Patents

Literature

699results about How to "Speed up the progress of the project" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

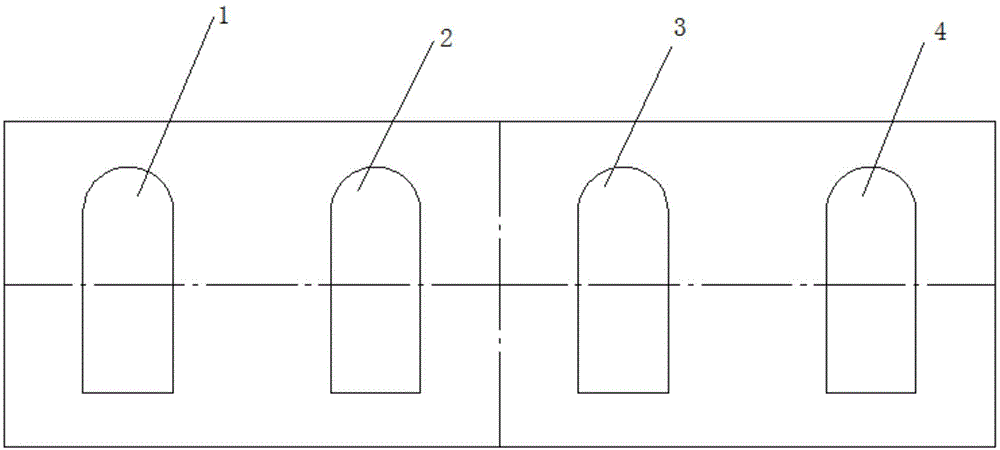

Large-section loess tunnel construction method

The invention discloses a large-section loess tunnel construction method, which comprises the following steps that: the whole section is divided into an upper part, a middle part, a lower part and a bottom part, wherein the middle part is divided into a middle left area, a middle right area and a middle intermediate area, the lower part is divided into a lower left area, a lower right area and a lower intermediate area, the four parts are excavated in a benching tunneling method with altitude differences, the upper part is 3-5m in front of the front middle part, the middle part is 3-5m in front of the front lower part, the lower part is 10m in front of the front bottom part, and the step-by-step tunneling excavation is carried out. The invention is suitable for collapsed loess areas, realizes the safe and reliable construction and saves a large number of temporary supporting steel frames. Due to the arc-shaped pilot tunnel method, the loop can be formed rapidly during excavation, the disturbance to the surrounding rock is low, the primary support is stable, the traditional construction method is further improved to be the 'two-step and four-part excavation method', and the construction cycle period is short. Moreover, the invention can speed up the progress of the project, shorten the construction period, and reduce the cost of the project.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

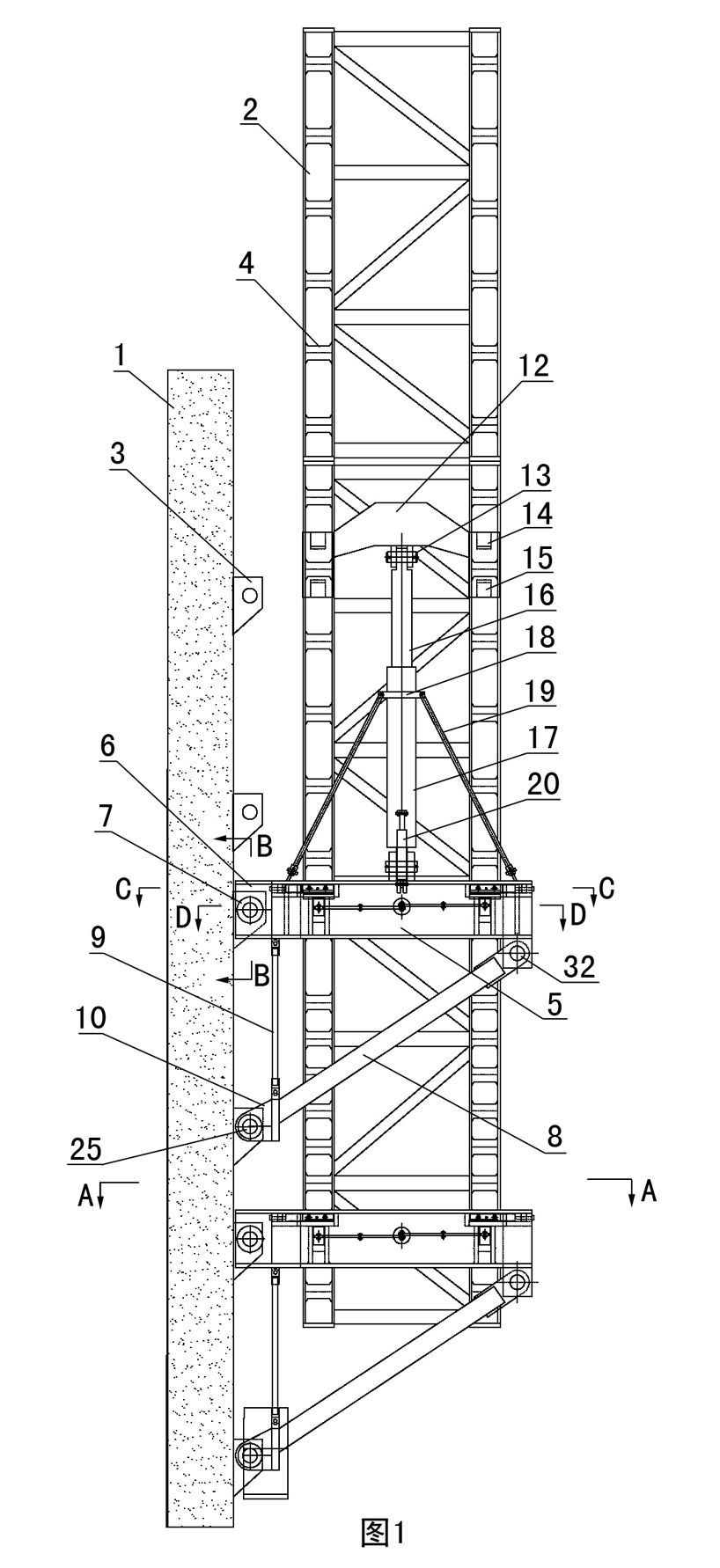

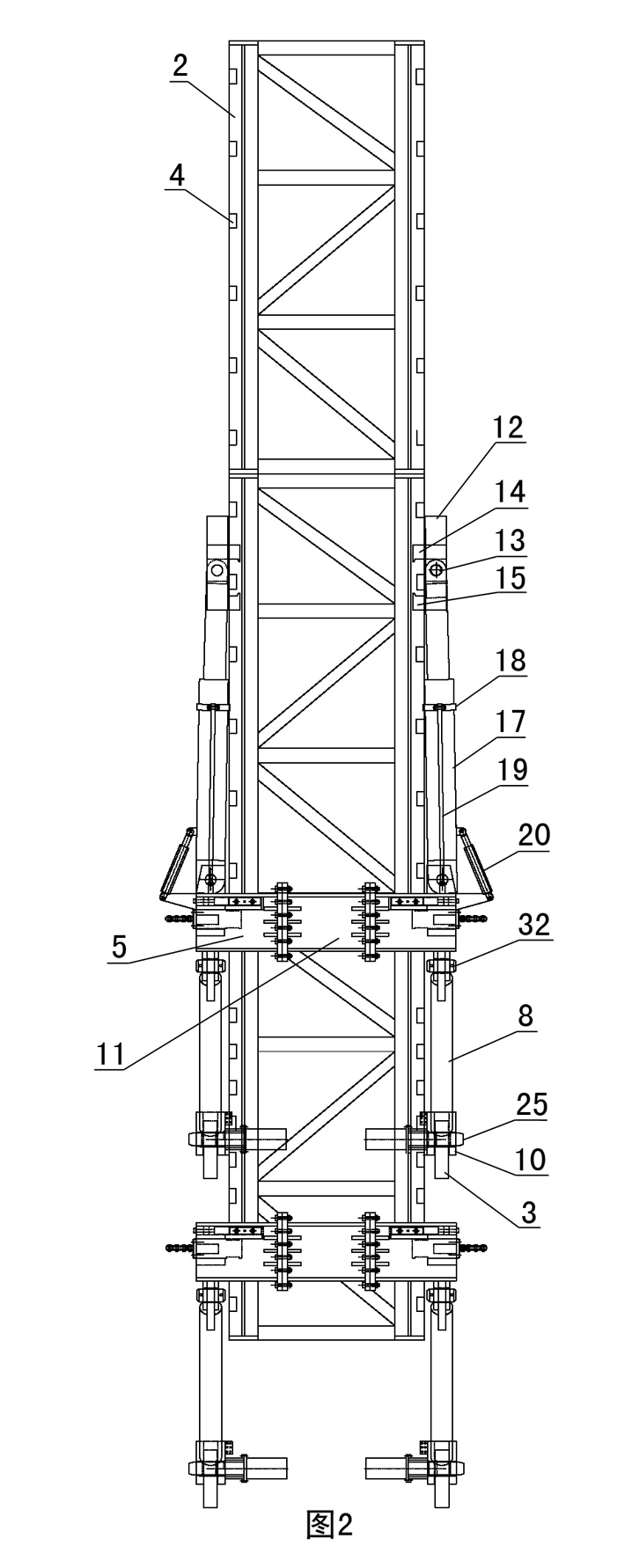

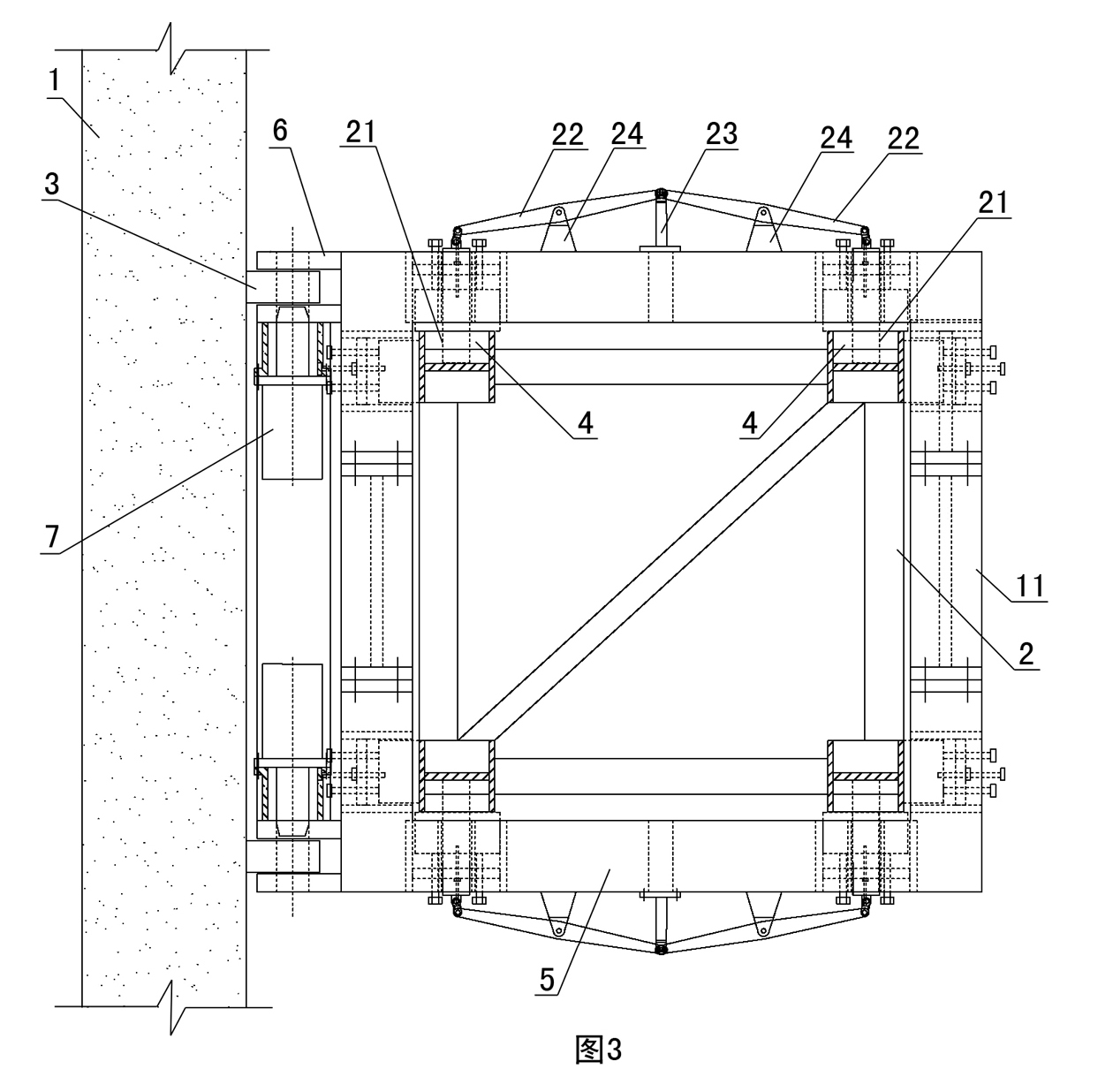

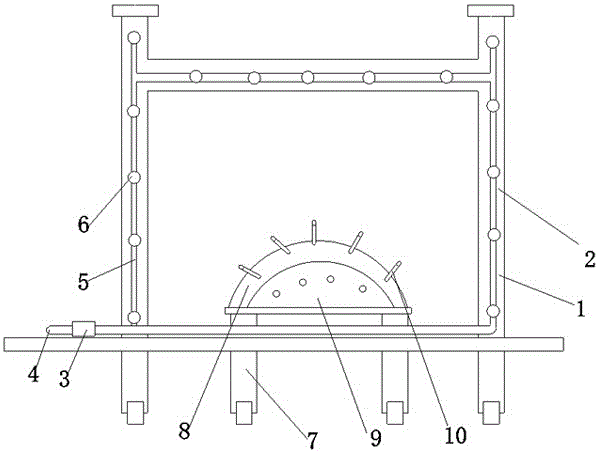

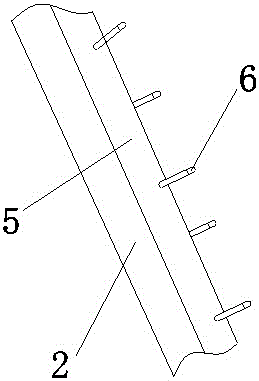

Hydraulic climbing system for wall-attached support frame

ActiveCN102071798AImprove construction efficiencyReduce construction costsForms/shuttering/falseworksScaffold accessoriesSupporting systemArchitectural engineering

The invention discloses a hydraulic climbing system for a wall-attached support frame. The system comprises a support upright post, a support frame device and a hydraulic jacking device, wherein the support frame device is detachably connected with a bracket which is fixed on a core barrel concrete wall and at least comprises an upper support frame device and a lower support frame device; both the upper support frame device and the lower support frame device are provided with upright post supporting devices and upright post clamping devices; climbing step blocks are vertically distributed at intervals on a column of the support upright post; and the support upright post is supported on the upright post supporting device through the climbing step blocks and is connected with the upper support frame device and the lower support frame device through the upright post clamping devices in a clamping way. In the system, an overall elevating template system, a construction steel platform system, a tower crane support system and the like are automatically elevated entirely along with the height increase of a building main body. The system has high safety, short climbing time and high construction efficiency, and can be used repeatedly in different projects.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

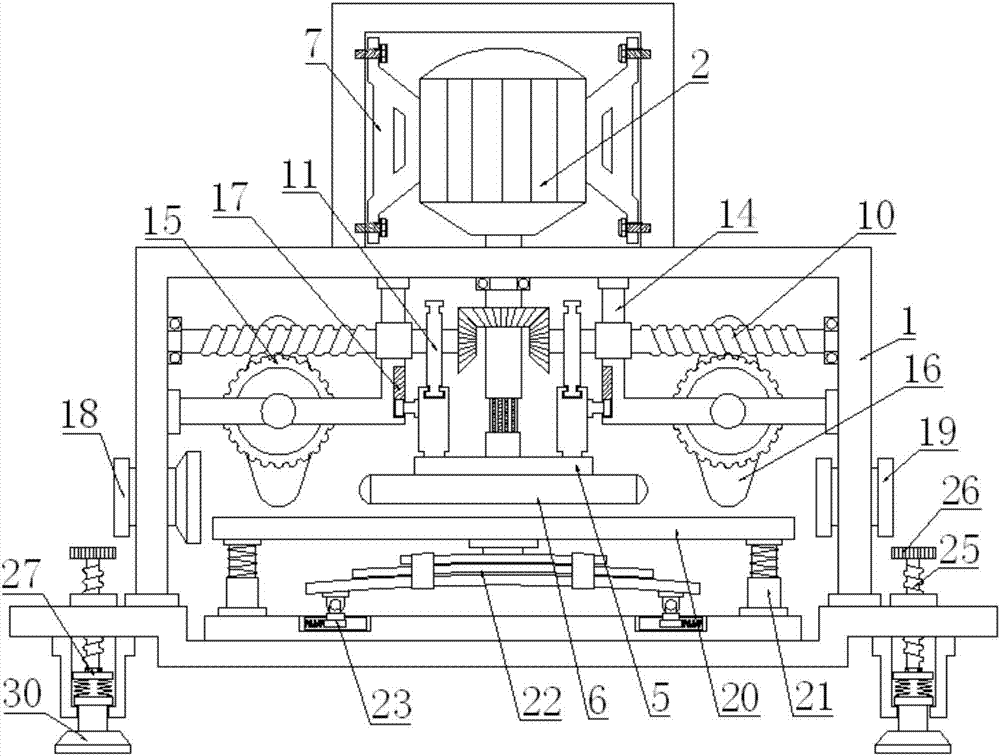

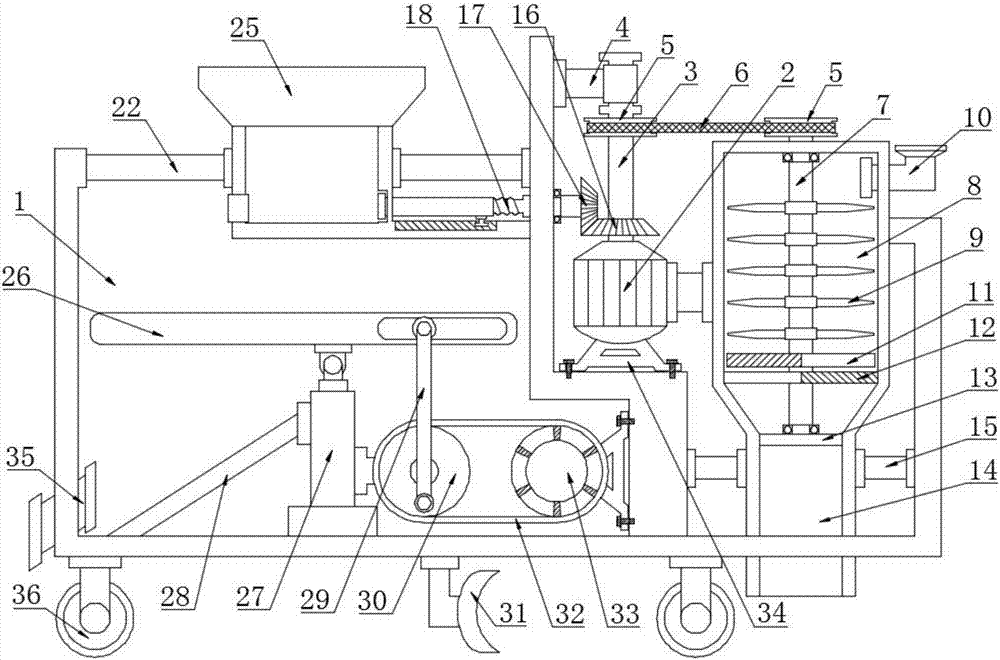

Efficient building steel plate polishing device

InactiveCN107984359AImprove grinding efficiencyReasonable structural designGrinding drivesGrinding feedersSheet steelDrive shaft

The invention discloses an efficient building steel plate polishing device. According to the technical scheme, a step shaft is sleeved with a driving shaft and is fixedly connected with an annular sliding groove, and the lower end of the annular sliding groove is fixedly connected with a grinding wheel; the upper part of the driving shaft is fixedly connected with a first bevel gear, a second bevel gear is fixedly connected with the end of a worm, the worm is sleeved with the upper part of a retainer, the retainer is fixedly connected with a device body, and a bearing at the other end of the worm is rotationally connected with the inner wall of the device body; and the worm is fixedly connected with an eccentric groove wheel, the lower end of the eccentric groove wheel is clamped at the upper end of a vertical supporting rod, and the lower end of the vertical supporting rod is connected with the annular sliding groove in a sliding mode. According to the device, through the driving shaft and the eccentric groove wheel, the grinding wheel can rotate to polish and move up and down at the same time, the worm rotates to drive the worm wheel to rotate, and then a steel plate can be driven to automatically and intermittently fed through a cam, the grinding wheel is separated from the steel plate when the steel plate is fed, and the grinding wheel polishes downwards when the steel plate is static; and the device is reasonable and practical in structural design, greatly improves the polishing efficiency of the building steel plate, is high in automation degree, and is beneficial toimproving the engineering progress.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

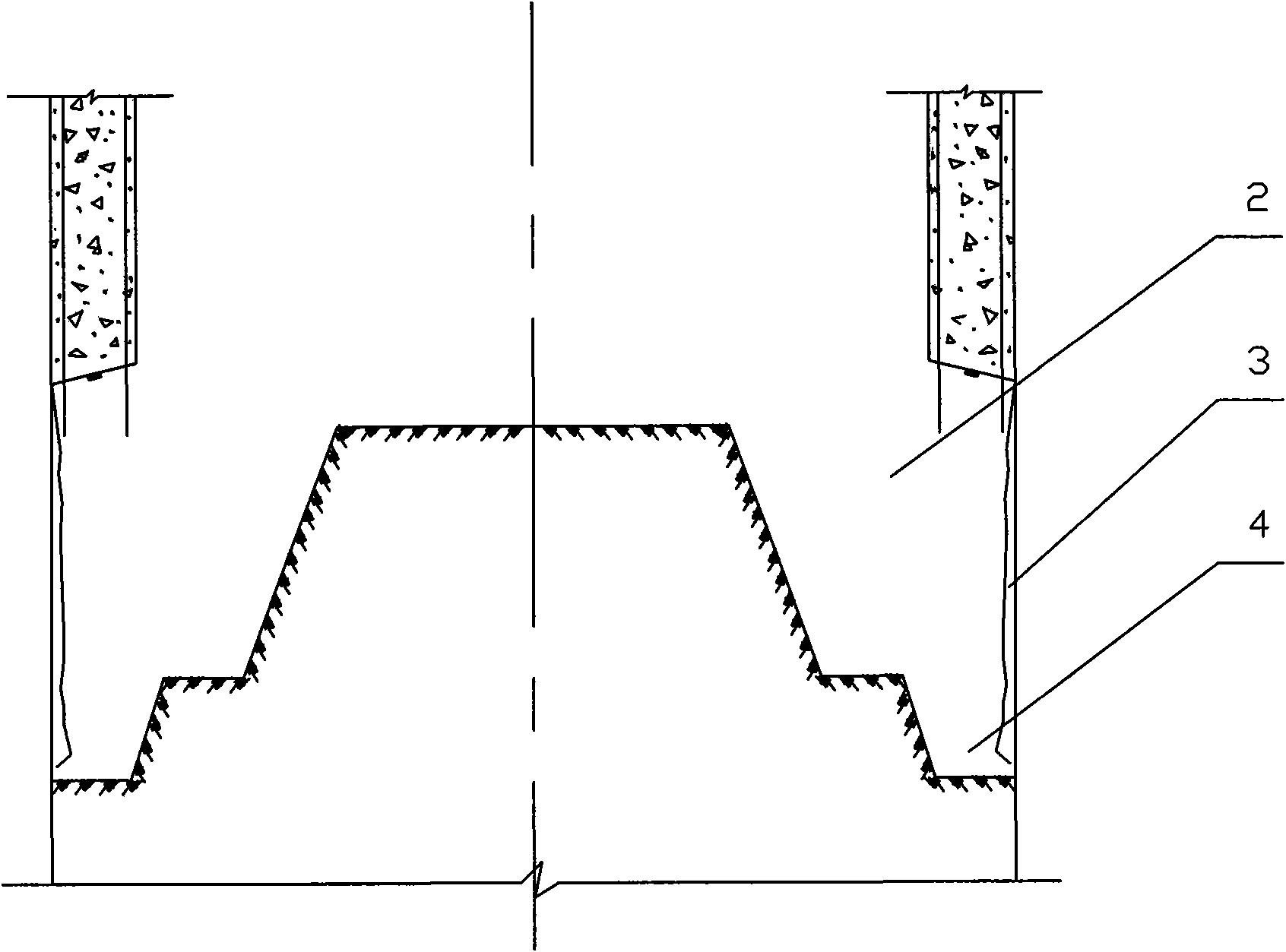

Foundation integrated processing construction method of cover type karst area

ActiveCN101864763ASpeed up the progress of the projectSave construction fundsSoil preservationBedrockSleeve valve

The invention relates to a foundation processing method, in particular to a foundation integrated processing construction method of a cover type karst area. The method comprises the following steps of: evacuating earth moving machinery when a foundation pit is excavated until a limestone formation is exposed in a large area; basically exposing rocks of the bottom of the foundation pit after excavating, wherein rock buds are exposed from a foundation base, and the storage quantity of damic earth among the rock buds does not influence the next procedure construction; adopting weakened loose blasting operation, aiming at solution cracks, intermountain gulches and locally crushing bedrocks, and mechanically crushing and clearing; adopting a complex geophysical prospecting technological means that a high-density resistivity method is combined with a geological radar, arranging a high-density electrical geophysical prospecting wire in a construction site according to an arrangement rule, meanwhile, arranging a detailed exploratory hole in a building planning position, and mechanically picking the solution cracks, the intermountain gulches and the locally crushing bedrocks; adopting sleeve valve cement flour and coal ash slurry injecting constriction and cement flour and coal ash slurry filling constriction by a solution cavity slurry-injection method; and filling and casting concrete. The invention can quicken a work progress and can save construction cost compared with other foundation processing modes.

Owner:CHINA 22MCC GROUP CORP +1

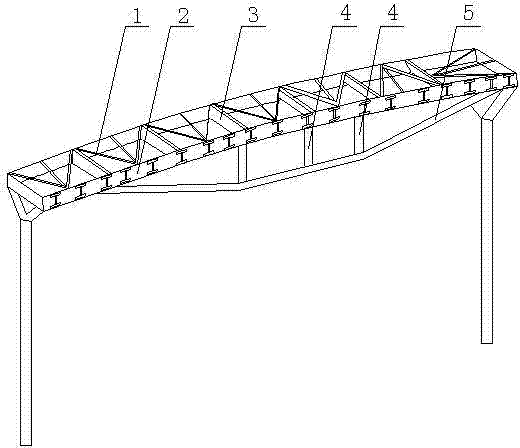

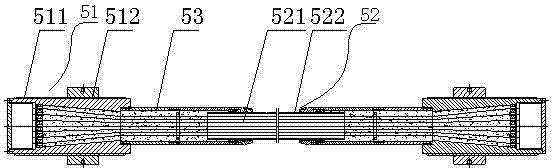

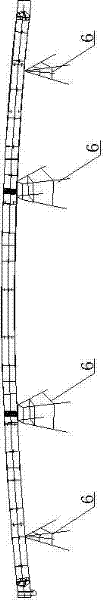

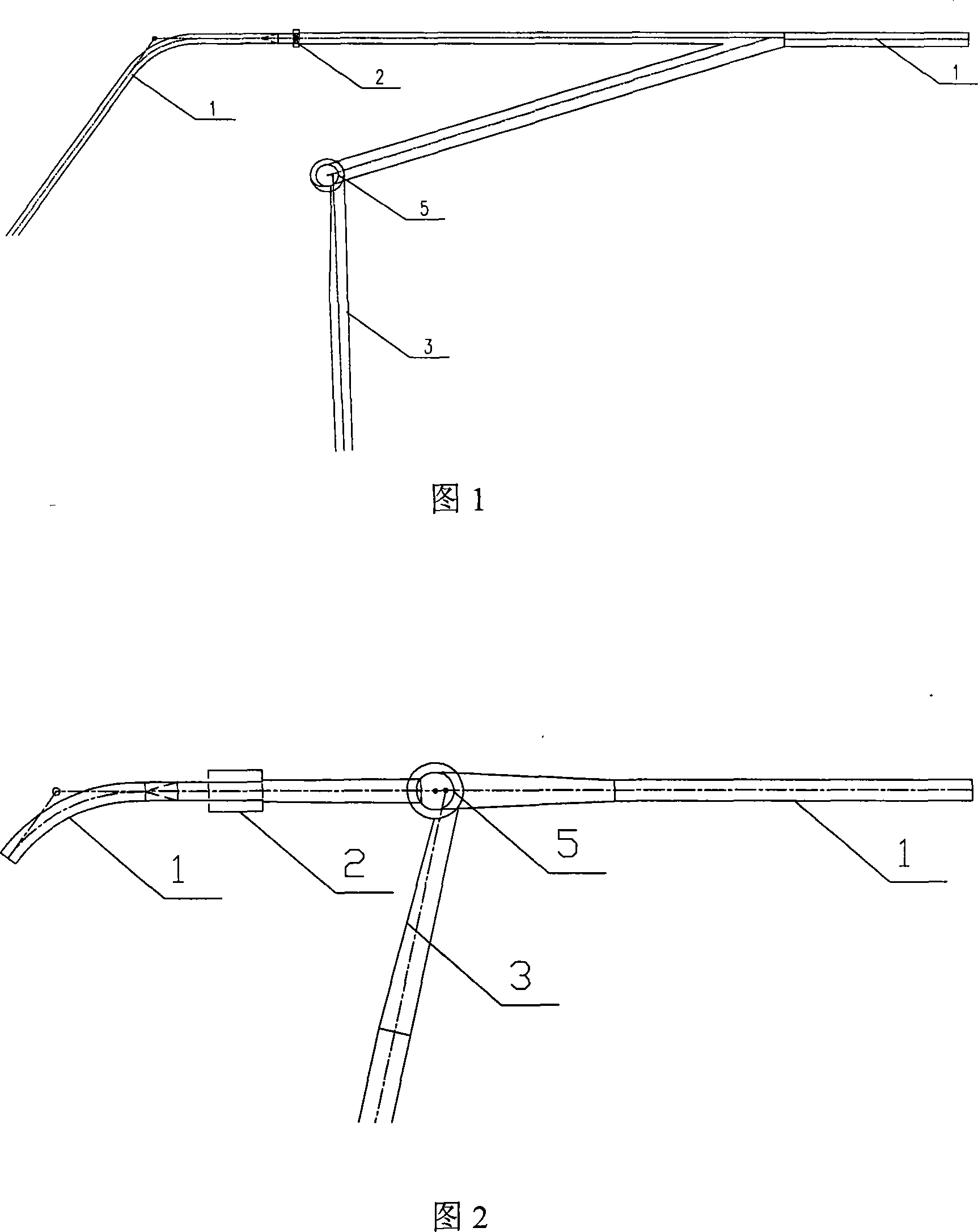

Long-span prestressed tension string beam and its construction method

InactiveCN102296750ASpeed up the progress of the projectShorten construction timeGirdersJoistsEngineeringLong span

The invention relates to a construction method of wide span prestressed beam string structure, which is capable of shortening construction time under the construction quality guaranteed. The construction method of the above beam string structure comprises the following steps of: 1) tension calculation under different working conditions; 2) simulation calculation; 3) stay cable processing; 4) supporting moulding bed assembly; 5) beam string structure assembly and welding; 6) stay cable installation; 7) beam string stay cable tensioning; 8) beam string hoisting; and 9) sampling observation of the tension value of the installed beam string structure to see whether the tension value conforms to the design.

Owner:中铁铁工城市建设有限公司

Anticorrosion construction technology and method for steel structure

InactiveCN107282388AGood adhesionAvoid crackingLiquid surface applicatorsAnti-corrosive paintsEpoxyBinding force

The invention relates to corrosion resistance of the surface of a steel structure, in particular to an anticorrosion construction technology and method for a steel structure. The technology comprises the steps of surface purification treatment, priming paint spraying and finish paint spraying. According to the technology, at first, the surface of the steel structure is mechanically or chemically treated, then a steel metal coating is coated with epoxy zinc rich priming paint to serve as a priming paint coating, and finally acrylic acid polyurethane finish paint is sprayed. An adhesive property of the epoxy zinc rich priming paint and a base body is good, the cracking phenomenon of a base layer is avoided, the face layer has better wear resistance and corrosion resistance, the binding force of the anticorrosion layer and the steel structure base body is high and reaches 15.0-20 Mpa on average, surface hardness reaches over HV410 and is much higher than the national standard, the long-acting anticorrosion purpose can be achieved, and the appearance of the structure is improved. Moreover, construction quality of the anticorrosion coating is ensured, the work progress is improved, and the maintenance cost of the steel structure is saved.

Owner:QINGDAO MINGZHU STEEL STRUCTURE CO LTD

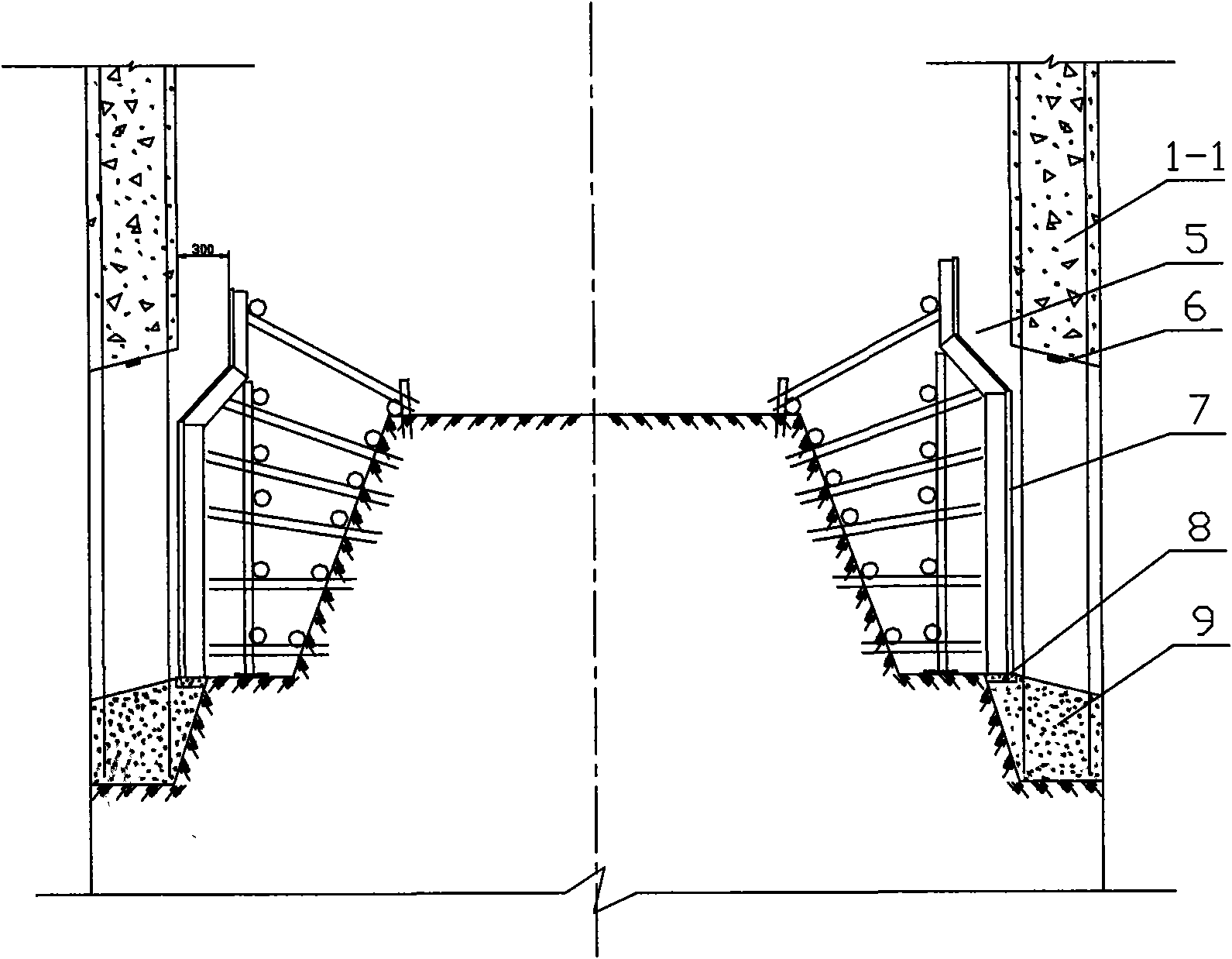

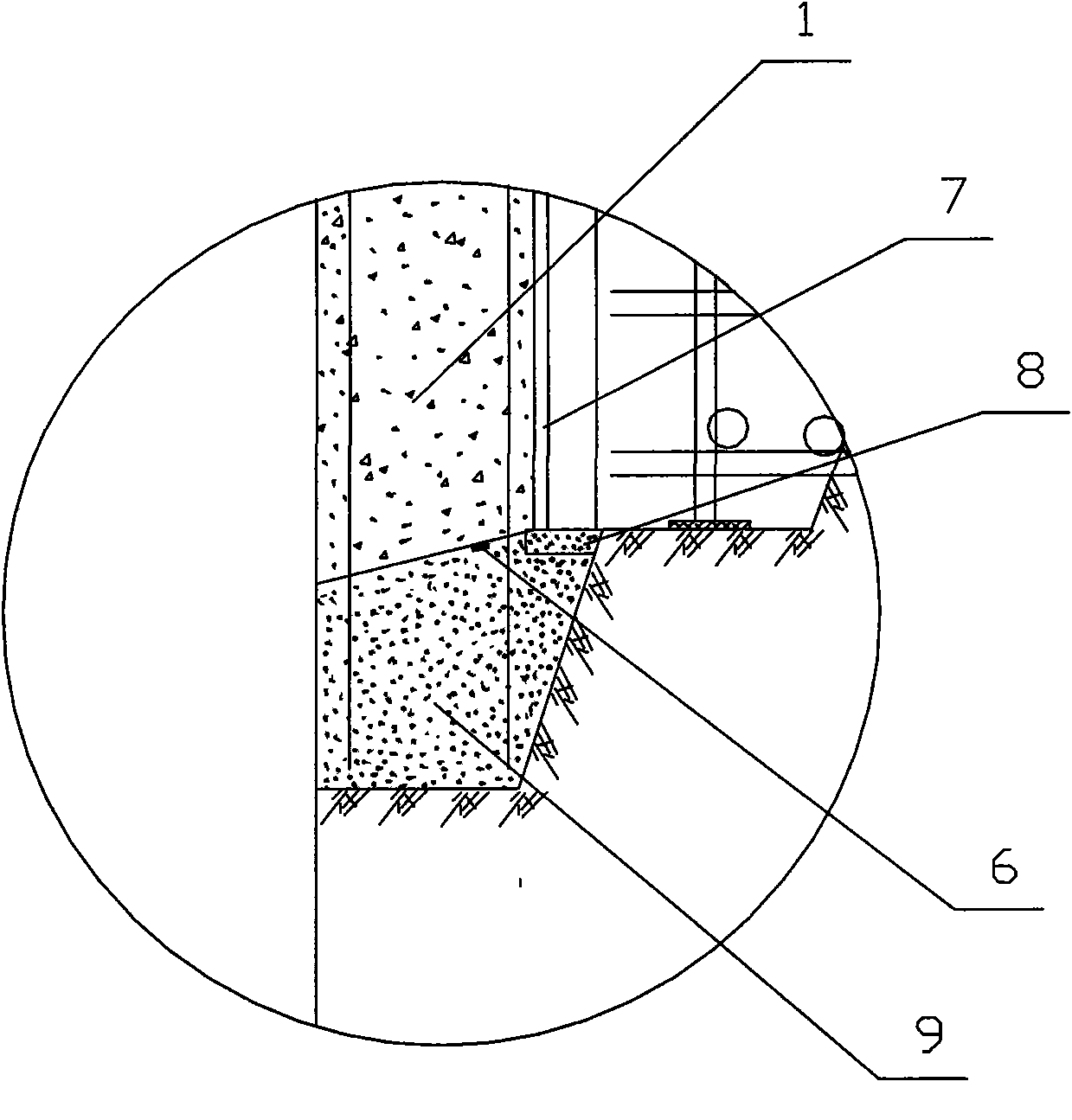

Top-down construction method of large underground structure outer wall

InactiveCN101672041AImprove ergonomicsGuarantee molding qualityArtificial islandsUnderwater structuresEngineeringRebar

The invention discloses a top-down construction method of a large underground structure outer wall, comprising the following steps: constructing a supporting pile; borrowing earth; binding a first section of outer wall and ring beam reinforcing steel bars, wherein the ring beam reinforcing steel bars are respectively fixedly connected with reinforcing steel bars in the first section of outer walland the reinforcing steel bars in the supporting piles; raising templates; pouring concrete, wherein the first section of outer wall, the ring beam and the supporting piles are integrated as a whole;and repeating the construction of borrowing earth, binding reinforcing steel bars, raising templates, pouring concrete until the bottom surface of the last section of outer wall reaches the designed elevation. The adoption of a pile hanging technique in the invention ensures safe construction, the adoption of a double anti-leakage technique ensures no leakage inside the outer wall, the adoption ofa fast molding technique accelerates the program progress, and the application of sizing steel templates ensures the appearance quality of the concrete thereby achieving a good effect.

Owner:TIANJIN 20 CONSTR

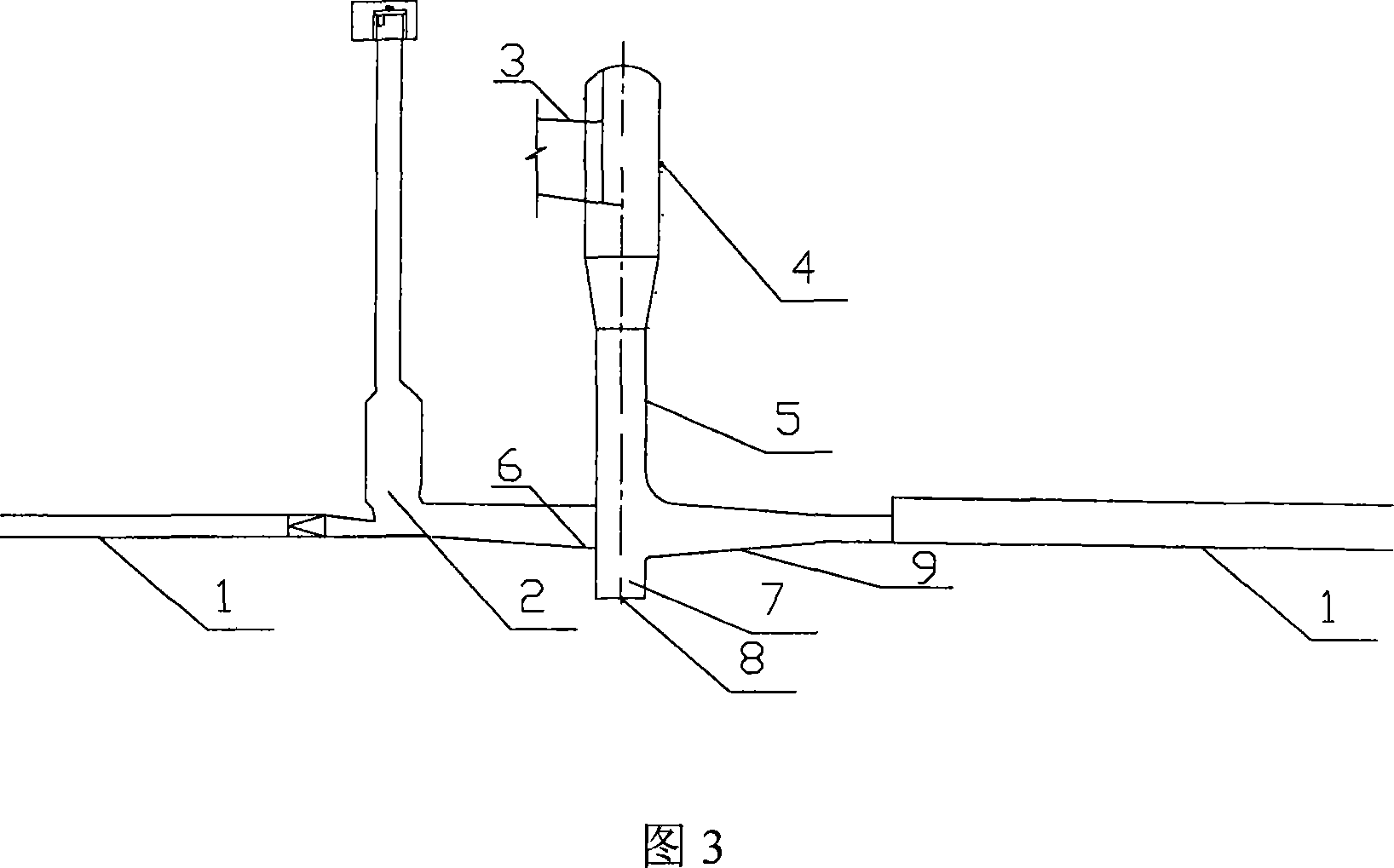

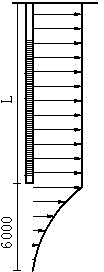

Vertical shaft rotational flow flood discharging tunnel and emptying tunnel or diversion tunnel square crossing arrangement hydraulic form

InactiveCN101215830ALow costSpeed up the progress of the projectBarrages/weirsWater-power plantsEngineeringHydraulic engineering

The invention discloses a hydraulic engineering type of a vertical crossing arrangement for a silo vortex flood discharging tunnel and a releasing tunnel or a diversion tunnel, which is characterized in that: the hydraulic engineering type is to make the flood discharging tunnel and the releasing tunnel or a diversion tunnel arranged in vertical crossing through a silo vortex chamber on the top of no pressure section behind a middle brake chamber of the releasing tunnel or the diversion tunnel, which combines the flood discharging tunnel behind the silo with the releasing tunnel or the diversion tunnel. The invention needs not to construct a section of drainage equipment from the silo exit to the connection place of two tunnels, and can avoid bad fluidization in a connection place of two tunnels in the prior inclined crossing technique scheme, has no particular requirements and limitations on the axis direction of the releasing tunnel or the diversion tunnel, can select a good and short path for construction according to the landform and geologic conditions, thereby greatly lowering cost, reducing engineering period, achieving the aim of a rapid start of operations.

Owner:SICHUAN UNIV +1

Deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate

InactiveCN102506623AAvoid uniformityAvoid problems that are mainly concentrated in the bottom of the blast zoneBlastingQuincunxDeep hole

The invention relates to a deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate. The method comprises the following steps of: 1) drilling boreholes on the bench of a blasting area through a triangular or quincunx-shaped hole arrangement method according to open deep-hole bench blasting design and requirements to obtain deep holes; 2) drilling a shallow borehole with hole diameter being less than or equal to 50mm in the middle between every two deep holes in the same row to obtain shallow holes; 3) respectively charging the deep holes and the shallow holes, laying initiating explosive cartridges and blocking the mouths of the deep holes and the shallow holes; and 4) conducting row-to-row sequential short-delay initiation according to initiation sequence in design requirements and blasting in one step. The deep-hole and shallow-hole combined bench blasting method capable of reducing blasting boulder rate has the advantages that the problem of high boulder rate of blocked sections in a deep-hole bench blasting method is solved, the blasting effect is improved, the subsequent excavating and loading efficiency is improved, the engineering progress is accelerated and the engineering cost is reduced.

Owner:LANZHOU UNIVERSITY

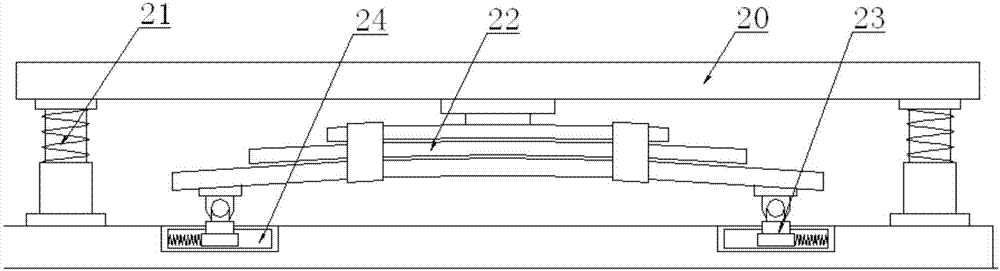

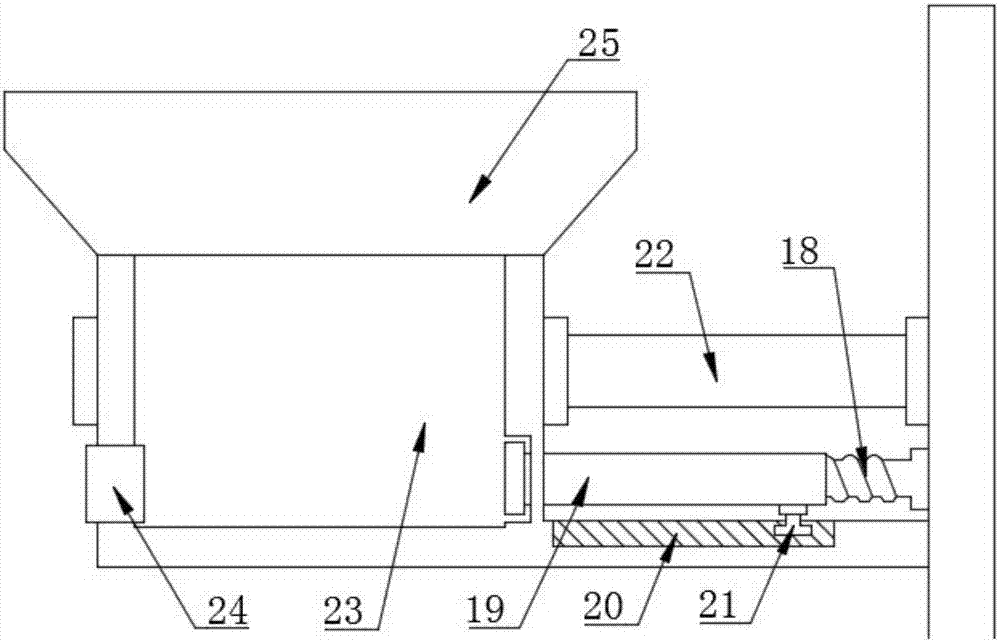

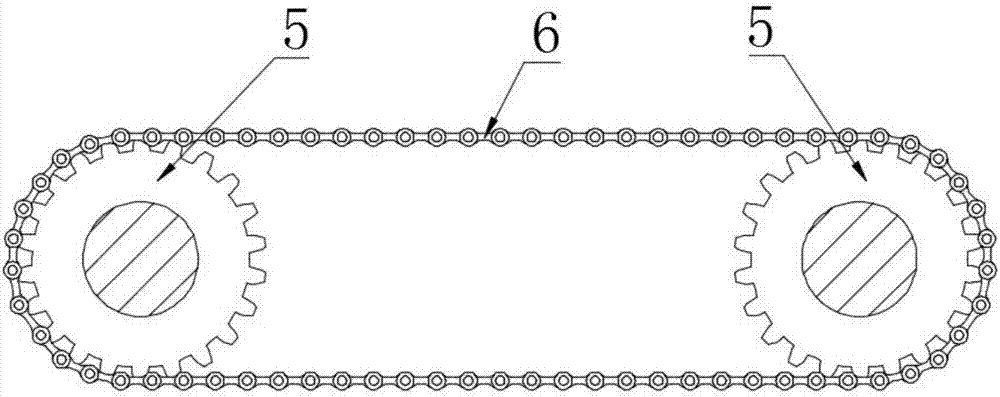

Building floor tile laying device

InactiveCN107575017AImprove laying efficiencyReasonable structural designBuilding constructionsBrickDrive shaft

The invention discloses a building floor tile laying device. The upper end of a driving shaft is connected with the right end of a sleeving rod in a sleeved mode; the left end of the sleeving rod is fixedly connected with a device body; the upper end of the driving shaft is fixedly connected with a chain wheel; the chain wheel is in engaged connection with the left end of a chain; the right end ofthe chain is engaged with a right chain wheel; the right chain wheel is fixedly connected with a driven shaft, and the upper end of the driven shaft is rotationally connected with a slurry tank through a bearing, and the lower end of the driven shaft is rotationally connected with a buffer plate; the buffer plate is fixedly connected with the lower portion of the slurry tank; the lower end of thedriven shaft is fixedly connected with a movable groove plate; and a fixed groove plate is arranged at the lower end of the movable groove plate. According to the building floor tile laying device, the driven shaft rotates to stir cement slurry; a lead screw drives a thread sleeve to move horizontally in a reciprocating mode, and thus single tile supply is achieved; and intermittent discharging is conducted under the effect of the movable groove plate, and a transverse plate is inclined in a reciprocating mode to be horizontal so as to lay tiles stably. The device is reasonable and applicablein structural design, the laying efficiency of the building floor tiles is improved greatly, and the automation degree is high, so that the function of simultaneous cement grouting and floor tile laying is achieved, and the engineering progress is accelerated.

Owner:刘晓菊

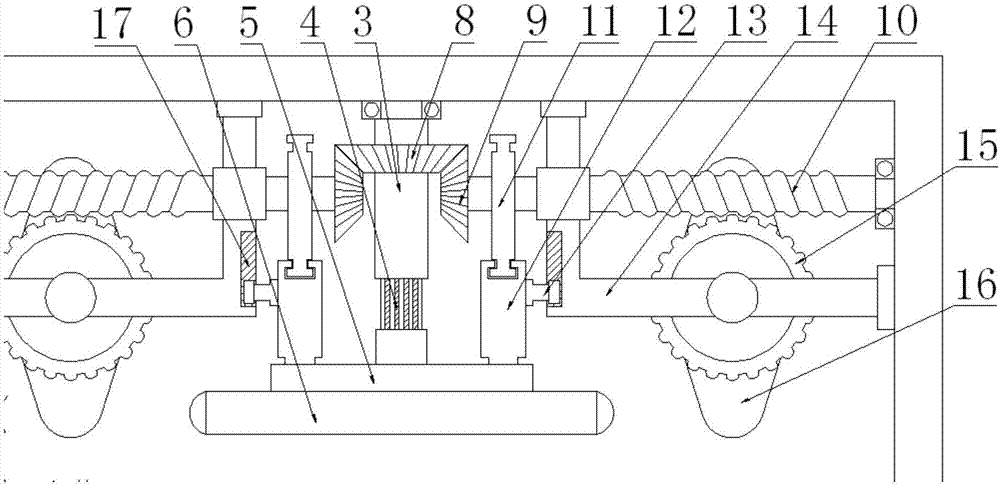

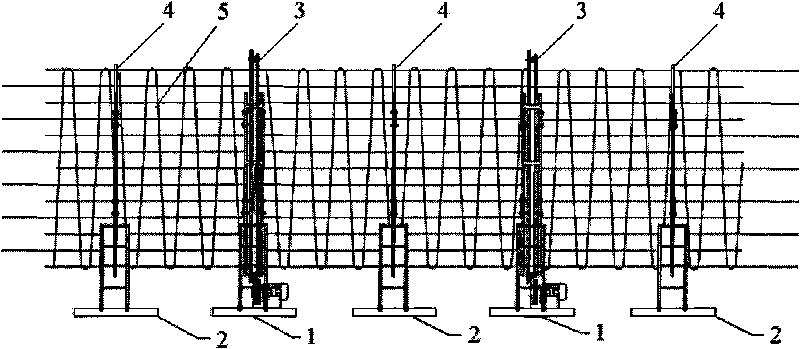

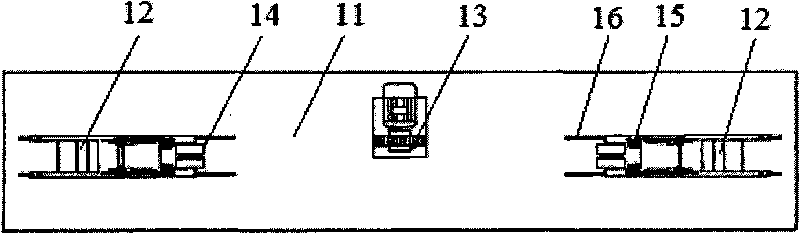

Manufacturing method of reinforcement cage of pouring pile with large diameter

ActiveCN101761071AImprove manufacturing precisionReduce the number of employeesBulkheads/pilesLow speedGear wheel

The invention discloses a manufacturing method of a reinforcement cage of a pouring pile with the large diameter, relating to the technical field of construction project. The invention aims at reducing the labor intensity while improving manufacturing accuracy and work efficiency. The method is characterized in that a manufacturing device consisting of a plurality of rolling bearing frame assemblies and transmission bearing frame assemblies is arranged according to a projection line of a central axis line of the reinforcement cage; openable ring mould assemblies are arranged on each transmission bearing frame assembly; inner walls of the ring mould assemblies are provided with a plurality of main reinforcement positioning grooves; main reinforcements of the reinforcement cage is lifted into the ring mould assemblies, the ring mould assemblies are driven through a low-speed drive gear to rotate so that each main reinforcement enters the main reinforcement positioning grooves and is fixedly welded with rectilinear hoops; and the ring mould assemblies are rotated and winded and reinforcing steel bars are rounded by using spot welding so as to realize mechanization manufacture of the reinforcement cage of the pouring pile with the large diameter. The method provided by the invention can realize high manufacturing accuracy and cage-making work efficiency of the reinforcement cage, can greatly reduce the labor intensity and reduce the worker amount of unit cage manufacture amount and is beneficial to quickening the project progress.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

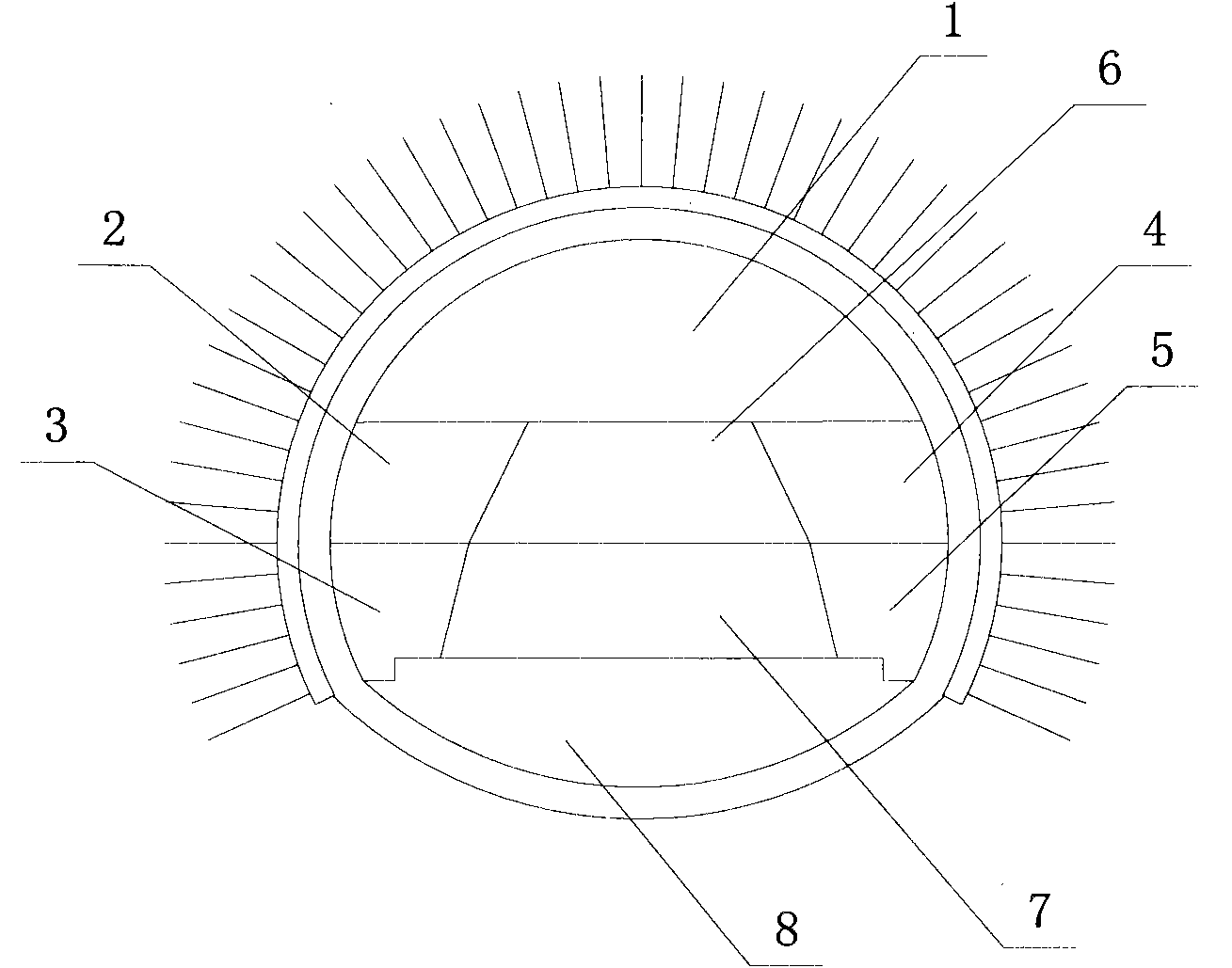

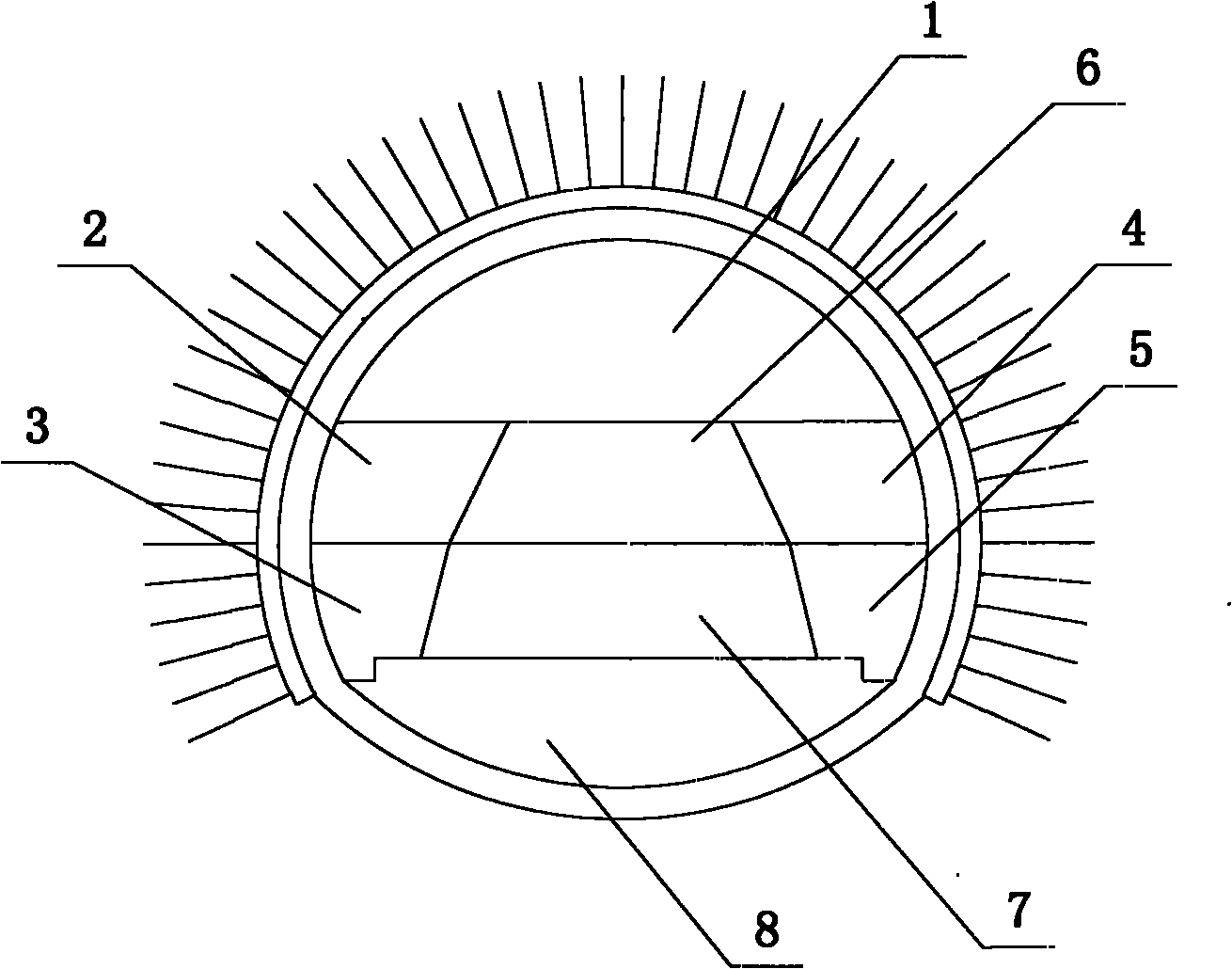

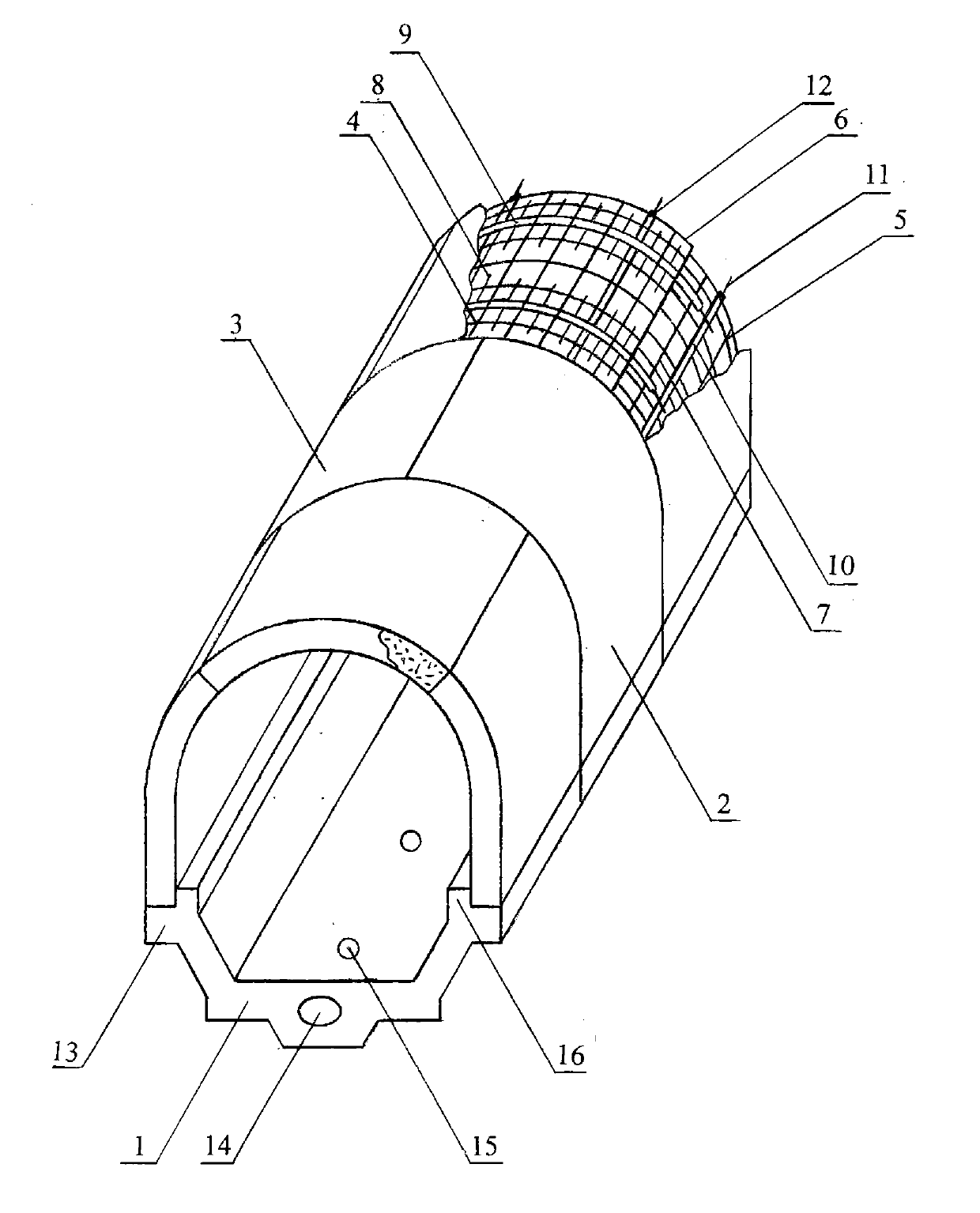

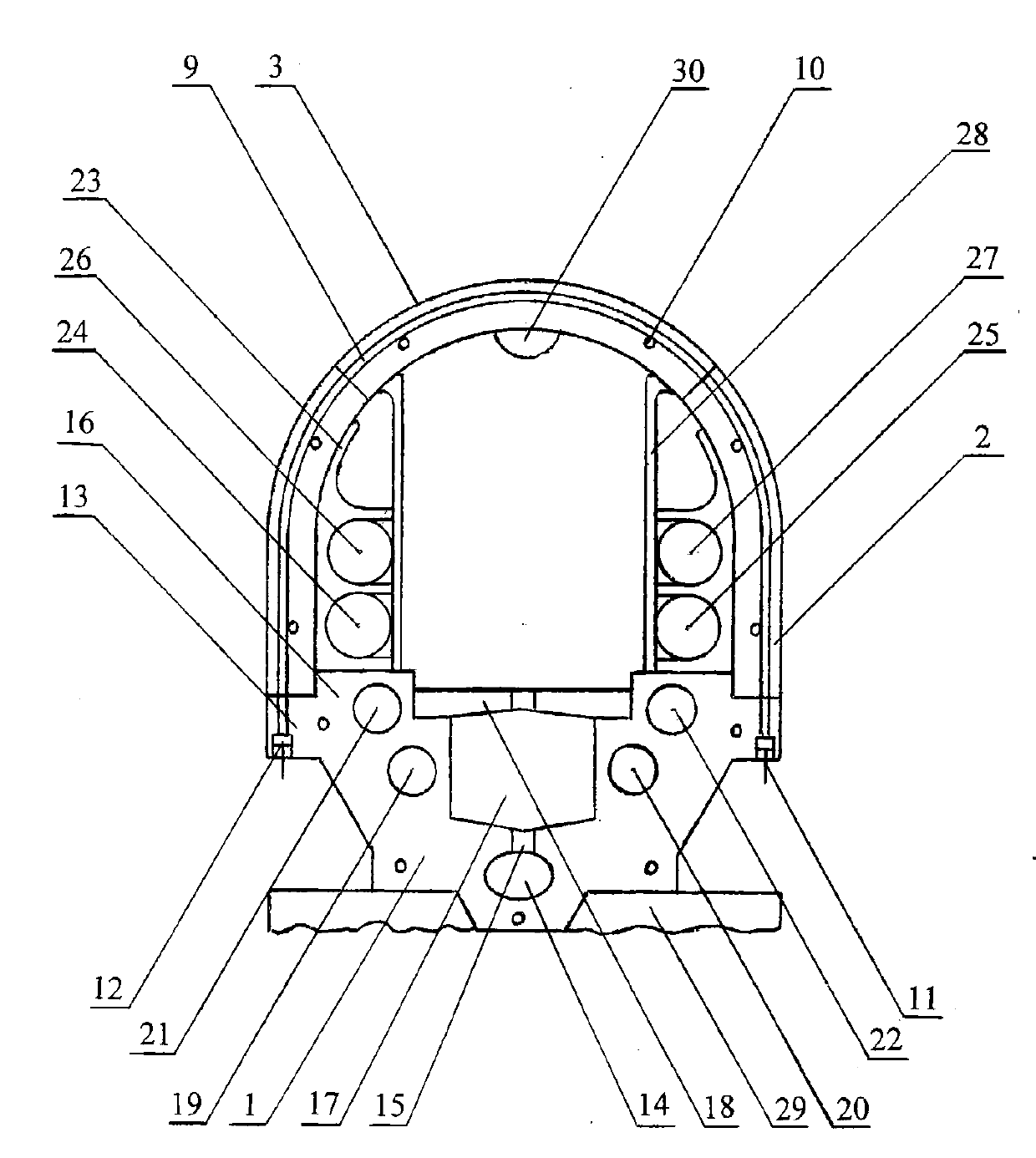

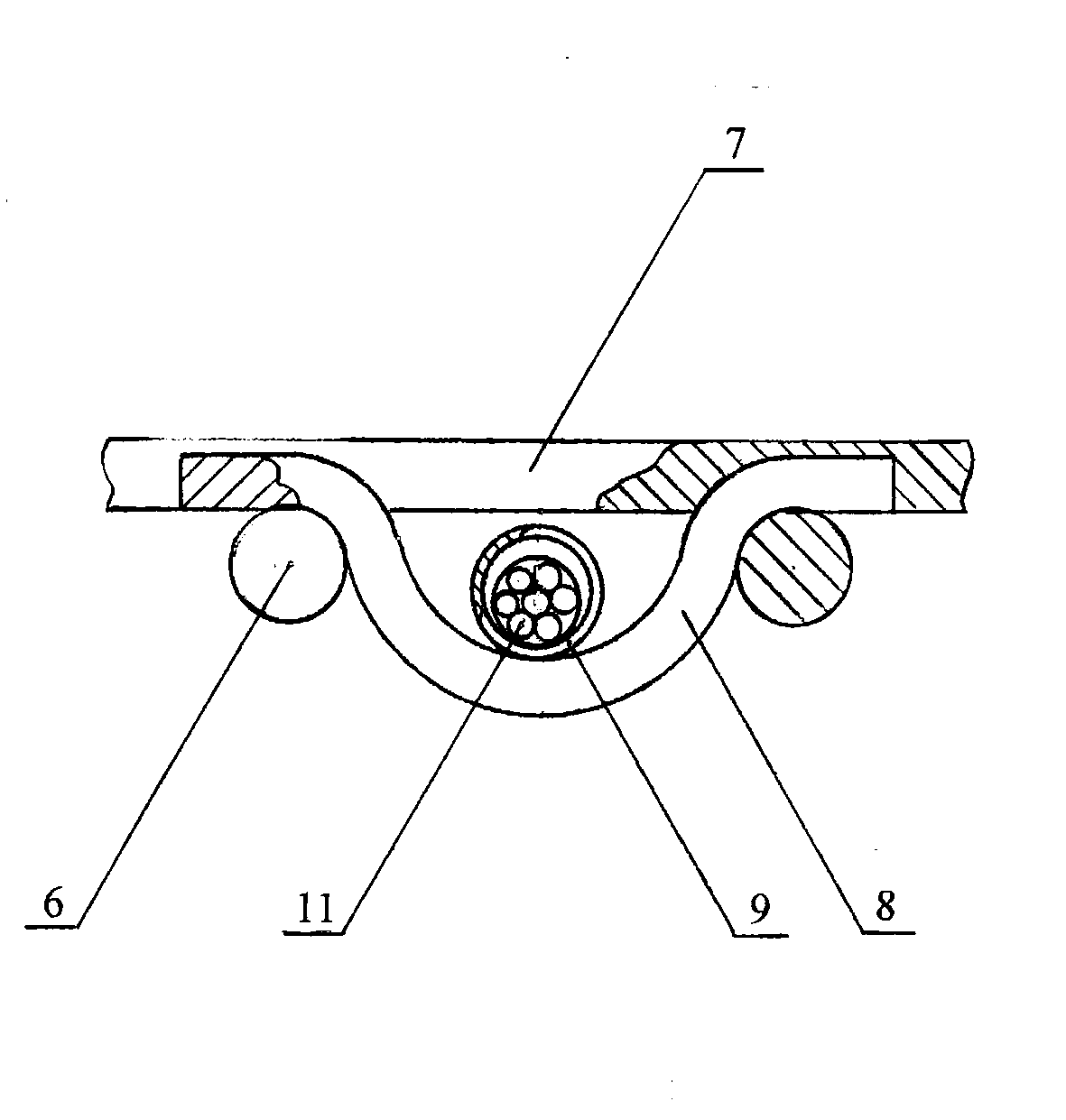

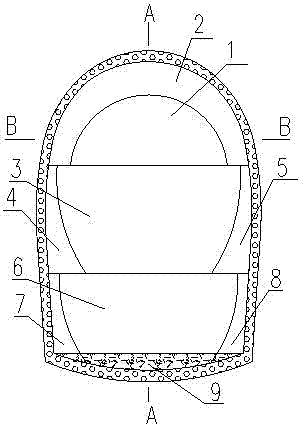

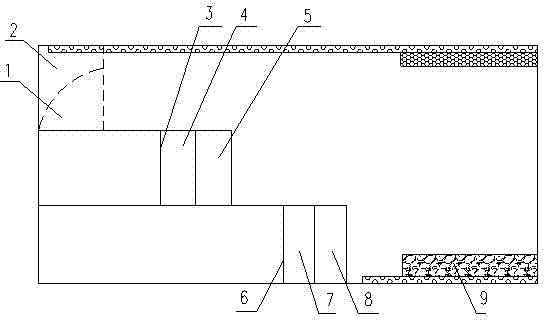

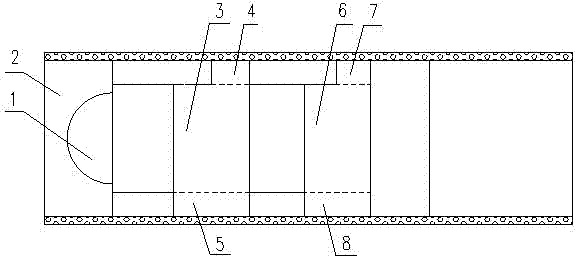

Multifunctional arched combined prestress underground pipe gallery for cisty and preparation process thereof

InactiveCN102995660AImprove shear resistanceImprove high pressure resistanceArtificial islandsUnderwater structuresHigh standardHigh pressure

The invention discloses a multifunctional arched combined prestress underground pipe gallery for a city, and a preparation process thereof. The multifunctional arched combined prestress underground pipe gallery consists of a concrete pipe sheet seat and an arched pipe body, wherein the arched pipe body is arranged on the pipe sheet seat and consists of the tube sheet. The pipe sheet seat and the pipe sheet are utilized, the underground pipe gallery is combined according to a structural mode of the arched pipe body to meet a high standard requirement on high pressure resistance, sedimentation resistance, torsion resistance, displacement resistance and earthquake resistance, so that the construction level of the city is improved. According to the topography of a town, a drainage network with a self-flow function is arranged, so that a design target of the functional pipe gallery and the safe pipe gallery is fulfilled.

Owner:张双里

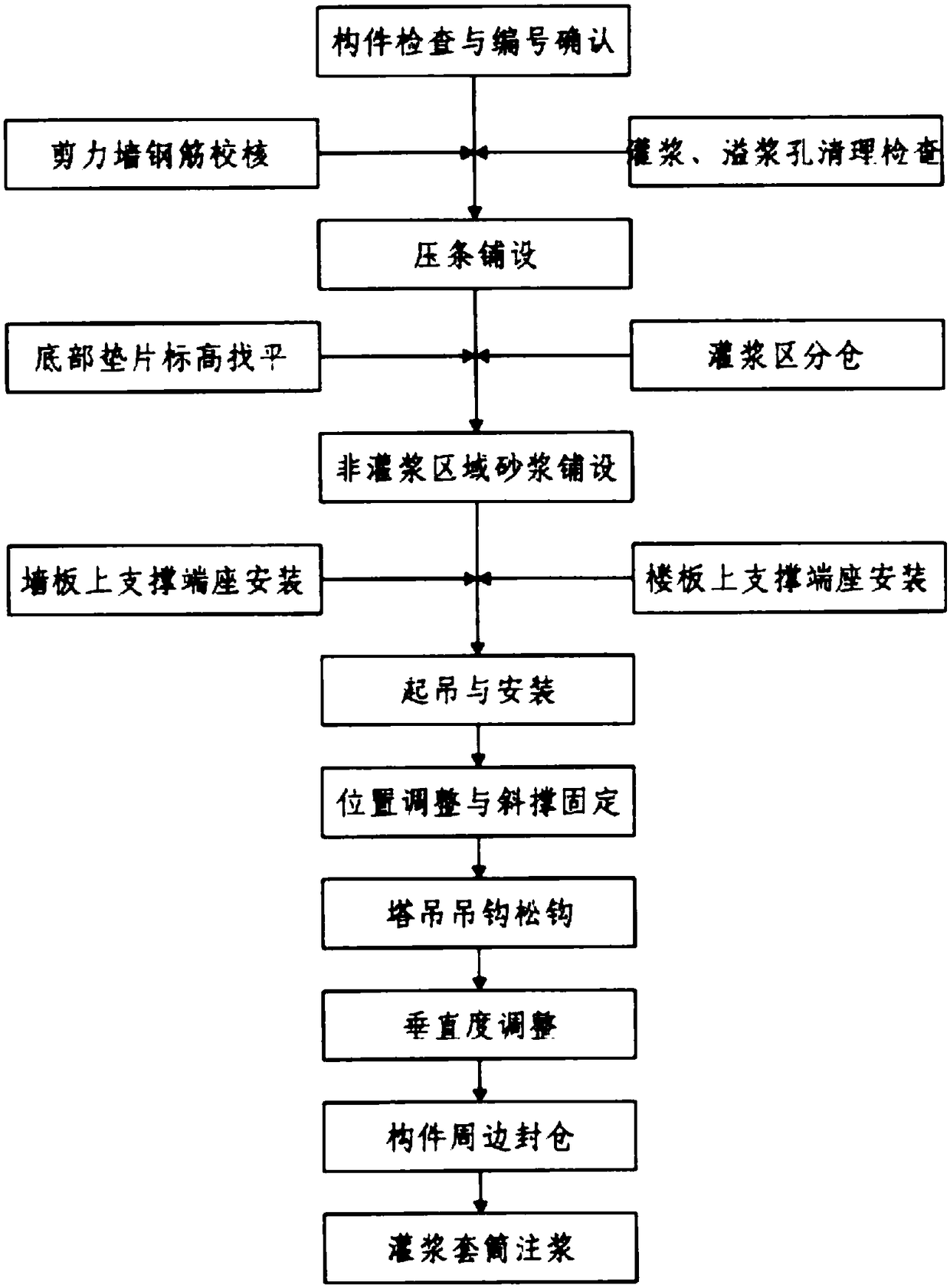

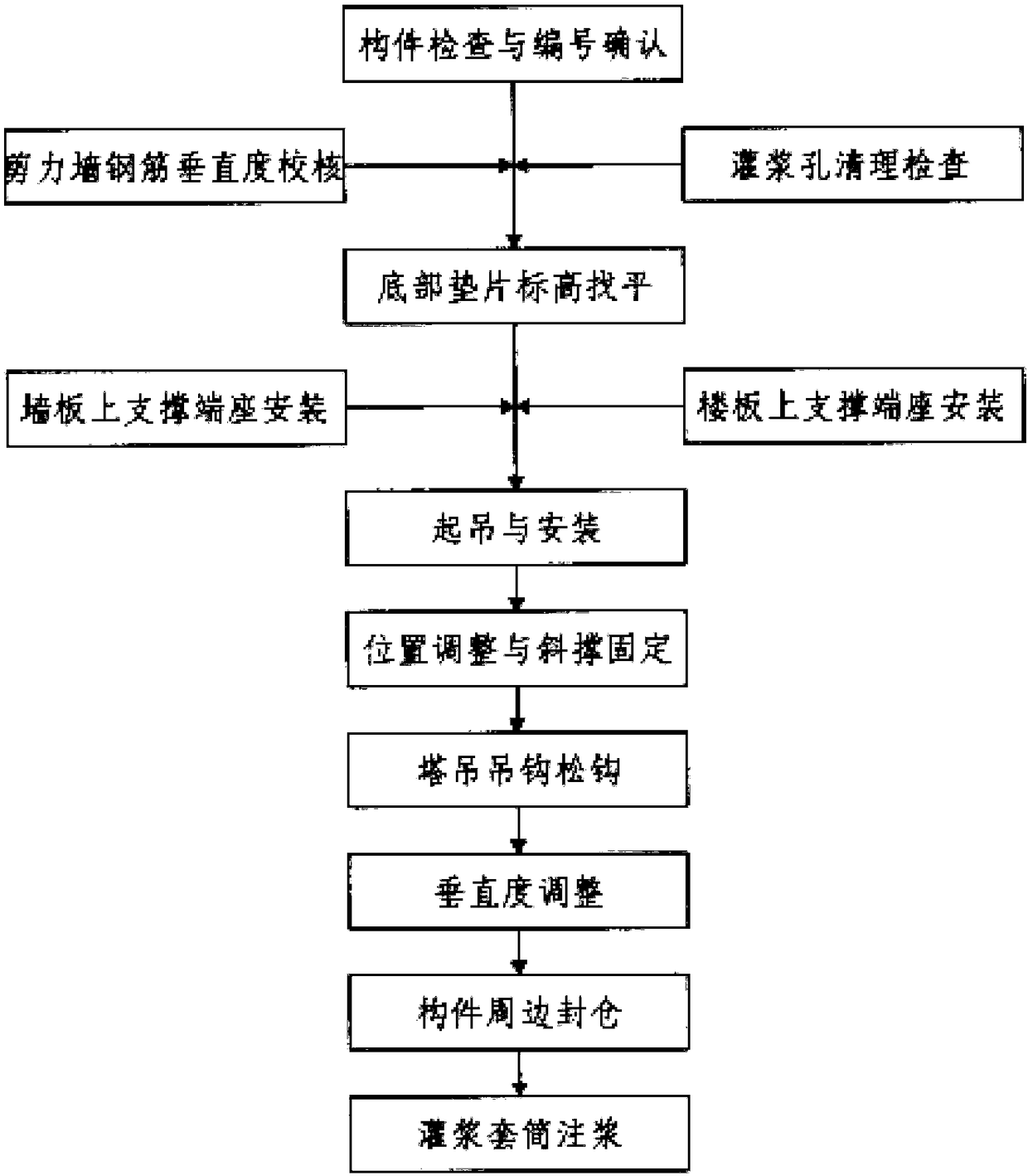

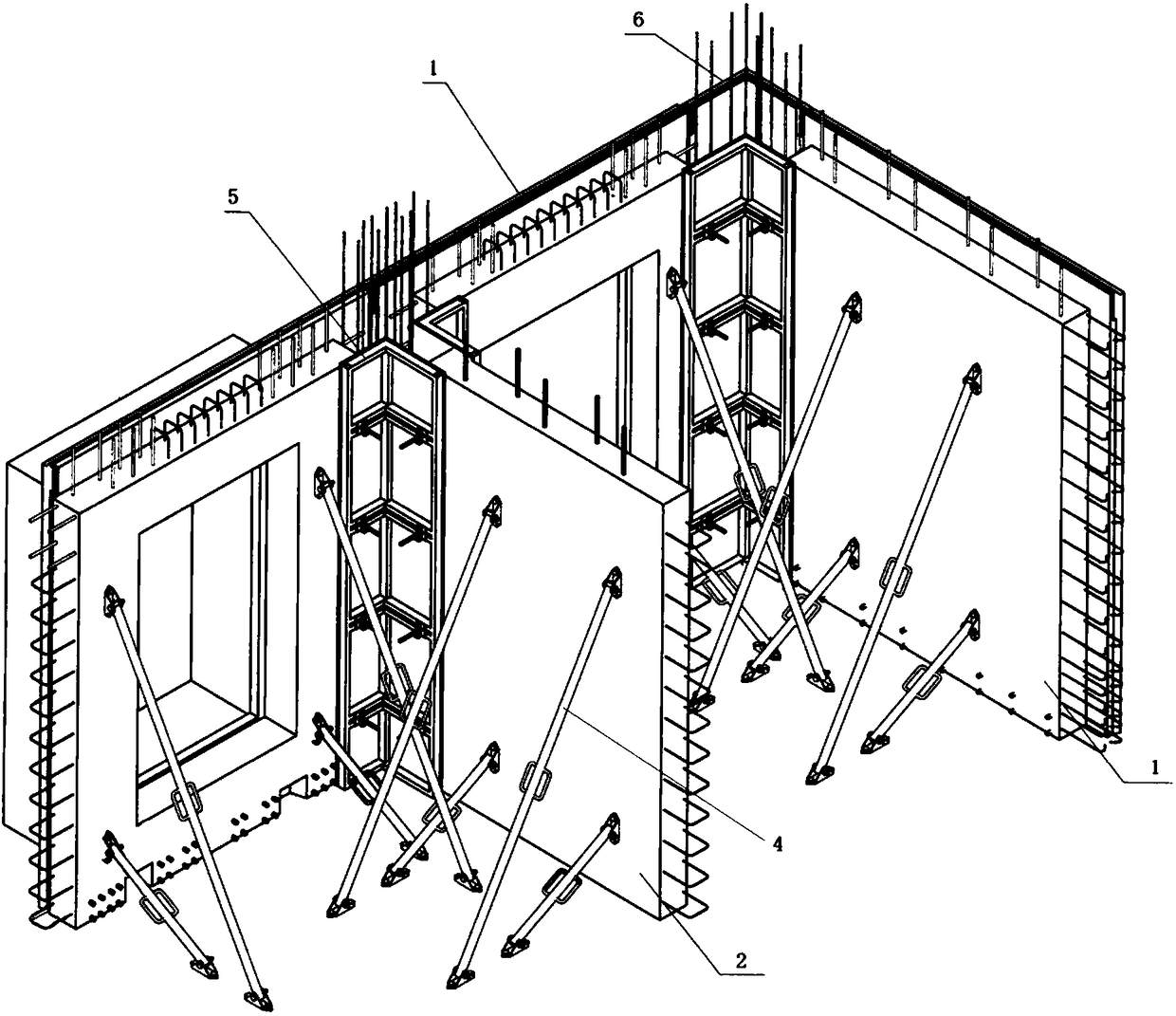

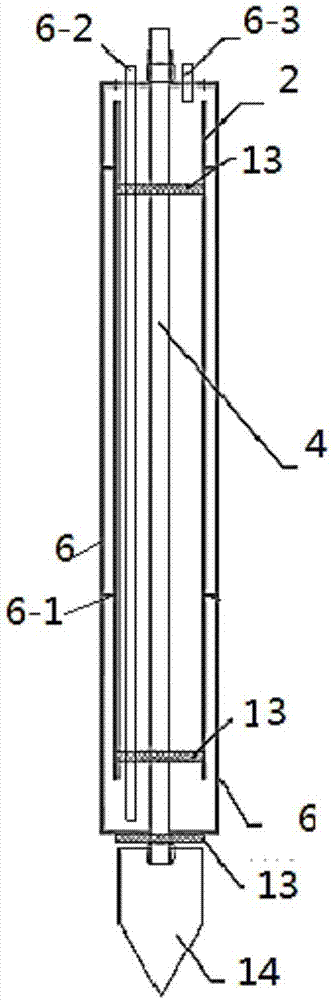

Construction method of prefabricated wallboard

InactiveCN108118900AImprove construction qualitySpeed up the progress of the projectBuilding material handlingTower craneWall plate

The invention discloses a construction method of a prefabricated wallboard. The construction method of the prefabricated wallboard comprises the following steps of 1, numbering the prefabricated wallboard after the wallboard is prefabricated in a factory, and transporting the prefabricated wallboard to a site; 2, checking components and confirming the number; 3, before hoisting, constructing the bottom laying position of the prefabricated wallboard; 4, hoisting and installing the prefabricated wallboard, wherein before the prefabricated wallboard is hoisted, upper and lower supporting end bases of an inclined strut are firstly installed, after the prefabricated wallboard is hoisted, the prefabricated wallboard is adjusted in position and is connected with the inclined strut to be fixed, then a tower crane hook is unhooked, the perpendicularity of the prefabricated wallboard is adjusted, finally, the periphery of the prefabricated wallboard is sealed, and a grouting sleeve is utilized to conduct mortar injecting. By means of the construction method of the prefabricated wallboard, a component assembly mode is adopted, a structural wallboard is divided into multiple blocks, after being prefabricated in the factory, the prefabricated wallboard is hoisted and installed on spot, and certain construction treatment is conducted, which helps to improve the construction quality, accelerate the engineering progress, and improve the building quality.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

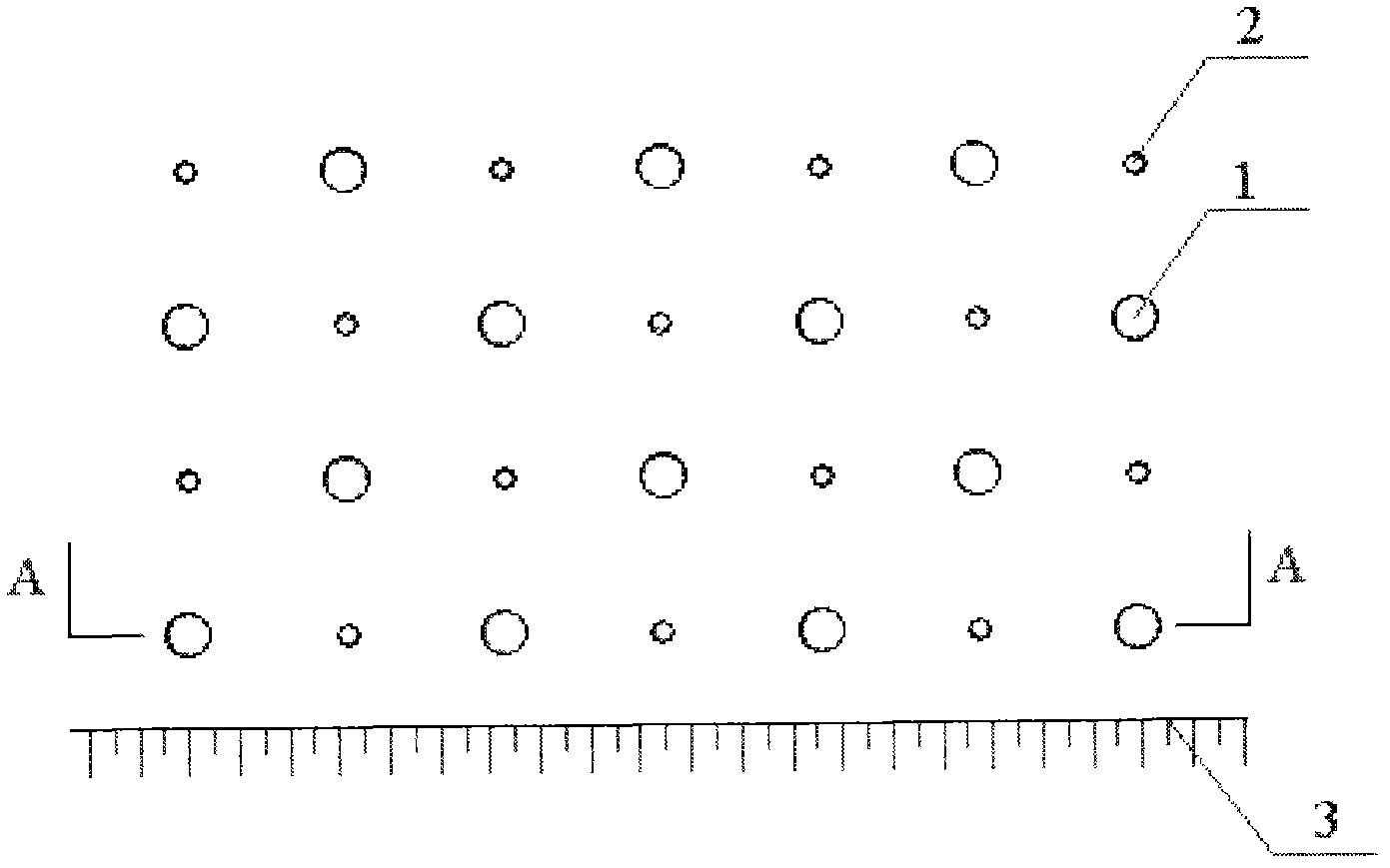

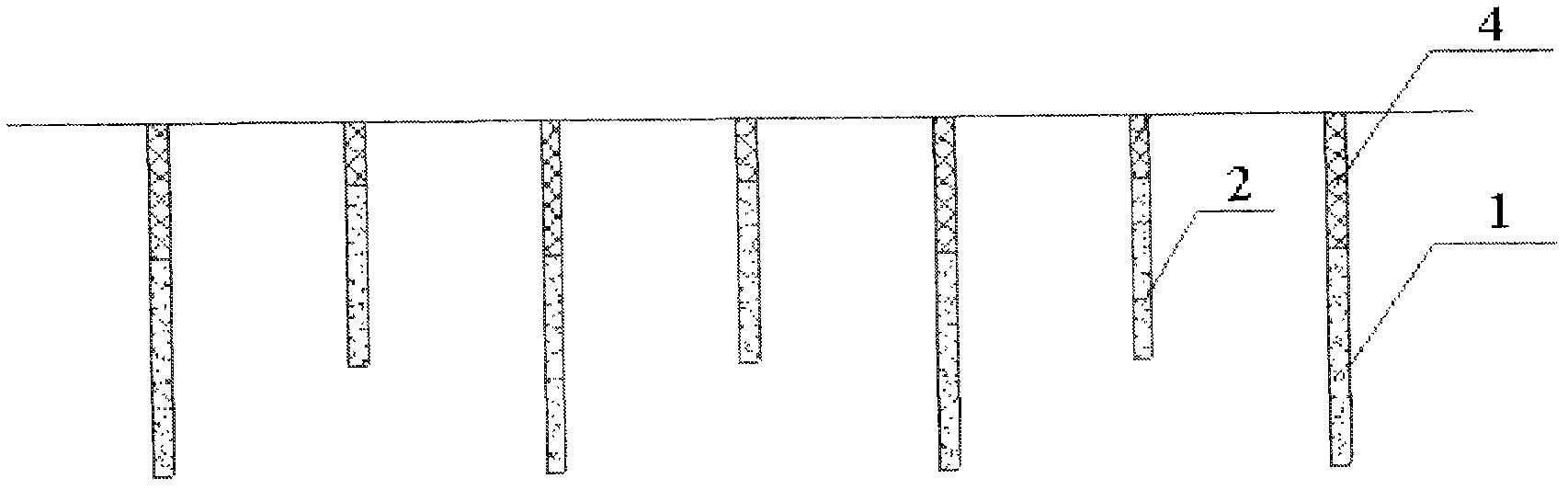

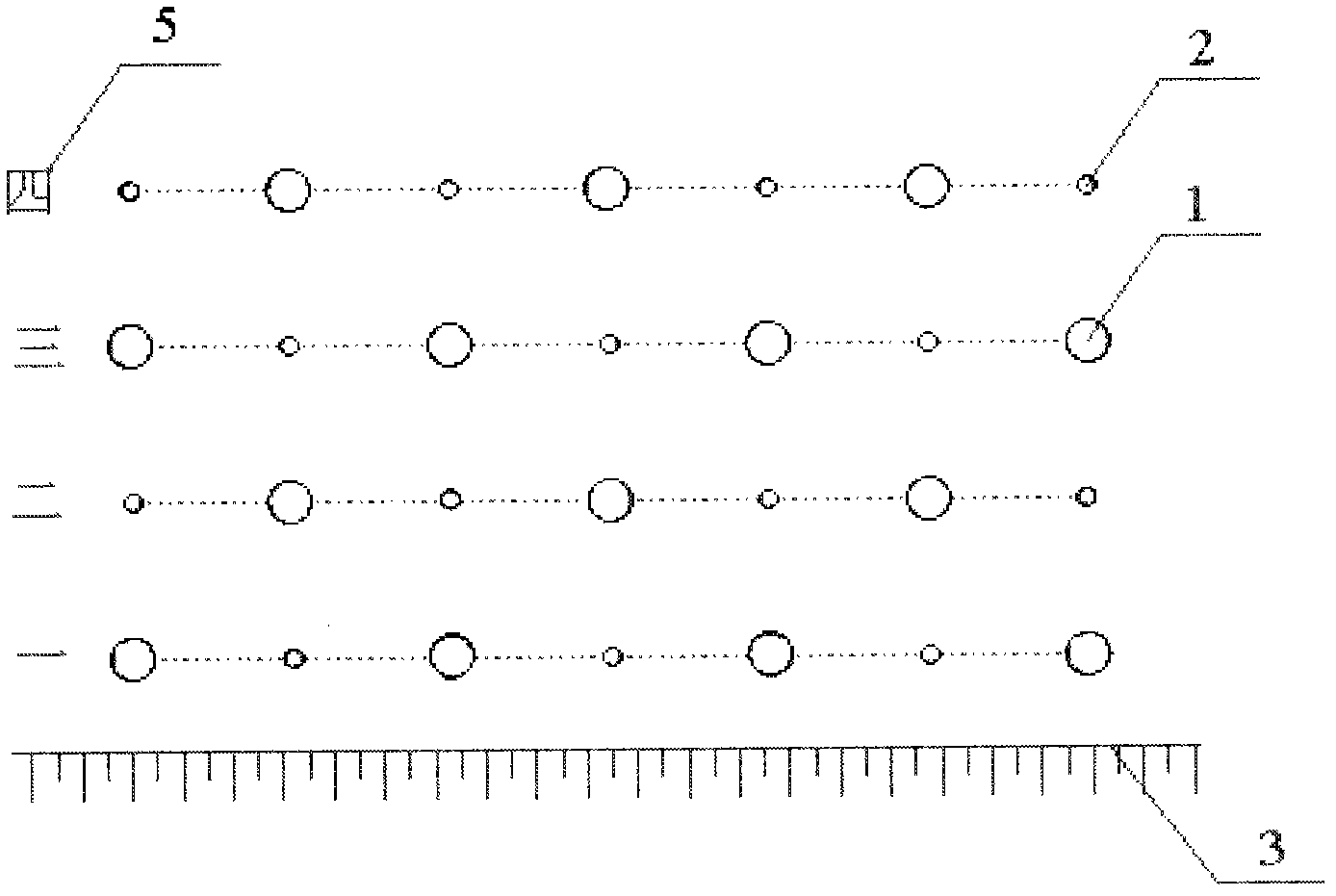

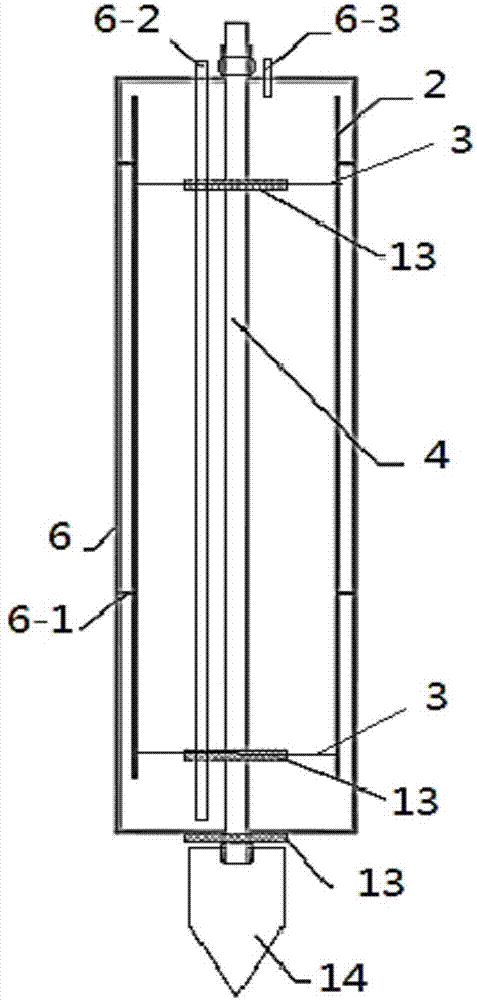

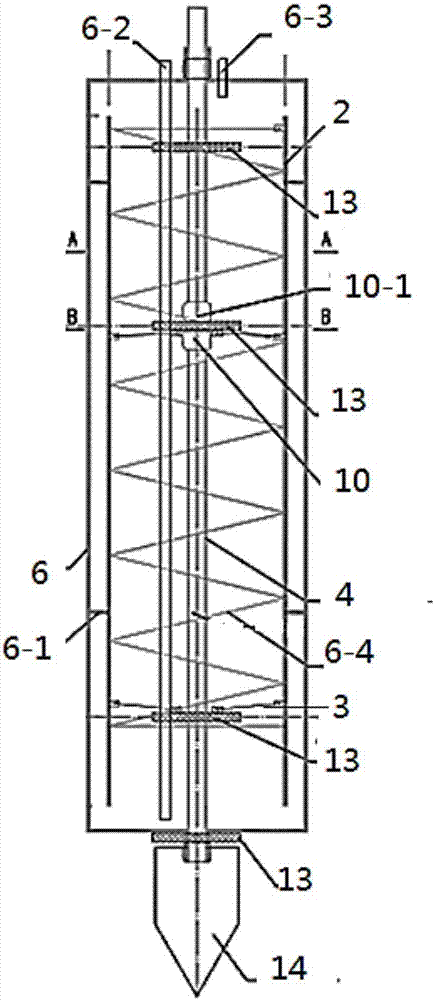

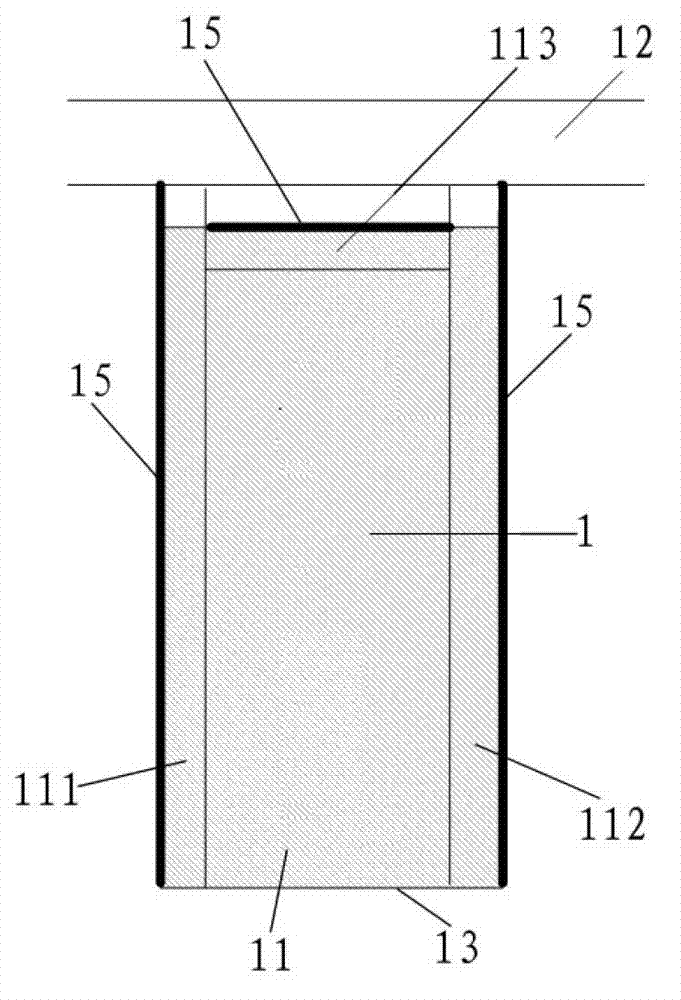

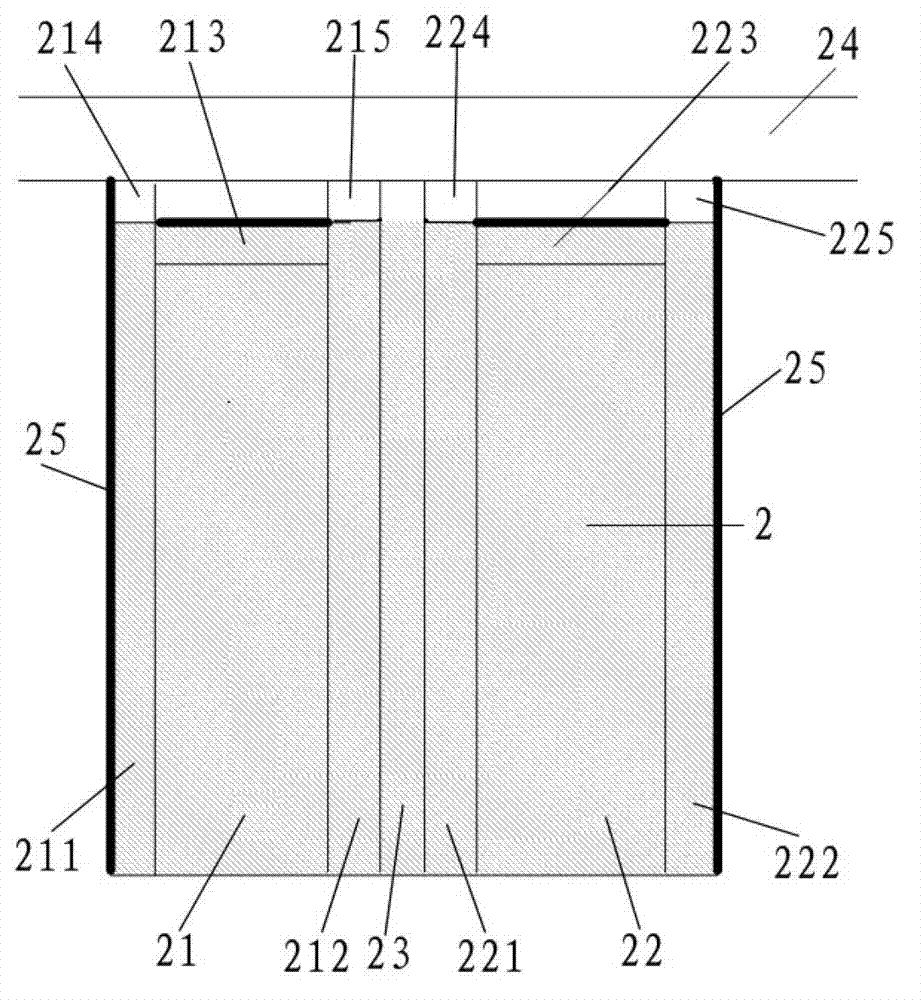

Bag expansion diameter-variable steel reinforcement cage and anchor rod or pile foundation

The invention discloses a bag expansion diameter-variable steel reinforcement cage. The bag expansion diameter-variable steel reinforcement cage comprises an axial rod, a circular ring or an annular plate, several longitudinal ribs, several rib strips and a ring-shaped fixator, the circular ring or the annular plate is perpendicular to the axial rod, one end of each longitudinal rib is uniformly fixed to the circular ring or the annular plate, the other end or the middle of each longitudinal rib is connected to one end of a corresponding rib strip, several longitudinal ribs surround the axialrod, the other end of each rib strip is connected to the ring-shaped fixator, and the ring-shaped fixator is fixed to or slides on the axial rod or a pile foundation rod; an outer bag covers the bottoms of the several longitudinal ribs, at least the bottom of the bag is sealed, and the bag with an expanded pile bottom end covers several longitudinal ribs; at least one slurry injecting opening anda slurry outlet with a one-way valve are formed in the bag.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

Anti-seepage method for mine underground reservoirs

ActiveCN102767395AImprove stability and securityRealize optimized developmentMining devicesMarine site engineeringWater reservoirGroundwater resources

The invention relates to an anti-seepage method for mine underground reservoirs. The anti-seepage method is used for solving the problem of seepage of underground reservoirs and includes performing anti-seepage treatment for roadway lateral walls and retracement passages of an underground reservoir composed of working surfaces, so that anti-seepage effect is achieved, and groundwater resources in mining areas are effectively protected. Anti-seepage engineering and coal mining are carried out synchronously, so that safety and stability of the underground reservoirs are enhanced while engineering progress is accelerated, influences on mine production are avoided, and optimized development of water protection and resource exploitation is achieved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

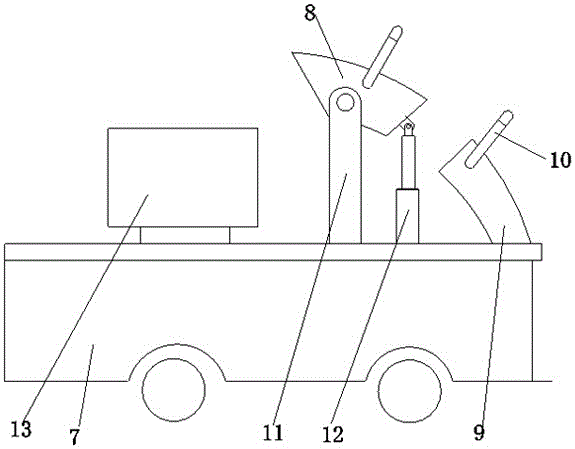

Device and method for quick dust falling during tunnel detonating

ActiveCN104989443AFar fall dustReduce dust fall timeDust removalFire preventionWater vaporEngineering

The invention discloses a device for quick dust falling during tunnel detonating. The device comprises a tunnel excavation trolley and a mobile trolley. A water pipe is arranged on a tunnel face of the tunnel excavation trolley. The water pipe is provided with a nozzle I which is arranged in an H shape on the water pipe. One end of the water pipe is provided with a booster pump close to a water pipe connector. A mobile type water spraying device is arranged on the mobile trolley. The invention discloses a method for quick dust falling during tunnel detonating. According to the device and method for quick dust falling during tunnel detonating, through a water vapor atomization device on the trolley and the mobile type water spraying device on the mobile trolley, water mist and water vapor are used for carrying out quick dust falling on dust, dust falling time is shortened, the work progress is accelerated, and working efficiency is improved.

Owner:SHANGHAI JIANKE ENG CONSULTING

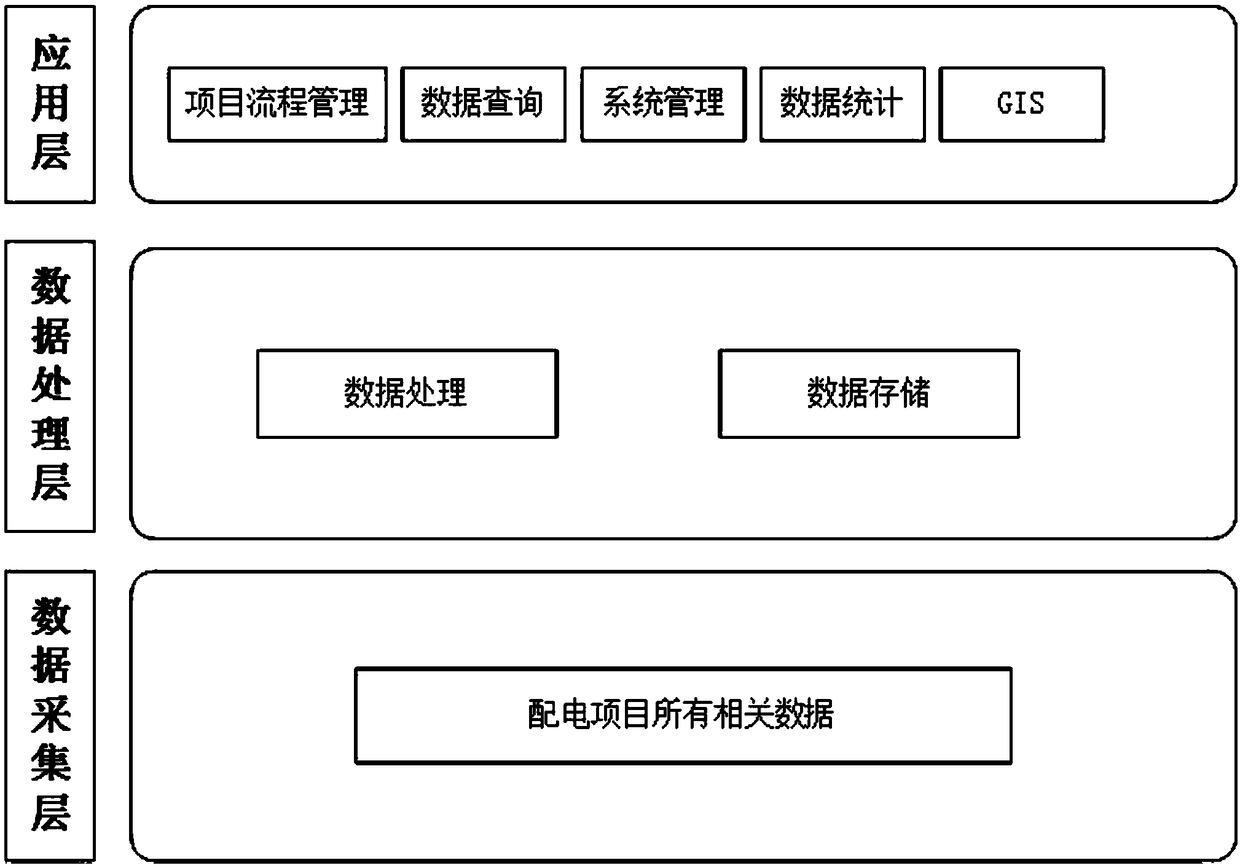

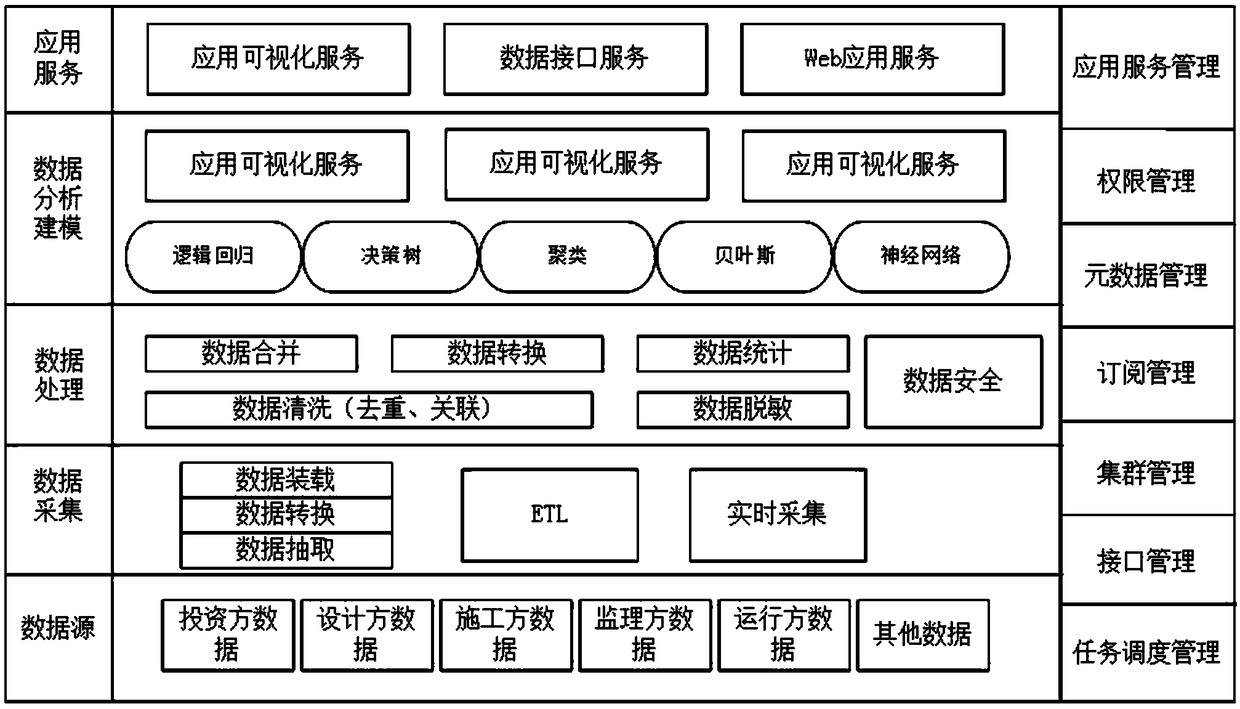

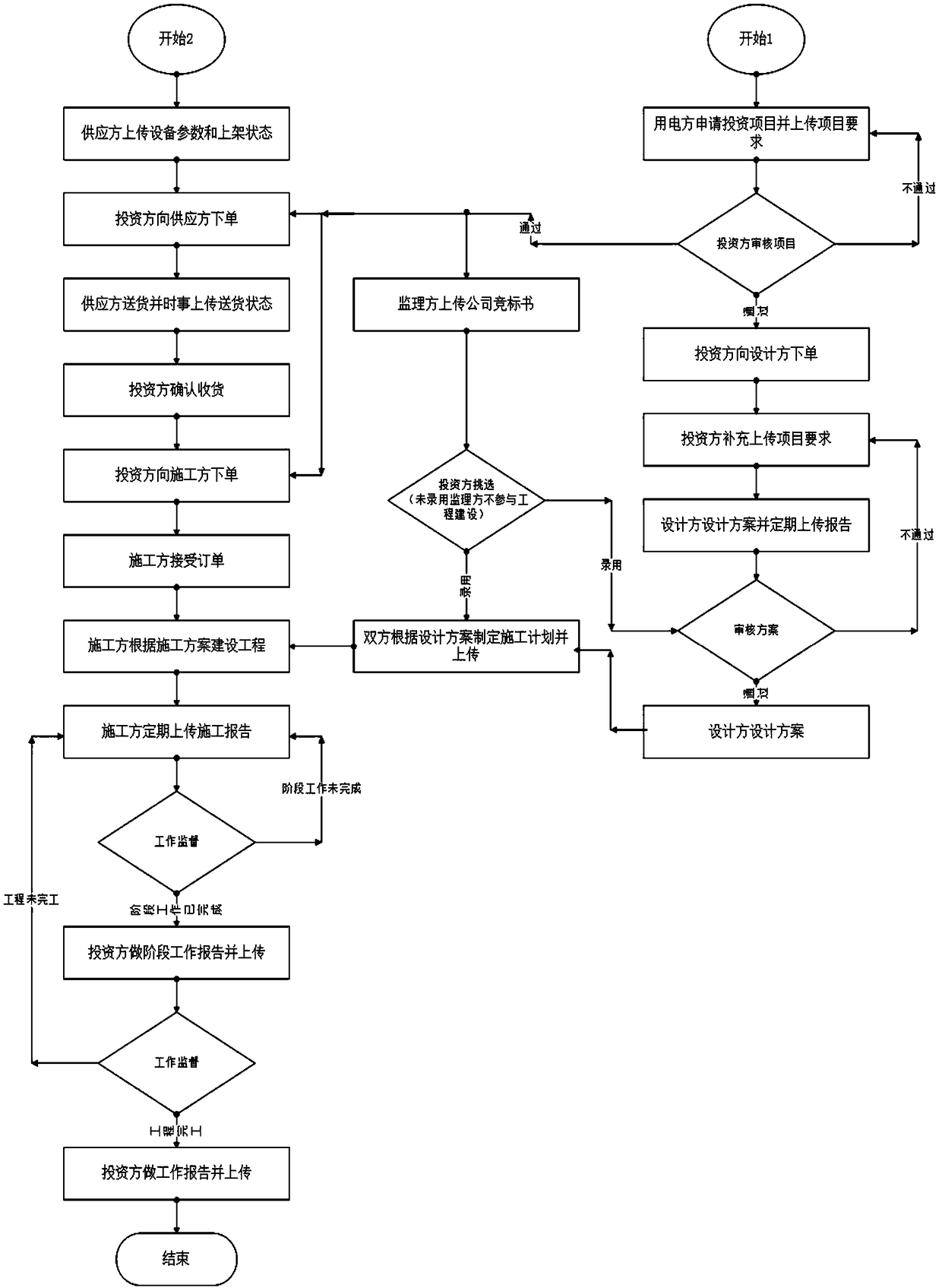

Distribution engineering construction intelligent integrated management system

ActiveCN109492991AEfficiently promote the construction processEnable secure sharingDatabase management systemsOffice automationData acquisitionIntelligent management

The invention discloses a distribution engineering construction intelligent integrated management system, which comprises a data acquisition layer, a data processing and storage layer and an application layer. Among them, the data acquisition layer collects the data of the units involved in the power distribution project; data processing and storage layer is responsible for data cleaning, conversion, storage and storage; the application layer is the intelligent management software of distribution project. The invention designs a scientific, safe and efficient distribution project management system combined with a big data cloud platform, which can intelligently overall manage each project participant in a distribution project construction, realize the construction information safety sharing of each participant, and efficiently promote the project construction process.

Owner:SOUTH CHINA UNIV OF TECH +1

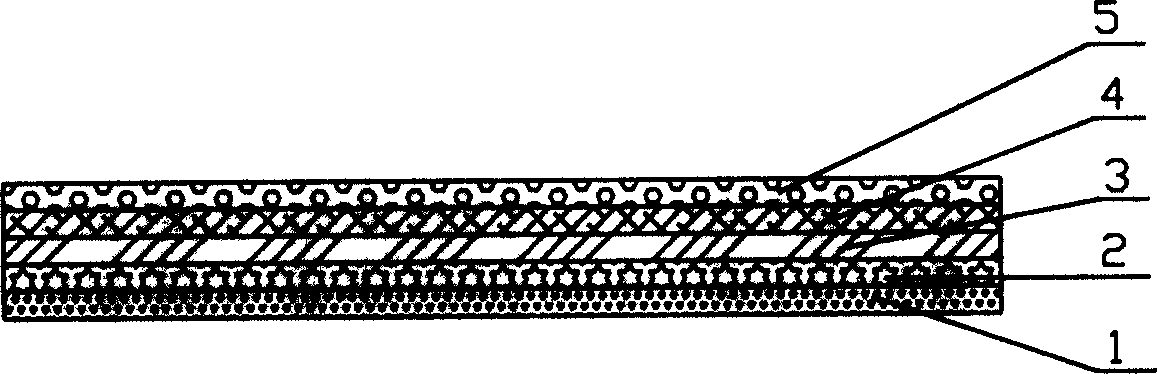

Composite water-proof coiled material and construction method by employing same

ActiveCN1544769AGood elasticity and deformation abilityHigh bond strengthBuilding insulationsBituminous layered productsWaterproofingSizing

The invention discloses a composite waterproof coiled material, from top to bottom, in turn including isolating layer, sizing material layer A, enhanced layer, sizing material layer B and close binder. The close binder can be bond closely with the structural layer of a building and set with particle layer. The invention discloses the constructing methods of pre-laying method and wet-laying method of this coiled material, where the pre-laying method can eliminate the procedure of laying protective layer in traditional construction and the wet-laying method can eliminate the procedure of making primary level making layer and has a few requirements for base level and can make waterproof construction. With respect to the existing techniques, it has the characters of simple structure, good waterproofing effect, strong anti-piercing ability, convenient use and maintenance, simple constructing method, etc.

Owner:SHENZHEN ZHUOBAO TECH

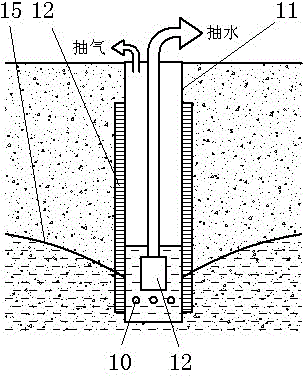

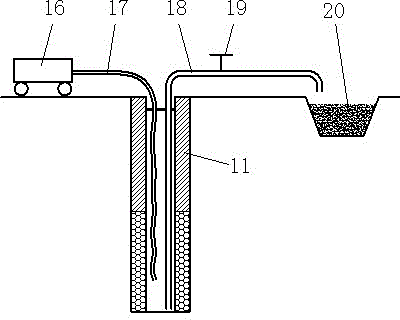

Construction method for super vacuum dewatering well and well tube structure used in construction method

InactiveCN104060621AAvoid the defects of vacuum decayReduce labor intensitySoil preservationStructural engineeringWell placement

The invention discloses a construction method for a super vacuum dewatering well and a well tube structure used in the construction method. The method comprises the following processes: measuring a well position, burying a mouth protecting tube, mounting a drilling machine, carrying well construction, drilling holes, cleaning holes for mud fluid displacement, descending a well tube, packing a filter material and cleaning the well. The method adopts the segmented well tube, ensures a permeable effect, isolates air from entering the super vacuum dewatering well, and overcomes the defect that the vacuum degree of a common vacuum deep well is reduced as air enters the well after the water level drops. During dewatering, the method can greatly improve the dewatering effect, reduce the engineering cost, accelerate the construction process, and reduce the labor intensity of workers. The process is easy to operate and master.

Owner:CHINA CONSTR FOURTH ENG DIV

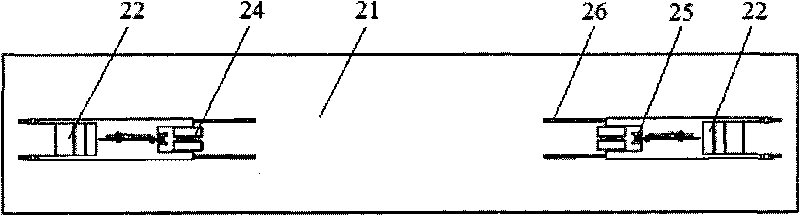

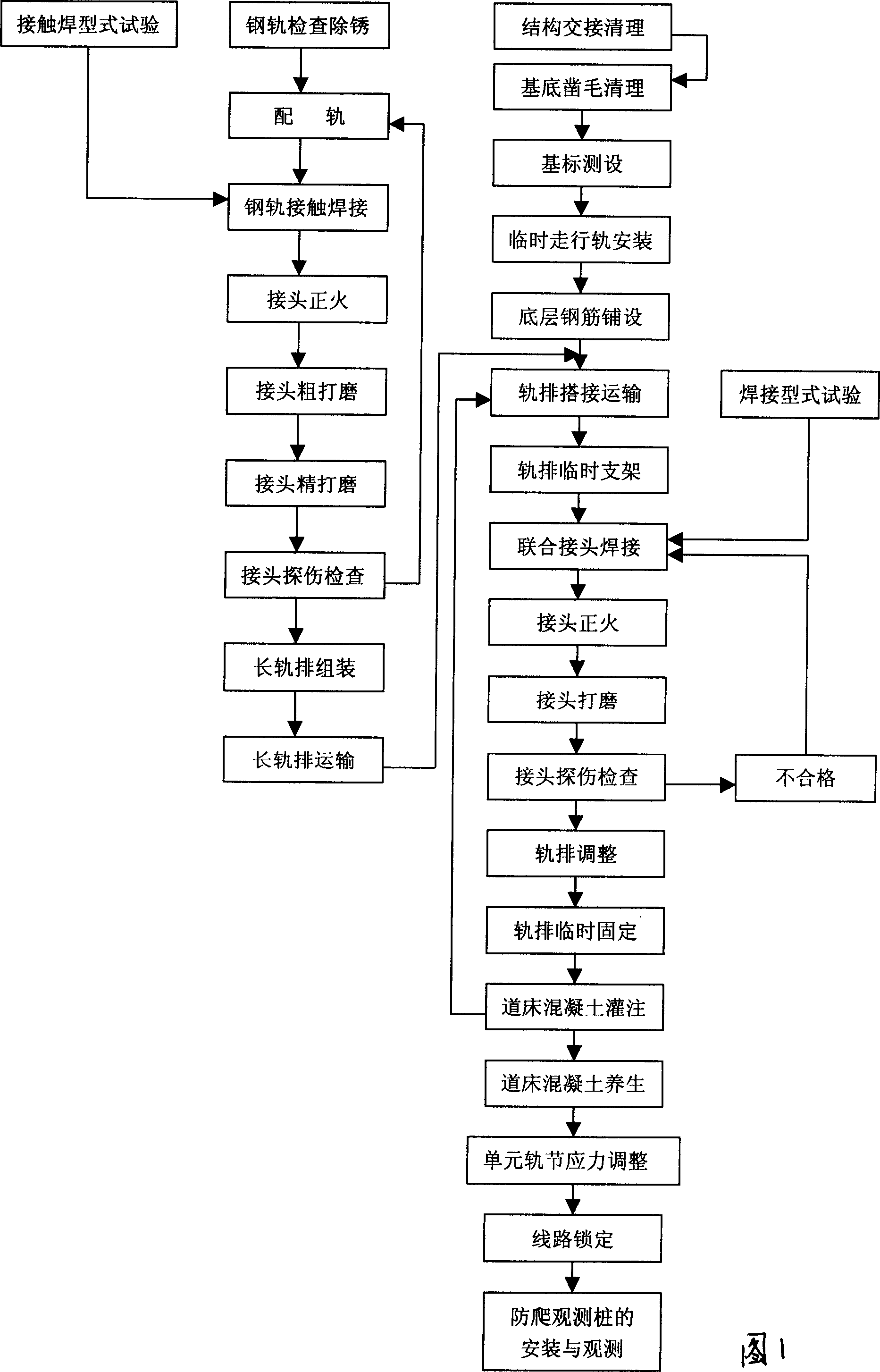

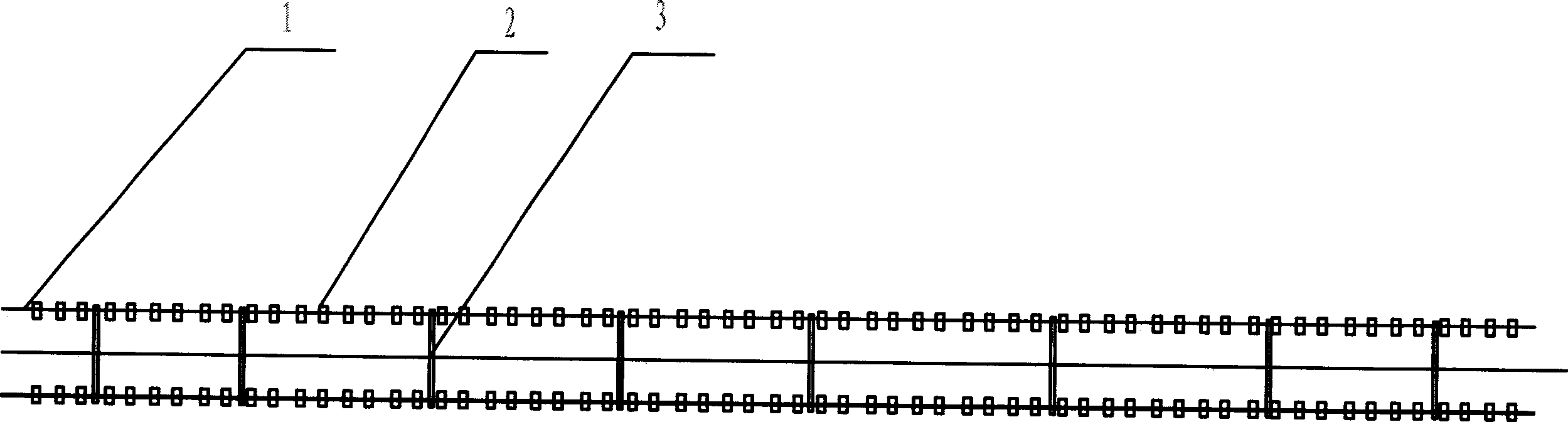

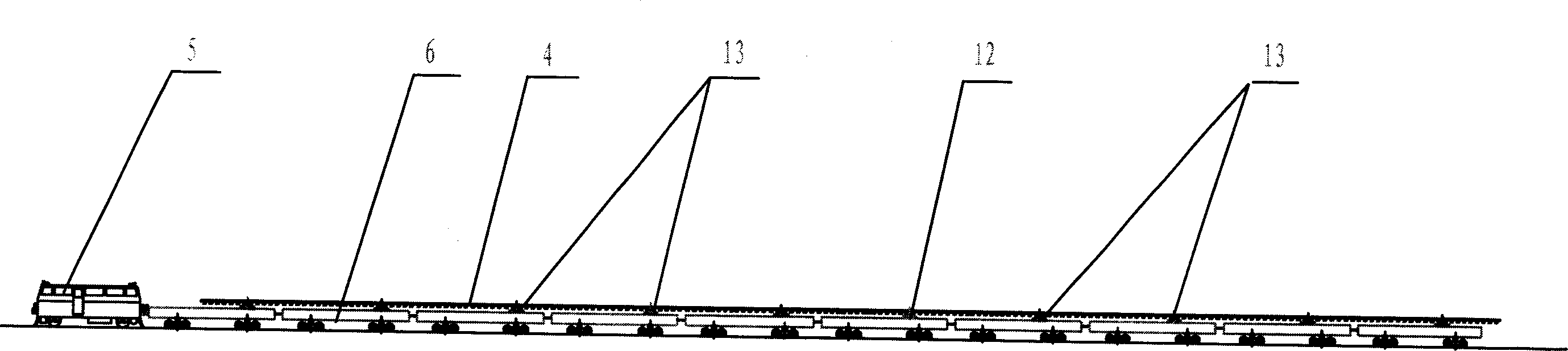

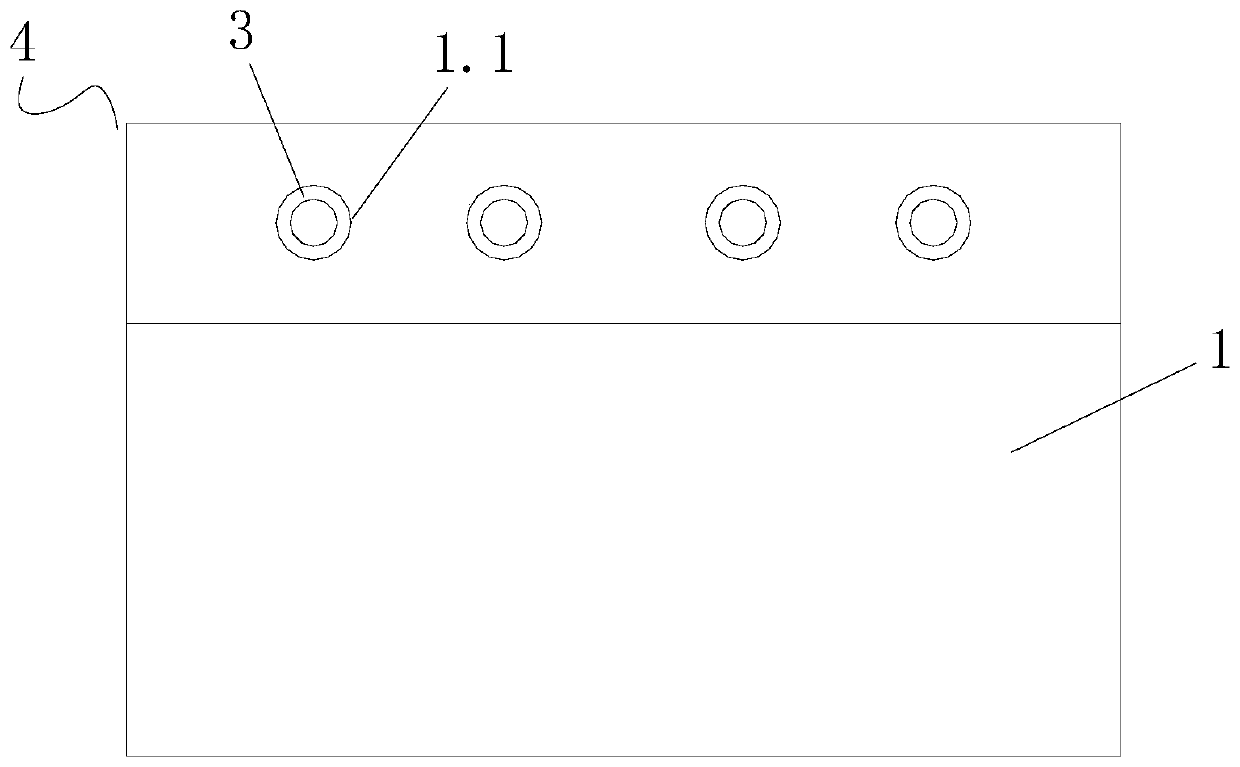

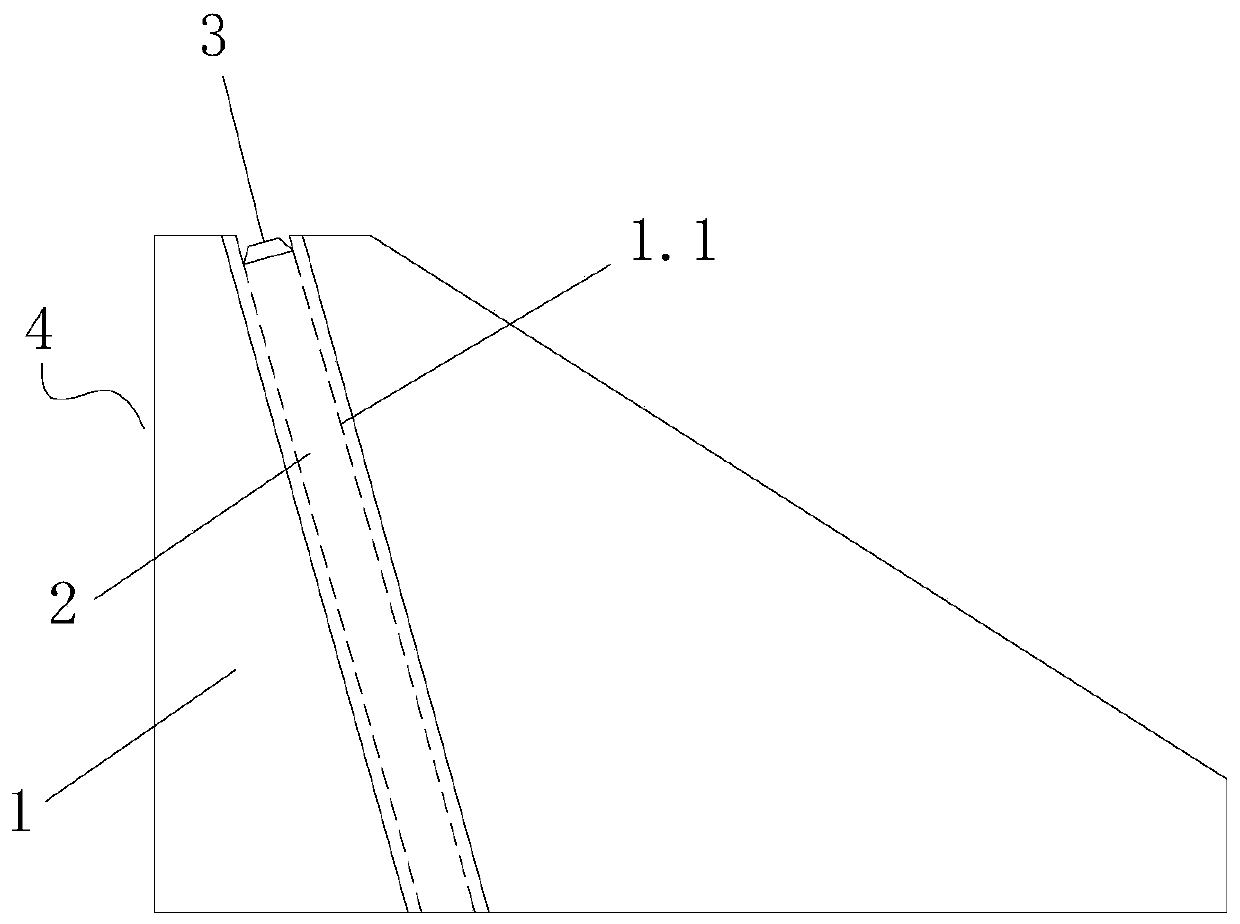

Short-sleeper long-lump integrated ballast bed seamless track construction method

ActiveCN1804216AReduce labor intensityReduce pollutionRailway track constructionAssembly lineShort-sleeper

The invention relates to a method for constructing short sleeper long rail row integrated seamless track, which welds at least three standard steel rails into long rail bar on the base ground and combines two long rail bars with short sleeper, fasteners, and steel rail into long rail row; uses light rail towing vehicle to move the long rail row into construction site and uses gantry cranes to move the long rail row to the mounting position to be adjusted, welded and temporary fixed; then processes railway bed irrigation and rail temperature fixing. The inventive method can transform traditional processes which should be completed inside the hole or light way construction site to the rail laying base; and it can utilizes assembly-line operation which can improve the rail row mounting quality, reduce the labor force, reduce the environmental pollution, shorten the construction period, confirm the welding quality between rails, avoid arranging the welding interface on the sleeper and confirm the shape of curve. In addition, since it utilizes mechanical integrated suspending and mounting inside the hole, it can accelerate the construction plan. The invention can mount, transport and weld the long rail with at least 125m length in one time.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

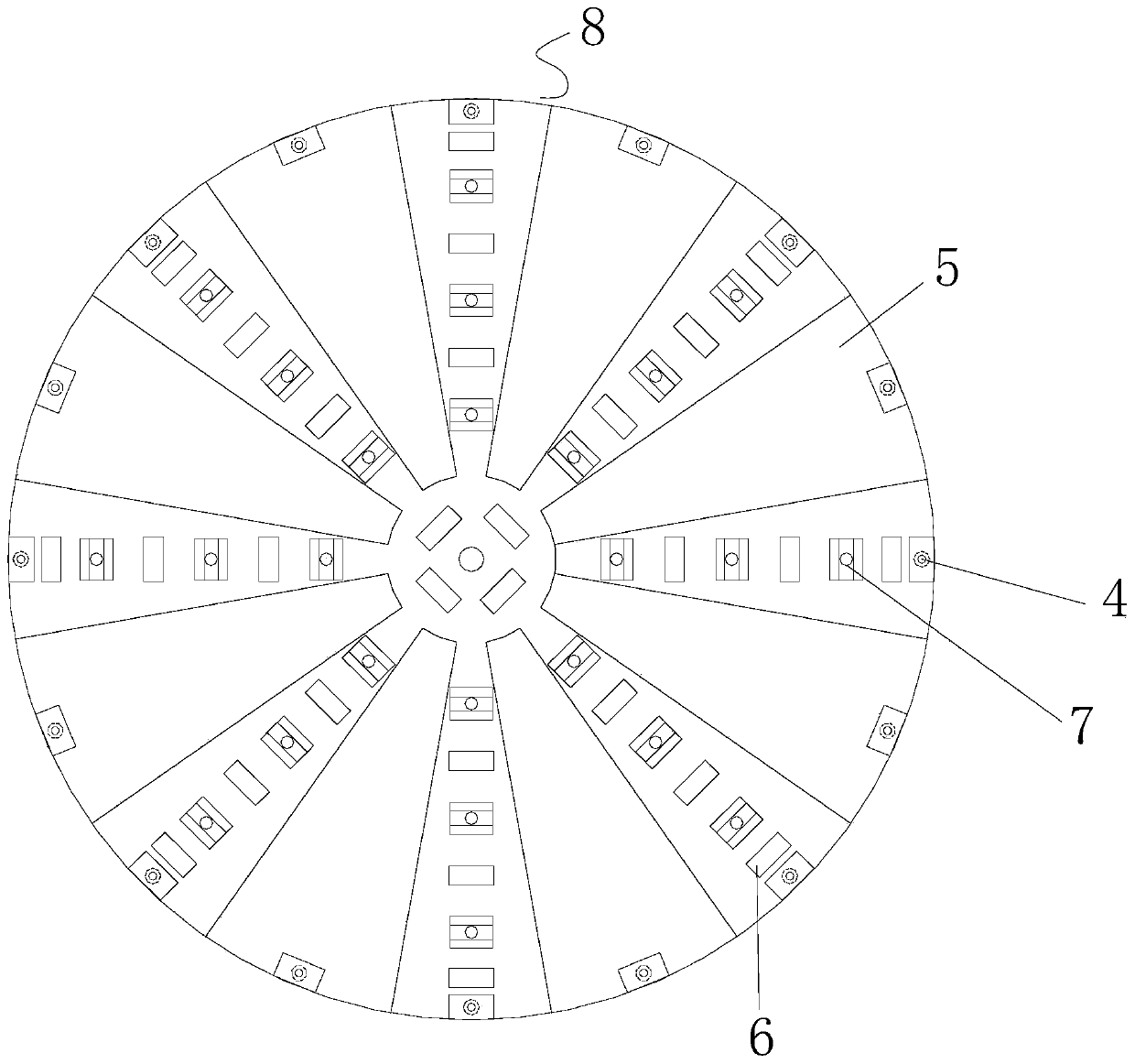

High-pressure water jet edge cutter and combined rock breaking and escaping TBM cutterhead and method thereof

The invention discloses a high-pressure water jet edge cutter which comprises an edge cutter mechanical structure, an edge cutter high-pressure water jet pipeline and an edge cutter high-pressure water jet nozzle. The edge cutter high-pressure water jet pipeline is located in the edge cutter mechanical structure. The edge cutter high-pressure water jet nozzle is embedded in the edge cutter mechanical structure and communicates with the edge cutter high-pressure water jet pipeline. The high-pressure water jet edge cutter has the advantages of realizing rock breaking through high-pressure waterjet and solving the problem that a TBM gets stuck. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping TBM cutterhead. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping method.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

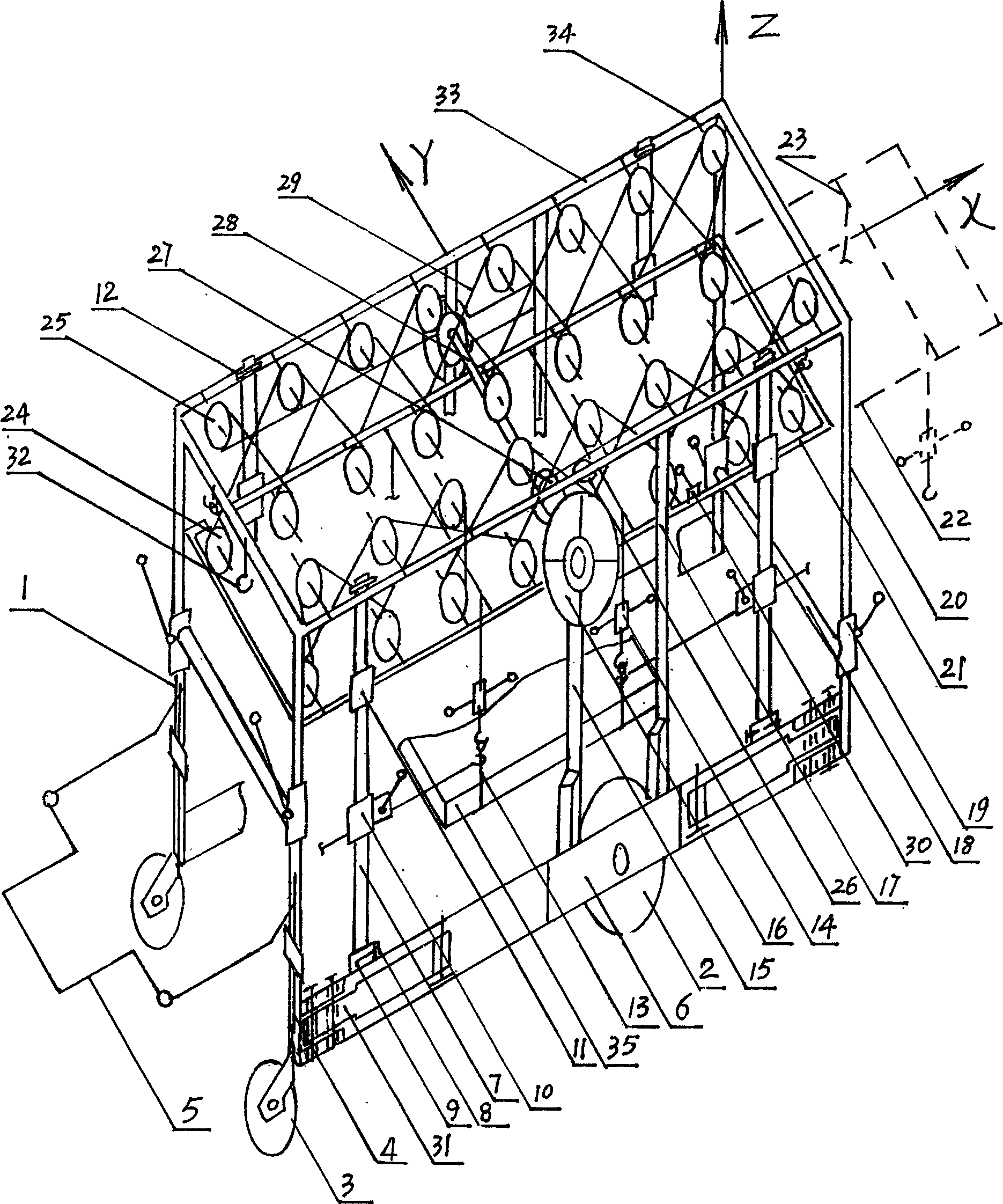

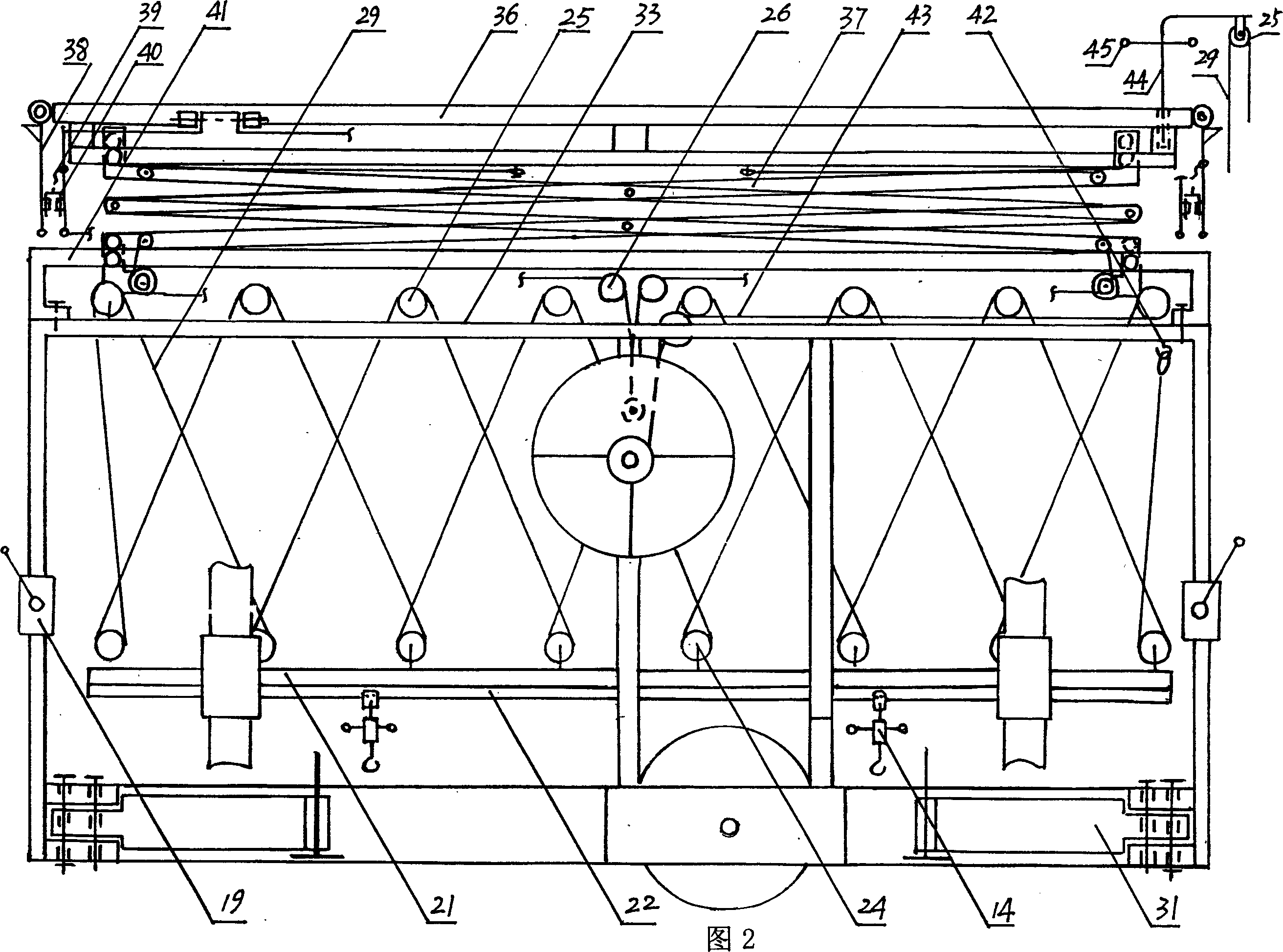

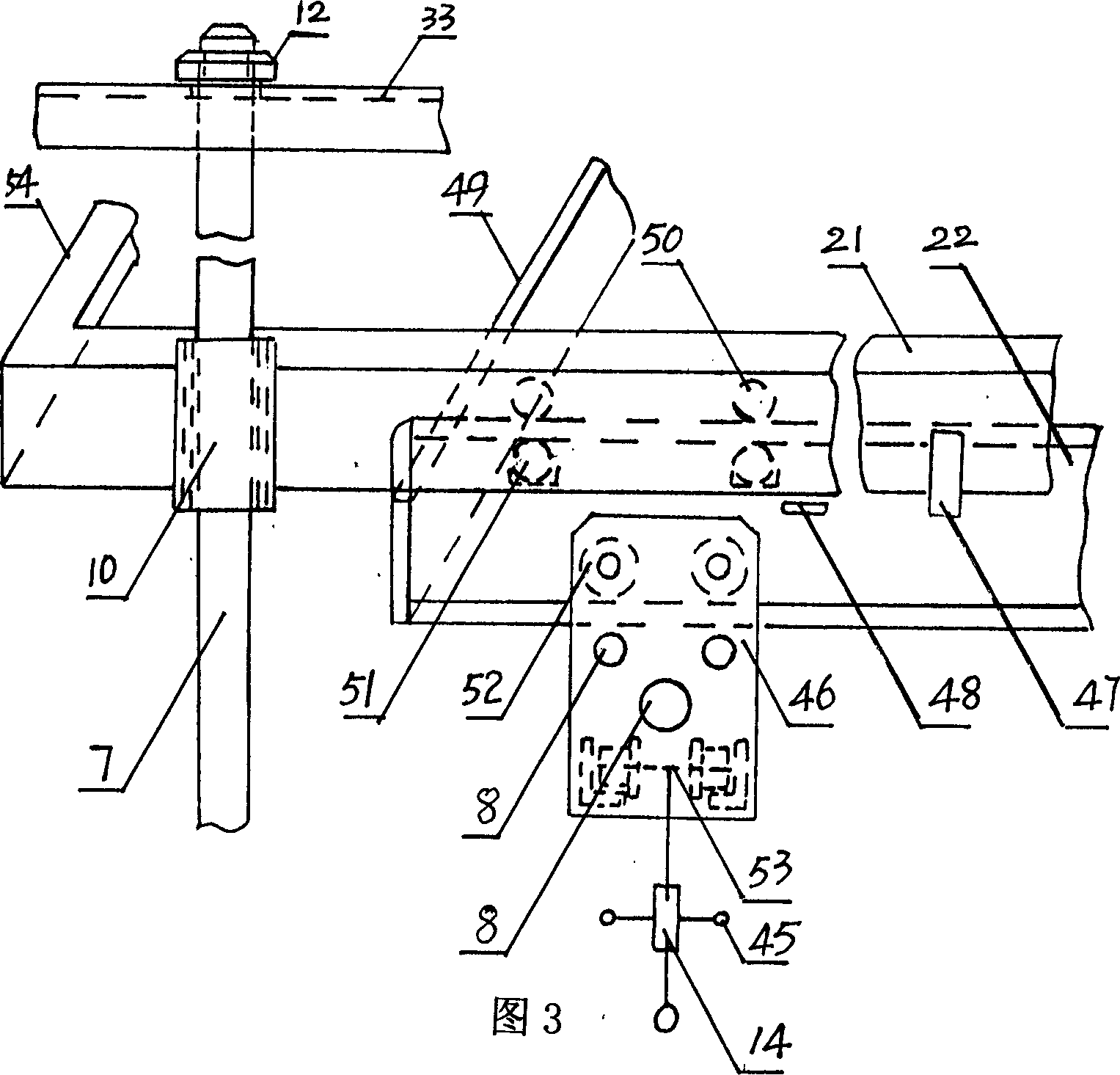

Multifunctional engineering installation vehicle

InactiveCN1544307AEasy to operateImprove installation qualityLifting devicesHydraulic cylinderPull force

The present invention discloses a multifunctional engineering installation vehicle used for engineering construction, which comprises a vehicular support frame, a walking and the like. In the vehicle as a gantry supporting frame structure, a extensible guide supporting frame for X axial movement is connected forwards with a Z axial direction tunable movable lift hook; at the C axial movement extensible guide supporting frame, there is an outside force acting at the Z axial direction, which can be a pull force of a armored rope or a cylinder rod clean and jerk force of the hydraulic cylinder and used for pushing the X axial movement extensible guide supporting frame for a vertical motion; a lifting platform is installed at the vehicle roof to execute pipe laying pipe laying, anti-corrosion, heat preservation, laying and maintenance of cable rope and crane span structure, and the like; the Z axial direction tunable movable lift hook inside the vehicle is used for lifting and loading articles of merchandise to realize installation of equipments; a labor saving and quick-releasing pipeline frame is allocated for carriage of pipelines; a ground tray is allocated, which is used for lifting, loading and transporting large and heavy workpieces. The multifunctional engineering vehicle is a powerful machinery for constructions, and the plurality of functions mentioned above greatly improves the installation quality, saves 2 times for the human energy and improves the work efficiency more than 10 times.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

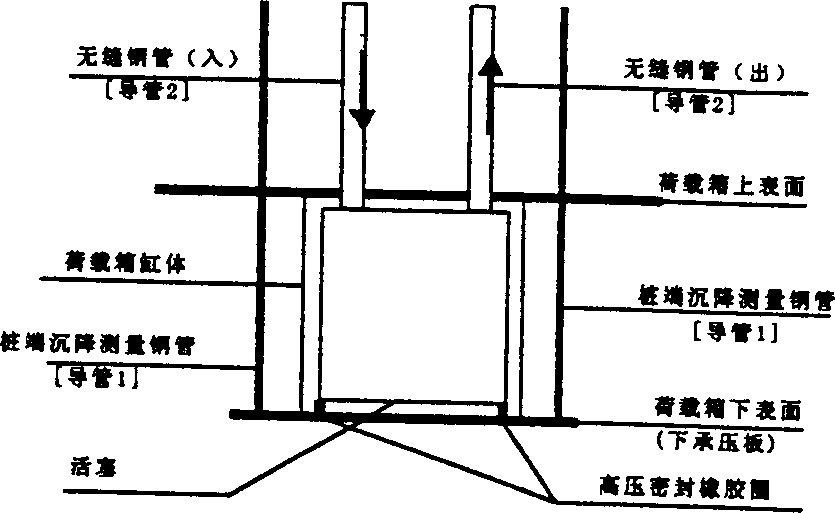

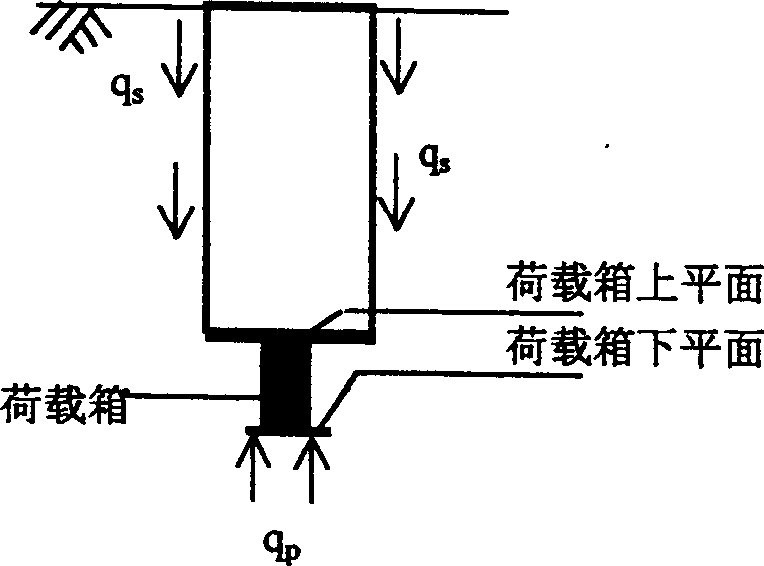

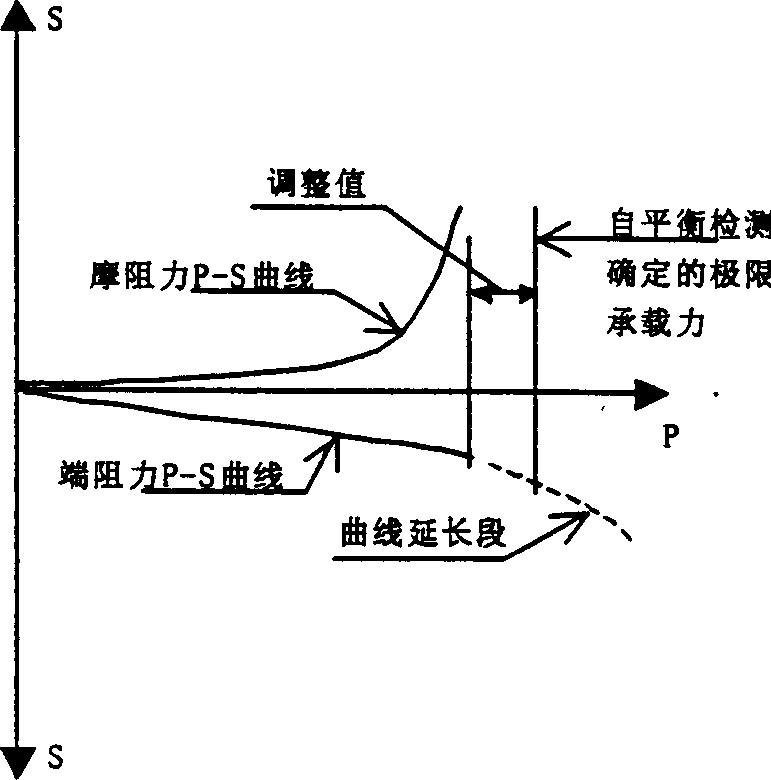

End-carrying type large-diameter pile pier vertical bearing capacity detecting method

InactiveCN1455055AReduce testing costsEnvironmental factors have little influenceFoundation testingRebarHigh pressure

The end-bearing type large-diameter pile pier vertical load-bearing capacity detection method includes the following steps: a. according to the geological prospecting material estimating end-bearing capacity and frictional resistance value, designing and making load box; b. welding the load box on the full-length reinforcing cage end portion, hoisting and placing the reinforcing cage into the pile hole; c. cleaning pile hole, check and acceptance and pouring concrete; d. after the concrete strength is reached to 70%, slow-speed retaining loading process or rapid-speed retaining loading process to detect the load-bearing capacity of pile; and e. high-pressure injecting flow state expansion concrete into the load box. Its detection cost is low and its detection data are safe and reliable.

Owner:董天文

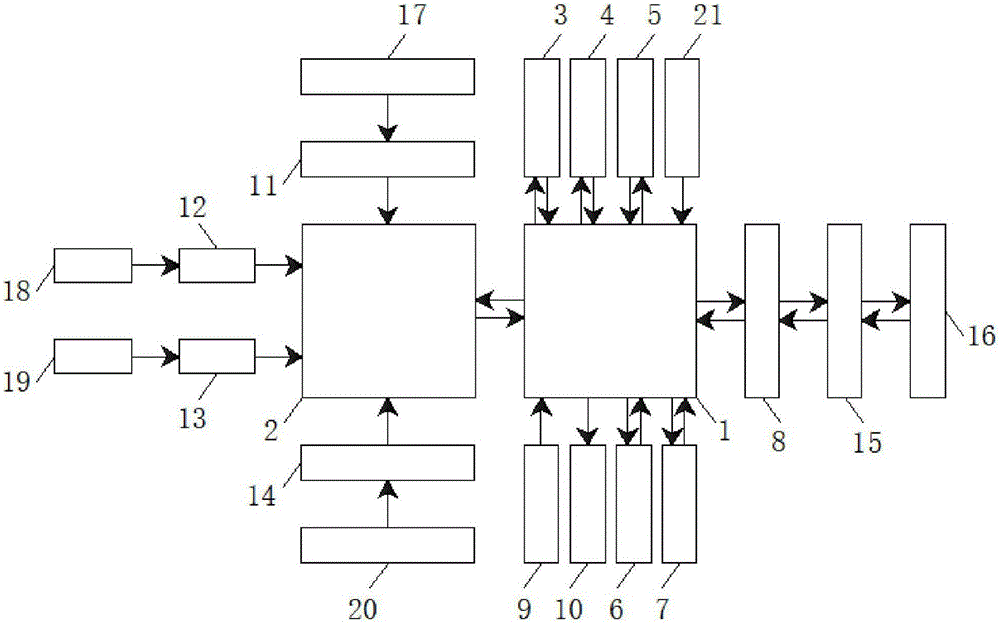

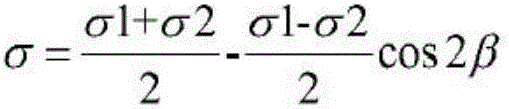

Shale reservoir ground stress prediction and modeling method

InactiveCN106772673AHigh degree of intelligenceGuaranteed accuracyGeological measurementsMicrocontrollerTransceiver

The invention discloses a shale reservoir ground stress prediction and modeling system, which comprises a single chip microcomputer controller and an integrated data collector, wherein the single chip microcomputer controller is electrically connected with the integrated data collector, a data processor, an RAM memory, an ROM memory, a database, a timer and a wireless radio frequency transceiver respectively; the output end of the single chip microcomputer controller is electrically connected with the input end of a stress simulator; the wireless radio frequency transceiver is connected with an external device through a GPRS network; the input end of the first data collector is electrically connected with the output end of a distance sensor; the input end of the second data collector is electrically connected with the output end of a pore pressure sensor; the input end of the third data collector is electrically connected with the output end of a stress sensor; and the input end of the fourth data collector is electrically connected with the output end of a strain sensor. the intelligent degree is high, and modeling and analysis on the shale reservoir ground stress can be effectively carried out.

Owner:SOUTHWEST PETROLEUM UNIV

Installation method for thermal insulation and decoration integrated facade panels

The invention relates to an installation method for thermal insulation and decoration integrated facade panels in the field of construction methods of the construction industry. The method includes the following steps: (Step 1) main wall surface treatment; (Step 2) datum line making; (Step 3) framing installation; (Step 4) thermal insulation and decoration integrated facade panel installation; (Step 5) gap filling; (Step 6) sealant filling; (Step 7) panel surface cleaning. When the method disclosed by the invention is adopted, integral installation is convenient, cost is reduced, the construction period is short, the load of facade panels is reduced greatly, the utilizability of space and land is enhanced, the application range is wide, temperature is kept, heat is insulated, energy consumption is reduced, structural destruction caused by the circulation of rain, snow, freezing, thawing, dryness and wetness is prevented, the worry about the water seepage of wall surfaces is eased after installation, the phenomenon that indoor wall surfaces go moldy is effectively prevented, and the thermal insulation and decoration integrated facade panels are environment-friendly and durable.

Owner:杭锦旗亿利朗新材料科技有限公司

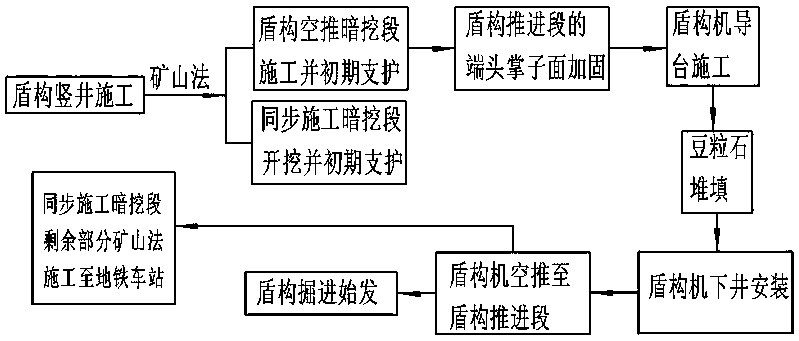

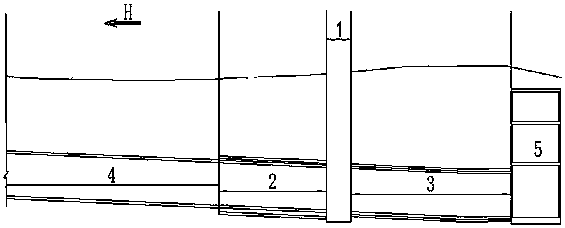

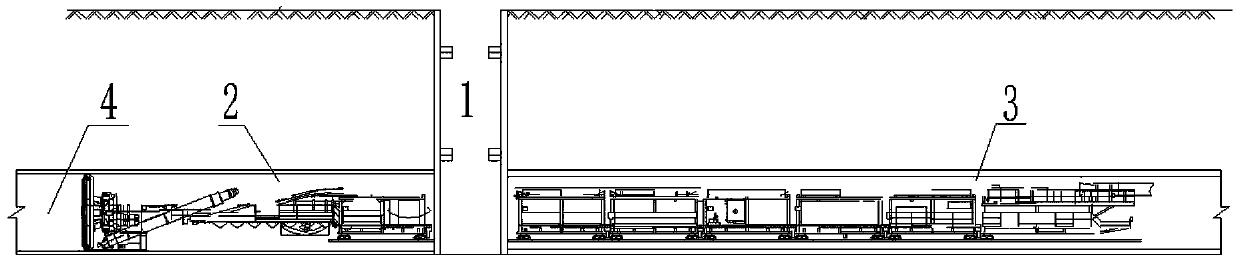

Method for constructing subway tunnel with complicated geology and without shield launching site

PendingCN107725060AReduce wearSpeed up the progress of the projectUnderground chambersTunnel liningEngineeringSubway station

The invention relates to the technical field of subway construction, in particular to a method for constructing subway tunnel with complicated geology and without shield launching site, which solves the problems of complicated geology in the subway section and failure to provide shield launching site on time in the exiting subway construction process. The method comprises the following steps of arranging a shield inclined shaft in a preset tunnel section; respectively constructing a shield empty-push hidden excavation section and a synchronous-construction hidden excavation section at both ends of the shield inclined shaft by a mine method, and timely applying primary support; connecting the shield empty-push hidden excavation section to a shield tunneling section; enabling a shield body and subsequent auxiliary equipment which are lowered and assembled by the shield inclined shaft to respectively adopt the splitting launching type to arrive at the shield pushing section via the shieldempty-push hidden excavation section, and performing shield tunneling launching; excavating the synchronous-construction hidden excavation section to a subway station by the mine method. The subway tunnel construction method has the advantages that compared with single shield construction method, the advantages of various working methods are fully played; the abrasion of a tool disc is reduced, the condition of frequent bin opening for tool replacing is avoided, the safety risk is decreased, the construction progress is quick, and the like.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

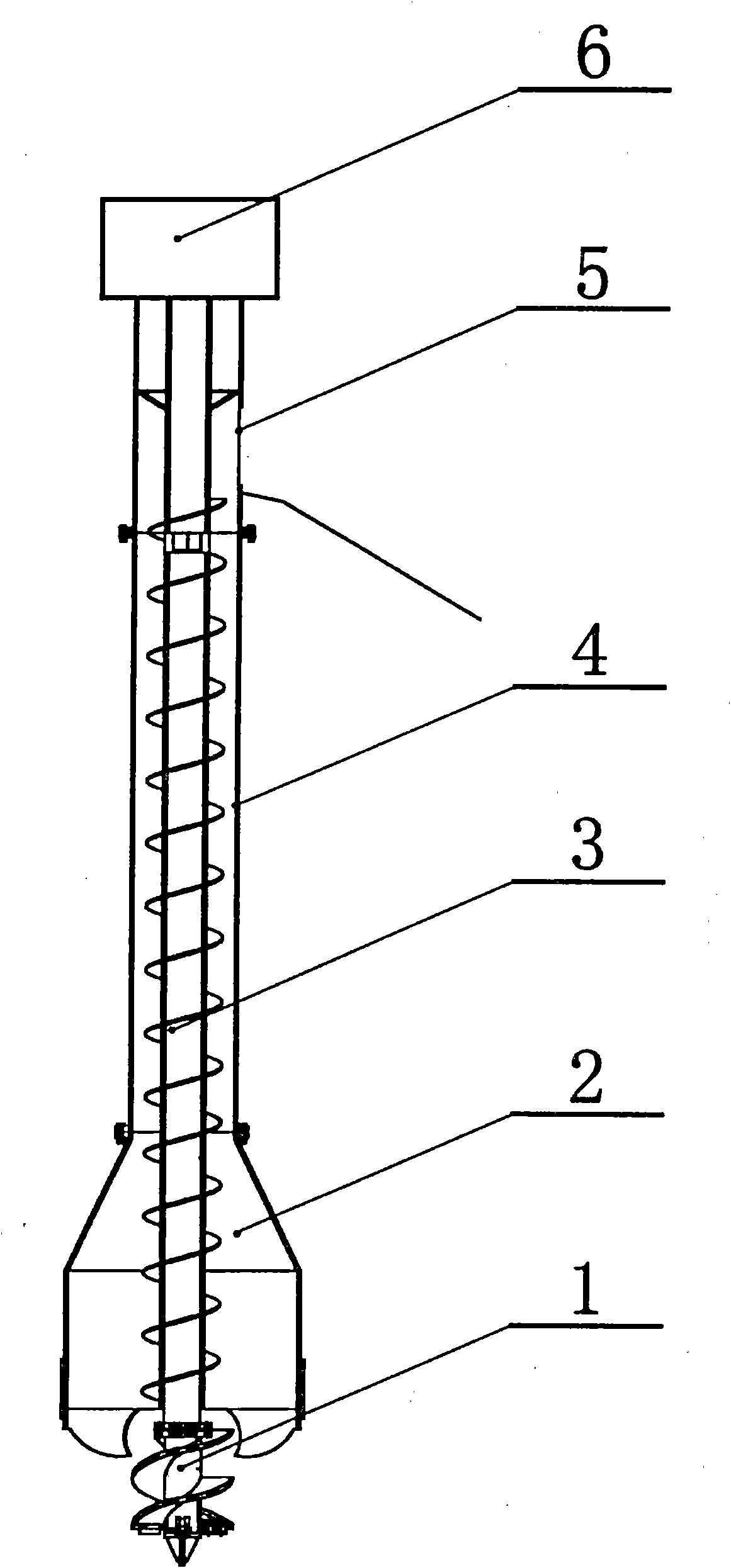

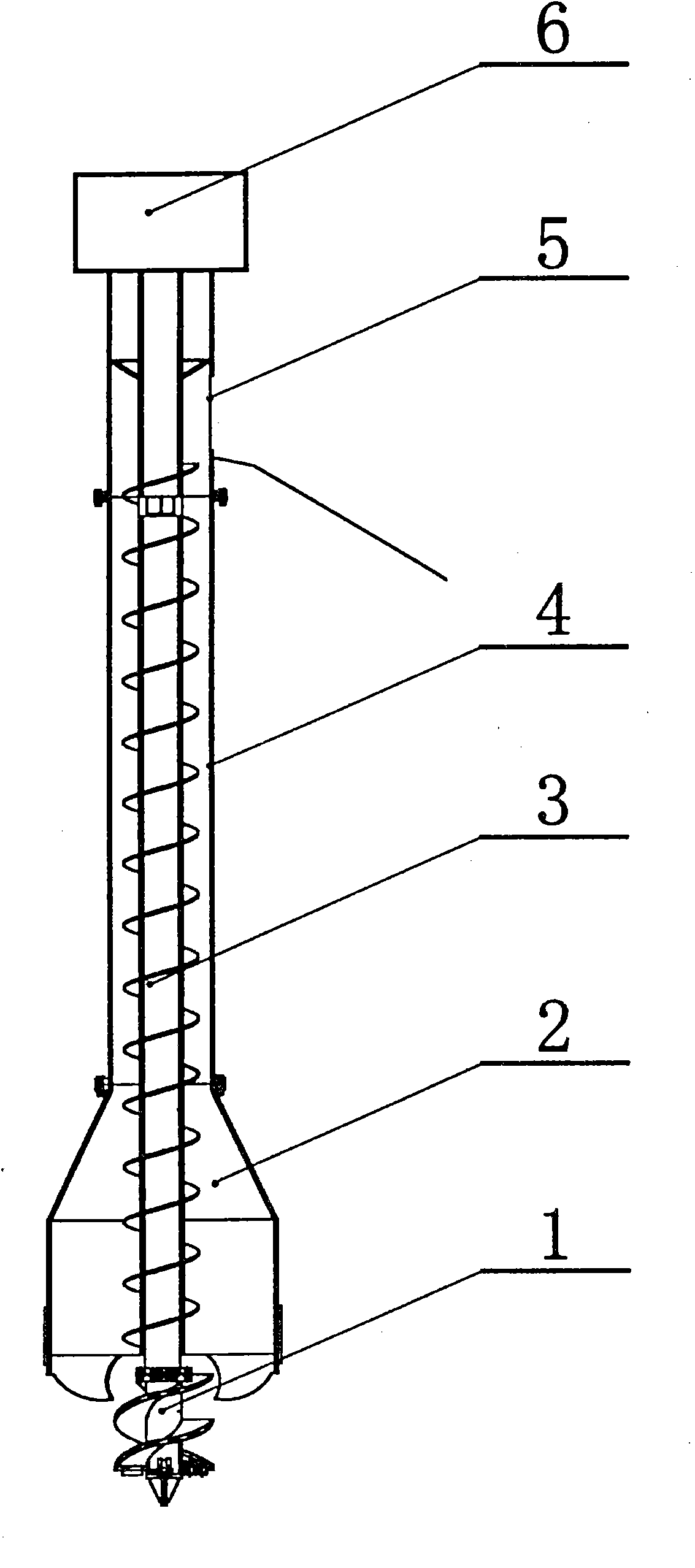

Compound rotary drilling rig drilling mechanism

The invention relates to a compound rotary drilling rig drilling mechanism which is provided with a long tube shape coat drill pipe of which the upper part is provided with a mud discharging port. The lower end of the coat drill pipe is fixedly connected with a heavy-calibre drill by a flange bolt; a spiral drill pipe coaxially rotating is arranged in the coat drill pipe; the bottom end of the rotary drill pipe is connected with a guiding drill; the coat drill pipe and the spiral drill pipe are in sectioned connection structure; two ends of the coat drill pipe and the spiral drill pipe are respectively provided with a quick-change connector capable of quickly splicing and installing; the upper part of the spiral drill pipe is connected with a motor; and meanwhile, the motor is meshed and connected with the gear on the coat drill pipe in a driving mode. The compound rotary drilling rig drilling mechanism has the construction function of a common drilling mechanism, can conveniently adjust the length of the drill pipe and carry out heavy-calibre drilling construction, can pump drilled mud and sand out of the drill pipe, effectively improves progress of works, solves the problem of poor stability caused by an over-high rotary drilling rig and is convenient to transport the rotary drilling rig.

Owner:毛杰

Medium ground tunnel milling excavating and mating mechanized construction method

InactiveCN103899318AAchieving Precise FormingReduce disturbanceTunnelsWorking environmentEngineering

The invention discloses a medium ground tunnel milling excavating and mating mechanized construction method. The construction method includes the steps that the center of an upper step is excavated by a large breaking hammer to be in a paraboloid shape, after the outer portion of the center of the upper step is excavated and trimmed by a milling excavator to form an excavation face perpendicular to the tunnel axis, the upper step is supported to form a stable bearing arch, then the core soil part of a middle step is excavated by the large breaking hammer until a drill rod of the large breaking hammer is drifted, the edge wall parts on the left side and the right side of the middle step are excavated and trimmed by the milling excavator, initial supporting is carried out, the core soil part of a lower step is excavated by the large breaking hammer, the edge wall parts on the left side and the right side of the lower step are excavated and trimmed by the milling excavator, initial supporting is carried out, deslagging is carried out, and the steps are repeated until excavation of a whole tunnel is completed. By means of the medium ground tunnel milling excavating and mating mechanized construction method, the advantages of mating mechanized construction of the milling excavator are sufficiently exerted, accurate molding of the tunnel profile is achieved, surrounding rock is small in disturbance, back break control is good, the working environment is good, the construction safety is high, and influences of vibration of blasting are avoided.

Owner:SHENHUA BAOSHEN RAILWAY

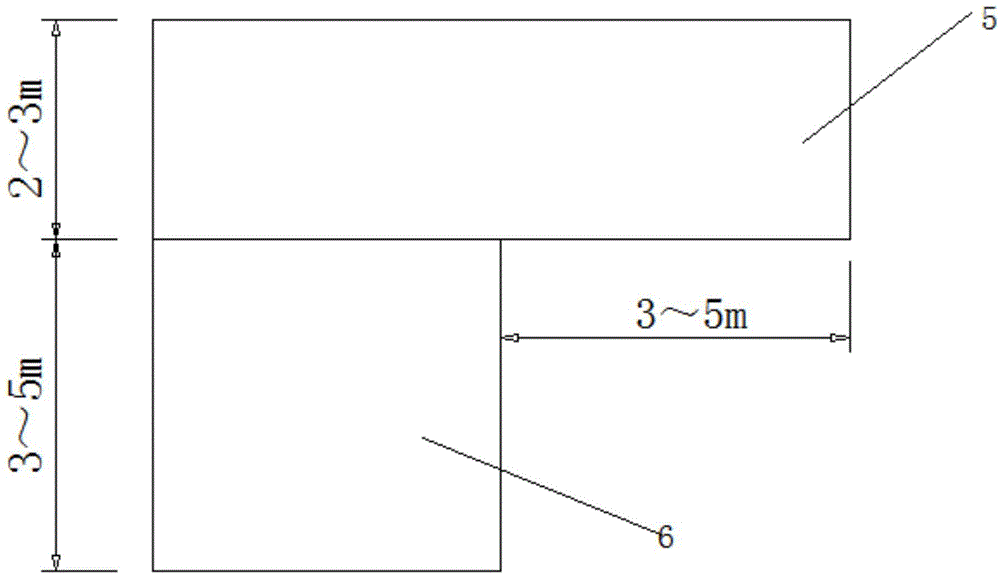

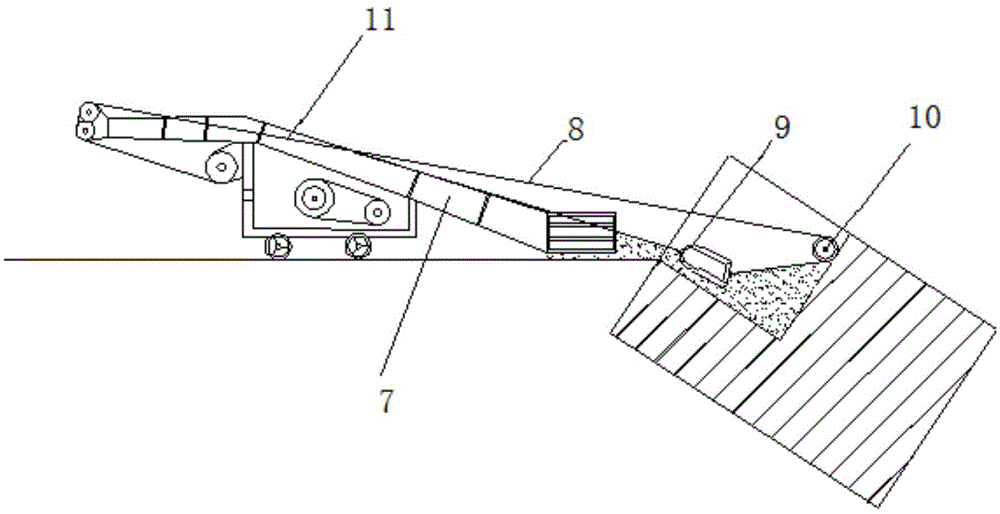

Arch bridge abutment tunnel type large-angle inclined pile construction method

InactiveCN104831733AAvoid settingSpeed up the progress of the projectExcavationsBulkheads/pilesShotcreteSlag

The invention discloses an arch bridge abutment tunnel type large-angle inclined pile construction method comprising the following steps: an inclined pile is divided into an upper step and a lower step which are separately excavated by weak blasting, the top half circle and the straight wall are 2-3m in total and are excavated first as the upper step, and the lower step begins to be excavated after the upper step is excavated 3-5m; inclined pile slag is extracted by a reciprocating circulation slag extractor, pile slag of the upper step is transshipped by the slag extractor to the bottom of the lower step and then conveyed from the bottom of the lower step to the outside of a hole, and the hole is cleaned manually; after excavation of each section of each step is completed, breast wall support is completed in time in a mode of breast wall anchoring and shotcreting support through a mortar rock bolt, a steel mesh, an I-shaped steel arch and sprayed concrete; and holing quality detection is carried out after excavation of the inclined pile is completed, and inclined pile body reinforcing bar and concrete construction is completed after the holing quality meets the design and specification requirements. By adopting the method of the invention, the project progress is accelerated, the construction cycle is shortened, the working efficiency of slag extraction is improved, and the difficulty in breast wall concrete construction is reduced.

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com