Nozzle arrangement

A nozzle device and housing technology, applied in the direction of spraying devices, spraying devices, cleaning methods and appliances, etc., can solve the problems of uneven flow rate, uneven treatment liquid volume, etc., and achieve the effect of flow rate balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

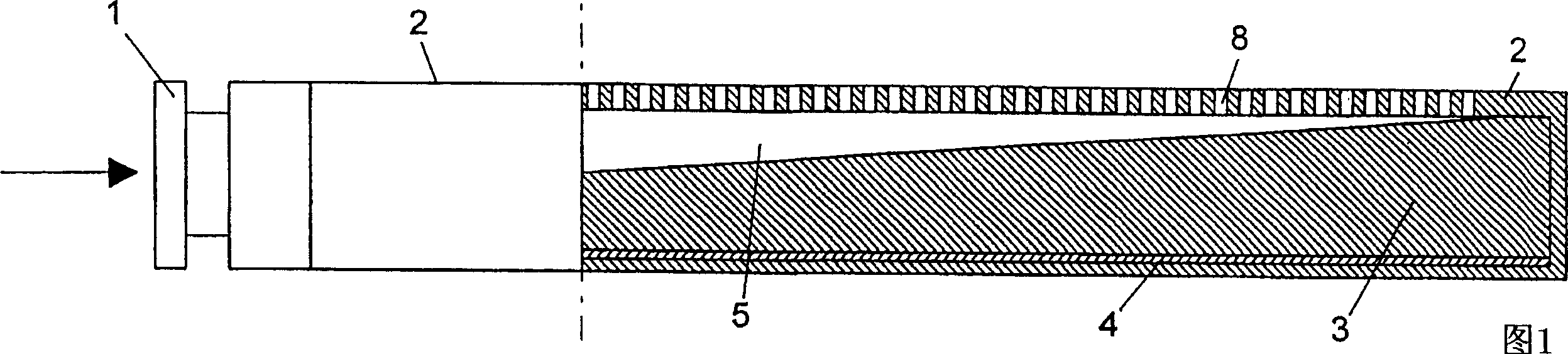

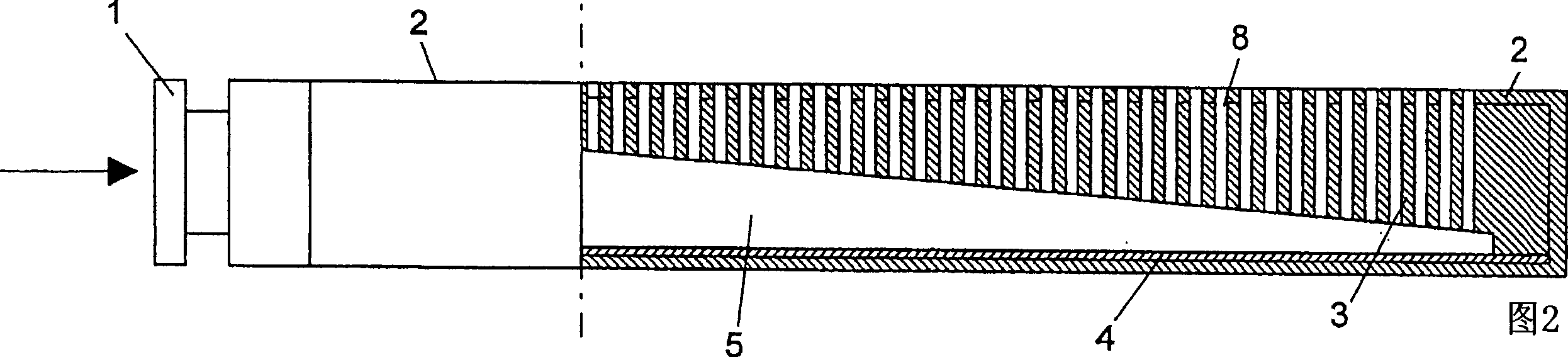

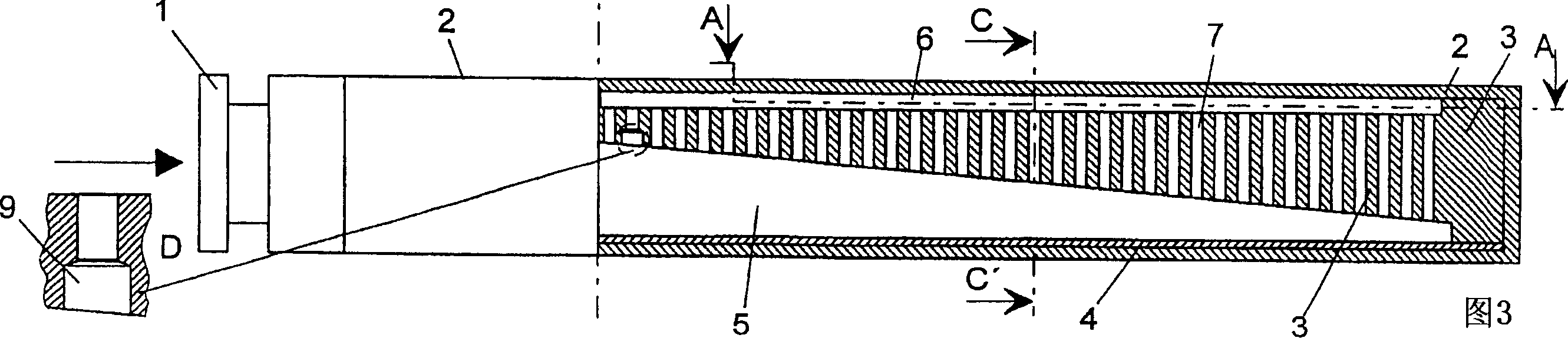

[0039] The nozzle arrangement shown in FIG. 1, which is particularly suitable for use as a flow nozzle in an electroplating system in which printed circuit boards pass through horizontally, comprises a housing 2 substantially in the shape of a parallelepiped. Arranged on the rear of the housing 2 is a connection sleeve 1 which is coupled to the fluid feed opening of the housing for feeding in process fluid. On the side of the casing 2 opposite to the workpiece to be processed or the product to be processed, rows of staggered slits or holes are provided, and these slits or holes form an output opening 8 for the processing liquid. In the illustrated embodiment, all slit delivery openings or holes 8 have the same dimensions, ie have the same length and width or the same diameter. However, different dimensions can also be chosen in order to produce a predetermined spray or stream pattern.

[0040] Inside the housing 2 there is provided a wedge-shaped insert 3, preferably made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com