Patents

Literature

292results about "Printed circuit liquid treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

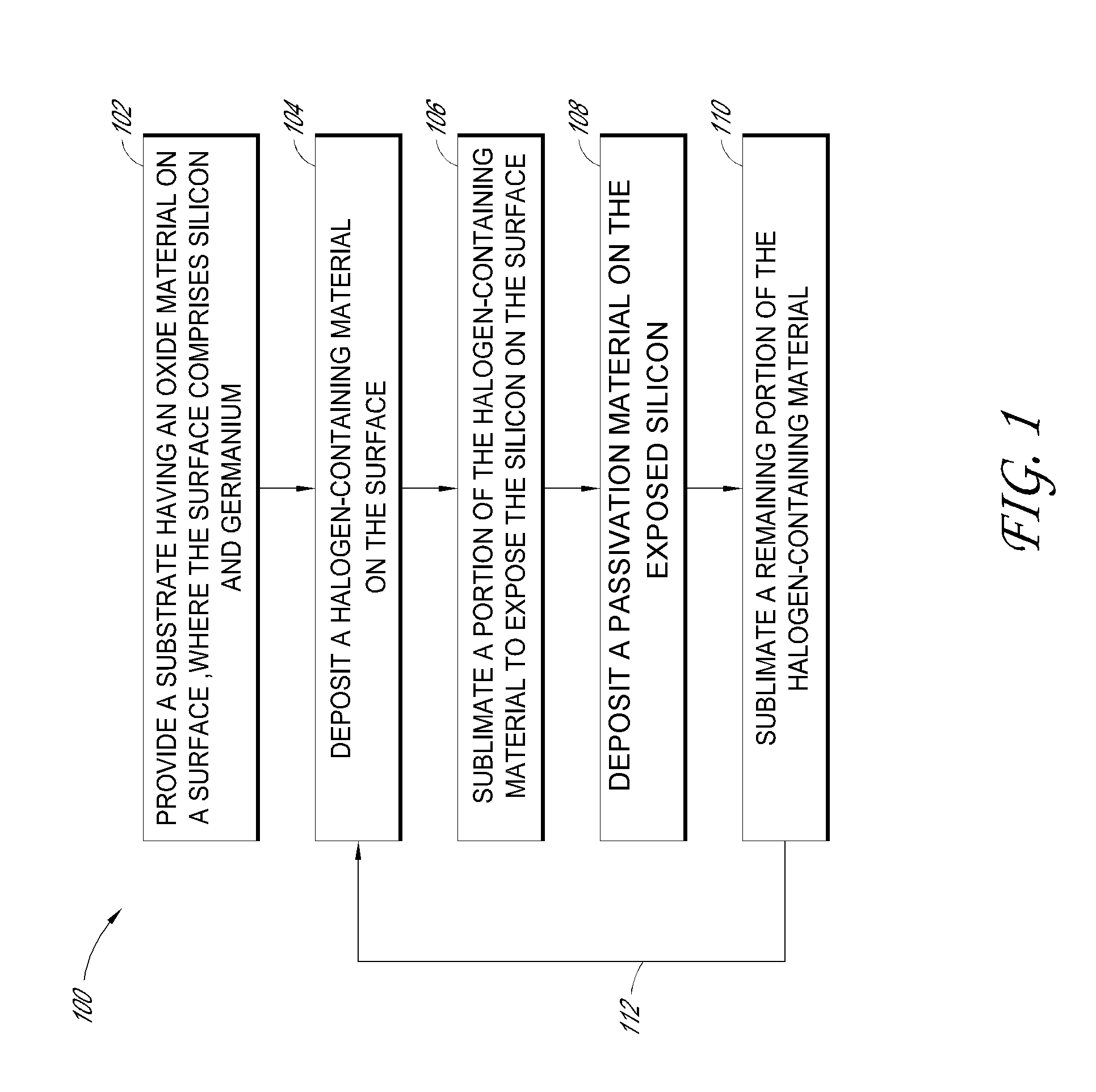

Germanium oxide pre-clean module and process

ActiveUS9474163B2Printed circuit liquid treatmentSemiconductor/solid-state device manufacturingChemical speciesHalogen

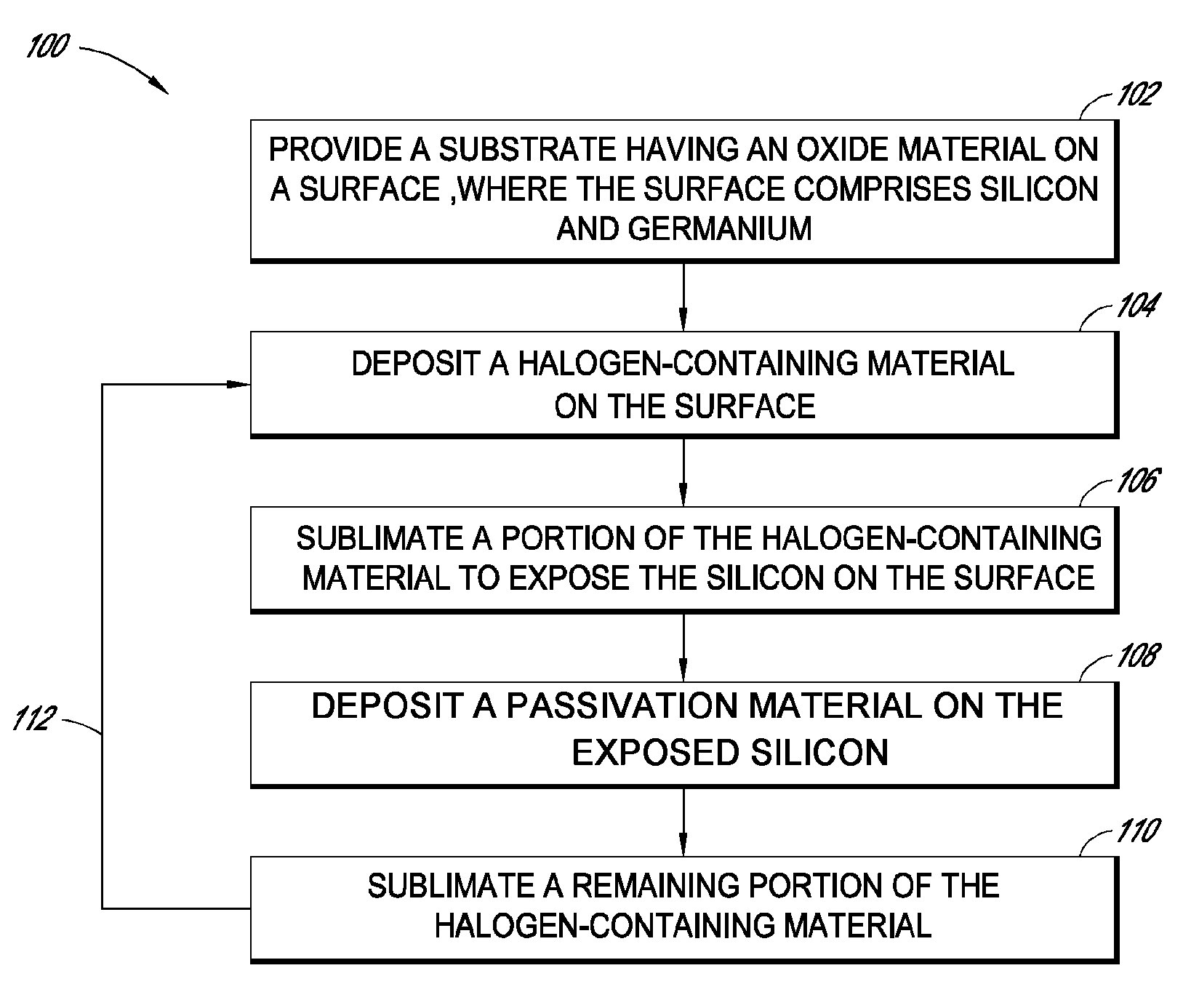

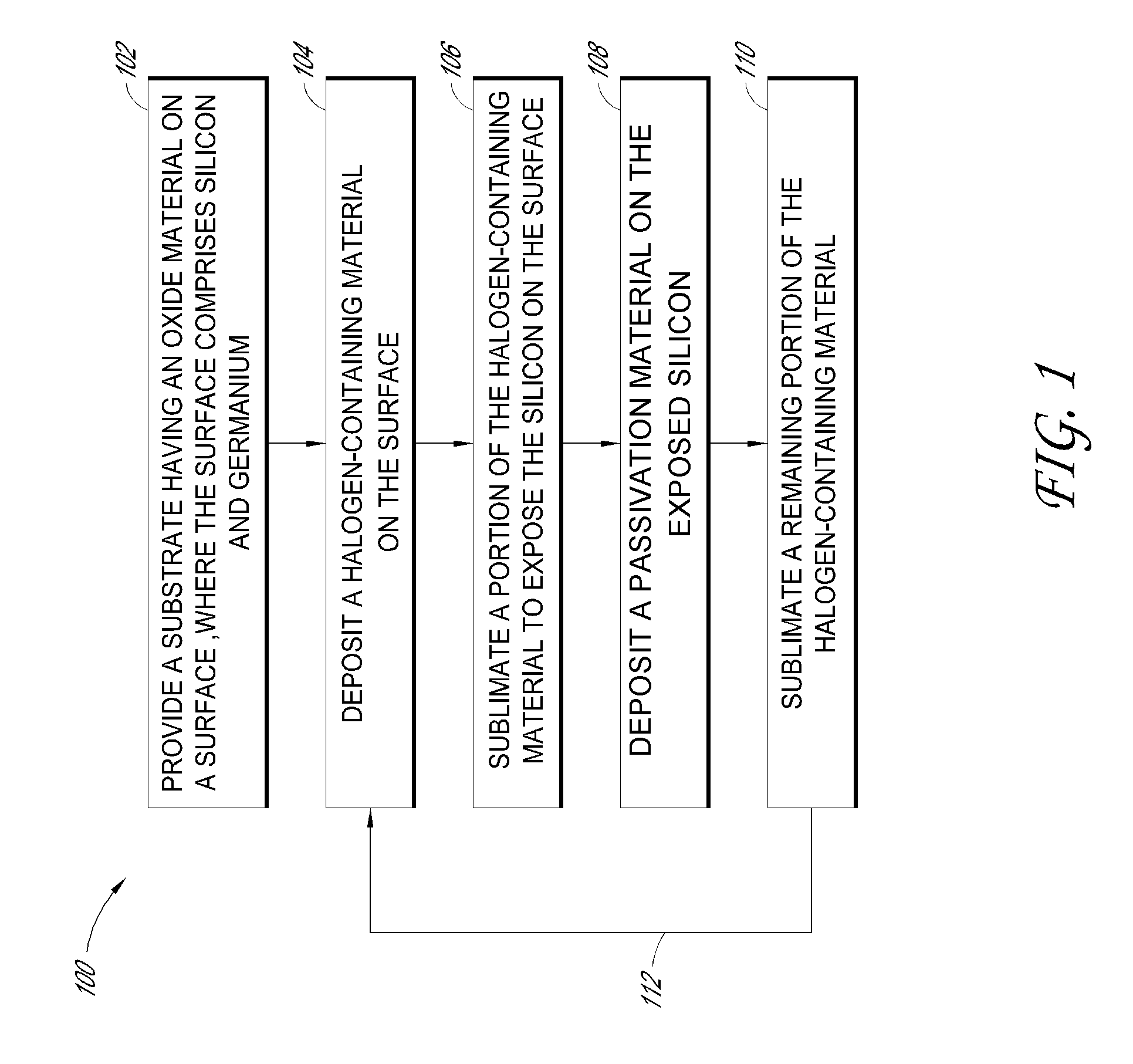

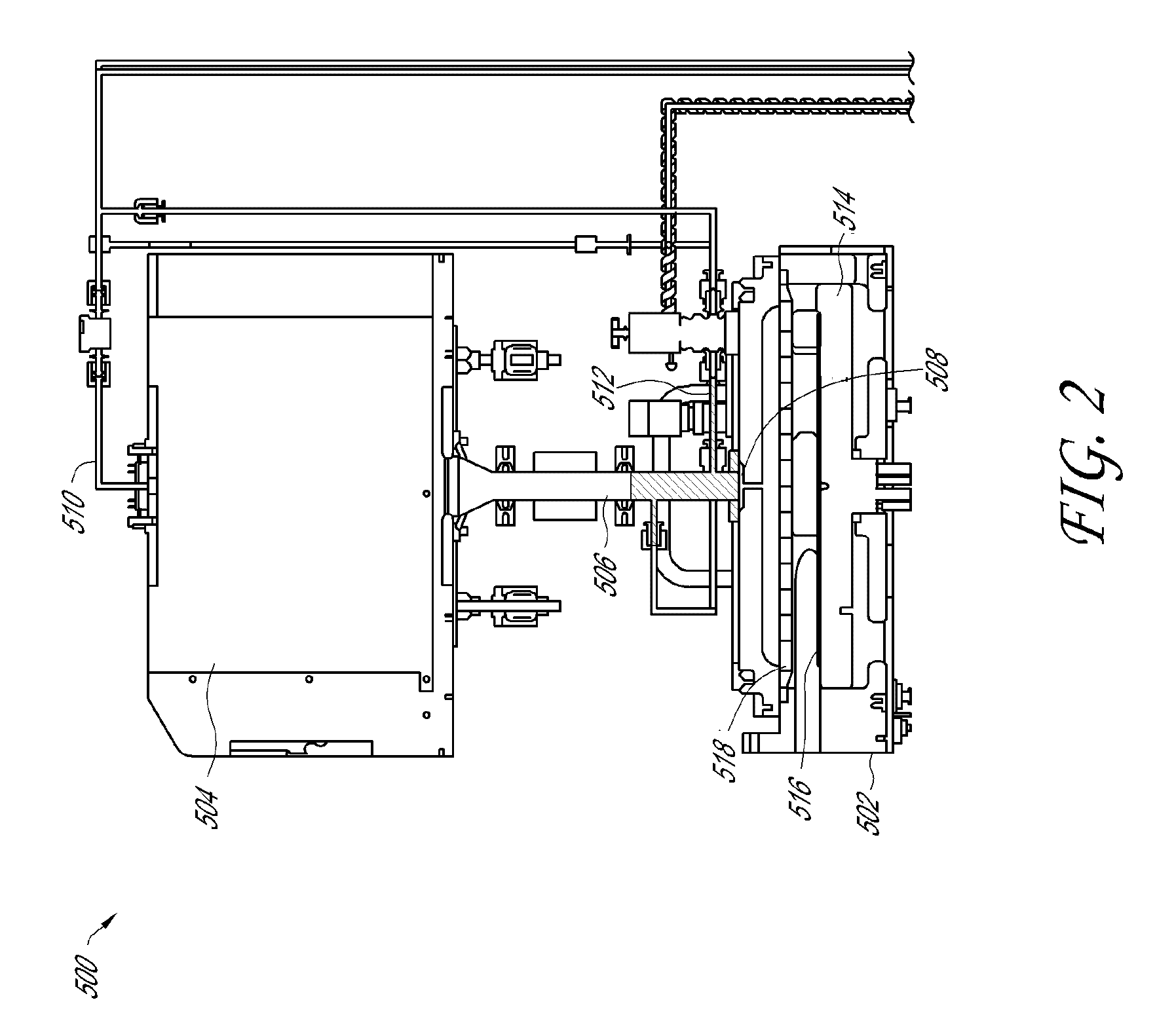

In some embodiments, a method for integrated circuit fabrication includes removing oxide material from a surface of a substrate, where the surface includes silicon and germanium. Removing the oxide material includes depositing a halogen-containing pre-clean material on a silicon oxide-containing surface and sublimating a portion of the halogen-containing pre-clean material to expose the silicon on the surface. A passivation film is deposited on the exposed silicon. The passivation film may include chlorine. The passivation film may prevent contamination of the silicon surface by chemical species from the later sublimation, which may be at a higher temperature than the earlier sublimation. Subsequently, a remaining portion of the halogen-containing pre-clean material and the passivation film are sublimated. A target material, such as a conductive material, may subsequently be deposited on the substrate surface.

Owner:ASM IP HLDG BV

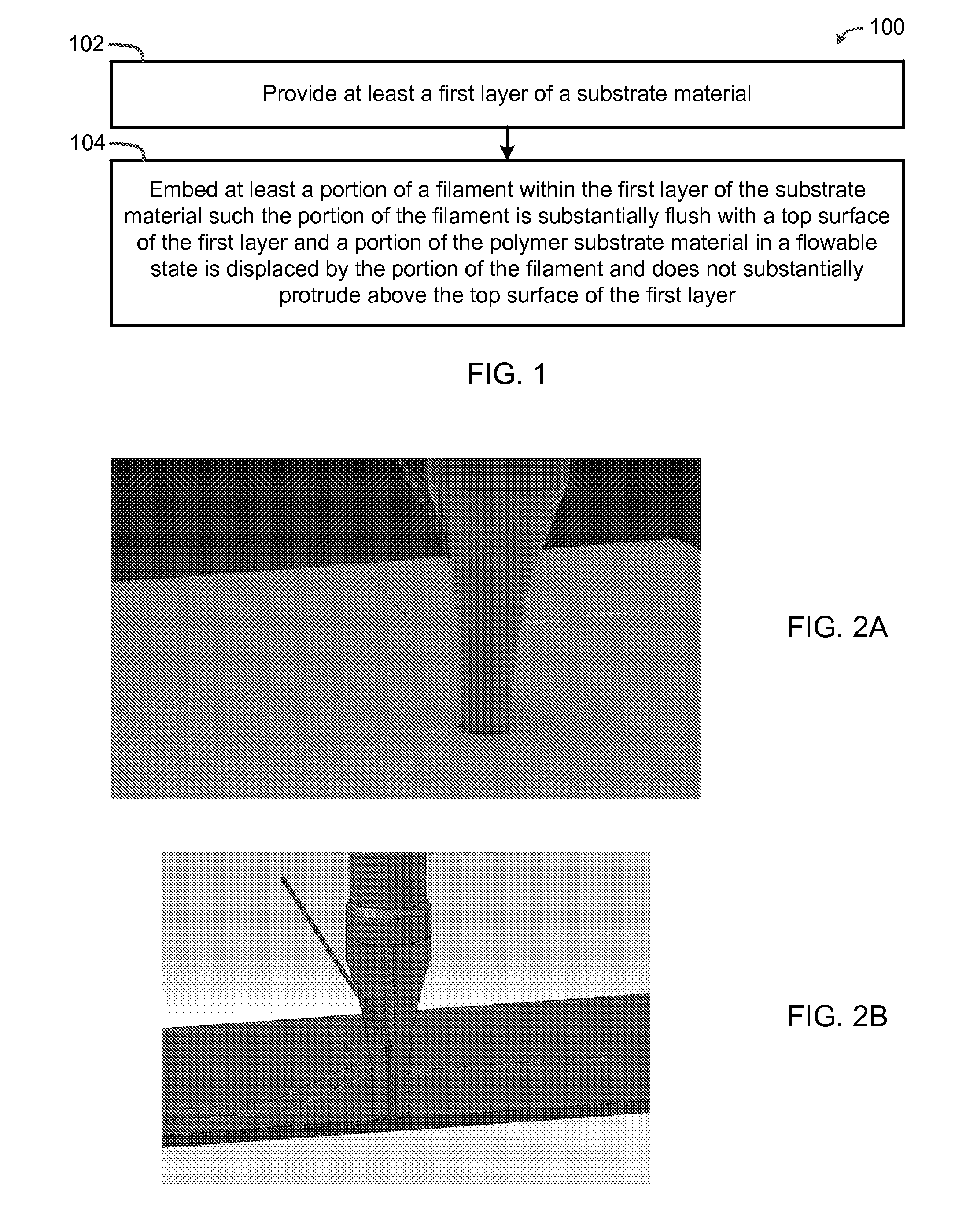

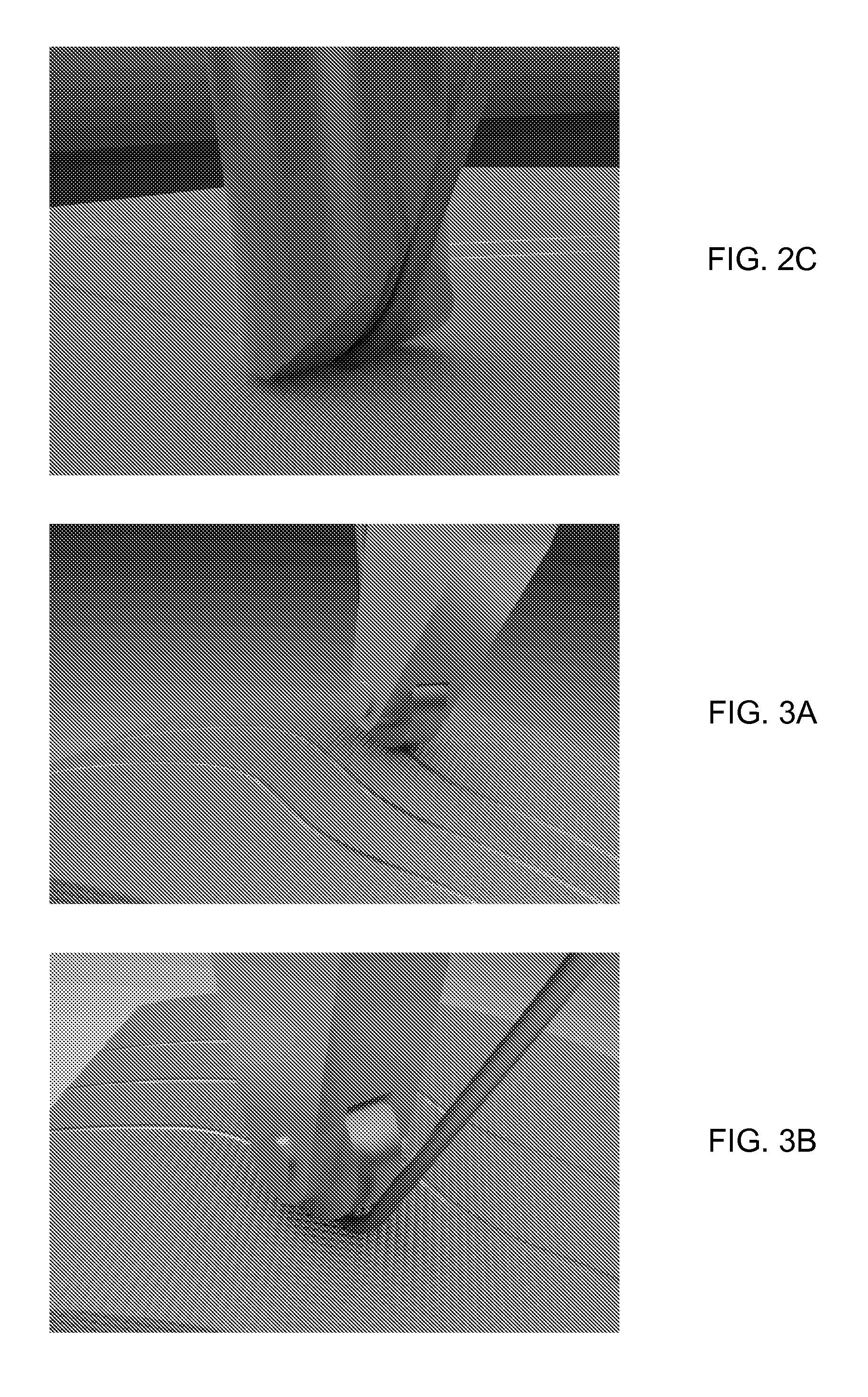

Methods and Systems For Connecting Inter-Layer Conductors and Components in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

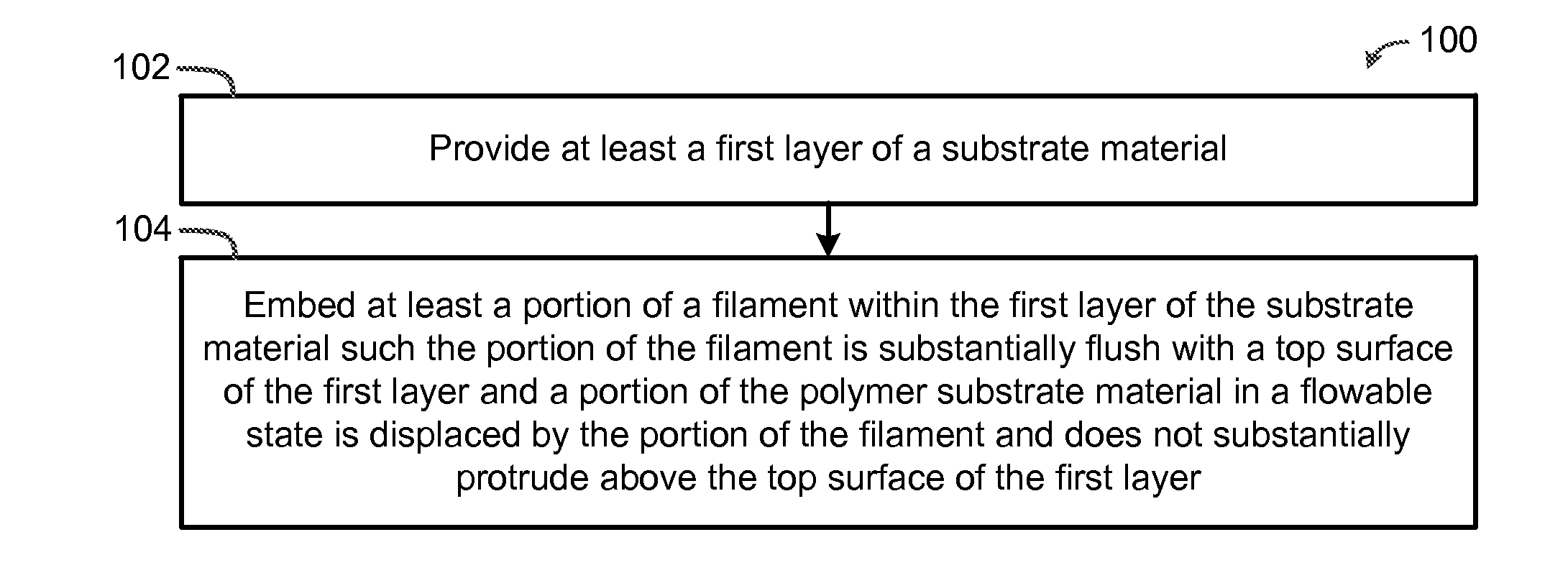

ActiveUS20140268607A1High mechanical strengthPrinted circuit assemblingLine/current collector detailsElectrical conductorElectrical connection

The present invention provides systems and methods for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

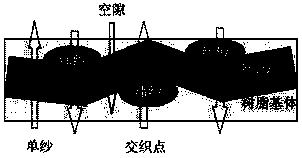

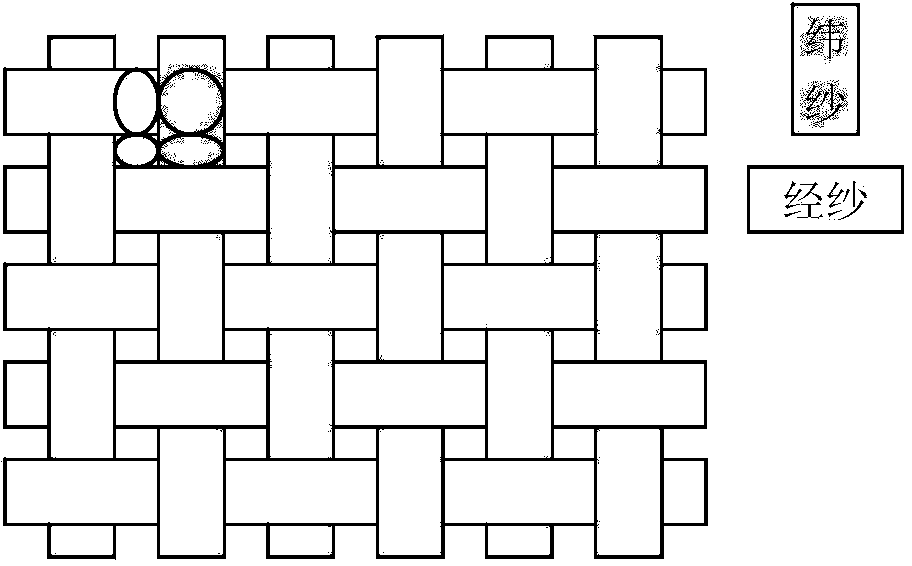

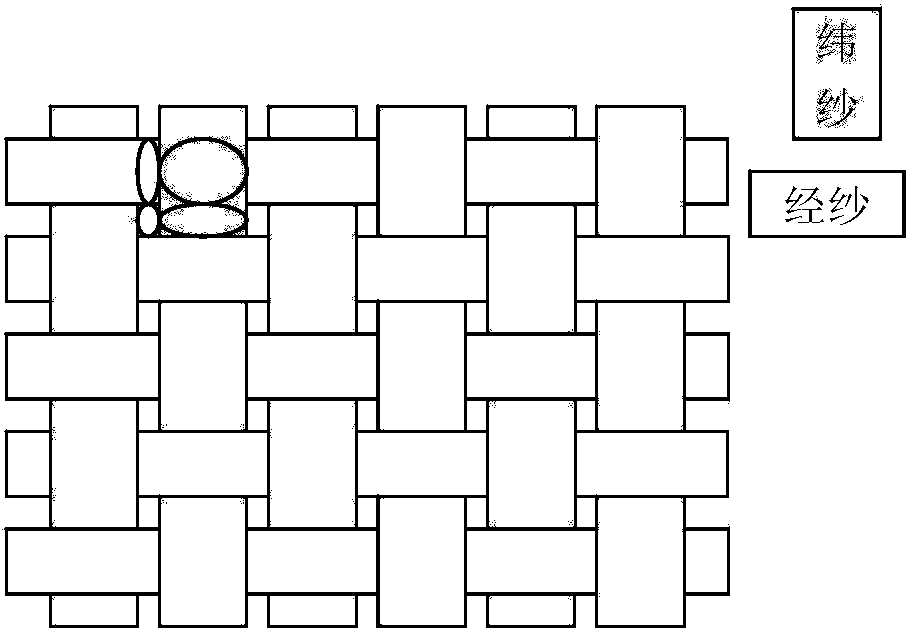

Circuit substrate and preparation method thereof

ActiveCN103755989ALow dielectric constantSolve the signal delay problemPrinted circuit liquid treatmentFilm/foil adhesivesGlass fiberSignal delay

The invention provides a preparation method of a bonding sheet forming a circuit substrate. The method comprises a step of pretreating a glass fabric by use of a pretreatment glue solution of which the dielectric constant (Dk) is the same with or close to the Dk value of the adopted glass fabric. The invention also provides a bonding sheet and a circuit substrate prepared by the method. The preparation method of the circuit substrate provided by the invention does not need equipment transformation and adjustment, the cost is relatively low, the difference of the dielectric constant of the prepared circuit substrate in the longitudinal direction and latitudinal direction is less, and the problem of signal delay can be effectively solved.

Owner:GUANGDONG SHENGYI SCI TECH

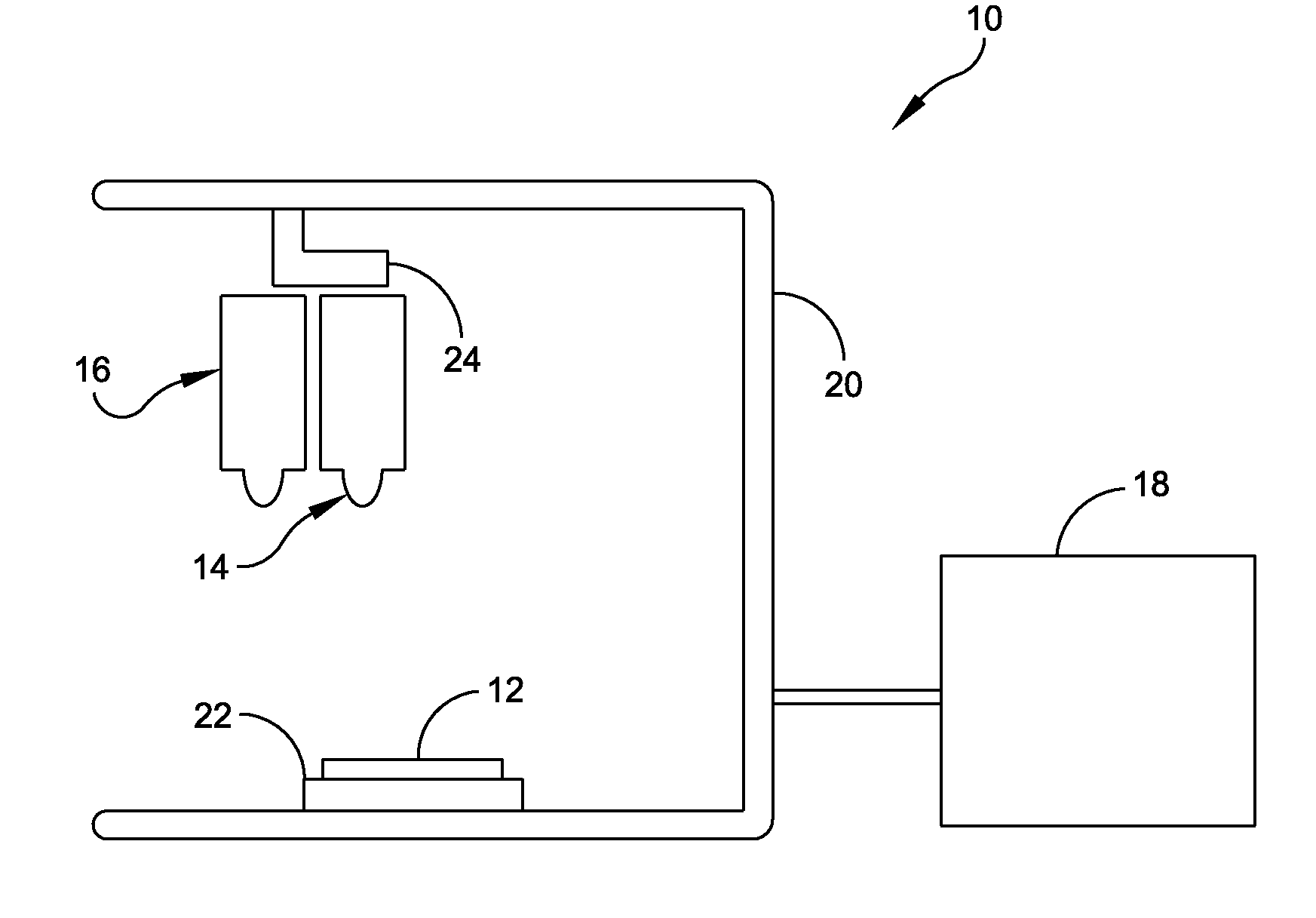

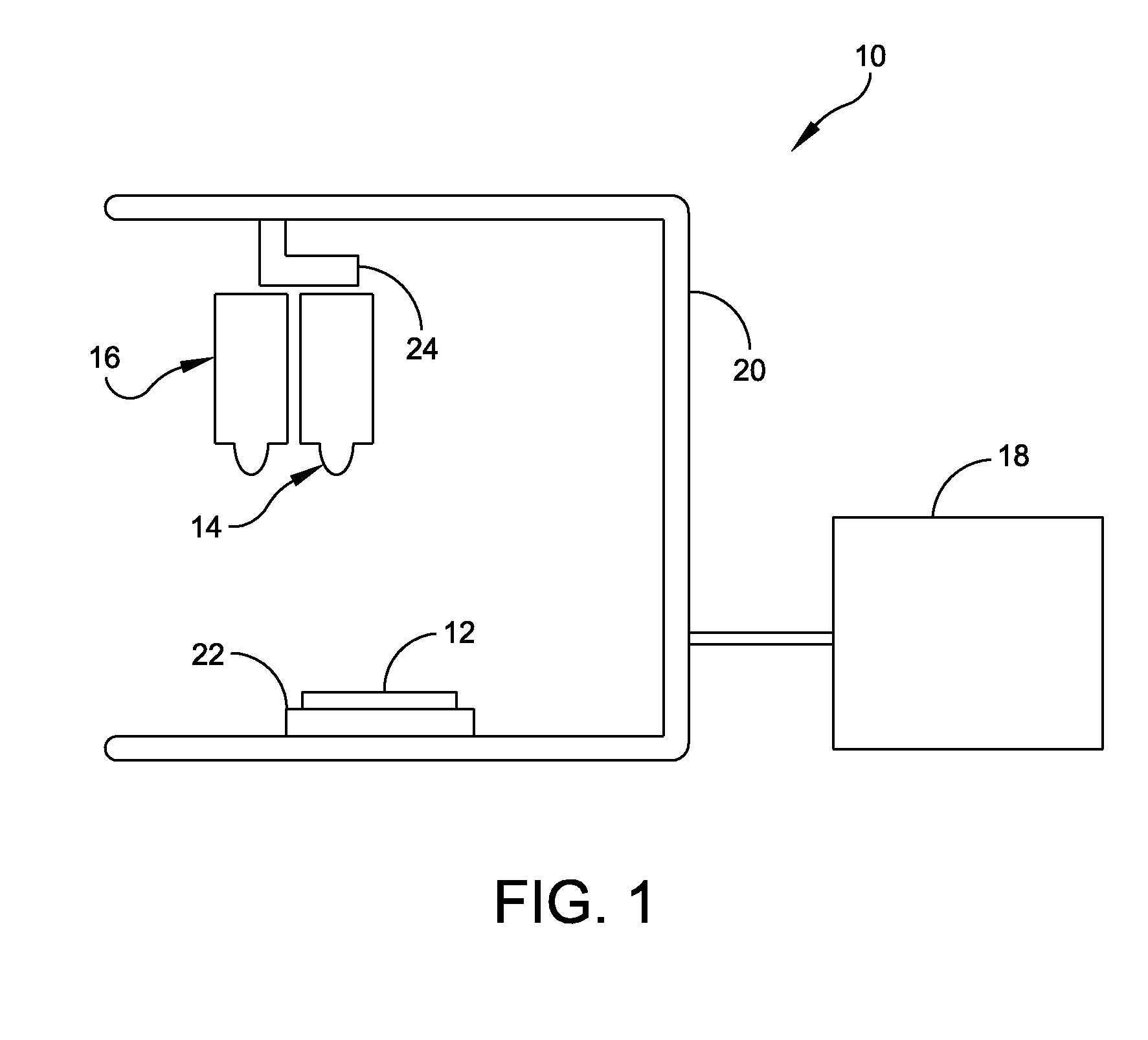

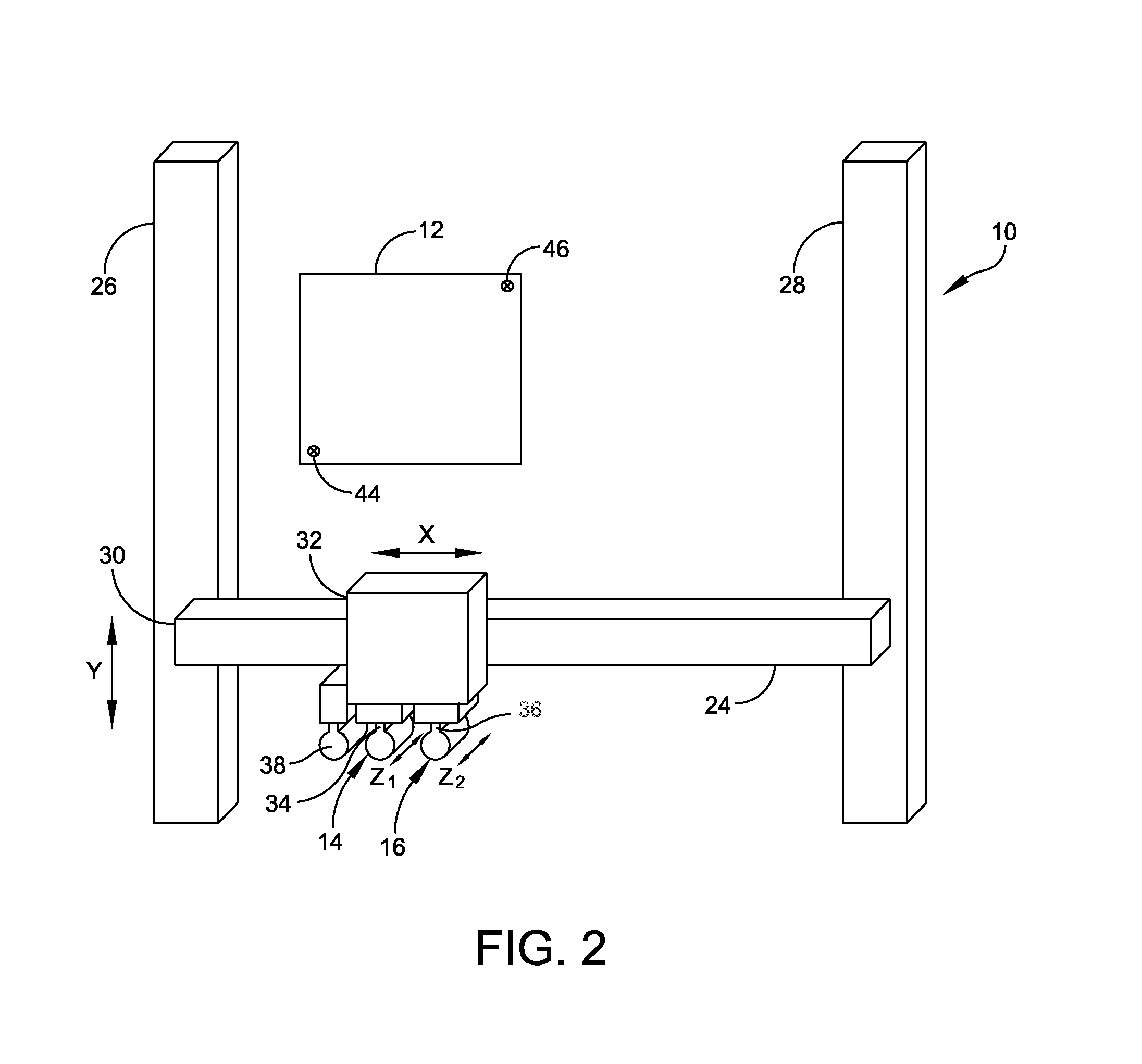

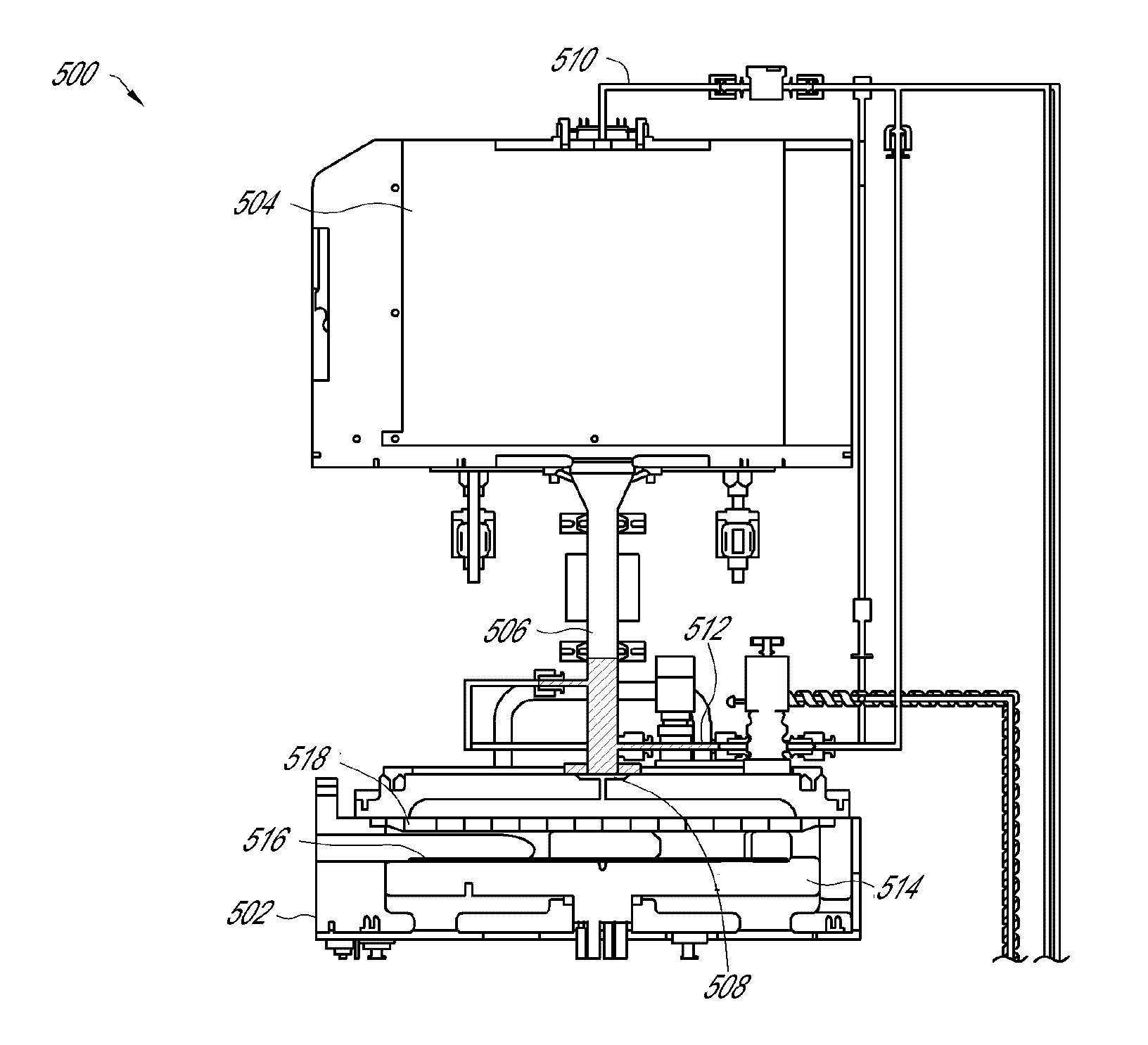

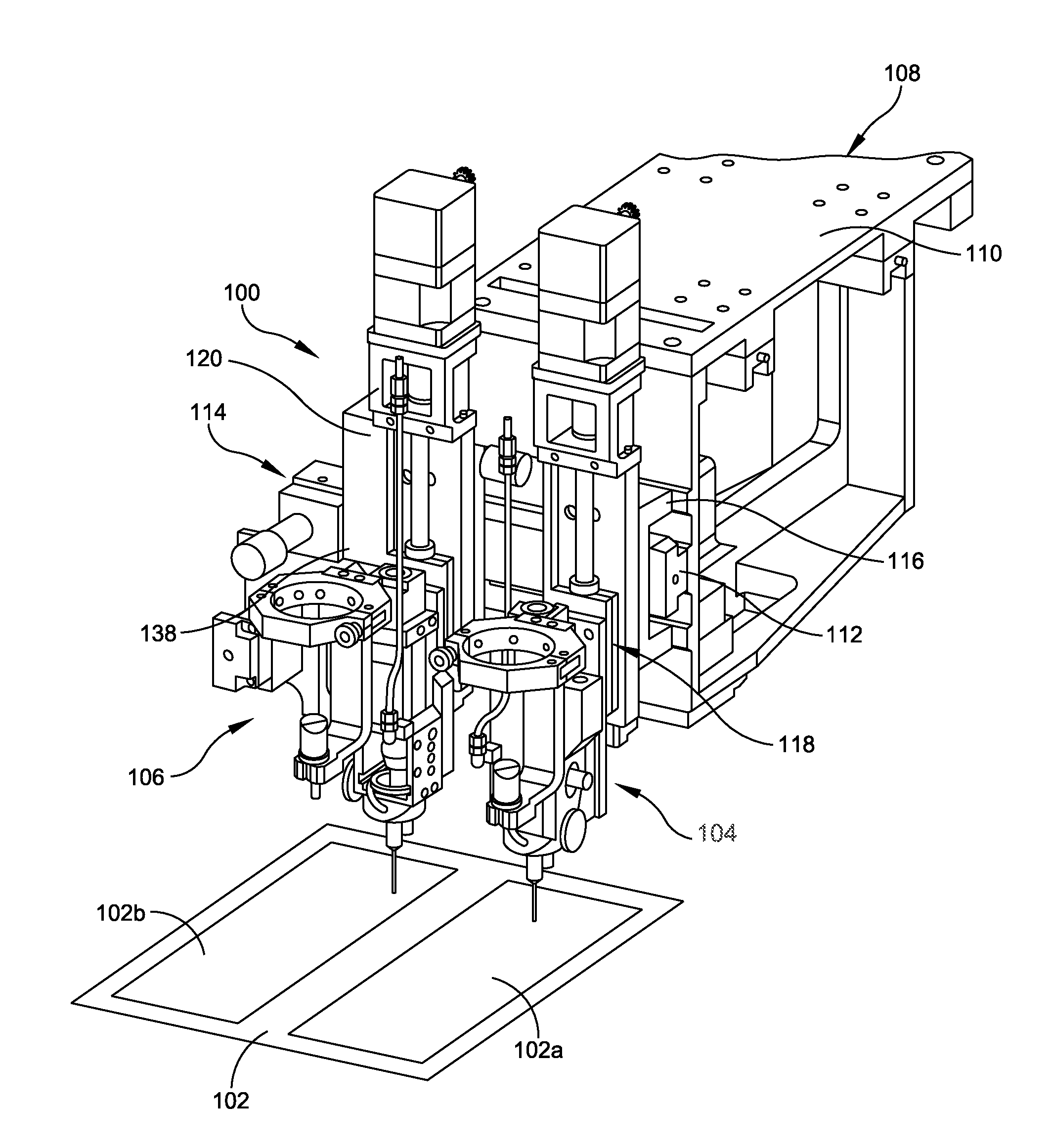

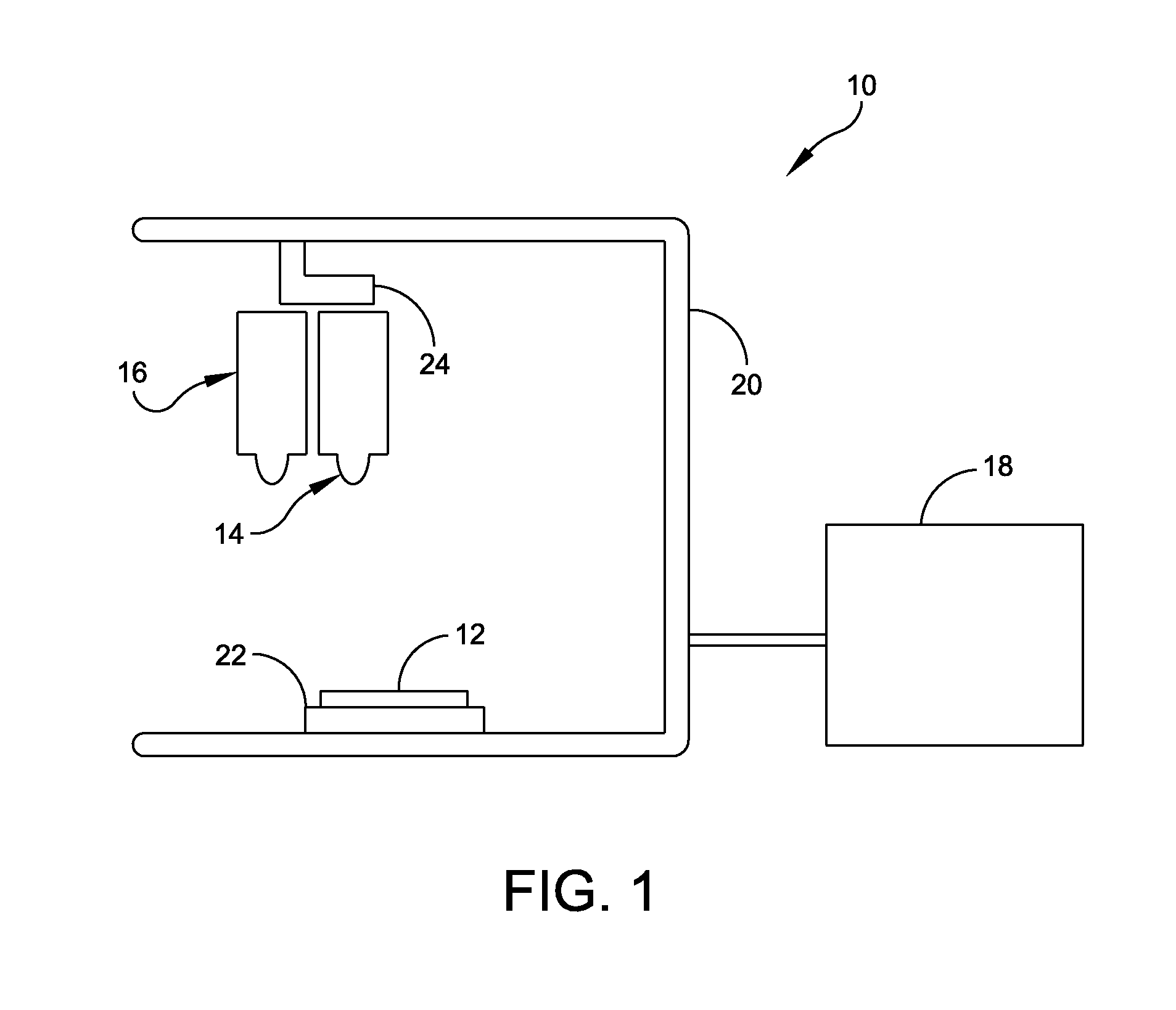

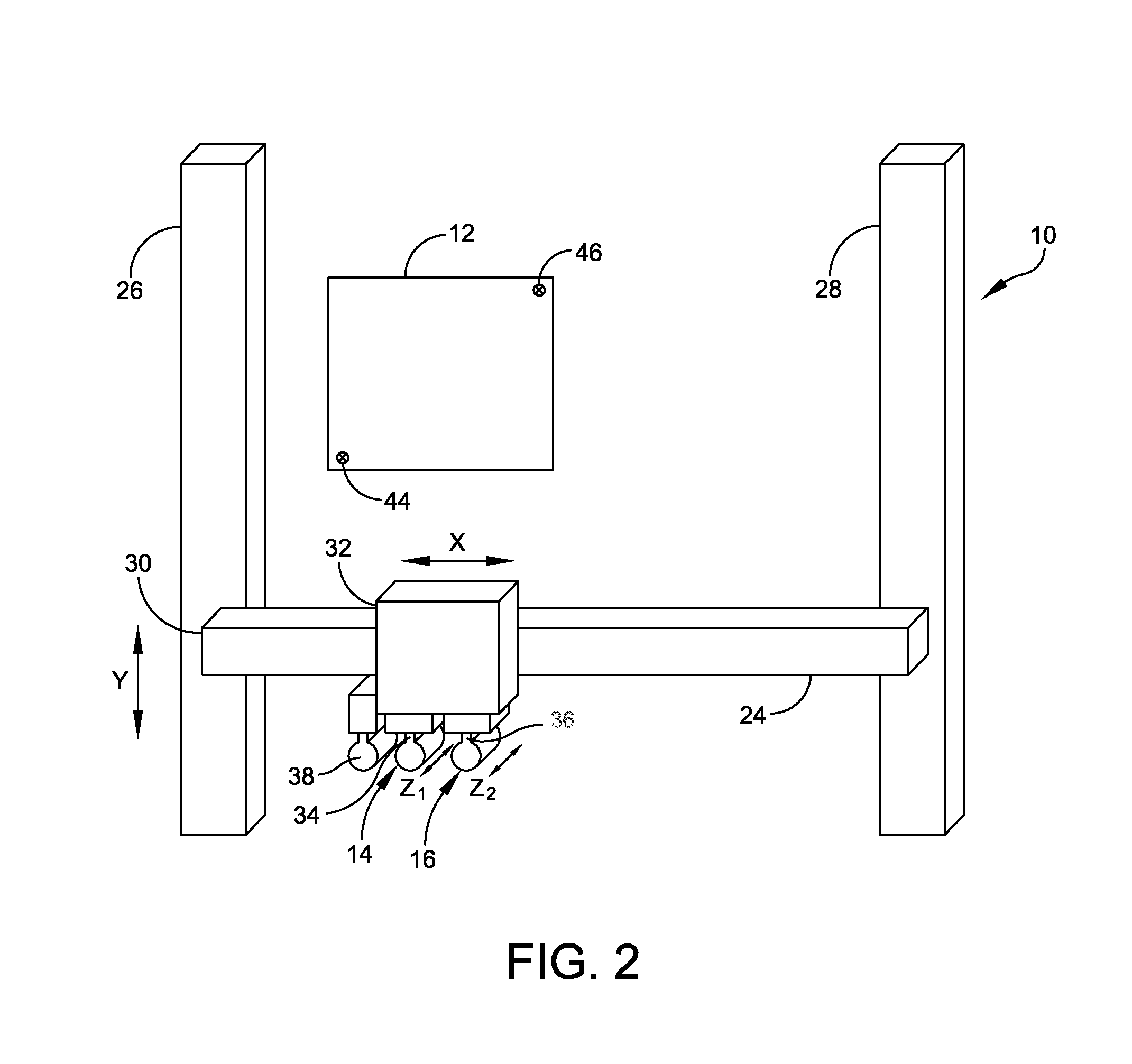

Method and apparatus for automatically adjusting dispensing units of a dispenser

ActiveUS20150093498A1Printed circuit assemblingPrinted circuit liquid treatmentEngineeringMechanical engineering

Owner:ILLINOIS TOOL WORKS INC

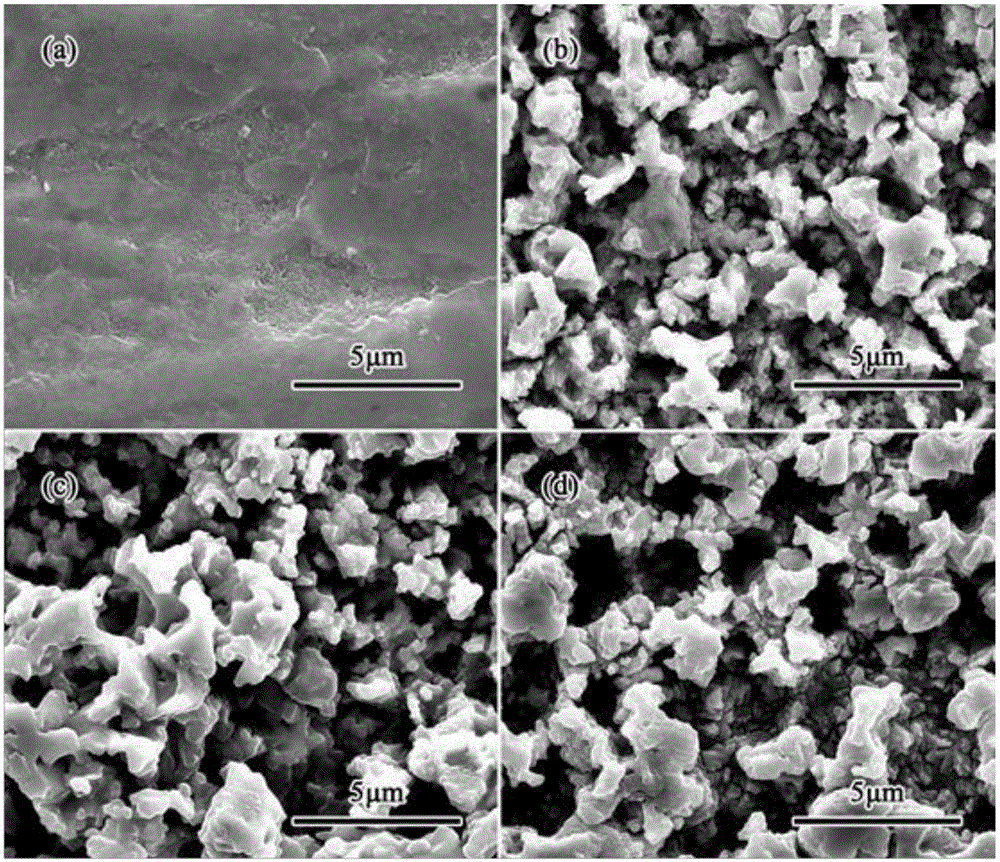

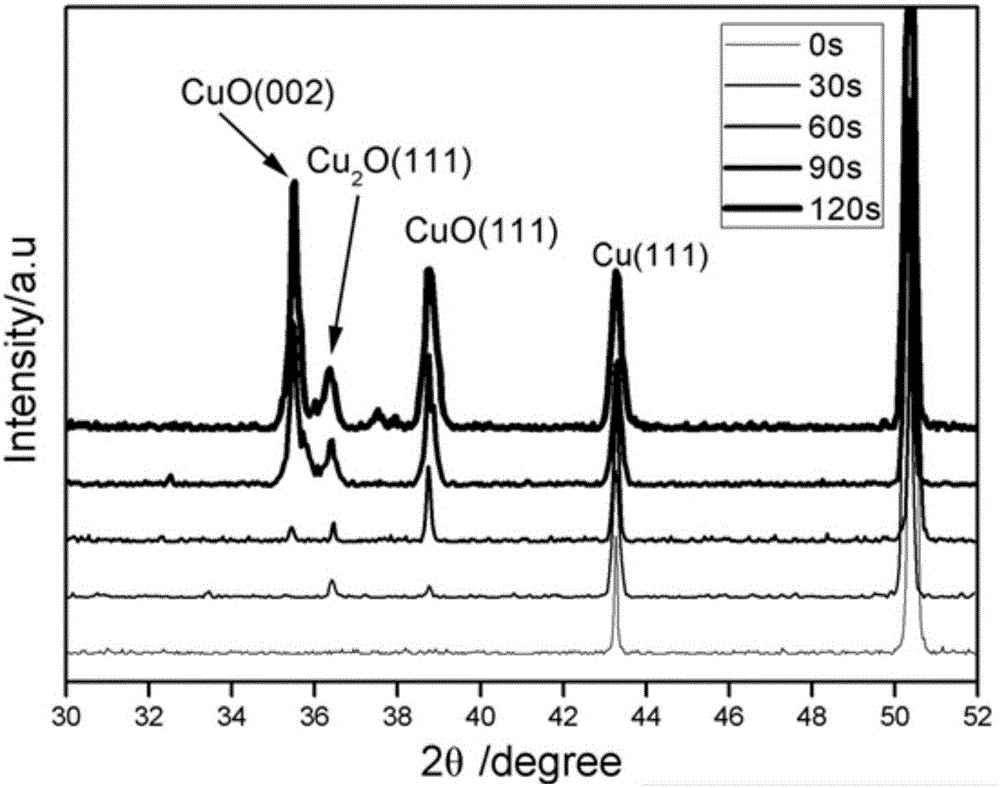

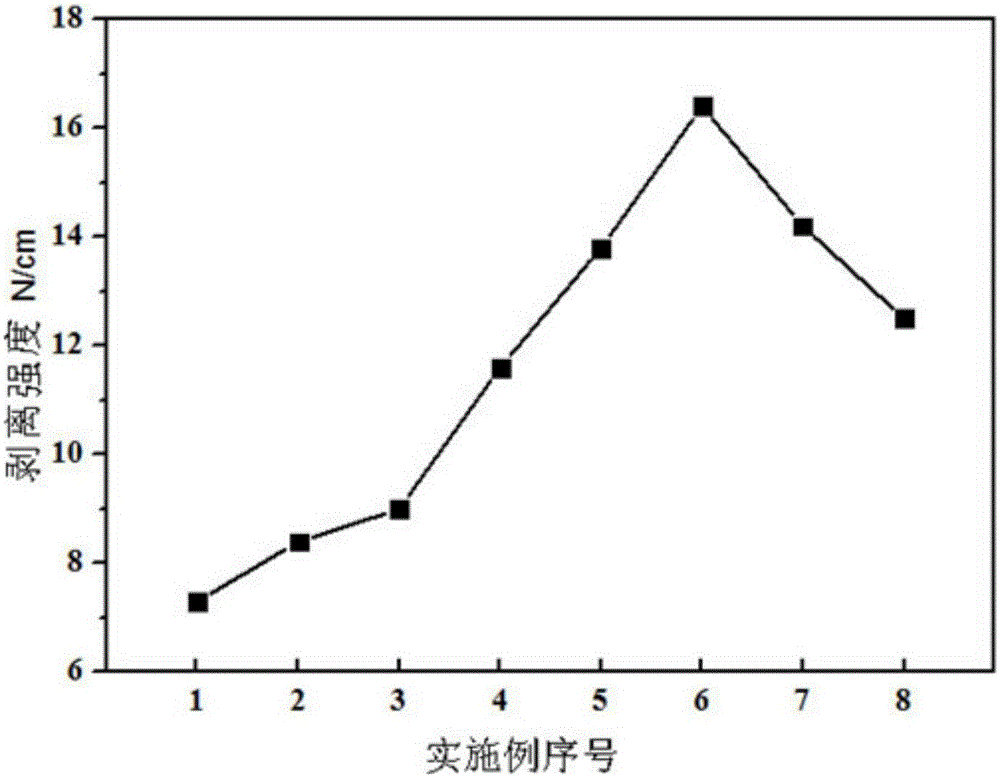

Copper surface roughening treatment solution and treatment method thereof

ActiveCN105050324ALarge specific surface areaImprove bindingPrinted circuit liquid treatmentSilanesPhysical chemistry

The invention discloses a copper surface roughening treatment solution, which comprises the following components: 98wt% of H2SO4 50 to 150g / L, volume concentration 30% of H2O2 40 to 60ml / L, a silane coupling agent 0.5 to 5g / L, dissolvable zinc salt 8 to 12g / L, a stabilizer 50 to 150g / L, a corrosion inhibitor composition 0.5 to 7.5g / L, and deionized water residual. Through treatment of the copper surface roughening treatment solution, a layer of dense and uniform honeycomb structure is formed on the copper surface, the structure can increase the specific surface area combined with semi-curing resin, and during a laminating process, a crosslinking reaction for resin curing is involved, a chemical bond is formed, and the binding force with the semi-curing resin is further enhanced.

Owner:GUANGDONG GUANGHUA SCI TECH

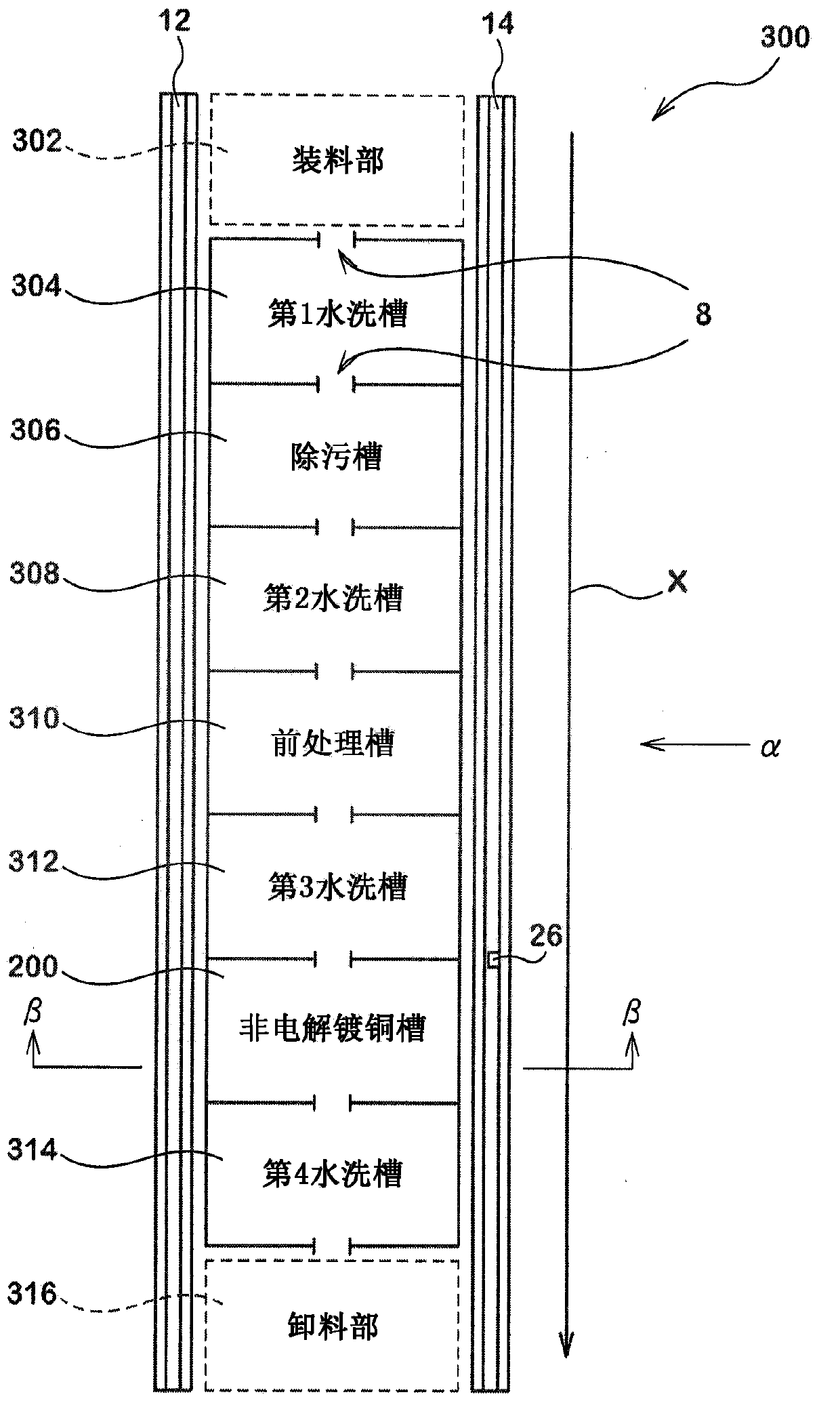

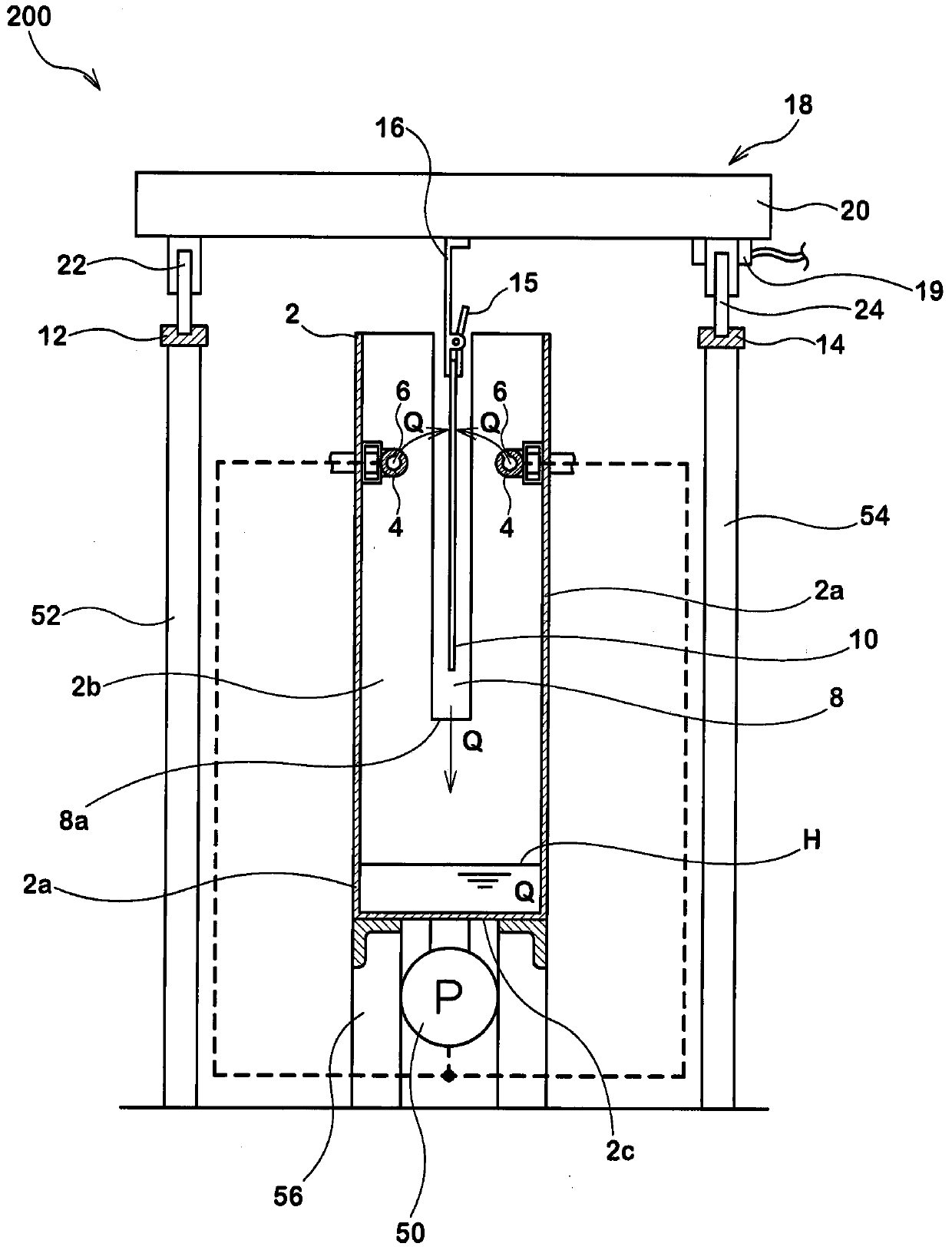

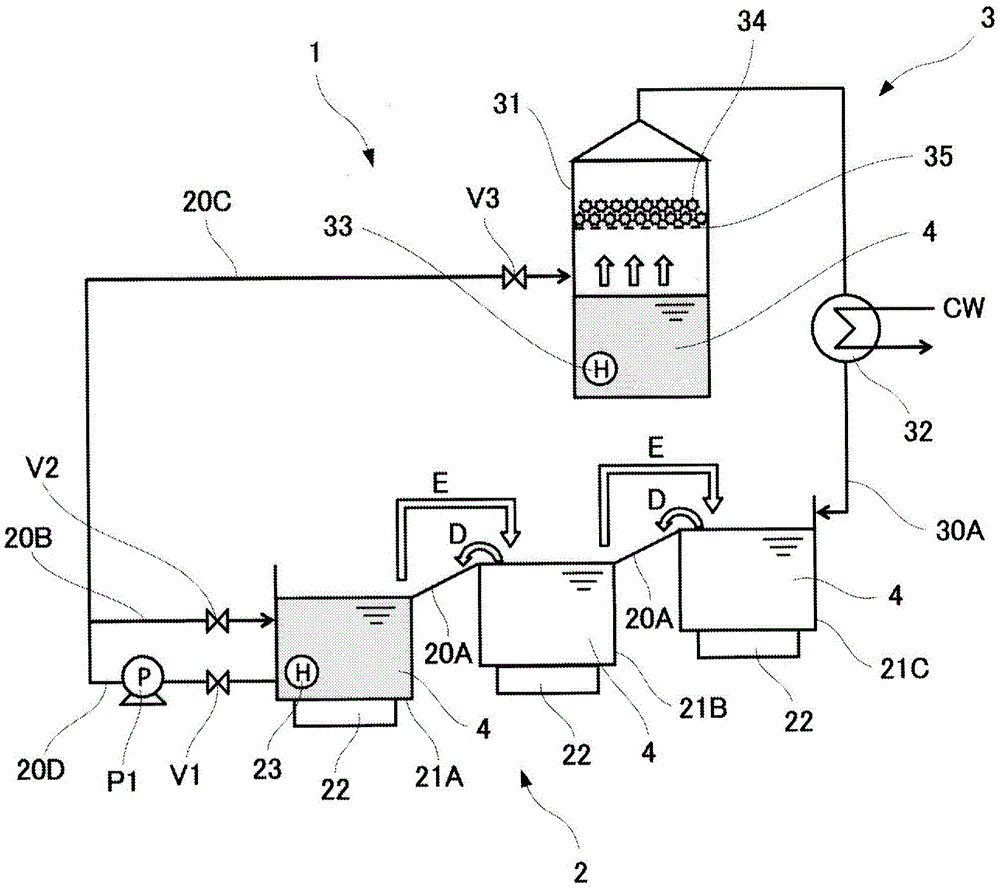

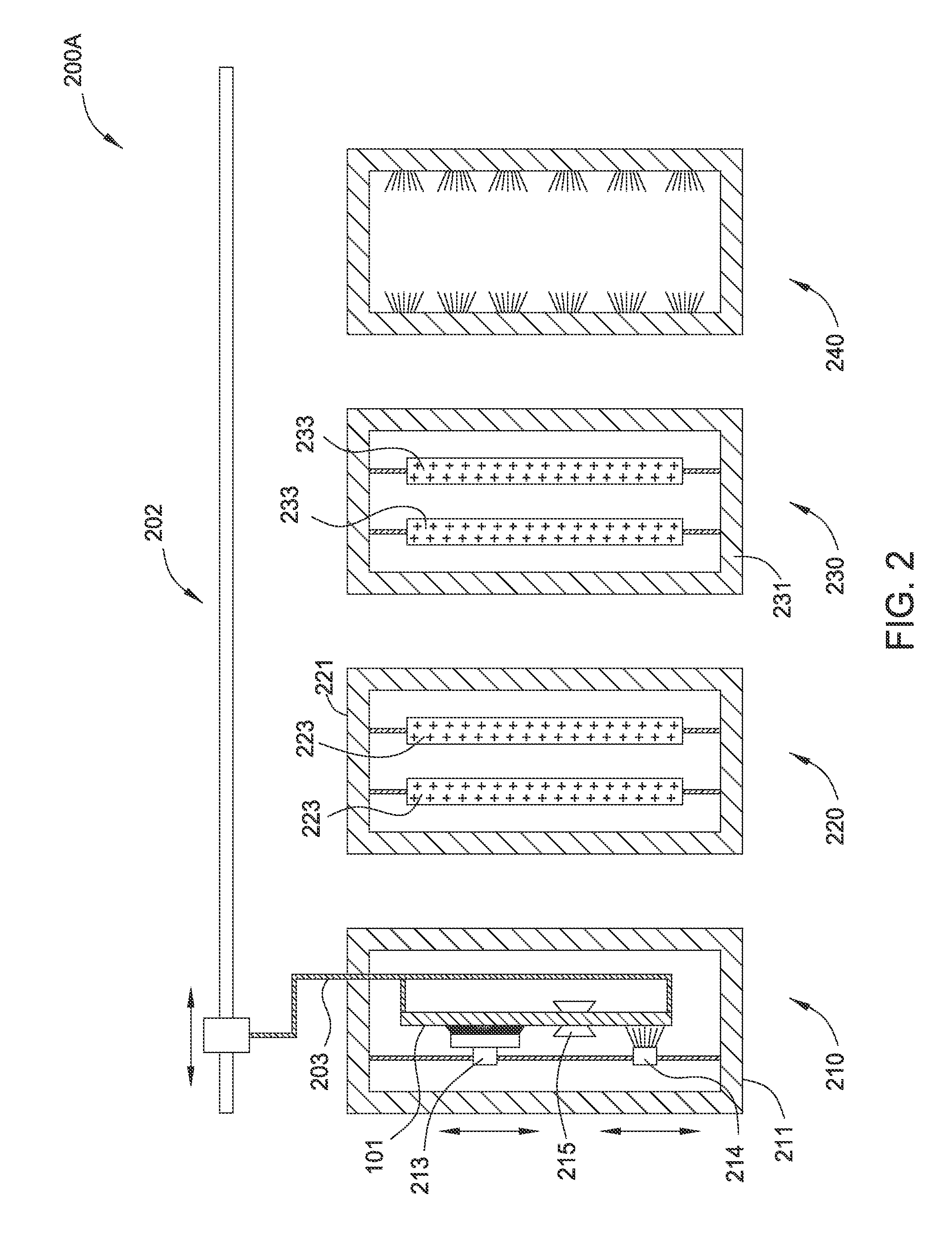

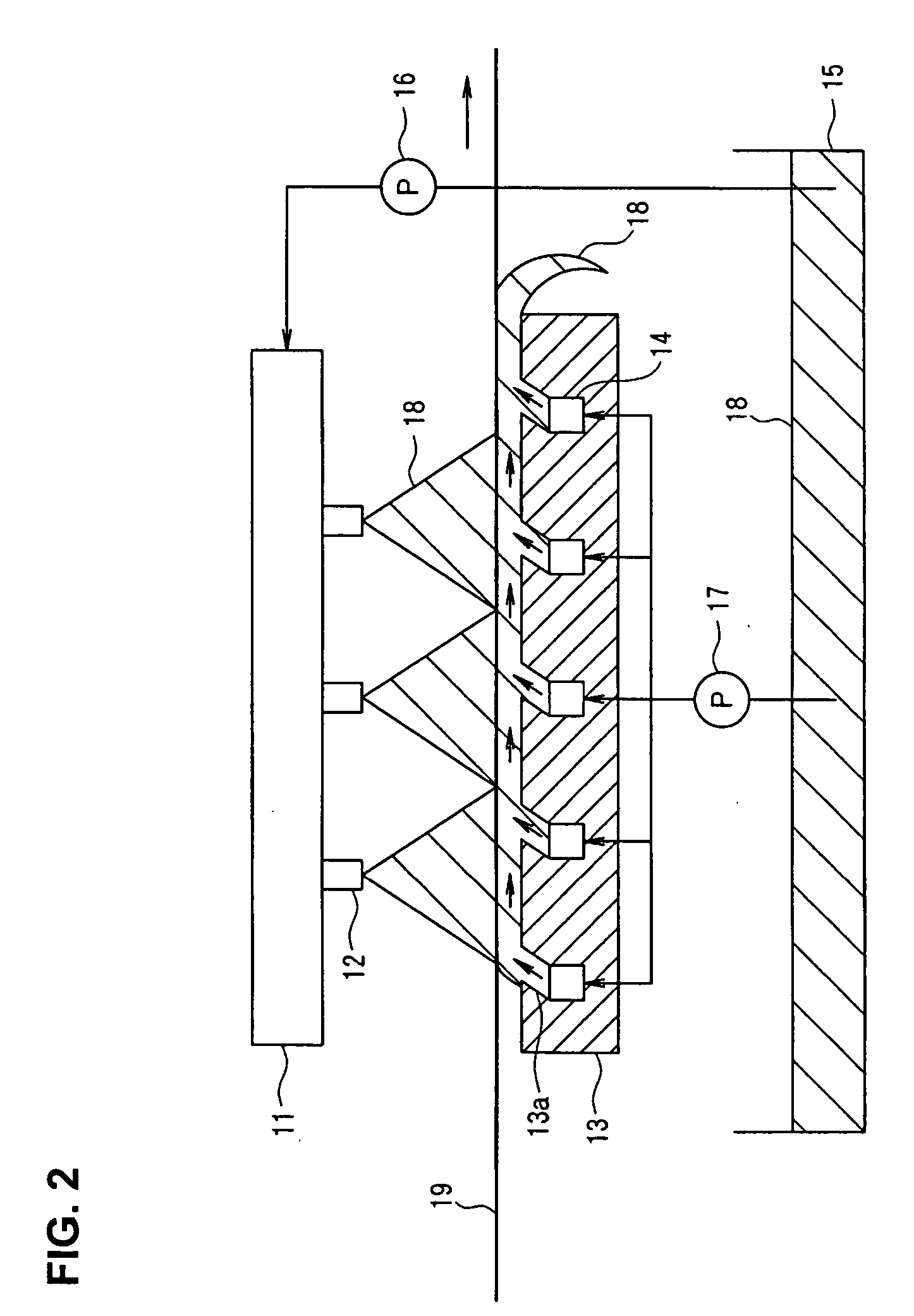

Surface treating apparatus, tank body and squirting device

ActiveCN103789816AEasy maintenancePrinted circuit liquid treatmentTanksCopper platingElectroless plating

The invention provides a surface treating apparatus, a tank body and a squirting device. To perform surface treatment such as electroless plating in a high quality on a workpiece which is held vertically, a liquid squirting part (4) which has a squirt port (6) is arranged inside of each tank such as an electroless copper plating tank (200); and a processing solution (Q) is squirted from the squirt port (6) of the liquid squirting part (4) toward a plate-like workpiece (10) obliquely upward to a horizontal plane, so that the processing solution (Q) is attached to the upper side of the plate-like workpiece (10) which is clamped by a transport hanger (16) inside of the tank body (2); and the processing solution (Q) is attached to the surface of the plate-like workpiece (10) while the processing solution (Q) is running down the plate-like workpiece (10).

Owner:C UYEMURA & CO LTD

Germanium oxide pre-clean module and process

In some embodiments, a method for integrated circuit fabrication includes removing oxide material from a surface of a substrate, where the surface includes silicon and germanium. Removing the oxide material includes depositing a halogen-containing pre-clean material on a silicon oxide-containing surface and sublimating a portion of the halogen-containing pre-clean material to expose the silicon on the surface. A passivation film is deposited on the exposed silicon. The passivation film may include chlorine. The passivation film may prevent contamination of the silicon surface by chemical species from the later sublimation, which may be at a higher temperature than the earlier sublimation. Subsequently, a remaining portion of the halogen-containing pre-clean material and the passivation film are sublimated. A target material, such as a conductive material, may subsequently be deposited on the substrate surface.

Owner:ASM IP HLDG BV

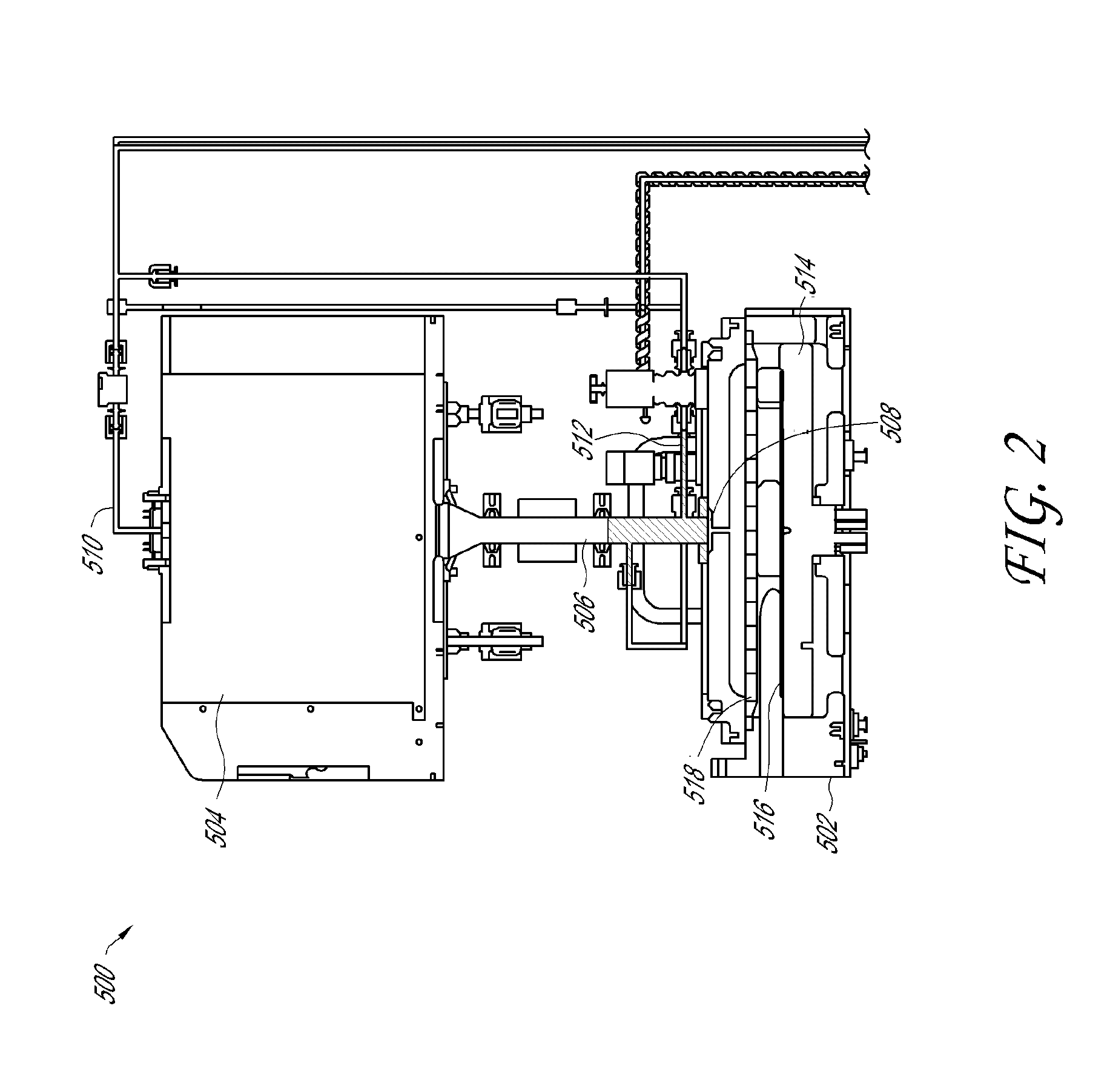

Method and apparatus for automatically adjusting dispensing units of a dispenser

ActiveUS9374905B2Printed circuit assemblingLiquid surface applicatorsMechanical engineeringEngineering

Owner:ILLINOIS TOOL WORKS INC

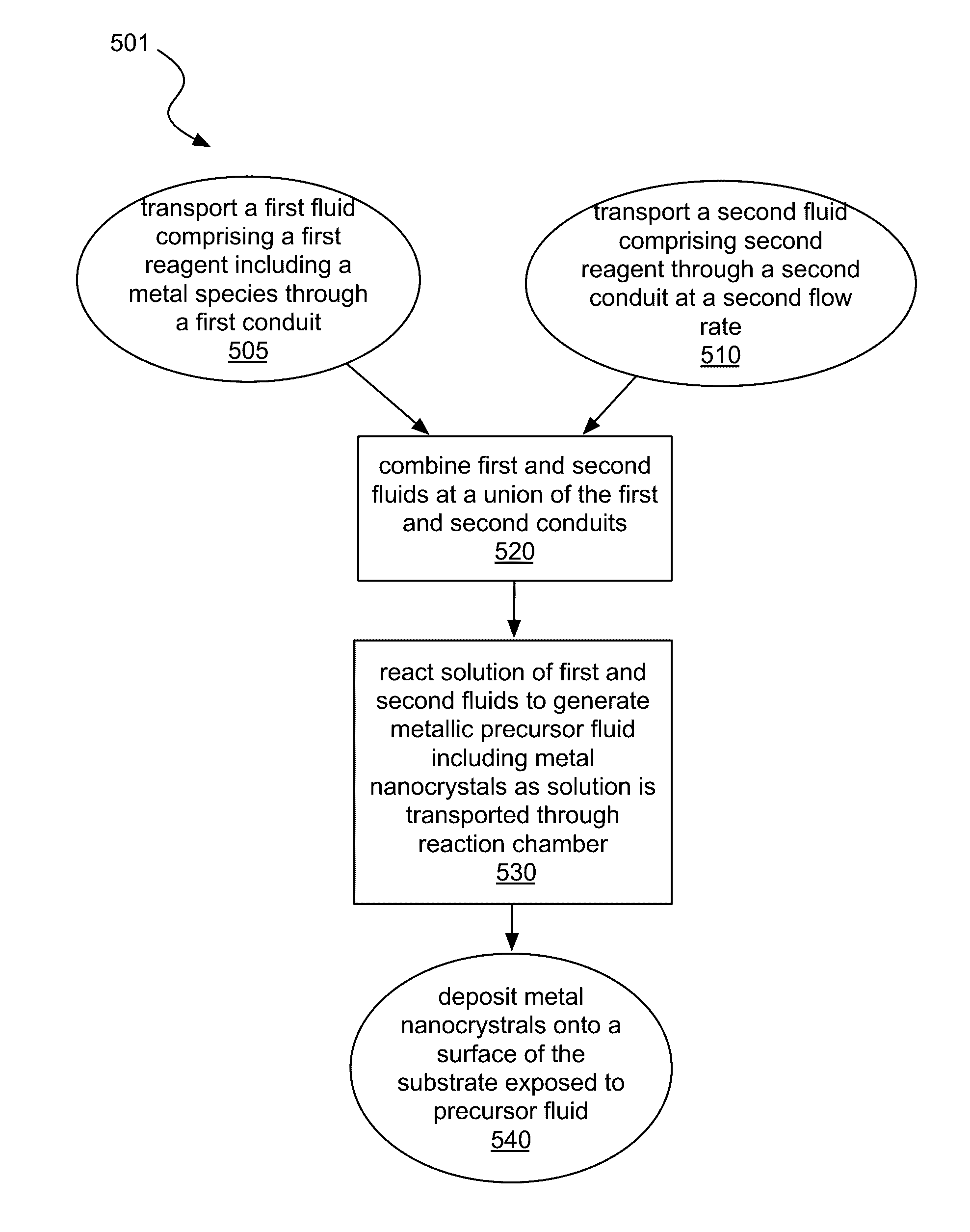

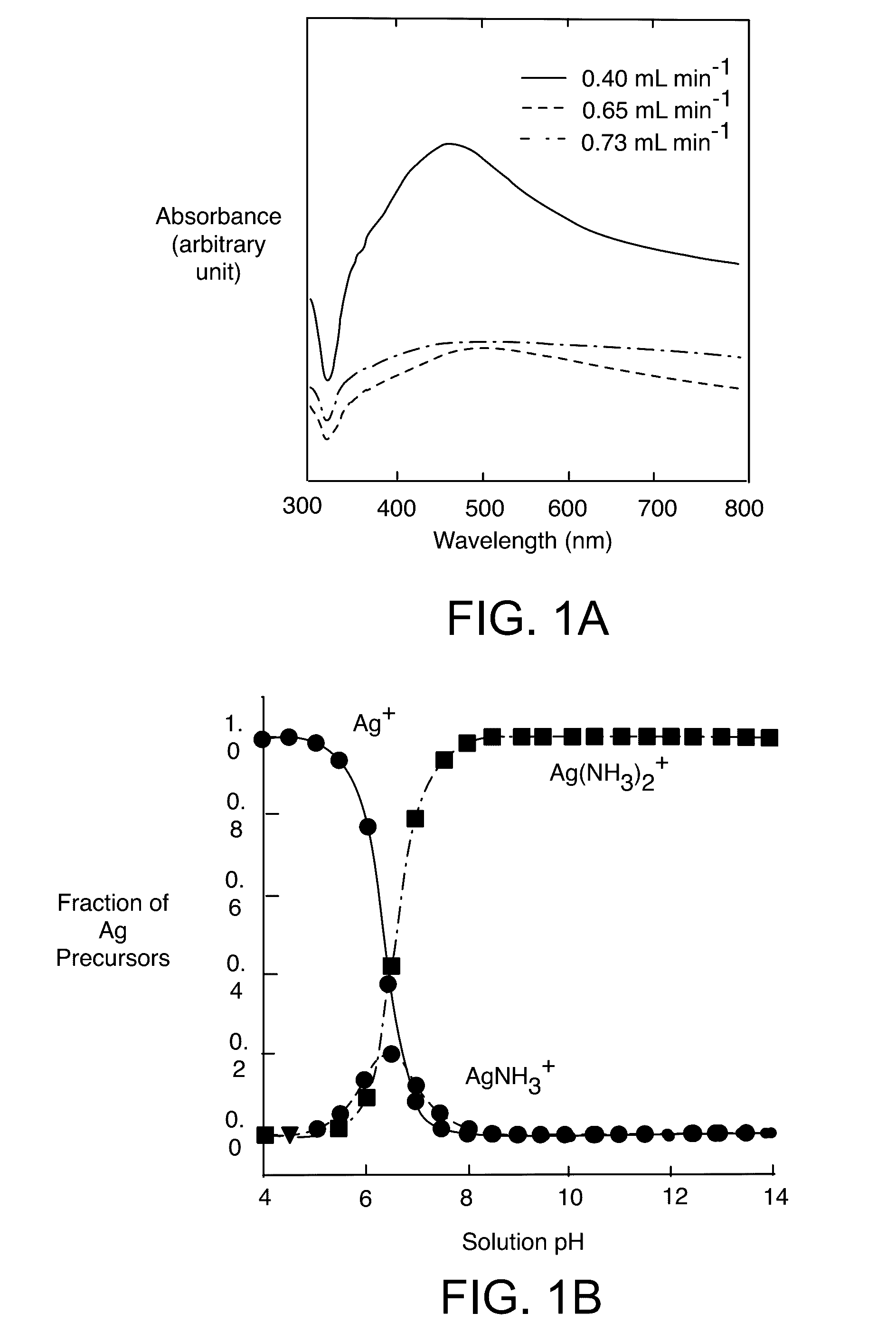

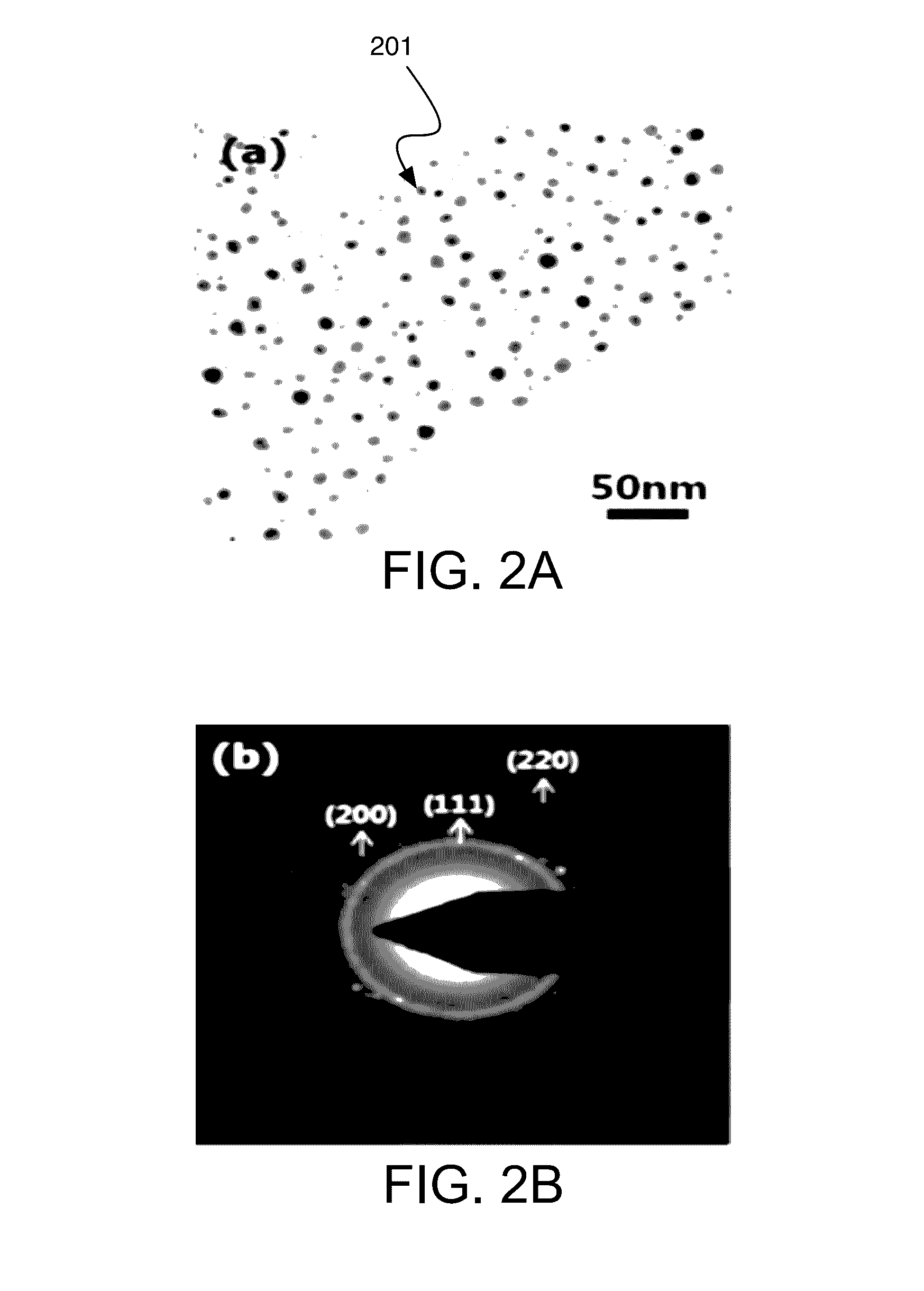

Microreactor-assisted printing of conductive traces with in-situ reactive inks

ActiveUS20160302305A1Printed circuit liquid treatmentPrinted circuit aspectsMicroreactorPolymer substrate

Highly conductive silver may be fabricated at room temperature using in-situ reactive silver precursor inks by microreactor-assisted printing without any post-processing. Reactive silver nanoinks, synthesized in-situ from the microreactor, may be directly delivered onto glass and polymeric substrates without any surface treatment to form a highly dense and uniform silver feature. The distribution of the reactive silver nanoinks can be controlled by adjusting the flow rate of the continuous flow. Silver lines may be fabricated using the in-situ reactive precursors delivered via a micro-channel applicator.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

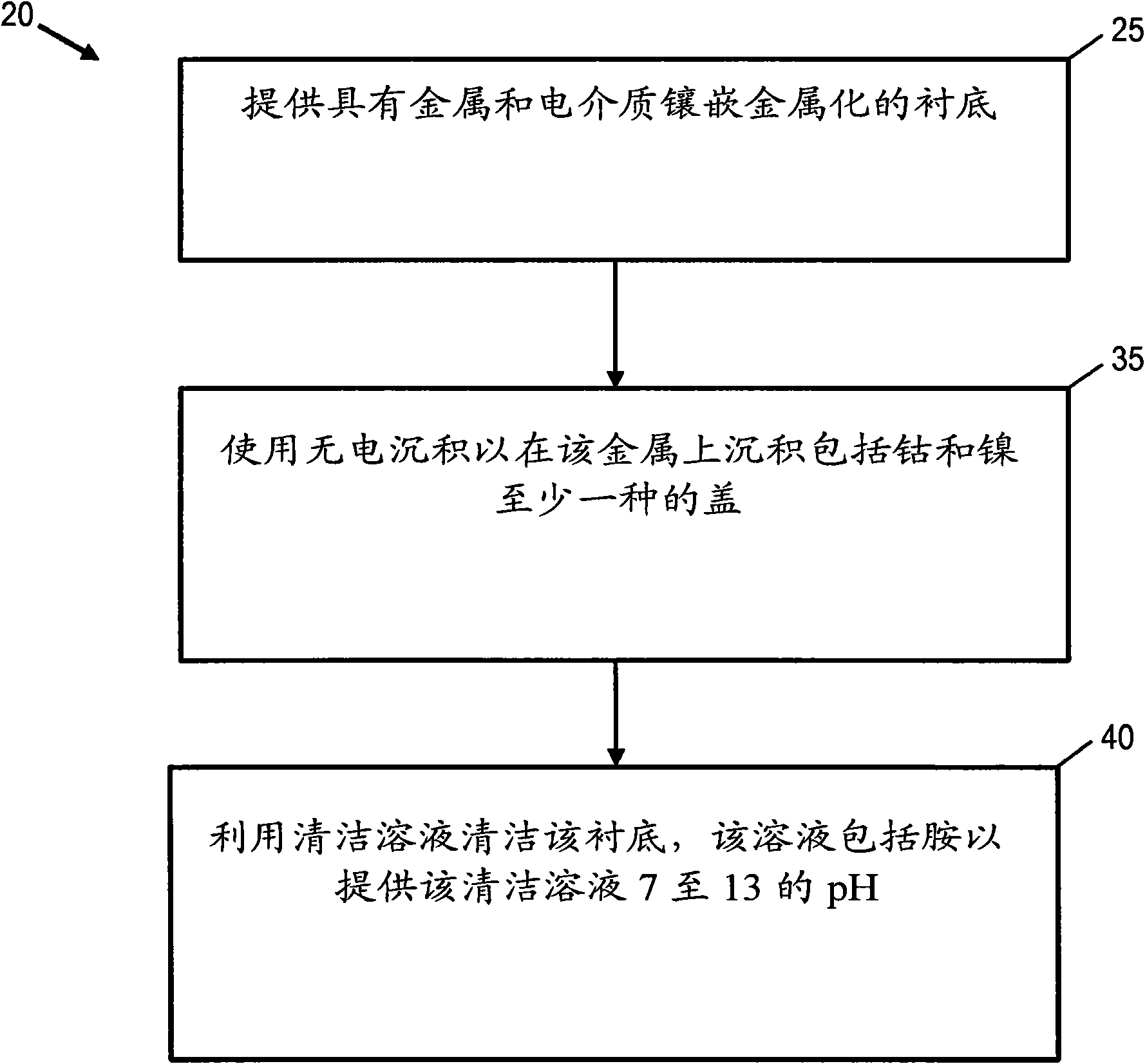

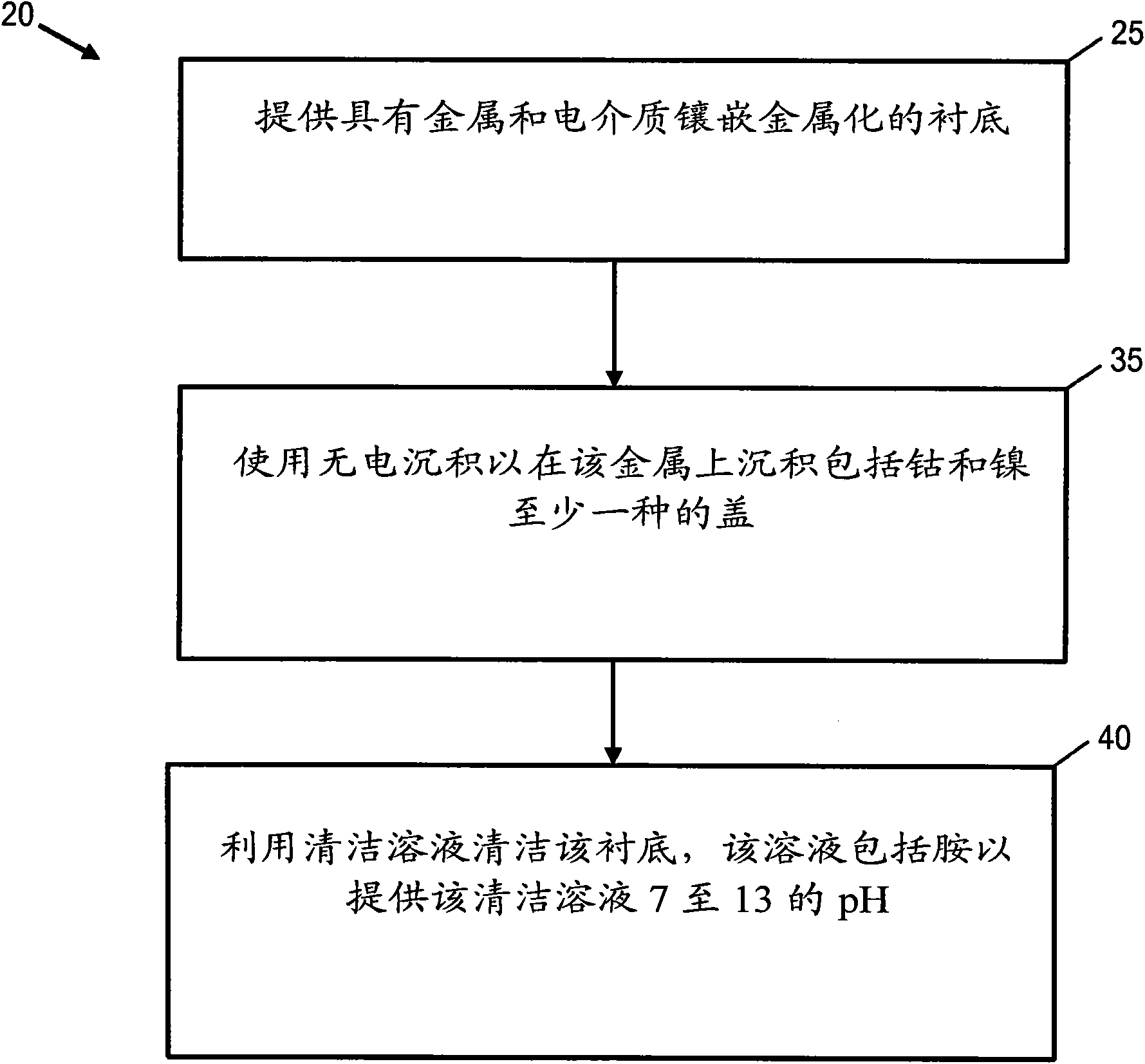

Post-deposition cleaning methods and formulations for substrates with cap layers

ActiveCN101971296APrinted circuit liquid treatmentNon-surface-active detergent compositionsNanotechnologyIntegrated circuit

One embodiment of the present invention is a method of fabricating an integrated circuit. The method includes providing a substrate having a metal and dielectric damascene metallization layer and depositing substantially on the metal a cap. After deposition of the cap, the substrate is cleaned with a solution comprising an amine to provide a pH for the cleaning solution of 7 to about 13. Another embodiment of the presented invention is a method of cleaning substrates. Still another embodiment of the present invention is a formulation for a cleaning solution.

Owner:LAM RES CORP

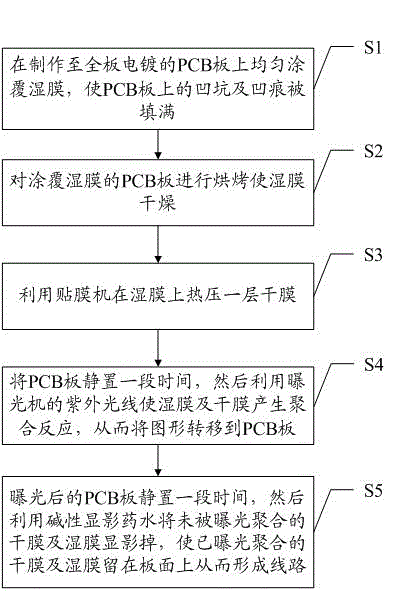

Fabrication method for printed circuit board (PCB) with irregularity in board surface

ActiveCN105142345ASolve the problem of gap and open circuitImprove manufacturing yieldPrinted circuit liquid treatmentUltraviolet lightsEngineering

The invention discloses a fabrication method for a printed circuit board (PCB) with irregularity in a board surface. The fabrication method comprises the following steps of: A, uniformly applying a wet film onto the PCB with plating on the whole board to make pits and dents on the PCB filled; B, roasting the PCB coated with the wet film to dry the wet film; C, hot-pressing a layer of dry film on the wet film by using a film lamination machine; D, allowingthe PCB to stand for a certain time, and leading the wet film and the dry film to have a polymerization reaction by using ultraviolet light rays of an exposure machine so as to transfer a pattern to the PCB; and E, allowing the PCB to stand for a certain time after an exposure, developing the dry film and the wet film which are not exposed and polymerized by using an alkaliphotograph potion, and leading the dry film and the wet film which are exposed and polymerized already to be reserved on the board surface so as to form a circuit. By the fabrication method, the problems of a gap and an open circuit appearing after etching the PCB with irregularity in the board surface are solved, and the fabrication yield is enhanced.

Owner:SHENZHEN KINWONG ELECTRONICS

Method of thin printed circuit board wet process consistency on the same carrier

InactiveUS20130270216A1Increase productionConserve costPrinted circuit liquid treatmentCircuit board tools positioningCopper platingEngineering

A method of thin printed circuit board wet process consistency on the same carrier, and more particularly to a printed circuit board in the developing, copper plating, stripping, etching and other wet processes uses the same frame as a carrier from the beginning to the end of the wet process, such that the thin printed circuit board is conducted a continuous and automatic wet process to avoid disassembly, storage and transportation between each process. Moreover, when using the flame, the thin printed circuit board is smooth and flattening in the wet process for avoiding “water effect,” the effective area is not exposed to any mechanical members for preventing scratches, and there are point contacts between the thin printed circuit board and the frame for preventing chemical residue. Accordingly, the present invention can not only enhance the yield of the thin printed circuit board but also shorten the production time.

Owner:KINSUS INTERCONNECT TECH

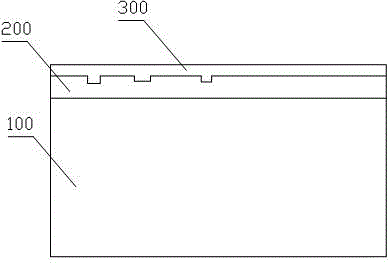

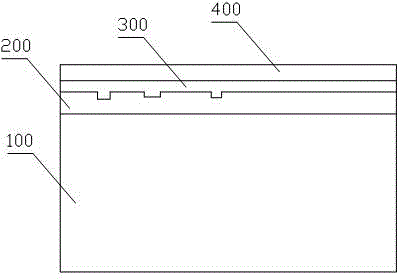

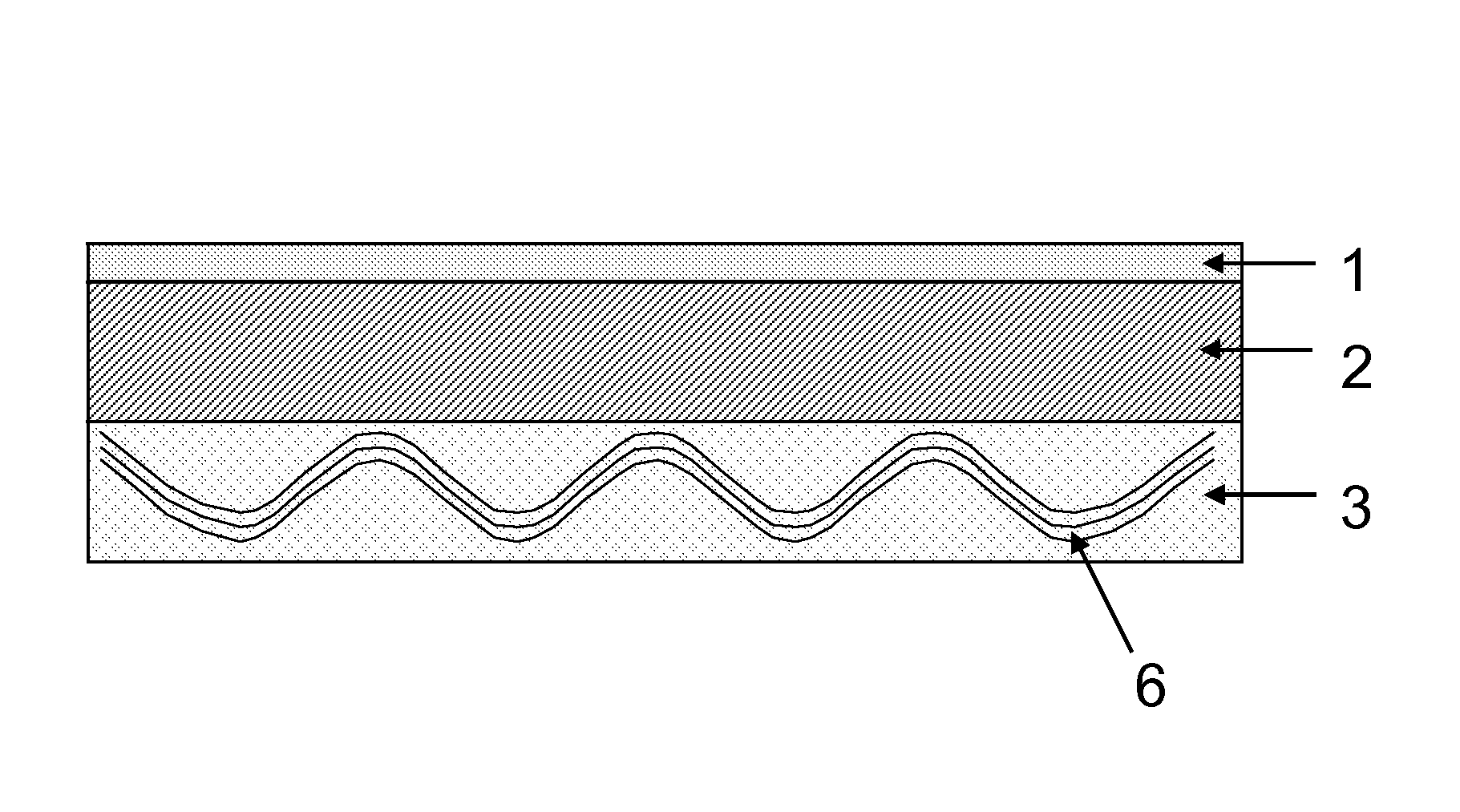

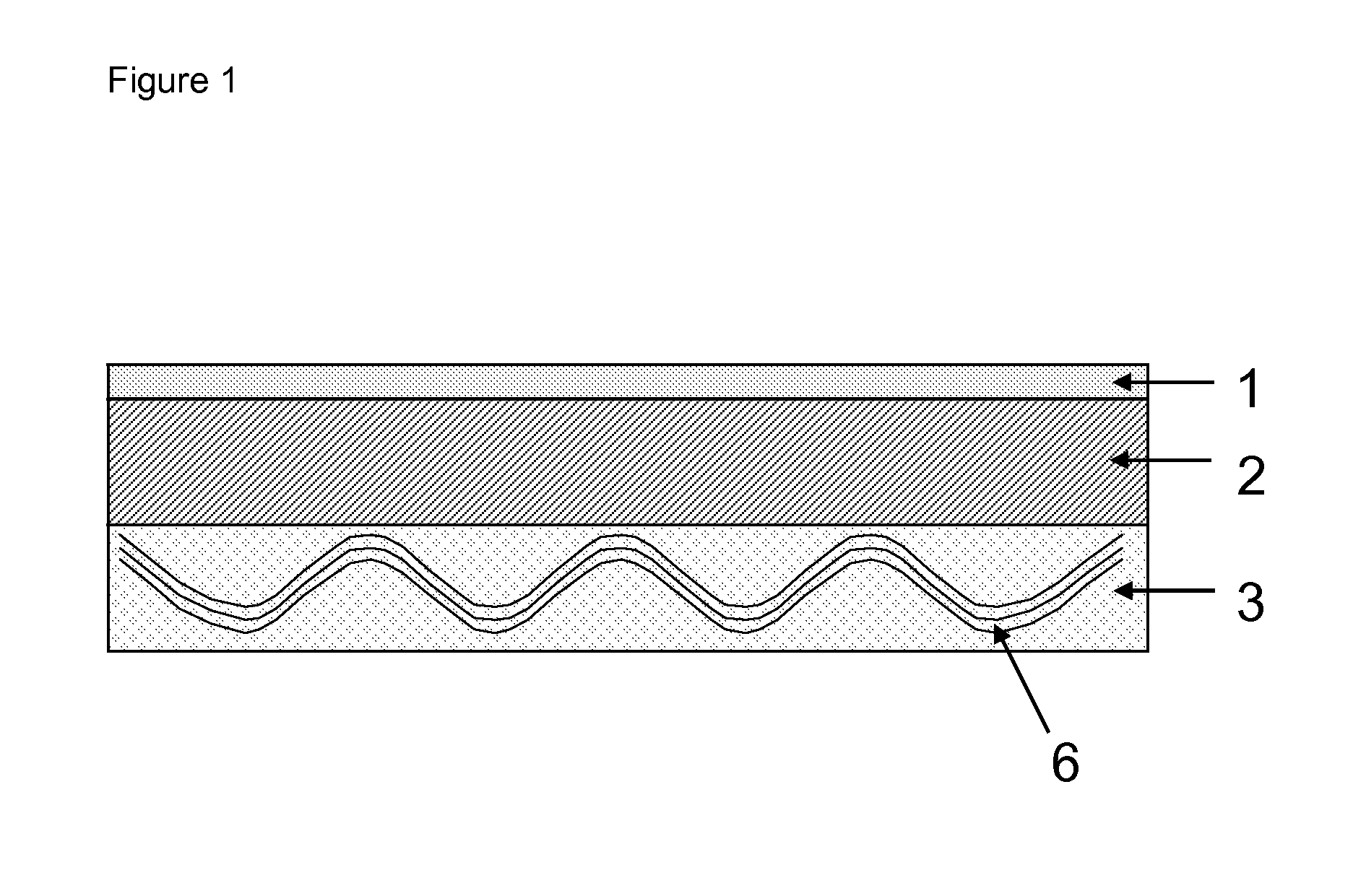

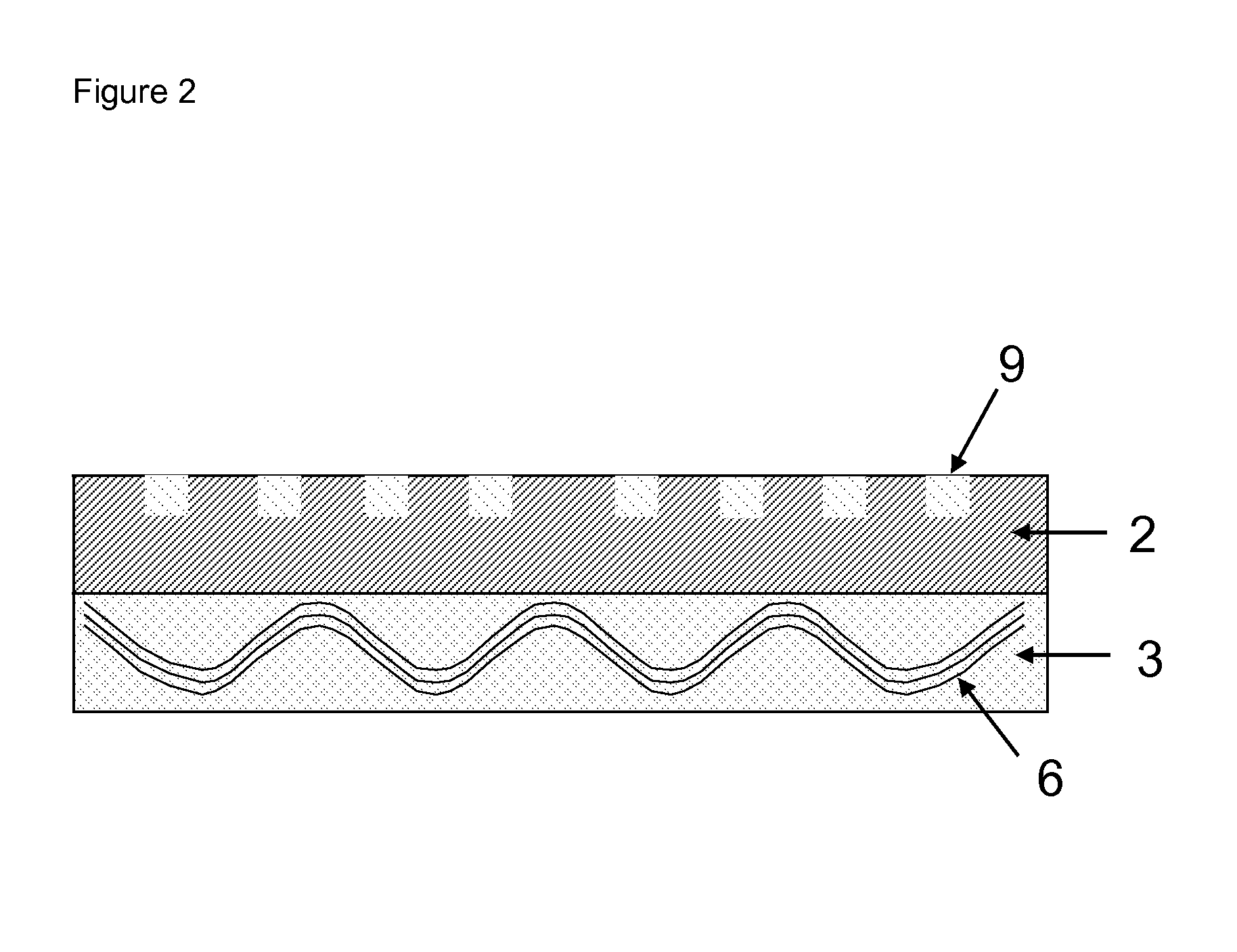

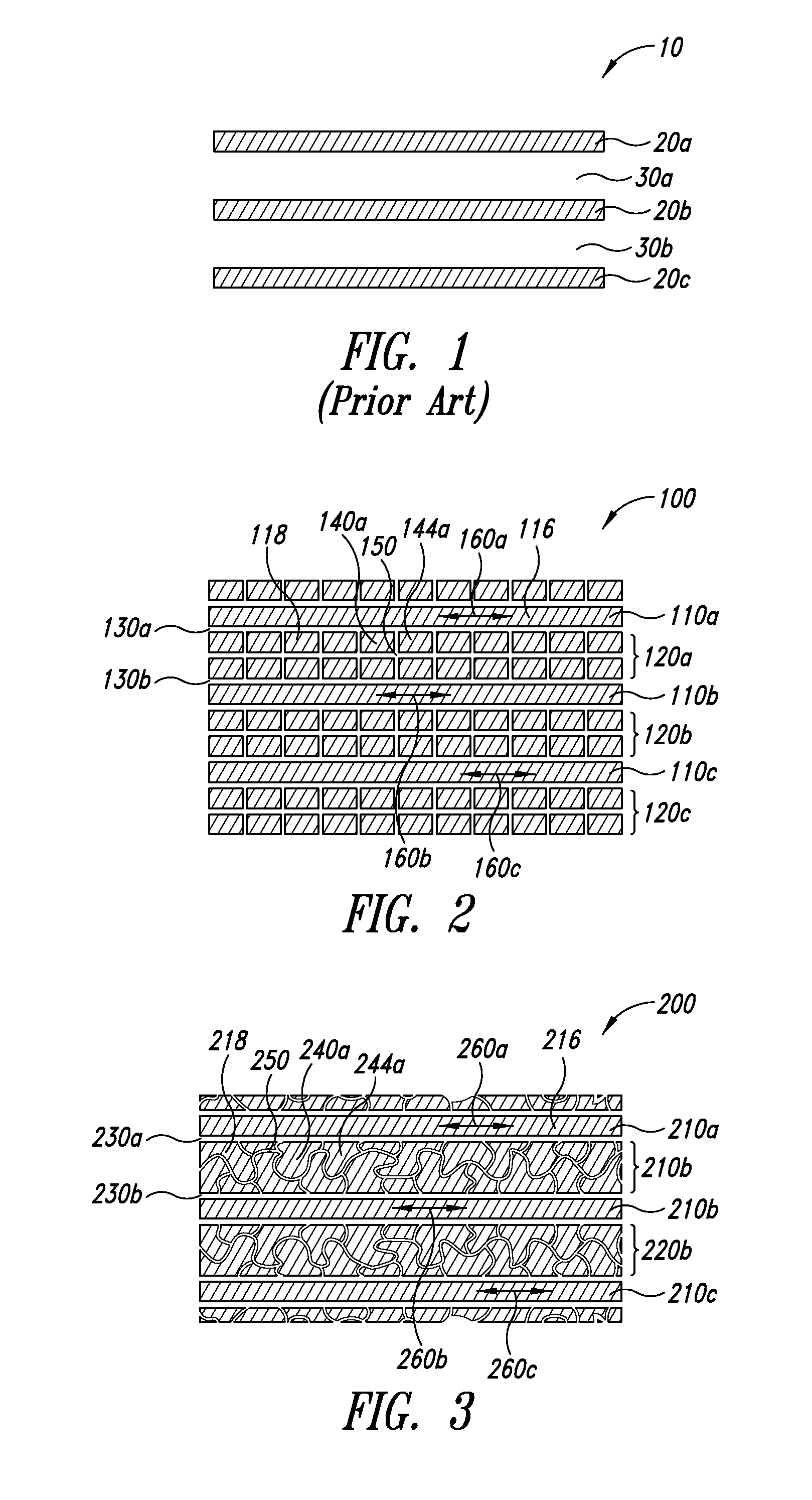

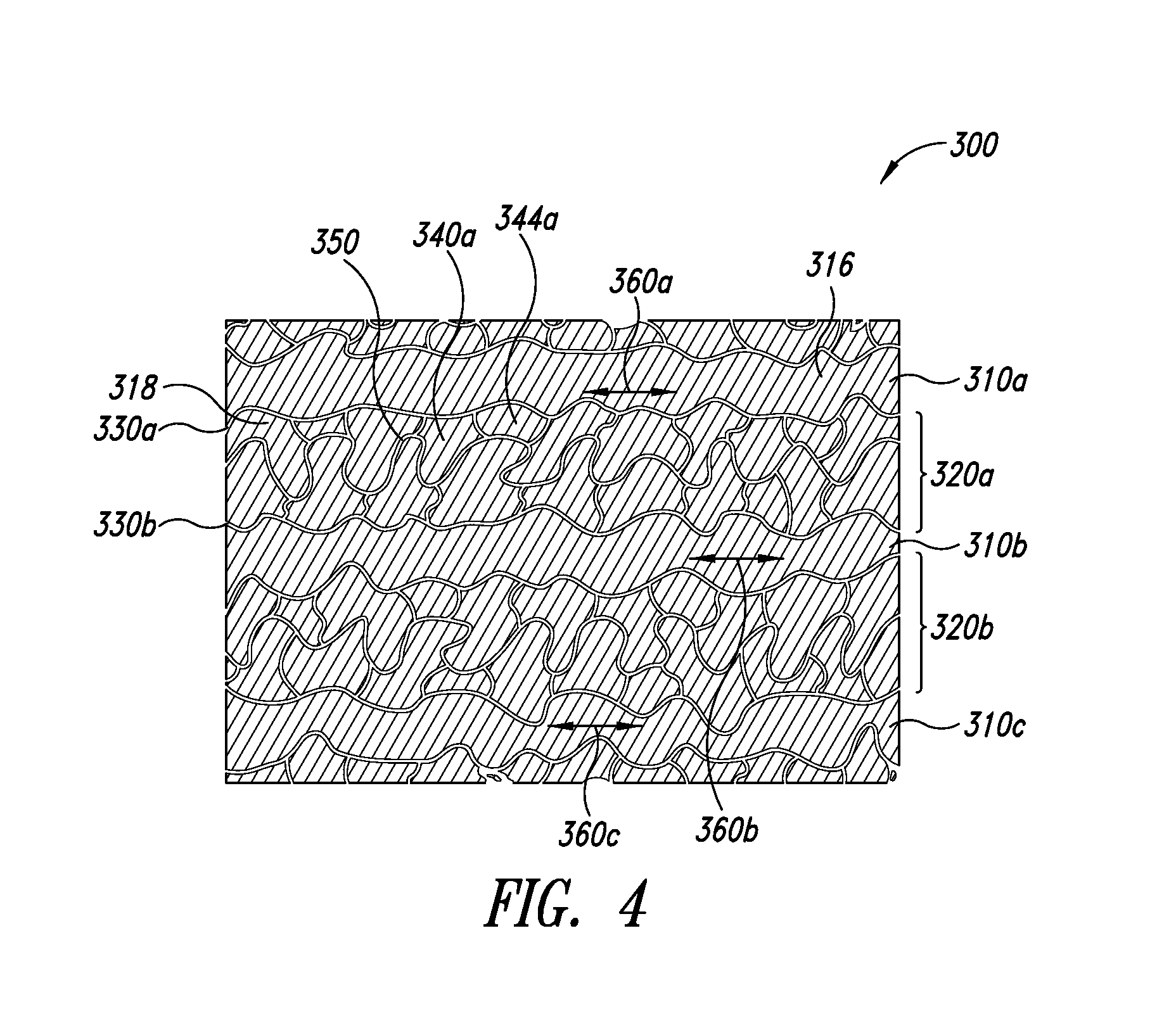

Composite build-up material for embedding of circuitry

InactiveUS20130199825A1Low VOC contentGood dimensional stabilityPrinted circuit liquid treatmentLight absorption dielectricsEngineeringMicrovia

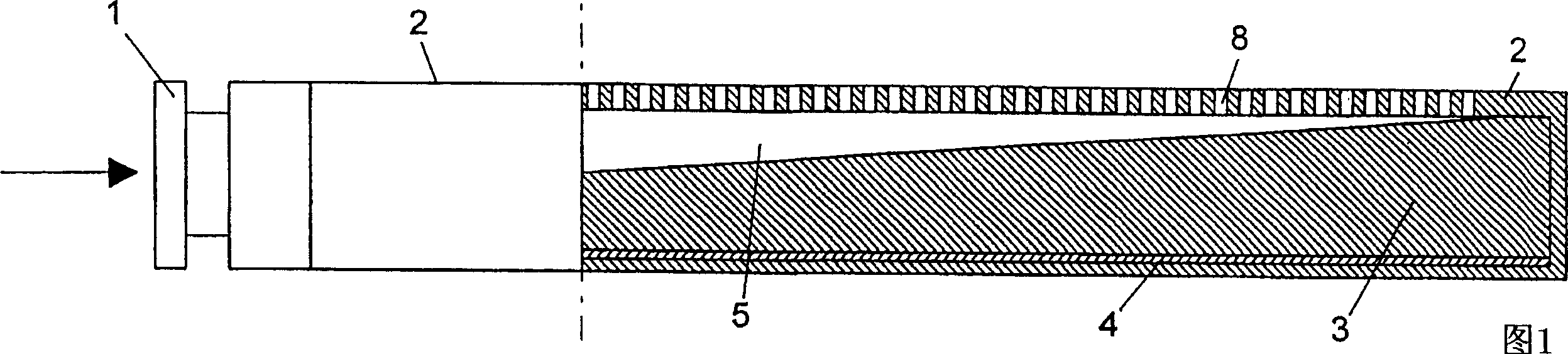

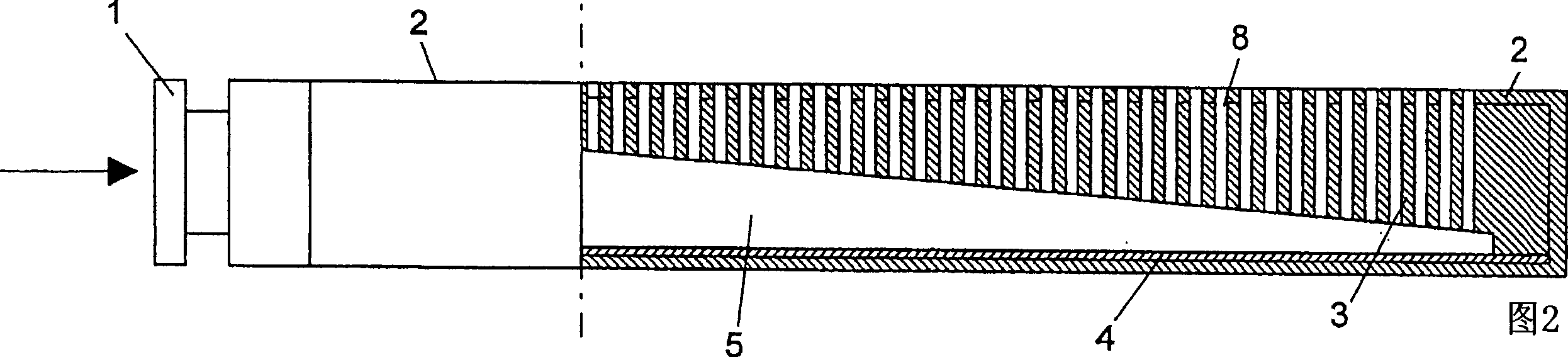

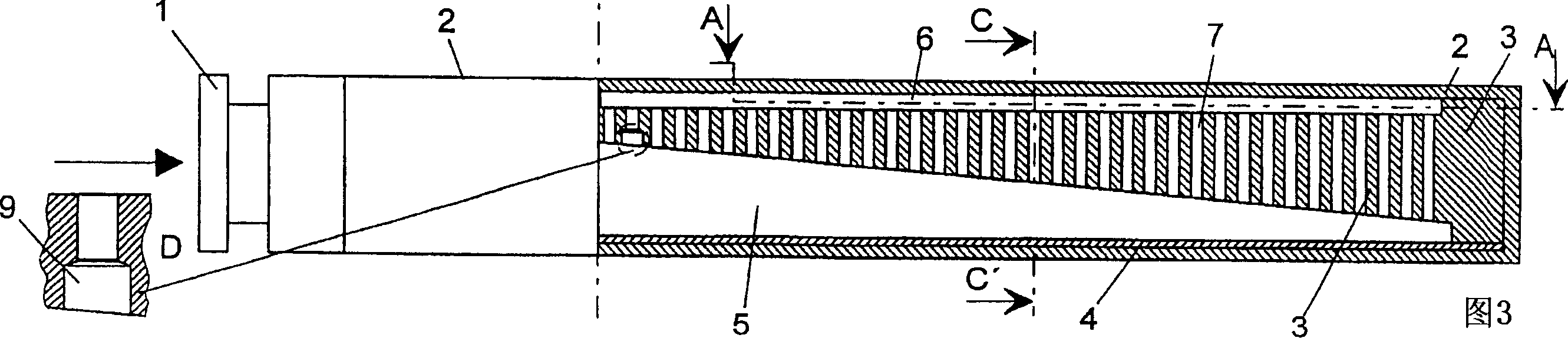

Disclosed are composite build-up materials for the manufacture of printed circuit boards, IC substrates, chip packages and the like. The composite build-up materials are suitable for embedding circuitry such as microvias, trenches and pads. The composite build-up materials comprise a carrier layer (1), a resin layer without reinforcement (2), and a resin layer with reinforcement (3). The circuitry (9) is embedded into the resin layer without reinforcement (2).

Owner:ATOTECH DEUT GMBH

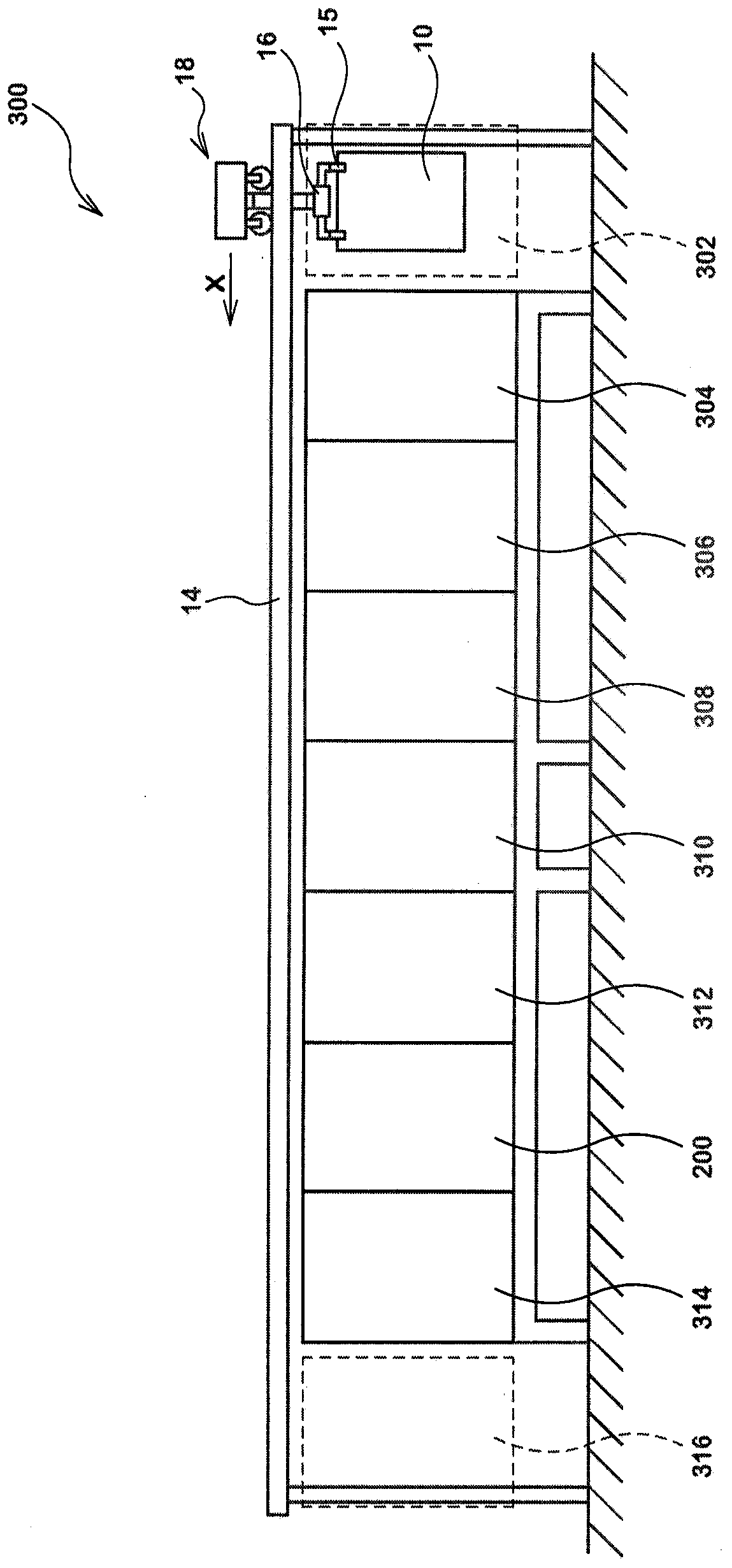

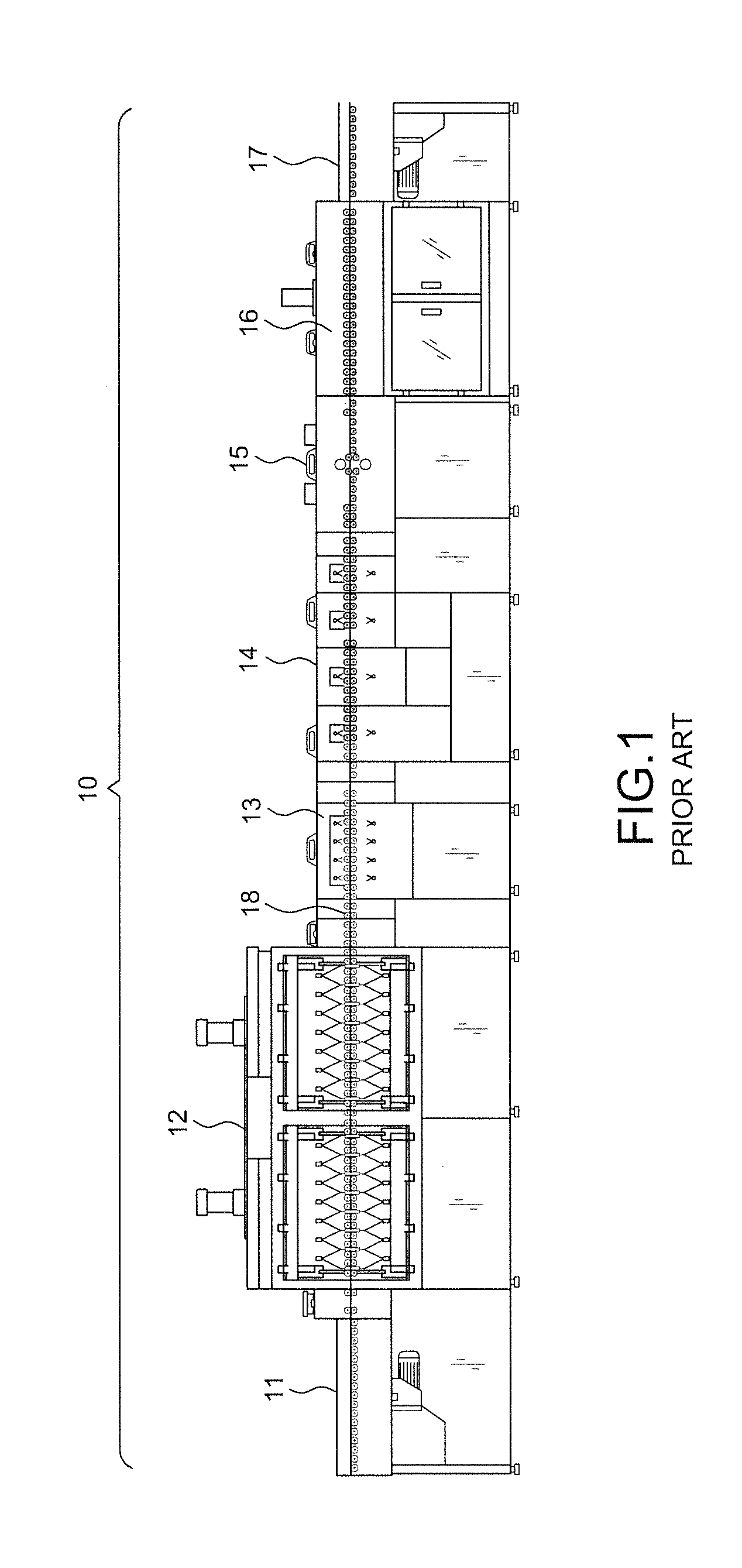

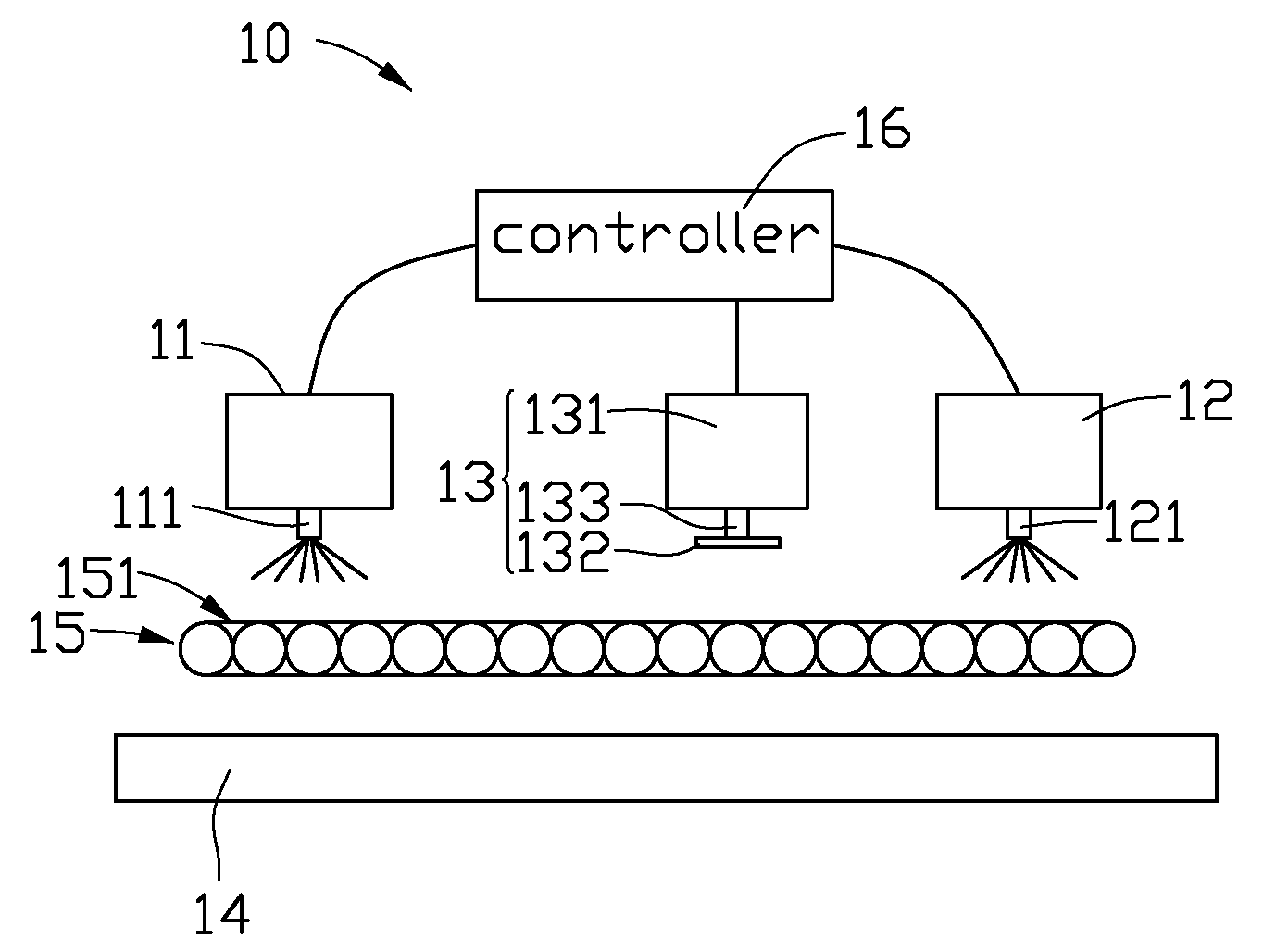

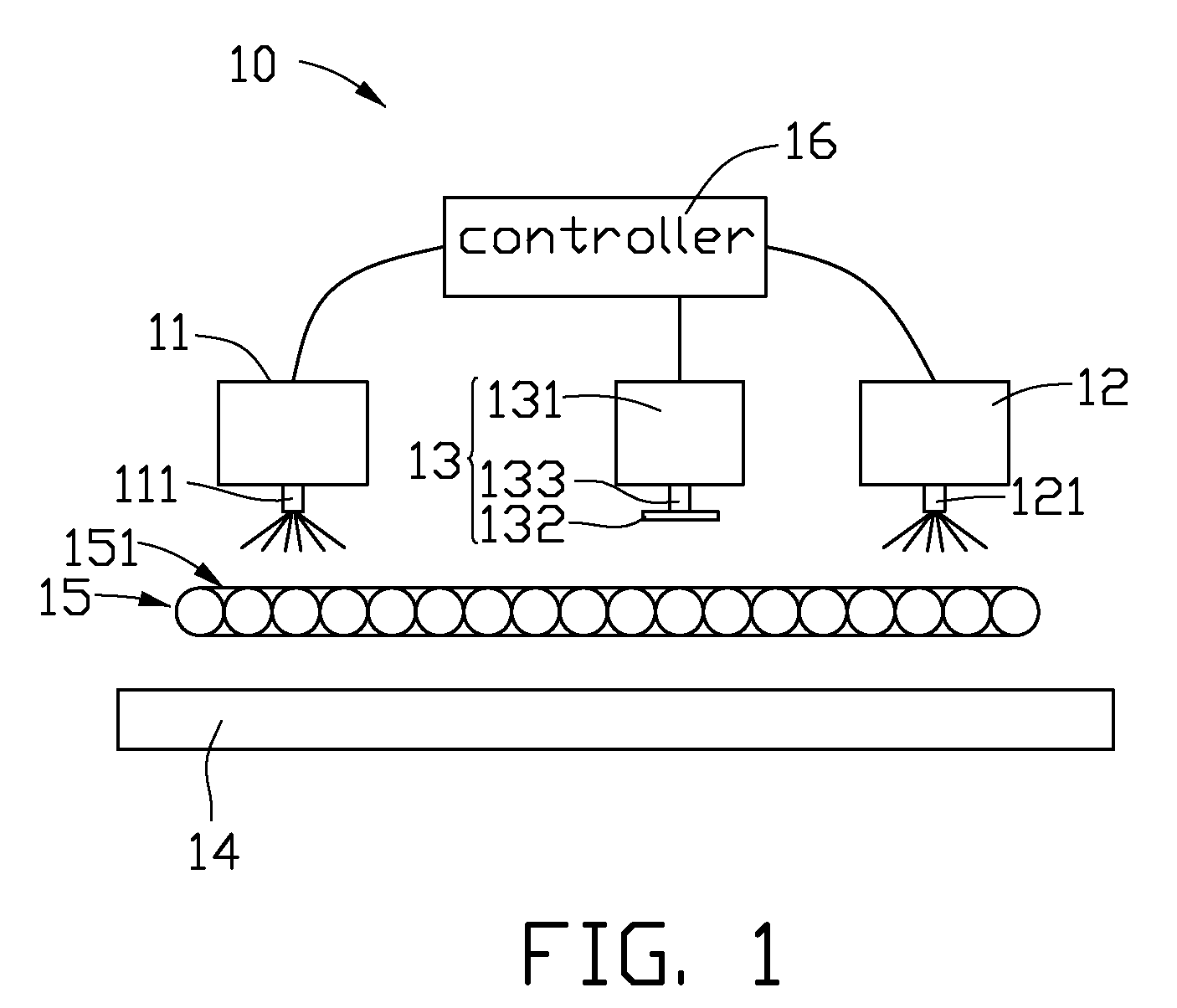

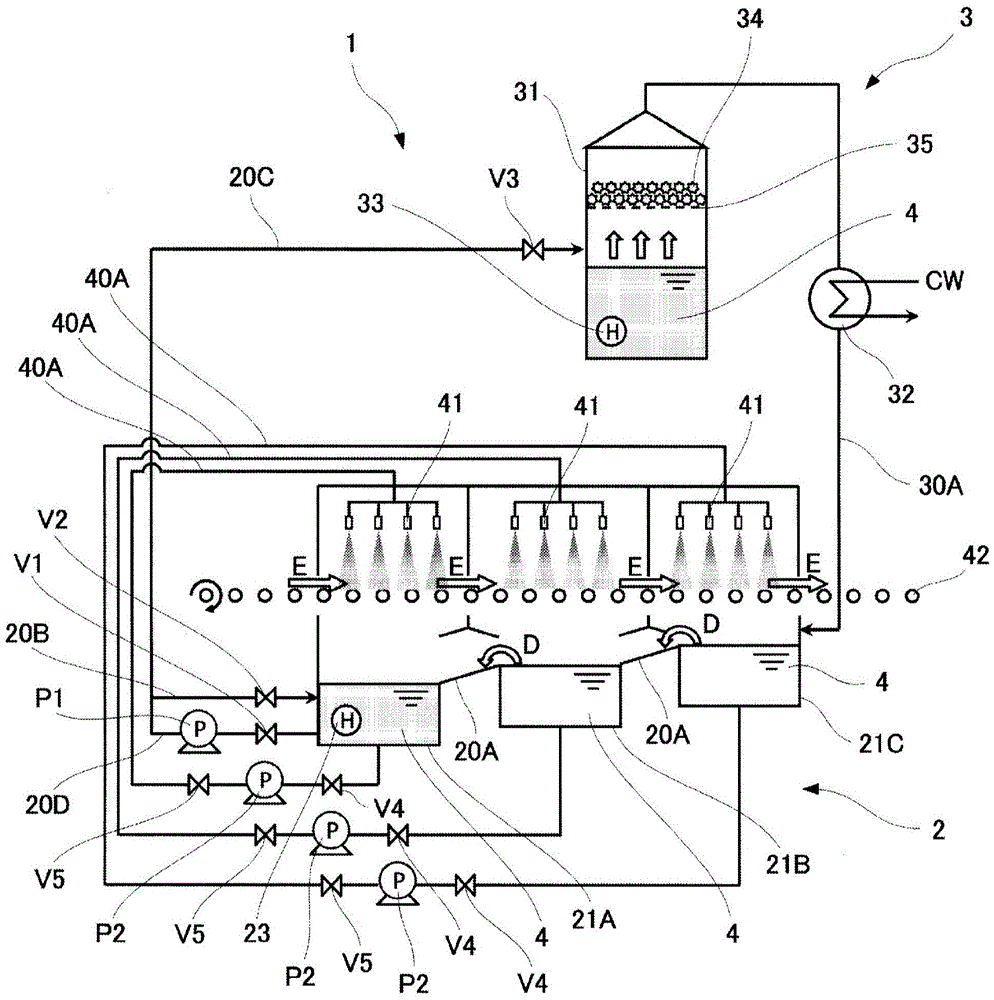

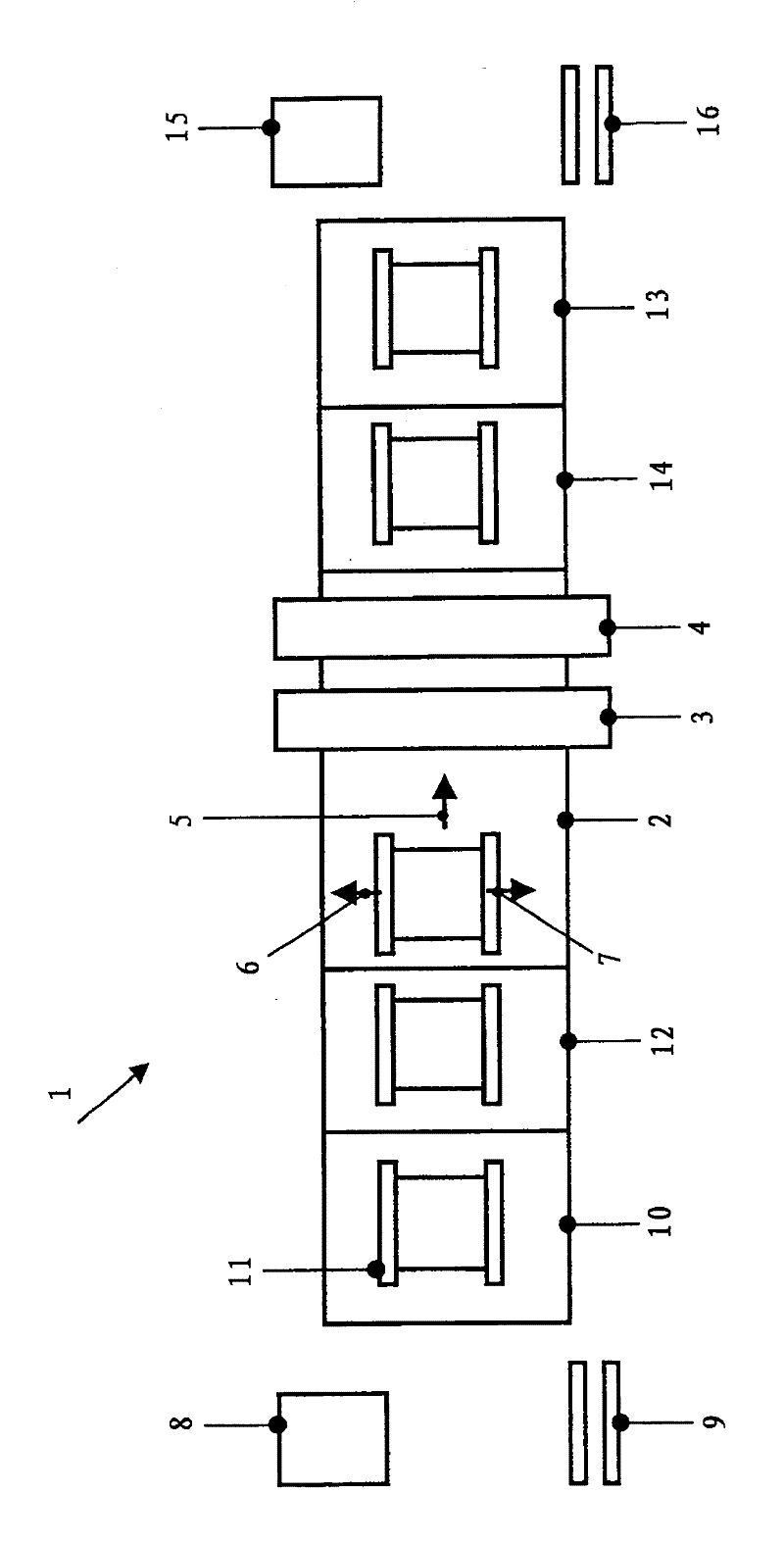

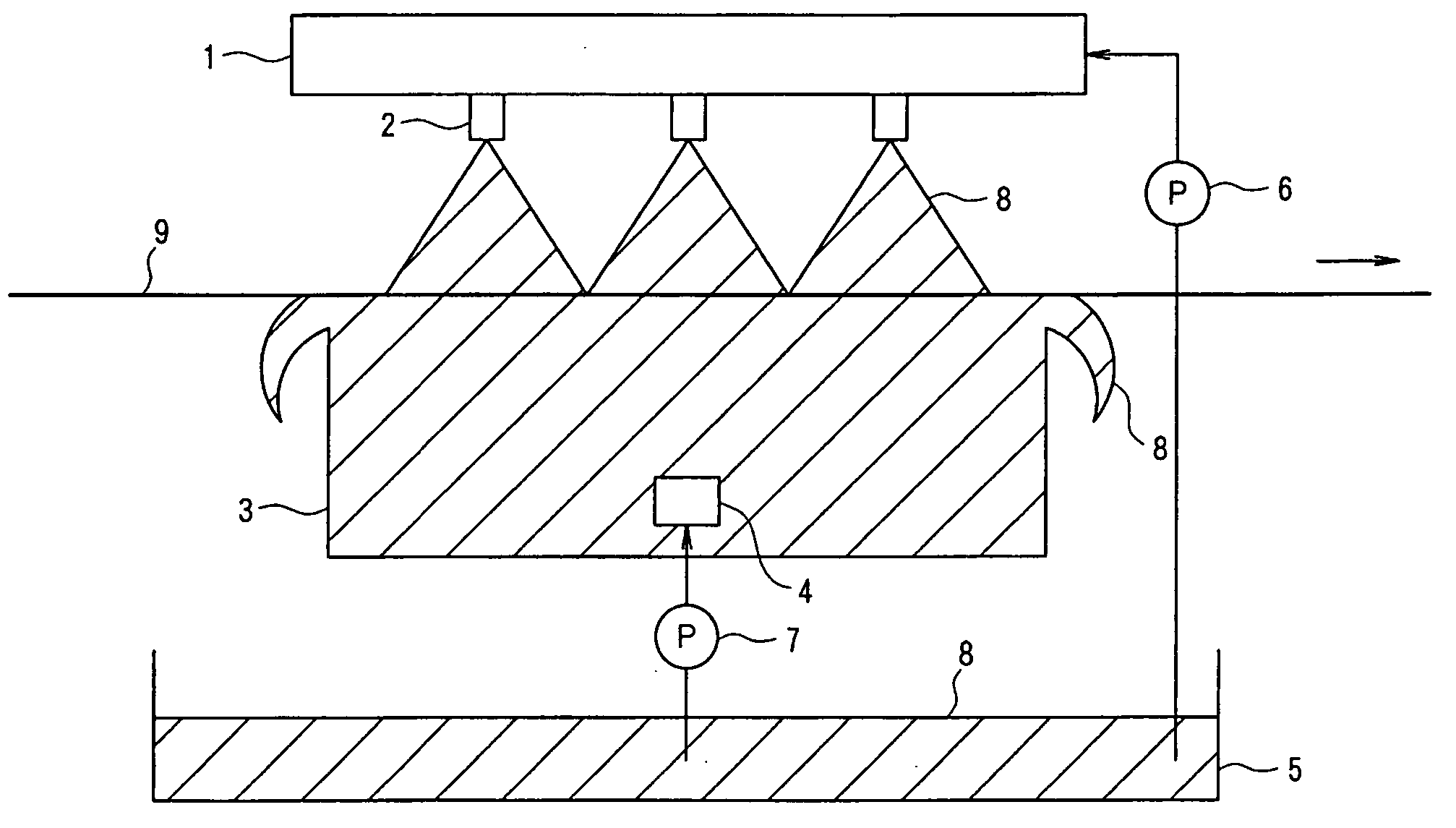

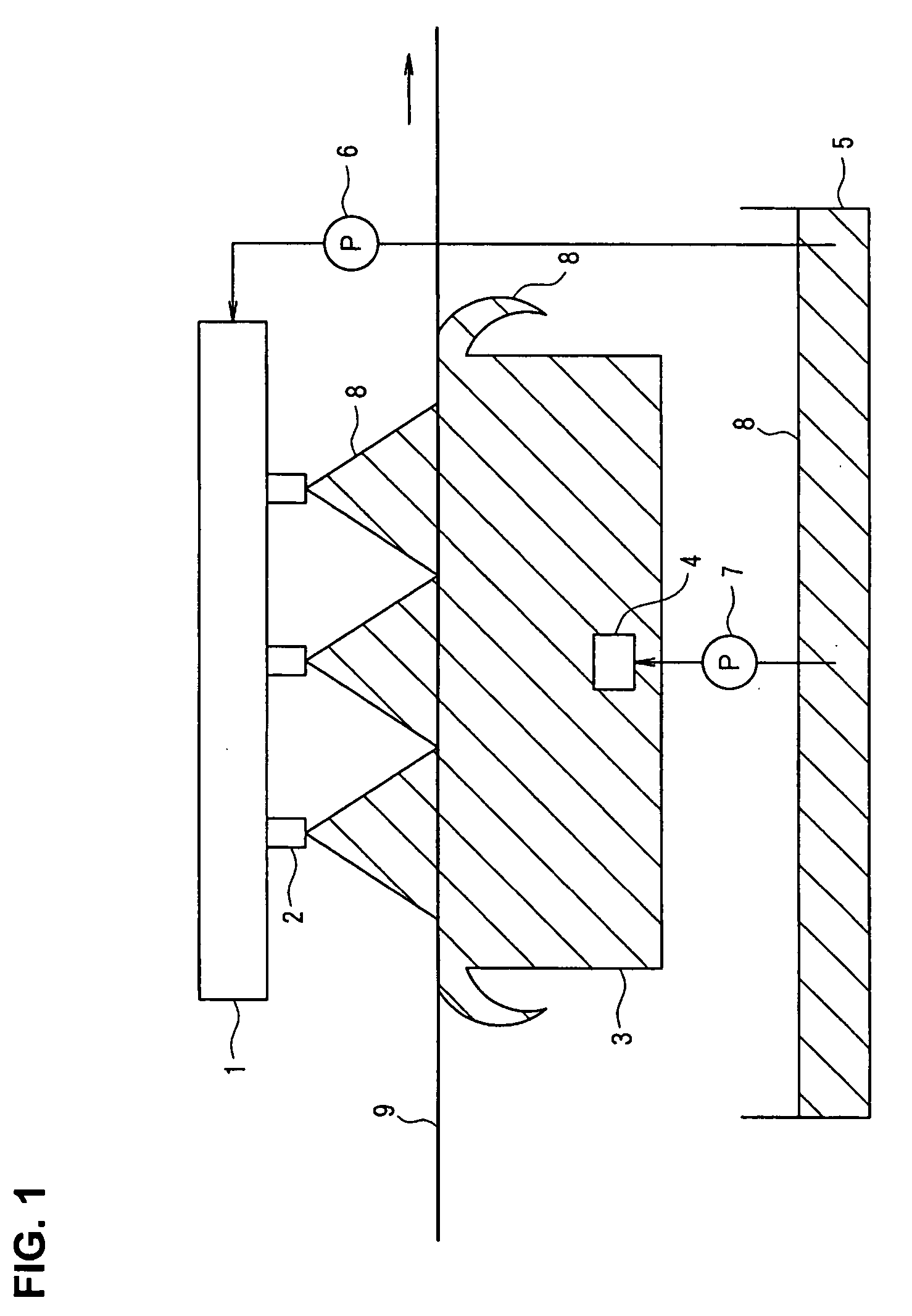

Wet processing system and wet processing method

InactiveUS20090314739A1Printed circuit liquid treatmentDecorative surface effectsEngineeringHandling system

An exemplary system for processing a workpiece comprises a conveyor, a first liquid spraying device, a second liquid spraying device, and a substrate positioning device. The conveyor is configured for conveying the workpiece along a conveying direction. The first and second liquid spraying devices for spraying liquid onto the workpiece transported on the conveyor face the conveyor and are arranged along the conveying direction. The substrate positioning device for reorienting the workpiece on the conveyor is installed between the first and second liquid spraying devices and faces the conveyor.

Owner:ZHEN DING TECH CO LTD

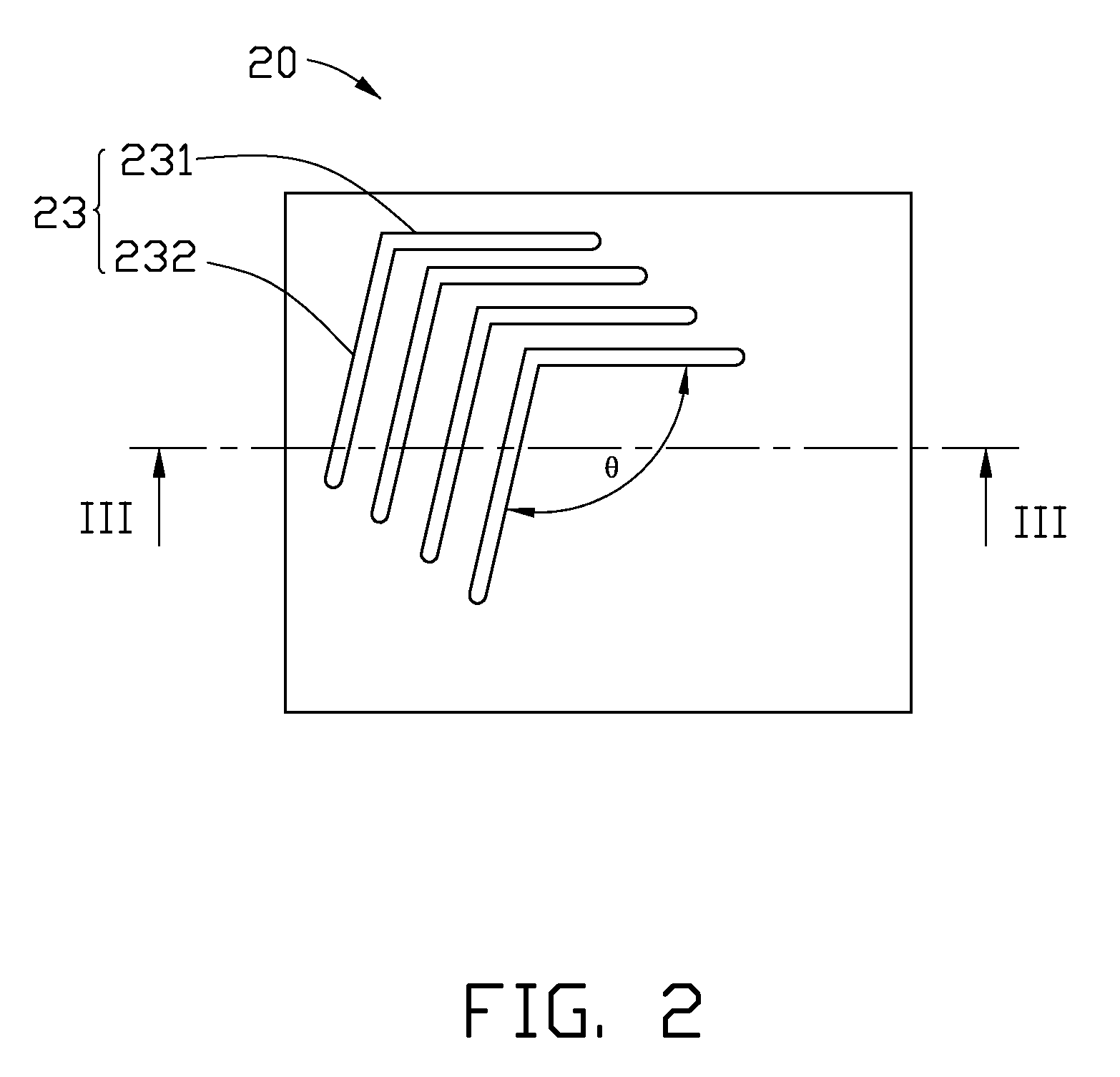

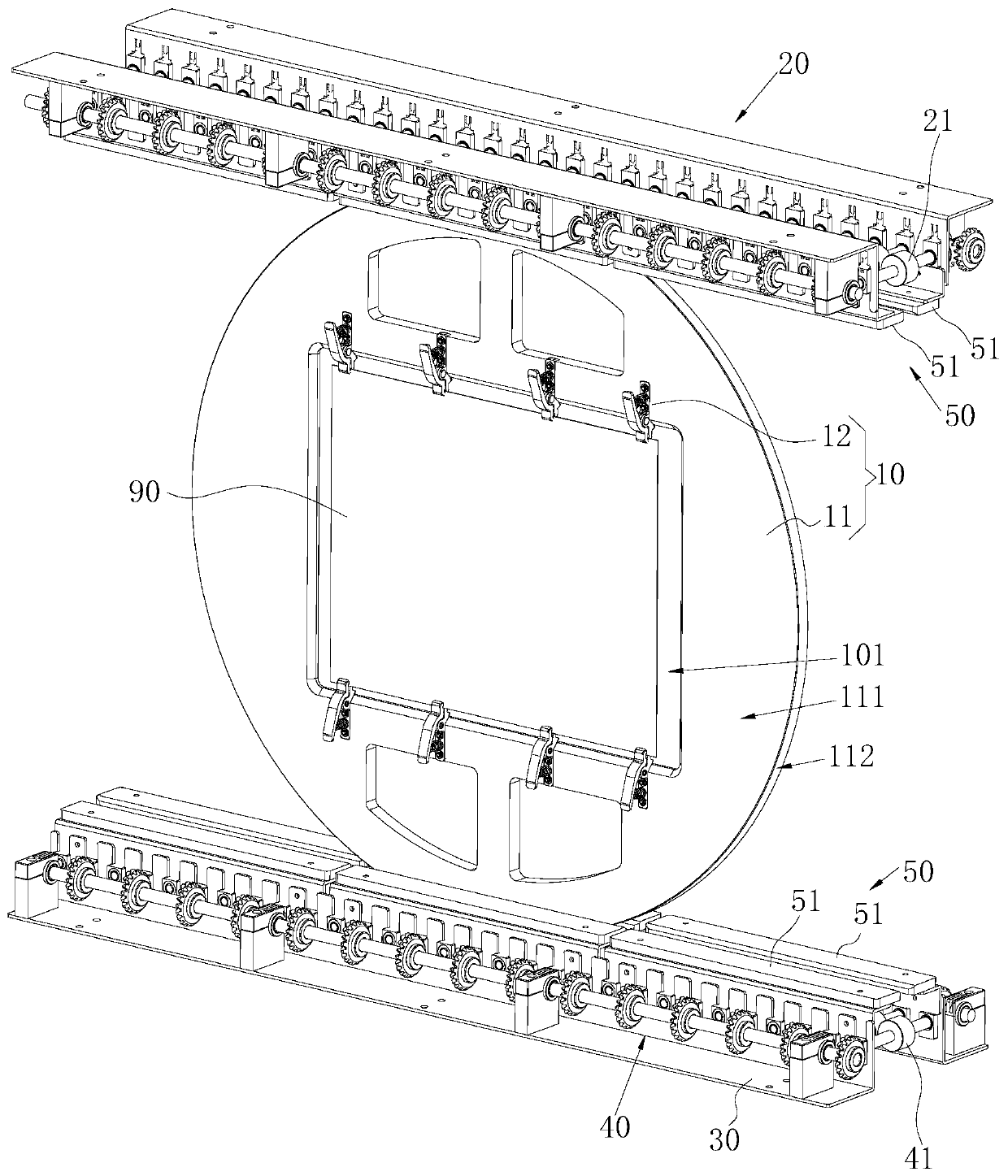

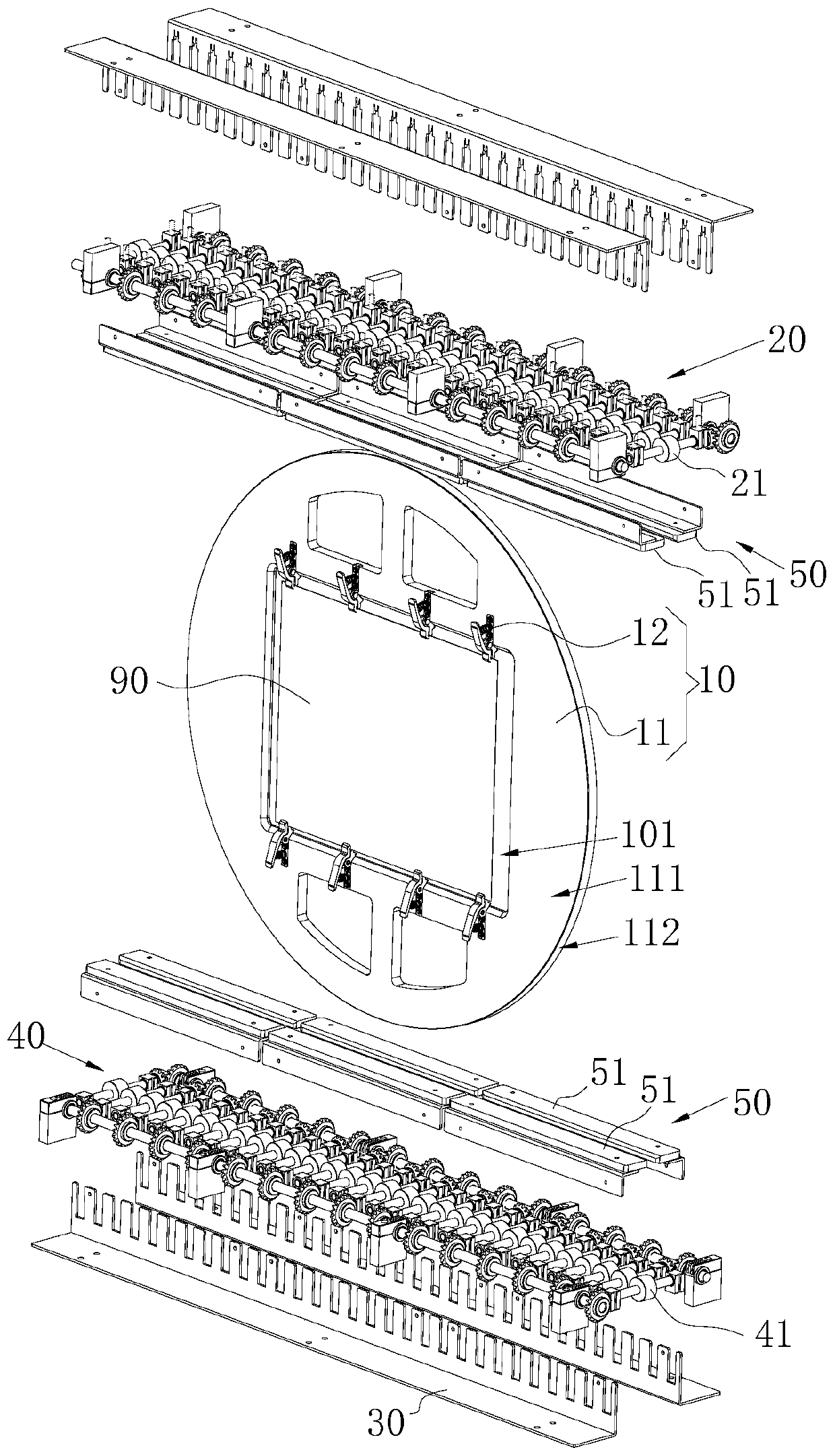

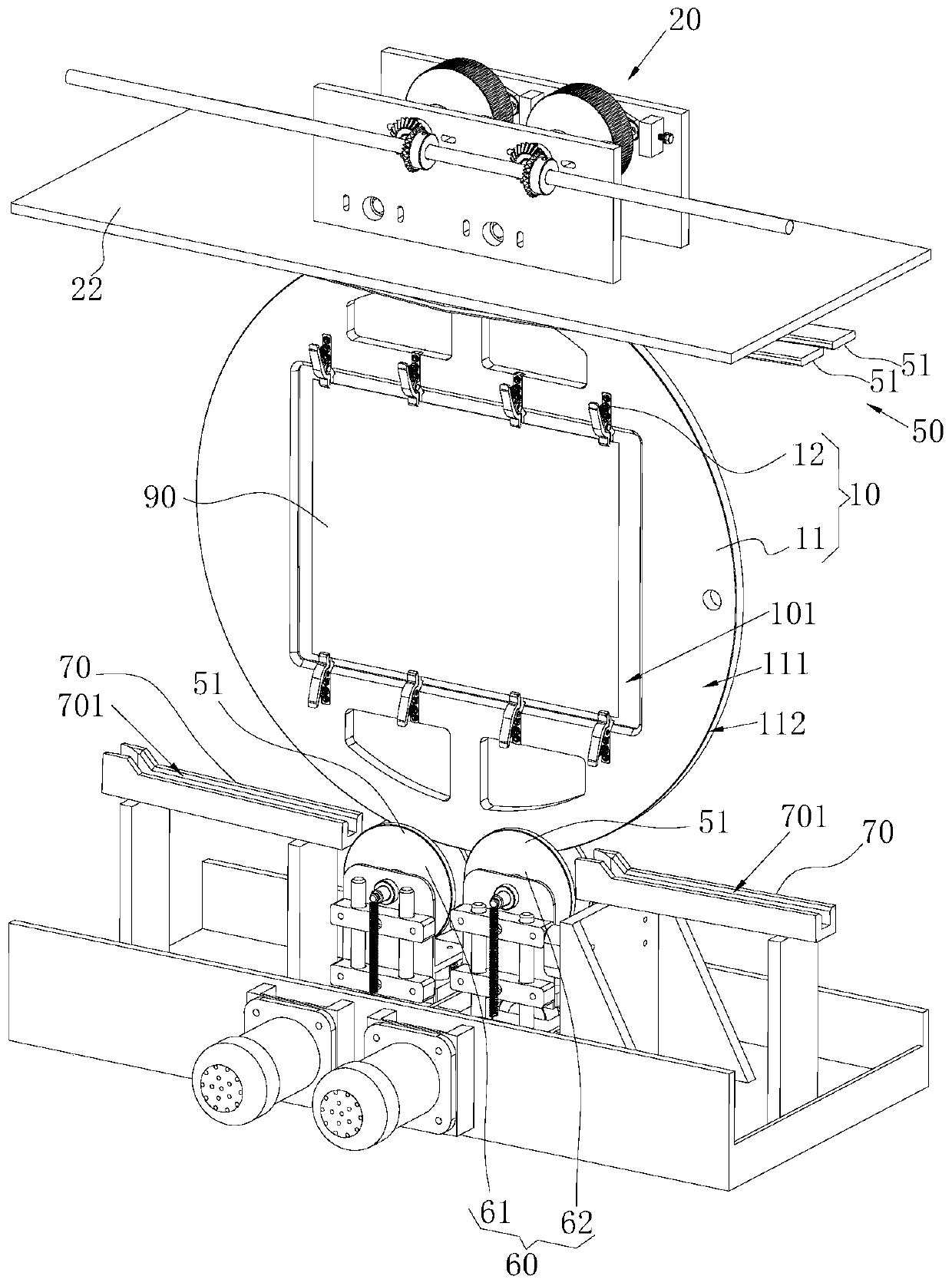

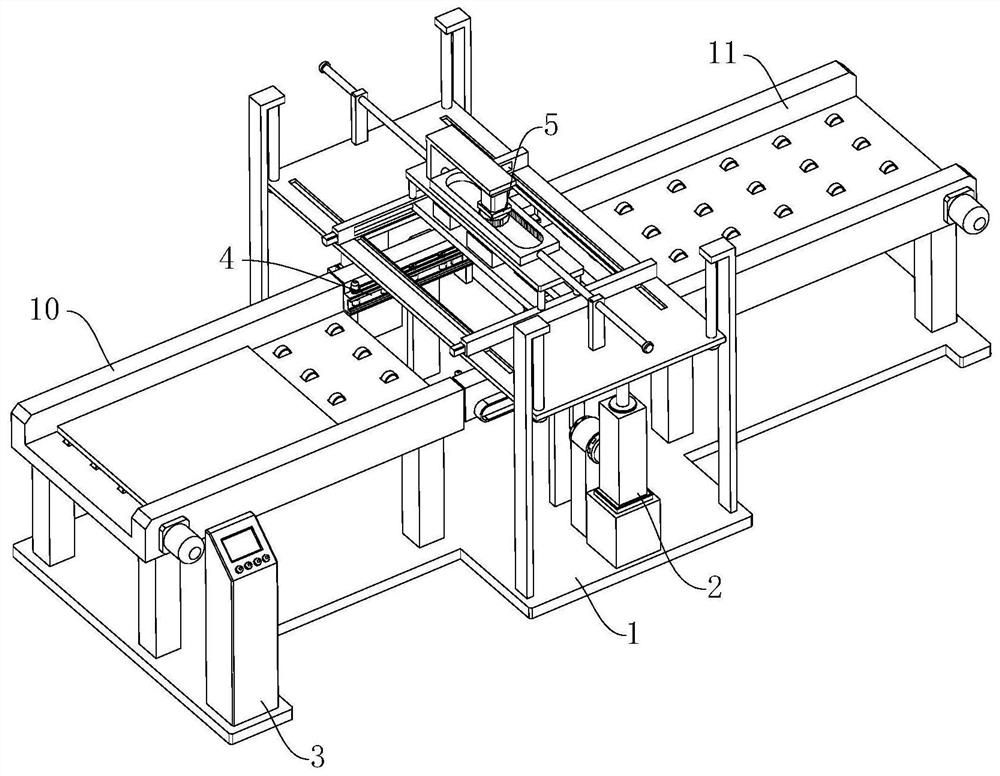

Liquid homogenizing device for printed circuit board

PendingCN111083875AUniform coverageAvoid the pool effectPrinted circuit liquid treatmentEngineeringMechanical engineering

The invention provides liquid homogenizing device for a printed circuit board. The device is used for treating the printed circuit board, the printed circuit board is provided with a to-be-treated surface and comprises a material carrying mechanism and a driving mechanism, and the material carrying mechanism is used for fixing the printed circuit board and enabling the plane where the printed circuit board is located to be perpendicular to the horizontal plane; and the driving mechanism is used for driving the material carrying mechanism to rotate around the rotating axis perpendicular to theto-be-treated surface. After the to-be-treated surface is soaked in the liquid medicine, the liquid medicine can uniformly flow to the area of the lower half part from the area of the upper half partunder the effect of gravity; the liquid medicine in each area sequentially flows downwards in the circumferential direction in the rotating process of the material carrying mechanism; and finally, uniform coverage of the liquid medicine in each area of the to-be-treated surface is realized, so that the pool effect during horizontal placement is avoided, excessive local area treatment caused by residual liquid medicine is prevented, and the condition of non-uniform treatment effect of the upper part and the lower part during vertical placement of the printed circuit board is avoided.

Owner:UNIVERSAL CIRCUIT BOARD EQUIP CO LTD

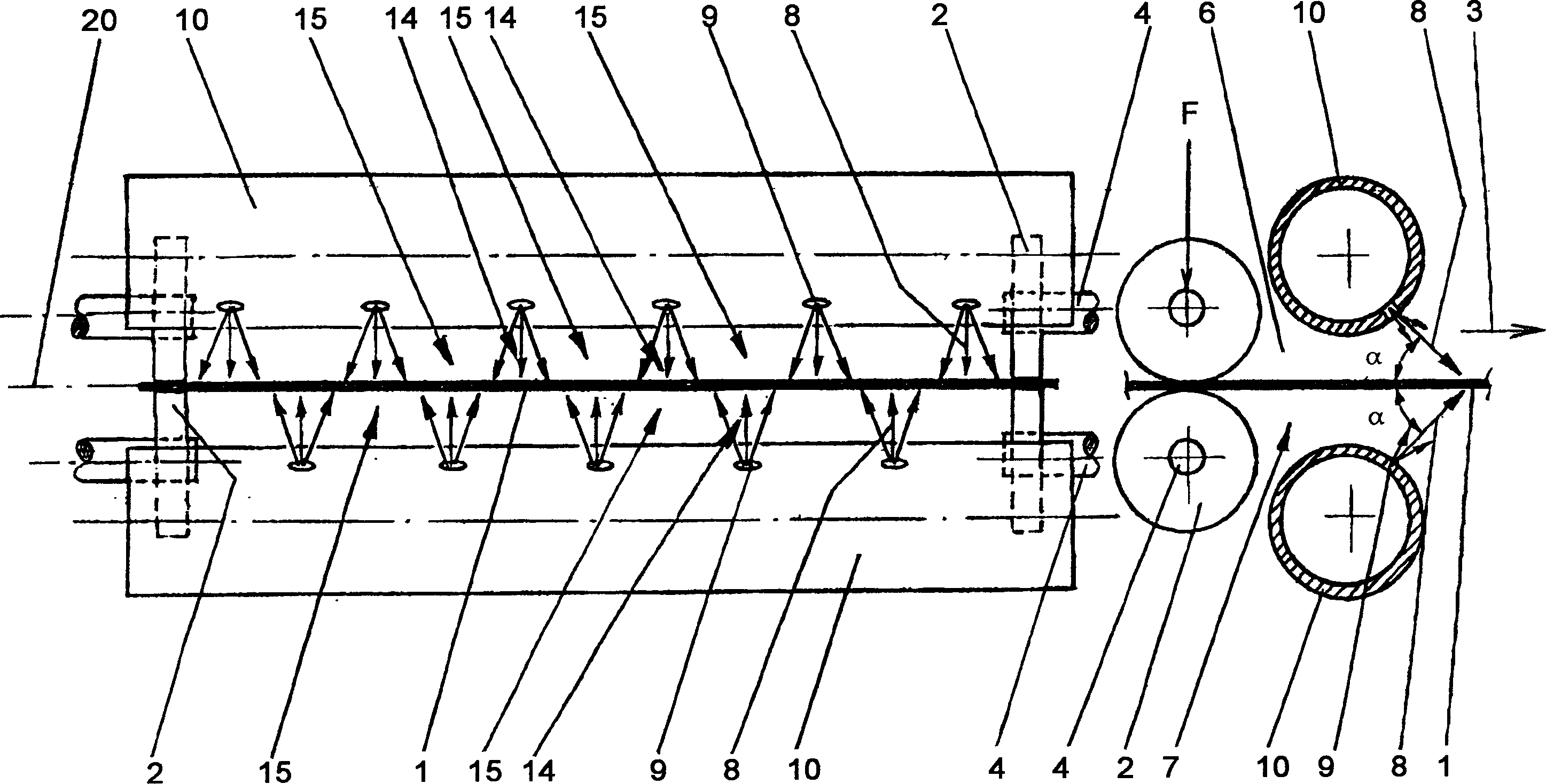

Nozzle arrangement

ActiveCN1711140ASmall sectionUniform flow ratePrinted circuit liquid treatmentSemiconductor/solid-state device manufacturingEngineeringPrinted circuit board

A nozzle arrangement is described which may in particular be used as a flow nozzle in galvanization systems with horizontal throughput of printed-circuit boards. The nozzle arrangement comprises a longitudinal housing (2) with at least one fluid feed opening to feed a treatment fluid for treating a work piece, for example a printed-circuit board, and preferably a plurality of slotted fluid delivery openings (8) for releasing the treatment fluid. In the housing (2) a fluid channel (5) is formed for feeding the treatment fluid from the fluid feed opening to the fluid delivery openings (8). In order to achieve the most even possible flow speed of the treatment fluid at the fluid delivery openings (8), (a) the throughput of the fluid channel (5) for the treatment fluid reduces continuously from the fluid feed opening in the longitudinal direction of the housing (2) and / or (b) before the delivery of the fluid from the fluid delivery openings (8) a storage chamber is provided.

Owner:ATOTECH DEUT GMBH

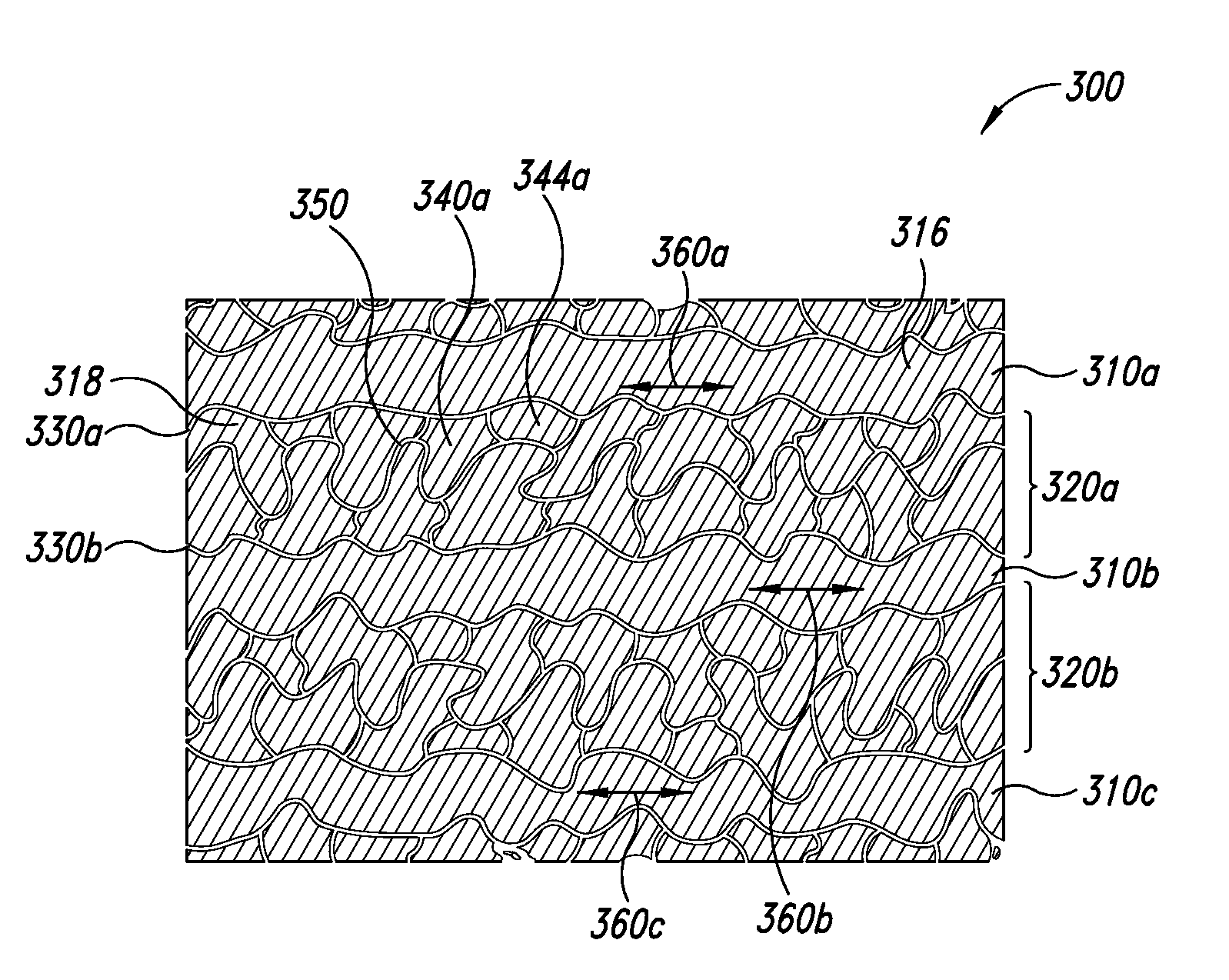

Conductive films having low-visibility patterns and methods of producing the same

ActiveUS20140158400A1Printed circuit liquid treatmentNon-conductive material with dispersed conductive materialVisibilityElectrical conductor

A patterned transparent conductor including a conductive layer coated on a substrate is described. More specifically, the transparent conductor has low-visibility patterns.

Owner:CHAMP GREAT INTL

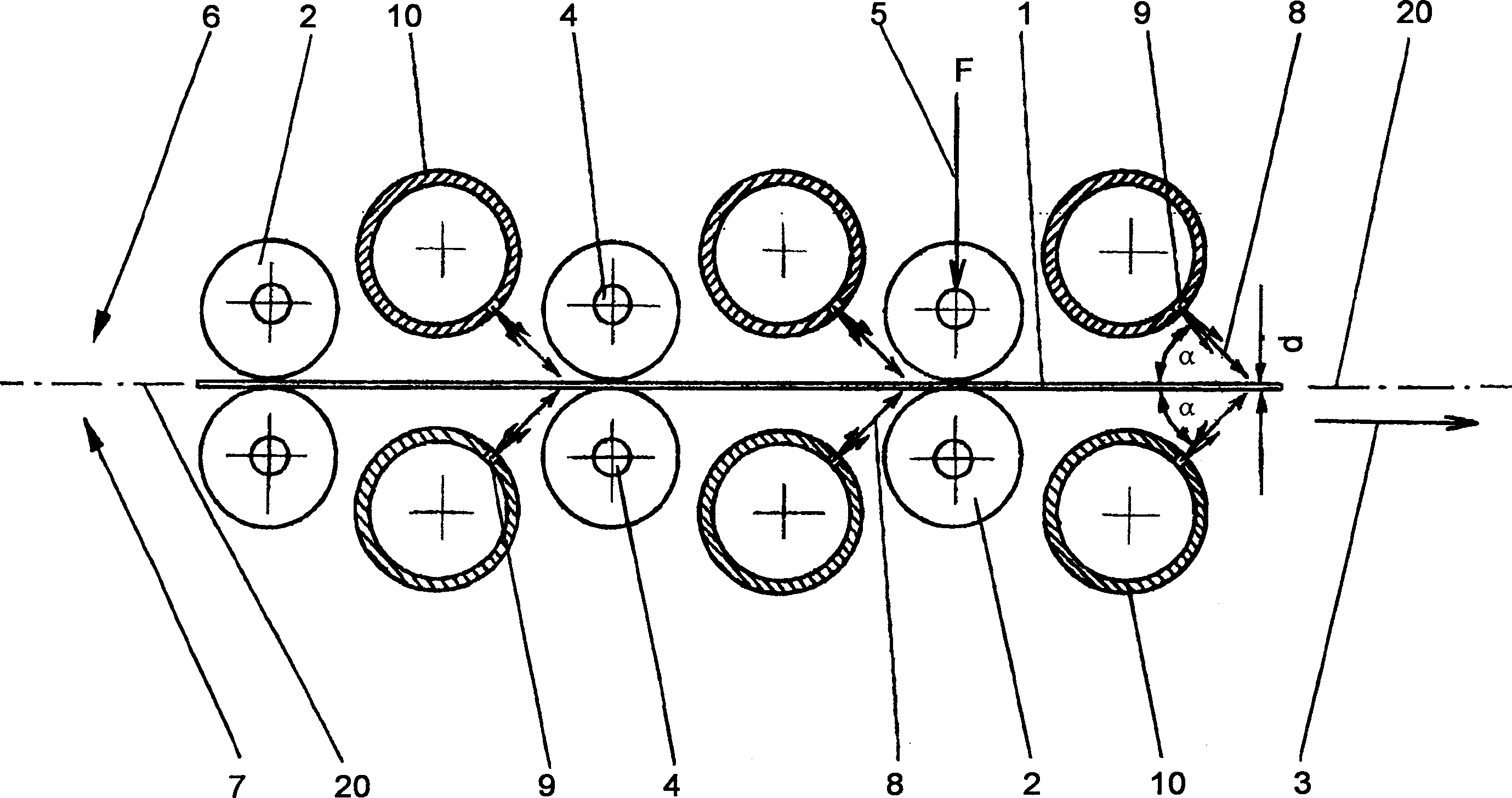

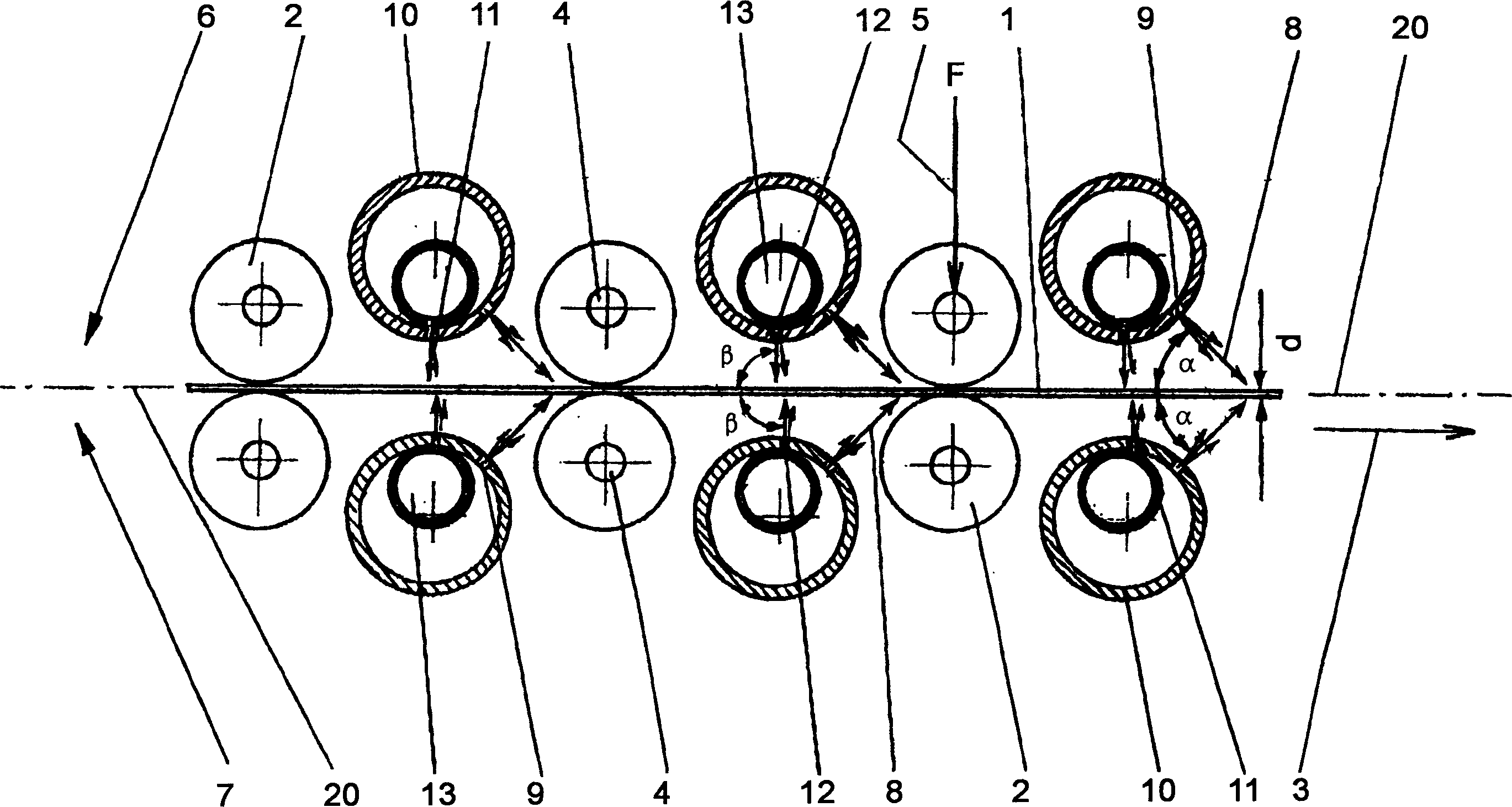

Method and device for contactless treatment of flat objects in through type treatment equipment

InactiveCN1638604AReduce deliveryPrinted circuit liquid treatmentElectrolysis componentsChemical treatmentPressure difference

The present invention relates to the conveying and processing of circuit boards and circuit films, wherein the conveying is horizontal in wet chemical pass-through processing equipment. The slightly inclined conveyor rollers grip the object at the edge and tension it during conveying. In the case of thin circuit films, the required stretching tensions for an uninterrupted transport can be so great that the dimensional accuracy necessary for precision circuit technology is lost. According to the invention, the required delivery reliability is achieved with a moderate stretching tension by means of an electrolyte flow ( 8 ) directed mirror-symmetrically to the object ( 1 ) in the delivery direction ( 3 ). For circuit boards with blind vias, an additional flow of electrolyte (11) is directed mirror-symmetrically close to vertically at the object (1). In order to realize the flow through the additional through-holes, a static pressure difference according to Bernoulli's theorem develops in the electrolyte on both sides of the body.

Owner:HOLLMULLER MASCHENBAU

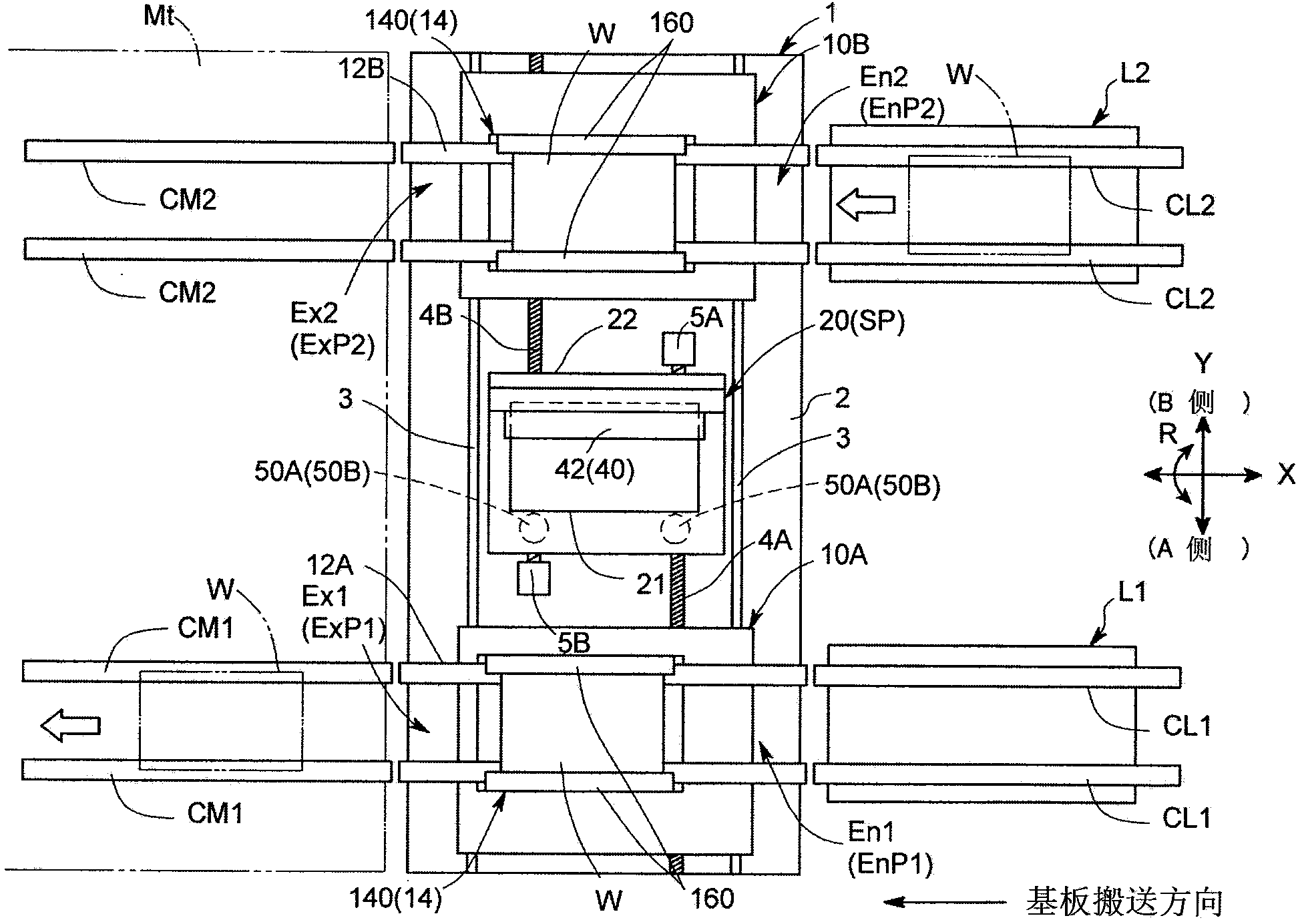

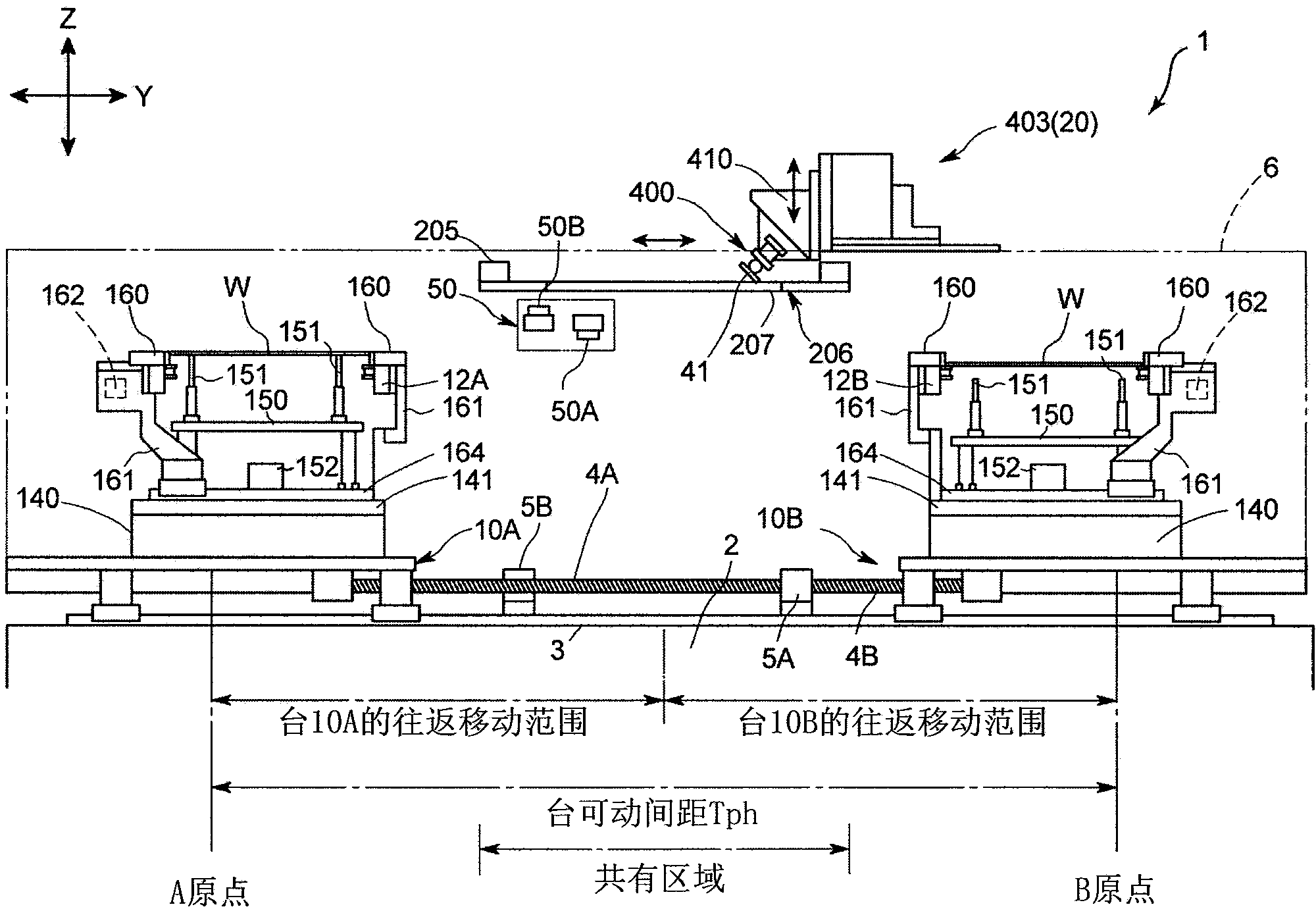

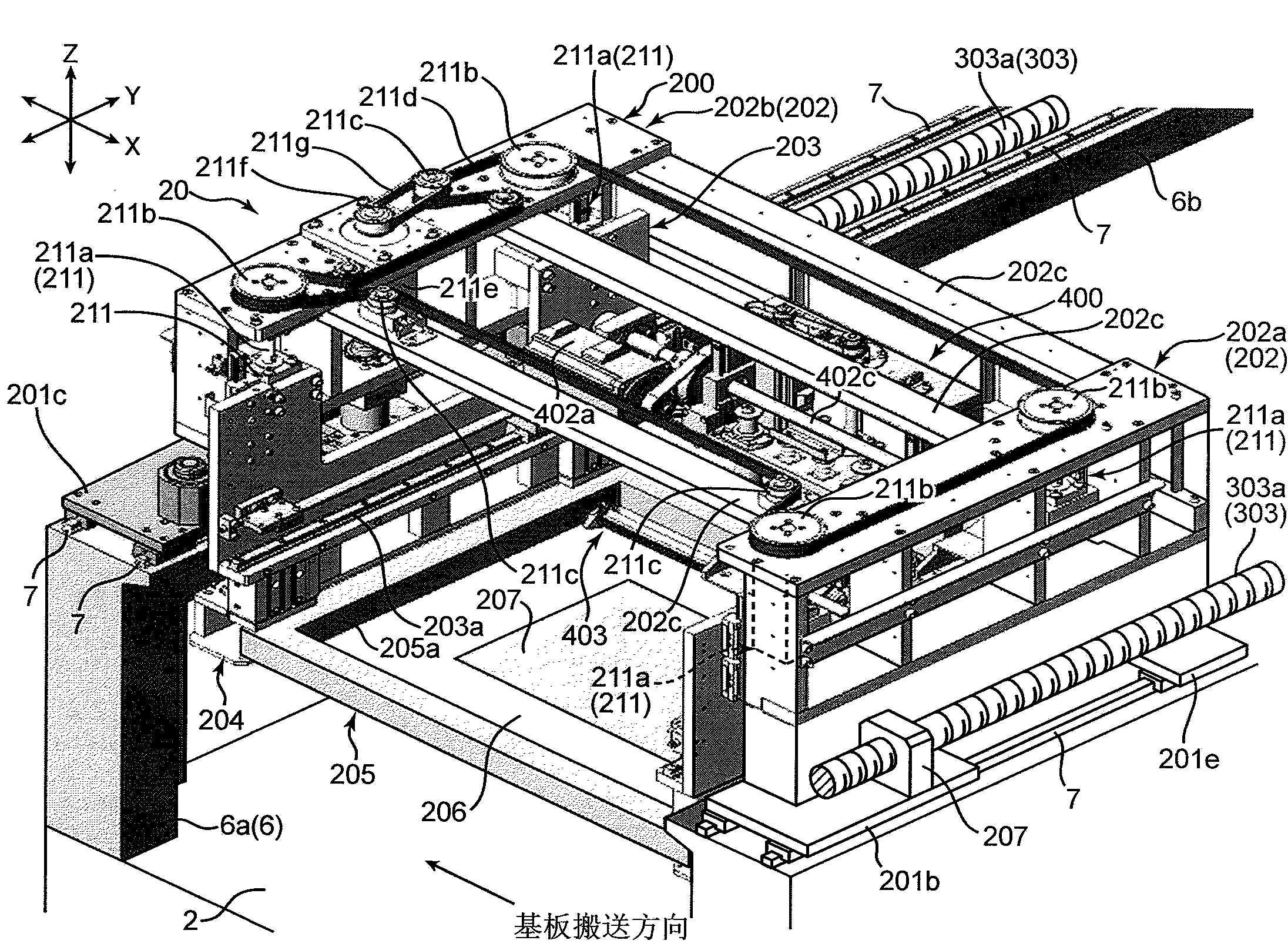

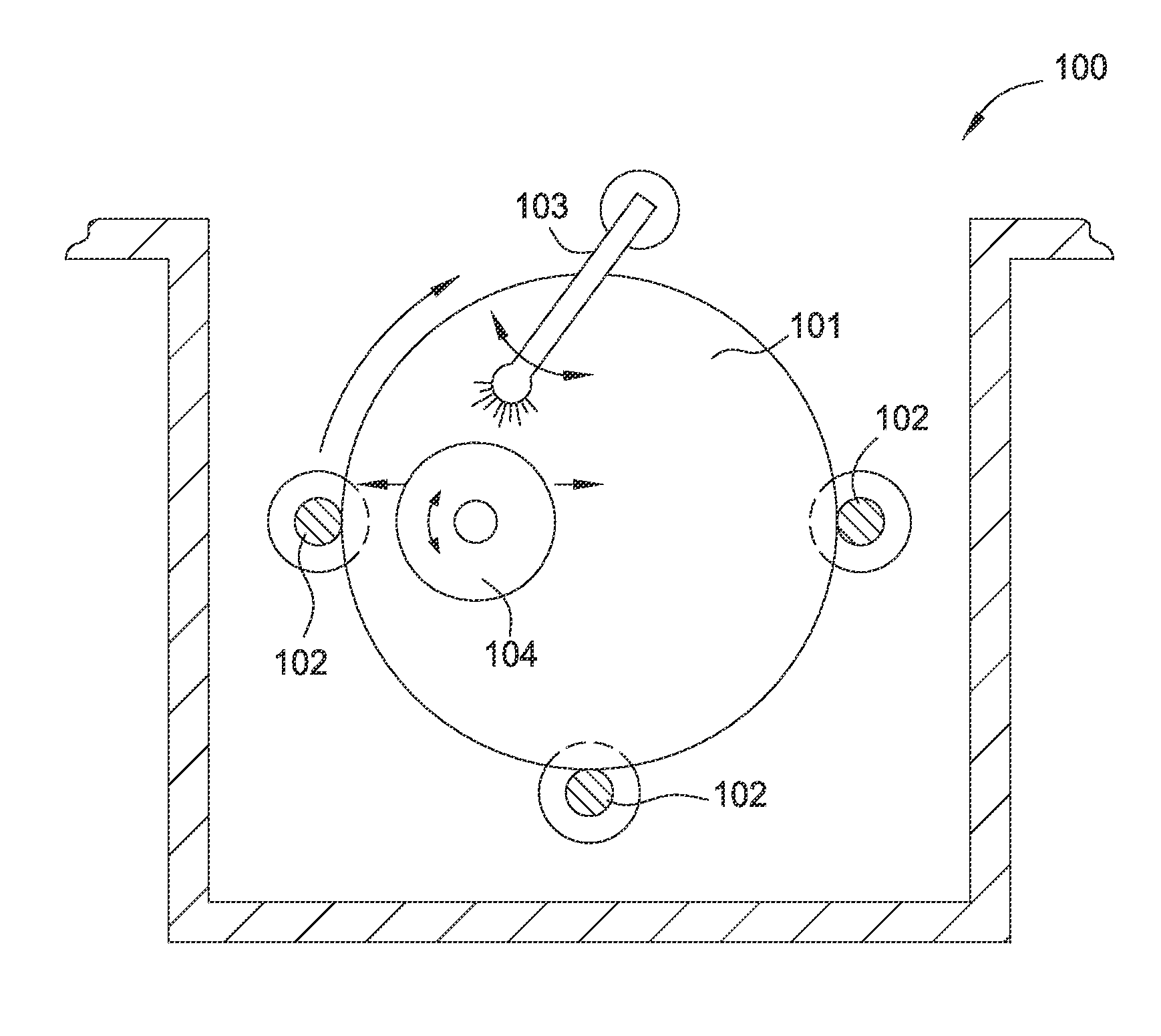

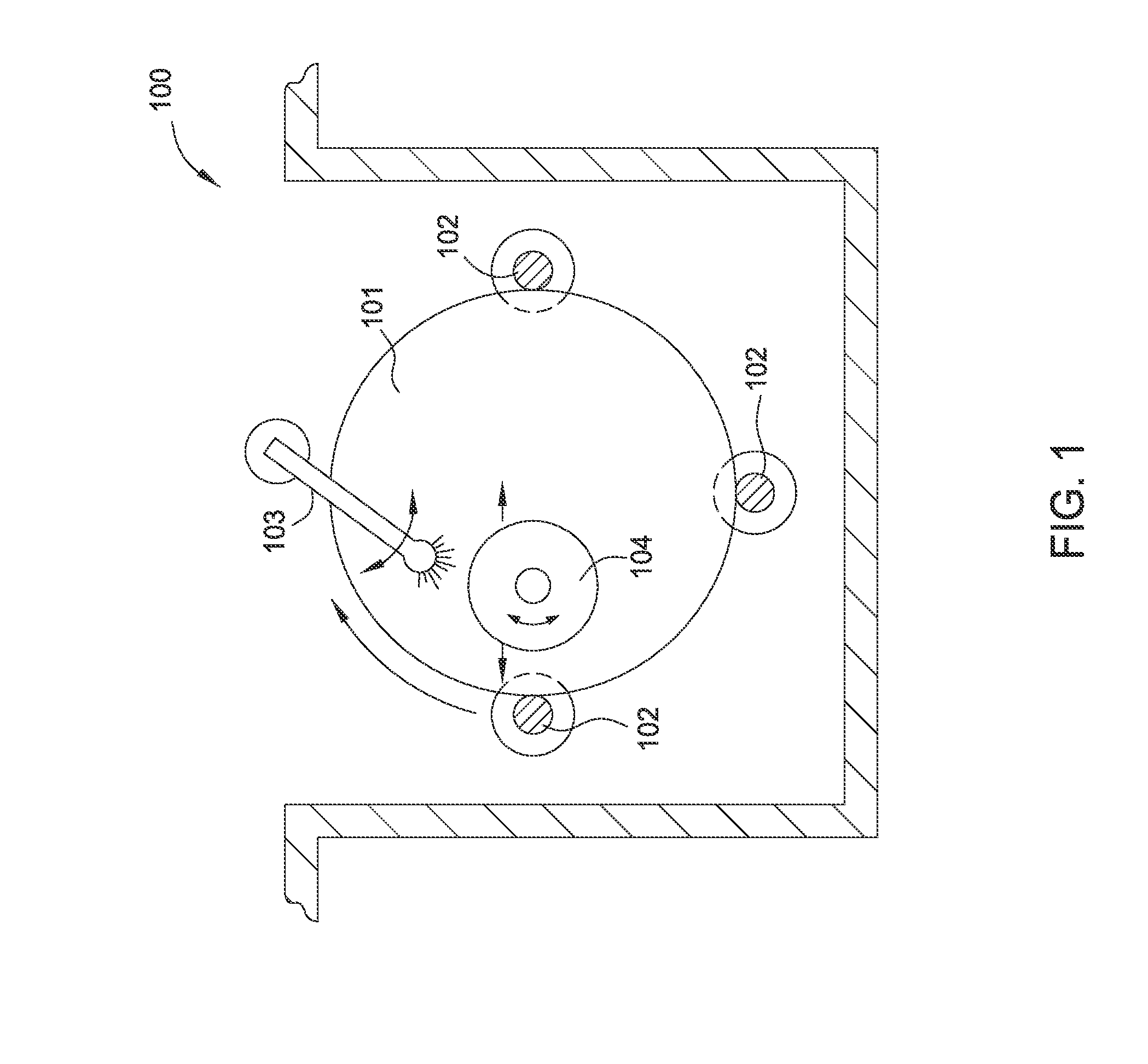

Screen printing device

ActiveCN103619595APrinted circuit assemblingPrinted circuit liquid treatmentScreen printingExecution unit

Disclosed is a screen printing device that has low redundancy, is low cost, and is compact, while maintaining high production efficiency, and that is able to be adapted to a dual-transport component mounting device. The present invention is provided with: a pair of substrate holding tables (10A, 10B) that are provided in order to hold substrates (W) that are to be printed, and are disposed in parallel along the y-axis direction perpendicular to the direction of transport of the substrates (W); and a printing execution unit (20) that executes a printing step alternatingly to the substrates (W) supported at the pair of substrate supporting tables (10A, 10B). A printing position (SP) at which both substrate supporting tables (10A, 10B) perform alternating printing is altered within the range at which one of the substrate supporting tables (10A (10B)) and the other substrate supporting table (10B (10A)) face each other by means of the printing execution unit (20) being driven along the y-axis direction by means of the control by a control unit (60).

Owner:YAMAHA MOTOR CO LTD

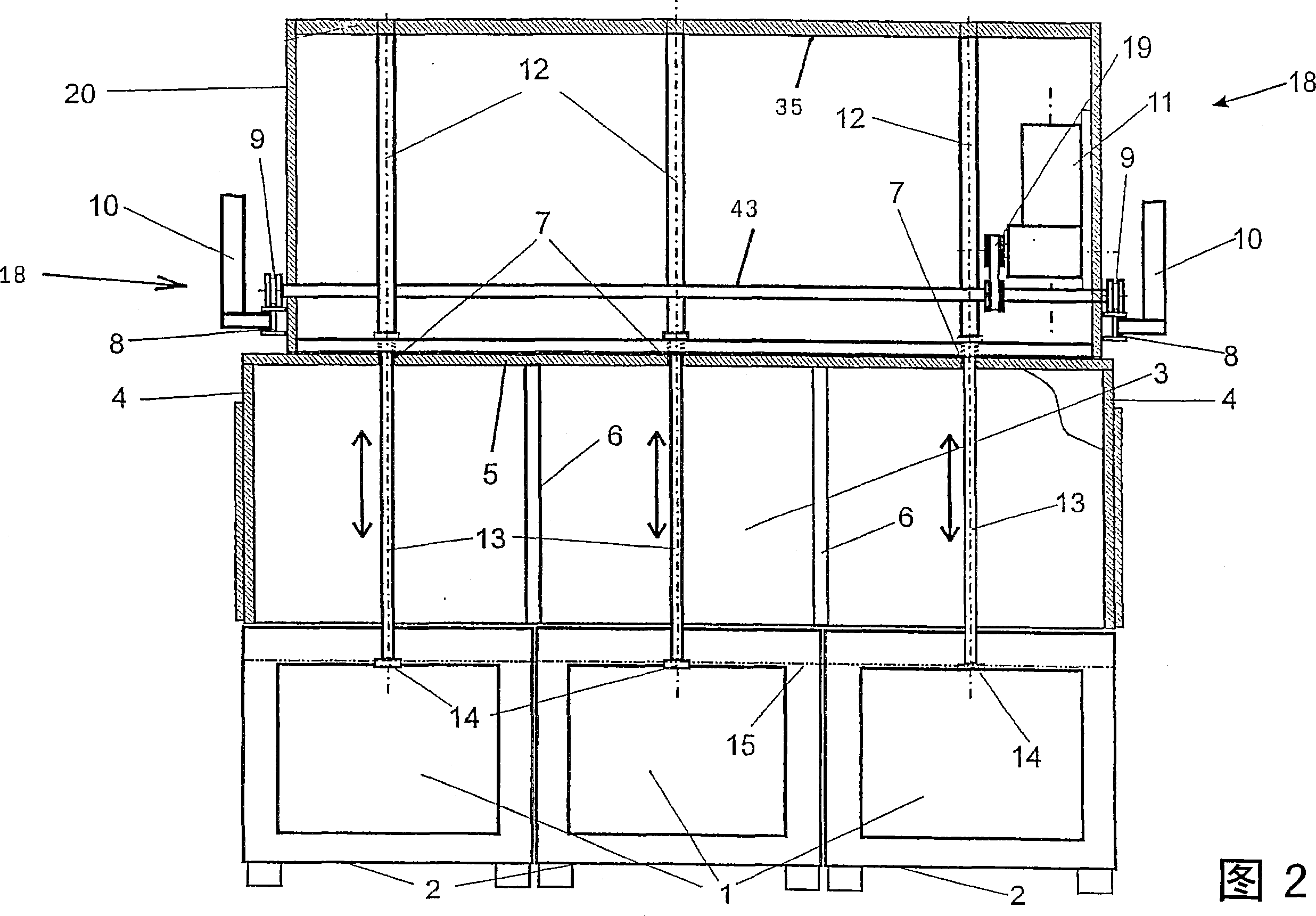

Device and method for electrolytically treating work pieces

InactiveCN101061259AReduce the overall heightLow space accommodationPrinted circuit liquid treatmentTanksSurface layerEngineering

The present invention provides methods for reducing the foreign body reaction against a structure implanted within an animal body. The methods include the step of providing an amount of an MMP-9 antagonist at the site of the implanted structure that is sufficient to reduce the foreign body response against the structure. The invention also provides implantable medical devices that include a surface layer that includes an amount of an MMP-9 antagonist sufficient to reduce the foreign body response against the device.

Owner:ATOTECH DEUT GMBH

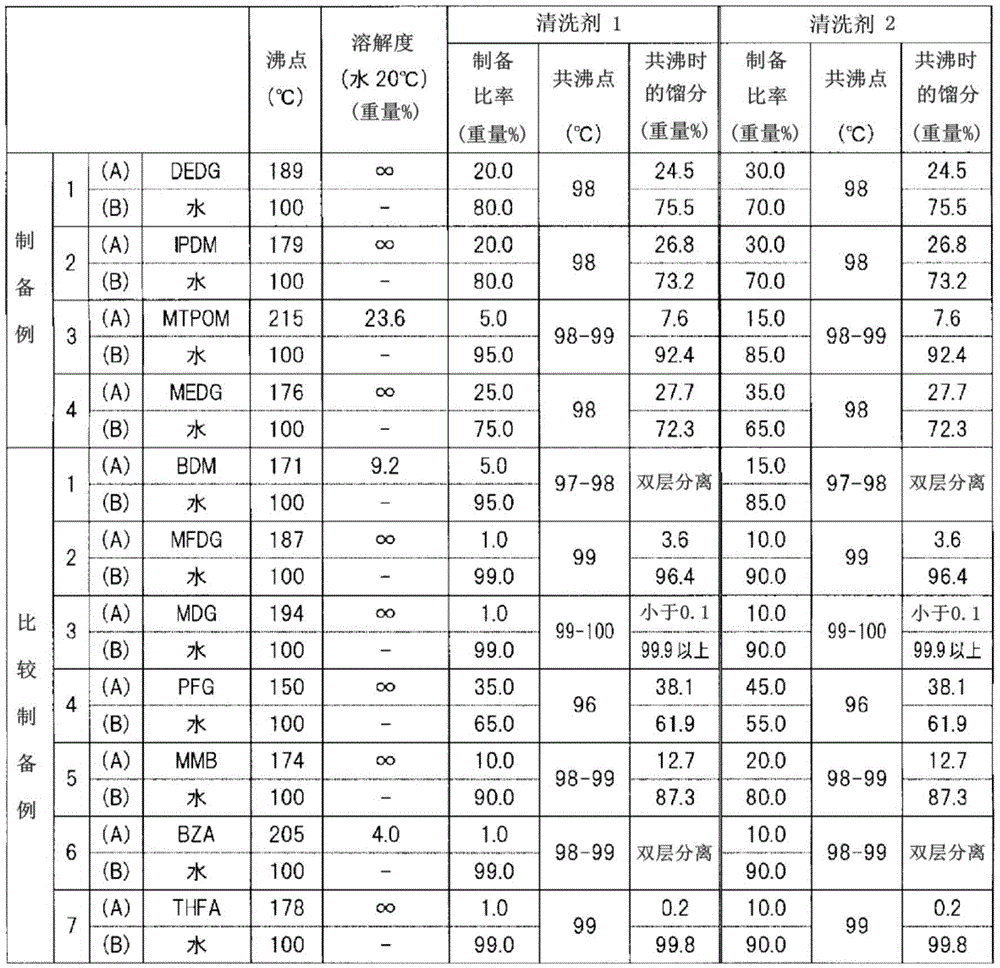

Recyclable azeotropic cleaning agent for industrial use, method for cleaning article, method for recycling azeotropic cleaning agent for industrial use, azeotropic cleaning agent for industrial use recycled by said recycling method, and cleaning/recycling apparatus

ActiveCN105658780AKeep dryImprove removal effectPrinted circuit assemblingPrinted circuit liquid treatmentDistillationSolvent

The objective of the present invention is to provide a glycol-based cleaning agent for industrial use, which has excellent ability of removing various kinds of industrial dirt such as solder pastes, flux residues and various oils adhering to articles, while having no flash point and being recyclable (recyclable by distillation) at atmospheric pressure. The present invention relates to a recyclable azeotropic cleaning agent for industrial use, which is characterized by containing an azeotropic mixture that contains (A) a glycol-based solvent represented by general formula (1) R1-O-[-CH2-CH(X)-O]n-R2 (wherein each of R1 and R2 represents an alkyl group having 1-3 carbon atoms, n represents 2 or 3, and X represents a hydrogen atom or a methyl group) and having a boiling point of 160-230 DEG C at atmospheric pressure, (B) water, and if necessary, (C) a tertiary amine having a boiling point of 160-230 DEG C at atmospheric pressure. This recyclable azeotropic cleaning agent for industrial use is also characterized in that: the azeotropic mixture contains the component (A), the component (B) and the component (C) respectively in an amount of 5-35 wt%, in an amount of 65-95 wt% and in an amount of 0-30 wt%; and the azeotropic mixture has an azeotropic point of 90-100 DEG C at atmospheric pressure.

Owner:ARAKAWA CHEM IND LTD

Method and apparatus for high efficiency post cmp clean using engineered viscous fluid

InactiveUS20160083676A1High viscosityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsViscous liquidEngineering

Owner:APPLIED MATERIALS INC

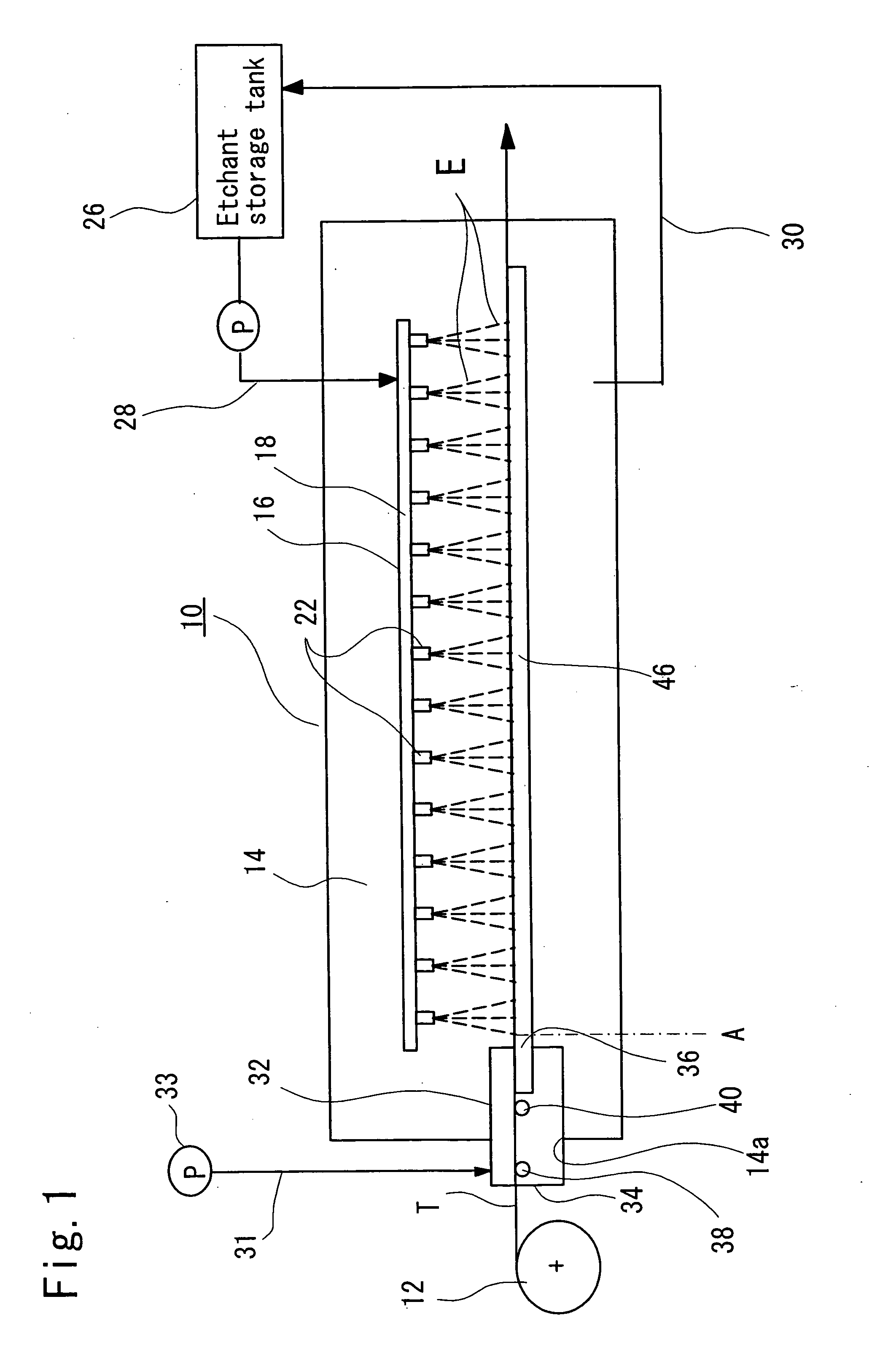

Etching device and circuit board etching method

InactiveCN102256447AImprove etch uniformityImprove uniformityPrinted circuit liquid treatmentSpraying apparatusElectricitySpray nozzle

The invention relates to an etching device which comprises a plurality of spray pipes, a plurality of sensors and a controller, wherein the spray pipes are successively arranged in parallel in a direction perpendicular to the transfer direction of a circuit board, each spray pipe comprises spray nozzles and a valve arranged on the spray pipe, the quantity of the spray nozzles on each spray pipe along the transfer direction of the circuit board is successively and gradually increased, the distances between every two adjacent spray nozzles on each spray pipe are equal, the spray nozzles on eachspray pipe are symmetrically distributed in relative to the same straight line perpendicular to the spray pipes, and the valve is used for controlling whether the spray nozzles located on the same spray pipe with the valve spray an etching liquid or not; the sensors are in one-to-one correspondence to the spray pipes and are used for sensing the position relationship between the circuit board andthe spray pipe corresponding to each sensor; and the controller is electrically connected with the sensors and the valves and is used for controlling the opening and closing of the valve corresponding to each sensor according to the sensing results so as to control whether the spray nozzles located on the same spray pipe with the valve spray the etching liquid or not. The invention also relates to a method for etching a circuit board by using the etching device.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

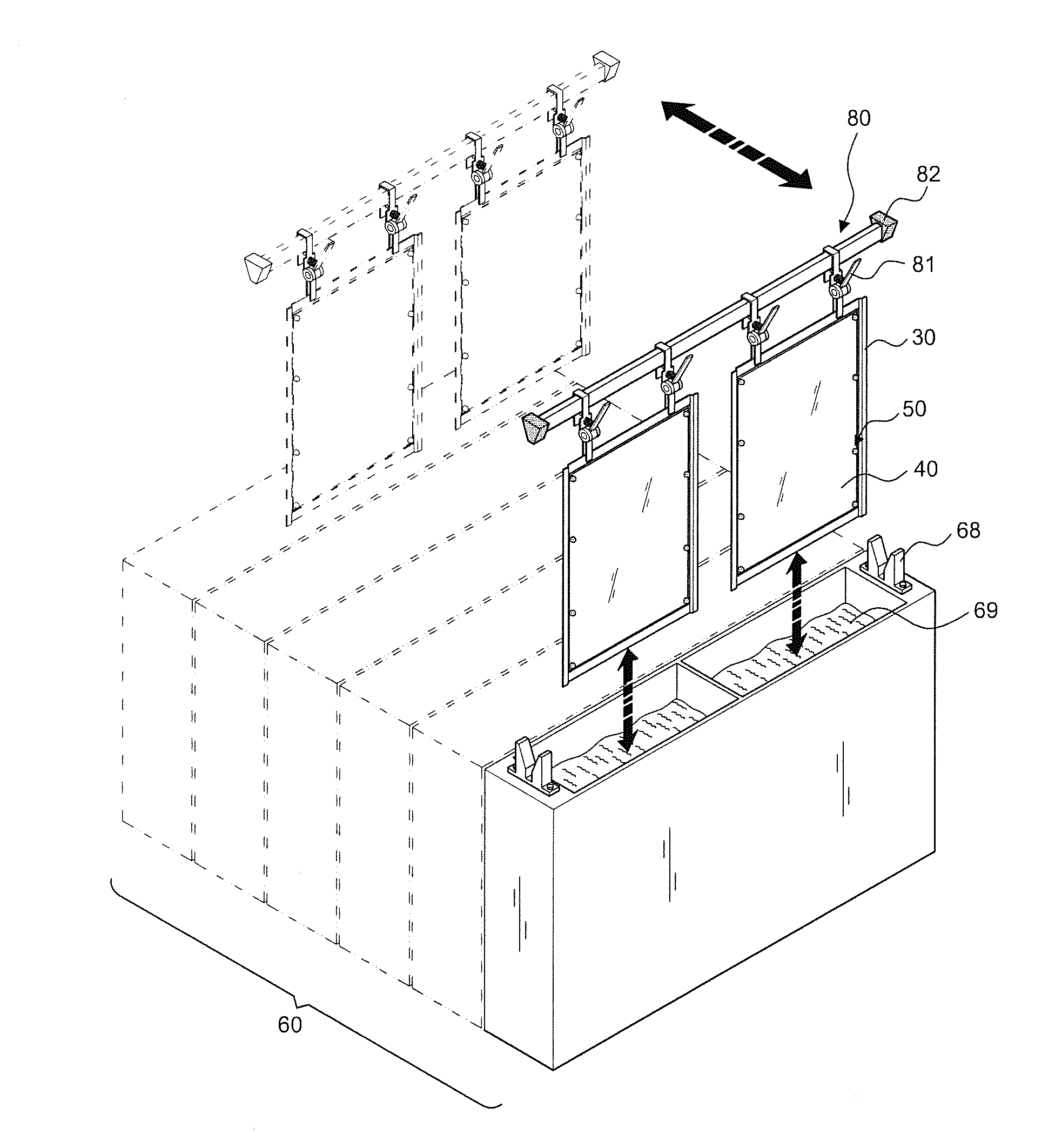

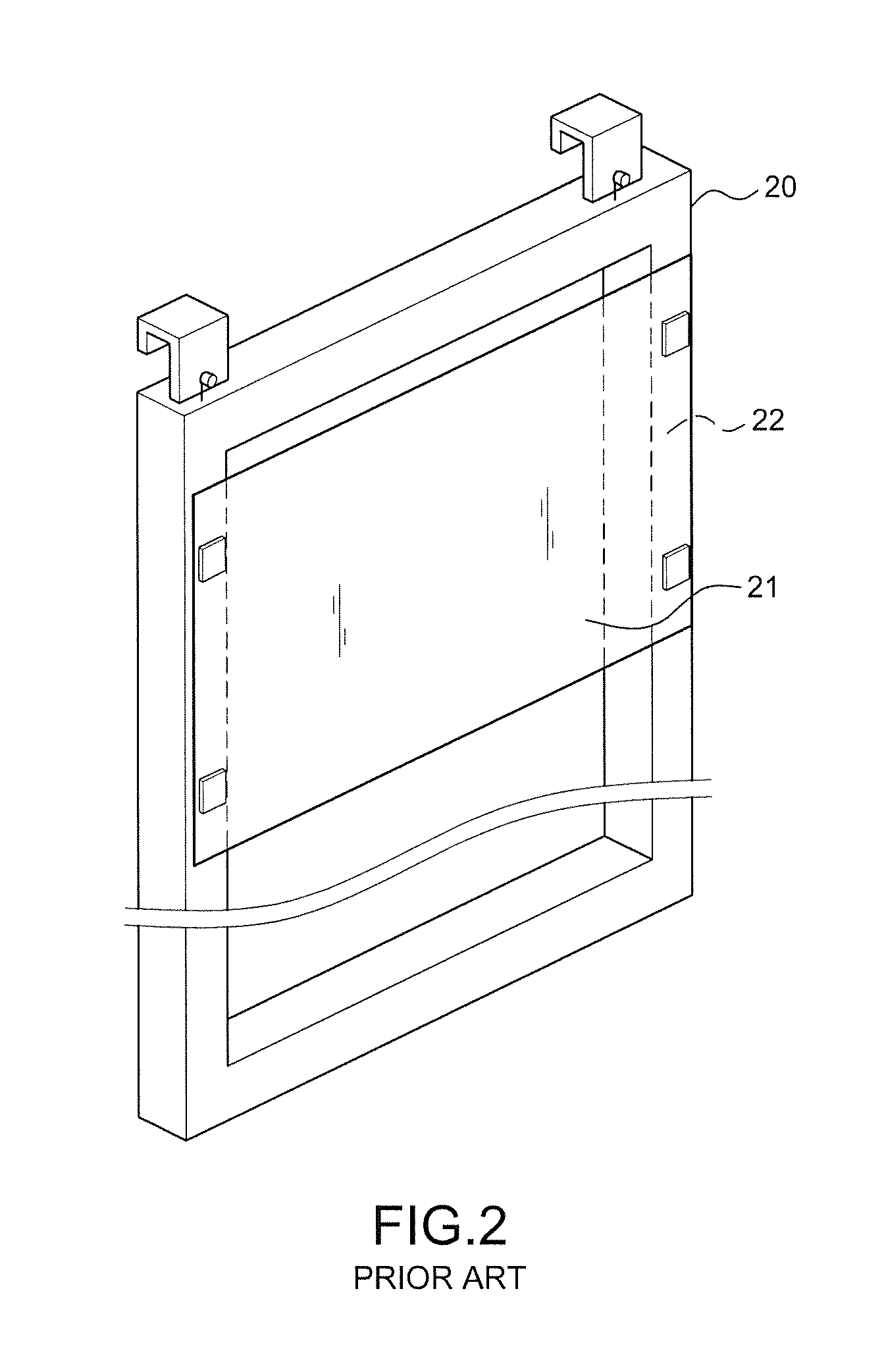

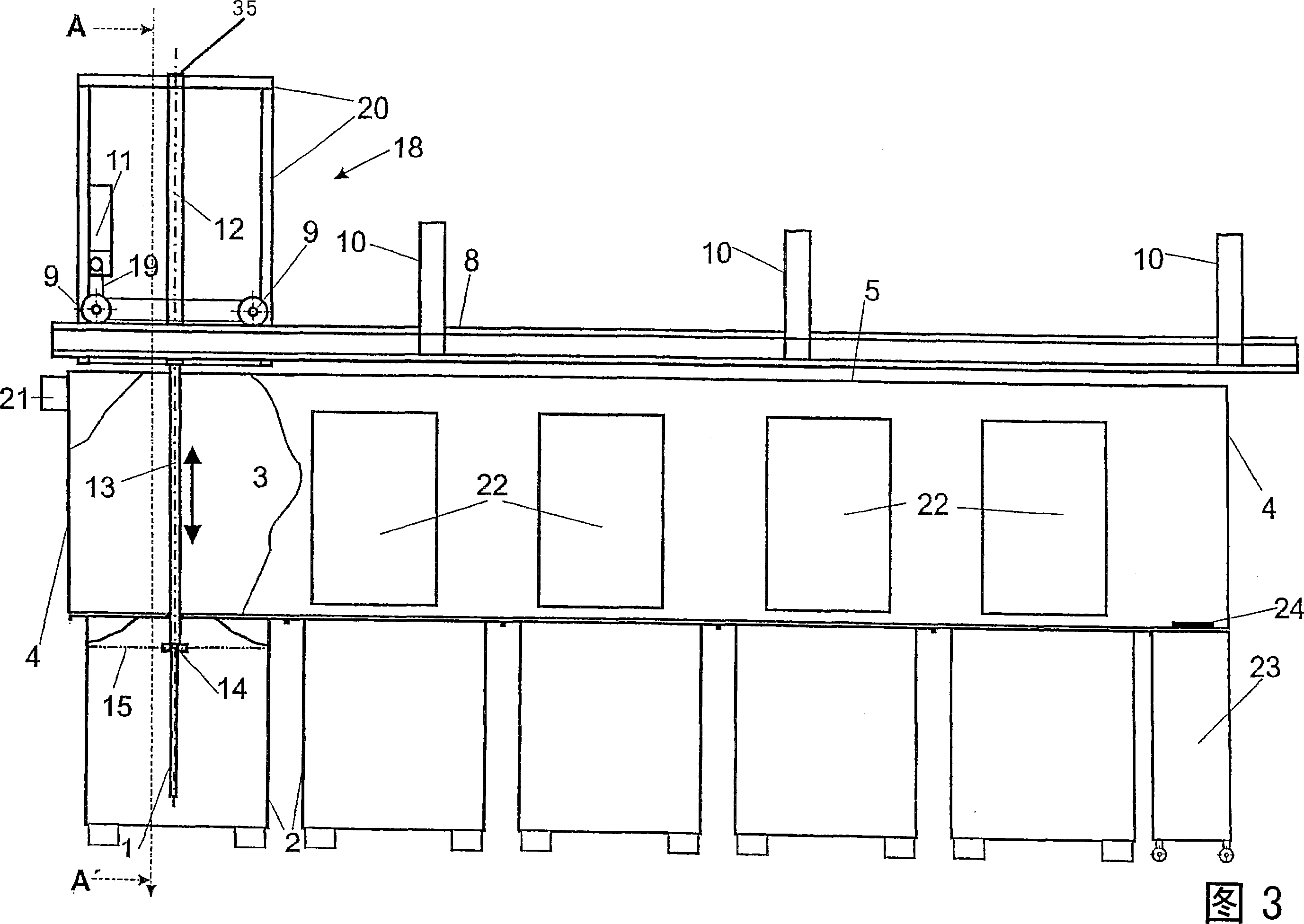

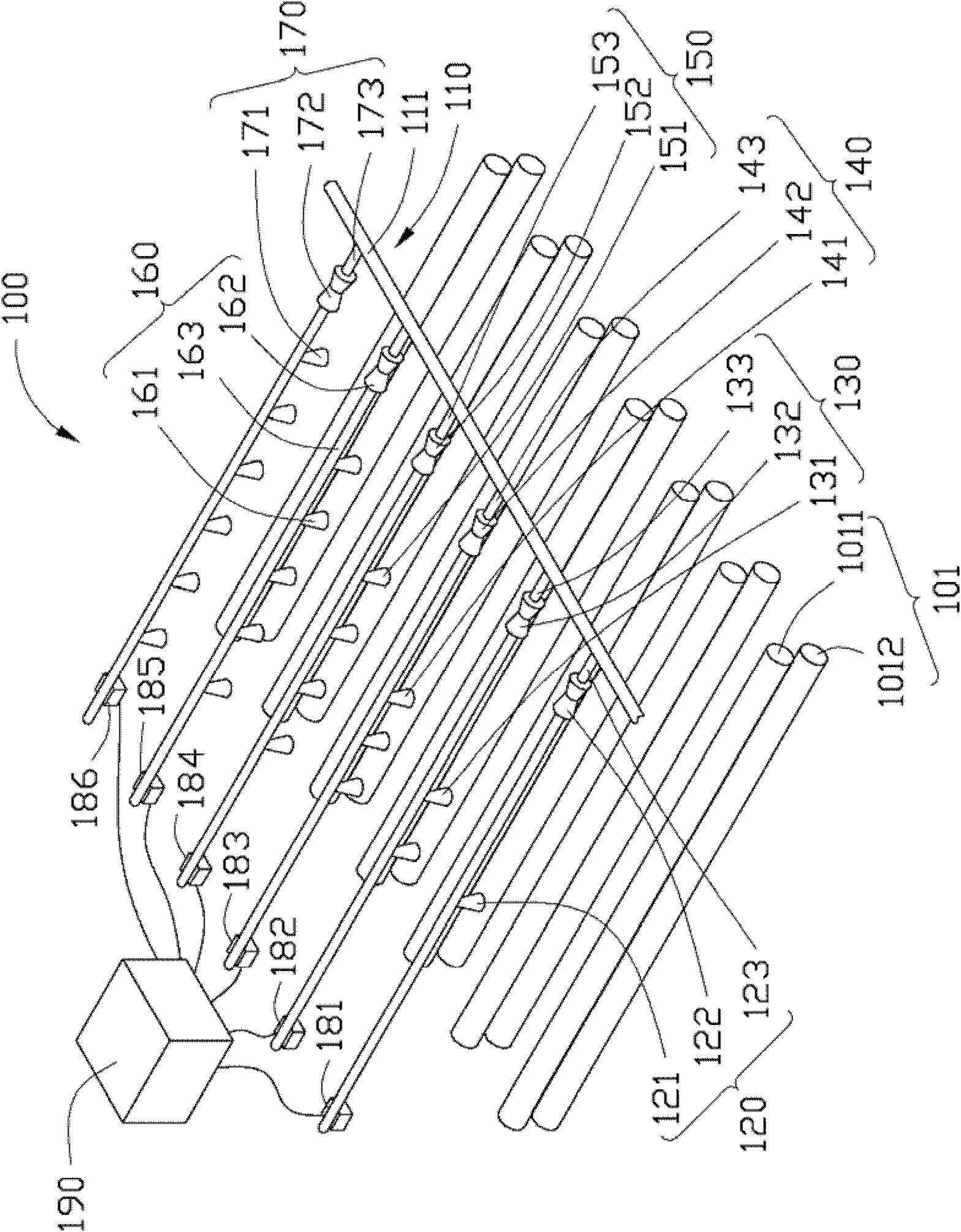

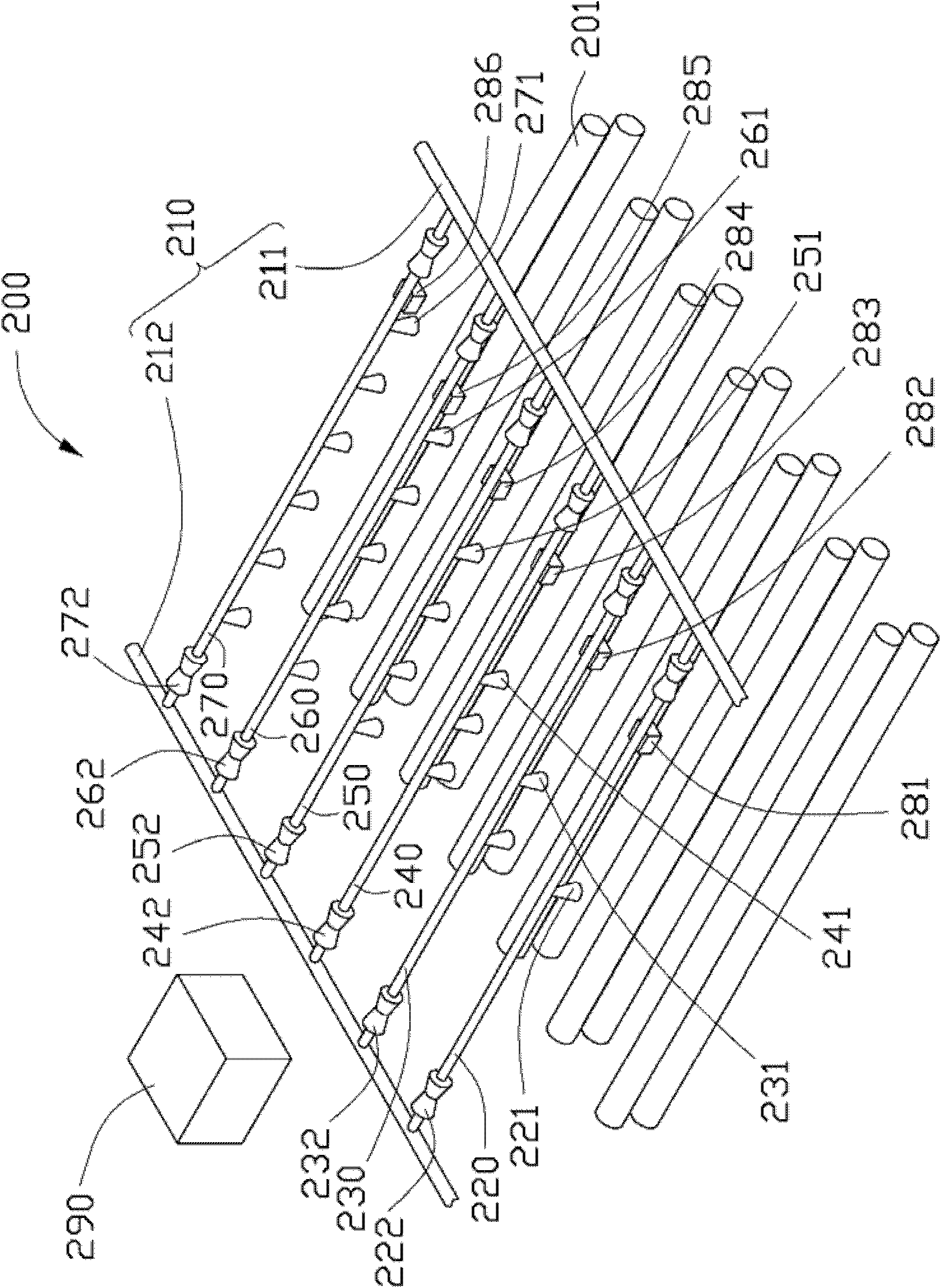

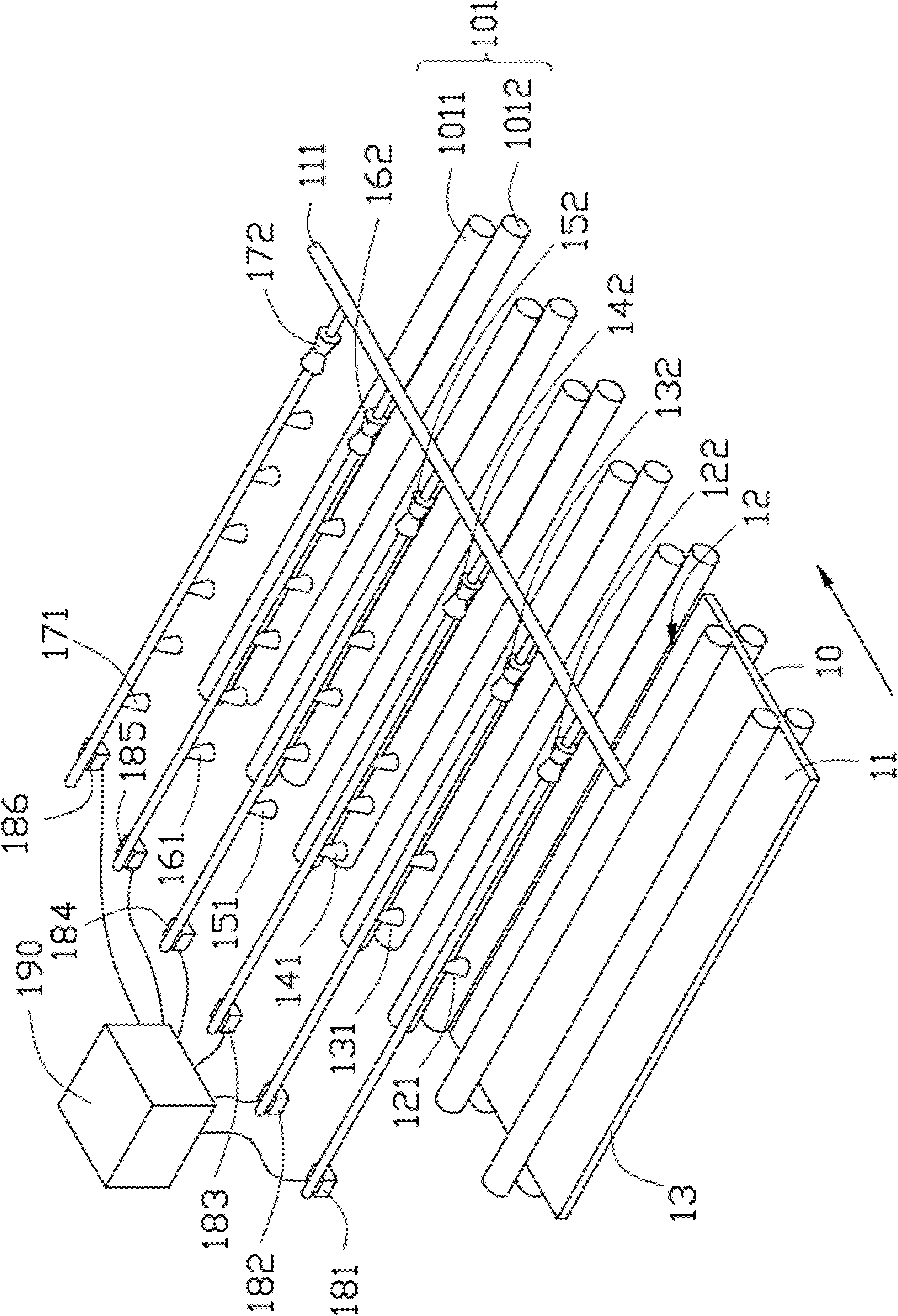

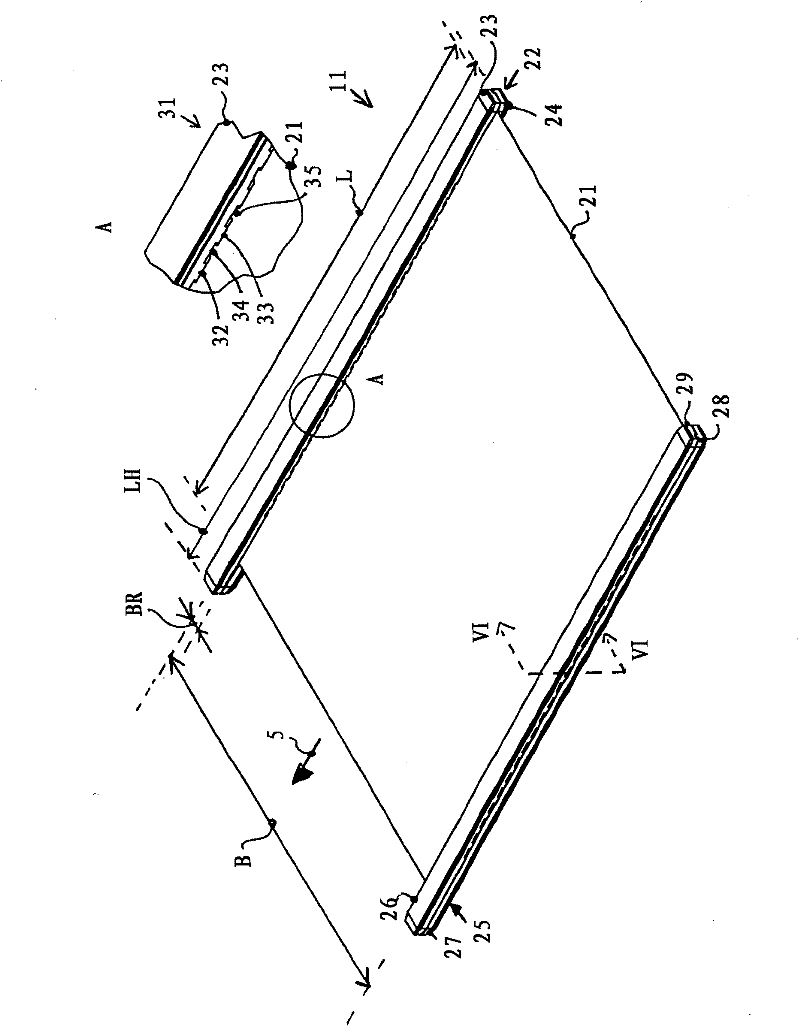

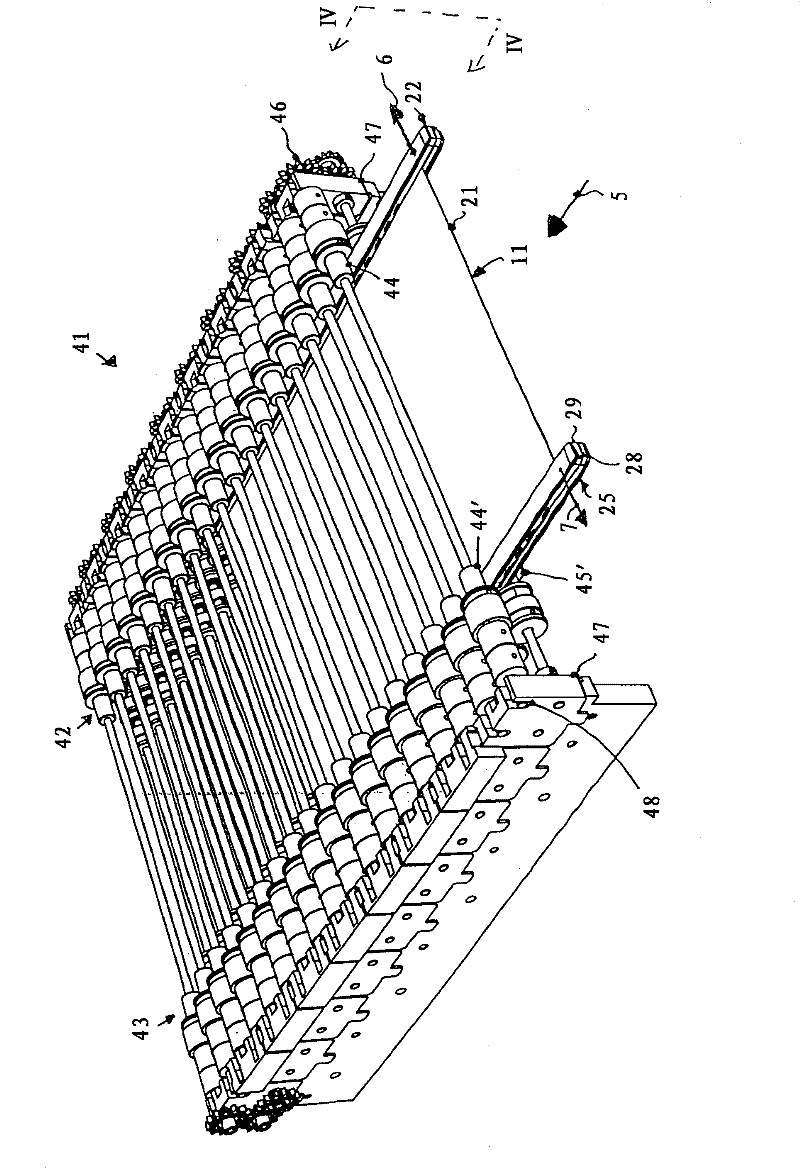

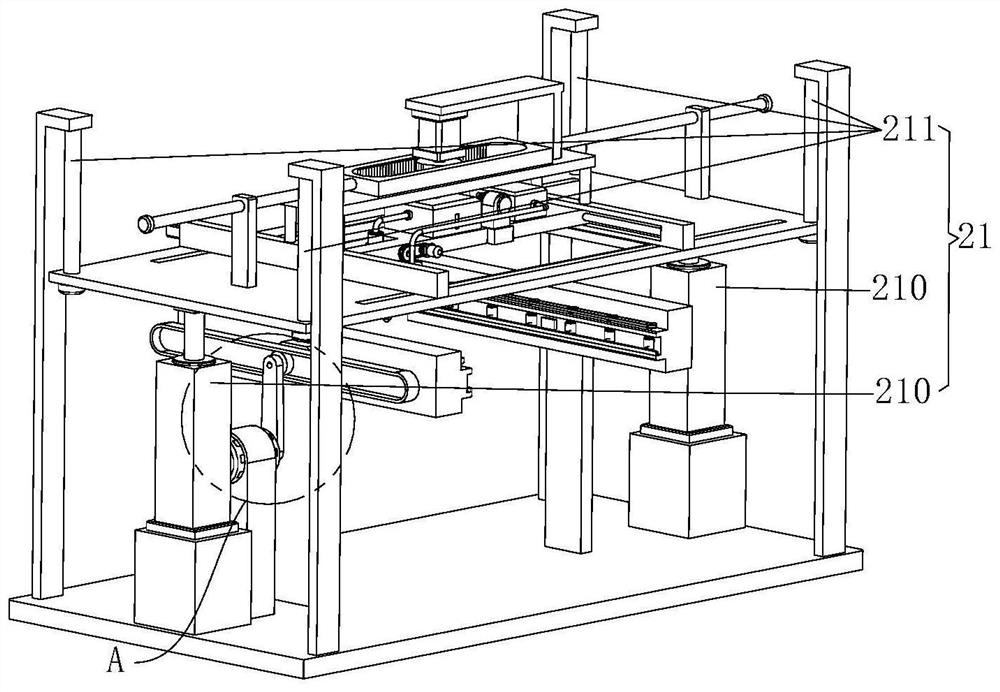

Method, retaining means, apparatus and system for transporting a flat material feedstock, and loading or unloading device

ActiveCN102405691ALow intrinsic stabilityTransportation safetyElectrolysis componentsPrinted circuit liquid treatmentChemical treatmentEngineering

In order to transport a flat material feedstock (21) in a system for the chemical and / or electro-chemical treatment of the material feedstock (21), in which the material feedstock (21) is transported in a transport plane in a transport direction (5), retaining means (22, 25) are attached to the material feedstock (21). The retaining means (22, 25) hold the material feedstock (21) at at least two points of an edge region of the material feedstock (21), said edge region being oriented in the transport direction (5) during the transport of the material feedstock (21). The retaining means (22, 25) are detachably coupled to a transport apparatus (41), which moves the retaining means (22, 25) in the transport direction in order to transport the material feedstock (21). At least during one transportation stage of the material feedstock (21), a force (6, 7) having a force component is applied to an area of the material feedstock (21), for example to the longitudinal edge region, said force component being located in the transport plane and extending transversely to the transport direction (5).

Owner:ATOTECH DEUT GMBH

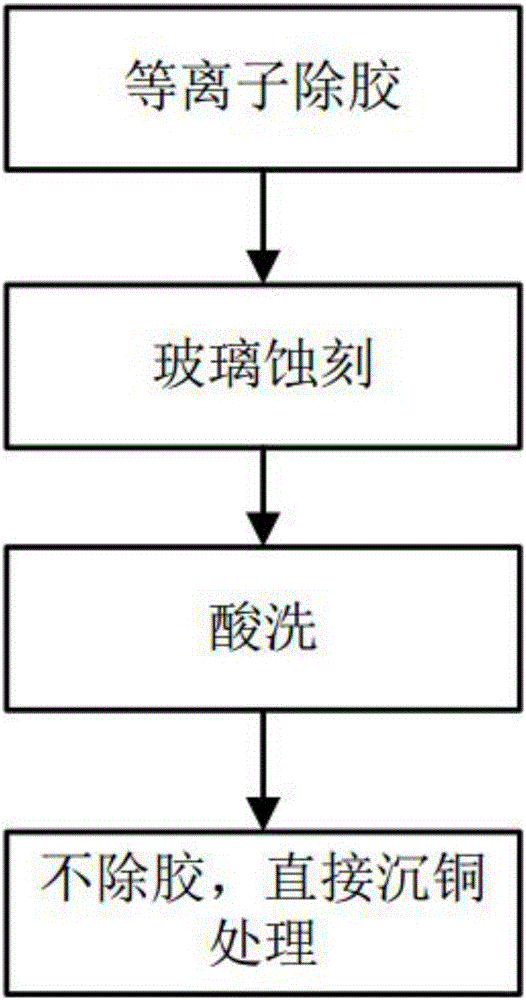

Multilayer PCB positive back etching process

The invention relates to the PCB manufacturing field and provides a multilayer PCB positive back etching process. According to the multilayer PCB positive back etching process, plasma adhesive cleaning processing on a PCB after a boring flow is carried out, secondly, glass etching processing is then carried out, and lastly, PCB manufacturing is accomplished according to the technology in the prior art. The process is advantaged in that through combining two etching modes of plasma adhesive cleaning and glass etching, glass fiber and epoxy resin in a prepreg of the PCB are enabled to reach a relatively balance fretting rate in an etching process, and a relatively ideal back etching effect is realized.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

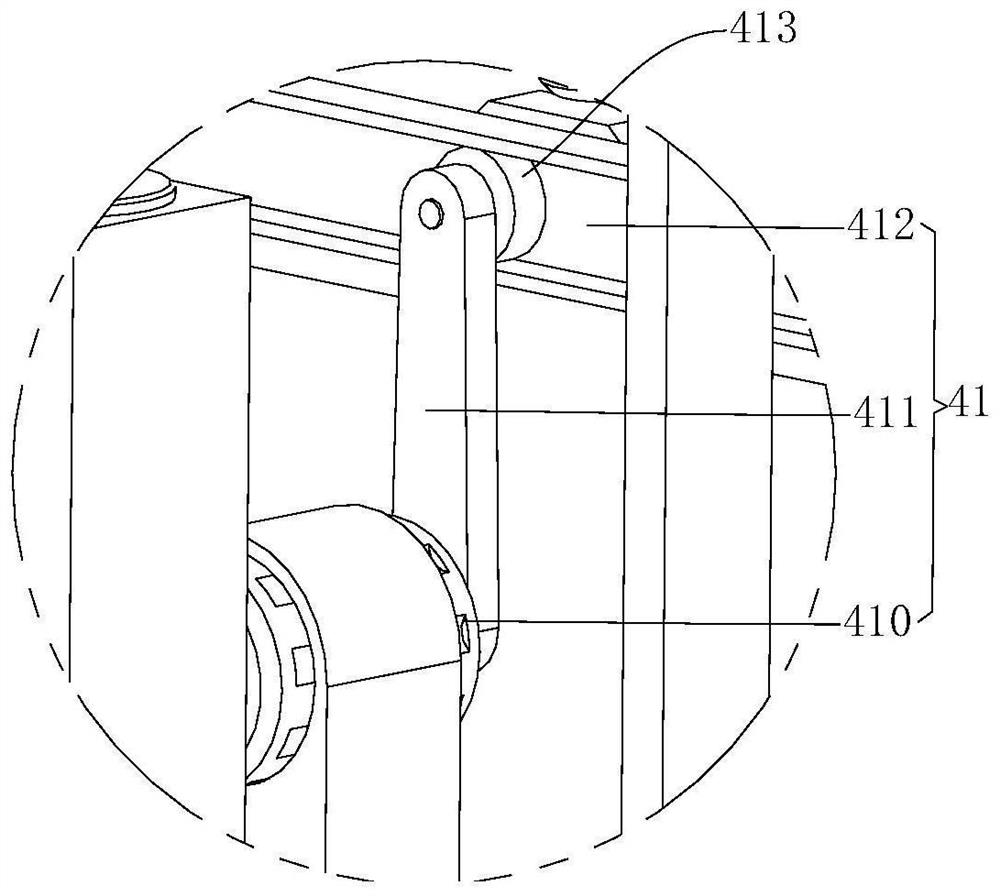

Circuit board glue printing device capable of automatically overturning

PendingCN111712040AAvoid runningAvoid wastingPrinted circuit liquid treatmentConveyor partsPhysicsEngineering

The invention relates to the technical field of circuit board dispensing, in particular to a circuit board glue printing device capable of automatically overturning. The device comprises a base and alifting mechanism, and the lifting mechanism comprises a lifting plate and a jacking assembly. The device further comprises a controller, a turnover mechanism and a dispensing mechanism, the turnovermechanism comprises a clamping assembly, a driving assembly and two carrying frames, and the dispensing mechanism comprises a transverse sliding assembly, a longitudinal sliding assembly and a glue injection assembly. A machining groove is formed in the lifting plate, the transverse sliding assembly is arranged at the top of the machining groove, and the longitudinal sliding assembly is arranged at the top of the transverse sliding assembly. The glue injection assembly is fixedly arranged at the top of the transverse sliding assembly, and the jacking assembly, the clamping assembly, the driving assembly, the transverse sliding assembly, the longitudinal sliding assembly and the glue injection assembly are all electrically connected with the controller. According to the circuit board glue printing device capable of automatically overturning and a working method, manual overturning is not needed, the overturning speed is high, meanwhile, the circuit board glue printing device can have arapid drying function and can guarantee the product quality.

Owner:何金昌

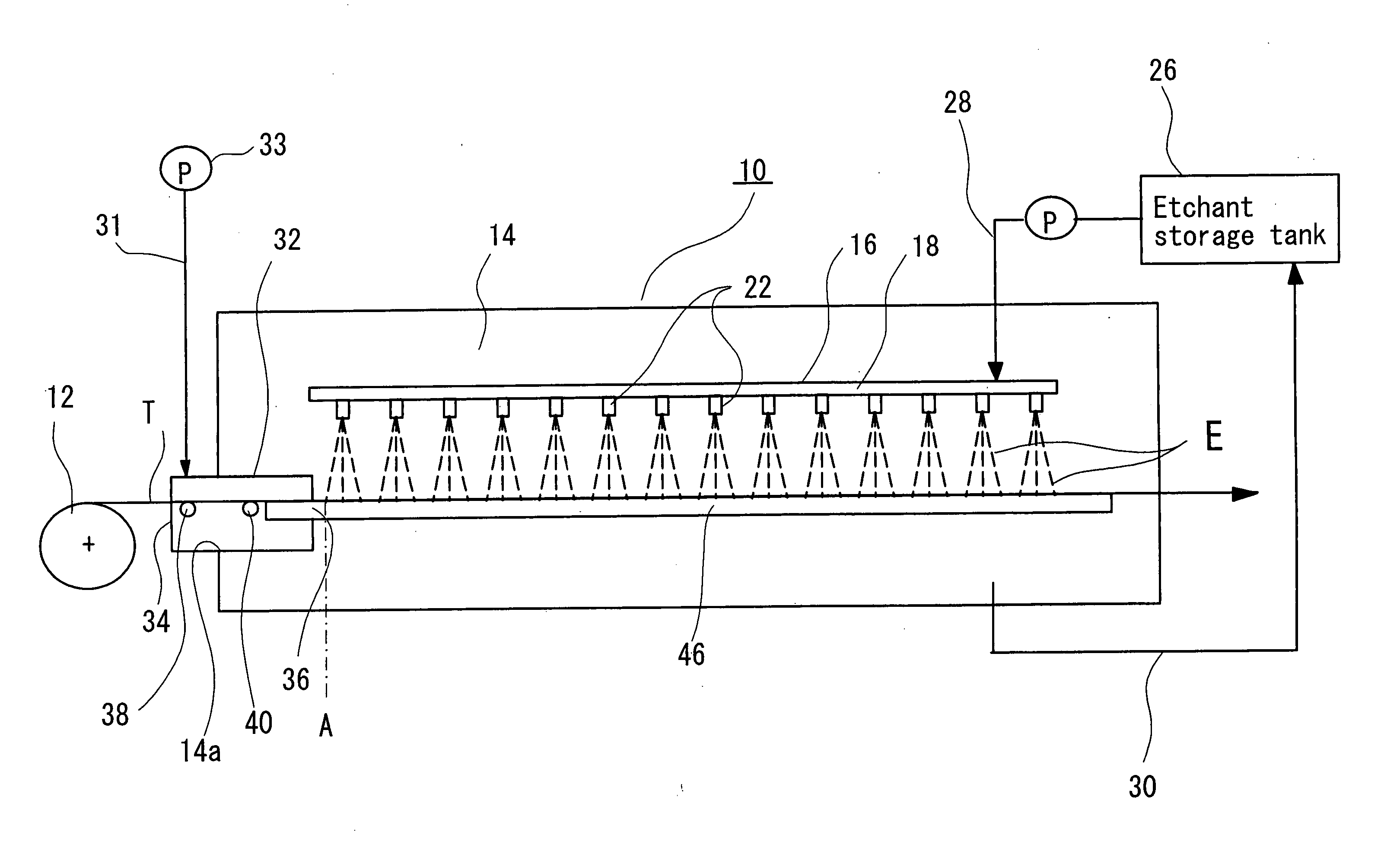

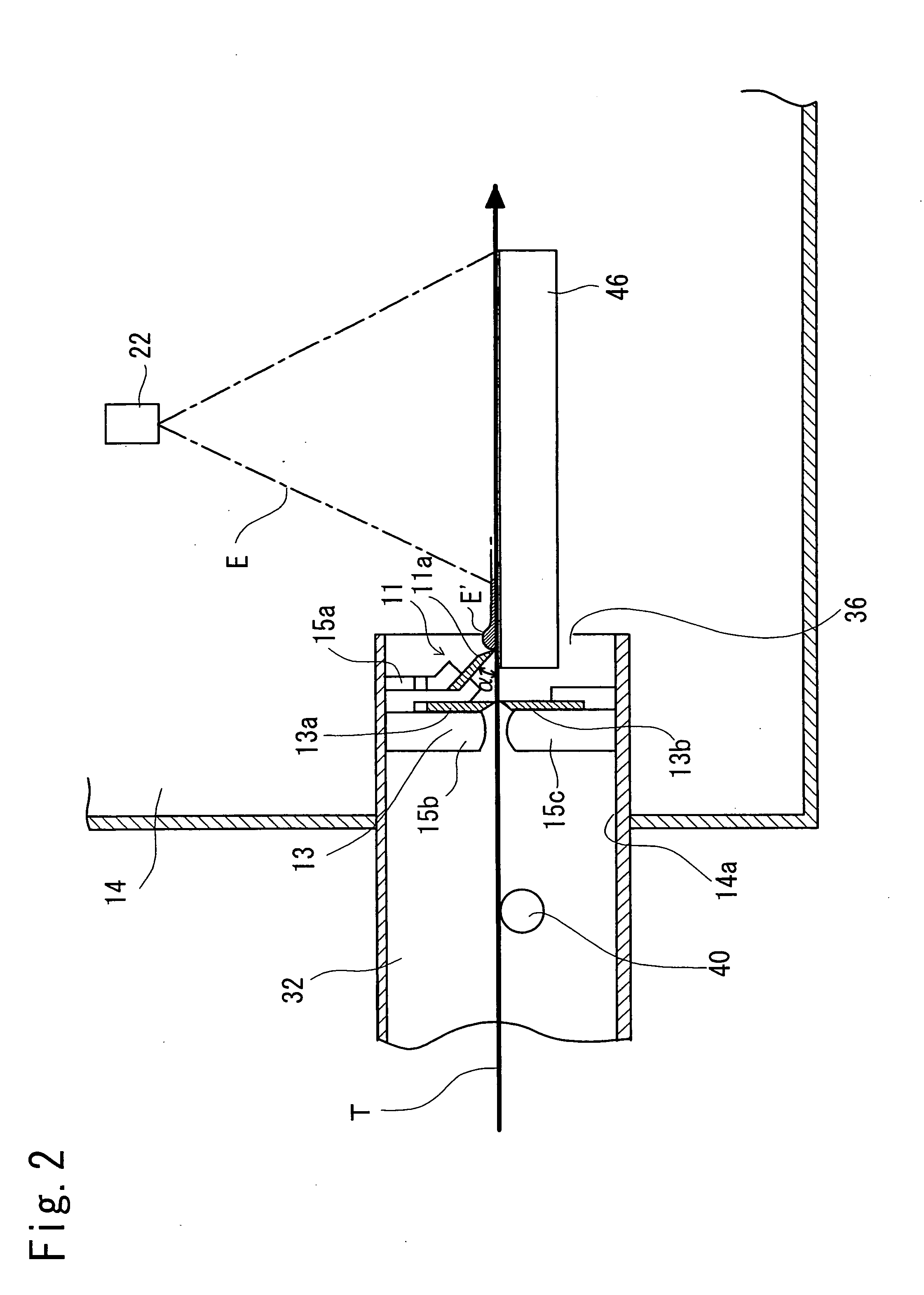

Liquid treating apparatus

InactiveUS20060154490A1Reliably carry-outAvoid it happening againPrinted circuit liquid treatmentSemiconductor/solid-state device manufacturingElectronic componentNozzle

A liquid treating apparatus includes an etchant discharging nozzle for discharging a treating solution (E) onto an upper surface of a film carrier tape for mounting an electronic component (T) from above and a treating solution contact prevention chamber disposed on an upstream side of a liquid treating start position (A) in which an etchant (E) discharged onto an upper surface of the film carrier tape (T) through an etchant discharging nozzle starts etching and serving to prevent the discharged solution from coming in contact with the film carrier tape (T) before the liquid treating start position (A). The apparatus also includes a liquid sealing lip member of a first infiltration preventing member and an upper lip component and a lower lip component of a second infiltration preventing member disposed in the treating solution contact prevention chamber.

Owner:MITSUI MINING & SMELTING CO LTD +1

Transfer apparatus, cleaning apparatus, chemical processing apparatus, and method for manufacturing circuit substrate

InactiveUS20050006026A1Prevent transfer controlAvoid tensionConveyorsPrinted circuit liquid treatmentCompound (substance)Engineering

Owner:SEIKO EPSON CORP

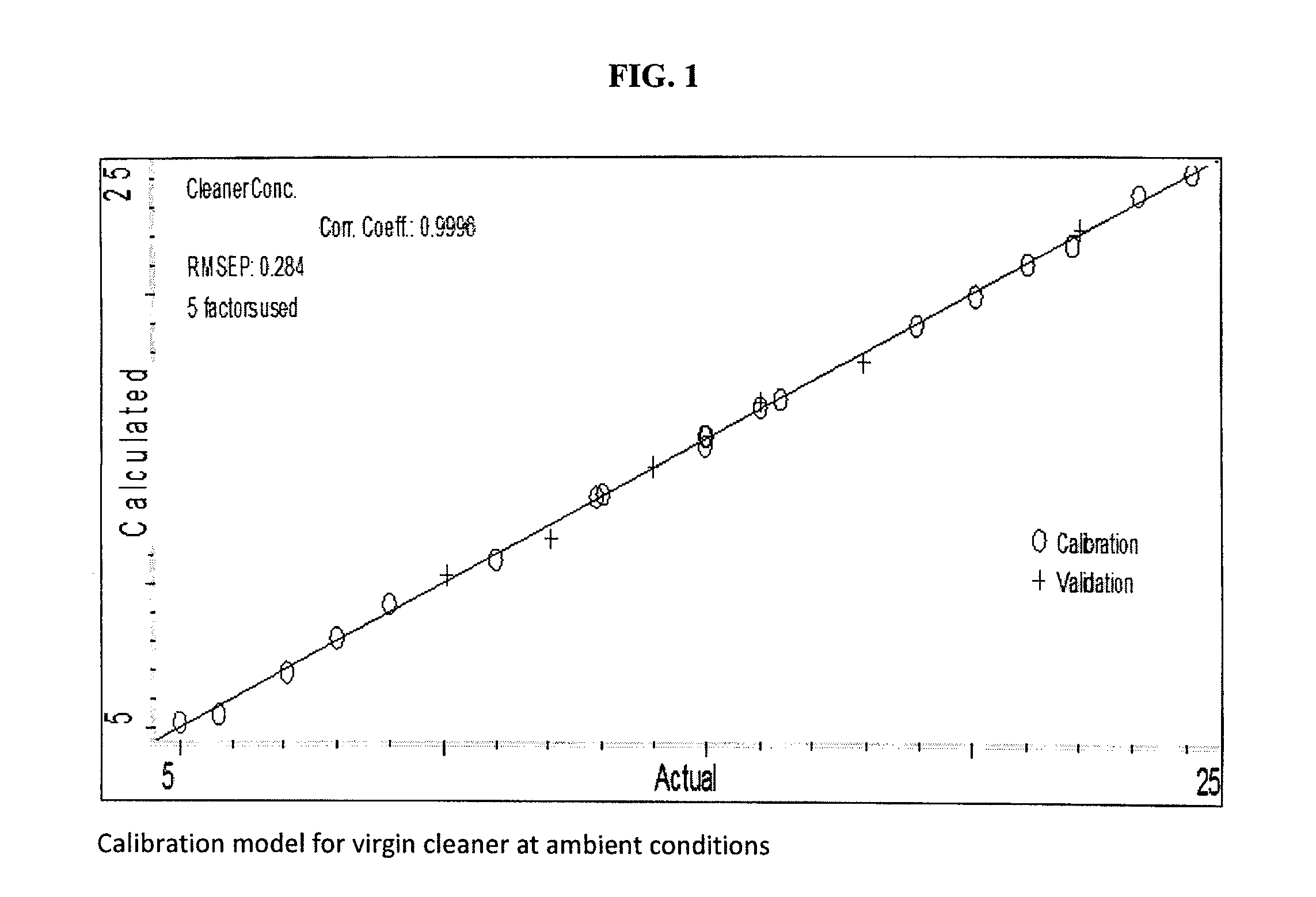

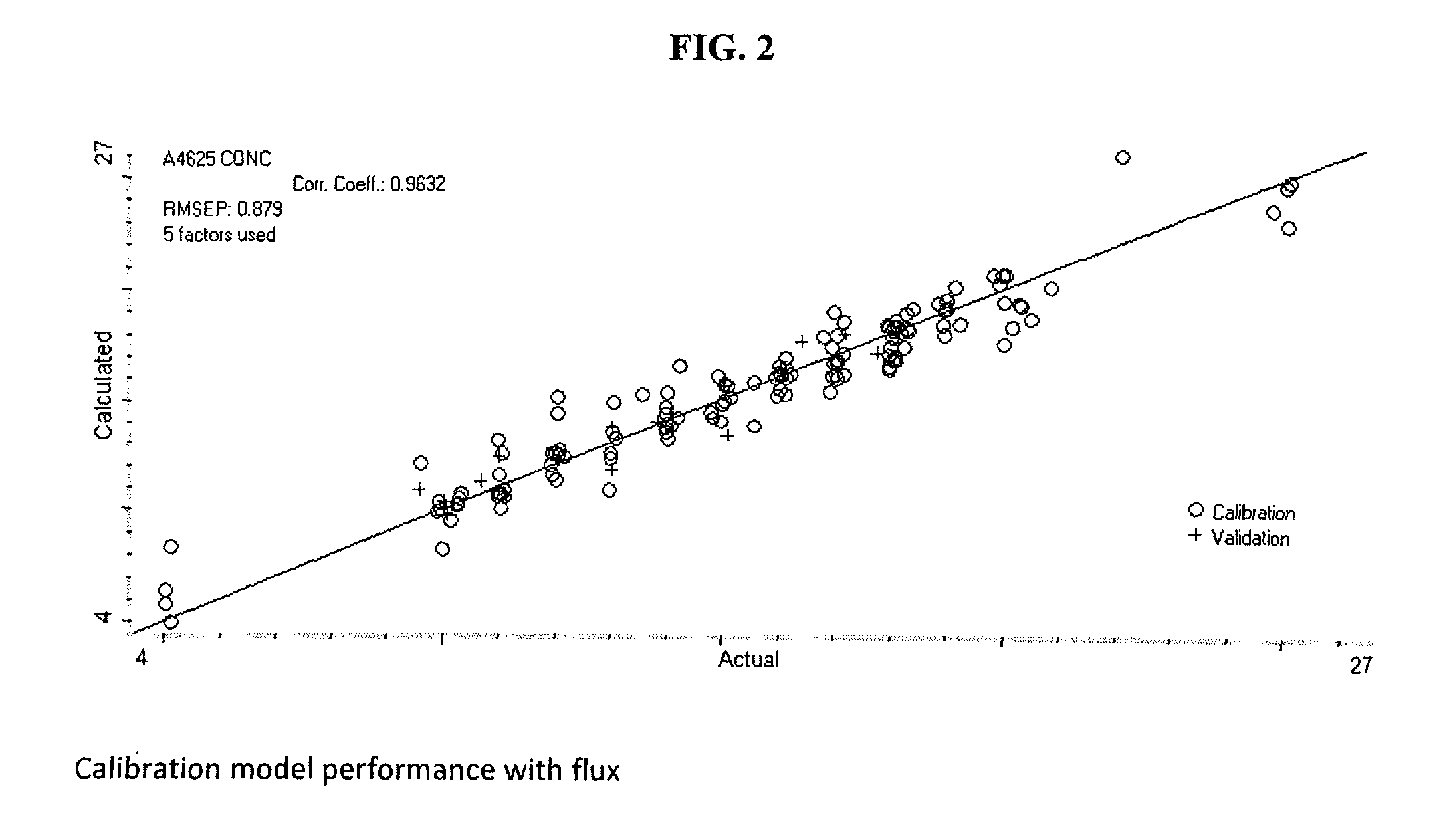

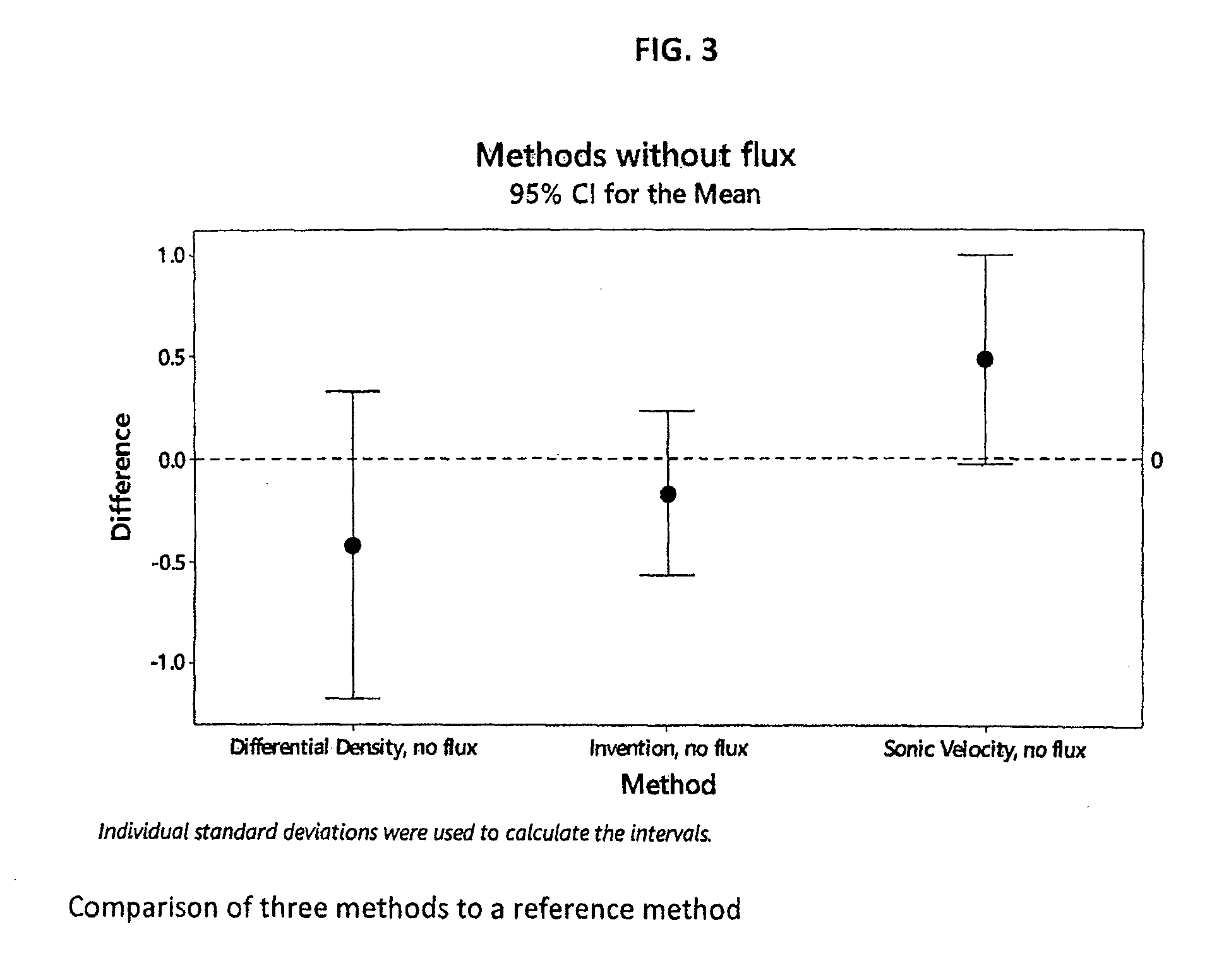

Method and apparatus for monitoring and controlling a cleaning process

InactiveUS20160047741A1Ensure effectivenessReduce processing costsRadiation pyrometryPrinted circuit liquid treatmentFiberLength wave

A method of accurately measuring the concentration of at least one of an aqueous cleaning agent and soil in an aqueous cleaning process which includes providing a source of near infrared light emitting useful amounts of light with wavelengths between approximately 0.8 μm and 2.5 μm, transmitting the near infrared light from the light source to a probe, contacting the probe with a cleaning bath sample such that one of the absorption and the reflection of the light at one or more wavelengths can be measured, transmitting the light that has interacted with the sample to a detector, measuring the change in light intensity at one or more wavelengths in the near infrared region using a near infrared detector, generating an electronic signal that is representative of the change in intensity, applying chemometric techniques to quantitatively determine the concentration of the cleaning agent and or soil, and outputting the measured cleaning agent or soil concentration. The light source is connected to the probe via a fiber-optic cable and the probe is connected to the detector via a fiber-optic cable.

Owner:KYZEN CORP

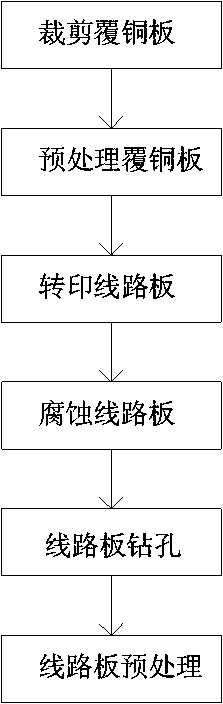

Environment-friendly novel circuit board manufacturing method

InactiveCN110859025AAffect healthPrinted circuit liquid treatmentDispersed particle filtrationMetallurgyAir blower

The invention discloses an environment-friendly novel circuit board manufacturing method, which comprises the following steps: a copper-clad board is cut to the size of a circuit board, and the size is not too large so as to save materials; the copper-clad board is preprocessed, the oxide layer on the surface of the copper-clad board is ground off with fine abrasive paper so as to ensure that carbon powder on heat transfer paper can be firmly printed on the copper-clad board when the circuit board is transferred; the circuit board is transferred, the printed circuit board is cut into a propersize, and the surface printed with the circuit board is attached to the copper-clad board; the circuit board is corroded, the circuit board is put into corrosive liquid for corrosion, and the circuitboard after the copper film is completely corroded is taken out; the circuit board is drilled, different drill needles are selected according to the thickness of the pins of electronic components to drill the circuit board; and the circuit board is pretreated, powdered ink covering the circuit board is ground off through fine abrasive paper, the circuit board is cleaned through clear water, afterthe water is dried, rosin water is smeared on the face, provided with the circuit, of the circuit board, and rosin solidification is accelerated through a hot-air blower.

Owner:绵阳市奇帆科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com