Machine tool guiding rail friction wear testing machine

A friction and wear test and guide rail technology, applied in the field of tribology, can solve the problem that the load range and measurement accuracy cannot meet the test requirements, and achieve the effects of improving data accuracy, avoiding vibration and impact, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

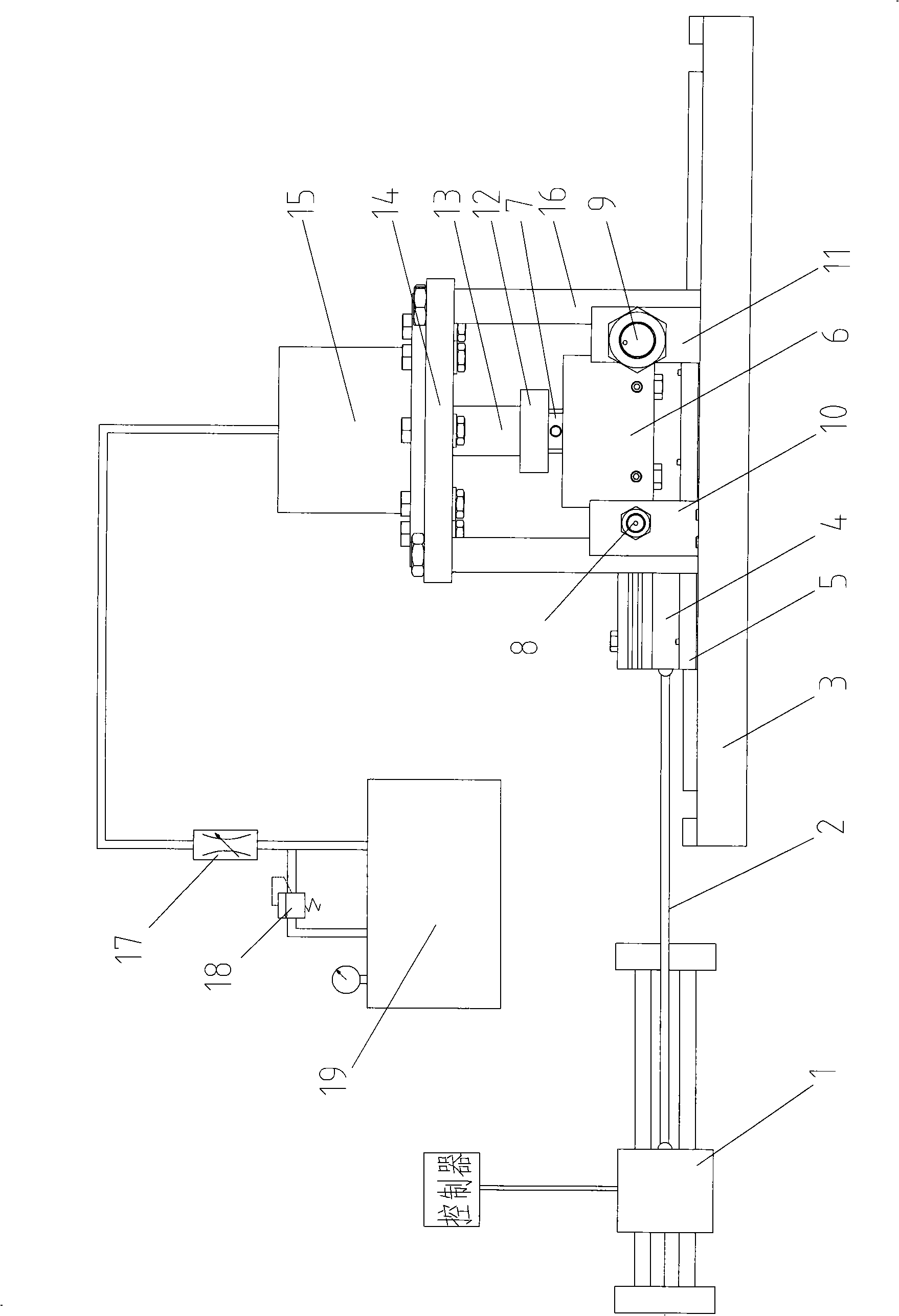

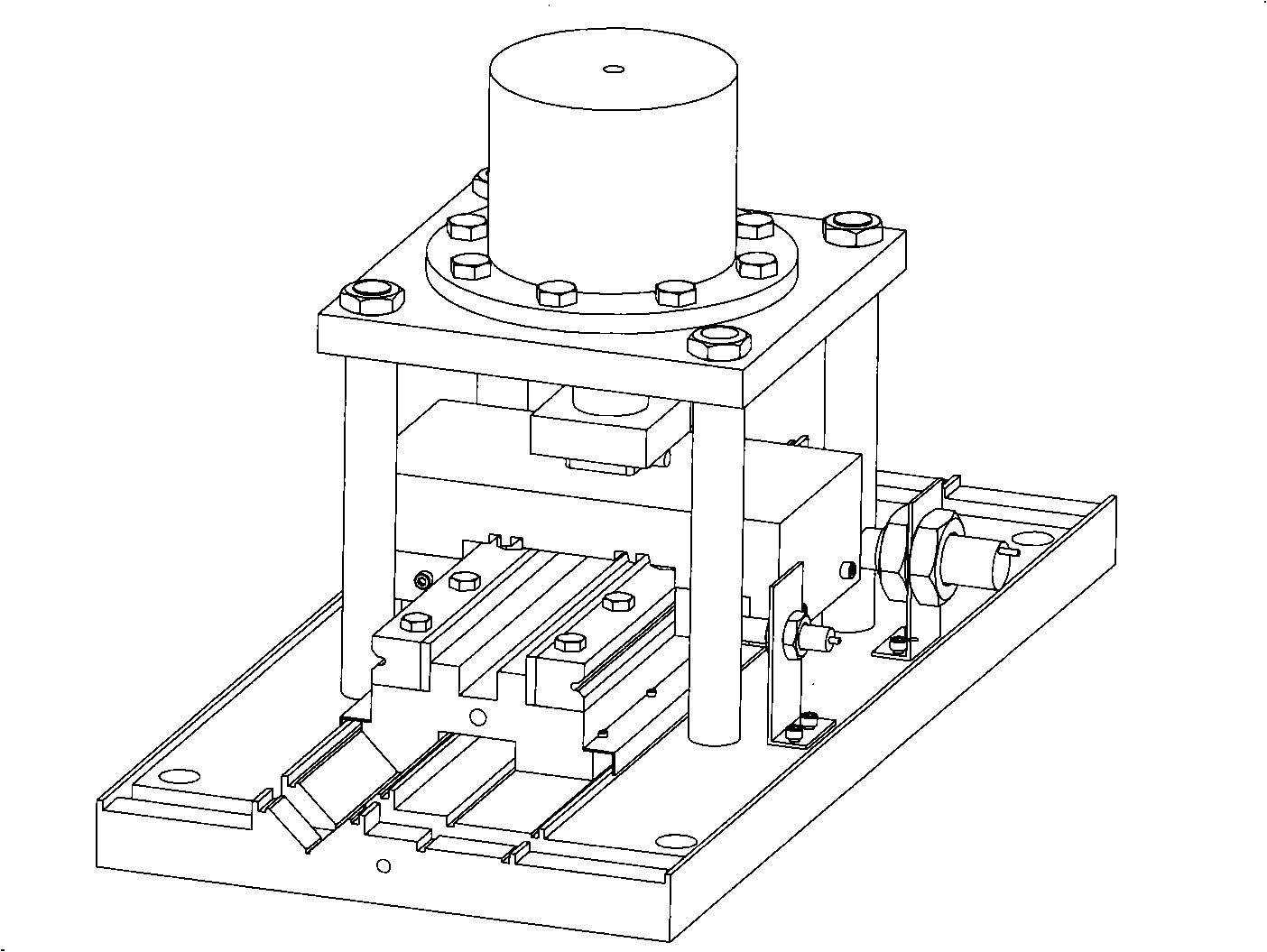

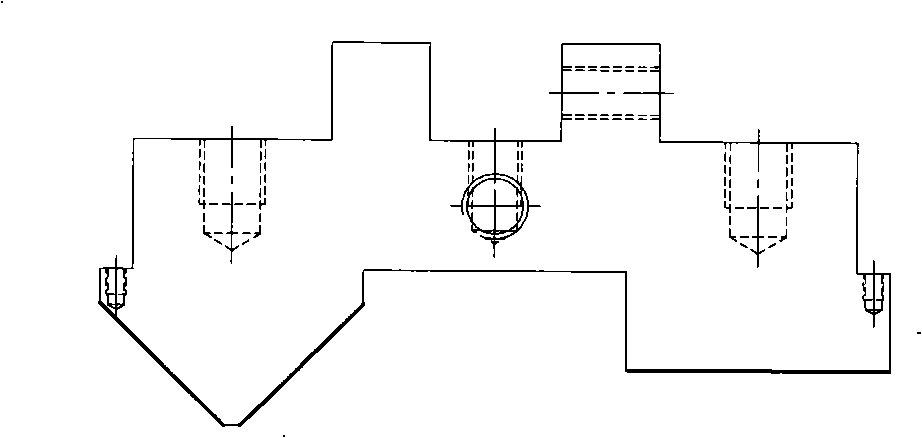

[0025] Such as figure 1 , figure 2 As shown, the present invention includes a test system and a measurement system. The test system includes a linear motor 1, a hinge 2, a base 3, a lower sample platform 4, an oil baffle 5, an upper sample clamp 6, a first sensor mounting bracket 10, a second Two sensor mounting brackets 11, upper mounting plate 12, piston 13, hydraulic cylinder cover plate 14, hydraulic cylinder 15, support rod 16, hydraulic oil station 19; lower sample platform 4 and lower sample platform 4 are set on the oil retaining plate 5 One side of the lower sample platform 4 is connected with the linear motor 1 through a hinge 2, and the other side of the lower sample platform 4 is respectively provided with a first sensor mounting bracket 10, a second sensor mounting bracket 11, an oil retaining plate 5, a lower sample platform 4, and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com