Patents

Literature

116 results about "Fretting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fretting refers to wear and sometimes corrosion damage at the asperities of contact surfaces. This damage is induced under load and in the presence of repeated relative surface motion, as induced for example by vibration. The ASM Handbook on Fatigue and Fracture defines fretting as: "A special wear process that occurs at the contact area between two materials under load and subject to minute relative motion by vibration or some other force." Fretting tangibly degrades the surface layer quality producing increased surface roughness and micropits, which reduces the fatigue strength of the components.

Generator rotor fretting fatigue crack repair

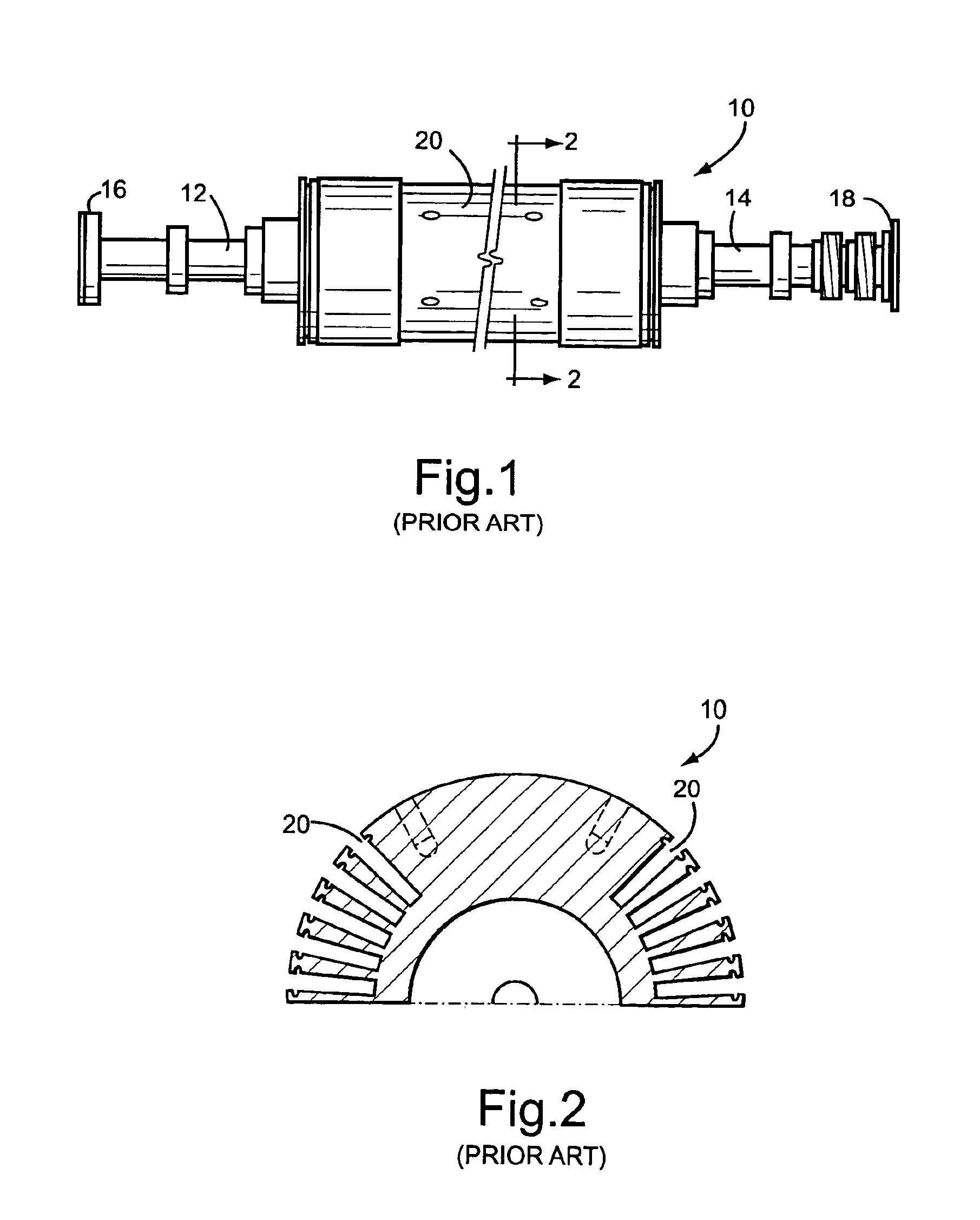

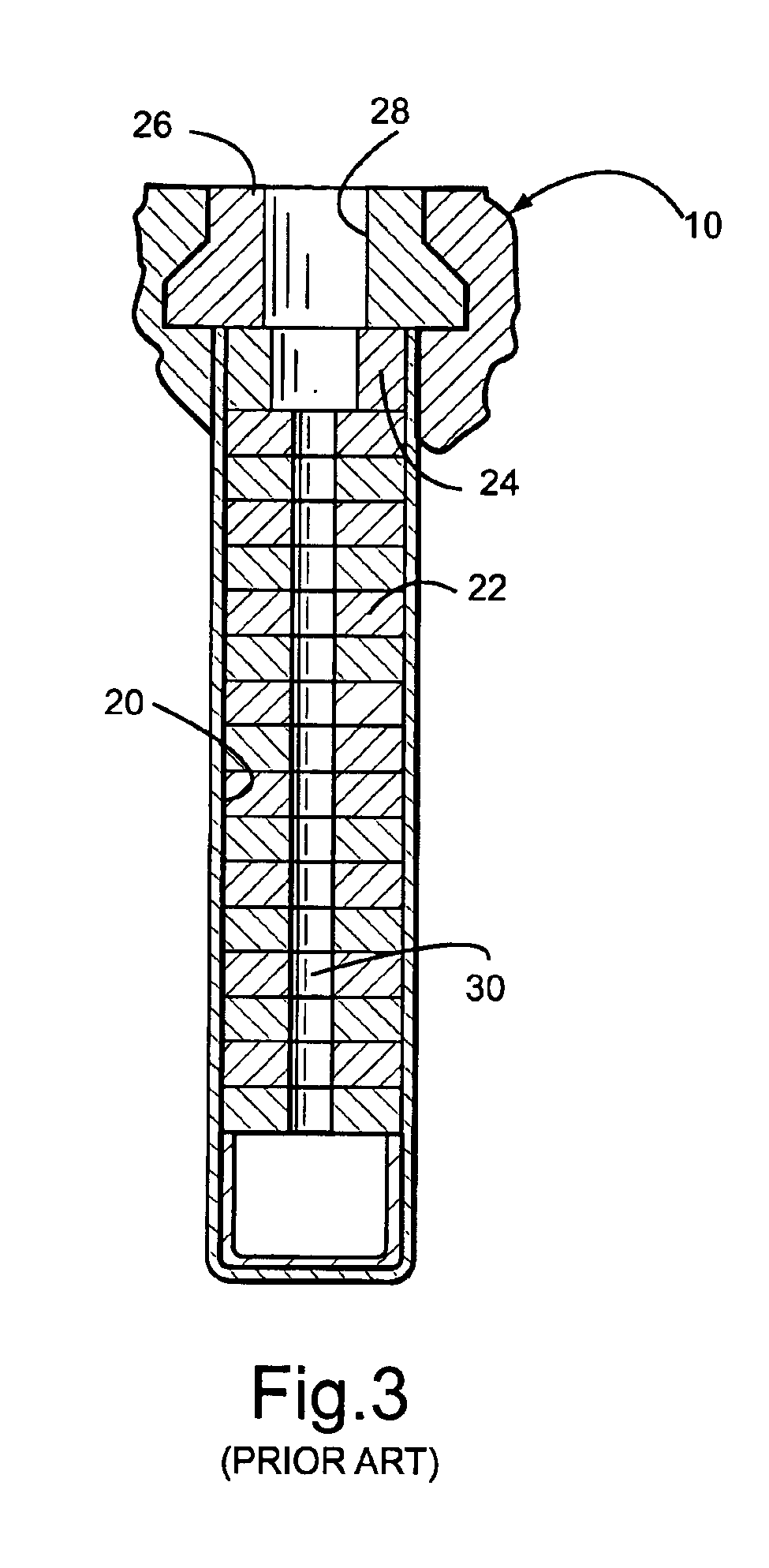

InactiveUS6849972B1Reduces the low and high cycle fatigue life of the rotorReduces low and high cycle fatigue lifeWindingsMagnetic circuit rotating partsFrettingClassical mechanics

A method of repairing a crack in at least one side of a dovetail portion of a generator rotor coil slot wall, the dovetail portion having received at least two axially adjacent steel wedges and including at least a radial entry surface, an inwardly tapered surface and an intermediate radial surface, the method comprising a) machining a groove at least partly along the inwardly tapered surface to remove damaged material from the coil slot wall; and b) replacing the at least two axially adjacent steel wedges.

Owner:GENERAL ELECTRIC CO

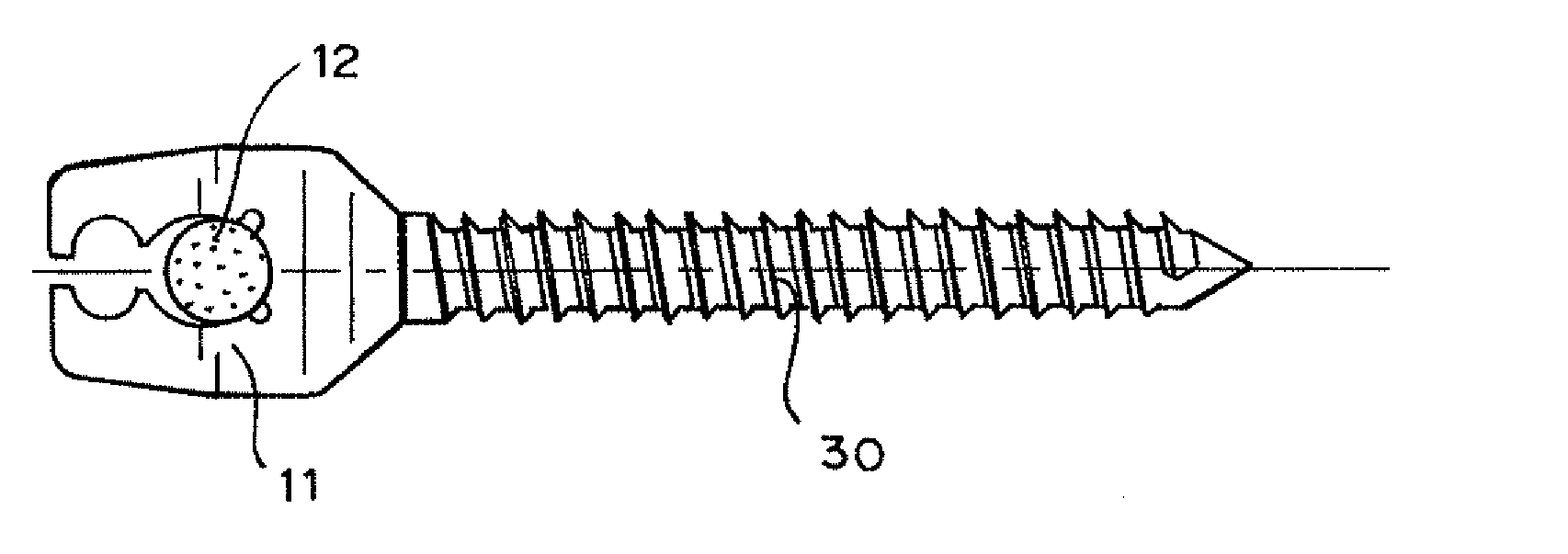

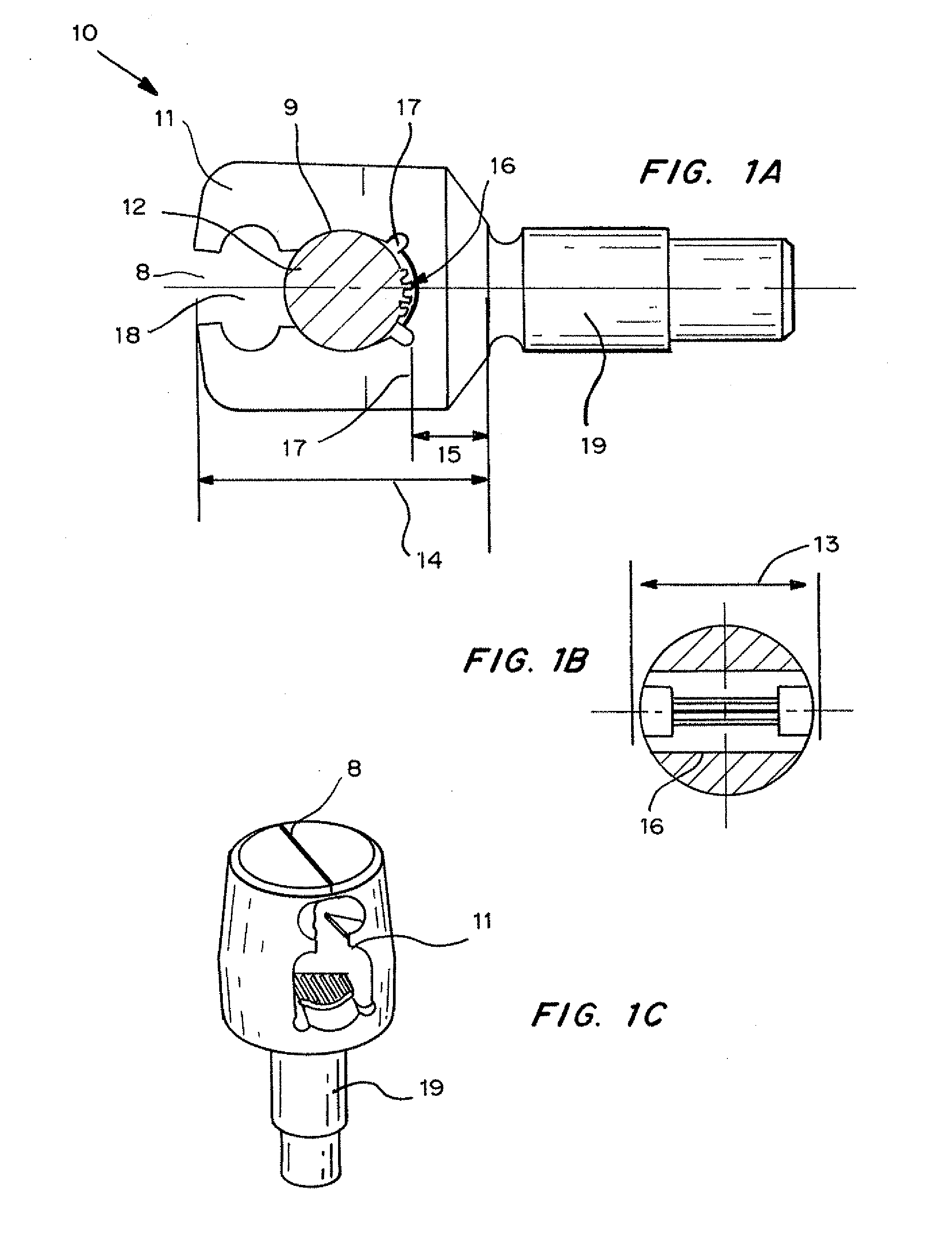

Shape memory locking device for orthopedic implants

ActiveUS20080065074A1Prevent loosening and frettingEasy to transformSuture equipmentsInternal osteosythesisMemory effectFretting

A mechanism to connect the supporting portions of orthopaedic implants such as in the head, spine, upper limb and lower limb and thereby prevent loosening and fretting at the implant interface of an orthopaedic implant construct has been developed based on shape memory effect and super-elasticity of shape memory materials such as nickel-titanium (nitinol or NiTi) shape-memory-alloy, without the use of typical threaded fastening technique. Advantages are conferred by making the entire device, not just connecting pieces, out of shape memory alloy and having shape memory effect and super-elasticity. Heating the memory head of the device will compress the connection portion without the use of an auxiliary device (e.g. coupling member) so that the connection portion can be completely clamped down by the memory head. Further advantages are provided through the use of a two-way shape memory effect in which the memory device can be closed or tightened by heating up the ambient temperature, and re-opened by cooling down the temperature.

Owner:THE UNIVERSITY OF HONG KONG

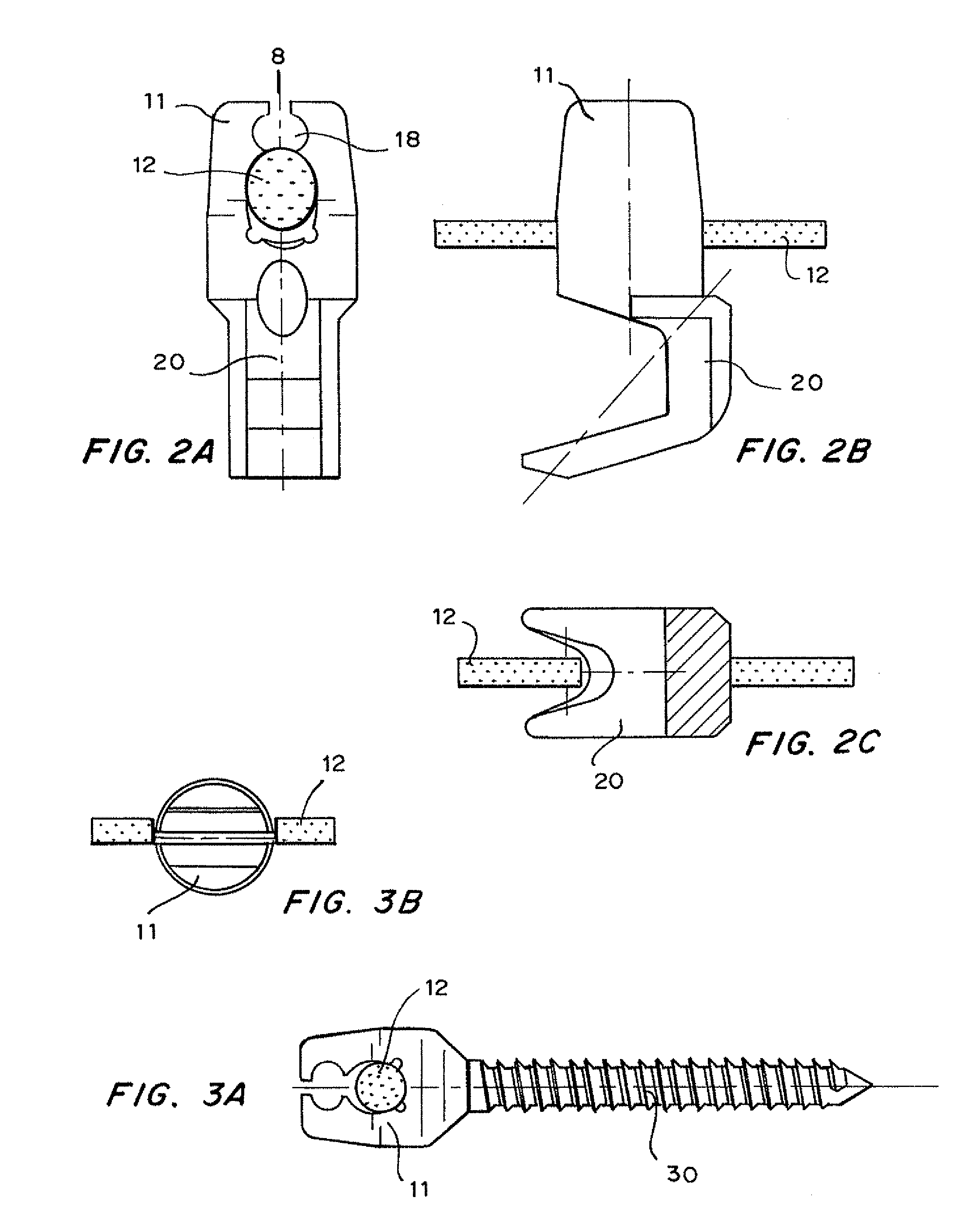

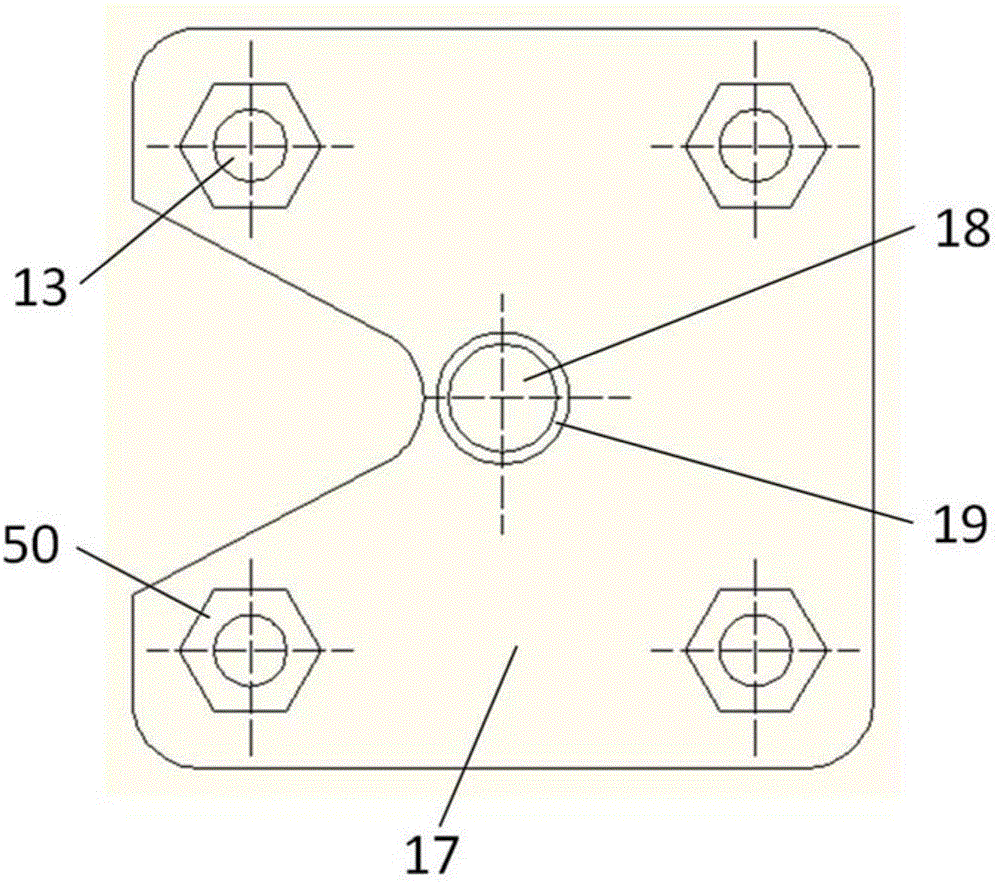

Point contact type fretting fatigue test device and point contact type fretting fatigue test method

The invention discloses a point contact type fretting fatigue test device and a point contact type fretting fatigue test method. The test device comprises a fretting bridge in direct contact with a sample, a loading ring with a ring surface perpendicular to the axial direction of the sample, and a loading bolt which passes through the wall of the loading ring to be in contact with the fretting bridge; the sample passes through the center of the ring surface of the loading ring; the contact surface of the fretting bridge and the sample is provided with a fretting bridge leg in the shape of a convex arc surface; the fretting bridge leg or the loading bolt is provided with a strain foil and is connected with a strain gauge; the point contact between the fretting bridge and the sample is achieved by the direct contact between the fretting bridge leg of the fretting bridge and the sample; the contact surface of the sample can generate slight relative movement and normal pressure is applied to the contact surface of the sample, by means of adjusting the loading bolt to apply pressure to the fretting bridge. Matched with a fatigue testing machine, the test device can be used for performing theoretical research on stretching tension, torsion and tension-torsion composite fretting fatigue modes.

Owner:SOUTHWEST JIAOTONG UNIV

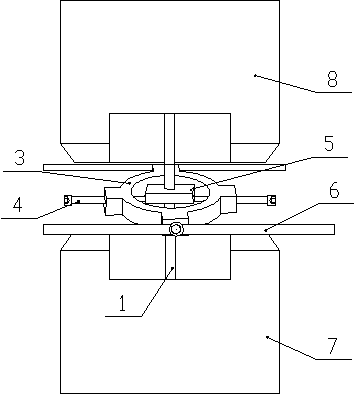

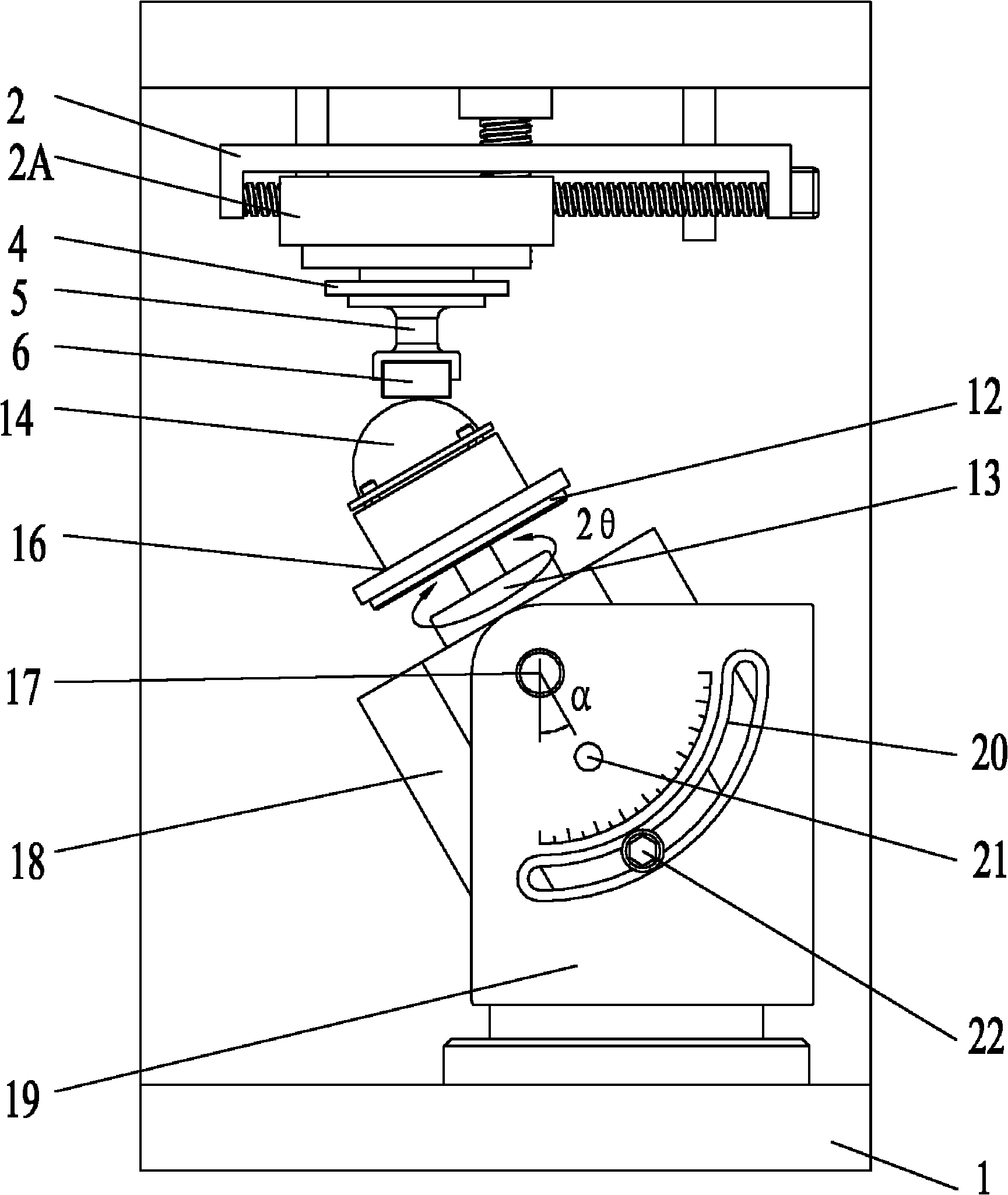

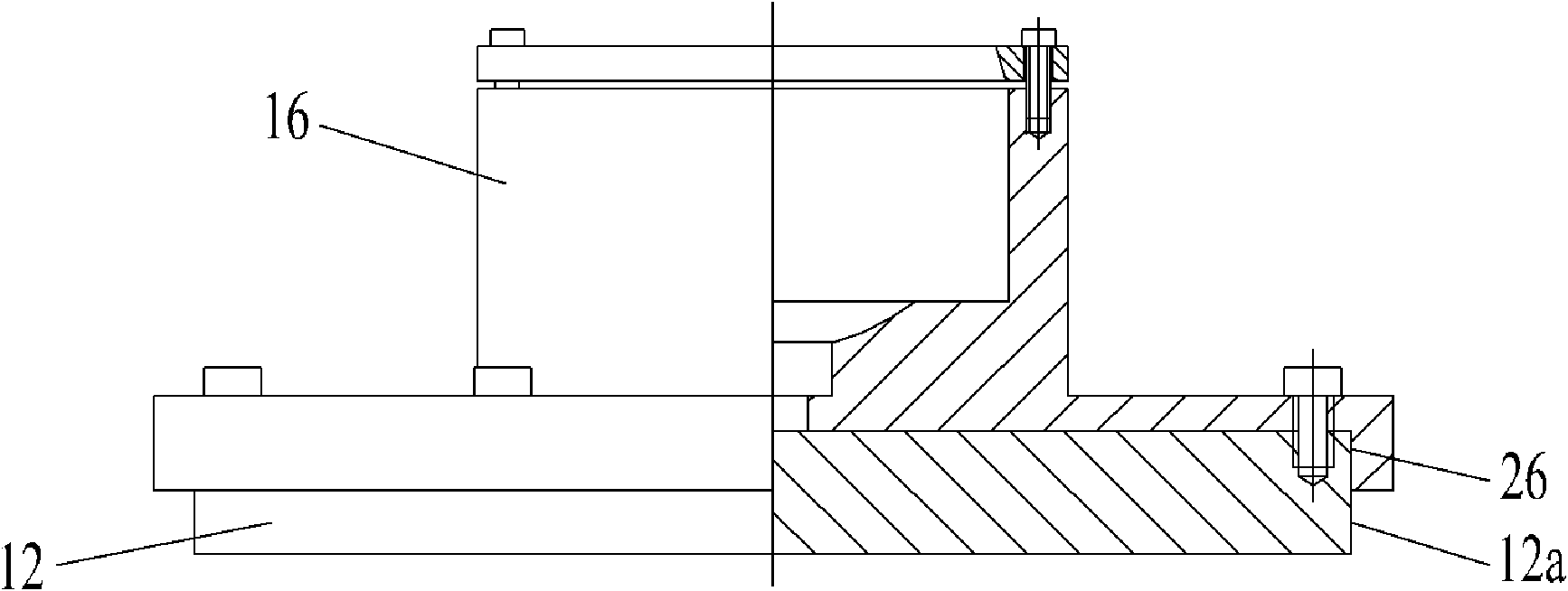

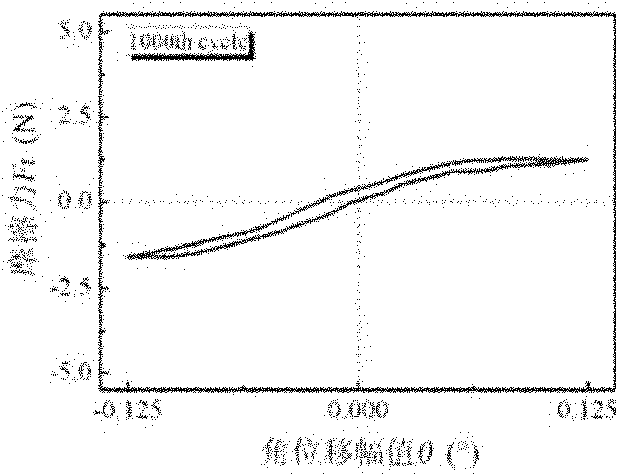

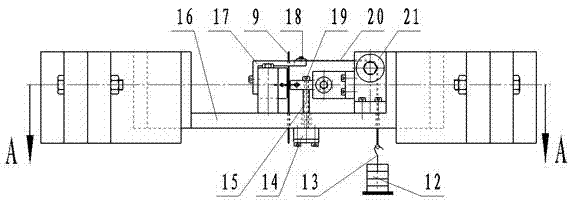

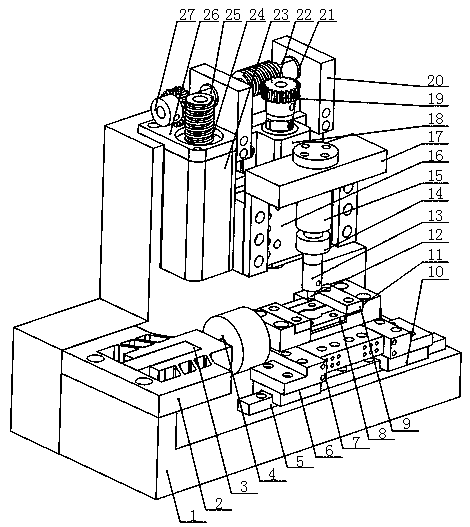

Test method and test device for torsional composite fretting friction wear

InactiveCN101963563AReal and effective analysisReal and effective testInvestigating abrasion/wear resistanceNormal loadFretting

The invention discloses a test method and a test device for torsional composite fretting friction wear. The method comprises the following steps that: a, an upper test piece is clamped on an upper fixture connected with a six-axis force / moment sensor, and a lower test piece is clamped by a lower fixture, wherein the lower fixture is fixed on an inclined rotary motor (13) shaft; b, a data acquisition control system controls the upper fixture and the upper test piece to move up and down and move left and right to make the upper fixture and the upper test piece contact and keep a set normal load Fn, and the data acquisition control system controls a rotary motor and the lower test piece to rotate in set parameters; and c, the six-axis force / moment sensor measures a tangential force, namely a frictional force Ft, the frictional force Ft is sent to the data acquisition control system, and the curve of the frictional force Ft and a rotary angle displacement amplitude theta is obtained through analysis to represent dynamic characteristics of torsional composite fretting. By the method, composite fretting damage of a component in complex stress is more really simulated; the precision of control and test is high; the repeatability of experimental data is good; and the automation degree is high.

Owner:SOUTHWEST JIAOTONG UNIV

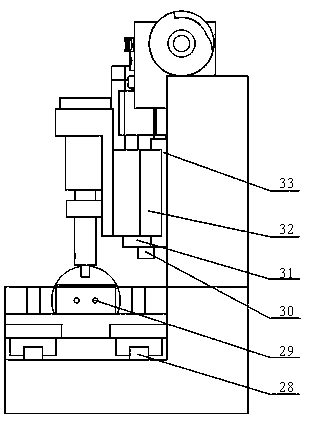

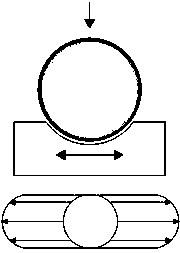

Bidirectional final motion test fixture and bidirectional final motion test method thereof

InactiveCN101608986ARealize two-way inchingShorten the lengthUsing mechanical meansMaterial strength using repeated/pulsating forcesFrettingEngineering

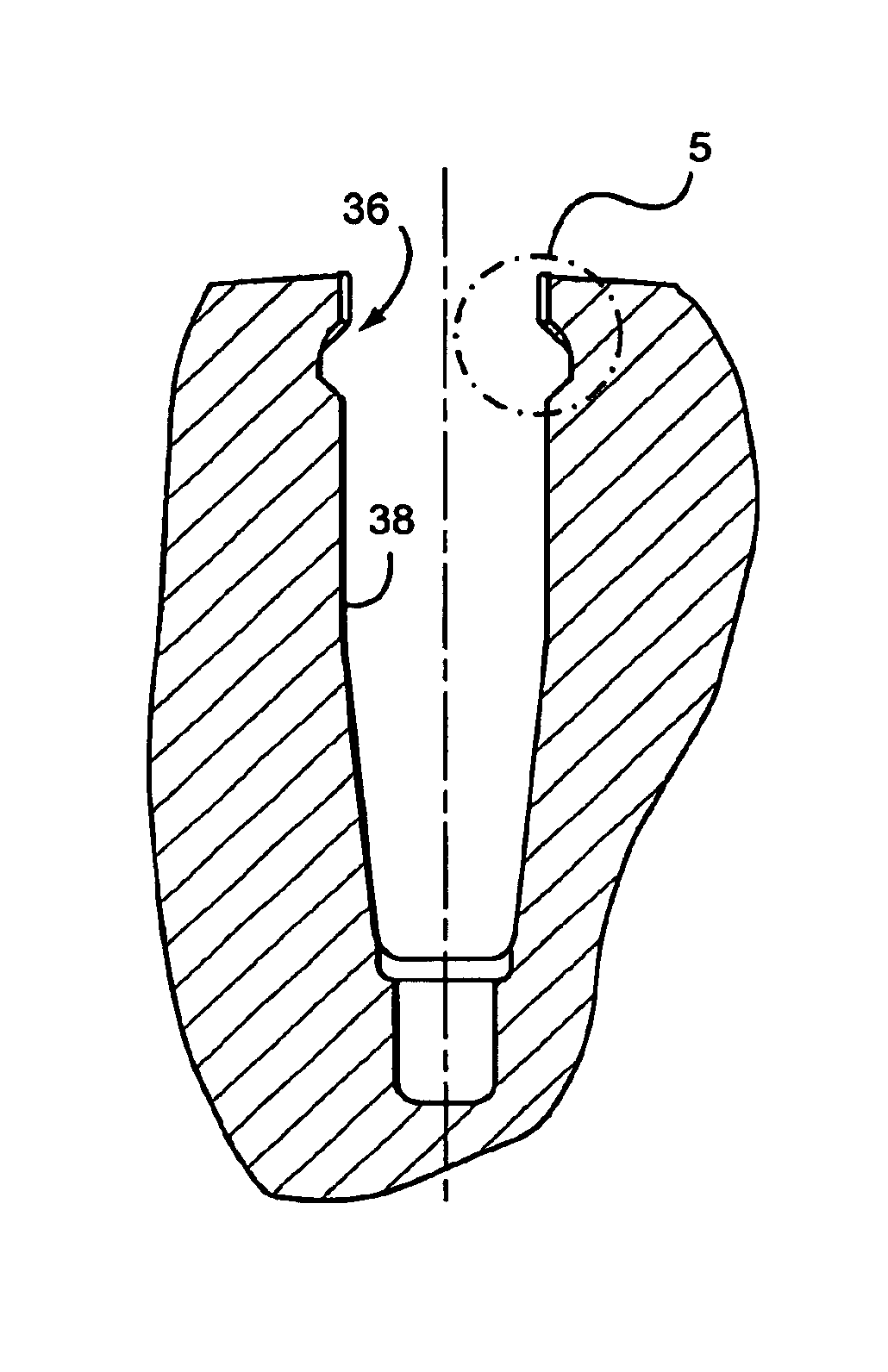

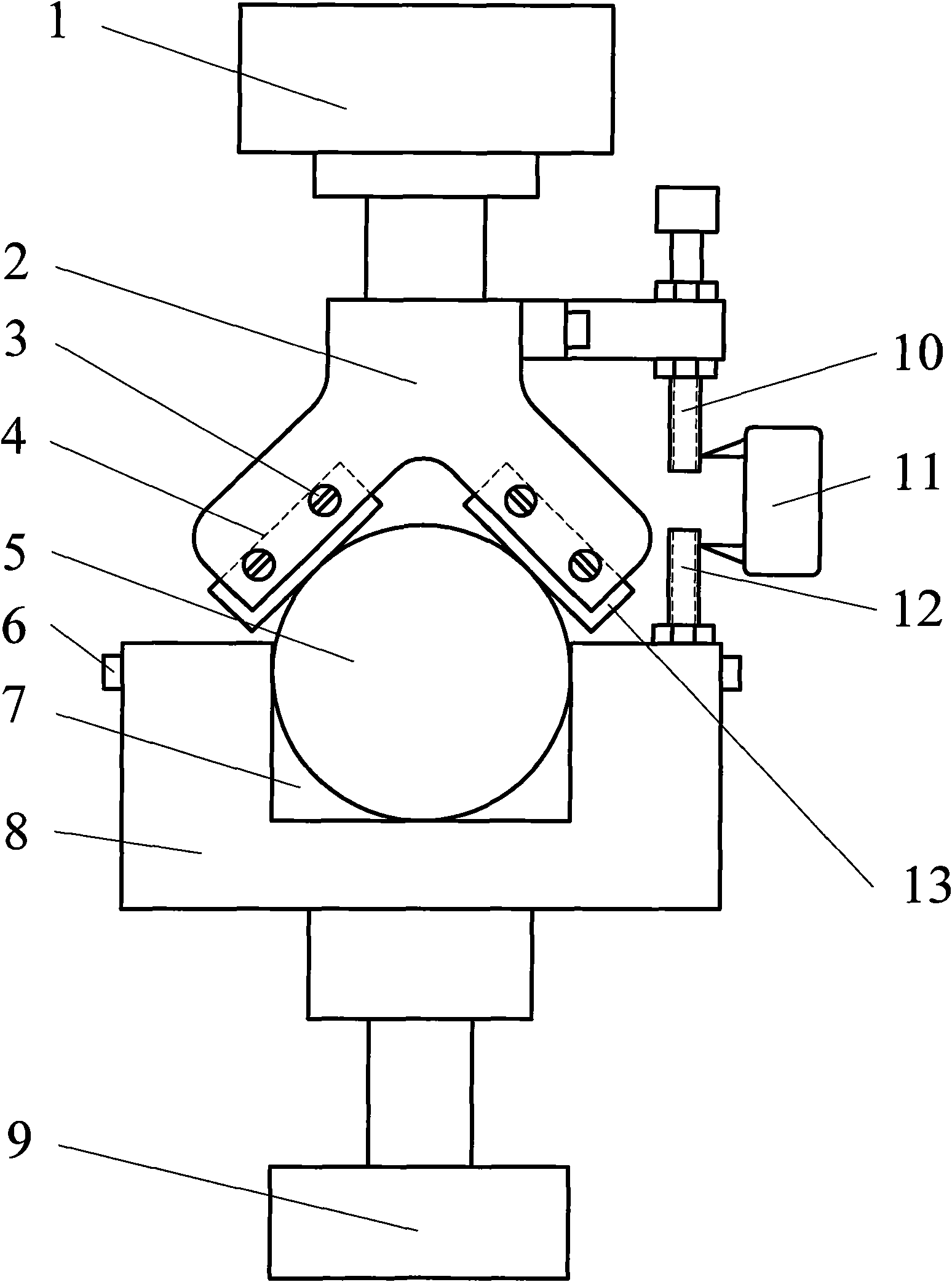

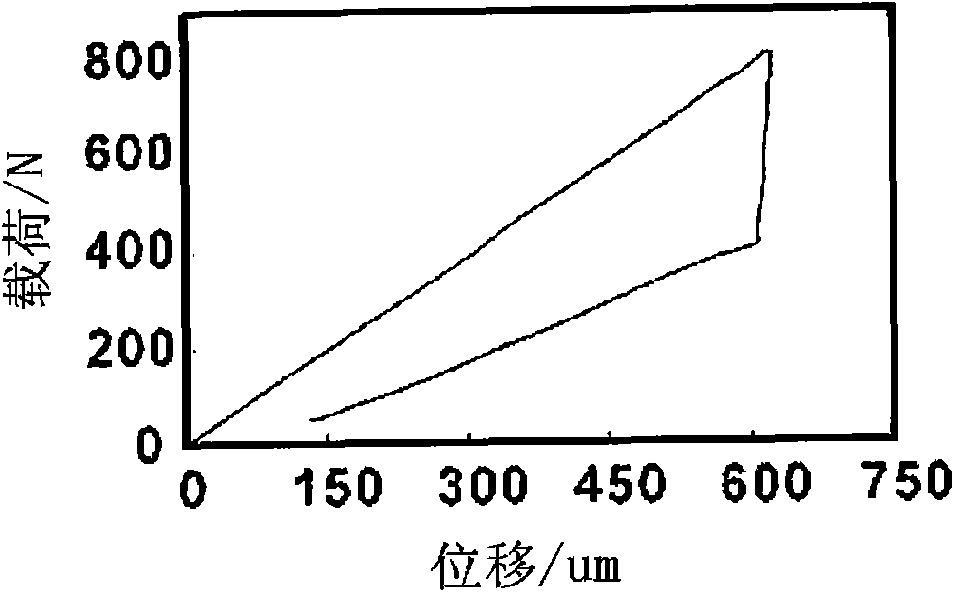

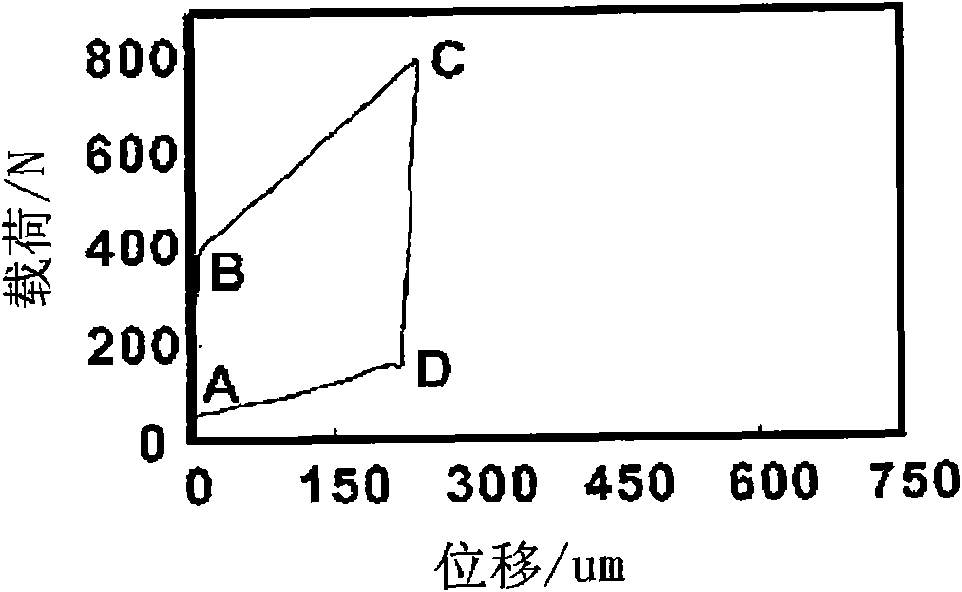

The invention relates to a bidirectional micro motion test fixture and a bidirectional micro motion test method thereof. The fixture is mainly in the structure that: a planar test-piece fixture (2) is in an inversed V shape, the opposite surfaces of the left and right sides of the lower part are all opened with a groove (4) fit to a planar test-piece (13), and the wall of the groove (4) is provided with a puller screw (3); a spherical test-piece fixture (8) is opened with a spherical test-piece cavity (7) fit to a spherical test-piece (5), and the wall of the spherical test-piece cavity (7) is provided with a puller screw (6); and the vertical axes of the spherical test-piece cavity (7), a piston (9) and the planar test-piece fixture (2) are coincided. One side of the upper part of the planar test-piece fixture (2) is connected with an upper vertical screw (10) while the spherical test-piece fixture (8) is connected with a lower vertical screw (12), and a displacement sensor is connected with the upper vertical screw (10) and the lower vertical screw (12). The test fixture can effectively simulate bidirectional fretting under spherical / surface contact condition, test tribology properties and estimate contact fatigue life of a coating under spherical / surface bidirectional micro motion condition on the existing hydraulic servo micro motion test platform.

Owner:SOUTHWEST JIAOTONG UNIV

Test method and device for monitoring steel wire fretting fatigue state

InactiveCN102353590AReal-time dynamic recording of tangential force changesReal-time dynamic recording of acoustic emission signalsMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceFrettingAcoustic emission

The invention discloses a test method and a device for monitoring a steel wire fretting fatigue state. The device comprises a base, a support column, a top beam, a hydraulic lifting platform and a horizontal loading device. The test method comprises the following steps that two ends of a tested steel wire passing through the horizontal loading device are fixed respectively; the tested steel wire is stretched until the tested steel wire bears a preset initial load; the horizontal loading device is moved so that loading steel wires in the horizontal loading device compress tightly the tested steel wire; the hydraulic lifting platform is controlled to move up and down to apply alternate loads to the tested steel wire; the tested steel wire generates fretting fatigue; a tangential force is transmitted to a spoke-type pull-press sensor through an internal thread connecting rod arranged on a loading block, wherein an acoustic emission sensor is arranged on an upper grip block of the top beam; and the test is stopped when the tested steel wire is broken because of fretting fatigue. The device can dynamically record a tangential force between contact steel wires and tested steel wire acoustic emission signals in an experimental process, and provides an effective basis for research on a steel wire fretting zone, crack generation and fracture mechanisms of a fretting zone, and influences of the crack generation and the fracture mechanisms on a fretting fatigue life. The device has a simple structure, is convenient for operation and has good effects.

Owner:CHINA UNIV OF MINING & TECH

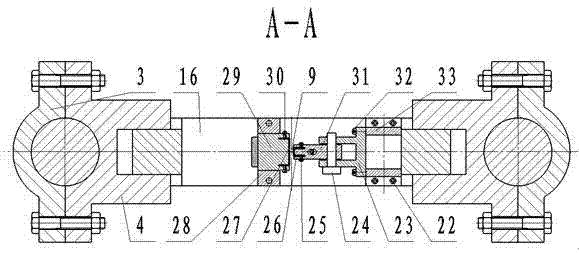

High-temperature high-pressure in-situ composite fretting test device

ActiveCN104374661AHigh control precisionReal-time adjustment of micro-motion amplitudeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFrettingAuxiliary electrode

The invention relates to the corrosion-resistant material fretting technology, in particular to a high-temperature high-pressure in-situ composite fretting test device, and solves the problems that composite fretting at high temperature and under high pressure is difficult to realize, fretting amplitude and frequency are difficult to measure and control accurately, radial load is difficult to accurately measure and adjust in real time, frictional force between friction pairs is difficult to measure, electrochemical signals are difficult to measure in the fretting process and the like. The device comprises a piezoelectric actuator, a tension and pressure sensor, a vibration exciter, a displacement sensor, linear guides, a high-pressure autoclave, a high-pressure autoclave cover, a working electrode / auxiliary electrode holder, a reference electrode holder, a hydraulic cylinder, a thermocouple, columns, a positioning plate, a first sample clamping device, a vertical movement shaft, a horizontal movement shaft, movement shaft guide brackets, an auxiliary electrode, a reference electrode, a working electrode, a guide platform plate, guide bars and the like. In-situ tangential fretting, radial fretting and bidirectional composite fretting are performed on surfaces of samples at high temperature and under high pressure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

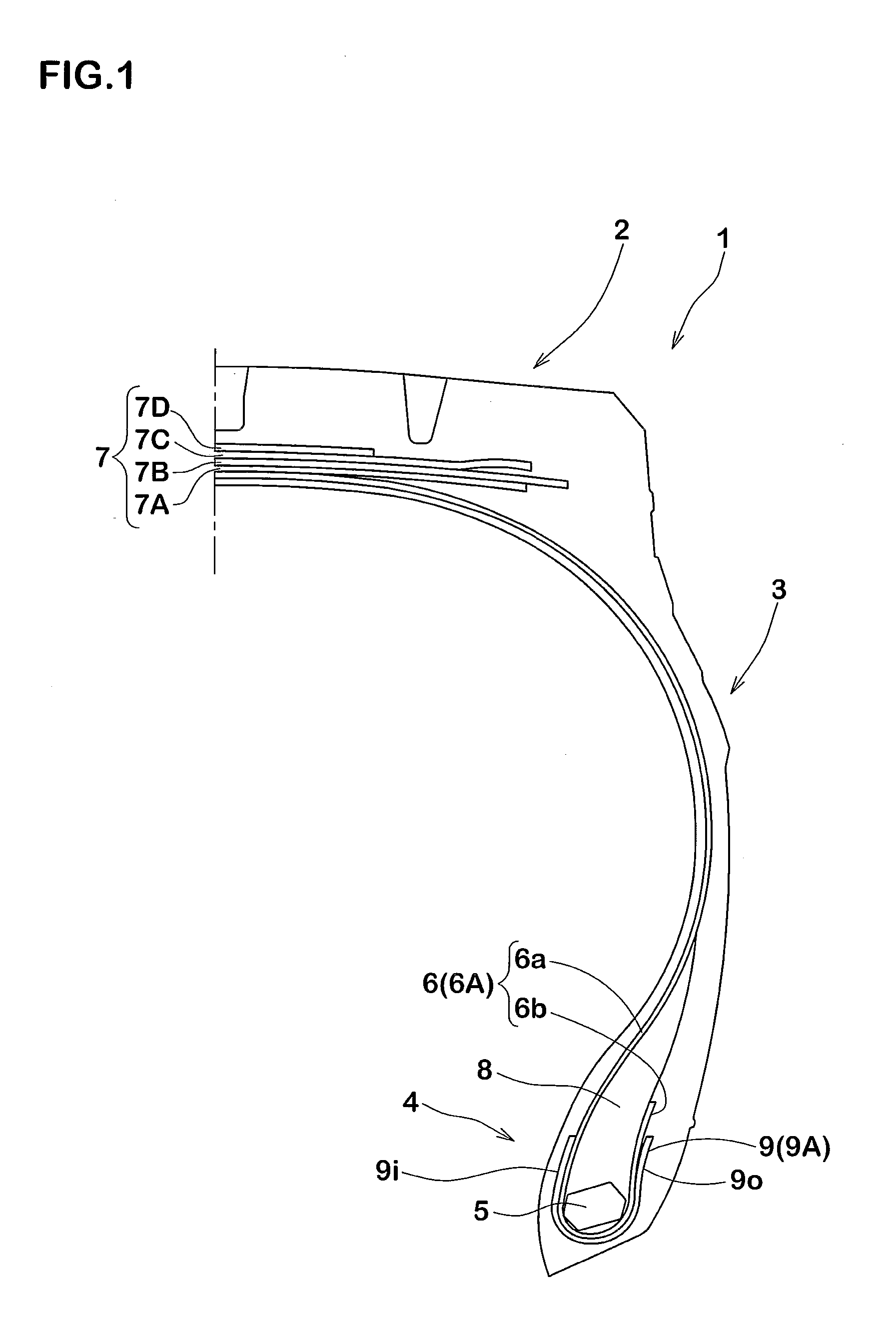

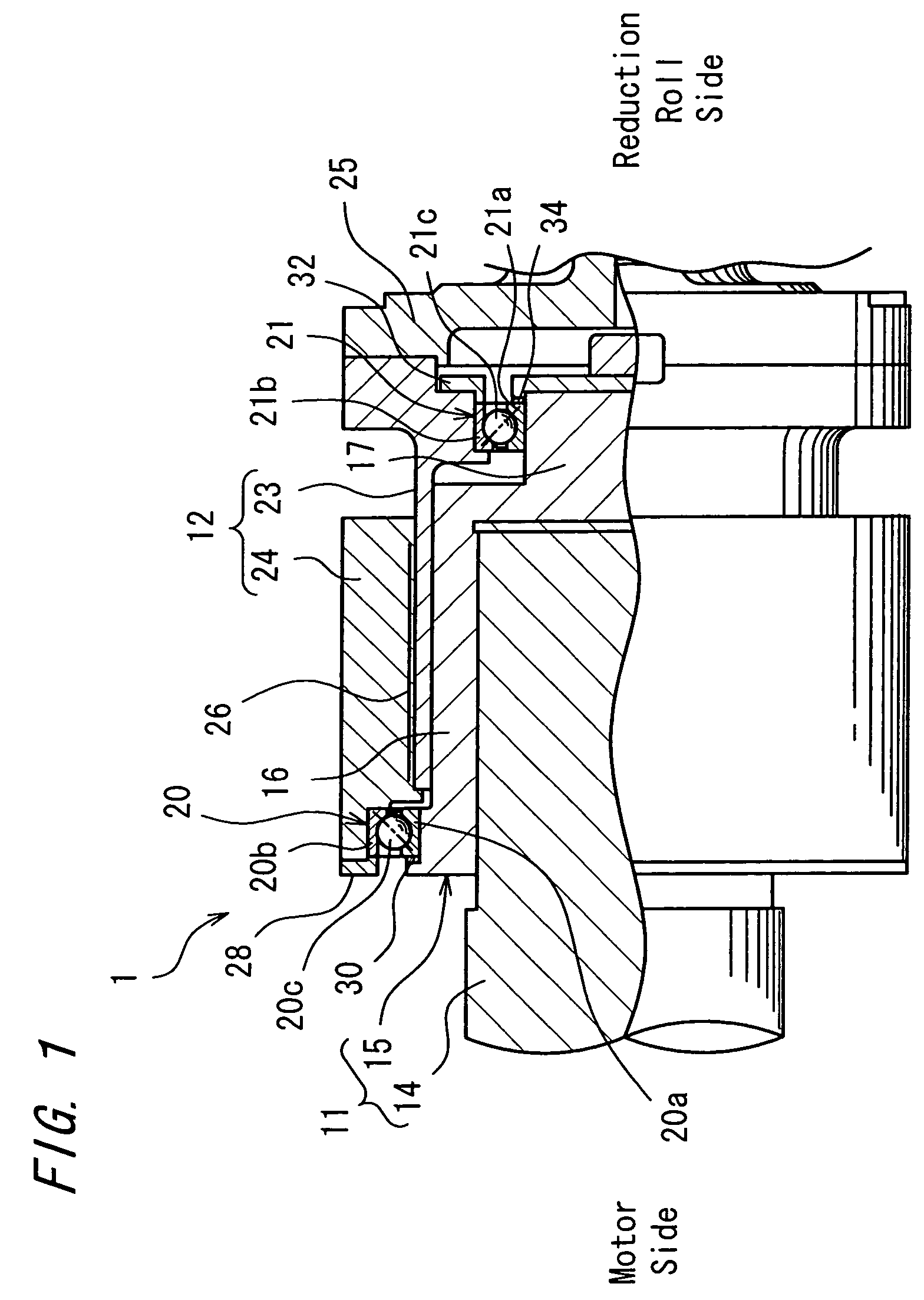

Autotensioner

InactiveUS20080058143A1Extended service lifeHighly preventive effectGearingBearing componentsFrettingEngineering

In an autotensioner of a type in which a boss of an oscillating member is pivotally fitted on a spindle of a stationary member through a bush including a metal part and a resin layer formed on the inner periphery of the metal part, the clearance in its initially assembled state between the outer periphery of the spindle and the inner periphery of the bush is 60 μm or less to make it difficult to cause fretting between the spindle and the bush even upon input of large short quick vibrations to the autotensioner and thereby extend the service life of the autotensioner. Furthermore, the spindle has a surface hardness of Hv 500 or more to prevent wear of the spindle itself from progressing even upon occurrence of fretting.

Owner:BANDO CHEM IND LTD

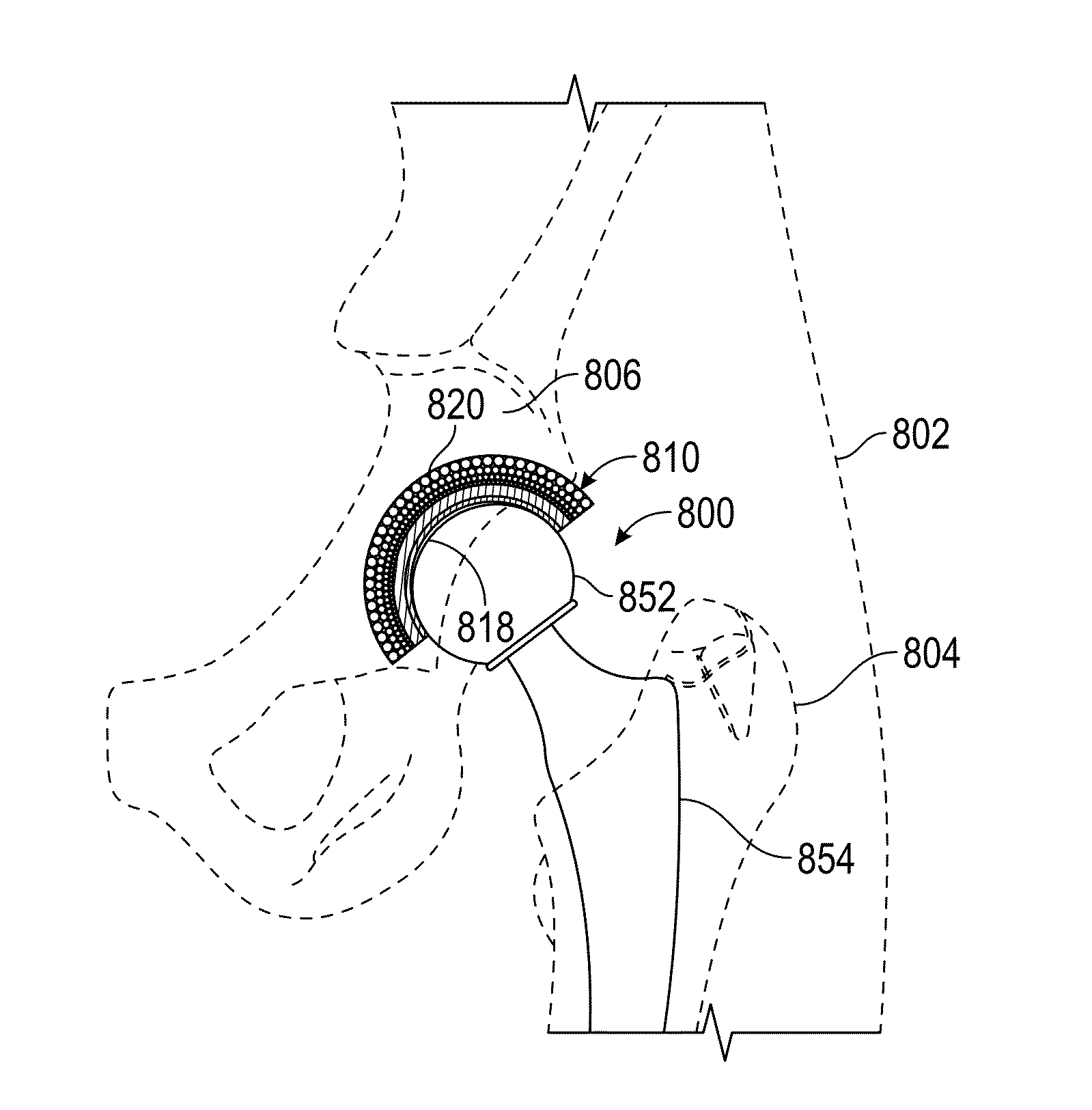

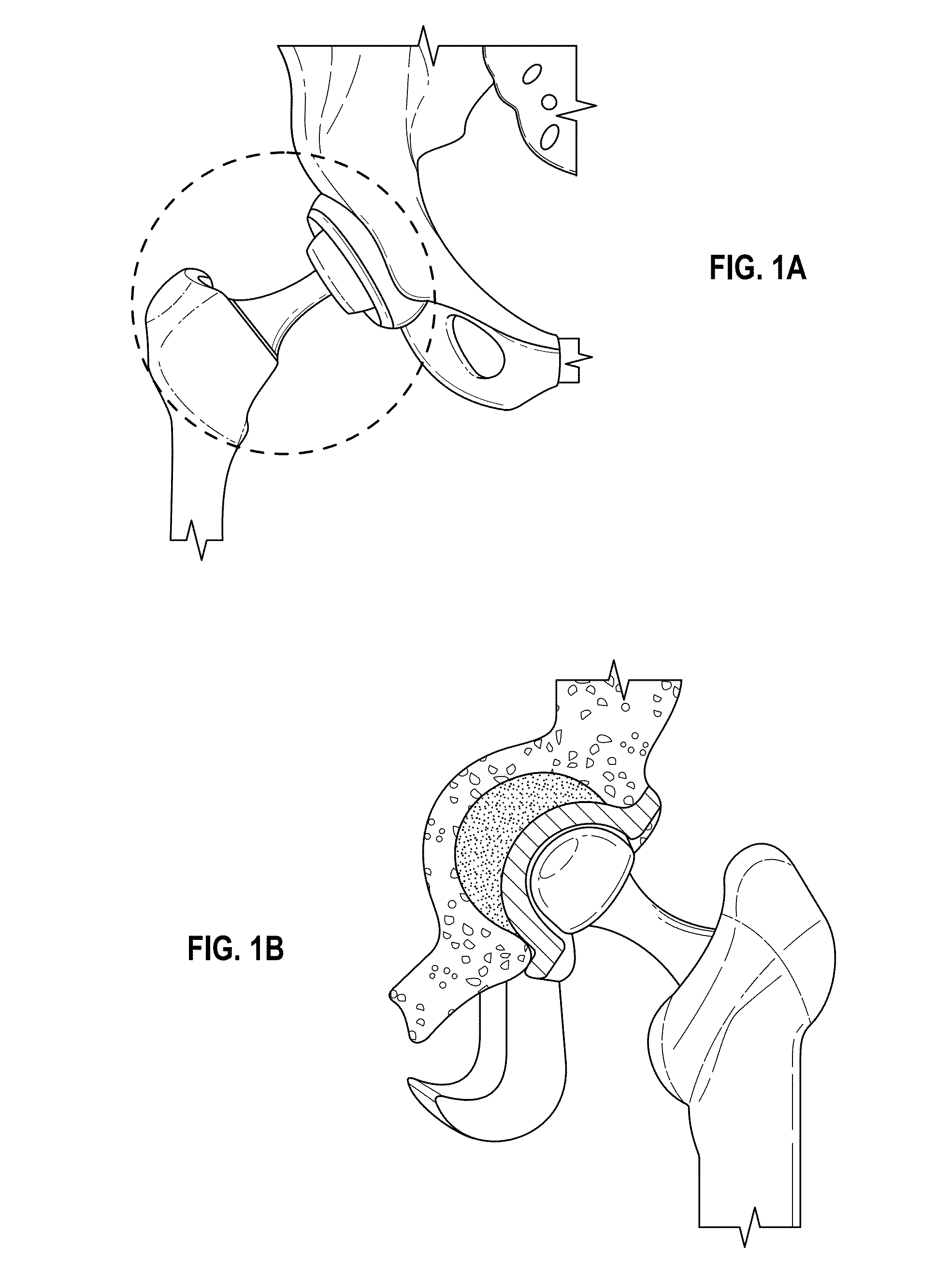

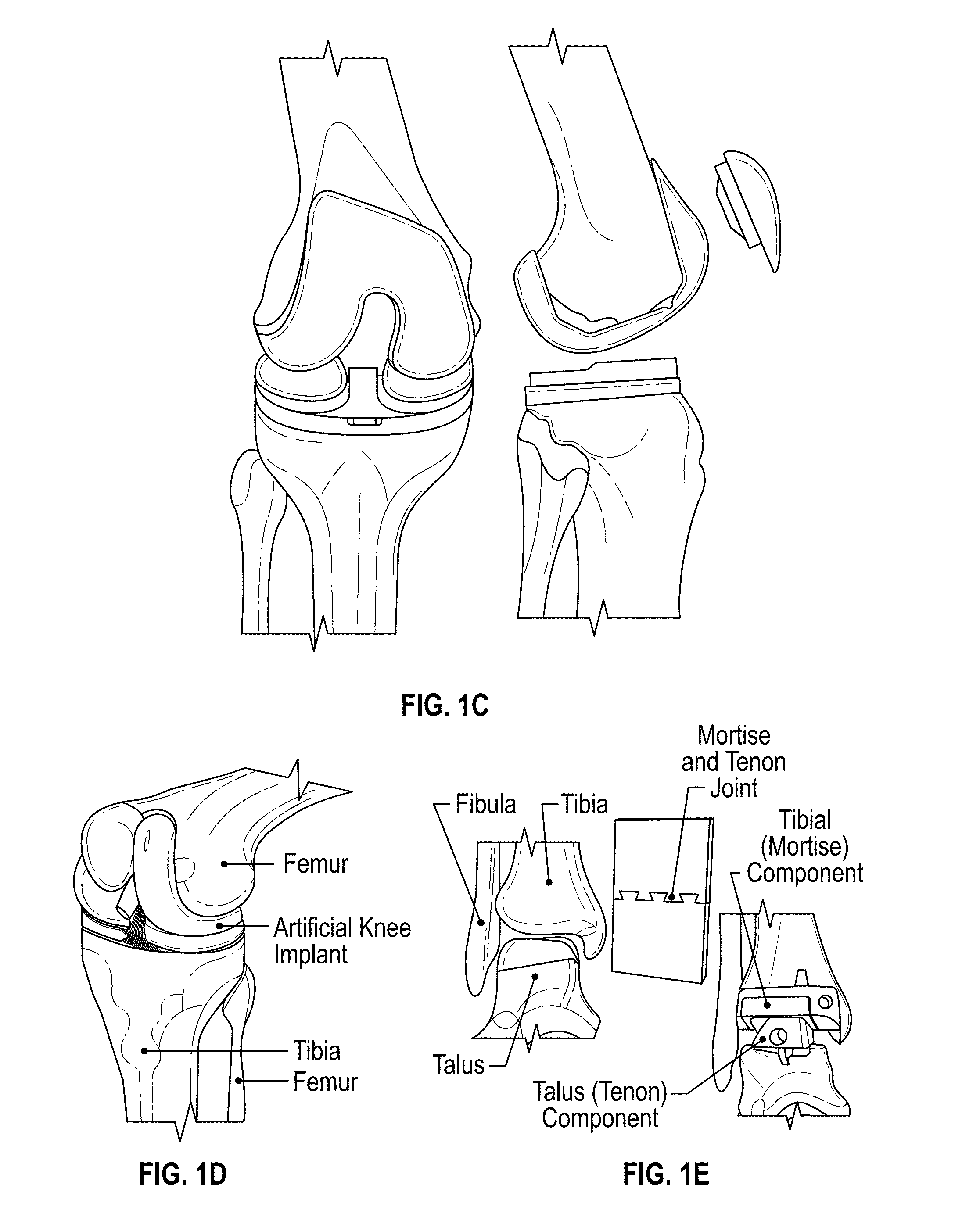

Joint Replacement or Joint Resurfacing Devices, Systems and Methods

ActiveUS20150359638A1Improve efficacyImprove performancePharmaceutical delivery mechanismJoint implantsPorosityArticular surfaces

Joint resurfacing and / or replacement devices, systems and methods that include thin film ternary ceramic coatings that are effective to provide reliable articulation and bearing surfaces and protection of both articular and modular junction surfaces from the potential for corrosion, wear, and fretting, and reduce the potential for release of metal ions from the joint systems. Isoelasticity is provided according to the particular joint resurfacing / replacement devices, systems and methods based on parameters that include material of construction, porosity and coating system. The thin film ternary ceramic coatings may be functionalized to enhance hydrophilicity and may be employed in any anatomical articulating joint region. Titanium alloy composite structures are provided that include an ultra-porous structured titanium alloy bone fixation surface and an opposed solid articular surface and a thin film ternary ceramic coating applied to one or both opposed surfaces.

Owner:ACUITIVE TECH

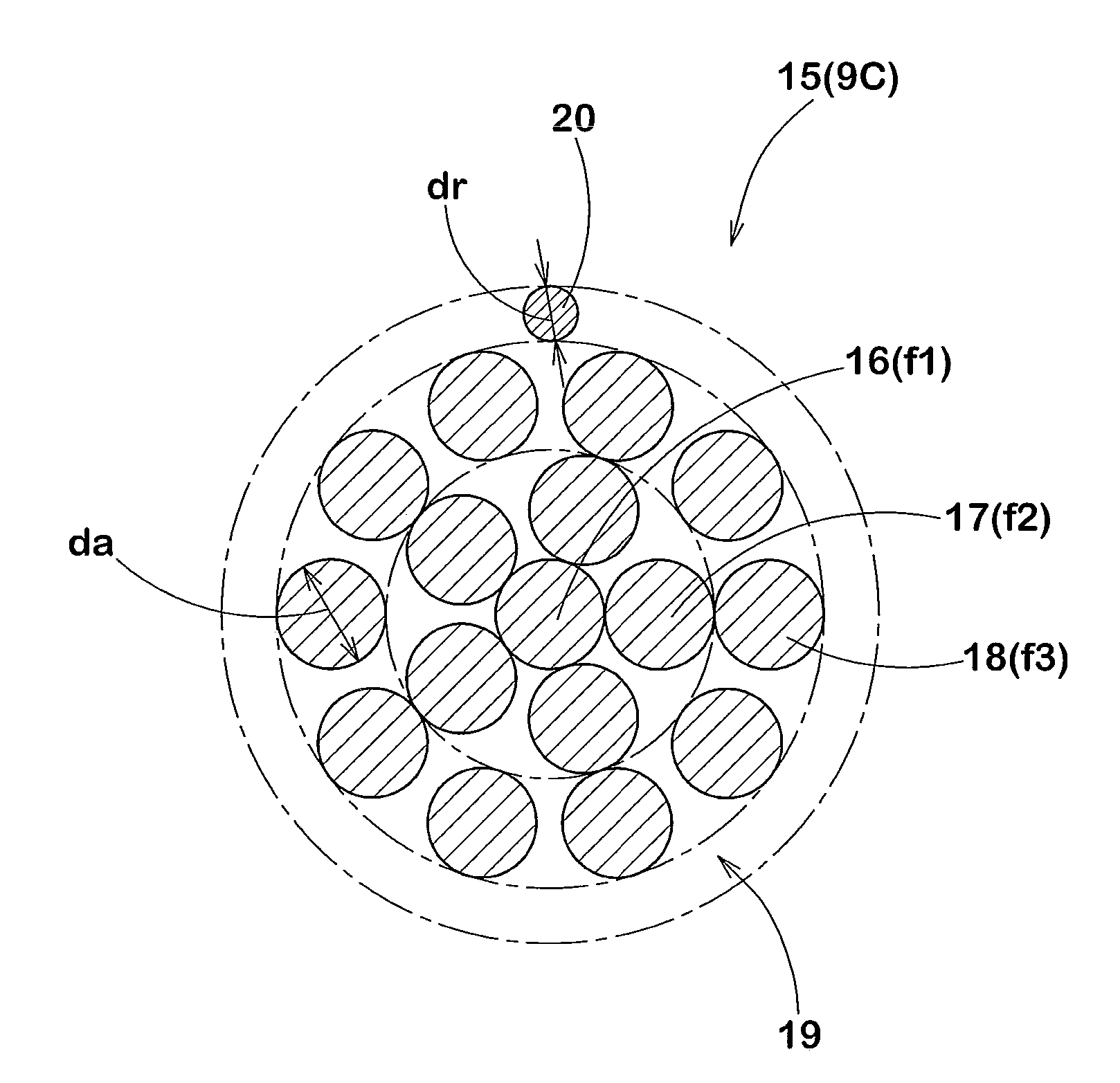

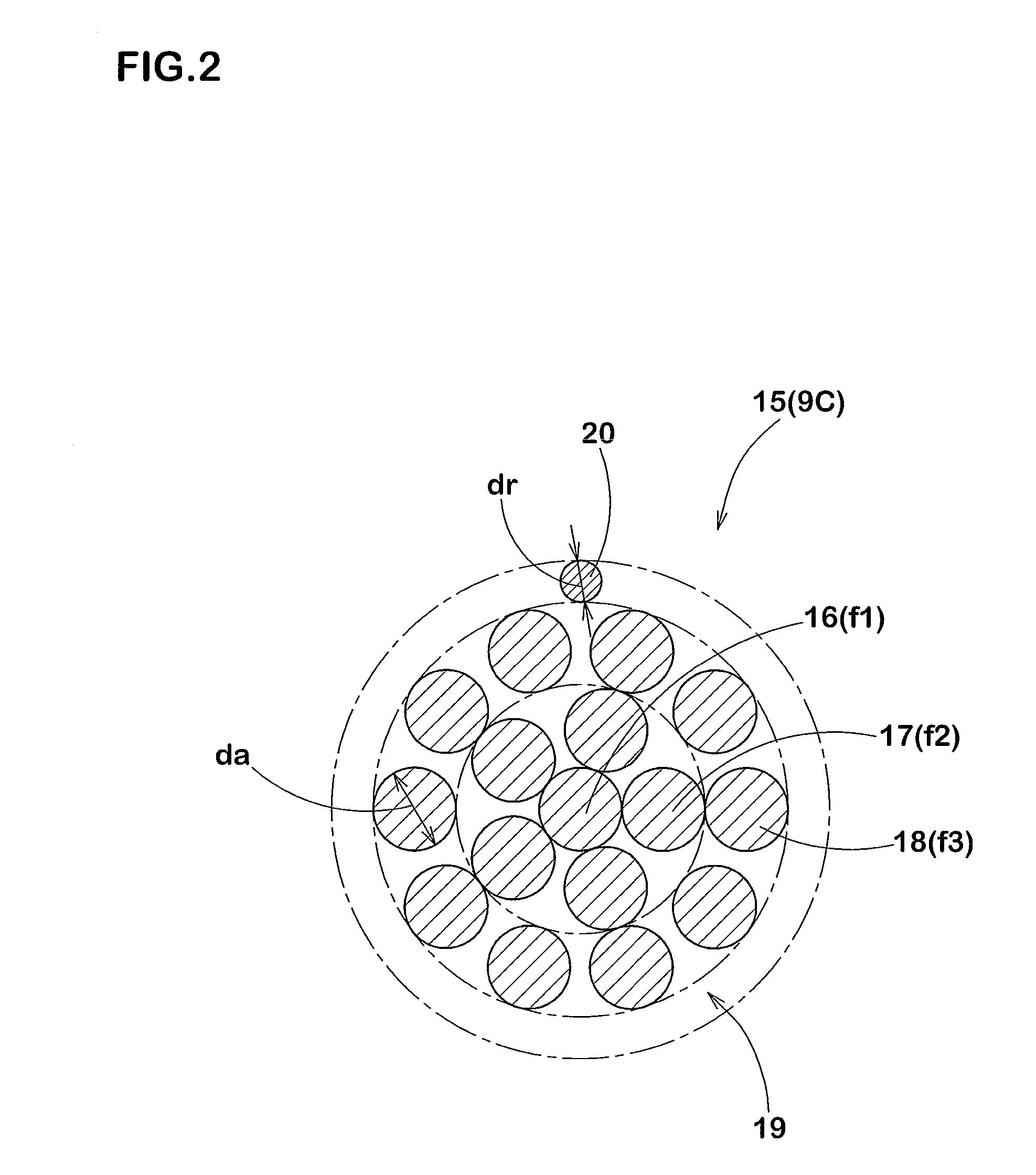

Steel cord for tire and pneumatic tire using the steel cord

InactiveUS20100300592A1Strong penetrating powerLow tensile strengthPneumatic tyre reinforcementsTyre beadsFrettingEngineering

It is an object of the present invention to reduce fretting between strands in a steel cord, to suppress reduction in cord strength caused by running, to enhance rubber penetrability, and to improve tire durability. The steel cord includes a cord main portion 19 of a triple layer-stranding structure including: a core 16 formed from one core strand f1, an inner sheath 17 including N (2 to 5) inner sheath strands f2 stranded with a stranding pitch Pi around the core; and outer sheath 18 formed from M (6 to 11) outer sheath strands f3 stranded with a stranding pitch Po around the inner sheath. Diameters of the strands f1, f2 and f3 are equal to each other, and stranding directions of the sheaths 17 and 18 are the same. A difference (|Ai−Ao|) between a stranding angle Ai of the inner sheath strand f2 and a stranding angle Ao of the outer sheath strand f3 is greater than 1° and smaller than 3°.

Owner:SUMITOMO RUBBER IND LTD

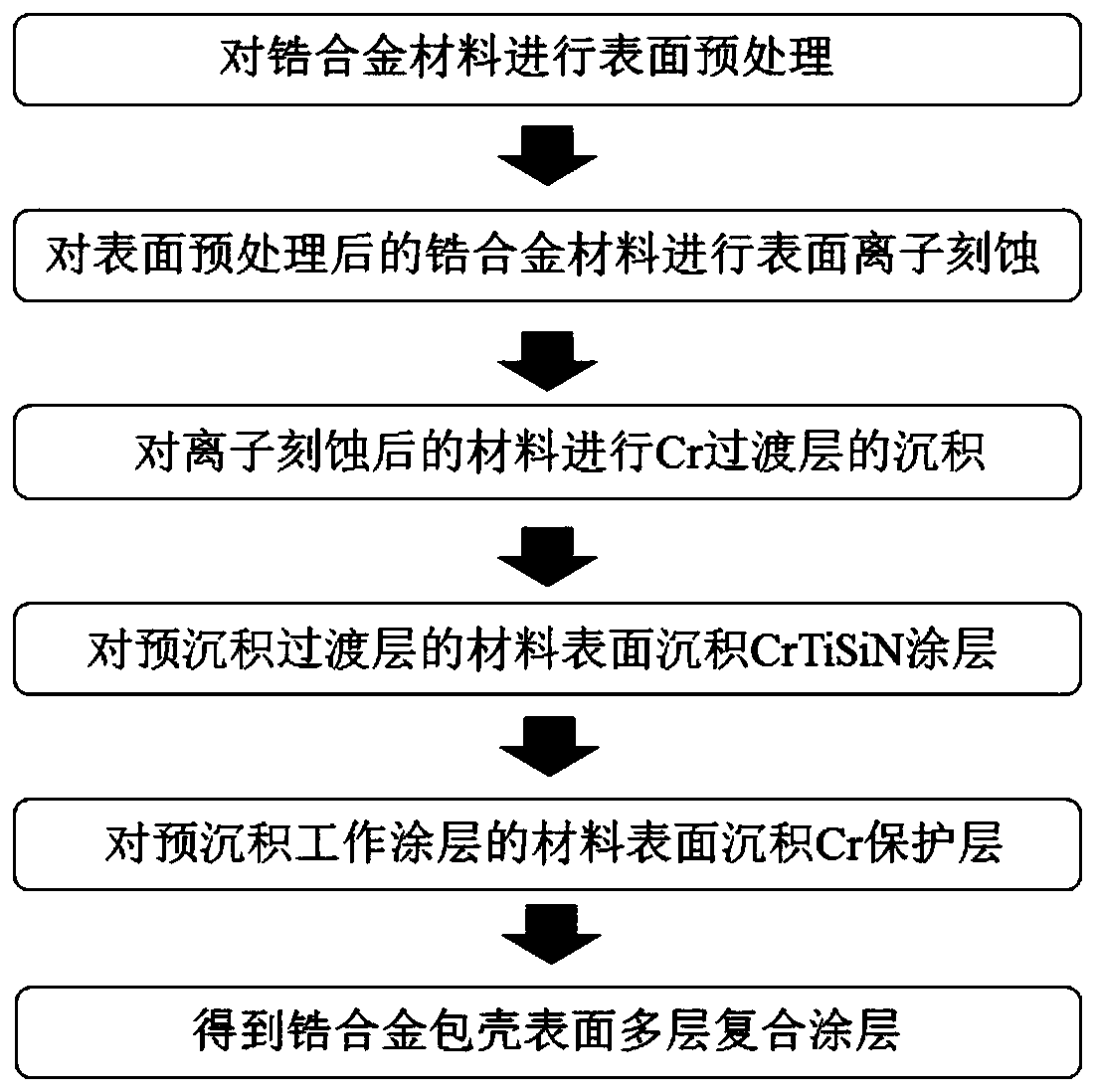

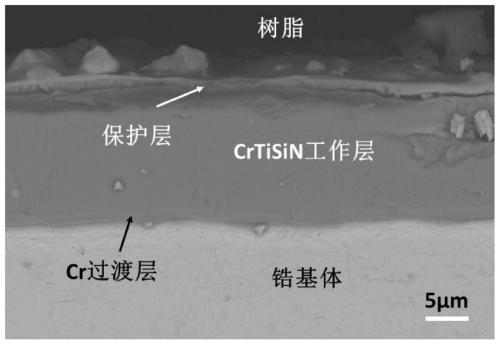

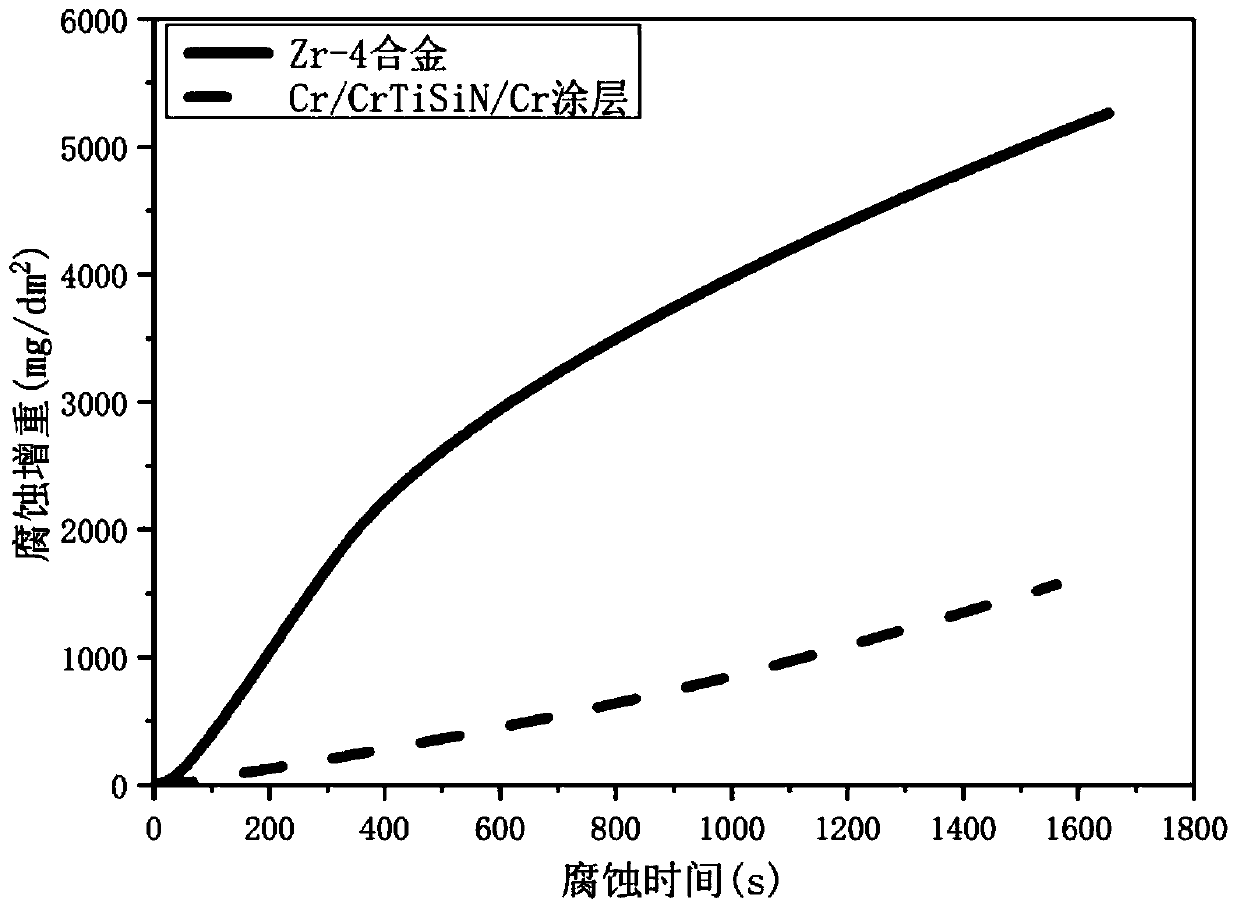

Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

ActiveCN111172503AImprove economyUniform thicknessVacuum evaporation coatingSputtering coatingFrettingNitrogen gas

The invention discloses a multilayer composite coating of a zirconium alloy cladding surface, and a preparation method thereof. According to the method, a multi-arc ion plating technology is adopted,and zirconium alloy materials are used as a base; high purity nitrogen is used as reaction gas, and high purity argon is used as protective gas; the vacuum degree, arc current, temperature, depositiontime, gas flow and other parameters of a vacuum chamber are regulated; and a three-layer composite coating, using Cr as a transition layer, a CrTiSiN as a working coating and Cr as a protective coating, are formed on the surface of the zirconium alloy materials through deposition. The coating is uniform and compact, and the binding force between the coating and the zirconium alloy base is strong;the cladding integrity is ensured, and generation of hydrogen is inhibited; and hydrogen explosion is avoided. The coating is extremely high in hardness, and the friction resistance of zirconium alloy can be improved effectively; the a cladding pipe is prevented from being failed due to fretting wear, and the safety and accident tolerance of a reactor are improved.

Owner:XI AN JIAOTONG UNIV

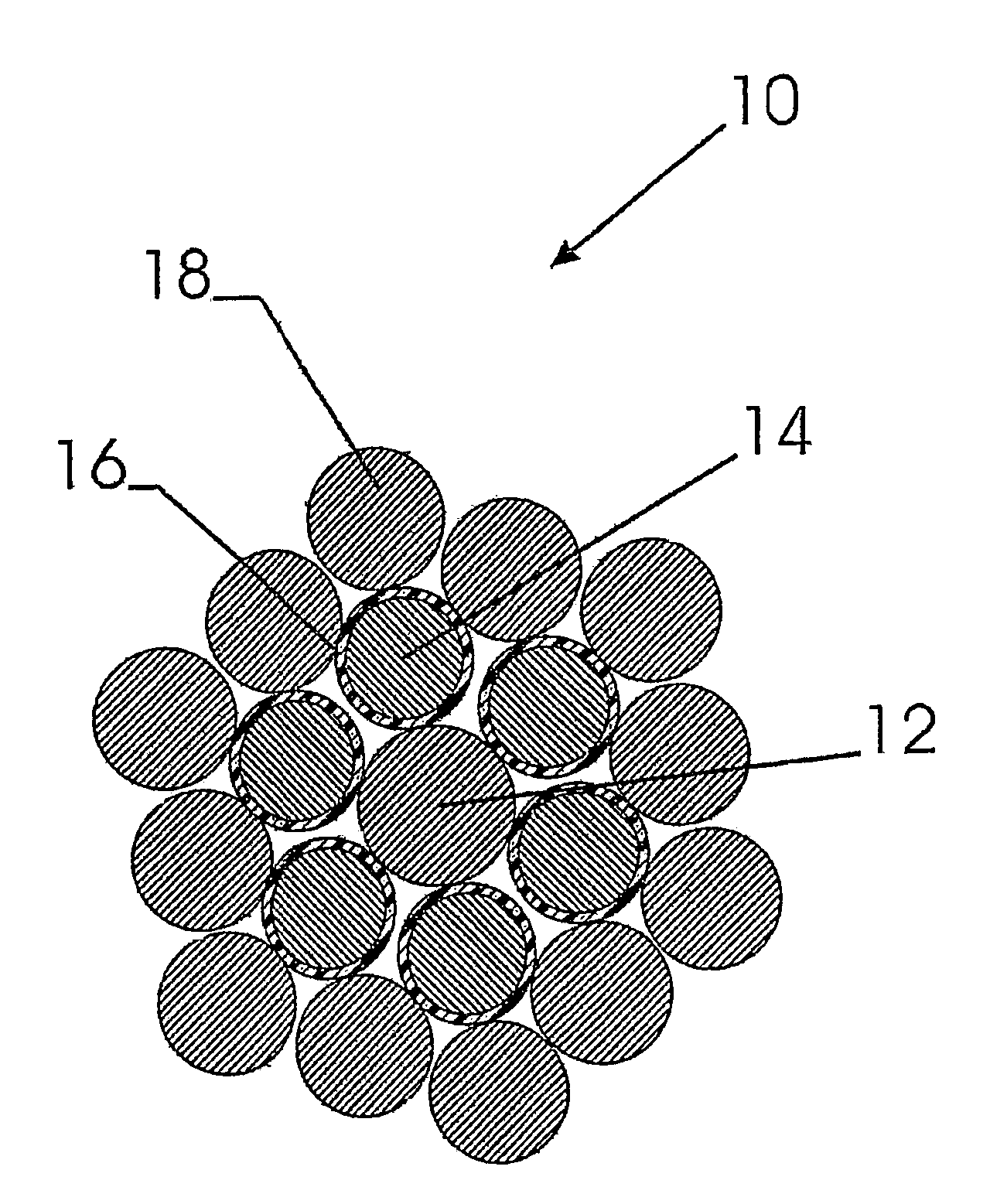

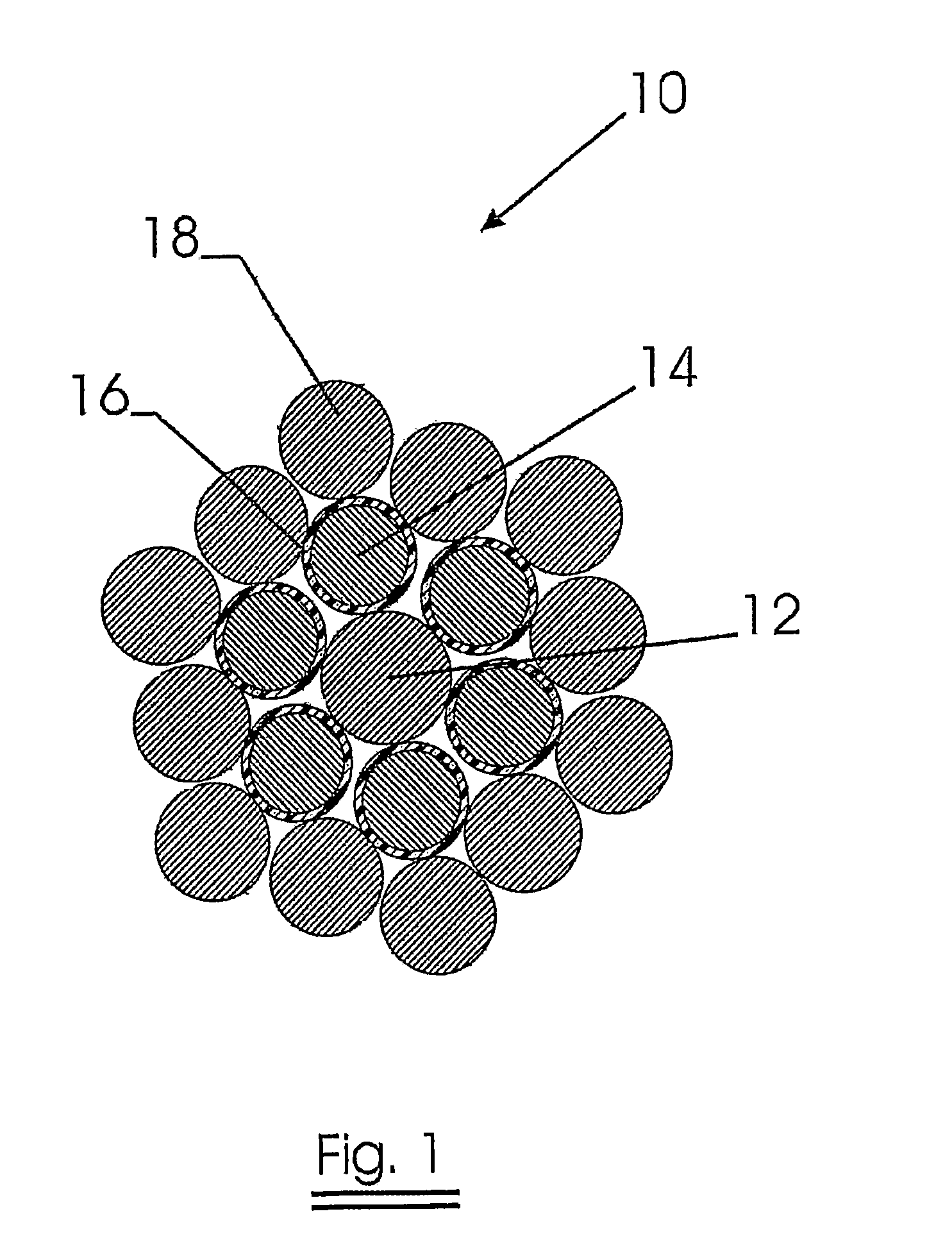

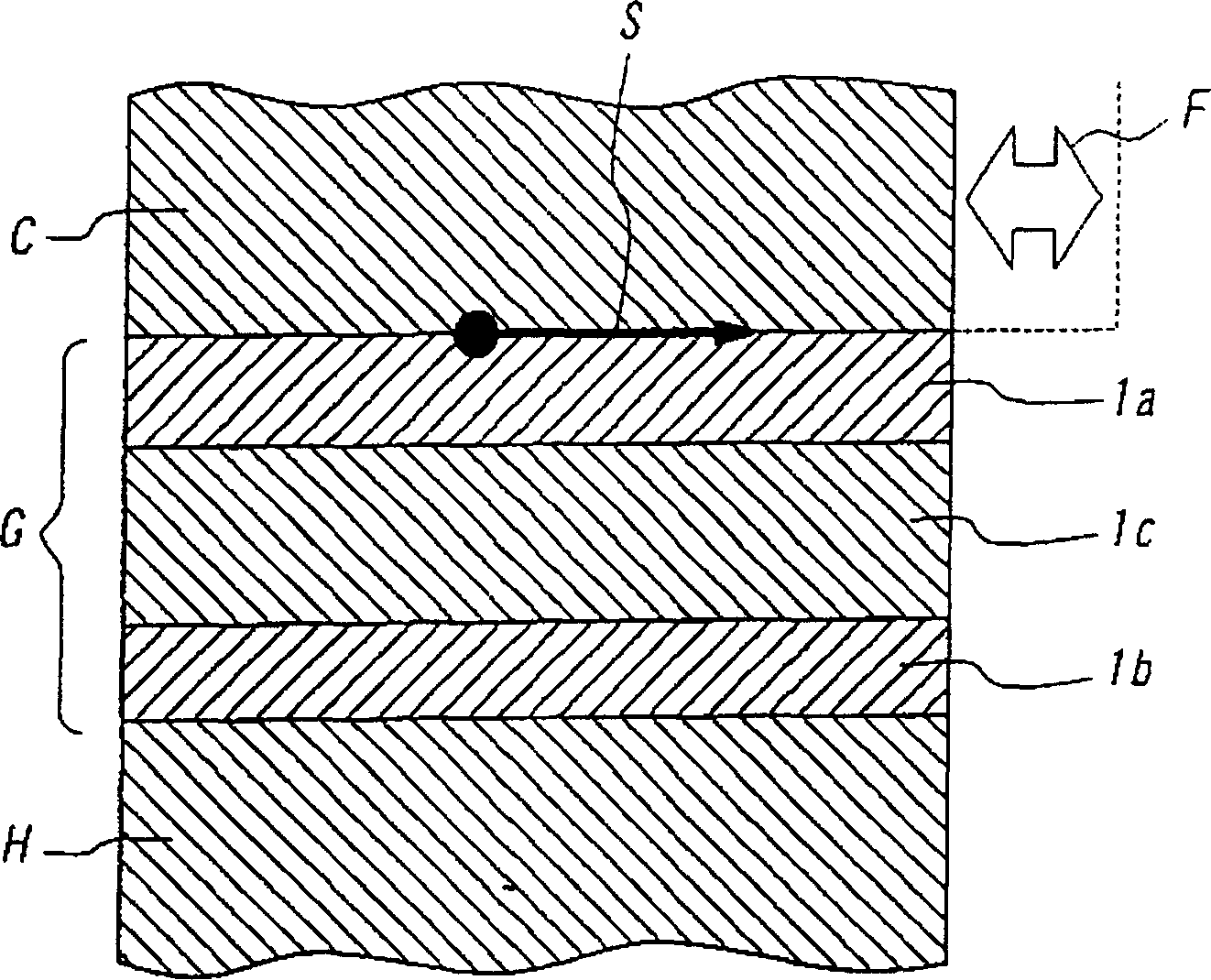

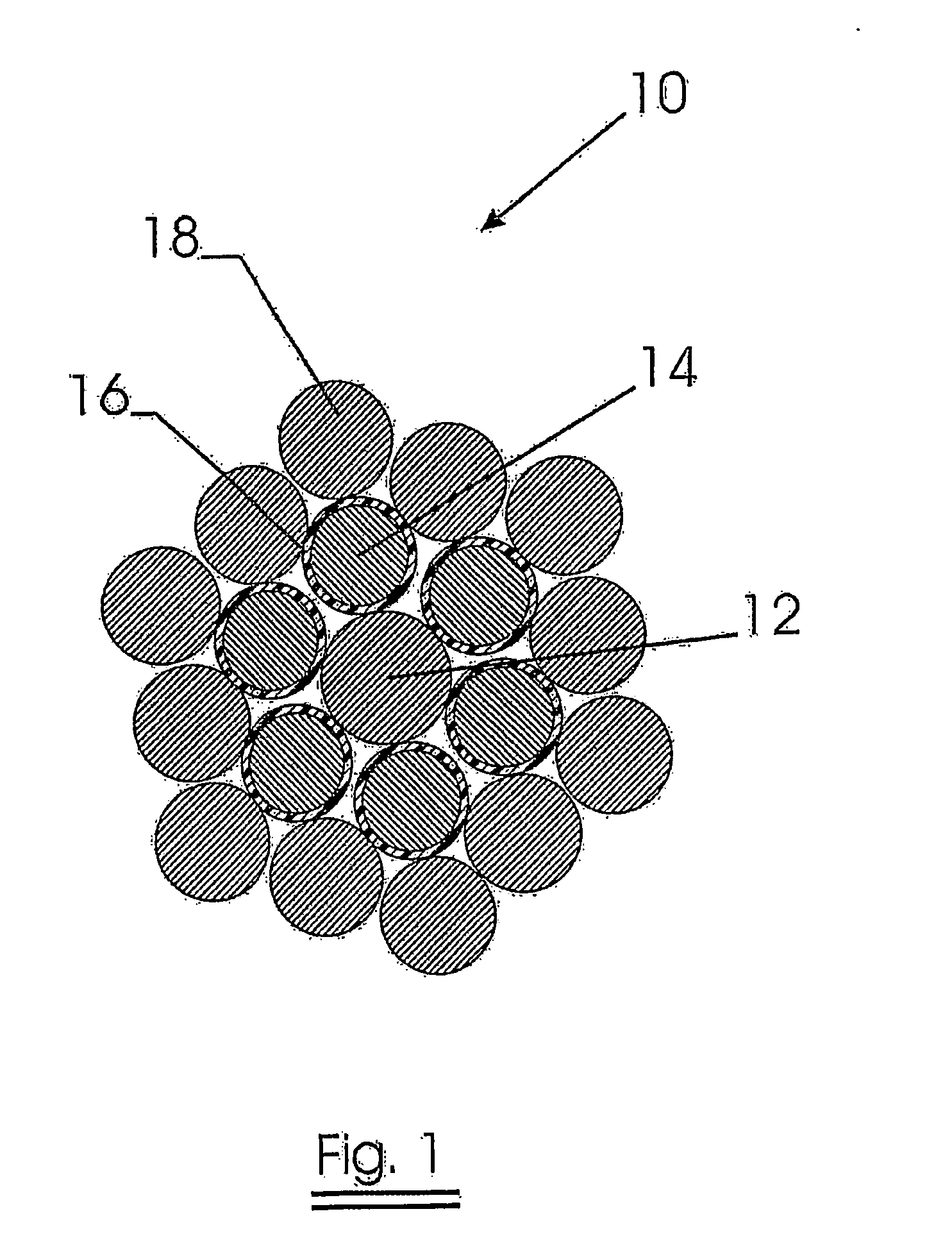

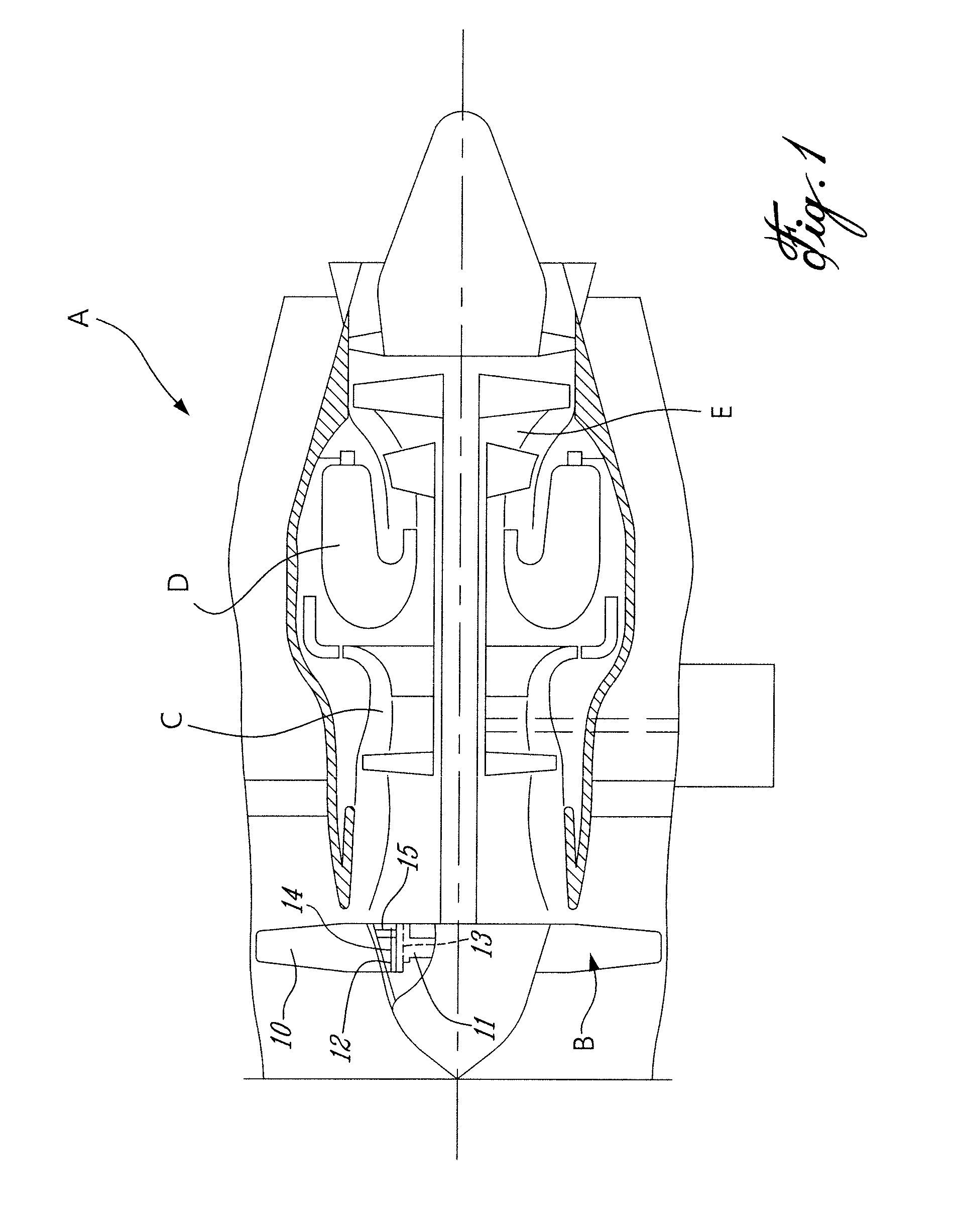

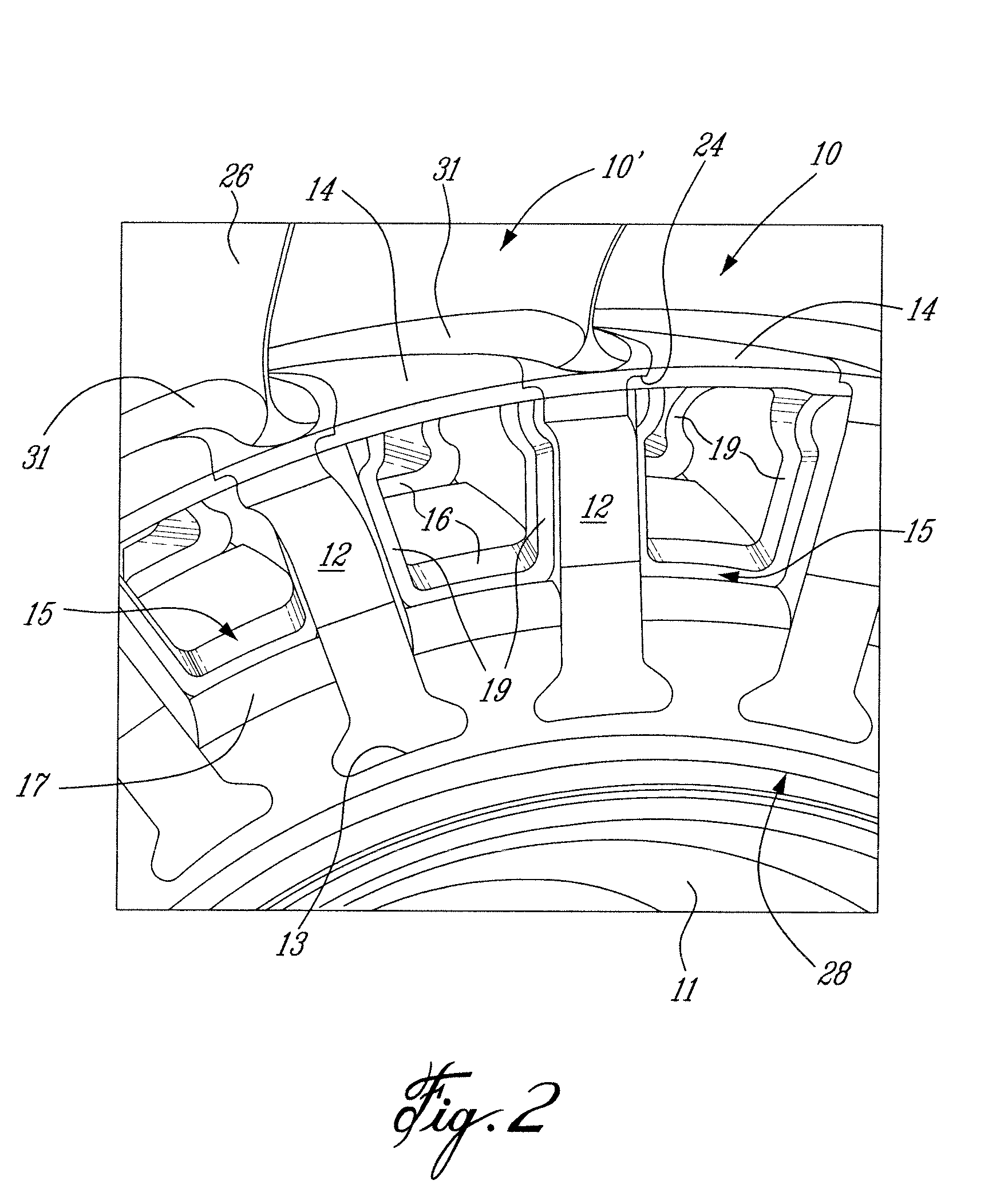

Multi-layer steel cord where intermediate filaments are coated with a polymer

InactiveUS7089723B2Improve fretting behaviourImprove the immunityPneumatic tyre reinforcementsCoatingsFrettingPolymer

A steel cord comprises a core with one or more core steel filaments and further comprises a first layer of intermediate steel filaments twisted around the core, and a second layer of second steel filaments twisted around the first layer. At least one of the intermediate steel filaments is individually coated by means of a polymer with a minimum thickness of 0.010 mm. The polymer reduces the fretting between the coated intermediate steel filaments and the other steel filaments and makes the steel cord suitable for reinforcement of carcass plies of a tire.

Owner:NV BEKAERT SA

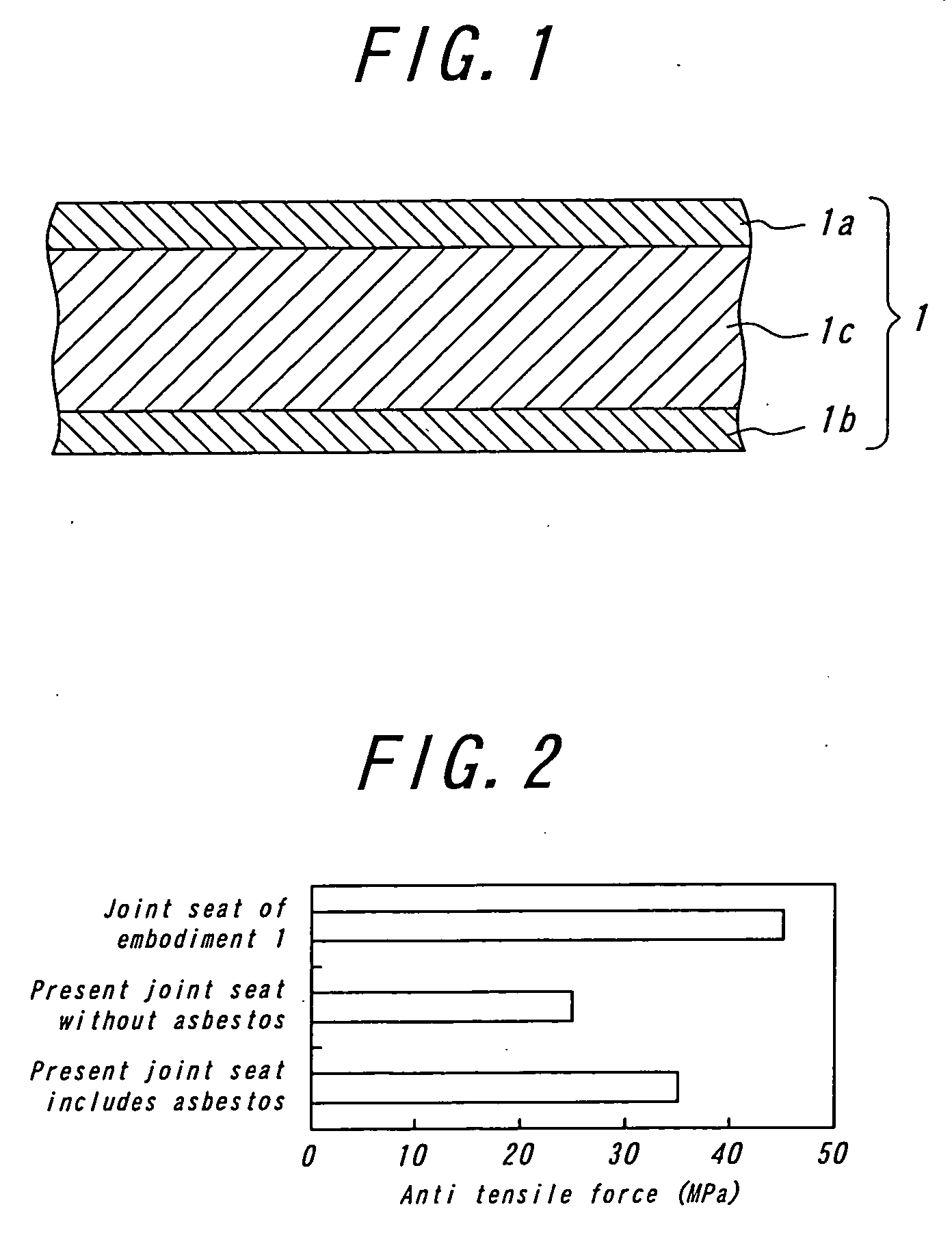

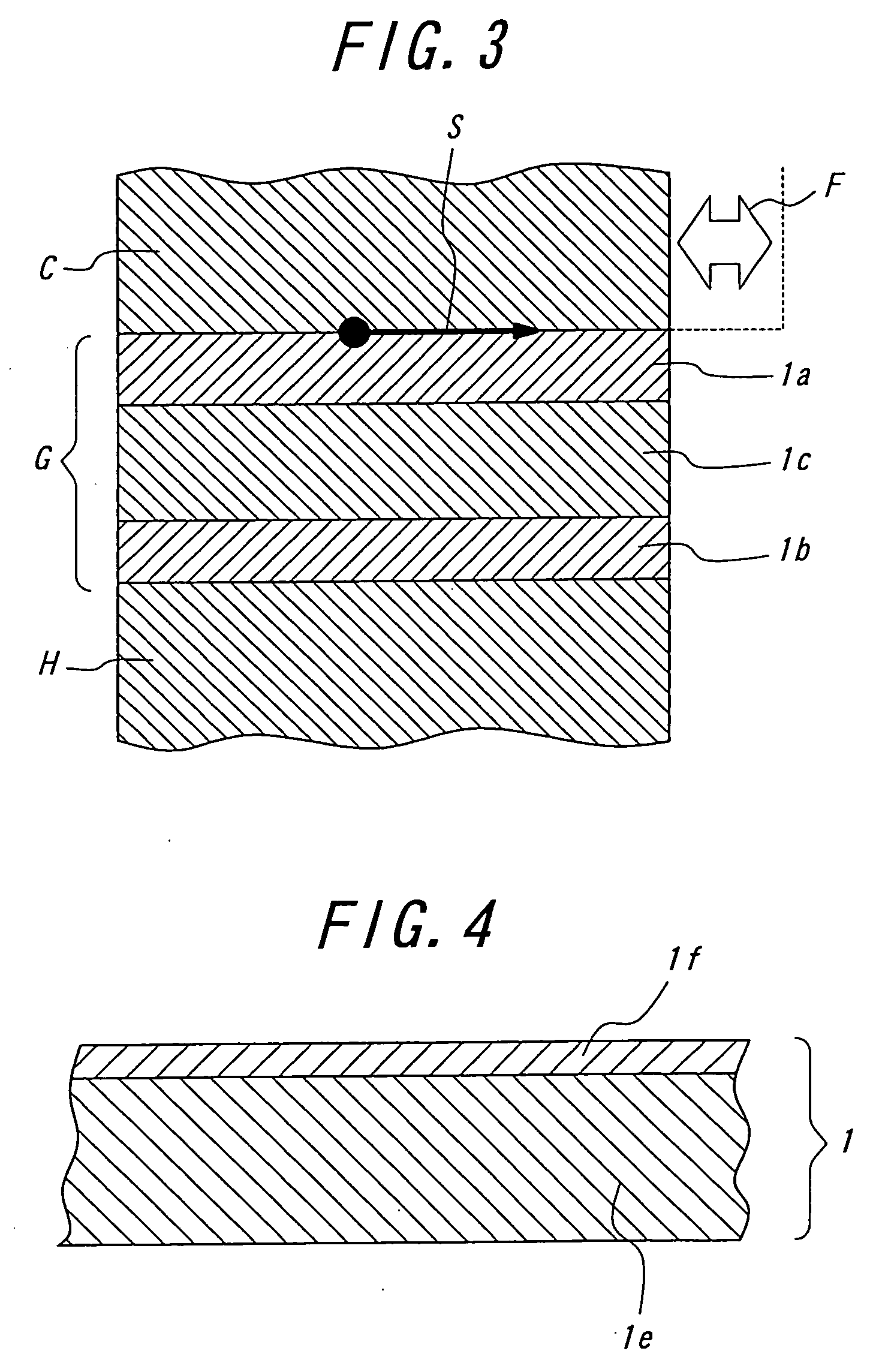

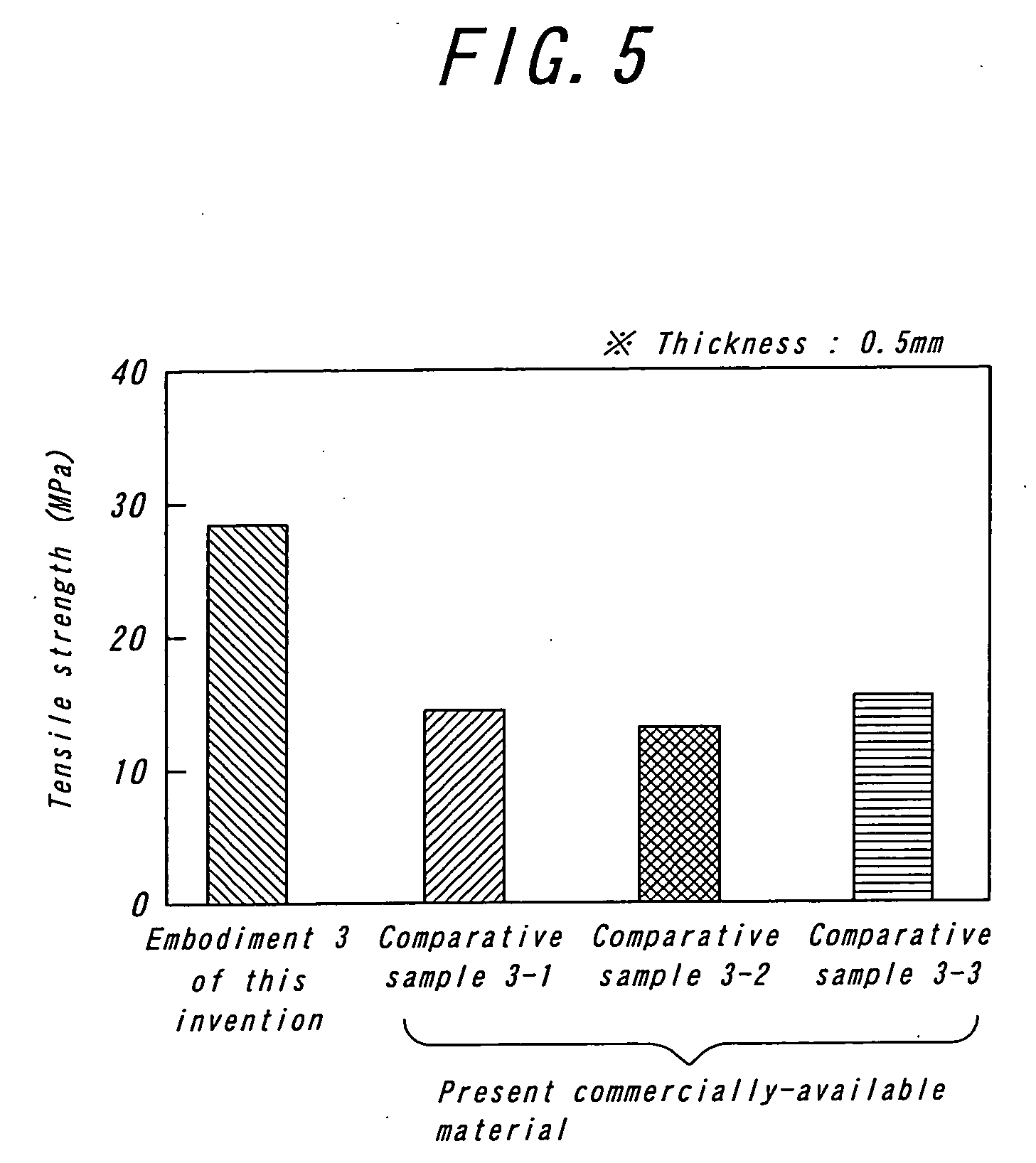

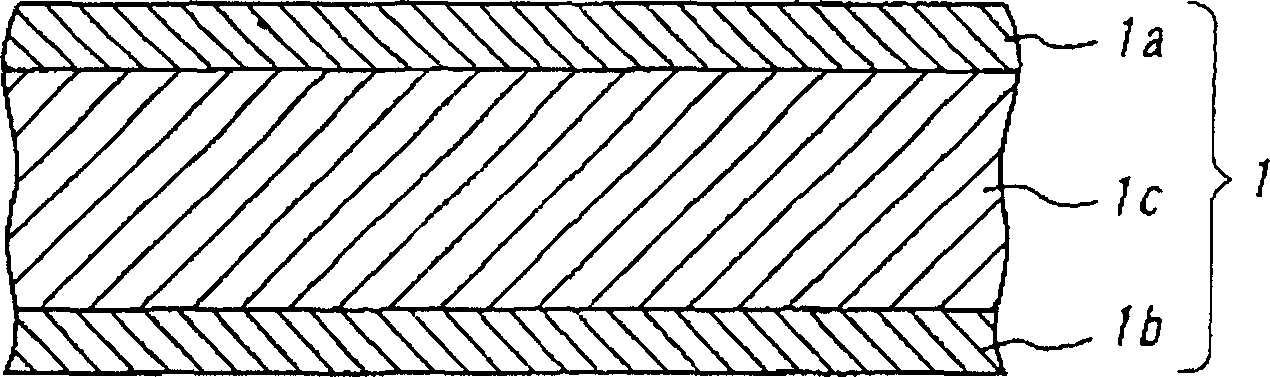

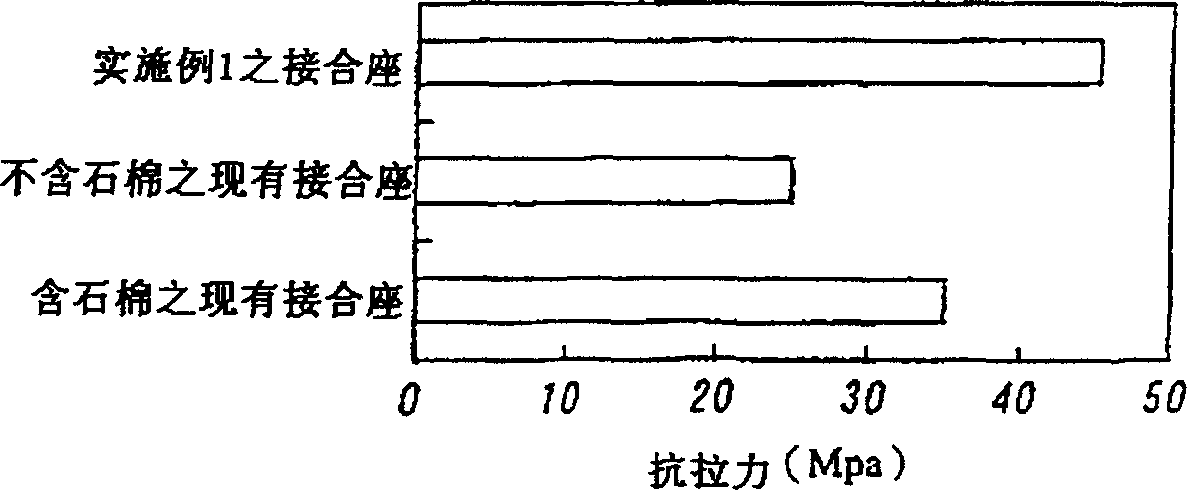

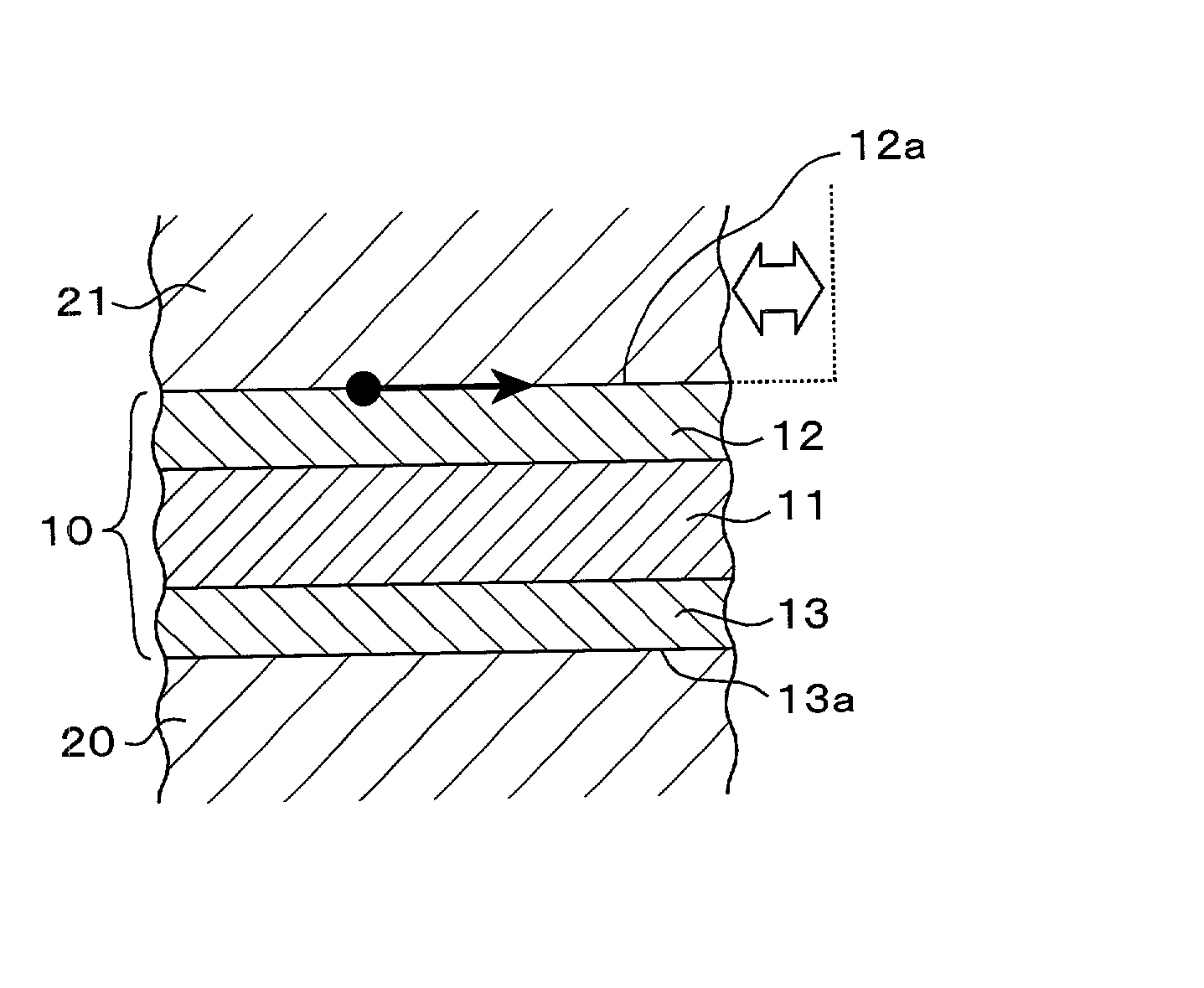

Gasket material

The gasket material that is manufactured from a joint seat which includes three layers, that is, a front surface layer (1a), a back surface layer (1b) and the middle layer (1c), and these layers have different composition of reinforced fiber and filler respectively, and this joint seat is made from an ingredient made by mixing and kneading rubber, reinforced fiber and filler, then pressurized laminating and vulcanizing the ingredient, this joint seat is characterized in that the reinforced fiber is as a sort of fibril which is composed from one or both of organic fiber and non-asbestos type inorganic fiber, and at least a part of the filler is spicular inorganic fiber and its composition is 10 wt %-45 wt %. According to this joint seat (1), a crack breakage of the gasket that the ingredient material is the joint seat (1) due to fretting is prevented.

Owner:NIPPON LEAKLESS IND CO LTD +1

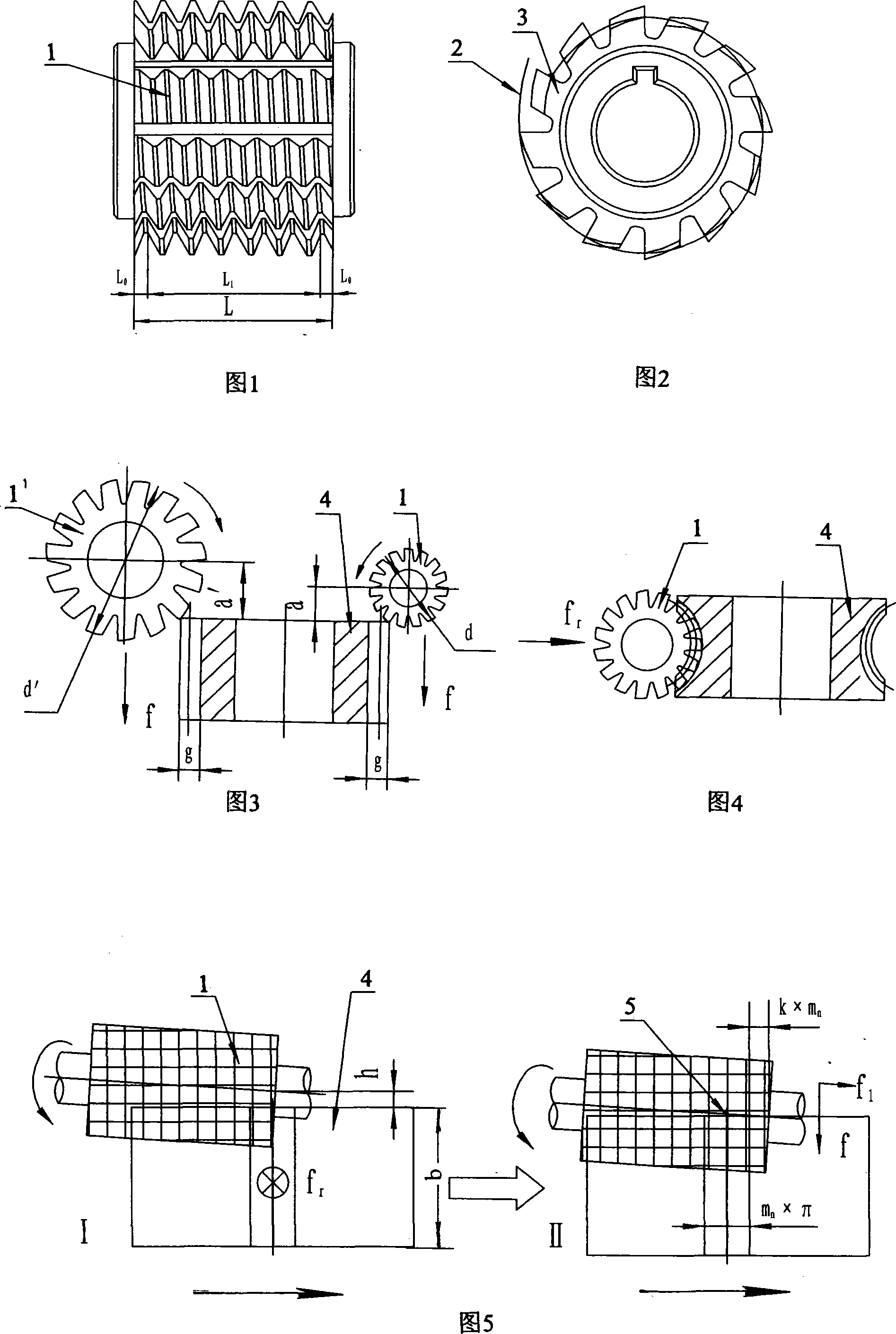

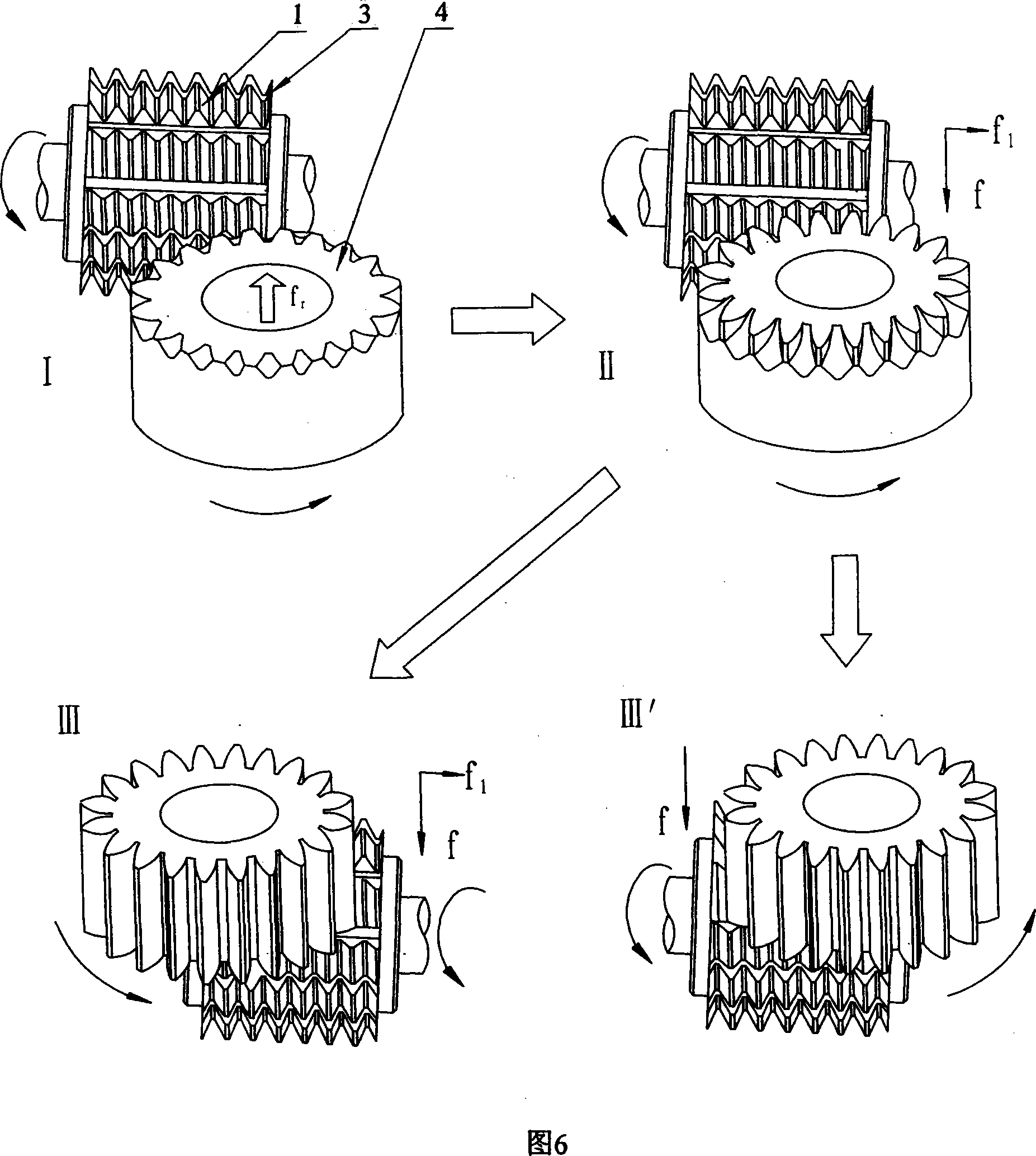

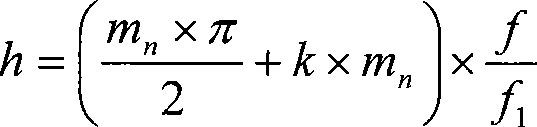

Hob complete utilization integrated gear hobbing method

A hobbing method for comprehensive utilization of hob; the relative position of the hob and workpiece can be calculated according to the parameters of processing gear and hob before hobbing; a certain distance h can be kept between the intersection point of the hob shaft central line and hob end face and the workpiece end plane; the intersection point of the hob end face and the hob external diameter generatrix aim at the workpiece axis center as the penetration point to implement radial intermittent hobbing, angle complete gear hobbing, angle hobbing full gear width processing and axial hobbing full gear width processing; The present invention integrates the advantages of original axial, radial and angle hobbing methods and overcomes the defects; in this way, the present invention solves the problem that the idle hobbing distance of the axial gear hobbing is prolonged and the production efficiency is reduced because of the increased external diameter of the hob. In this way, the incomplete gears on the two end faces of the hob can be fully utilized and the production efficiency and the hob service life are increased; with the present invention, the hob fretting is even; the production cost is reduced; in addition, the present invention provides a feasible processing technology for choosing large-external diameter, high-precision, high-efficiency hob processing gear which is not seriously fretted; the method can be conveniently implemented on numerically-controlled hobbing machine.

Owner:NINGBO XIASHA GEARS

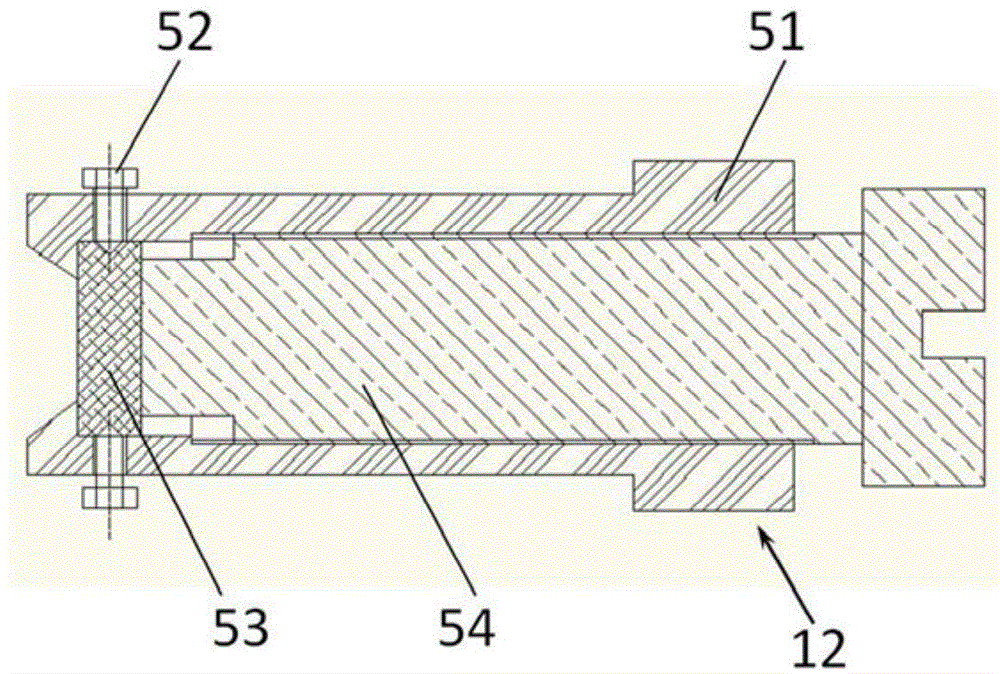

Morse taper protective sleeve

A removable orthopedic protective sleeve adapted to be applied over the male Morse taper of modular orthopedic implants thereby preventing contamination of the taper contact surface from blood, body fluid or tissue particles responsible for electrochemical corrosion and fretting at the level of Morse taper. Said sleeve having a conical tube shape and a rim at its upper narrow end. A plurality of vertical grooves situated on the outer surface of the protective sleeve will split open as the female Morse taper of the articular ball is slidingly pushed downward and seated over the male taper. The split sleeve is then removed after the male and female tapers are assembled in-situ.

Owner:JOINT INNOVATION TECH LLC

Piezoelectric driving type low-temperature in-situ high-frequency reciprocating fretting friction and wear test platform

PendingCN109060575APrecise and stable transmissionReasonable structure layoutInvestigating abrasion/wear resistanceFrettingX-ray

The invention relates to a piezoelectric driving type low-temperature in-situ high-frequency reciprocating fretting friction and wear test platform and belongs to the field of precision in-situ testing. A test pressure loading unit is powered by a precision servo motor. A two-stage worm gear reduction mechanism is cooperated with a screw nut pair so as to perform precise pressure loading. A high-frequency reciprocating unit is arranged on the lower side, an advanced piezoelectric ceramic drive technology is adopted, and an independently designed flexible hinge is cooperated to output high-frequency fretting displacement; a low-temperature precision clamping unit is accurately clamped by upper and lower fixtures and is low-temperature loaded by a liquid nitrogen pipe in the lower fixture; adata acquisition unit comprises a tension sensor, a pressure sensor, and a dual-colorimetric infrared thermometer. The piezoelectric driving type low-temperature in-situ high-frequency reciprocatingfretting friction and wear test platform in the invention has the advantages of reliable principle, compact size, compact structure and high frequency, and has good compatibility with a microscopic imaging system with an open space structure such as a mainstream optical microscope, a Raman spectrometer and an X-ray diffractometer.

Owner:JILIN UNIV

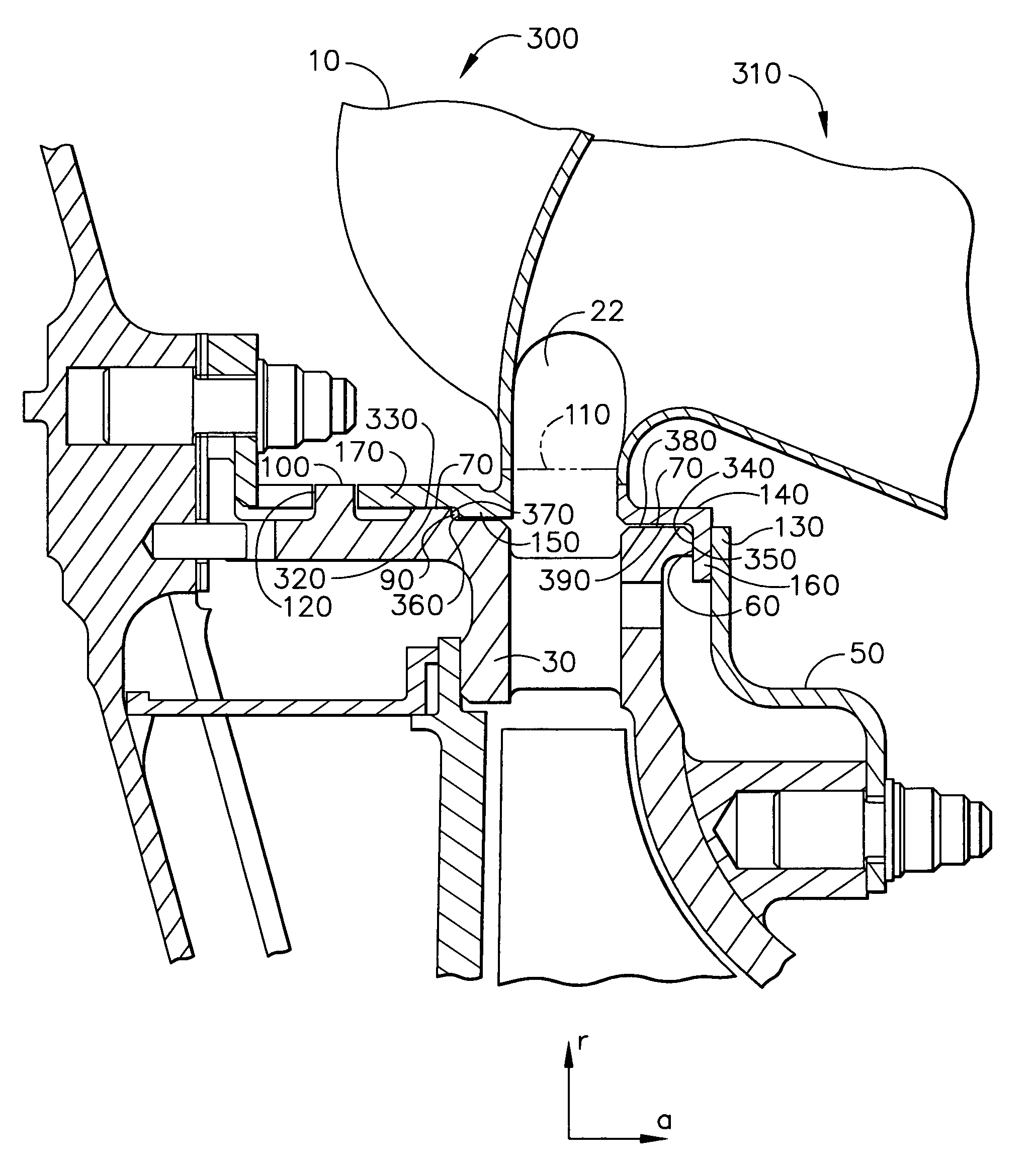

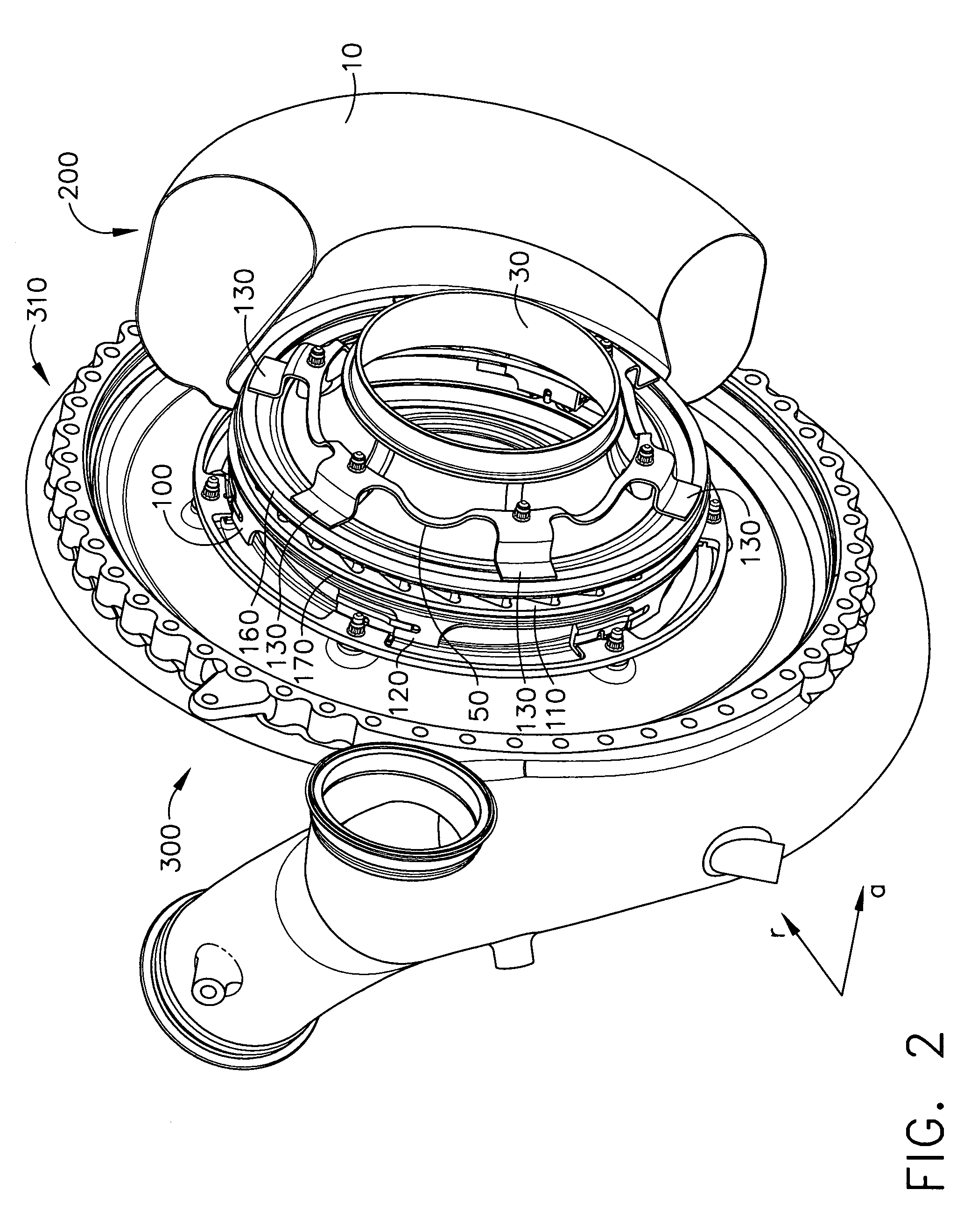

Multi-action on multi-surface seal with turbine scroll retention method in gas turbine engine

A gas turbine engine comprises a turbine scroll inside a combustor housing, discouragers with 90-degree bending angles, a radial nozzle contacting a forward bayonet on the forward side of the turbine scroll at a bayonet engagement point and a B-width measured between the discouragers. Retaining ring maintains the size of the B-width. The turbine scroll may have eight surfaces sealing at four locations and a provision to maintain constant “B-width” for the thin sheet metal scroll within the combustion system. The design allows the scroll to operate at high temperature while maintaining lowest possible thermal and mechanical stresses. It can be easily assembled with excellent capability to control gas leakage and minimal component interface wearing or fretting. The gas turbine engine is adapted for aircraft, spacecraft, missiles, and other flight vehicles, especially high performance, high cycle flight vehicles.

Owner:HONEYWELL INT INC

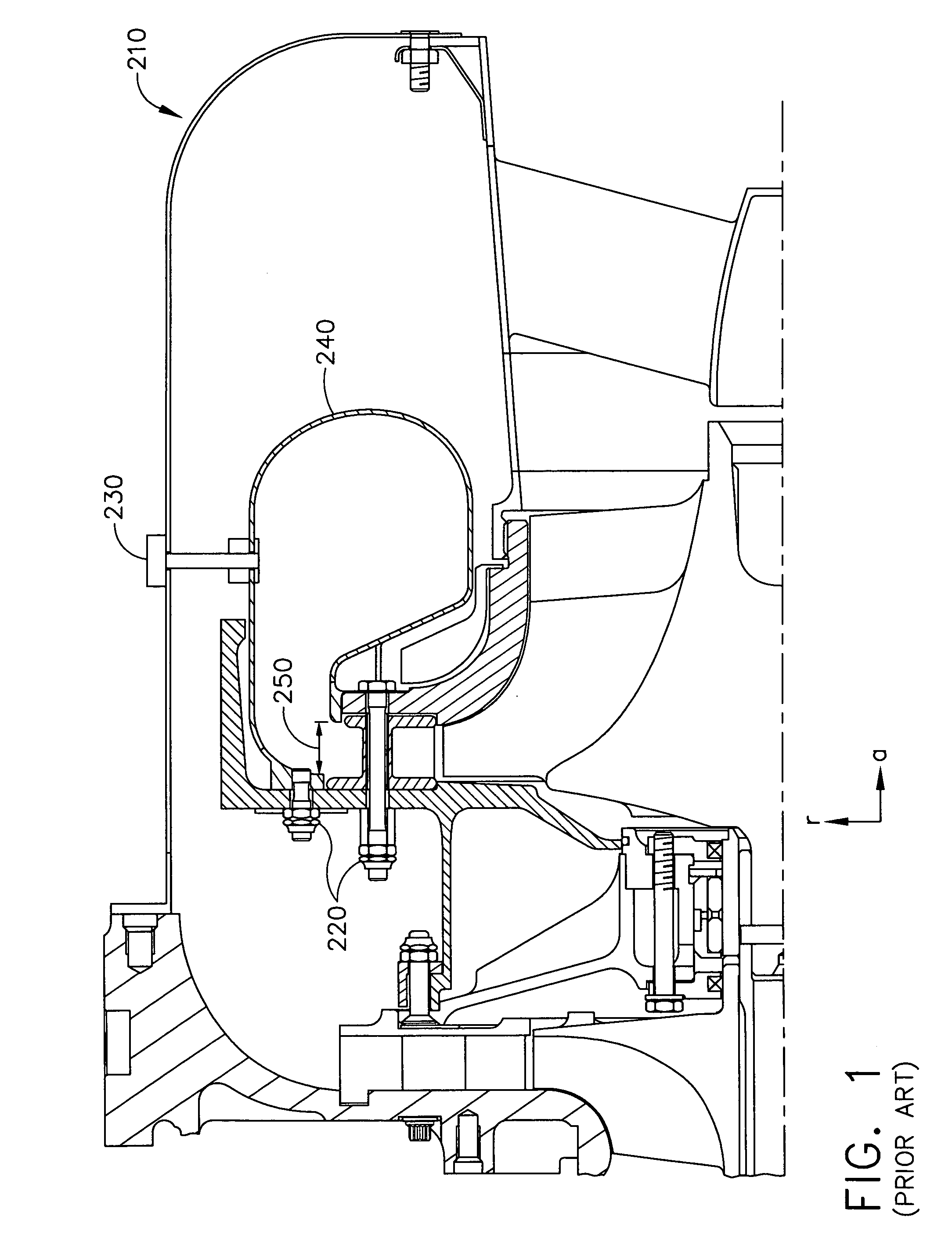

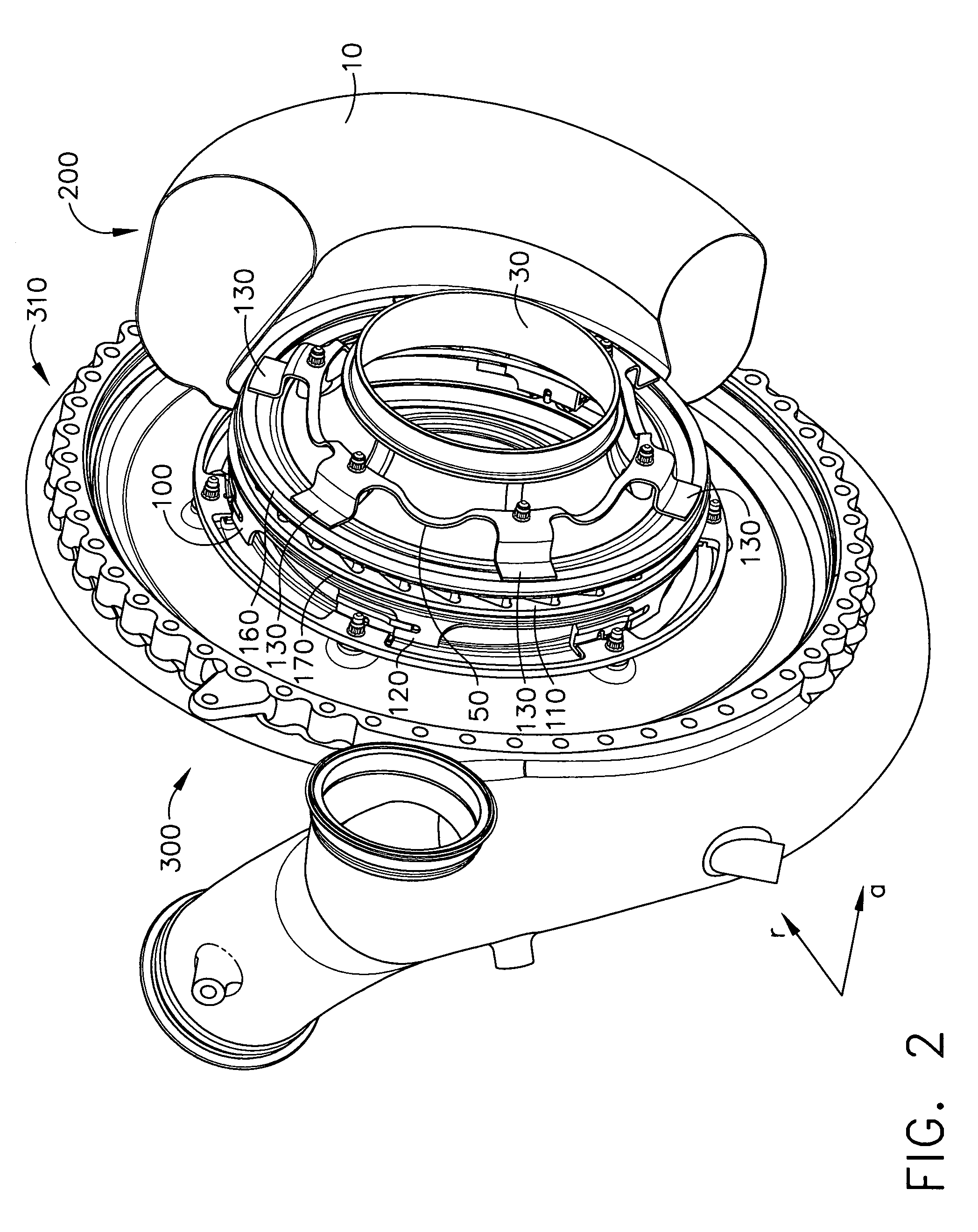

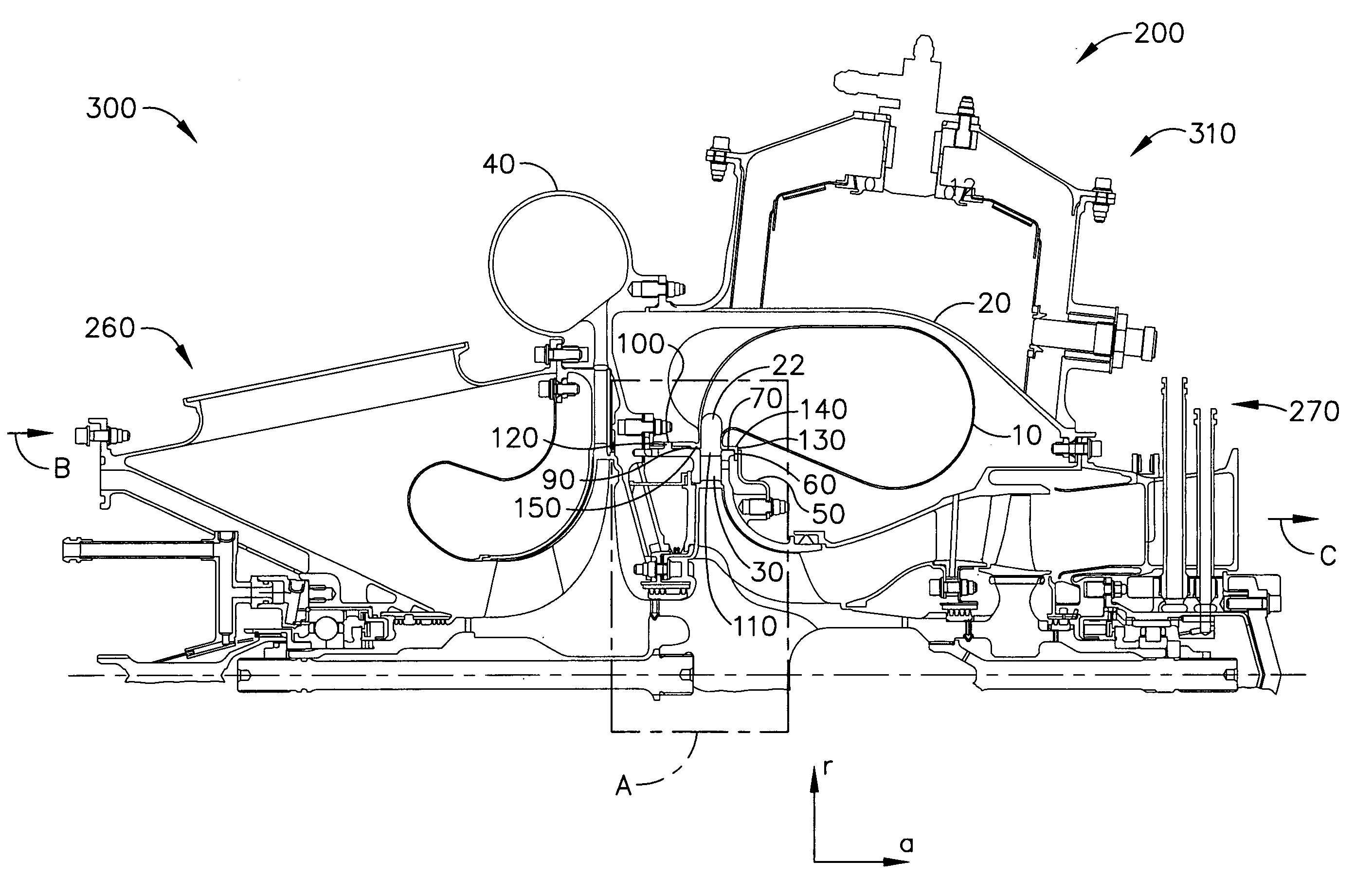

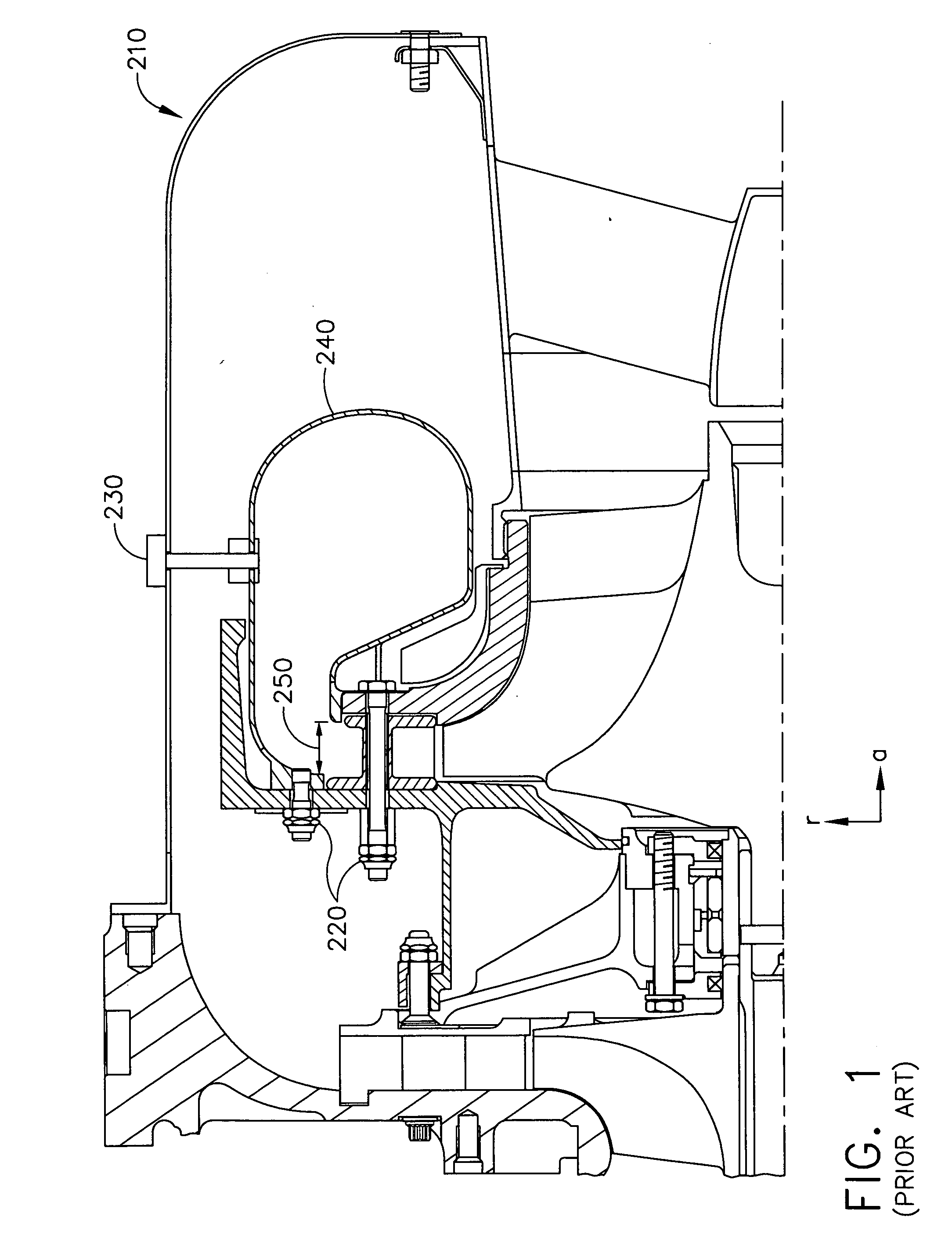

Multi-action on multi-surface seal with turbine scroll retention method in gas turbine engine

InactiveUS20050076643A1Constant B-widthAvoid suffocationContinuous combustion chamberGas turbine plantsCombustion systemFretting

A gas turbine engine comprises a turbine scroll inside a combustor housing, discouragers with 90-degree bending angles, a radial nozzle contacting a forward bayonet on the forward side of the turbine scroll at a bayonet engagement point and a B-width measured between the discouragers. Retaining ring maintains the size of the B-width. The turbine scroll may have eight surfaces sealing at four locations and a provision to maintain constant “B-width” for the thin sheet metal scroll within the combustion system. The design allows the scroll to operate at high temperature while maintaining lowest possible thermal and mechanical stresses. It can be easily assembled with excellent capability to control gas leakage and minimal component interface wearing or fretting. The gas turbine engine is adapted for aircraft, spacecraft, missiles, and other flight vehicles, especially high performance, high cycle flight vehicles.

Owner:HONEYWELL INT INC

Gasket raw material

The gasket material that is manufactured from a joint seat which includes three layers, that is, a front surface layer (1a), a back surface layer (1b) and the middle layer (1c), and these layers have different composition of reinforced fiber and filler respectively, and this joint seat is made from an ingredient made by mixing and kneading rubber, reinforced fiber and filler, then pressurized laminating and vulcanizing the ingredient, this joint seat is characterized in that the reinforced fiber is as a sort of fibril which is composed from one or both of organic fiber and non-asbestos type inorganic fiber, and at least a part of the filler is spicular inorganic fiber and its composition is 10 wt %-45 wt %. According to this joint seat (1), a crack breakage of the gasket that the ingredient material is the joint seat (1) due to fretting is prevented.

Owner:NIPPON LEAKLESS IND CO LTD +1

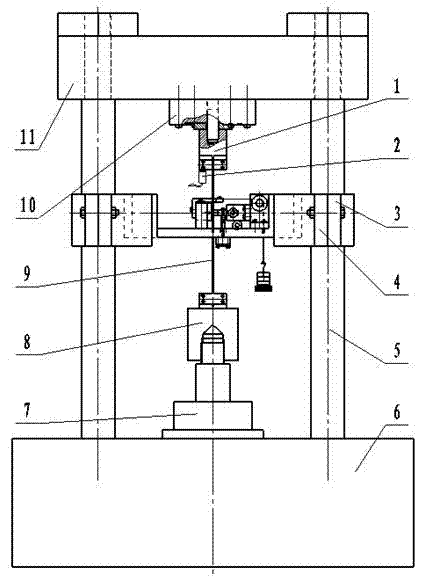

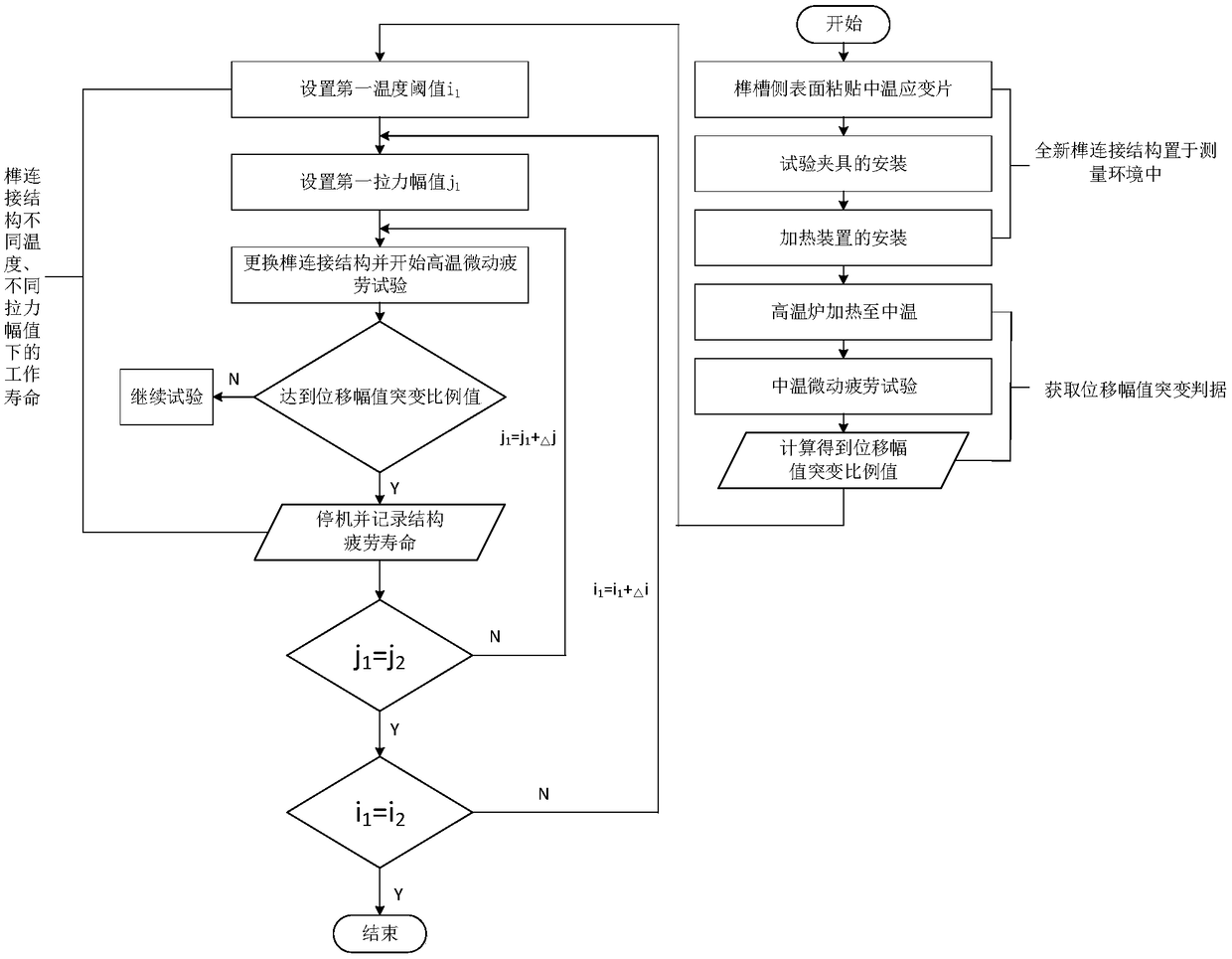

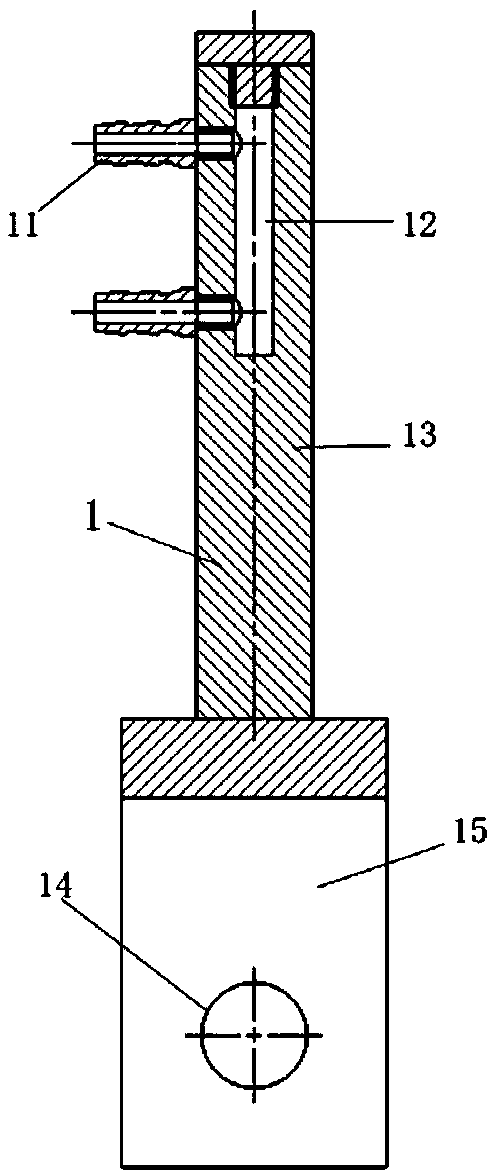

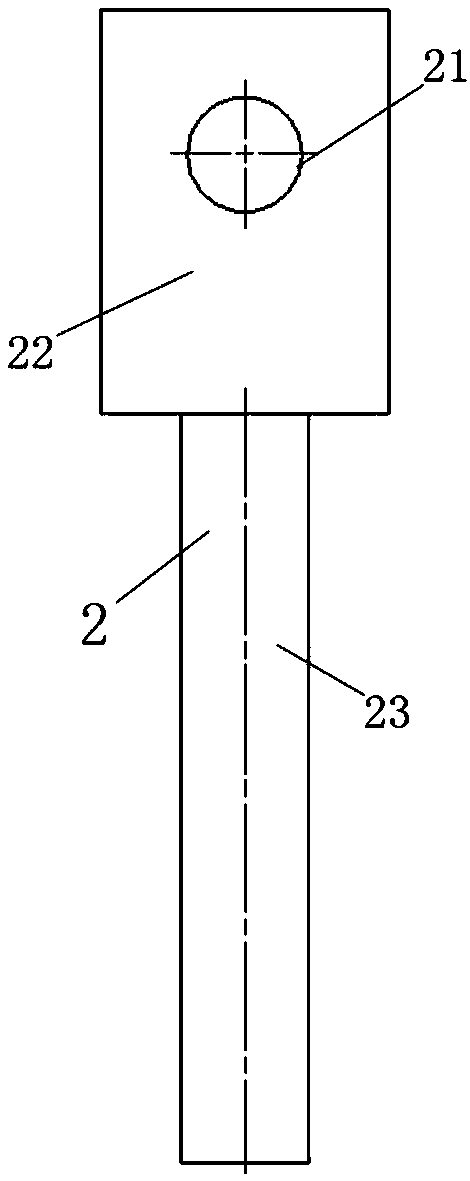

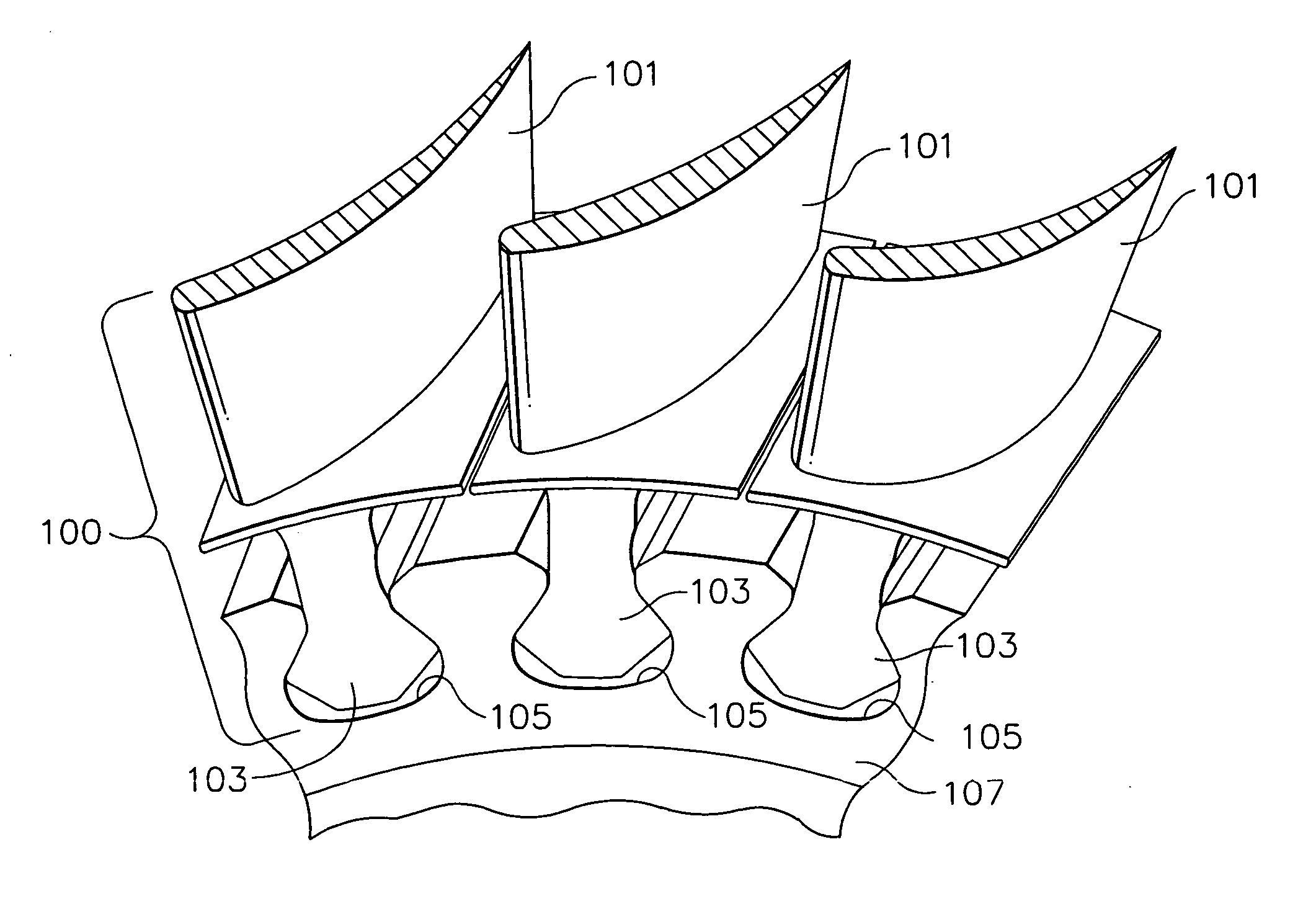

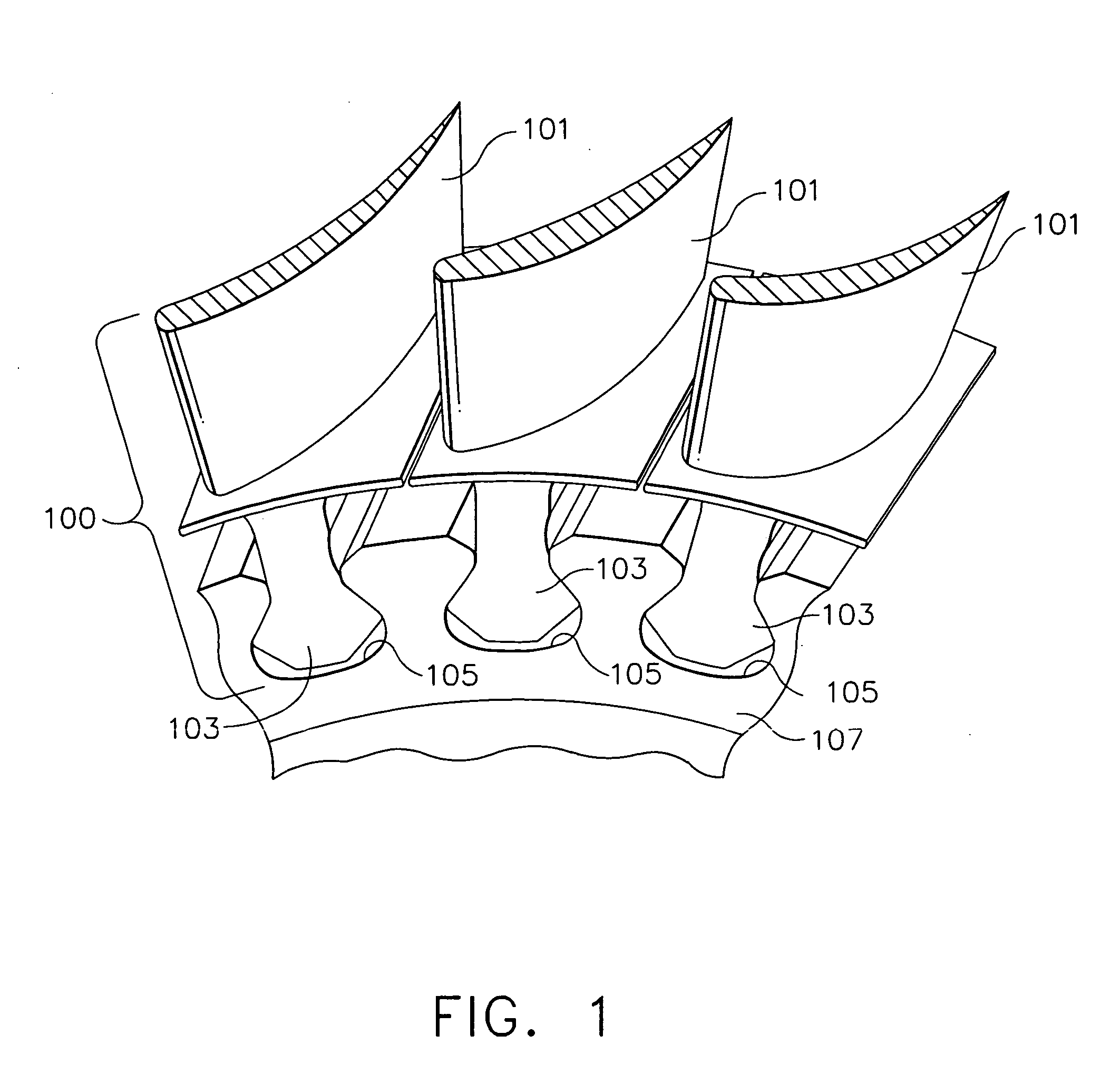

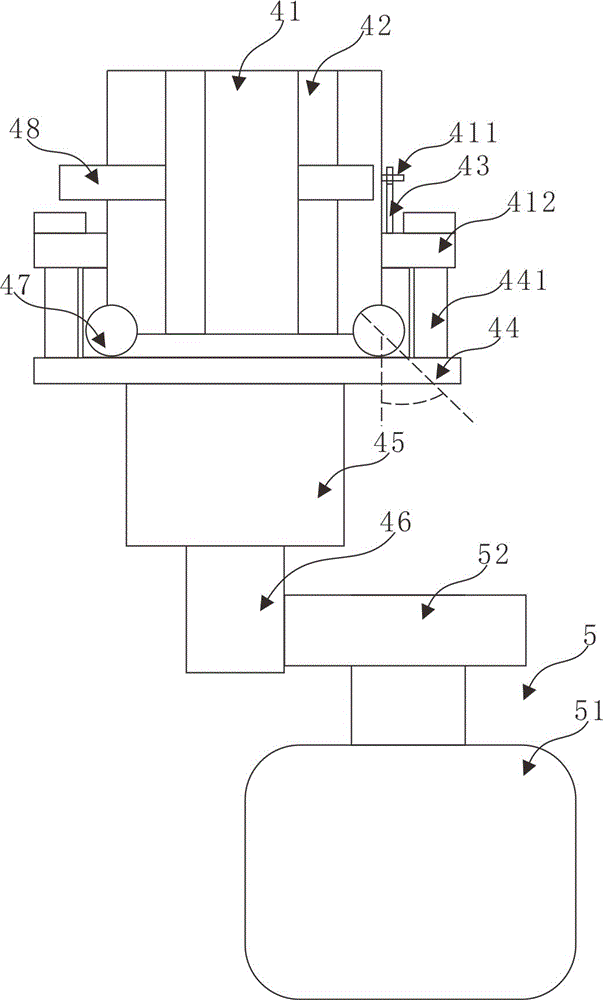

Method for testing high-temperature fretting fatigue life of tenon joint structure

ActiveCN108732035AEasy to implementLow costMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFrettingEngineering

The invention discloses a method for testing high-temperature fretting fatigue life of a tenon joint structure. The method for testing the high-temperature fretting fatigue life of the tenon joint structure comprises the following steps: determining strain or displacement of crack initiation, and installing test equipment; then starting a medium temperature fretting fatigue test; determining a judgment standard of the displacement and strain during crack initiation; and finally, performing a high-temperature fretting fatigue test and determining the high-temperature fretting fatigue life of the tenon joint structure. The fretting fatigue test of the tenon joint structure at the high temperature is successfully completed, and the test is low in cost and capable of simply and accurately acquiring the crack initiation life data of the tenon joint structure, so the method disclosed by the invention is high in operability, wide in application range and high in prediction accuracy and has considerable engineering application prospects. The invention further discloses a test-piece fixture for high-temperature fretting fatigue life test of the tenon joint structure. The fixture comprises an upper fixture with a water-cooling device, a lower fixture and a fixing assembly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

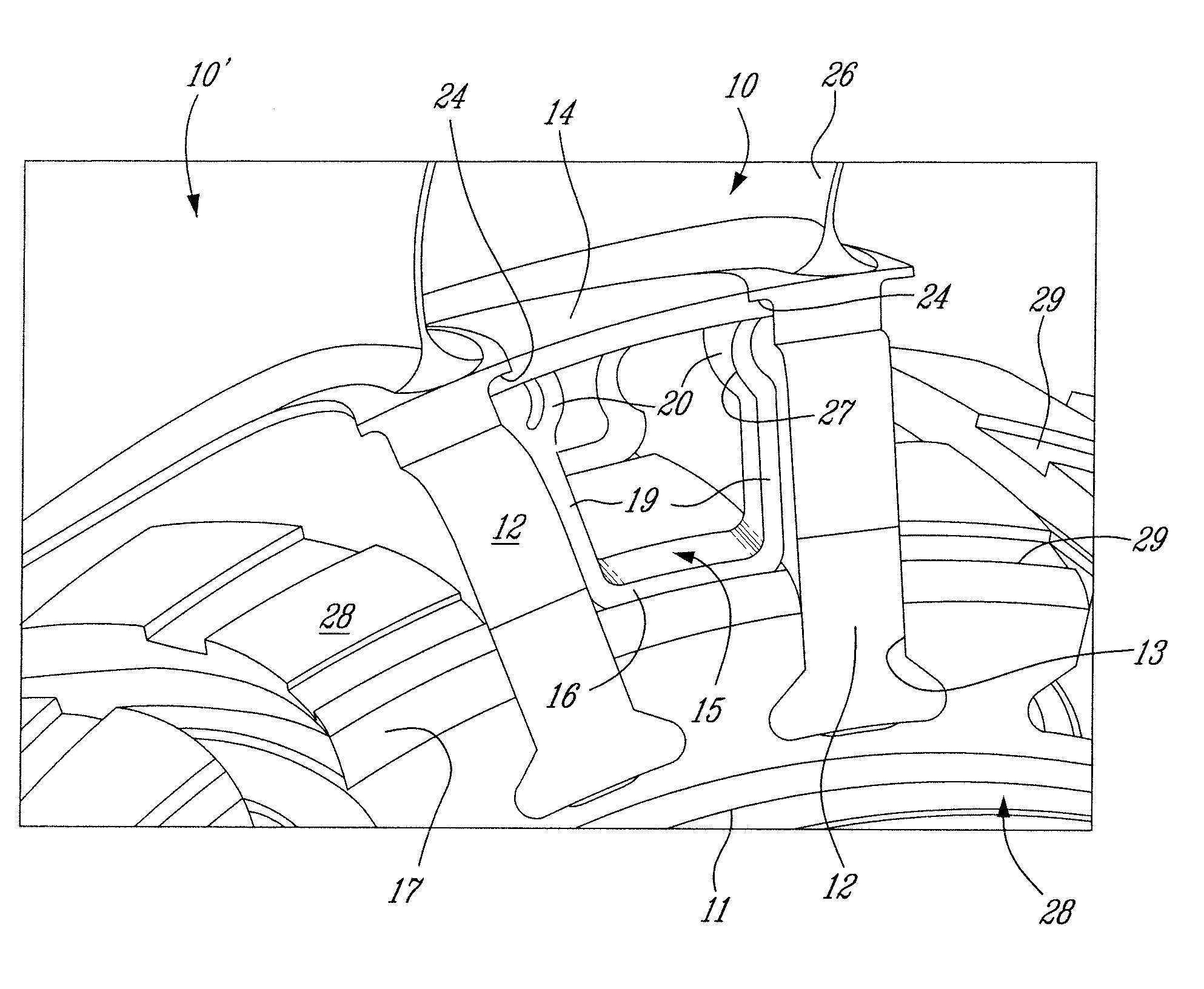

Multi-layer steel cord where intermediate filaments are coated with a polymer

InactiveUS20050037197A1Improve adhesionReduce absorptionPattern printingPneumatic tyre reinforcementsFrettingIntermediate filament

A steel cord (10) comprises a core with one or more core steel filaments (12) and further comprises a first layer of intermediate steel filaments (14) twisted around the core, and a second layer of second steel filaments (18) twisted around the first layer. At least one of the intermediate steel filaments is individually coated by means of a polymer (16) with a minimum thickness of 0.010 mm. The polymer (16) reduces the fretting between the coated intermediate steel filaments (14) and the other steel filaments and makes the steel cord suitable for reinforcement of carcass plies of a tire.

Owner:NV BEKAERT SA

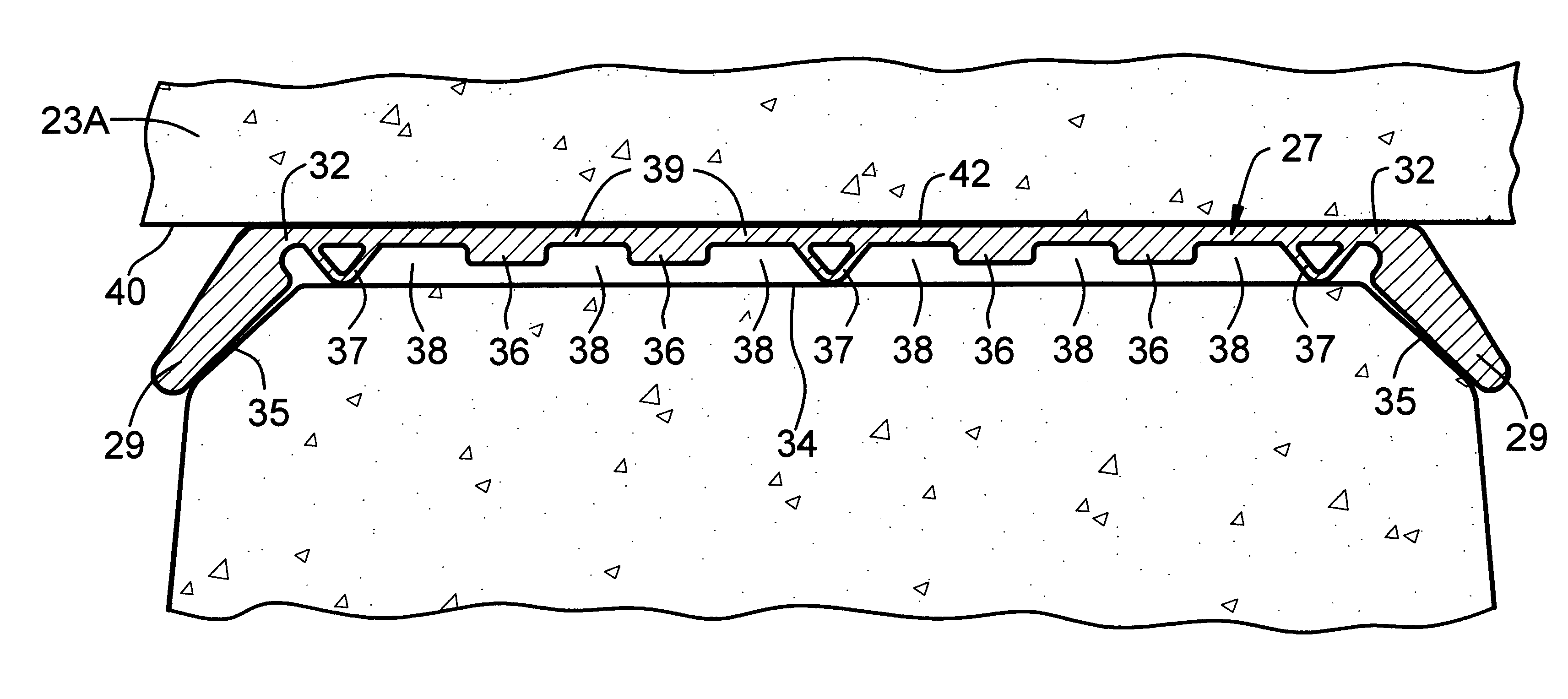

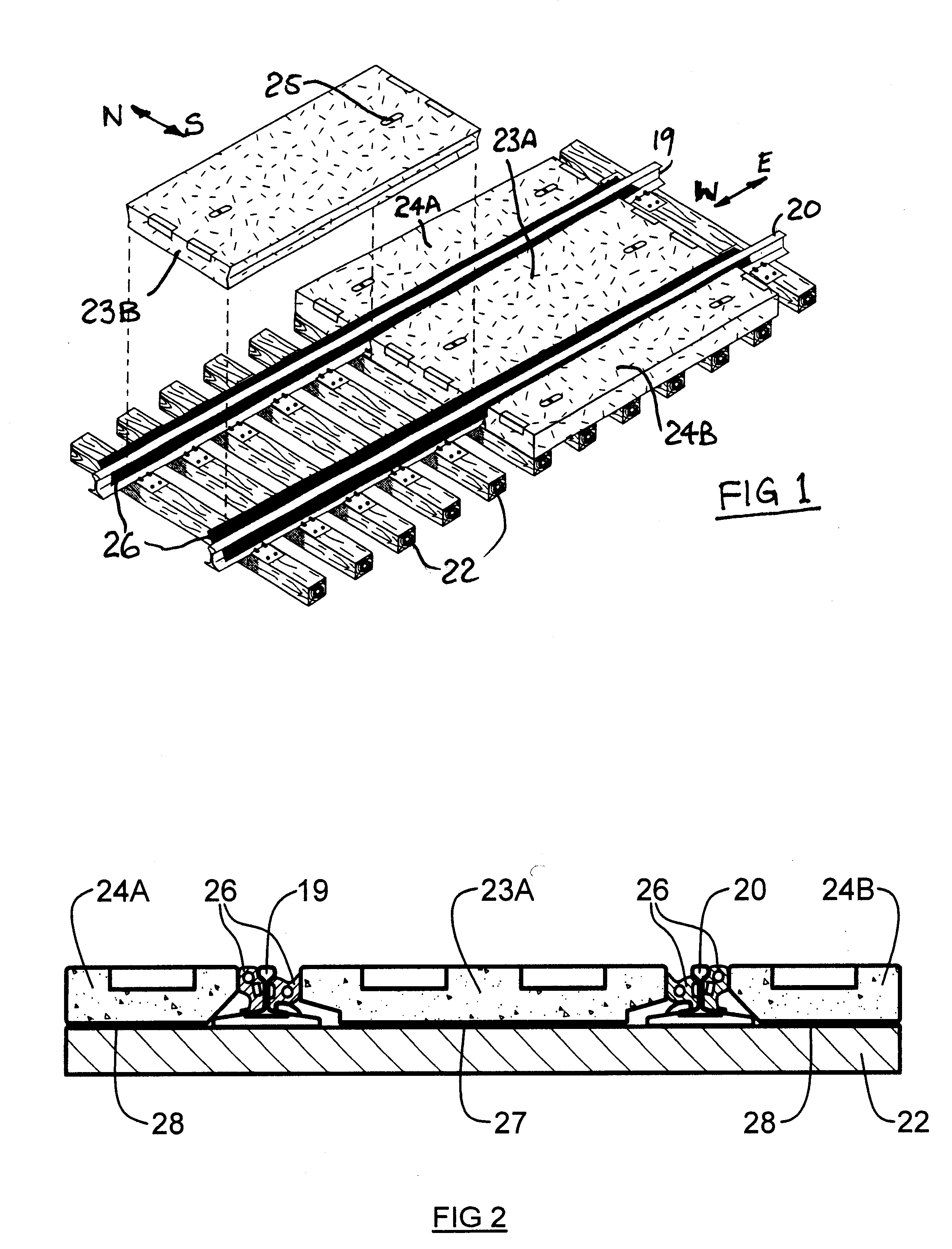

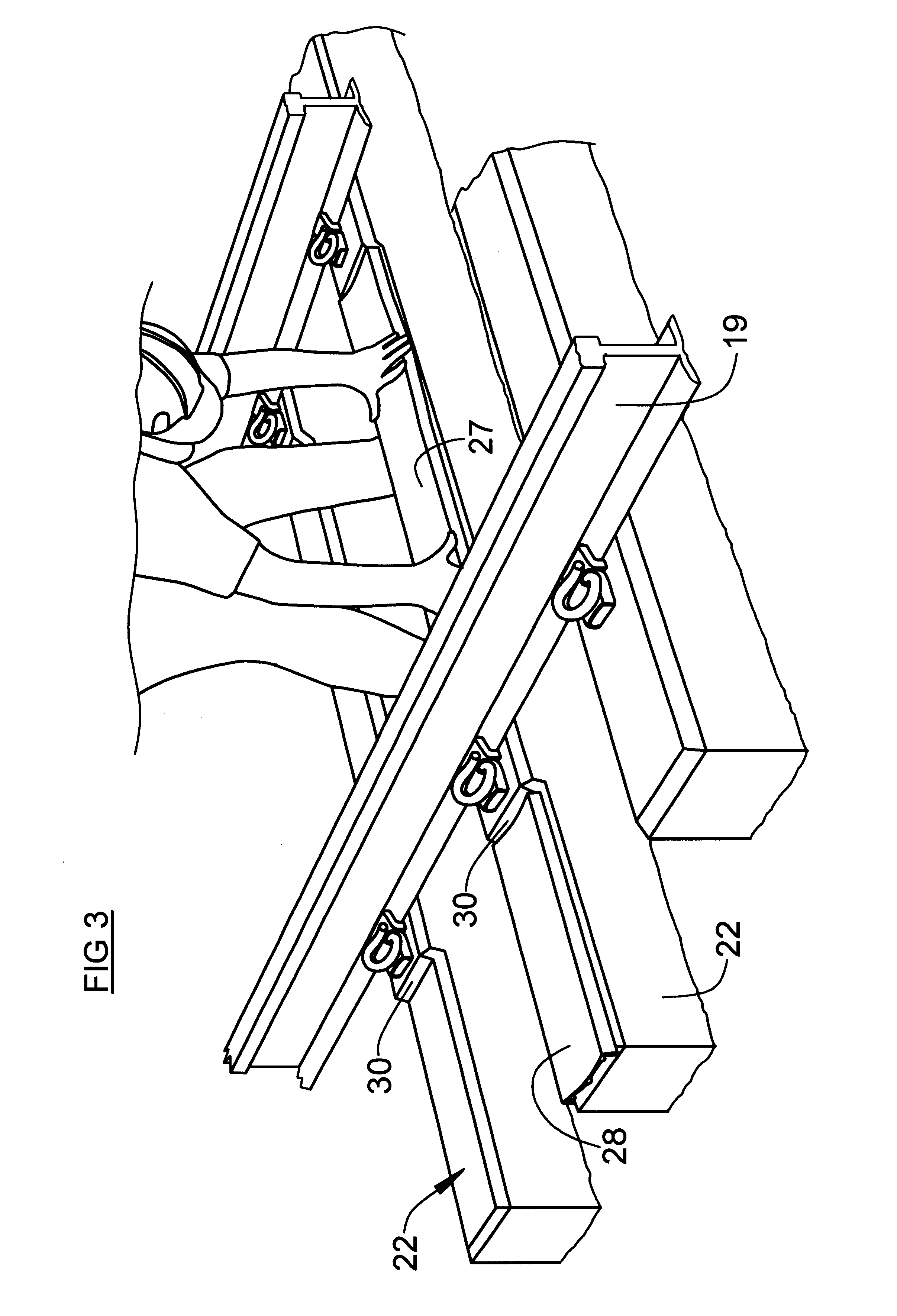

Resilient caps for cross-ties at railway crossings

Pre-cast concrete panels are commonly provided at road-rail crossings, to serve as the roadway, but such panels have been liable to premature failure. Rubber caps are placed over the cross-ties, between the panel and the ties, to isolate the panel from the stresses that arise when the panel contacts the ties directly. The caps are ribbed. Two kinds of ribs are provided, some solid and rectangular, others triangular and hollow. The ribbed panels provide resilience and hysteresis over a range of conditions, to prevent fretting and cracking of the panel.

Owner:PERFORMANCE POLYMERS

Titanium treatment to minimize fretting

InactiveUS20060289088A1Reduce sensitivityCorrosion resistanceSolid state diffusion coatingFrettingCarbide

A method for surface treating a titanium gas turbine engine component. The method includes providing a gas turbine engine component having a titanium-containing surface. The component is heated to a temperature sufficient to diffuse carbon into the titanium and below 1,000° F. The surface is contacted with a carbon-containing gas to diffuse carbon into the surface to form carbides. Thereafter, the carbide-containing surface is coated with a lubricant comprising a binder and a friction modifier. The binder preferably including titanium oxide and the friction modifier preferably including tungsten disulfide. The coefficient of friction between the surface and another titanium-containing surface is less than about 0.6 in high altitude atmospheres.

Owner:CASE WESTERN RESERVE UNIV +1

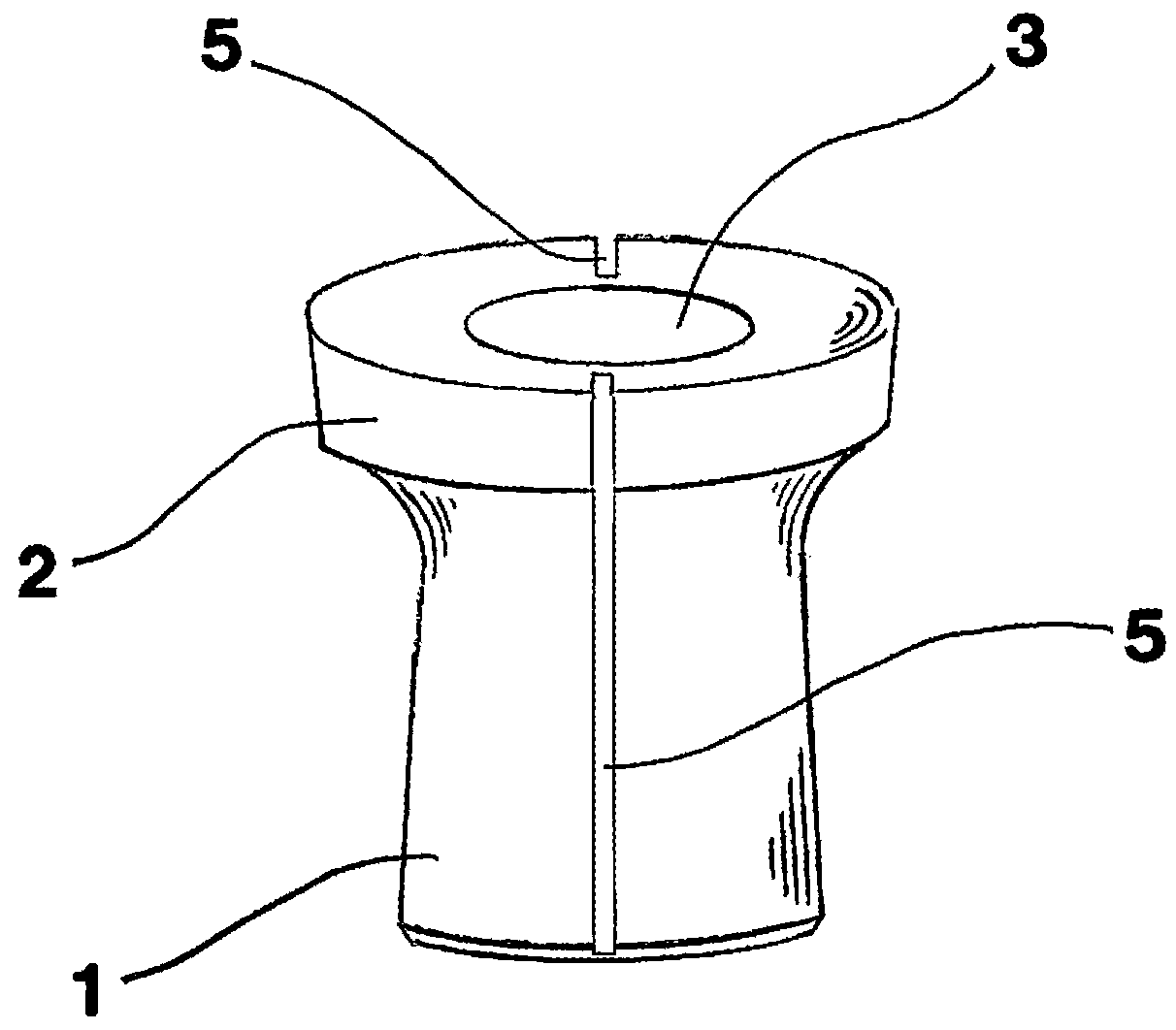

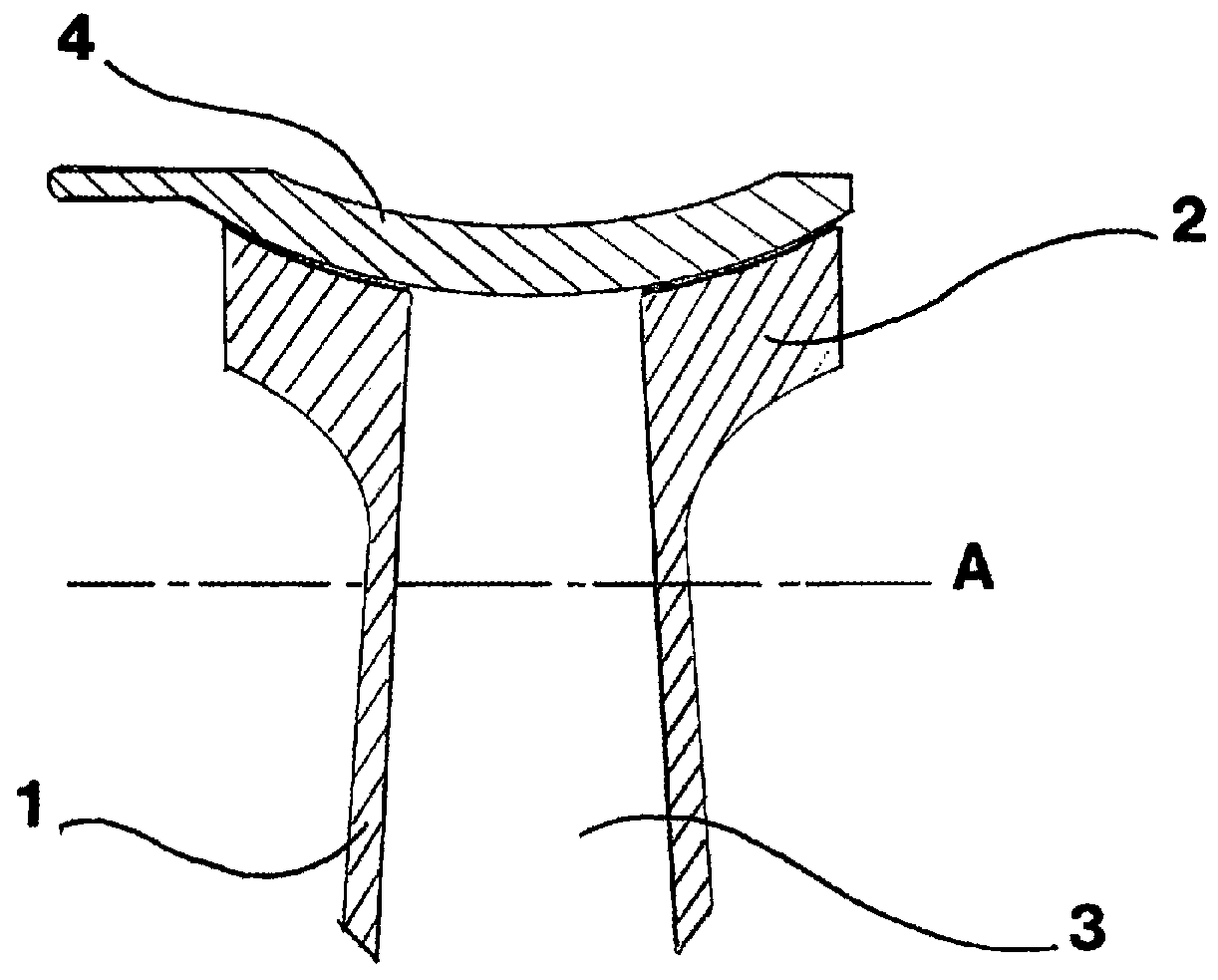

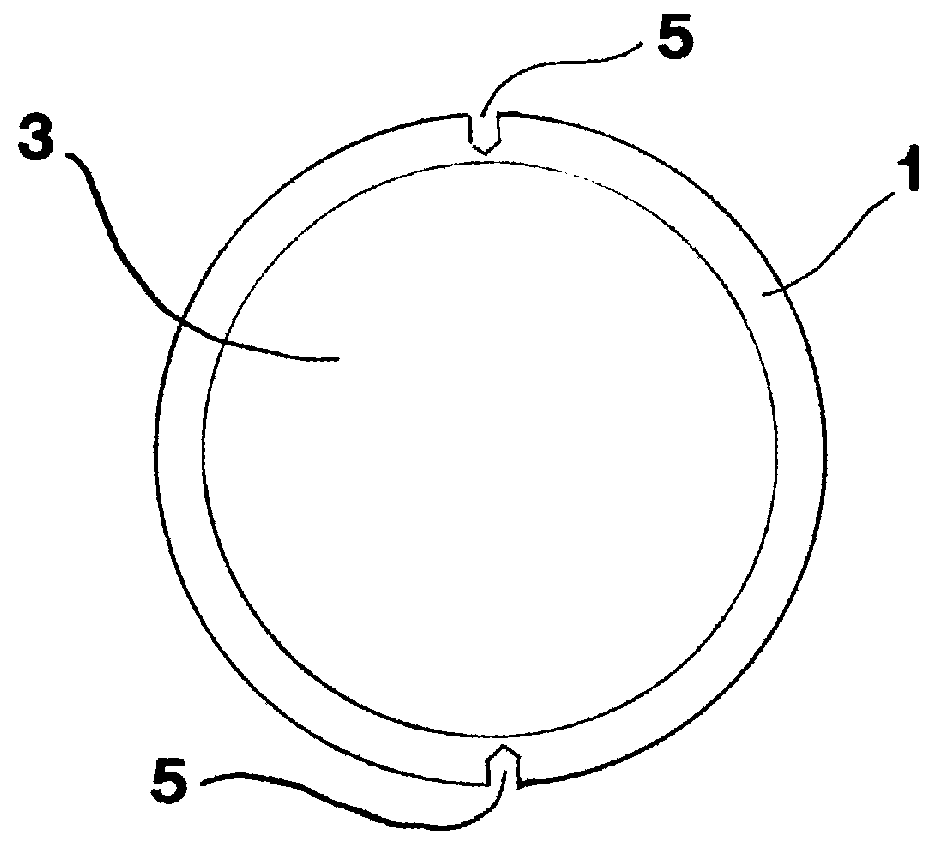

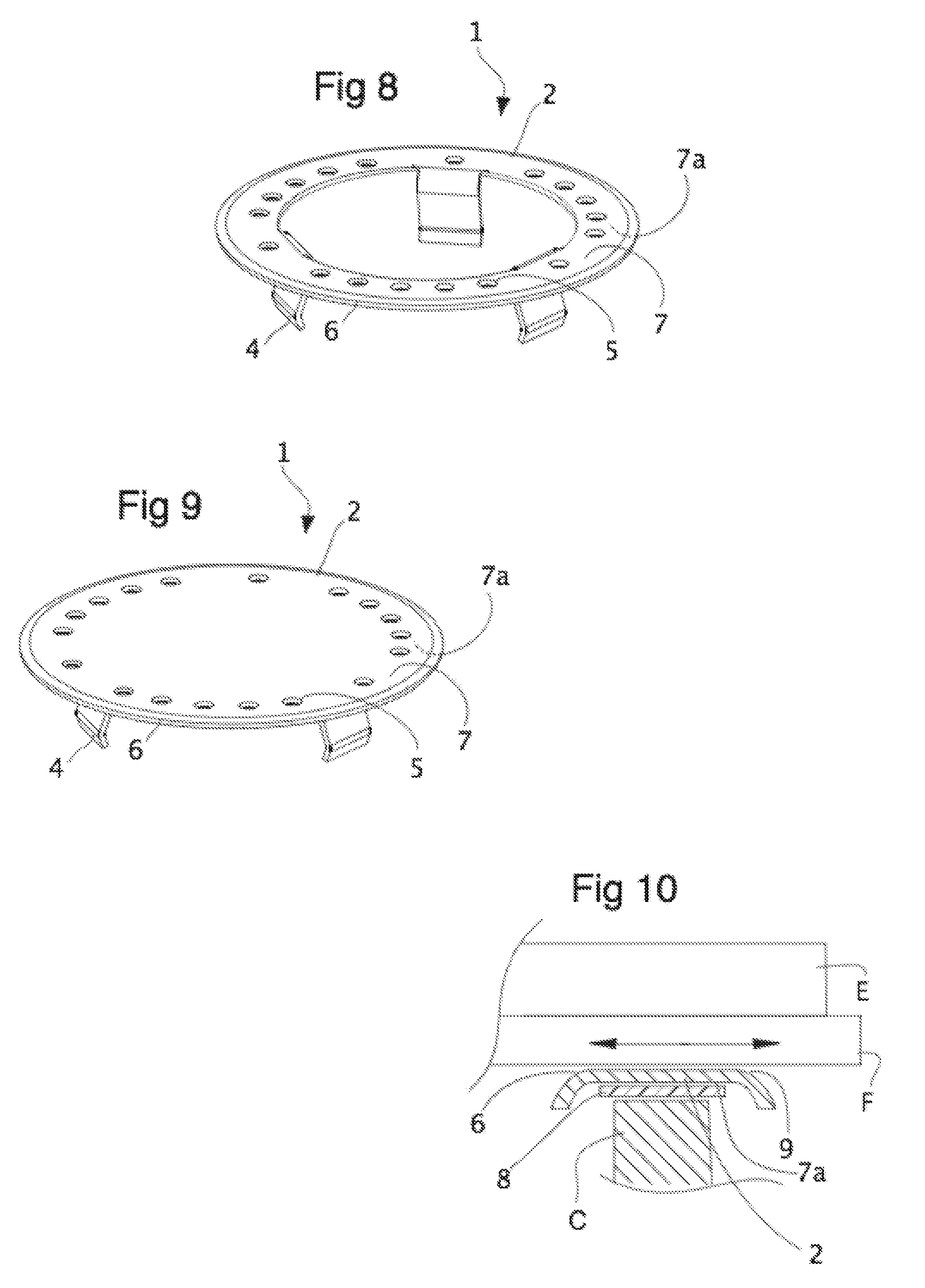

Piston-side brake shim

ActiveUS20100133050A1Improve the lubrication effectEqually distributedNoise/vibration controlSlack adjustersFrettingEngineering

The present invention is a shim or shim assembly that clips onto a brake caliper piston. It is generally a rimmed round (disc or annular) shape to cap the edges of the caliper piston and includes surface features for lubrication, and improved fitting. Reduced noise from frictional fretting is provided along with protection of piston's outer rim. Reduced thermal transfer into the piston is also provided.

Owner:NUCAP IND

Method for producing bricks from urban domestic sludge

A method for treating and utilizing urban domestic sludge and making bricks is carried out by fermenting urban domestic sludge, compressing, fretting and heating above 70 degree at compact opening of brick maker, placing heated sludge into mud-pressing tank, pumping vacuum, inducing extracted gas into water with hydrochloric acid and mixing treated mud with shale to produce bricks. It costs low, has less pollution for underground water and saves land resource and energy resource.

Owner:刘仁富

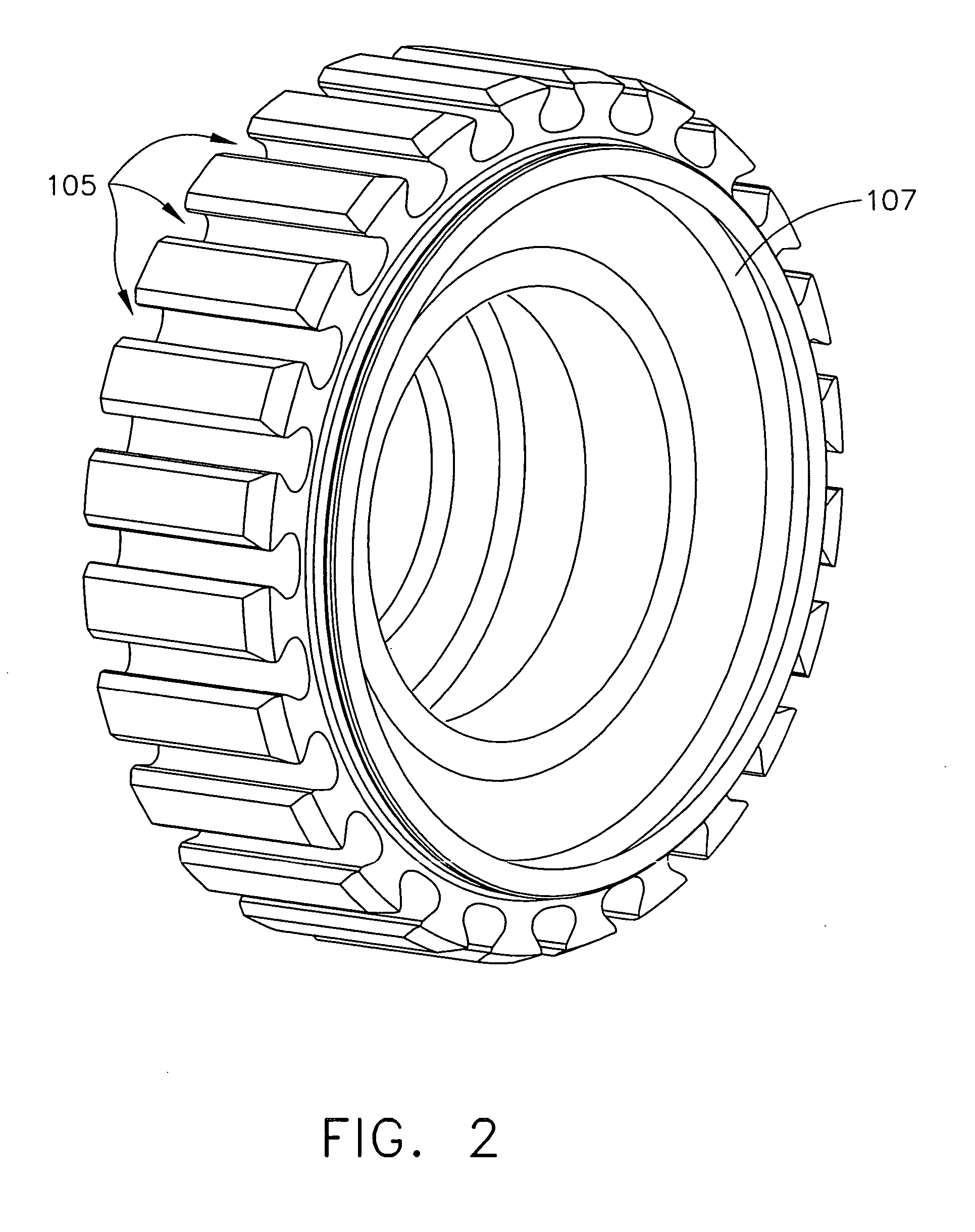

Fan blade Anti-fretting insert

A fan blade anti-fretting insert is described whereby to reduce wear between the root portion of a fan blade and the root slot of the rotor fan hub of a turbo fan engine to which the fan blade are secured. The anti-fretting insert can be formed of a composite spring material having a memory and is dimensioned and shaped to be fitted between the fan blade platform and the outer surface portion of the rotor fan hub between adjacent fan blades, whereby to apply a pushing force against the platform and consequently to the fan blades secure thereto thereby applying a resulting pulling force on the root portion of the fan blades to prevent rocking of the root portion in their root slots formed in the rotor fan hub.

Owner:PRATT & WHITNEY CANADA CORP

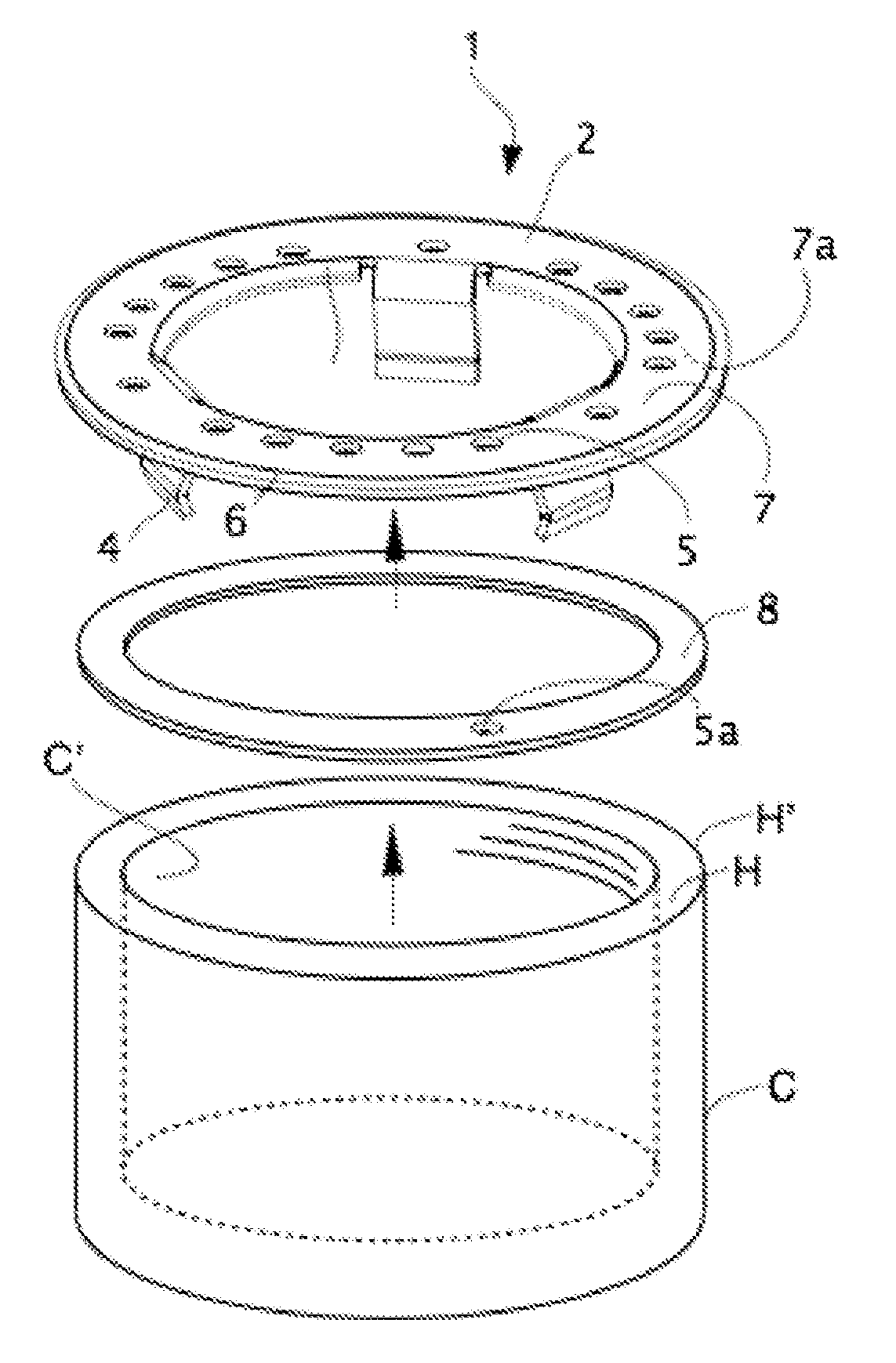

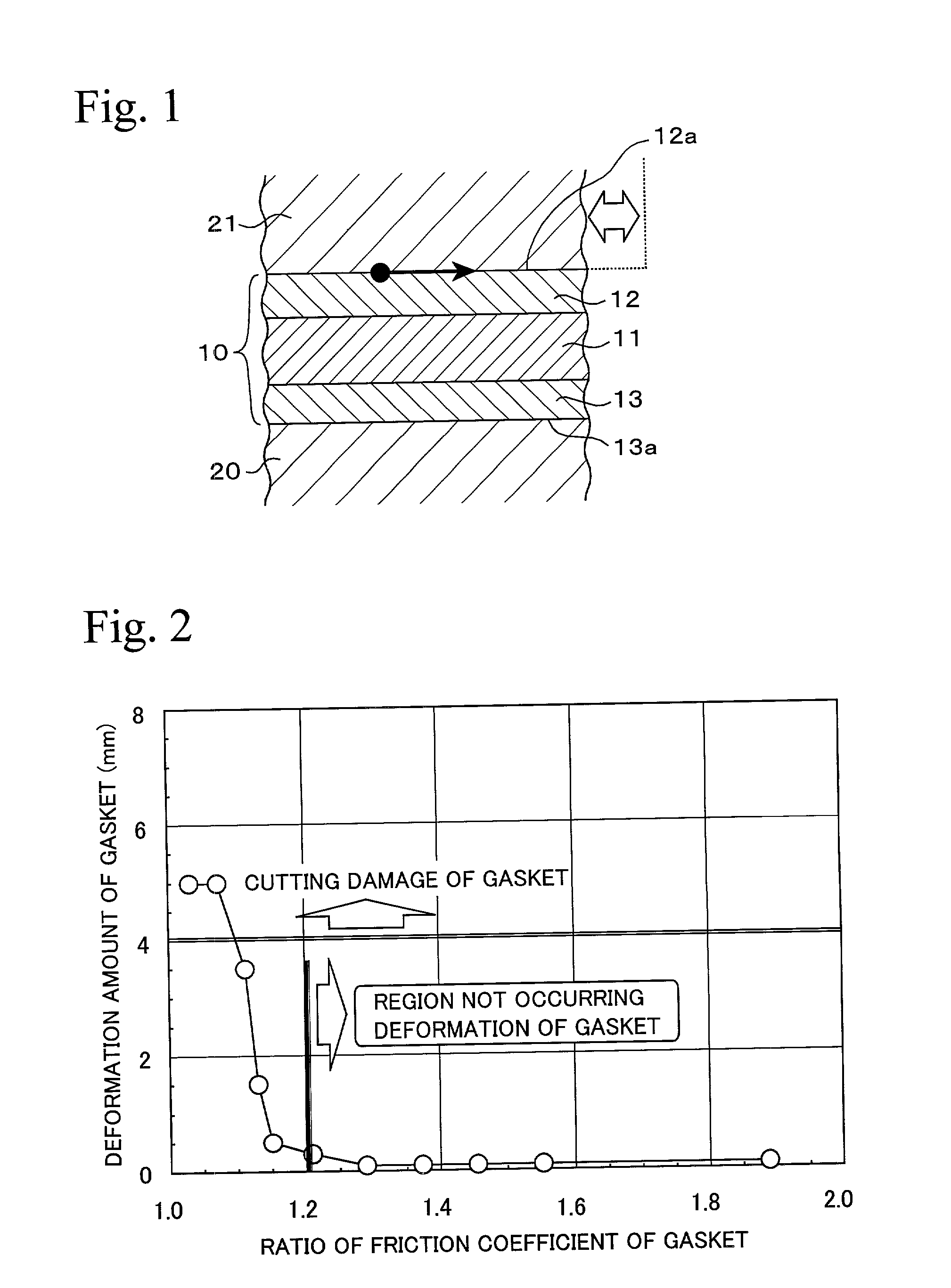

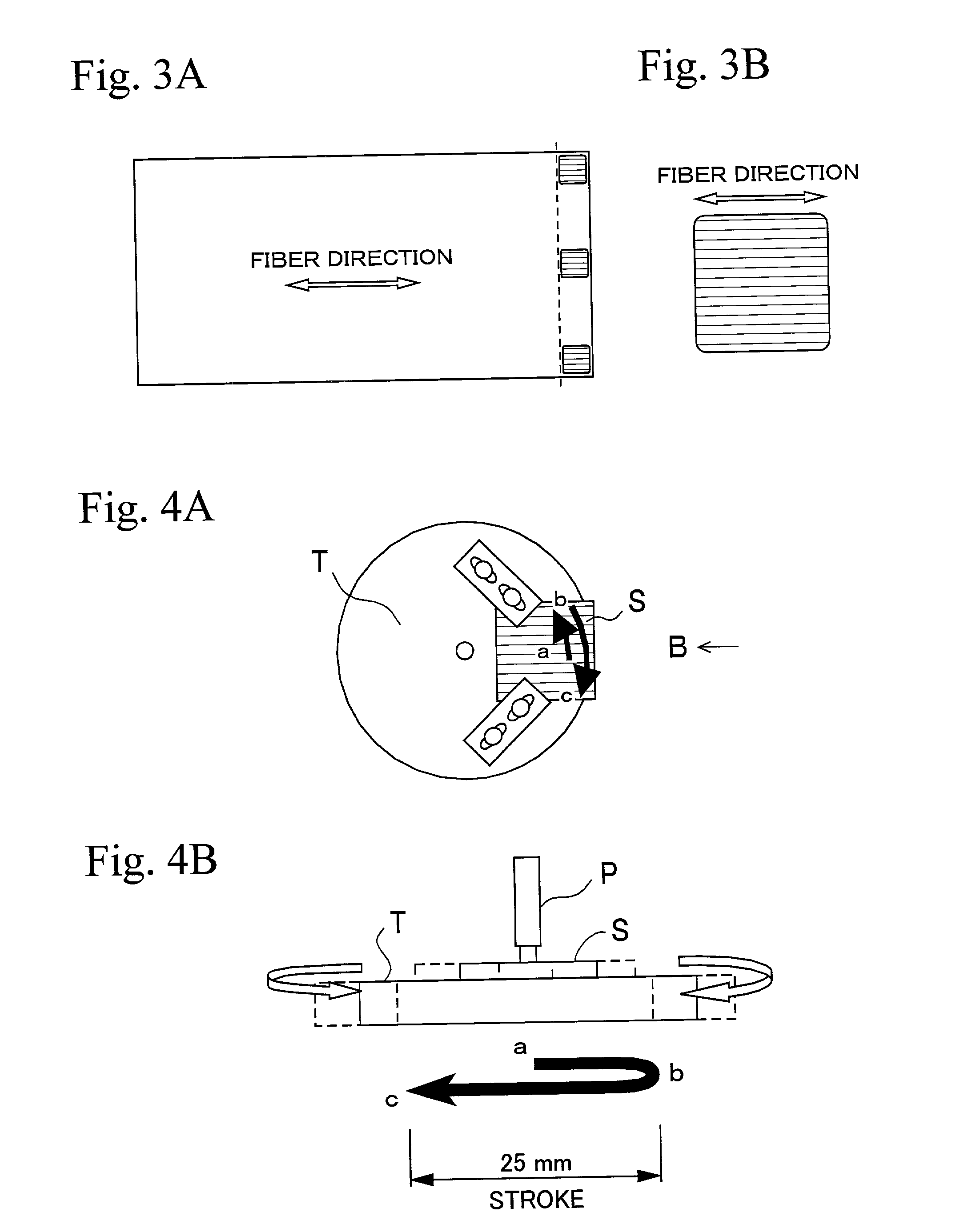

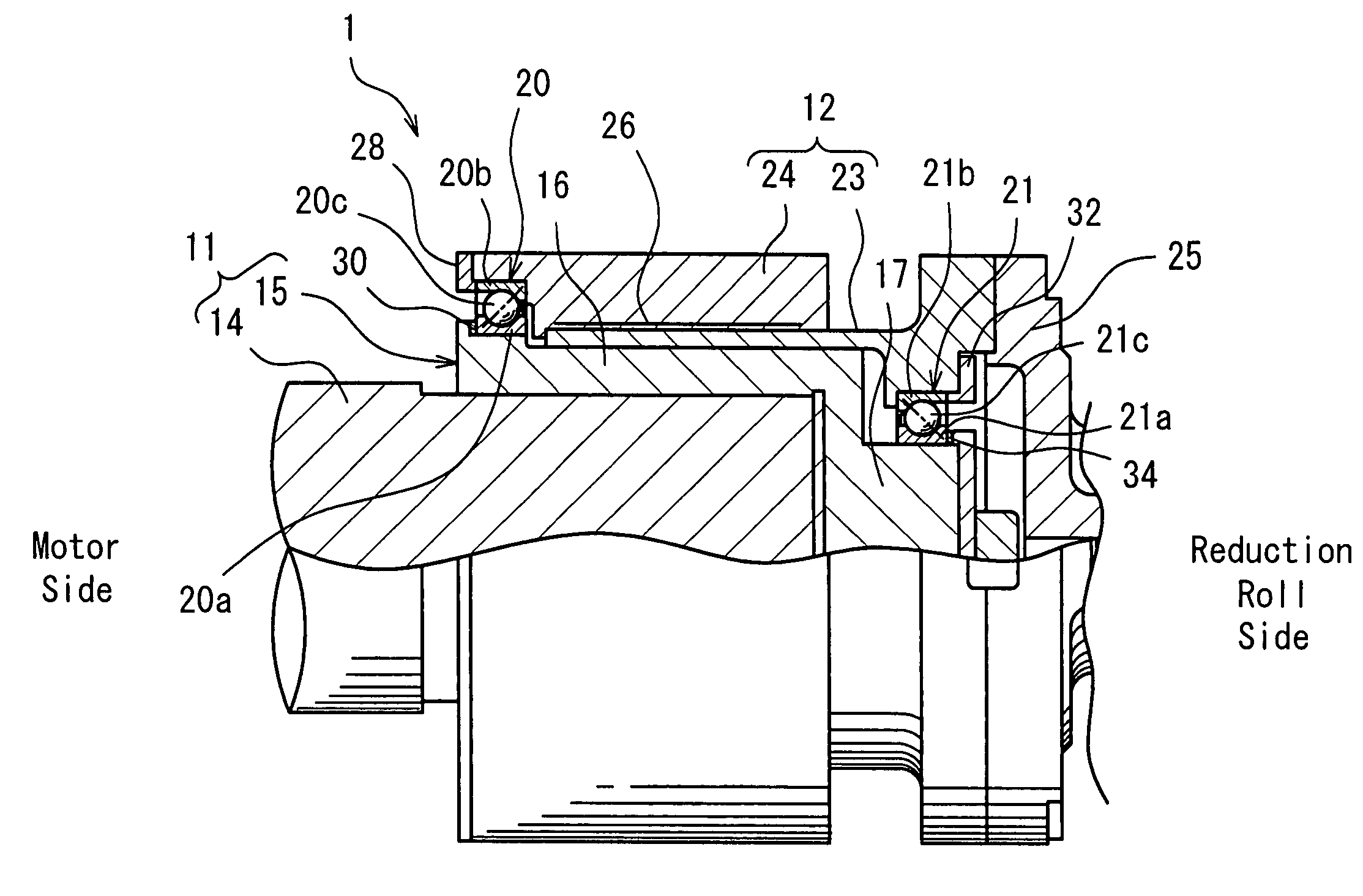

Compound sheet gasket

InactiveUS20020089126A1Small coefficient of frictionDamage to suppressedEngine sealsOther chemical processesFrettingComposite plate

A compound sheet gasket which exhibits superior sealing durability to fretting is provided. The compound sheet gasket is mounted between a housing and a cover provided at an opening of the housing, and the friction coefficient of any one surface of a front surface adhered to the housing by the flexibility thereof and a rear surface adhered to the cover by the flexibility thereof, is set to be 1.15 times or more that of the other.

Owner:HONDA MOTOR CO LTD +1

Torque releasing device

InactiveUS7025185B2Avoid it happening againPrevented from sustaining smearingFluid pressure sealed jointsSlip couplingBall bearingFretting

In a torque releasing device, a bearing is composed of an angular contact ball bearing, raceway surfaces of which are applied with a pre-load in order that the occurrence of fretting at the bearing during torque transmission may be prevented. Thus is ensured that the torque is securely released.

Owner:KOYO SEIKO CO LTD

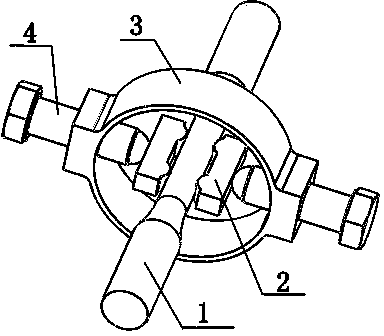

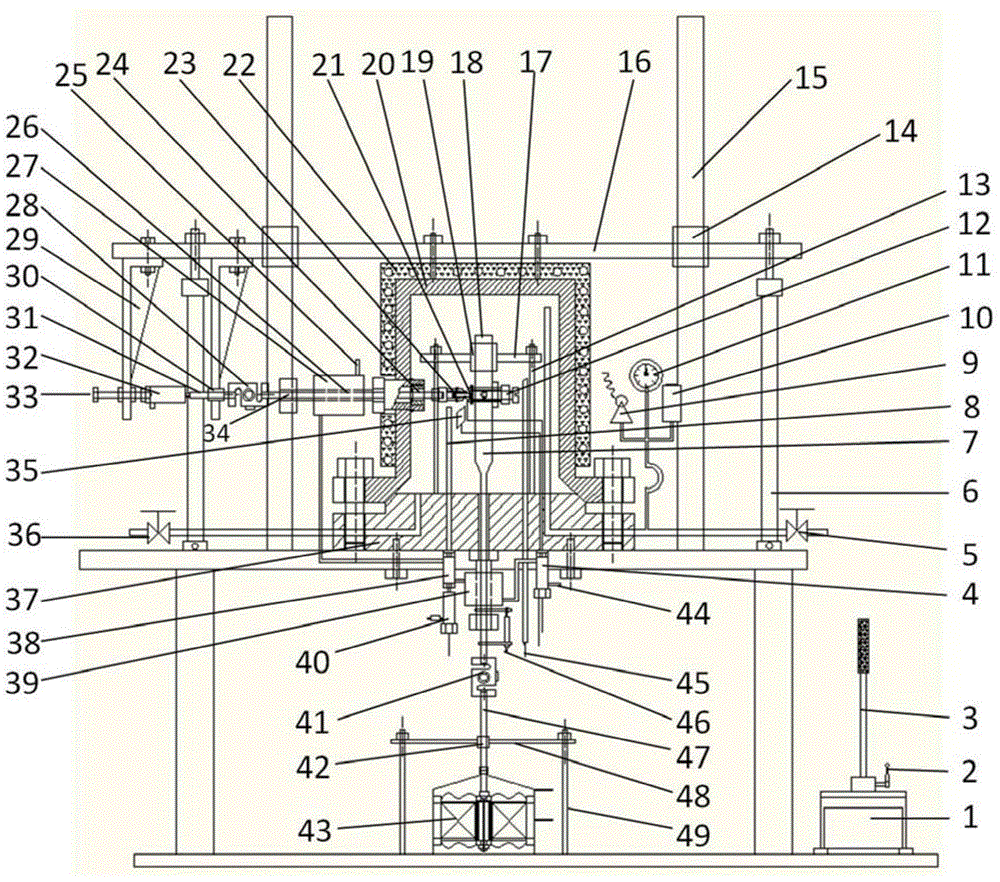

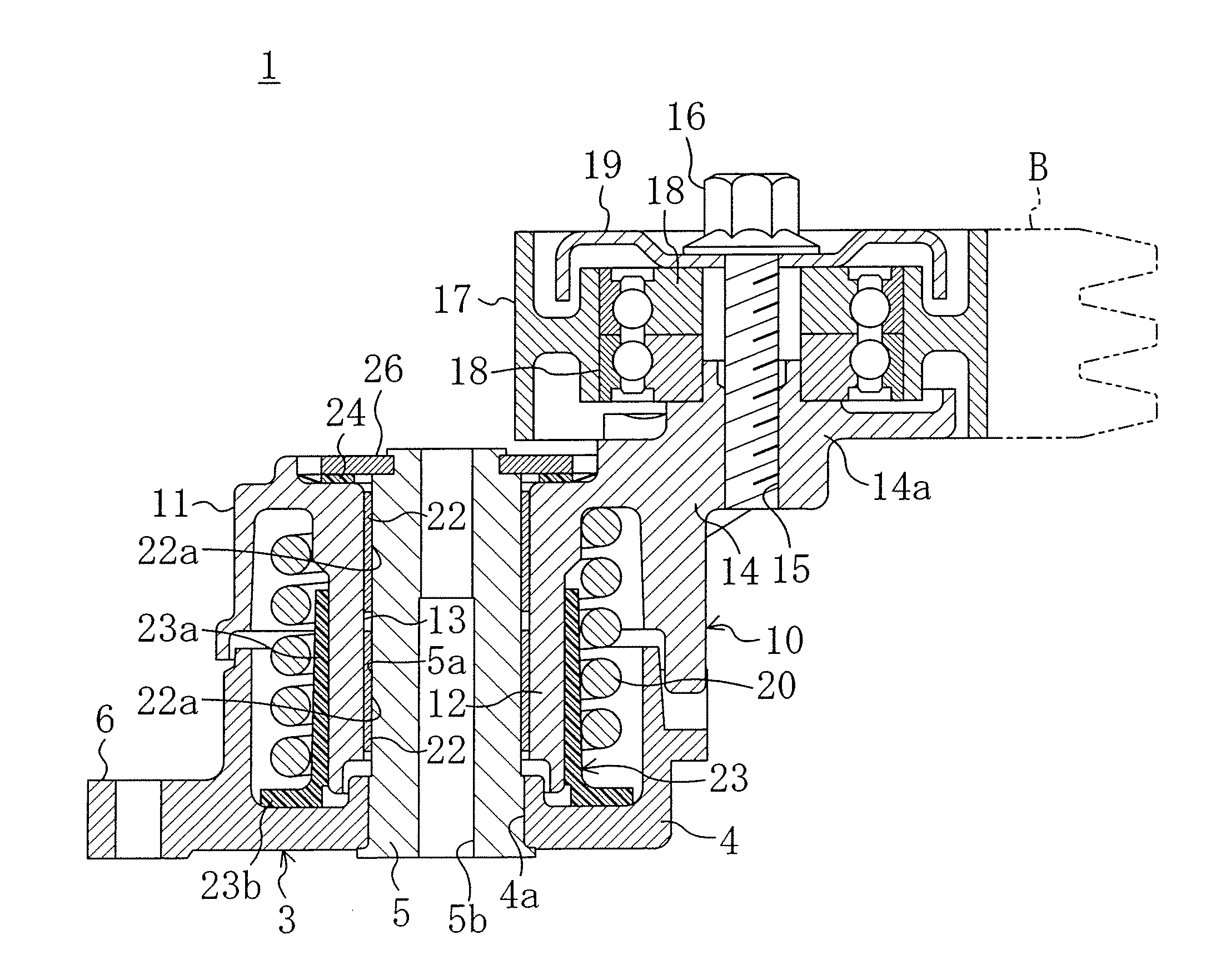

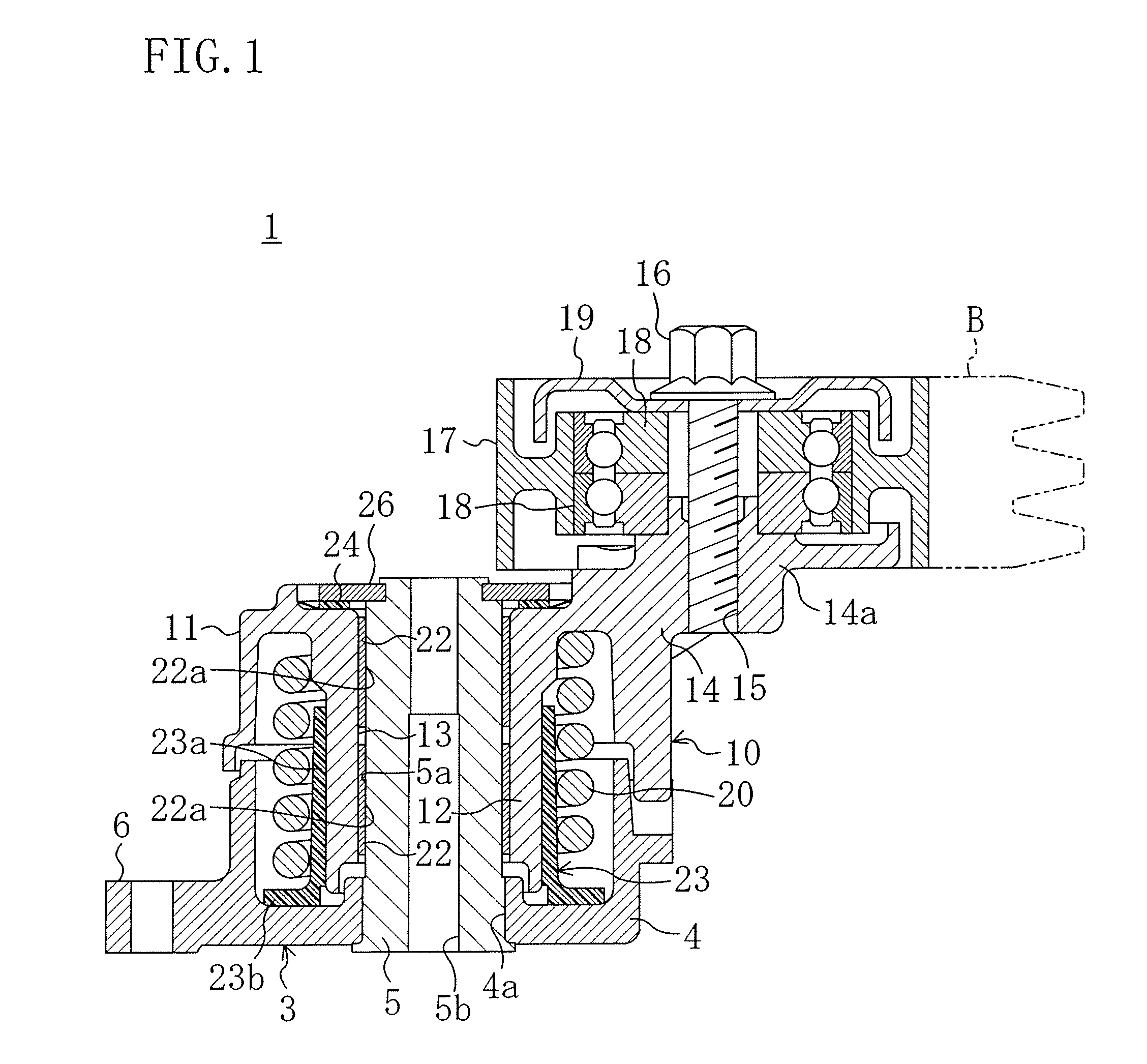

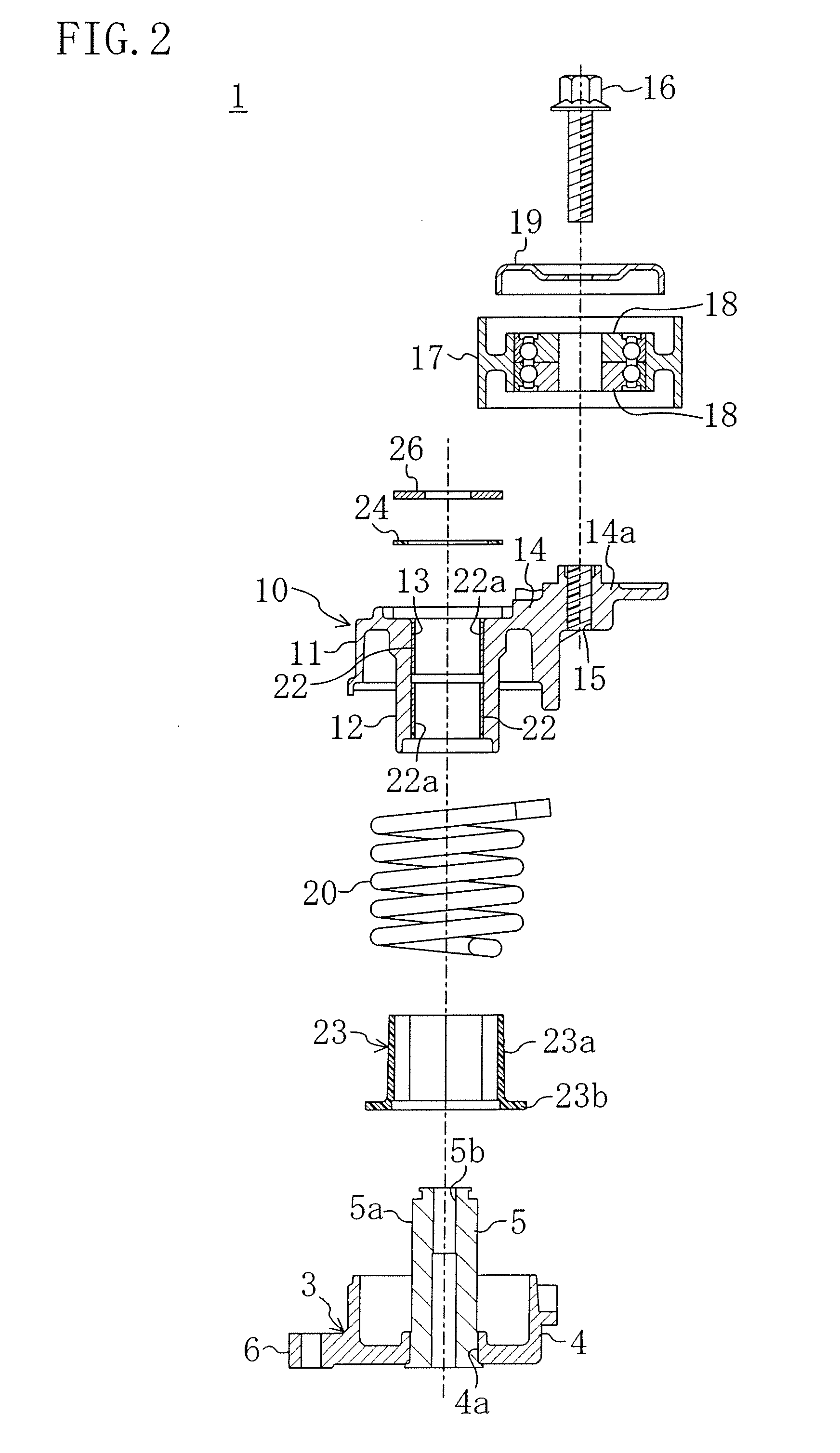

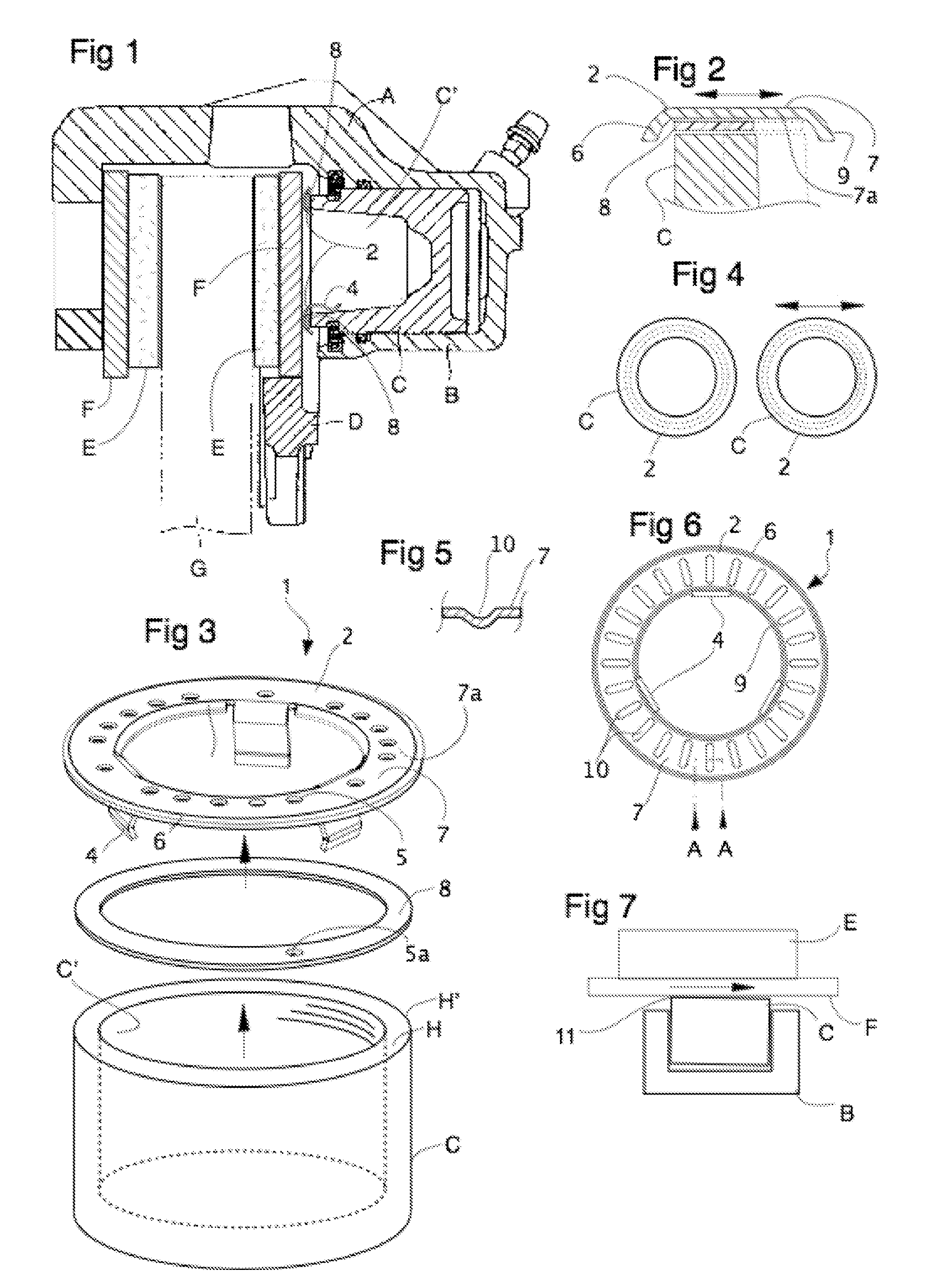

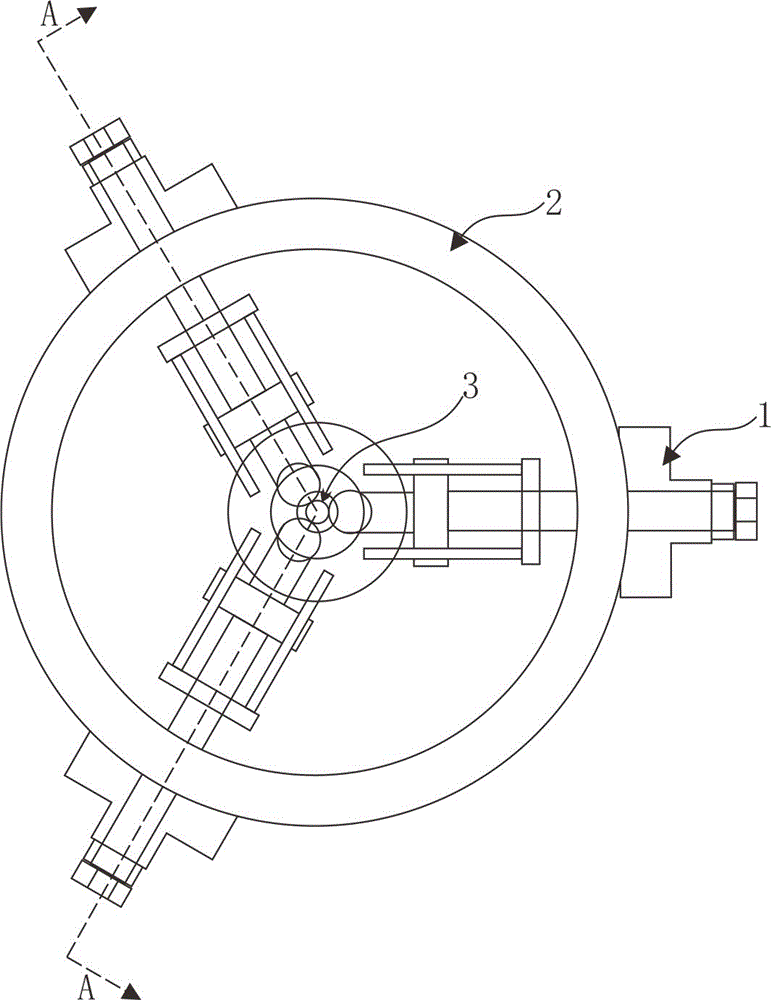

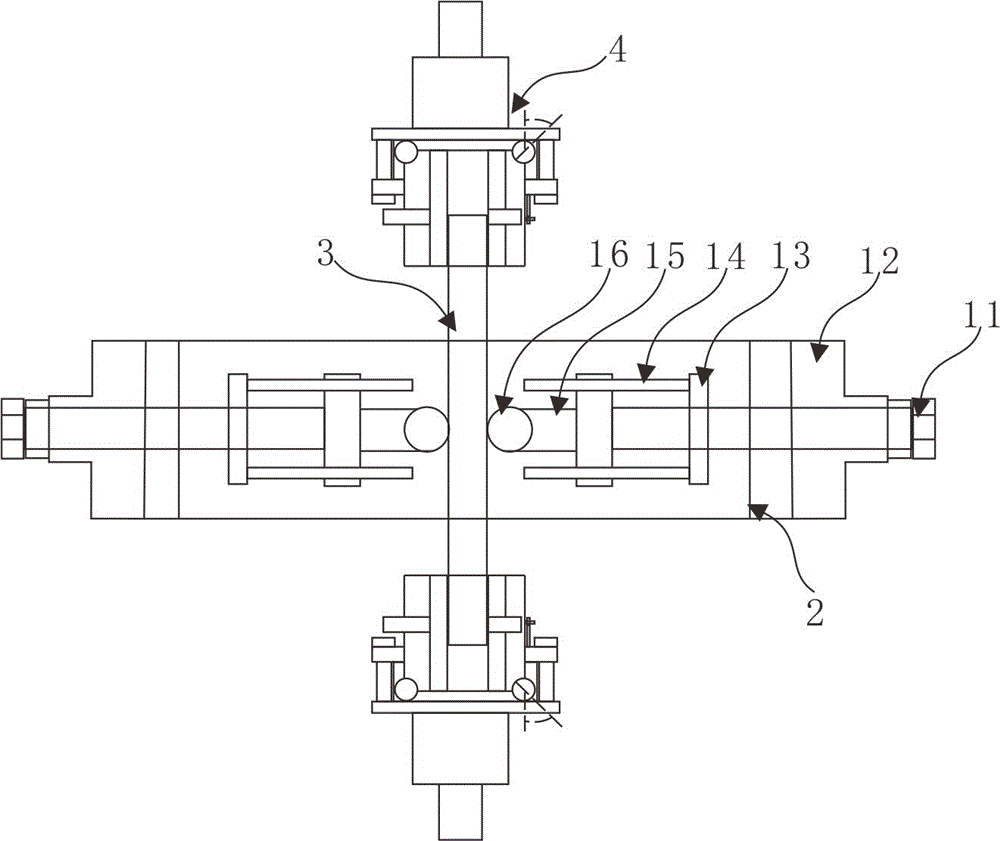

Tension-torsion combined fretting fatigue testing device and testing method thereof

The invention discloses a tension-torsion combined fretting fatigue testing device and a testing method thereof. The tension-torsion combined fretting fatigue testing device comprises a mounting ring, radial positioning devices, loading devices, power devices and image collection devices, wherein the image collection devices are used for collecting radial images of a sample shaft; a three-dimensional sensor is arranged in a contact position between each radial positioning device and a sample shaft; each loading device comprises a sleeve; a ring-shaped boss is arranged in the middle of each sleeve; at least three arc-shaped grooves are formed in the edge of the bottom of each sleeve; clamping plates are arranged in each sleeve at equal intervals; each clamping plate is mounted in a threaded hole of each sleeve through a stud fixedly arranged on the clamping plate; after balls are placed in the arc-shaped grooves of each sleeve, the lower end of the sleeve is placed in a receiving tank; a fixing shaft is fixedly connected with a worm rod through a coupler; each power device comprises an electromotor; a worm wheel arranged on an output shaft of each electromotor is meshed with the worm rod; an angle collector used for collecting rotation angles of the sample shaft during test is arranged on each ring-shaped boss.

Owner:SOUTHWEST JIAOTONG UNIV

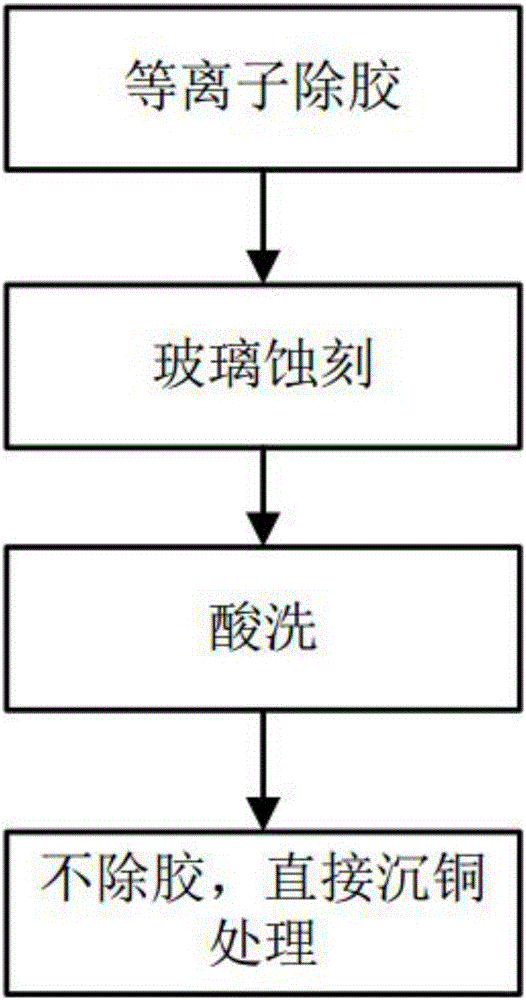

Multilayer PCB positive back etching process

The invention relates to the PCB manufacturing field and provides a multilayer PCB positive back etching process. According to the multilayer PCB positive back etching process, plasma adhesive cleaning processing on a PCB after a boring flow is carried out, secondly, glass etching processing is then carried out, and lastly, PCB manufacturing is accomplished according to the technology in the prior art. The process is advantaged in that through combining two etching modes of plasma adhesive cleaning and glass etching, glass fiber and epoxy resin in a prepreg of the PCB are enabled to reach a relatively balance fretting rate in an etching process, and a relatively ideal back etching effect is realized.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com