Method for underpinning roof structure and expanding column space of steel structure factory building

A plant column and steel structure technology, which is applied in building structure, building maintenance, construction, etc., can solve the problems of occupying the space outside the plant column, obvious traces of renovation, and inconvenient construction and installation, so as to reduce the project cost and reduce the external space , The effect of convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

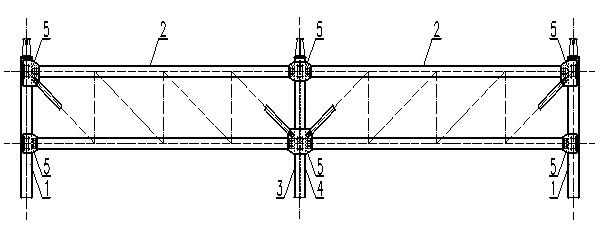

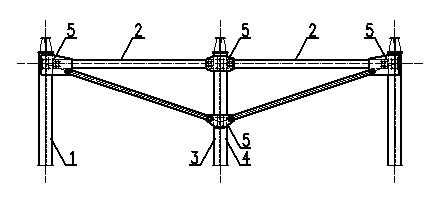

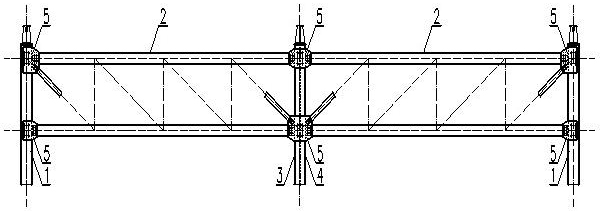

[0022] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. As shown in the figure, the method for enlarging the column distance of a steel structure factory building in the underpinning roof structure of the present invention is to make brackets 2 in sections according to the original column distance in the area where the column distance of the factory building needs to be expanded. , then the two ends of the bracket 2 made in sections are firmly connected with the supporting steel column 1 or the steel column 3 to be extracted, and a complete bracket is formed in the entire length section of the extraction column, and then the steel column 3 to be extracted is cut off. Section 4 of the column. figure 1 For the schematic diagram of removing one column, the length of the bracket 2 is half of that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com