Patents

Literature

2155 results about "Fluidic channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidic channels. Fluidic micro and nanochannels are another type of post-processed CMOS devices that have a variety of applications including detection, and characterization of cells and viruses in a fluidic media and classification and sequencing of a variety of biomolecules such as proteins, carbohydrates and DNAs.

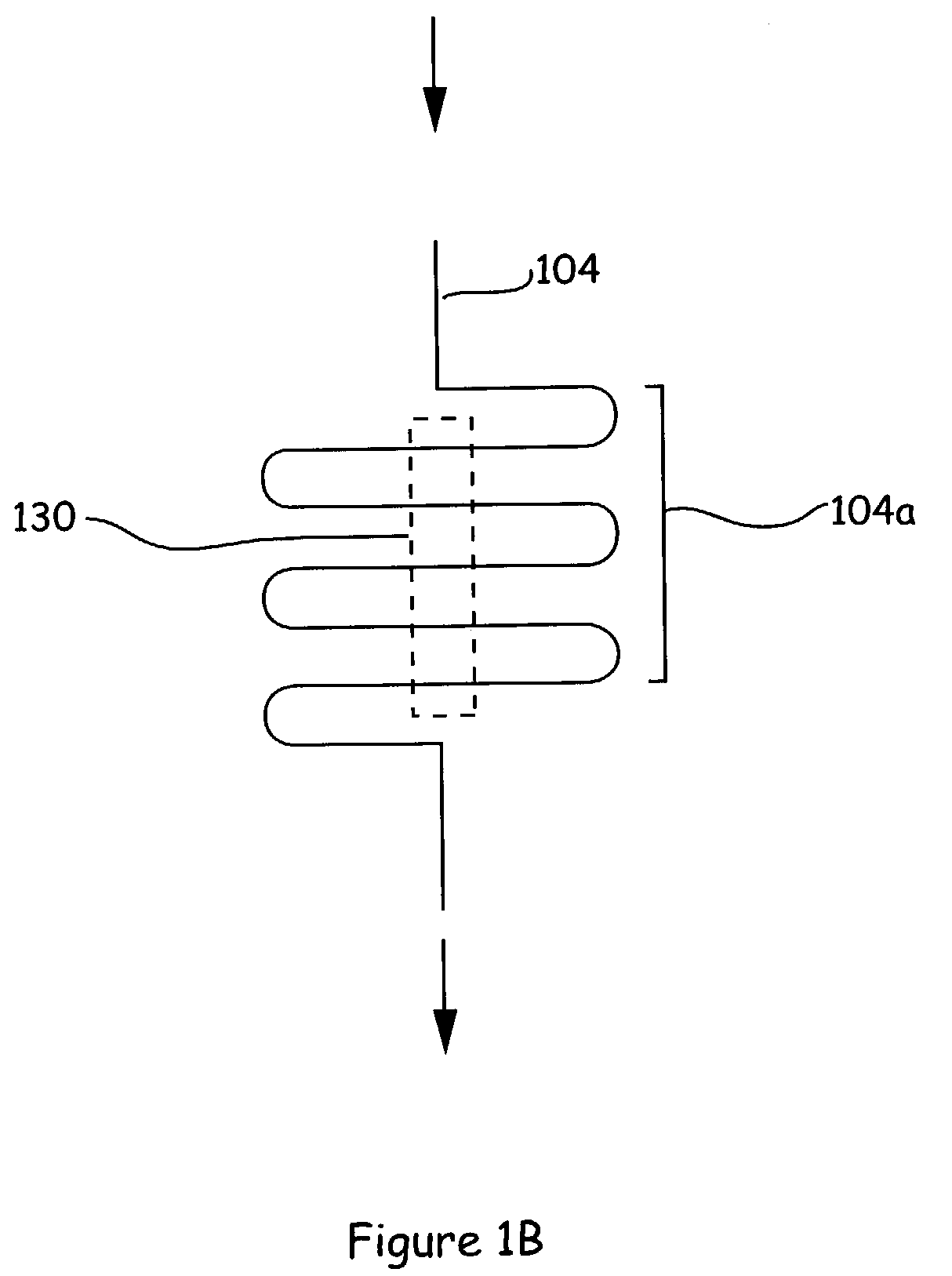

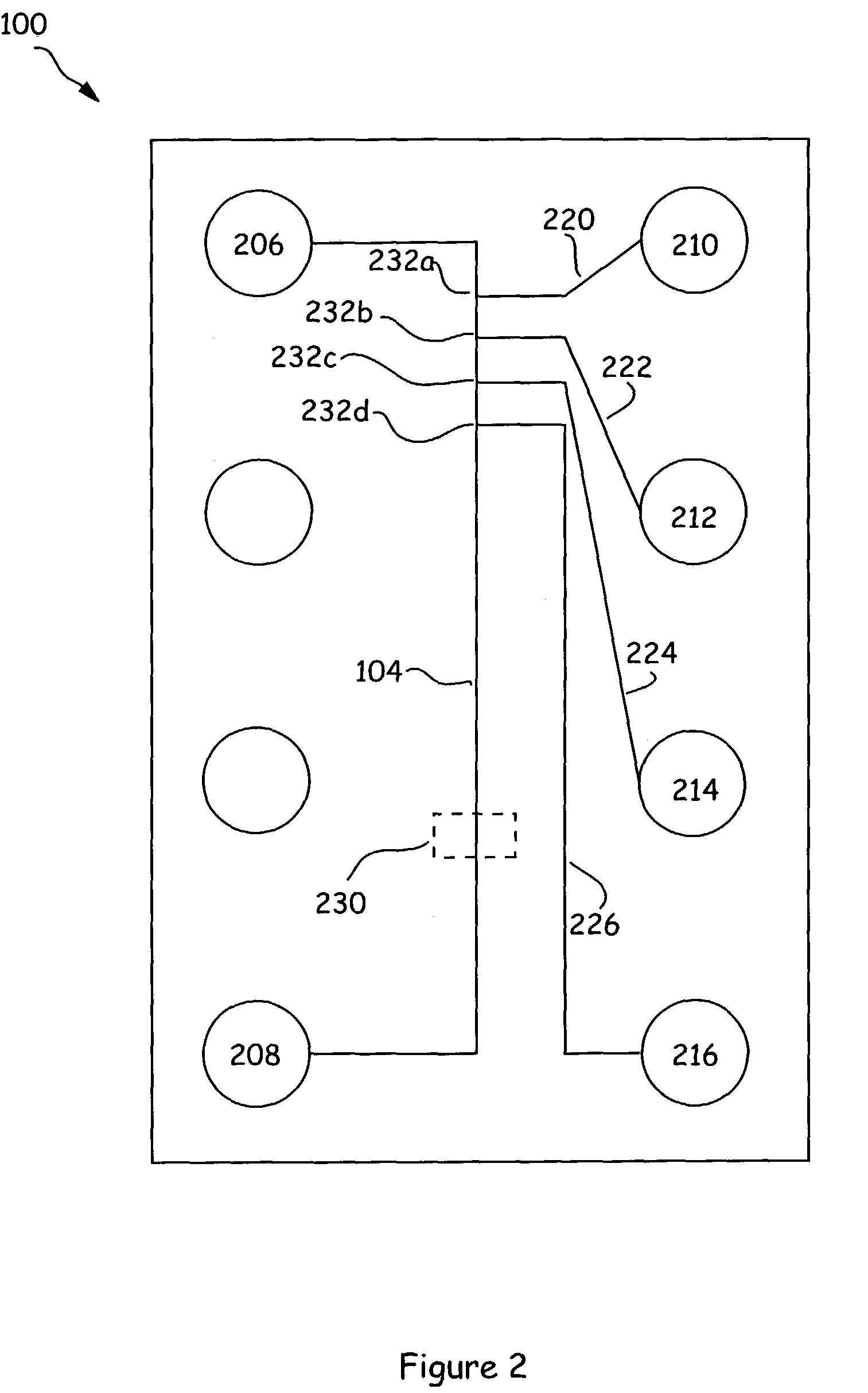

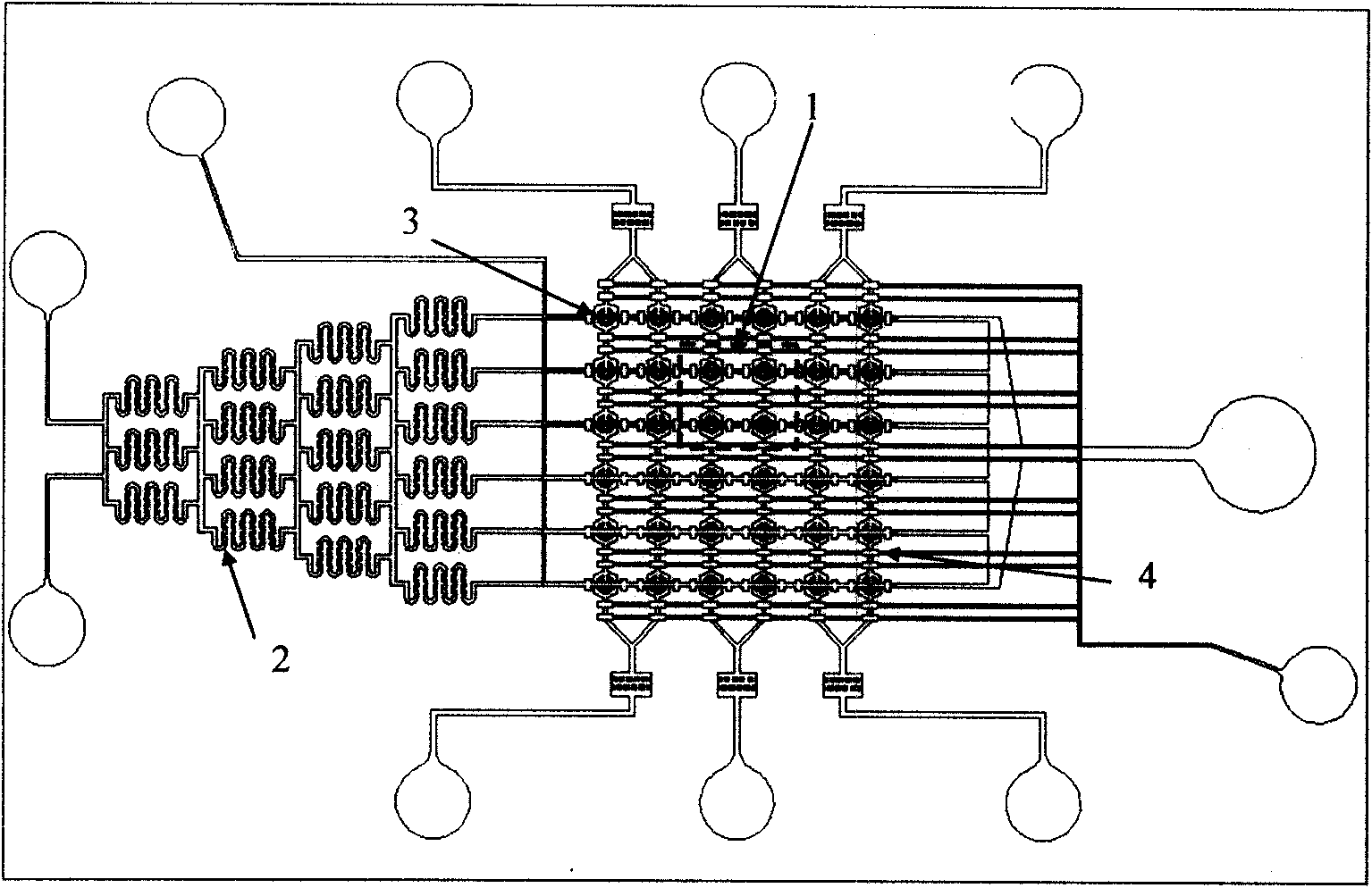

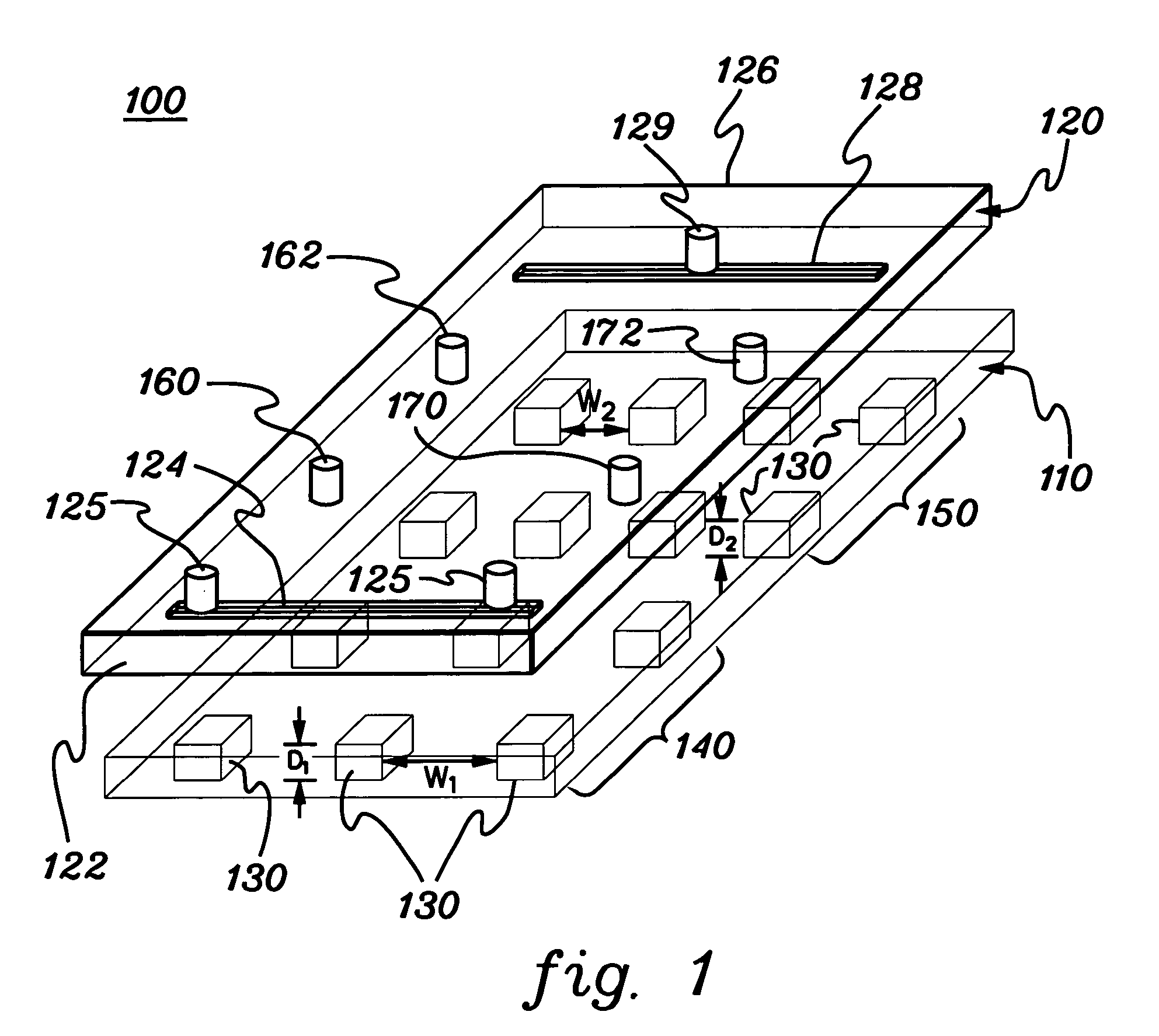

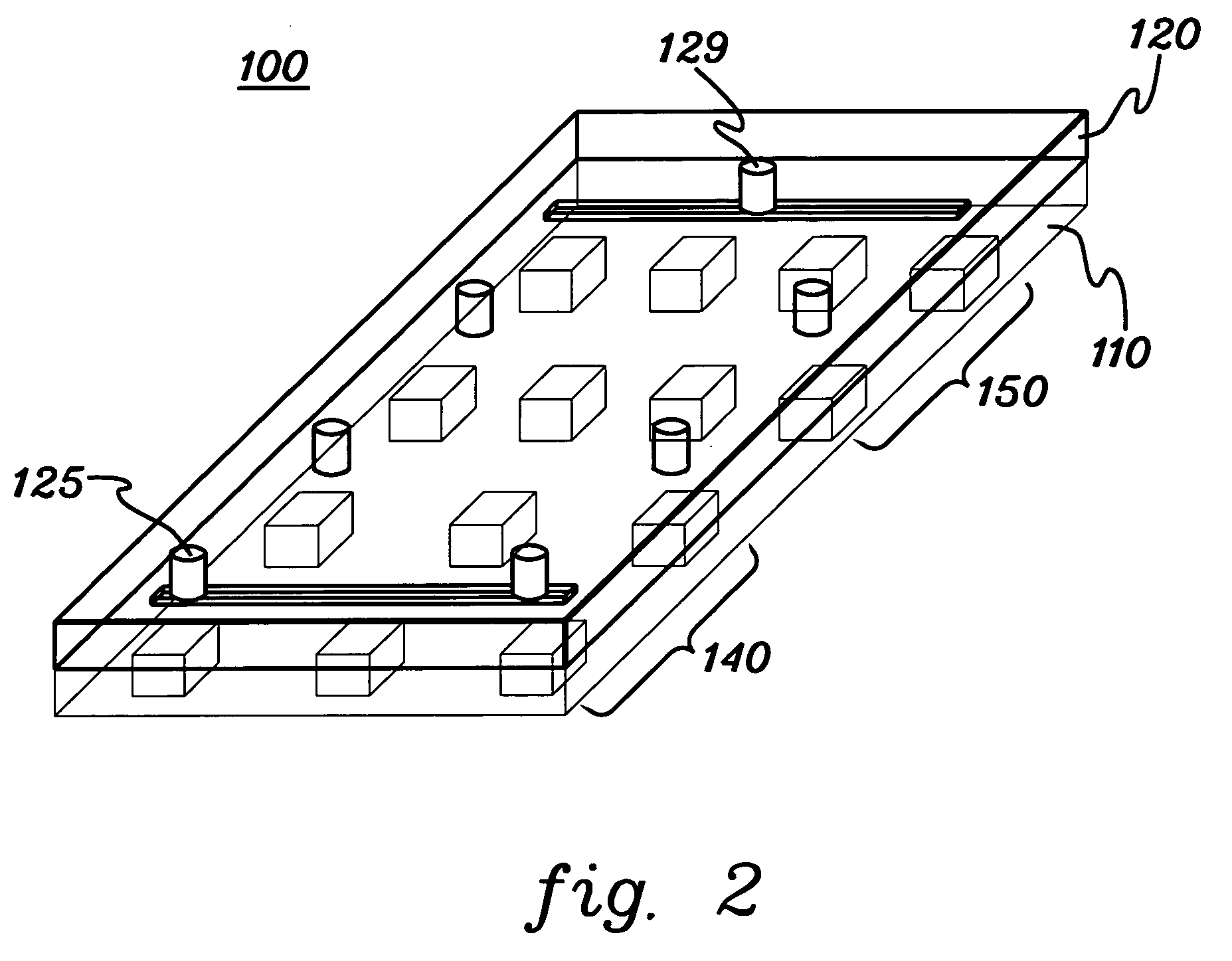

Nucleic acid amplification utilizing microfluidic devices

InactiveUS6960437B2Bioreactor/fermenter combinationsBiological substance pretreatmentsRegulation temperatureEngineering

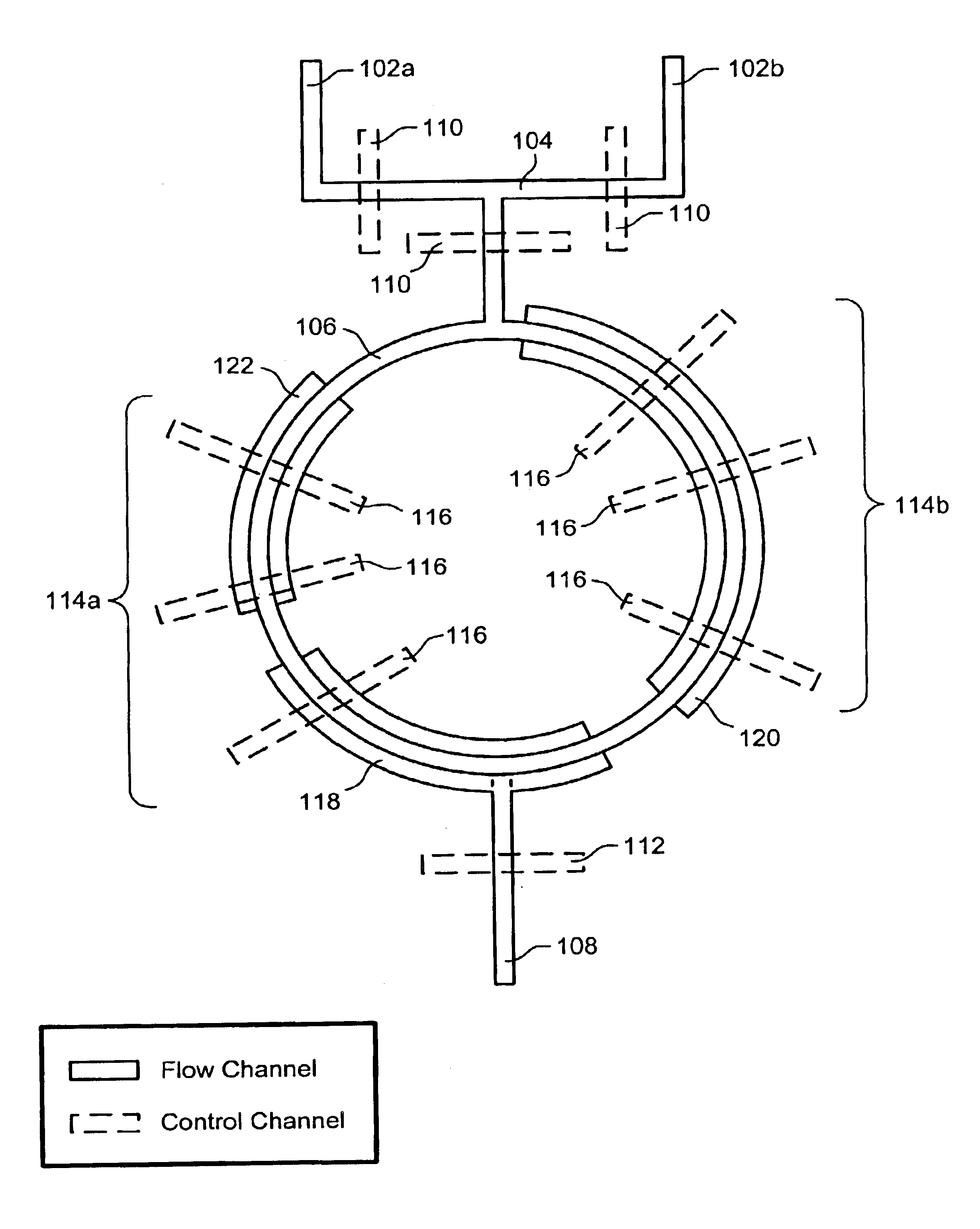

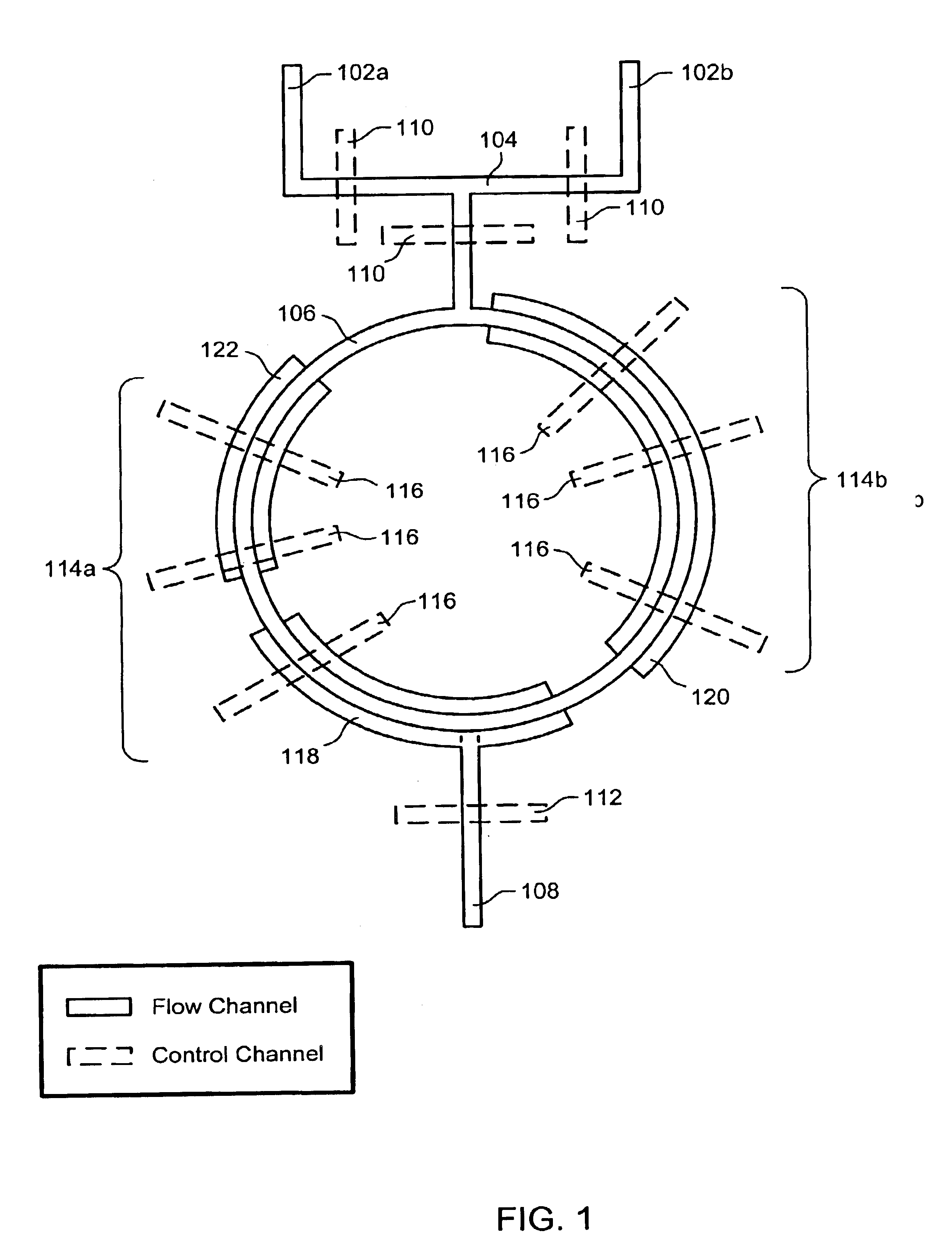

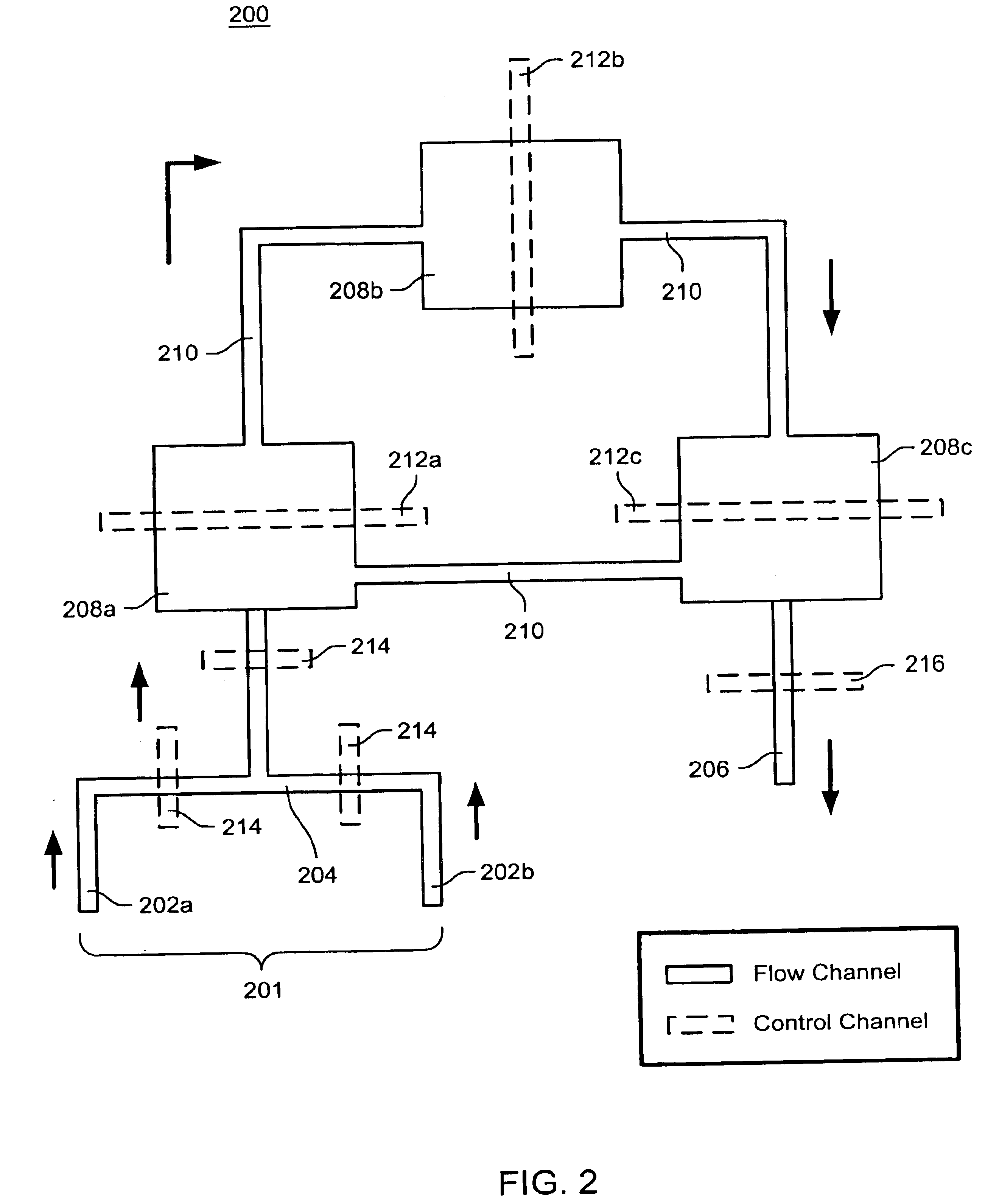

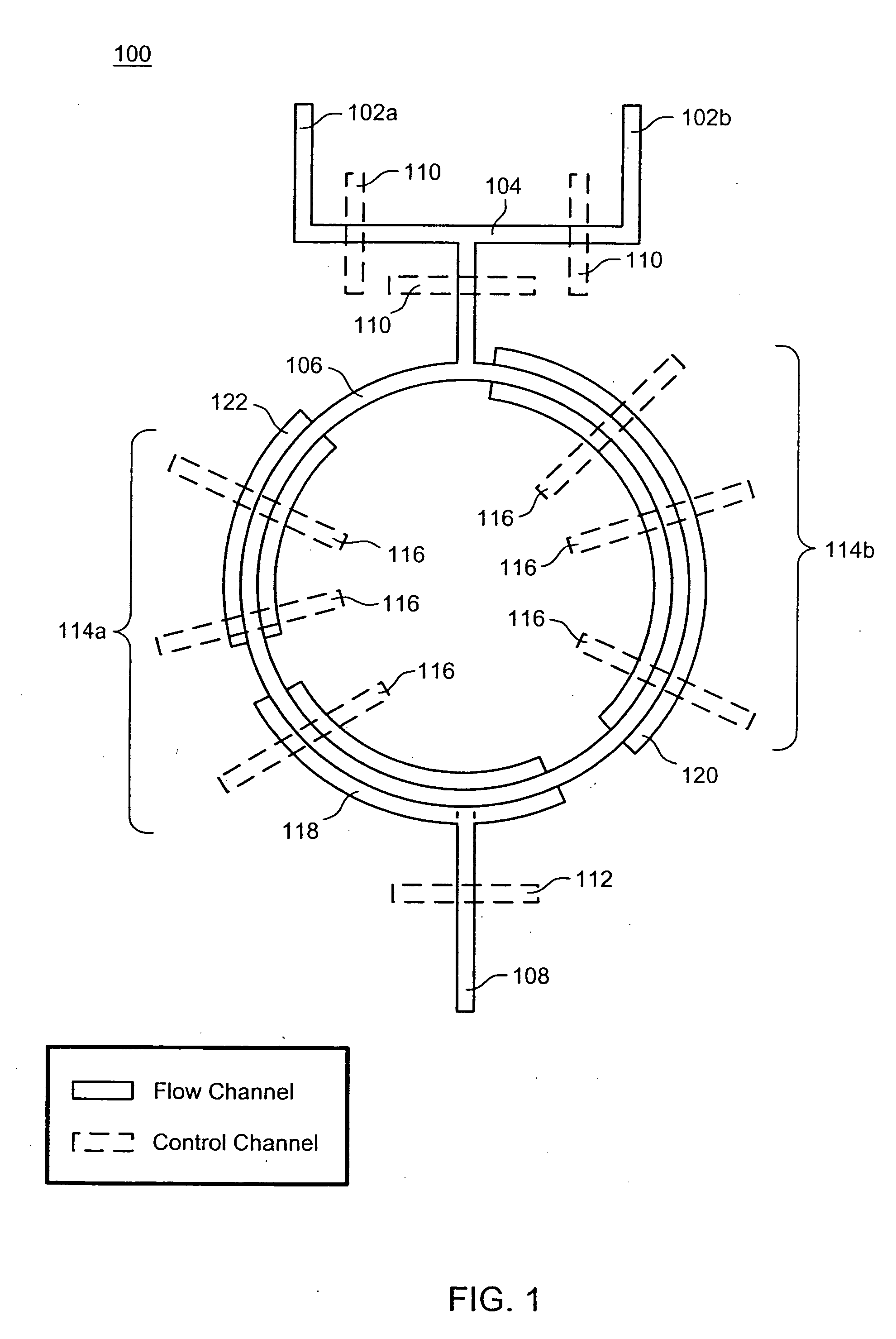

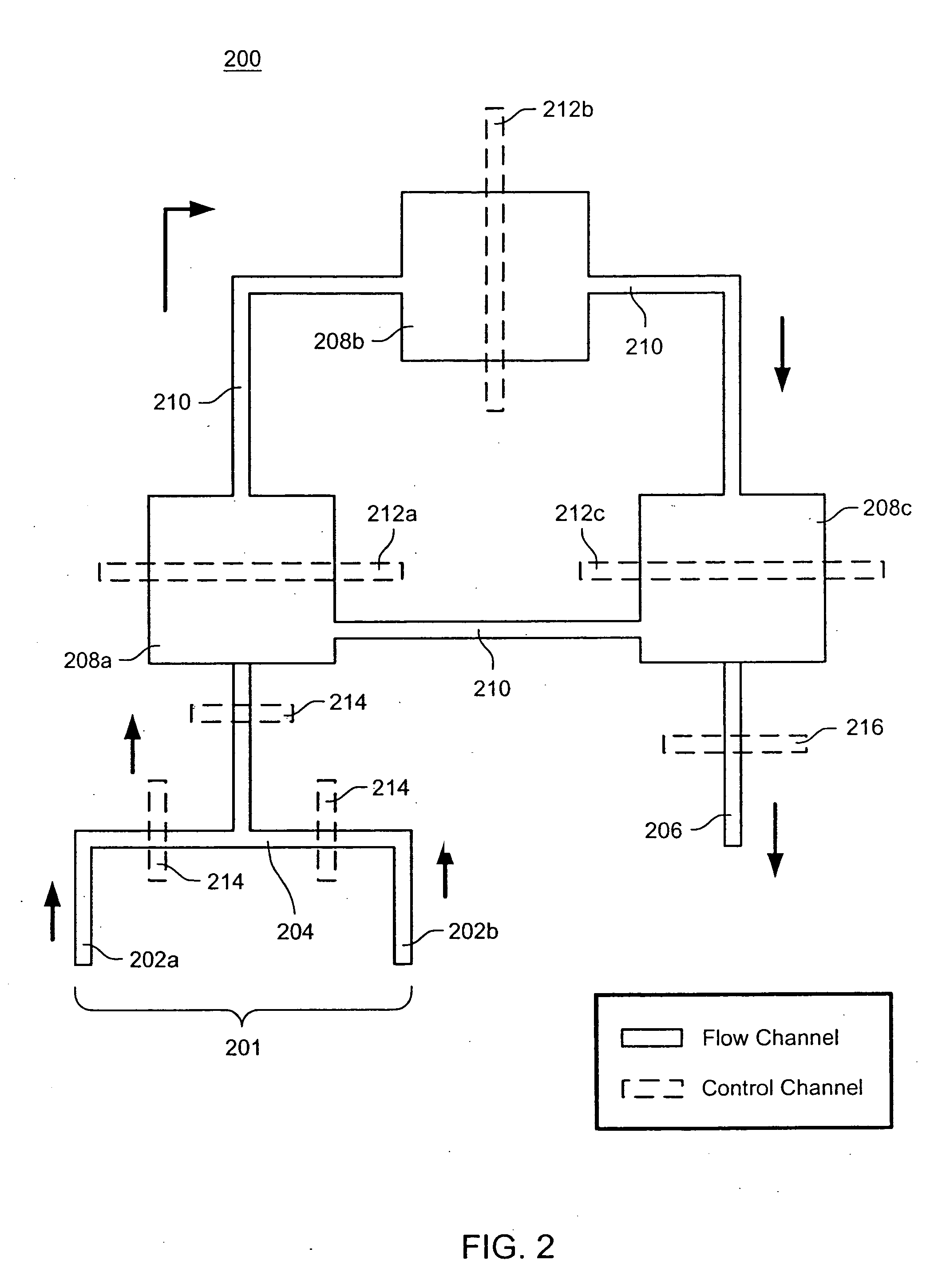

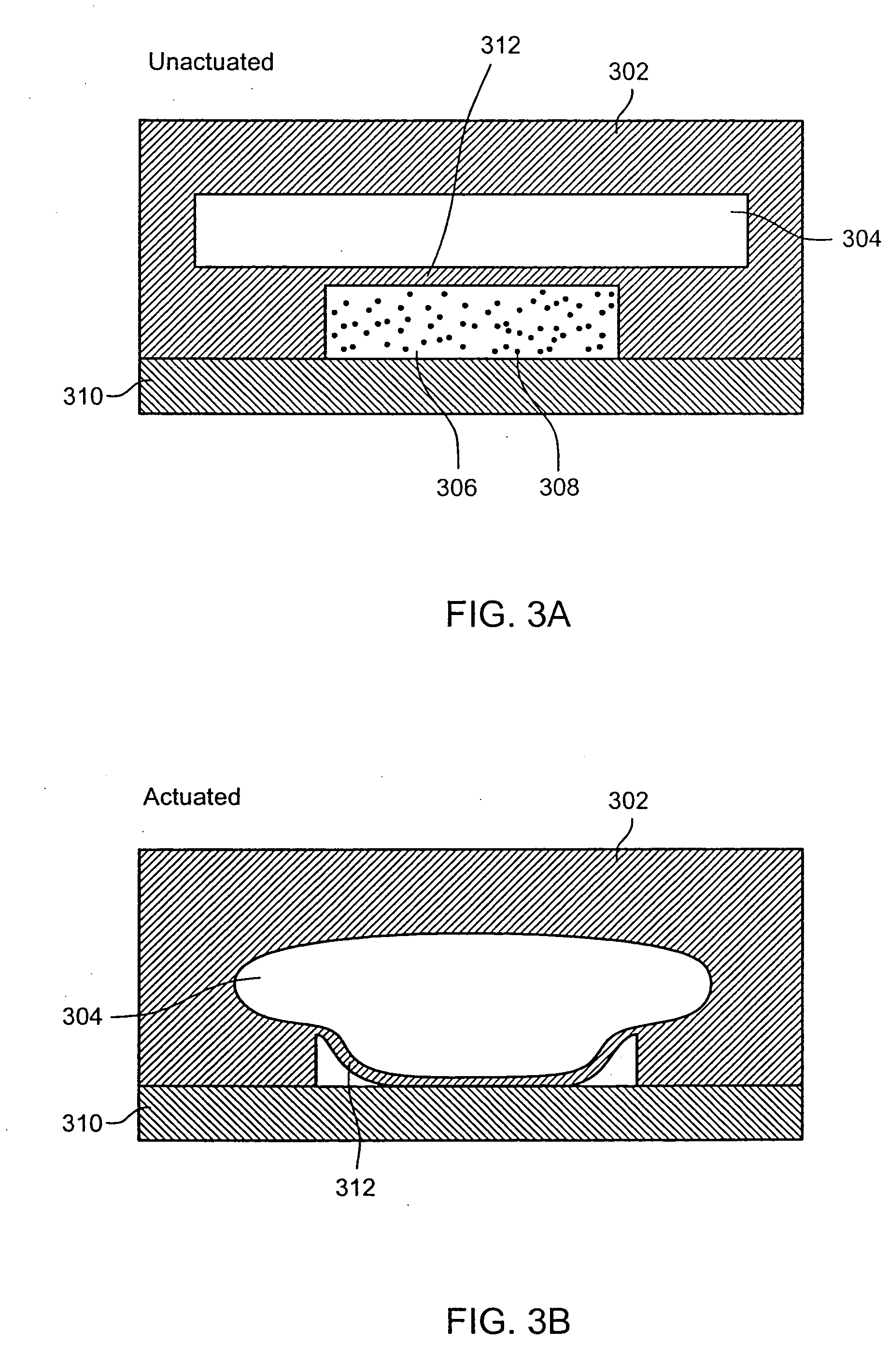

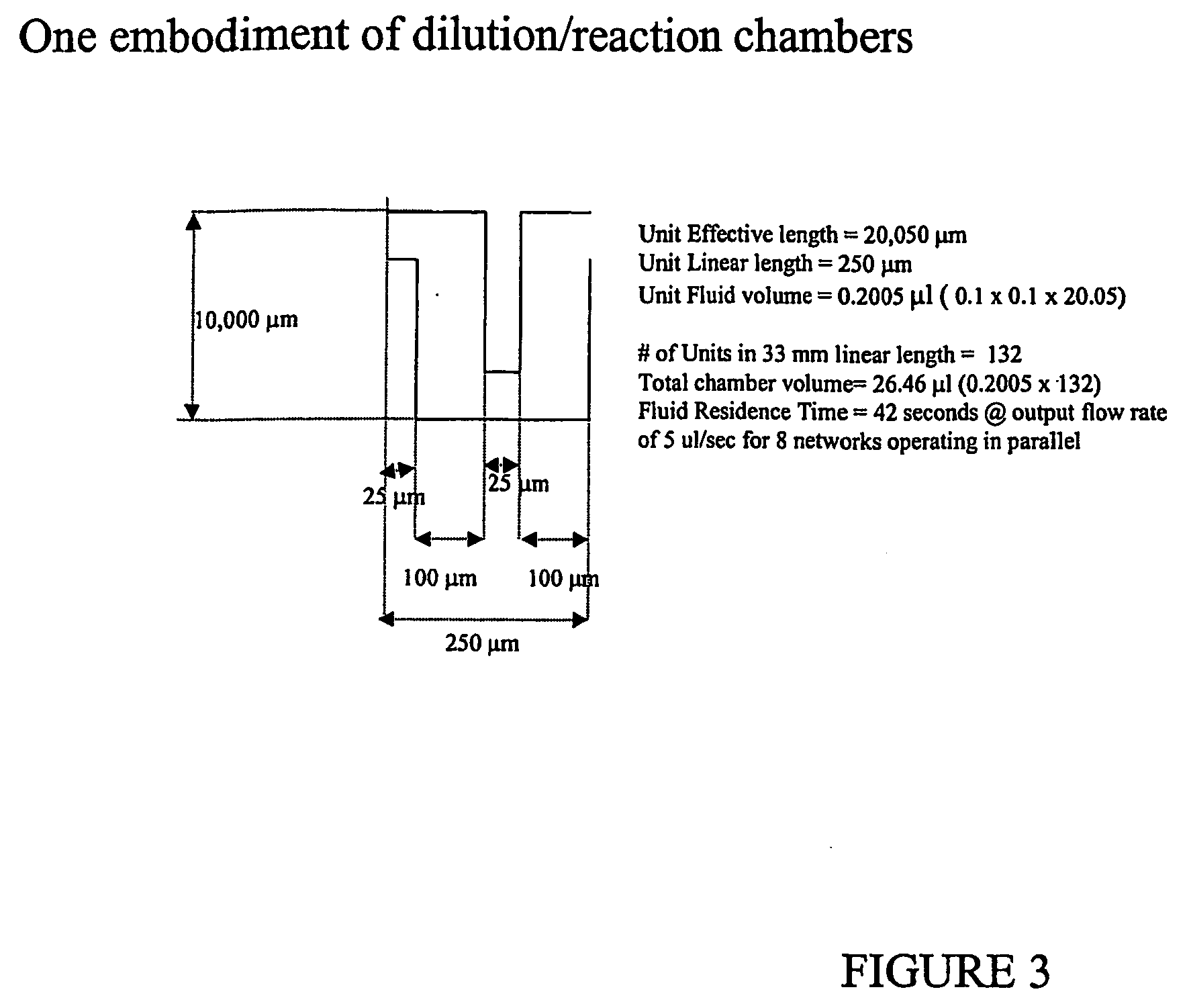

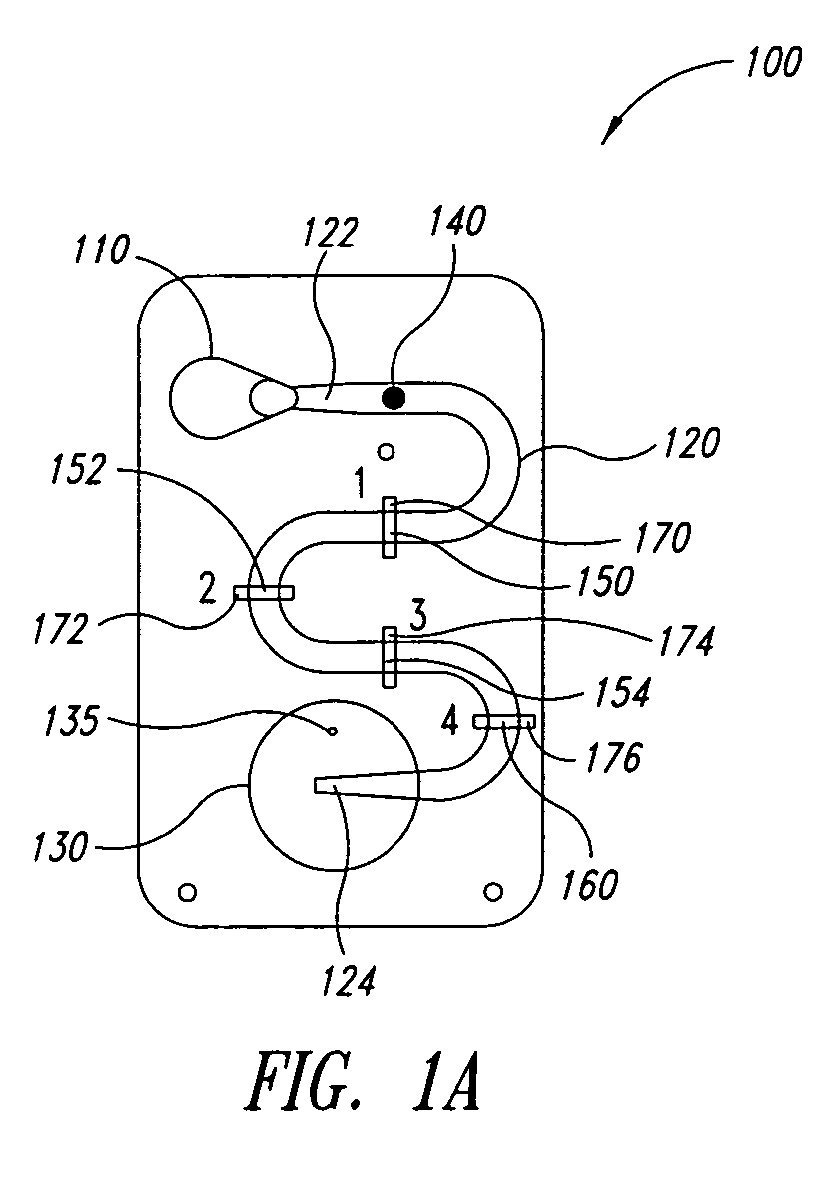

The present invention provides microfluidic devices and methods using the same in various types of thermal cycling reactions. Certaom devices include a rotary microfluidic channel and a plurality of temperature regions at different locations along the rotary microfluidic channel at which temperature is regulated. Solution can be repeatedly passed through the temperature regions such that the solution is exposed to different temperatures. Other microfluidic devices include an array of reaction chambers formed by intersecting vertical and horizontal flow channels, with the ability to regulate temperature at the reaction chambers. The microfluidic devices can be used to conduct a number of different analyses, including various primer extension reactions and nucleic acid amplification reactions.

Owner:CALIFORNIA INST OF TECH

Nucleic acid amplification using microfluidic devices

InactiveUS20050221373A1Facilitate amplification reactionBioreactor/fermenter combinationsHeating or cooling apparatusRegulation temperatureEngineering

The present invention provides microfluidic devices and methods using the same in various types of thermal cycling reactions. Certaom devices include a rotary microfluidic channel and a plurality of temperature regions at different locations along the rotary microfluidic channel at which temperature is regulated. Solution can be repeatedly passed through the temperature regions such that the solution is exposed to different temperatures. Other microfluidic devices include an array of reaction chambers formed by intersecting vertical and horizontal flow channels, with the ability to regulate temperature at the reaction chambers. The microfluidic devices can be used to conduct a number of different analyses, including various primer extension reactions and nucleic acid amplification reactions.

Owner:CALIFORNIA INST OF TECH

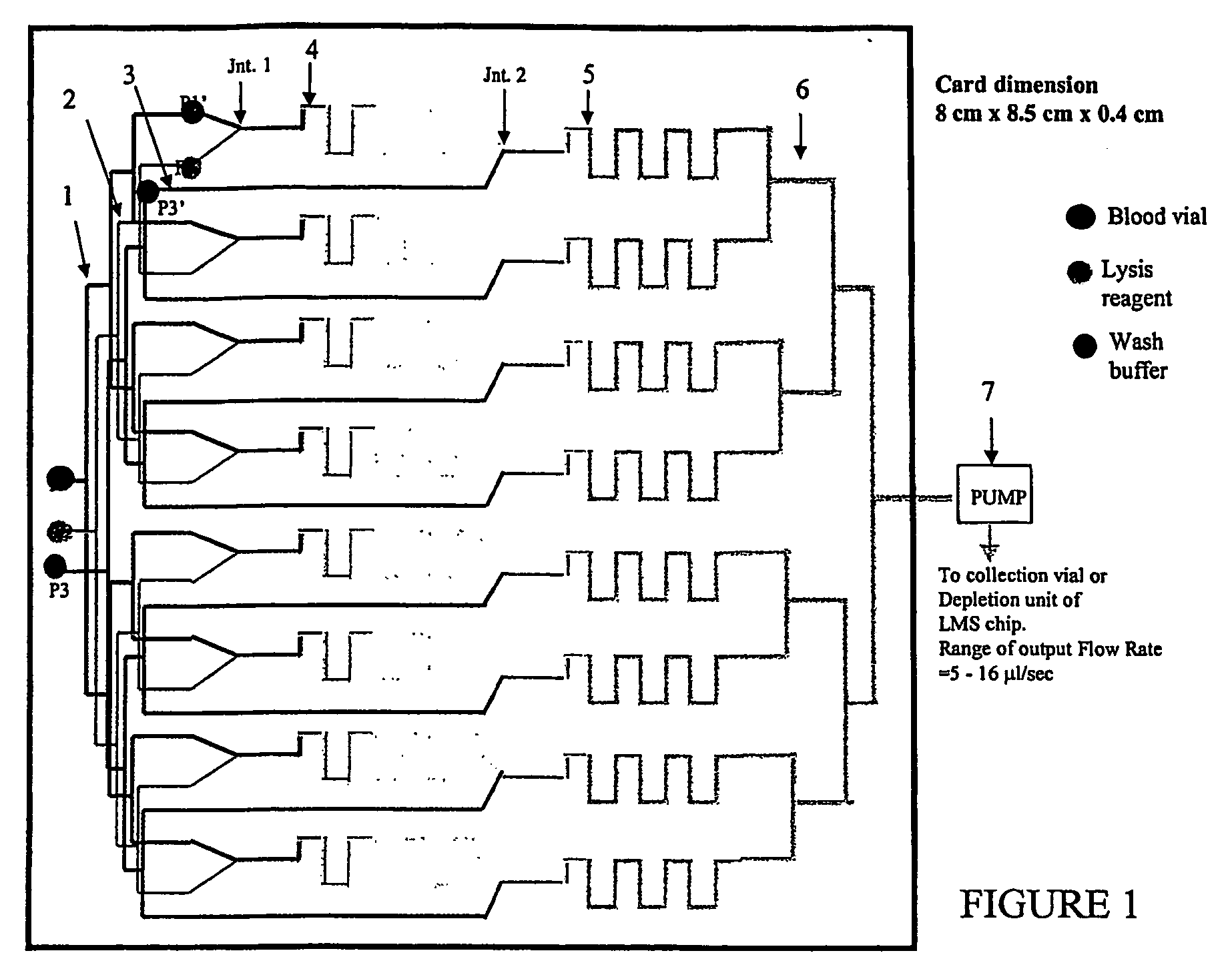

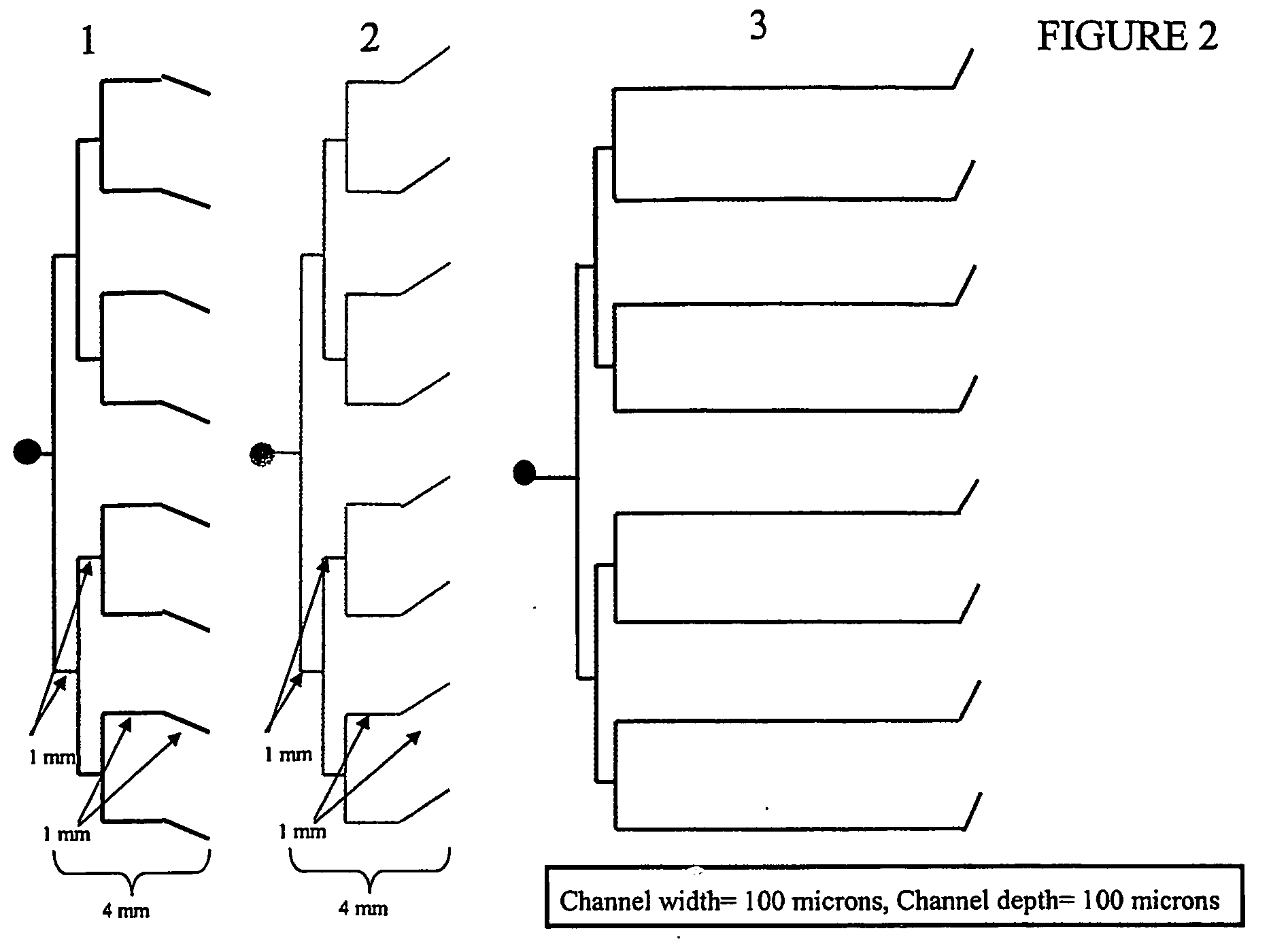

Microfluidic device for cell separation and uses thereof

ActiveUS20060134599A1Simple methodBioreactor/fermenter combinationsMaterial nanotechnologyAntigenMembrane permeabilization

The invention features methods for separating cells from a sample (e.g., separating fetal red blood cells from maternal method begins with the introduction of a sample including cells into one or more microfluidic channels. In one embodiment, the device includes at least two processing steps. For example, a mixture of cells is introduced into a microfluidic channel that selectively allows the passage of a desired type of cell, and the population of cells enriched in the desired type is then introduced into a second microfluidic channel that allows the passage of the desired cell to produce a population of cells further enriched in the desired type. The selection of cells is based on a property of the cells in the mixture, for example, size, shape, deformability, surface characteristics (e.g., cell surface receptors or antigens and membrane permeability), or intracellular properties (e.g., expression of a particular enzyme).

Owner:THE GENERAL HOSPITAL CORP

Fluid injection

ActiveUS20120132288A1Avoid enteringValve arrangementsFlow mixersBiomedical engineeringFluid injection

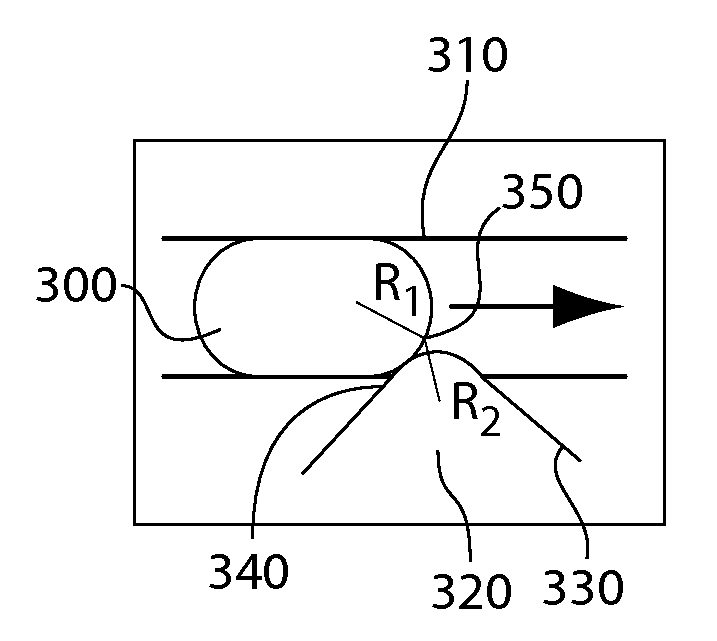

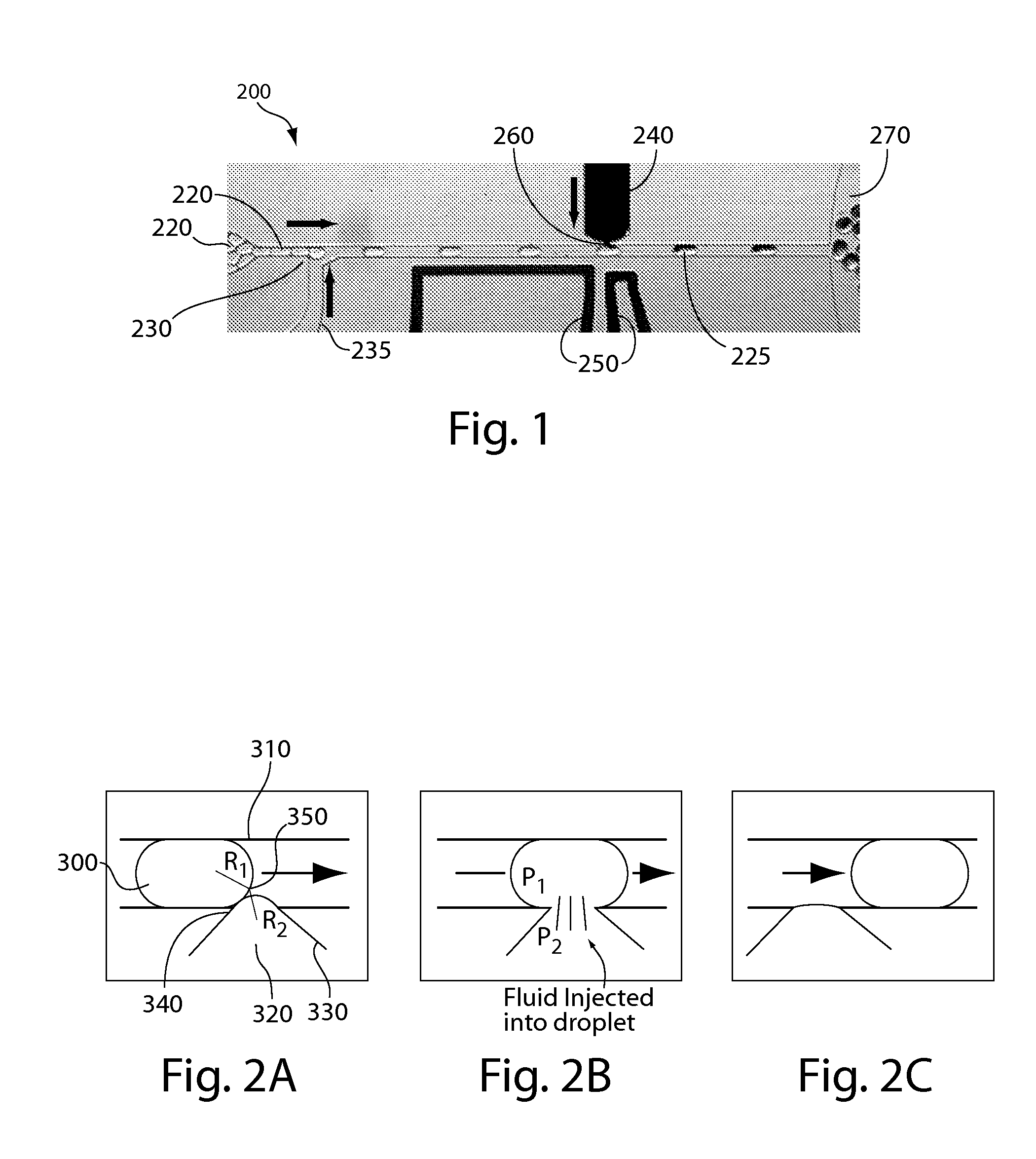

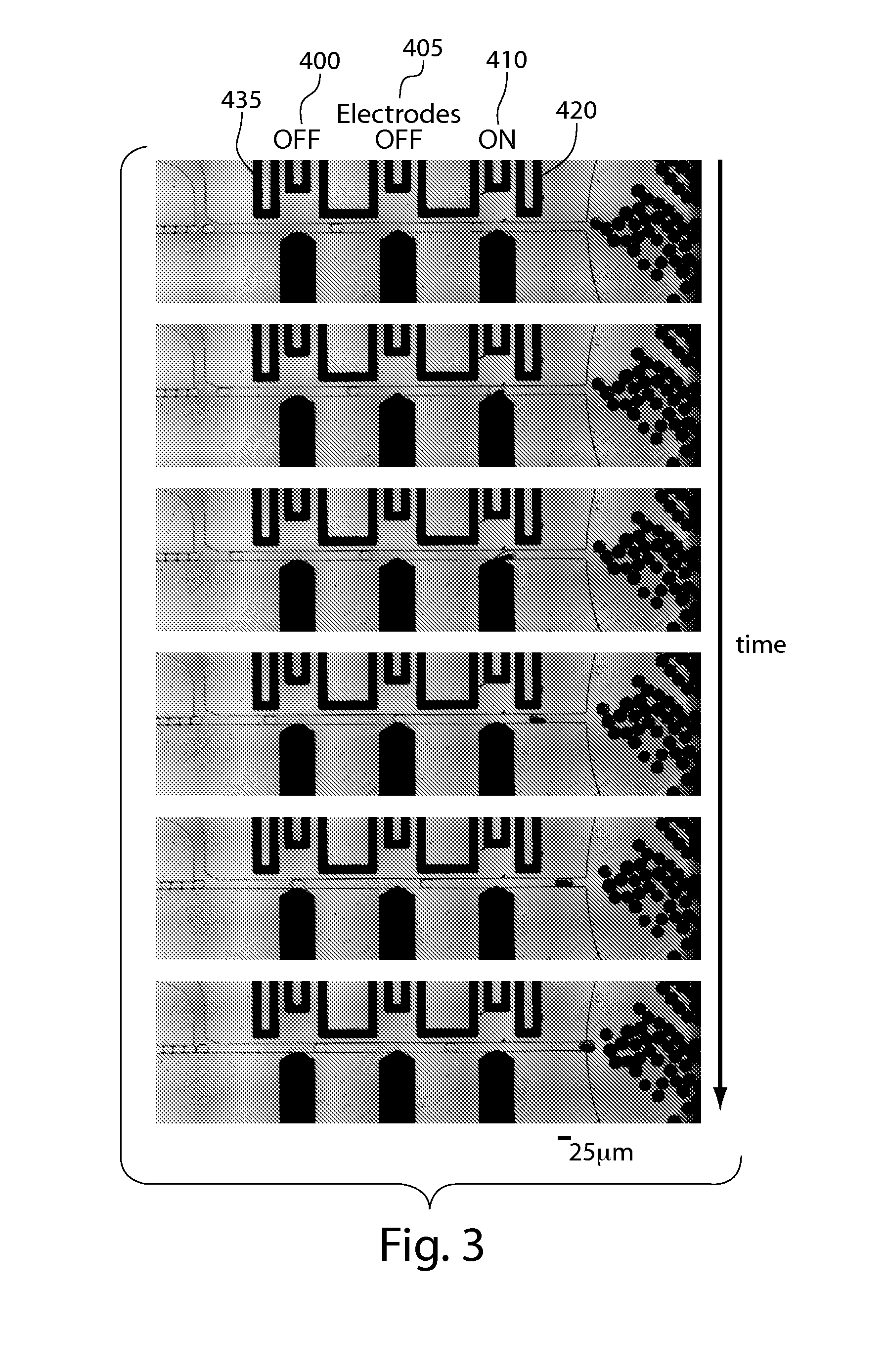

The present invention generally relates to systems and methods for the control of fluids and, in some cases, to systems and methods for flowing a fluid into and / or out of other fluids. As examples, fluid may be injected into a droplet contained within a fluidic channel, or a fluid may be injected into a fluidic channel to create a droplet. In some embodiments, electrodes may be used to apply an electric field to one or more fluidic channels, e.g., proximate an intersection of at least two fluidic channels. For instance, a first fluid may be urged into and / or out of a second fluid, facilitated by the electric field. The electric field, in some cases, may disrupt an interface between a first fluid and at least one other fluid. Properties such as the volume, flow rate, etc. of a first fluid being urged into and / or out of a second fluid can be controlled by controlling various properties of the fluid and / or a fluidic droplet, for example curvature of the fluidic droplet, and / or controlling the applied electric field.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Control of operation conditions within fluidic systems

InactiveUS20050238545A1Electrolysis componentsFixed microstructural devicesSolid componentEngineering

Methods of controlling environmental conditions within a fluidic system, where such environmental conditions can affect the operation of the system in its desired function, and fluidic channels, devices and systems that are used in practicing these methods. Such methods are generally directed to environmental control fluids, the movement of such fluids through these systems, and the interaction of these fluids with other components of the system, e.g., other fluids or solid components of the system.

Owner:CAPLIPER LIFE SCI INC

Microfluidic laminar flow detection strip

InactiveUS20070042427A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAntibody conjugateEngineering

The present invention relates to microfluidic laminar flow detection strip devices and methods for using and making the same. The disclosed devices comprise: a first inlet; a microfluidic channel having a first end and a second end, wherein the first end is fluidly connected to the first inlet; a bellows pump fluidly connected to the second end of the microfluidic channel, wherein the bellows pump comprises an absorbent material disposed therein; a dried reagent zone within the microfluidic channel, wherein the dried reagent zone comprises a first reagent and a control reagent printed thereon, the first reagent comprising a first detection antibody conjugated to a dyed substrate bead or functionalized for colorimetric development, and the control reagent comprising a control detection antibody conjugated to a dyed substrate bead or functionalized for calorimetric development; a first bound antibody zone within the microfluidic channel, wherein the first bound antibody zone comprises a first bound antibody printed thereon; and a control zone within the microfluidic channel, wherein the control zone comprises a control bound antibody printed thereon.

Owner:PERKINELMER HEALTH SCIENCES INC

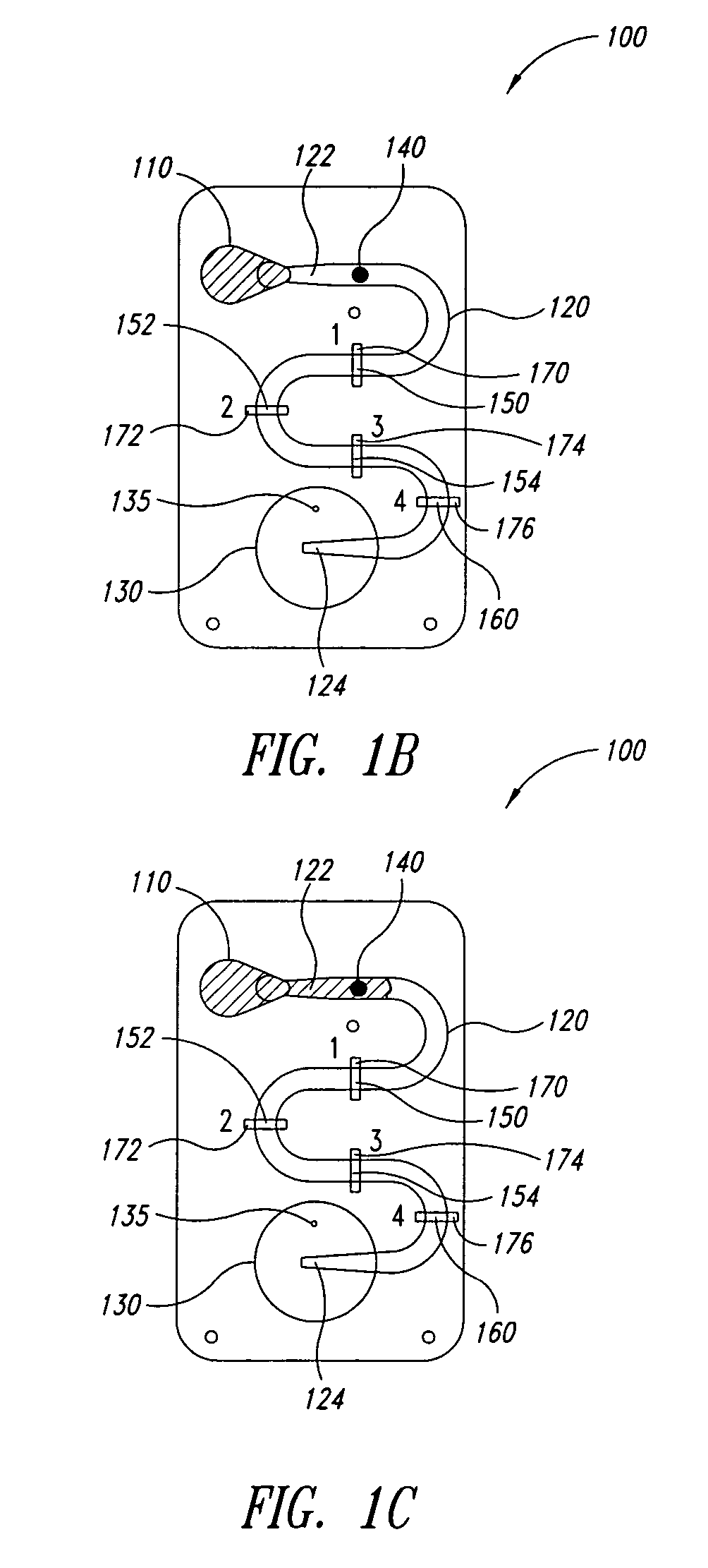

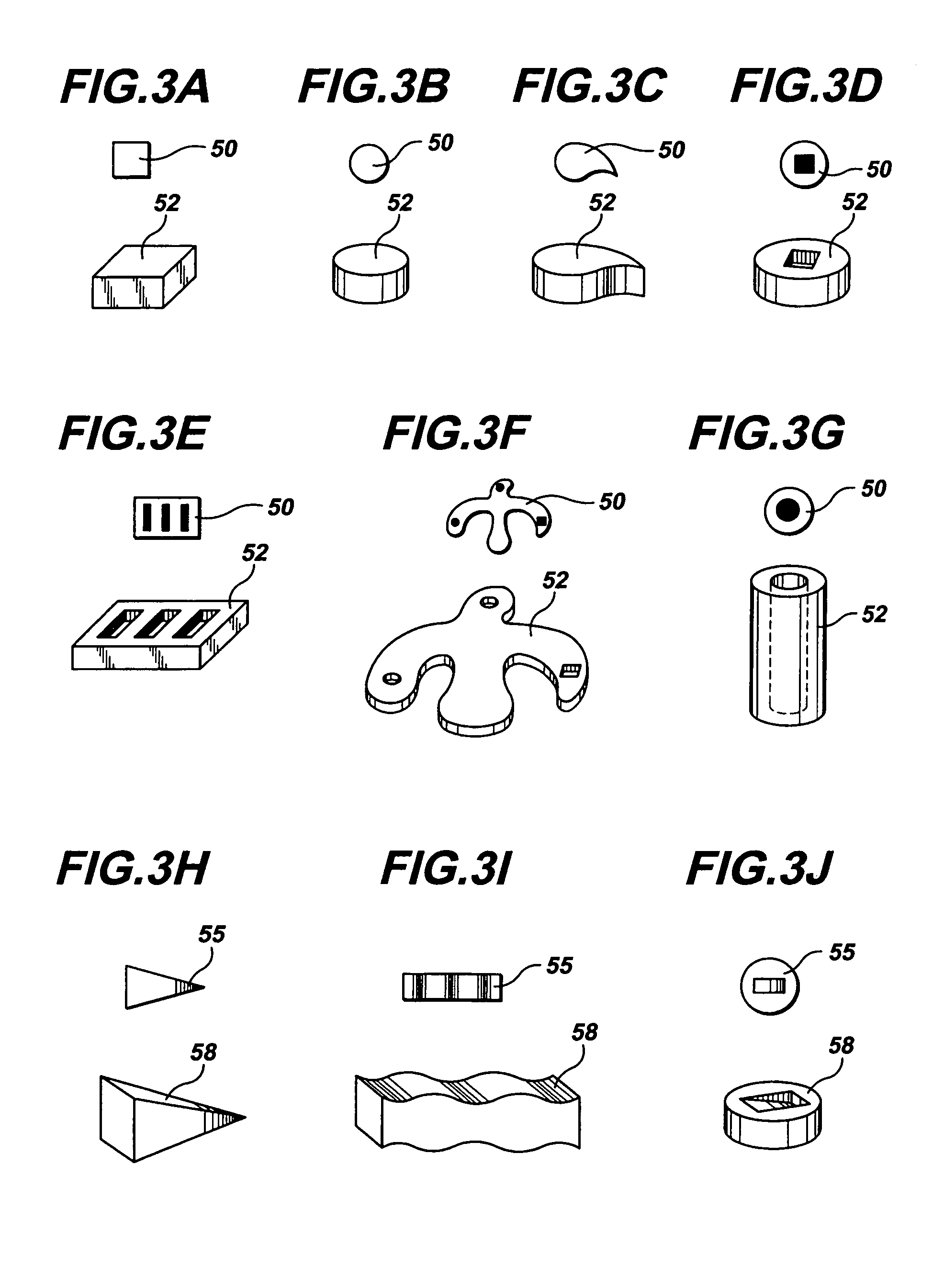

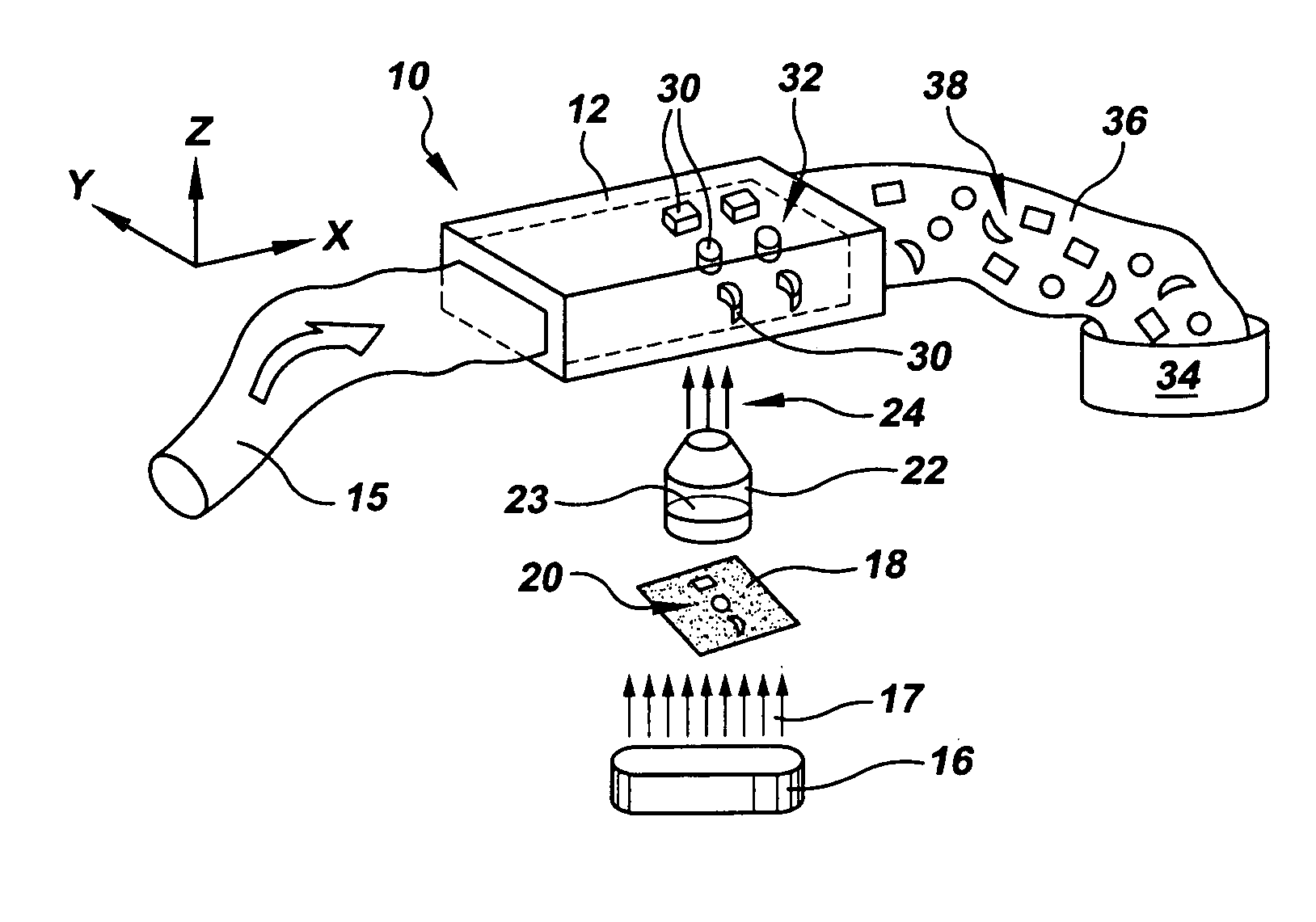

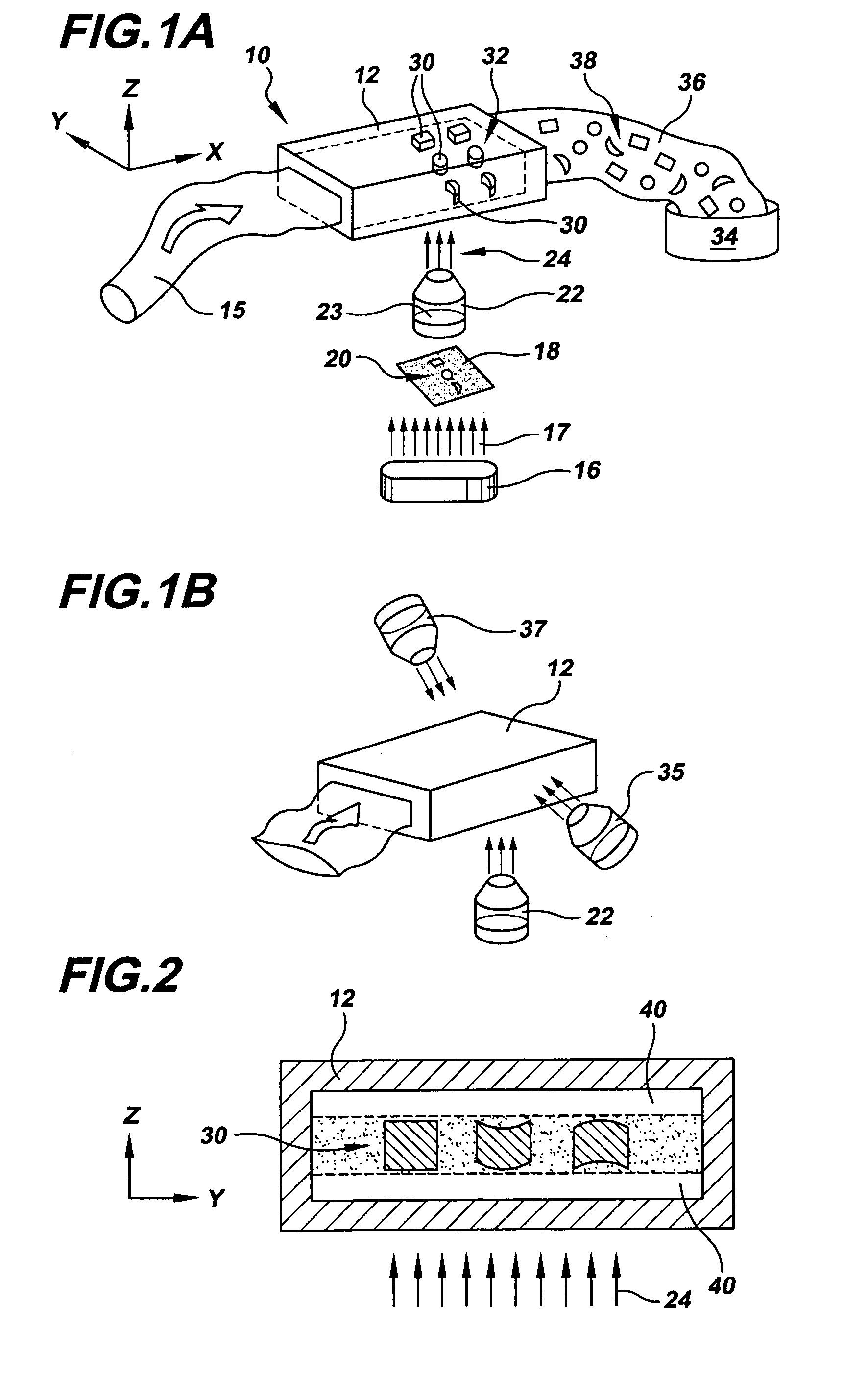

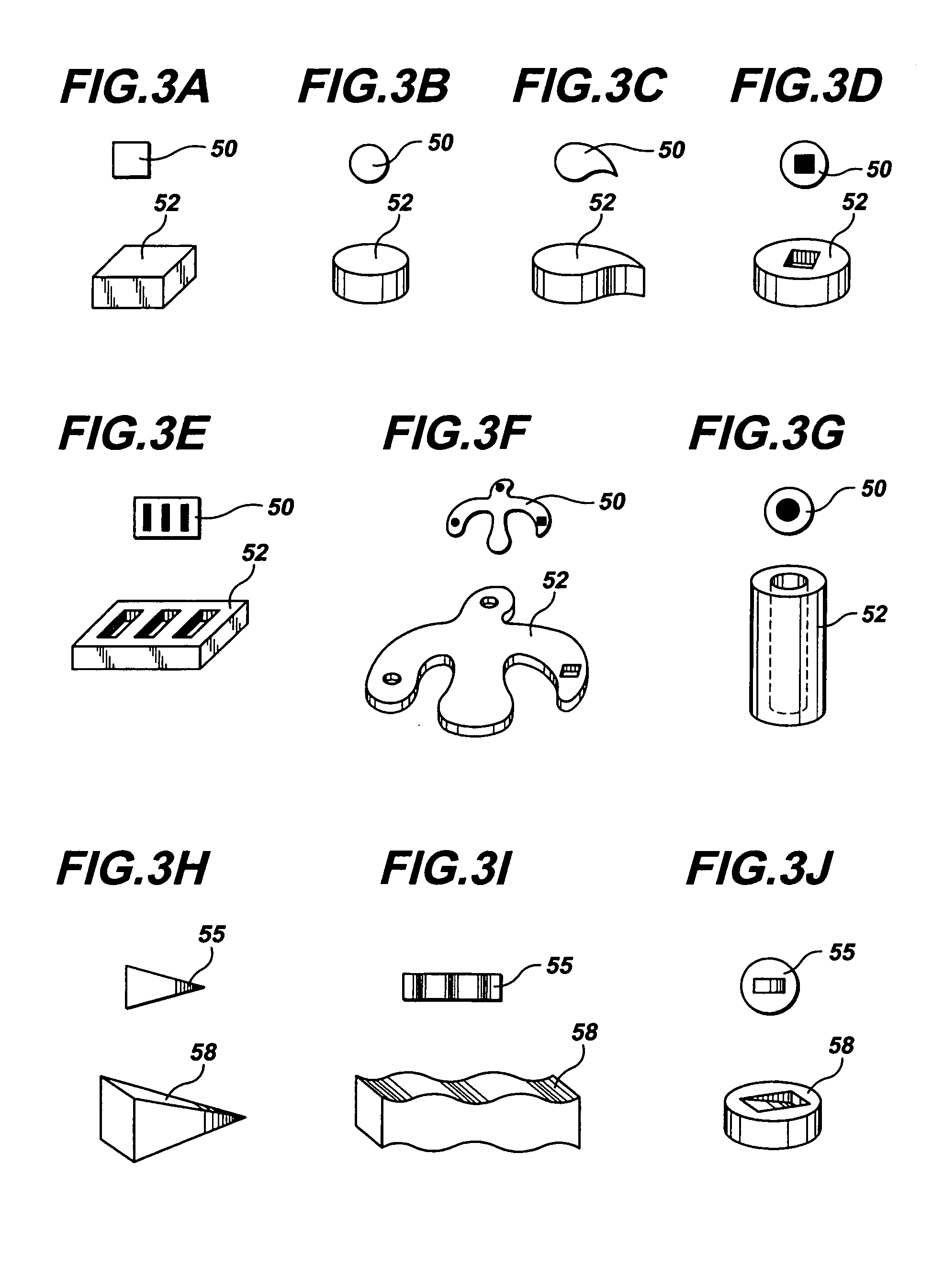

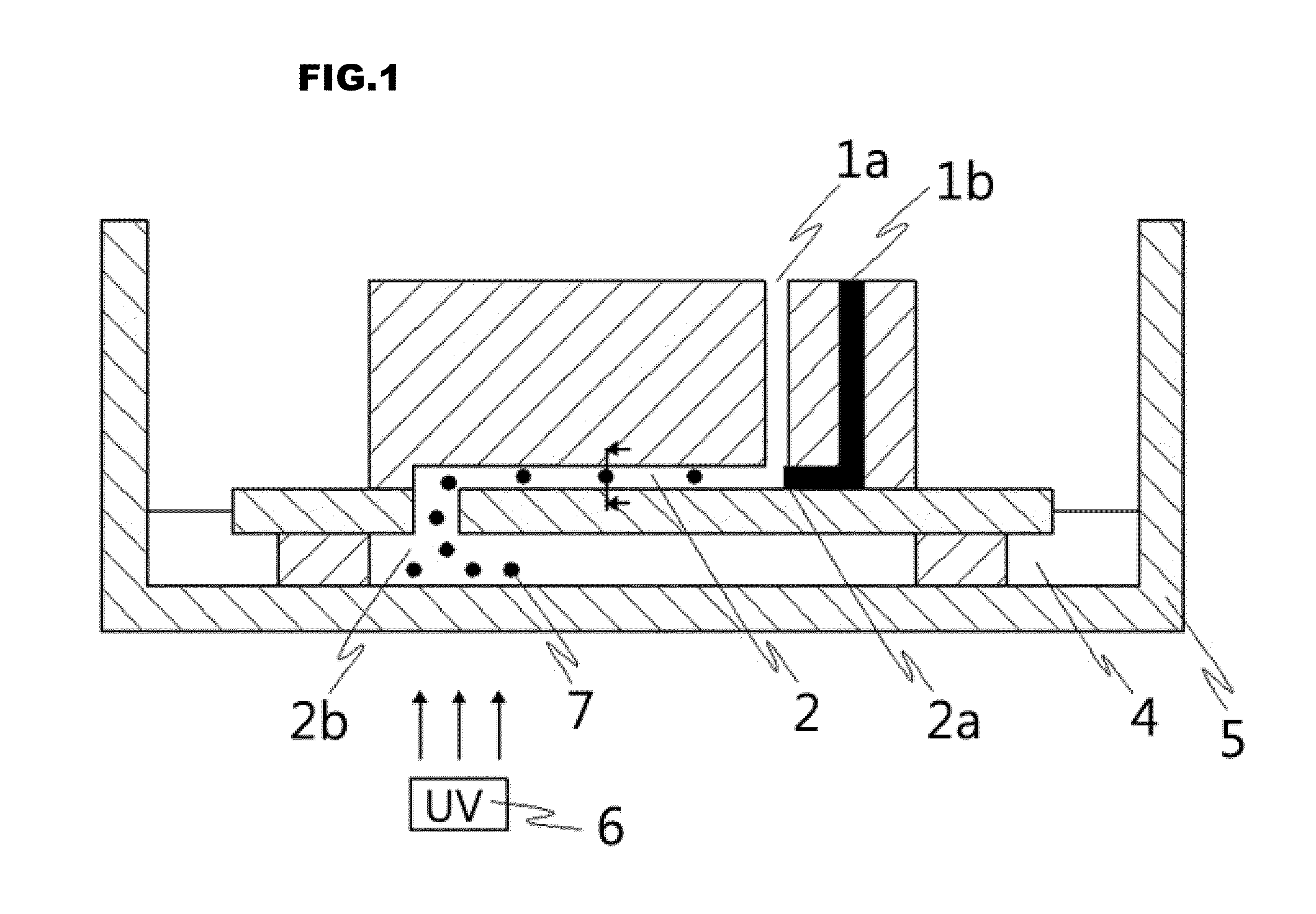

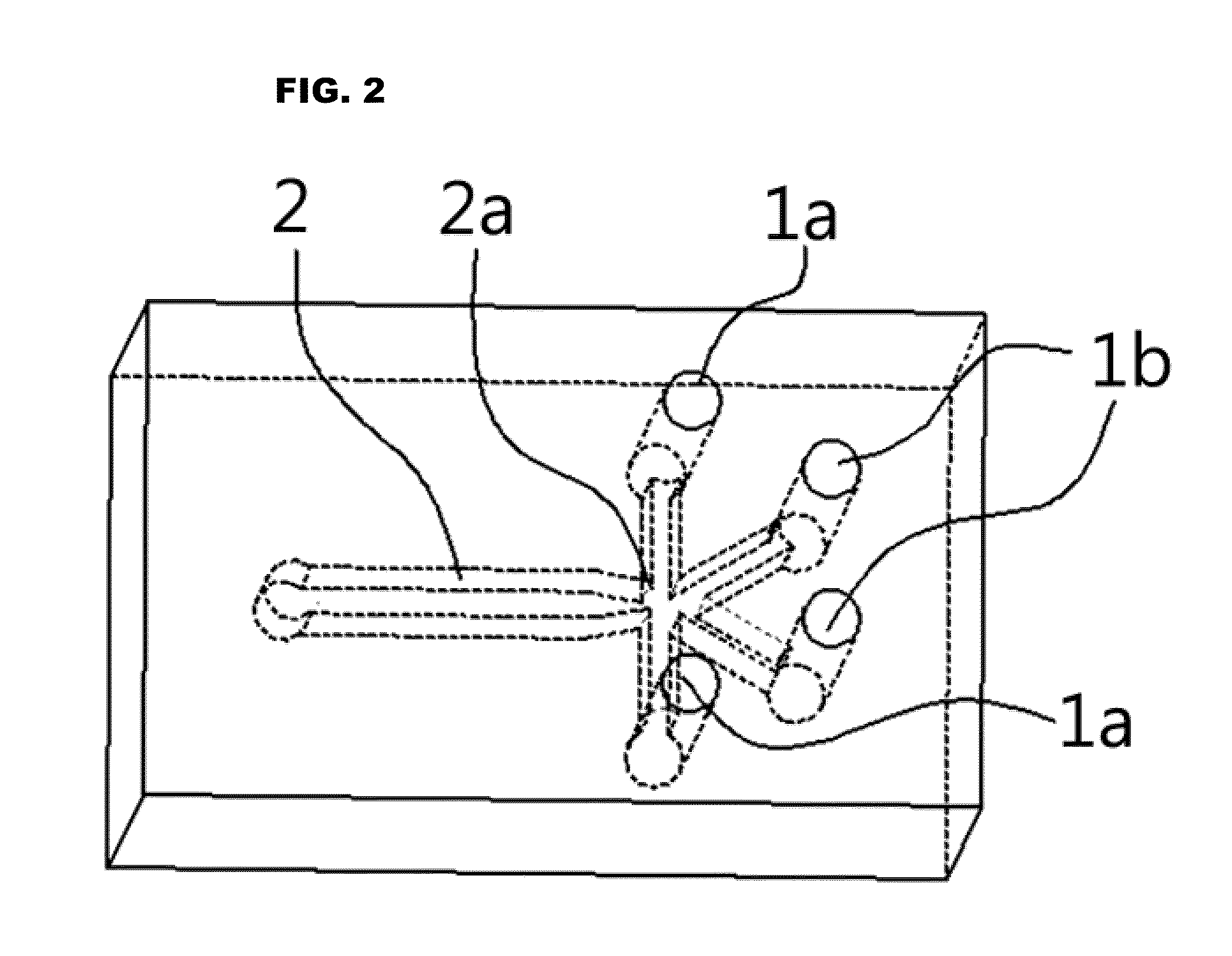

Microstructure synthesis by flow lithography and polymerization

In a method for synthesizing polymeric microstructures, a monomer stream is flowed, at a selected flow rate, through a fluidic channel. At least one shaped pulse of illumination is projected to the monomer stream, defining in the monomer stream a shape of at least one microstructure corresponding to the illumination pulse shape while polymerizing that microstructure shape in the monomer stream by the illumination pulse.

Owner:MASSACHUSETTS INST OF TECH

Process for filling microfluidic channels

The present invention provides novel methods and devices for filling at least one microfluidic channel with a gas or with a degassed fluid. In particular the methods and devices of the invention are useful in completely filling substantially all areas of a microfluidic device with a gas or with a degassed fluid without incorporating bubbles within such microfluidic devices.

Owner:CAPLIPER LIFE SCI INC

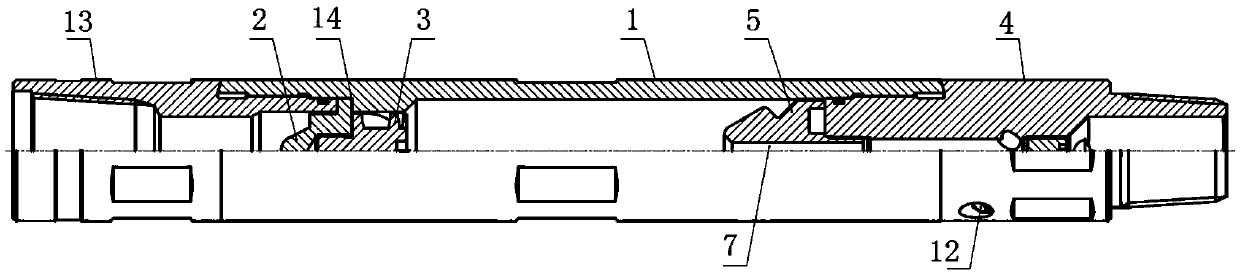

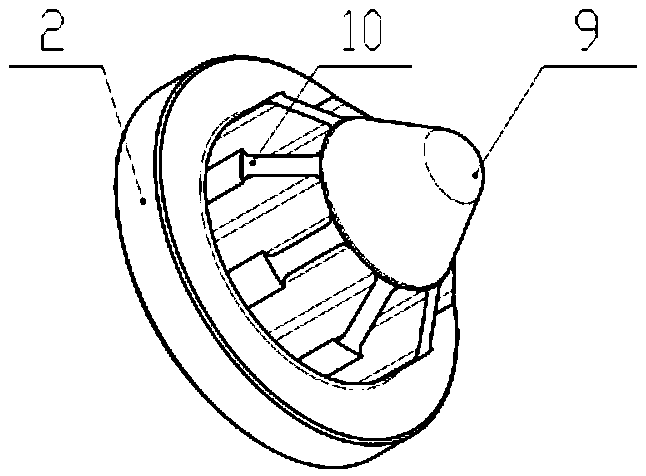

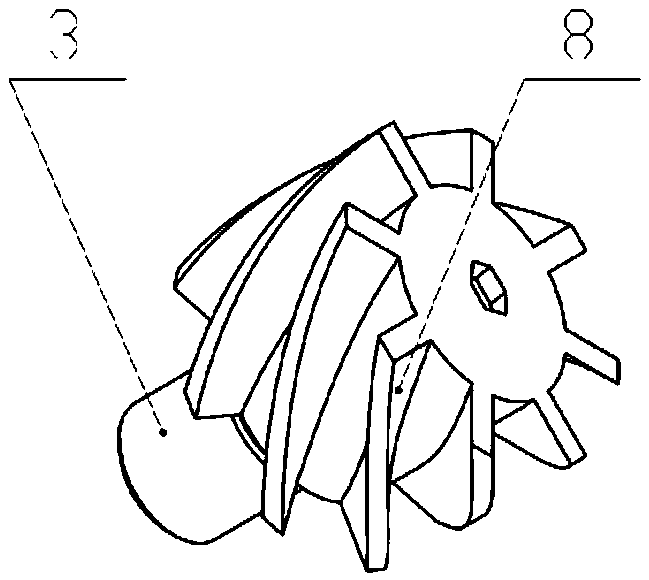

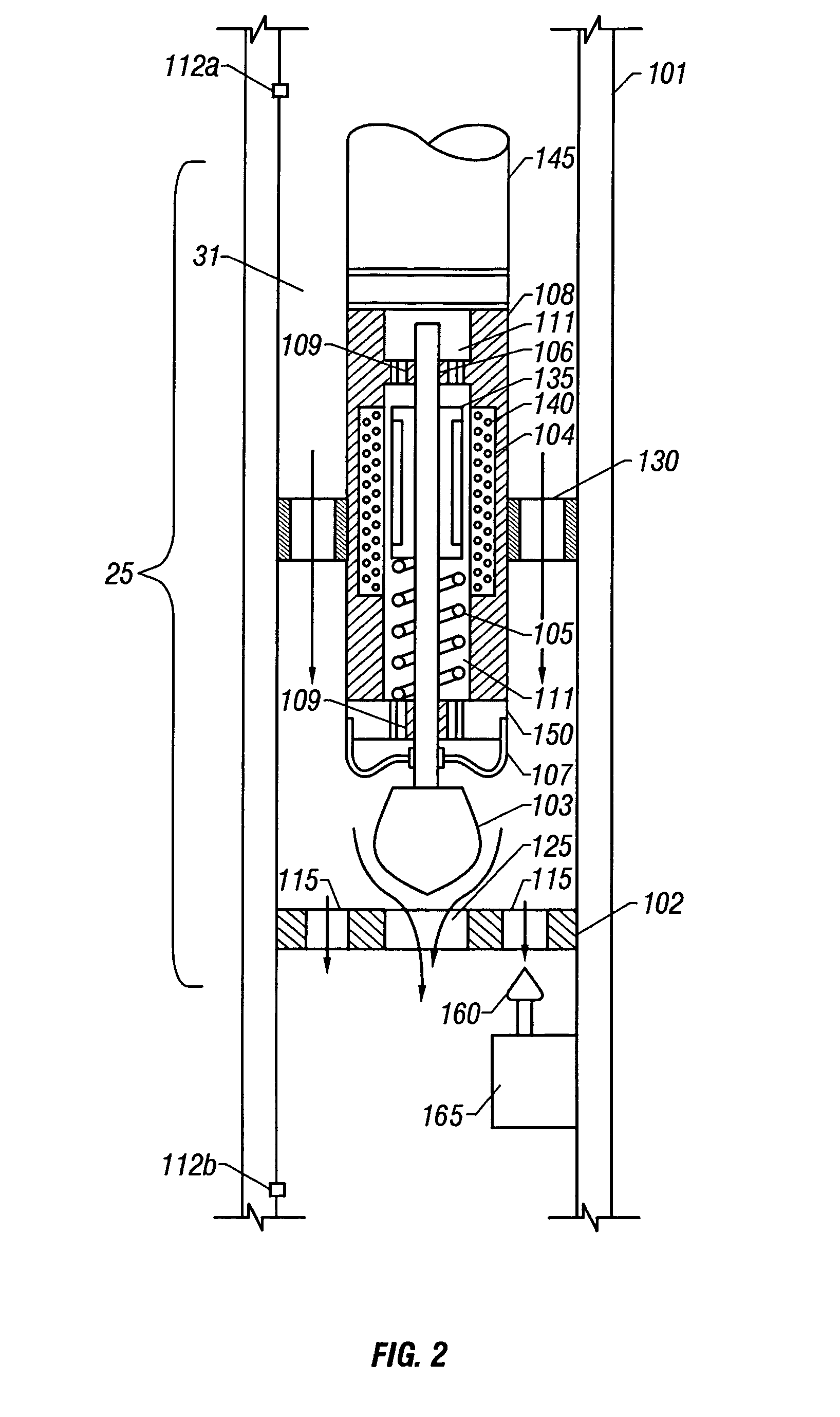

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

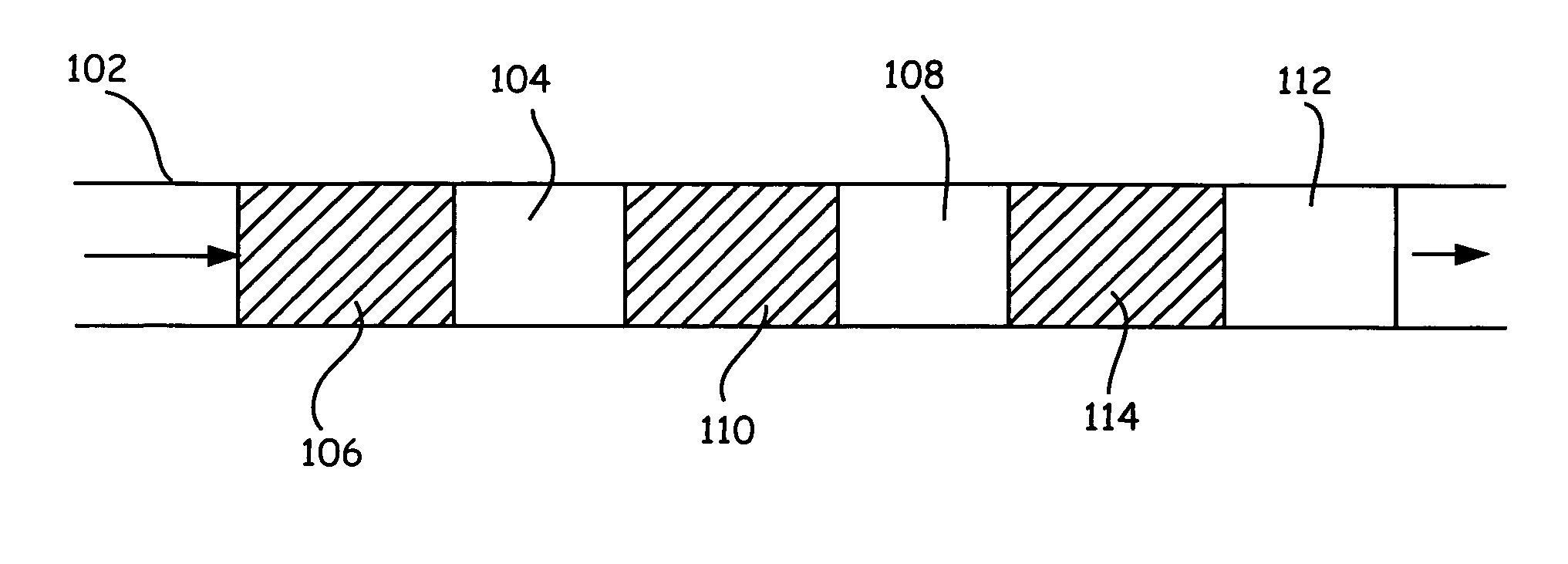

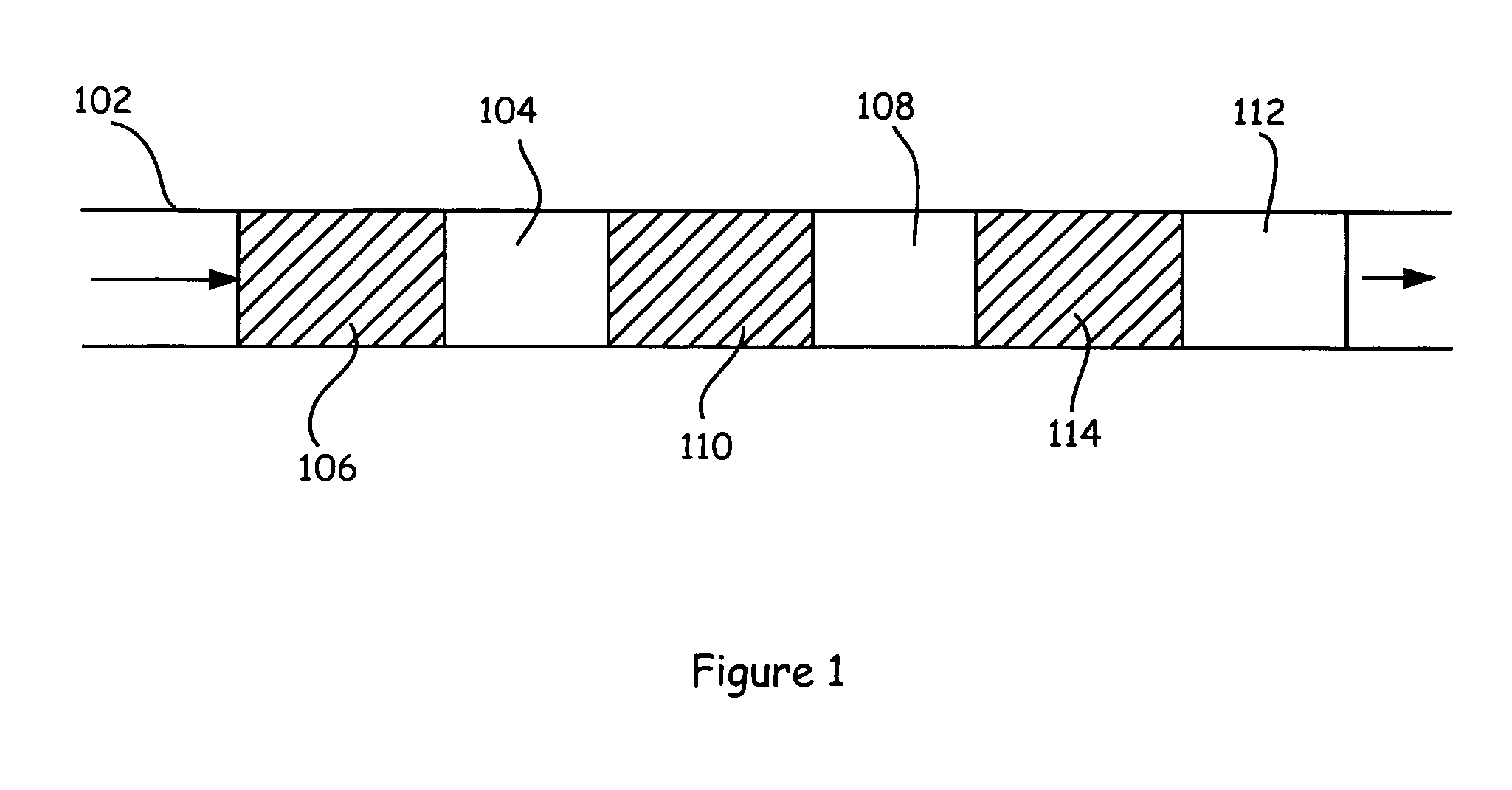

Devices, systems and methods for time domain multiplexing of reagents

InactiveUS7276330B2Bioreactor/fermenter combinationsBiological substance pretreatmentsTime domainReaction zone

Time dependent iterative reactions are carried out in microscale fluidic channels by configuring the channels such that reagents from different sources are delivered to a central reaction zone at different times during the analysis, allowing for the performance of a variety of time dependent, and / or iterative reactions in simplified microfluidic channels. Exemplary analyses include the determination of dose responses for biological and biochemical systems.

Owner:CAPLIPER LIFE SCI INC

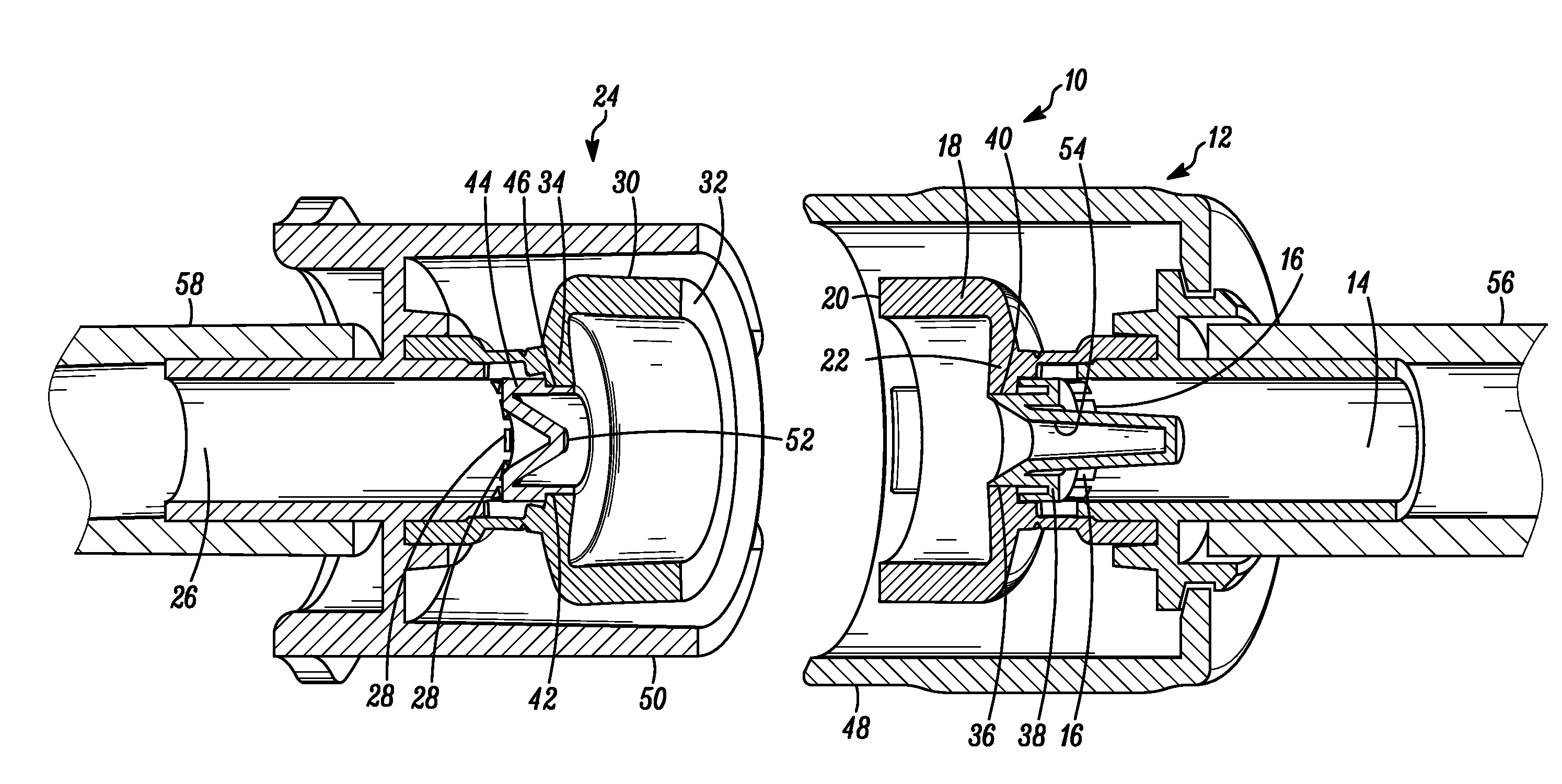

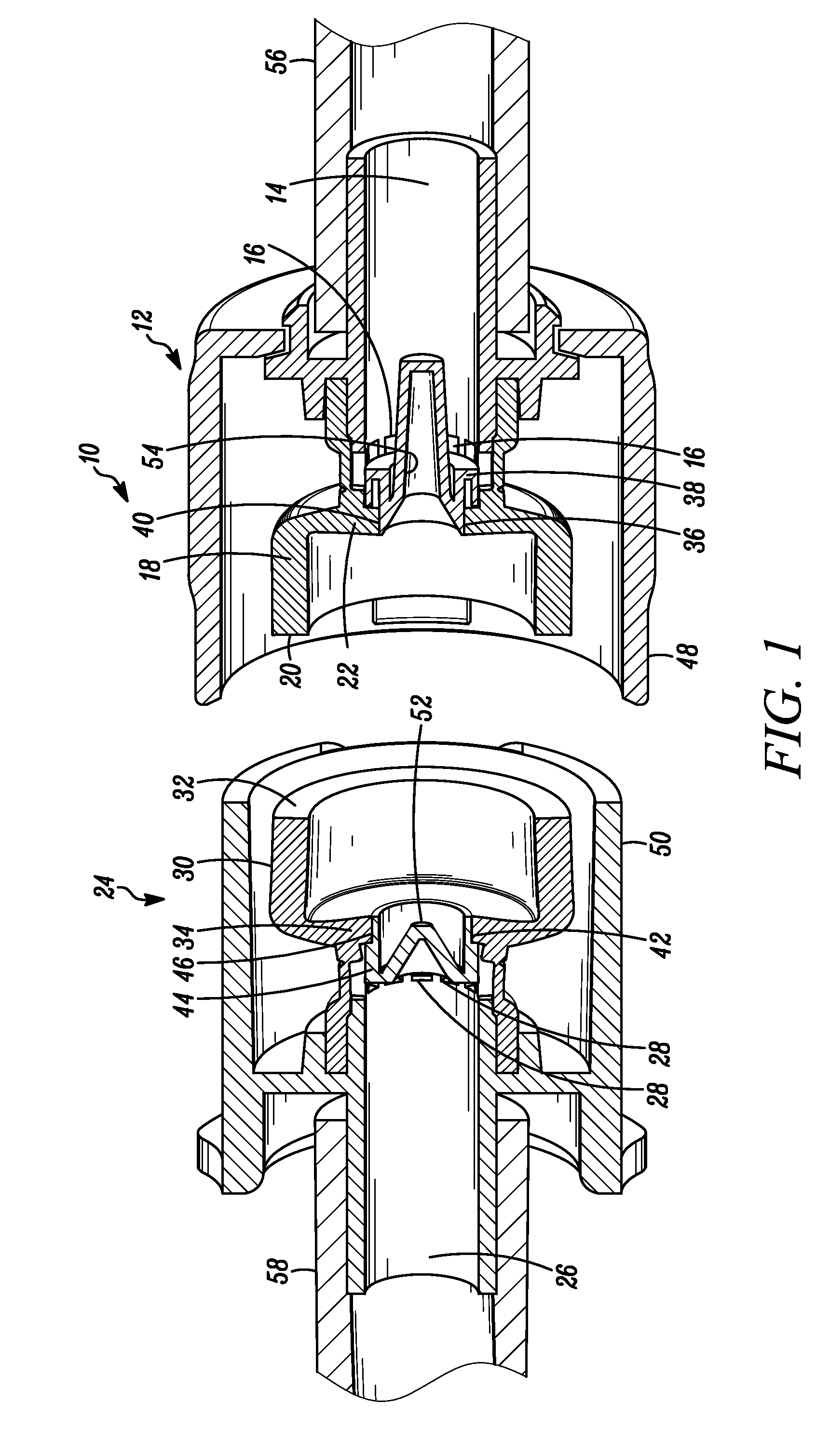

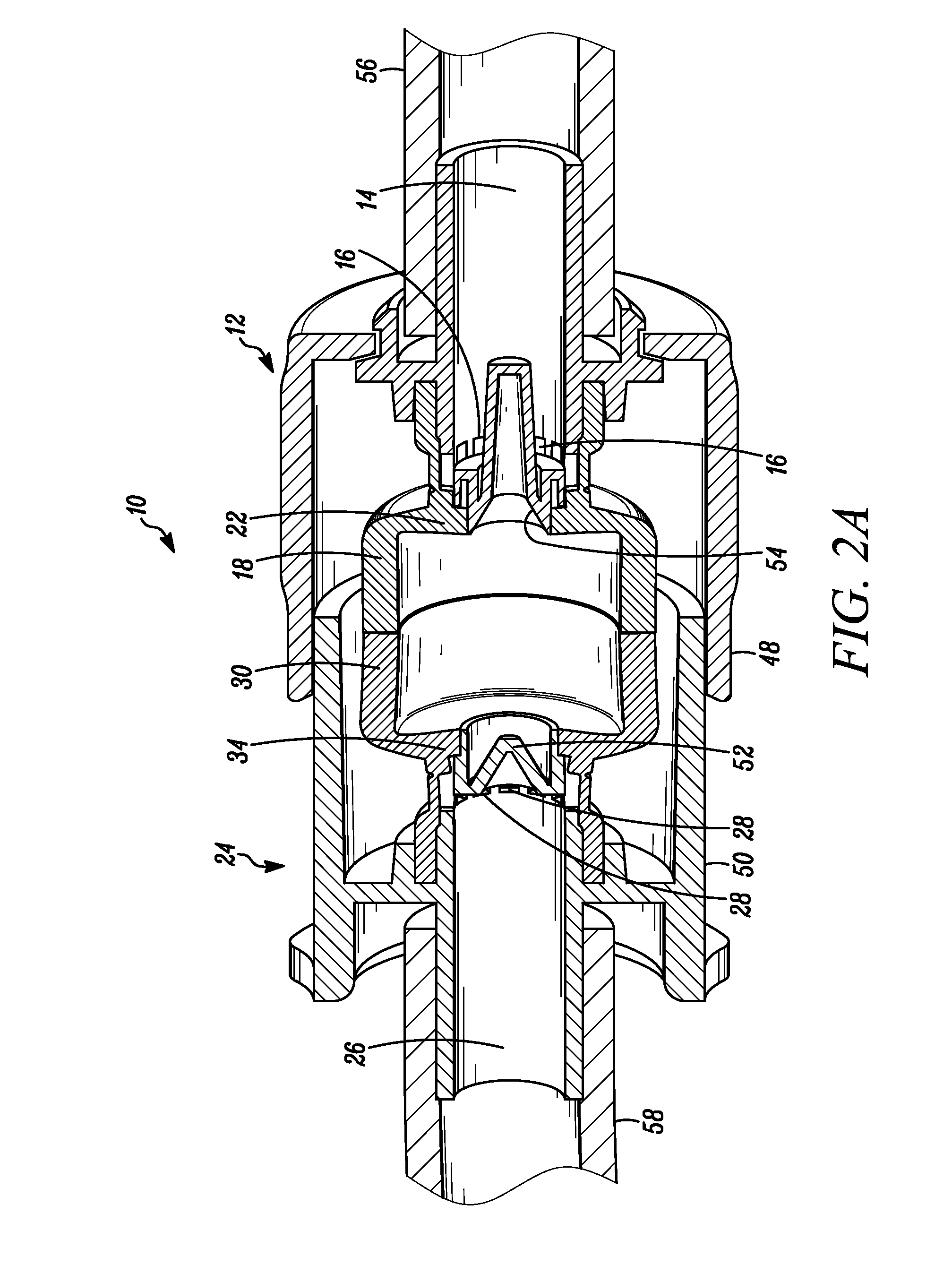

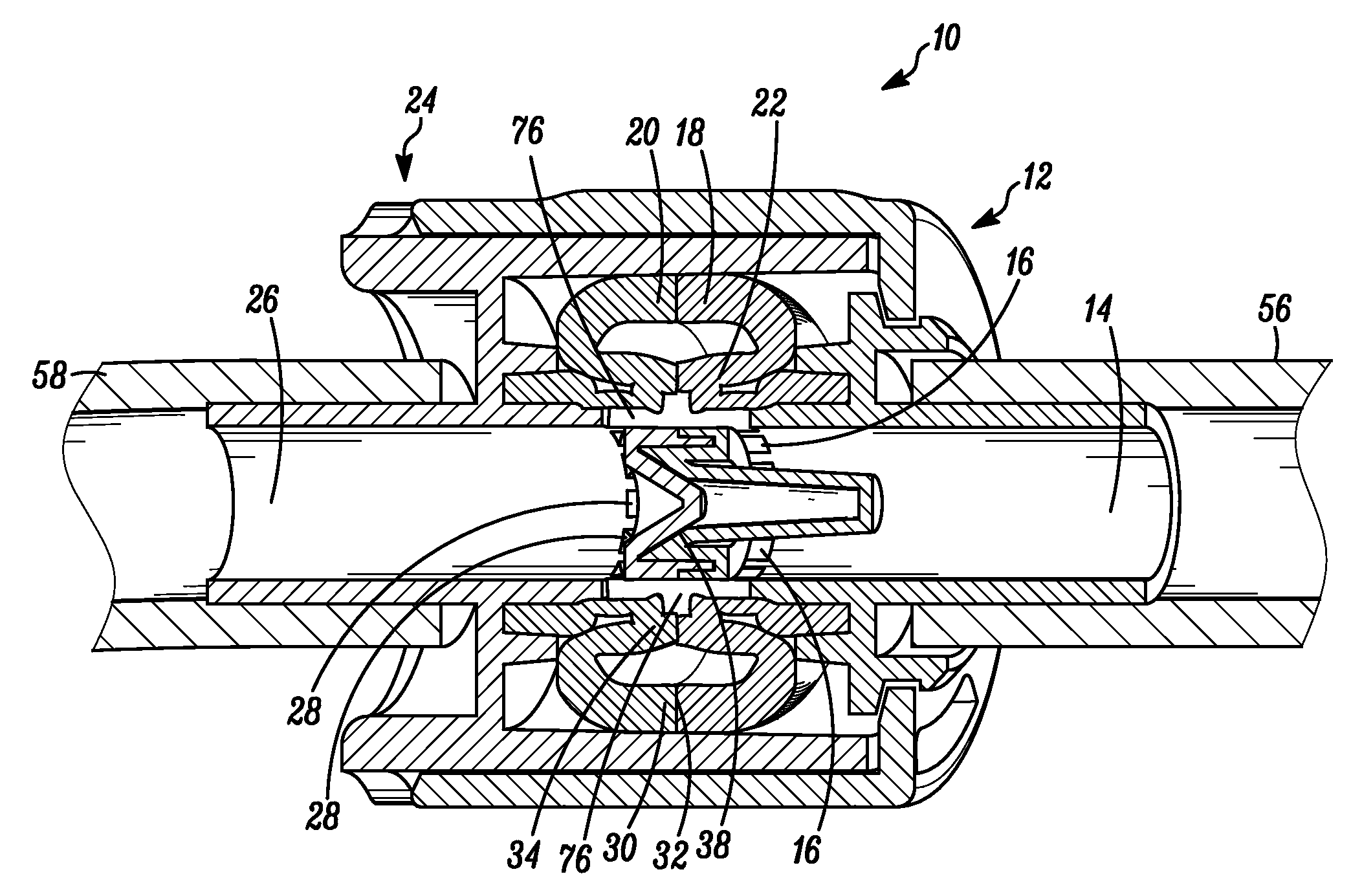

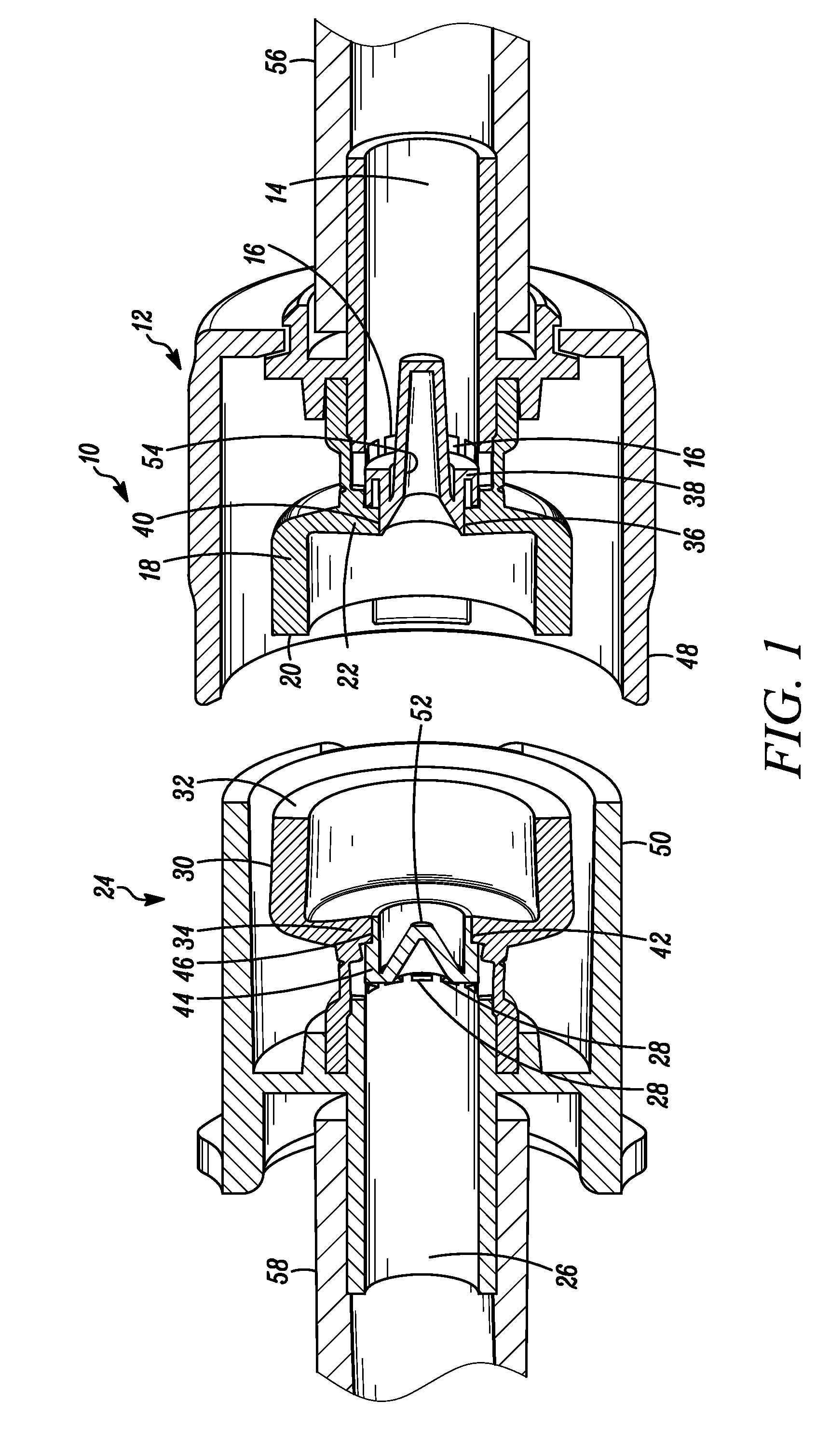

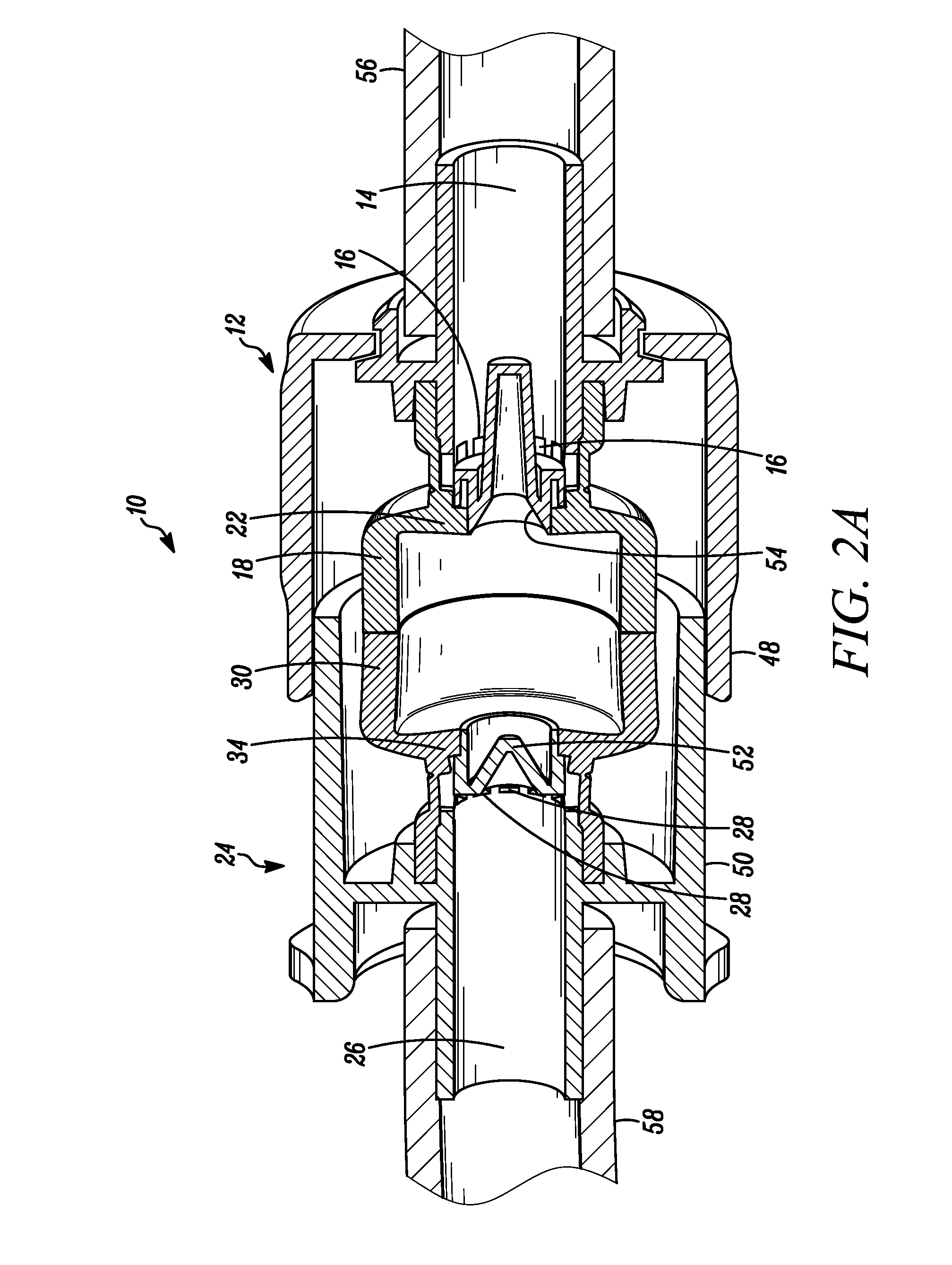

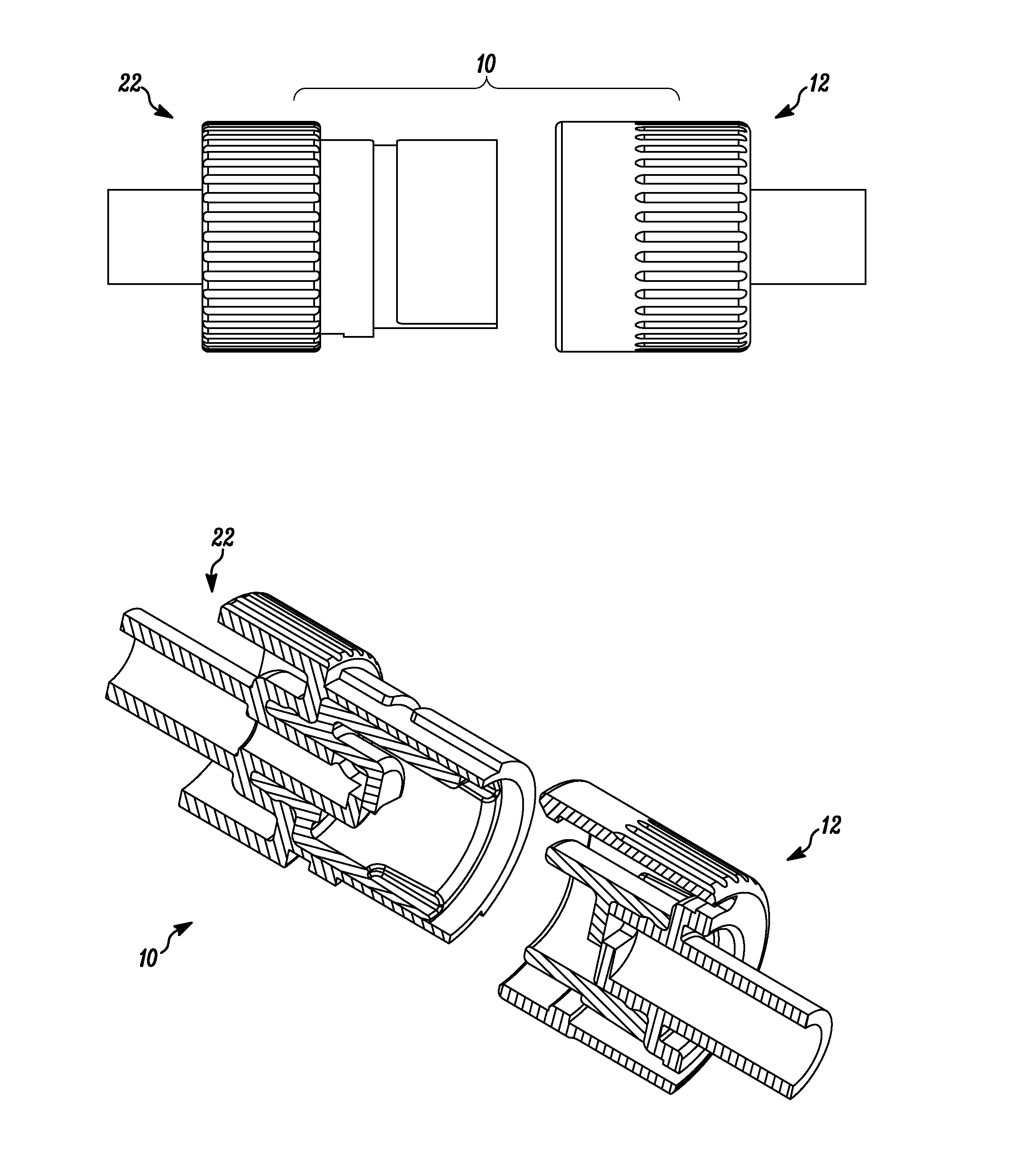

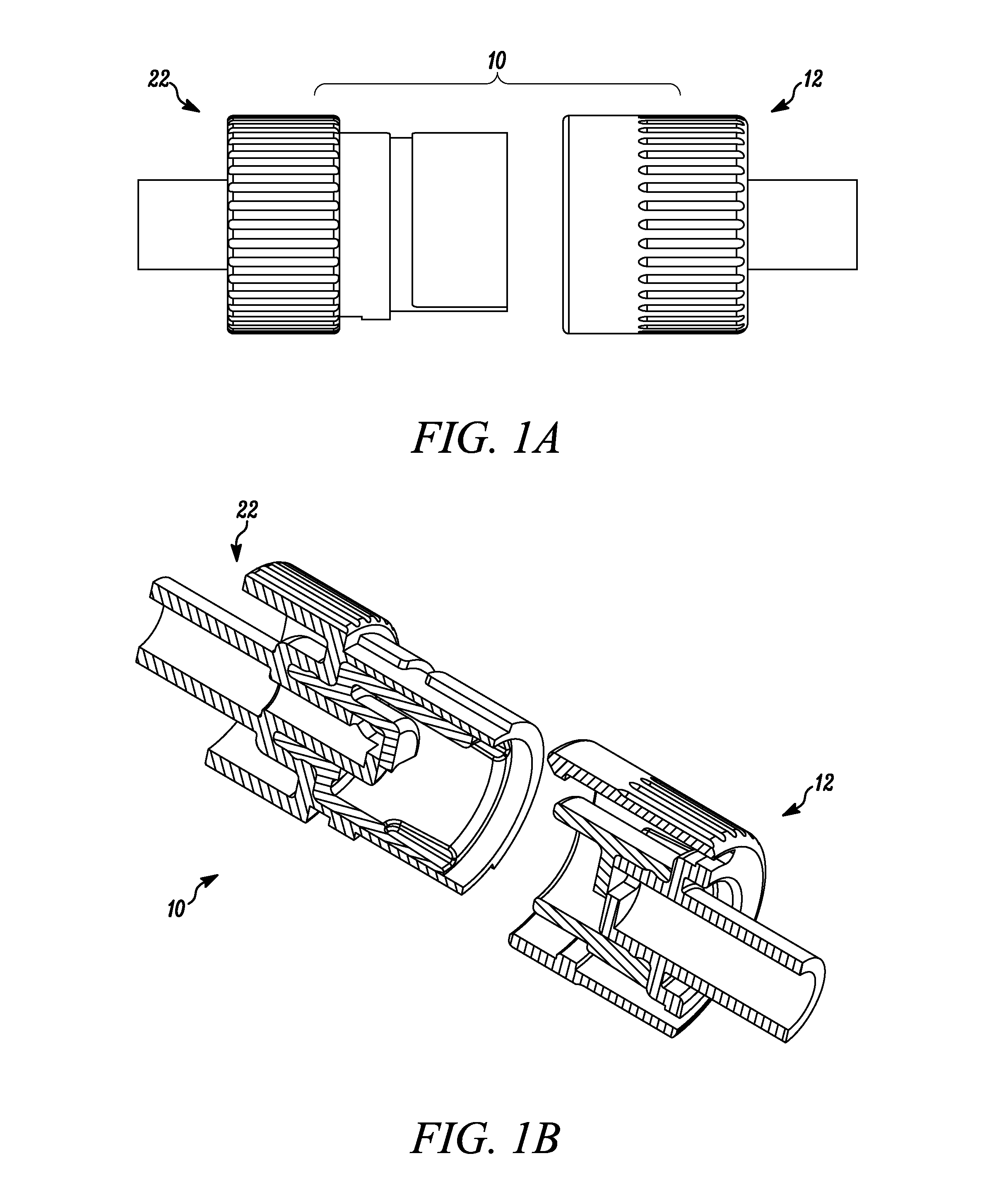

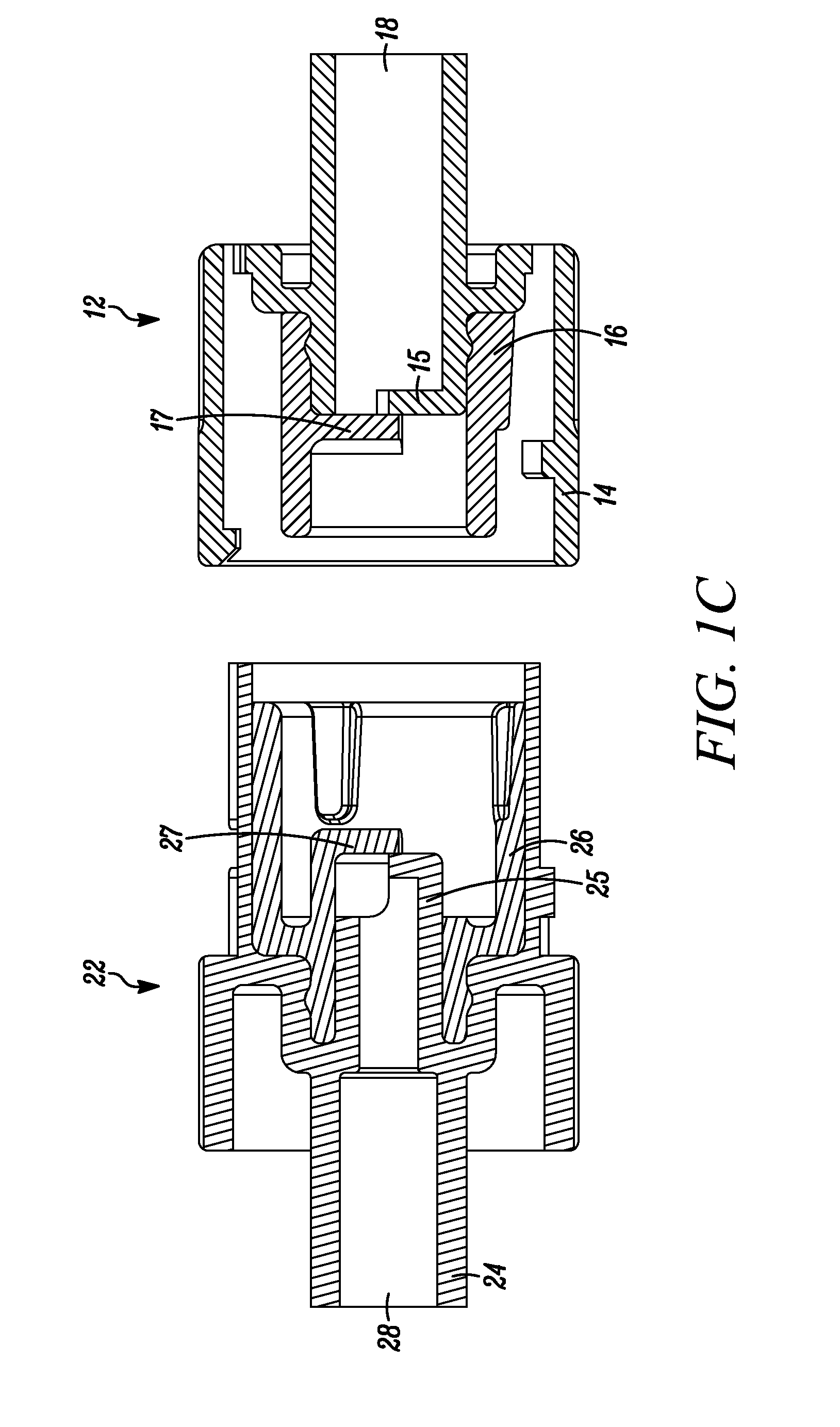

Aseptic connector with deflectable ring of concern and method

ActiveUS20110240158A1Avoid pollutionReadily apparentCouplingsBranching pipesSurgeryMechanical engineering

Owner:INTACT CLOSED TRANSFER CONNECTORS LLC

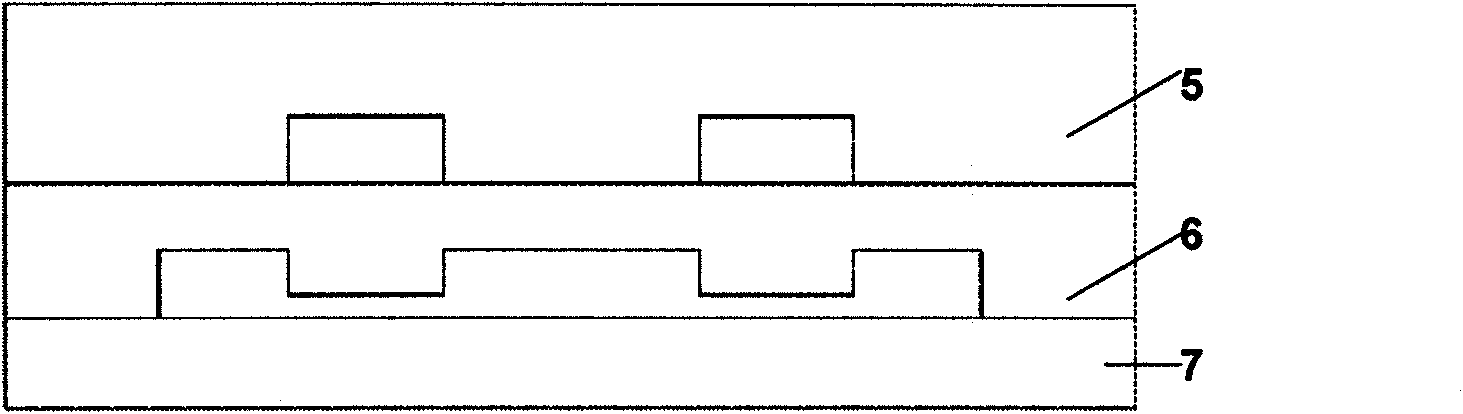

Microfluidic cell array chip for high-throughput medicament screening, method and use

InactiveCN101629143AResolving disordered cell distributionLess reagent consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsPhotoresistWidth ratio

The invention relates to a microfluidic cell array chip for high-throughput medicament screening, a preparation method thereof and use thereof. The microfluidic cell array chip for high-throughput medicament screening is characterized by sequentially comprising a valve-controlled channel layer, a fluid channel layer and a glass layer suitable for the anchorage growth of cells from top down. The chip can be used in high-throughput medicament screening by the parallel action of different medicament concentrations on various cells. The chip is manufactured by a multixposure one-development Su-8 negative photoresist process and multilayer PDMS bonding and has a structure with a high depth-to-width ratio. The microfluidic cell array chip provided by the invention can realize low reagent consumption and high-throughput co-culture of various cells, parallel analysis of the stimulation effect of different medicament concentrations on different cells and the real-time observation and detection of a slide of the cells and provide a fire-new technical platform and a method for high-throughput medicament screening and cell-medicament researches.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Microstructure synthesis by flow lithography and polymerization

In a method for synthesizing polymeric microstructures, a monomer stream is flowed, at a selected flow rate, through a fluidic channel. At least one shaped pulse of illumination is projected to the monomer stream, defining in the monomer stream a shape of at least one microstructure corresponding to the illumination pulse shape while polymerizing that microstructure shape in the monomer stream by the illumination pulse.

Owner:MASSACHUSETTS INST OF TECH

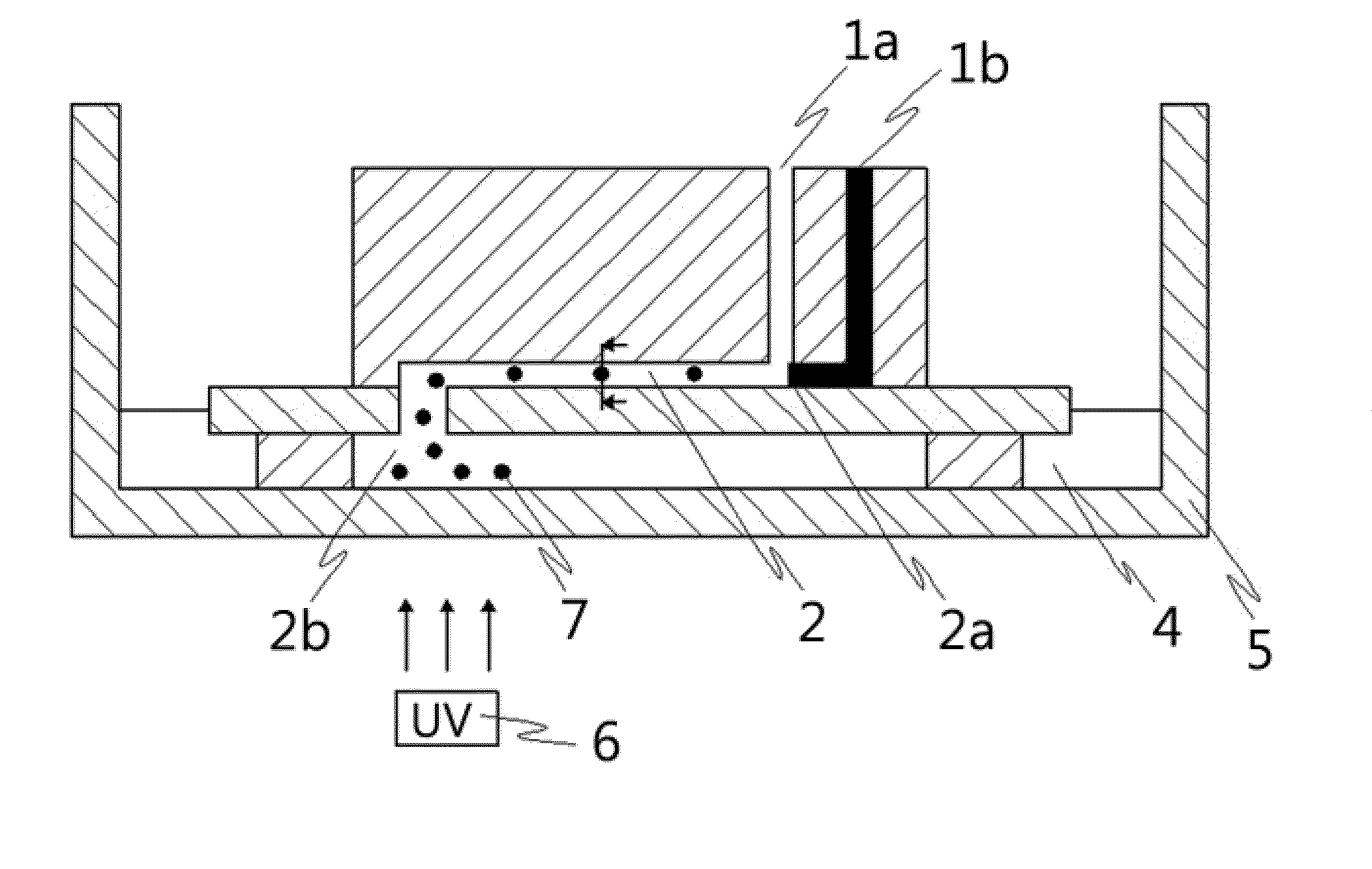

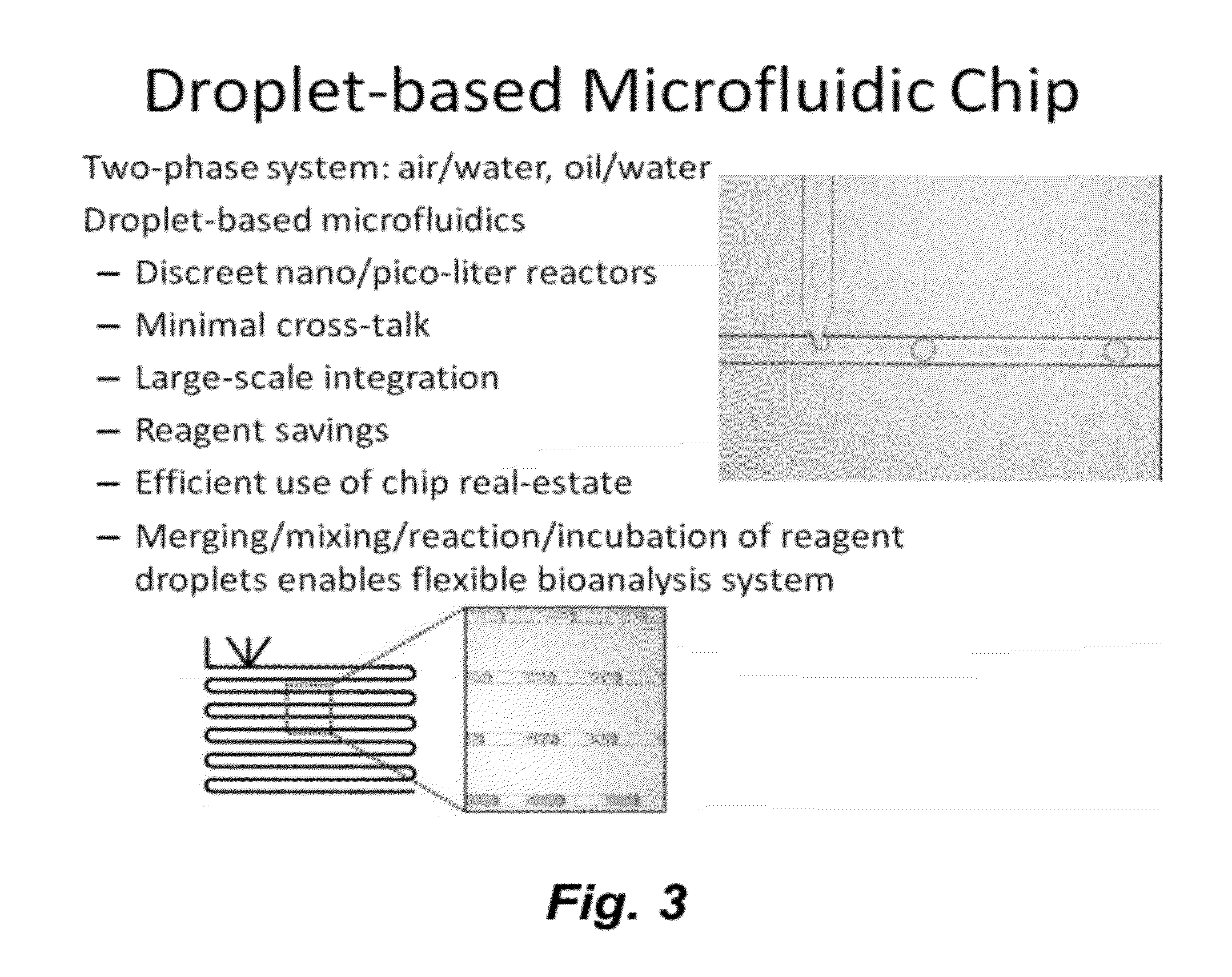

Preparation method for micro-capsule using a microfluidic chip system

InactiveUS20100187705A1Simpler and easy to prepareAmide active ingredientsMicroballoon preparationChemical treatmentDroplet-based microfluidics

A method for preparing microcapsules using a droplet-based microfluidic chip. Monodisperse microcapsules, which are hollow or can be loaded with a desired material, are prepared using a droplet-based microfluidic chip through the movement of a monomer molecule from the inside of droplets to the interface of droplets, the diffusion of a photoinitiator to the interface of droplets, and the suppression of radical activity by oxygen in droplets. The method involves the use of a simple microfluidic channel and selectively photopolymerizing the shell of the droplets without needing the use of a chemically treated microfluidic channel or a complex microfluidic channel.

Owner:THE IND & ACADEMIC COOPERATION & CHUNGNAM NAT UNIV

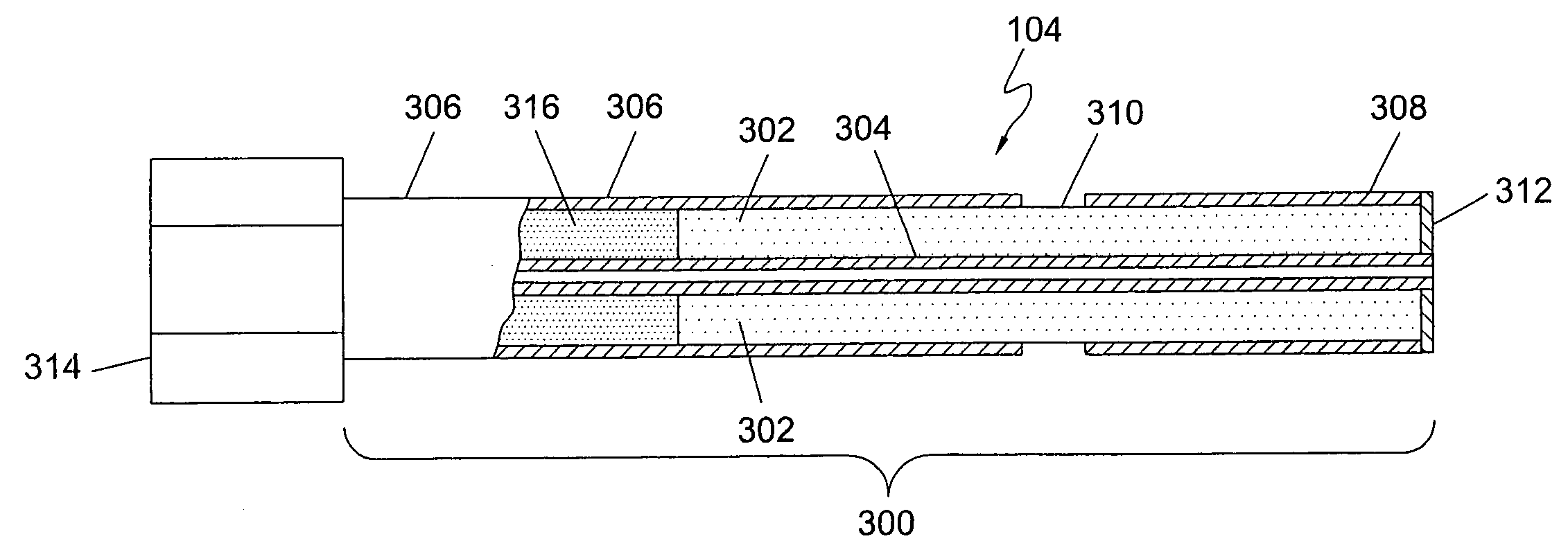

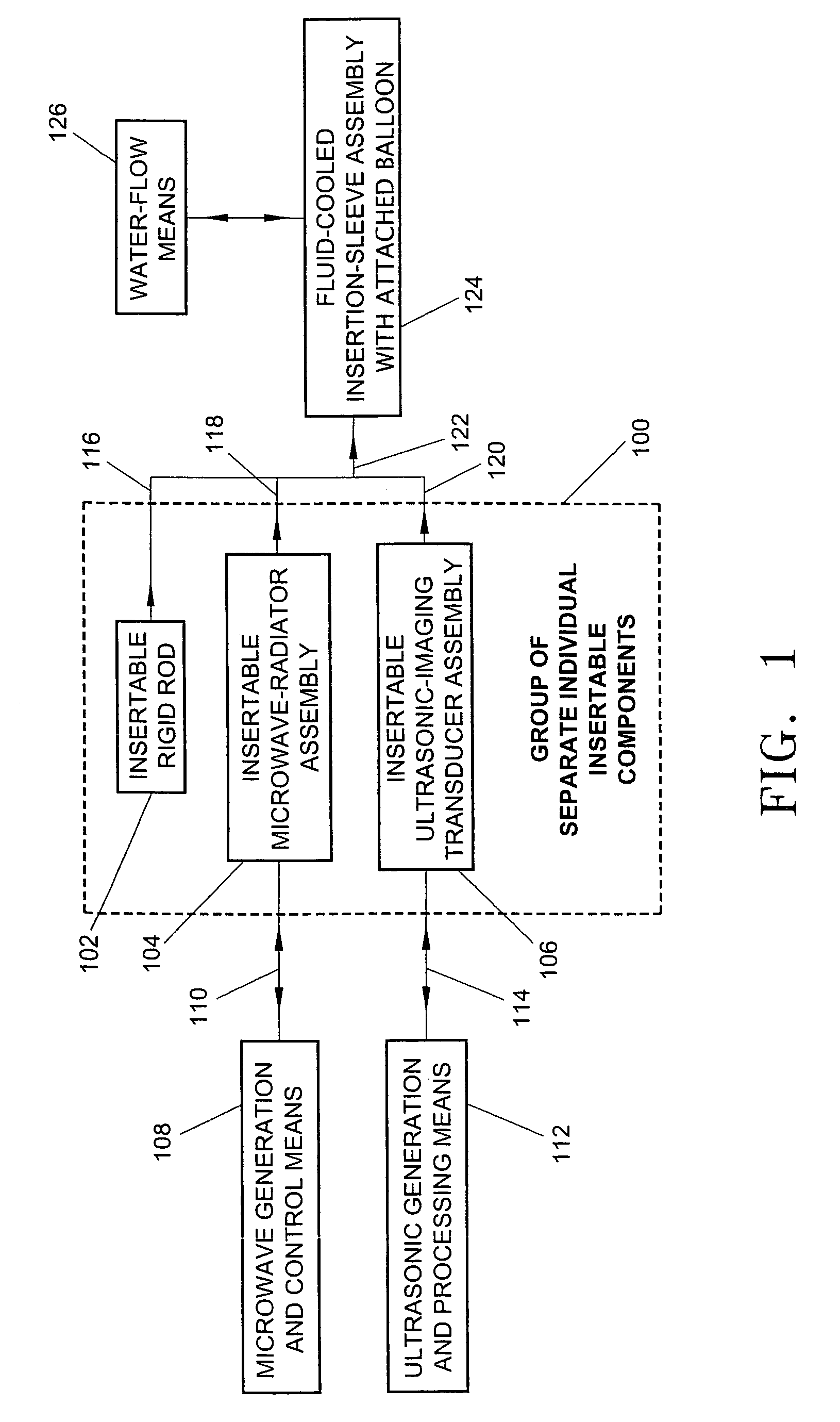

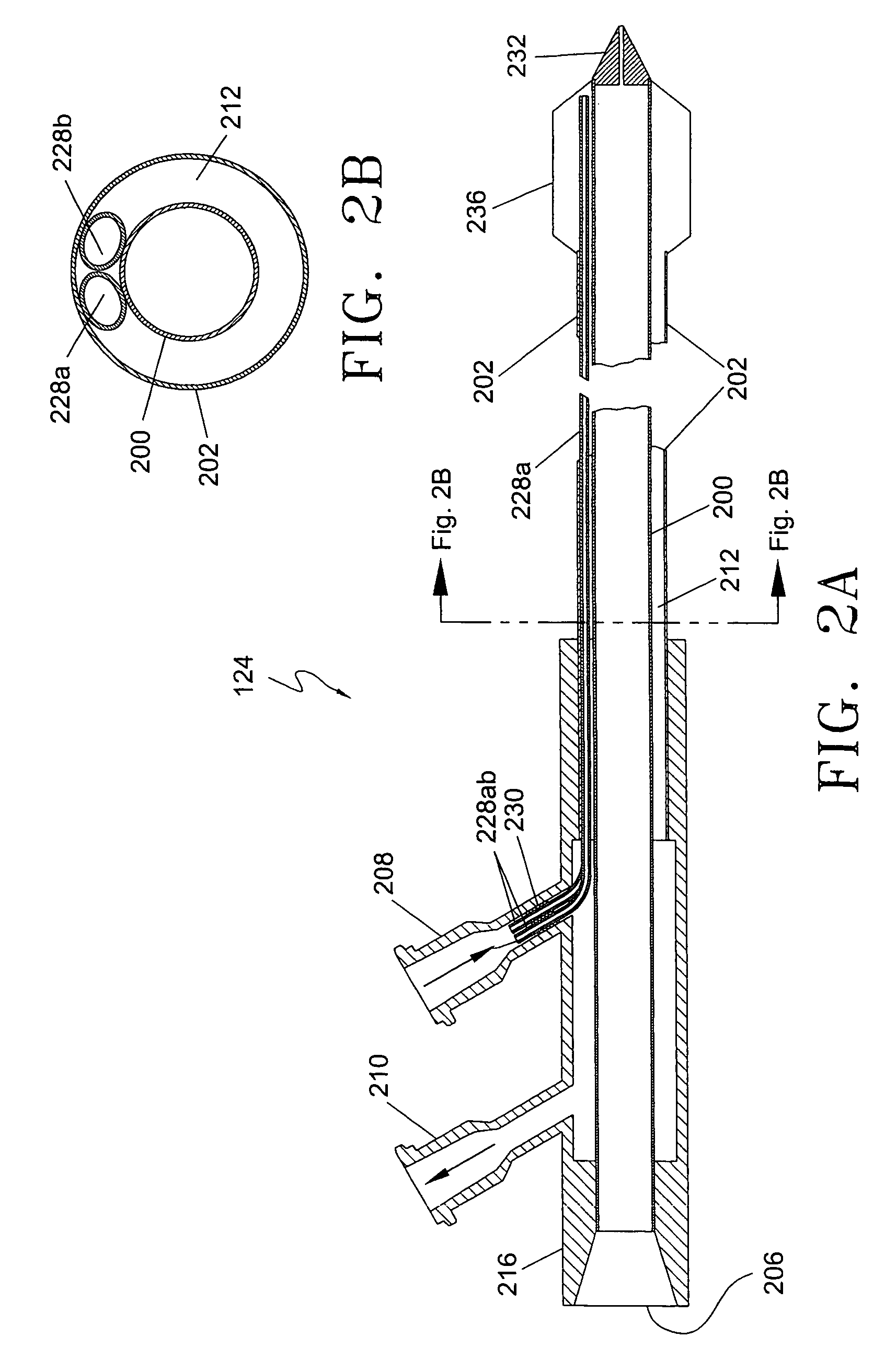

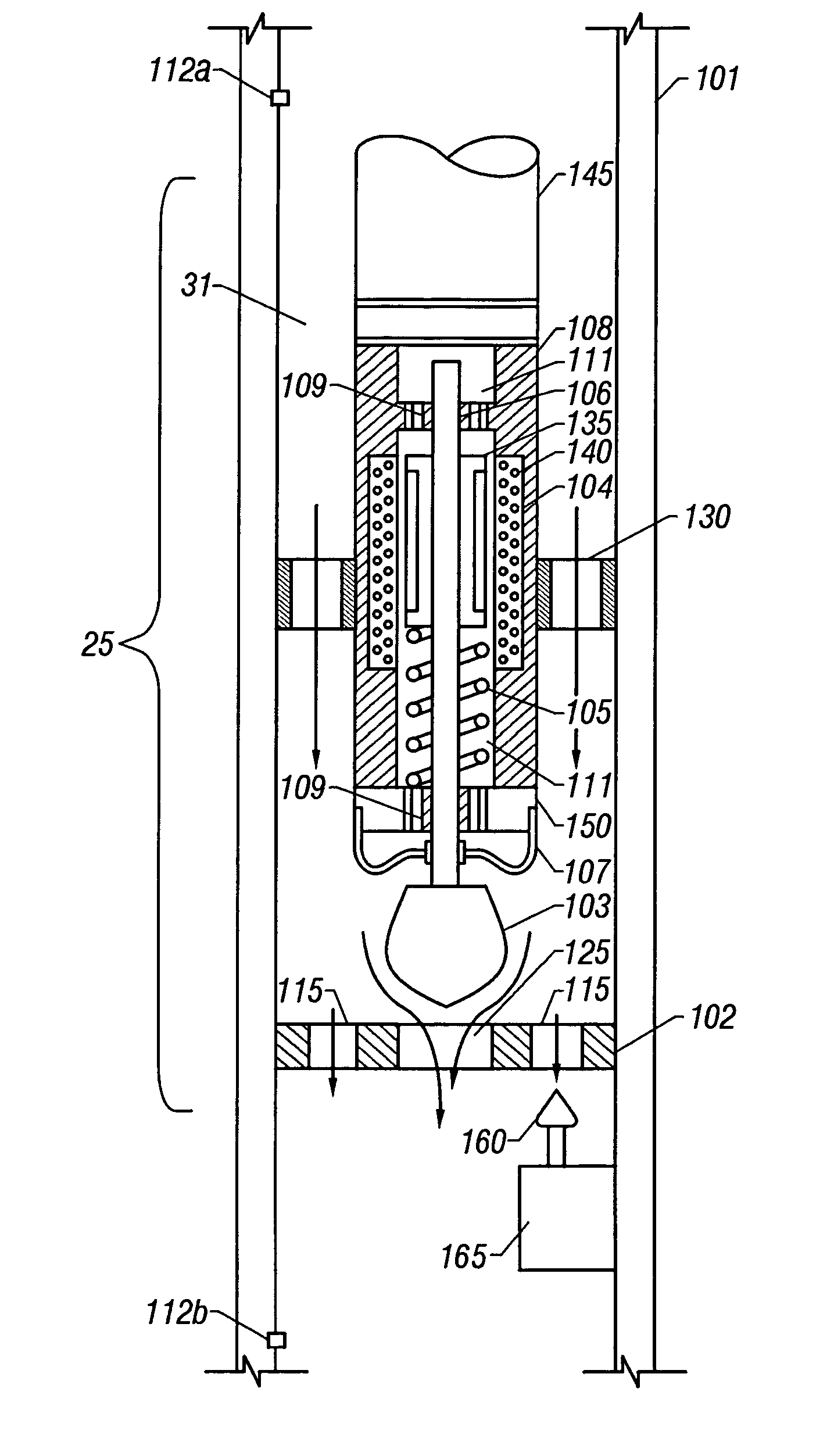

Interstitial microwave system and method for thermal treatment of diseases

A minimally-invasive fluid-cooled insertion sleeve assembly, with an attached balloon and distally-located penetrating tip, into which sleeve any of a group comprising a rigid rod, a microwave-radiator assembly and an ultrasonic-imaging transducer assembly may be inserted, constitutes a probe of the system. The sleeve assembly comprises spaced inner and outer plastic tubes with two fluid channels situated within the coaxial lumen between the inner and outer tubes. The fluid coolant input flows through the fluid channels into the balloon, thereby inflating the balloon, and then exits through that coaxial lumen. An alternative embodiment has no balloon. The method employs the probe for piercing sub-cutaneous tissue and then ablating deep-seated tumor tissue with microwave-radiation generated heat.

Owner:MMTC LTD +1

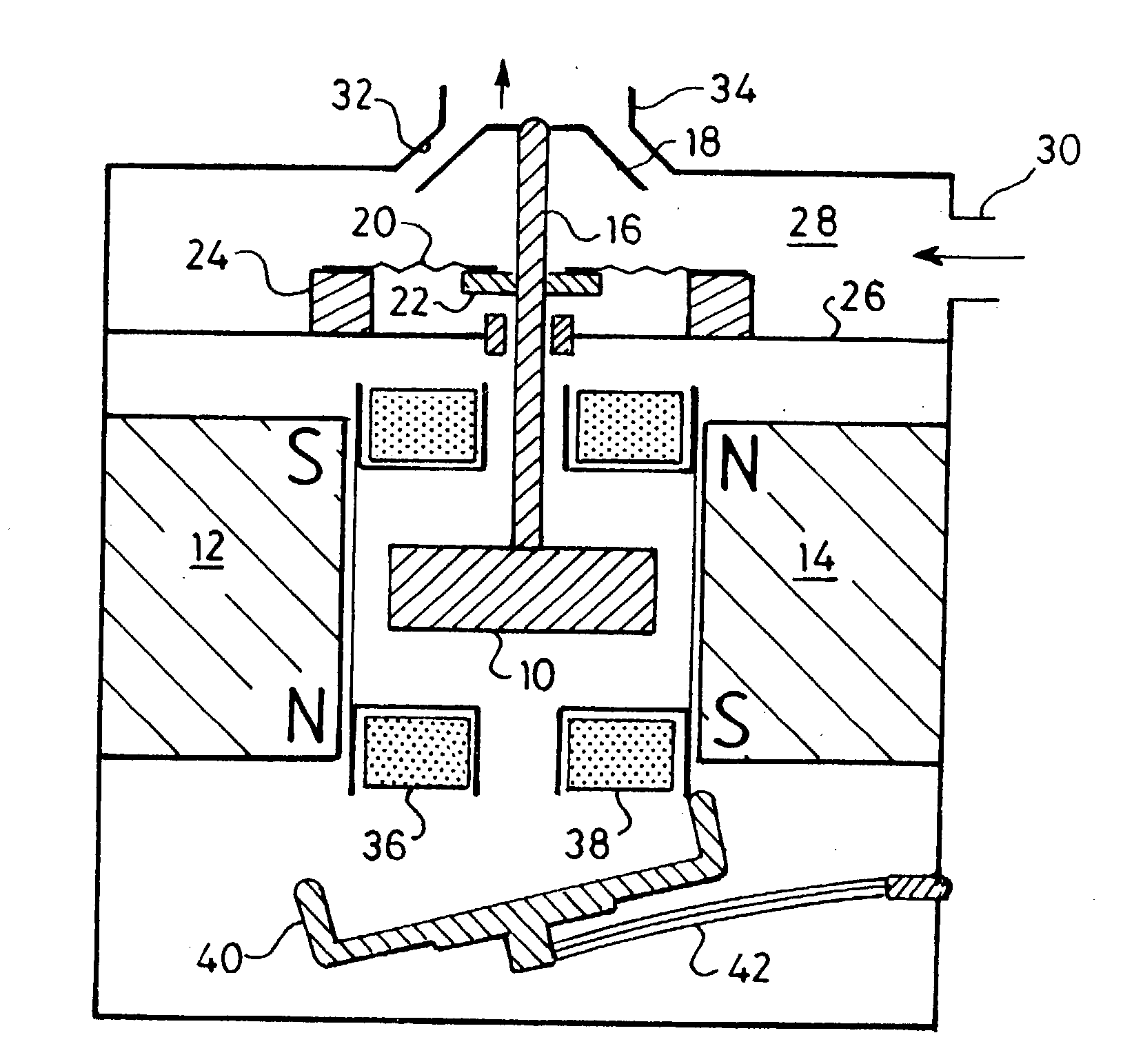

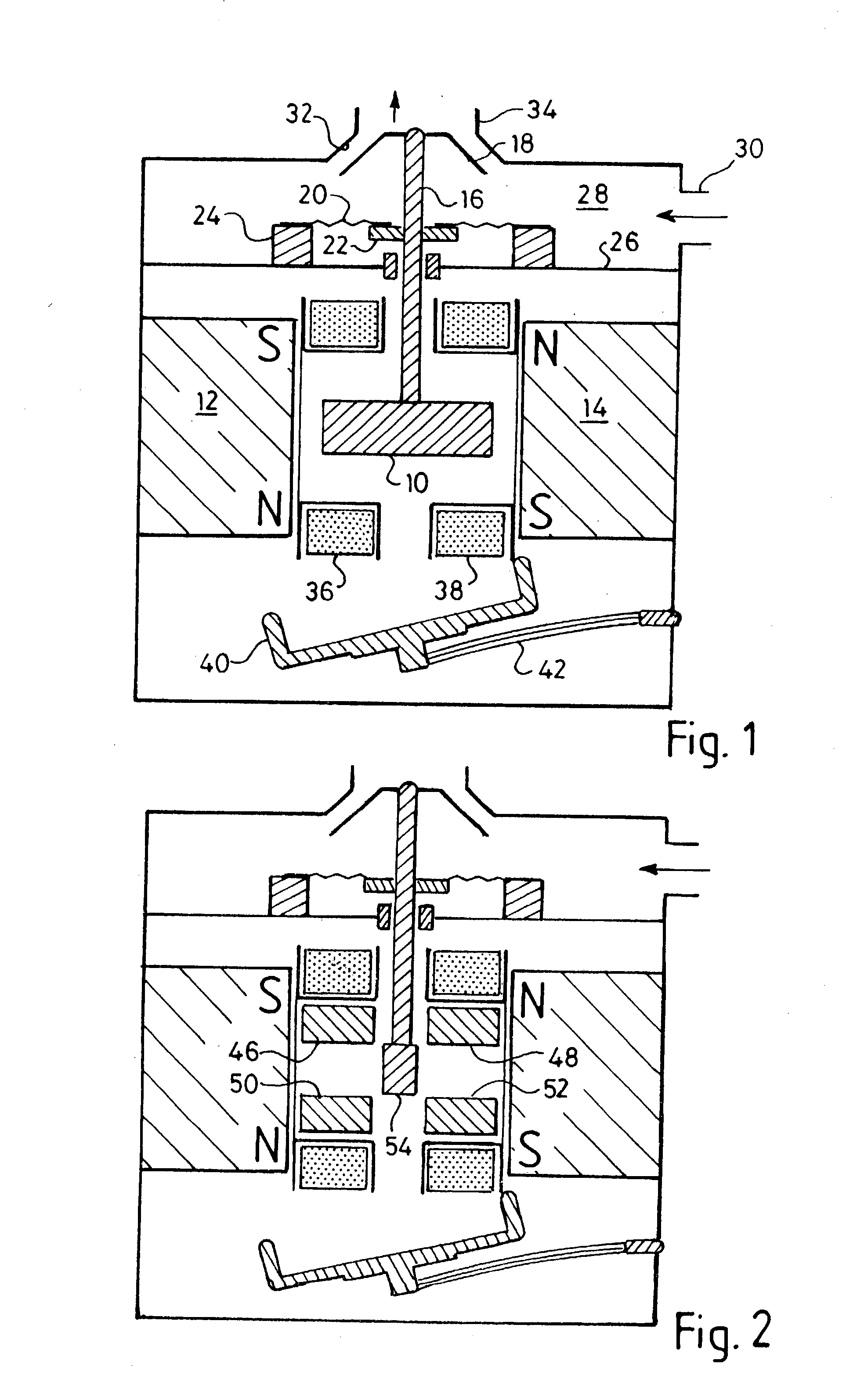

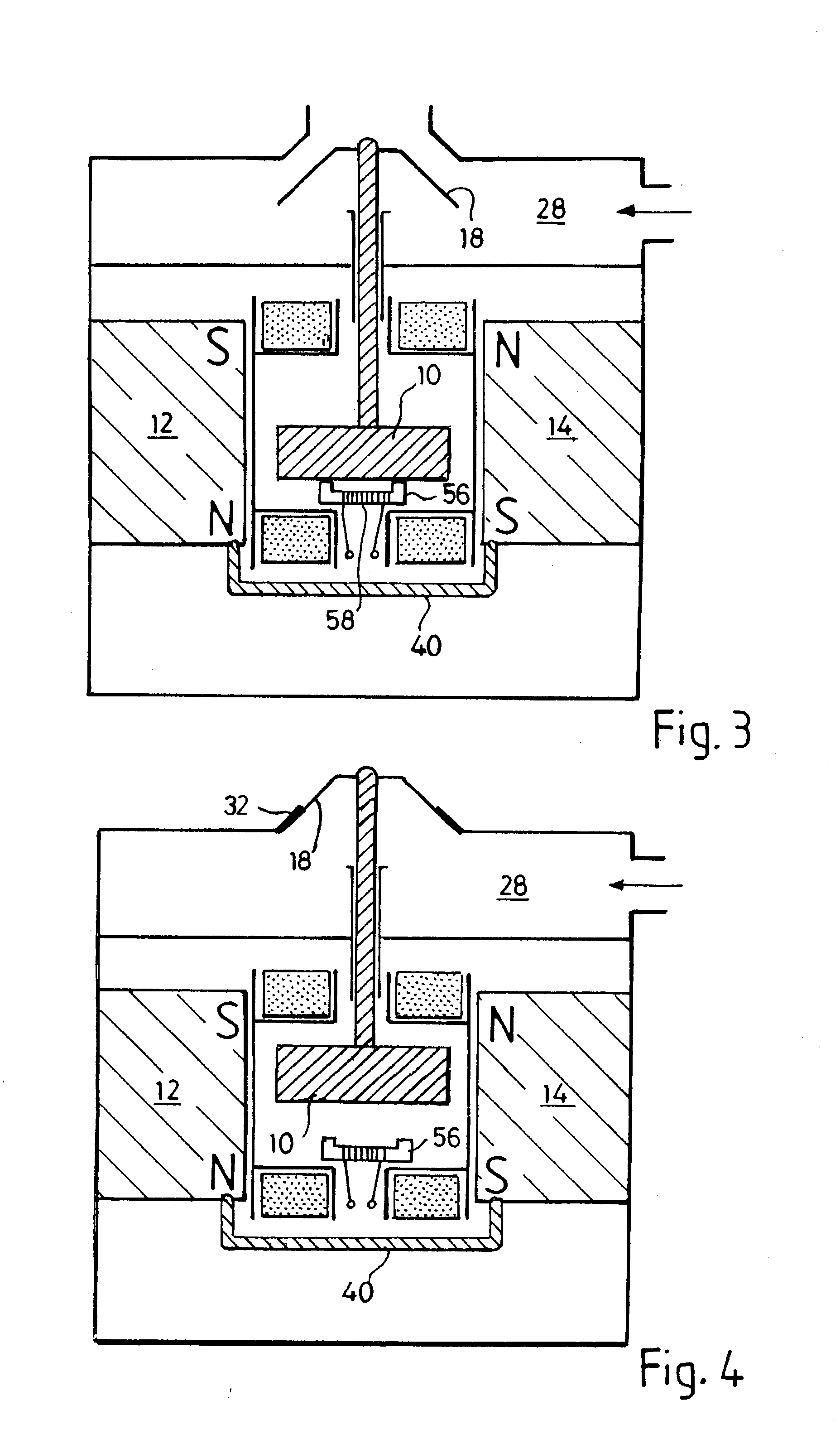

Electromagnetic actuator and integrated actuator and fluid flow control valve

InactiveUS20040025949A1Rapid responseLow driving energyOperating means/releasing devices for valvesPipeline systemsMagnetic polesEngineering

A magnetic device is formed from a permanent magnet generating magnetic flux, an armature which can occupy two positions between four poles and an electromagnet winding to which current can be supplied to produce a magnetic flux in one direction or the other, the flux from the winding causing the armature to move into one position and continue to remain in that position after the current flow ceases. The device can be incorporated into a fluid valve to act as a drive for opening and closing the valve. It may also serve as the drive for opening and closing electrical contacts. Monostable operation can be achieved by locating a magnetic flux shunt at one end of the armature travel. A holding solenoid may be incorporated. A pivoting armature in a fluid tight chamber comprises a fluid flow controlling device. It can adopt either of two home positions in contact with two magnetic poles and is retained by magnetic flux from a permanent magnet. Fluid can flow into and out of the chamber via a first passage. A second passage extends through one of the poles to an opening in the pole face which is covered by the armature when the latter occupies one home position but is uncovered when the armature occupies its other home position. A third fluid passage extends through and leads to a second opening in another pole, which is covered when the armature occupies its said other home position. Passages in the poles house energy storing springs each of which is compressed as the armature approaches the pole. A push rod can extend through a passage in one of the poles for conveying armature movement externally of the device.

Owner:CAMCOM

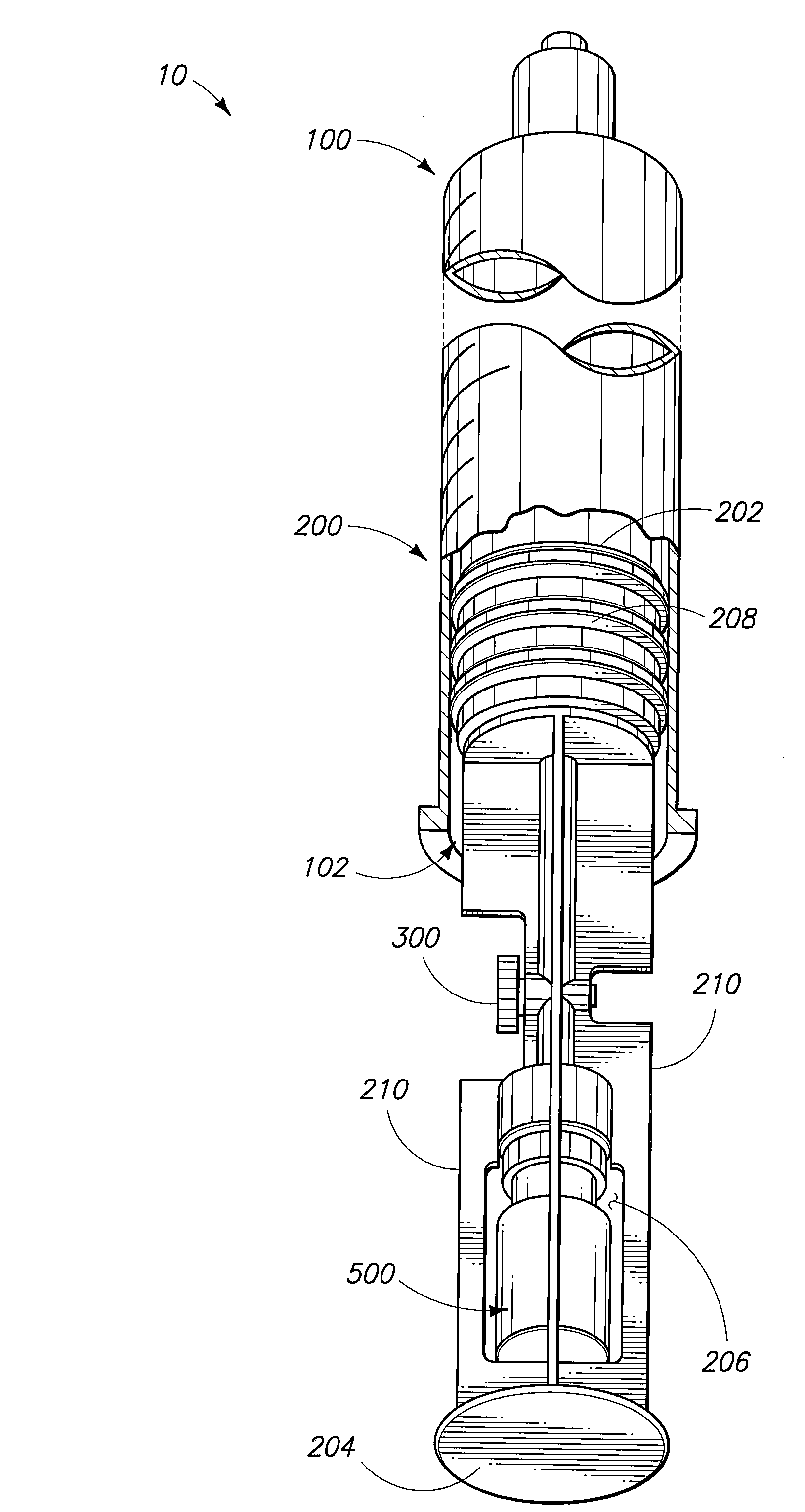

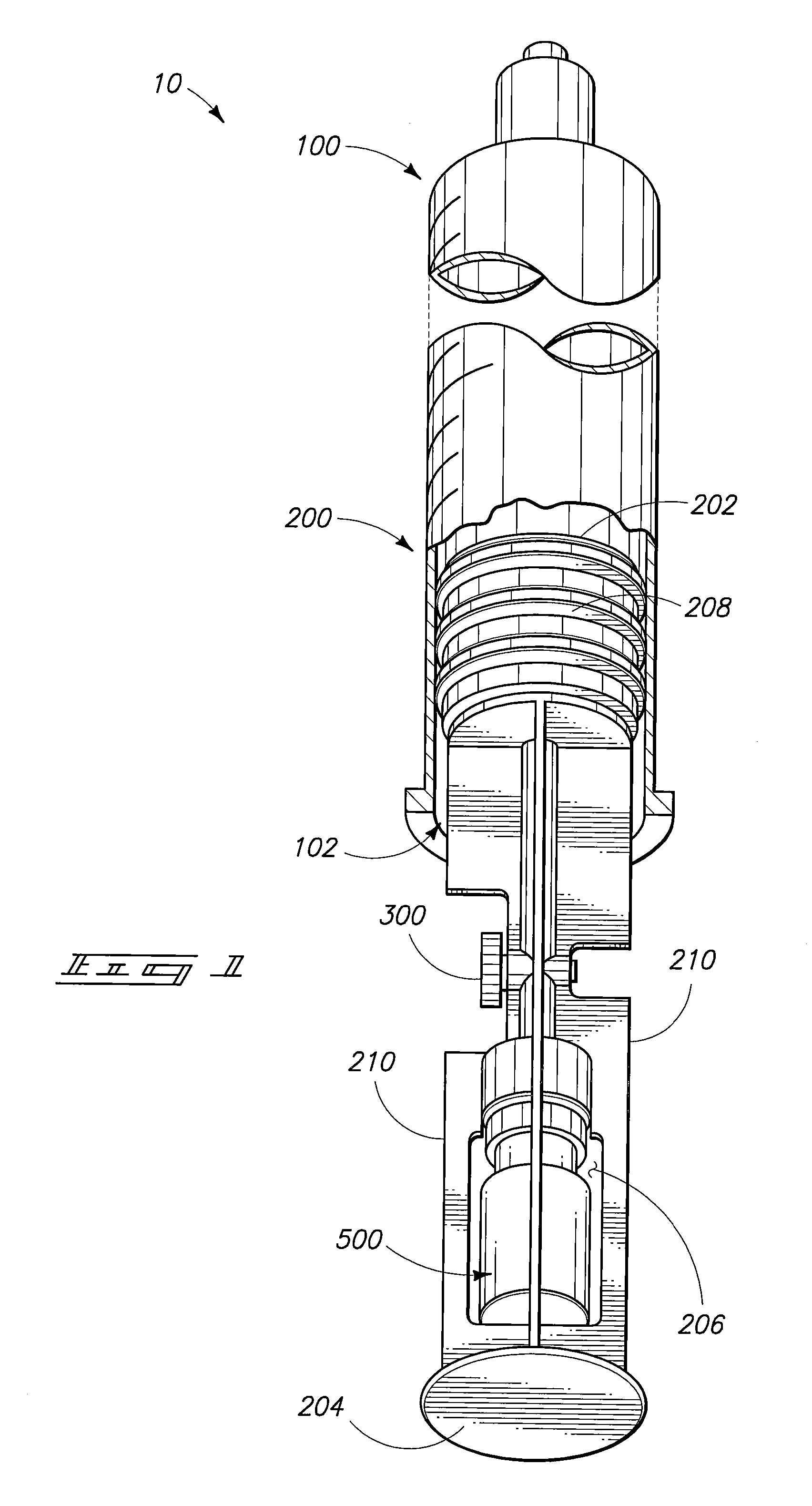

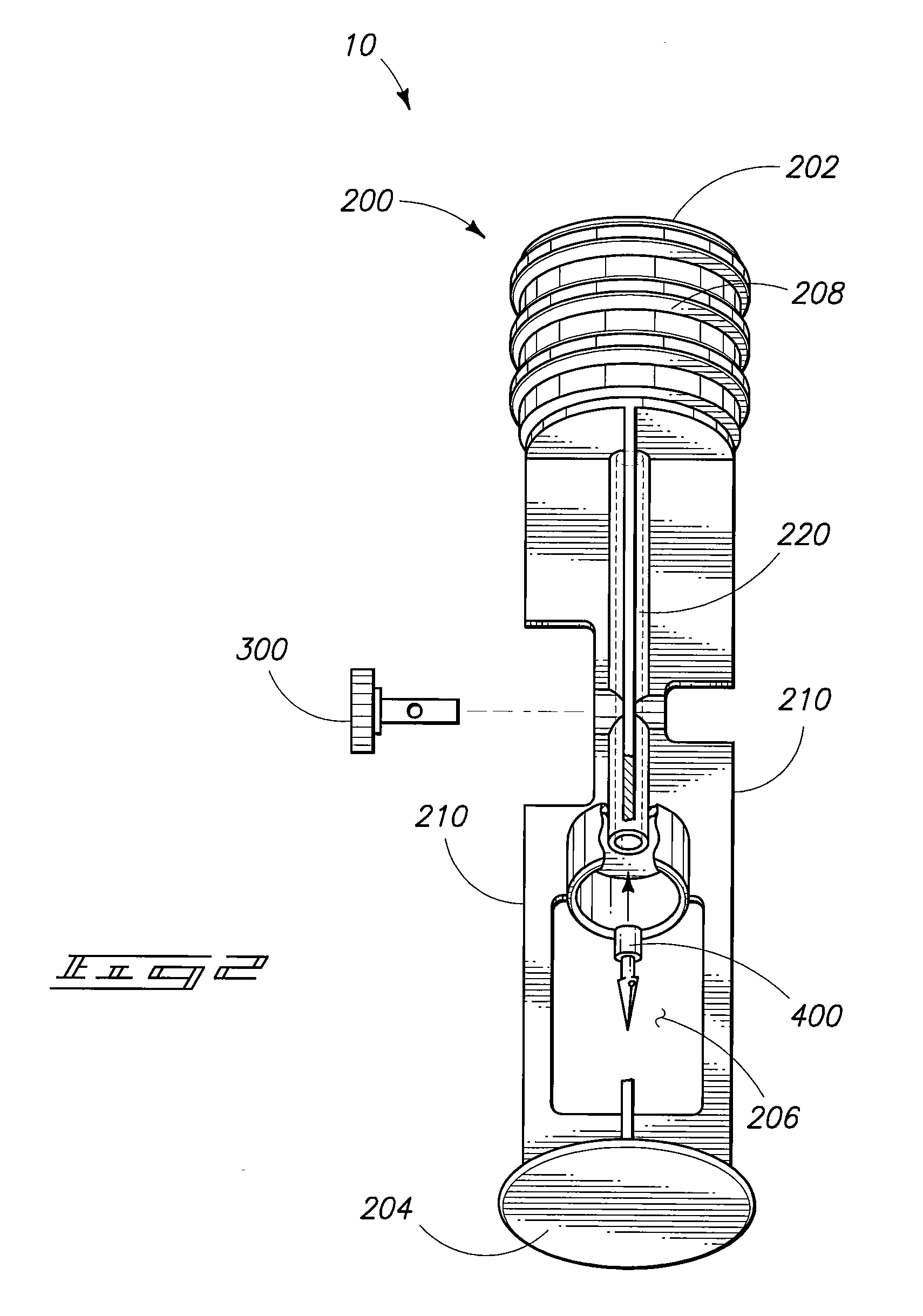

Syringe Devices, Components of Syringe Devices, and Methods of Forming Components and Syringe Devices

A syringe device includes a syringe barrel and piston having a fluid passageway extending from a vial port. Another syringe device includes a syringe barrel, a piston sleeve and an insert. A channel extends along a side of the insert. A valve controls fluid communication between the channel and the syringe barrel. Another syringe device has a syringe barrel, a piston sleeve and an insert. A valve controls fluid communication between a compartment within the insert and the syringe barrel. A method of preparing a medication includes providing a component within a syringe barrel and another component within a compartment of a piston insert. A seal is over-molded onto a tip of the insert and an end of a piston sleeve. The sleeve is rotated relative to the insert to establish fluid communication between the compartment and the barrel chamber.

Owner:HYPROTEK INC

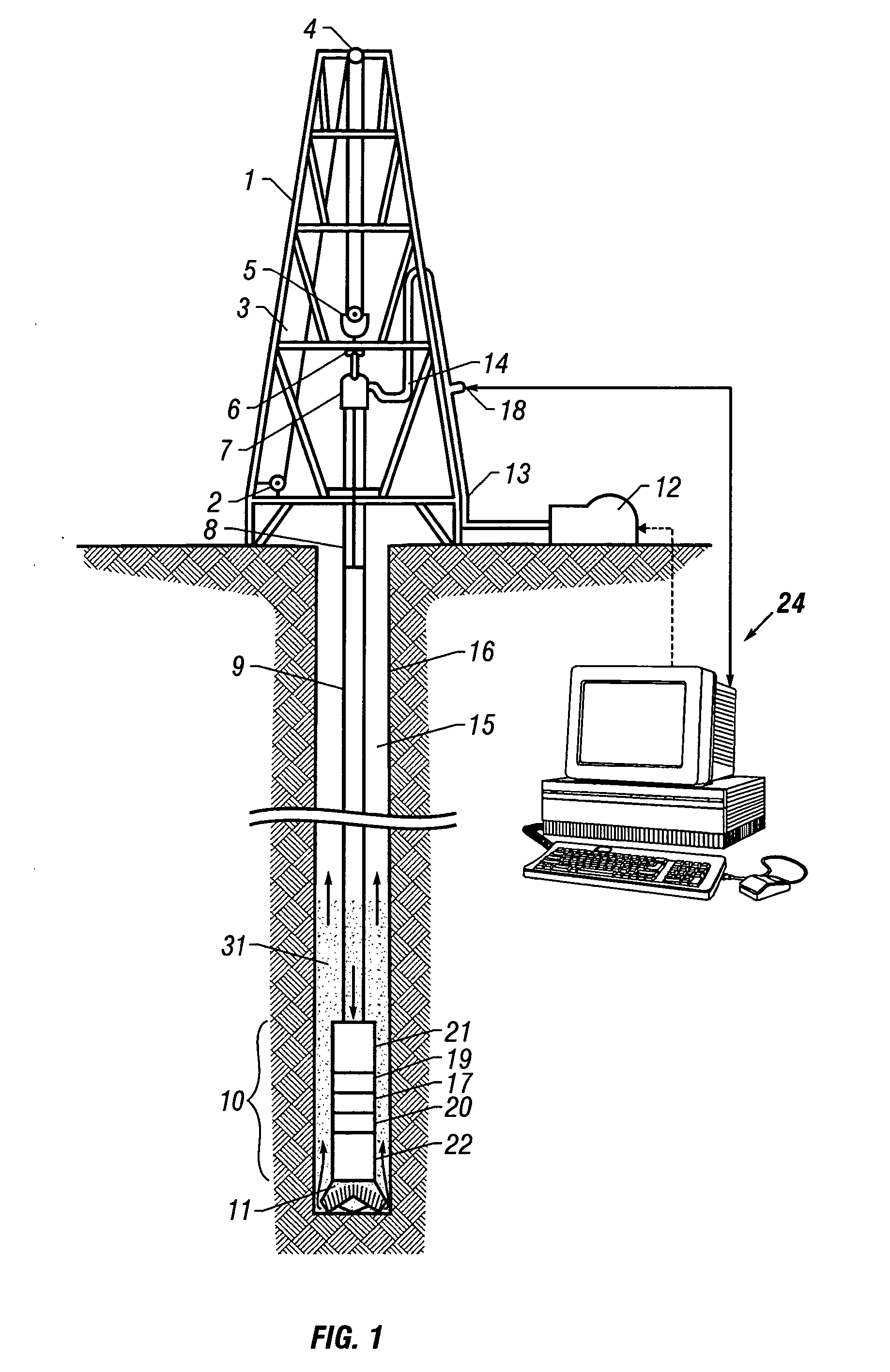

Reciprocating pulser for mud pulse telemetry

A method of transmitting pressure pulses from a downhole location through a flowing fluid in a wellbore comprises using a linear actuator to controllably move a reciprocating member axially back and forth between a first position and a second position to at least partially obstruct flow of the flowing fluid to generate the pressure pulses. A reciprocating pulser for generating pressure pulses in a fluid flowing in a wellbore, comprises a fluid passage that allows flow of the fluid through the pulser, and a reciprocating member. A linear actuator is coupled to the reciprocating member, such that the linear actuator moves the reciprocating member in a first axial direction and then in a reverse direction to at least partially obstruct flow of the fluid through the pulser to generate pressure pulses in the flowing fluid.

Owner:BAKER HUGHES INC

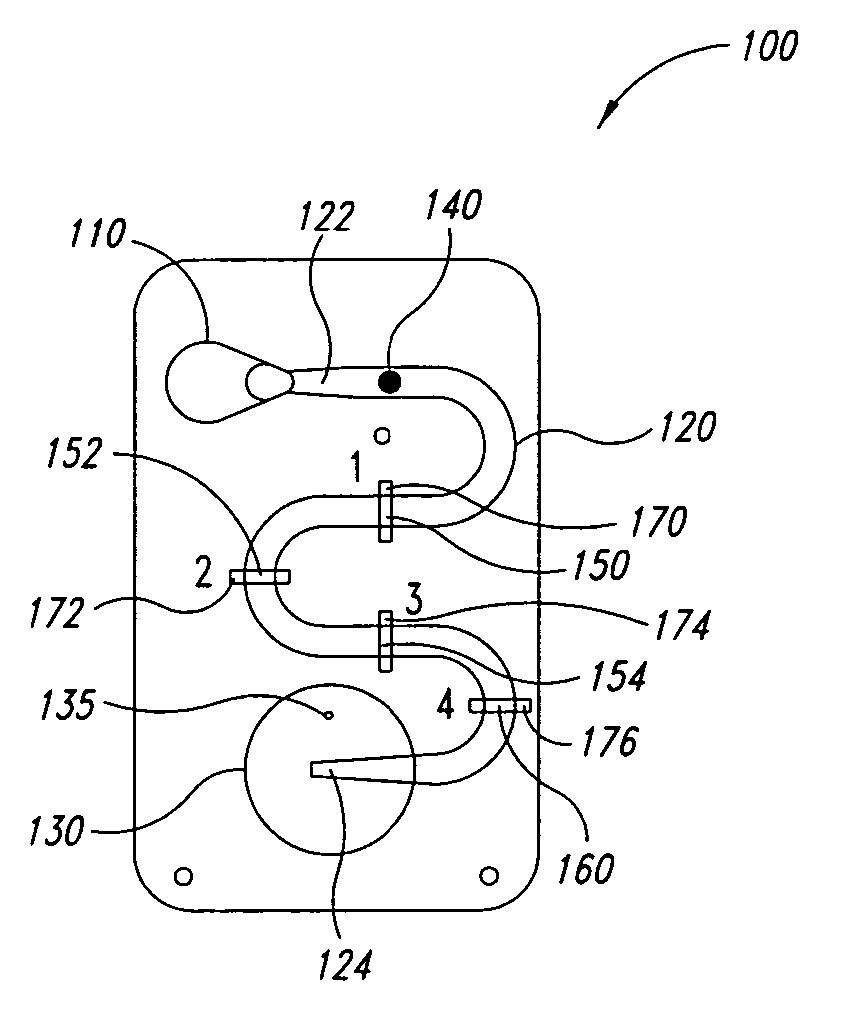

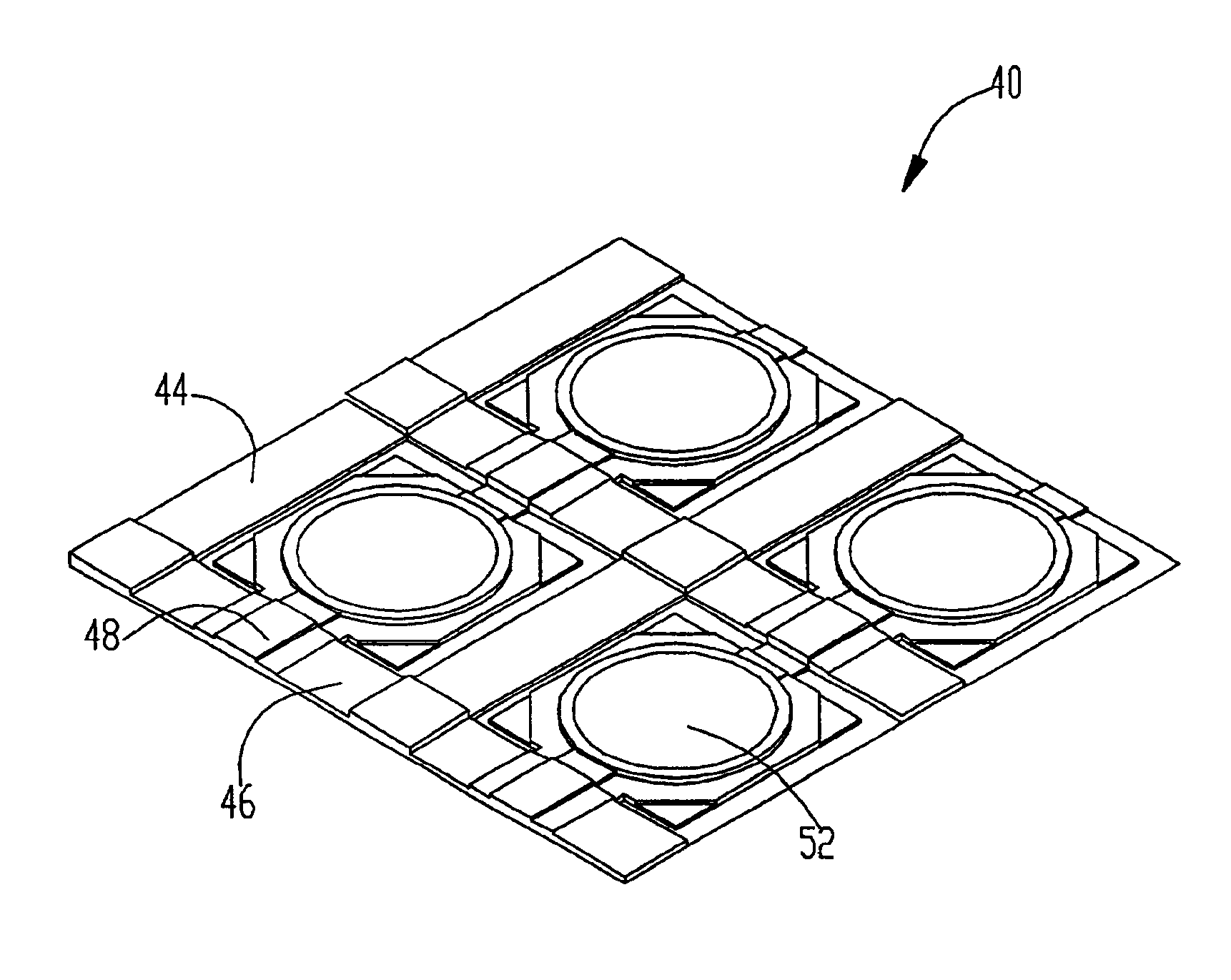

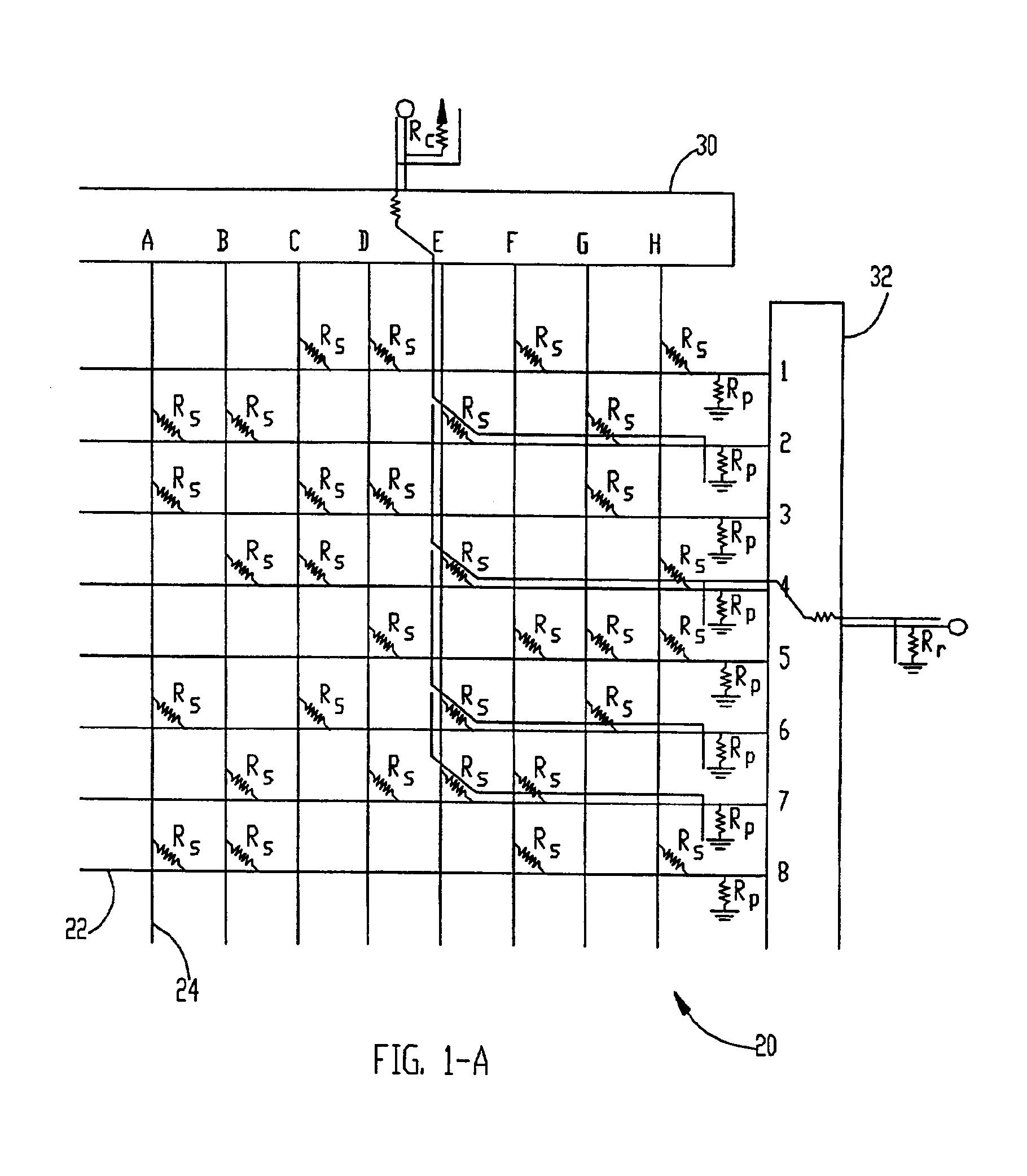

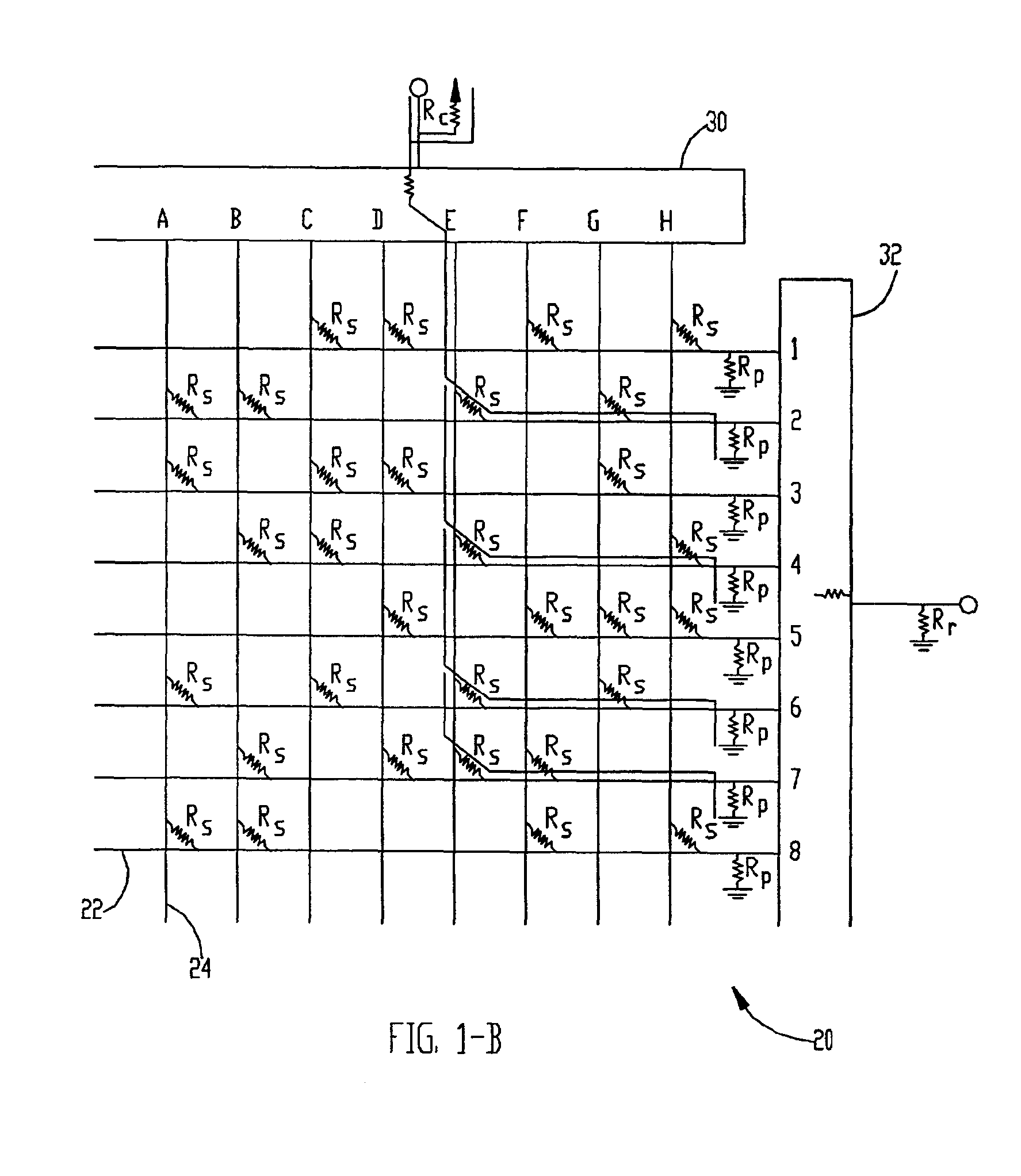

Fingerprint sensors using membrane switch arrays

InactiveUS6889565B2Electrostatic/electro-adhesion relaysResistance/reactance/impedenceMembrane switchEngineering

A sensor for identifying fingerprints or other skin textures includes an array of cells each including a membrane switch. Each switch includes a fixed lower electrode disposed on a chip substrate, and a flexible membrane disposed over the lower electrode and capable of flexing downward to establish electrical contact between the lower electrode and an upper electrode. The upper electrode can form the membrane itself or a layer of the membrane, or can be attached to other membrane layers. Switches situated underneath skin ridges change state (e.g. are closed) by the applied pressure, while switches underneath skin valleys remain in their quiescent state (e.g. open). Adjacent switch chambers are connected by fluid tunnels which allow the passage of air between the chambers. Each chamber is substantially closed to the exterior of the sensor, such that particles from the environment cannot contaminate the switch contact surface defined between the switch electrodes. The cells are preferably not hermetically sealed, such that the pressure within the chamber interiors can stay equal to the external (atmospheric) pressure in varying environmental conditions. The membrane design of the cells according to the preferred embodiment allows improved sensor robustness, enhanced resistance to impact forces, decreased vulnerability to particle contamination, and reduced inter-cell crosstalk.

Owner:LENOVO PC INT

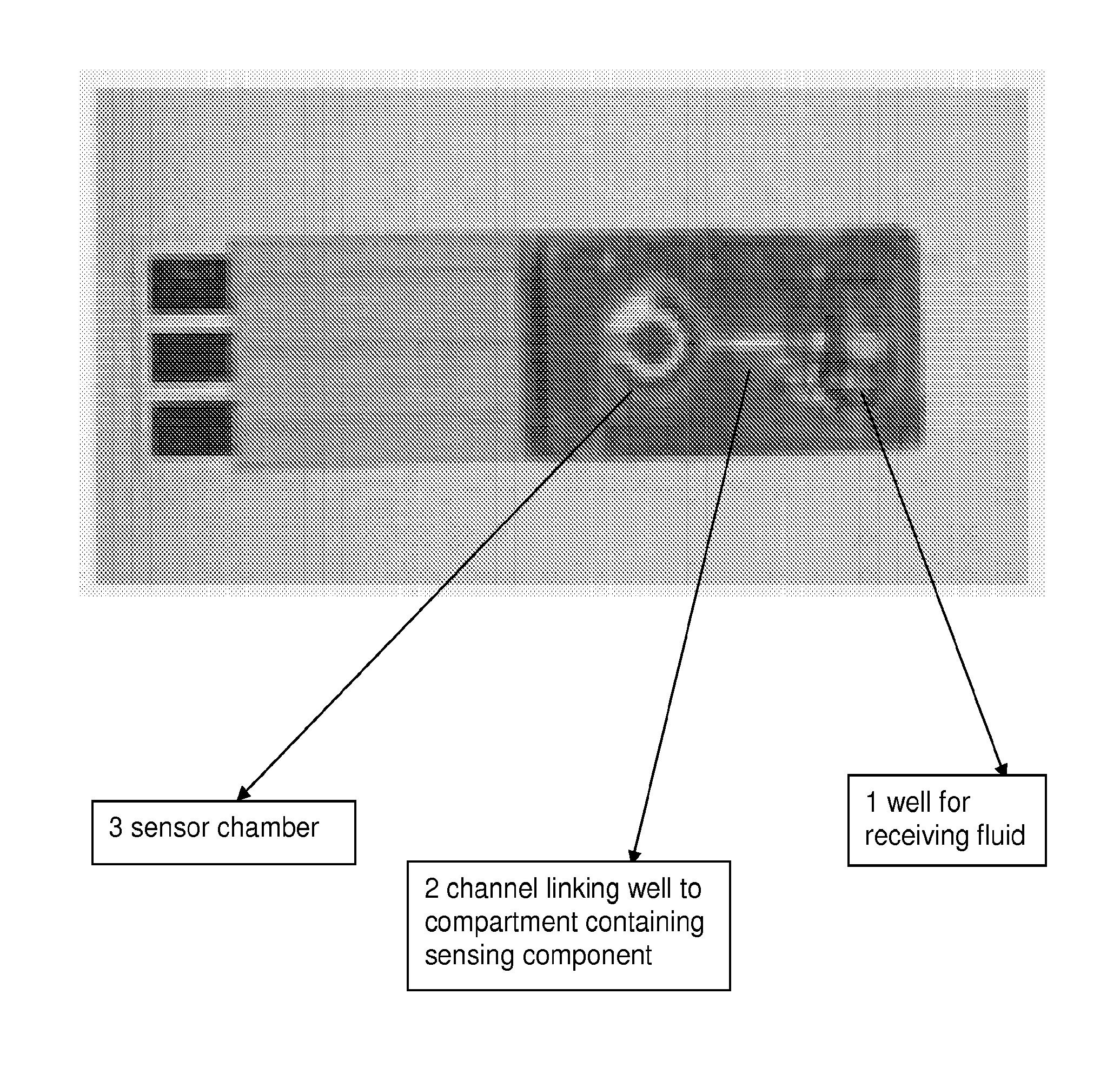

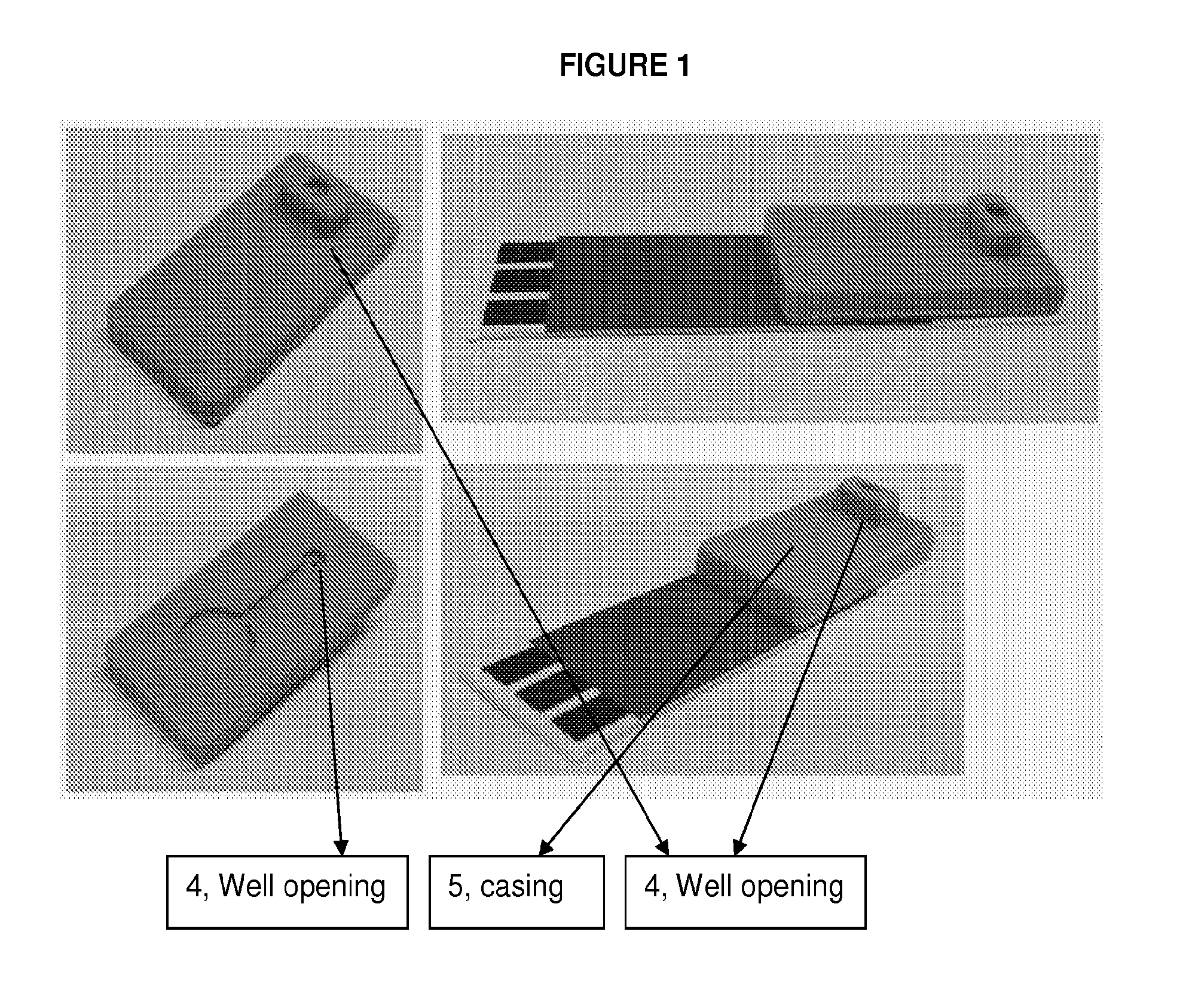

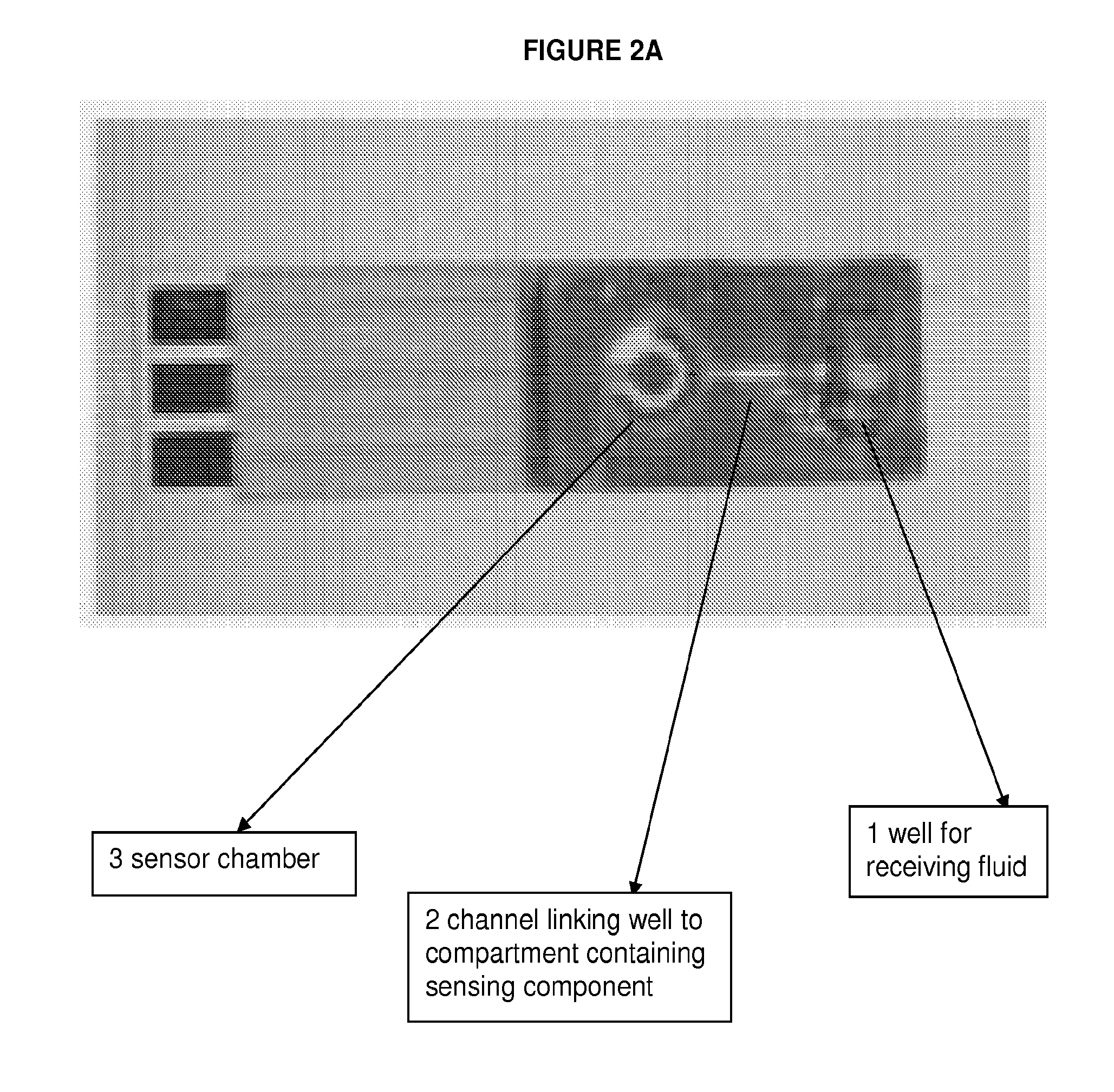

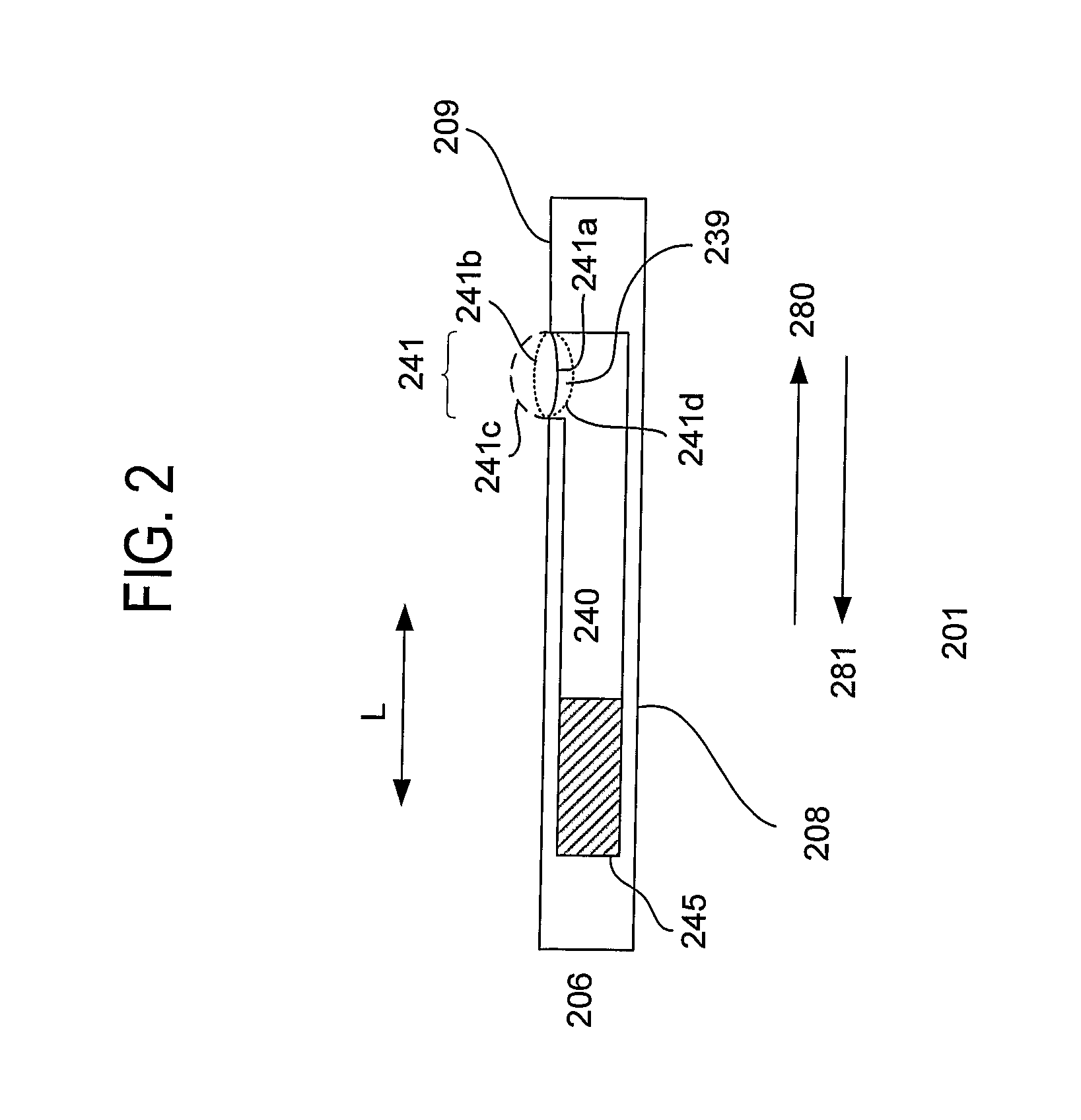

Integrated device for surface-contact sampling, extraction and electrochemical measurements

ActiveUS20120088258A1Weather/light/corrosion resistanceMicrobiological testing/measurementAnalyteEngineering

The invention relates to a device and method for non-invasive detection of an analyte in a fluid sample. In one embodiment, the device comprises: a collection chamber containing an absorbent hydrogel material; a fluidic channel connected to the collection chamber; a sensing chamber connected to the fluidic channel, wherein the device is comprised of a compressible housing that allows transfer of fluid collected by the collection chamber to be transferred to be extracted and withdrawn to the sensing chamber upon compression of the device, wherein the sensing chamber contains a material that specifically detects the analyte and wherein the sensing chamber is operably linked to a processor containing a potentiostat that allows detection of the analyte using electrochemical sensing.

Owner:ARIZONA STATE UNIVERSITY

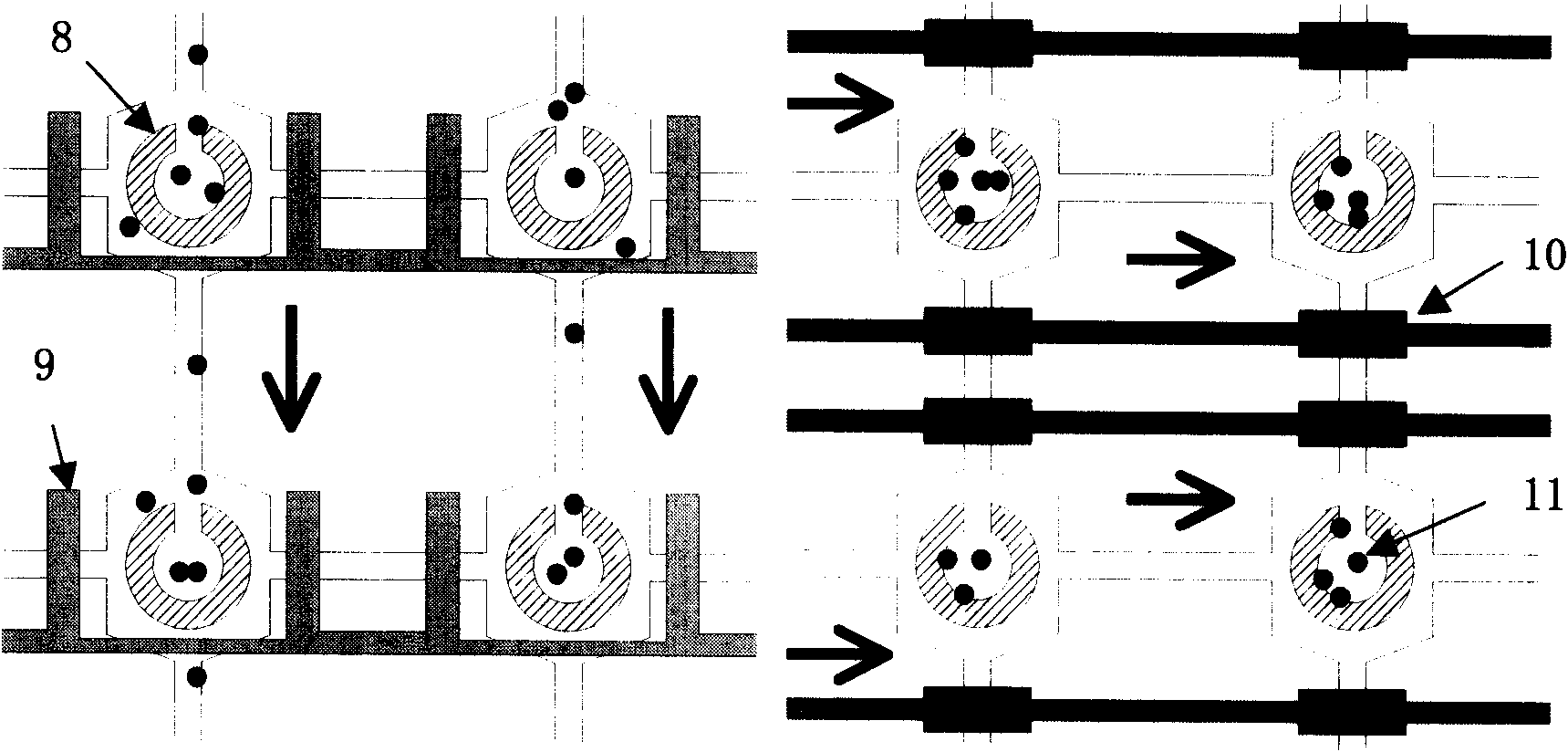

Apparatus and method for sorting microstructures in a fluid medium

InactiveUS20060051265A1Bacterial antigen ingredientsMaterial analysisBiomedical engineeringColumn space

Owner:HEALTH RES INC

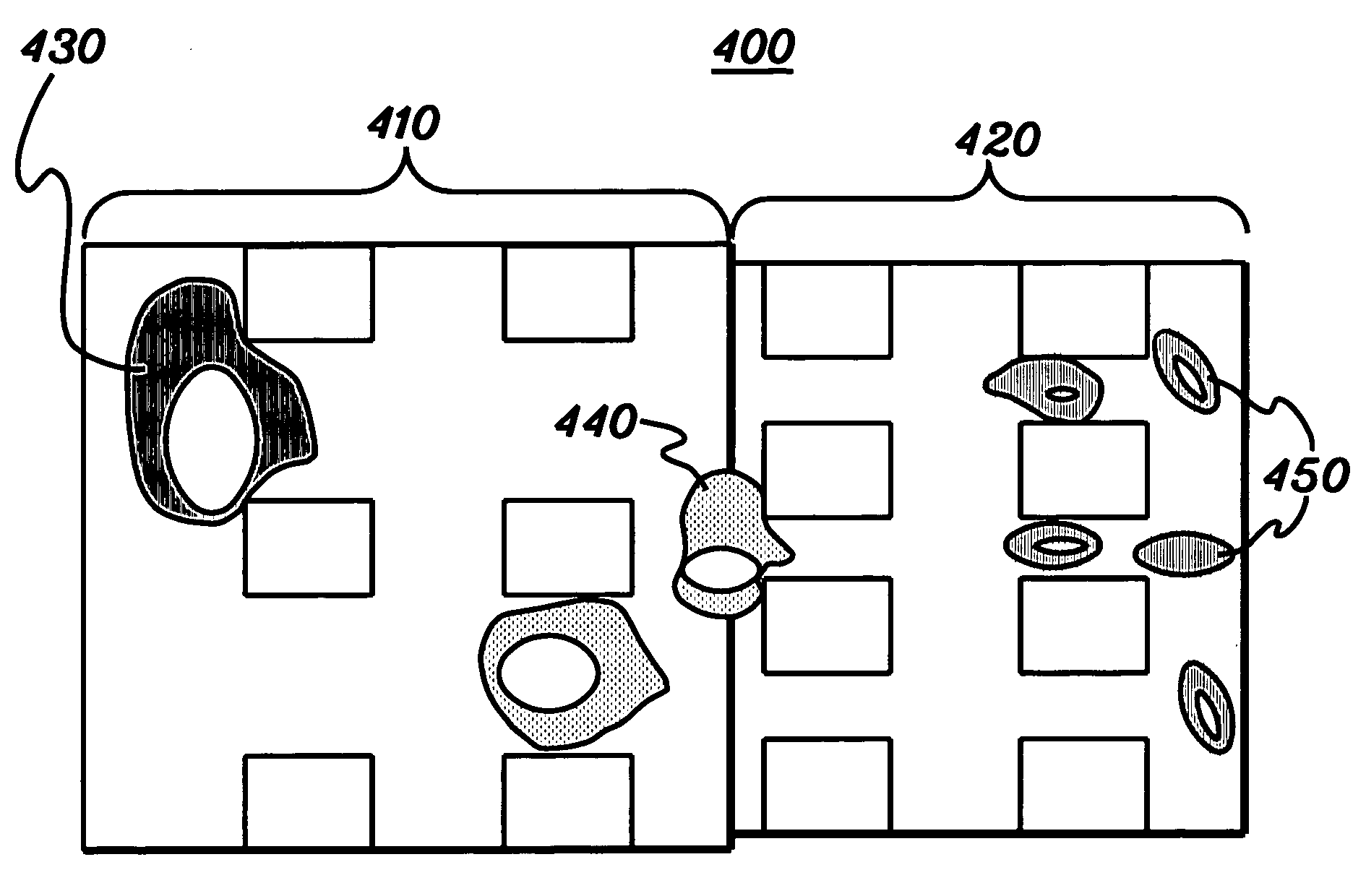

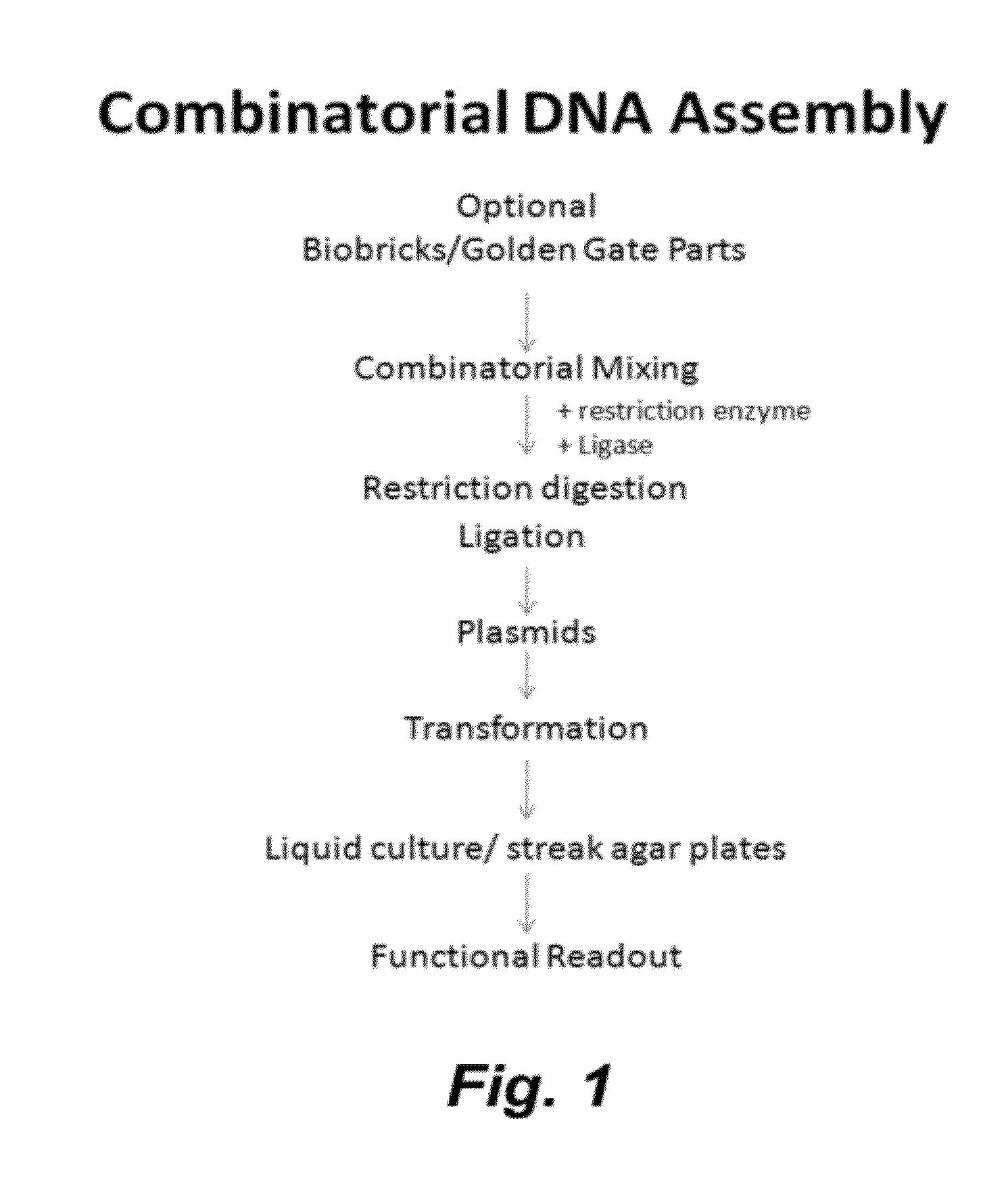

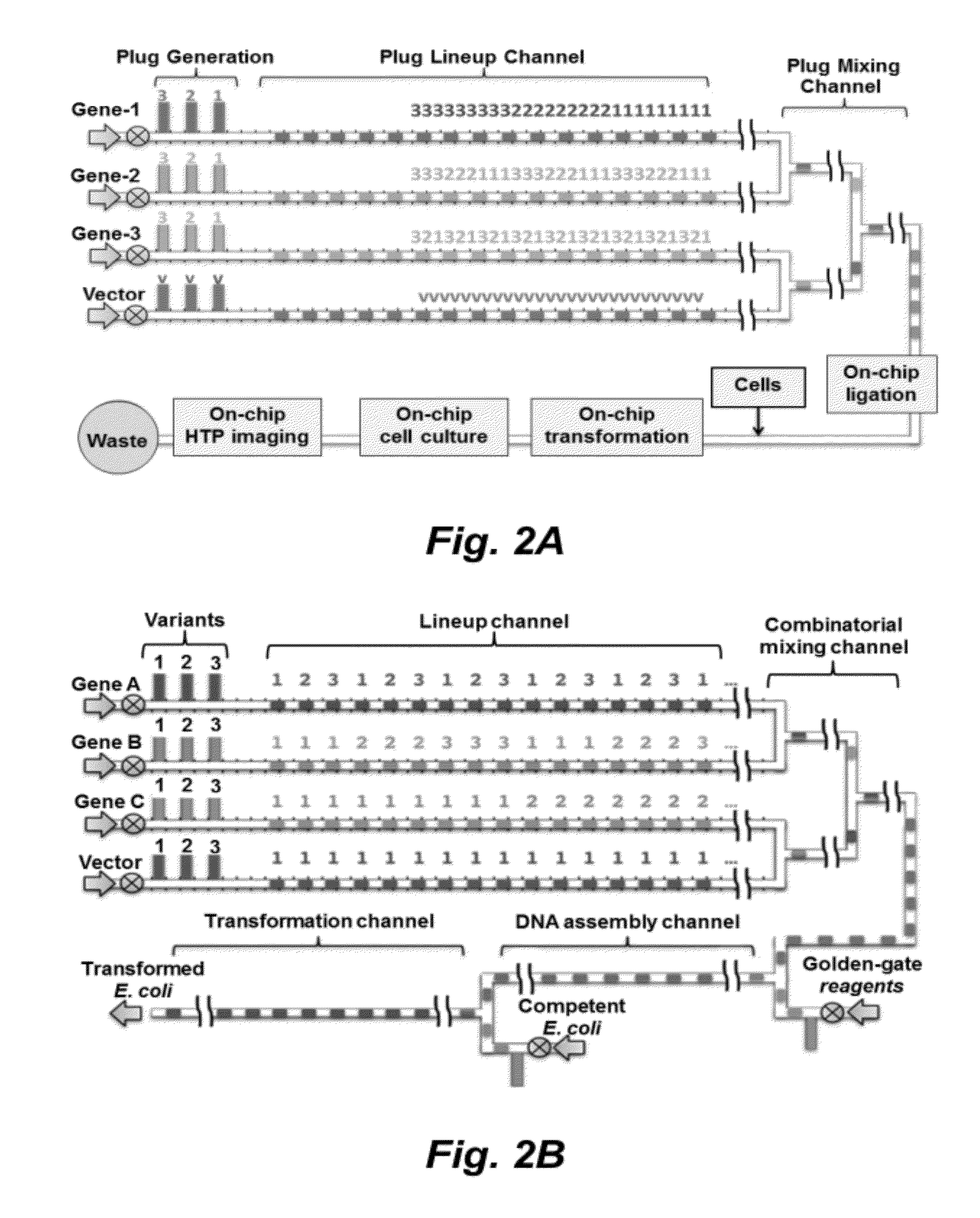

Microfluidic platform for synthetic biology applications

ActiveUS20120258487A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologySynthetic biology

This invention provides methods and compositions for assembling biological constructs (e.g., plasmids, transformed cells, etc.). In certain embodiments the methods involve encapsulating separate components of said biological construct each in a fluid droplet confined in a fluid channel; optionally mixing droplets from different fluid channels to for a sequenced order of droplets carrying different components of said biological construct in a channel or chamber; and optionally combining two or more droplets each containing different components of said biological construct to permit said components to react with each other in one or more reactions contributing to the assembly of said biological construct.

Owner:RGT UNIV OF CALIFORNIA +1

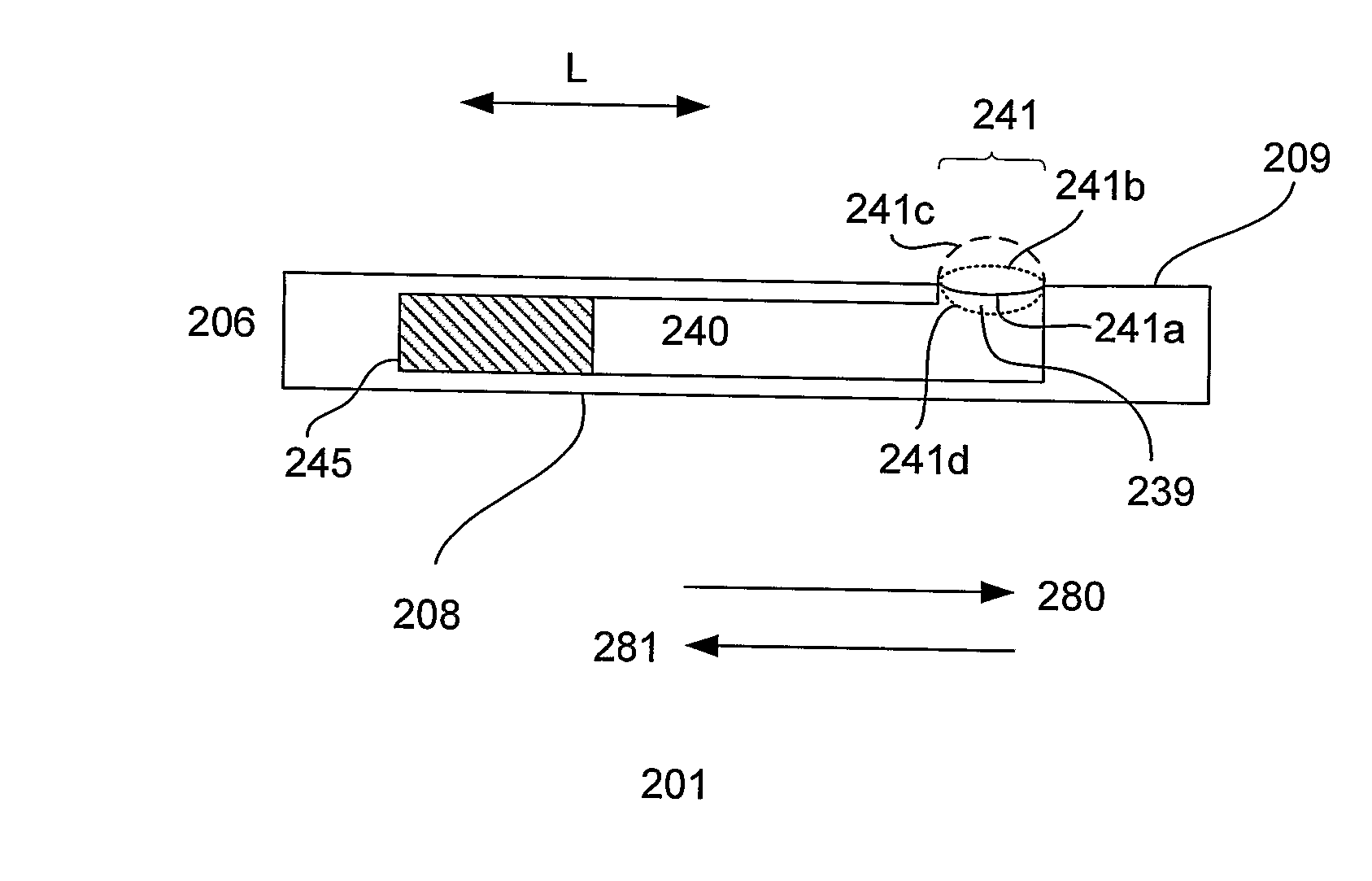

Variable Focus Microlens

A microlens chip comprises a variable focus fluidic microlens and actuator. The actuator varies the pressure in a fluidic channel in the microlens chip which is coupled to an aperture opening containing the microlens. Applying an electric field to the actuator creates changes in fluid pressure in the fluidic channel, which in turn changes the radius of curvature (i.e., focal length) of the fluidic microlens.

Owner:AGENCY FOR SCI TECH & RES

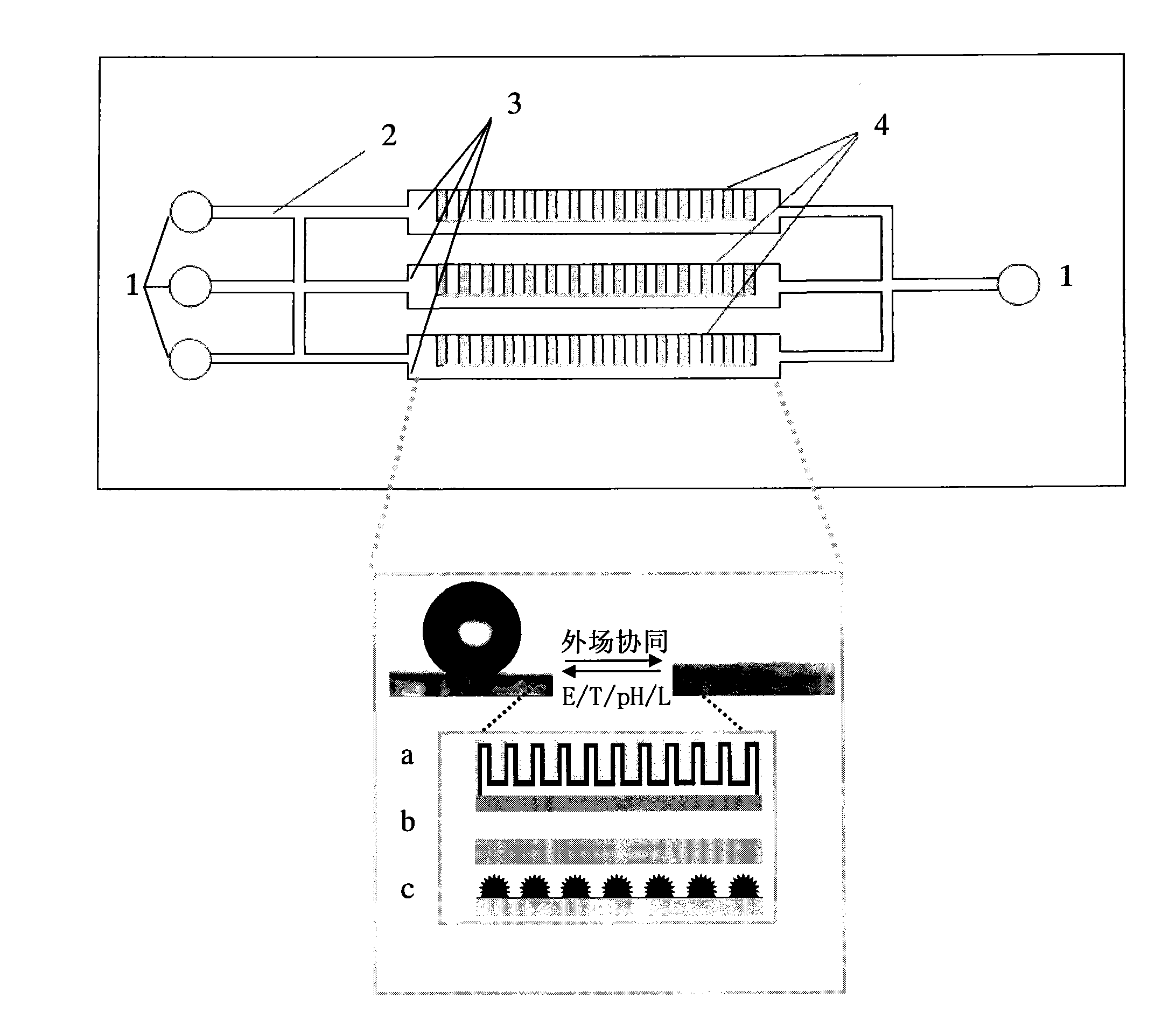

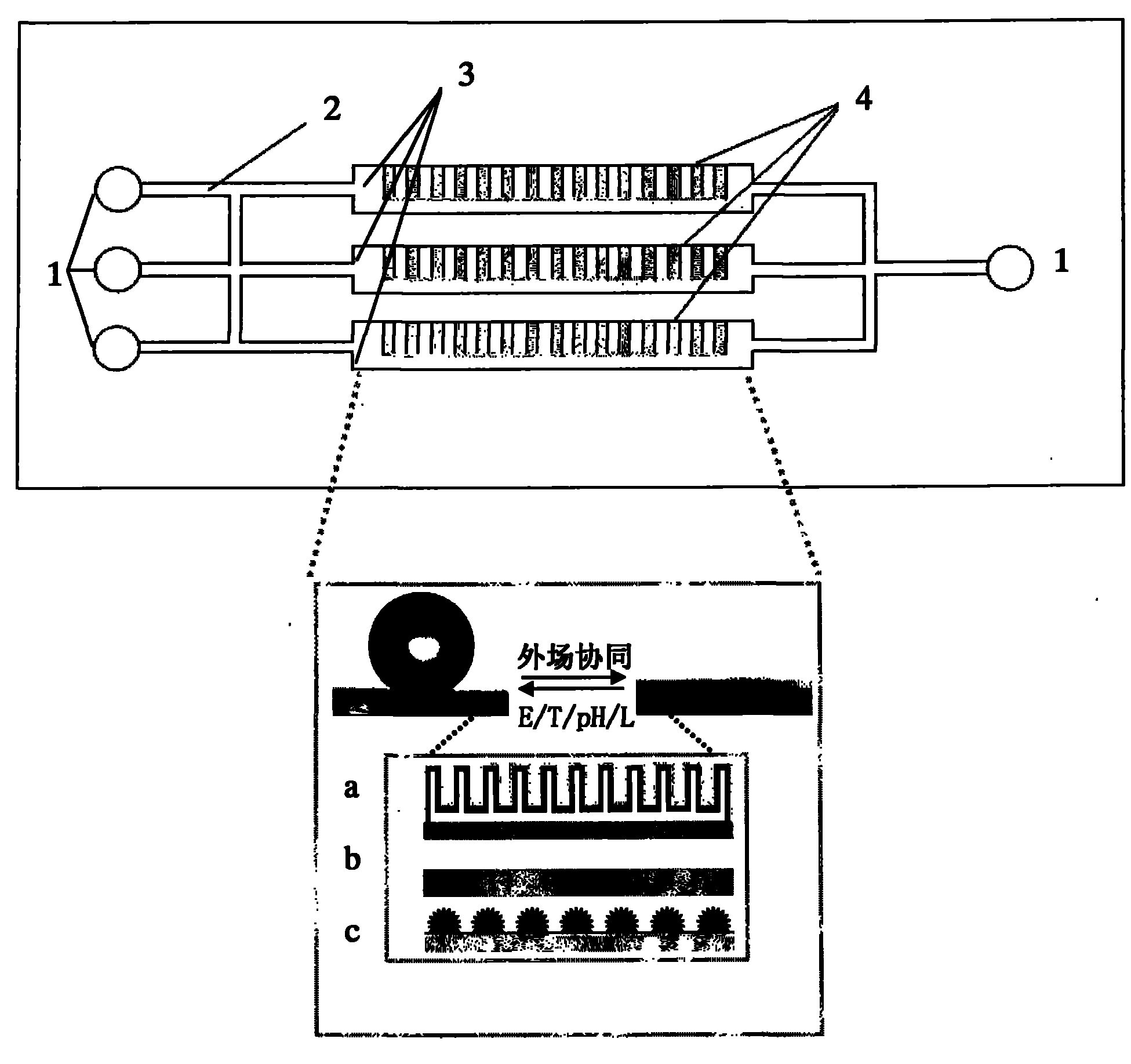

Microfluidic chip and manufacturing method thereof

InactiveCN102059161AIntelligent control of flow stateRapid reversible transitionLaboratory glasswaresChemical/physical/physico-chemical processesChemical compositionMicrometer

The invention relates to a microfluidic chip and a manufacturing method thereof. The microfluidic chip comprises an upper chip unit and a lower chip unit; the surfaces of the chip units are respectively provided with a liquid storing hole, a liquid channel communicated with the liquid storing holes and a microchannel communicated with the liquid channel; the upper chip unit and the lower chip unit are attached to each other and the microchannel is sealed between the two chip units; the microfluidic chip also comprises a micro valve, wherein the micro-valve main body is one of the following structures: a three-dimensional micrometer and three-dimensional nanometer hierarchical structure of polymers formed on the microchannel in array arrangement, a three-dimensional micrometer structure ofpolymers formed on the microchannel in array arrangement or a three-dimensional nanometer structure of polymers formed on the microchannel in array arrangement; the polymers can generate specific responses to an external field under the action of the external field; and the specific responses are reversibility transformation of one or more of surface chemical compositions of the polymers, the above structures and surface properties, thus realizing controllable operations for the flow state of a microfluid in the microchannel. The micro valve in the microfluidic chip is manufactured in situ and miniaturized on the microfluidic chip, thus realizing switch gradient control for the flow of the microfluid and fast switch reversibility transformation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Aseptic connector with deflectable ring of concern and method

Owner:INTACT CLOSED TRANSFER CONNECTORS LLC

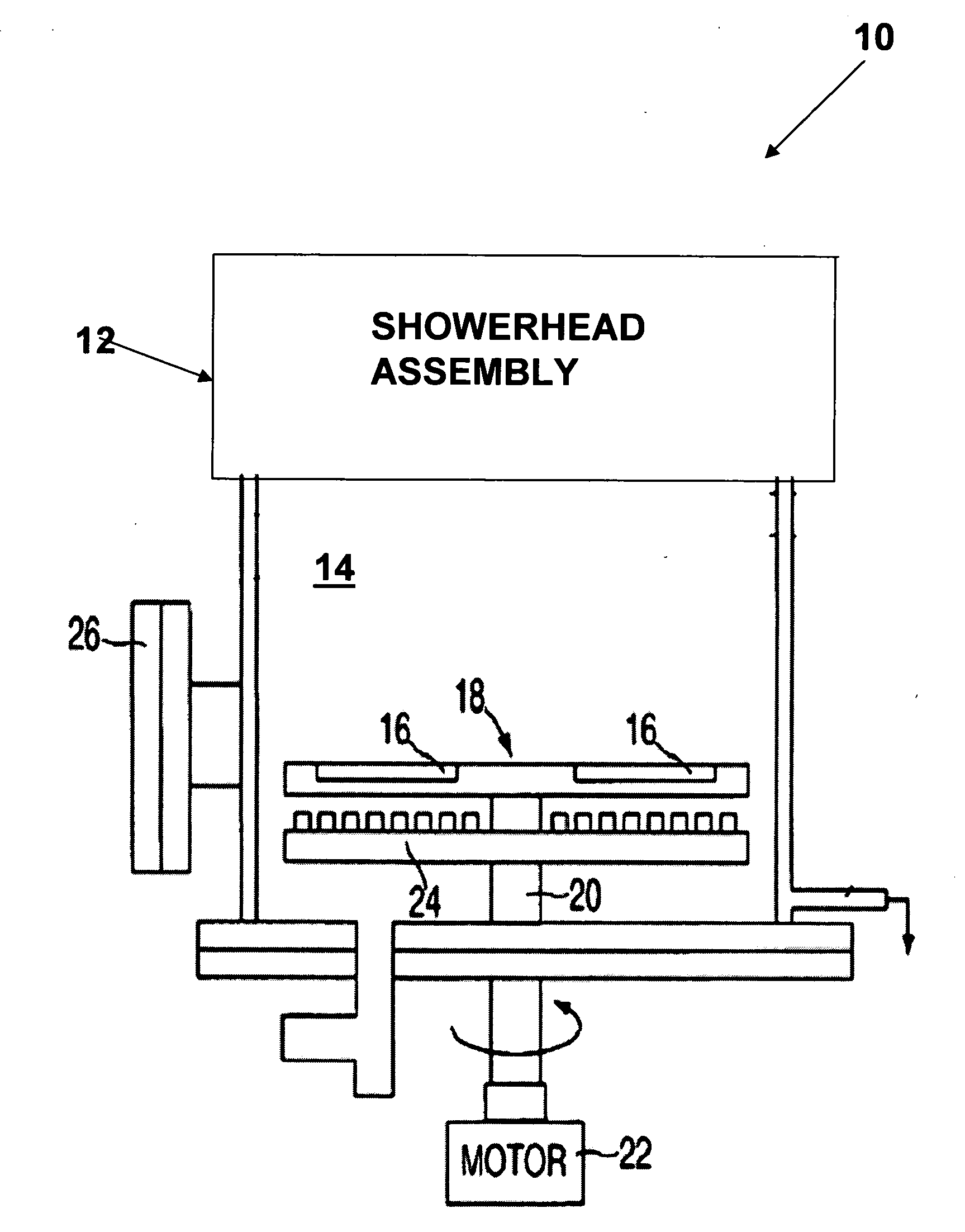

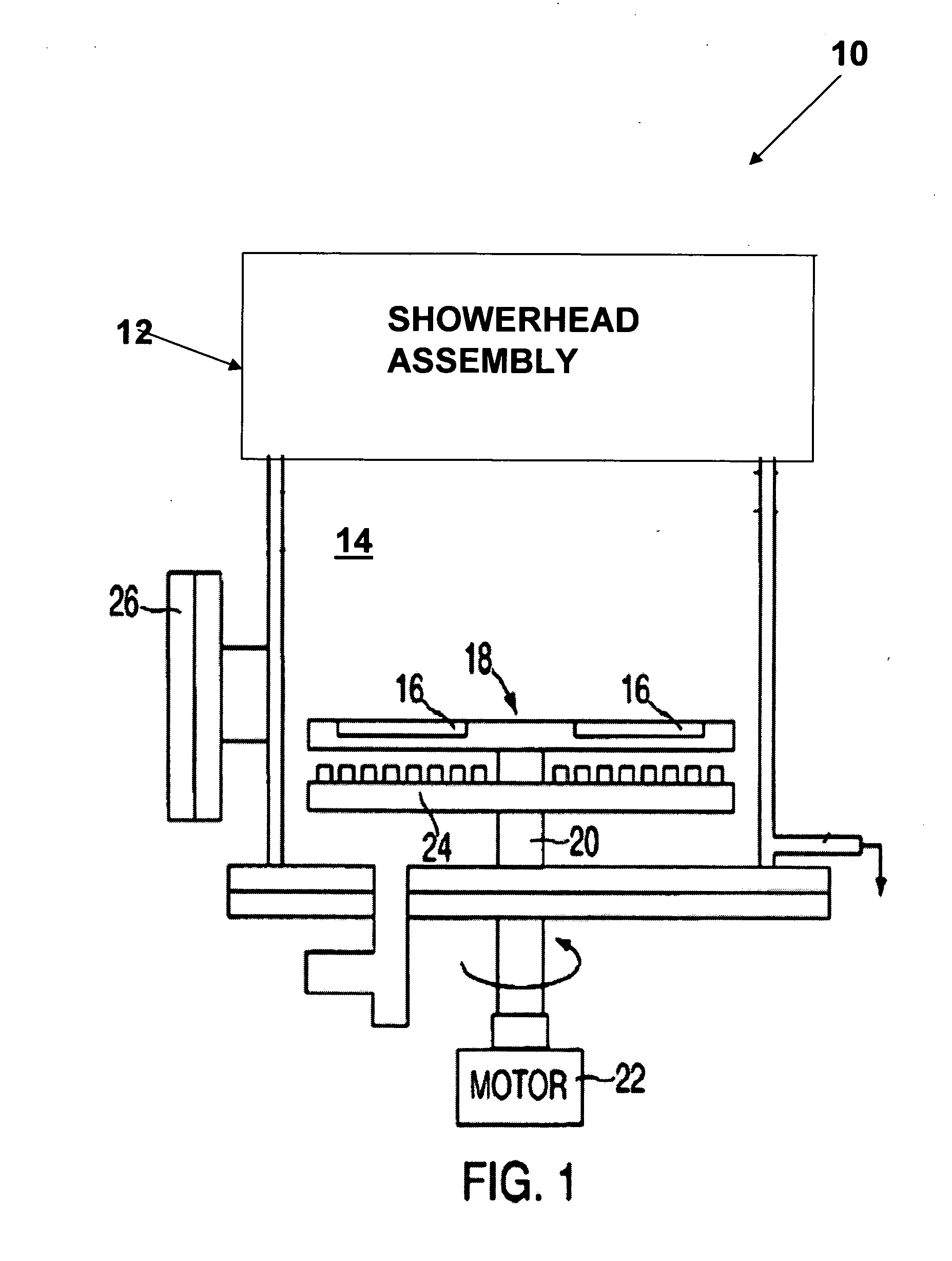

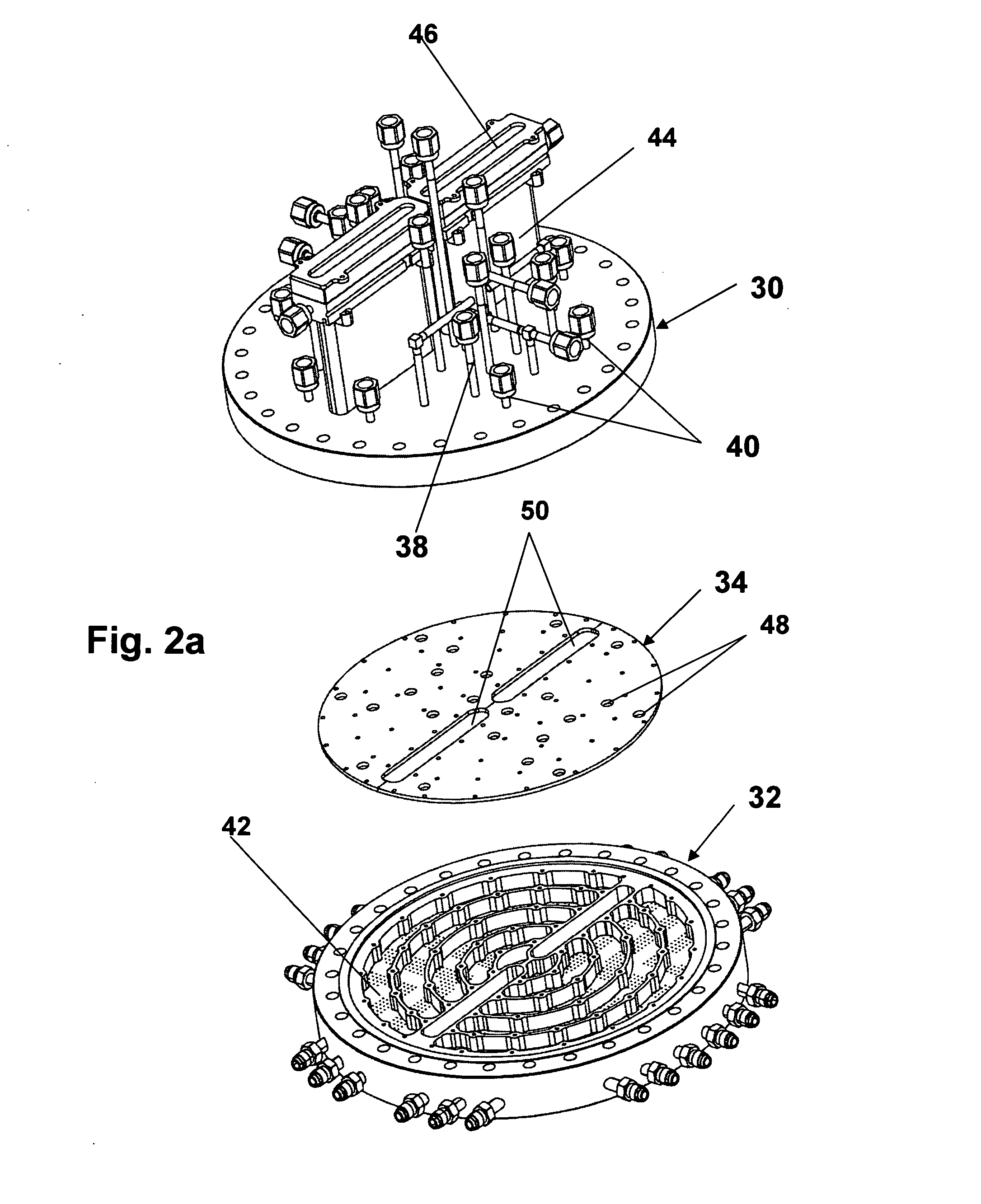

Showerhead for chemical vapor deposition (CVD) apparatus

InactiveUS20080236495A1Simple designEvenly distributedChemical vapor deposition coatingEngineeringChemical vapor deposition

A reactant vapor distribution assembly for Chemical Vapor Deposition (CVD) apparatus which includes an upper flange which has a plenum disposed on its lower face and vapor injectors for injecting reactant vapors into the plenum. The distribution assembly also includes a lower flange having a peripheral rim surrounding a lower wall and a plenum on its upper face, certain of the vapor injectors are used to inject reactant vapors into this plenum. The lower flange includes fluid channels bored in the lower wall beneath the plenum and a number of gas flow openings bored in the lower wall of the lower flange to permit the precursor gases to flow from the plenum into the deposition chamber. The fluid channels may be used to heat or cool the flange. The lower flange has no welds or joints facing the hostile environment of the deposition chamber and all critical parts of the lower flange may be formed from a single billet of material.

Owner:STRUCTURED MATERIALS

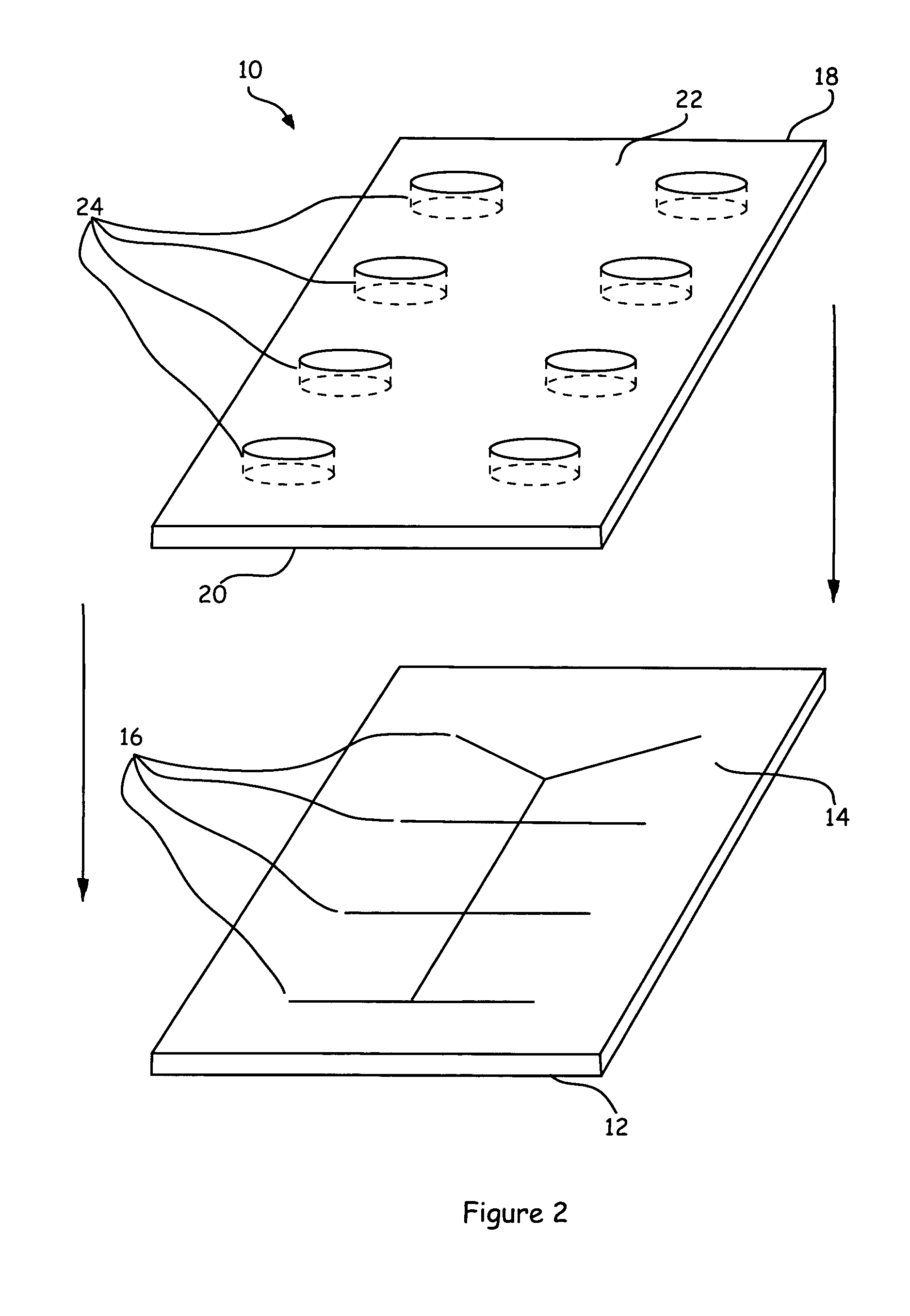

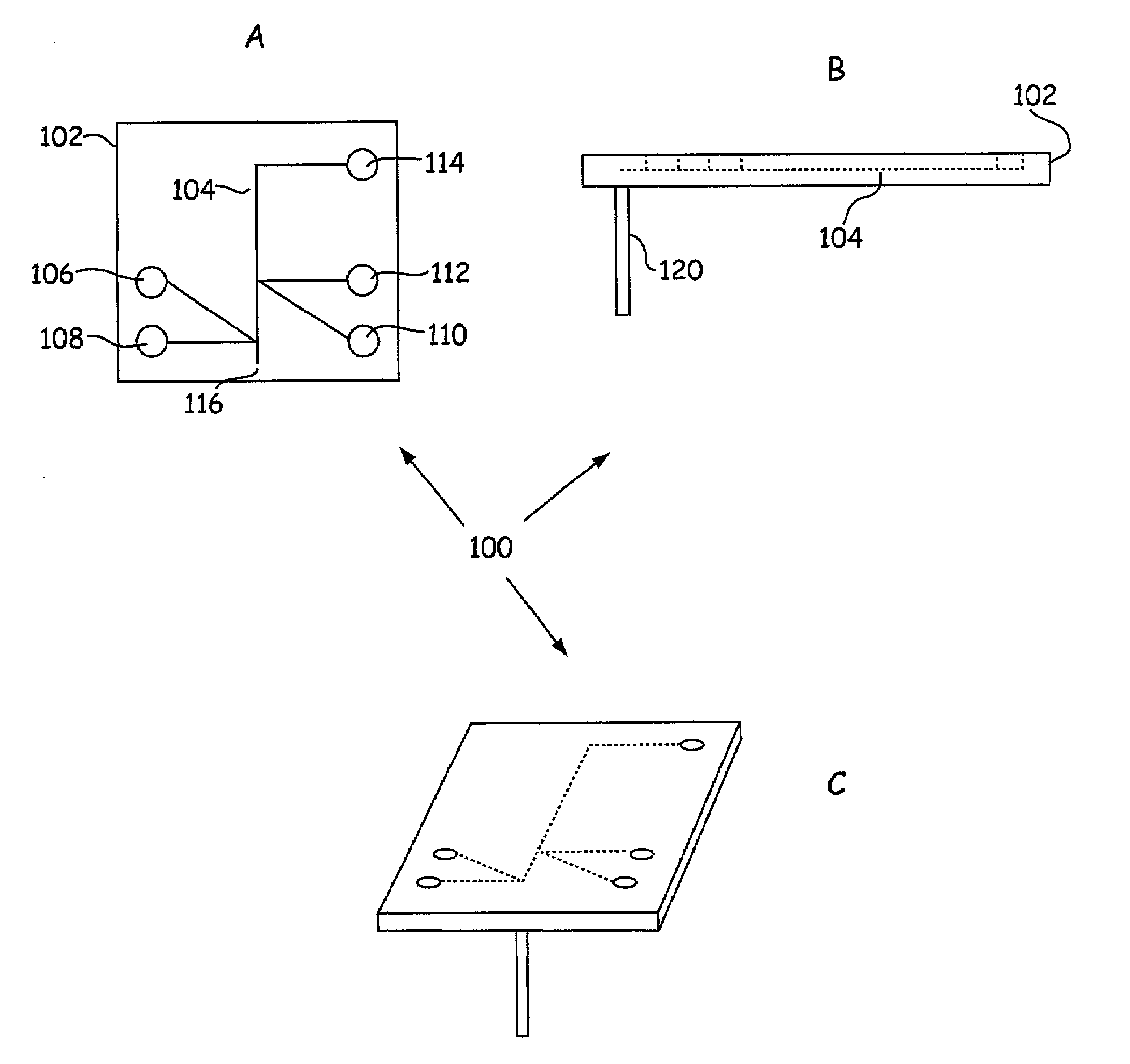

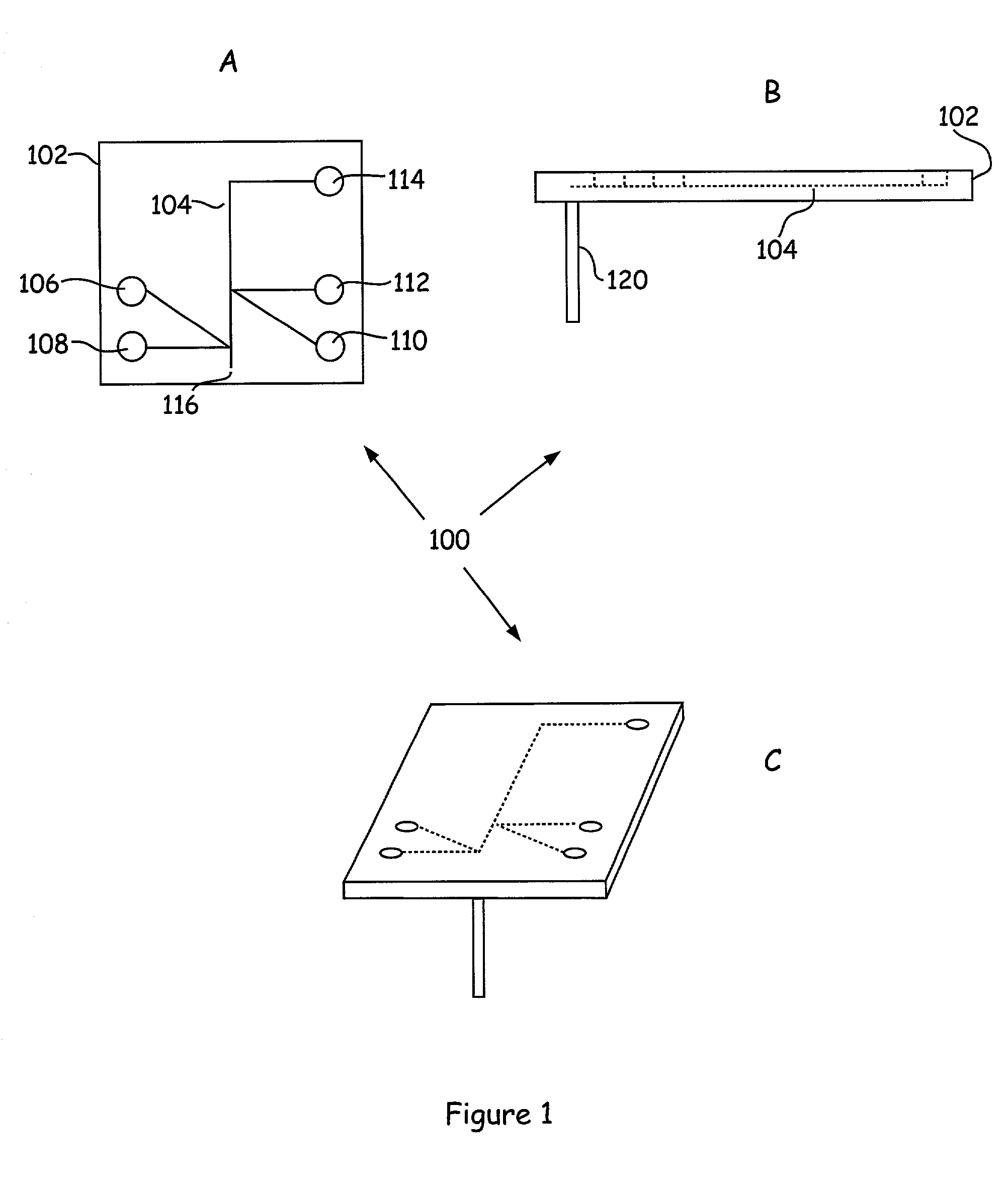

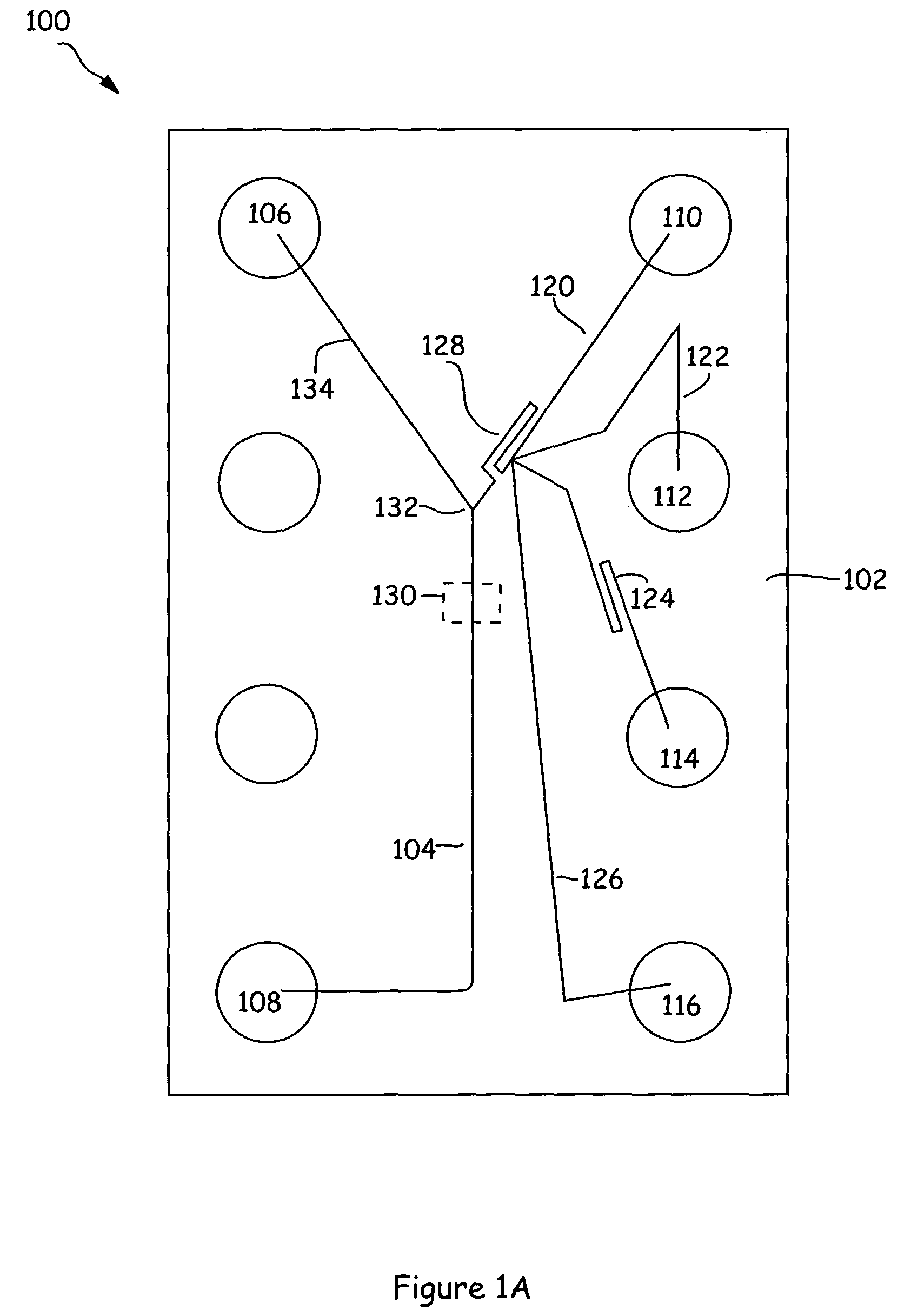

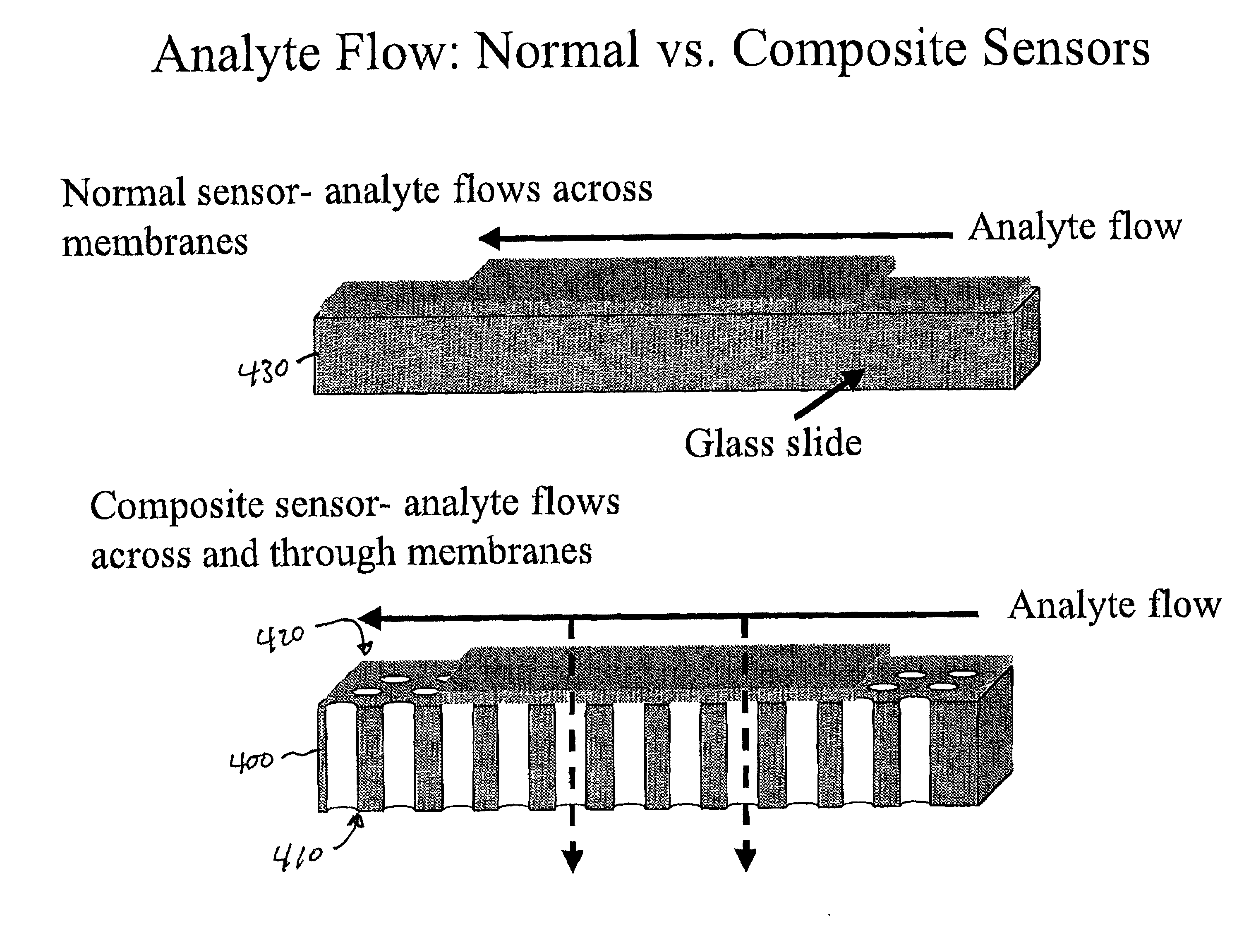

Spatiotemporal and geometric optimization of sensor arrays for detecting analytes fluids

InactiveUS7122152B2Easy to transportIncreasing analyte fluxWave amplification devicesFixed microstructural devicesSensor arrayAnalyte

Sensor arrays and sensor array systems for detecting analytes in fluids. Sensors configured to generate a response upon introduction of a fluid containing one or more analytes can be located on one or more surfaces relative to one or more fluid channels in an array. Fluid channels can take the form of pores or holes in a substrate material. Fluid channels can be formed between one or more substrate plates. Sensor can be fabricated with substantially optimized sensor volumes to generate a response having a substantially maximized signal to noise ratio upon introduction of a fluid containing one or more target analytes. Methods of fabricating and using such sensor arrays and systems are also disclosed.

Owner:AEROVIRONMENT INC +2

Connector and related method

InactiveUS20120042971A1Reduce the possibilityBlock fluid flowPipe couplingsCouplingsEngineeringNozzle

A connector for transferring a fluid includes a first connector and a second connector. Each connector includes a first outer portion including a first obstructive portion and defining a first fluid passageway for receiving a fluid therein. Each connector further includes a first central nozzle coupled to the first outer portion. The central nozzle includes a first engagement member. The first central nozzle is movable between a first position and a second position with rotation of the first outer portion. In the first position, the first obstructive portion and the first engagement portion substantially overlap to impede fluid flow through the first fluid passageway. In the second position, at least one of the first engagement member and the first obstructive member is displaced to allow fluid flow through the first fluid passageway.

Owner:PY DANIEL

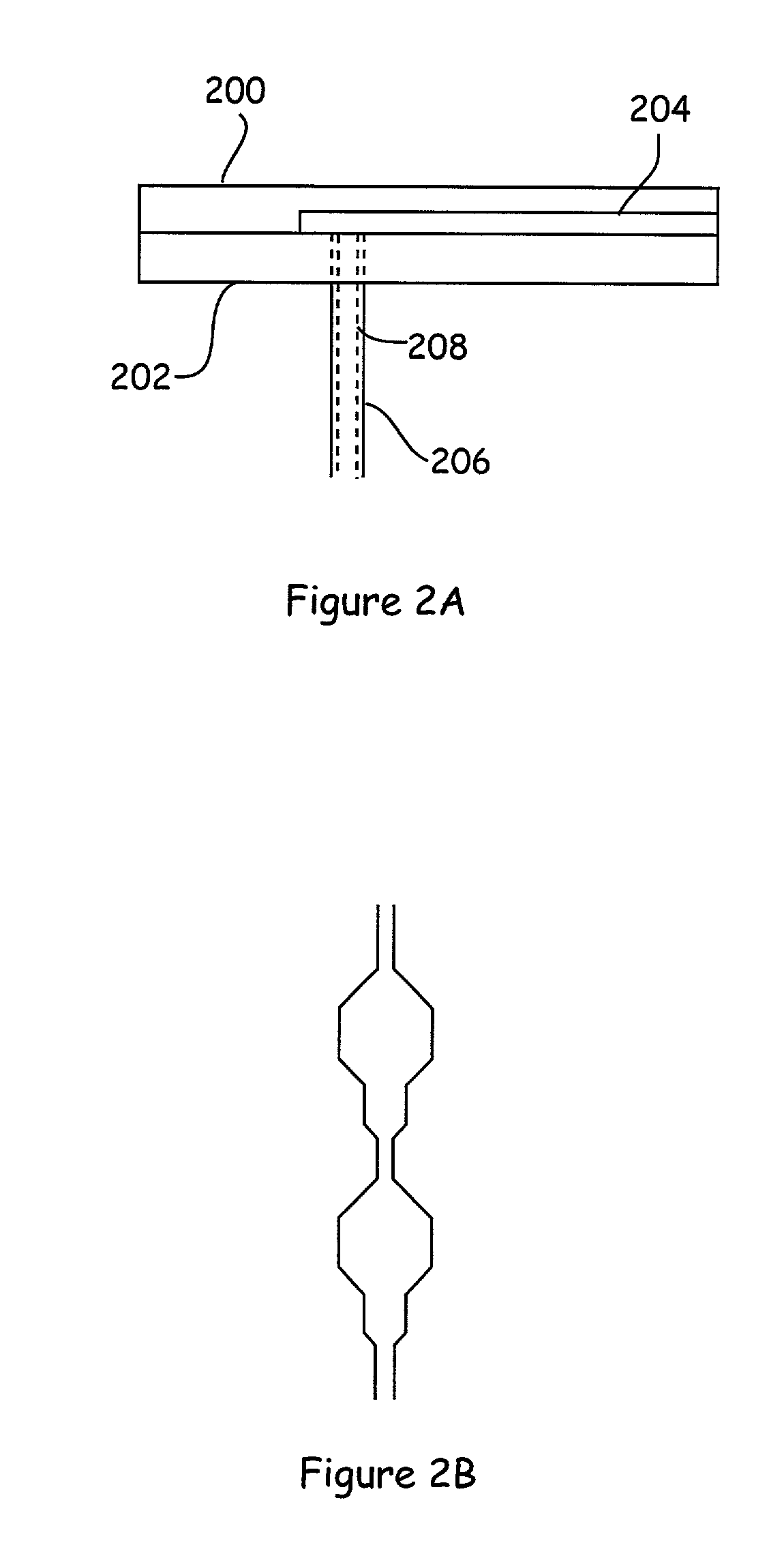

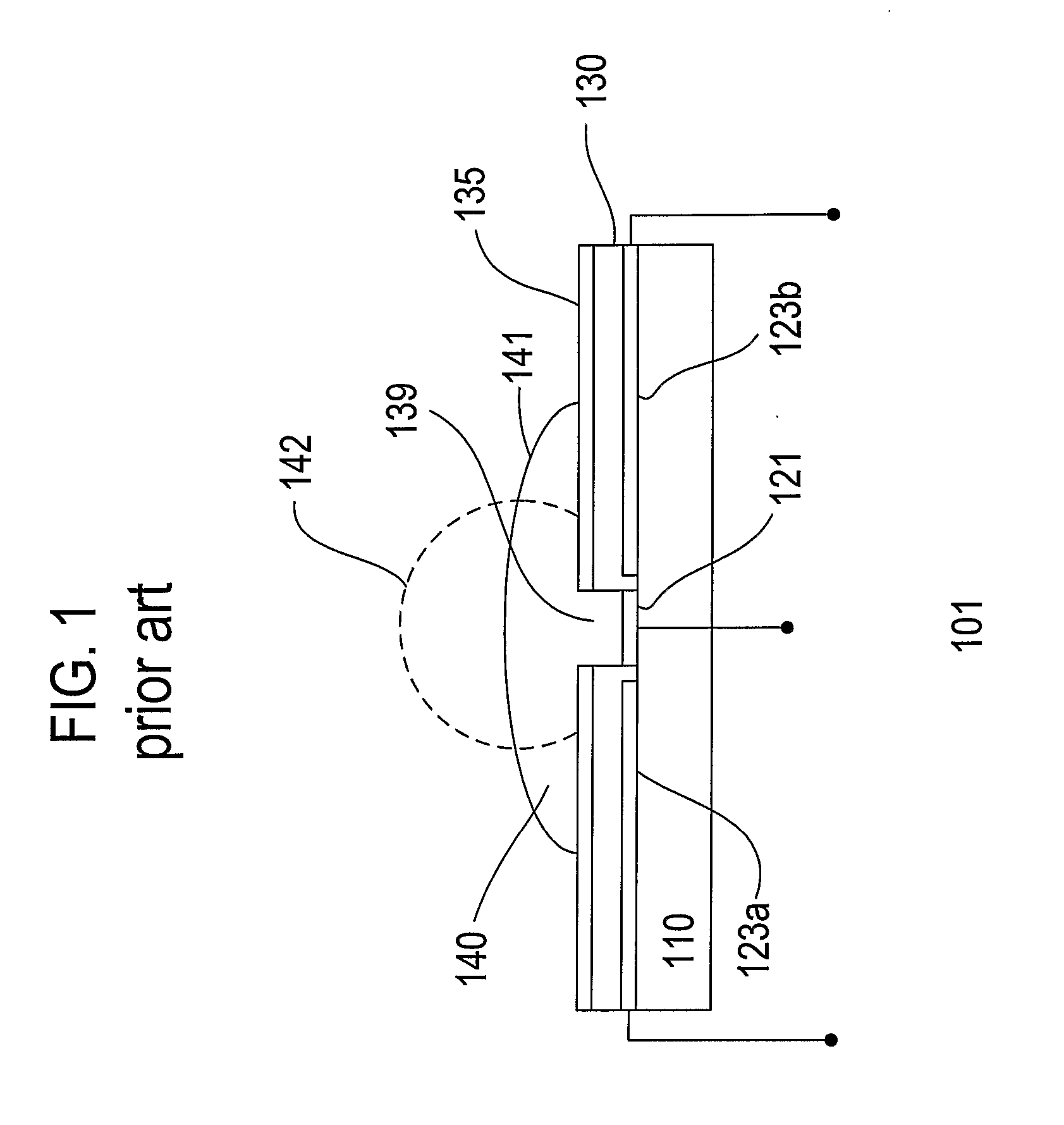

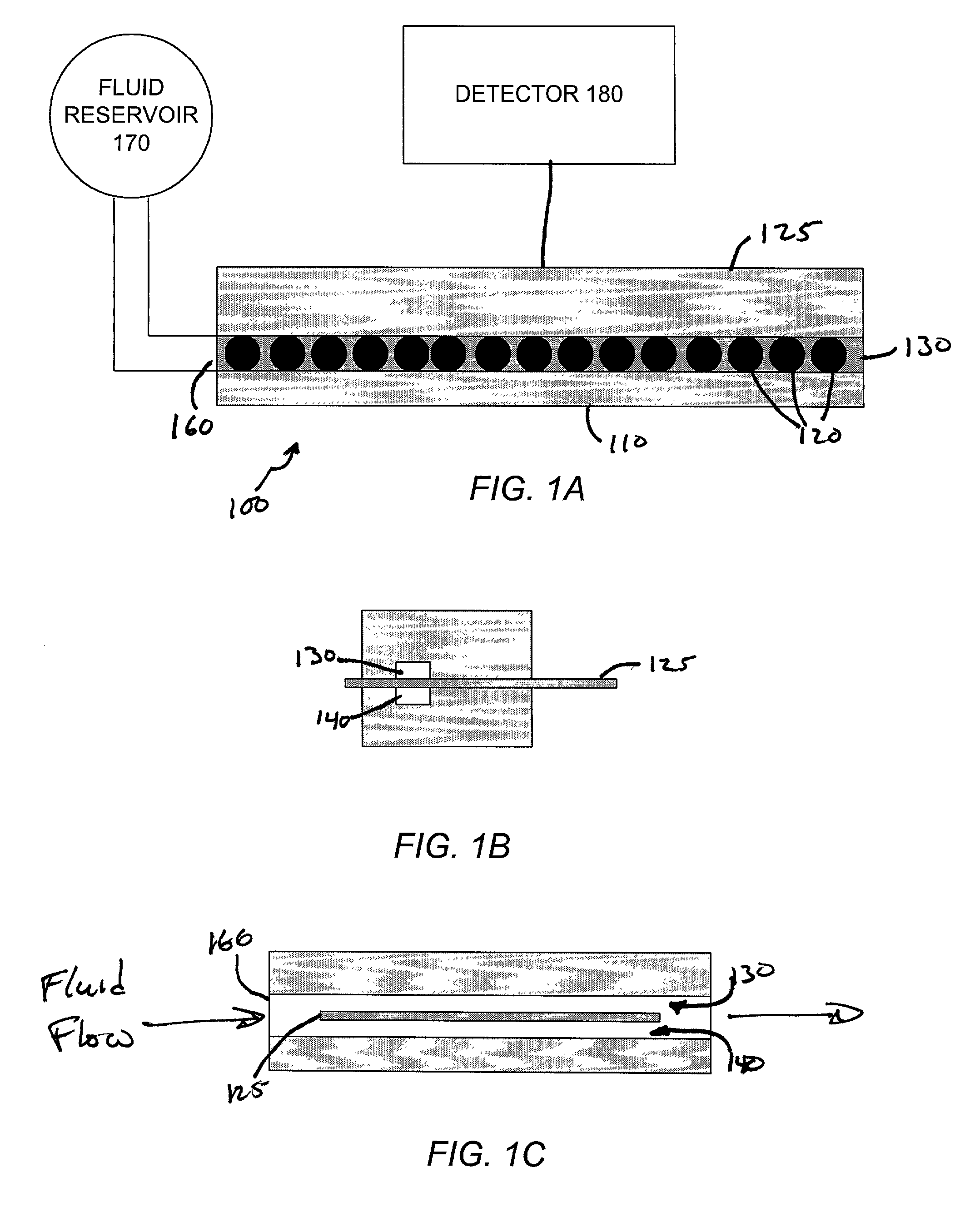

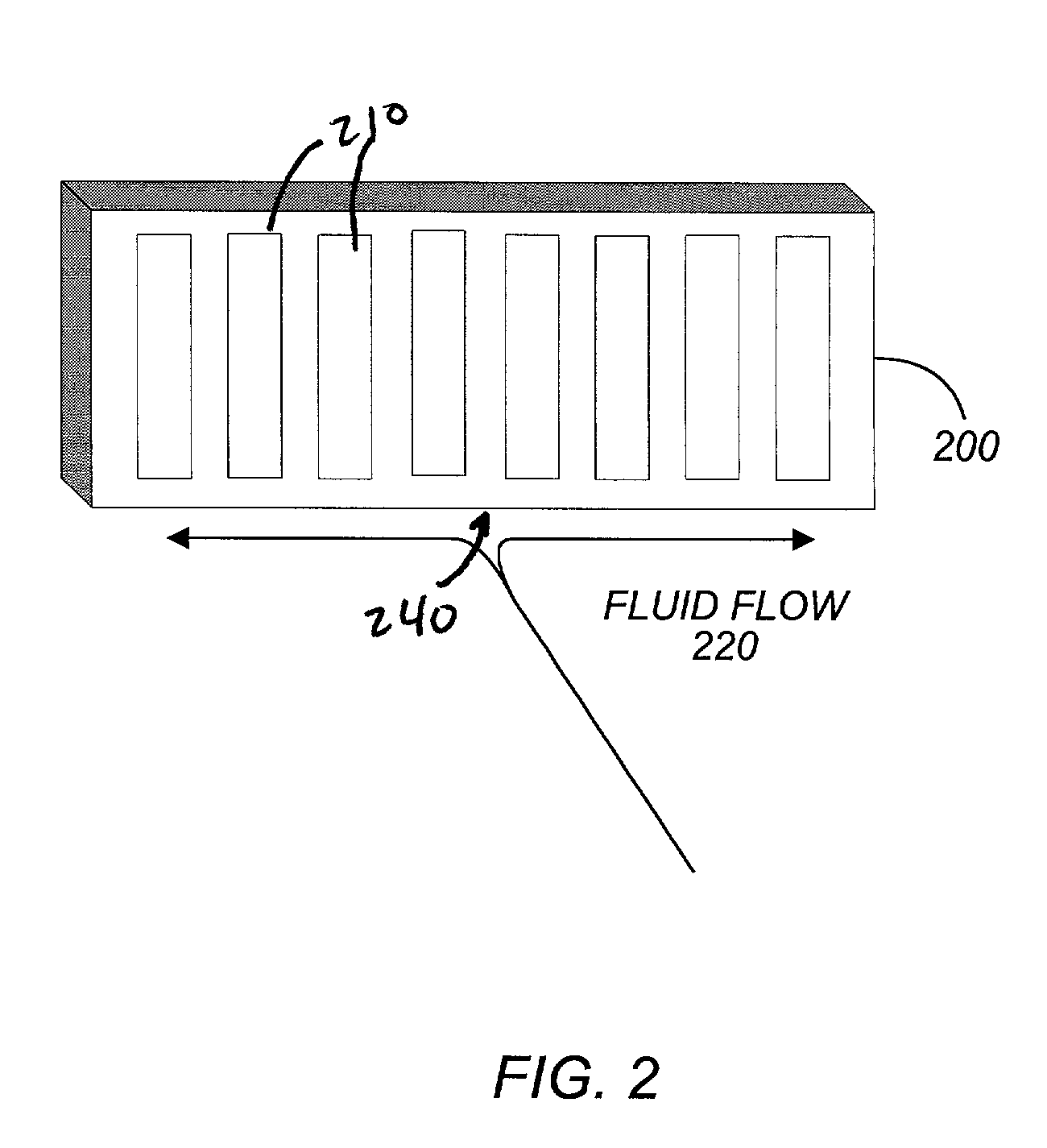

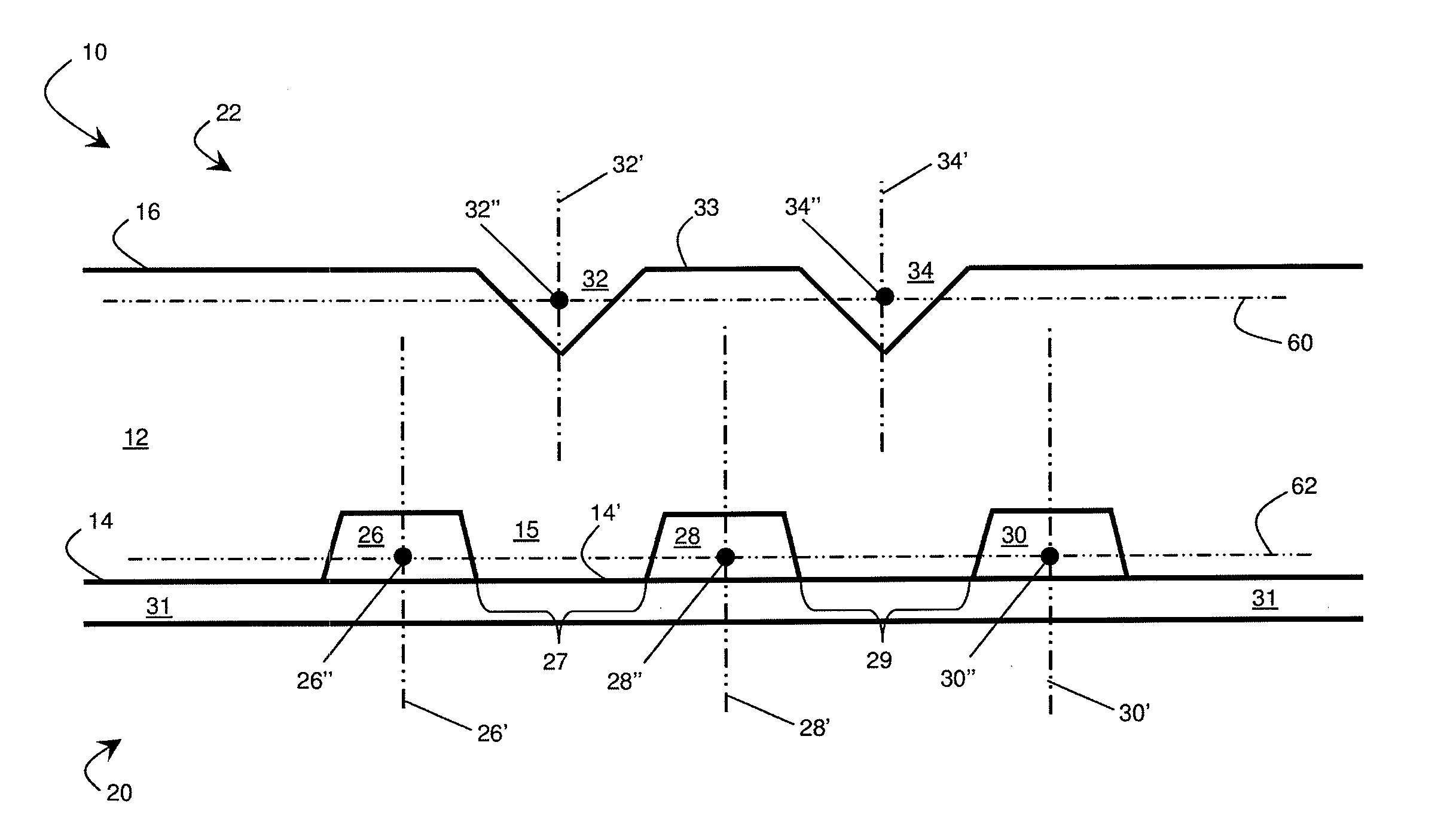

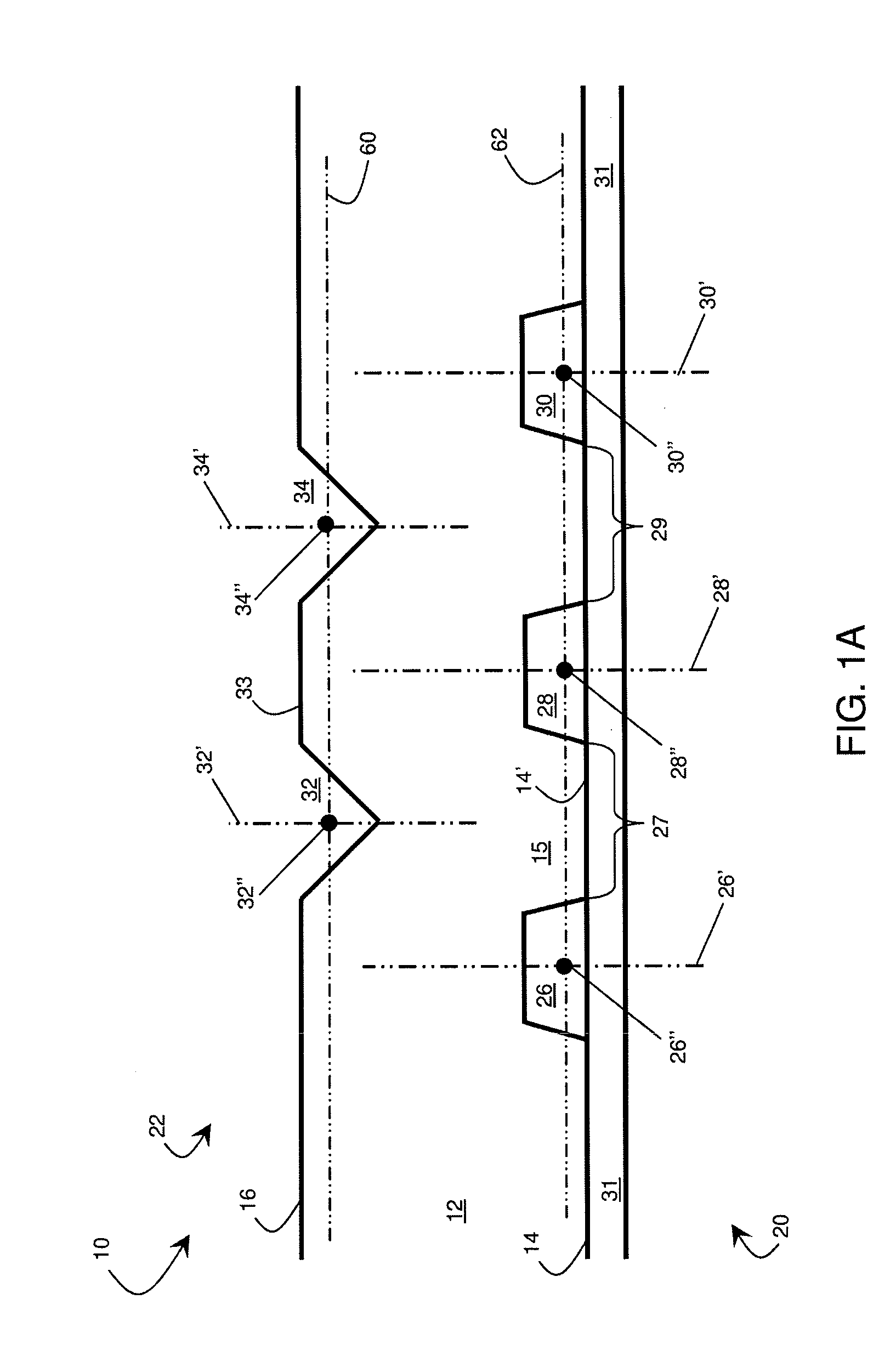

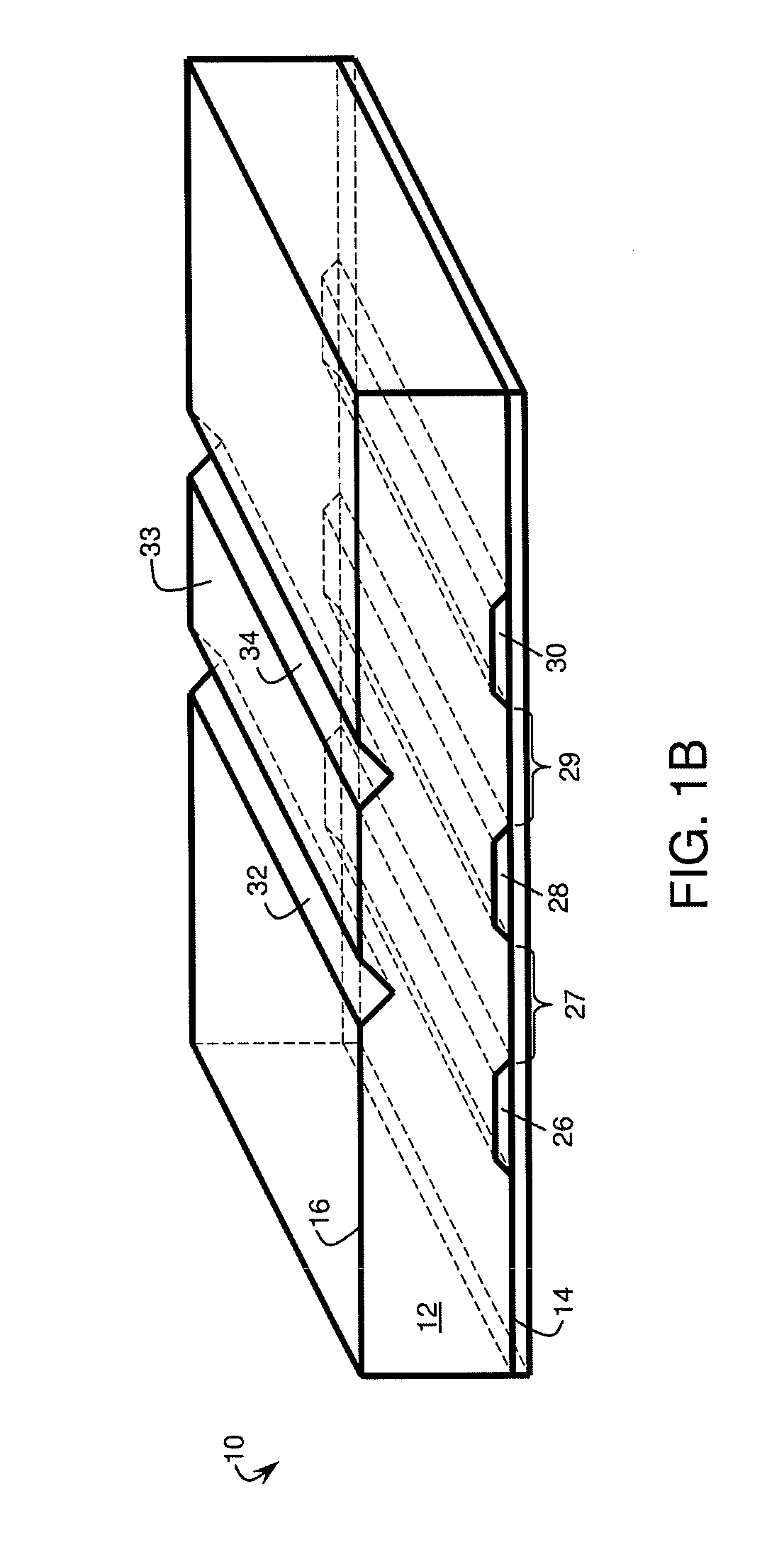

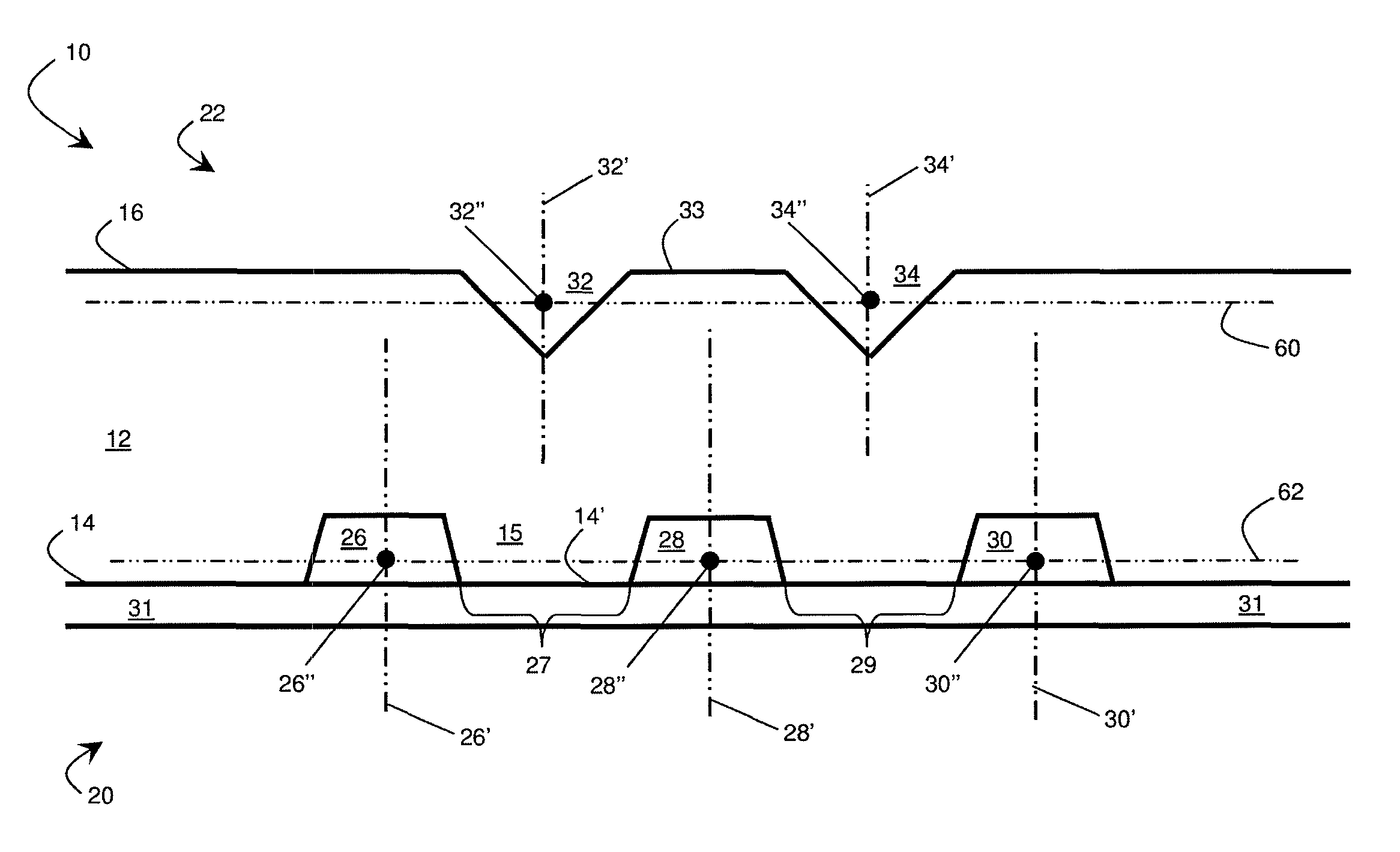

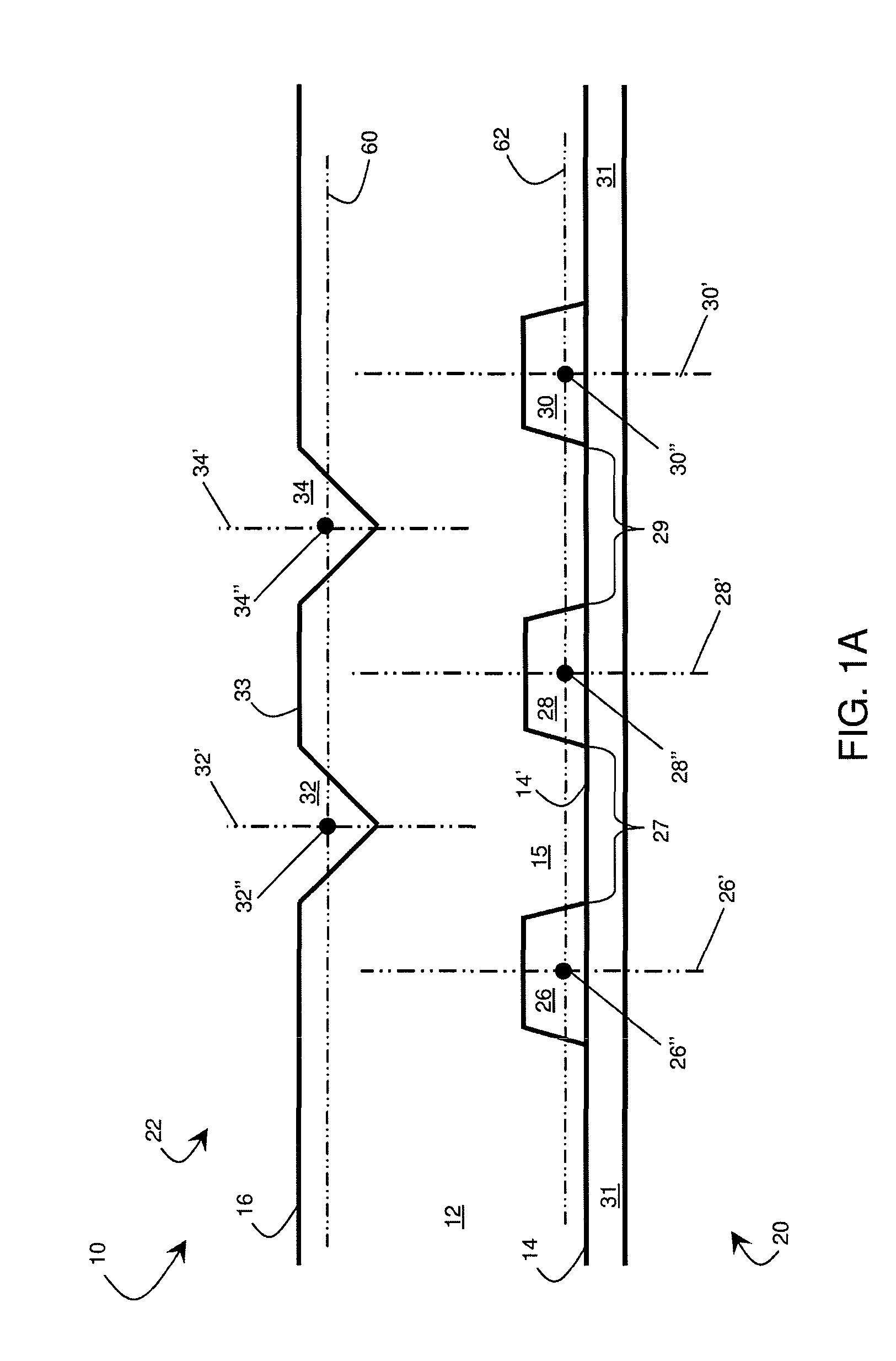

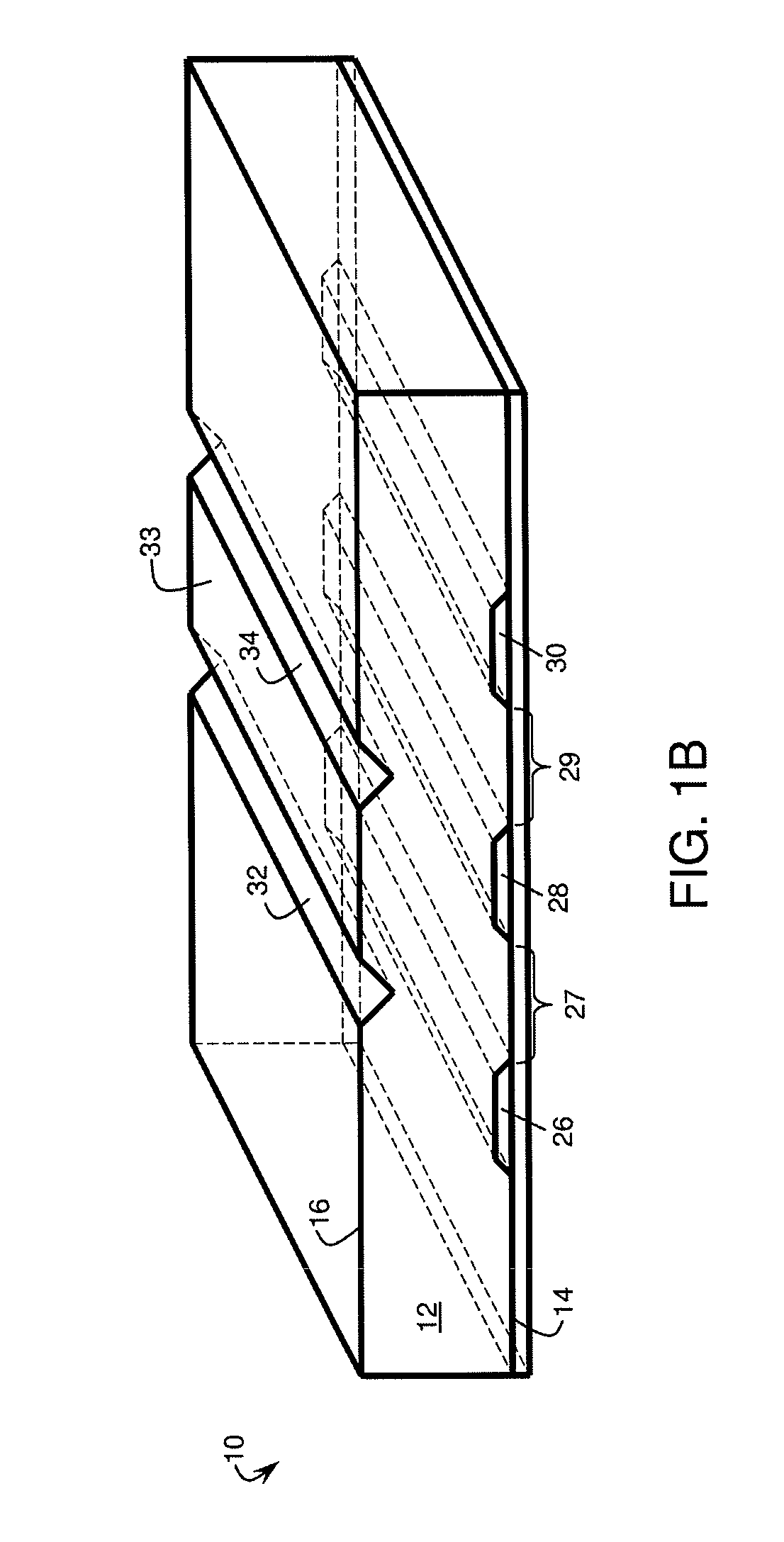

Structures for controlling light interaction with microfluidic devices

ActiveUS20100196207A1Microbiological testing/measurementChemiluminescene/bioluminescenceManufacturing cost reductionDevice material

Systems and methods for improved measurement of absorbance / transmission through fluidic systems are described. Specifically, in one set of embodiments, optical elements are fabricated on one side of a transparent fluidic device opposite a series of fluidic channels. The optical elements may guide incident light passing through the device such that most of the light is dispersed away from specific areas of the device, such as intervening portions between the fluidic channels. By decreasing the amount of light incident upon these intervening portions, the amount of noise in the detection signal can be decreased when using certain optical detection systems. In some embodiments, to the optical elements comprise triangular grooves formed on or in a surface of the device. The draft angle of the triangular grooves may be chosen such that incident light normal to the surface of the device is redirected at an angle dependent upon the indices of refraction of the external medium (e.g., air) and the device material. Advantageously, certain optical elements described herein may be fabricated along with the fluidic channels of the device in one step, thereby reducing the costs of fabrication. Furthermore, in some cases the optical elements do not require alignment with a detector and, therefore, facilitate assembly and / or use by an end user.

Owner:OPKO DIAGNOSTICS

Structures for controlling light interaction with microfluidic devices

ActiveUS8221700B2Microbiological testing/measurementChemiluminescene/bioluminescenceManufacturing cost reductionDevice material

Systems and methods for improved measurement of absorbance / transmission through fluidic systems are described. Specifically, in one set of embodiments, optical elements are fabricated on one side of a transparent fluidic device opposite a series of fluidic channels. The optical elements may guide incident light passing through the device such that most of the light is dispersed away from specific areas of the device, such as intervening portions between the fluidic channels. By decreasing the amount of light incident upon these intervening portions, the amount of noise in the detection signal can be decreased when using certain optical detection systems. In some embodiments, the optical elements comprise triangular grooves formed on or in a surface of the device. The draft angle of the triangular grooves may be chosen such that incident light normal to the surface of the device is redirected at an angle dependent upon the indices of refraction of the external medium (e.g., air) and the device material. Advantageously, certain optical elements described herein may be fabricated along with the fluidic channels of the device in one step, thereby reducing the costs of fabrication. Furthermore, in some cases the optical elements do not require alignment with a detector and, therefore, facilitate assembly and / or use by an end user.

Owner:OPKO DIAGNOSTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com