End face torsion frictional wear testing machine and method

A torsional friction and wear test technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve problems such as the inability to realize torsional motion forms, and achieve the effects of simple structure, loading accuracy, and reducing torsional friction and wear problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

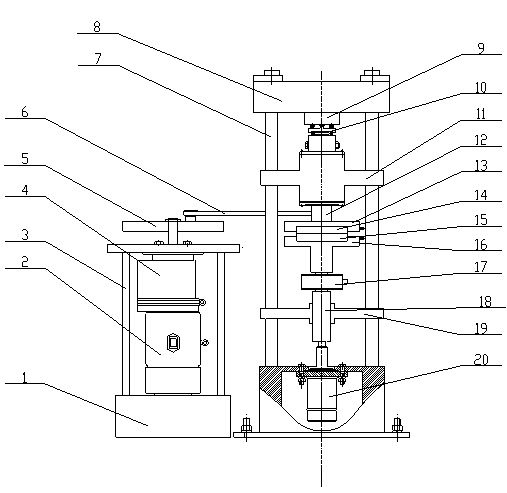

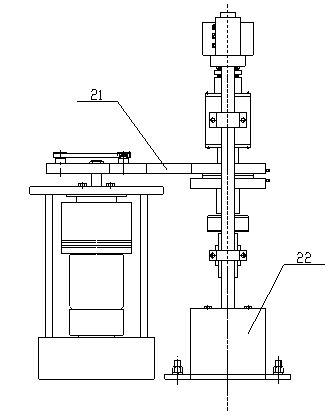

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

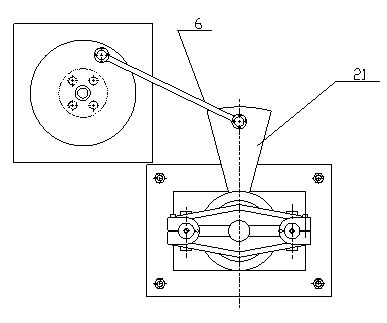

[0021] The end face torsion friction and wear testing machine of the present invention is mainly composed of a transmission device and a pressure loading device. The transmission device includes a servo motor 2 vertically installed on the base 1, and the output shaft of the servo motor 2 is connected with a motor frame 3. The reducer 4, the output shaft of the reducer 4 is connected with the eccentric wheel 5, and the connecting rod 6 is arranged on the eccentric wheel 5; 8 is a fixed frame, the top beam 8 of the fixed frame is connected with a force sensor 9, a thrust ball bearing 10, a fixed piece 11 set in the column 7, a main shaft 12 and a turntable 13, and the turntable 13 is connected with the main shaft 12 with screws, and the turntable 13 is provided with the turntable connection plate 21 that is connected with connecting rod 6, and the turntable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com