Patents

Literature

472 results about "Wear testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear testing. Several standard test methods exist for different types of wear to determine the amount of material removal during a specified time period under well-defined conditions. ASTM International Committee G-2 standardizes wear testing for specific applications, which are periodically updated. The Society for Tribology and Lubrication ...

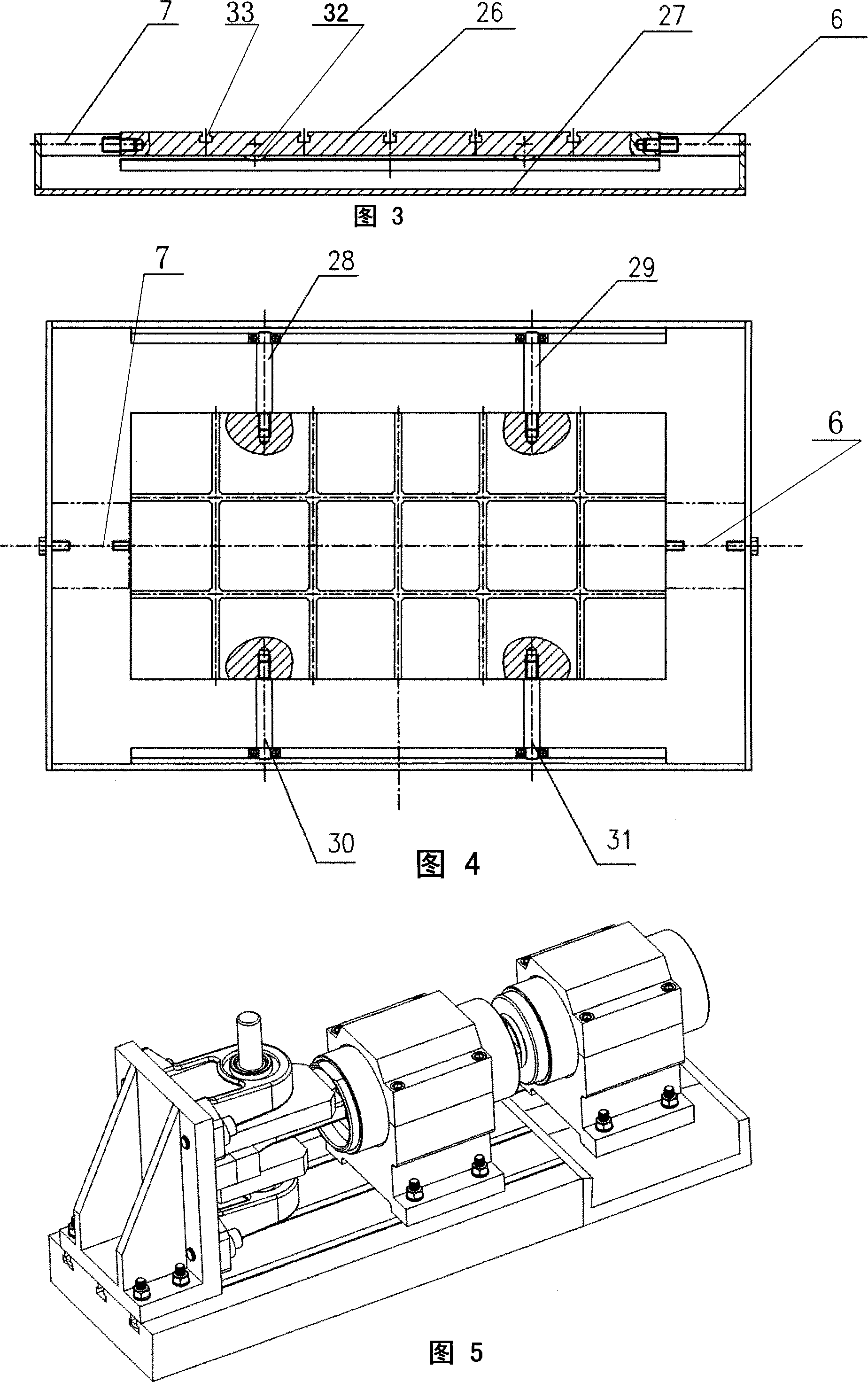

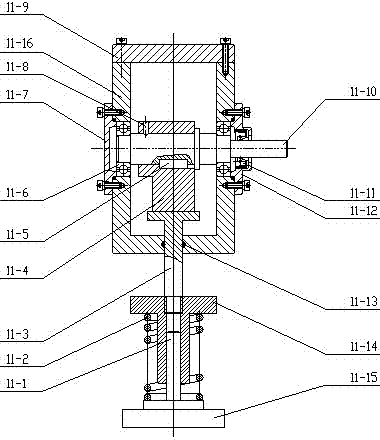

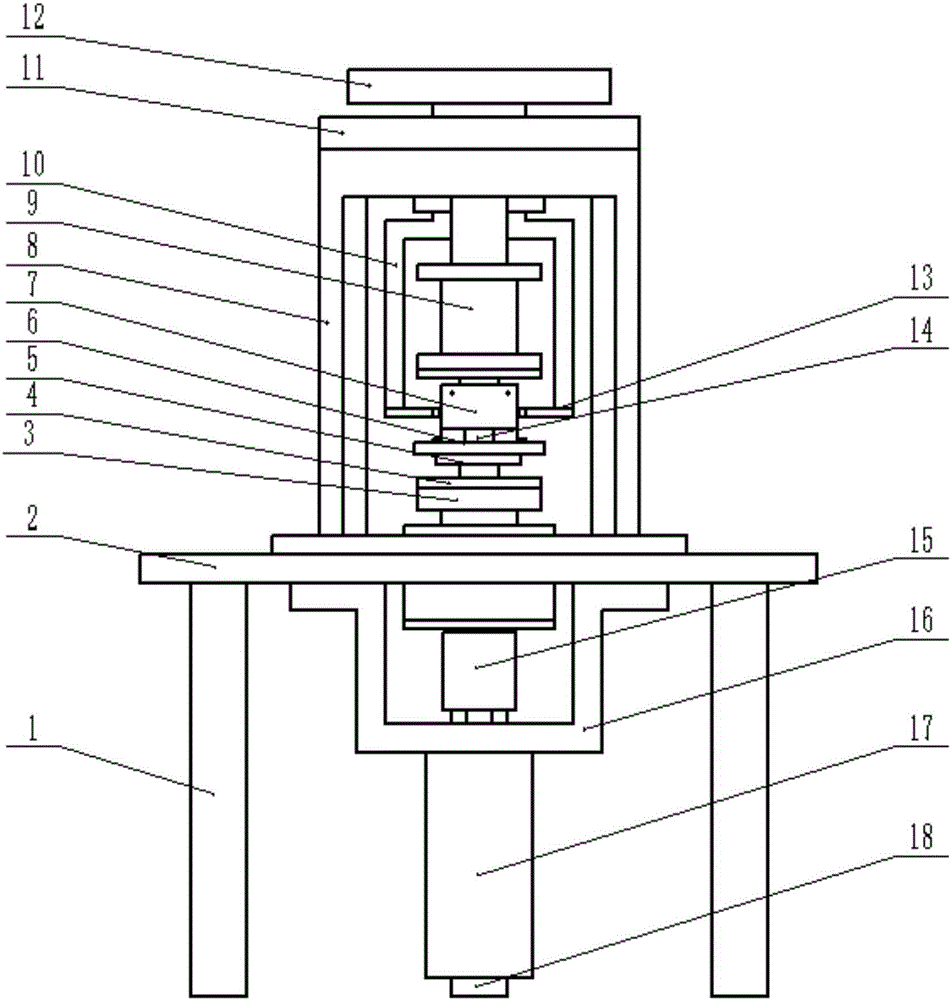

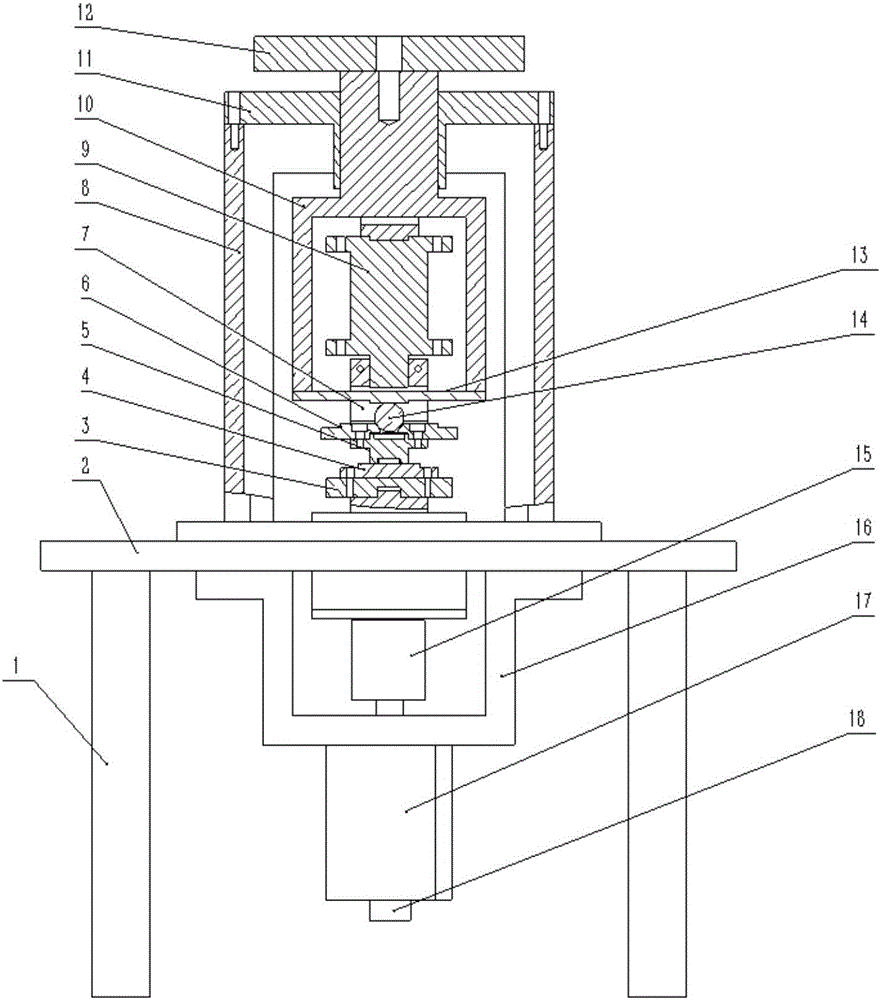

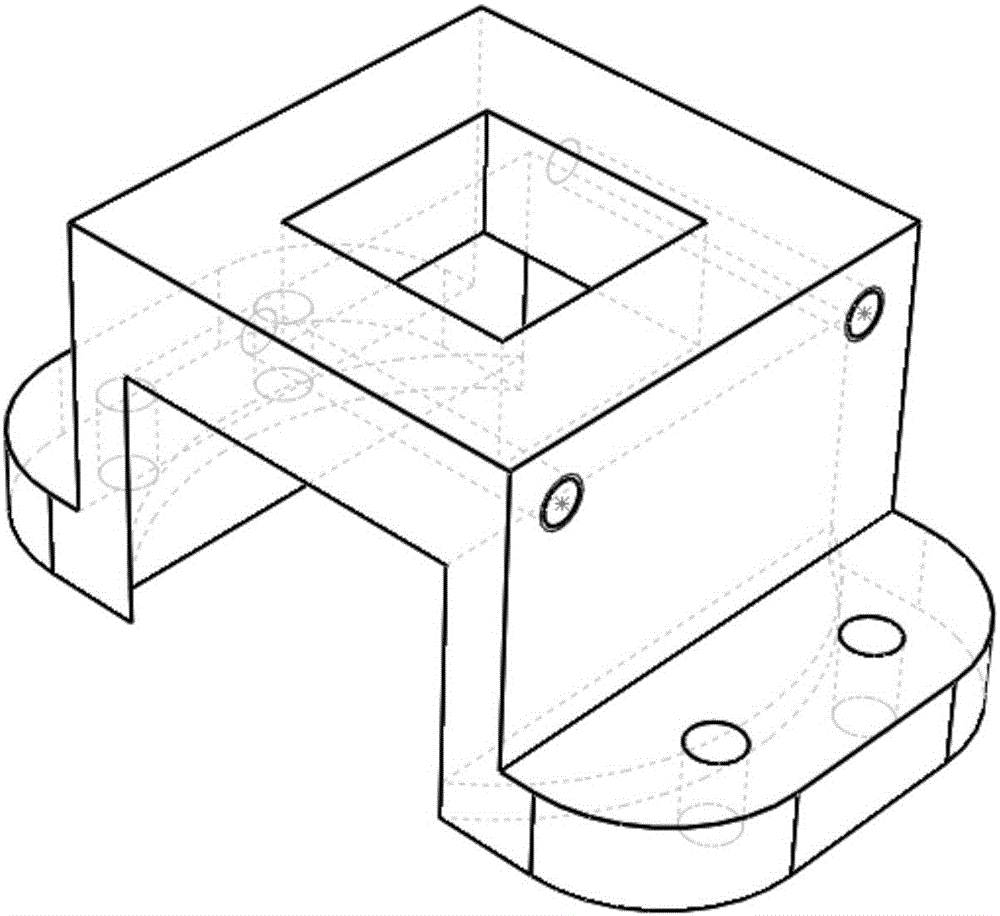

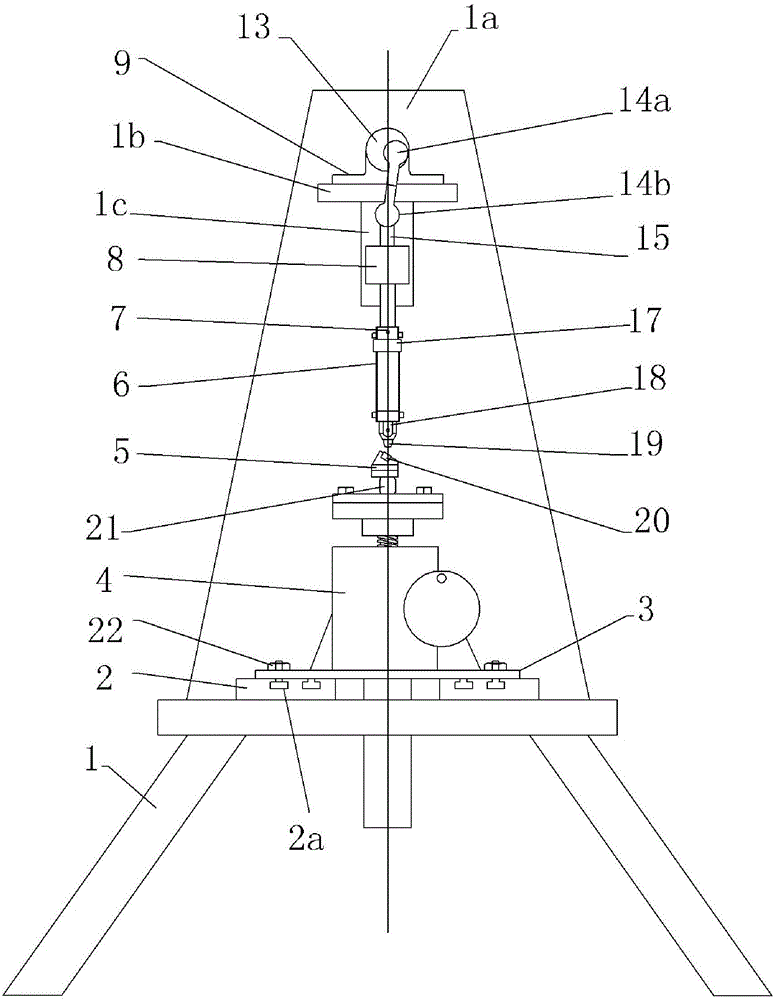

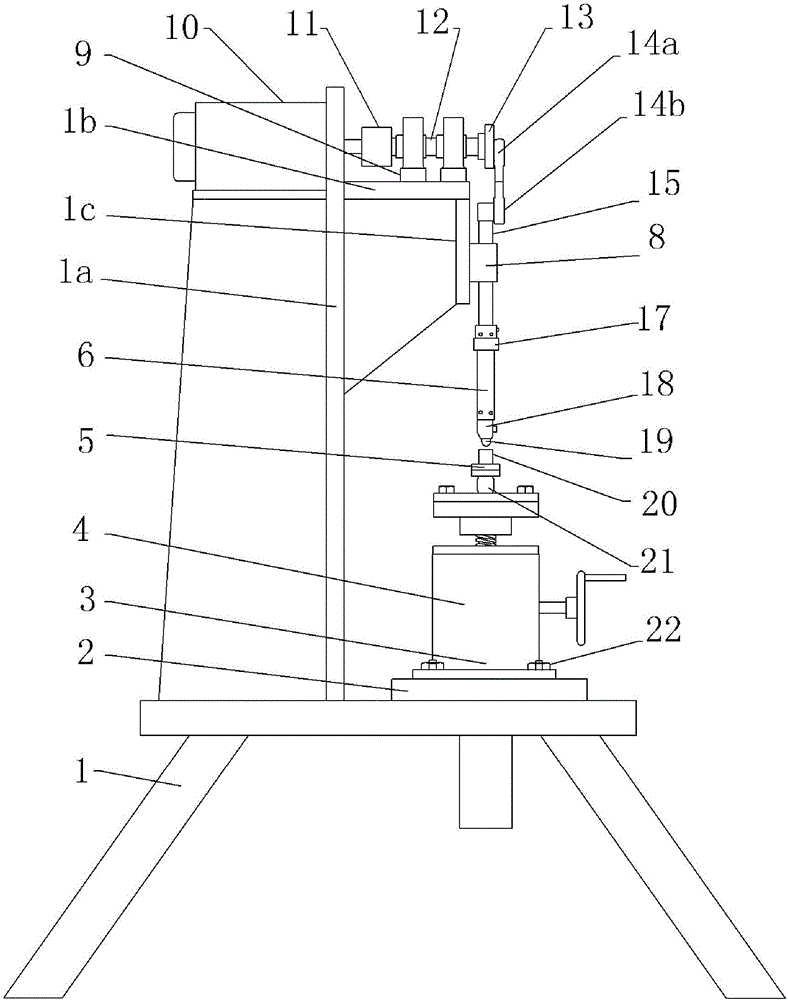

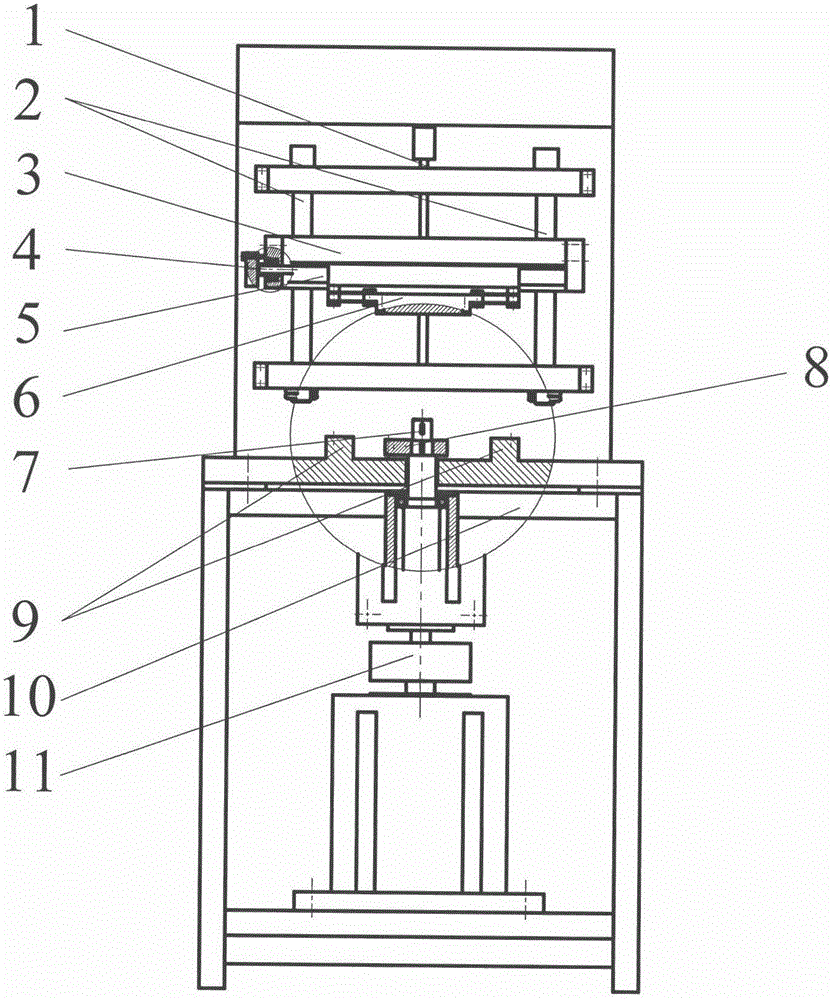

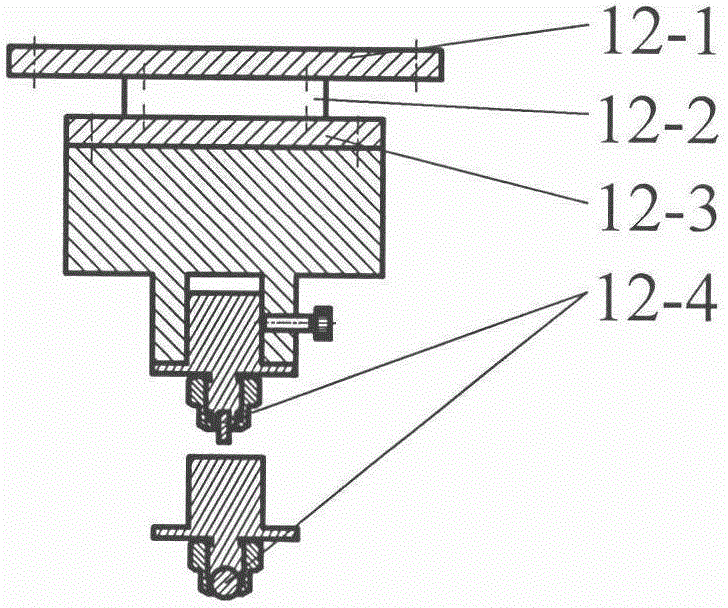

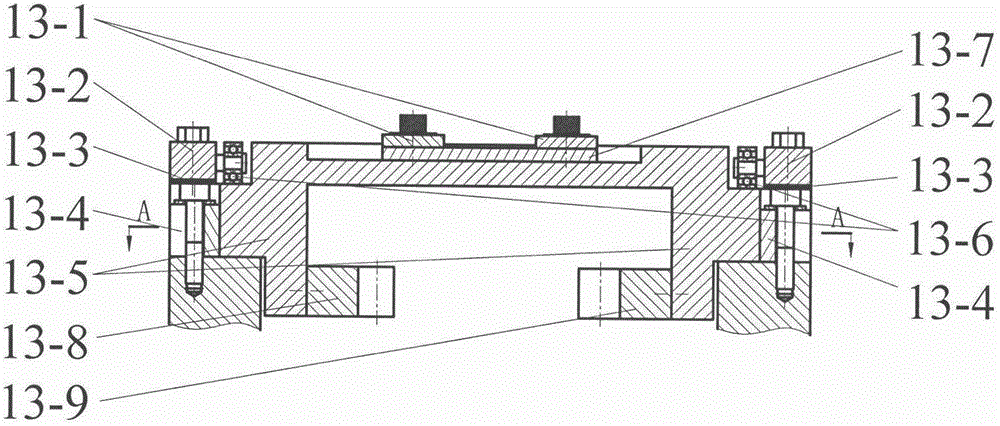

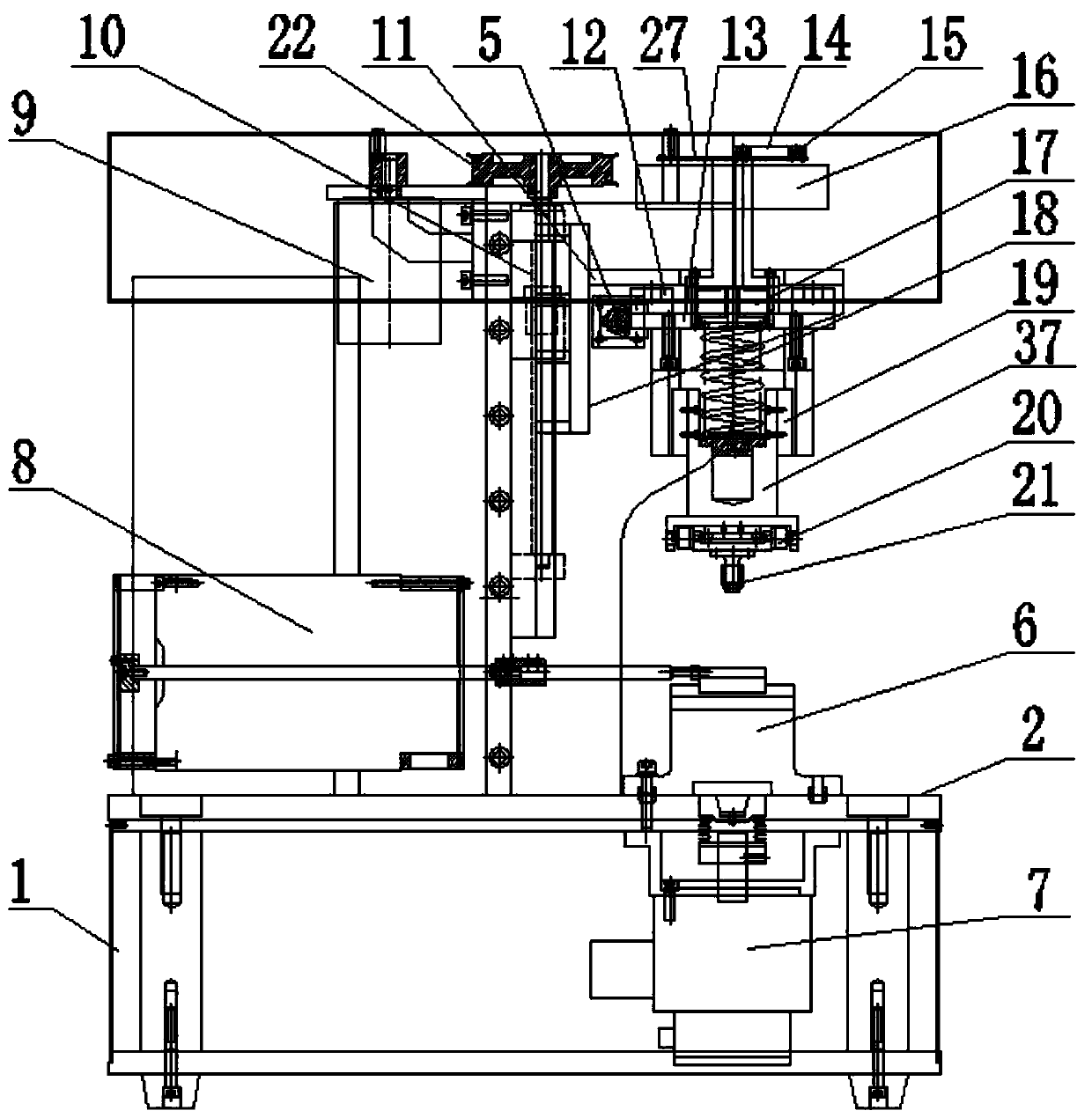

Multifunctional vacuum friction and wear testing machine

ActiveCN102759489APrecise position adjustmentAvoid time costInvestigating abrasion/wear resistanceDrivetrainEngineering

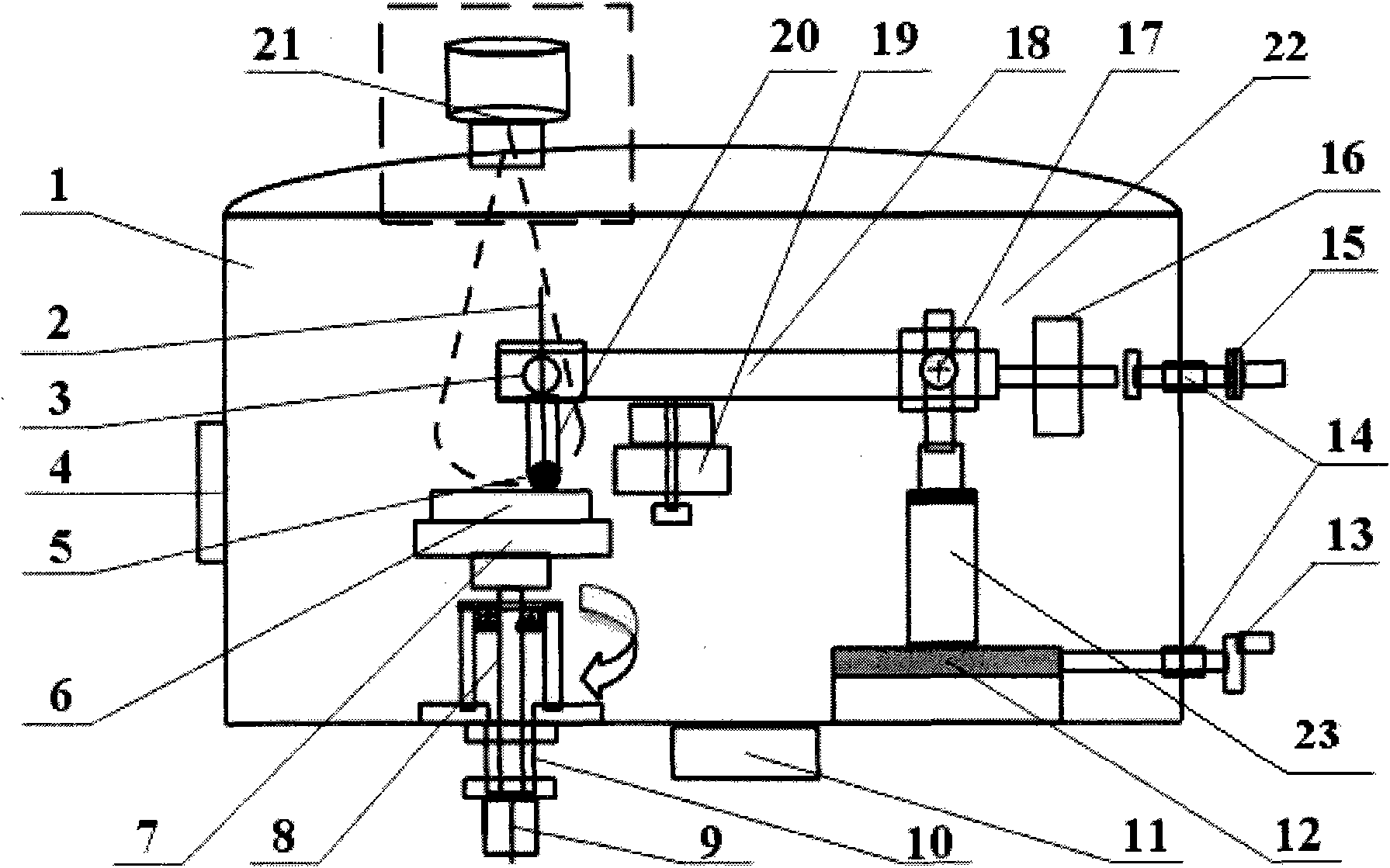

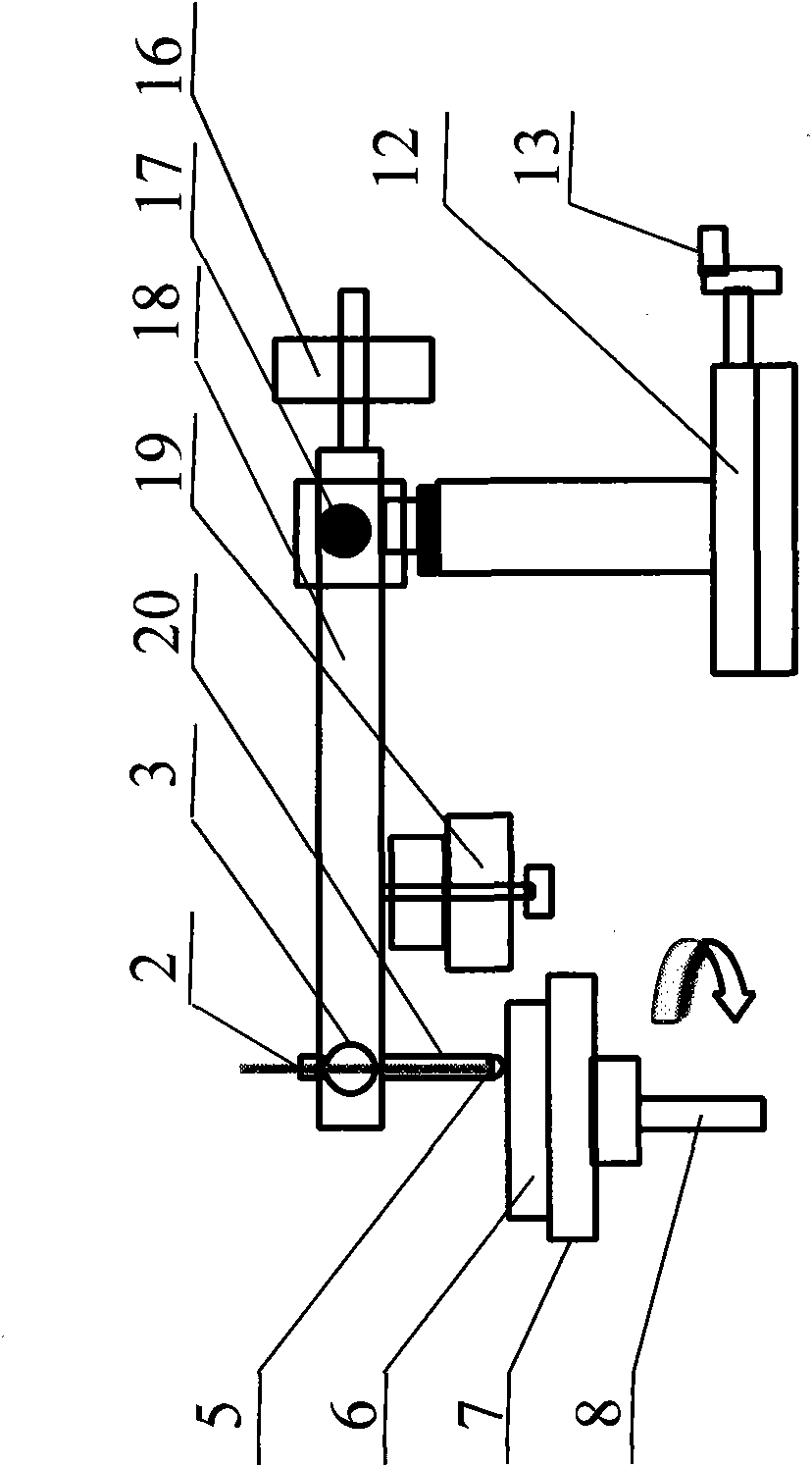

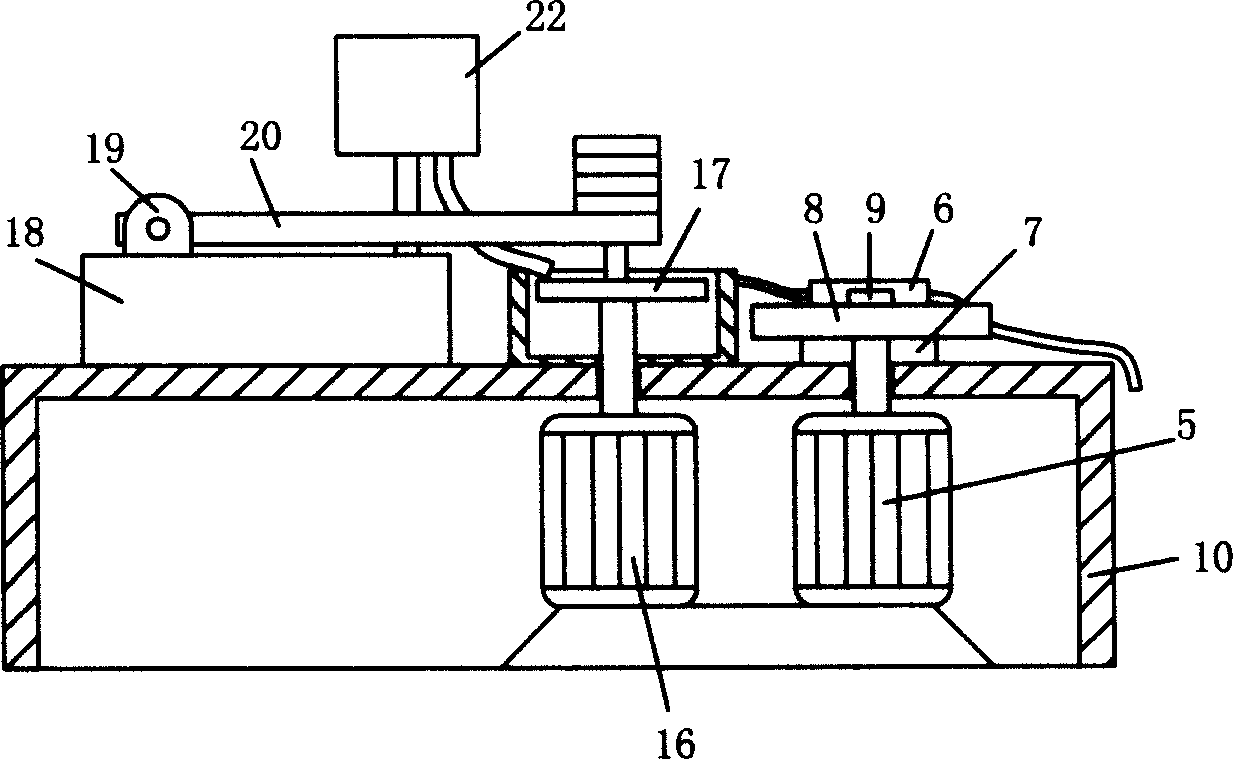

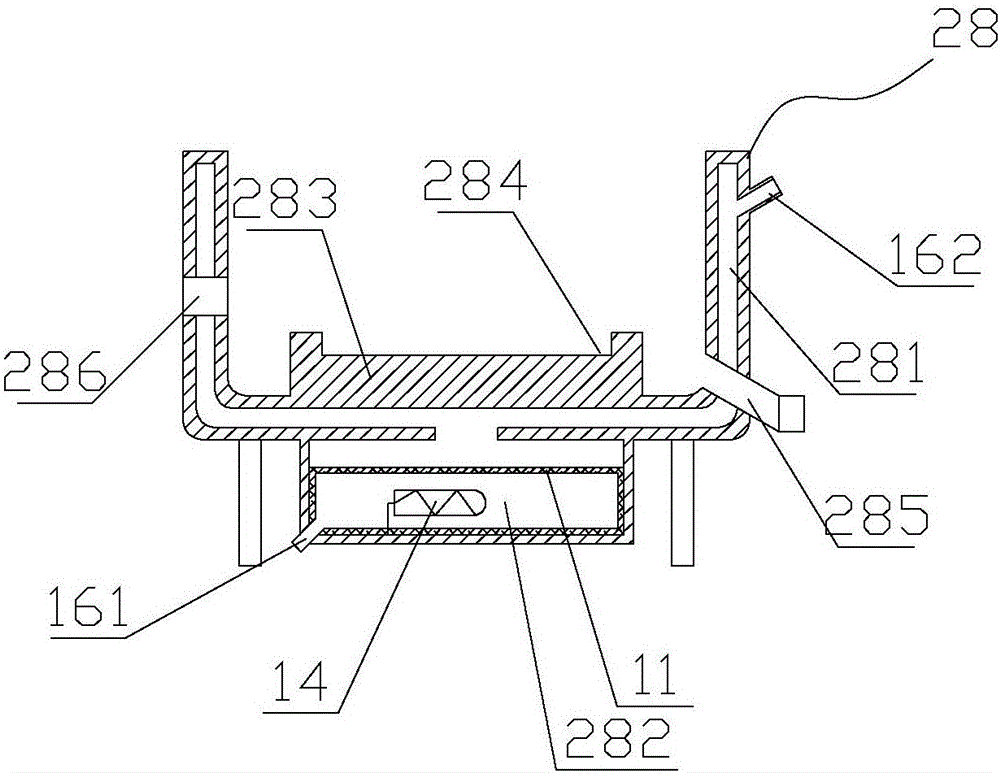

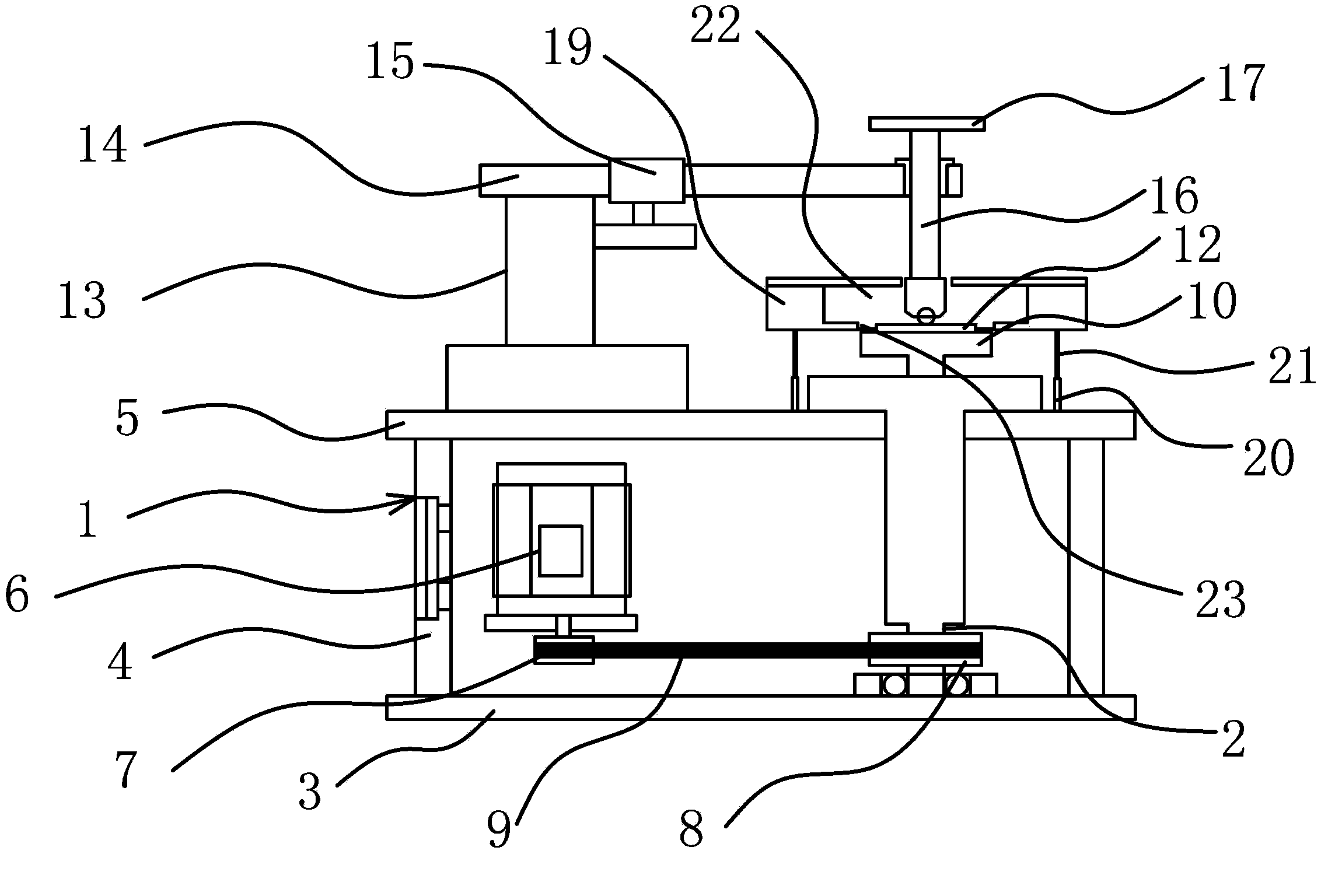

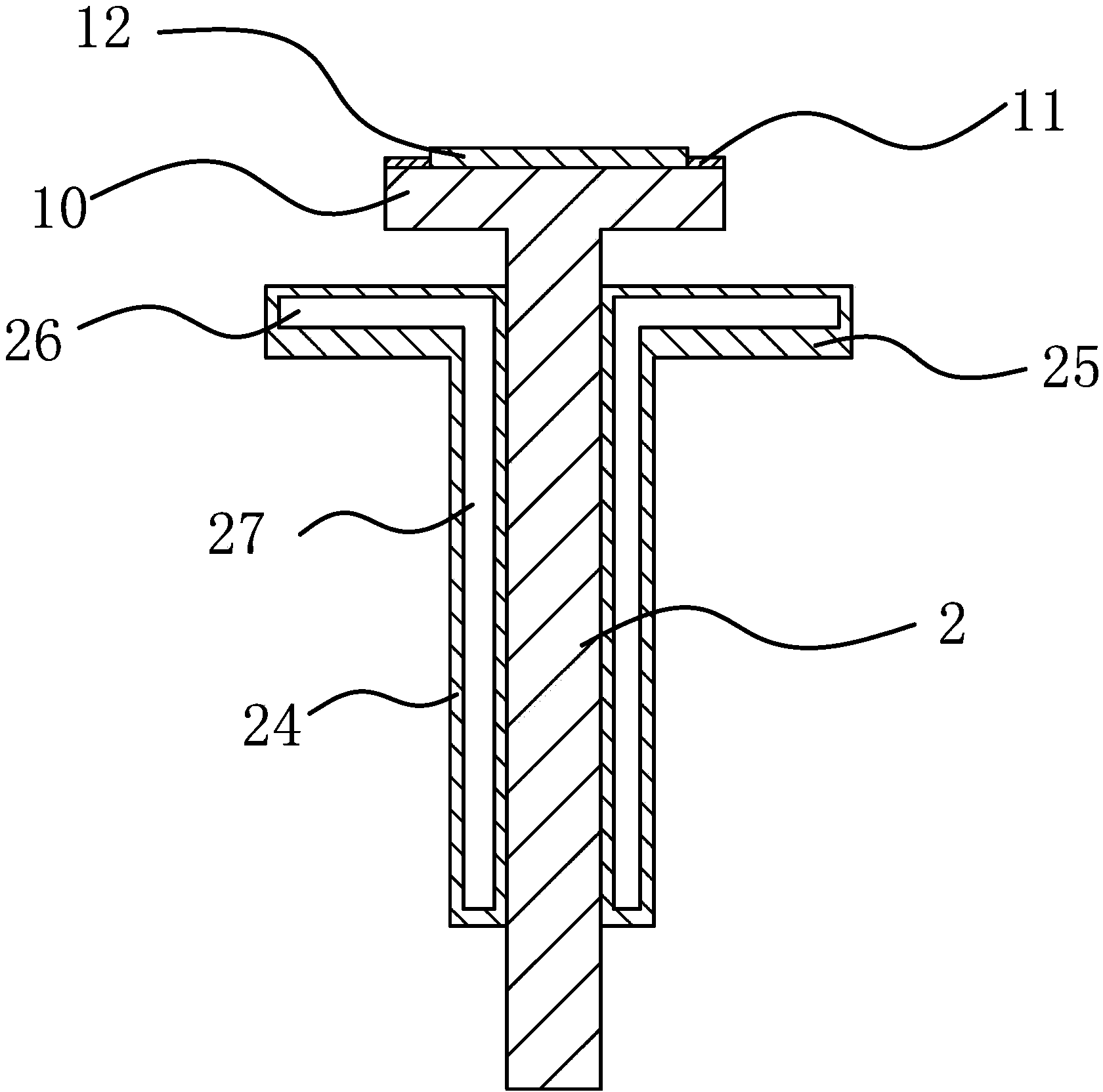

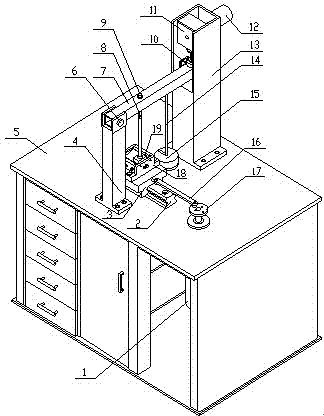

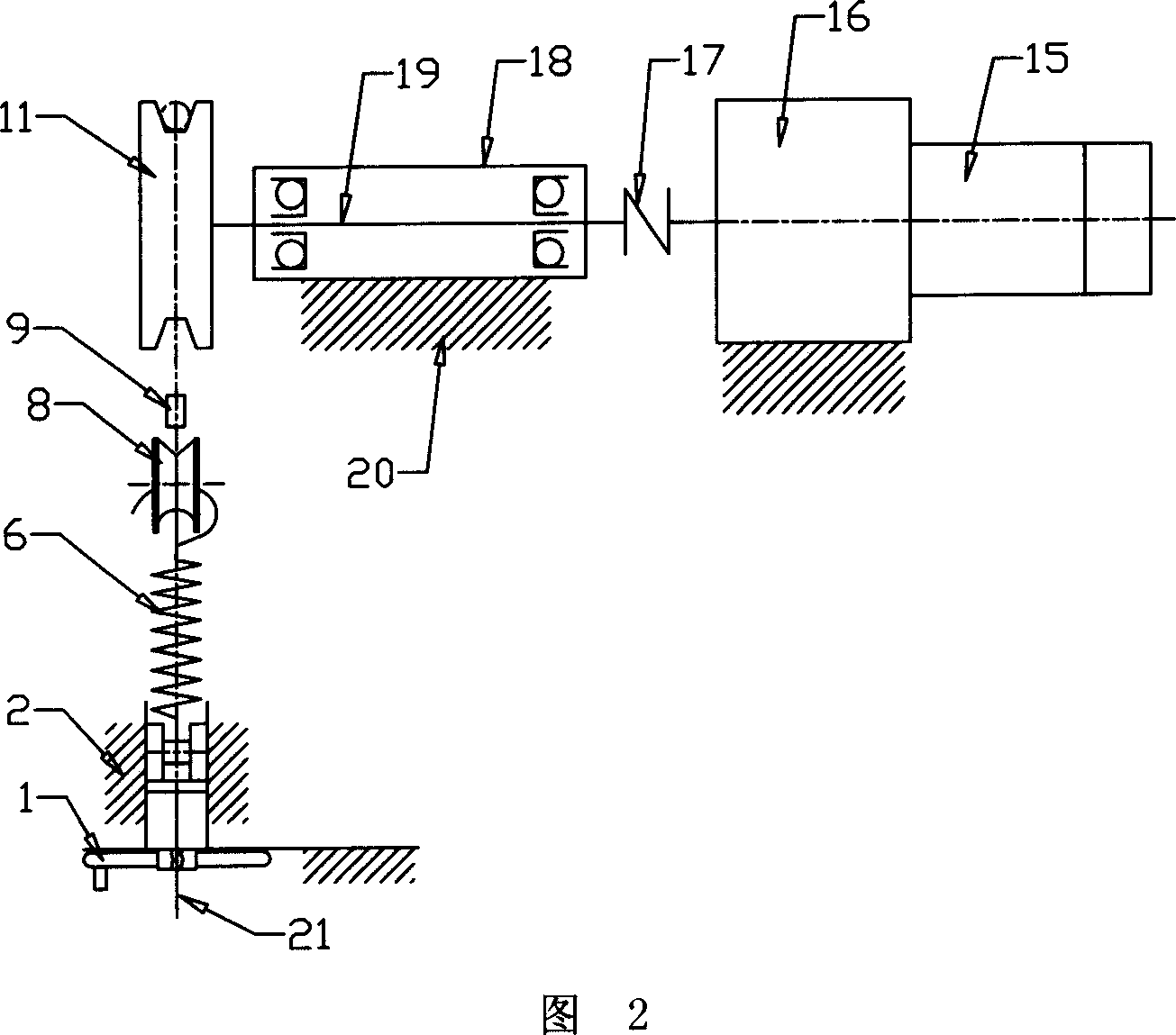

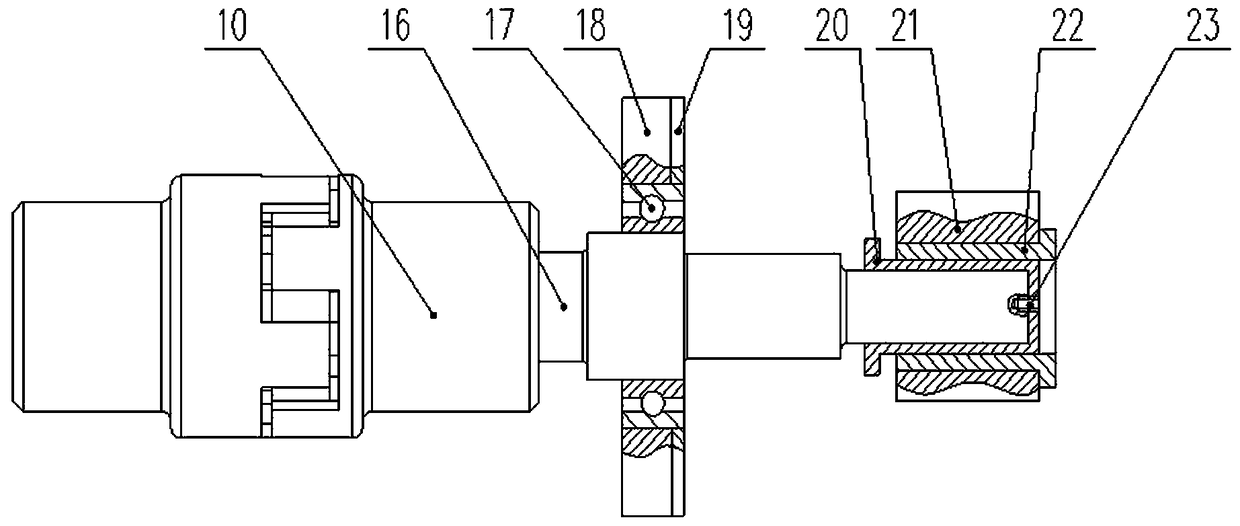

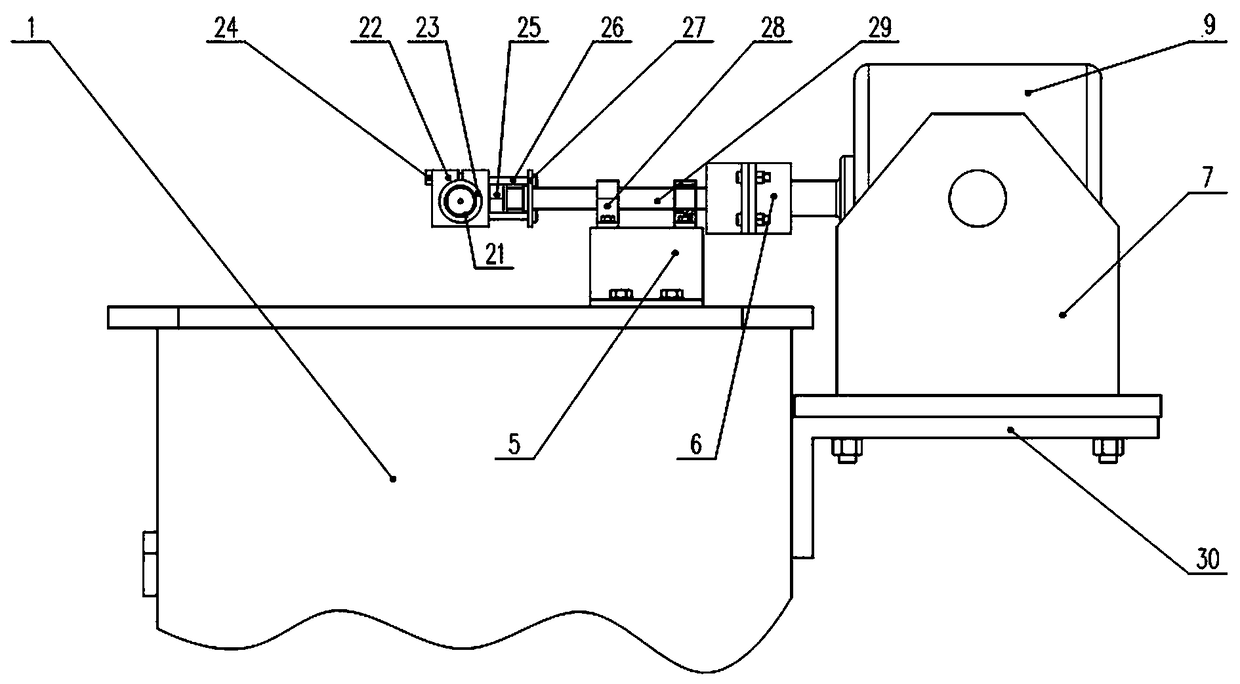

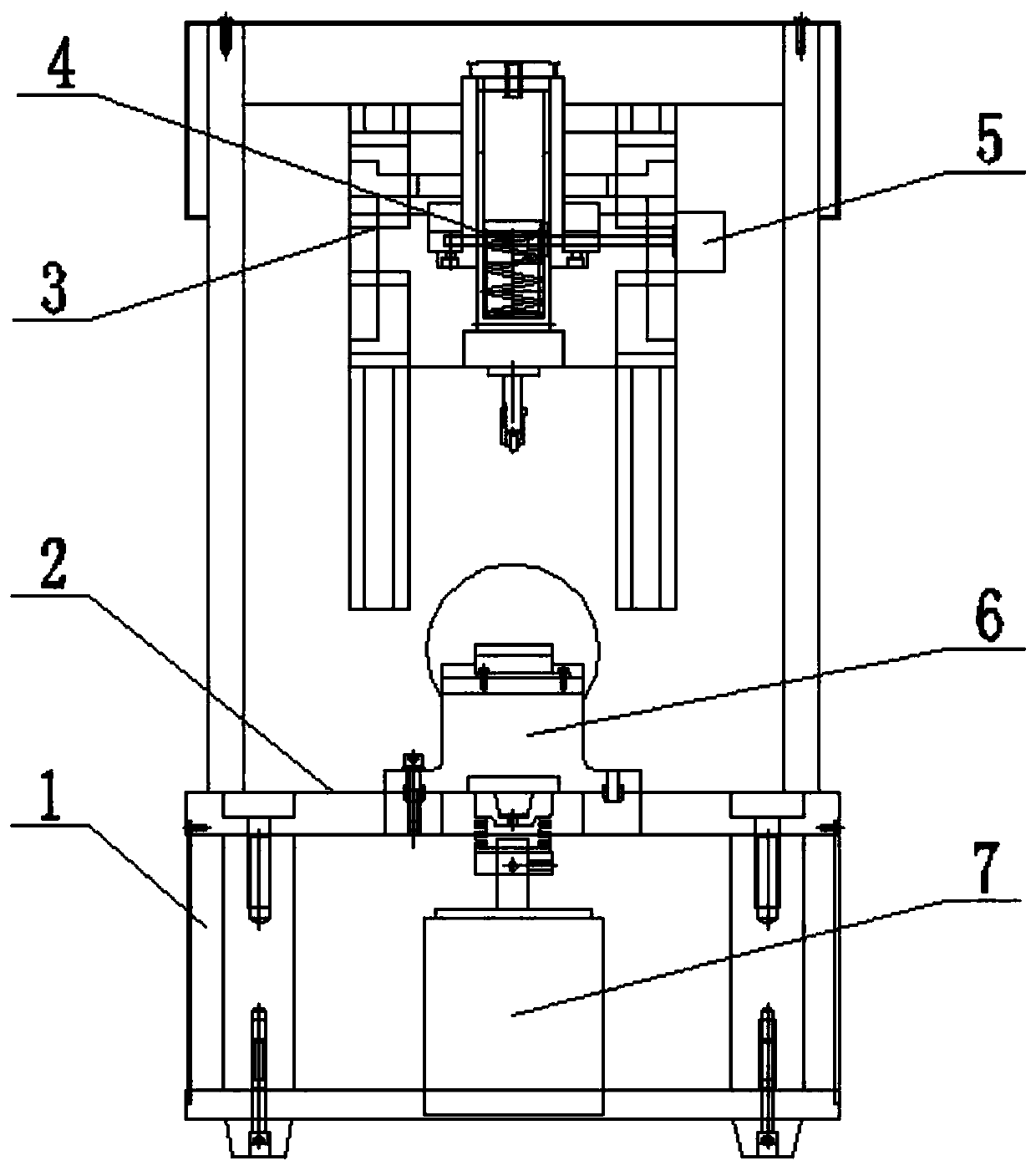

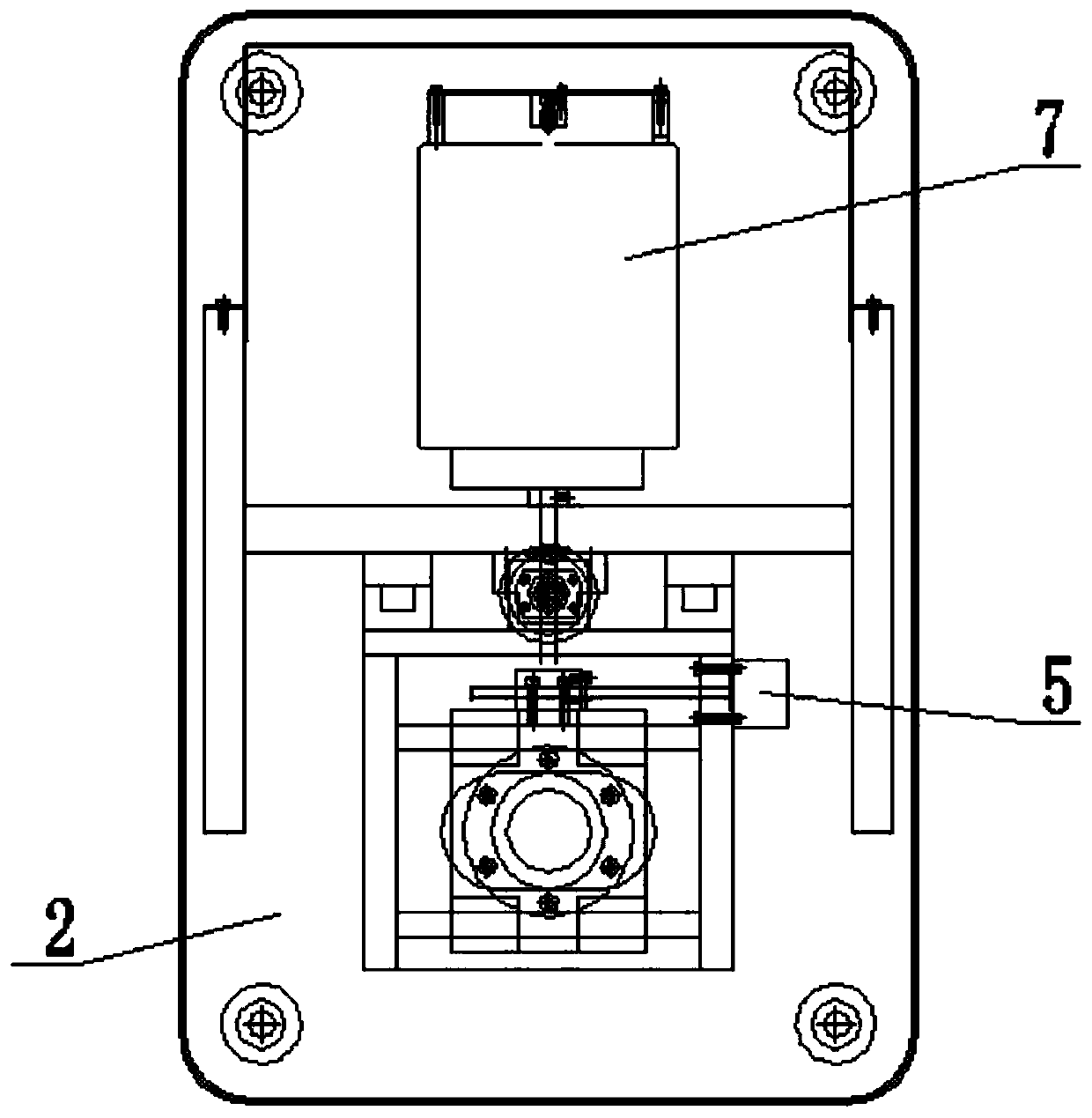

The invention provides a multifunctional vacuum friction and wear testing machine, which not only can simulate special environmental atmospheres such as vacuum, radiation and corrosion, but also can conduct tribology tests in a relatively wide speed and load range by using various contact manners (ball-disc and pin-disc). The multifunctional vacuum friction and wear testing machine mainly comprises a vacuum system, a friction and wear system, a power transmission system, a control system, and the like, wherein the friction and wear system comprises a lever structure (22) used for fixing a test sample fixture (20) and capable of freely rotating in a horizontal direction and a vertical direction; the lever structure (22) comprises a cantilever beam (18) and a vertical arm (23) which are arranged in a perpendicular manner; the cantilever beam (18) is connected with the vertical arm (23) through a two degree of freedom bearing structure (17); positions of the cantilever beam (18) and the vertical arm (23) can be adjusted in the horizontal direction and the vertical direction through the control of a manipulator (15) and a hand wheel structure (13), so that the test sample fixture (20) can accurately move within two degrees of freedom; and a temperature sensor (2) and a pressure sensor (3) are mounted on the test sample fixture (20), so as to detect / monitor friction coefficients and temperature variations during the tribology tests.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Multifunctional micro friction wear testing machine

InactiveCN101017129AGreat driving forceLess exerciseUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceWear testing

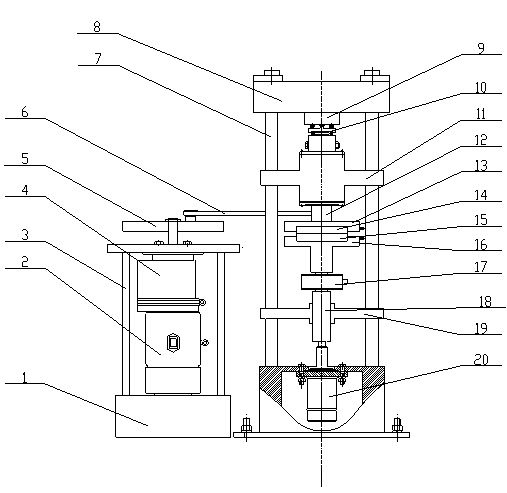

This invention relates to one multi-function micro friction test machine, which comprises drive device, move device connected to the drive one and load and measurement device on the move device and lift bench of the measurement device, wherein, it uses hanging spring board and connection bar are hinged with drive device and move device to make the slide bench generate one small range reverse line move under bar push with constant vibration range and small error; it uses motor to drive connection bar push slide to generate large vibration reverse line move.

Owner:CHINA UNIV OF MINING & TECH

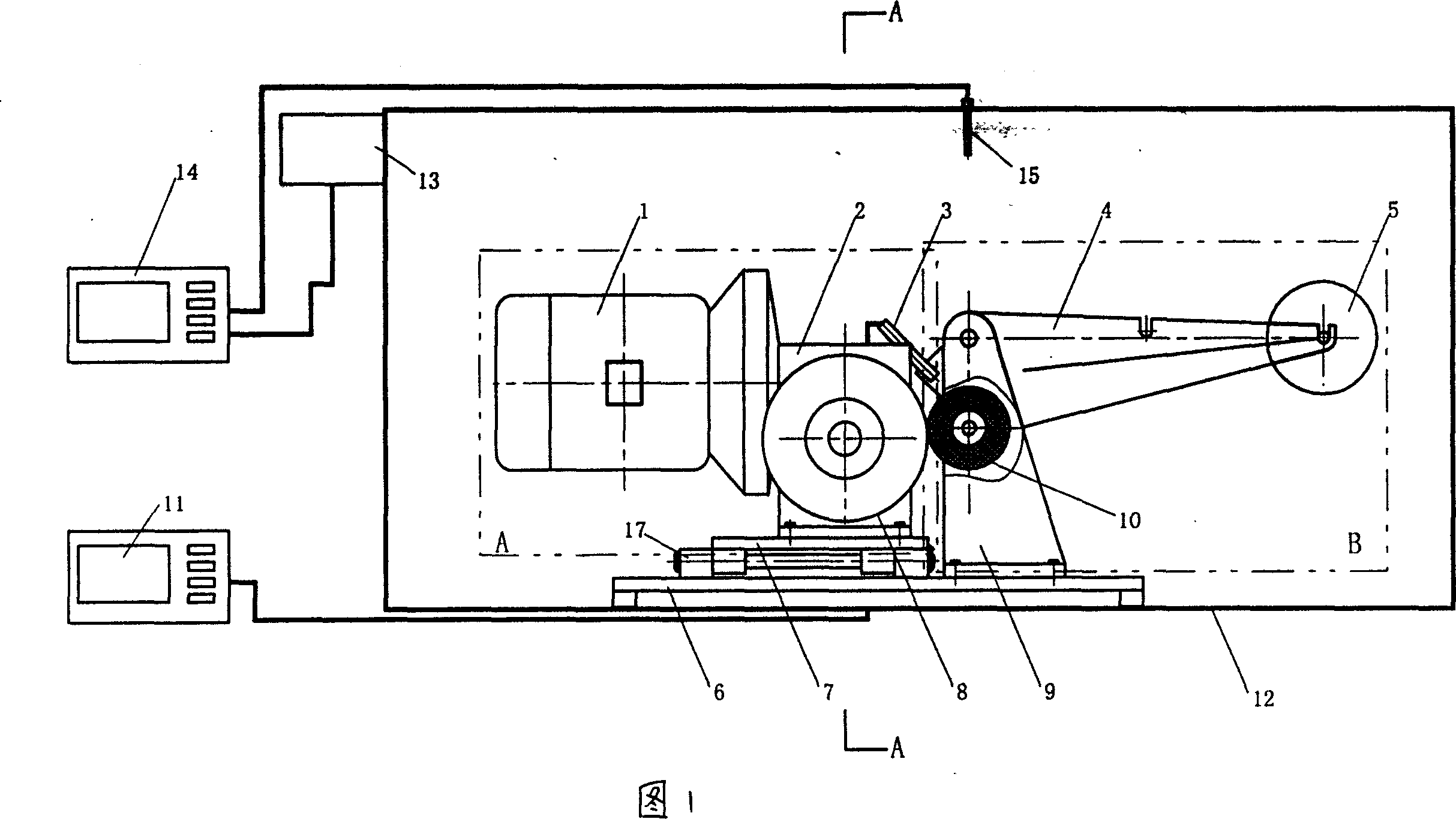

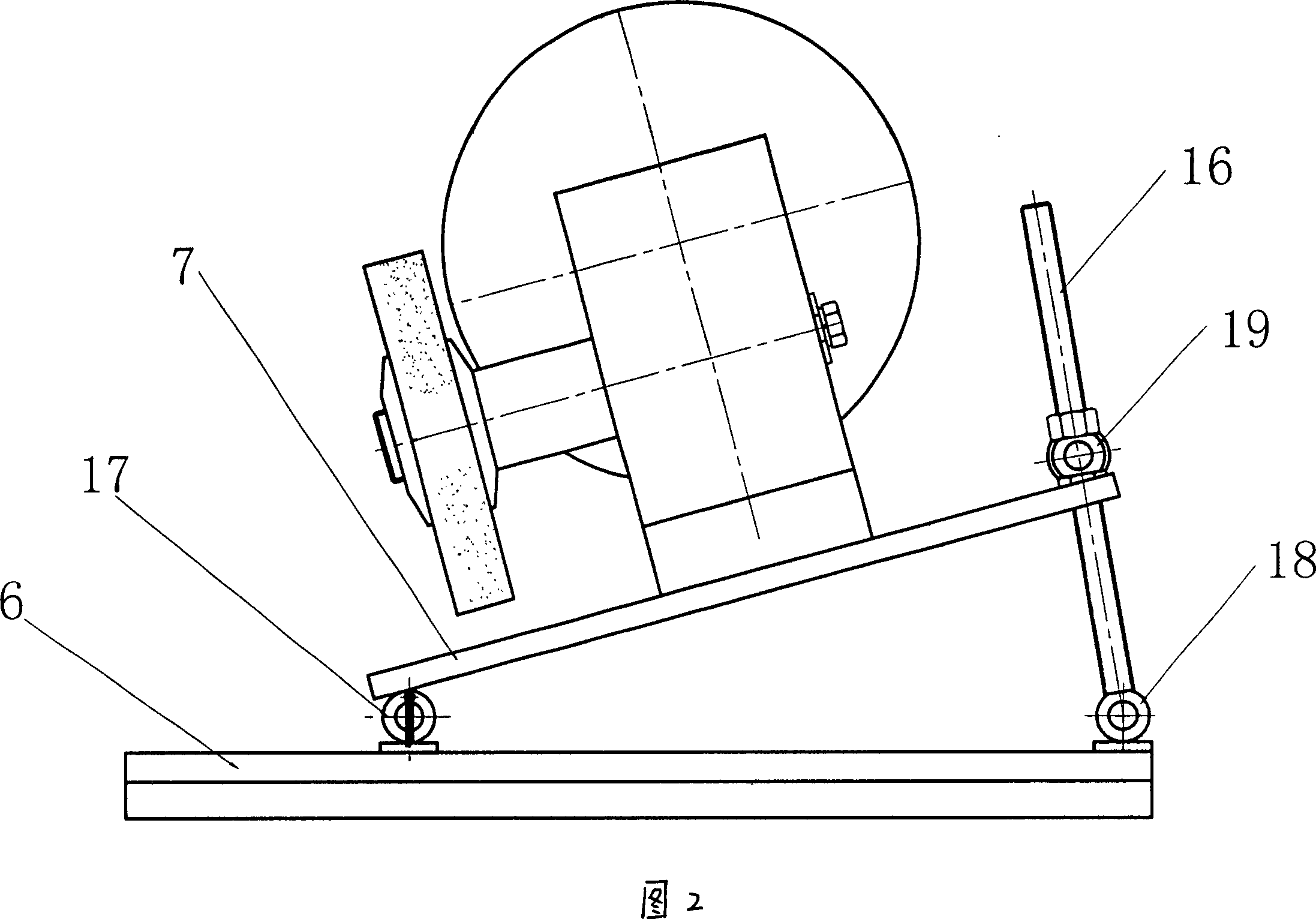

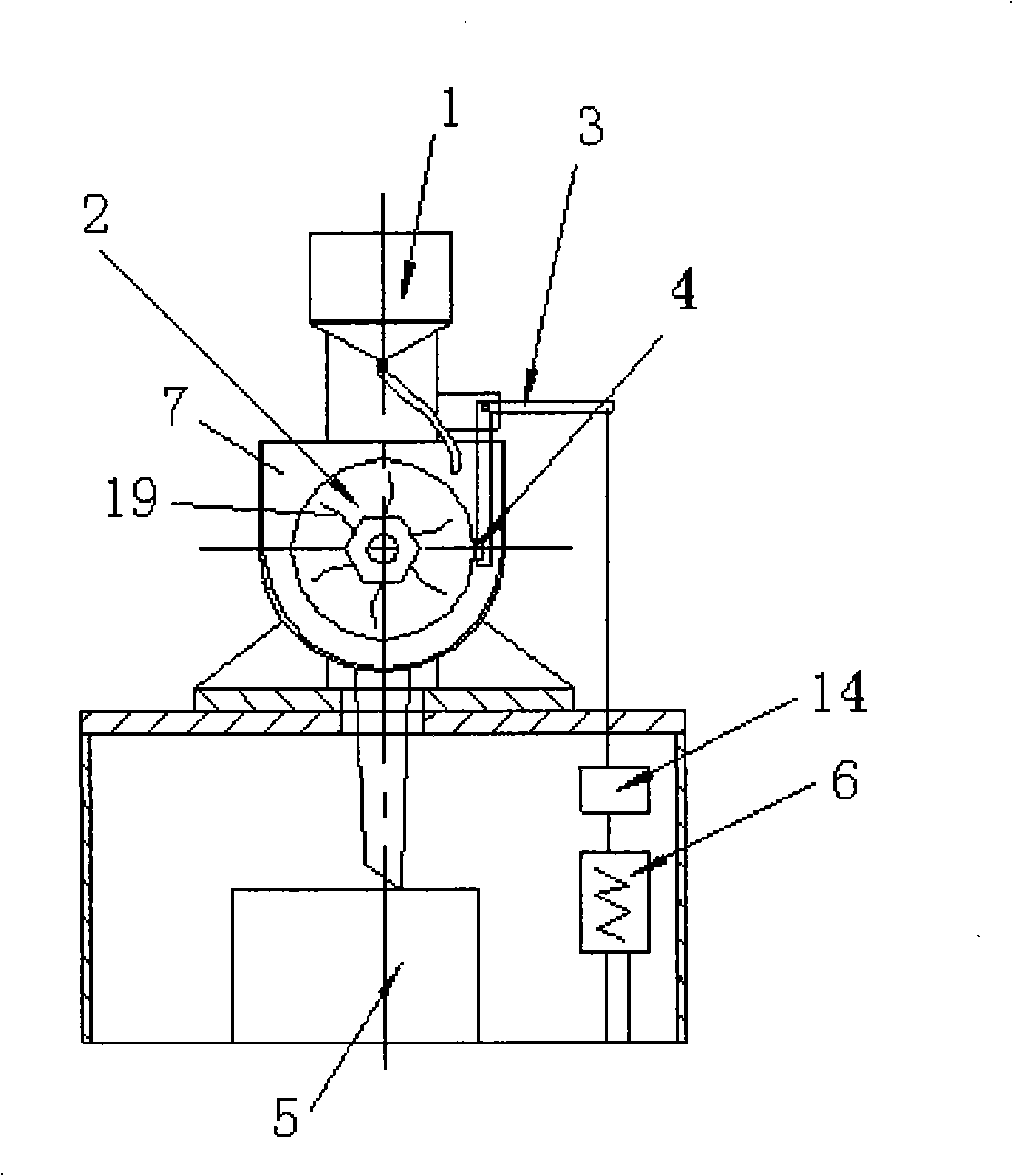

Rubber abrasion test equipment

InactiveCN101013074AReflects real wear resistanceFacilitates continuous batch testingUsing mechanical meansVehicle tyre testingWear testingElectric machinery

The invention discloses a rubber wear test equipment, which includes the wear machine main-body, thermo-regulating device, speed-regulating device, angle-regulating device and temperature measurement device, in which the wear machine main-body is divided into driven system A and follower system B, the driven system A installed in the motor seat, the follower system B directly installed on the base through the bolts, and the driven system A includes a speed regulating motor, a speed controller and the wheel, the follower system B including a load lever, a weight, a frame and a sample rubber tire. In the wear testing of this invention, temperature, speed, load, wear angle are all adjustable to achieve different speed, different load, different angle wear testing, and it can fully simulate the tire different practical using conditions. It overcomes the defects of Akron wear machine that the test temperature, load and speed are all constant value and less than the tire actual value, and the experimental results show that the invention can better reflect the real wear resistance of rubber tires in different environmental conditions.

Owner:SOUTH CHINA UNIV OF TECH

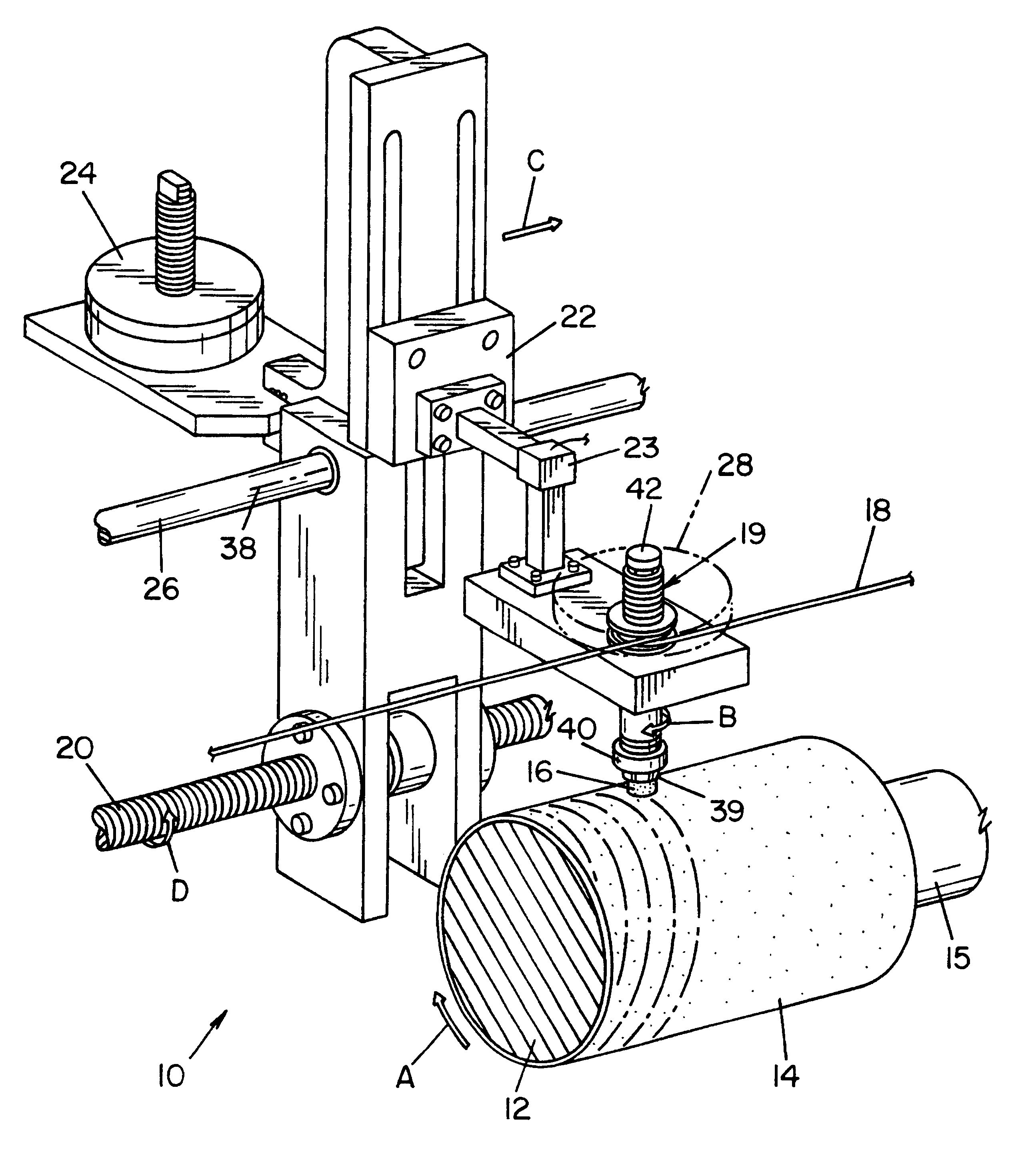

Abrasion tester

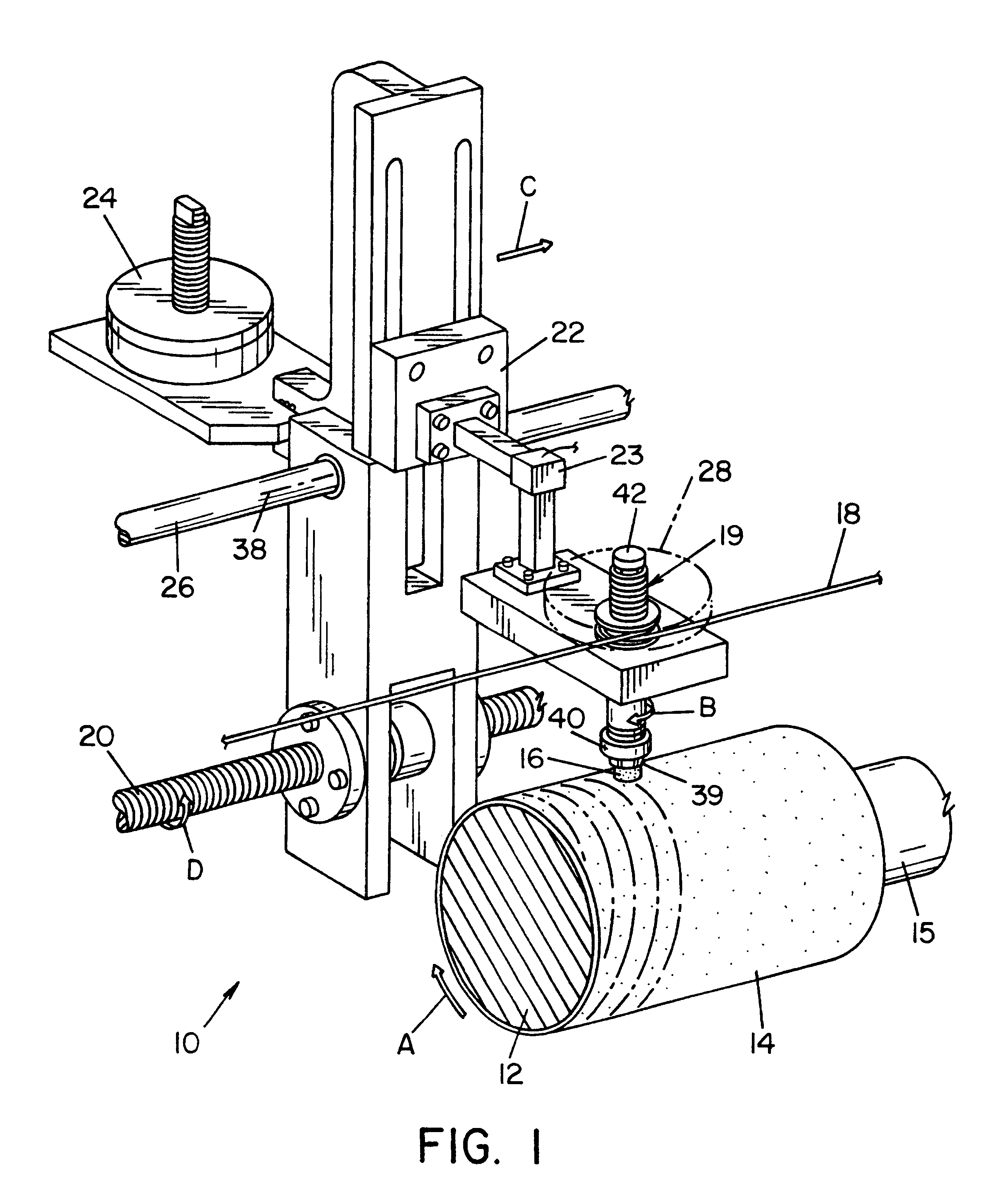

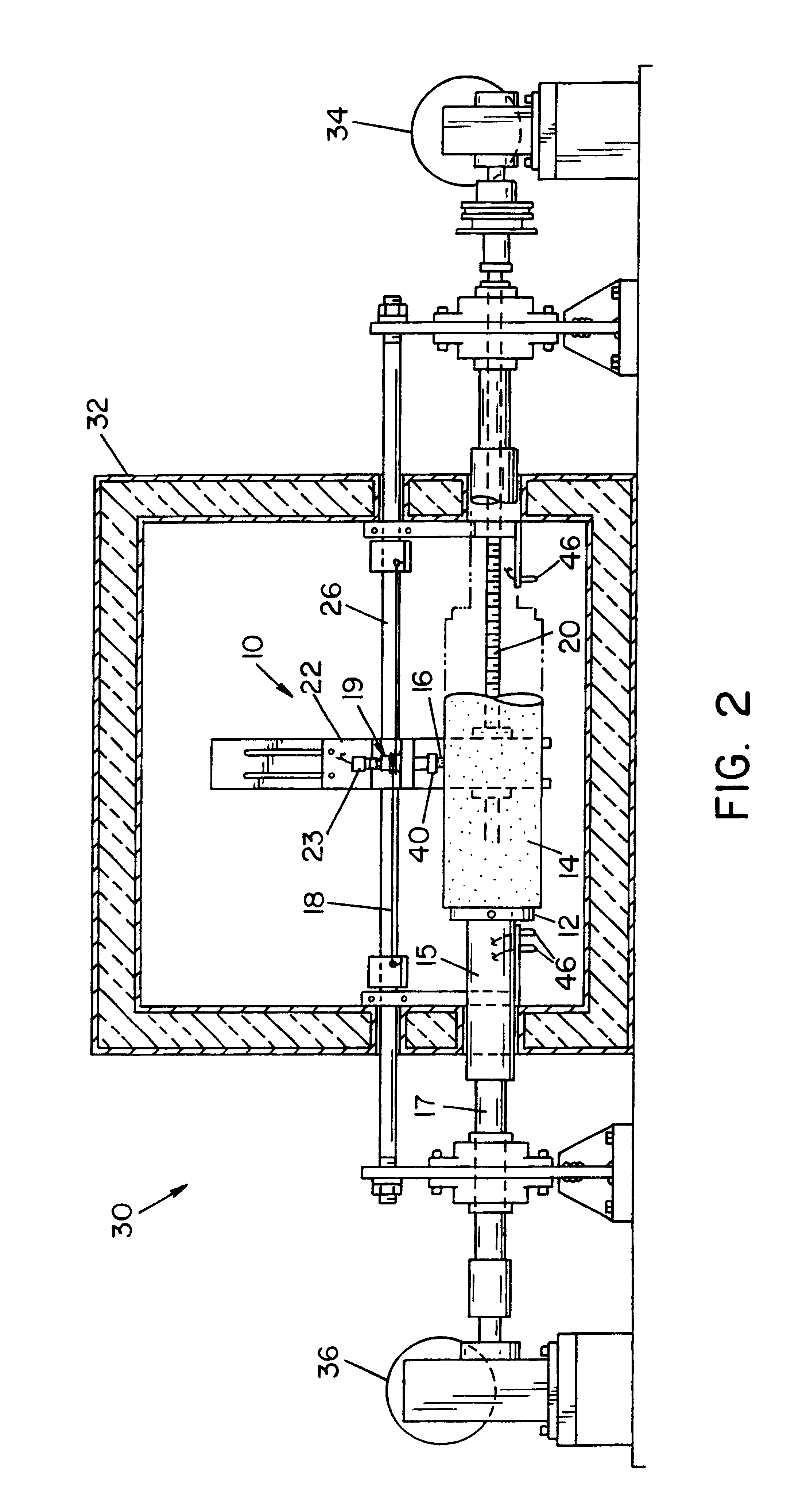

InactiveUS6412330B1Drag minimizationMinimal frictionUsing mechanical meansMaterial testing goodsRough surfaceWear testing

An apparatus for measuring abradability of a sample comprises a rotating drum with a rough surface and a means for contacting a sample with the rough surface while the drum is rotating. The sample may be caused to rotate relative to the drum, and to translate across the drum while the drum is rotating. Environmental controls may be used to control the temperature and the atmospheric conditions of the test. In the method of the invention, energy consumed by contact between the sample and the drum, as well as the weight loss of the sample, may be measured.

Owner:THE GOODYEAR TIRE & RUBBER CO

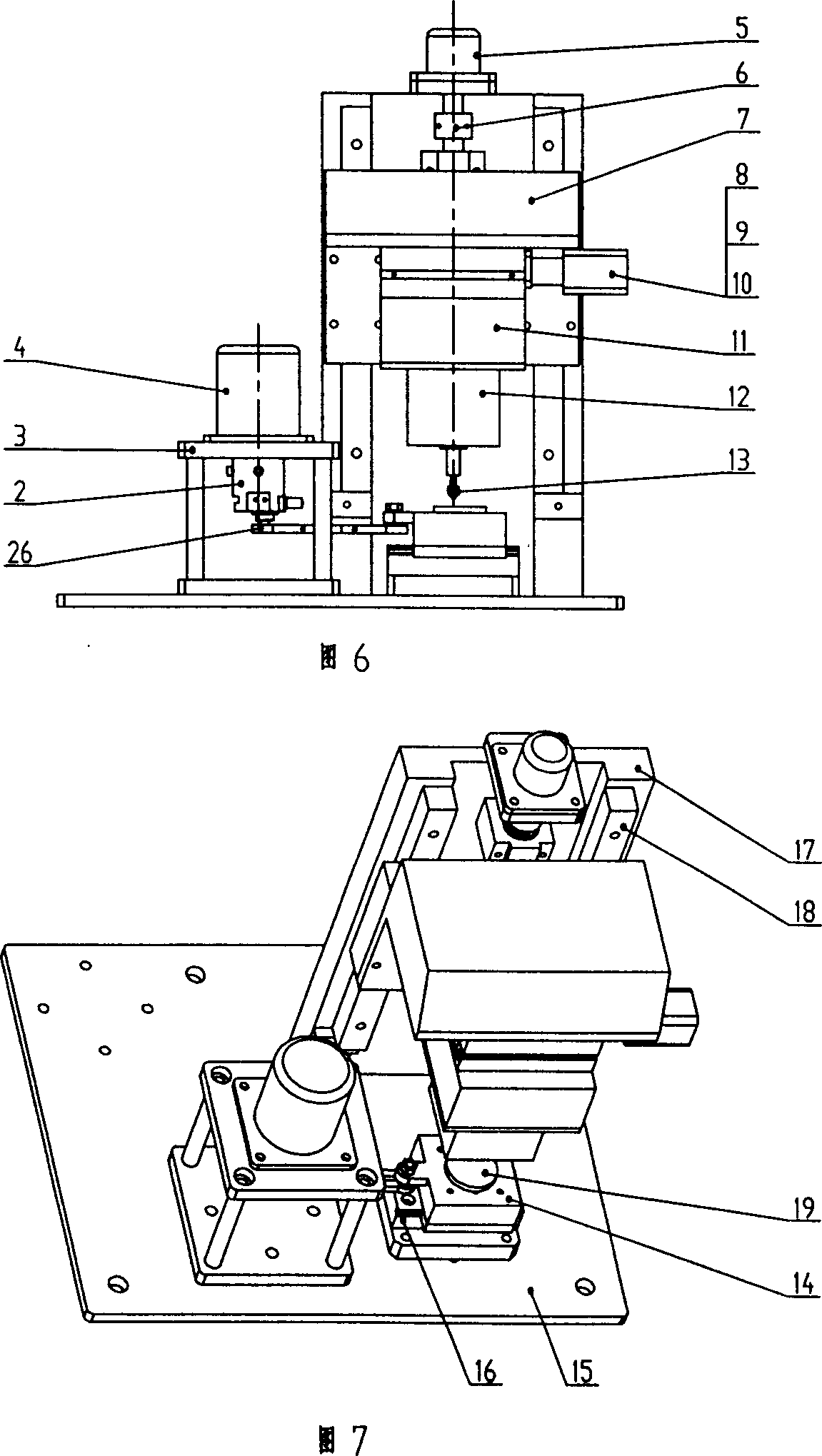

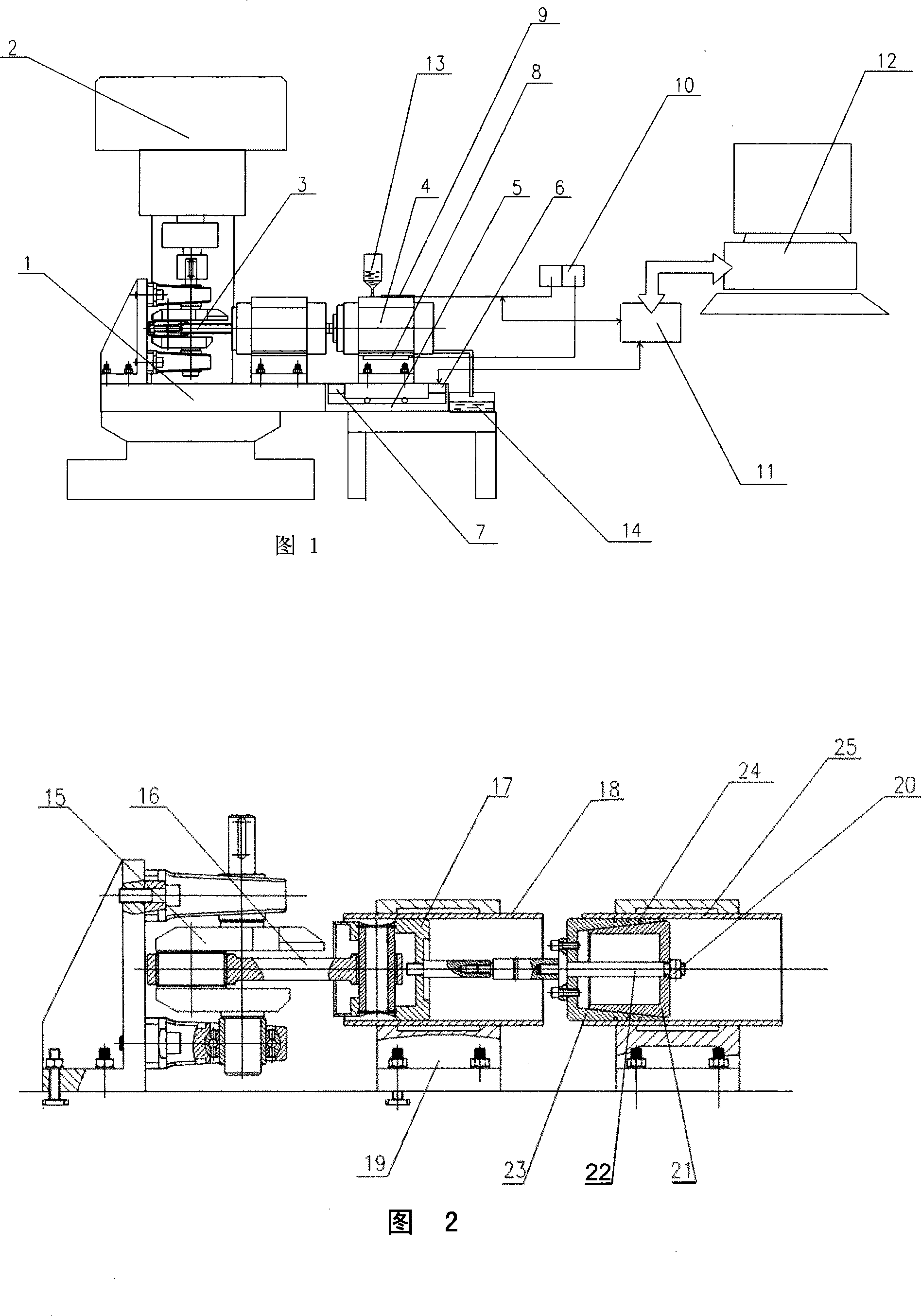

Reciprocal and rotary type incorporated frictional wear test machine

InactiveCN1595100ANo need to disassembleGuaranteed accuracyInvestigating abrasion/wear resistanceCircular discWear testing

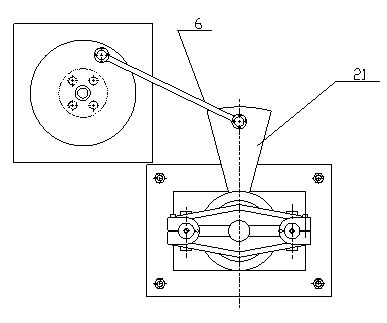

This invention discloses two kinds of friction wearing testing machine of integration of reciprocating and rotating, which comprises base socket , reciprocating structure, rotating structure and upper-specimen control device, wherein, the reciprocating structure comprises reciprocating motor, slide block, slide rail, crank, connecting bar; and the rotating structure comprises rotating drive motor and rotating disc; and the upper-specimen control device comprises spring arm, guide rail and slide holder or spring arm , rotating parts and base socket. This invention integrates the reciprocating structure friction wearing machine and rotating friction wearing machine into one structure through special designed base socket and upper-specimen control device and it needn't disassembly specimen and ensures the accuracy of the experience data.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Constant temperature wiggly corrosive wear testing device and test method thereof

InactiveCN101598660ATorsional Corrosion Wear RealizationRealize constant temperature torsion corrosion wear testWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceWater bathsWear testing

The invention relates to a constant temperature wiggly corrosive wear testing device and a test method thereof. A medium cavity of a high ball discharge test piece is arranged on the periphery of a lower clamp of the testing device, and the cavity is filled with test medium; the wall of the cavity is of a sandwich layer structure, the lower part of the sandwich layer is provided with a water inlet, the upper part is provided with a water outlet, the water inlet is connected with a constant temperature water bath kettle by a miniature water pump, and the water outlet is directly connected with the constant temperature water bath kettle, thereby forming a constant temperature water circulation system; an auxiliary electrode and a reference electrode are immersed in test medium of the medium cavity; and the auxiliary electrode, the reference electrode and the upper end face of an upper test piece are respectively connected with the corresponding port of a microprocessor controlled electrochemical workstation by conducting lines so as to form an electrochemical corrosion test system. The testing device and the method thereof can conveniently wear materials in the constant temperature test medium by wiggly corrosion, thereby much more factually and accurately testing the wiggly corrosive wear property of the materials in the specific corrosion medium; and the testing device and the method thereof provide much more accurate and reliable test basis for corresponding design, so that the properties and the service lives of equipment and apparatus can be increased.

Owner:SOUTHWEST JIAOTONG UNIV

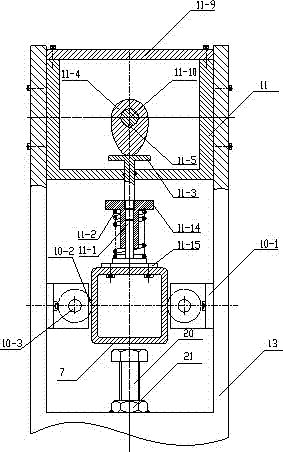

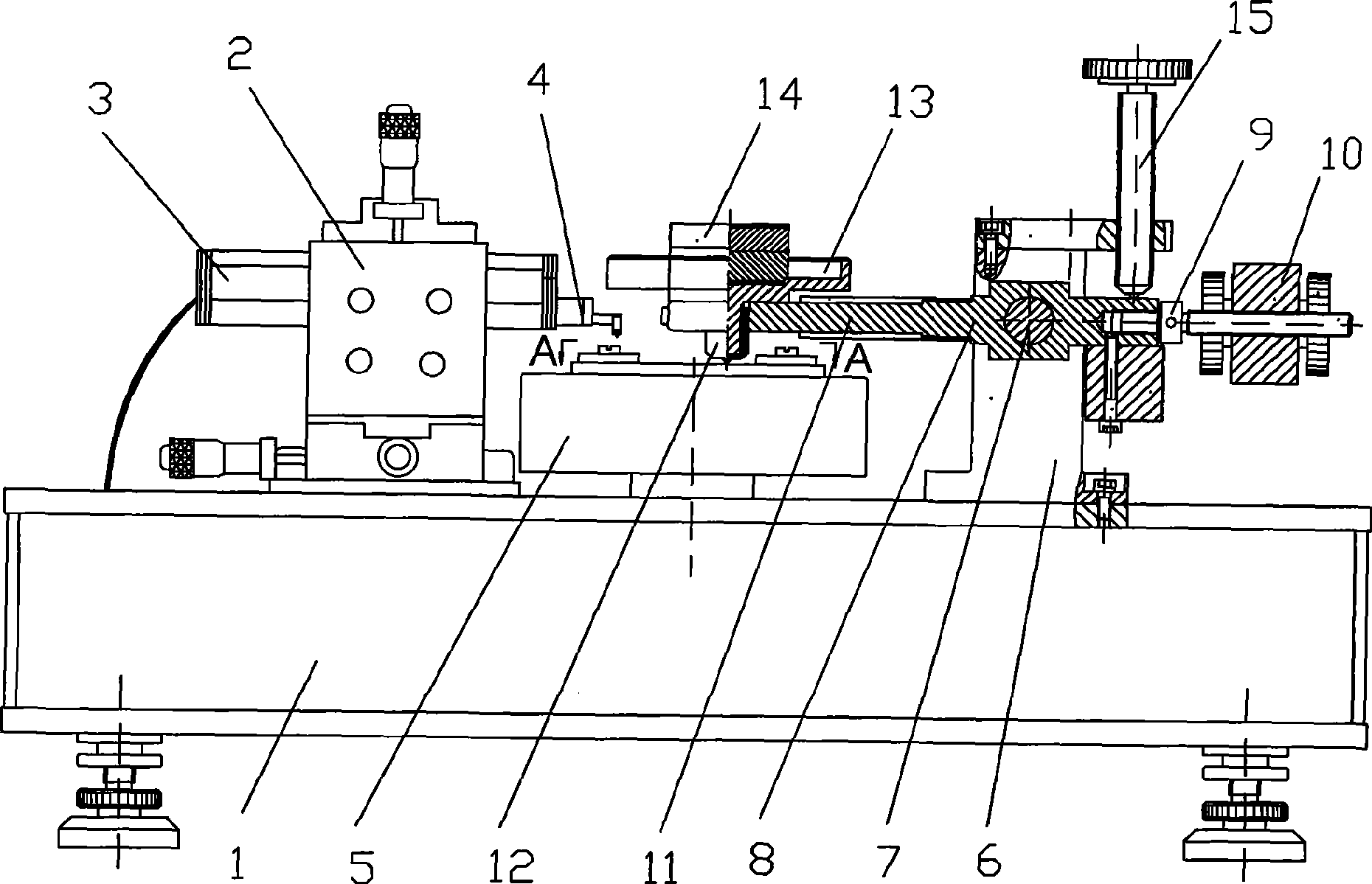

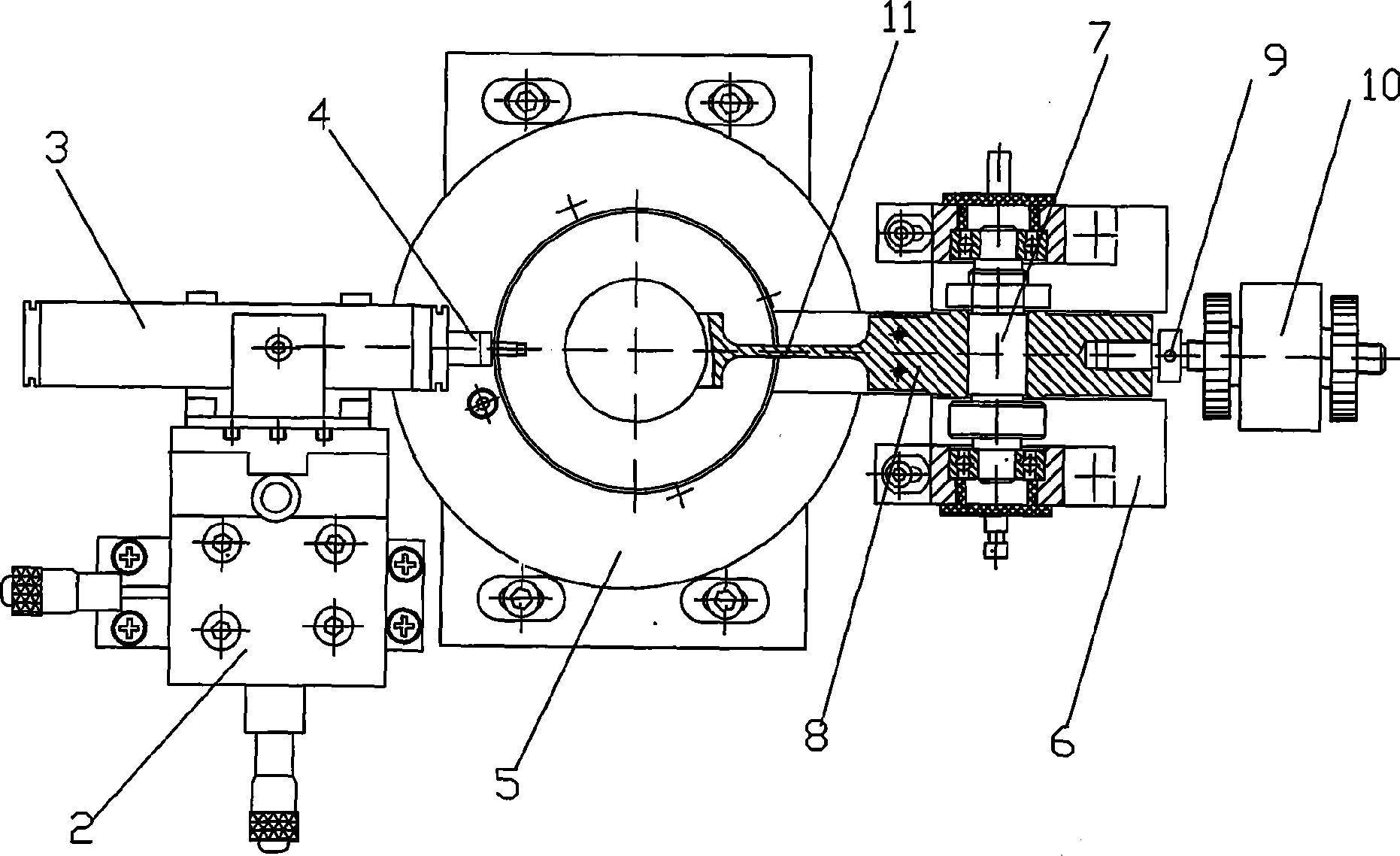

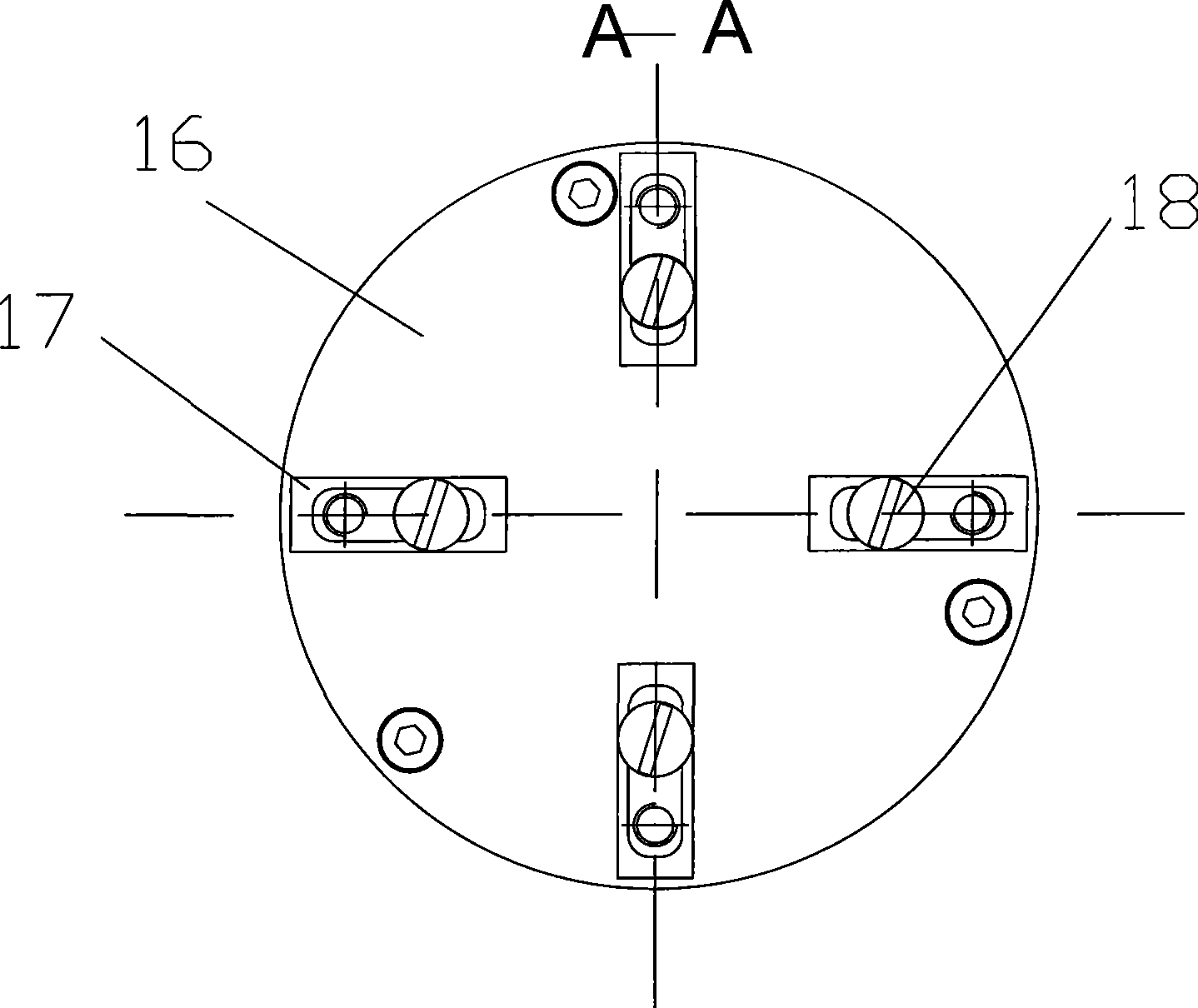

Reciprocating type piston ring-cylinder sleeve friction wear testing machine

InactiveCN101158619ATemperature monitoringMonitor frictionMachine part testingInternal-combustion engine testingEngineeringInternal combustion engine

The invention provides a friction and abrasion tester for reciprocating piston ring-cylinder liner. The invention relates to the technical field of mechanism friction and abrasion, in particular to a friction and abrasion tester for reciprocating piston ring-cylinder liner as a friction paring element practically applied in an internal-combustion engine. A motor driven crankshaft connecting rod mechanism of the tester moves in linear reciprocation through a slide block and a guide sleeve of a guide mechanism, a loading system adopts extrusion-high strength bolting structure to change the pressure from a piston ring of the high strength bolting to the cylinder liner, a lubricator and an oil collector of a lubricating device are positioned on the loading mechanism corresponding to the position of the cylinder liner, sensors of a friction tester and a temperature measurement and a control device are connected to a data collecting card of a data collecting and monitoring device and a computer through interfaces. The invention adopts the practically applied piston ring-cylinder liner of an internal-combustion engine as a friction paring element, load, speed, temperature, lubricant supply experimental parameters can be changed; the invention can monitor temperature, friction experimental data and process experimental data.

Owner:KUNMING UNIV OF SCI & TECH

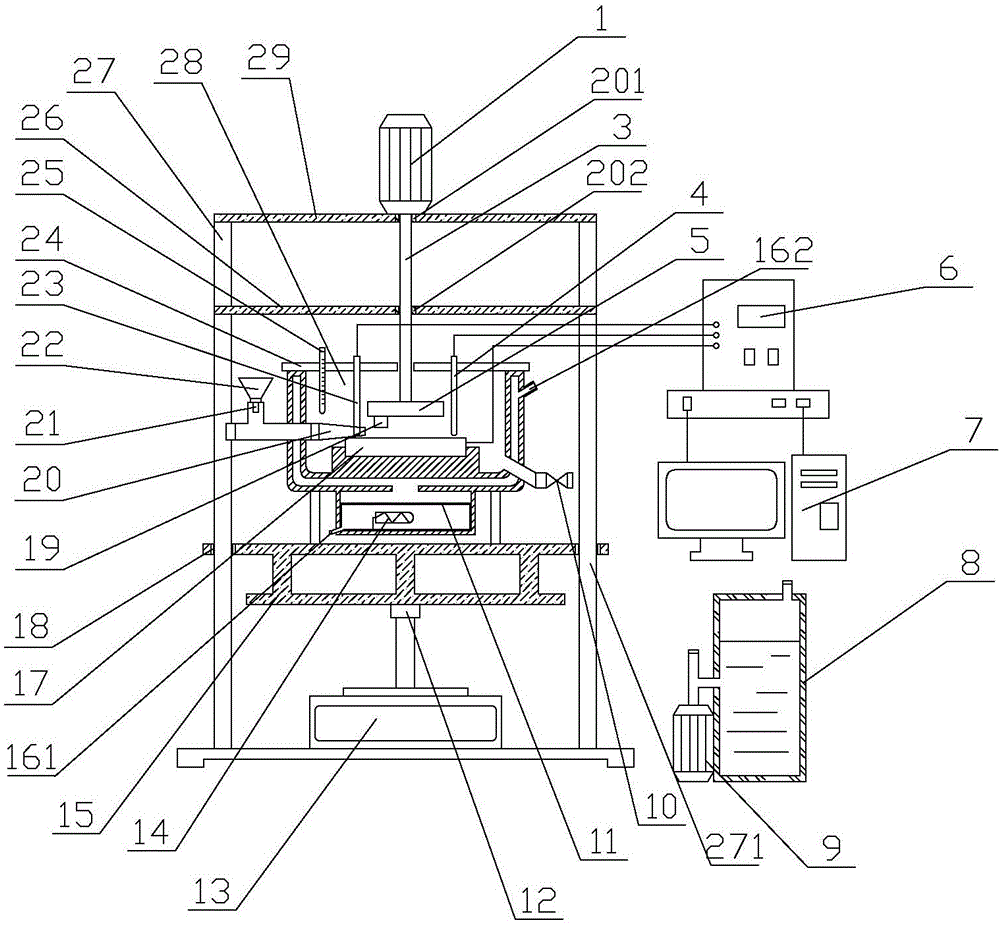

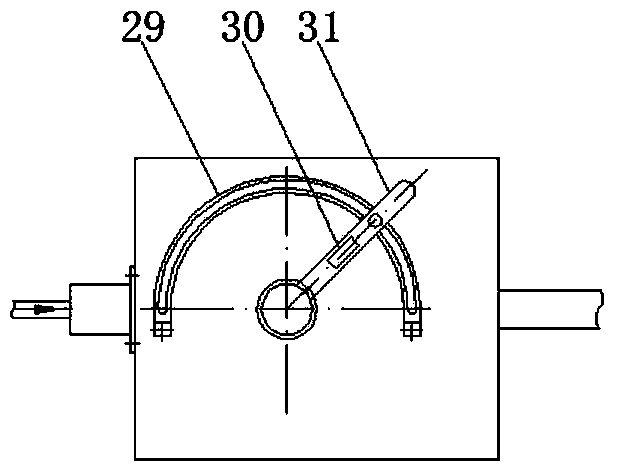

Rotary multi-contact corrosive wear testing apparatus

ActiveCN105784525AGuaranteed stabilityLittle external interferenceWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePeristaltic pumpSolid particle

The invention relates to a rotary multi-contact corrosive wear testing apparatus, comprising a servo motor, a fixture, a reaction container, an electrochemical test system, a loading device and a fluid impact system. The fixture is connected with a transmission shaft of the servo motor and rotates around the axis of the transmission shaft, the fixture is fitted with a specimen, and the fixture drives the specimen to rotate while rotating; a working electrode is placed in a reaction tank and reacts with the specimen for corrosive wear reaction, and a loading system comprises a loading table, a linear bearing, a pressure sensor and a hydraulic cylinder; the fluid impact system comprises a peristaltic pump, a fluid insulation tank, an impact nozzle, a feed hopper, an adjustable discharge port and a valve. The apparatus of the invention enables rotary friction in multiple contact manners to better observe grinding marks, can simulate corrosive wear behaviors of material under fluid impact and enables the addition of solid particles in a fluid when necessary; the influence of external disturbances upon testing results can be reduced, and signal stability in electrochemical testing can be guaranteed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High temperature friction wear testing machine

InactiveCN103364296AAvoid stickingEasy to disperseInvestigating abrasion/wear resistanceWear testingThermal insulation

The invention provides a high temperature friction wear testing machine, belongs to the technical field of material wear tests, and solves the technical problems that the test precision of the testing machines in the prior art is low and the like. The high temperature friction wear testing machine comprises a frame. The frame is provided with a rotating shaft, and is also provided with a driving device. The top end of the rotating shaft is provided with a tray, the surface of the tray is coated with a thermal insulation layer, and a friction disk is fixed on the surface of the tray. The frame is provided with a bracket, and the bracket is provided with a beam. The beam is provided a force value sensor, and a loading rod is arranged at one end of the beam. A specimen holder is arranged at the bottom end of the loading rod. The high temperature friction wear testing machine comprises a high temperature furnace. The high temperature furnace is provided with a heating cavity, and the bottom end of the loading rod is inserted in the heating cavity. An opening is arranged at the bottom part of the heating cavity, the tray is located out of the opening, and the friction disk is located in the heating cavity. The high temperature friction wear testing machine has the advantages of high test precision and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

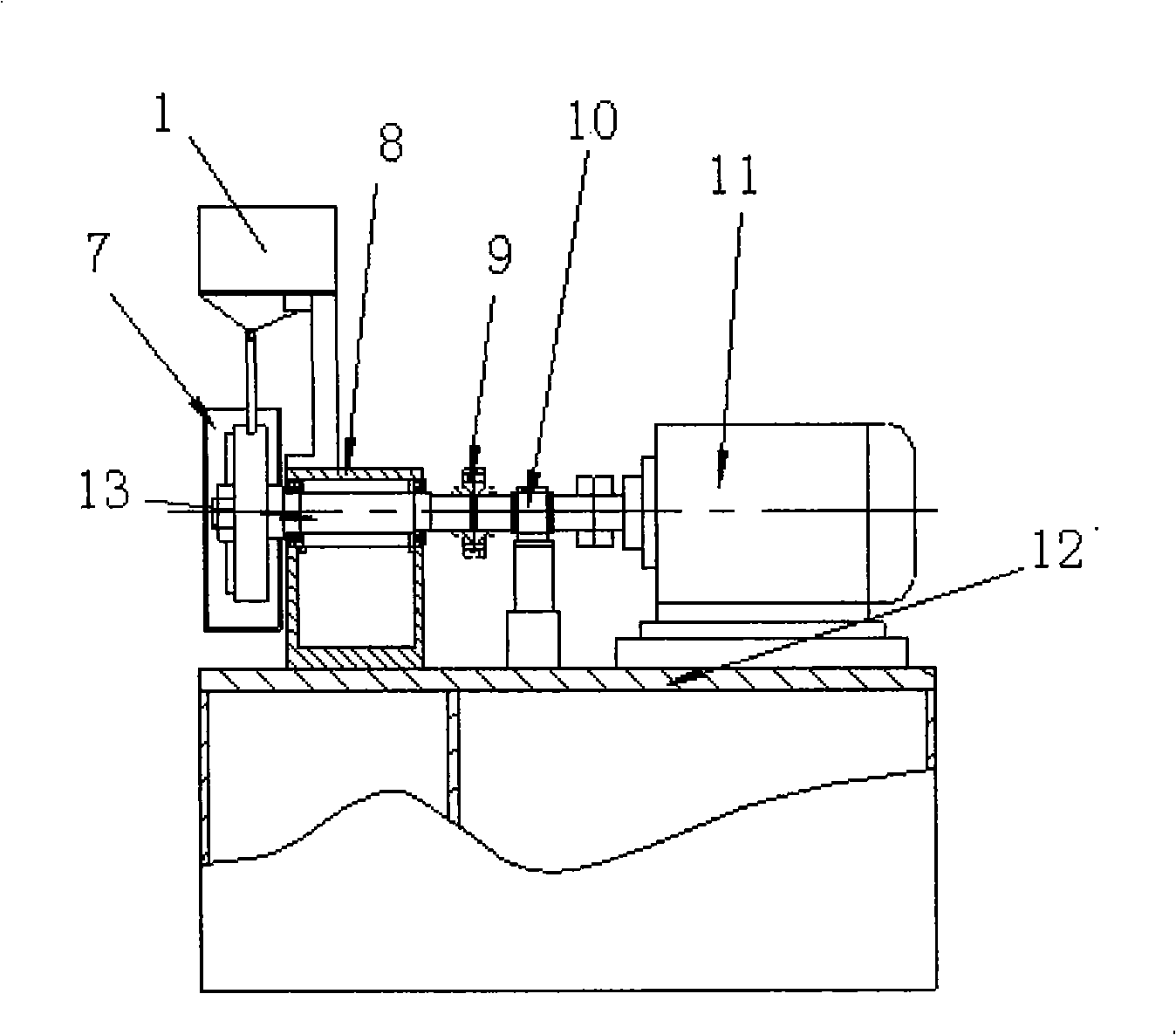

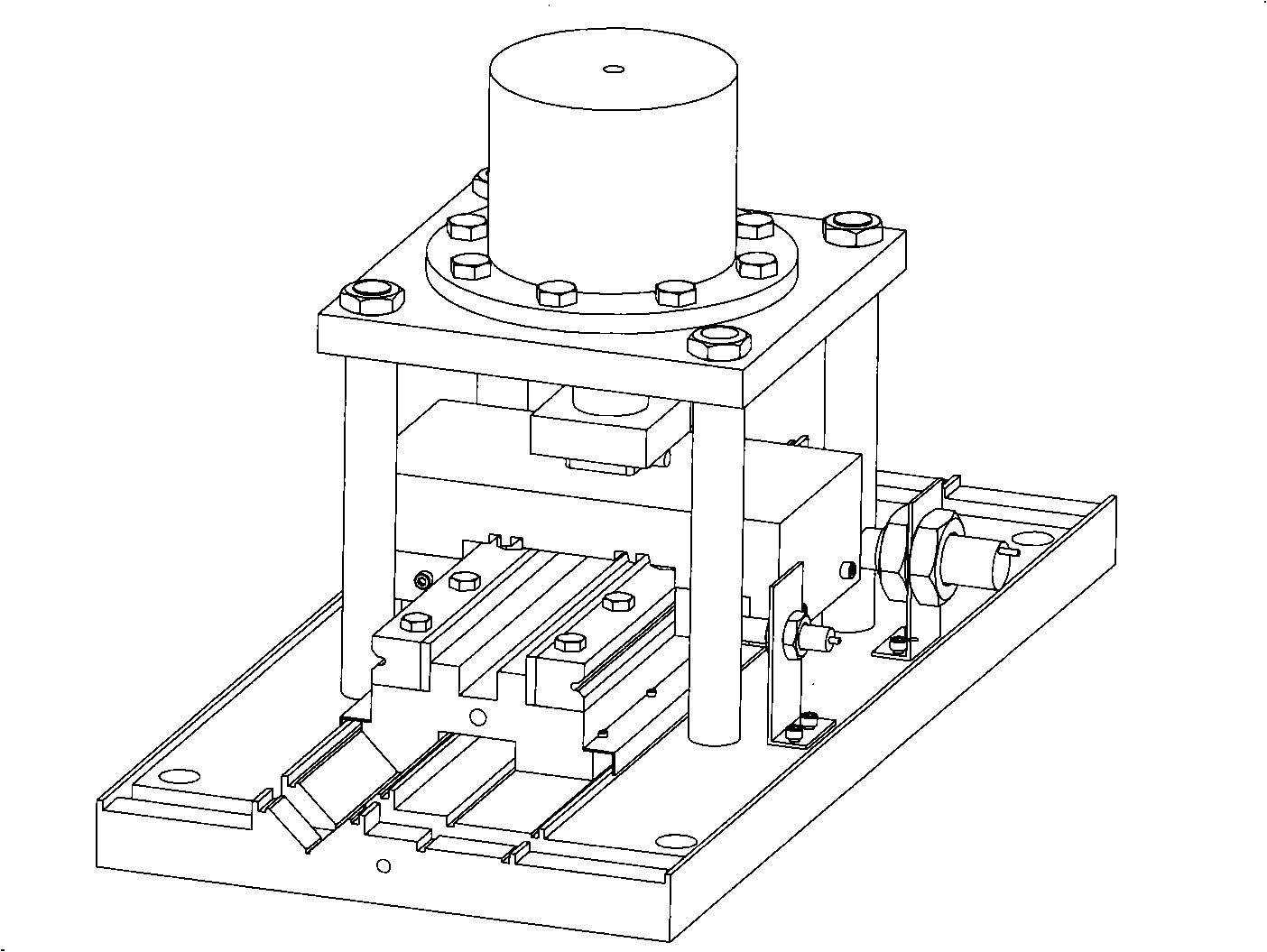

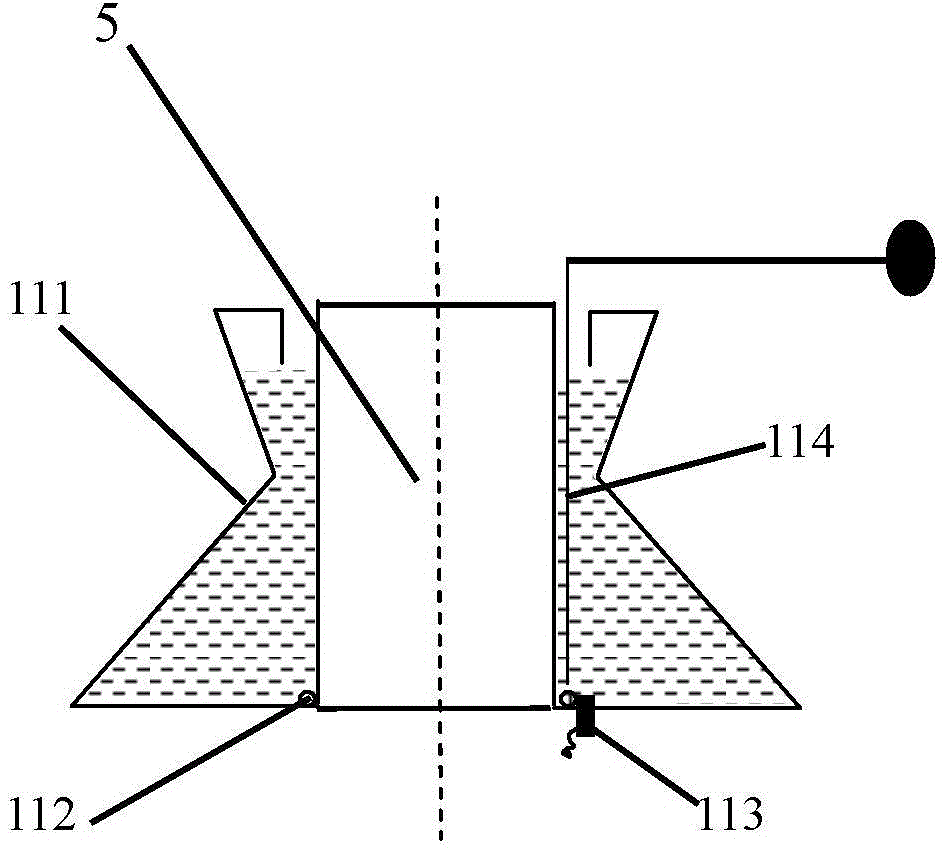

Friction and wear test device for variable load cylinder liner and piston ring

InactiveCN102288502ASimulation is accurateNot subject to assembly errorsInvestigating abrasion/wear resistanceWear testingPiston ring

A variable-load cylinder-sleeve piston-ring frictional wear testing device is mainly composed of a main shaft motor, a guide rail, a sliding table, left and right uprights, a work table, a lever, a loading rod, a swing limiter, a load changer, an inner concave cambered-surface lower clamp and an outer convex cambered-surface upper clamp. An alternating force is generated by the load changer, and then is amplified by the lever to act on a test piece, thereby realizing radial loading of a piston ring to a cylinder sleeve; a variable load is measured in real time by a pressure sensor between theload changer and the lever; friction is measured by a foil gauge on the loading rod; the swing amplitude of the lever is reduced by the swing limiter; the loading rod comes into contact with the outer convex cambered-surface upper clamp through a ball pair to guarantee that the loading direction is vertically downward; the rotating speed of the motor is controlled by means of a program so as to carry out frictional wear tests at different speeds. The testing device is simple in structure, various in testing functions and high in accuracy.

Owner:CHINA UNIV OF MINING & TECH

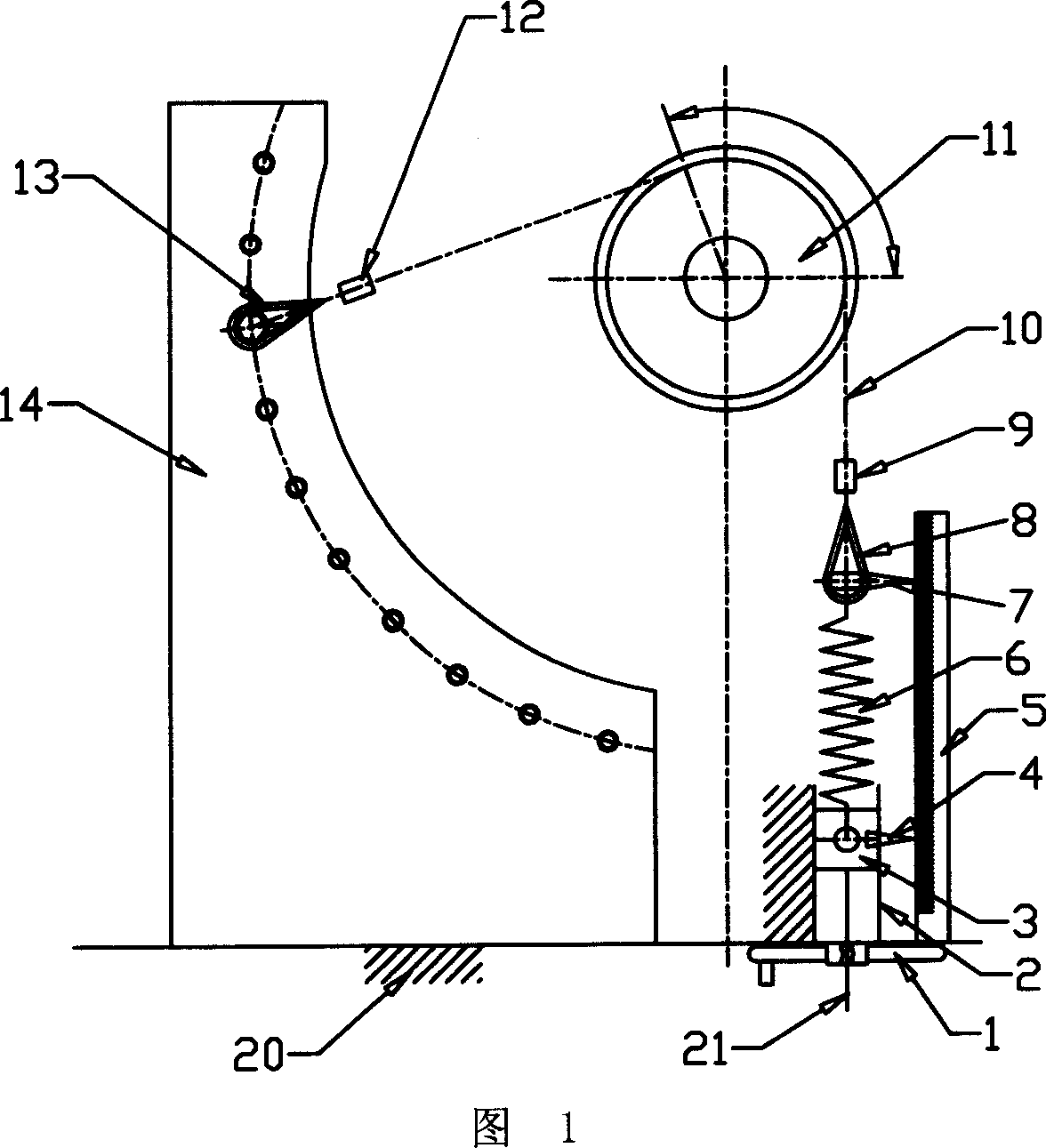

Friction wear testing machine

ActiveCN101344470AHigh simulationSimple production processUsing mechanical meansInvestigating abrasion/wear resistanceWear testingElectric machinery

The invention discloses a friction wear testing machine and comprises an abrading agent slot, a grinding steel wheel that is suspended in the abrading agent slot, a boosting lever that has a vertical arm suspended between the grinding steel wheel and a lateral wall of the abrading agent slot, a servo sand slot that has a sand discharging mouth and a transmission pipe, a servo spring loading mechanism that is connected with a horizontal arm of the boosting lever, a load sensor that is serially connected between the servo spring loading mechanism and the boosting lever and a temperature sensor that is arranged on the back of a sample. A main shaft of the grinding steel wheel is arranged on a bearing holder, connected with a torque sensor through a flexible coupler and connected with a frequency-varied speed-regulating drive motor, and a computer adjusts and detects the sand discharge amount of the sand slot, the rotating speed and the torque of the frequency-varied speed-regulating drive motor, and the loading capacity of the servo spring loading mechanism in real time, and can detect and record the rotational frequency of the grinding steel wheel and sample temperature in real time. The friction wear testing machine can detect and analyze the abrasion resistance and the frictional behaviour of hard alloy products under the conditions close to real working conditions.

Owner:株洲长江硬质合金工具有限公司

Machine tool guiding rail friction wear testing machine

InactiveCN101339112ABreakthrough the shortcoming of short lifeReduce coefficient of frictionMachine part testingInvestigating abrasion/wear resistanceWear testingEngineering

The invention provides a friction and wear testing machine of guide rail of machine tool and relates to a friction and wear testing device of guide rail pair, belonging to the technological field of tribology. The testing device comprises a testing system and a measuring system. An oil blocking plate in the testing system is provided with an upper sample platform, an oil blocking plate, a lower sample platform, a first sensor mounting bracket and a second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are respectively arranged on a base; a flat V guide rail is arranged between the lower sample platform and the base; an upper sample fixture is arranged between the first sensor mounting bracket and the second sensor mounting bracket; the first sensor mounting bracket and the second sensor mounting bracket are connected with a cover plate respectively by a support rod. The novel friction and wear testing machine of the machine tool can simulate the actual working condition, and directly adopt the guide rail as the sample. Moreover, the testing machine can not only be used for rapidly assessing the material of the guide rail pair and the lubricating medium, but also can be used for the accelerated life test of the straight guide rail pair and the rolling guide rail pair.

Owner:SOUTHEAST UNIV

Small load impact wear testing machine

InactiveCN101021461APrecise frequency controlPrecise Control of IntensityUsing mechanical meansInvestigating abrasion/wear resistanceWear testingRepeatability

The invention discloses a testing machine of small-load attacking wear. Stand board is fixed behind base. Exciter with a downward roof bar is equipped in front of top of. End of exciter roof bar connects piezoelectric impedance sensor and upper sample holding device in turn. Lower sample holding device is fixed under the sample holding device on the base. The testing machine suits for tests with small-load attacking, which has merits including high automatic degree, stable working load, good persistent-working ability, high precision and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

Elevator dray driving sliding contact fatigue wear testing machine

InactiveCN1932472AUsing mechanical meansInvestigating abrasion/wear resistanceWear testingPull force

The invention relates to abrasion machine of the elevator towing contacting tiredness. The variable-frequency electric machine drives the towing wheel to rotate by the shaft coupling and the bearing block after the reducer; one end of the cable wire is connected to the arc framework and the other is connected to the draught spring after fixing the two end with the lantern ring by the clap; it changes the pressure and the friction force between the cable wire and the wheel slot by changing the tension force of the cable wire by loading the hand wheel to draw the spring. So it can get the friction force by the fore-and-aft pulling force. So the invention can test the sliding friction and the abrasion character in the different condition to provide the data for designing the elevator towing.

Owner:SHANGHAI JIAO TONG UNIV

End face torsion frictional wear testing machine and method

InactiveCN102175598AImprove performanceExtend your lifeUsing mechanical meansMaterial analysisHydraulic cylinderBall bearing

The invention discloses an end face torsion frictional wear testing machine and an end face torsion frictional wear testing method. The testing machine comprises a transmission device and a pressure loading device, wherein the transmission device comprises a servo motor, a speed reducer, an eccentric wheel and a connecting rod; and the pressure loading device comprises a force sensor, a thrust ball bearing, a fixing piece, a spindle, a turntable, a turntable connecting rod, a tray, a torque sensor, a lifting shaft, a sliding sleeve and a hydraulic cylinder. A test piece is axially pressurized through the hydraulic cylinder, a connecting rod transmission mechanism drives the test piece to perform frictional torsion, a frictional torque value is measured through the torque sensor, and a positive pressure value is measured through the force sensor so as to obtain a friction coefficient. An end-face contact torsion frictional wear test under different working conditions can be simulated by setting different positive pressures, torsion frequencies and the like, and the frictional torque is accurately measured; and the loading is stable and accurate, the impact is low, and dynamic loading can be realized. Moreover, the machine is simple in structure, convenient to operate and good in testing effect.

Owner:CHINA UNIV OF MINING & TECH

Friction wear testing machine for on-line measurement

InactiveCN101504357ARealize online measurementEasy to collectUsing mechanical meansInvestigating abrasion/wear resistanceWear testingMeasurement device

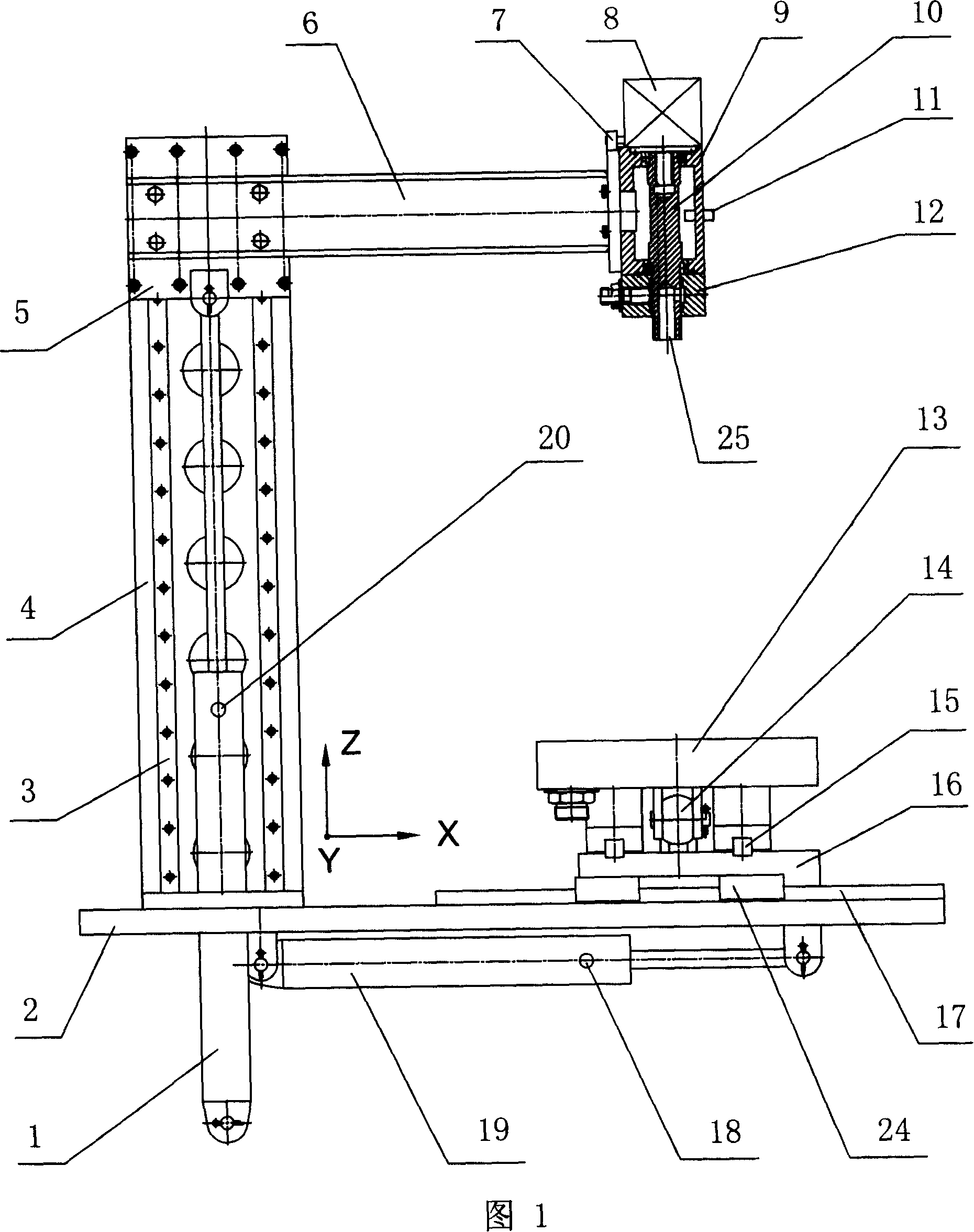

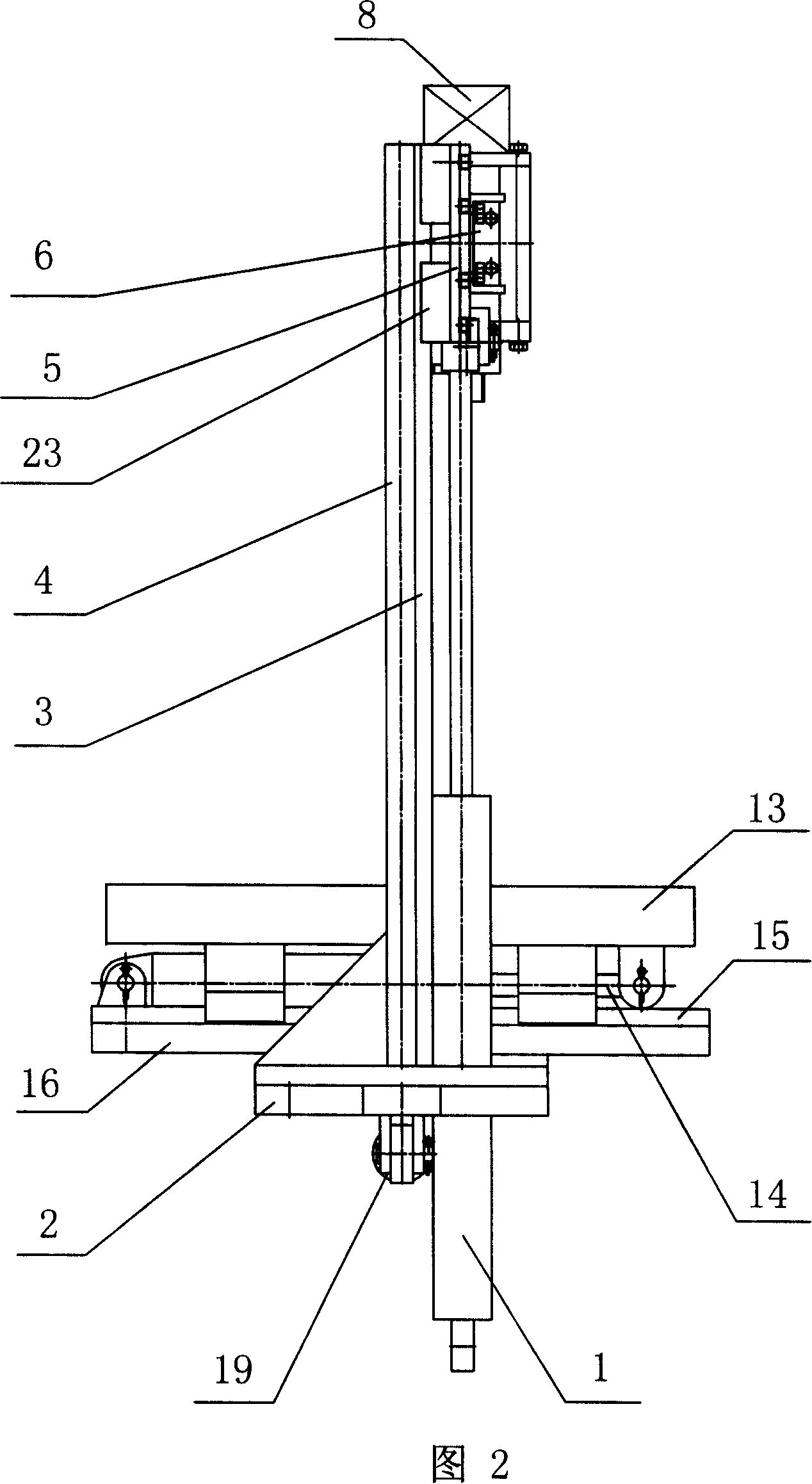

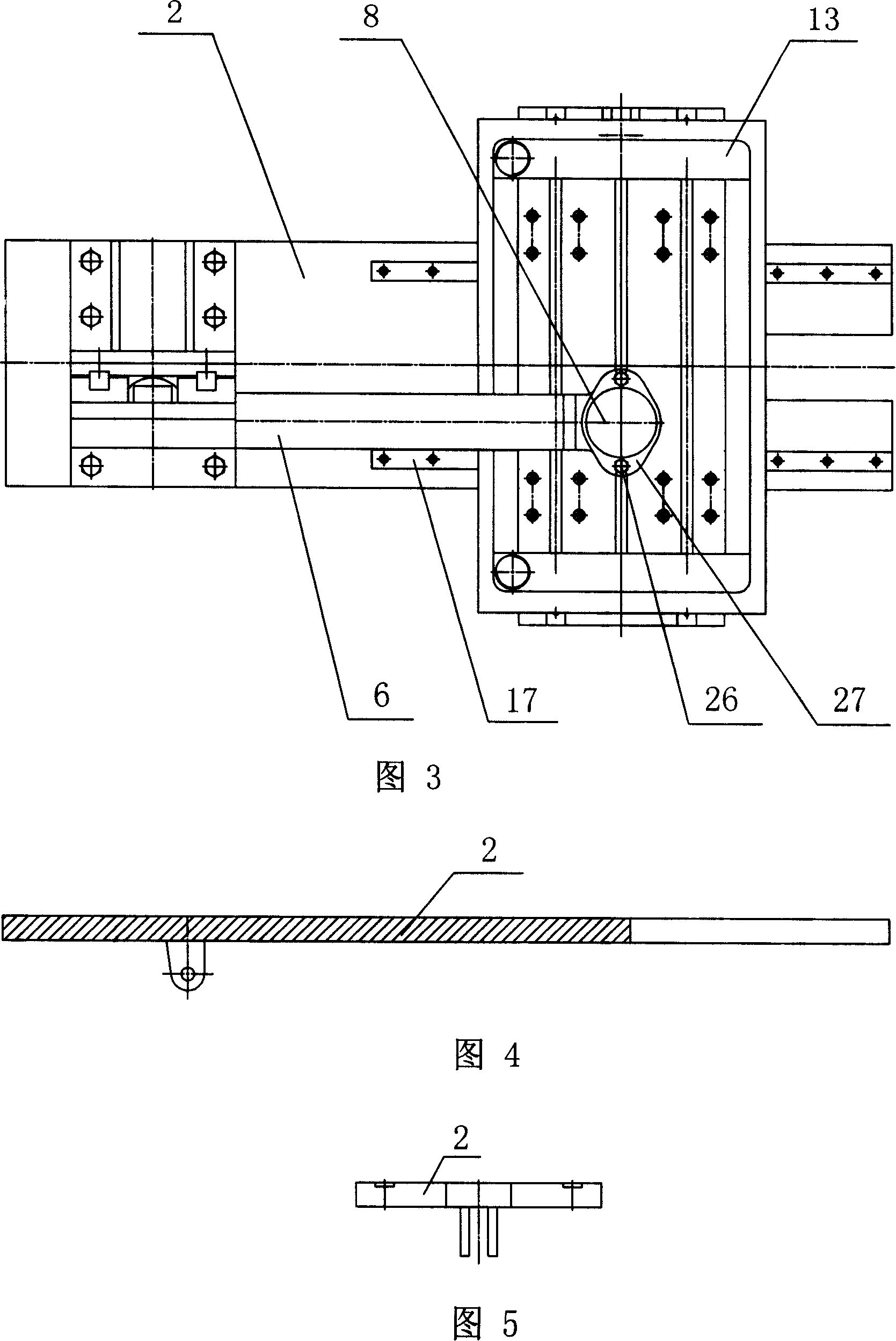

The invention discloses a friction wear testing machine for on-line measurement, which comprises an experiment table, a friction wear experiment device arranged on the experiment table and a surface topography measurement device. The friction wear testing machine is characterized in that the friction wear experiment device comprises a stress beam, and a support and a rotating platform which are arranged on the experiment table, the rotating platform fixes a lower specimen, and the support is positioned at one side of the rotating platform; the support is provided with a rotating shaft which is fixed with a walking beam, one end of the walking beam is fixed with a balance weight lever which is provided with a balancing weight, the other end of the walking beam is fixed at one end of the stress beam, the other end of the stress beam is fixed with a collet which is fixed with an upper specimen, and the collet is provided with a scale pan which is provided with weights; the stress beam is provided with a force sensor for measuring the friction force between the upper specimen and the lower specimen; and the surface topography measurement device comprises a three-coordinate adjustment table arranged on the experiment table, the three-coordinate adjustment table is provided with a surface contourgraph, and a probe of the surface contourgraph extends above the rotating platform.

Owner:XI AN JIAOTONG UNIV

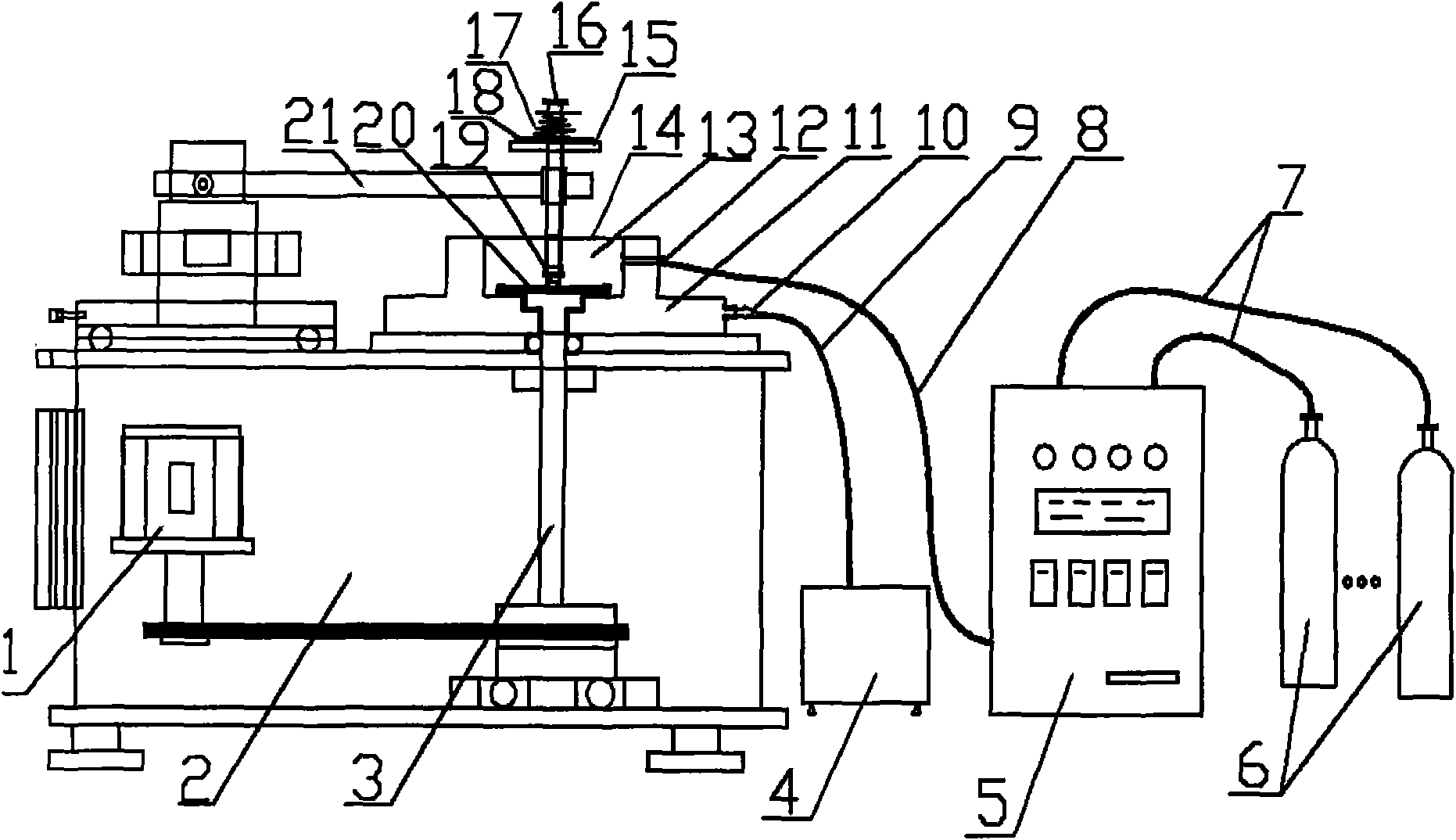

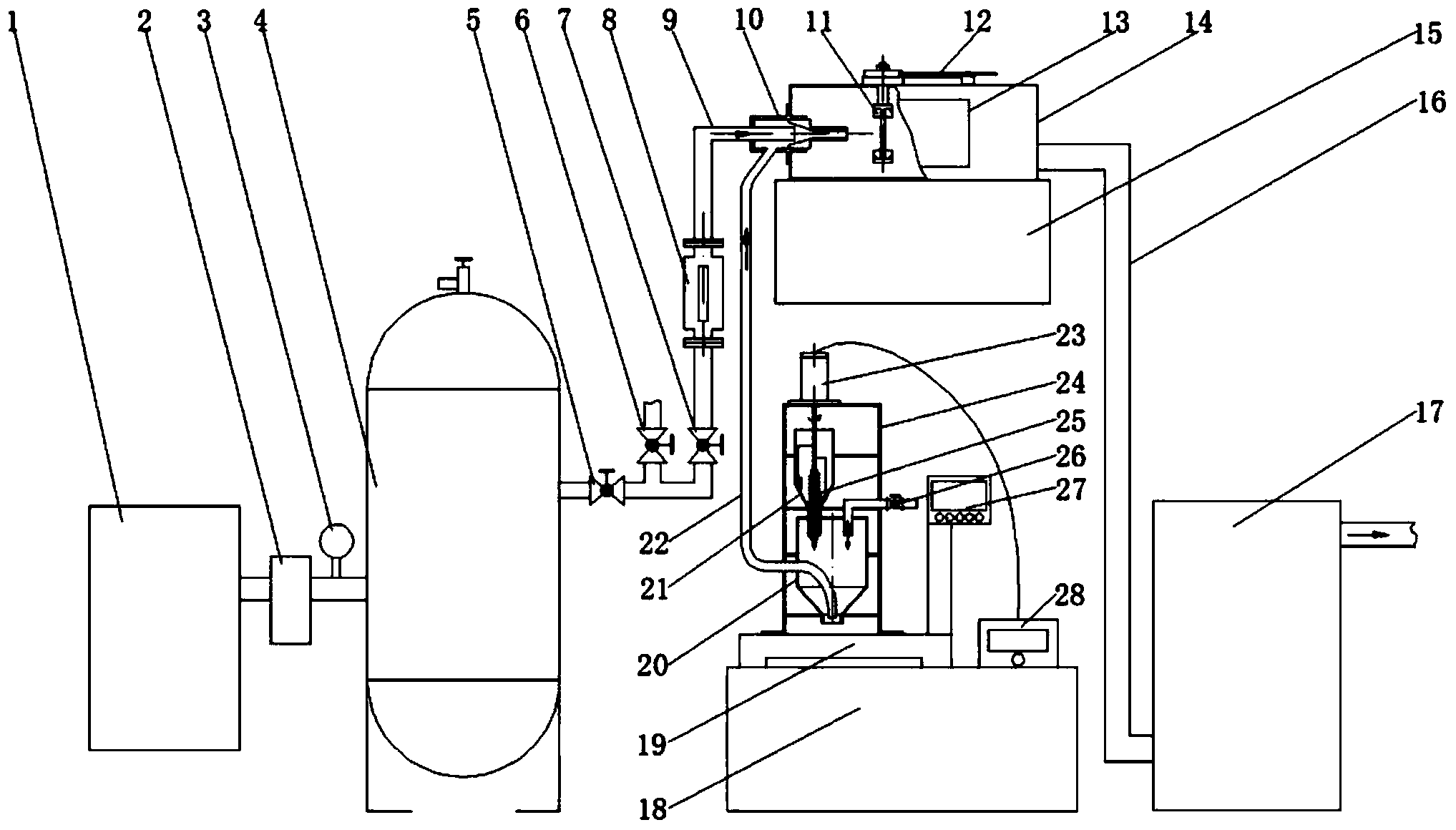

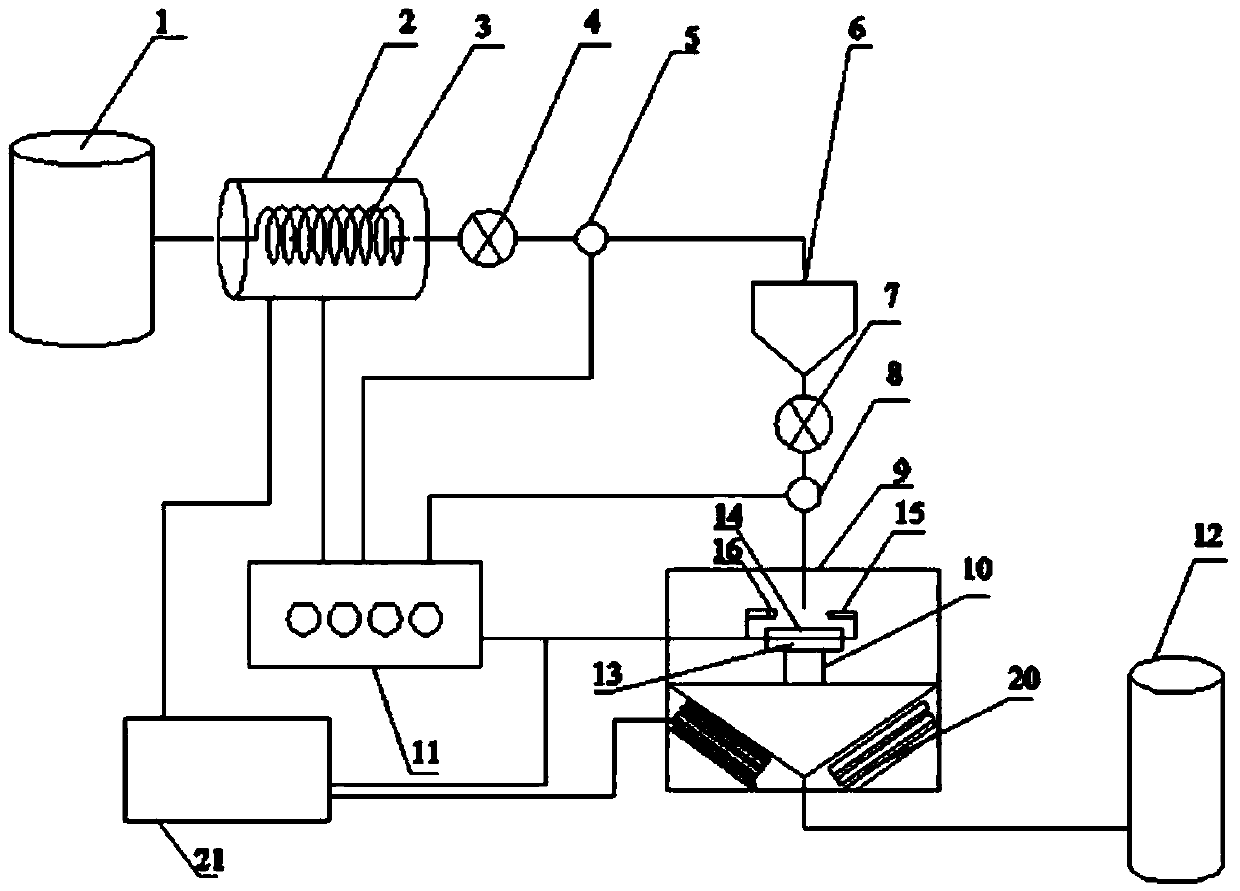

Method and device for controlling accurate ratio of various gas atmospheres of frictional wear testing machine

InactiveCN101685056AOvercome precisionOvercome cost performanceControlling ratio of multiple fluid flowsInvestigating abrasion/wear resistanceOperation safetyWear testing

The invention discloses a method for controlling an accurate ratio of various gas atmospheres, which is used for a high-temperature gas atmosphere frictional wear testing machine, and a device thereof. The device consists of a plurality of gas input branches, a gas atmosphere mixing box, a test environmental gas chamber device, a temperature control device and a cooling system; the pressures of aplurality of gas sources are reduced to a given pressure by a pressure reducing valve; the flow ratio of all gas atmospheres is controlled by the mass flow controller; the mixed gas atmosphere is sentto the ambient temperature gas chamber needed in the test by a gas channel; and in a semi-closed environmental gas chamber, the sliding frictional wear test of a ball / disk or pin / disc in the high-temperature gas atmosphere environment is performed by relatively turning dual faces. The method realizes the accurate control of the ratio of various gas atmospheres and the ambient temperature and meets the gas supply requirements for the continuous frictional wear tests; and the device has a simple structure and can be safely and reliably operated, so that the aims of accurately controlling the ratio of various gas atmospheres and realizing low cost are achieved.

Owner:HENAN UNIV OF SCI & TECH

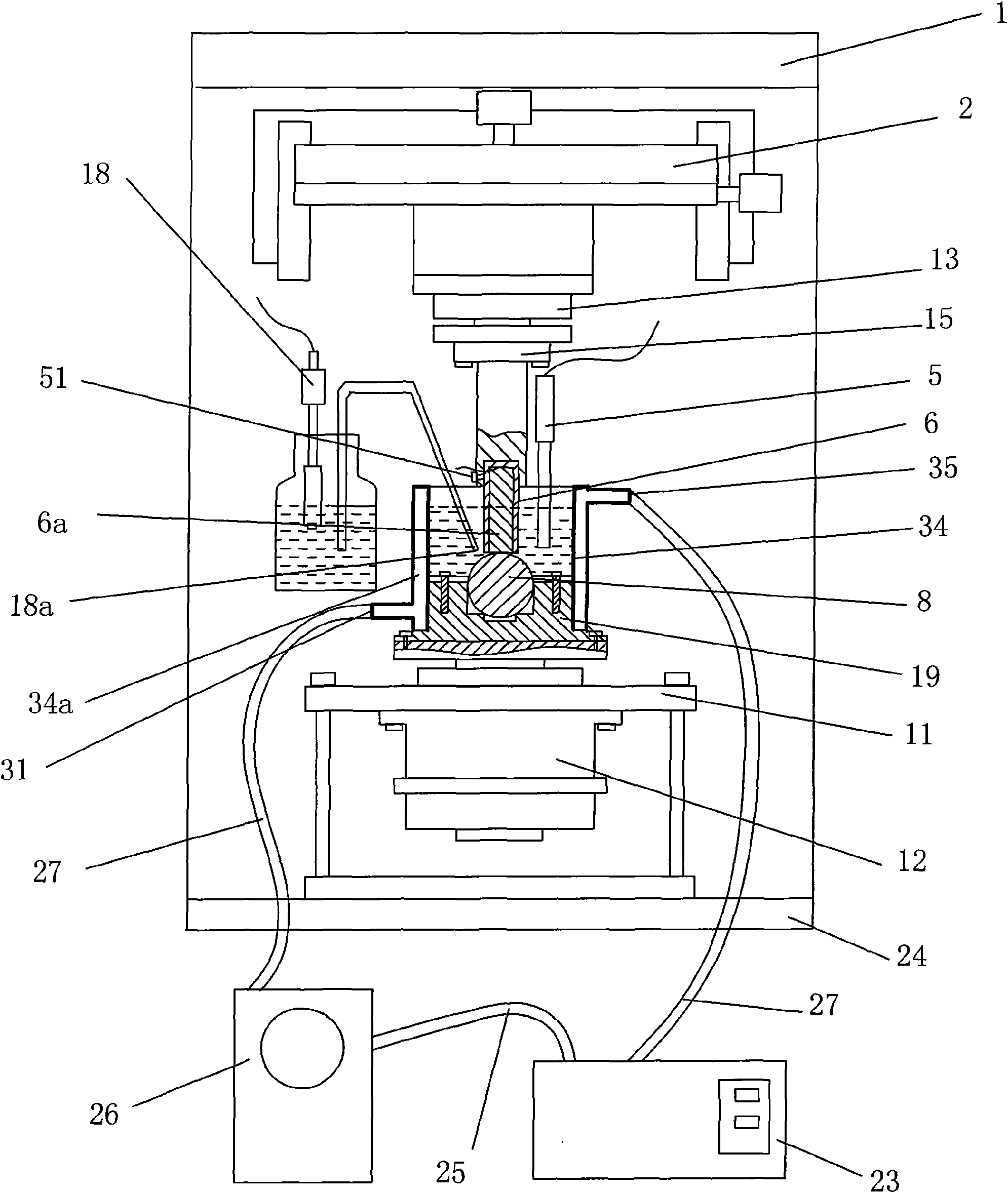

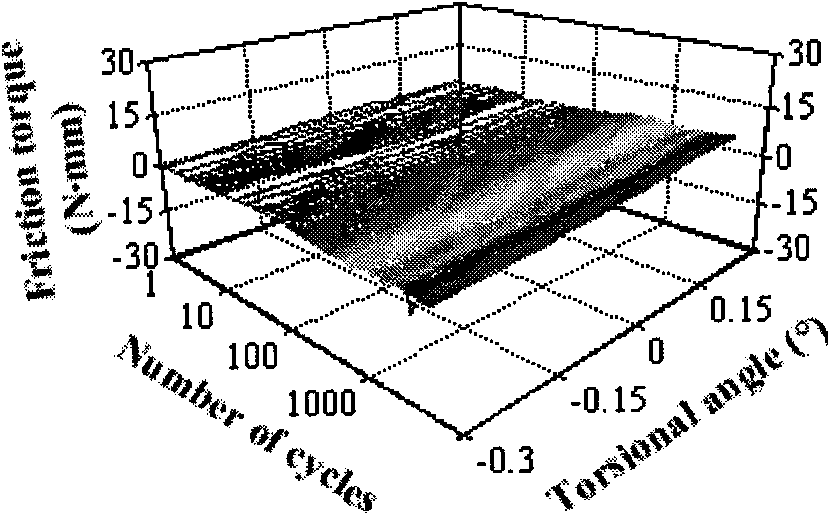

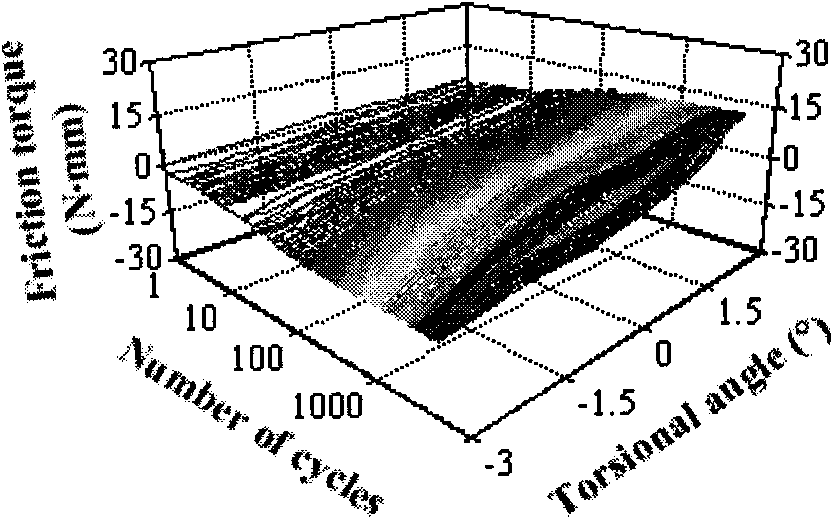

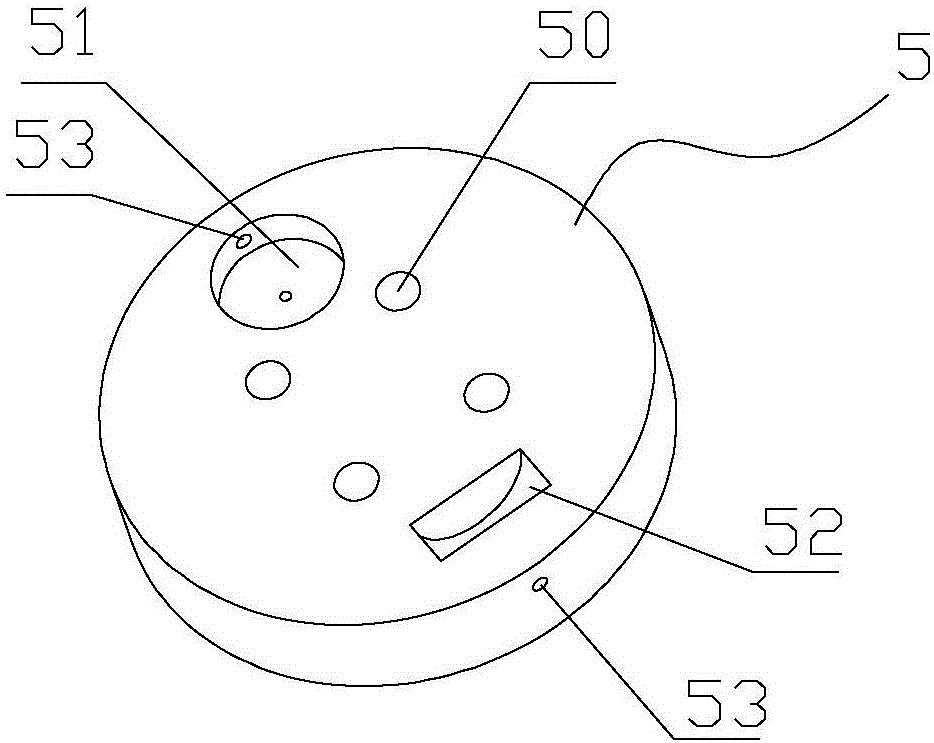

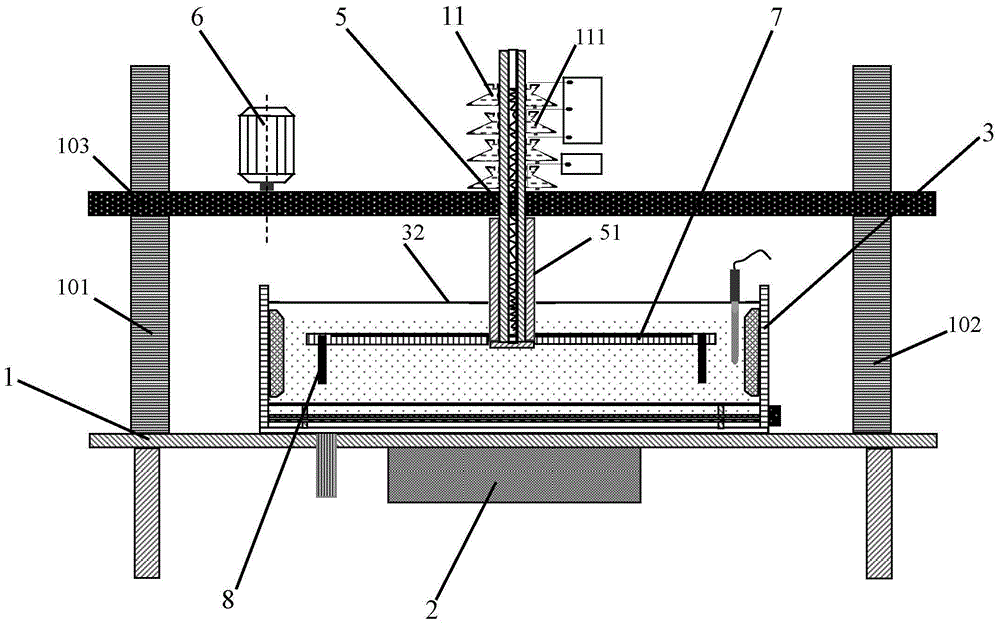

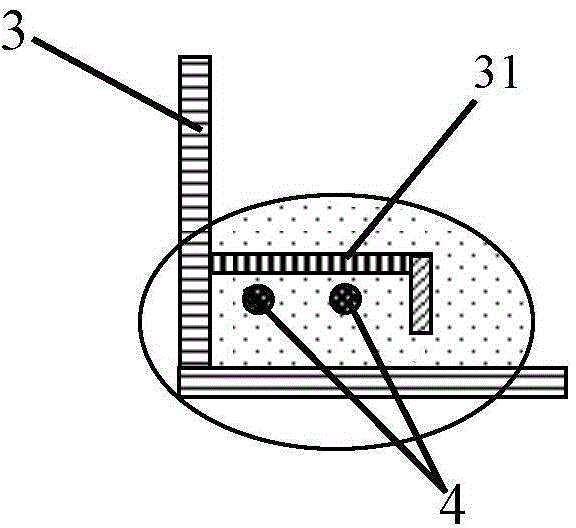

Surface-to-surface contact torsional fretting friction-wear testing system and control method thereof

ActiveCN107179254AAvoid results that affect test efficiencyGuaranteed stabilityInvestigating abrasion/wear resistanceFriction torqueWear testing

The invention discloses a surface-to-surface contact torsional fretting friction-wear testing system and a control method thereof. The testing system comprises a loading device, a positioning and clamping device, a friction pair, a driving device, a data acquisition device and a computer measurement and control system, wherein the loading device is used for applying positive pressure to the friction pair through a loading steel ball and keeping surface contact load in an operation process of the friction pair to be stable. A torque sensor, a driving motor signal and an angular displacement signal of the data acquisition device are connected with a computer data acquisition and control system; angular displacement amplitudes of a fretting friction pair are recorded and controlled and a change condition of a fretting friction torque is output in real time. The testing system and the control method thereof, provided by the invention, have the characteristics of convenience for operation, stable loads and relatively high angular displacement amplitude precision and can be used for reflecting torsional fretting friction-wear properties of an actual working condition better and the like; torsional fretting friction research under different loads, frequencies and angular displacement amplitudes can be carried out.

Owner:HUAZHONG UNIV OF SCI & TECH

Micro-arc oxidation process for reducing surface friction coefficient of titanium alloy

InactiveCN101280450AImprove bindingHigh hardnessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

Disclosed is micro-arc oxidation process to reduce the friction coefficient of titanium alloy surface, which has the process steps of (1) the chemical degreasing, (2) the micro-arc oxidation that the basic parameters are trisodium phosphate of 1-30g / L, tungsten sodium of 0-10g / L, sodium silicate of 0-50g / L, tartaric acid of 0-20g / L, glycerol of 0-10g / L and sodium hydroxide of 5-10g / L, (3) the post-processing that the hot oil immersion treatment is proceeded for the film after the oxidation. Through the invention, the high-performance ceramic membrane with strong cementing property, high hardness and low coefficient friction can be obtained on the titanium surface. Through the testing of a high-temperature friction and wear testing machine of MM-U5G screen material end surface, the friction coefficient of the titanium micro-arc oxidation film is 0.1 to 0.5. During the observation of the oxidation film after the experiment, the shedding and wear phenomenon is not found.

Owner:NANCHANG HANGKONG UNIVERSITY

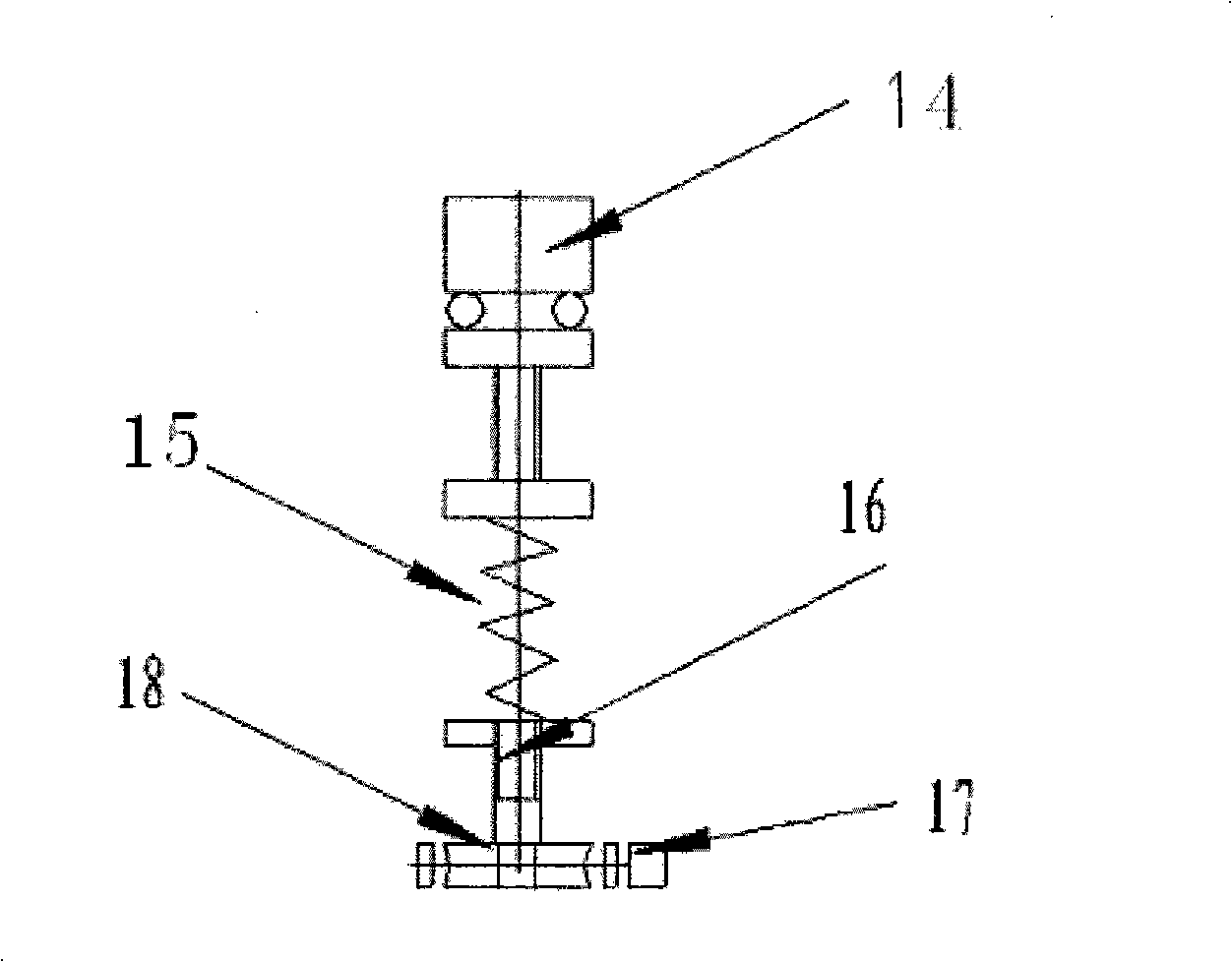

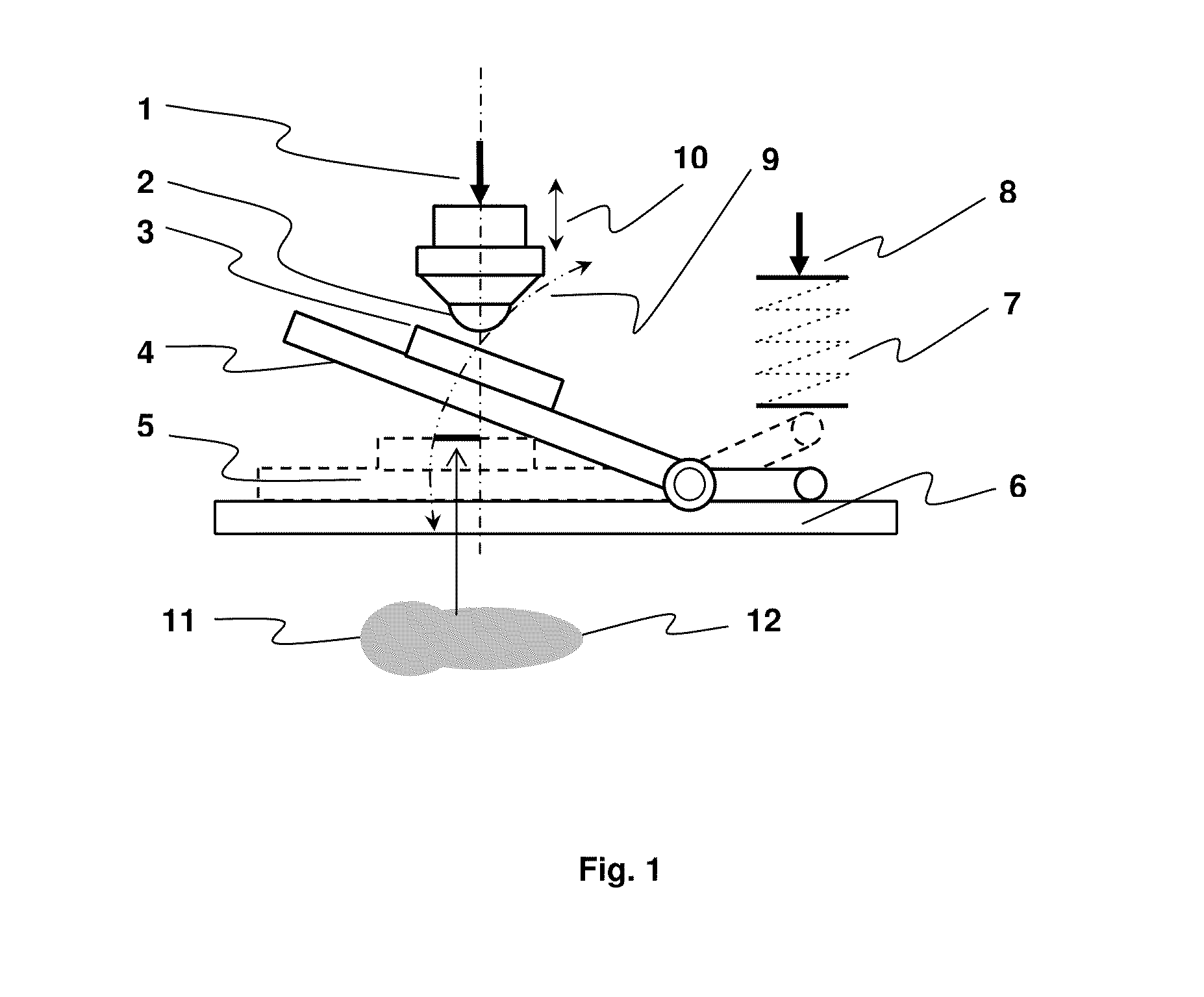

Impacting-sliding composite frictional wear testing device and method thereof

ActiveCN105891036ASimple structureReduce processing costsInvestigating abrasion/wear resistanceElectricityWear testing

The invention discloses an impacting-sliding composite frictional wear testing device and a method thereof. The method comprises the following steps that a spherical upper test piece is clamped on an upper clamp and a planar lower test piece is clamped by using a lower clamp; the lower clamp is controlled to move up and down by a precise screw lifting platform so that the upper test piece and the lower test piece come into contact; a servo motor drives the upper test piece to do up-down reciprocating motion at set frequency f, times N and displacement S by an eccentric disc, an upper knuckle bearing, a lower knuckle bearing, an impacting shaft, a spring leaf and an upper clamp, and carries out reciprocating impact on the lower test piece; in the impacting process, the spring leaf is deformed under the action of stress, so that impacting-sliding composite frictional wear between the upper test piece and the lower test piece is realized; and simultaneously, the force borne by the lower test piece is tested by a three-dimensional dynamic piezoelectric sensor connected with the lower clamp and is transmitted to a data acquisition control system, and a friction coefficient-cycle time curve is obtained by analysis. The impacting-sliding composite frictional wear testing device and the method disclosed by the invention have the advantages that the material can conveniently generate rigidity-adjustable impacting-sliding composite frictional wear, the automation degree is high and the repeatability of experimental data is good.

Owner:SOUTHWEST JIAOTONG UNIV

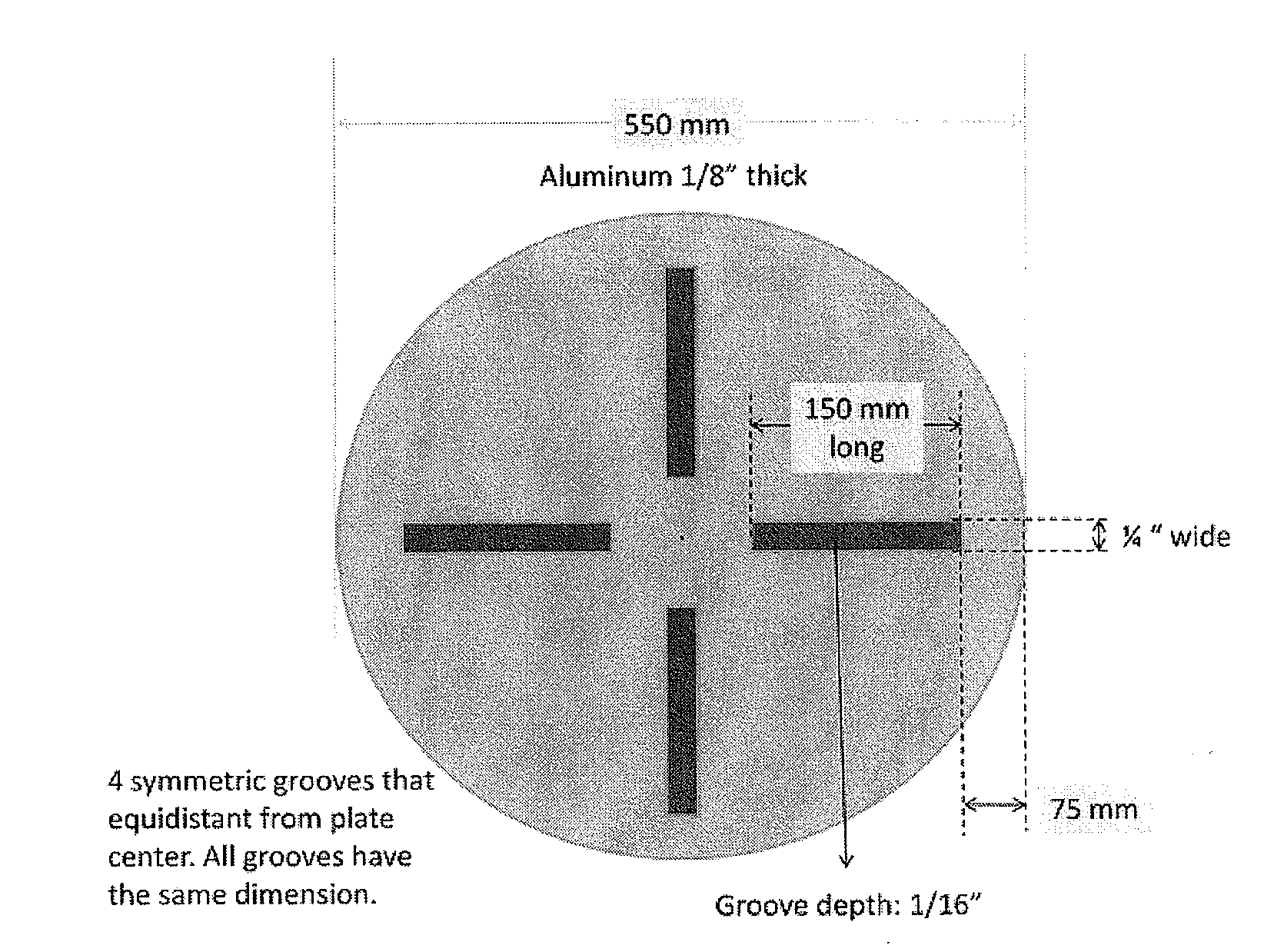

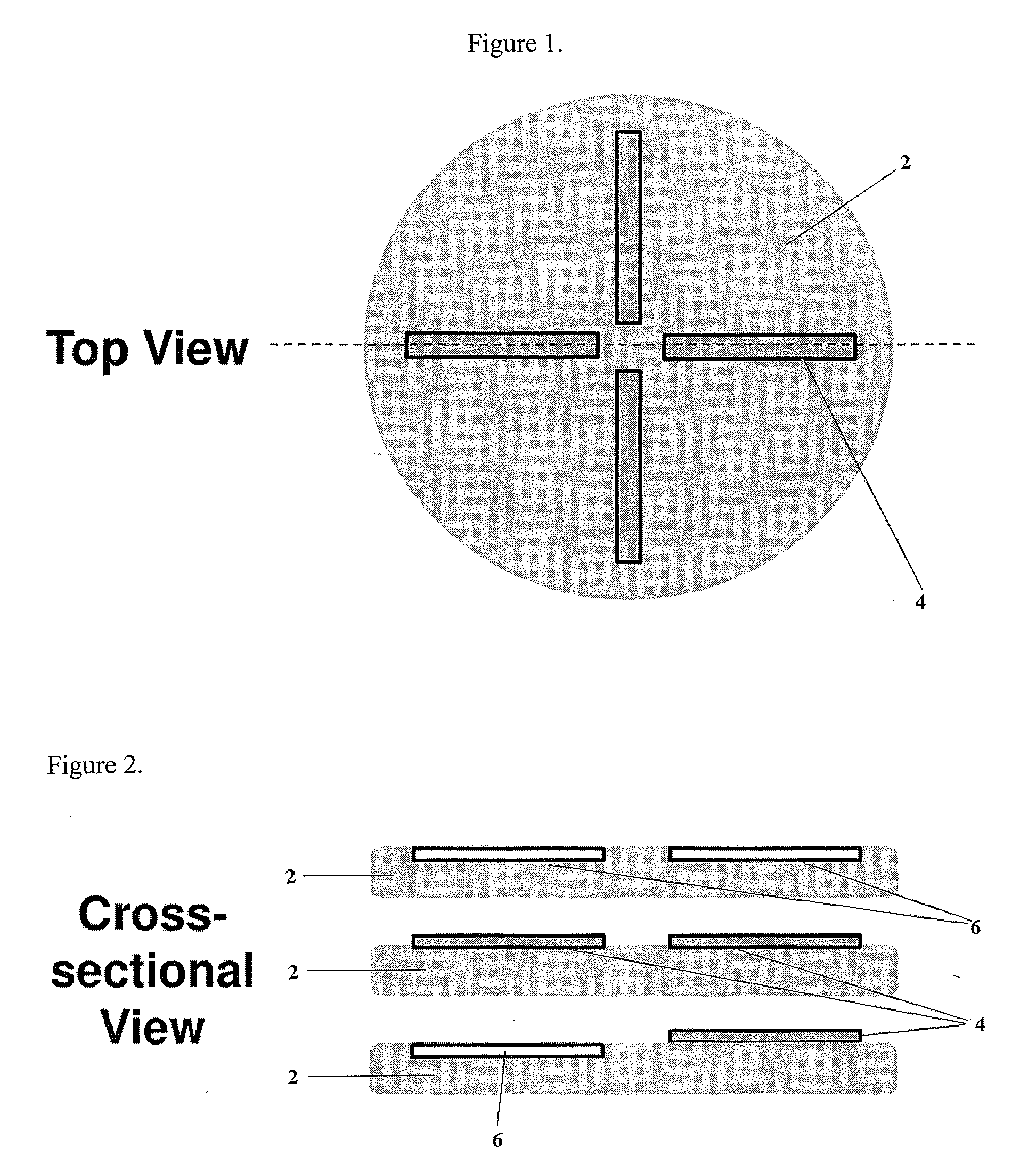

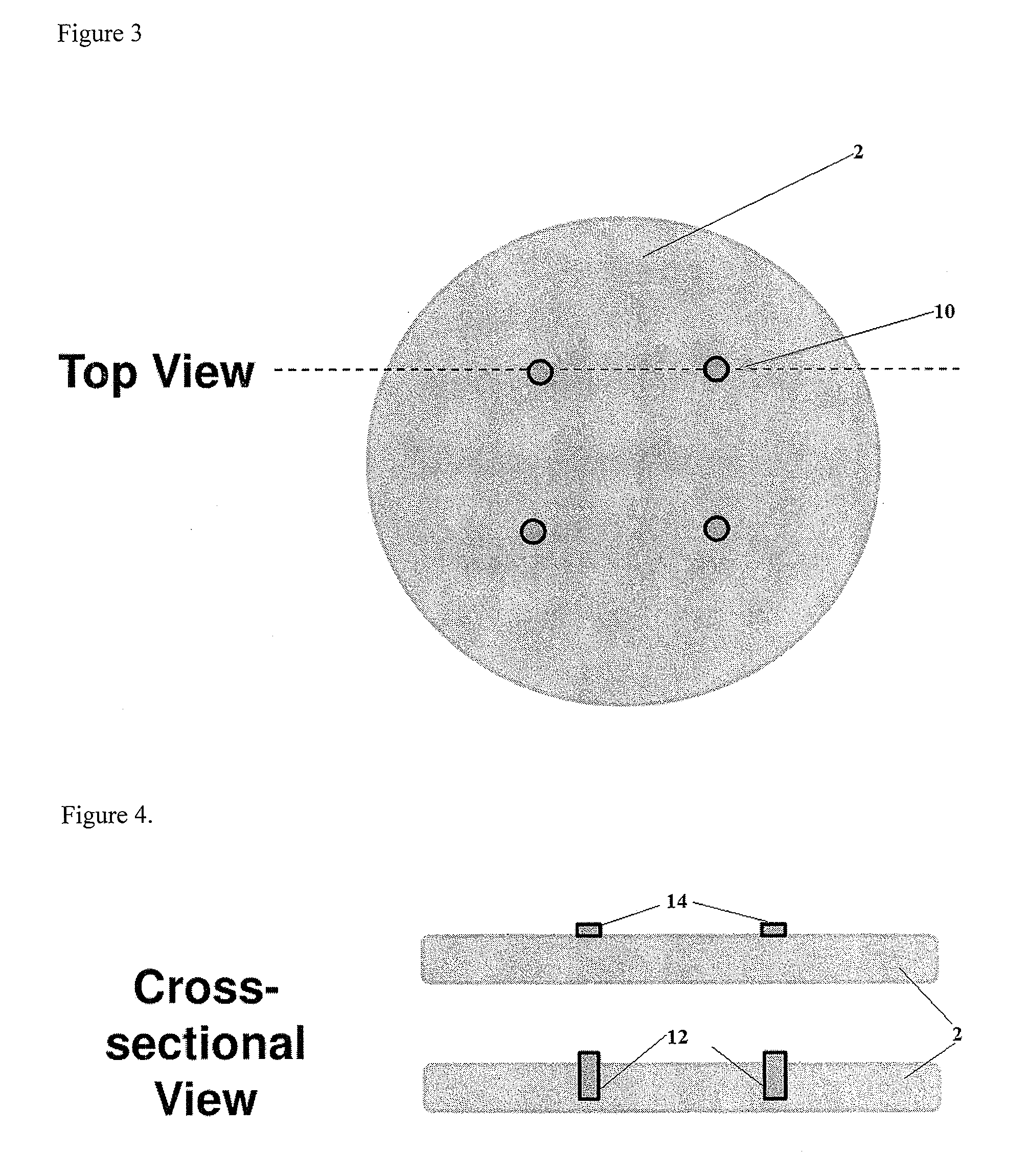

Method and apparatus for accelerated wear testing of aggressive diamonds on diamond conditioning discs in cmp

The present invention is a method and apparatus for accelerated pulling and fracturing of aggressive diamonds on a CMP diamond conditioner disc wherein aggressive diamonds of known position are pulled or fractured by contacting the diamond conditioner disc to a plate or sheet of a hard material or a plate or sheet containing discrete structures of hard material relative to which the diamond disc is in motion at a determinable and reproducible rate for a determinable and reproducible period of time and the number and position of the pulled or fractured aggressive diamonds are determined following the completion of said contact.

Owner:ARACA

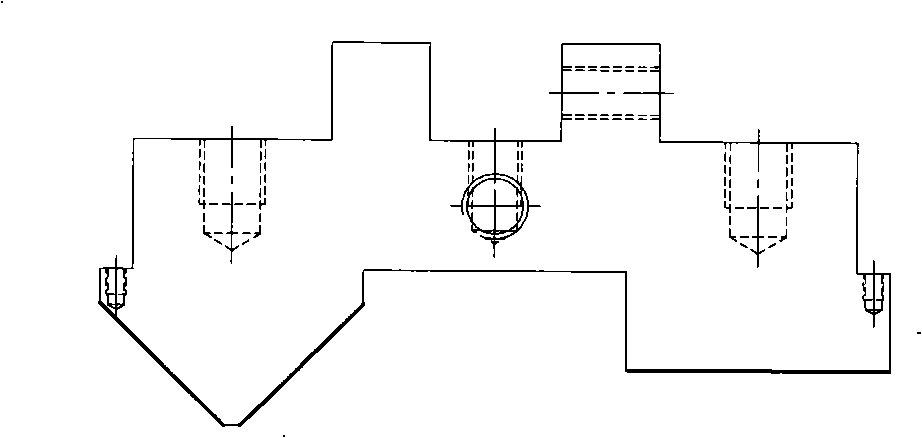

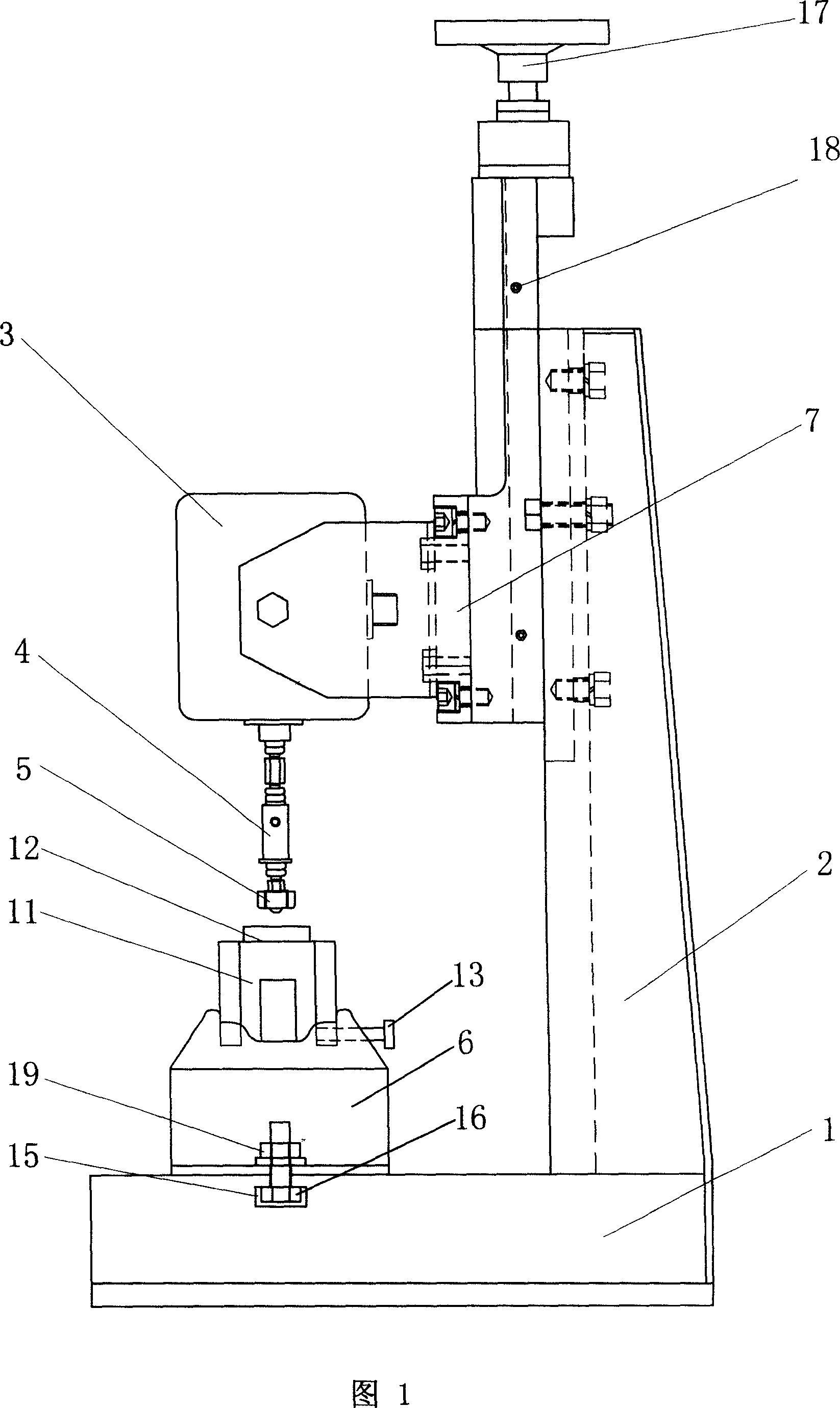

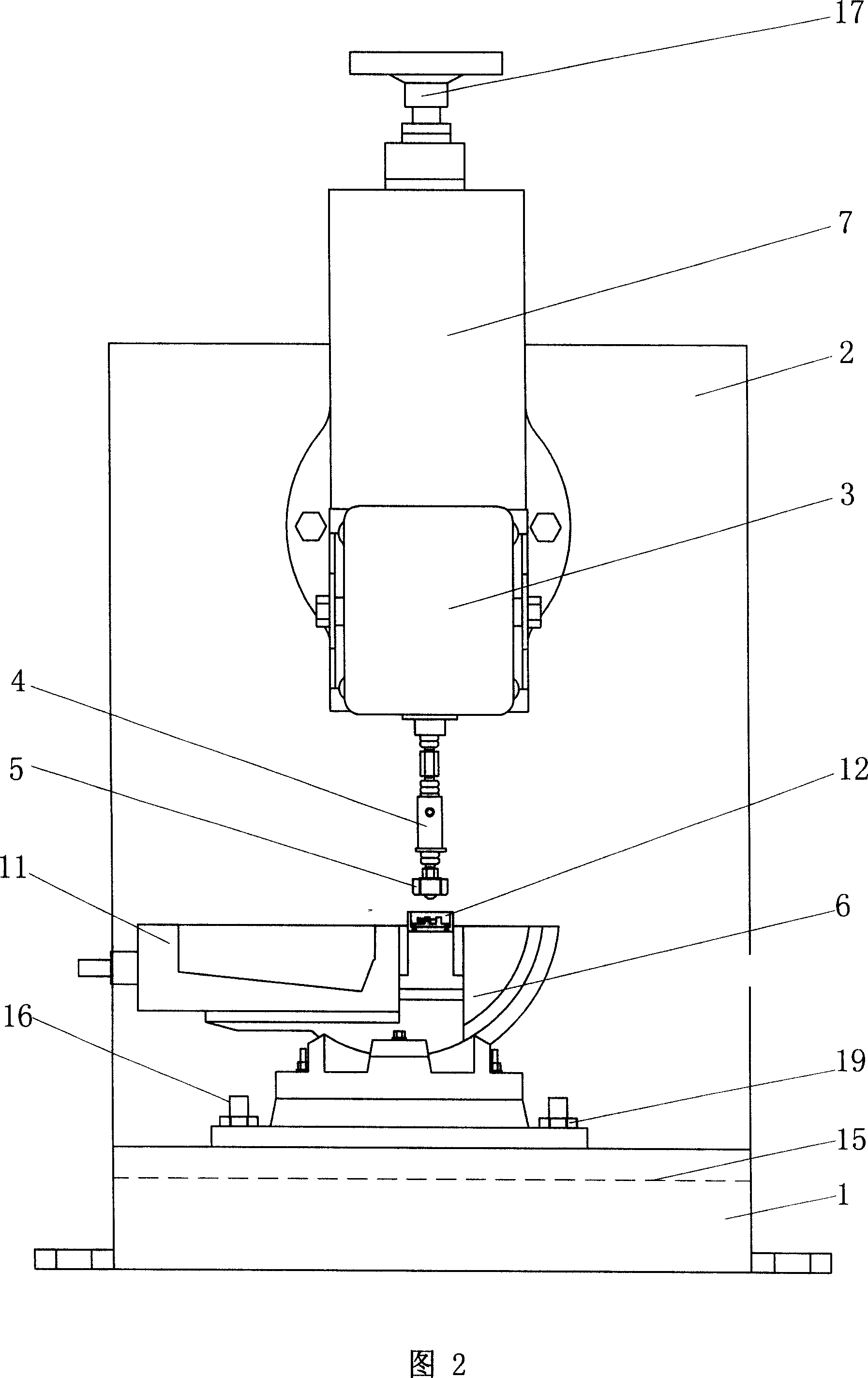

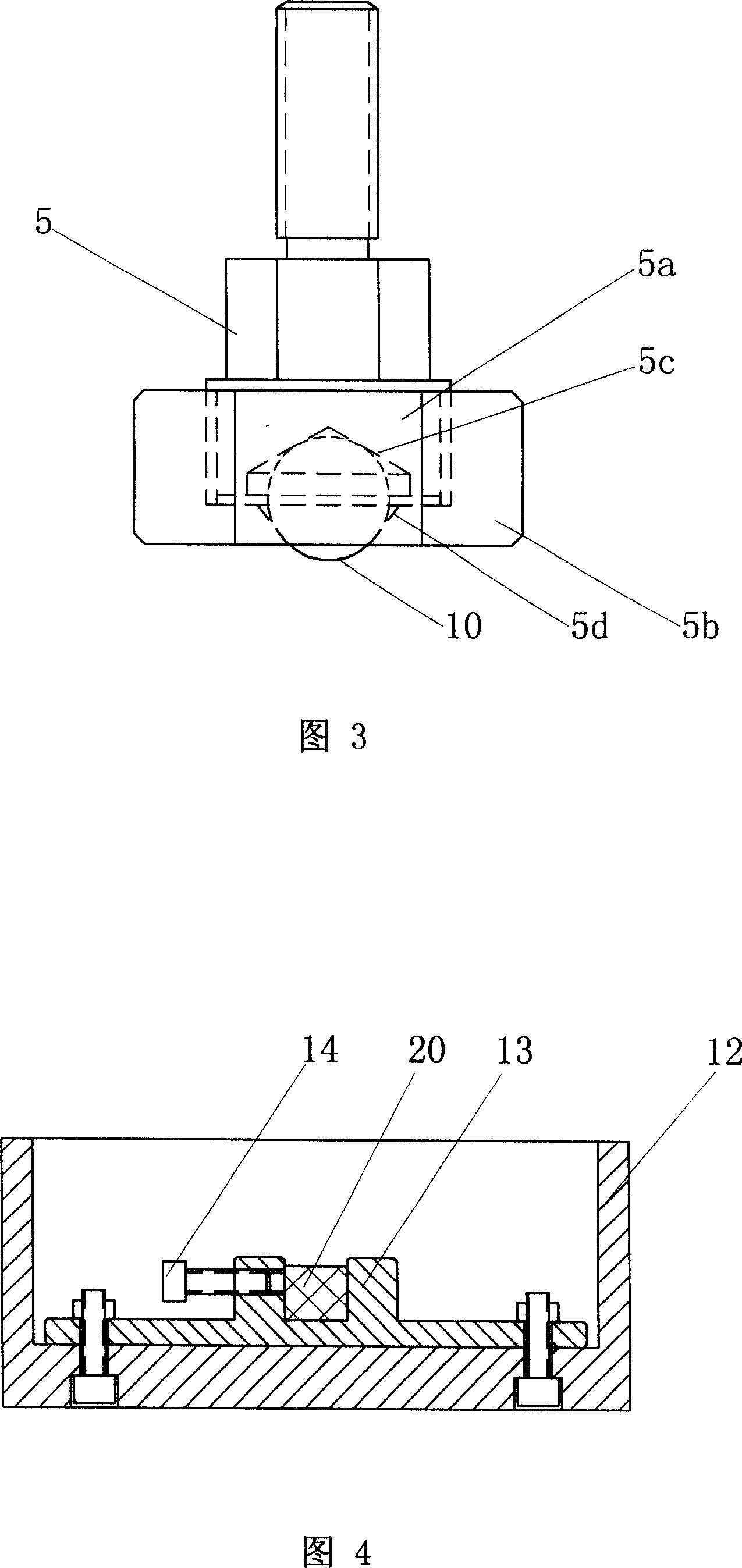

Multifunctional friction wear testing machine

InactiveCN104655511ASimple structureLow costUsing mechanical meansInvestigating abrasion/wear resistanceWear testingEngineering

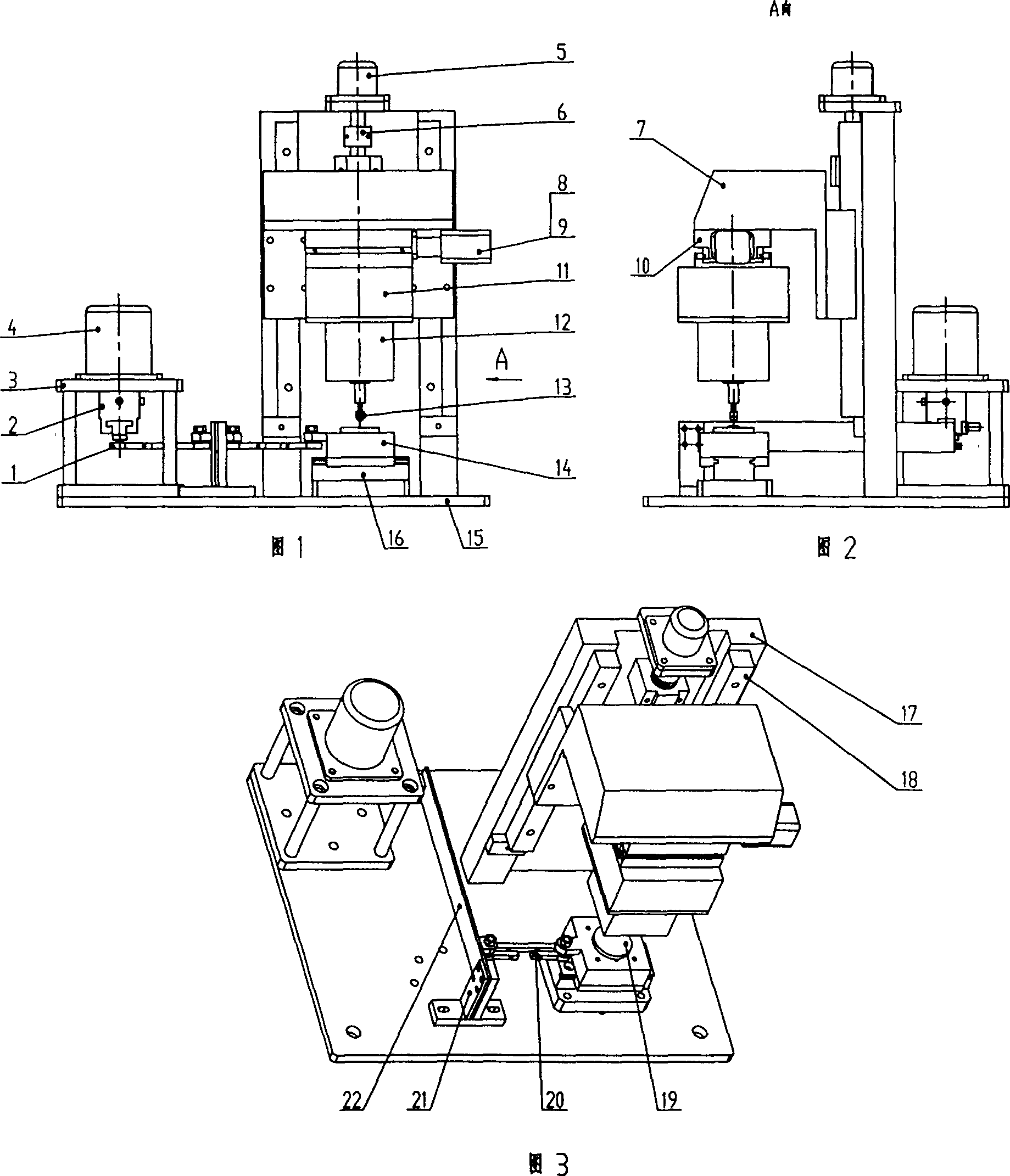

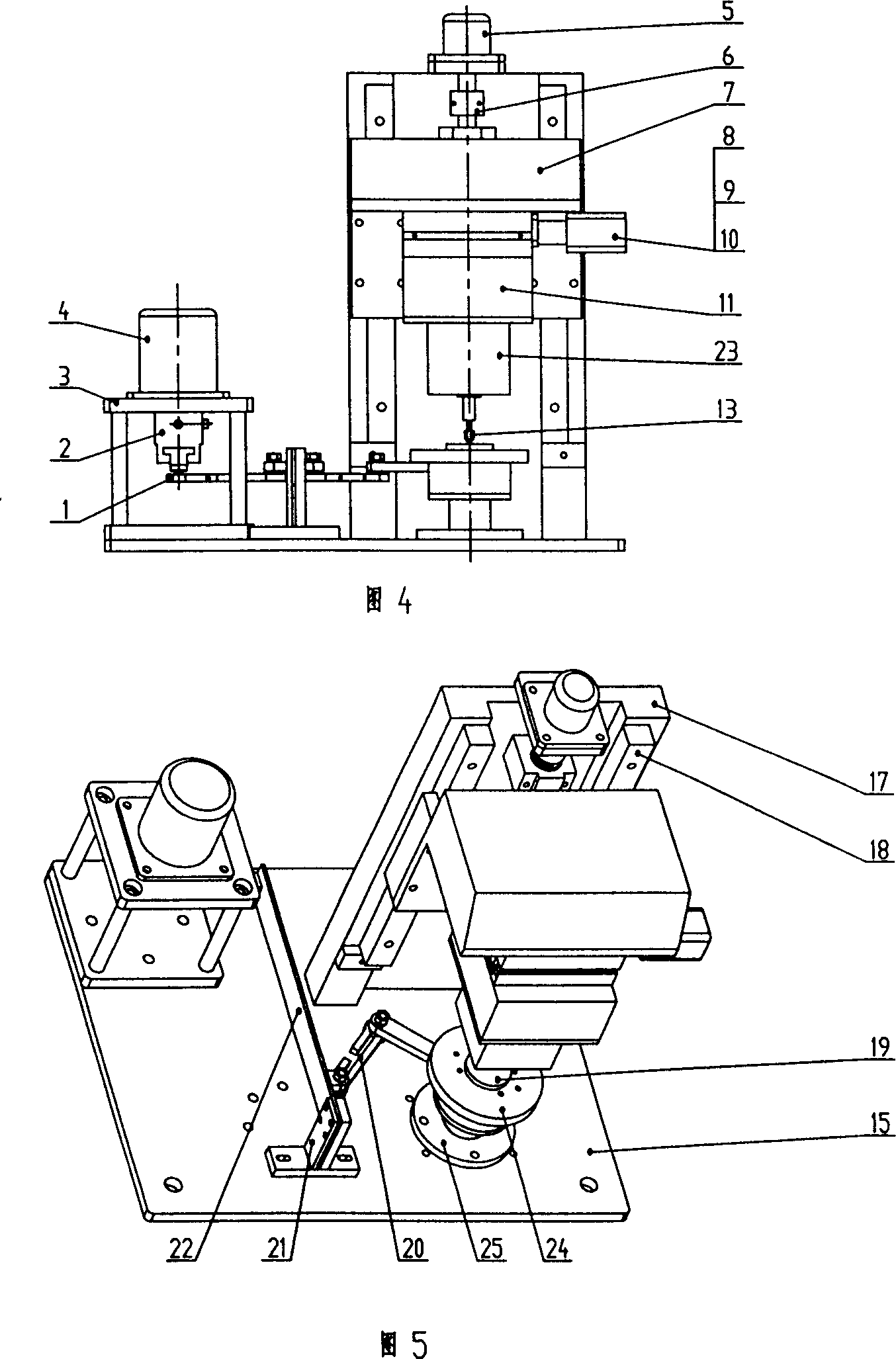

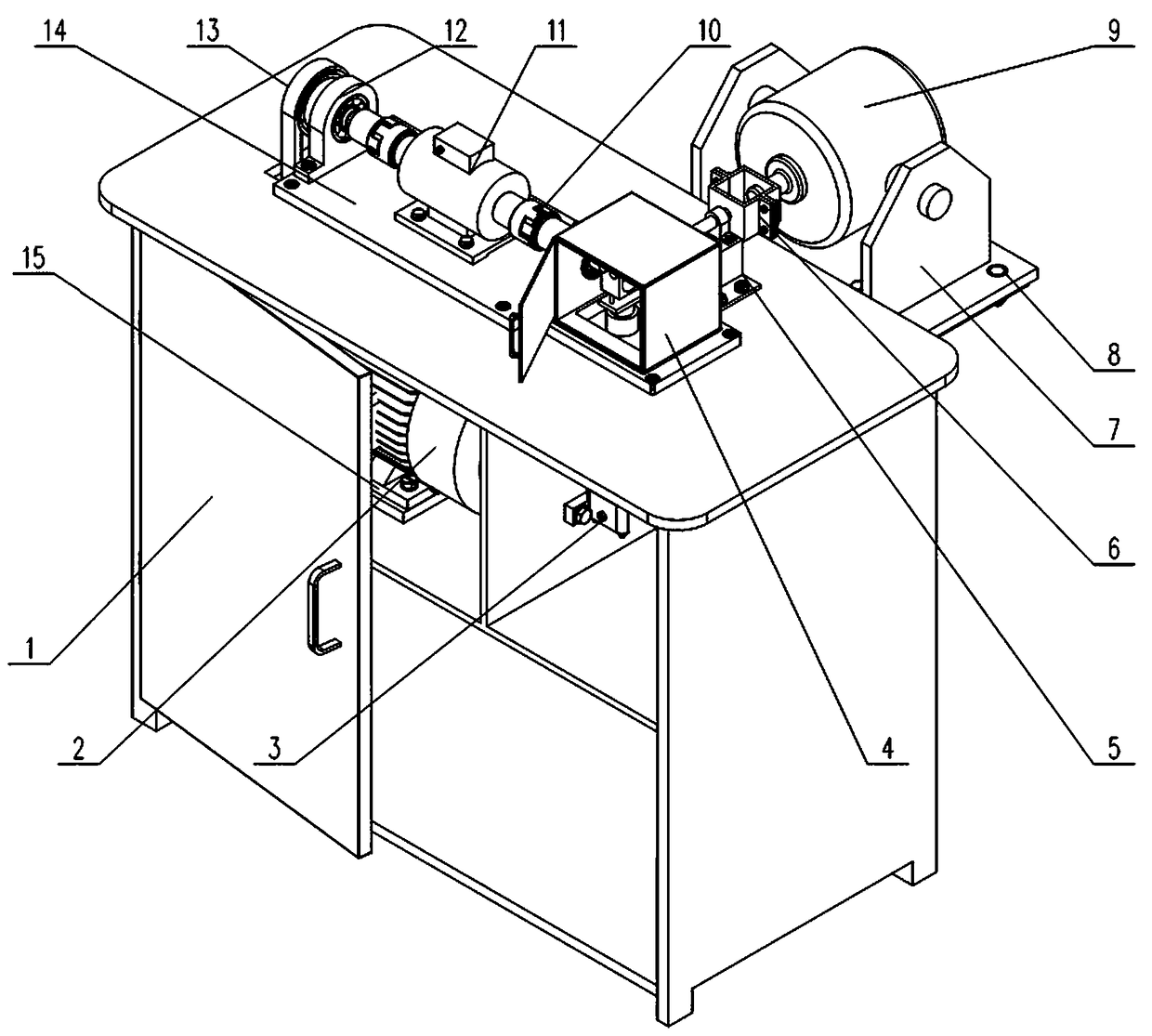

The invention discloses a multifunctional friction wear testing machine, which comprises a vertical screw rod, a vertical guide post, a cantilever support, a horizontal screw rod, a horizontal guide post, an upper friction pair connecting seat, a rotary main shaft, an intermittent gear, a rectangular guide rail, a rack, a synchronous belt drive, a pin (ball) upper friction pair assembly, a reciprocating lower fiction pair assembly, an end-face upper friction pair assembly, an end-face lower friction pair assembly and a rotary disk lower fiction pair assembly. The multifunctional friction wear testing machine is characterized in that the different paired friction pair assemblies are exchanged on the upper friction pair connecting seat and the rotary main shaft, so that determination of tribological parameters between the pin (ball) upper friction pair assembly and the reciprocating lower fiction pair assembly, between the end-face upper friction pair assembly and the end-face lower friction pair assembly, and between the pin (ball) friction pair assembly and the rotary disk lower fiction pair assembly is realized. The testing machine can perform tribological experiments of three friction pairs with different forms. Compared with an existing friction wear testing machine, the multifunctional friction wear testing machine is complete in function, simple in structure and low in cost.

Owner:NANJING FORESTRY UNIV

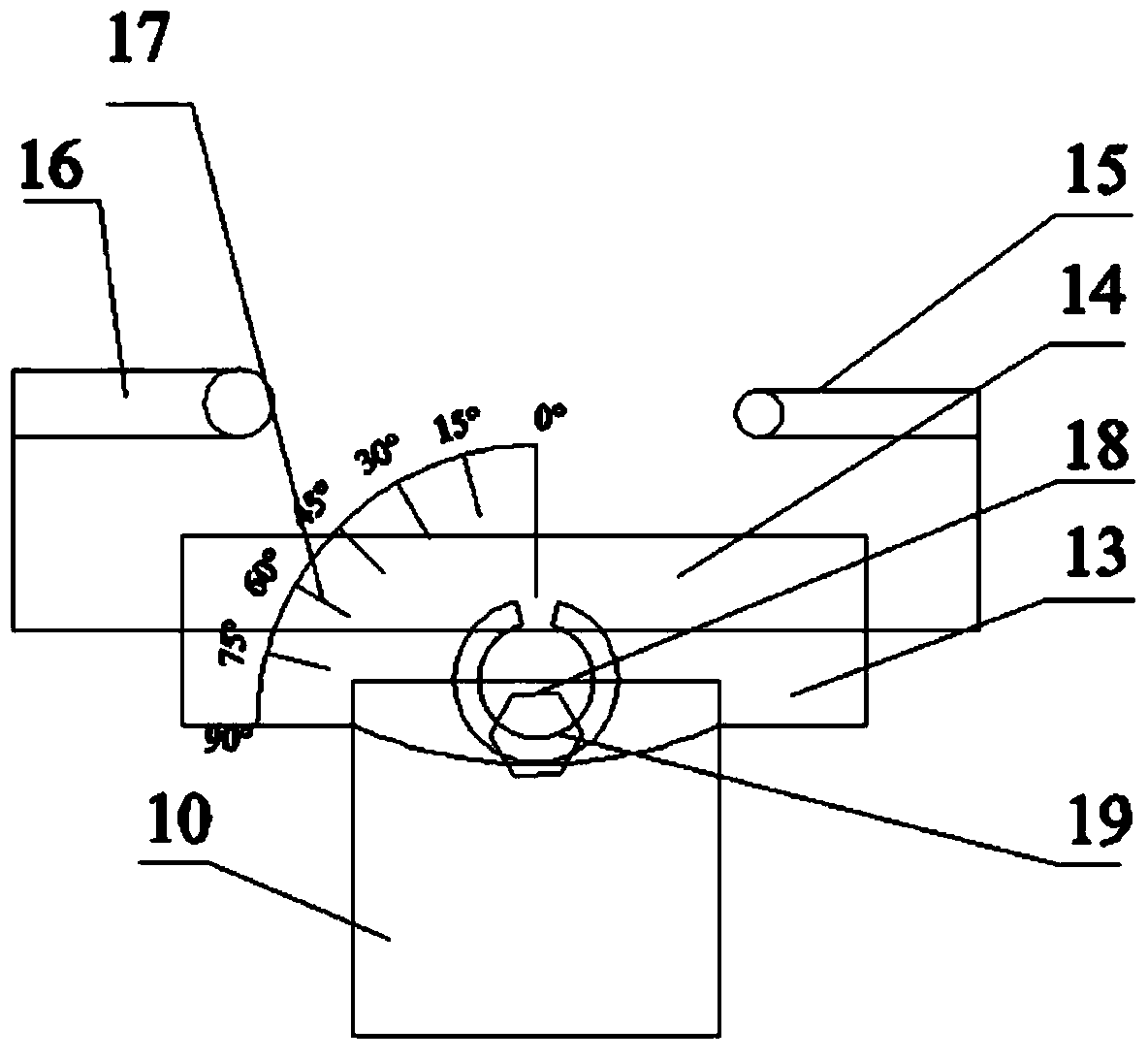

Air flow sand-blasting-type erosive wear testing machine

InactiveCN103760048AEasy to adjustSmooth feedingInvestigating abrasion/wear resistanceWear testingExhaust valve

The invention discloses an air flow sand-blasting-type erosive wear testing machine. The air flow sand-blasting-type erosive wear testing machine comprises a high-speed air flow unit, a screw rod charging unit, an erosive testing unit and a purifying and dedusting unit, wherein the high-speed air flow unit and the screw rod charging unit are both communicated with an inlet of the erosive testing unit; the dedusting unit is communicated with an outlet of the erosive testing unit; the screw rod charging unit comprises an electronic scale, a material storage chamber, a charging funnel, a charging screw rod and a screw rod electromotor, wherein the electronic scale is provided with the material storage chamber; the material storage chamber is provided with the charging funnel communicated with the material storage chamber; the charging funnel is provided with the charging screw rod driven by the screw rod electromotor, and the material storage chamber is communicated with a suction spray gun by a charging pipeline; the screw rod electromotor is controlled by a controller. According to the erosive wear testing machine, the air flow impact speed can be up to 0m / s-200m / s by regulating an air exhaust valve and a flow meter. The erosive angle is changed between 0 degree and 90 degrees by a specimen rotary table. The uniform charging can be ensured by means of a screw rod charger.

Owner:SHANDONG UNIV

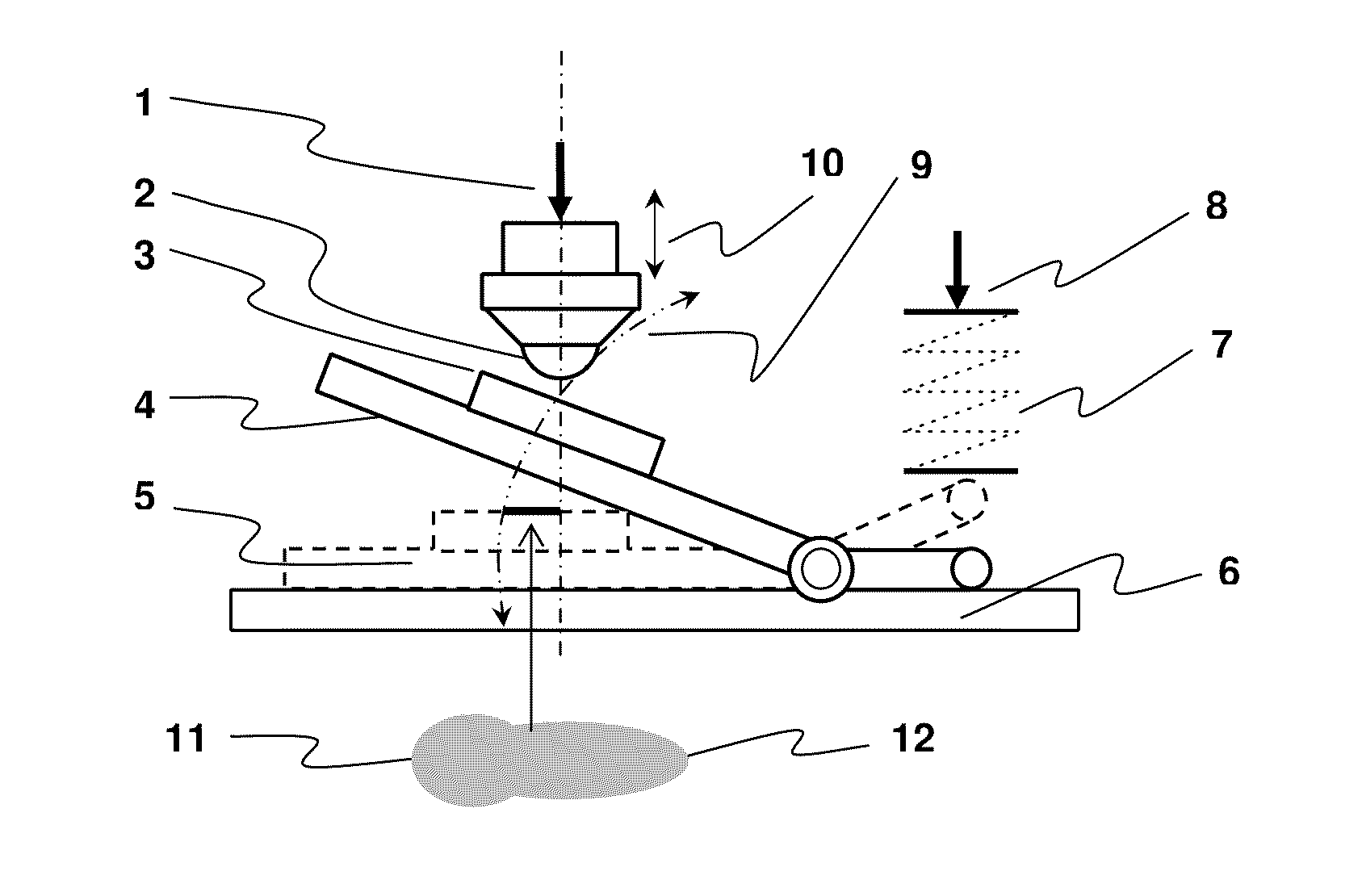

High-temperature pressurization airflow solid particle erosive wear testing device

The invention discloses a high-temperature pressurization airflow solid particle erosive wear testing device. The high-temperature pressurization airflow solid particle erosive wear testing device comprises an air compressor, a high-temperature air heater, an electronic high-temperature control valve and an air flowmeter, wherein the air compressor, the high-temperature air heater, the electronic high-temperature control valve and the air flowmeter are connected in sequence through pipes. An air outlet pipe of the air flowmeter is connected with an upper cavity of a closed type solid particle feeder, and a discharging port pipe of the solid particle feeder stretches into a box through a solid flow regulating valve and a solid flowmeter. A specimen holder is arranged inside the box, a specimen heater is arranged on the specimen holder, an outlet of the solid flowmeter right faces the position above the specimen heater, and an infrared speed meter and a high-speed camera are arranged above the specimen heater. The high-temperature pressurization airflow solid particle erosive wear testing device can be widely applied to the field of erosive wear and suitable for high-temperature erosive wear testing of various materials.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

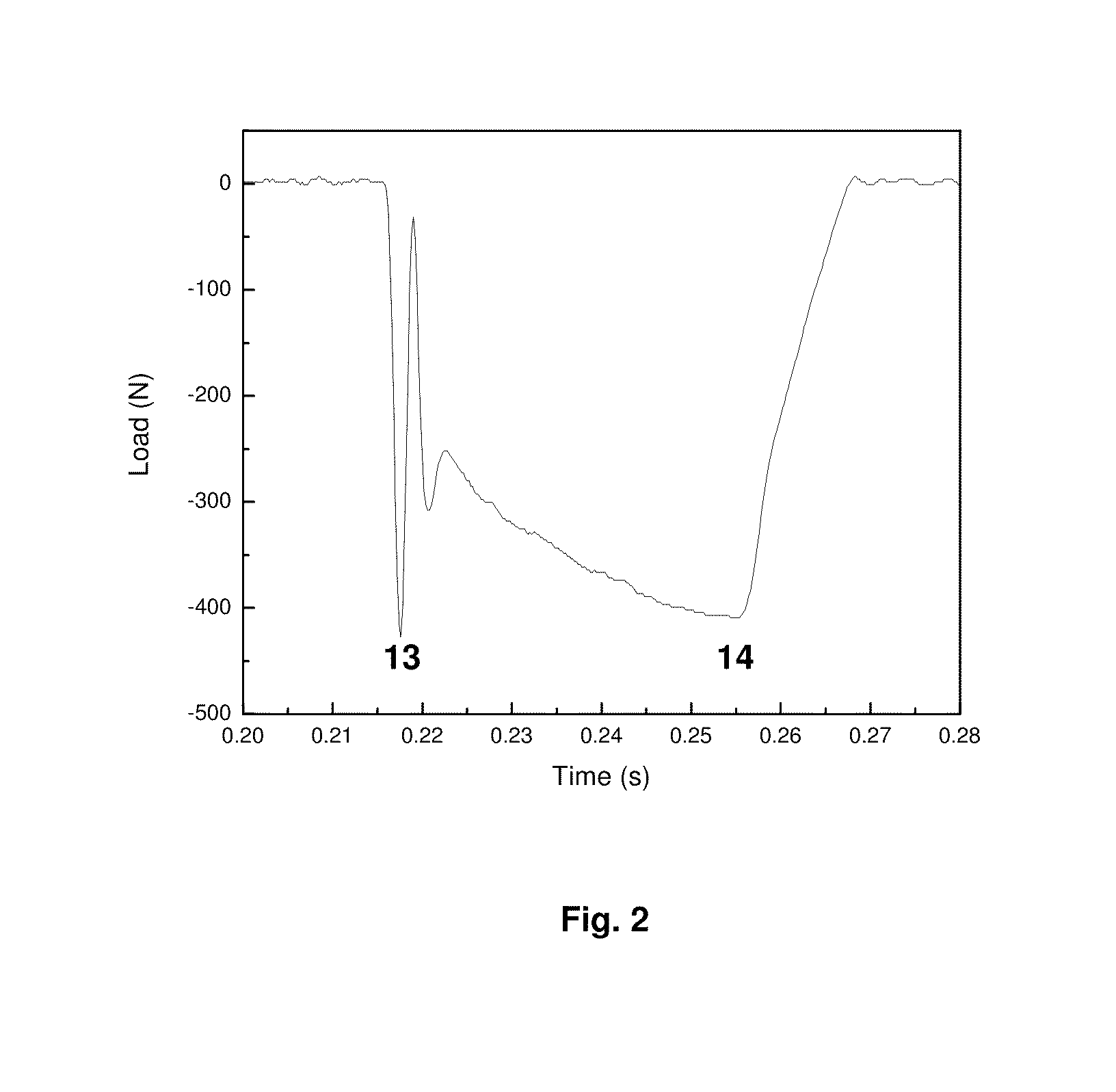

Cyclic Impact-Sliding Fatigue Wear Testing Instrument

ActiveUS20110314894A1Acceleration measurementMaterial strength using repeated/pulsating forcesWear testingContact pressure

This invention deals with a testing instrument that is used to investigate failure behavior of items subject to impact and sliding forces. The testing instrument produces an impact motion and a sliding motion in each testing cycle with maximum contact pressure similar to actual stresses applied to the items during real applications. The invented instrument simulates wear conditions and failure behaviors of biomedical implants, components, tools and coatings which are observed in practical applications.

Owner:NIE YINING +1

Double-column rotary corrosive-wear testing machine

ActiveCN105806772ASolve the precise test problem of relative speedAchieve deliveryWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceTemperature controlPlatinum

The invention provides a double-column rotary corrosive-wear testing machine, comprising a testing stand, which is provided with two columns, wherein a crossbeam is arranged on the columns and a through hole is formed in the center of the crossbeam; a crossbeam elevating and driving mechanism, which is arranged on the test stand and connected with the crossbeam; a testing drum, which is arranged on the center of the test stand, wherein an annular temperature control / cooling pipeline is arranged in the lower part of the testing drum; a transmission shaft, which passes through and is arranged in the through hole in the crossbeam; a sample clamping disc, which is fixed at the lower end of the transmission shaft, wherein the upper end surface of the sample clamping disc is provided with an annular groove, and the outer sides of the annular groove are provided with installation through holes; working electrodes, i.e., to-be-tested samples, which are inserted into the installation through holes; an auxiliary electrode, i.e., an annular platinum wire, which is arranged in the annular groove of the sample clamping disc; reference electrodes, which are uniformly distributed on the sample clamping disc at positions corresponding to the working electrodes; and a dynamic connection pool, which comprises annular dovetail cups, wherein the annular dovetail cups sleeve the upper part of the transmission shaft, leading-out circular rings are arranged at the bottom of the inner sides of the annular dovetail cups, the outer sides of the leading-out circular rings are provided with wiring copper columns penetrating the bottoms of the cups, the interior of each annular dovetail cup is provided with an electric needle, the lower ends of the electric needles are certain distance away from the leading-out circular rings, and the working electrodes, the auxiliary electrode and the reference electrodes are connected with the dynamic connection pool through leads.

Owner:BAOSHAN IRON & STEEL CO LTD

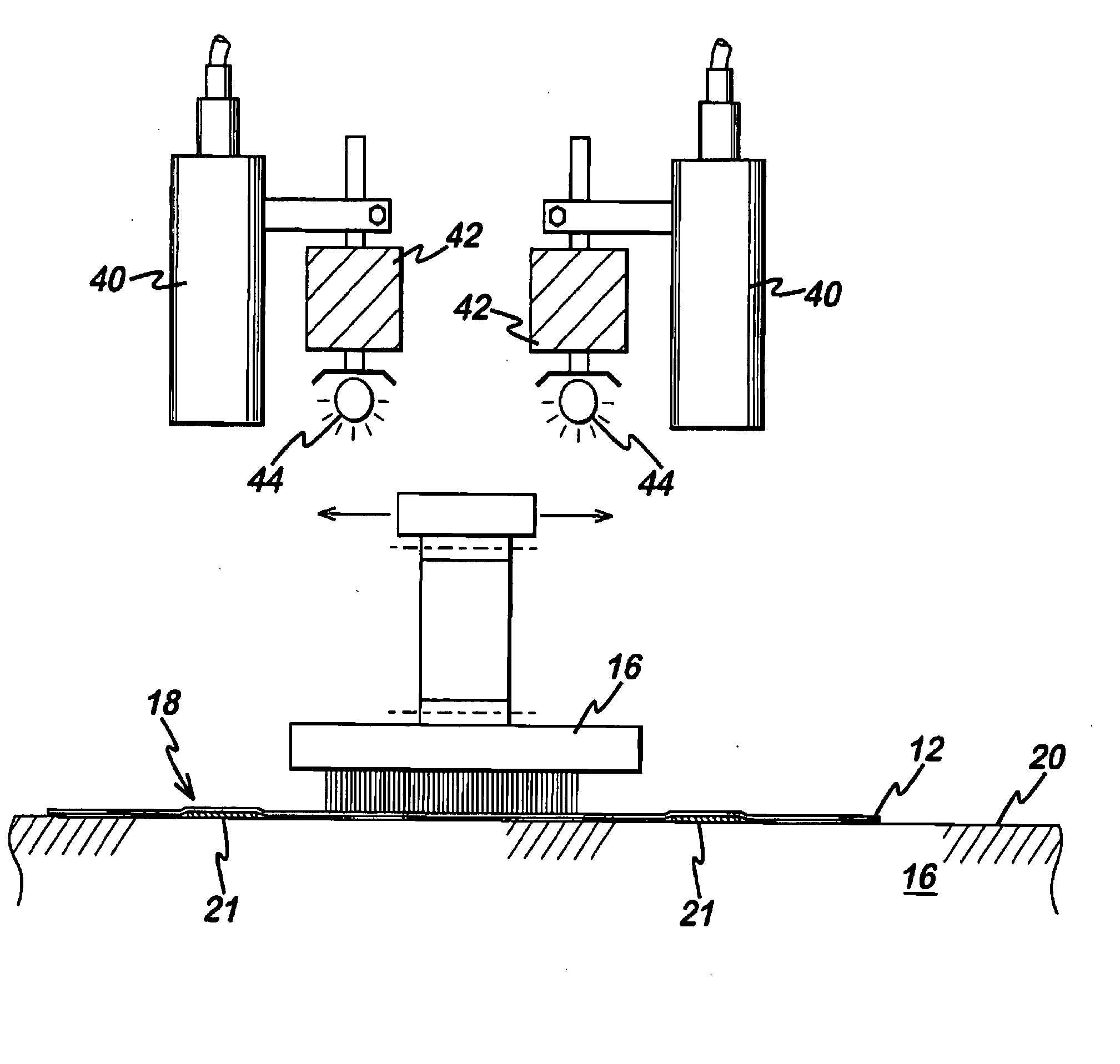

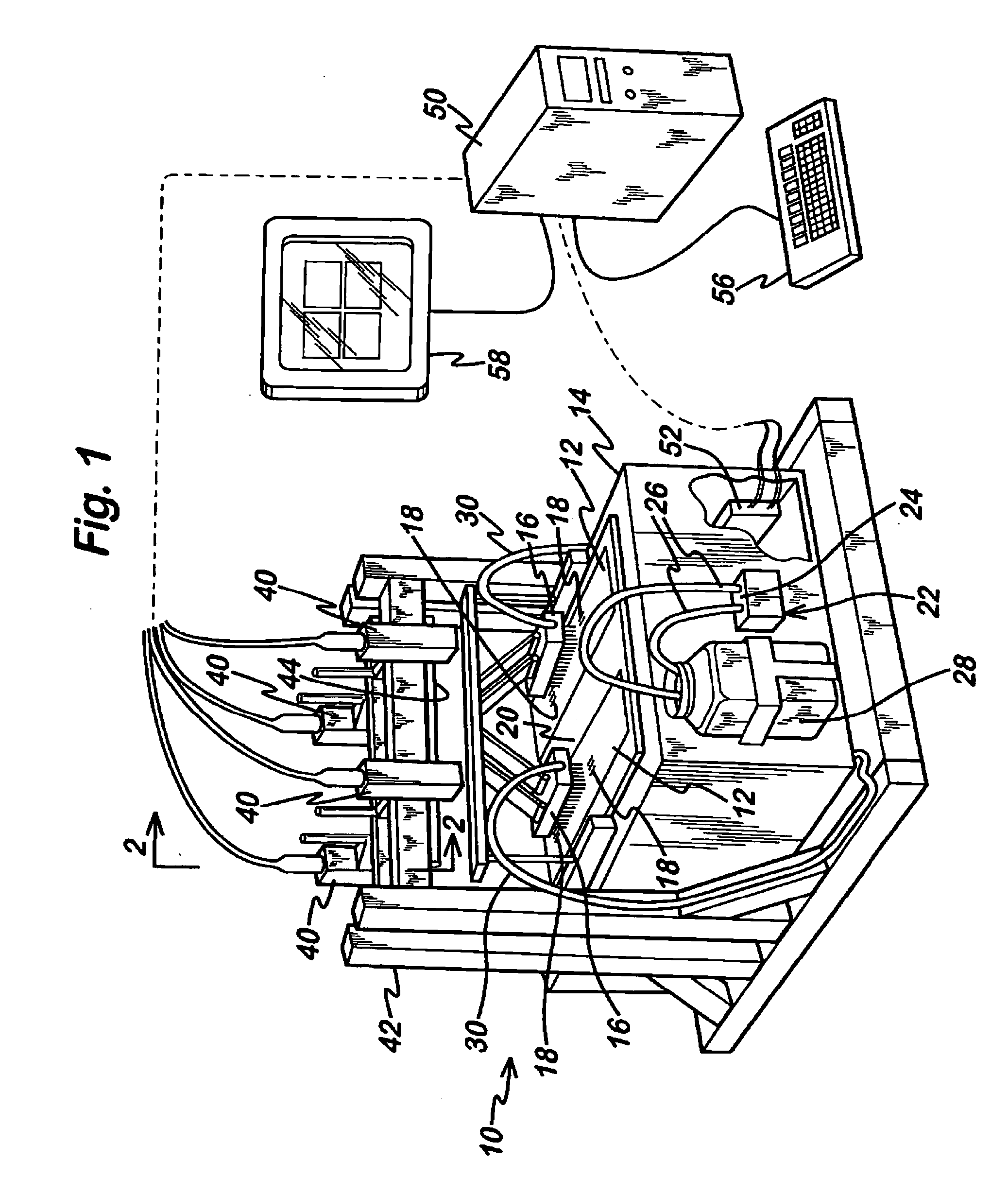

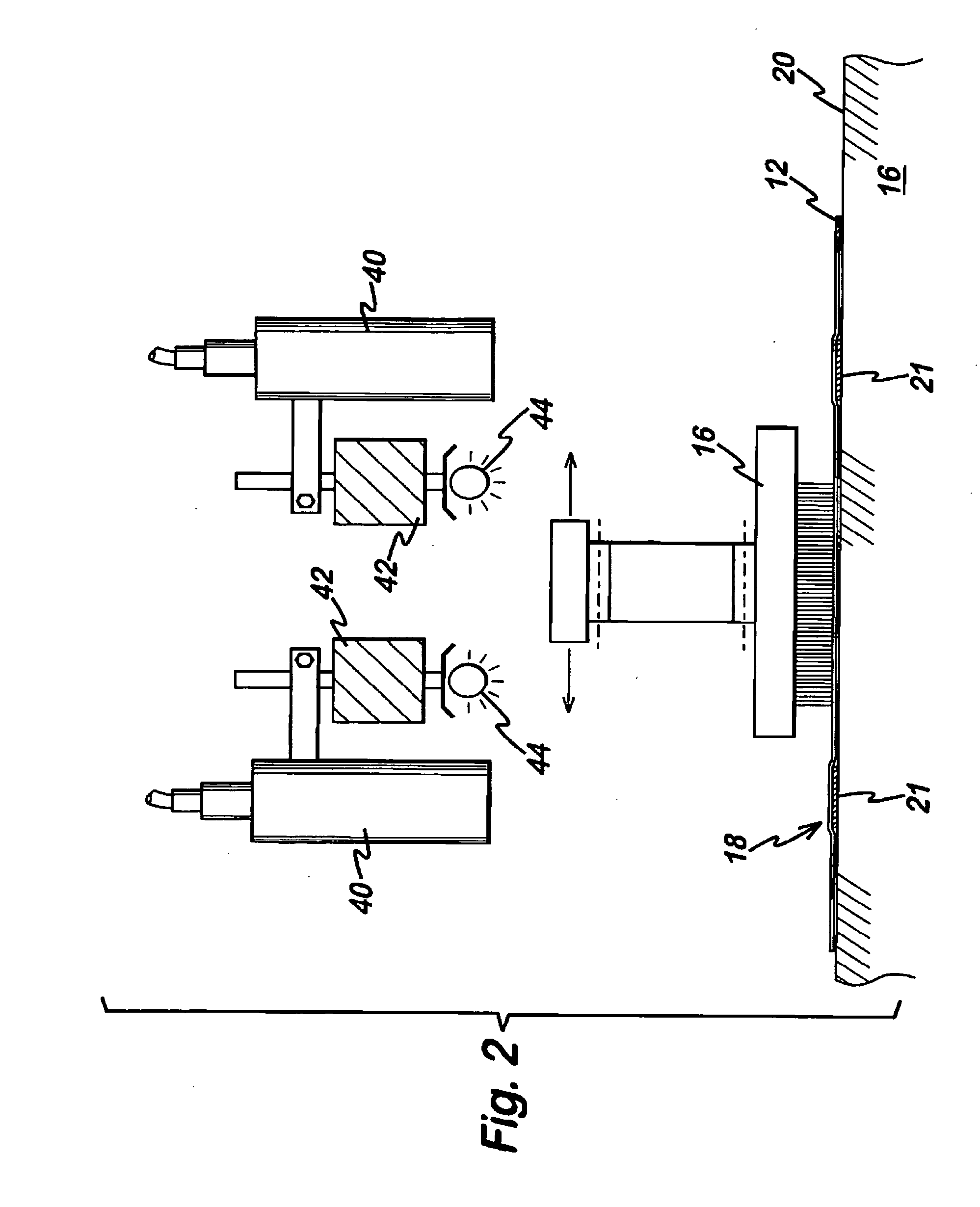

Wear test system

A wear test system for monitoring wear of a sample including a test material located on a base surface of a contrasting color. The system includes a scrub machine with a scrub device mounted for movement over a defined path on the sample. A camera is located above the defined path in a test monitoring area, and a controller is connected to the scrub machine and the camera. The controller creates time evolved composite wear data for wear of the test material from the sample.

Owner:SCHMITT EDWARD A

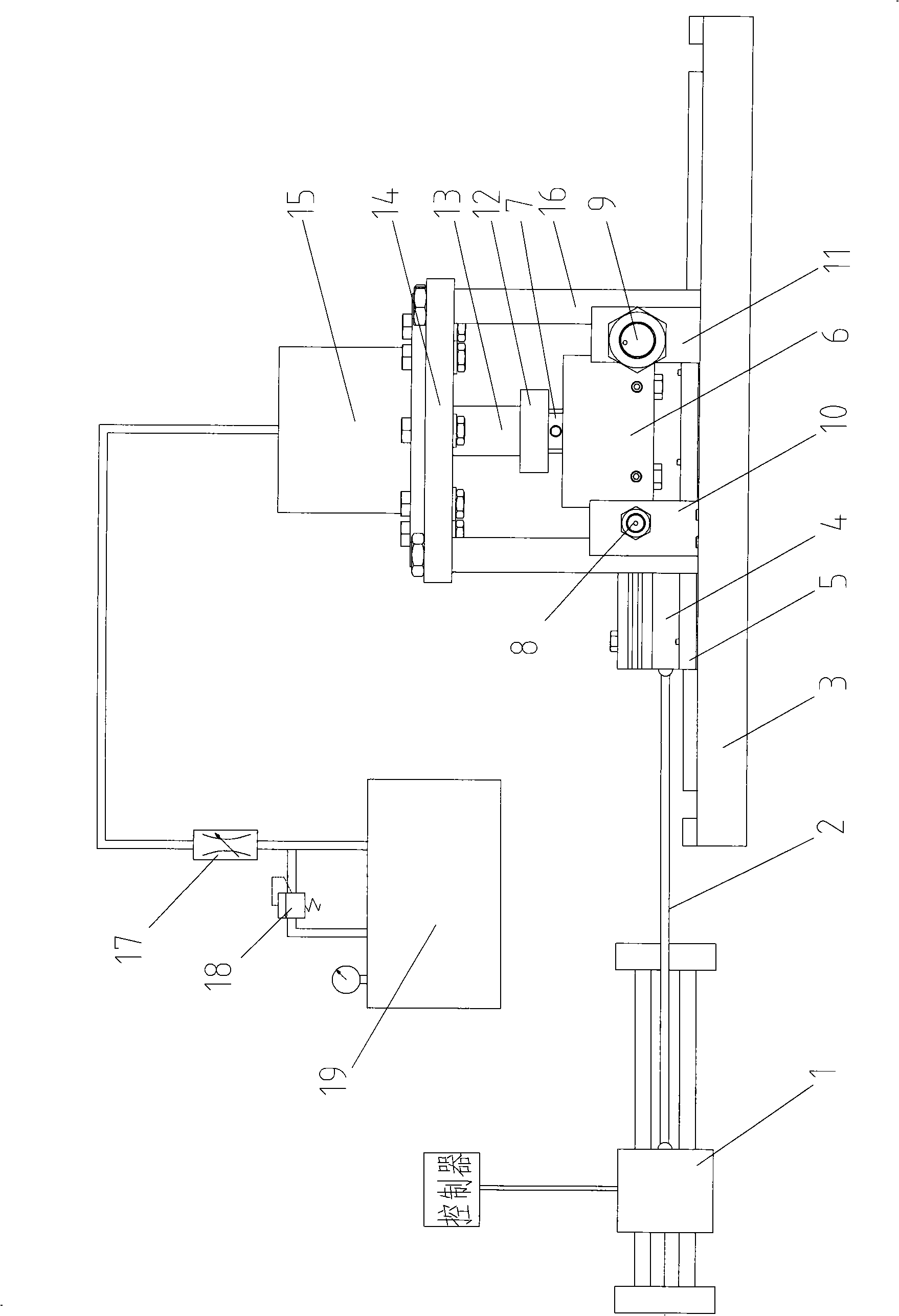

Multifunction friction wear testing machine

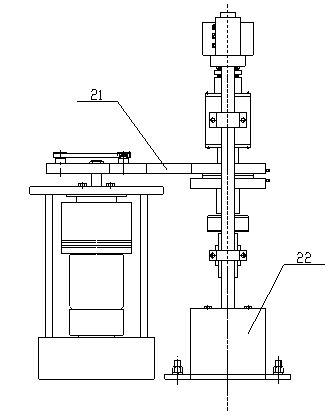

InactiveCN101021466AScientific experiment dataExperimental data is reliableStructural/machines measurementUsing mechanical meansHydraulic cylinderHydraulic motor

The invention relates to an experimental device to detect and analyze wearing of superhard tool. It is a multifunctional rubbing-wearing experimental machine. It is characterized in that: it contains first hydraulic cylinder (1), soleplate (2), first guide (3), upright column (4), gliding block joint plate (5), crossbeam (6), torque sensor (7), hydraulic motor (8), headstock (9), principle axis (10), rotary transducer (11), workbench (13), third hydraulic cylinder (14), third guide (15), slip board (16), second guide (17), second hydraulic cylinder (19) and first pressure sensor (20). Set (20) in (1) and rotate speed measuring flag on principle axis of hole in (11). (11) and (9) are connected. (7) is composed of a twist bar (28) and two torque meter pressure sensors (29). The invention can realize drilling, sawing and milling of tool, test torque, drilling speed and infix pressure parameters of superhard tool during working.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Bearing impact friction-wear testing machine

ActiveCN109084981AMachine bearings testingInvestigating abrasion/wear resistanceWear testingImpact system

The invention discloses a bearing impact friction-wear testing machine. The bearing impact friction-wear testing machine comprises a test stand, a main drive system, a friction pair system, a radial impact system, a hydraulic loading system, a temperature and humidity control system, a signal acquisition and detection system and a computer. The working condition in the friction pair system duringa bearing friction-wear test is changed through the main drive system, the hydraulic loading system and the temperature and humidity control system, and the vibration condition in the vibration bearing operation is simulated by the radial impact system; and the bearing friction-wear output parameters in the friction pair system are collected and monitored in real time by the signal acquisition anddetection system, and are transmitted to the computer through a data acquisition card for data processing and analysis so as to carry out a friction-wear test of a bearing under the coupling effect of impact and friction. The bearing impact friction-wear testing machine provides an effective testing platform for studying the wear behavior of the bearing under the coupling effect of the impact andfriction, and the collected test parameters can be used as judging criterions for bearing wear state identification.

Owner:CHINA UNIV OF MINING & TECH

Rotary reciprocating frictional wear testing machine

PendingCN110530752AHigh precisionPrecise frequency controlInvestigating abrasion/wear resistanceWear testingReciprocating motion

The invention discloses a rotary reciprocating frictional wear testing machine which comprises a rack provided with a rack workbench, a rotation test device, a linear reciprocating test device, a testforce loading mechanism and a sample clamping module. The rotation test device comprises a rotation driving motor. The rotary driving motor is vertically arranged in the rack and is positioned at a lower part of the rack workbench. The linear reciprocating test device comprises a reciprocating motion linear motor which is a voice coil motor. The reciprocating motion linear motor is horizontally arranged on the rack, an axis of the reciprocating motion linear motor perpendicularly intersects with an axis of the rotary driving motor, the sample clamping module is detachably mounted on the rackworkbench and is coaxial with the axis of the rotary driving motor. The test force loading mechanism comprises a lifting mechanism and a force application mechanism, the lifting mechanism is arrangedon the rack, the force application mechanism comprises a force application shaft, a measurement sensor connected to the force application shaft and an upper sample clamp connected to a lower end of the force application shaft, and the force application mechanism is connected to the lifting mechanism.

Owner:济南益华摩擦学测试技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com