Patents

Literature

99 results about "Column space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In linear algebra, the column space C of a matrix A is the set of all possible linear combinations of its column vectors. Let K be a field. The column space of an m × n matrix with components from K is a linear subspace of the m-space Kᵐ. The dimension of the column space is called the rank of the matrix. A definition for matrices over a ring K is also possible. The column space of a matrix is the image or range of the corresponding matrix transformation.

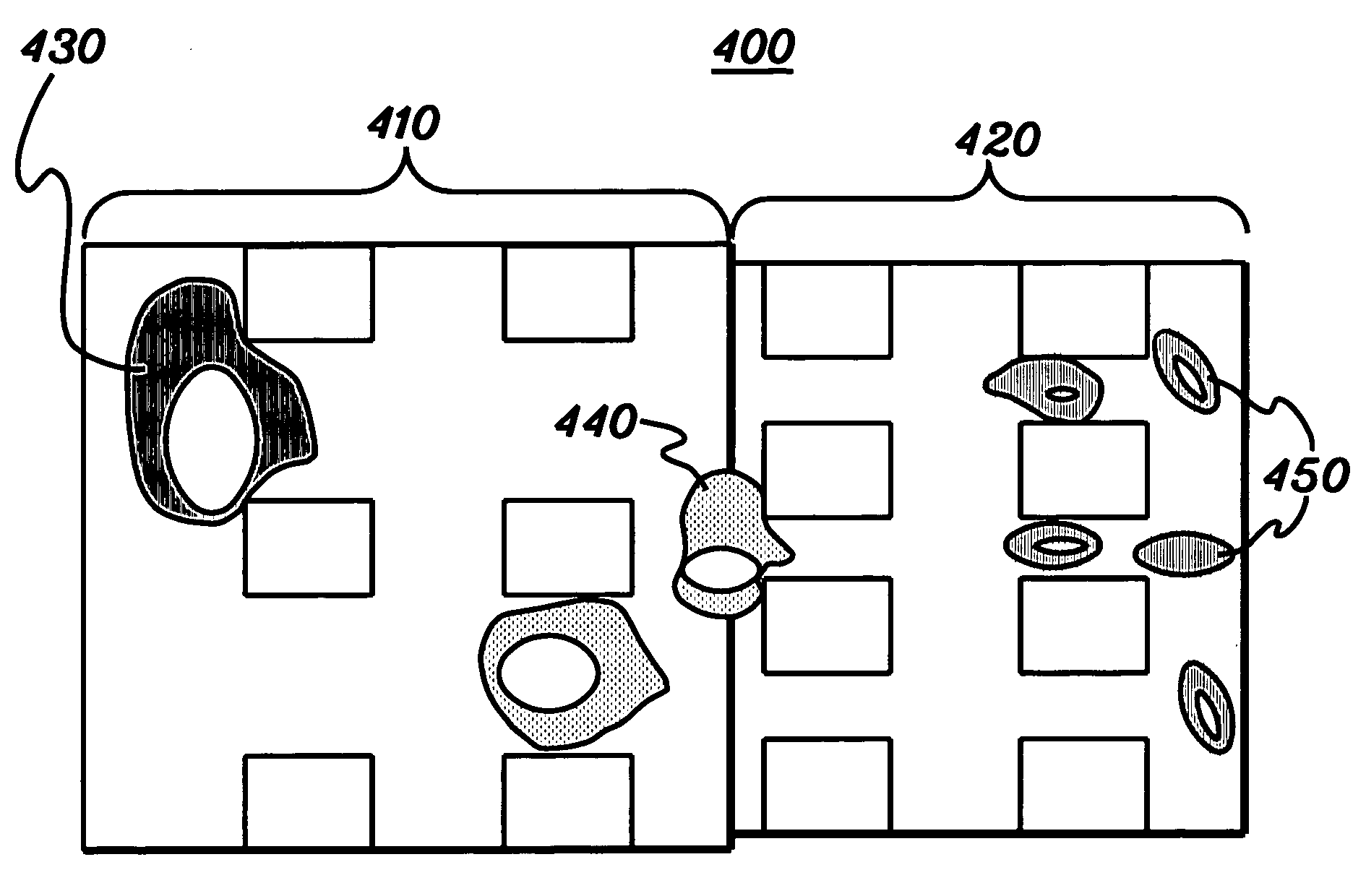

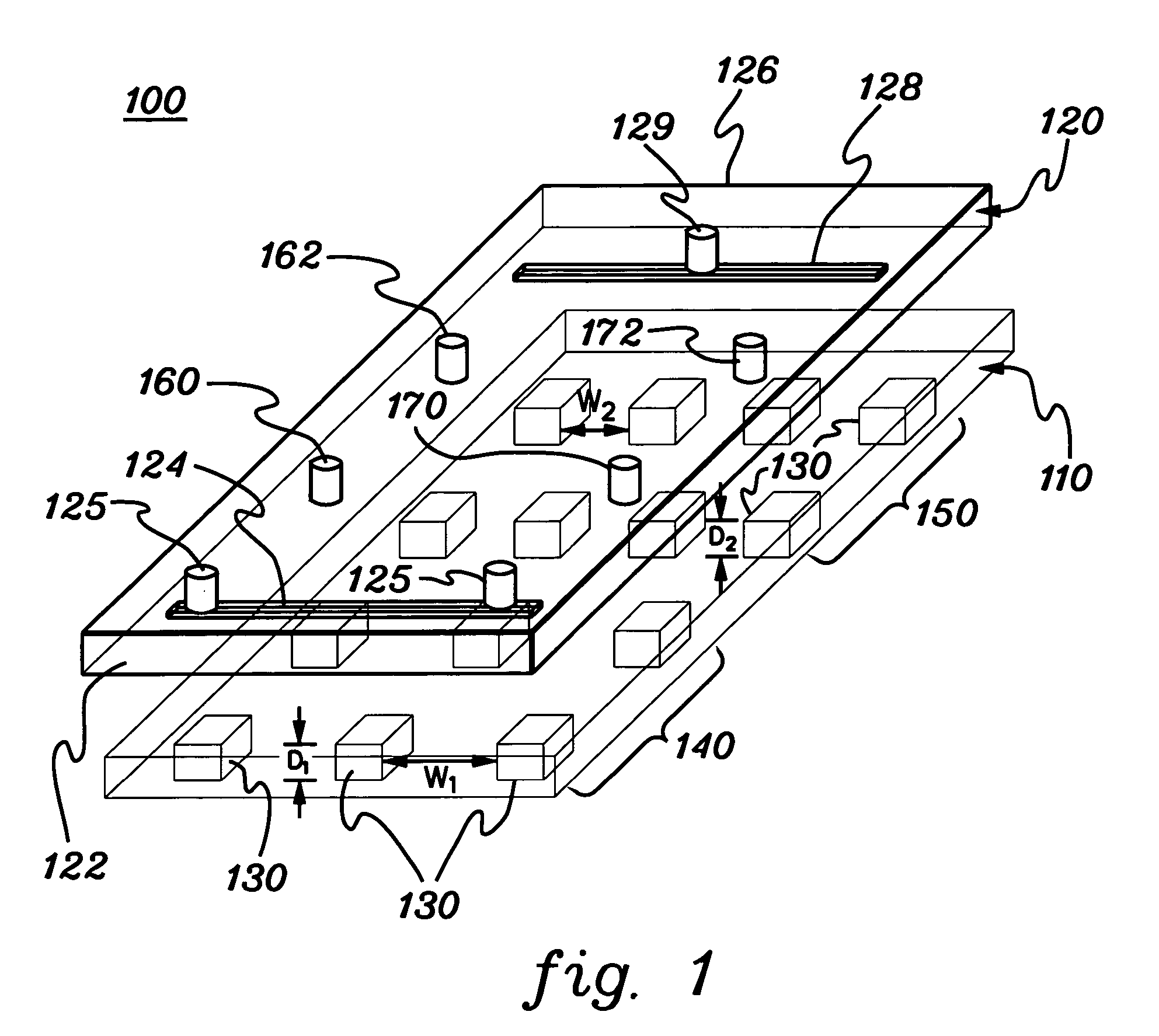

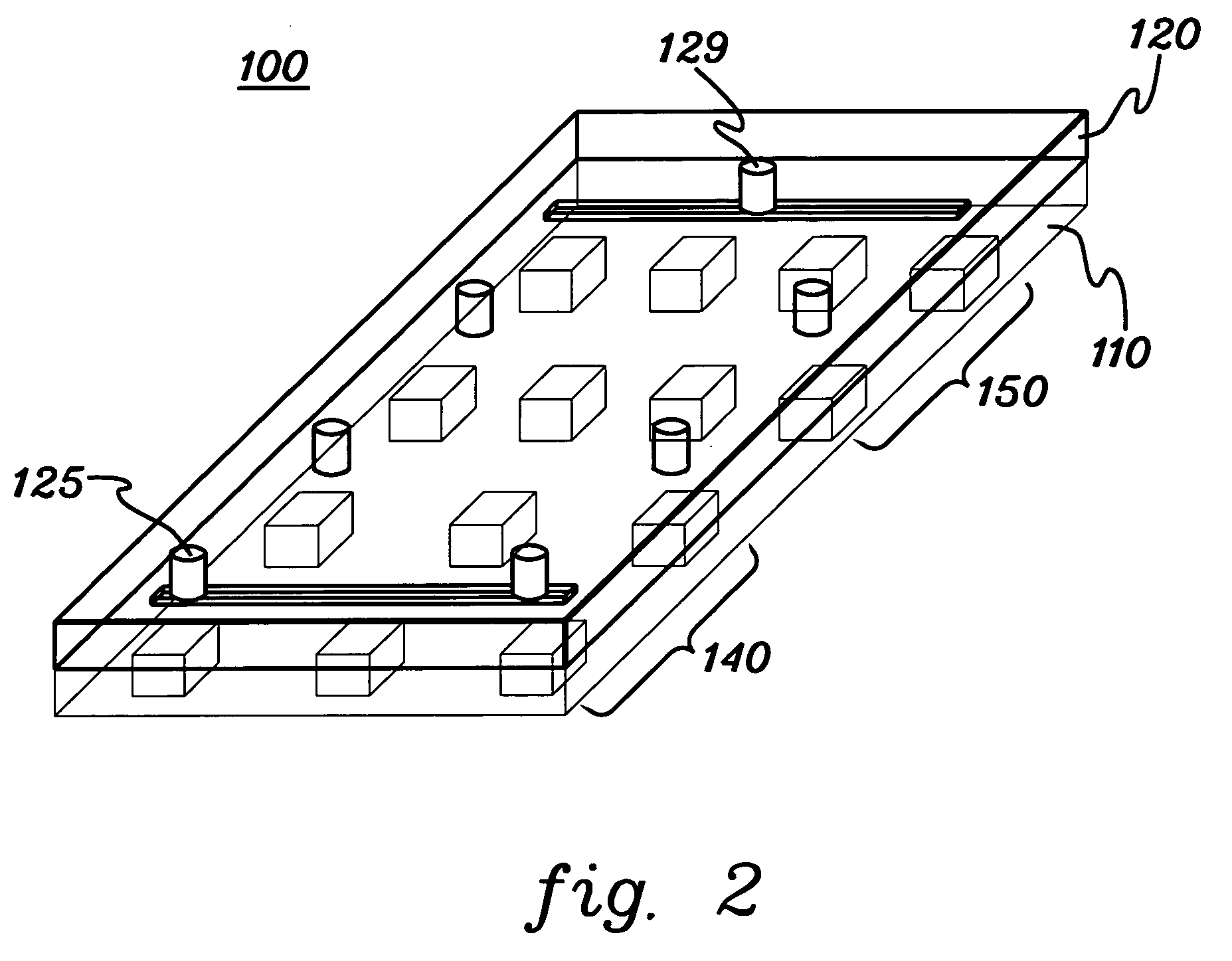

Apparatus and method for sorting microstructures in a fluid medium

InactiveUS20060051265A1Bacterial antigen ingredientsMaterial analysisBiomedical engineeringColumn space

Owner:HEALTH RES INC

Bore construction method by bore explosion

The present invention provides a deep shaft one-step explosion well-forming construction method, and it is characterized by that three types of blast-holes can be drilled on the full face of the deepshaft, first type is of rock presplitting holes which are distributed along periphery of circular well to make peripheral smoothwall blasting, second type is of rock breaking holes which are distributed on the inner side of peripheral presplitting holes, and third type is of pulverizing holes with are distributed in the axis zone of shaft. The presplitting hole adopts non-coupled air column spaced charging powder, and the breaking hole and pulverizing hole adopt conventional non-coupled continuously-charging powder.

Owner:中国人民解放军工程兵第四十一旅

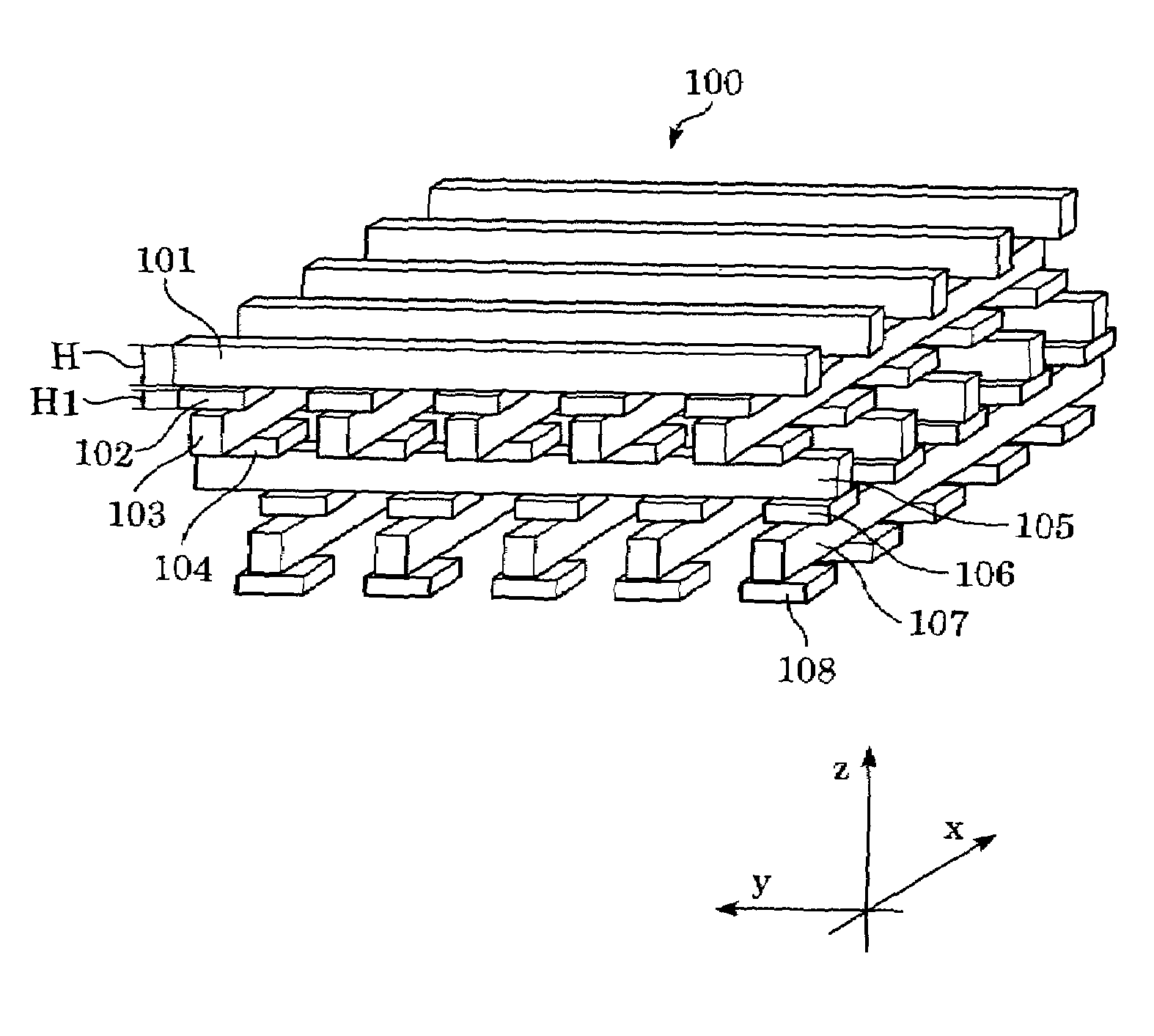

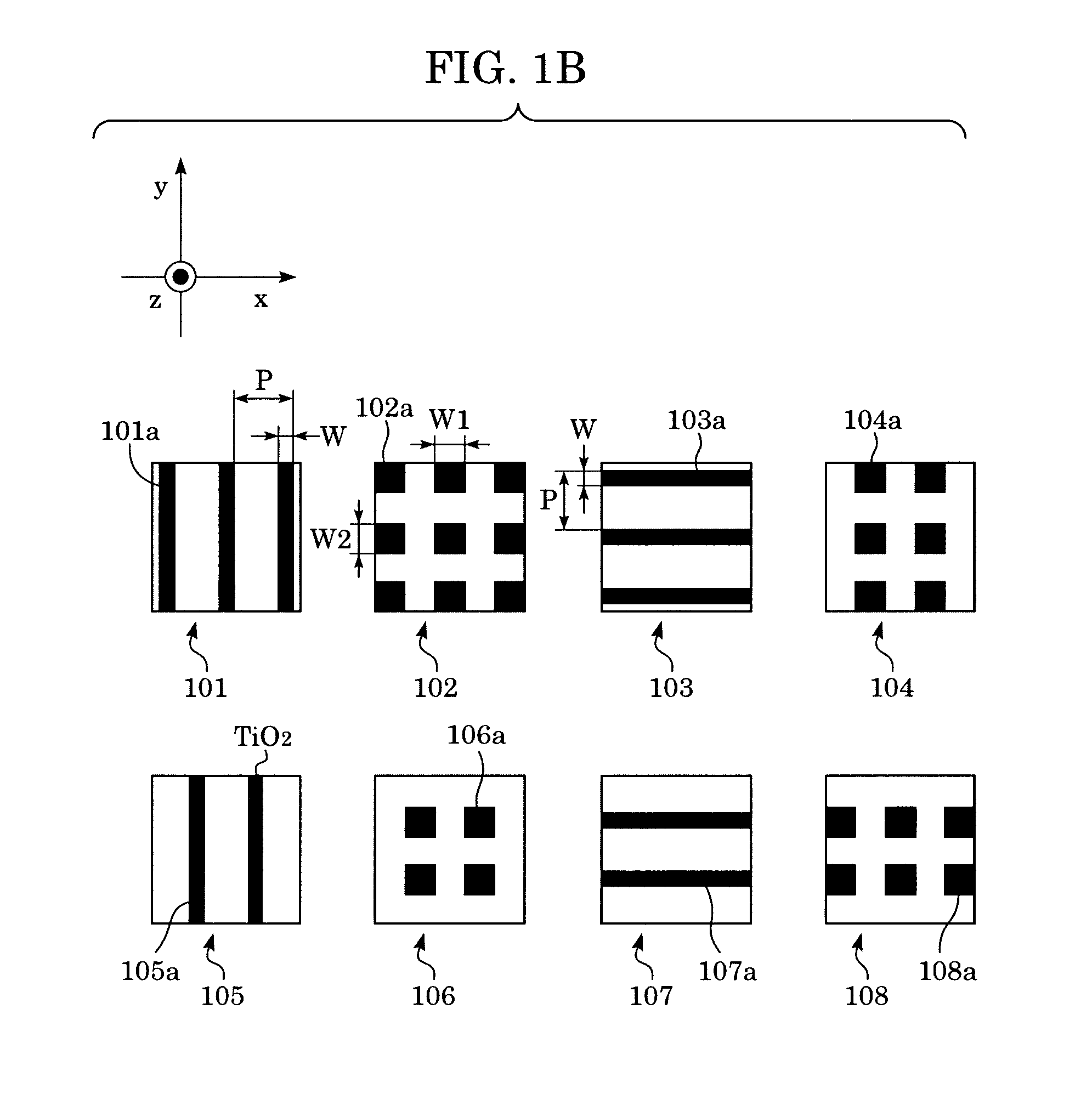

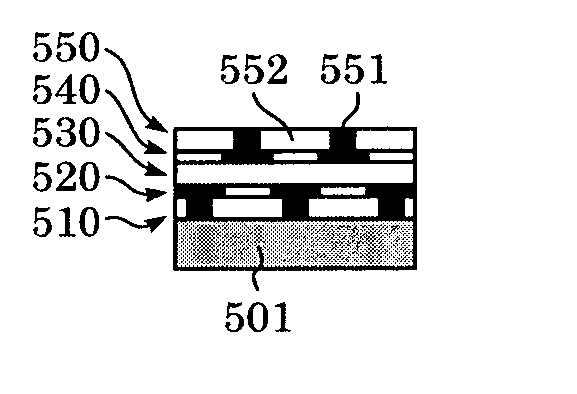

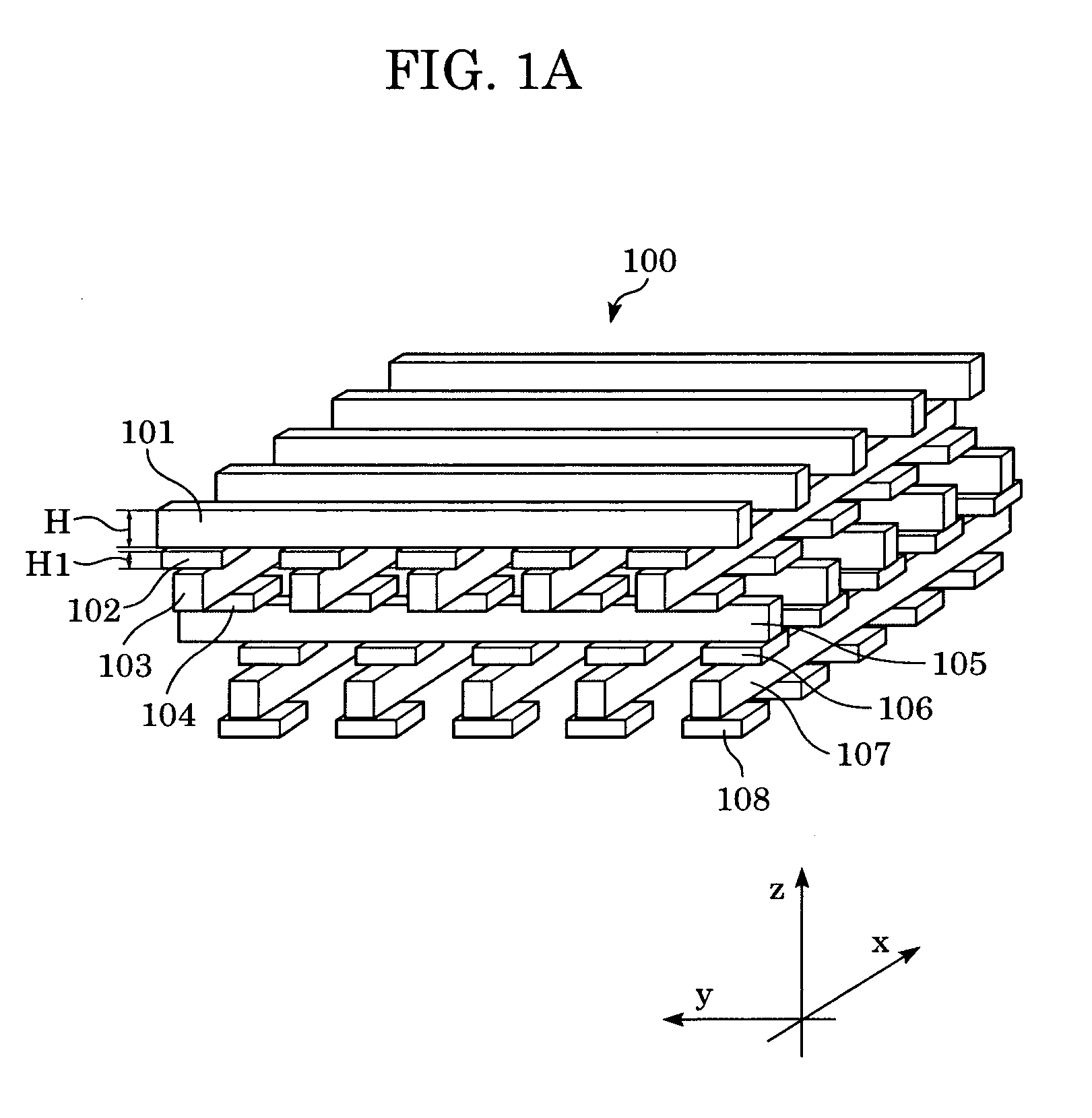

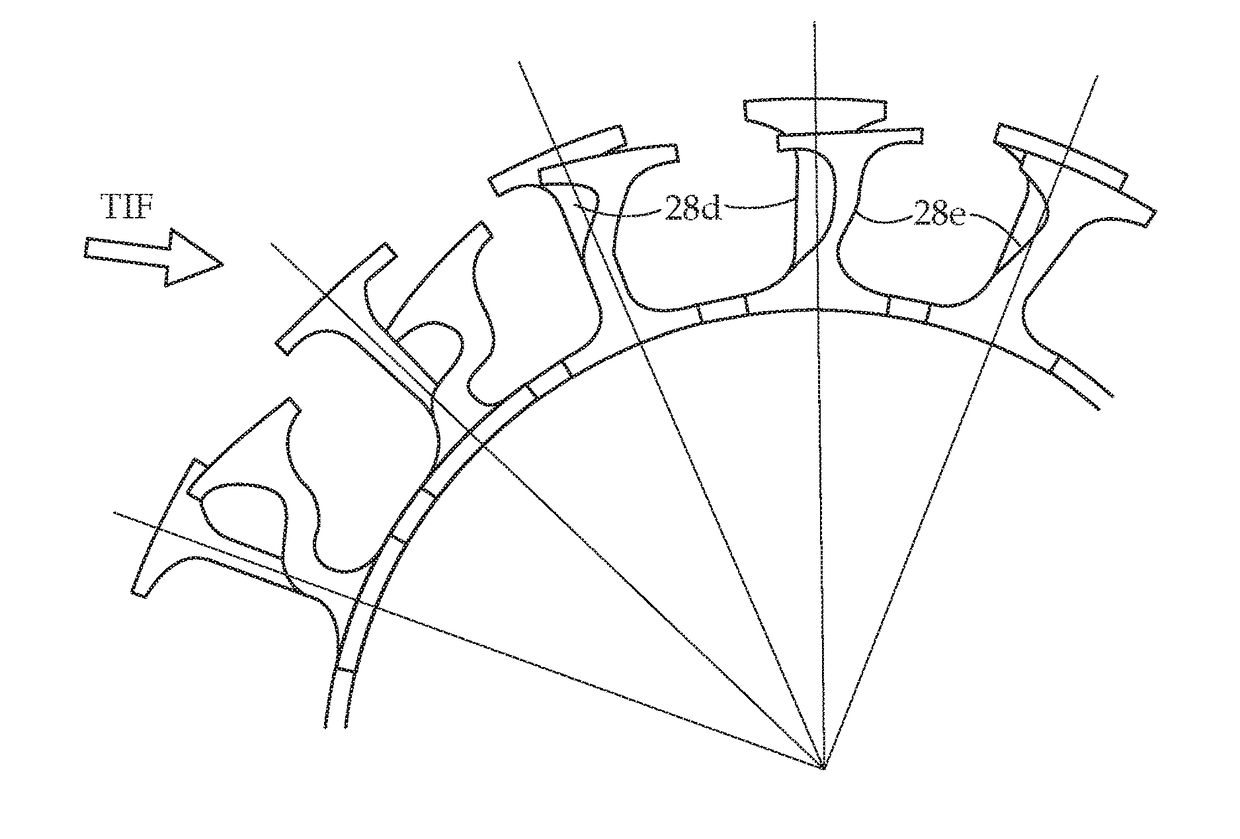

Three-dimensional periodic structure, functional element including the same, and light-emitting device

InactiveUS7085467B2Easy to produceLaser optical resonator constructionNanoopticsPhotonicsLight emitting device

A three-dimensional periodic structure exhibiting a complete photonic band gap in a wide wavelength range and being readily produced, as well as a functional element including the same, is provided. In the three-dimensional periodic structure exhibiting a photonic band gap according to the present invention, layers composed of a plurality of square columns spaced apart by a predetermined interval are stacked sequentially with additional layers therebetween, rectangular parallelepipeds contained in the additional layers are disposed at the positions corresponding to the intersections of the square columns, and 1.21≦W1 / W≦2.39 and W / W1<W2 / W are satisfied, where W1 and W2 represent lengths of sides of the rectangular parallelepiped and W represents the width of the square column, each in a plane parallel to the layer containing the square columns.

Owner:CANON KK

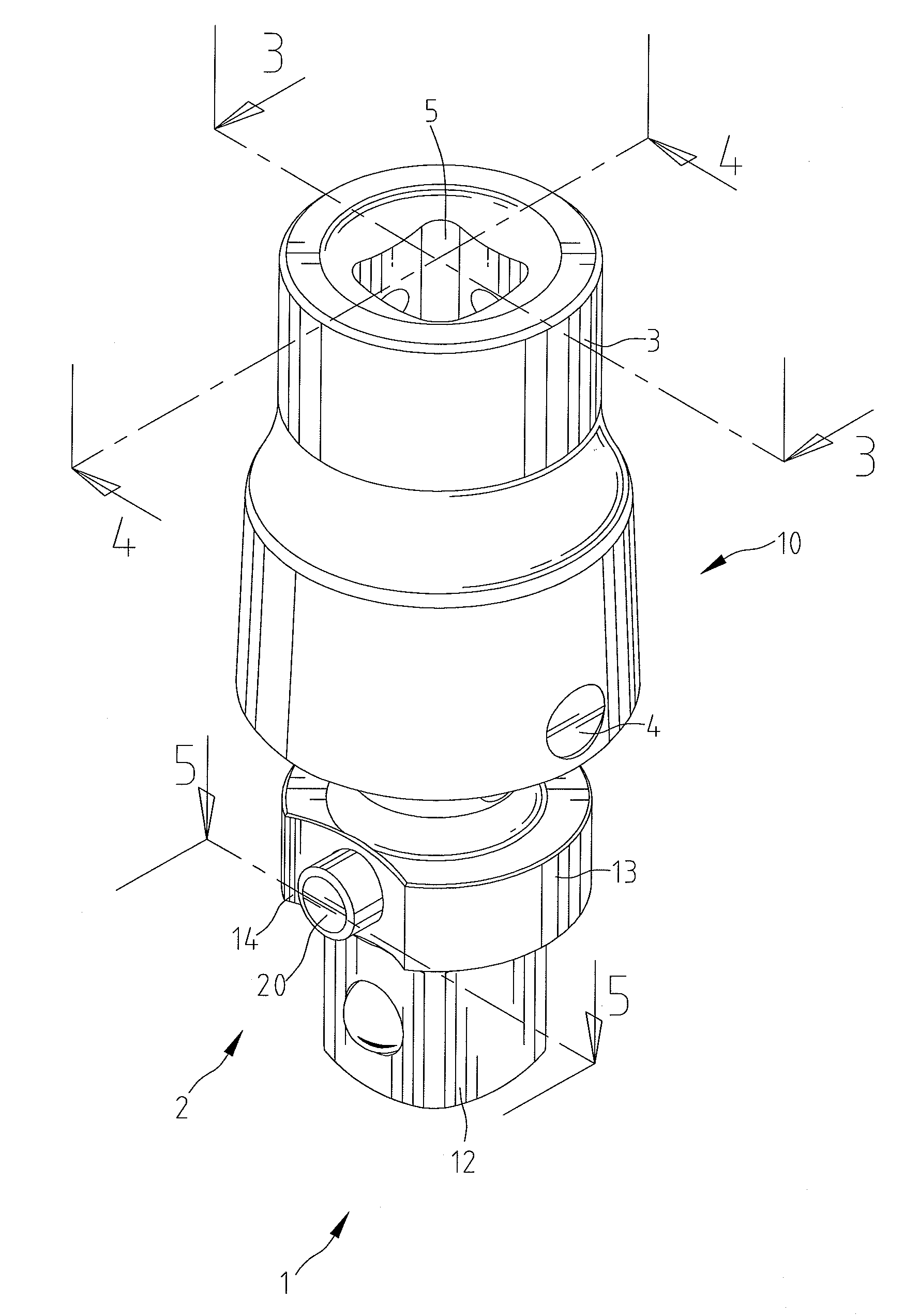

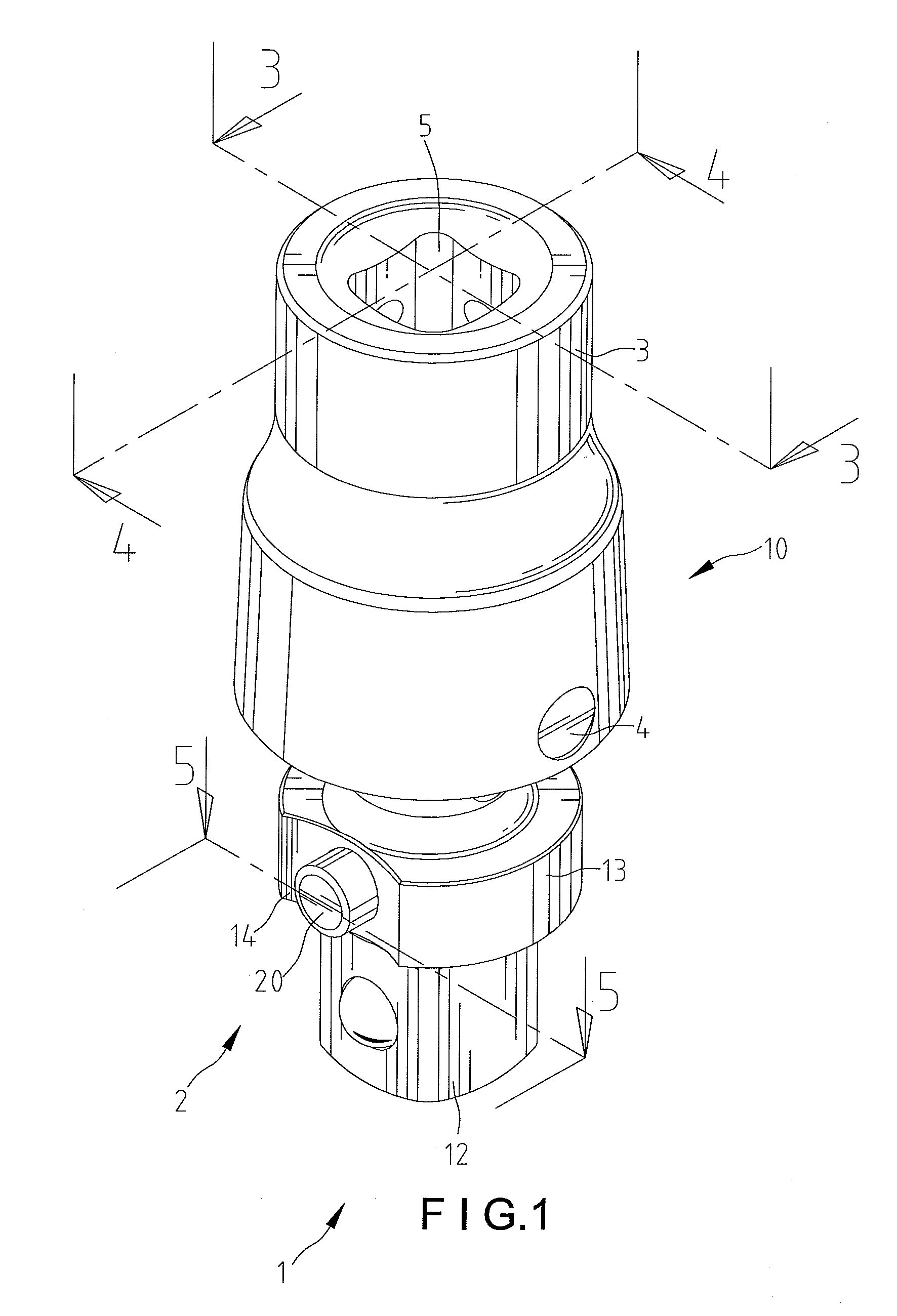

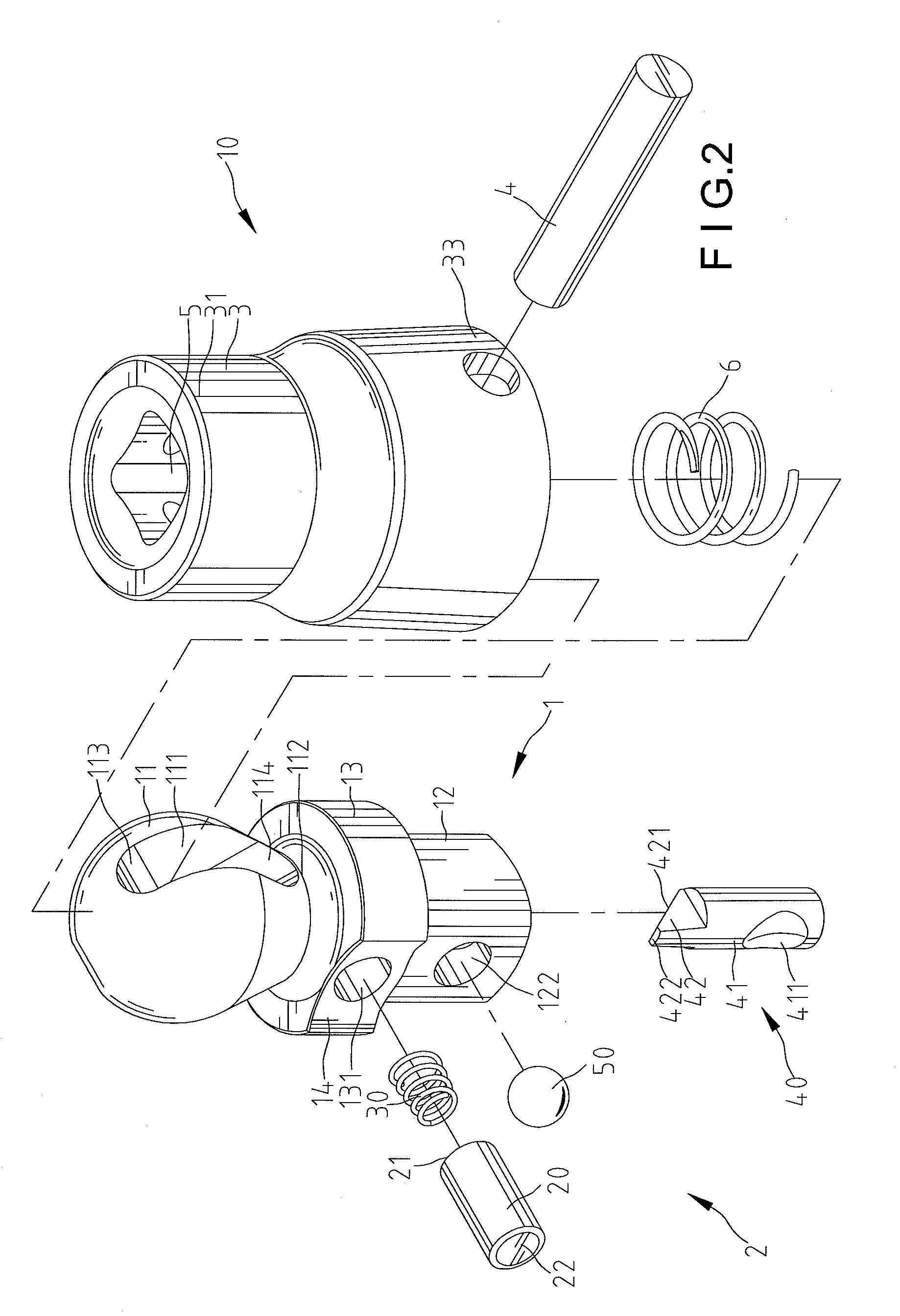

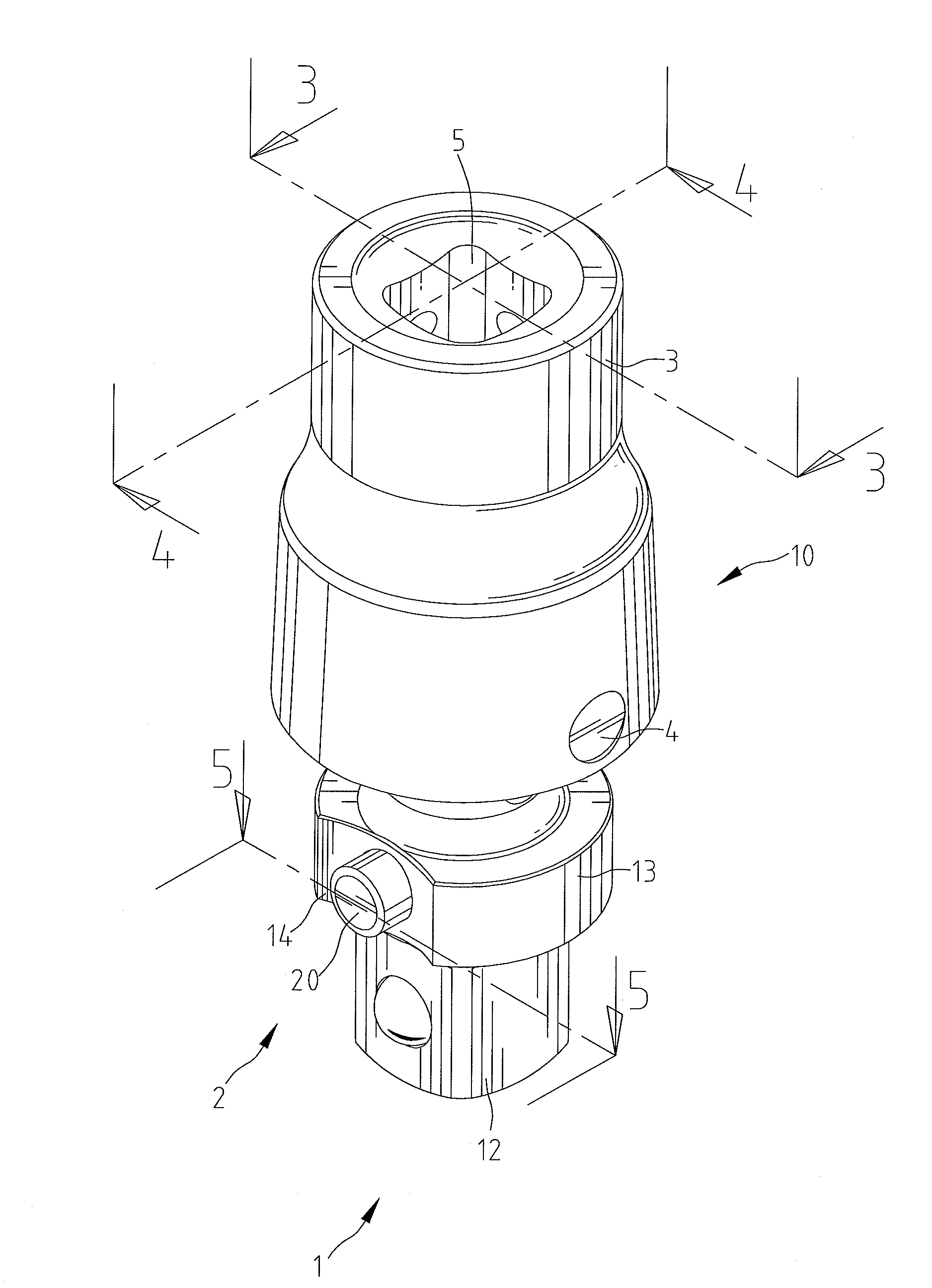

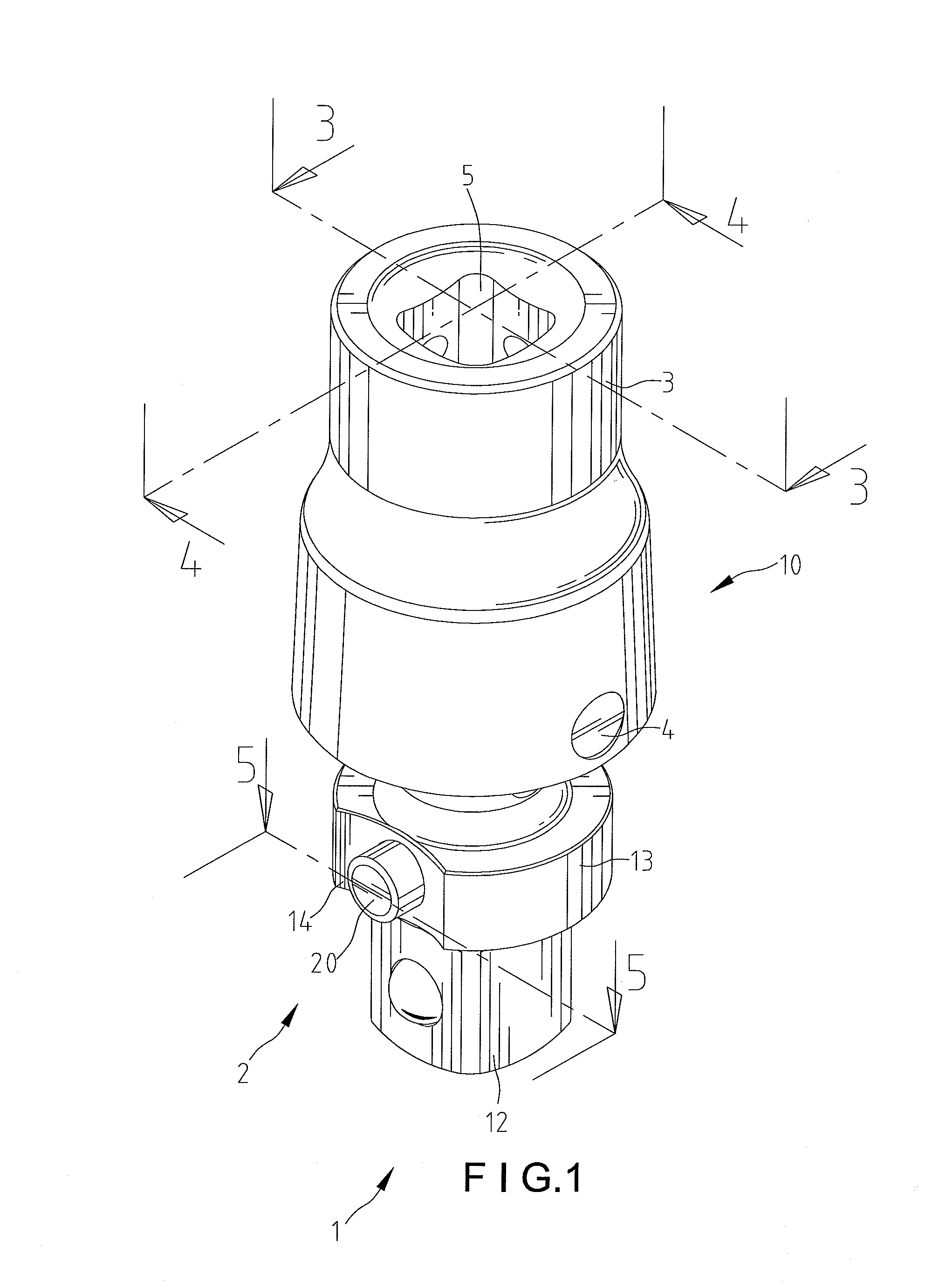

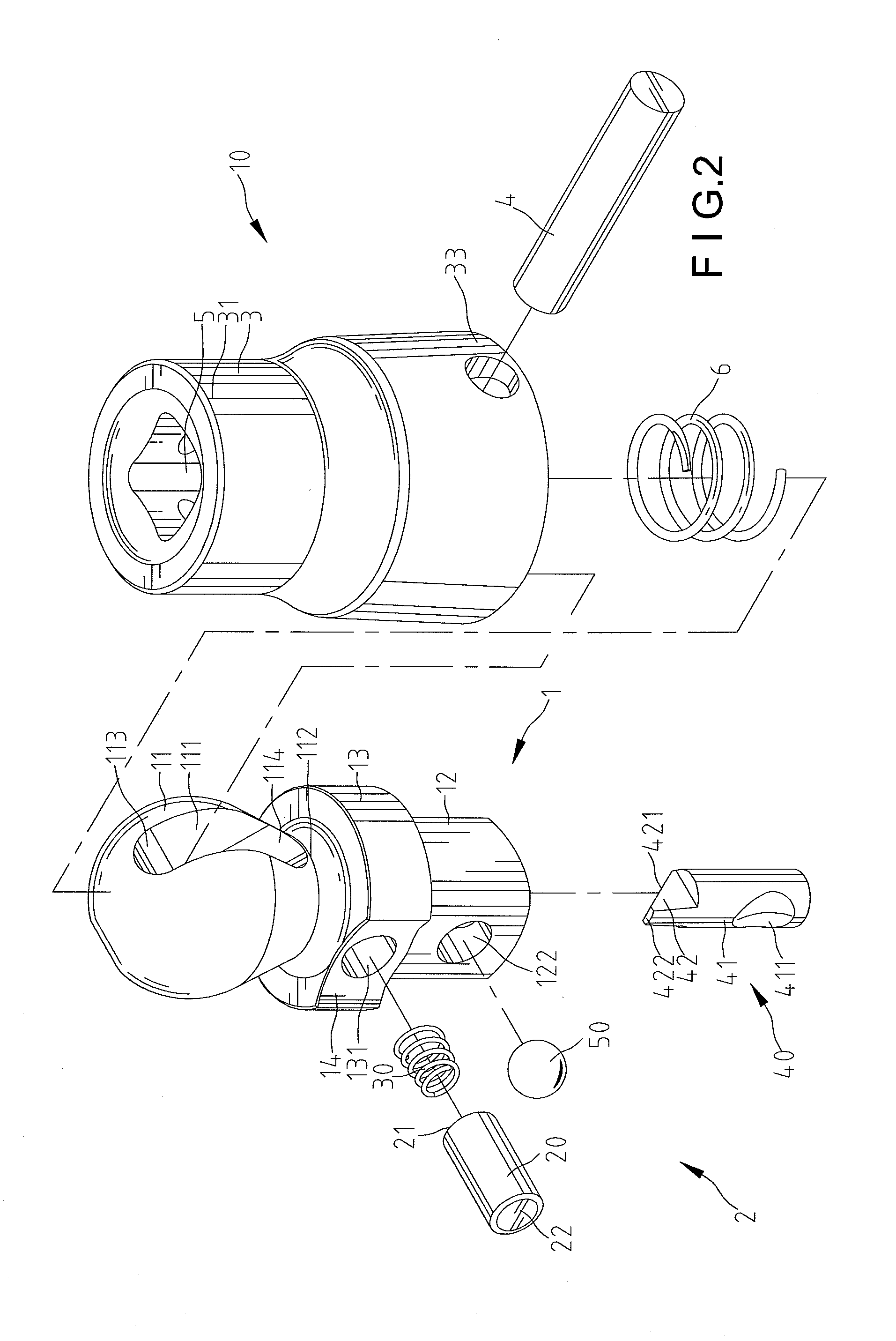

Universal joint

A universal joint includes a coupling member having an end for coupling with a tool. A body includes a rounded base pivotably mounted to the other end of the coupling member. The body further includes a drive column spaced from the rounded base along an axis. A reinforcing section is intermediate the rounded base and the drive column. The reinforcing section includes an outer periphery having a recessed portion with a receptacle extending in a radial direction perpendicular to the axis. A control member is moveably received in the receptacle to control coupling of the drive column and an object to be driven. In any case, a spacing from an outer end of the control member to the axis in the radial direction is substantially not larger than a spacing from the outer periphery of the reinforcing section to the axis in the radial direction.

Owner:HU BOBBY

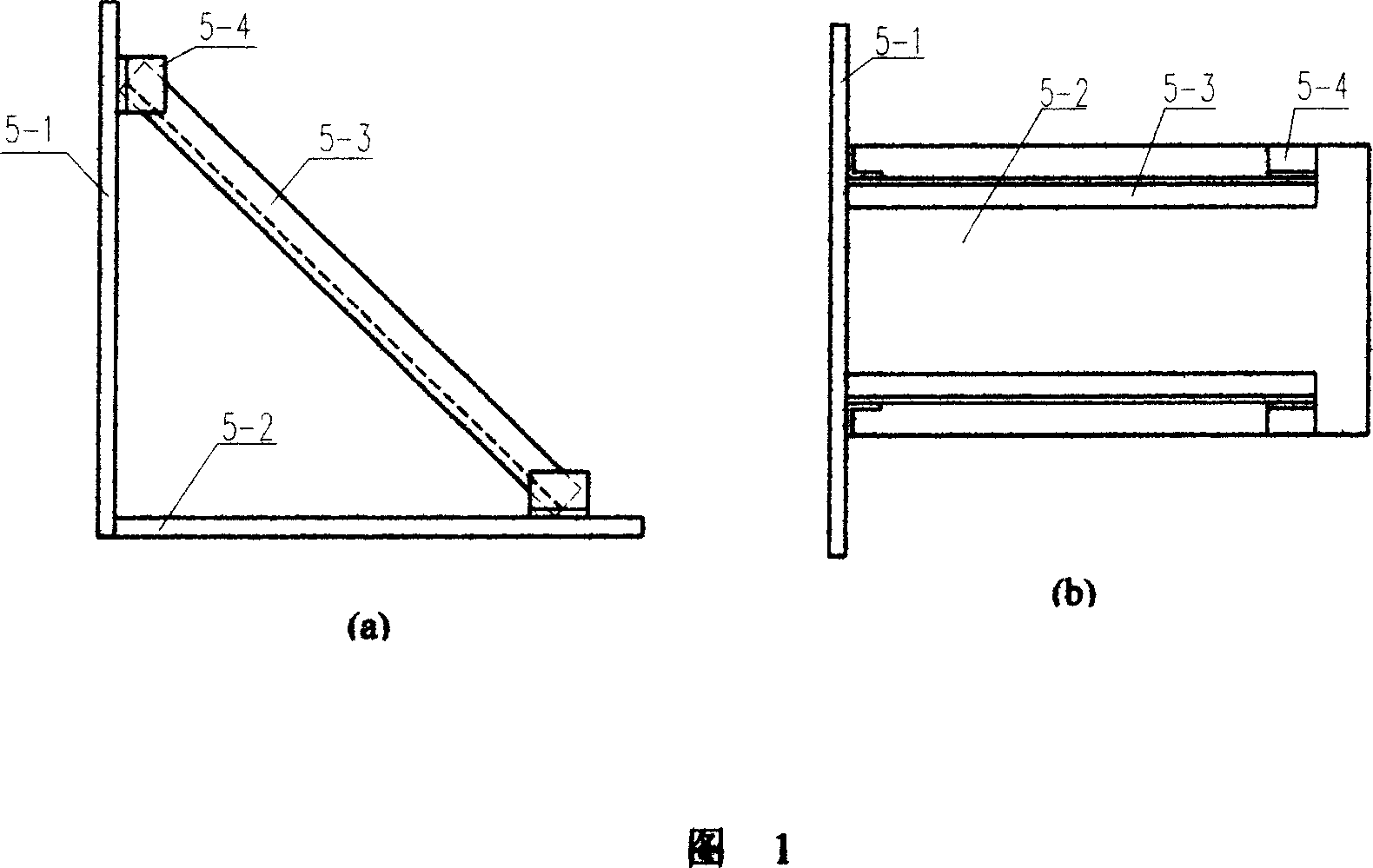

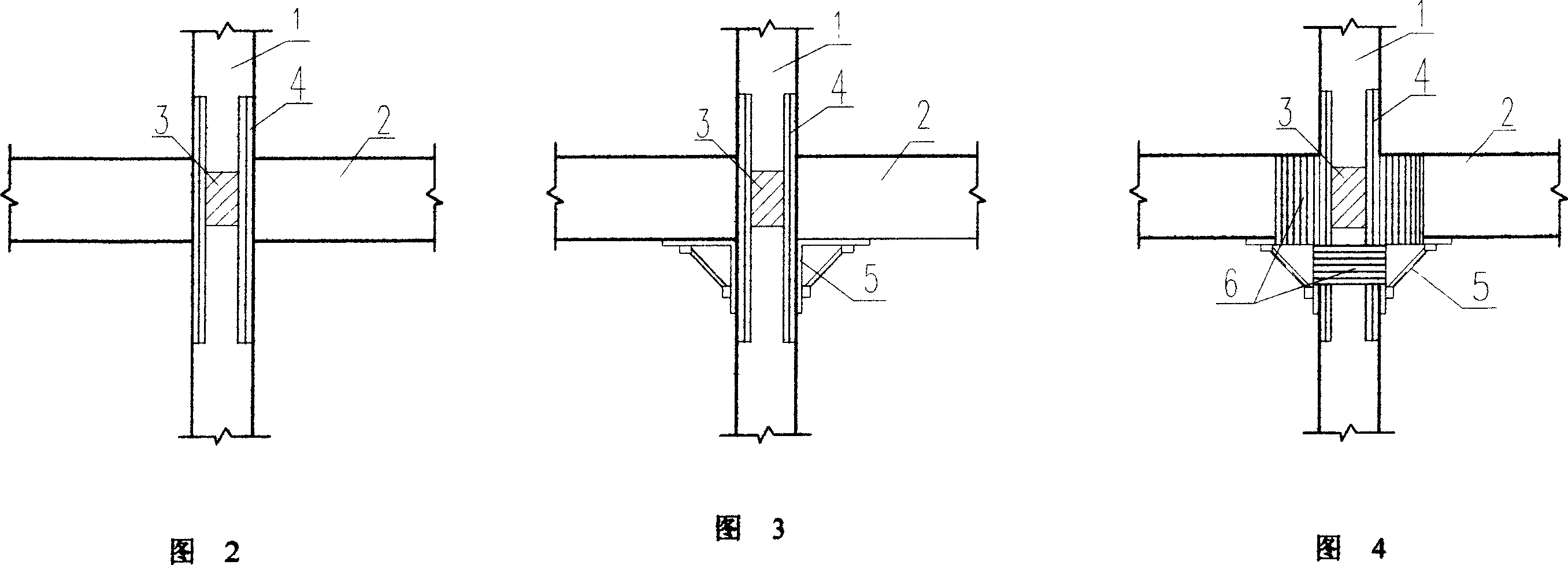

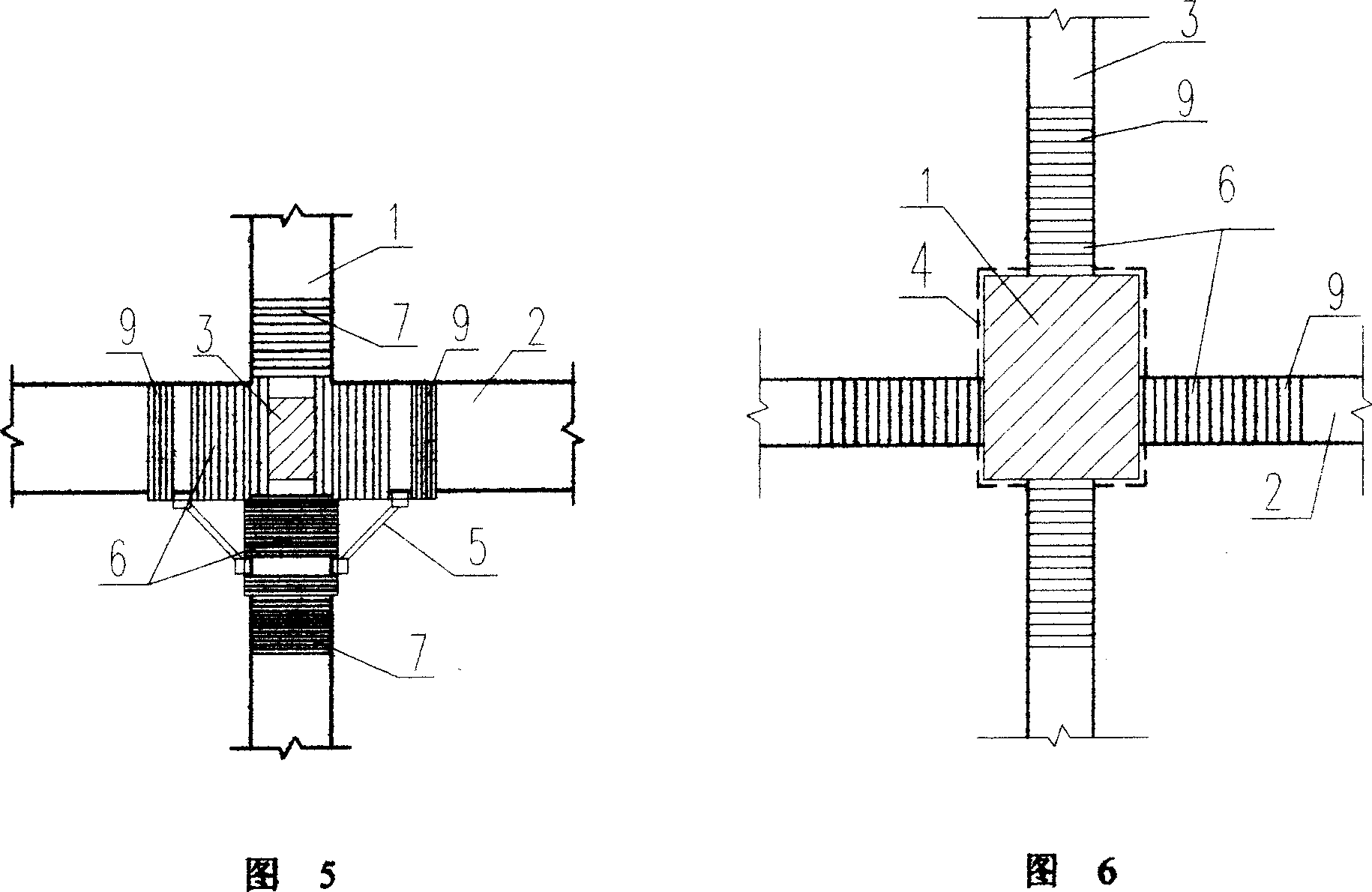

Method for reinforcing space nodes of beam column built from concrete

The present invention discloses a method for strengthening concrete beam-column space node. Said method includes the following steps: firstly grinding peripheral surface of concrete beam-column node, cleaning, leveling by using leveling glue and applying base glue, then vertically sticking two layers of vertical carbon fiber fabric to the internal columns of two sides of beam, utilizing carbon fiber fabric to bind triangular steel clips onto the column and beam and binding two heads of said vertical carbon fiber fabric onto the column. Said strengthening method can greatly raise yield strength, limit strength and rigidity of node.

Owner:GUANGZHOU UNIVERSITY

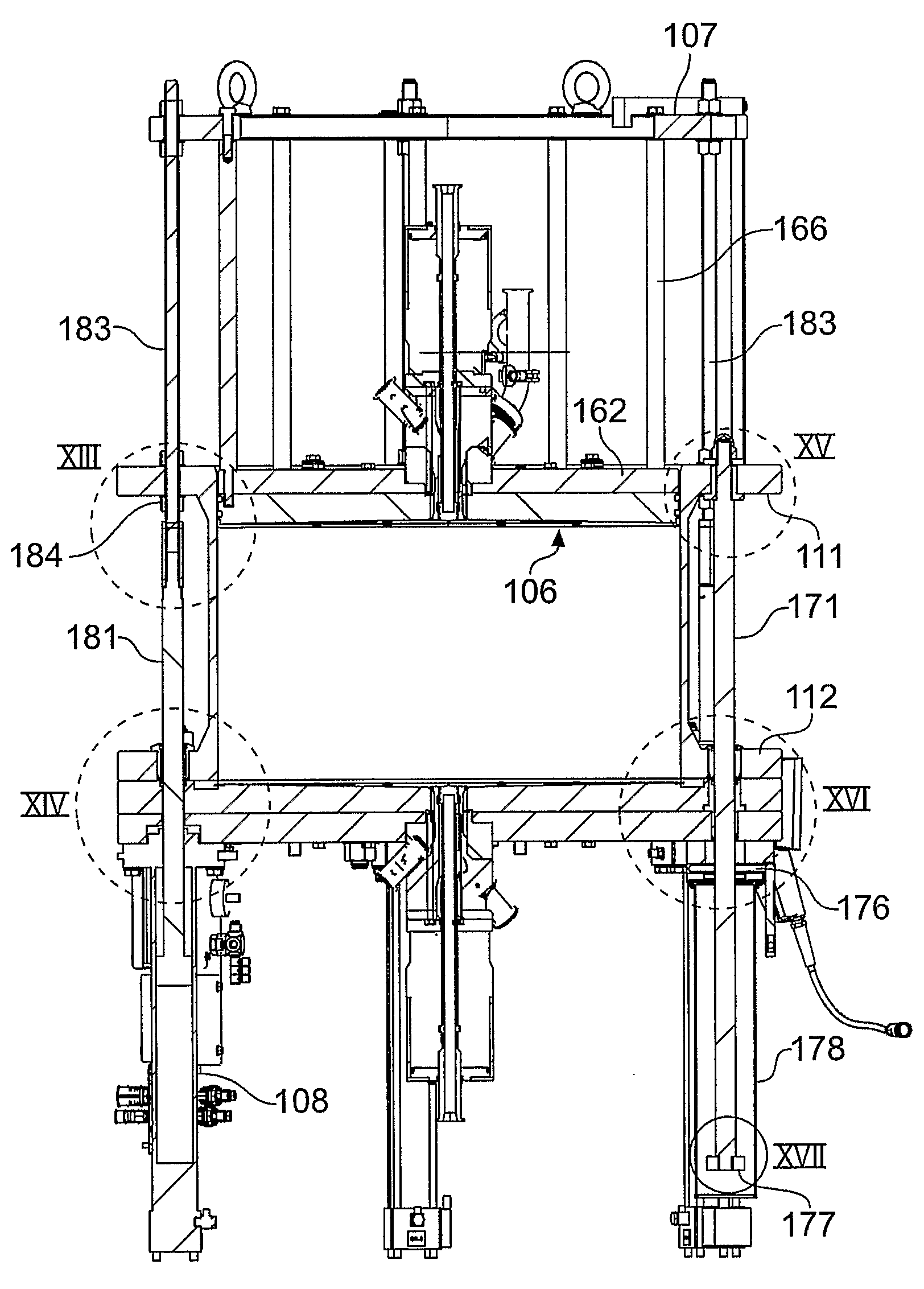

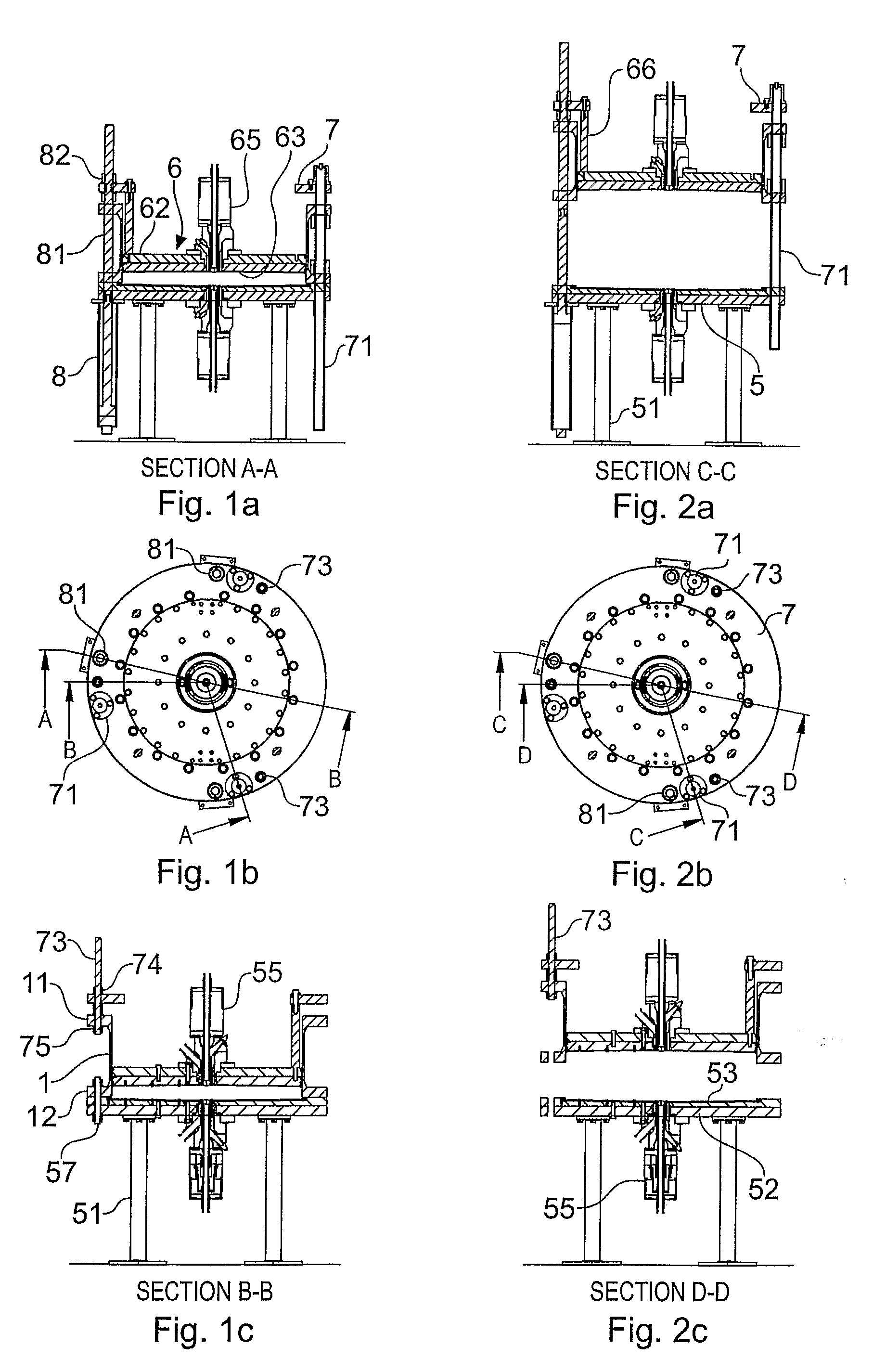

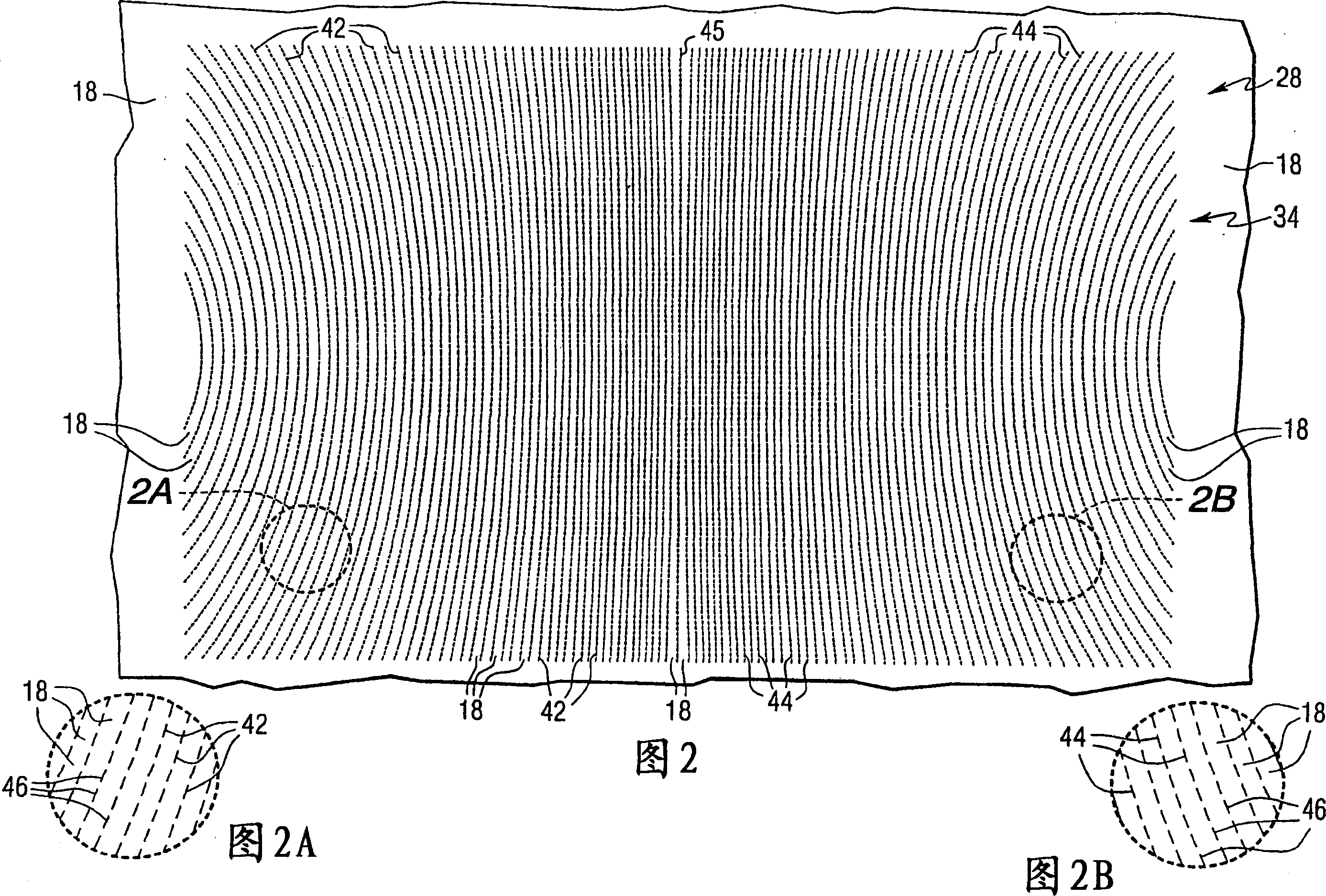

Chromatography columns and their operation

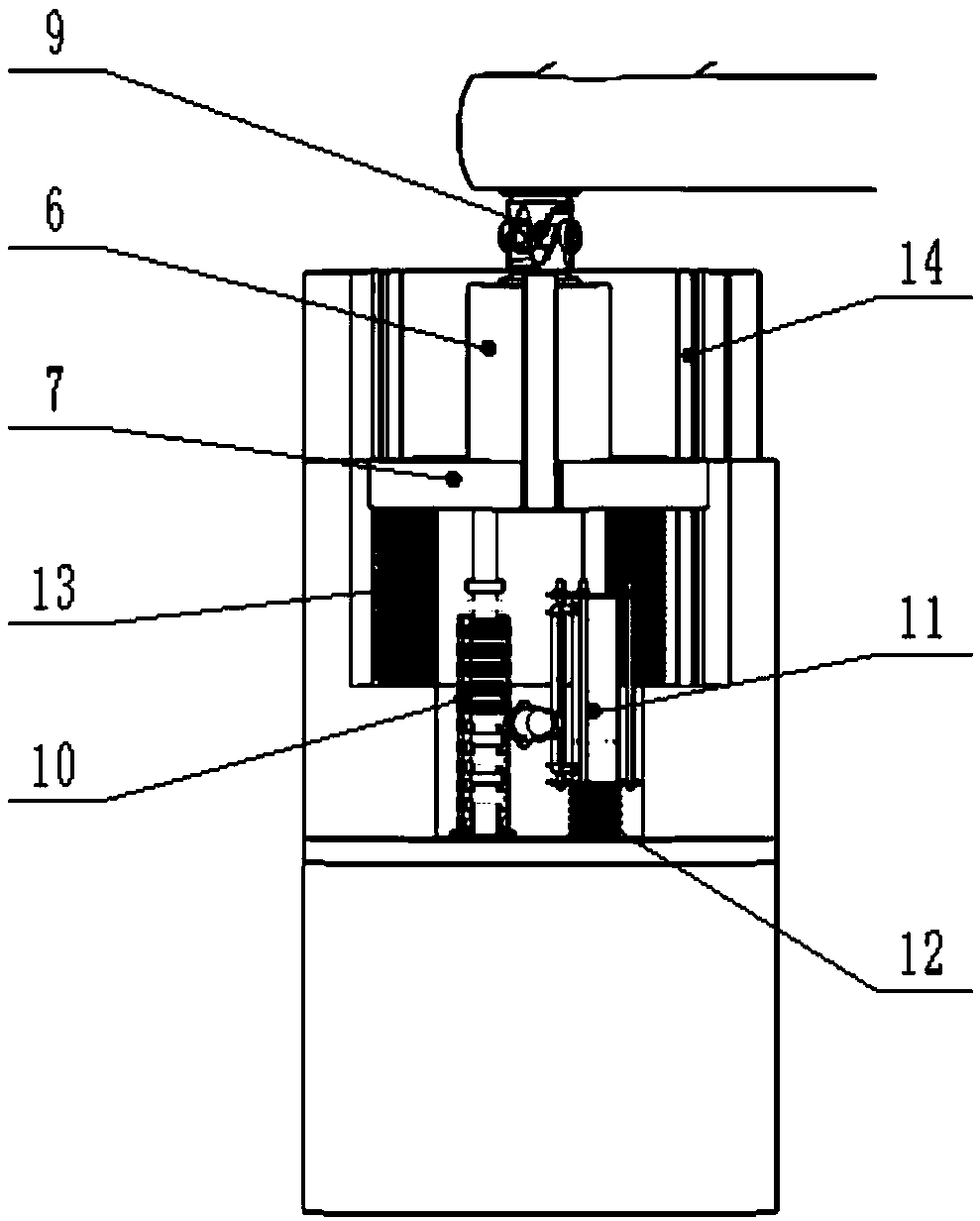

ActiveUS7604747B2Lower height requirementSimple procedureIon-exchange process apparatusComponent separationEngineeringChromatography column

A method of operating chromatography column apparatus comprising a column tube (101) and first and second discrete end cell structures, associated with the respective ends of the column tube and positionable to close off the column tube and define therein a column space for retaining chromatography medium in use of the apparatus. The first end cell portion comprises a piston portion (106) fitting slidably in the column tube. The column tube and the second end cell structure are separated to provide an access spacing between them. The piston portion (106) of the first end cell structure is advanced through the column tube to expose it at the open second end of the column tube, for maintenance of the piston portion thus exposed. Corresponding chromatography apparatus is another aspect of the disclosure.

Owner:SARTORIUS STEDIM CHROMATOGRAPHY SYST LTD

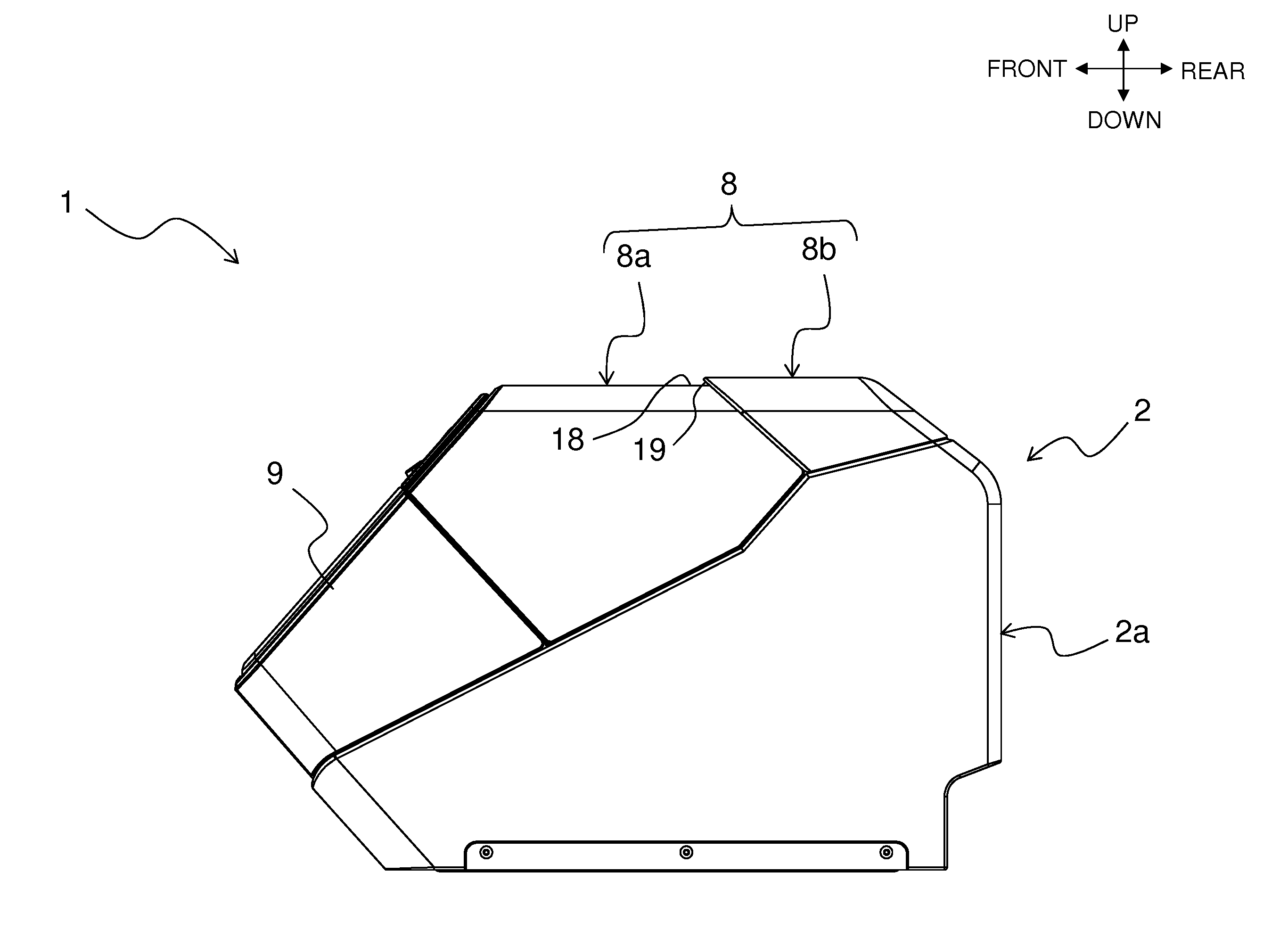

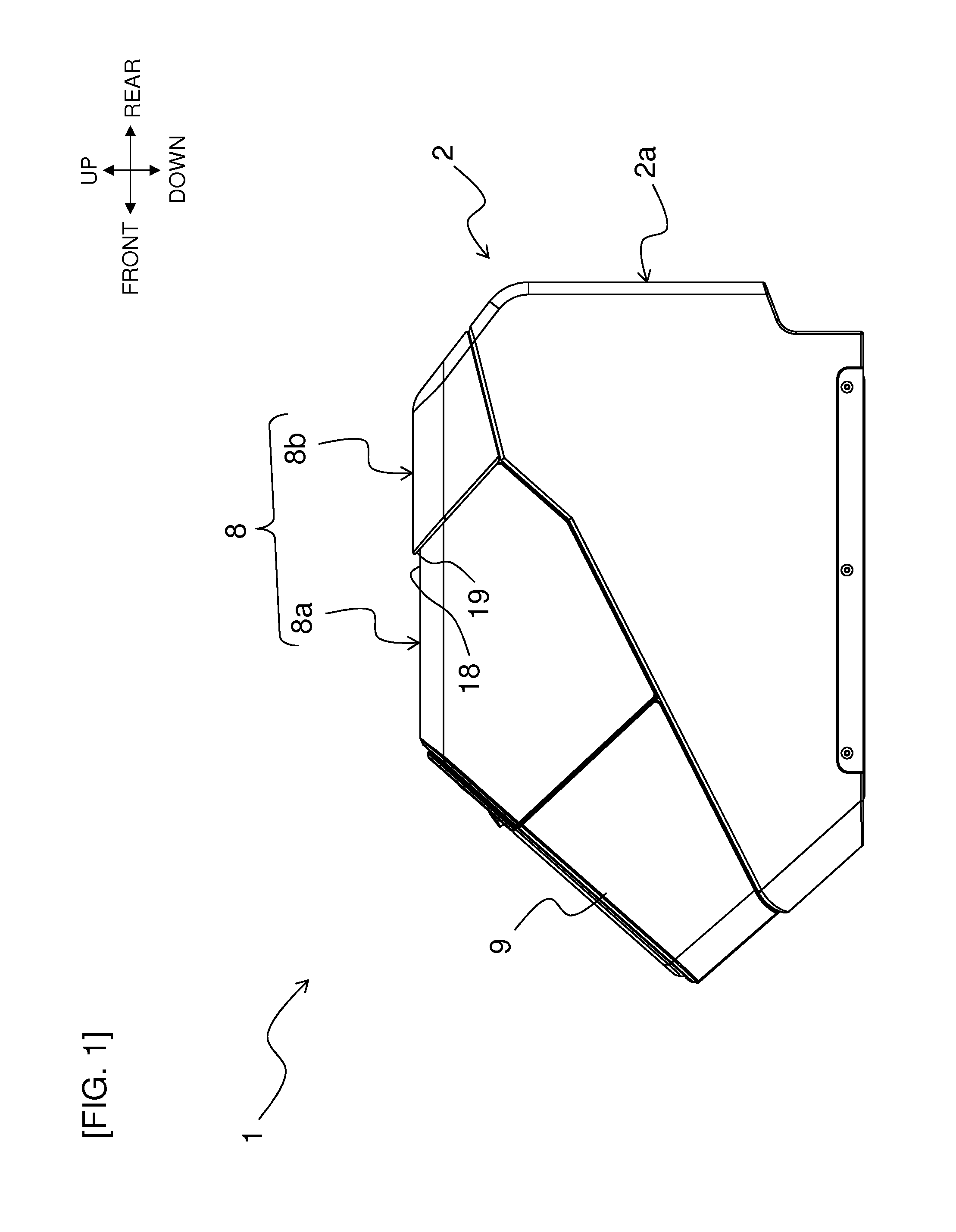

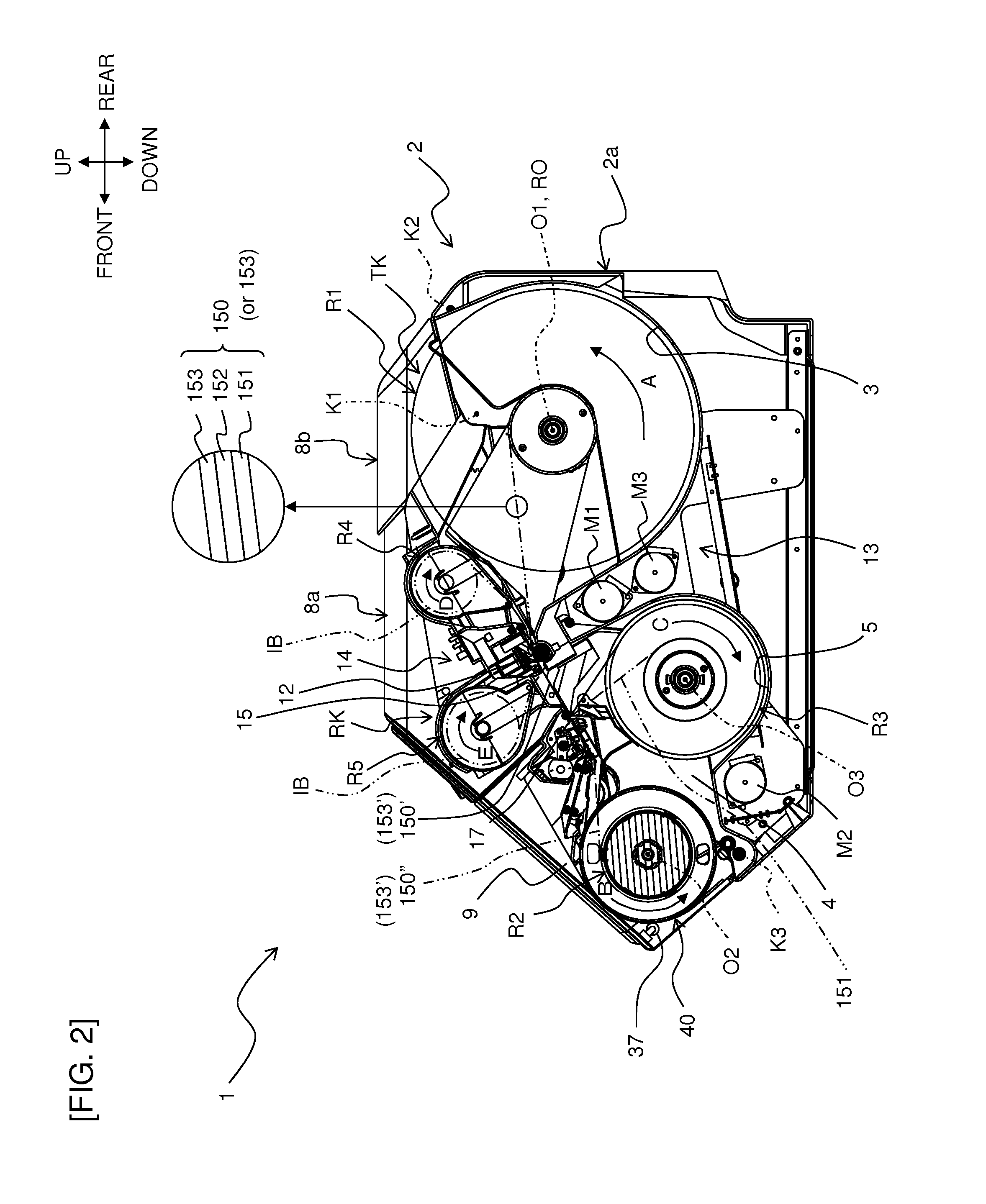

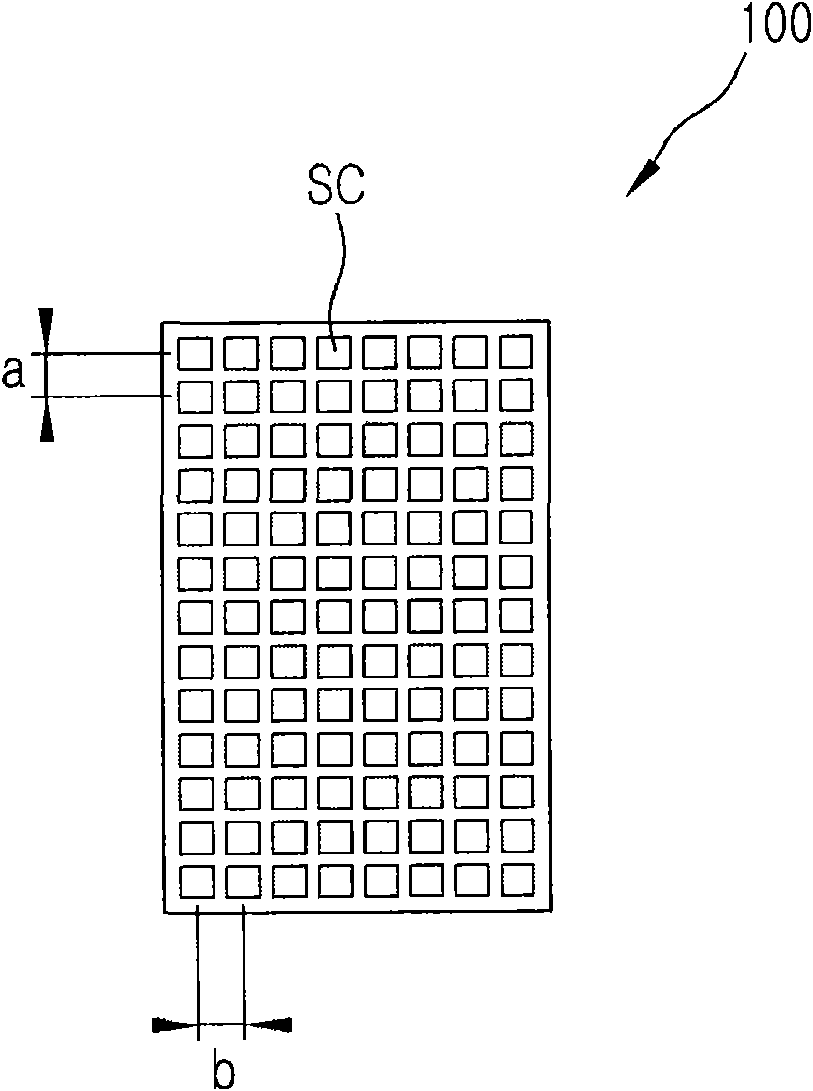

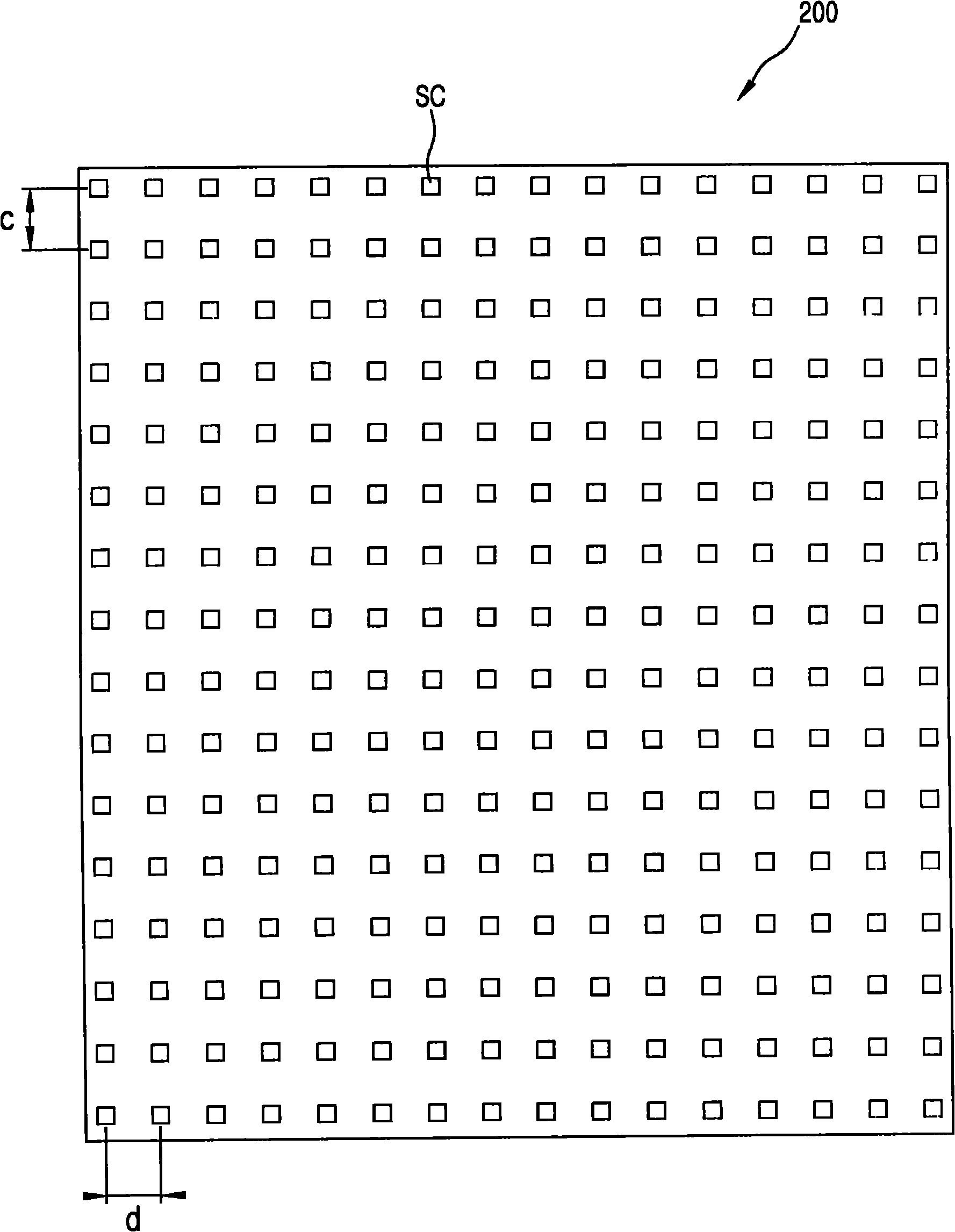

Recording Medium and Recorded Matter

ActiveUS20150037545A1Maintain continuityImprove aestheticsDecorative surface effectsDuplicating/marking methodsComputer scienceColumn space

The disclosure discloses a non-transitory computer-readable recording medium storing print data editing program. The program executes steps including a background patter print data generating, a disposition setting, and a disposition adjusting. In the disposition adjusting, at least one spacing adjustment of column spacing adjustment and row spacing adjustment is performed. The column spacing adjusts the column spacing so that a length of the sides parallel with the angle of inclination in the disposition adjustment region becomes an integer multiple of a total length of a length of the background pattern print data along the row direction and the column spacing. The row spacing adjustment adjusts the row spacing so that a length of the sides orthogonal to the angle of inclination becomes an integer multiple of a total length of a length of the background pattern print data along the column direction and the row spacing.

Owner:BROTHER KOGYO KK

Chromatography columns and their operation

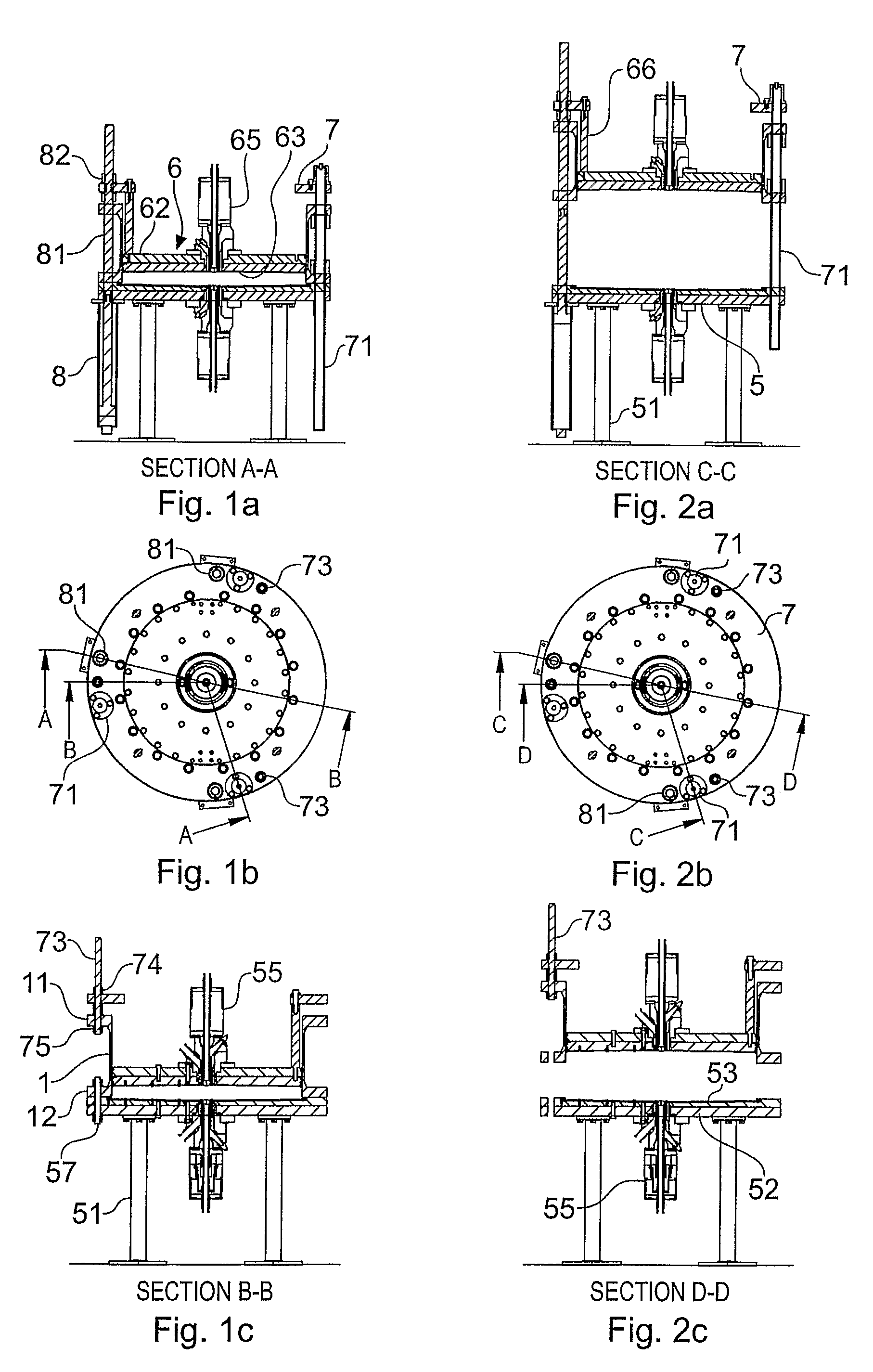

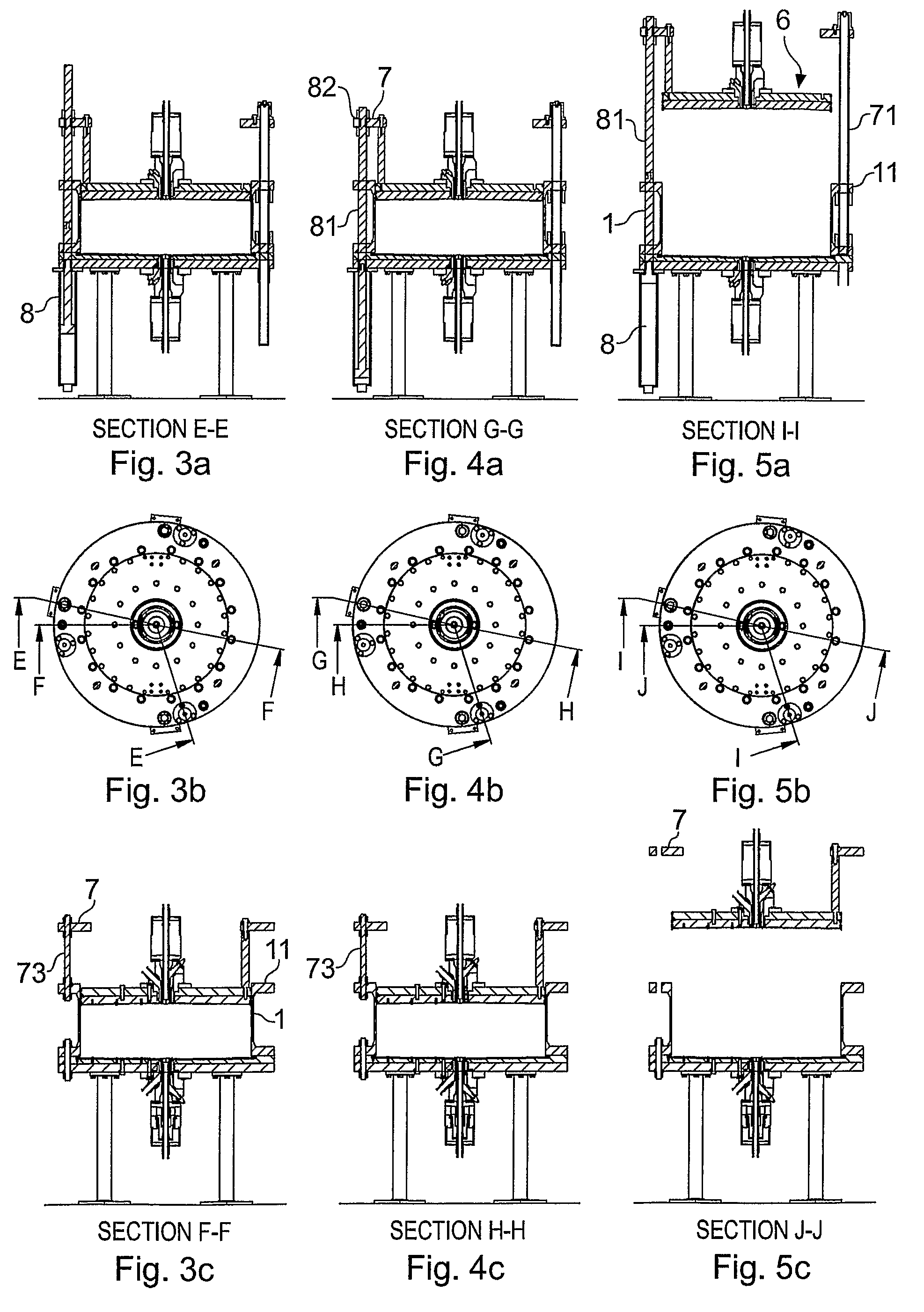

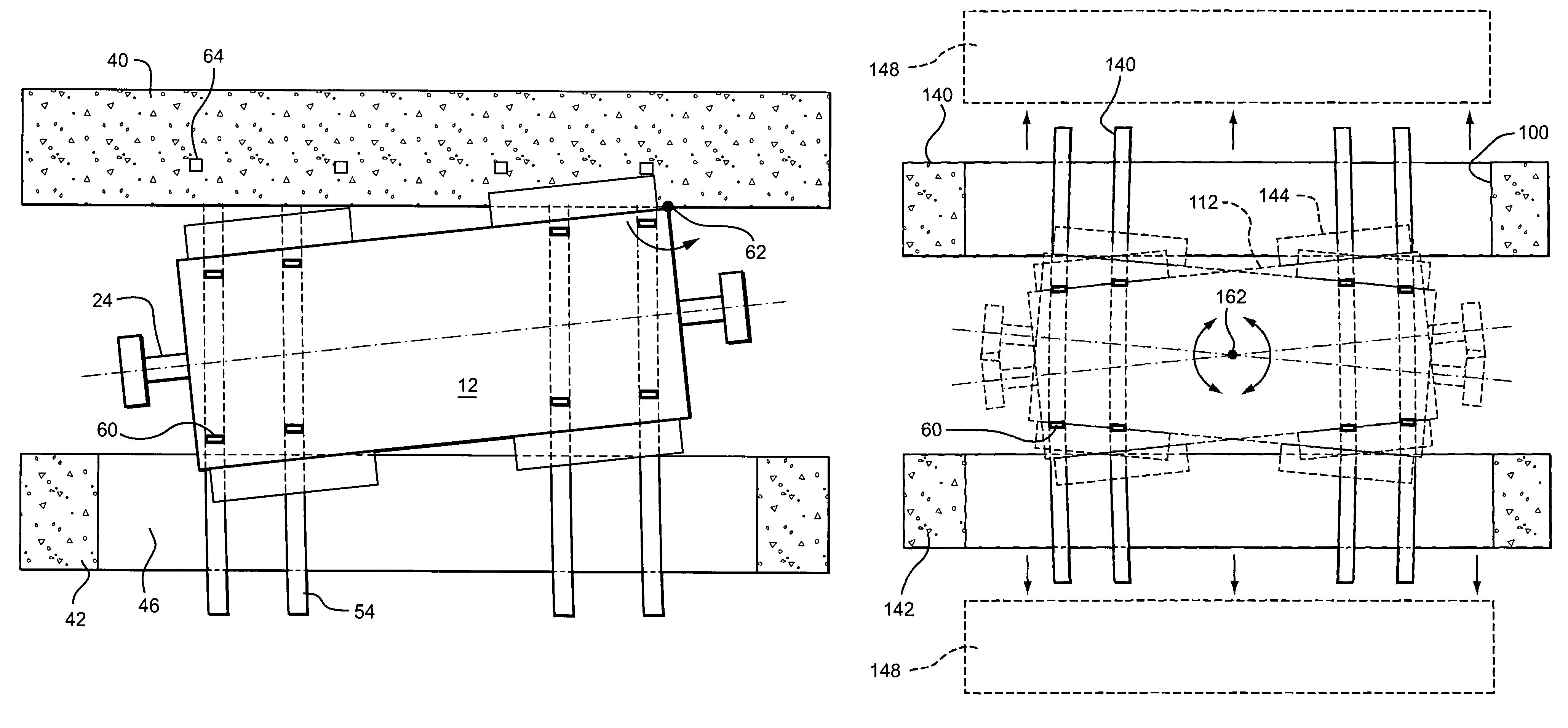

ActiveUS20070138098A1Simplifies drive connectionBulky and complicated and expensiveIon-exchange process apparatusComponent separationEngineeringChromatography column

A method of operating chromatography column apparatus comprising a column tube (101) and first and second discrete end cell structures, associated with the respective ends of the column tube and positionable to close off the column tube and define therein a column space for retaining chromatography medium in use of the apparatus. The first end cell portion comprises a piston portion (106) fitting slidably in the column tube. The column tube and the second end cell structure are separated to provide an access spacing between them. The piston portion (106) of the first end cell structure is advanced through the column tube to expose it at the open second end of the column tube, for maintenance of the piston portion thus exposed. Corresponding chromatography apparatus is another aspect of the disclosure.

Owner:SARTORIUS STEDIM CHROMATOGRAPHY SYST LTD

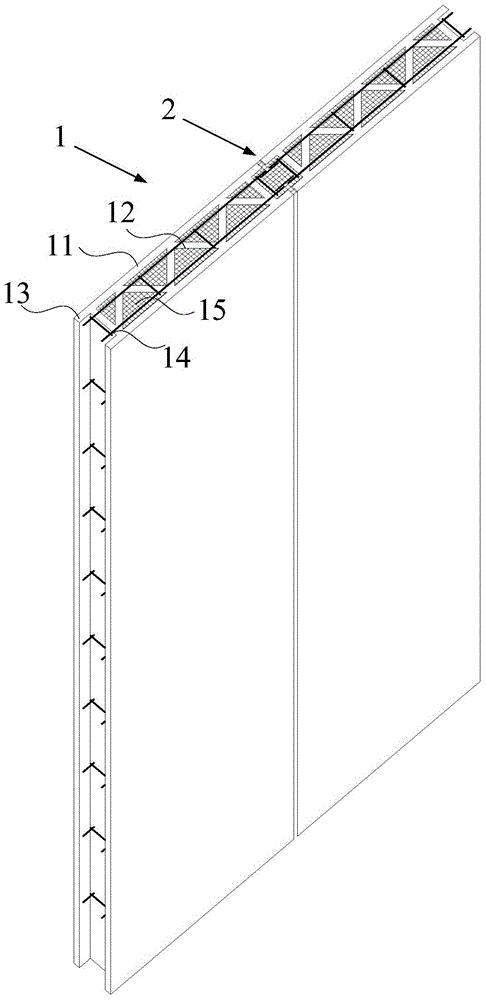

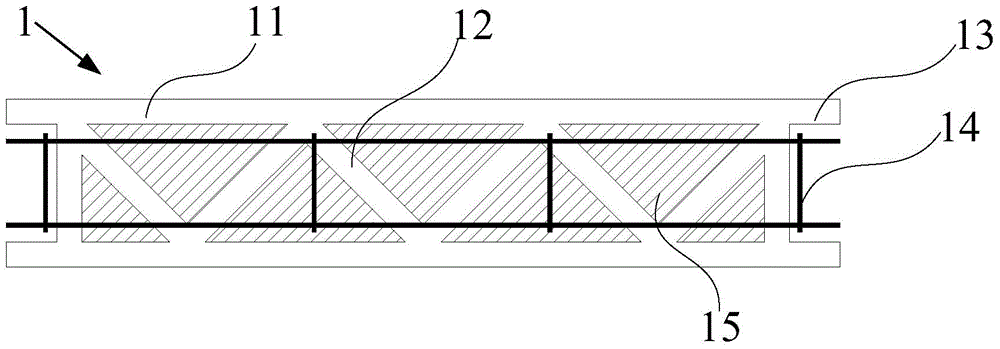

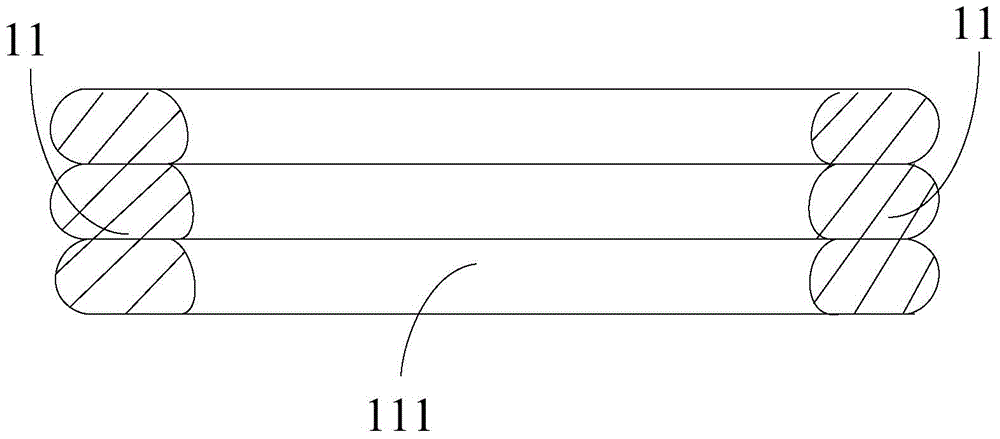

3D printing internal parting wall and construction method of 3D printing internal parting wall

The invention discloses a 3D printing internal parting wall and a construction method of the 3D printing internal parting wall. The 3D printing internal parting wall comprises a plurality of prefabricated internal parting wall units formed according to the 3D printing technology and arranged side by side, first packing materials arranged in the prefabricated internal parting wall units, steel wire gauze sheets arranged in column space and second packing materials arranged in the column space, wherein butt joint grooves are formed in the two ends of each prefabricated internal parting wall unit, and the column space is formed by butt joint of every two adjacent butt joint grooves. A truss system is applied to an internal parting wall system, overall printing molding is achieved through a 3D printing machine, and the building requirements of walls with special-shaped building models are met; meanwhile, the performance of 3D printing materials is sufficiently played, the automatic degree is high, a large amount of manpower and a large number of materials are saved, and building rubbish is not generated. Continuous concave-convex lines are formed on the surfaces of the prefabricated internal parting wall units; the connection strength between the prefabricated internal parting wall units and the packing materials is improved; compared with a smooth surface, the force of friction is improved, and the combination strength is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

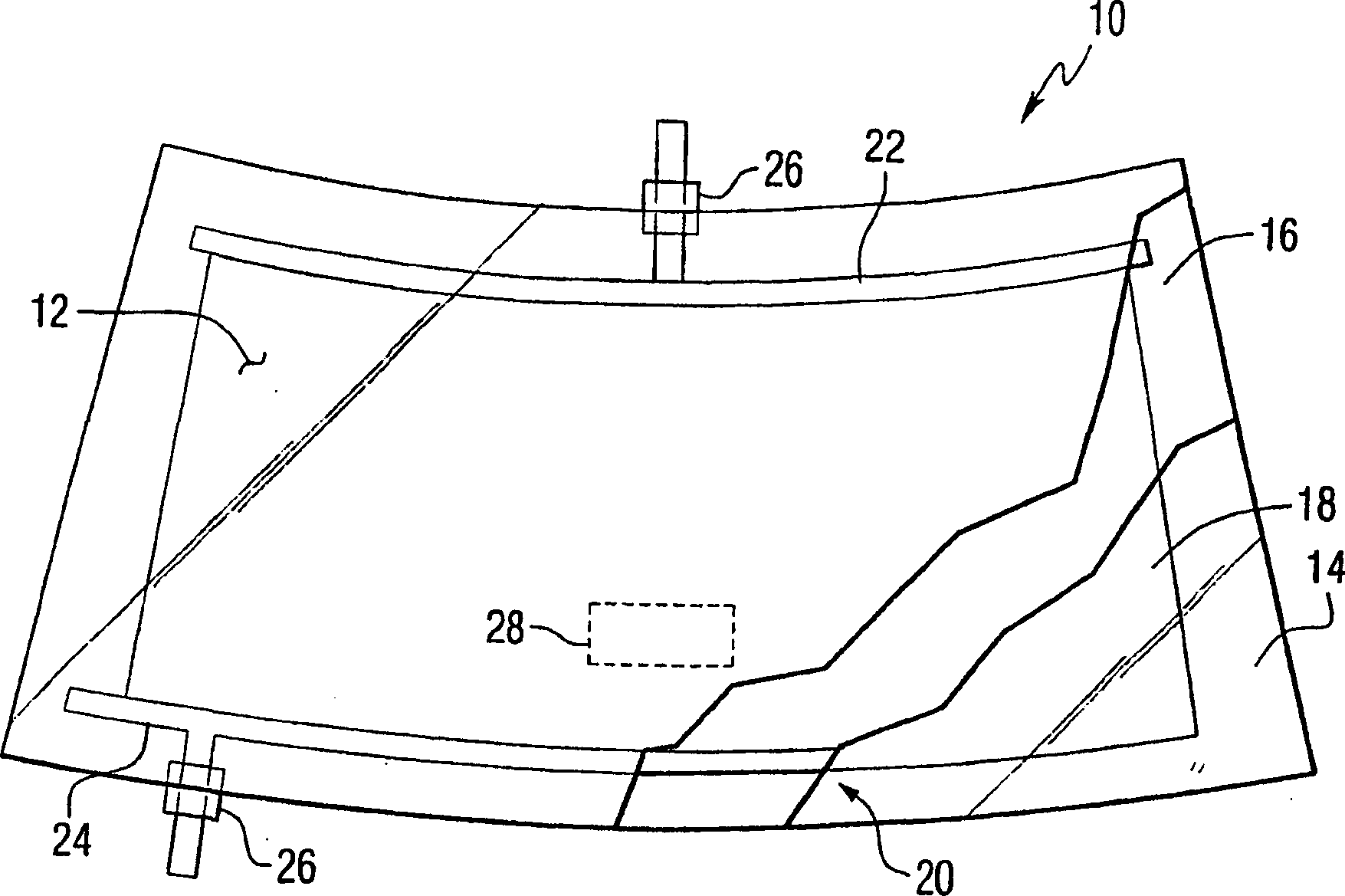

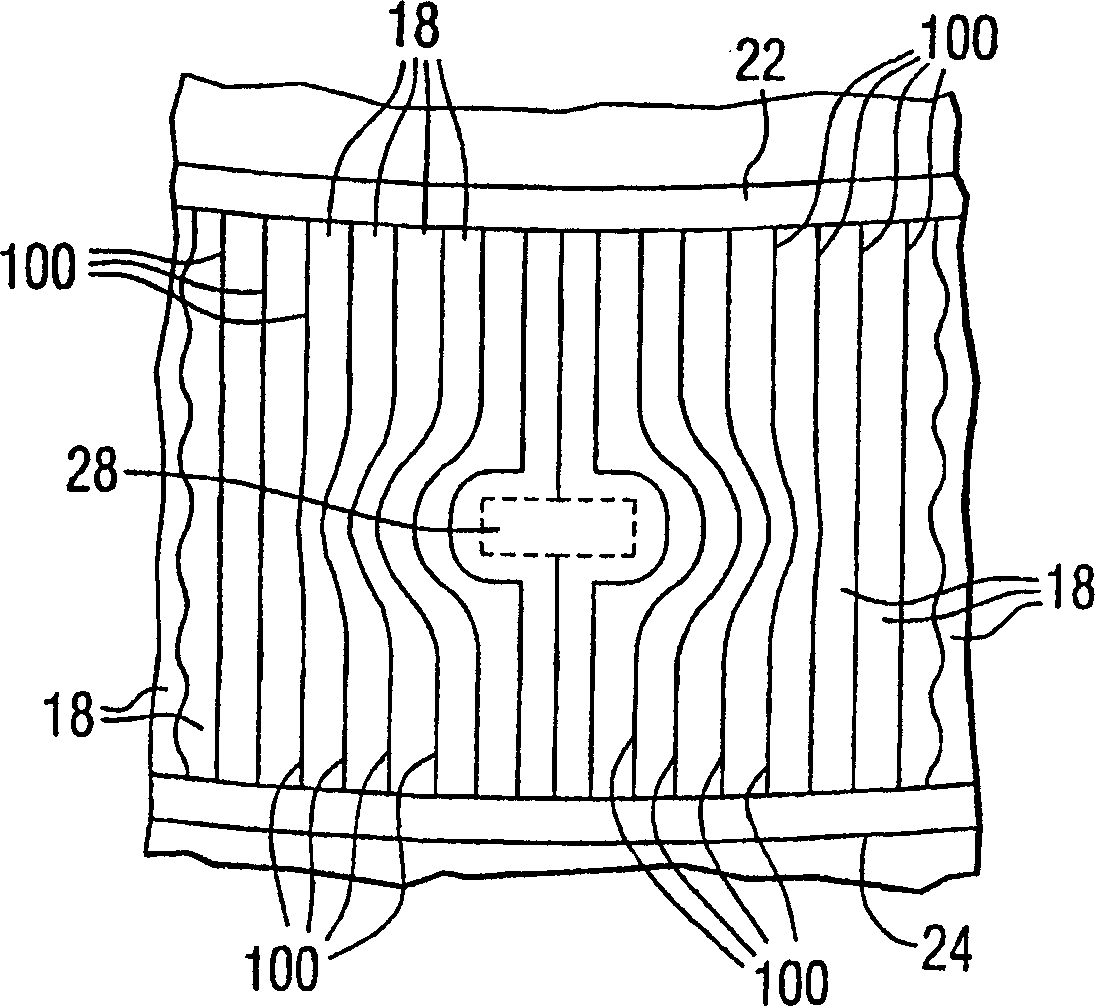

Conductive frequency selective surface utilizing arc and line elements

ActiveCN1784929AAntenna supports/mountingsTransparent/reflecting heating arrangementsElectromagnetic spectrumLength wave

An electrically conductive coating for an automotive heatable windshield having a communication window with an enhanced frequency selective surface having pass regions (uncoated regions) and blocking regions (coated regions) arranged to pass and Blocks predetermined wavelengths of the electromagnetic spectrum. In one non-limiting embodiment, the frequency selective surface includes a pattern having a first plurality of arcuate discontinuities on one side of the delimiting discontinuities, and a second plurality of arcuate discontinuities on the other side of the delimiting discontinuities. Multiple arc breaklines. Extended continuous barrier areas are between adjacent discontinuous lines. The arcuate discontinuities of one group are embedded within each other, and the arcuate discontinuity having the largest radius of curvature adjacently divides the discontinuity. Each discontinuous line has alternating blocking and passing regions. In another embodiment, the enhanced frequency selective surface has a plurality of columns separated from each other by continuously elongated blocking regions. Each column includes a pass area, and each pass area has a perimeter, and the block area is within and spaced from the perimeter. The perimeters of the pass regions are in contact with each other, and the barrier regions adjacent to the pass regions are spaced apart from each other. The elongated blocking area between the discontinuity and the column extends to the perimeter of the communication window. In this manner, current is passed through the coating, through the communication window to eliminate hot and cold spots around and within the perimeter of the communication window.

Owner:VITRO FLAT GLASS LLC

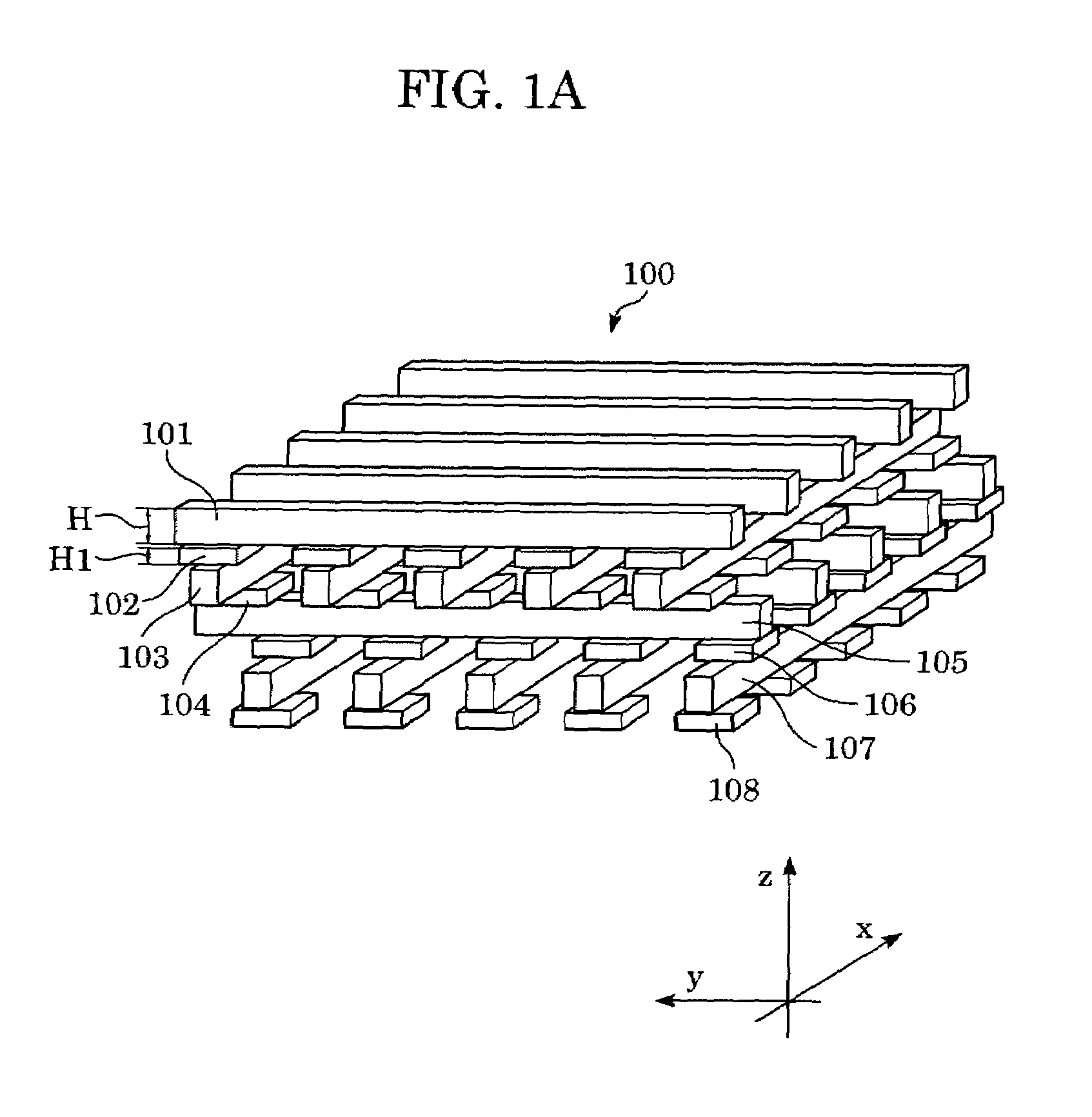

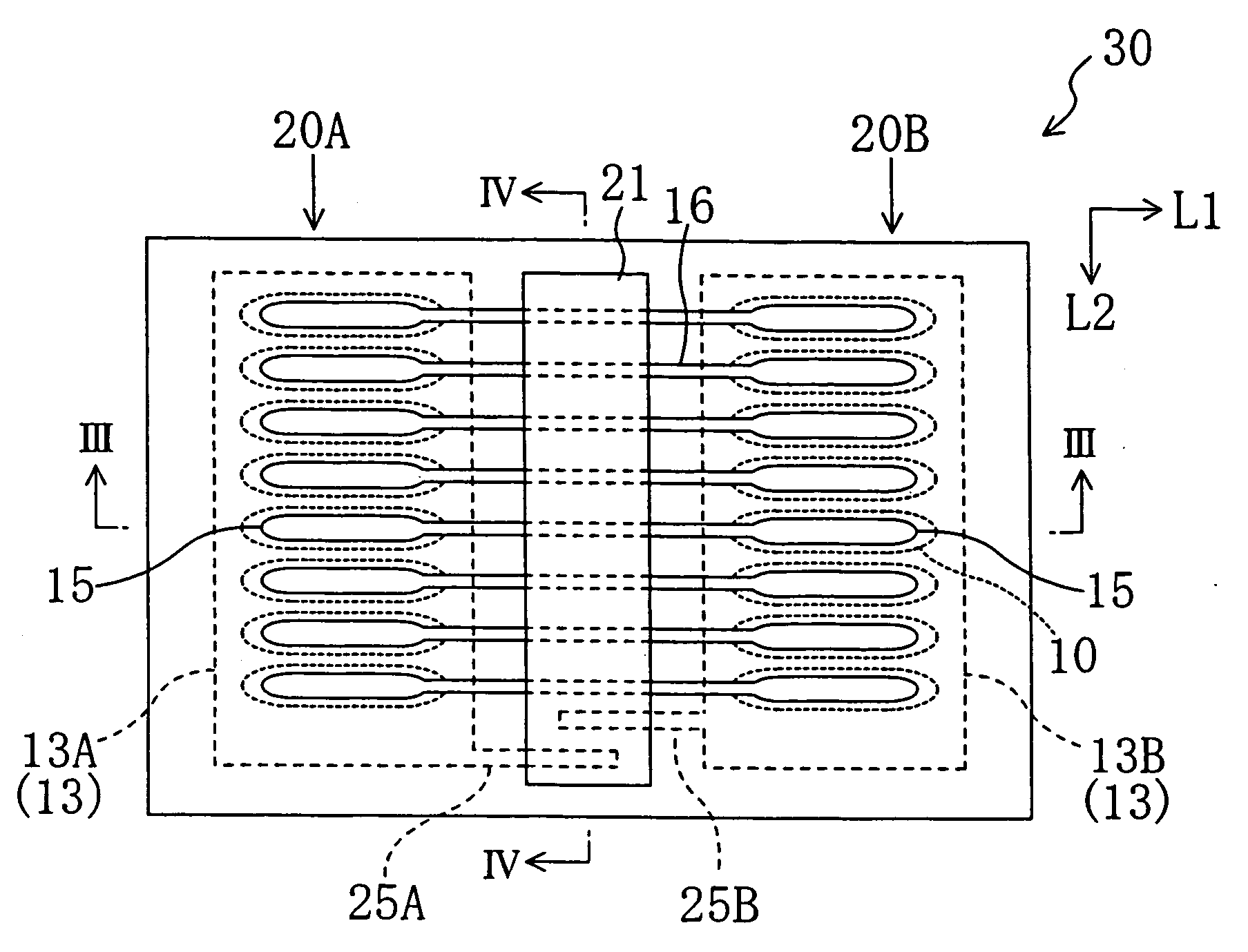

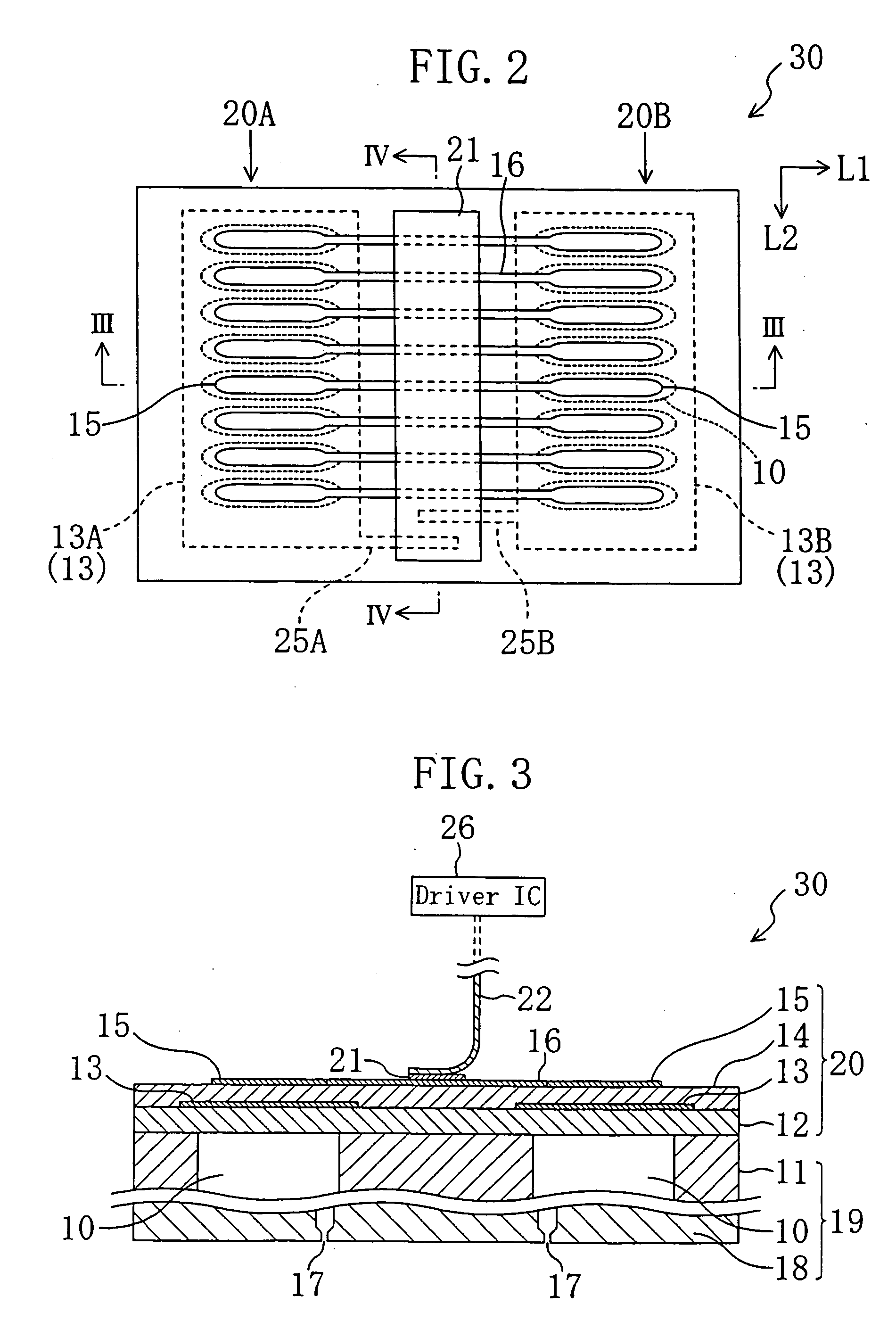

Ink jet head and ink jet recording apparatus

InactiveUS20050052492A1Reduce decreaseSuppress mutationOther printing apparatusPrintingElectricityEngineering

An ink jet head includes: actuators each including a scanning electrode, a piezoelectric element and a recording electrode and arranged in a matrix pattern of n rows by m columns (where n and m are natural numbers equal to or greater than two) in terms of electrical circuit; and a driving circuit for supplying a scanning signal to the scanning electrodes for each column, while supplying a recording signal to each row of the recording electrodes in synchronization with the scanning signal. The actuators are geometrically arranged in n rows by m columns. A relay terminal, extending in a vertical direction, is provided in at least one inter-column space between vertical columns of the actuators for relaying signals from the driving circuit to the recording electrodes and the scanning electrodes. The recording electrodes and the scanning electrodes are connected to the relay terminal via lead wires extending in a horizontal direction.

Owner:PANASONIC CORP

Three-dimensional periodic structure, functional element including the same, and light-emitting device

InactiveUS20050196118A1Easy to produceLaser optical resonator constructionNanoopticsPhotonicsLight emitting device

A three-dimensional periodic structure exhibiting a complete photonic band gap in a wide wavelength range and being readily produced, as well as a functional element including the same, is provided. In the three-dimensional periodic structure exhibiting a photonic band gap according to the present invention, layers composed of a plurality of square columns spaced apart by a predetermined interval are stacked sequentially with additional layers therebetween, rectangular parallelepipeds contained in the additional layers are disposed at the positions corresponding to the intersections of the square columns, and 1.21≦W1 / W≦2.39 and W / W1<W2 / W are satisfied, where W1 and W2 represent lengths of sides of the rectangular parallelepiped and W represents the width of the square column, each in a plane parallel to the layer containing the square columns.

Owner:CANON KK

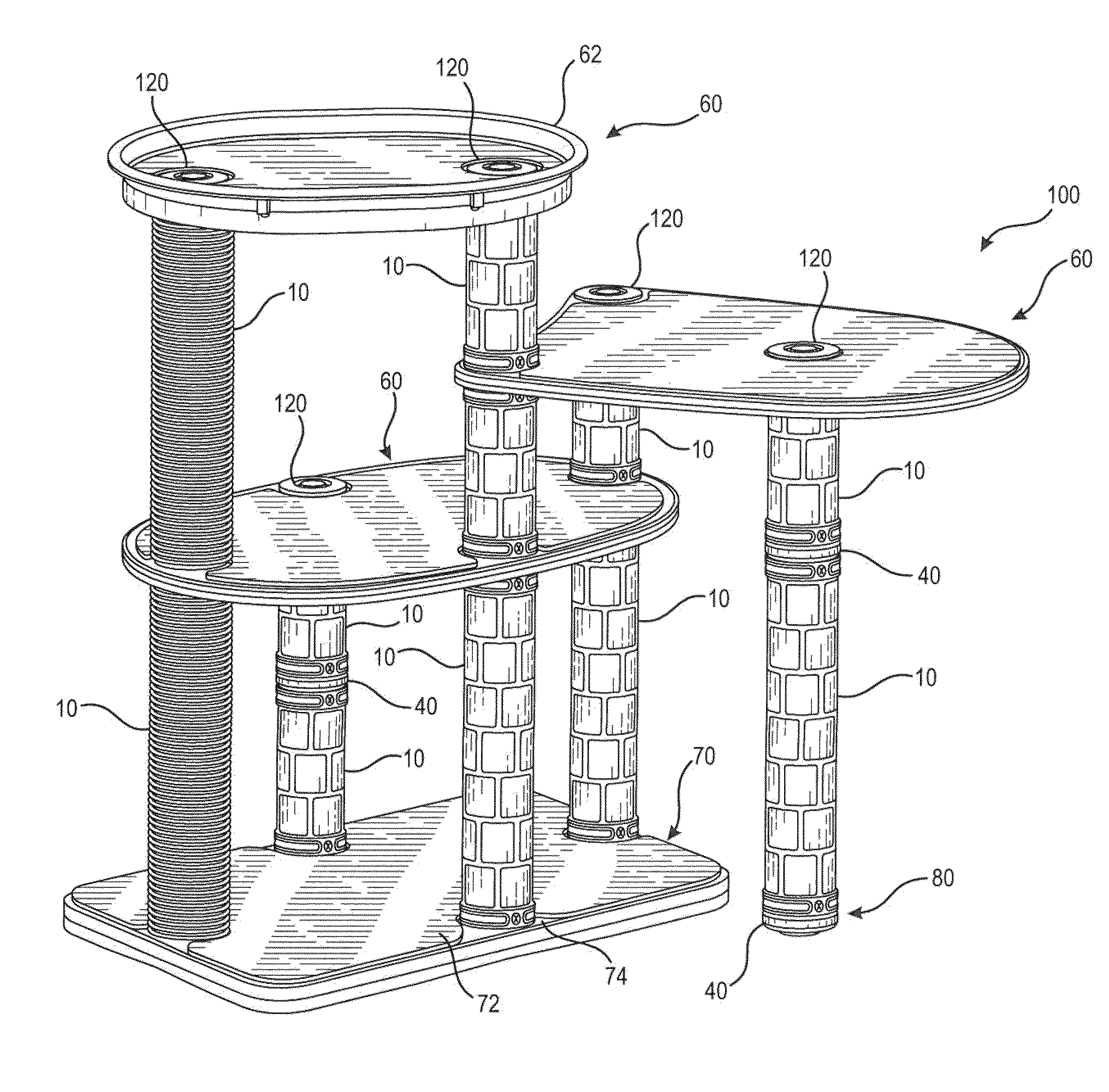

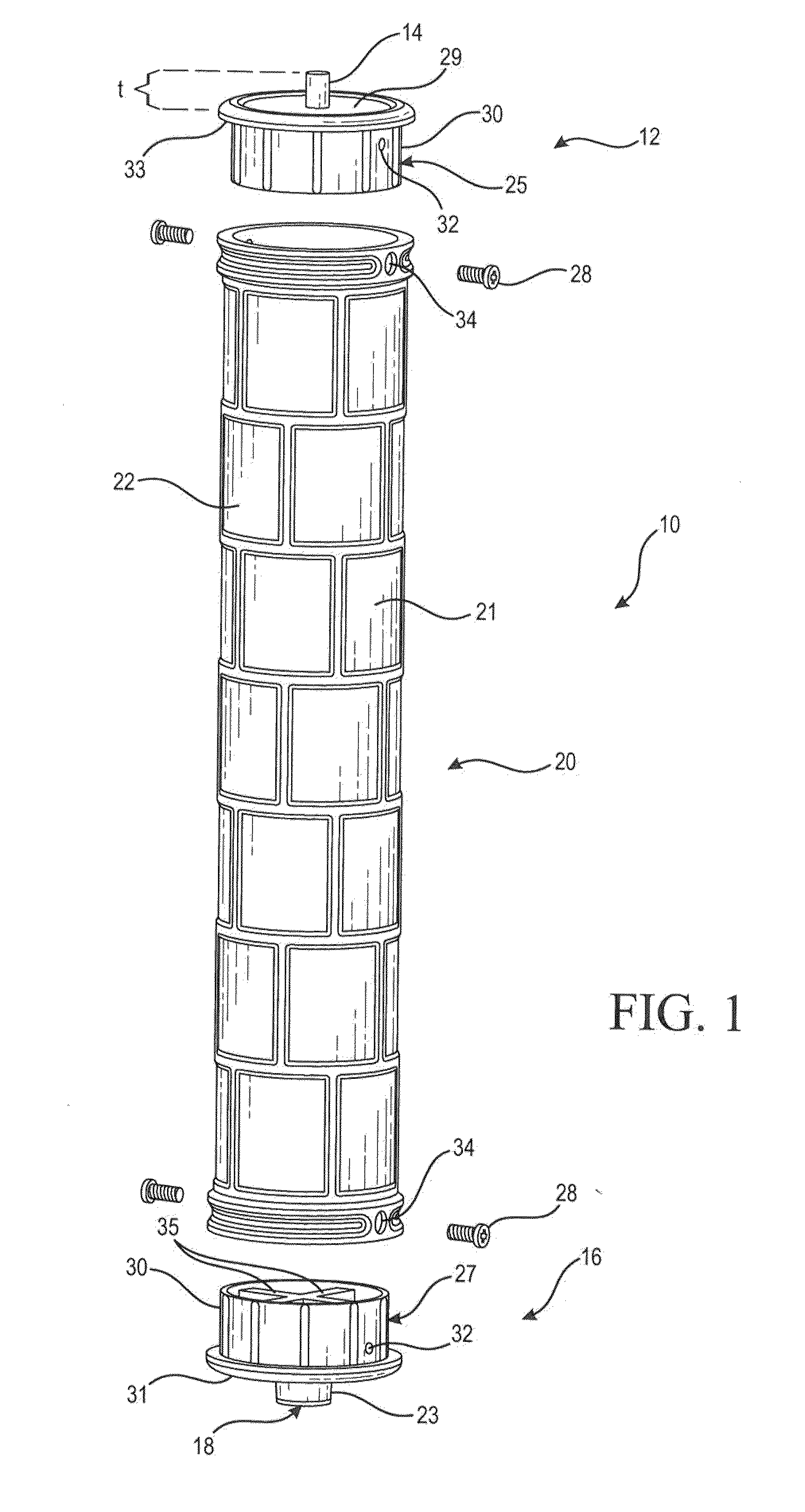

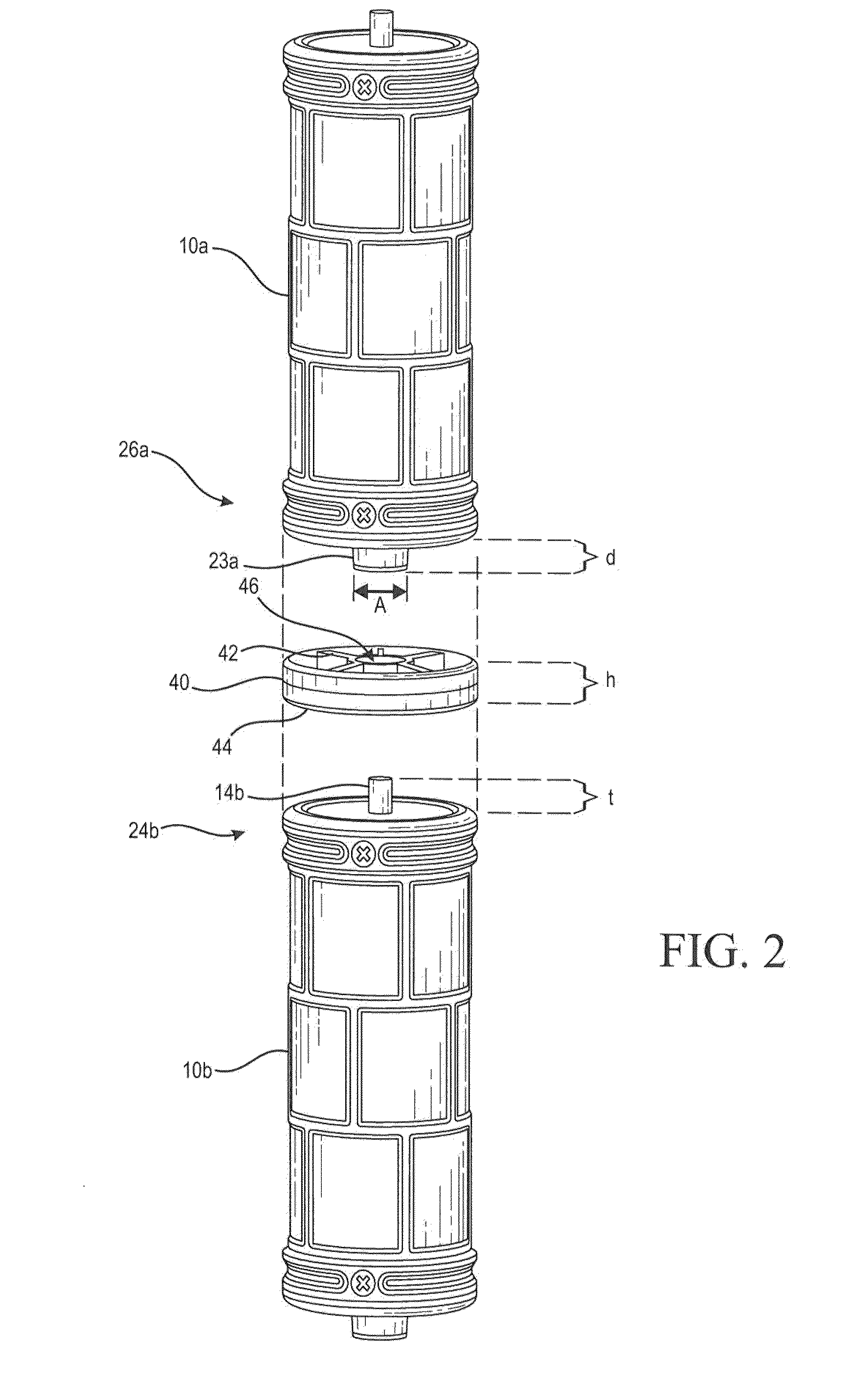

Modular animal exercise structure

A modular play structure for animals has base and platform pieces with connector mechanisms, such countersunk bores, spaced apart by a standard distance. Thus platforms and bases can be oriented in multiple directions and are interchangeable. Columns space the bases and platforms vertically. Columns may be of varying height, preferably with different heights described by a common factor. Stacked columns are connected end-to-end with a spacer of the same thickness as a platform interposed therebetween. Columns are oriented in the same direction with female and male ends connecting with platform, base, and adjacent columns.

Owner:SOLV IT PROD

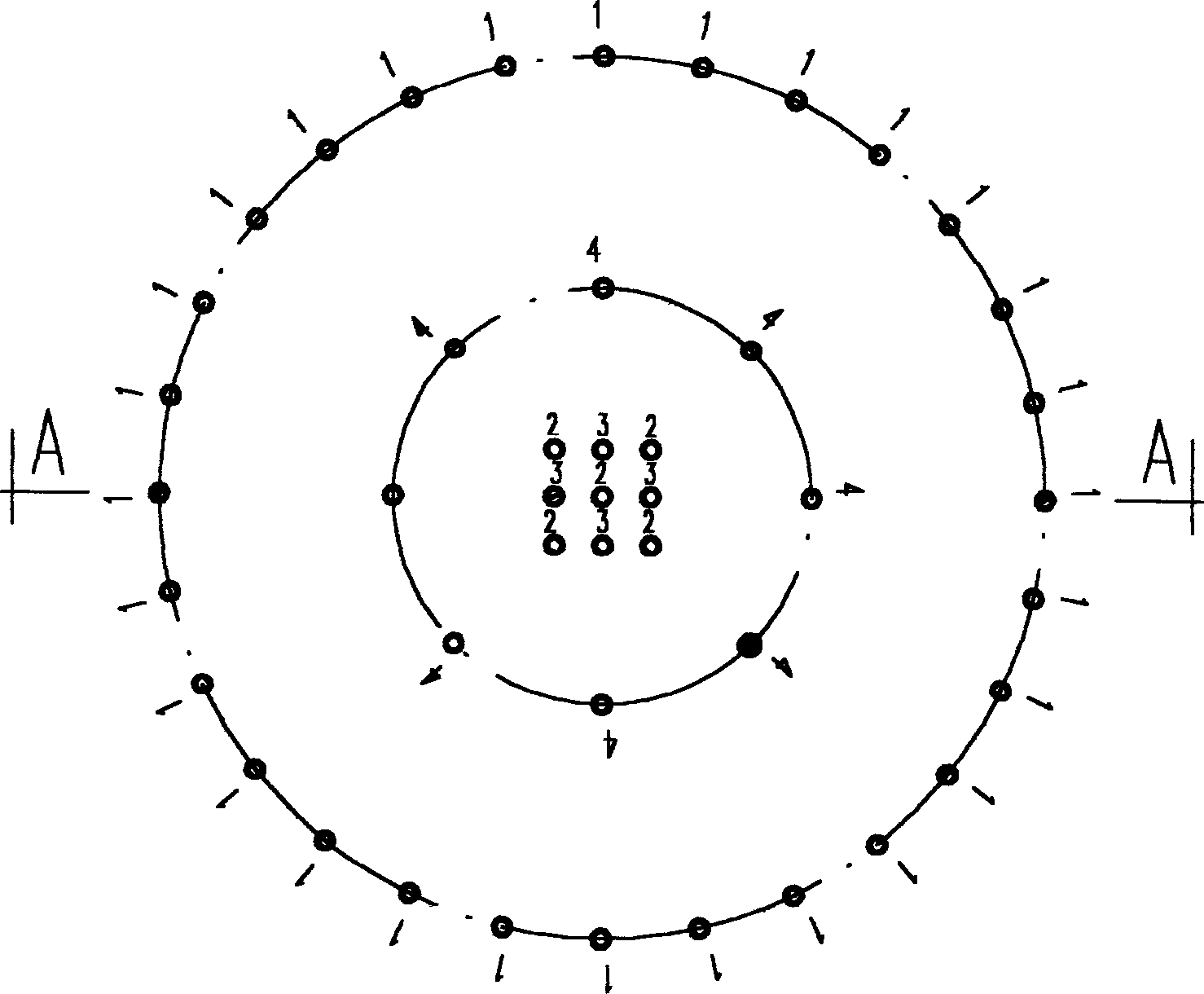

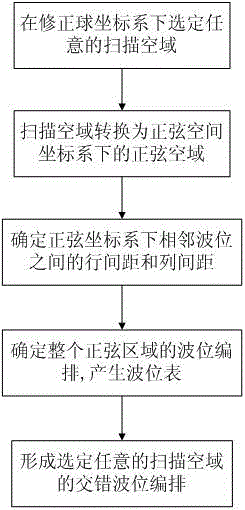

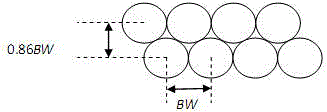

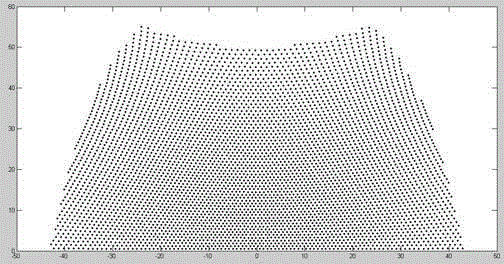

Airspace staggered wave position arranging method for phased array radar

InactiveCN104316907AUniform arrangement modeAvoid variabilityWave based measurement systemsRadarOverlap ratio

The invention discloses an airspace staggered wave position arranging method for a phased array radar. The airspace staggered wave position arranging method for the phased array radar includes steps that 1) selecting a scanning airspace under a correction ball coordinate system; 2) converting the scanning airspace under the correction ball coordinate system into a sine airspace under a sine space coordinate system through coordinates; 3) confirming the line space and column space between adjacent wave positions under the sine coordinate system; 4) confirming the wave position arrangement of the whole sine region to generate a wave position table; 5) removing the wave positions outside the airspace range set by a user to form the staggered wave position arrangement of the scanning airspace. The airspace staggered wave position arranging method for the phased array radar uses the sine coordinate system to carry out wave position arrangement on the whole airspace based on covering the required airspace, avoids the change of the wave beam shape along with the wave beam directing, realizes the uniform arrangement of the wave position under the sine coordinate system, guarantees that the 3 dB coverage rate arrives at 90% while the overlapping ratio is 0, and has broad application prospect.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

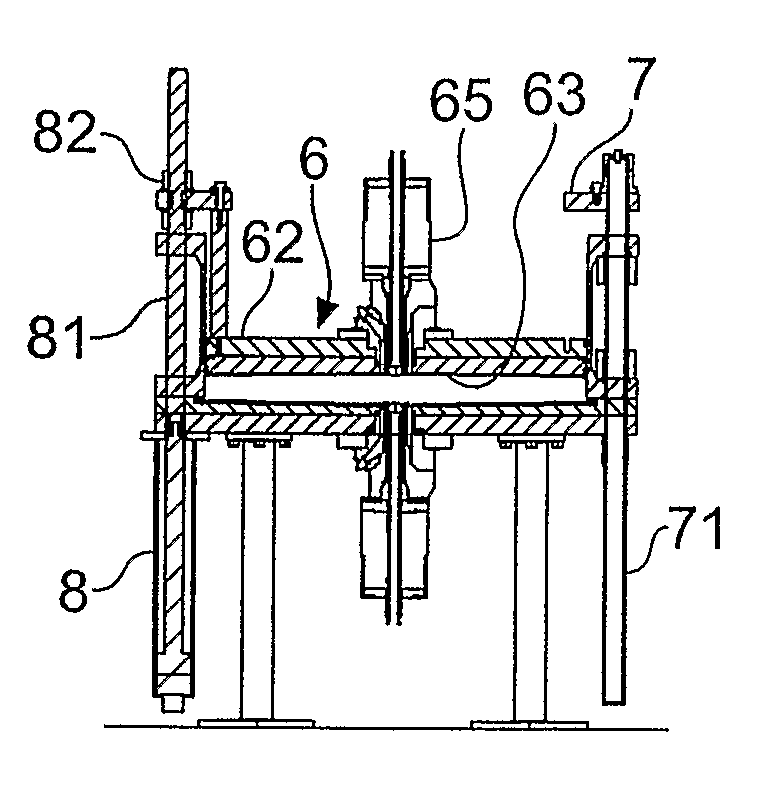

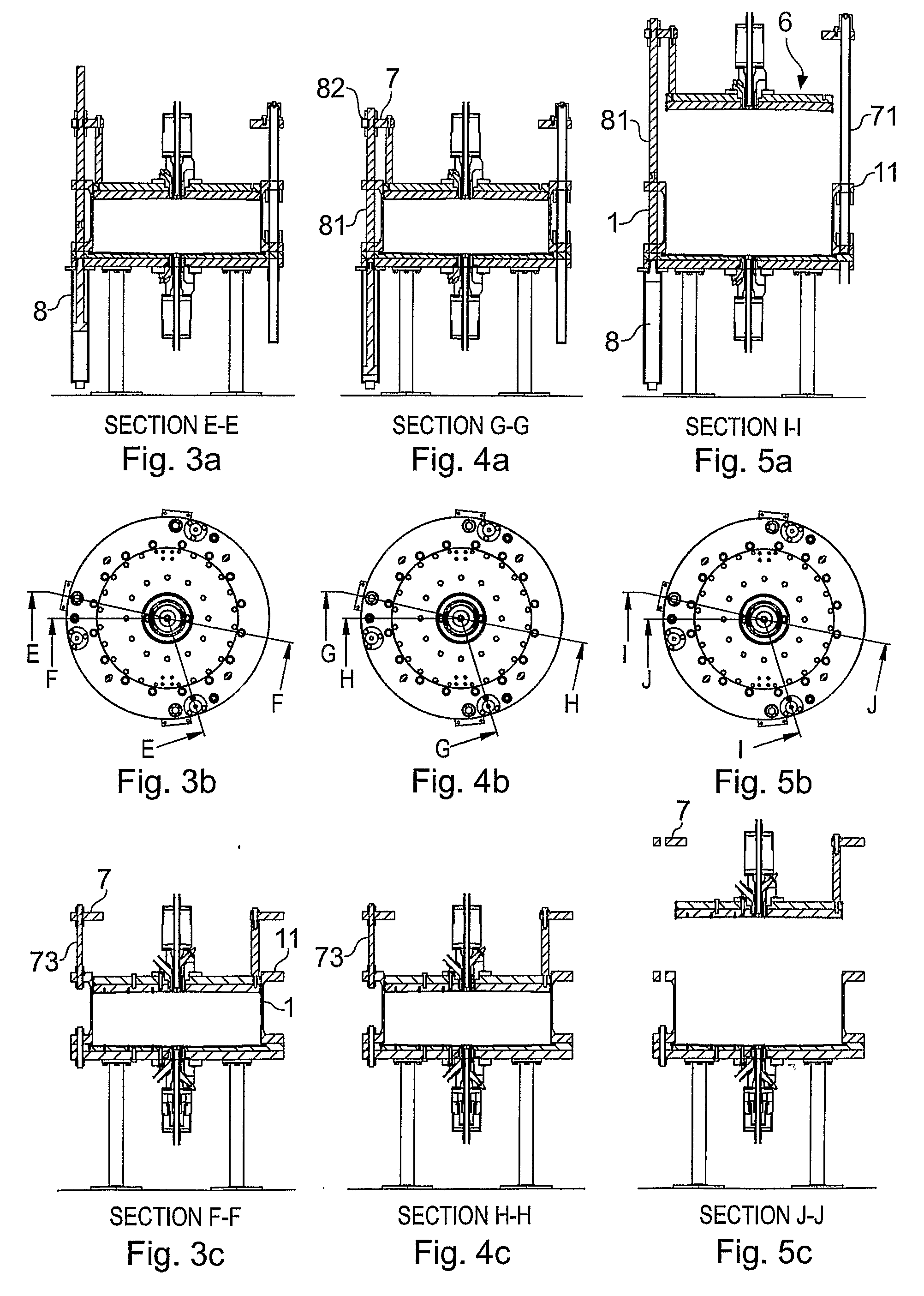

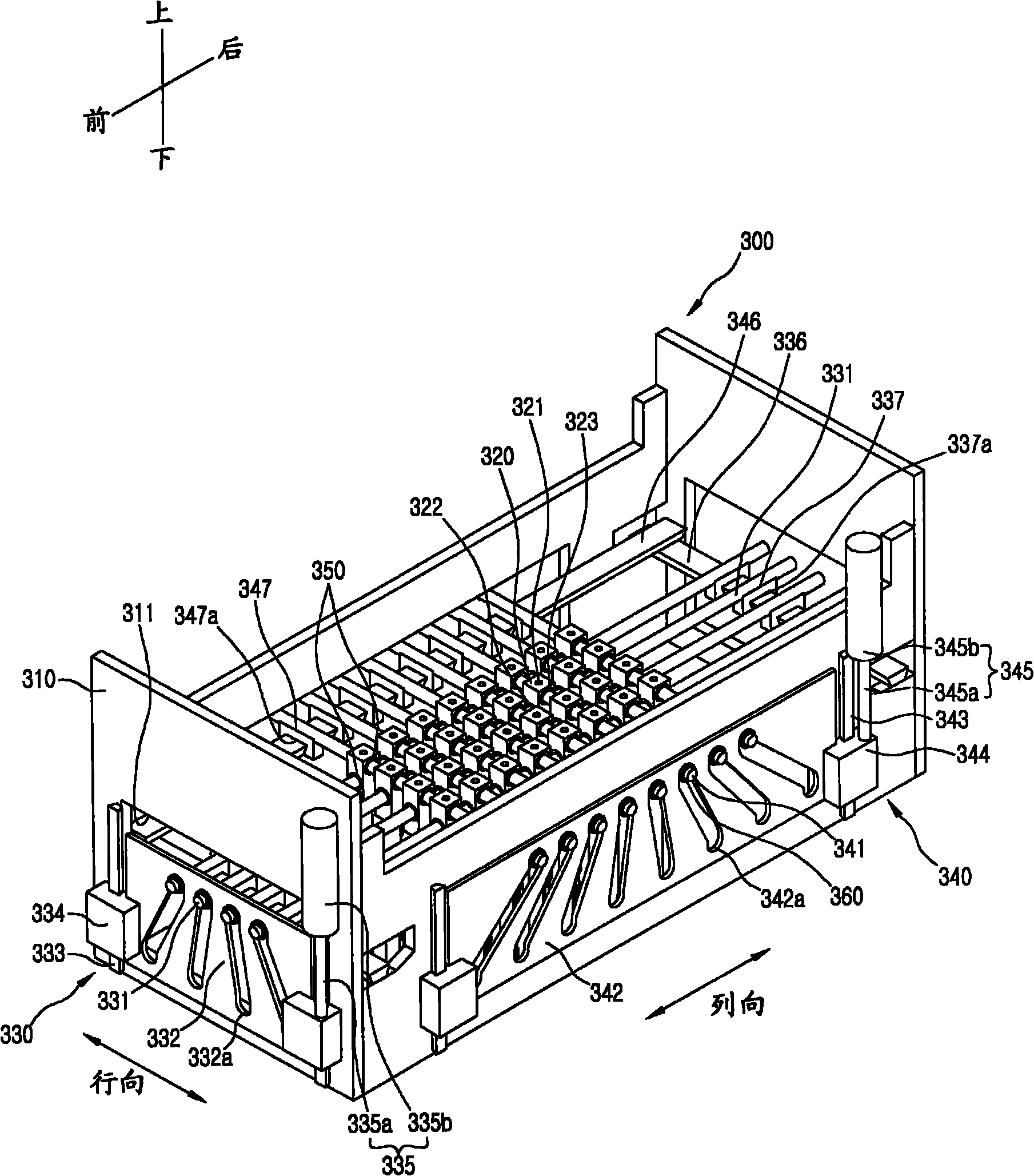

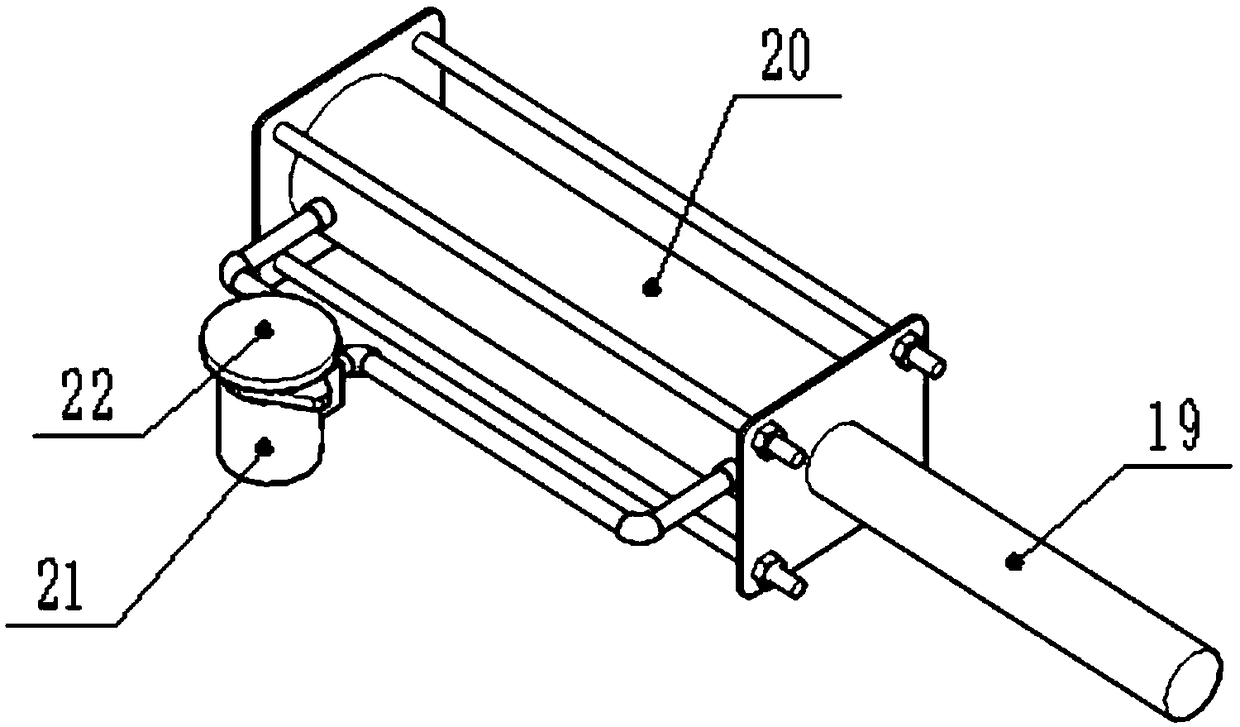

Picking and placing device of test sorting machine

ActiveCN101767095ASimple compositionReduce in quantitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufacturing cost reductionEngineering

The present invention discloses a picking and placing device of a test sorting machine. The picking and placing device comprises a pick-up device that is arranged in a state of multiplying N rows by M columns, wherein, the N and M are respectively natural numbers that is bigger than or equal to 2, a line spacing adjusting device for leading the moving of the pick-up device in the column direction and adjusting the row spacing of the pick-up device, a column spacing adjusting device for leading the moving of the pick-up device in the row direction and adjusting the column spacing of the pick-up device. The present invention has advantages of simplifying the structure of a picking and placing device, reducing the cost of manufacture and improving the speed of transferring a semiconductor component from a user tray to a test tray.

Owner:TECHWING CO LTD

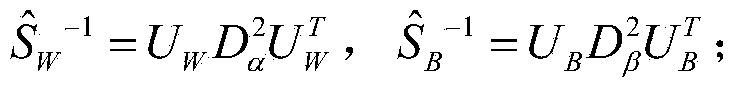

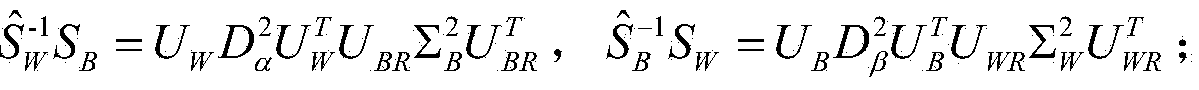

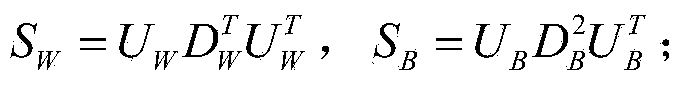

Human face feature extraction and classification method

ActiveCN103902979AStrong characteristicEliminate weaknessesCharacter and pattern recognitionFeature vectorFeature Dimension

The invention relates to a human face feature extraction and classification method. The method includes the following steps that feature dimension reduction is performed on human face images through a 2D-PCA method, and a high-dimensional image matrix is converted into a low-dimensional image matrix; the low-dimensional image matrix is converted into one-dimensional column vectors; according to the one-dimensional vectors of images of a training set, an intra-class divergence matrix S<W> and an inter-class divergence matrix S in the training set are solved, and eigenvalue decomposition is performed on the S<W> and the S respectively, wherein the eigenvalue decomposition formulae are as follows: and ; D<alpha> is used for estimating , D<beta> is used for estimating , and the formulae and can be obtained; the column space W<1> of and the column space W<2> of are respectively solved, and the optimum projection space W=[W<1>,W<2>] of a feature extraction algorithm with two stages of LDA based on 2D-PCA is obtained; the low-dimensional image matrix in the first step is projected into the optimum projection space W, and then feature vectors of the images are obtained; classifier training is performed on the feature vectors obtained in the sixth step through an SVM+NDA model, and a final human face classifier is obtained.

Owner:ZHEJIANG UNIV

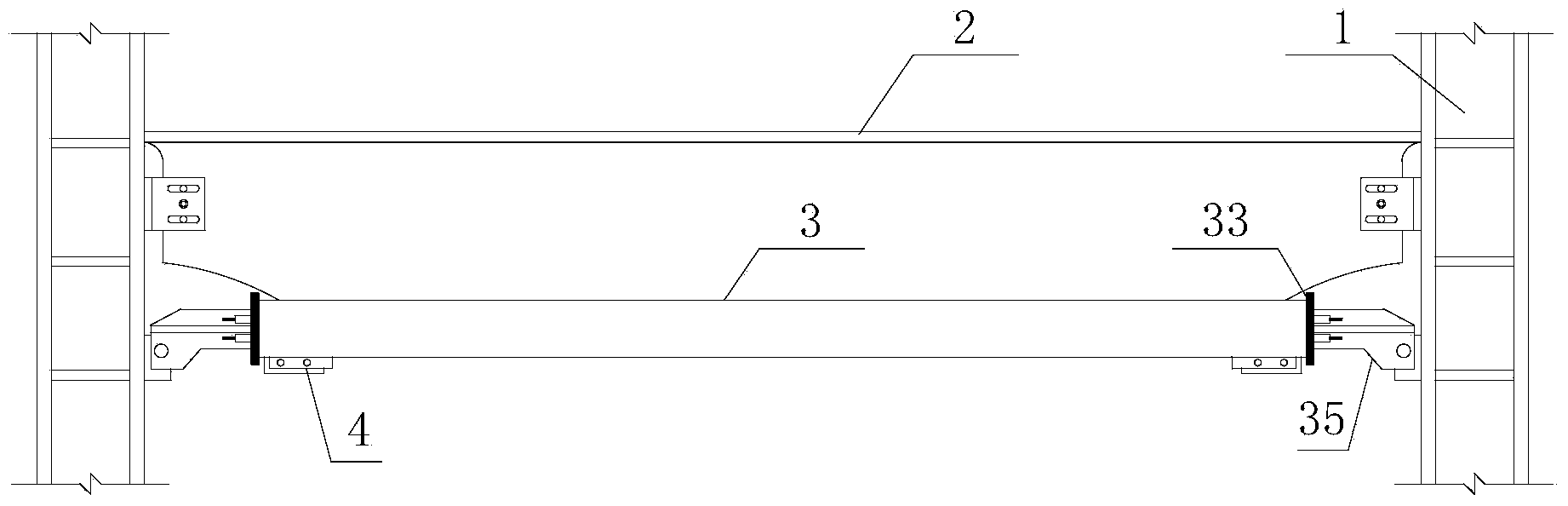

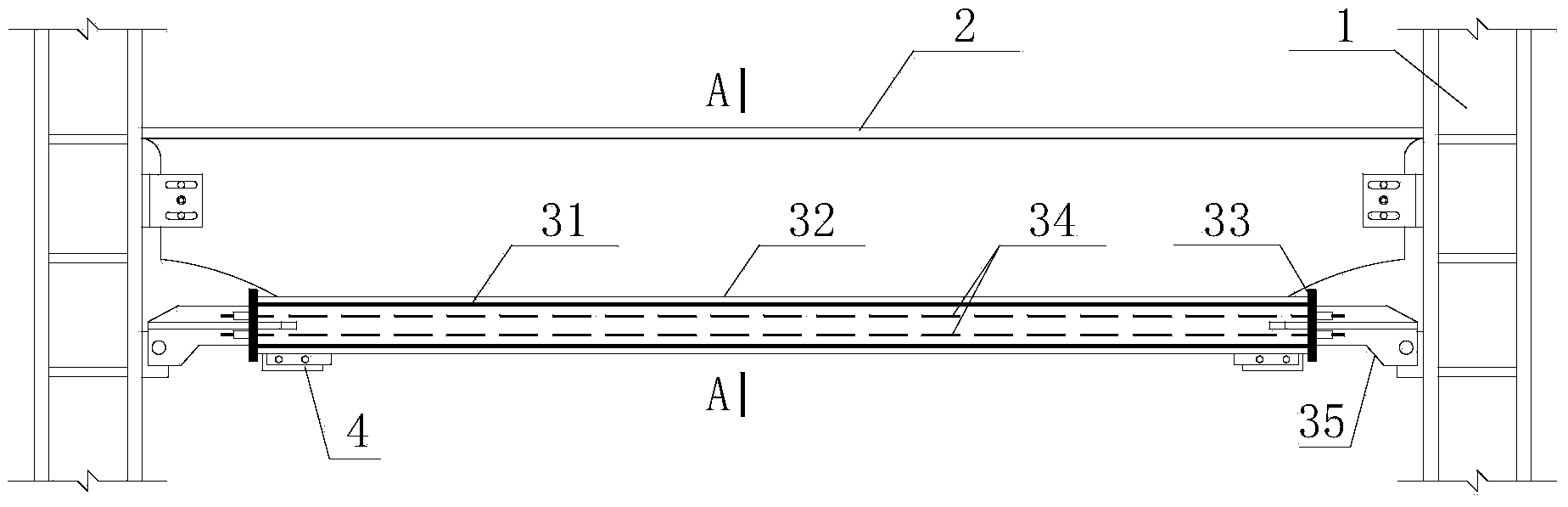

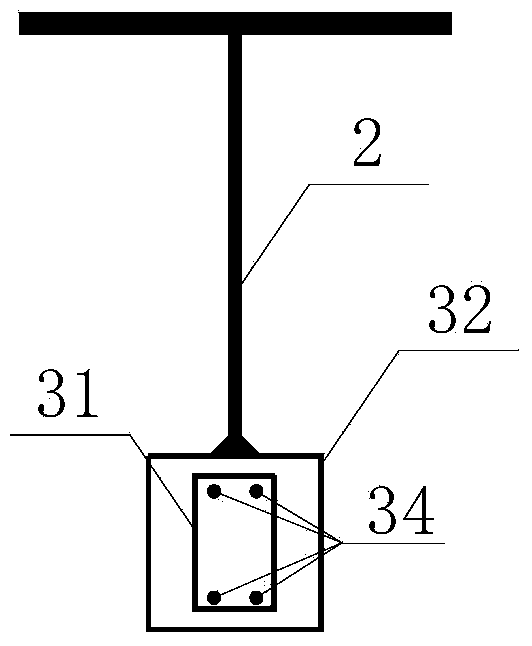

Post-tensioning prestress type self-centering steel frame structure

The invention discloses a post-tensioning prestress type self-centering steel frame structure. The post-tensioning prestress type self-centering steel frame structure comprises at least one structural unit. Each structural unit comprises two steel frame columns, a T-shaped steel beam, a self-centering connecting piece and friction energy consumption parts, wherein the T-shaped steel beam is used for connecting the upper ends of the steel frame columns, the self-centering connecting piece is located on the lower side of the T-shaped steel beam and used for connecting the steel frame columns, and the friction energy consumption parts are located on the lower portion of the self-centering connecting piece. Each self-centering connecting piece comprises an inner sleeve, an outer sleeve, end plates, pretensioning rods and connectors, wherein the inner sleeve is sleeved with the outer sleeve, the end plates are located at the two ends of the sleeves, the pretensioning rods are arranged in the inner sleeve and anchored on the end plates, and the connectors are connected with the ends of the inner sleeve. Each friction energy consumption part comprises an inner friction plate, an outer friction plate and a friction gasket, wherein the inner friction plate is connected with the inner sleeve, the outer friction plate is connected with the lower side face of the outer sleeve, the friction gasket is arranged between the inner friction plate and the outer friction plate, and the sliding direction of the inner friction plate and the sliding direction of the outer friction plate are arranged in the axial direction of the outer sleeve. Column space is kept unchanged when the columns are laterally deformed, and the strength, the rigidity and the ductility of the structure can be flexibly and independently adjusted and controlled in the design process.

Owner:SOUTHEAST UNIV

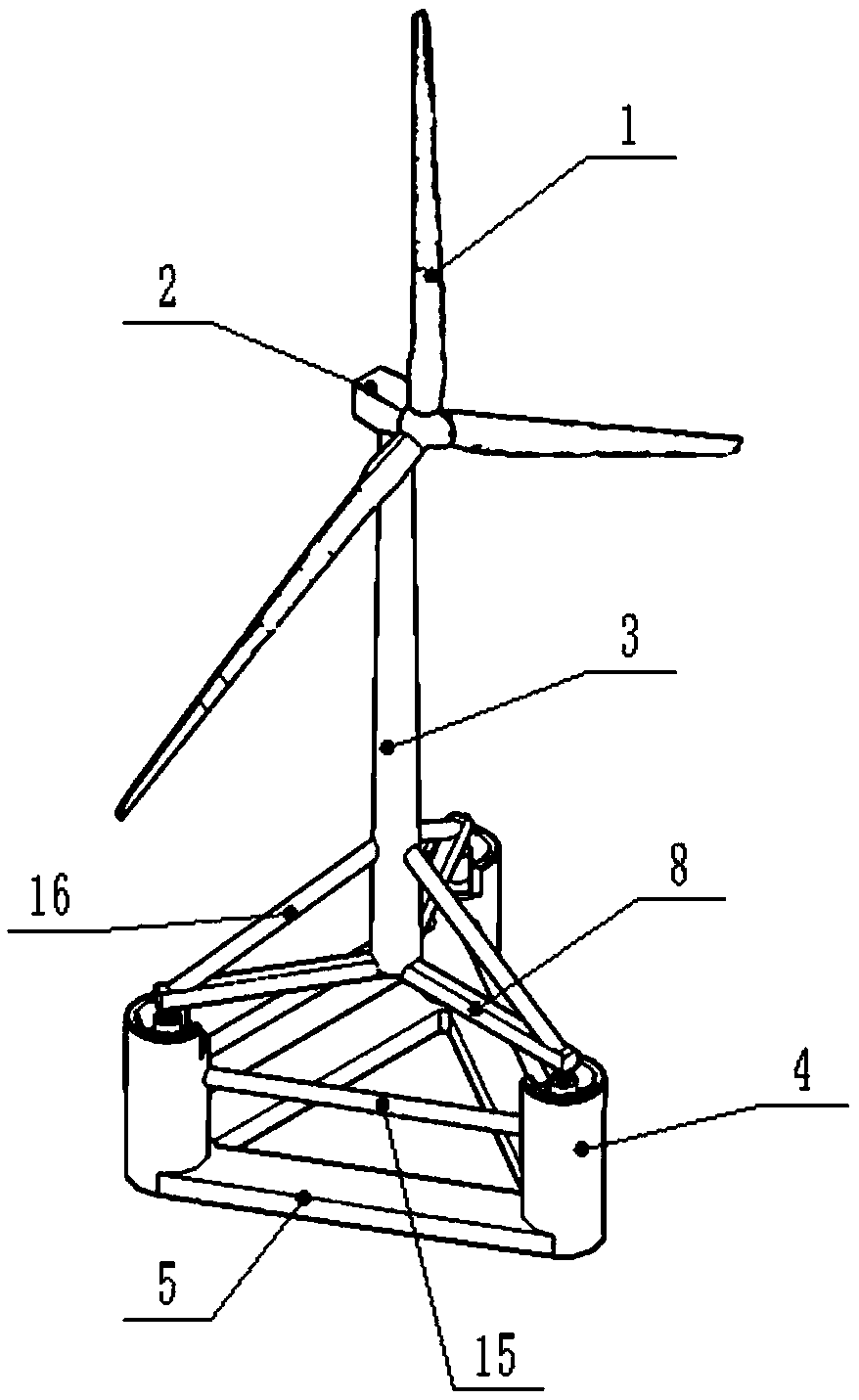

Novel energy drawing-shock absorbing deep sea wind power generating floating type semi-submersible platform

PendingCN109441733AGuaranteed uptimeThe damping coefficient is continuously adjustableWind energy with electric storageWind motor supports/mountsFatigue damageEngineering

The invention relates to the field of offshore wind power generation, in particular to a novel energy drawing-shock absorbing deep sea wind power generating floating type semi-submersible platform. The novel energy drawing-shock absorbing deep sea wind power generating floating type semi-submersible platform comprises a draught fan blade, a draught fan, a tower barrel and a semi-submersible platform body; the semi-submersible platform body comprises three floating barrels and a triangular floating box; and a wave energy drawing-shock absorbing system is installed in the floating barrels and comprises a power generator, an inertia container, a return spring and a plurality of bearing springs. According to the semi-submersible platform, according to the sea condition or the actual requirement, by adjusting the load power of the power generator and the hydraulic oil flowing speed of the inertia container, influences on normal running of an upper draught fan by the vertical swinging, transverse rocking and longitudinal rocking freedom degree wave frequency response caused by wave loads and the problems of fatigue damage and the like are inhibited, and meanwhile, wave energy is converted into electric energy; and the energy drawing-shock absorbing system serves as a passive control system and fully utilizes the platform stand column space, the shock absorbing performance of the system is reliable, meanwhile, wind power generating and wave energy power generating are integrated, and the whole system has good economical efficiency.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Jet tray with large liquid holdup

InactiveCN1736528AThe separation efficiency is not lowMeet the requirements of liquid holding capacityFractional distillationDistillationPlate column

Owner:HEBEI UNIV OF TECH

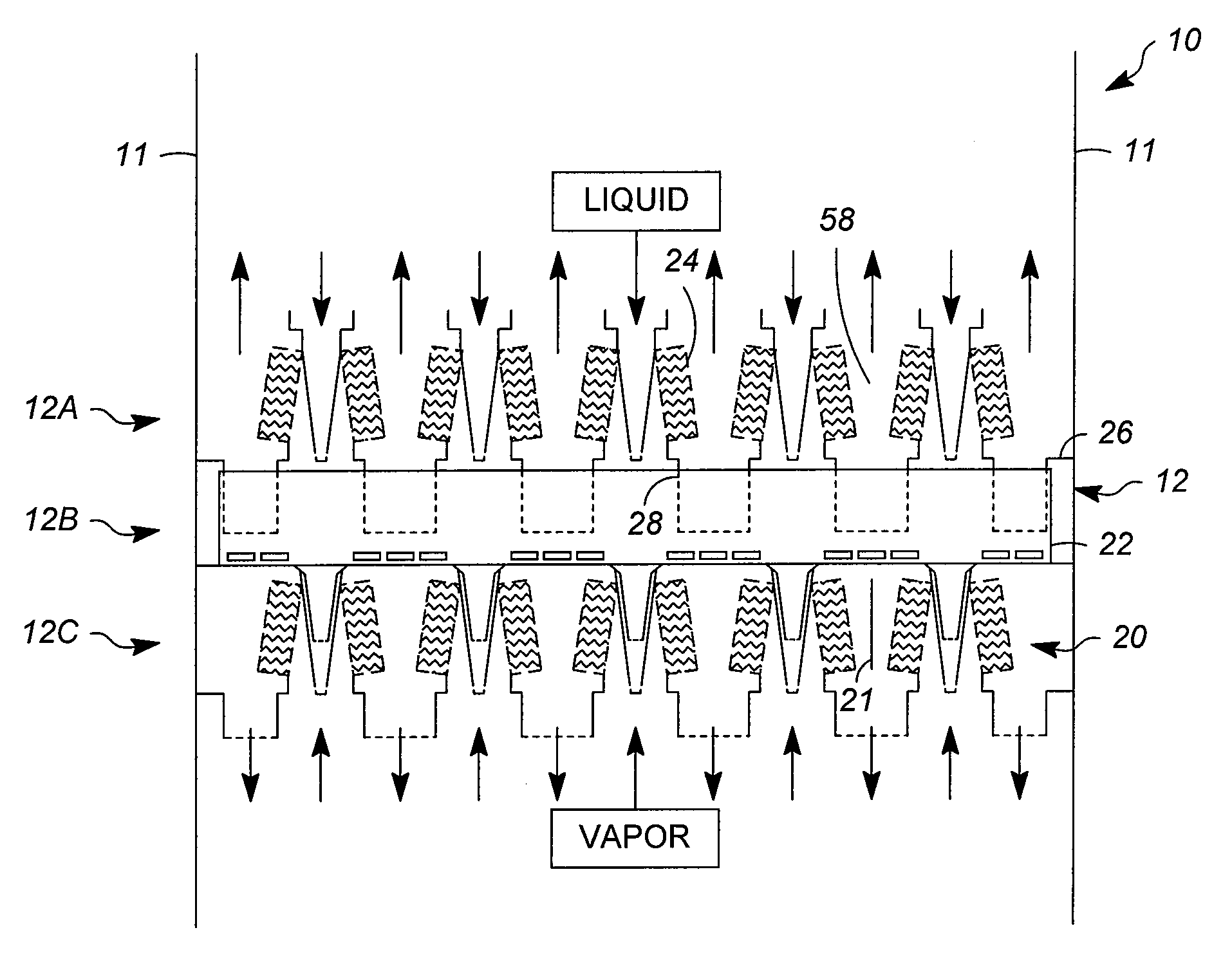

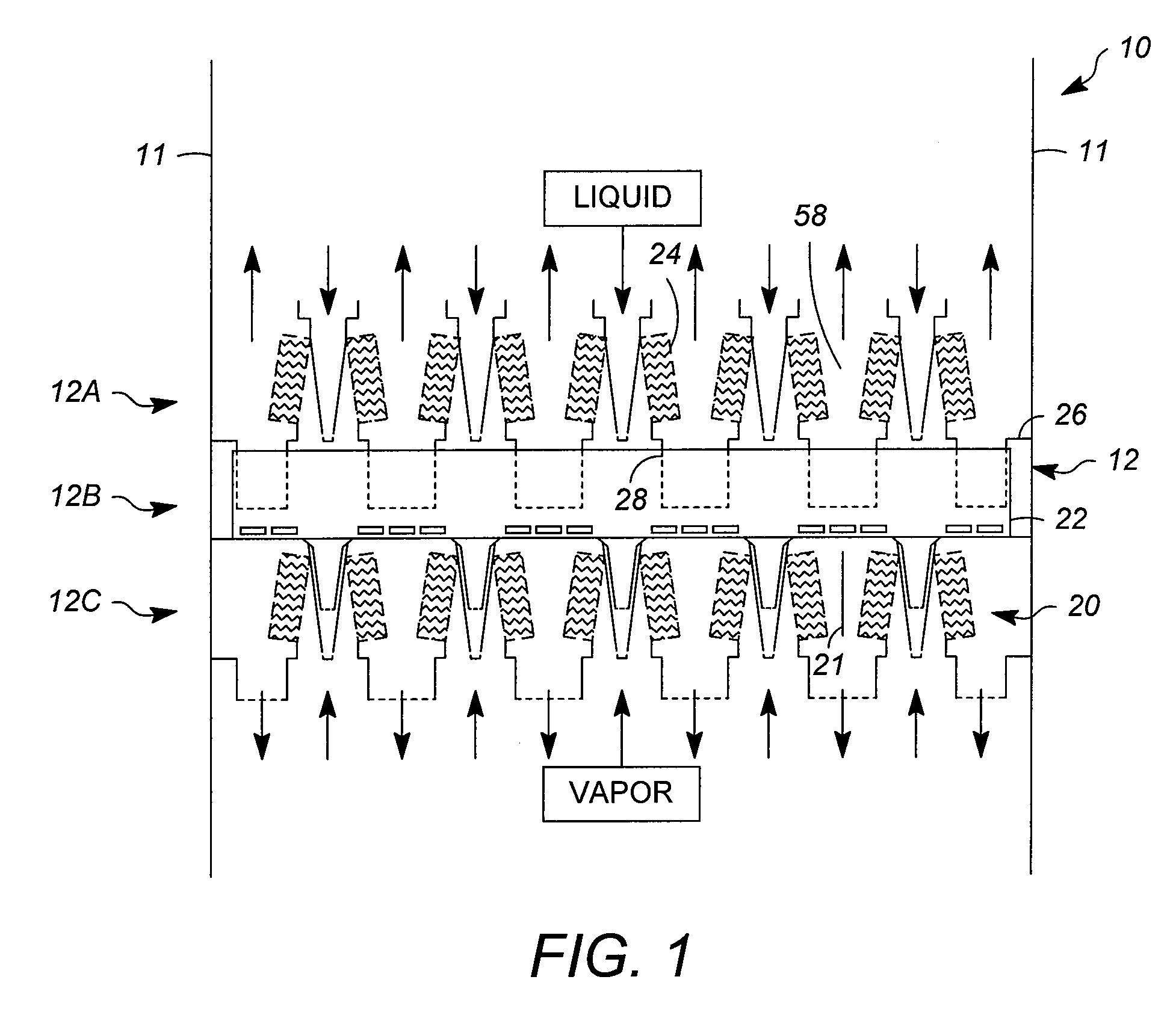

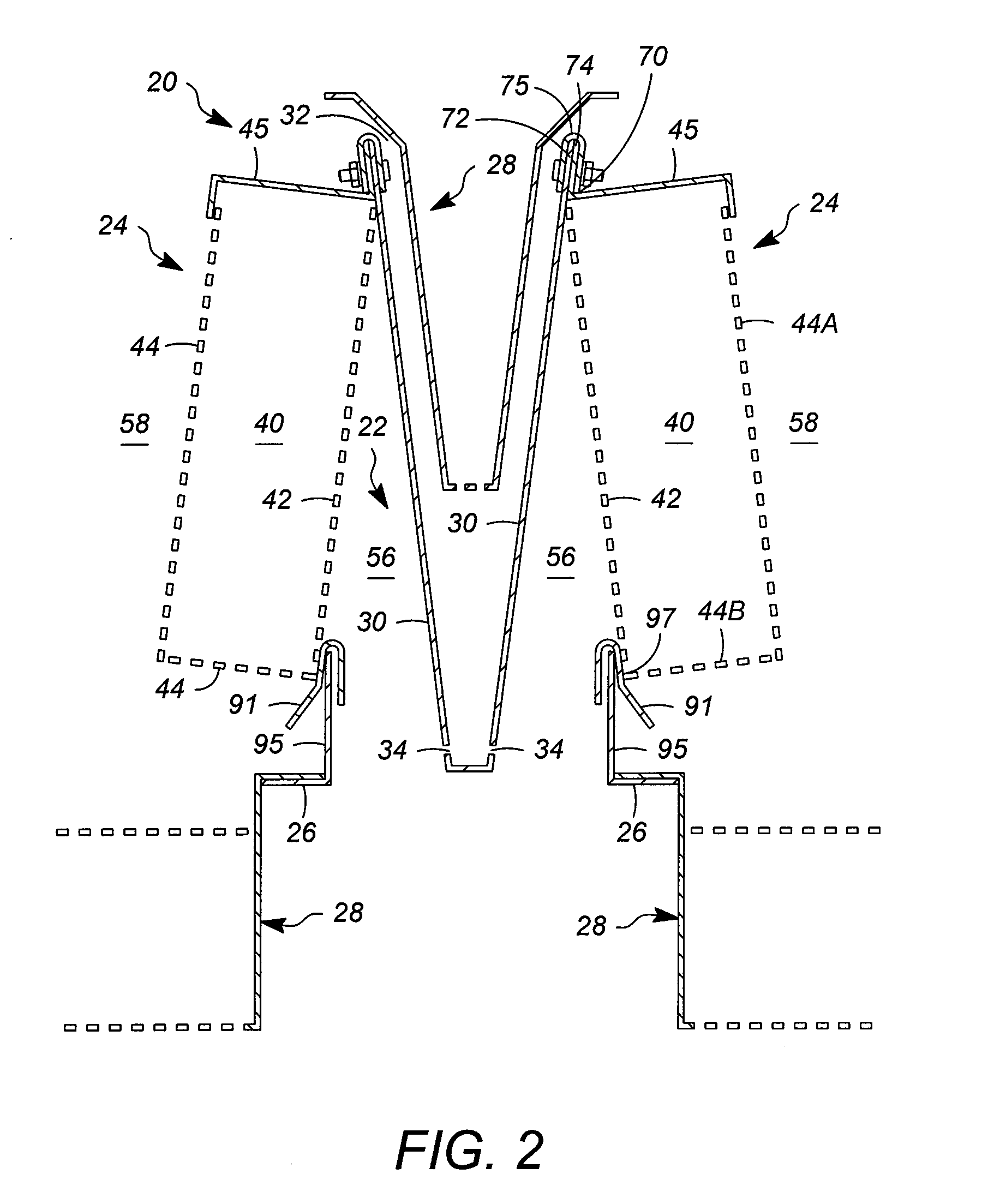

Contacting stages for co-current contacting apparatuses

ActiveUS20100242730A1Reducing liquid handling capabilityLarge capacityCatalytic crackingLiquid degasificationVapor liquidEngineering

Improved contacting stages for carrying out vapor-liquid contacting are described. Particular aspects are directed to co-current vapor-liquid contacting devices with non-parallel contacting stages that provide an efficient usage of column space for fluid flow and contacting, in order to achieve high capacity, high efficiency, and low pressure drop. The fabrication of such contacting stages is improved using one or more structural enhancements, preferably a combination of enhancements, to achieve easy installation and significantly improved rigidity between the various parts and thereby avoid movement / separation of these parts. This reduces the possibility of fluid leakage across, and consequently vapor and / or liquid bypassing of, the contacting stage.

Owner:UOP LLC

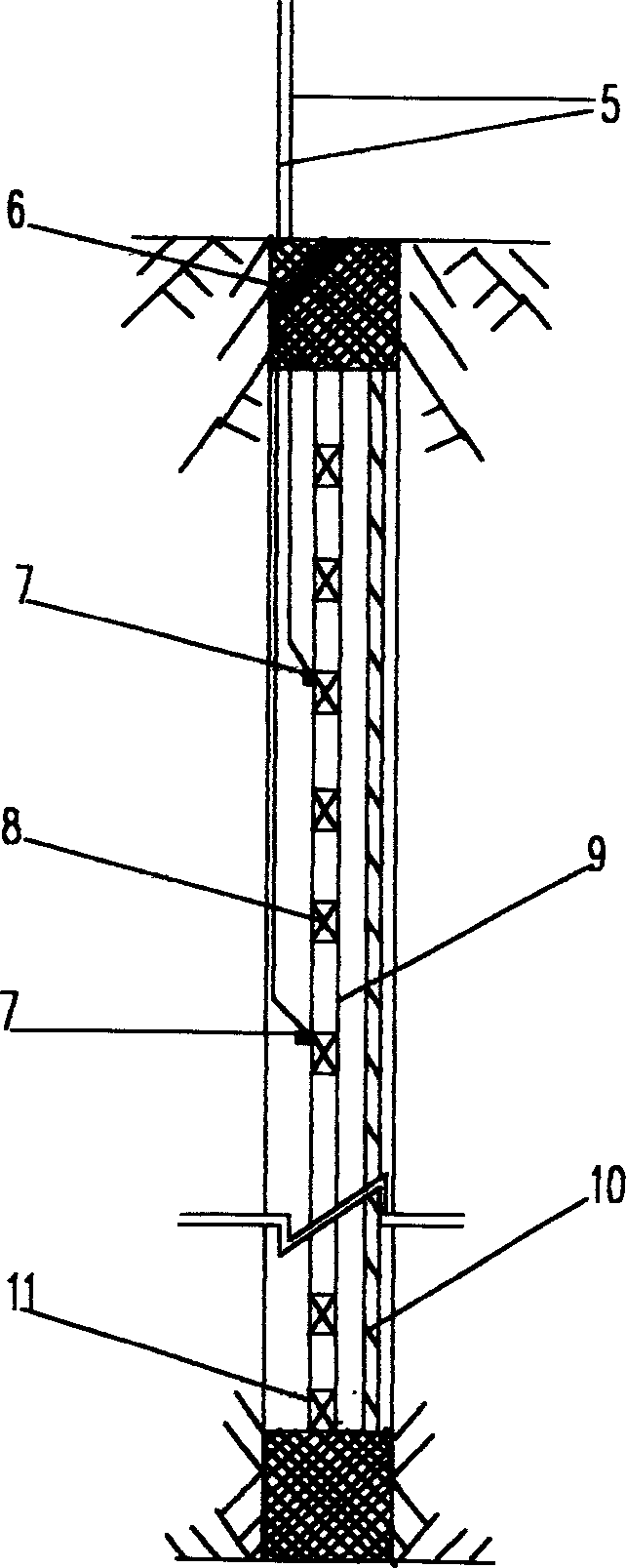

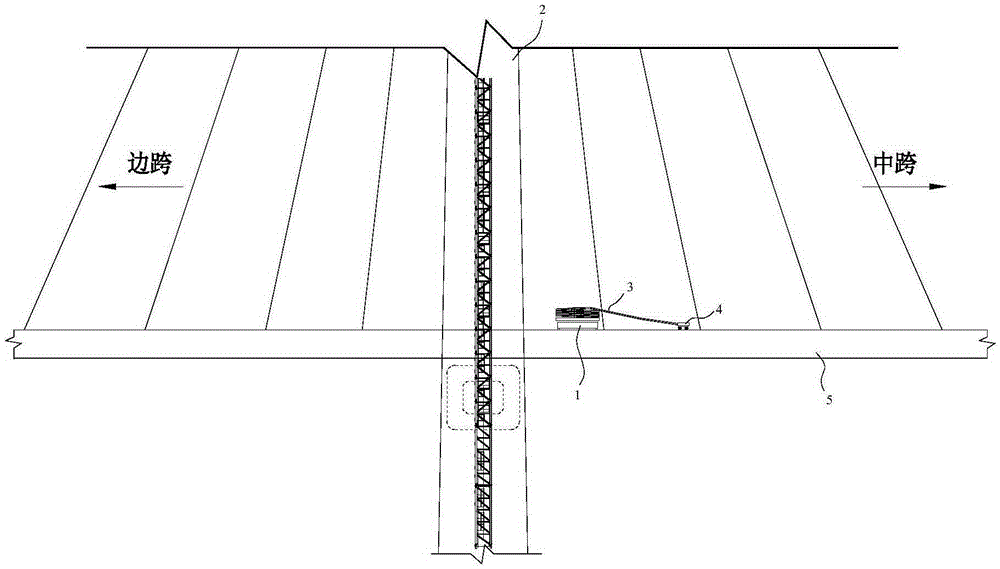

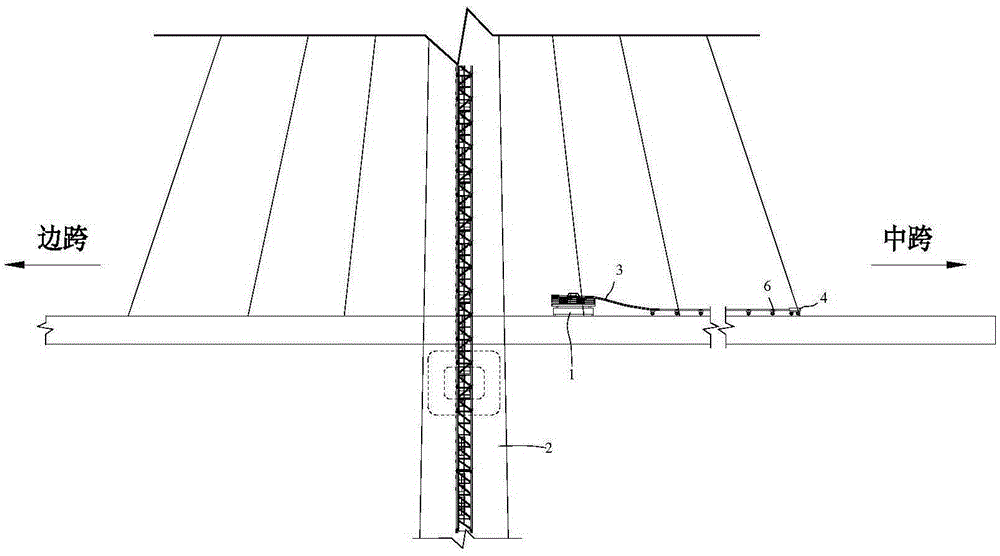

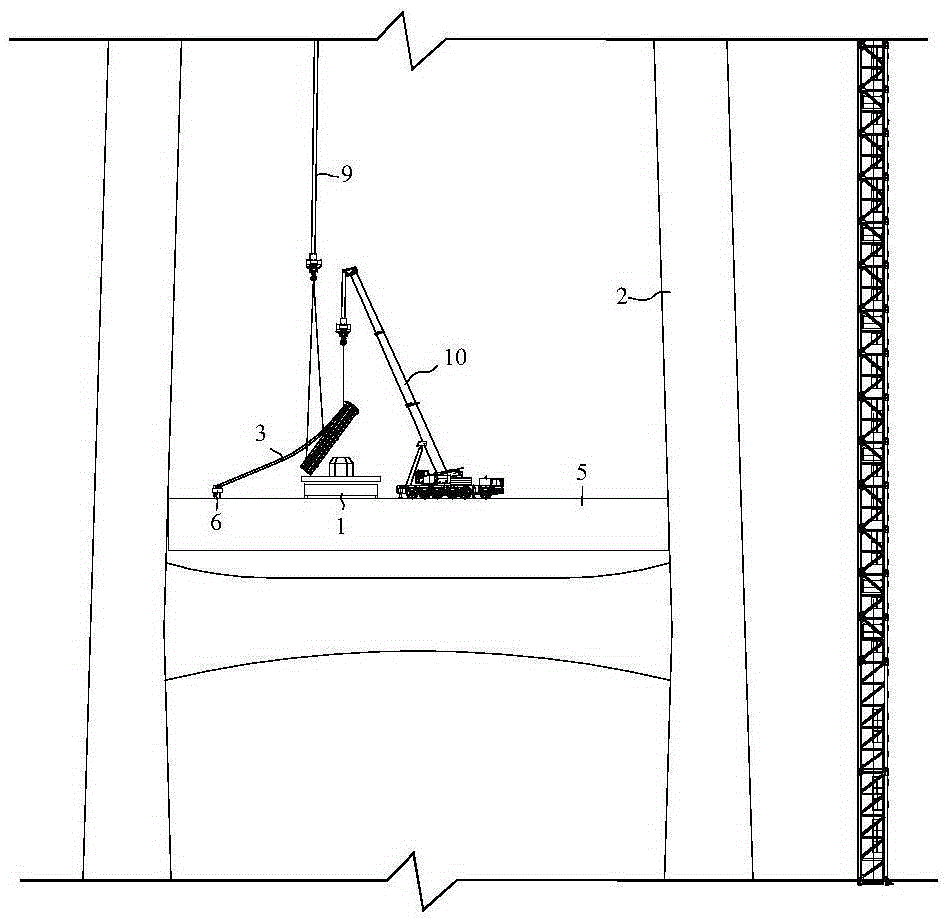

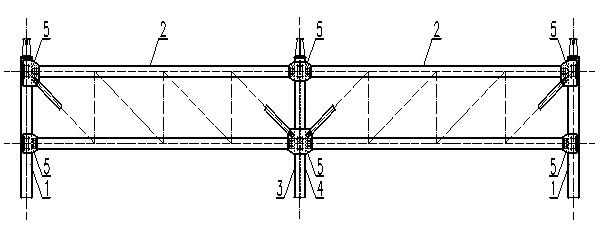

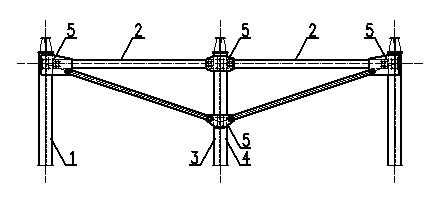

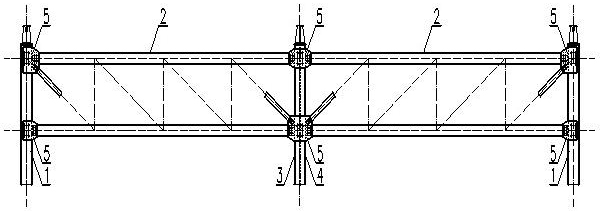

Hanging mounting method of long heavy stay cable under space limited condition

ActiveCN105401523AReduce wasteAddress too much tractionBridge structural detailsBridge erection/assemblyTowerColumn space

The invention discloses a hanging mounting method of a long heavy stay cable under a space limited condition. The hanging mounting method comprises mounting of a first stay cable body on the center span side of a cable tower and a second stay cable body on the side span side of the cable tower and comprises the following steps of S10, tower end mounting of the first stay cable body; S20, beam end mounting of the first stay cable body; S30, tower end hard traction of the first stay cable body; S40, tower end mounting of the second stay cable body; S50, beam end mounting of the second stay cable body; and S60, synchronous different-place tensioning. A tower-first beam-second hanging manner is adopted in the stay cable bodies on the center span side and the side span side for hanging, and the problems that in the beam-tower end hanging scheme of the long heavy stay cable, during rear-tower-end hanging, traction force is too large, and safety is poor are solved. Meanwhile, beam end and tower end synchronous different-place tensioning is adopted, the problems that upper tower column space is small and narrow, and construction is difficult are solved, the phenomenon that when the stay cable bodies are tensioned each time, a set of tensioning extending rods are cut to be wasted is avoided, material waste is reduced, and the construction cost is reduced.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

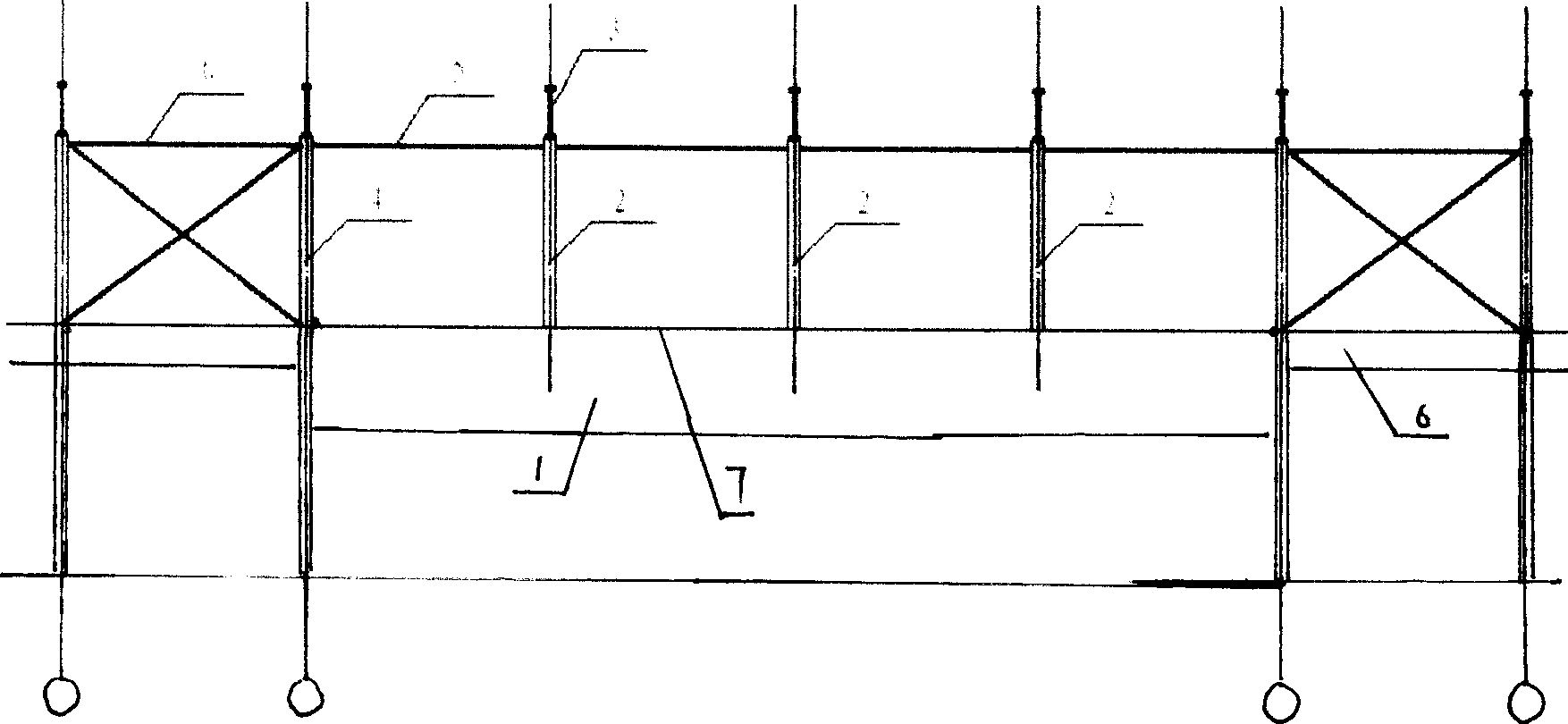

Method for underpinning roof structure and expanding column space of steel structure factory building

InactiveCN102140849AShorten the production and installation lengthLow costBuilding repairsEngineeringSteel columns

The invention discloses a method for underpinning a roof structure and expanding a column space of a steel structure factory building, which comprises the following steps of: manufacturing a bracket sectionally according to the original column space in an area where the column space of the factory building is needed to be expanded; firmly connecting the two ends of the sectionally manufactured bracket with a support steel column or a steel column to be extracted respectively and forming a complete bracket in a full-length section of the extracted column; and cutting the needless column section of the steel column to be extracted. By the method for underpinning the roof structure and expanding the column space of the steel structure factory building, the length of the bracket can be shortened, the bracket is convenient to construct and install, the construction progress can be accelerated, construction cost is reduced, the factory building has concise and attractive appearance, and the method can be widely applied to the conventional steel structure factory building modification construction.

Owner:CISDI ENG CO LTD

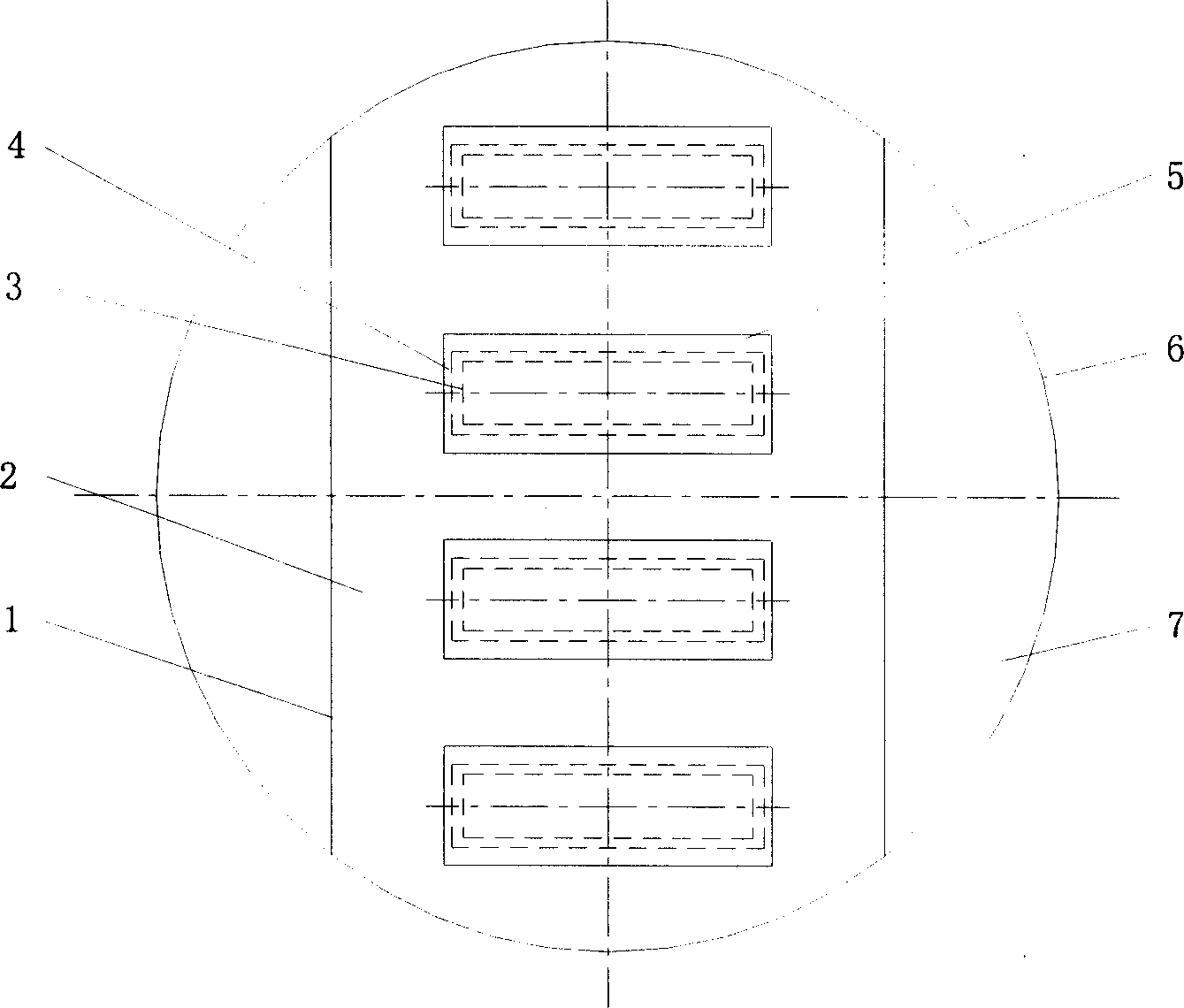

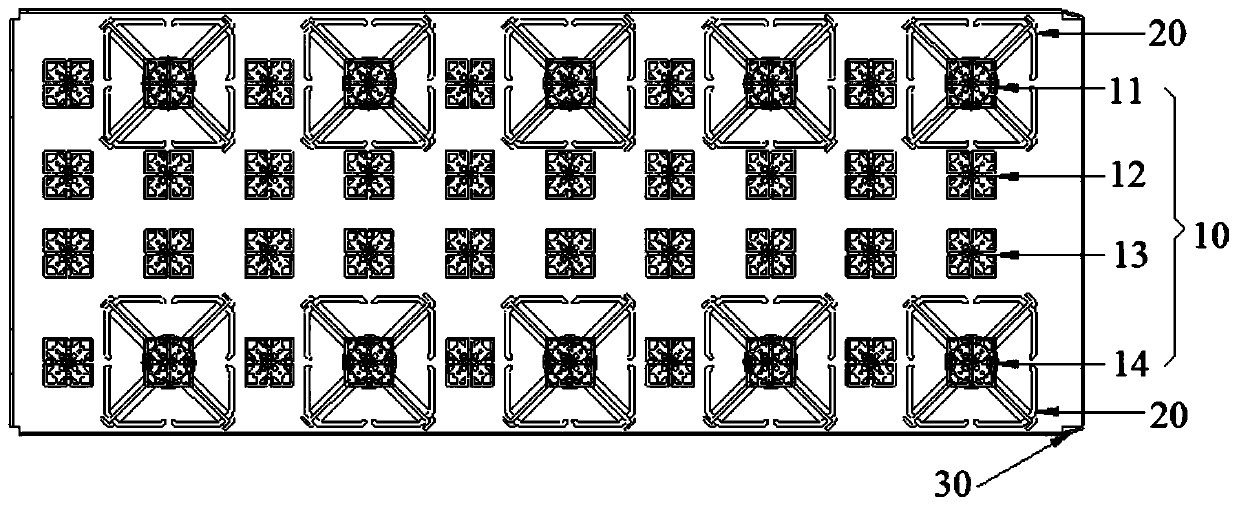

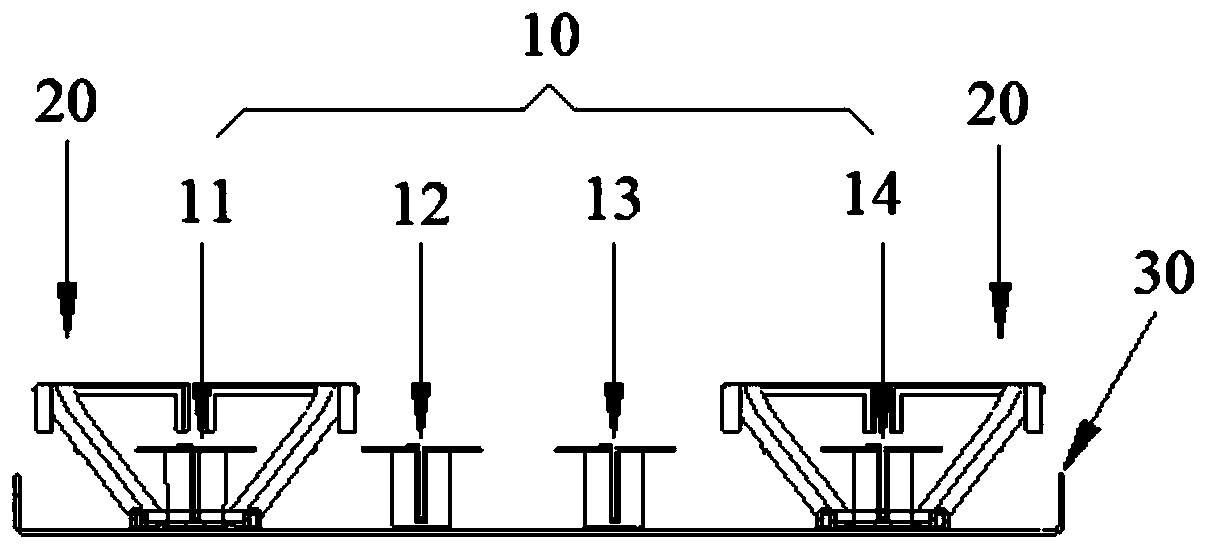

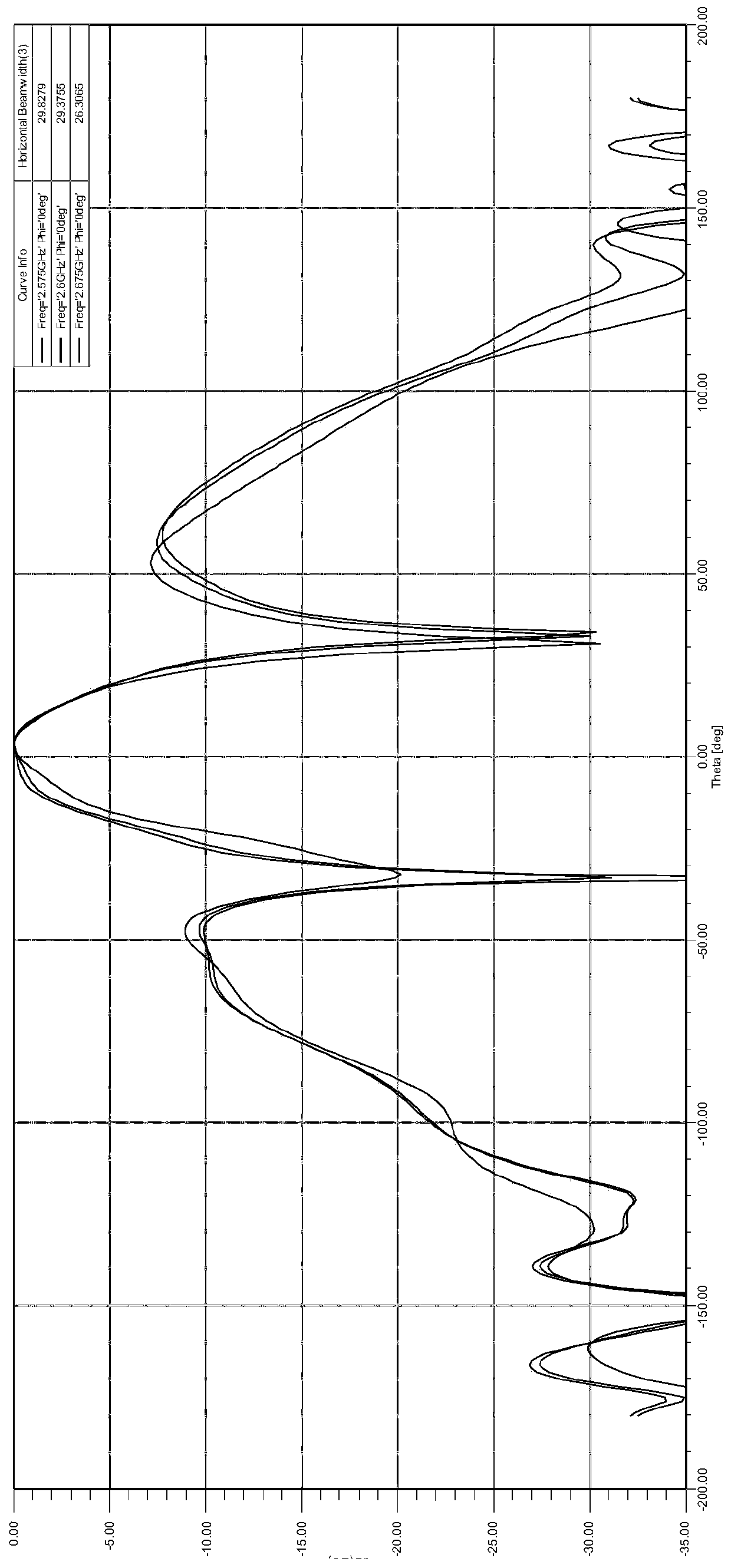

Multi-frequency narrow-beam antenna array and antenna

ActiveCN109755759ASuperior Wavewidth ConvergenceGood electrical performanceRadiating elements structural formsAntennas earthing switches associationColumn spaceAntenna array

The invention provides a multi-frequency narrow-beam antenna array and an antenna, and relates to the technical field of mobile communication. The multi-frequency narrow-beam antenna array comprises four columns of high-frequency arrays, wherein any two columns of the high-frequency arrays are provided with combiners at the input ends of radiation units respectively; each combiner is used for separating frequency signals of two different frequency bands from the corresponding high-frequency array, and three different frequency bands exist in the frequency signals separated by the two columns of high-frequency arrays by the combiners, wherein the two columns of the high-frequency arrays are combined by the combiners to generate same-frequency-band frequency signals which are combined to form a first high-frequency narrow-beam array; and a second high-frequency narrow-beam array and a third high-frequency narrow-beam array are formed by combining the frequency signals of two different frequency bands generated in the combining mode with the two columns of high-frequency arrays without the combiner in a one-to-one mode. According to the multi-frequency narrow-beam antenna array provided by the invention, combining is performed firstly and then merging is carried out, and the high-frequency narrow-beam arrays can achieve excellent wave width convergence and excellent electrical performance by flexibly deploying the column spacing between two adjacent columns.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

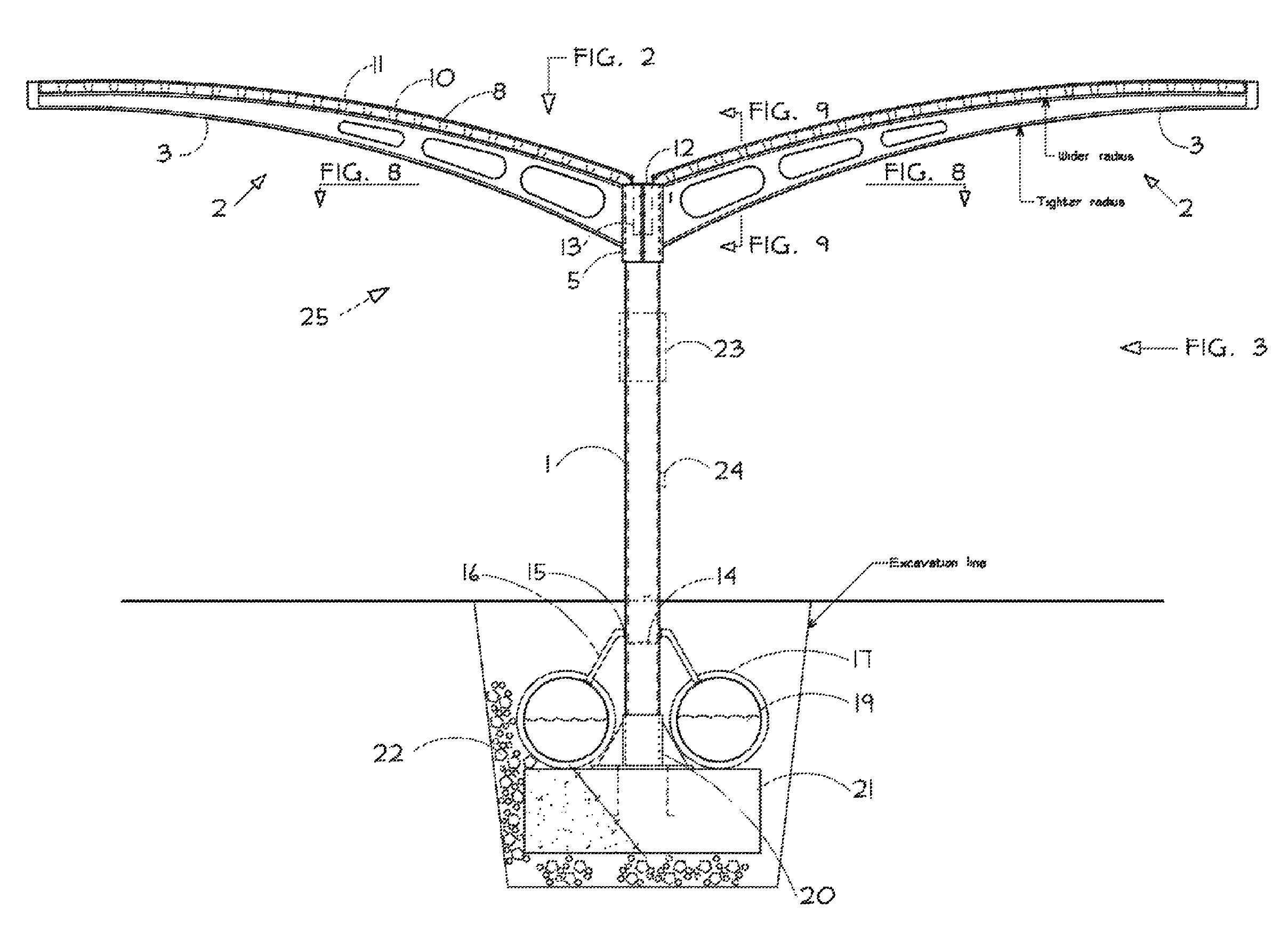

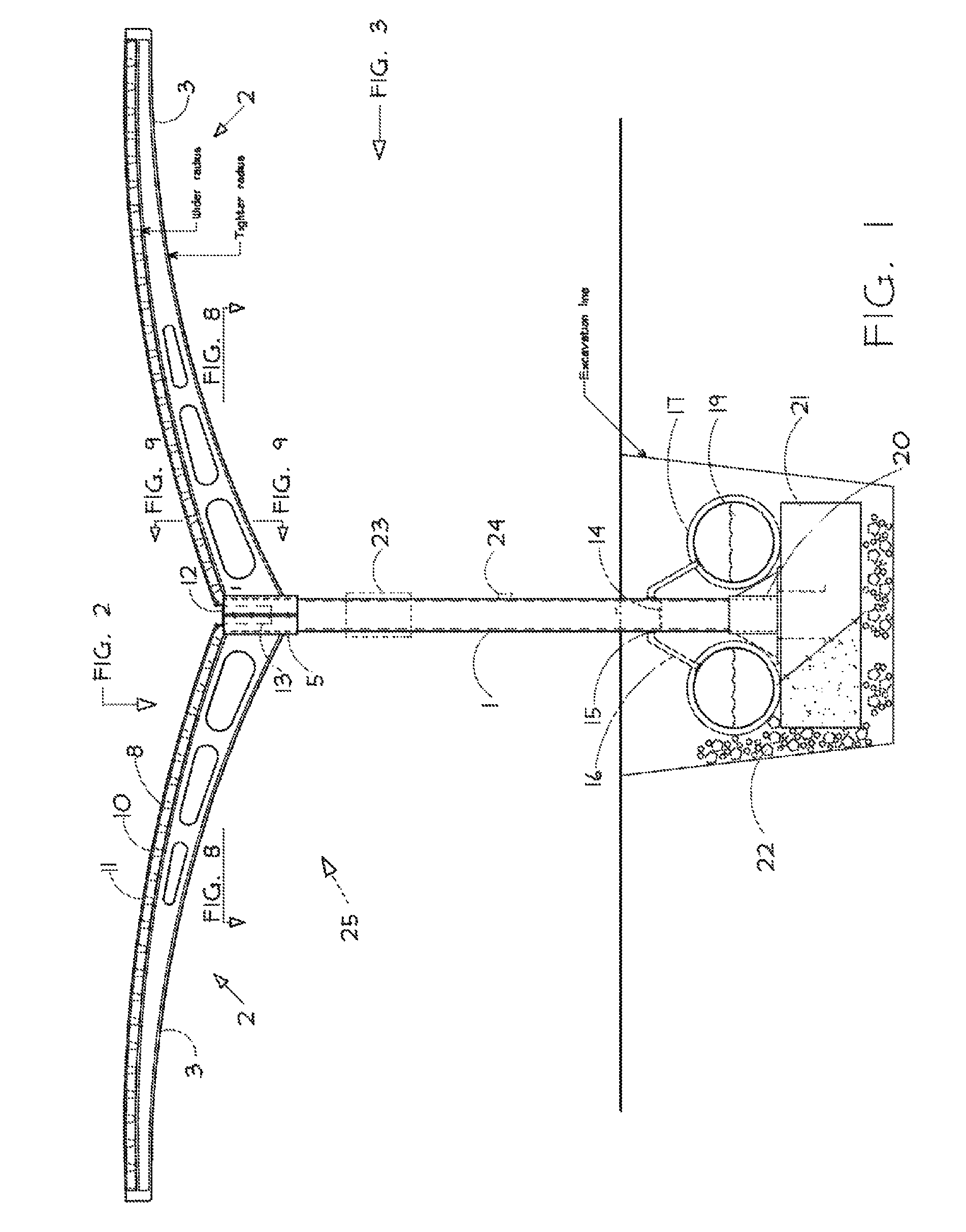

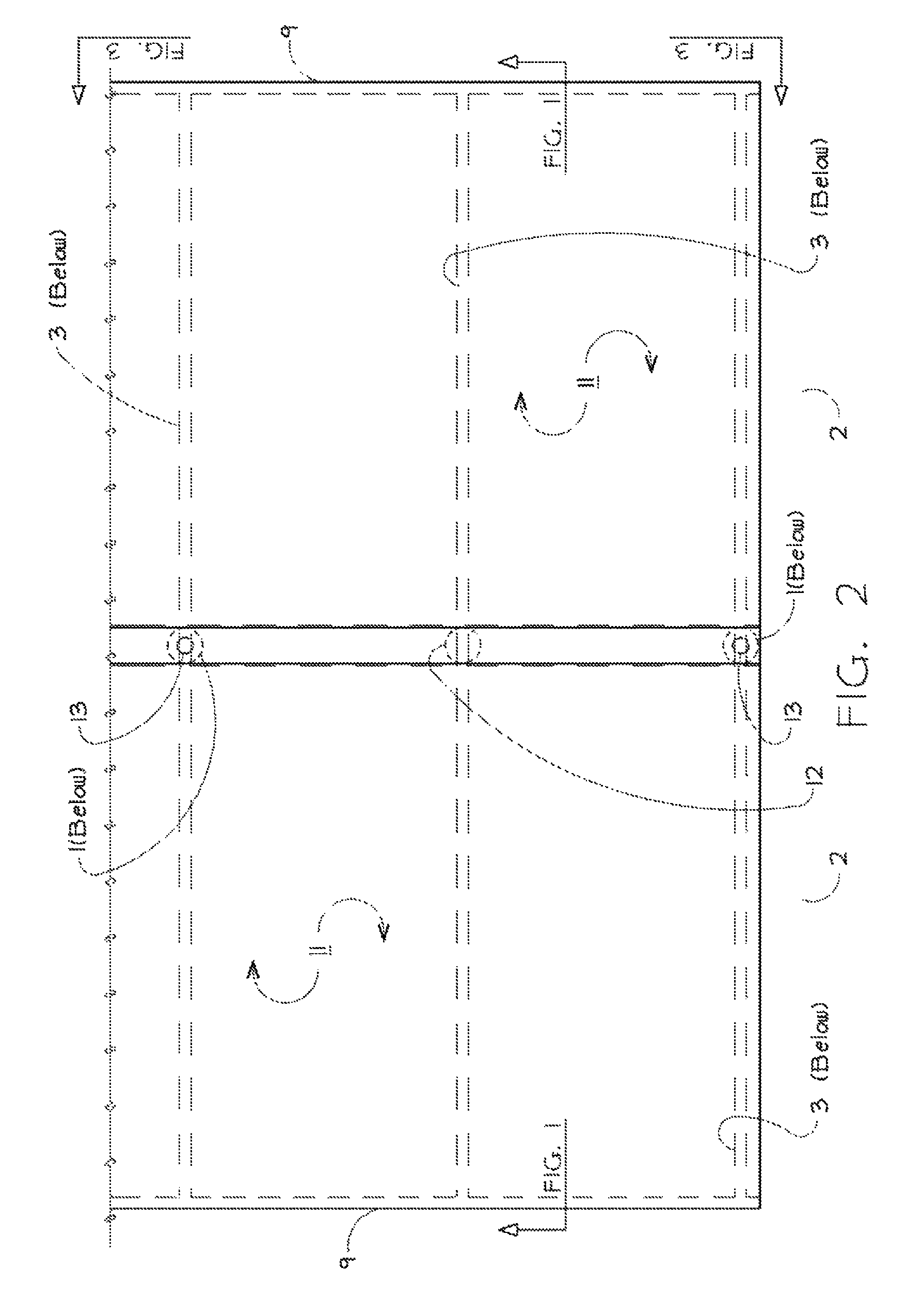

Arcuate-winged solar canopy assembly

ActiveUS9153718B2Easy to collectHighest daily and historic demandPhotovoltaic supportsSolar heating energyEngineeringColumn space

Owner:RICHARDSON DONALD S

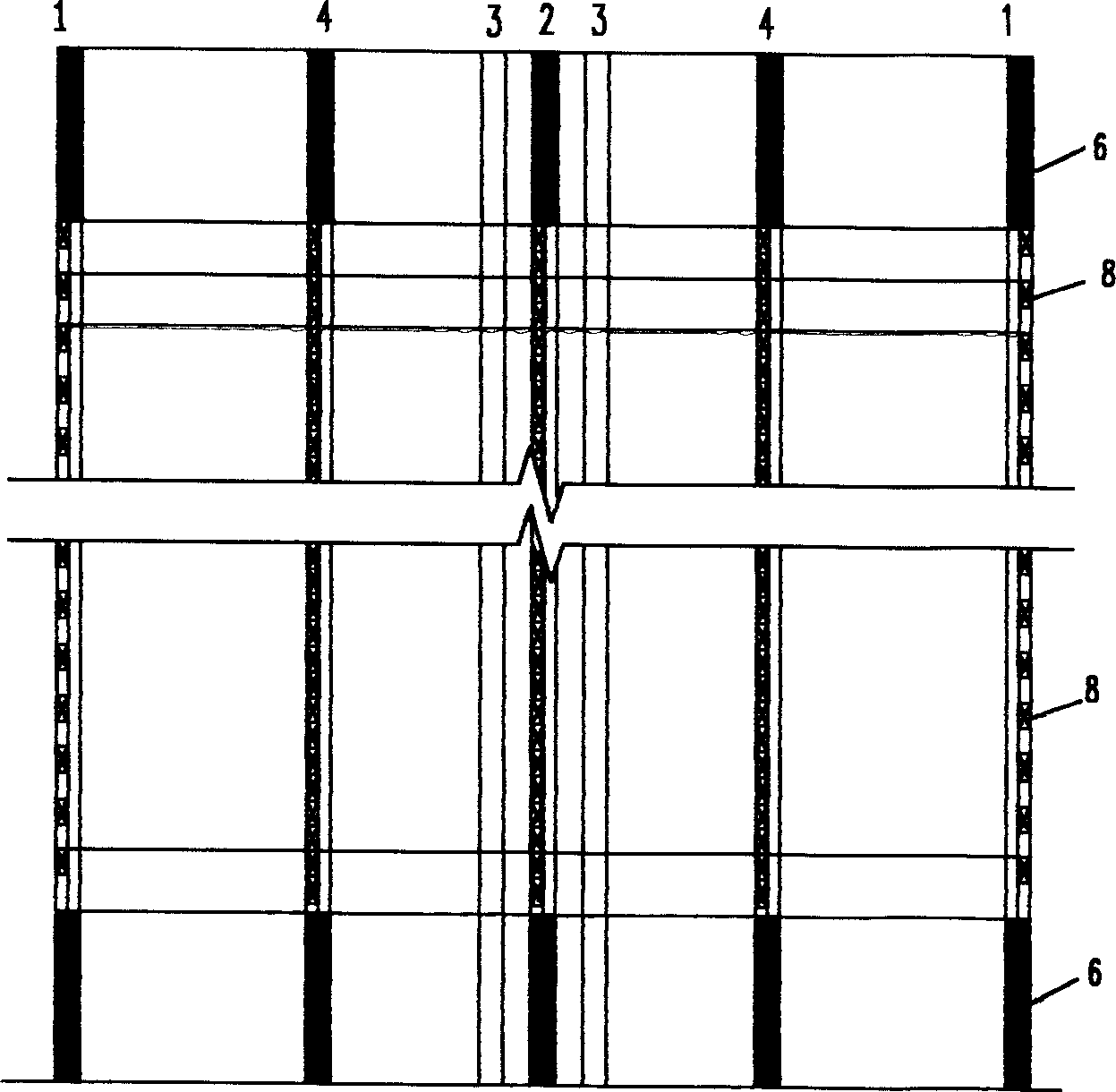

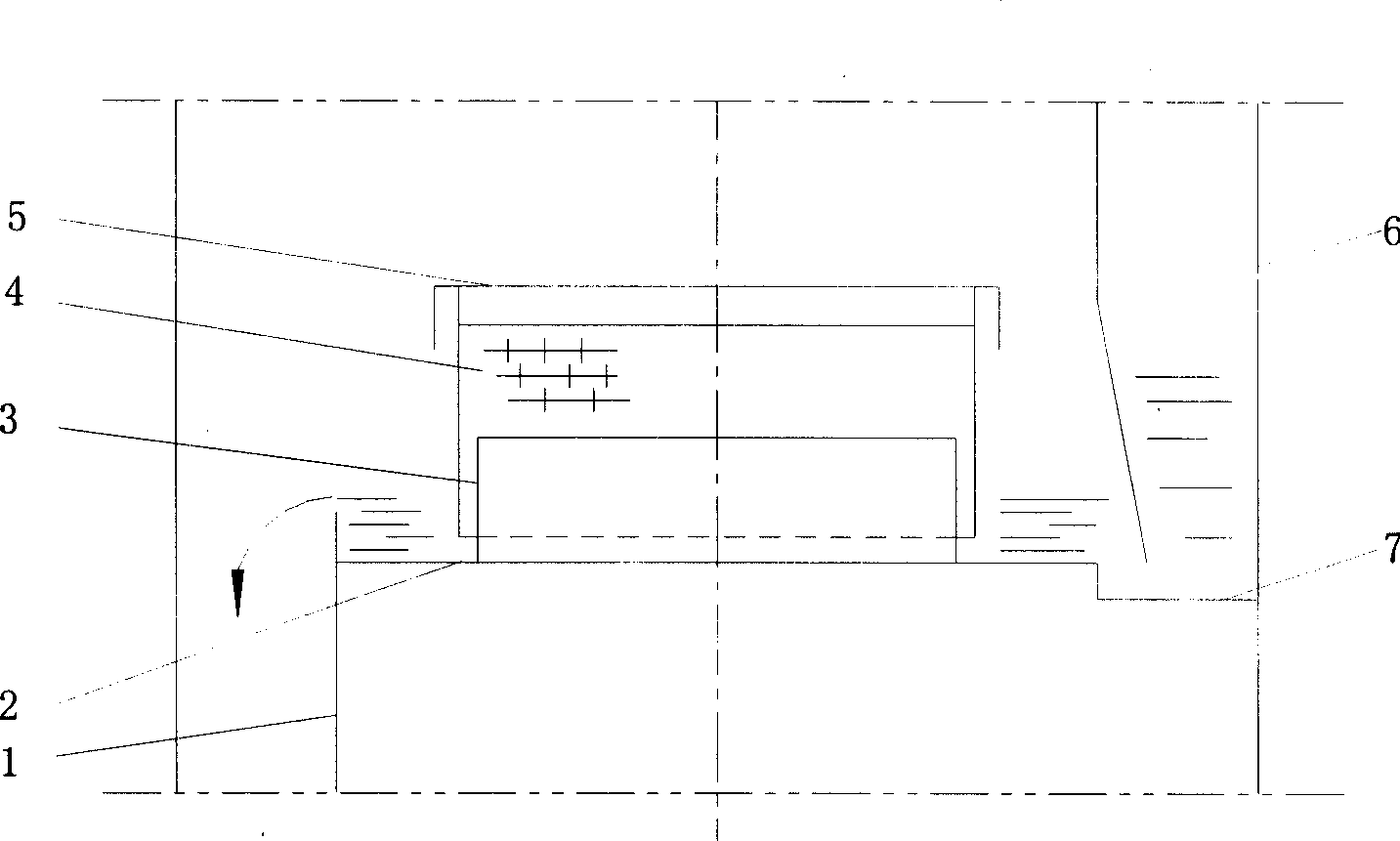

Supporting method of factory building roof system at super large column-removed spacing

InactiveCN101397814AUniform stiffnessUnified layoutBuilding roofsEconomic benefitsStructural engineering

The invention discloses a method for supporting a factory-building roofing system at a huge pumping column space, which relates to the technical field of construction structure design. According to normal column space (6), an on-beam steel column (2) is added in corresponding position on the top surface of a large box-shaped crane beam (1) at the huge pumping column space (7); the top of the on-beam steel column (2) is articulated with a steel roof truss (3), and the foot of the on-beam steel column (2) is articulated with the large box-shaped crane beam (1). The method effectively solves the problem of how to support a factory-building roofing system at a huge pumping column space and causes the arrangement of the roofs to be more unified and the whole rigidity of the factory buildings to be evener, thereby achieving good technical effect and economic benefits. The method is mainly used for the design of the supporting of a factory-building roofing system at a huge pumping column space.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

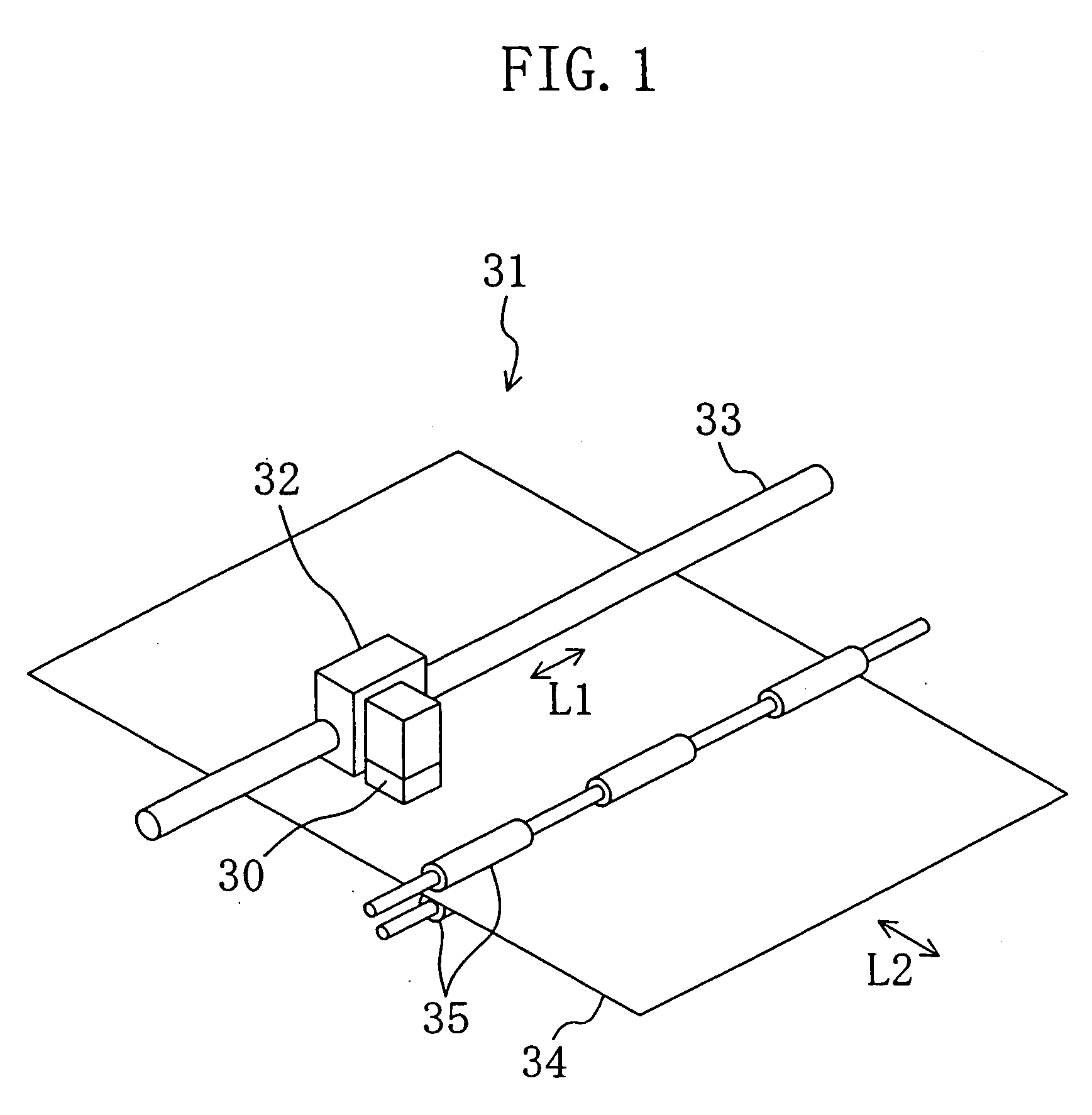

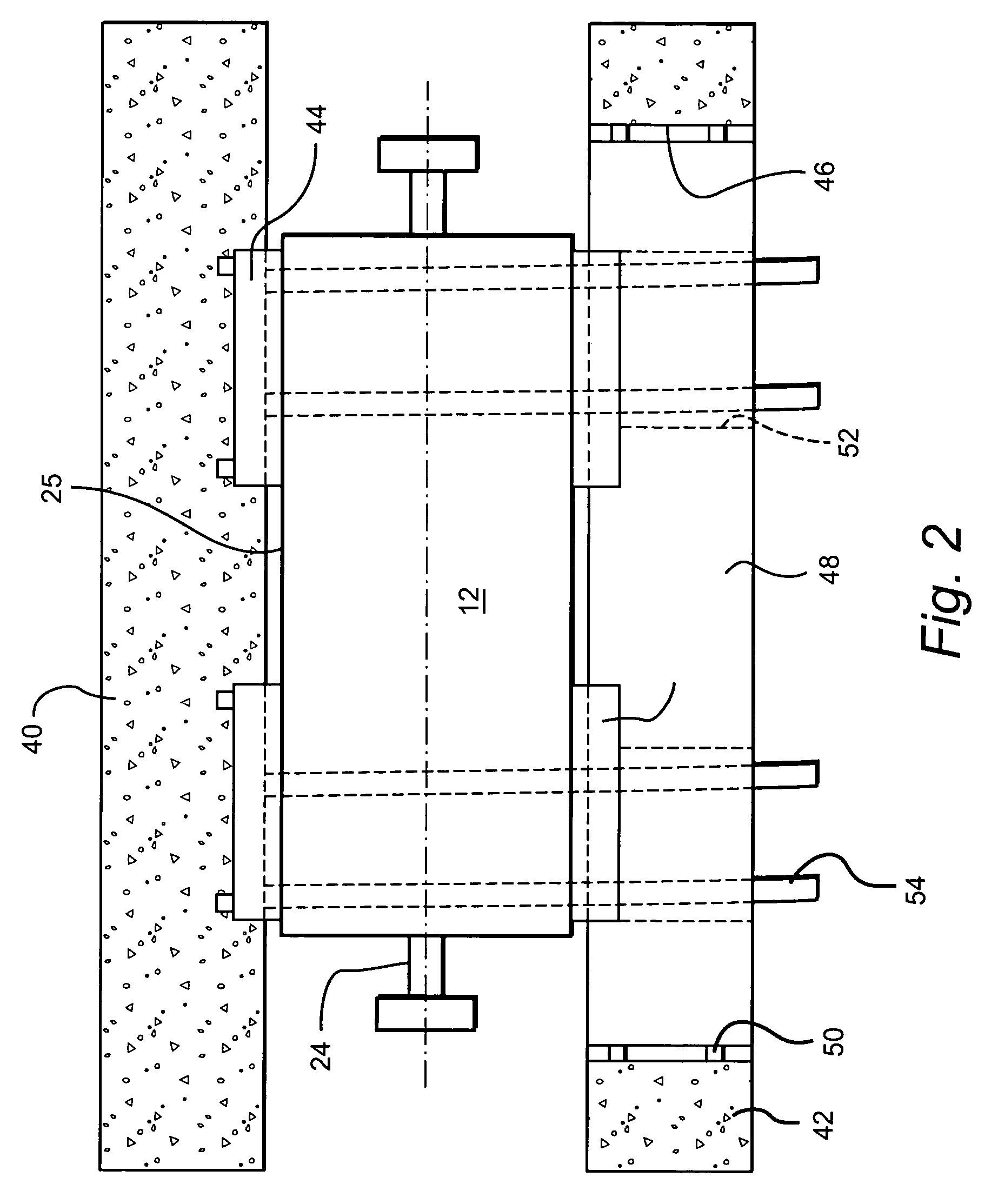

Methods of generator rotor removal in a combined-cycle stag application

InactiveUS7281308B2Reduce planting costsReduces plant downtimeGas turbine plantsManufacturing stator/rotor bodiesEngineeringVertical axis

Support feet of a generator are mounted on foundation columns spaced laterally one from the other, with one column having a block in a recess for receiving the feet on one side of the generator. Guides on a radius and supported by the generator foundation extend through notches on the underside of the block. To locate an end of the generator displaced horizontally from the turbines, the generator is unloaded from the foundation and the block is removed. The generator is then loaded onto the guides and pivoted about a vertical axis to locate at least one end out of alignment with the axis of the turbines enabling removal of the generator rotor in an axial direction.

Owner:GENERAL ELECTRIC CO

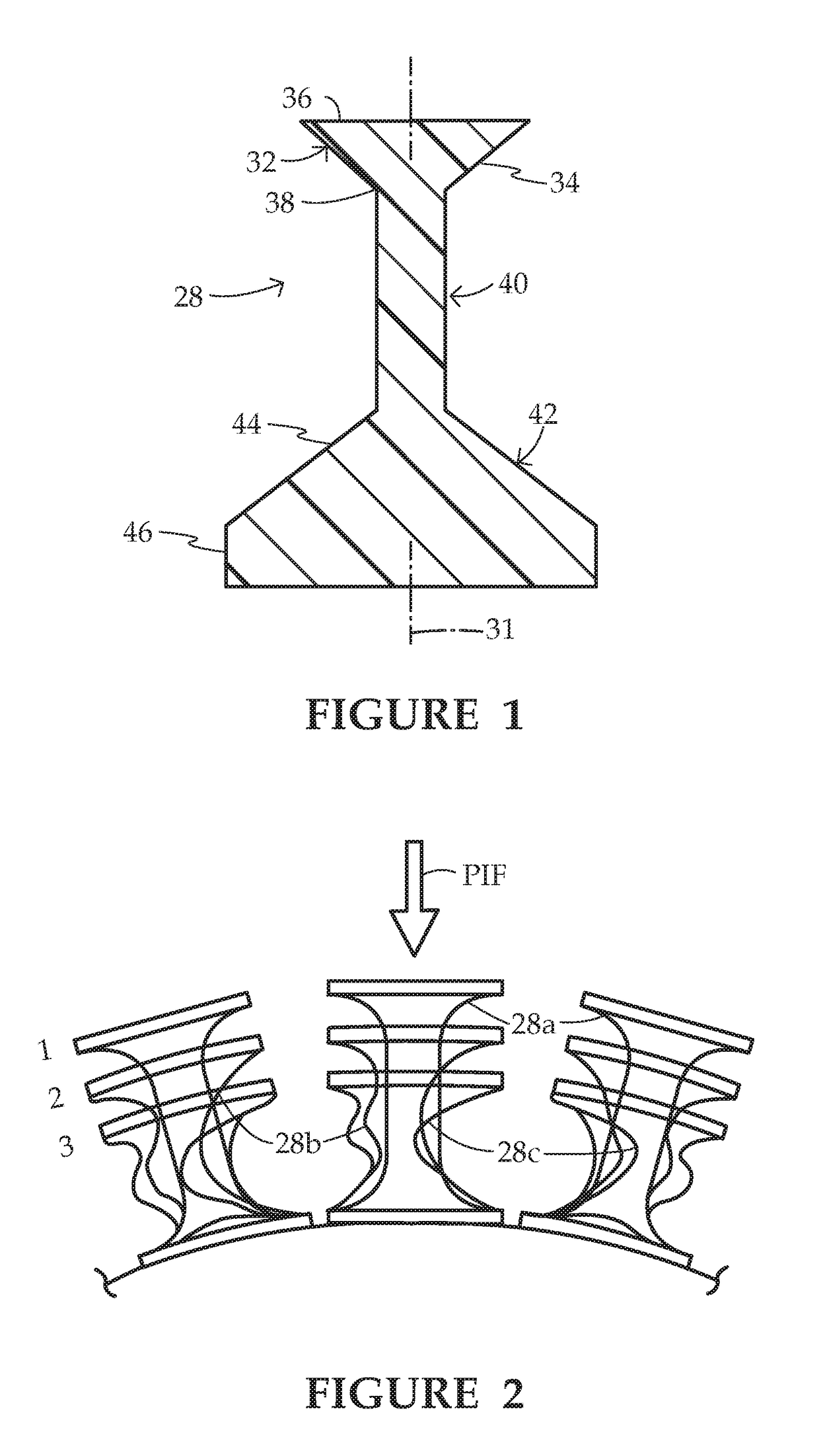

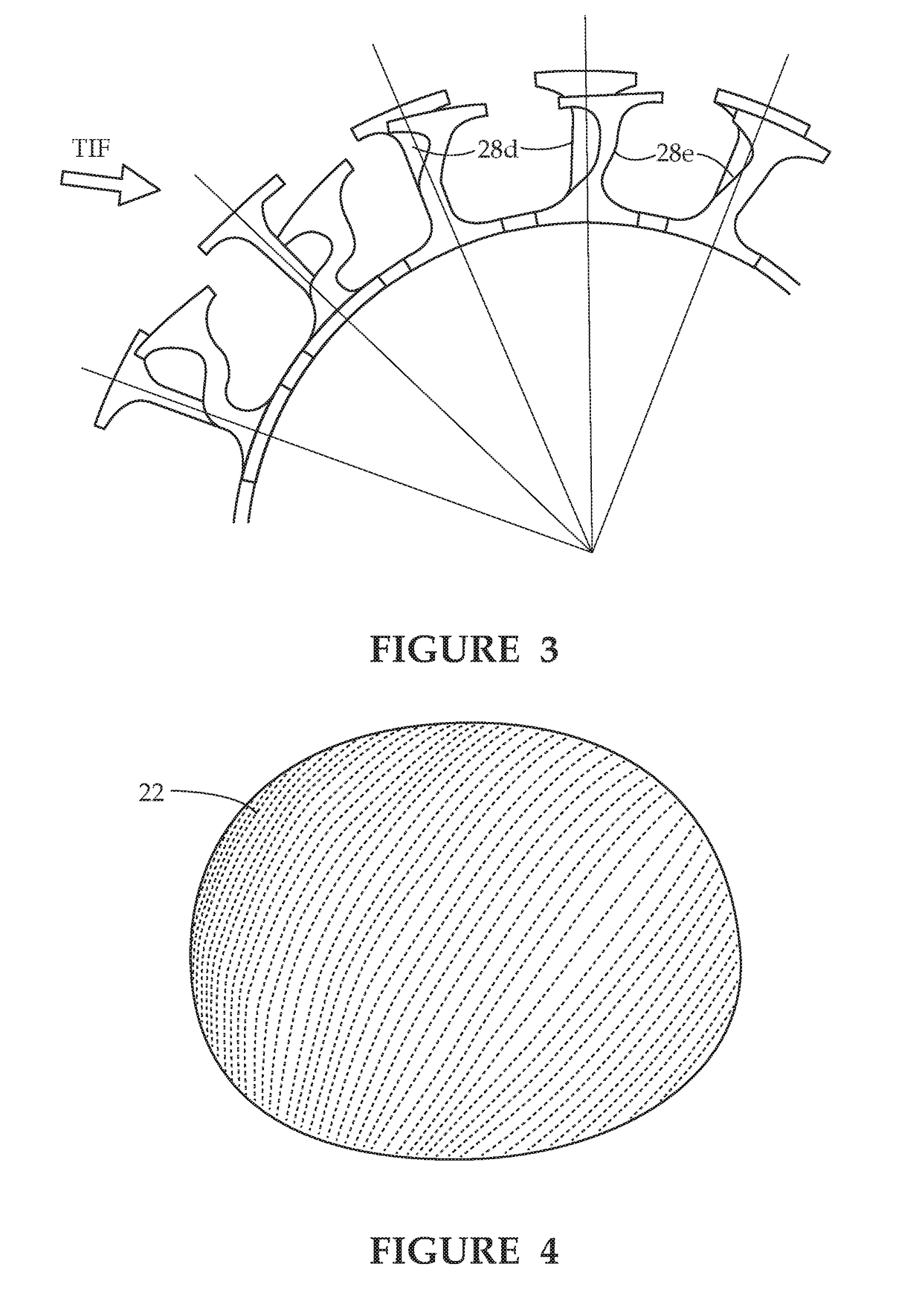

Energy dissipating helmet

ActiveUS20180249778A1Improve protectionLittle strengthLamination ancillary operationsProtective equipmentEngineeringImpact zone

A helmet has inner and outer shells separated by a plurality of interconnected relatively soft columns or posts. The columns each have a middle post or pillar section, a capital that is of larger diameter than the post, and a base also of larger transverse dimension than the post. When an impact above a design threshold occurs on the outer shell, the columns, particularly the post sections thereof, near the impact location compress and buckle, dissipating impact kinetic energy, while columns spaced from the impact zone stretch and support more of the impact force. The applied force is therefore reduced and spread out over a relatively large area, and a resultant wave created within the column manifold disperses additional heat, further reducing the force and torque applied on the outer shell and transmitted to the inner shell and onto the skull of a helmet user. A method and mold for fabricating the column manifold are also disclosed.

Owner:BRANDT RICHARD A +1

Universal joint

A universal joint includes a coupling member having an end for coupling with a tool. A body includes a rounded base pivotably mounted to the other end of the coupling member. The body further includes a drive column spaced from the rounded base along an axis. A reinforcing section is intermediate the rounded base and the drive column. The reinforcing section includes an outer periphery having a recessed portion with a receptacle extending in a radial direction perpendicular to the axis. A control member is moveably received in the receptacle to control coupling of the drive column and an object to be driven. In any case, a spacing from an outer end of the control member to the axis in the radial direction is substantially not larger than a spacing from the outer periphery of the reinforcing section to the axis in the radial direction.

Owner:HU BOBBY

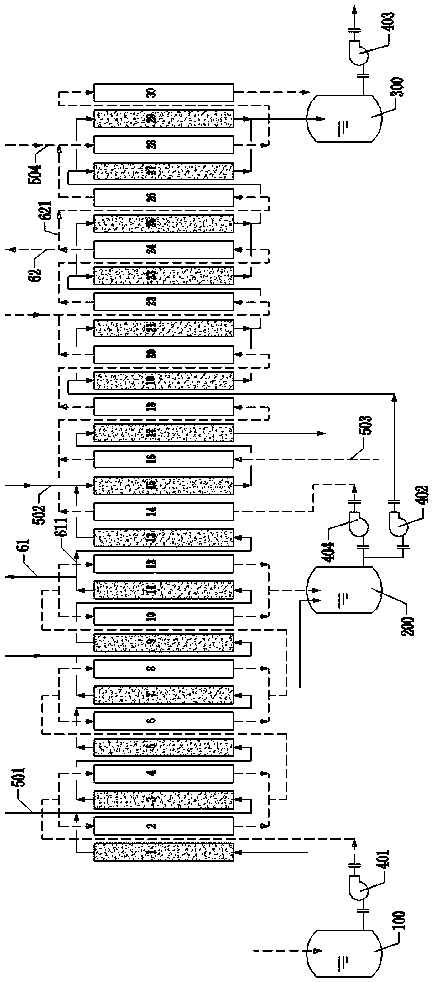

Continuous ion exchange technology for removing inorganic salt and adopted system

PendingCN109225355ATo achieve the purpose of efficient useReduce usageCation exchangersIon exchange beds cleaning/rinsingInorganic saltsBuffer tank

The invention discloses a continuous ion exchange technology for removing inorganic salt. The continuous ion exchange technology comprises the following steps: pumping raw materials into a resin column system in continuous moving through a raw material tank, wherein the resin column system is provided with a plurality of resin columns, the resin columns are sequentially arranged according to sequence numbers, the resin columns rotate along a number decreasing direction, every stepping is in two column space, the resin columns in even numbers are internally filled with cation resin and form a cation removing system, and the resin columns in odd numbers are internally filled with anion resin and form an anion removing system; enabling the raw materials to enter the resin column system through the cation removing system, then entering a buffer tank after cation removing, then pumping the raw materials into the anion removing system, and enabling feed liquid after anion removing to enter aproduct tank. The invention also discloses a system adopted by the continuous ion exchange technology. The continuous ion exchange technology disclosed by the invention can replace a traditional stationary bed technology, the purpose of efficiently applying resin can be achieved, the using amount of the resin, water and a reclaiming agent can be reduced, wastewater emission can be reduced, two different types of resin can be integrated into a set of system, and the technology is simplified.

Owner:SEPATEC ENVIRONMENTAL PROTECTION TECH XIAMEN

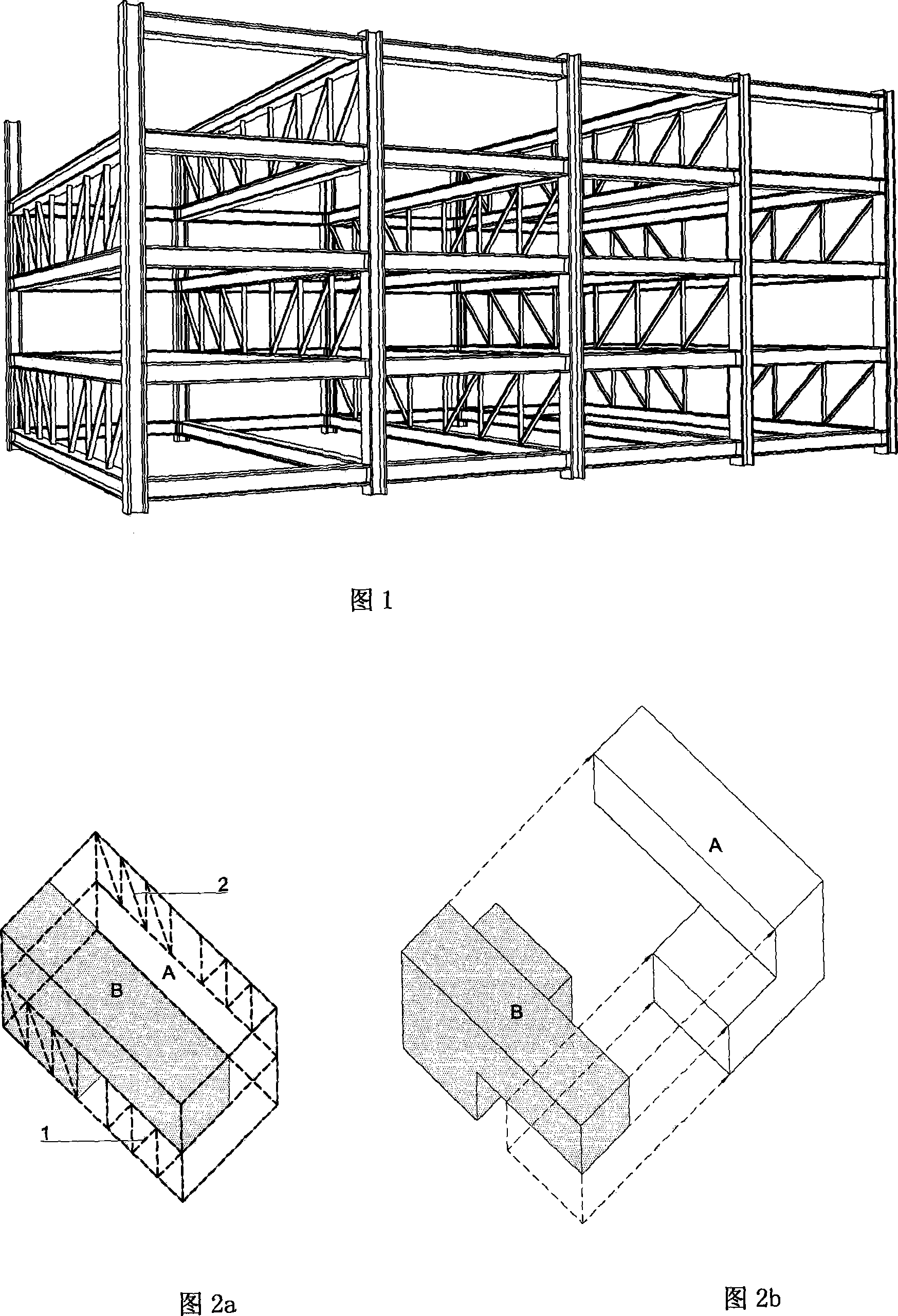

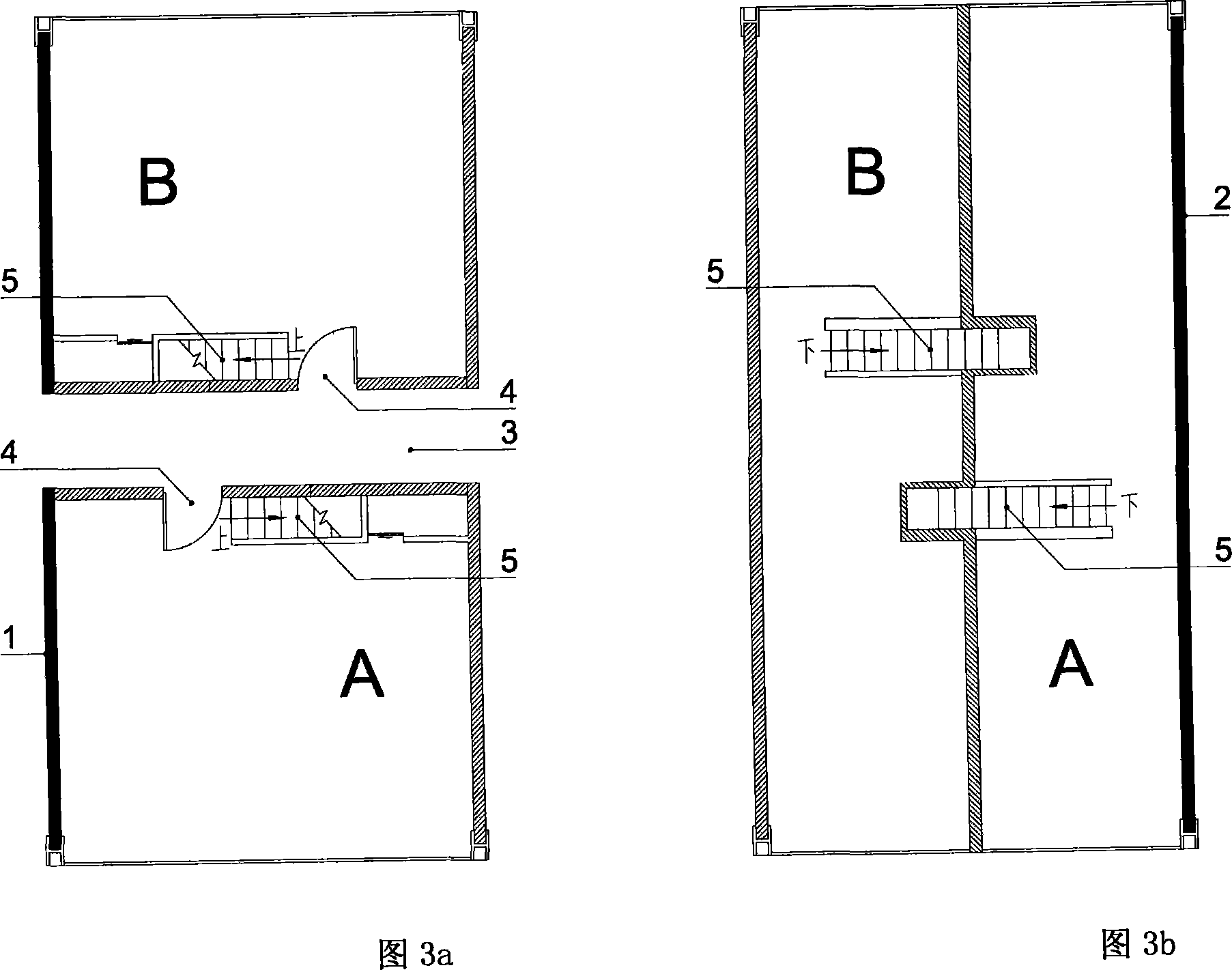

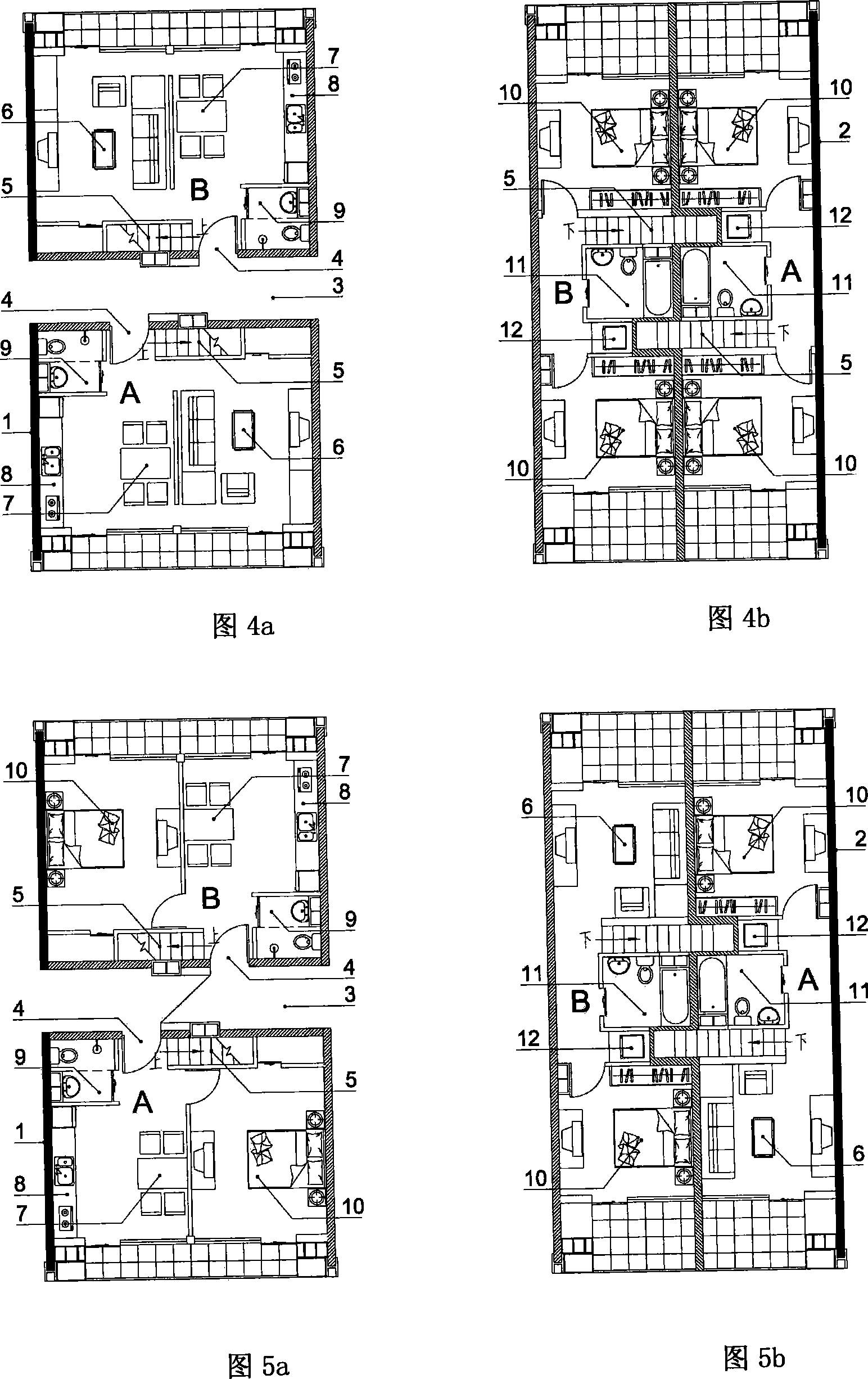

South-north facing alternation steel longeron home building house type with two units as combination

The invention relates to a residential house type taking two houses as a combined north-south penetrated staggered steel truss, in particular to a residential house type. The house type is designed by adopting the multi-storey type house type, every two house types are taken as a standard unit body, a standard unit body comprises a column spacing bay room and an upper floor and a lower floor. On the plane of a house entrance floor, two house types are respectively entered into a house in the southward direction and the northward direction of a public inner corridor across the plane, and the public inner corridor is penetrated through the middle internode position of a truss frame in a staggered steel truss system; two house types reach the multiple stories of the two house types through two inner wall clinging to the east direction and the west direction and indoor spring layer stairs relative to the direction; one the multi-storey plane, two residential house types are arranged in parallel to be penetrated through the whole construction depth, and a north-south penetrated space is formed. The invention solves the problem of the north-south ventilation and the south light of the middle obstruction house type of the public inner corridor at the construction depth in the staggered steel truss residence through the design of the house type staggered and occlude transversely and longitudinally, to ensure the staggered steel truss residential house type to obtain the possibility of being widely applied.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com