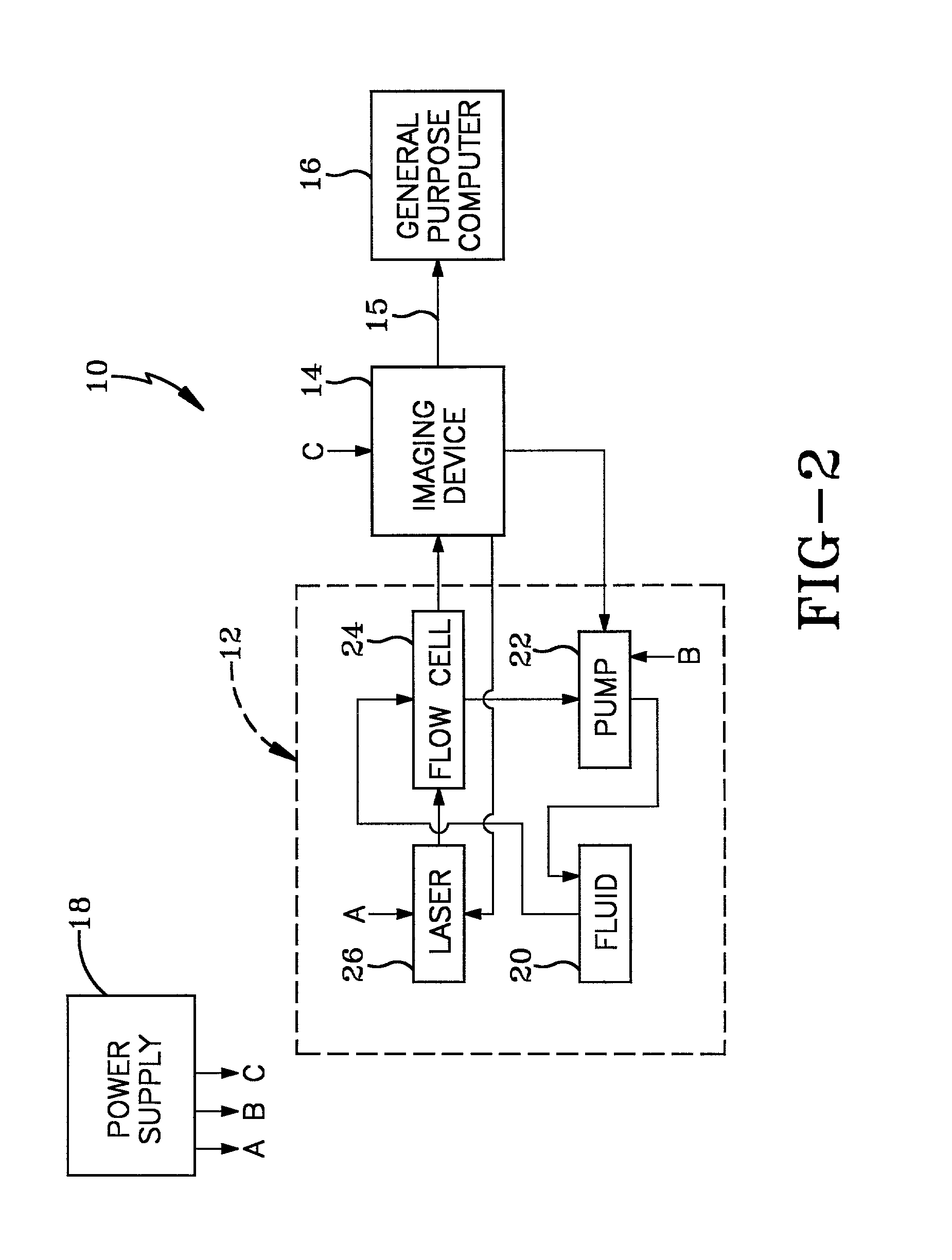

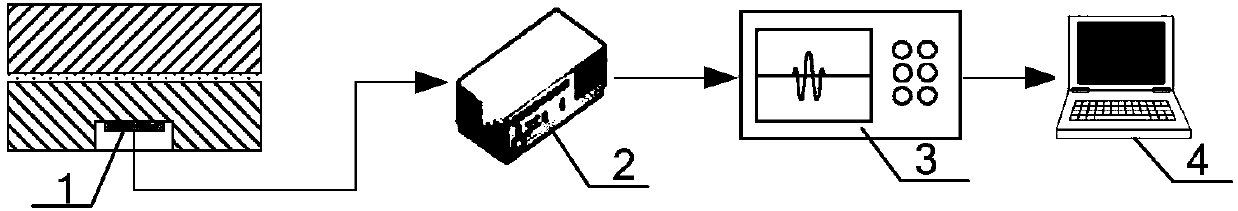

Tribological debris analysis system

InactiveUS7019834B2Character and pattern recognitionParticle size analysisGeneral purpose computerOptical flow

A tribological debris analysis system includes a general purpose computer; and a tribological sensor system for generating data. The sensor system includes an optical flow cell a pump for pumping a fluid through the optical flow cell, a laser for illuminating the fluid flowing through the optical flow cell, and an imaging device for detecting any debris in the fluid illuminated by the laser. The imaging device sends the object information—in either the form of object elements or objection segments—representative of the debris to the general purpose computer for analysis. The general purpose computer classifies the debris according to size, any trends associated with the size of the debris, generating shape features of the imaged debris and identifying a type of object wear based upon the shape features.

Owner:LOCKHEED MARTIN CORP

High silicon gradient composite aluminum alloy cylinder sleeve material and preparation method thereof

InactiveCN101709414AImprove mechanical propertiesImprove tribological propertiesDie castingMechanical property

The invention discloses a high silicon gradient composite aluminum alloy cylinder sleeve material and a preparation method thereof. The material comprises the following components in percentage by weight: 13.0-27.0 percent of Si, 0.3-2.0 percent of Fe, 0.5-5 percent of Ni, 1.5-4.0 percent of Cu, 0.3-0.8 percent of Mg, 0.3-0.8 percent of Mn, 0.1-0.5 percent of V, 0.05-0.1 percent of Sr, 0.04-0.1 percent of RE, 0.01-0.1 percent of P and the balance of Al. The preparation method comprises the following steps of: carrying out composition design and accurate batching on the materials with preliminary alloys; fusing, covering, refining and inoculation treating; centrifugal casting for forming; thermal treating; and machining and hone machining. The invention is characterized in that a gradient tribology function composite material is obtained by adopting a Sr-P-RE ternary composite modification treatment technology and a centrifugal casting technology controlled by a variable frequency motor, the preparation cost is lower than that of spray deposition technology and a powder metallurgic technology, and the mechanical property and the tribology property of a product is more advantageous than that of the product prepared by a die casting technology; moreover, the prepared cylinder sleeve has more advantageous processing quality and usage effect, and has the advantage of good compatibility with a piston aluminum alloy auxiliary cylinder.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

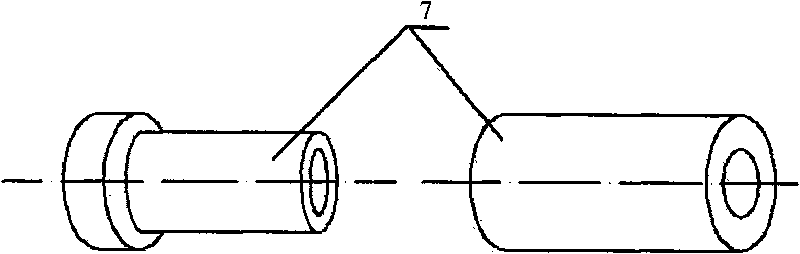

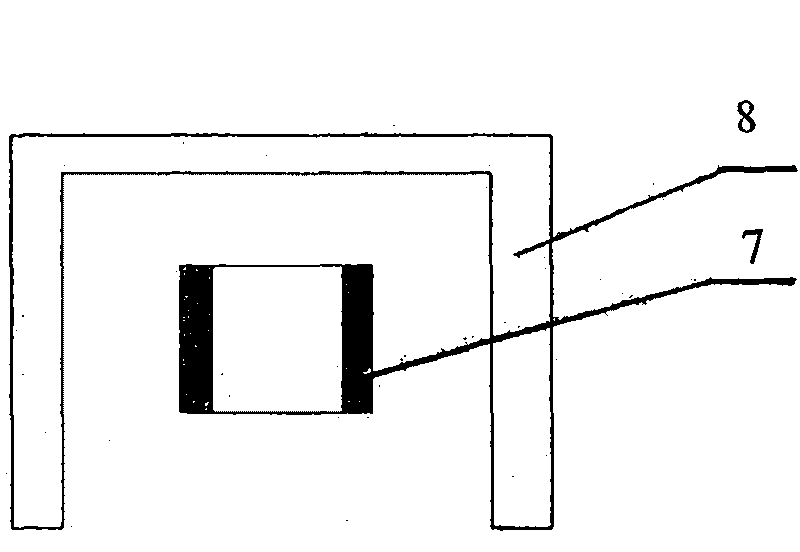

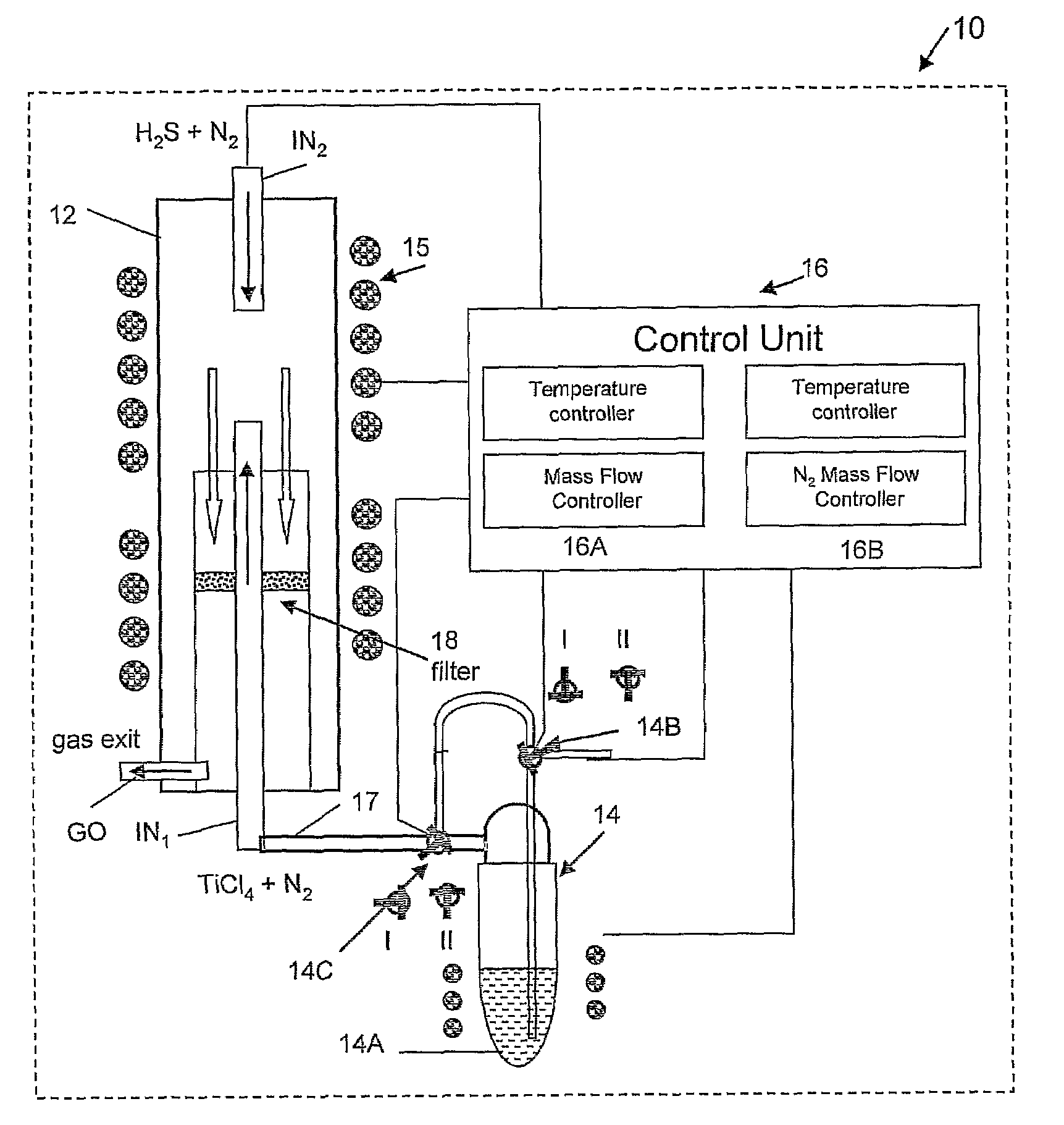

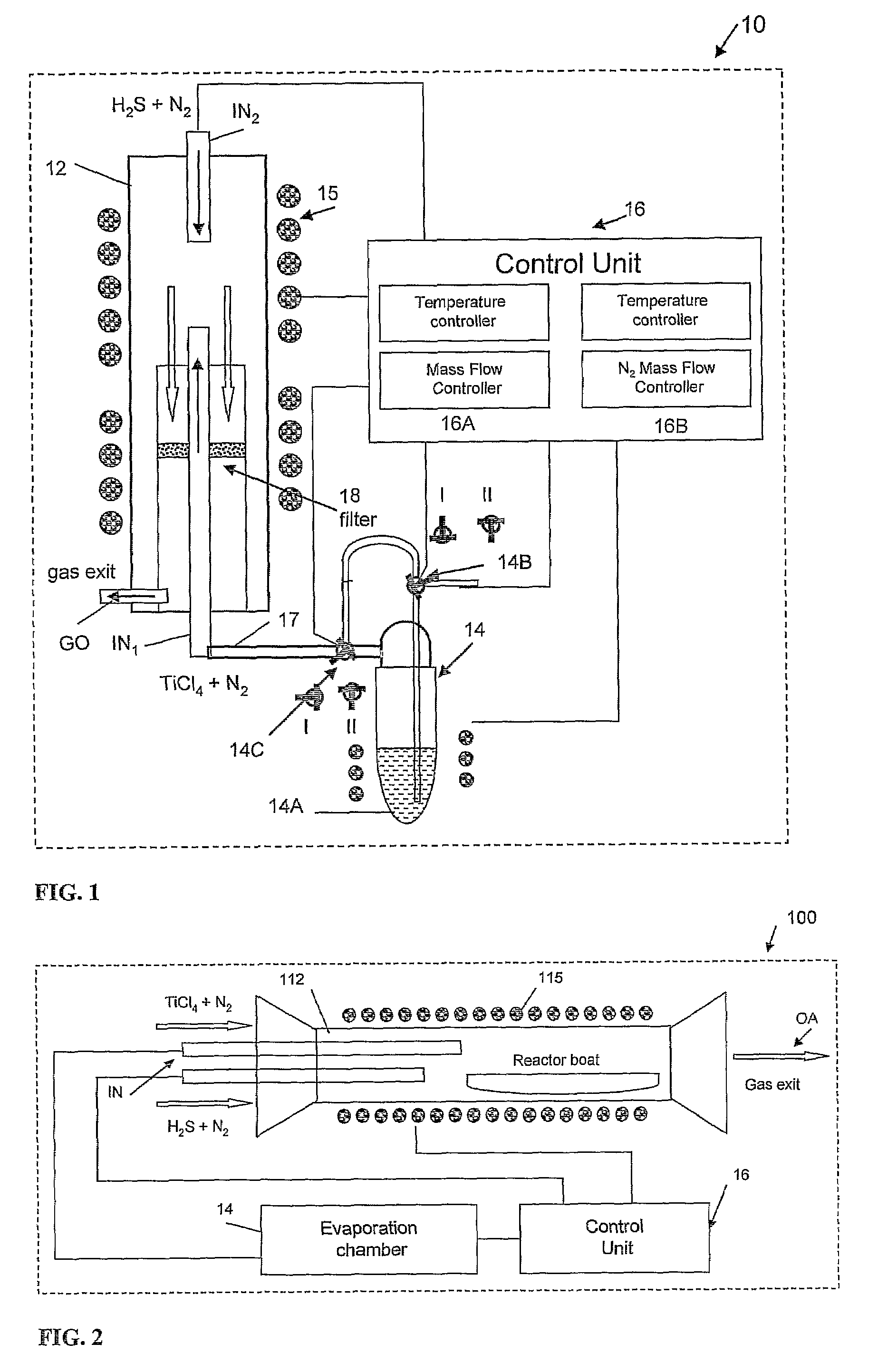

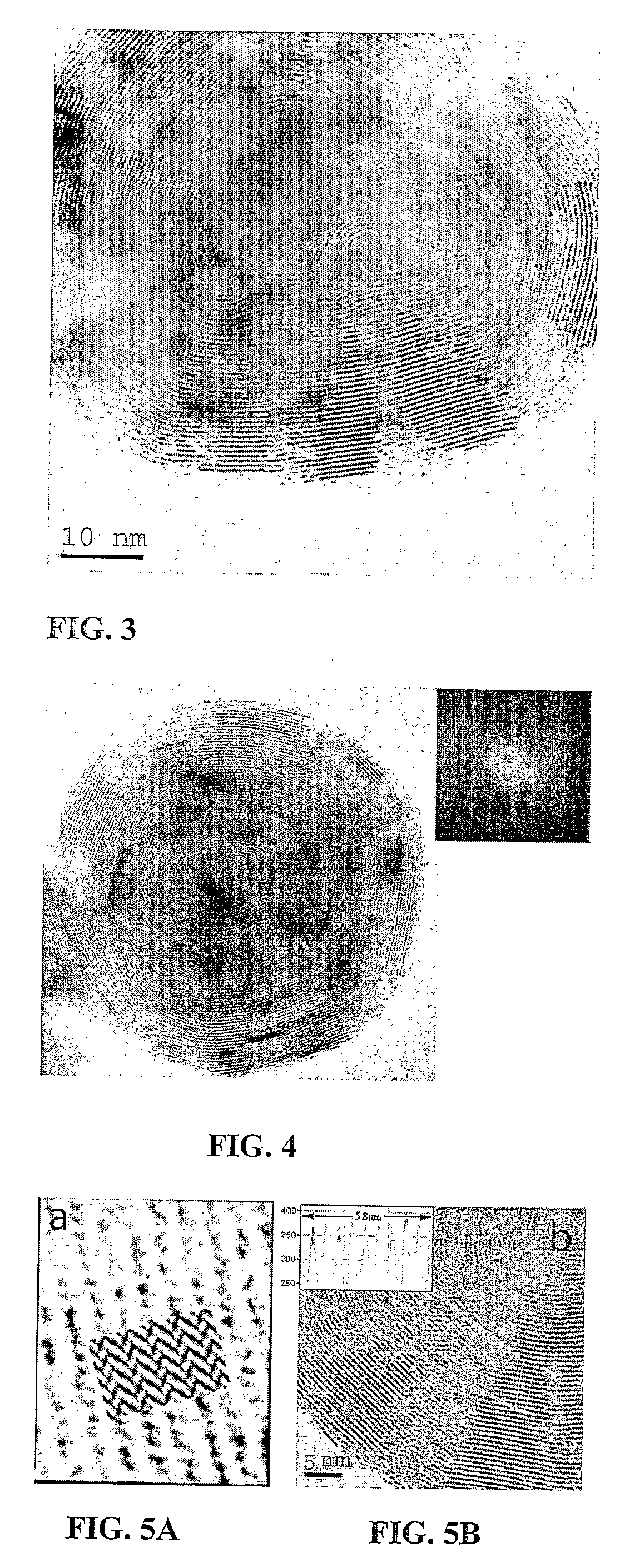

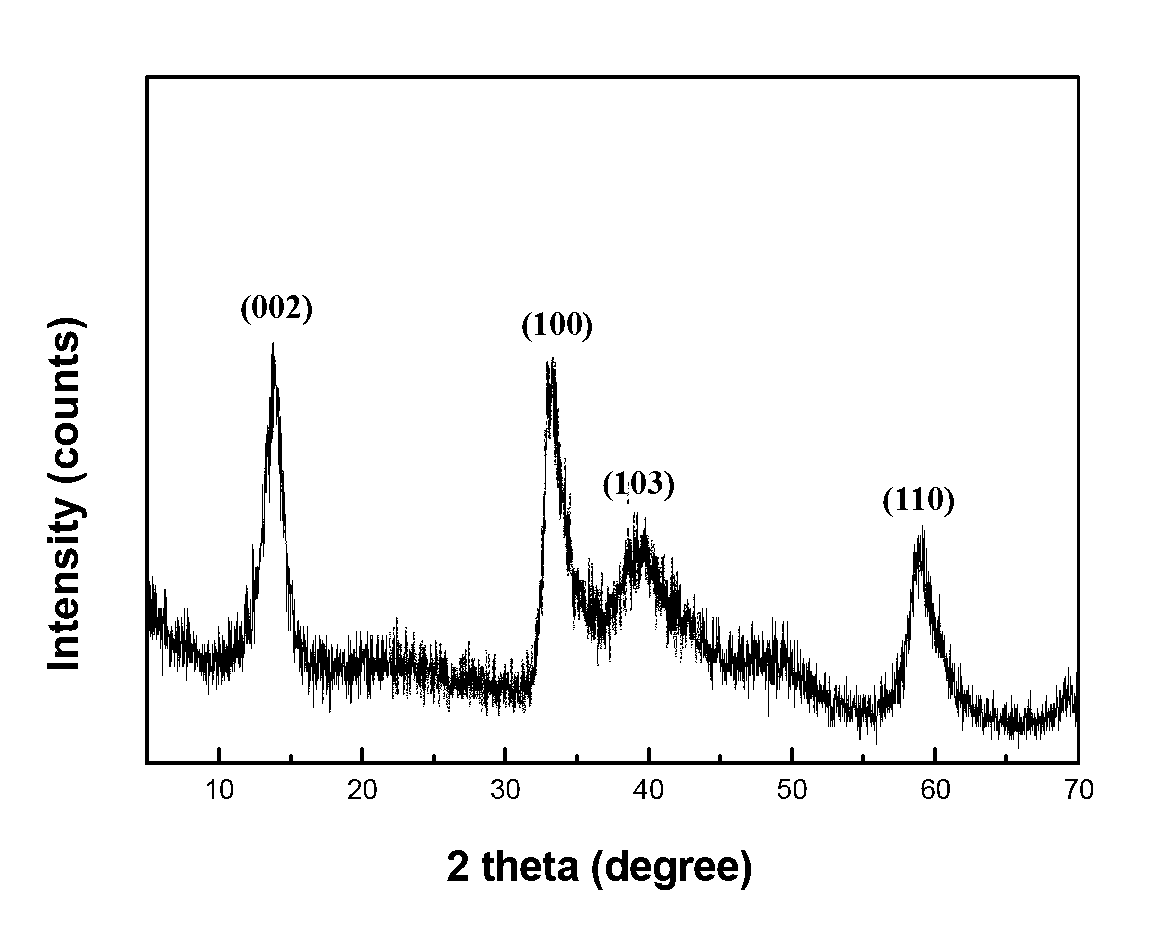

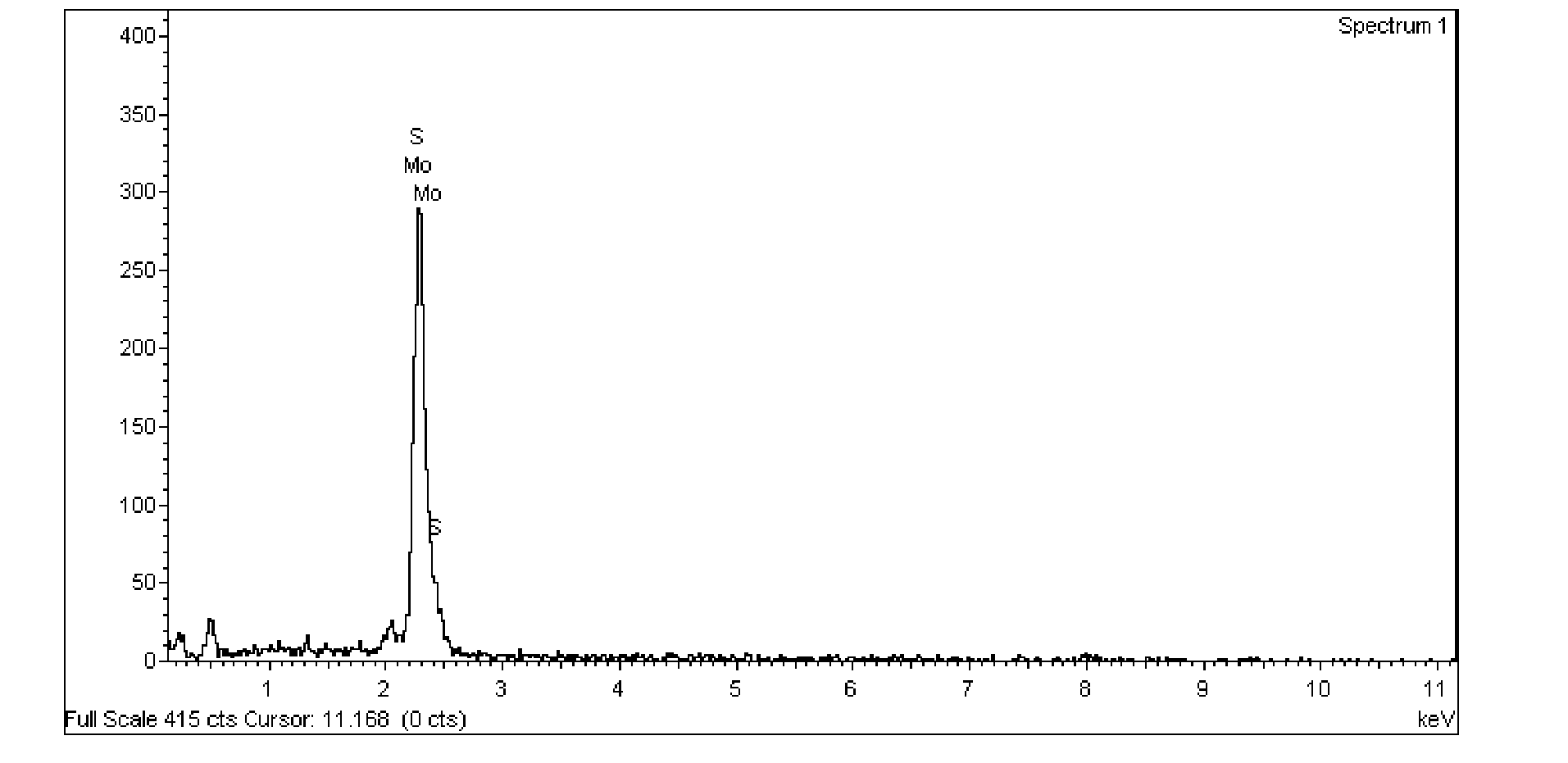

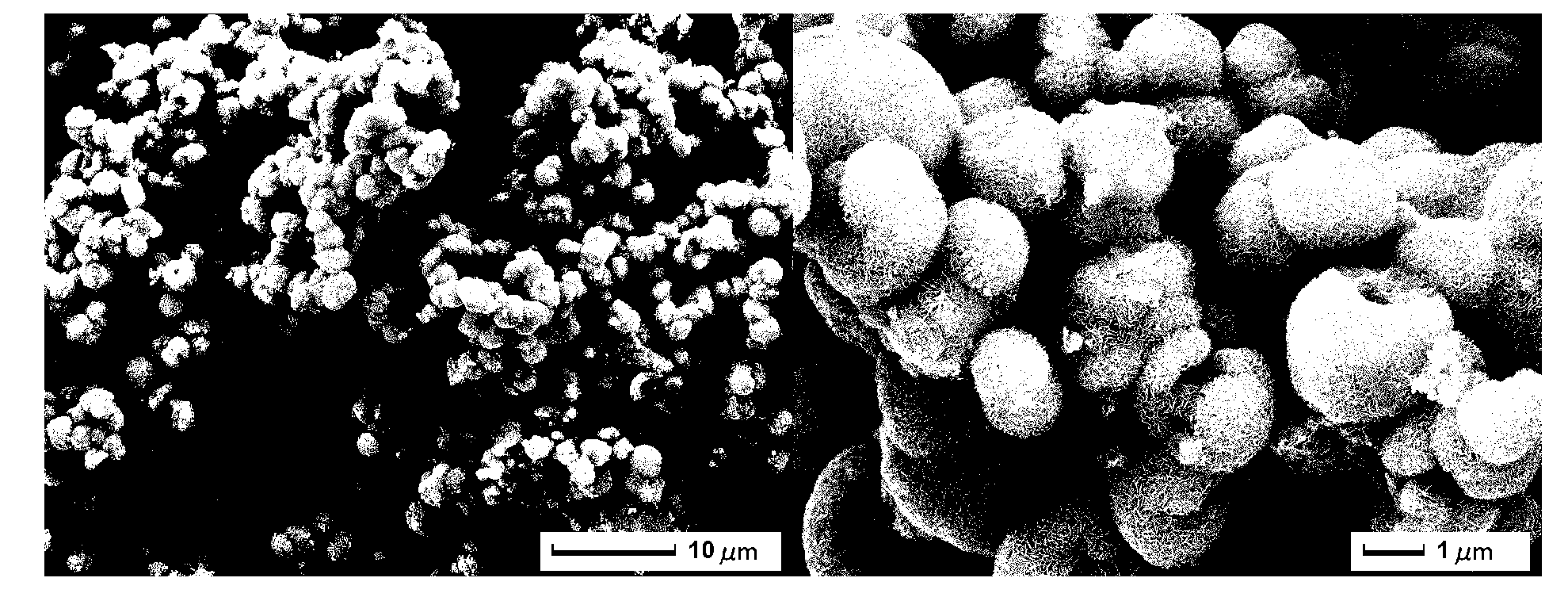

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

Preparation method of flower-shaped hollow molybdenum disulfide microspheres

InactiveCN102701281ASimple processLow costNanotechnologyMolybdenum sulfidesMaterials preparationMicrosphere

The invention relates to a preparation method of flower-shaped hollow molybdenum disulfide microspheres, belonging to the technical field of nanometer material preparation. The method provided by the invention comprises the following steps of: (1) solution preparation: dissolving (NH4)2MoO4, CS(NH2)2, NH2OH.HCl and a surfactant into water, dissolving to obtain the solution, and then adjusting the pH value to 5-6.5 by acid; (2) agitating the solution obtained in step (1), and then transferring to a reaction kettle, sealing and reacting at a constant temperature, and then cooling to the room temperature to obtain the reaction product; (3) separating the reaction product, washing and drying to obtain the flower-shaped hollow molybdenum disulfide microspheres. The shape of the flower-shaped hollow molybdenum disulfide microspheres prepared by the method provided by the invention is controllable. The method provided by the invention is simple in process and low in cost; the prepared product is high in purity and high in yield, has an important application in the field of tribology and photochemistry, and is expected to be applied to large-scale industrial production.

Owner:无锡润鹏复合新材料有限公司

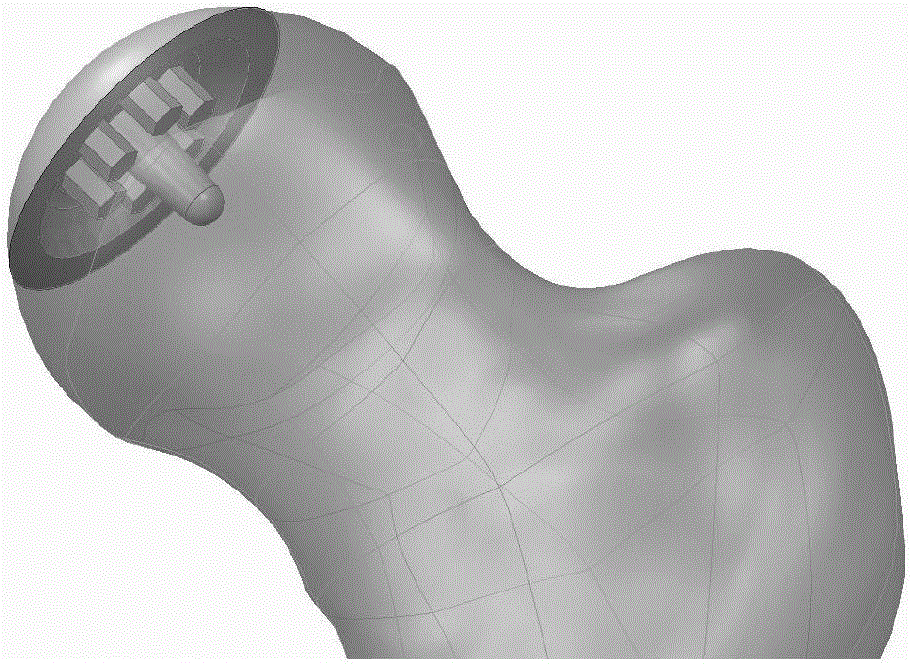

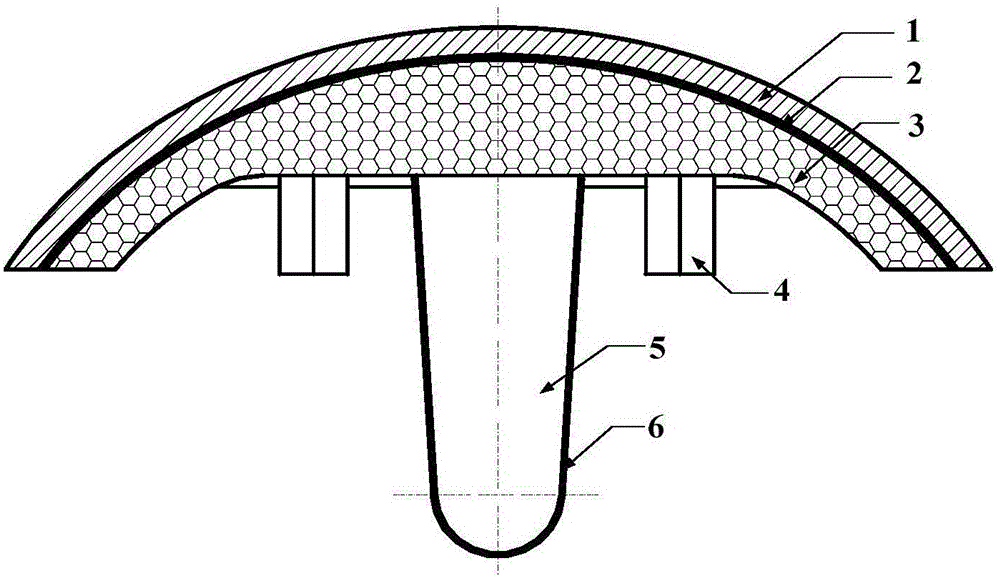

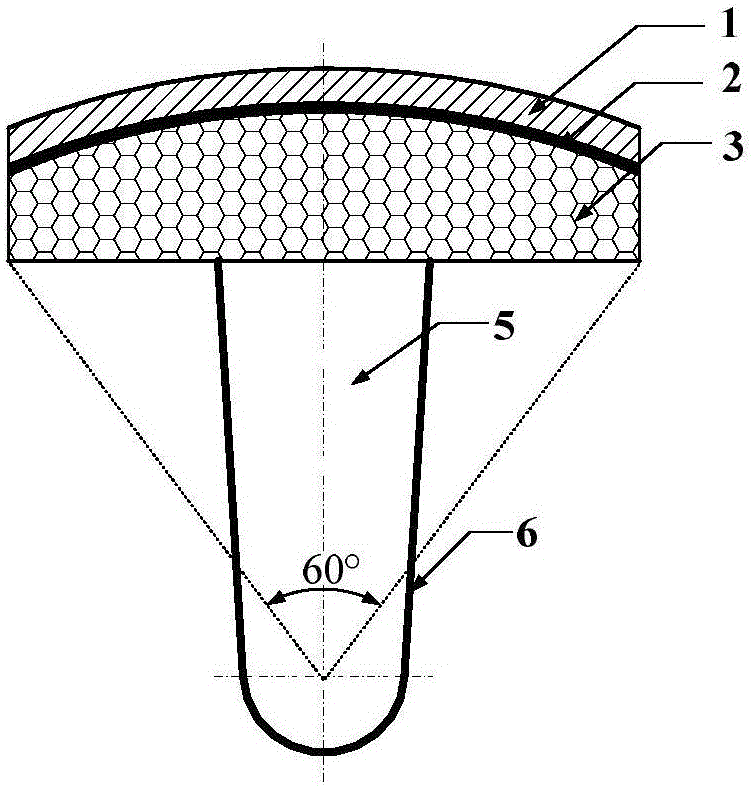

Biomimetic artificial hip joint with internal growth function

ActiveCN105105875AImprove tribological propertiesImprove fault toleranceJoint implantsHip jointsArticular surfacesBiomechanics

The invention discloses a biomimetic artificial hip joint with an internal growth function. The joint is composed of an artificial cartilage layer, an interface bonding layer and a porous bracket, wherein the artificial cartilage layer and the porous bracket have elliptic surfaces; the surface wrapping angle of the joint is 60-120 degrees; when the wrapping angle is 80-120 degrees, 3-6 convex columnar bodies, which are uniformly distributed, are designed on the inner surface of a prosthesis along the peripheral direction; a porous coating with biological activity is prepared on the outer surface of a femoral component and materials of the coating have gradient changes from inside to outside; the porous bracket is designed into a porous structure with gradient according to a finite element optimization result, and the pore diameter is 300-800 microns; the porosity is 20%-85%. According to the biomimetic artificial hip joint disclosed by the invention, bone mass and biomechanical characteristics of thigh bones can be kept to the greatest extent; the biomimetic artificial hip joint has good mechanical properties and tribological properties; the growth of bone cells is induced or promoted so as to guarantee effective interface bonding intensity between a prosthesis implantation material and a natural bone, the stability of the planted prosthesis is improved and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV

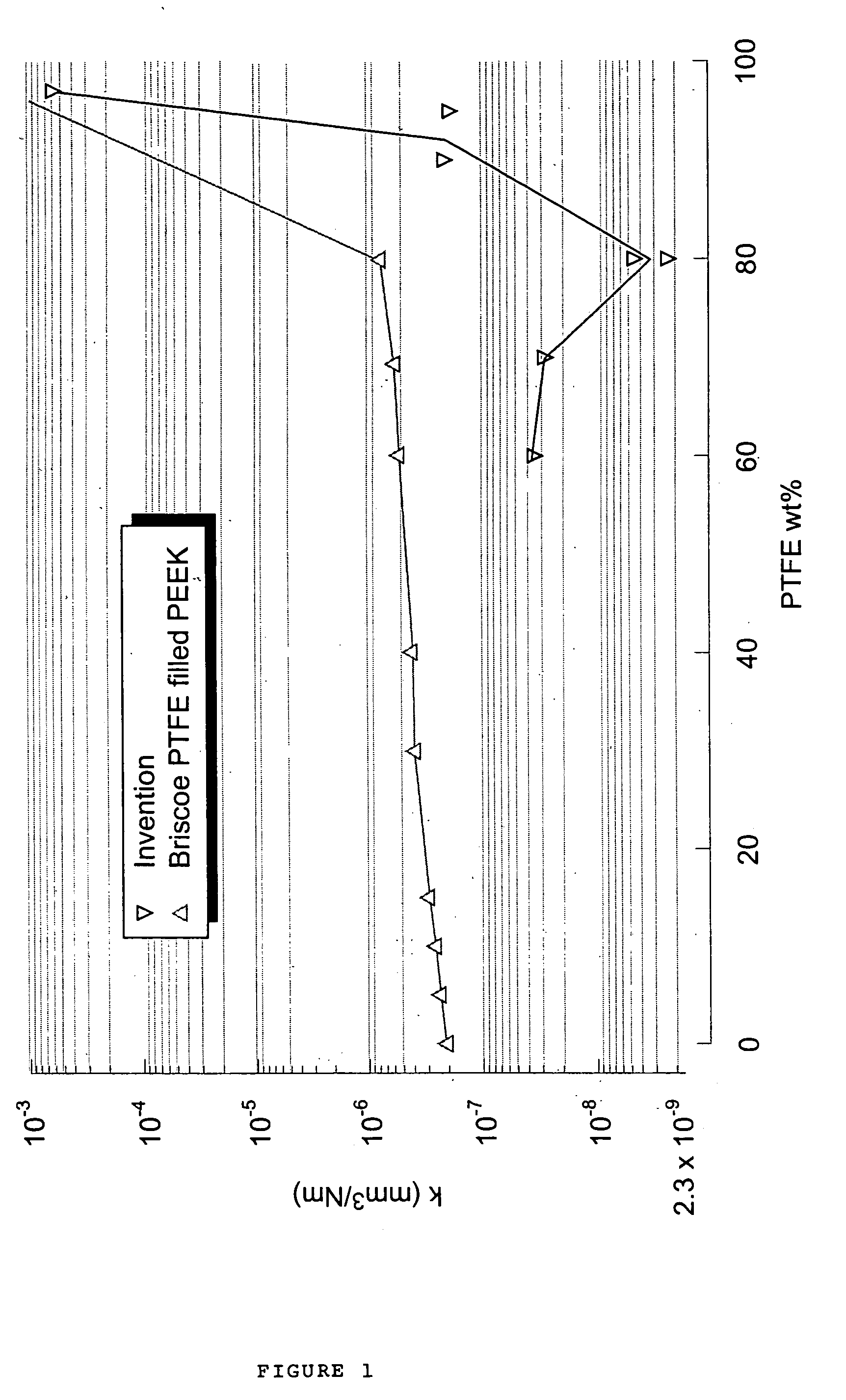

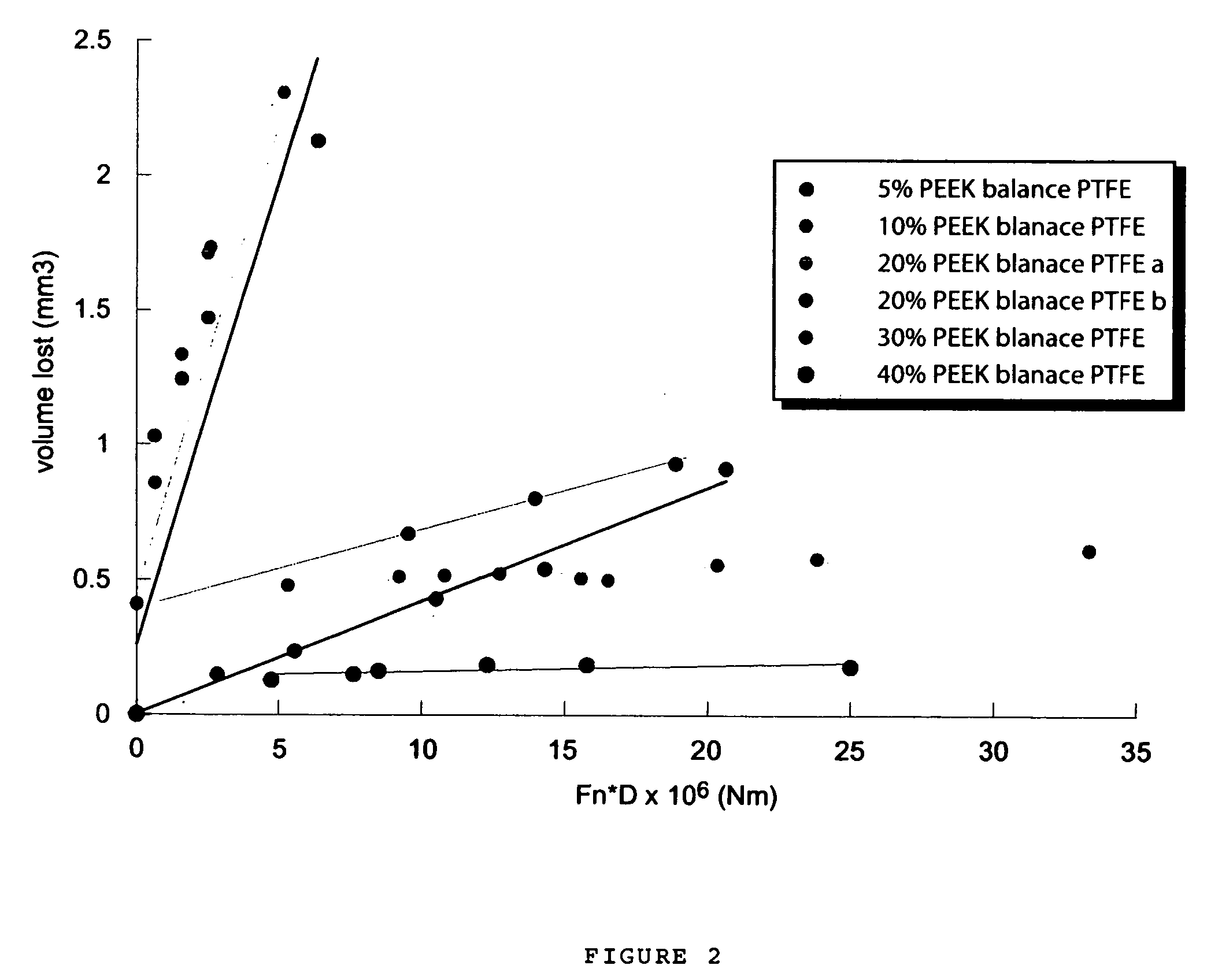

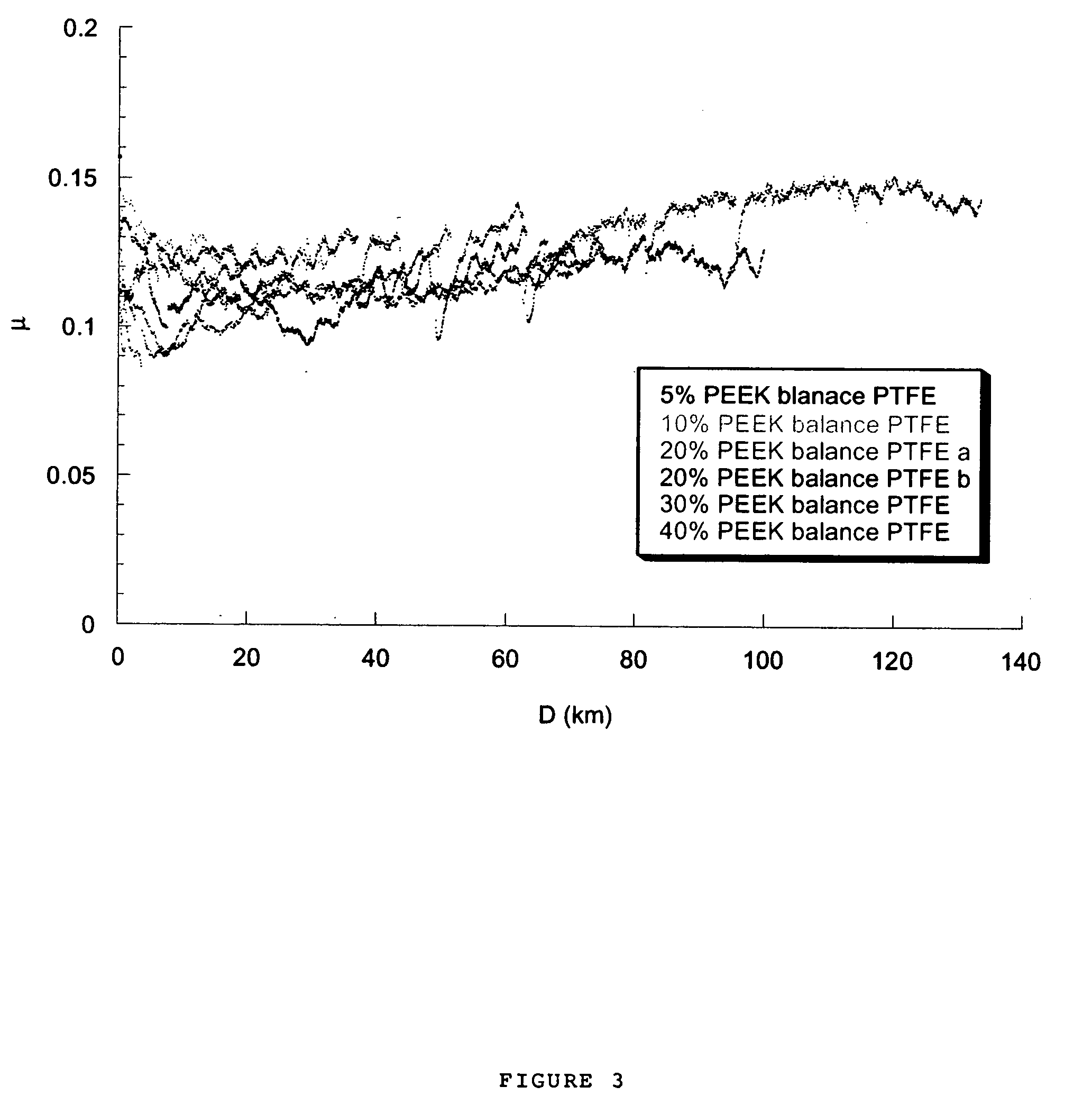

Low friction and low wear polymer/polymer composites

InactiveUS20060030681A1Improve tribological propertiesReduce wearCoatingsSpecial surfacesPolymer sciencePolyether ether ketone

A composite material having superior tribological properties includes a first polymer being a transfer film forming polymer and a second polymer mixed with the first polymer. The first polymer is at least 10 weight % of the composite and the composite provides a wear rate of <10−7 mm3 / Nm and an average friction coefficient of said composite no more than 0.15. The first polymer can be PTFE and the second polymer a polyaryletherketone (PEEK). A method of forming composites includes the steps of providing a plurality of transfer film forming polymer particles and second polymer particles, and molding or extruding the particles at a temperature sufficient to allow softening and mobilization of at least one of the transfer film forming polymer particles and the plurality of strengthening phase polymer particles to form an interconnected network, wherein the composite formed provides a wear rate of <10−7 mm3 / Nm.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

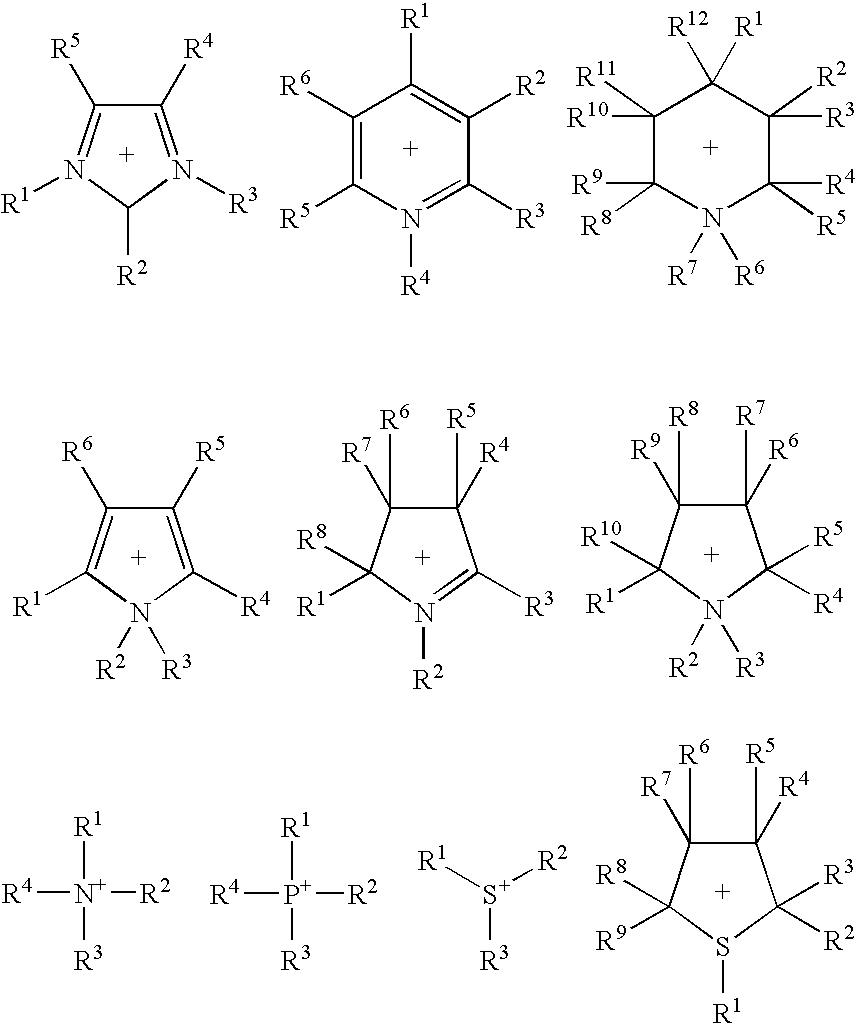

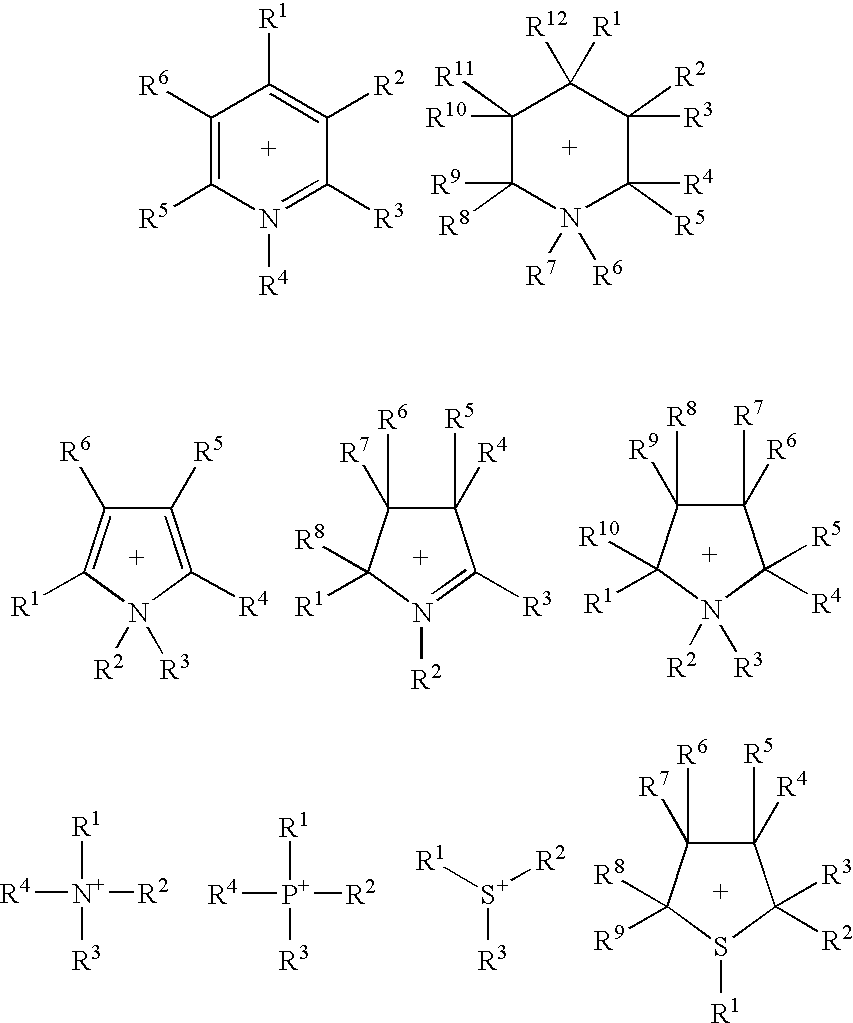

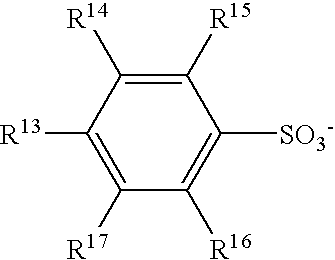

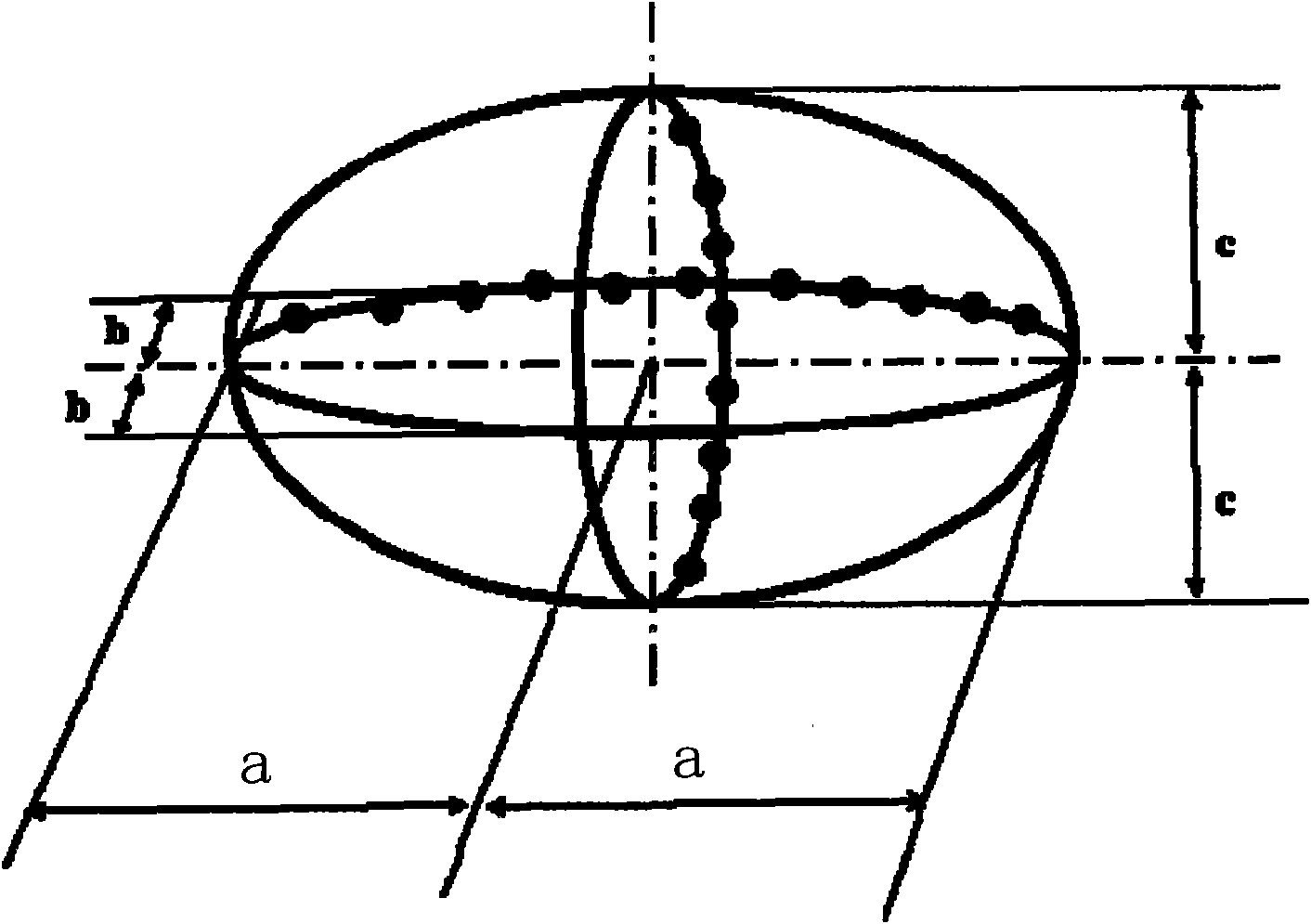

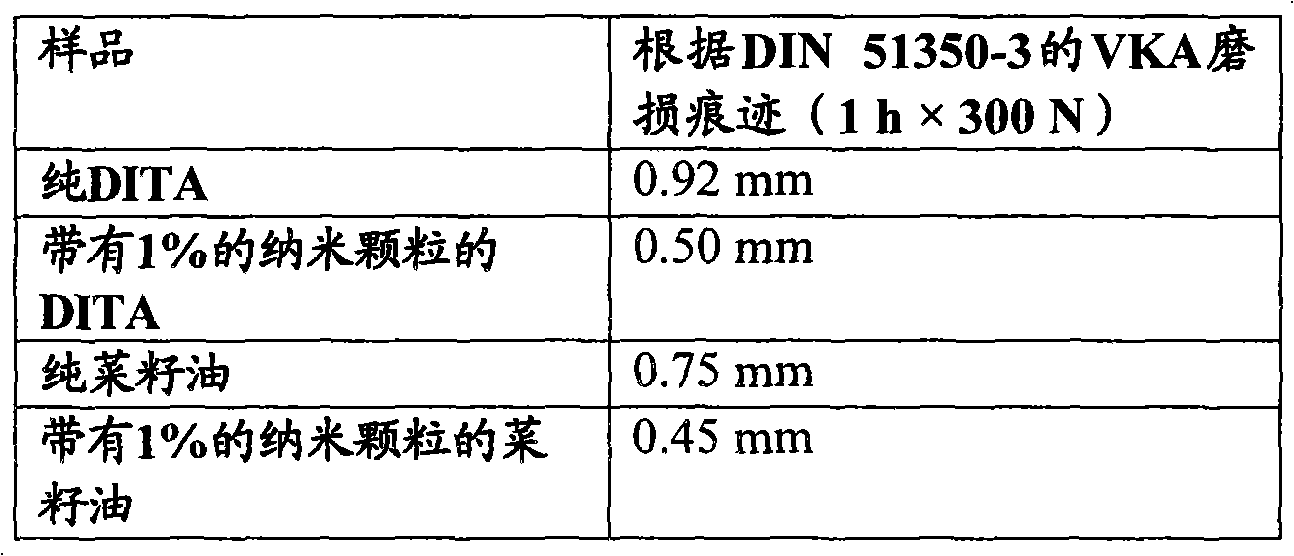

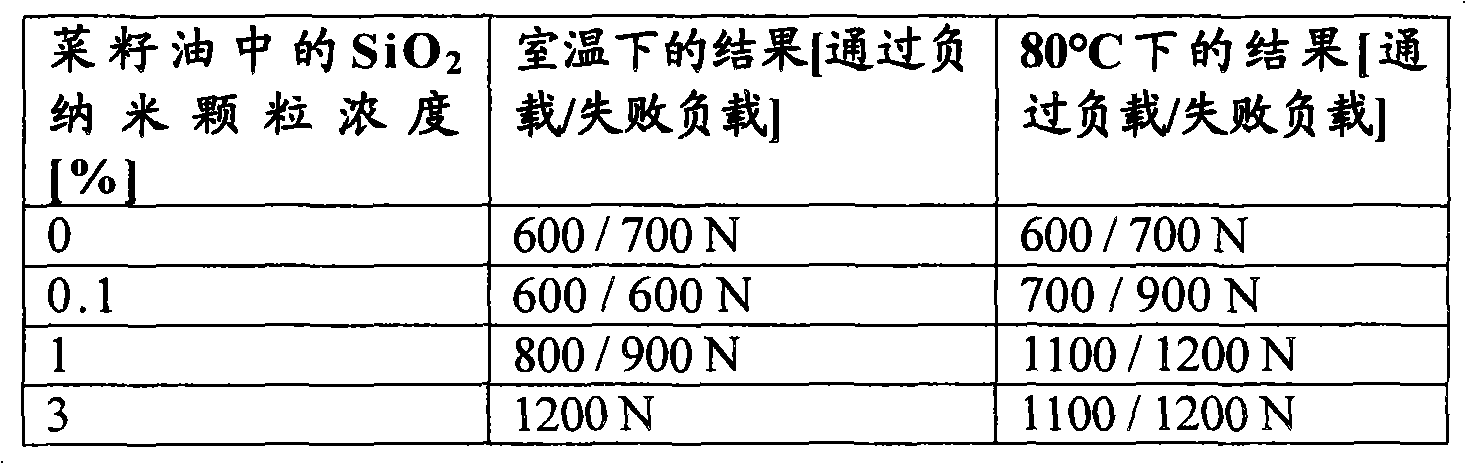

Additive for lubricant for improving the tribologic properties, a method for its production and application

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

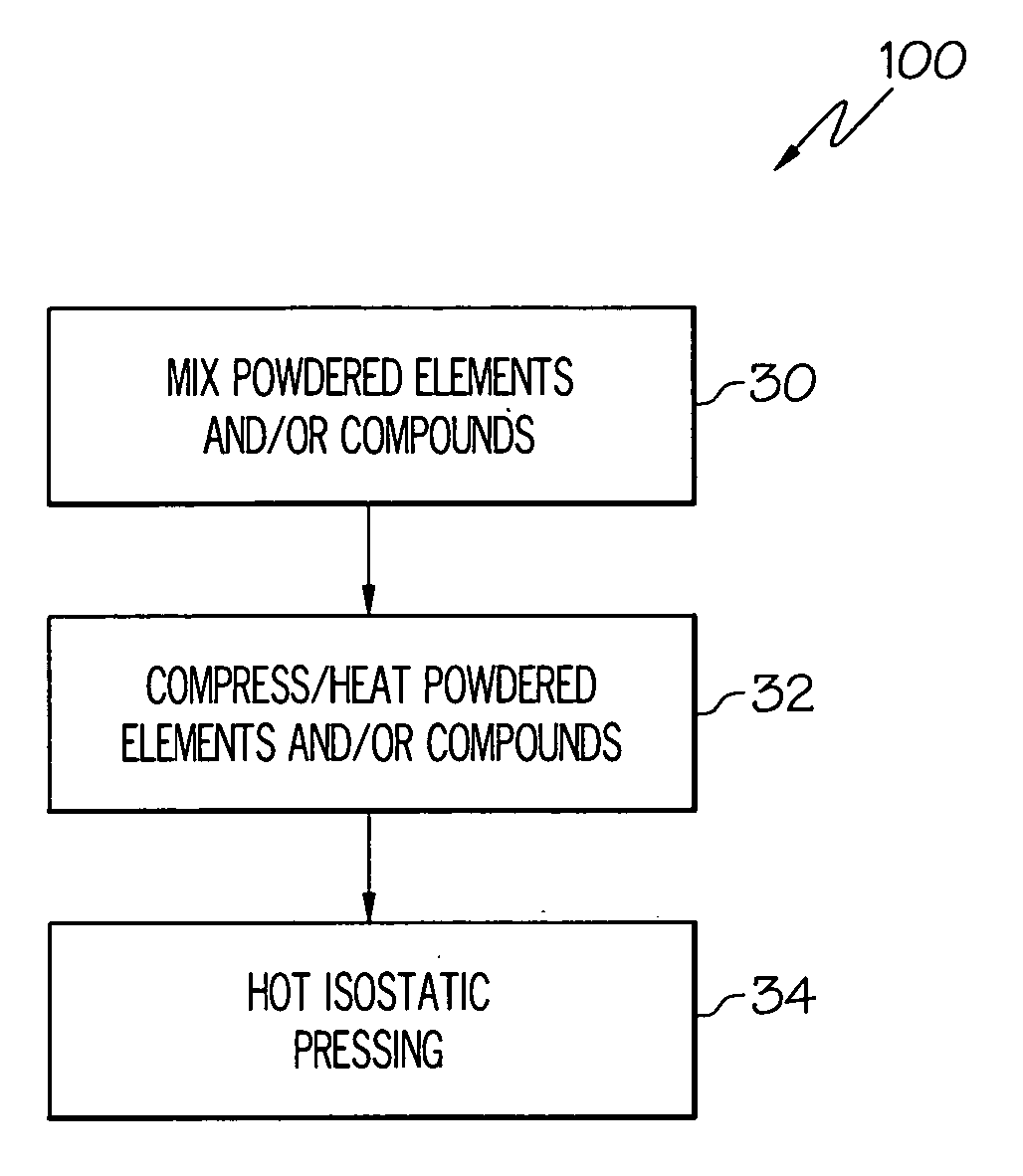

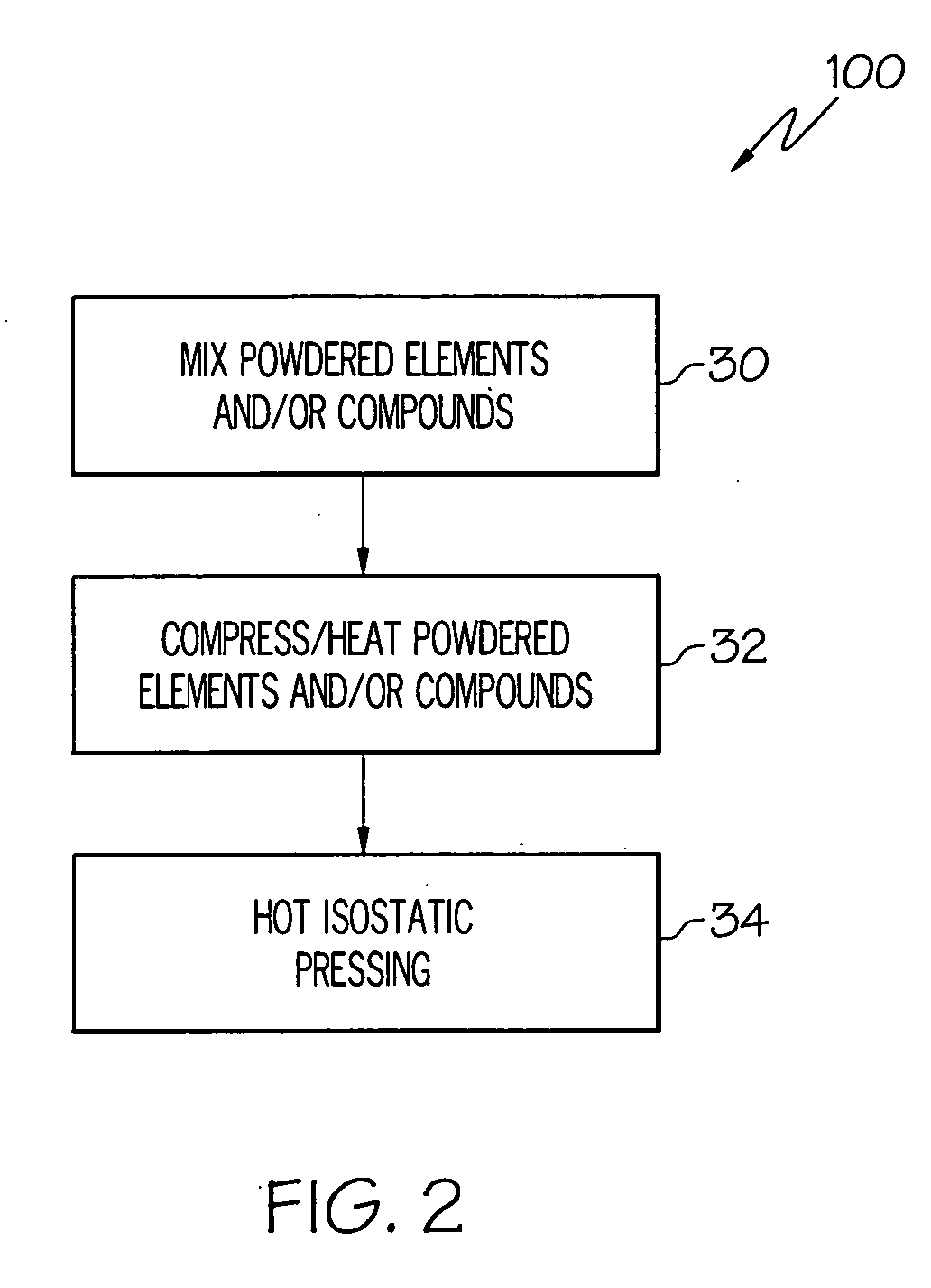

Ternary carbide and nitride materials having tribological applications and methods of making same

A turbomachinery component includes a substrate having a surface, the surface being a material consisting essentially of at least one compound having the chemical formula Mn+1AXn, wherein M is at least one early transition metal selected from groups IIIB, IVB, VB, and VIB, A is at least one element selected from groups IIIA, IVA, VA, VIA, and VIIA, X is one or both of carbon and nitrogen, and n is an integer between 1 and 3. The component is made by forming a compact and sintered substrate with the material, or by coating a substrate with the material.

Owner:DREXEL UNIV +1

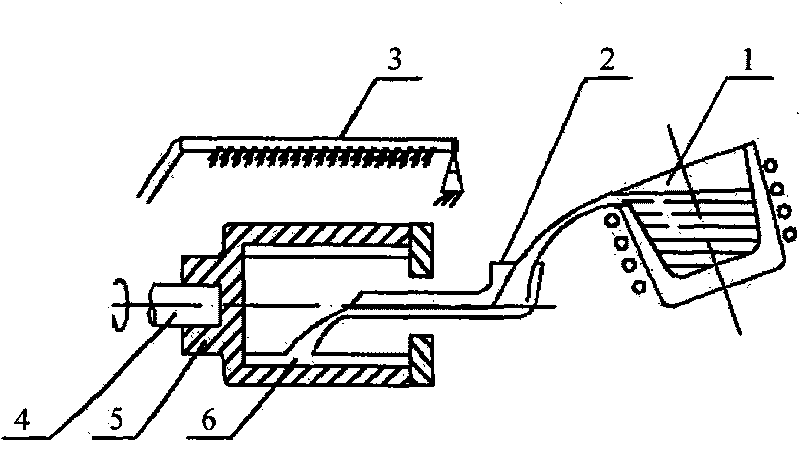

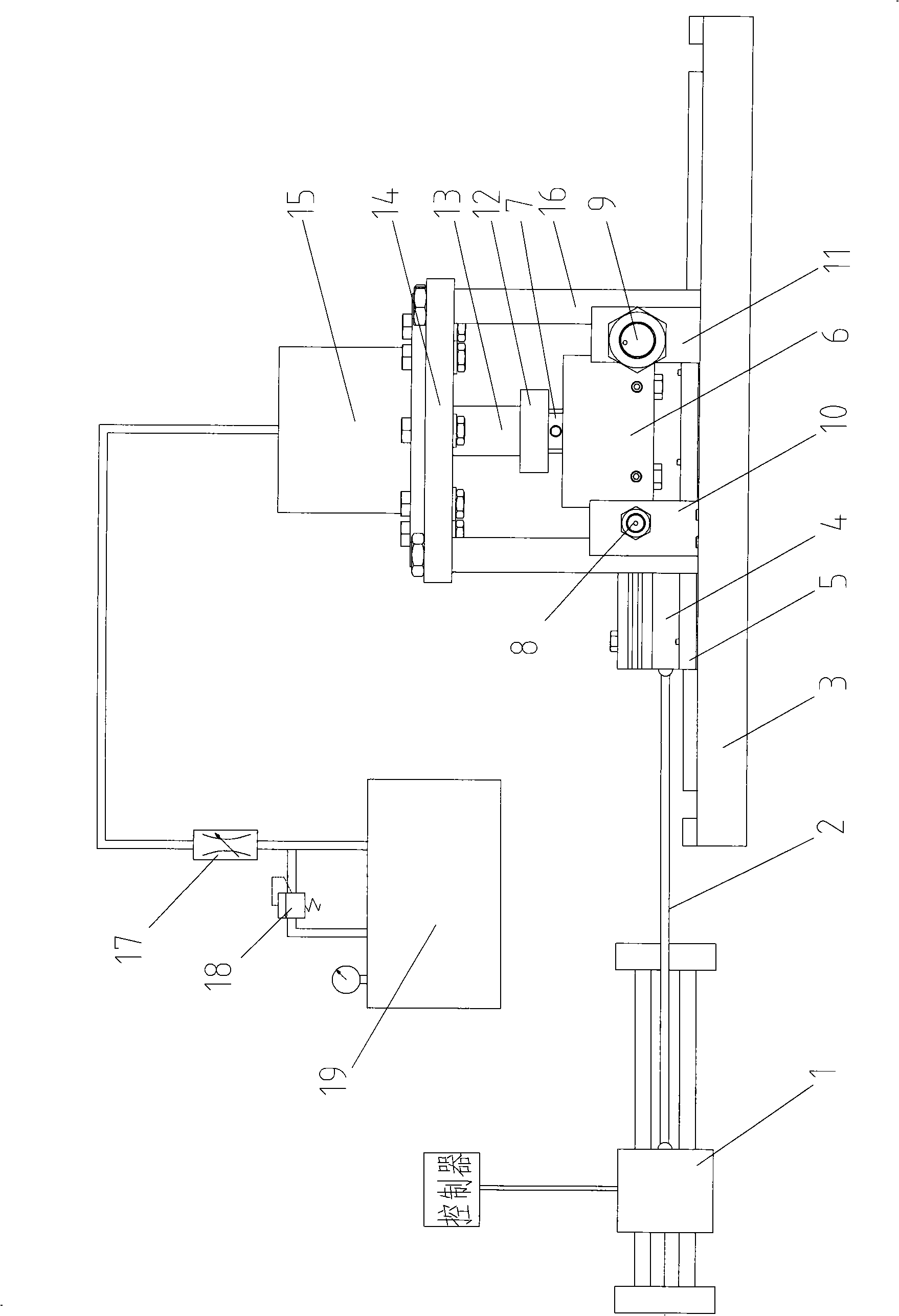

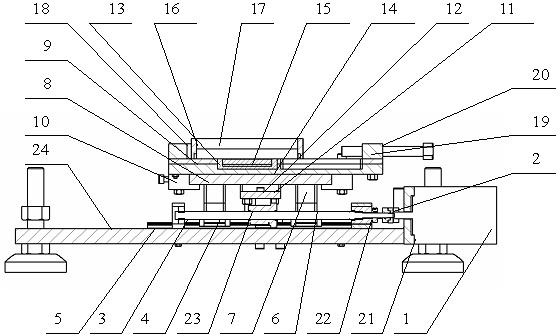

Machine tool guiding rail friction wear testing machine

InactiveCN101339112ABreakthrough the shortcoming of short lifeReduce coefficient of frictionMachine part testingInvestigating abrasion/wear resistanceWear testingEngineering

The invention provides a friction and wear testing machine of guide rail of machine tool and relates to a friction and wear testing device of guide rail pair, belonging to the technological field of tribology. The testing device comprises a testing system and a measuring system. An oil blocking plate in the testing system is provided with an upper sample platform, an oil blocking plate, a lower sample platform, a first sensor mounting bracket and a second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are respectively arranged on a base; a flat V guide rail is arranged between the lower sample platform and the base; an upper sample fixture is arranged between the first sensor mounting bracket and the second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are connected with a cover plate respectively by a support rod. The novel friction and wear testing machine of the machine tool can simulate the actual working condition, and directly adopt the guide rail as the sample. Moreover, the testing machine can not only be used for rapidly assessing the material of the guide rail pair and the lubricating medium, but also can be used for the accelerated life test of the straight guide rail pair and the rolling guide rail pair.

Owner:SOUTHEAST UNIV

Nanoparticle jet flow minimum quantity lubrication grinding lubricant supply system

ActiveCN102658526APlay the role of cooling and lubricationImprove thermal conductivityGrinding/polishing safety devicesJet flowNanoparticle

The invention relates to a nanoparticle jet flow minimum quantity lubrication grinding lubricant supply system. A minimum quantity lubrication grinding lubricant is prepared by adding nanoscale solid particles into a degradable grinding liquid, the lubricant is turned into pulse liquid drops with fixed pressure, variable pulse frequency and invariant liquid drop diameter, and the pulse liquid drops are sprayed into a grinding region in the form of jet flow under the action of an air isolating layer formed by high-pressure gas. The system has all advantages of a minimum quantity lubrication technology, has higher cooling performance and excellent tribological characteristic, and plays an important role; and grinding burn is avoided effectively, the workpiece surface quality is enhanced, and efficient, low-consumption, environment-friendly, resource-economic, low-carbon and clean production is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

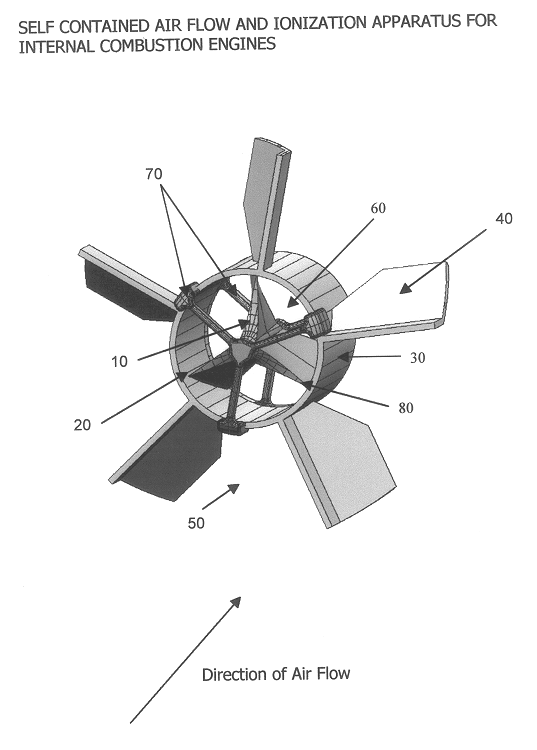

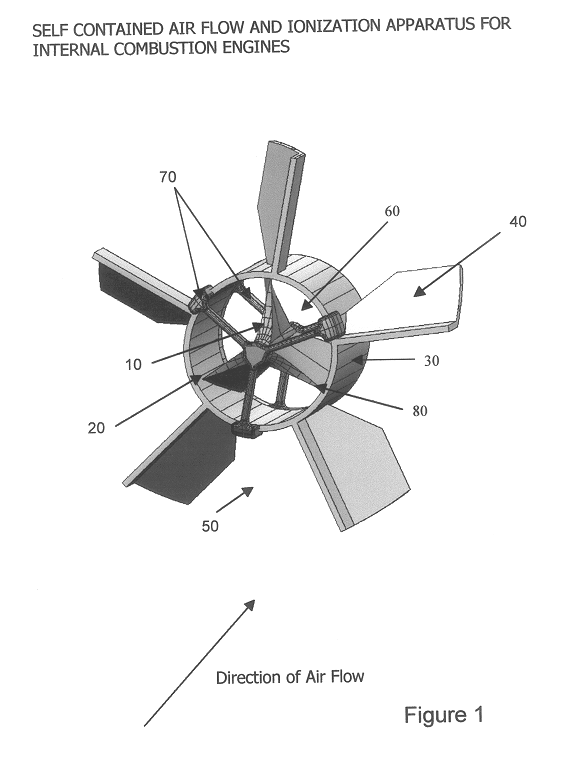

Self contained air flow and ionization method, apparatus and design for internal combustion engines

InactiveUS6601570B2Pump componentsCombustion-air/fuel-air treatmentExternal combustion engineEngineering

This invention method combines numerous disciplines to enhance the performance of internal combustion engines. No prior art embodies the discipline of physics in the creation of a swirling vortex, principles of electrostatics in using tribology and coulomb forces, the utilization of dielectric properties of polymers in an air driven rotating electrophorus and the chemistry of enhanced combustion gases and combustion itself in a single self-contained apparatus and does so without the convention and application of external voltage.

Owner:ZETMEIR KARL D

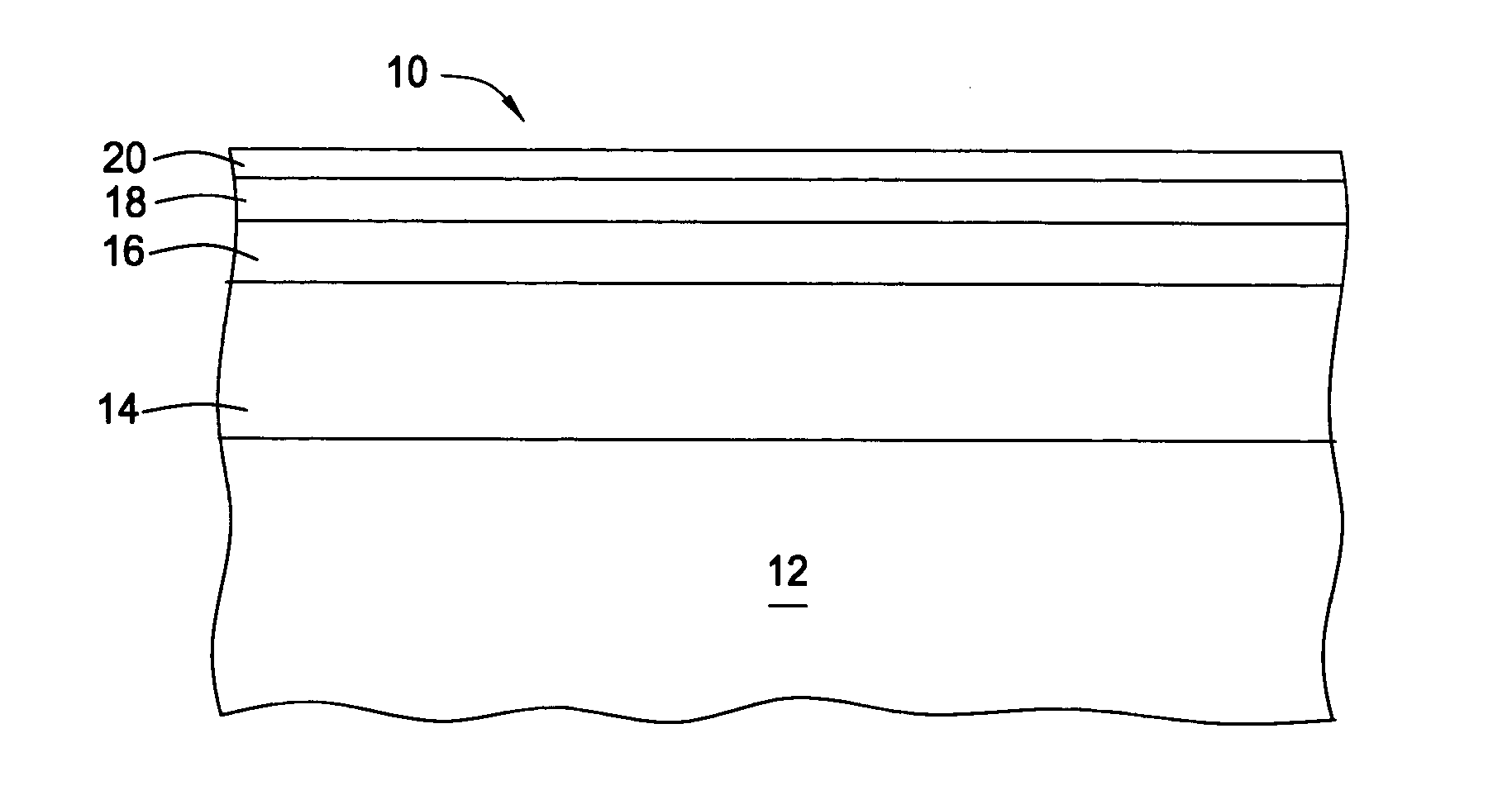

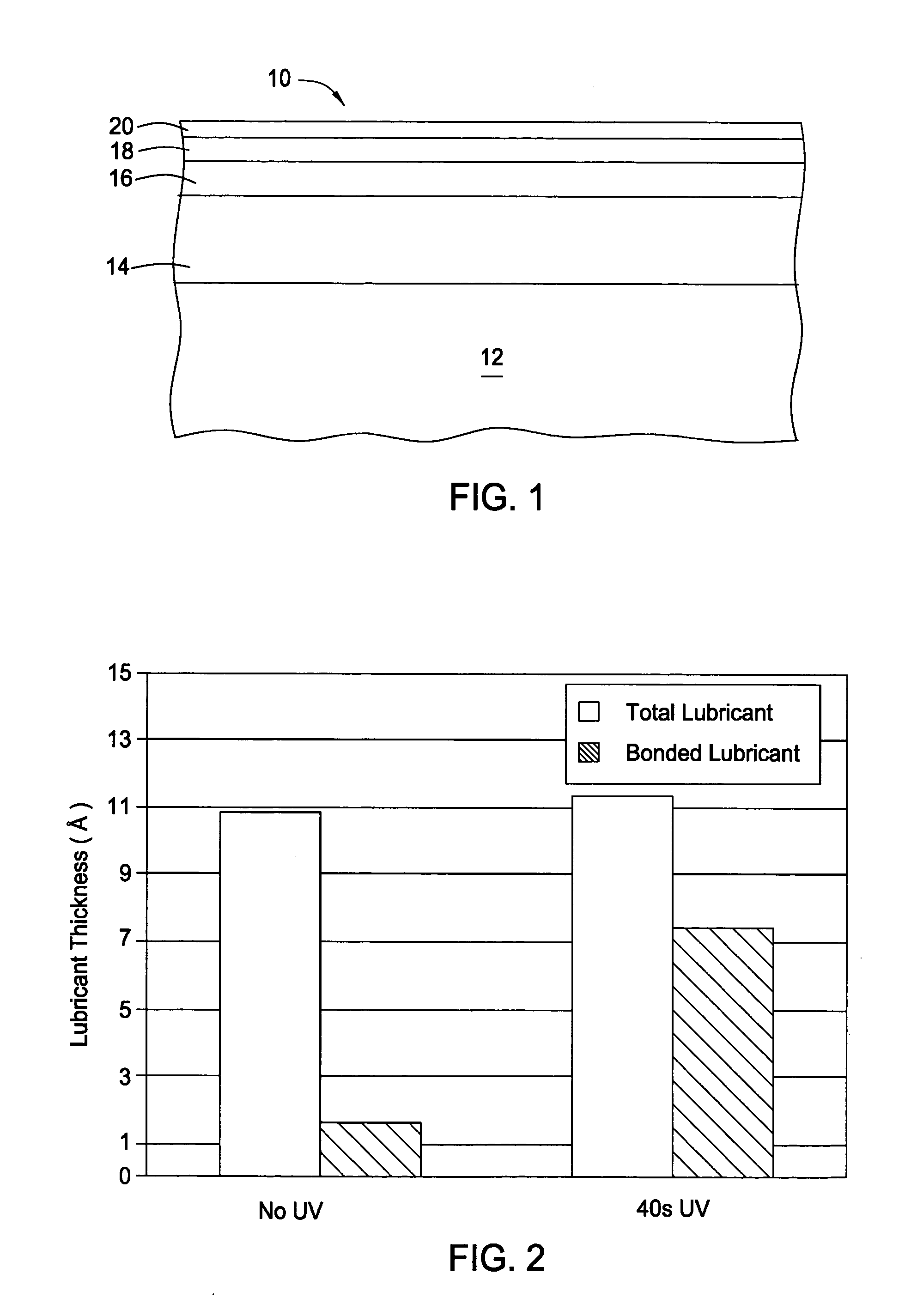

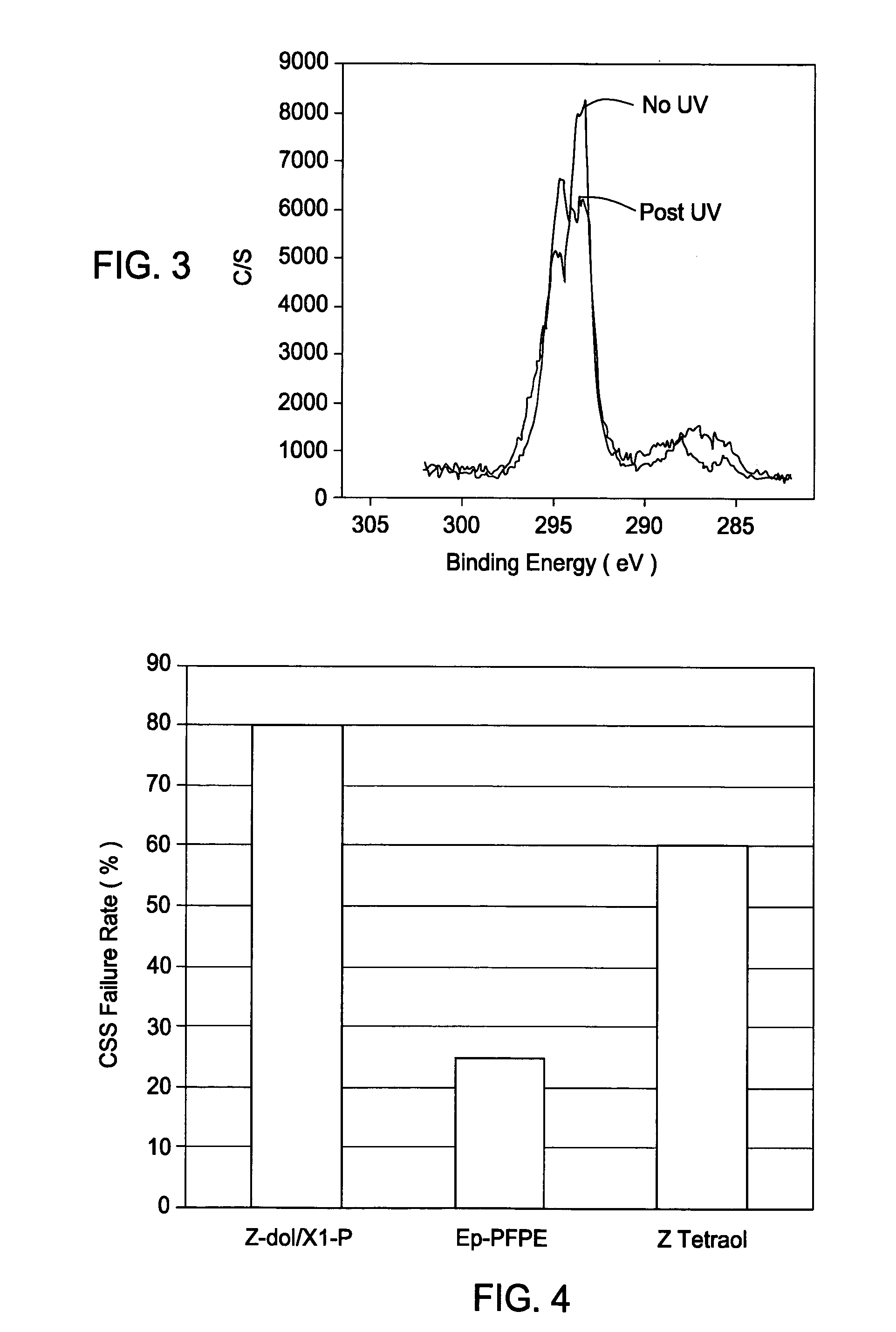

Ultra-thin lubricant film for advanced tribological performance of magnetic storage media

InactiveUS20050037932A1Protective coatings for layersSnowboard bindingsChemical LinkageLight irradiation

A perfluoropolyether lubricant topcoat having at least one end-group having an epoxide ring is applied to a magnetic recording medium. Post-lubing treatment, such as ultraviolet (UV) light irradiation, of the perfluoropolyether lubricant topcoat initiates chemical bonding between the epoxide end-group and the medium surface. The lubricant of the present invention provides improved tribological performance over conventional lubricants.

Owner:SEAGATE TECH LLC

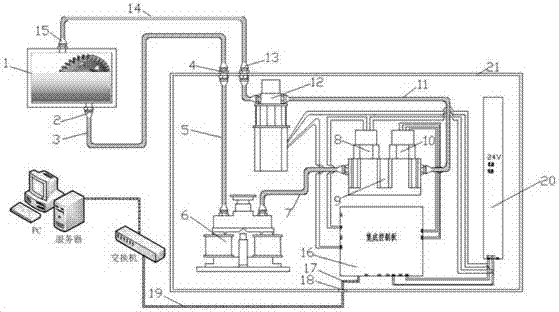

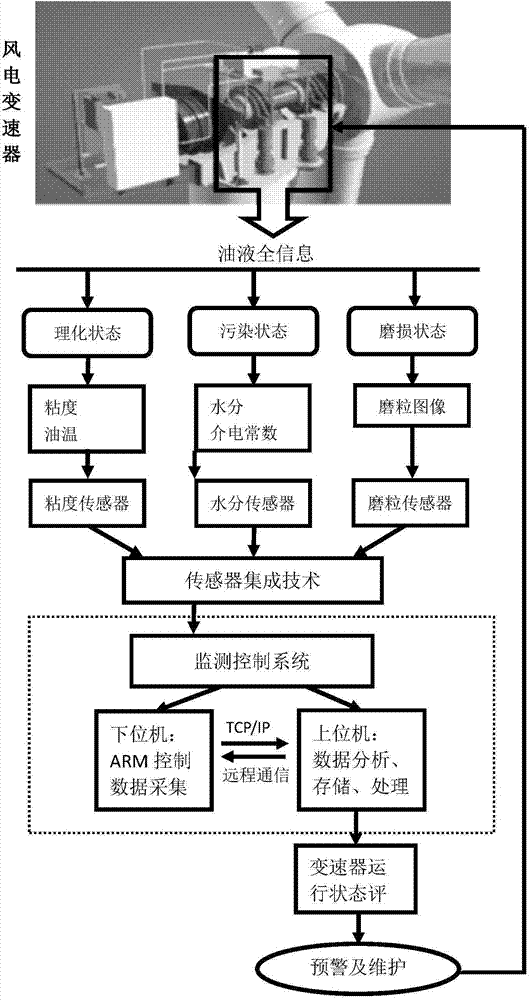

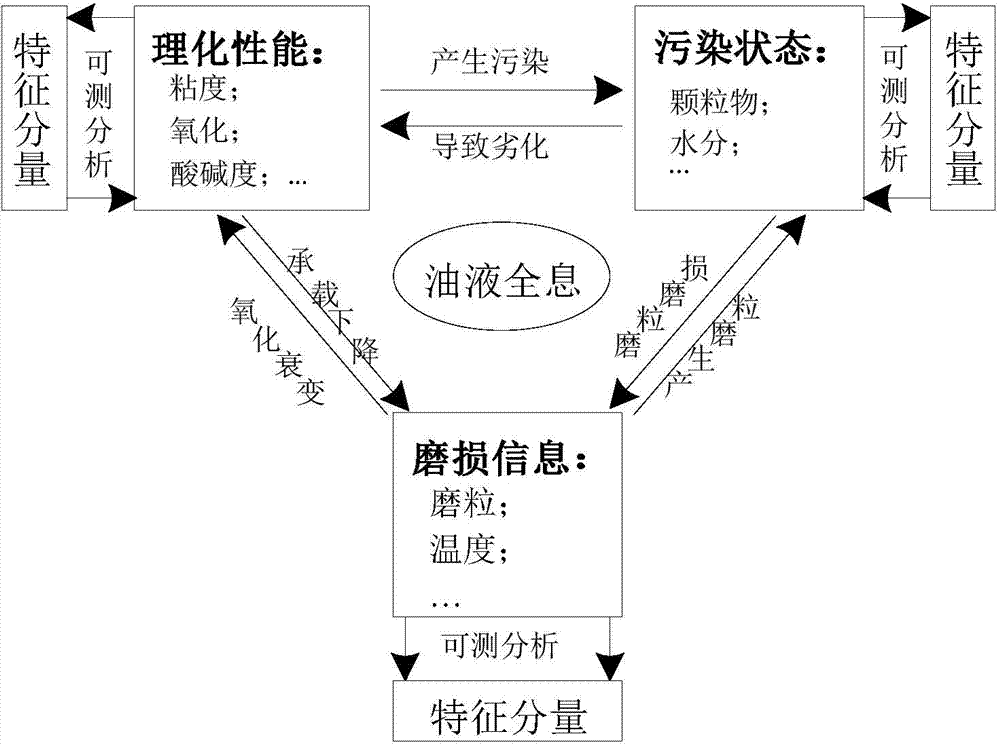

Online monitoring method for lubricating oil of wind-power transmission

ActiveCN104764489AAvoid secondary crushingAvoid interferenceMeasurement devicesElectric power transmissionRelational model

Provided is an online monitoring method for lubricating oil of a wind-power transmission. The online monitoring method for the lubricating oil of the wind-power transmission comprises the following steps that performance analysis is carried out on a tribology system of a gear case of the wind-power transmission, and a comprehensive information monitoring method which is based on three aspects, namely an abrasion, a lubricating oil physical and chemical performance and pollution is proposed; an integral information monitoring system is established through testable analysis, and viscosity, water and an abrasive grain are adopted to be used as testable characteristics corresponding to the three classes of information of the abrasion, the lubricating oil physical and chemical performance and the pollution; by utilizing the embedded type integral sensor technology, real-time obtaining of the information is achieved; by adopting a TCP / IP network communication protocol, remote monitoring is achieved; a relation model of the abrasion, a lubrication oil product and the pollution are established, and inducements of the abrasion or lubricating malfunctions are speculated. Online perfect information obtaining is achieved, the analysis on origins of malfunctions is provided, the effective monitoring method for a running state of the gear case of the wind-power transmission is achieved, and according to positioning of an abrasive malfunction, an oil replacing suggestion and other maintaining suggestions, the important engineering significance for lowering the triology malfunction and prolonging the complete machine service life is achieved.

Owner:XI AN JIAOTONG UNIV

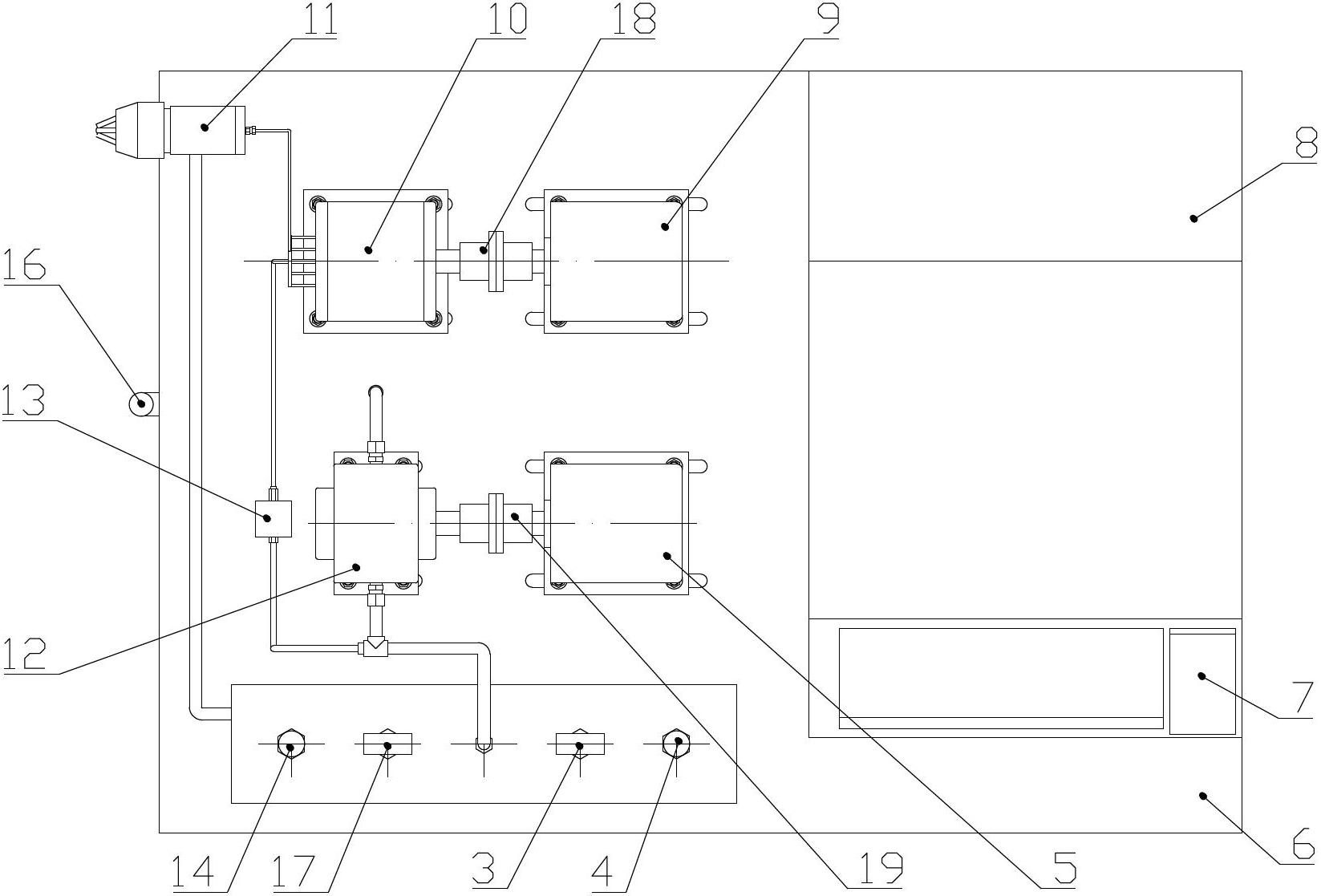

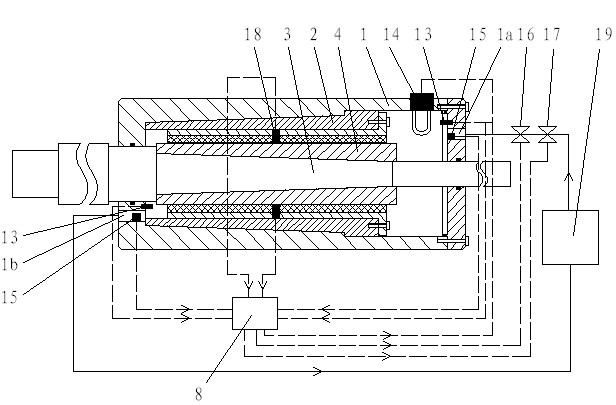

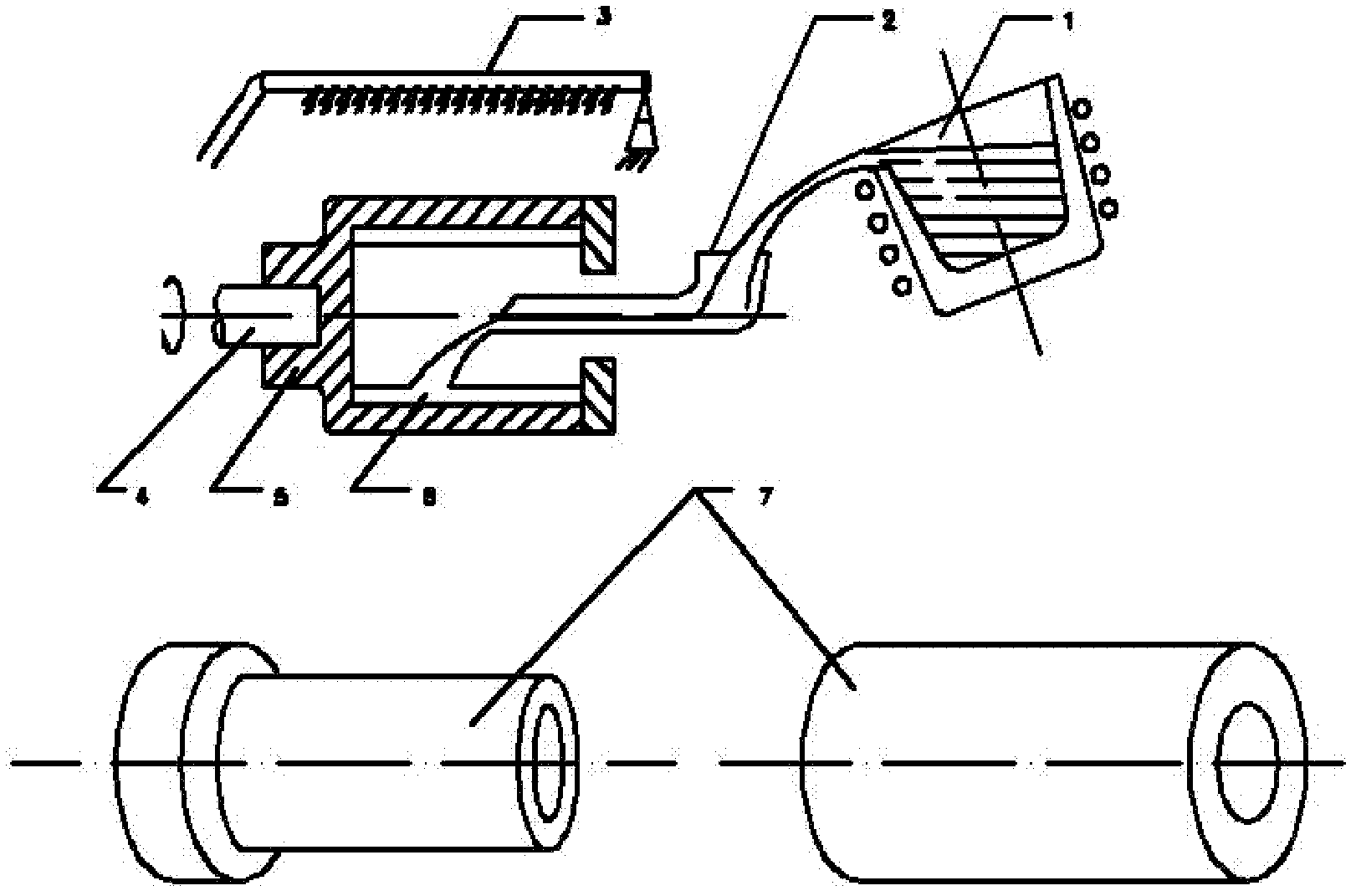

Multifunctional tribology performance test system

InactiveCN102628747AReal performance testPerformance testing is completeMachine bearings testingEngineeringTribology

The invention discloses a multifunctional tribology performance test system, which comprises a test cabin body, a bearing sleeve, a test shaft, a shaft sleeve, a test shaft driving device, a loading device and a comprehensive performance test unit. An installation space of a piece to be tested is arranged between the shaft sleeve and the bearing sleeve. Two ends of the test cabin body are respectively in rotation sealing fit with the test shaft, and a lubricant inlet and a lubricant outlet are arranged on the test cabin body. The comprehensive performance test unit comprises a computer, a torque rotating speed detection device, a loading force detection device, a lubricant temperature detection device, a liquid film thickness detection device and a lubricant flow detection device. The multifunctional tribology performance test system can simultaneously conduct radial and axial loading, simulates actual complex working conditions of the piece to be tested truly, achieves tests of tribology comprehensive performance such as rotating speed, torque, temperature rise, friction characteristic, test loading force, production validation (PV) value, dynamic rigidity and dynamic damping, and is capable of really and comprehensively testing and verifying the comprehensive performance of the piece to be tested.

Owner:重庆奔腾智能装备技术有限公司

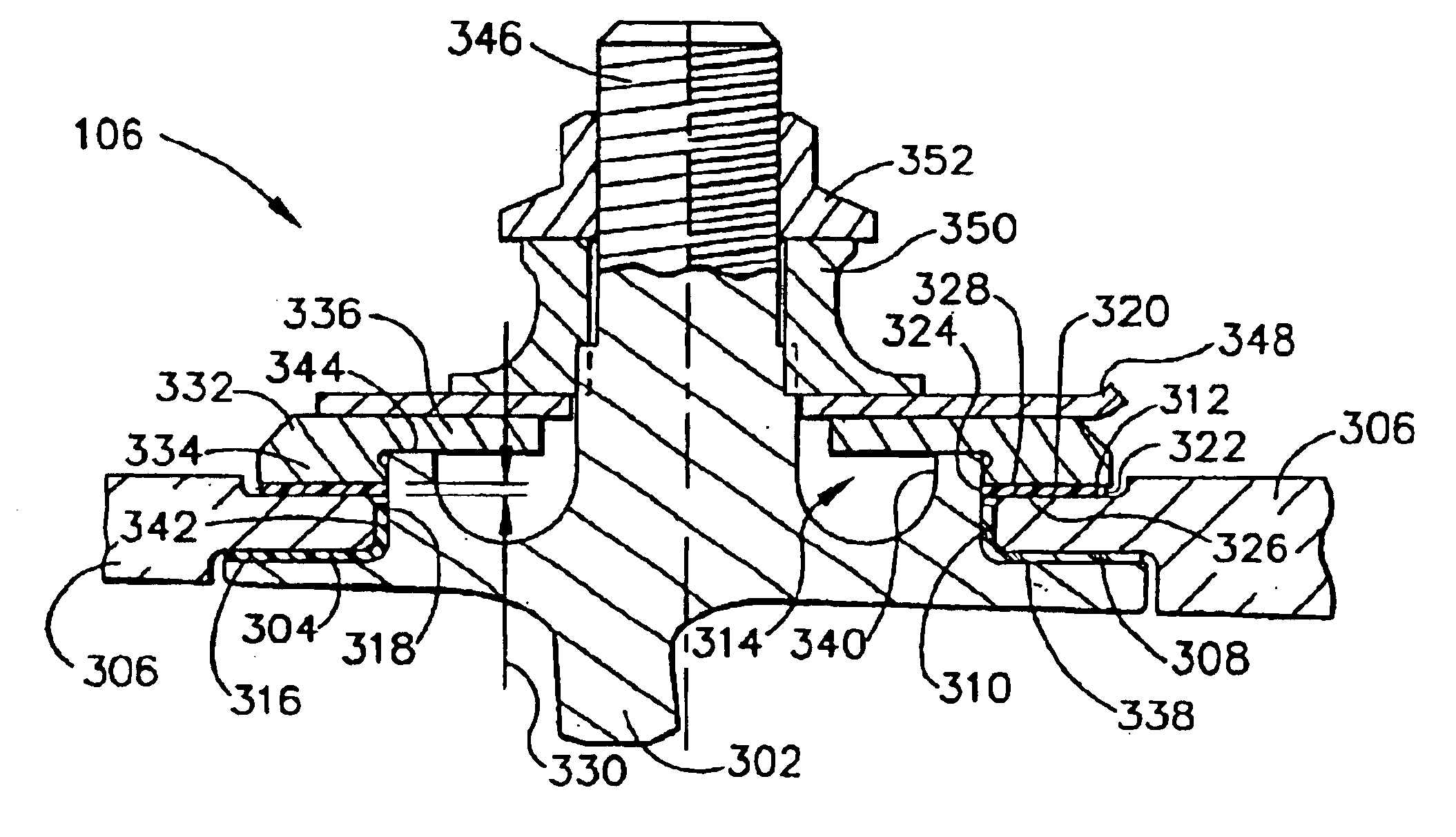

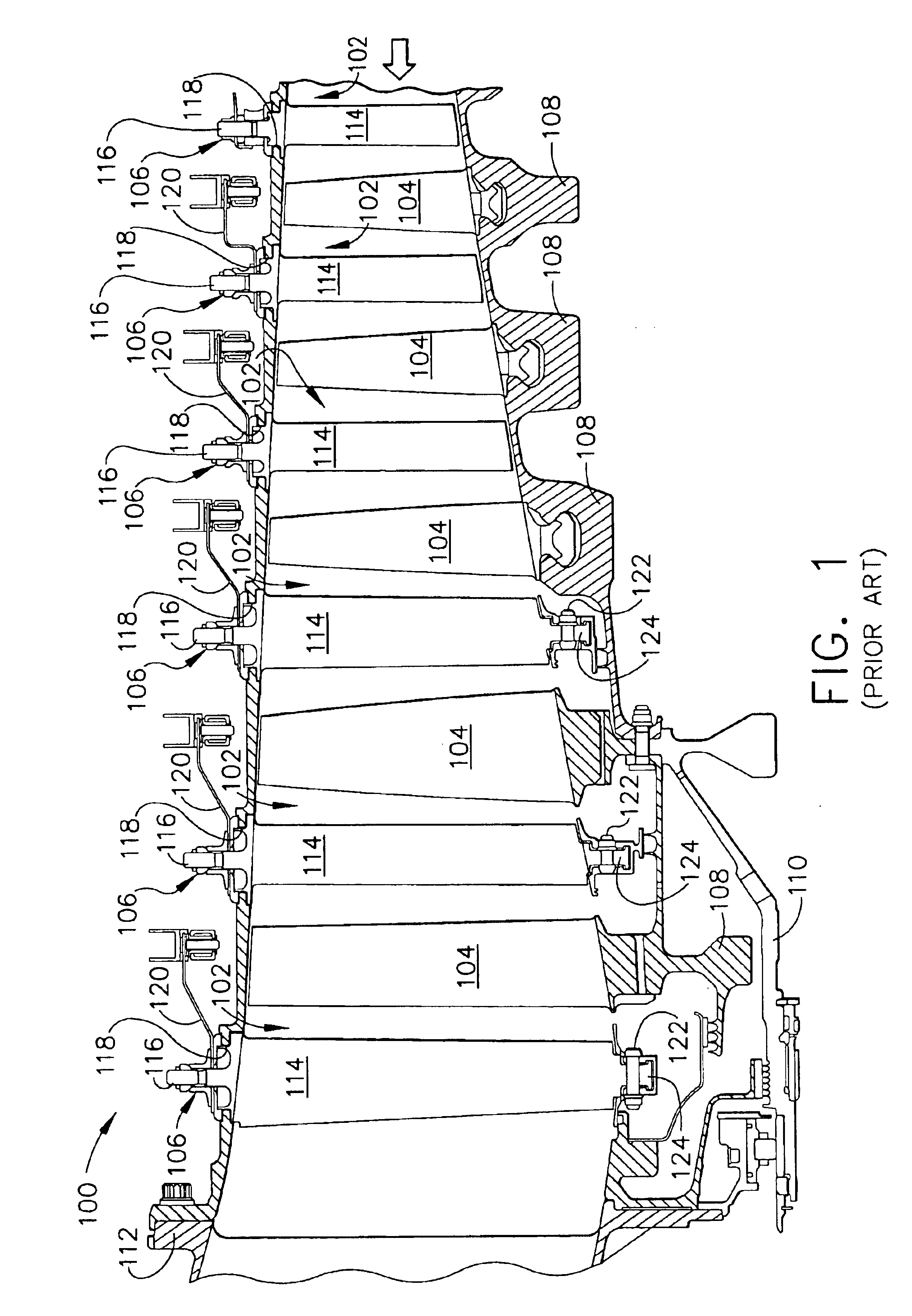

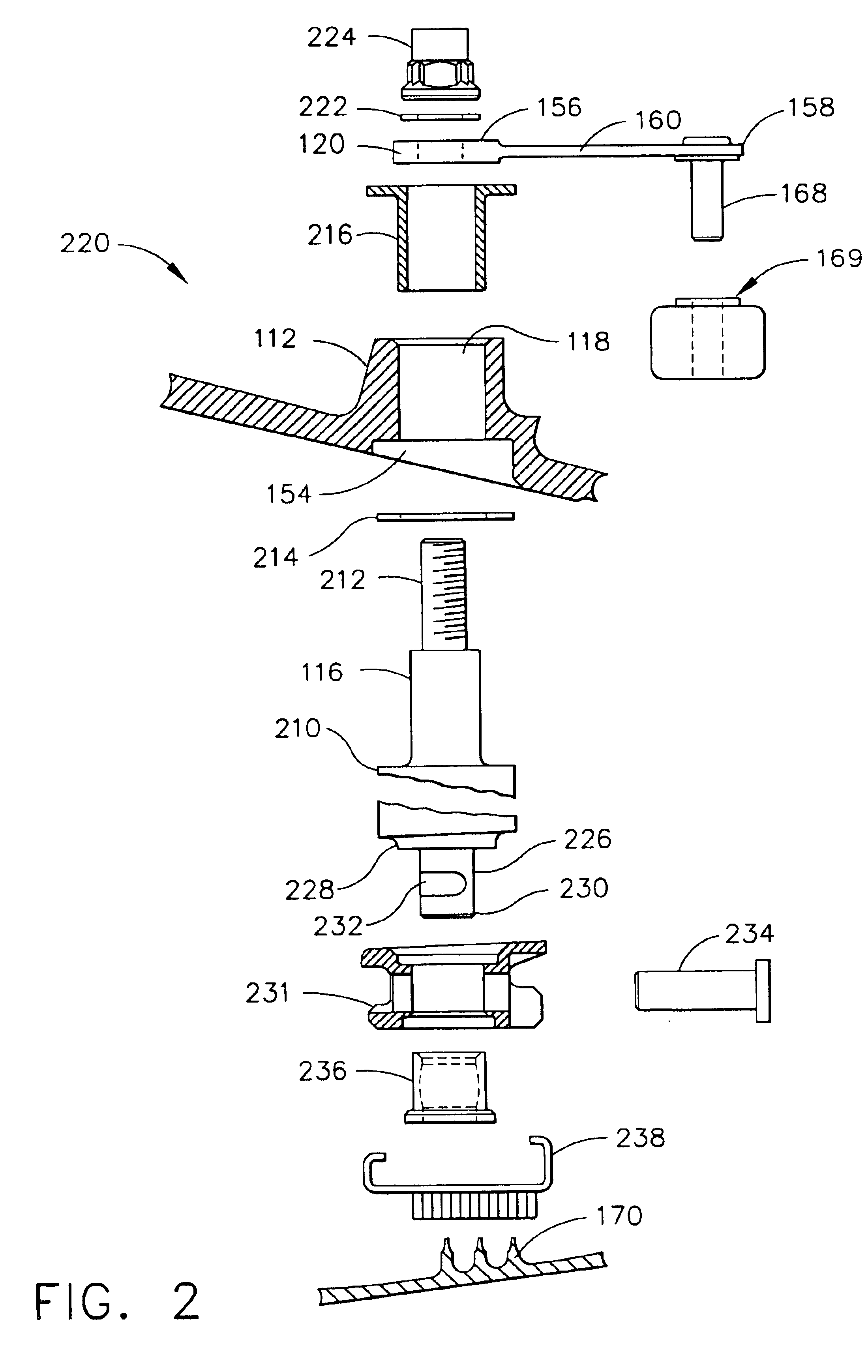

Tribologically improved design for variable stator vanes

InactiveUS6887035B2Increased durabilityFacilitate effectivenessWind motor controlPump componentsEngineeringPressure difference

A bushing and washer forming a bearing assembly at the outer radial end of a stator vane, the outer bearing assembly, and the bearing assembly at the inner radial end of the stator vane, the inner bearing assembly, that facilitate durability, effectiveness and reduced cost. Both the inner and outer bearing assemblies are designed to rotate relative to the vane shaft and the respective mating shroud or case to even out the wear around the circumference of the bushing. When a rotating bushing is used, a flange on the bushing is designed to be positioned on the inside of the case, so that a pressure differential across the case applies a force to the vane to move it outwardly against the flange and the flange against the case, thereby minimizing air leakage.

Owner:GENERAL ELECTRIC CO

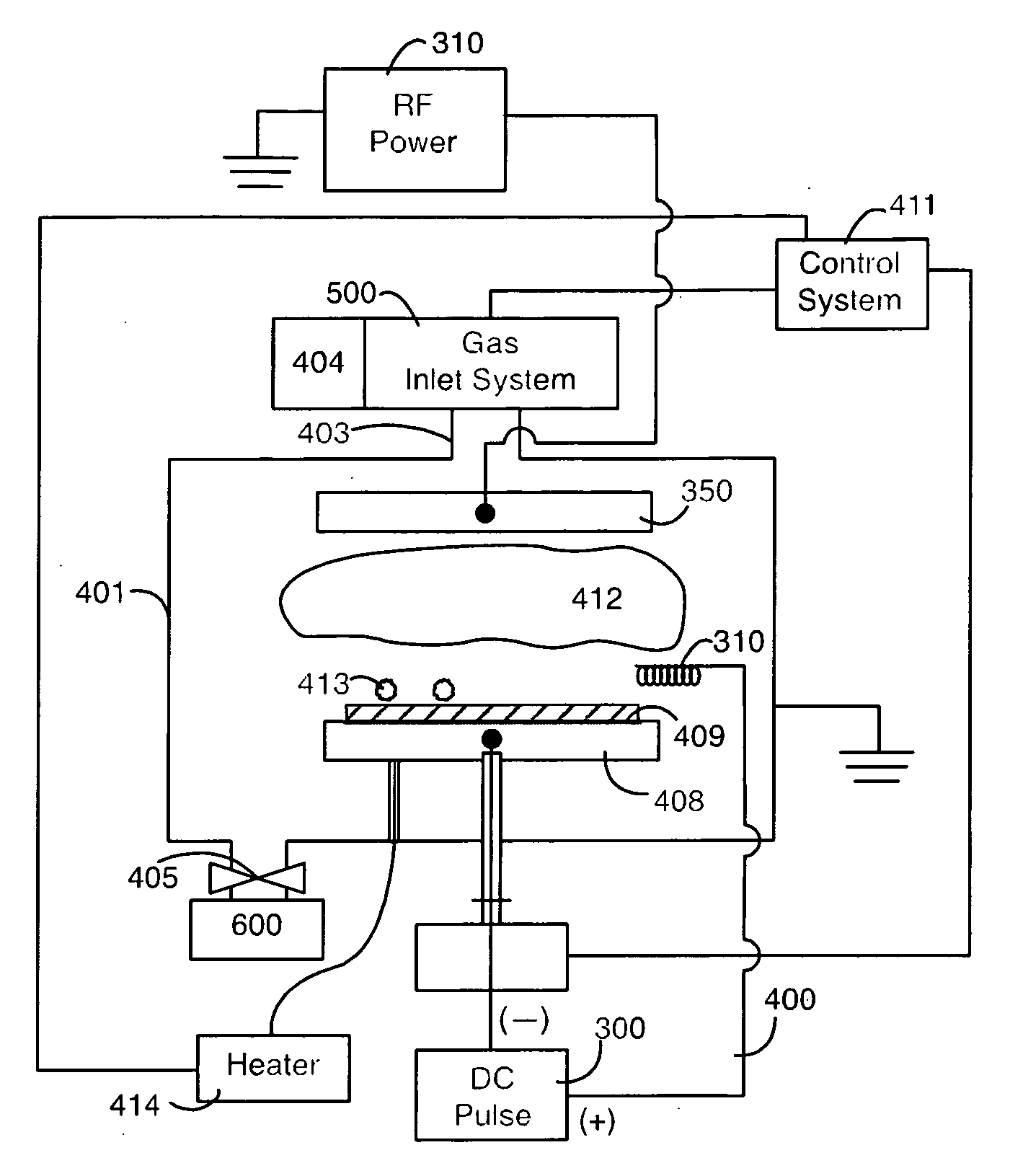

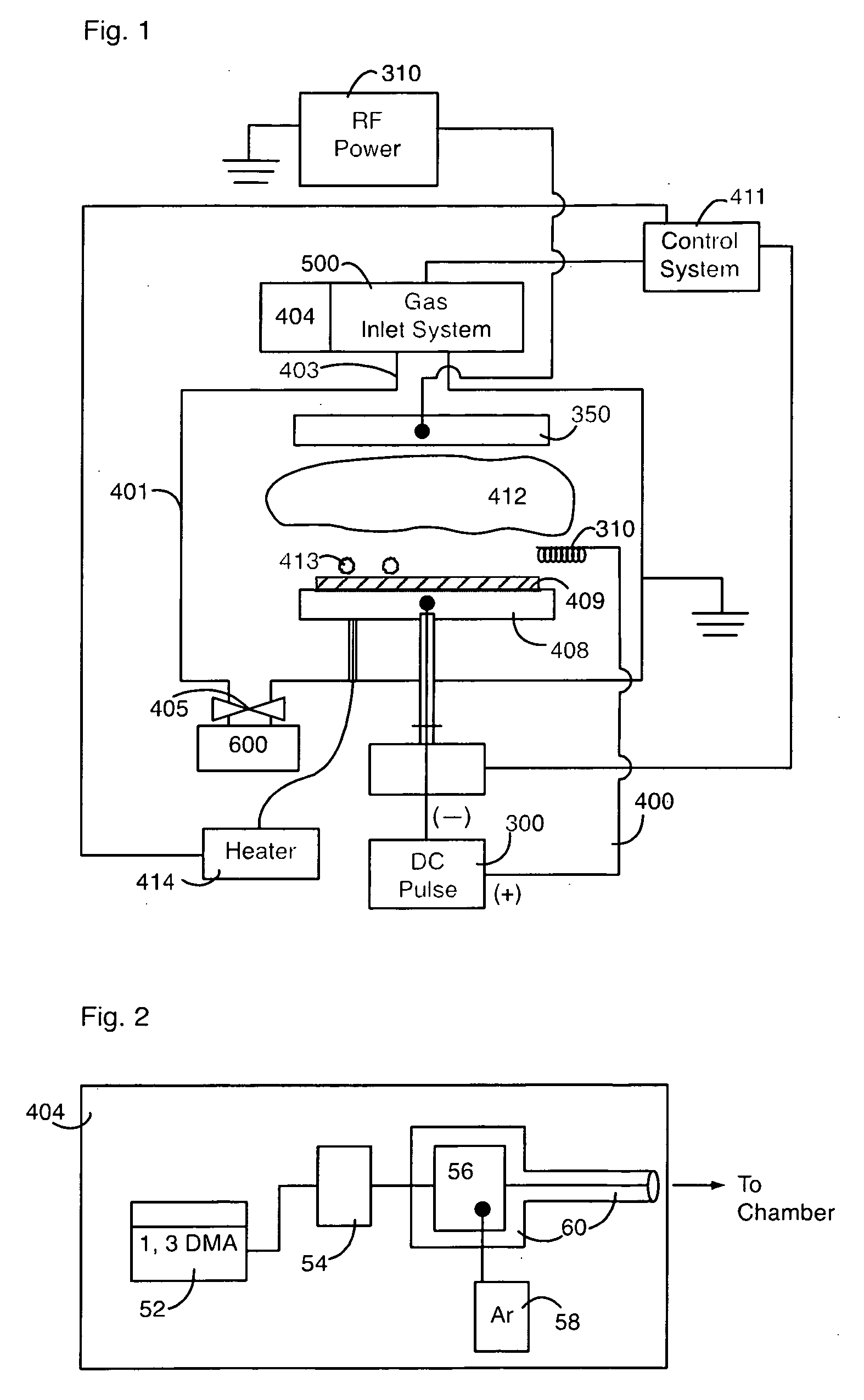

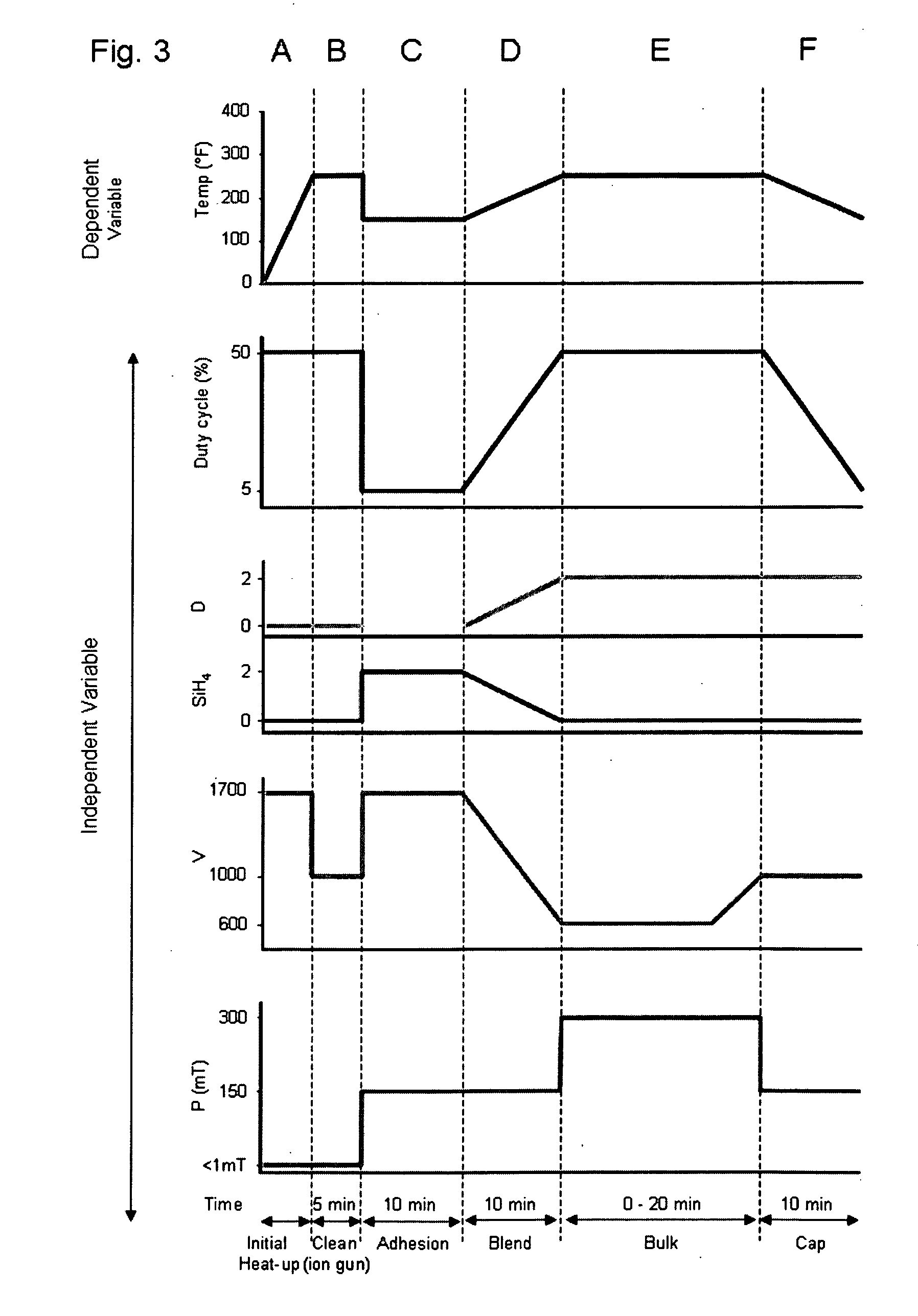

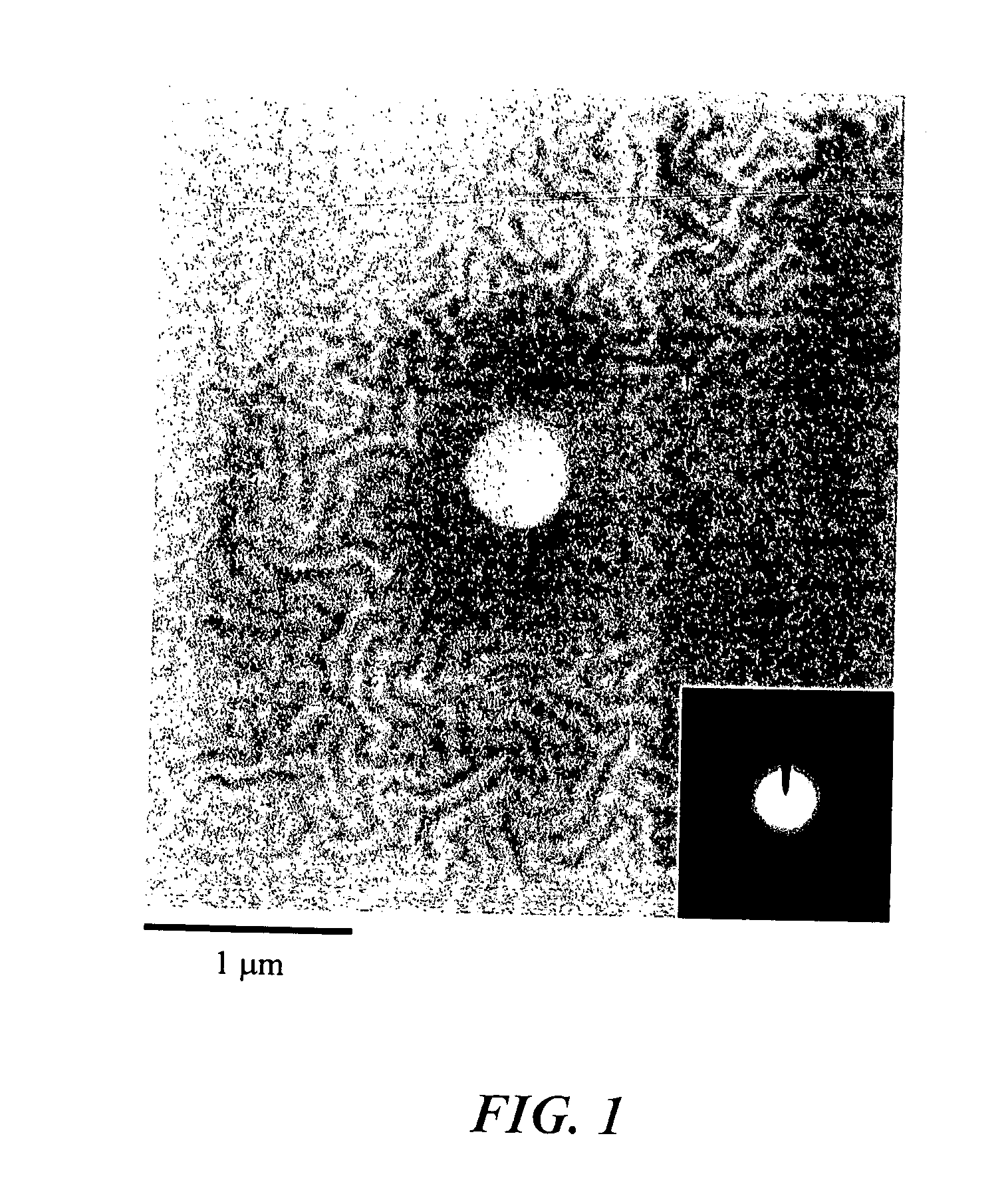

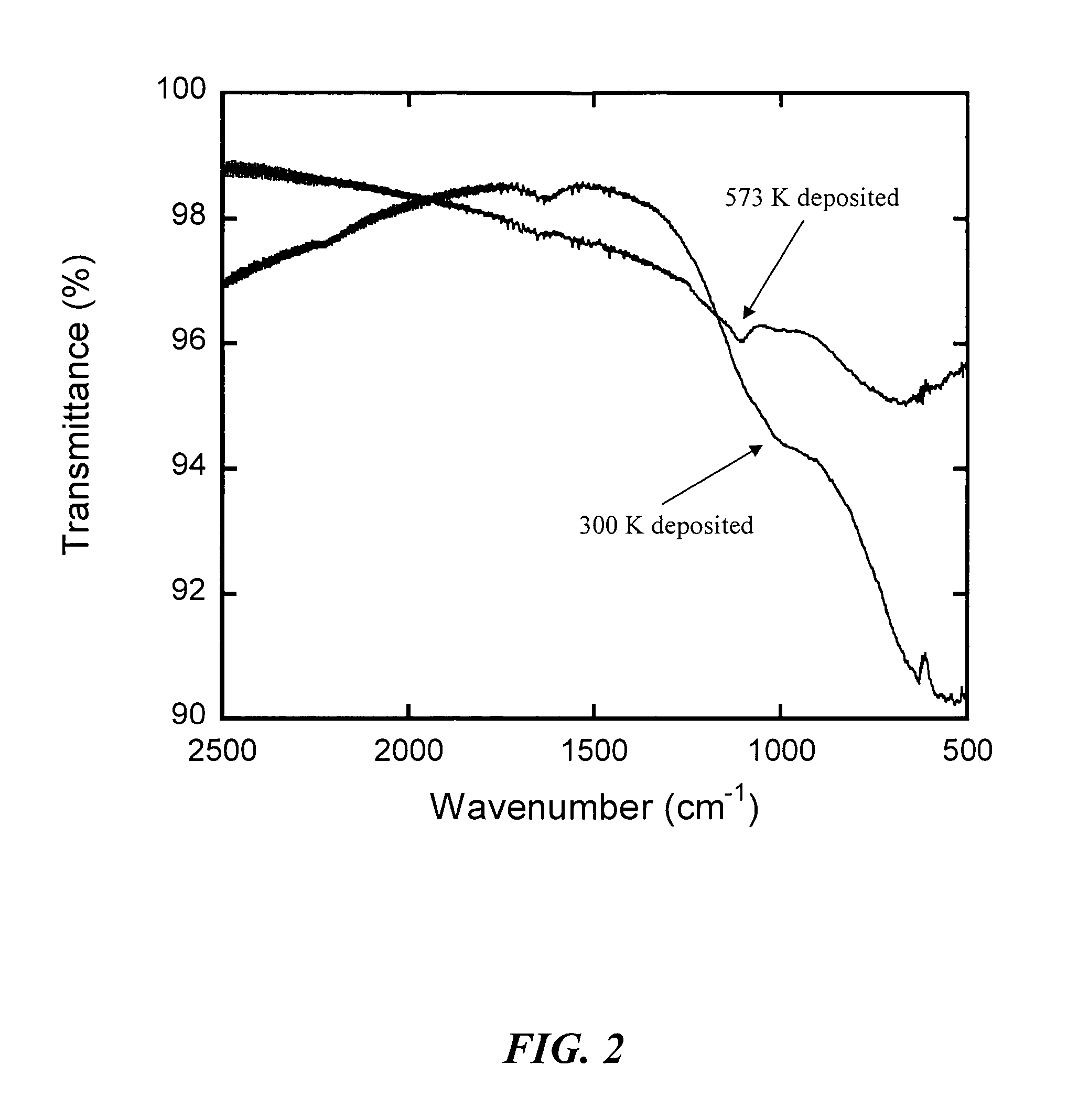

Method for producing amorphous carbon coatings on external surfaces using diamondoid precursors

InactiveUS20090029067A1Desirable mechanical and tribological propertyFast depositionChemical vapor deposition coatingPlasma techniqueGas phaseRefractive index

The invention relates to a method for forming high sp3 content amorphous carbon coatings deposited by plasma enhanced chemical vapor deposition on external surfaces. This method allows adjustment of tribological properties, such as hardness, Young's modulus, wear resistance and coefficient of friction as well as optical properties, such as refractive index. In addition the resulting coatings are uniform and have high corrosion resistance. By controlling pressure, type of diamondoid precursor and bias voltage, the new method prevents the diamondoid precursor from fully breaking upon impact with the substrate. The diamondoid retains sp3 bonds which yields a high sp3 content film at higher pressure. This enables a faster deposition rate than would be possible without the use of a diamondoid precursor.

Owner:CHEVROU USA INC

Method for preparing aluminosilicate mineral polymer materials

InactiveCN1634795AEliminate leftImprove machinabilityClaywaresRoom temperatureUltimate tensile strength

The present invention discloses a method for preparing alumino-silicate based mineral polymeric material. The invention takes alumino-silicate as solid constituent, and alkaline mixed liquor as liquid constituent, which serves as an excitant of the mineral polyreaction. A physical stirring method is applied to mix the liquid constituent and the solid constituent, after pressure moulding, mineral polymeric material is obtained. The method has the following characteristics: cheap raw material, simple equipment and technology, being mouldable under room temperature; the mineral polymeric material prepared by the invention has a certain strength and toughness; the technology used by the invention makes the performance of the mineral polymeric material is easy to get further improvement by addition, such as strengthen, toughen and improve tribology performance and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation of high-hardness diamond-like multi-layer film

InactiveCN101298656AIncreasing the thicknessReduce hardnessVacuum evaporation coatingSputtering coatingVacuum chamberVacuum arc

The invention discloses a preparation method of a multilayer diamond-like film with high hardness, which comprises the following steps: a substrate is sputter cleaned, the diamond-like film is deposited by a depositing method with magnetic filtering and cathode vacuum arc, and the depositing method comprises steps of closing a vacuum chamber, vacuumizing the vacuum chamber to the pressure of 10<-3> Pa, turning on a pot lead cathode arc source, exerting negative bias voltage from minus 50 V to minus 200 V on the substrate and simultaneously and periodically letting in argon of 99.99 percent; furthermore, a control period lasts for 120 to 600 seconds, the time for letting in the argon is 10 to 50 percent of the control period, and the argon pressure in the vacuum chamber during argon inletting is 0.01 to 0.1 Pa; time for shutting off the argon is 90 to 50 percent of the control period, and the vacuum degree of the vacuum chamber at the time is 10<-4> to 10<-3> Pa; the number of the control periods is 3 to 50. The preparation method of the multilayer diamond-like film with high hardness has simple technique, low cost, produced films with strong bonding force, high hardness, large thickness, small stress and excellent mechanical and tribology performance; as well as wide application space in the industrial application field.

Owner:SOUTHWEST JIAOTONG UNIV

Graded aluminium alloy cylinder liner material and preparing method thereof

ActiveCN103160715AImprove tribological performanceSmall expansion coefficientHigh magnesiumCentrifugal force

The invention relates to a graded aluminium alloy cylinder liner material and a preparing method thereof. The graded aluminium alloy cylinder liner material is characterized by containing following component, by weight, 15.0%-25.0% of Si, 3.0%-7% of Ni, 0.8%-1.8% of Mg, 0.5%-2.5% of Cu, 0.3%-0.7% of Mn, 0.04%-0.10% of RE, 0.01%-0.10% of P, and the balance aluminium. The preparing steps comprise burdening according to alloy components; smelting, covering, refining, purifying, and modifying; centrifugal force field forming; heat treating; and obtaining required end products after machining and honing. According to the graded aluminium alloy cylinder liner material and the preparing method thereof, by means of the alloy formula containing high content of Si, Mg and Ni, structural texture containing the high content of Si, Mg2Si and Ni is formed beneficially, and the prepared graded cylinder liner material has the advantages of being resistant to high temperature, resistant to abrasion, and low in dilatation coefficient. Meanwhile, the P-RE double compound modification process technique and a centrifugal force field controlled by a variable frequency motor are utilized, primary silicon and eutectic silicon phase texture are strongly refined, and tribology performance of the cylinder liner is greatly improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

Preparation method of rare earth modified carbon fiber/ polypropylene composite material

InactiveCN1807496ASolve the problem of poor interface binding forceImprove mechanical propertiesAcetic acidPolypropylene composites

This invention is related to the method for making a rare-earth modification carbon fibre / polypropylene composite material. Firstly we use rare-earth modifier to do surface-modifying treatment to carbon fibre, then we compound the treated rare-earth modifier and polypropylene, add some molybdenum disulfide, blend mechanically, control the mass percent of carbon fibre to 10-20% of mixed powder, then we fill the mixed powder into non-corrodible steel mold to extrusion forming, sinter under high-temperature to produce rare-earth modification carbon fibre / polypropylene composite material. The components of rare-earth modifier contain rare earth compounds, ethanol, dimethylenedinitrilotetraacetic acid, ammonium chloride, nitric acid and carbamide. The process of this method is simple, low cost, no pollution to environment, the produced composite material has good mechanics and frictional behaviour.

Owner:SHANGHAI JIAO TONG UNIV

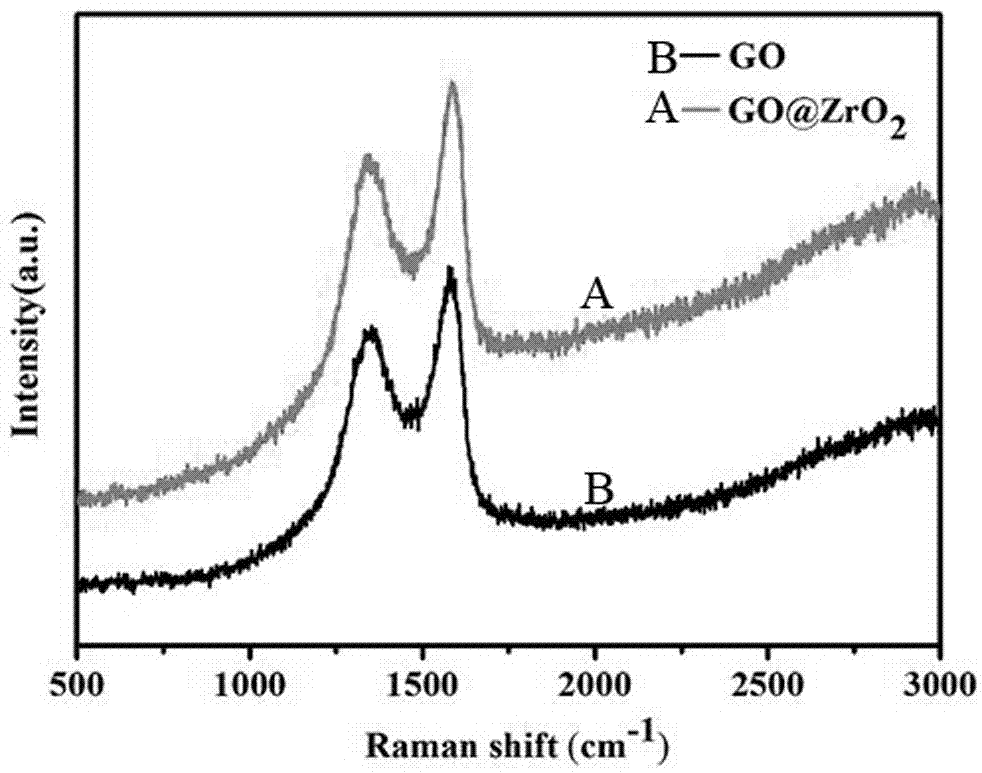

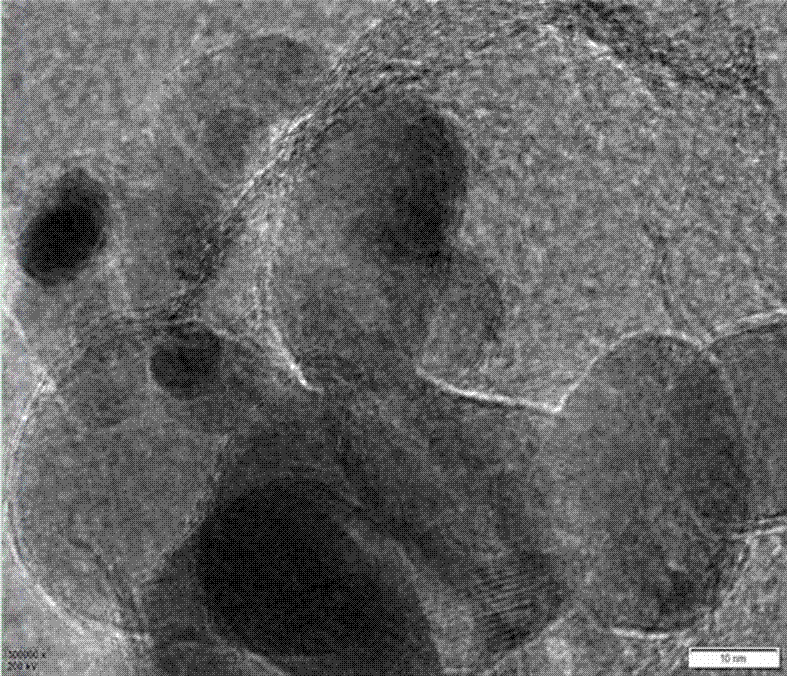

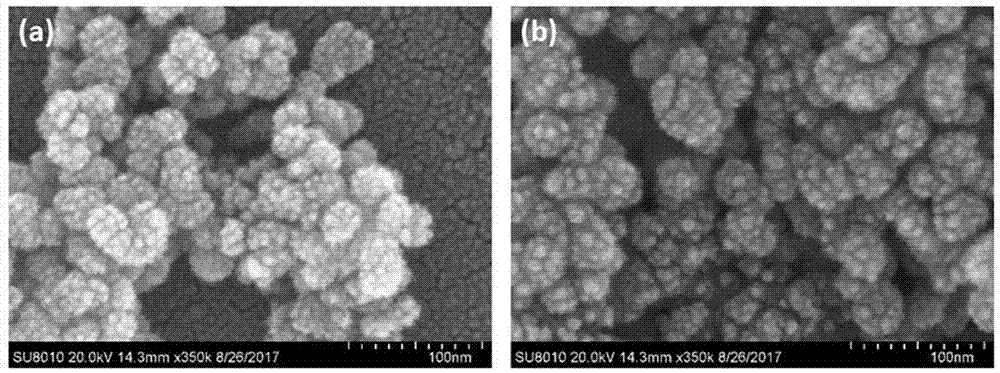

Nanoparticle/graphene oxide composite modified high polymer material and preparation thereof

ActiveCN107880484AImprove mechanical propertiesImprove tribological propertiesPolymer scienceOxide composite

The invention belongs to the field of high polymer composites and particularly relates to a nanoparticle / graphene oxide composite modified high polymer material and a preparation method thereof. The composite is prepared from nanoparticle / graphene oxide composite particles and a macromolecular polymer matrix, wherein the nanoparticle / graphene oxide composite particles are synthesized with an electrostatic self-assembly method, that is, an amino modified nanoparticle dispersion liquid is ionized to have positive charges while graphene oxide contains a large quantity of carboxyls and hydroxyls and is ionized to have negative charges, particles with positive and negative charges are sufficiently contacted, and electrostatically self-assembled nanoparticle and graphene oxide composite particles are obtained. The prepared nanoparticle / graphene oxide composite modified high polymer material has excellent mechanical and tribological performance, is simple and efficient to prepare and has goodapplication prospects in automobiles, aerospace, electronic and electrical engineering, machinery, weapons and other fields.

Owner:ZHONGBEI UNIV

Hydrothermal synthetic method for coating carbon nanometer tube with molybdenum sulphide

InactiveCN1613918AReduce usageLow reaction temperaturePigment treatment with non-polymer organic compoundsThioureaCarbon nanotube

Compound nano pipes coated by molybdenum sulphide are produced by water heating synthesis, including: first to put the molybdate and thiourea in the water and the mass percent of molybdate is 0.2%-1.5%, the thiourea is 0.2%-2.0%, then disperse the nano pipes of C in the solvent by the super sonic wave, and the mass percent of it is 0.1%-0.5%, the mixture is then put into the non-corrosive steel tank which is full of Teflon to react, at 200-250deg.C for 20-40h. The 2-6 phase of molybdenum sulphide obtained by the transmission electron microscopic and energy scattering analyze. They can be used to prepare high performance compound material of tribology, catalytic carrier, and microprobe. The process is simple, and it could avoid using the H2S.

Owner:ZHEJIANG UNIV

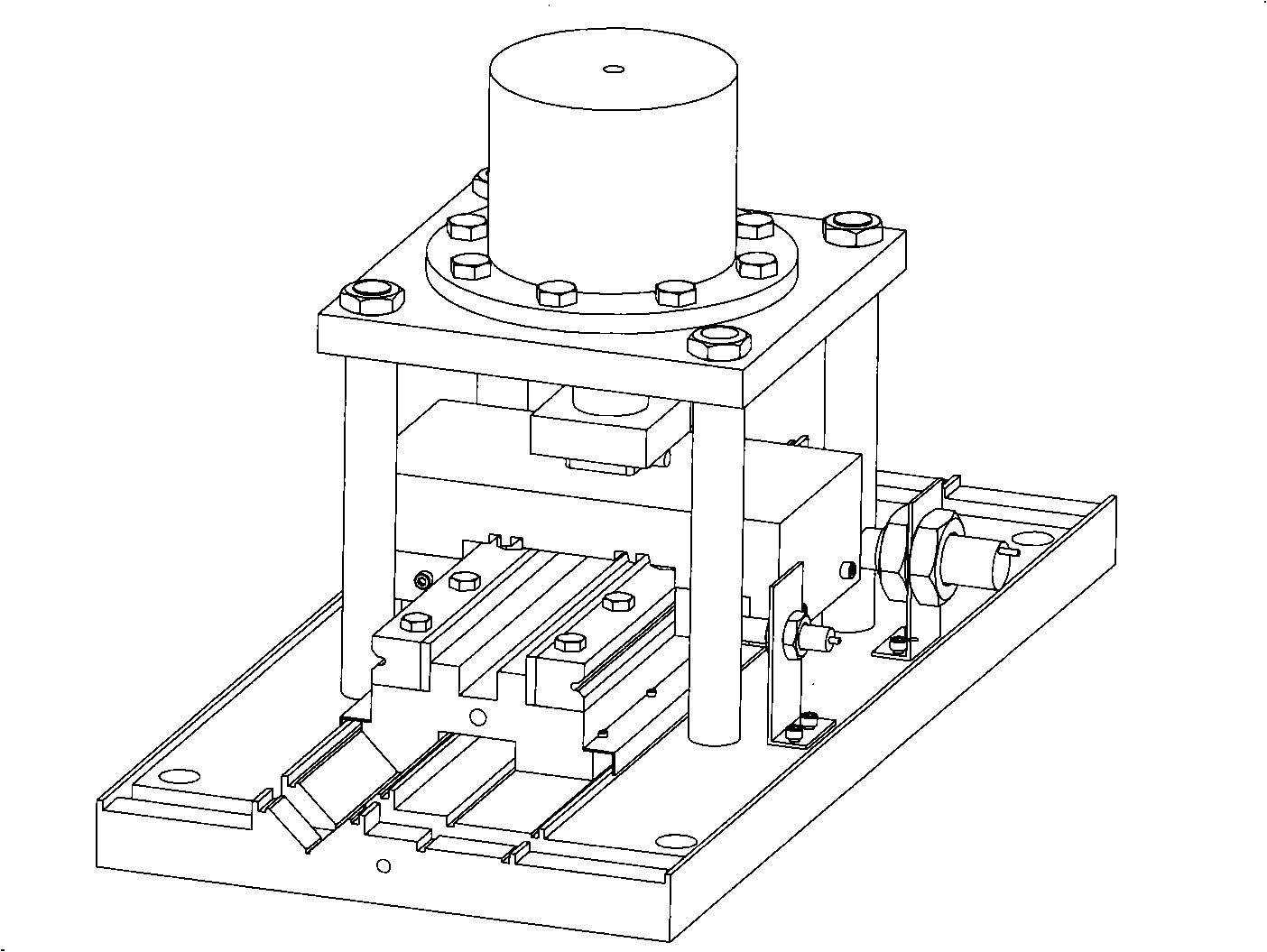

Reciprocating motion friction experiment device

ActiveCN102519817AImprove compatibilityPowerfulInvestigating abrasion/wear resistanceReciprocating motionEngineering

The invention relates to a reciprocating motion friction experiment device. The device comprises a base and a force measuring part, wherein a linear reciprocating motion part is arranged on the base; a motion platform is arranged on the linear reciprocating motion part; an experiment disk is arranged on the platform; a support part is fixed on the base; a strip-type substrate connected with a rotating shaft is arranged on the support part and rotates around the rotating shaft; the axis of the rotating shaft is vertical to the motion direction of the motion platform; a transmission part is fixed on the upper part of the substrate; the lower part of the substrate is connected with a loading part in a sliding mode; the upper end of the loading part is elastically connected with the lower end of the transmission part through a spring to form elastic force loading; an experiment pin clamping piece is arranged at the lower end of the loading part; and the force measuring part includes a first force measuring sensor arranged between the spring and the loading part and a second force measuring sensor arranged between the base and the lower end of the substrate along the motion direction of the motion platform. A correlation between the motion and load of an experiment sample and frictional wear is measured through an experiment. The device has high compatibility and strong functions and is easy to operate and low in cost.

Owner:SHANGHAI UNIV

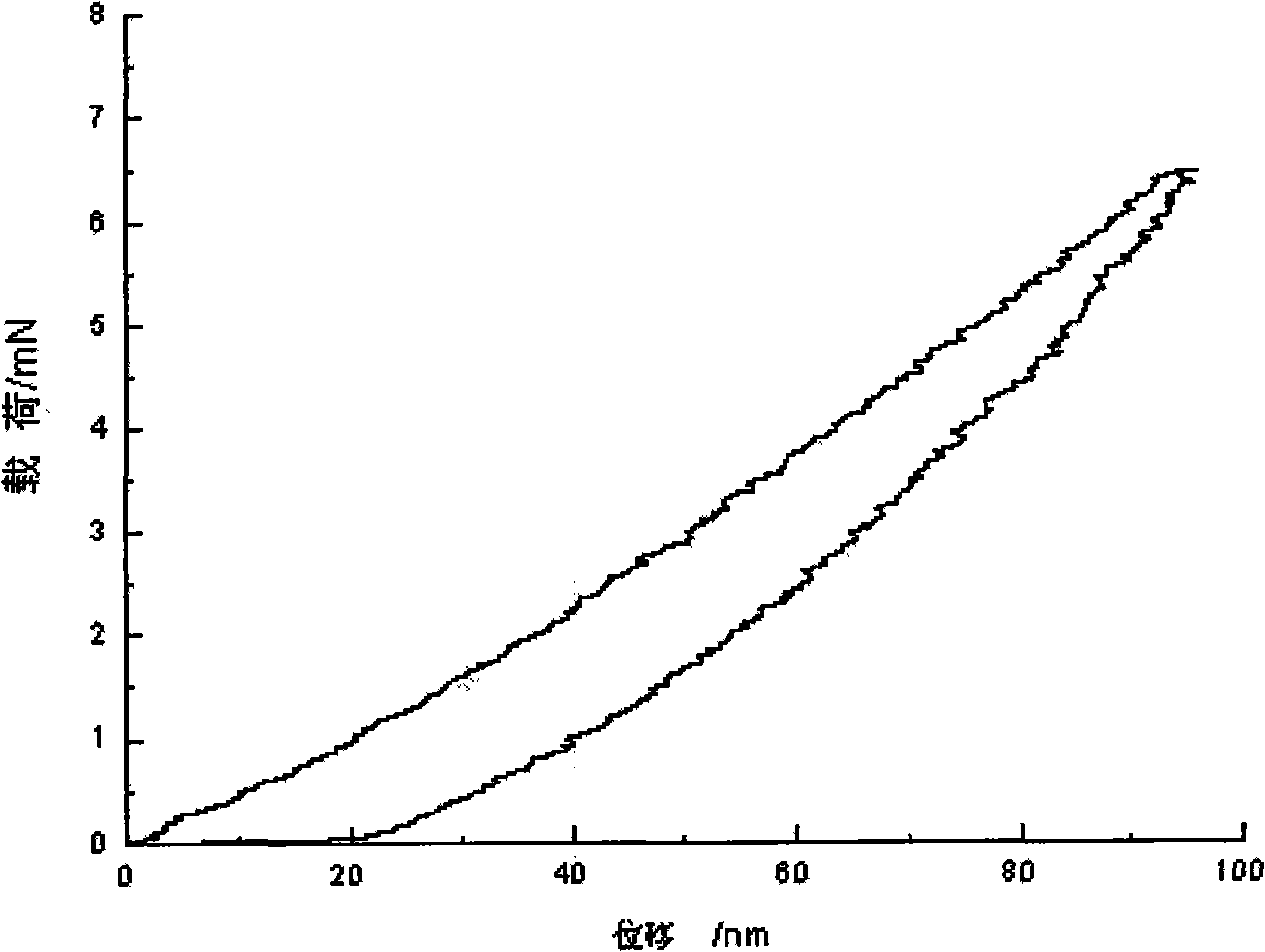

Ultra-hard low friction coating based on AlMgB14 for reduced wear of MEMS and other tribological components and system

InactiveUS20050100748A1Superior protective coatHigh hardnessVacuum evaporation coatingSolid-state devicesMicroelectromechanical systemsAlloy

Performance and reliability of microelectromechanical system (MEMS) components enhanced dramatically through the incorporation of protective thin film coatings. Current-generation MEMS devices prepared by the LIGA technique employ transition metals such as Ni, Cu, Fe, or alloys thereof, and hence lack stability in oxidizing, corrosive, and / or high temperature environments. Fabrication of a superhard, self-lubricating coating based on a ternary boride compound AlMgB14 is described in this letter as a potential breakthrough in protective coating technology for LIGA microdevices. Nanoindentation tests show that hardness of AlMgB14 films prepared by pulsed laser deposition ranges from 45 GPa to 51 GPa, when deposited at room temperature and 573 K, respectively. Extremely low friction coefficients of 0.04-0.05, which are thought to result from a self-lubricating effect, have also been confirmed by nanoscratch tests on the AlMgB14 films. Transmission electron microscopy studies show that the as-deposited films are amorphous, regardless of substrate temperature; however, analysis of FTIR spectra suggests that the higher substrate temperature facilitates formation of the B12 icosahedral framework, therefore leading to the higher hardness.

Owner:IOWA STATE UNIV RES FOUND

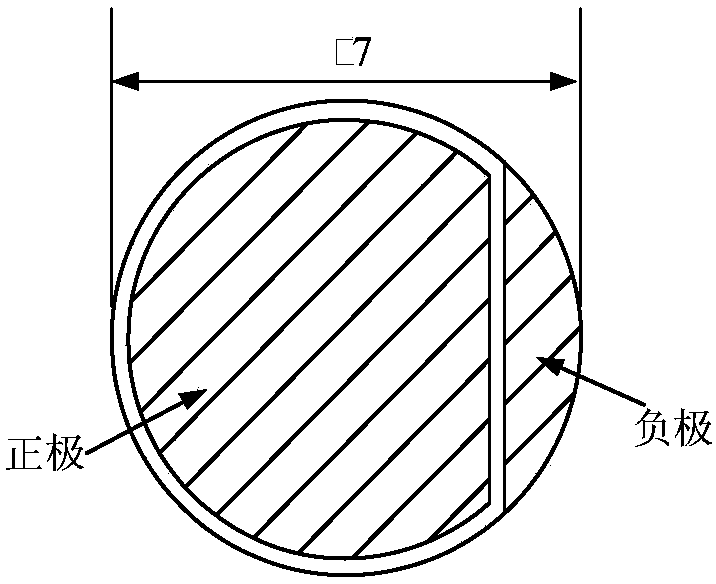

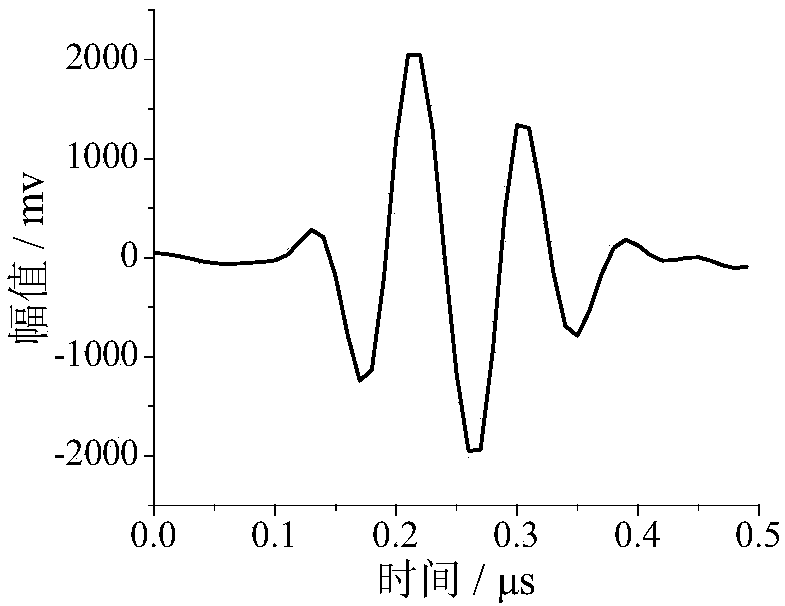

Total-range lubricating film thickness ultrasonic detection device and method

ActiveCN106989703AAccurate measurementRealize detectionUsing subsonic/sonic/ultrasonic vibration meansSingle CenterMeasurement precision

The present invention discloses a total-range lubricating film thickness ultrasonic detection device and method. Amplitude values and phase values of the sound pressure reflection coefficients of ultrasonic waves on a lubricating layer are employed to perform measurement precision complementation of the lubricating films with different ranges, and aiming at the lubricating films with different thickness ranges, the amplitude values and phase values of the sound pressure reflection coefficients of the ultrasonic waves on the lubricating layer are employed to obtain the accurate value of each range lubricating film thickness. The total-range lubricating film thickness ultrasonic detection device and method can realize accurate measurement of the total-range lubricating film thickness through an ultrasonic sensor with single center frequency and can provide convenience for online monitoring of a tribology element lubrication state.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com